Plasma arc torch and method for improved life of plasma arc torch consumable parts

a technology of plasma arc torch and consumable parts, which is applied in plasma technique, manufacturing tools, welding apparatus, etc., can solve the problems of gas heating and ionization, and achieve the effect of increasing the useful life of consumable parts and enhancing the convective cooling of consumable parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

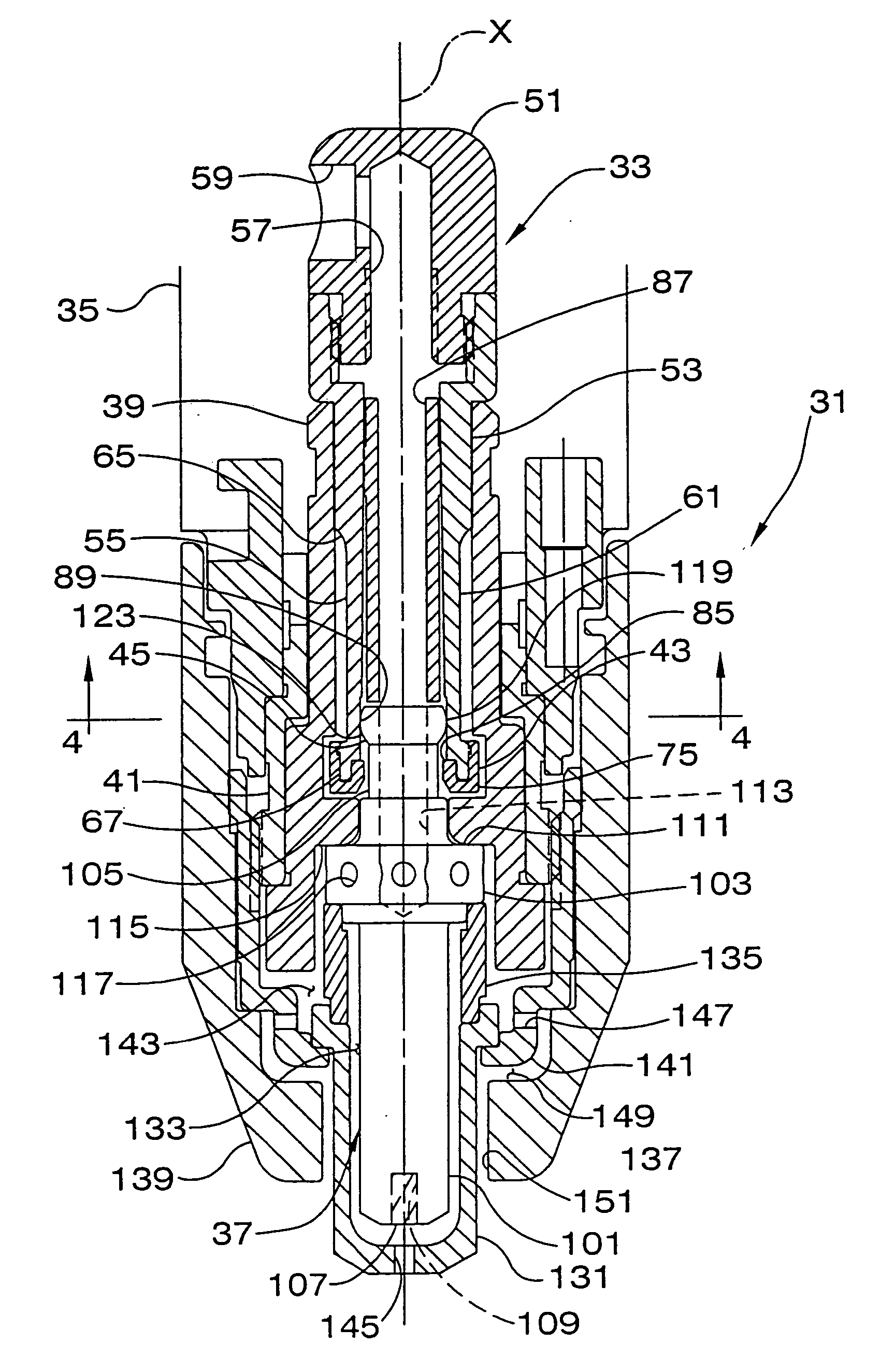

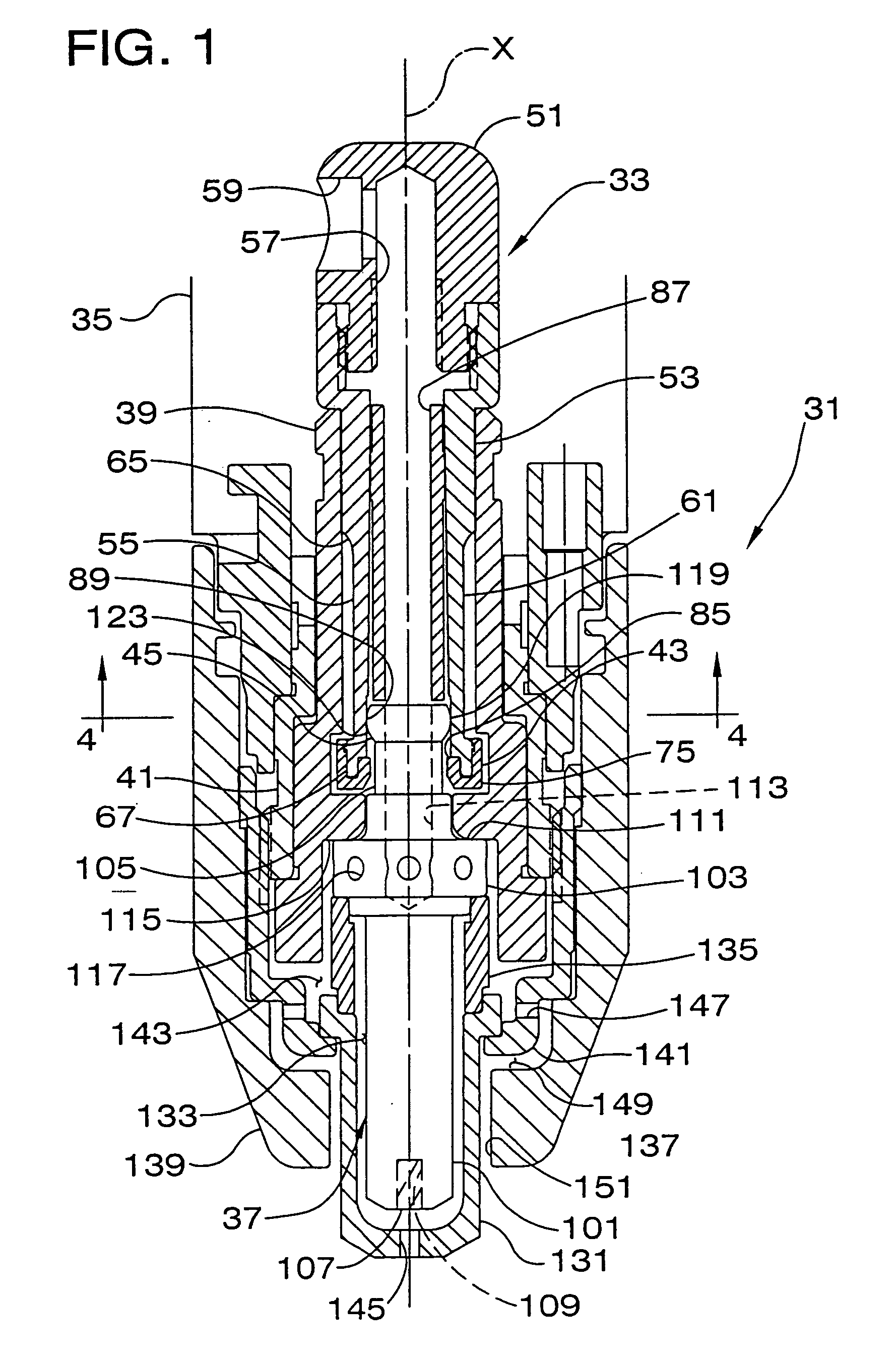

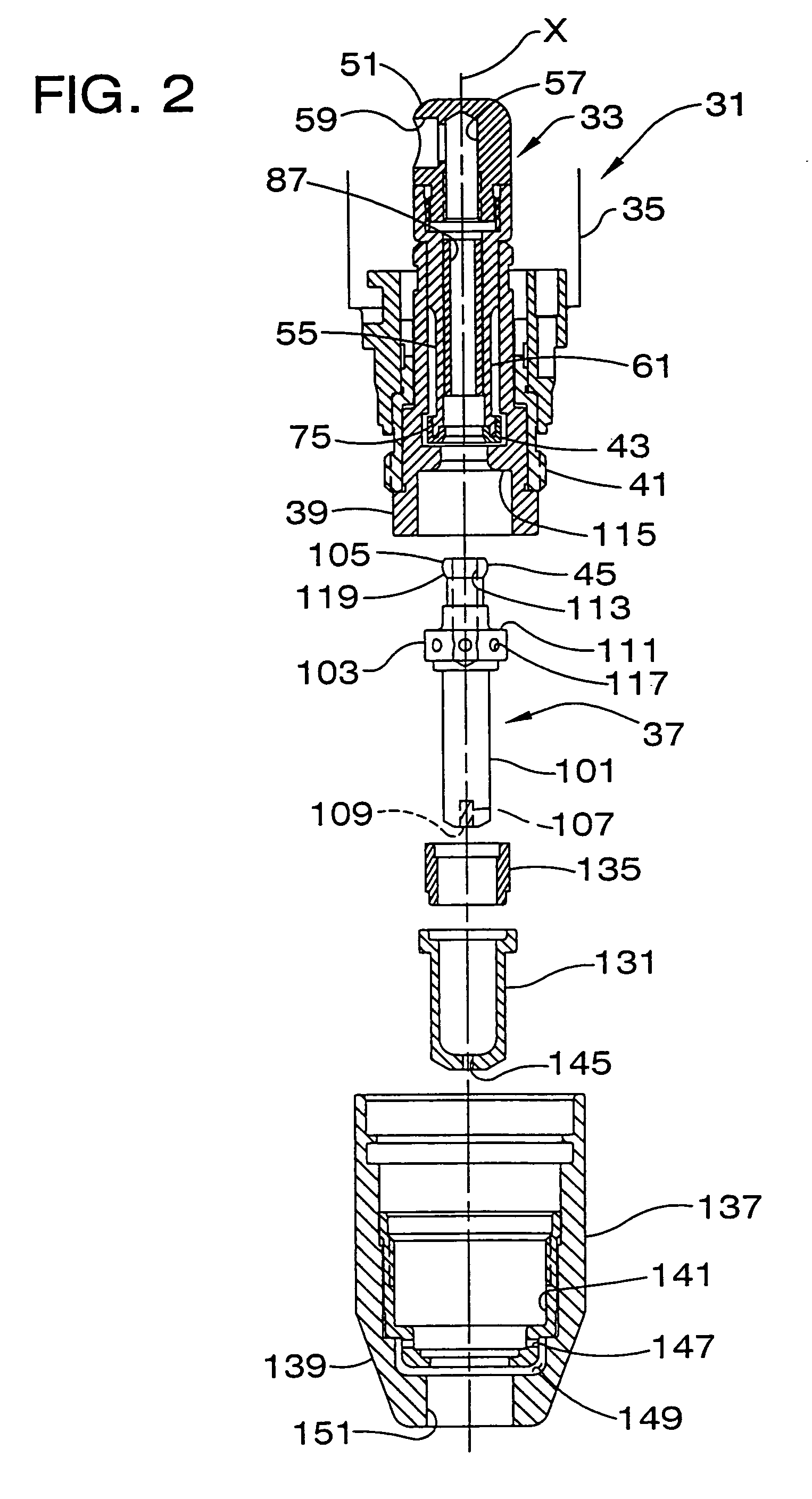

[0057] As illustrated in FIGS. 1-5 and described above, the plasma torch of this first embodiment incorporates an interconnecting cathode 33 and electrode 37 in which the electrode is inserted into the cathode. Alternatively, the electrode 37 may instead be sized and configured for surrounding the cathode 33, with the electrode detent 45 extending radially inward from the electrode connecting end 105 and the cathode detent 43 projecting radially outward from the cathode connecting end 55 such that the cathode prongs 61 are deflected inward upon relative telescoping movement of the cathode and electrode.

[0058]FIGS. 6-9 illustrate a second embodiment of a plasma torch of the present invention in which an electrode 237 (as opposed to the cathode 33 of the first embodiment) has a connecting end 305 comprising resilient longitudinally extending prongs 361. As with the first embodiment described above, the torch of this second embodiment includes a cathode, generally indicated at 233, the...

second embodiment

[0059] In this second embodiment, the central insulator 239 and electrode 237 are formed with radially opposed detents, generally designated 243 and 245, respectively. These detents 243, 245 are interengageable with one another when the electrode 237 is inserted in the torch head 231 to inhibit axial movement of the electrode relative to the central insulator outward from the torch.

[0060] As shown in FIG. 6, the cathode 233 is substantially similar to the cathode 33 of the first embodiment, comprising a head 251, a body 253 and a lower connecting end 255. A central bore 257 extends longitudinally substantially the entire length of the cathode 233 to direct a working gas through the cathode. The connecting end 255 of the cathode 233 is generally of rigid construction and is formed of brass, free of the electrically insulating sleeve 87 and end caps 75 described above in connection with the first embodiment. The diameter of the inner surface of the cathode connecting end 255 is jogged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inner diameter D1 | aaaaa | aaaaa |

| inner diameter D2 | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com