Glass powder for semiconductor passivation packaging and preparation method of glass powder

A glass powder and semiconductor technology is applied in the field of glass powder for semiconductor passivation and encapsulation and its preparation, which can solve the problems of poor stability, poor protection effect, breakdown and the like, and achieve the effects of simple operation and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

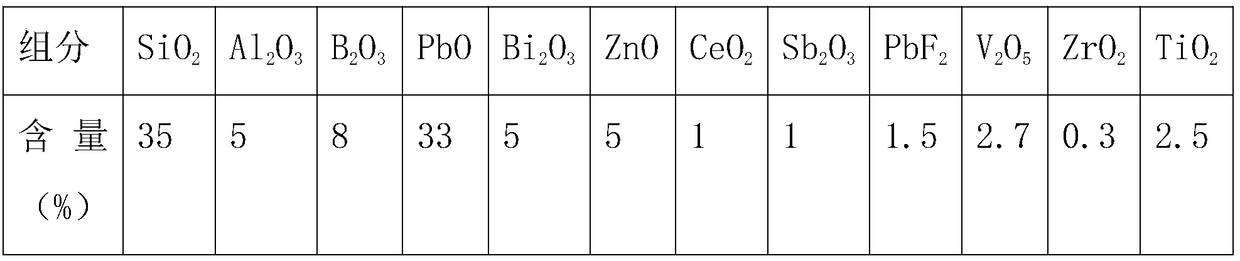

[0021] A glass powder for semiconductor passivation and packaging. The composition in percent by mass is shown in Table 1.

[0022] Table 1 Example 1 Composition Table

[0023] Component

SiO 2

Al 2 O 3

B 2 O 3

PbO

content(%)

45

5

10

40

[0024] The preparation method of the glass powder includes the following steps:

[0025] 1) Calculate SiO according to the mass percentage of the components shown in Table 1. 2 , Al 2 O 3 , B 2 O 3 And the mass of PbO, after weighing the SiO 2 , Al 2 O 3 , B 2 O 3 Mix well with PbO to obtain a mixture of glass powder formula components;

[0026] 2) Put the mixture obtained in step 1) into a platinum crucible or alumina, heat it in a high-temperature resistance furnace, and smelt it into a uniform glass at 1250°C;

[0027] 3) Rolling the molten glass obtained in step 2) into 0.5mm thick shards through a heat-resistant stainless steel water-cooled continuous rolling mill;

[0028] 4) The smashed glass flakes obtained in step 3) are added to the coru...

Embodiment 2

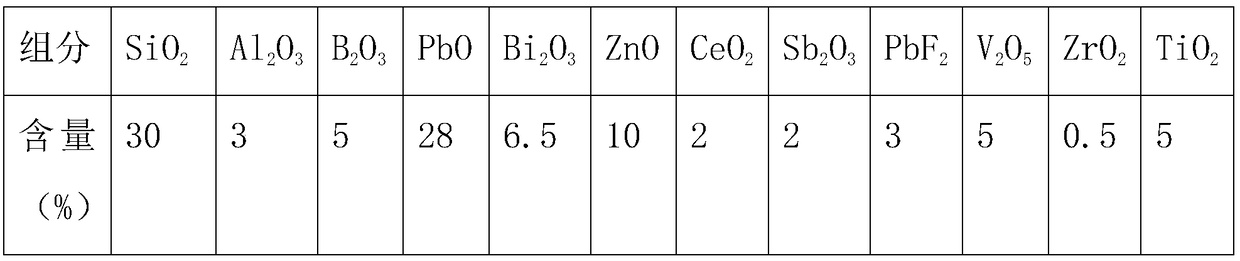

[0030] A glass powder for semiconductor passivation and packaging. The composition in percent by mass is shown in Table 2.

[0031] Table 2 Example 2 Composition Table

[0032]

[0033] The preparation method of the glass powder includes the following steps:

[0034] 1) Calculate SiO according to the mass percentage of the components shown in Table 1. 2 , Al 2 O 3 , B 2 O 3 , PbO, Bi 2 O 3 , ZnO, CeO 2 , Sb 2 O 3 , PbF 2 , V 2 O 5 , ZrO 2 And TiO 2 After weighing, the components are fully mixed uniformly to obtain a mixture of glass powder formula components;

[0035] 2) Put the mixture obtained in step 1) into a platinum crucible or alumina, heat it in a high-temperature resistance furnace, and smelt it into a uniform molten glass at 1260°C;

[0036] 3) Rolling the molten glass obtained in step 2) into 0.5mm thick shards through a heat-resistant stainless steel water-cooled continuous rolling mill;

[0037] 4) The smashed glass flakes obtained in step 3) are added to the corundum tank b...

Embodiment 3

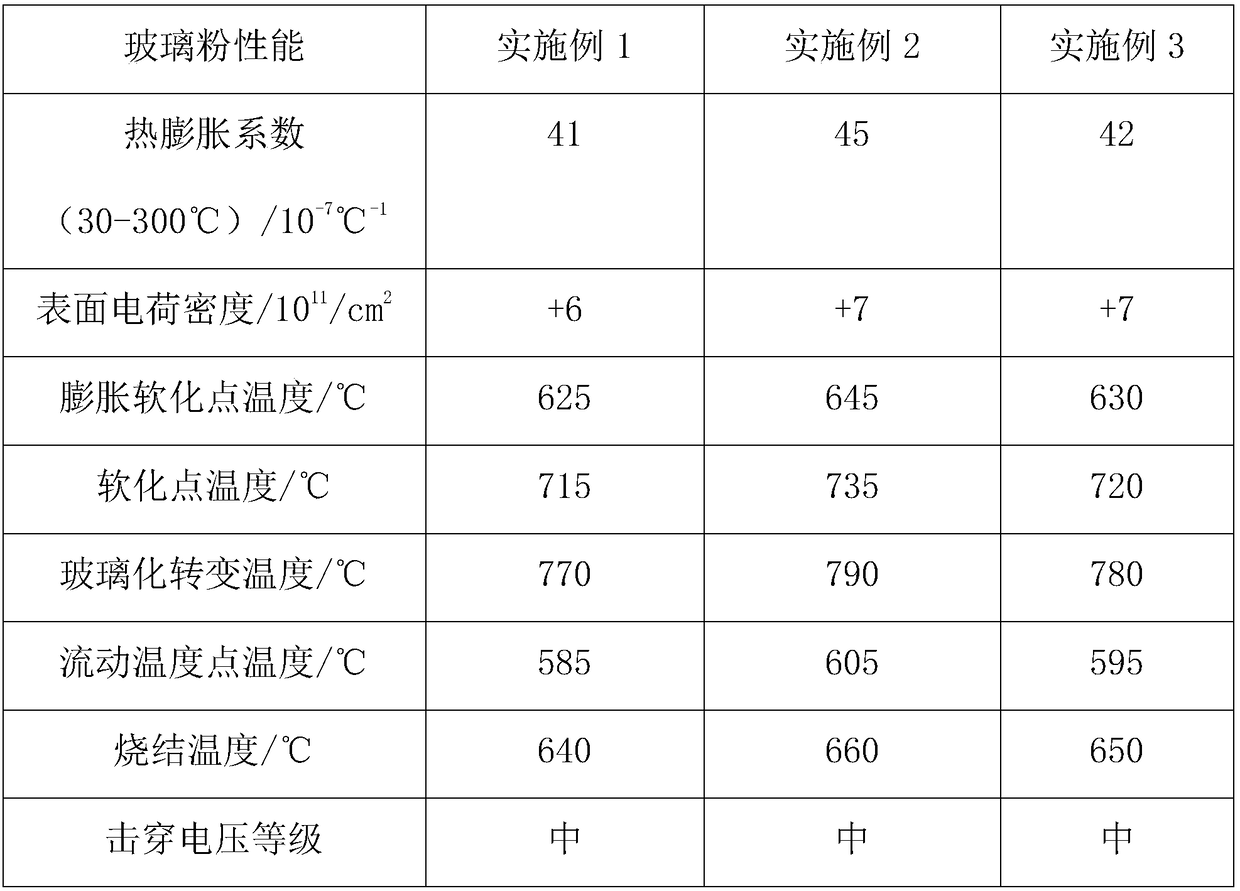

[0039] A glass powder for semiconductor passivation encapsulation. The composition in percent by mass is shown in Table 3.

[0040] Table 3 Example 3 component table

[0041]

[0042] The preparation method of the glass powder includes the following steps:

[0043] 1) Calculate SiO according to the mass percentage of the components shown in Table 1. 2 , Al 2 O 3 , B 2 O 3 , PbO, Bi 2 O 3 , ZnO, CeO 2 , Sb 2 O 3 , PbF 2 , V 2 O 5 , ZrO 2 And TiO 2 After weighing, the components are fully mixed uniformly to obtain a mixture of glass powder formula components;

[0044] 2) Add the mixture obtained in step 1) into a platinum crucible or alumina, heat it in a high-temperature resistance furnace, and smelt it into a uniform molten glass at 1280°C;

[0045] 3) Rolling the molten glass obtained in step 2) into 0.5mm thick shards through a heat-resistant stainless steel water-cooled continuous rolling mill;

[0046] 4) The smashed glass flakes obtained in step 3) are added to the corundum tank bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com