Patents

Literature

182 results about "Crop harvester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

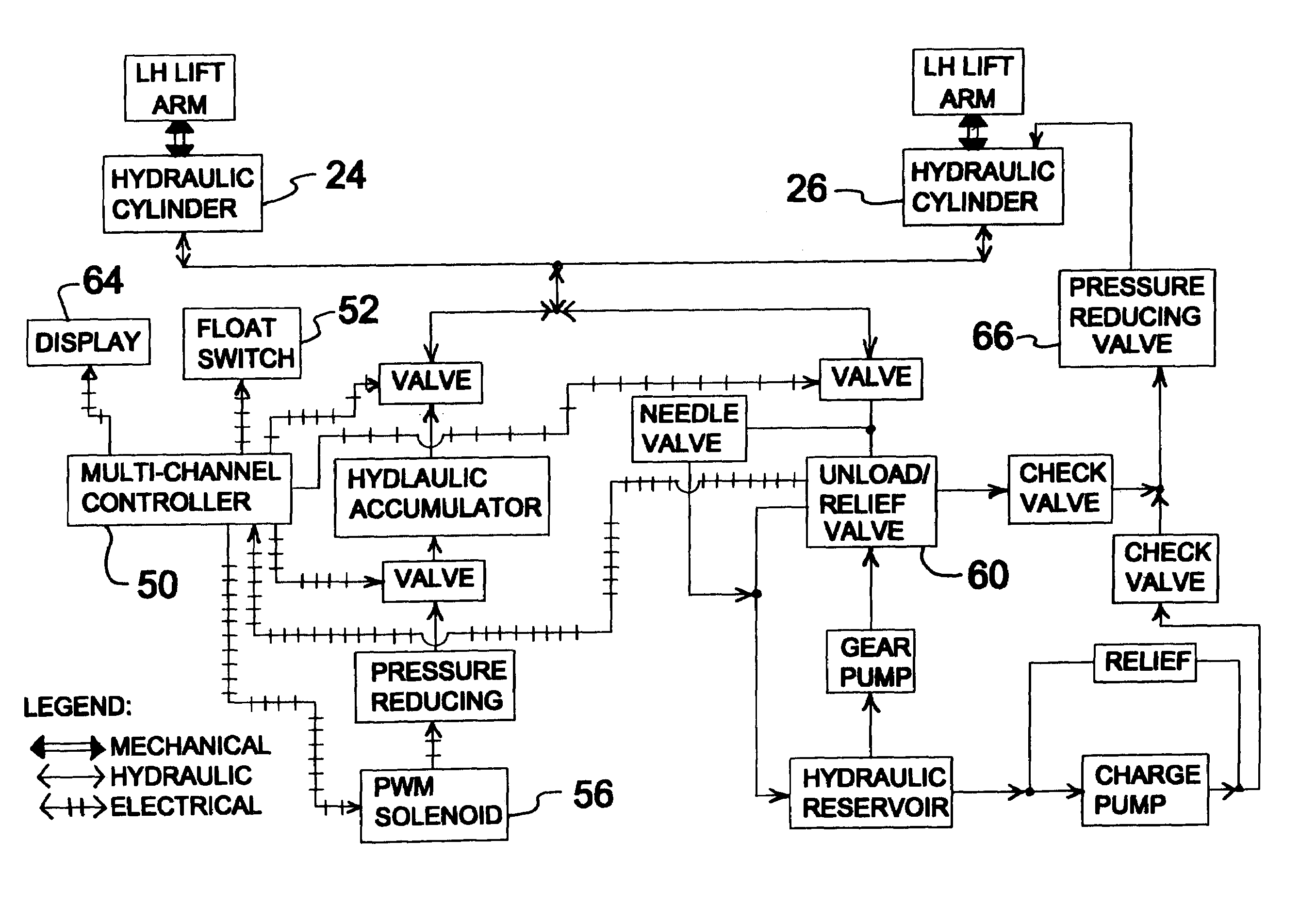

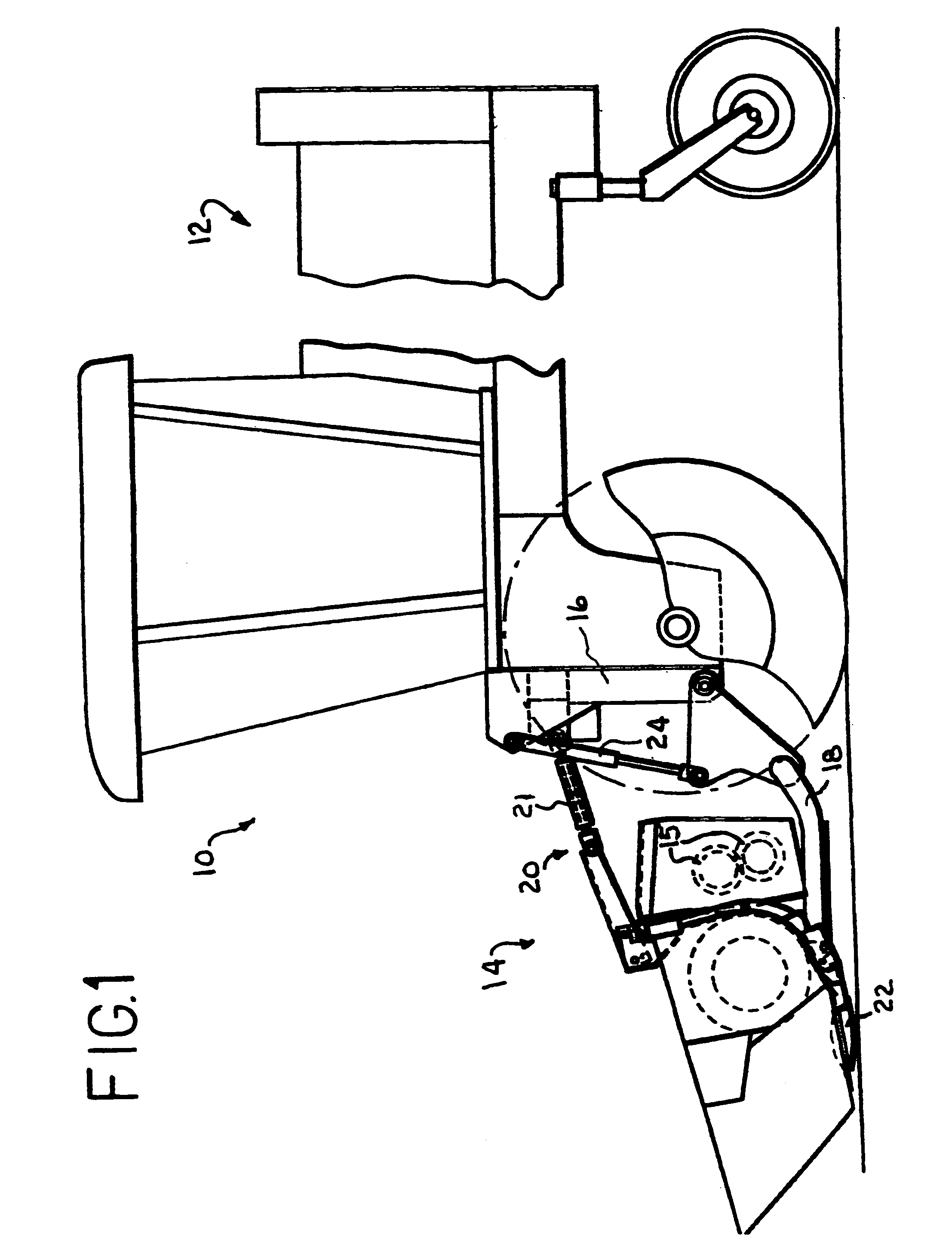

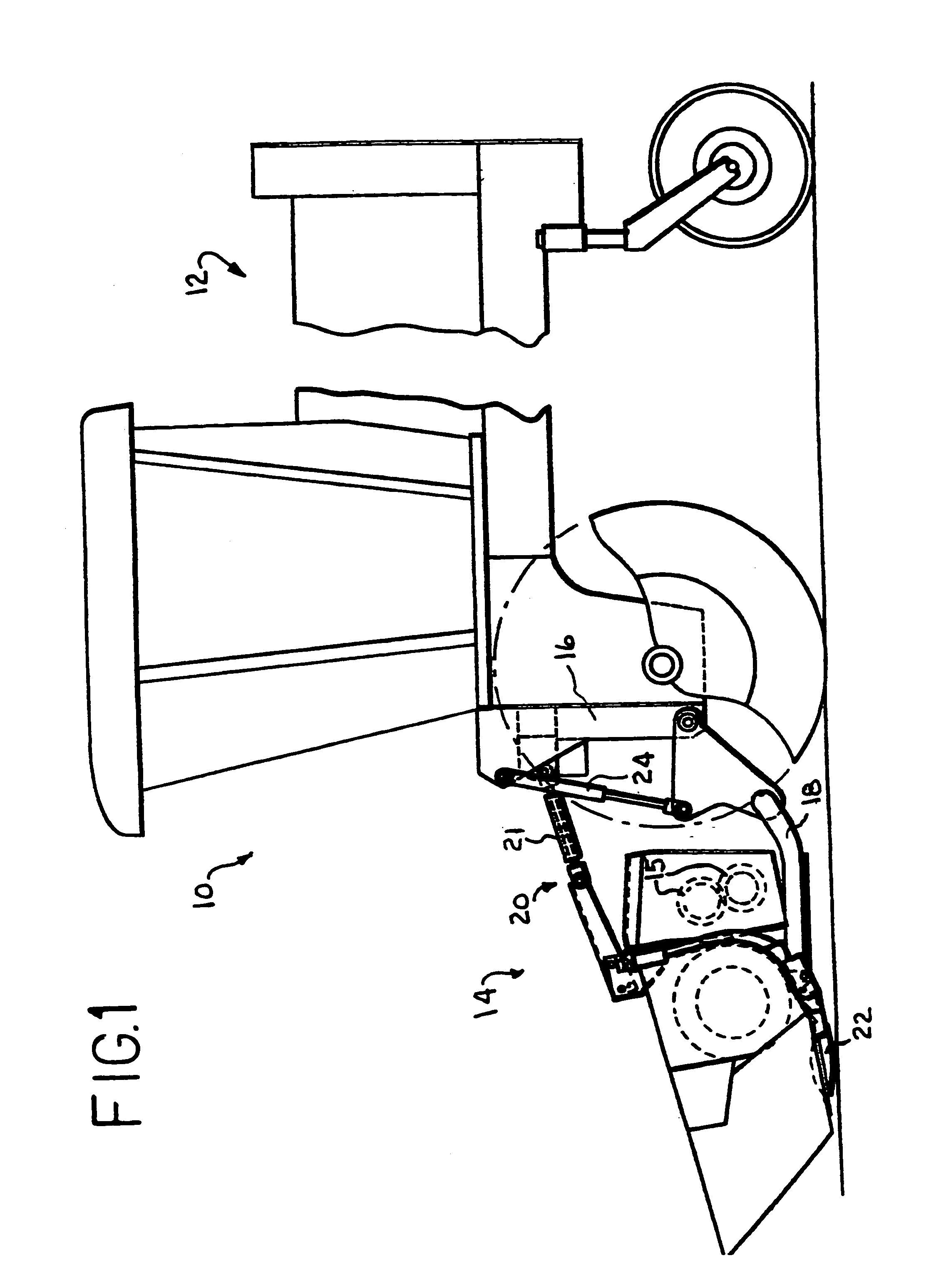

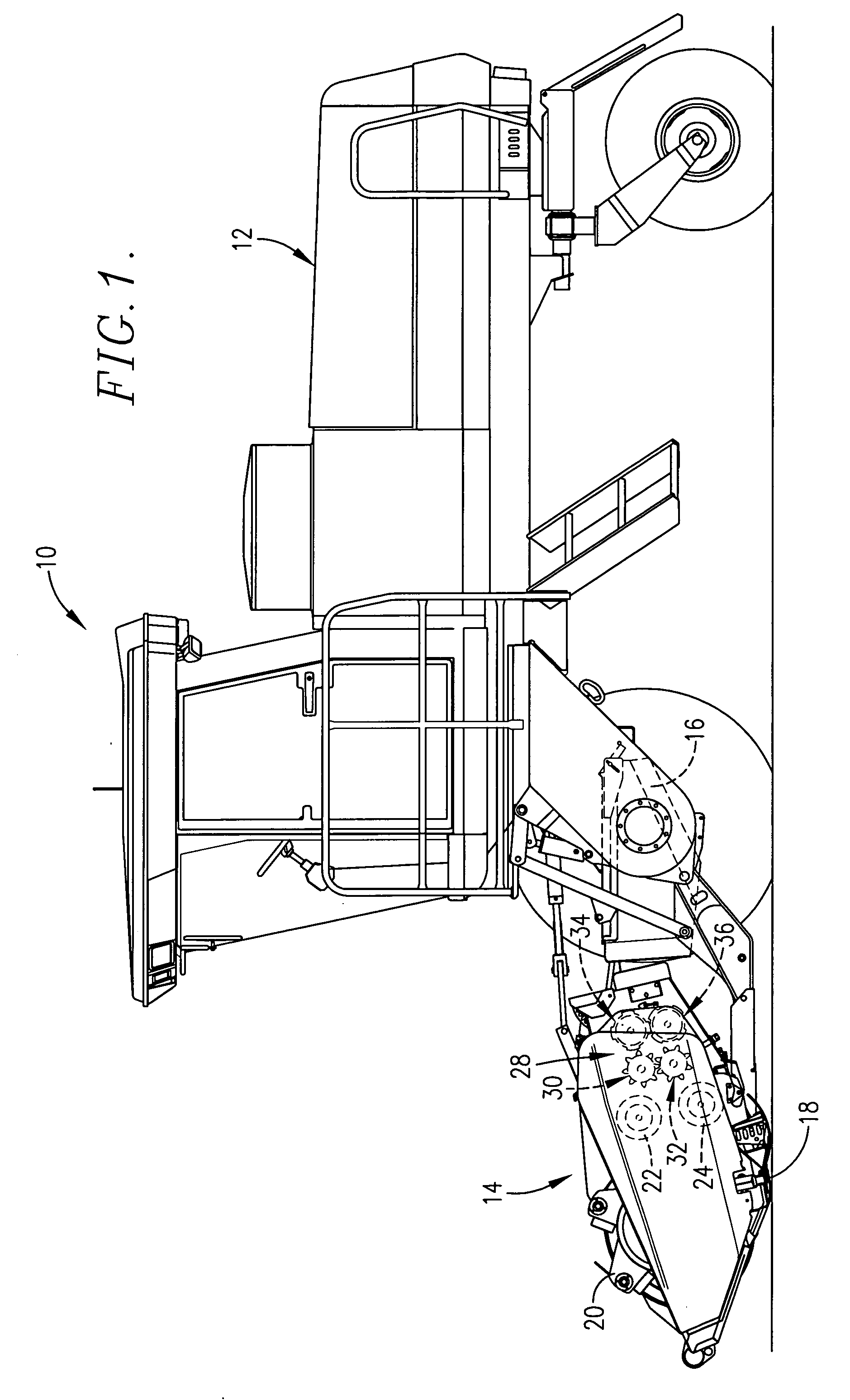

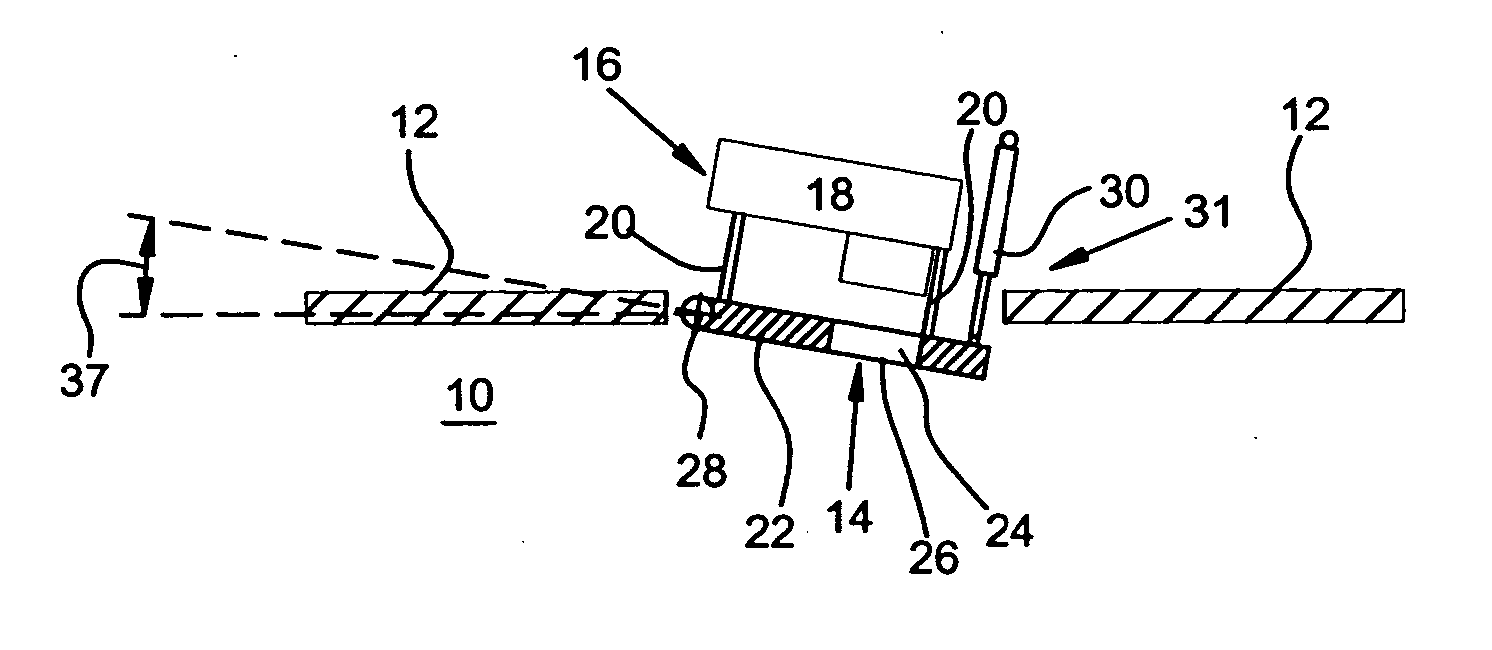

Header lift system with hydraulic counterweight

InactiveUS6901729B1Good flexibilityFew pointMowersAgricultural undercarriagesGravity centerEngineering

A hydraulic lift / flotation system for the header of a crop harvesting machine wherein each side of the header is supported by a single cylinder, which performs both the flotation and lift functions. To accommodate unbalanced headers (center of gravity not centered between the lift arms), hydraulic oil is sent to the return side of the lift cylinder on the lighter side of the header, thus resulting in even raising, lowering and float.

Owner:CNH IND AMERICA LLC +1

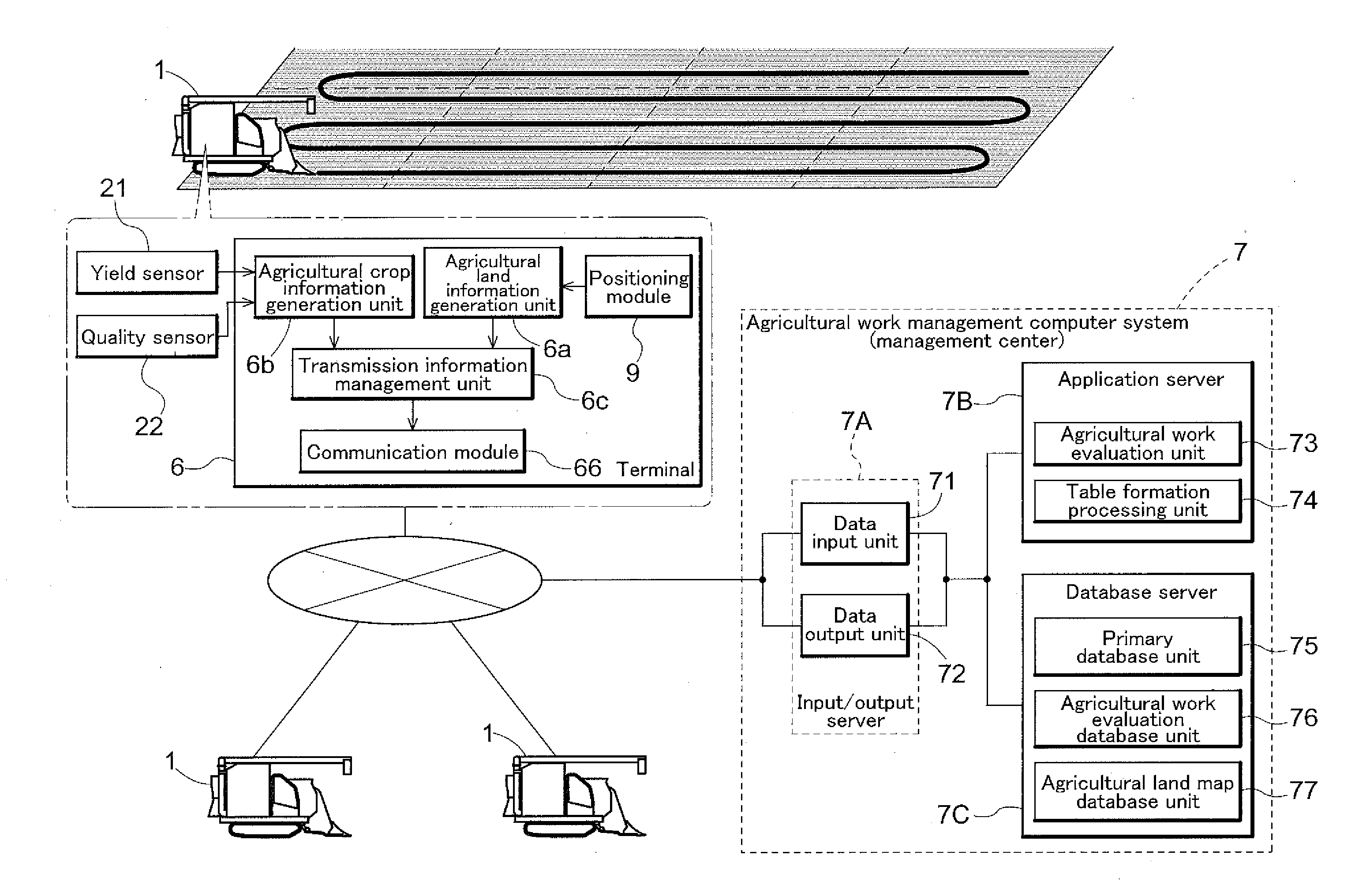

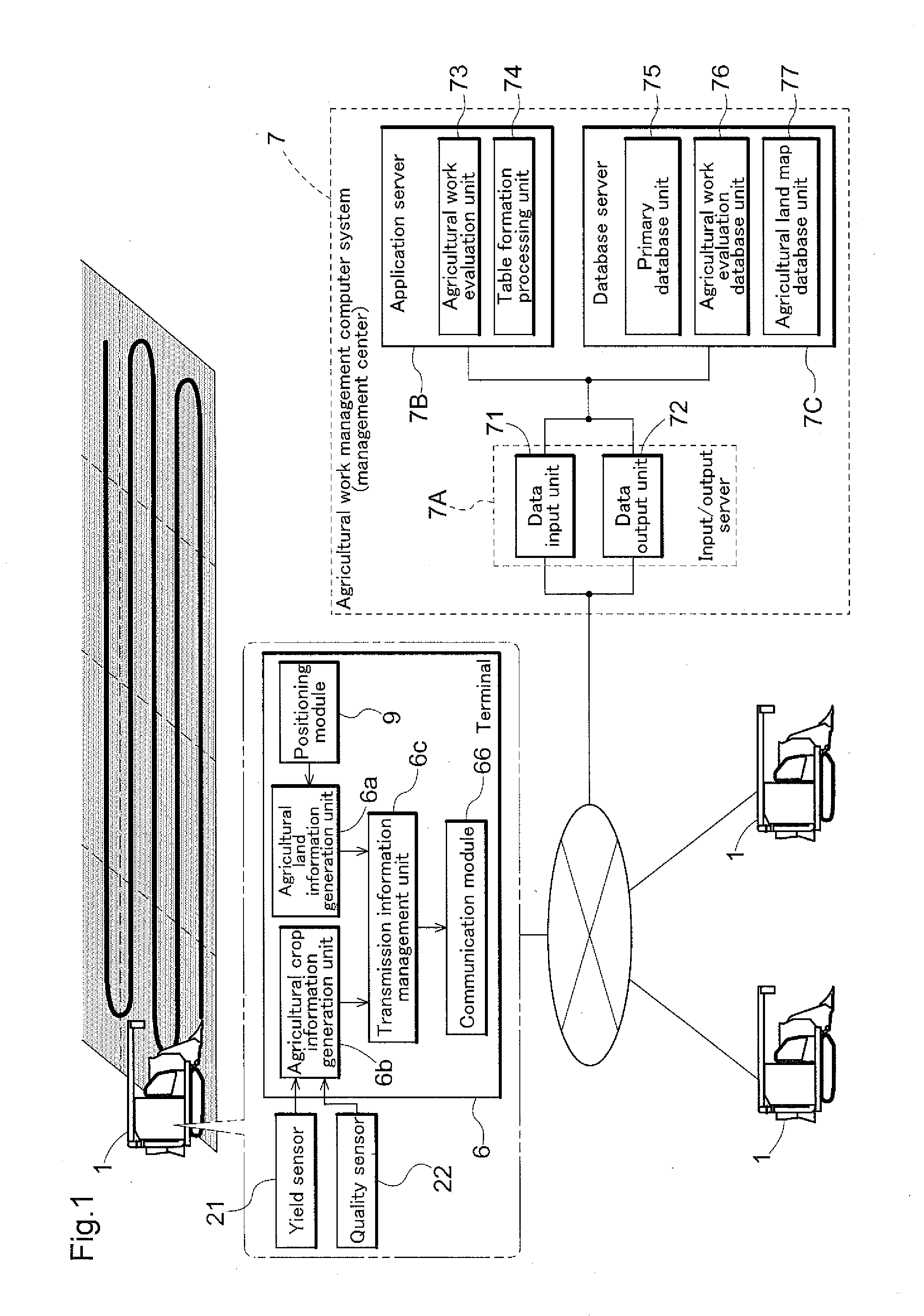

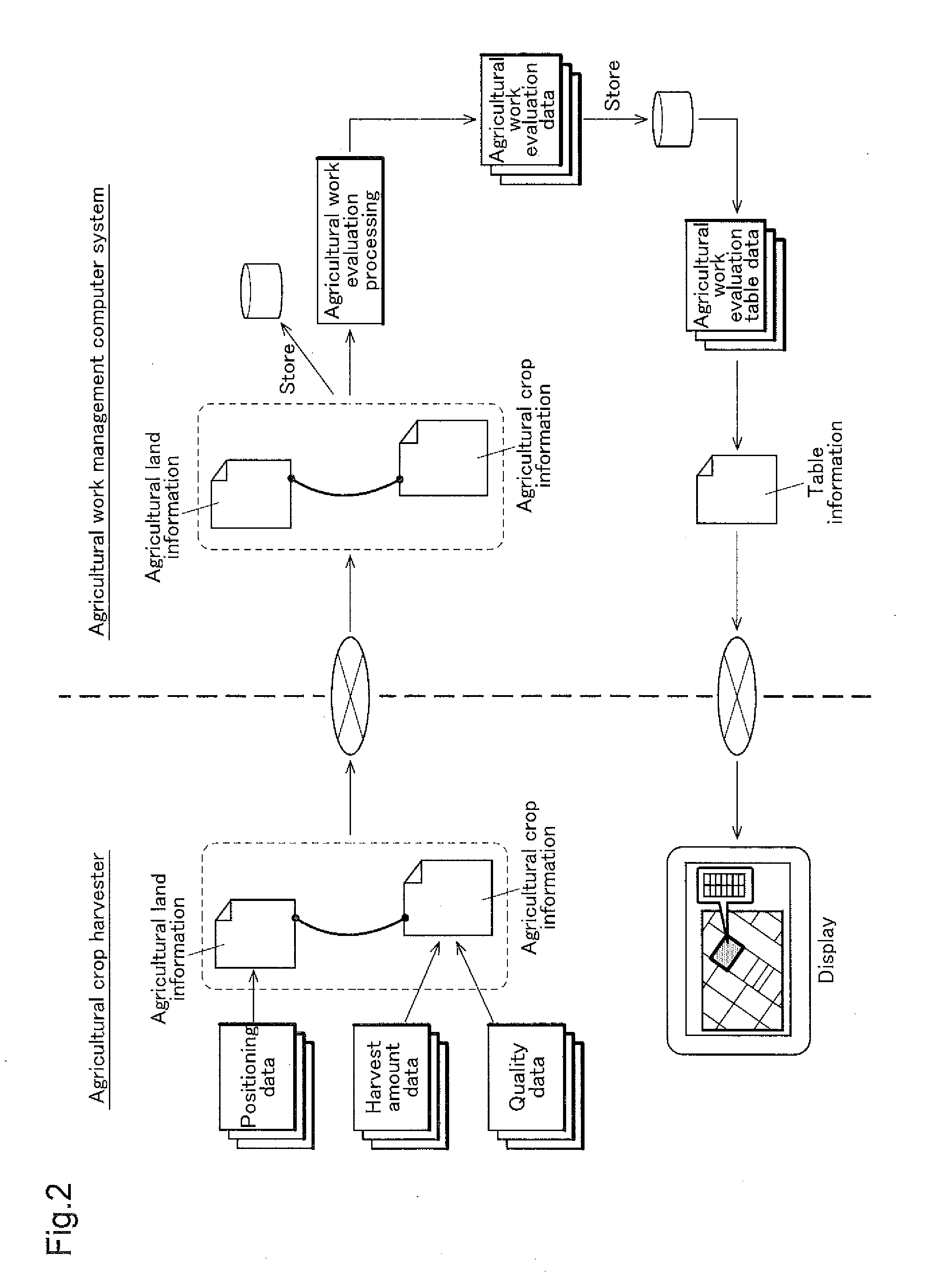

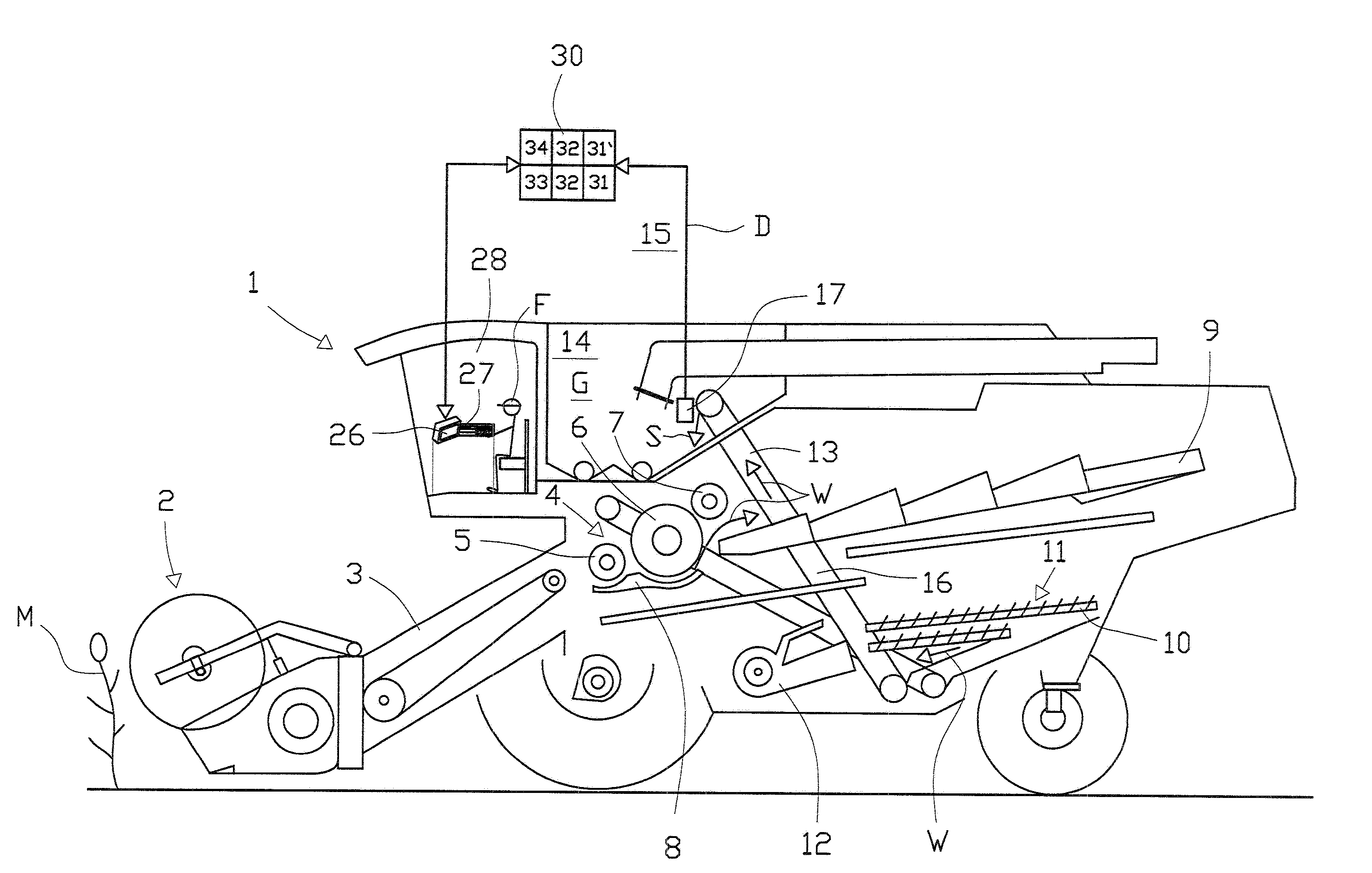

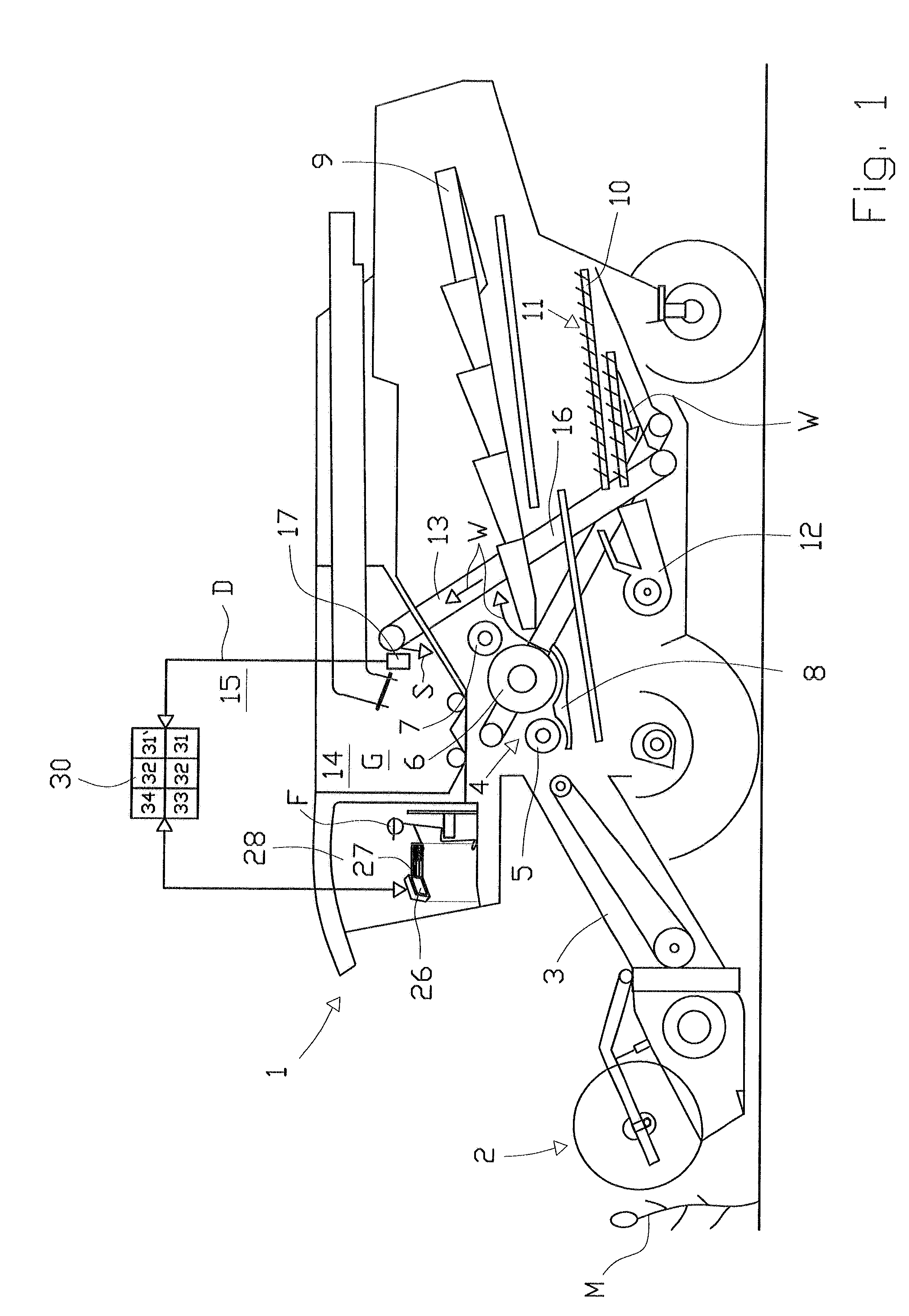

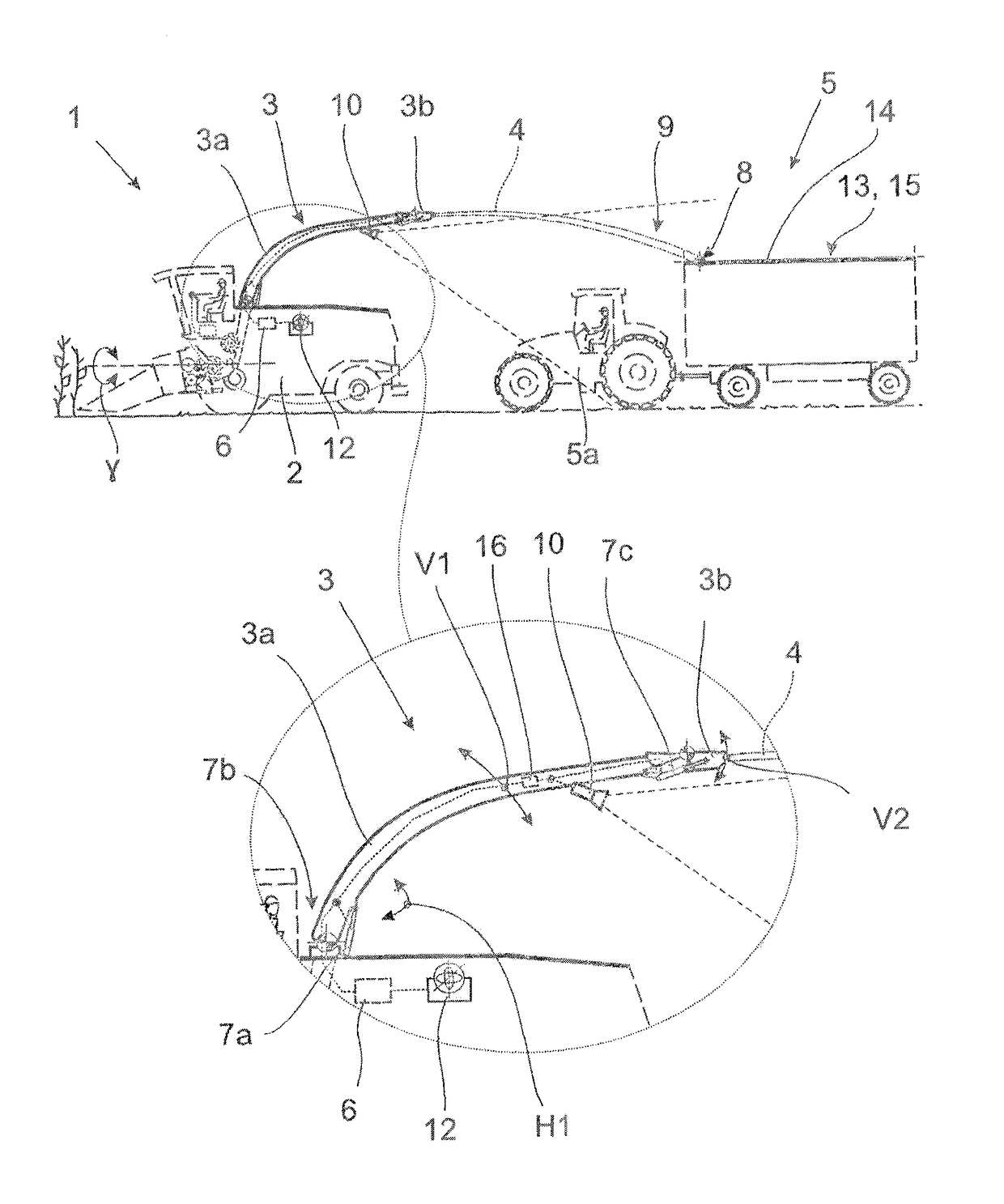

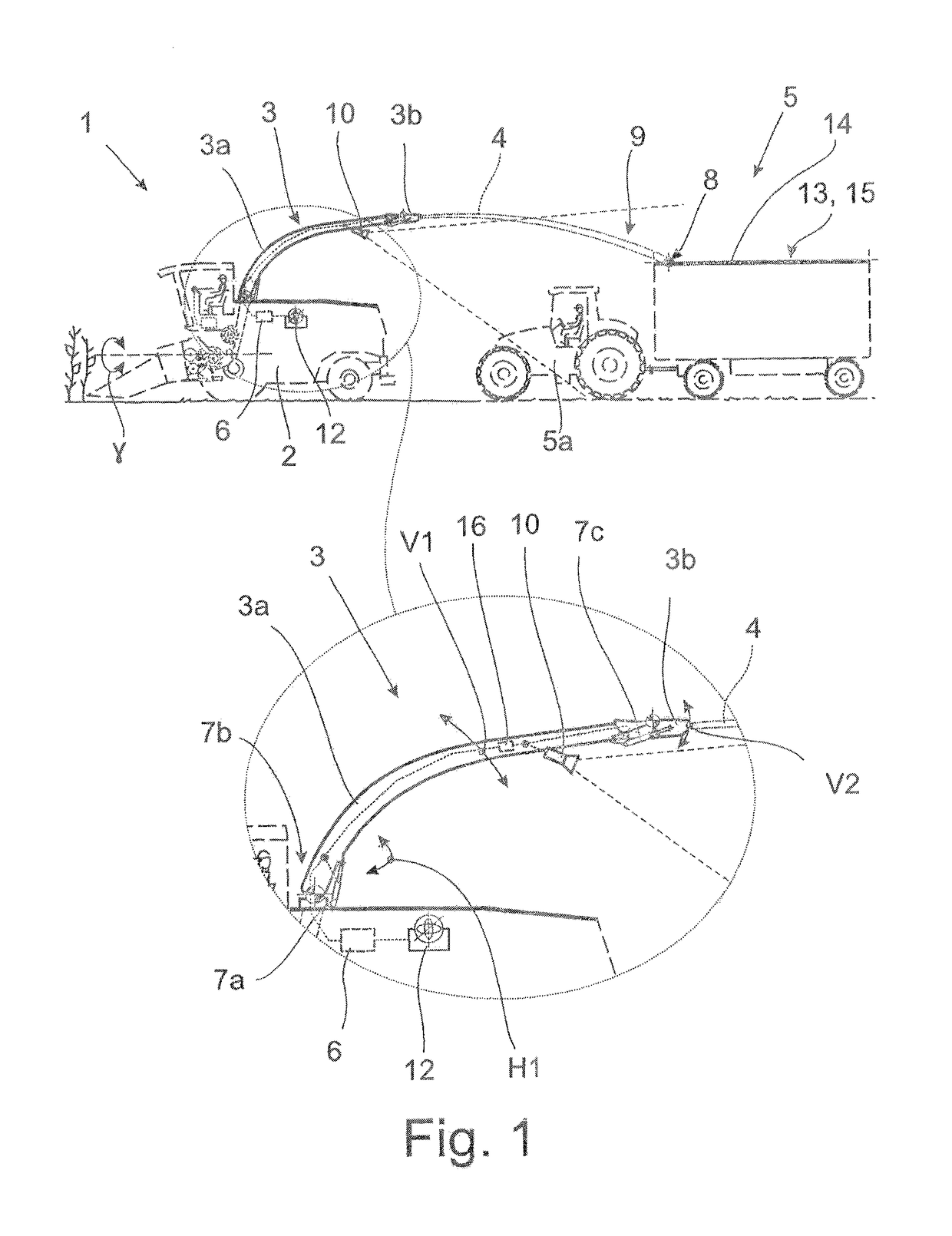

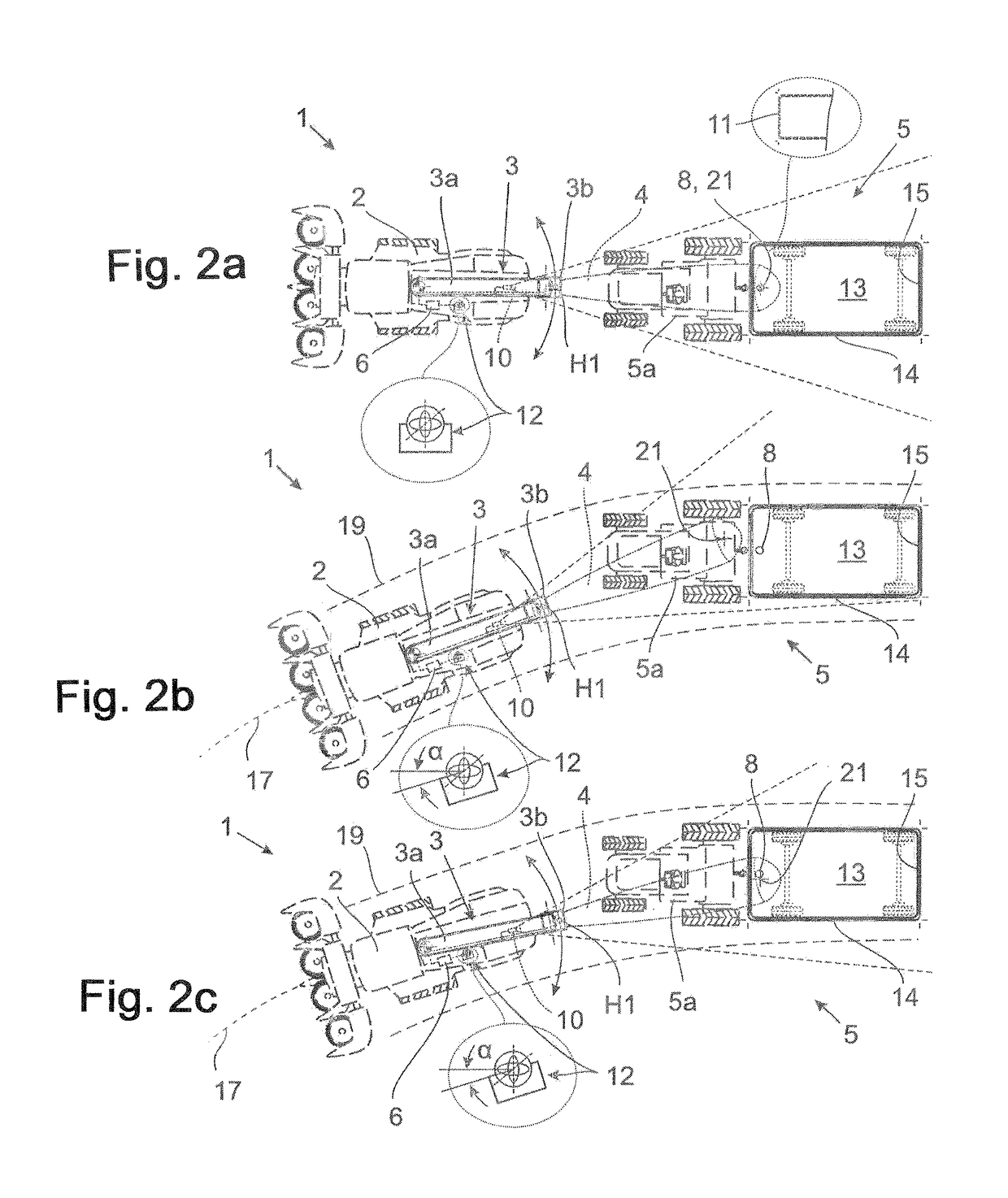

Agricultural Work Management System and Crop Harvester

ActiveUS20150242799A1Easy to useEasy to measureParticular environment based servicesMowersAgricultural landQuality data

An agricultural work management system includes: a data input unit configured to receive, from an agricultural crop harvester, harvesting position data indicating a harvesting work position as agricultural land information, harvest amount data indicating a harvest amount of the agricultural crop harvested in the agricultural land, and quality data indicating the quality thereof as agricultural crop information; a database server configured to store the agricultural land information and the agricultural crop information such that they can be associated with each other; an agricultural work evaluation unit configured to perform agricultural work evaluation on the agricultural land based on the agricultural land information and the agricultural crop information; and a data output unit configured to send out the agricultural work evaluation data generated by the agricultural work evaluation unit.

Owner:KUBOTA LTD

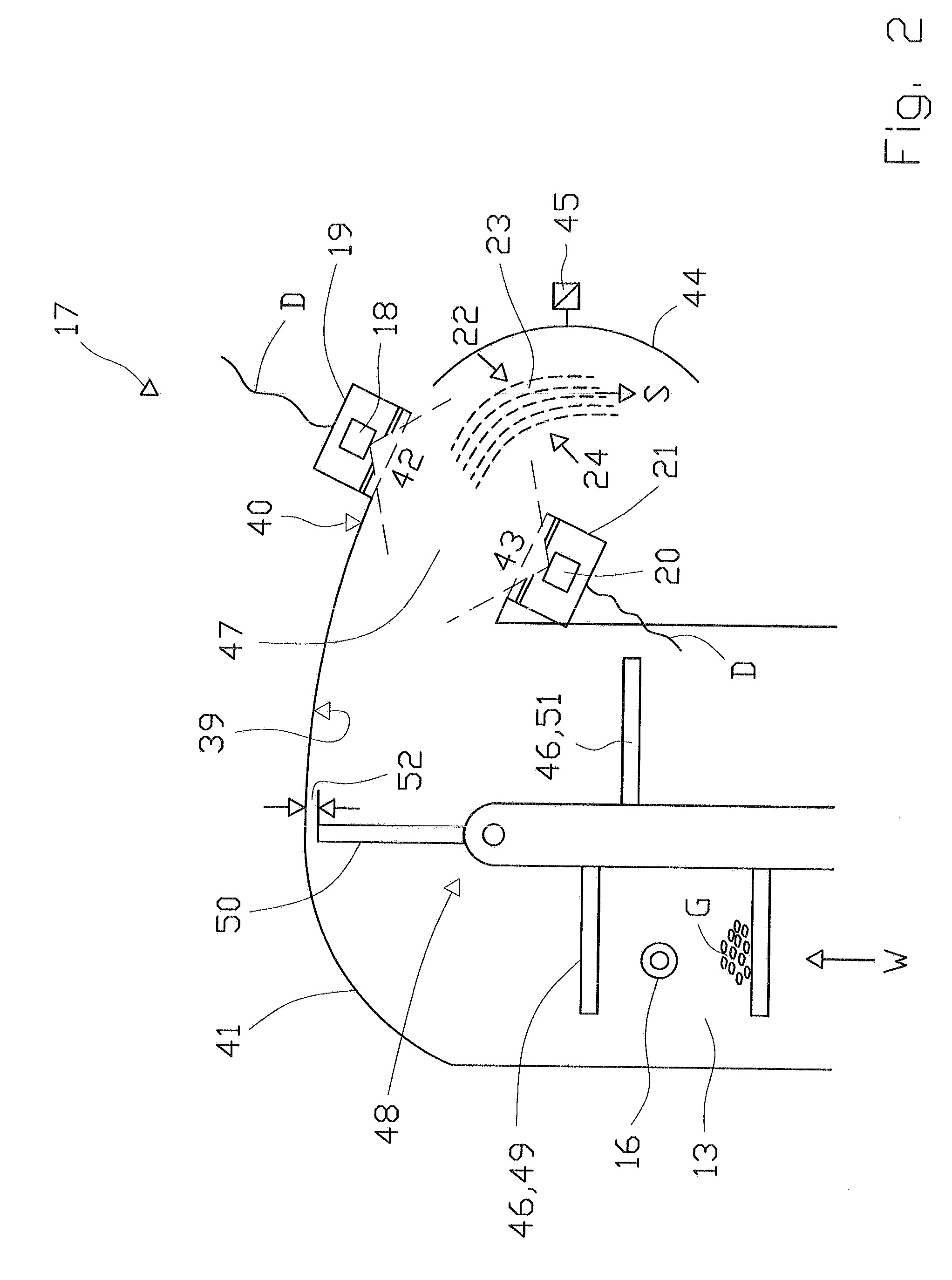

Device for detection and determination of the composition of bulk material

ActiveUS20120004815A1Easy to detectAnalogue computers for trafficMowersGrain elevatorImage recording

A device for detection and determination of a composition of a bulk material, has an image recording unit, at least one control unit, at least one memory unit, and a selection unit to enable a qualified determination to be made, during a transfer of a crop material flow into a container of an agricultural harvesting machine, of a composition of a crop during processing of the crop material, so that adjustment parameters of working assemblies of the agricultural harvesting machine are changeable during the processing of the crop material, wherein the image recording unit has at least two image detectors for recording images or image series of the crop material flow at equidistant intervals or permanently, wherein one of the image detectors is disposed substantially perpendicularly to a top side of a surface of the crop material flow emerging from a grain elevator head or a discharge chute, and another one of the two image detectors is disposed substantially perpendicularly to an underside of a surface of the crop material flow.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

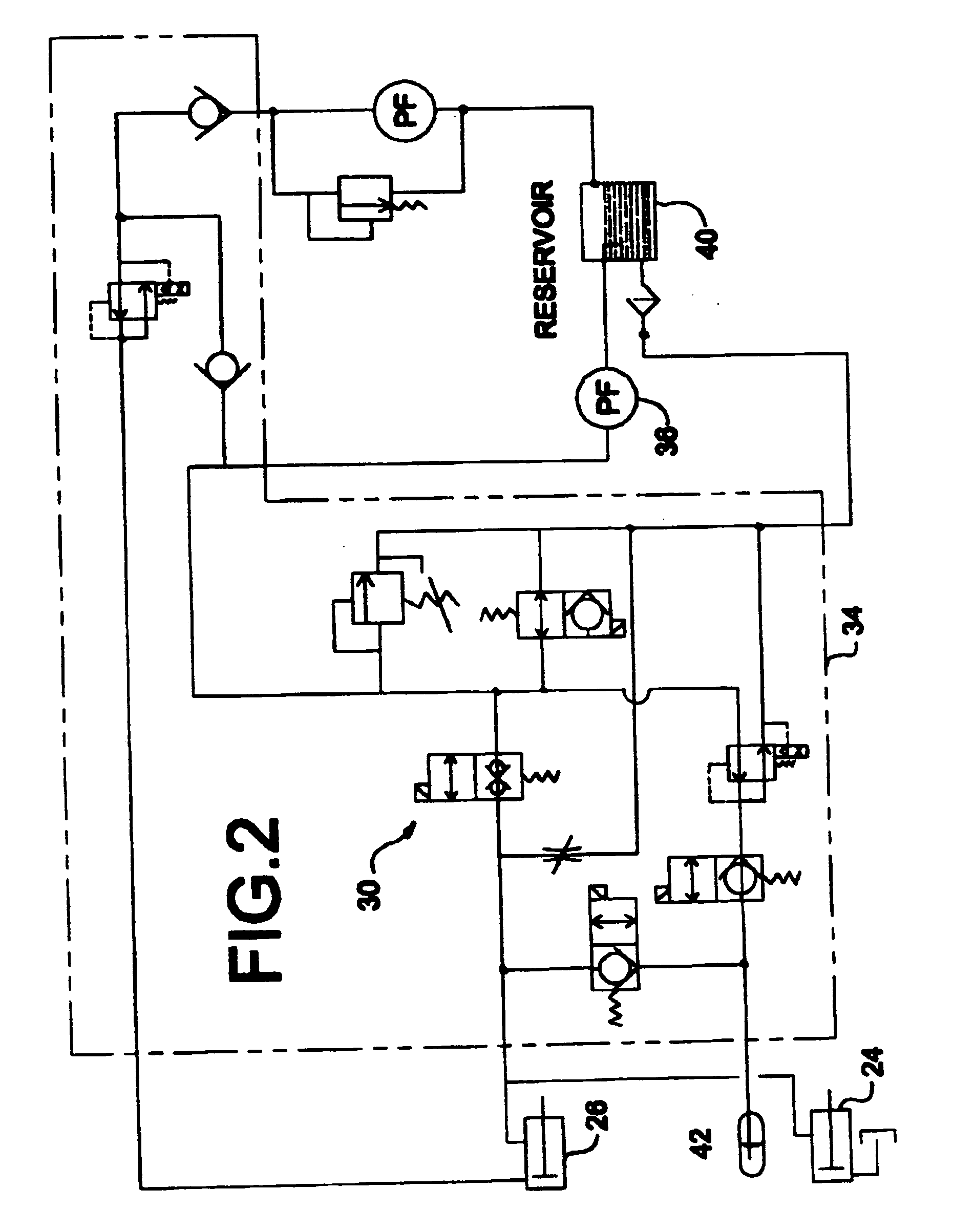

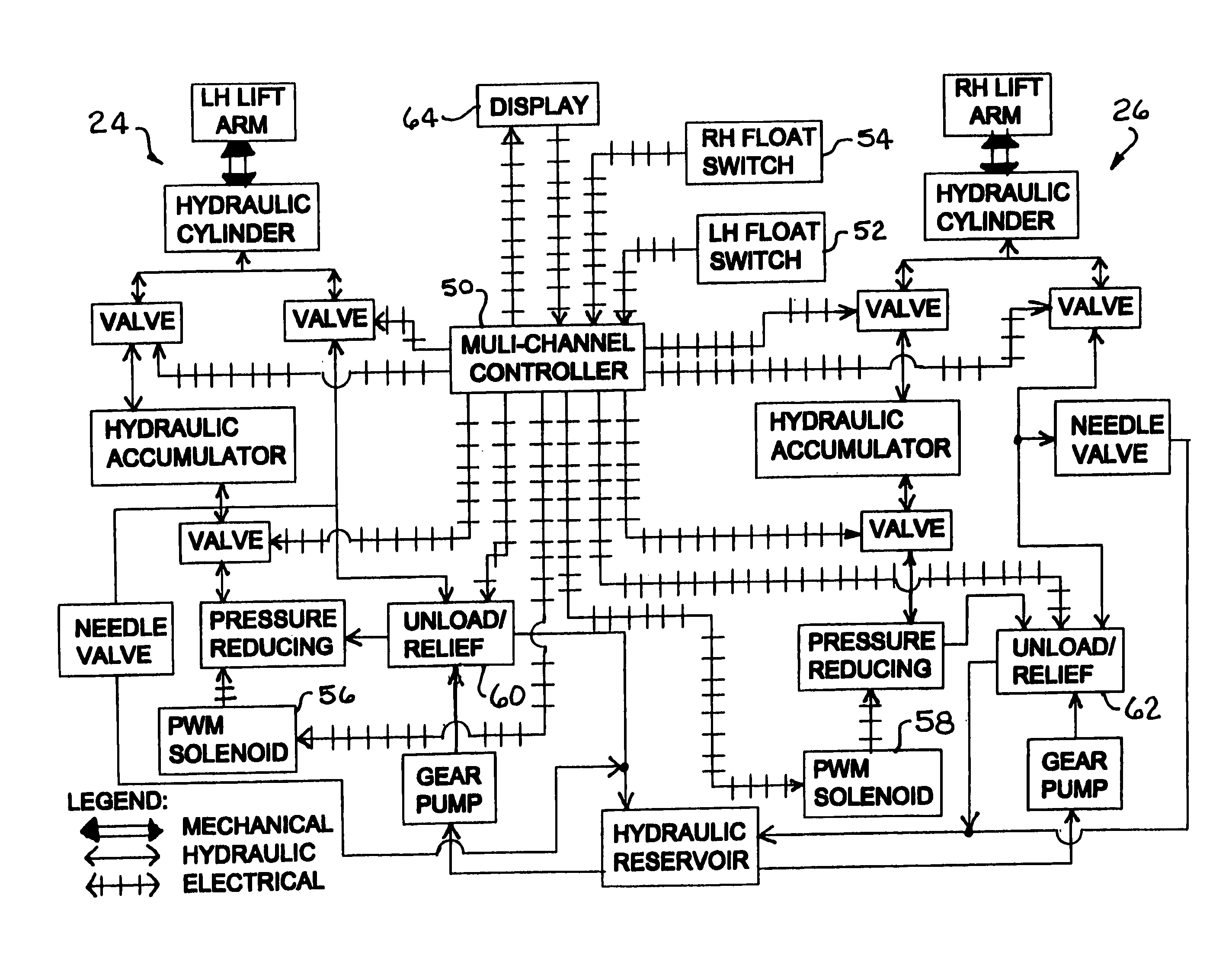

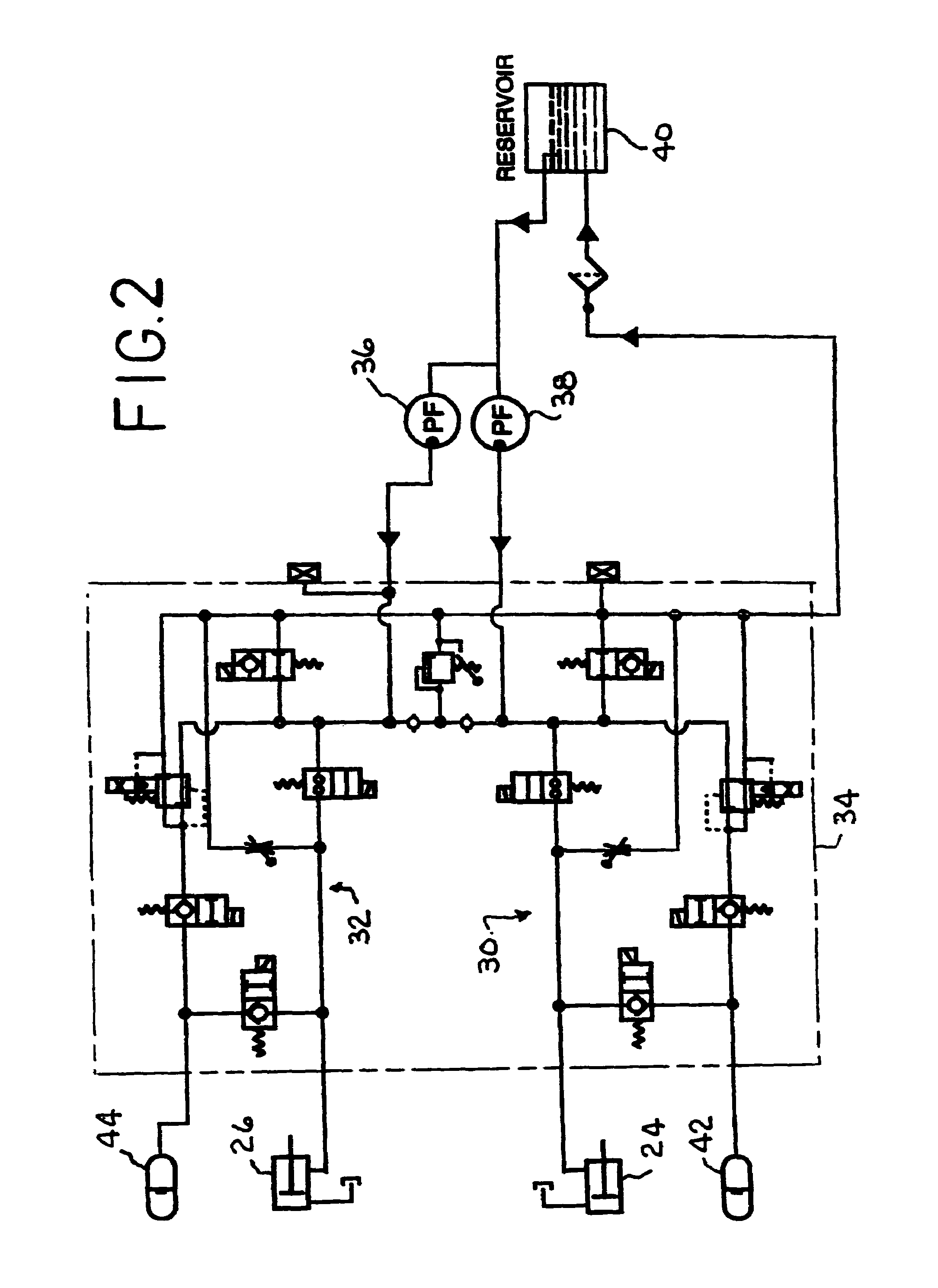

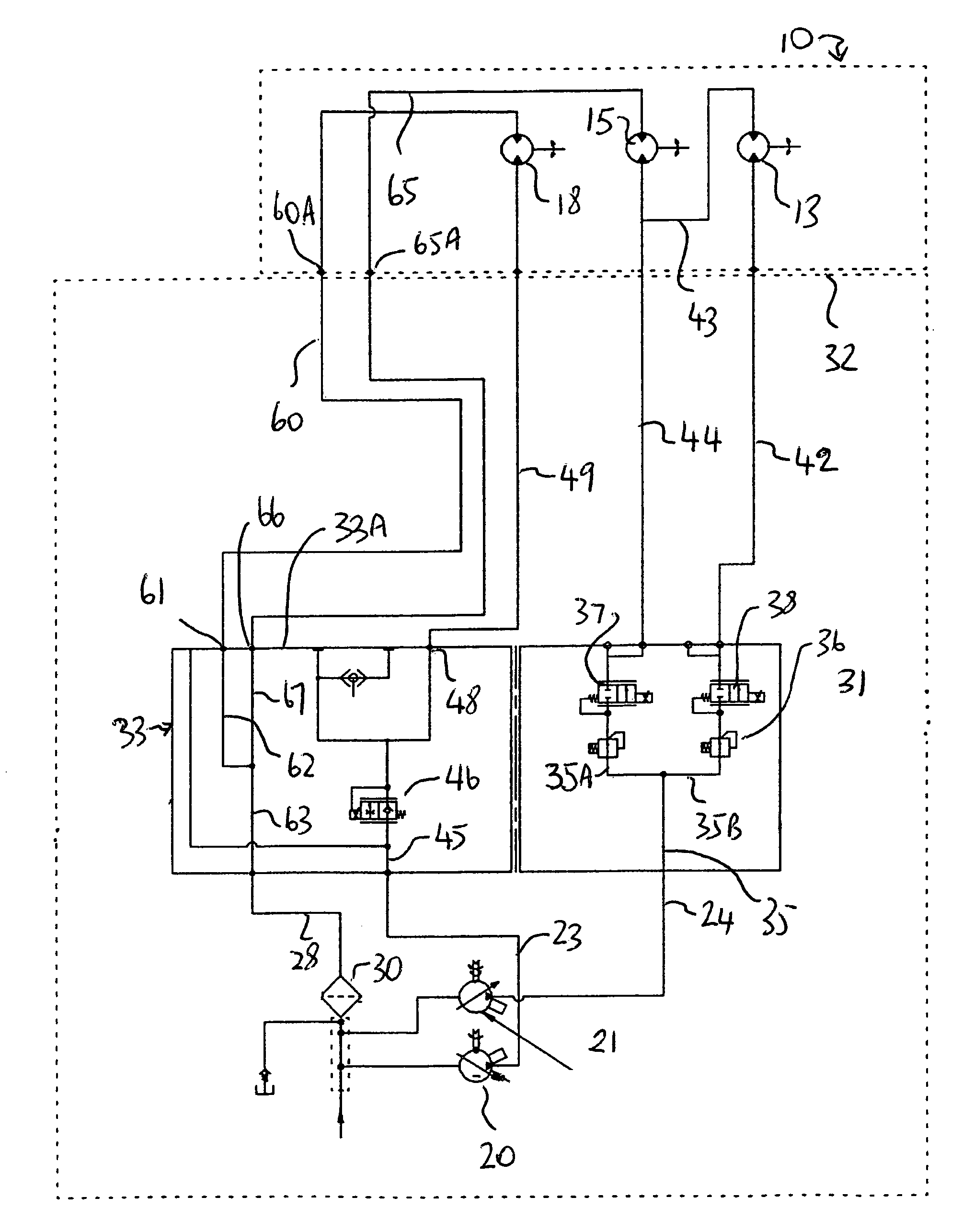

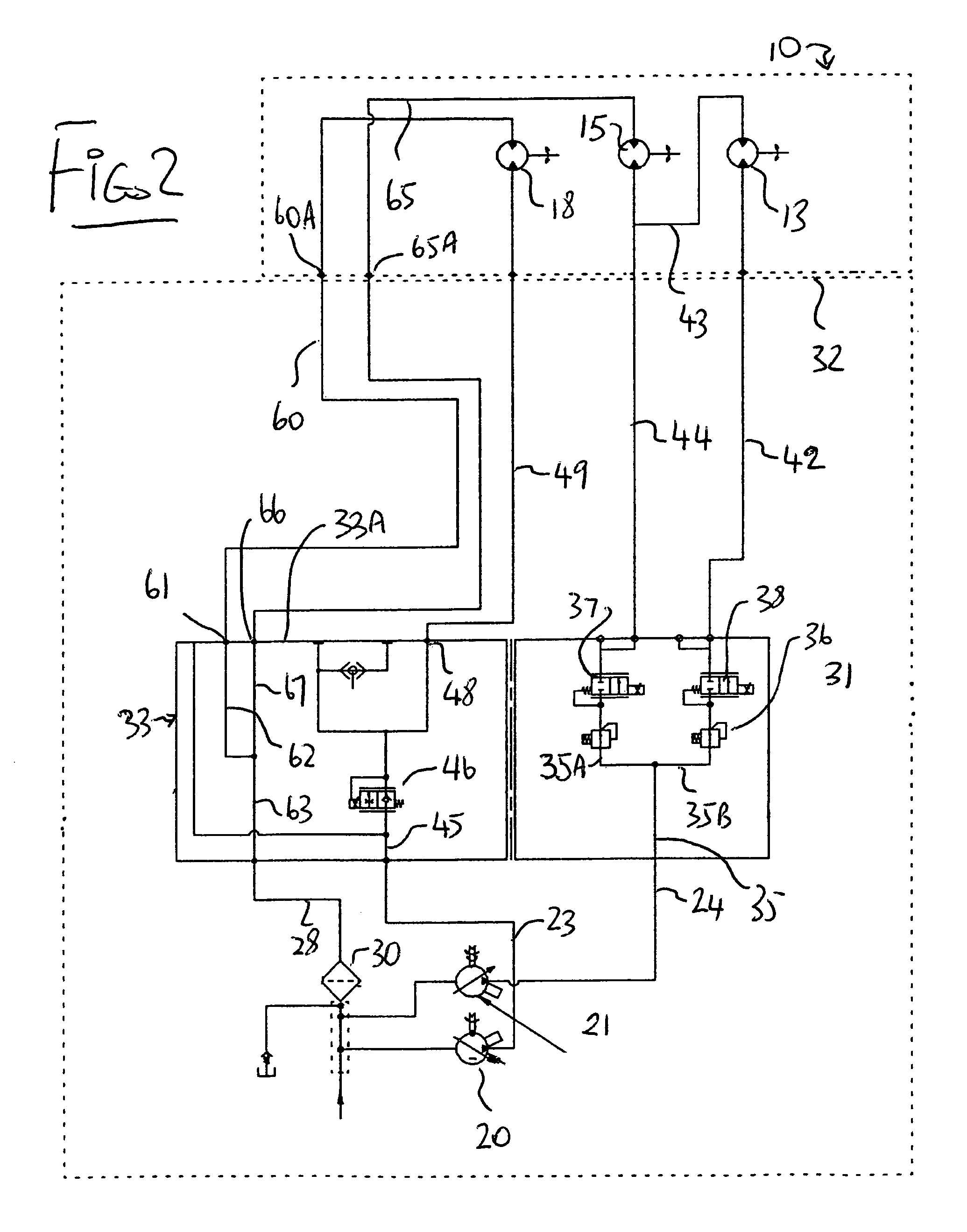

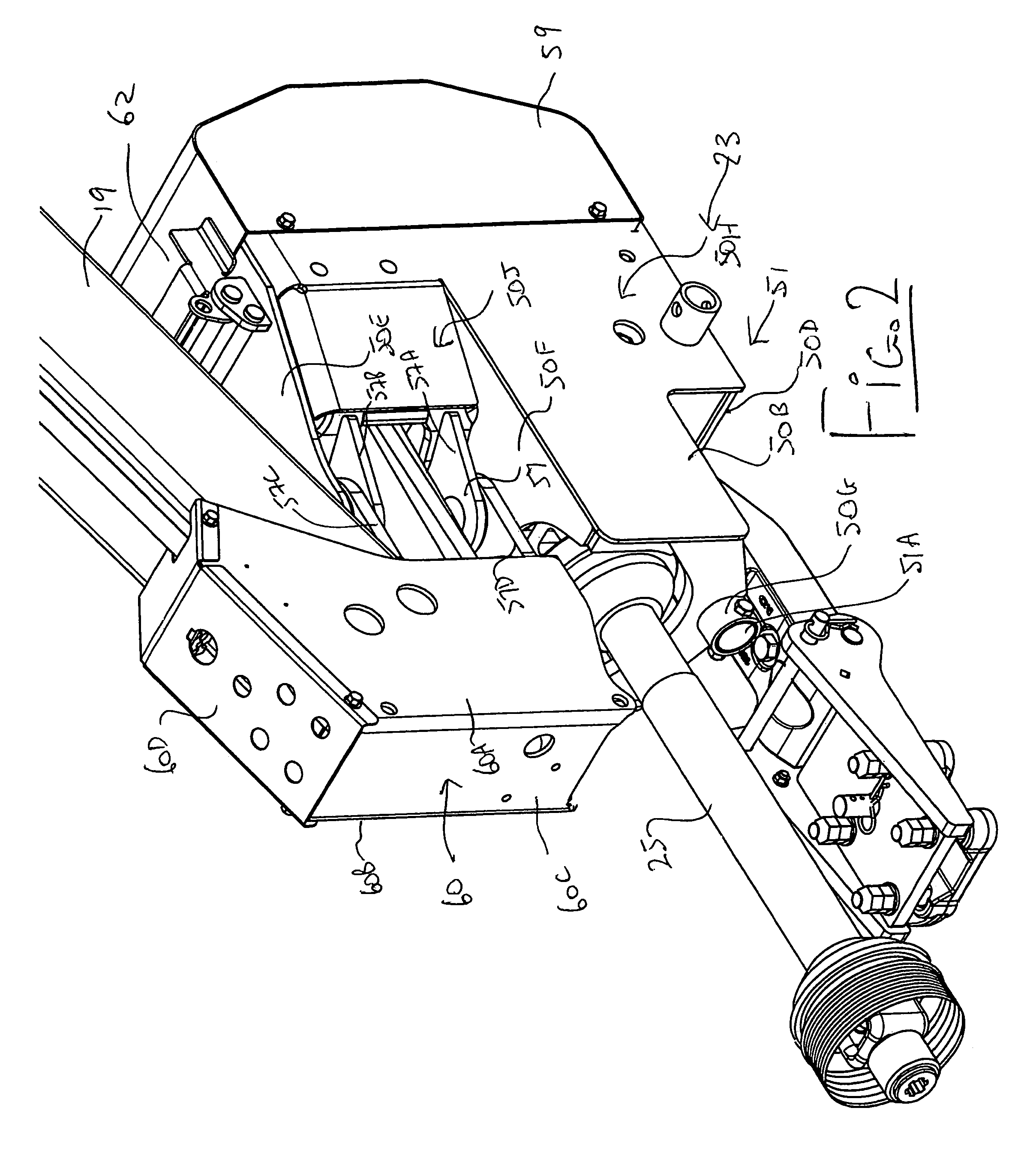

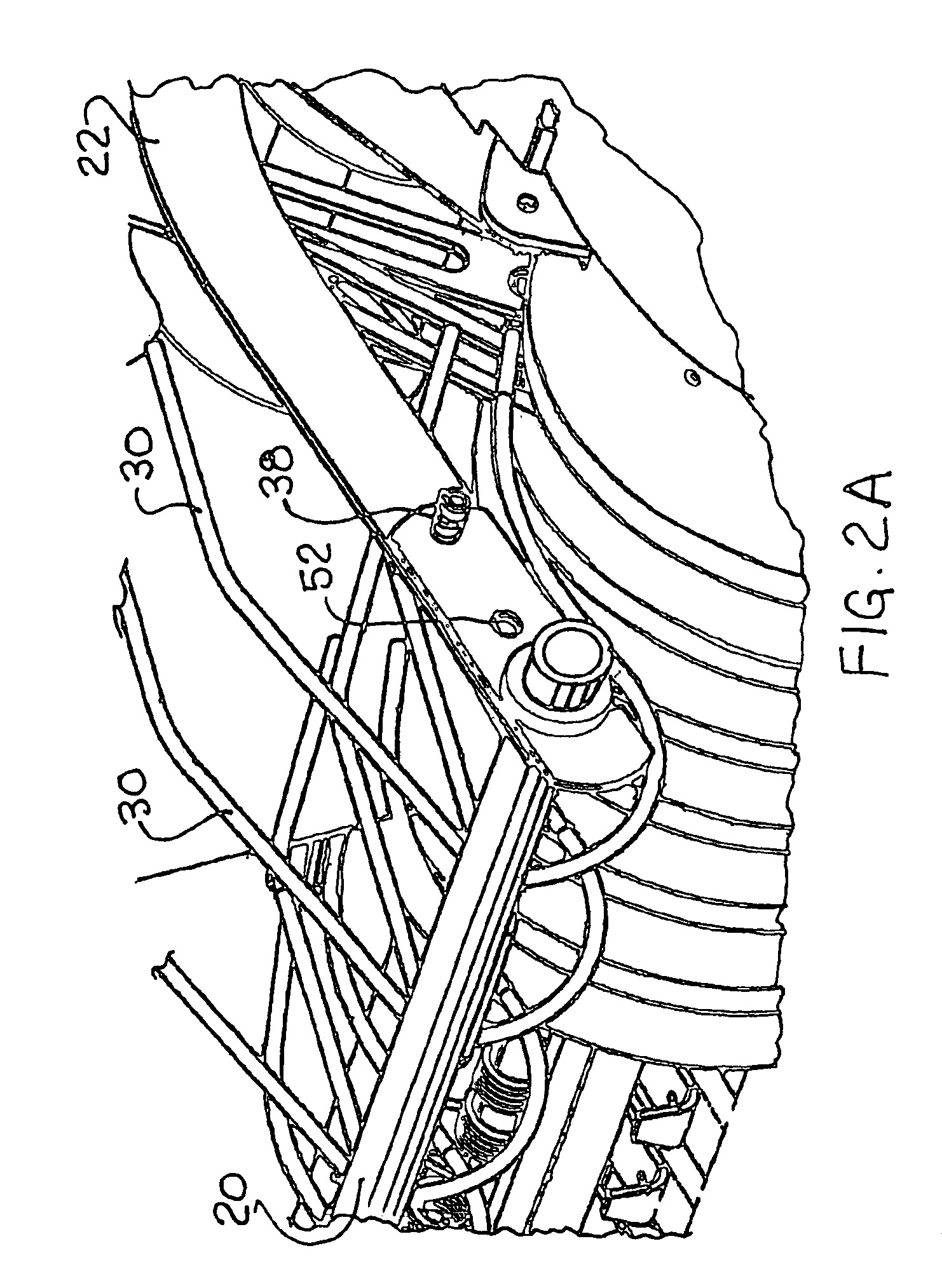

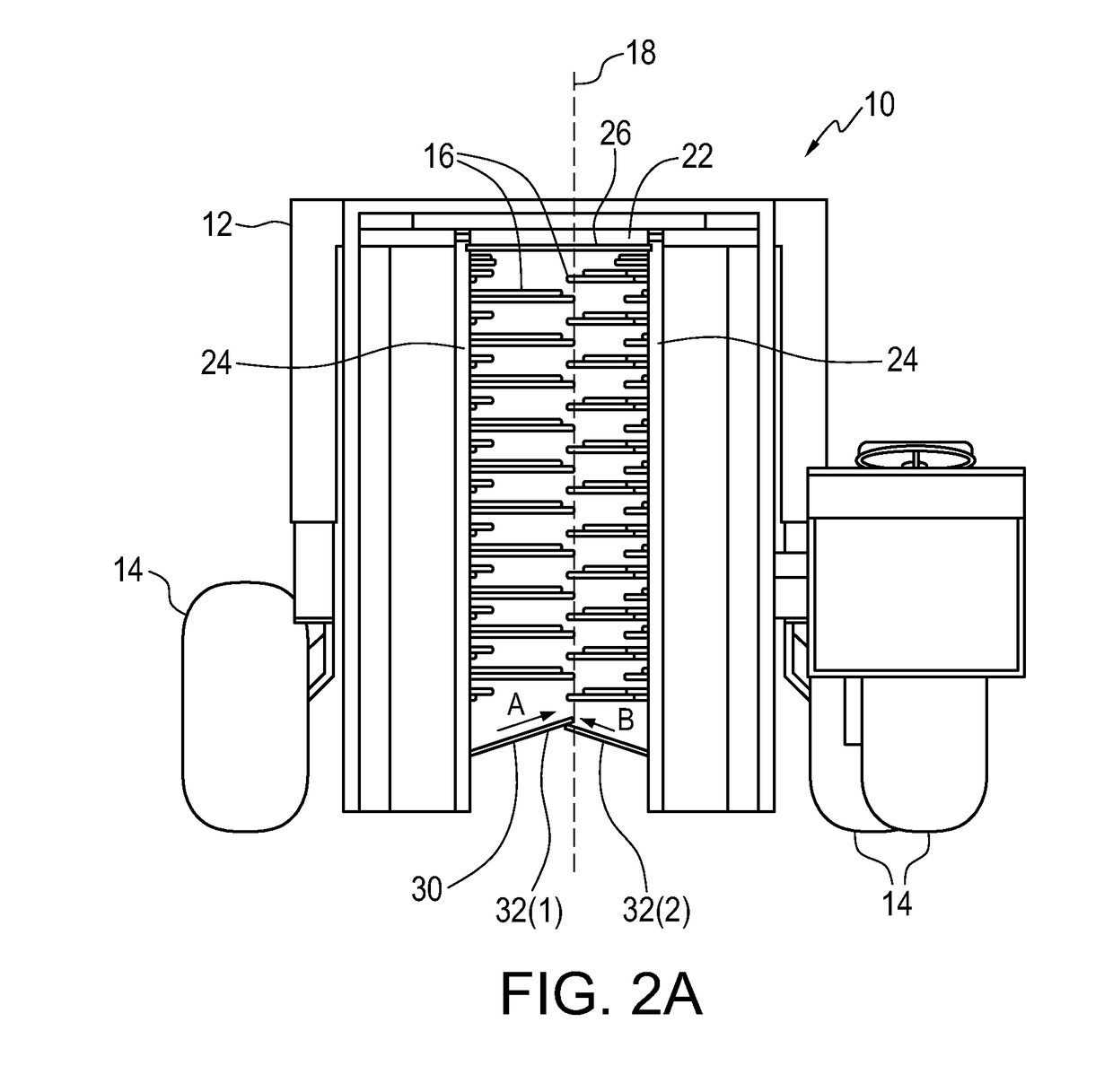

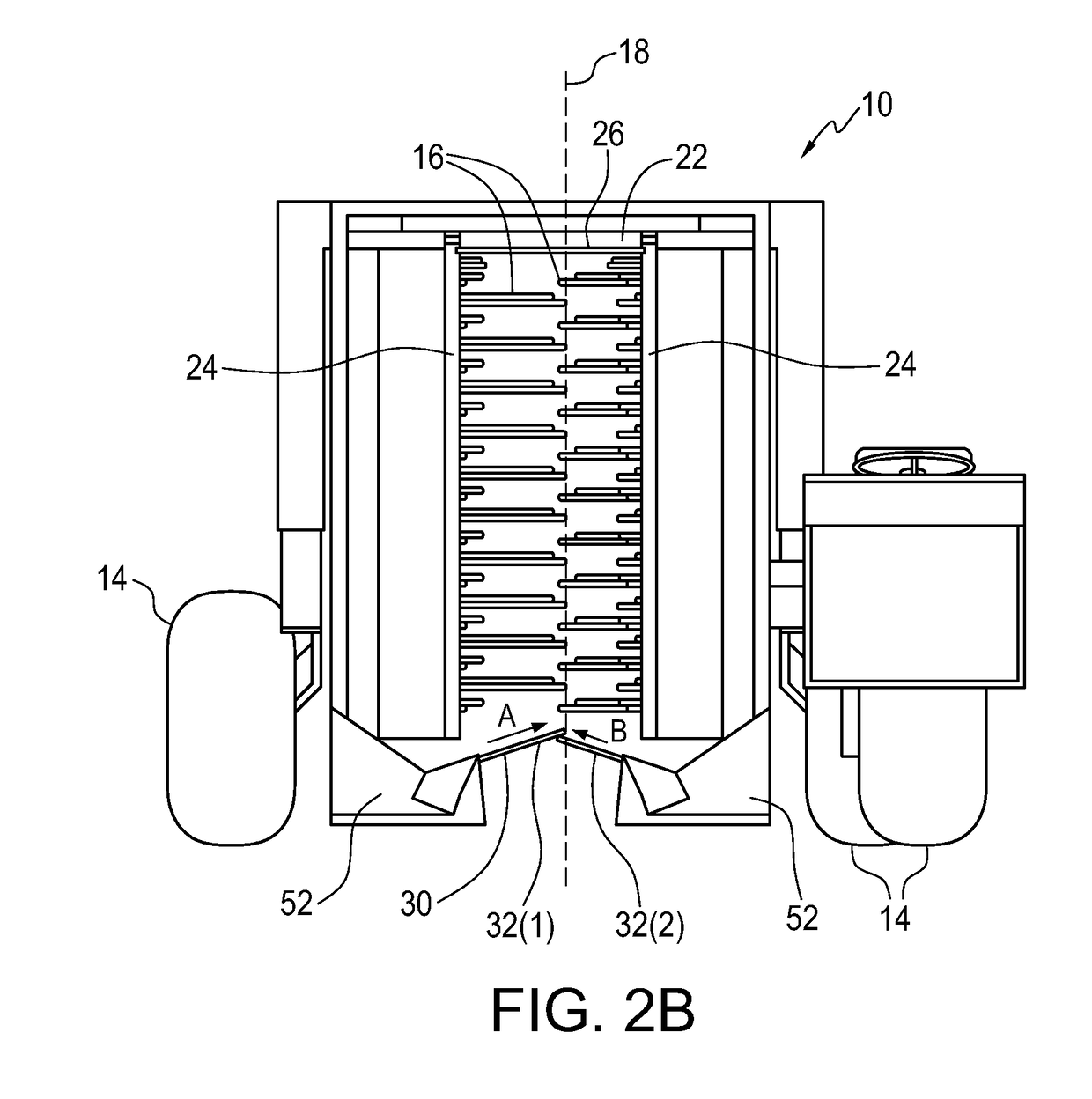

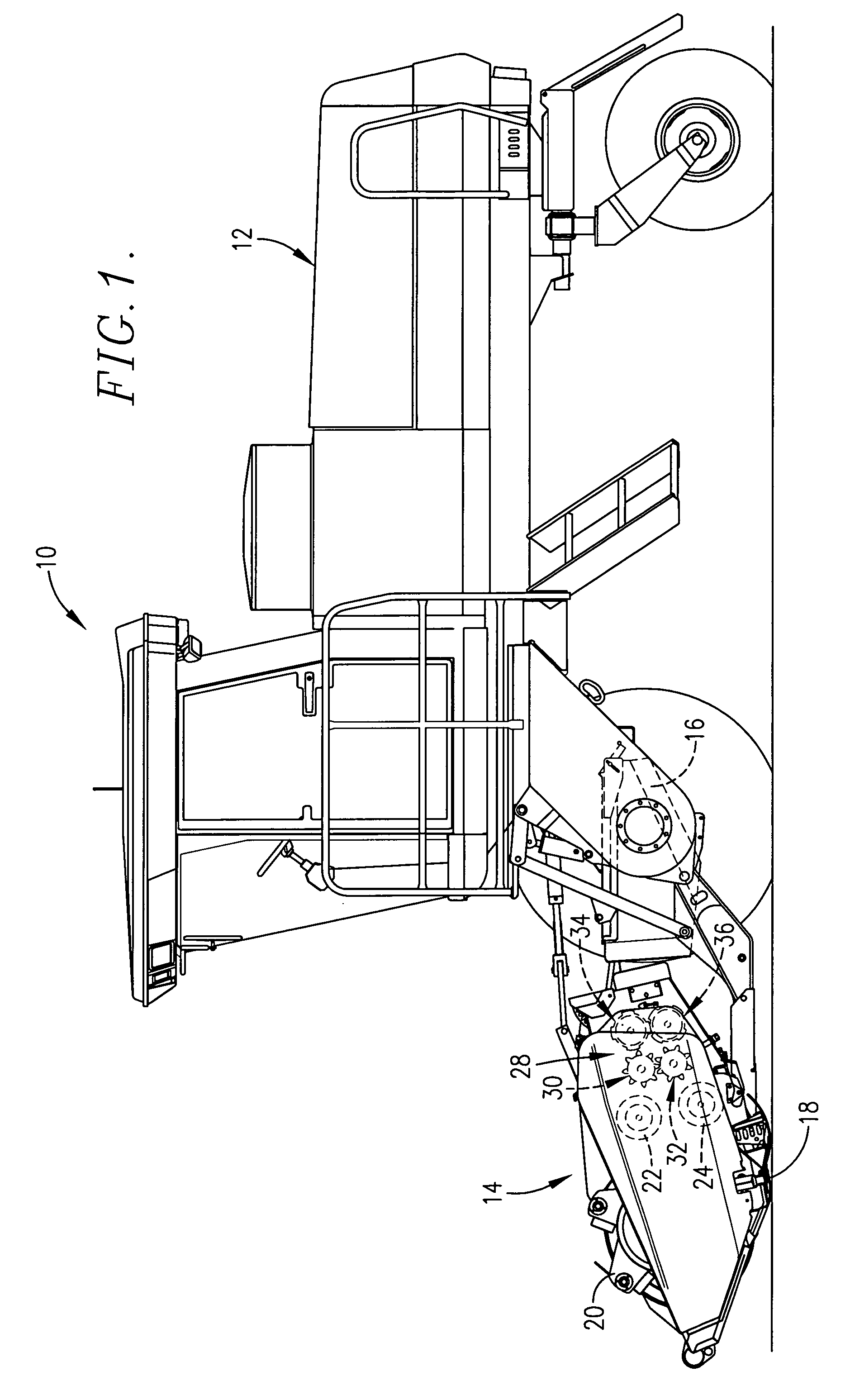

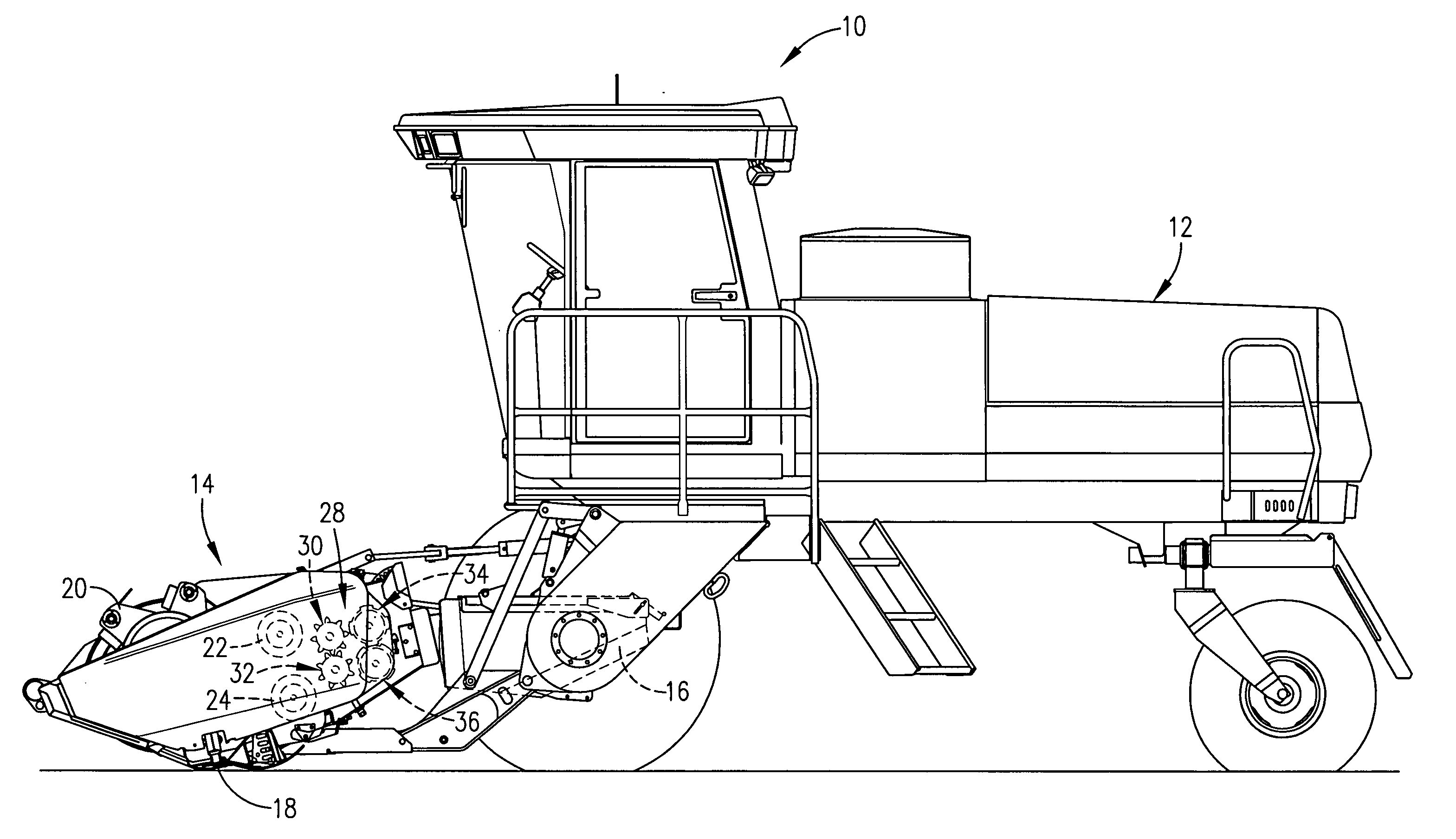

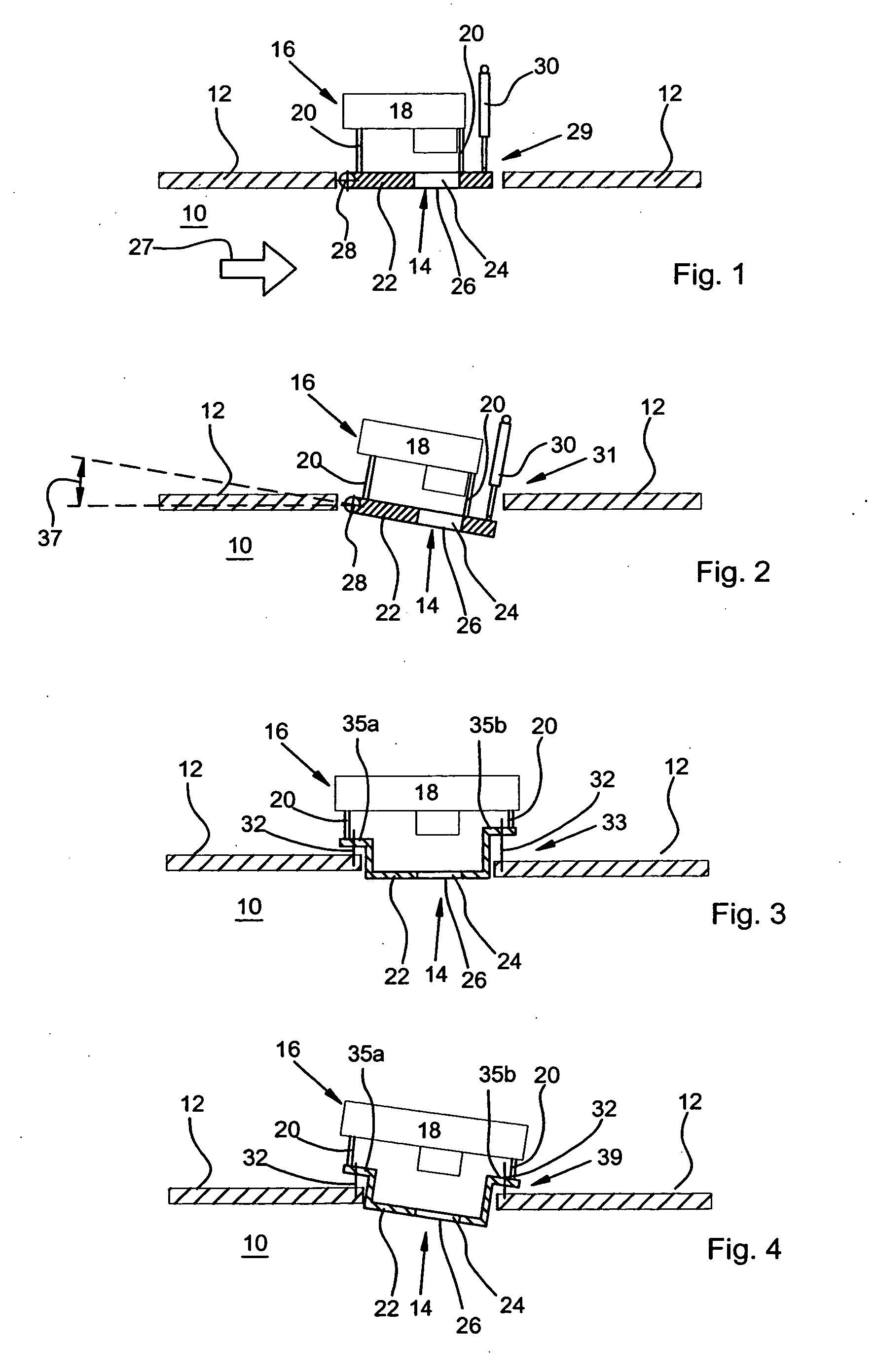

Independent hydraulic header lift and flotation system

A hydraulic lift / flotation system for the header of a crop harvesting machine wherein each side of the header is supported by a single cylinder, which performs both the flotation and lift functions. For even lifting and flotation of an unbalanced header, each cylinder has its own control valve, pump, and accumulator. The operator sets the desired flotation force by actuating rocker switches; one switch position allows hydraulic oil to enter an accumulator to reduce header contact force with the ground. The other position allows oil to exit the accumulator to increase header contact force with the ground. To evenly float an unbalanced header, separate switches adjust each side independently. Once the flotation forces are set, the control valves will return to this preset flotation condition whenever float mode is selected, regardless of subsequent header lift and lower operations.

Owner:CNH IND AMERICA LLC

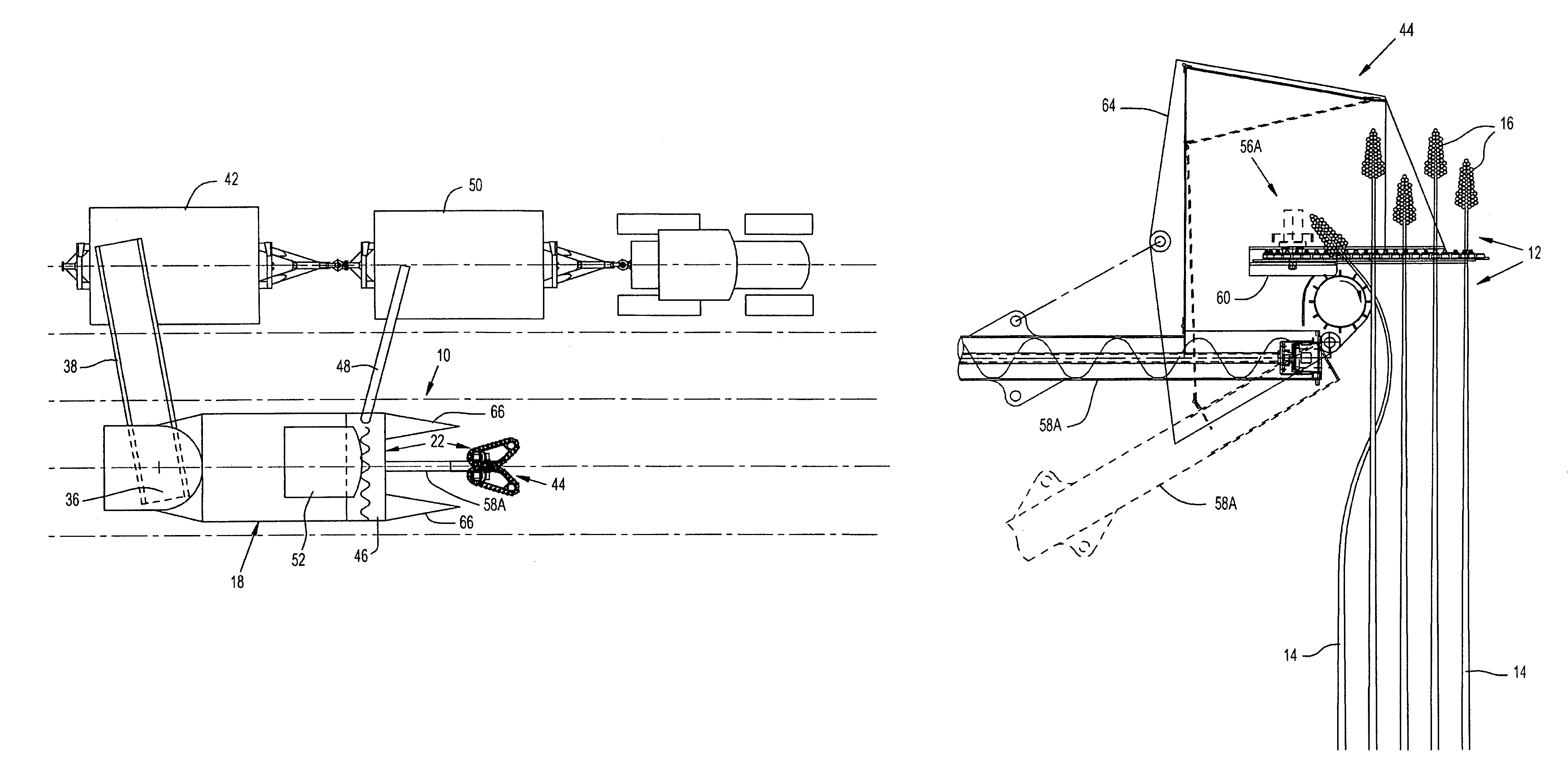

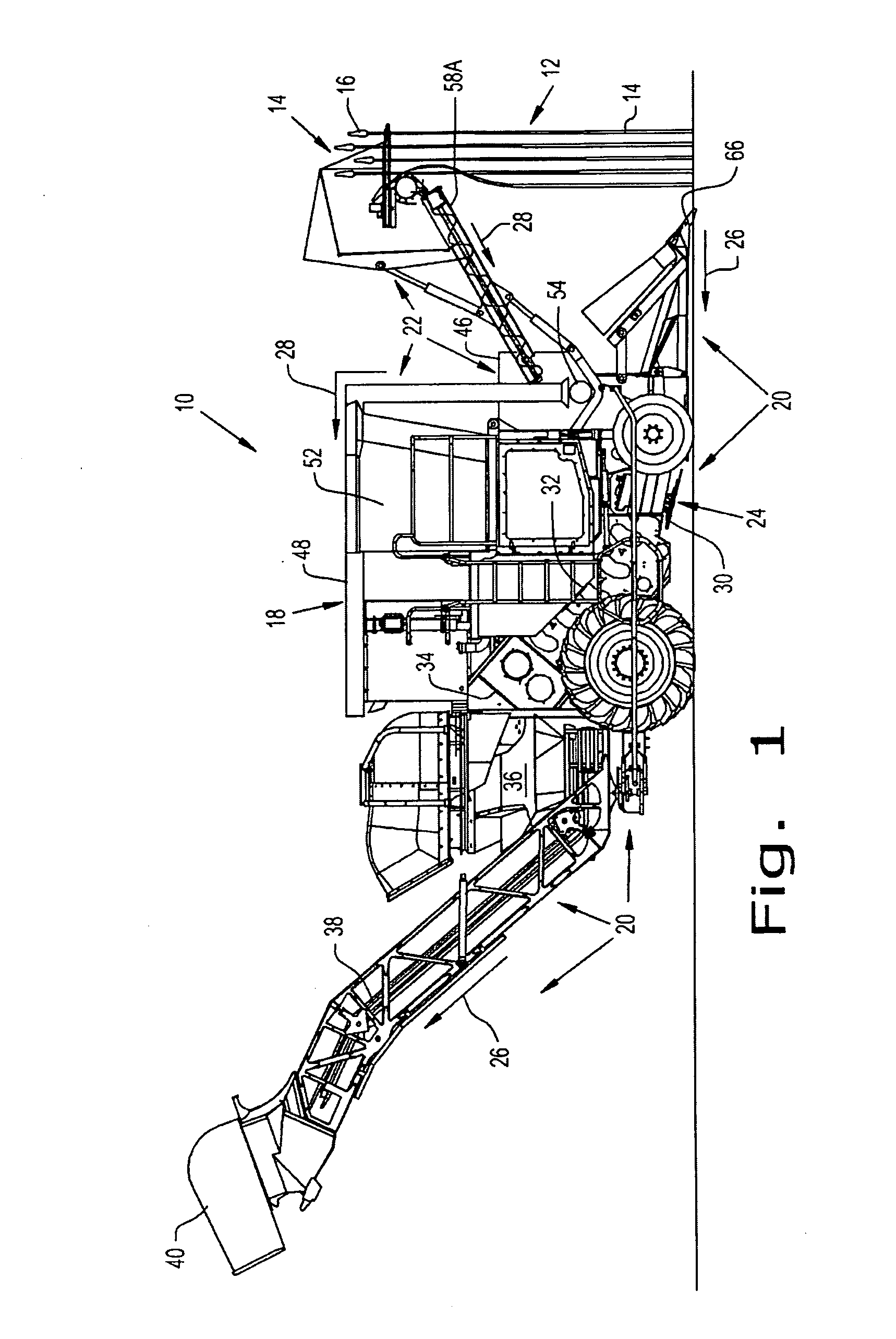

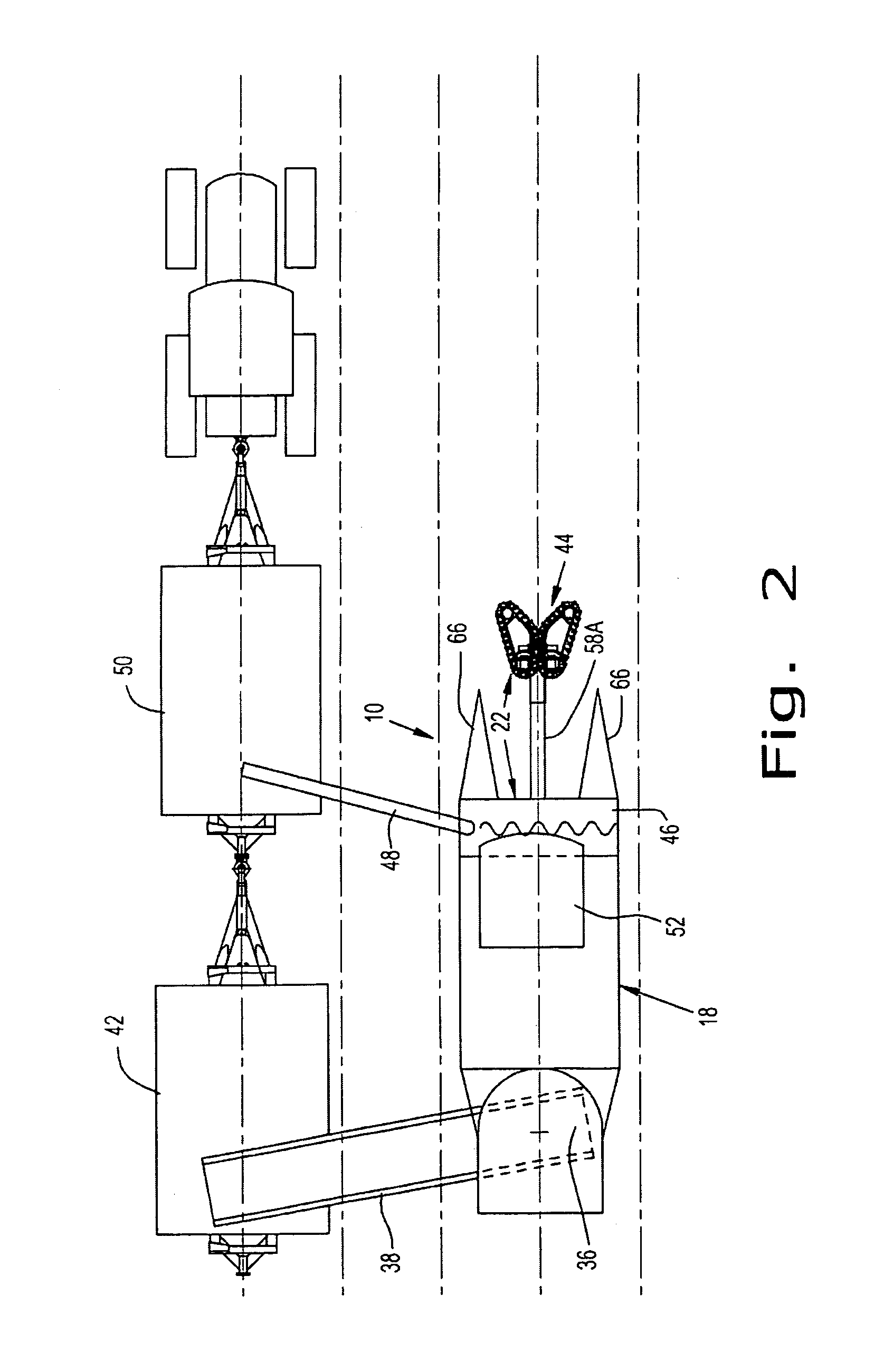

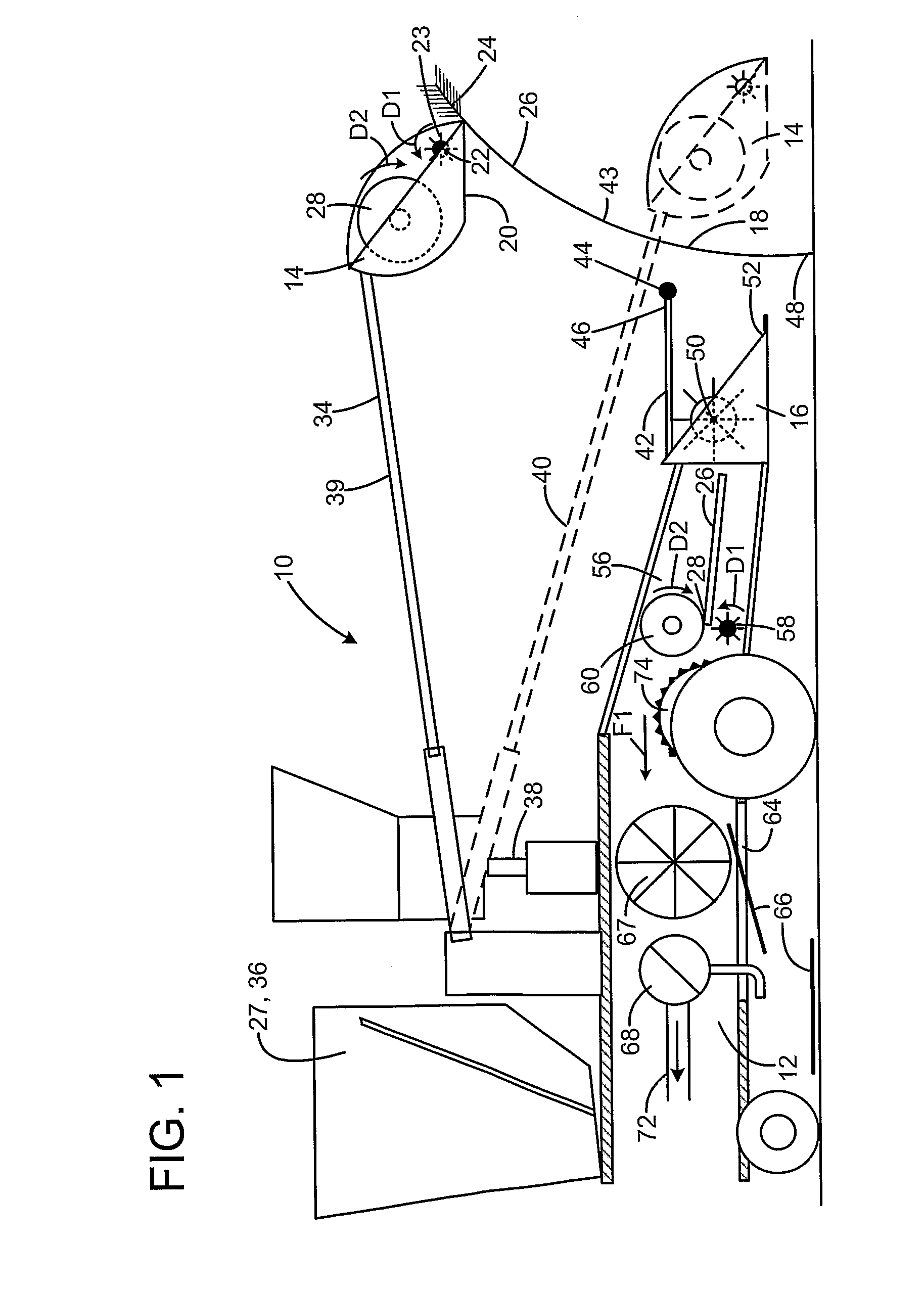

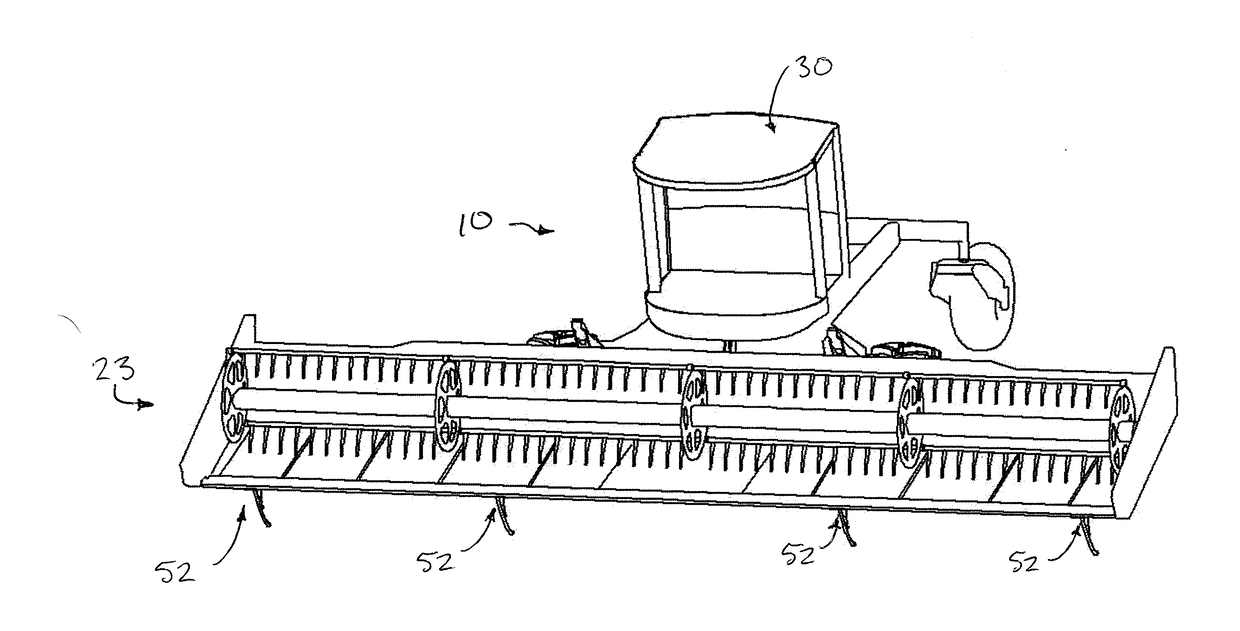

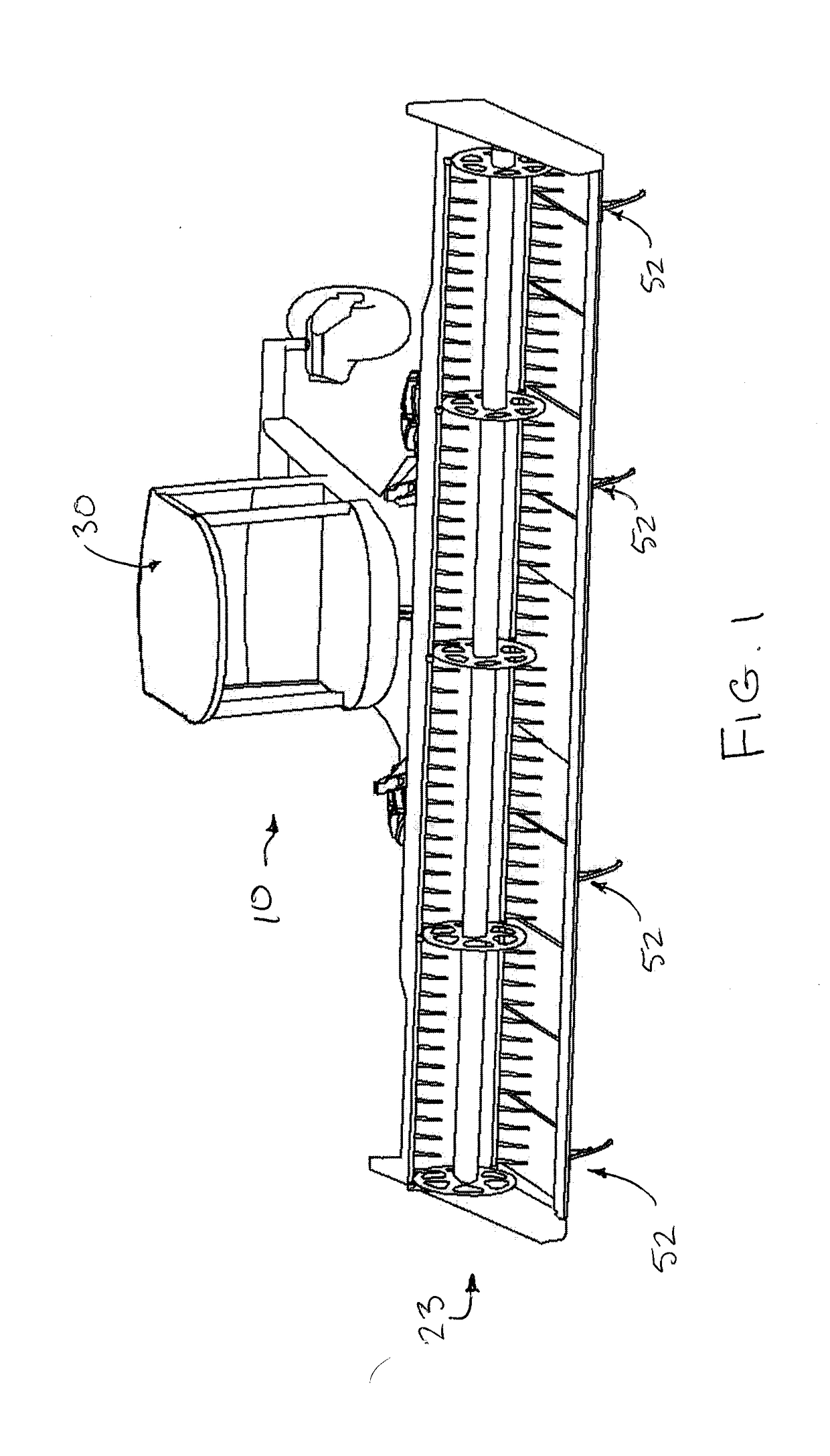

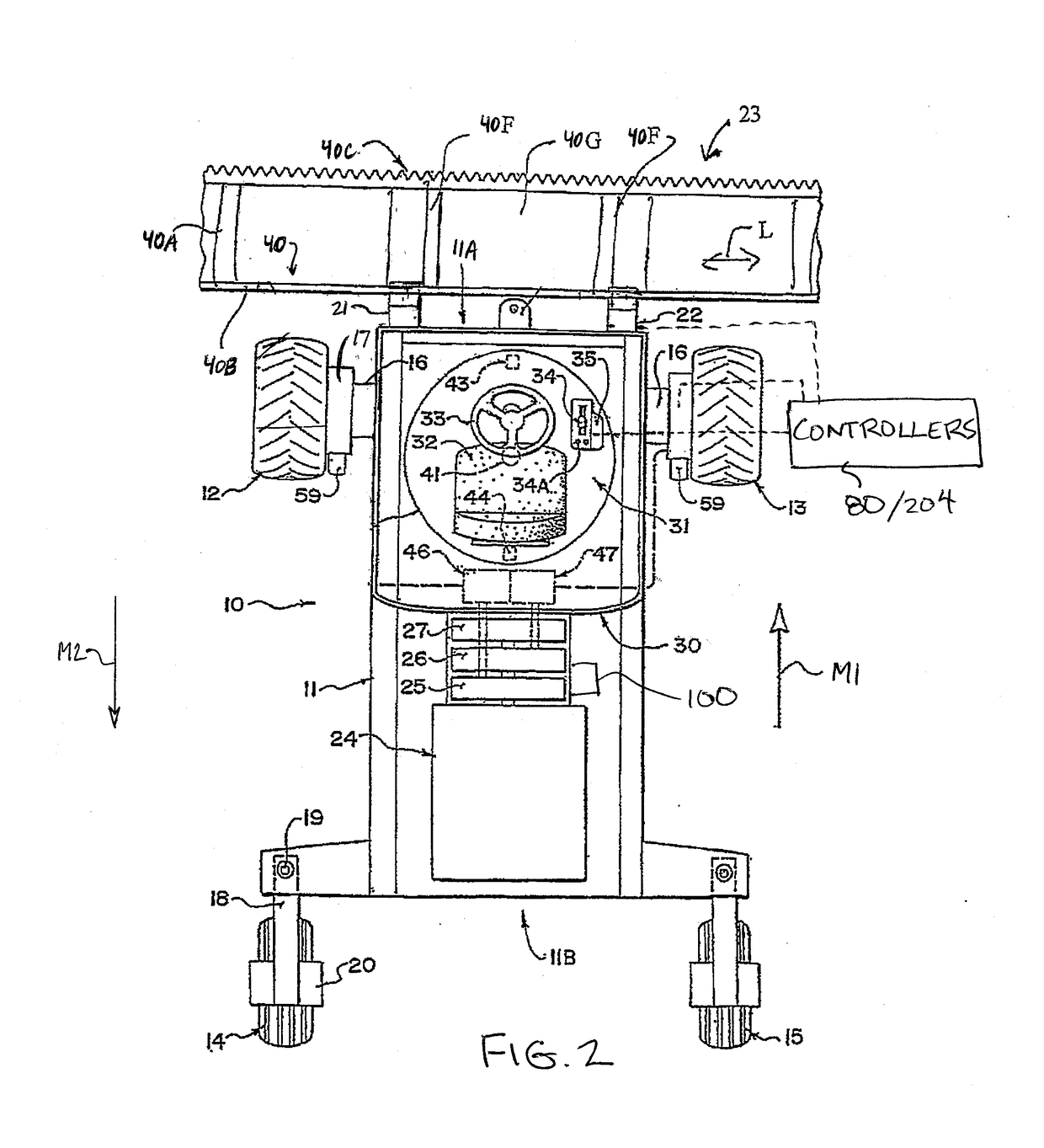

Agricultural harvester with simultaneous and independent seed and biomass processing

A harvester for crops including biomass crop material and seed heads. The harvester includes a base unit, a biomass harvester sub-system for harvesting the biomass crop material, and a seed harvester sub-system for harvesting the seed heads. The biomass harvester sub-system includes a biomass harvester carried by the base unit. The seed harvester sub-system is carried by the base unit and operable independent from the biomass harvester sub-system, whereby the biomass crop material and seed heads are processed independently from each other within the harvester.

Owner:DEERE & CO

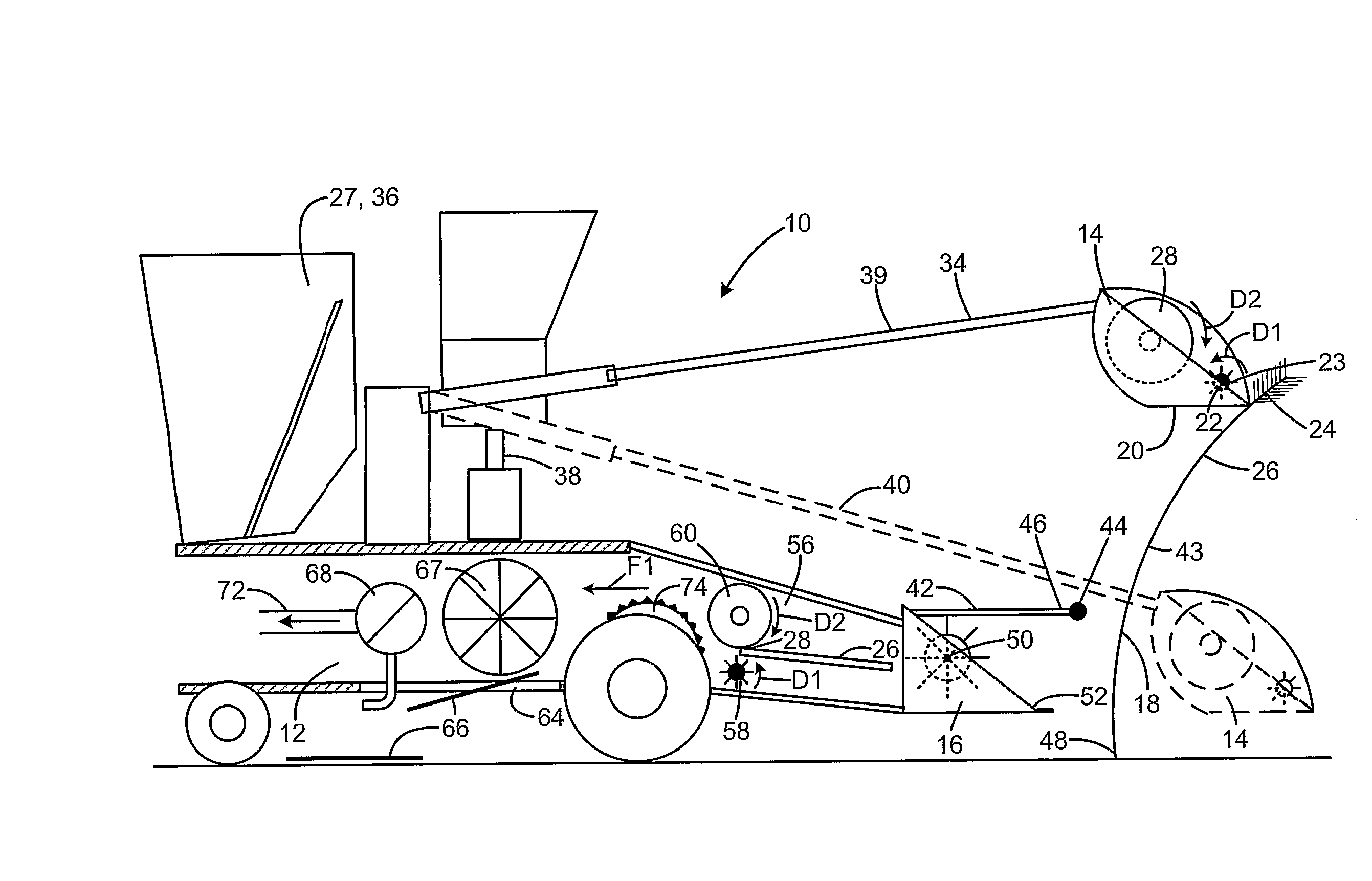

Harvesting device

The method is for harvesting a crop. A harvesting device (10) is provided that has an upper harvesting device (16) and a lower harvesting device (16). The upper harvesting device is in front of the lower harvesting device. The upper harvesting device detaches crop sections (24) of stalk sections (26) of crops (18). An intermediate engagement member (42) bends the stalk sections forwardly and the lower harvesting device cuts root sections (28) of the crops.

Owner:MALMROS DAN +3

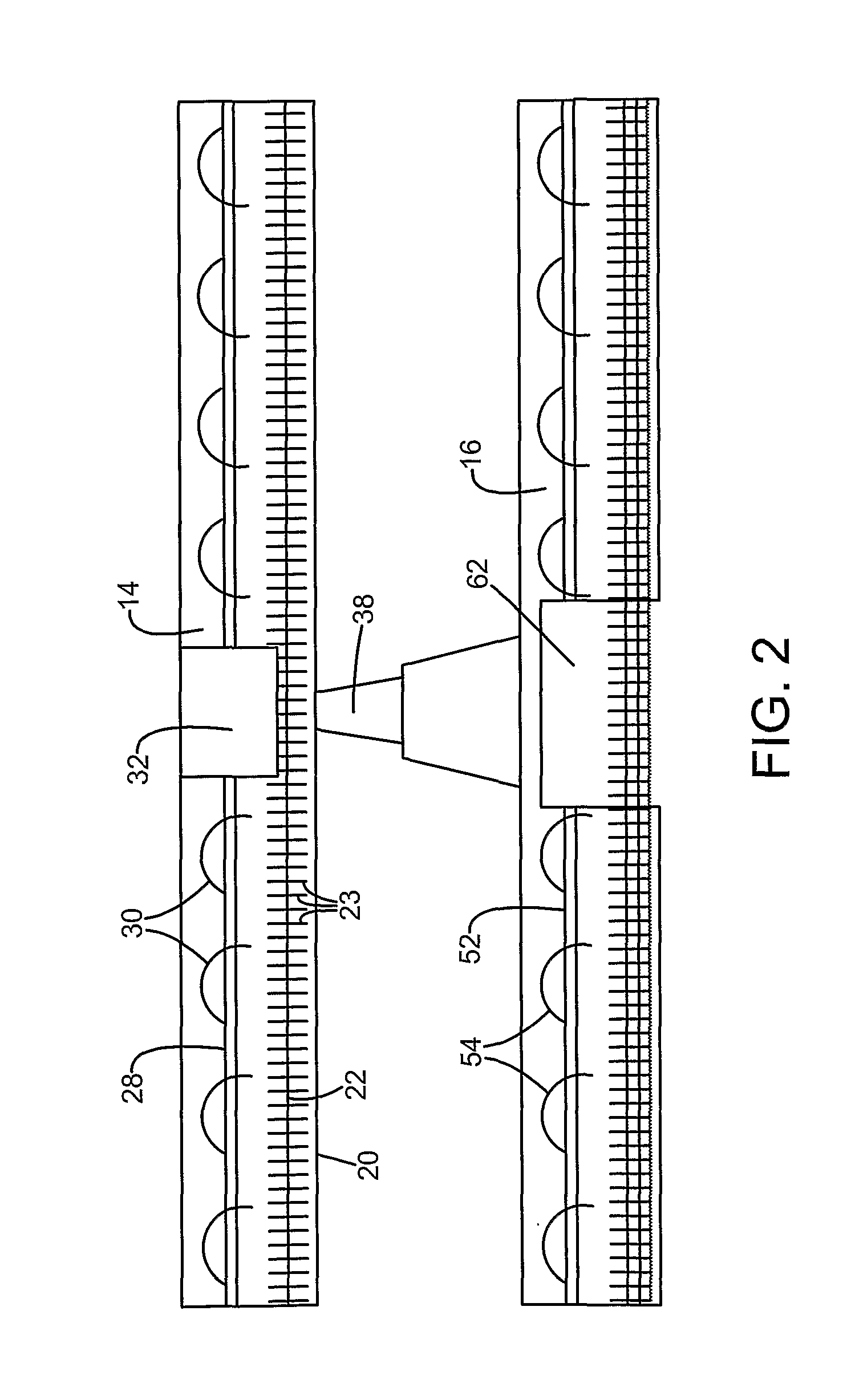

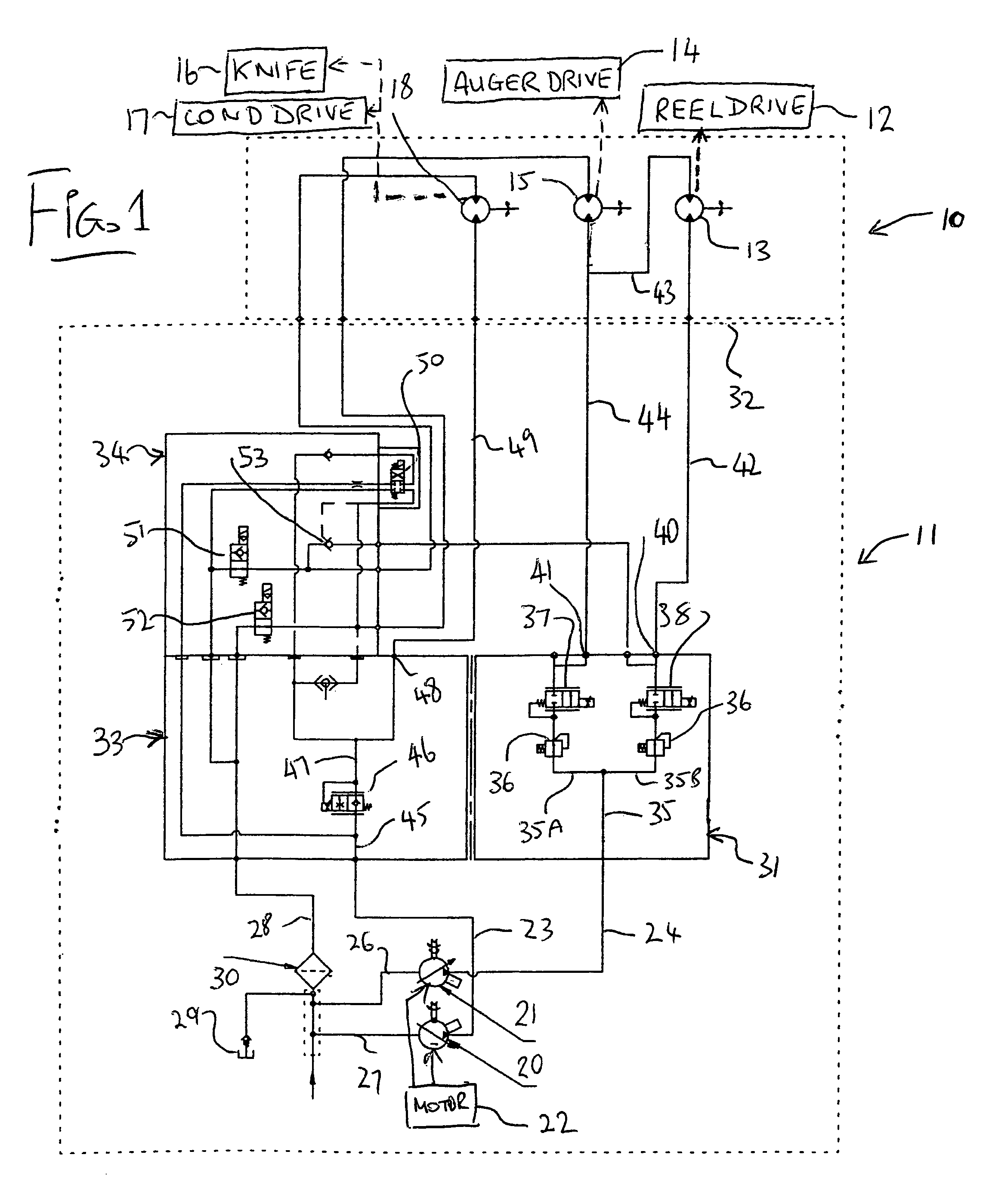

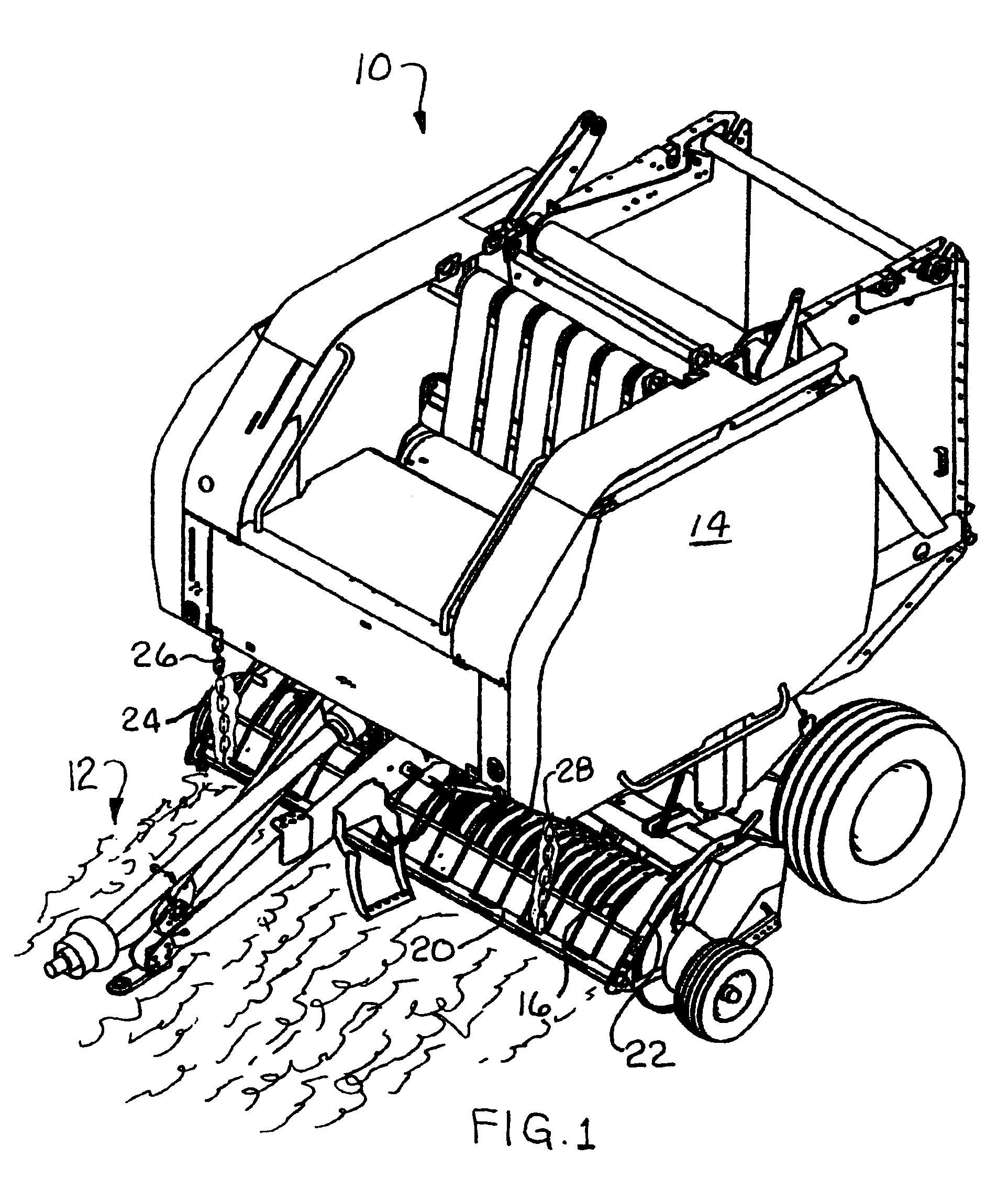

Crop harvesting header with drive reversal

A crop harvesting machine including a header mounted on a tractor is hydraulically driven by a pair of pumps on the tractor and a series of motors on the header. A first circuit control includes variable rate valves controlling the rate of supply of fluid from the unidirectional pumps to the motors to vary rate of the knife, conditioner, reel and converging systems in a forward harvesting direction. A second circuit controls reverse rotation of at least some of the elements for releasing a blockage by taking the fluid from one of the pumps and passing it through the separate second circuit to the required motors in series. The second circuit is provided in a separate block which can be omitted and thus constitutes an option. The drive of the motors in reverse direction in series ensures that they are driven at common speed without need from individual speed control. The use of unidirectional pumps and the separate circuits for forward and reverse allows the use of a single return and a filter at the return which is advantageous in a system which allows disconnection of couplings to allow the header to be replaced.

Owner:MACDON INDS

Crop harvesting machine

Owner:CLAAS E SYST GMBH

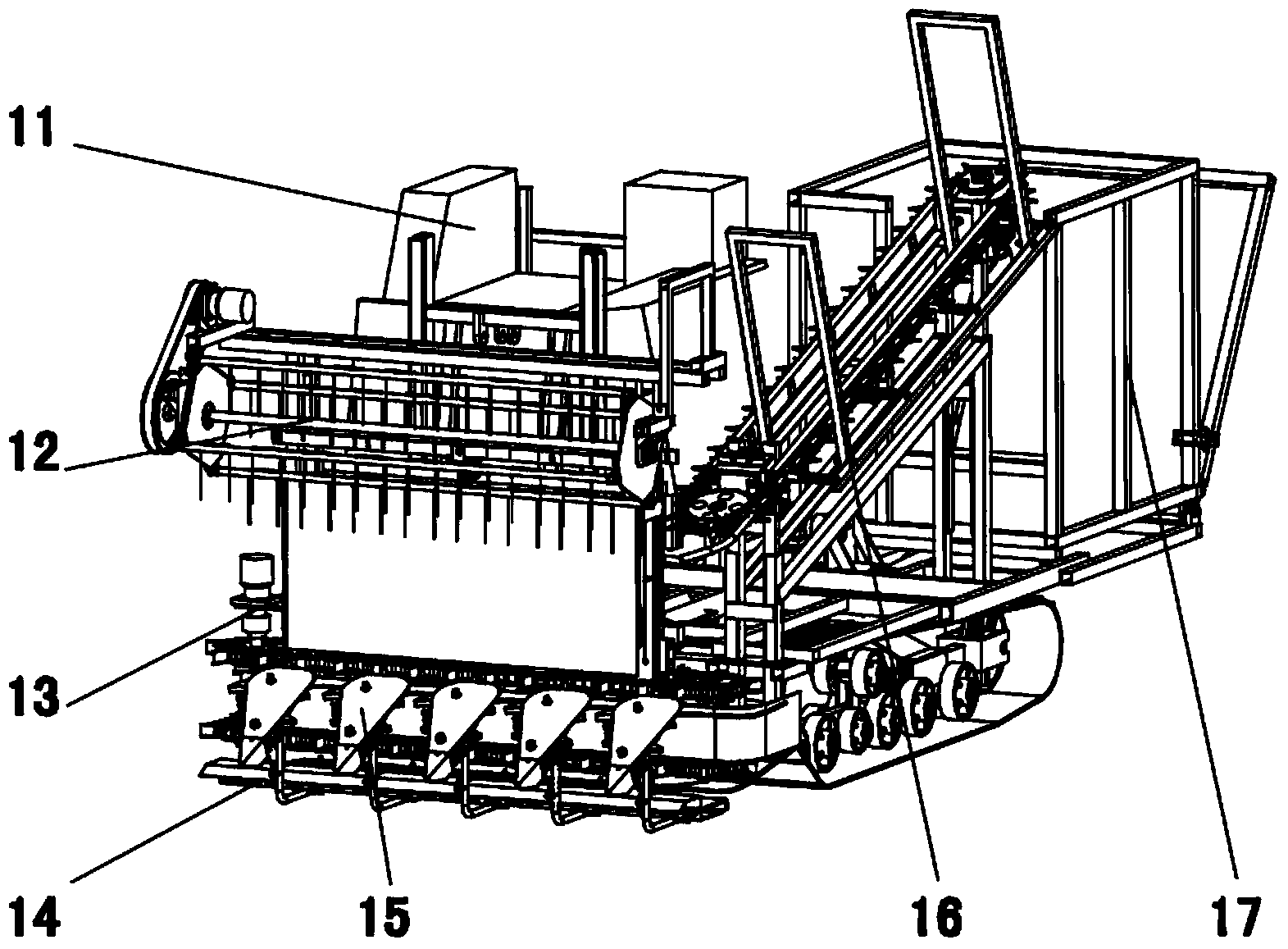

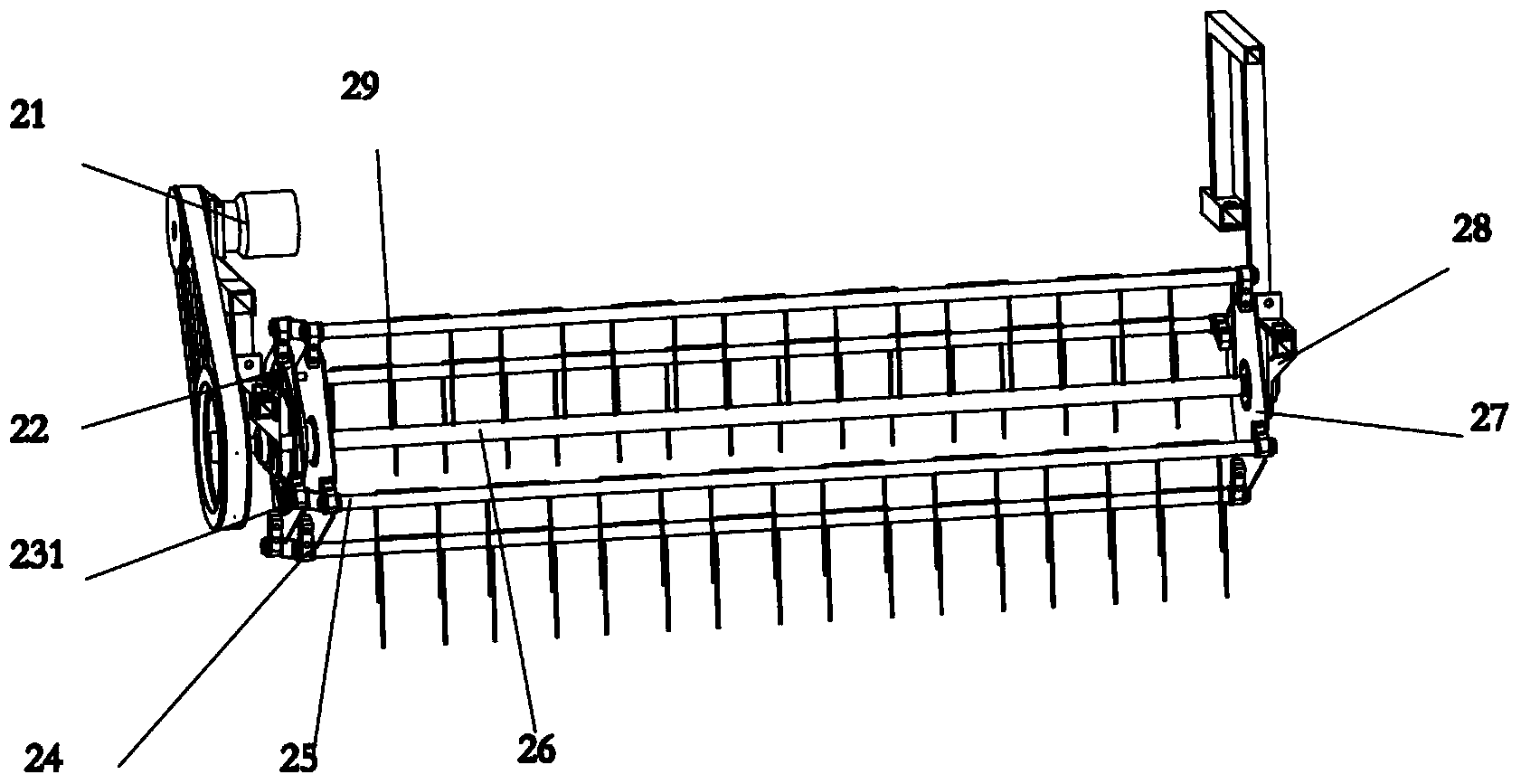

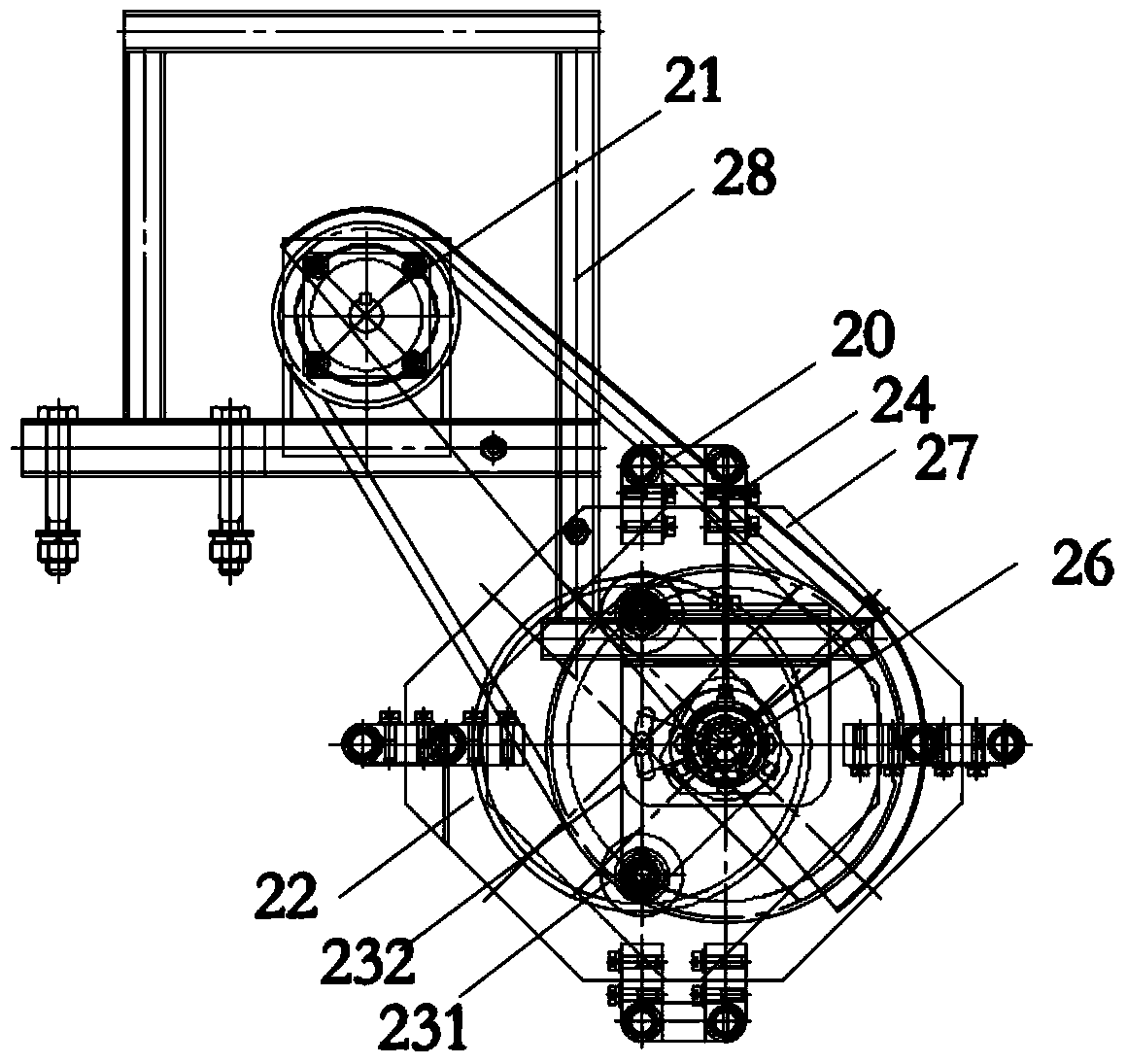

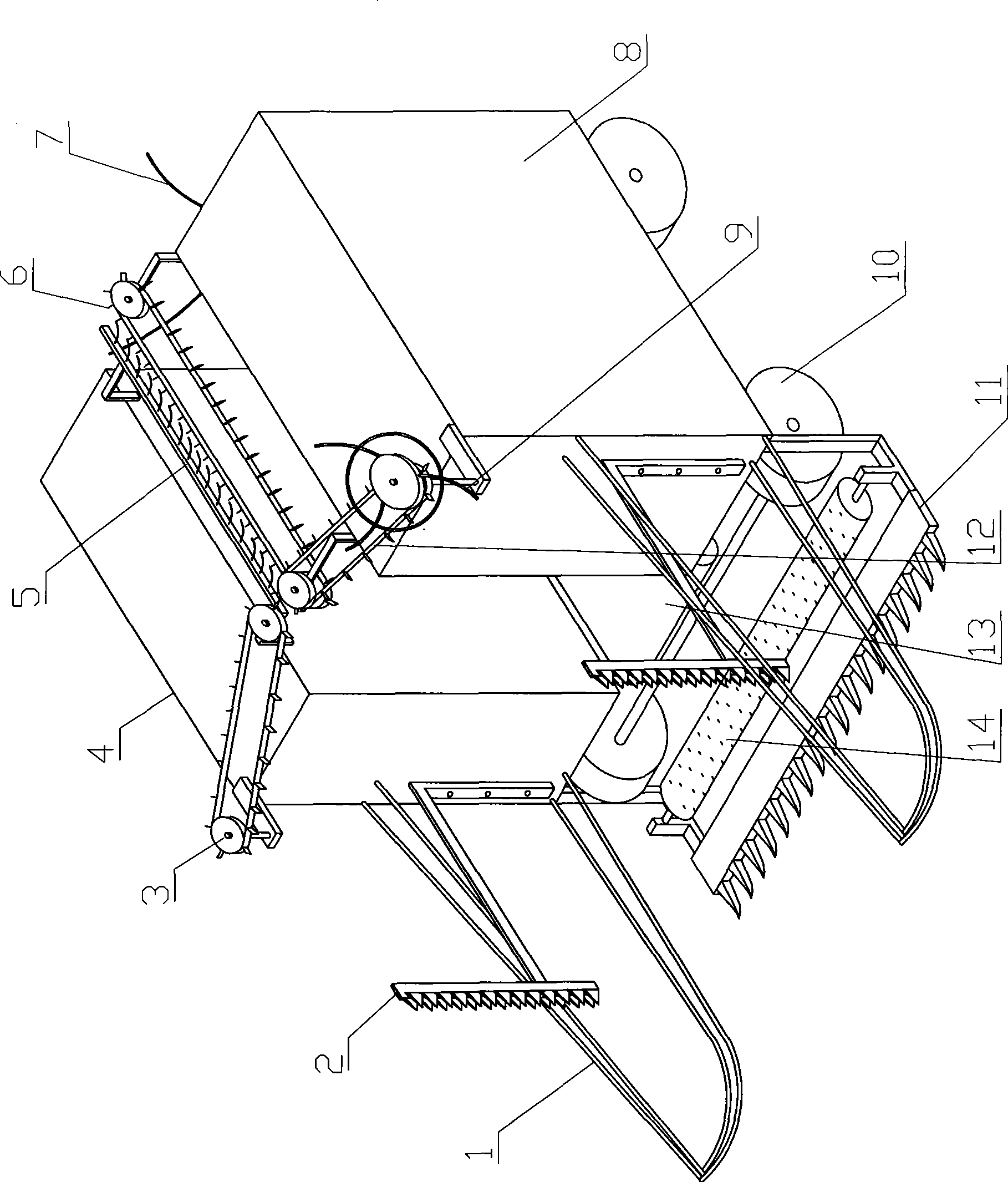

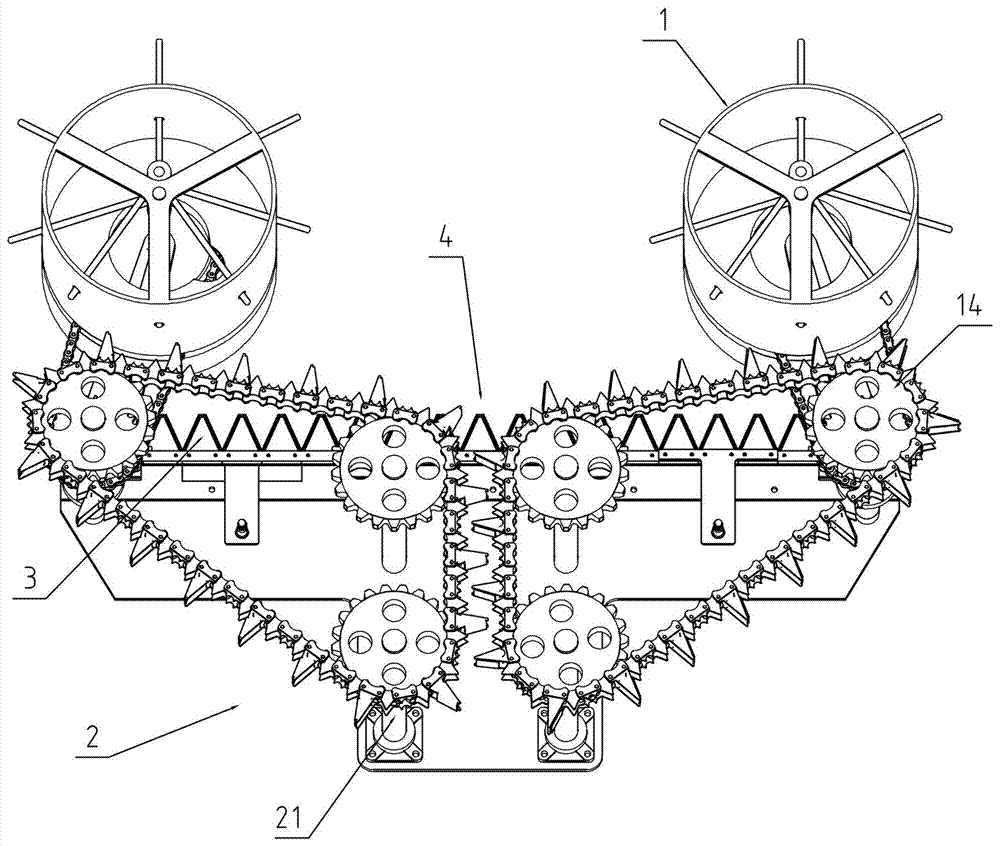

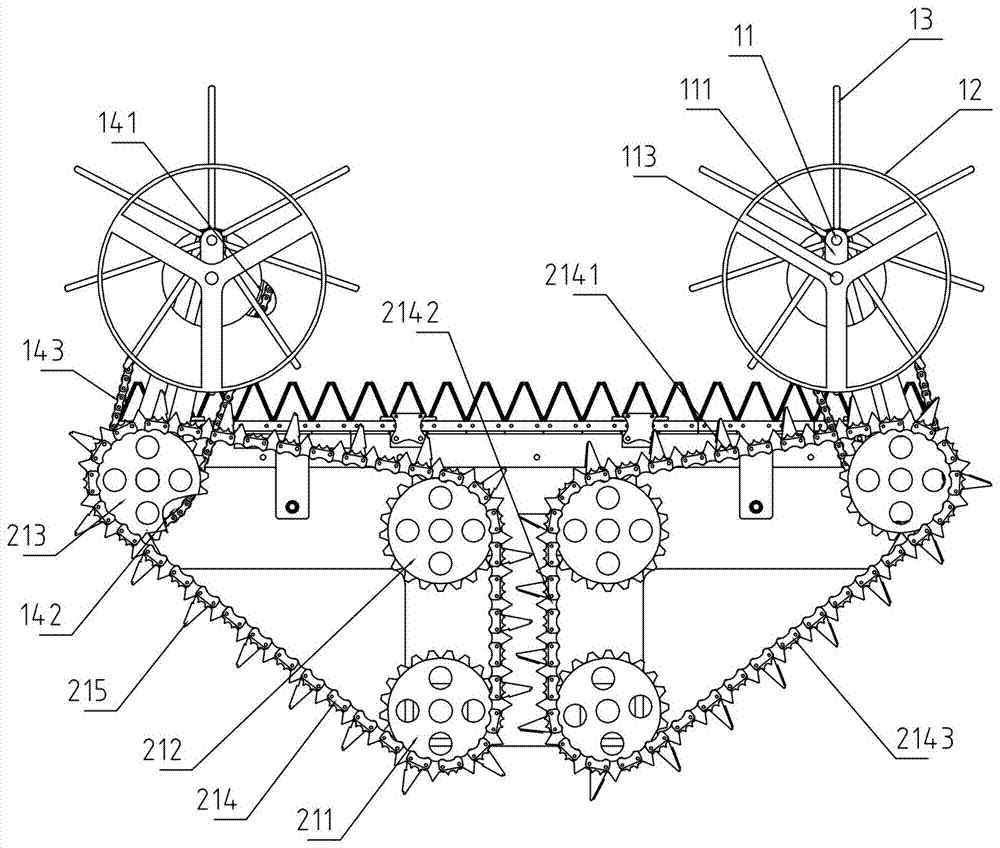

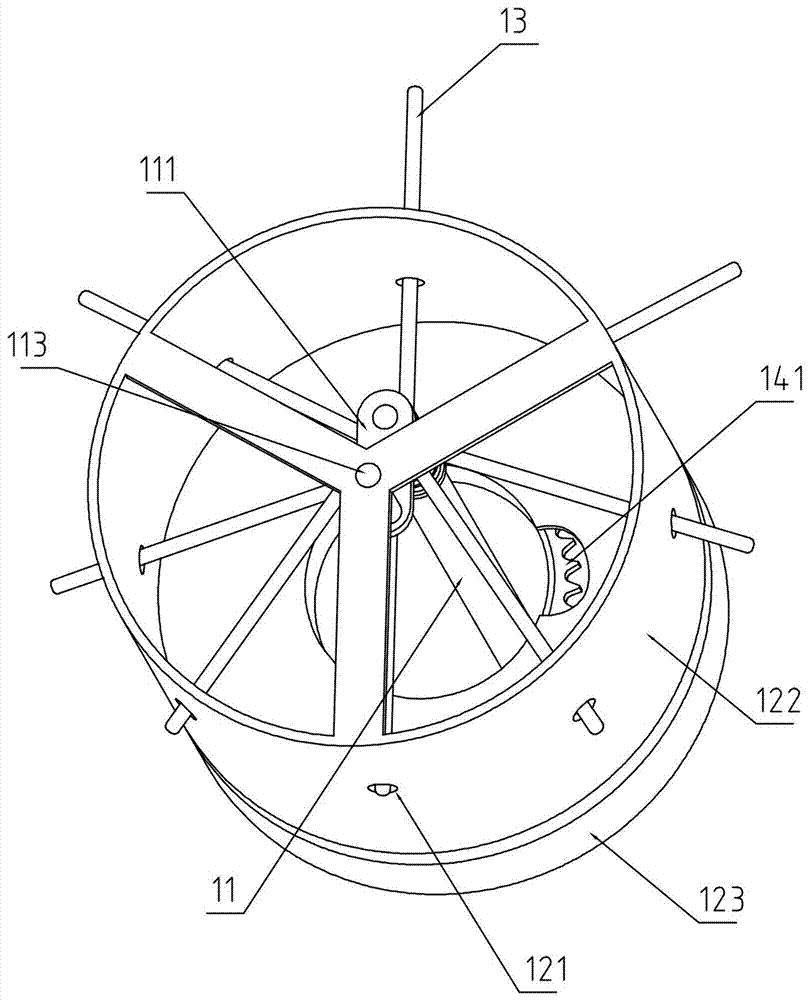

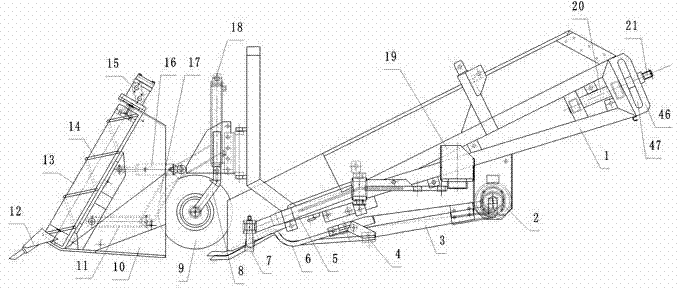

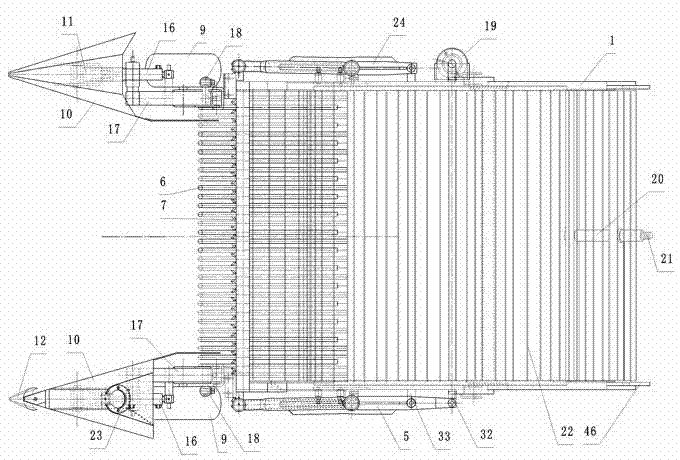

High and thick-stalk crop harvester

InactiveCN103430692ALong-term reliable and stable workIdeal Fueling EffectHarvestersTransverse forceChain type

The invention relates to a high and thick-stalk crop harvester belonging to the technical field of agricultural machinery. The high and thick-stalk crop harvester comprises cutting apparatuses, a lower crop poking apparatus, a transverse forced clamping and conveying device, a conveyer chain type longitudinal forced clamping and conveying device and a stalk collecting box. The high and thick-stalk crop harvester further comprises an upper crop poking device positioned above the lower crop poking device, wherein the upper crop poking device comprises a crop poking shaft, two ends of the crop poking shaft are respectively fixedly connected with a center plate, horizontal crop poking rods are hinged between the two center plates, radially extending scrabbling teeth are distributed on the crop poking rods at intervals, eccentric center plates are movably sleeved on the crop poking shaft, the peripheries of the eccentric center plates are hinged with one ends of crank throws, corresponding to the crop poking rods, and the other ends of the crank throws are connected with the end of an adjacent crop poking rod in angular positions that the scrabbling teeth always face downwards. According to the high and thick-stalk crop harvester, the alternating stress is avoided, and the harvester can reliably and stably work for a long time.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

Pollen harvesting

Pollen is harvested from plants by mounting a suction nozzle on a vehicle such as a crop harvester or crop sprayer so as to be carried thereby and arranged on the vehicle so as to be located in the field adjacent the plants as the vehicle moves across the ground. A suction pump is mounted on a trailer behind the vehicle for communicating, though a series of ducts passing along side the vehicle, an air stream through the nozzle such that the air stream causes the pollen from the plants to be drawn into the nozzle. A separating system including cyclones and filtration bags is mounted on the trailer for extracting the pollen from the air stream.

Owner:HALWAS CHRISTOPHER J +2

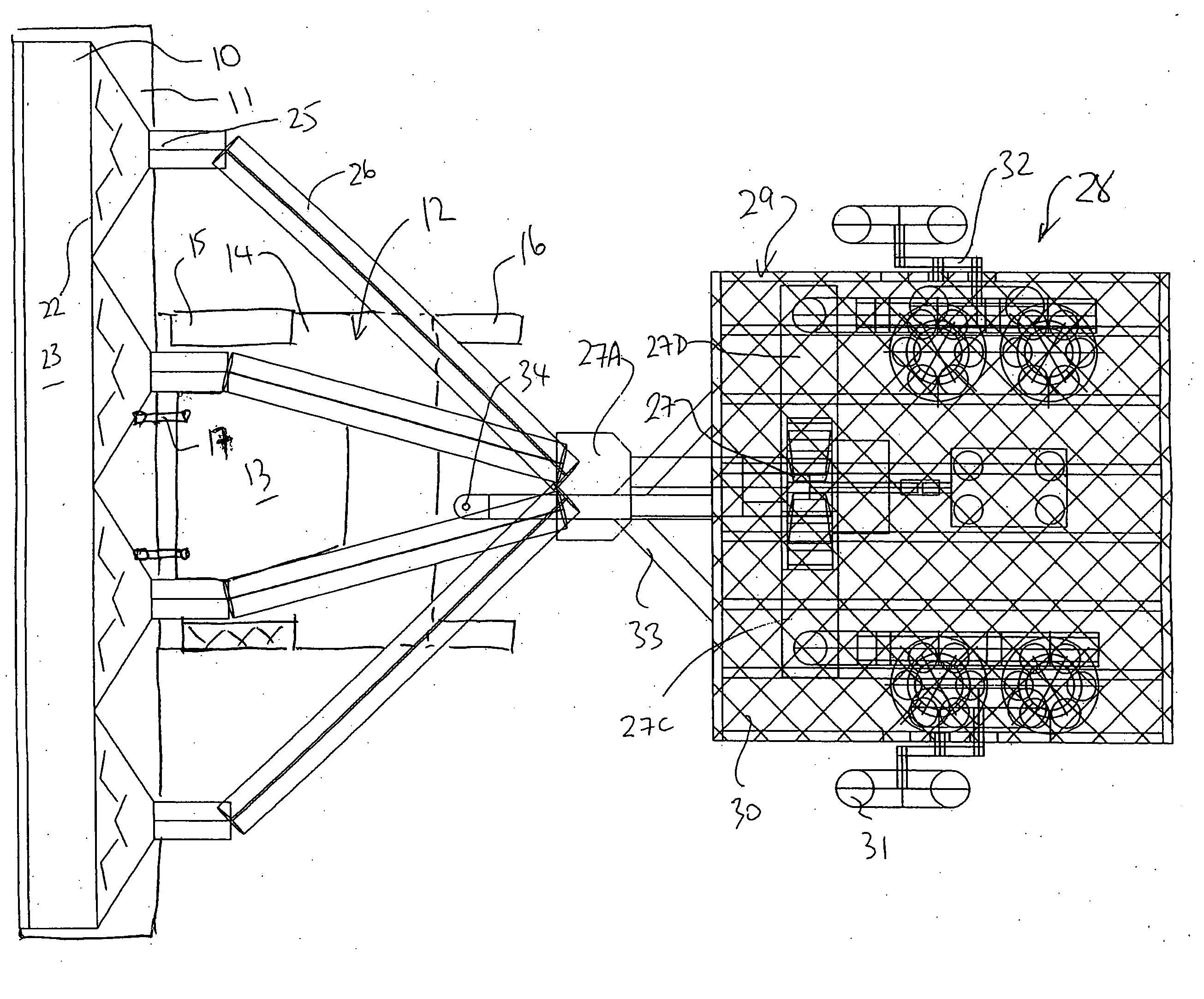

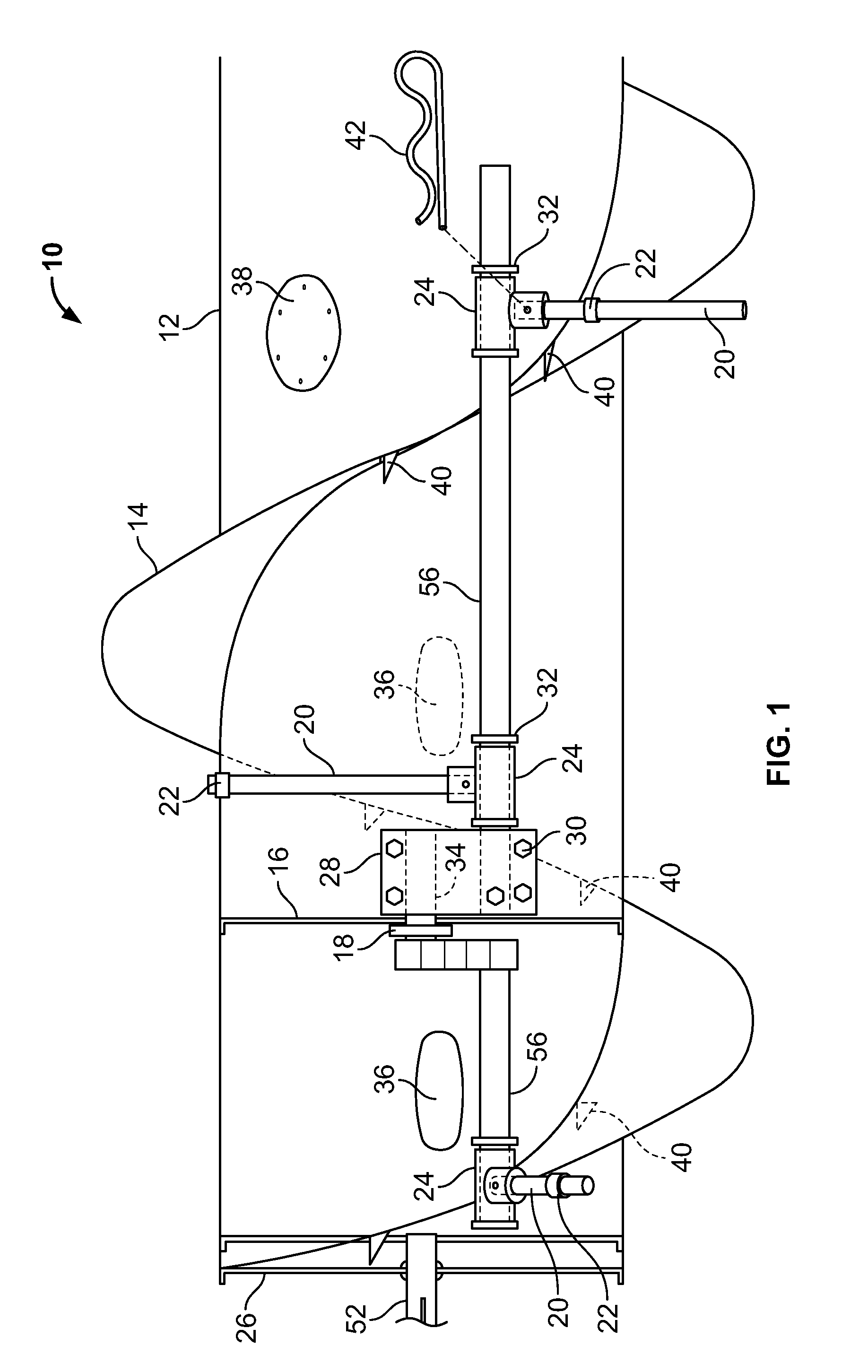

Connection of the hitch arm of a pull-type crop harvesting machine to a tractor

ActiveUS7308947B2Reducing and eliminating flexingAuxillary drivesAgricultural machinesCouplingEngineering

Owner:MACDON INDS

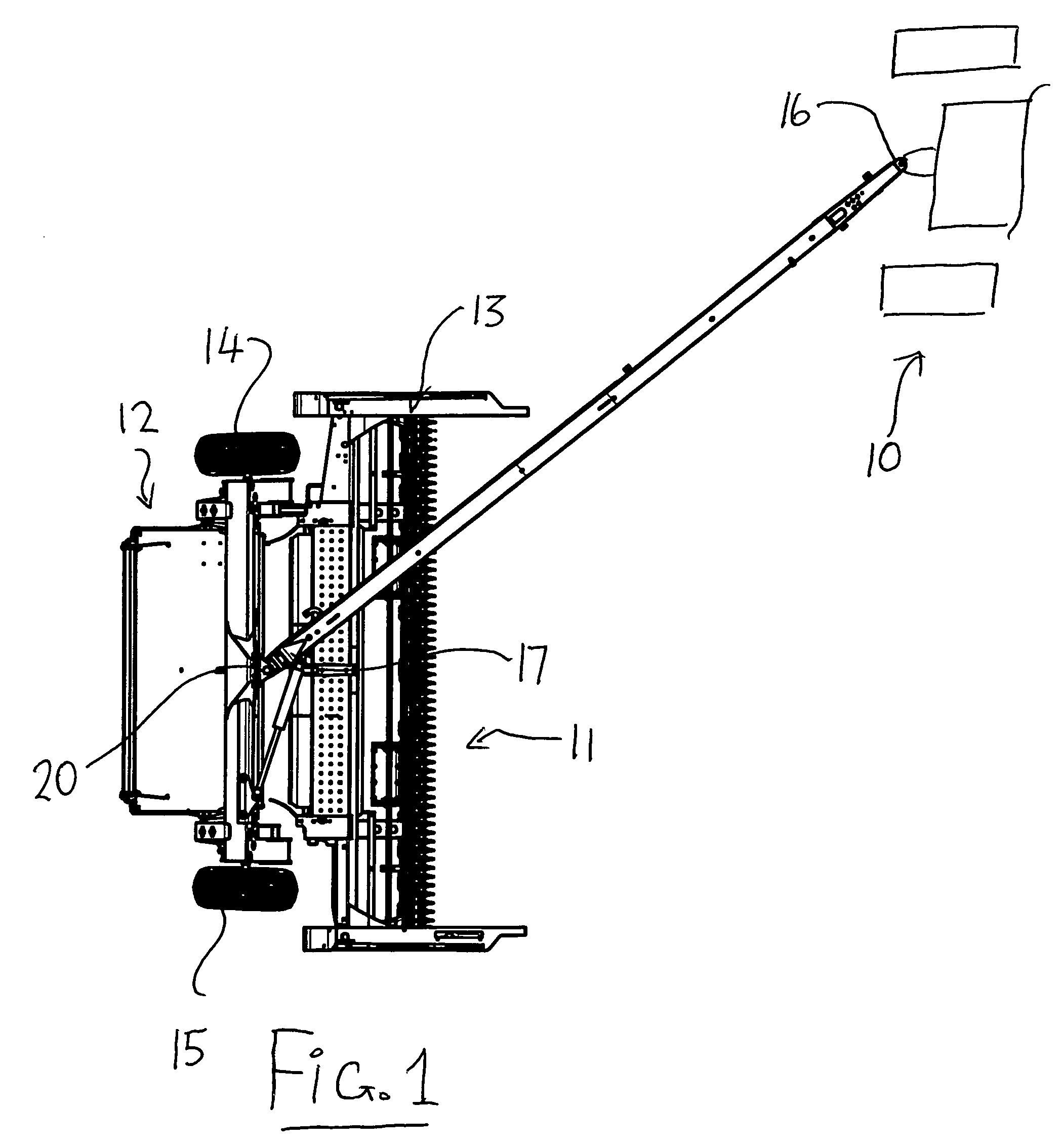

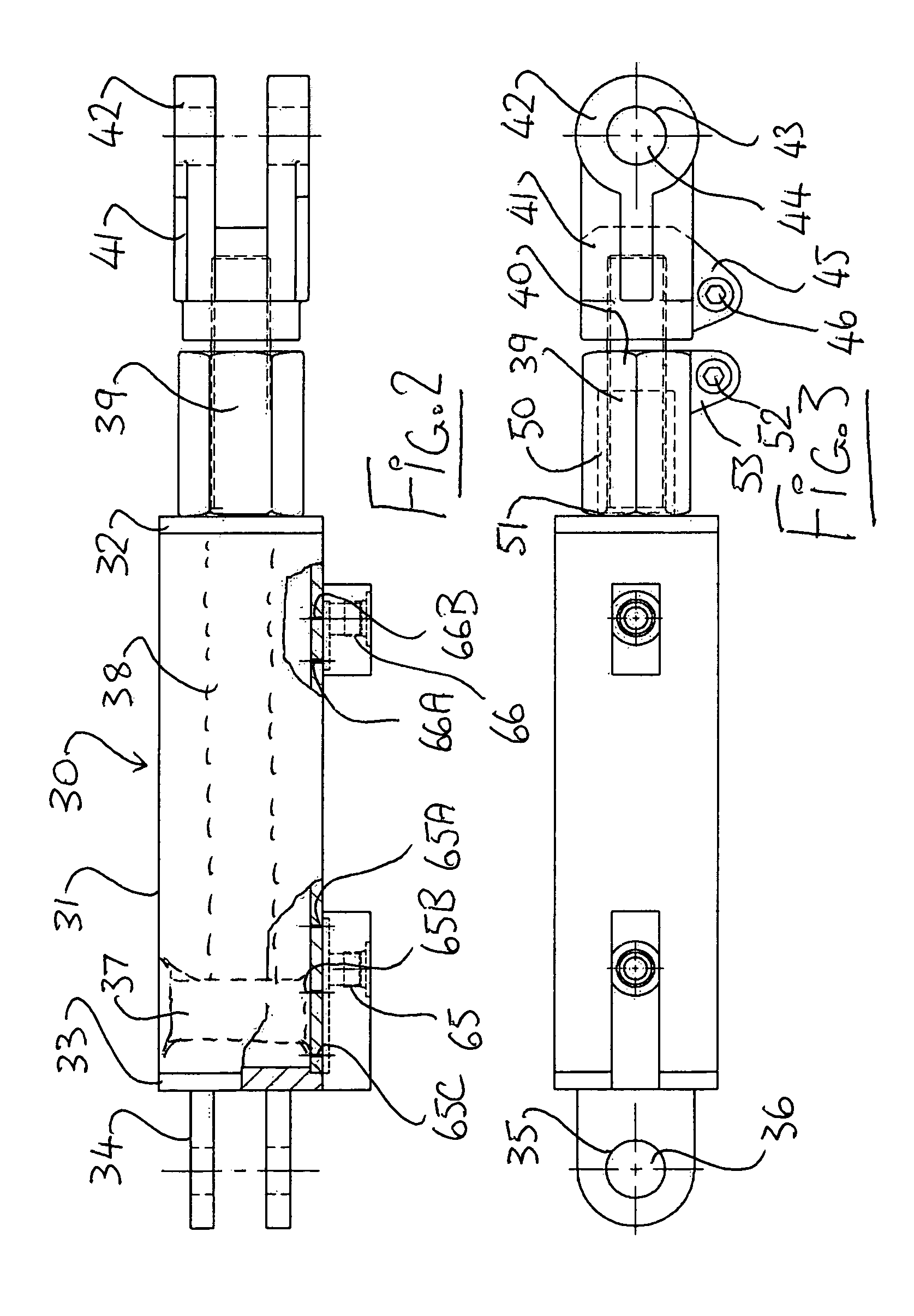

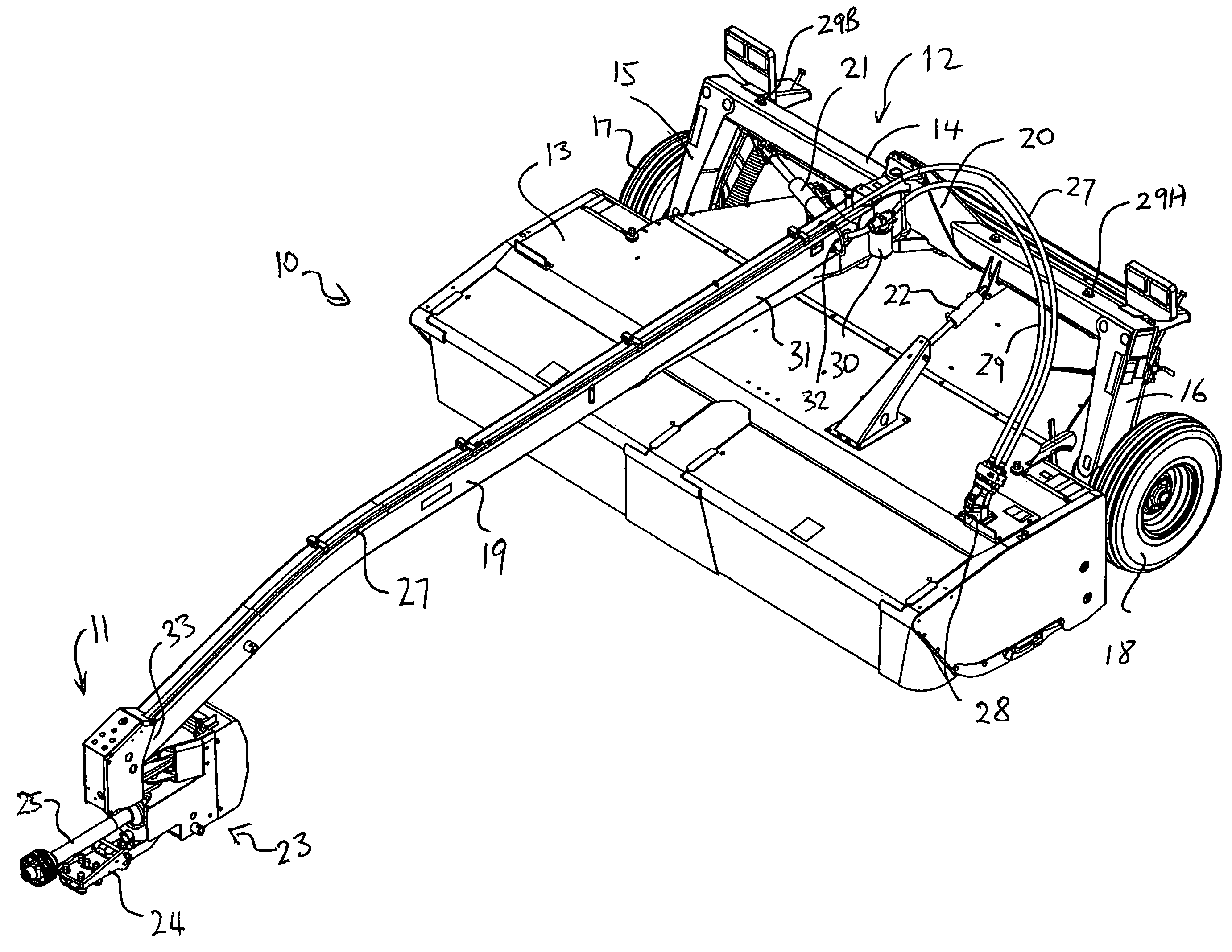

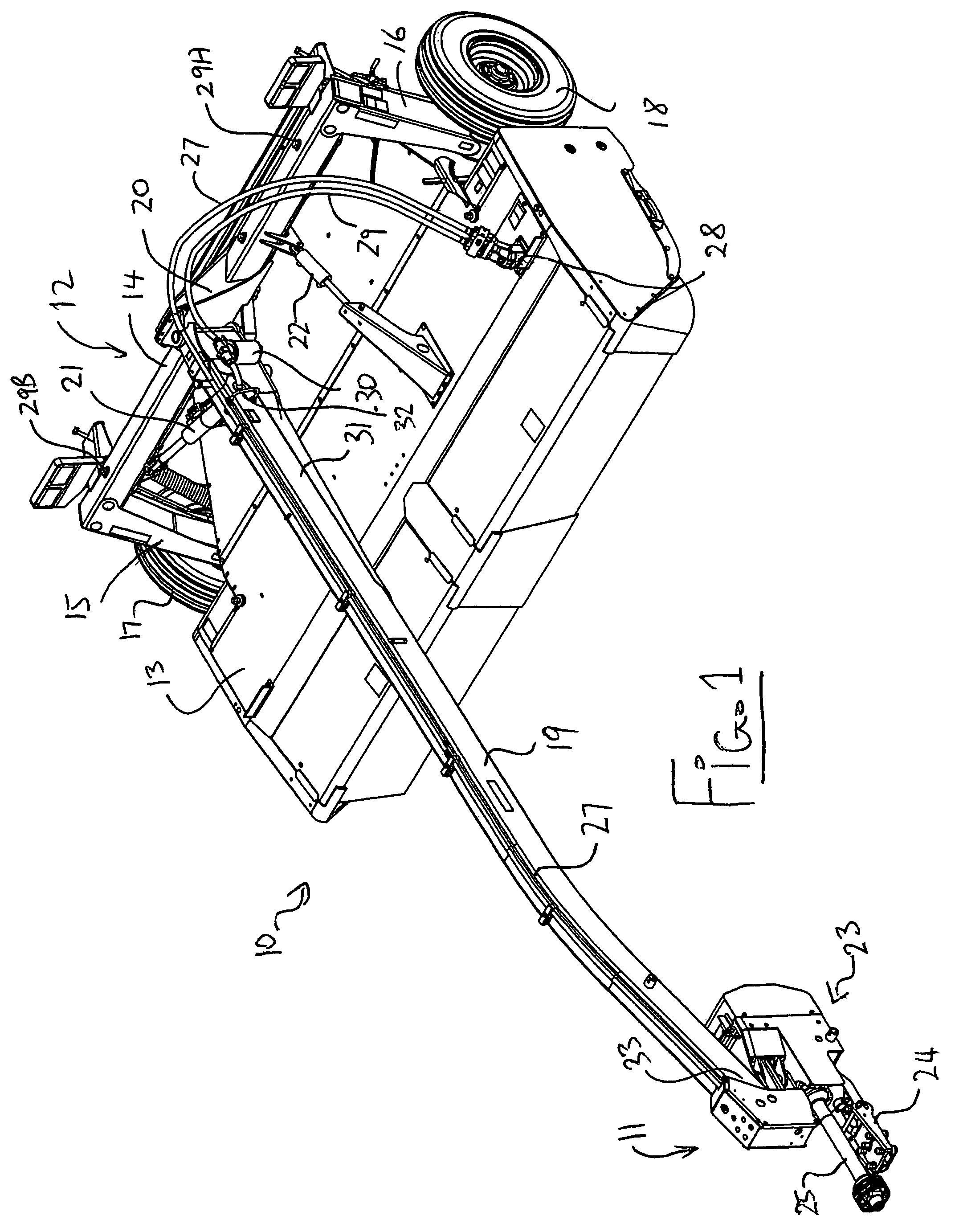

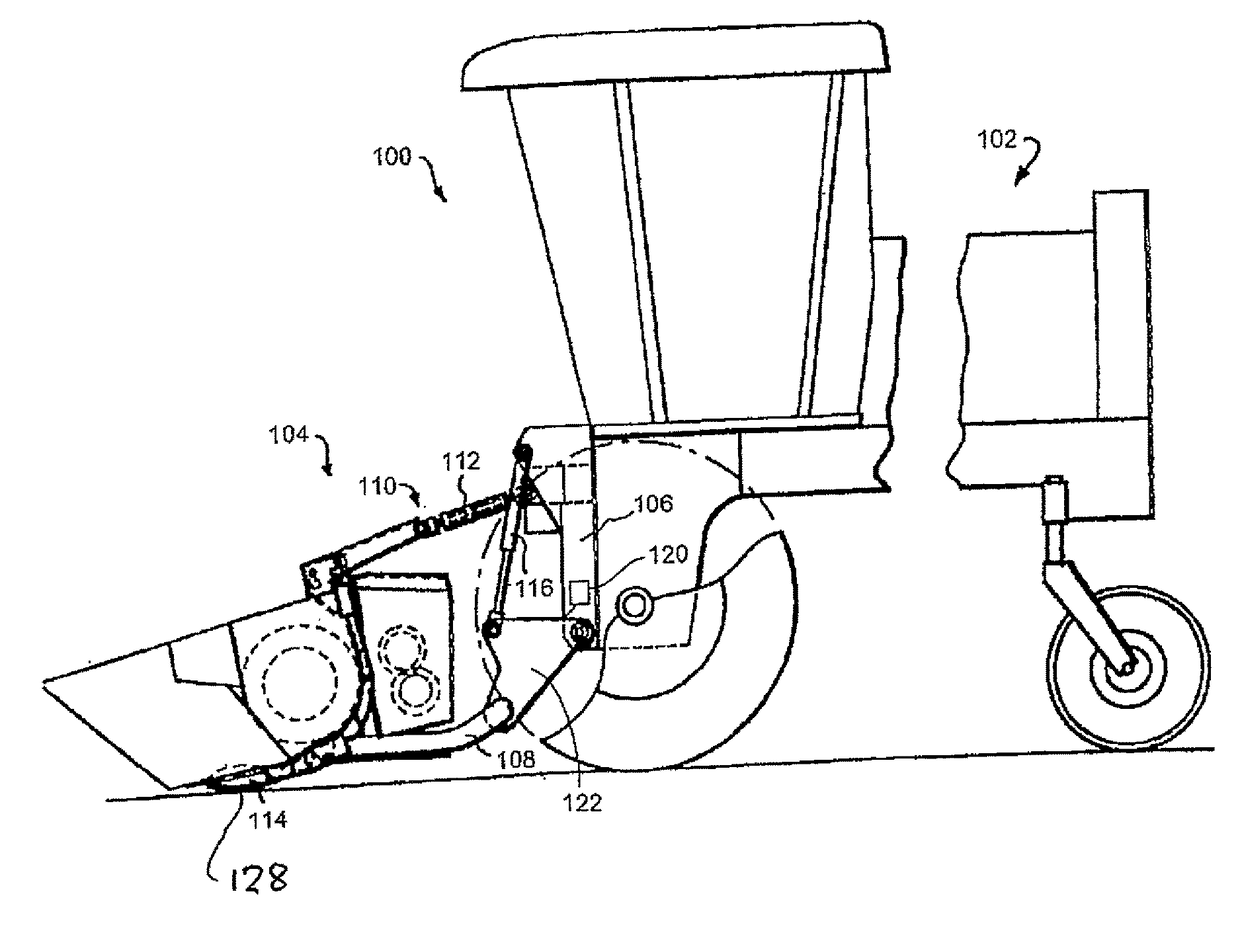

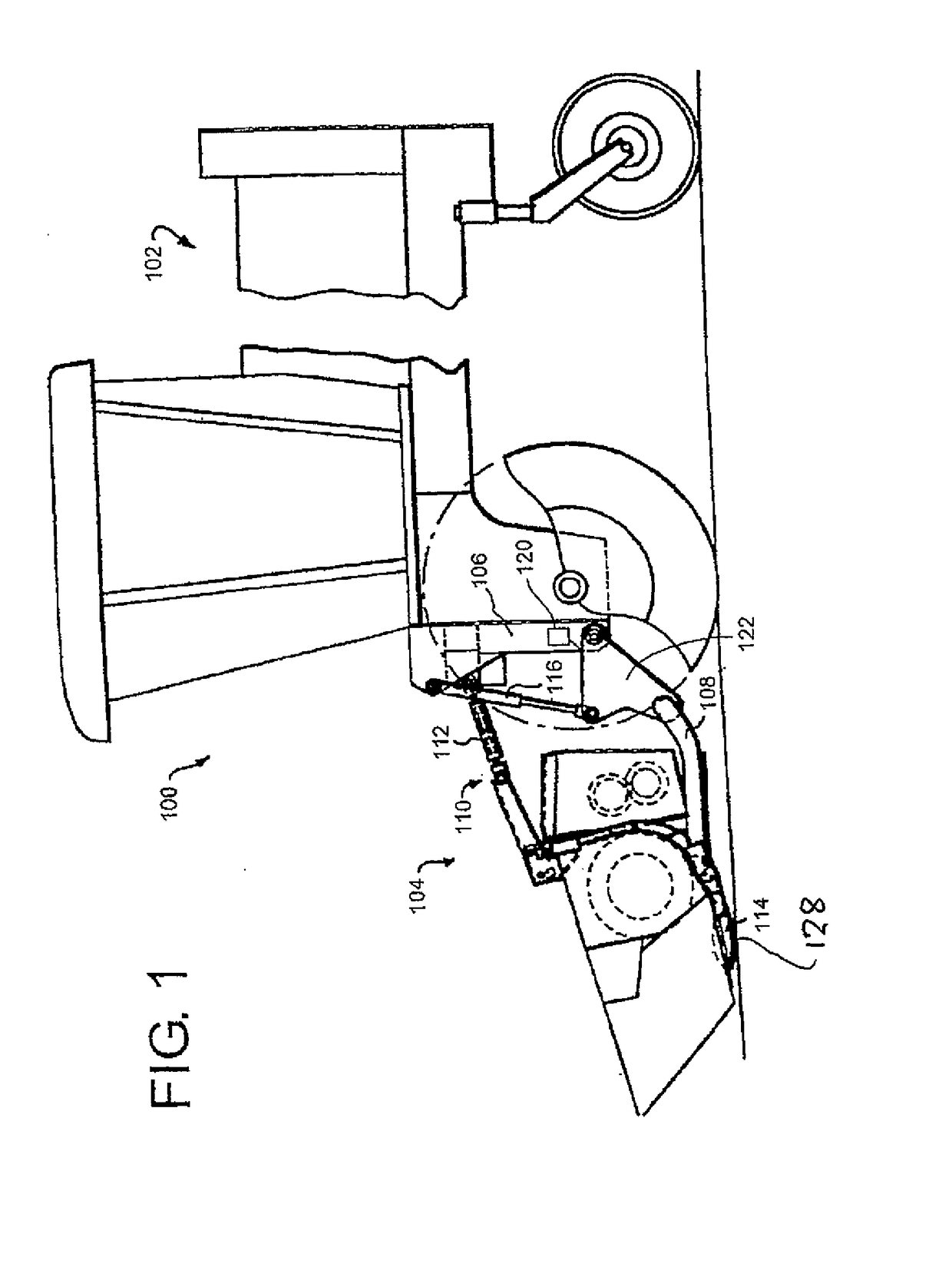

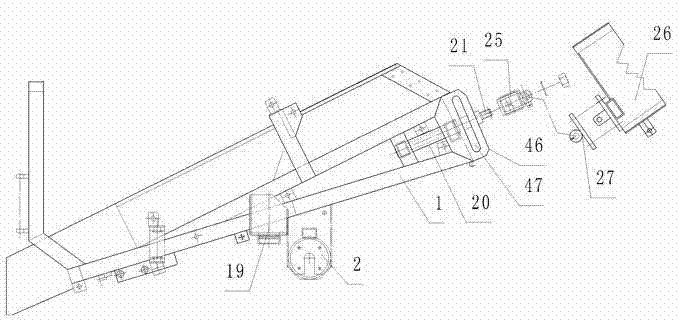

Adjustment of the hitch arm of a pull-type crop harvesting machine

A pull-type crop harvesting machine has a header carried on a frame mounted on ground wheels with a hitch arm extending from the frame over the header to a hitch coupling of a tractor. The hitch arm is mounted for pivotal movement about a generally upright axis such that in a first position the tractor tows the frame in echelon to one side and in a second position the tractor tows the frame in echelon. The movement is actuated by a hydraulic cylinder and stopped at one end of the movement by the piston with a rod coupling being adjustably mounted on the rod to adjust the end position. At the other end of the movement, the position is defined by a stop member mounted on the piston rod and adjustable relative thereto. Each end of the cylinder includes a cushion effect by using separate orifices for the fluid ports which slow fluid flow as the piston approaches the ends of the cylinder.

Owner:MACDON INDS

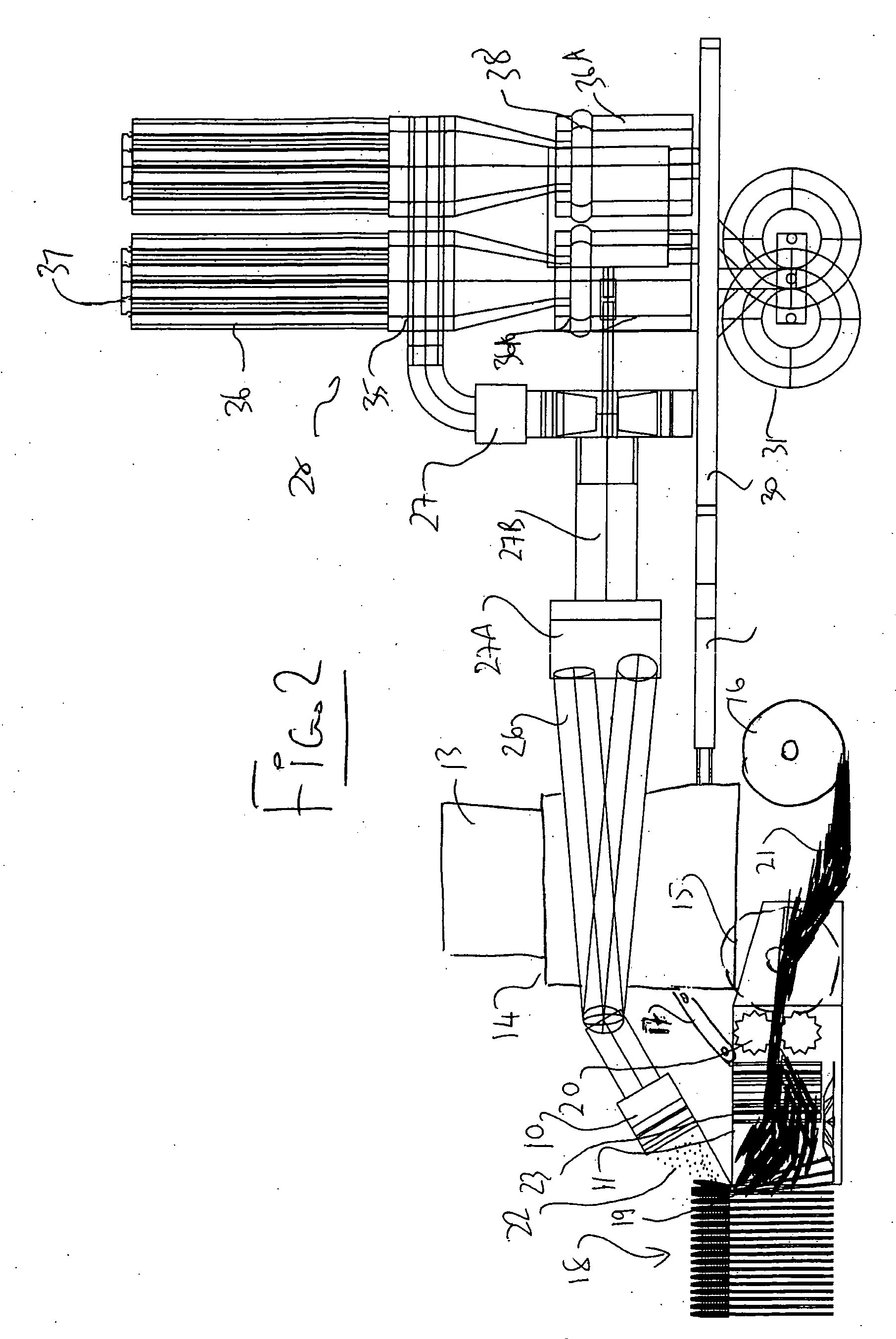

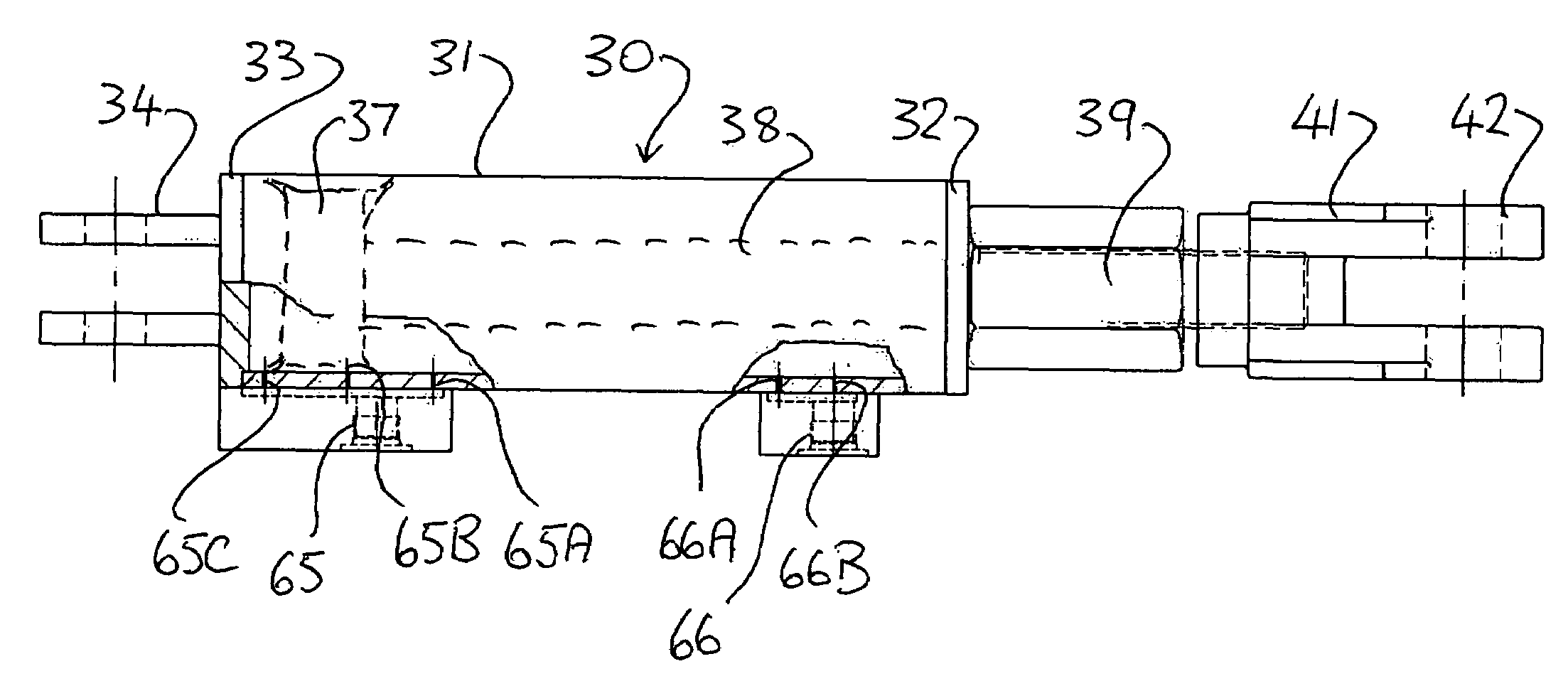

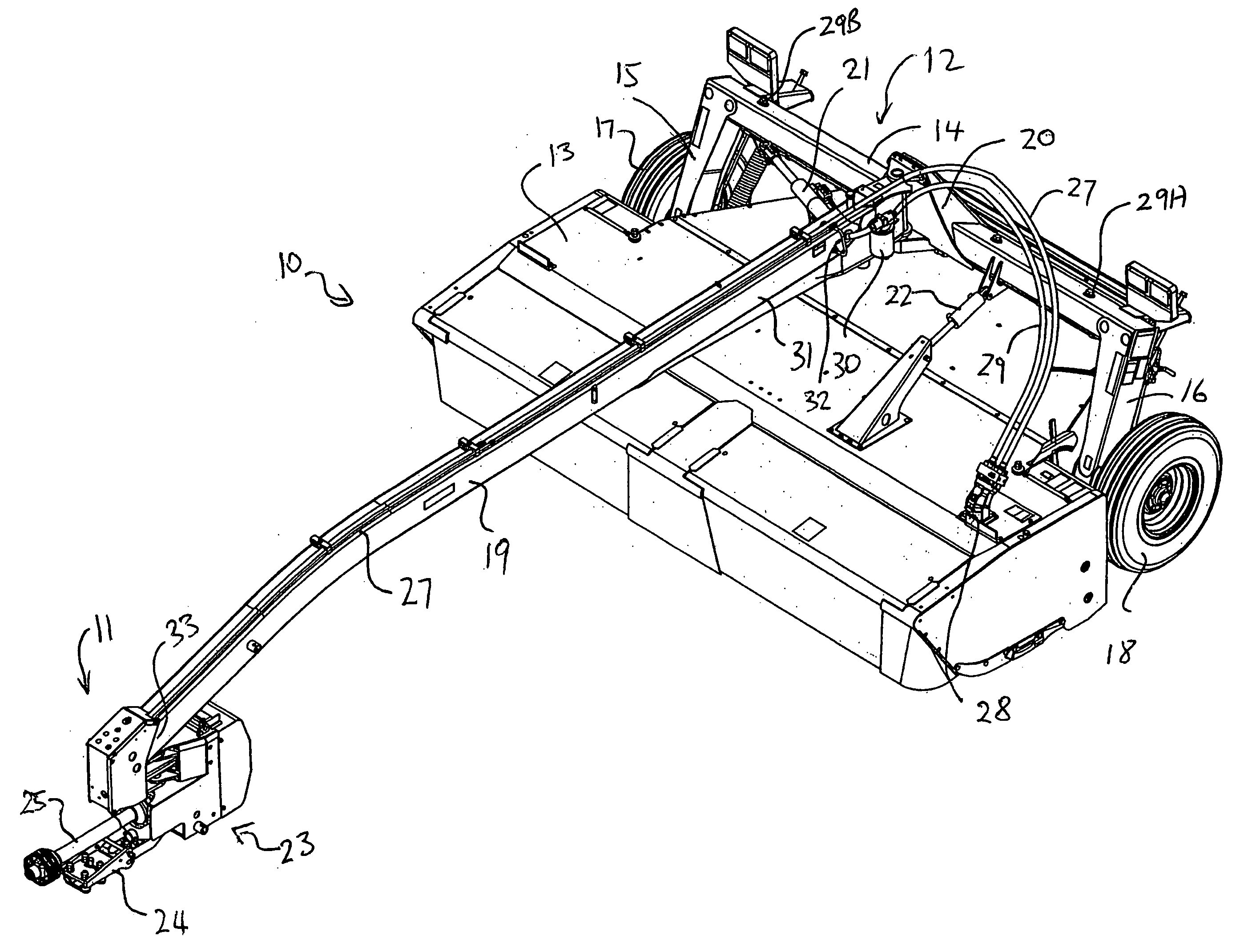

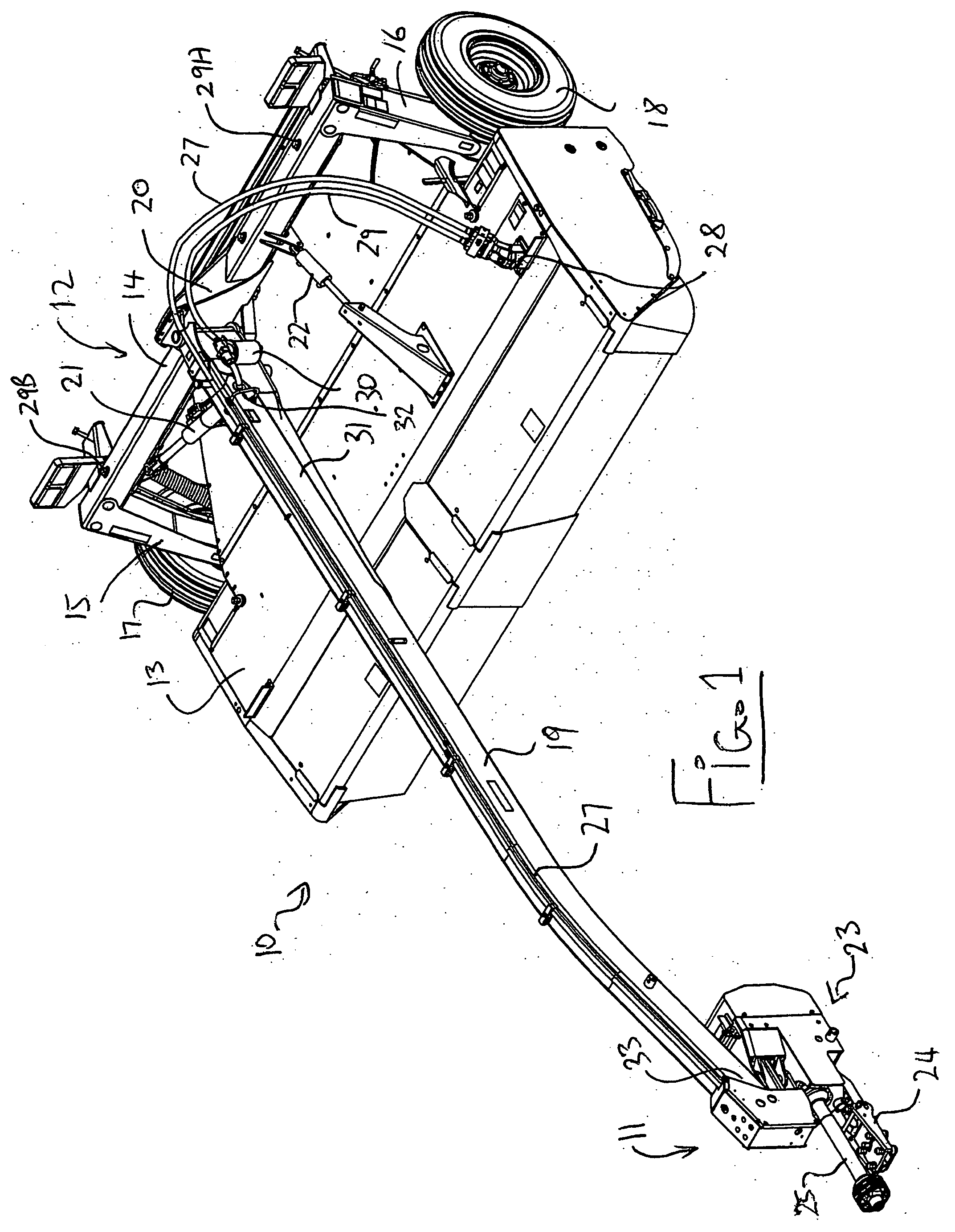

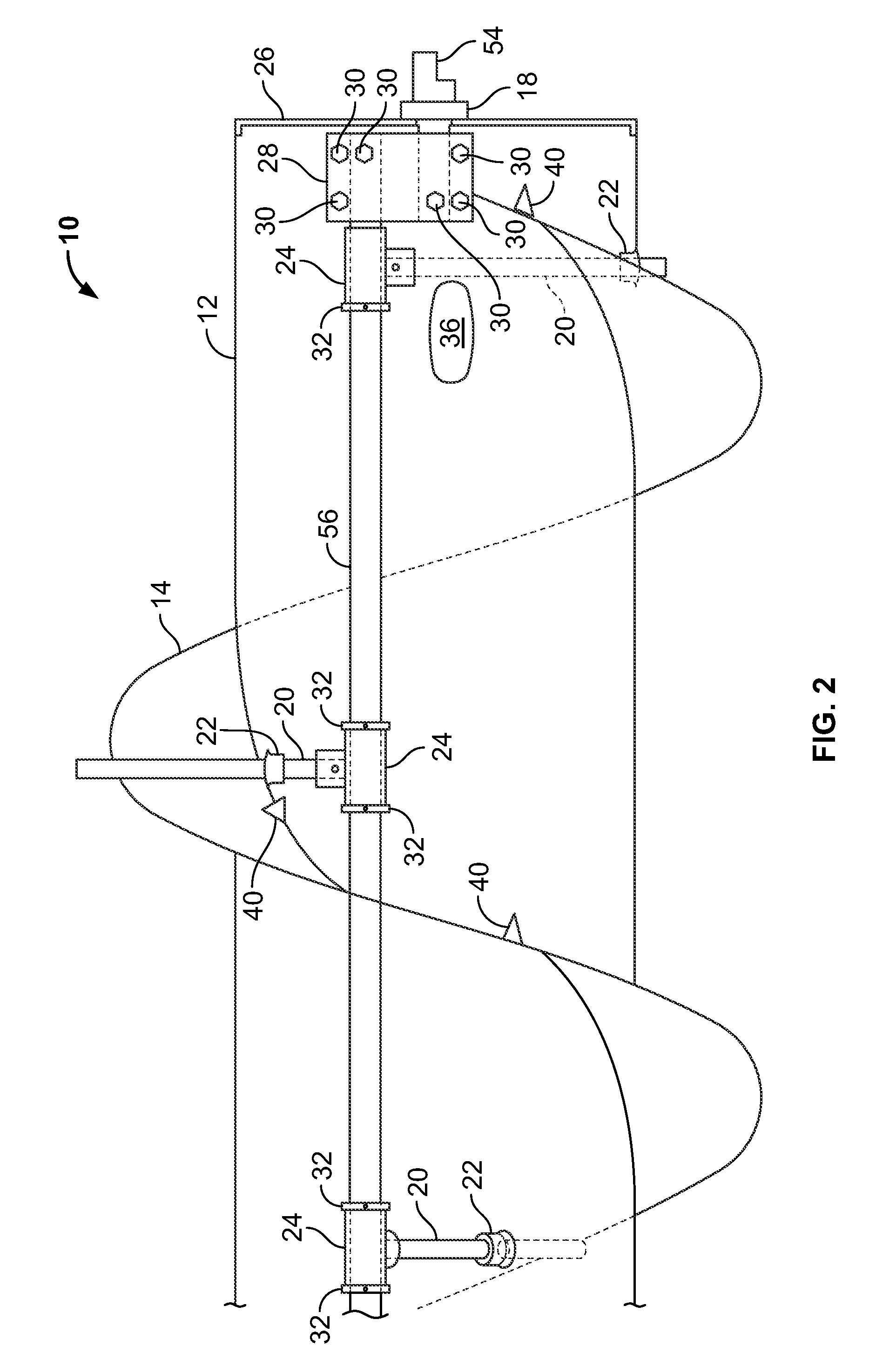

Hydraulic drive arrangement for the cutter of a pull-type crop harvesting machine

InactiveUS7306252B2Simple mechanical connectionReduce weightAgricultural machinesMowersCircular discHydraulic circuit

A pull-type crop harvesting machine has disk cutter carried on a frame mounted on ground wheels with a hitch arm extending from the frame over the header to a hitch connector of a tractor. The hitch arm is mounted for pivotal movement about a generally upright axis such that in a first position the tractor tows the frame in echelon to one side and in a second position the tractor tows the frame in echelon. The disks are hydraulically driven by a pump at the front end of the hitch arm and a motor at the frame with the hydraulic circuit including a sump tank defined by a hollow interior of the hitch arm and a cooling radiator defined by a tubular frame member which is preferably located at the disk drive as a support therefore as it is cooled by the air flow from the disks and contact with the crop and carries a low volume of fluid.

Owner:MACDON INDS

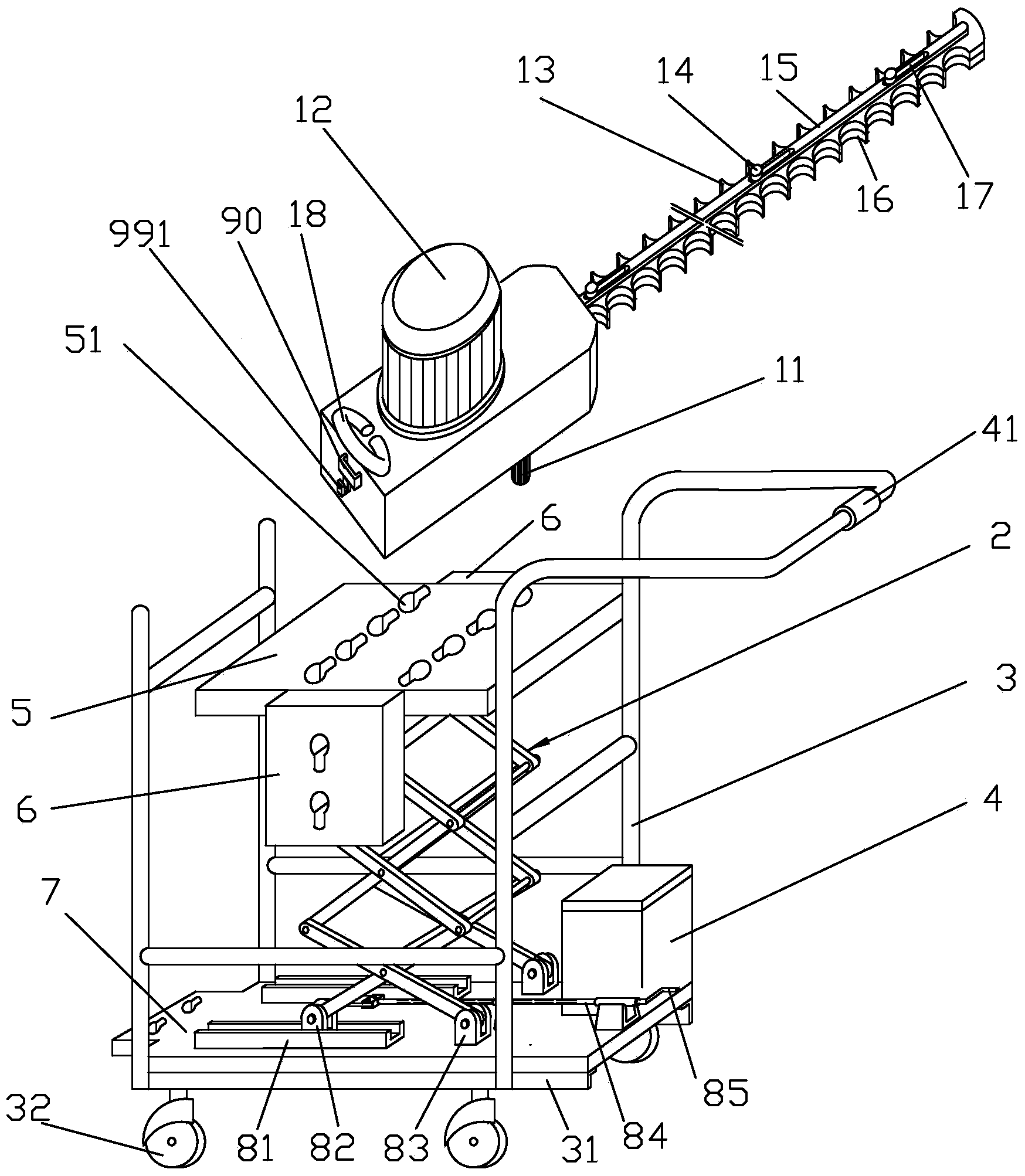

Hand-push type multifunctional plant pruning machine

ActiveCN103907484AReduce labor intensityAchieve pruningHedge trimming apparatusMowersEngineeringCrop harvester

The invention relates to plant pruning equipment, in particular to a hand-push type multifunctional plant pruning machine which comprises a four-wheeled trolley, an electric hedge trimmer and a scissors fork type lifter. The electric hedge trimmer comprises a power portion and knife scissors, a high bedplate which is used for supporting the electric hedge trimmer is arranged on the top of the scissors fork type lifter, the electric hedge trimmer can be of a unidirectional drive or bidirectional drive structure, two vertical columns are arranged at the bottom of the power portion of the electric hedge trimmer, two front legs at the bottom of the scissors fork type lifter are movably supported on guide rails, and two rear legs at the bottom of the scissors fork type lifter are rotatably connected with a bottom plate; a low bedplate is formed by the front end of the bottom plate; side upright plates are hinged to at least one side of the high bedplate, and a plurality of through holes which are used for supporting the electric hedge trimmer and are matched with the columns in an insertion manner are respectively formed in the high bedplate, the side upright plates and the low bedplate. The hand-push type multifunctional plant pruning machine has the advantages that the labor intensity of workers can be relieved, the hand-push type multifunctional plant pruning machine is high in pruning quality, the electric hedge trimmer can be bidirectionally driven, is particularly applicable to pruning green belts and is particularly suitable to be used as a crop harvester or a lawn mower, and the work efficiency can be obviously improved.

Owner:ZHEJIANG DAYANG SEWING MACHINE

Wind guard latch retainer

ActiveUS6935094B1Reliable constructionReduce manufacturing costLoadersMowersEngineeringAgricultural crops

Owner:CNH IND AMERICA LLC +1

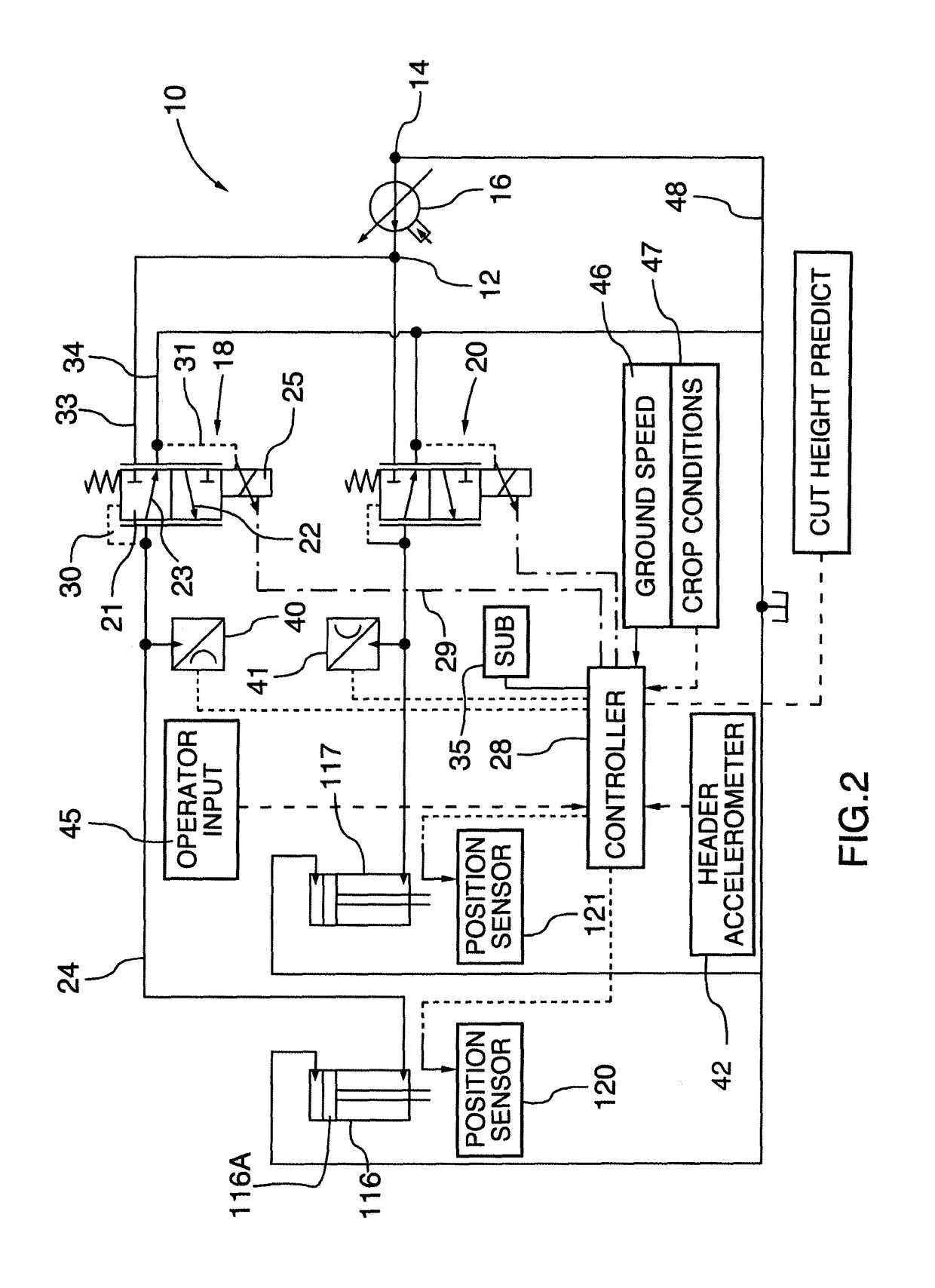

Crop machine with an electronically controlled hydraulic cylinder flotation system

ActiveUS9968033B2Avoid necessityDecreasing/increasing float pressureAgricultural machinesServomotor componentsHydraulic cylinderControl signal

Owner:MACDON INDS

Hydraulic drive arrangement for the cutter of a pull-type crop harvesting machine

InactiveUS20070199293A1Simple mechanical connectionReduce weightAgricultural machinesMowersHydraulic circuitEngineering

A pull-type crop harvesting machine has disk cutter carried on a frame mounted on ground wheels with a hitch arm extending from the frame over the header to a hitch connector of a tractor. The hitch arm is mounted for pivotal movement about a generally upright axis such that in a first position the tractor tows the frame in echelon to one side and in a second position the tractor tows the frame in echelon. The disks are hydraulically driven by a pump at the front end of the hitch arm and a motor at the frame with the hydraulic circuit including a sump tank defined by a hollow interior of the hitch arm and a cooling radiator defined by a tubular frame member which is preferably located at the disk drive as a support therefore as it is cooled by the air flow from the disks and contact with the crop and carries a low volume of fluid.

Owner:MACDON INDS

Crop catching apparatus and crop harvesting machine employing the same

A crop-catching apparatus for use in a crop harvesting machine includes one or more plate members and one or more fluid conduits. The plate member(s) each have a surface adapted for catching falling crops, a front end and a back end, and a leading edge. The back end(s) are configured to pivotally mount on the crop harvesting machine. The front end(s) are configured to rest at a higher elevation with respect to the pivotally mounted back end(s). The conduit(s) are defined within at least one of the plate member(s) for carrying one or more fluids, and include one or more fluid inlets defined on the at least one of the plate member(s) for receiving the one or more fluids; and one or more fluid outlets defined on the at least one of the plate member(s) running at least partially along the leading edge(s) of the at least one of the plate member(s). The fluid outlet(s) are configured such that the one or more fluids exit therefrom to divert a direction of fall of the crops. A crop harvesting machine also employs a crop-catching apparatus.

Owner:SIDHU RUPINDER SINGH +1

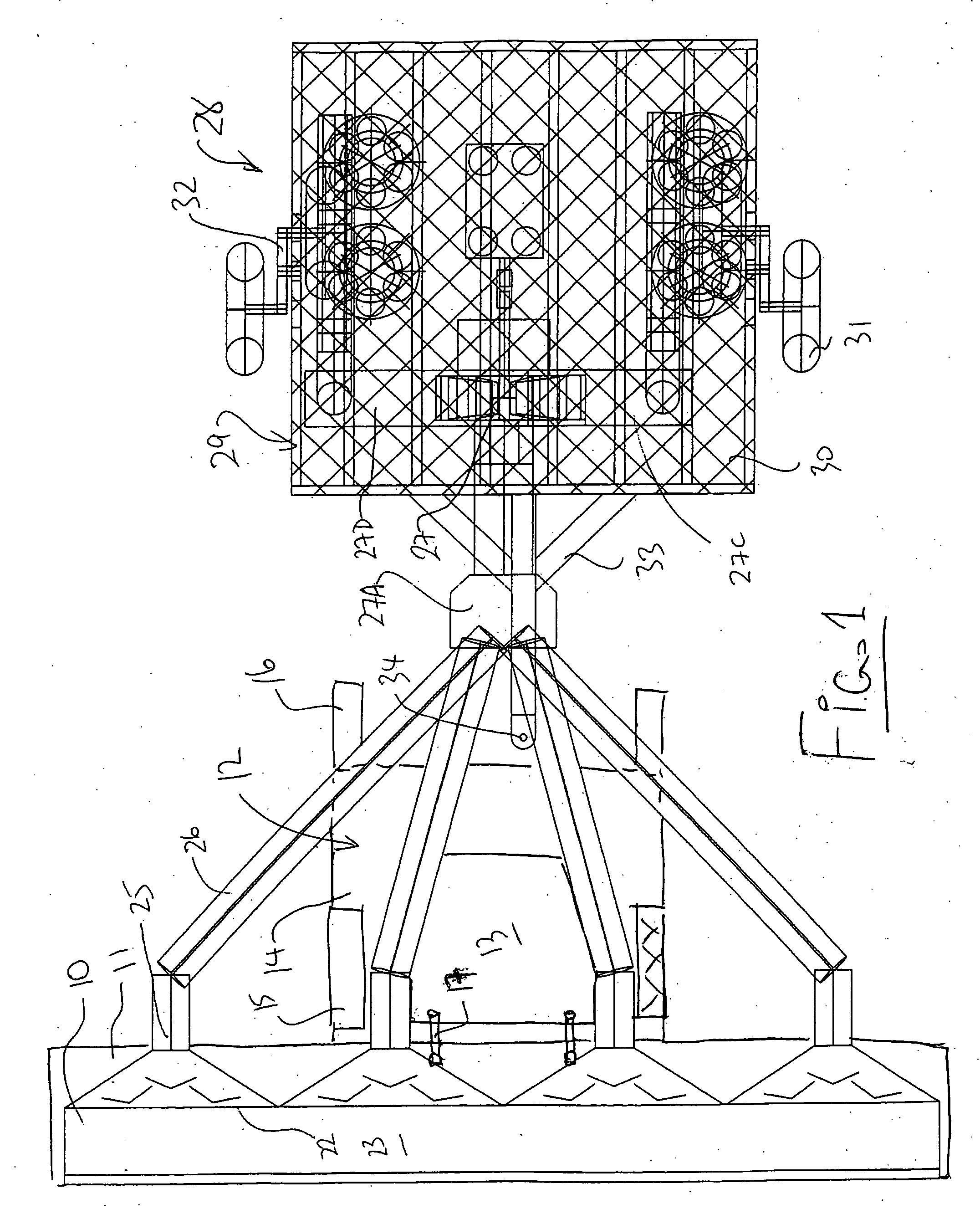

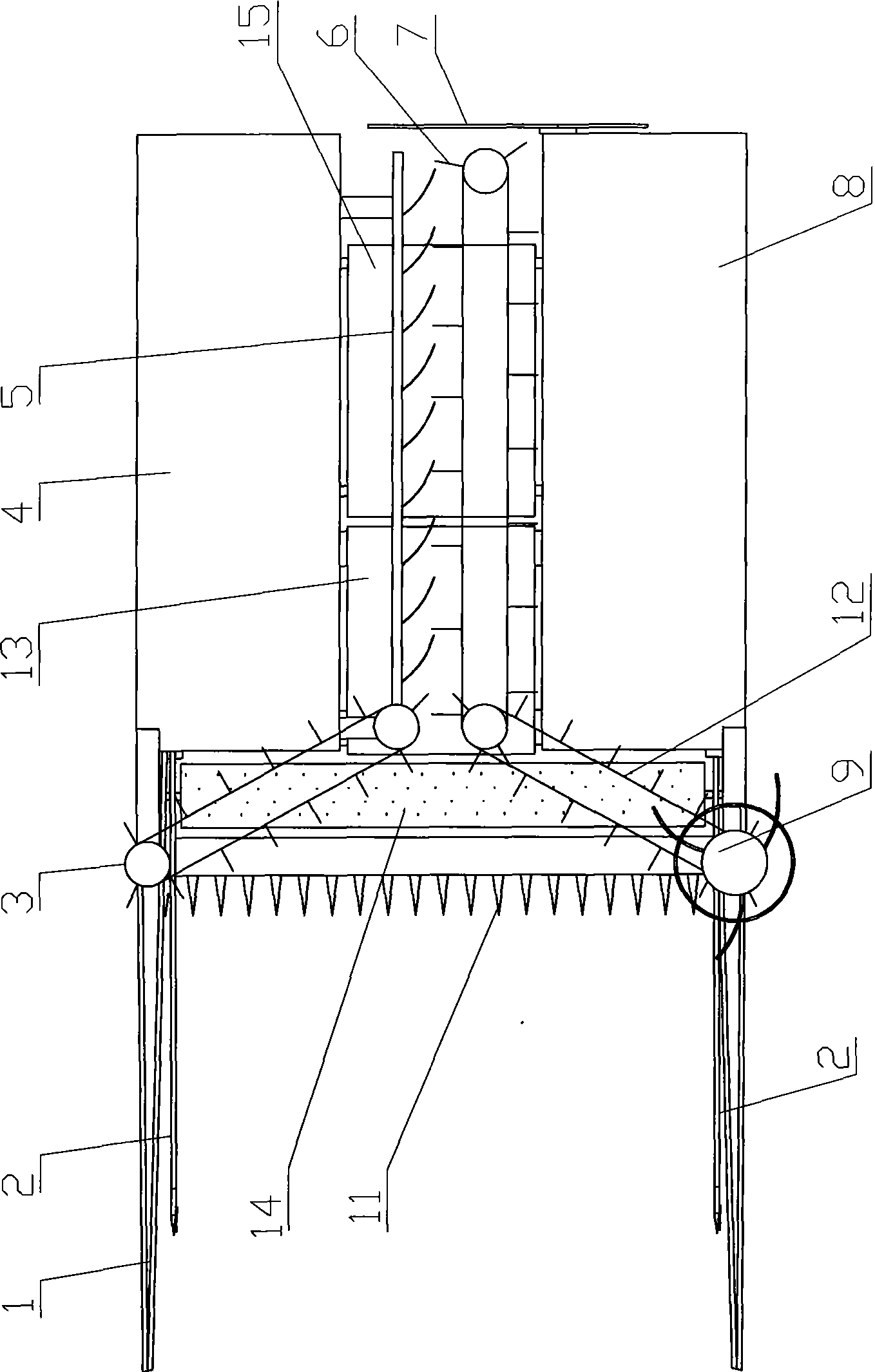

Machine for harvesting tall stalk crops

InactiveCN101461300AHarvest does not affectHarvest suitable forMowersAgricultural undercarriagesEngineeringCrop harvester

The invention discloses a tall rod crop harvester, comprising a vehicle and a horizontal cutting knife horizontally arranged at the front of the vehicle, wherein a crop channel along the driving direction of the vehicle is arranged at the center of the vehicle body of the vehicle. When in harvest, the crop moves toward the rear part of the harvester through the crop on the harvester, for collecting the crop at the rear part of the harvester, no manual is required to clear the way before harvesting the crop, and the crop is arranged at the rear part of the harvester in bunch after the harest, and no manual removal is required, the next harvest is not affected. The invention is suitable for the tall rod crop of the reed and the corn straw and the like.

Owner:程广森

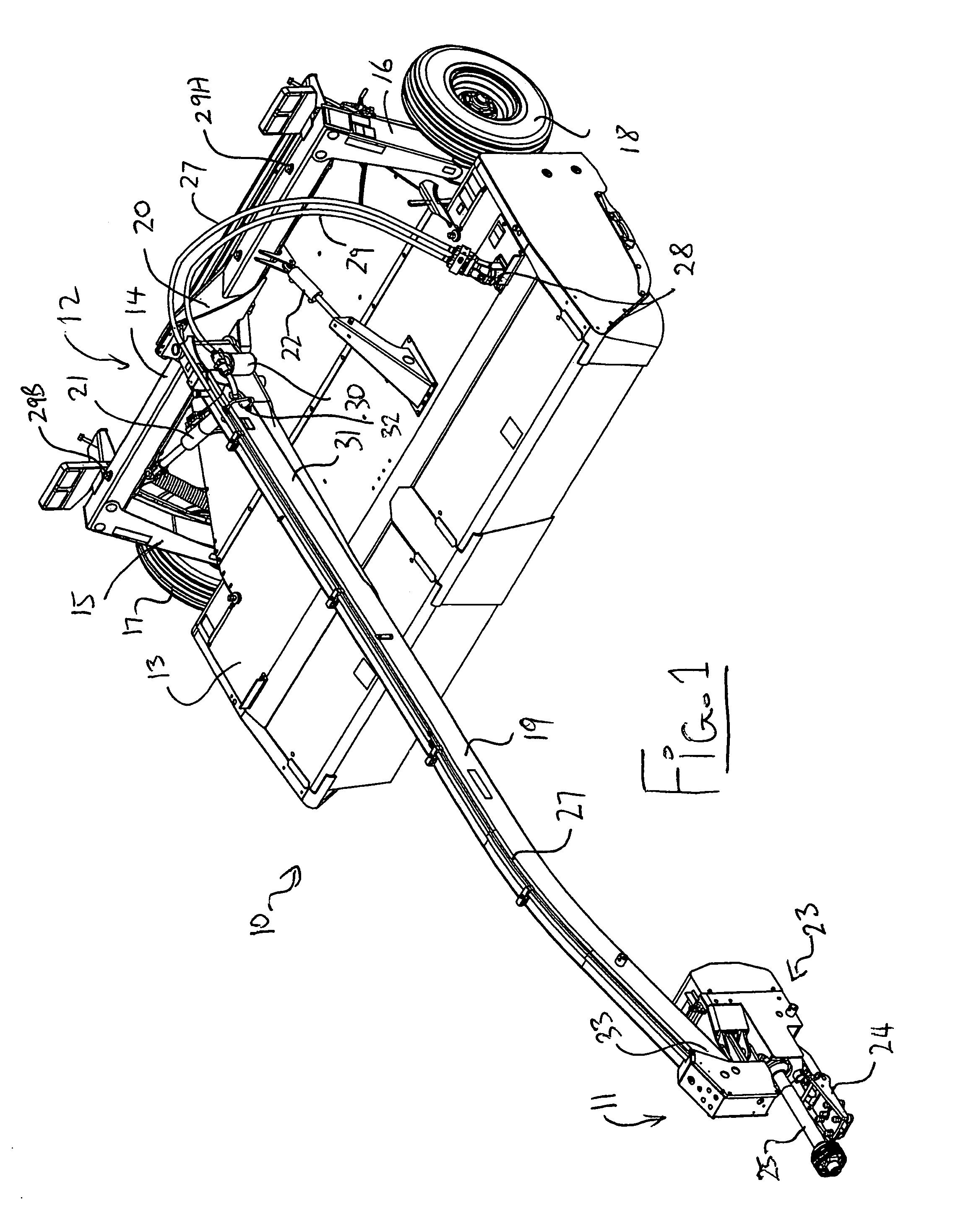

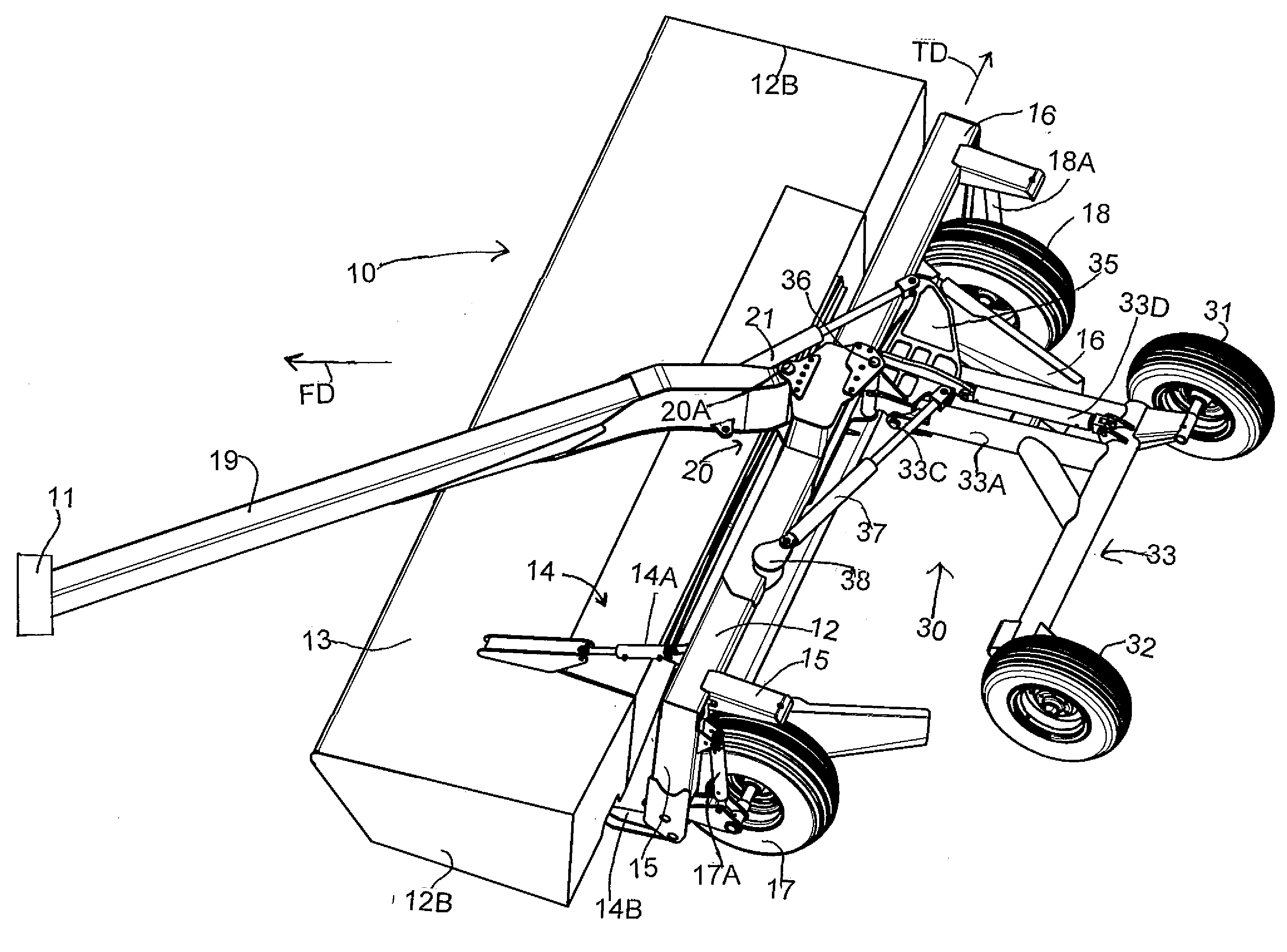

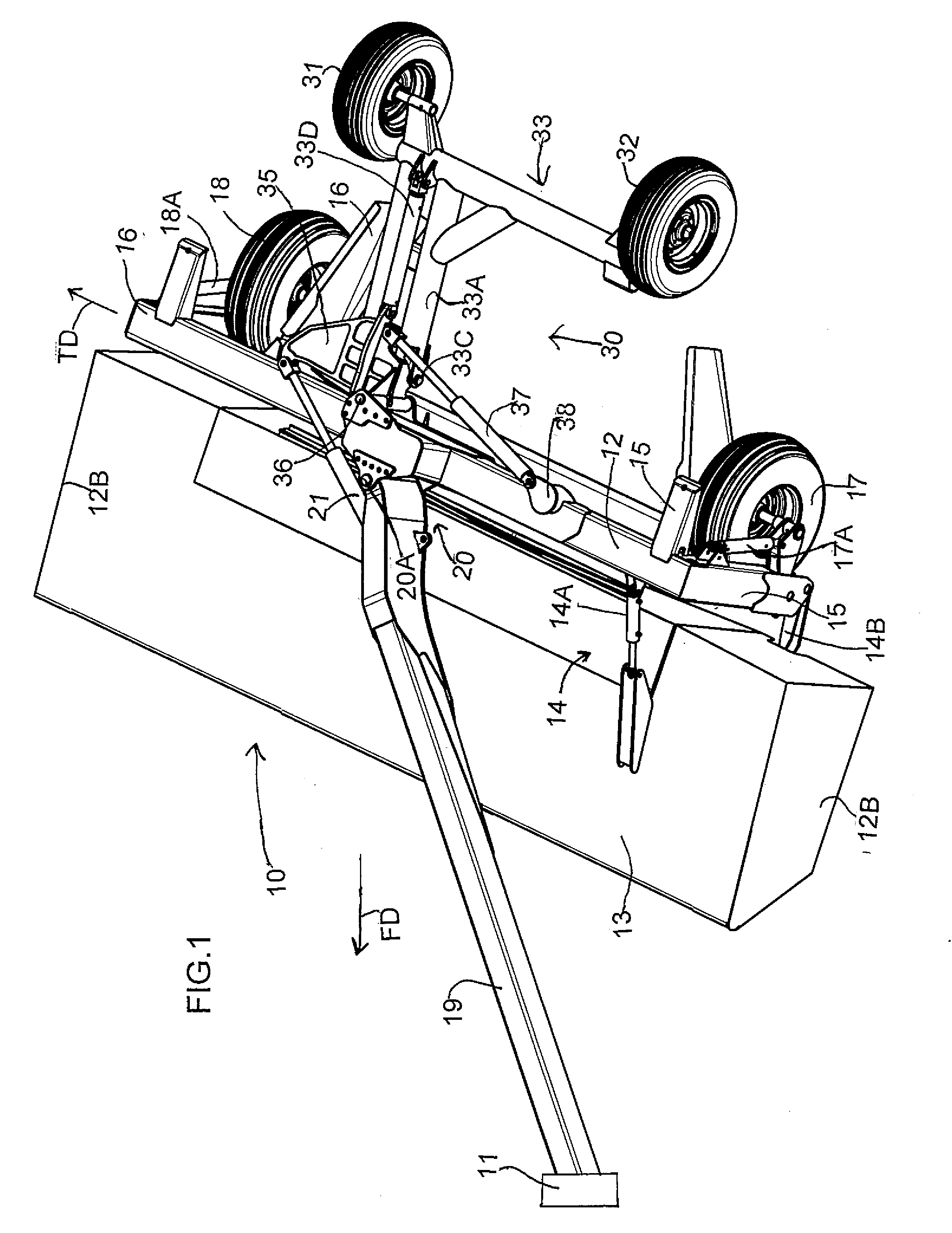

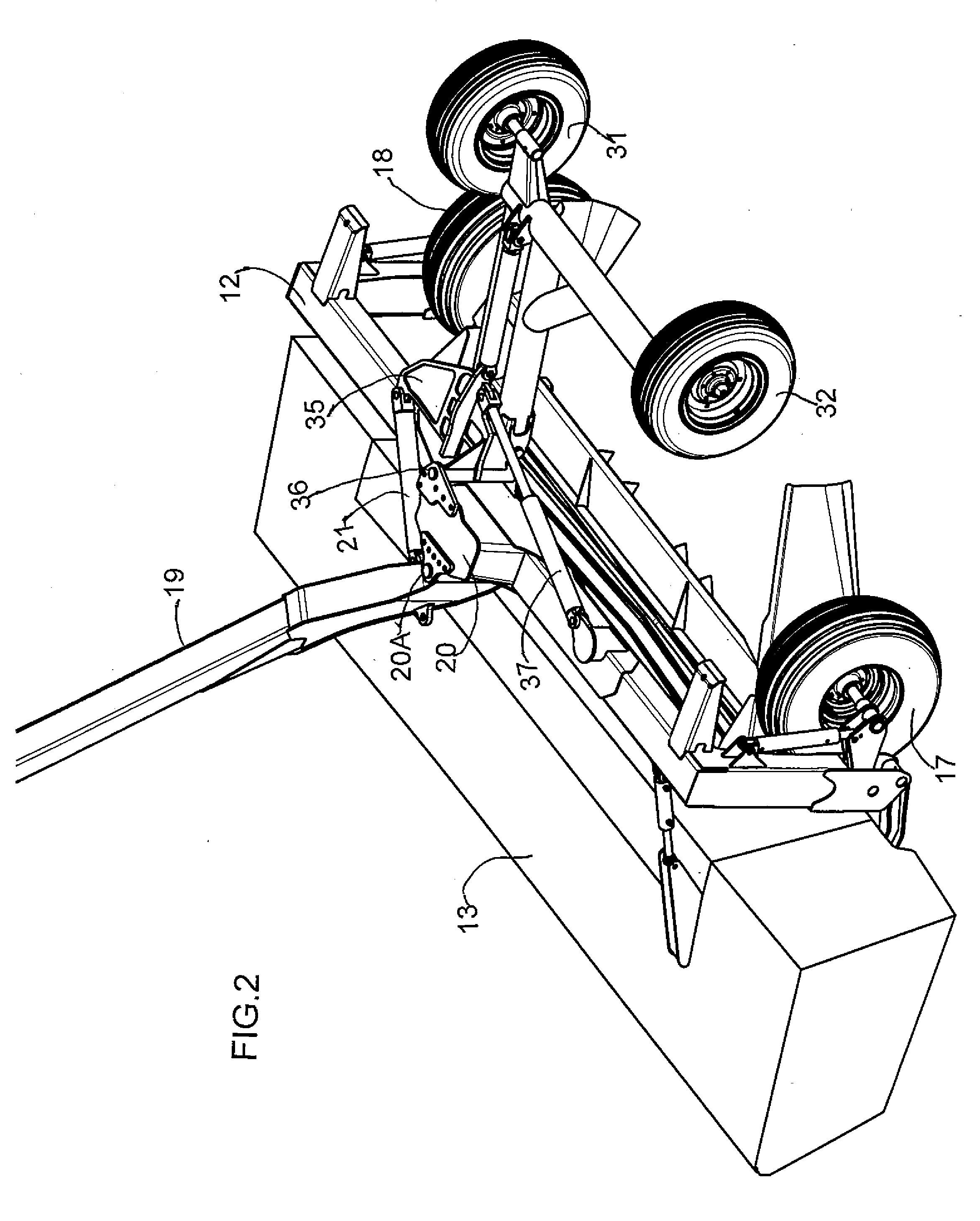

Pull-type crop harvesting machine transport system actuated at a predetermined angle of the hitch

ActiveUS20130284469A1Quickly and conveniently movedEasy to liftAgricultural machinesHarrowsTransport systemMower

A pull-type crop engaging machine such as a rotary mower comprises a frame mounted on transversely spaced field ground wheels for movement with a hitch arm extending to a tractor and a transport assembly attached behind the frame for moving downwardly to a transport position so that in the transport position the hitch arm extends from one end of the frame generally in the transverse direction for towing the machine in the transverse direction. The transport includes a transport ground wheel which acts to raise the frame to pass underneath the crop engaging system to support the machine on the wheel, on a second wheel behind the frame and on the hitch. The movement of the hitch and the wheel is connected and started at a position of the hitch so that the machine remains balanced. A shield behind the frame includes a portion which moves with the transport wheel.

Owner:MACDON INDS +1

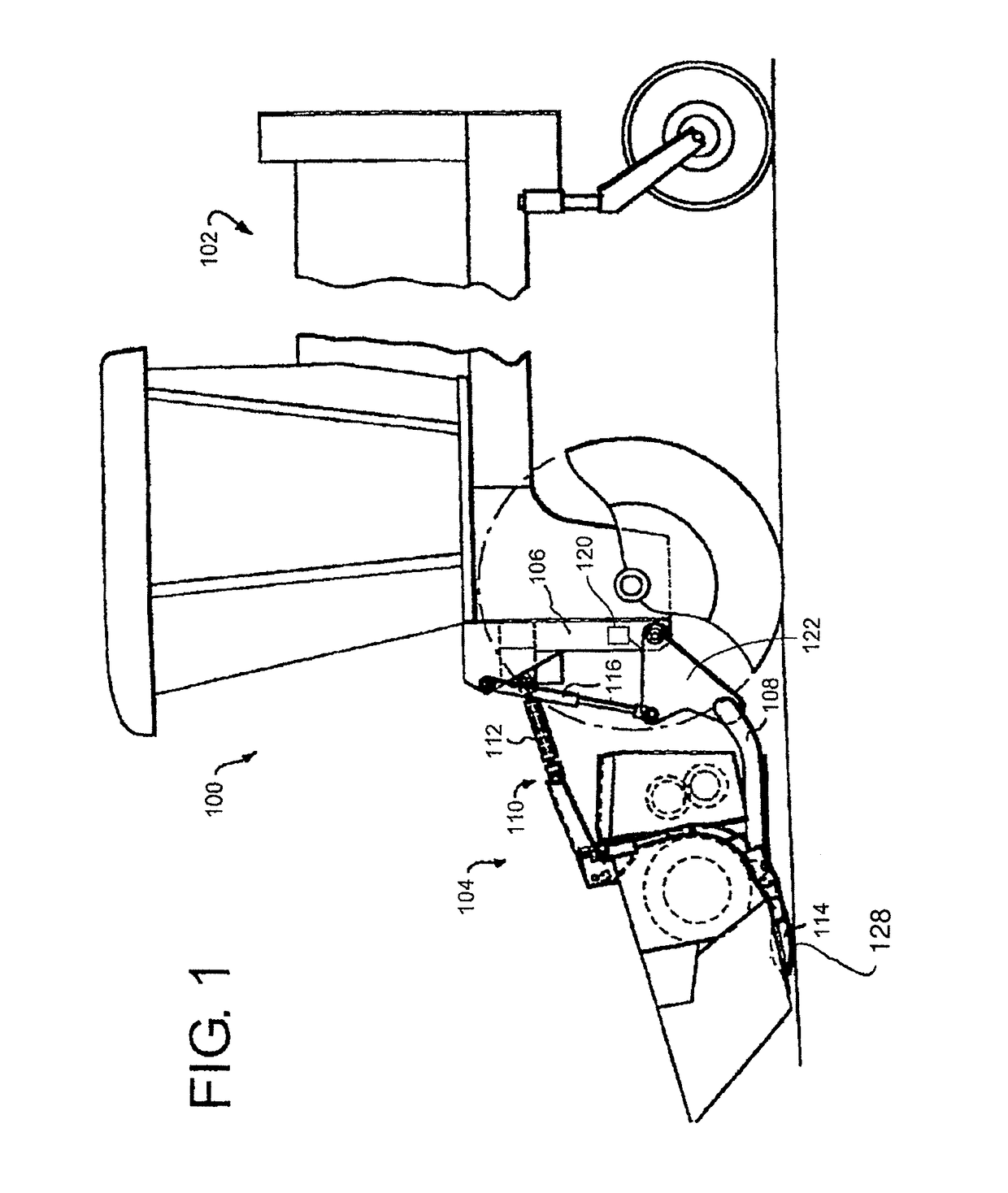

Crop Harvesting Machine Including Retractable Sensor Fingers with Adjustable Ground Pressure and Header Tilt Control

A crop harvesting machine with a cutter bar on a header frame has a height control system which uses depending sensor fingers arranged in contact with the ground so as to measure a height of the cutter bar above the ground. The sensor fingers are controllably retractable under actuation from an operator in the cab or automatically in response to prescribed conditions being met. The actuator used in retracting the sensor fingers can also be used to adjustably control ground pressure of the sensor fingers in the deployed position of the sensor fingers engaging the ground. The header height is adjusted using laterally spaced apart hydraulic linkages which can be operated at different elevations relative to one another responsive to different height signals relating height of opposing ends of the header frame relative to the ground to also control tilt of the header relative to the harvester frame.

Owner:MACDON INDS

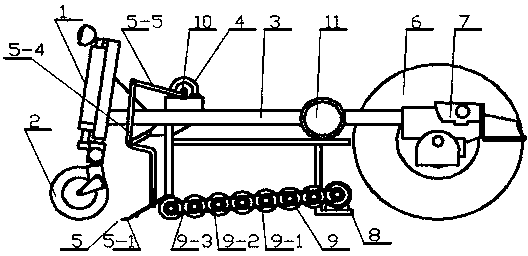

High stalk crop harvester

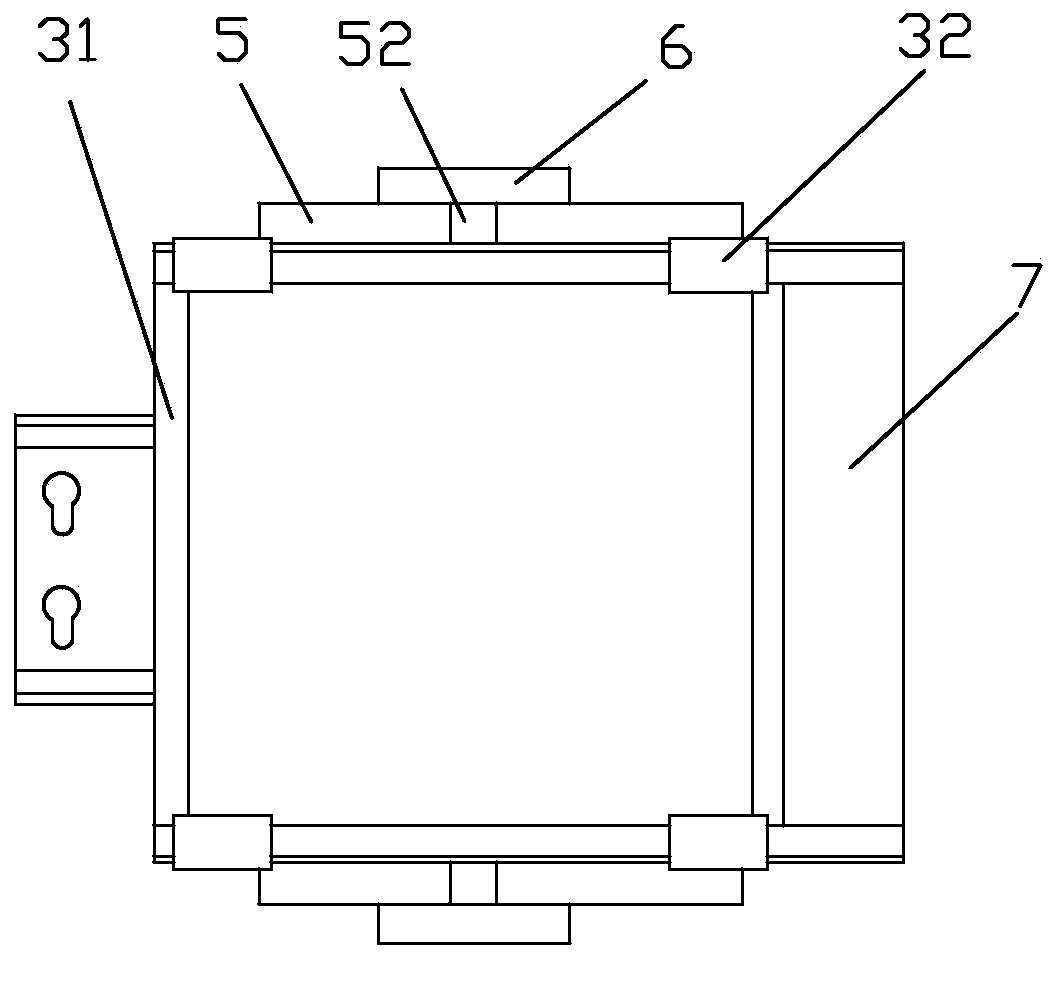

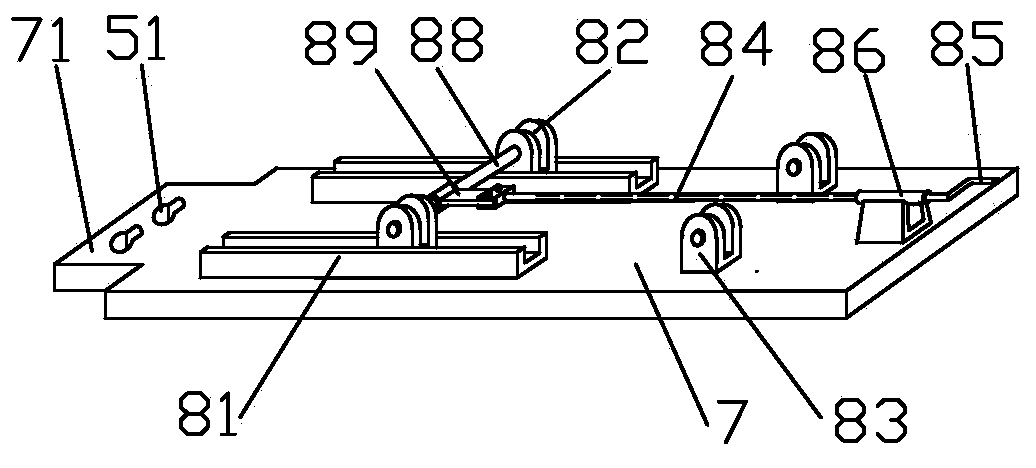

ActiveCN107114060ARealize telescopic movementAvoid direct calls toHarvestersEngineeringCrop harvester

The invention discloses a high stalk crop harvester. The high stalk crop harvester is characterized by comprising a motor vehicle and a cutting knife device, the motor vehicle is provided with a crop channel and a crop clamping and delivering device, and further comprises toggling cylinder devices, two toggling cylinder devices are located at the two sides, in the width direction, of the crop clamping and delivering device, and the toggling cylinder devices comprise fixed shafts, guide sleeves, toggling pointers and driving components; the fixing shafts and the guide sleeves are parallel and eccentric, one end of each fixed shaft is fixedly connected with the motor vehicle, the other end of each fixed shaft is provided with a crank to be rotatably connected with the corresponding guide sleeve, one end of each crank is fixedly connected with the corresponding fixed shaft, the other end of the crank is rotatably connected with the center axial line of the corresponding guide sleeve, and when the driving components drive the guide sleeves to rotate along the center axial lines of the guide sleeves, the toggling pointers rotatably connected to the fixed shafts can slide axially in slide holes. According to the high stalk crop harvester, when high stalk crops are conveyed to a conveying chain, the high stalk crops can be effectively prevented from being directly hit to the conveying chain, and therefore the harvest of the high stalk crops has a good effect.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

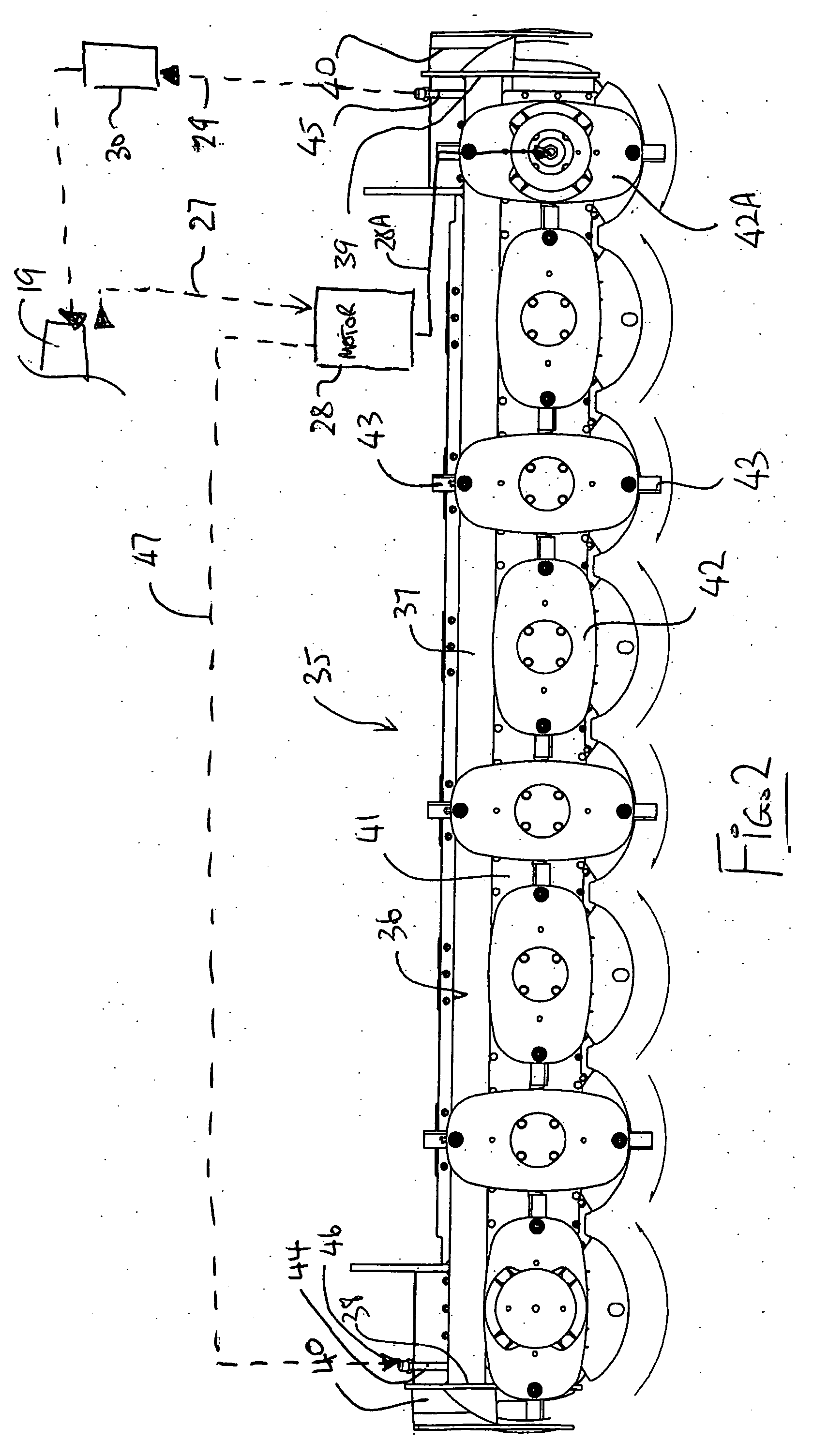

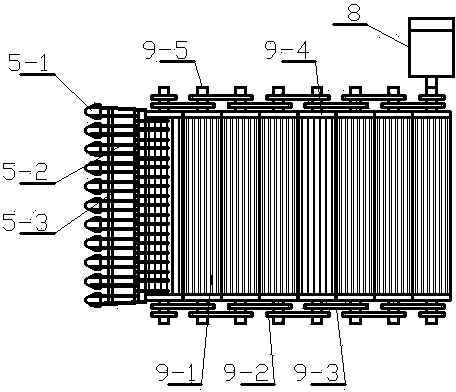

Multifunction underground crop harvester

The invention relates to a multifunction underground crop harvester which comprises a vehicle body, a power system, a guiding mechanism, a walking mechanism, a conveying sifting mechanism, a vibration device and a soil scraping mechanism. The conveying sifting mechanism is arranged on the lower portion of the vehicle body. The vibration device enables the conveying sifting mechanism to carry out vibration soil sifting. The soil scraping mechanism is arranged on the front portion of the conveying sifting mechanism. The conveying sifting mechanism comprises a plurality of grid-shaped rollers which are arrayed in the vehicle body length direction in parallel and are connected with the vehicle body in a rotating mode. Adjacent rollers are in transmission connection through chains and chain wheels. The harvester is reasonable in structure, a roller type separating sieve is used, flexibility and convenience are achieved, maintaining is convenient, and good practical value is achieved.

Owner:李垒

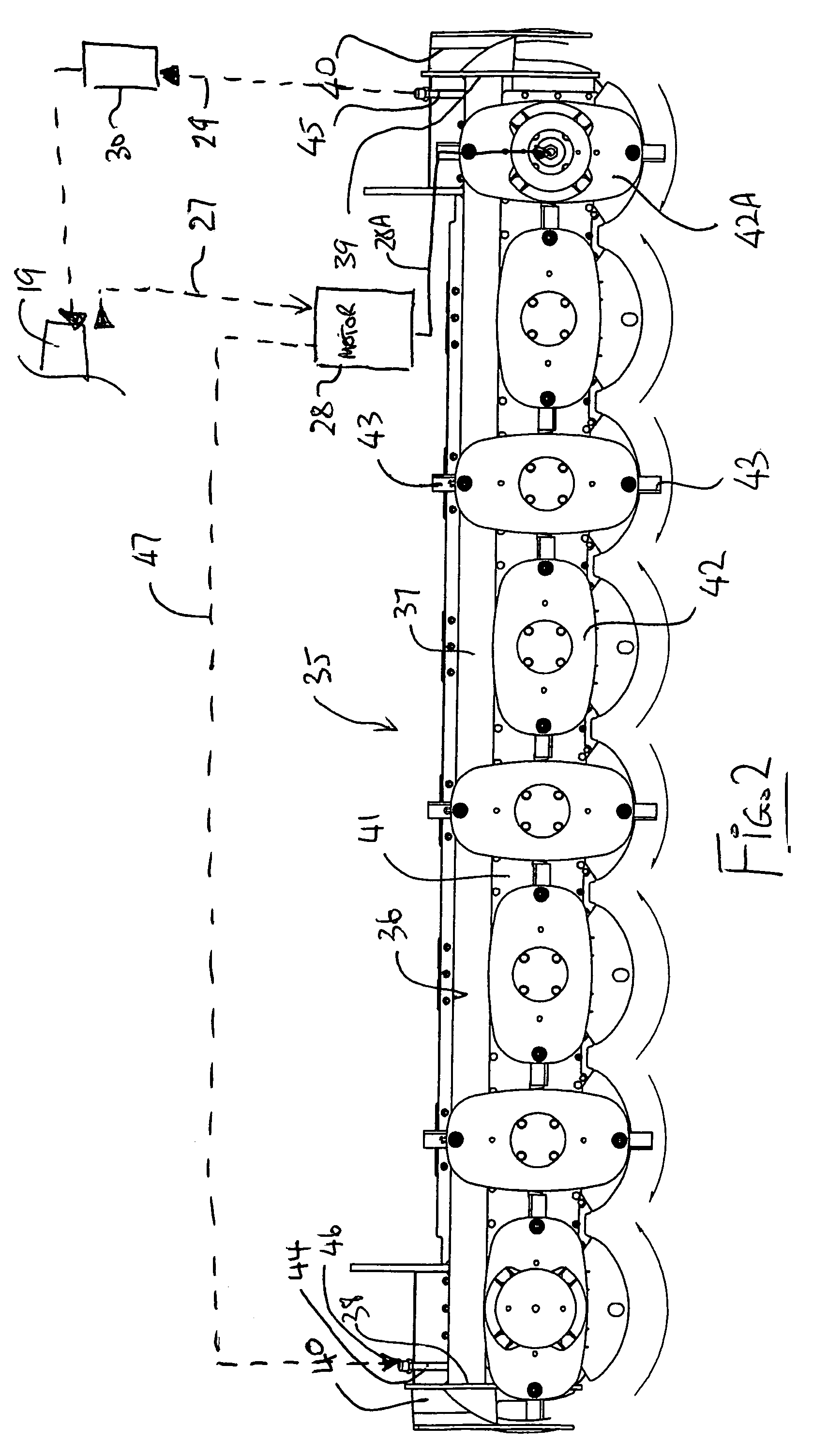

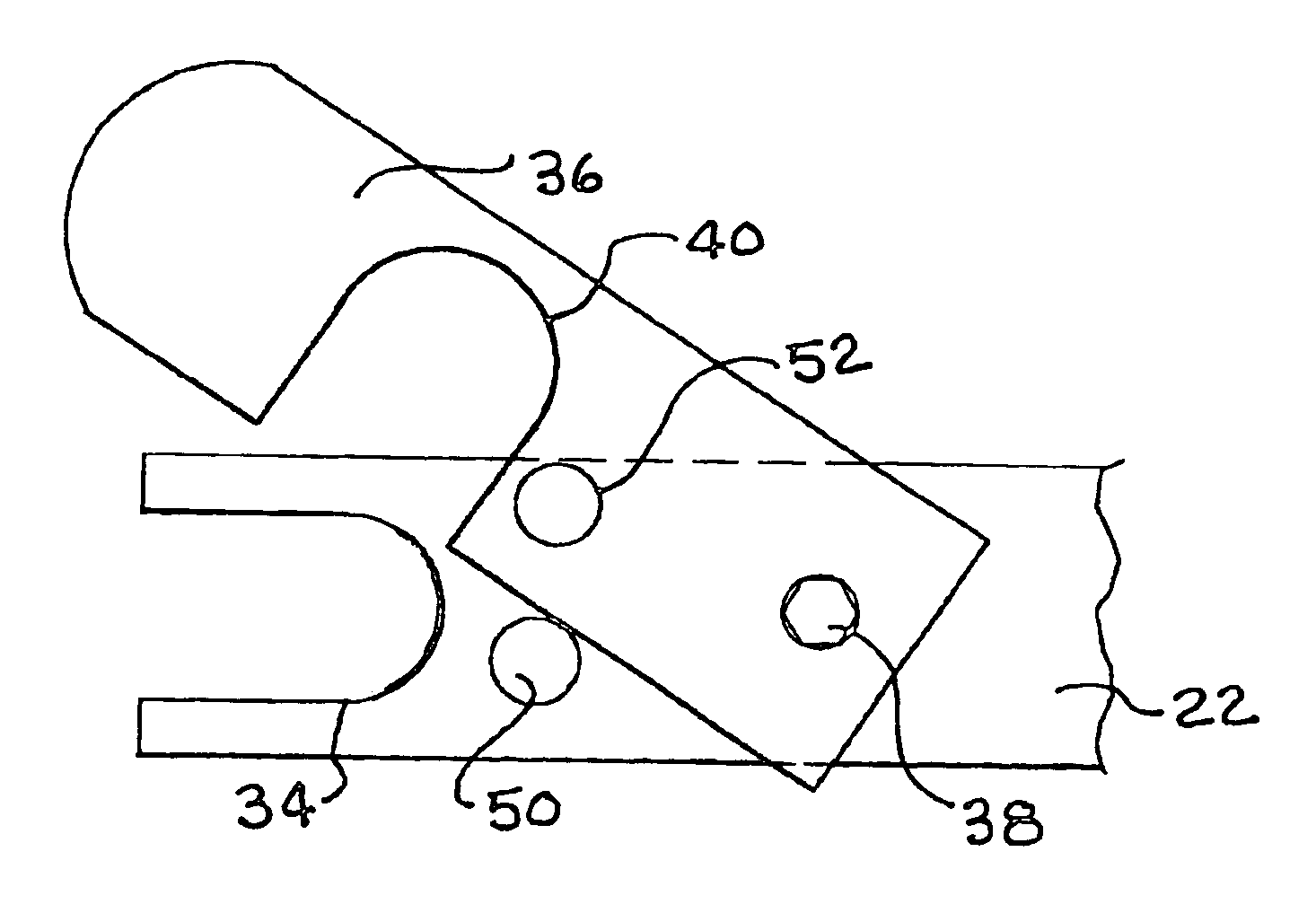

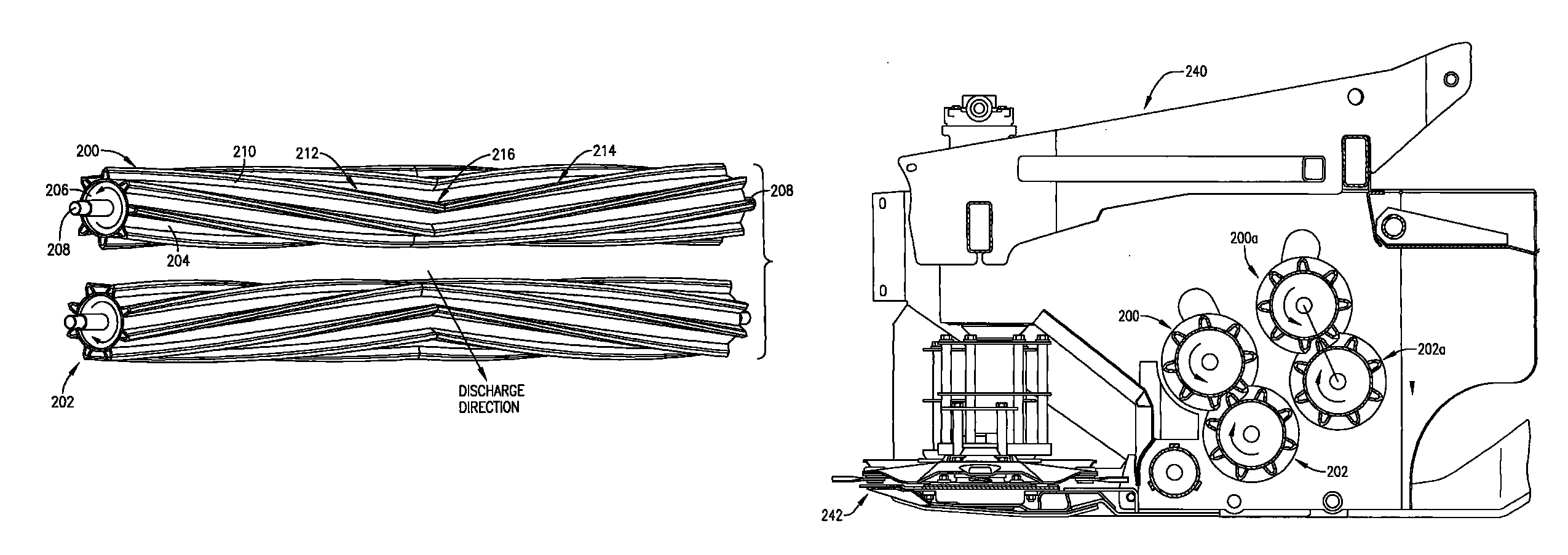

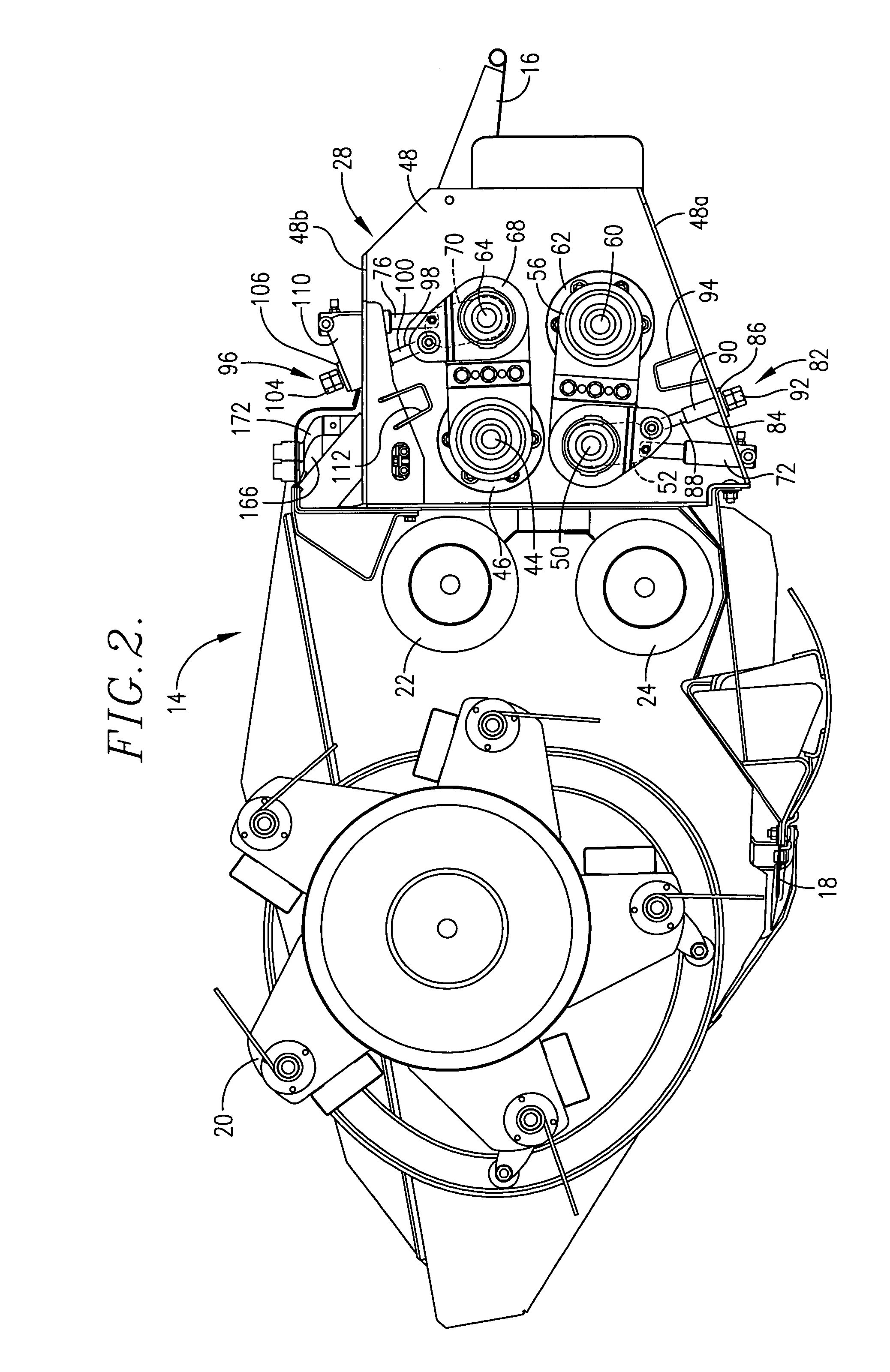

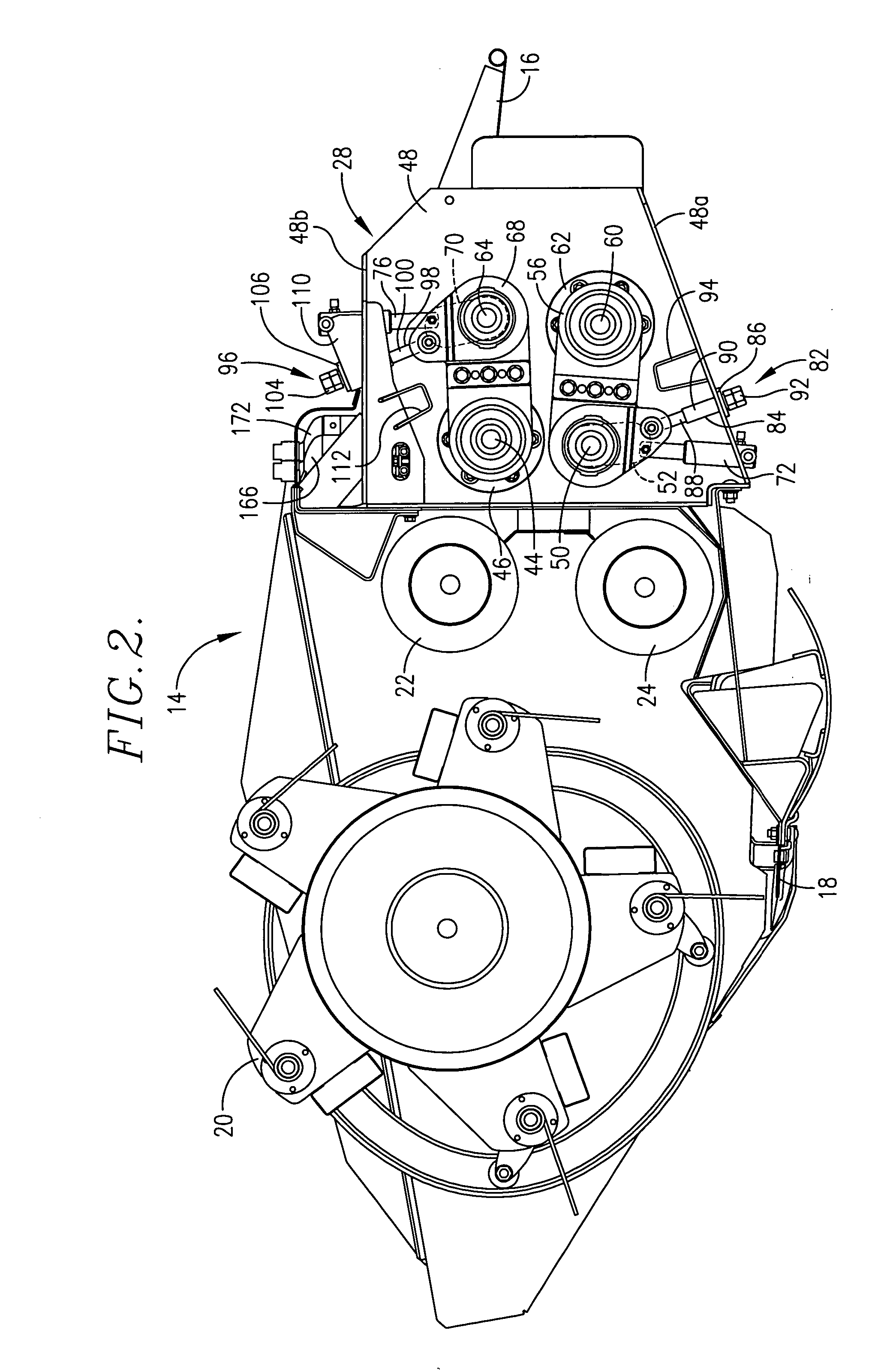

Crop harvester having metal conditioner rolls with herringbone rib pattern

The conditioning rolls of a crop harvester have intermeshing metal ribs arranged in a herringbone pattern, each rib comprising a pair of end-to-end segments that converge spirally from opposite ends of the roll to a centermost apex. Alternative embodiments provide a single pair of metal herringbone rolls, two pairs of metal herringbone rolls, or a front pair of metal herringbone rolls and a rear pair of compressible surface herringbone rolls.

Owner:AGCO CORP

Crop harvester having metal conditioner rolls with herringbone rib pattern

The conditioning rolls of a crop harvester have intermeshing metal ribs arranged in a herringbone pattern, each rib comprising a pair of end-to-end segments that converge spirally from opposite ends of the roll to a centermost apex. Alternative embodiments provide a single pair of metal herringbone rolls, two pairs of metal herringbone rolls, or a front pair of metal herringbone rolls and a rear pair of compressible surface herringbone rolls.

Owner:AGCO CORP

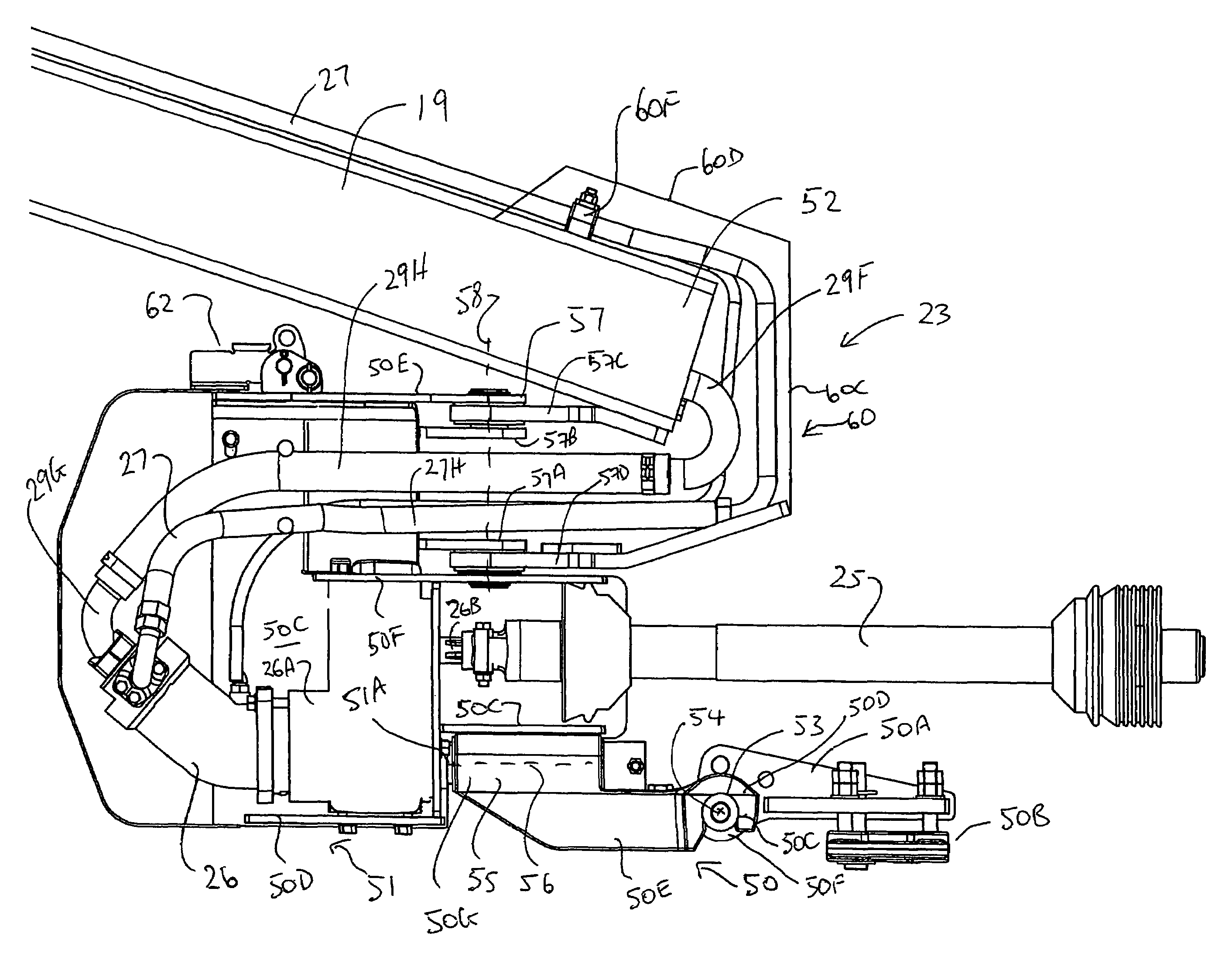

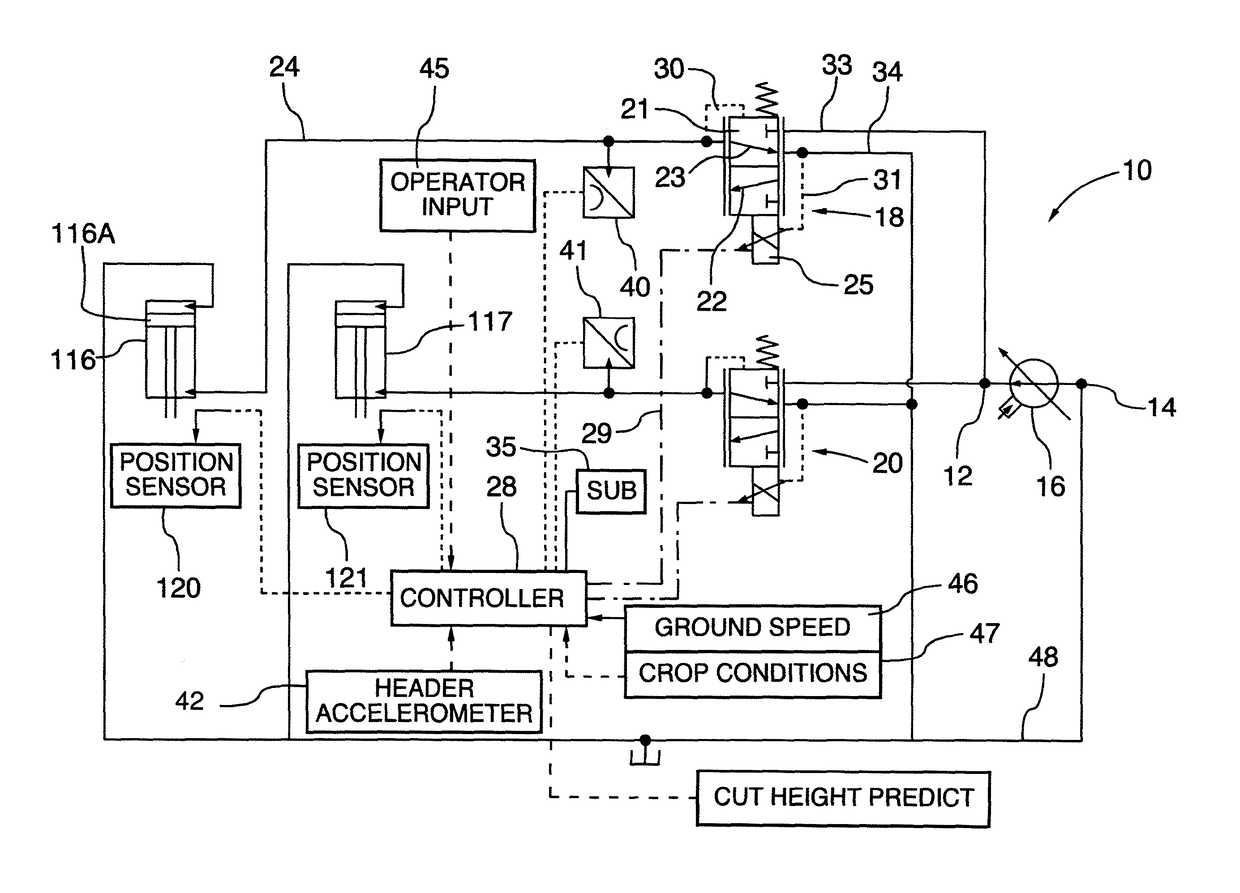

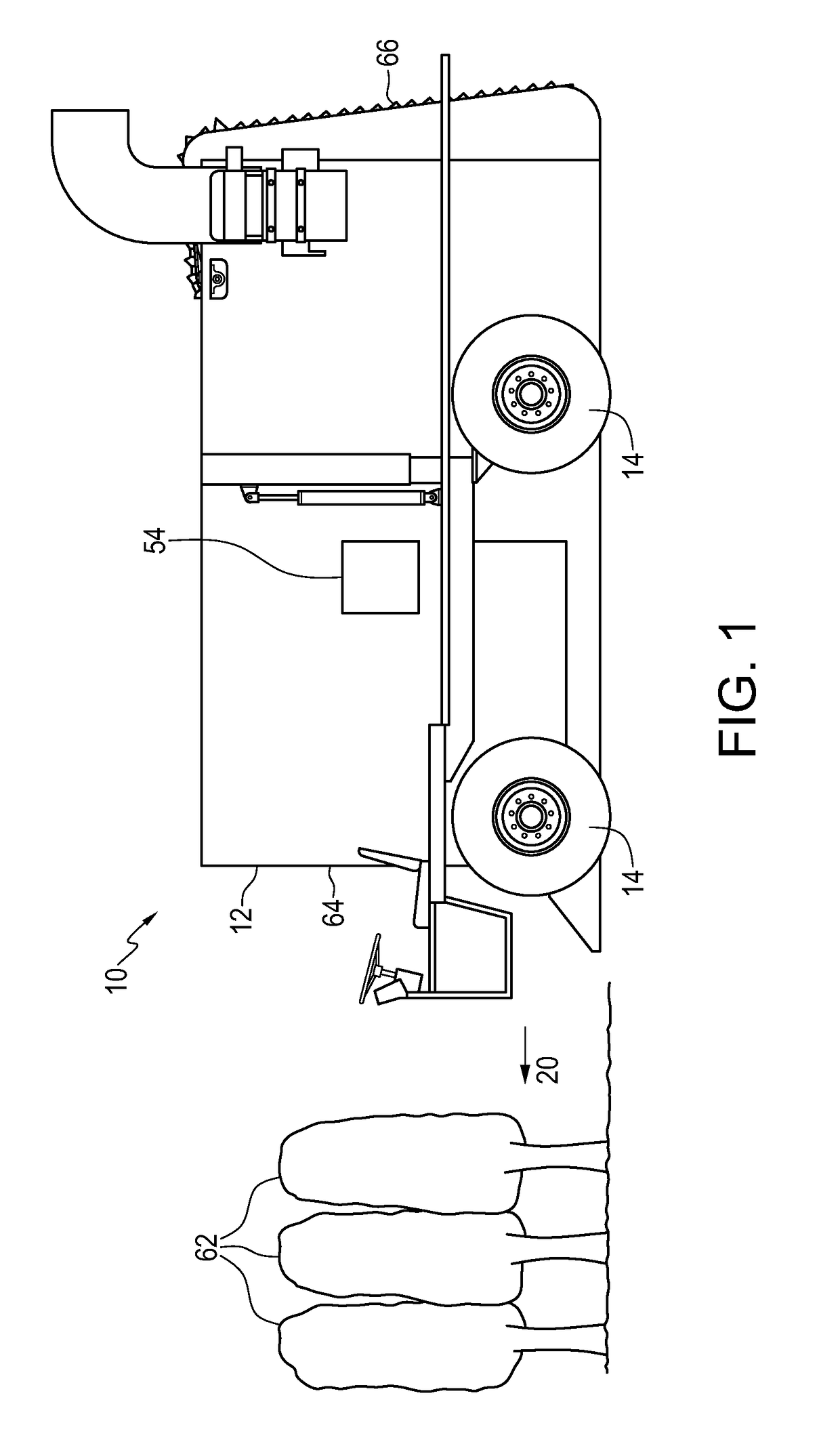

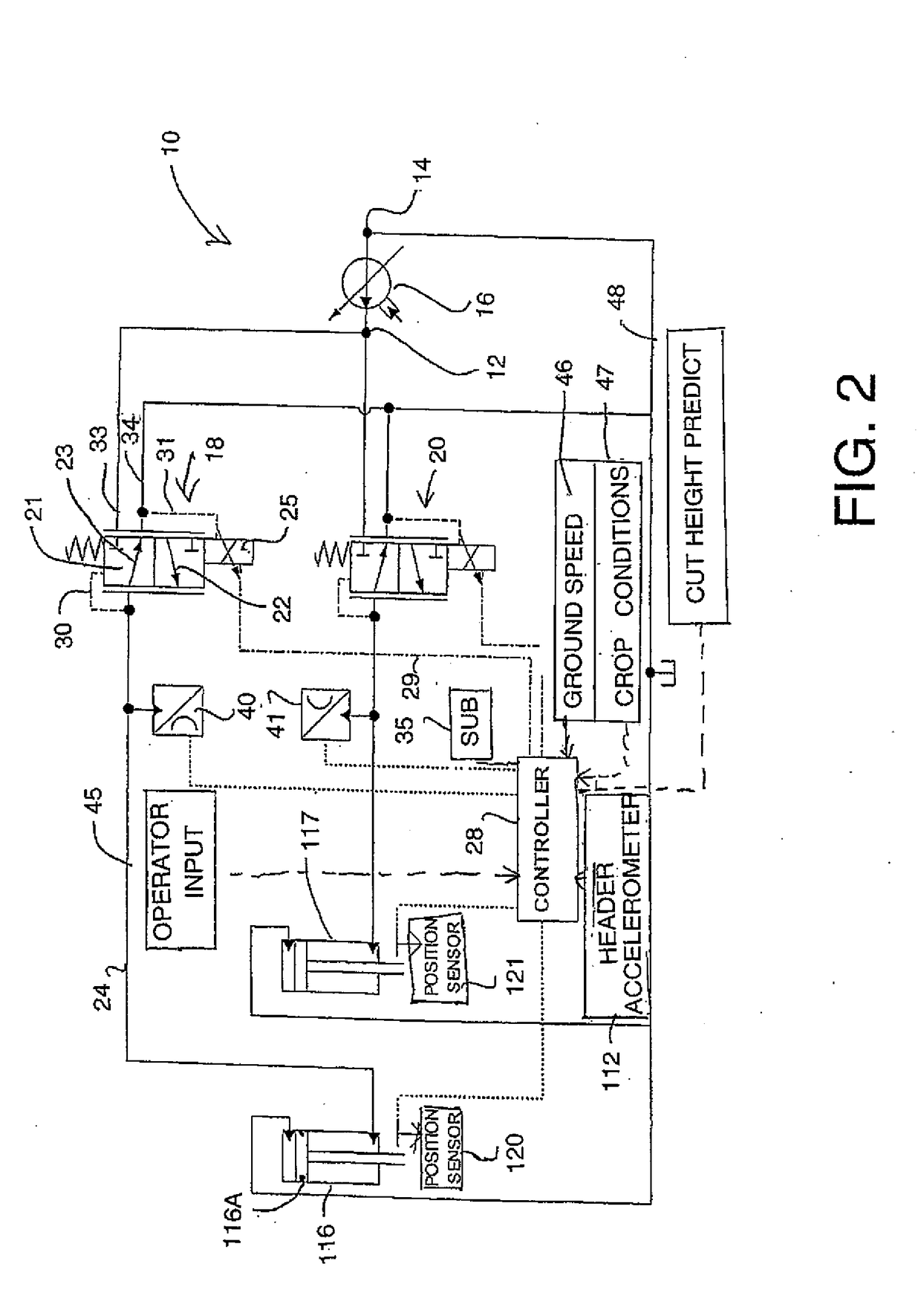

Crop Machine with an Electronically Controlled Hydraulic Cylinder Flotation System

InactiveUS20170359955A1Improve responseReduce lifting forceAgricultural machinesServomotor componentsHydraulic cylinderReciprocating motion

In a crop harvesting machine there is provided a pair of hydraulic float cylinders for a header relative to a vehicle, where a float pressure to the cylinders is directly controlled by an electronic control supplying a variable control signal to a PPRR valve arrangement to maintain the float pressure at a predetermined value. At the set pressure a predetermined lifting force is provided to the header. A position sensor is used to generate an indication of movement and / or acceleration. The electronic control is arranged, in response to changes in the sensor signal, to temporarily change the control signal to vary the lifting force and thus change the dynamic response of the hydraulic float cylinder. In order to reduce static friction so that the system can react quickly, an arrangement is provided for causing relative reciprocating movement in an alternating wave pattern between the piston and cylinder.

Owner:MACDON INDS

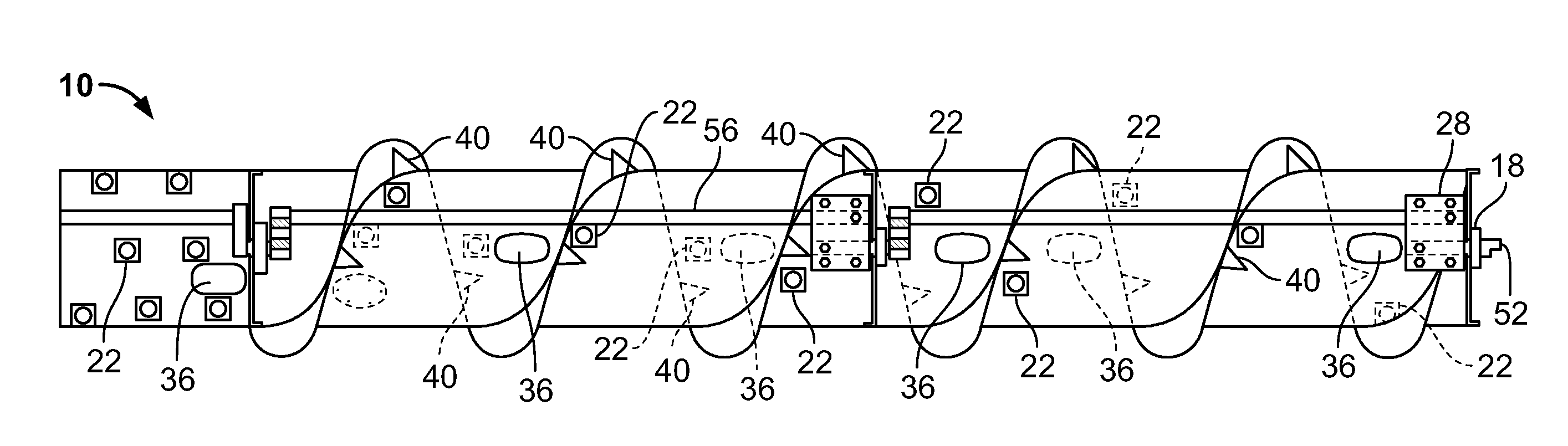

Crop harvester

A crop harvester includes: a rotatable auger tube having a gathering section; flighting disposed in a spiral pattern on the outer surface of the gathering section so that, when the auger tube is rotated, the flighting moves material within a perimeter of the flighting laterally and creates a neutral zone behind the flighting that is generally free of material; and gathering fingers disposed in the neutral zone that, when the auger tube is rotated, extend beyond the perimeter of the flighting to gather the material, tuck the material toward the auger tube, and then retract within the perimeter of the flighting.

Owner:MARRS EVEN FLO HEADERS

Picking head used in tomato harvester

The invention relates to a picking device used in a crop harvester, in particular to a picking head used in a tomato harvester. The picking head comprises a frame, a seedling separator, a contour wheel, a conveying device, a cutting knife mechanism and a shifting fork mechanism. The picking head is characterized in that: the frame is provided with a frame steering mechanism; the frame steering mechanism comprises a rotary sleeve arranged at the rear part of the frame and a rotary shaft; circular connecting plates are arranged at two ends of the rear part of the frame respectively; the frame is connected with a bracket through the rotary sleeve and the rotary shaft; the bracket is a connecting member for connecting the frame and a main truck frame; the middle part of the bracket is hinged with the main truck frame; two ends of the bracket are respectively hinged with the circular connecting plates arranged on the frame; and the two ends of the bracket are respectively connected with the main truck frame through fixed seats. The picking head has the advantages of reasonable structure, few faults, high work efficiency, good harvesting quality, economic efficiency and practicability.

Owner:SHIHEZI AVIC GUIZHOU AGRI MACHINERY EQUIP

Measurement device

InactiveUS20060027750A1Reduces possible sensor transmission failureAvoid changeRadiation pyrometryMowersMeasurement deviceCrop harvester

A measurement device for detecting agricultural crops located within a conveyor channel. The measurement device includes a light-transmitting panel positioned adjacent to the conveyor channel and is configured to be movable between an operational position and a cleaning position. The measurement device includes a sensor positioned with respect to the light-transmitting panel so as to detect the agricultural crops in the conveyor channel through the light-transmitting panel. A harvesting machine is particularly adapted to utilize the measurement device.

Owner:DEERE & CO

Technology for manufacturing stationary cam and movable disk cam component of transmission box of crop harvester

The invention discloses a technology for manufacturing a stationary cam and movable disk cam component of a transmission box of a crop harvester. The stationary cam and movable disk cam component of the transmission box of the crop harvester is made from an alloy powder material according to the processes of mixing, primarily pressing, pre-sintering, re-pressing, re-sintering, finishing, machining and surface steam blacking, wherein the alloy powder material comprises the following components by weight pecent: 6-8% of Cu, 1-4% of Ni, 0.5-1% of Mo, 0.2-0.5% of S, 1-2% of C, 0.5% of zinc stearate and the balance of Fe powder. The technology disclosed by the invention is simple, technology difficulty is low, materials can be obviously saved, and the stationary cam and movable disk cam component of the transmission box of the crop harvester which has high compactness, high strength and high abrasion resistance and can not cause mutual seizure phenomenon during meshing friction under higher load can be manufactured by adopting the manufacturing technology.

Owner:TAIZHOU KECHENG AUTOMOBILE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com