Patents

Literature

1325results about How to "Reduce test costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

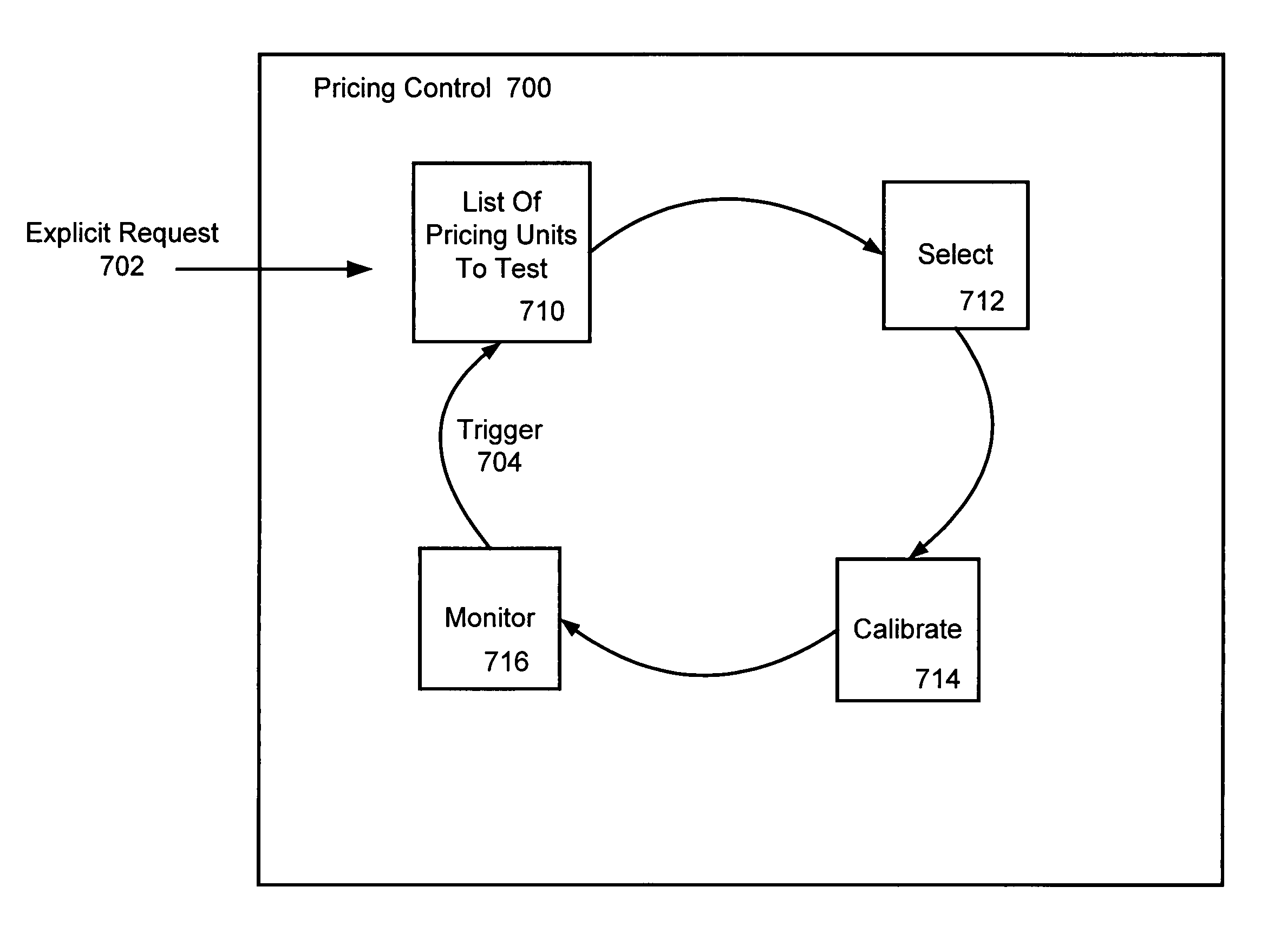

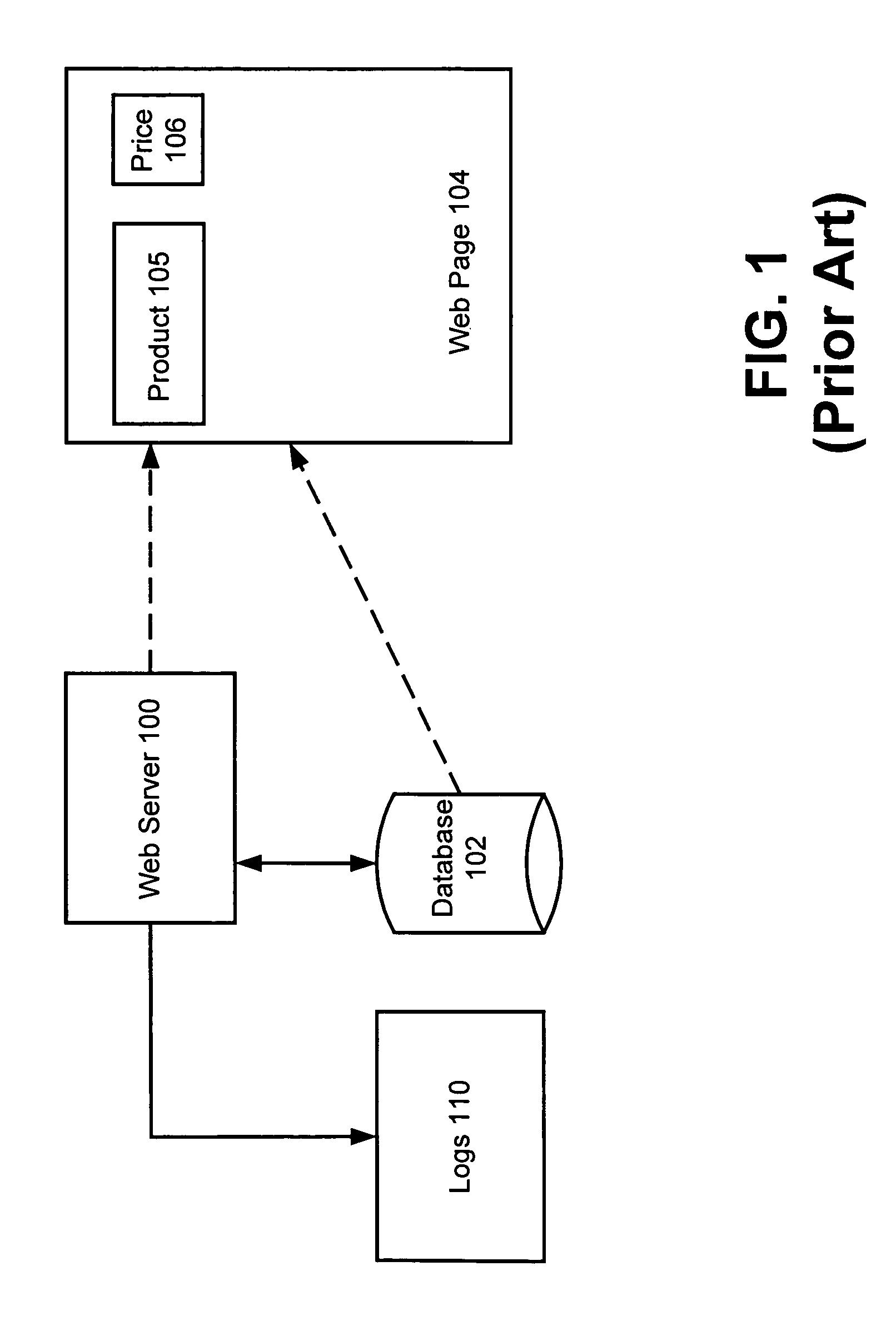

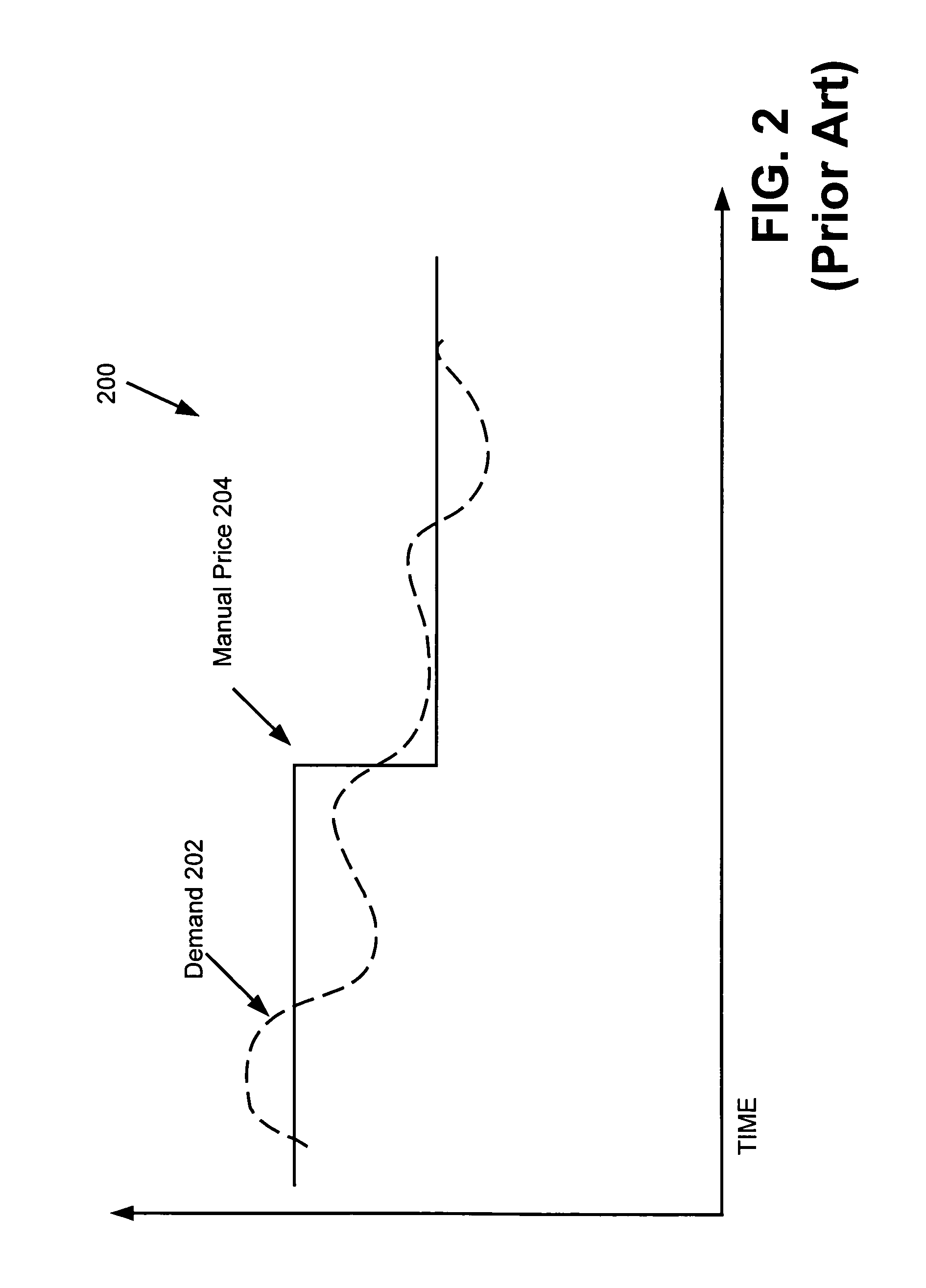

Method and apparatus for automatic pricing in electronic commerce

InactiveUS7970713B1Increased cost of testingReduce testing costsMarket predictionsBuying/selling/leasing transactionsE-commerceMajorization minimization

Owner:OIP TECH

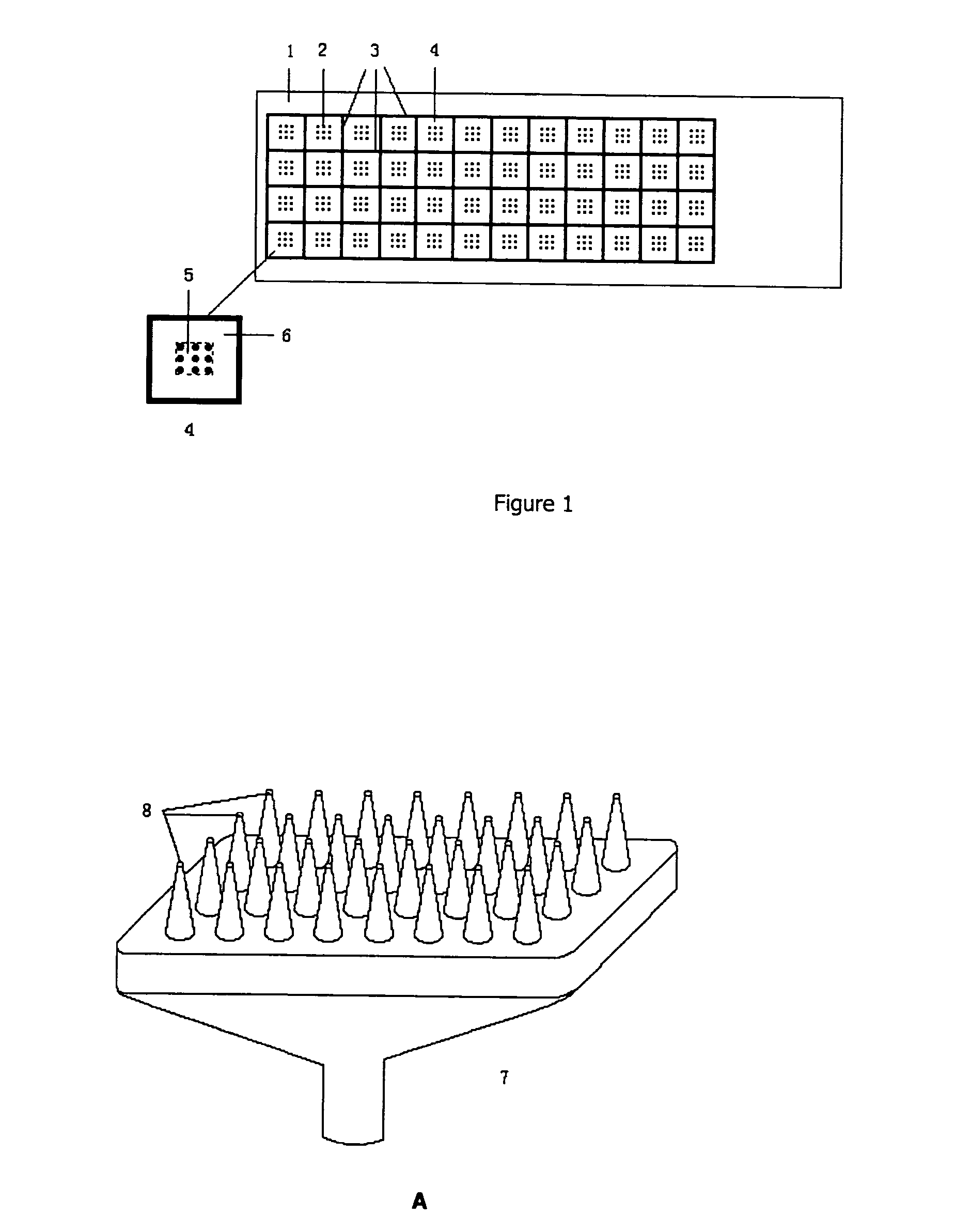

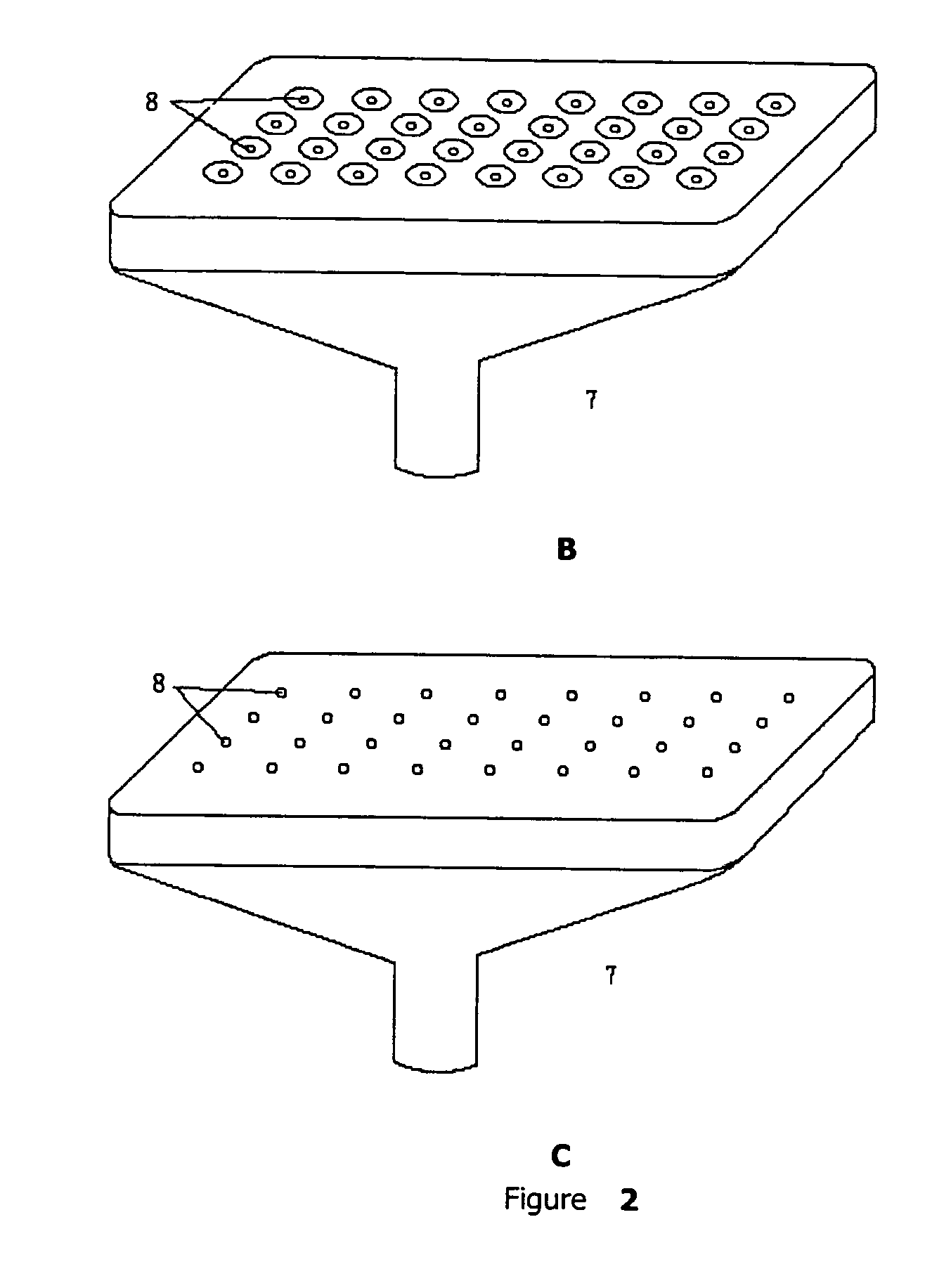

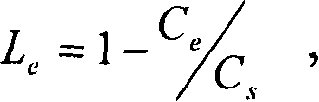

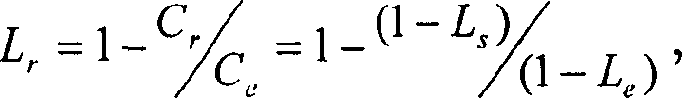

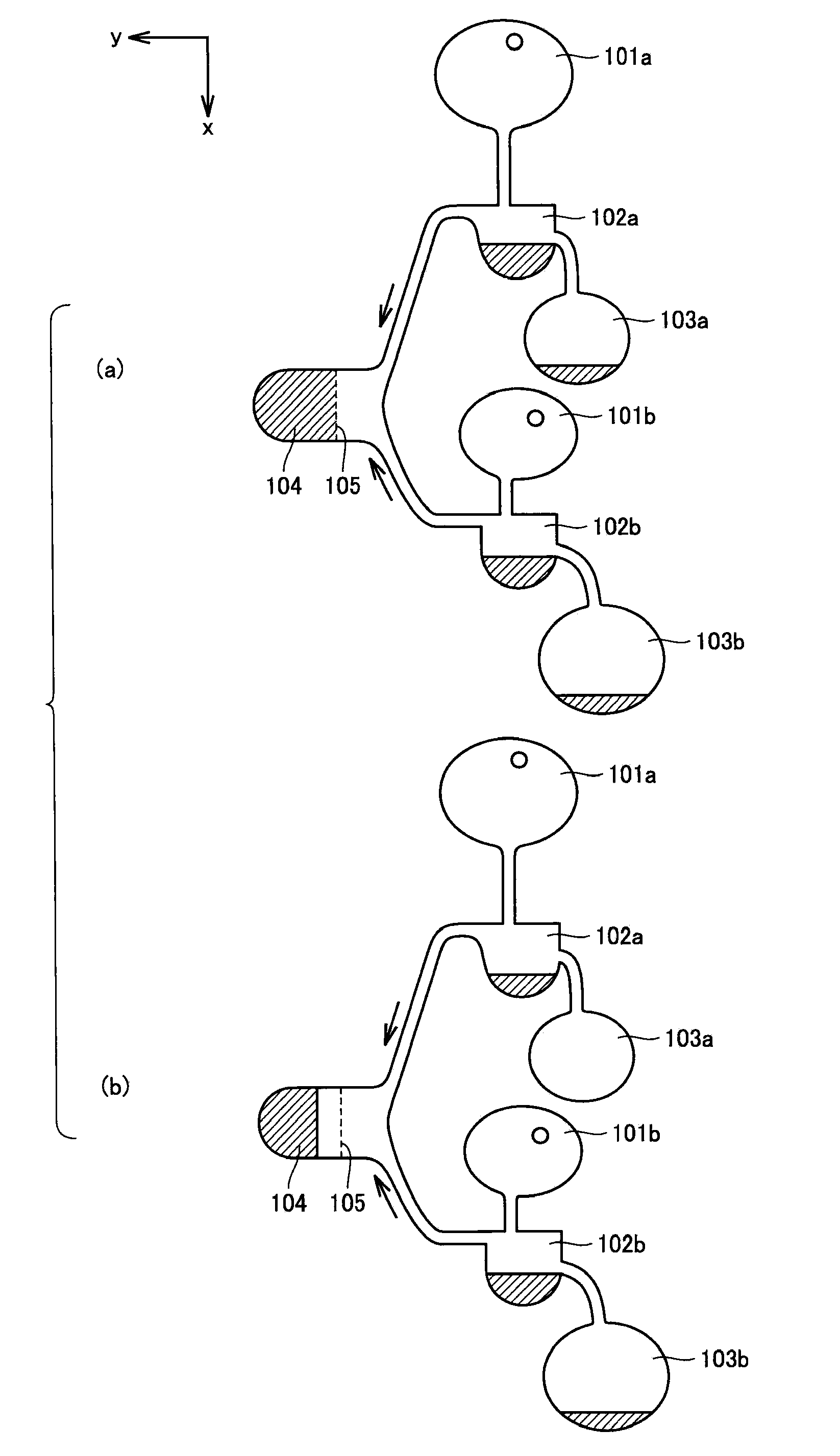

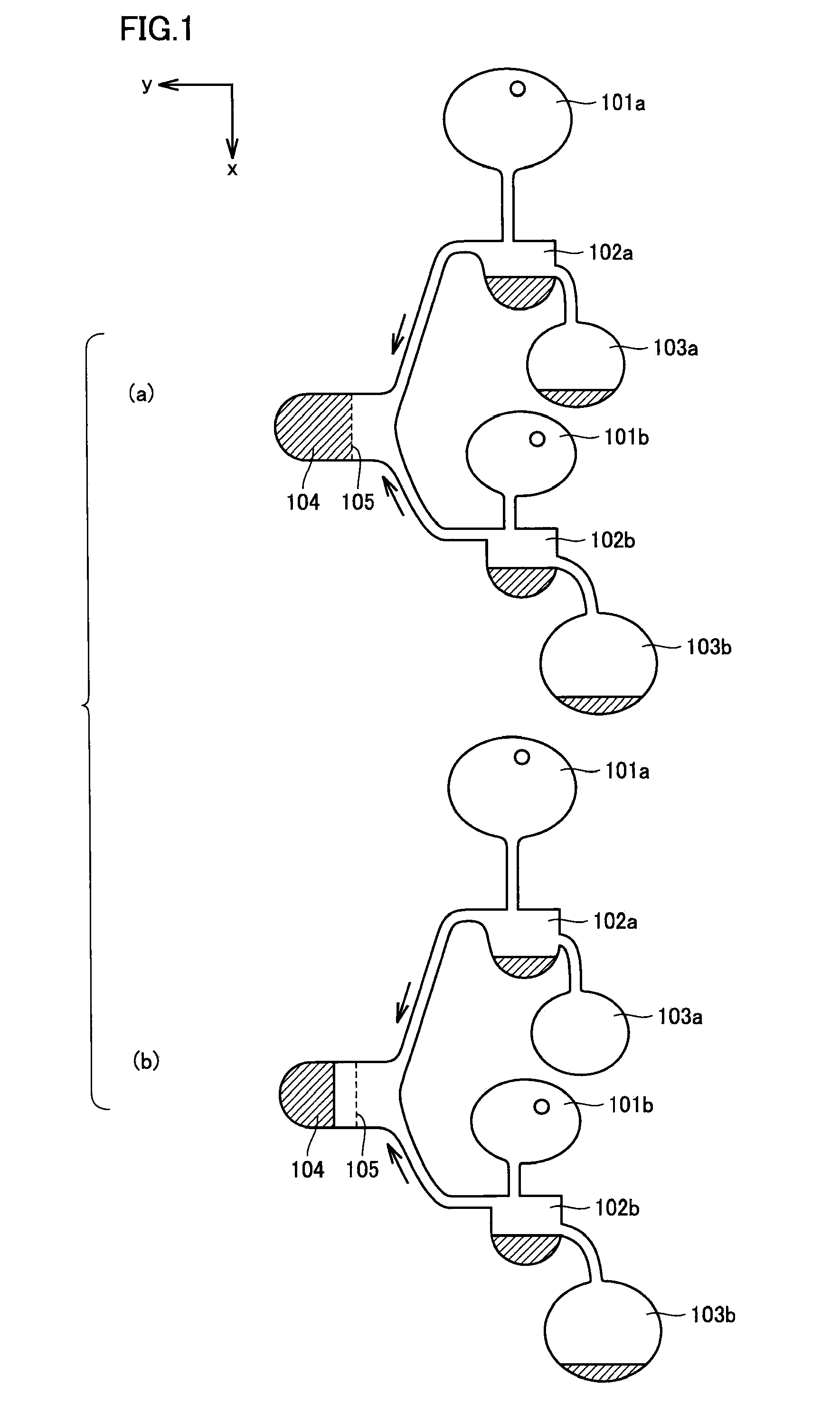

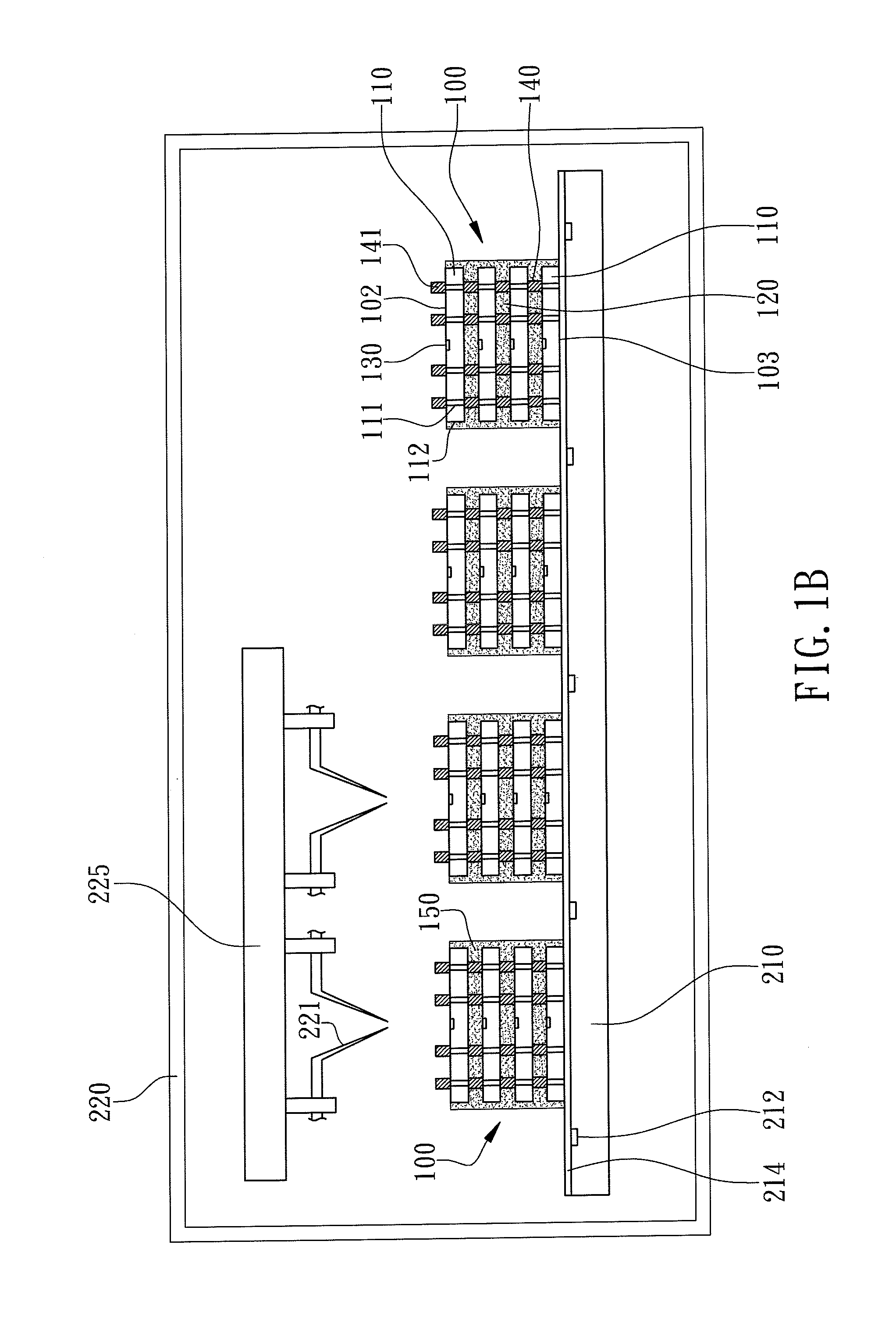

Testing method of analytic chip of multiple reactors, the analytic chip, and the testing device

InactiveUS20070207060A1Easy to integrateEfficient testingLaboratory glasswaresColor/spectral properties measurementsComputer scienceTest set

This invention involves the testing device of analytic chip with multiple reactors, which includes a). one-way-cleaning system for one-way-cleaning of remnant sample in said reactor; or / and b).fluidity-decreasing system for fluidity-decreasing of remnant sample; or / and c). sample spotting system for sample subjecting by spotting. With the said testing device, analytic chip testing can be easily conducted with high integration, high efficiency and safety.

Owner:CHENGDU KUACHANG MEDICAL IND CO LTD

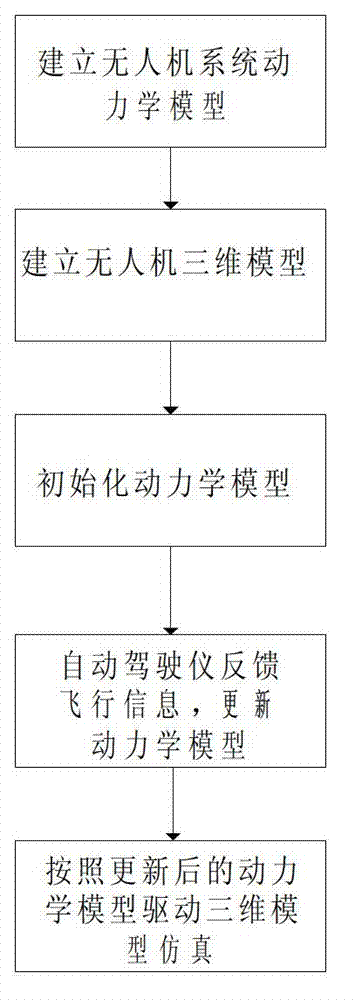

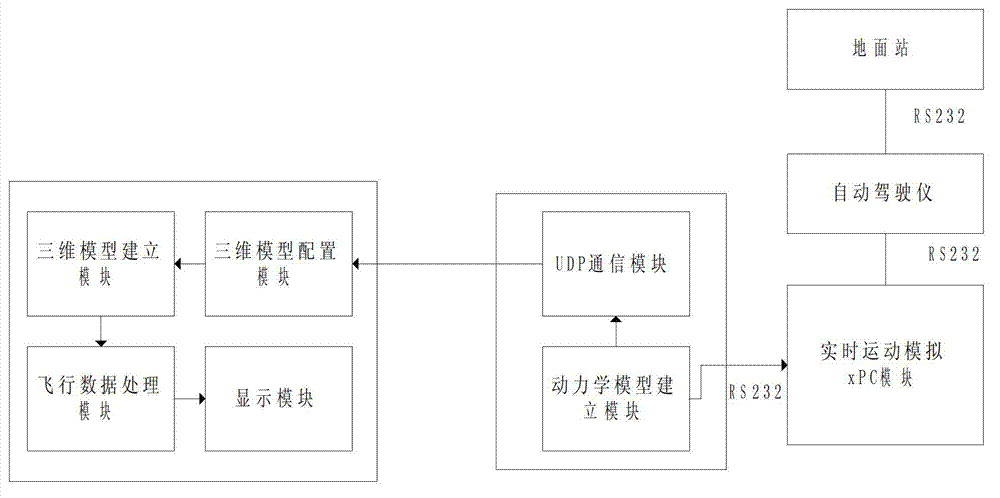

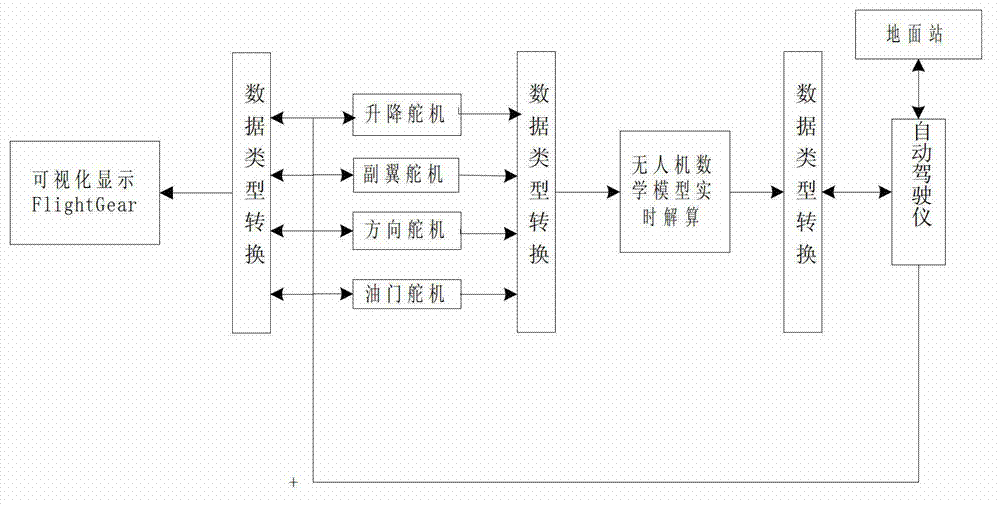

Method and system for semi-physical simulation test of visual unmanned aerial vehicle flight control

InactiveCN102789171AImprove Simulation EfficiencyReduce riskSimulator controlDynamic modelsUncrewed vehicle

The invention relates to a method and a system for a semi-physical simulation test of visual unmanned aerial vehicle flight control and belongs to the technical field of visual system simulation. The method includes building a dynamic model of an unmanned aerial vehicle system, initializing the dynamic model, enabling an unmanned aerial vehicle to fly along the track provided by the ground, feeding flight rudder quantity information to the dynamic model to be updated, driving a three-dimensional model of the unmanned aerial vehicle through the updated dynamic model to conduct simulation and outputting simulation image and data in real time. A system based on the method is further provided. The method and the system provide effective ways and development environment for design, experiments and verification of the flight control law, have the advantages of being simple, flexible, quick, vivid and real-time, improve simulation efficiency of a flight control system, reduce test risk and test cost of the unmanned aerial vehicle and shorten development period.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

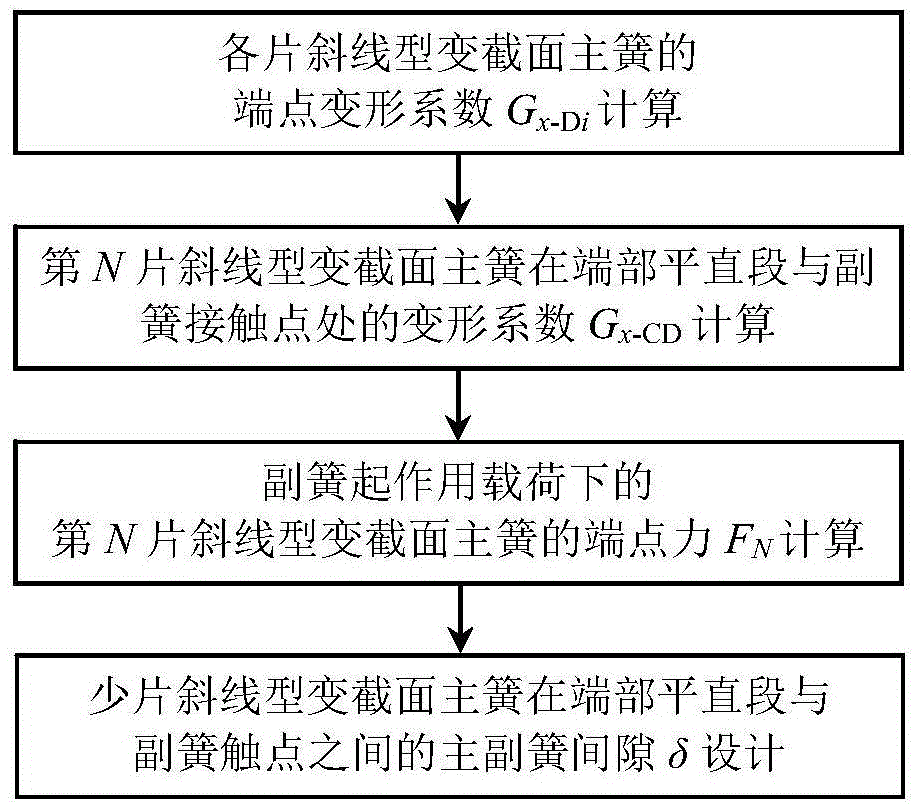

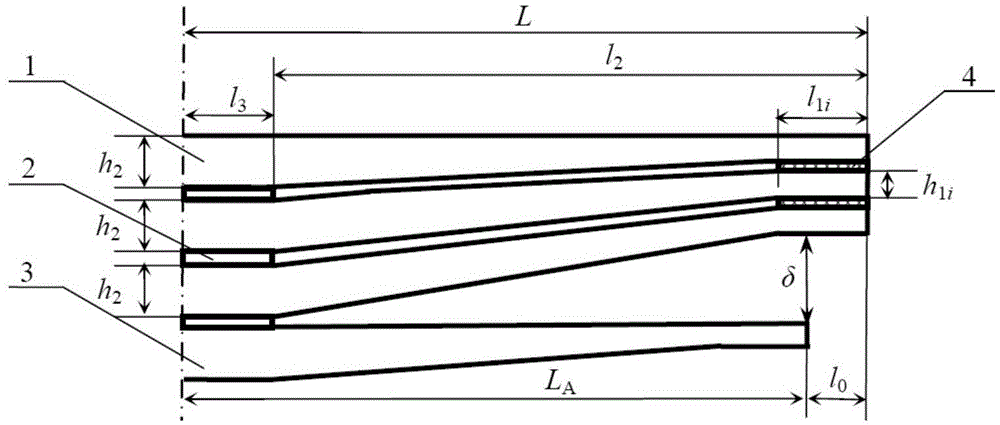

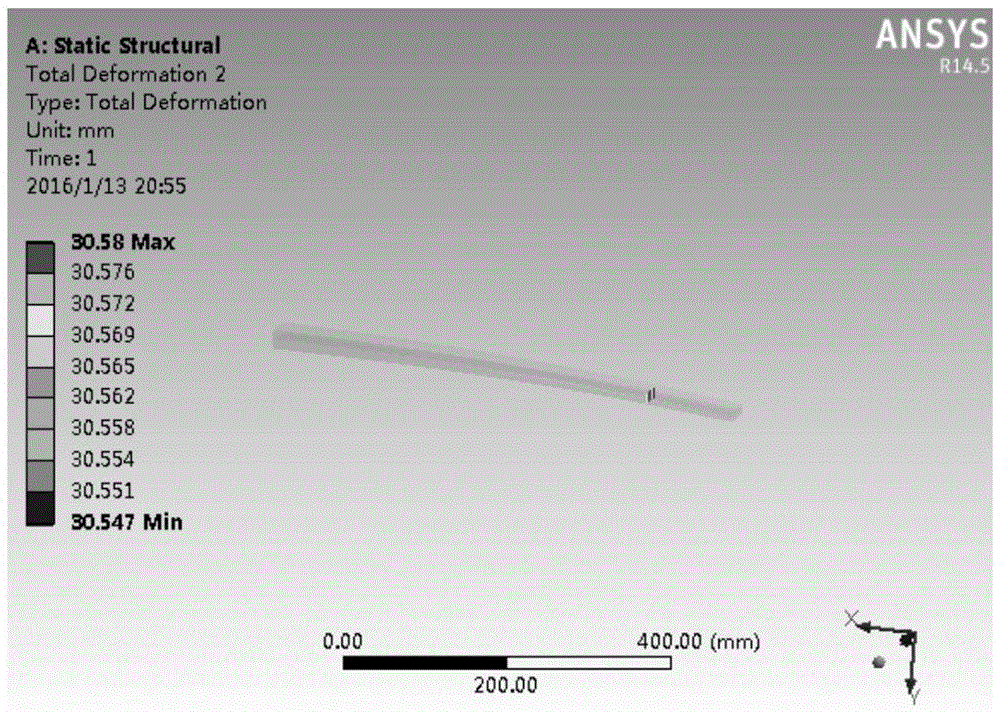

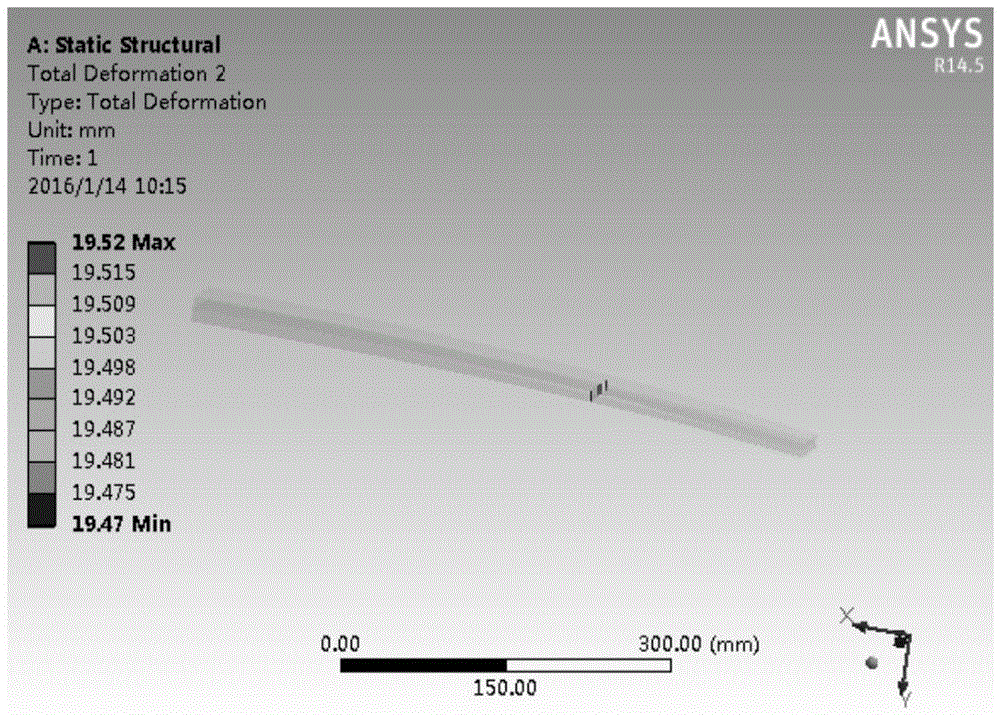

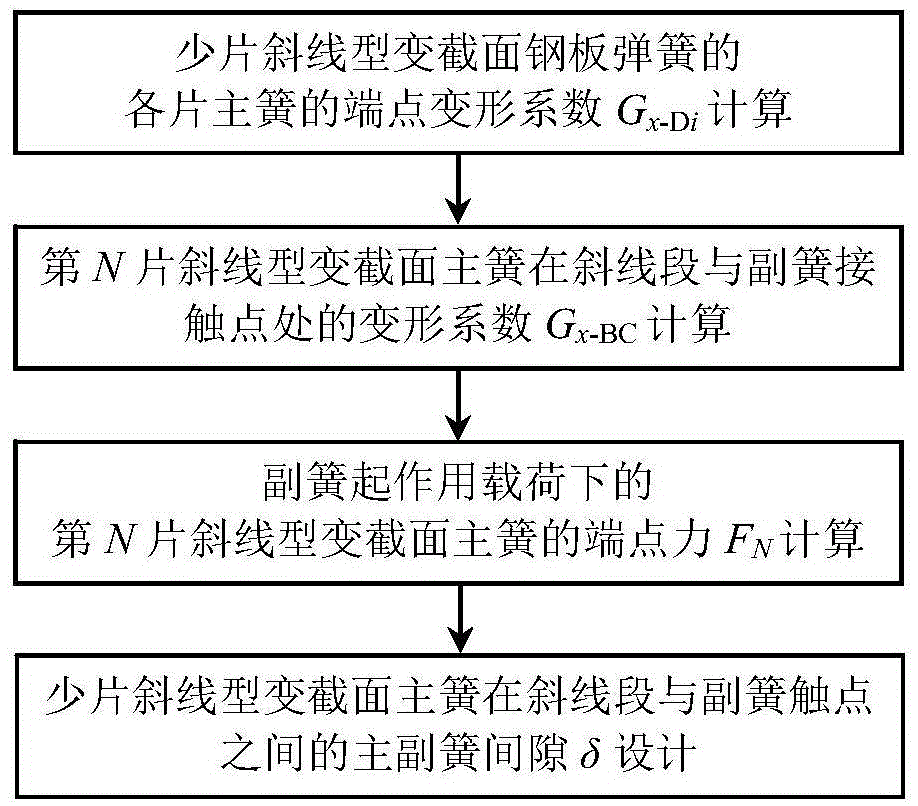

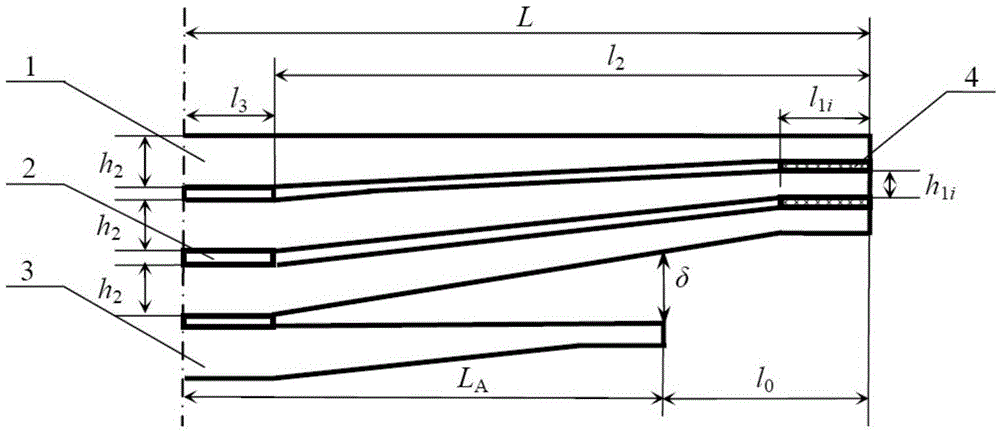

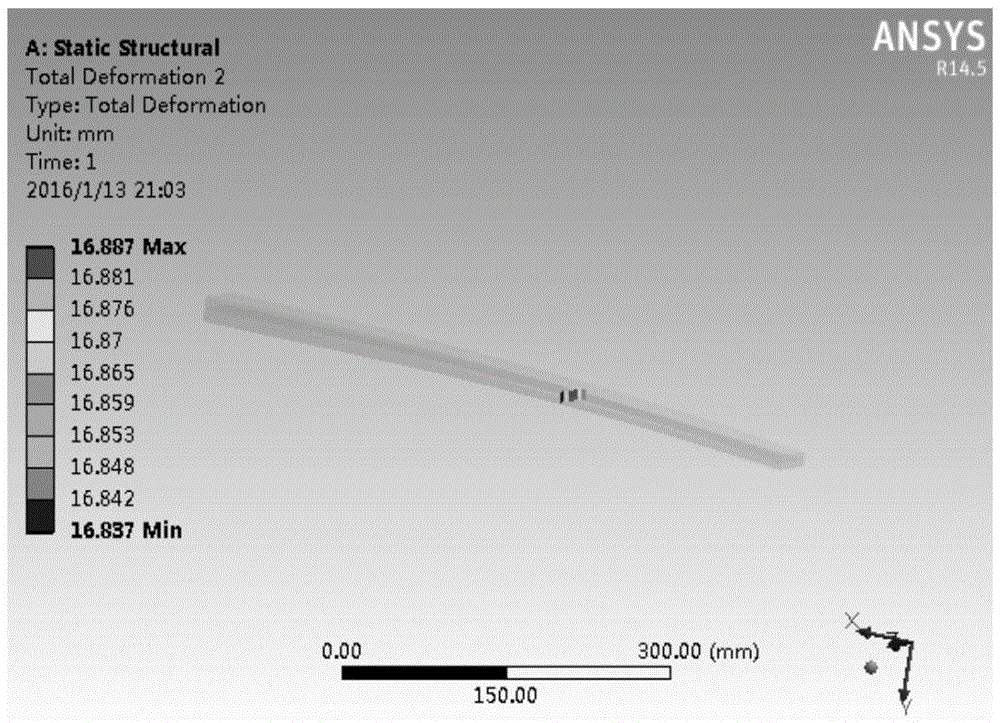

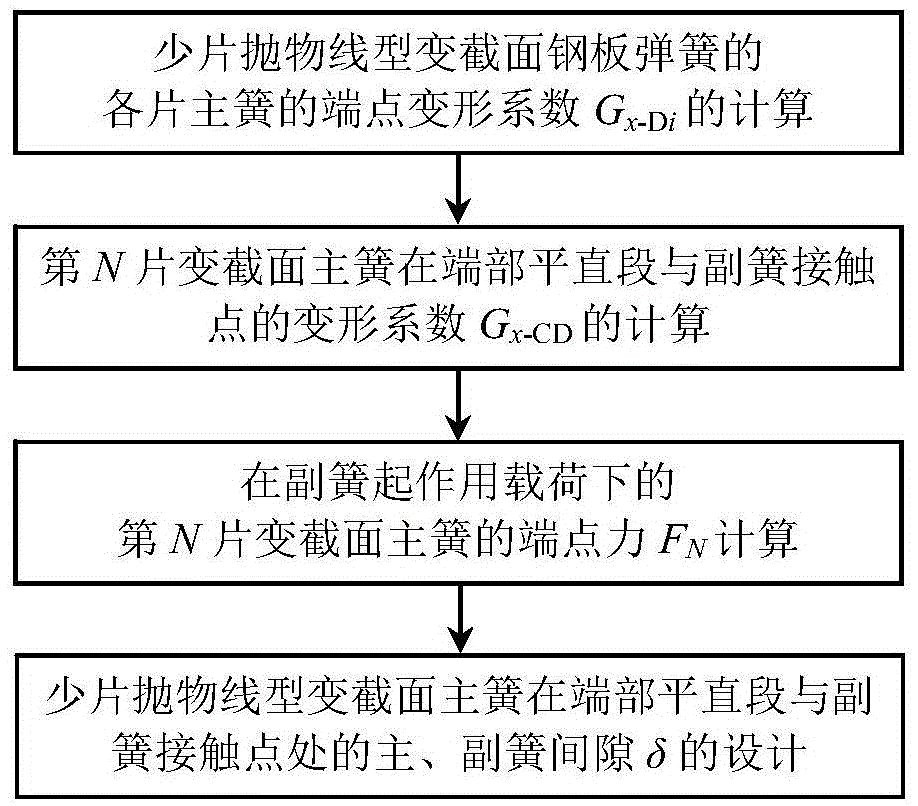

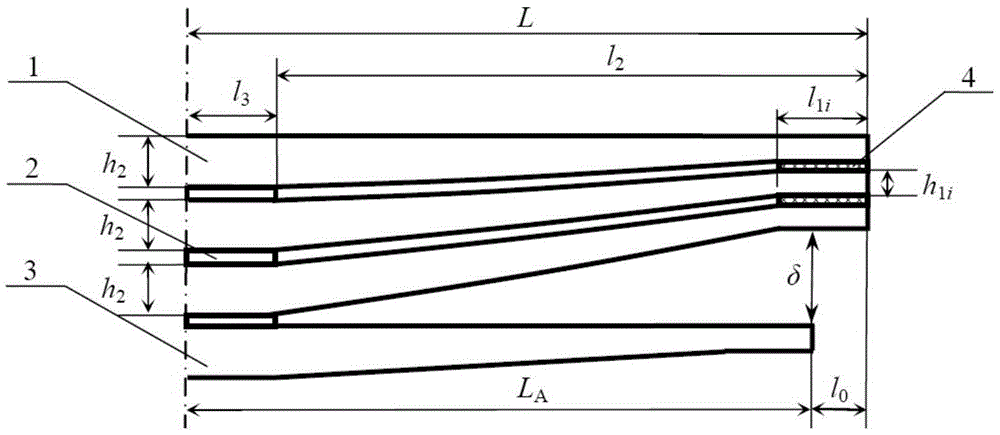

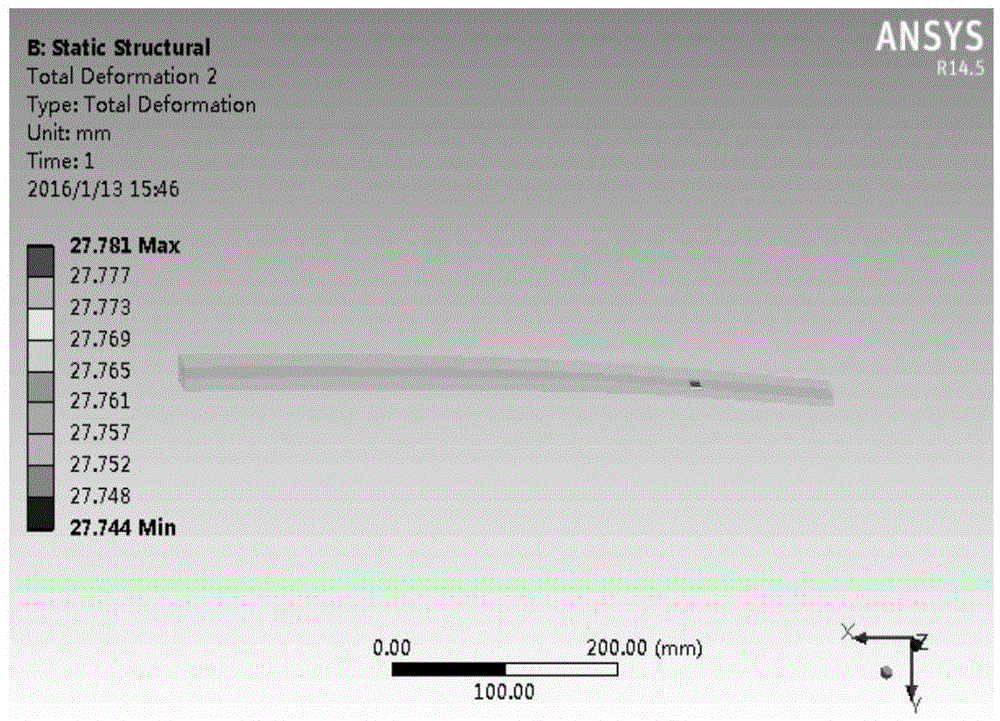

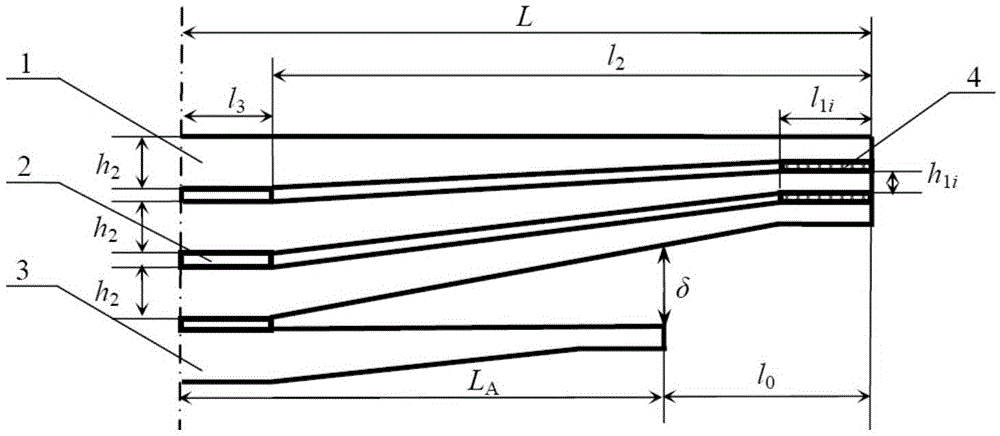

Method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs

ActiveCN105526290AExact design valueReliable design valueGeometric CADLeaf springsEngineeringDesign values

The invention relates to a method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs, and belongs to the technical field of suspension steel plate springs. The method includes determining endpoint deformation coefficients of the various main springs and deformation coefficients G<x-CD> of contact points of the end straight sections of the N main springs and the auxiliary springs according to structure sizes and elastic modulus of the various diagonal variable-section main springs; acquiring endpoint force F<N> of the N main springs according to acting load of the auxiliary springs and the endpoint deformation coefficients of the various main springs; designing the main and auxiliary spring gaps between contact points of the end straight sections of the main springs and the auxiliary springs according to the thicknesses h<2> of roots of the N main springs, the endpoint force F<N> and the deformation coefficients G<x-CD>. The method has the advantages that as known from simulation verification, design values of the gaps of the end straight sections of the diagonal few-leaf variable-section main springs and the auxiliary springs can be accurately and reliably obtained by the aid of the method, and accordingly the product design level and performance and the vehicle ride comfort can be improved; the design and experiment costs can be reduced, and the product development speeds can be increased.

Owner:山东恒日悬架弹簧股份有限公司

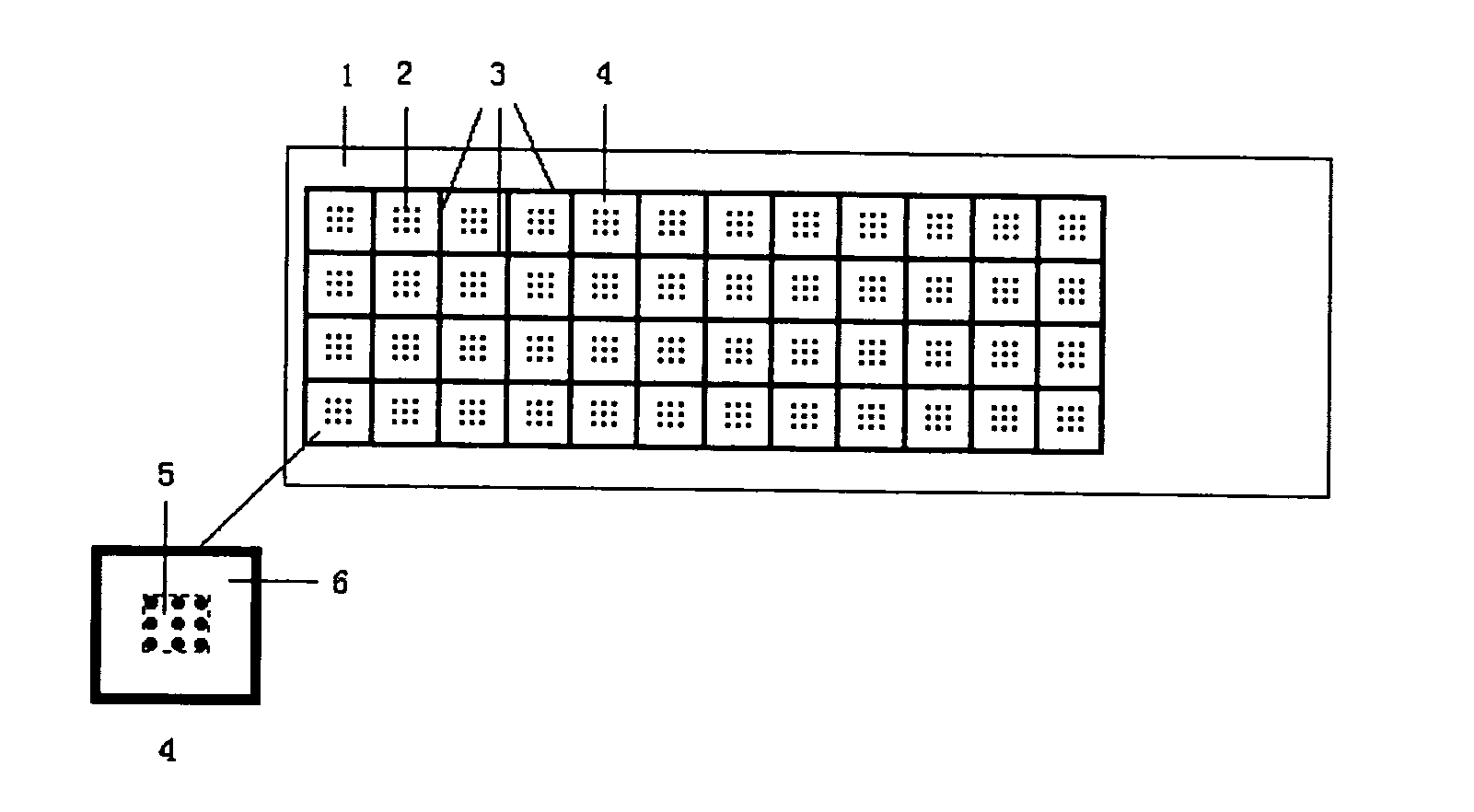

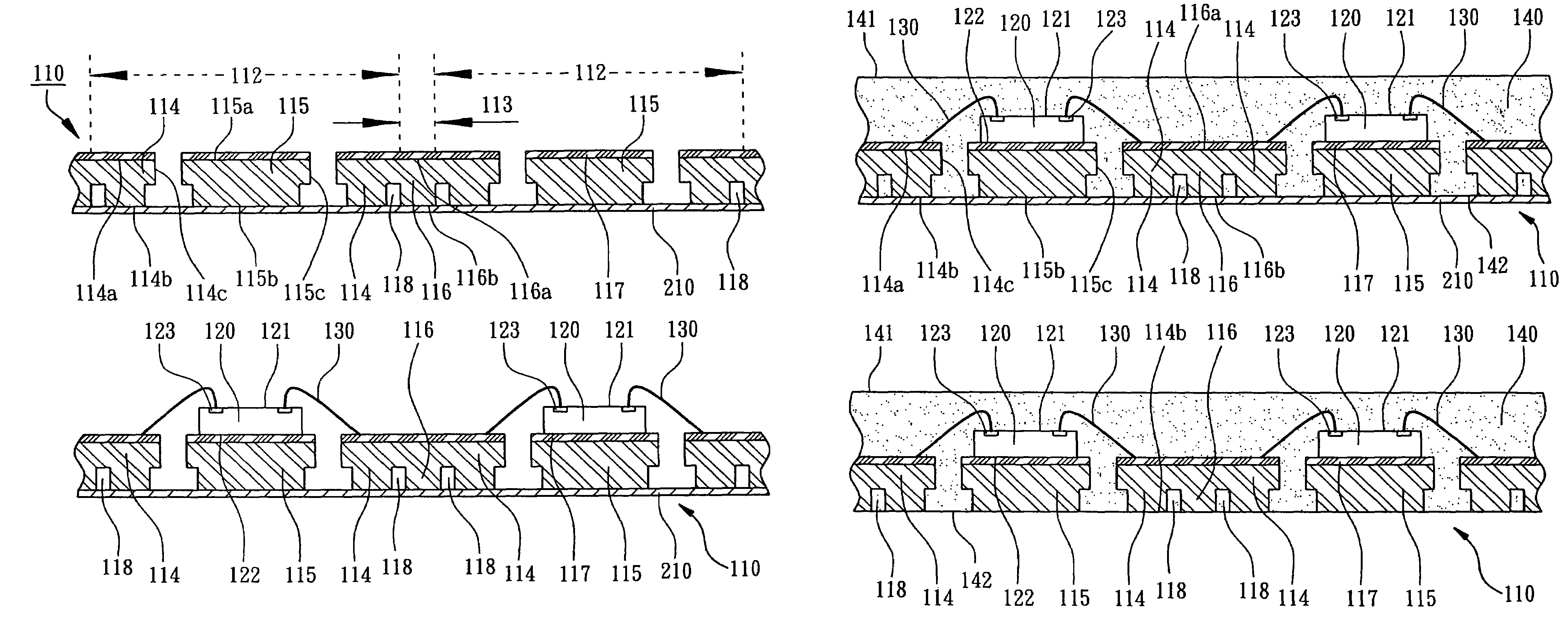

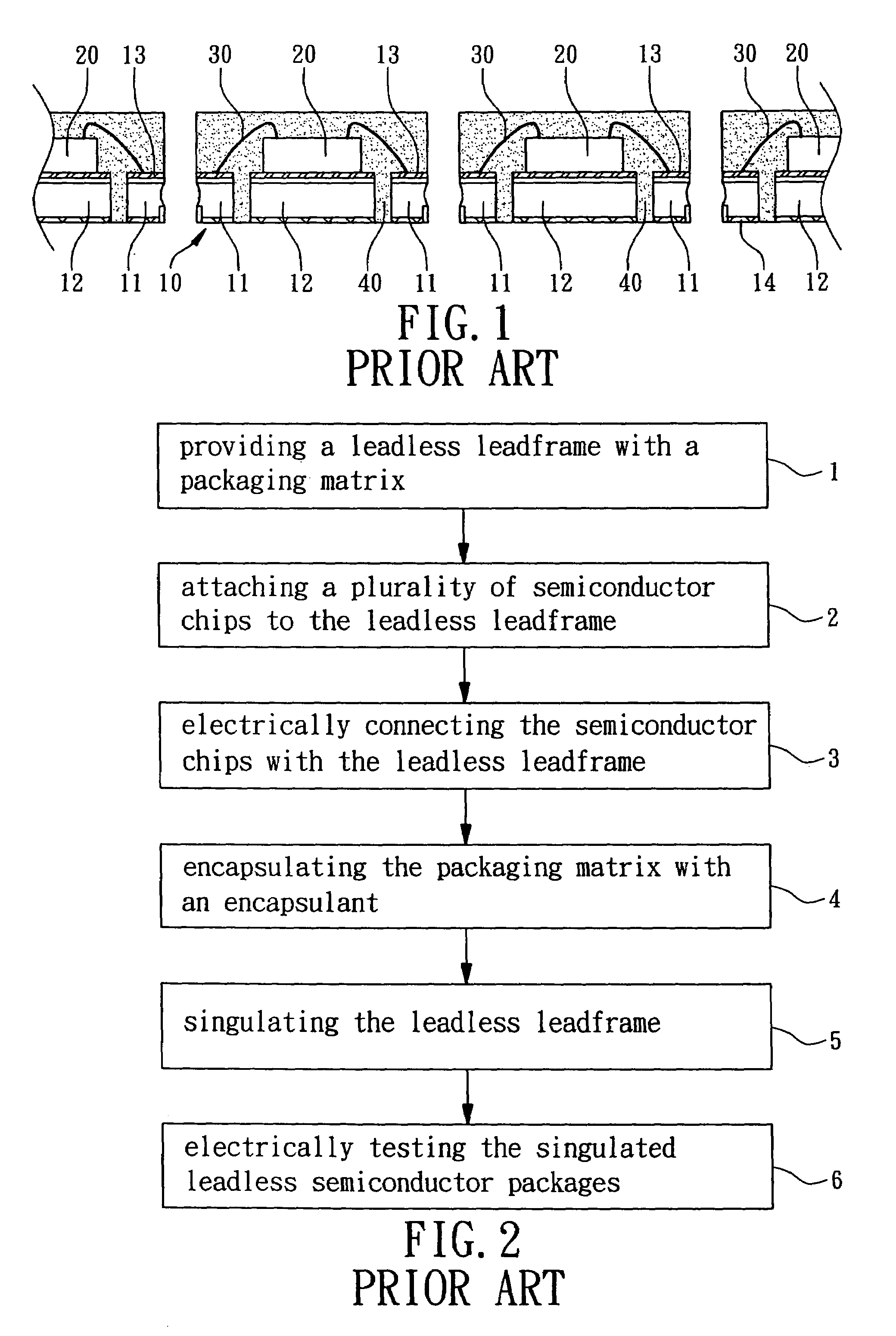

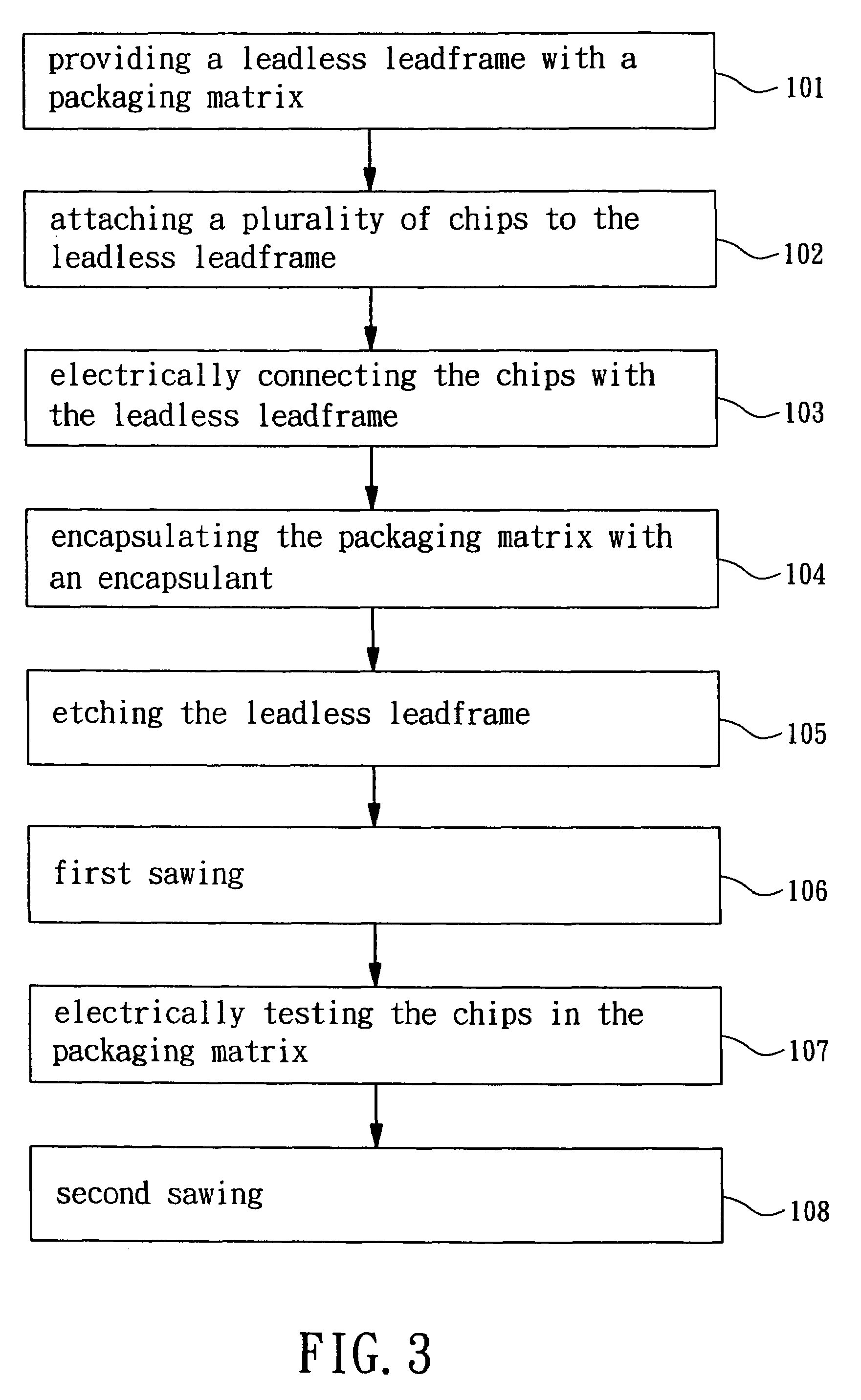

Process for manufacturing leadless semiconductor packages including an electrical test in a matrix of a leadless leadframe

ActiveUS20050287709A1Reduce test costReduce wearSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringElectroplating

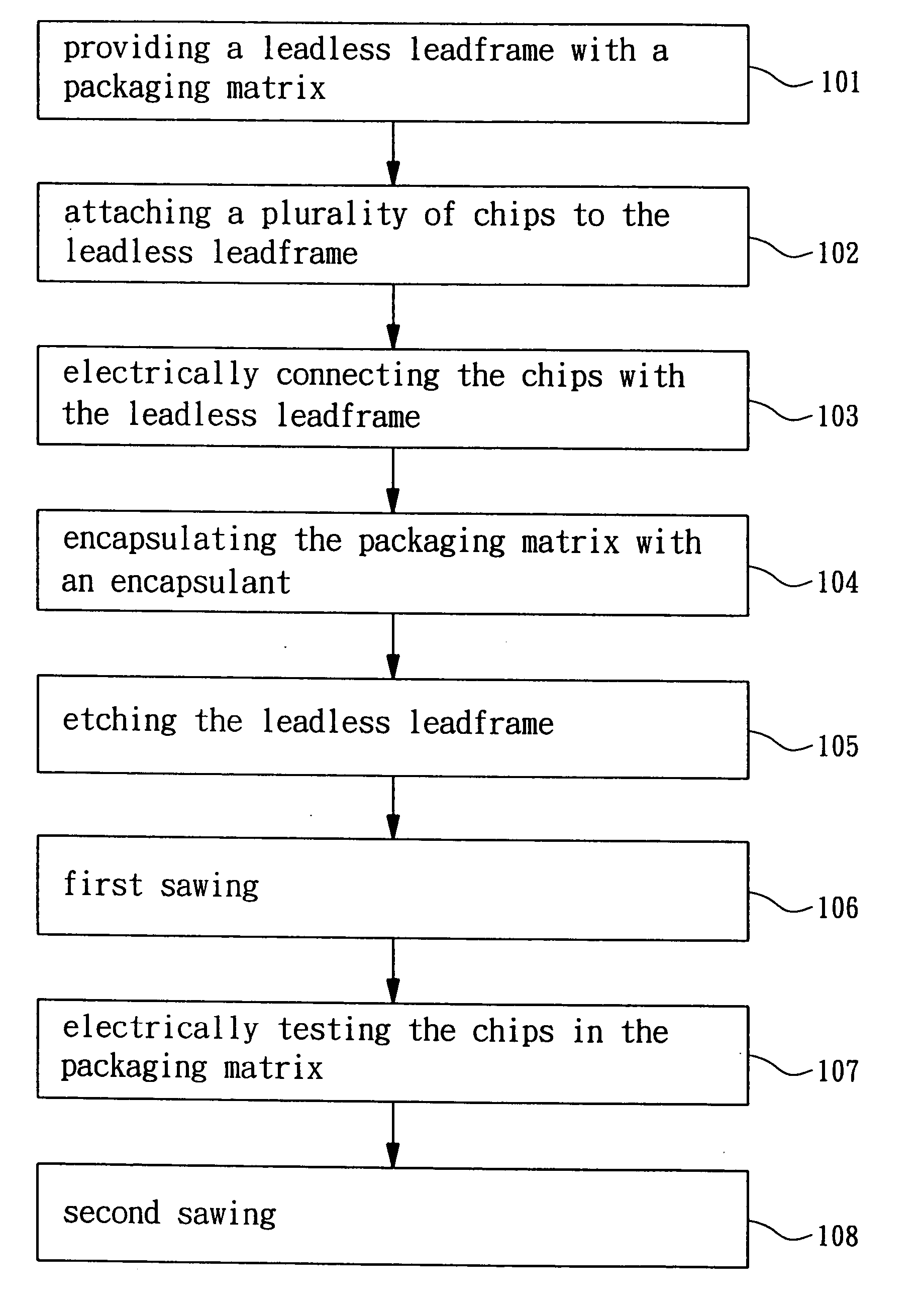

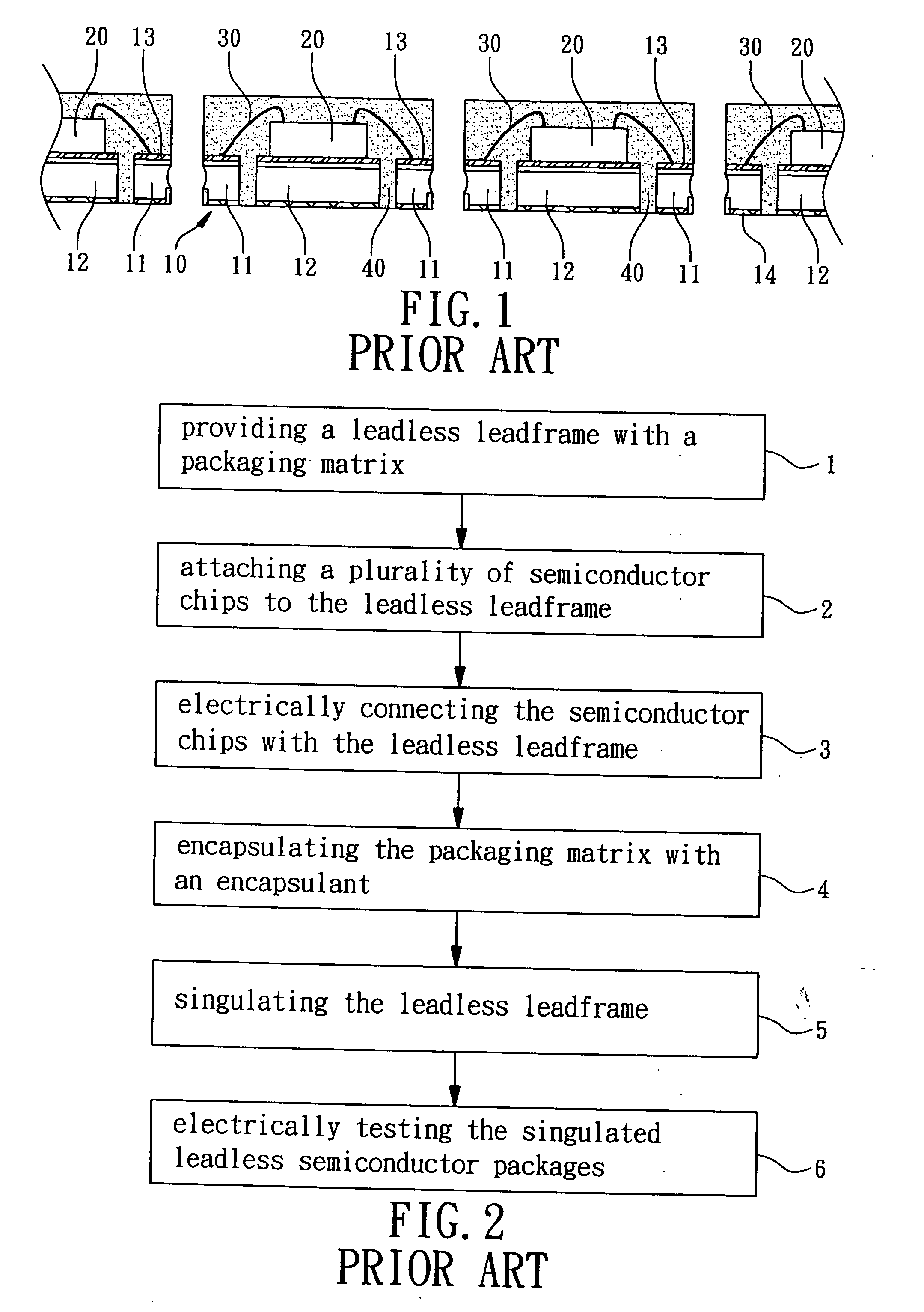

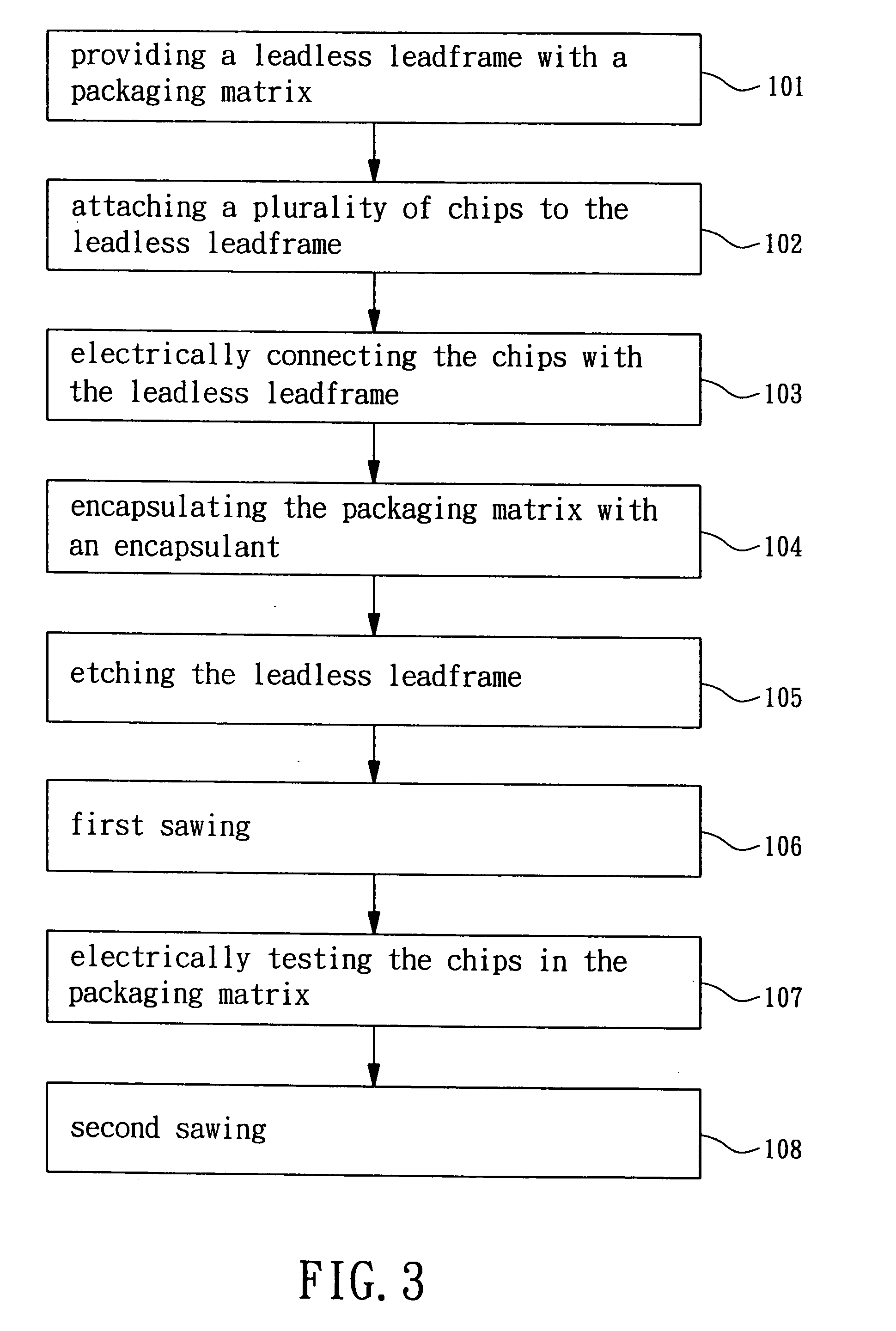

A process for manufacturing a plurality of leadless semiconductor packages includes an electrically testing step to test encapsulated chips in a matrix of a leadless leadframe. Firstly, a leadless leadframe having at least a packaging matrix is provided. The packaging matrix defines a plurality of units and a plurality of cutting streets between the units. The leadless leadframe has a plurality of leads in the units and a plurality of connecting bars connecting the leads along the cutting streets. A plated metal layer is formed on the upper surfaces of the leads and the upper surfaces of the connecting bars. After die-attaching, wire-bonding connection, and encapsulation, the leadless leadframe is etched to remove the connecting bars, then two sawing steps are performed. During the first sawing step, the plated metal layer on the upper surface of the connecting bars is cut out to electrically isolate the leads. Therefore, a plurality of chips sealed by an encapsulant on the packaging matrix can be electrically tested by probing which is performed between the first sawing and the second sawing. Thereafter, the encapsulant is cut to form a plurality of individual package bodies of the leadless semiconductor packages during the second sawing.

Owner:ADVANCED SEMICON ENG INC

System and method for conducting comprehensive measurement and association analysis to time delay and drop

InactiveCN1777126AImprove operation and maintenance efficiencyWide adaptabilityData switching networksMeasurement deviceTransceiver

The system is composed of measuring devices (including transceiver, analytic unit, and com. control unit) located at two ends of route of network to be tested, and feedback device (including feedback unit and com. control unit). The transceiver and feedback unit realizes interaction of testing stream between two ends of route of network, and fills in tested data for each packet in testing procedure. Being connected to each other, com. control units at two ends control and implement interaction of test data. Test stream is a string of test packet pair. Each test packet pair is back-to-back two packets with small length. If a packet is lost, the other packet is in use for representing time delay. Thus, time delay and packet lose can be measured. Analytic unit carries out associative analysis for the said two kinds of measured data, and evaluate overall state as well as determines and distinguish different causes for packet lose and congestion fault, and shows analytic result.

Owner:史文勇

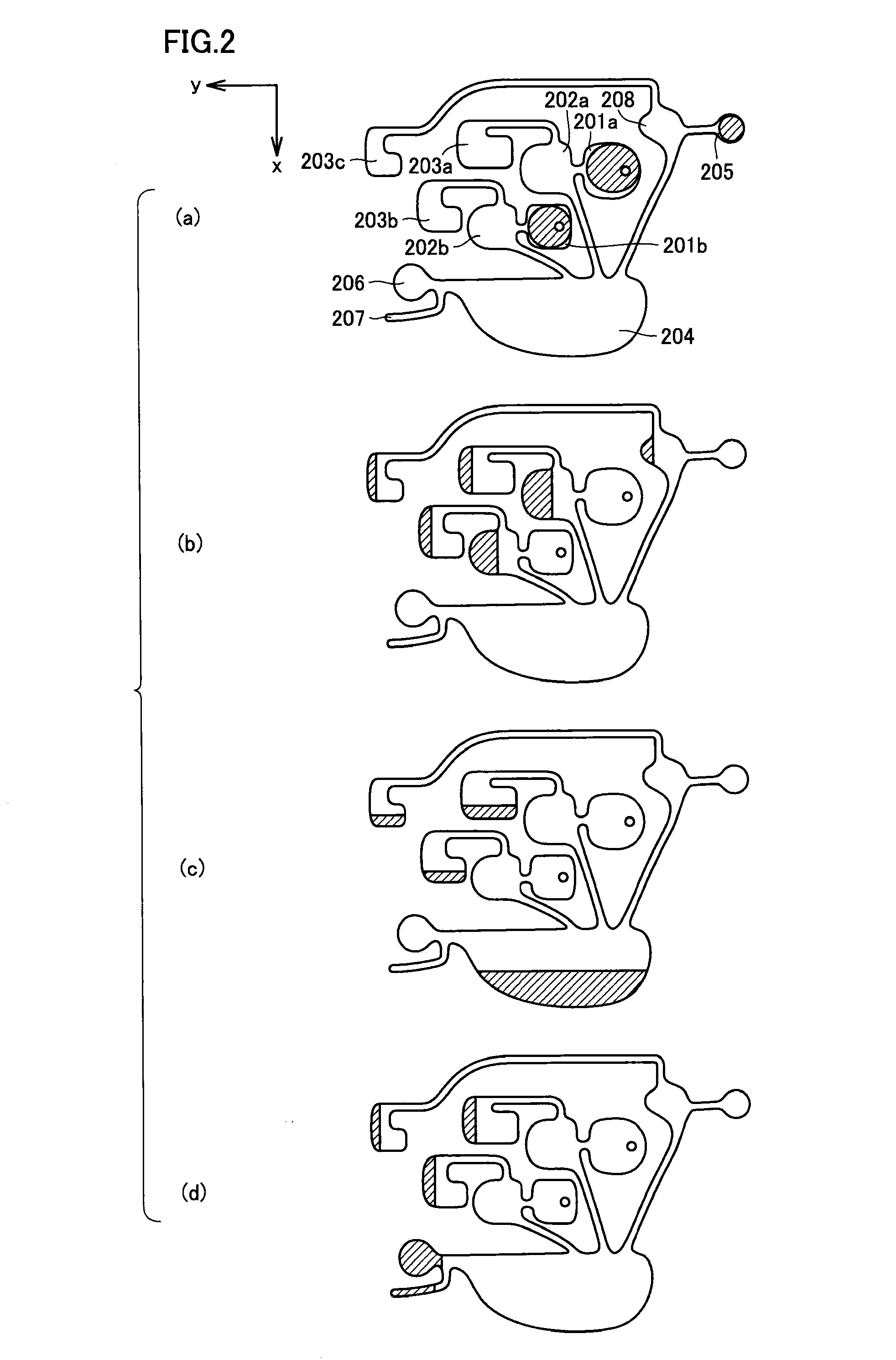

Method of Determining Whether Liquid Amount and/or Quality of Liquid Reagent Are/Is Normal in Liquid-Reagent-Containing Microchip and Liquid-Reagent-Containing Microchip

ActiveUS20080156079A1Simplify mannerLow costLaboratory glasswaresTesting metalsAnalytical chemistryReagent

A method of determining whether a liquid amount and / or quality of a liquid reagent held in a reagent holding portion are / is normal or not in a microchip that includes the steps of measuring each liquid reagent held in the reagent holding portion with a first measuring portion, mixing, at least, two or more types of measured liquid reagents in a first mixing portion, and evaluating the liquid amount and / or quality of obtained liquid mixture and determining, based on the evaluation, whether or not the liquid amount and / or quality of the liquid reagents are / is normal, as well as a liquid-reagent-containing microchip are provided. A method of easily determining whether a liquid amount and / or quality of liquid reagents in a microchip are / is normal or not and a microchip in which the method can be performed are provided.

Owner:HORIBA LTD

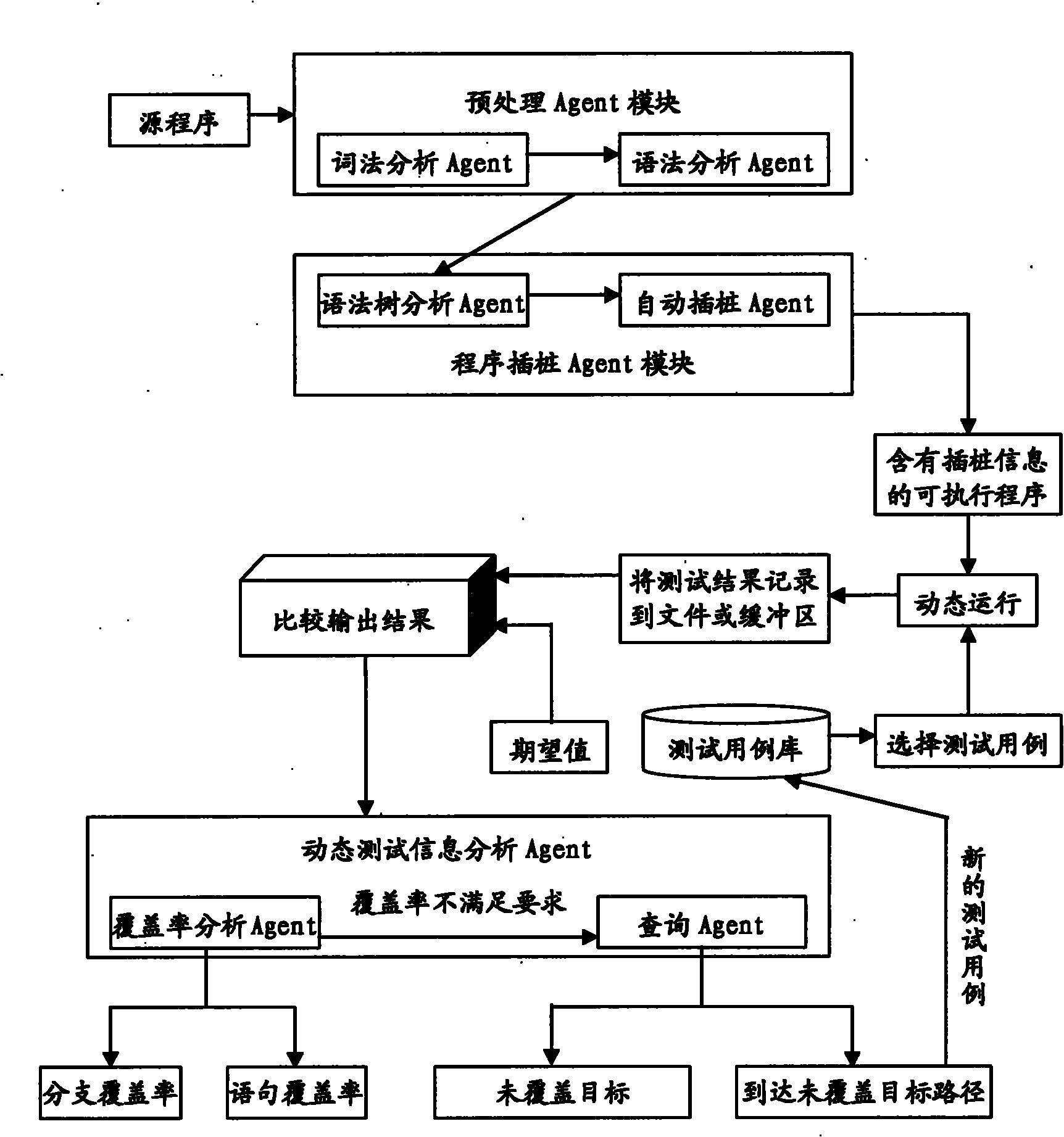

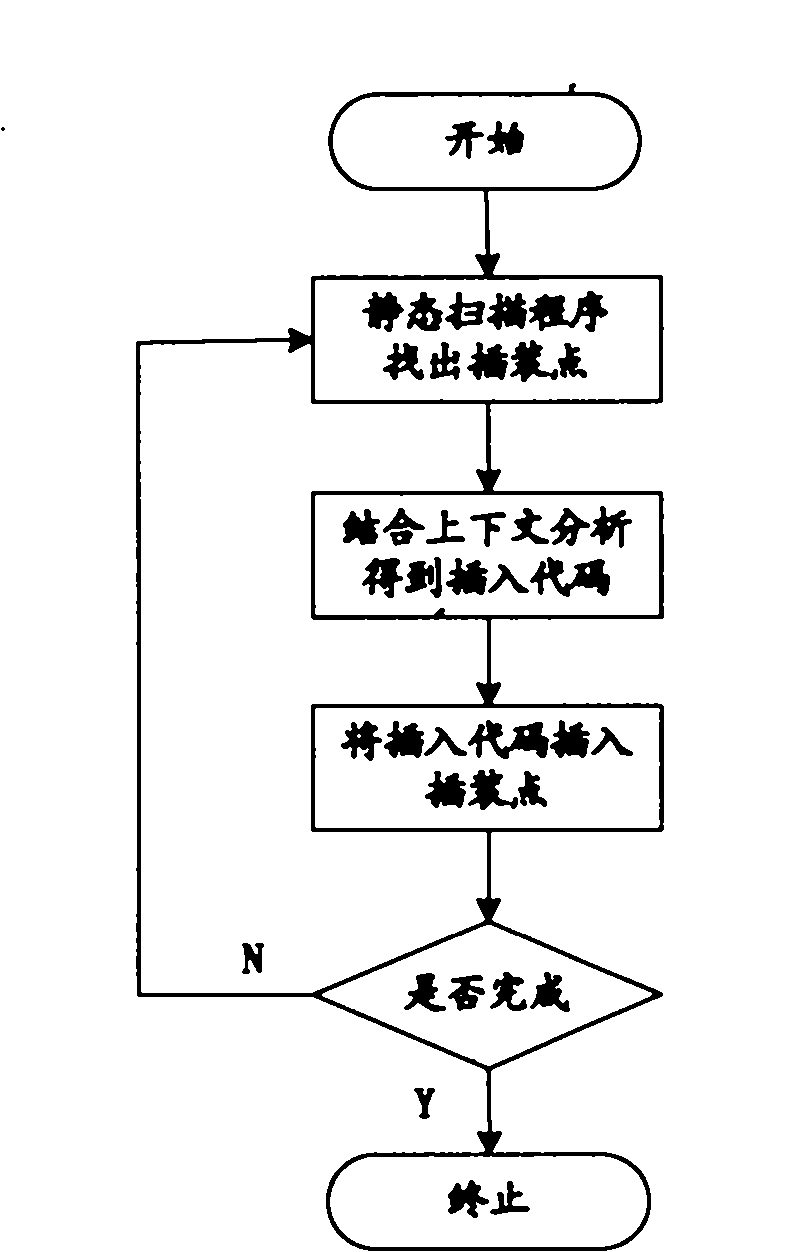

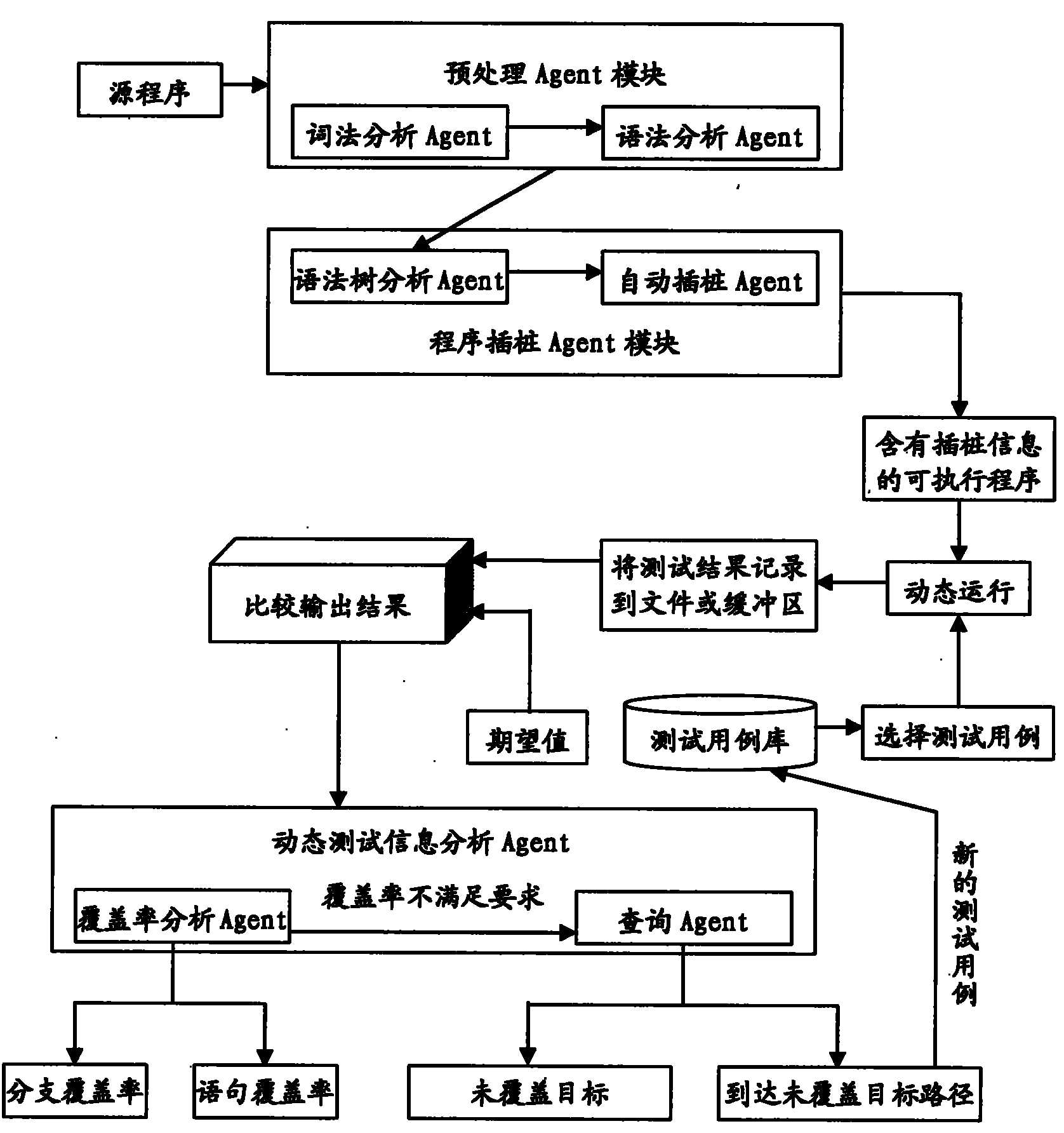

Embedded software intelligent testing method based on Agent

InactiveCN101833500AReduce interventionImprove automated testing efficiencySoftware testing/debuggingOperational systemInformation analysis

The invention relates to an embedded software intelligent testing method based on Agent, which is an improved software testing method using a Linux system as an embedded operation system core, mainly comprising three Agent modules: a pre-processing Agent module, a program instrumentation Agent module and a dynamic test information analysis Agent module. The pre-processing Agent module comprises a lexical analysis Agent and a grammar analysis Agent that are used for generating a grammar tree structure of a source program; the program instrumentation Agent module comprises a grammar tree analysis Agent and an automatic instrumentation Agent that are mainly used for analyzing the grammar tree, finding out the key point of the source program, and automatically inserting probe functions in the source program so as to acquire the dynamic information during the operation of the program; and the dynamic test information analysis Agent module comprises a cover ratio analysis Agent and an inquiry Agent that are mainly used for testing the sentence and the branch cover ratio of the source program, and automatically inquiring the relevant conditions of the uncovered target in the source program when the cover ratio cannot satisfy the requirements. The invention can be applied to different programs simply and conveniently, thereby greatly improving the efficiency of the software automation test with strong commonality.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Process for manufacturing leadless semiconductor packages including an electrical test in a matrix of a leadless leadframe

ActiveUS7125747B2Reduce test costsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductor packageSealant

A process for manufacturing a plurality of leadless semiconductor packages includes an electrically testing step to test encapsulated chips in a matrix of a leadless leadframe. Firstly, a leadless leadframe having at least a packaging matrix is provided. The packaging matrix defines a plurality of units and a plurality of cutting streets between the units. The leadless leadframe has a plurality of leads in the units and a plurality of connecting bars connecting the leads along the cutting streets. A plated metal layer is formed on the upper surfaces of the leads and the upper surfaces of the connecting bars. After die-attaching, wire-bonding connection, and encapsulation, the leadless leadframe is etched to remove the connecting bars, then two sawing steps are performed. During the first sawing step, the plated metal layer on the upper surface of the connecting bars is cut out to electrically isolate the leads. Therefore, a plurality of chips sealed by an encapsulant on the packaging matrix can be electrically tested by probing which is performed between the first sawing and the second sawing. Thereafter, the encapsulant is cut to form a plurality of individual package bodies of the leadless semiconductor packages during the second sawing.

Owner:ADVANCED SEMICON ENG INC

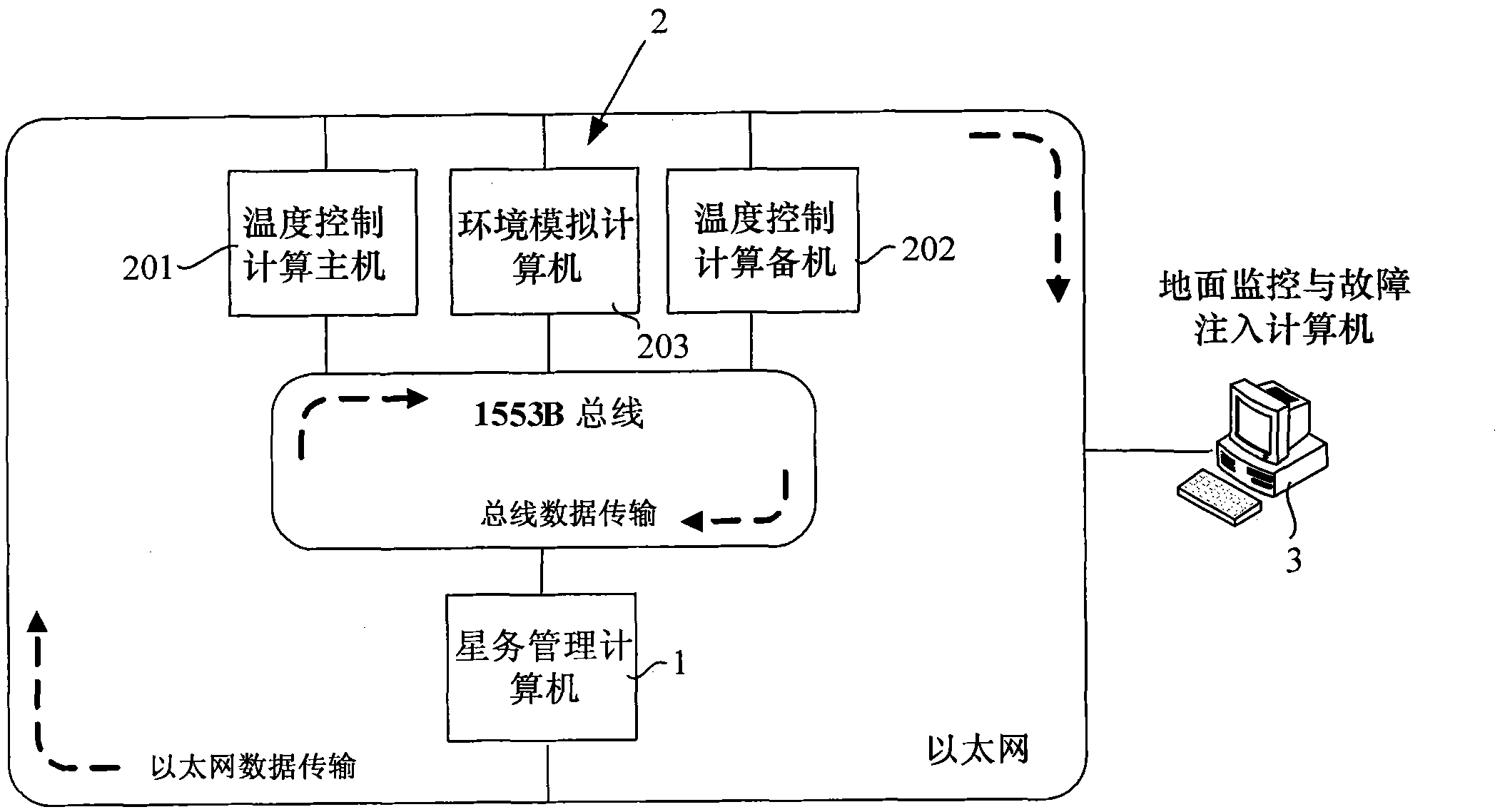

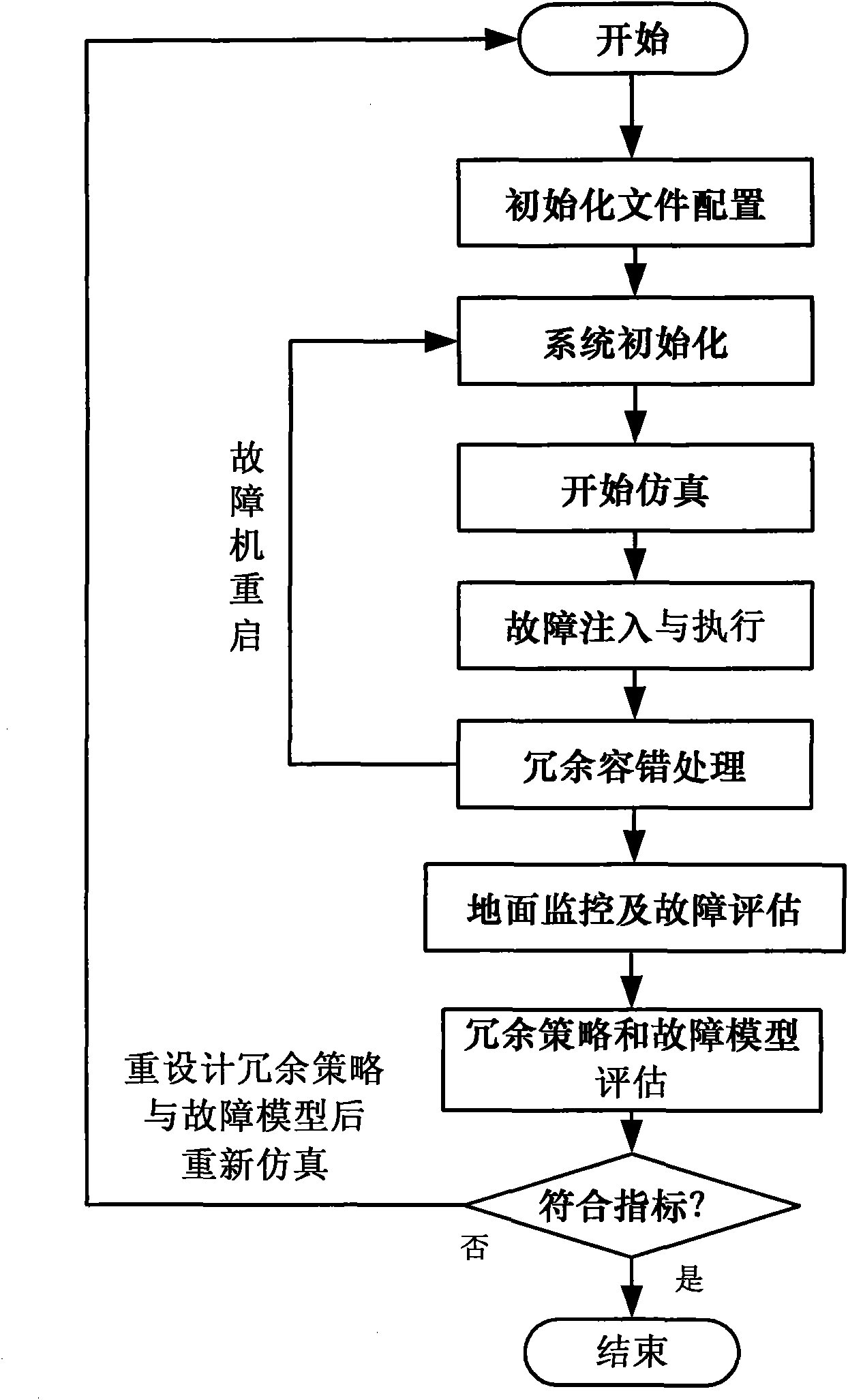

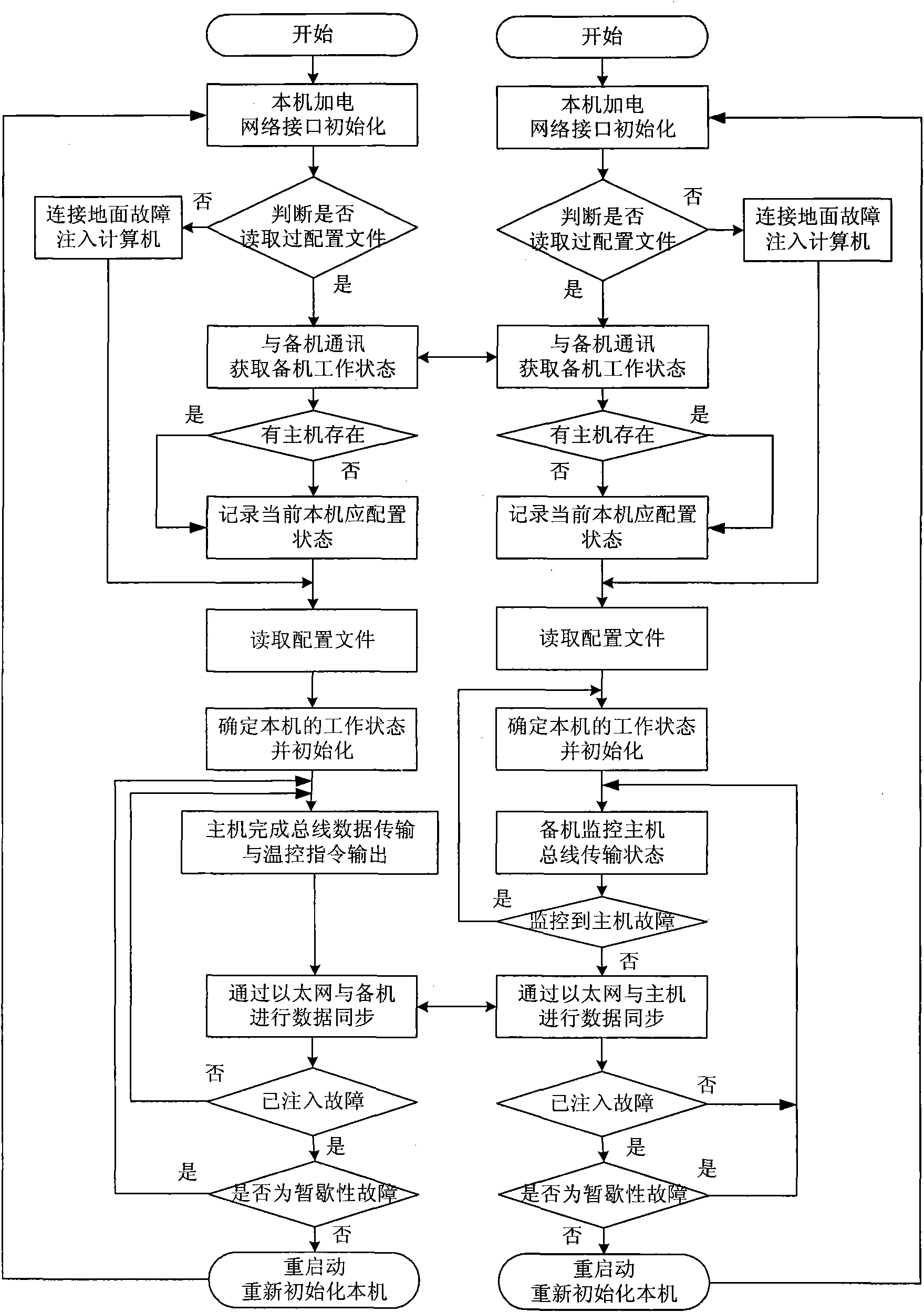

Embedded satellite-borne fault-tolerant temperature control system and verification method thereof

InactiveCN101819445AIn line with the development trendWith real development prospectsTemperatue controlError detection/correctionFault toleranceTemperature control

The invention discloses an embedded satellite-borne fault-tolerant temperature control system and a verification method thereof. The system comprises a satellite management computer, an on-satellite temperature control system and a ground monitoring and fault injection computer; the on-satellite temperature control system comprises a temperature control calculation host machine, a temperature control calculation standby machine and an environmental simulation computer; and the temperature control calculation host machine and the temperature control calculation standby machine are temperature control computers. The verification method comprises the following steps of: 1, initializing a file allocation; 2, initializing the system; 3, beginning simulation; 4, injecting and executing a fault; 5, processing redundant fault tolerance; 6, monitoring the ground and evaluating the fault; and 7, evaluating a fault model and a redundancy strategy of the temperature control system. The fault injection and the verification process of the whole running stage of the real satellite-borne temperature control system are completely realized; and the method is simple, convenient and reliable, and greatly reduces the test time and expense for the practical system.

Owner:BEIHANG UNIV

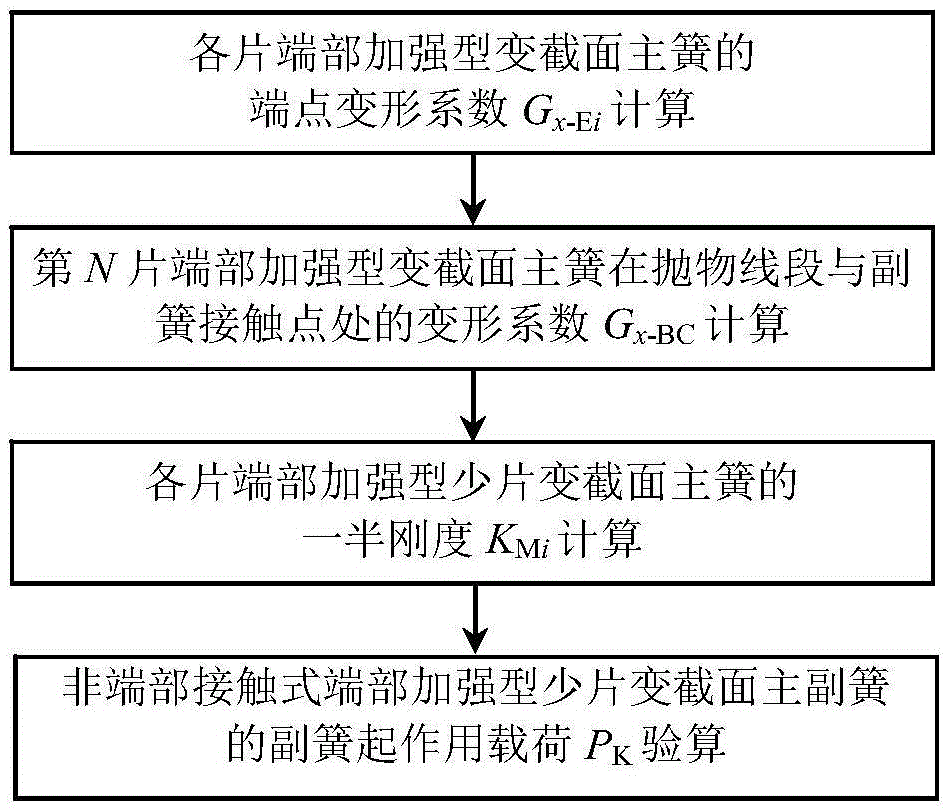

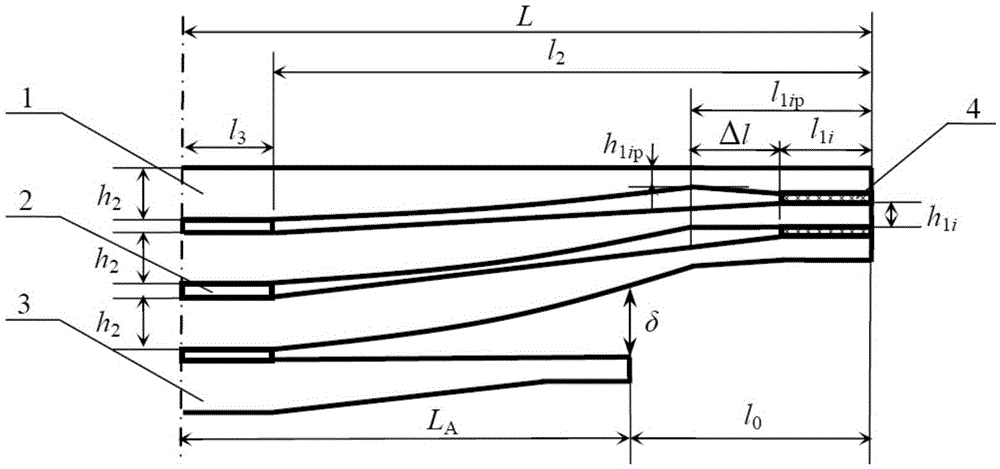

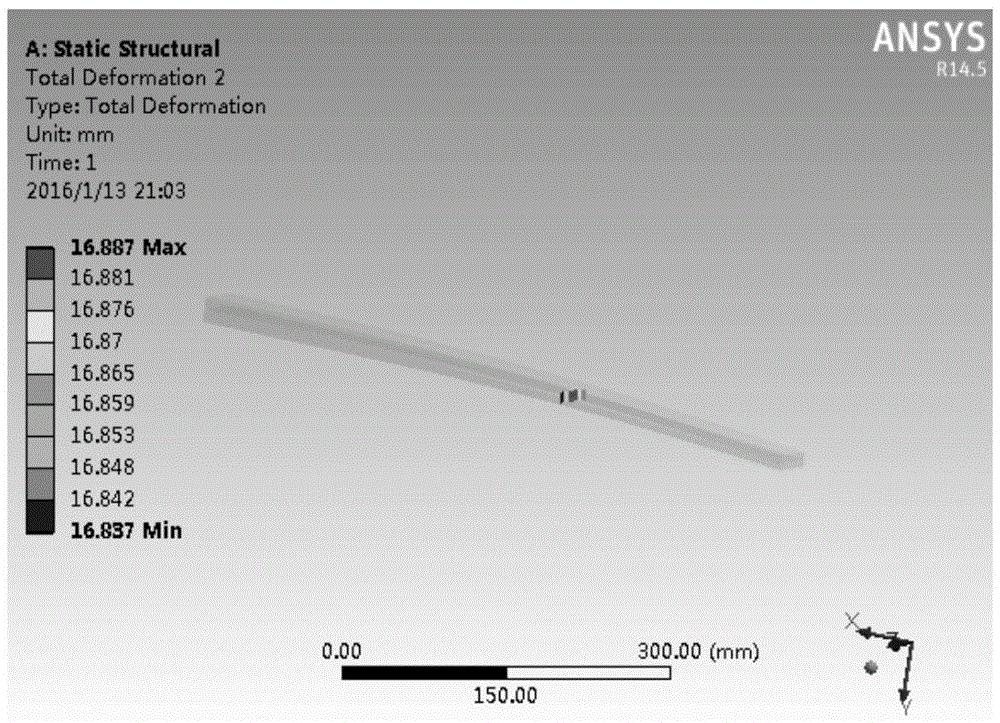

Auxiliary spring work load checking method of non end part contact type end part strengthened few-leaf main and auxiliary springs

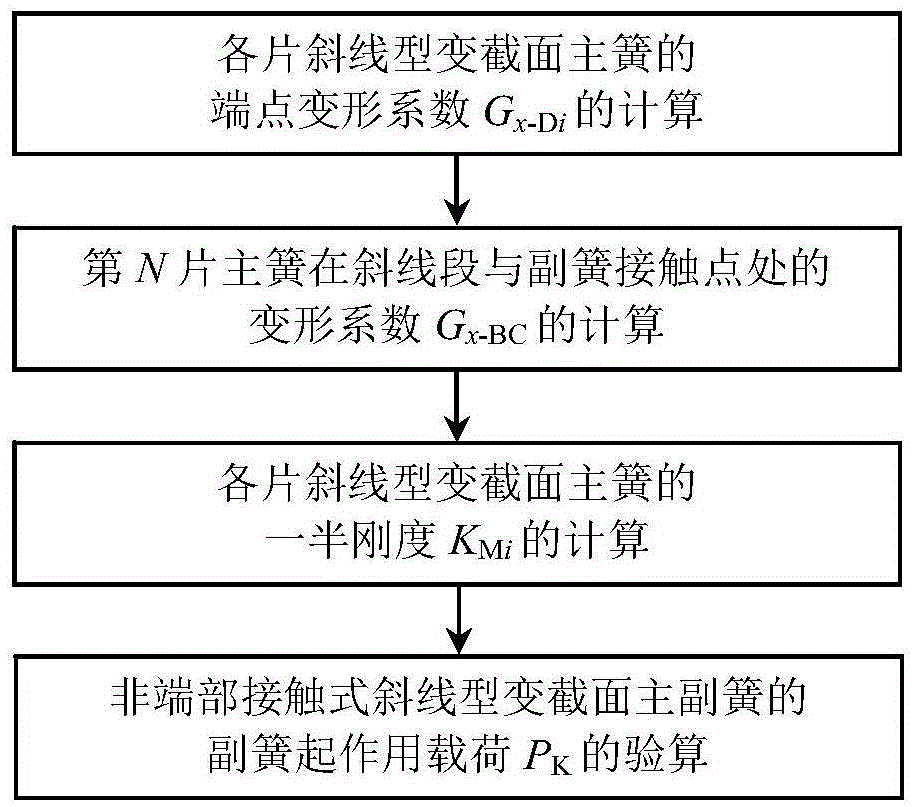

ActiveCN105590009AImprove the design levelThe checking method is reliableDesign optimisation/simulationSpecial data processing applicationsContact typeEngineering

The invention relates to an auxiliary spring work load checking method of a non end part contact type end part strengthened few-leaf main and auxiliary springs belonging to the suspension steel plate spring technical field. According to the method of the invention, firstly, according to the structure size and the elastic modulus of each end part strengthened few-leaf cross-section variable main spring, the end point deformation coefficient Gx-Ei and the half rigidity KMi of each main spring, and the deformation coefficient Gx-BC at the contact point of the Nth main spring and an auxiliary spring on a parabolic segment can be determined; then, according to the half rigidity KMi of each main spring, the thickness h2 of a root straight section, the Gx-BC of the Nth main spring and a main and auxiliary spring interval Delta design value, the auxiliary spring work load of the non end part contact type end part strengthened few-leaf cross-section variable main and auxiliary springs is checked. Through the emulation proof, in adoption of the method of the invention, the accurate and reliable auxiliary spring work load checking value can be obtained; therefore, the design levels and performances of the few-leaf cross-section variable main and auxiliary springs and the smoothness of a vehicle are improved; moreover, the design and test cost is saved; and the product development speed is accelerated.

Owner:SHANDONG AUTOMOBILE SPRING FACTORY ZIBO CO LTD

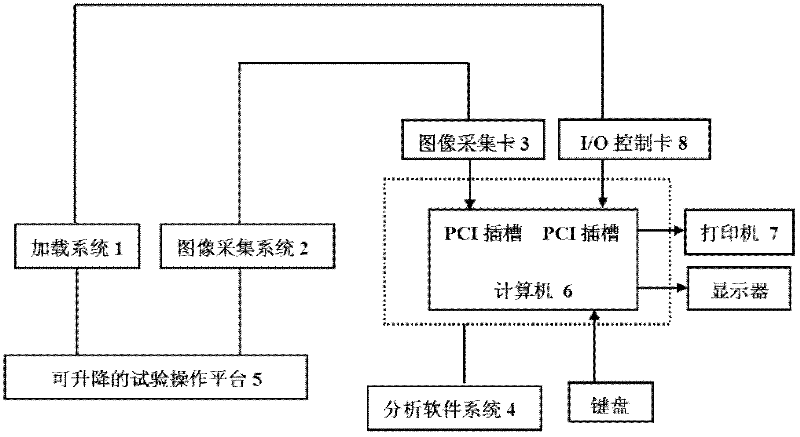

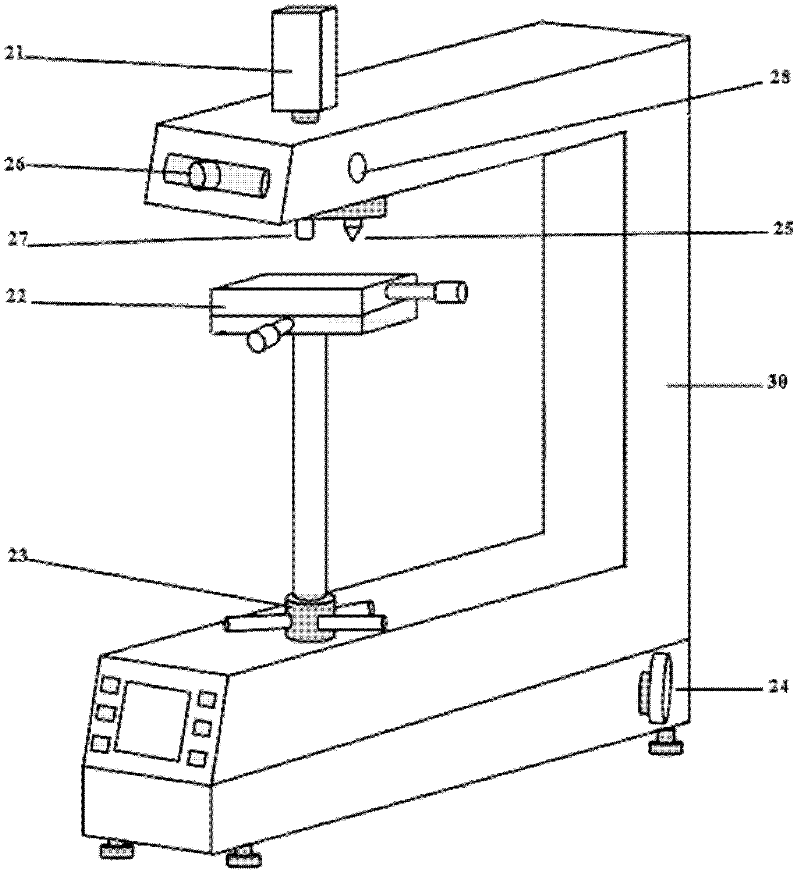

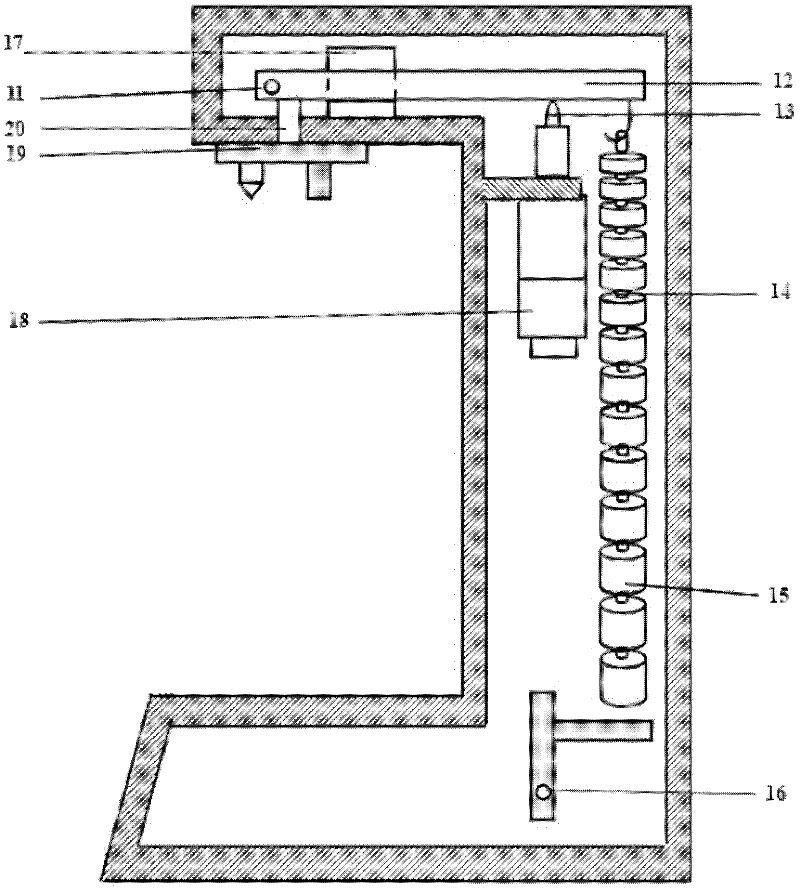

Device for testing hardness, fracture toughness and residual stress of brittle material with indentation method

ActiveCN102393341AAutomate analysisLower acquisition costsInvestigating material hardnessElectric machineryFilm material

The invention discloses a device for testing the hardness, fracture toughness and residual stress of a brittle material with an indentation method, belonging to the technical field of material property representation. The device comprises a frame and an image acquiring system, wherein the frame is provided with an eye lens, a height-adjustable testing operation platform and an adjusting rotating wheel; a loading system is arranged in the frame, and comprises a fixing support base, a lever, a mandrel, a hanging rod, a middle main shaft and a second motor; and a first motor and the second motor of the loading system are connected with a computer through an I / O (Input / Output) control card. In the invention, the conventional digital image low-load Vickers hardness meter is improved, so that the micro-hardness of a material can be directly tested, and the fracture toughness and residual stress of an interface system of the brittle material and a brittle coating film material can be directly tested; and the device can be widely applied to departments such as industrial enterprises, universities, academies and the like for rapidly detecting relevant indexes.

Owner:XIANGTAN UNIV

Method for designing few-leaf oblique line type variable-section main springs in gaps between oblique line segments and auxiliary spring

ActiveCN105550487AImprove the design levelQuality improvementGeometric CADDesign optimisation/simulationLine segmentOblique line

The invention relates to a method for designing few-leaf oblique line type variable-section main springs in the gaps between oblique line segments and an auxiliary spring, and belongs to the technical field of suspension steel plate springs. According to the structural sizes and the elasticity moduli of the oblique line type variable-section main springs, the endpoint deformation coefficient Gx-Di of each main spring and the deformation coefficient Gx-BC of the Nth main spring at the contact point of the corresponding oblique line segment and the auxiliary spring are determined first; then, according to the required auxiliary spring acting load design value and the endpoint deformation coefficient Gx-Di of each main spring, endpoint force FN of the Nth main spring is obtained; then, according to the thickness h of the root straight section of the Nth main spring, the Gx-BC and the FN, main spring and auxiliary spring gaps between the oblique line segment of the main springs and the contact point of the auxiliary spring are designed. Through simulation verification, it can be known that the main and auxiliary spring gap design value meeting the auxiliary spring acting load requirement can be obtained by means of the method, and the product design level, product performance and vehicle smoothness are improved. Meanwhile, design and testing cost is reduced, and product development speed is increased.

Owner:JIANGSU HAIHONG MACHINERY MFG

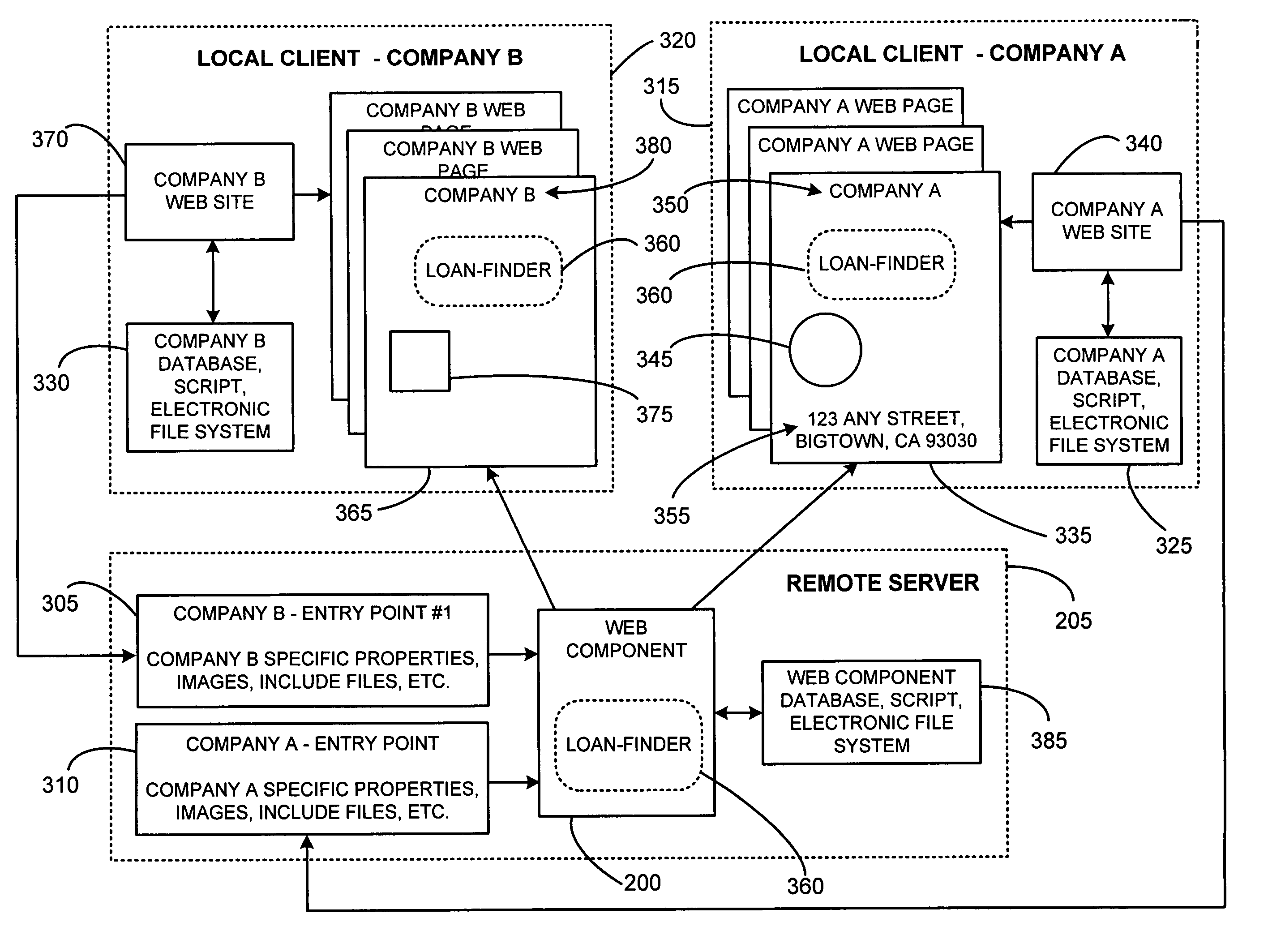

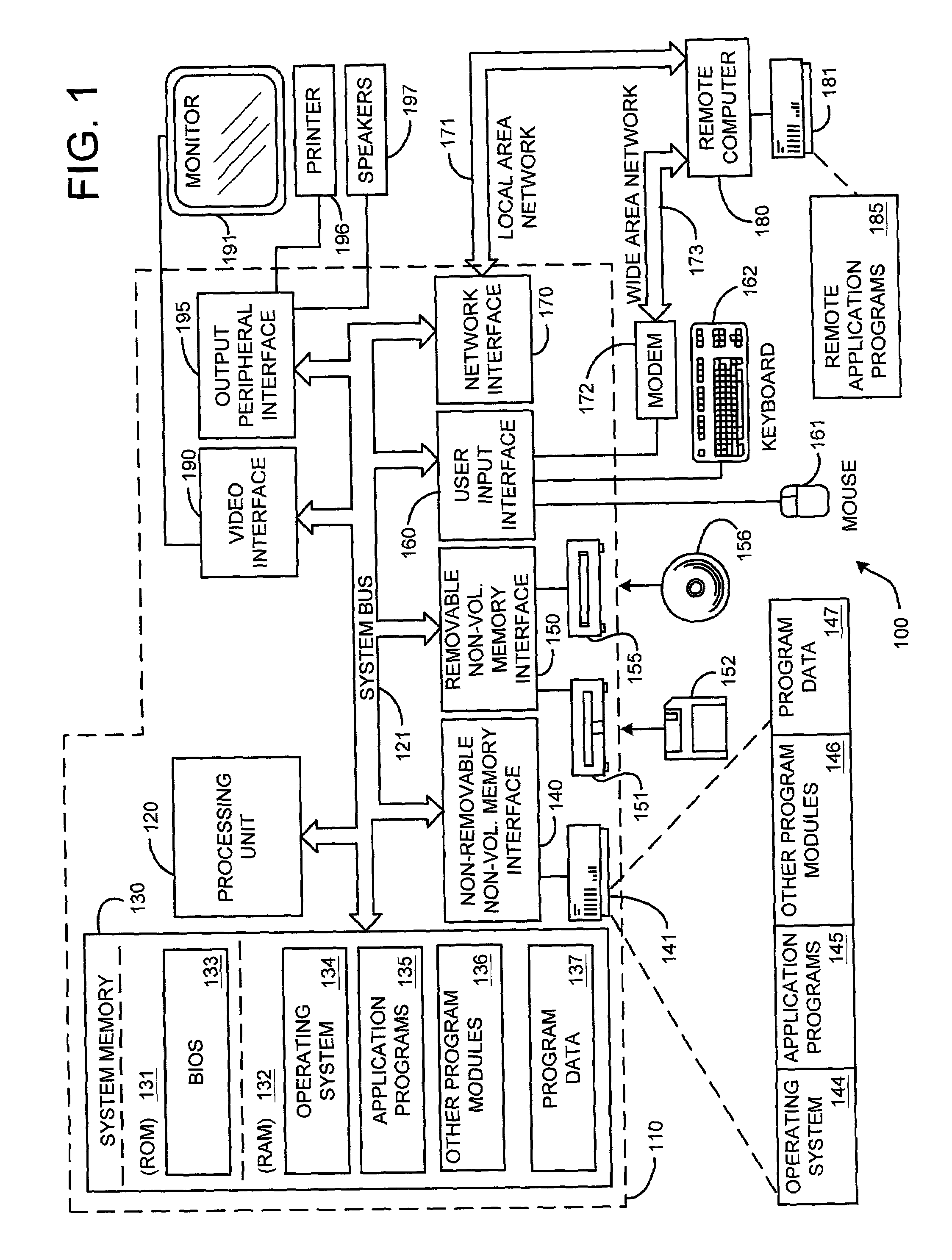

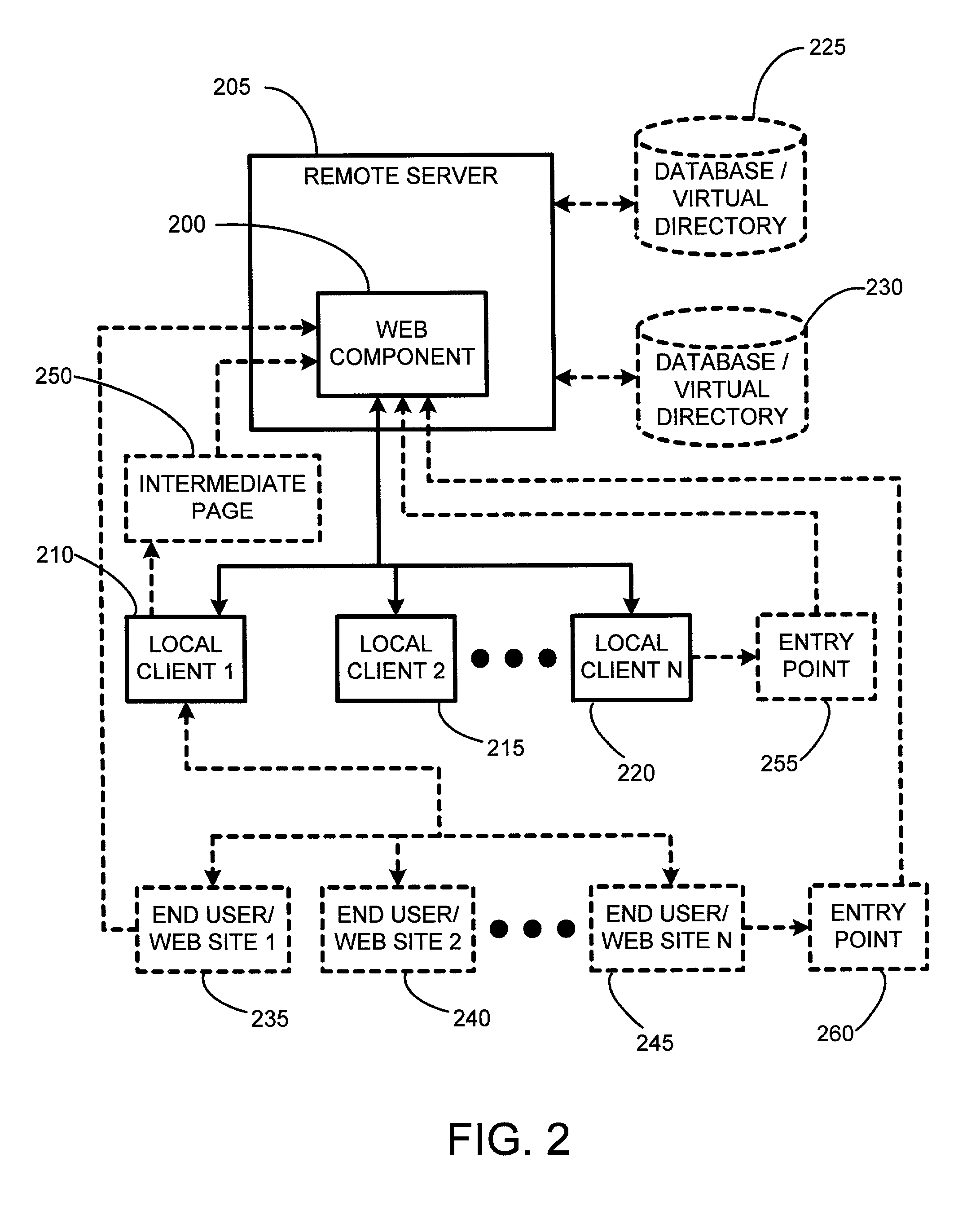

System and method for using dynamic web components to remotely control the security state of web pages

ActiveUS7000107B2Reduce test costsFaster time-to-marketDigital data processing detailsUser identity/authority verificationAutomatic controlWeb browser

The present invention involves a new system and process for automatically controlling whether a displayed web page and associated frames displayed within a window of a web browser are secure or non-secure. For example, whether the displayed web page and associated frames are provided via a secure socket layer (SSL), i.e. a web page from an HTTPS address (secure), or simply via an HTTP address (non-secure), respectively. Specifically, the present invention uses a dynamic “Web Component” to remotely control web page security states. Further, the Web Component according to the present invention uses the same script and HTML for all implementations or instantiations of the Web Component, regardless of which, or how many, unique local clients make use of the Web Component. This code reuse is accomplished by using entry web pages, or “entry points,” as described in further detail below, to set the value of function properties or parameters of the Web Component for dynamically and controlling the security state of a web page having at least two frames. The script and / or HTML source code of the Web Component pages does not change based on each new implementation or instantiation. Consequently, little setup work is required for each implementation, and only a basic verification test pass is needed for each unique automatically customized Internet web page.

Owner:MICROSOFT TECH LICENSING LLC

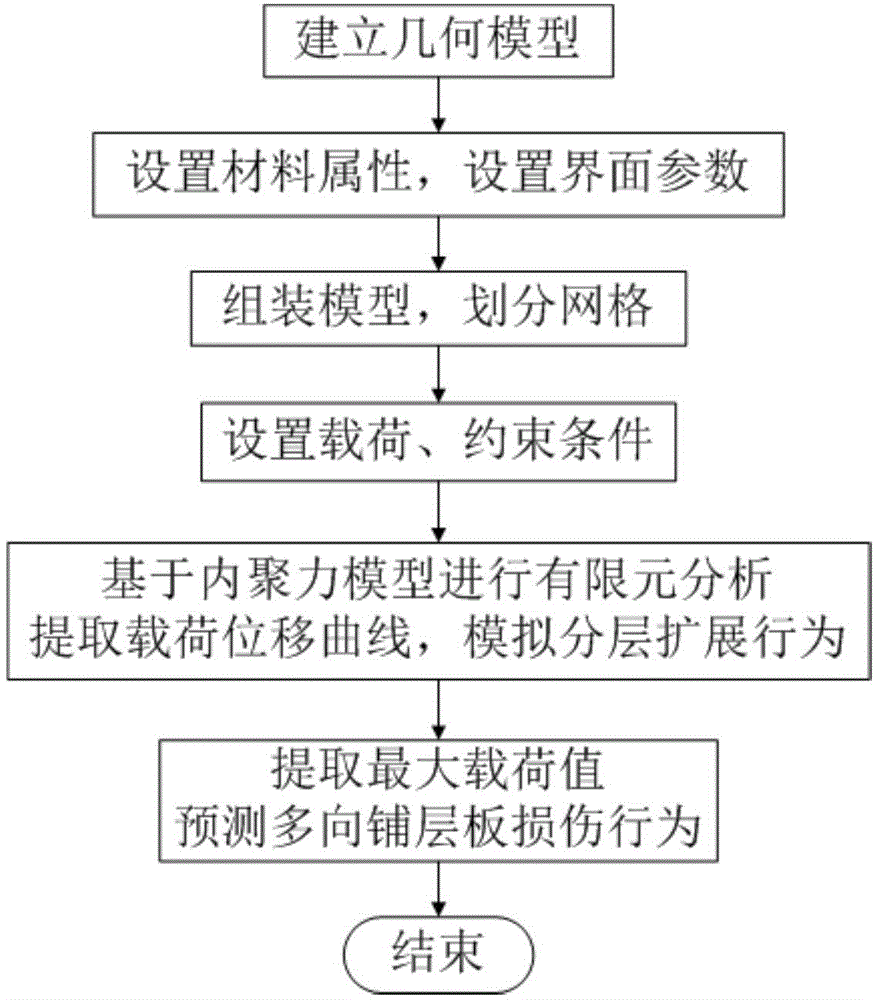

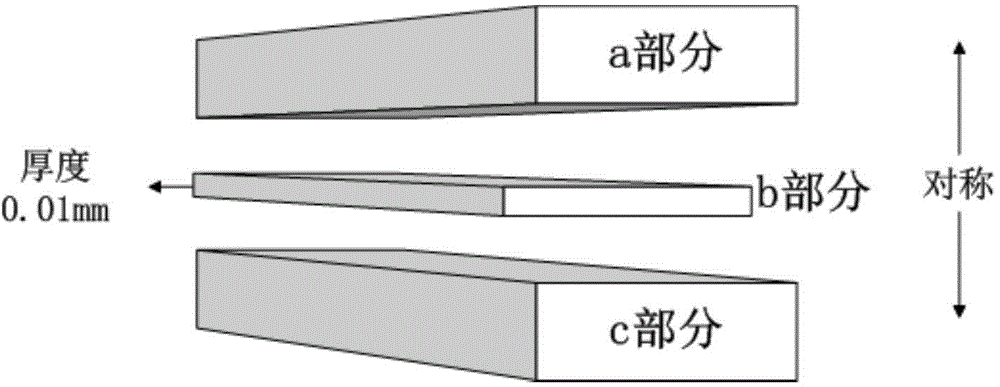

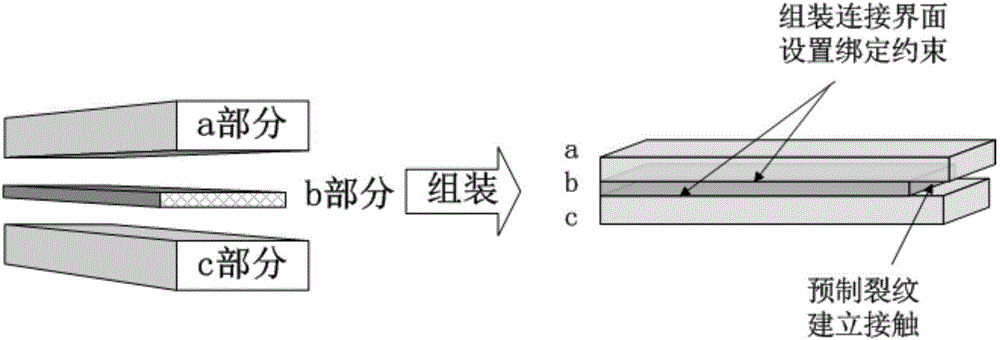

Delamination propagation behavior simulation method of composite material multidirectional laminated plate on basis of cohesion model

InactiveCN103605865AShorten the development cycleReduce test costsSpecial data processing applicationsEngineeringMaterial structure

The invention relates to a delamination propagation behavior simulation method of a composite material multidirectional laminated plate on the basis of a cohesion model. The method includes the following steps that (1) a geometric model is built according to structural parameters of a composite material multidirectional laminated plate test piece, (2) key parameters capable of reflecting interfacial behaviors are calculated, and material attributes are respectively set, (3) meshing is carried out on the geometric model of the composite material multidirectional laminated plate test piece, a module is assembled, and a three-dimensional finite element model is built, (4) a load and boundary conditions of the finite element model are determined according to practical situations and the load state of a composite material structure, (5) the finite element model based on the cohesion model is calculated and analyzed, a load displacement curve of a loading point is extracted, delamination propagation behaviors of the composite material multidirectional laminated plate are simulated to obtain the largest load value of the load displacement curve, and damage behaviors of the multidirectional laminated plate are predicted.

Owner:BEIHANG UNIV

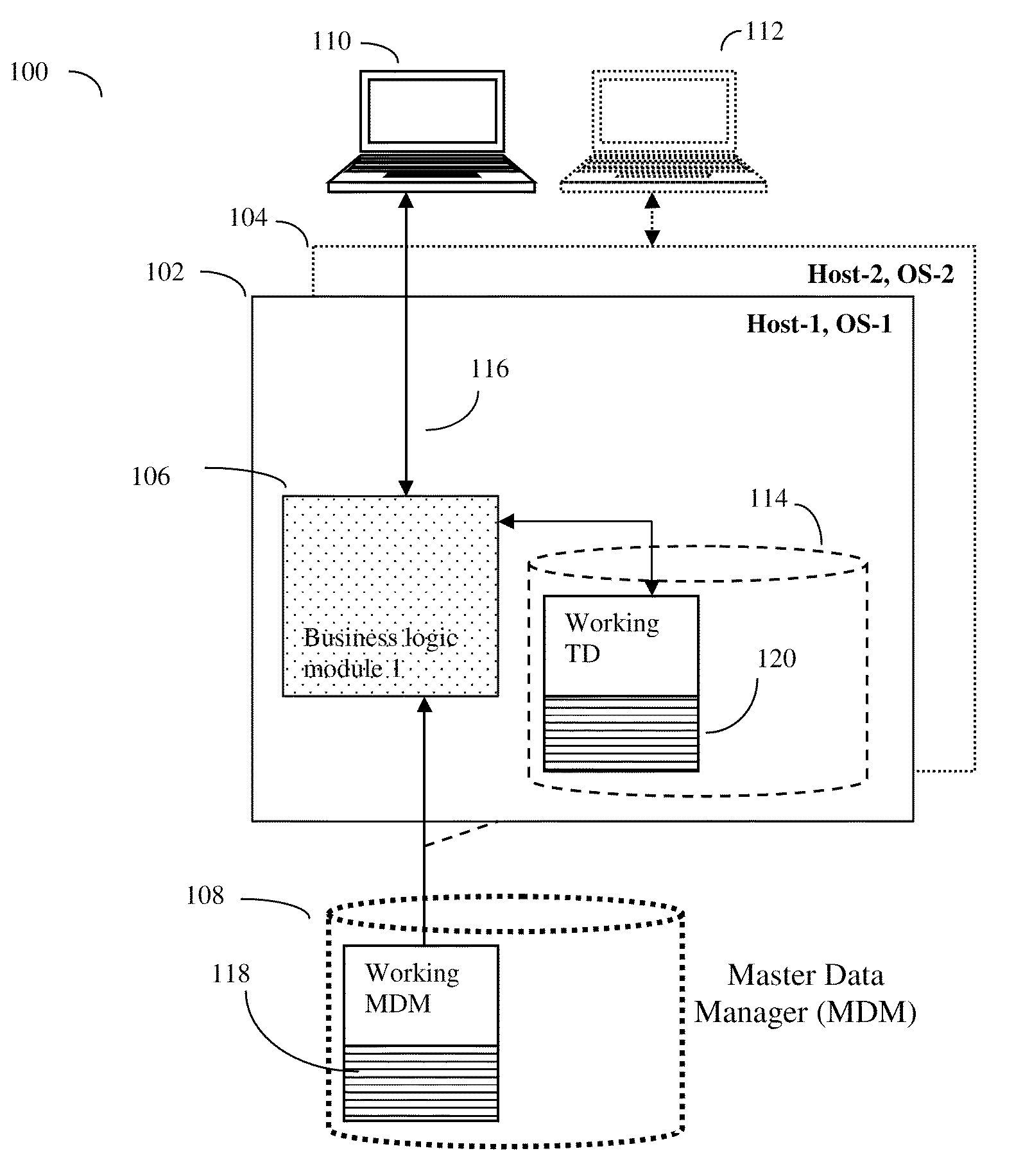

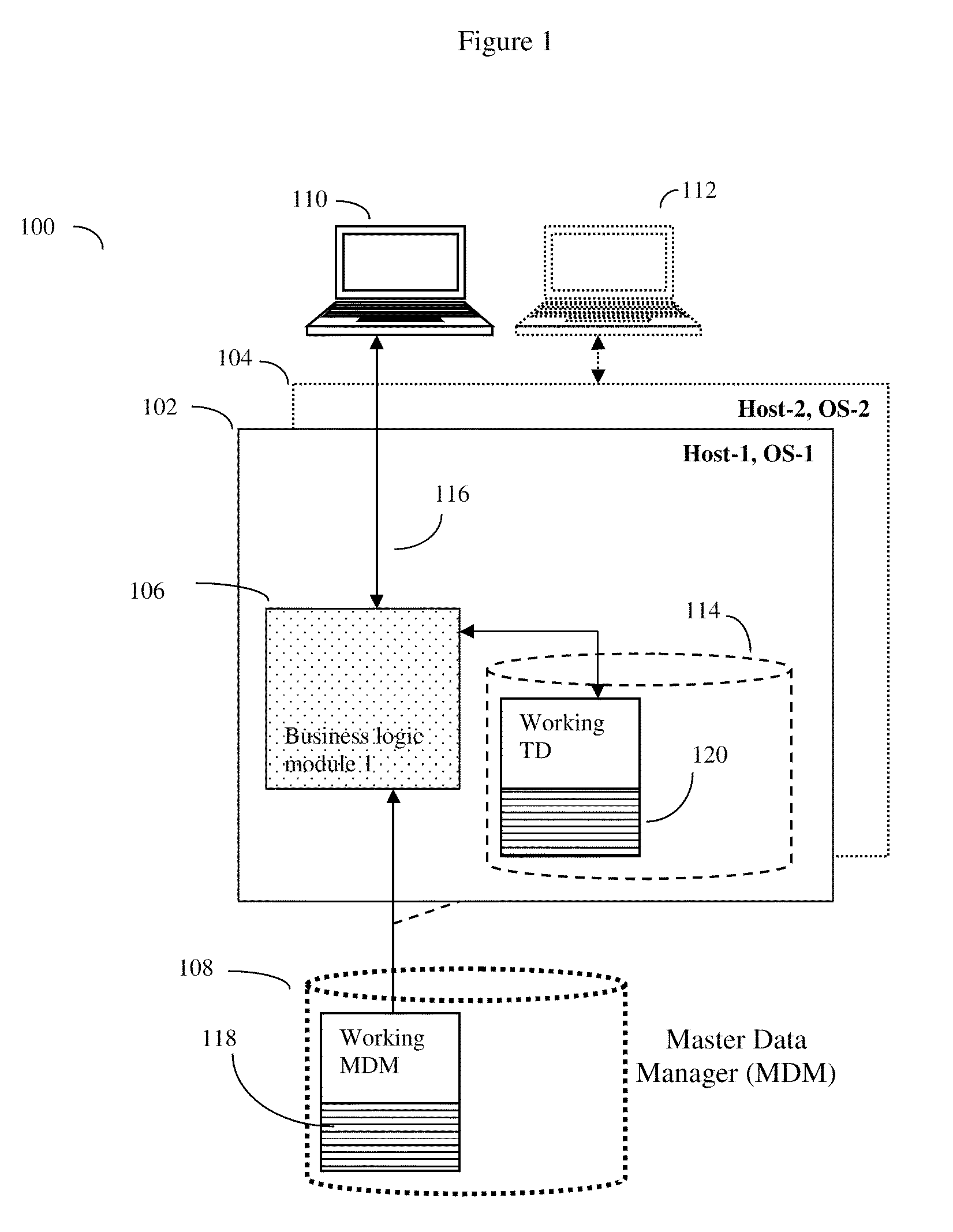

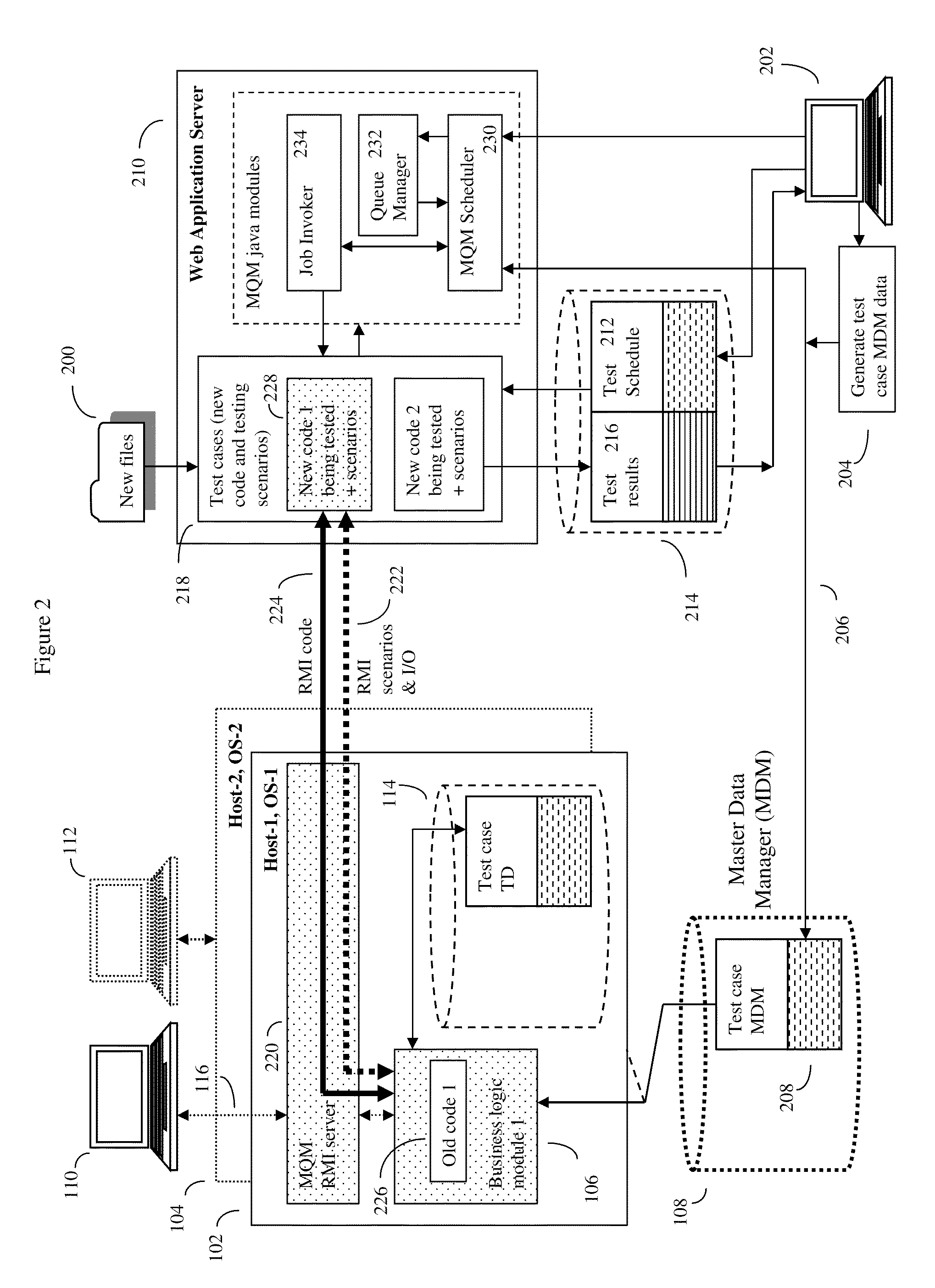

System to plan, execute, store and query automation tests

ActiveUS20100332535A1Solve low usageReduce testing costsDigital data processing detailsError detection/correctionOperational systemProgram planning

An automation testing platform that will enable simultaneous testing of new product code over variety of Operating Systems by calling remote machines. In one embodiment, the system is an SAP master data management based system such as NetWeaver, and the testing platform places important testing information onto the master data database itself. The platform then calls and controls the remote machines using distributed computing methodology such as the Java RMI protocol. The system provides the ability to run automated tests according to different technologies, OS, platforms and codelines, and allows for an automatic test portfolio to be managed from a single test catalog. The results can be represented by a variety of configurable user interface reports. The system has an ability to use legacy automation code, and can report on the quality, reliability and stability of the new product code along various configurable key performance indicators.

Owner:SAP AG

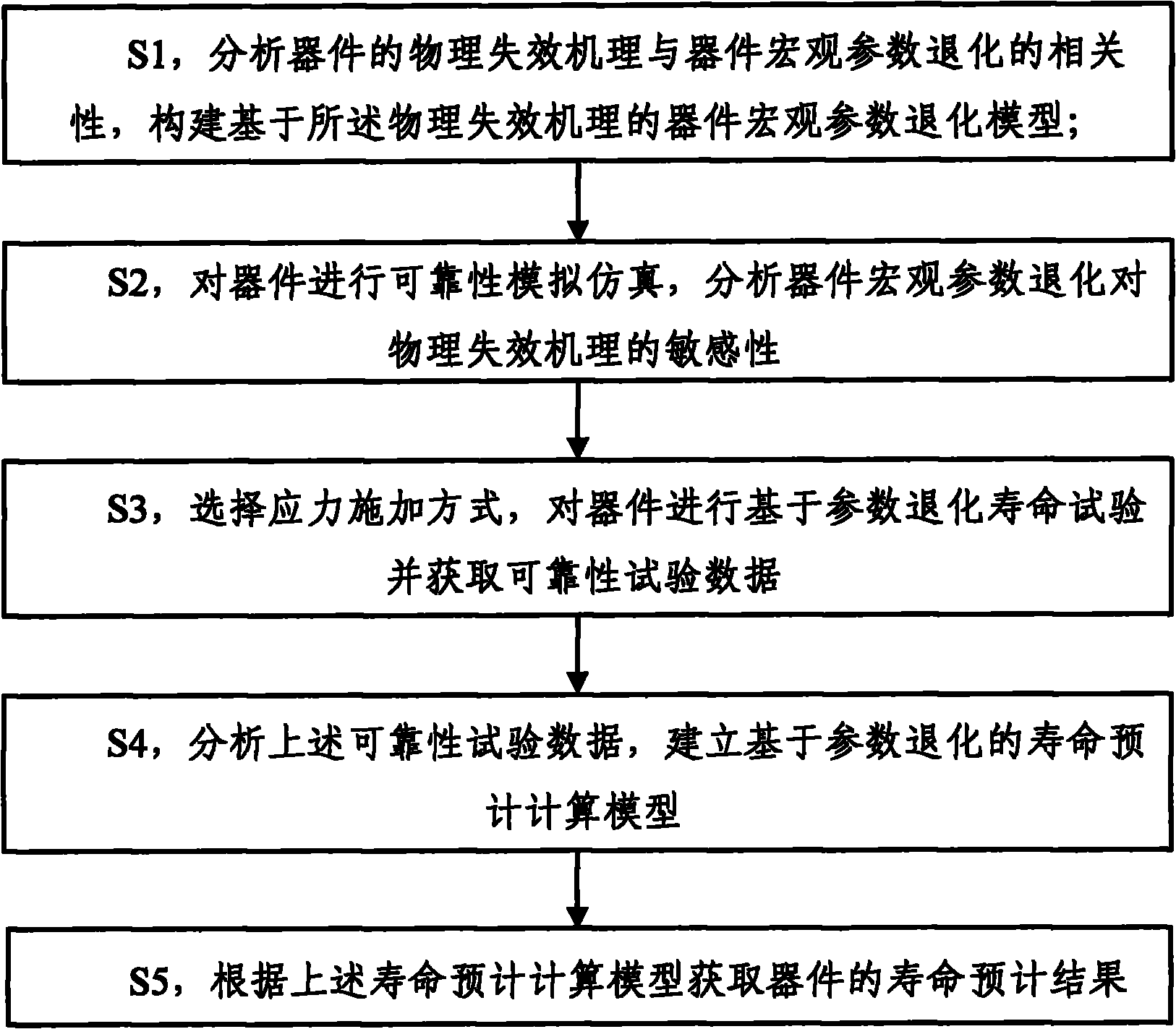

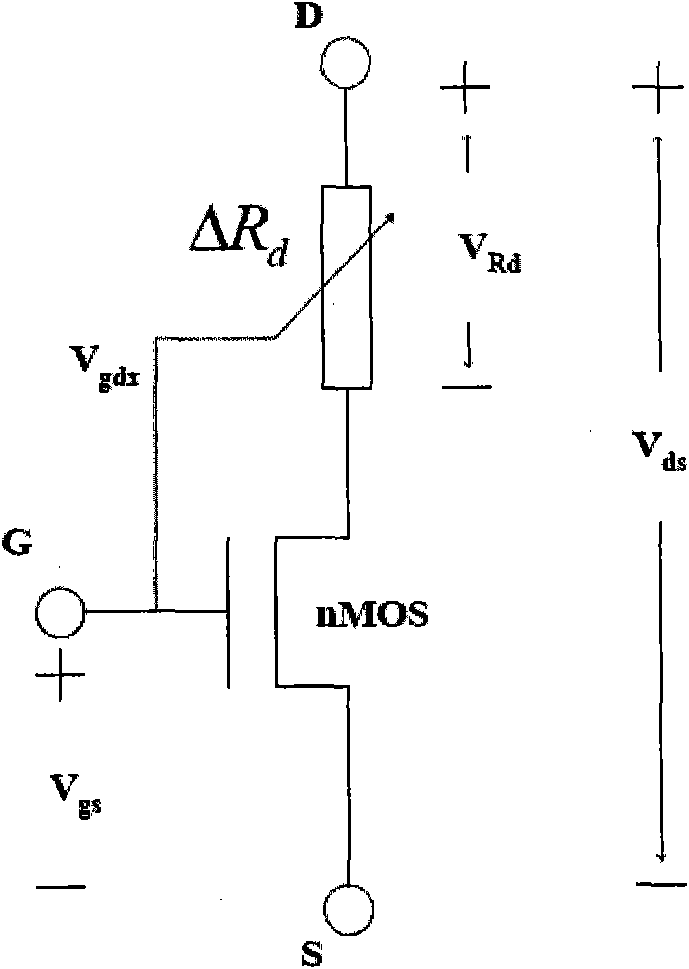

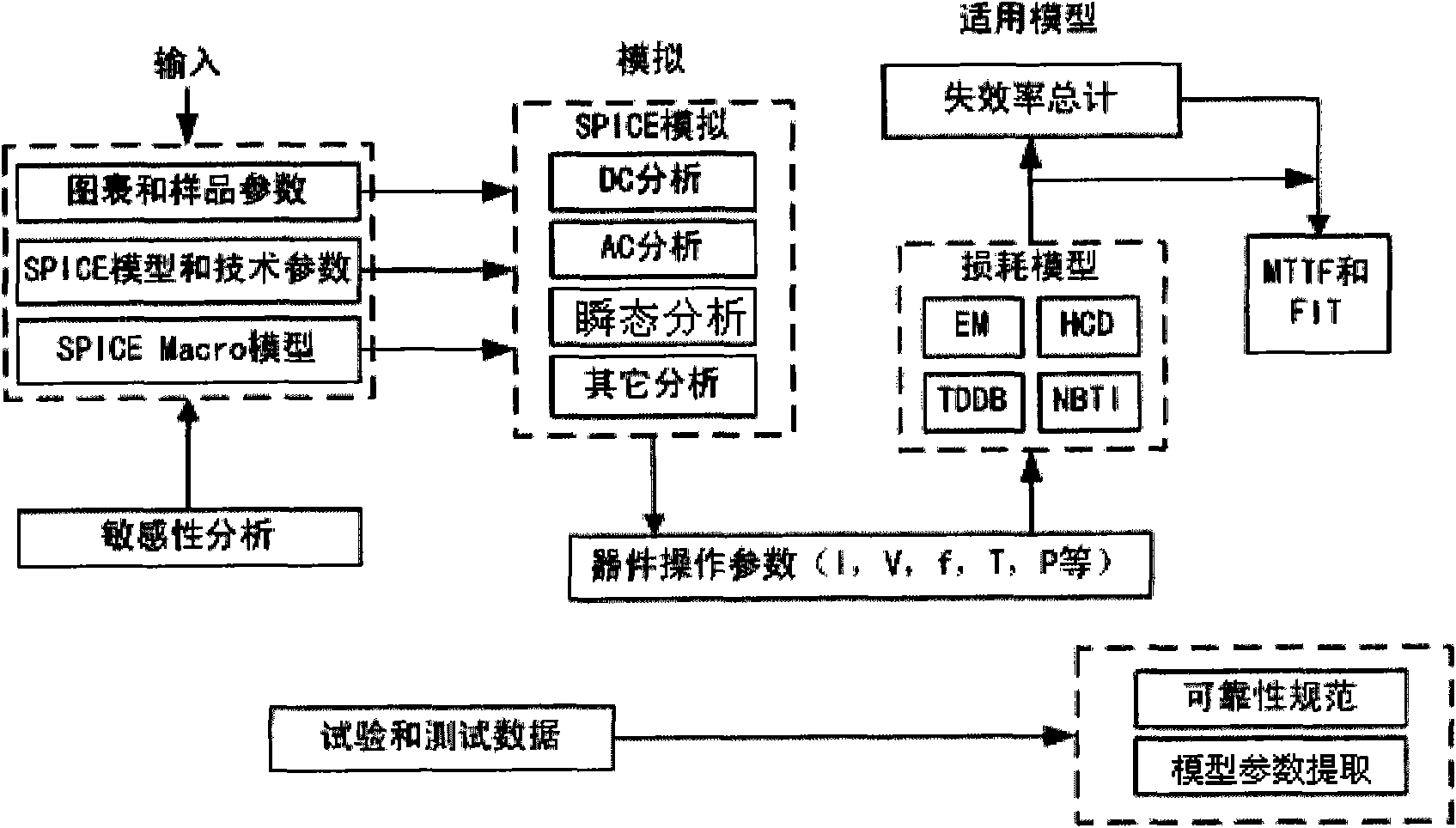

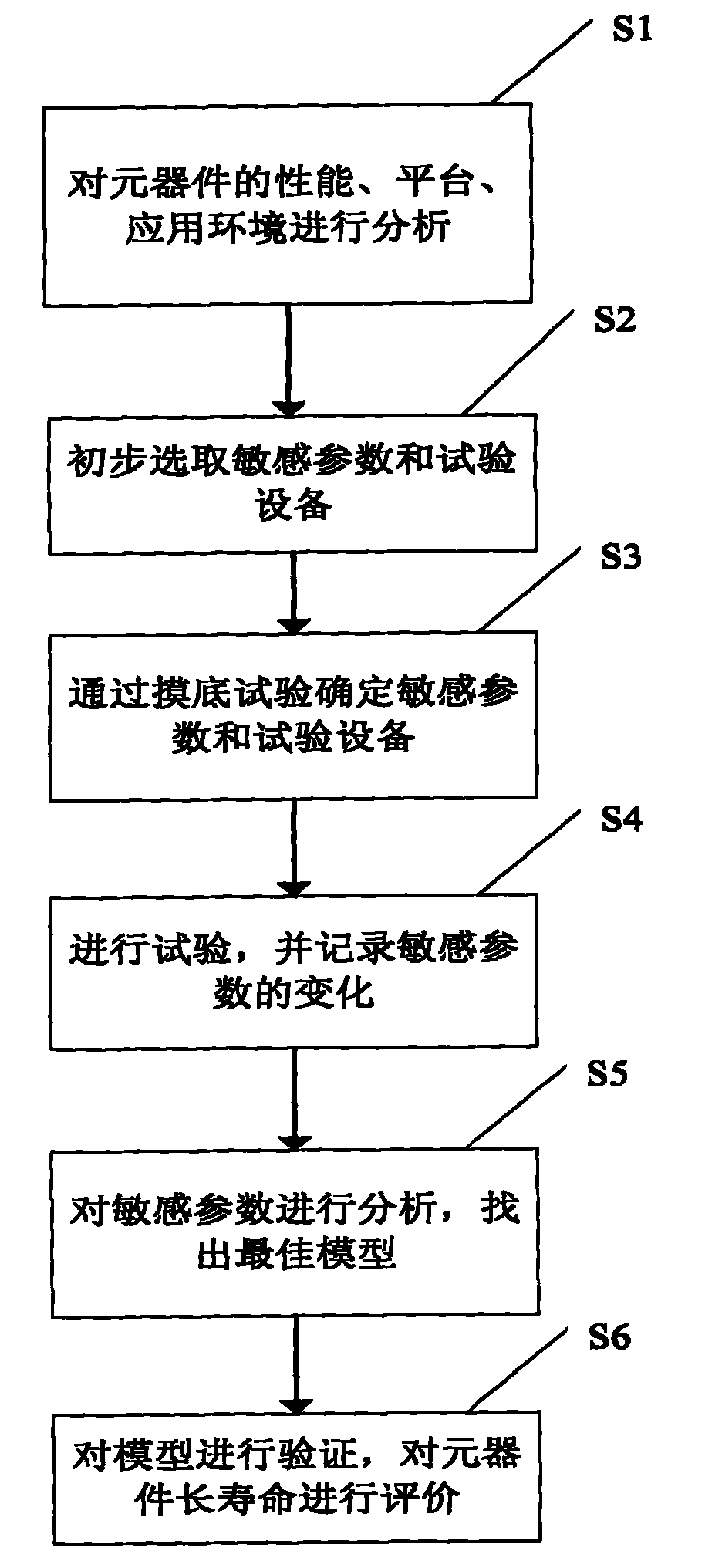

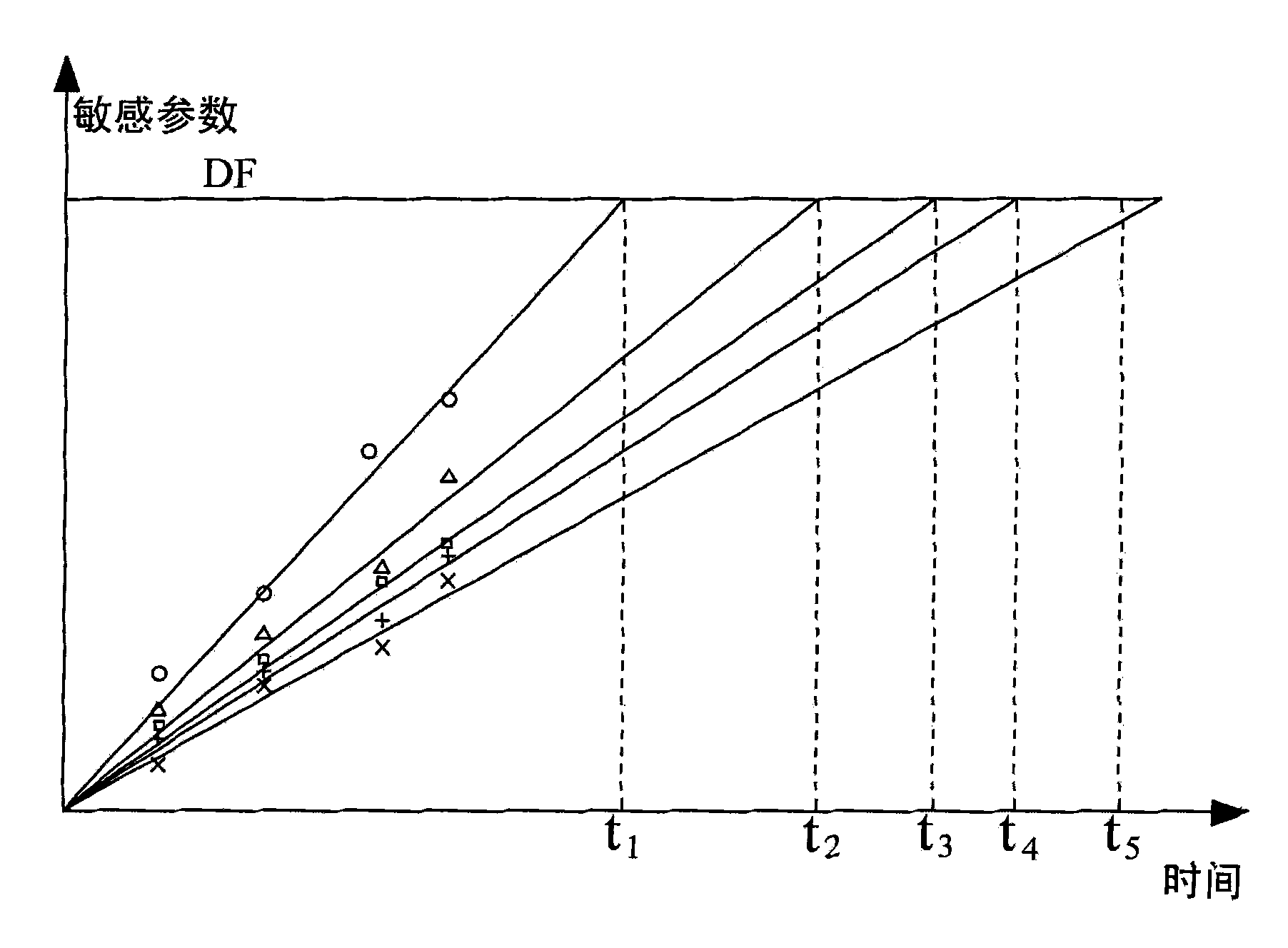

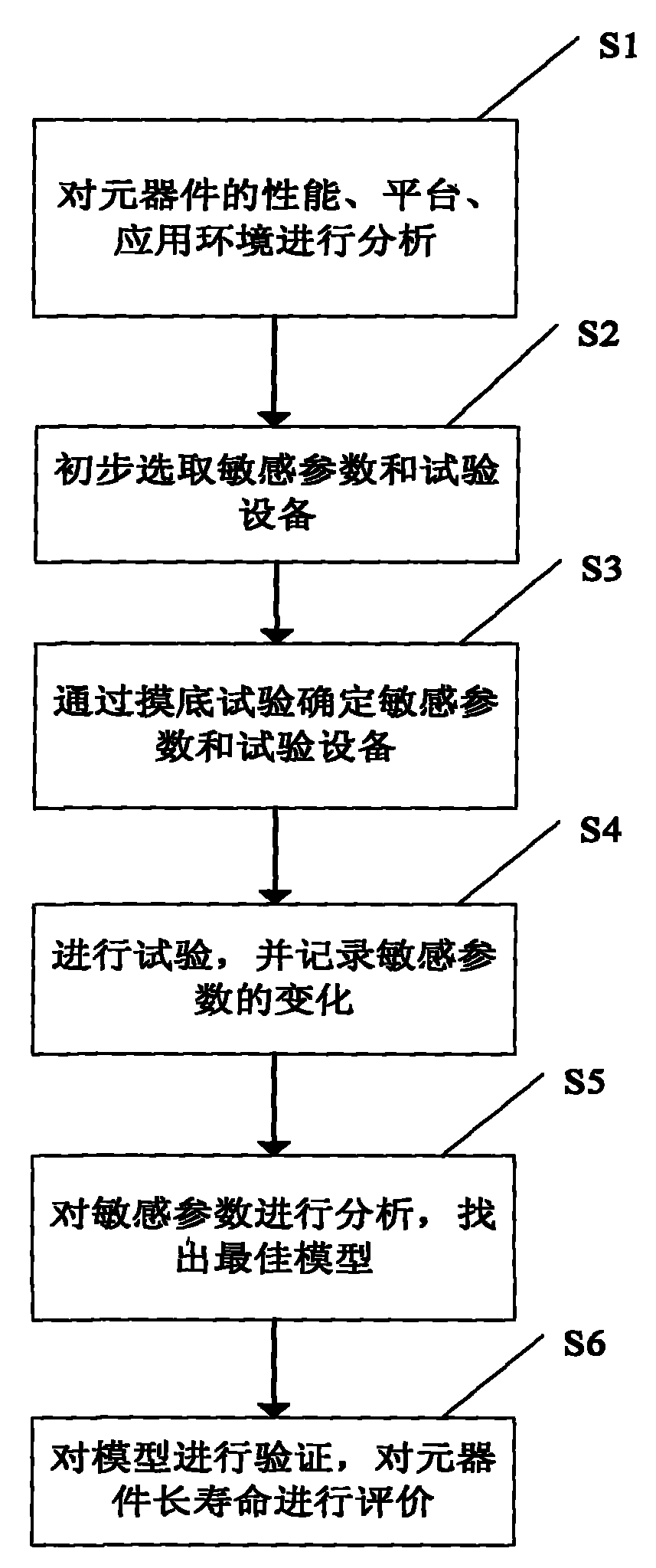

Method and system for estimating service life of MOS (Metal Oxide Semiconductor) device

InactiveCN102567560AExtend your lifeResolve accuracySpecial data processing applicationsTest sampleComputational model

The invention discloses a method for estimating service life of an MOS (Metal Oxide Semiconductor) device. The method comprises the steps of: analyzing the relevance of a physical failure mechanism and a device macroparameter degradation, constructing a device macroparameter degradation model based on the physical failure mechanism; carrying out reliability analog simulation on a device, analyzing the sensitivity of the device macroparameter degradation to the physical failure mechanism; selecting a stress applying mode, carrying out a parameter degradation service life-based test on the device and obtaining reliability test data; analyzing the reliability test data, establishing a parameter degradation-based service life estimating computing model; and obtaining a service life estimating result of the device according to the service life estimating computing model. By using the method, the problems of accuracy and maneuverability of the traditional device service life predicting method under the novel technical conditions are solved, the quantity of test samples is reduced, the testing cost is lowered, and the accuracy of predicting the testing result is improved.

Owner:BEIJING SHENGTAOPING TEST ENG TECH RES INST

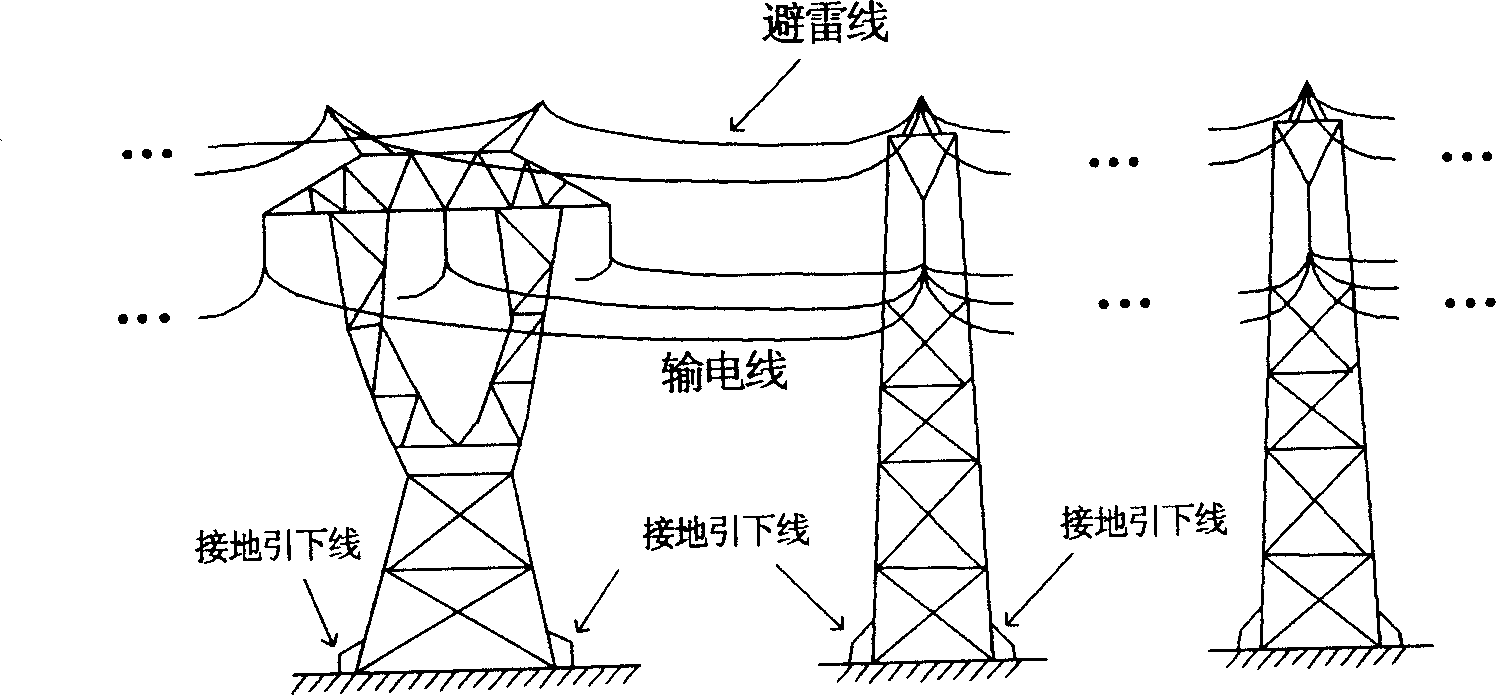

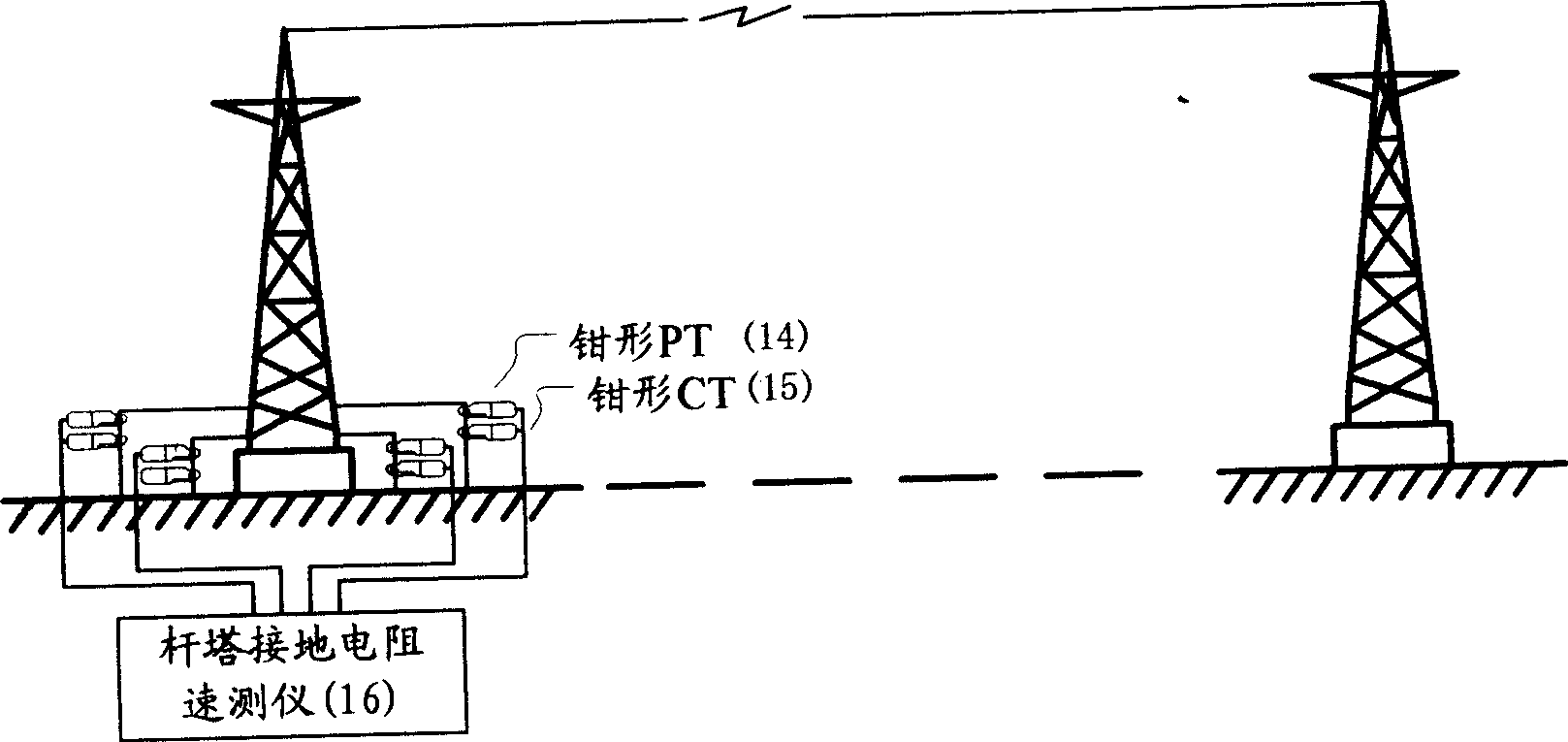

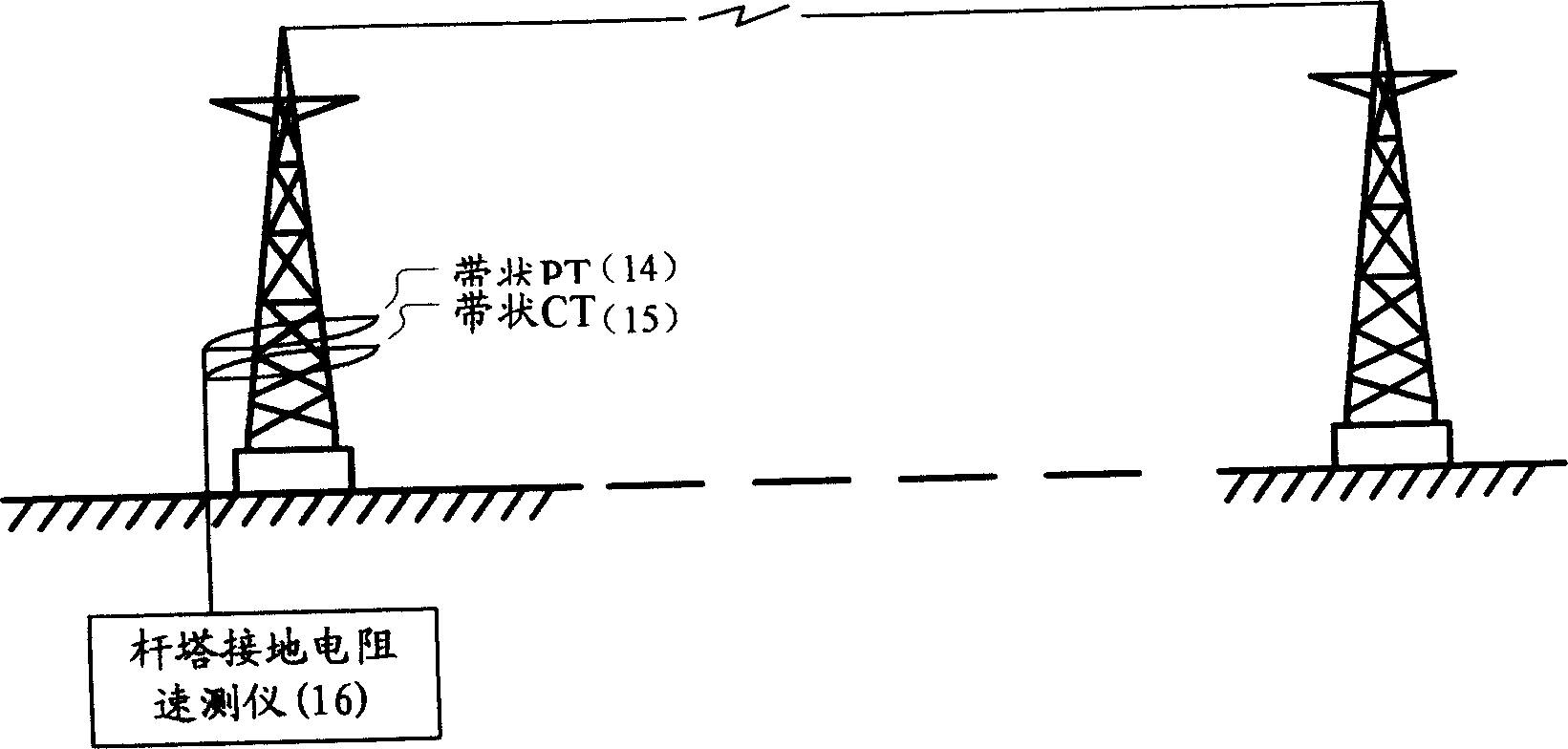

Pole tower earthing resistance quick testing method without unfastening wire and device

ActiveCN1828313AImprove measurement efficiencyHigh intelligenceEarth resistance measurementsElectrical resistance and conductanceVoltage drop

Wherein, with embed-meter method, applying split-core current transformer (PT) and split-core current transformer (CT) with same wire number as the tower ground wire to clamp all tower ground wires; or applying strip-shape PT and CT to enclose whole tower; filtering and analyzing the measured data to obtain the real and imaginary parts of fundamental wave component of voltage and current signals; calculating with special voltage-drop algorithm to obtain the target resistance. This invention improves efficiency, and reduces cost.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST

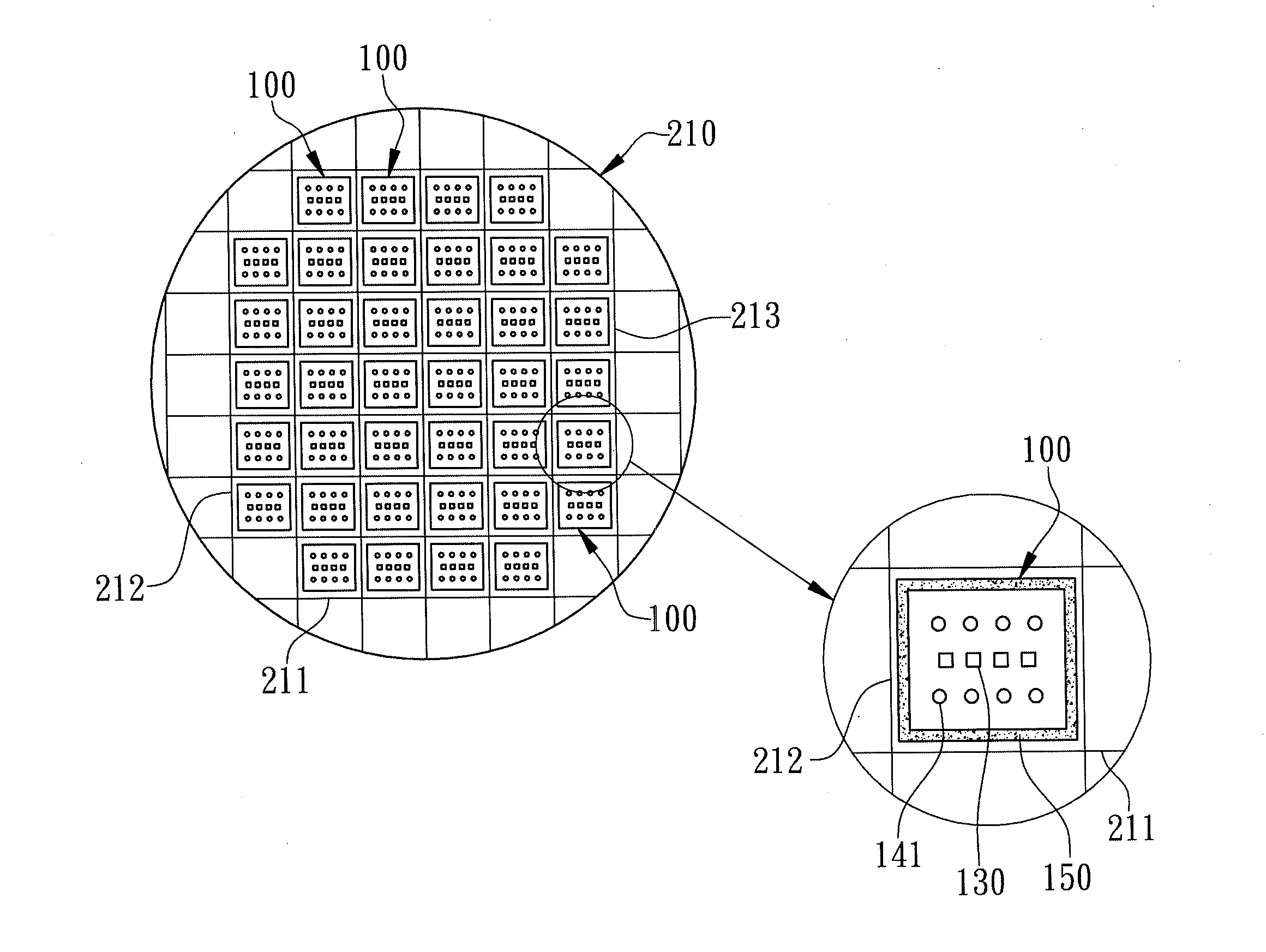

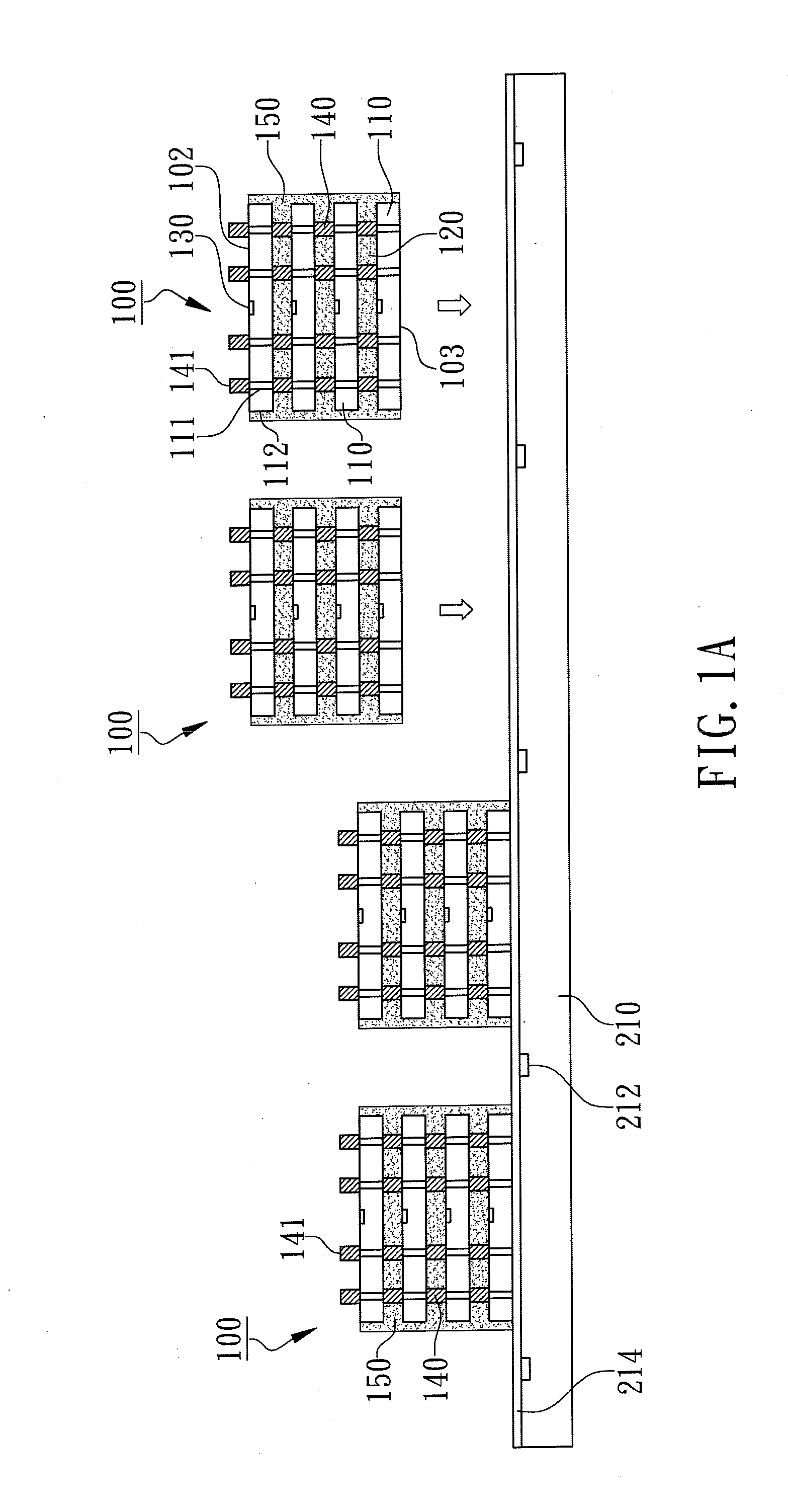

Method for wafer-level testing diced multi-chip stacked packages

InactiveUS20140051189A1Reduce test costsSemiconductor/solid-state device testing/measurementSolid-state devicesAdhesiveElectrical connection

Disclosed is a method for wafer-level testing a plurality of diced multi-chip stacked packages. Each package includes a plurality of chips with vertically electrical connections such as TSVs. Next, according to a die-on-wafer array arrangement, the multi-chip stacked packages are fixed on a transparent reconstructed wafer by a photo-sensitive adhesive, and the packages are located within the component-bonding area of the wafer. Then, the transparent reconstructed wafer carrying the multi-chip stacked packages can be loaded into a wafer tester for probing. Accordingly, the wafer testing probers in the wafer tester can be utilized to probe the testing electrodes of the stacked packages so that it is easy to integrate this wafer-level testing method especially into TSV packaging processes.

Owner:POWERTECH TECHNOLOGY

Method for evaluating long life of component

The invention discloses a method for evaluating long life of a component. The method comprises the following steps of: analyzing characteristics, an application platform and an application environment of the component; initially determining a stress level and sensitive parameters of a test; determining an application sequence of stress factors, responding to an analytical method for the sensitive parameters, and determining test equipment; performing an official test, namely recording sensitive parameter values of a component accelerated life test at certain time intervals to display changes of the sensitive parameters of the component accelerated life test along with time; performing graphical analysis by using graphic software, and selecting the best accelerator model and lifetime forecasting model; and verifying whether the models are valid, if so, evaluating the long life of the component, otherwise, redetermining the parameters. The method has the advantages of short test period, low testing expenses, general applicability, scientificity, no need of a preset model, suitability for small increments and capability of evaluating the long life of components adopting new technology and having long life.

Owner:BEIJING SHENGTAOPING TEST ENG TECH RES INST

Design method for few parabolic type variable cross-section main spring end and auxiliary spring gaps

ActiveCN105608300AImprove the design levelQuality improvementDesign optimisation/simulationSpecial data processing applicationsSteel platesElastic modulus

The invention relates to a design method for few parabolic type variable cross-section main spring end and auxiliary spring gaps, and belongs to the technical field of suspension steel plate springs. The method comprises the steps that according to the structural size and elastic modulus of each parabolic type variable cross-section main spring, an end point deformation coefficient of each main spring and a deformation coefficient Gx-CD of the Nth main spring on the contact point of an auxiliary spring and the end straight section; then, according to the auxiliary spring acting load design requirement value and the end point deformation coefficient of each main spring, the endpoint force FN of the Nth main spring is obtained; then, according to the thickness h2 of the straight section at the root of the Nth main spring, the FN and the Gx-CD, the main and auxiliary gaps between the contact points of the auxiliary springs and the end straight sections of the main springs are designed. According to simulation verification, the accurate and reliable main and auxiliary spring gap design values can be obtained by means of the method, the auxiliary spring acting load design requirement is met, and the product design level and performance and the vehicle ride comfort are improved; meanwhile, the product development speed is increased, and the design and testing expenses are lowered.

Owner:慕贝尔汽车部件(太仓)有限公司

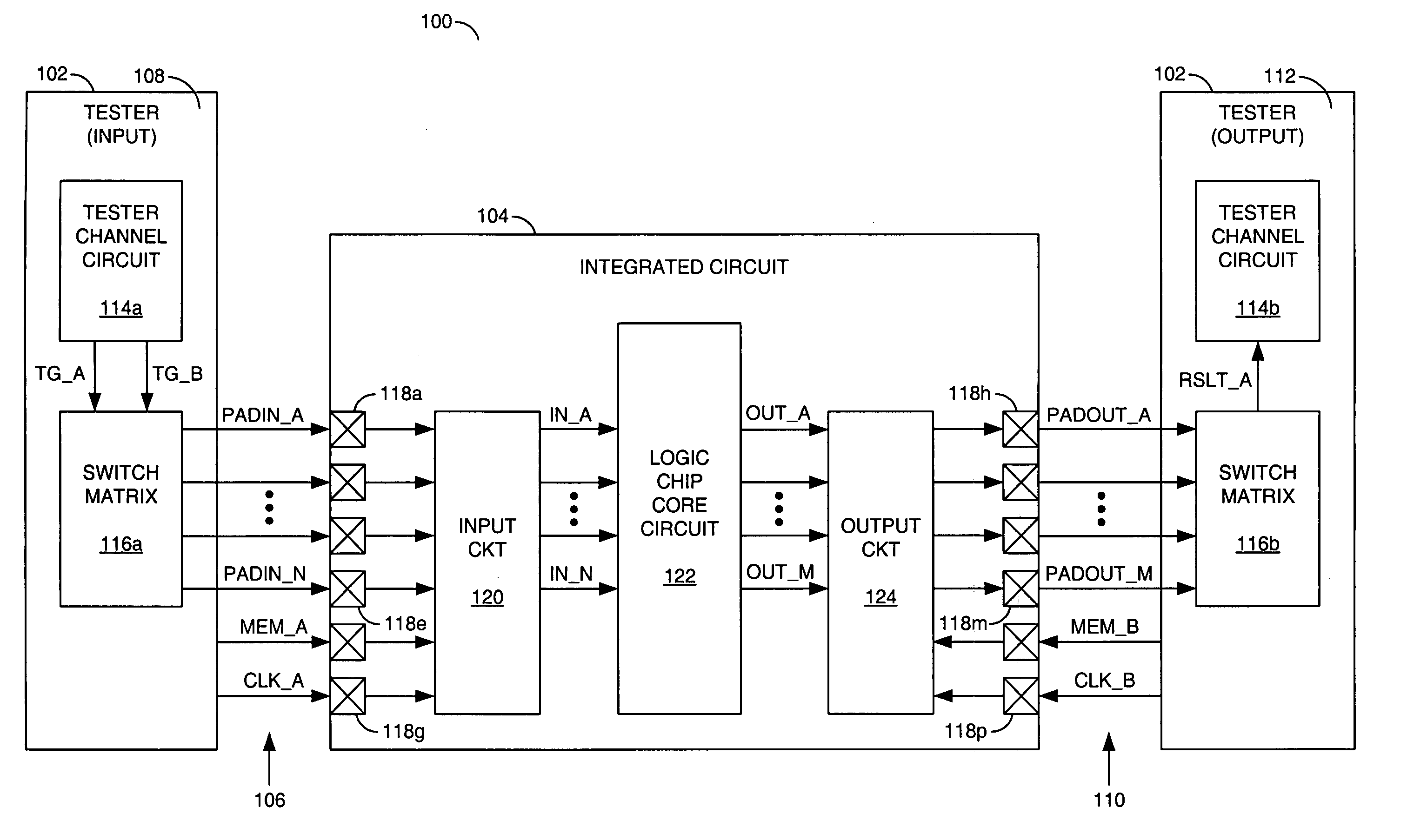

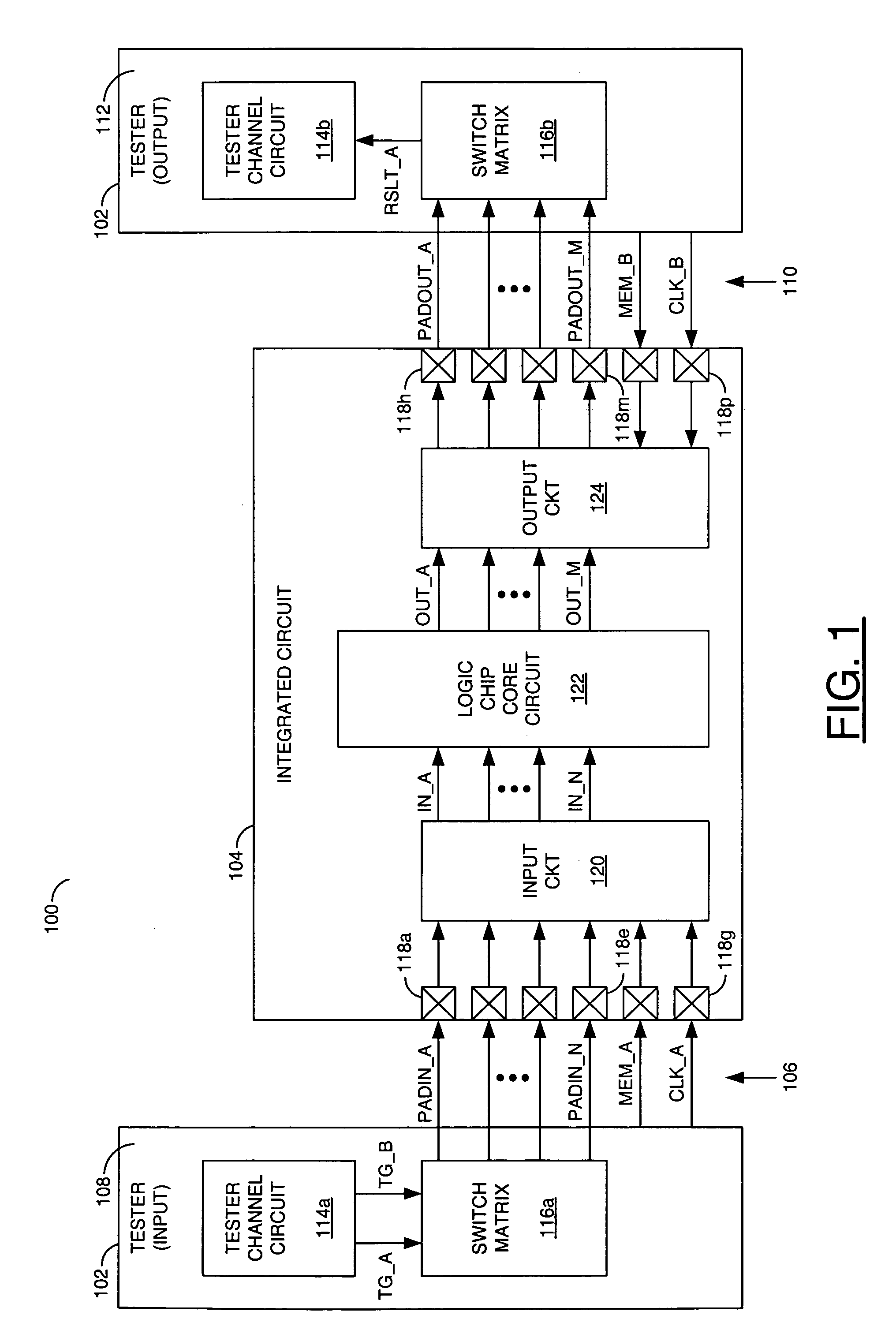

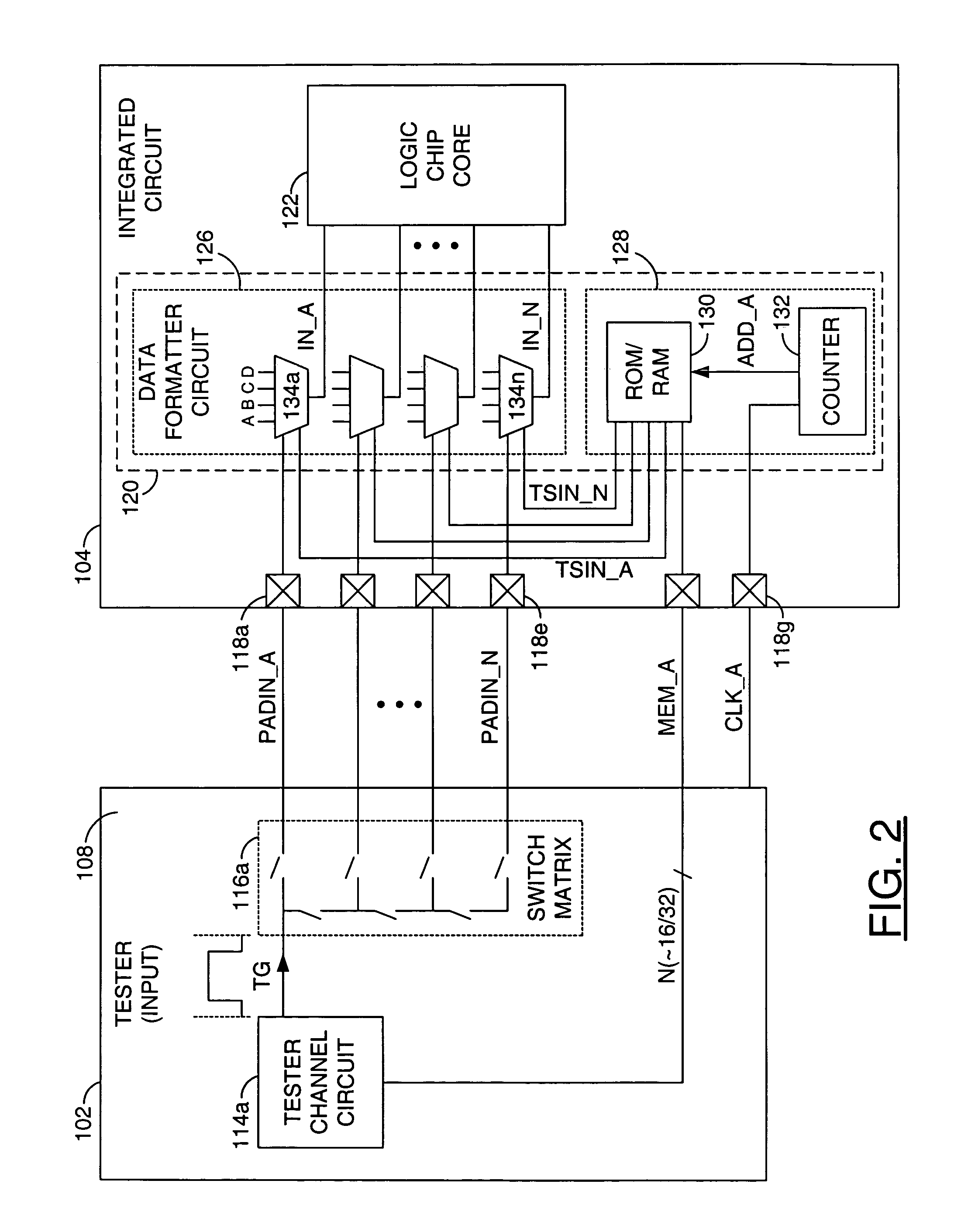

Reducing tester channels for high pinout integrated circuits

InactiveUS6971045B1Short test timeReduce testing costsDigital circuit testingError detection/correctionEngineeringOperation mode

An integrated circuit generally comprising a plurality of input pads, an input circuit, and a core circuit. The input pads may be configured to receive a plurality of first input signals. The input circuit may be configured to generate a plurality of second input signals (i) equal to the first input signals while in an operational mode and (ii) responsive to a plurality of test vectors with timing generation determined by the first signals while in a test mode. The core circuit may be responsive to the second input signals.

Owner:MONTEREY RES LLC

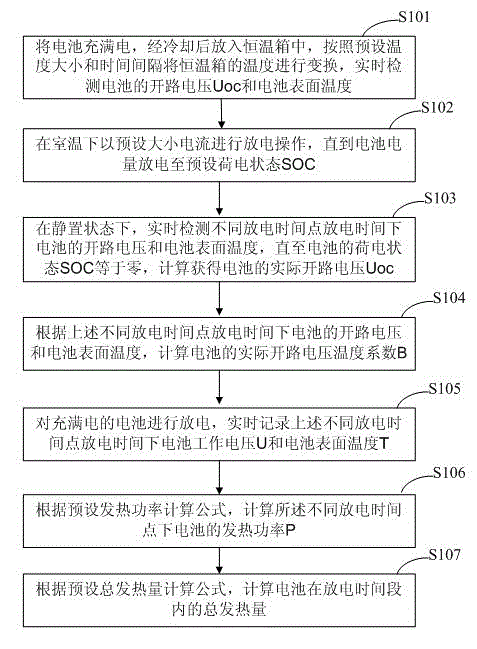

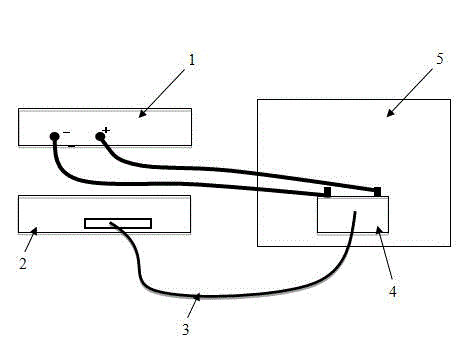

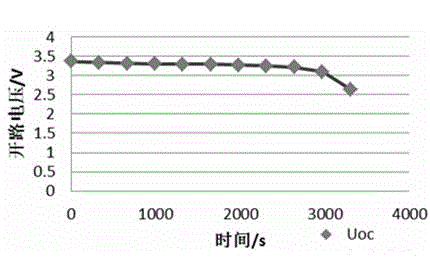

Lithium ion battery thermal performance testing method

InactiveCN102944575AEasy to implementImprove overall efficiencyMaterial heat developmentCalorimeterTemperature coefficientLithium electrode

The invention discloses a lithium ion battery thermal performance testing method. The method comprises the steps of: placing a fully-charged battery in a constant-temperature box, and detecting an open-circuit voltage and the surface temperature of the battery in real time; carrying out discharging operation by a preset current until the battery is discharged to a preset charge state; detecting the open-circuit voltage and the surface temperature of the battery at different discharge time points until the battery charge state is equal to zero to obtain an actual open-circuit voltage and an actual open-circuit voltage temperature coefficient B of the battery; discharging the fully-charged battery, and detecting a work voltage U and the surface temperature T of the battery in real time at different discharge time points; and calculating the heating power P of the battery at different discharge time points. The lithium ion battery thermal performance testing method disclosed by the invention can conveniently and reliably test the thermal performance of the lithium ion battery during discharge, and can accurately acquire the heating power, the change of heating power over time and the total heating amount of the lithium ion battery during discharge.

Owner:TIANJIN LISHEN BATTERY

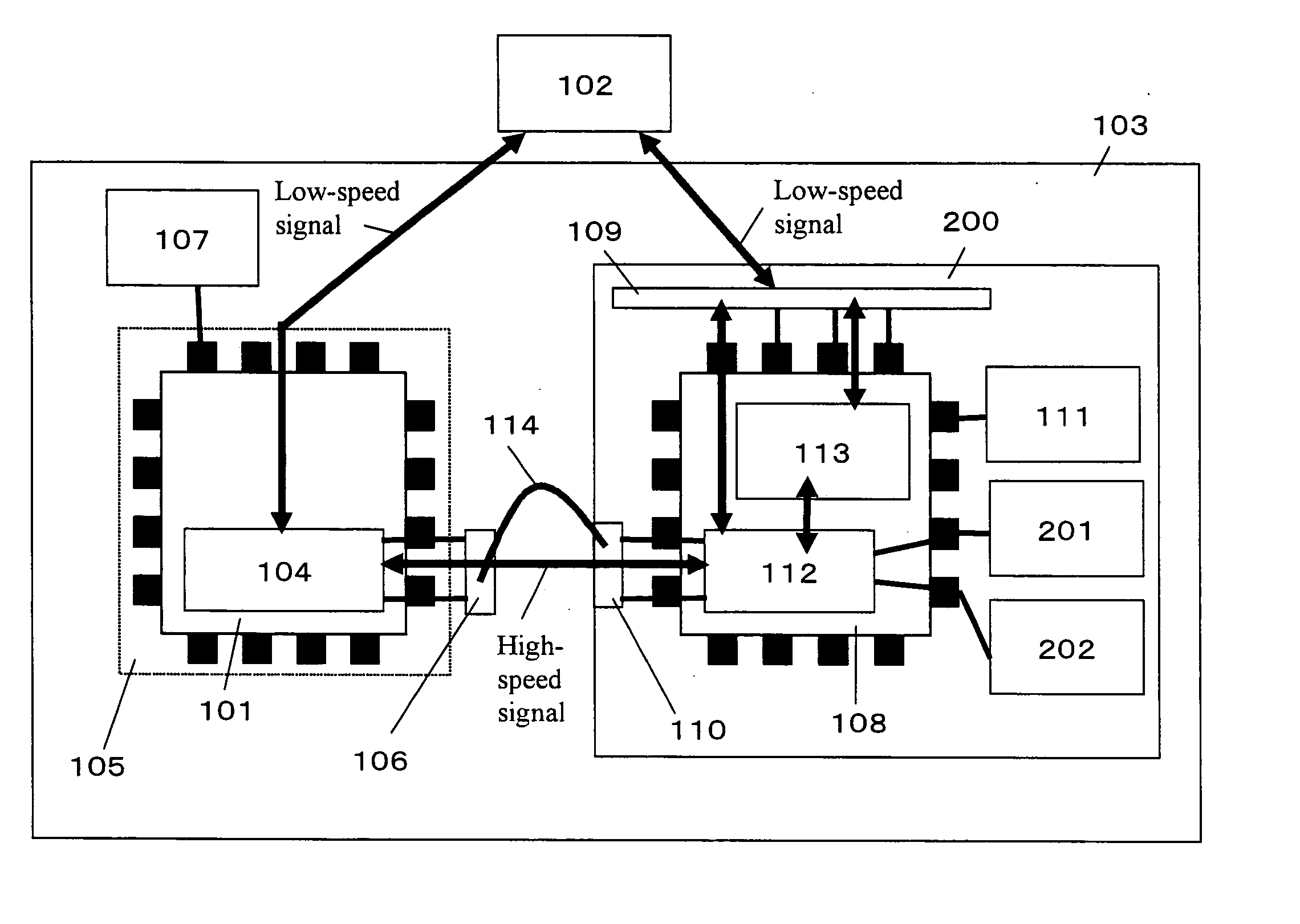

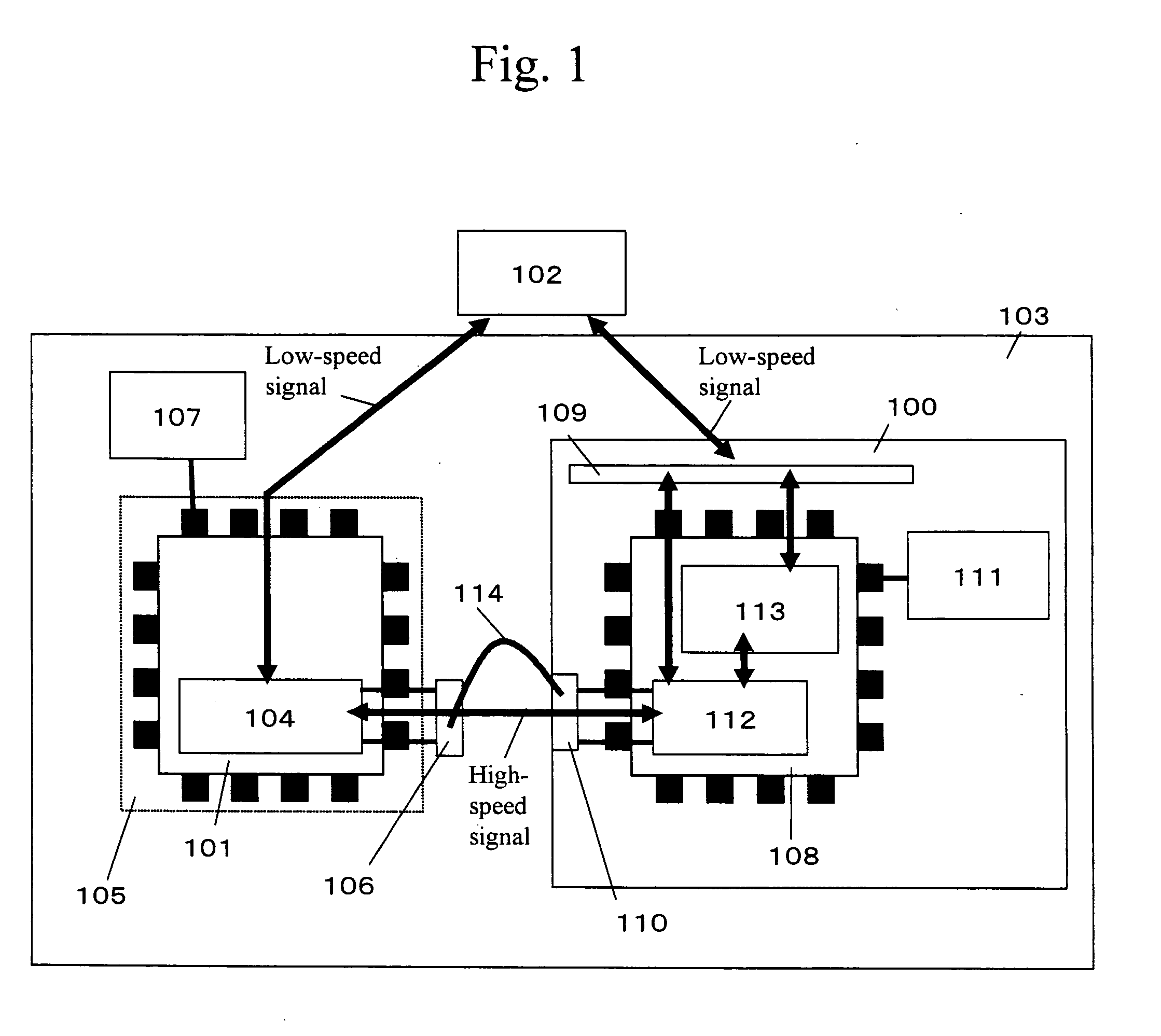

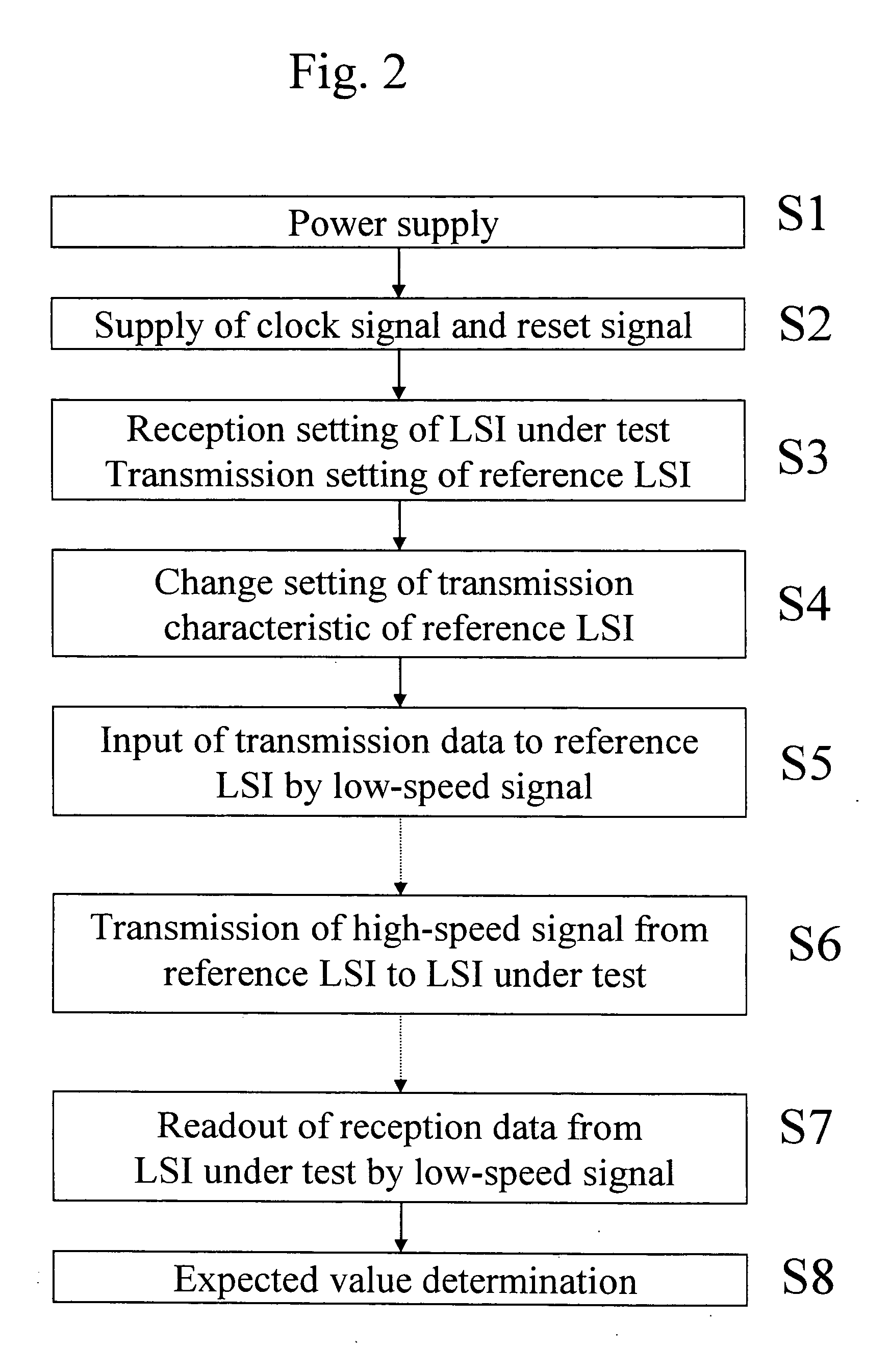

High-speed interface circuit test module, module under high-speed interface circuit test, and high-speed interface circuit test method

InactiveUS20050258856A1Efficient executionReduce test costsDigital circuit testingData switching networksLow speedComputer module

In the shipment test of an LSI provided with a high-speed interface circuit, both cost reduction and a high test guarantee level are realized. The following are provided: a high-speed interface circuit that is mounted on a load board interfacing with an LSI tester, is provided with a circuit converting the signal speed, and is capable of changing the transmission and reception characteristics; a controller that controls the transmission and reception characteristics of the high-speed interface circuit; a clock generator that generates the clock supplied to the high-speed interface circuit; a first connector provided specifically for the high-speed interface, connected to the high-speed interface circuit and provided with a signal port for performing high-speed signal communication with a circuit under test; and a second connector connected to the high-speed interface circuit and the LSI tester and provided with a signal port and a power port for performing low-speed signal communication with the high-speed interface circuit.

Owner:PANASONIC CORP

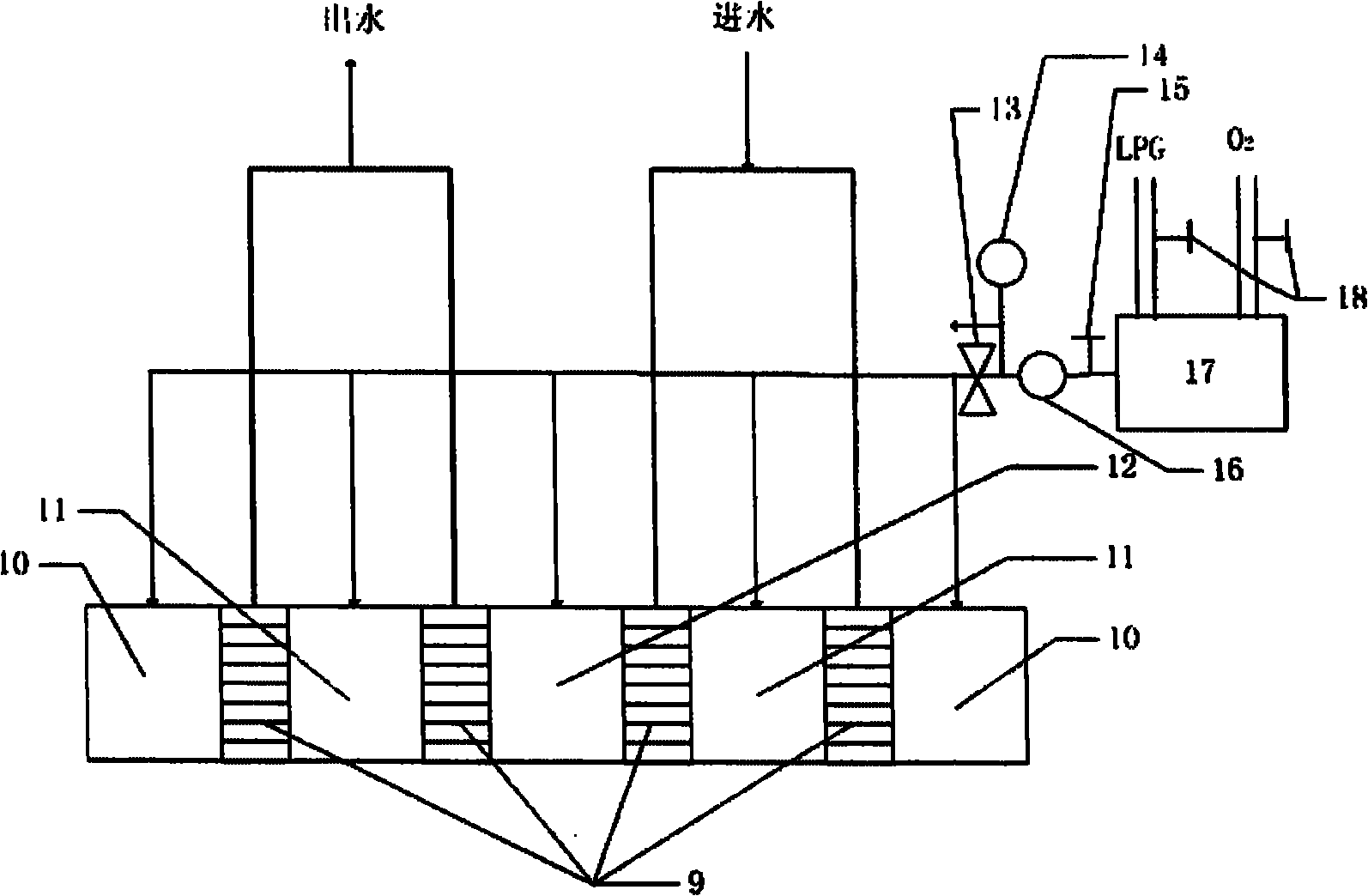

Heated structural member thermal shock and thermal fatigue test stand

InactiveCN101893536AReduce test costsShorten the development cycleThermometers using electric/magnetic elementsUsing electrical meansCombustorThermal fatigue

The invention relates to a structural member test unit, aiming at providing a heated structural member thermal shock and thermal fatigue test stand which comprises a movable test bench for a test piece erecting stage, wherein a travelling mechanism is arranged below the test piece erecting stage and comprises a sliding sleeve, a guide rail, a rack, a gear, a transmission shaft and a servo motor; the sliding sleeve and the rack are fixed below the test piece erecting stage, and the guide rail is sleeved in the sliding sleeve; a heating station is arranged on the test bench, and the two sides of the heating station are respectively and symmetrically provided with a cooling station; and a burner of a fuel gas heating system is arranged at the heating station, and each cooling station is provided with a compressed air or cooling water outlet. The invention provides a real machine assessment system which can replace the existing thermal fatigue / thermal shock tests of heated parts such as pistons, cylinder covers and the like; and under the condition of no engine model machine, the heated structural member thermal shock and thermal fatigue test stand can carry out hot strength assessment operation on the heated parts such as pistons, cylinder covers and the like, thus not only saving test expenses but also shortening development period.

Owner:ZHEJIANG UNIV

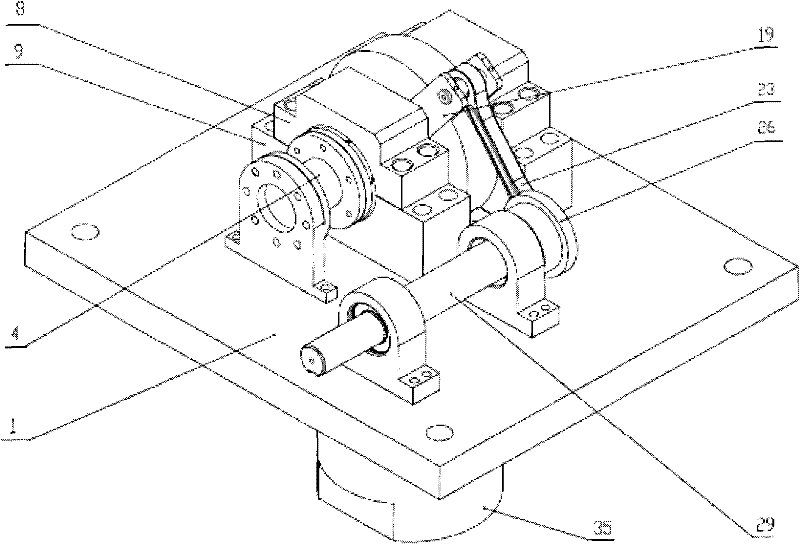

Frictional wear simulation test bench of wobble friction pair

InactiveCN102175544AAdjustable speedAdjustable loading frequencyEngine testingInvestigating abrasion/wear resistanceData acquisitionEngineering

The present invention relates to a frictional wear simulation test bench of a wobble friction pair, which is mainly composed of the following components: a frame workbench, a main shaft drive unit, a friction pair simulation swing mechanism, a hydraulic loading device, a hydraulic control system and a PC control system. The PC control system of the simulation test bench collects the signals of a torque sensor, a pressure sensor and a rotating speed sensor; and can realize the following functions: controlling an amplitude and a frequency of a loading force; operating and controlling a test program; collecting, processing and storing data; displaying and printing test data and a test curve. The frictional wear test follows a system correlation principle, a principle that the temperature fields are similar, a limit principle, a principle that the wear mechanisms are same, and a wear test simulation determination standard. A practical wobble friction pair is used as a test object. The frictional wear simulation test bench of the wobble friction pair has the following characteristics: compact structure, adjustable load amplitude, adjustable rotating speed, adjustable loading frequency, capability of simulating different working conditions of an engine, and capability for measuring the frictional wear characteristics of different types of wobble friction pairs.

Owner:ZHONGBEI UNIV +1

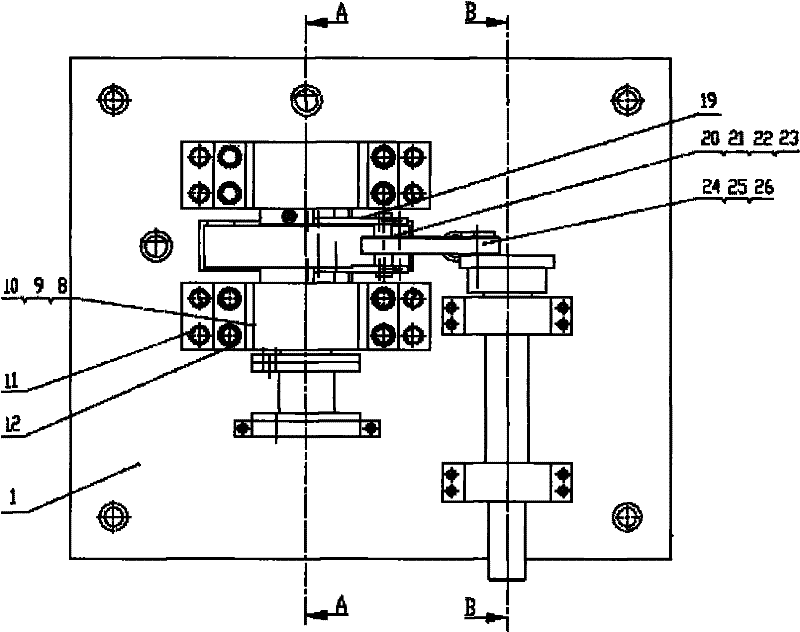

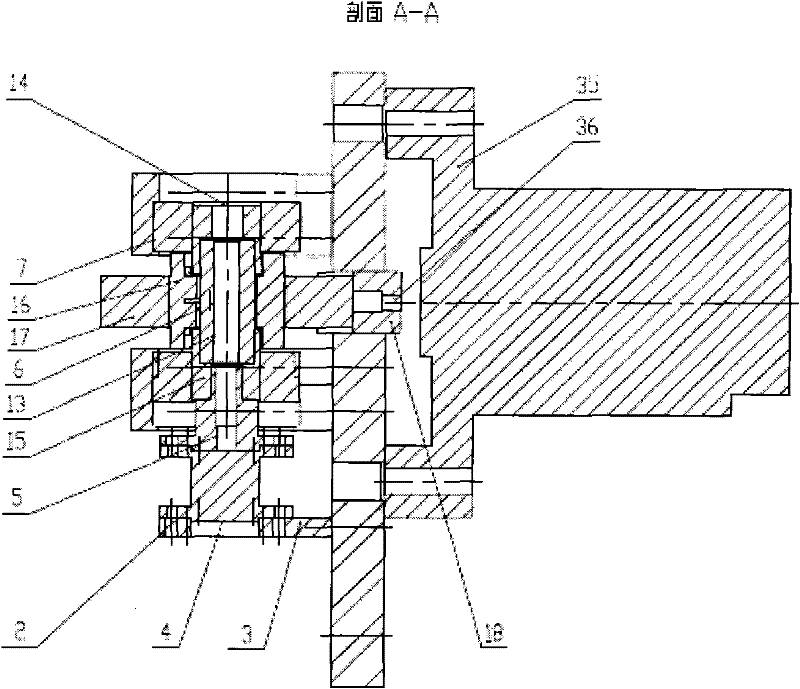

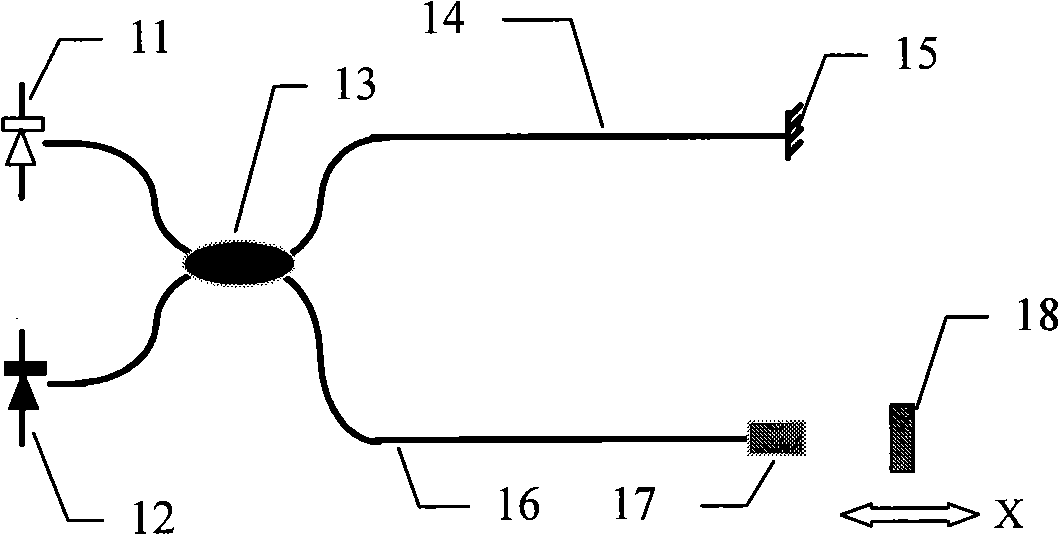

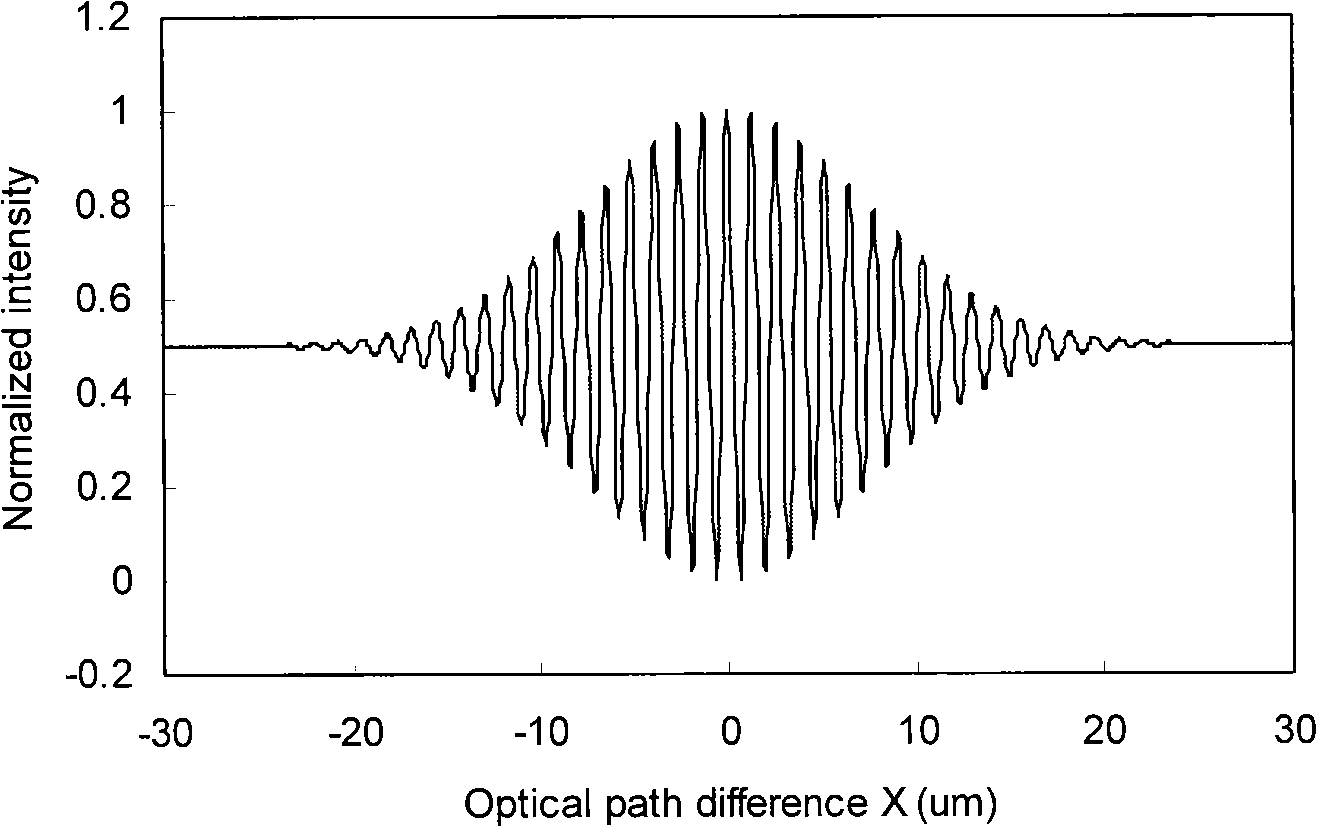

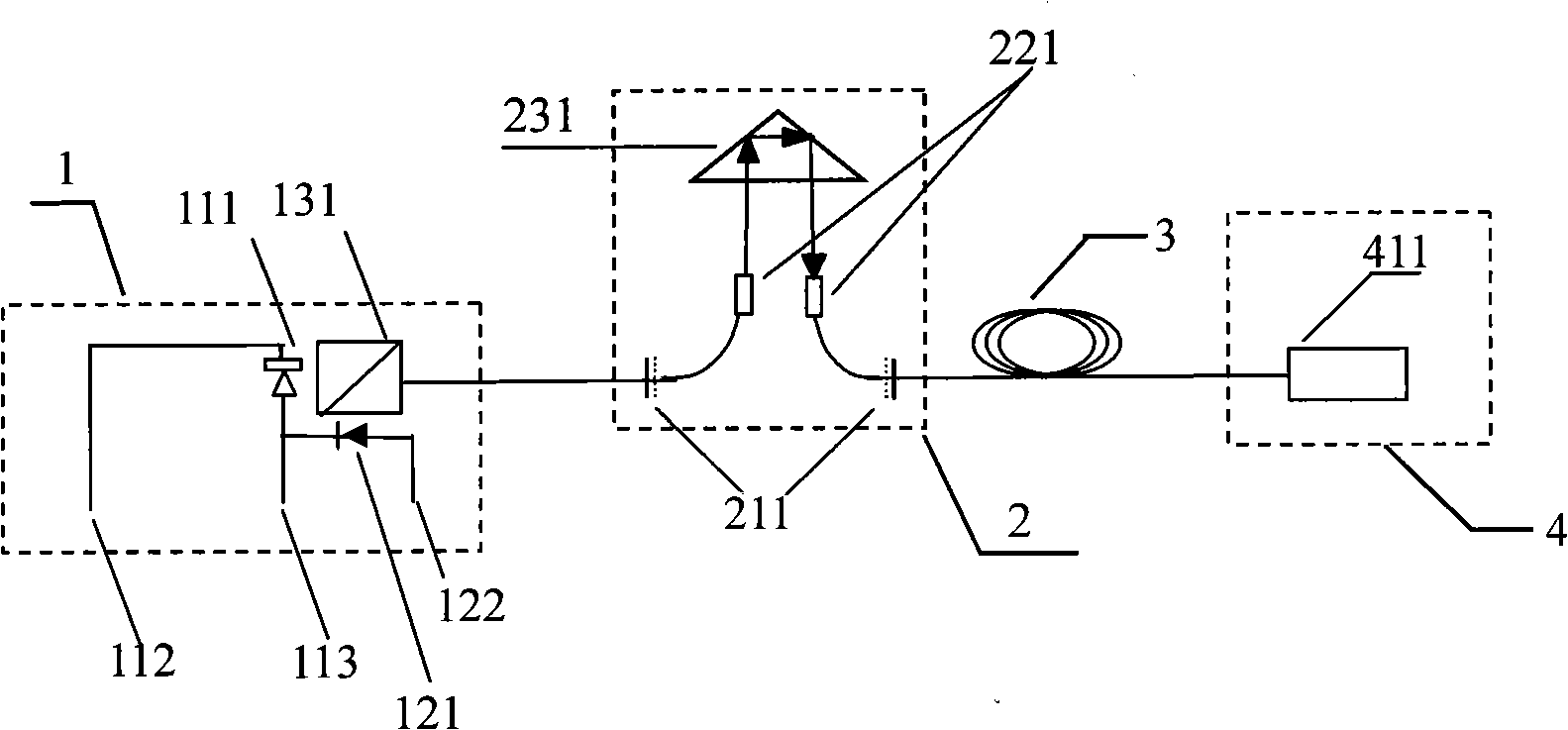

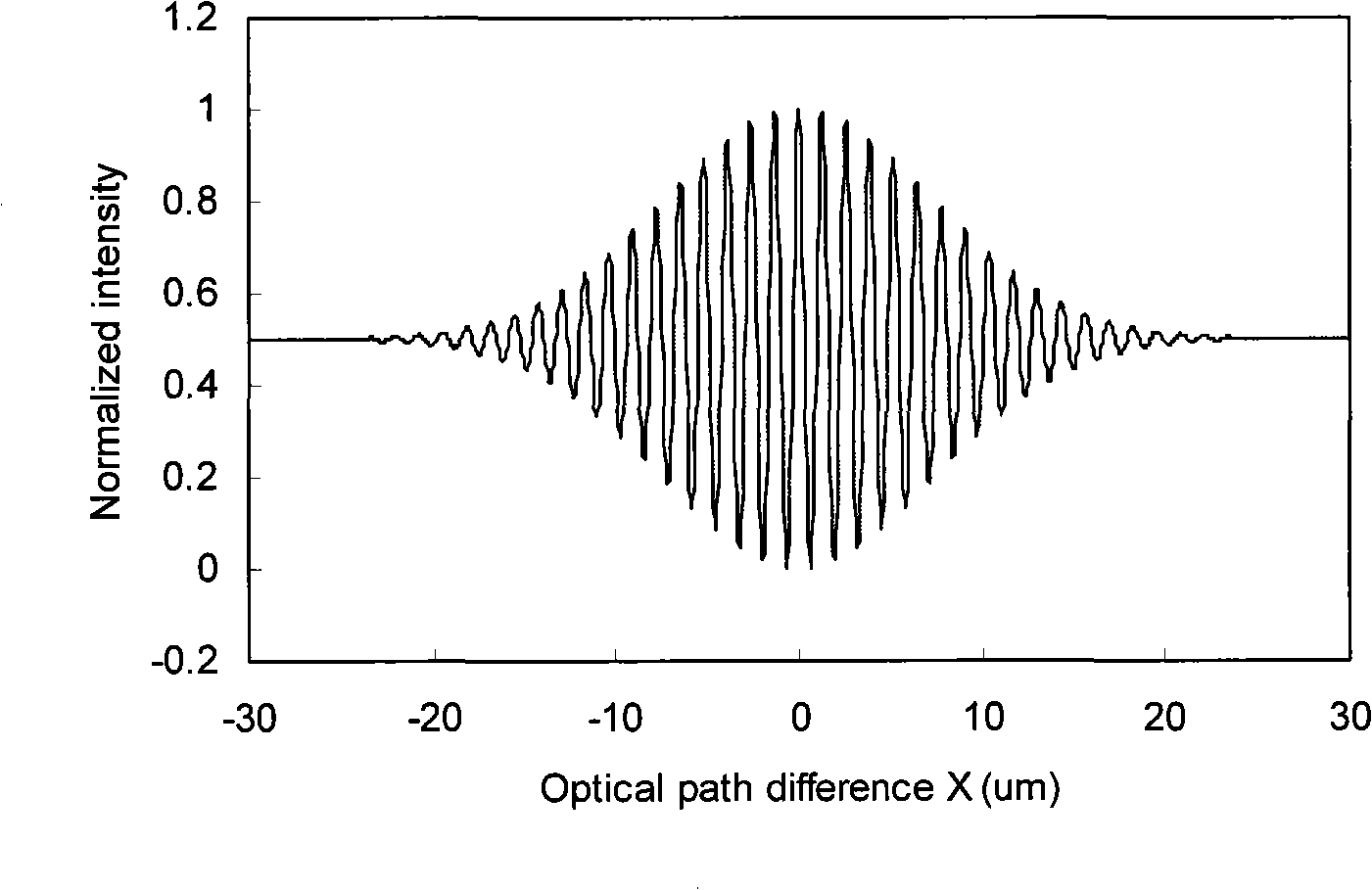

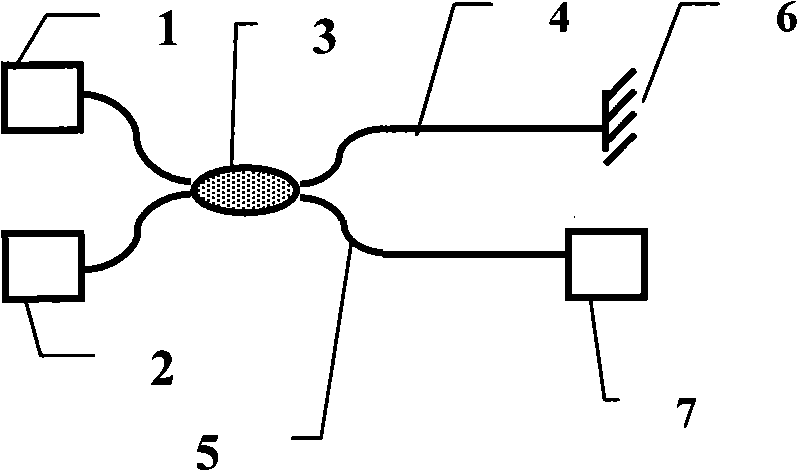

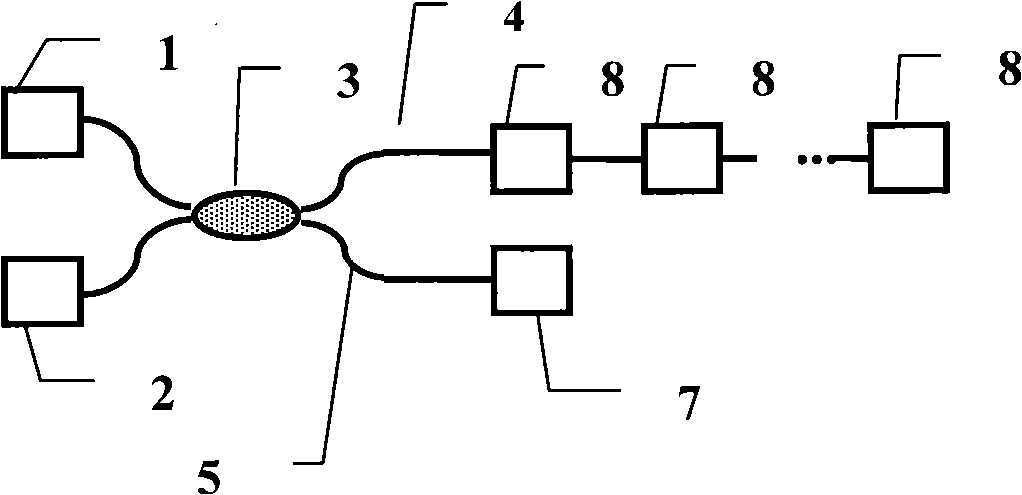

Distributed optical fiber white light interference sensor array based on adjustable Fabry-Perot resonant cavity

InactiveCN101324445AWith common light path structureImprove temperature stabilityCoupling light guidesConverting sensor output opticallySensor arrayBeam splitter

The invention provides a distributed fiber white-light interference sensor array based on tunable Fabry-Perot resonant cavity, which is composed of a duplex photoelectric device, a tunable Fabry-Perot resonant cavity, a single-mode connection fiber and a sensor, wherein the tunable Fabry-Perot resonant cavity is composed of a scanning prism, a self-focusing lens, and a single-mode optical fiber with partial reflection surface; the duplex photoelectric device is composed of a wide-spectrum light source with a common base, an emitter and a collector, a photodetector, and a beam splitter prism; the beam with a certain spectral width is emitted by the light source to the resonant cavity directly through the beam splitter prism and is reflected multiple times by the left and the right surfaces of the resonant cavity to obtain a signal light; and the signal light outputted from the right cavity surface enters the sensor through the single-mode connection fiber, reflected by the left and the right end faces of the sensor, returns along the original path to the resonant, and is outputted from the left cavity surface to the photodetector. The distributed fiber white-light interference sensor array has a common light path structure and has the advantages of good temperature stability, simplest optical fiber path structure, low cost and high practicality.

Owner:HARBIN ENG UNIV

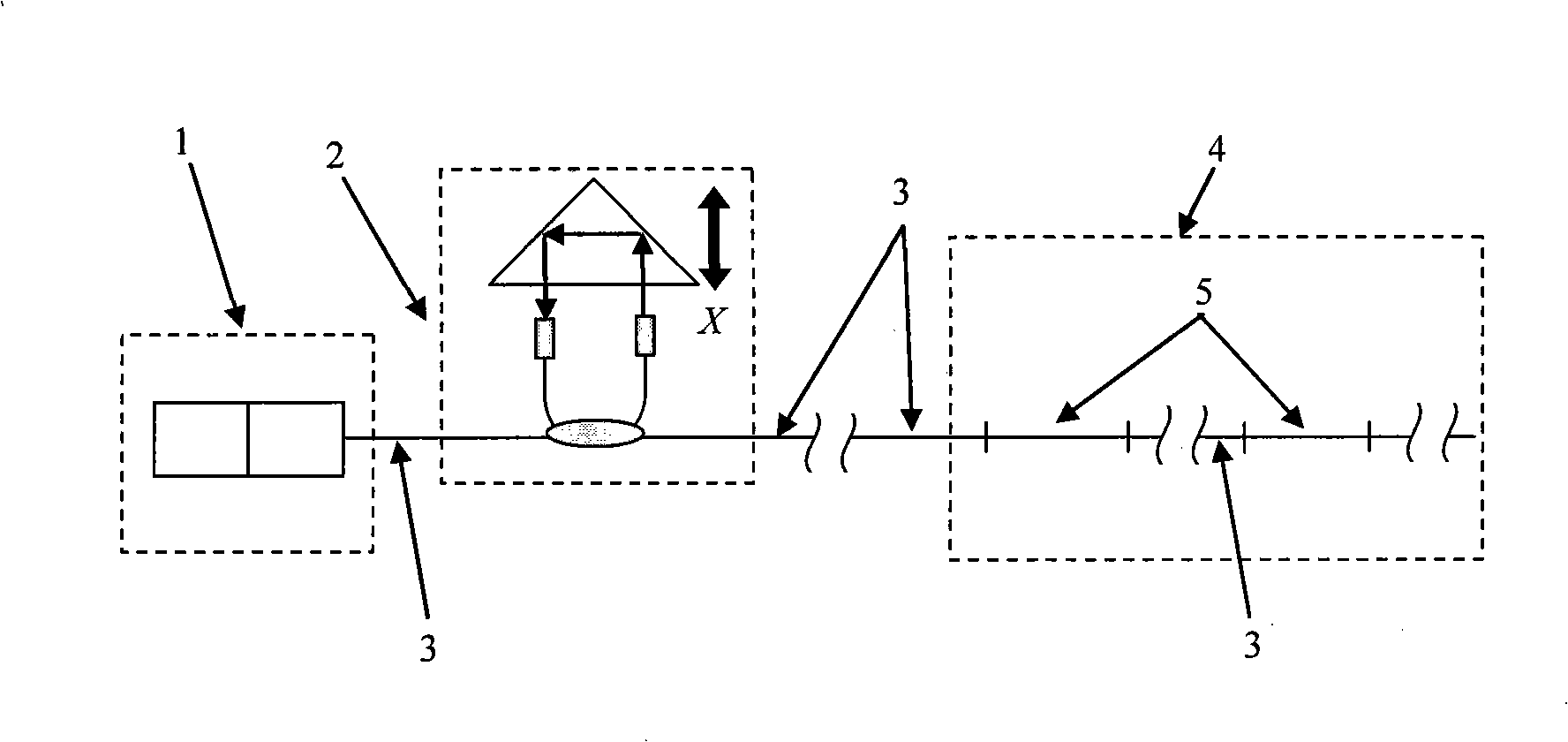

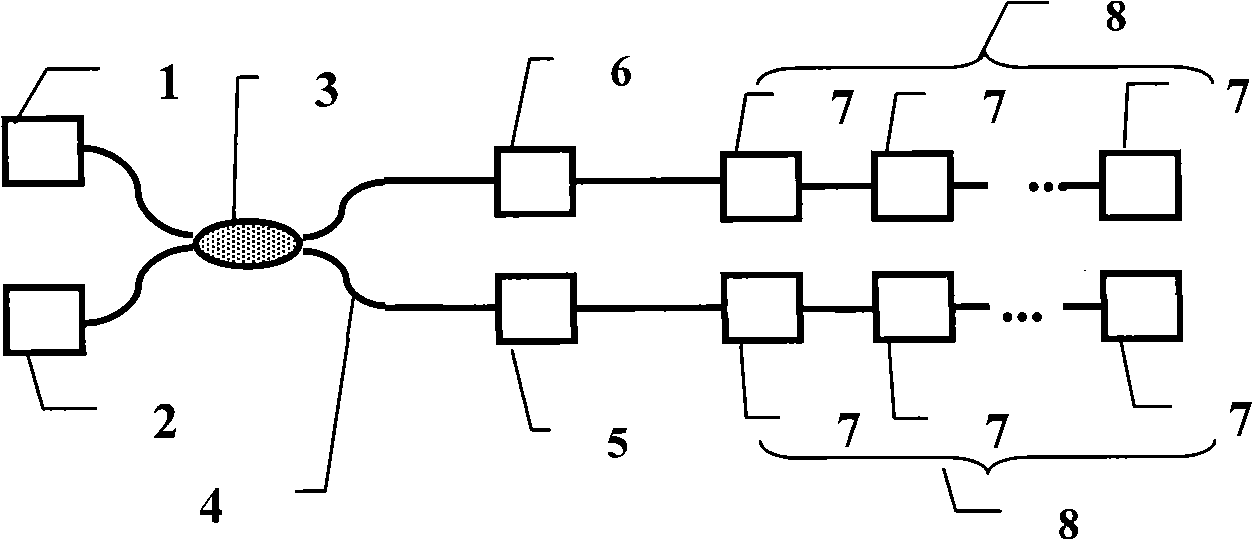

Simplifying type multiplexing white light interference optical fiber sensing demodulating equipment

InactiveCN101324444ASimple structureEasy to implementCoupling light guidesConverting sensor output opticallyPhotodetectorOpto electronic

The invention provides a simplified multiplexing white light interference fiber sensing demodulating device, which comprises a single-fiber two-way optical transmitting / receiving module, an optical fiber resonant cavity, a single-mode transmission fiber, and an optical fiber sensing array, wherein the single-fiber two-way optical transmitting / receiving module is composed of a semiconductor light source as the transmitting terminal, a semiconductor photodetector as the receiving terminal and related devices packaged together; and an optical fiber annular cavity is composed of an optical fiber coupler, an optical fiber self-focusing lens and a movable corner reflector. The device can achieve enquiry and measurement of a plurality of optical fiber sensors by embedding the single-fiber two-way optical transmitting / receiving module and the optical fiber resonant cavity in the single-mode optical fiber, and has the advantages of simple structure, easy implementation, no length restriction of the transmission cable, no influence caused by the external environment, and good stability and reliability. The device can be used for the measurement of physical quantities such as distributed deformation, strain and temperature, and can be used for multi-task sensing, multi-element sensing, local strain sensing, large-scale deformation sensing, etc.

Owner:HARBIN ENG UNIV

Method for checking useful load of auxiliary springs of non-end contact diagonal main and auxiliary spring

ActiveCN105653883AImprove transportation efficiencyImprove securityInformaticsSpecial data processing applicationsEngineeringOblique line

The invention relates to a method for checking a useful load of auxiliary springs of a non-end contact diagonal primary and auxiliary spring, and belongs to the technical field of suspension steel plate springs. The method comprises the following steps: firstly, determining an endpoint deformation coefficient and the half rigidity of each main spring, as well as a deformation coefficient Gx-CB of the contact point between an Nth main spring and the auxiliary spring at an oblique line segment according to a structural dimension and an elastic modulus of the diagonal variable cross-section main spring with non-isostructural end parts; then, checking the useful load of the auxiliary springs of the non-end contact few-leaf diagonal variable cross-section main and auxiliary spring according to the thicknesses of root straight sections of the main springs, Gx-CB of the Nth main spring, the half rigidity of each main spring and a design value of the clearance Delta between the main springs and the auxiliary springs. The simulated verification shows that an accurate checking value of the useful load of the auxiliary springs of the non-end contact diagonal main and auxiliary spring can be obtained by using the method, the design level and performance of products are improved, the vehicle running smoothness is improved, meanwhile, the design, manufacturing and test costs are reduced, and the product development speed is increased.

Owner:平邑经济开发区投资发展有限公司

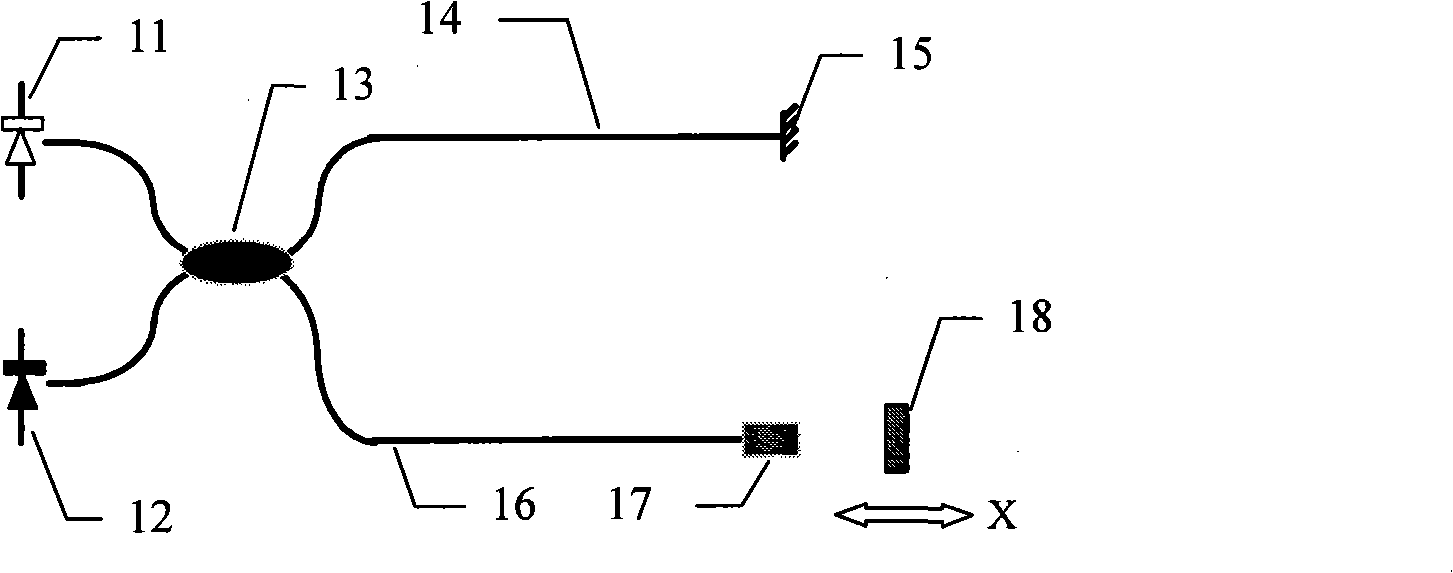

Twin array Michelson optical fiber white light interference strain gage

InactiveCN101329168AGuaranteed real-timeSimplify complexityThermometers using physical/chemical changesUsing optical meansPhotodetectorLight beam

The invention provides a white light interferometer strain gauge of twin array Michelson optical fibers, which consists of a broad-band light source, an photodetector, a coupler, a single-mode connecting optical fiber, an optical attenuator, an optical delay line and a sensing array that is composed of twin optical fiber sensors, wherein, broad-band light emitted by the broad-band light source is split by the coupler, one light beam is transmitted into an array that consists of an arm optical fiber sensor by the optical attenuator, the other light beam is transmitted into the array that consists of another arm optical fiber sensor by the optical delay line, and light signals that are returned by the two arms are transmitted into the photodetector for detection and analysis by the coupler. The white light interferometer strain gauge of the twin array Michelson optical fibers is characterized in that the white light interferometer strain gauge can realize the measurement of strain and temperature at the same time, reduces the influence of temperature to the measurement by utilizing the temperature compensation technique, and simultaneously, simplifies system complexity, lowers testing cost, ensures the real-time property of testing and improves testing reliability; furthermore, the white light interferometer strain gauge has simple structure, easy implementation, low cost and price and easy acquisition.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com