High and thick-stalk crop harvester

A technology for harvesters and stalks, which is applied to harvesters, agricultural machinery and implements, and applications, and can solve problems such as unsatisfactory harvesting effects, blockages, and lack of hoisting devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

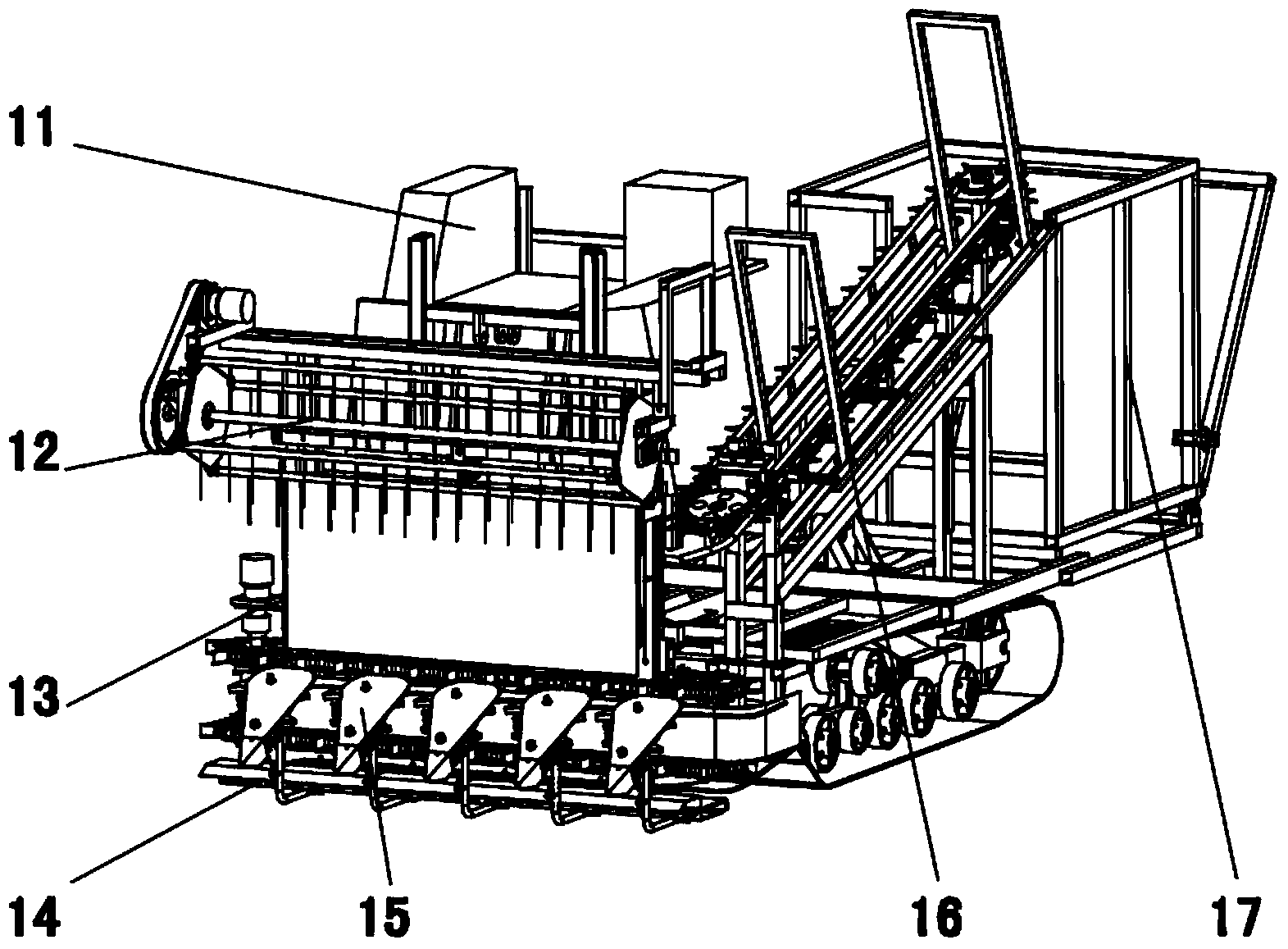

[0021] The basic structure of the harvester for tall and thick stalk crops in this embodiment is as follows: figure 1 As shown, it comprises a shaving-type horizontal cutting device 14 positioned at the front and lower part of the walking machinery frame, a group of horizontally arranged toothed conveyor belt lower reeling devices 15 positioned on the cutting device 14, and two horizontal reeling devices up and down by the lower reeling device 15. The horizontal forced clamping conveying device 13 formed around the conveying chain, the conveyor chain type longitudinal forced clamping conveying device 16 located on one side of the lateral forced clamping conveying device 13, and the straw collection box 17 located at the rear end of the longitudinal forced clamping conveying device 16 , also includes the upper reeling device 12 positioned above the lower reeling device, the uppermost part in the figure is the chassis 11.

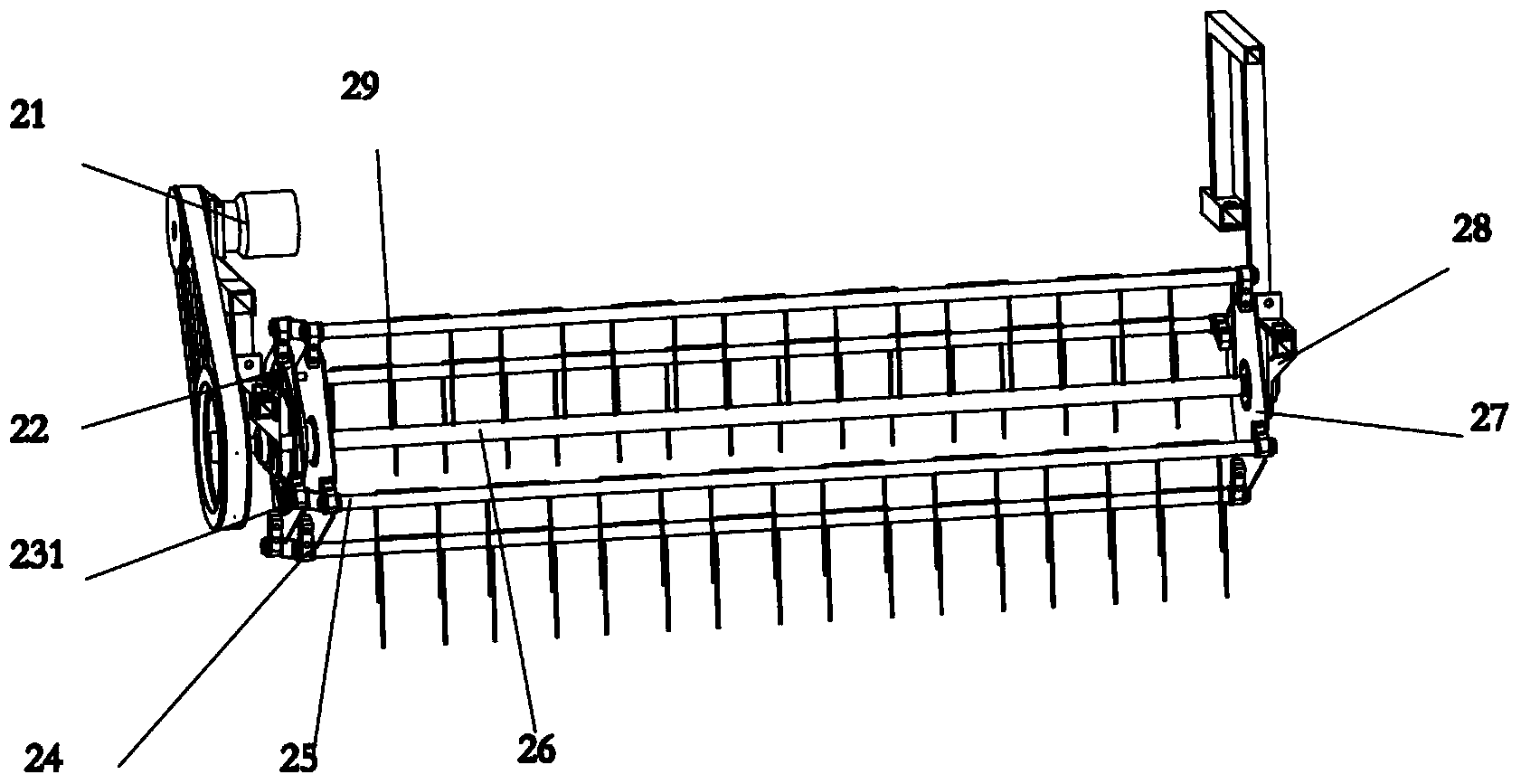

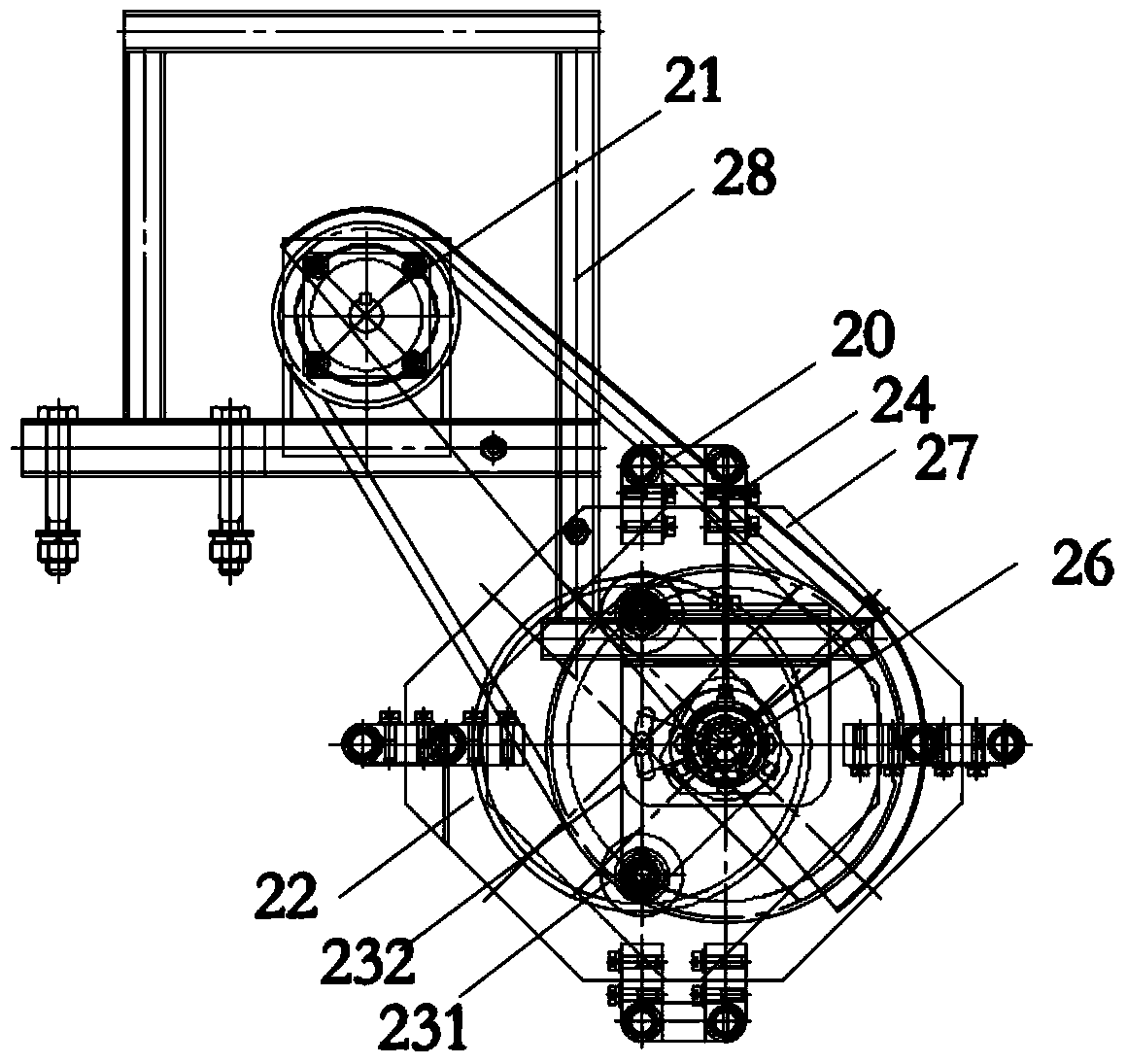

[0022] The concrete structure of upper reeling device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com