Intelligent automatic root tuber crop harvester

A technology for cutting roots and harvesting machines, which is applied in the direction of digging harvesters, harvesters, excavators, etc., can solve the problems of long mechanical transmission chain, low degree of automation, and poor adaptability, and achieve short mechanical transmission chain and convenient frequency. Tuning, driving smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings by taking the intelligent automation harvester for harvesting peanuts as an example.

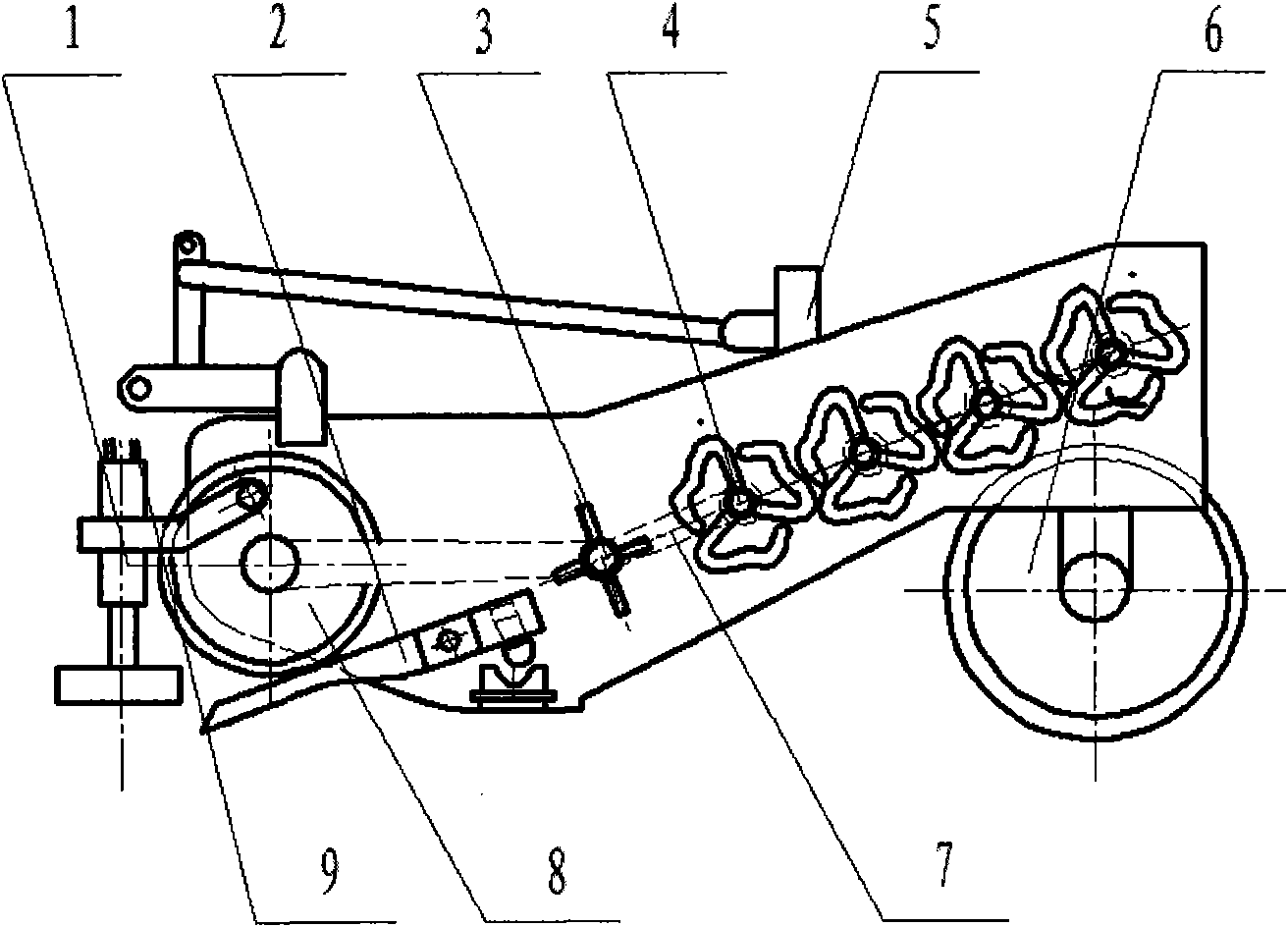

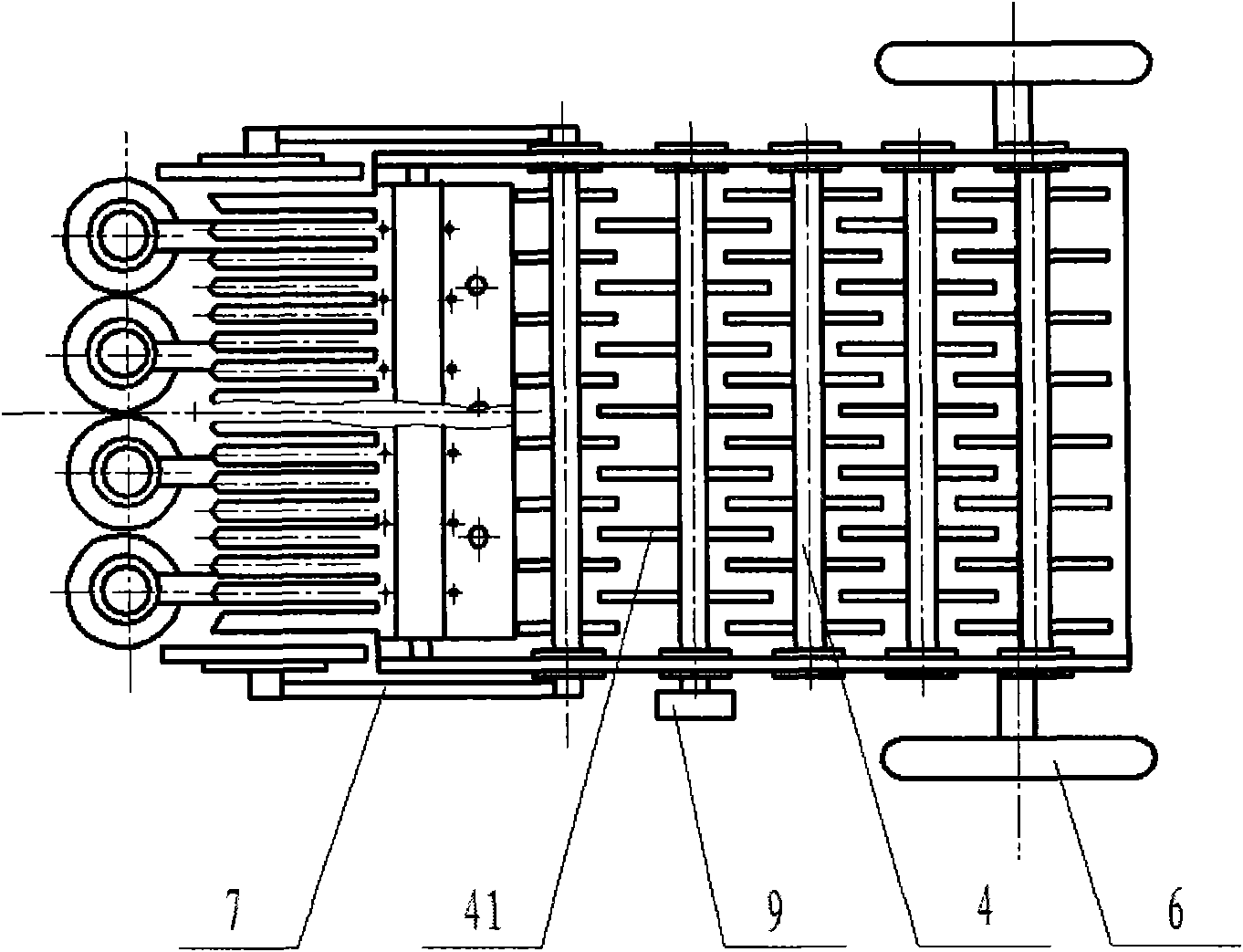

[0040] Such as figure 1 , figure 2 As shown, the intelligent and automated root crop harvester of the present invention includes a vibratory compaction crushing mechanism 1, an electromagnetic vibration excavation mechanism 2, a crushing soil feeding device 3, a conveying separation mechanism 4, a suspension frame device 5, and a ground wheel 6. Mechanical transmission system 7, vine cutting depth limit device 8, hydraulic drive device 9 and central controller.

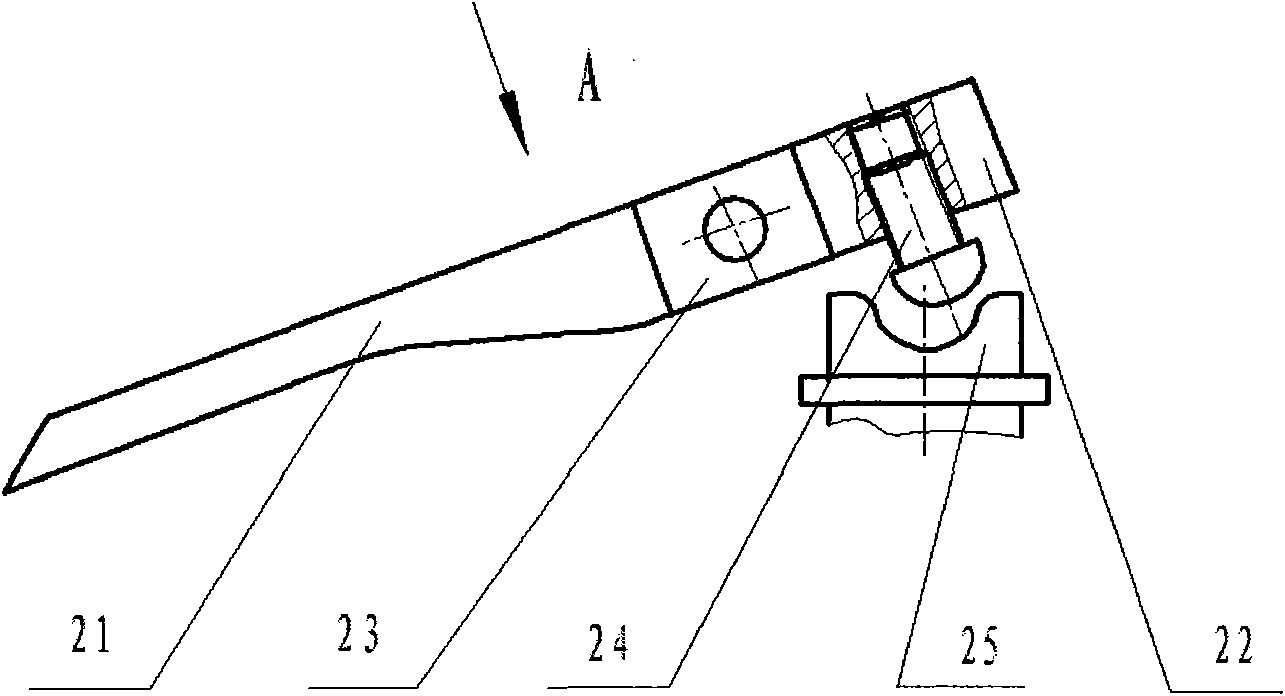

[0041] Such as figure 1 , figure 2 , Figure 6 As shown, the described vibratory compaction crushing mechanism 1 is mainly provided with a vibratory compaction crushing disc 11, a piston rod 12, a piston sleeve 13, a connecting rod 15 and a connecting flange 14. The vibratory compaction crushing mechanism 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com