Patents

Literature

932 results about "Convective heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Convective heat transfer, often referred to simply as convection, is the transfer of heat from one place to another by the movement of fluids. Convection is usually the dominant form of heat transfer in liquids and gases. Although often discussed as a distinct method of heat transfer, convective heat transfer involves the combined processes of unknown conduction (heat diffusion) and advection (heat transfer by bulk fluid flow).

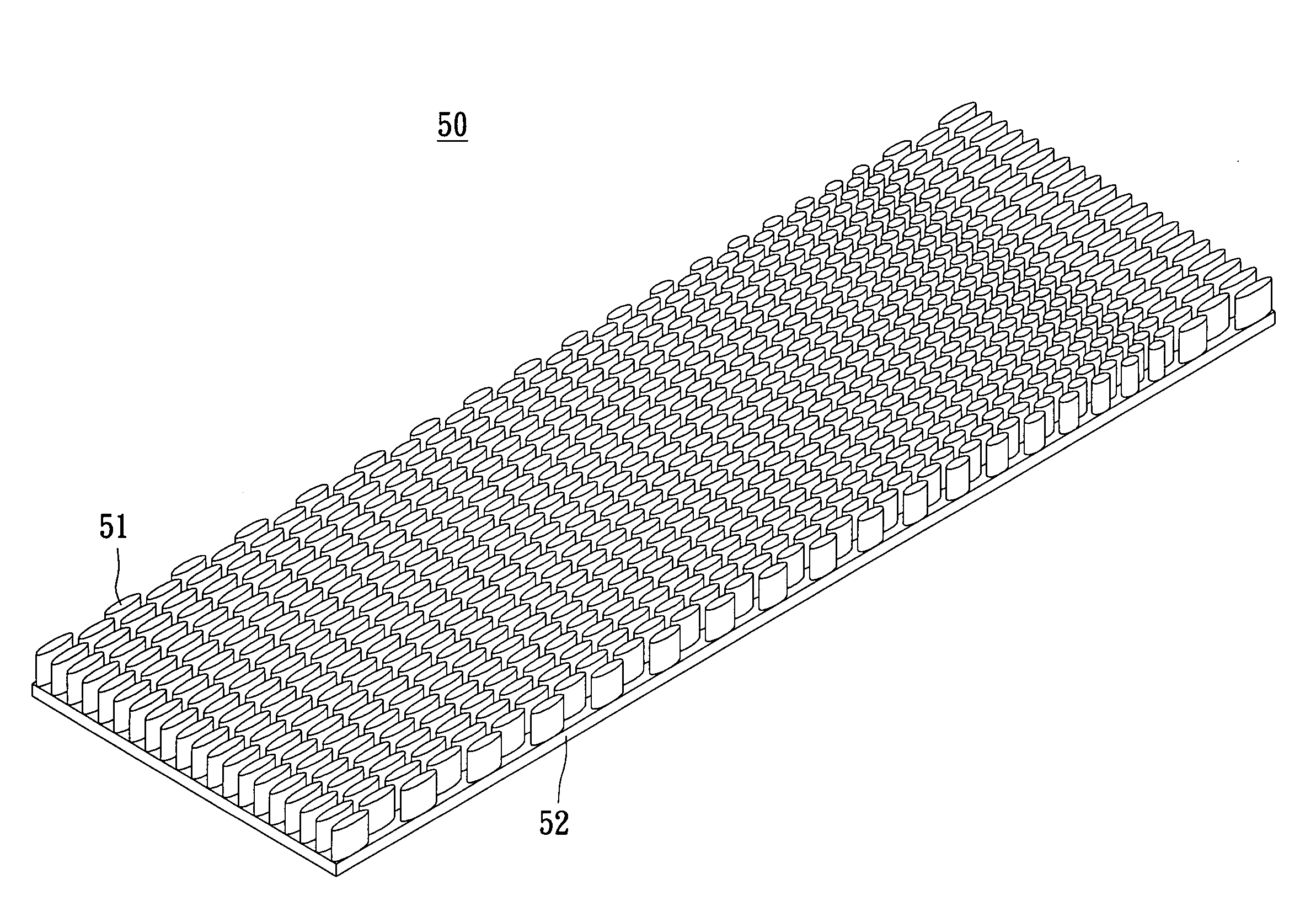

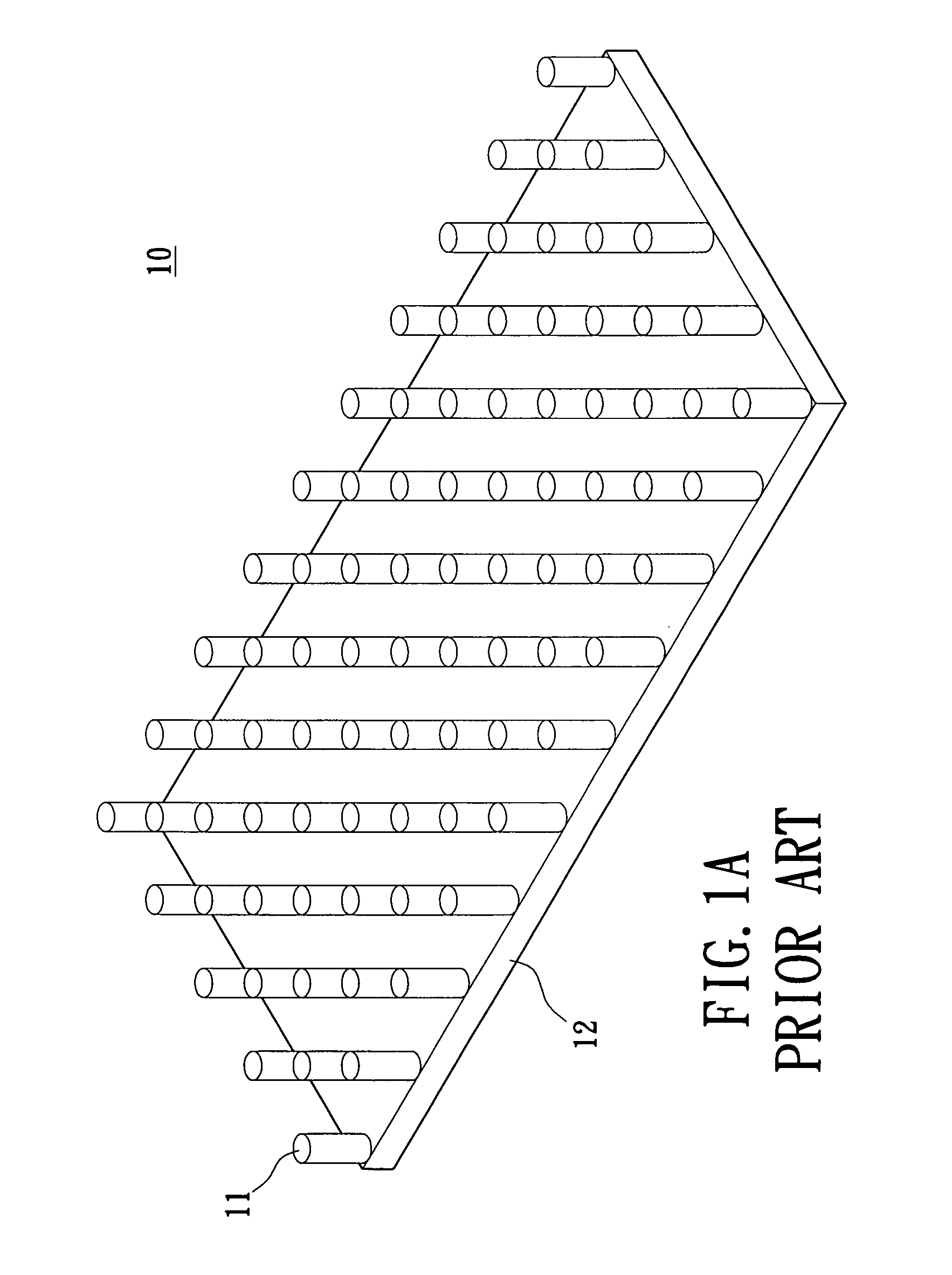

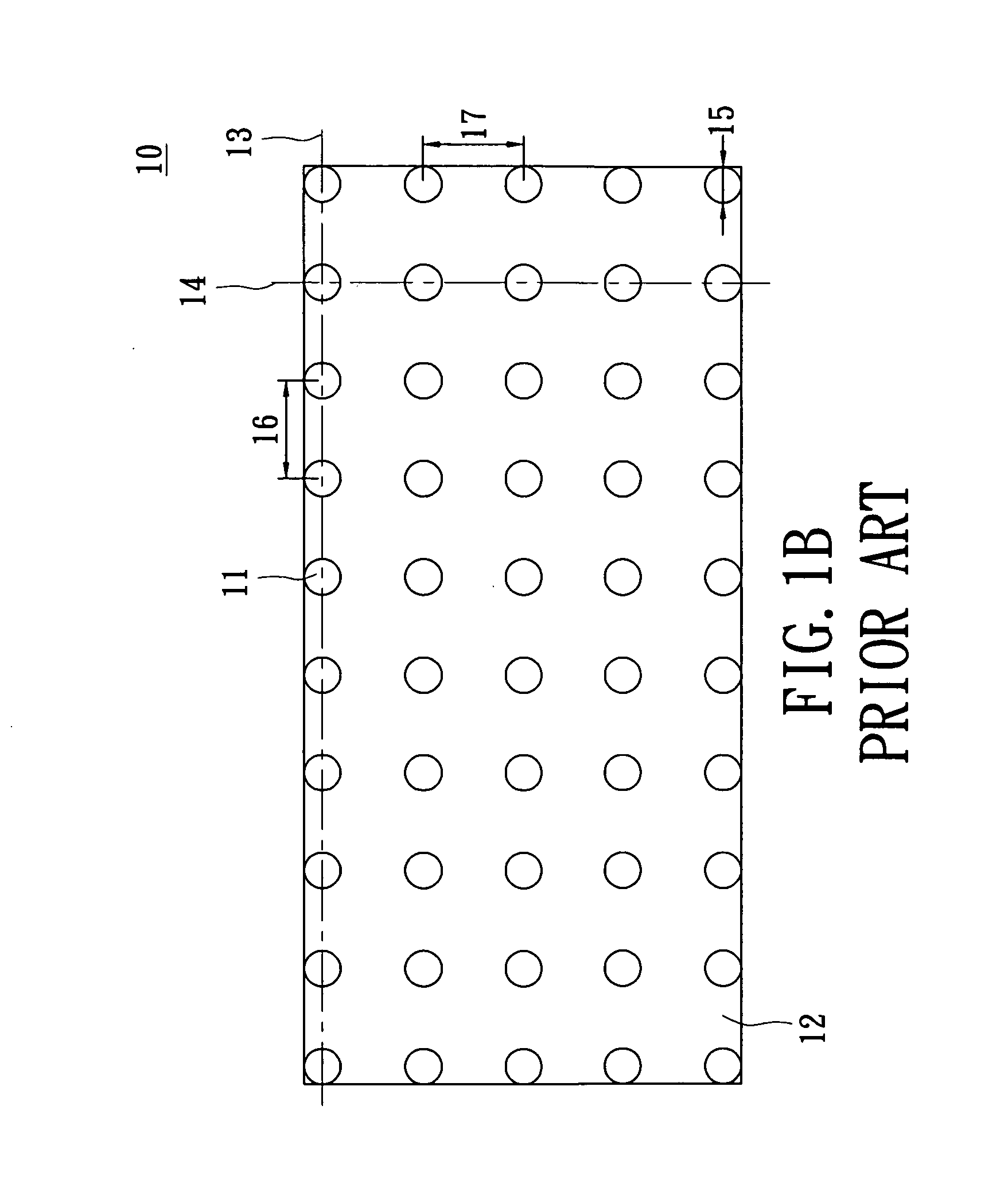

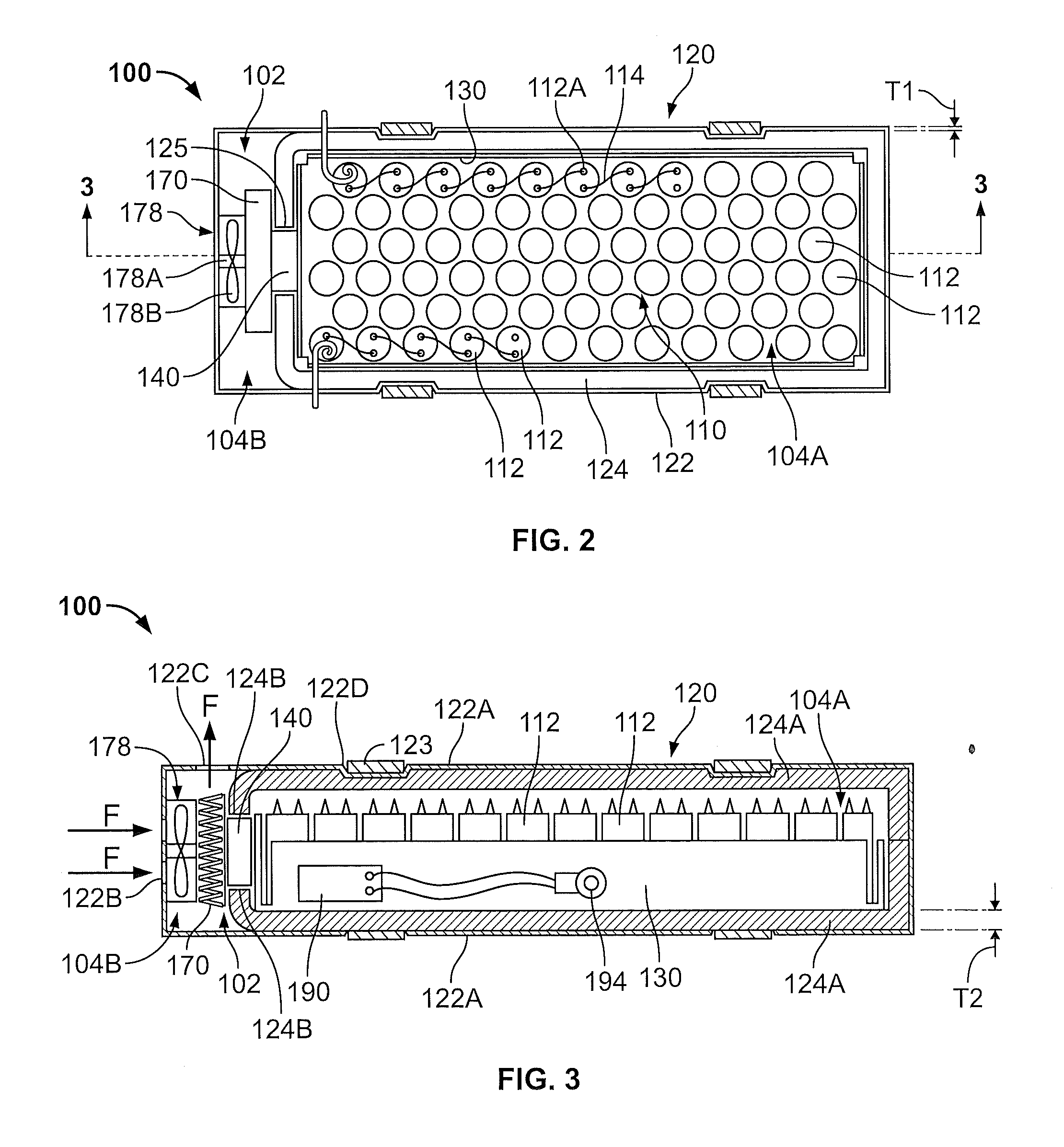

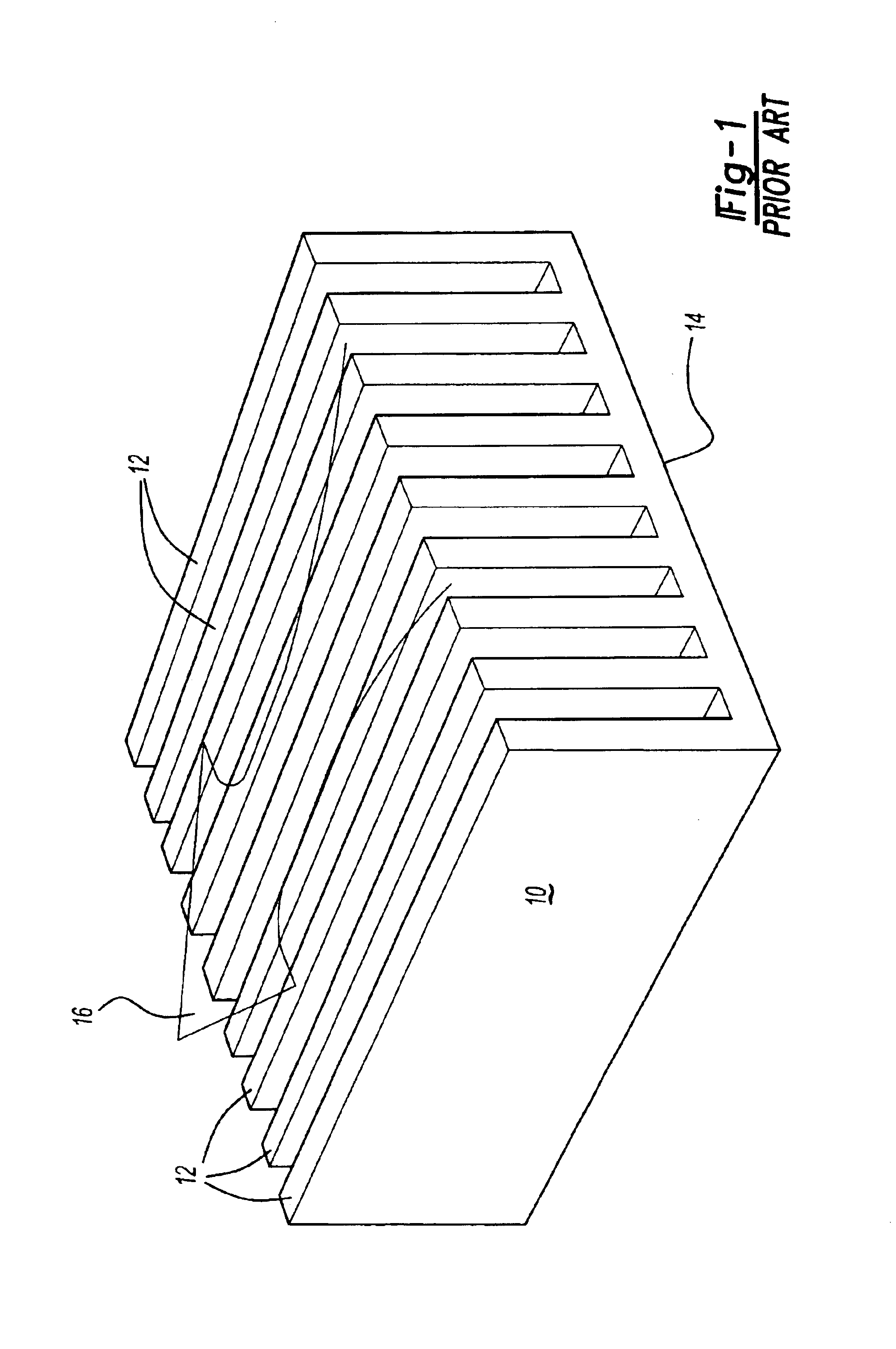

Non-linear fin heat sink

InactiveUS20090145581A1Improve power densityDissipating/removing heatSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

A non-linear fin heat sink is provided for dissipating / removing heat uniformly from a device, where the heat generation is non-uniform over that device, while also providing a small and relatively lightweight heat sink. The heat sink has extended surface protrusions that are optimally shaped in recognition of convective heat transfer, conductive heat transfer, and flow resistance allowing the heat sink to offset the temperature rise of a coolant media and provide enhanced cooling for the coolant temperature, deliver optimized cooling efficiency per the local physical properties of the coolant media, be used with a fluid for effectuating heat transfer; either liquid coolant, gas coolant or a combination thereof. Furthermore the heat sink features turbulence enhancement of the coolant stream by a pin array through which coolant stream passes, such fin array featuring a non-linear shape, spacing, and height pattern to provide optimal cooling while simultaneously reducing volume and flow resistance.

Owner:THERMAL TECH

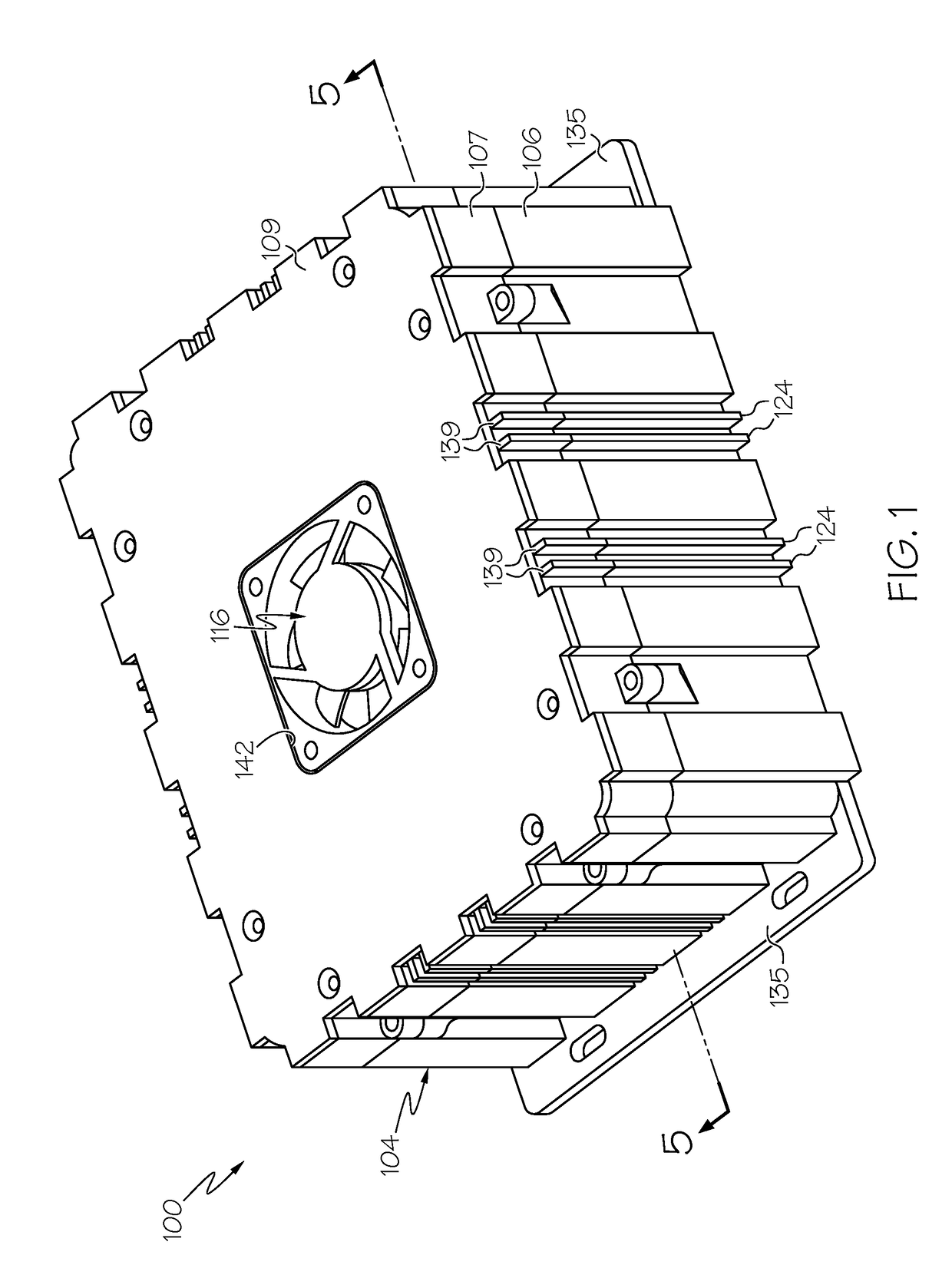

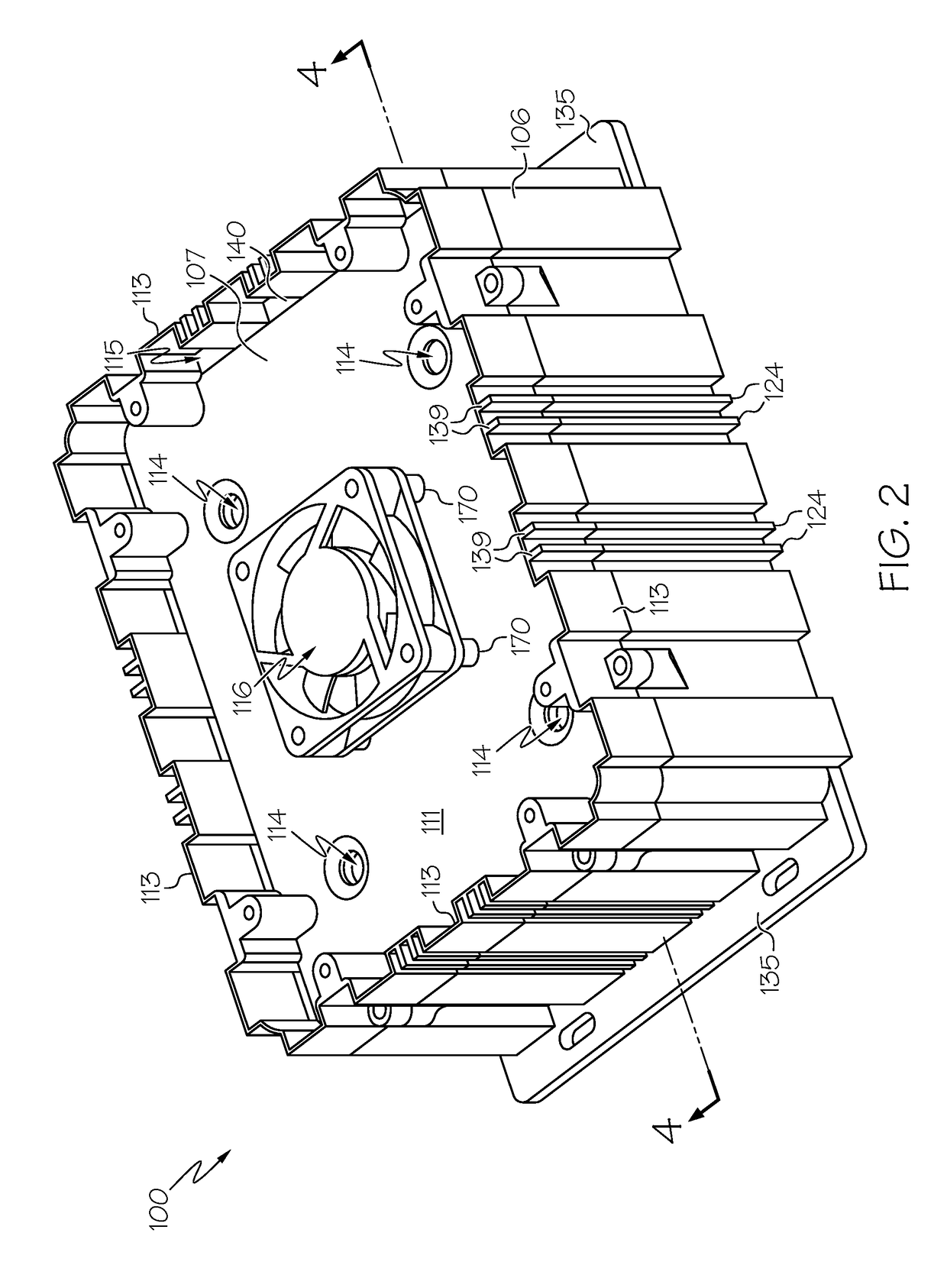

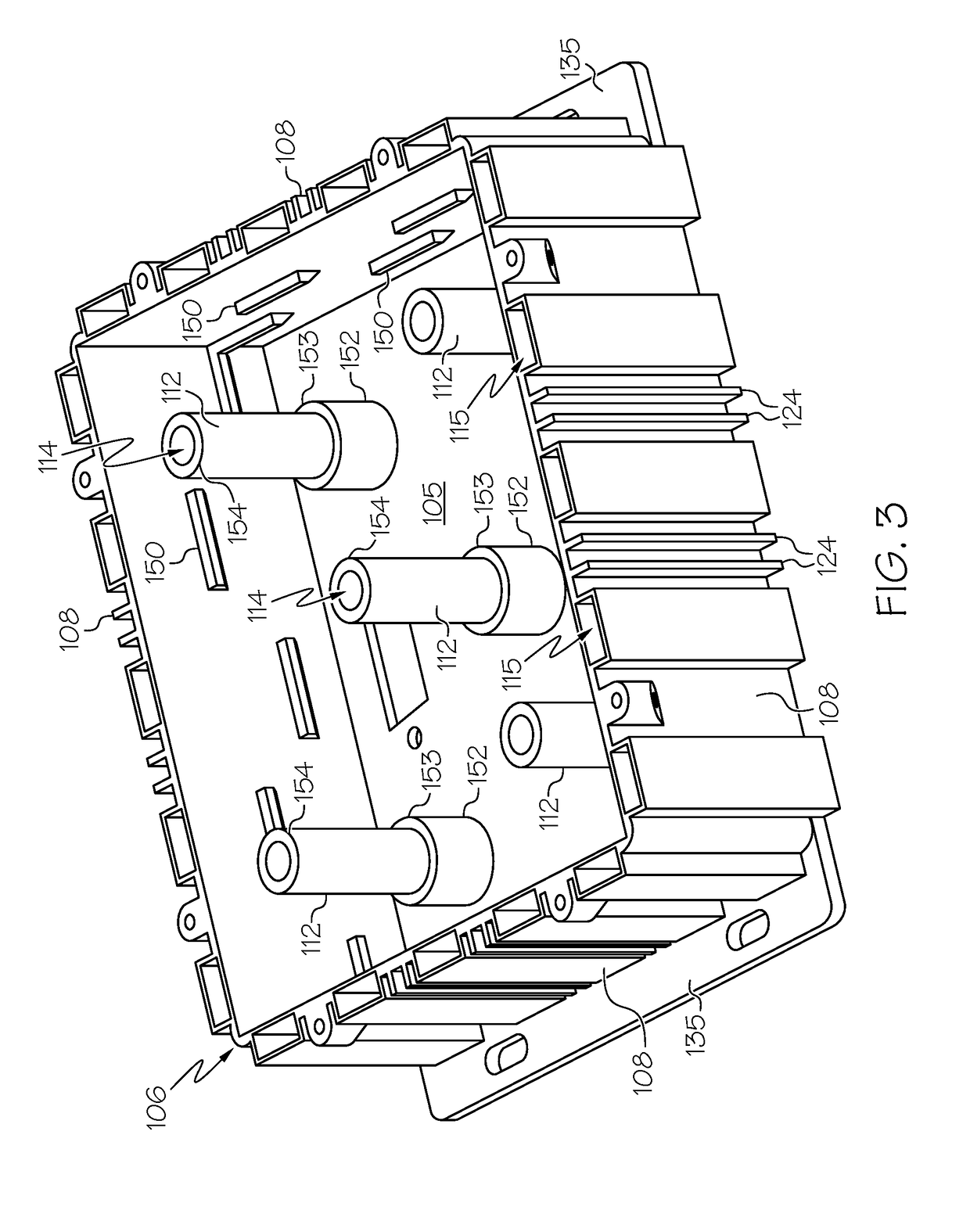

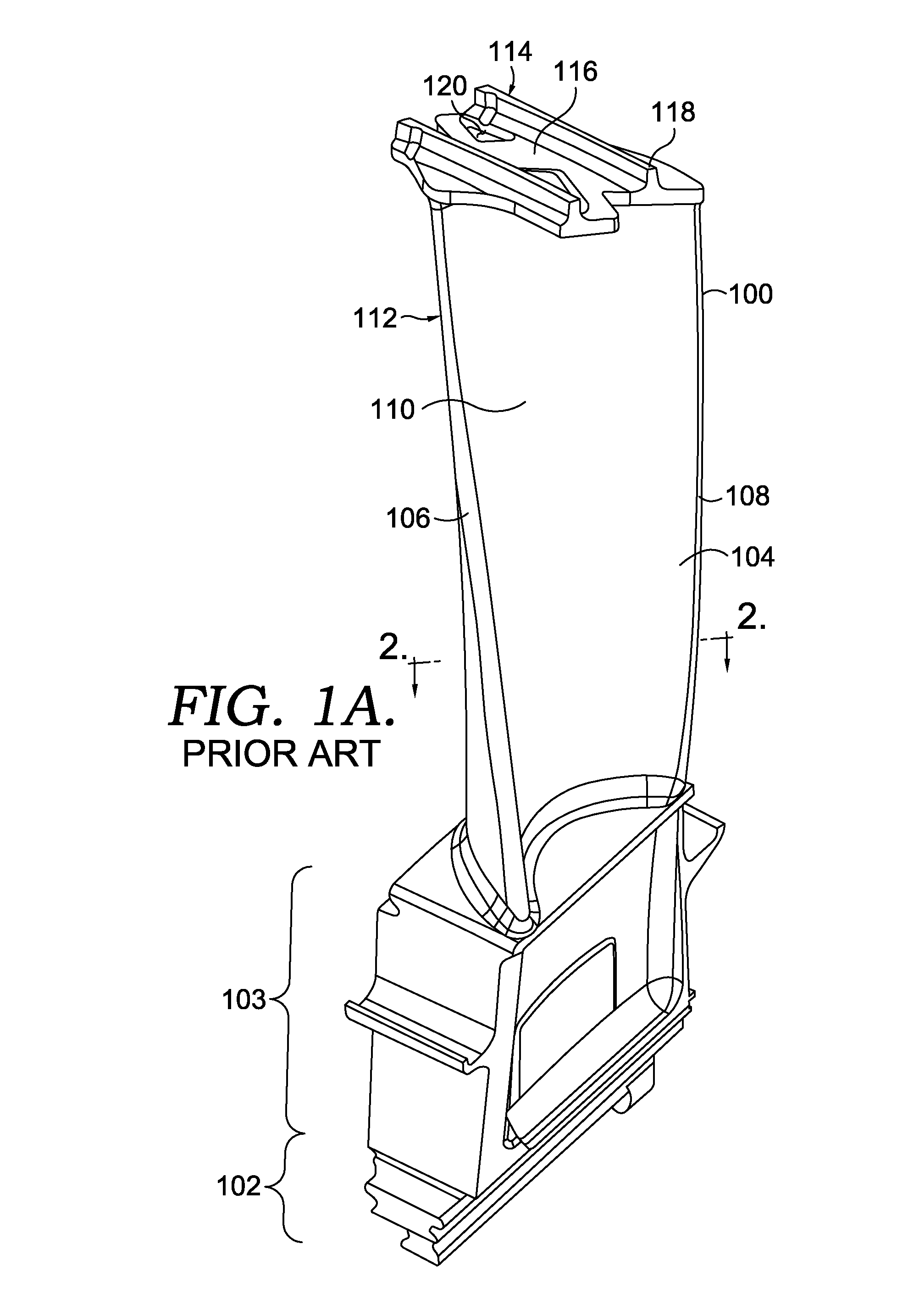

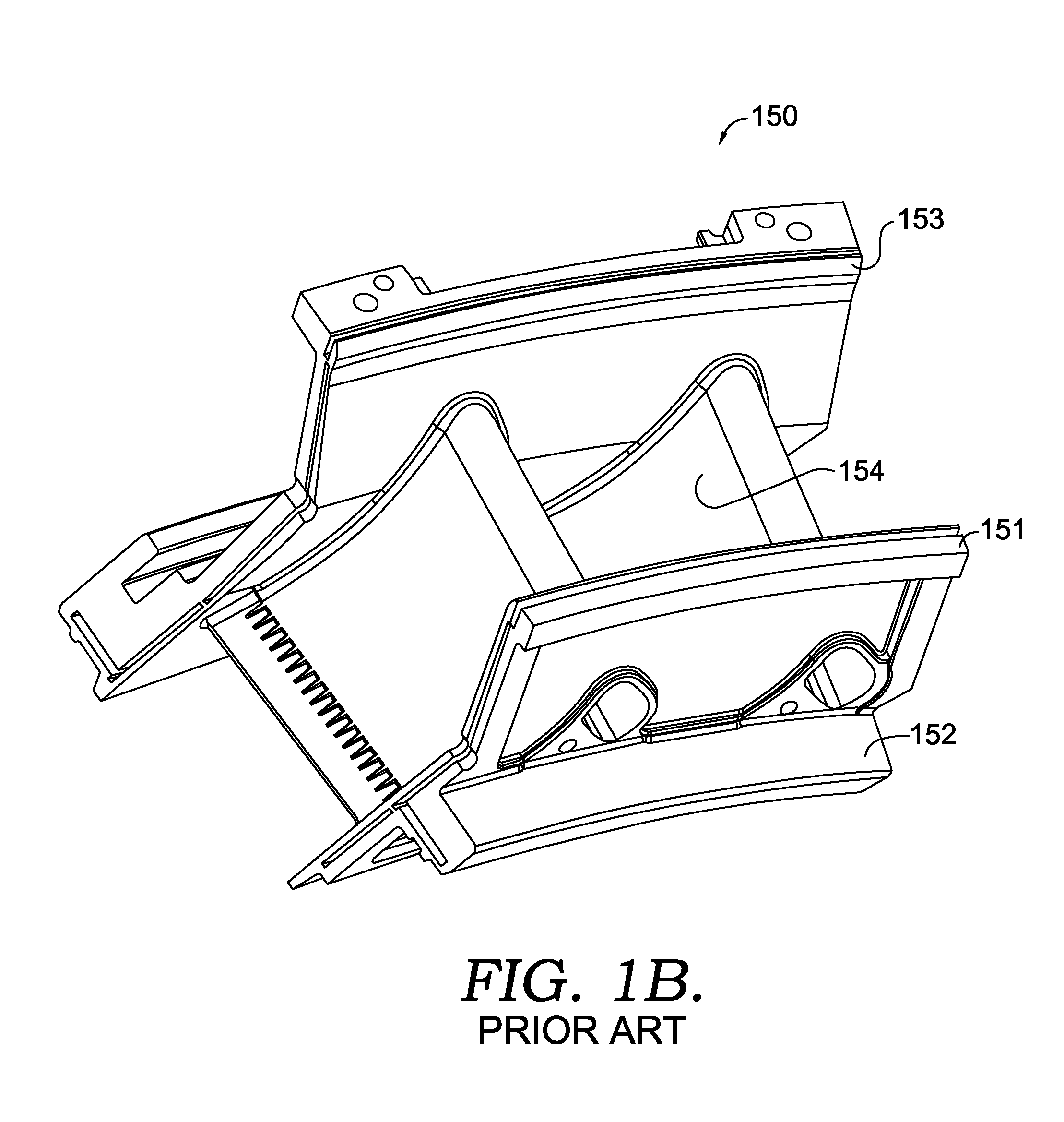

Support structure for electronics having fluid passageway for convective heat transfer

ActiveUS10178800B2Printed circuit board receptaclesCooling/ventilation/heating modificationsEngineeringElectronic component

A support structure for an electronic component a chassis and a standoff that is attached to the chassis. The standoff is configured to support the electronic component and separate the electronic component at a distance away from the chassis. The standoff is configured to receive heat generated by the electronic component. The standoff includes a fluid passageway. The fluid passageway is configured to allow a cooling fluid to flow therethrough for convective heat transfer from the standoff to the cooling fluid.

Owner:HONEYWELL INT INC

Flat heat pipe radiator and application thereof

InactiveUS20100220439A1Small sizeDistanceDigital data processing detailsSemiconductor/solid-state device detailsImpellerEngineering

A flat radiator with flat type heat pipe and its application for portable computers is provided. The heat pipe in a radiator use tubular type and plate type structures. An air convective extended heat exchange surface surrounds and is over against the fan impeller, such that the radiator is extremely compacted, and the heat transport distance in heat pipe is shortened. Further introducing enhanced convective heat transfer structure and setting the fins according to the aerodynamics improve the heat dissipating capacity. The restrictions to a radiator when installing are reduced, which helps to implement the standardization of the radiator series. Also portable computers using the radiator are provided.

Owner:QIN BIAO

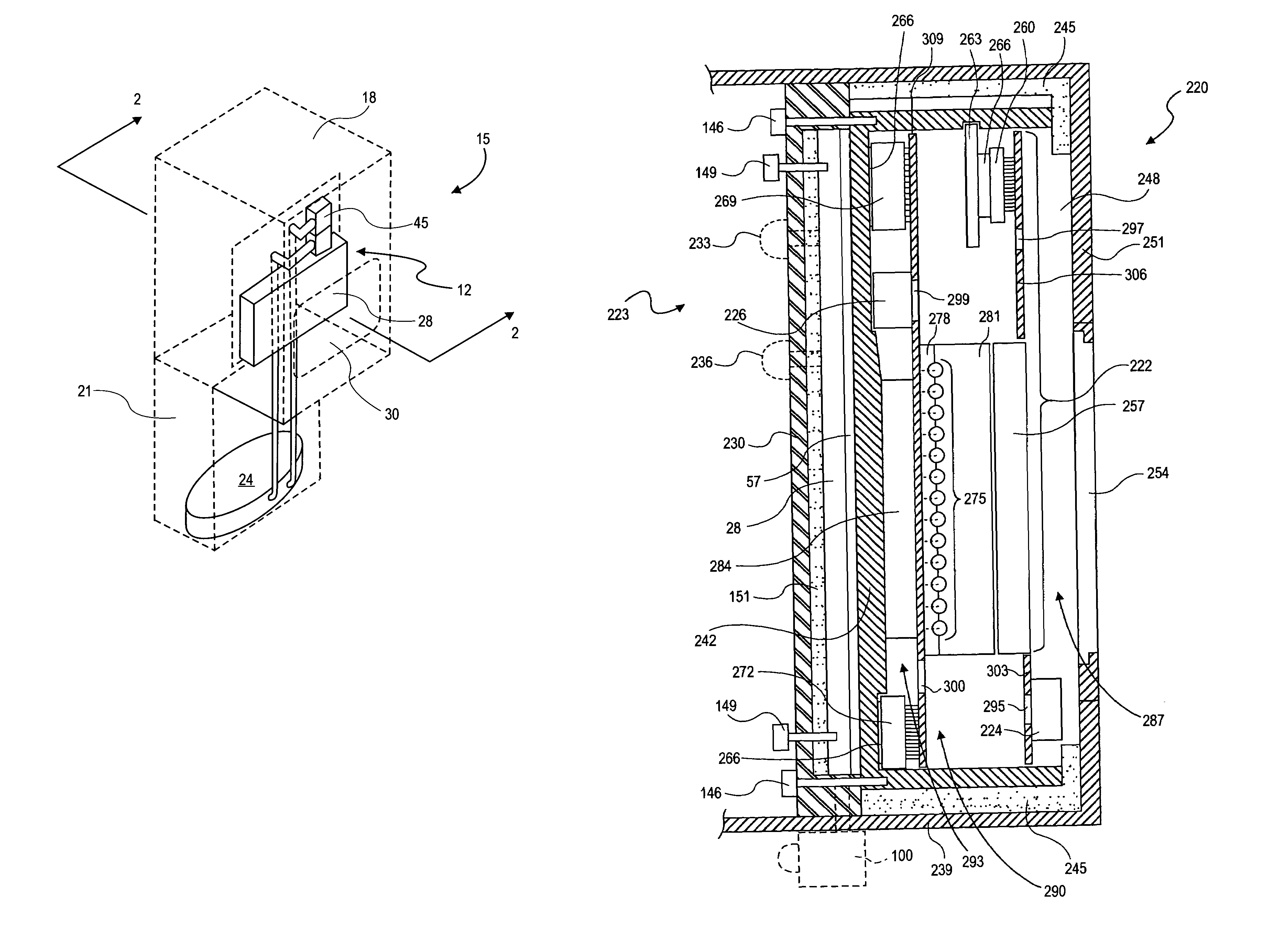

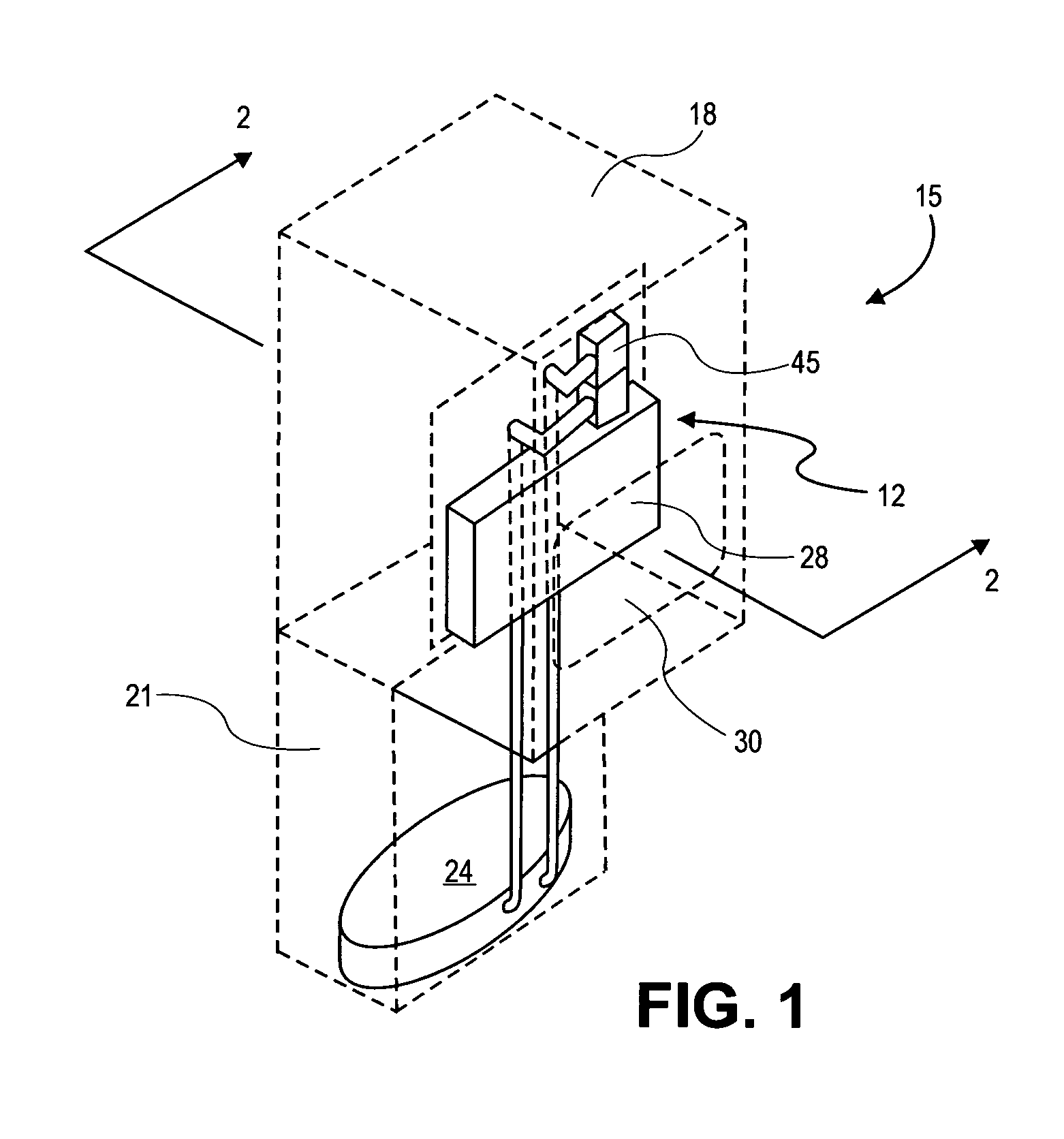

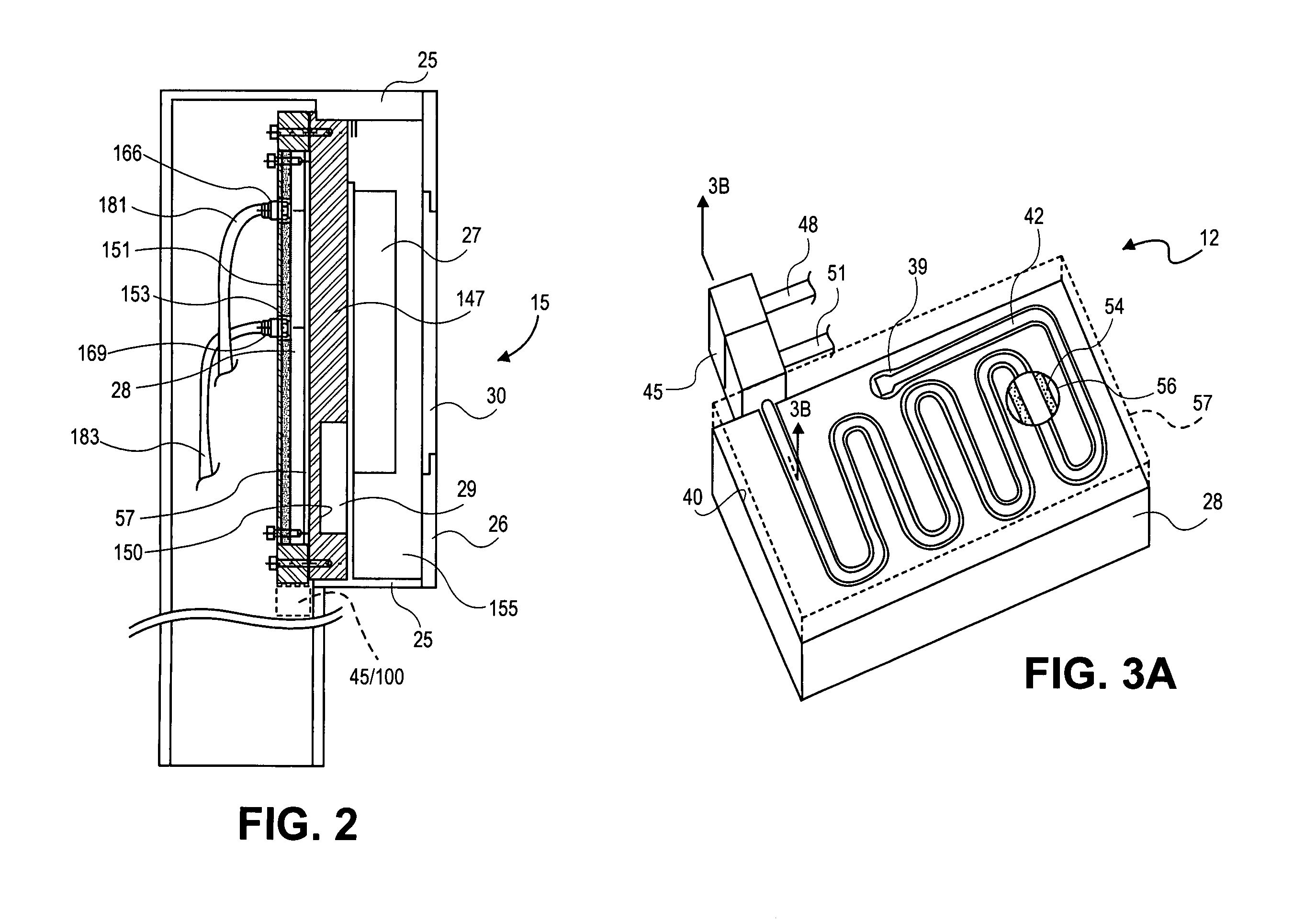

Cooling system for an electronic display

InactiveUS7161803B1Temperature fluctuationImprove life expectancyModifications for display panelsIndirect heat exchangersGas phaseCollector device

A cooling system for an electronic display may include a heat collector plate with internal gas and liquid phase lines. The cooling plate may be thermally isolated together with electronic components of the display within an enclosure of the display, while external lines carry liquid and gas phase refrigerant outside the enclosure to and from the heat collector plate. The external lines may be similar in size to each other and may be connected to the heat collector outside the heat collector plate by a manifold. The heat collector plate contacts a base plate of the electronic display in a thermally conductive relation to transfer heat from electronic components within the display to the gas phase refrigerant. Fans may be included for additional convective heat transfer. A single compressor may be fluidly connected to multiple heat collector plates in respective electronic displays.

Owner:FRONTLINE SYST

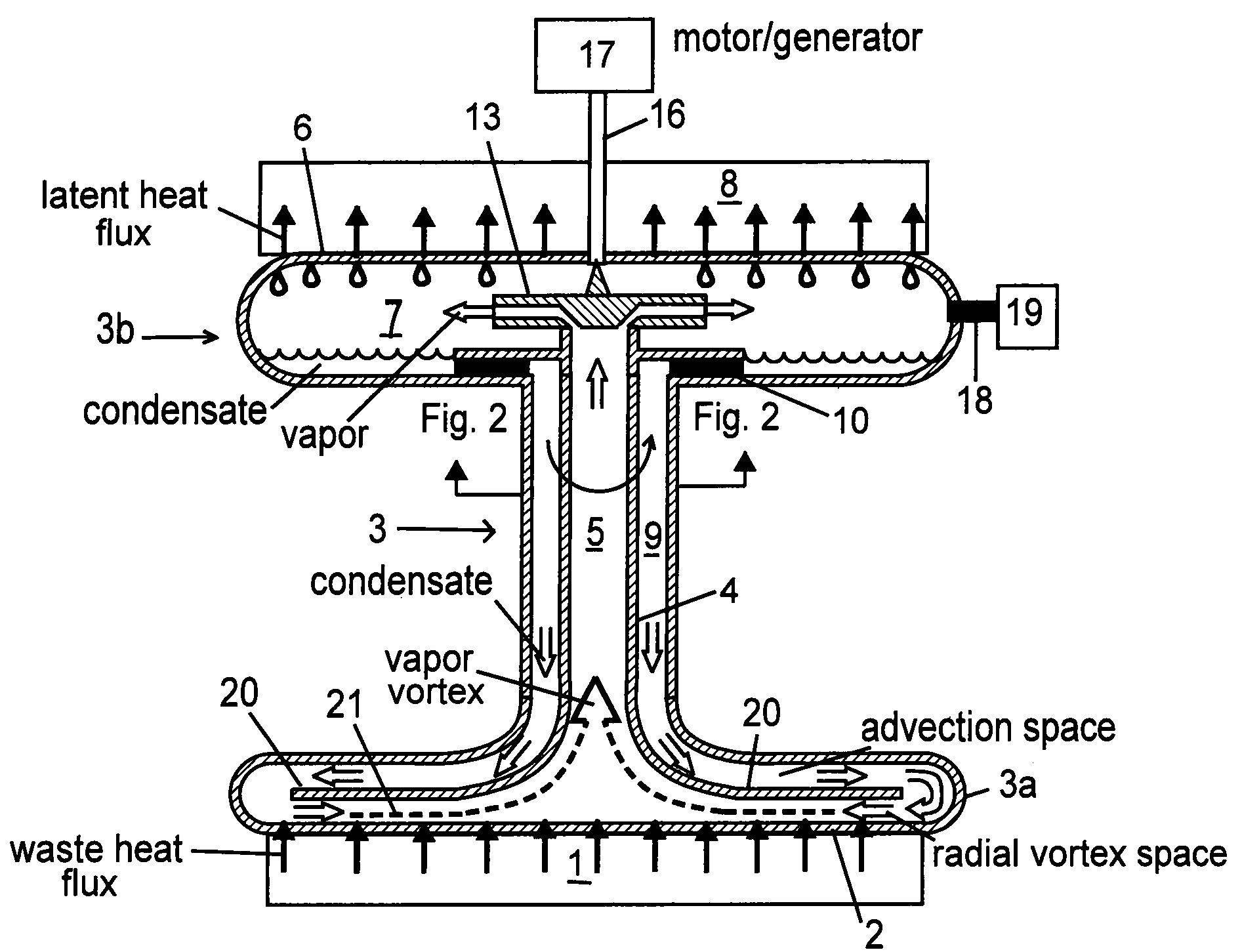

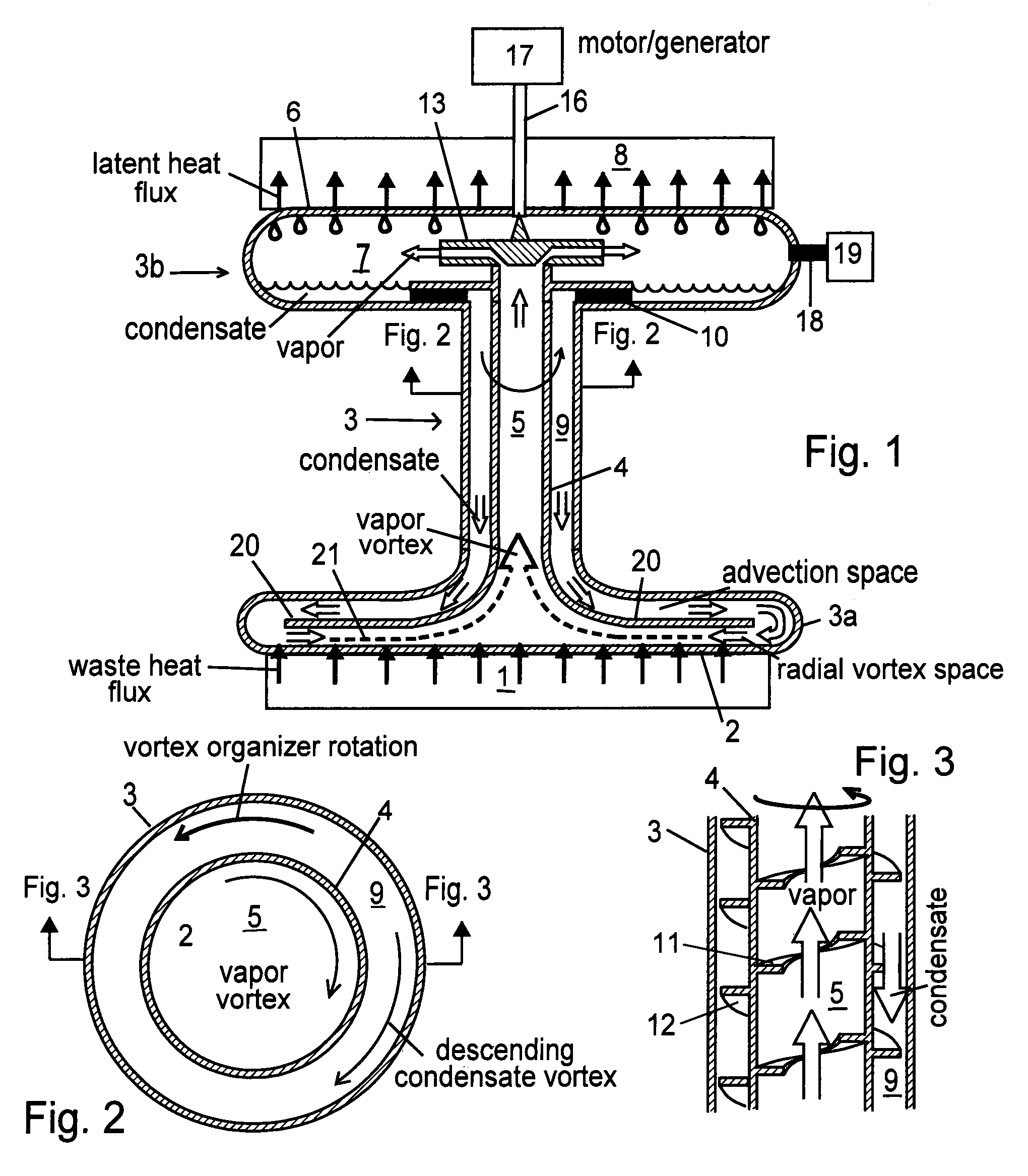

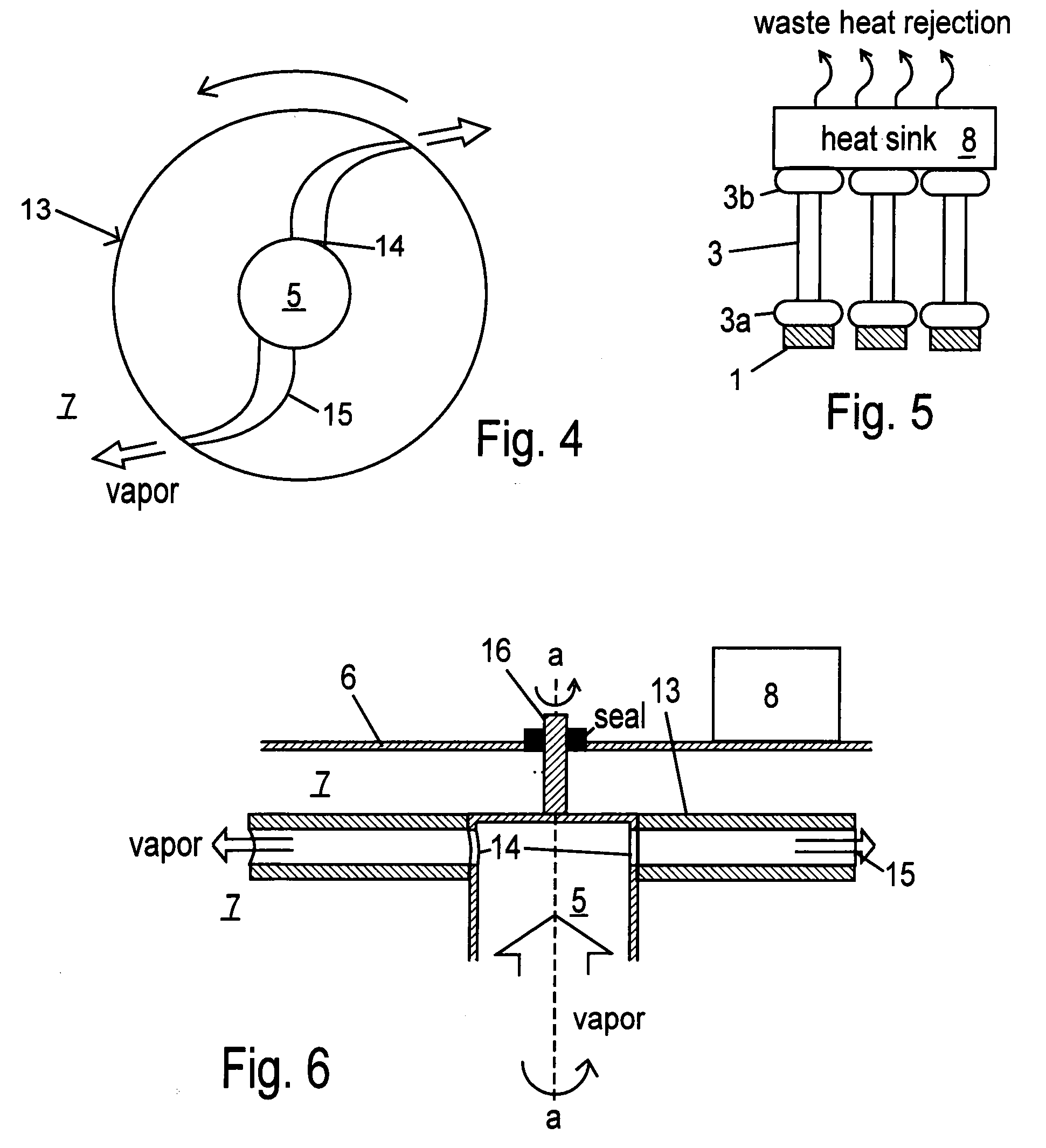

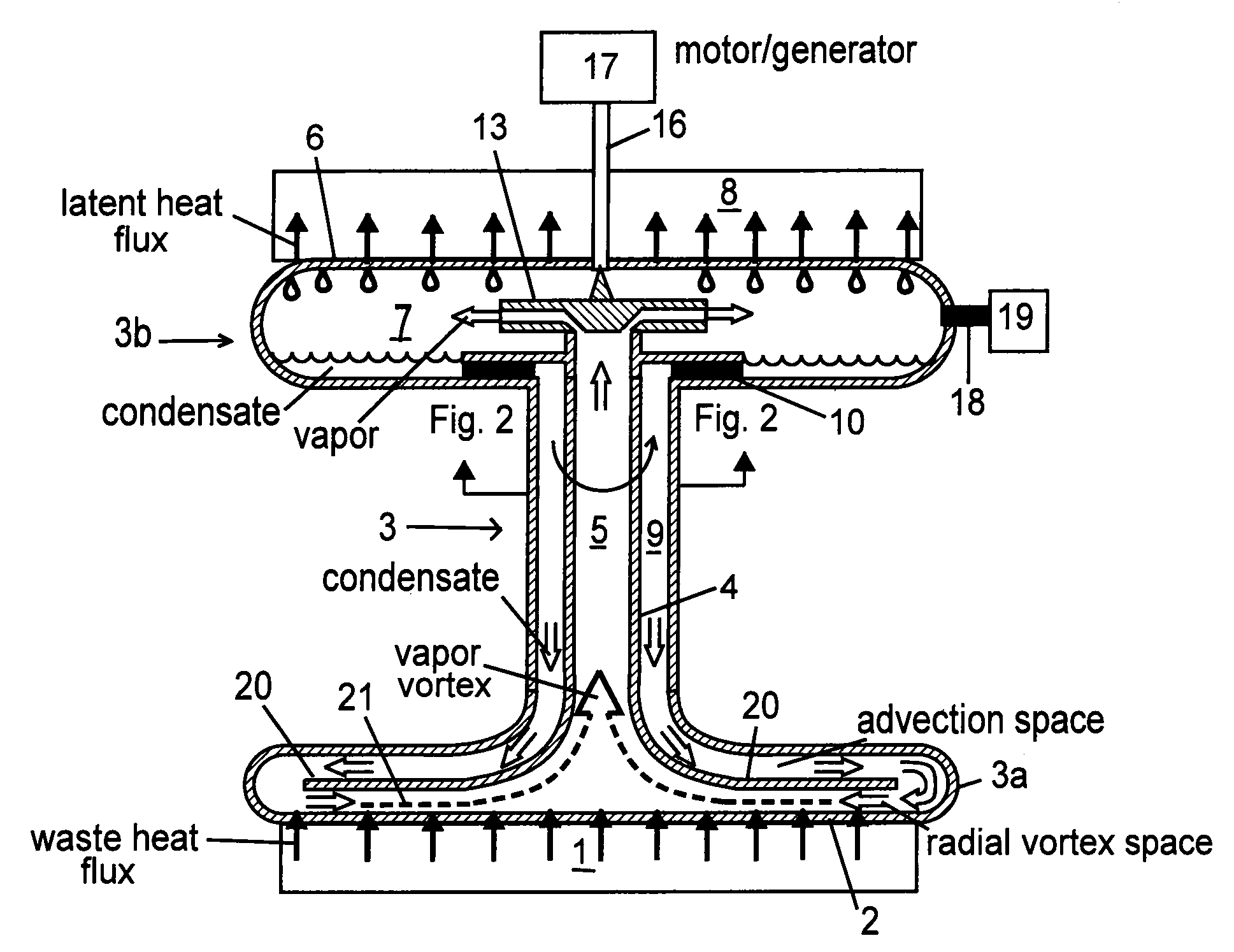

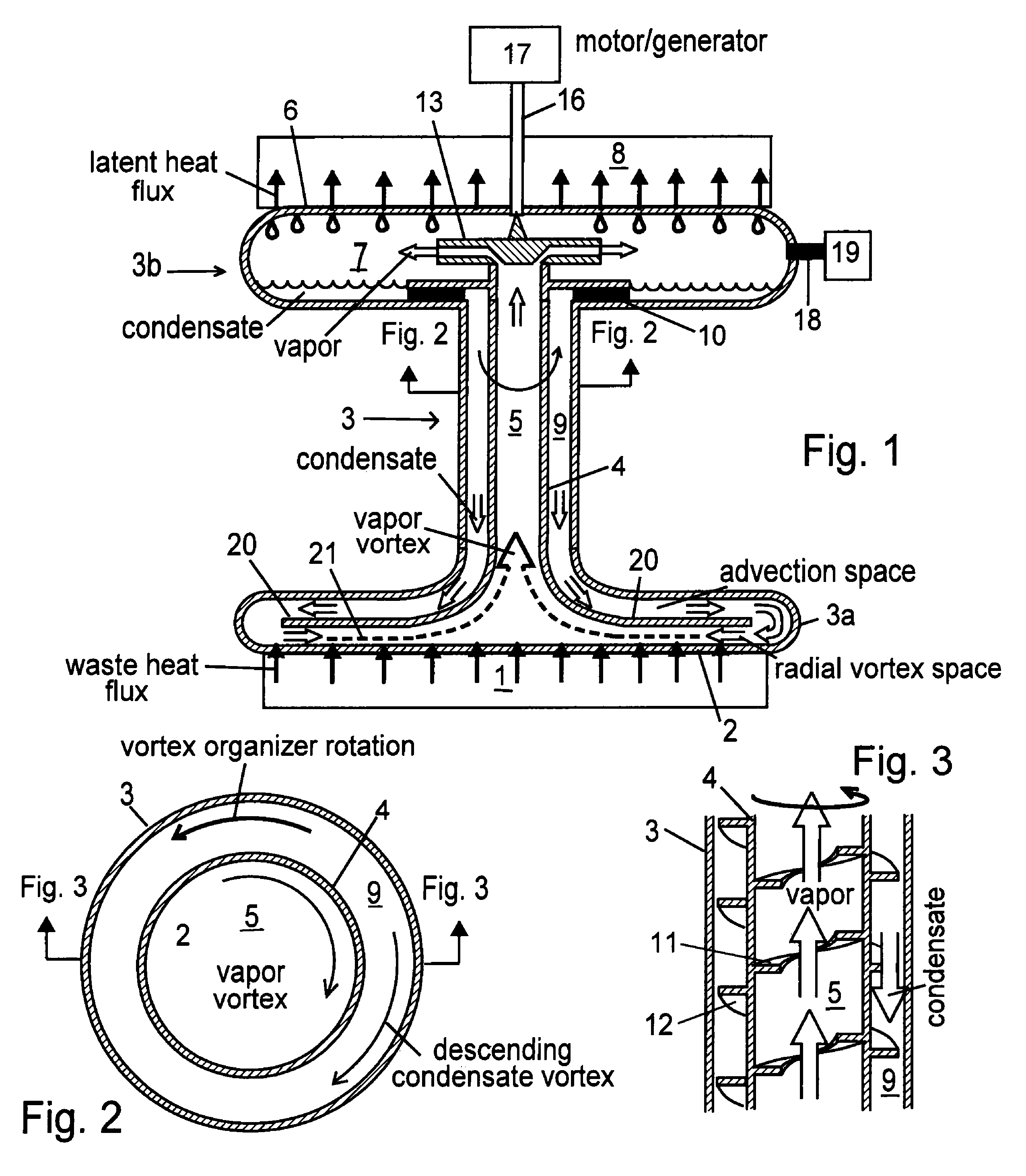

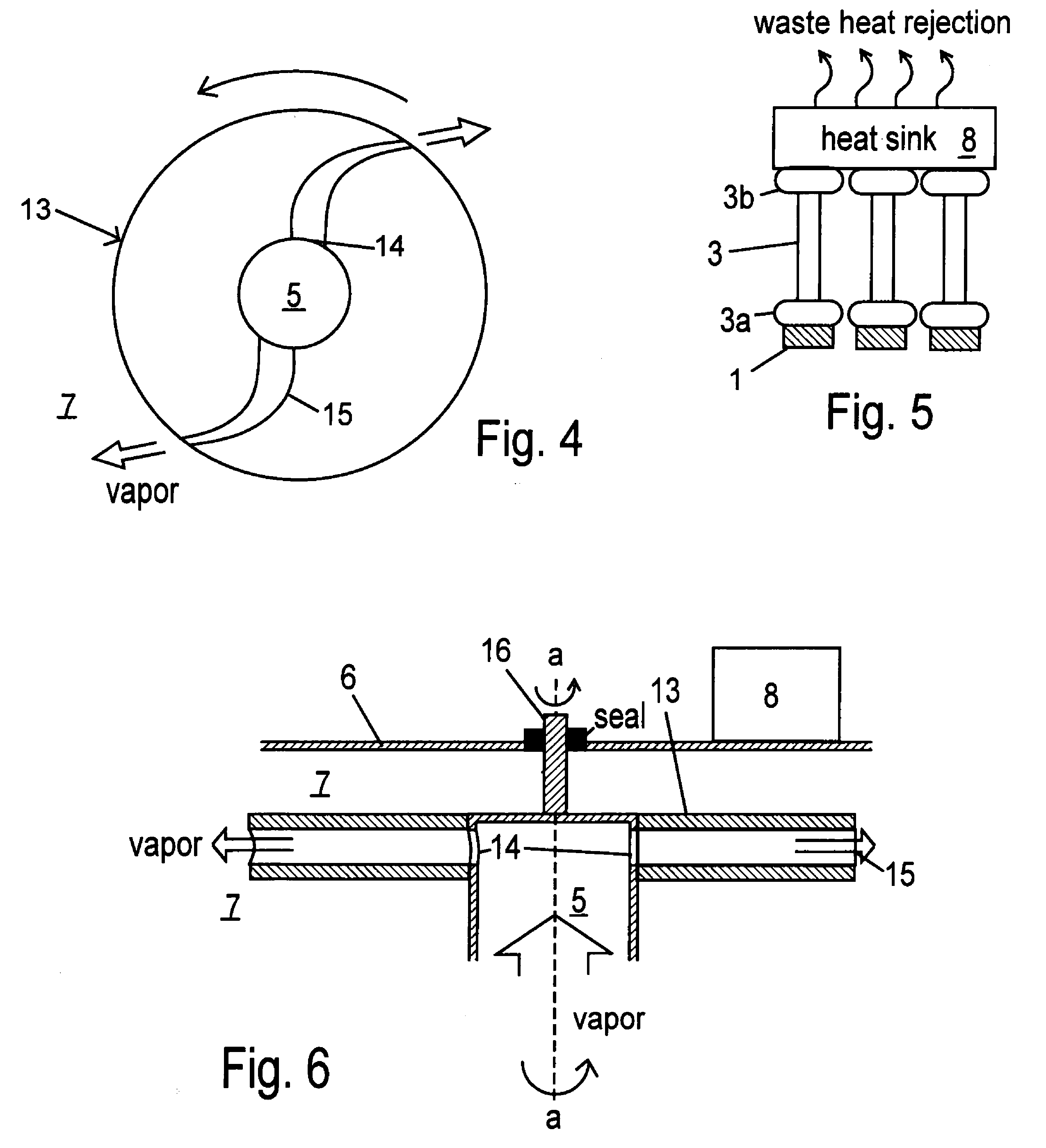

Vapor vortex heat sink

ActiveUS20090242174A1Powerful power generationSemiconductor/solid-state device detailsSolid-state devicesWorking fluidHeat flux

A hermetic Rankine cycle in a sealed casing powers an internal centrifugal condensate pump with an internal vapor turbine during forced convective heat transfer between a heat source and a heat sink. No work is imported into the cycle during operation. A centrifugal pumping disk shears the working fluid against a heating surface, sweeping evolving vapor into radial vortices which provide sink flow conduits to a vapor space at the center of the cylindrical turbine. Convective mass flow through the vapor space to the condensing end of the casing spins the turbine and the centrifugal pumping disk which is connected to it. Vapor is continuously swept from the heating surface, so bubbles do not form and superheat while blocking heat flux into liquid working fluid. Vapor is sucked through the radial vortices into the central vapor space and into the condensing end of the casing along the low pressure gradients in vortex cores established by cooling power. A high heat flux surface is thereby thermally connected to a conventional heat sink having high cooling power, for maximal heat extraction at data centers or other heat sources. Vapor vortices organize counterflow of vapor and condensate in a continuous mass flow cycle, and extract work from heat. Organic working fluids can be used in the casing to make even low temperature waste heat a power source.

Owner:MCCUTCHEN CO

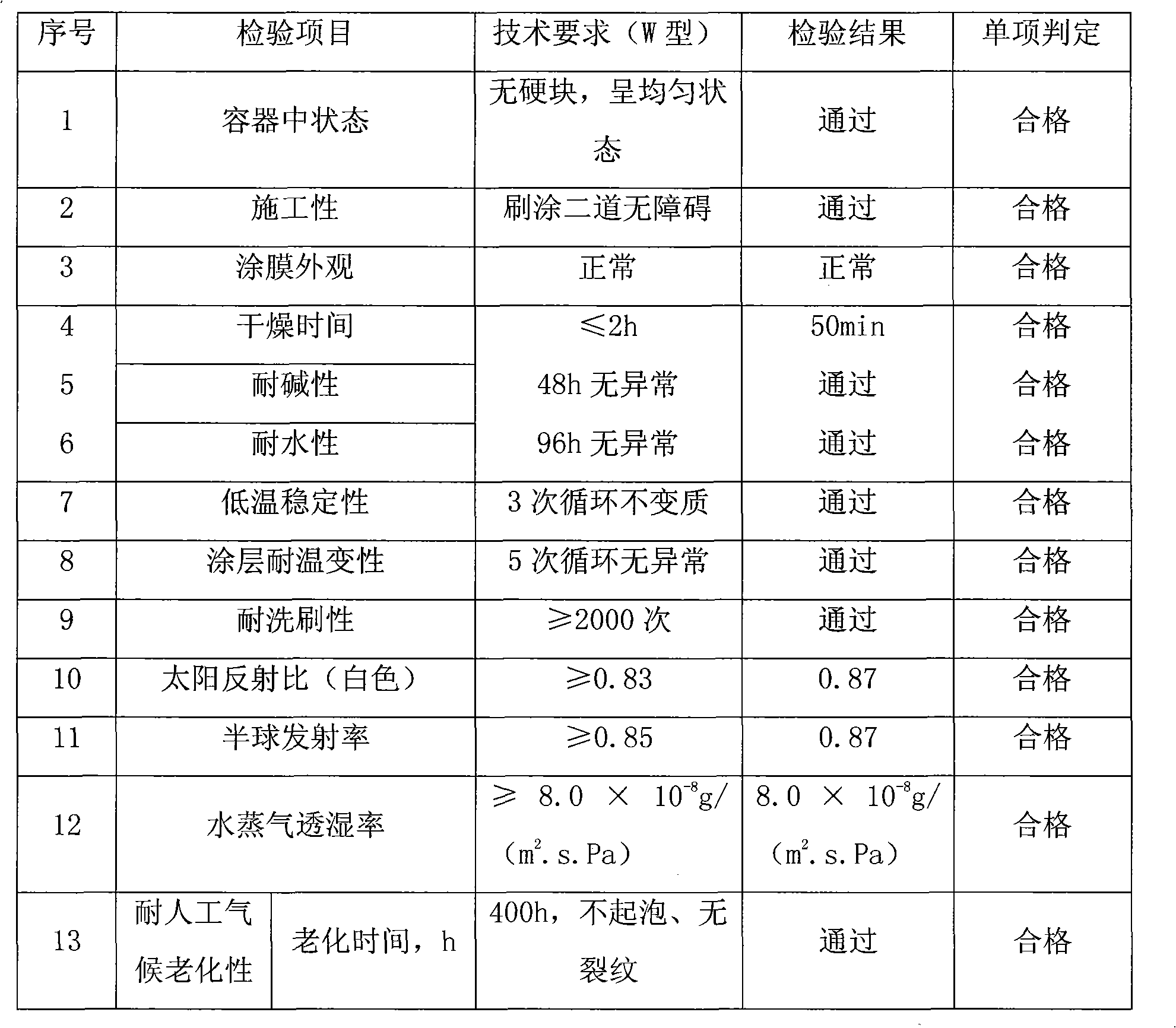

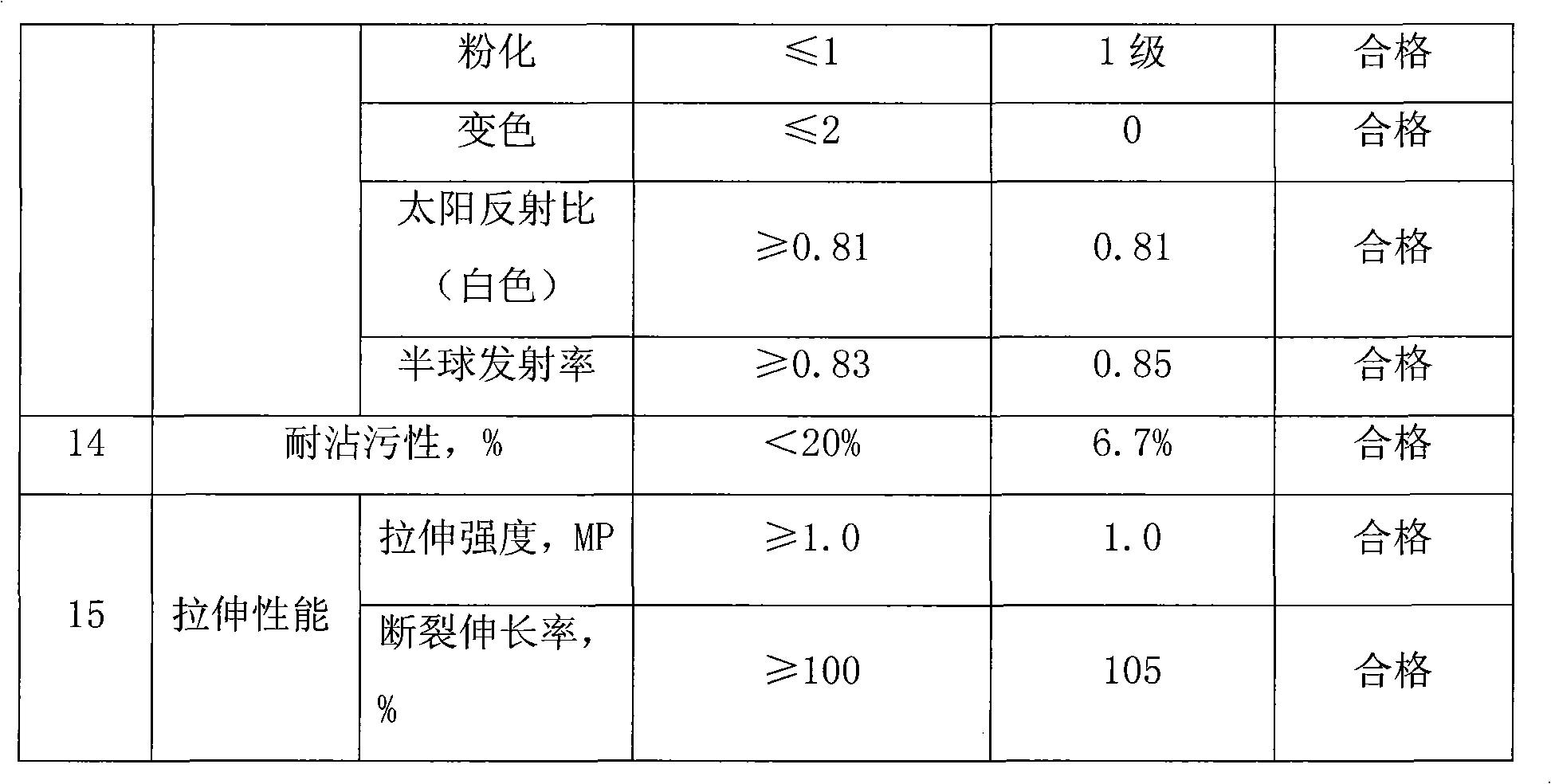

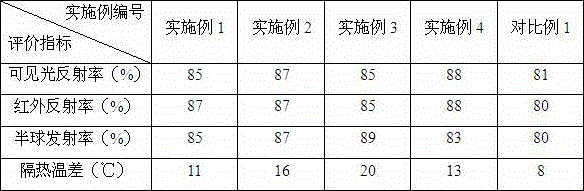

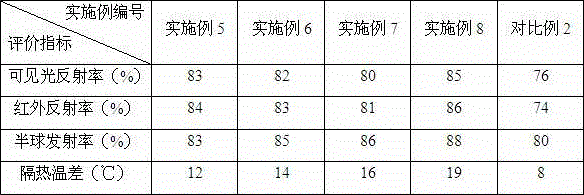

Reflective heat-insulation coating and preparation method thereof

ActiveCN101565581AGood weather resistanceLower thermal equilibrium temperatureReflecting/signal paintsMicrosphereHeat balance

The embodiment of the invention provides a reflective heat-insulation coating and a preparation method thereof. The reflective heat-insulation coating comprises the following raw materials of aqueous pure crylic acid resin, aqueous elastic resin, titanium dioxide, ceramic hollow microspheres, infrared powder, a flame retardant, water, an organic dispersant, a film-forming additive, an antifreeze, a thickener, an anti-foaming agent, a wetting agent, a preservative and a pH value regulator. The coating is a single-component aqueous coating, has no toxicity and good weatherability; extremely fine hollow microsheres are closely arranged by multi-stage in the coating to form a vacuum layer so as to have extremely strong reflection and obstruction function to the solar radiation heat and can effectively reduce the radiation heat transfer and convection heat transfer, thus reducing the heat balance temperature on the surface of the article. The reflective heat-insulation coating leads the building space and the facility container to be warm in winter and cool in summer, reduces the heat island effect and energy consumption of the air conditioner, has obvious energy-saving effect, and reduces the surface temperature by 20 DEG C to a maximum extent and reduces the internal temperature by 5-10 DEG C compared to the normal coating.

Owner:厦门富思特新材料科技有限公司

Building coating with heat insulation function and preparation method thereof

InactiveCN106118307AGood thermo-optic comprehensive performanceWith thermal insulation functionReflecting/signal paintsBuilding energyMetallurgy

The invention provides a building coating with a heat insulation function and a preparation method thereof. The building coating with the heat insulation function is divided into an internal wall coating and an external wall coating, wherein each of the internal wall coating and the external wall coating is composed of a basic carrier for film forming of the coating, a heat insulating material, a heat reflecting material, a heat radiating material, filler, an assistant and water. The preparation method comprises the following steps: preparation of heat insulating material slurry, preparation of function material slurry, grinding of slurry, and paint mixing. The film forming thickness of the building coating is 0.2-0.3mm, so that the building coating belongs to a thin building energy-saving coating; the internal and external wall building coatings have higher heat conducting resistance and lower convection heat transfer, so that the building coating has different heat radiating effects under different temperature environments in different seasons and has the heat insulation function; the building coating is high in safety and long in service life; and the preparation method is simple and is suitable for industrial production.

Owner:马承银

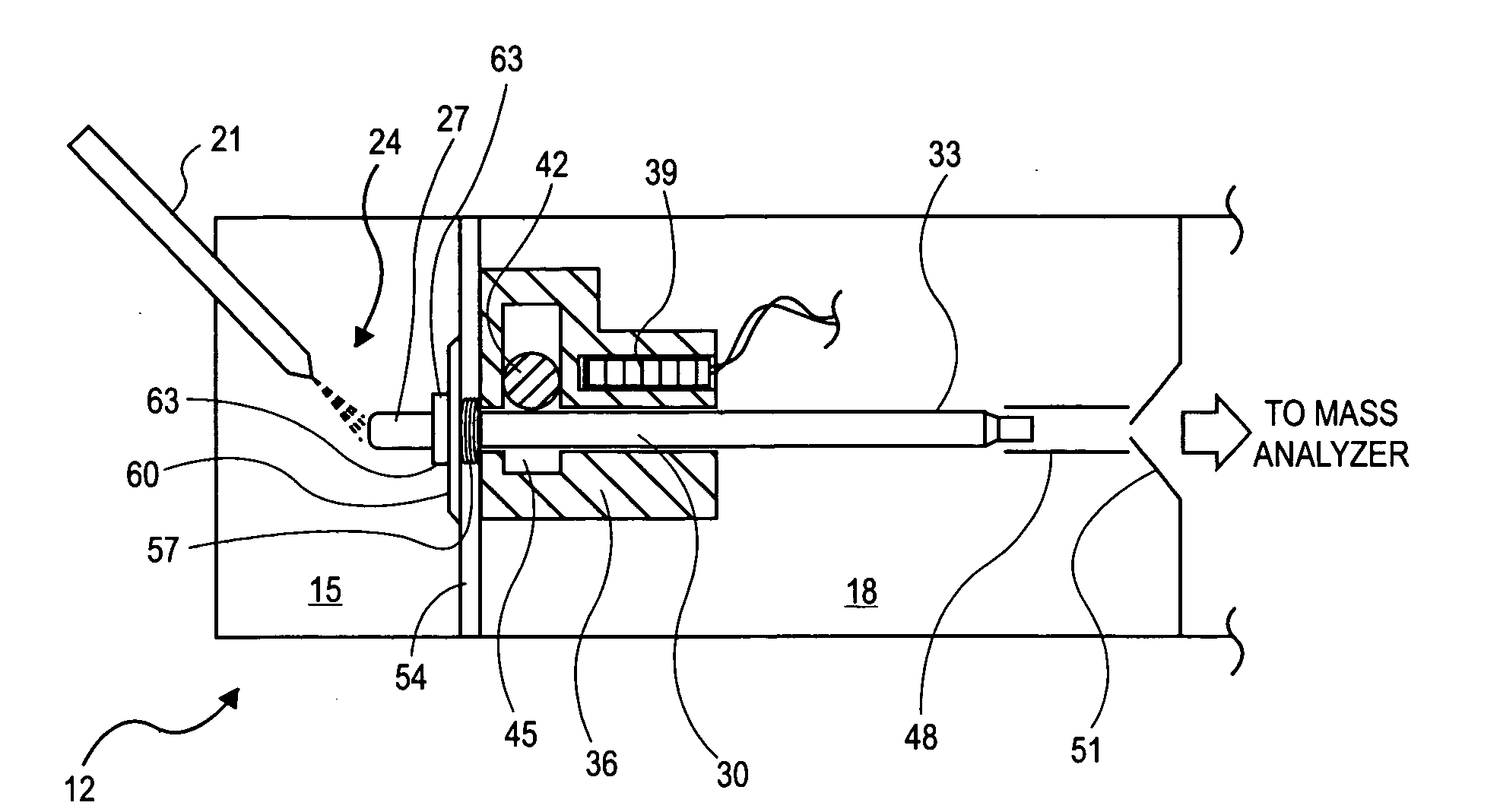

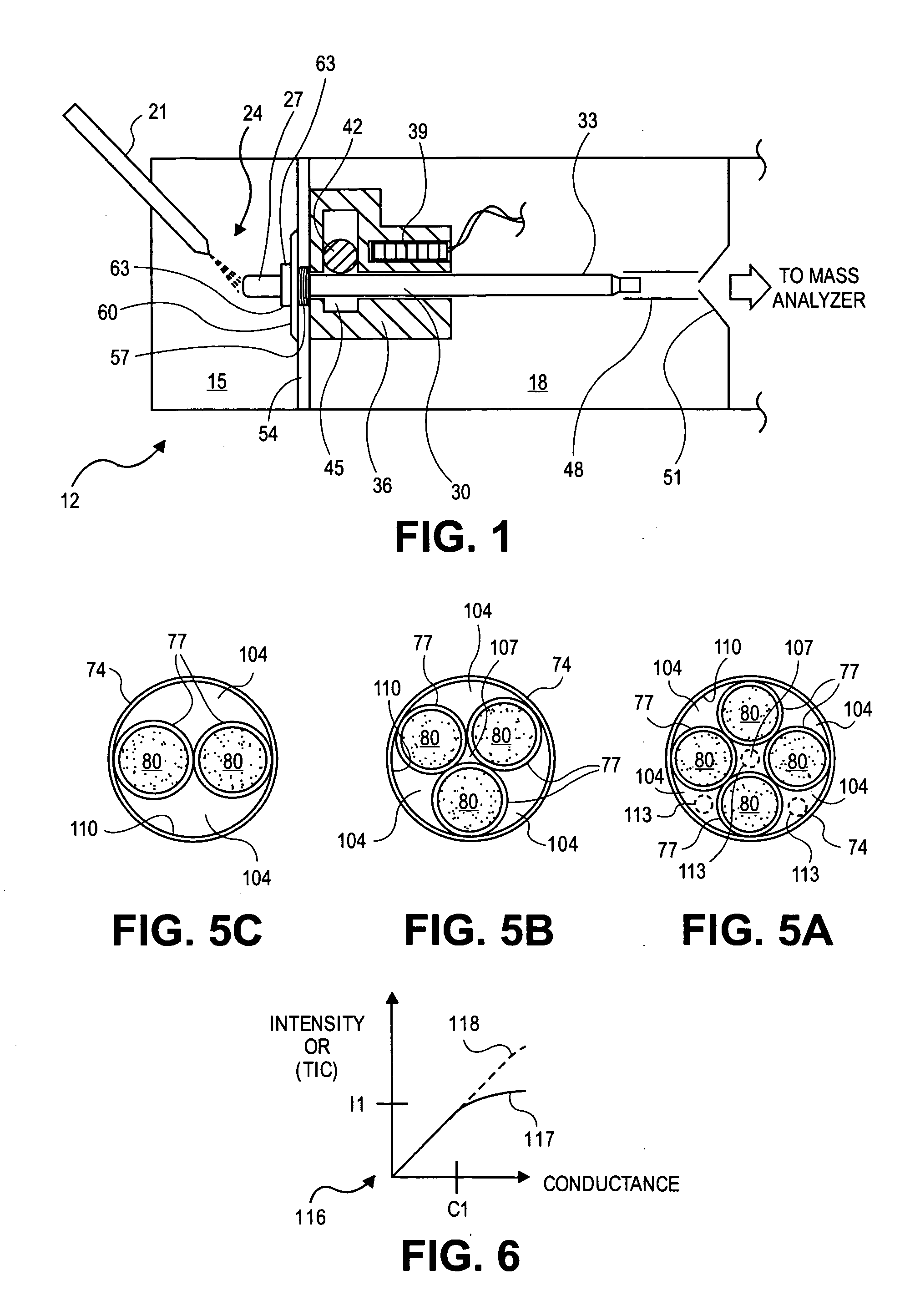

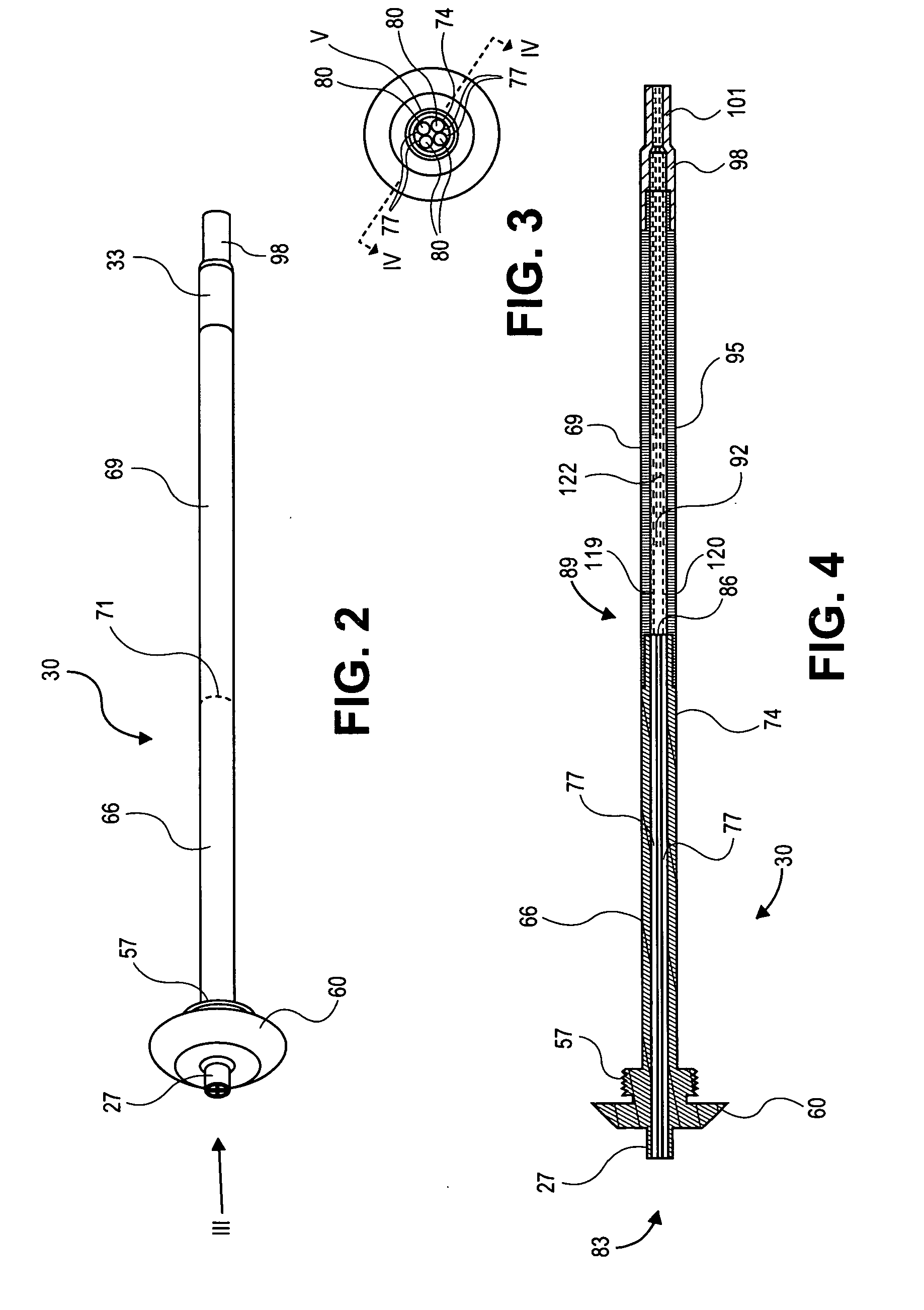

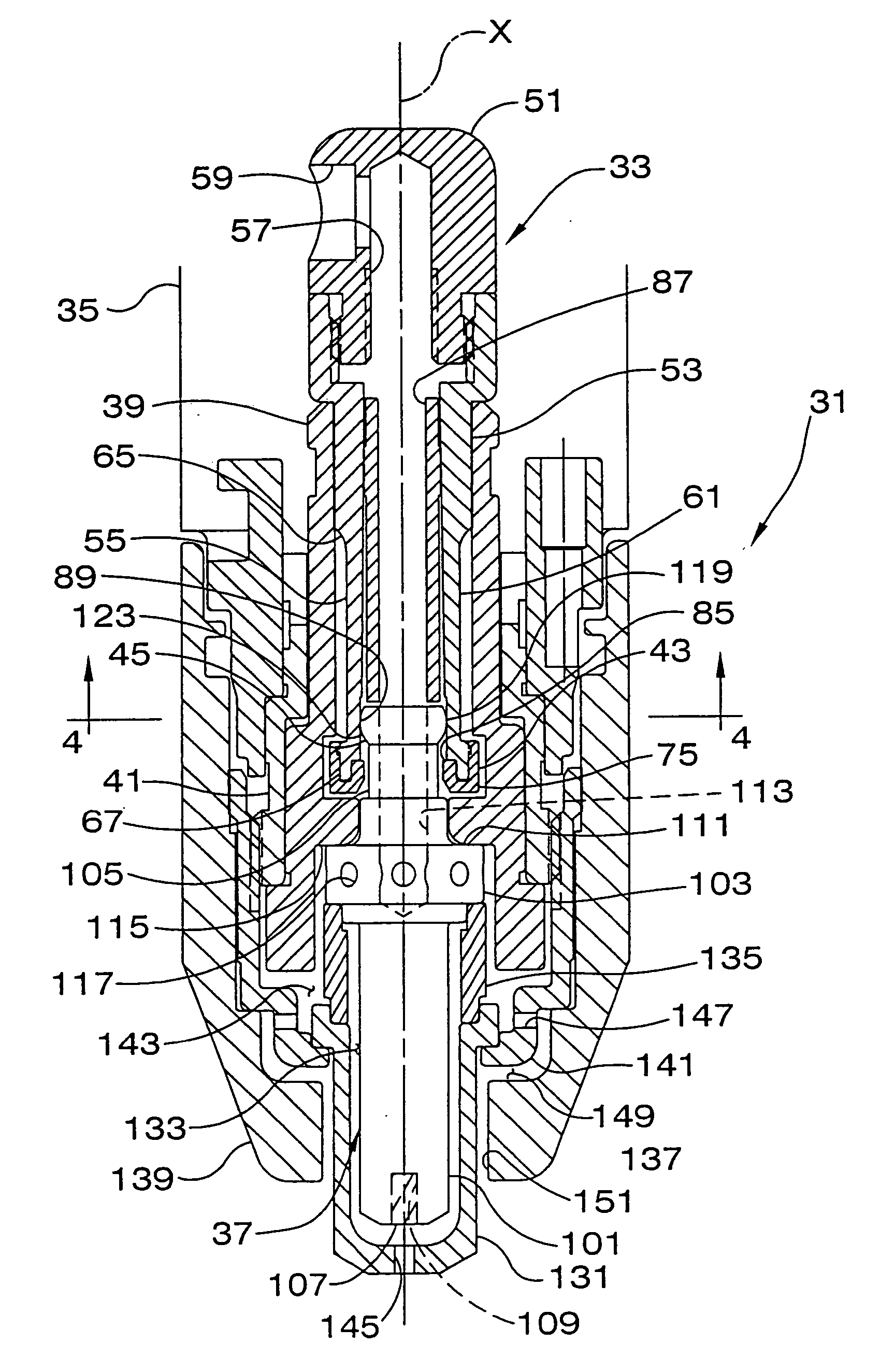

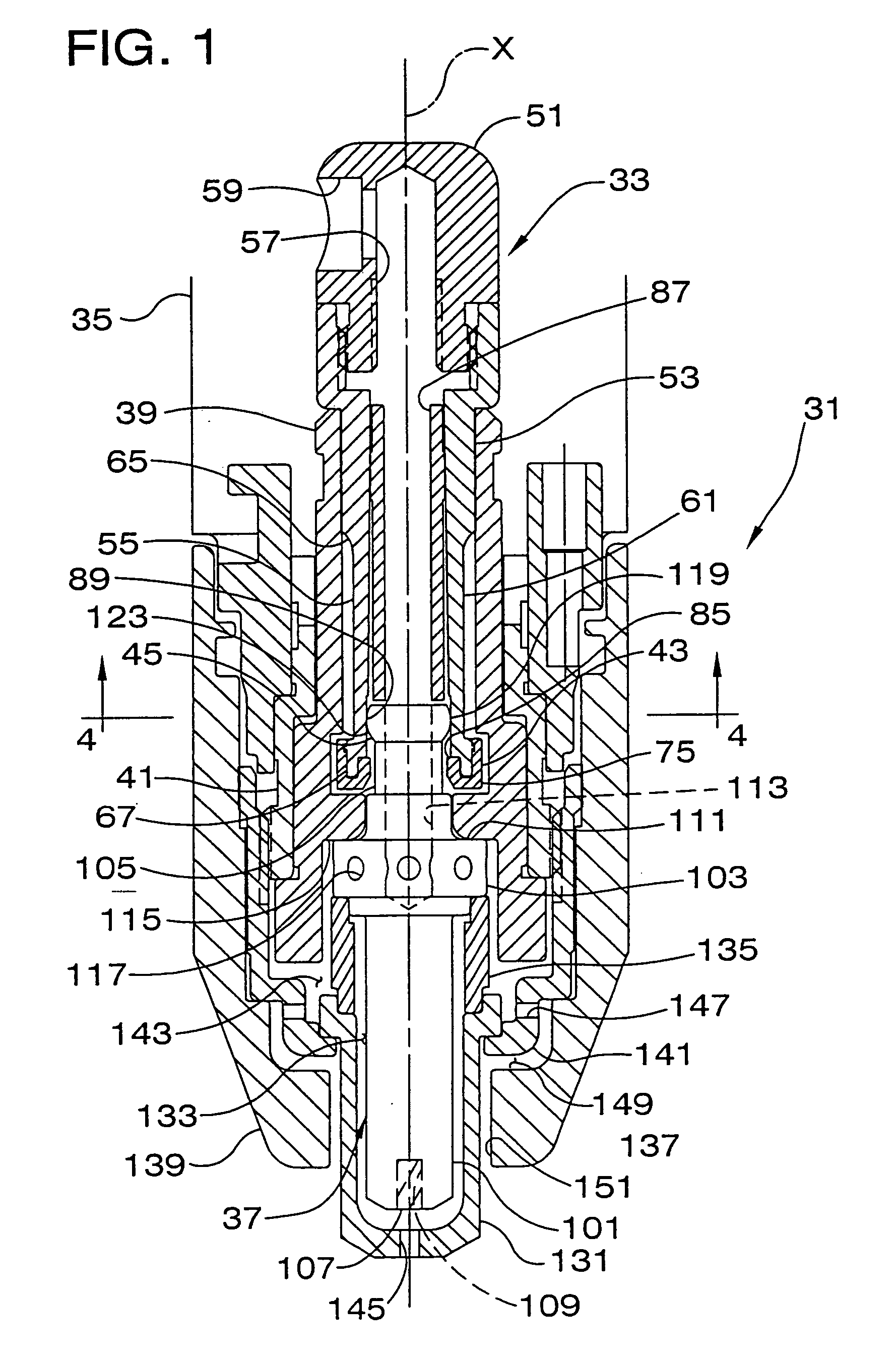

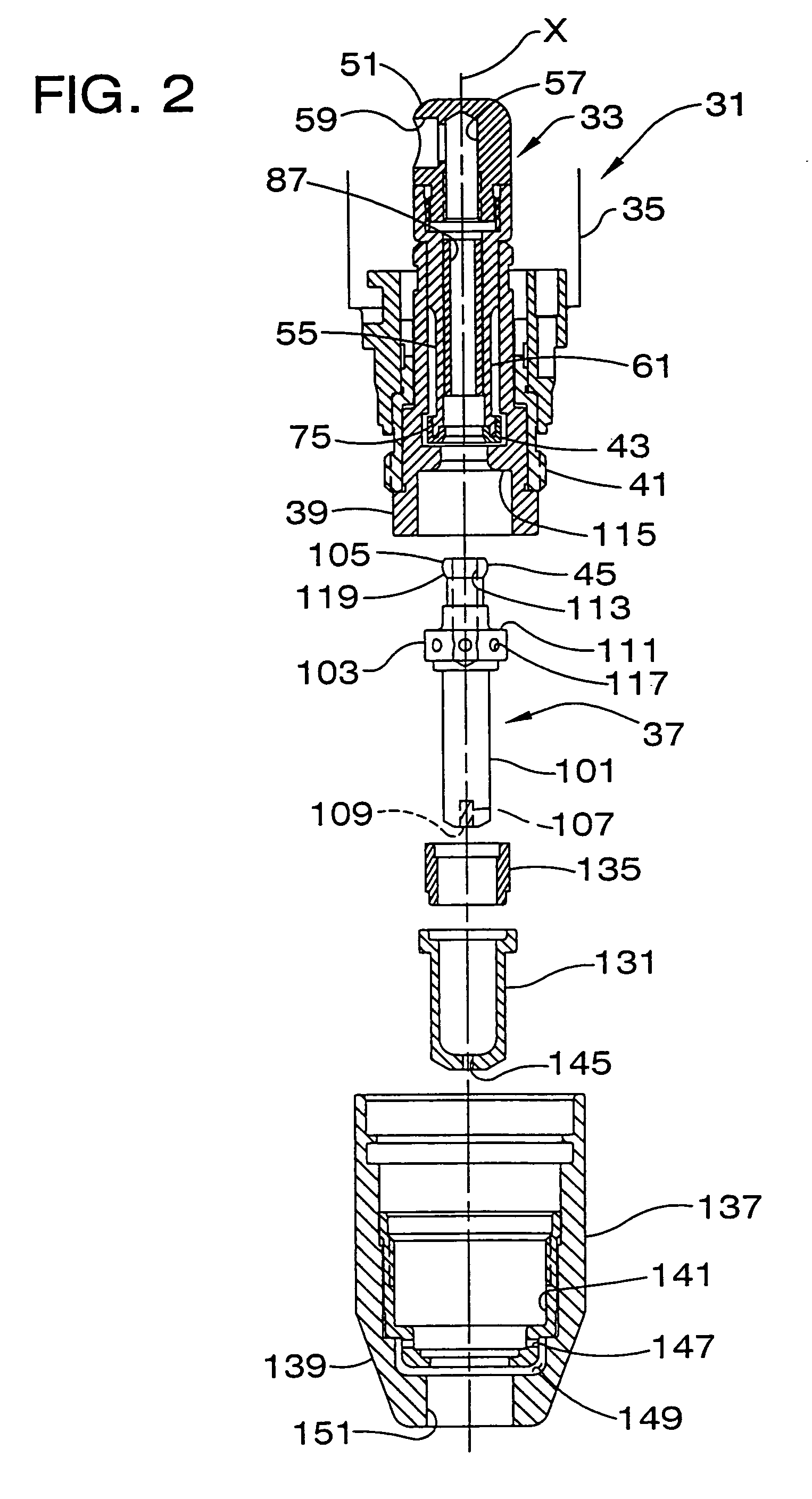

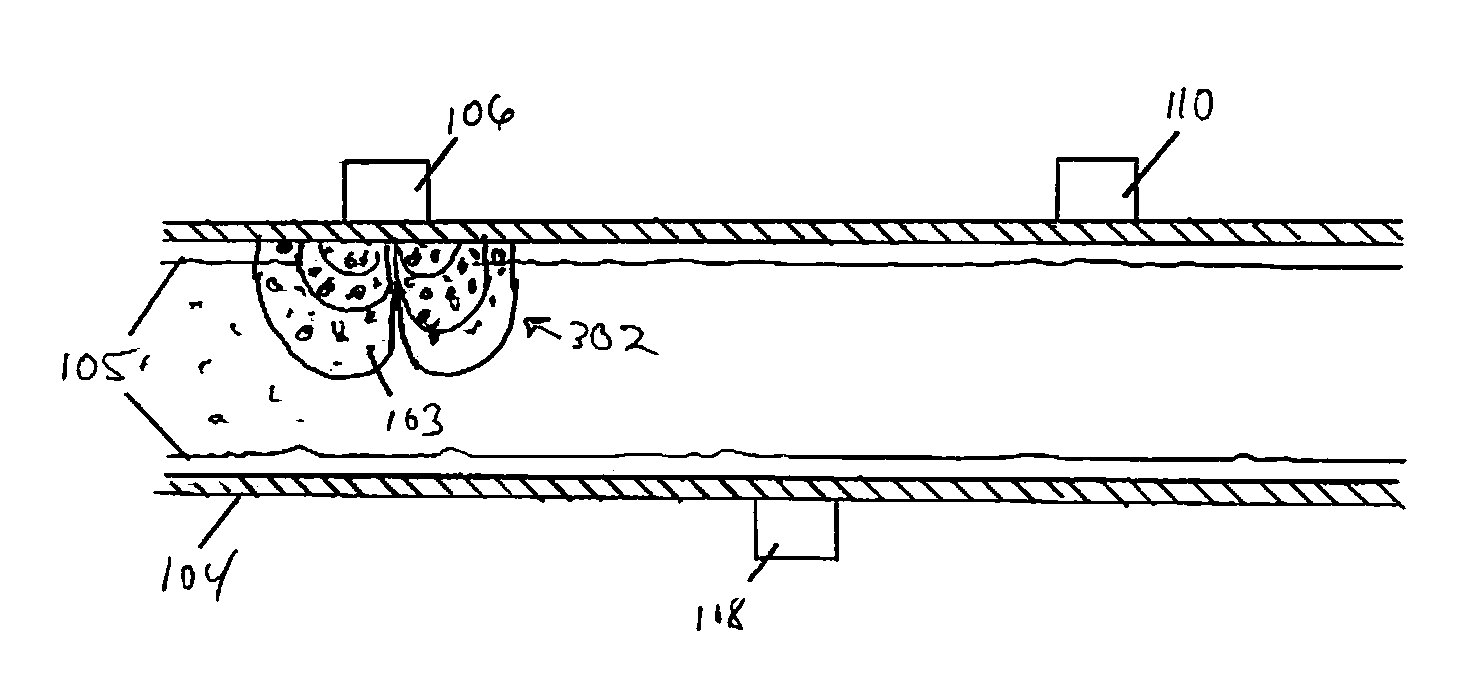

Plural bore to single bore ion transfer tube

ActiveUS20080142698A1High ion/gas flow rateIncrease the number ofIsotope separationMass spectrometersIon transferEngineering

An ion source includes an ion transfer tube having two segments for transporting a sample fluid containing ions between a first chamber and a second chamber maintained at a reduced pressure relative to the first chamber. A first segment may include a plurality of channels and heat conductive walls forming the plurality of channels. The plurality of channels and walls forming the channels promote efficient convective heat transfer to the sample fluid, thereby enabling operation at relatively high sample fluid flow rates, resulting in an increase in the number of ions that may be delivered to a mass analyzer. A second segment forms a single common channel that receives a plurality of sample streams and enables them to combine into a single ion stream that may be introduced as a single gas stream expansion into the second chamber.

Owner:THERMO FINNIGAN

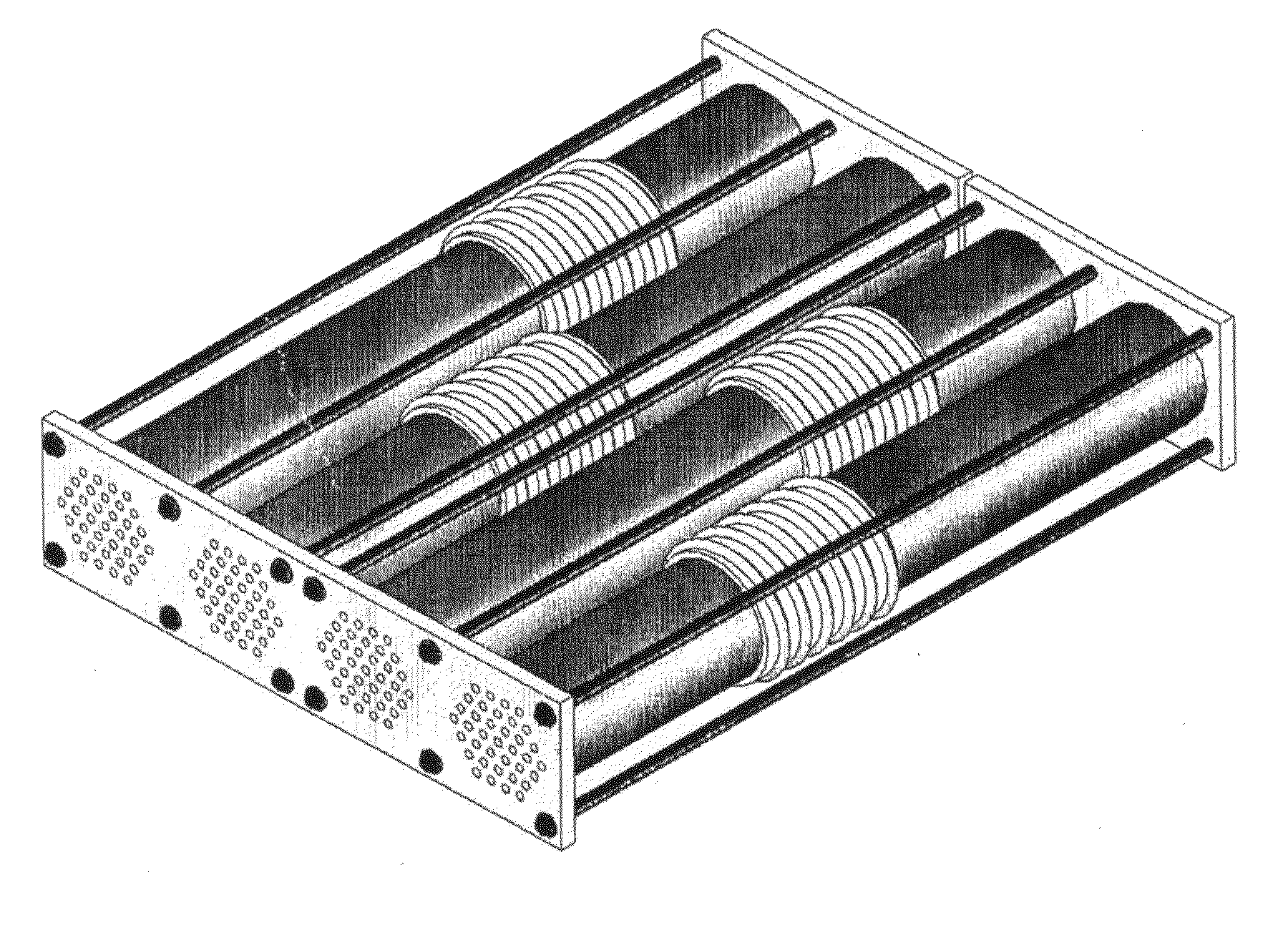

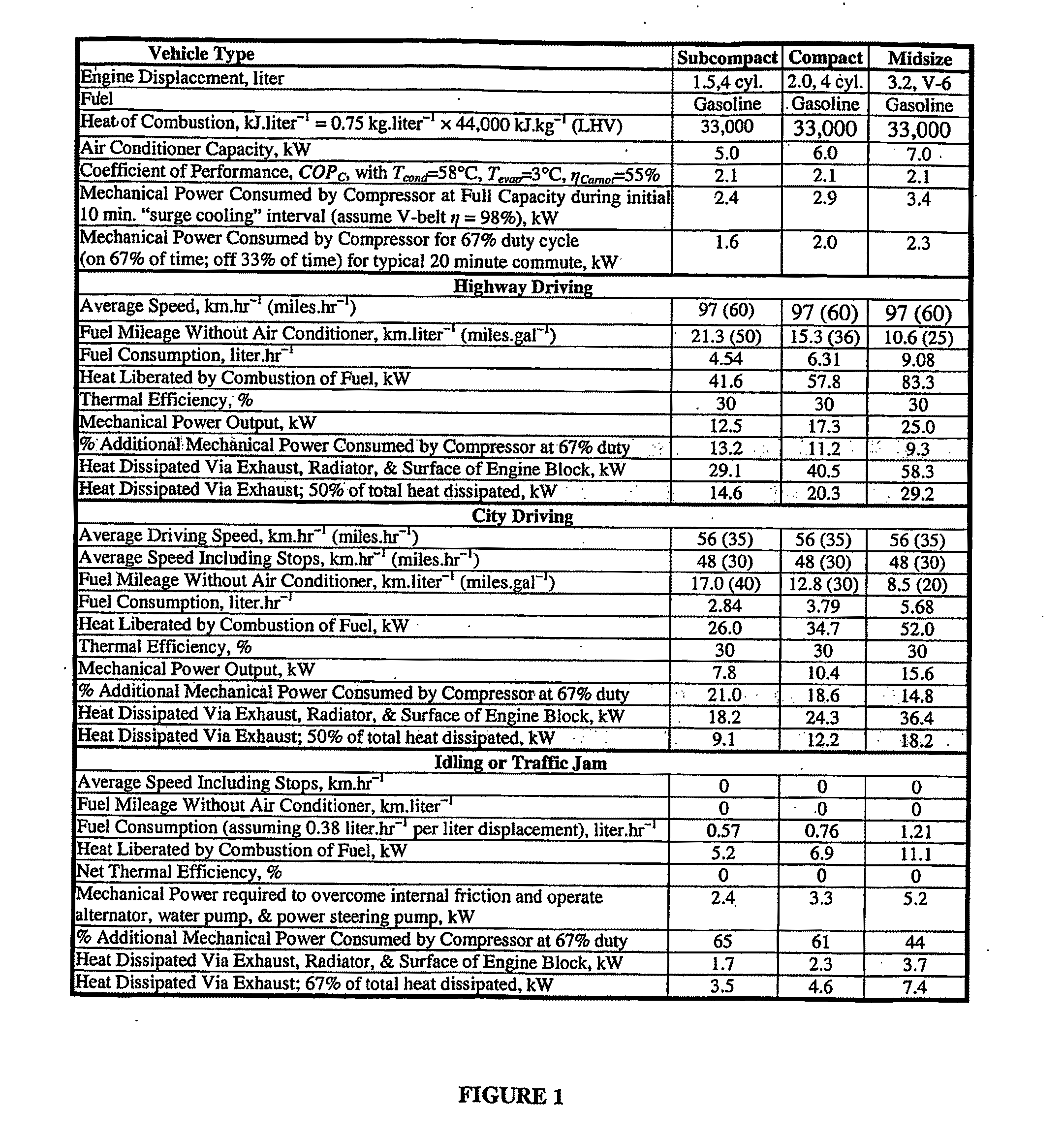

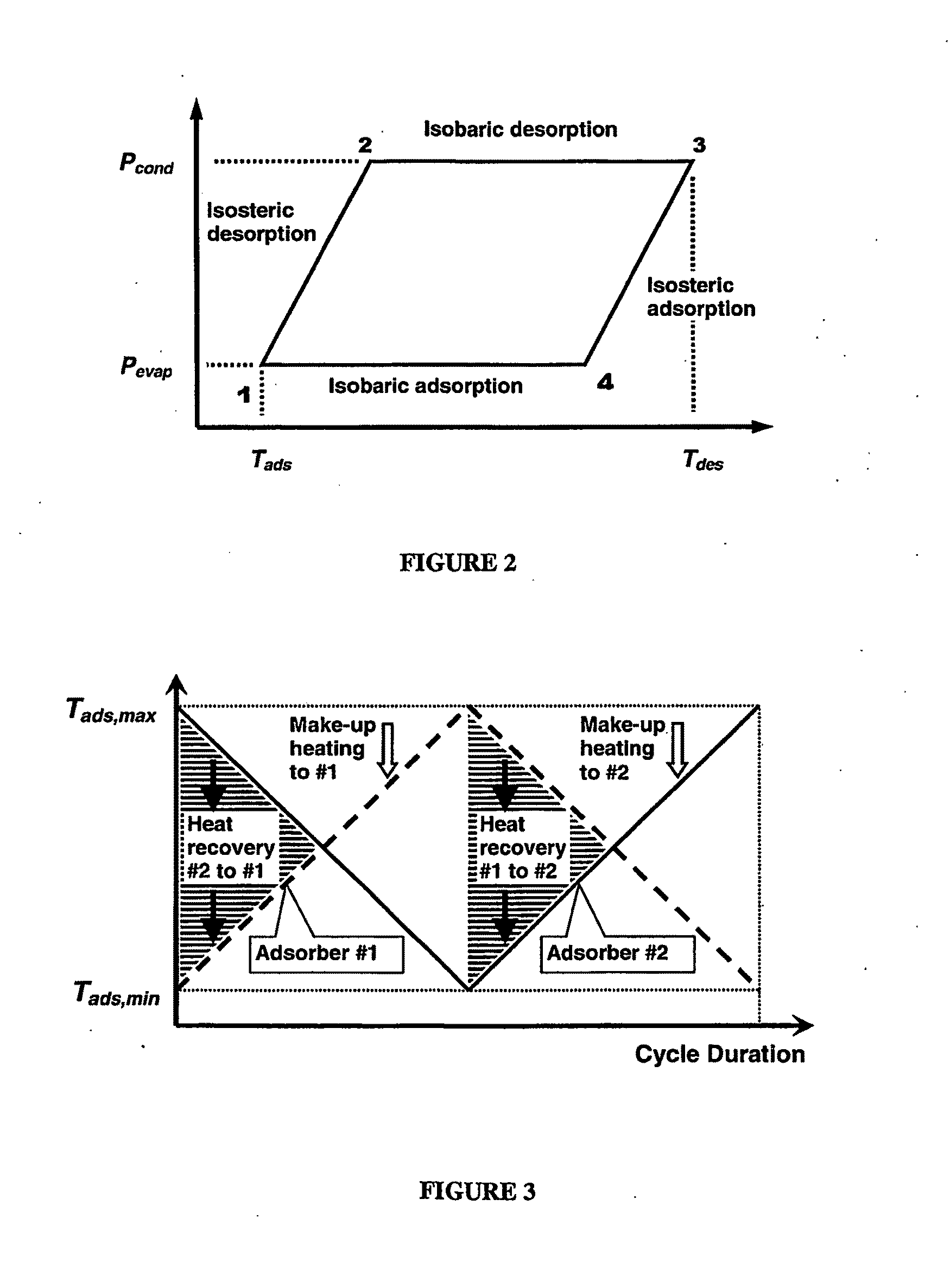

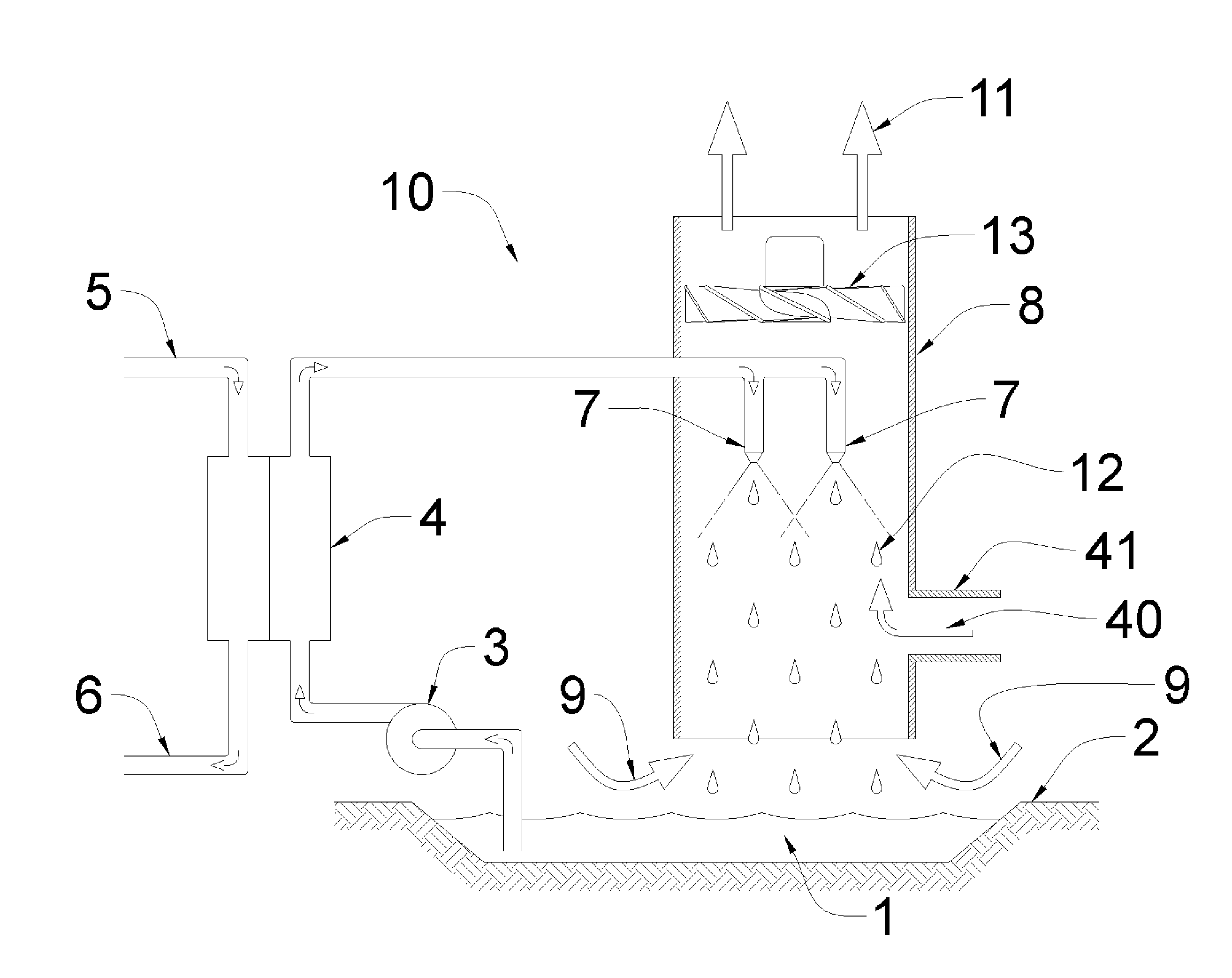

Automotive adsorption heat pump

InactiveUS20110005267A1Efficient and reliableLess expensiveClimate change adaptationVehicle heating/cooling devicesSorbentFresh air

An adsorber unit has an outer shell, a plurality of internal tubes extending through the shell for carrying heat transfer fluid, each tube having outwardly projecting fins along its entire length, and a solid adsorbent material in the shell surrounding the tubes such that the fins project into the adsorbent material, the fins being of a material (e.g., metal) of higher thermal conductivity than the adsorbent material. Metal wool loosely packed inside the tubes, or internal radial fins swaged into the tubes, increase internal surface area thereby enhancing convective heat transfer. Metal wool loosely packed between the external fins, or fine wire metal coils lightly squeezed between the external fins, further increase external surface area of the heat exchanger in contact with the adsorbent thereby enhancing contact heat transfer. Performance is enhanced because the external fins and wool or wire coils transport heat more efficiently to all regions of the adsorbent, and permit less non-adsorbent heat exchanger material (e.g., metal) to be used for a given amount of adsorbent. Two or more such units are used in an adsorption heat pump. This design utilizes existing components (e.g., shell-&-tube heat exchanger, internally and externally finned tubing, and metal wool or wire coils) in a novel manner heretofore untried. In one exemplary embodiment, automobile air conditioning, exhaust heat is used to power such an air conditioner. The significant additional power used by the mechanical compressor of an automobile (12%-17% during commuting for subcompact to midsize cars) can be nearly eliminated by powering the air conditioner with otherwise wasted exhaust heat. The adsorbent is heated and cooled by light oil (called Heat Transfer Fluid, HTF) which in turn is heated and cooled by exhaust and fresh air. Such indirect heating and cooling achieves the required efficiency, and allows using phase change material (e.g., wax) to store and therefore fully utilize exhaust heat. A refrigerant reservoir is included which provides immediate cooling after start-up of a cold engine, while the exhaust system and heat pump are still heating up in order to start pumping refrigerant. Eliminating the mechanical compressor increases fuel mileage by 14-18% for midsize, compact, MS and subcompact cars, or 4.6-6.0% annually, given a four-month cooling season.

Owner:LAMBERT MICHAEL A +1

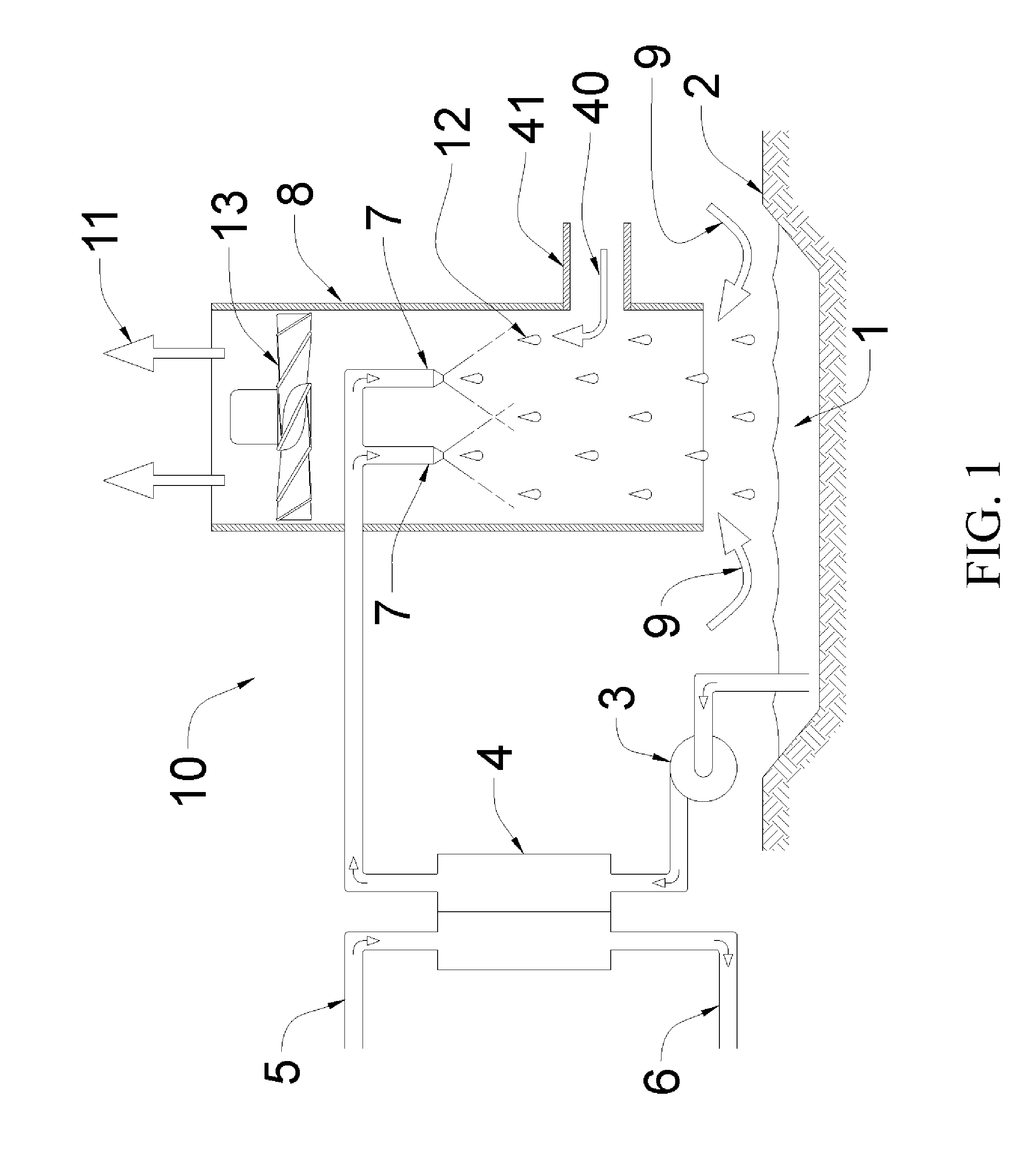

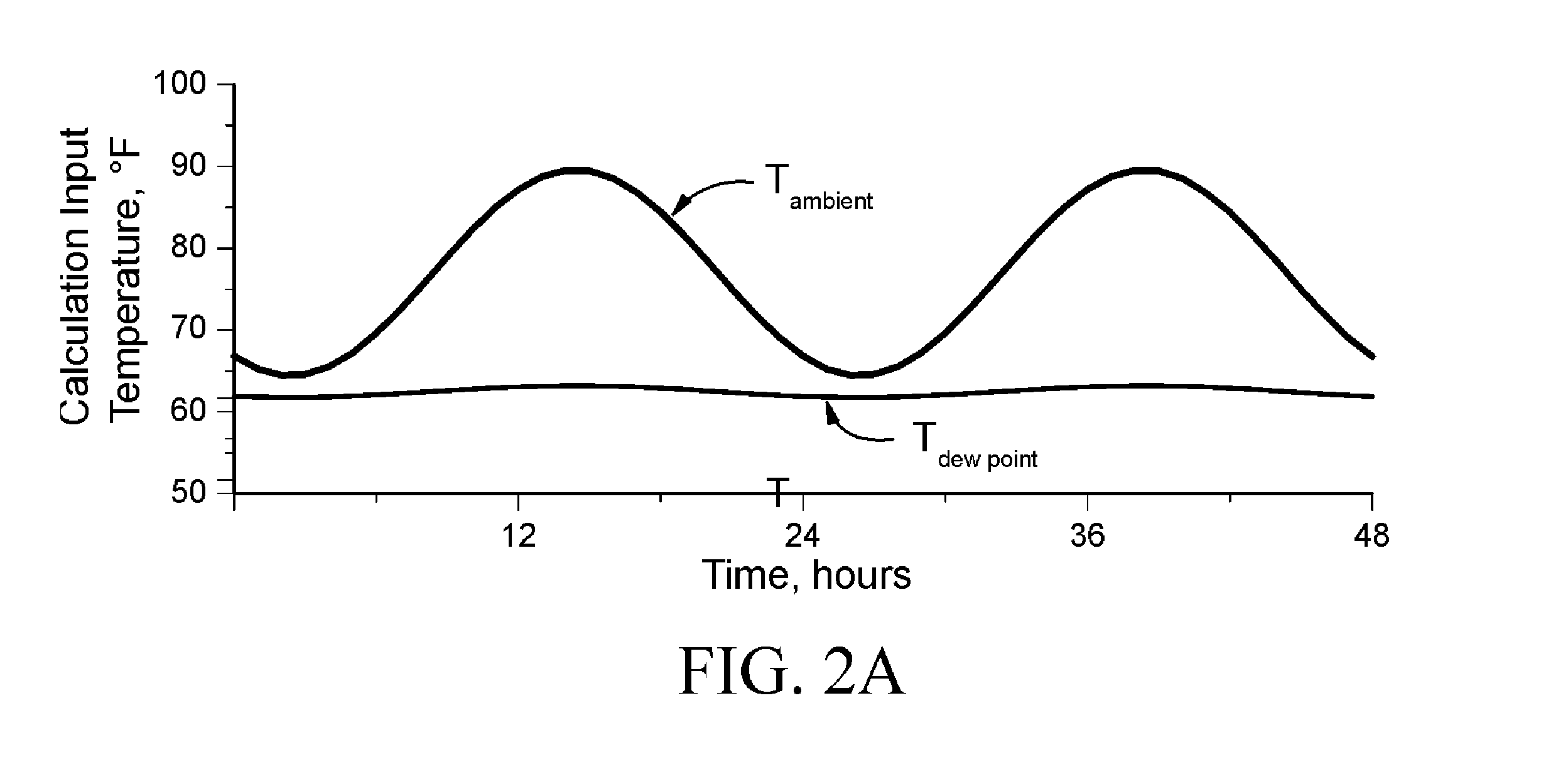

Heat dissipation systems with hygroscopic working fluid

InactiveUS20130305752A1Minimize water consumptionMinimize consumptionSteam/vapor condensersTrickle coolersThermal energyWorking fluid

A heat dissipation system apparatus and method of operation using hygroscopic working fluid for use in a wide variety of environments for absorbed water in the hygroscopic working fluid to be released to minimize water consumption in the heat dissipation system apparatus for effective cooling in environments having little available water for use in cooling systems. The system comprises a low-volatility, hygroscopic working fluid to reject thermal energy directly to ambient air. The low-volatility and hygroscopic nature of the working fluid prevents complete evaporation of the fluid and a net consumption of water for cooling, and direct-contact heat exchange allows for the creation of large interfacial surface areas for effective heat transfer. Specific methods of operation prevent the crystallization of the desiccant from the hygrosopic working fluid under various environmental conditions.

Owner:ENERGY & ENVIRONMENTAL RES CENT FOUNDATIO

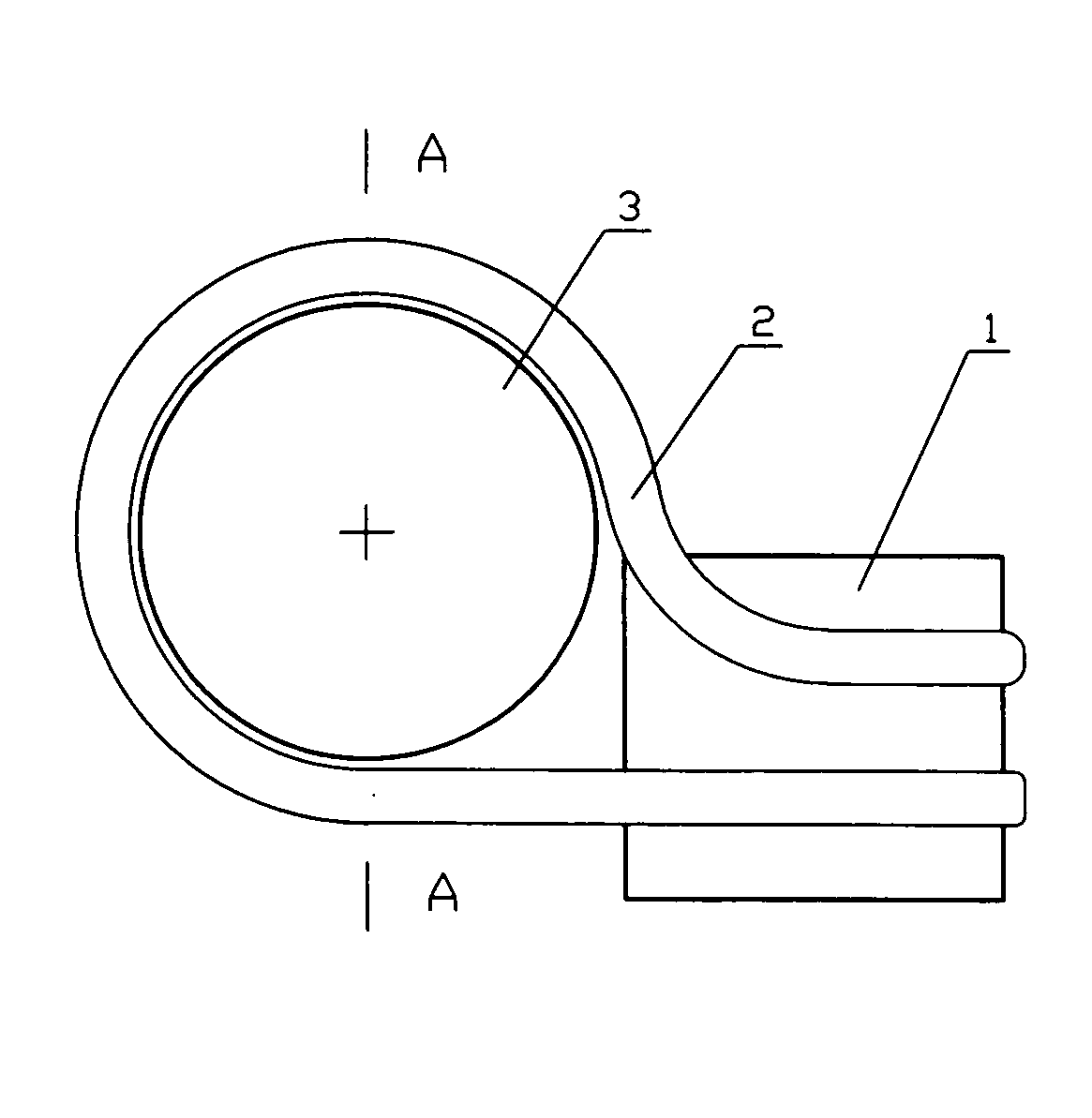

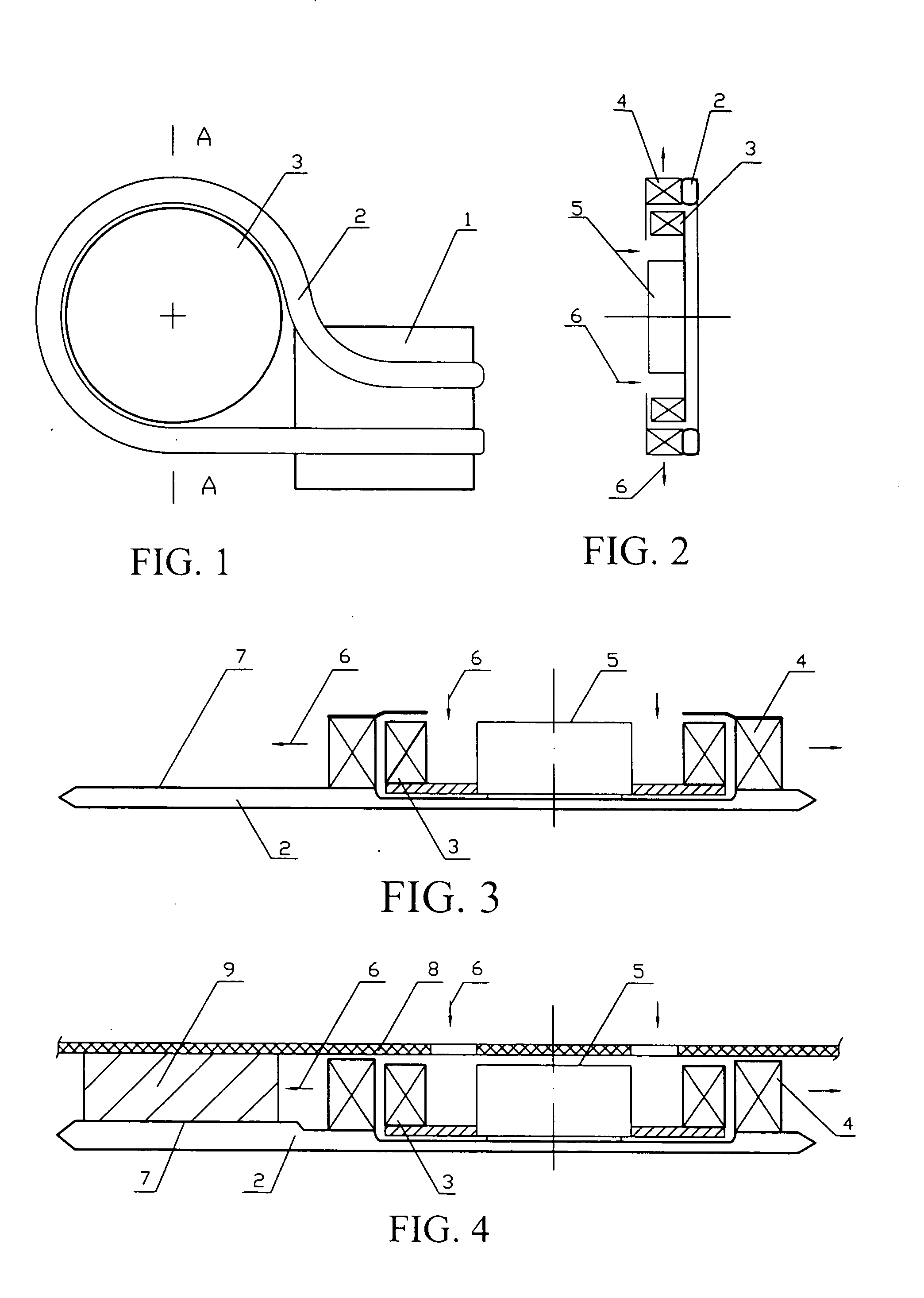

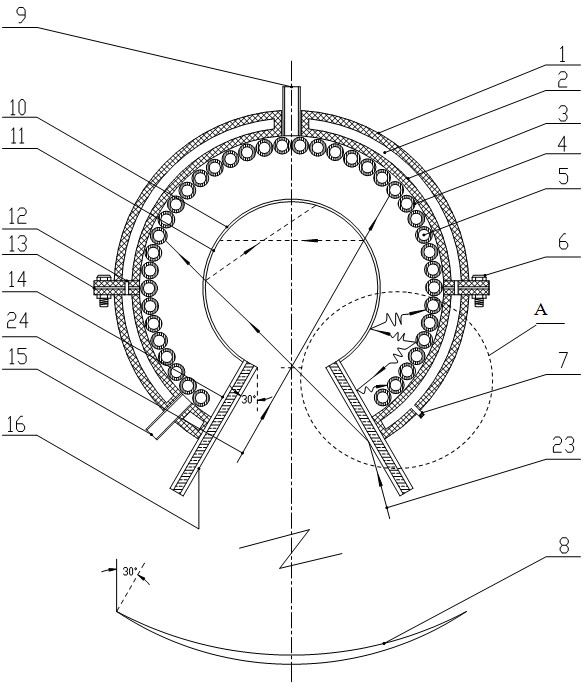

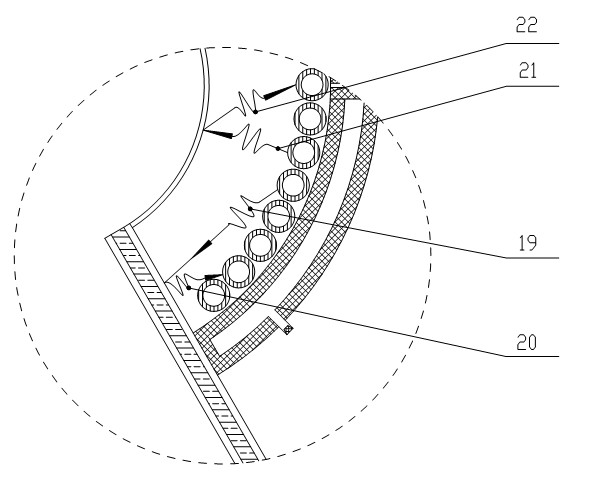

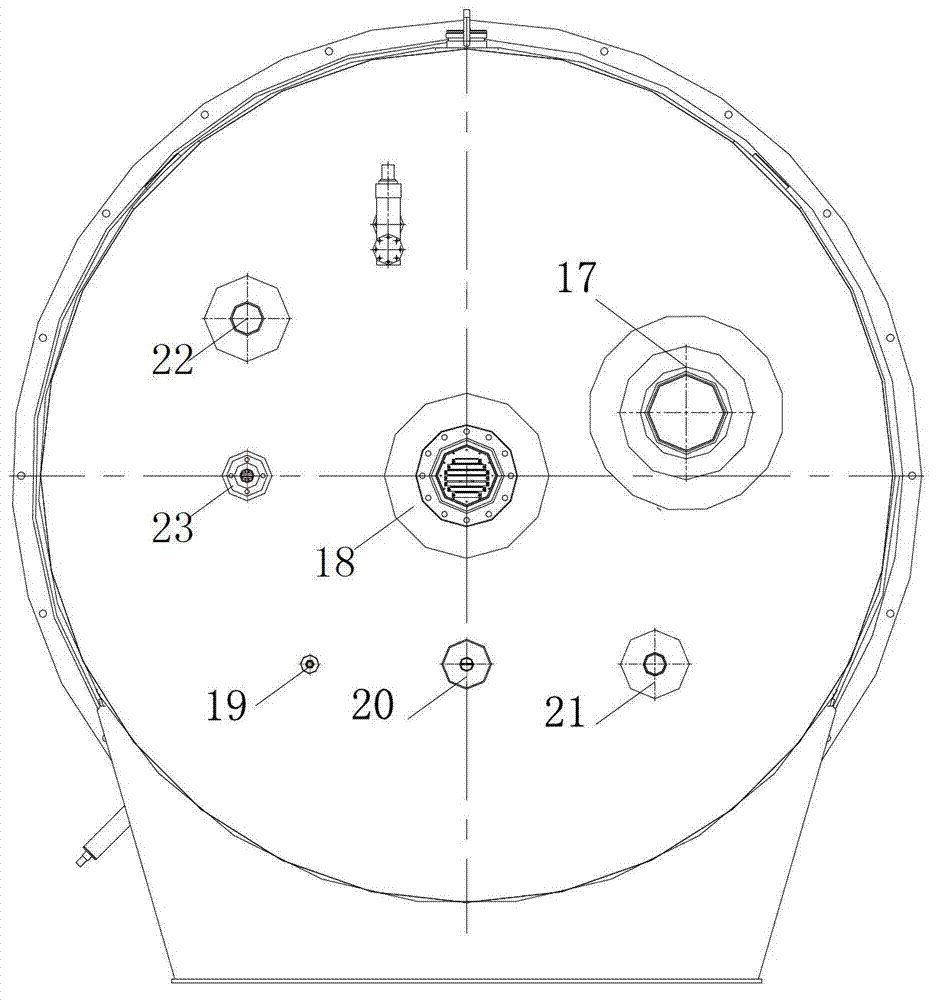

Spherical cavity type solar heat absorber with inwardly concave glass cover

InactiveCN102322694AImprove capture abilityNot easy to spillSolar heating energySolar heat devicesGlass coverEngineering

The invention discloses a spherical cavity type solar heat absorber with an inwardly concave glass cover. The heat absorber is mainly used for collecting sunlight and converting the sunlight into heat energy in a butterfly type solar high-temperature heat utilization system. The heat absorber mainly comprises a heat exchange coil pipe, the inwardly concave glass cover, an outer shell, an inner shell, a vacuum layer, a reflective wind shield and a heat conductive fluid. Different from the traditional opening type heat absorber and the cavity type heat absorber with the glass window at the cavity opening, the cavity type heat absorber disclosed by the invention is the opening type spherical heat absorber with the inwardly concave glass cover, therefore, the cavity type heat absorber not only has the light capturing capacity of the opening cavity type heat absorber but also has low heat loss of the cavity type heat absorber with the glass window at the cavity opening; meanwhile, the cavity type heat absorber is provided with the reflective wind shield, therefore, the capturing on deviated light can be strengthened, and the heat radiation on the inner wall and the convection heat transfer loss resulted from external natural wind can be reduced; and the cavity type heat absorber comprises the vacuum layer between the inner shell and the outer shell, therefore, the lost heat throughthe shells can be effectively reduced.

Owner:SOUTH CHINA UNIV OF TECH

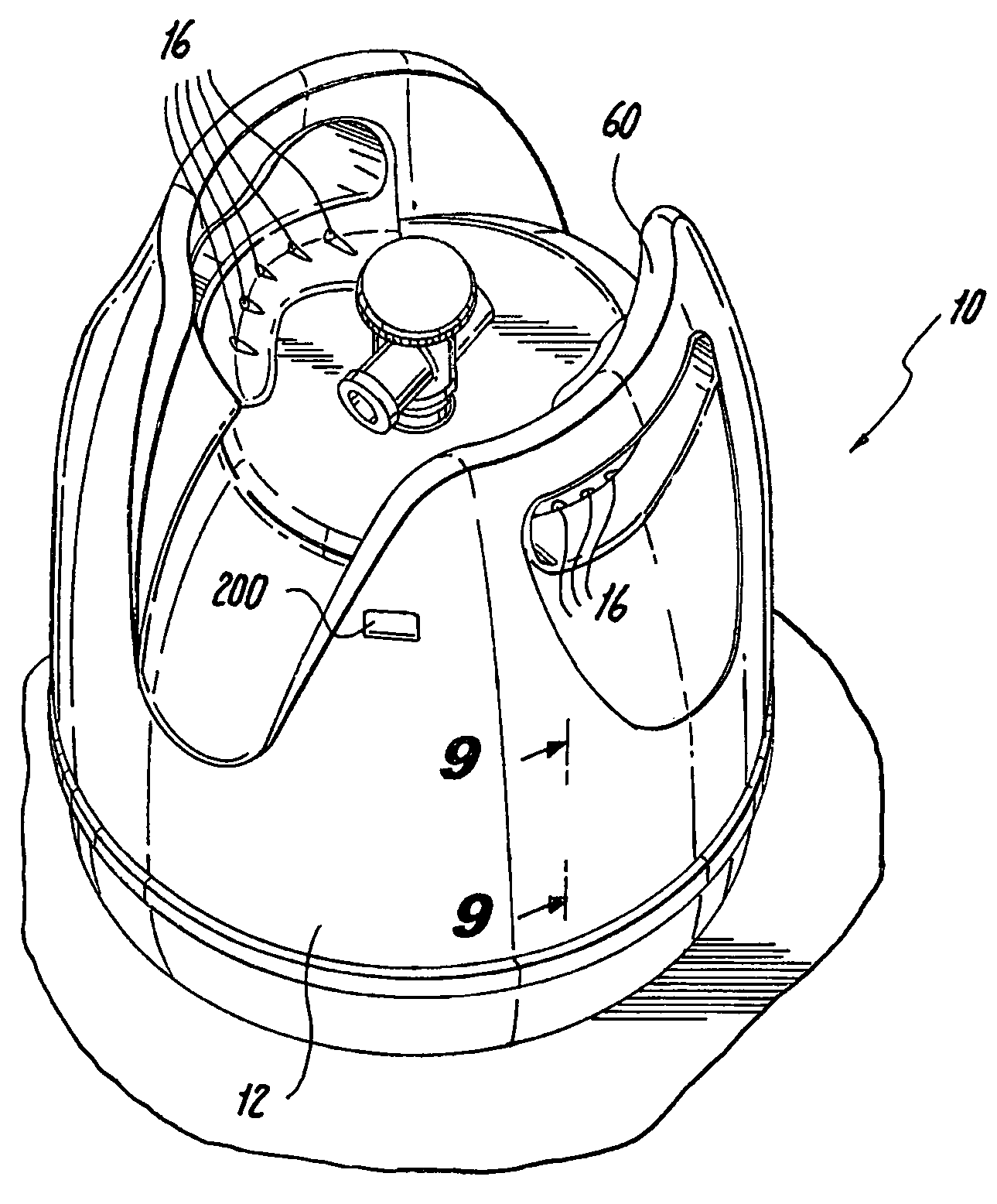

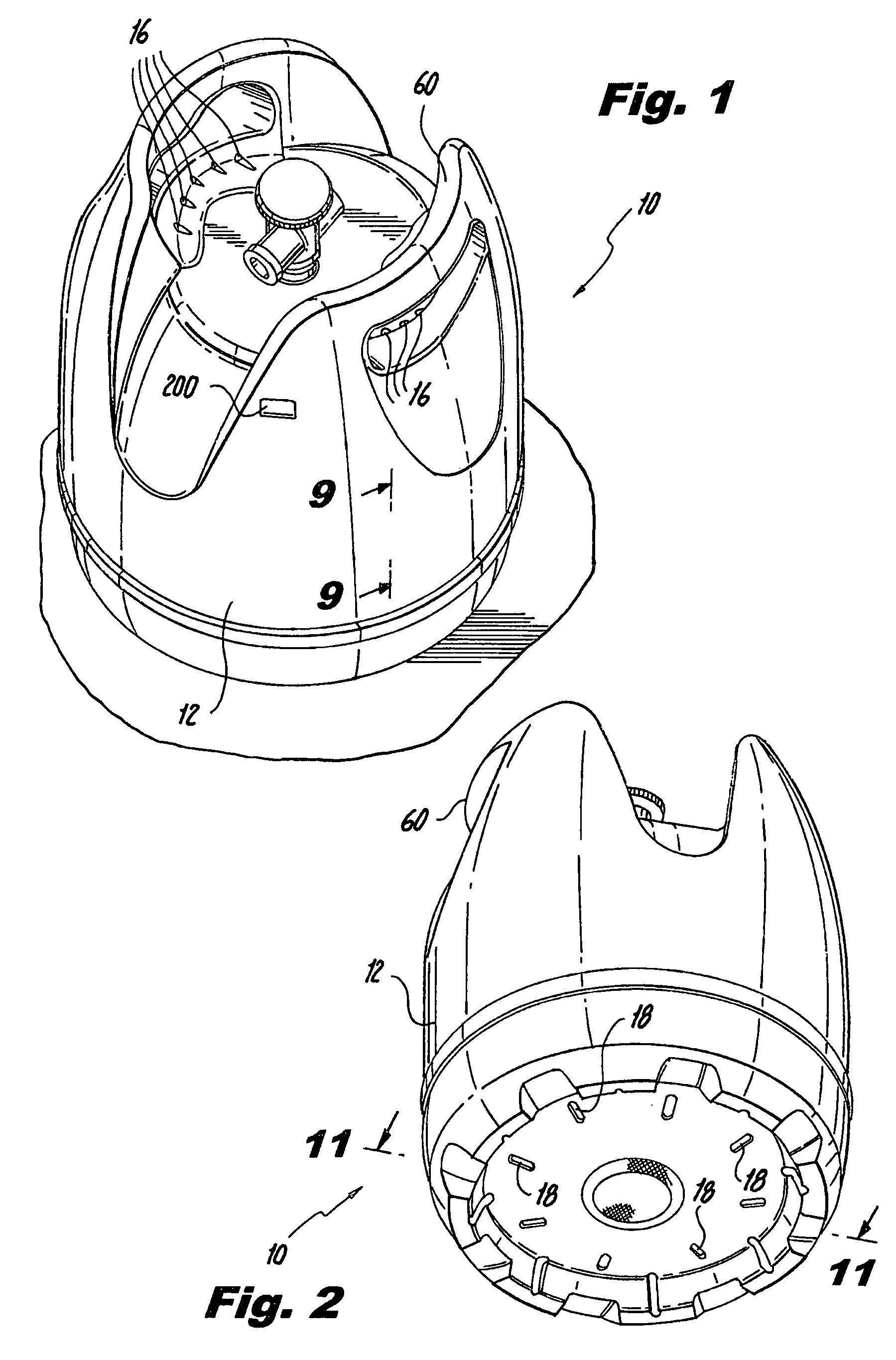

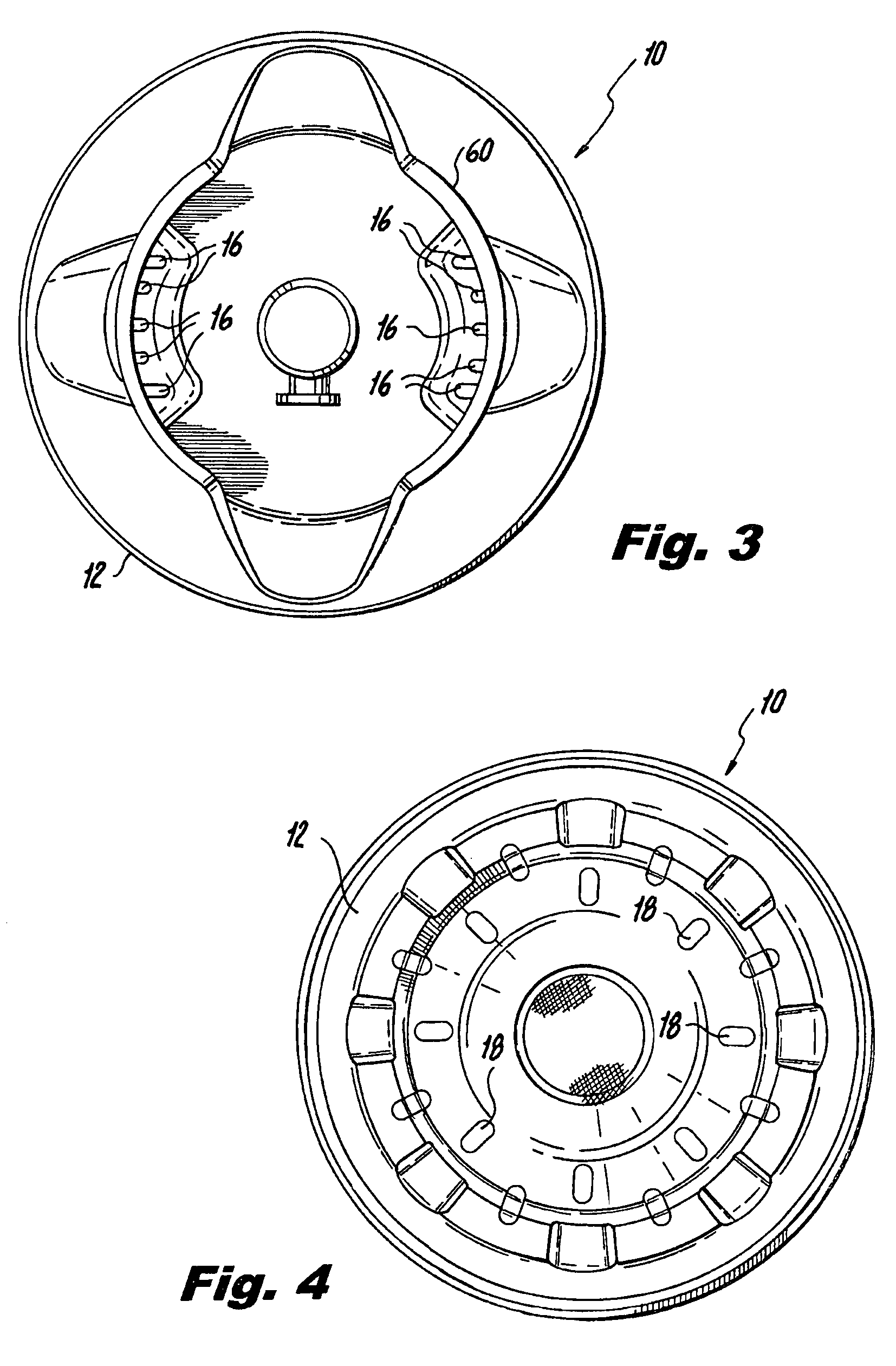

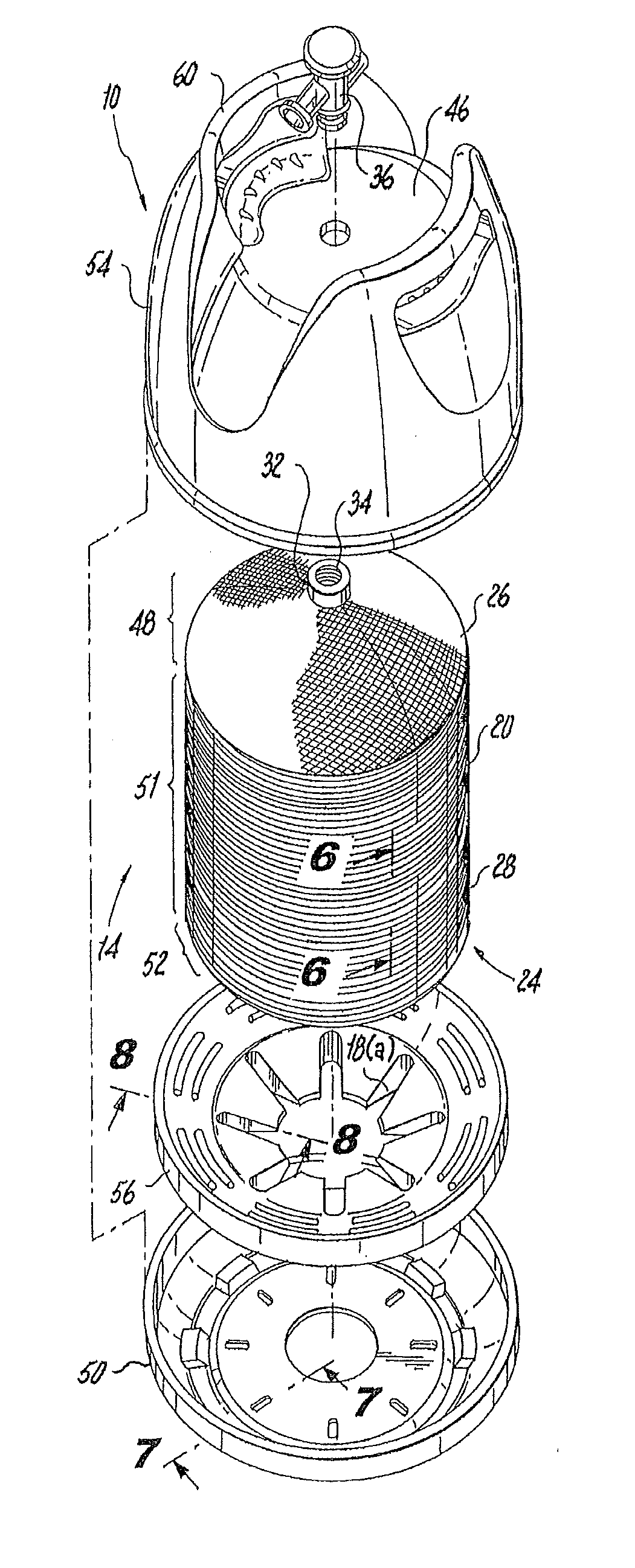

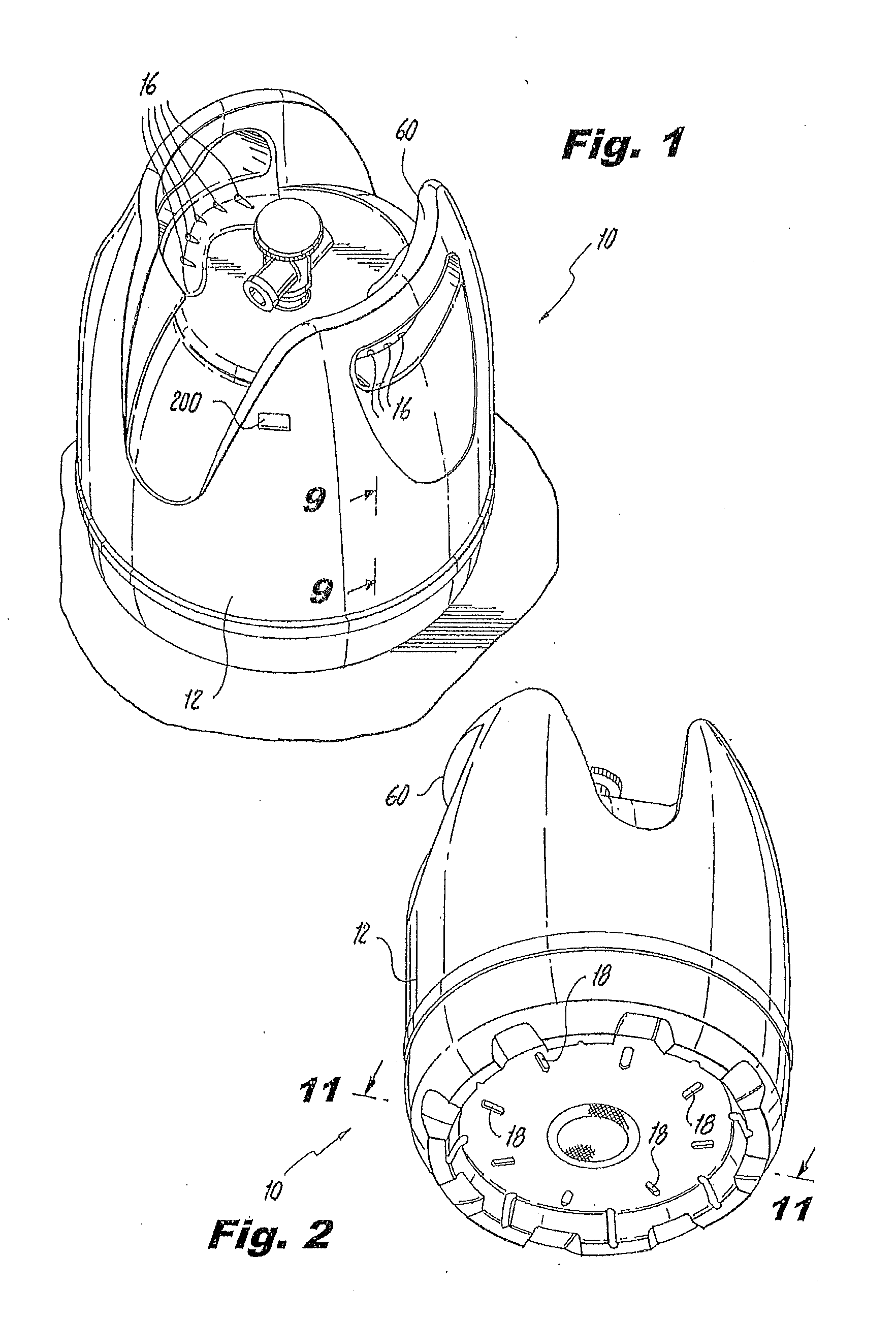

Vapor vortex heat sink

InactiveUS7980078B2Semiconductor/solid-state device detailsSolid-state devicesHeat fluxWorking fluid

A hermetic Rankine cycle in a sealed casing powers an internal centrifugal condensate pump with an internal vapor turbine during forced convective heat transfer between a heat source and a heat sink. No work is imported into the cycle during operation. A centrifugal pumping disk shears the working fluid against a heating surface, sweeping evolving vapor into radial vortices which provide sink flow conduits to a vapor space at the center of the cylindrical turbine. Convective mass flow through the vapor space to the condensing end of the casing spins the turbine and the centrifugal pumping disk which is connected to it. Vapor is continuously swept from the heating surface, so bubbles do not form and superheat while blocking heat flux into liquid working fluid. Vapor is sucked through the radial vortices into the central vapor space and into the condensing end of the casing along the low pressure gradients in vortex cores established by cooling power. A high heat flux surface is thereby thermally connected to a conventional heat sink having high cooling power, for maximal heat extraction at data centers or other heat sources. Vapor vortices organize counterflow of vapor and condensate in a continuous mass flow cycle, and extract work from heat. Organic working fluids can be used in the casing to make even low temperature waste heat a power source.

Owner:MCCUTCHEN CO

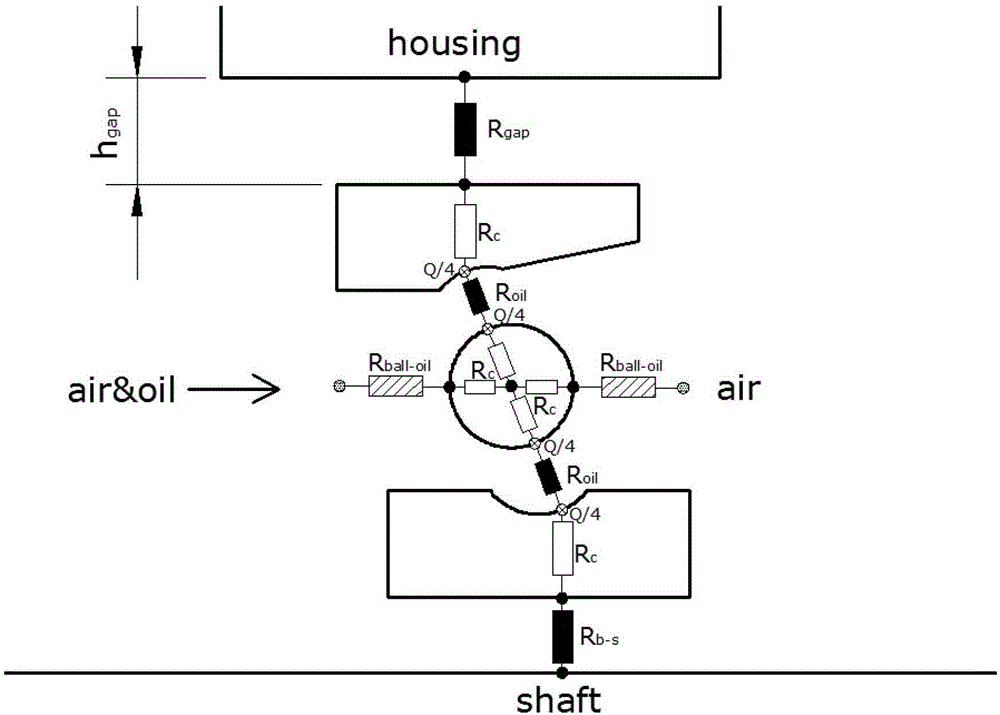

Thermal network modeling method applied to electric spindle steady temperature field

ActiveCN102867088AA Method for Accurate Thermal Boundary Condition DescriptionAccurate calculationAerodynamics improvementSpecial data processing applicationsMathematical modelPhysical model

The invention discloses a thermal network modeling method applied to an electric spindle steady temperature field. The method comprises the following steps of (1) building an electric spindle axisymmetric two-dimensional model; (2) building an equivalent thermal network of an axis; (3) calculating the overall heating value of a bearing and a motor, and distributing the heat to heating nodes; (4) according to heat transfer theory empirical formulas under different radiation conditions, calculating a convective heat transfer coefficient for heat exchange between a boundary node and fluid; (5) equalizing heat transfer between the nodes into ideal geometric heat transfer, obtaining conduction heat resistance of each part and boundary thermal-convection resistance, and building a heat transfer physical model; and (6) building a mathematical model and selecting a solution algorithm. A thermal network method is applied to a high-speed main shaft system with two heat sources, i.e. the bearing and the motor, and a complex convective heat exchange boundary, so that the difficulty in solving the characteristic temperature of each part of a complex assembling body of the main shaft is reduced. Compared with the method of solving a heat transfer differential equation, the thermal network modeling method is a quick and accurate steady temperature field calculation method.

Owner:XI AN JIAOTONG UNIV

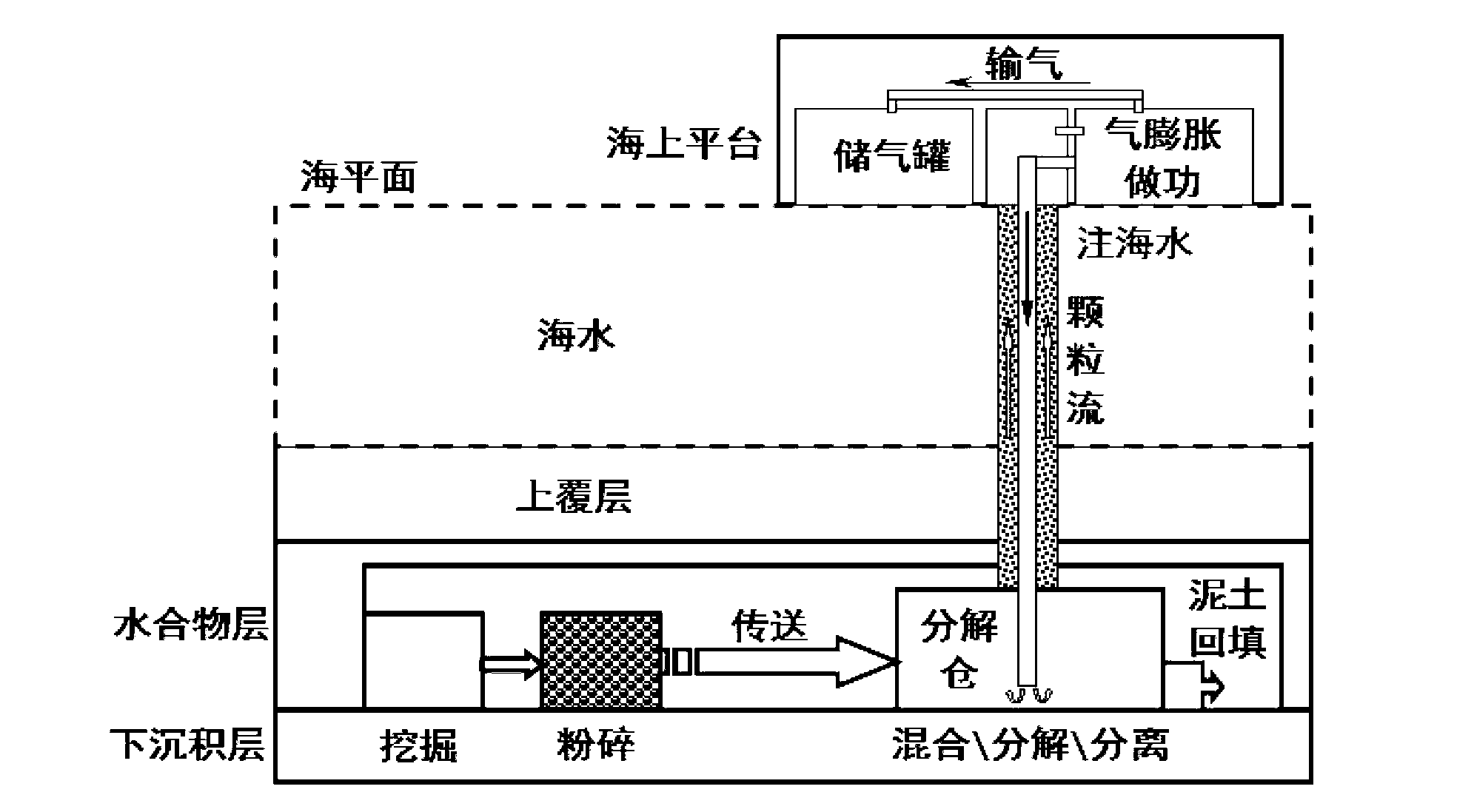

Mechanical-thermal hydrate exploiting method

The invention discloses a mechanical-thermal hydrate exploiting method. The mechanical-thermal hydrate exploiting method comprises the following steps: excavating a hydrate stratum, crushing hydrate sediment into hydrate sediment granules, and conveying the hydrate sediment granules into a decomposing chamber; stirring and mixing relatively hot seawater and the hydrate sediment granules in the decomposing chamber, partially decomposing the hydrate sediment granules, separating the obtained mixture, and removing the separated sediment; upwardly conveying the remaining mixture along an exploiting shaft, further decomposing the hydrate in the mixture in the conveying process, and separating the remaining mixture and generated gas from the sediment in the mixture; and collecting the obtained gas on an exploiting platform. By the method, hydrate decomposing heat can be supplied by a huge heat source from seawater and convective heat transfer; expansion energy of gas which is generated in a centralized way can be made full use; backfill of the sediment can restore certain stratum strength; and leakage of the hydrate decomposing gas from a covering layer can be avoided.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

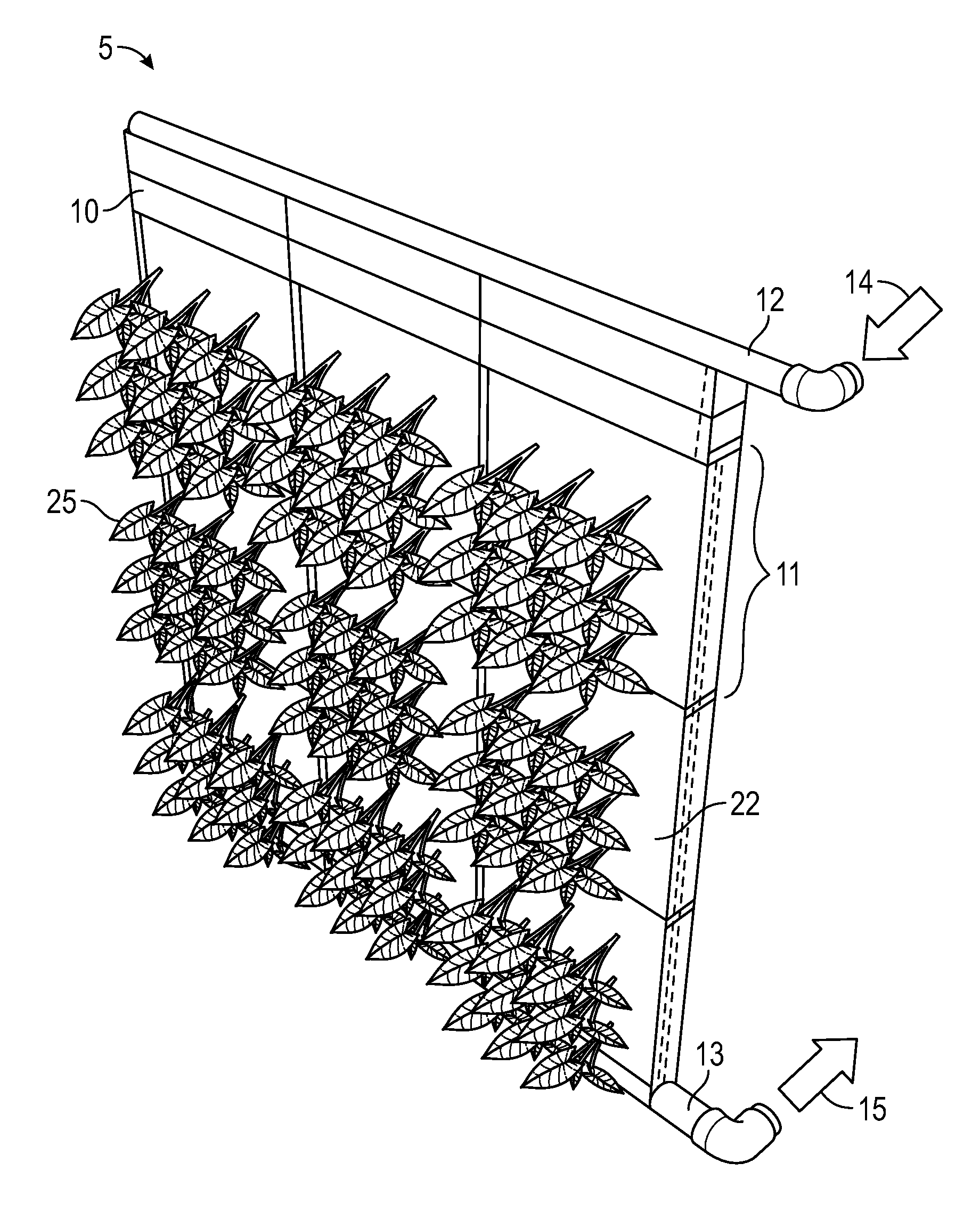

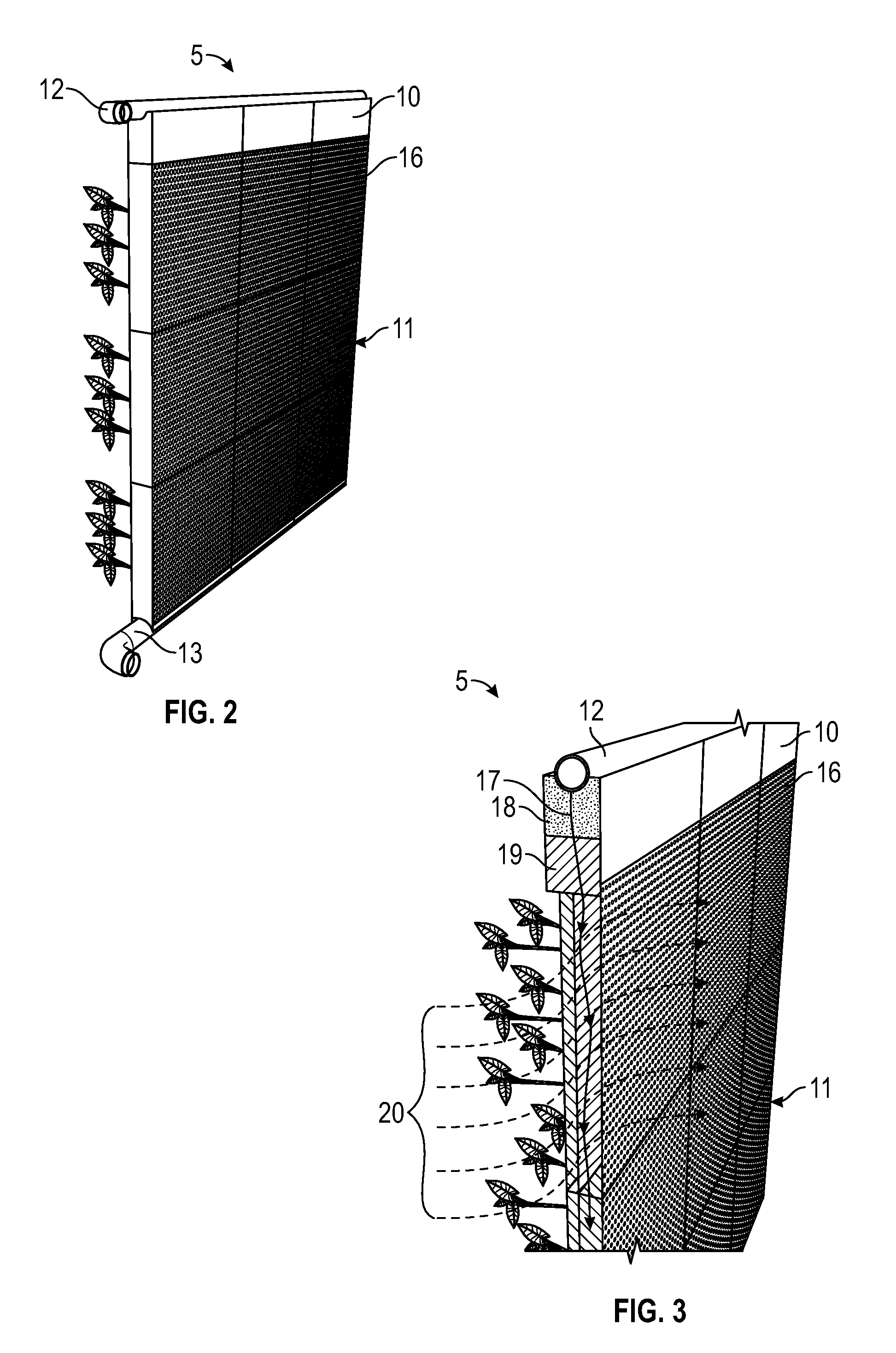

Modular Living Green Wall System to Provide Heat Rejection

InactiveUS20150289452A1Facilitates rejection/heat exchangeEasy maintenanceSelf-acting watering devicesWatering devicesPorous substrateWarm water

Modular living green wall systems are provided that supply water-cooled heat rejection for building cooling, power generation, industrial, chemical, and other processes that rely on heat rejection to the ambient environment for their efficient operation. Warm water from the process requiring heat rejection is circulated vertically through channels of porous media of the system and is cooled by evaporative and / or convective heat transfer to the ambient air that flows over and / or through the porous media across or counter to the water flow direction. Cool water leaving the system is piped to a heat exchanger of the process to provide the requisite cooling and is returned warm to the modular green wall system to complete the circulation loop. Modular living green wall systems may be assembled using plant modules and water treatment modules that are nested together to form continuous porous vertical water flow channels and a water recirculation system. The plant modules may consist of an inner porous media layer and an exposed porous substrate layer attached to each other and a stackable module housing. The water treatment module may be housed in a compatible stackable housing containing horizontal layers of filtration media. These modules are stacked in an interlocking manner and may be attached to an existing building support structure or alternatively be used to form a free standing living green wall.

Owner:YALE UNIV

Hybrid pressure vessel with separable jacket

A pressure vessel is provided including an inner tank formed from a tank liner surrounded by a wound layer of composite filaments. A protective jacket is disposed on the inner tank that facilitates stacking and portability of the pressure vessel and helps to define an air passage for convective heat transfer between the hybrid tank and the environment.

Owner:AMTROL LICENSING INC

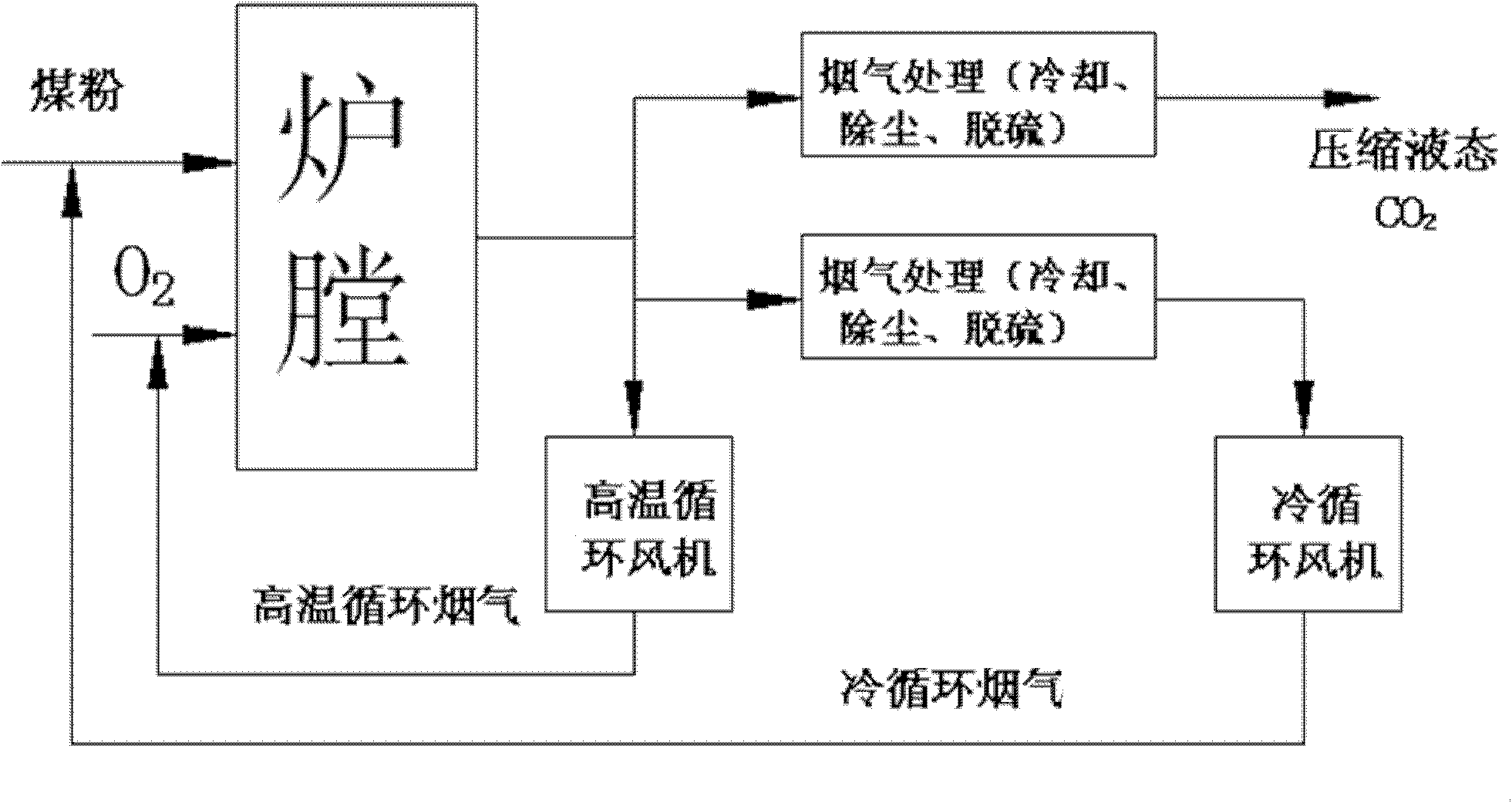

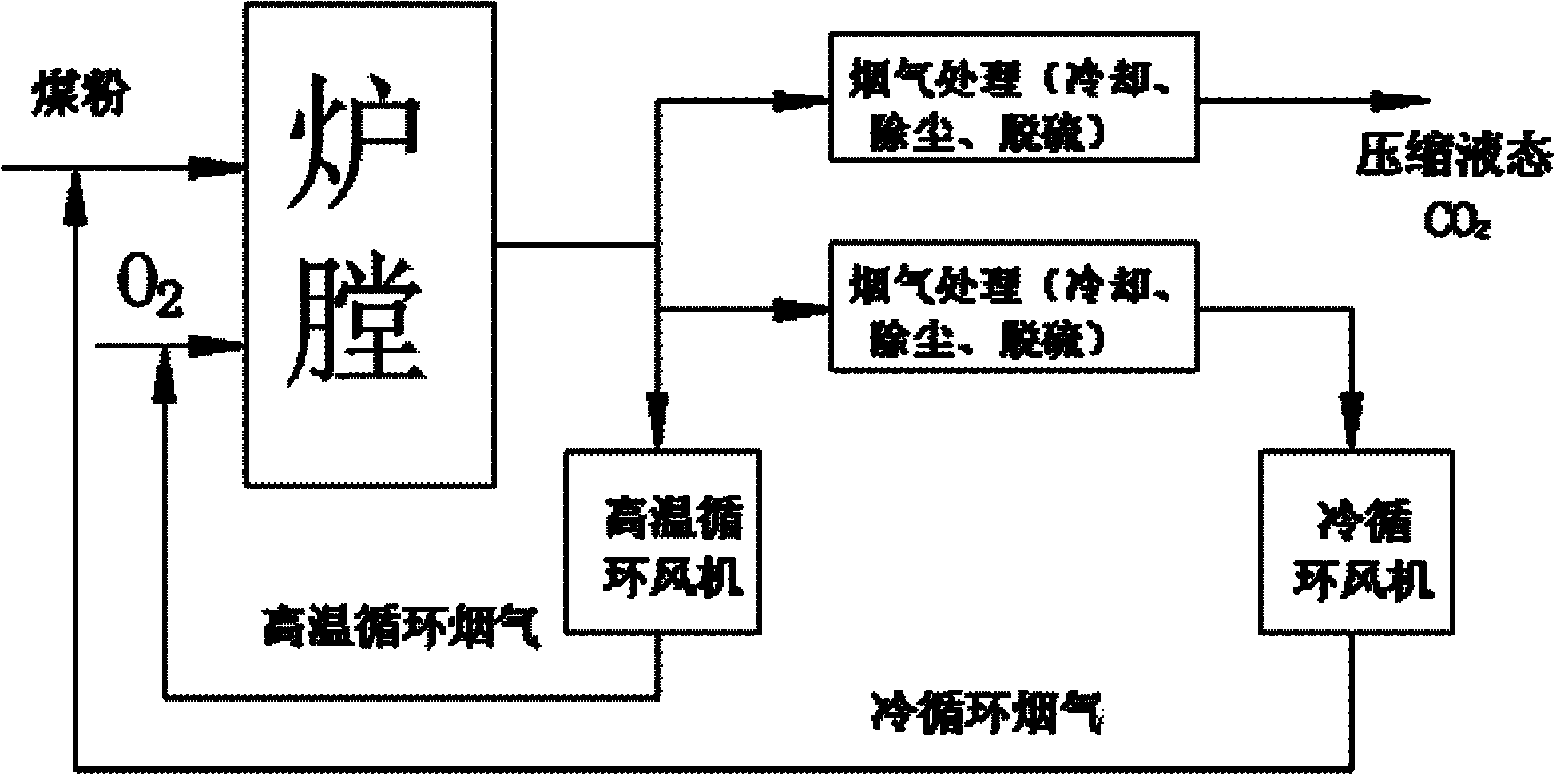

Method for re-circulating combustion of flue gas of pulverized coal fired boiler

InactiveCN101839474ASteam temperature increasedHigh thermal efficiencyFluidized bed combustionCarbon compoundsCO2 contentHearth

The invention provides a method for re-circulating combustion of flue gas of a pulverized coal fired boiler, belongs to a method for circulating combustion of oxygen gas (O2) and carbon dioxide (CO2) of pulverized coal, and aims to solve the problems of low heat efficiency and poor burn-out property existing in the conventional combustion method. The method comprises the steps of: 1,igniting and combusting: conveying the pulverized coal to a furnace hearth by using the circulation flue gas, and simultaneously conveying O2 to the furnace hearth for ignition; 2, circulating the flue gas: dividing the high-temperature flue gas generated by combustion into two parts, and performing cooling, dust removal and desulfurization compression on the first part to obtain liquid CO2; dividing the second part into two paths, conveying the first path to an entrance of the furnace hearth by using a high-temperature circulation fan, and mixing the first path of the flue gas and O2; and performing cooling, dust removal and desulfurization on the second path, and conveying the second path carrying the pulverized coal to the furnace hearth by using a cold circulation fan. The method has the advantages of adjusting the steam temperature of the boiler by using the high-temperature flue gas, enhancing convective heat transfer, increasing the steam temperature of the boiler, improving the heat efficiency of the boiler and the denitration rate, increasing the CO2 content after the high-temperature flue gas is cooled, reducing emission load of NOx, lowering CO2 capturing and collecting cost, and meeting the national energy conservation and environmental protection standard.

Owner:HUAZHONG UNIV OF SCI & TECH

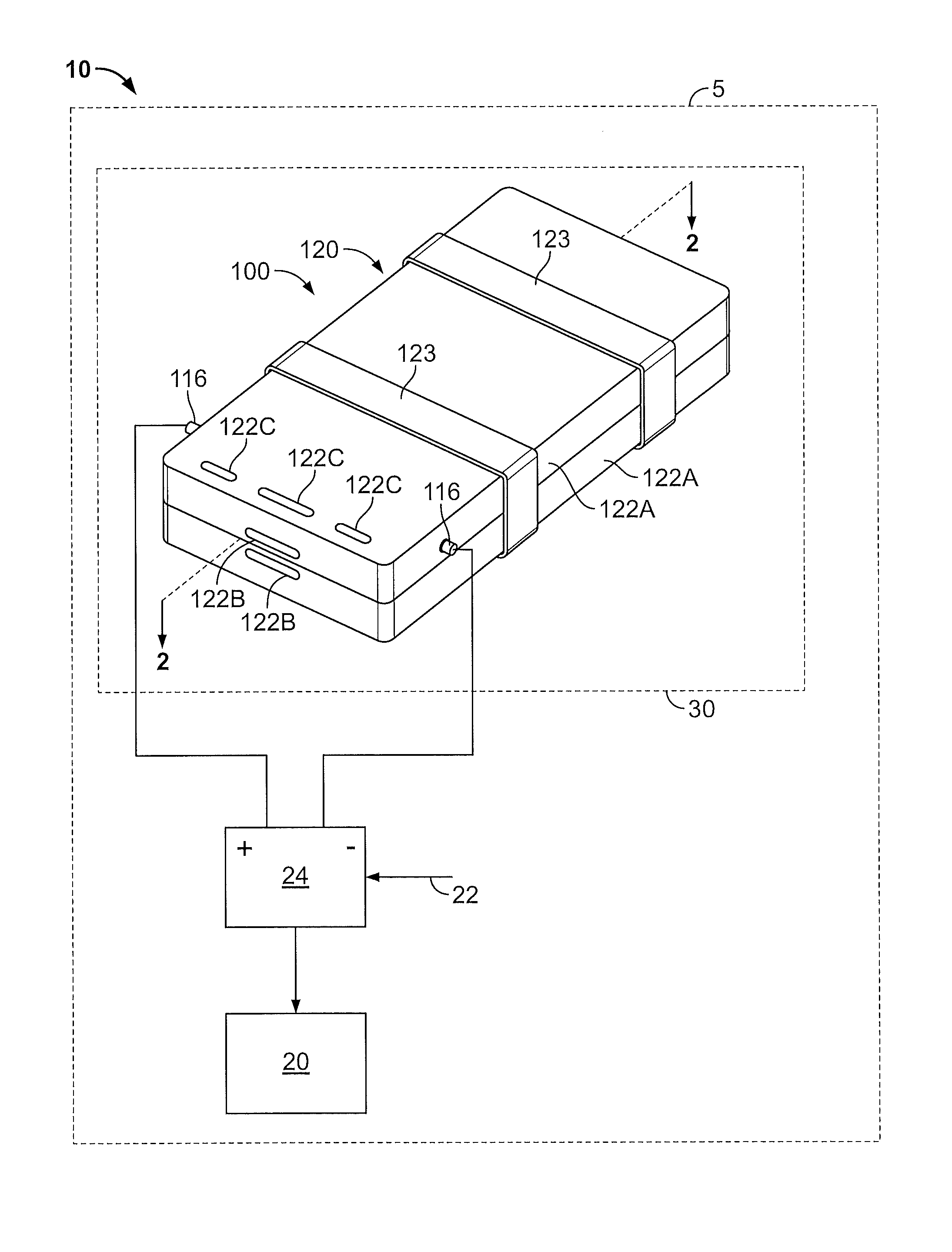

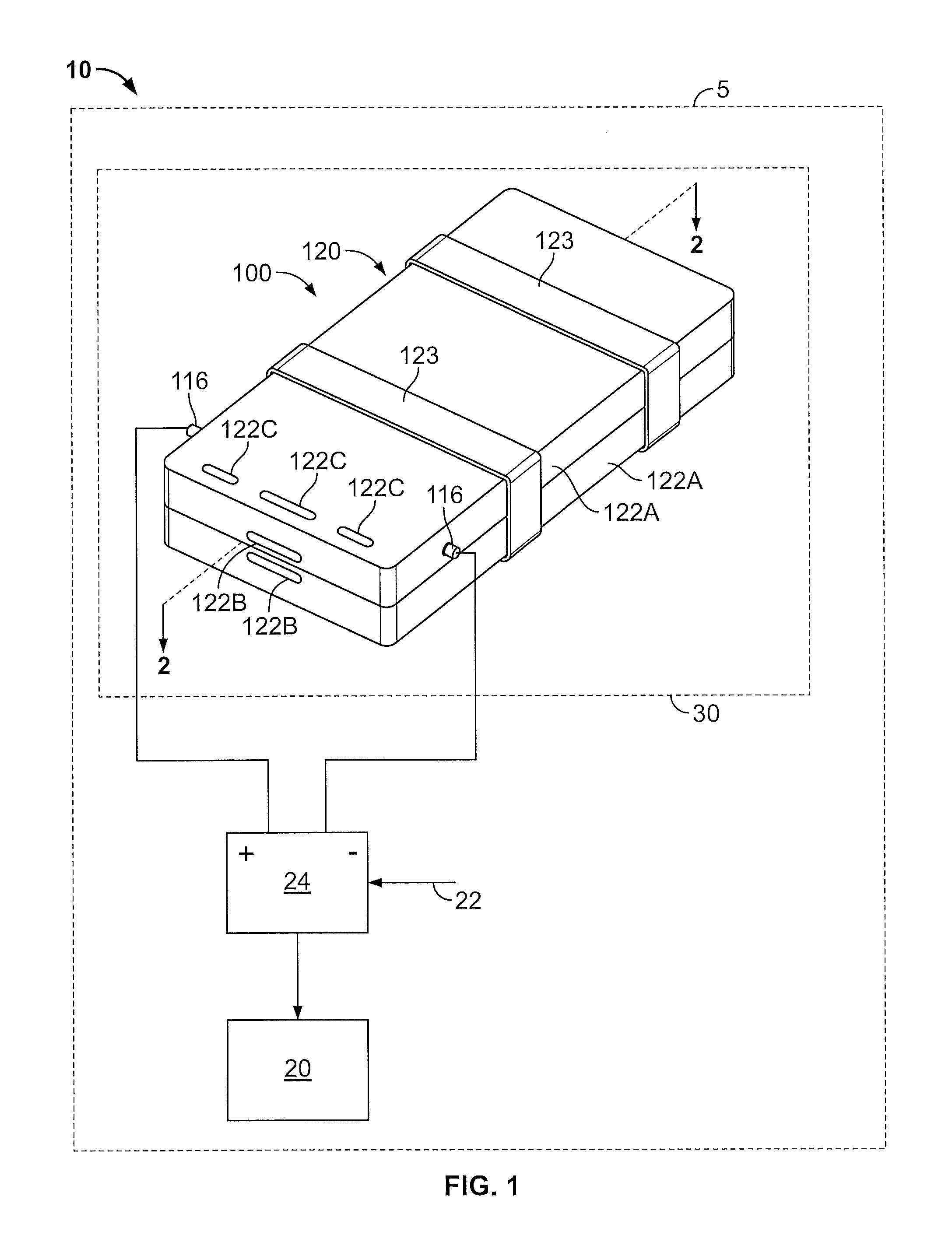

Temperature controlled battery pack assembly and methods for using the same

InactiveUS20110300420A1Thermoelectric device manufacture/treatmentCell temperature controlThermoelectric coolingTemperature control

A temperature controlled battery pack assembly includes a housing defining a battery chamber and including thermal insulation surrounding at least a portion of the battery chamber. At least one battery cell is contained in the battery chamber. The thermal insulation inhibits thermal transfer between the at least one battery cell and the surrounding environment. A thermal bridge conductor is disposed in the battery chamber and engages the at least one battery cell. The battery pack assembly further includes a thermoelectric cooler device having an inner surface and an outer surface. The thermoelectric cooler device is operable to actively transfer heat between the inner and outer surfaces using the Peltier effect. A heat sink device is in contact with or connected to the outer surface to enable thermal conduction between the outer surface and the heat sink device. The battery pack assembly includes a fan operable to force a flow of a heat transfer fluid across the heat sink device and into the environment to enable convective heat transfer between the heat sink device and the environment. The thermal bridge conductor is in contact with or connected to the inner surface to enable thermal conduction between the inner surface and the thermal bridge conductor.

Owner:EATON CORP

Plasma arc torch and method for improved life of plasma arc torch consumable parts

InactiveUS20060237399A1Enhances convective coolingUseful life of the consumable parts is increasedArc welding apparatusPlasma techniqueEngineeringTorch

Owner:THERMAL DYNAMICS

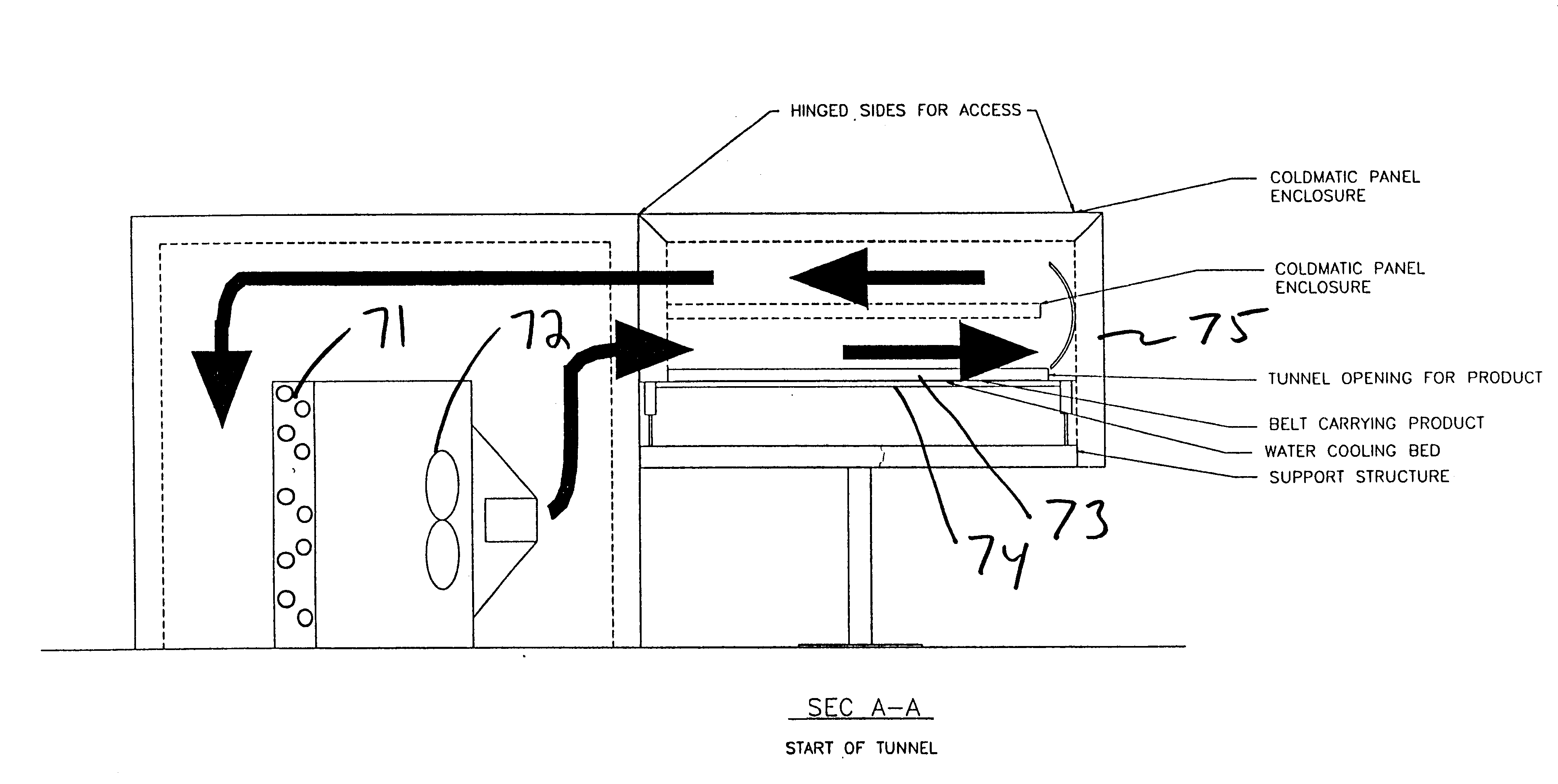

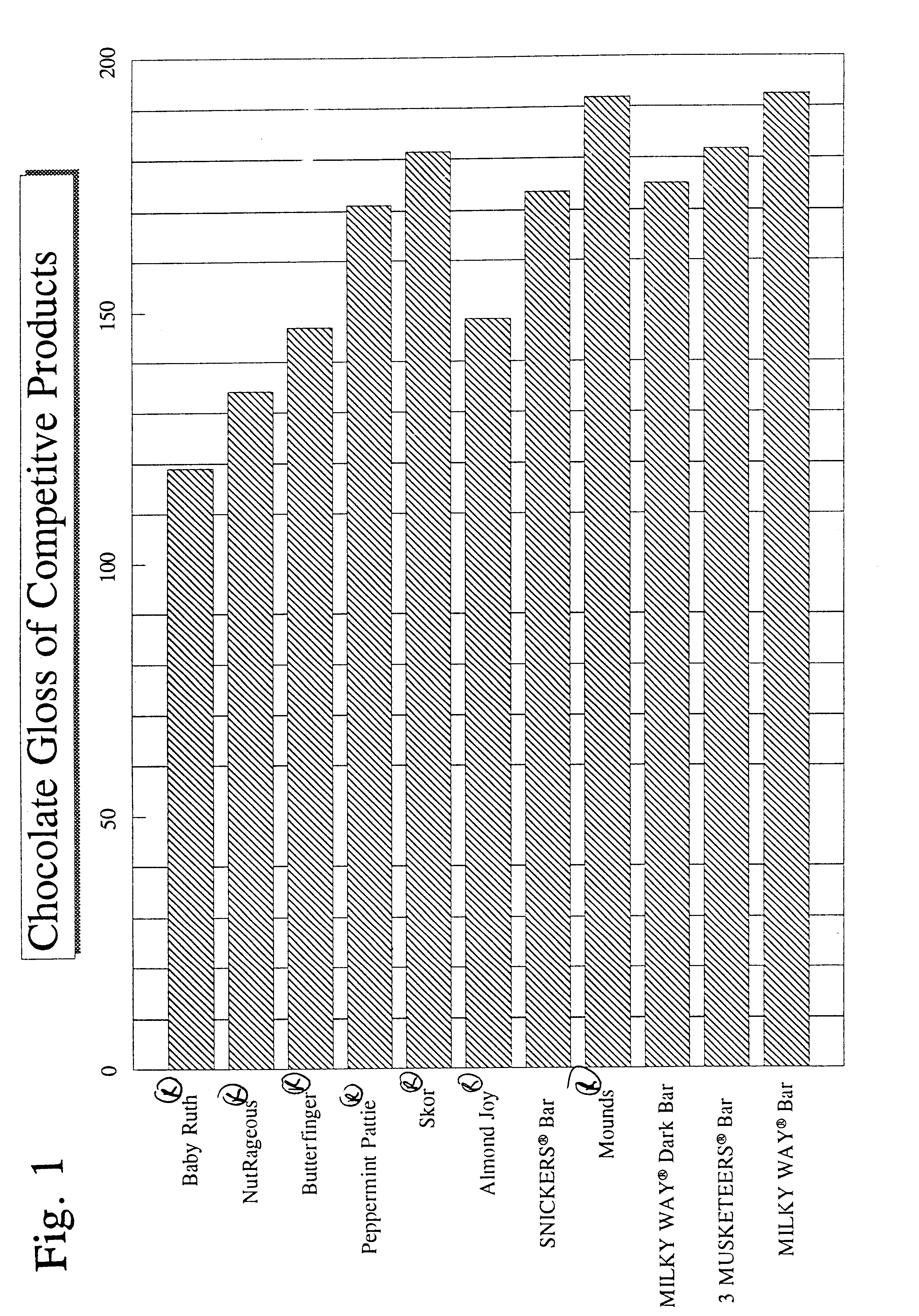

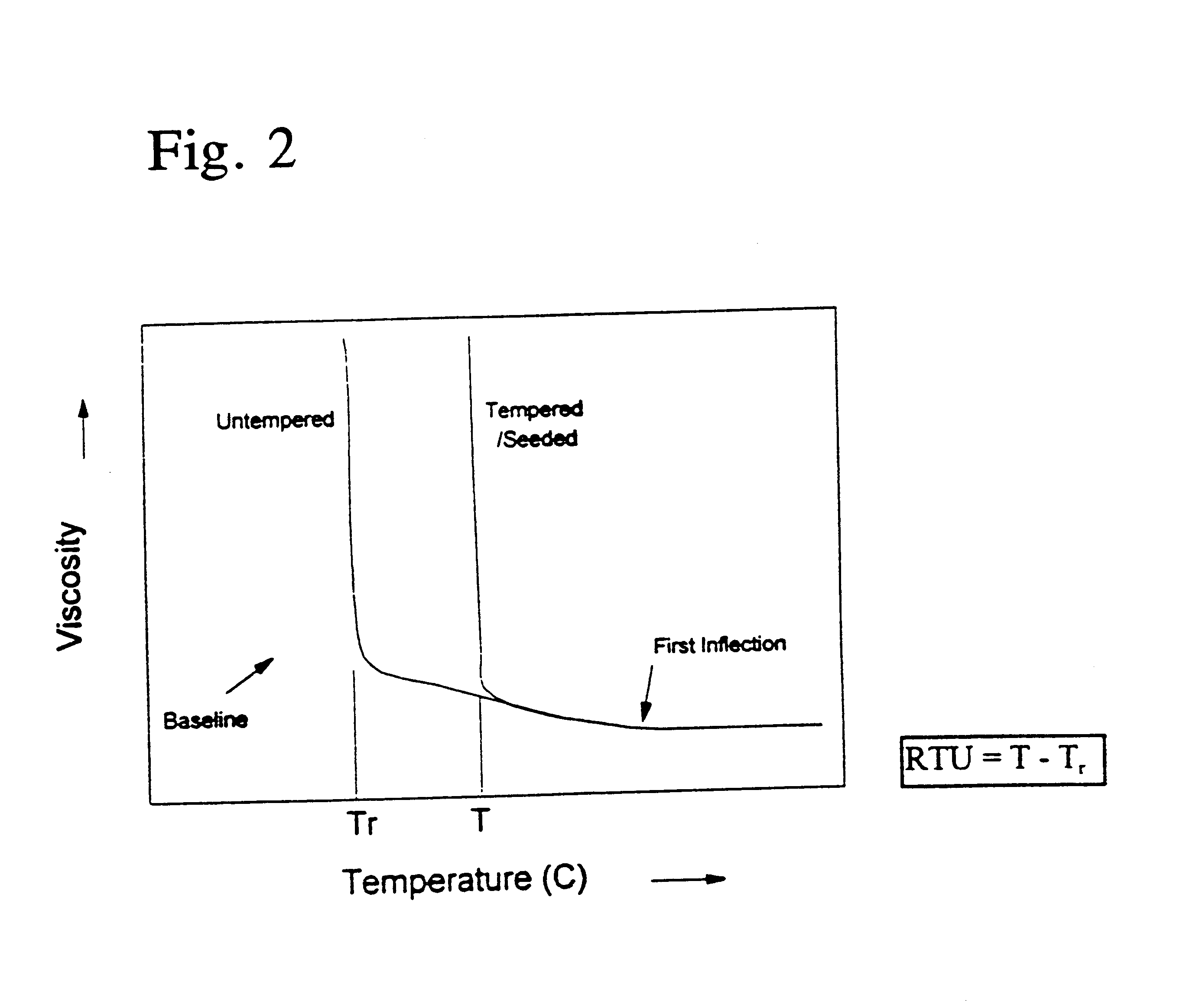

Methods of setting chocolate and products produced by same

InactiveUS6419970B1Aggressive coolingRapid coolingMilk preservationWort preparationEngineeringHardness

The present invention discloses improved methods of making chocolates utilizing fast and aggressive cooling to form a set chocolate, chocolate products produced using same and cooling systems and apparatuses for performing same. The resultant rapidly cooled chocolate has many improved properties including enhanced gloss, improved bloom resistance and hardness. Moreover, the rapid cooling allows for the improved retention of fine detail and / or decoration on the chocolate product. The rapid cooling can be achieved without the use of chilled plungers or cold molds, but instead utilizes increased convective heat transfer coefficients and / or lower operating temperatures. The melted chocolate composition set by the rapid cooling can be of conventional temper, low temper or ultra-low temper chocolate and still result in a stable finished chocolate product allowing for the use of lower fat content formulations.Another aspect of the invention relates to a method of using a controlled humidity environment in a rewarm zone after the cooling zone to form a thermally robust chocolate product having enhanced resistance to heat abuse, yet which still has good gloss.

Owner:MARS INC

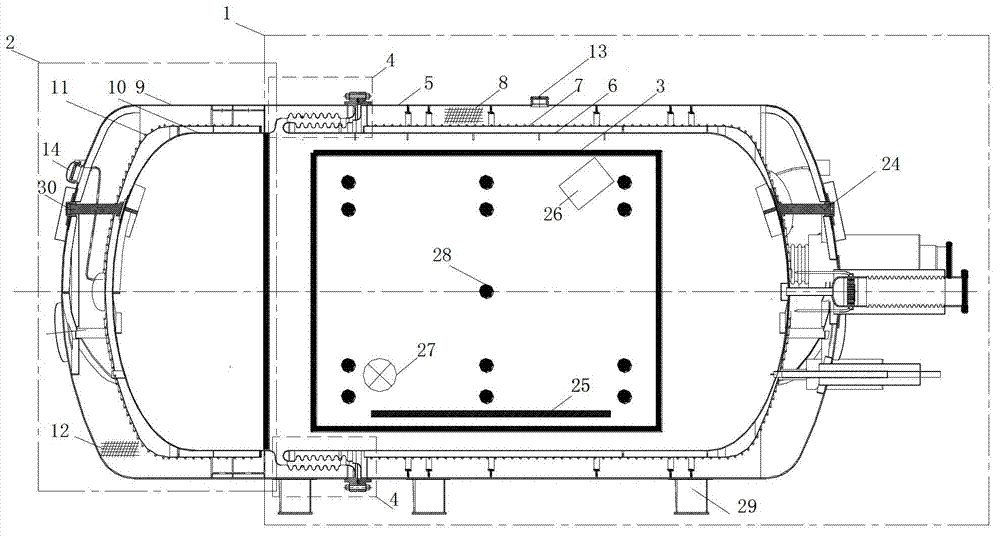

High/low temperature space environment simulating container with high temperature change rate

ActiveCN102890006AFast heating and cooling rateGood temperature uniformityStructural/machines measurementSpace environmentNatural convection

The invention relates to a high / low temperature space environment simulating container with a high temperature change rate, comprising a main cabin body, a cabin door, a head sink arranged in the main cabin body, a door sealing structure for connecting the main cabin body and the cabin door, an insulating channel passing through the main cabin body, a sample carrier table, a high / low temperature camera assembly, a high / low temperature fluid stirrer, a temperature measuring system, a pressure measuring system and a vacuumizing structure. A non-high-vacuum environment is formed in the container and is filled with helium; besides radiative heat transfer same as the heat transfer manner of a heat vacuum tank, natural convection heat transfer, even forced convection heat transfer, is added in the cabin, so heat transfer speed is increased greatly, a high / low temperature environment (68K-373K) with a high temperature change rate and even temperature is provided to a sample to be measured. The high / low temperature space environment simulating container is stable, safe and reliable to work.

Owner:SHANGHAI JIAO TONG UNIV

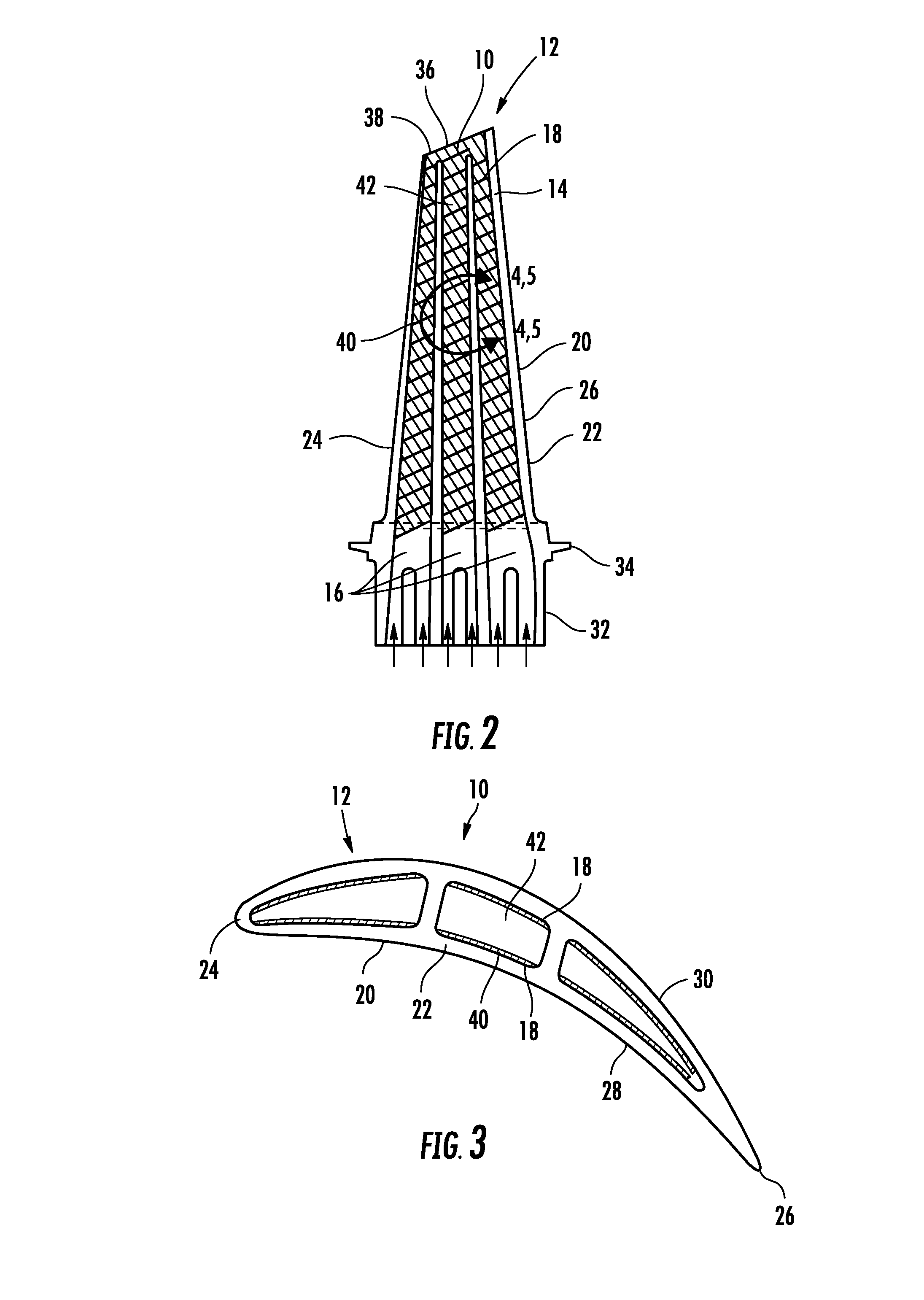

Cooling channel for airfoil with tapered pocket

The present invention includes systems and methods for providing cooling channels located within walls of a turbine airfoil. These cooling channels include micro-circuits that taper in various directions along the length and width of the airfoil. In addition, these cooling channels have a variety of shapes and areas to facilitate convective heat transfer between the surrounding air and the airfoil.

Owner:ANSALDO ENERGIA IP UK LTD

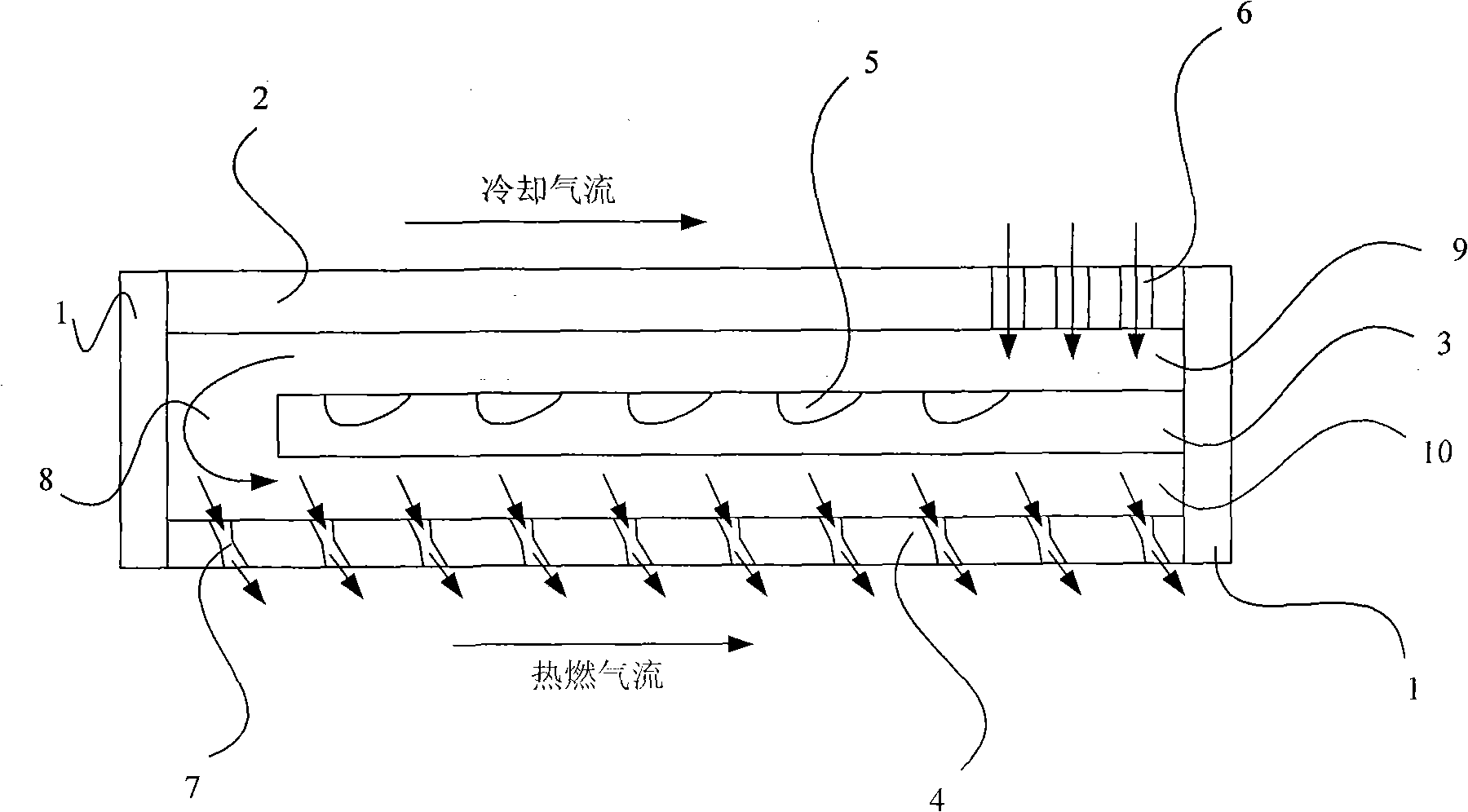

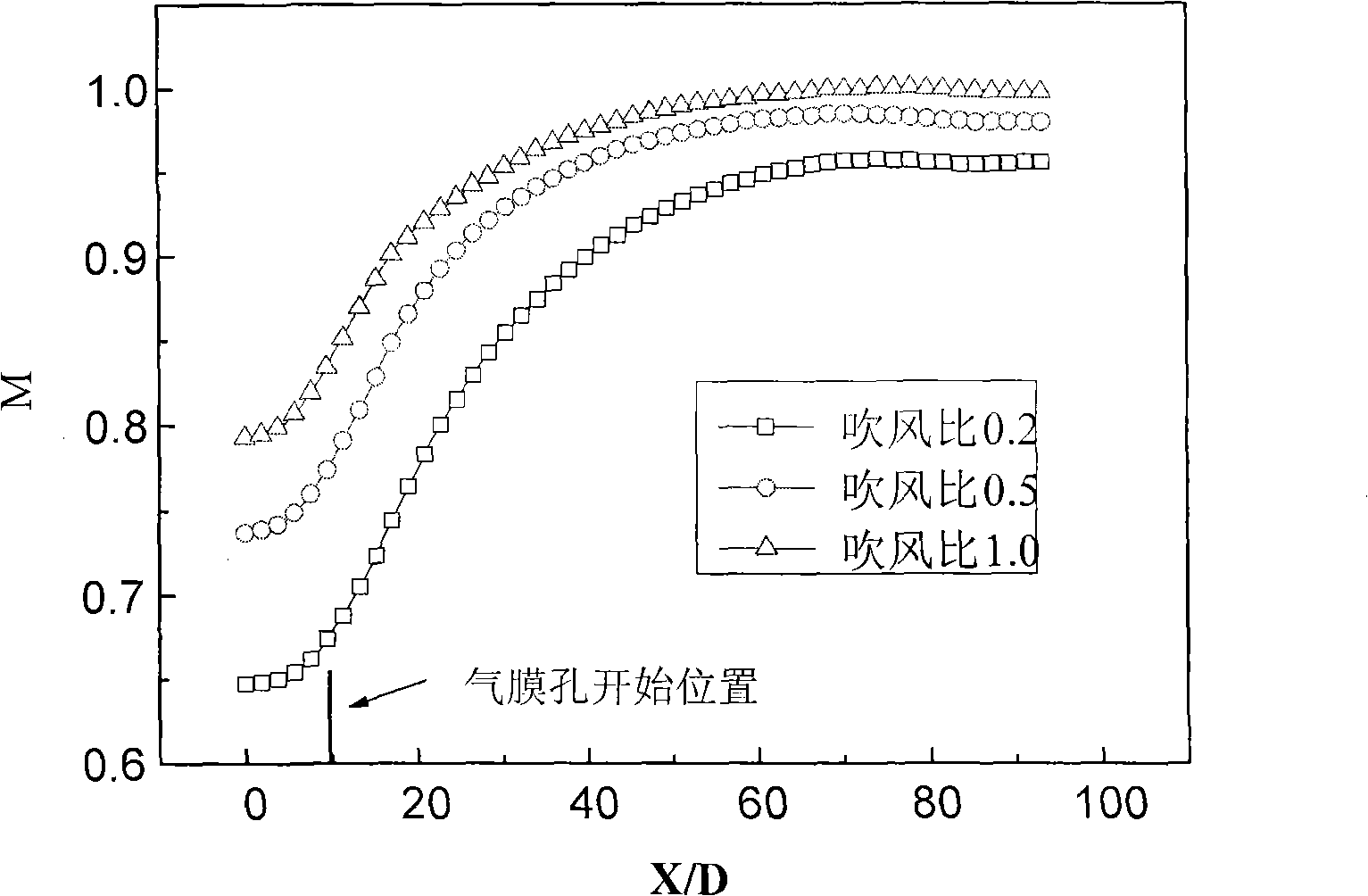

Reentry type compound cooling structure

InactiveCN101526228AImprove heat transfer efficiencyEnhanced convective heat transferContinuous combustion chamberCooling channelConvective heat transfer

The invention discloses a reentry type compound cooling structure which comprises an external wall, a middle wall, an internal wall and end walls. The back segment of the external wall is provided with an impact opening; a cooling air slot with certain interval is formed between the middle wall and the front end wall; the internal wall is a cooling structure of a multi-inclined-hole wall, and cooling air flows in a reentry way among the walls of three layers. An impact flow mode is adopted for cooling air. The air flows from back to front in an upper cooling channel composed of the external wall and the middle wall. The heat exchange efficiency of the front segment of the middle wall can be effectively improved by the function of bytyl cellular pits on the middle wall. The air enters a lower cooling channel from the cooling air slot, flows in the reentry way and flows out of the internal wall from a shrinkable and expandable air film hole, and the air film protection is formed at the hot lateral of the internal wall. The shrinking air intake of the shrinkable and expandable air film hole can effectively improve the convective heat transfer of the internal wall of the shrinkable and expandable air film hole, and the expanding gassing can lower the penetration capability of jet flows, strengthen the cover effect of the air film on the hot lateral of the internal wall and effectively protect flame tubes. The cooling structure has the advantages of simple structure, convenient manufacturing and convenient popularization and application.

Owner:BEIHANG UNIV

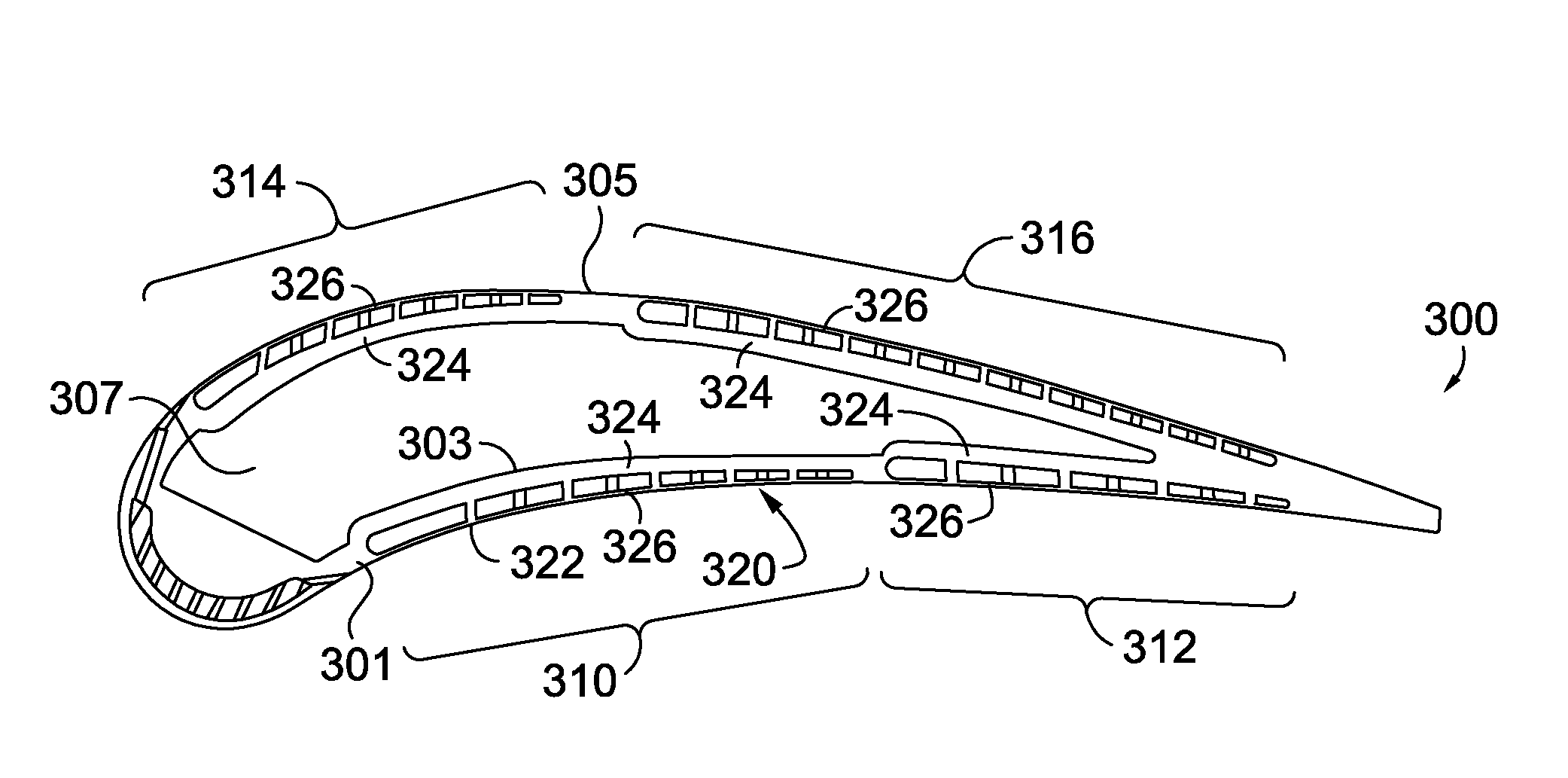

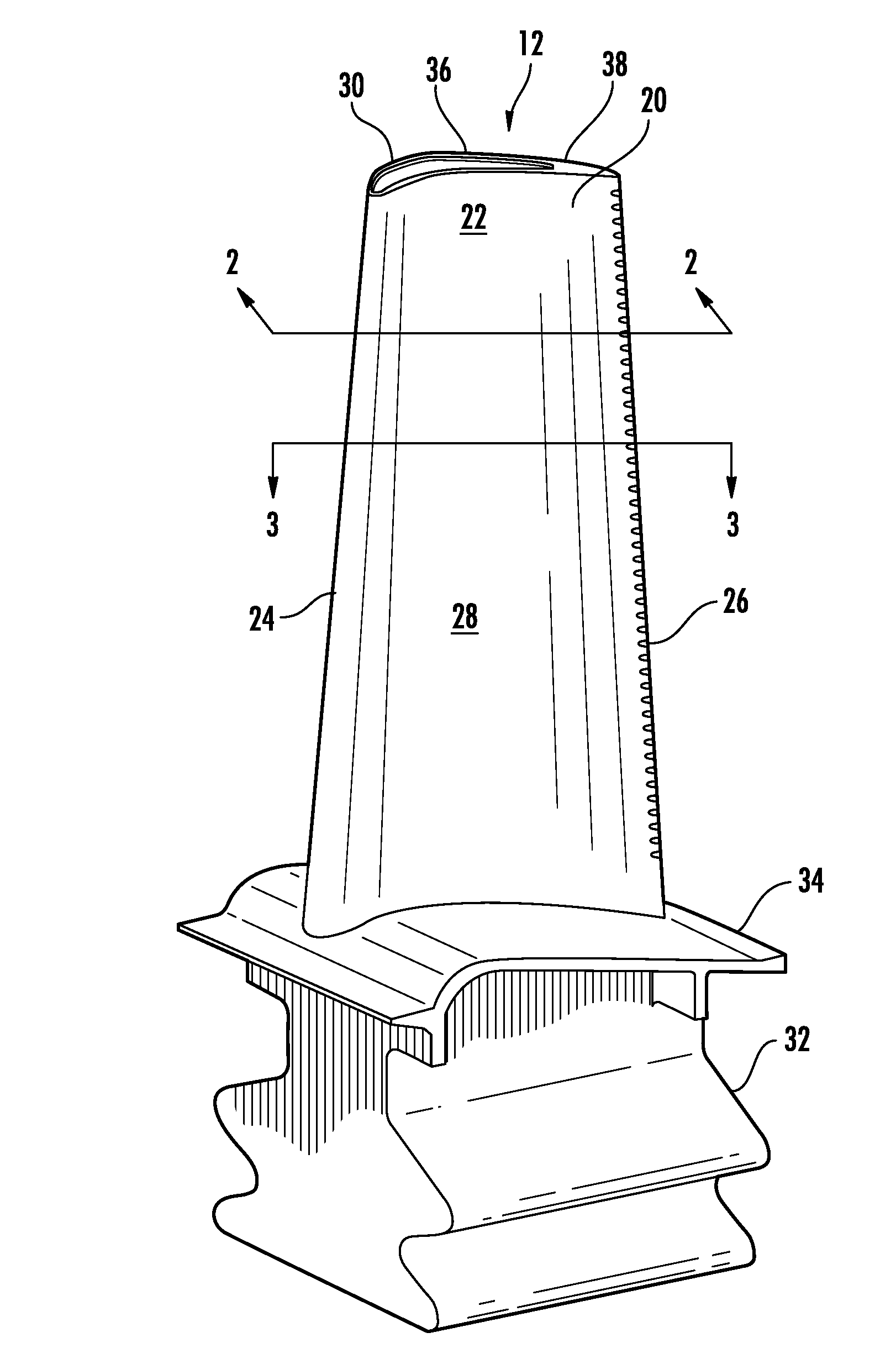

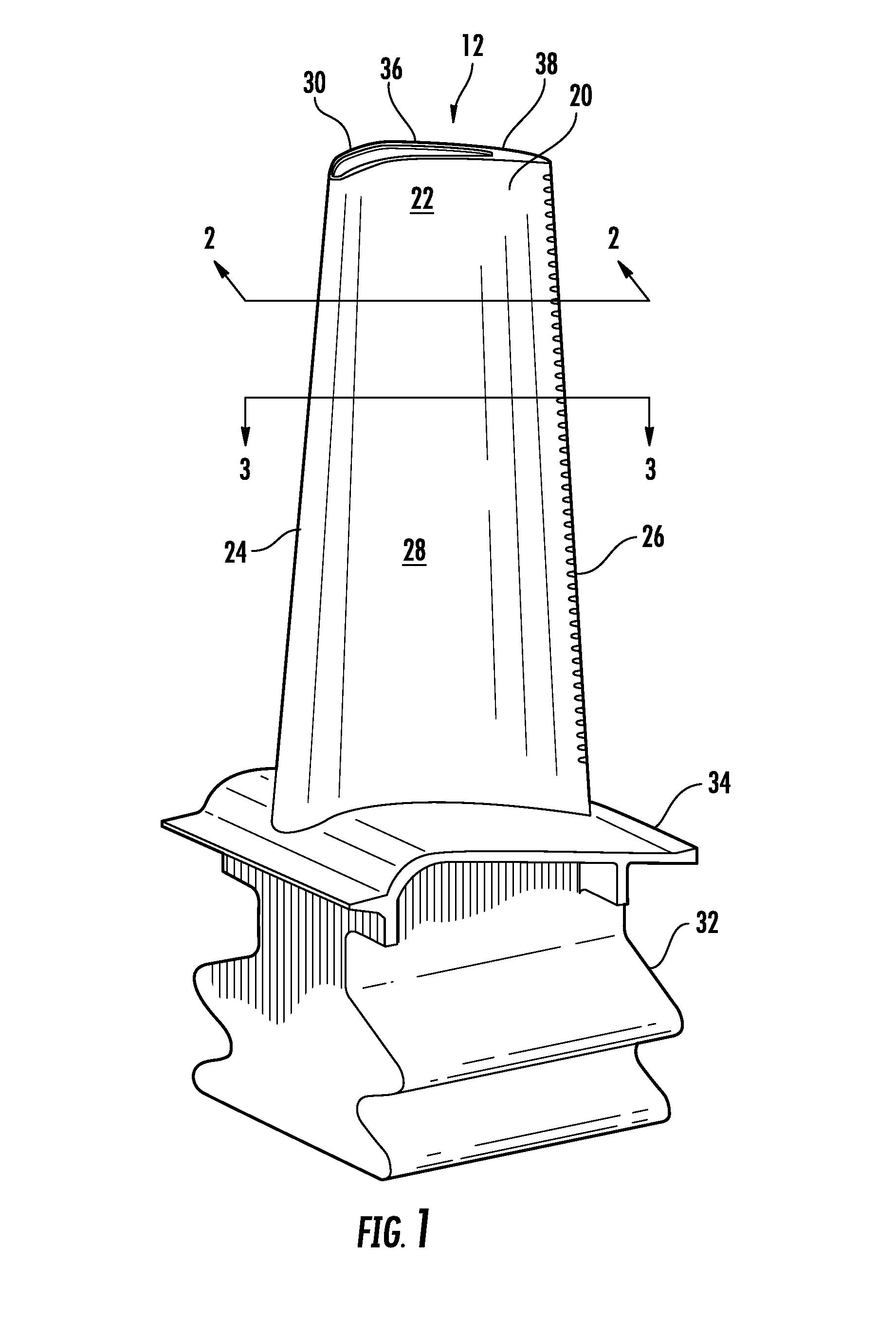

Turbine Airfoil with an Internal Cooling System Having Enhanced Vortex Forming Turbulators

ActiveUS20100226761A1Highly effective conventionHigh internal convective cooling potentialPump componentsEngine fuctionsHigh rateTurbine

A turbine airfoil usable in a turbine engine and having at least one cooling system. At least a portion of the cooling system may include one or more cooling channels having a plurality of turbulators protruding from an inner surface and positioned generally nonorthogonal and nonparallel to a longitudinal axis of the airfoil cooling channel. The cooling channel may also include a plurality of vortex enhancers protruding from an inner surface forming the cooling channel and positioned nonparallel to the turbulators. In one embodiment, the vortex enhancers may be positioned generally orthogonal to the turbulators. The configuration of turbulators and vortex enhancers creates a higher internal convective cooling potential for the blade cooling passage, thereby generating a high rate of internal convective heat transfer and attendant improvement in overall cooling performance. This translates into a reduction in cooling fluid demand and better turbine performance.

Owner:SIEMENS ENERGY INC

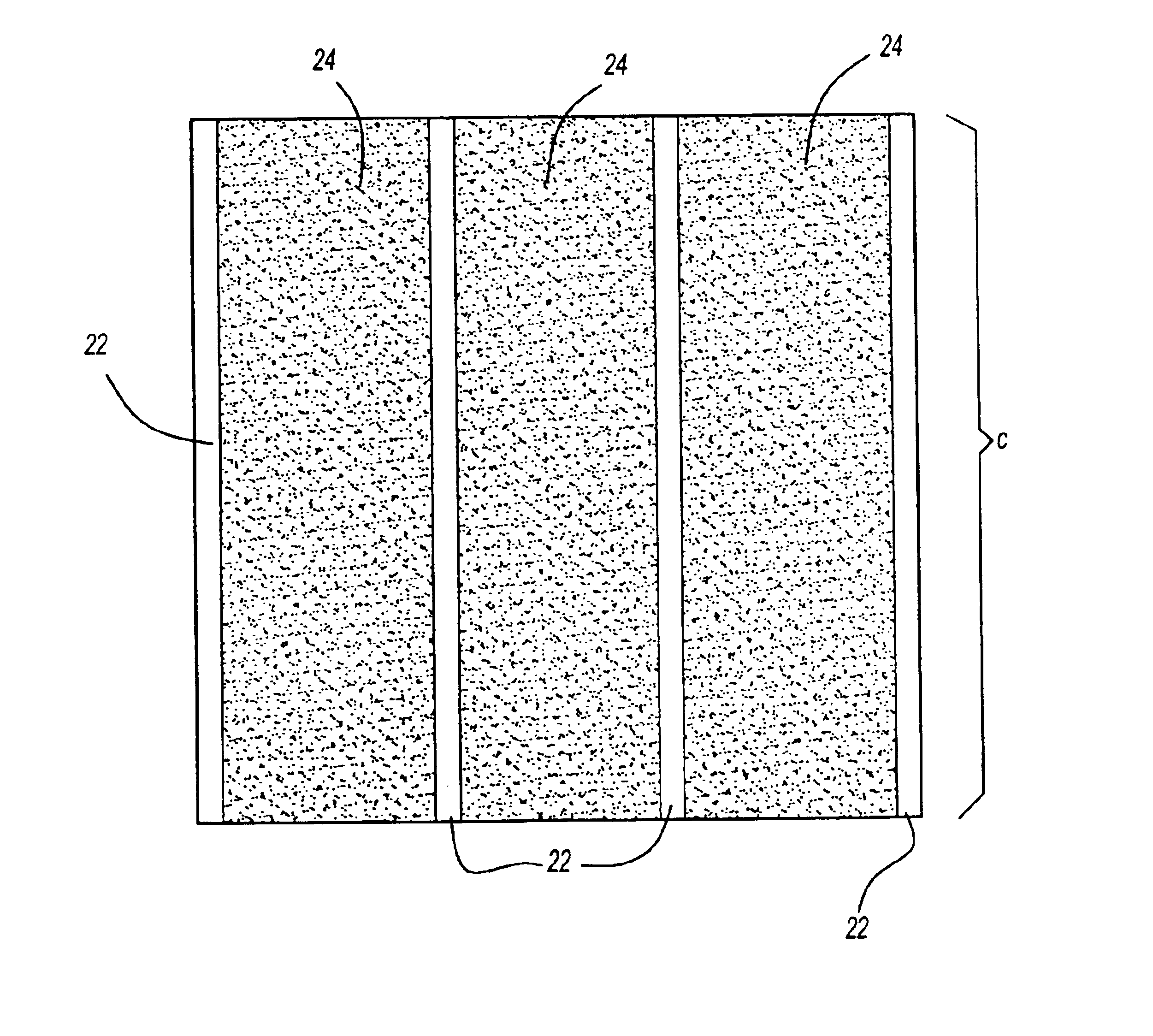

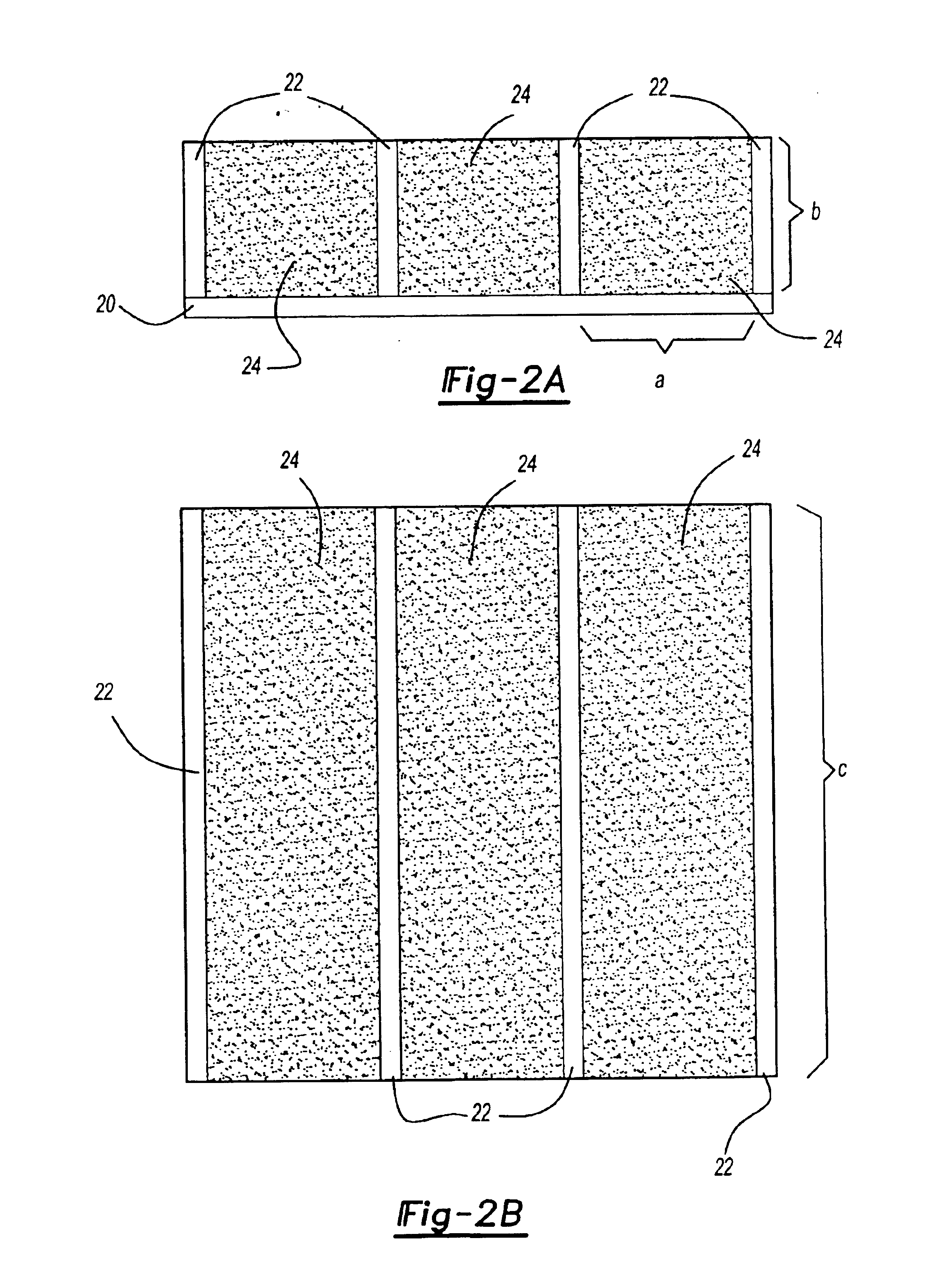

High performance heat exchange assembly

InactiveUS6840307B2Reduce thermal resistanceIncrease waste heatSemiconductor/solid-state device detailsSolid-state devicesReticulated foamEngineering

Heat sinks are provided that achieve very high convective heat transfer surface per unit volume. These heat sinks comprise a spreader plate, at least two fins and at least one porous reticulated foam block that fills the space between the fins.

Owner:DELPHI TECH INC

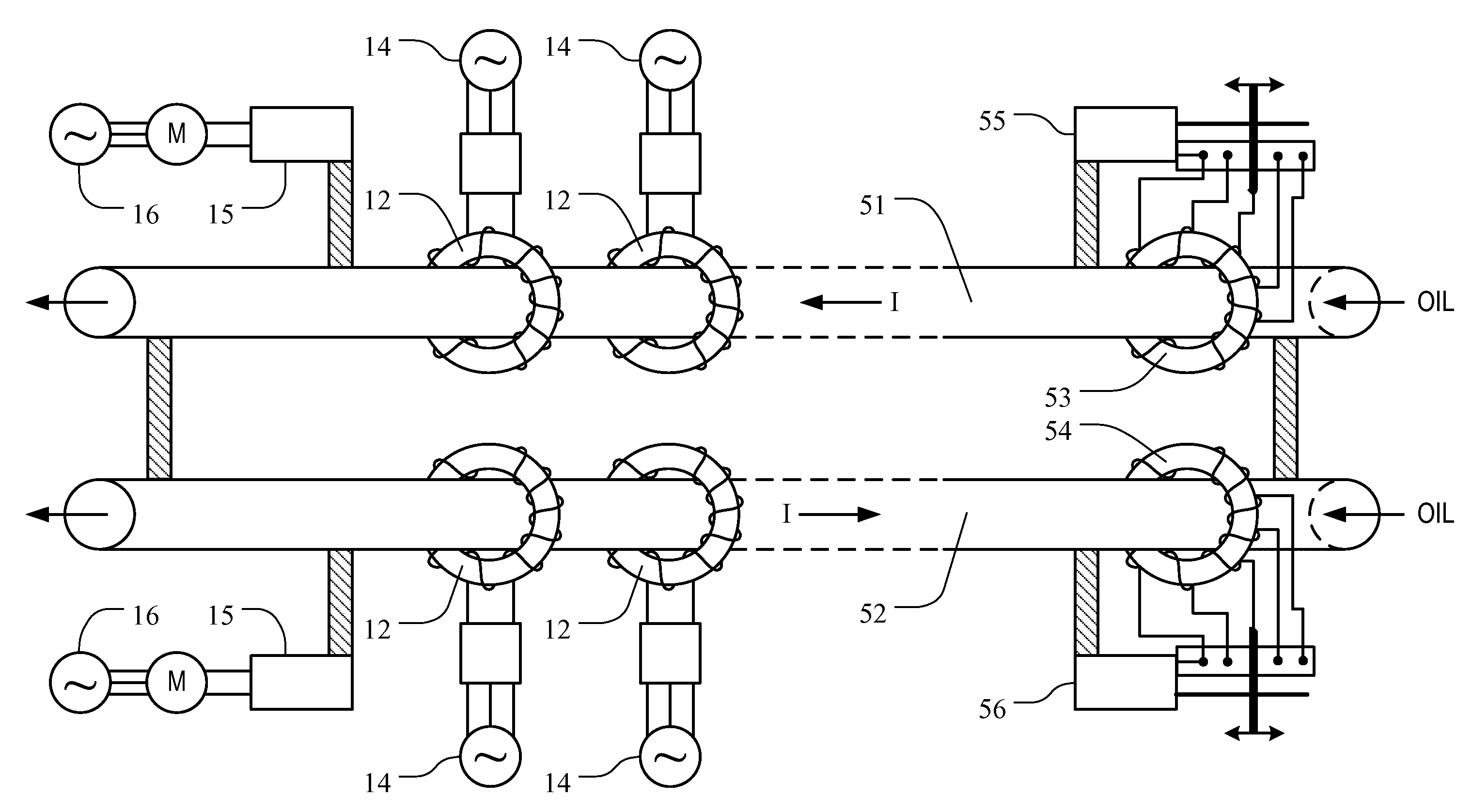

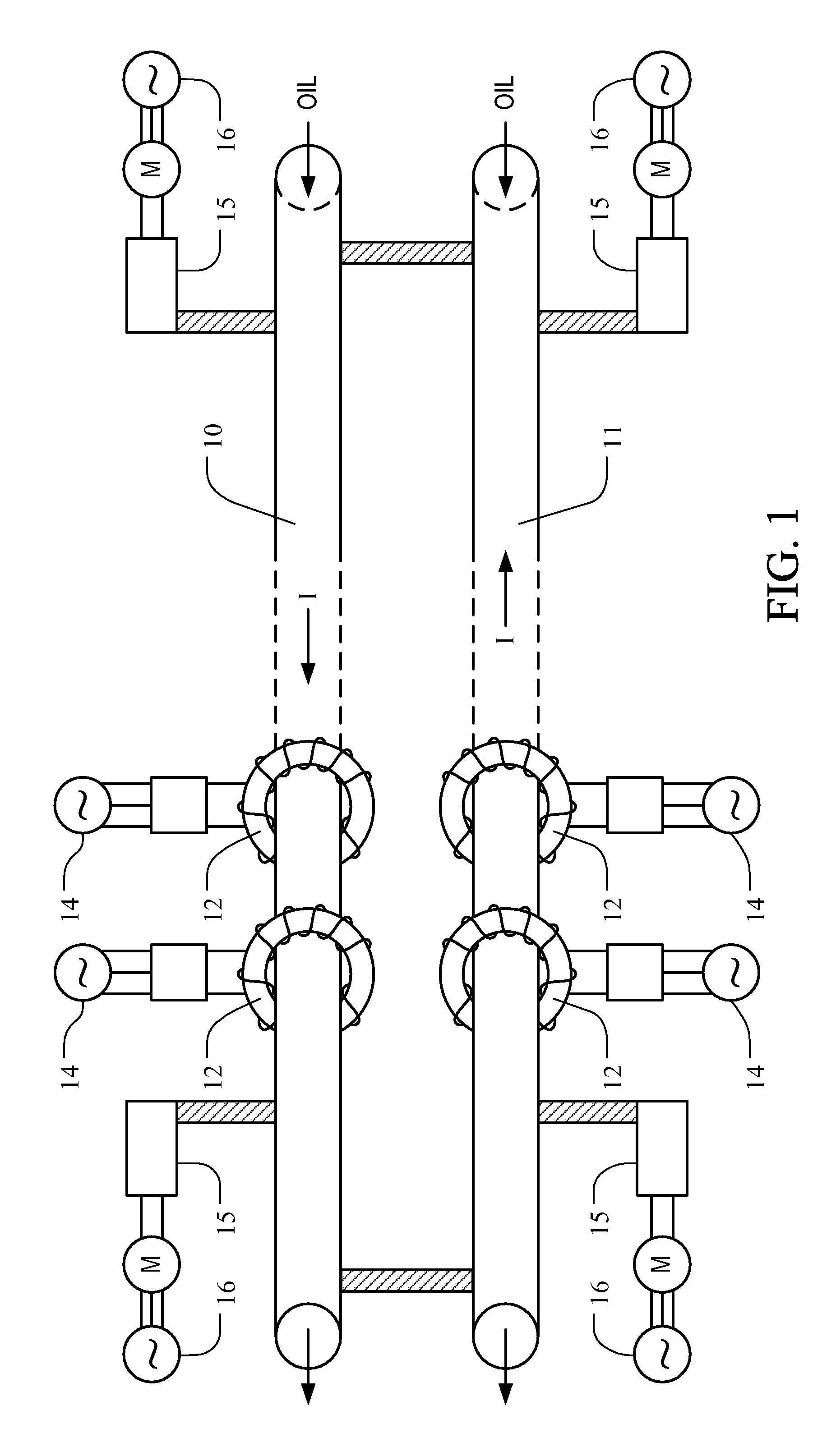

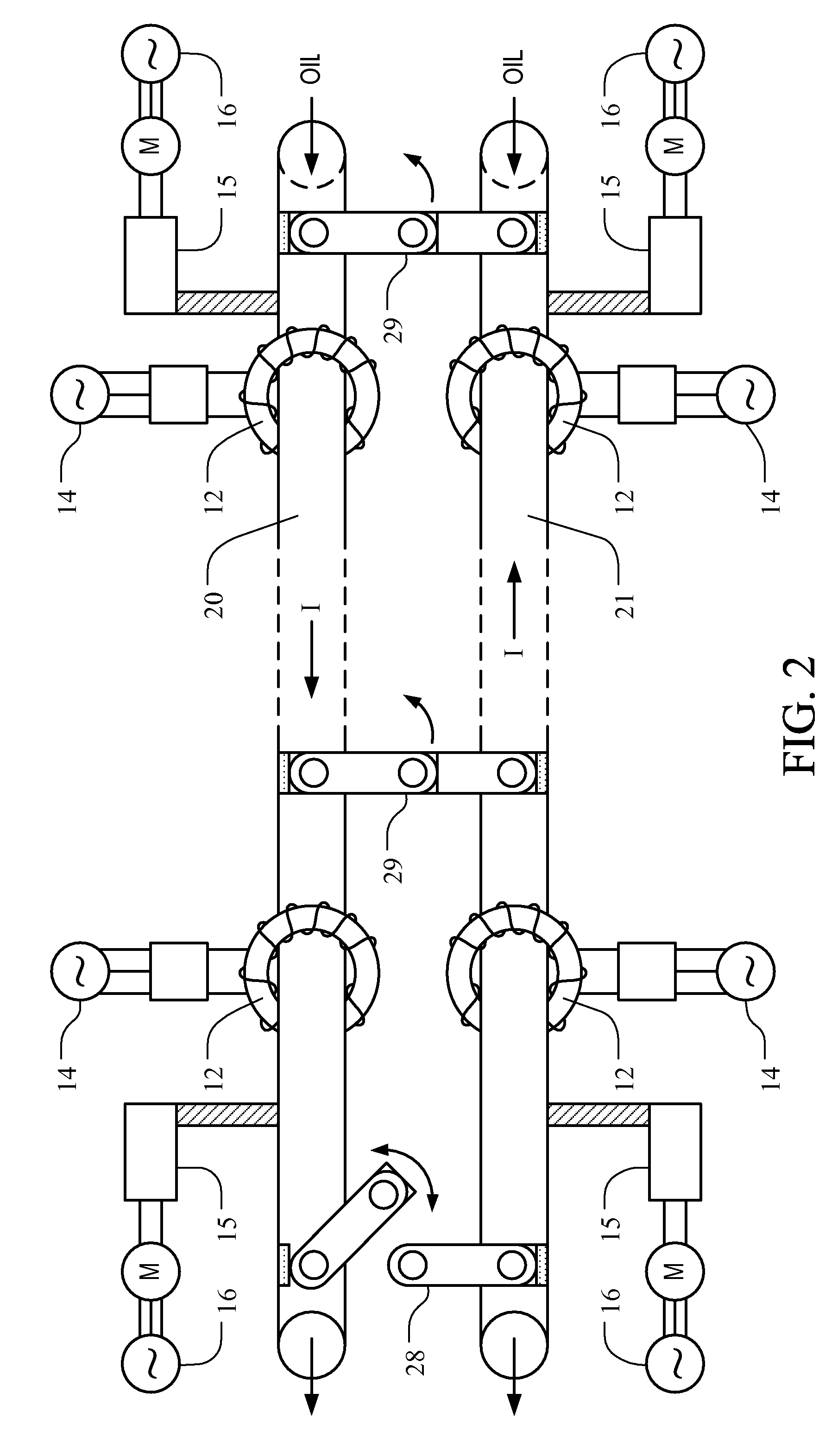

System and method for pipeline heating

InactiveUS20100101663A1Easy to transportEasy to controlValve members for heating/coolingPipe heating/coolingLow voltageTransformer

A fluid flow within a transportation pipeline is heated with low voltage, high current electrical energy induced into a conductive closed loop structure by one or more transformers. The closed loop structure is preferably a fluid transportation pipeline constructed of electrically conductive sections of pipeline. The amount of current induced is sufficient in relation to the inherent resistivity of the conductive sections to cause the generation of heat within the pipeline sections. By conductive and convective heat transfer, the heat induced into the pipeline structure is transferred to a fluid flow within the pipeline. The current is preferably an alternating current of frequency which causes a majority of the current to travel at or near the outer surfaces of the pipeline sections which increases the effective resistivity of the sections and heat generation therein.

Owner:GRANBORG BERTIL

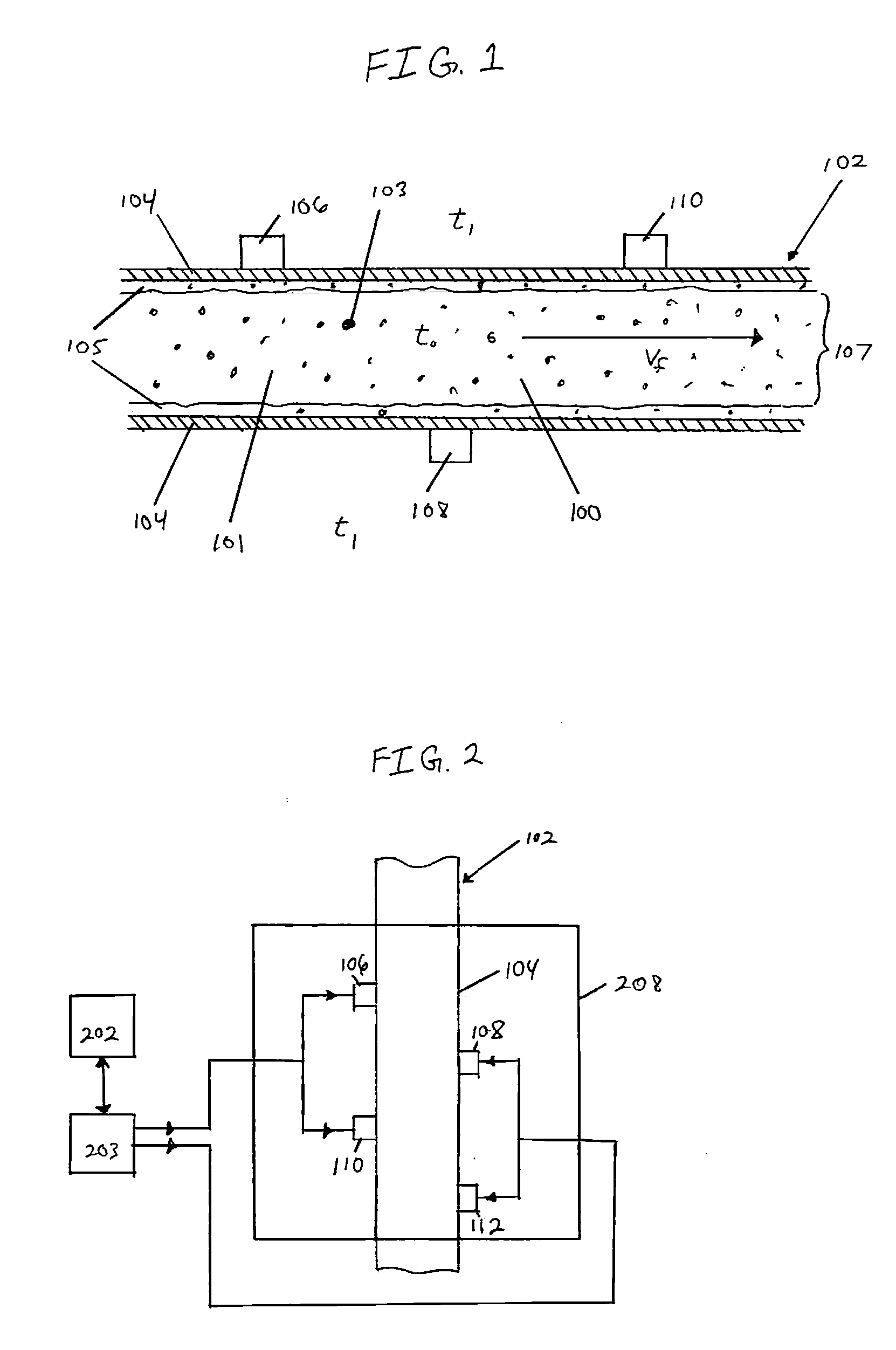

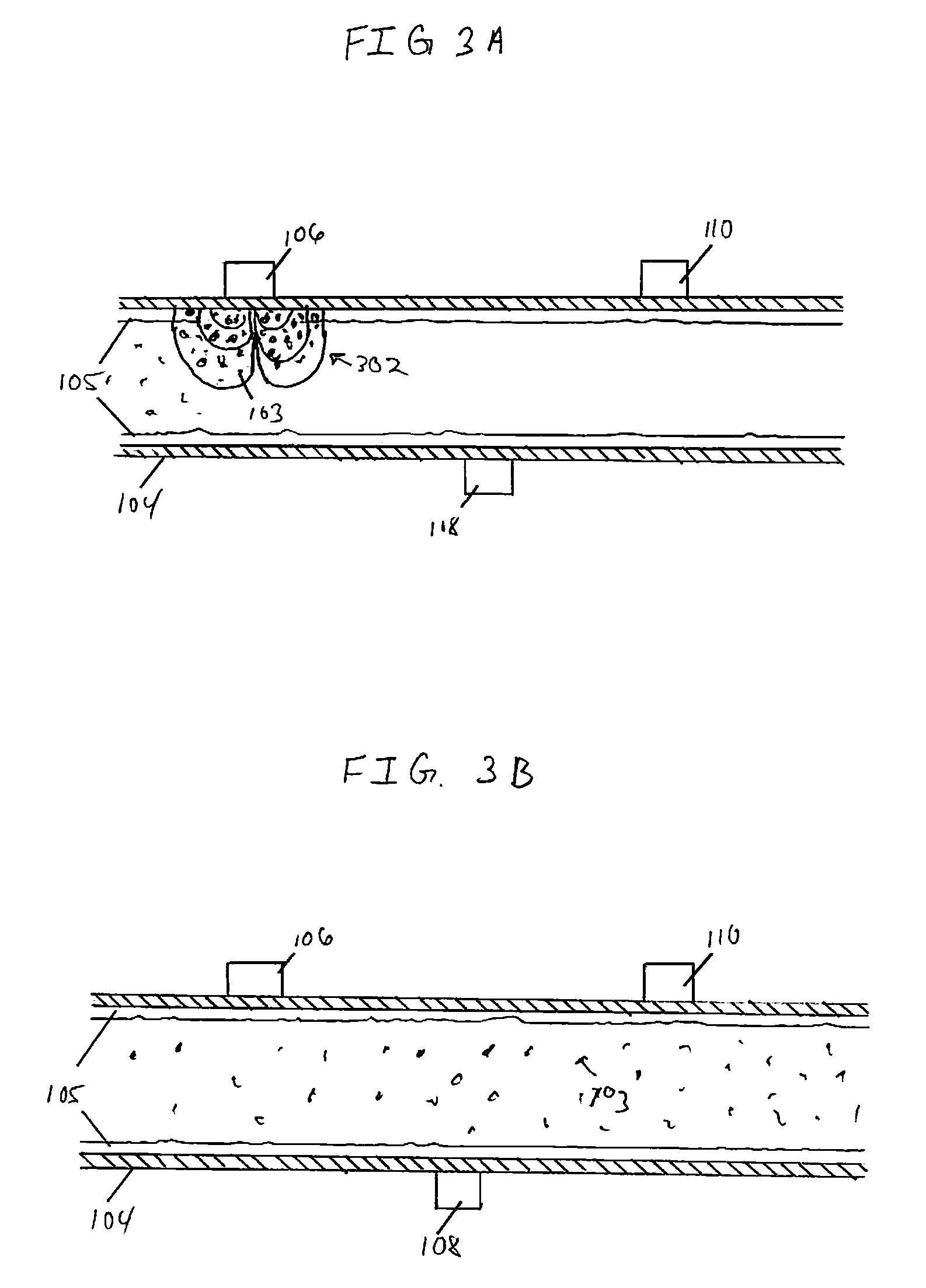

System and method for convective heat transfer utilizing a particulate solution in a time varying field

InactiveUS20070039721A1Improve thermal conductivityImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesParticulatesEnhanced heat transfer

A system combines the thermal conductivity characteristics of certain solids with the high specific heat values of appropriate fluids to enhance the overall heat transfer characteristics of a heat exchanger. The system comprises a fluid channel disposed in a heat exchanger unit with a slurry as the convective heat transfer medium. The slurry comprises an appropriate fluid with field reactive particles suspended therein. Field emitters are located along the walls of the fluid channel whereby the distribution of particles within the slurry is manipulated to achieve enhanced heat transfer characteristics.

Owner:UNITED STATES OF AMERICA

Hybrid pressure vessels for high pressure applications

A pressure vessel is provided including an inner tank formed from a tank liner surrounded by a wound layer of composite filaments. A protective jacket is disposed on the inner tank that facilitates stacking and portability of the pressure vessel and helps to define an air passage for convective heat transfer between the hybrid tank and the environment.

Owner:AMTROL LICENSING INC

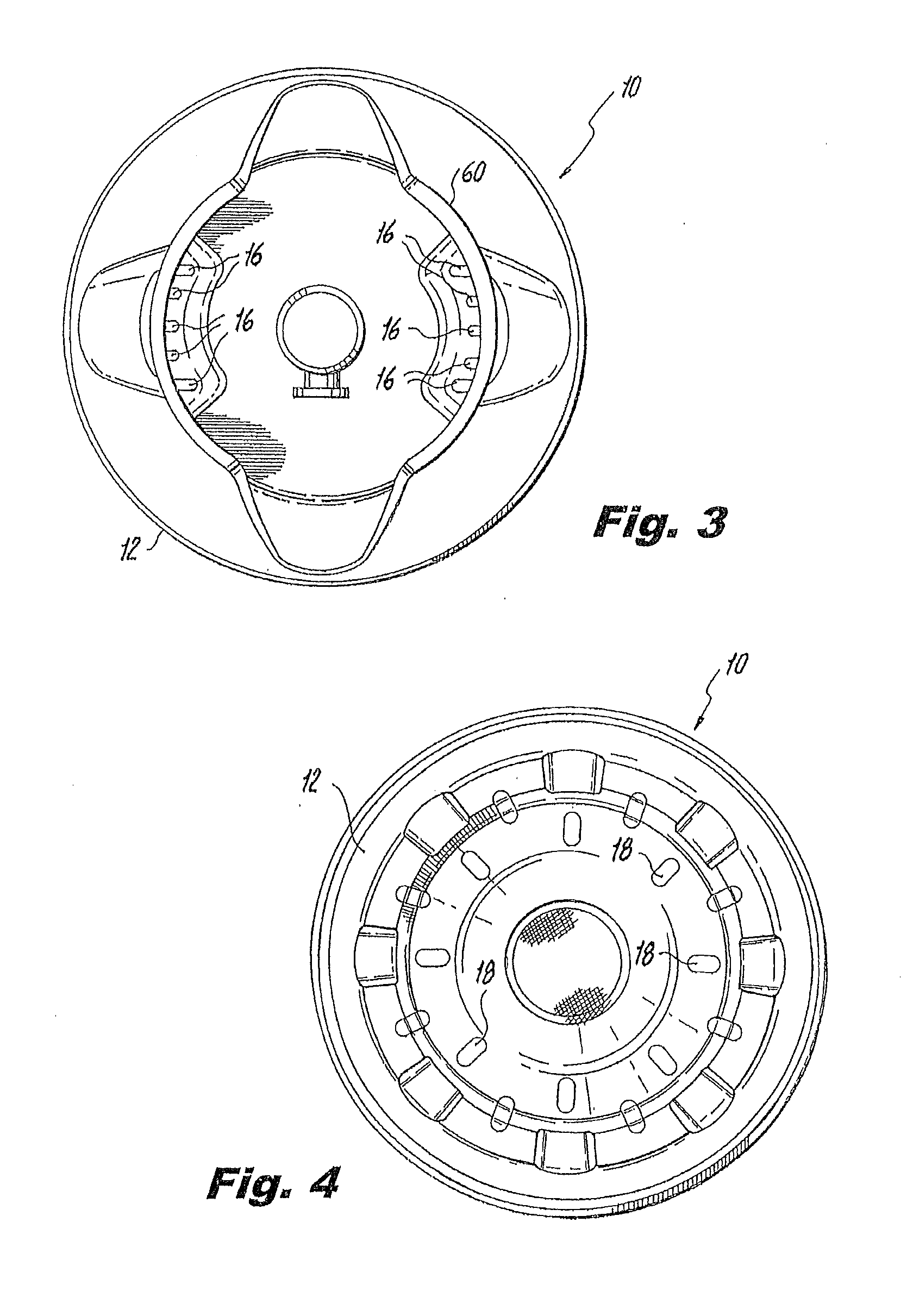

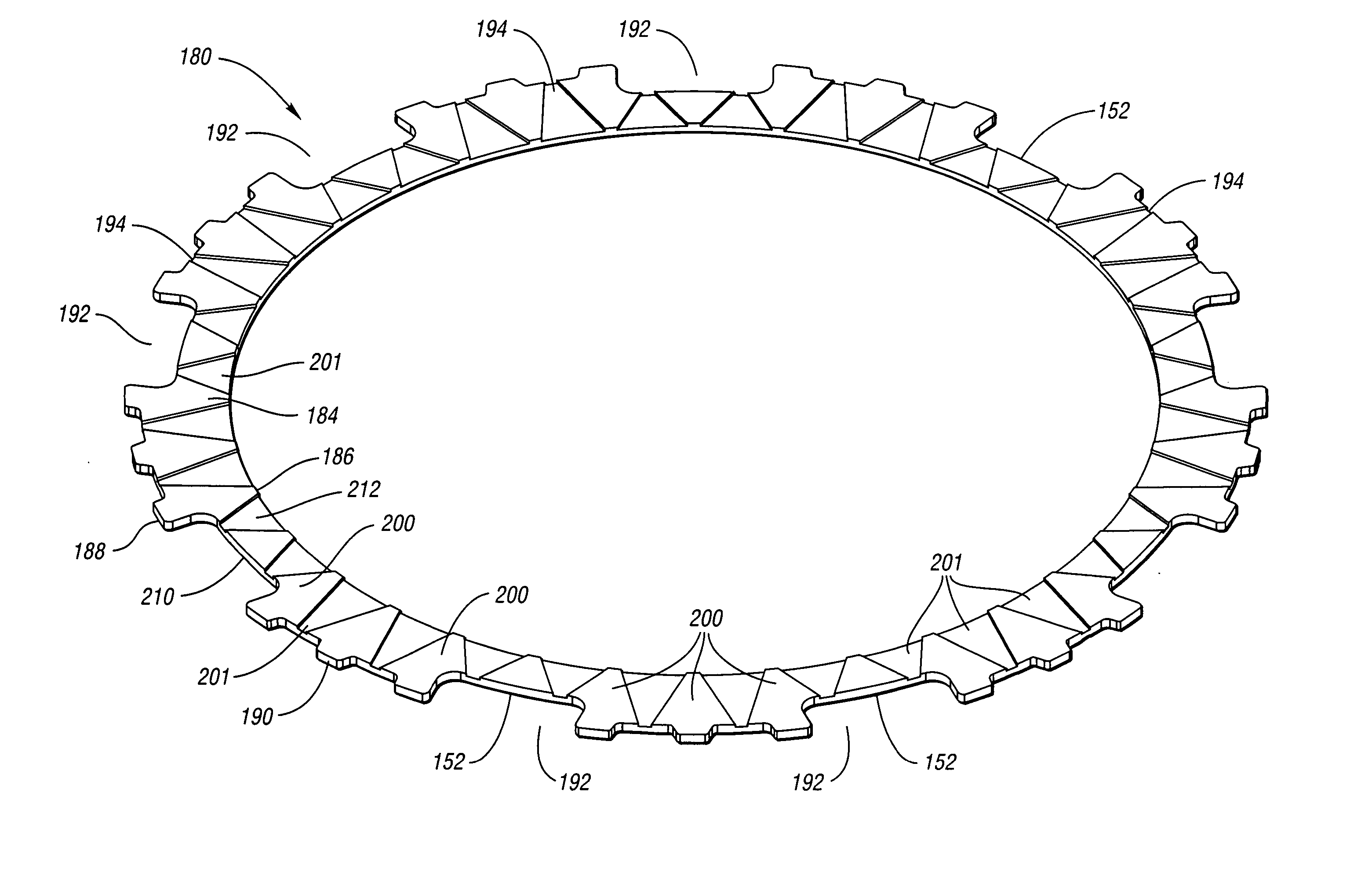

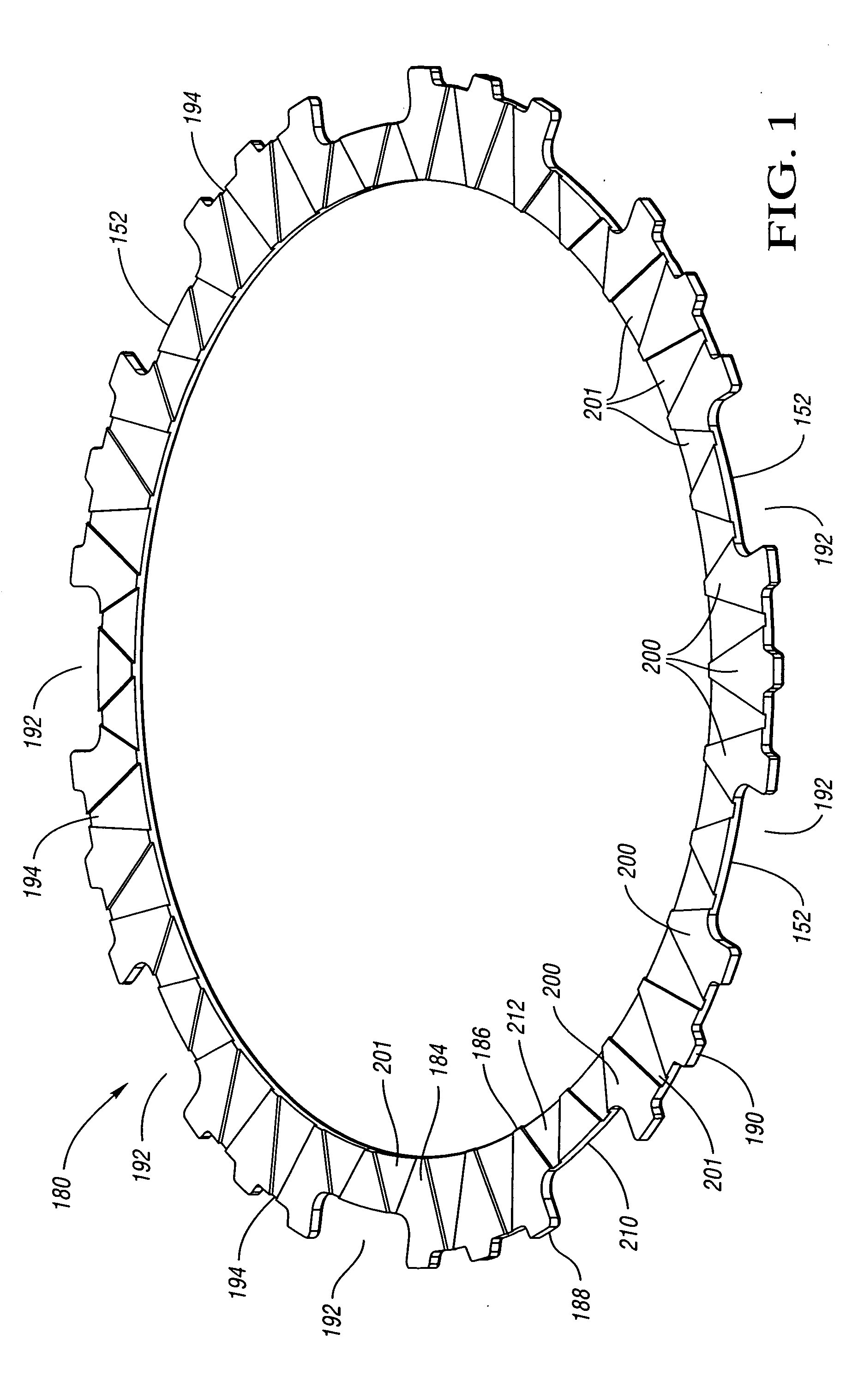

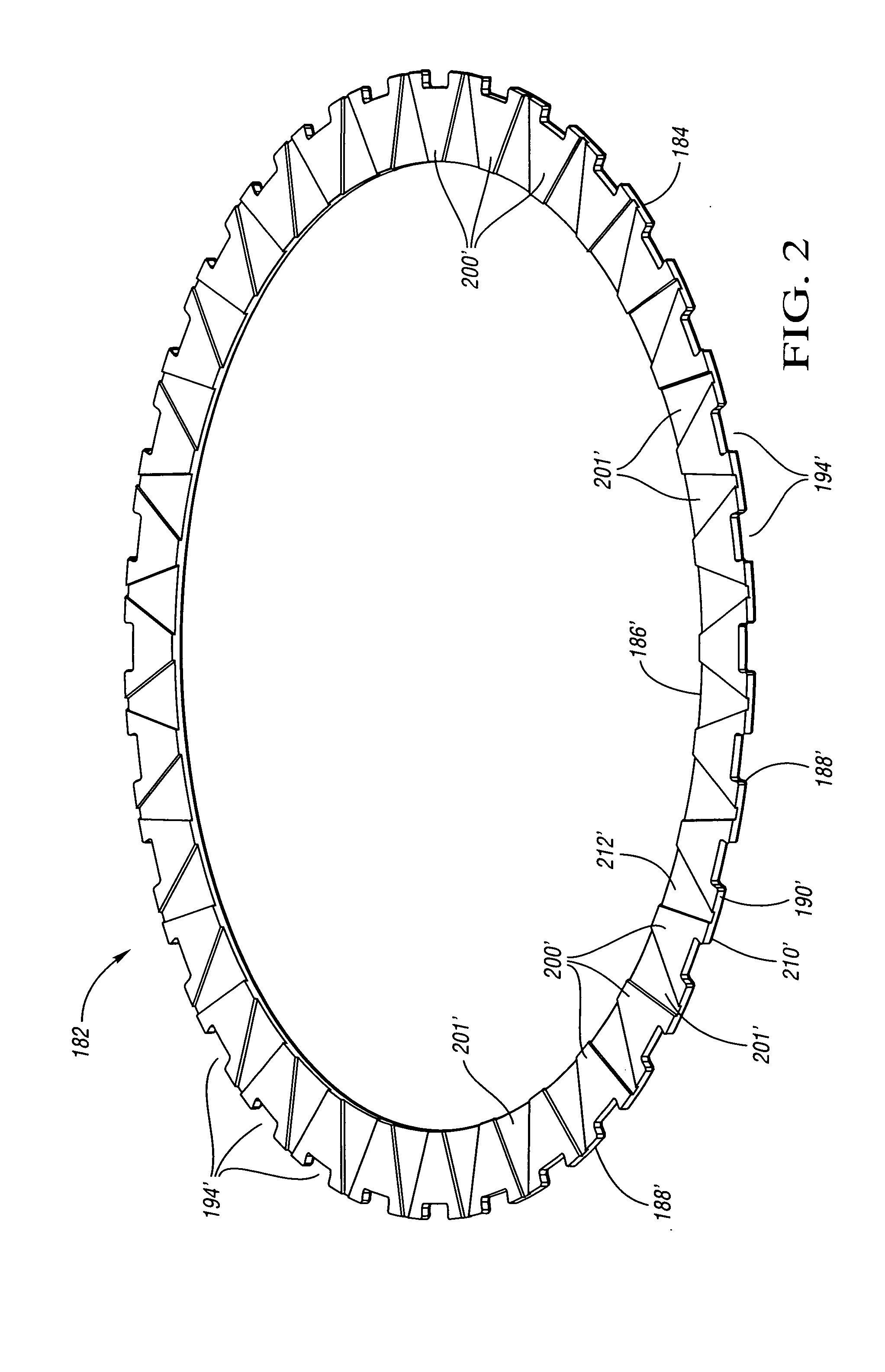

Segmented clutch plate for automatic transmission

InactiveUS20050126878A1Stable and reliable clutch performanceIncrease heat transfer areaFriction clutchesFriction liningAutomatic transmissionEngineering

The cooling performance of a wet disc clutch pack is improved by using a segmented steel reaction plate. The segmented configuration of the reaction plate forms a triangular shaped groove with an unsegmented reaction plate. The groove channels cooling lubricant in a manner to increase the convective heat transfer area for the flow of cooling lubricant, whereby to improve the cooling of the clutch pack.

Owner:GENERAL MOTORS COMPANY

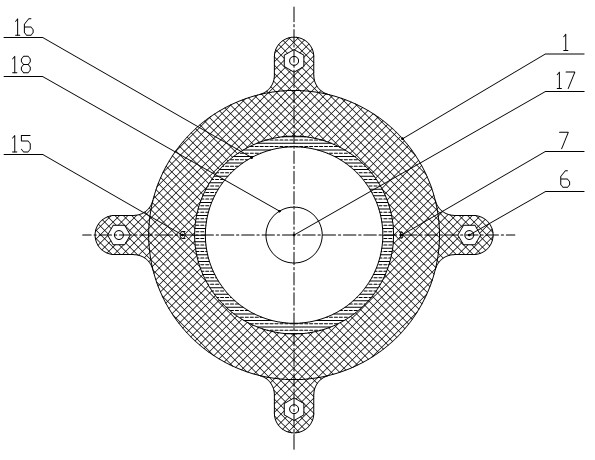

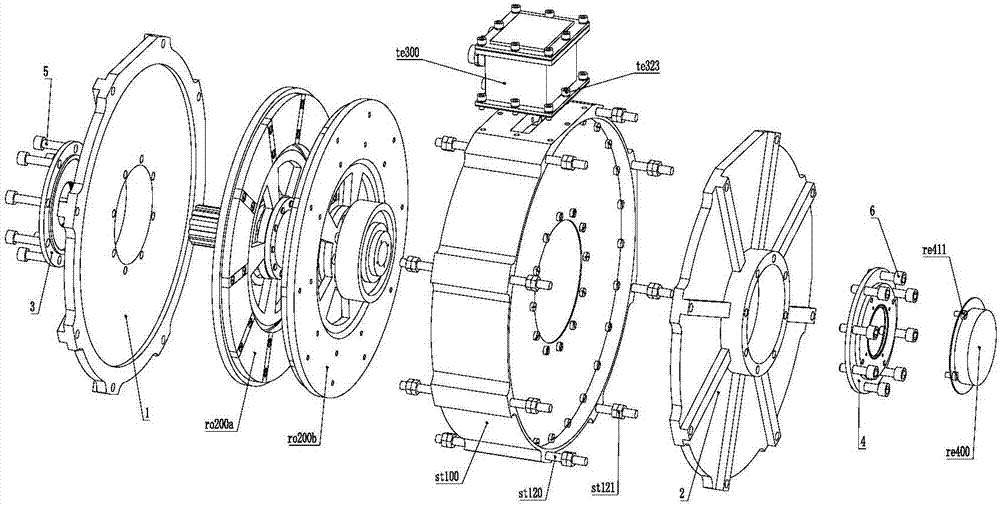

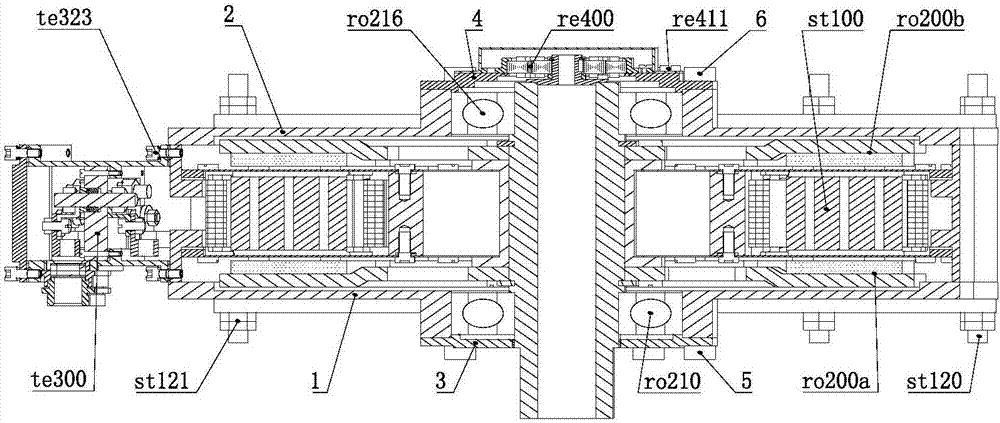

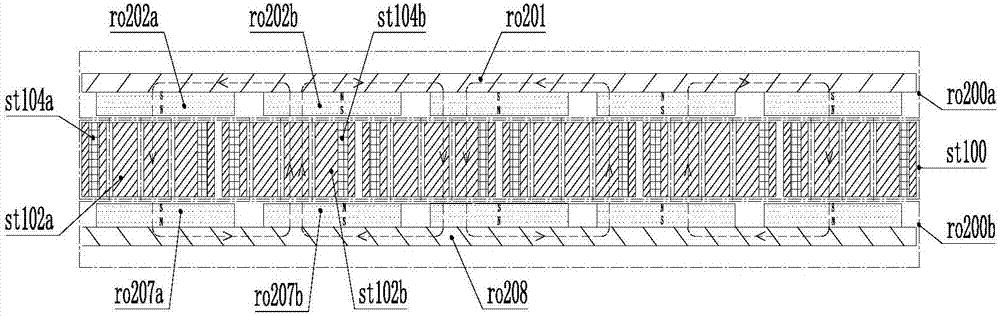

Disc type axial-flux motor with oil-immersed circularly cooled stator and segmented armatures

InactiveCN107196480AImprove power densityIncreased torque densityStructural associationCooling/ventillation arrangementSurface mountingTorque density

The invention discloses a disc type axial-flux motor with an oil-immersed circularly cooled stator and segmented armatures. A framework with double rotors and single stator is adopted; and a main shaft is designed. Each rotor adopts a magnetic steel surface-mounting type structure; and a whole stator oil-immersion circulation cooling and heat dissipation mode is adopted for temperature rise management. The disc type axial-flux motor with the oil-immersed circularly cooled stator and the segmented armatures comprises a stator assembly, a driving end rotor assembly, a non-driving end rotor assembly, a wire outlet box assembly and a rotary transformer assembly. An engine base is provided with an oil inlet joint and an oil outlet joint, both of which can carry out oil-immersion circulation cooling for the stator and have the advantages such as high convective heat transfer efficiency, big heat exchange area and fast heat transfer speed. The disc type motor adopting such a heat dissipation structure can achieve higher power density and higher torque density, is more compact in structure and is suitable for the occasions with strict requirements on the motor mounting space in future.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com