Engine crankcase exhaust gas recirculation system and engine having the same

A recirculation system, crankcase technology, applied in engine components, crankcase ventilation, machine/engine, etc., can solve the problems of reduced efficiency of superchargers and intercoolers, affecting the normal operation of the engine, and high engine oil consumption. The effect of reducing carbon deposits on the valve, long-term reliable and stable work, and reducing oil consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

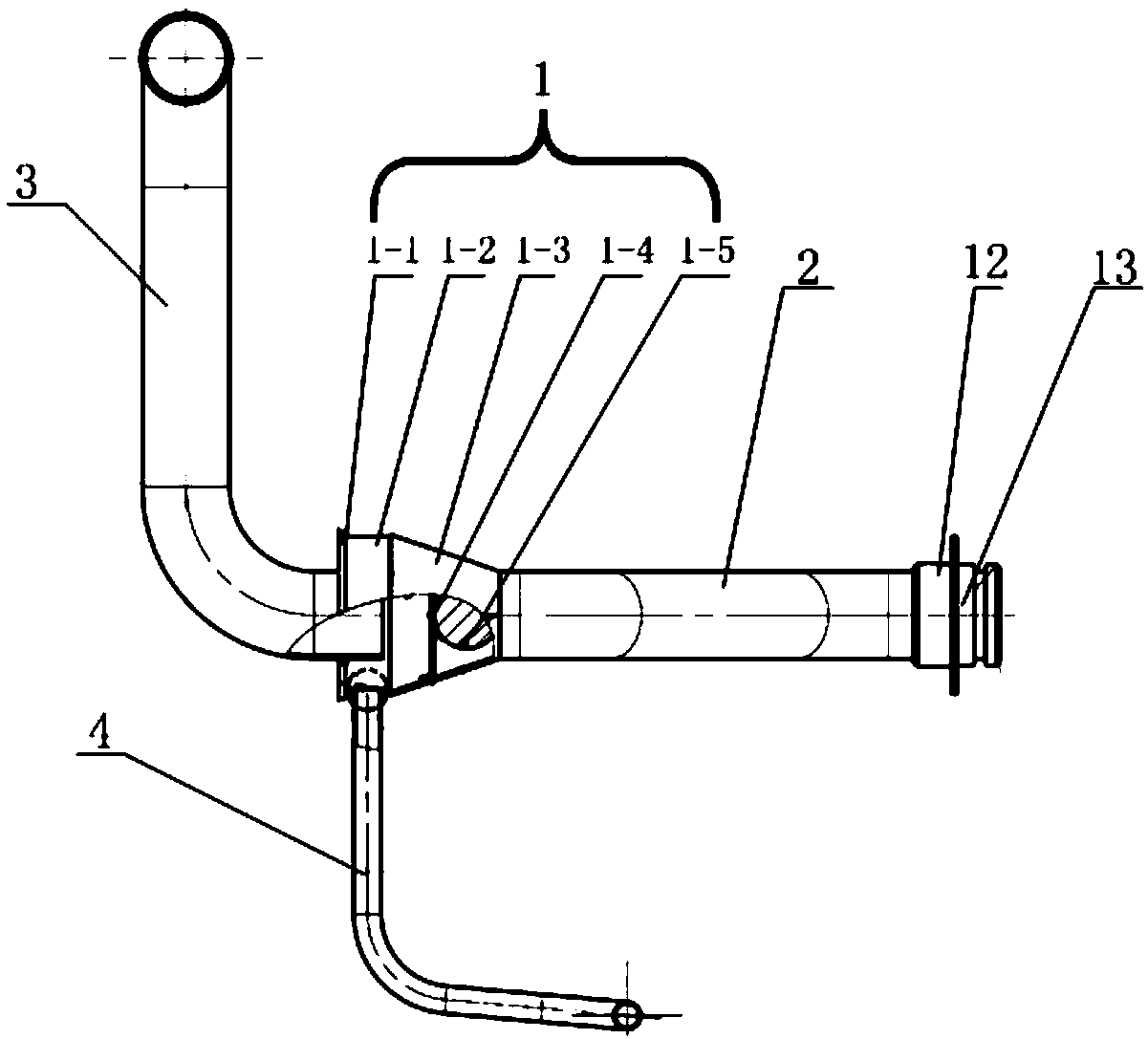

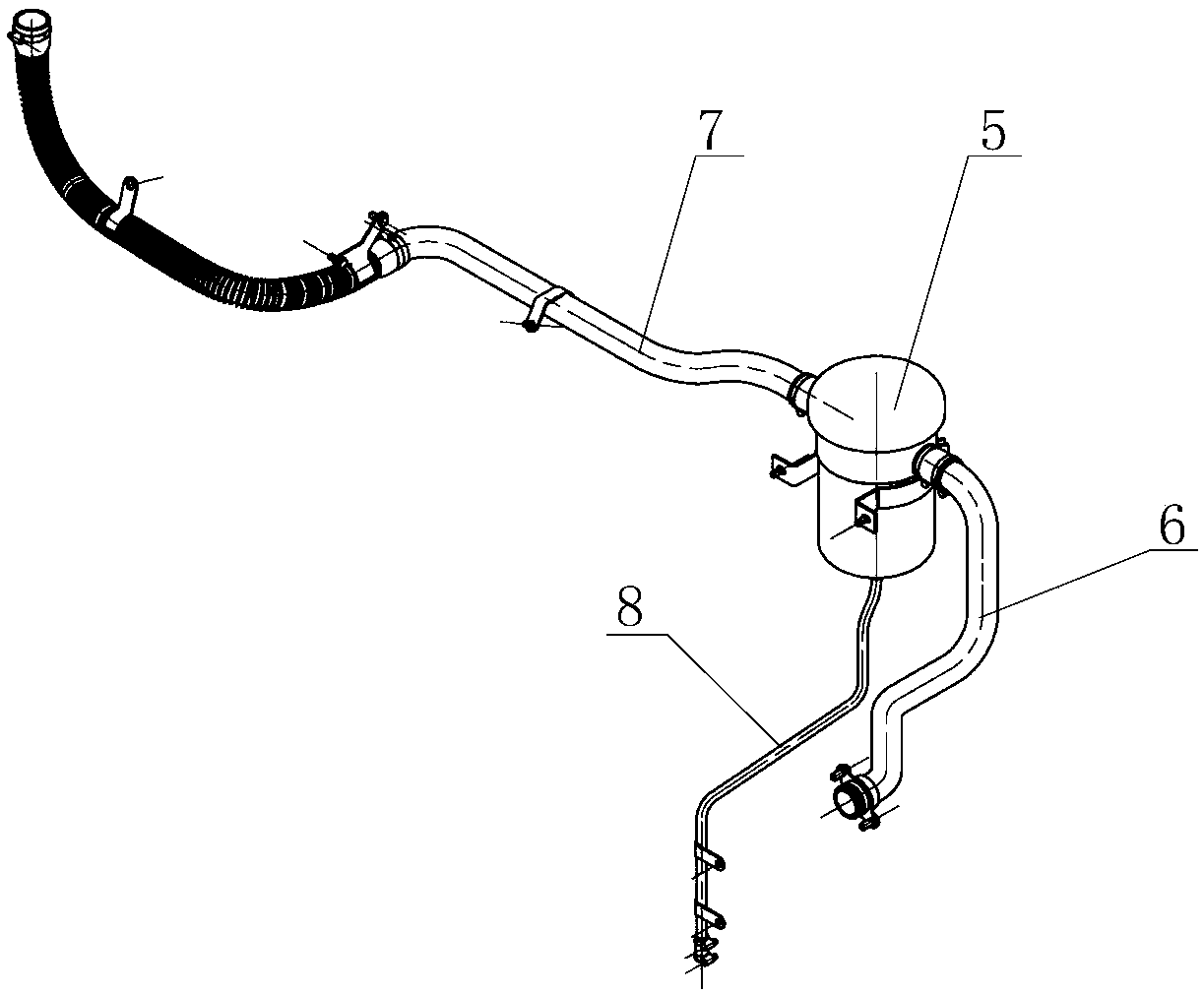

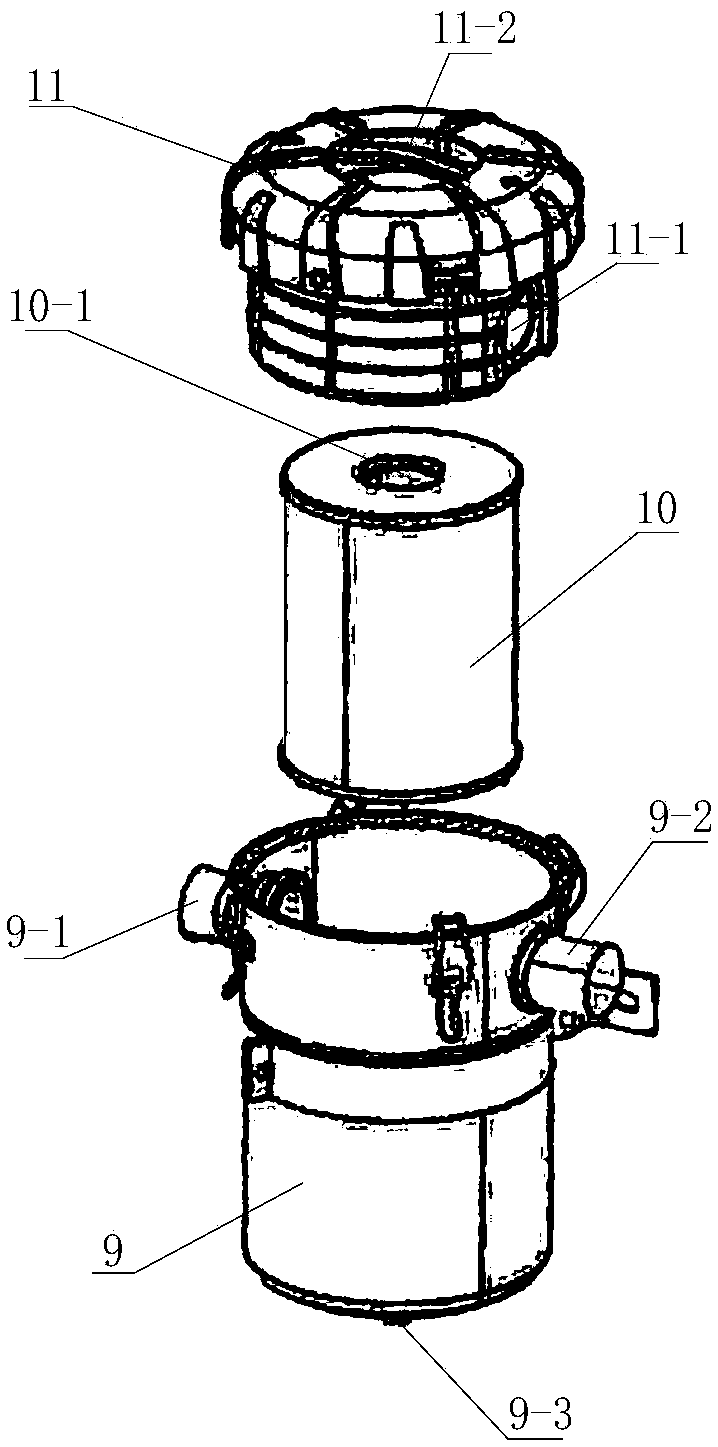

[0028] On the one hand, the present invention provides a kind of engine crankcase exhaust gas recirculation system, such as Figure 1 ~ Figure 3 As shown, it includes the first-stage labyrinth and steel wool coarse filter connected in sequence and the second-stage high-precision filter element filtration system, in which:

[0029] The first stage of labyrinth and steel wool type coarse filter comprises coarse filter 1, the input end of coarse filter 1 is connected with the first air inlet pipe 2, the output end of coarse filter 1 is connected with the first air outlet pipe 3, coarse filter 1 (the bottom refers to the figure 1 The lowest point of the middle coarse filter 1) is connected with the first oil return pipe 4;

[0030] The second stage of high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com