Patents

Literature

58results about How to "Prevent phase separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

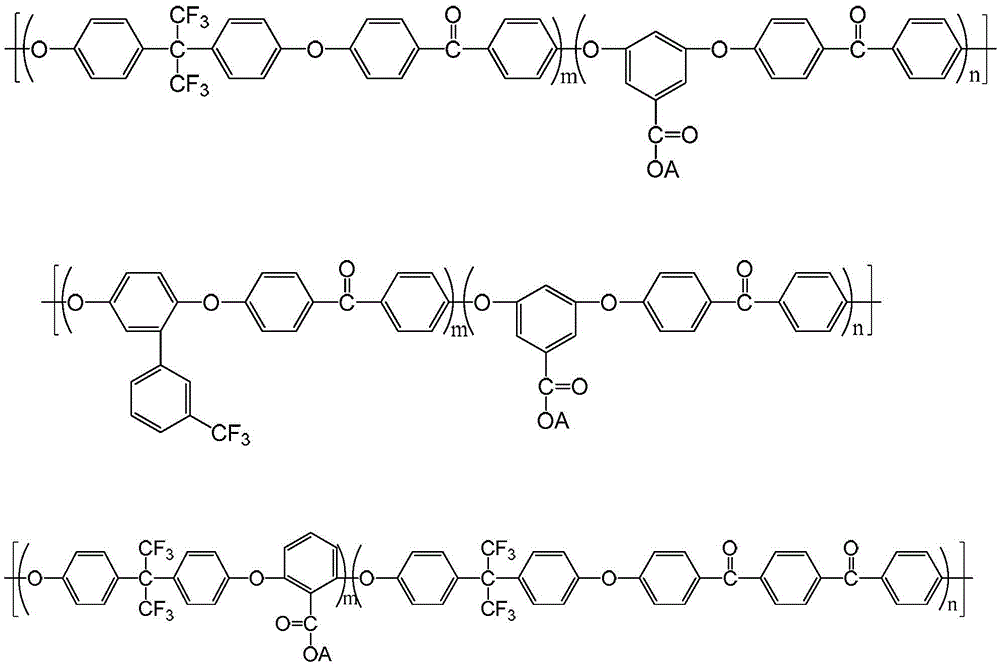

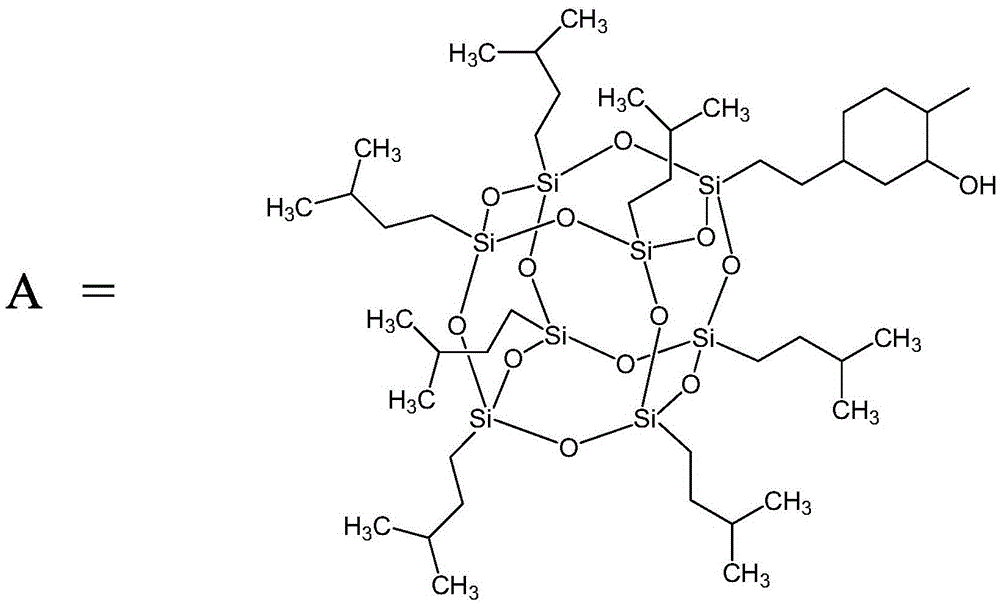

PEAK (polyaryletherketone) polymer with POSS (polysilsesquioxane) structure and preparation method

The invention relates to a PEAK (polyaryletherketone) polymer with a POSS (polysilsesquioxane) structure and a preparation method and belongs to the field of high polymer materials. The PEAK polymer containing carboxyl and fluorine is prepared by introducing a carboxyl structure into a fluorine-containing PEAK main chain structure through nucleophilic substitution. The polymer has excellent heat stability, good dissolving property and lower dielectric constant. Further, POSS containing hydroxyl functional groups is grafted to a fluorine-containing PEAK side chain structure through Friedel Crafts acylation reaction, so that characteristics of POSS and fluorine-containing PEAK are organically combined, the dielectric constant of a material is further reduced, the heat resistance of the material is improved, and different using requirement are met.

Owner:吉林省聚科高新材料有限公司

Low-temperature co-fired ceramic material highly matched with high-temperature conductive silver paste and preparation method of low-temperature co-fired ceramic material

The invention discloses a low-temperature co-fired ceramic material highly matched with high-temperature conductive silver paste and a preparation method of the low-temperature co-fired ceramic material. The low-temperature co-fired ceramic material is prepared by sintering the following components in percentage by mass (100% in total): 35%-50% of CaO, 30%-45% of B2O3 and 15%-25% of SiO2. The prepared low-temperature co-fired ceramic material contains a large quantity of microfine crystal grains (CaSiO3) and a small amount of glass and is typical microcrystalline glass ceramic; and the low-temperature co-fired ceramic material is low in dielectric constant and extremely low in loss, good in matching rate with high-temperature conductive silver paste, good in panel flatness and good in comprehensive property, and the dielectric constant and the loss in multiple frequency bands are stable.

Owner:昆明云基新材料有限公司

Anion-exchange membrane and preparation method thereof

ActiveCN102580572AImprove stabilityPrevent phase separationSemi-permeable membranesAnion exchangersCross-linkPolymer science

The invention discloses an anion-exchange membrane and a preparation method thereof. The preparation method comprises the following steps of: mixing a macromolecular reinforcing agent, a polymerizing monomer, an initiator and a cross-linking agent to obtain a casting solution; sequentially coating and heating the casting solution to form a macromolecular copolymer; and then carrying out quaterisation treatment to obtain the anion-exchange membrane. According to the invention, the cross-linking agent containing multifunctional groups is added to the preparation process of the anion-exchange membrane; benzyl chloride groups in the macromolecular copolymer, formed by polymerizing monomers, and amino groups contained in the cross-linking agent are nucleophilically substituted, and meanwhile, cardo in the macromolecular reinforcing agent and primary amine groups contained in the cross-linking agent are lactamized, so that the macromolecular reinforcing agent and the macromolecular copolymer are cross-linked by using the cross-linking agent, the phase-splitting between the macromolecular copolymer and the macromolecular reinforcing agent is avoided, and the stability of the membrane is improved. Meanwhile, the method can be used for avoiding use of an organic solvent and has remarkable economic and environmental benefits.

Owner:UNIV OF SCI & TECH OF CHINA

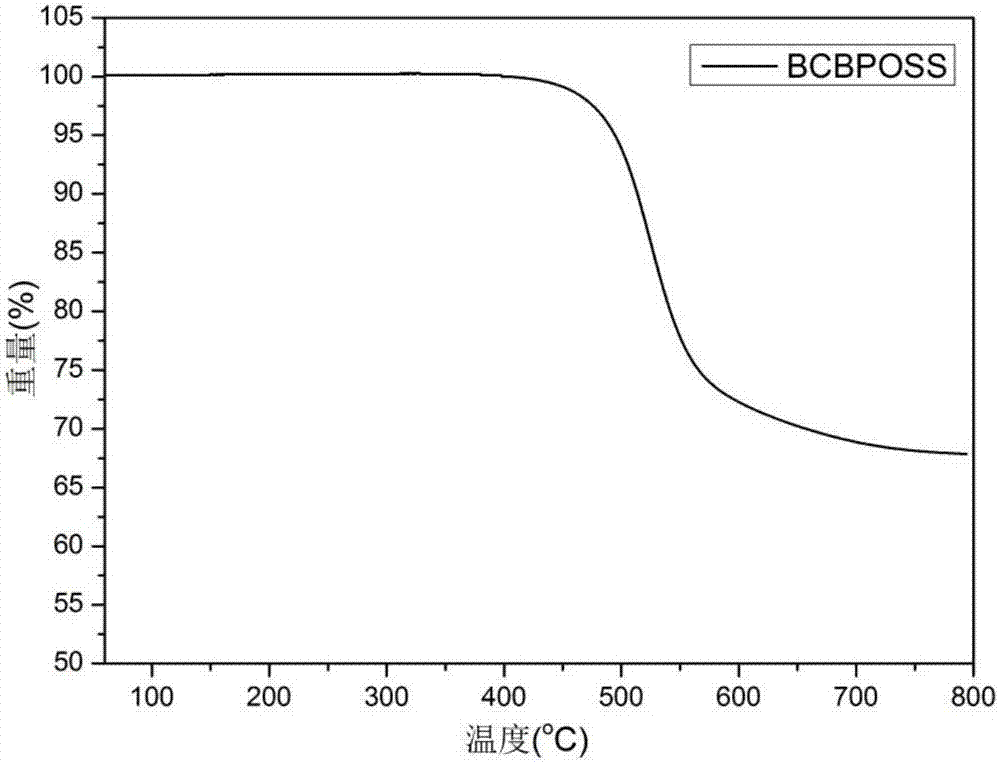

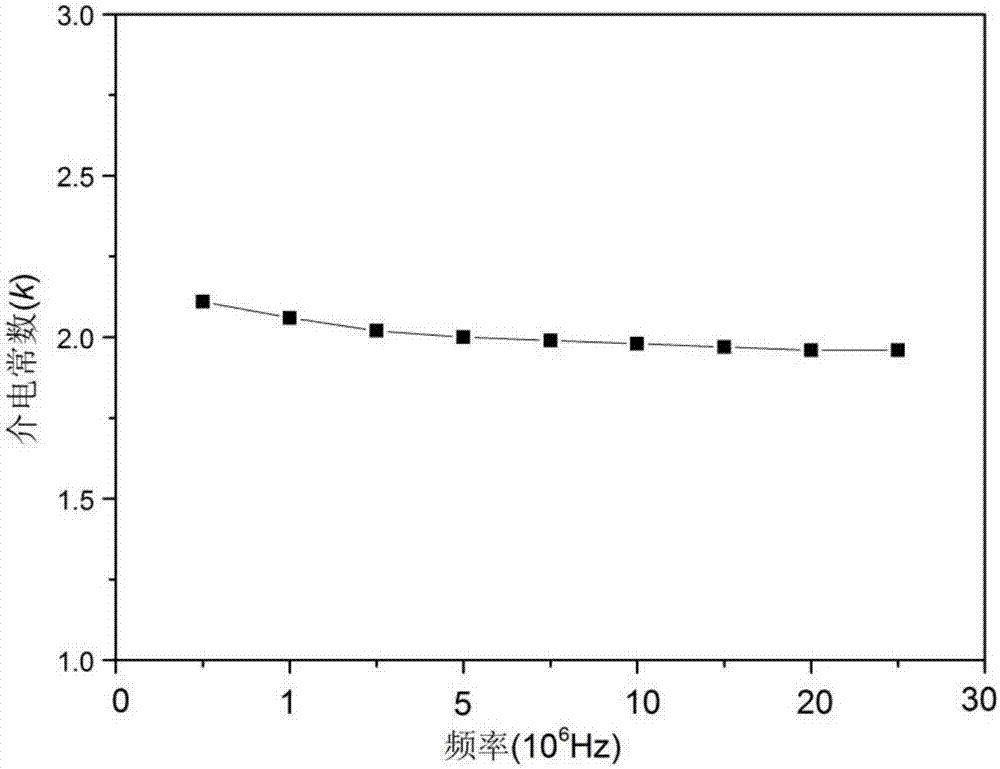

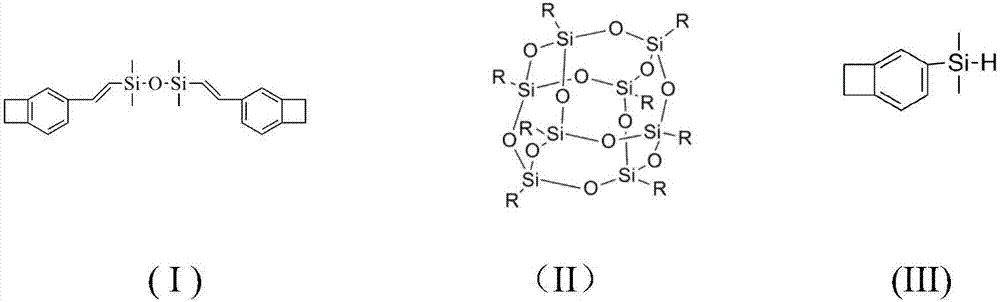

Preparation methods of benzocyclobutene functionalized cage type polysilsesquioxane (POSS) and resins of benzocyclobutene functionalized cage type polysilsesquioxane

InactiveCN107325287AImprove thermal stabilityLow dielectric propertiesCoatingsChemistryAddition reaction

The invention discloses preparation methods of benzocyclobutene functionalized cage type polysilsesquioxane (POSS), shown in a formula (IV), and resins of the benzocyclobutene functionalized cage type POSS. The preparation method of the benzocyclobutene functionalized cage type POSS comprises the steps of adding a toluene solution of OVPOSS and 4-(1,1-dimethyl-1-hydrogen)silicon-base benzocyclobutene into a reactor, replenishing the reactor with nitrogen for protecting, adding a tetrahydrofuran solution of chloroplatinic acid, carrying out a reaction at the temperature of 60-90 DEG C, separating and purifying the materials obtained after the reaction is finished so as to obtain the benzocyclobutene functionalized cage type POSS. The benzocyclobutene functionalized cage type POSS can be further prepared into body polymers or solution polymers, and can be added into matrix resins so as to form nano composite materials. According to the preparation methods, the POSS is cleverly introduced into the benzocyclobutene resin by means of a simple and efficient hydrosilylation reaction. The resins prepared by the methods provided by the invention have excellent heat stability, mechanical properties and electrical properties, thus being suitable for being used as interlayer dielectric films or packaging materials in the fields such as micro-electronics industry and national defense aerospace. The formula (IV) is described in the description.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Natural fiber/thermosetting polylactic acid composite material and preparation method thereof

InactiveCN103073863APrevent phase separationImprove long-term stabilityPolymer scienceEngineering plastic

The invention belongs to the technical field of a high molecular material and particularly relates to a natural fiber / thermosetting polylactic acid composite material and a preparation method thereof. The material is formed by natural fibers and thermosetting polylactic acid. The specific preparation method comprises the following steps of: carrying out surface treatment on the natural fibers and uniformly dispersing into a star-shaped polylactic acid melt modified by an unsaturated anhydride terminal group; and initiating a polymerization reaction by radiation or thermally initiating the polymerization reaction by a free radical initiator to carry out cross-linking and curing to obtain the natural fiber / thermosetting polylactic acid composite material. Compared with the pure polylactic acid, the mechanical property and the heat stability of the composite material are greatly improved; and the composite material can be used for preparing engineering plastic with demanding requirements. After being abandoned, the composite material disclosed by the invention can be completely degraded in a natural environment, belongs to an environment-friendly material and has a wide application prospect.

Owner:TONGJI UNIV

Inorganic phase-change energy-storage material and preparation method thereof

ActiveCN106047302AImprove thermal conductivityFast heat conductionHeat-exchange elementsWater storagePhase change

The invention discloses an inorganic phase-change energy-storage material. The energy-storage material is prepared form 94-97 parts of energy-storage basis materials, 0.2-1.0 part of functional additive, 2.0-3.5 parts of nucleating agent and 0.8-1.5 parts of surfactant. The inorganic phase-change energy-storage material is stable in performance, low in price, rich in raw material, convenient to prepare, large in latent heat of phase change, nontoxic and high in heat conductivity, and the inorganic phase-change energy-storage material can be widely applied to multiple fields such as a solar low-temperature heat-storage system and a household daily heat preservation and household hot water storage system.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

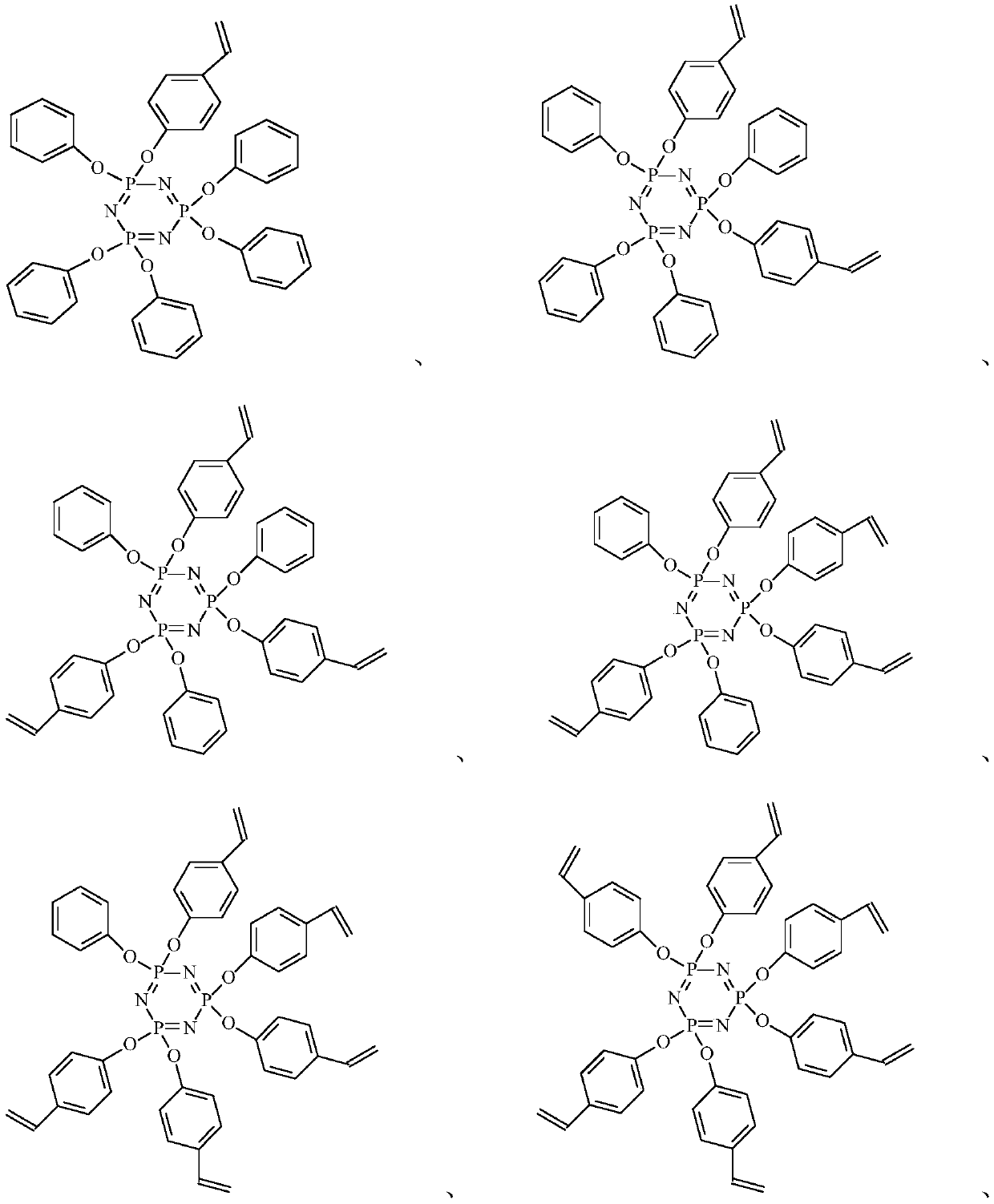

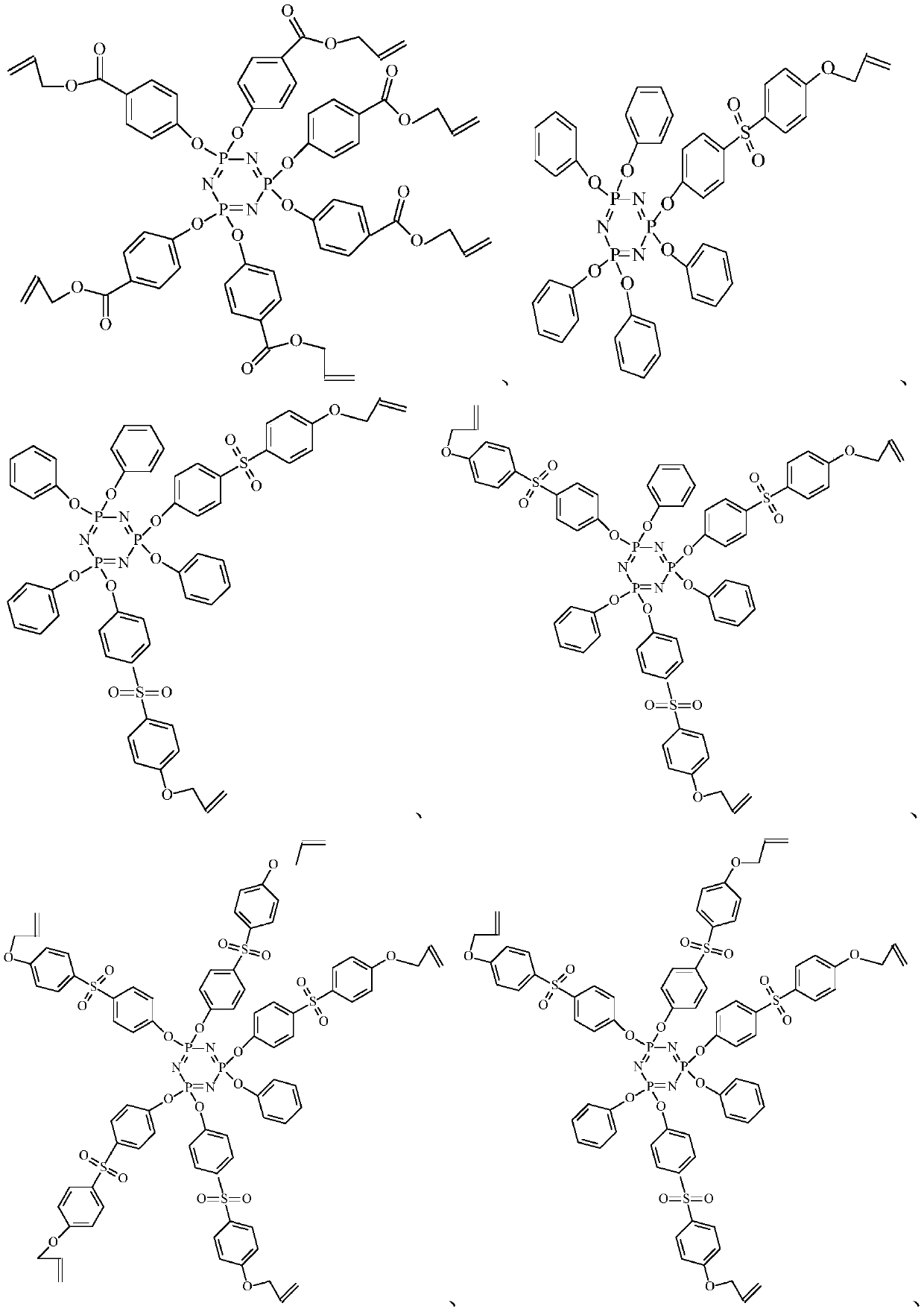

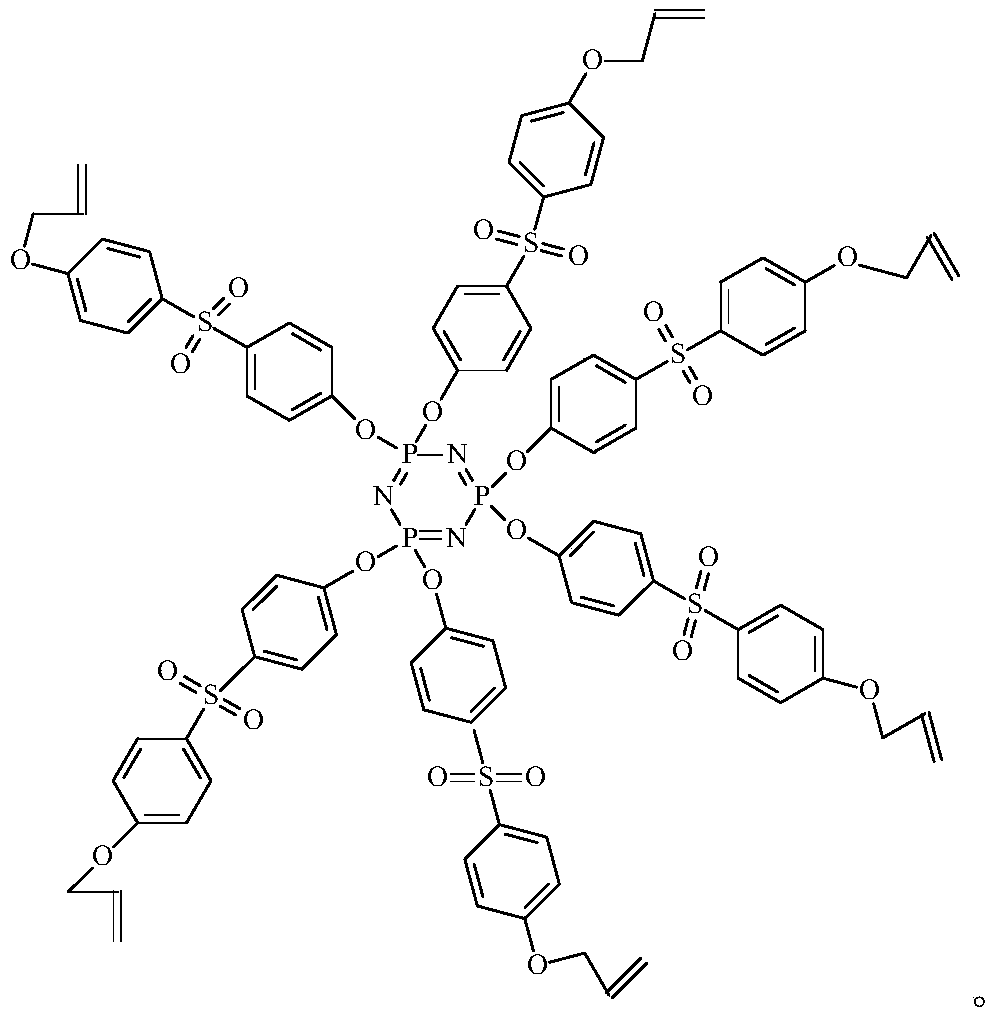

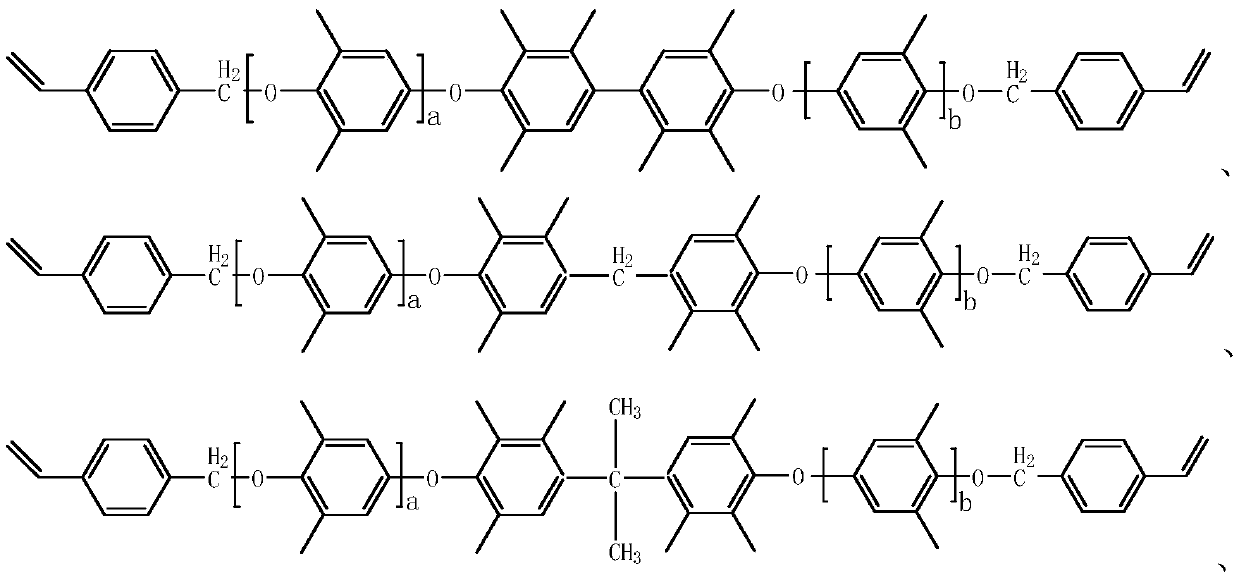

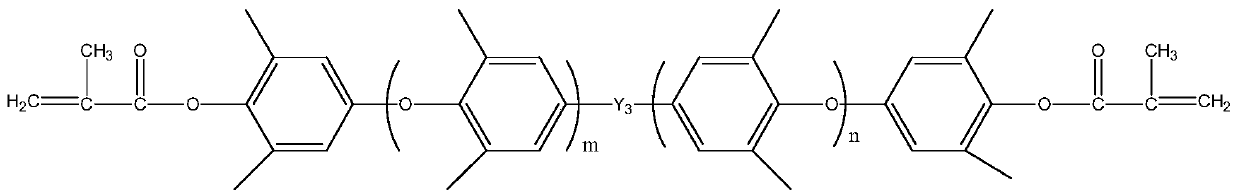

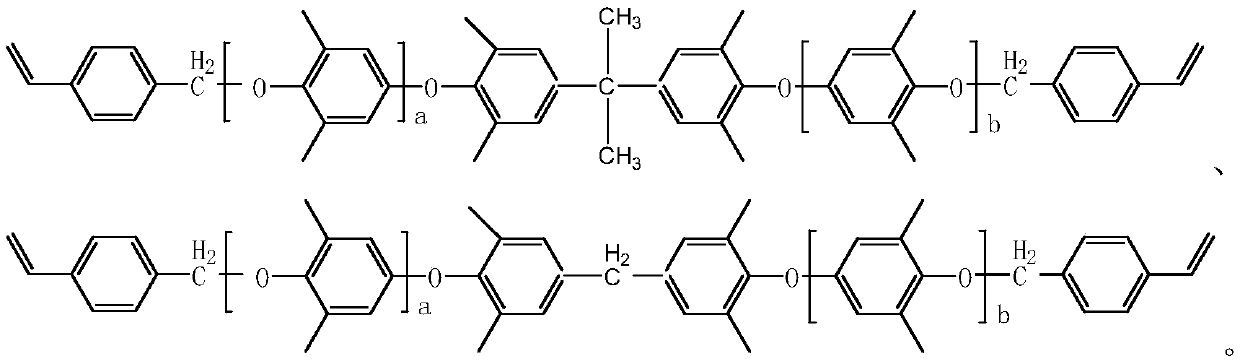

Halogen-free polyphenyl ether resin composition, and prepreg and laminated board prepared from halogen-free polyphenyl ether resin composition

ActiveCN110527037AHomogeneous compatibilityLow dielectric constantSynthetic resin layered productsMetal layered productsCross-linkDielectric loss

The invention discloses a halogen-free polyphenyl ether resin composition. The composition comprises the following components: (a) 100 parts of polyphenyl ether resin containing carbon-carbon unsaturated bonds; (b) 5-60 parts of a phosphorus-containing compound containing carbon-carbon unsaturated bonds; and (c) 0-10 parts of an initiator. According to the invention, the phosphorus-containing compound containing carbon-carbon unsaturated bonds is used as a cross-linking agent for polyphenyl ether and a compound containing carbon-carbon unsaturated bonds, so that the polyphenyl ether and the compound containing carbon-carbon unsaturated bonds can be well and uniformly compounded together, and a lower dielectric constant and a lower dielectric loss value are obtained. Experimental data proves that the resin composition and the laminated board prepared from the resin composition can meet requirements of current 5G products.

Owner:SHENGYI TECH SUZHOU

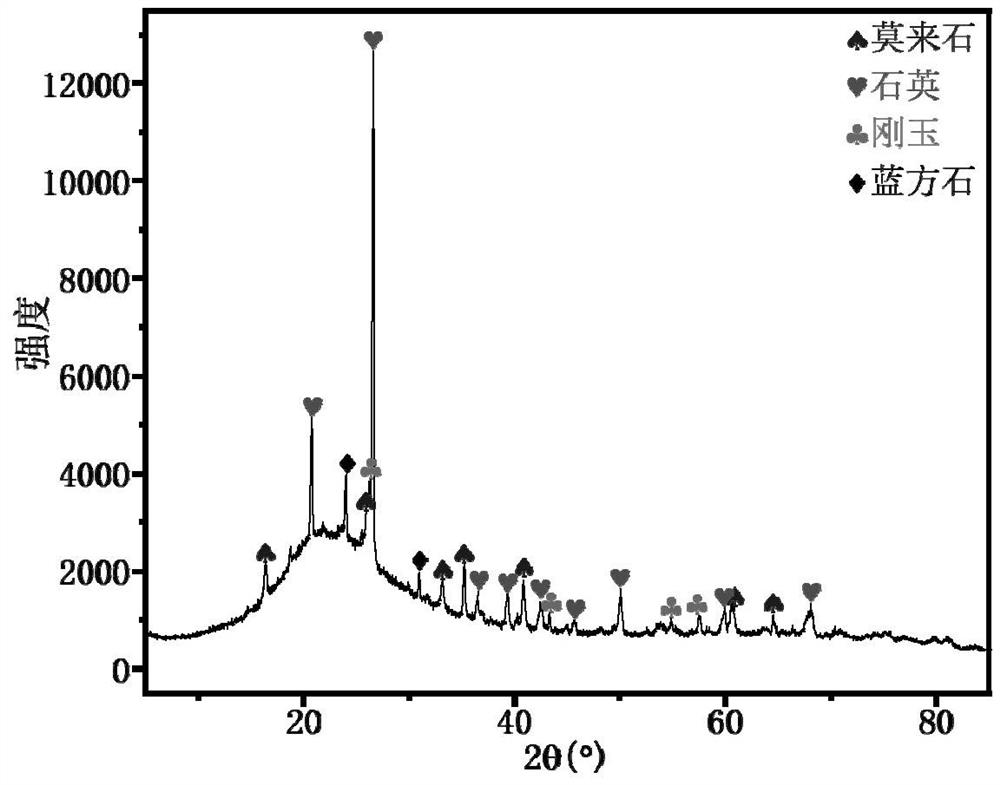

Mutton fat jade ceramic tile and preparation method thereof

ActiveCN111995382AGood light transmissionHigh light transmittanceCeramic materials productionKaolin clayPotassium feldspar

The invention discloses a mutton fat jade ceramic tile and a preparation method thereof. The preparation method comprises the following steps that a mutton fat jade green body is prepared, and mineralcompositions of the mutton fat jade green body comprise, by mass, 42.0%-50.0% of light-transmitting potassium feldspar, 37.0%-43.0% of acicular light-transmitting kaolin and 7.0%-21.0% of fused quartz sand; a design pattern is printed on the mutton fat jade green body in an ink-jet mode; and a mutton fat jade protective glaze is applied to the mutton fat jade green body subjected to ink-jet printing of the designed pattern, and firing is conducted to obtain the mutton fat jade ceramic tile. The mineral composition of the mutton fat jade protective glaze includes the following components in percentage by mass: 35.0 to 45.0 percent of light-transmitting potassium feldspar, 20.0 to 30.0 percent of acicular light-transmitting kaolin, 12.0 to 18.0 percent of fused quartz, 4.0 to 6.0 percent ofcorundum, 6.0 to 8.0 percent of barium carbonate and 1.0 to 3.0 percent of zinc oxide.

Owner:MONALISA GRP CO LTD

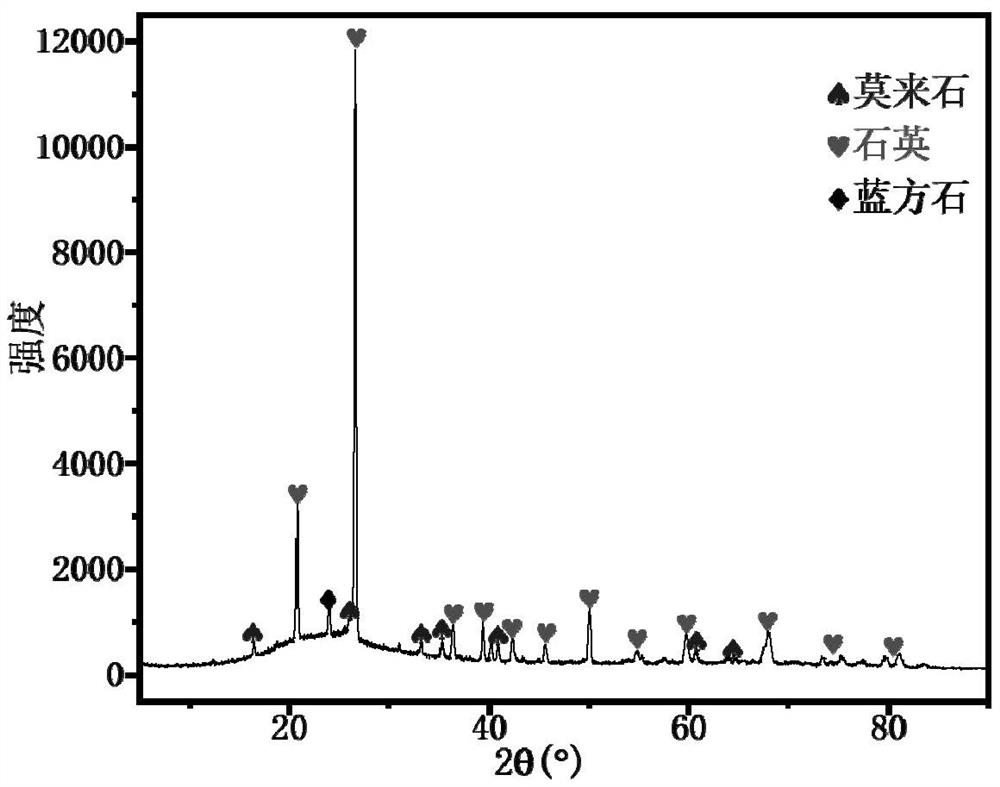

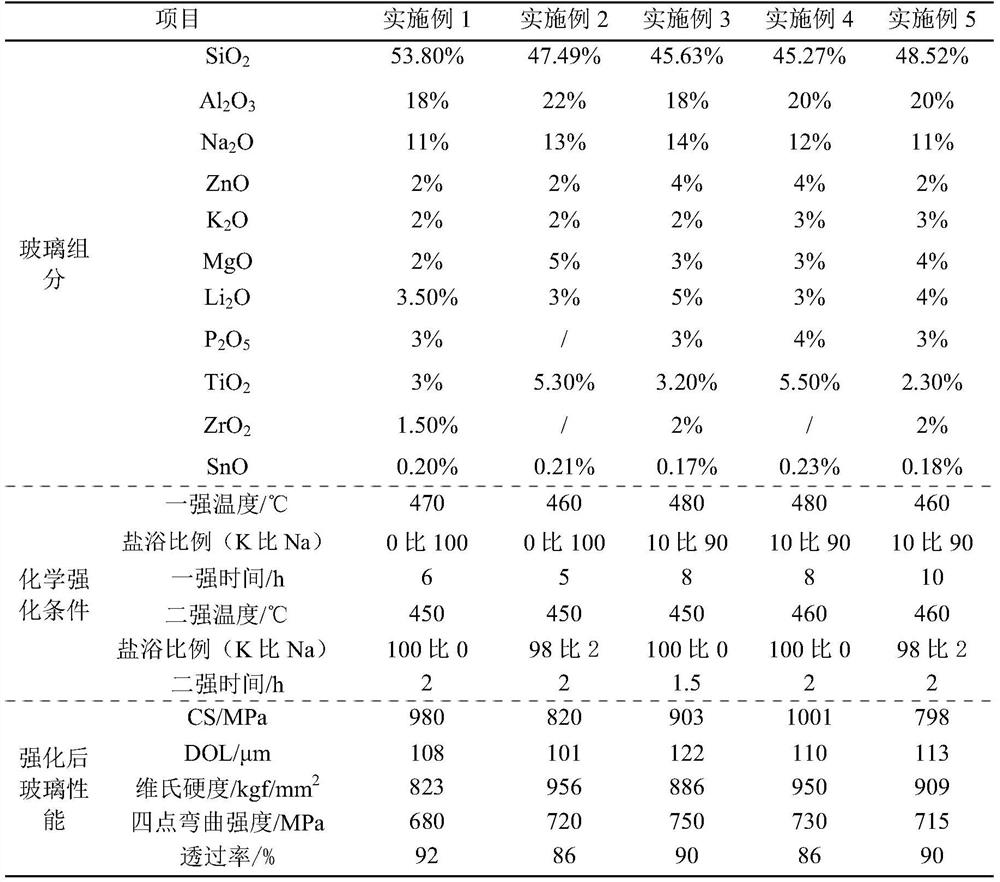

Lithium-aluminum-silicon microcrystalline glass as well as strengthening method and application thereof

InactiveCN112919813AGood chemical stabilityModerate melting temperatureGlass tempering apparatusTelephone set constructionsPotassium nitrateIon exchange

The invention discloses lithium-aluminum-silicon microcrystalline glass as well as a strengthening method and application thereof. The glass comprises the following components in percentage by mass: 45%-75% of SiO2, 10%-25% of Al2O3, 0-4% of ZrO2, 3%-5% of Li2O, 10%-18% of Na2O, 0-5% of K2O, 0-6% of P2O5, 0-7% of TiO2, 2%-7% of MgO, 0-10% of ZnO and 0-1% of SnO. The strengthening method comprises the following steps: preparing raw materials, and performing melting and molding to obtain mother glass; carrying out heat treatment to obtain microcrystalline glass; carrying out ion exchange on the microcrystalline glass in molten salt at the temperature of 390-500 DEG C for 3-10 hours to obtain primarily strengthened microcrystalline glass; and finally, soaking the glass ceramic subjected to primary strengthening in molten salt consisting of potassium nitrate and sodium nitrate for 1-2.5 hours to obtain the lithium-aluminum-silicon glass ceramic.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

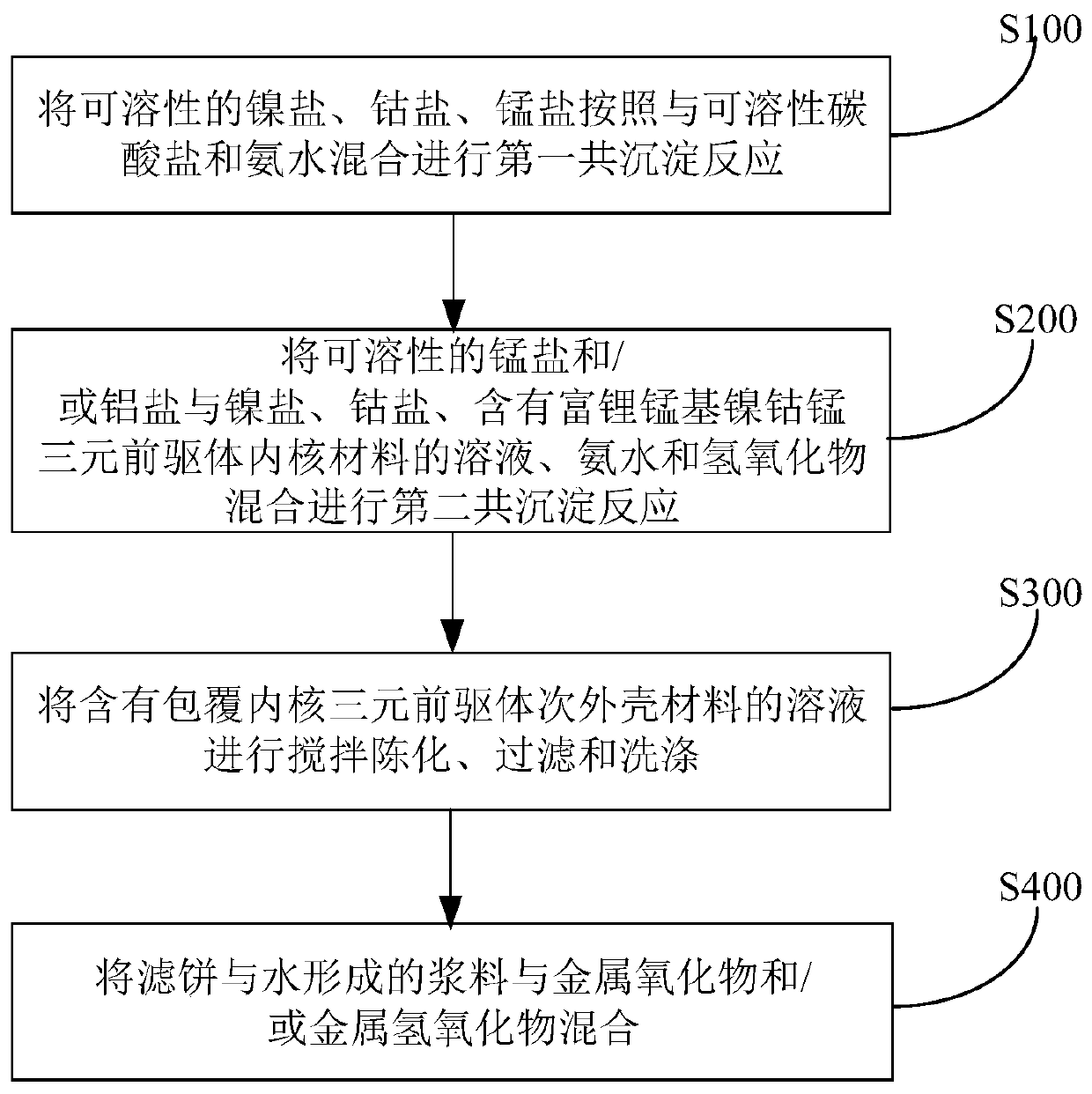

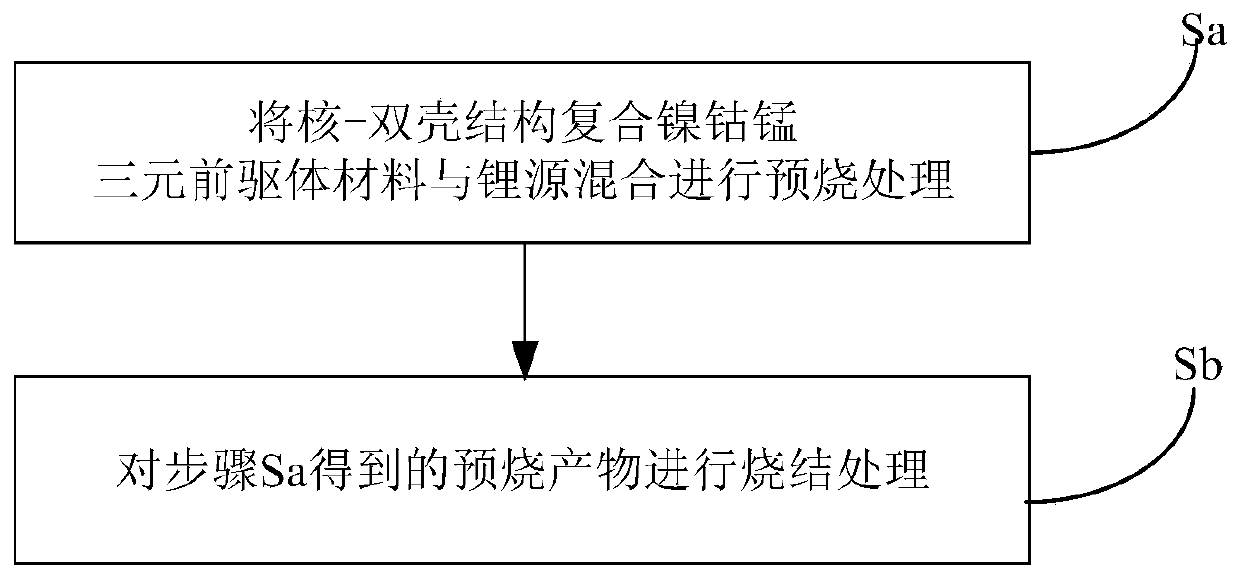

Core-double-shell structure composite nickel-cobalt-manganese ternary precursor material and preparation method and application thereof

ActiveCN111092205AInhibition of irreversible phase transitionsIncrease specific energyCell electrodesLi-accumulatorsElectrical batteryManganese

The invention discloses a core-double shell structure composite nickel-cobalt-manganese ternary precursor material and a preparation method and an application thereof. The core-double shell structurecomposite nickel-cobalt-manganese ternary precursor material comprises an inner core, a secondary shell layer and an outermost shell layer, wherein a chemical formula of the inner core material is Nix1Coy1Mn(1-x1-y1)CO3, x1 is greater than 0 and less than 1, y1 is greater than 0 and less than 1, and 1-x1-y1 is greater than 0 and less than 1, at least one part of an outer surface of the inner coreis coated with the secondary shell layer, a chemical formula of a material of the secondary shell layer is Nix2Coy2M(1-x2-y2)(OH)2, M is Mn and / or Al, x2 is larger than 0 and smaller than 1, y2 is larger than 0 and smaller than 1, and 1-x2-y2 is larger than 0 and smaller than 1, an outermost shell layer coats at least one part of an outer surface of the secondary shell layer and is made of metal hydroxide and / or metal oxide. The material is advantaged in that the single battery prepared from a positive electrode material prepared from the core-double shell structure composite nickel-cobalt-manganese ternary precursor material can realize long cycle life on the basis of high specific energy, so a vehicle loaded with the battery has excellent cruising ability, and use requirements of consumers are met.

Owner:中冶瑞木新能源科技有限公司

Outlet rubber mouth of air conditioner motor

InactiveCN105418989AImprove insulation performancePromote recoveryCarbon blackButadiene-styrene rubber

The invention discloses an outlet rubber mouth of an air conditioner motor. The outlet rubber mouth comprises the following raw materials in parts by weight: 1.5-2.5 parts of sulfur powder, 60-80 parts of natural rubber, 20-40 parts of styrene butadiene rubber, 10-30 parts of carbon black, 10-30 parts of white carbon black, 1-5 parts of coupling agent, 80-150 parts of magnesium hydroxide, 15-35 parts of chlorinated paraffin, 30-50 parts of naphthenic oil, 0.5-2 parts of microcrystalline wax, 5-8 parts of zinc oxide, 1-1.5 parts of stearic acid, 0.3-0.8 part of scorch retarder, 0.8-2 parts of accelerator M, 0.3-1 part of accelerator DM, 0.5-1.5 parts of accelerator CZ, 0.3-1 part of accelerator TMTD, 0.8-2 parts of anti-aging agent RD, 0.8-2 parts of anti-aging agent MB and 80-120 parts of argil. The outlet rubber mouth has good aging resistance and excellent insulating property, is low in cost and has long service life.

Owner:宁国中奕橡塑有限公司

Glass and method for producing same

ActiveCN105377786APrevent phase separationElectroluminescent light sourcesSolid-state devicesChemistry

Owner:NIPPON ELECTRIC GLASS CO LTD

Hollow glass microspheres as well as preparation method and application thereof

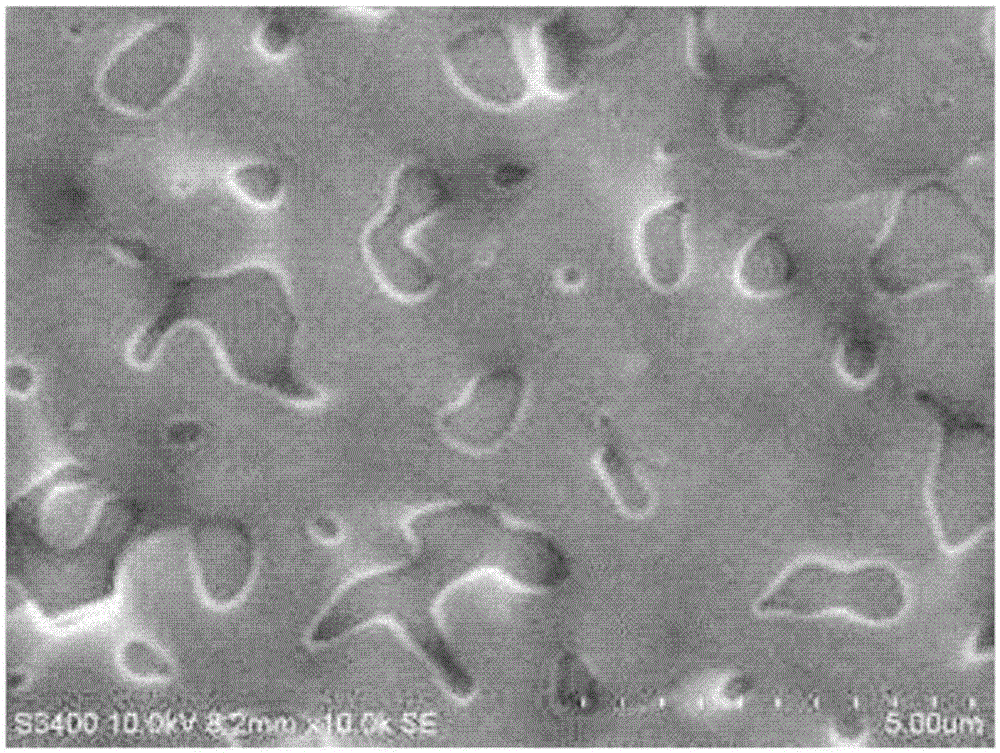

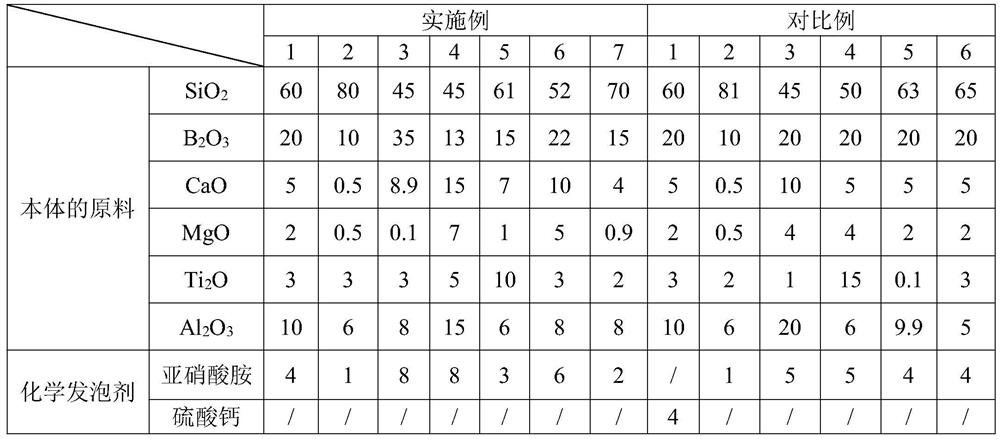

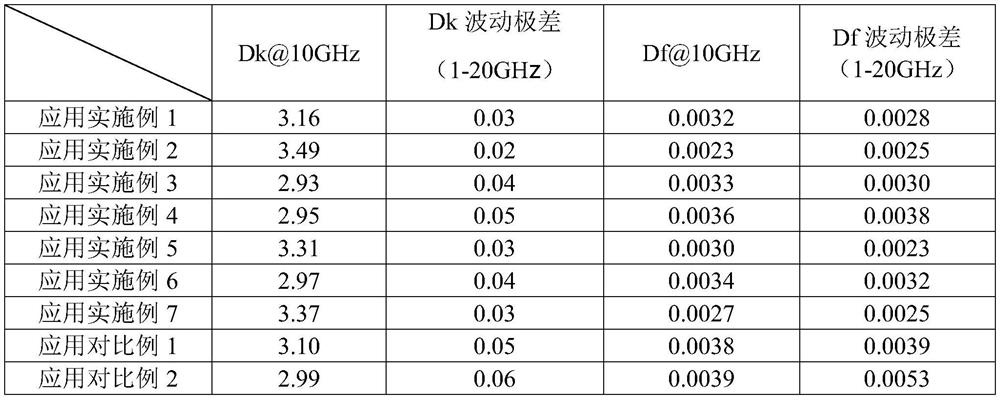

ActiveCN112479595APromote formationPrevent phase separationCircuit susbtrate materialsMicrosphereHemt circuits

The invention relates to a hollow glass microsphere as well as a preparation method and application thereof; the hollow glass microsphere comprises a body and a closed cavity arranged in the body. Theraw materials of the body comprise, by mass, 45%-80% of silicon dioxide, 6%-15% of aluminum oxide, 10%-35% of boron oxide, 0.1%-15% of calcium oxide, 0.1%-7% of magnesium oxide and 2%-10% of titaniumdioxide. By controlling the composition and mass percentage of the raw materials of the body, the hollow glass microsphere with stable structure and excellent dielectric property can be obtained, andwhen the hollow glass microsphere is applied to a circuit substrate, the circuit substrate with lower and more stable Dk and Df can be obtained.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

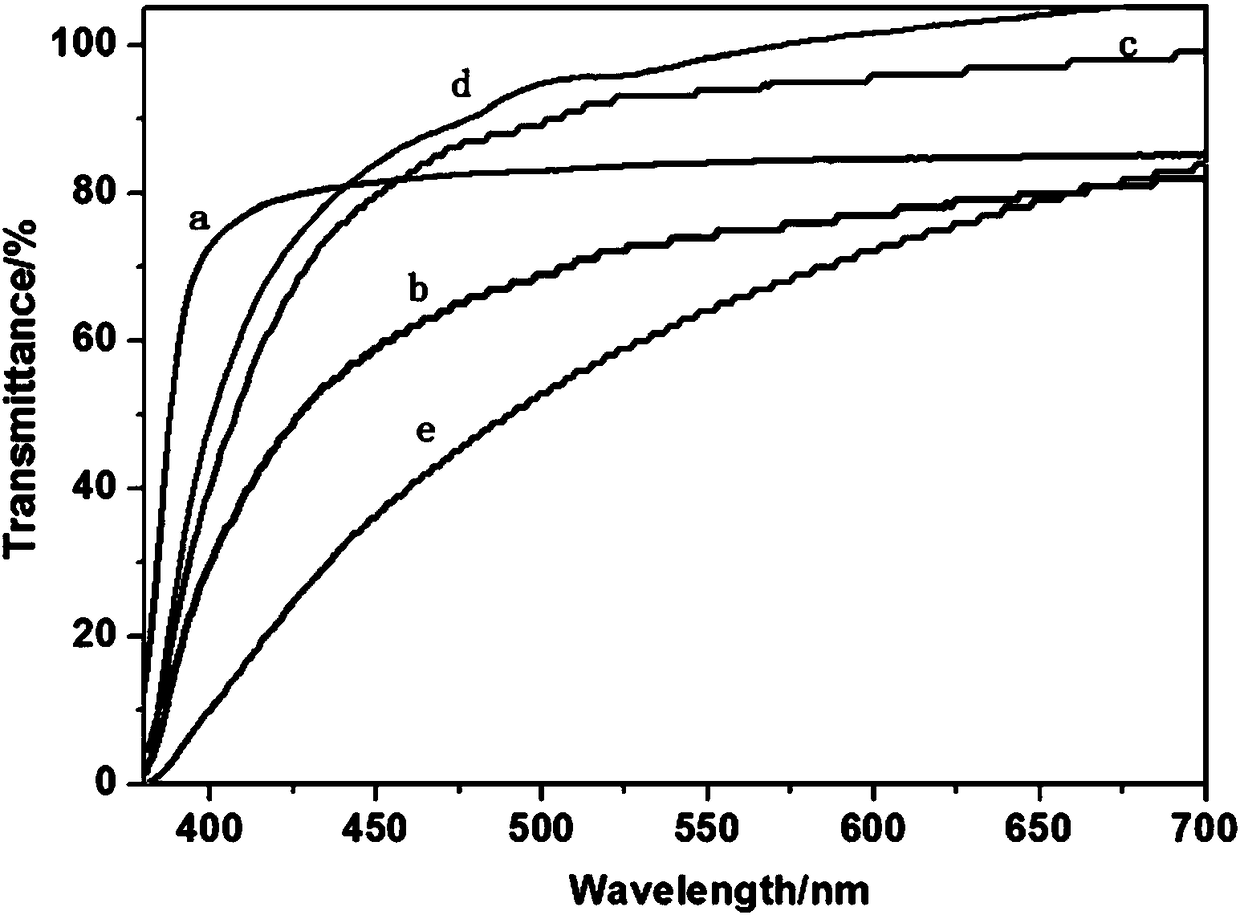

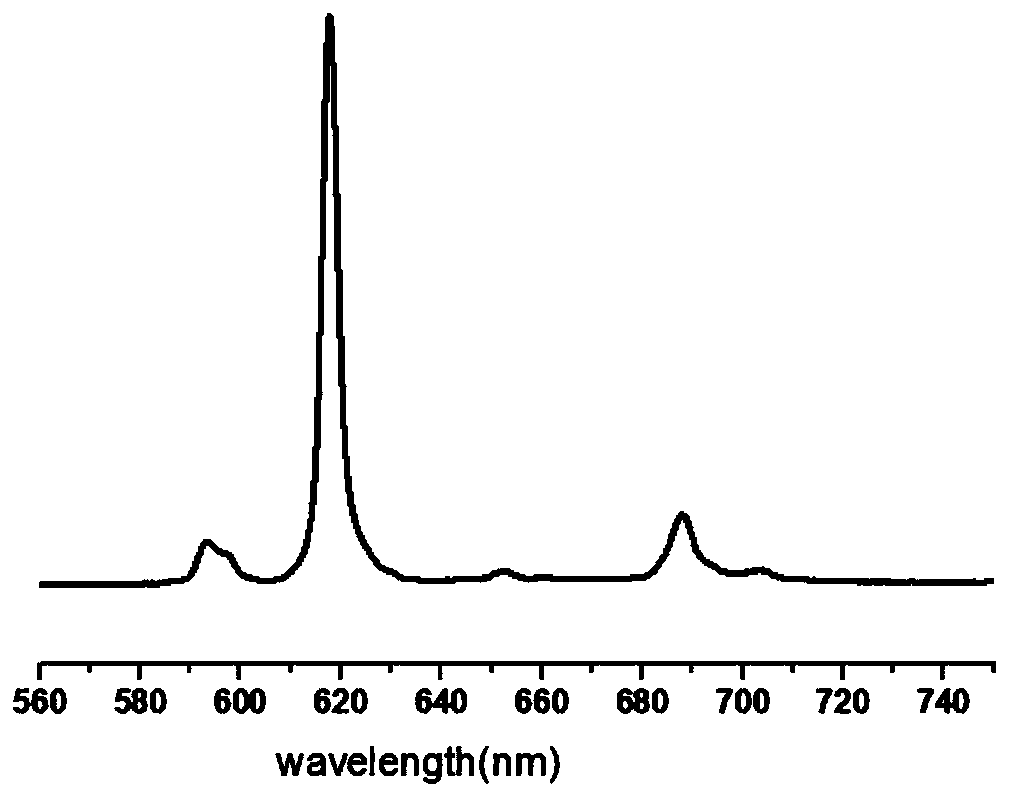

Organic plastic scintillator and preparing method thereof and light conversion device

ActiveCN108467444AGuaranteed purityImprove stabilityX-ray/infra-red processesConversion screensEnergy particleSide effect

The invention discloses an organic plastic scintillator and a preparing method thereof and a light conversion device, and belongs to the technical field of organic plastic scintillators. The preparingmethod includes the steps that liquor of a vinyltoluene solution with dispersed 2,5-diphenyloxazole is degassed in a sealed container, the obtained product is heated to 125 DEG C to 150 DEG C for thefirst time and reacted for 4 h to 8 h, and then is slowly cooled to the normal temperature, and a precursor is obtained; the precursor is heated to 120 DEG C to 140 DEG C for the second time and solidified to be cooled to the normal temperature. An implementation method of the organic plastic scintillator is simple and convenient, the formula is simple, raw materials are environmentally friendly, the organic plastic scintillator prepared with the method is free of bubbles, free of embrittlement, good in stability, free of toxic and side effects and high in light transmittance, resolution ratio and response speed. The organic plastic scintillator is prepared with the method. The light conversion device comprises the organic plastic scintillator and can be used for detecting and diagnosinghigh-energy particles and radial rays.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

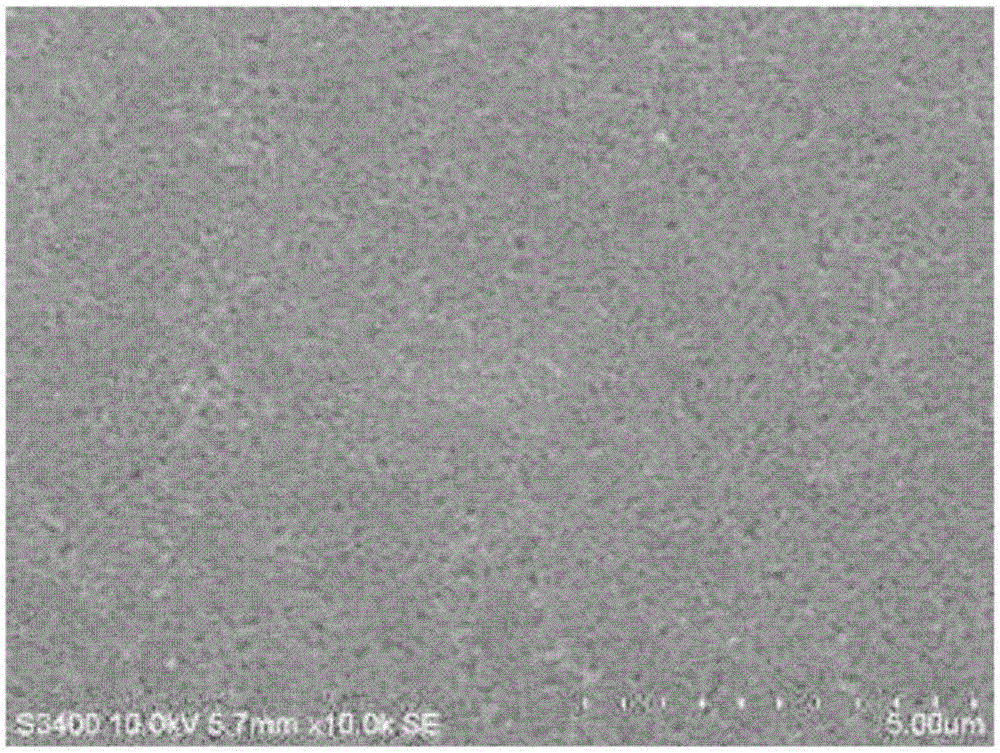

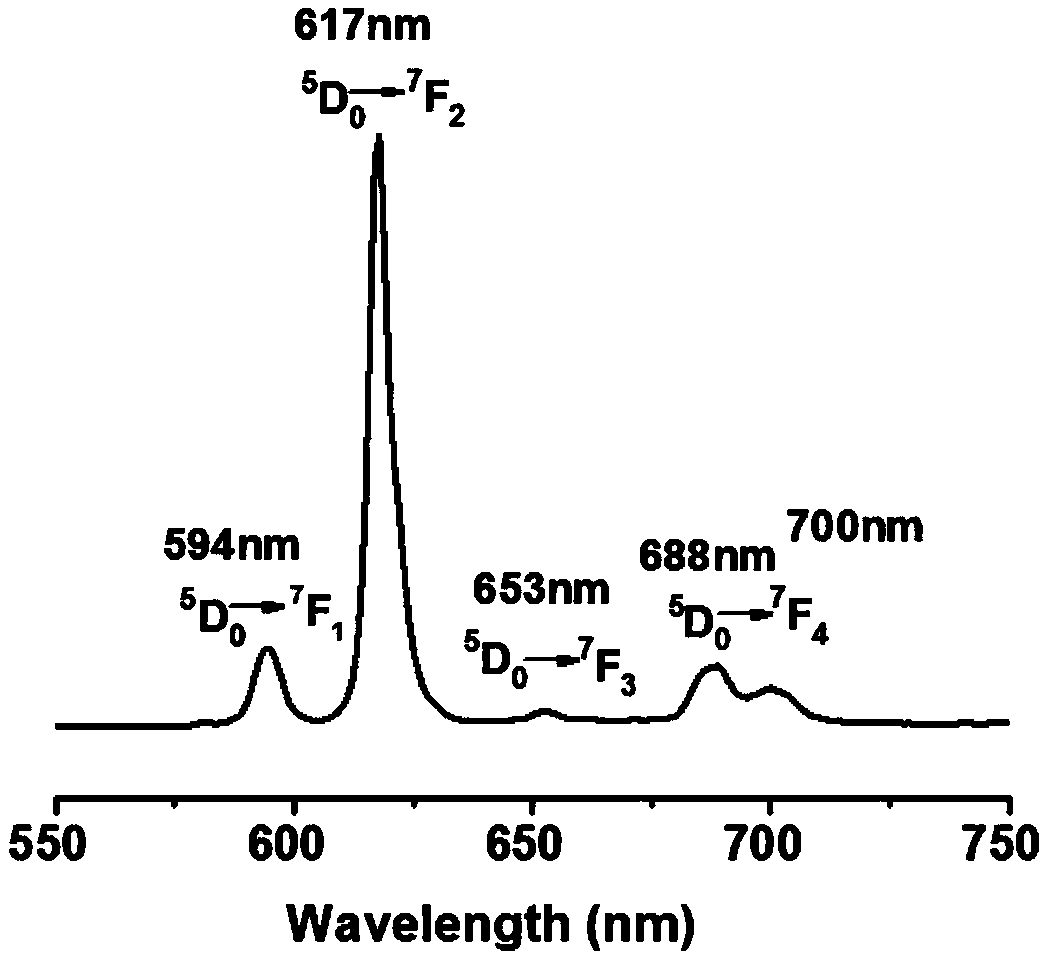

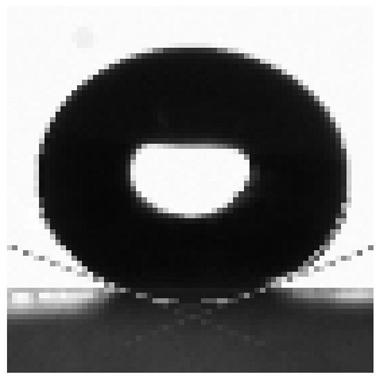

High-hydrophobicity high temperature-resistant fluorescent coating preparation method

InactiveCN108359344AAvoid fluorescence instability such as concentration quenching and agglomerationUniform particle sizeLuminescent paintsOrganic solventPhase splitting

The invention provides a high-hydrophobicity high temperature-resistant fluorescent coating preparation method, which belongs to the technical field of a hydrophobic fluorescent coating. The preparation method comprises the following steps: dispersing polymeric microsphere in an organic solvent, performing coordination on the polymeric microsphere and a micromolecule ligand and a rare earth compound, and coating a matrix with a solution after coordination to obtain the high-hydrophobicity fluorescent coating. The coating takes microsphere as a unit for spot-light illumination, luminescence isuniform, and no phase-splitting problem is generated. The particle size of the polymeric microsphere is at a micron order, enough roughness can be provided, cracking cannot be generated on the coating, and the high hydrophobicity of the coating can be guaranteed. The preparation method has the advantages of simple process and economy, and can be used for industrial production.

Owner:DALIAN UNIV OF TECH

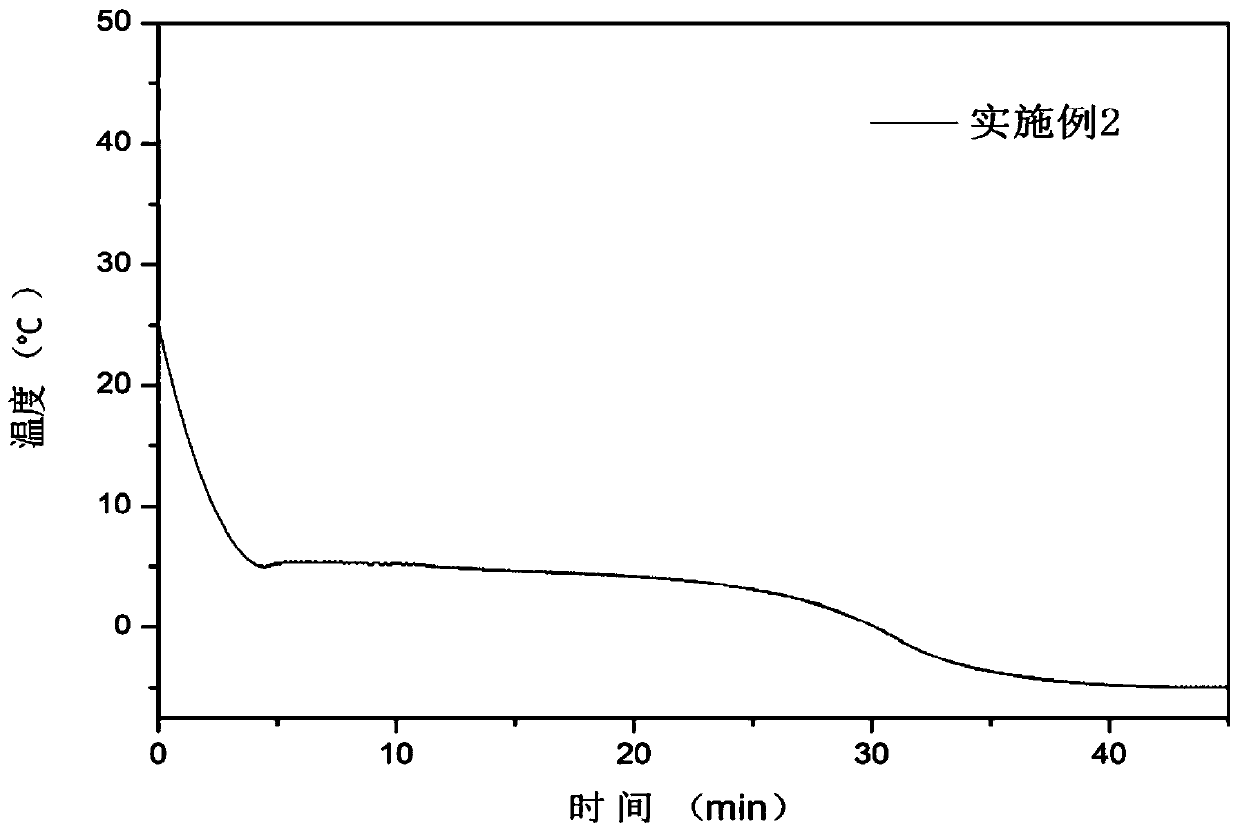

Phase-change cold storage compound and preparation method thereof

InactiveCN111320969AHigh thermal conductivityPrevent phase separationHeat-exchange elementsPhysical chemistryCarbon nanomaterials

The invention relates to a phase-change cold storage compound and a preparation method thereof. The phase-change cold storage compound comprises sodium sulfate decahydrate, a nucleating agent, a thickening agent and a temperature regulator. Wherein based on 100 parts by mass of the sodium sulfate decahydrate, the mass parts of the nucleating agent, the thickening agent and the temperature regulator are respectively 0.5-5 parts, 0.5-5 parts and 10-20 parts; wherein the phase-change cold storage compound further comprises a carbon nano material, and based on 100 parts by mass of the sodium sulfate decahydrate, the mass part of the carbon nano material is 1-5 parts. By optimizing the formula design of the phase-change cold storage composite material, the composite material has the characteristics of safety, no toxicity, low production cost, small degree of supercooling, high cold storage density and good material stability, and can be applied to use scenes needing 4-8 DEG C, such as a phase-change cold storage system of an air conditioner.

Owner:内蒙古信敏惠纳米科技有限公司

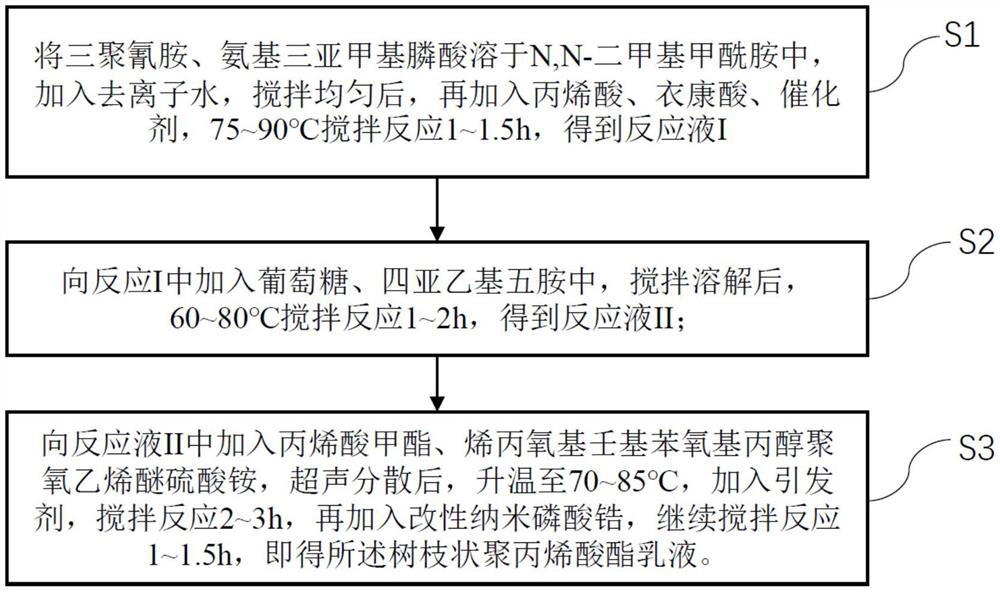

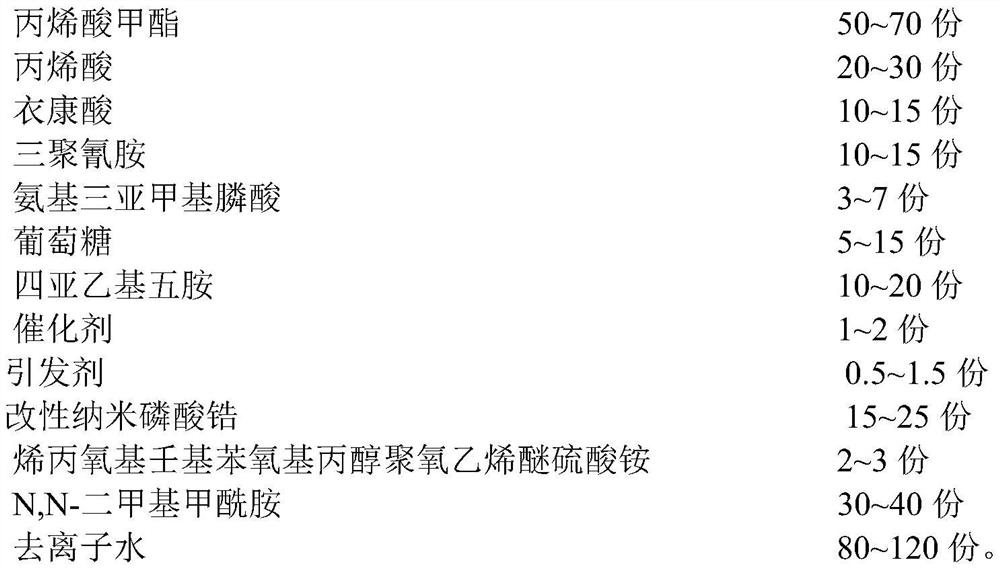

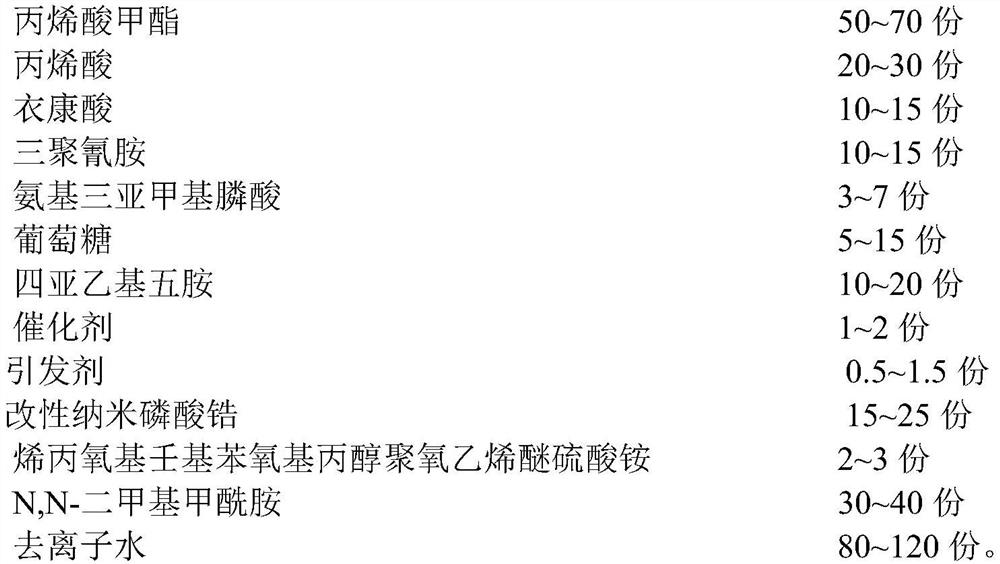

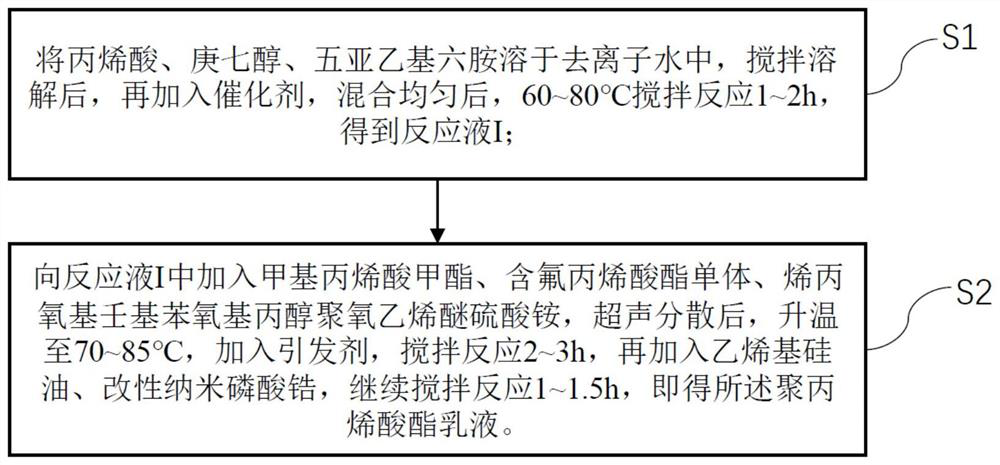

Antibacterial anti-aging flame-retardant dendritic polyacrylate emulsion and preparation method thereof

The invention discloses an antibacterial anti-aging flame-retardant dendritic polyacrylate emulsion and a preparation method thereof. The antibacterial anti-aging flame-retardant dendritic polyacrylate emulsion comprises the following raw materials in parts by mass: 50 to 70 parts of methyl acrylate, 20 to 30 parts of acrylic acid, 10 to 15 parts of itaconic acid, 10 to 15 parts of melamine, 3 to 7 parts of amino trimethylene phosphonic acid, 5 to 15 parts of glucose, 10 to 20 parts of tetraethylenepentamine, 1 to 2 parts of a catalyst, 0.5 to 1.5 parts of an initiator, 15 to 25 parts of modified nano zirconium phosphate, 2 to 3 parts of allyloxy nonylphenoxy propanol polyoxyethylene ether ammonium sulfate, 30 to 40 parts of N, N-dimethylformamide and 80 to 120 parts of deionized water. The preparation method comprises the following steps: carrying out amidation reaction on-NH2 in melamine and amino trimethylene phosphonic acid and-COOH in acrylic acid and itaconic acid, carrying out esterification reaction and amidation reaction on glucose and tetraethylenepentamine serving as an inner core and free-COOH of a system, or carrying out reaction on glucose and tetraethylenepentamine and-H2PO3, and carrying out copolymerization on the obtained product and methyl acrylate under the action of an initiator so as to obtain a polyacrylate branched chain inner shell, and crosslinking thepolyacrylate branched chain inner shellwith the modified nano zirconium phosphate to realize molecular modification.

Owner:朱浩

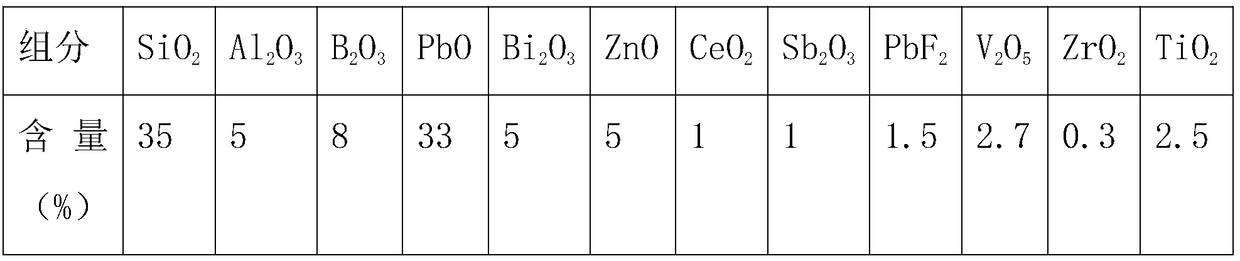

Glass powder for semiconductor passivation packaging and preparation method of glass powder

InactiveCN108863089AMeet the requirements of passivated packagesStrong enoughSemiconductorMaterials science

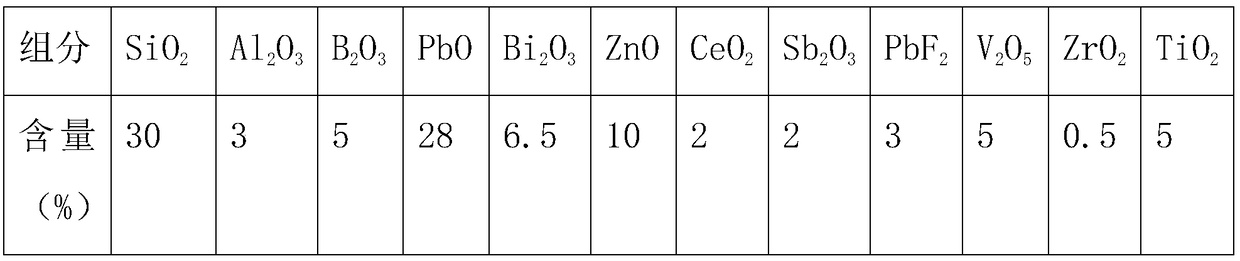

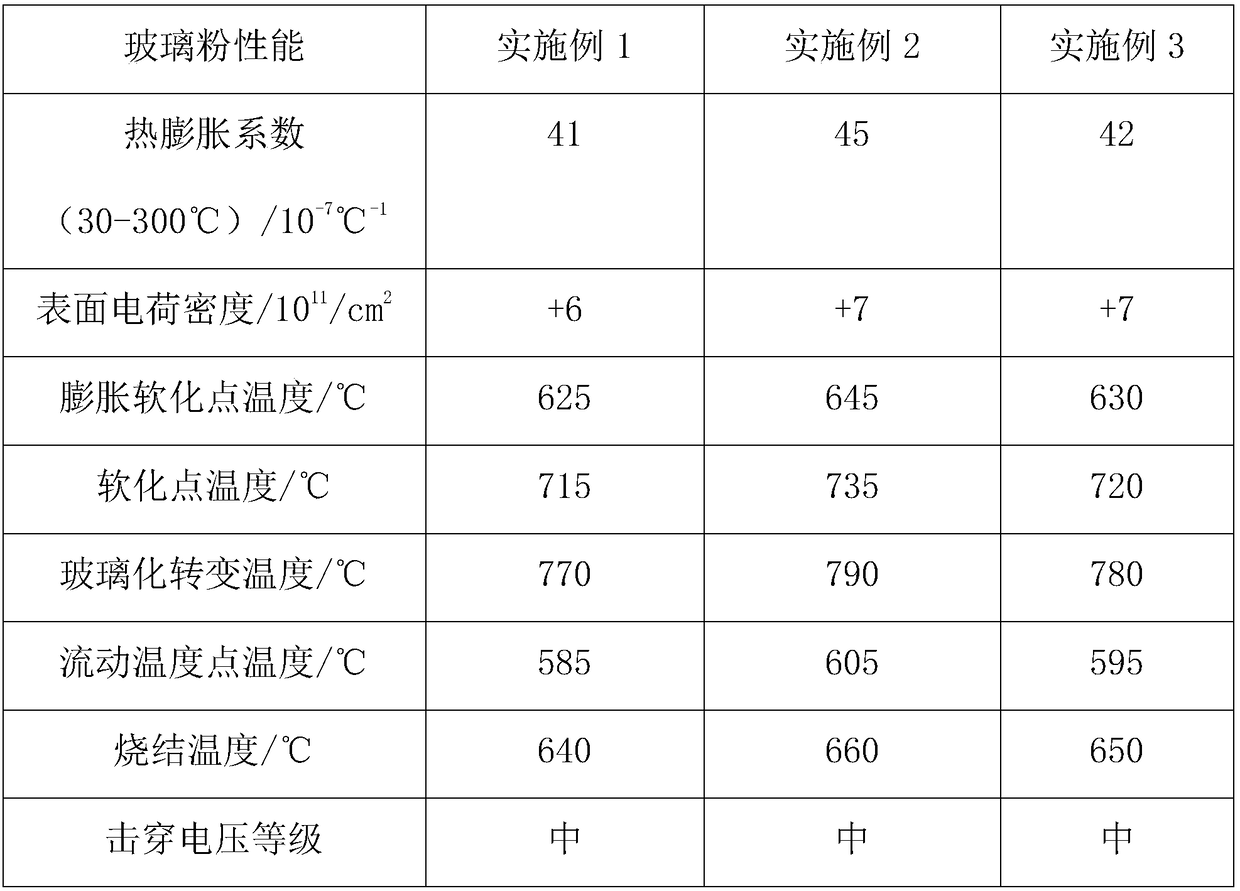

The invention provides glass powder for semiconductor passivation packaging and a preparation method of the glass powder. The glass powder is prepared from the following ingredients in percentage by mass: 30-60% of SiO2, 3-10% of Al2O3, 5-15% of B2O3, 28-55% of PbO, 0-10% of Bi2O3, 0-20% of ZnO, 0-2% of CeO2, 0-2% of Sb2O3, 0-3% of PbF2, 0-5% of V2O5, 0-0.5% of ZrO2 and 0-5% of TiO2. According tothe preparation method of the glass powder for the semiconductor passivation packaging, the operation is simple, the cost can be effectively saved, the prepared glass powder can meet requirement on the semiconductor passivation packaging, meanwhile, the glass powder has enough strength and breaking tenacity and can effectively resist comprehensive damage caused by illumination, cold, heat, wind, rain, bacteria and the like to the surface of a semiconductor device.

Owner:张其峰

Ultrahigh-pressure high-temperature synthesizing method of second-phase particle simulation material in aluminium alloy

The invention discloses a method for preparing a second-phase particle simulation material in aluminium alloy under the ultrahigh-pressure high-temperature condition. The method comprises the steps that based on the chemical component stoichiometric ratio of second-phase particles in the aluminium alloy, pure metal powder is adopted for suppressing biscuits, GPa-grade high pressure is applied to an artificial diamond six-surface diamond presser, then the biscuits are heated to the high temperature, and the temperature is preserved for some time; finally, under the high-pressure keeping effect,the biscuits are cooled to the indoor temperature. By adopting the ultrahigh-pressure high-temperature synthesizing method, the simulation material with the phase same with the second-phase particlesin the aluminium alloy, accurate chemical components and sample size meeting the requirement of a conventional electrochemical test can be prepared, and therefore the foundation is laid for indirectresearch of the corrosion electrochemistry behavior of the second-phase particles in the aluminium alloy by adopting a simulated electrode method.

Owner:CHANGZHOU UNIV

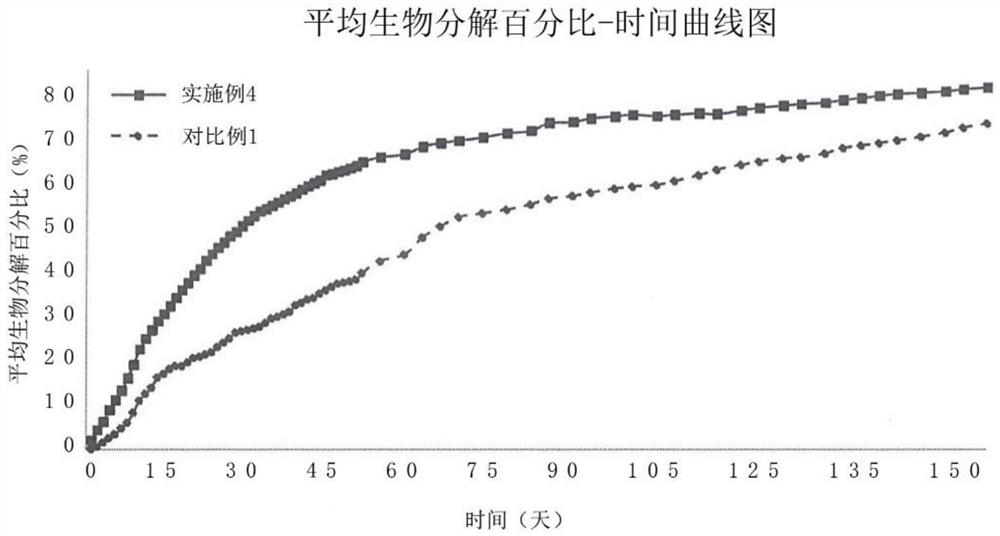

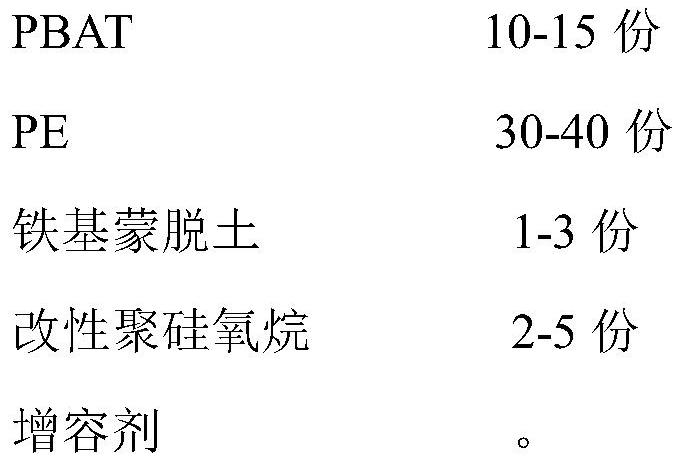

Degradable plastic mulching film based on PBAT and preparation method of degradable plastic mulching film

ActiveCN113372594AGood compatibilityStable homogeneous phaseClimate change adaptationBulk chemical productionPolymer scienceExtreme weather

The invention discloses a degradable plastic mulching film based on PBAT. The degradable plastic mulching film comprises the following components: PBAT, PE, iron-based montmorillonite and modified polysiloxane. Wherein the modified polysiloxane is a product prepared by carrying out condensation reaction on hydrogen-containing silicone oil and polyalcohol monomethyl ether. The modified polysiloxane can greatly improve the compatibility between the PBAT and the PE and the blending uniformity between the PBAT and the PE and other auxiliaries, so that the composite material has stable and uniform mechanical properties and degradability when being used as a degradable plastic mulching film, and phase separation hardly occurs under extreme weather conditions.

Owner:广东永鑫华新型材料有限公司

Halogen-free polyphenyl ether resin composition, and prepreg and laminated board prepared therefrom

ActiveCN110615876AHomogeneous compatibilityLow dielectric constantSynthetic resin layered productsElectrical equipmentCross-linkDielectric loss

The invention discloses a halogen-free polyphenyl ether resin composition, which comprises the following components: (a) 100 parts of polyphenyl ether resin containing carbon-carbon unsaturated bonds;(b) 5-60 parts of a phosphorus-containing compound containing carbon-carbon unsaturated bonds; and (c) 0-10 parts of an initiator. According to the invention, the phosphorus-containing compound containing carbon-carbon unsaturated bonds is used as a cross-linking agent for polyphenyl ether and the compound containing carbon-carbon unsaturated bonds; according to the resin composition and the laminated board prepared from the resin composition, polyphenyl ether and a compound containing carbon-carbon unsaturated bonds can be well and uniformly compatible together, a lower dielectric constant and a lower dielectric loss value are obtained, and experimental data prove that the resin composition and the laminated board prepared from the resin composition can meet the requirements of current 5G products.

Owner:SHENGYI TECH SUZHOU

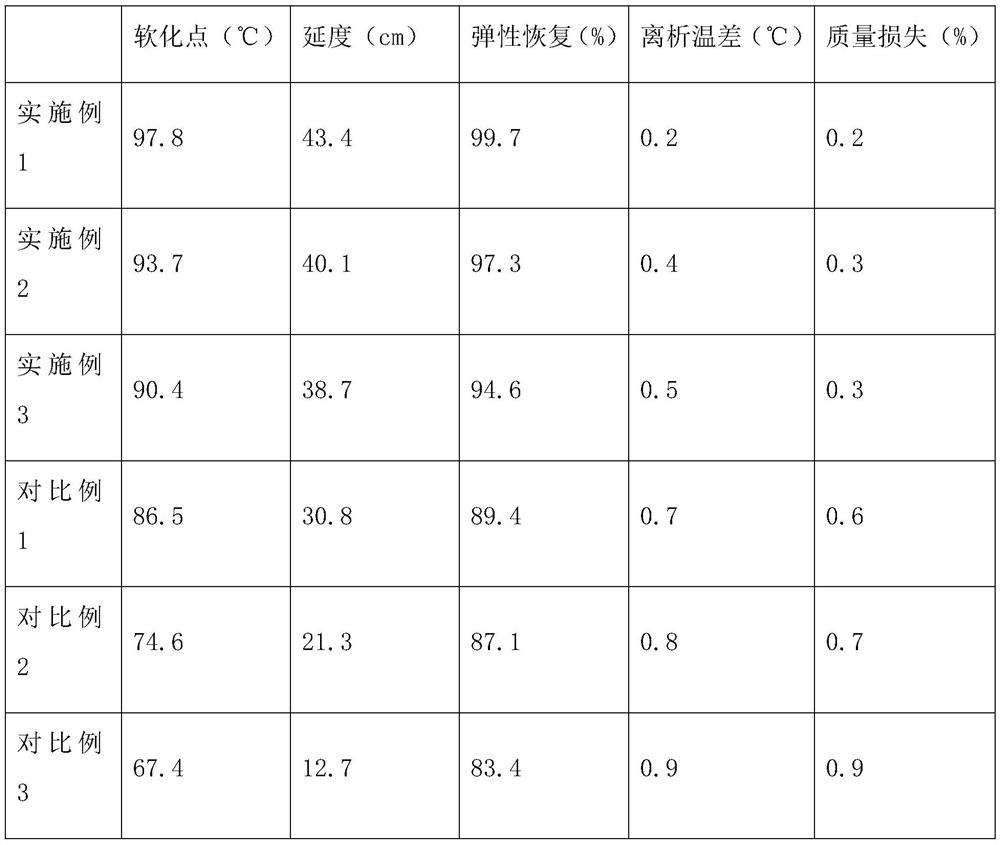

Wear-resistant SBS modified asphalt and preparation method thereof

The invention discloses wear-resistant SBS modified asphalt and a preparation method thereof, the wear-resistant SBS modified asphalt comprises the following components in parts by weight: 90-100 parts of asphalt, 2-6 parts of modified SBS and 7-13 parts of modified nanoparticles, and the modified SBS comprises the following components: SBS, vinyl chloride, vinyl acetate, methanol, a photoinitiator, a catalyst and diisocyanate. According to the invention, through blending reaction of the isocyanato phenolic acid terminated modified SBS, the epoxy group-containing modified nano particles and the asphalt, the compatibility of the SBS in the asphalt is improved, the phase separation phenomenon is prevented, the stability is improved, the SBS modified asphalt forms a three-dimensional network structure, the nano particles are coated, the limitation on the molecular chain is enhanced, the internal stress is weakened, and the wear resistance and the mechanical property are improved.

Owner:江阴市新远见工程有限公司

A kind of preparation method of superhydrophobic self-cleaning fluorescent coating

ActiveCN108409911BUniform particle sizeUniform coordinationAntifouling/underwater paintsLuminescent paintsSuperhydrophobeOrganic solvent

The invention provides a preparation method for a superhydrophobic self-cleaning fluorescent coating, and belongs to the technical field of superhydrophobic fluorescent coatings. The preparation method comprises the following steps: preparing fluorine-containing carboxyl polymer particles; and dispersing the polymer particles into an organic solvent, performing coordination with a small-molecularligand and a rare earth compound, and performing coating to obtain the superhydrophobic fluorescent coating. Microspheres prepared by the method provided by the invention have a particle size of aboutmicrometers and can provide sufficient roughness, a fluorine-containing monomer ensures the surfaces of the microspheres to have low surface energy, and the prepared superhydrophobic fluorescent coating has a contact angle which can reach 150 degrees or more, can be applied to different substrates, and has a self-cleaning function; and the method used in the invention is simple and economic, andcan be applied to industrial production.

Owner:DALIAN UNIV OF TECH

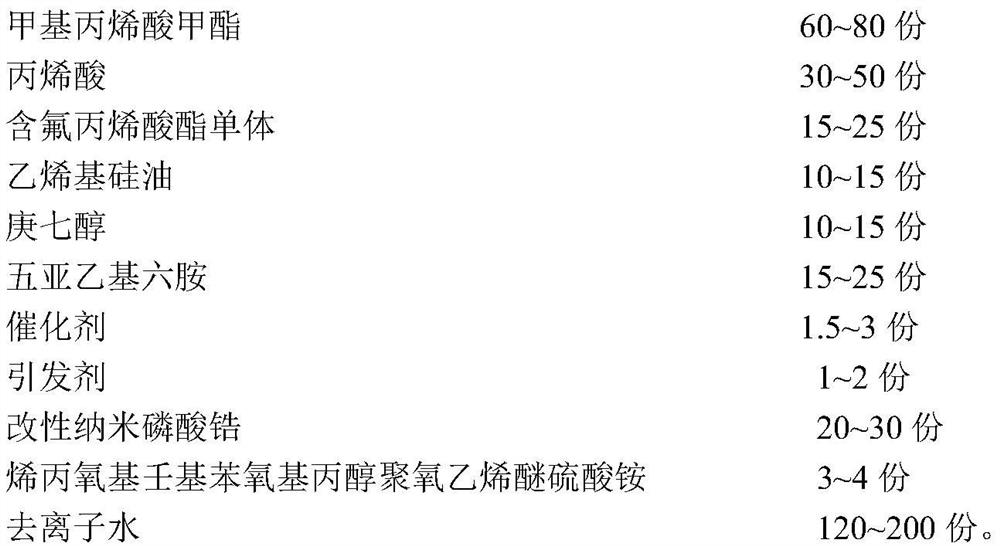

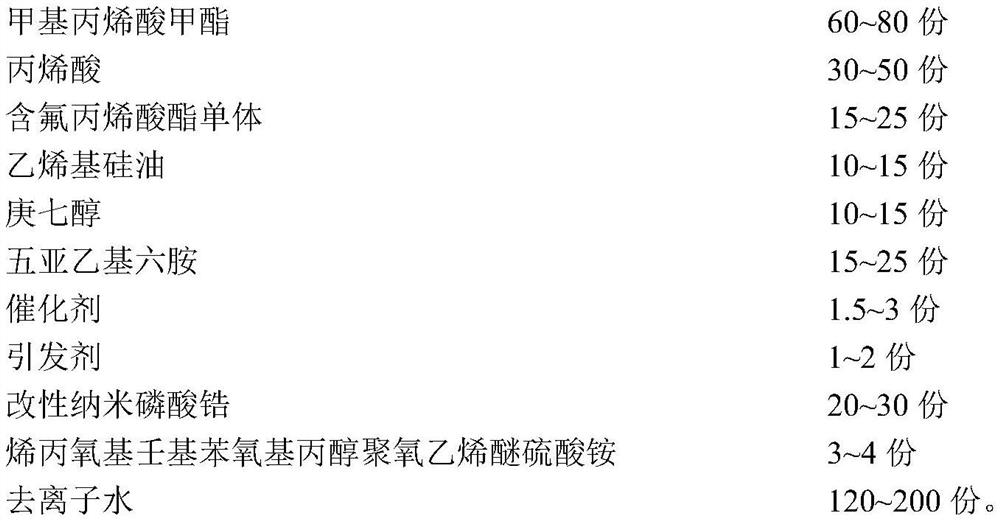

Antibacterial hydrophobic dendritic polyacrylate emulsion and preparation method thereof

The invention discloses an antibacterial hydrophobic dendritic polyacrylate emulsion and a preparation method thereof. The polyacrylate emulsion comprises the following raw materials in parts by mass: 60-80 parts of methyl methacrylate, 30-50 parts of acrylic acid, 15-25 parts of a fluorine-containing acrylate monomer, 10-15 parts of vinyl silicone oil, 10-15 parts of heptanol, 15-25 parts of pentaethylenehexamine, 1.5-3 parts of a catalyst, 1-2 parts of an initiator, 20-30 parts of modified nano zirconium phosphate, 3-4 parts of allyloxy nonylphenoxy propanol polyoxyethylene ether ammonium sulfate and 120-200 parts of deionized water. According to the preparation method, heptanol and pentaethylenehexamine are used as inner cores for the first time, esterification reaction and amidation reaction are carried out on the inner cores and -COOH in an acrylic monomer, addition polymerization is carried out on the inner cores, methyl methacrylate and a fluorine-containing acrylate monomer under the action of an initiator, and a fluorine-containing polyacrylate branched chain inner shell is formed; and further graft copolymerization with vinyl silicone oil and modified nano zirconium phosphate is implemented to form the antibacterial, anti-aging and hydrophobic dendritic polyacrylate emulsion with a core-inner shell-outer shell structure.

Owner:朱浩

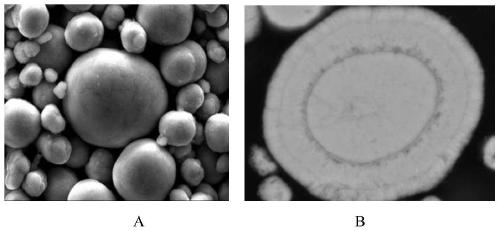

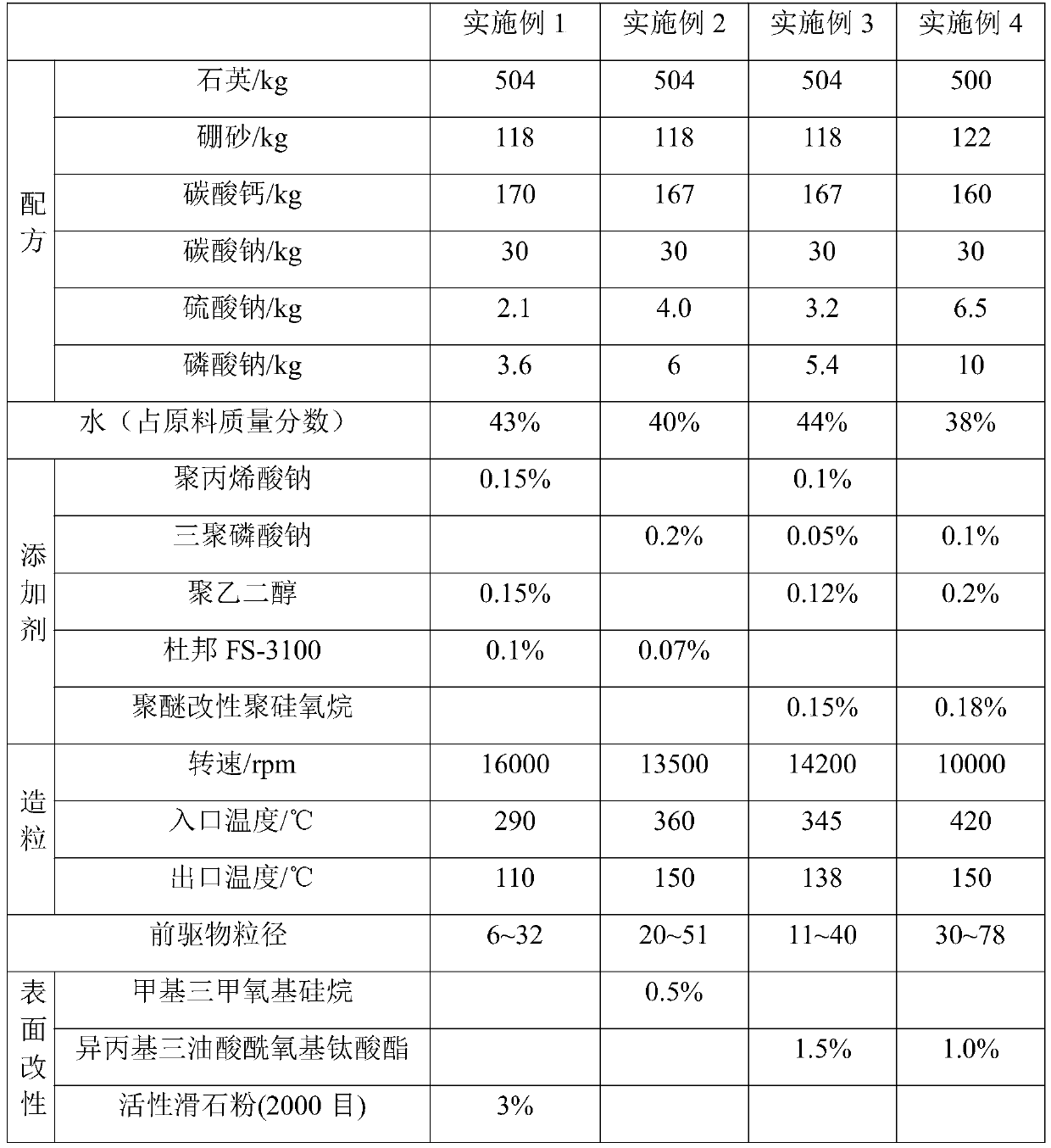

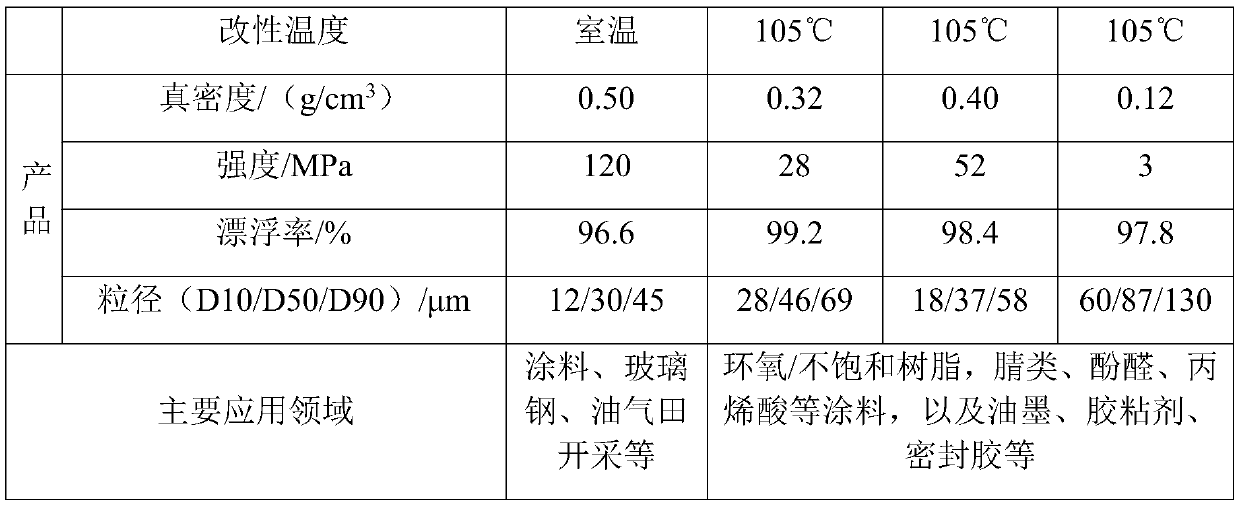

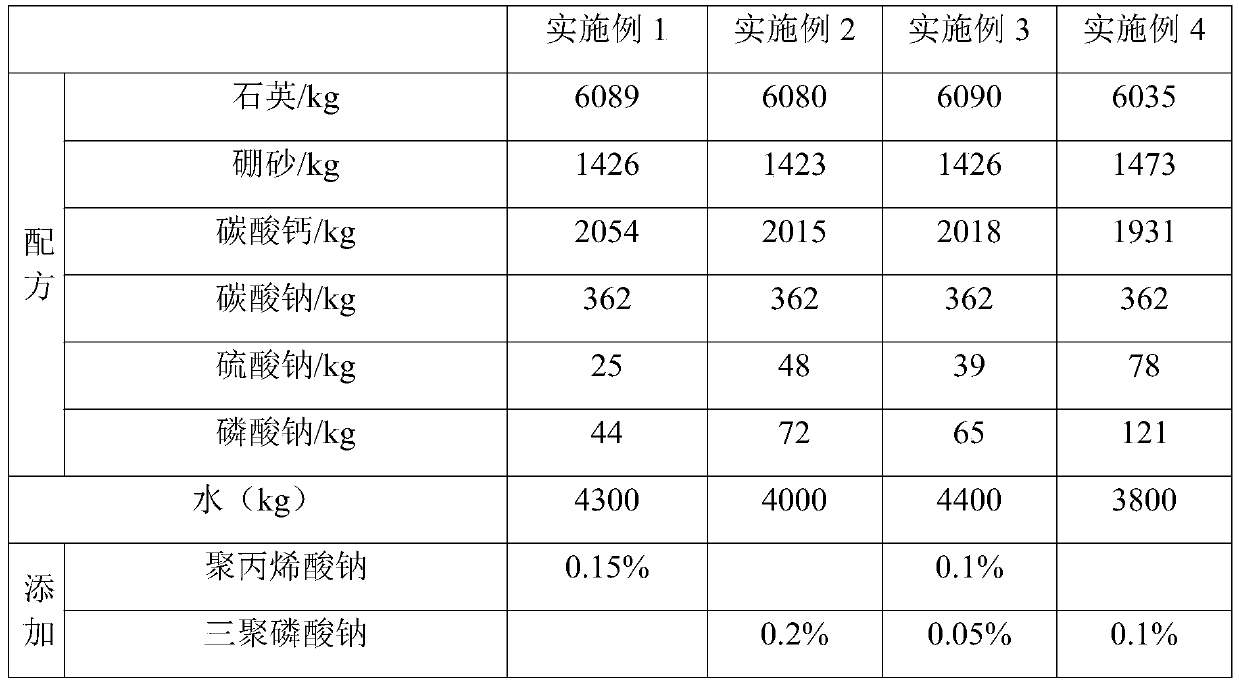

Industrialization method for preparation of hollow glass beads based on precursor process

The invention discloses an industrialization method for preparation of hollow glass beads based on precursor process. The production technology includes the steps of: 1) preparation of slurry: accurately weighing all components of basic raw materials, a stable dispersing agent and a surfactant; wherein the basic raw materials comprise quartz, borax, calcium carbonate, sodium carbonate, sodium sulfate and sodium phosphate; 2) preparation of a precursor; 3) preparation of hollow glass beads; and 4) surface modification. The stable dispersion slurry prepared by the method provided by the invention has high solid phase content and low surface tension and viscosity, the energy consumption of spray granulation is remarkably reduced, and also the prepared precursor has small particle size span and uniform components, the floating rate of the hollow glass beads can be higher than 96% through combination with a high-temperature negative-pressure vitrification process, and low-temperature circulating air is employed to reinforce the hollow glass bead. The method provided by the invention adopts dry surface modification, has no need for drying again, broadens the application fields of the hollow glass beads while simplifying the technological process, and solves the problem of narrow application field of hollow glass beads.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Production method of hollow glass beads high in floating rate

The invention discloses a production method of hollow glass beads high in floating rate. A production technology of the production method of the hollow glass beads high in floating rate comprises thesteps: (1) producing slurry, wherein basic material components, a stabilizing dispersion agent and a surfactant are accurately weighed, wherein the basic material components are quartz, borax, calciumcarbonate, sodium carbonate, sodium sulfate and sodium phosphate; (2) producing a precursor; (3) producing hollow glass beads; and (4) conducting surface modification. The stable dispersive slurry produced through the method is high in solid content and low in surface tension and viscosity, not only is energy consumption of spray granulation significantly reduced, but also the produced precursoris small in particle size span and even in component, by combining a high-temperature negative-pressure vitrification technology, the floating rate of the hollow glass beads is higher than 96.5%, thesurface smoothness is also high, and low-temperature recirculating air is adopted for enhancing the hollow glass beads. According to the production method of the hollow glass beads high in floating rate, the raw materials are easy to obtain, the hollow glass bead yield is high, the technology process is simple, energy consumption is low, the production cost is low, and the product application range is wide.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

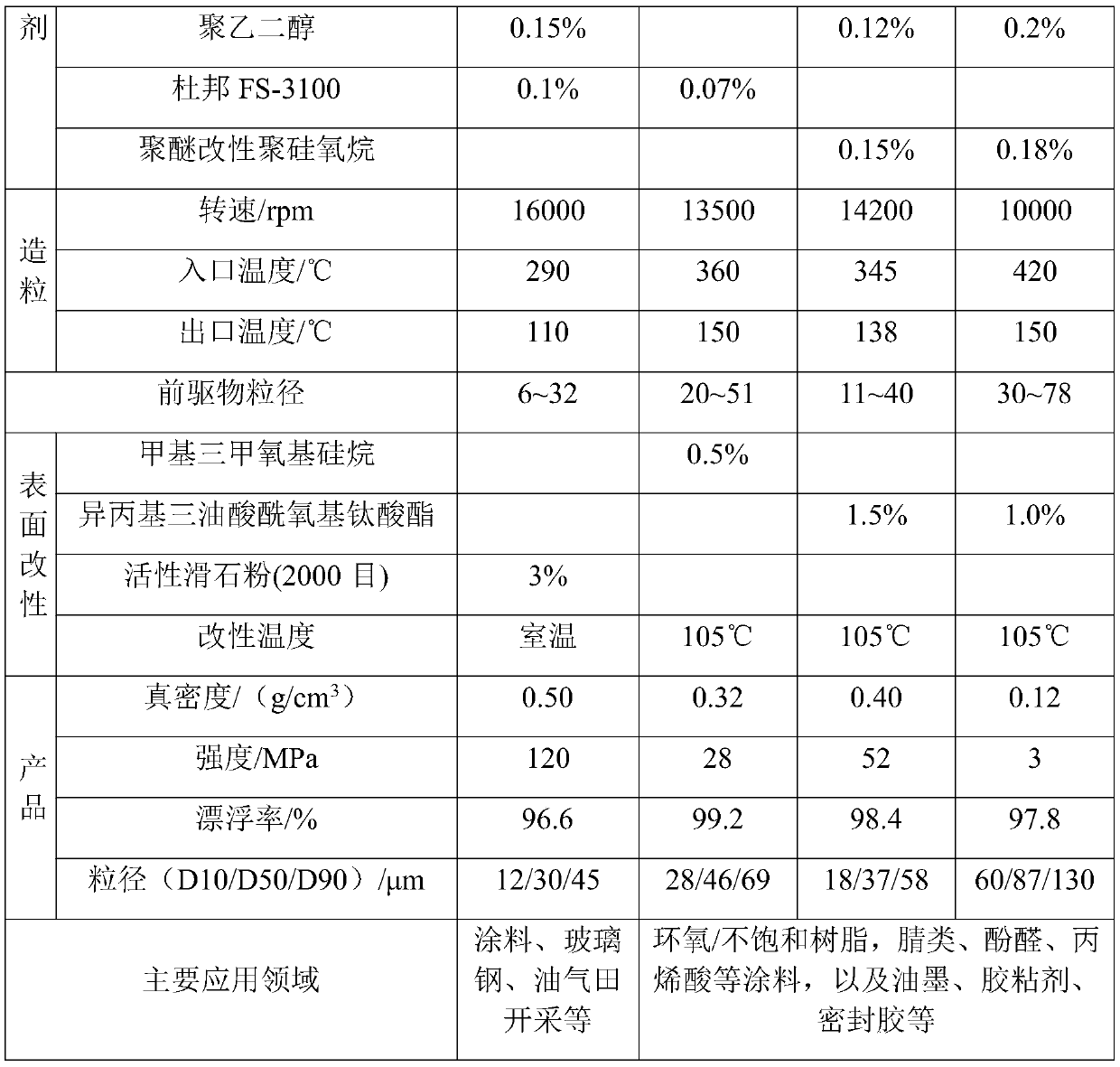

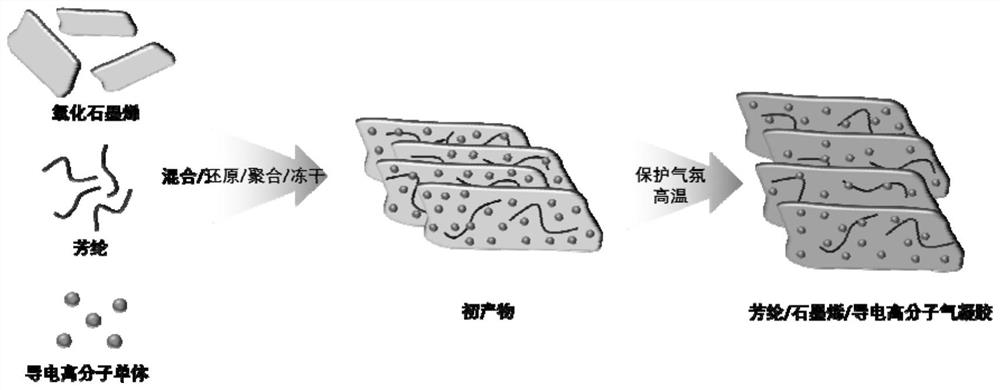

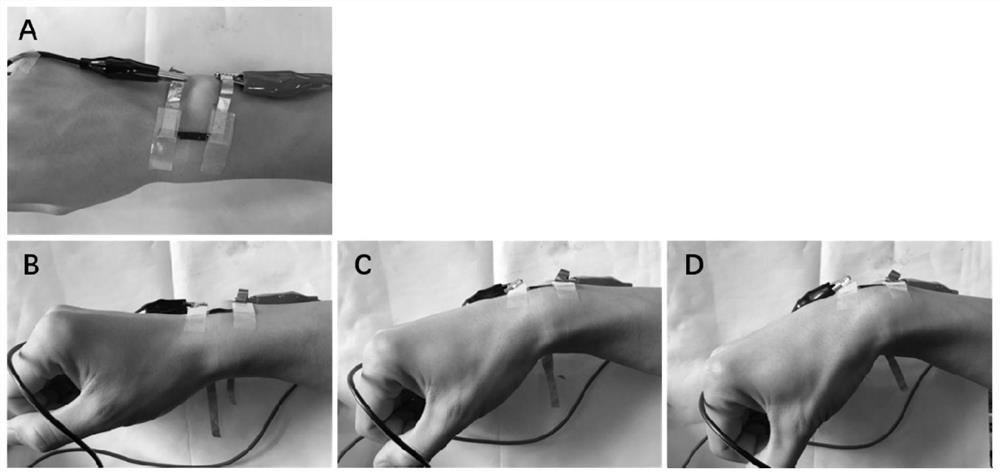

Preparation method of aramid fiber/graphene/conductive polymer aerogel composite pressure sensing material

PendingCN113201168AImprove conductivityGood flexibilityCarbon preparation/purificationConductive polymerGraphene

The invention discloses a preparation method of an aramid fiber / graphene / conductive polymer aerogel composite pressure sensing material. The preparation method comprises the following steps of (1) preparing an aramid fiber solution, (2) preparing an aramid fiber / graphene / conductive polymer monomer solution, (3) preparing aramid fiber / graphene / conductive polymer hydrogel, (4) preparing an aramid fiber / graphene / conductive polymer aerogel initial product, and (5) preparing the aramid fiber / graphene / conductive polymer aerogel composite pressure sensing material. The aramid fiber / graphene / conductive polymer aerogel composite pressure sensing material prepared by the invention is high in conductivity and good in flexibility, and also has high compressive deformation performance and high fatigue resistance.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

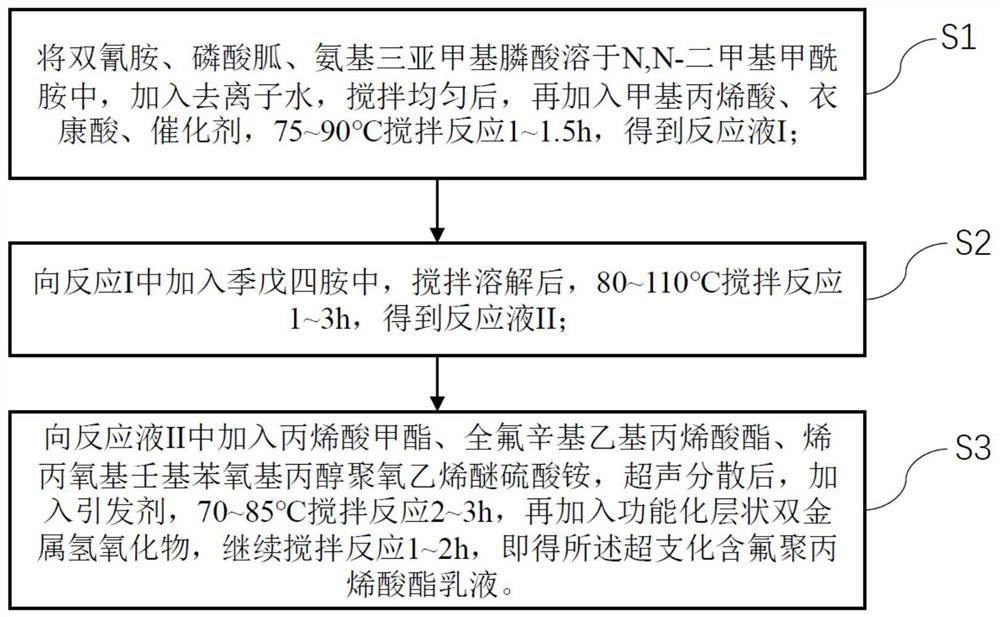

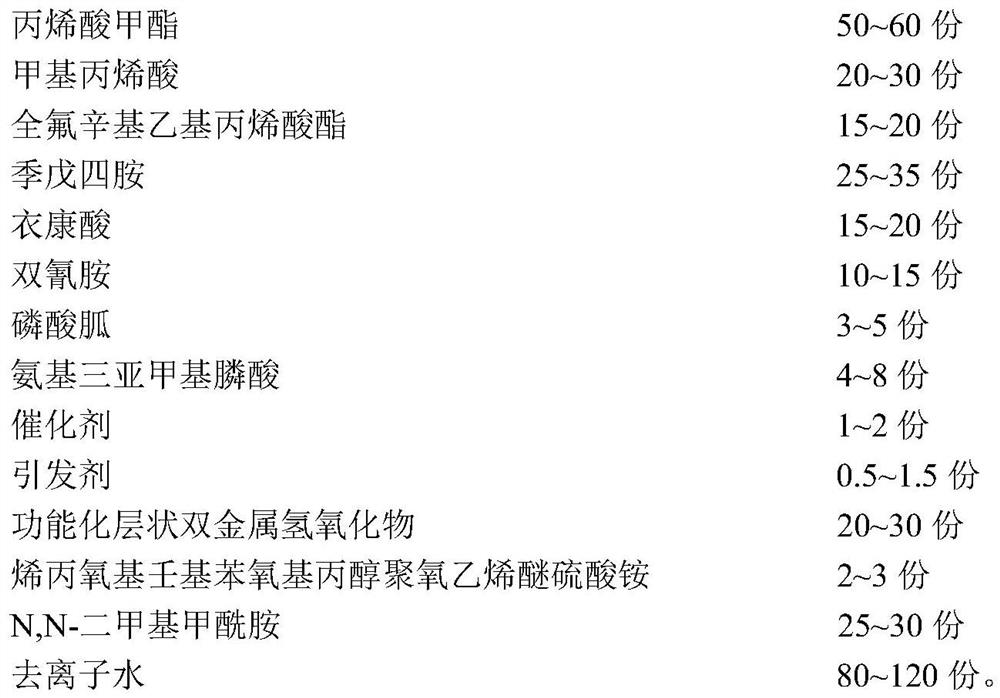

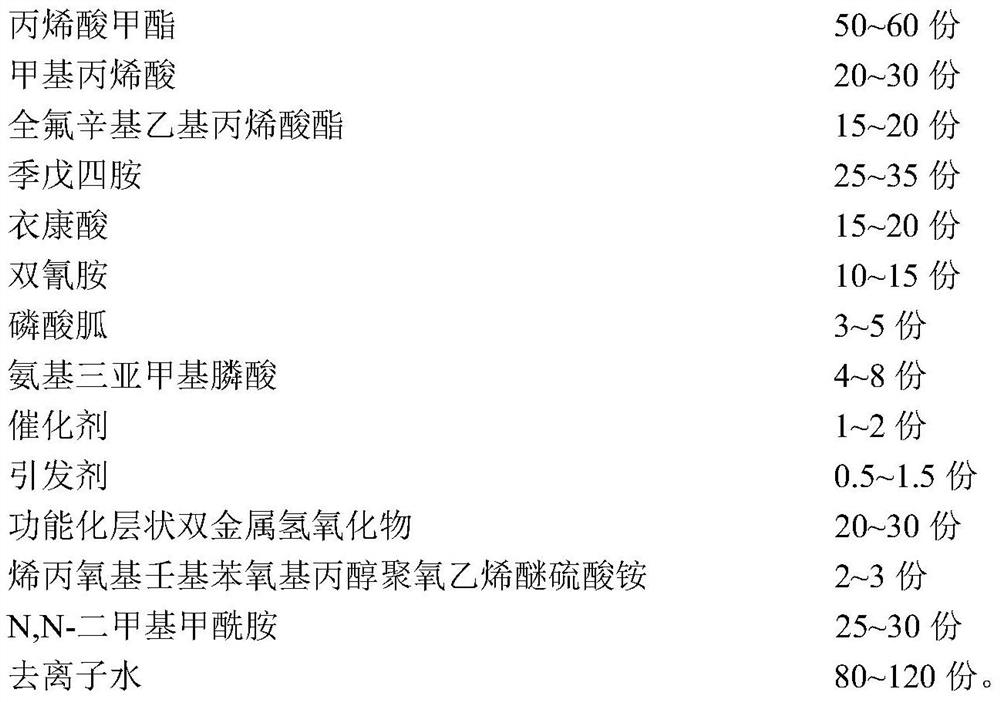

Anti-aging self-flame-retardant hyperbranched fluorine-containing polyacrylate emulsion and preparation method thereof

The invention discloses an anti-aging self-flame-retardant hyperbranched fluorine-containing polyacrylate emulsion and a preparation method thereof. The anti-aging self-flame-retardant hyperbranched fluorine-containing polyacrylate emulsion comprises the following raw materials in parts by mass: 50-60 parts of methyl acrylate, 20-30 parts of methacrylic acid, 15-20 parts of perfluorooctyl ethyl acrylate, 25-35 parts of pentaerythritol tetramine, 15-20 parts of itaconic acid, 10-15 parts of dicyandiamide, 3-5 parts of guanidine phosphate, 4-8 parts of amino trimethylene phosphonic acid, 1-2 parts of a catalyst, 0.5-1.5 parts of an initiator, 20-30 parts of functionalized layered double hydroxides, 2-3 parts of allyloxy nonylphenoxy propyl alcohol polyoxyethylene ether ammonium sulfate, 25 to 30 parts of N, N-dimethyl formamide and 80 to 120 parts of deionized water. The fluorine-containing hyperbranched fluorine-containing polyacrylate emulsion prepared by the method disclosed by the invention has excellent self-flame-retardant, antibacterial and anti-aging characteristics, high molecular weight, excellent solubility, hydrophobic and oleophobic properties and high film-forming stability.

Owner:朱浩

Oral Care Compositions and Methods for Increasing Stability of the Same

ActiveUS20190175466A1Prevent phase separationCosmetic preparationsToilet preparationsIsopropylene glycolPropylene glycol

Anhydrous oral care compositions and methods for preventing phase separation in the anhydrous oral care composition are disclosed. The oral care composition may include an orally acceptable vehicle, a thickening system, and a whitening agent. The orally acceptable vehicle may include propylene glycol, and the thickening system may include a polymeric thickener. The polymeric thickener may be or include a copolymer of 2-acrylamidomethylpropanesulphonic acid or a salt thereof.

Owner:COLGATE PALMOLIVE CO

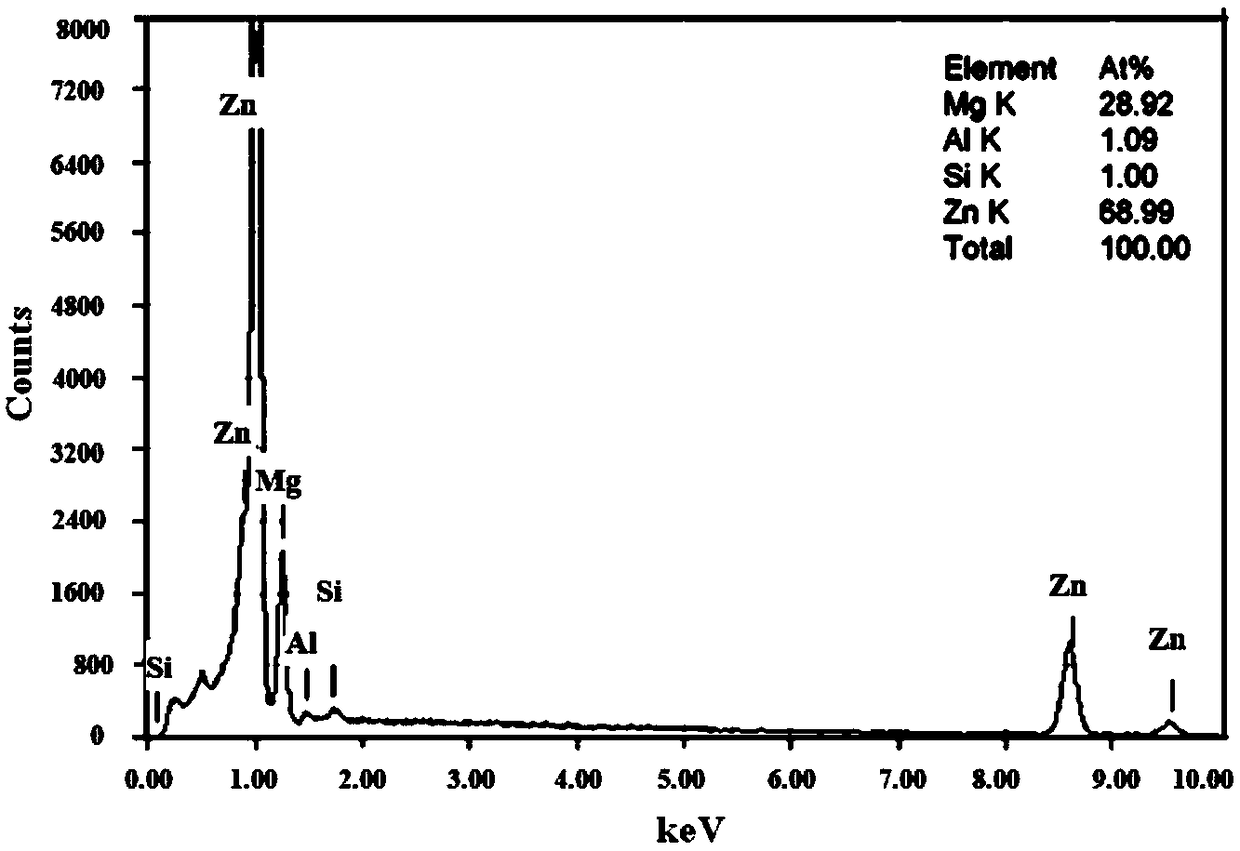

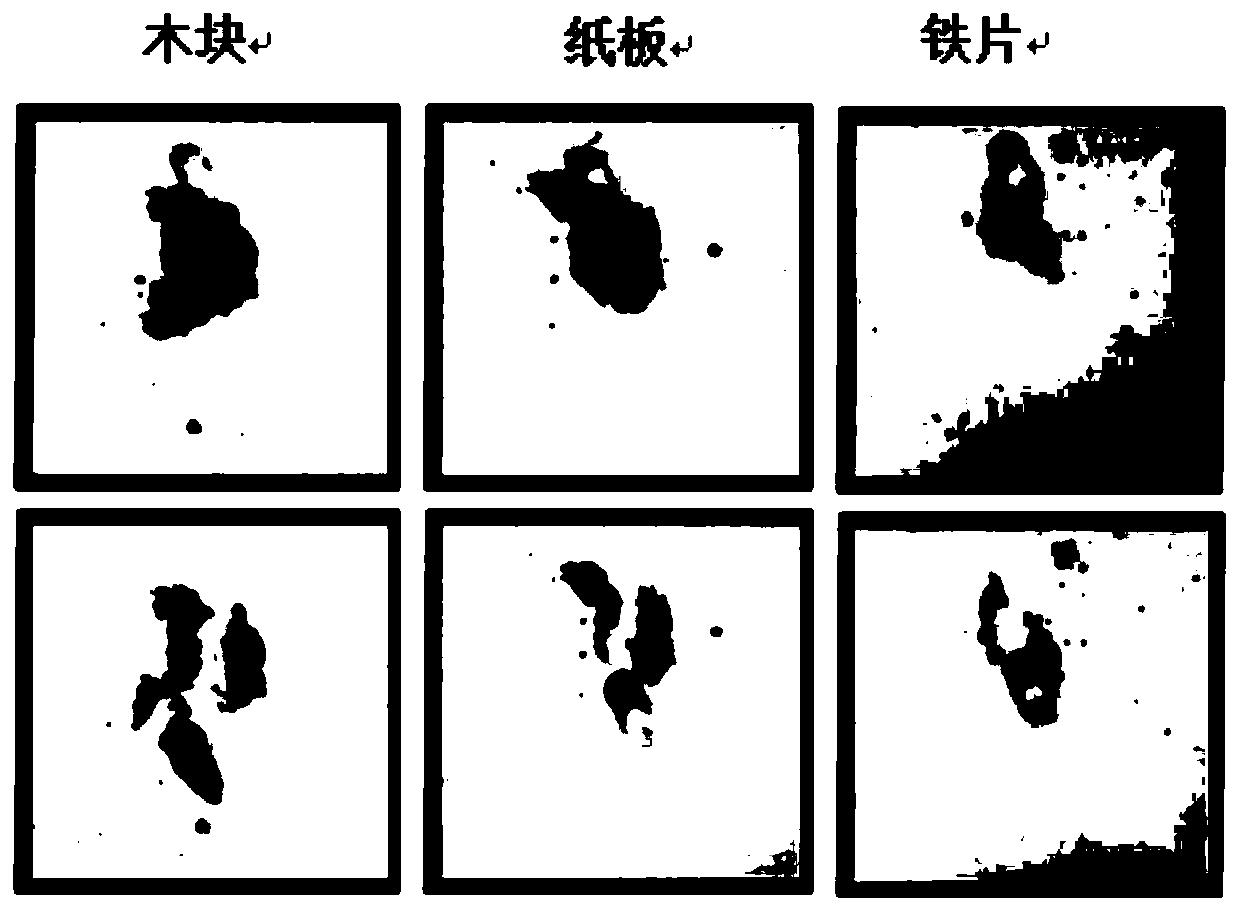

MgZnO film and band gap adjusting method and application thereof

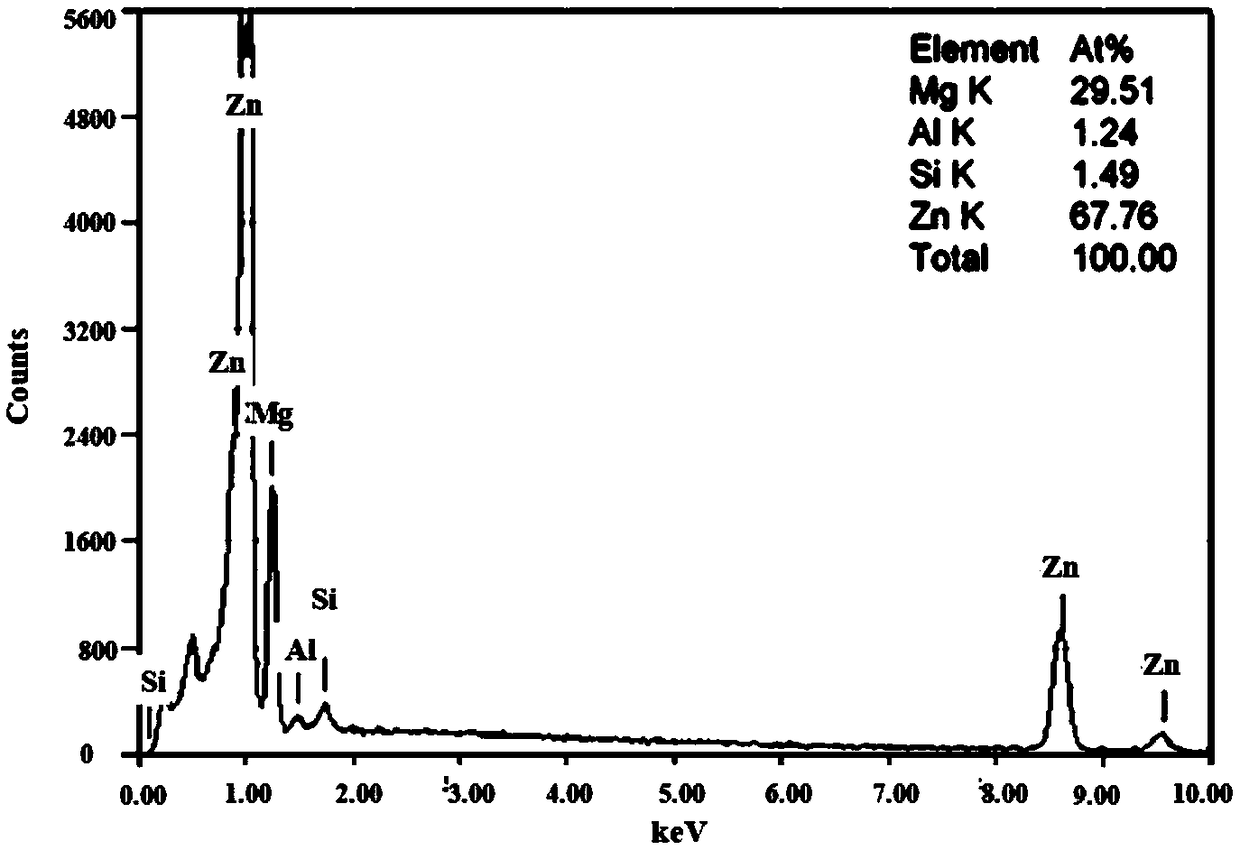

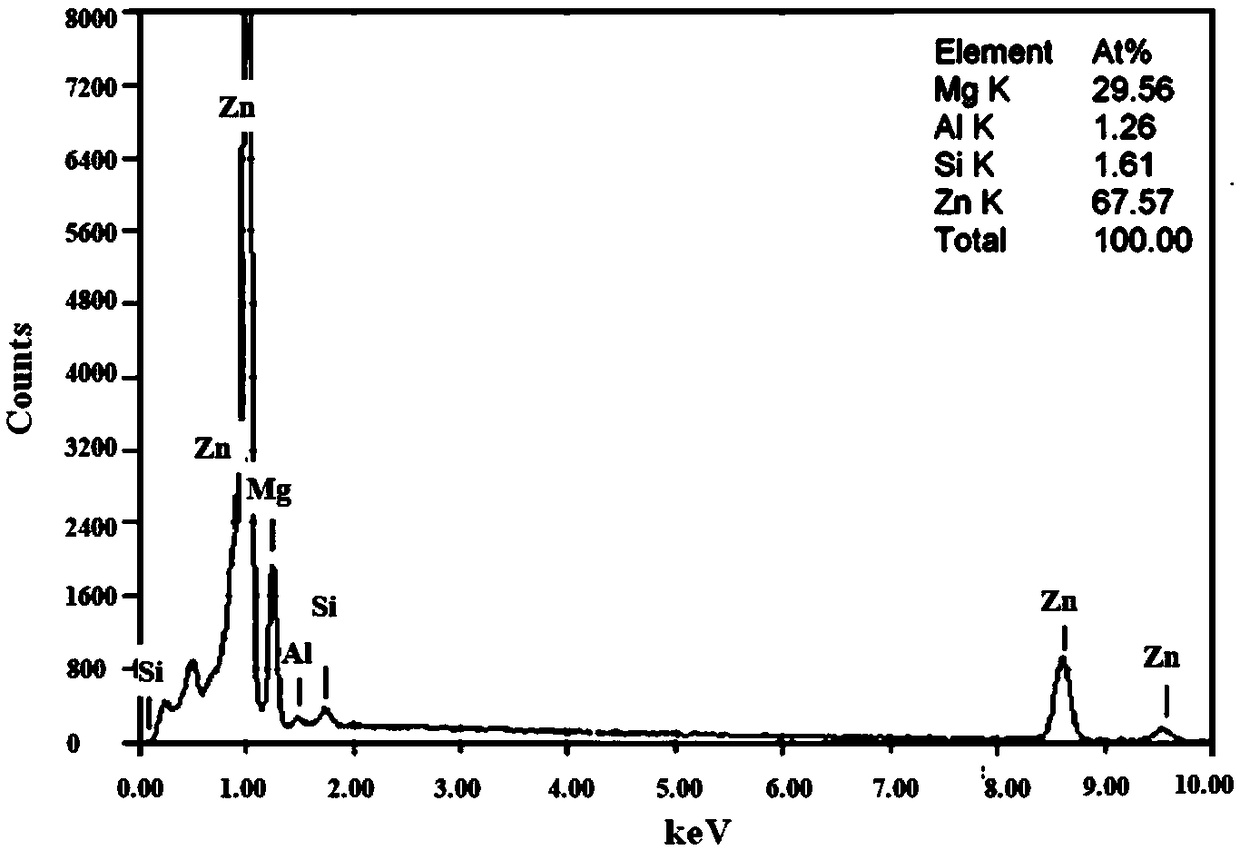

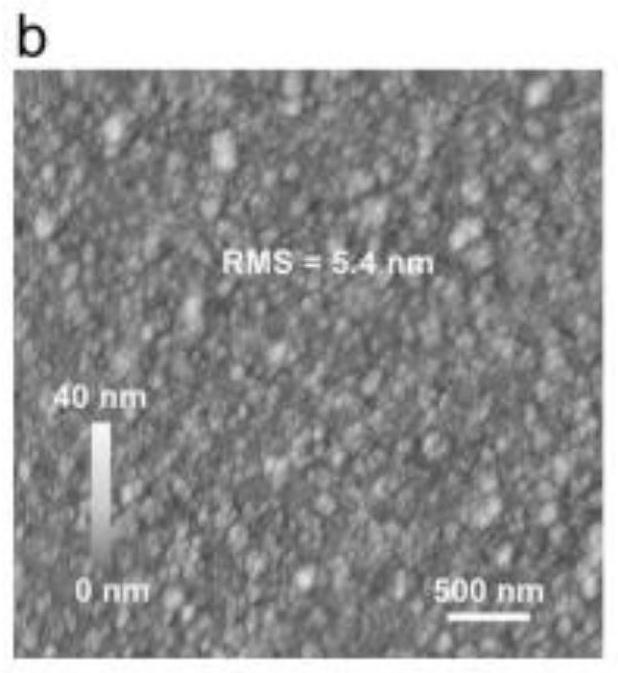

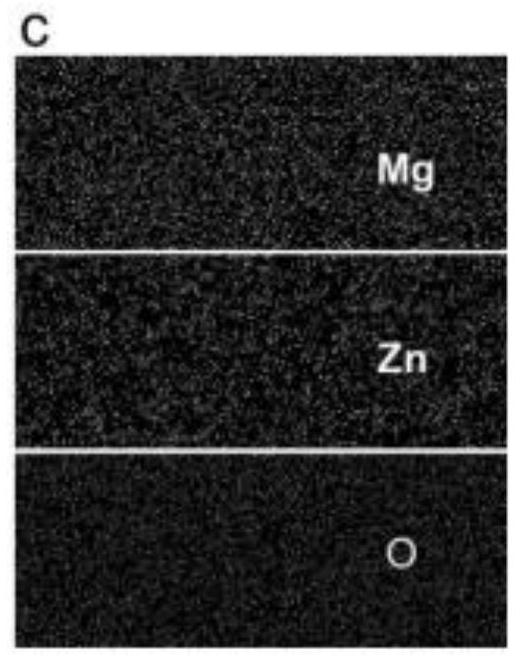

PendingCN114203841APrevent phase separationSemiconductor/solid-state device testing/measurementSemiconductor devicesPhase splittingPhotoconductive detector

The invention relates to the technical field of MgZnO film band gap adjustment, in particular to a MgZnO film and a band gap adjustment method and application thereof, and the method comprises the following steps: observing the MgZnO film according to an SEM diagram, an AFM diagram and an EDS diagram of the MgZnO film; an MgZnO thin film is obtained based on an ALD technology and a low-temperature growth technology, and a planar photoconductive detector is prepared; a semiconductor parameter analyzer is adopted to test the characteristics of the planar photoconductive detector; performing a photoresponse switch test on the device; and performing transmission spectrum test analysis on the returned sample to determine whether the device has spectral selectivity or not, so that phase splitting of the film can be avoided.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com