Mechanical-thermal hydrate exploiting method

A technology for hydrate and hydrate sediments, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc. It can solve the problems of limited decomposition range, consumption, and low production efficiency, and achieve high convective heat transfer efficiency and avoidance of The effect of leakage and high mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

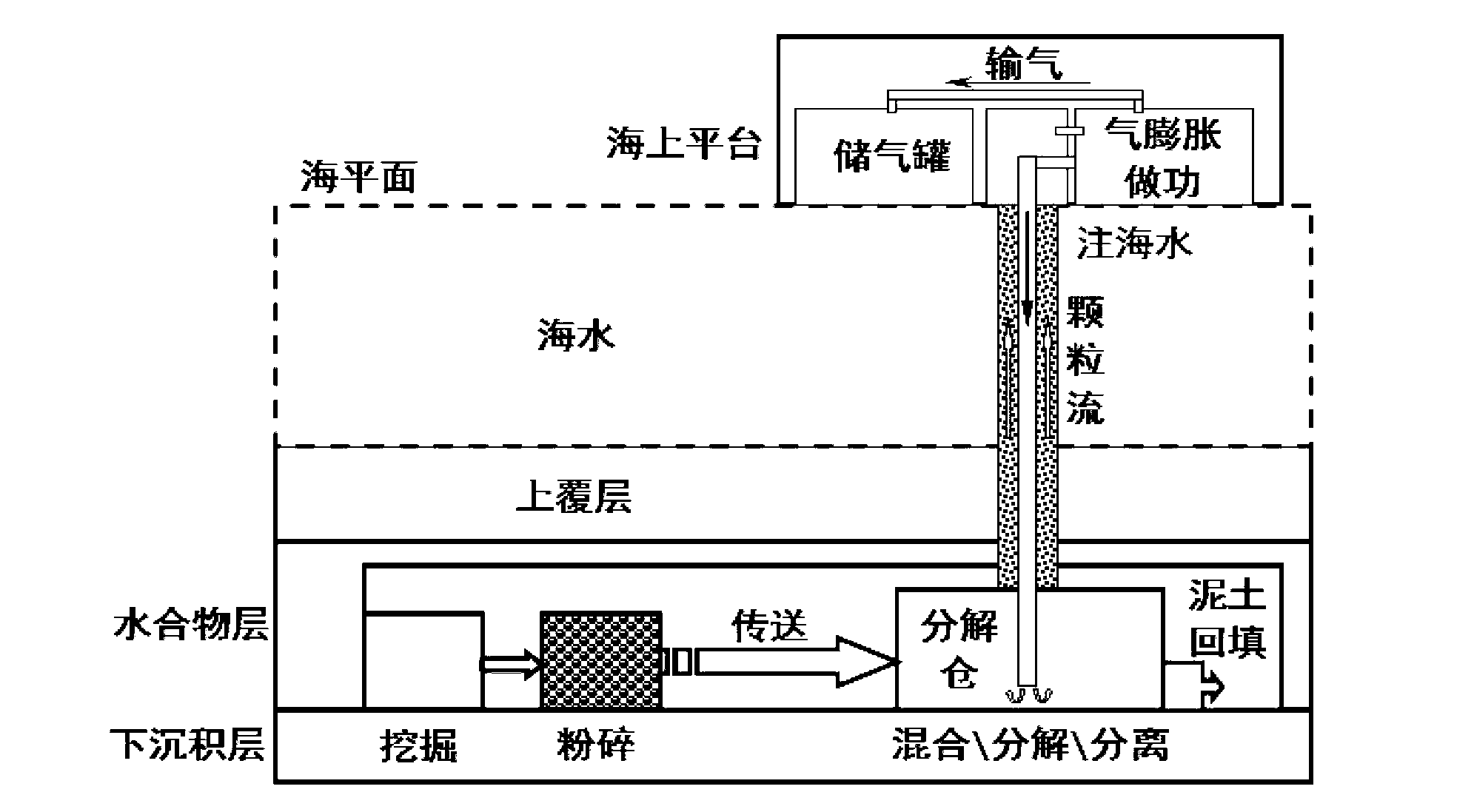

[0029] Mechanical-thermal mining of hydrate is a new mining method proposed in view of the slow heat transfer efficiency and low mining efficiency of existing mining methods. Its basic idea is to excavate hydrate formations with mechanical equipment and The hydrate is crushed into particles; then in the pre-designed hydrate decomposition chamber, the supply of hot seawater, the mixing of small particles and seawater, and the partial separation and backfill of sediments, hydrates, water and gas are carried out; Then the hydrate deposits, water, and gas are transported upwards along the production wellbore, and the hydrates decompose to produce gas and the sediments separate and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com