Frictional wear simulation test bench of wobble friction pair

A technology for simulating test benches and friction and wear. It is used in engine testing, wear resistance testing, machine/structural component testing, etc. It can solve the problem of difficult hydraulic loading, low load stability, low spring loading accuracy, and high cost of control parts. problems, to achieve the effect of improving the level of comparability, improving the test efficiency and reducing the test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

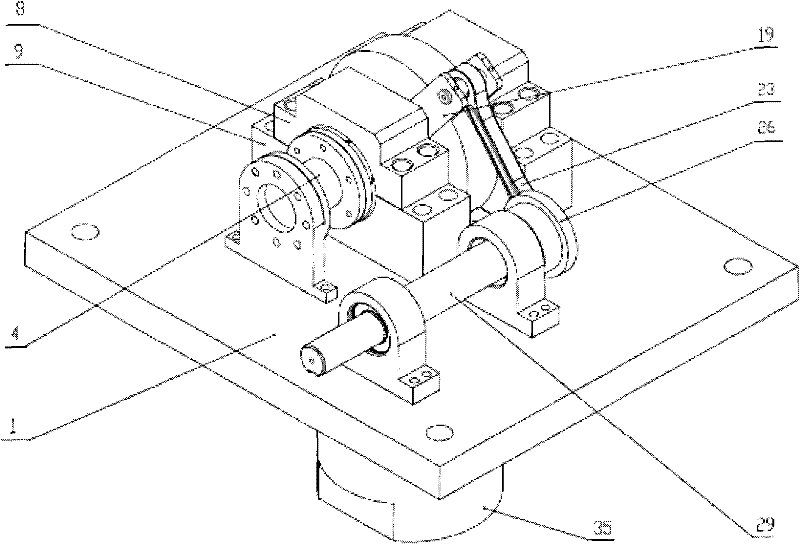

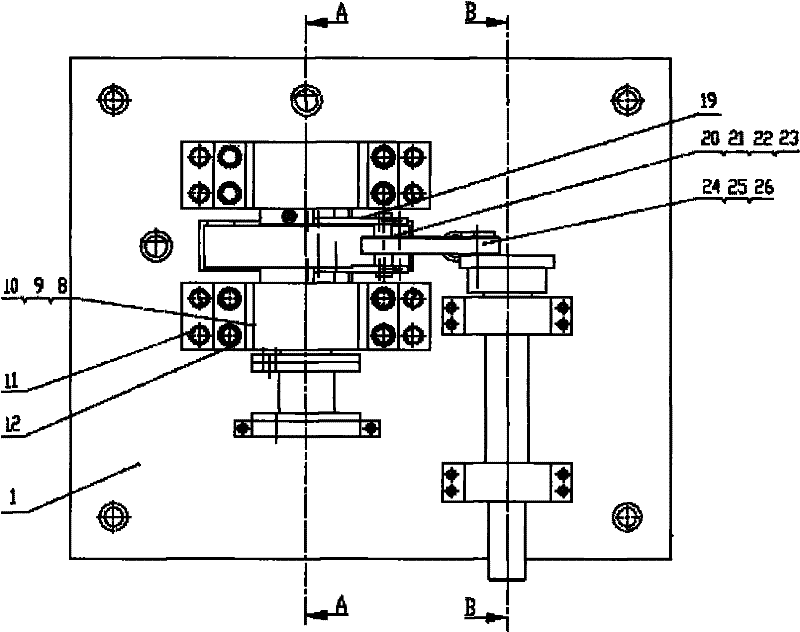

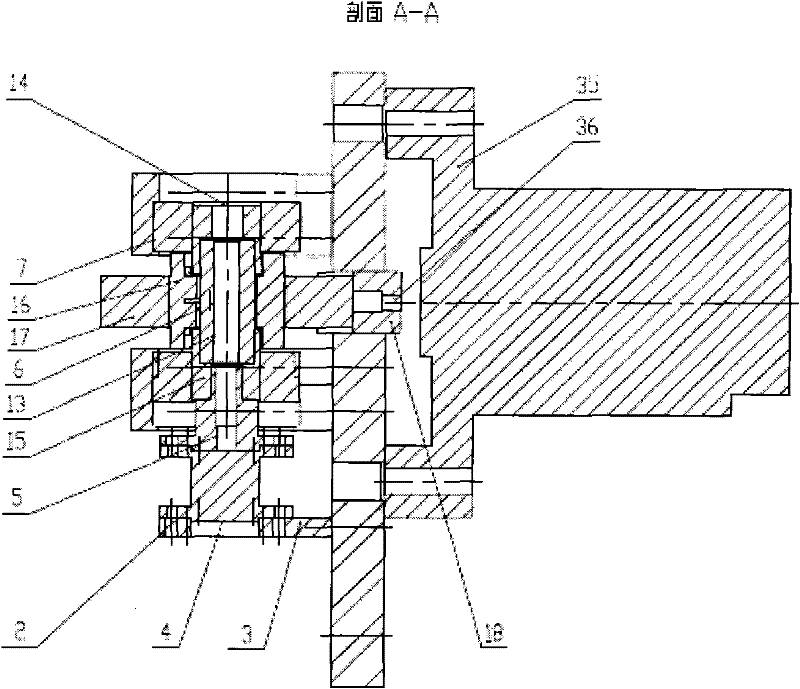

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] figure 1 , figure 2 and image 3 As shown, the friction and wear simulation test bench for the swing friction pair is mainly composed of a frame workbench, a spindle drive device, a friction pair simulation swing mechanism, a hydraulic loading device, a hydraulic control system, and a PC control system; spindle drive devices with different speeds will be provided It is fixed on the frame workbench 1 through the bearing seat, and the friction pair simulation swing mechanism for installing the sliding bearing 6 and the piston pin 13 in the friction pair parts is also fixed on the frame workbench 1 through the upper and lower bearing seats 8 and 9. Above, the oil cylinder 35 of the hydraulic loading system is also fixed under the frame workbench 1 by bolts. The rack table can be welded by profiles and steel plates, or it can be cast in parts and then consolidat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com