Ultraviolet curing coating composition with high wear resistance and fingerprint resistance and preparation method thereof

A curing coating, anti-fingerprint technology, used in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor friction resistance, improve surface smoothness, excellent wear resistance, and improve resistance to friction. The effect of grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

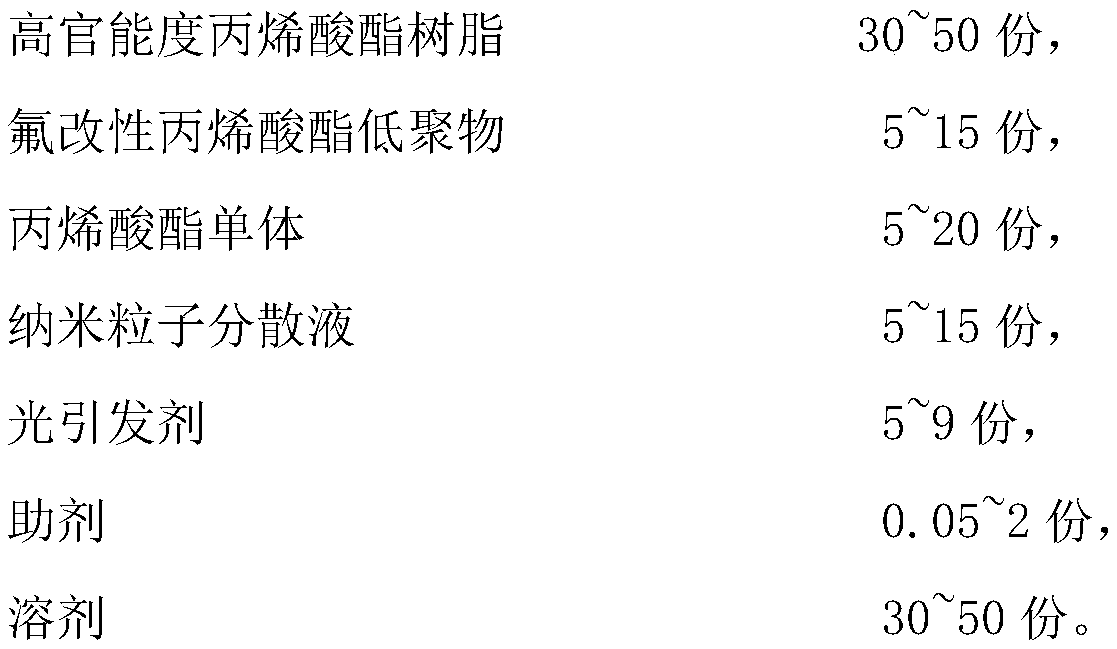

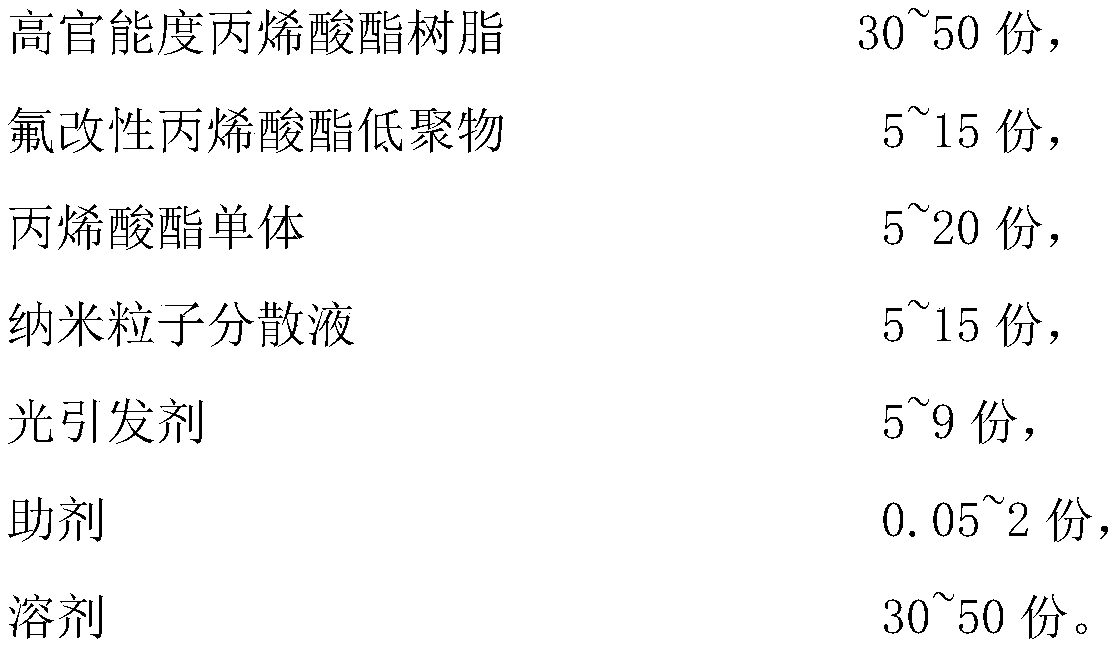

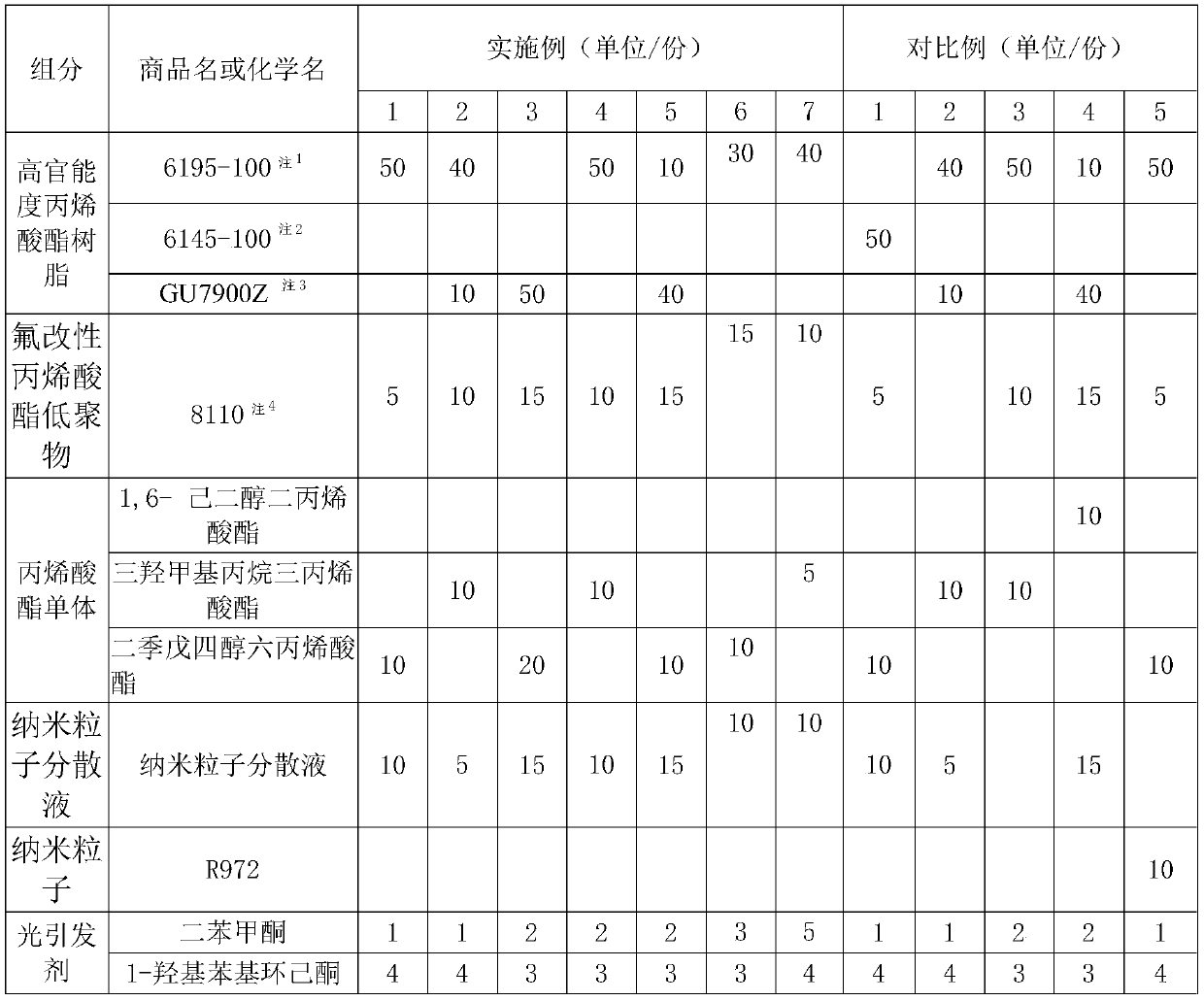

[0034] Examples 1-5 respectively provide a high wear-resistant, anti-fingerprint UV-curable coating composition, the components and contents of which are shown in Table 1.

[0035] The mixed solvent shown is a mixed solvent of butyl acetate, n-propyl acetate, isopropanol, and propylene glycol methyl ether with a mass ratio of 2:3:3:1.

[0036] The preparation method of described coating composition comprises the steps:

[0037] A. Place the high-functionality acrylate resin, fluorine-modified acrylate oligomer, acrylate monomer, nanoparticle dispersion, and solvent in a reaction kettle, stir and mix evenly;

[0038] B, add described photoinitiator, stir until dissolving completely;

[0039] C. Add the auxiliary agent and stir until it is uniformly dispersed to obtain the high wear-resistant and anti-fingerprint UV-curable coating composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com