Patents

Literature

280 results about "Steel wool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel wool, also known as iron wool, wire wool, steel wire or wire sponge, is a bundle of very fine and flexible sharp-edged steel filaments. It was described as a new product in 1896. It is used as an abrasive in finishing and repair work for polishing wood or metal objects, cleaning household cookware, cleaning windows, and sanding surfaces.

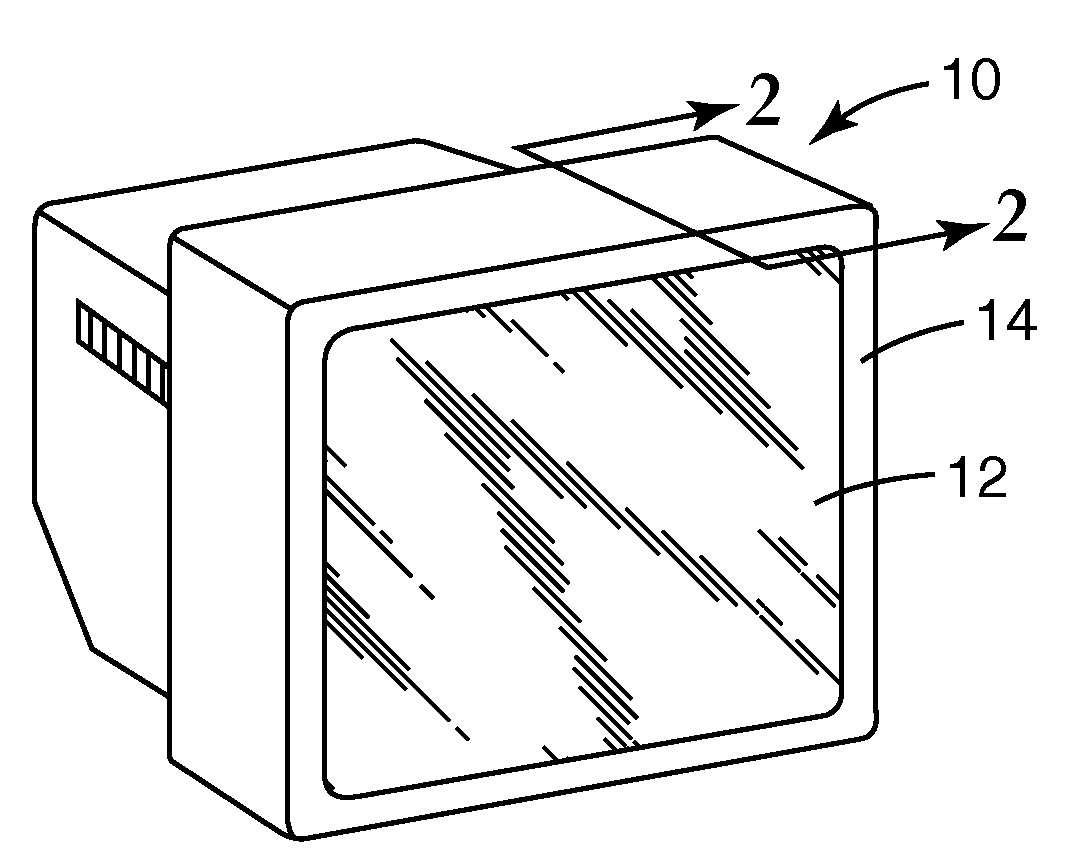

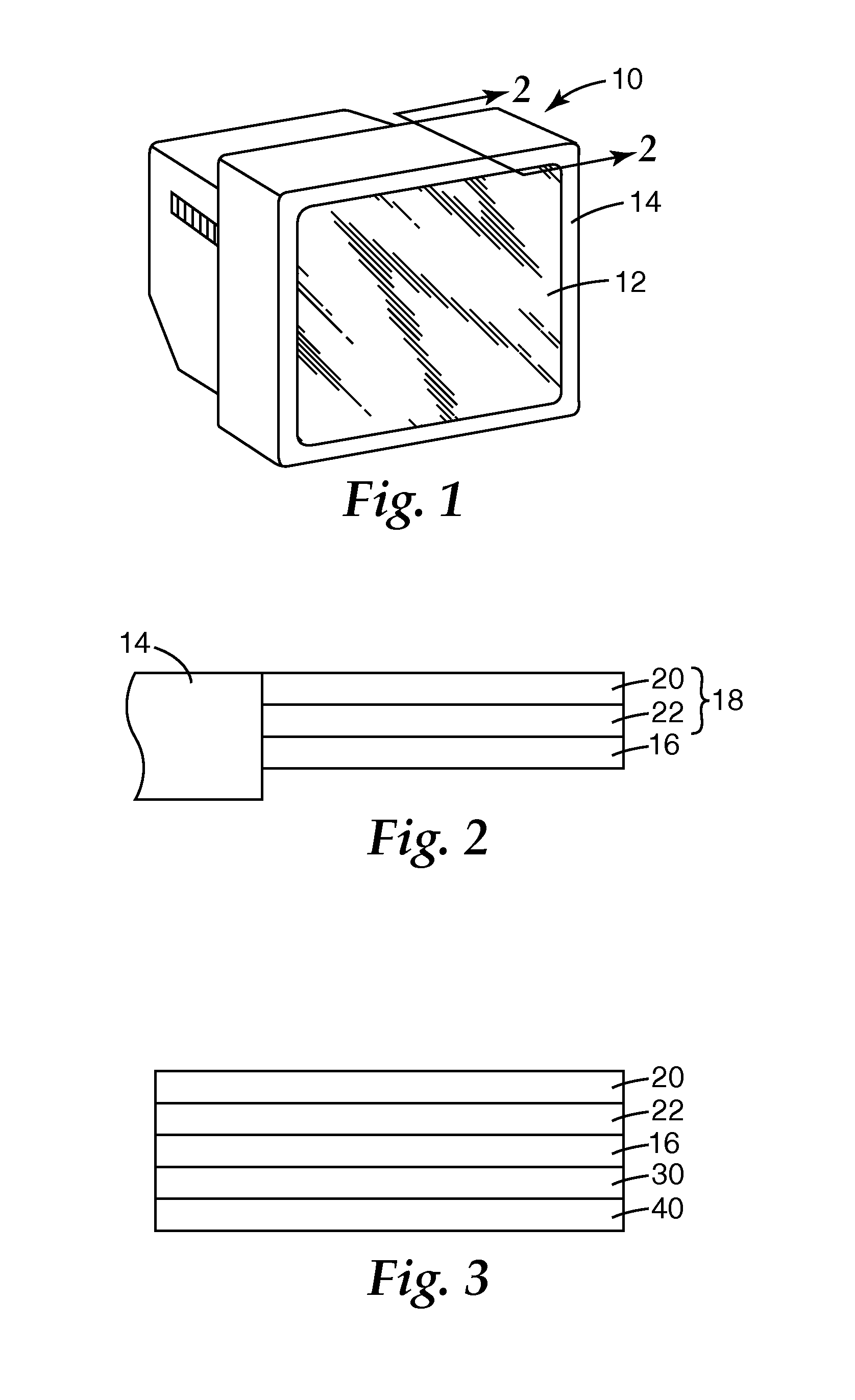

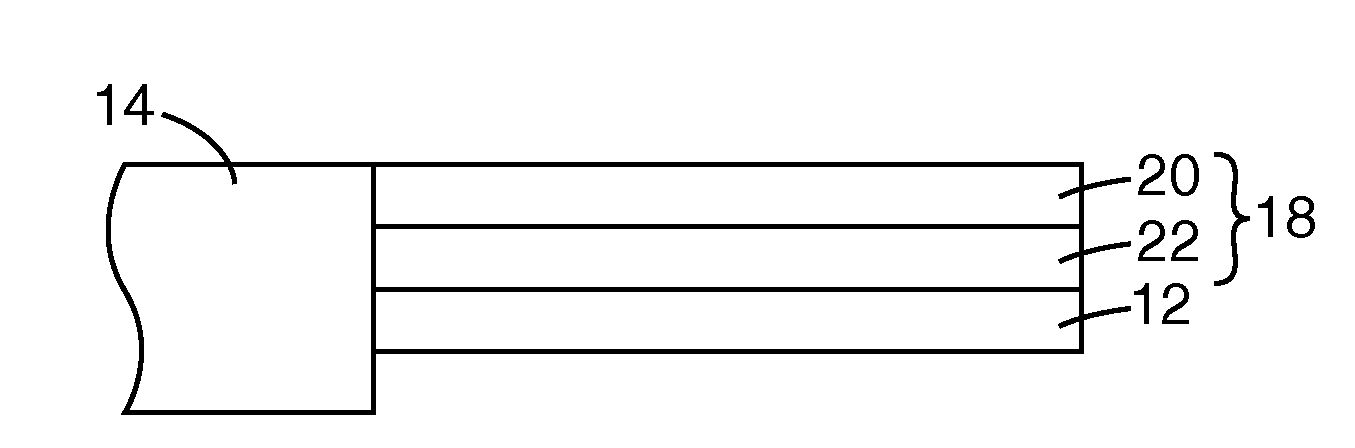

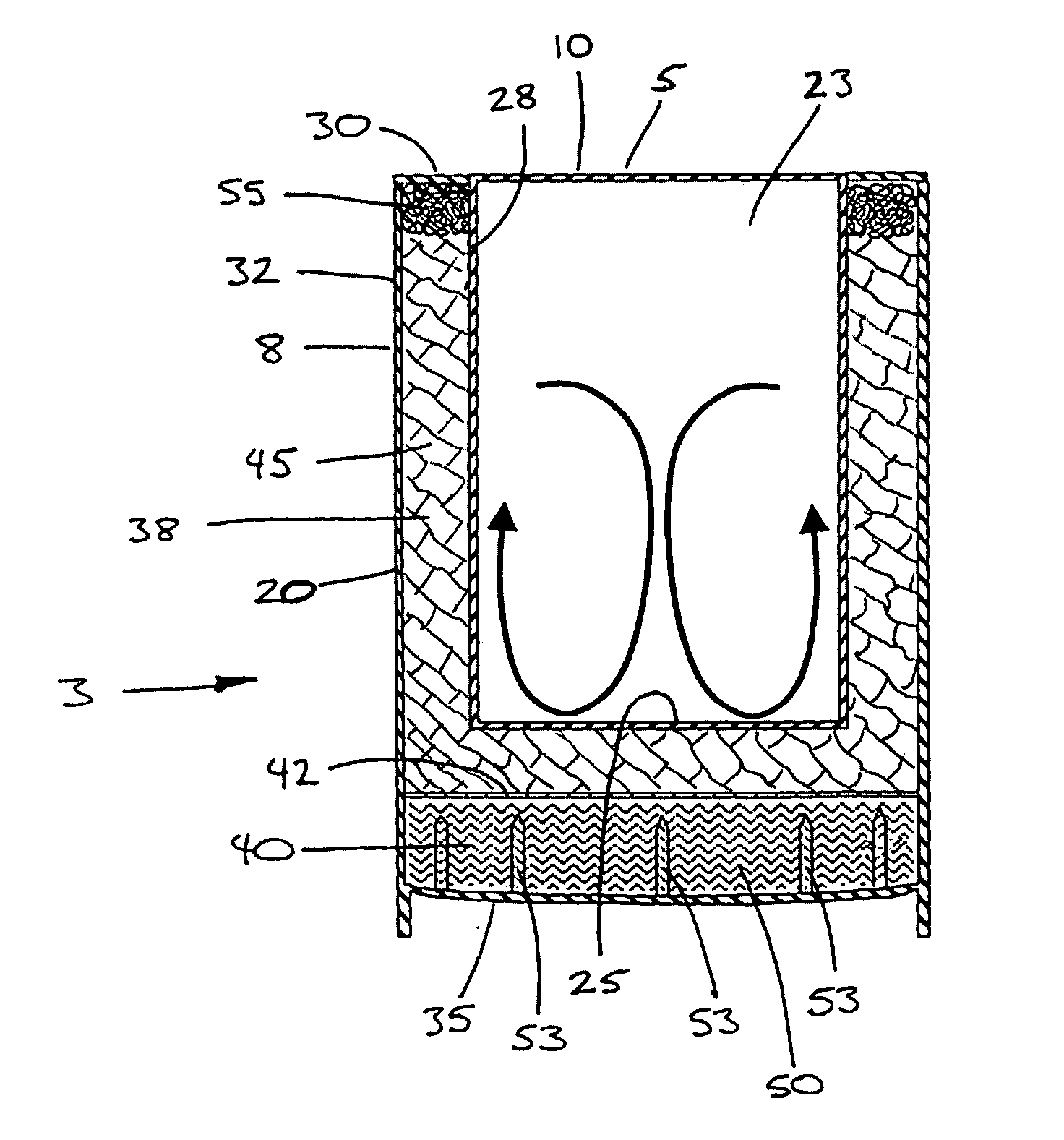

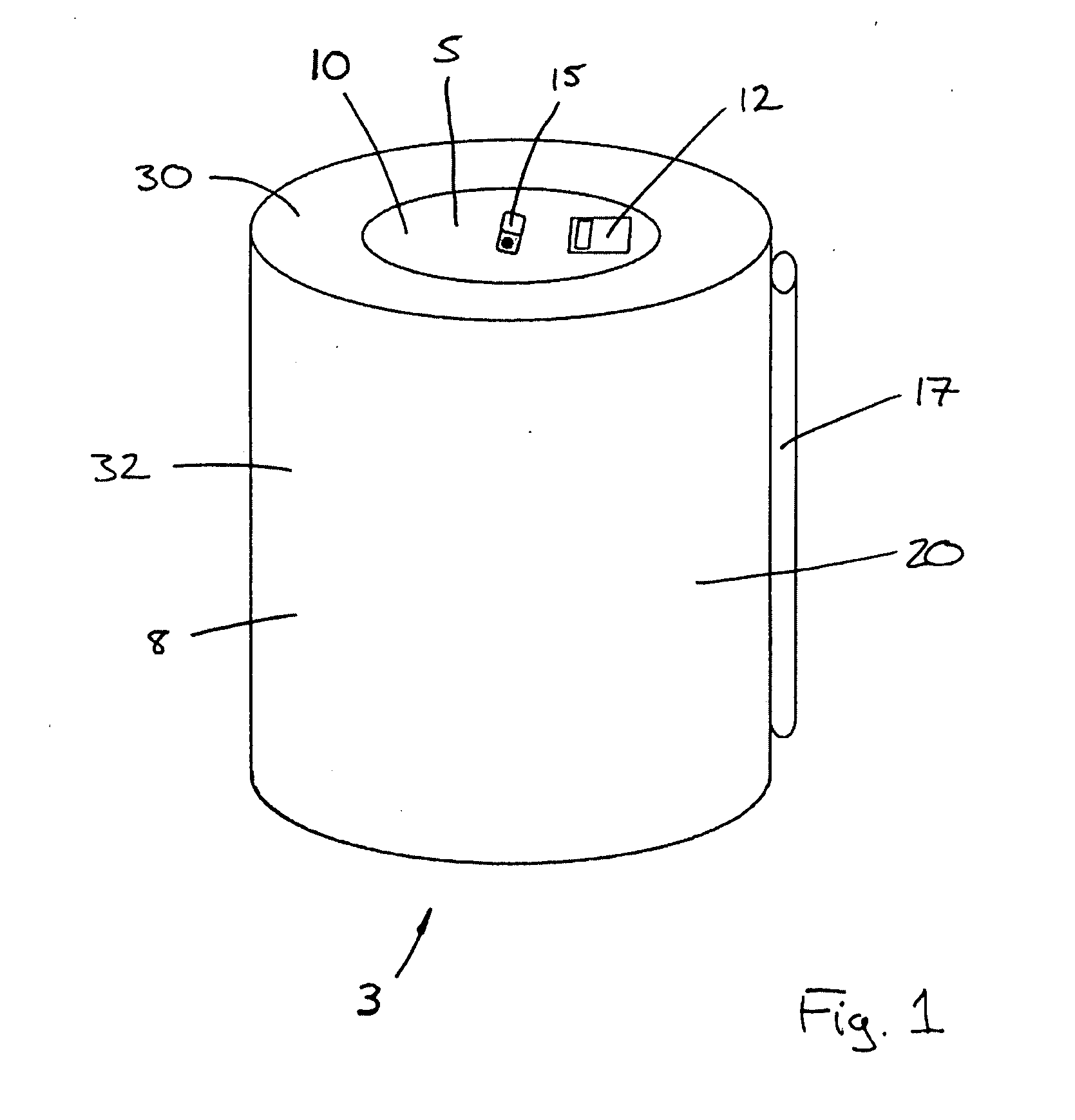

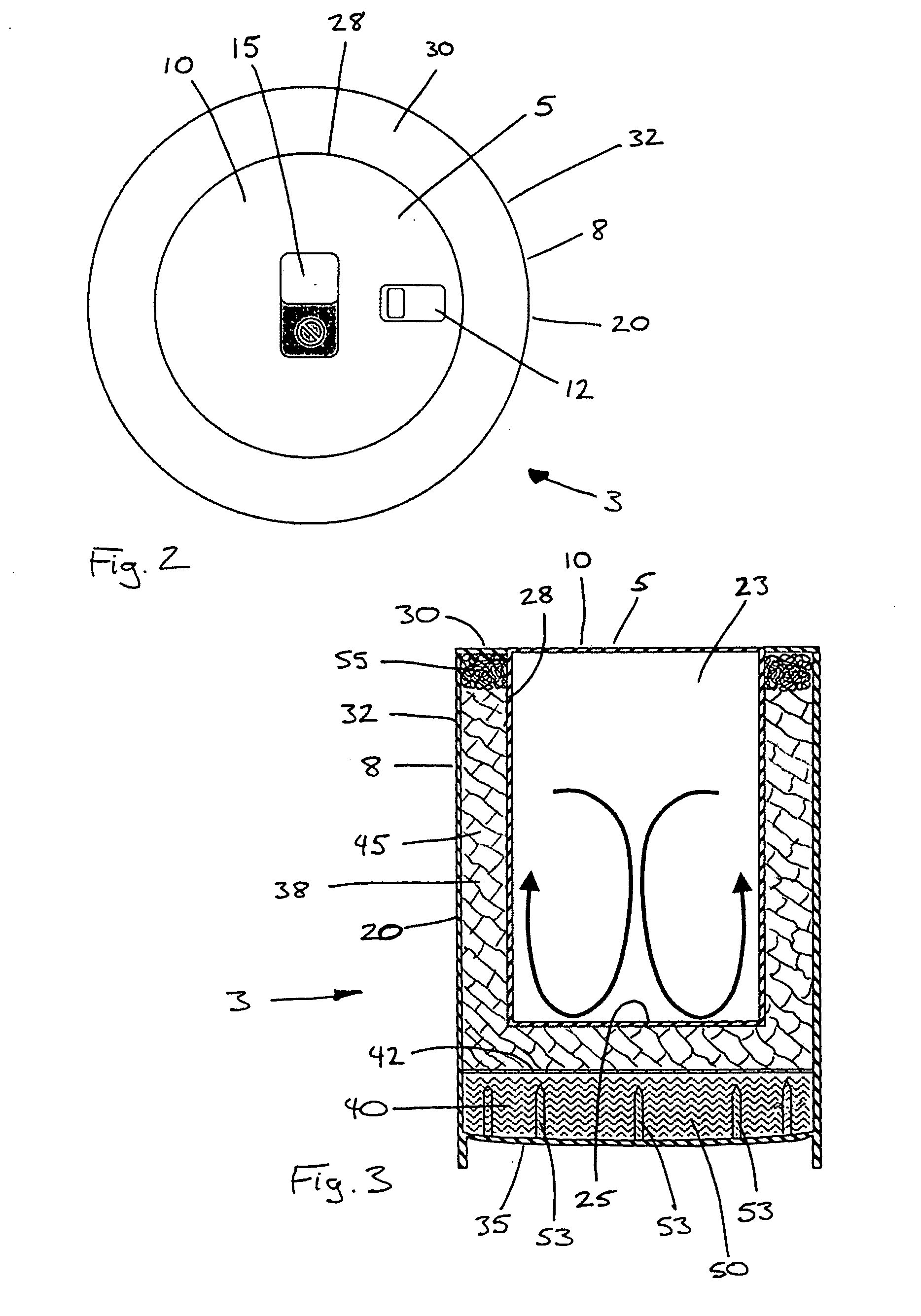

Self-contained temperature-change container assemblies

InactiveUS6877504B2Exothermal chemical reaction heat productionOther heat production devicesSteel woolEngineering

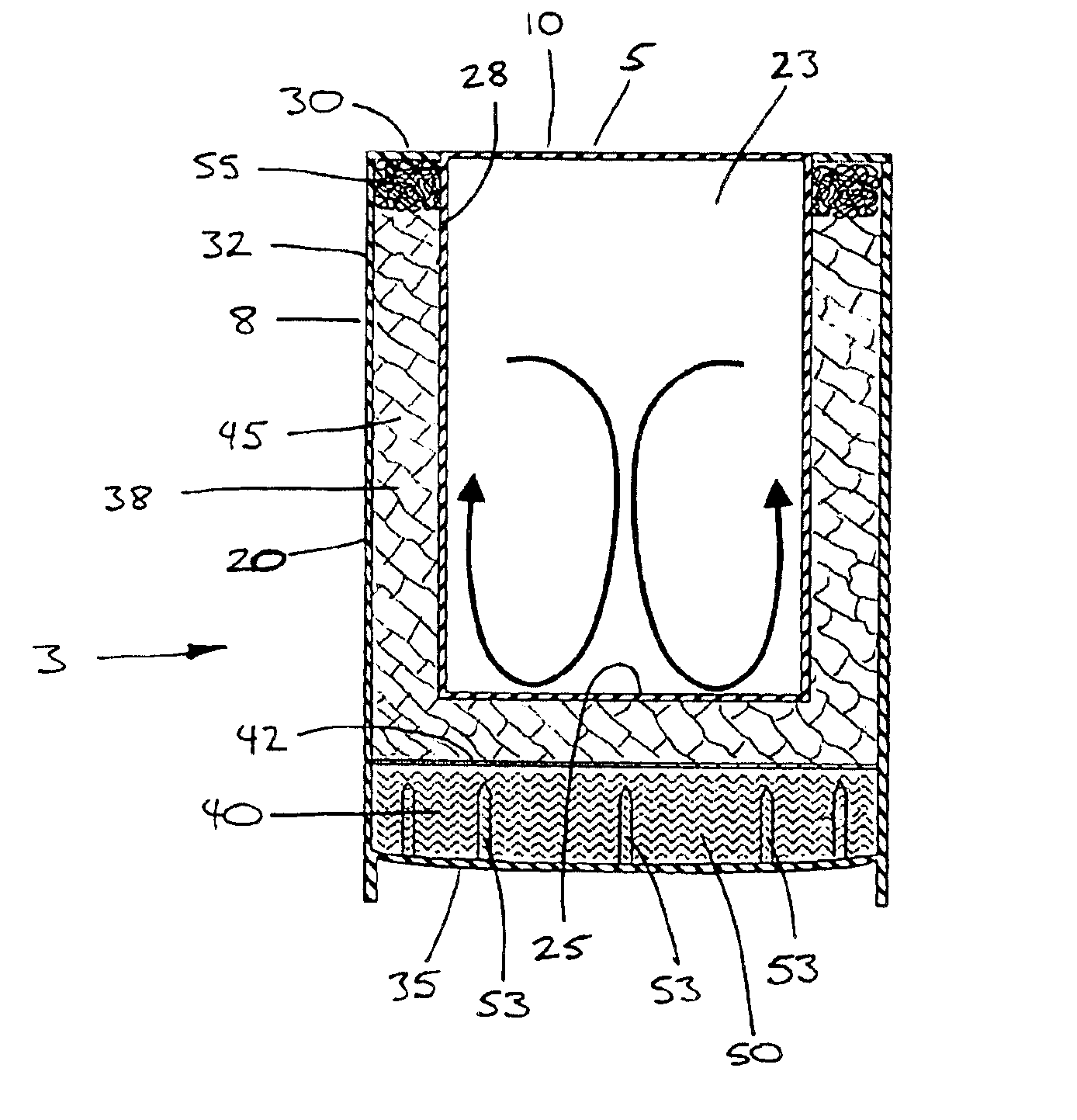

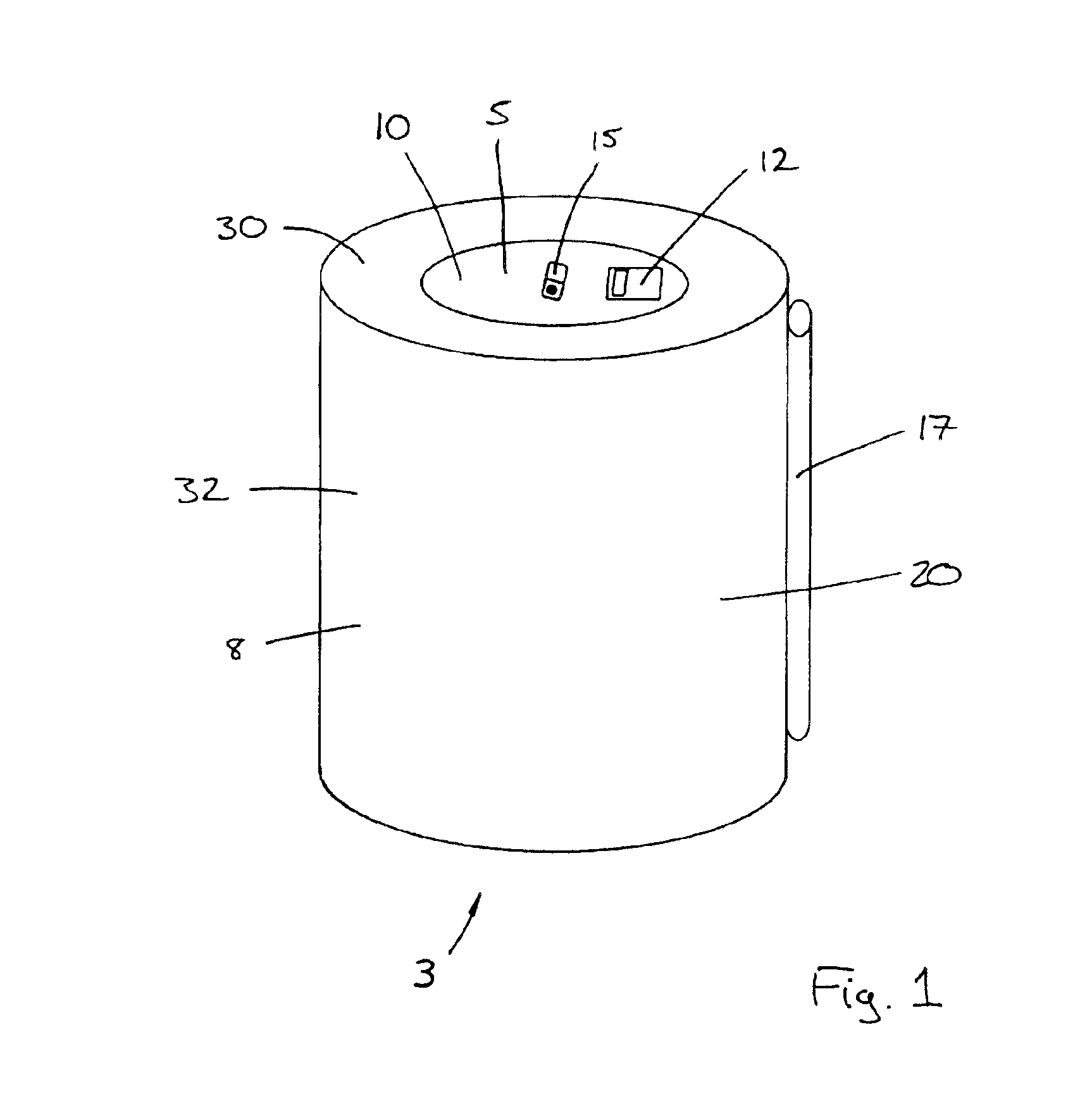

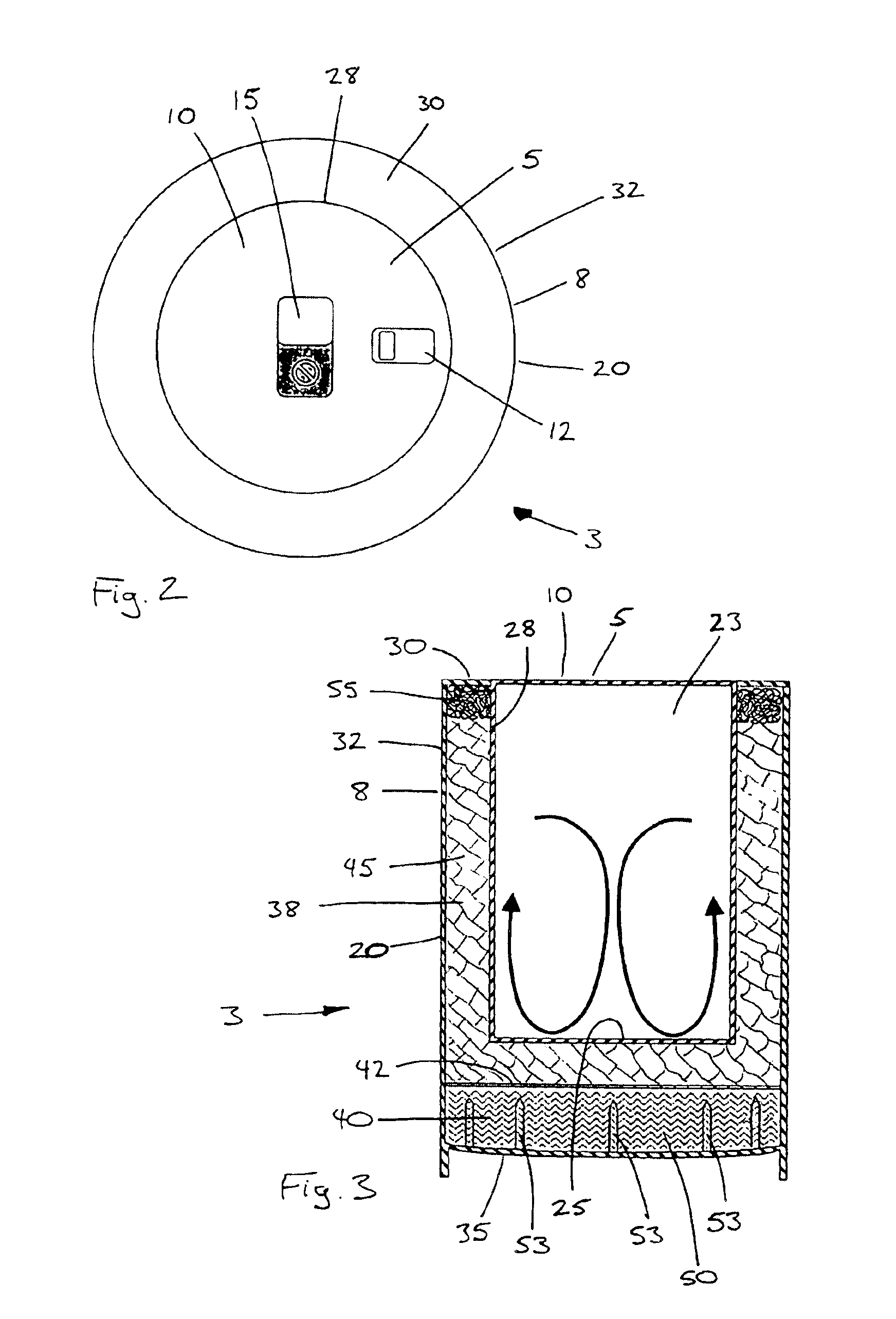

A container assembly heats or cools a product inside an inner container. An outer jacket at least partially surrounds the inner container, with a first internal volume and a second internal volume in the space between the outer jacket and the inner container. A first temperature-change reagent is contained inside the first internal volume, and a second temperature-change reagent is held in the second internal volume, with a reagent separator between the two. Several penetrators are disposed to penetrate the reagent separator to produce openings through the separator and through which the two reagents can mix. Steel wool inside the first internal volume acts as a steam condenser. The outer jacket includes a jacket top ring secured around an upper surface of a standard can, a jacket body secured to the jacket top, and a flexible jacket bottom that carries several spikes molded onto the jacket bottom.

Owner:SELF HEATING TECH CORP

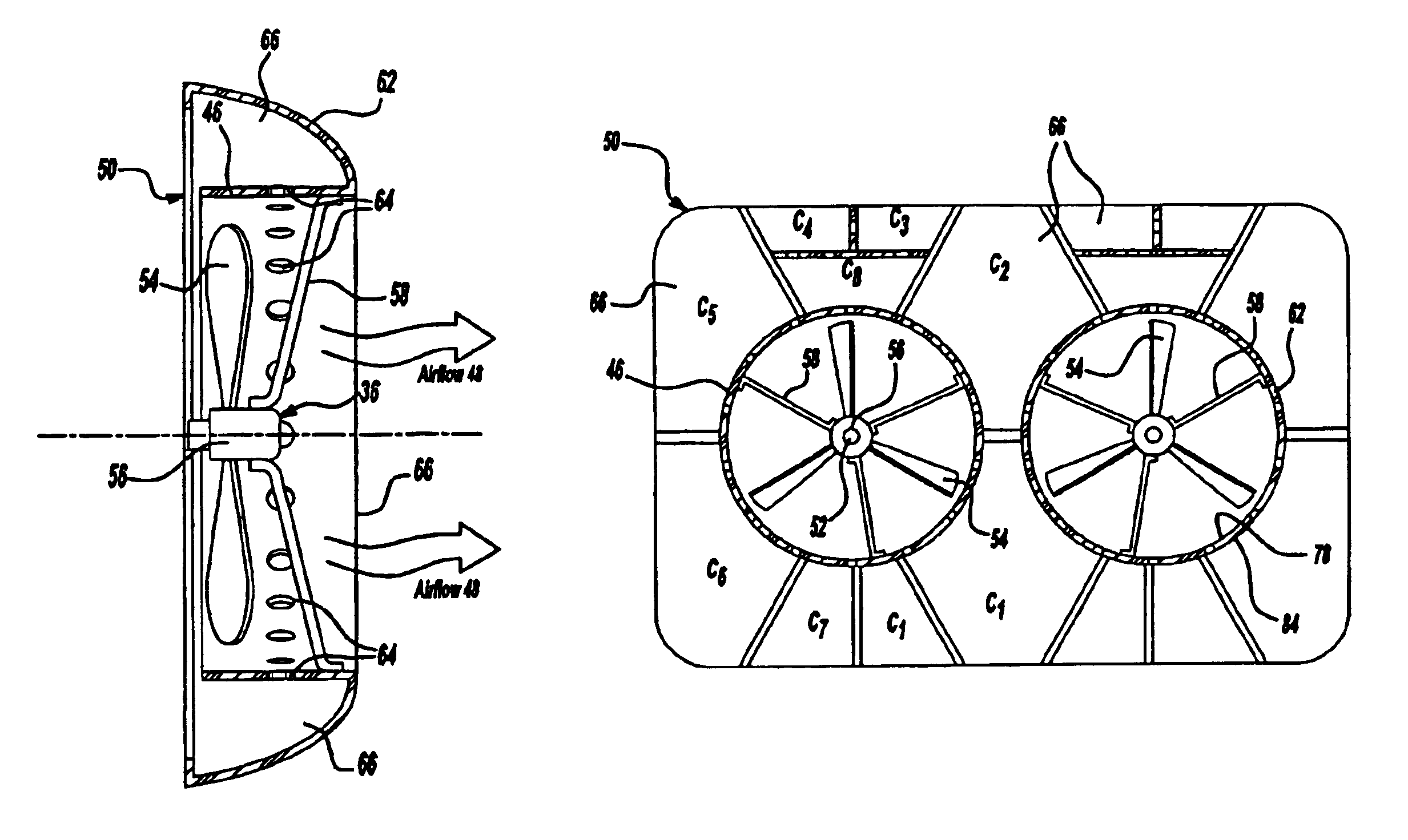

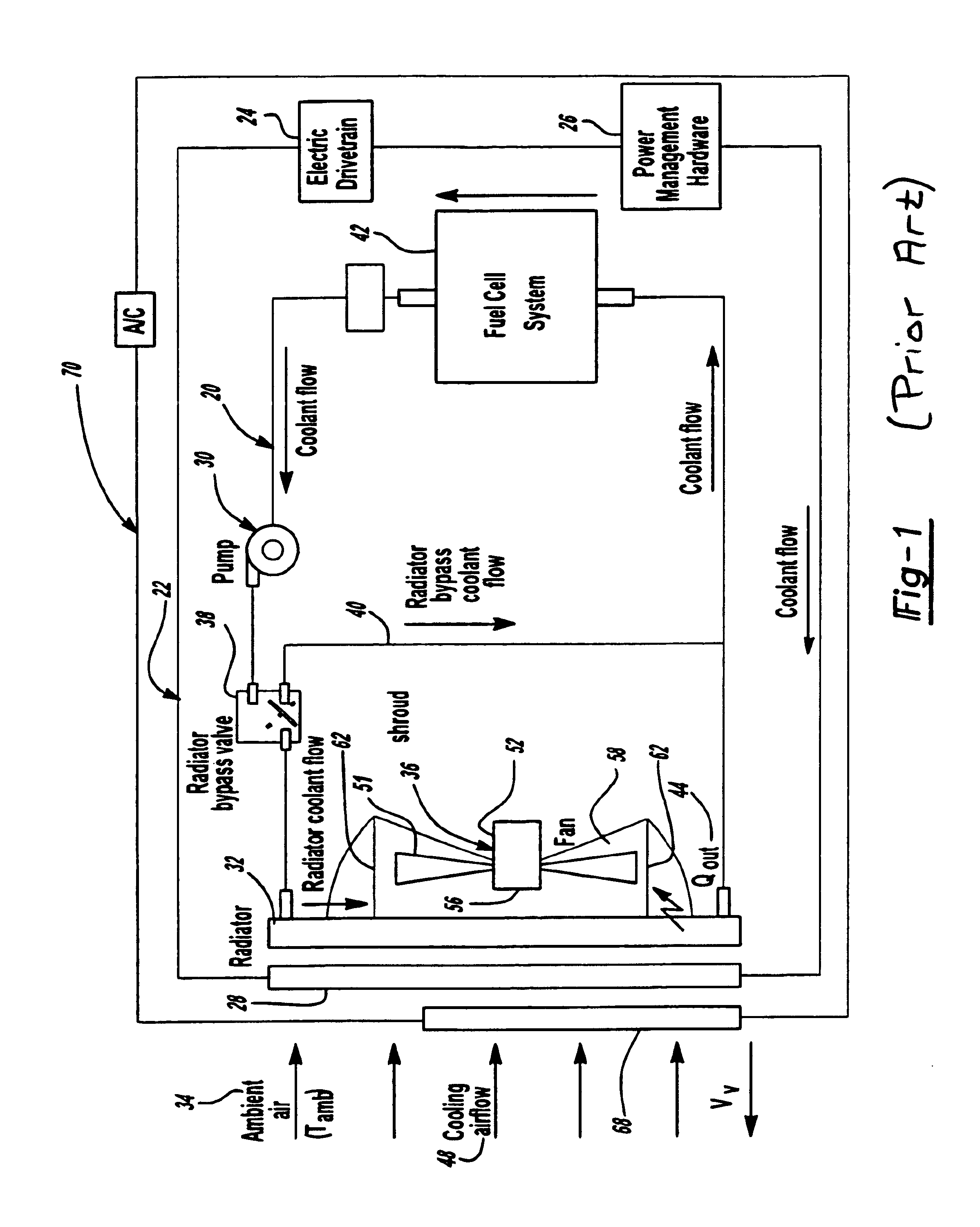

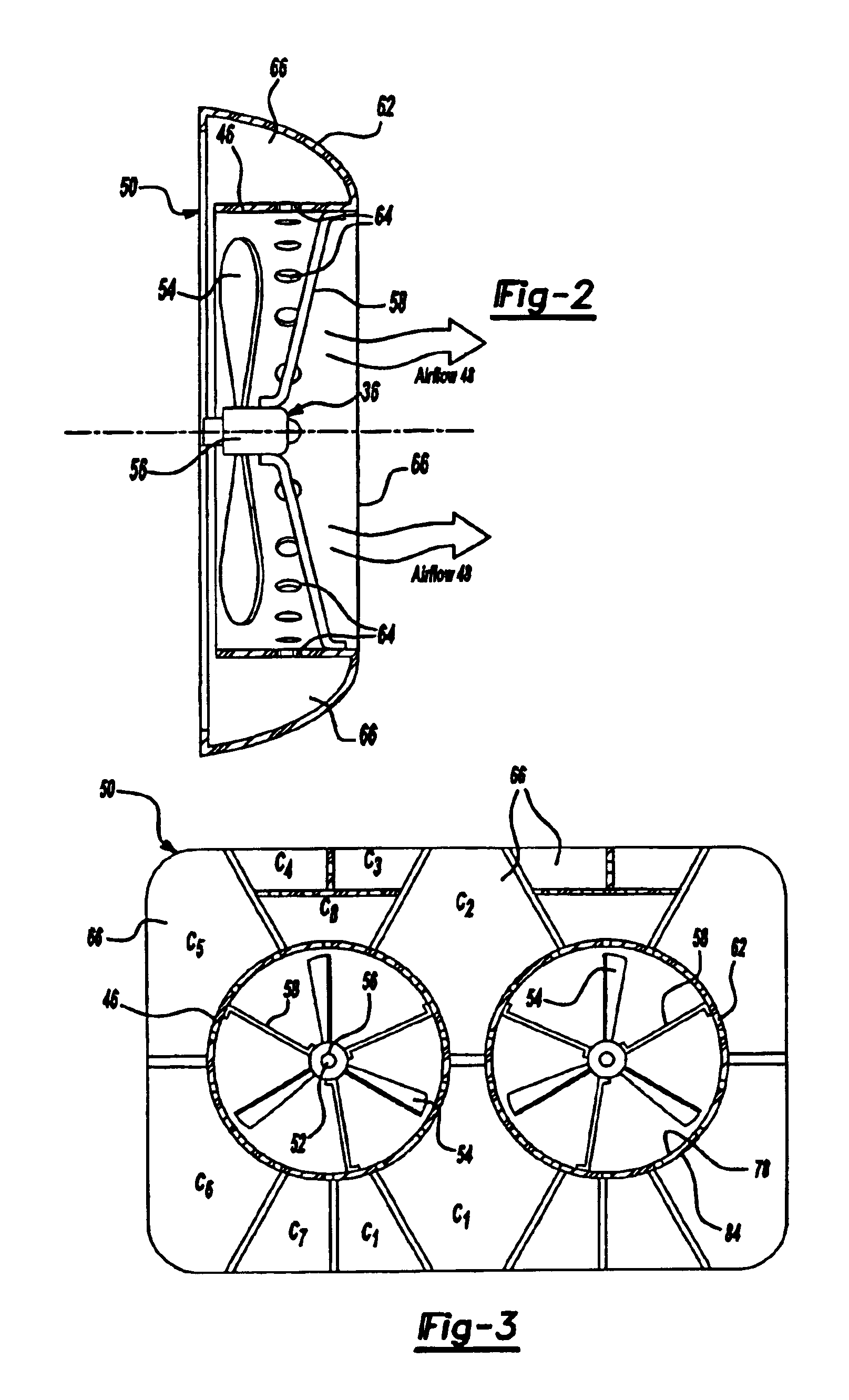

Fan shroud with built in noise reduction

The present invention is a system and method to significantly reduce noise associated with air-moving devices such as an axial flow fan using a fan shroud and barrel combination with built in silencers such as Helmholtz resonators. The invention can be applied to a variety of applications such as a thermal management system for a fuel cell powered vehicle. The resonator can be a hollow cavity in networks attached to an outer or inner barrel or shroud and tuned to reduce noise at predetermined noise frequency ranges within the airflow. The invention can also attach stator members on the inner surface of the outer barrel to further reduce noise. Additional sound absorbing material, such as steel wool, can be disposed within the resonator cavity.

Owner:FORD MOTOR CO

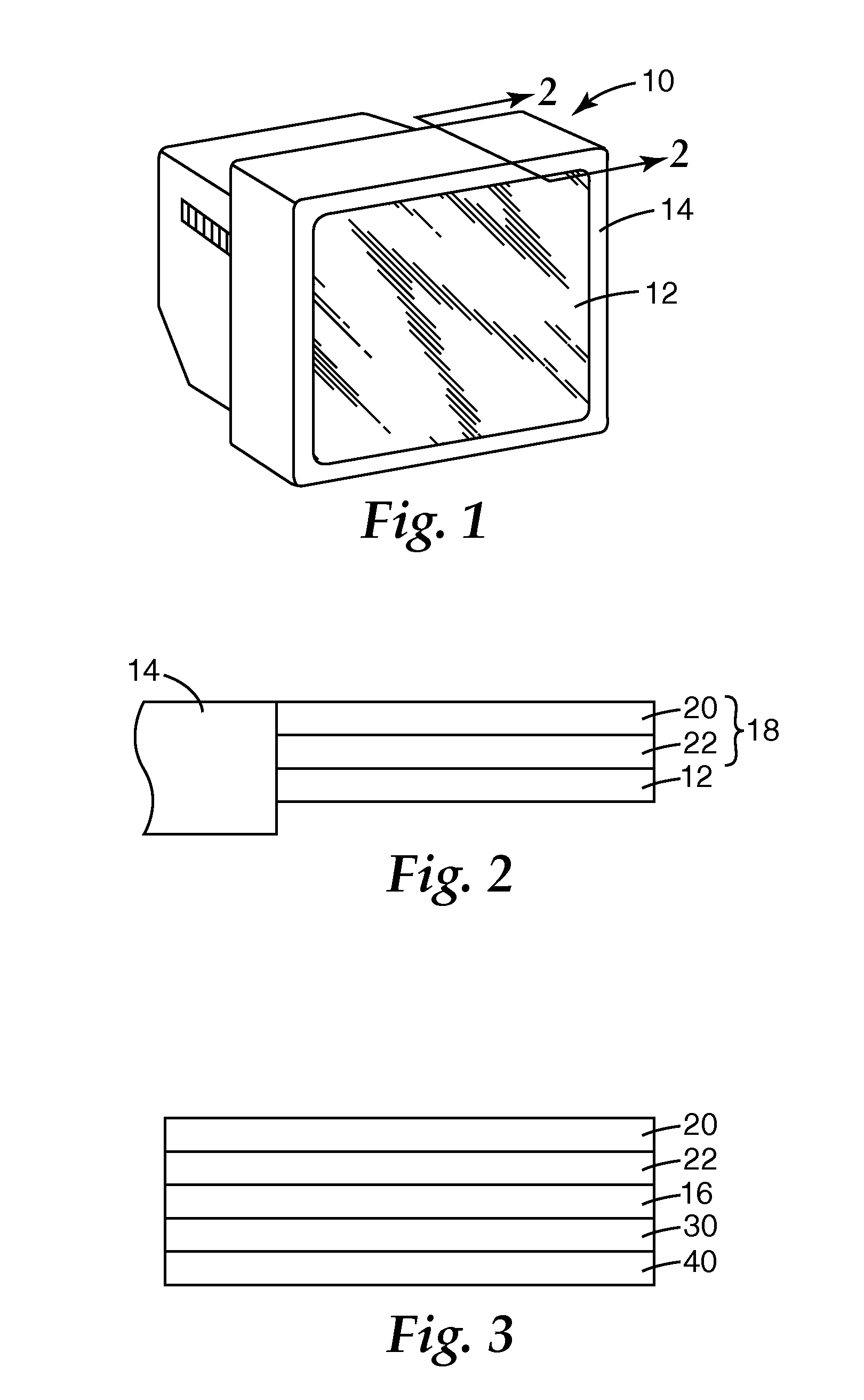

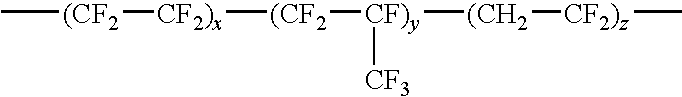

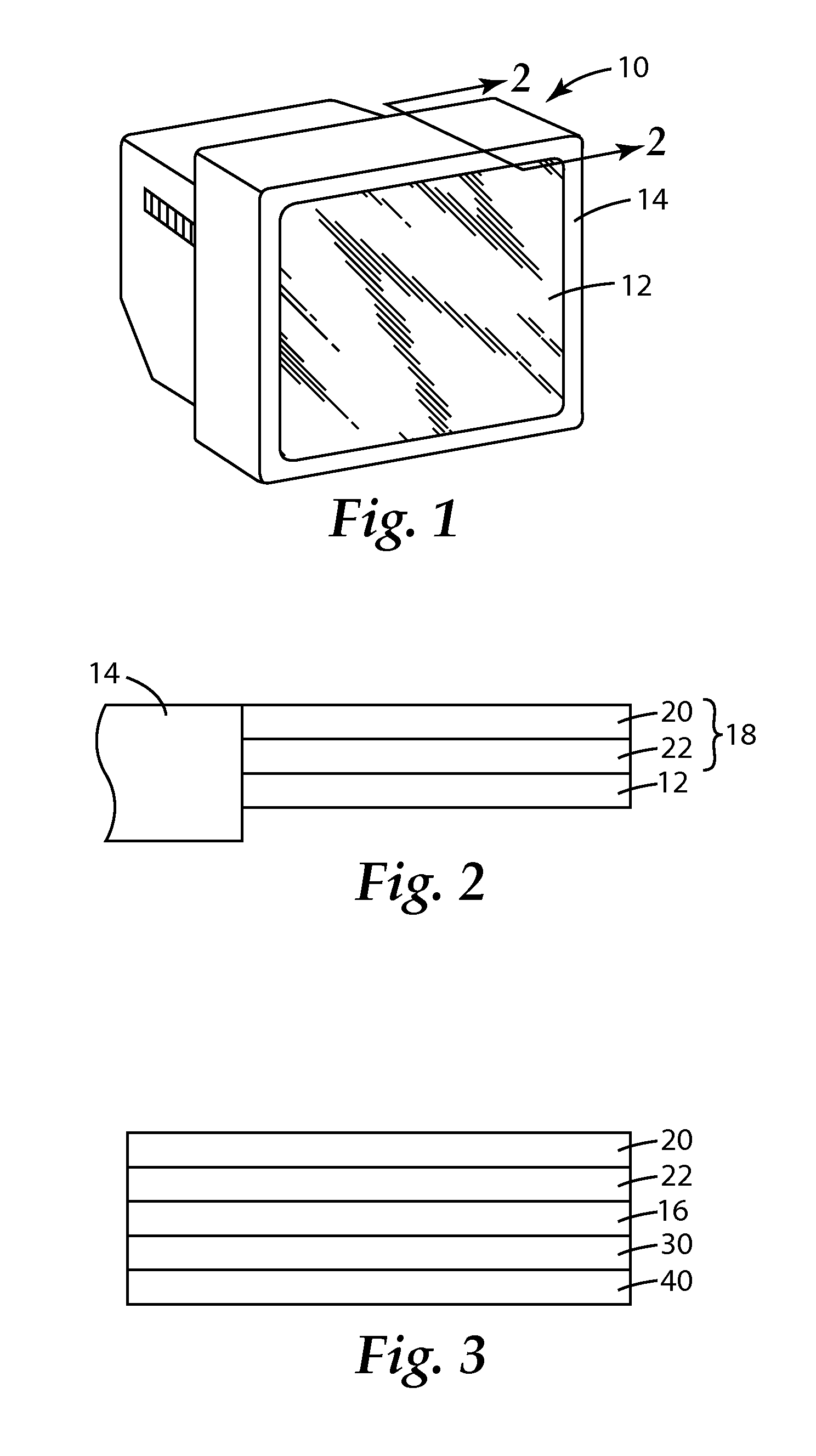

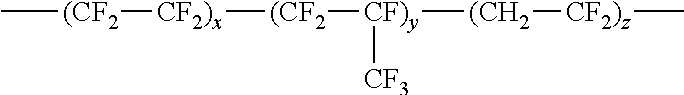

Durable antireflective film

Antireflective films are described having a surface layer comprising a the reaction product of a polymerizable low refractive index composition comprising at least one fluorinated free-radically polymerizable material and surface modified inorganic nanoparticles. A high refractive index layer is coupled to the low refractive index layer. In one emboidiment, the high refractive index layer comprises surface modified inorganic nanoparticles dispersed in a crosslinked organic material. The antireflective film is preferably durable, exhibiting a haze of less than 1.0% after 25 wipes with steel wool using a 3.2 cm mandrel and a mass of 1000 grams.

Owner:3M INNOVATIVE PROPERTIES CO

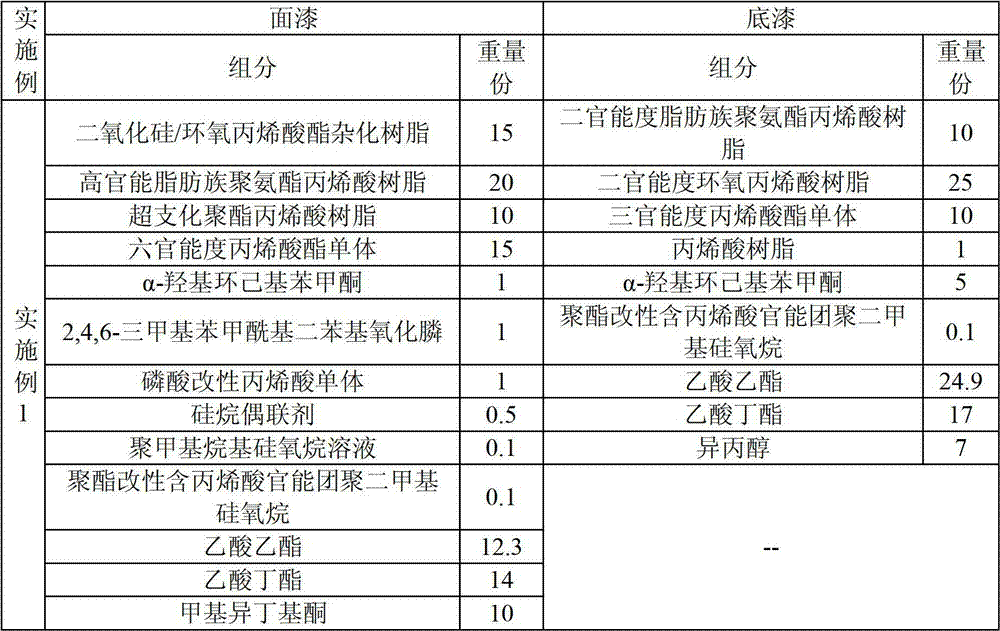

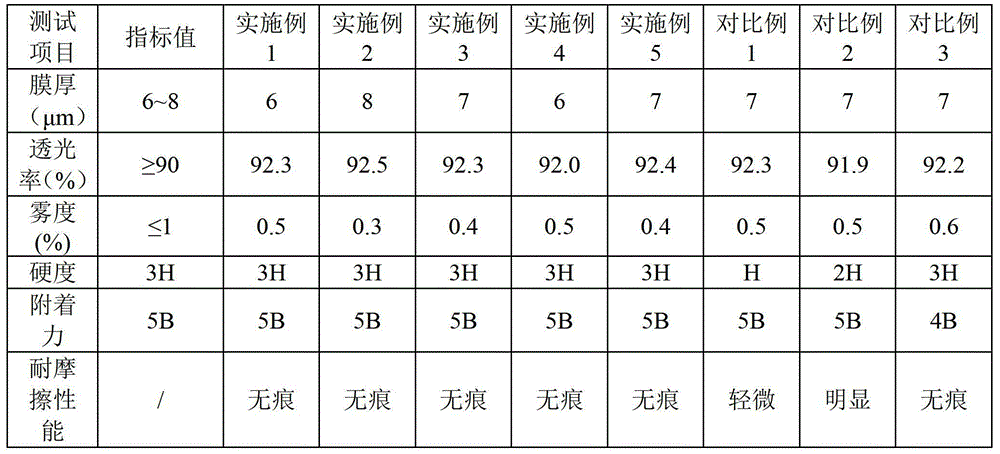

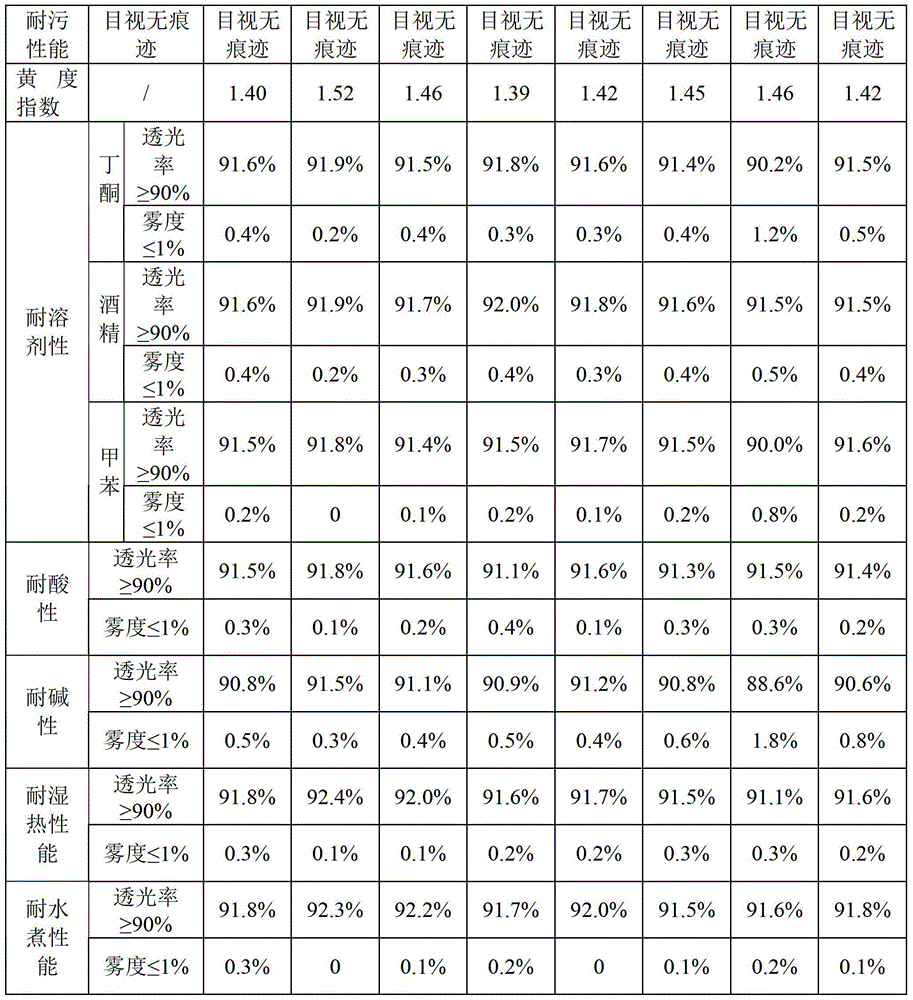

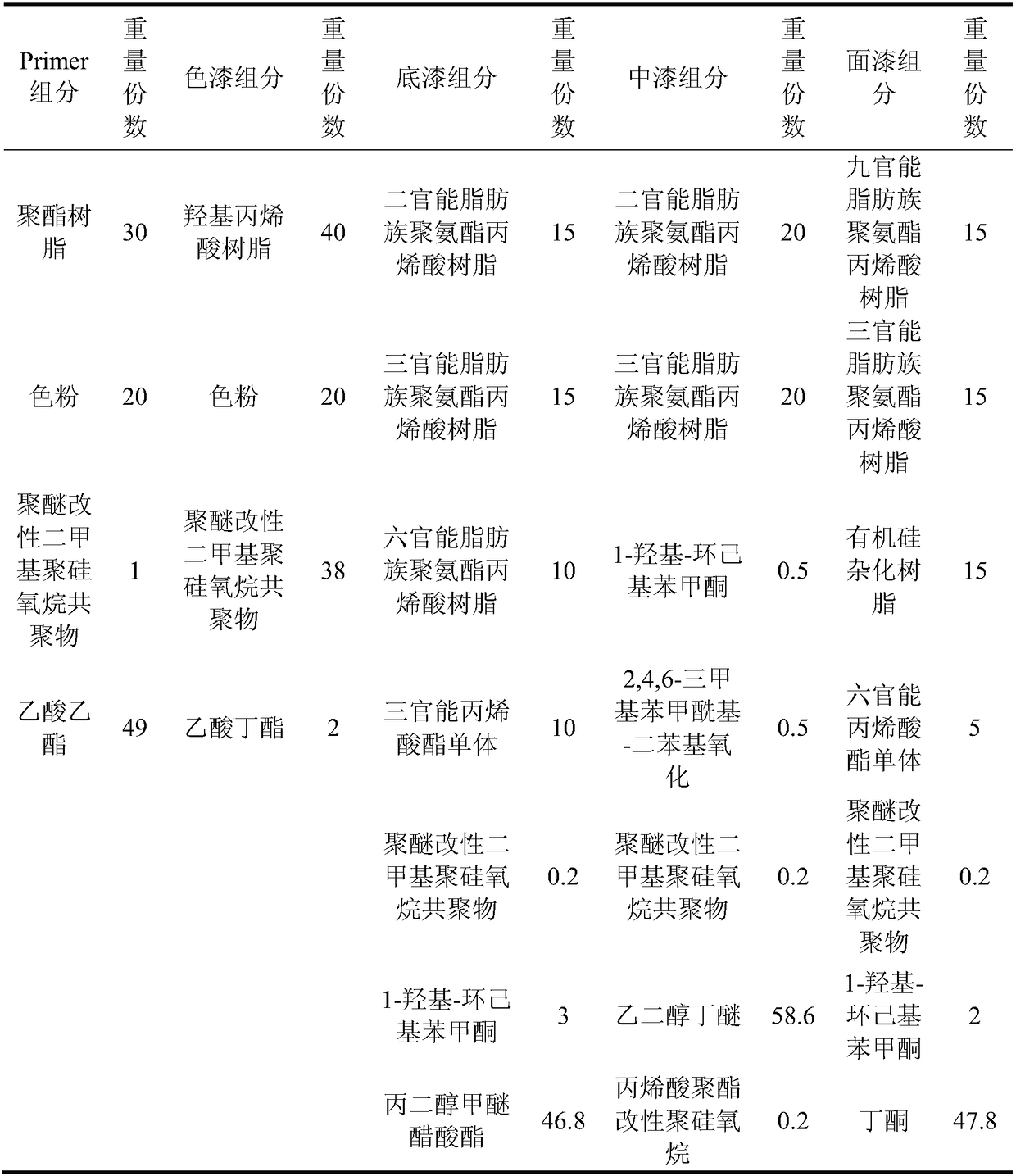

Two-coating type ultraviolet light curing paint

ActiveCN102898939AImprove bindingImprove wear resistancePolyurea/polyurethane coatingsEpoxy resin coatingsAcrylic resinHyperbranched polyester

The invention provides two-coating type ultraviolet light curing paint, which comprises primer and finish paint, wherein the finish paint comprises 15 to 25 weight parts of high-functionality polyurethane crylic acid resign, 10 to 15 weight parts of hyperbranched polyester acrylic resin, 10 to 20 weight parts of organic-inorganic hybrid resin, 10 to 15 weight parts of hexa-functionality acrylate monomers, 2 to 5 weight parts of photoinitiators, 1 to 2 weight parts of adhesion promoters, 20 to 60 weight parts of diluents and 0.2 to 2 weight parts of auxiliaries. The two-coating type ultraviolet light curing paint solves the technical problems that the wear-resisting and steel wool friction resistance degrade of the existing ultraviolet light curing paint is low, the vacuum coating variety is single, and the cost is high.

Owner:HUNAN SOKAN NEW MATERIAL

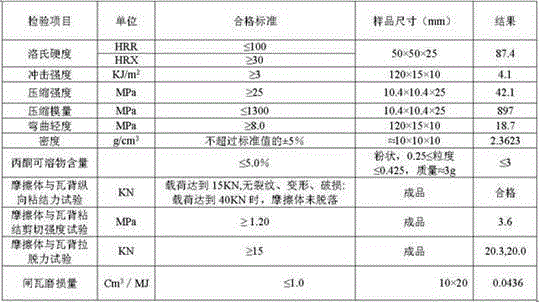

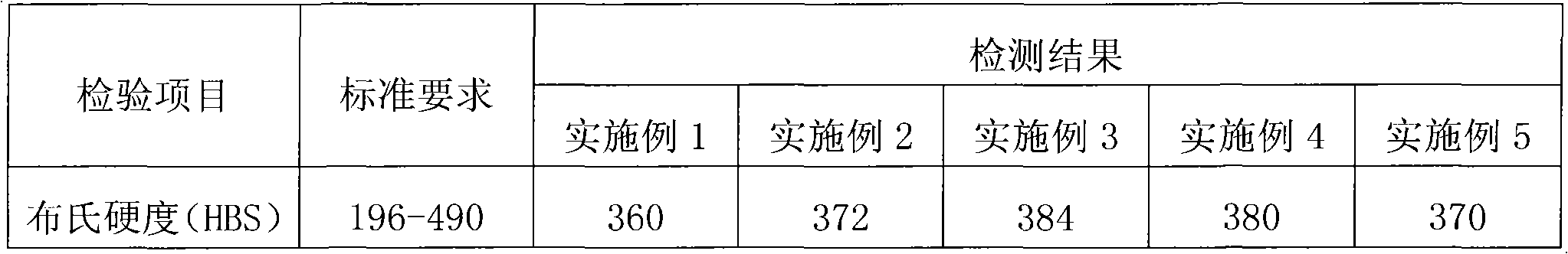

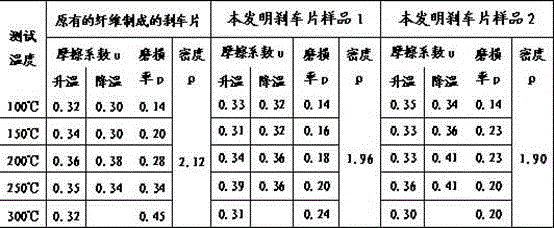

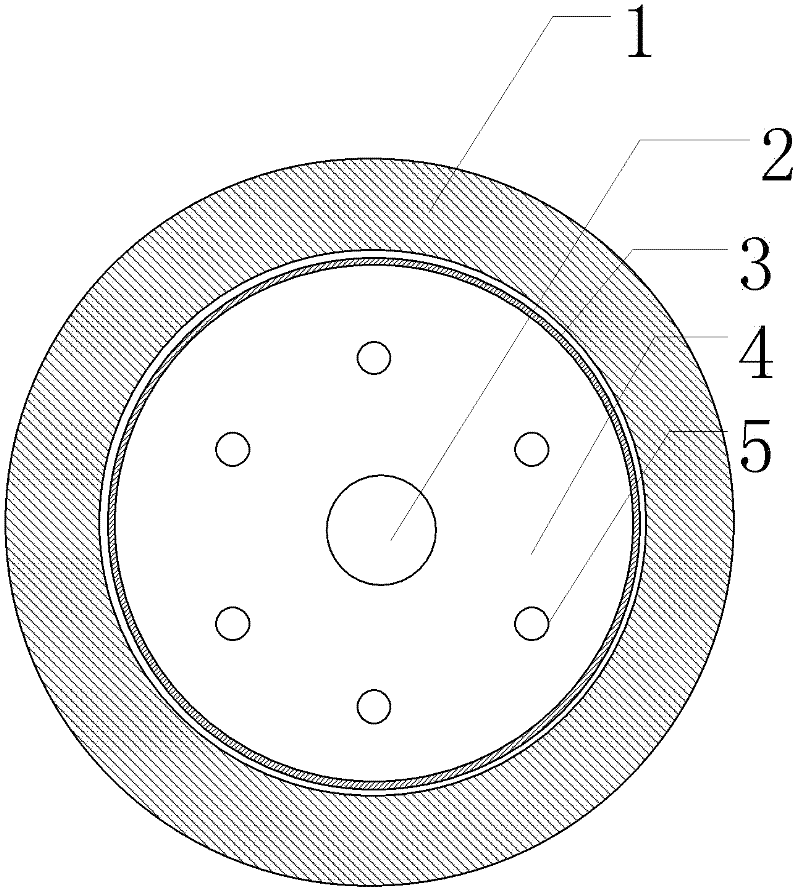

Brake block friction material

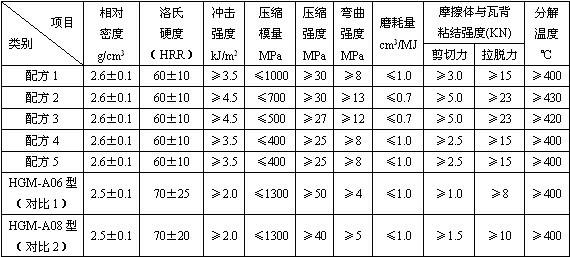

InactiveCN101158383AAvoid damageGood resistance to high temperature and heat decayFriction liningFiberTemperature resistance

The invention discloses a brake shoe friction material, belonging to brake shoe material. Based on the traditional half-metal formula, the invention is pressed according to the production method of general brake shoe with the weight proportions of 5%-10% of the modified colophony, 5%-15% of the barium sulfate, 15%-20% of the steel wool, 5%-10% of the friction powder, 8% of the tyre powder, 4%-10% of the graphite, 5%-10% of the coke powder, 5%-10% of the potash feldspar, 2% of the light calcium carbonate, 2% of the antimony sulfide, 4% of the natural fiber, 2% of the rigid fiber, 5%-15% of the meerschaum, 6% of the iron powder, 2% of the zircon, 5%-10% of the vermiculite, 1% of the nitrile, 2% of the carbon, and 3% of the copper fiber. The invention has the advantages of good high-temperature and hot recession resistance, selecting the colophony with high temperature resistance as the bonder, hardly damaging the dual parts, selecting the friction material and metallurgy material with small hardness, and cheap cost.

Owner:XUZHOU COLLEGE OF INDAL TECH

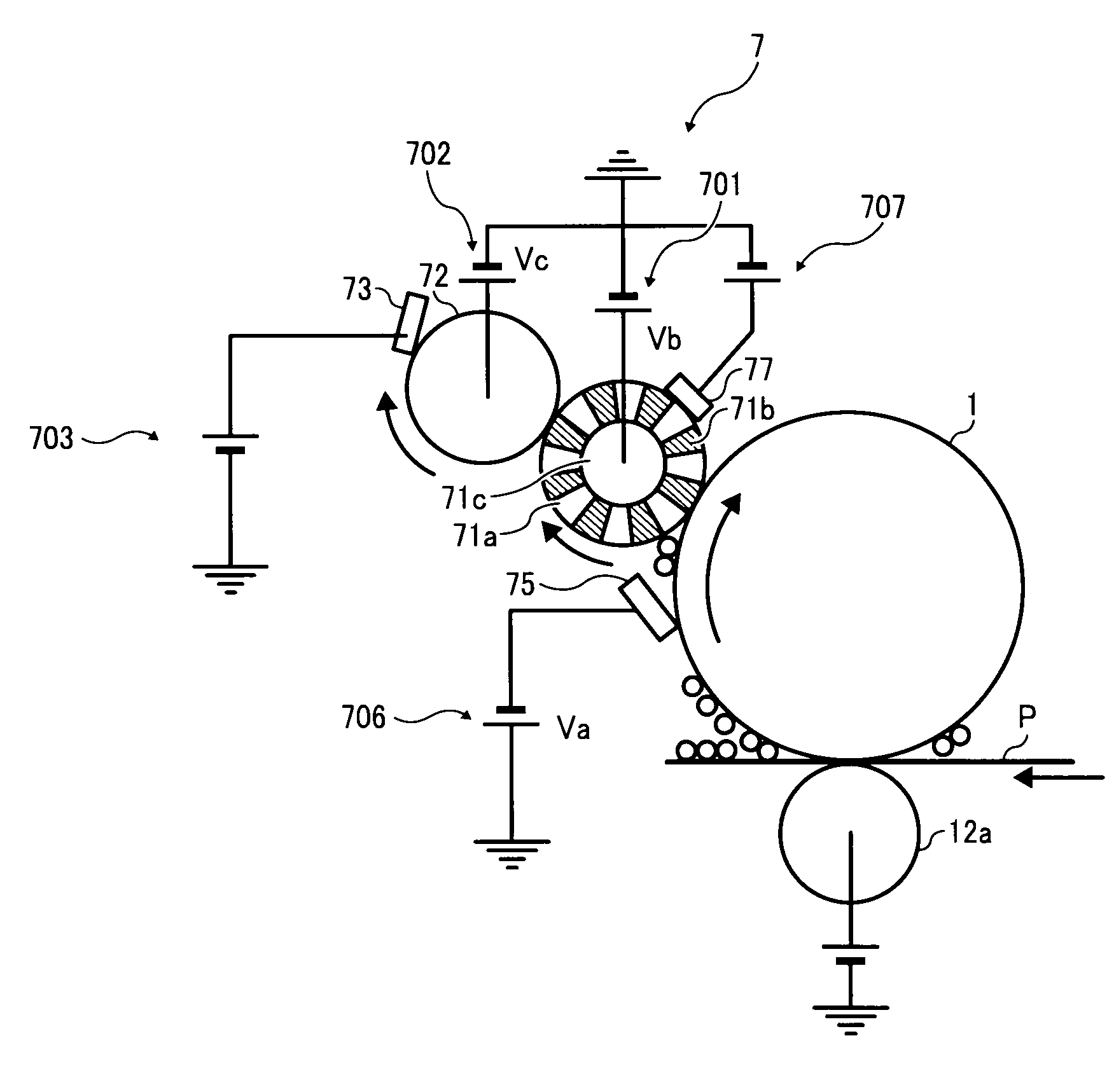

Cleaning device, image forming apparatus including the device, and process cartridge including the device

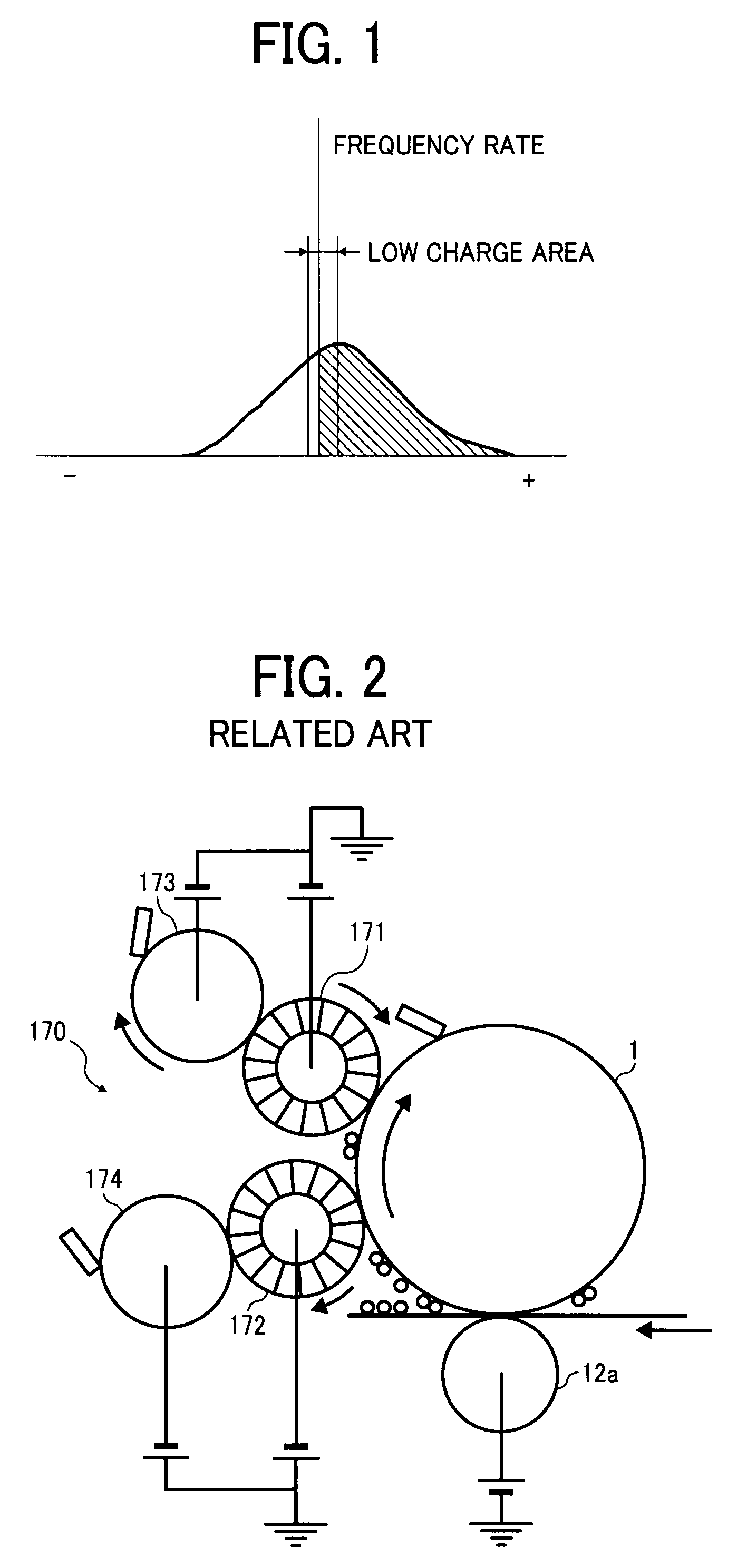

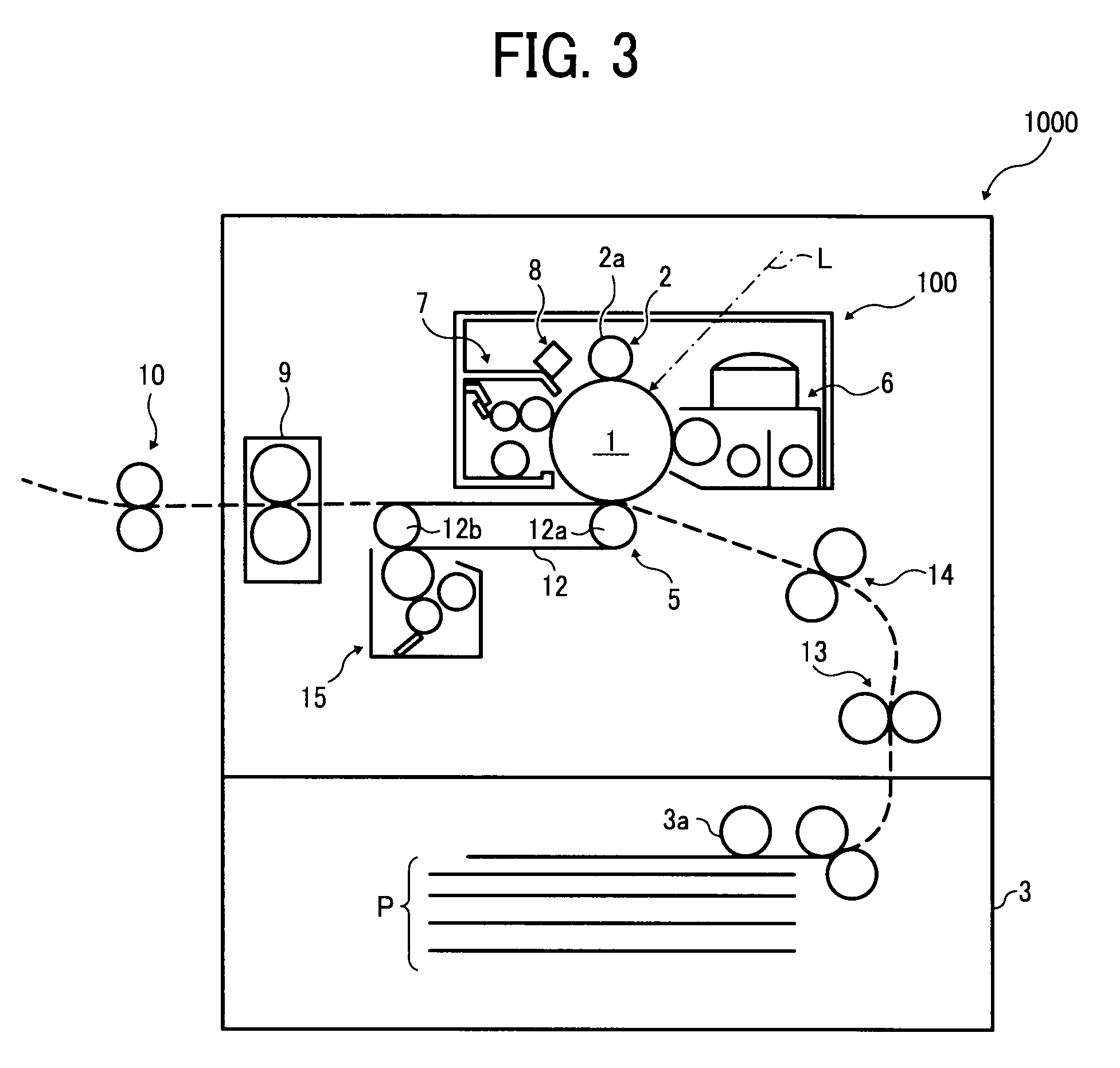

A cleaning device includes a cleaning member, a collection member, an electrical field generator, and a separation member. The cleaning member has a surface capable of moving while contacting a surface of a cleaning target to remove toner on the surface of the cleaning target. The collection member has a surface capable of moving while contacting the surface of the cleaning member to collect the toner on the surface of the cleaning member. The electrical field generator generates an electrical field to move the toner from the cleaning member to the collection member. The separation member contacts the surface of the collection member to separate the toner on the surface of the collection member. The collection member has a centerline average surface roughness of not more than 0.1 μm and shows a surface hardness rank of B or higher in a steel-wool scratch test.

Owner:RICOH KK

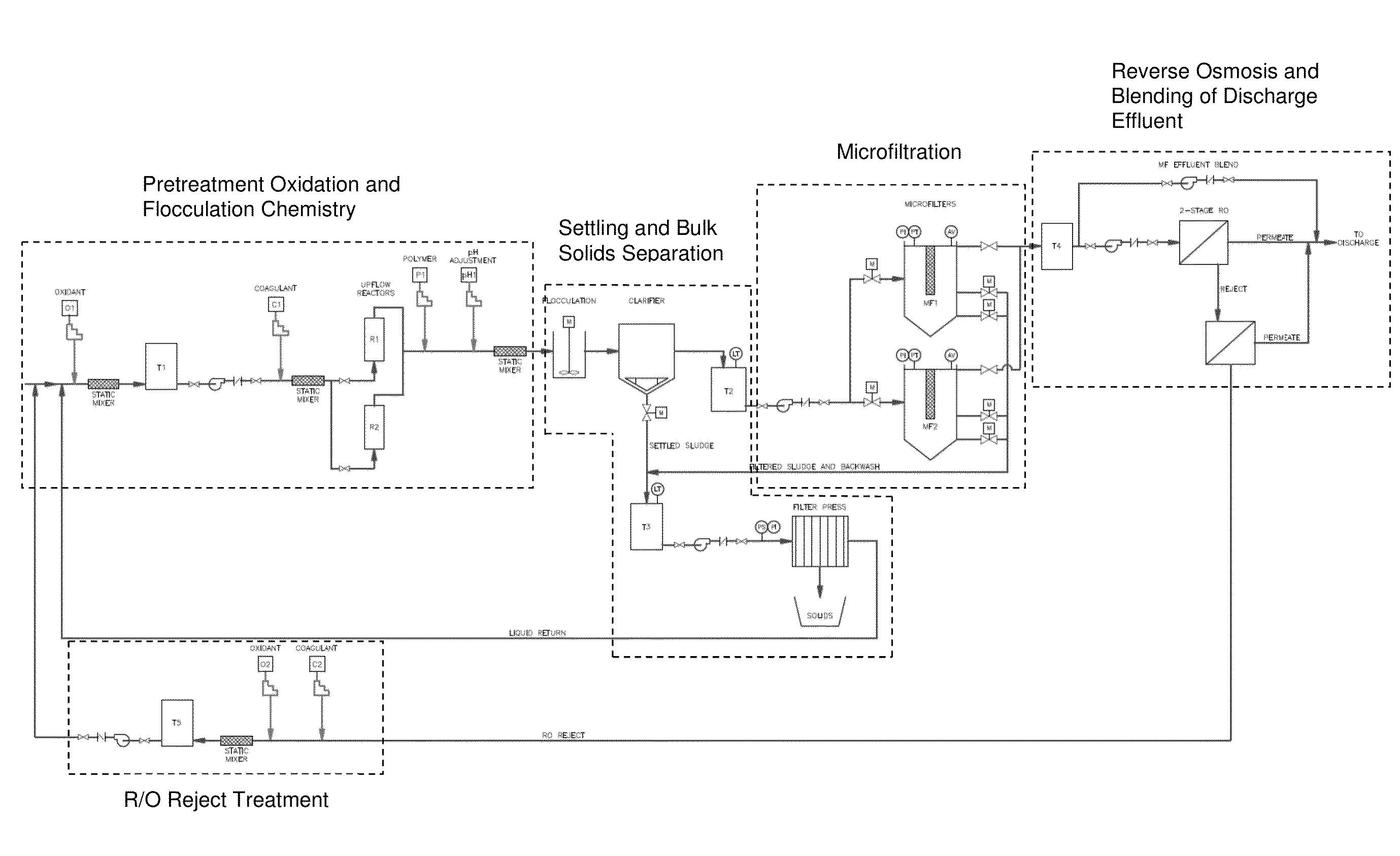

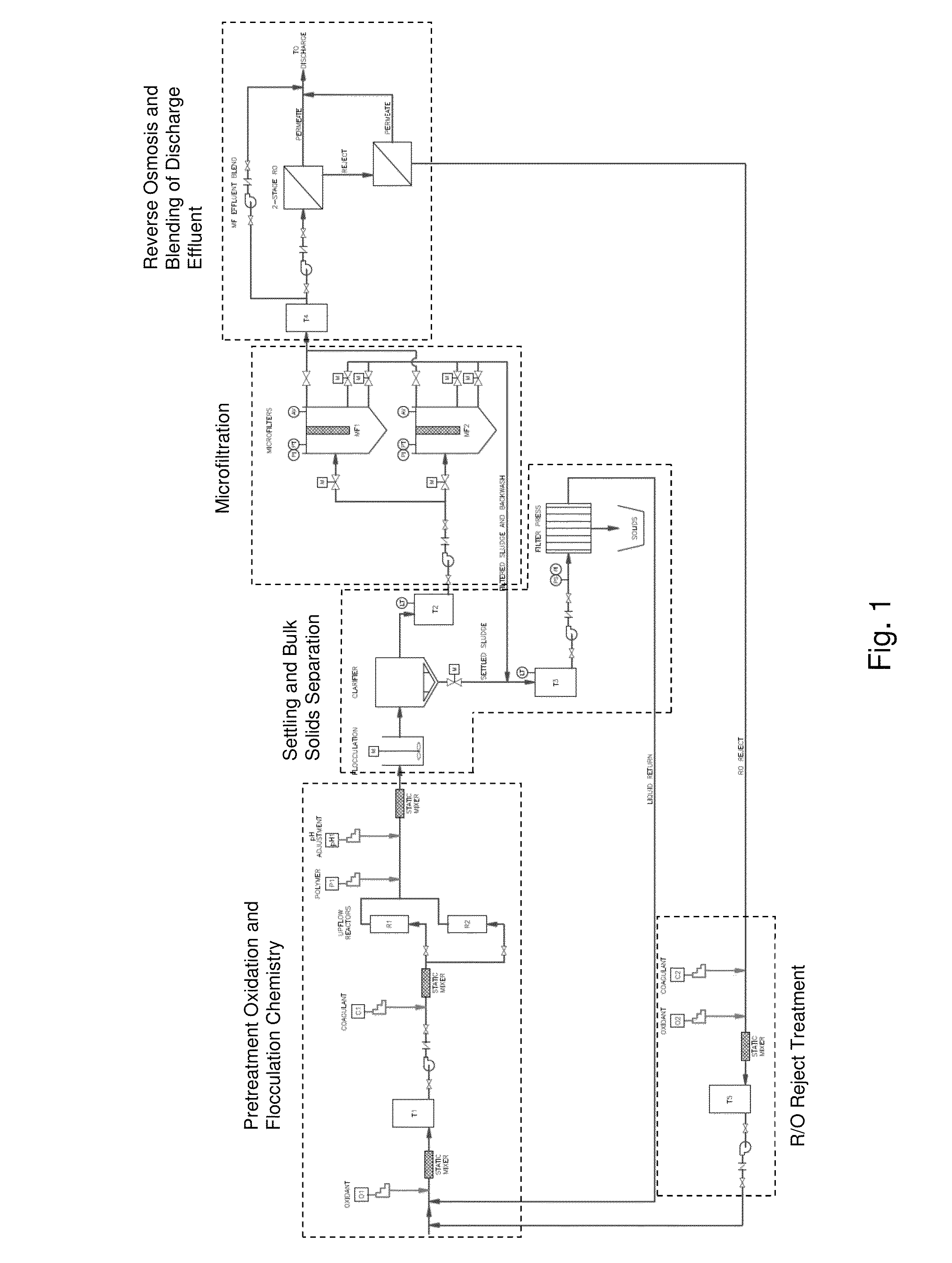

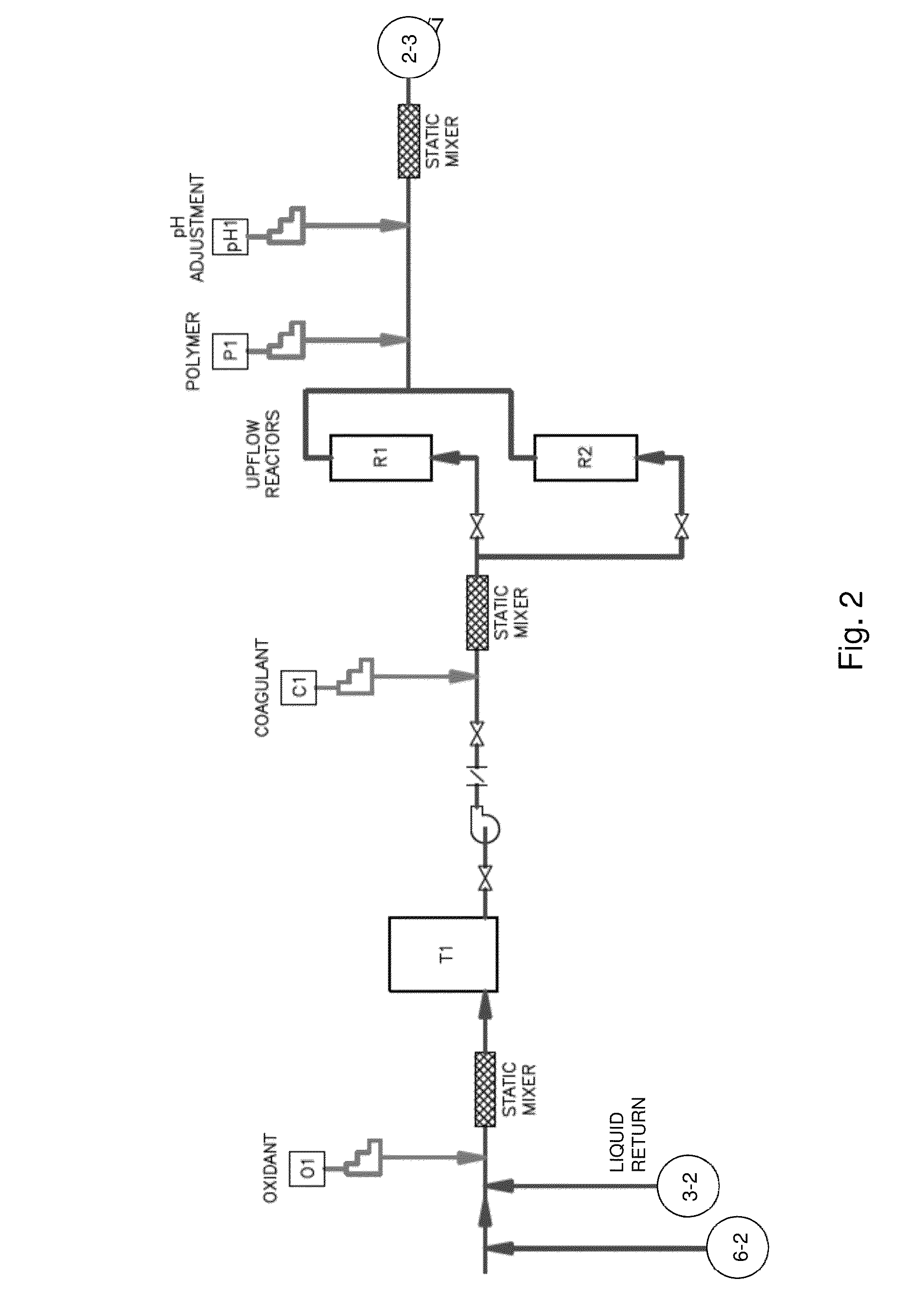

Treatment of contaminated impound water

ActiveUS20130270189A1Increased physical sizeLittle or no corrosionWaste water treatment from quariesSedimentation separationSteel woolWastewater

Systems and methods for treating contaminated impound water are disclosed which include a pretreatment stage wherein contaminated water is oxidized, pH adjusted, treated with a coagulant, and treated with a polymer to form a flocculent comprising bulk solids and fine particles. The oxidizing step may include two or more stages, one of which is a treatment with ferrous iron generated from iron filings or steel wool. Bulk solids are removed, and the liquid portion containing fine particles is applied to a low pressure microfiltration unit to remove the fine particles resulting in a microfilter effluent. The microfilter effluent may be directly fed to a reverse osmosis (R / O) unit. The R / O reject may be recycled to another R / O unit (second pass). The R / O permeate may be blended as needed with the microfiltration effluent to provide the final discharge effluent with reduced contaminant levels and maximized throughput. The R / O second pass reject water is further oxidized and recycled back to the front of the system to be retreated.

Owner:WATER SOLUTIONS TECH LLC

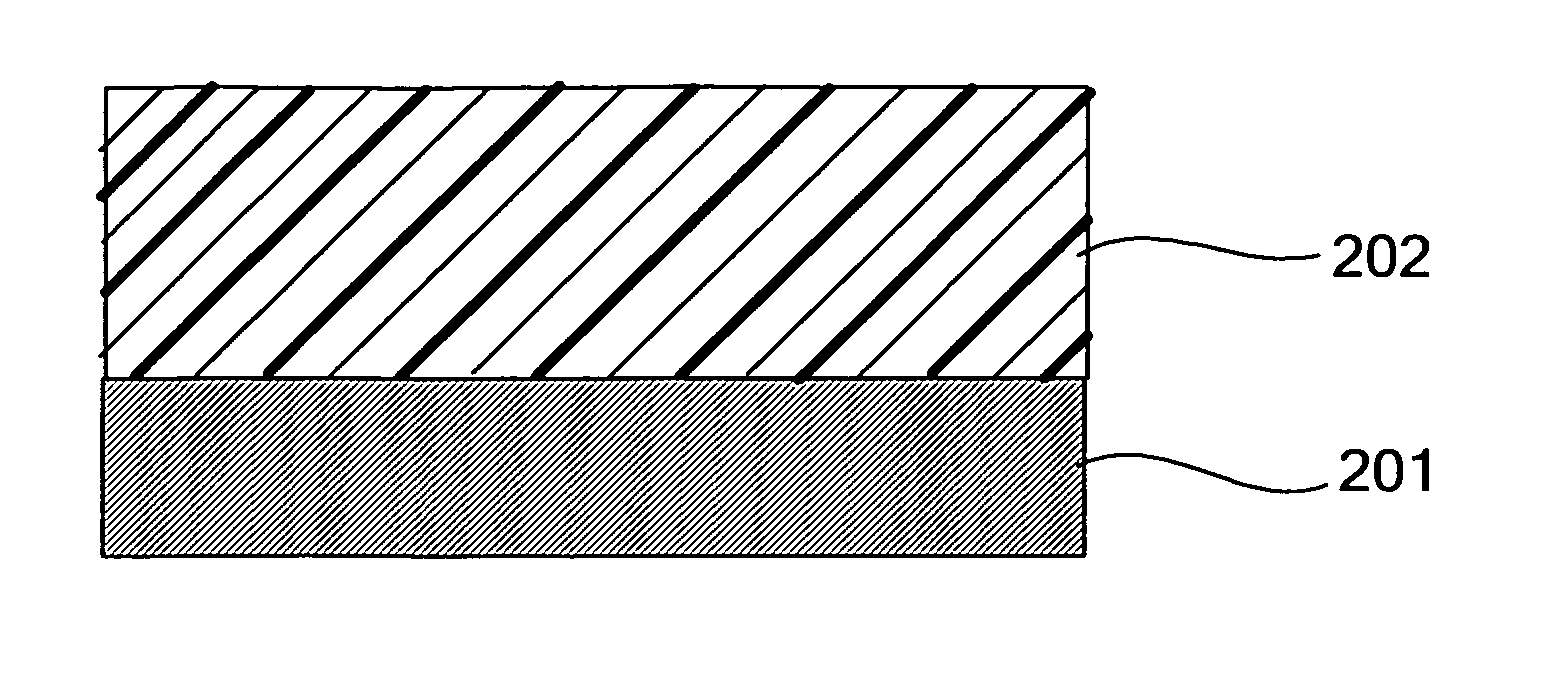

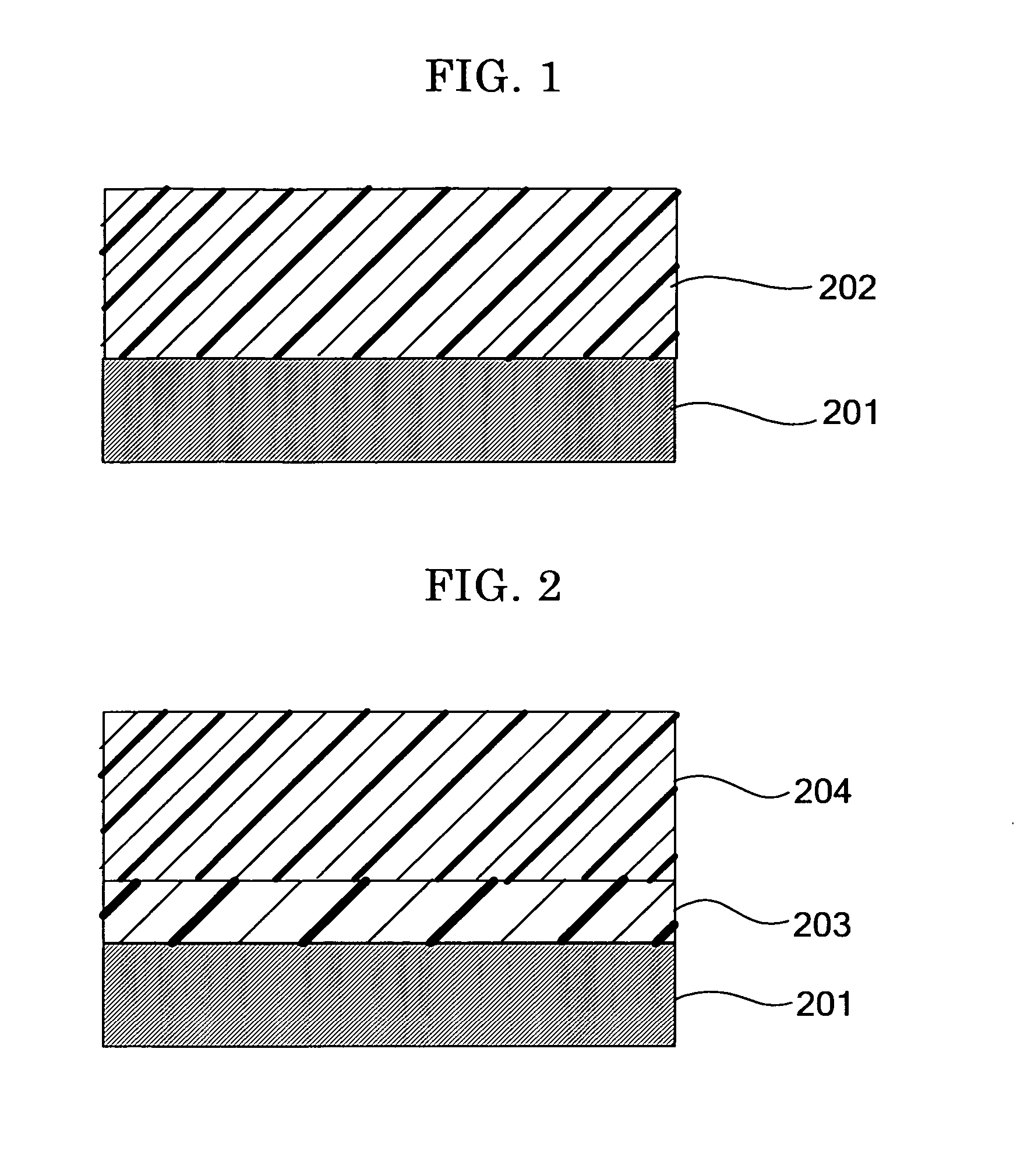

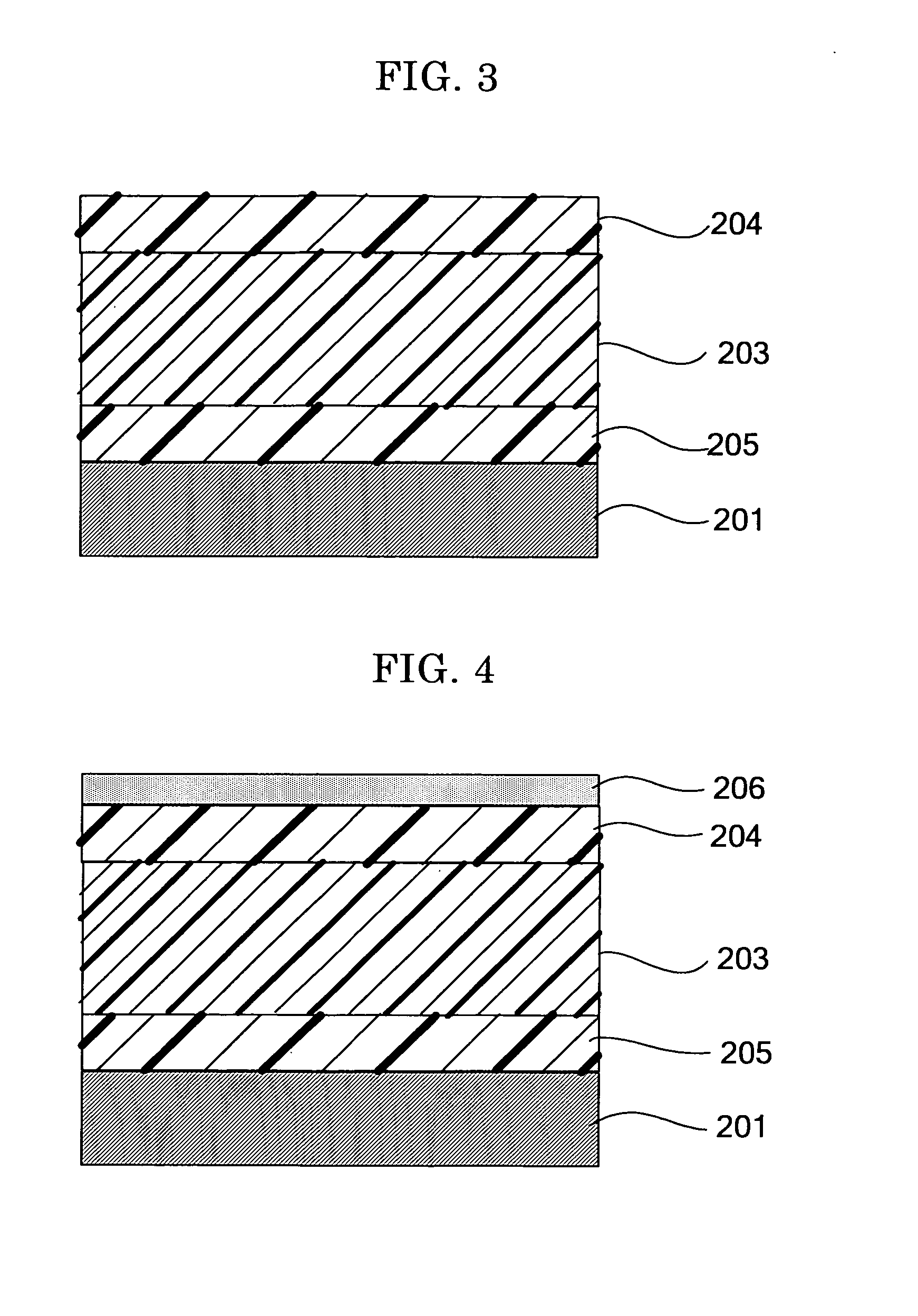

Latent electrostatic image bearing member, and process cartridge, image forming apparatus and image forming method

InactiveUS20060286473A1Simplified protective materialStrong resistanceElectrographic process apparatusElectrographic processes using charge patternSurface layerImage formation

A latent electrostatic image bearing member including at least a support, a photoconductive layer on the support and a surface layer on the photoconductive layer, wherein a film having the same composition as the surface layer is formed on a slide glass such that the film had a thickness of 5 μm; and the haze value measured after rubbing the film with a steel wool of #000 and a load of 500 gf for 50 times is 10% or less.

Owner:RICOH KK

Ultraviolet solidifying protection paint applied for polyester substrate surface

The invention discloses an ultraviolet-curing protective paint applicable to the surface of a polyester substrate, the compositions of the weight percent are as followings: 10 to 35 wt percent of bis-functional aliphatic polyurethane acrylates, 5 to 25 wt percent of multifunctional aliphatic polyurethane acrylates, 5 to 40 wt percent of novolac epoxy acrylates, 5 to 20 wt percent of pure acrylic ester of macromolecule, 5 to 40 wt percent of chloride polyester acrylates and 0.01 to 1 wt percent of addition agent, the ultraviolet-curing protective paint is applicable to the surface of the polyester substrate PET, the protective paint has excellent adhesion and high temperature resistance, the sticking membrane is normal at the high temperature of 180 DEG C and hot pressing for 30 seconds, at the same time, the surface of the polyester substrate PET has the advantages of excellent abrasion resistance and no friction mark after rubbing repeatedly a steel wool.

Owner:HUIZHOU CHANGRUNFA PAINT

High-friction coefficient composition brake shoe and production method thereof

The invention relates to a high-friction coefficient composition brake shoe. The high-friction coefficient composition brake shoe comprises a steel backing and a friction material, the friction material comprises the following raw materials including, by weight, 1-5 parts of aramid fiber, 8-12 parts of butadiene-acrylonitrile rubber, 0.5-1 part of stearic acid, 0.3-1 part of an accelerant, 0.6-1 part of sulphur, 0.5-1 part of zinc oxide, 4-7 parts of phenolic resin, 10-20 parts of inorganic composite fiber, 8-15 parts of iron powder, 10-20 parts of barium sulfate, 7-15 parts of kibdelophane powder, 5-10 parts of steel wool fiber, 1-3 parts of bauxite, 8-15 parts of potassium feldspar powder, 2-5 parts of mica, 2-5 parts of flake graphite, 5-10 parts of sepiolite fiber and 2-5 parts of molybdenum disulfide. By means of the high-friction coefficient composition brake shoe, the change of the speed of the wear rate of the high-friction coefficient composition brake shoe can be basically identical to the change of the adhesion coefficient of a wheel track, the abrasion loss when a vehicle is braked is less, failure can not occur in braking, and the traffic safety is guaranteed. The invention provides a production method of the high-friction coefficient composition brake shoe at the same time.

Owner:HEBEI XINJI TENGYUE INDAL

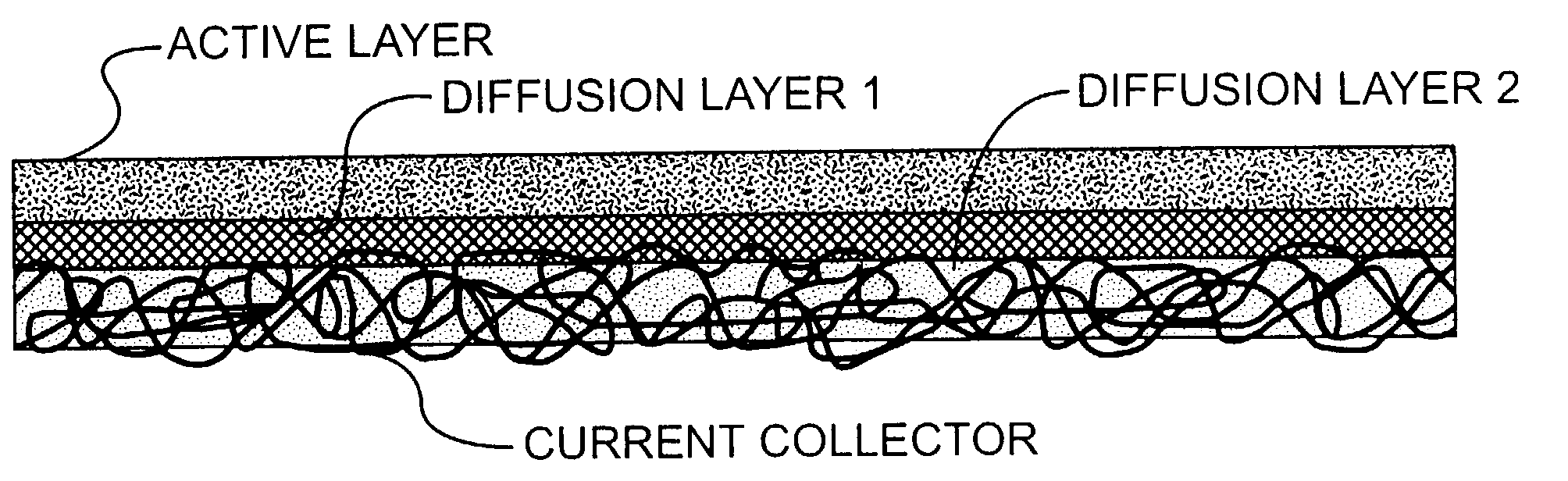

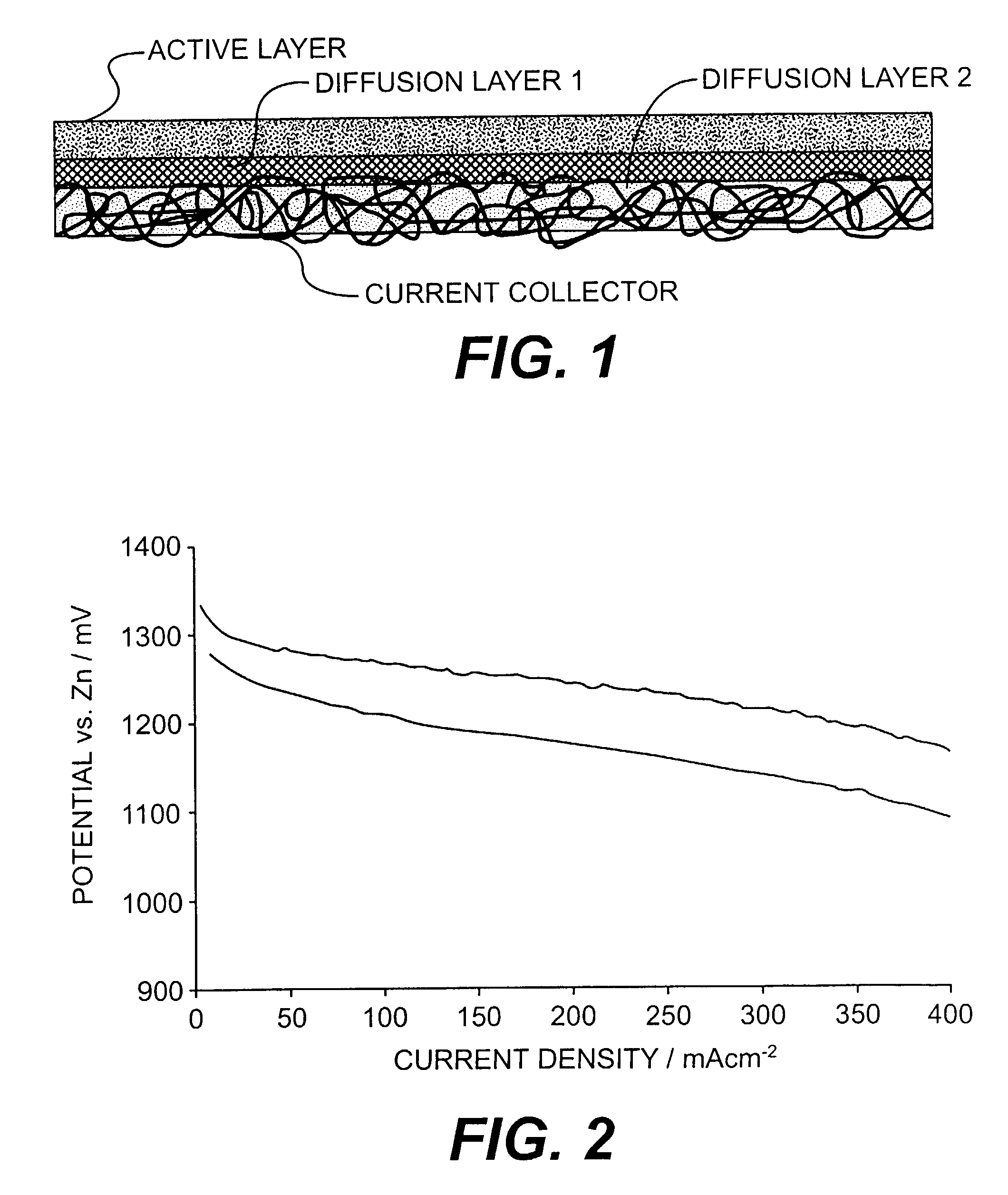

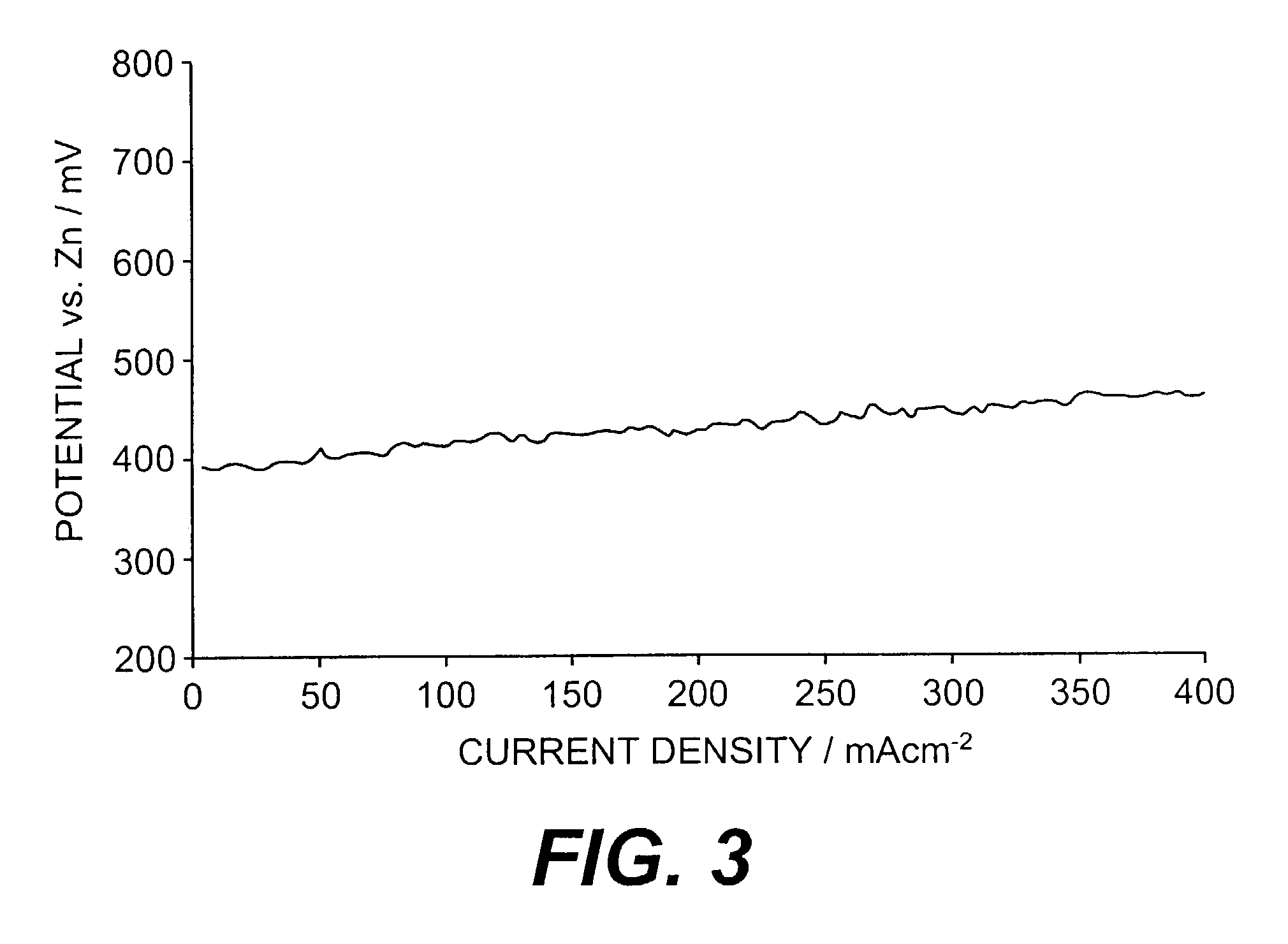

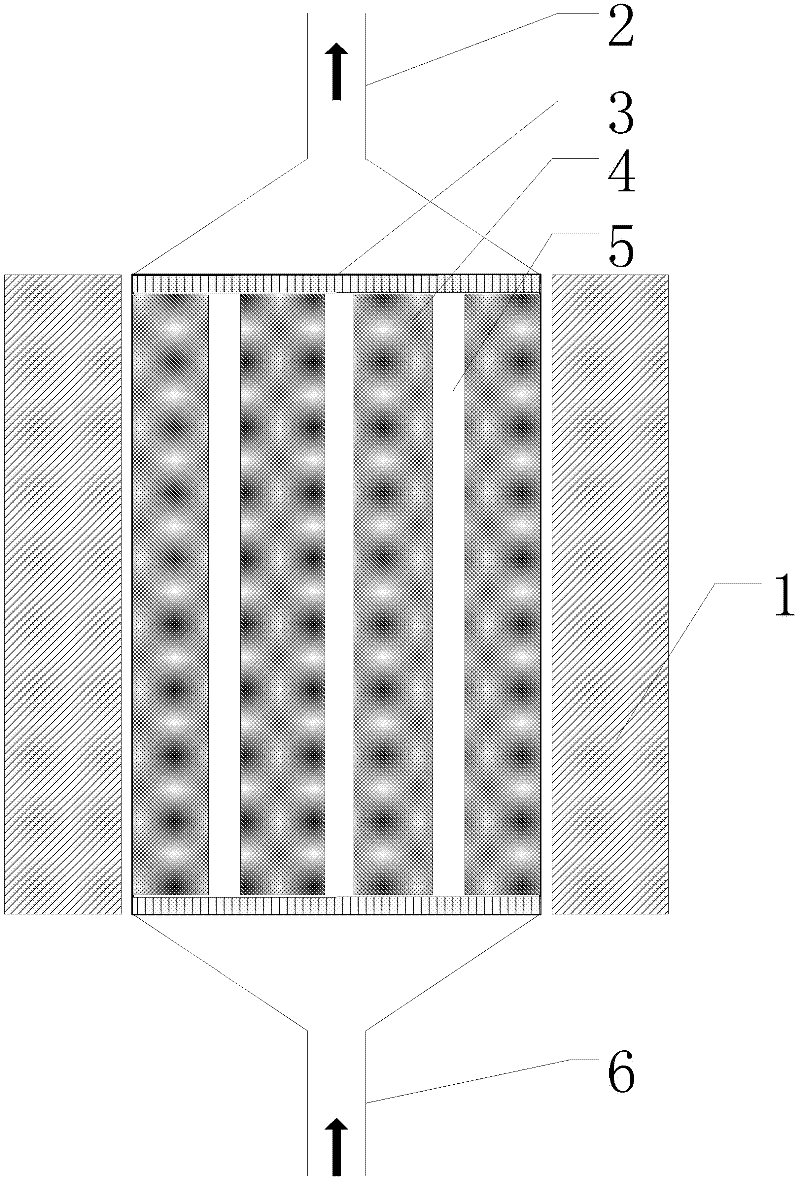

Electrodes for alkaline fuel cells with circulating electrolyte

InactiveUS7014944B2Dimensionally stableReduce in quantityFuel cells groupingElectrolyte stream managementFiberActivated carbon

Fuel cell electrodes are described which comprise a non-woven network of conductive fibers, such as a carbon fleece, nickel foam sheet or stainless steel wool layer, plus additional activated carbon material, carrying one or more catalyst components and at least one polymeric substance as binder and / or repellancy agent to establish three zone interfaces (liquid-solid-liquid) or three phase interfaces (gas-liquid-solid). The electroactive catalyzed material is embedded into the conductive structure by specified deposition processes, such as coating, blading or spraying.

Owner:APOLLO ENERGY SYSTEMS +4

Brake pad and preparation method thereof

ActiveCN101813147AImprove thermal performanceImprove wear resistanceFriction liningCelluloseMetal framework

The invention relates to a brake pad, which comprises a metal framework and a friction material bonded on the metal framework, wherein the friction material comprises 8 to 12 parts of phenolic resin, 20 to 30 parts of potassium titanate whisker, 3 to 7 parts of cellulose, 5 to 9 parts of friction powder, 10 to 15 parts of mineral fibers, 2 to 5 parts of aramid fibers, 3 to 8 parts of steel wool fibers and 25 to 35 parts of barium sulfate. The preparation method comprises the steps of material preparation, material mixing, hot-forming, heat treatment, grinding and spraying. The phenolic resin plays a bonding role; the potassium titanate whisker and the cellulose reinforce a basal body and stabilize a friction factor and have a high friction performance; the mineral fibers and the friction powder interact to improve and stabilize the friction factor and have high heatfading stability; the aramid fibers and the steel wool fibers can increase the strength of products and improve the heat conductivity of the products; and the barium sulfate improves heat performance and wear resistance. The brake pad has the advantages of small metal material content, medium hardness, high water resistance, small damages to coupling elements in braking and long service life.

Owner:山东金力新材料科技股份有限公司

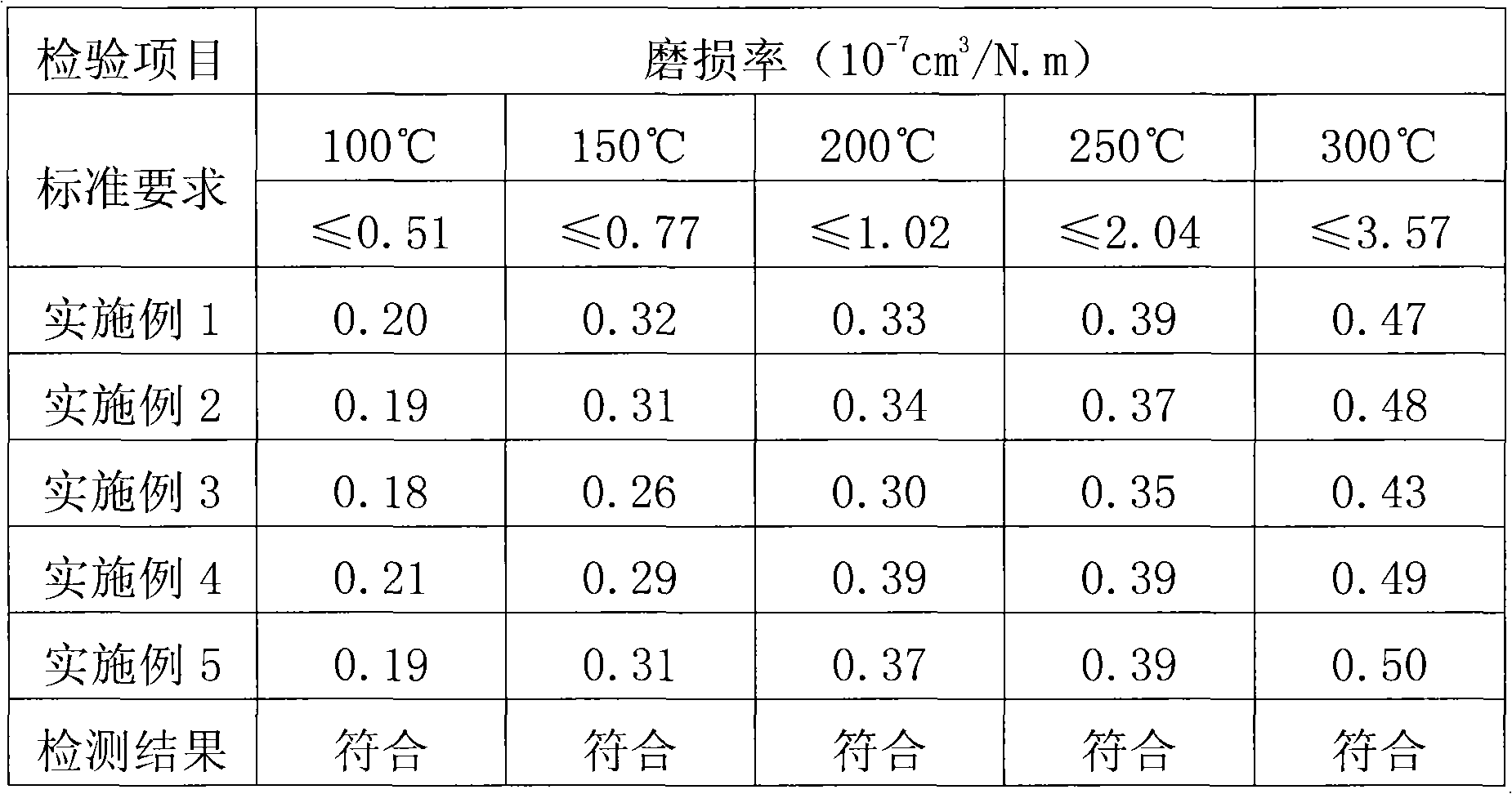

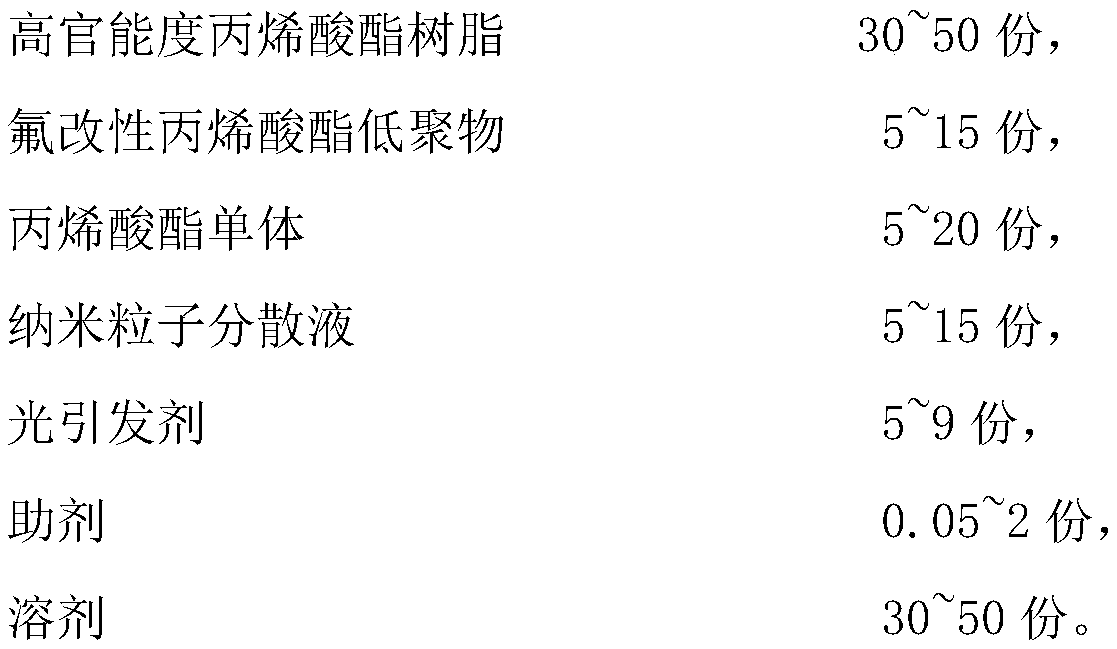

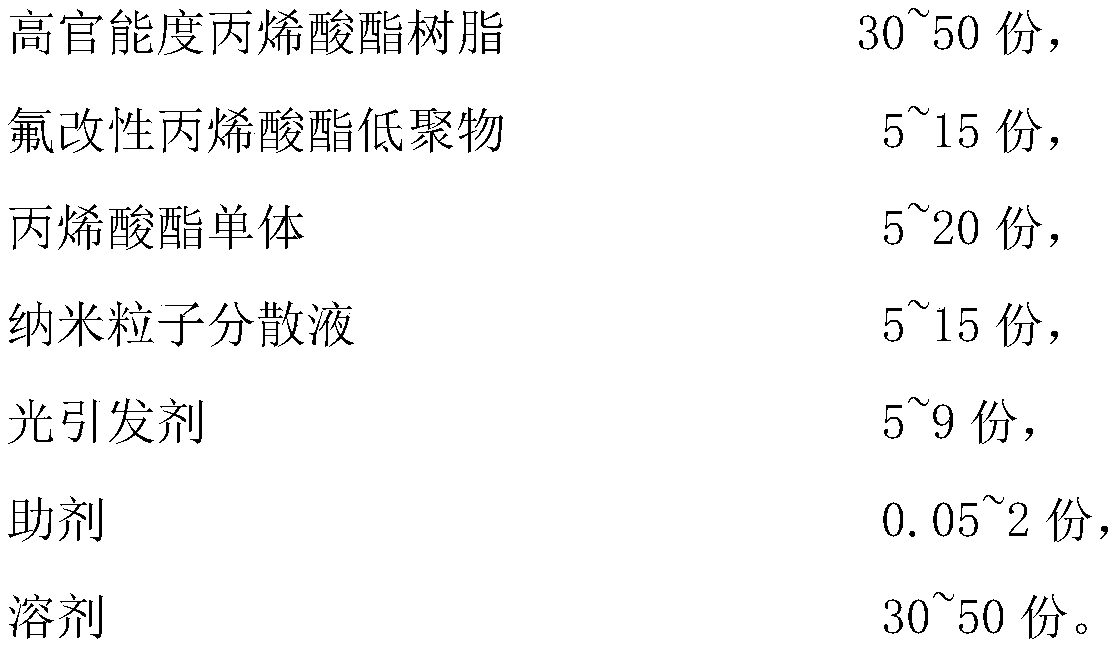

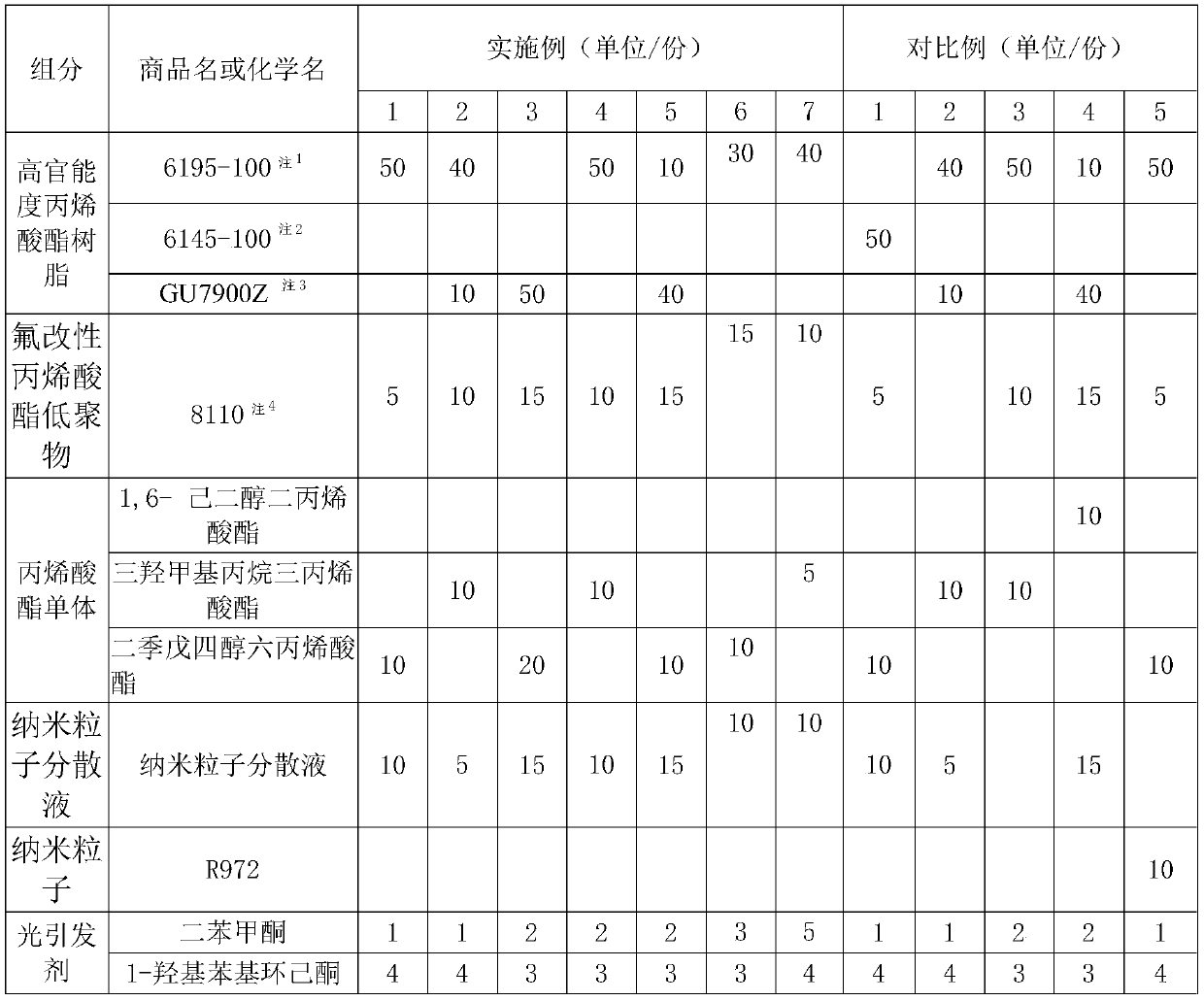

Ultraviolet curing coating composition with high wear resistance and fingerprint resistance and preparation method thereof

InactiveCN111100545AHigh steel wool wear-resistantImprove anti-fingerprintPolyurea/polyurethane coatingsPolyester coatingsPolymer scienceOligomer

The invention provides an ultraviolet curing coating composition with high wear resistance and fingerprint resistance and a preparation method thereof. The composition is prepared from the following components in parts by weight: 30-50 parts of high-functionality acrylate resin, 5-15 parts of fluorine-modified acrylate oligomer, 5-20 parts of an acrylate monomer, 5-15 parts of nanoparticle dispersion liquid, 5-9 parts of a photoinitiator, 0.05-2 parts of an auxiliary agent and 30-50 parts of a solvent. Compared with the prior art, the steel wool of the prepared ultraviolet curing coating composition is excellent in wear resistance and has fingerprint resistance and hand sweat resistance; and the coating has high hardness, is suitable for surface protection of plastic base materials, has excellent comprehensive performance, and can be applied to the related fields of mobile phone plastic rear covers, mobile phone films and the like.

Owner:SHANGHAI WEIKAI CHEM +2

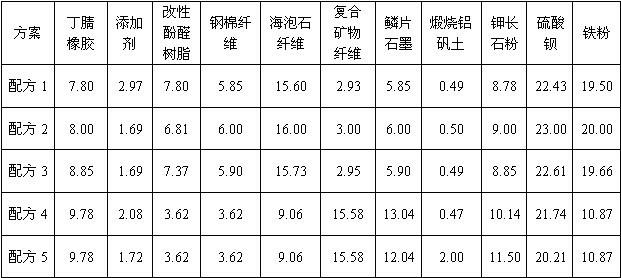

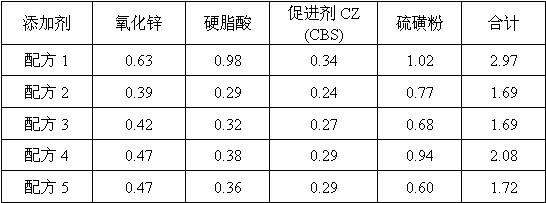

Composition brake shoe for railway freight car, and method for manufacturing same

ActiveCN102661340AHigh bonding strengthReduce wearOther chemical processesBraking membersCrazingSlag

The invention discloses a composition brake shoe for a railway freight car, and a method for manufacturing the same. A friction piece of the composition brake shoe for the railway freight car is synthetised by using following materials by weight parts: 6-10 parts of nitrile rubber, 2-8 parts of modified phenolic resin, 3-6 parts of steel wool fibers, 9-16 parts of sepiolite fibers, 2-16 parts of composite mineral fibers, 5-13 parts of graphite, 0.4-2 parts of calcined bauxite, 20-24 parts of barium sulfate, 8-12 parts of potassium feldspar powder, 10-20 parts of iron powder, and 1-3 parts of additives. The friction piece of the composition brake shoe is formed through the steps of dosing, banburying or mixing, crashing, hot press molding and curing forming, and thermal processing. The composition brake shoe is capable of well satisfying various performance indexes requested in PRC (People's Republic of China) railway industrial standard TB / T2403-2010, and can be applied to railway freight cars traveling at the highest speed of 120km / h and axle load of the composition brake shoe is not greater than 25 tons; besides, the composition brake shoe has stable friction properties and excellent friction resistance, and is low in attrition to wheels and low in braking noise; and as a result, potential quality hazards ( such as brake shoe body breakage, slag and block dropping, metal inlaying and hot cracks) endangering traveling safety are fundamentally solved.

Owner:CHONGQING YUHONG RAIL CAR ACCESSORIES CO LTD

Durable antireflective film

Antireflective films are described having a surface layer comprising a the reaction product of a polymerizable low refractive index composition comprising at least one fluorinated free-radically polymerizable material and surface modified inorganic nanoparticles. A high refractive index layer is coupled to the low refractive index layer. In one embodiment, the high refractive index layer comprises surface modified inorganic nanoparticles dispersed in a crosslinked organic material. The antireflective film is preferably durable, exhibiting a haze of less than 1.0% after 25 wipes with steel wool using a 3.2 cm mandrel and a mass of 1000 grams.

Owner:3M INNOVATIVE PROPERTIES CO

Ultraviolet curing paint

InactiveCN102329557ABalance hardnessBalanced AdhesionPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides ultraviolet curing paint, which comprises the following components in parts by weight: 15-40 parts of high-functional aliphatic polyurethane acrylic resin, 3-10 parts of bi-functional aliphatic polyurethane acrylic resin, 10-15 parts of high-functional acrylic monomer, 3-6 parts of single-functional acrylate monomer, 1-3 parts of adhesion promoter, 1-5 parts photoinitiator, 20-6- parts of diluent and 0.5-2 parts of auxiliaries. After the ultraviolet curing paint provided by the invention is coated, the hardness and the adhesion of an obtained paint film can be balanced, so that the obtained paint film has the advantages that the hardness reaches 5H under the condition of 1kg of load, the resistant times reaches 600 under steel wool, and the RCA wear testing times reach 2000, and has good surface adhesion on the surfaces of PC (Polycarbonate), ABS (Acrylonitrile Butadiene Styrene), PMMA (Polymethyl Methacrylate), PC / ABS and PA (Polyamide) materials.

Owner:HUNAN SOKAN NEW MATERIAL

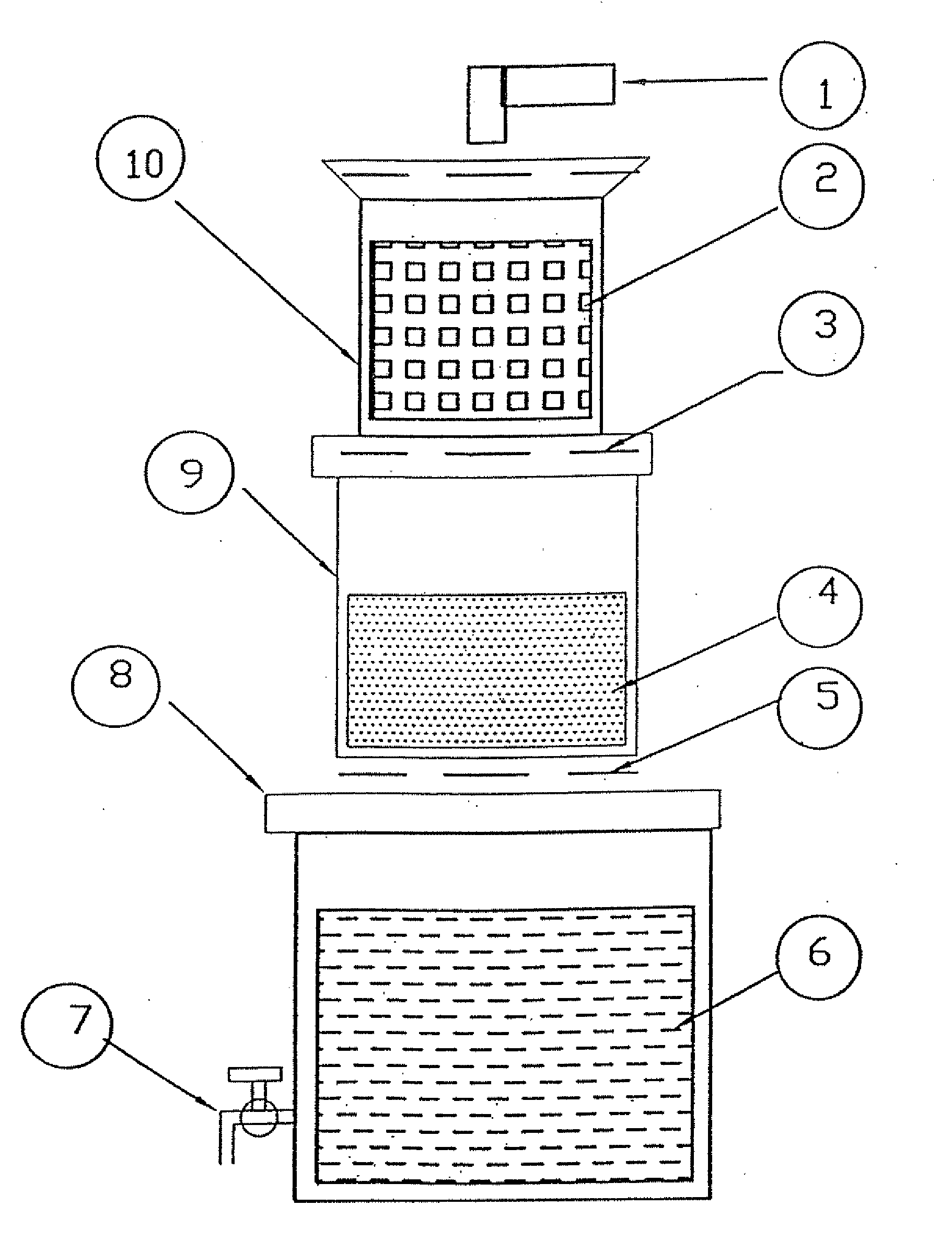

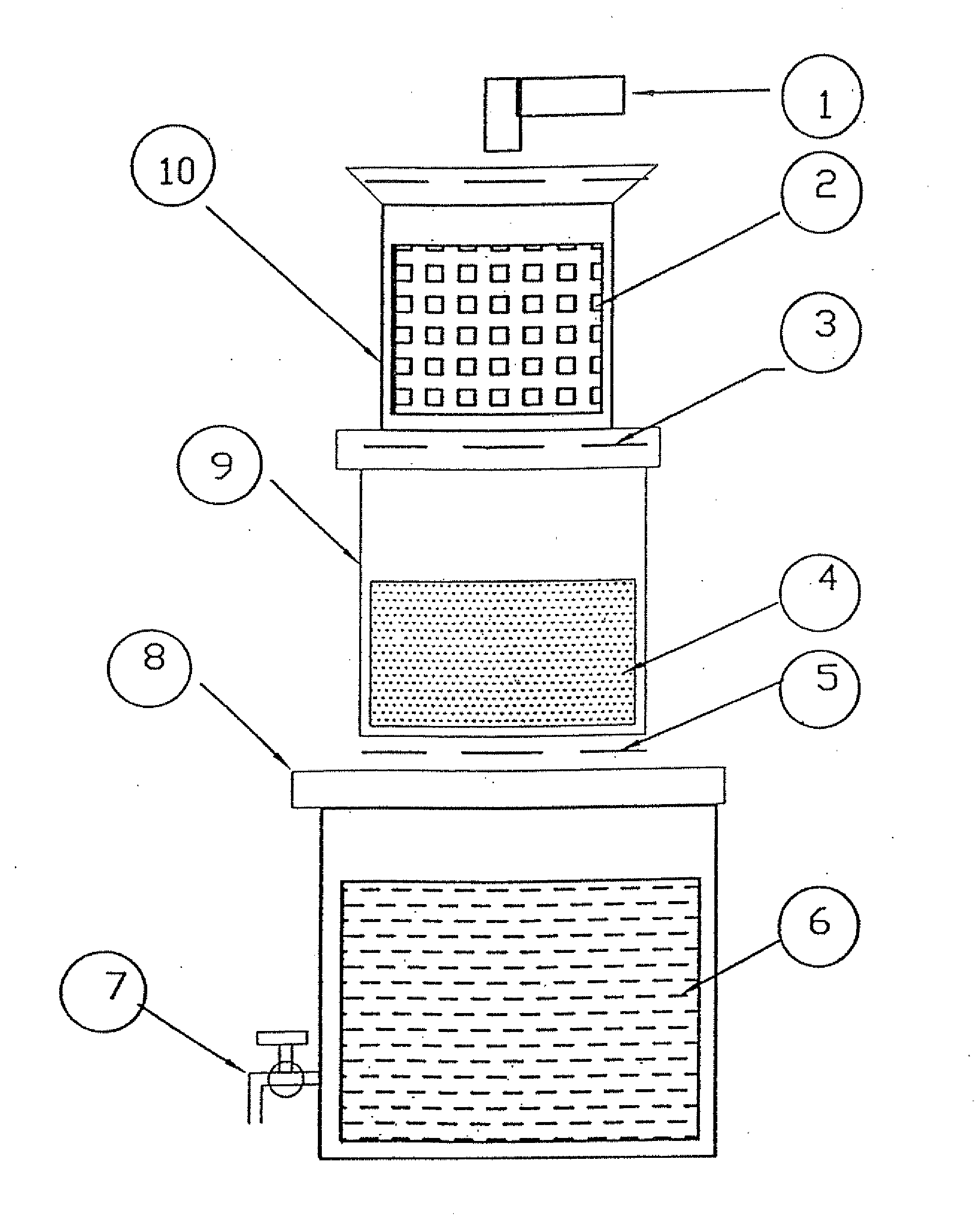

Filtering Device for the Removal of Arsenic from Water

InactiveUS20080308484A1Cheap and affordableLow priceWater cleaningWater contaminantsArsenatePlastic materials

A filtering device for the removal of arsenic from the ground water / surface water. The filtering device of the present invention uses steel wool and sand as the raw material for the removal of arsenic from water and the entire outer body of the device can be made from cheaper material like plastic material or stainless steel. The filtering device works on the simple principle of co-precipitation of arsenic with metals, followed by adsorption and filtration through treated sand. The metal, steel wool, used in the device is a processed waste generated from a steel plant thereby making the device extremely cheaper and versatile. In the filtering device of the present invention, iron arsenate and iron arsenite are co-precipitated by the reaction of steel wool with arsenic in water. The device uses treated river sand simultaneously for the removal of iron leached out during reaction.

Owner:DIRECTOR GENERAL DEFENCE RES & DEV ORG

Self-contained temperature-change container assemblies

InactiveUS20050000508A1Exothermal chemical reaction heat productionOther heat production devicesSteel woolEngineering

A container assembly heats or cools a product inside an inner container. An outer jacket at least partially surrounds the inner container, with a first internal volume and a second internal volume in the space between the outer jacket and the inner container. A first temperature-change reagent is contained inside the first internal volume, and a second temperature-change reagent is held in the second internal volume, with a reagent separator between the two. Several penetrators are disposed to penetrate the reagent separator to produce openings through the separator and through which the two reagents can mix. Steel wool inside the first internal volume acts as a steam condenser. The outer jacket includes a jacket top ring secured around an upper surface of a standard can, a jacket body secured to the jacket top, and a flexible jacket bottom that carries several spikes molded onto the jacket bottom.

Owner:SELF HEATING TECH CORP

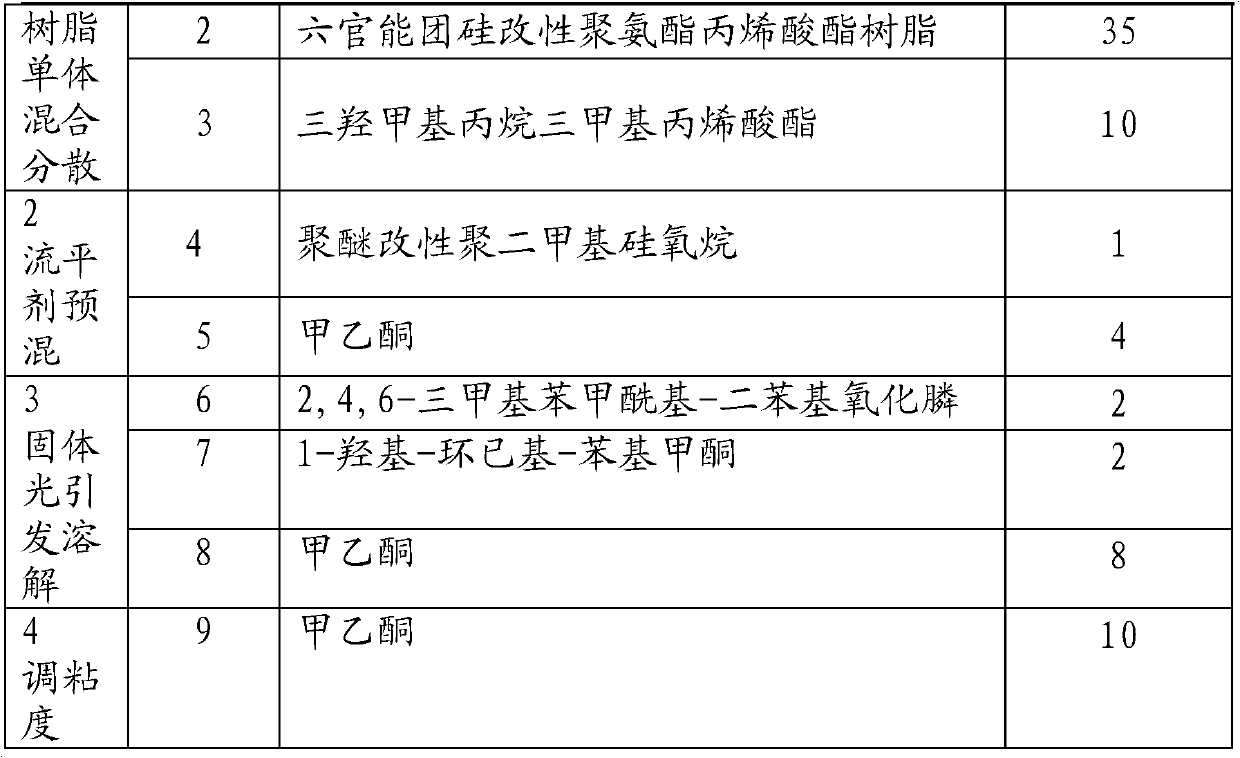

UV curable coating used for IML, its preparation method and application

ActiveCN103333604AHigh hardnessImprove stain resistancePolyurea/polyurethane coatingsPolyester coatingsPolymer scienceOrganic solvent

The invention discloses a UV curable coating used for IML, its preparation method and application. The UV curable coating used for IML comprises: 10-20 parts of aliphatic polyurethane acrylate, 5-15 parts of hyperbranched polyester acrylate, 5-15 parts of an active diluent, 0.1-1 part of a leveling agent, 0.5-2 parts of nanoparticles, 1-2 parts of a photoinitiator, and 50-70 parts of an organic solvent. The preparation method includes: mixing the reactive diluent, the leveling agent and the organic solvent evenly; then adding the aliphatic polyurethane acrylate and the hyperbranched polyester acrylate, mixing them uniformly, then adding the nanoparticles and the photoinitiator, and mixing them uniformly, thus obtaining the UV curable coating used for IML. The UV curable coating used for IML can be used for preparing hard films for IML, and can effectively reduce the cost. The obtained hard films for IML have high hardness, excellent resistance to steel wool scraping and stain resistance.

Owner:GUANGZHOU HUMAN CHEM

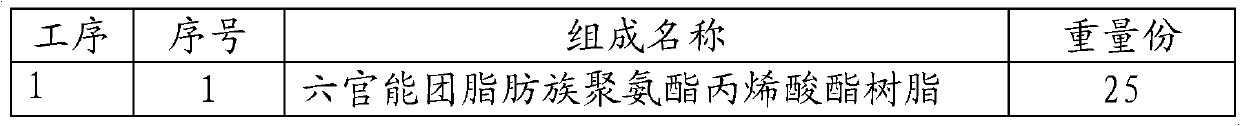

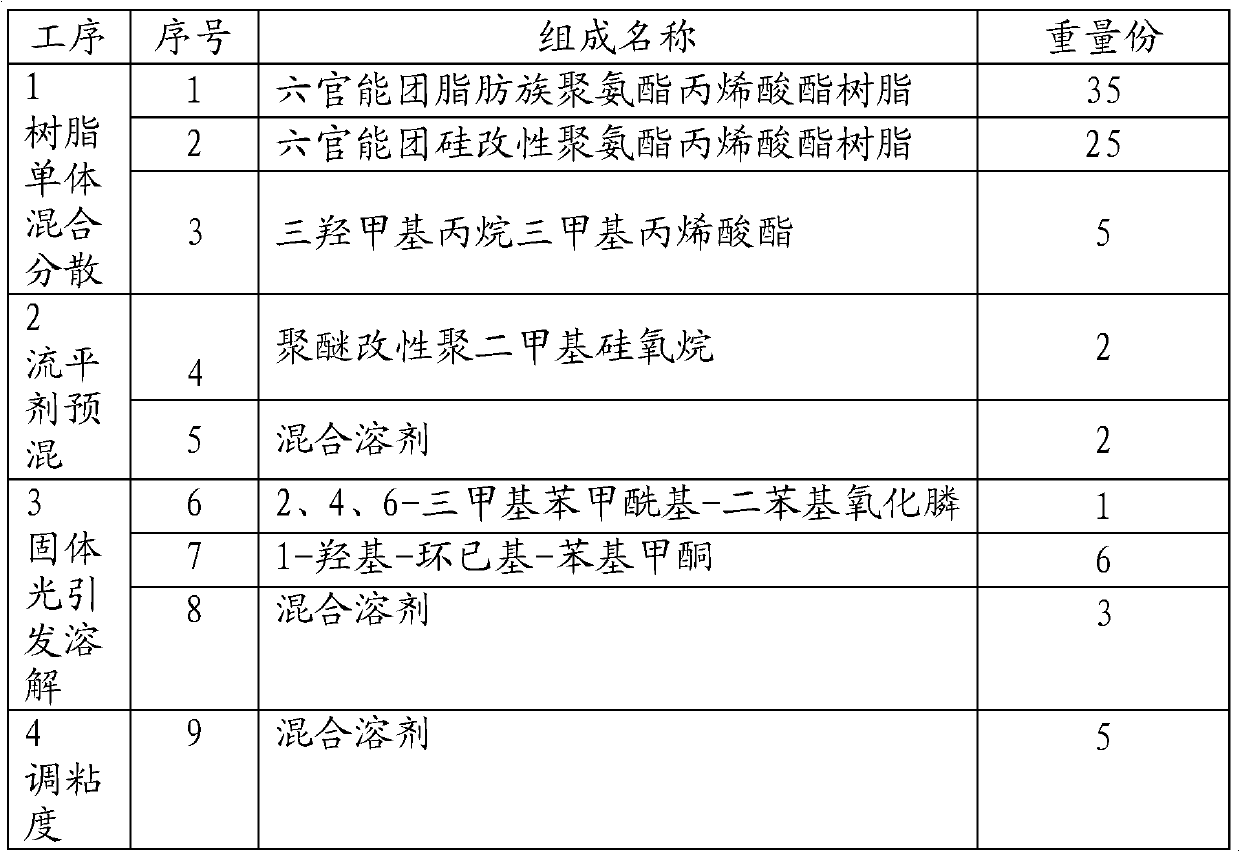

Steel wool-resistant high-hardness ultraviolet (UV) radiation cured coating, and preparation and using methods thereof

InactiveCN102585690AGood adhesionHigh surface hardnessPretreated surfacesPolyurea/polyurethane coatingsAcrylic resinAcrylonitrile

The invention provides a steel wool-resistant high-hardness ultraviolet (UV) radiation cured coating, and preparation and using methods thereof. The coating comprises the following components in part by weight: 25 to 35 parts of six-functional group aliphatic series polyurethane acrylic resin, 25 to 35 parts of six-functional group silicon modified polyurethane acrylic resin, 5 to 10 parts of trimethylolpropane trimethacrylate, 1 to 2 parts of polyether modified polydimethylsiloxane, 1 to 2 parts of diphenyl(2,4,6-trimethylbenzoyl)phosphine oxide, 2 to 6 parts of 1-hydroxycyclohexyl phenyl ketone, and 10 to 22 parts of solvent. The coating is prepared to overcome the defects in the conventional UV cured coating, and is particularly suitable for high-hardness coating which is required by plastic keys such as acrylonitrile-butadiene-styre (ABS) keys, poly carbonate (PC) keys and the like, and can widely applied to coating of various plastic parts of communication, computer and consumer (3C) products, and digital products; and the high requirement of the UV coating is met.

Owner:深圳市嘉卓成科技发展有限公司

Recipe of brake disk material with metal sulfide

The present invention is recipe of brake disk material with metal sulfide. The brake disk material consists of adhesive of phenolic resin, butyronitrile modified phenolic resin, silicon modified phenolic resin or their composition 5-10 wt%; reinforcing material of steel wool fiber, aramid fiber pulp or composition of ceramic fiber and aramid fiber pulp 20-30 wt%; grinding material of ferric oxide, magnesia, alumina and friction powder composition 10-20 wt%; lubricant of inorganic lubricant and metal sulfide composition or organic lubricant and metal sulfide composition 15-25 wt%; and stuffing of barium sulfate, calcium carbonate and magnesia composition 30-50 wt%. The brake disk made of the material can form one layer of lubricating film in the friction interface without forming hard point and has greatly reduced low frequency noise.

Owner:信义集团公司

Bamboo charcoal composite fiber friction material and brake pad fabricated therefrom, and method for preparing same

ActiveCN102977850AGood self-lubricating performanceImprove compactnessOther chemical processesFriction liningCarbonizationBamboo charcoal

The invention discloses a bamboo charcoal composite fiber friction material and a brake pad fabricated therefrom, and a method for preparing the same, wherein bamboo charcoal obtained from the bamboo wood through carbonization, grinding and sieving is dry-blended with organic plant fibers, and then wet-blended with a coupling agent, thereby obtaining the bamboo charcoal composite fiber friction material provided by the invention; the brake pad is fabricated from the bamboo charcoal composite fiber friction material provided by the invention, mineral fibers, resins, blanc fixe, chemigum, alumium oxide, graphite, glass fibers, steel wool and tire powder through stirring and mixing, hot press molding and curing heat treatment; the bamboo charcoal composite fiber friction material can be applied to fabricating various brake pads, especially suitable for fabricating the brake pads of the automobile braking system; and the bamboo charcoal composite fiber friction material has the advantages of low attrition rate, good heat fading resistance, long service life, low weight, wide raw material source and low cost.

Owner:华泰汽车配件工业(南平)有限公司

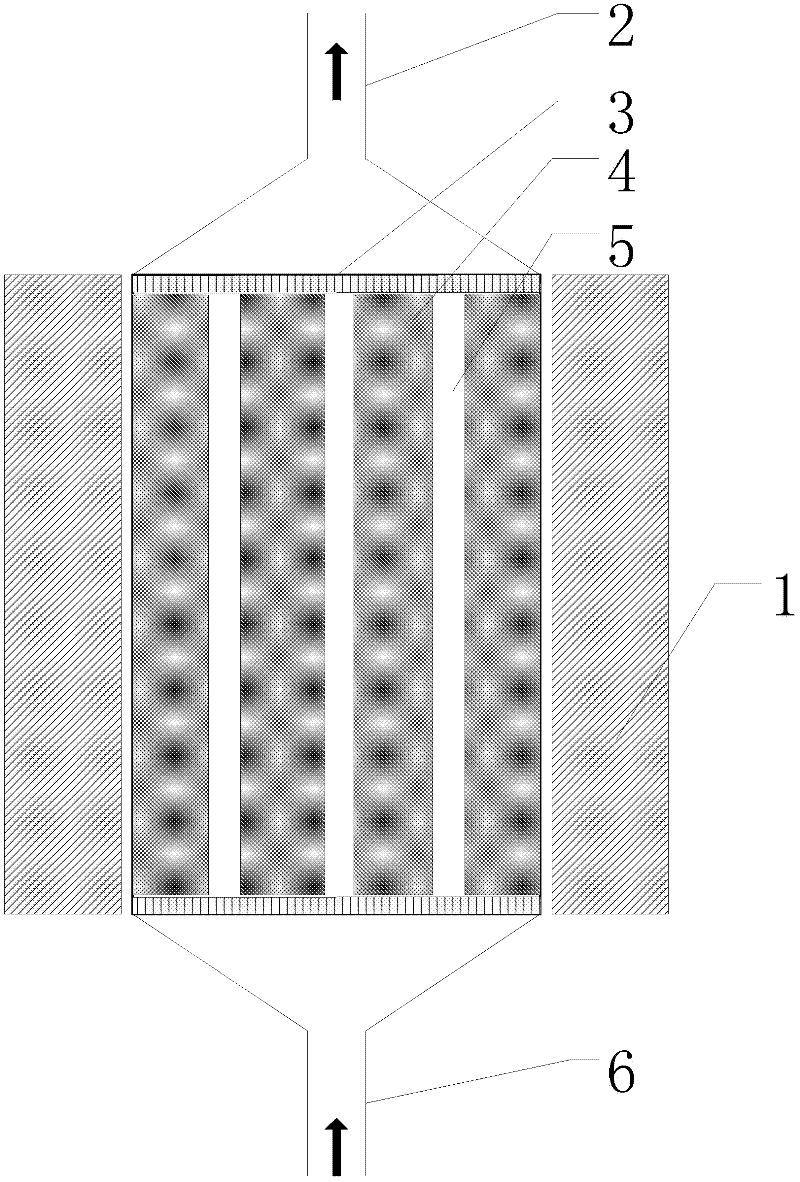

Pollution-free tube-bundle separation-type permanent-magnet separating device being suitable for separating superfine magnetic particles

InactiveCN102327810AIncrease the magnetic field strengthSimple structureHigh gradient magnetic separatorsRotational axisSteel wool

The invention relates to a pollution-free tube-bundle separation-type permanent-magnet separating device being suitable for separating superfine magnetic particles, which comprises a permanent-magnet magnetic field and a separating room, wherein a plurality of separating tubes are installed inside the separating room, and magnetic conduction media such as threadlike steel wool or steel emery are installed at the outer side of each separating tube. An annular permanent magnet is fixed on a rotating shaft at the outer side of the separating room. A C-shaped permanent magnet is adopted to produce high magnetic density and gradient, the magnetic field is applied to the periphery of the tube bundle through the filled magnetic conduction substances, and the fluid is separated from the magnetic conduction substances through the separating tubes so as to prevent the fluid from corroding and polluting the steel wool and the like. The device has a simple structure, is convenient to operate, is suitable for separating the magnetic carrier or catalyst from the fluid, and is particularly suitable for separating the weak magnetic superfine particles in the fluid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

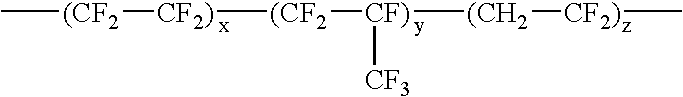

Durable antireflective film

Antireflective films are described having a surface layer comprising a the reaction product of a polymerizable low refractive index composition comprising at least one free-radically polymerizable fluoropolymer and surface modified inorganic nanoparticles. A high refractive index layer is coupled to the low refractive index layer. In one embodiment, the high refractive index layer comprises surface modified inorganic nanoparticles dispersed in a crosslinked organic material. The antireflective film is preferably durable, exhibiting a haze of less than 1.0% after 25 wipes with steel wool using a 3.2 cm mandrel and a mass of 1000 grams.

Owner:3M INNOVATIVE PROPERTIES CO

Old treatment method of antique furniture

InactiveCN105015259AImprove qualityIncrease valueNatural patternsWood working apparatusLacquerSteel wool

The invention relates to an old treatment method of antique furniture. The method comprises the steps of: (1) treatment of a basal material; (2) sanding treatment; (3) ground color spraying; (4) color fixation; (5) sanding again; (6) cloth printing; (7) primer spraying again; (8) fading of the furniture surface color through wiping the treated furniture surface by steel wools; (9) sanding again; (10) spot spraying; and (11) finish paint spraying. The method has the following beneficial effects: the method uses a basal material treatment process for forming tearing traces on the furniture surface to embody an antique style, and uses multiple times of sanding and painting treatments for enabling the antique furniture to present the layered old feeling and to achieve a vivid effect; and in the treatment process, the surface paint of the antique furniture is not liable to fall through multiple times of painting treatments, so that the style is kept for a long time, the furniture quality is improved, and the furniture value is enhanced.

Owner:GUANGHE BEIJING CULTURE CREATIVE CO LTD

Low temperature carbonization pre-oxygen thread car clutch sheet or brake sheet and production process thereof

InactiveCN101354068ALow costMeet the use requirementsOther chemical processesFriction liningCarbonizationOxygen

The invention relates to vehicle accessories, namely an automobile clutch disc and a brake block of low temperature carbonized and pre-oxidized wires and a production technique thereof. The friction material of the accessories is made from raw materials by weight percent as follows: 5 to 10 percent of low temperature carbonized and pre-oxidized wire, 15 to 18 percent of phenolic resin, 6 to 11 percent of rutile, 9 to 11 percent of chromite powder, 5 to 10 percent of manganese steel wool, 5 to 10 percent of aluminium oxide, 6 to 11 percent of red copper powder, 6 to 11 percent of wollastonite powder, 5 to 6 percent of feldspar powder, 6 to 11 percent of titanium dioxide, 8 to 13 percent of barium sulfate, 3 to 5 percent of quartz sand, 1 to 3 percent of graphite powder and 6 to 8 percent of graphite electrode powder. The production technology comprises steps of section-cutting of low temperature carbonized and pre-oxidized wire, material-mixing, ethanol-spraying, particle-producing, cold-model manufacturing, hot forming, hot processing and putting in a storage. The accessories have low cost and better mechanical property, friction performance and braking performance.

Owner:JIANGSU HONGFENG FRICTION GOODS

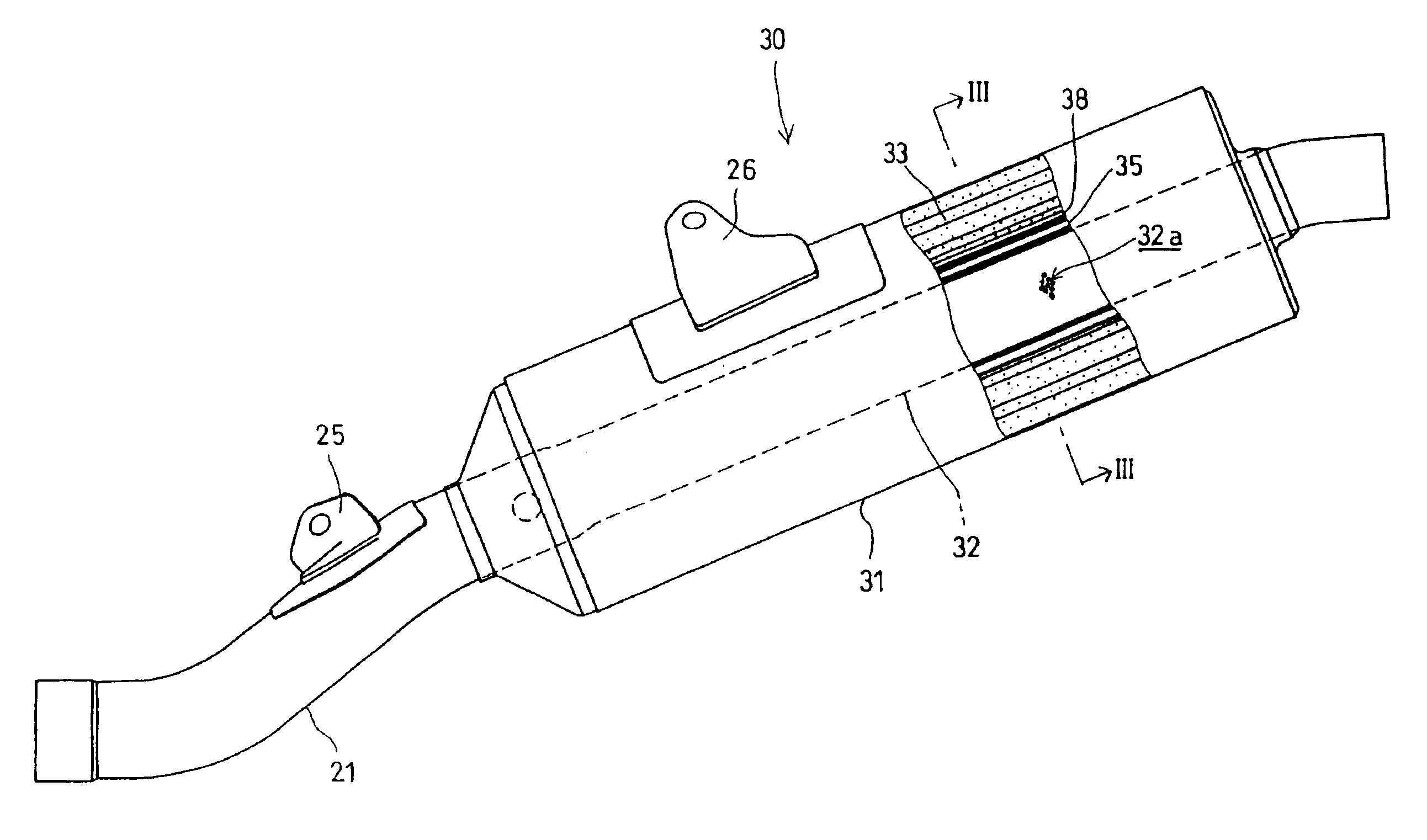

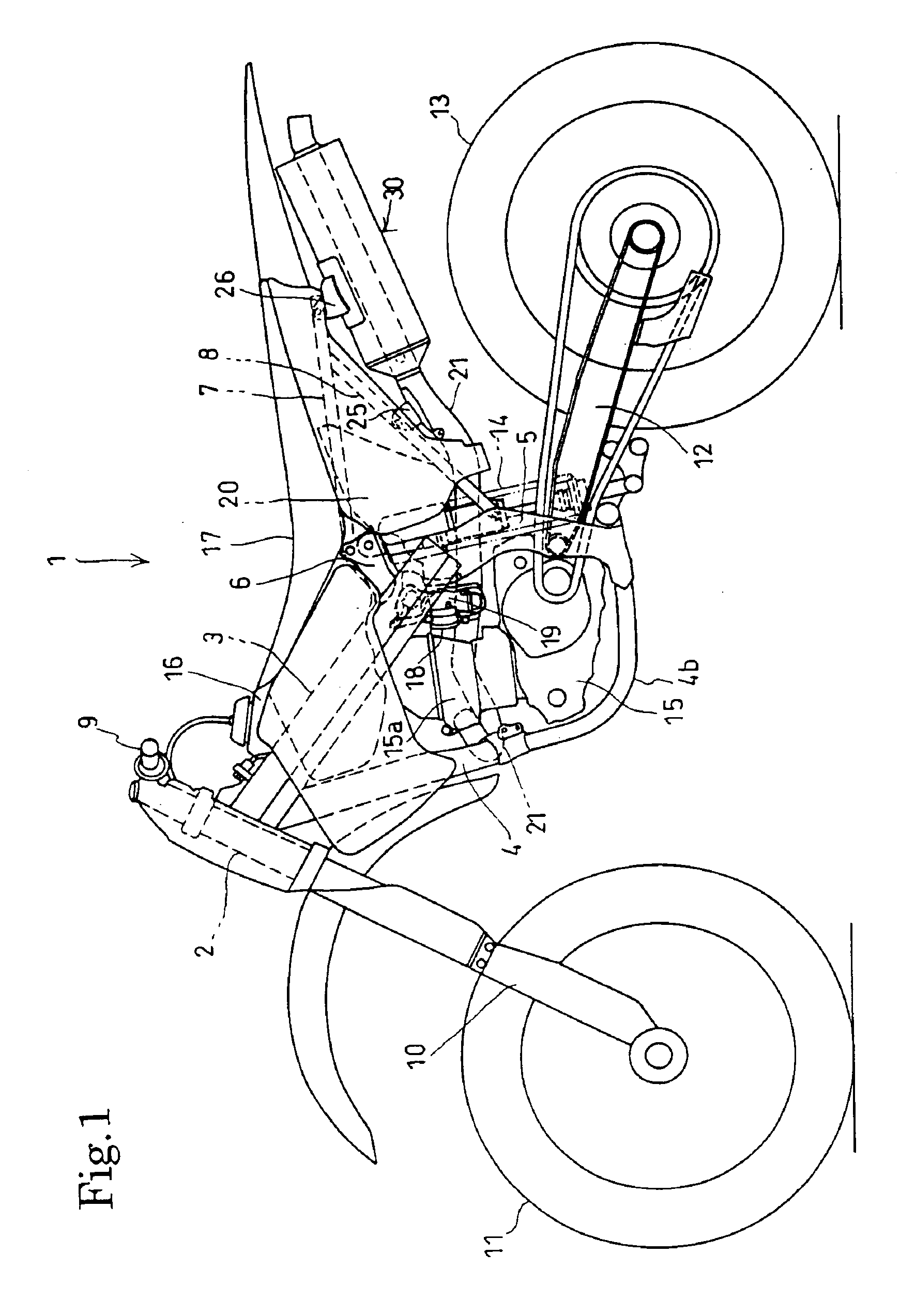

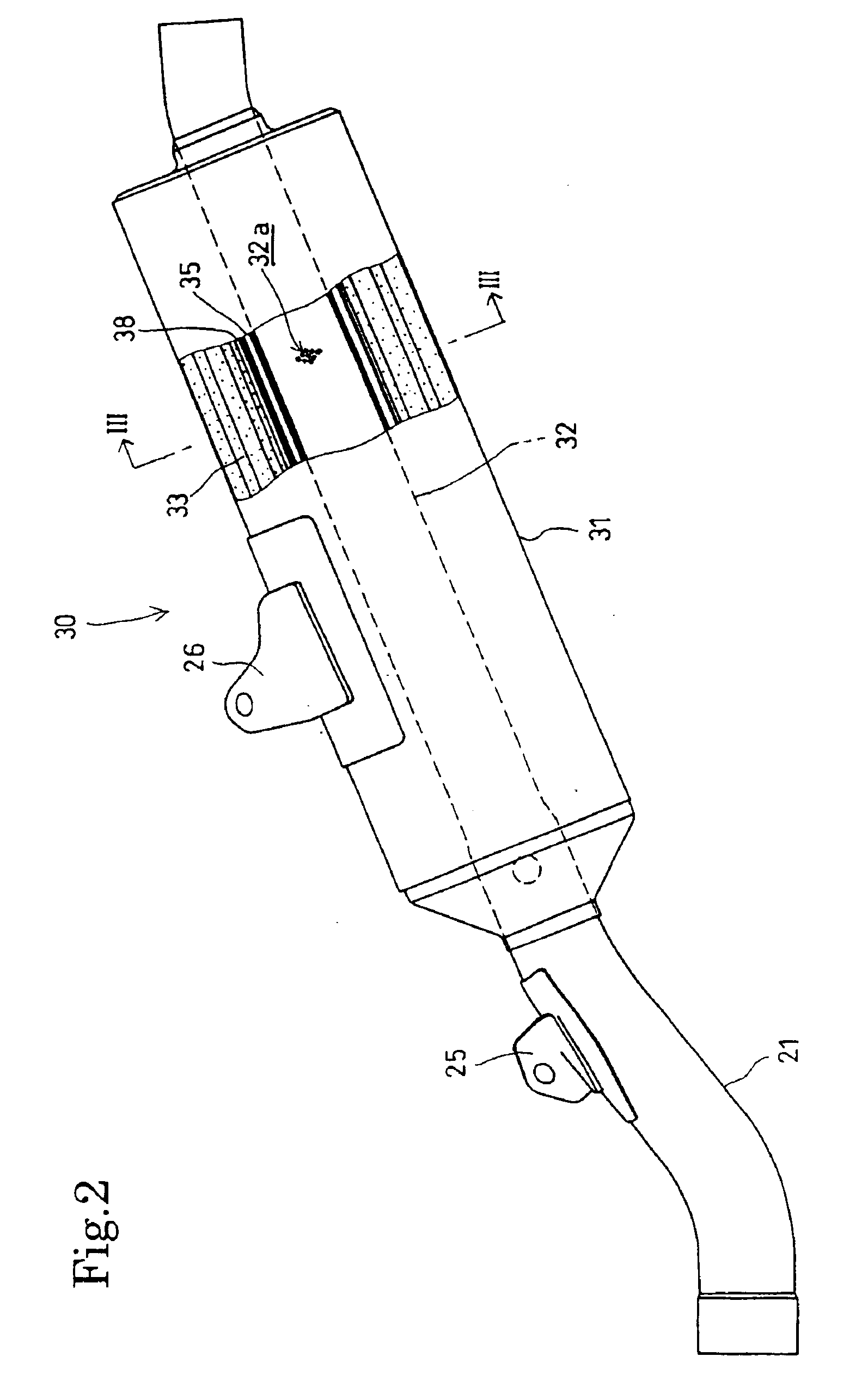

Exhaust muffler

An exhaust muffler for an internal combustion engine included in a motorcycle includes a perforated inner pipe (32), an outer pipe (31) coaxially surrounding the inner pipe (32), and a glass wool mat (33) packed in a space between the inner pipe (32) and the outer pipe (31). A three-layer protective structure is formed by winding an inner stainless steel wire mesh (34) wound around the inner pipe (32), winding a stainless steel wool mat (35) around the inner stainless steel wire mesh (934), and winding an outer stainless steel wire mesh (36) around the stainless steel wool mat (35). The glass wool mat (33) is wound around the three-layer structure. The three-layer structure extends the life of the glass wool mat (33) even if the temperature and pressure of the exhaust gas discharged by the internal combustion engine increase.

Owner:HONDA MOTOR CO LTD +1

Oil-resistant anti-aging rubber cable material

InactiveCN105949547AImprove reinforcement effectImprove the reinforcing effect and improve the chemical stability of rubberRubber insulatorsFiberButadiene-styrene rubber

The invention discloses an oil-resistant anti-aging rubber cable material which is prepared from the raw materials including, by weight, 3-4 parts of vinyl phenyl silicone oil, 5-7 parts of chlorosulfonated polyethylene powder, 4-5 parts of sulfur, 2-3 parts of palm wax, 7-9 parts of steel wool fiber, 16-20 parts of fluoro-rubber, 12-14 parts of barite powder, 7-9 parts of carbon black, 2-3 parts of ascorbyl palmitate, 2-3 parts of emulsified methyl silicone oil, 0.5-1 part of triphenyl phosphate, 45-56 parts of styrene-butadiene rubber, 55-60 parts of chloroprene rubber, 55-70 parts of natural rubber, 30-40 parts of hollow glass micro beads, 3-5 parts of polytetrafluoroethylene, 1-1.3 parts of a silane coupling agent kh550, 12-16 parts of epoxy resin E44, 0.06-0.1 parts of diethylene triamine, 0.1-0.2 parts of an accelerator M, 2.6-3 parts of a silane coupling agent kh570, and a proper amount of distilled water. The cable material is excellent in mechanical performance, is not liable to cause circuit fault and is valuable to promote.

Owner:ANHUI CABLE

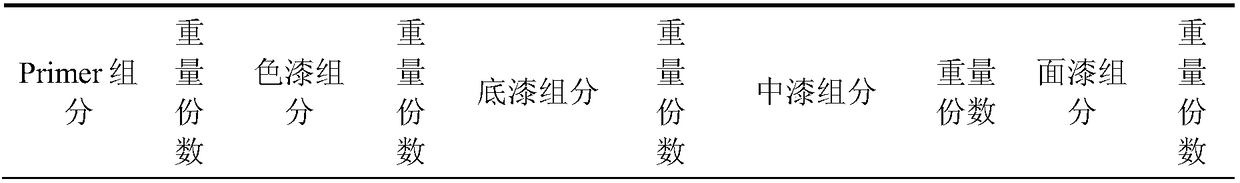

Plating coating system, and metal piece product with imitation ceramic effect

ActiveCN108276900AHigh hardnessImprove boiling resistancePolyurea/polyurethane coatingsPolyester coatingsAcrylic resinCoating system

The invention discloses a plating coating system, and a metal piece product with an imitation ceramic effect. The plating coating system comprises a UV (Ultraviolet) primer, and a UV intermediate coatand a UV finishing coat coated on a coating layer, wherein the UV primer is prepared from the following components in parts by mass: 10 to 20 parts of bifunctional aliphatic polyurethane acrylic resin, 10 to 15 parts of trifunctional aliphatic polyurethane acrylic resin, 10 to 15 parts of six-functional aliphatic polyurethane acrylic resin, 10 to 15 parts of trifunctional acrylate monomer, 2 to 5parts of photoinitiator, 35 to 60 parts of diluent, and 0.01 to 0.5 part of accessory ingredient; the coating layer is made of one or two of titanium and silicon. The metal piece product with the imitation ceramic effect is good in appearance texture effect and good in adhesive force, and has effects on resisting water boiling and steel wool.

Owner:HUNAN SOKAN NEW MATERIAL

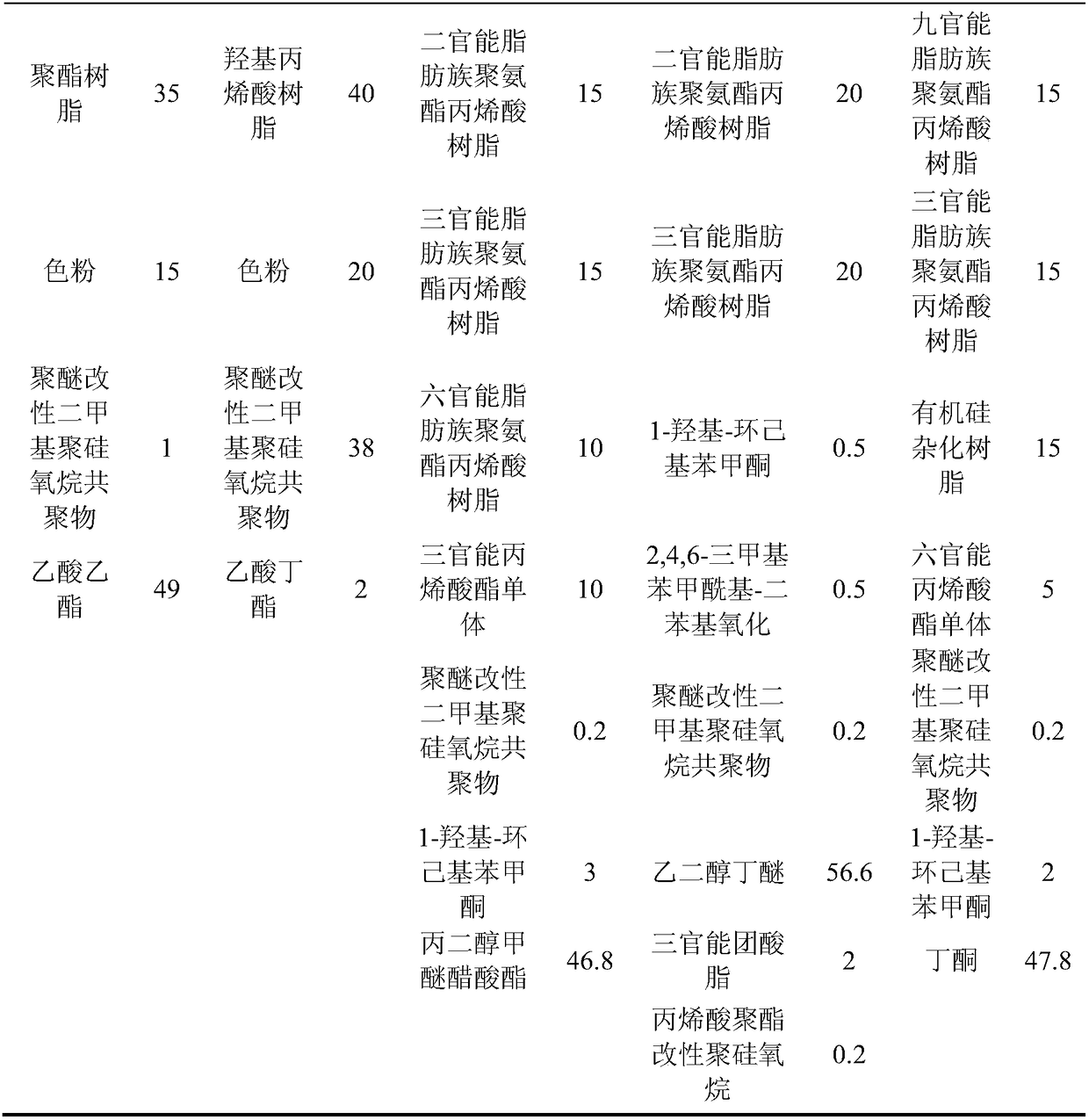

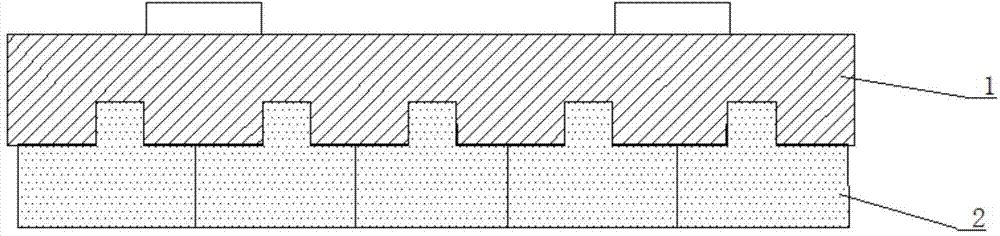

Yaw brake pad made of various materials

ActiveCN103591196ANormal braking performanceHigh hardnessWind motor controlMachines/enginesFiberPotassium

The invention discloses a yaw brake pad made of various materials. The yaw brake pad is composed of a steel back (1) and a friction layer (2), and the friction layer (2) is formed by sequentially arranging a heat-resistant layer (21), a friction-resistant layer (22) and a denoising protection layer (23) from inside to outside. The heat-resistant layer (21) contains boron-modified phenolic resin and vanadium trioxide, so that hardness, heat resistance and instant high temperature resistance of the friction layer are improved; the friction-resistant layer (22) contains steel wool fibers, quartz sand and potassium hexatitanate, so that friction coefficient and friction resistance of the friction layer are improved; the denoising protection layer (23) contains materials, large in nonmetal content, like flake graphite, molybdenum disulfide and antimony sulfide, so that the yaw brake pad is low in noise during working, and noise inside the yaw brake pad can be shielded. Friction performance, friction resistance and denoising effect of the yaw brake pad are obviously improved, service life of the yaw brake pad is longer than that of a common yaw brake pad, and the only defect of the yaw brake pad is that contact parts are worn slightly.

Owner:贵州新安航空机械有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com