Patents

Literature

1448 results about "CHEEK DIMPLES" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cheek dimples when present, show up when a person makes a facial expression. A chin dimple is a small line on the chin that stays on the chin without making any facial expressions.

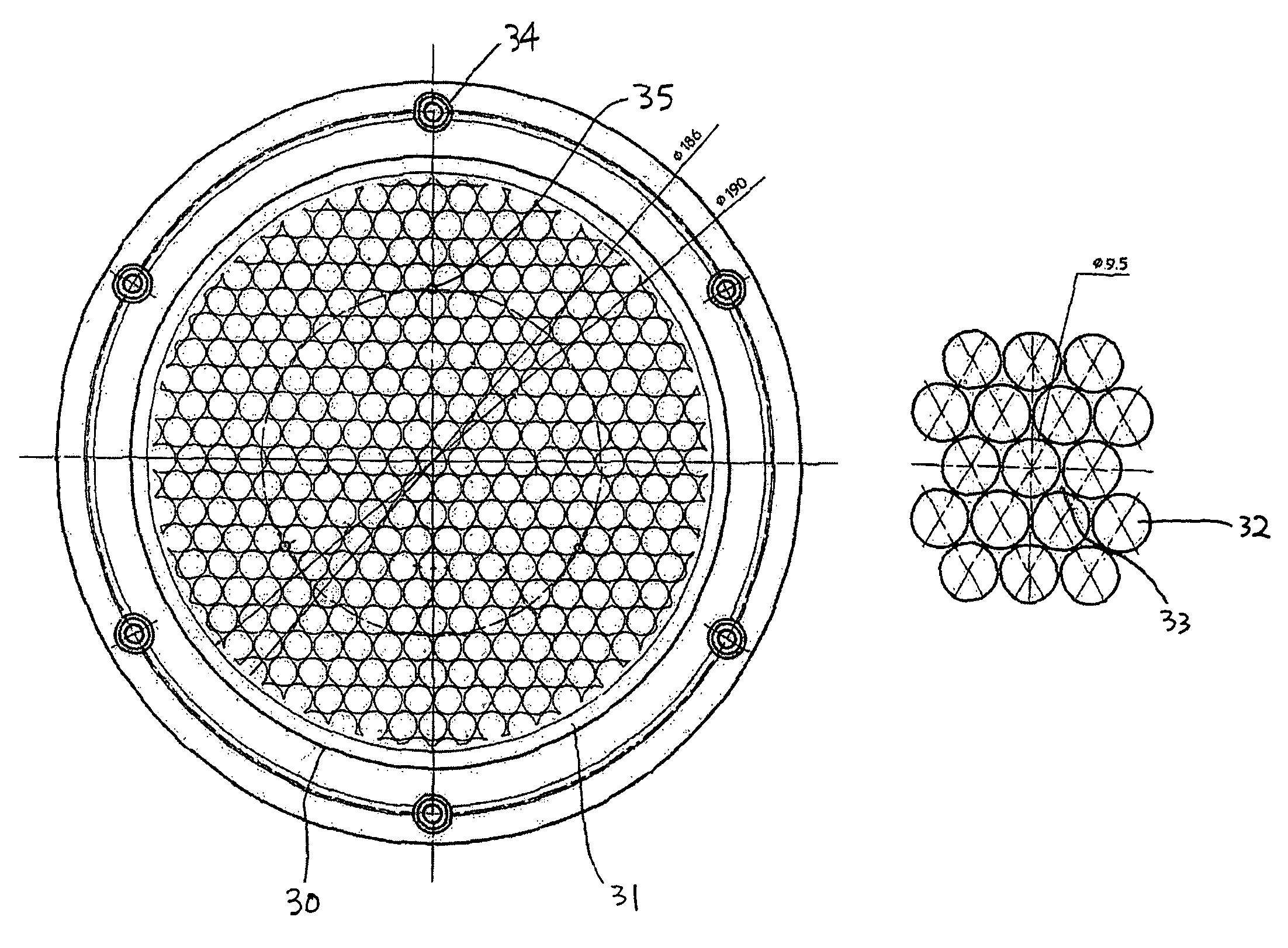

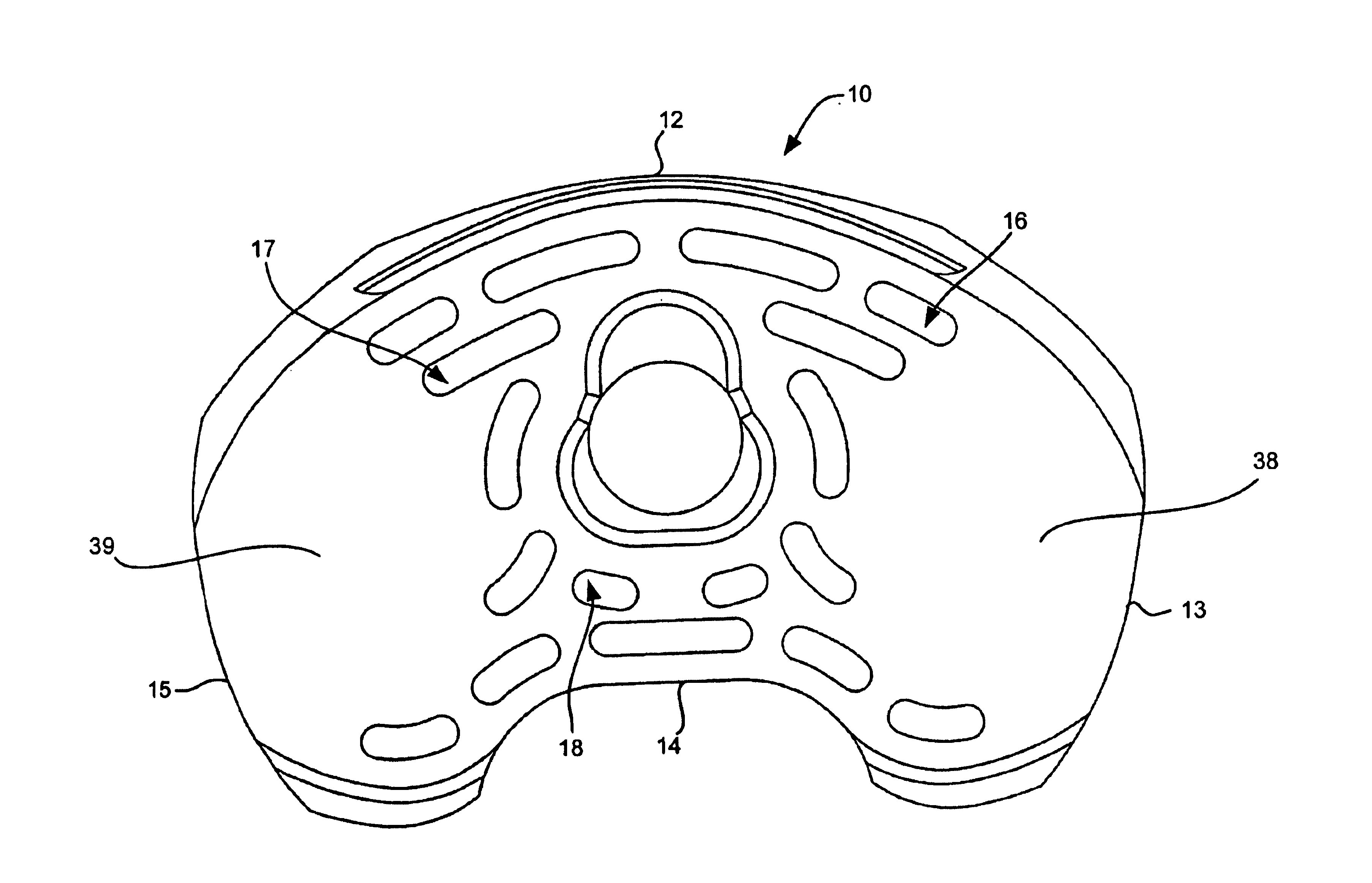

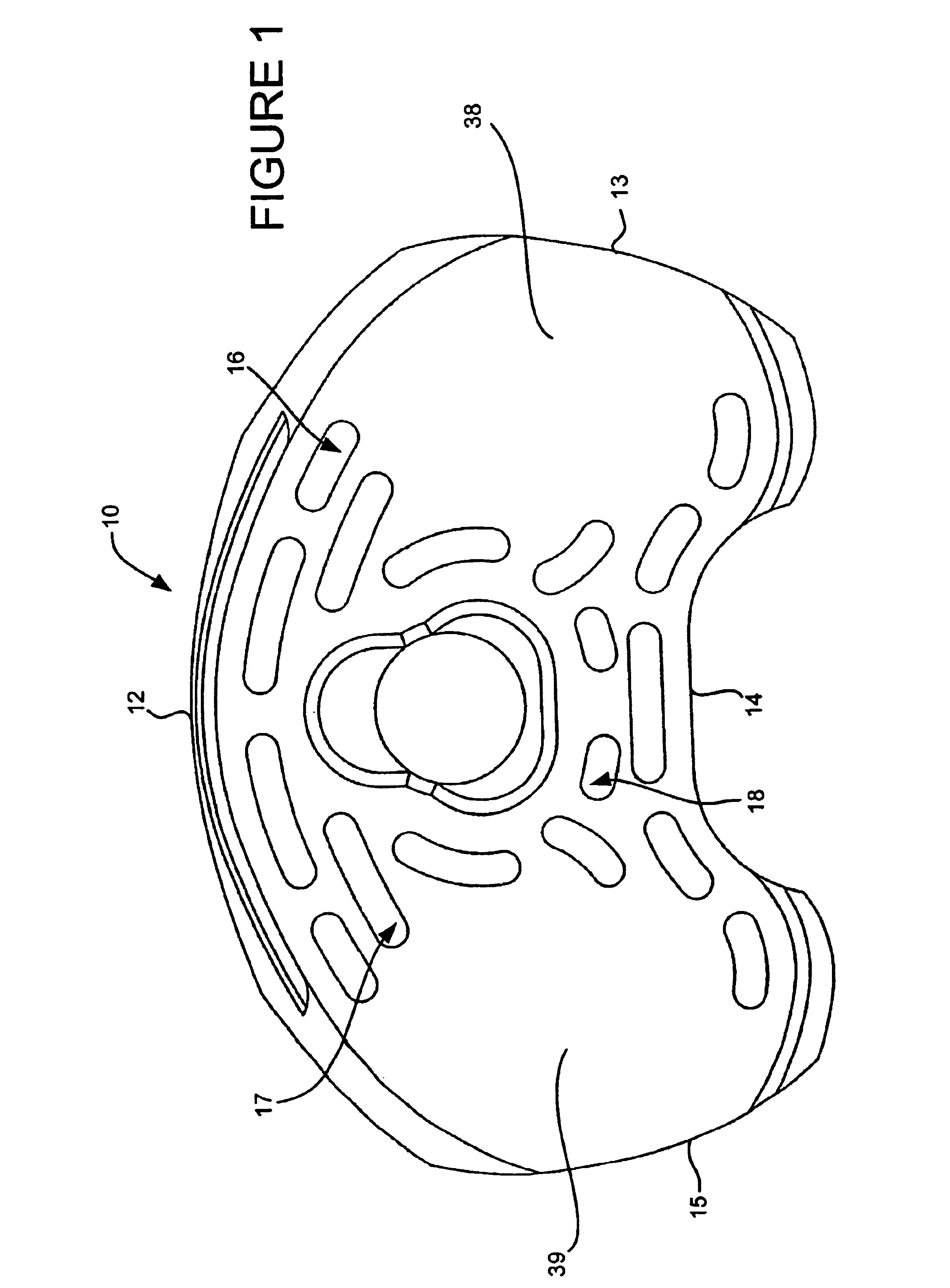

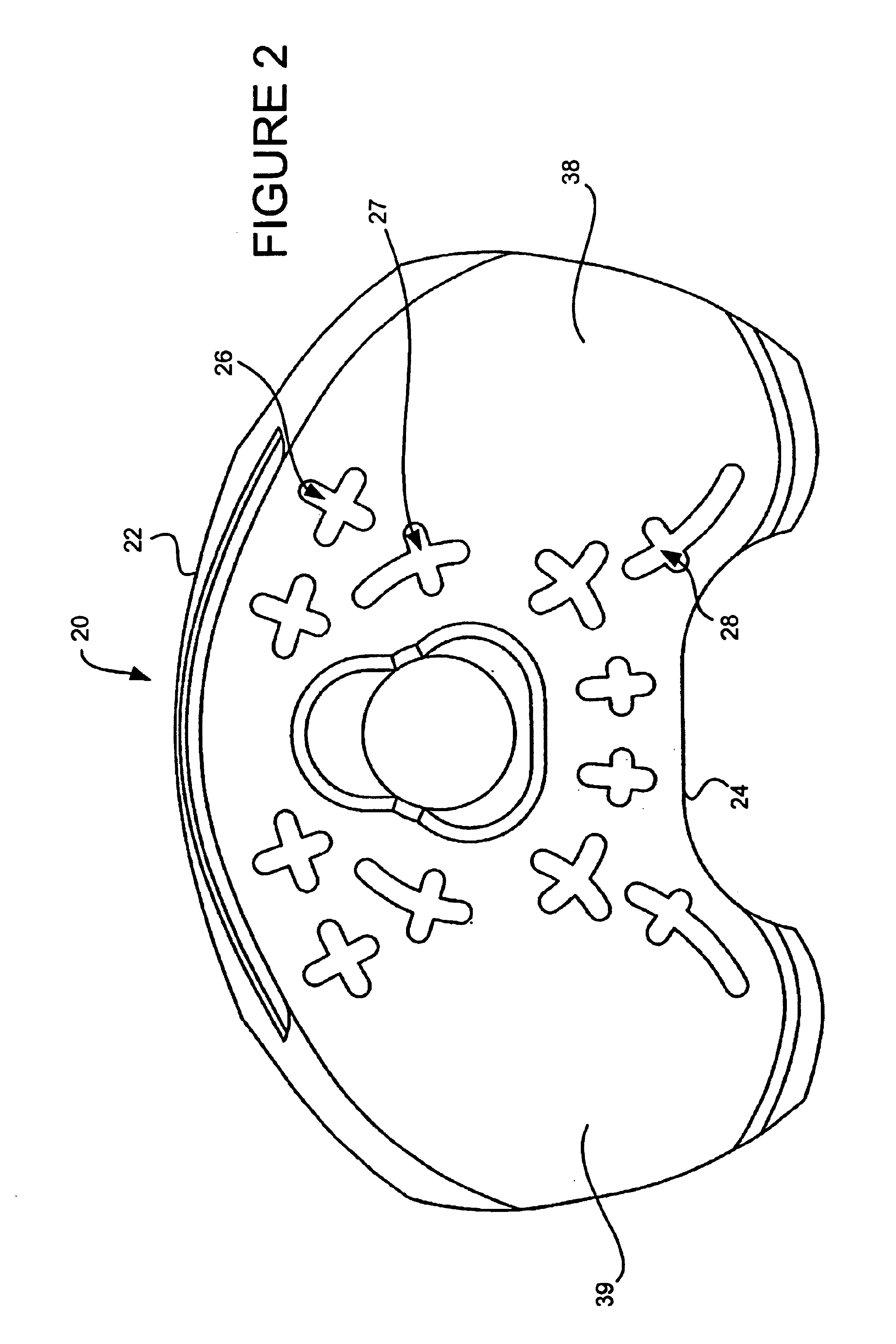

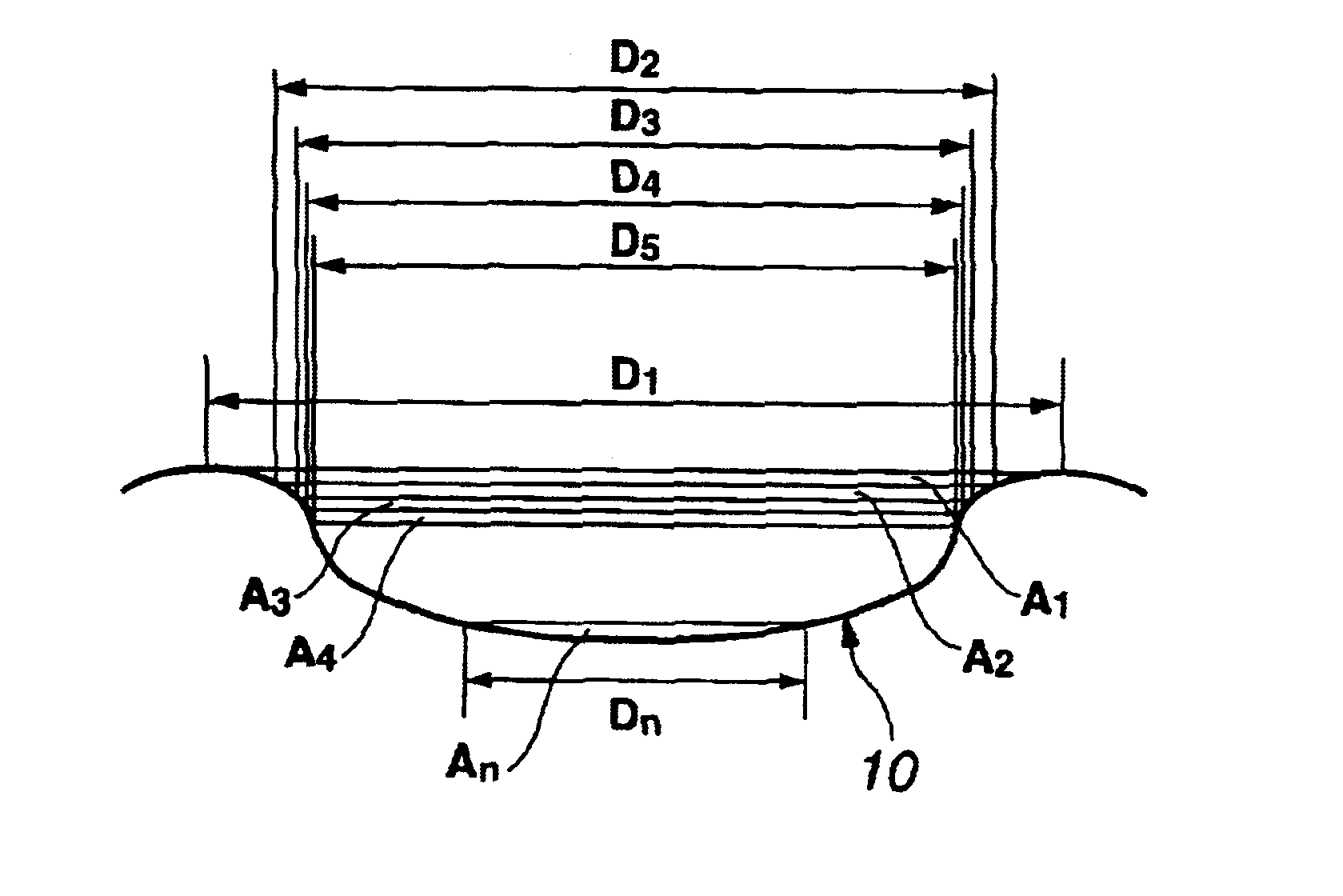

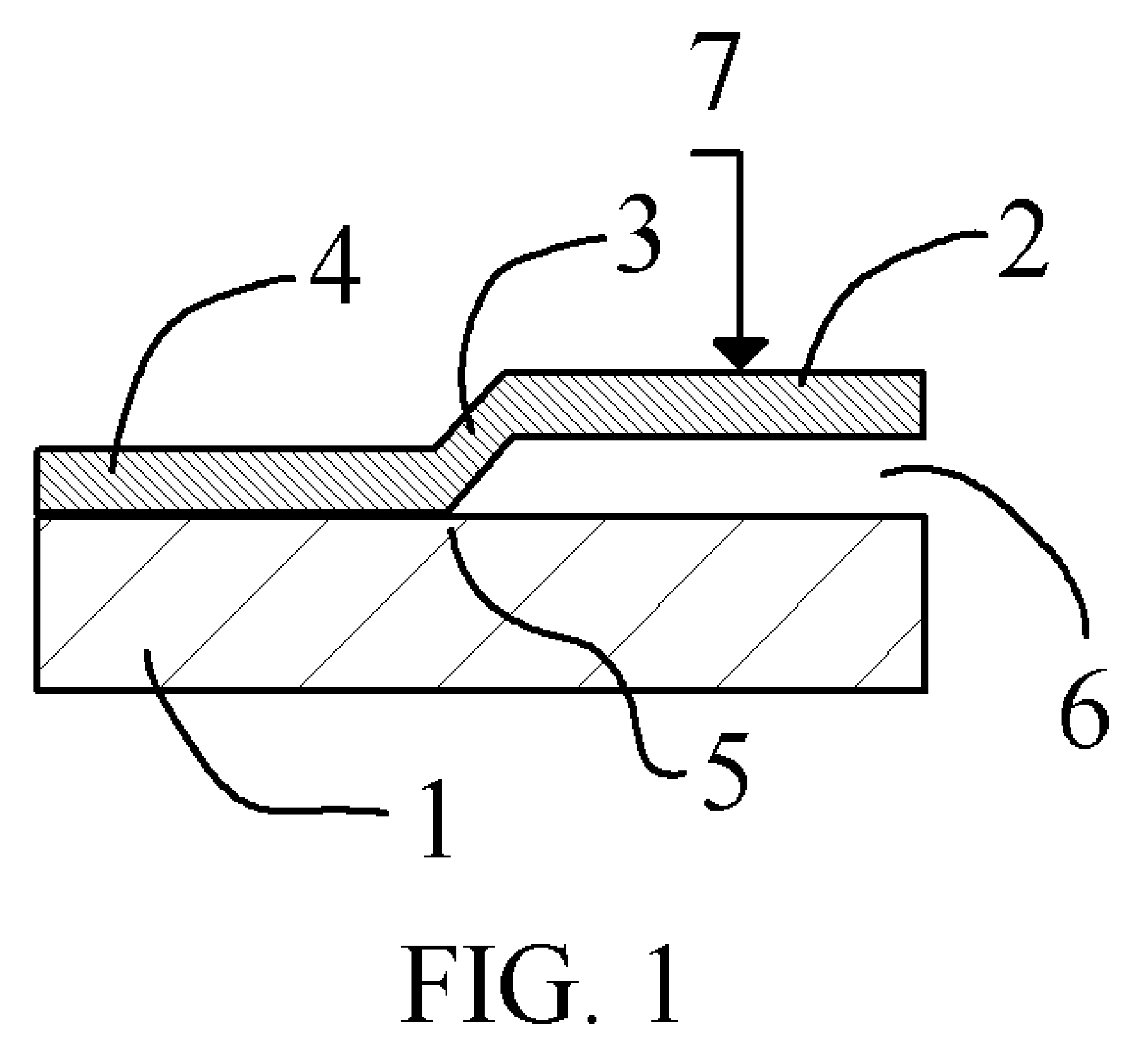

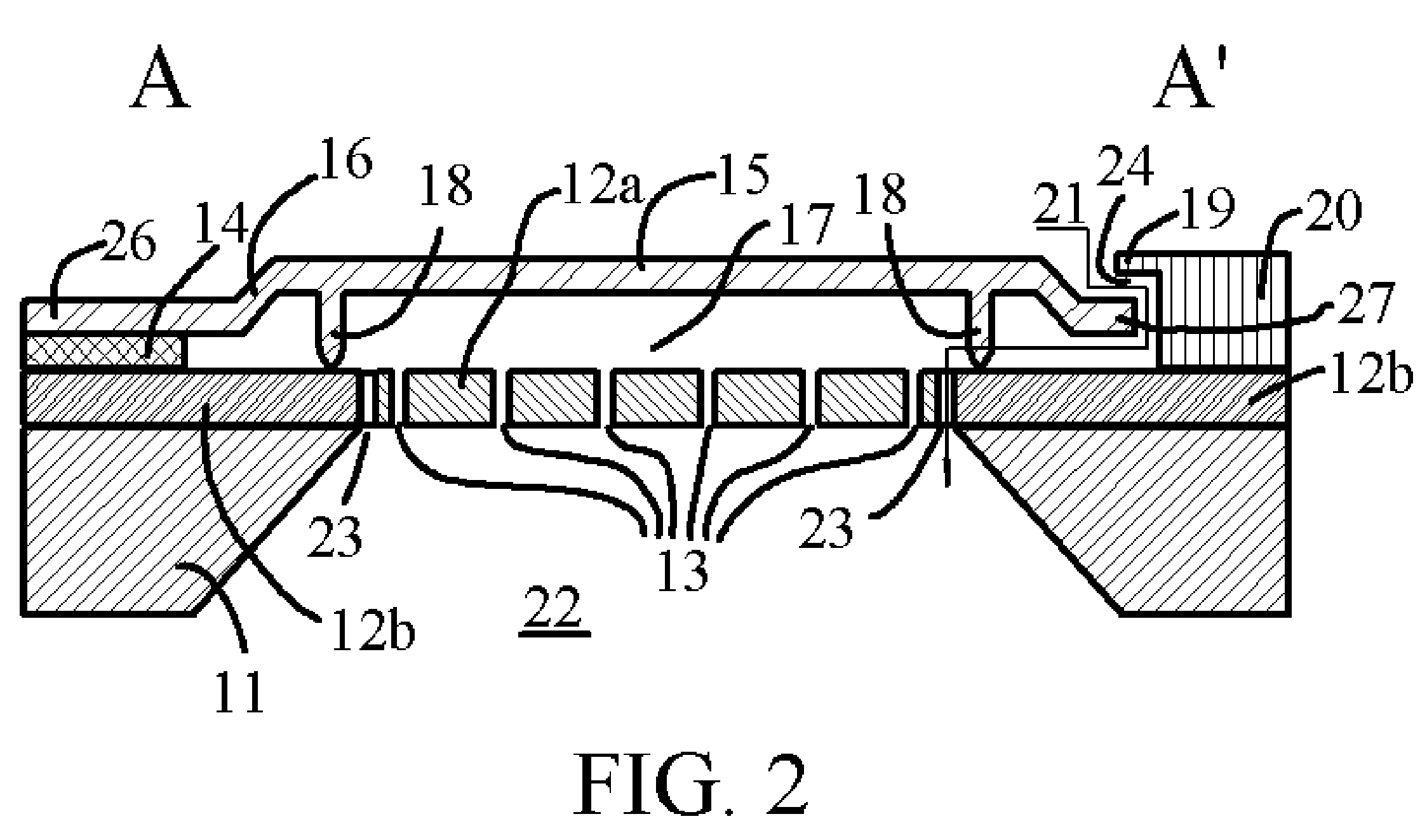

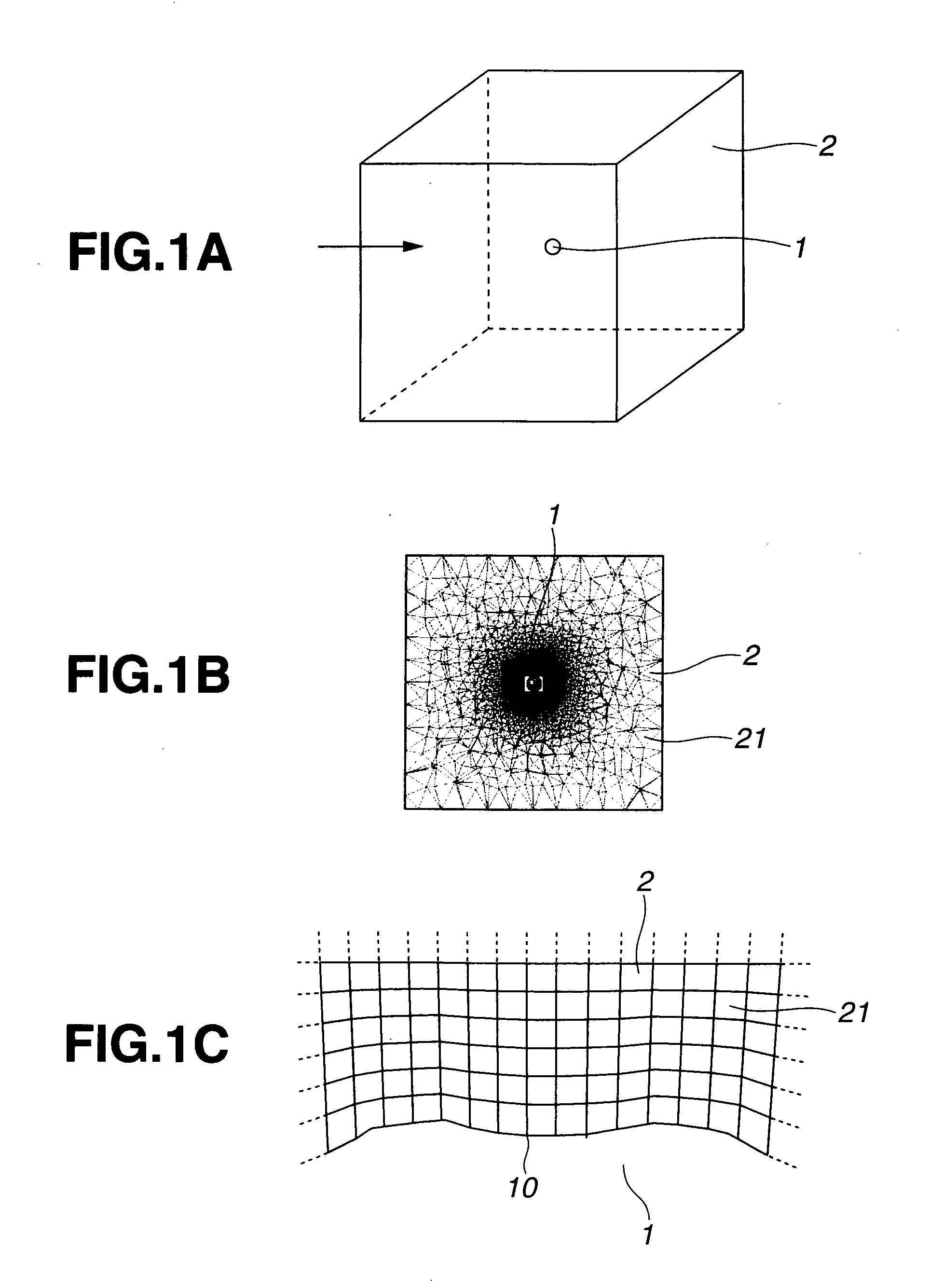

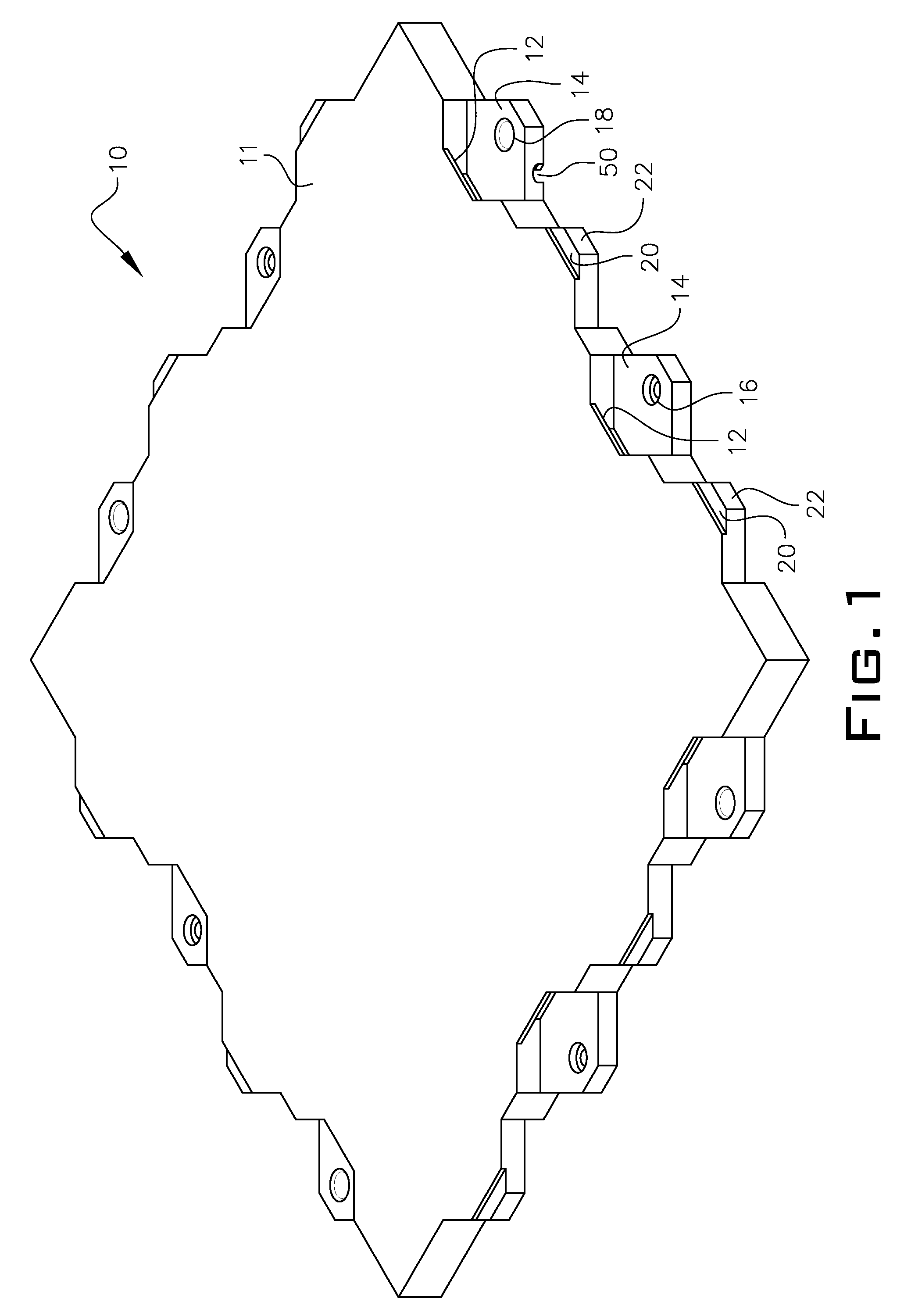

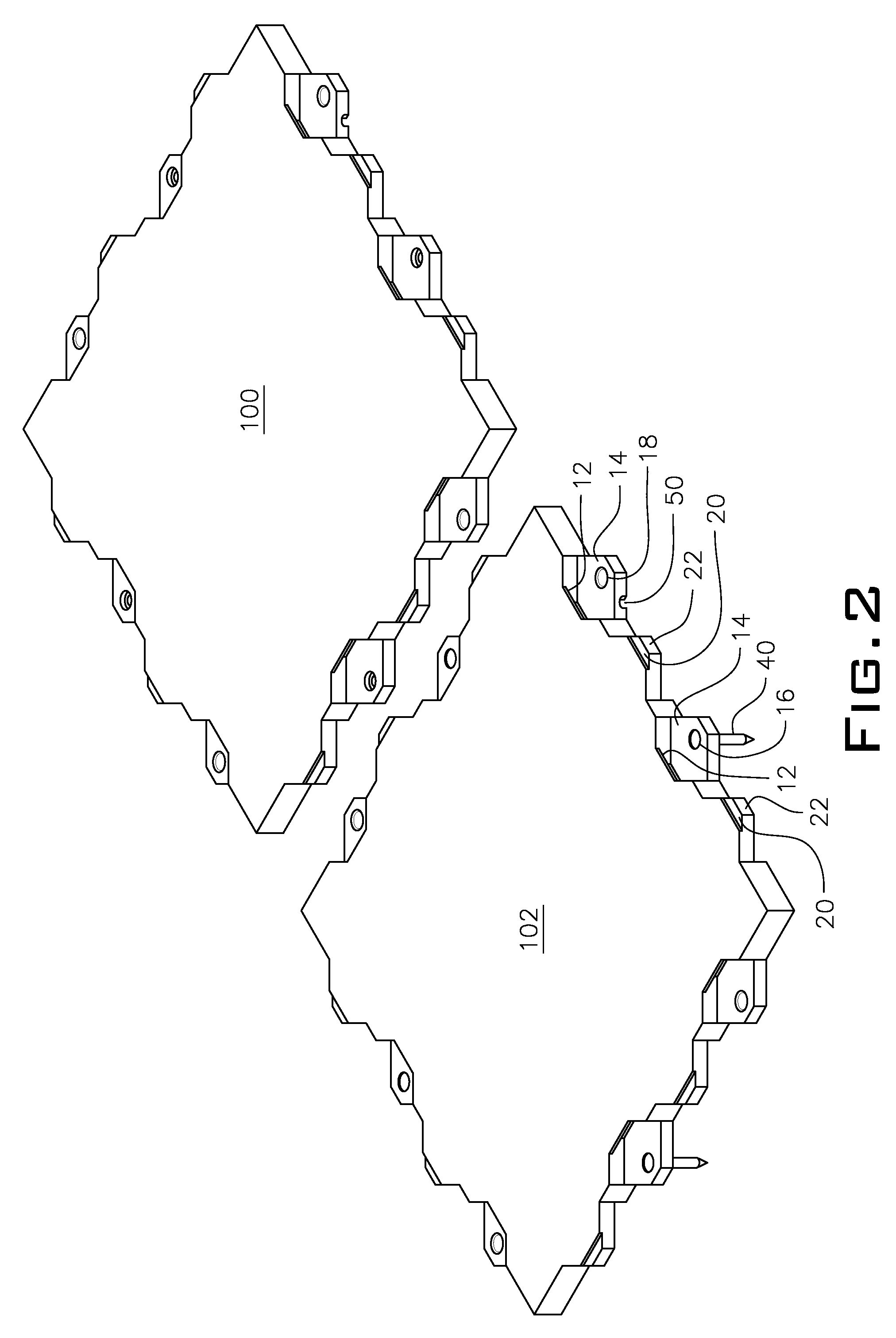

Substrate-supporting device

ActiveUS7691205B2Improve controllabilityStable and satisfactory controllabilityVacuum evaporation coatingSemiconductor/solid-state device manufacturingSupport surfaceCHEEK DIMPLES

A substrate-supporting device for CVD having a substrate-supporting region includes: a substrate-supporting surface which is a continuous surface defining a reference plane on which a substrate is placed; and multiple dimples having bottom surfaces lower than the reference plane. The respective dimples are isolated from each other by a portion of the substrate-supporting surface.

Owner:ASM JAPAN

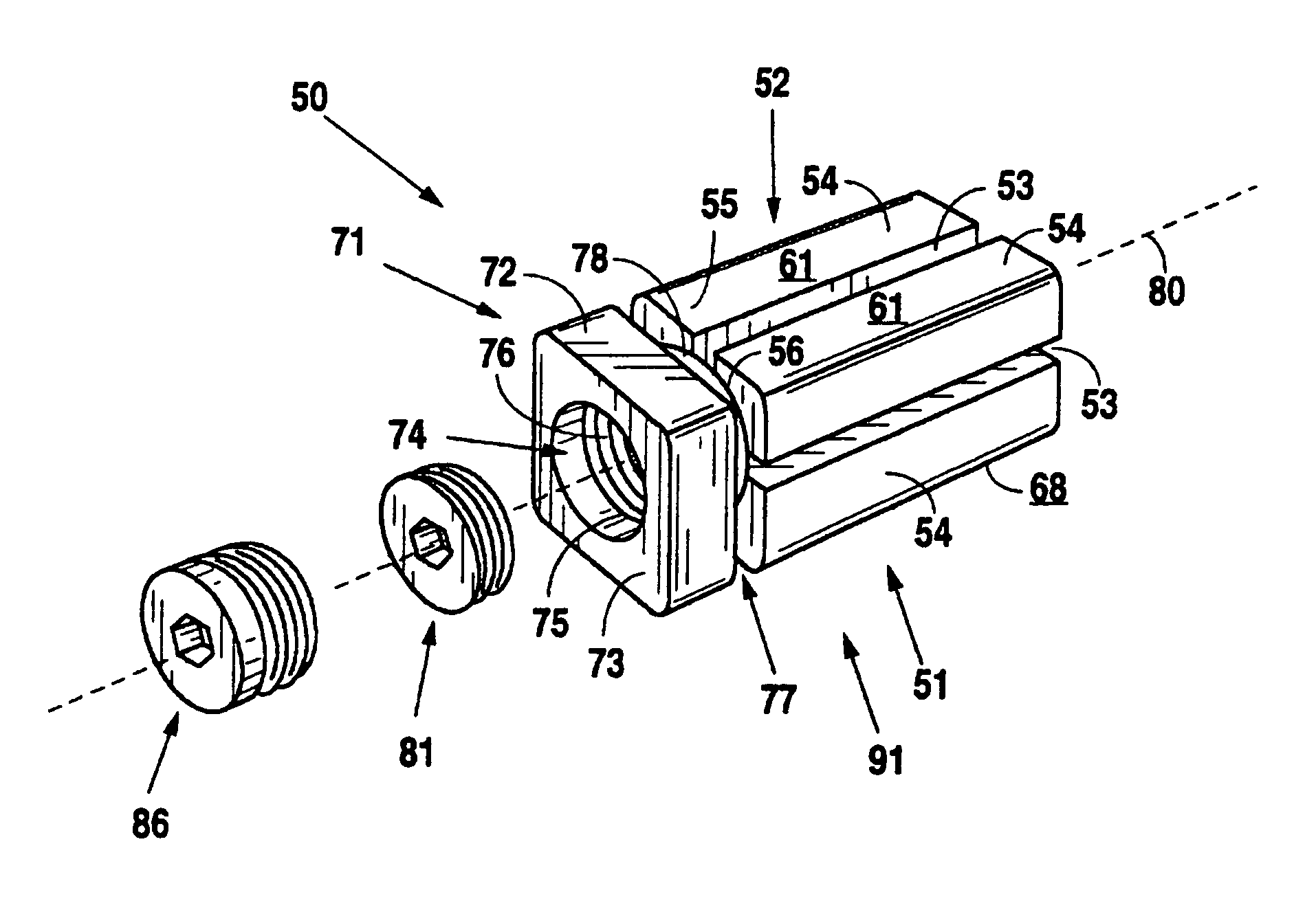

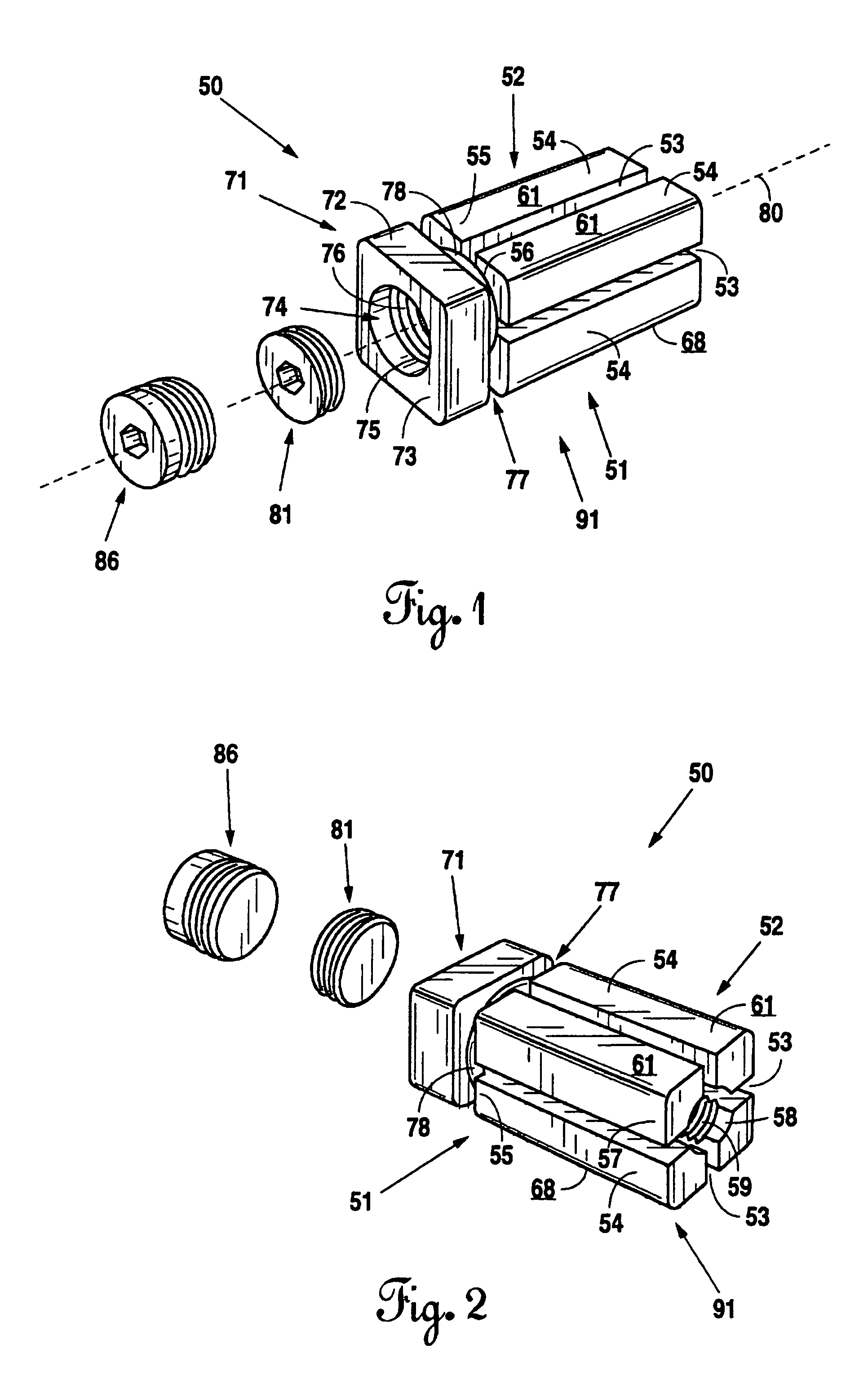

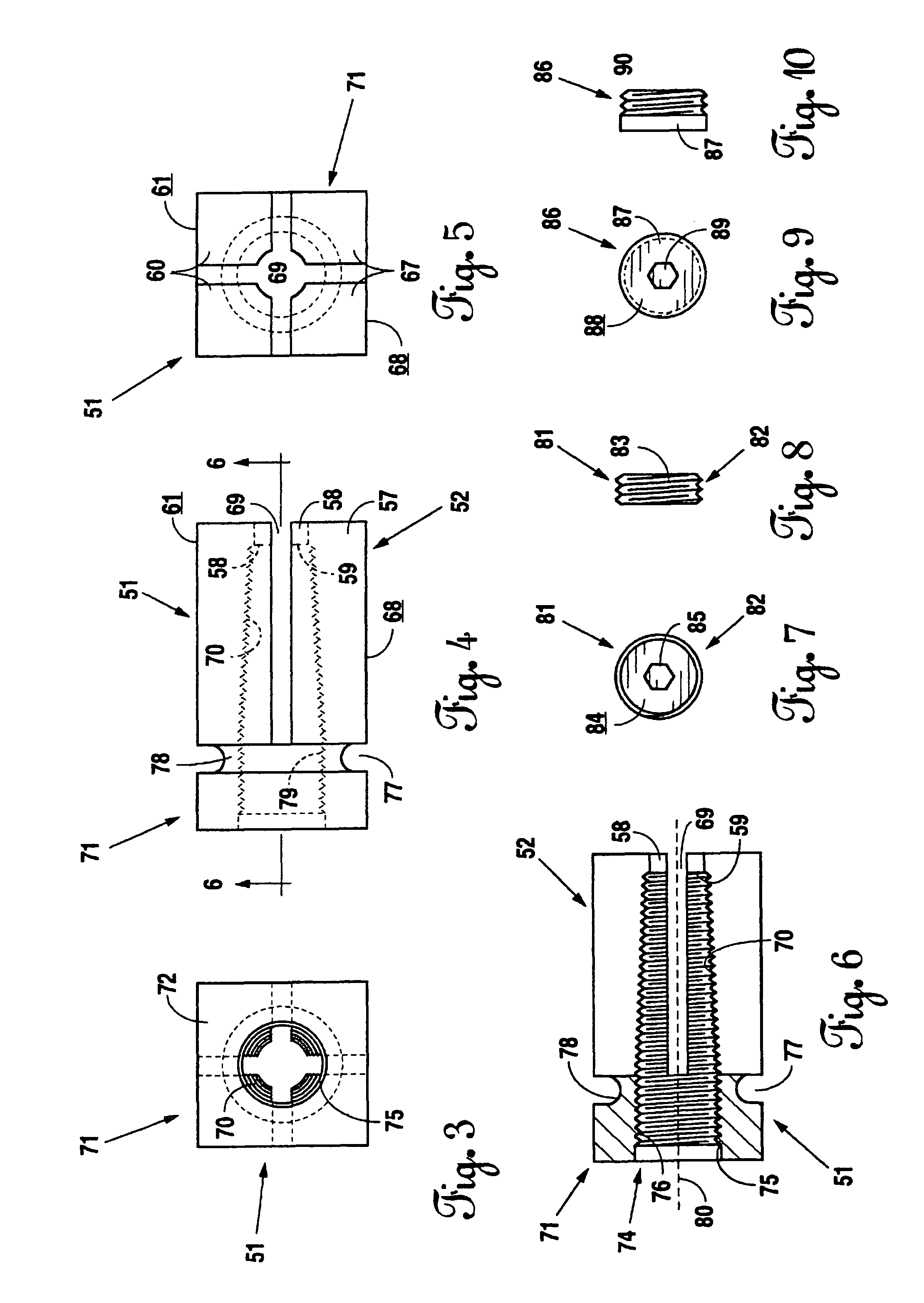

Expandable lordosis stabilizing cage

An expandable stabilizing cage includes a body having a fixed cage section, an expandable cage section, formed as a number of elongate blocks, and a relief between the fixed and expandable cage sections. An orifice, which through the expandable cage section decreases in diameter with increased distance along the central axis of the body away from the fixed cage section, is provided through the body. The expandable stabilizing cage also includes a wafer, which, when inserted into the orifice through the body, causes outward flaring of the elongate bars for fixing the expandable stabilizing cage securely in place in the intervertebral disc space between two adjacent vertebral bodies. Upper elongate blocks have substantially planar upper surfaces. Lower elongate blocks have substantially planar lower surfaces. The surfaces may be provided with surface irregularities for facilitating stable engagement with adjacent vertebral bodies, exemplary irregularities including denticles, dimples, scores, grooves or small protuberances.

Owner:SIMMONS JR JAMES W

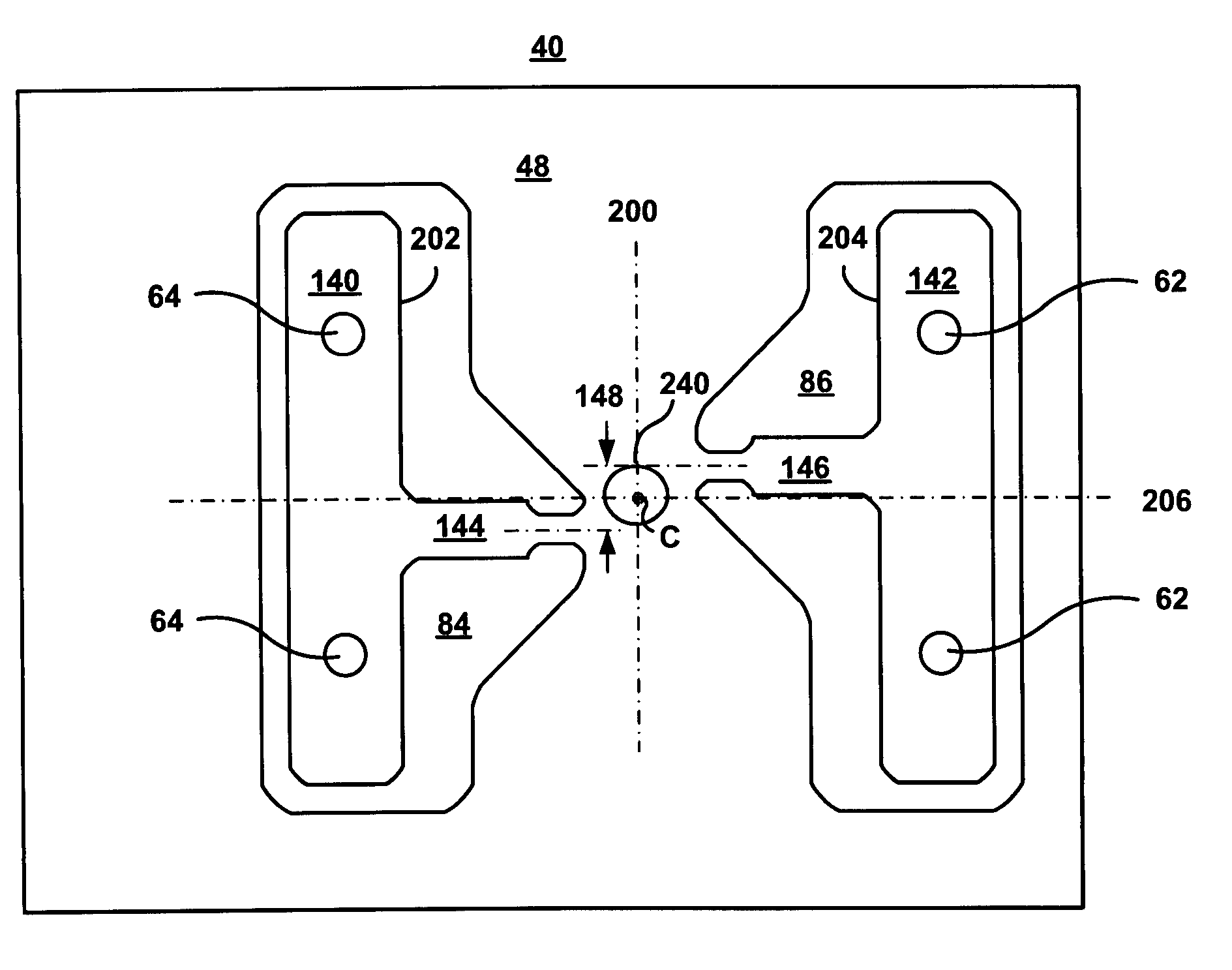

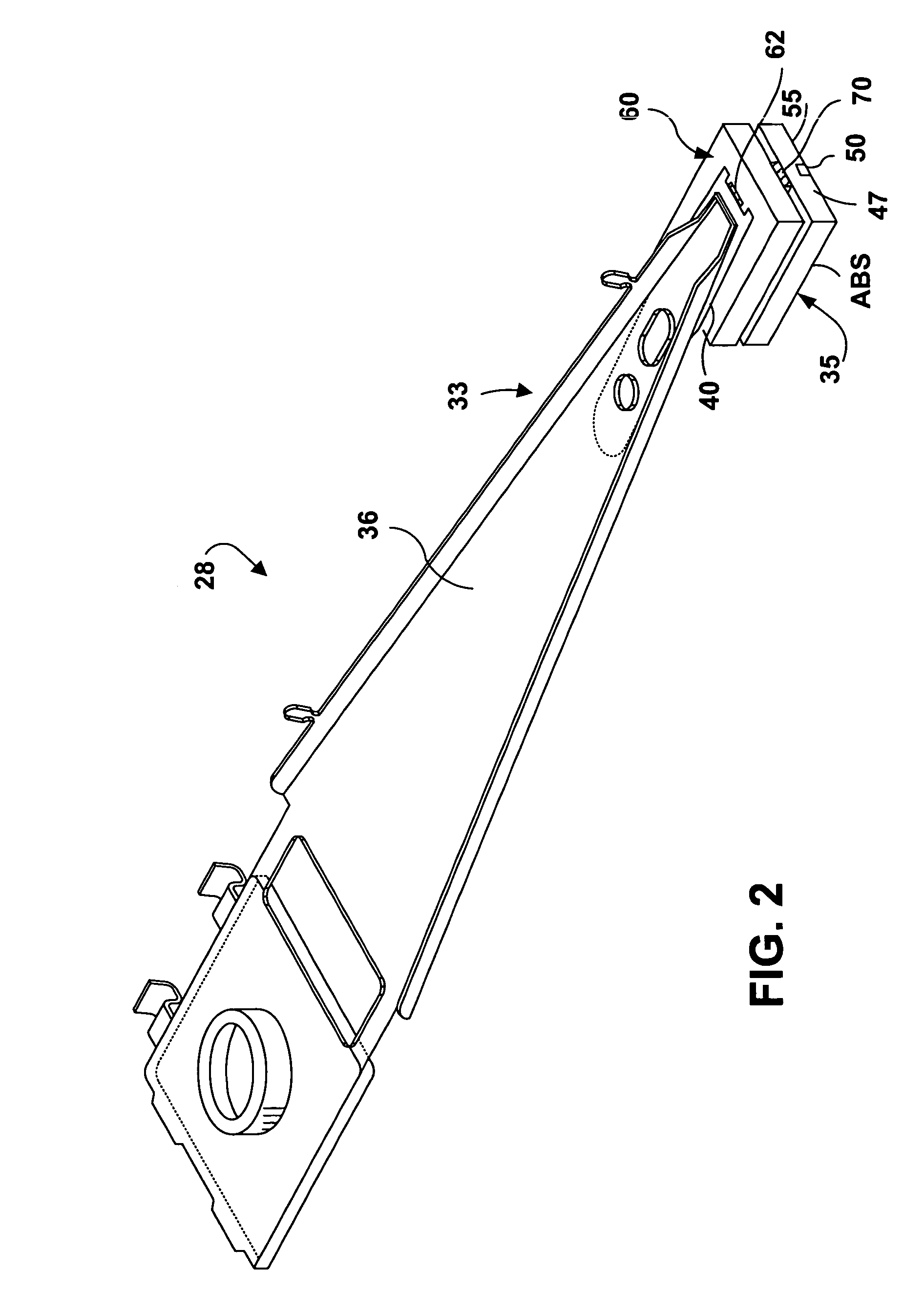

Dimple pivot post for a rotary co-located microactuator

InactiveUS7057857B1Eliminate deformationImprove performanceRecord information storageMounting/attachment of transducer headAdhesiveEngineering

A rotary microactuator-based head-gimbal assembly design controls the unwanted deflection of a flexure in a data storage device and eliminates hinge deformation. The head-gimbal assembly maintains the co-planarity of the hinged islands in the microactuator under the applied load acting on the flexure and two associated hinged islands. The dimple post is placed at the dimple loading region of the flexure tongue and has the same height as adhesive dams on paddles secured to the hinged islands. The dimple post is formed by branching one of the existing conductive traces covered by a photoresist layer to the dimple loading region on flexure tongue. In an alternative embodiment, the dimple post is secured to the dimple loading region of the flexure tongue by means of adhesives with a variety of viscosity and elastic moduli.

Owner:WESTERN DIGITAL TECH INC

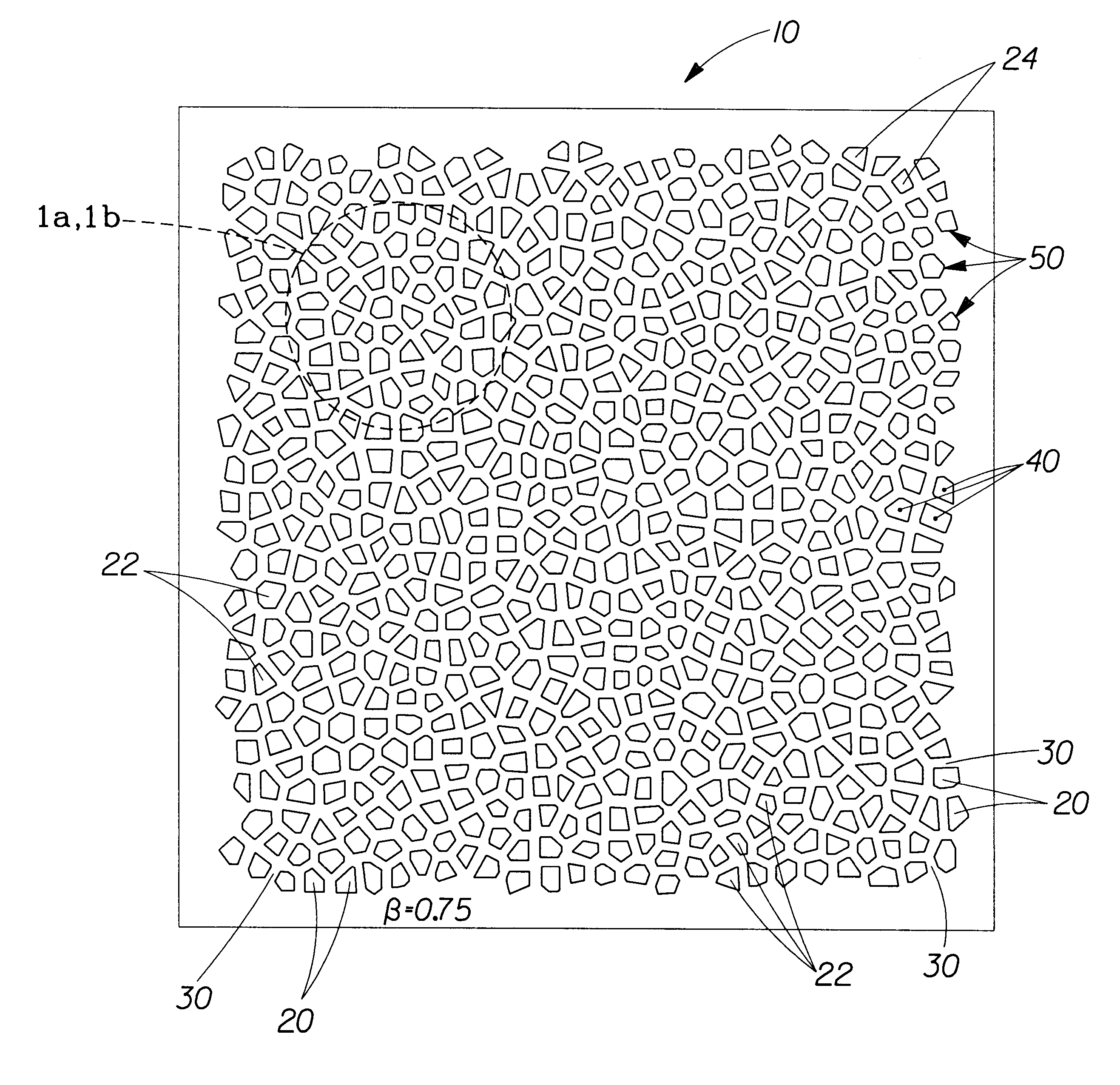

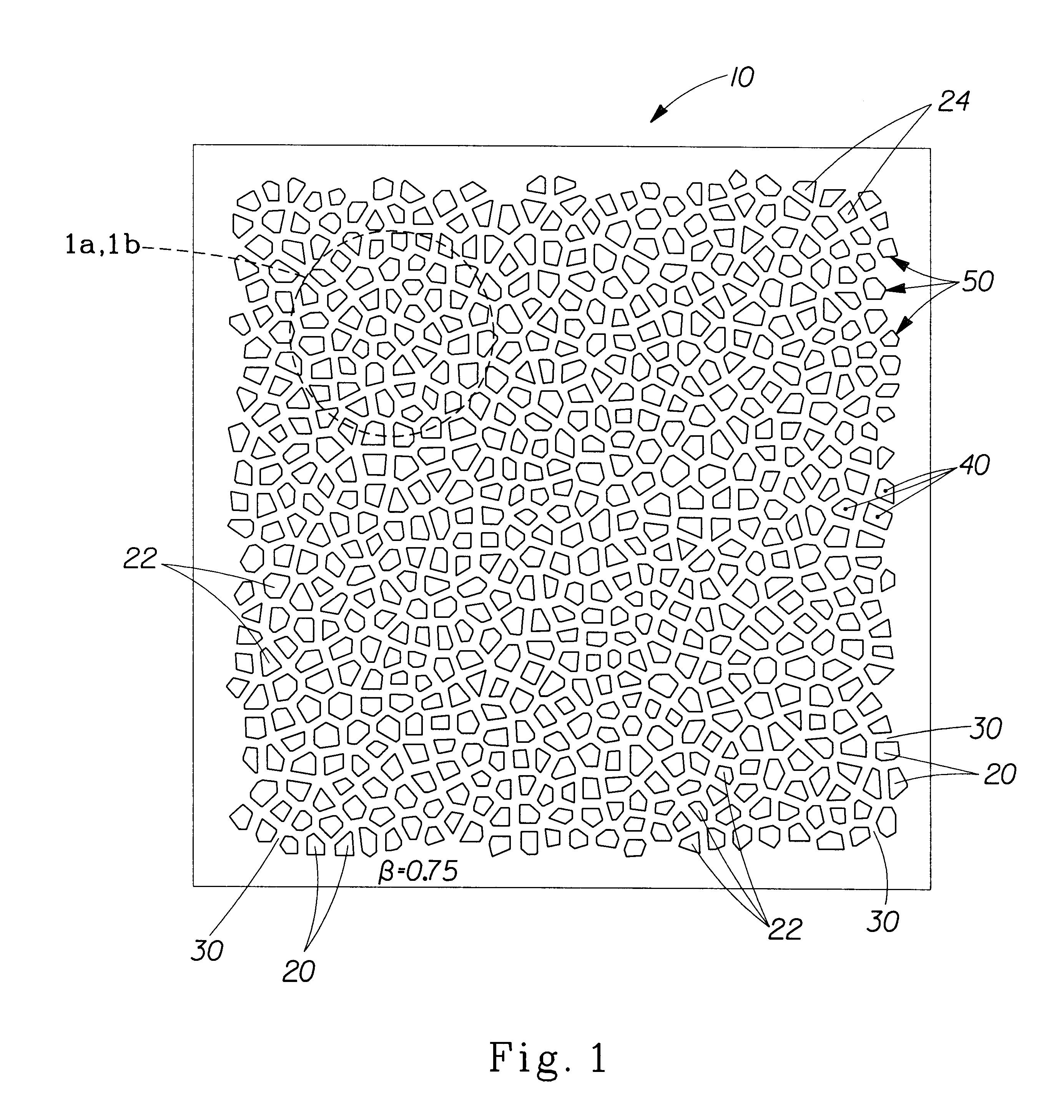

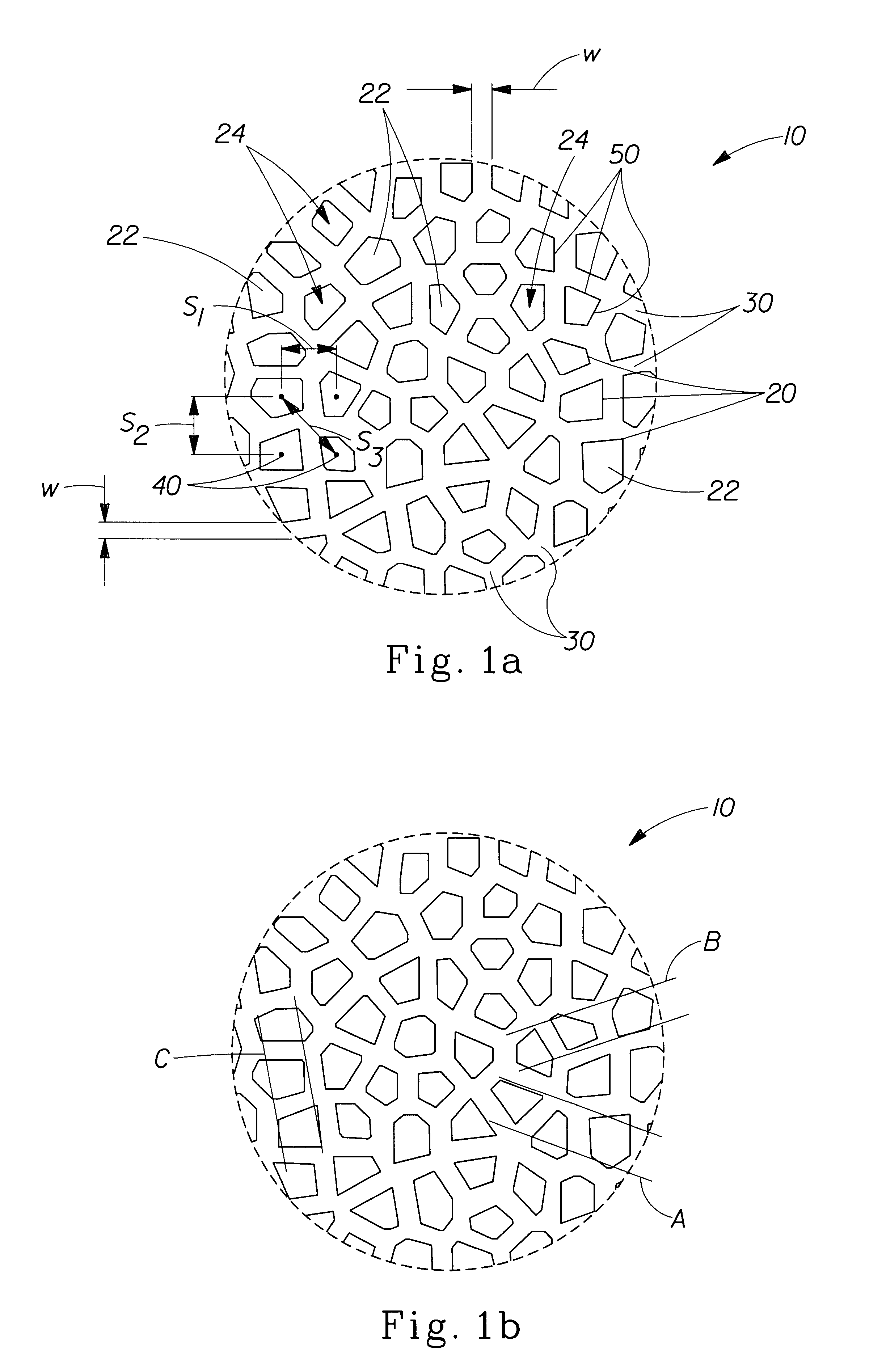

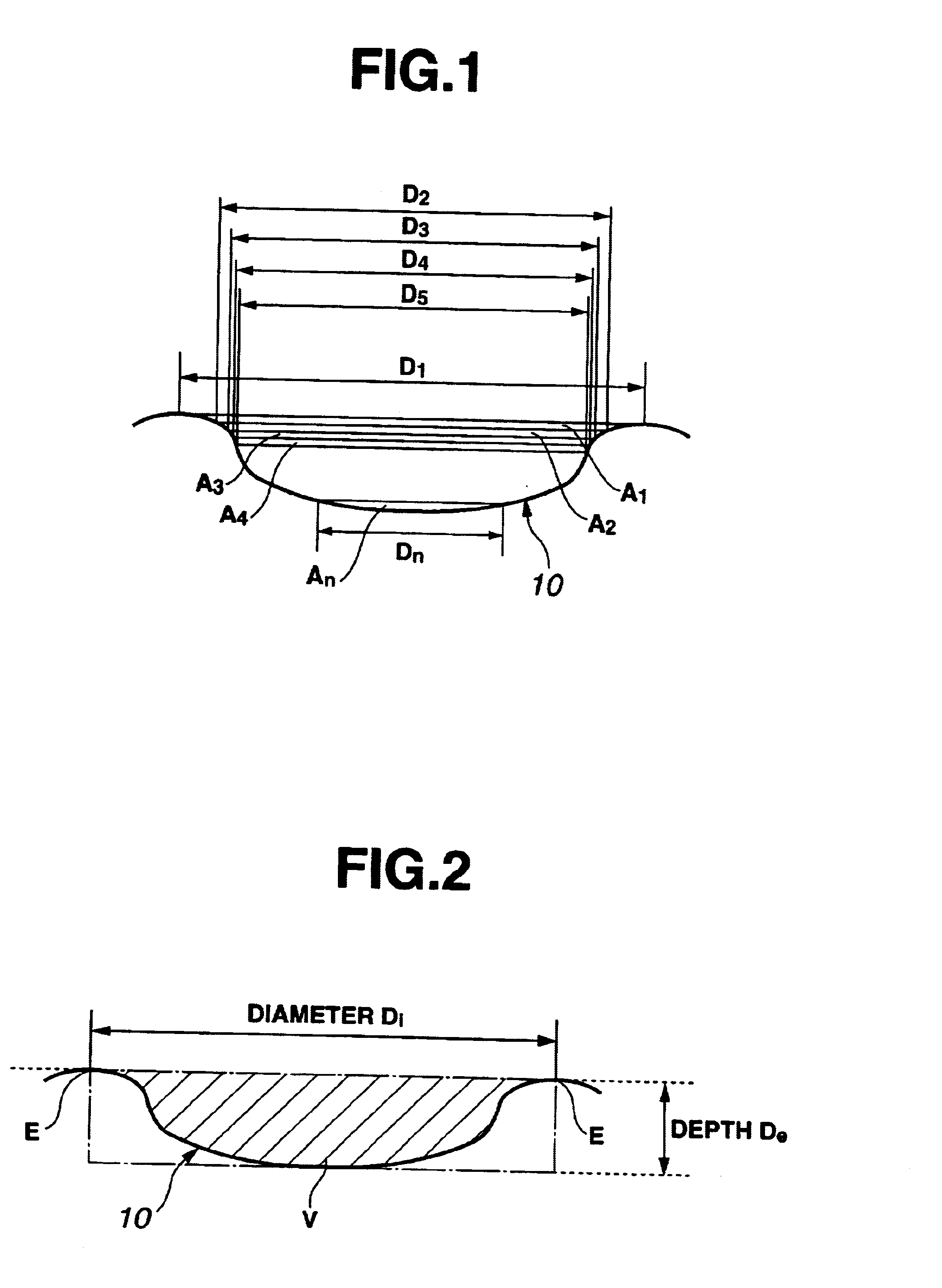

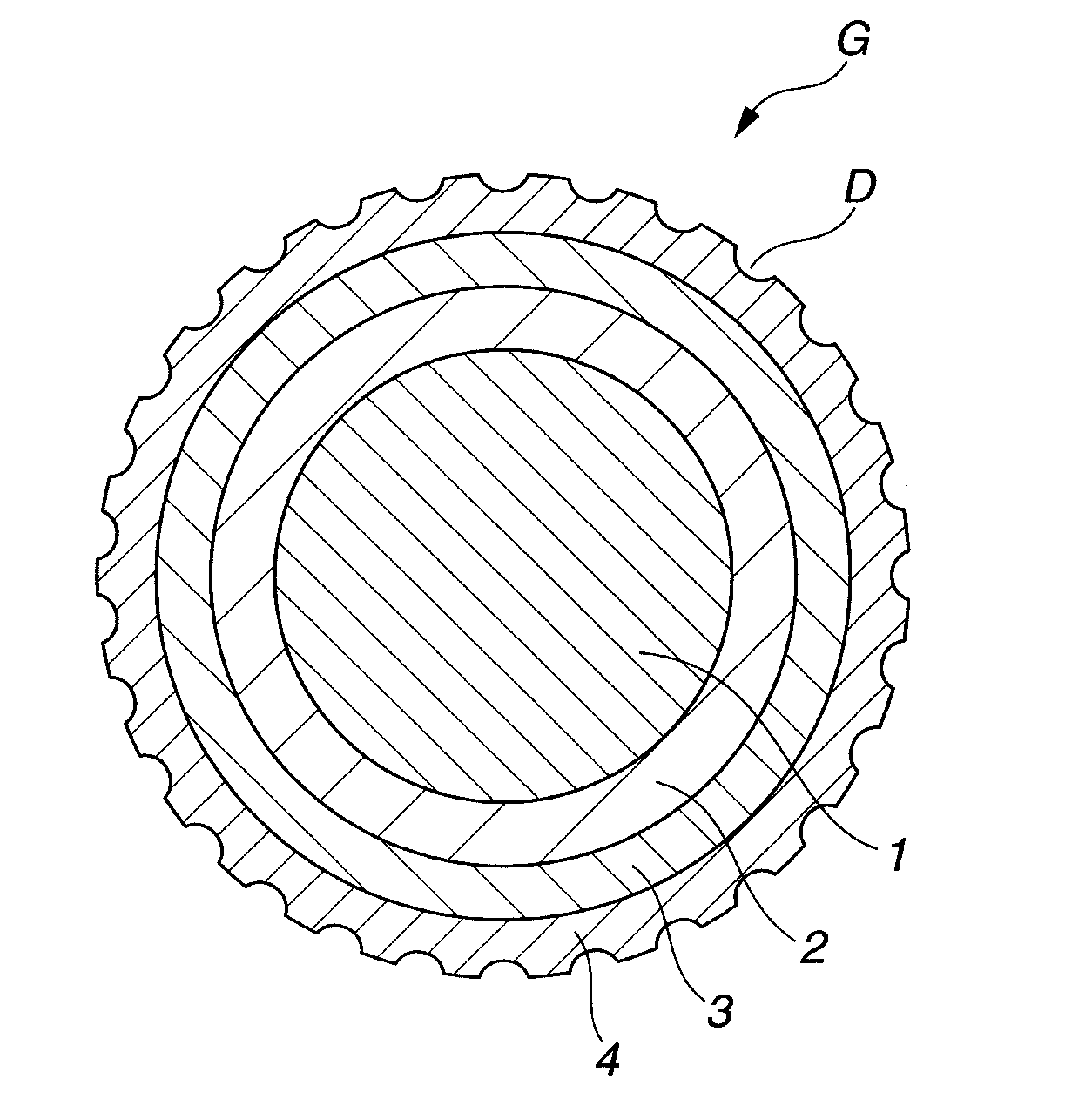

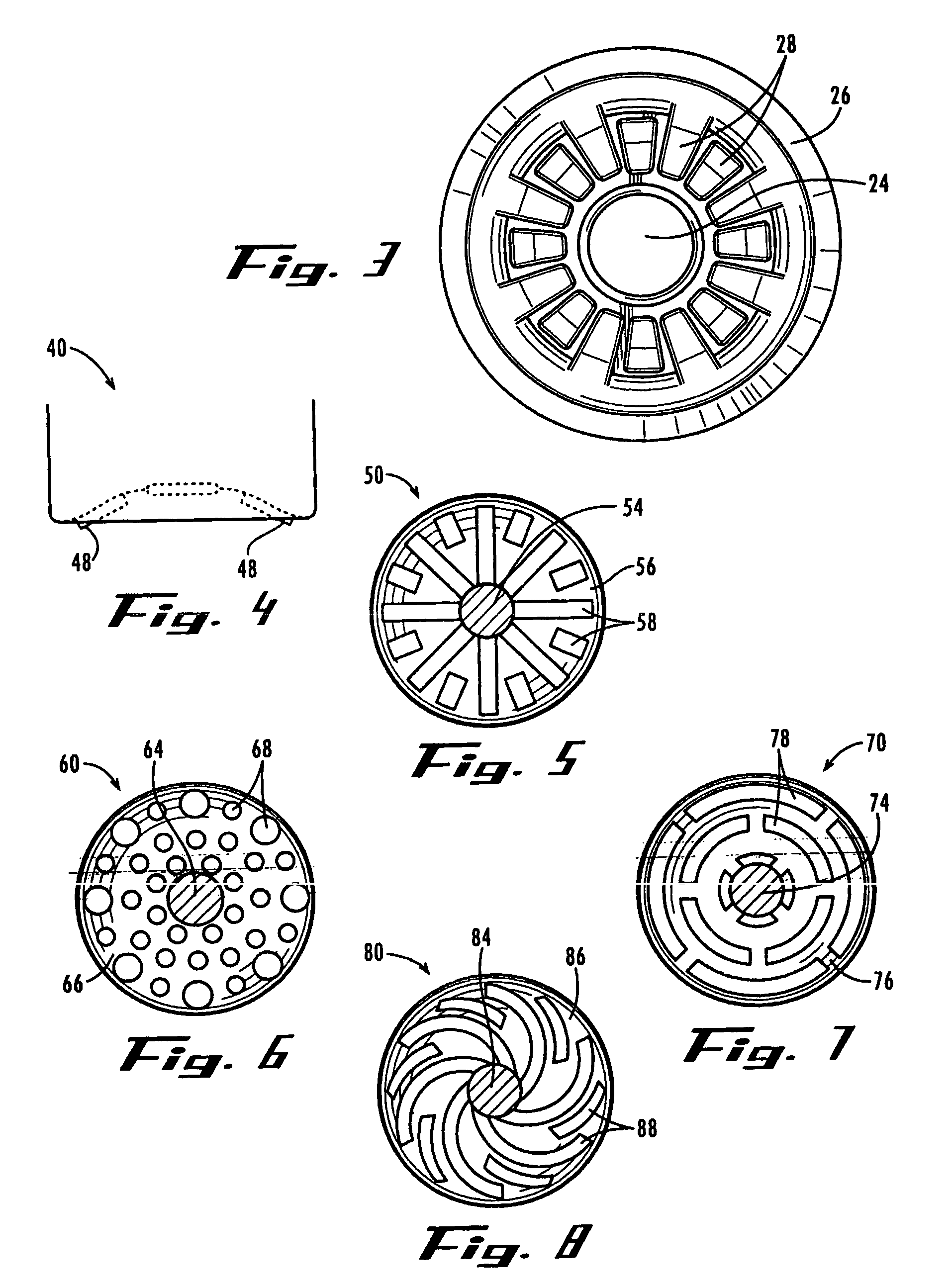

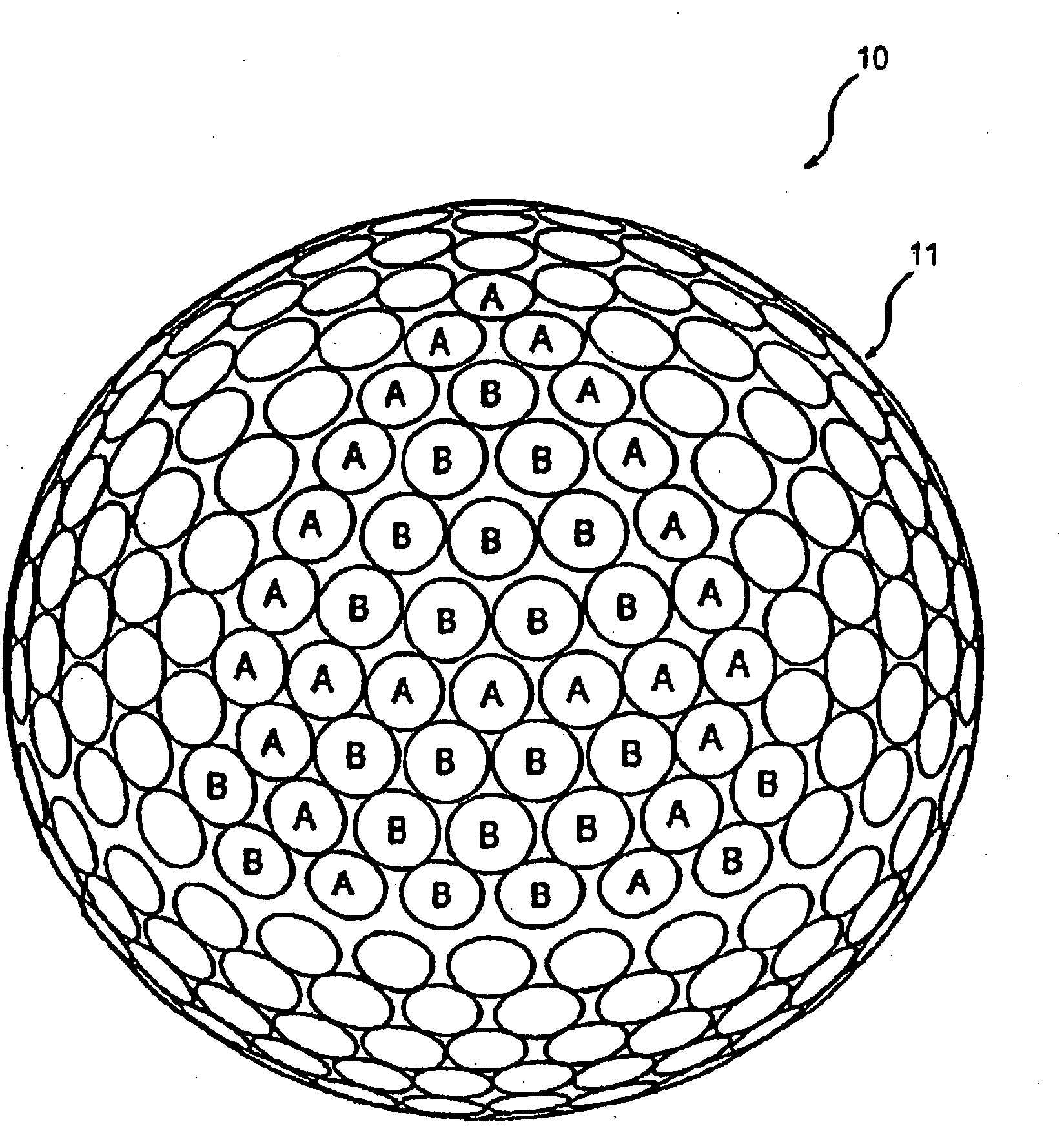

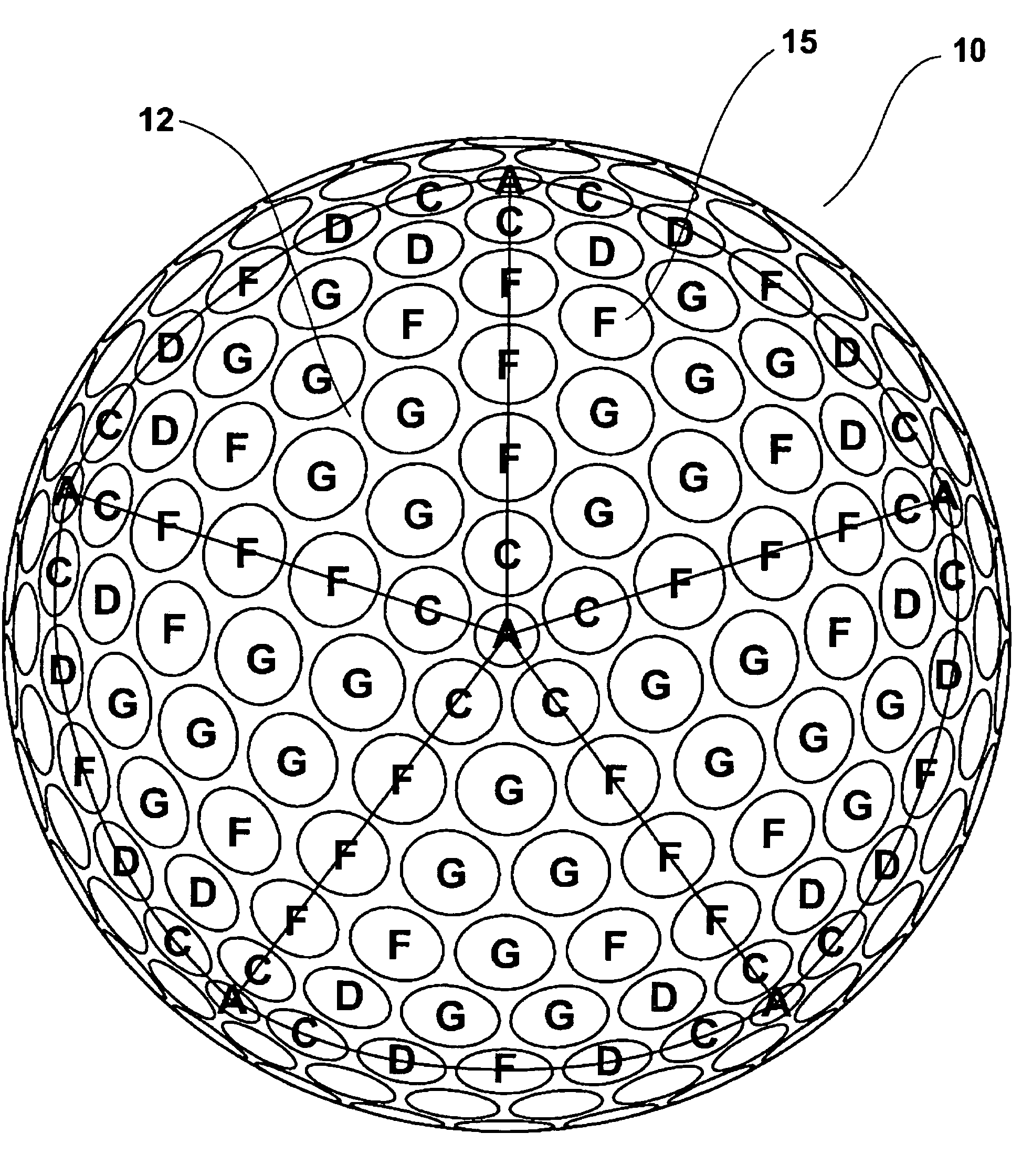

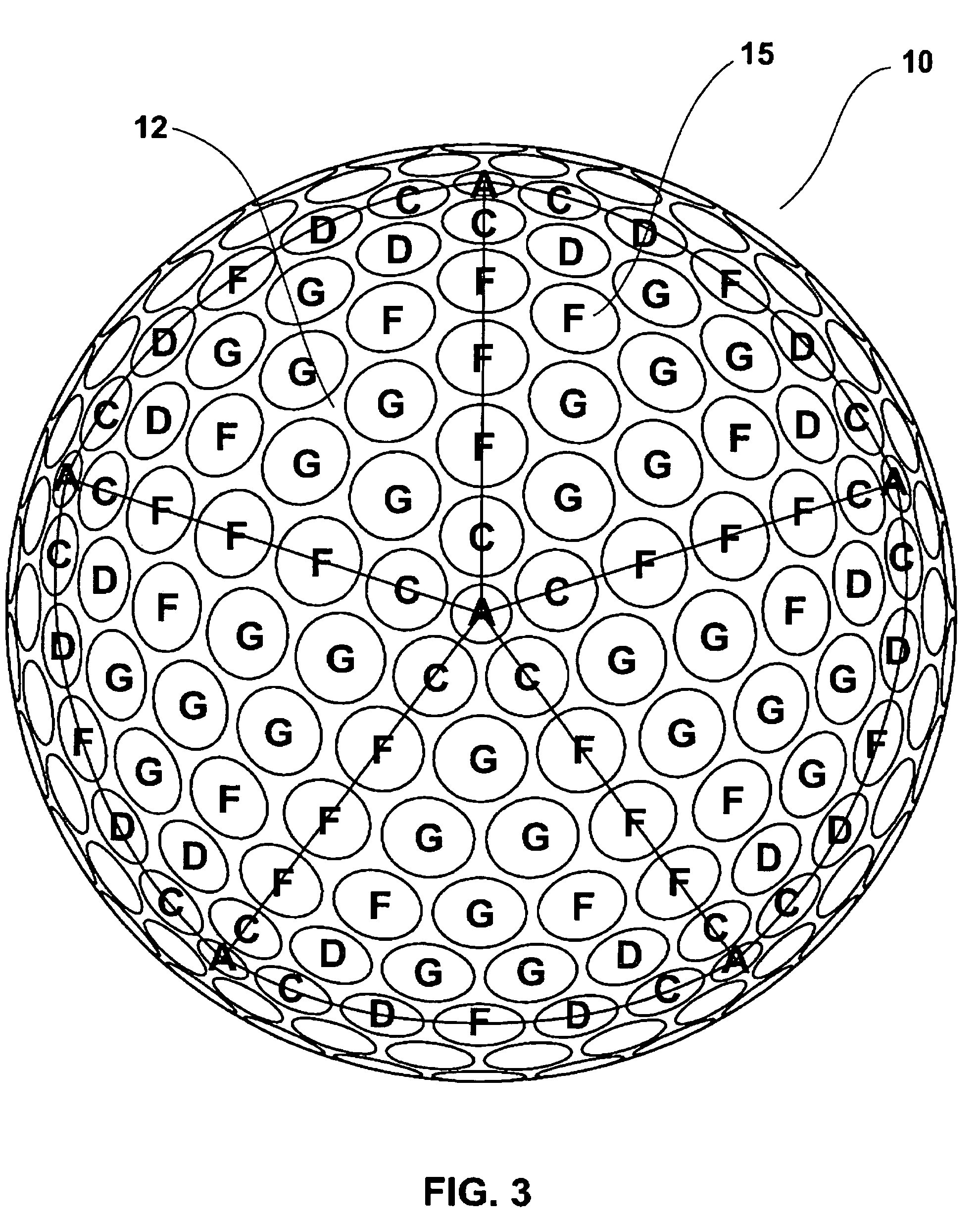

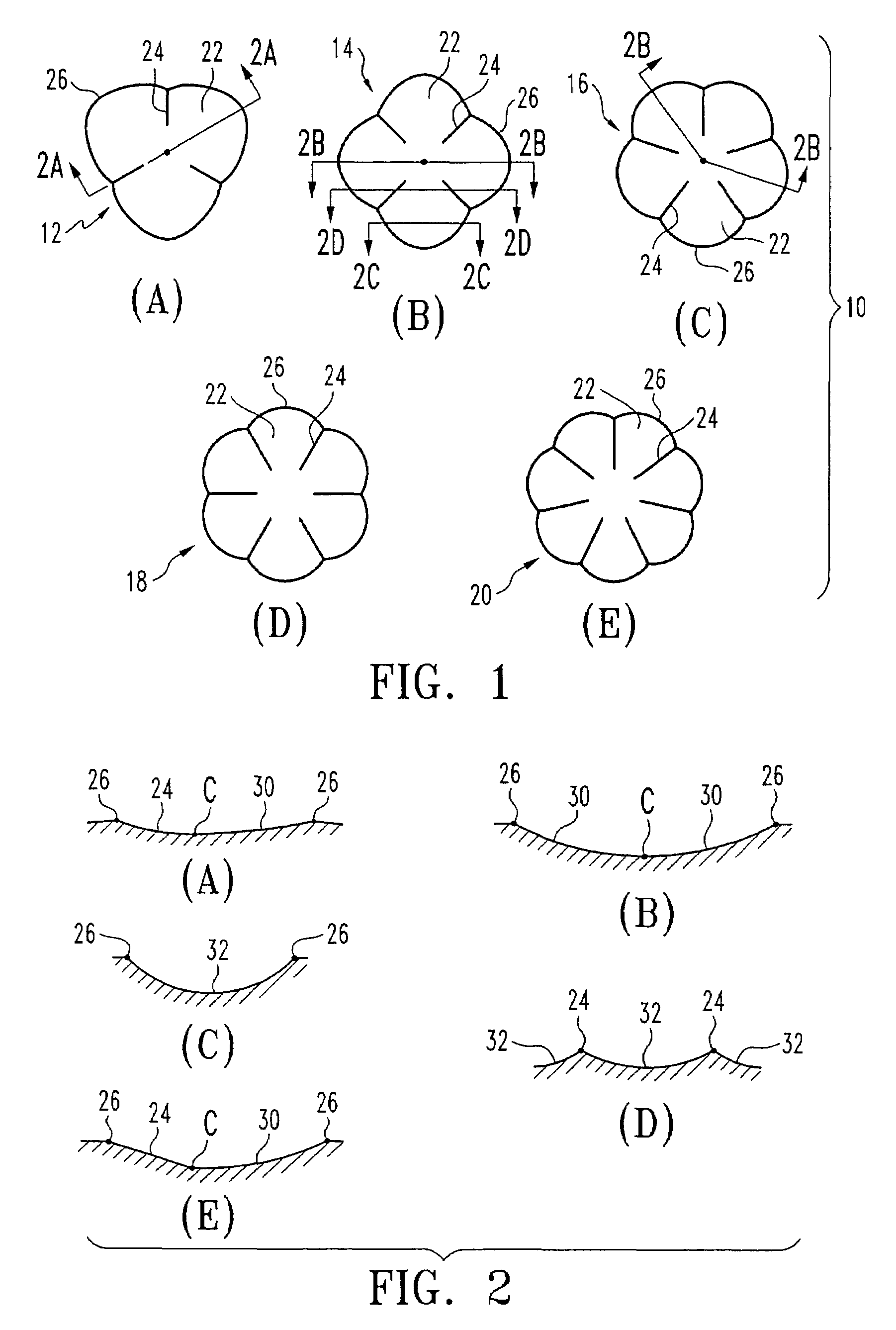

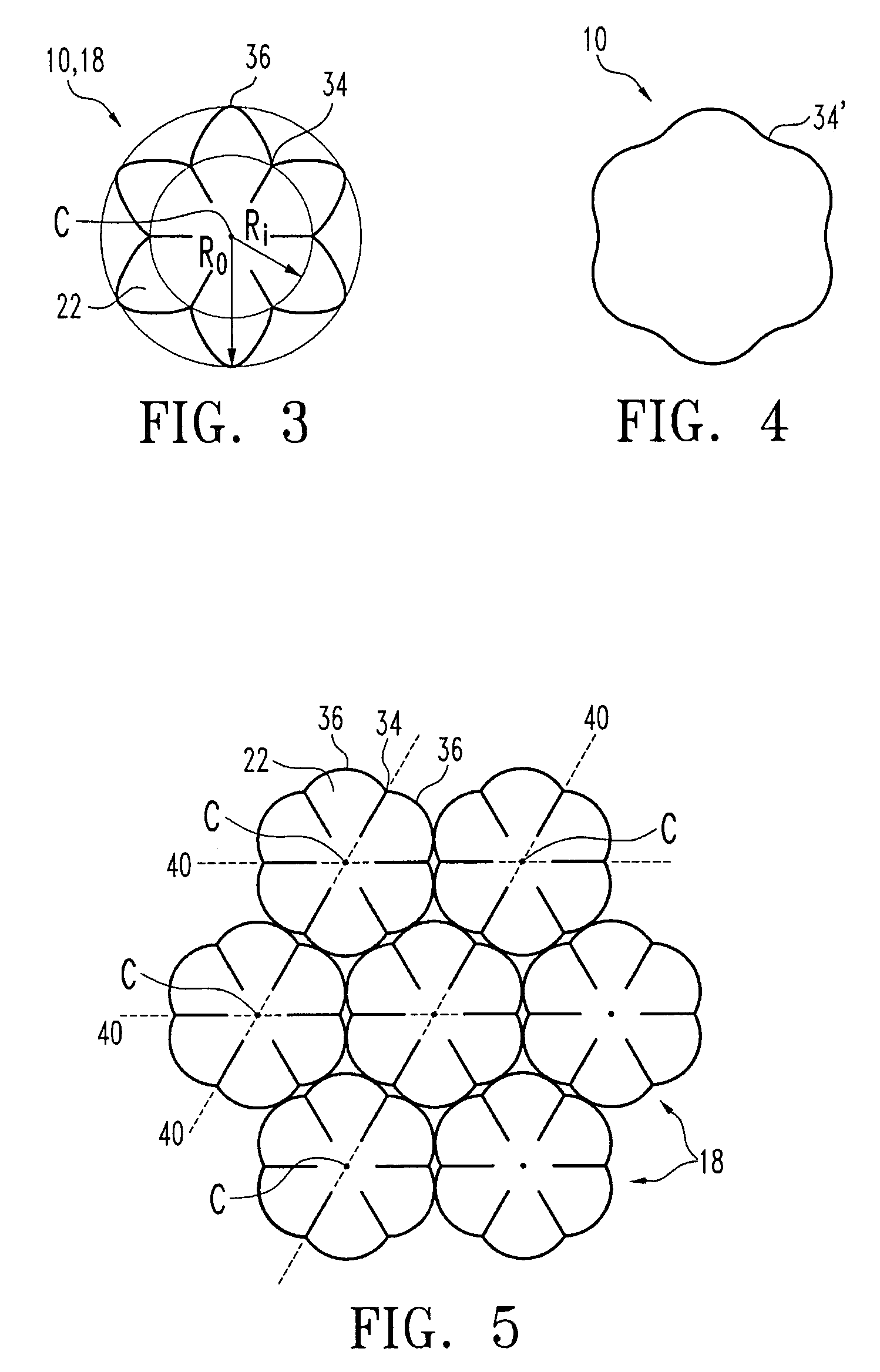

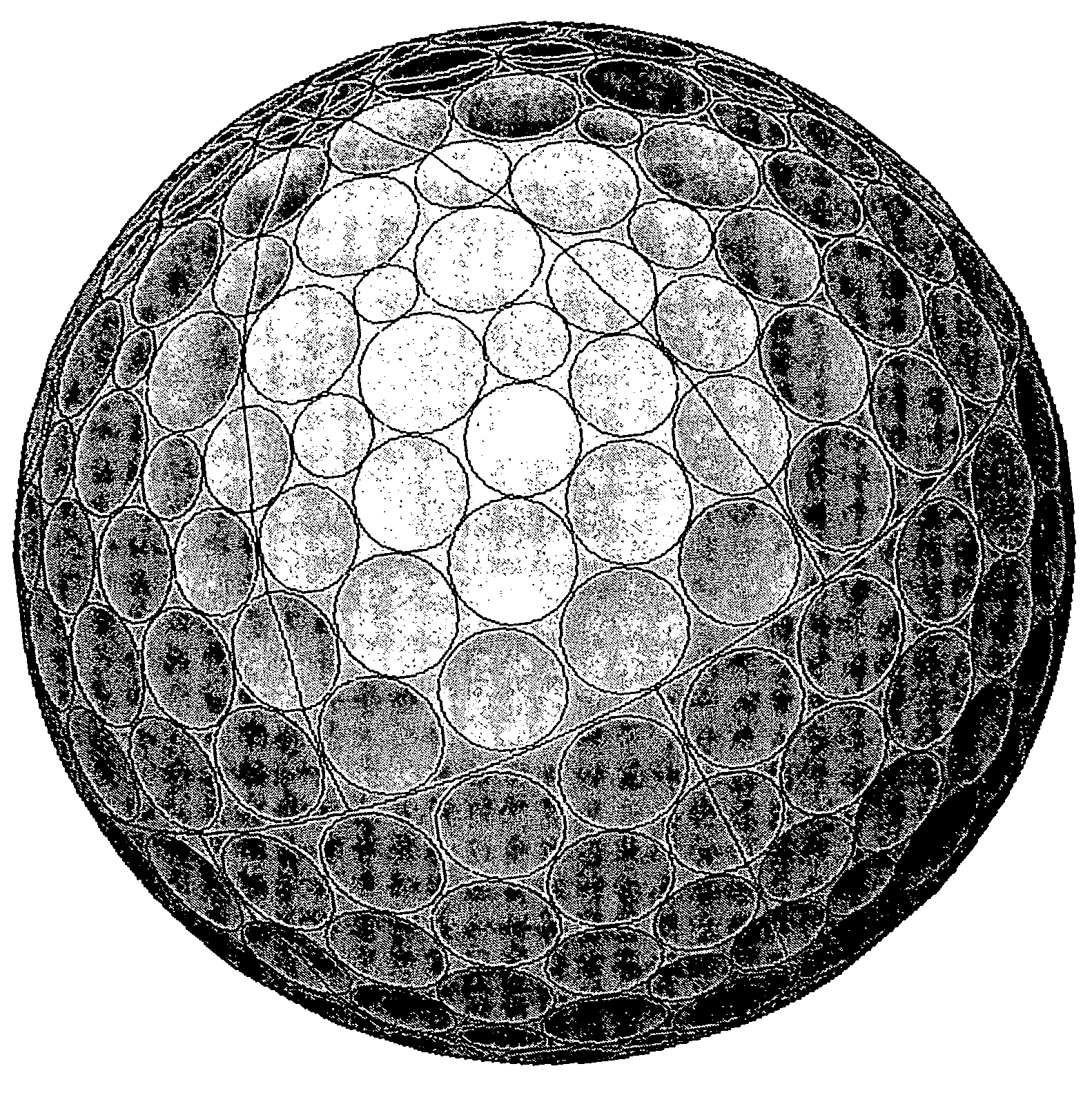

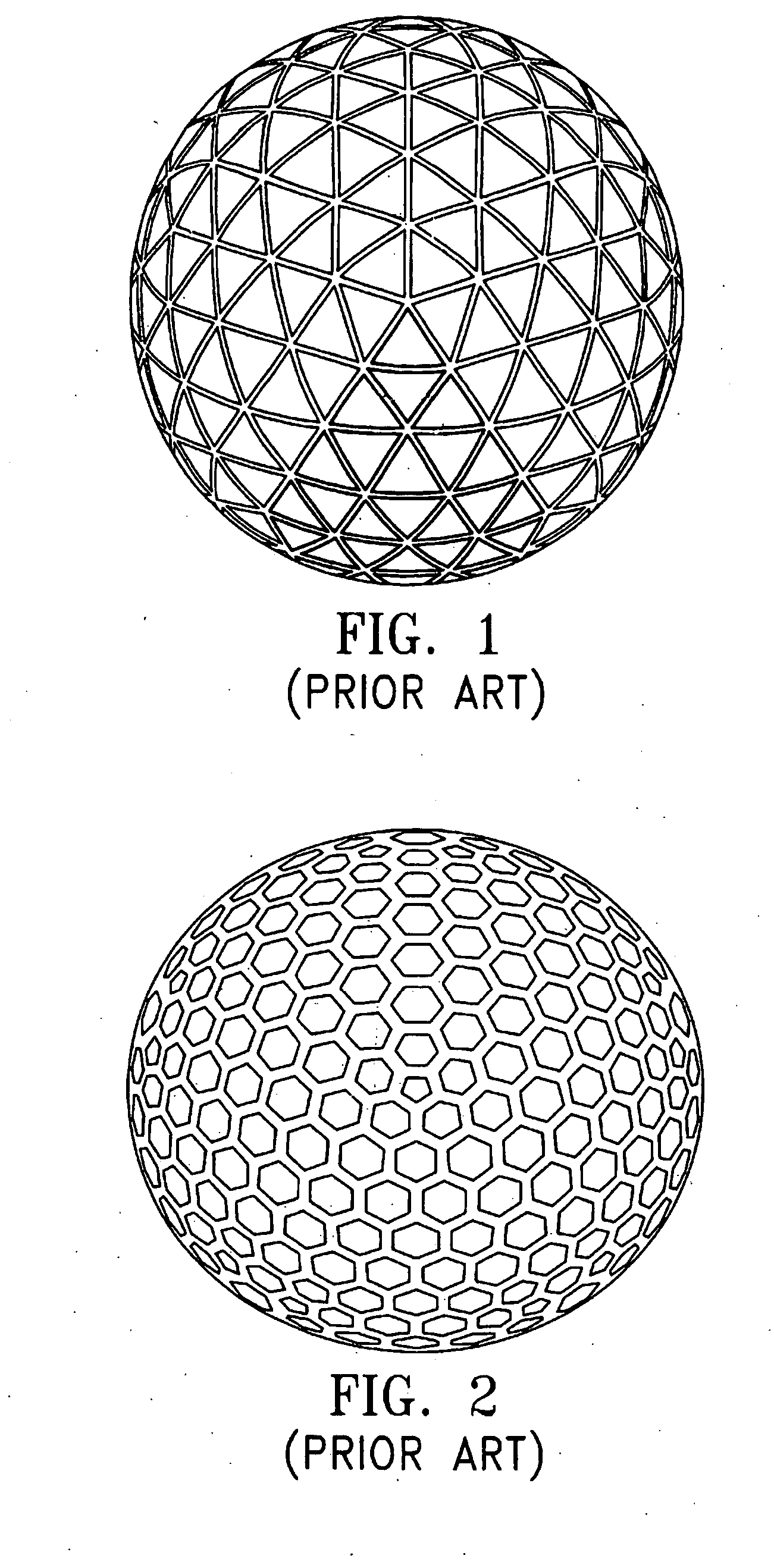

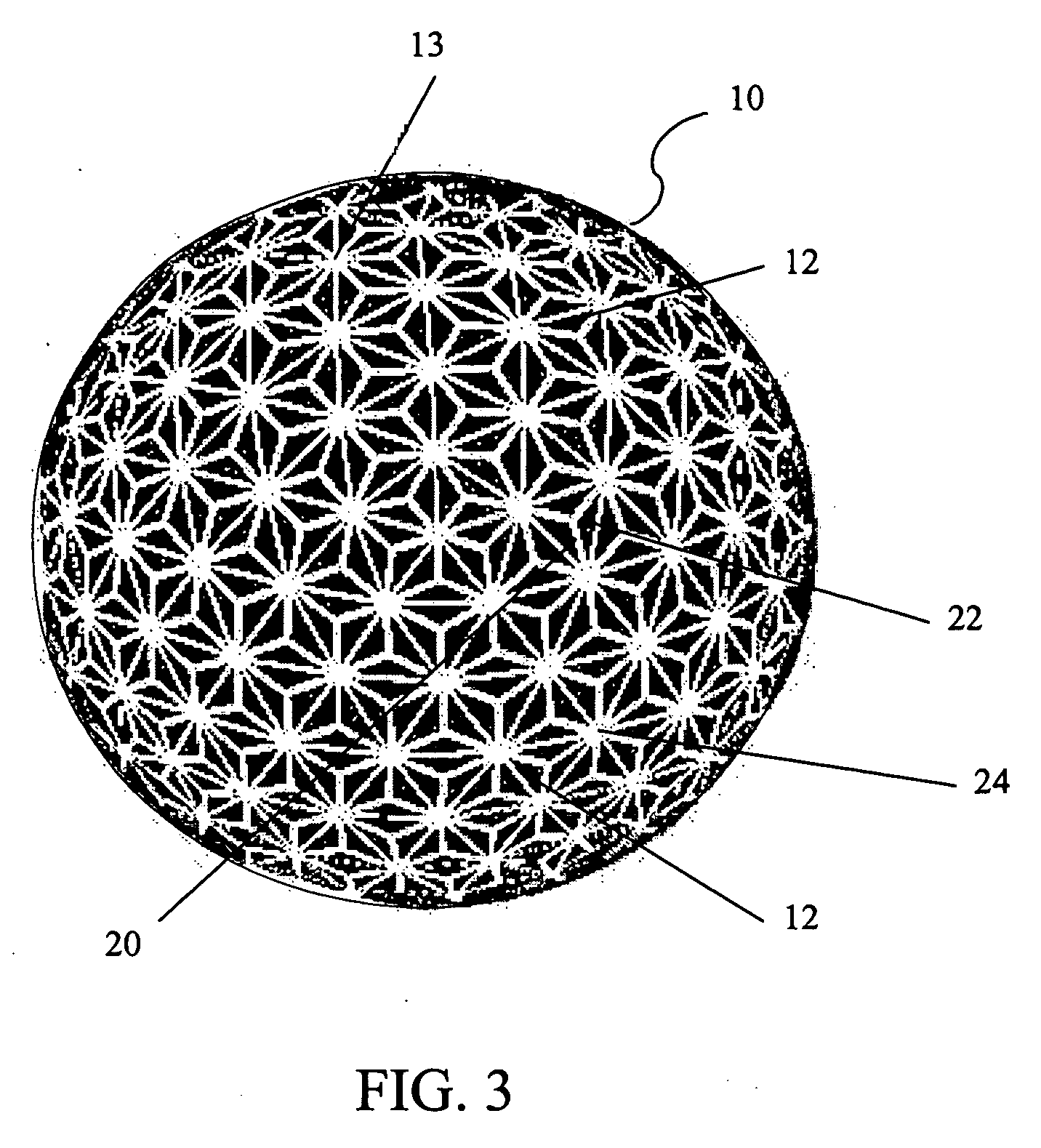

Golf ball with non-circular shaped dimples

In a non-limiting exemplary embodiment of the present invention, a golf ball has a surface comprising a plurality of dimples arranged in an amorphous pattern. In an additional embodiment of the invention, a golf ball has a surface comprising a plurality of spaced dimples, wherein the dimples each comprise a non-circular shape and are spaced by land portions having substantially uniform widths. In an additional embodiment of the present invention, a golf ball has a surface formed with a plurality of non-circular, multi-sided shaped dimples and interposed lands having substantially consistent widths between adjacent dimples. In yet another alternative embodiment of the present invention, an exemplary method of making a golf ball having a dimpled surface is provided. The process comprises generating an amorphous pattern of non-circular shaped dimples and then transferring the amorphous pattern to the surface of the golf ball.

Owner:THE PROCTER & GAMBLE COMPANY

Surfaces and processes for wear reducing in orthopaedic implants

Artificial implants having reduced area to provide reduced wear are provided. The reduced area is particularly located at areas where greatest wear is exhibited. In a particular embodiment of a mobile bearing knee implant, the area is reduced on the mobile bearing insert underside, where it contacts a tibial component. The reduced area may be any shape of indentations, for example, grooves, dimples, straight patterns, curved patterns, crossing patterns, holes, channels or slots. The indentations may be various sizes, and have been found to be particularly effective if covering about 10% to about 20% of the insert at depths between about 1-2 mm.

Owner:SMITH & NEPHEW INC

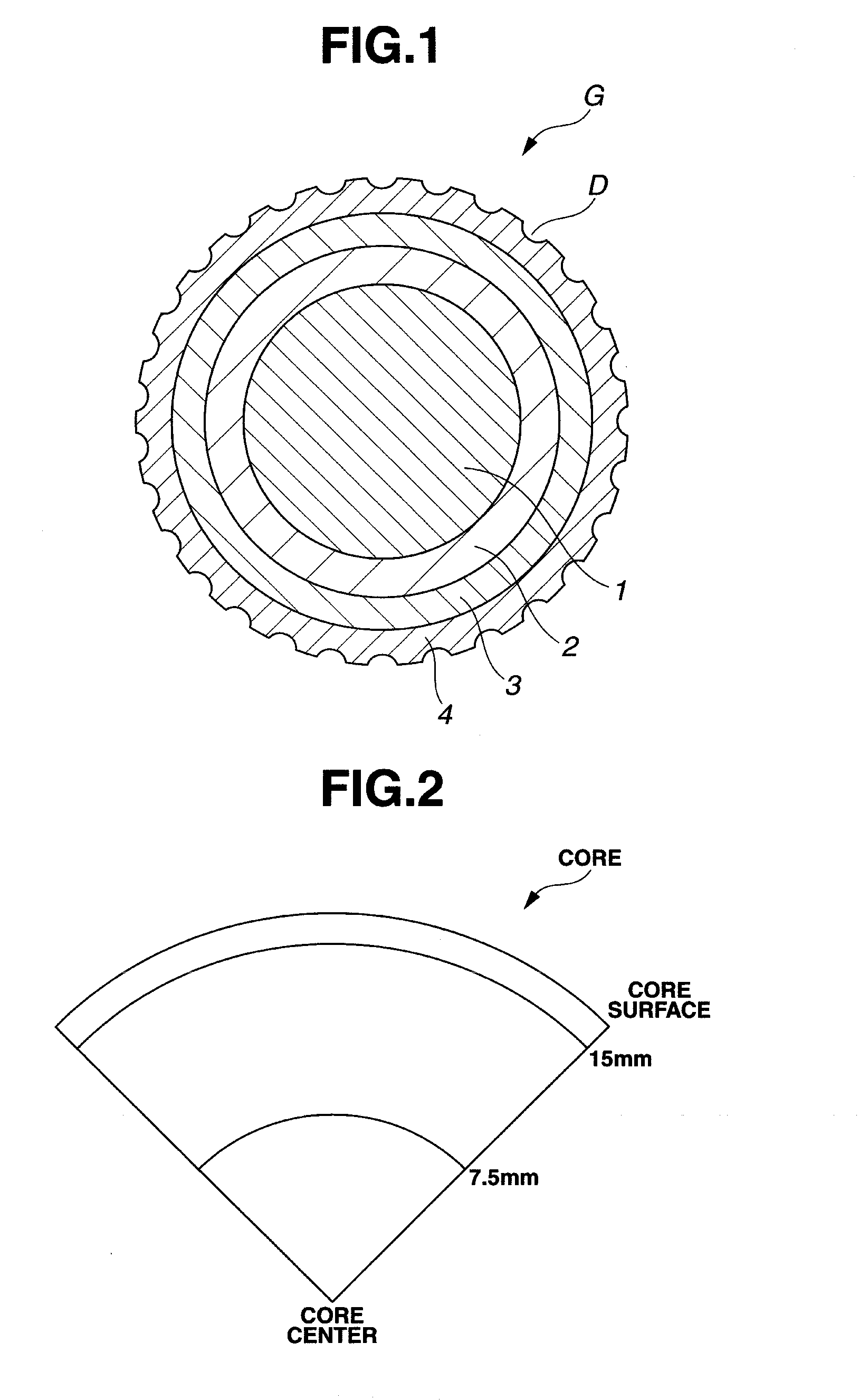

Multi-piece solid golf ball

InactiveUS6739986B2Stretching flight performanceExtended driving distancePolyurea/polyurethane coatingsGolf ballsLow speedHardness

In a multi-piece solid golf ball comprising a solid core and a cover of two inner and outer layers enclosing the solid core and formed on the surface with a plurality of dimples, the solid core in its entirety has a hardness distribution falling within the range of JIS-C hardness 50-85, the difference between maximum and minimum JIS-C hardnesses in the solid core falls within 5%, the cover inner layer has a JIS-C hardness of 70-90, the cover outer layer has a JIS-C hardness of 60-80, the sum of high-speed region dimple operative volumes HDOV of respective dimples is 170-310, the sum of low-speed region dimple operative volumes of respective dimples LDOV is 200-310, and the overall dimple volume is 260-360 mm<3>.

Owner:BRIDGESTONE SPORTS

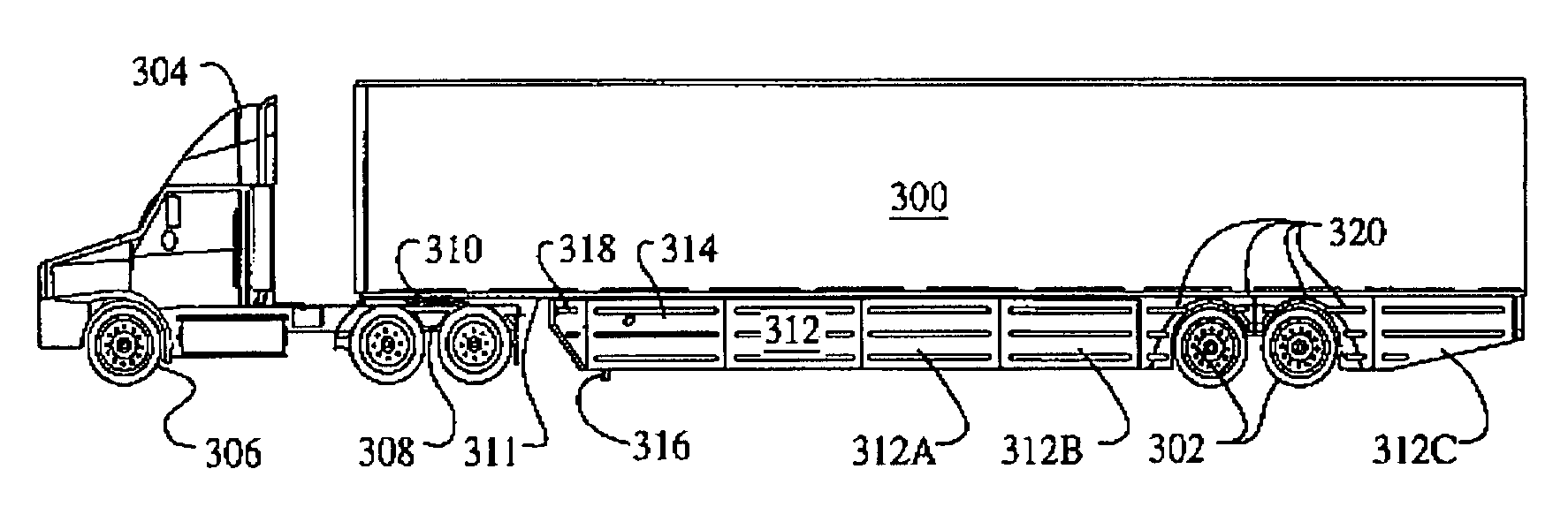

Trailer skirt panel

ActiveUS7578541B2Reducing aerodynamic drag on road vehiclesIncrease air flowVehicle seatsWindowsAerodynamic dragEngineering

A skirt panel is provided herein for interconnection to another abutted similar skirt panel for attachment beneath a lower, outer longitudinally-extending edge of a trailer including a rear wheel assembly of a tractor-trailer rig, thereby to provide a continuous fairing extending downwardly from the trailer. The skirt panel includes a monolithic, generally-rectangular composite reinforced thermoplastic structure, having vertical lateral side edges configured and arranged for connection to associated vertical lateral side edges of abutting similar skirt panels. This provides a longitudinally-extending fairing for extending contiguously on each side of the trailer, a front face of the thermoplastic structure being provided with a plurality of longitudinally-extending, vertically-spaced-apart arcuate protrusions. The outer face of the thermoplastic panel preferably also is provided with dimples. The reinforcing comprising a panel secured to an inner face of the skirt panel and is provided with laterally-extending means whereby abutting skirt panels are secured to one another; whereby, when said fairing is secured to a lower portion of said trailer, the fairing extends downwardly from the trailer to from 60% to 80% of the distance to the road, so that a portion of any impinging air is directed laterally around the wheels of the rear wheel bogeys to reduce the aerodynamic drag of the trailer and of the wheel assembly.

Owner:ZF COMPOSITES NORTH AMERICA LTD

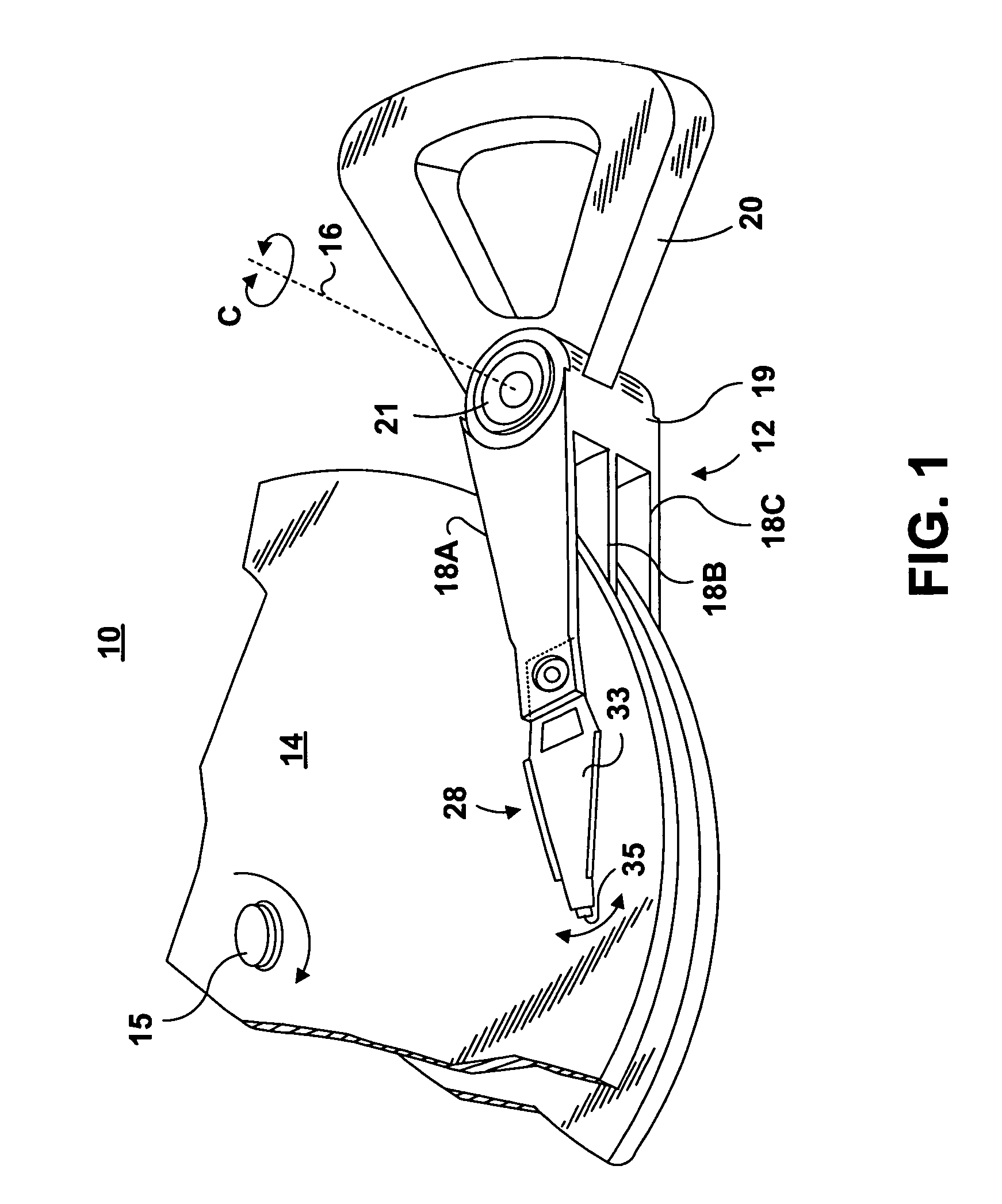

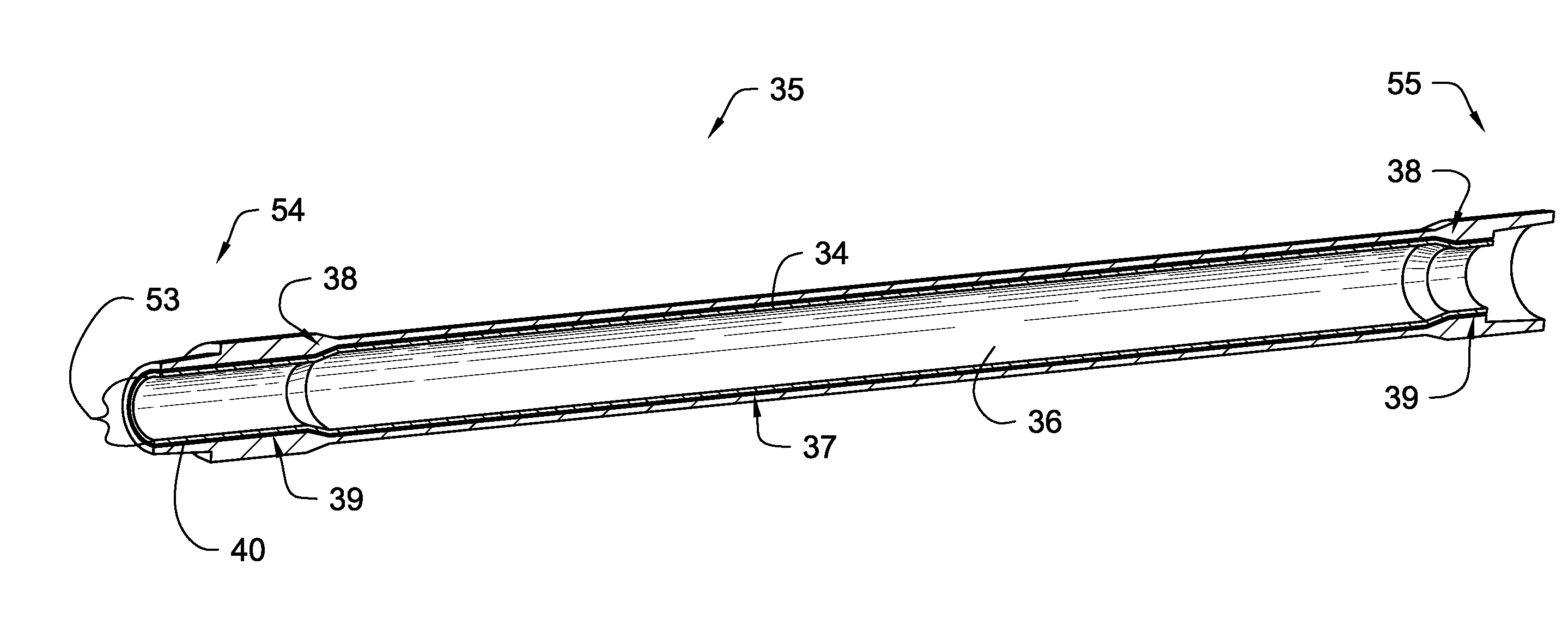

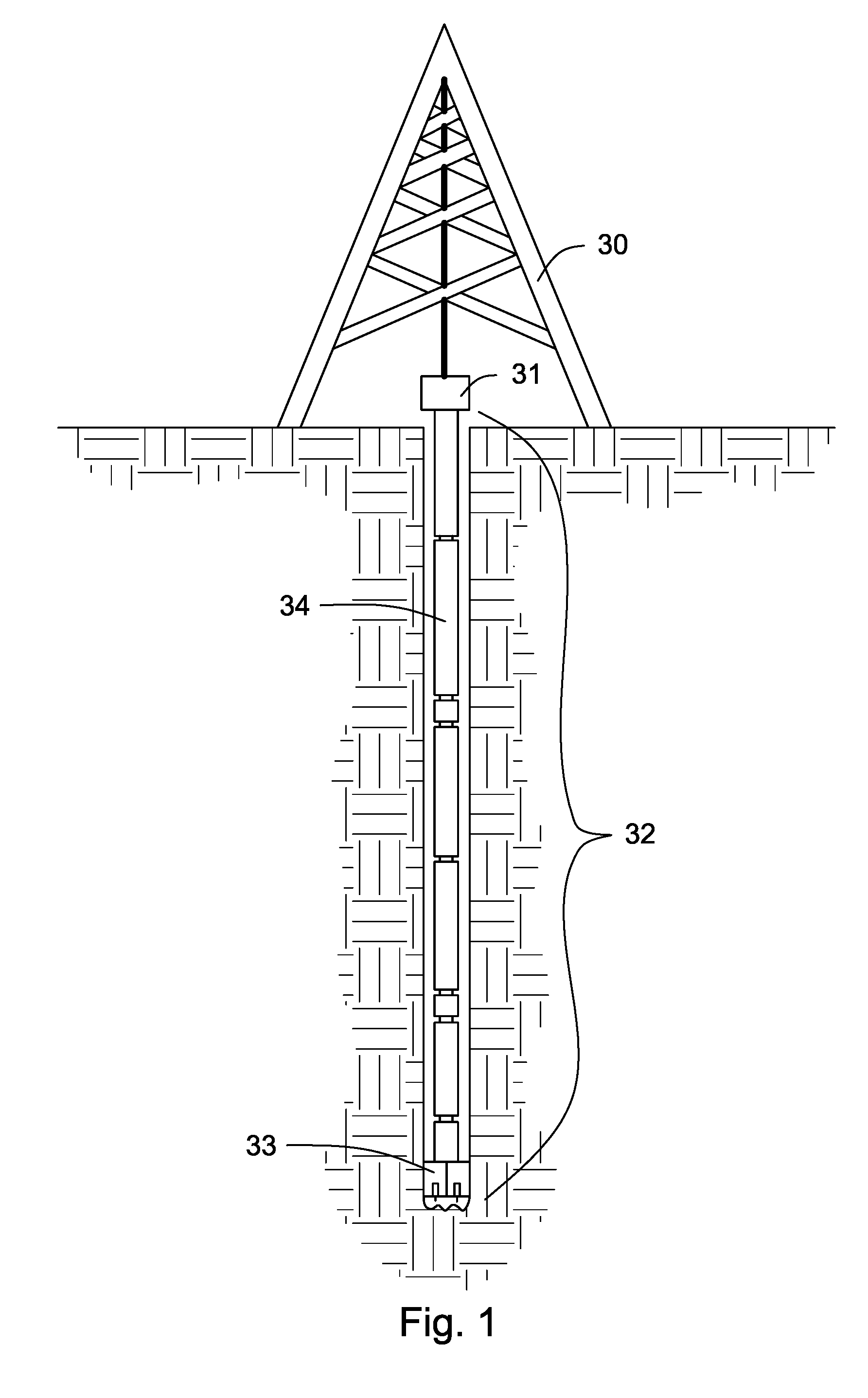

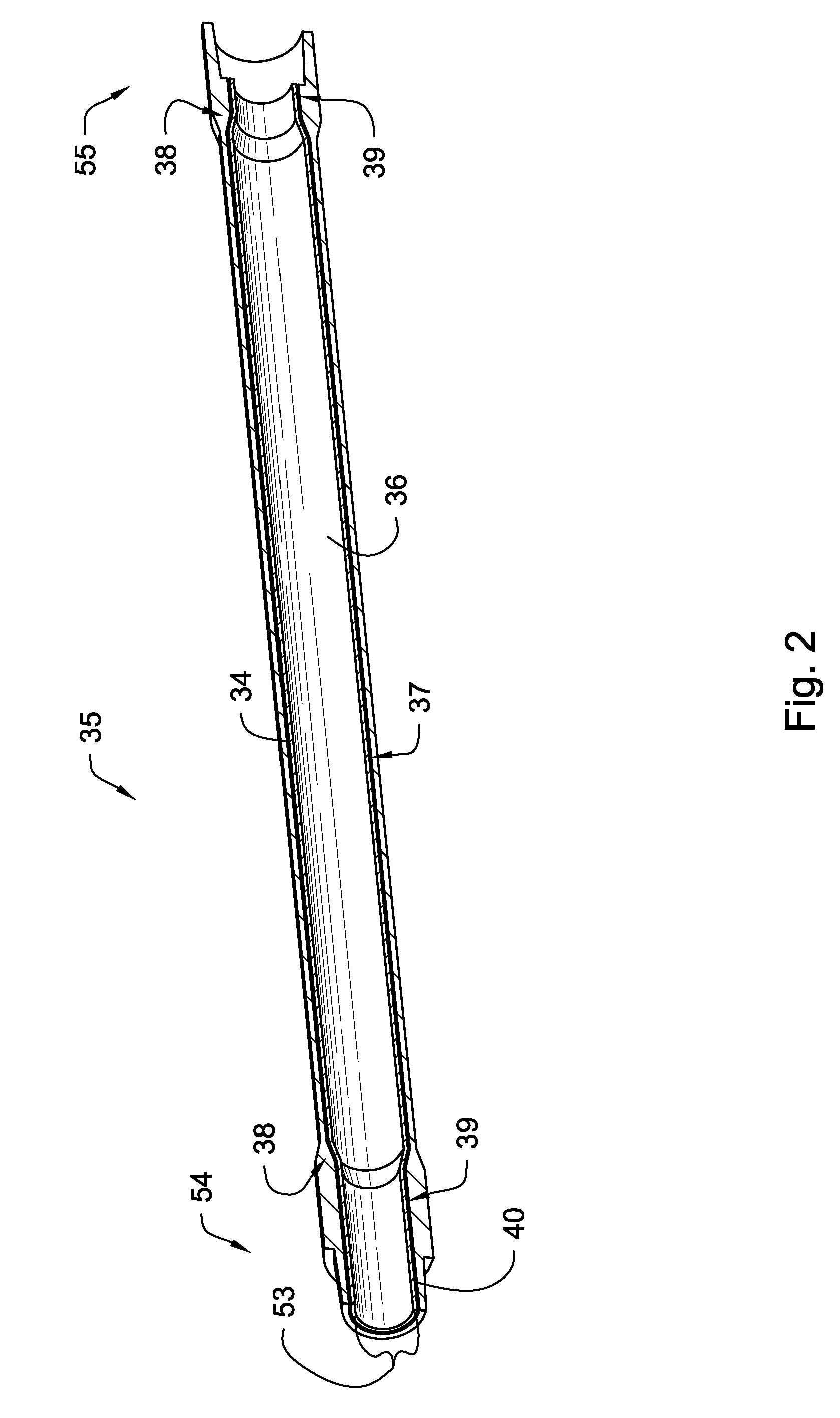

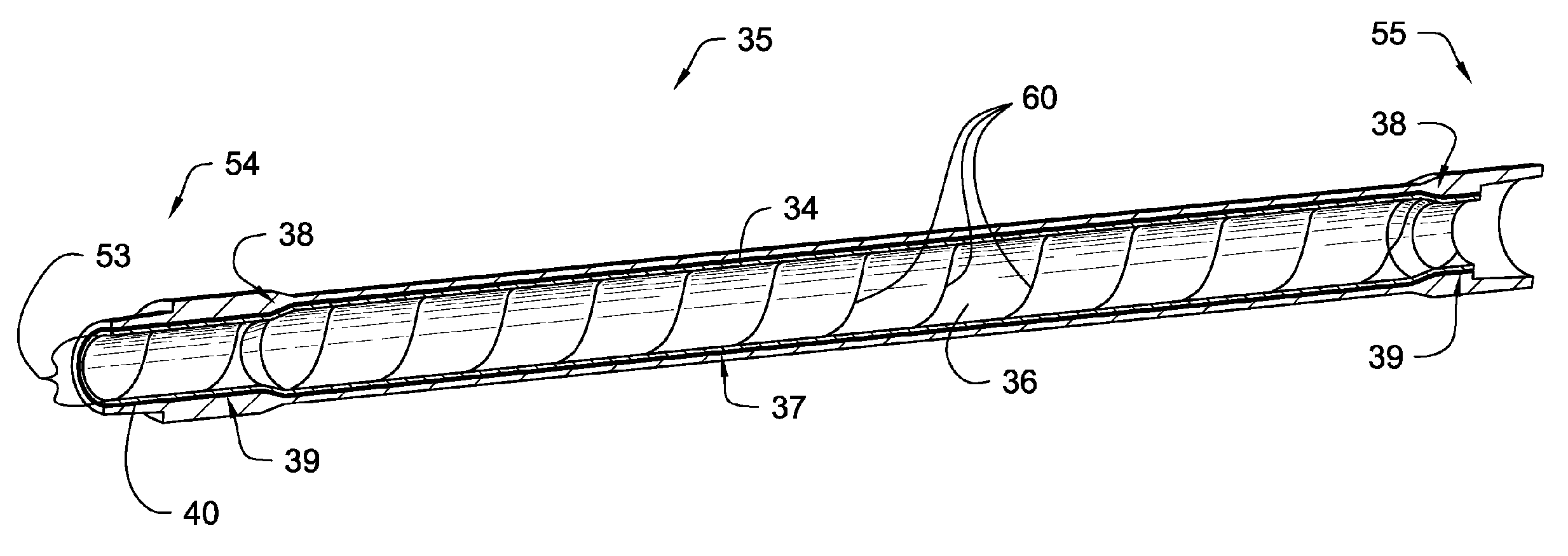

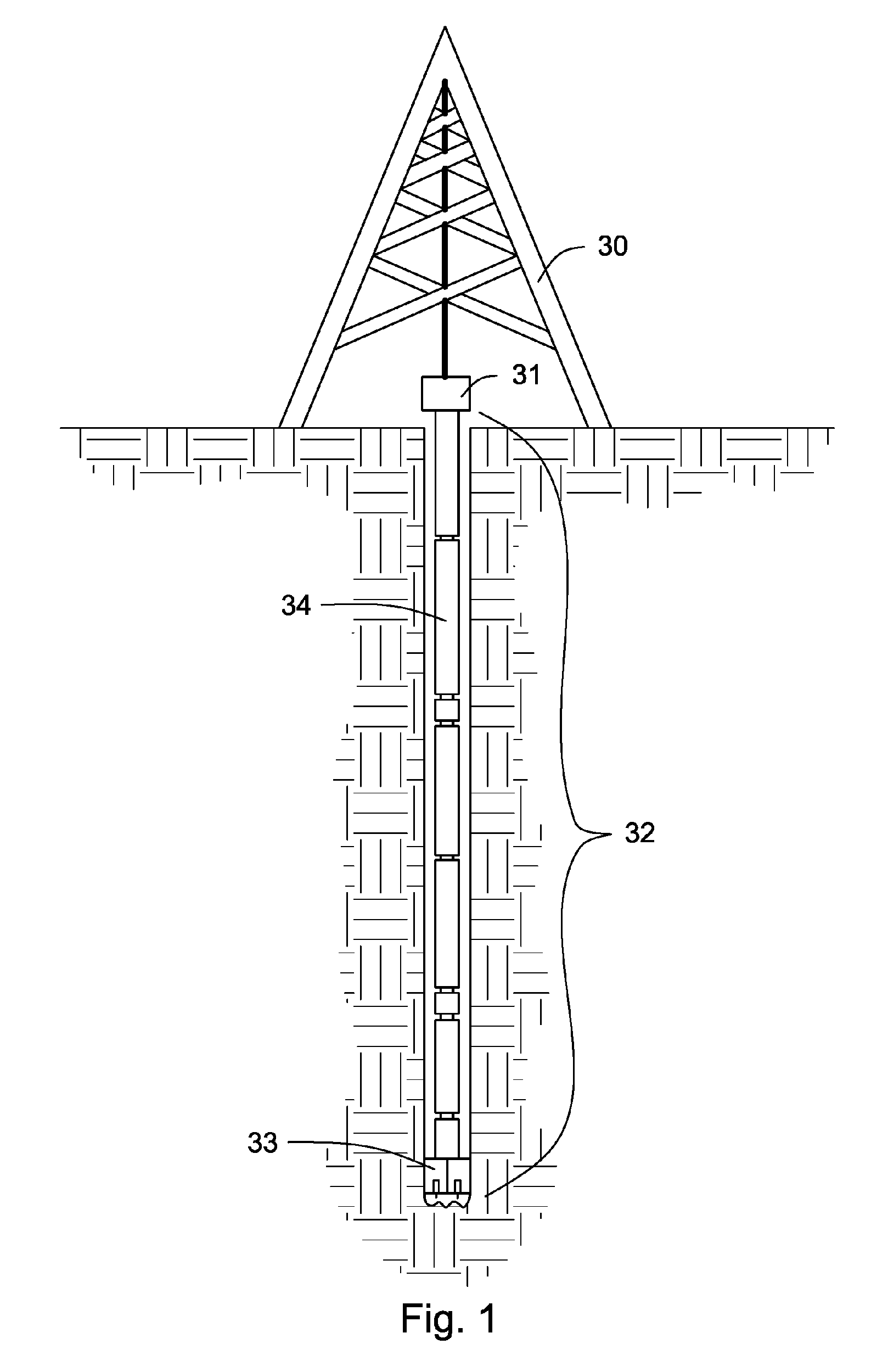

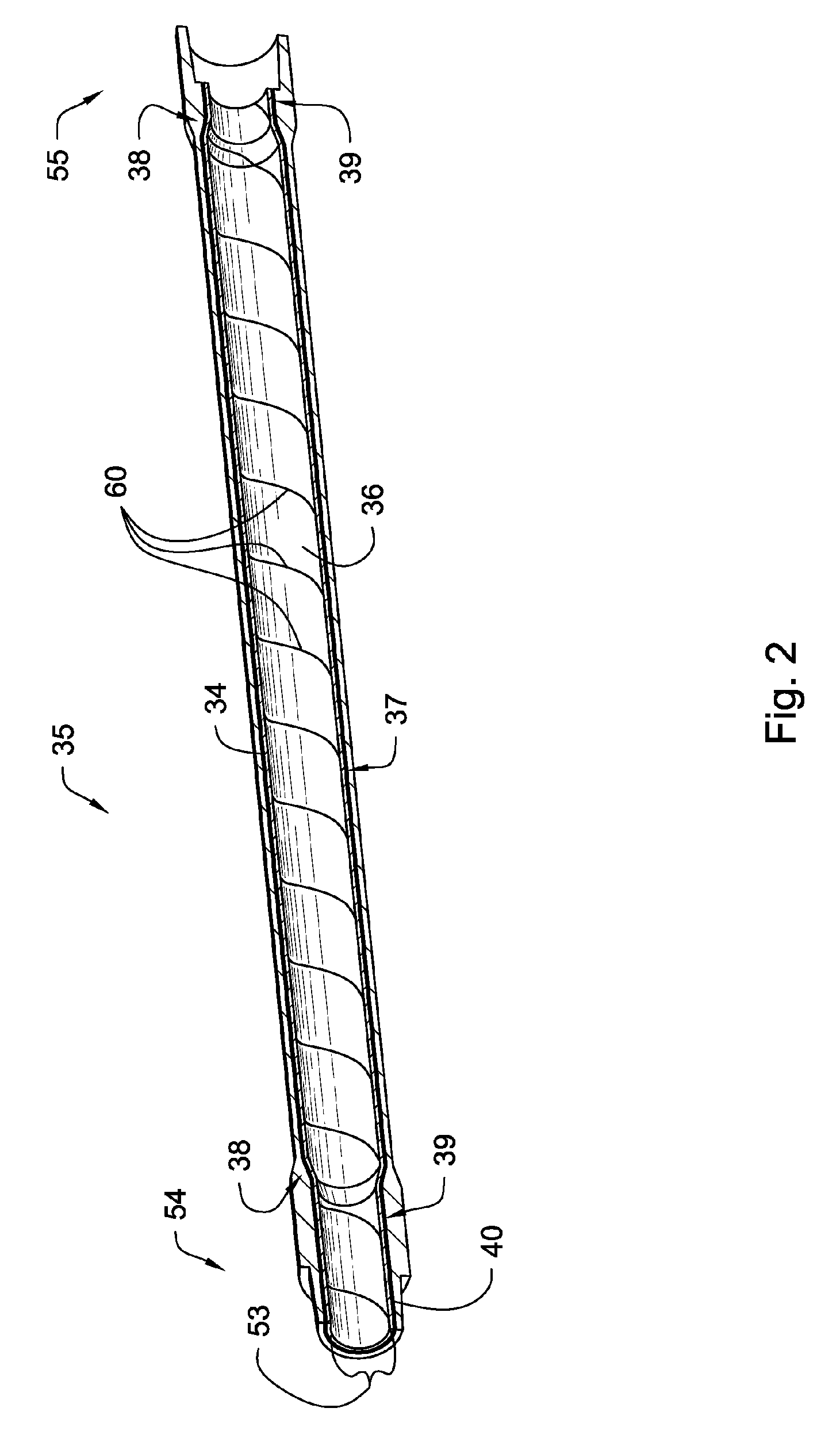

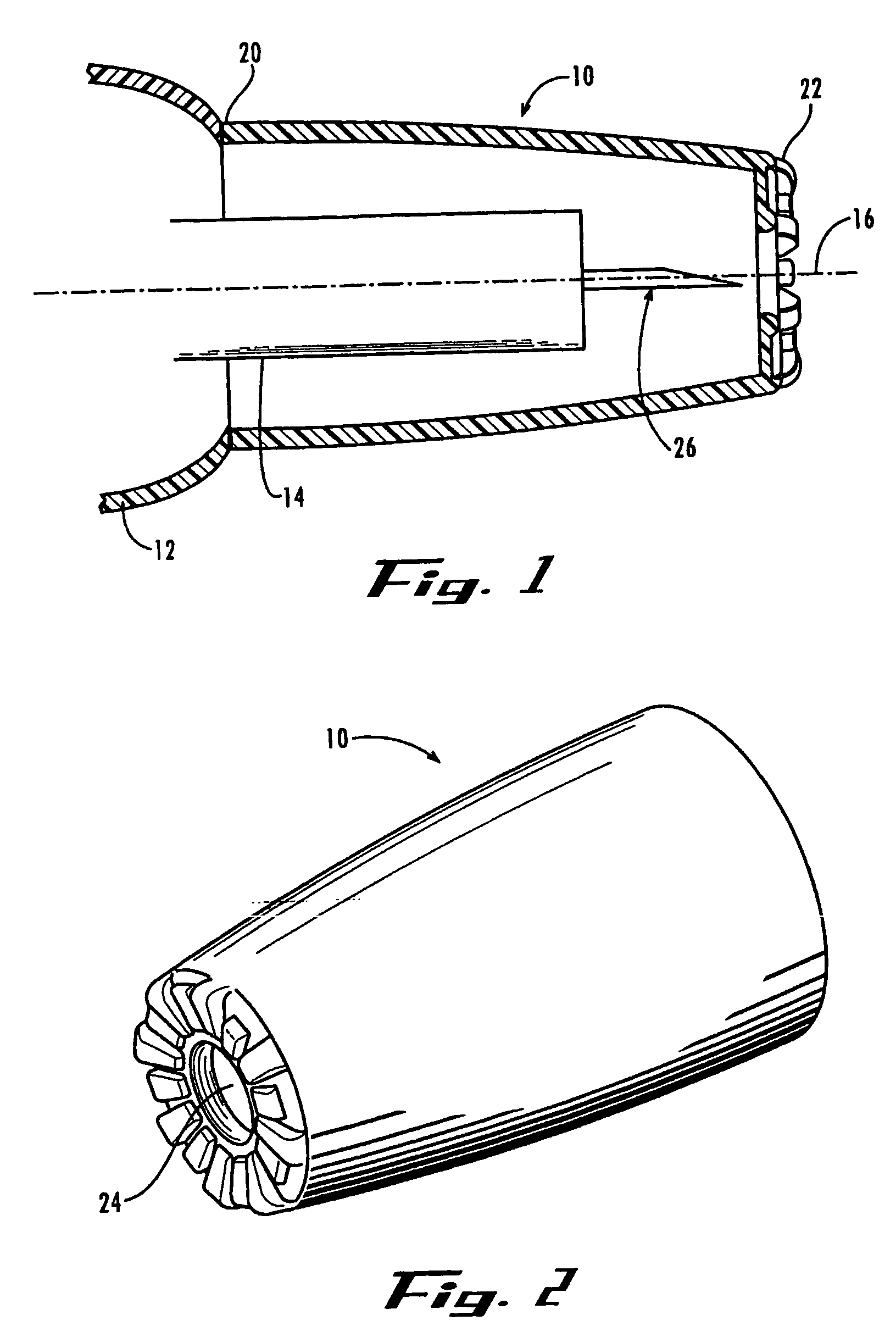

Conformable Apparatus in a Drill String

An apparatus in a drill string comprises an internally upset drill pipe. The drill pipe comprises a first end, a second end, and an elongate tube intermediate the first and second ends. The elongate tube and the ends comprising a continuous an inside surface with a plurality of diameters. A conformable metal tube is disposed within the drill pipe intermediate the ends thereof and terminating adjacent to the ends of the drill pipe. The conformable metal tube substantially conforms to the continuous inside surface of the metal tube. The metal tube may comprise a non-uniform section which is expanded to conform to the inside surface of the drill pipe. The non-uniform section may comprise protrusions selected from the group consisting of convolutions, corrugations, flutes, and dimples. The non-uniform section extends generally longitudinally along the length of the tube. The metal tube may be adapted to stretch as the drill pipes stretch.

Owner:INTELLISERV

Apparatus in a Drill String

InactiveUS20050082092A1High strengthIncrease profitDrilling rodsFluid removalCHEEK DIMPLESEngineering

An apparatus in a drill string comprises an internally upset drill pipe. The drill pipe comprises a first end, a second end, and an elongate tube intermediate the first and second ends. The elongate tube and the ends comprising a continuous an inside surface with a plurality of diameters. A conformable spirally welded metal tube is disposed within the drill pipe intermediate the ends thereof and terminating adjacent to the ends of the drill pipe. The conformable metal tube substantially conforms to the continuous inside surface of the metal tube. The metal tube may comprise a non-uniform section which is expanded to conform to the inside surface of the drill pipe. The non-uniform section may comprise protrusions selected from the group consisting of convolutions, corrugations, flutes, and dimples. The non-uniform section extends generally longitudinally along the length of the tube.

Owner:INTELLISERV

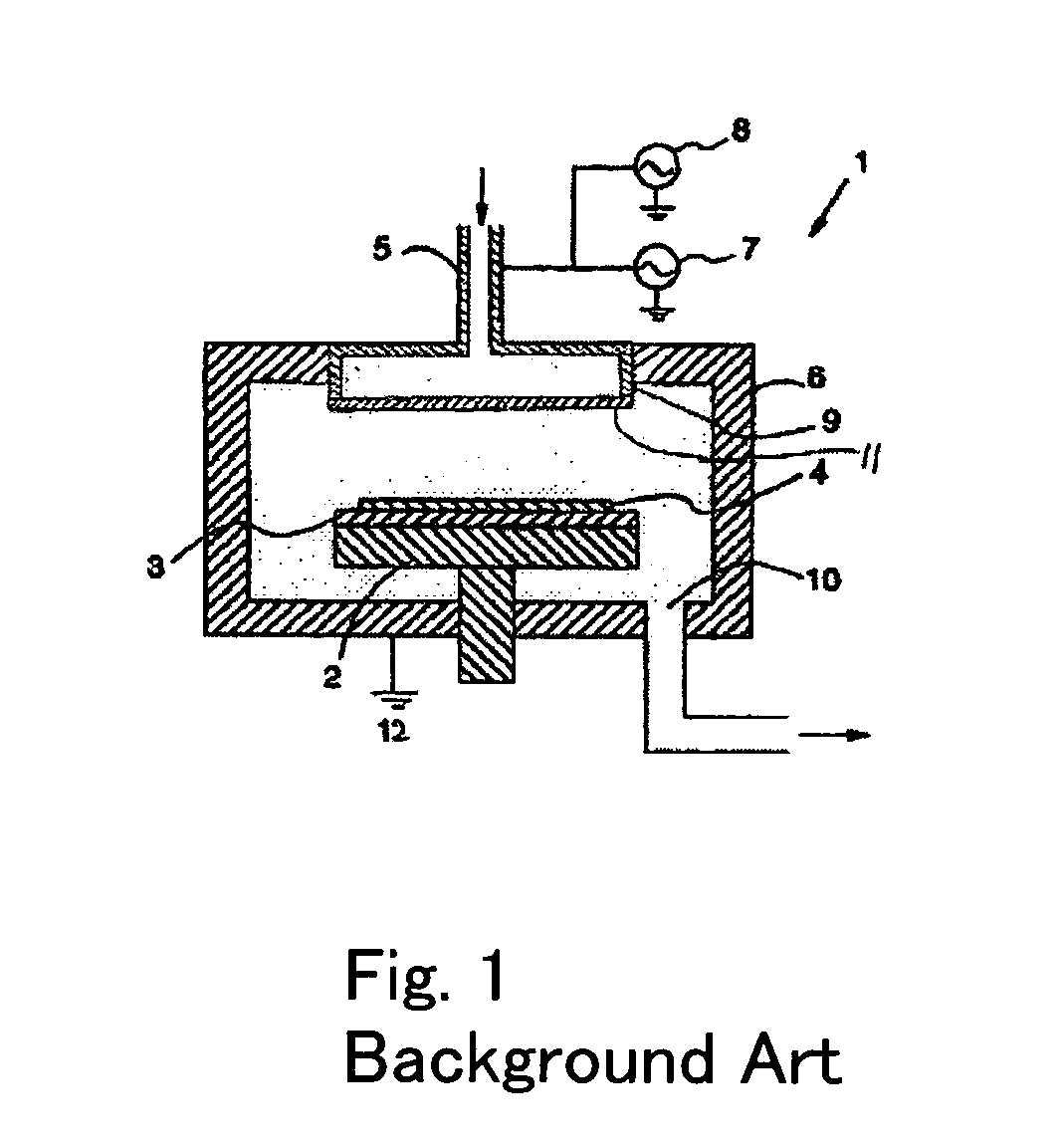

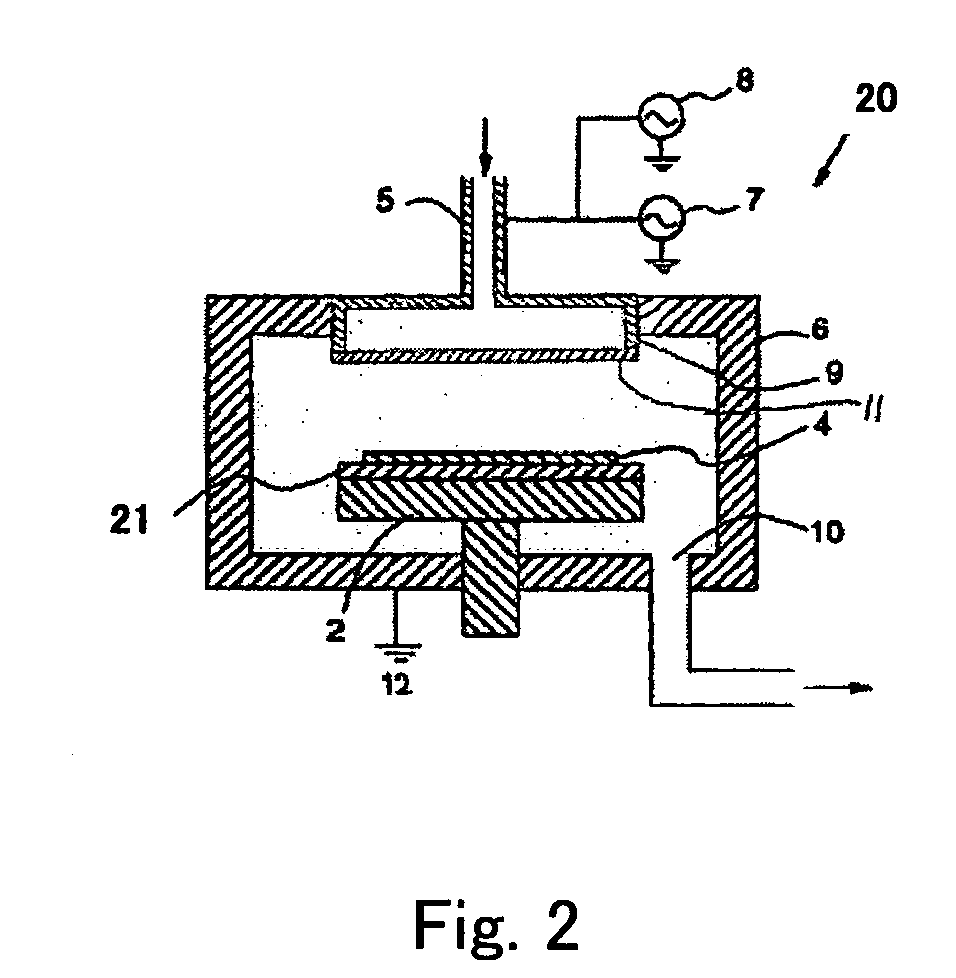

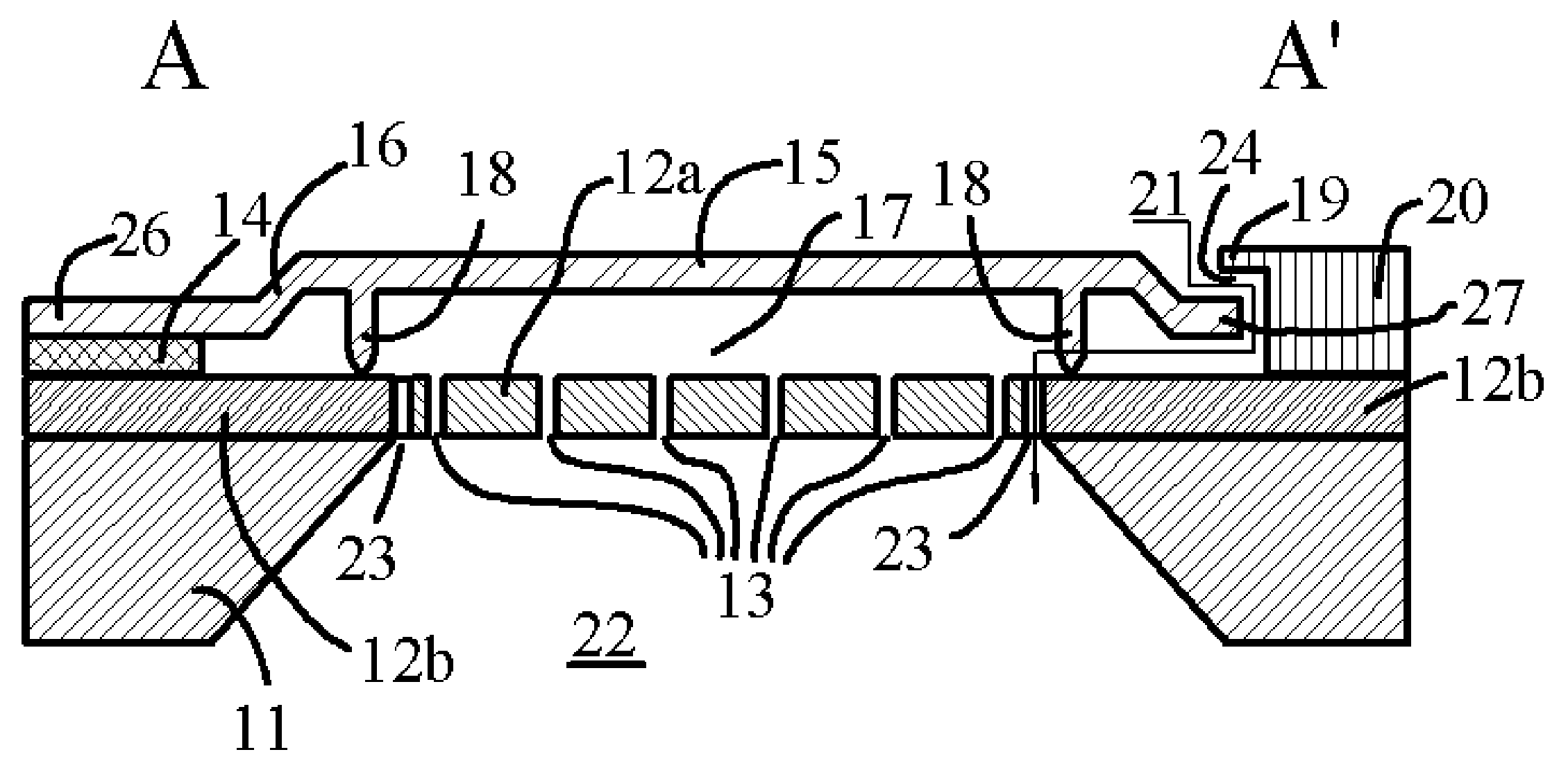

Micromachined Capacitive Microphone

InactiveUS20060280319A1Wide and flat frequency responseHigh sensitivitySemiconductor electrostatic transducersDeaf-aid setsElectrical conductorEngineering

This invention relates to a micromachined capacitive microphone having a shallowly corrugated diaphragm that is anchored at one or more locations on the support has a plurality of dimples to support itself and rest freely on the perforated backplate. The diaphragm whose ends are not anchored is bounded by the taps of edge rail. Also disclosed includes: a fixed perforated backplate having one or more regions; an adjustable cantilever formed by the diaphragm, the support and the backplate; a plurality of dimples maintaining vertical separation between diaphragm and backplate; and the patterning of conductor electrodes carried by diaphragm and backplate.

Owner:GENERAL MEMS CORP

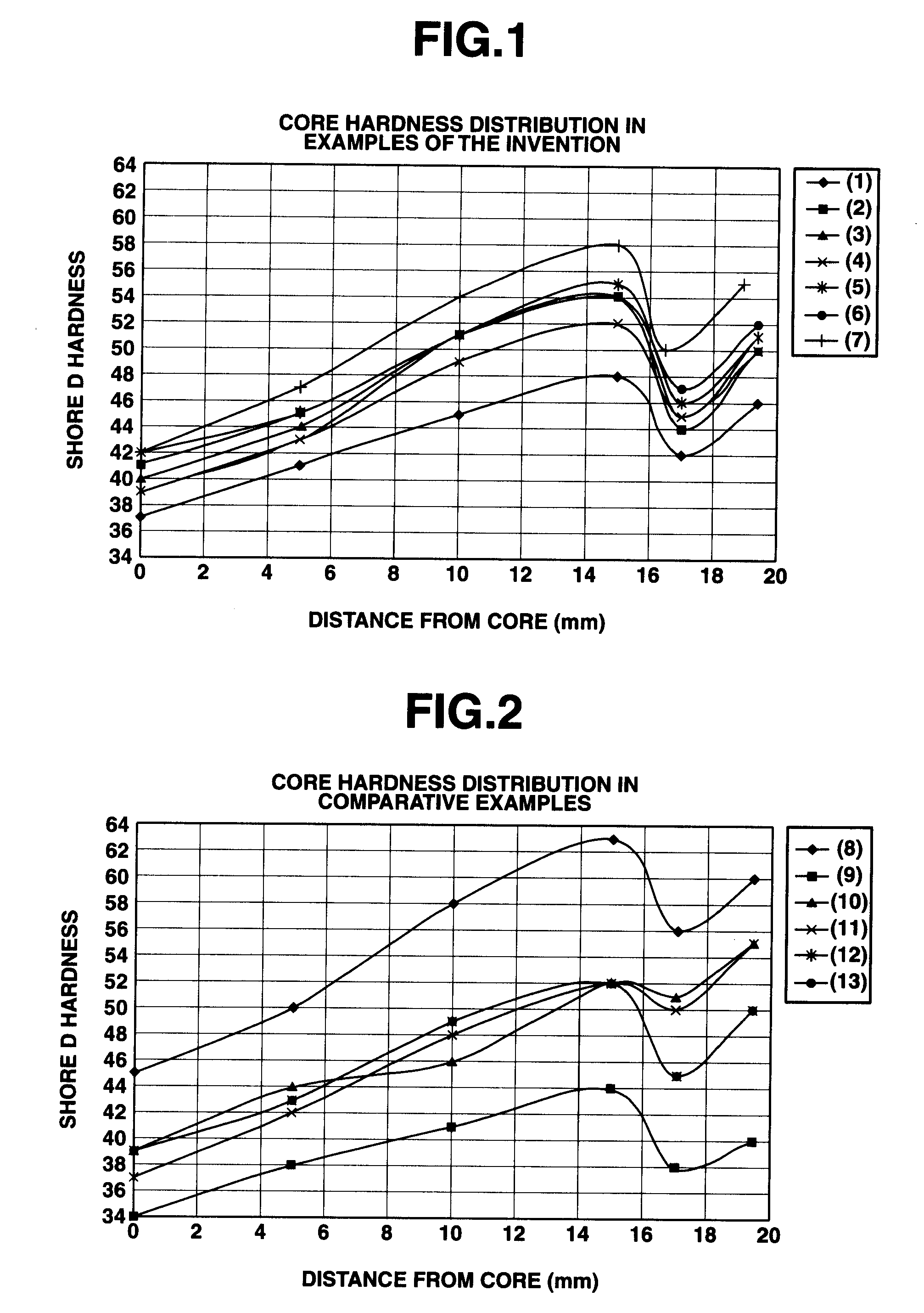

Solid golf ball

InactiveUS20080194357A1Improve spin performanceIncrease distanceGolf ballsSolid ballsThermoplasticPolymer science

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, and an inorganic filler. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a thermoplastic or thermoset polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

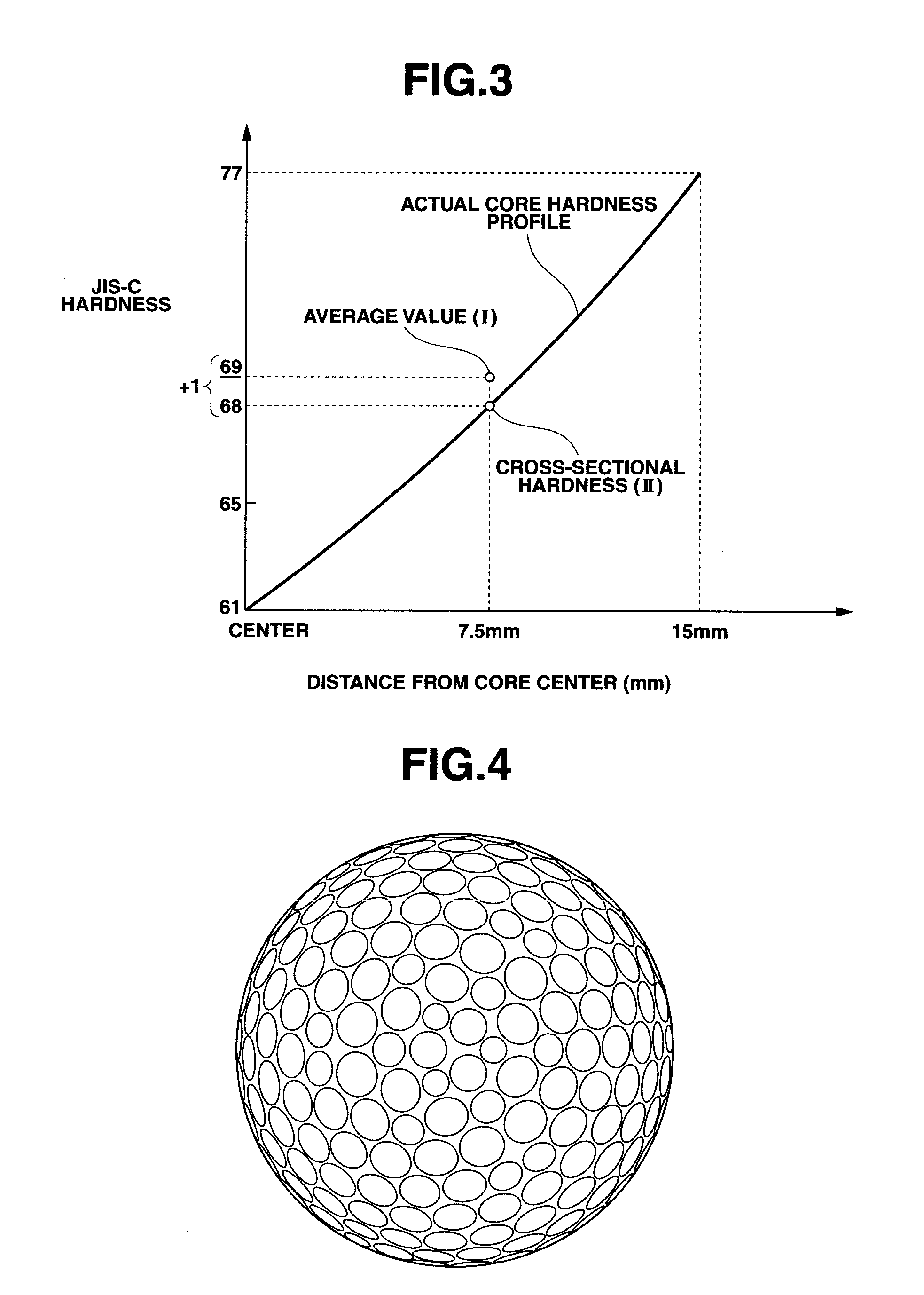

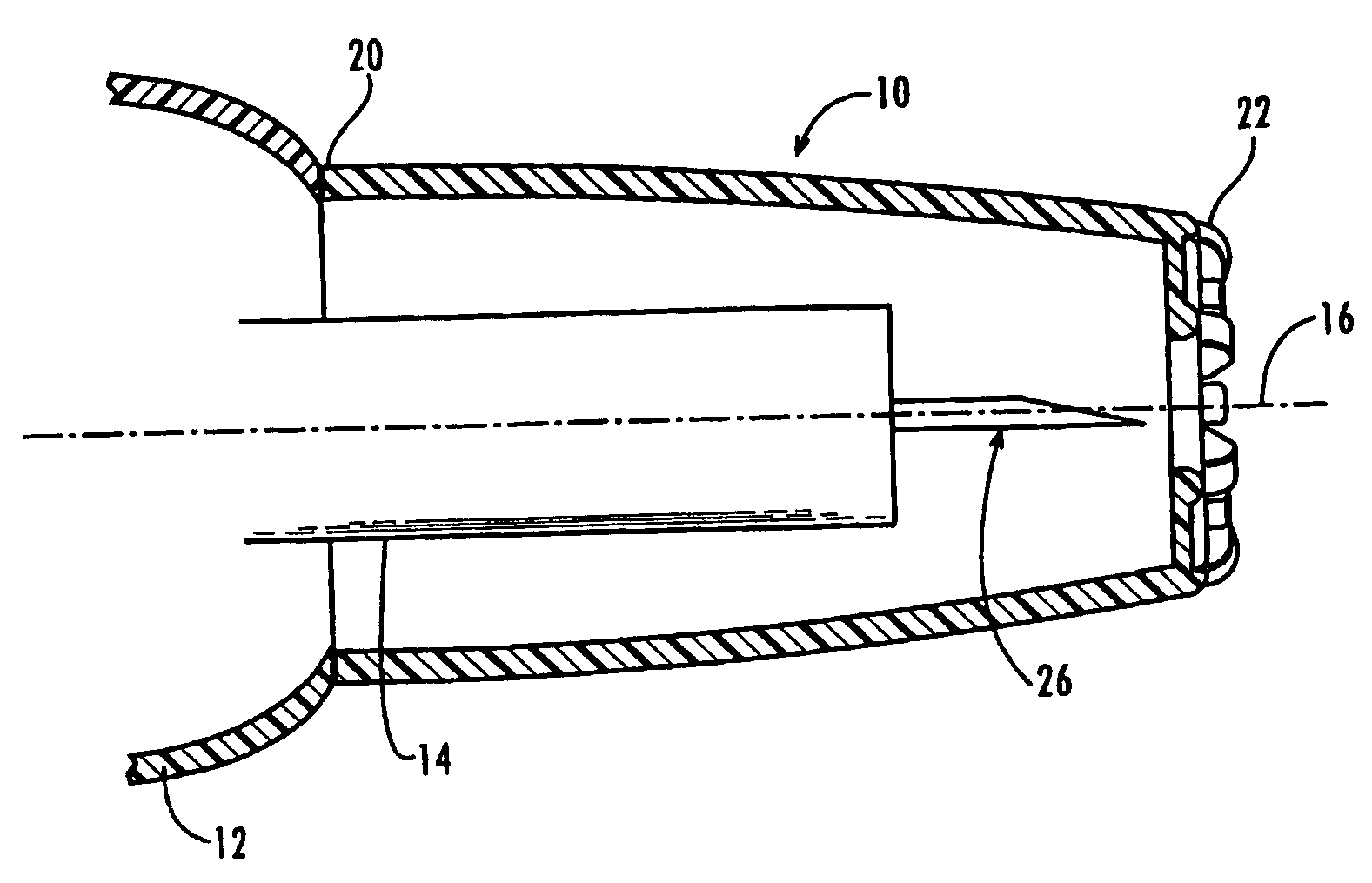

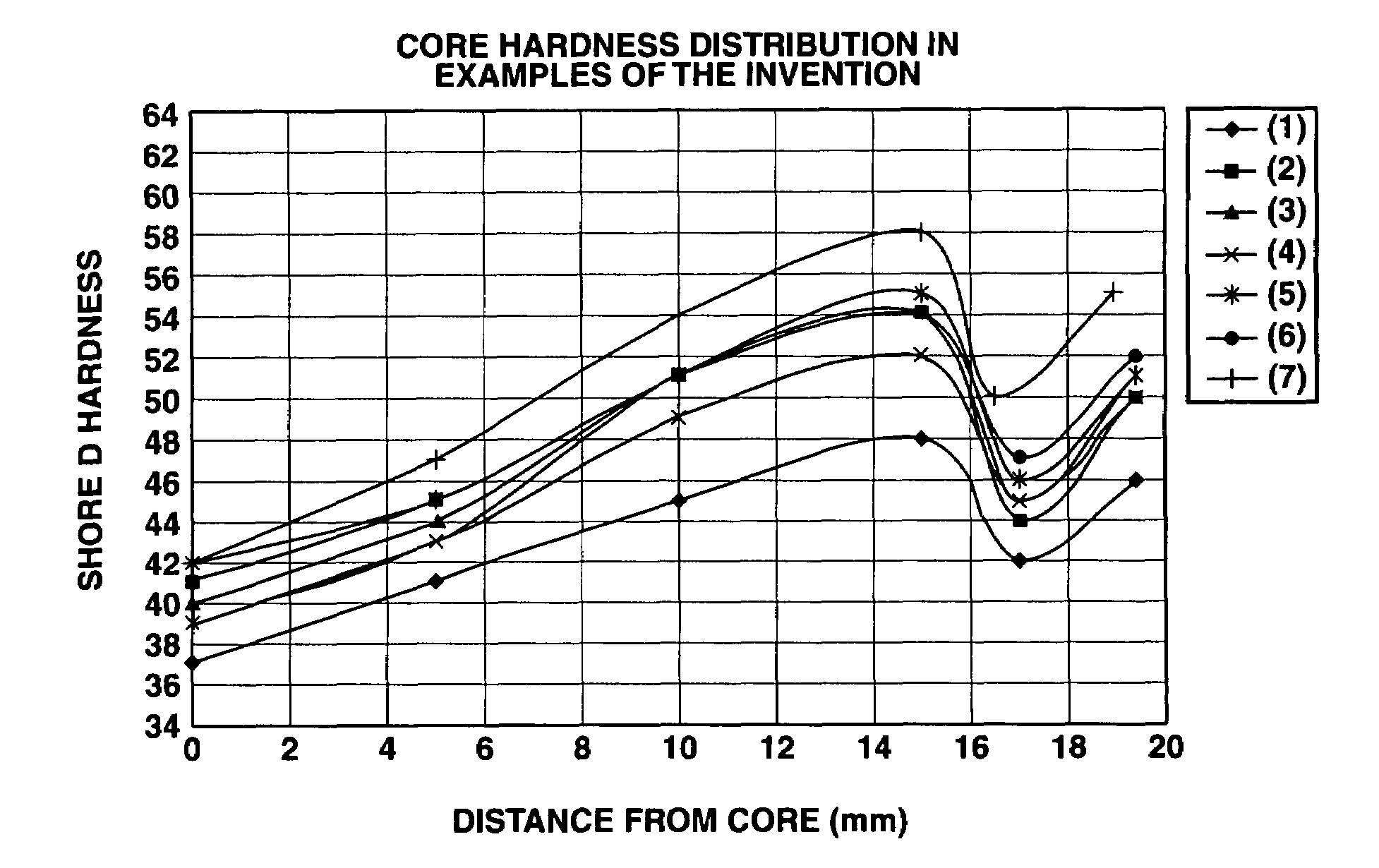

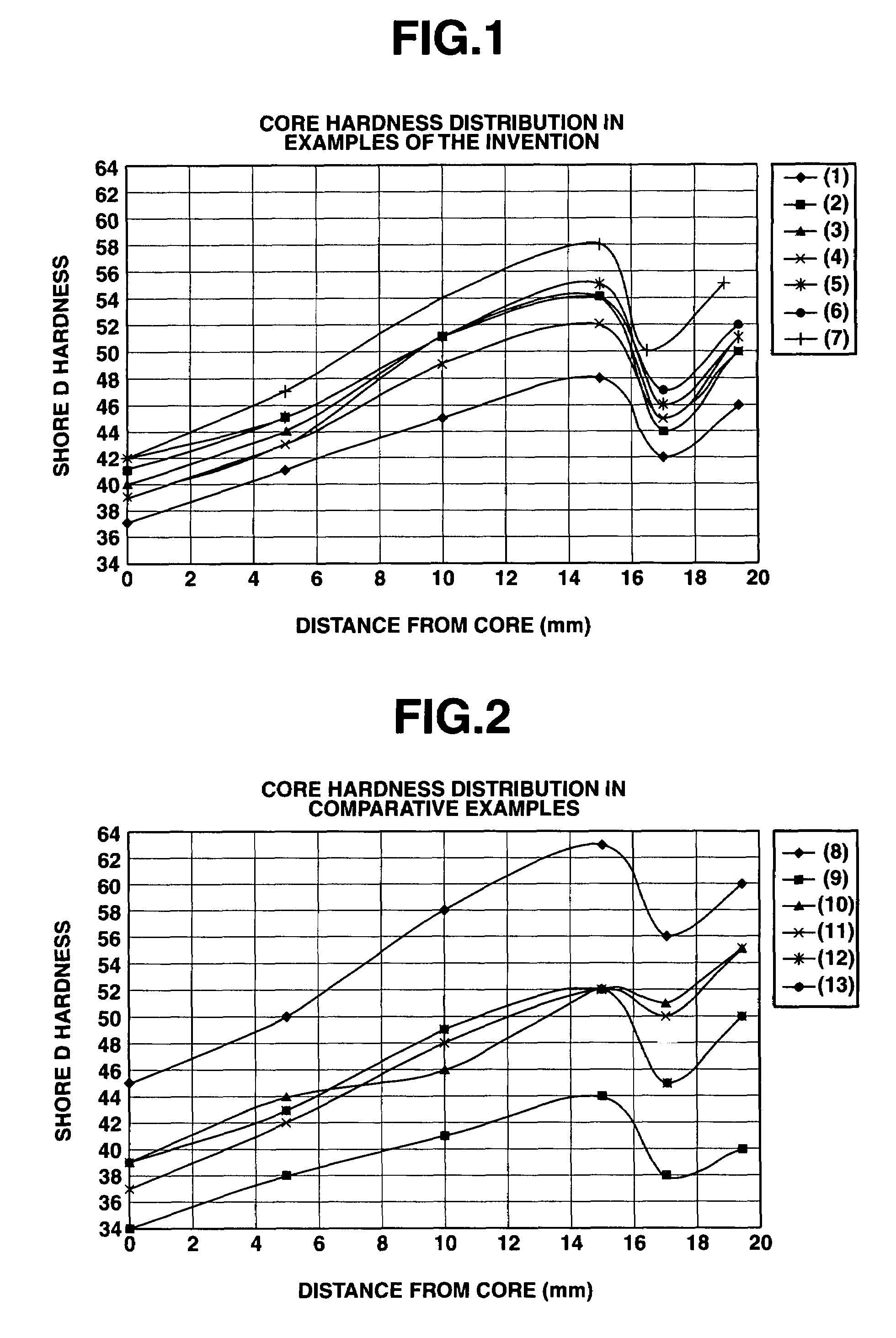

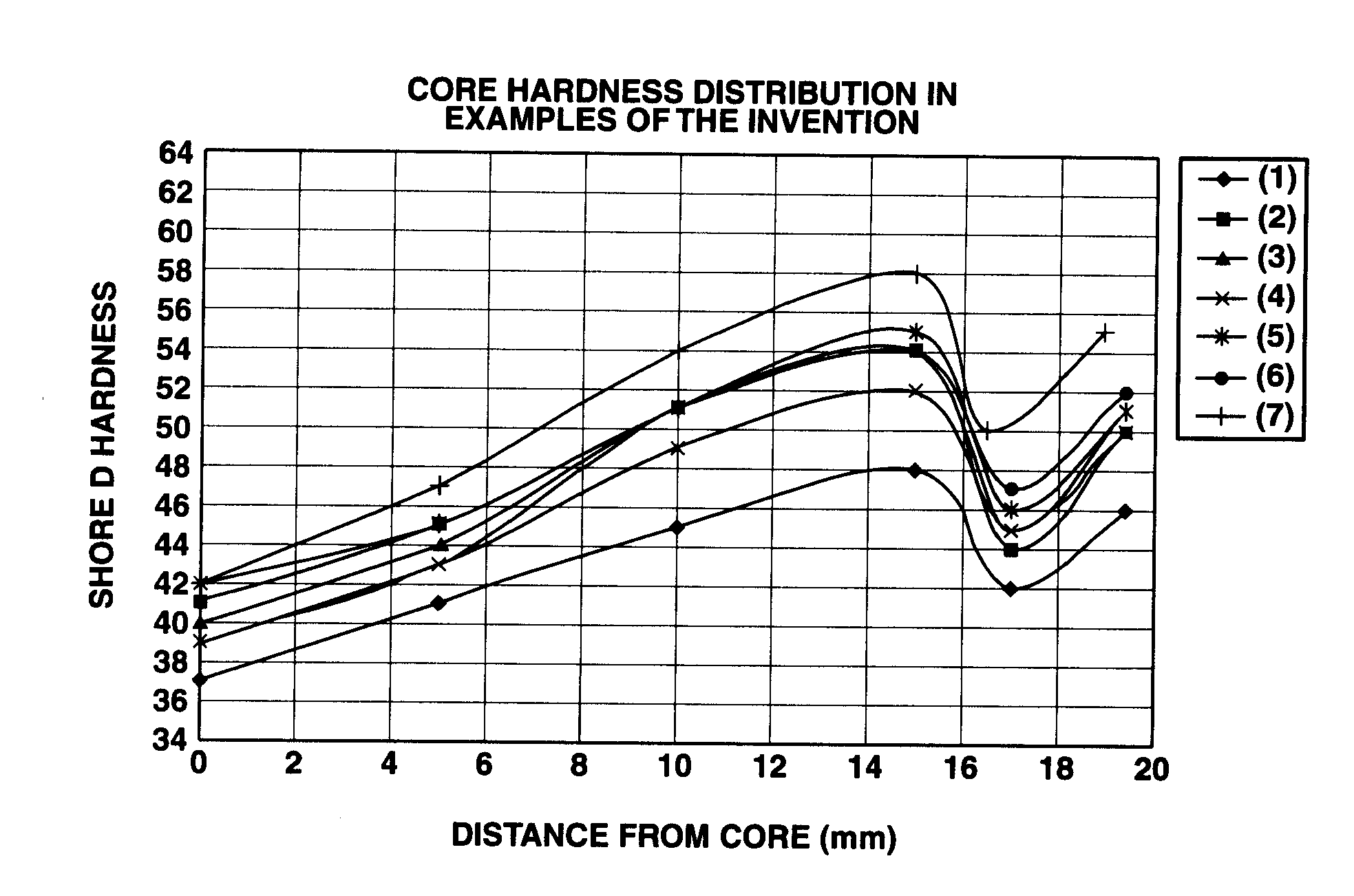

Multi-piece solid golf ball

ActiveUS20100273575A1Reduce speedImprove wear resistanceGolf ballsSolid ballsRubber materialInter layer

The present invention provides a multi-piece solid golf ball having a core, an envelope layer encasing the core, an intermediate layer encasing the envelope layer, and a cover which encases the intermediate layer and has formed on a surface thereof a plurality of dimples. The core is formed primarily of a rubber material and has a hardness which gradually increases from a center to a surface thereof, the hardness difference in JIS-C hardness units between the core center and the core surface being at least 15 and, letting (I) be the average value for cross-sectional hardnesses at a position about 15 mm from the core center and at the core center and letting (II) be the cross-sectional hardness at a position about 7.5 mm from the core center, the hardness difference (I)−(II) in JIS-C units being not more than ±2. The envelope layer, intermediate layer and cover have hardnesses which satisfy the condition:cover hardness>intermediate layer hardness>envelope layer hardness.The golf ball of the invention has an improved distance, and also has an excellent durability to cracking on repeated impact and an excellent scuff resistance.

Owner:BRIDGESTONE SPORTS

Endcap for a fluid sampling device

InactiveUS20060287664A1Blood volume expansionEnhances sample collectionSensorsBlood sampling devicesBiomedical engineeringPlasma viscosity

An endcap for a lancing device having an opening formed therein for passing a lancet tip, and a contact face surrounding the opening, with at least one spaced rib, dimple or projection thereon. In various embodiments, multiple ribs are spaced around the opening in a helical, circular or radial array. The contact face can be planar, concave or convex. The endcap increases the surface area in contact with the skin around the sampling site to enhance blood flow and prevent premature wound closure during sample collection.

Owner:FACET TECH LLC

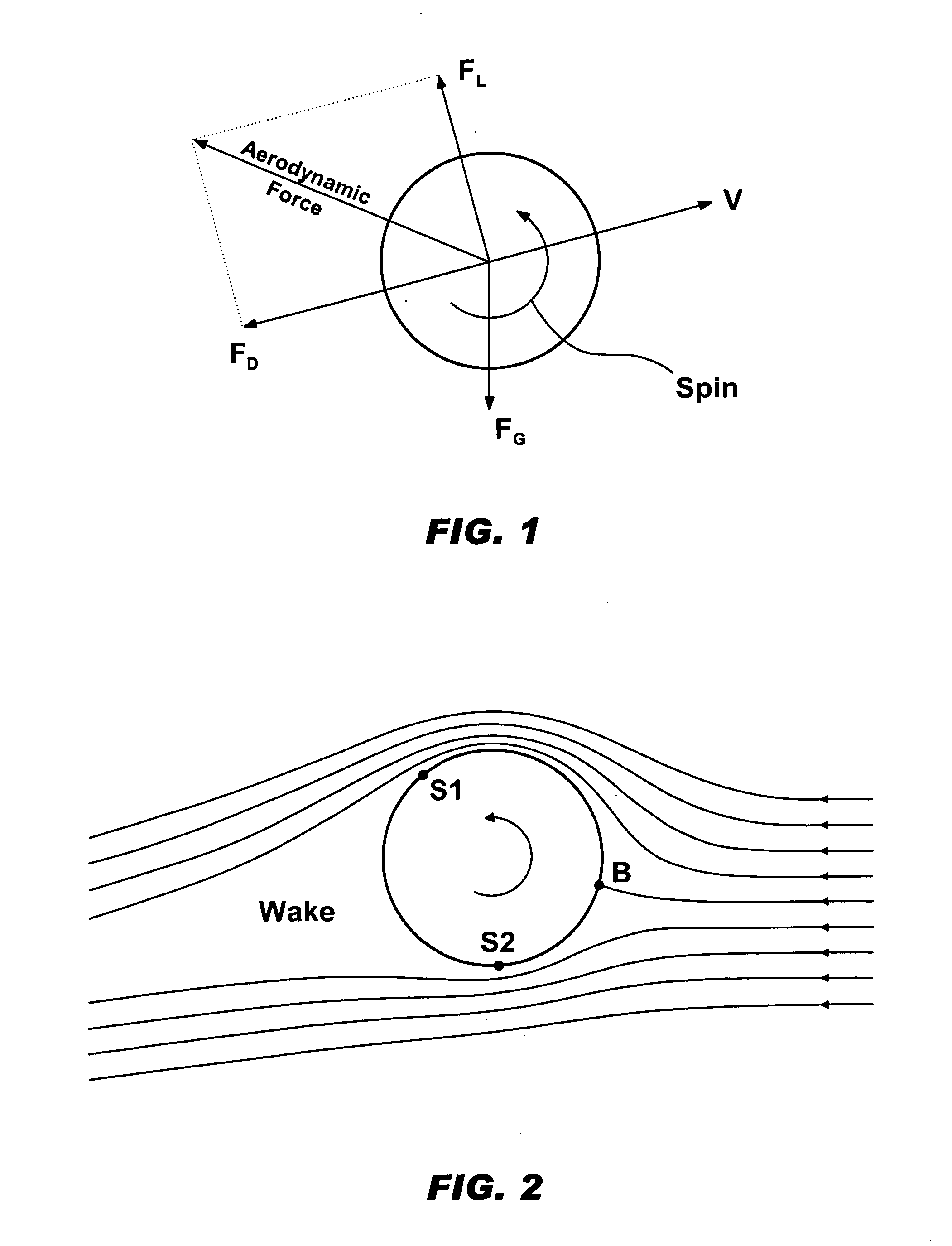

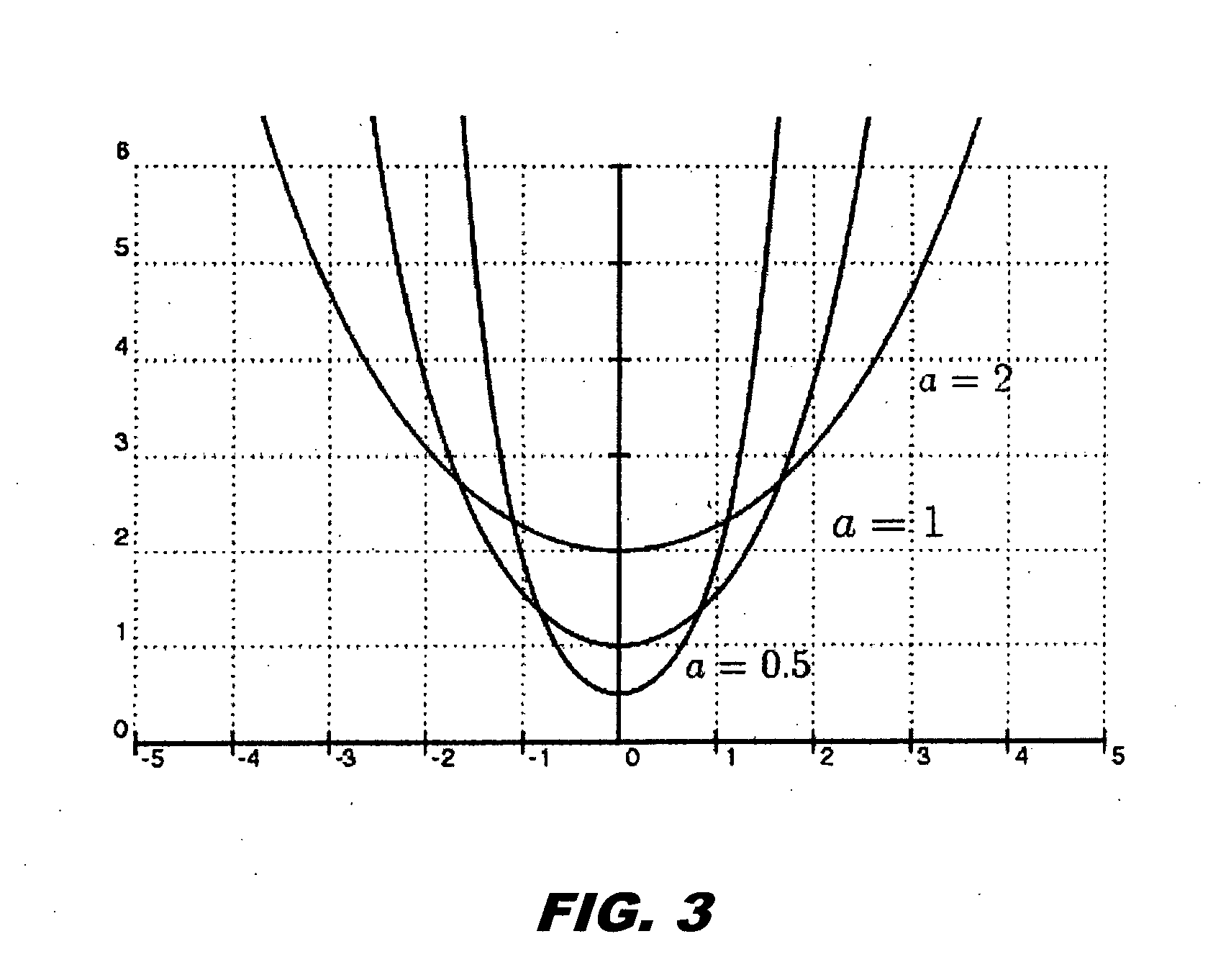

Golf ball dimples with a catenary curve profile

A golf ball having an outside surface with a plurality of dimples formed thereon. The dimples on the ball have a cross-sectional profiles formed by a catenary curve. Combinations of varying dimple diameters, shape factors, and chordal depths in the catenary curve are used to vary the ball flight performance according to ball spin characteristics, player swing speed, as well as satisfy specific aerodynamic magnitude and direction criteria.

Owner:ACUSHNET CO

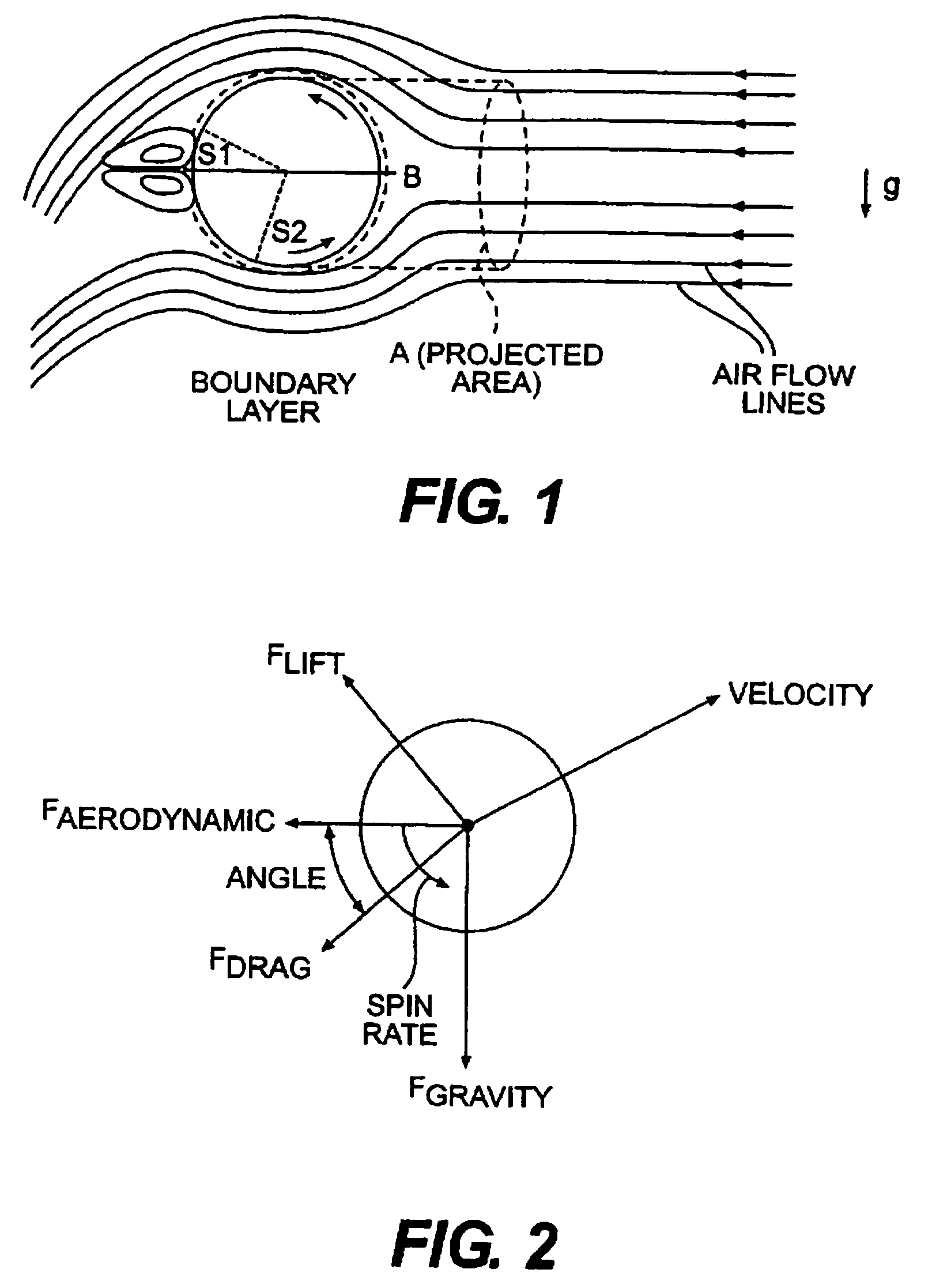

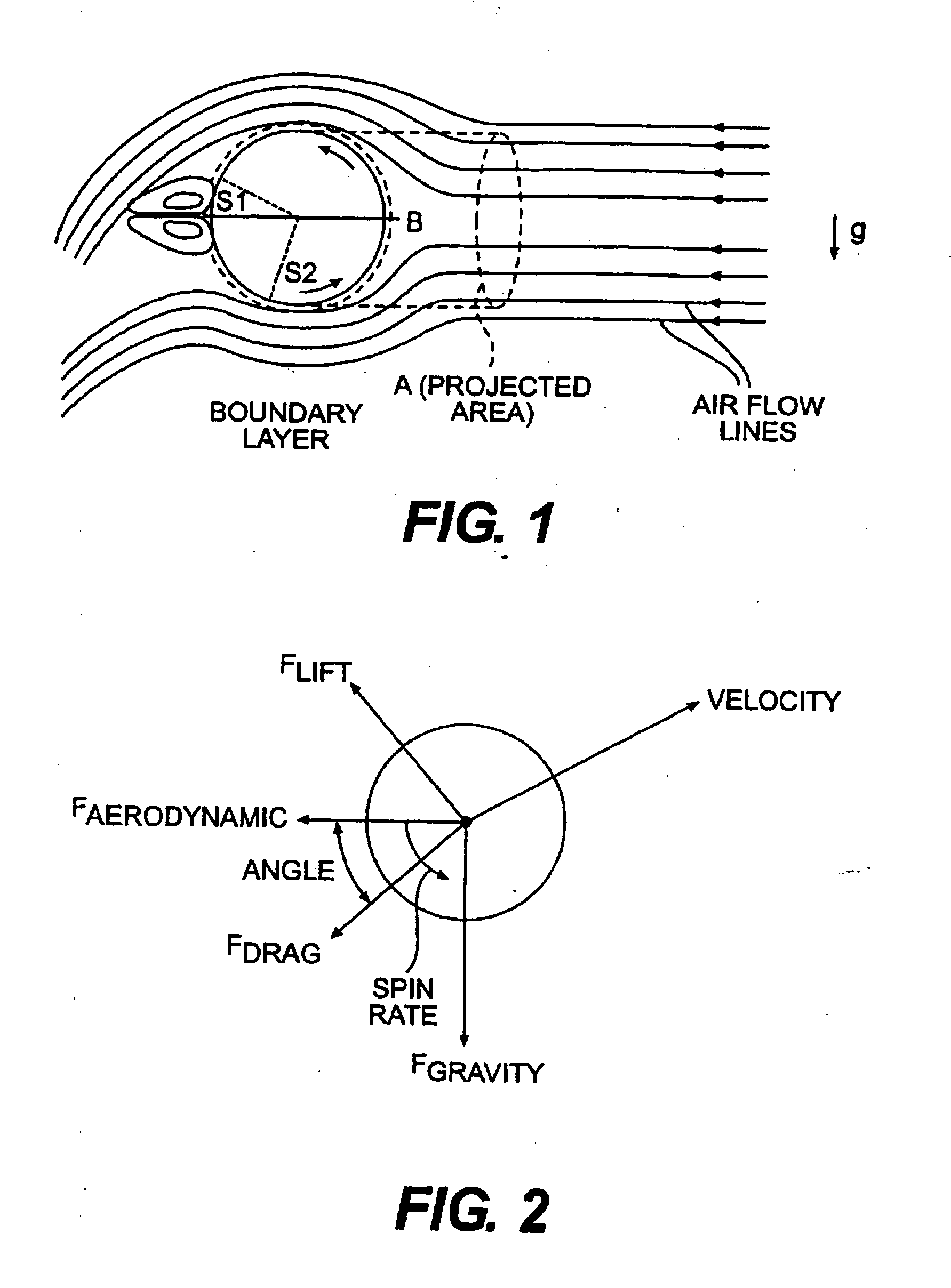

High performance golf ball having a reduced-distance

A high performance golf ball having a reduced overall distance while maintaining the appearance of a high performance trajectory. The golf ball includes a combination of low CoR core and cover materials coupled with a less aerodynamic dimple pattern that achieves a reduction in carry and overall distance of 15 and 25 yards versus a conventional golf ball, while still providing the look, sound, feel and apparent flight of a conventional golf ball. A high performance golf ball having a reduced distance is also achieved by controlling dimensionless coefficients of lift / weight and drag / weight at certain Reynolds numbers and spin ratios for various CoR.

Owner:ACUSHNET CO

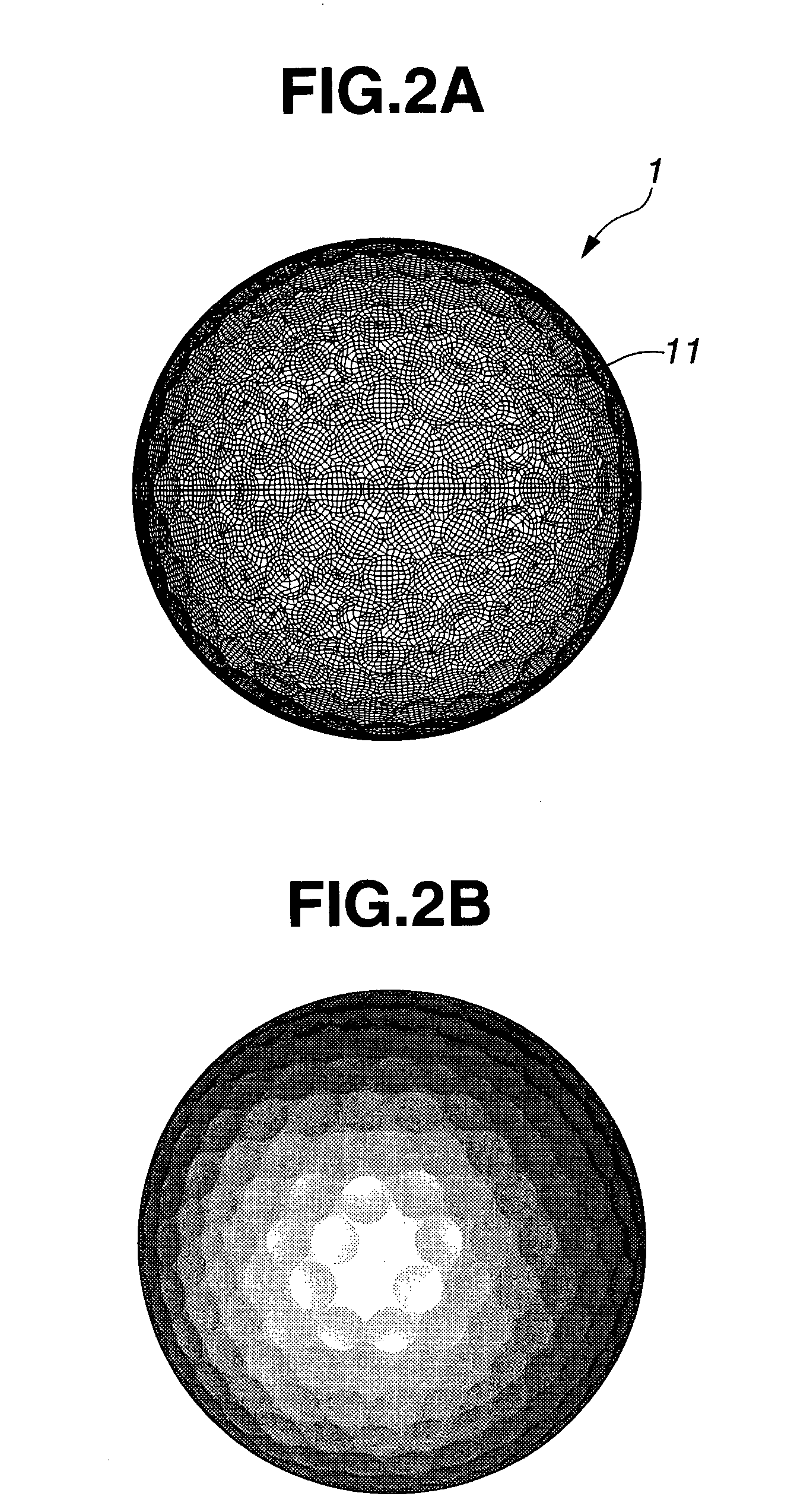

Ballistic trajectory simulation method and flight simulation method for golf ball

InactiveUS20070010342A1Efficient developmentShorten the timeAerodynamic testingDesign optimisation/simulationEngineeringGolf Ball

A ballistic trajectory method for a golf ball is disclosed wherein a ballistic trajectory of a golf ball having a plurality of dimples formed on the surface thereof when the golf ball is hit to fly at an arbitrary number of rotations and an arbitrary initial speed can be estimated and ballistic trajectory and flight characteristics of the golf ball can be evaluated without depending upon experimental evaluation which is based on an actual model thereby to allow a golf ball to be developed efficiently. The ballistic trajectory of the golf ball when the golf ball is hit to fly is estimated by successively calculating the flight distance and the height of the ball after every lapse of a very short period of time after the ball is hit to fly until it drops to the ground making use of arithmetic operation by a computer.

Owner:BRIDGESTONE SPORTS

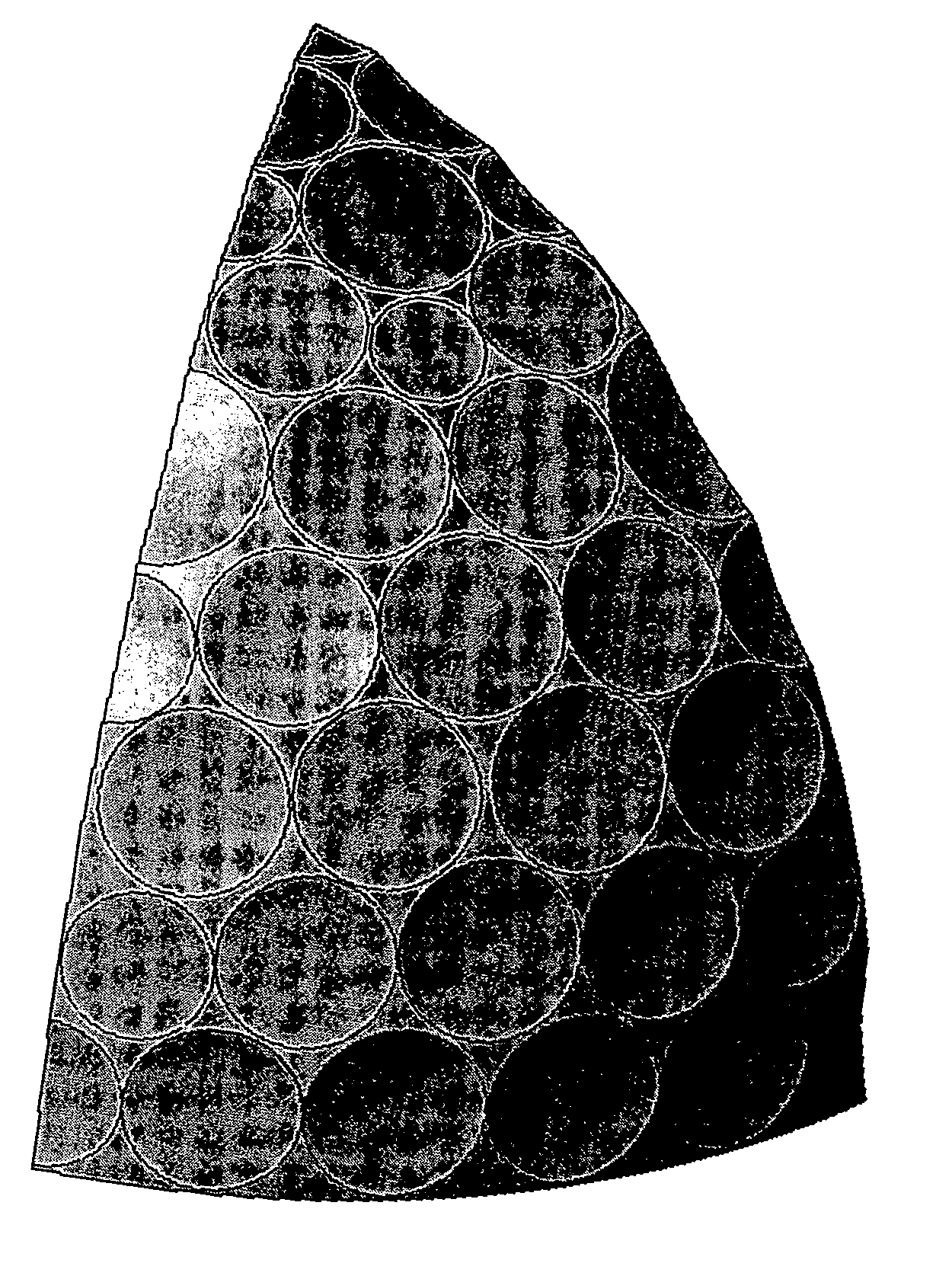

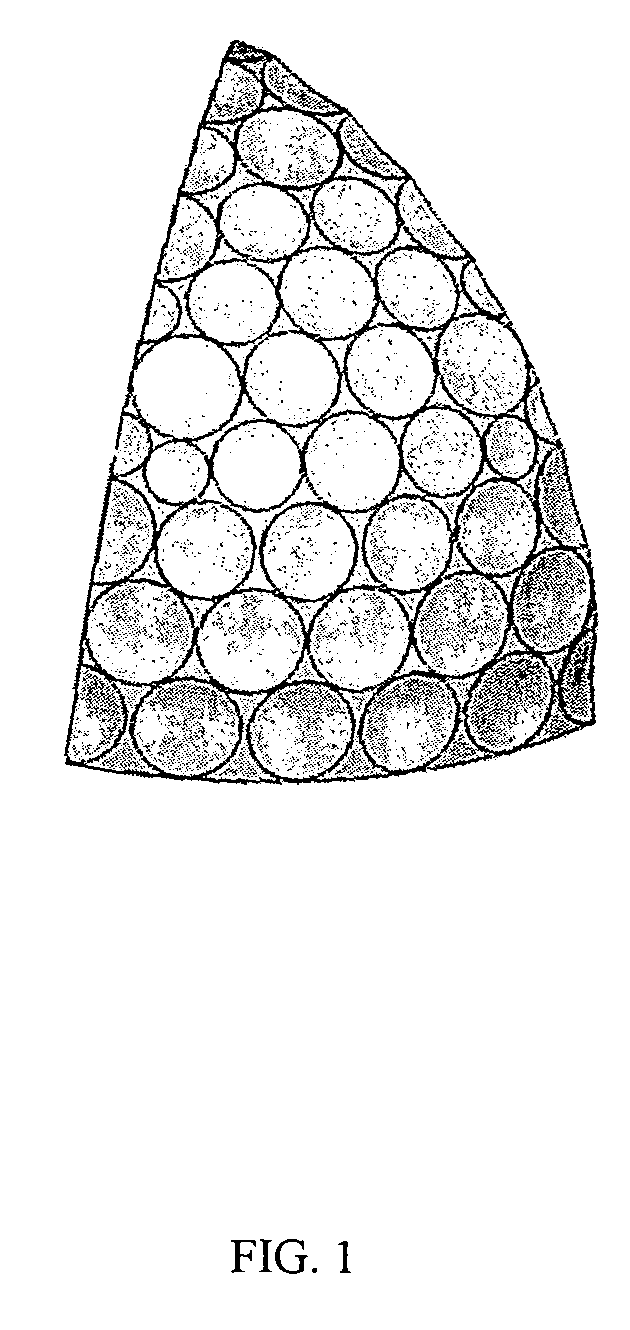

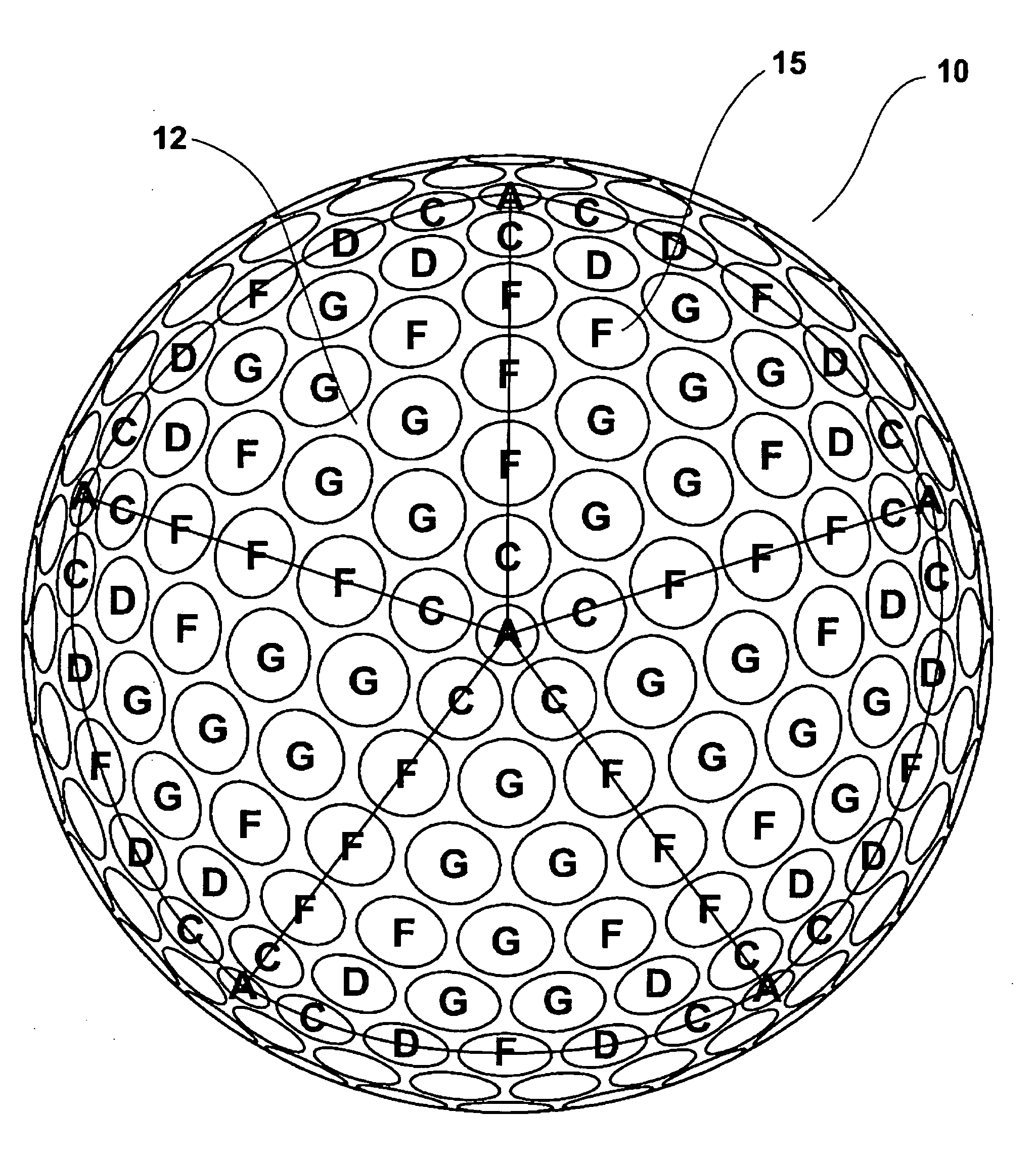

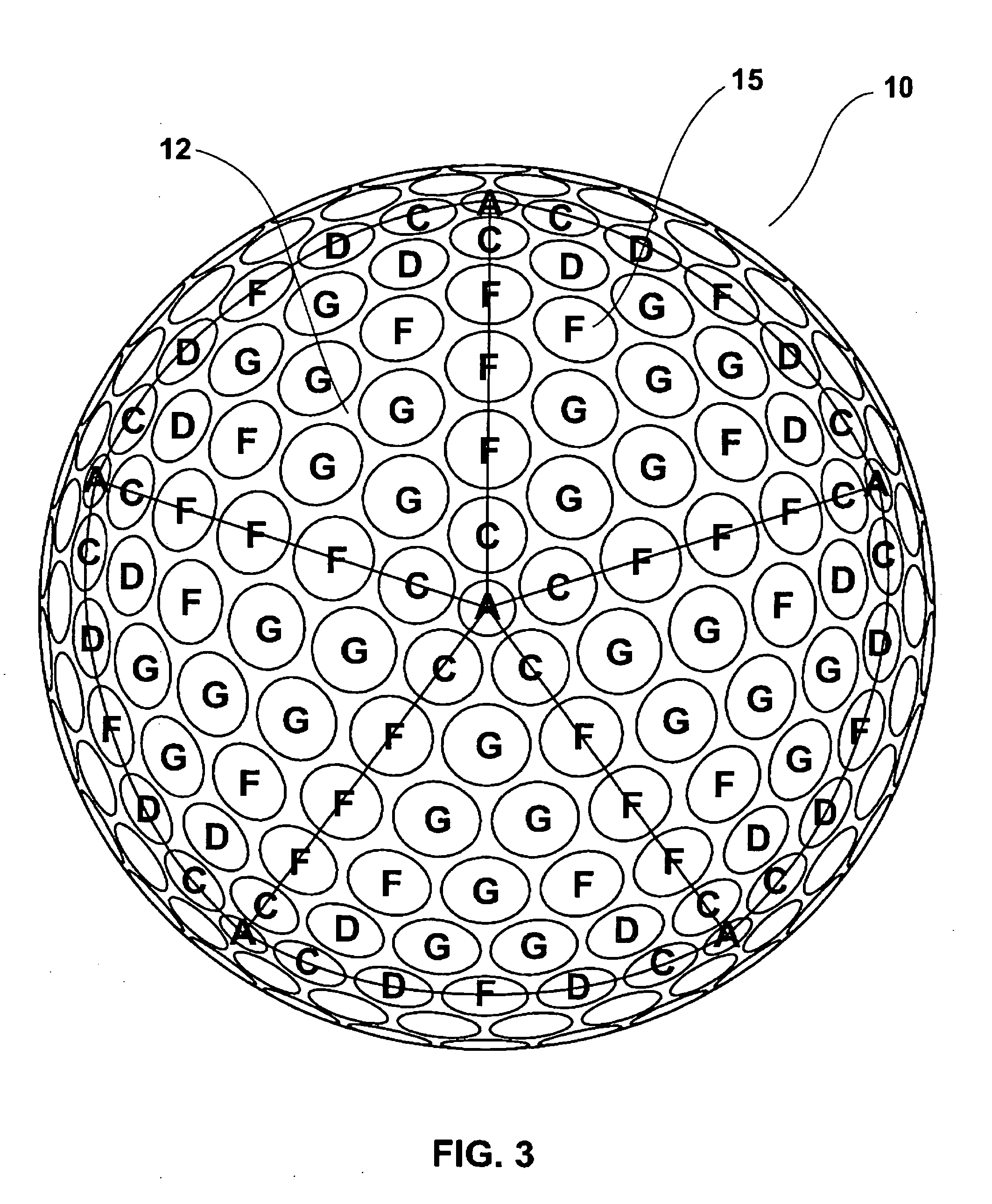

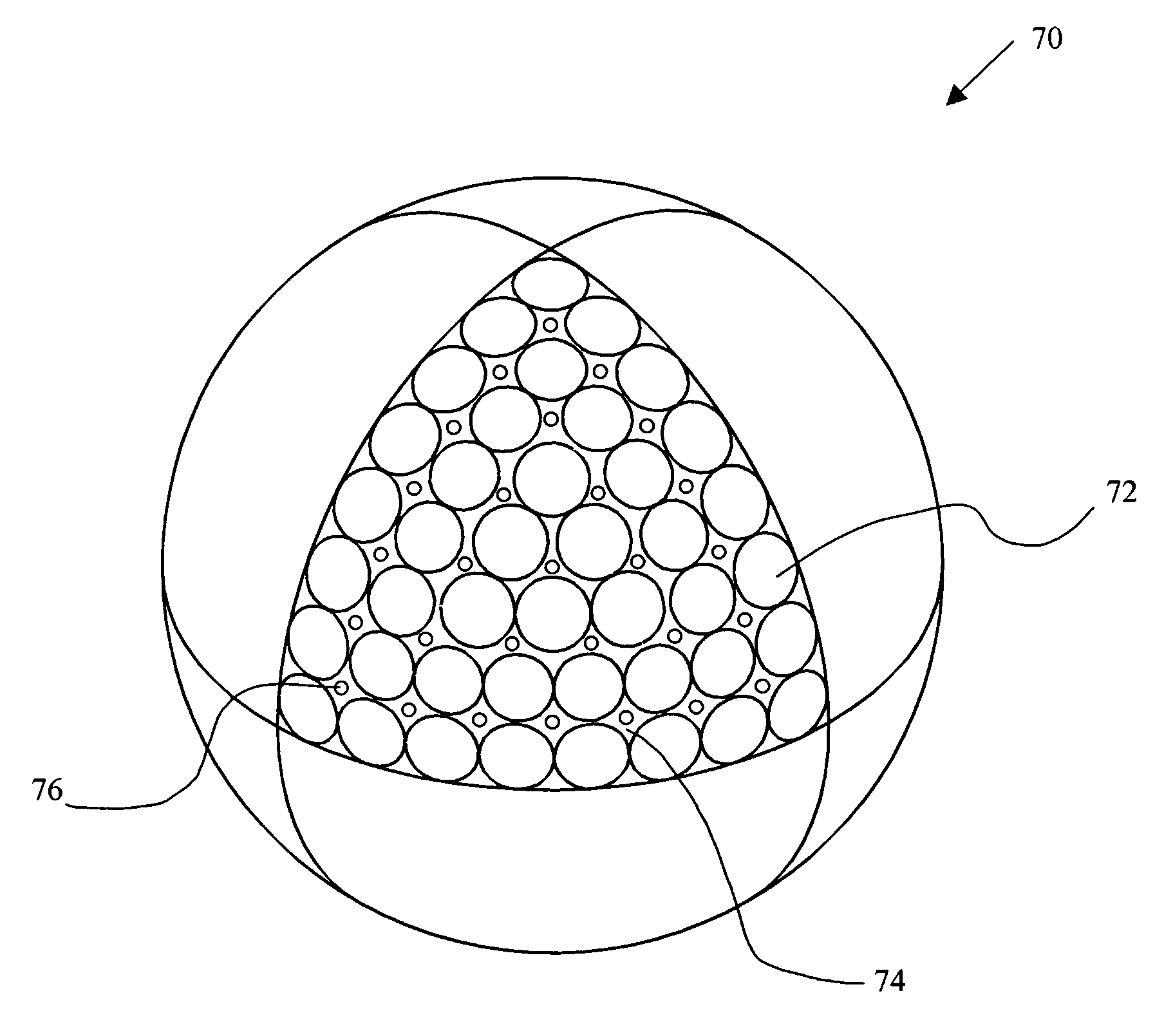

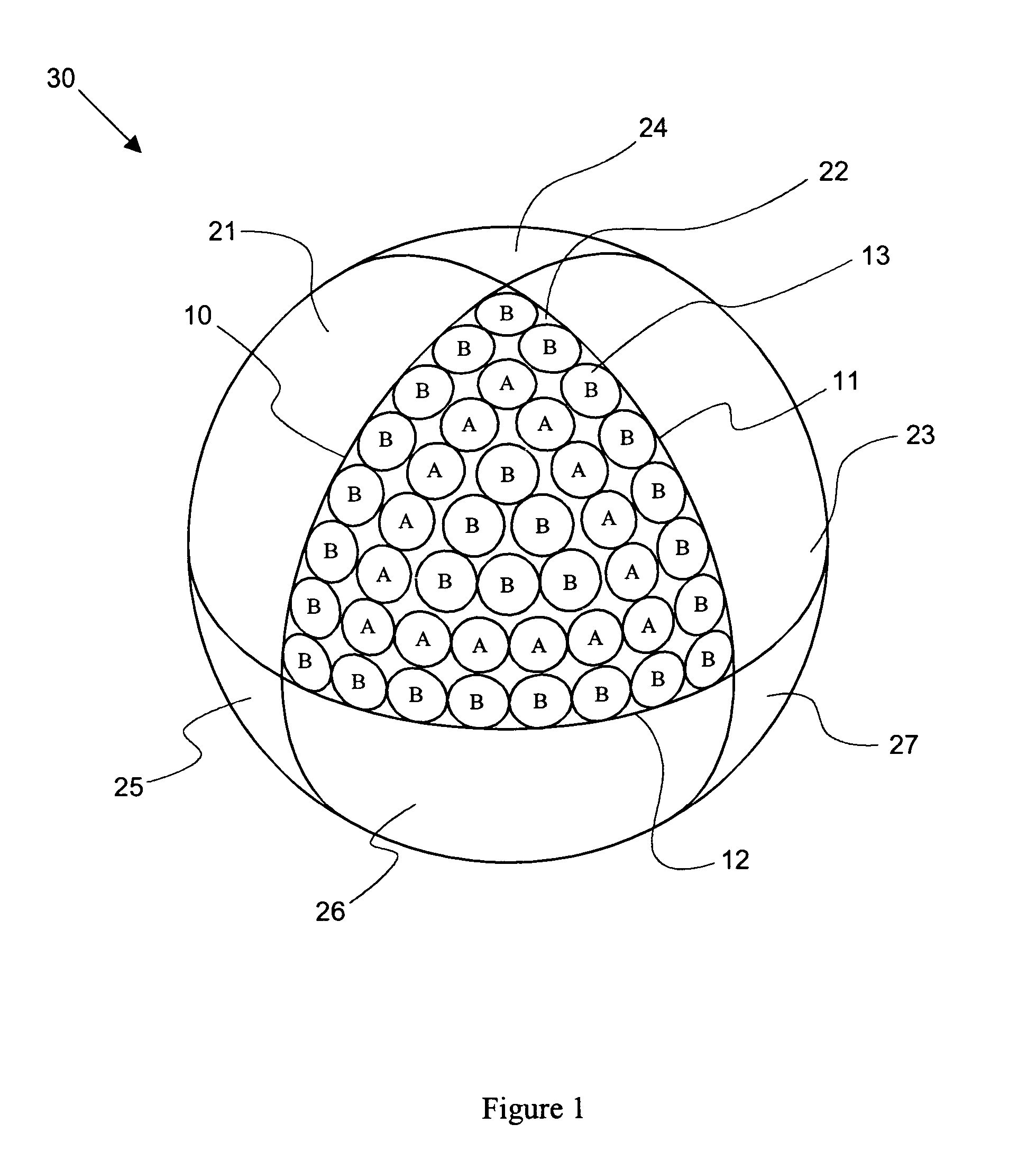

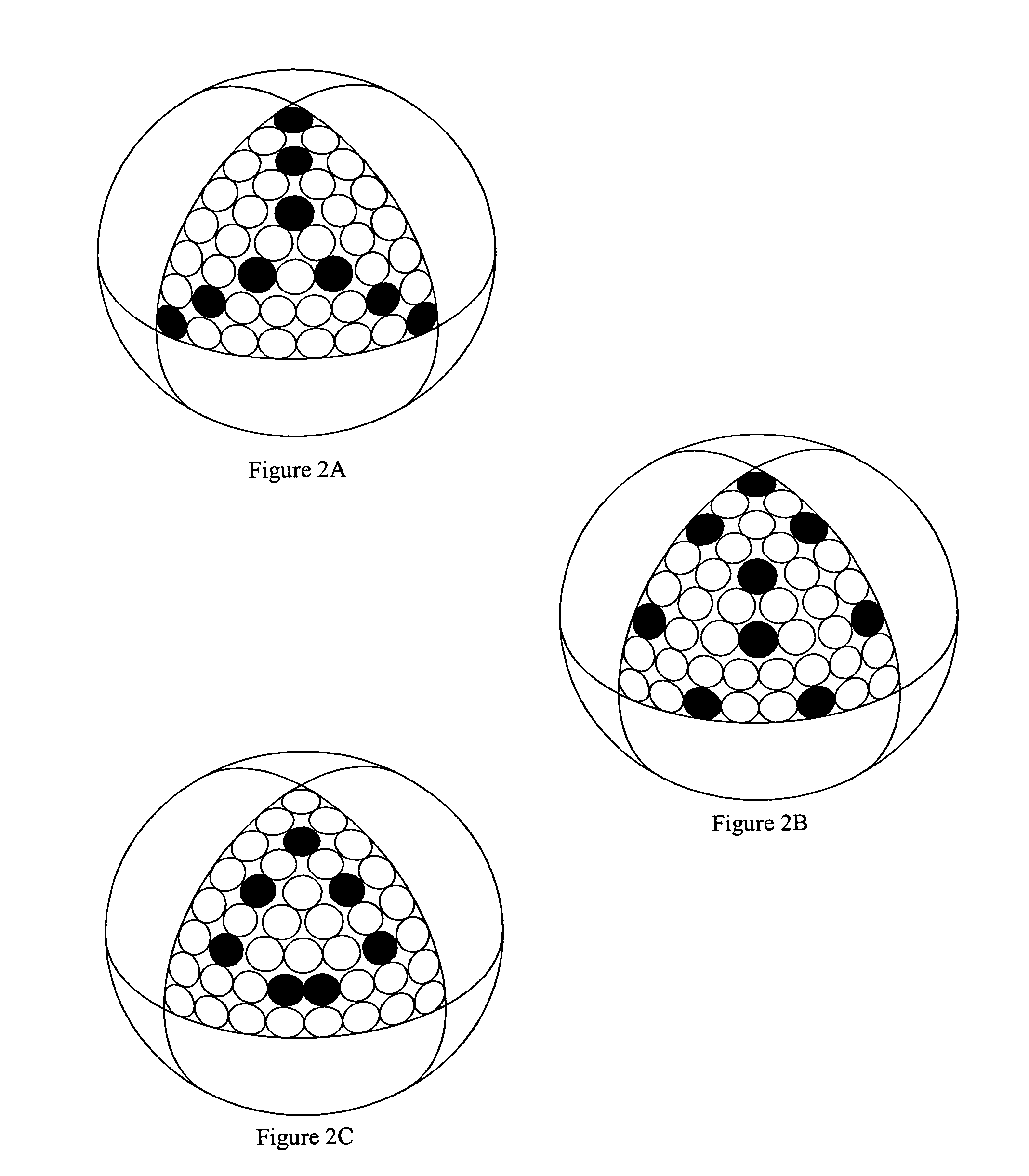

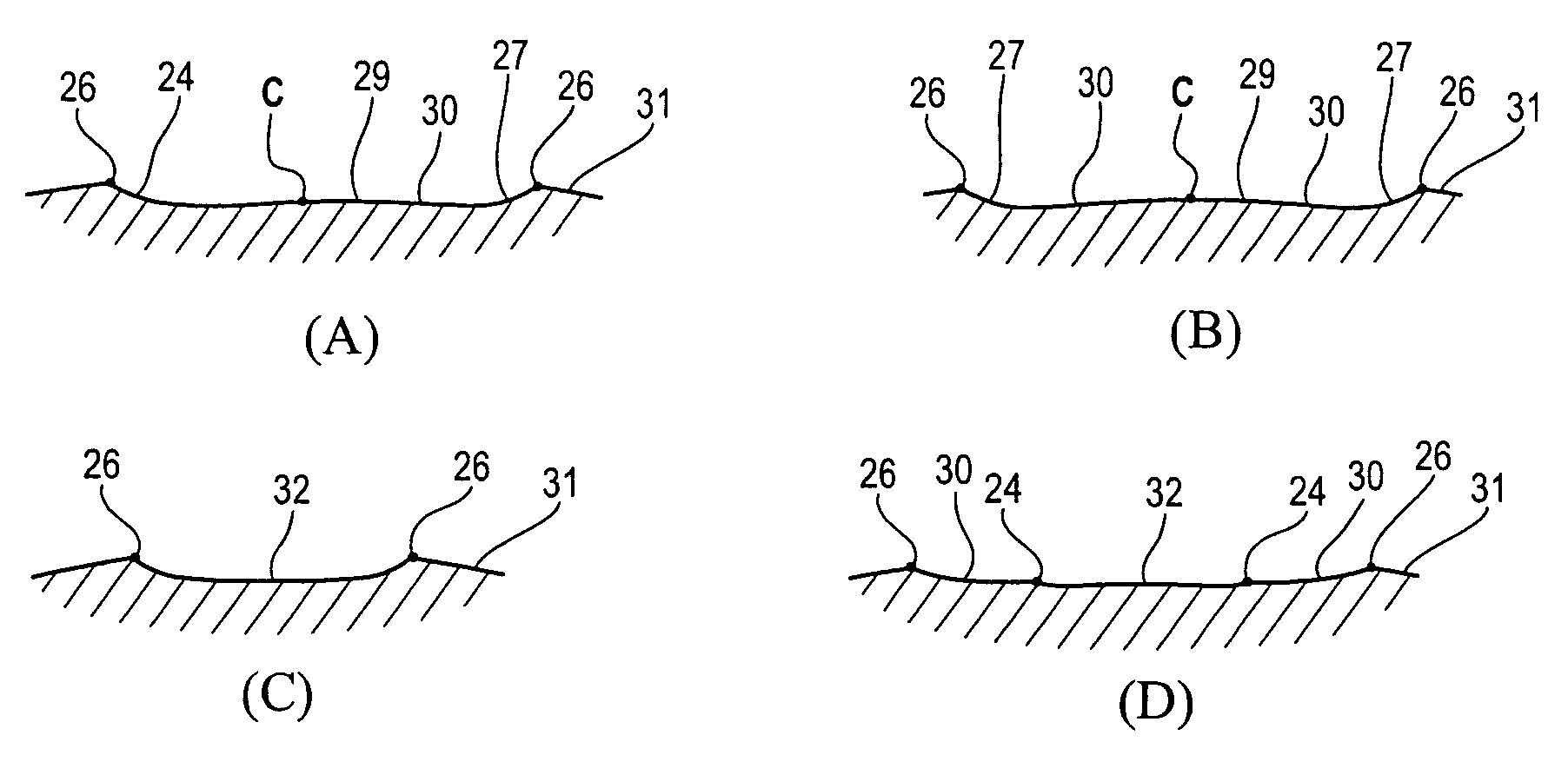

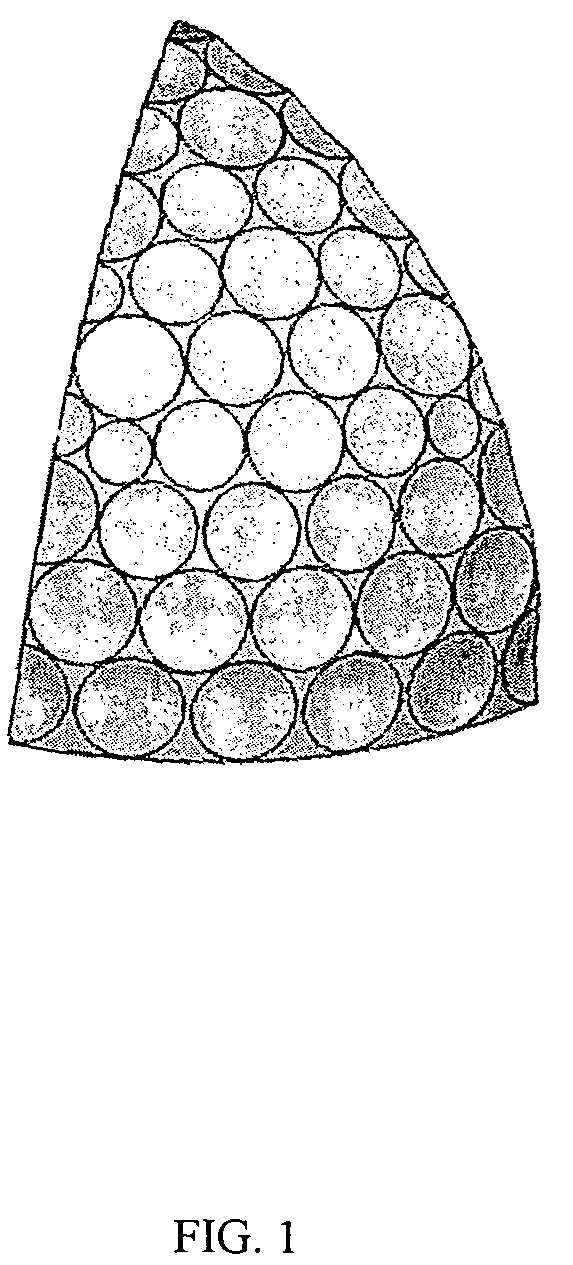

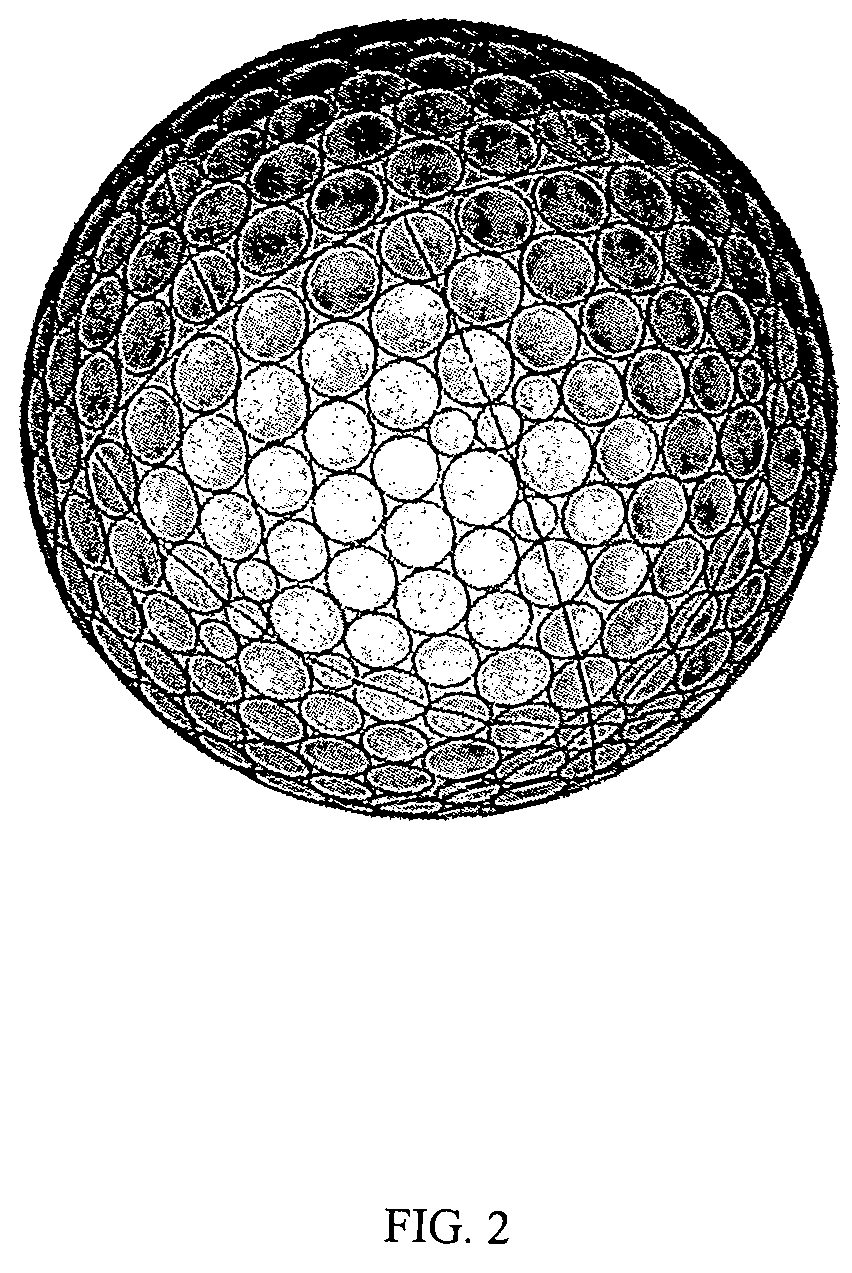

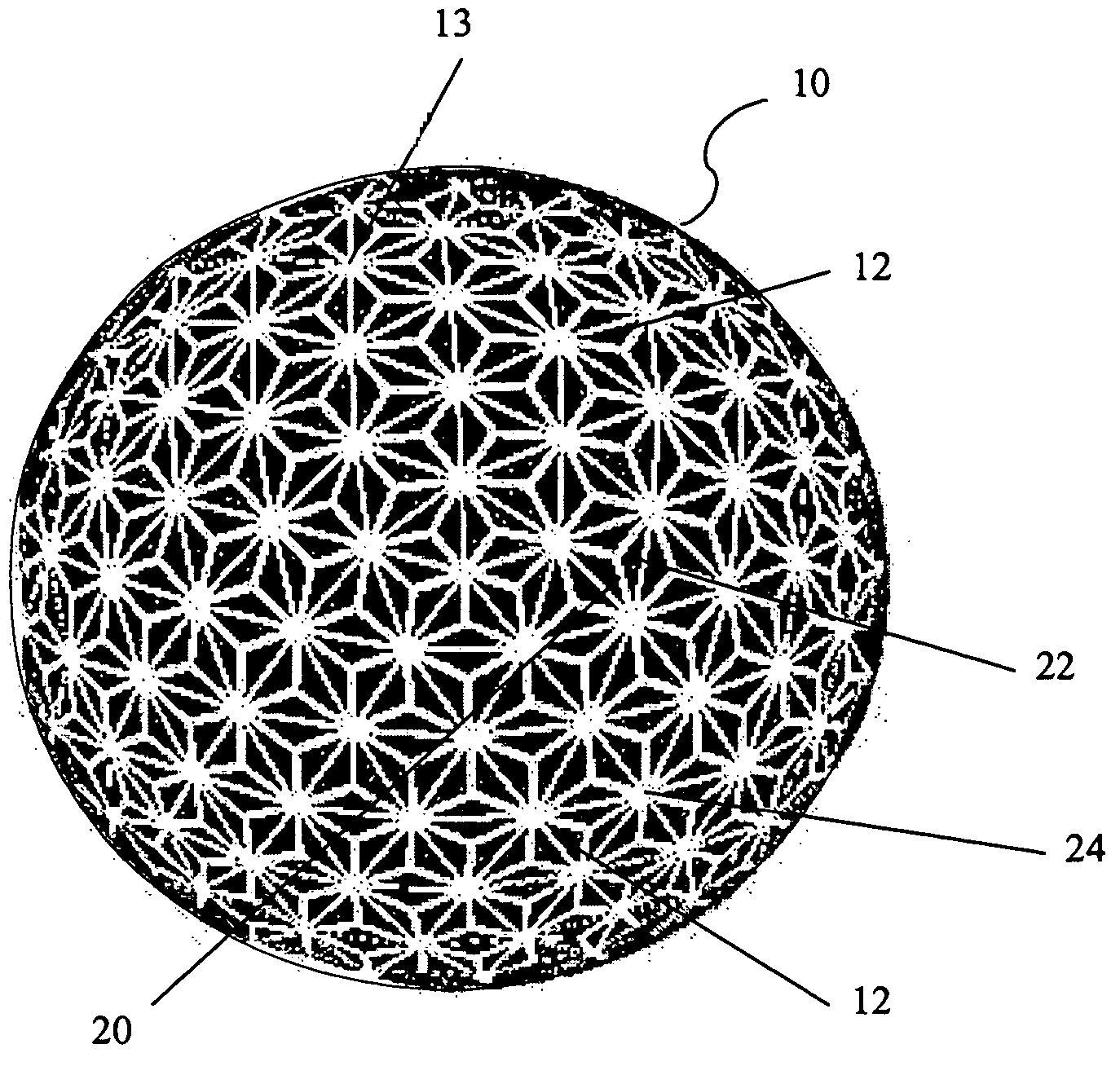

Dimple patterns for golf balls

A golf ball dimple pattern based on a hexagonal dipyramid polyhedron is disclosed. Preferably, the dimple pattern disclosed by the present invention includes dimples that are arranged such that at least a portion of neighboring dimples have one or more predetermined diameter ratios. The dimples are arranged based on six substantially similar mating dimple sections on each hemisphere. Each of the six substantially similar mating dimple sections on each hemisphere share a dimple positioned at the pole of that hemisphere. The dimple pattern is capable of achieving a surface coverage of about 82% or greater.

Owner:ACUSHNET CO

High performance golf ball having a reduced-distance

A high performance golf ball having a reduced overall distance while maintaining the appearance of a high performance trajectory. The golf ball includes a combination of low CoR core and cover materials coupled with a less aerodynamic dimple pattern that achieves a reduction in carry and overall distance of 15 and 25 yards versus a conventional golf ball, while still providing the look, sound, feel and apparent flight of a conventional golf ball. A high performance golf ball having a reduced distance is also achieved by controlling dimensionless coefficients of lift / weight and drag / weight at certain Reynolds numbers and spin ratios for various CoR.

Owner:ACUSHNET CO

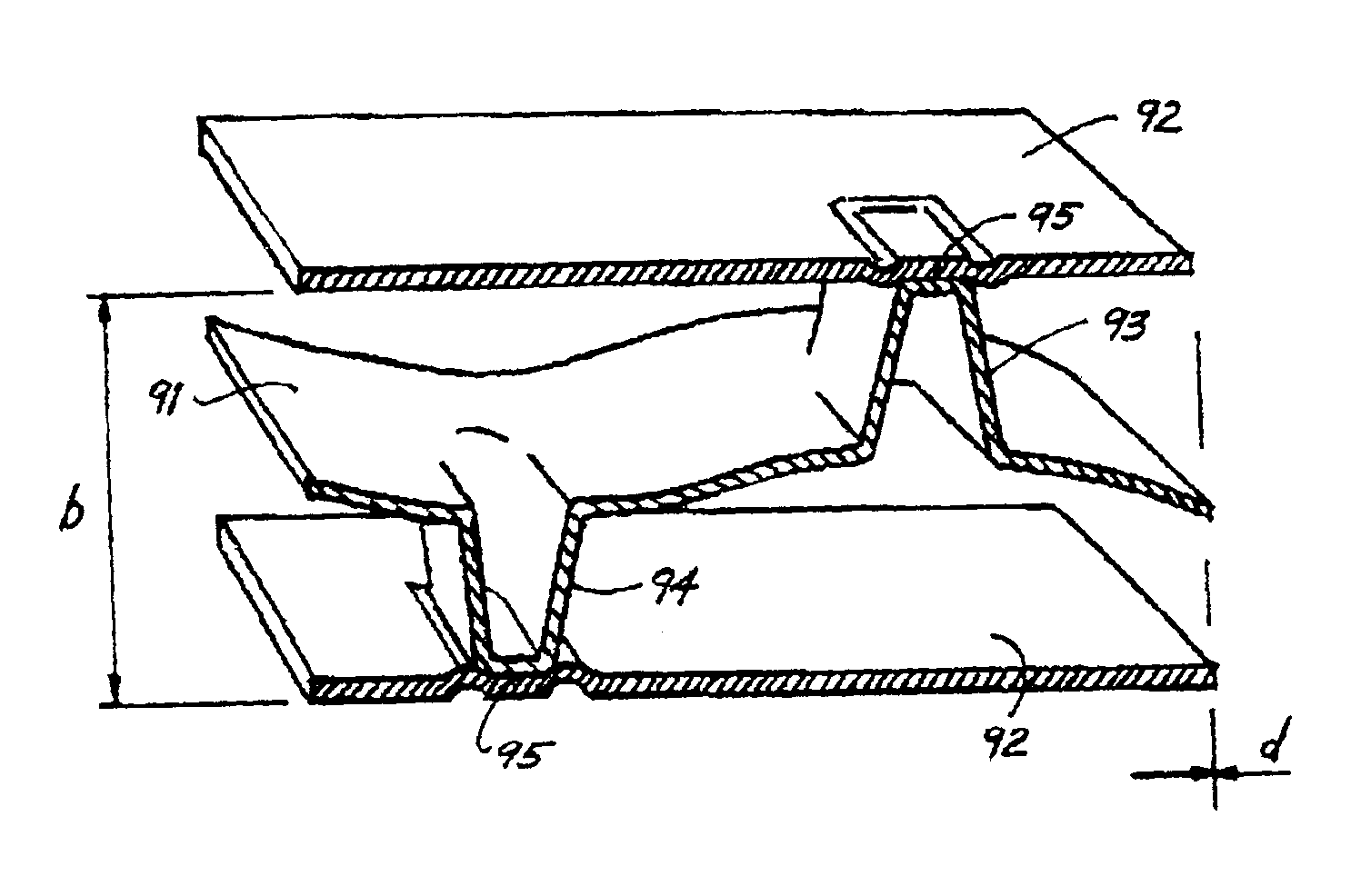

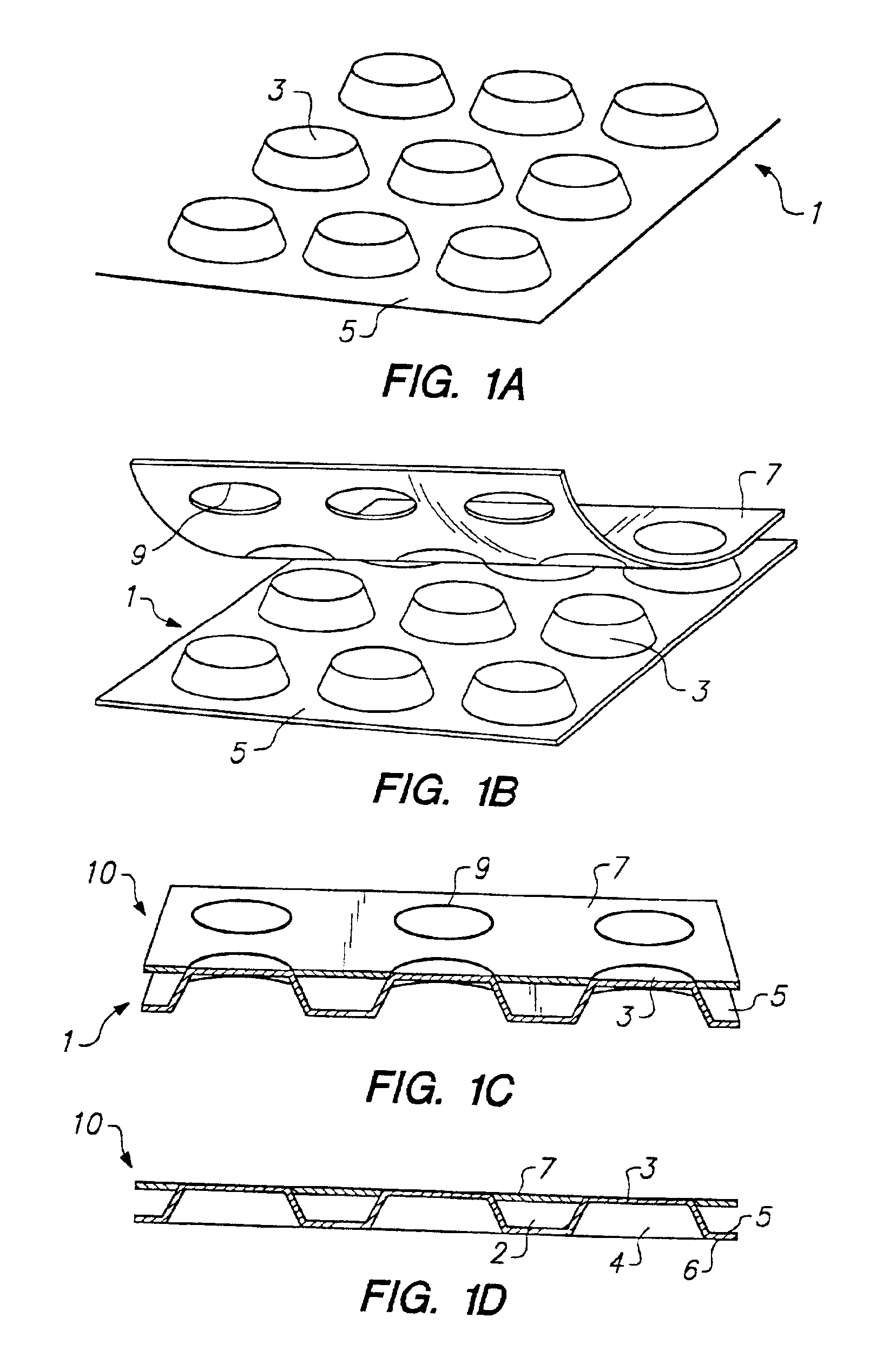

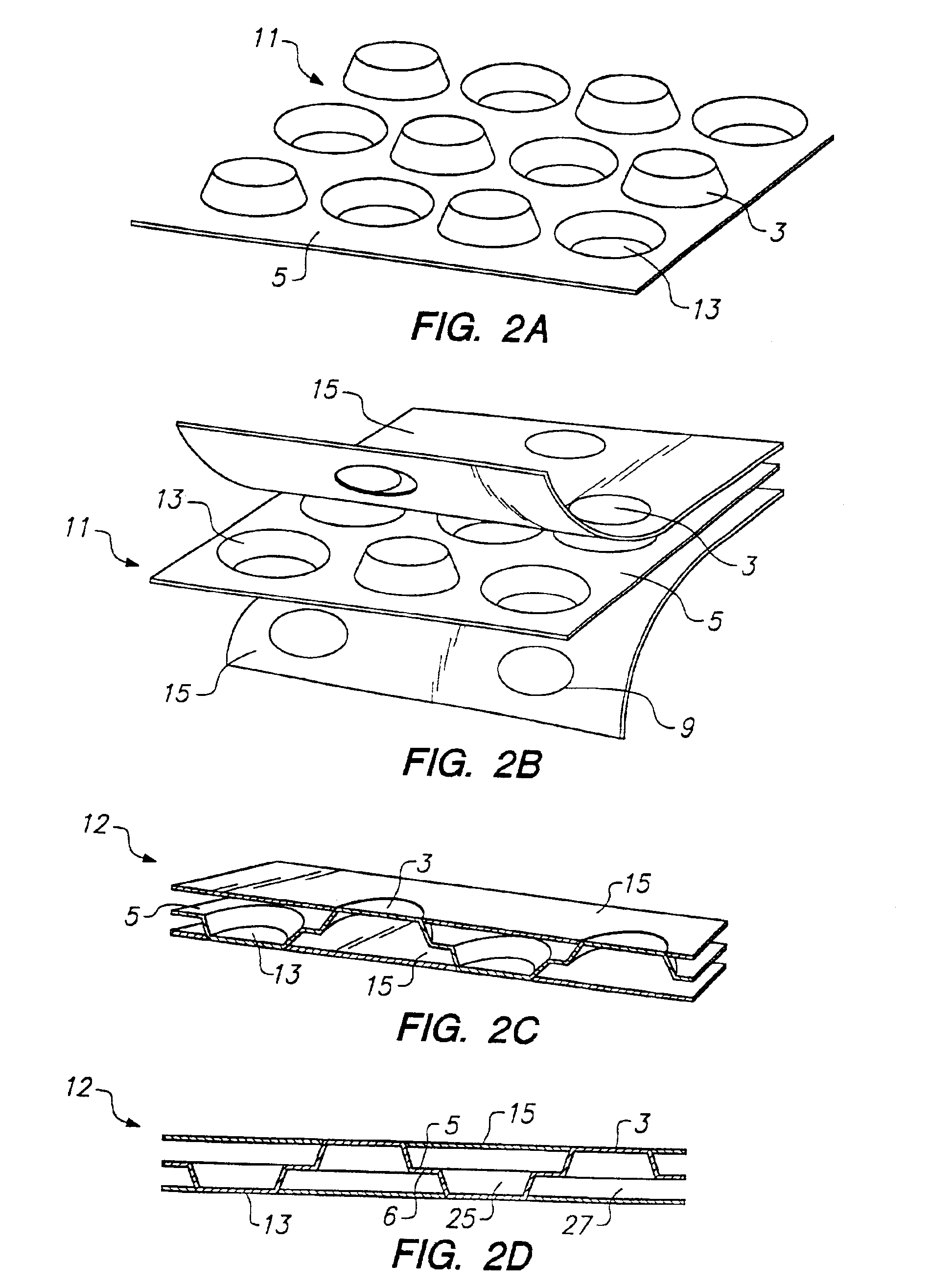

Structural dimple panel

A dynamic structural panel having one or more compliant dimple layers connected together by one or more reinforcing layers engaging ends of dimples on the dimple layer to create a cavity between the layers. The dimples are spaced apart from one another to form a dimple layer region. The dimple layer region may be either curved relative to the dimples or corrugated, thereby providing compliancy for the dynamic structural panel. The connection of the dimple layer and reinforcing layers creates an integral structural panel that can be planar by having identical heights of the dimples on the dimple layer to create a planar panel (flat) or nonplanar (curved) by varying the heights of the dimples on the dimple layer or through planar spacing adjustment. The panel can be modified in various ways such as by choice of materials and / or geometries of the various layers and / or incorporation of additional structural features.

Owner:CLARK BRIAN H

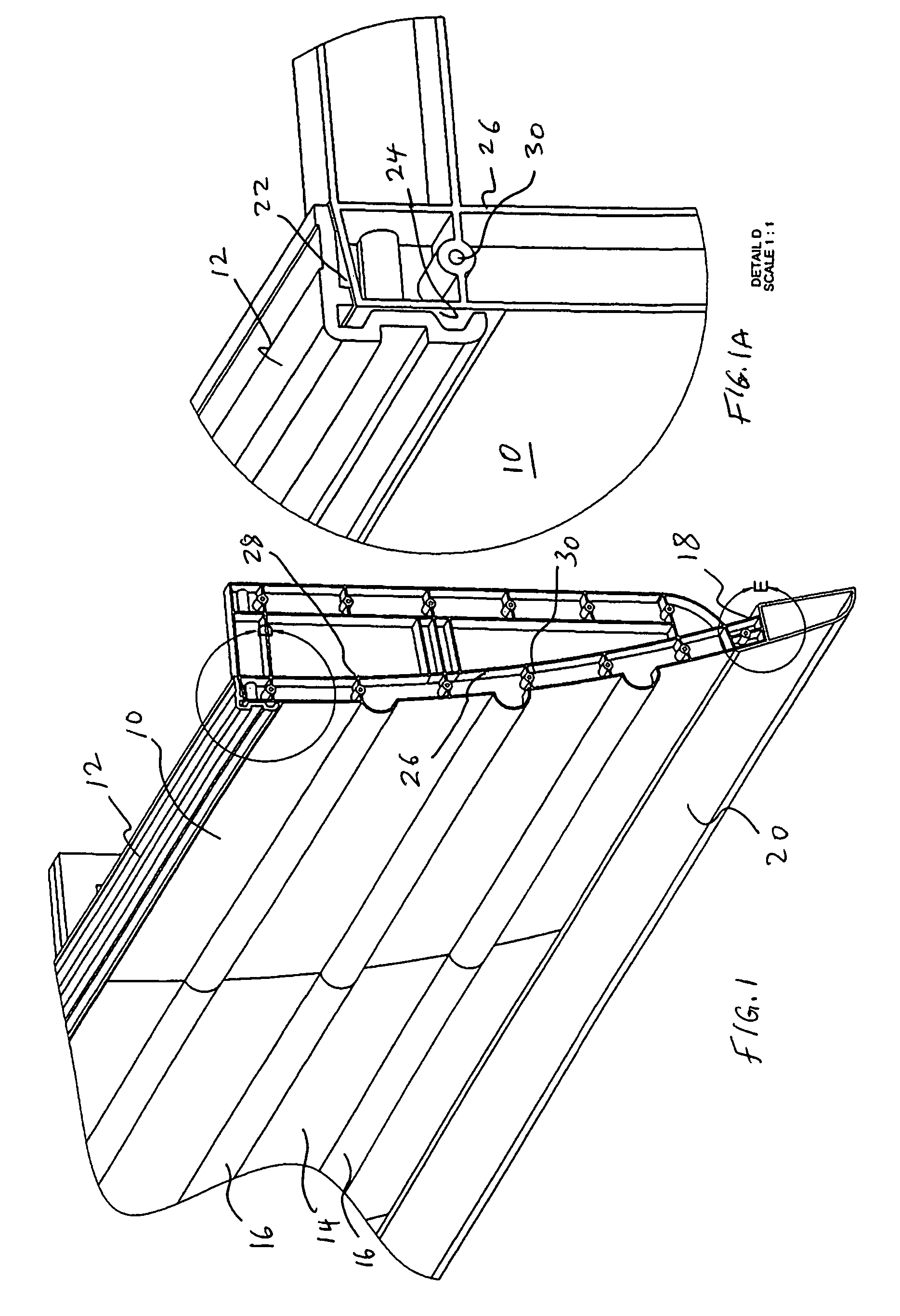

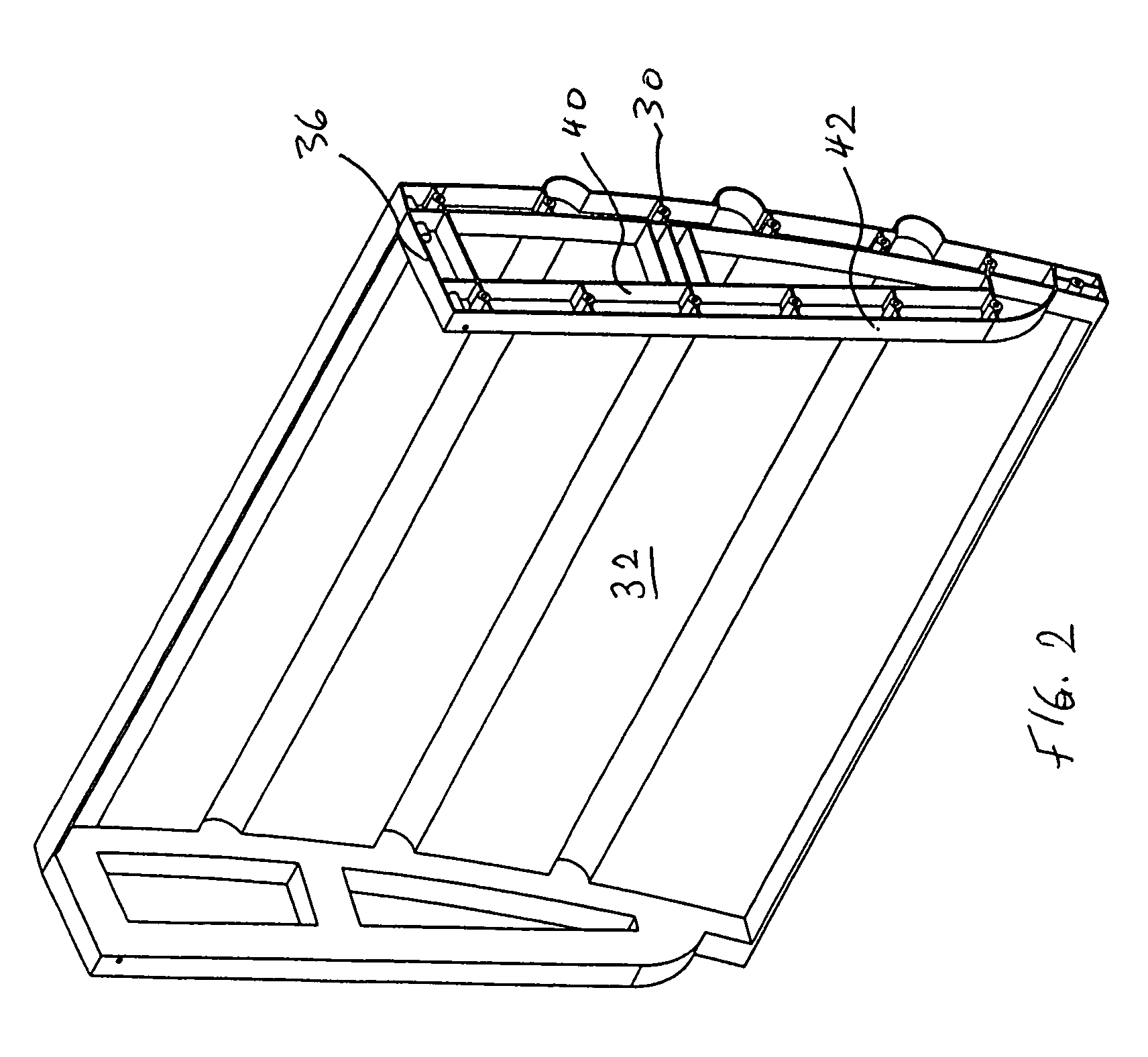

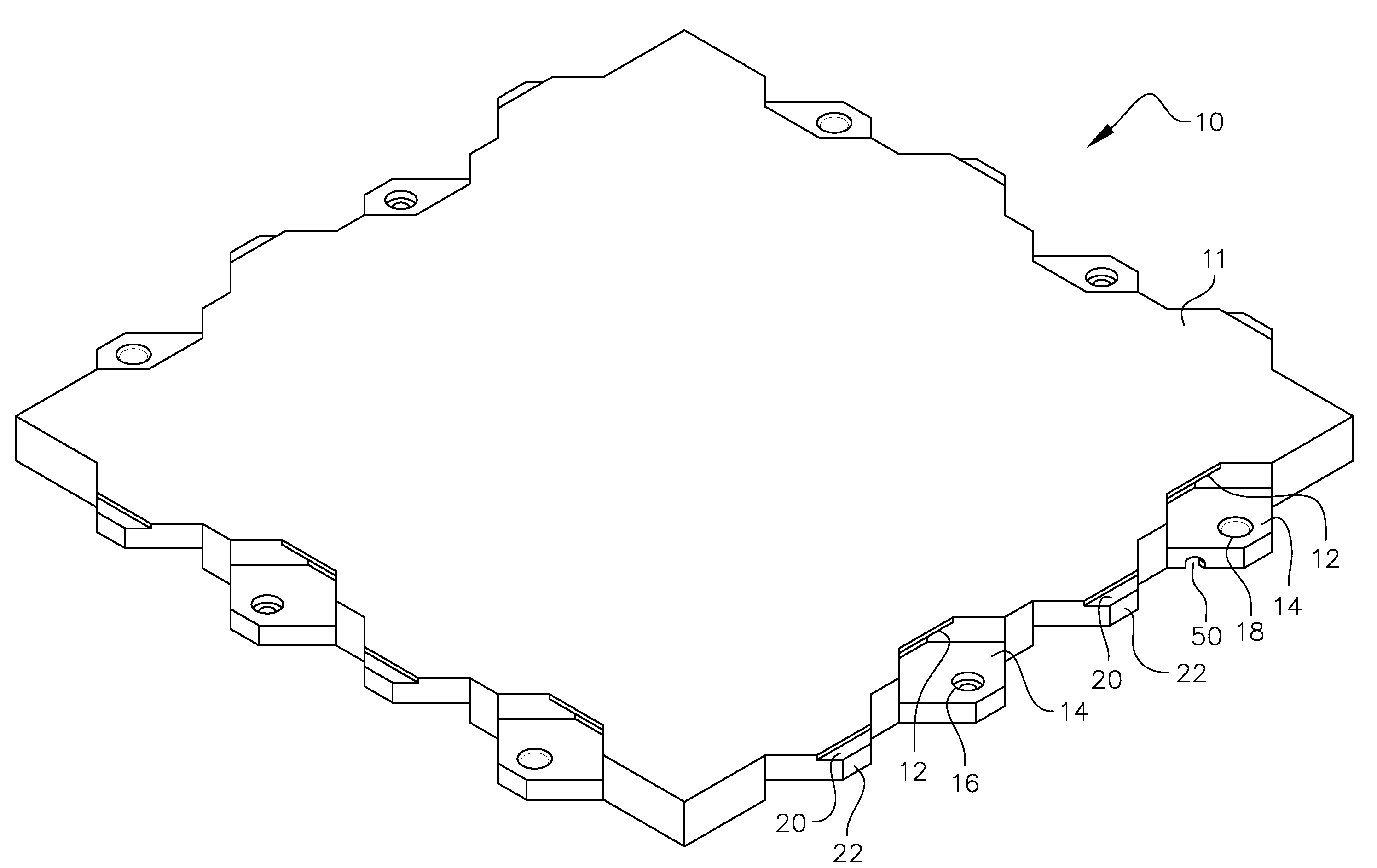

Interlocking floor system

ActiveUS7516587B2Easy to disassembleEasy to assembleRoof covering using tiles/slatesTreadsBrickEngineering

Multiple polymeric panels molded as a rigid integral body having a planar top surface and a bottom grid structure are interlocked together mechanically along side edges. Each side edge has alternating upwardly and downwardly facing steps with concave dimples on one and mating convex projections on the other for securely interlocking adjacent panels to each other. The steps of adjacent panels interlock with each other to form a complete floor system. The multiple polymeric panels can be molded to simulate flooring materials such as brick or overlaid with sections of linoleum, carpet, synthetic grass, tile or wood flooring. Alternately, the assembled panels can be covered with a sheet of decorative material.

Owner:CH3 SOLUTIONS LLC

Solid golf ball

InactiveUS7344455B1Reduce rigidityImprove performanceGolf ballsSolid ballsPolymer scienceAntioxidant

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed primarily of a polyurethane material and has a thickness of 0.5 to 2.5 mm, a Shore D hardness at the surface of 50 to 70 and a flexural rigidity of 50 to 300 MPa. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

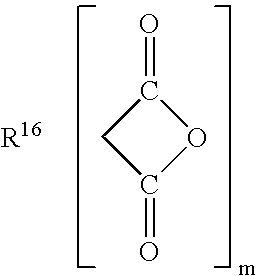

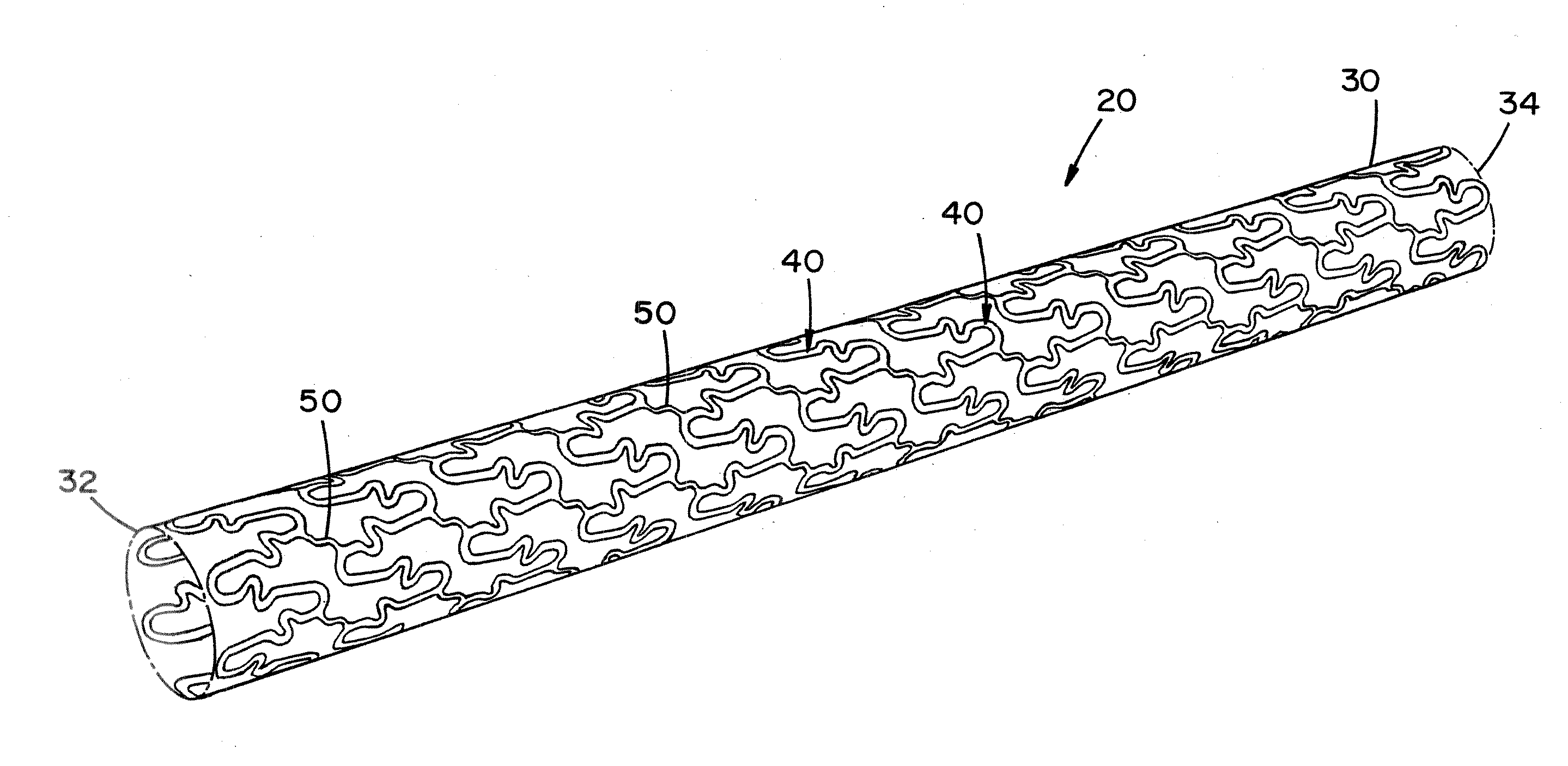

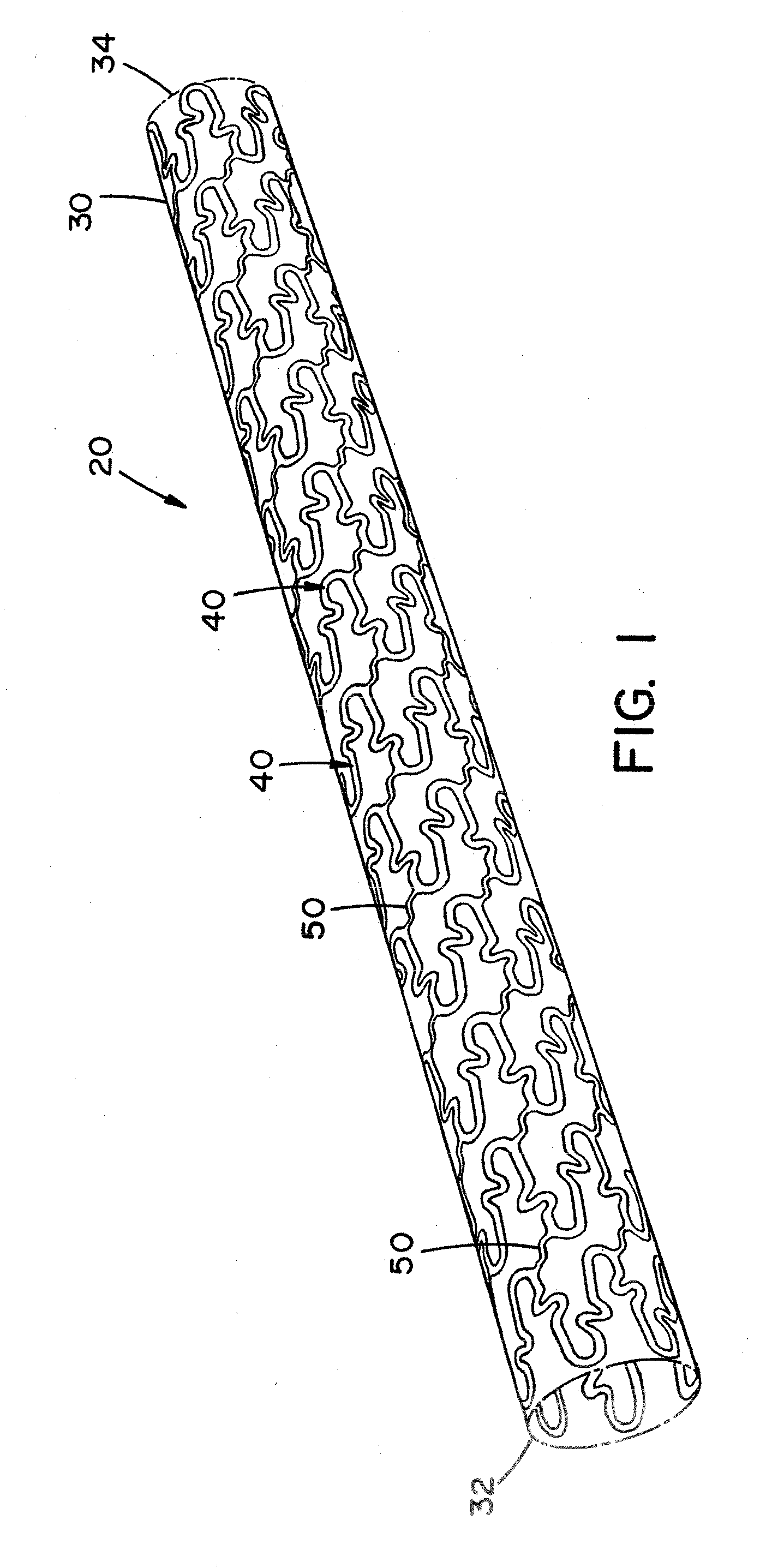

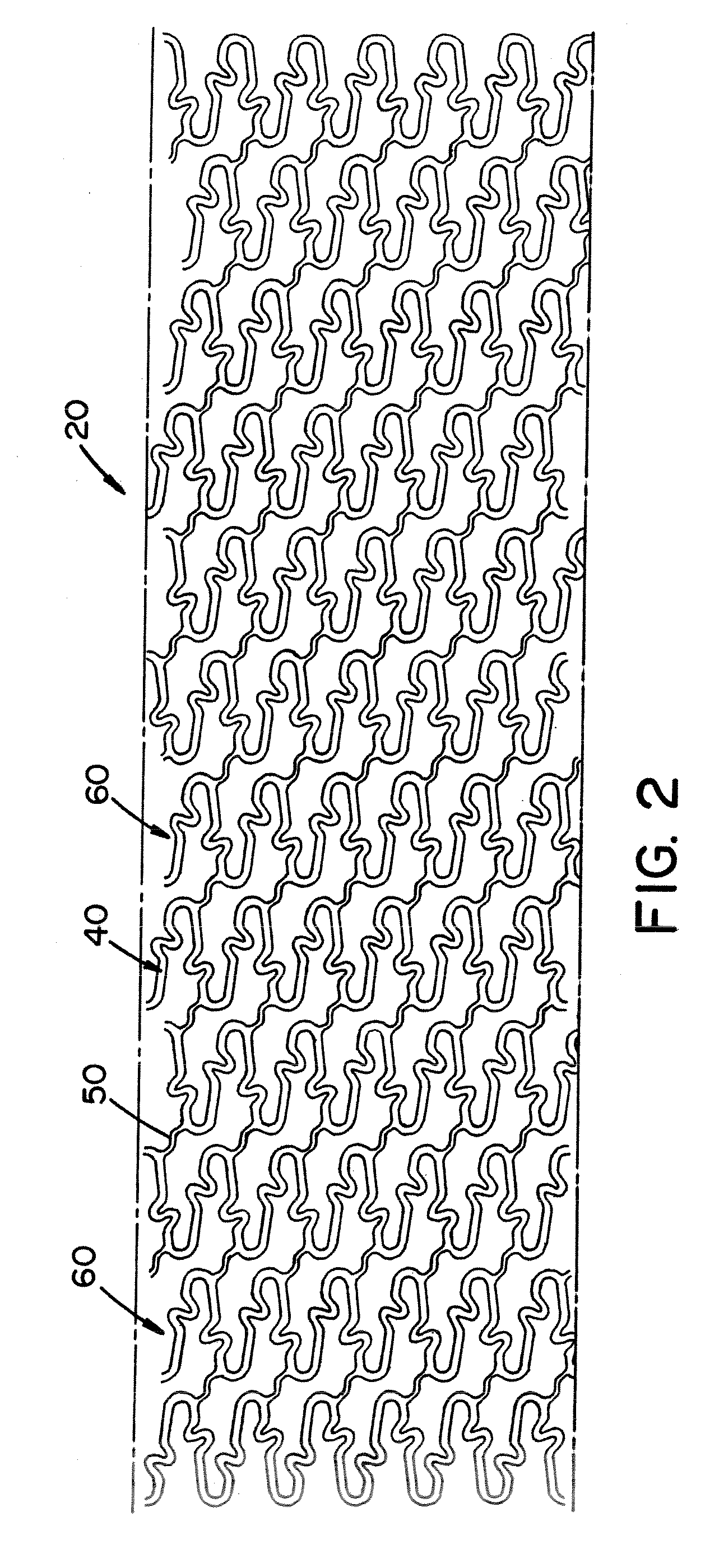

Stent

An expandable stent for use within a body passageway. The stent includes at least two struts and a connector securing together said two struts. At least one of said struts includes an elbow section and an undulating section. The apex of at least one strut can include at least one a dimple, divot and / or slot.

Owner:ICON MEDICAL CORP

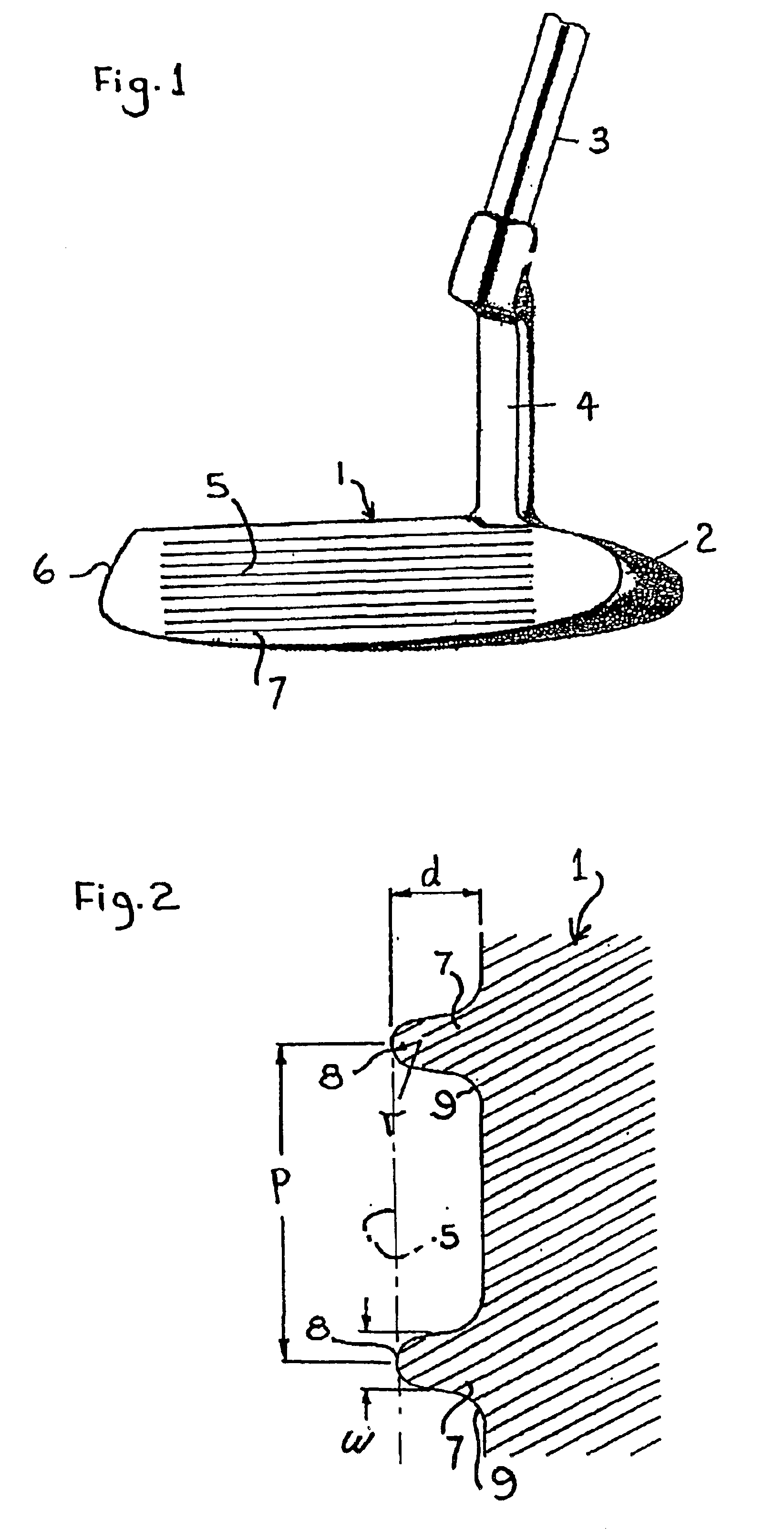

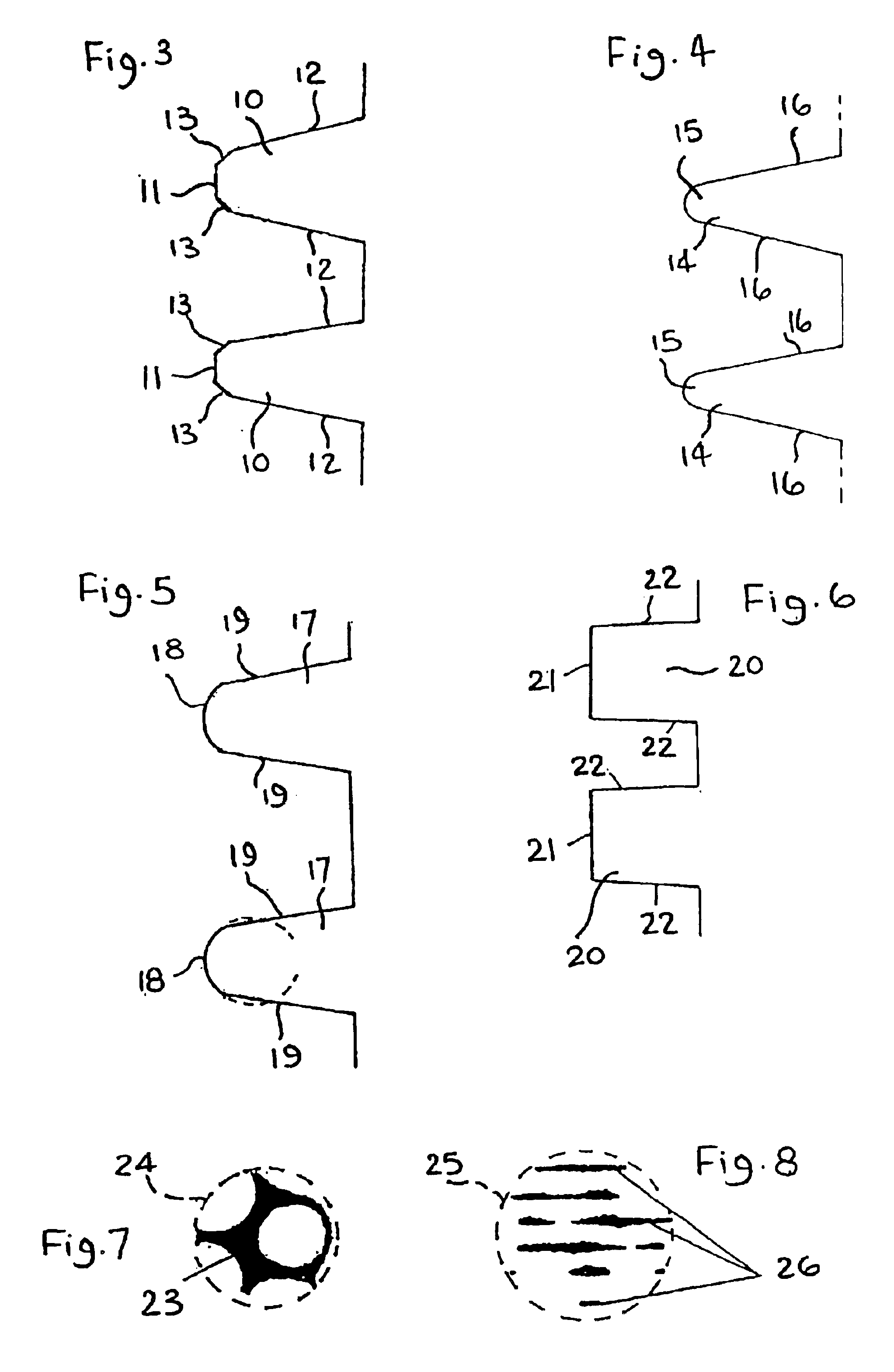

Golf-putters

Owner:LINDSAY NORMAN MATHESON

Solid golf ball

InactiveUS20080194359A1Large deformationIncreased durabilityGolf ballsSolid ballsAntioxidantRare earth

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes from 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, from 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer has a thickness of from 0.5 to 1.9 mm, and a Shore D hardness at the surface of from 50 to 70. The ball has at least one intermediate layer between the core and the cover, any one of which intermediate layer or layers has a surface hardness in Shore D units of from 40 to 60, the intermediate layer or layers having a total thickness of from 0.9 to 7.0 mm. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

Surface pattern for golf balls

A golf ball surface pattern including depressions and protrusions is disclosed and claimed. In one embodiment, the depressions and protrusions are positioned on the ball according to a known dimple pattern, with some of the dimples being replaced with protrusions. In another embodiment, the depressions are positioned on the ball according to a known dimple pattern, and protrusions are positioned on the land areas. Alternatively, protrusions can be positioned on the ball according to a known dimple pattern, and depressions positioned on the land areas. The turbulence generators (dimples and protrusions) that are positioned on the land areas can be positioned manually or with a distribution scheme. In another embodiment, the turbulence generators are positioned according to a scheme based on the principles of electromagnetic theory.

Owner:ACUSHNET CO

Golf ball dimples

Owner:ACUSHNET CO

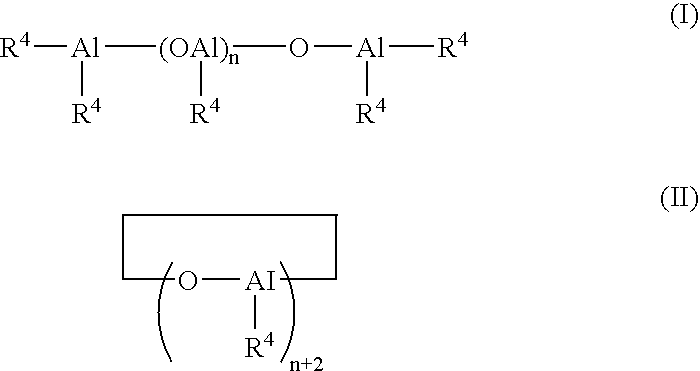

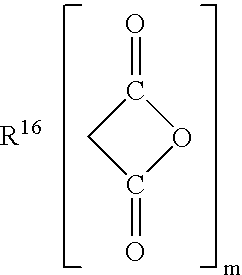

Solid golf ball

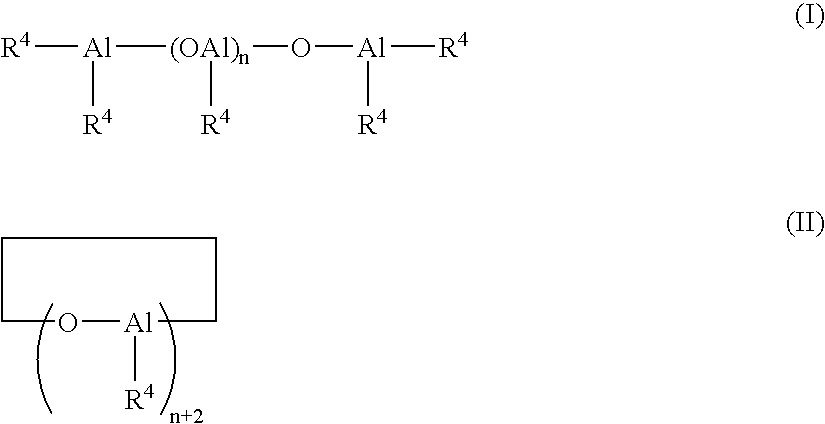

InactiveUS20080214325A1Increase elasticityImprove low temperature performanceGolf ballsSolid ballsAntioxidantRare earth

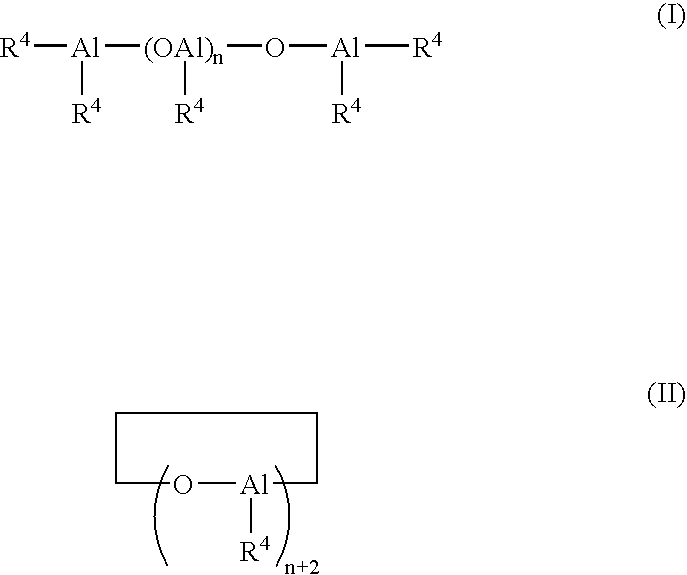

The invention provides a solid golf ball having a solid core and a cover layer that encases the core and has an outermost layer on an outside surface of which are formed a plurality of dimples. The solid core is formed of a rubber composition composed of 100 parts by weight of a base rubber that includes from 60 to 100 parts by weight of a polybutadiene rubber having a cis-1,4 bond content of at least 60% and synthesized using a rare-earth catalyst, from 0.1 to 5 parts by weight of an organosulfur compound, an unsaturated carboxylic acid or a metal salt thereof, an inorganic filler, and an antioxidant. The solid core has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 4.0 mm, and has a specific hardness distribution. The cover layer is formed by injection molding a single resin blend composed primarily of (A) a polyurethane material and (B) a polyisocyanate compound, which resin blend includes a polyisocyanate compound in at least some portion of which all the isocyanate groups on a molecule remain in an unreacted state. The cover layer has a thickness of from 0.5 to 2.5 mm and a Shore D hardness at the surface of from 50 to 70. The golf ball has a deformation, when compressed under a final load of 130 kgf from an initial load of 10 kgf, of from 2.0 to 3.8 mm. The solid golf ball is advantageous overall in competitive use.

Owner:BRIDGESTONE SPORTS

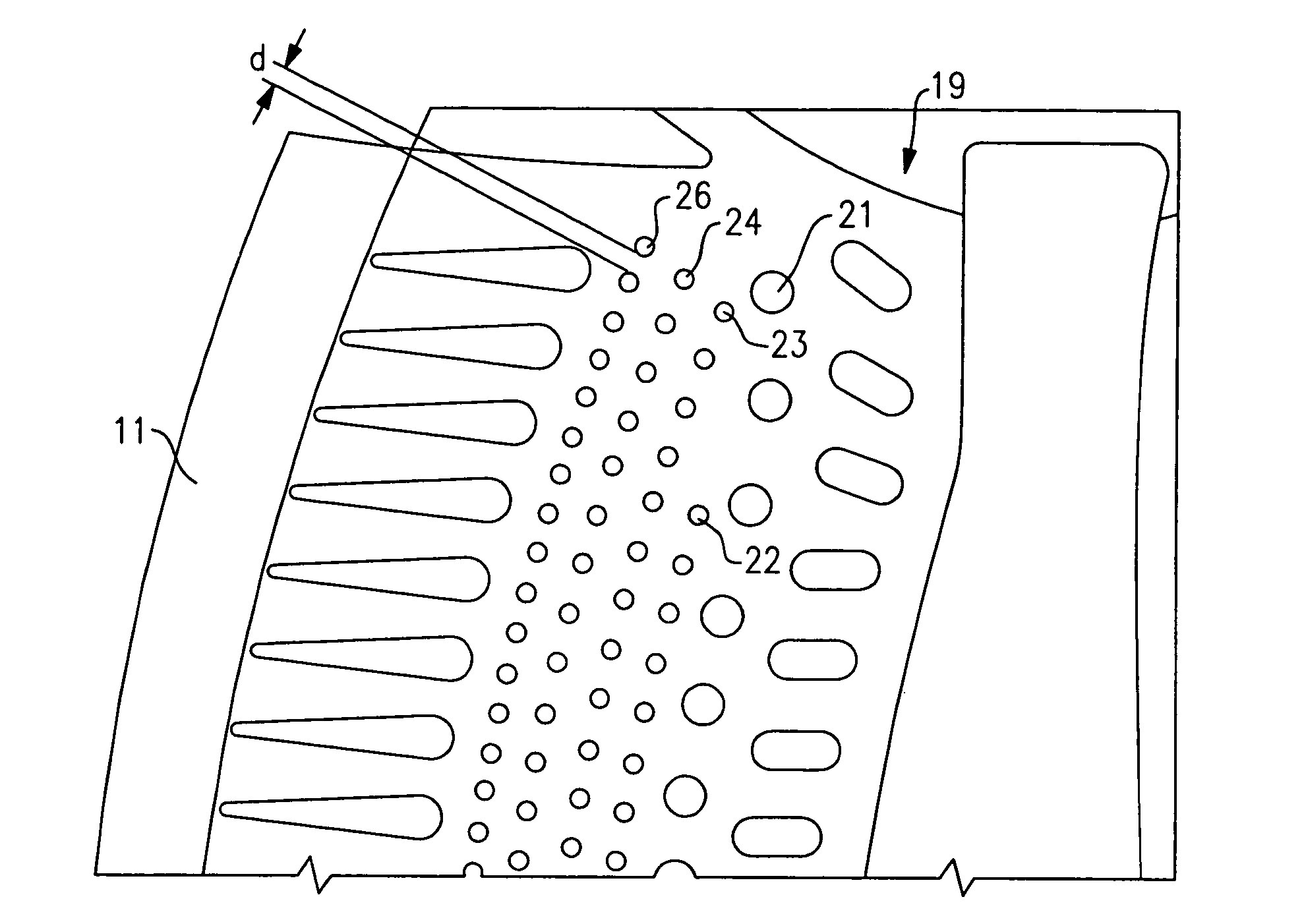

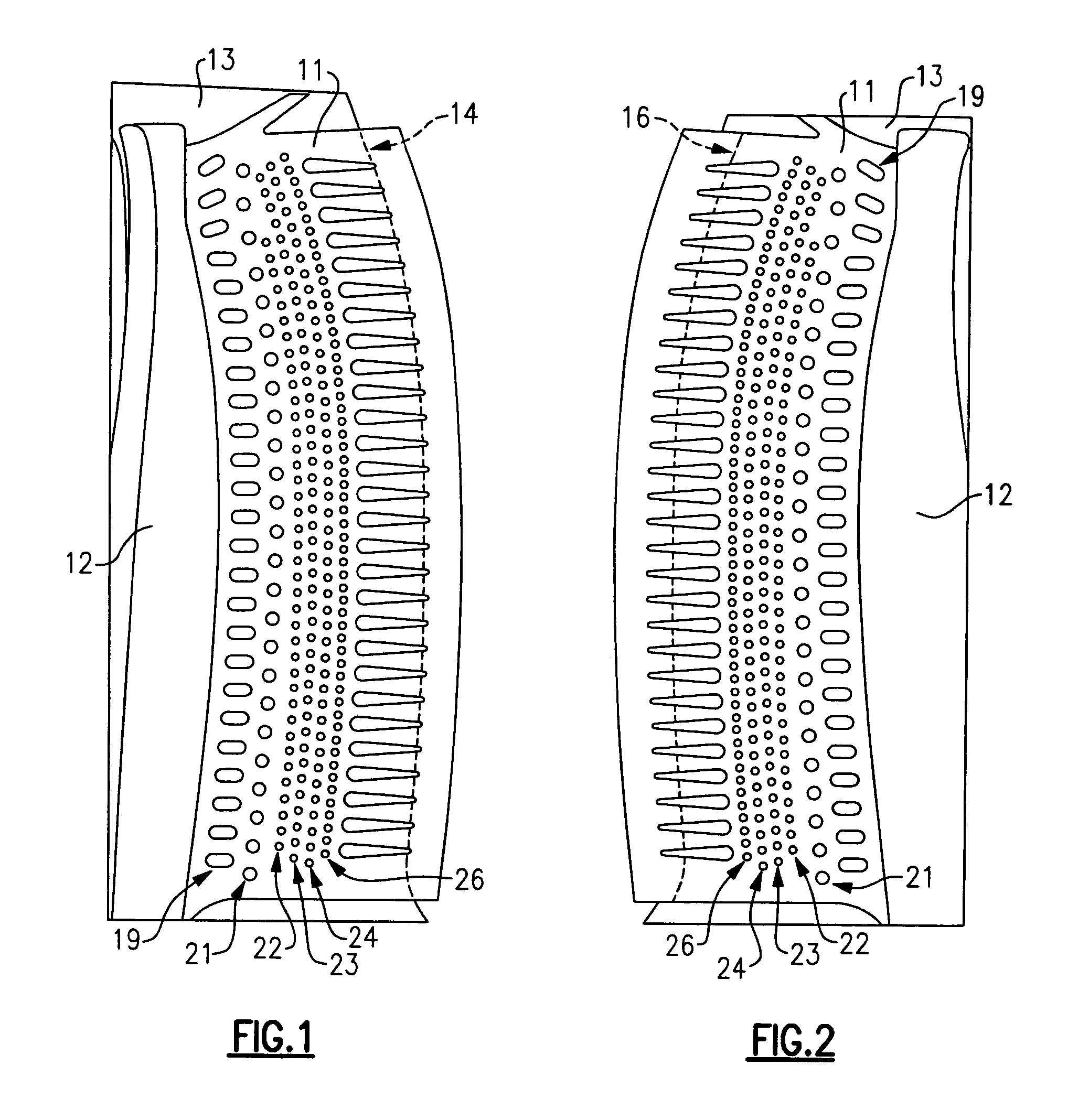

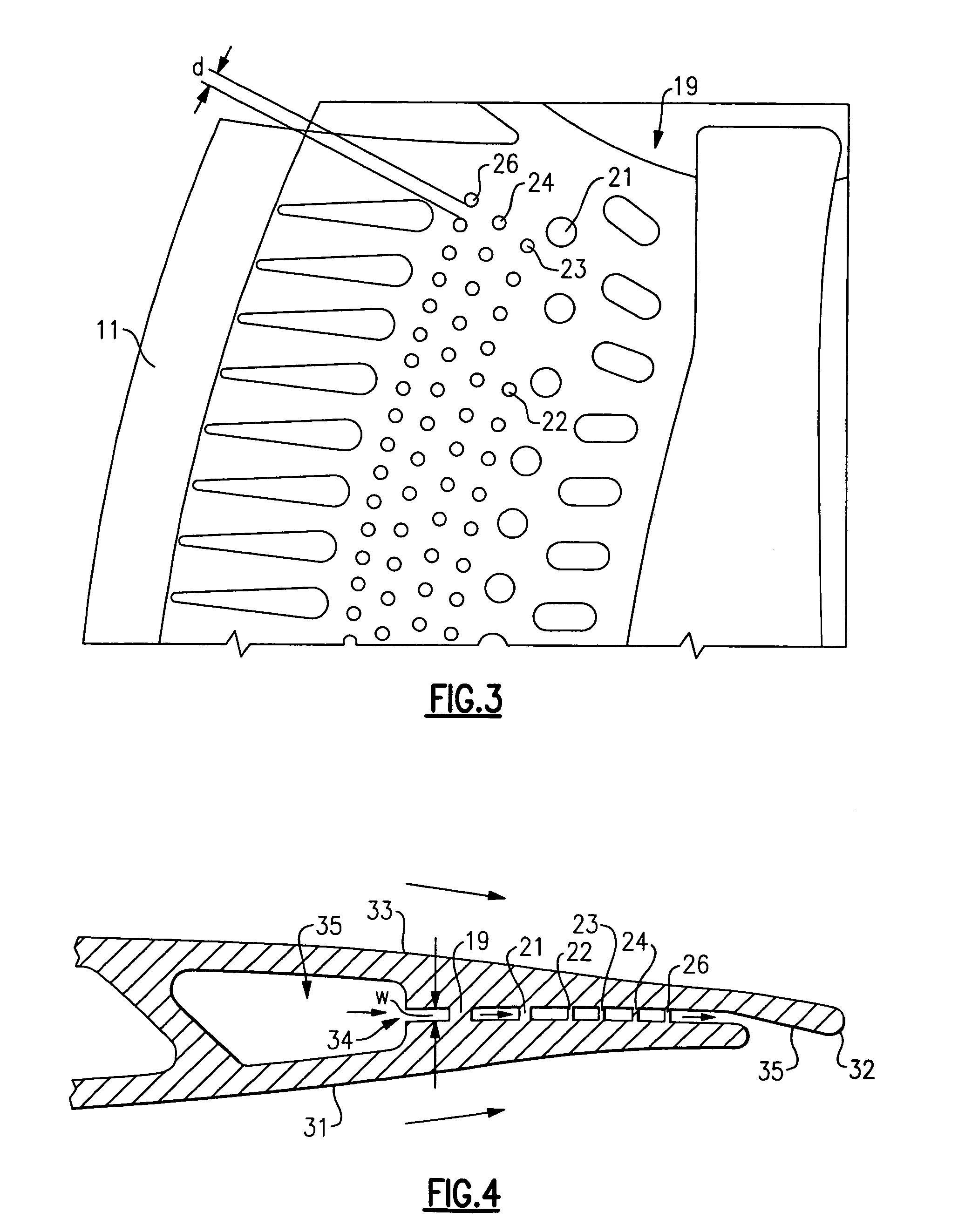

Airfoil trailing edge cooling

A turbine airfoil includes a span wise extending cavity formed from a ceramic mold and a slot extending from the cooling air cavity to a trailing edge being formed by a refractory metal core. The refractory metal core facilitates the reduction in the size of the slot and also in the reduction in the size of pedestals which pass transversely through the slot to interconnect the pressure side to the suction side of the airfoil. The blade has a cutback feature to expose a back surface on the inner side of the suction side wall with dimples being formed on the back surface so as to enhance heat transfer characteristics thereof. Provision is made for fabricating the dimples by way of a photo etching process.

Owner:RTX CORP

Dimple patterns for golf balls

A golf ball dimple pattern based on a hexagonal dipyramid polyhedron is disclosed. Preferably, the dimple pattern disclosed by the present invention includes dimples that are arranged such that at least a portion of neighboring dimples have one or more predetermined diameter ratios. The dimples are arranged based on six substantially similar mating dimple sections on each hemisphere. Each of the six substantially similar mating dimple sections on each hemisphere share a dimple positioned at the pole of that hemisphere. The dimple pattern is capable of achieving a surface coverage of about 82% or greater.

Owner:ACUSHNET CO

Golf ball with varying land surfaces

A golf ball comprising a substantially spherical outer surface and a plurality of dimples formed thereon is provided. The dimples include polygonal dimples that are arranged such that the sides of adjacent polygonal dimples are substantially parallel to each other, and wherein the land area comprises first spacings and second spacings between adjacent dimples. The first spacings and the second spacings have substantially constant width between any two adjacent dimples and the width of the first spacings is different from the width of the second spacings. Circular dimples and circular land areas may also be included in the dimple pattern. The dimple pattern is easily adjusted to manipulate the aerodynamic efficiency of the golf ball.

Owner:ACUSHNET CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com