Patents

Literature

737results about How to "Eliminate deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

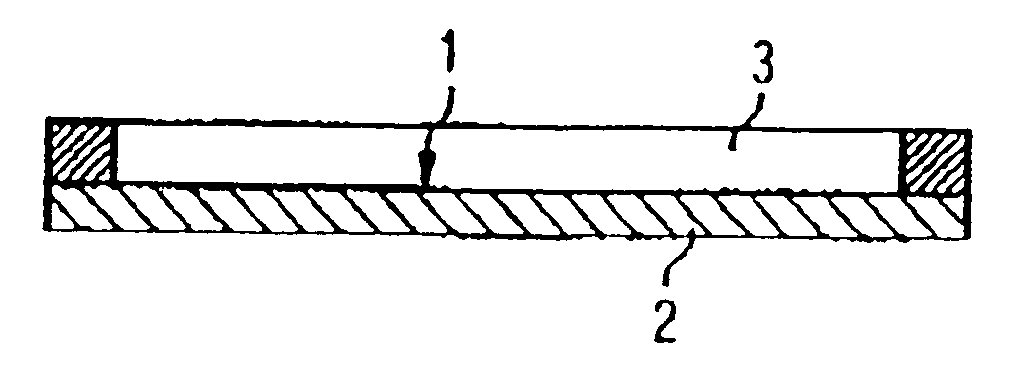

Electrodeposited copper foil with its surface prepared, process for producing the same and use thereof

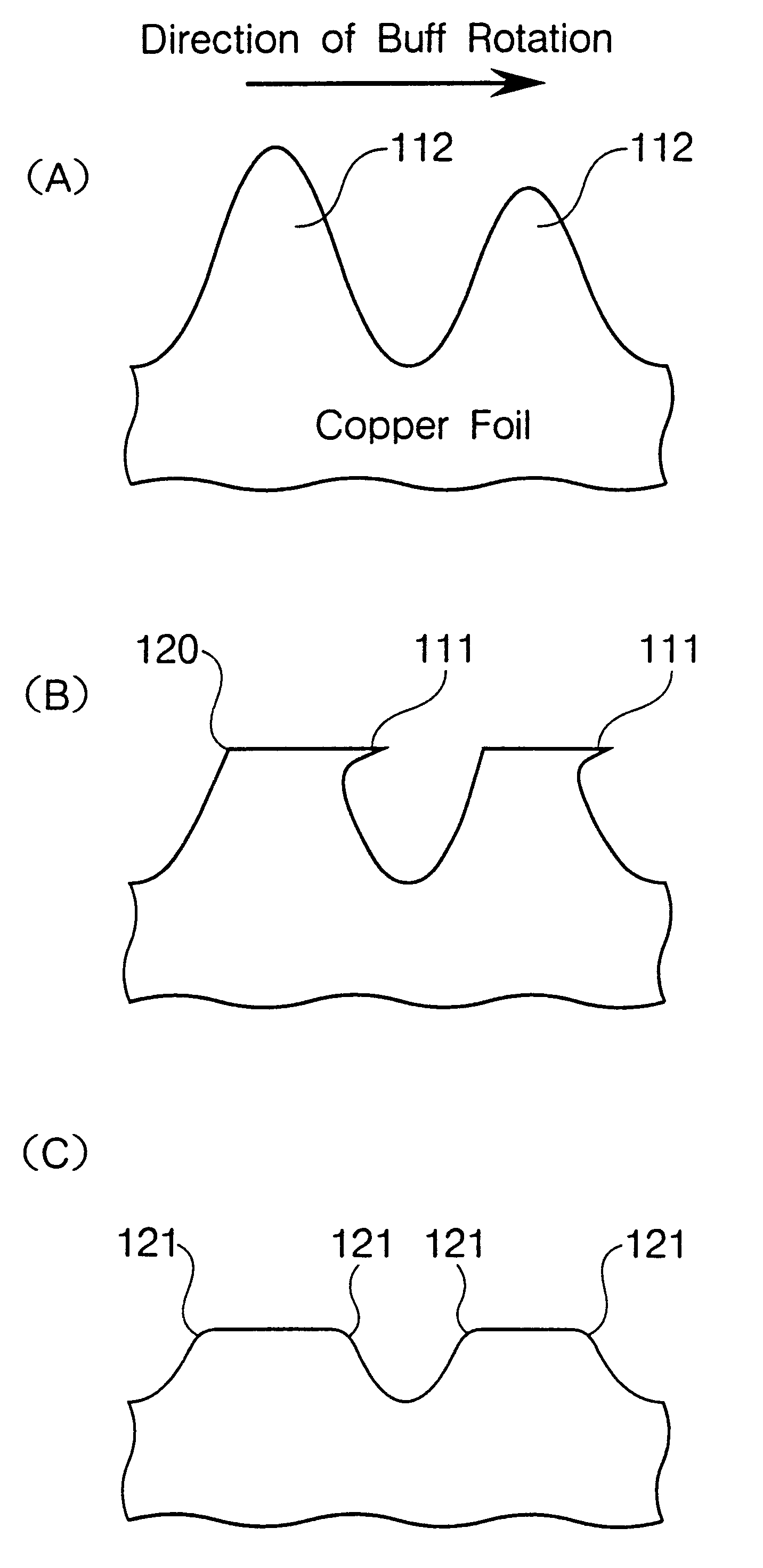

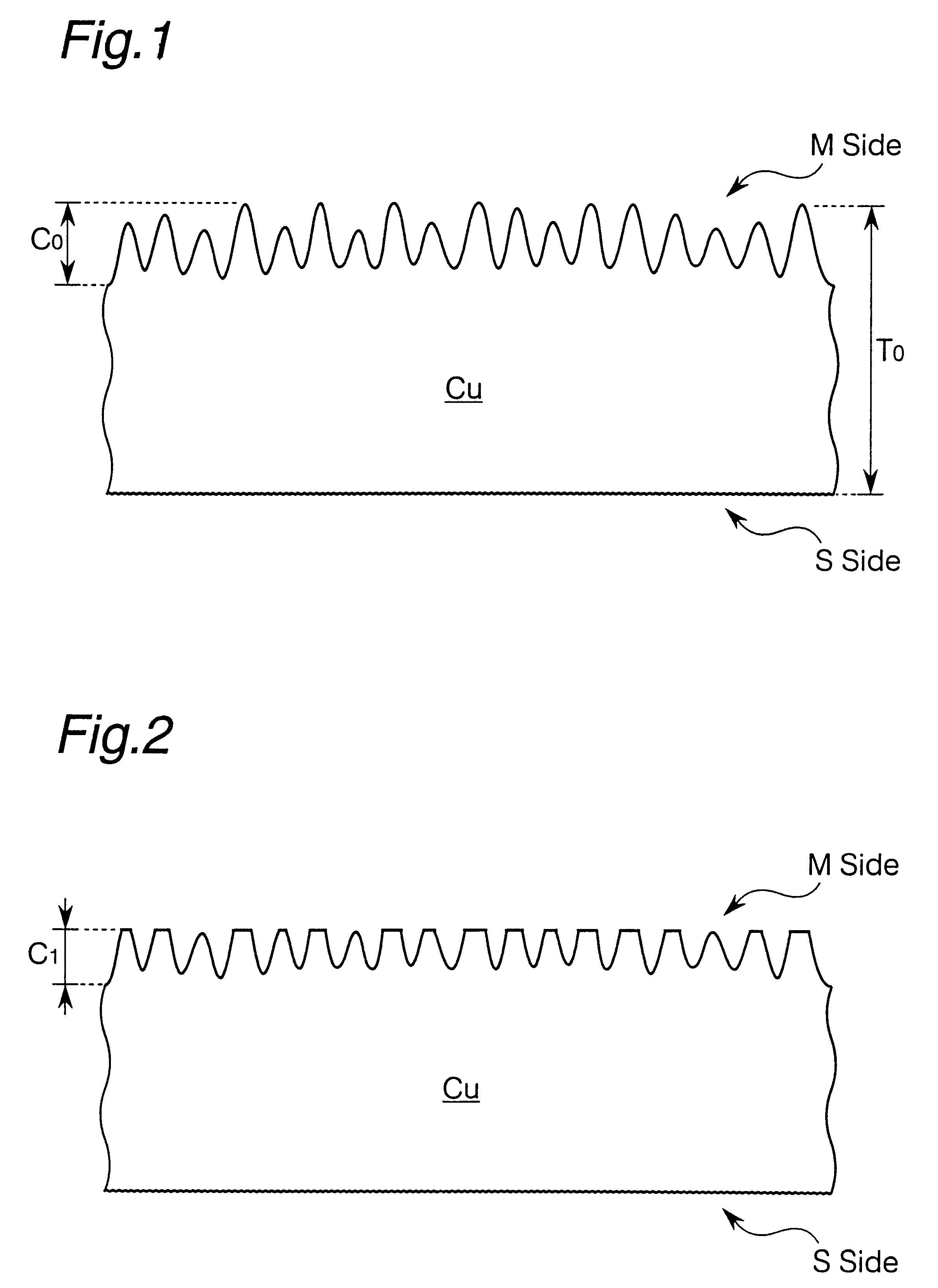

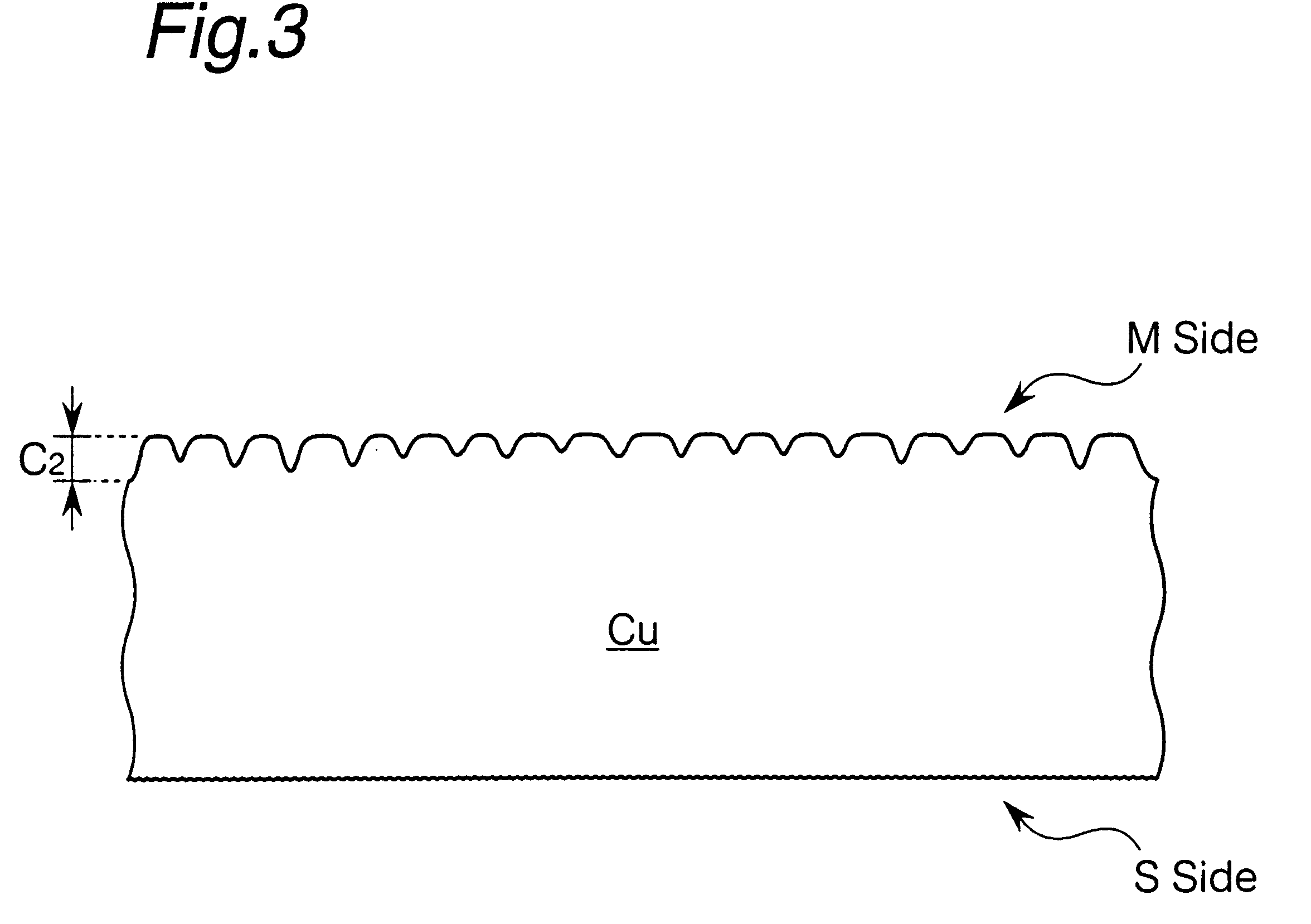

InactiveUS6475638B1Eliminate deformationHigh peel strengthInsulating substrate metal adhesion improvementLapping machinesSurface roughnessCopper foil

A process for producing an electrodeposited copper foil with its surface prepared, comprising the steps of: subjecting an electrodeposited copper foil having a shiny side and a matte side whose average surface roughness (Rz) is in the range of 2.5 to 10 mum to at least one mechanical polishing so that the average surface roughness (Rz) of the matte side becomes in the range of 1.5 to 3.0 mum; and subjecting the matte side having undergone the mechanical polishing to a selective chemical polishing so that the average surface roughness (Rz) of the matte side becomes in the range of 0.8 to 2.5 mum. The invention further provides an electrodeposited copper foil with its surface prepared, produced by the above process, and still further provides PWBs and a multilayer laminate of PWBs, produced with the use of the above electrodeposited copper foil with its surface prepared. The mechanical polishing followed by chemical polishing of the matte side enables obtaining an electrodeposited copper foil with its surface prepared, the matte side of which exhibits excellent properties, and hence enables obtaining PWBs and a multilayer PWBs which have excellent properties.

Owner:MITSUI MINING & SMELTING CO LTD

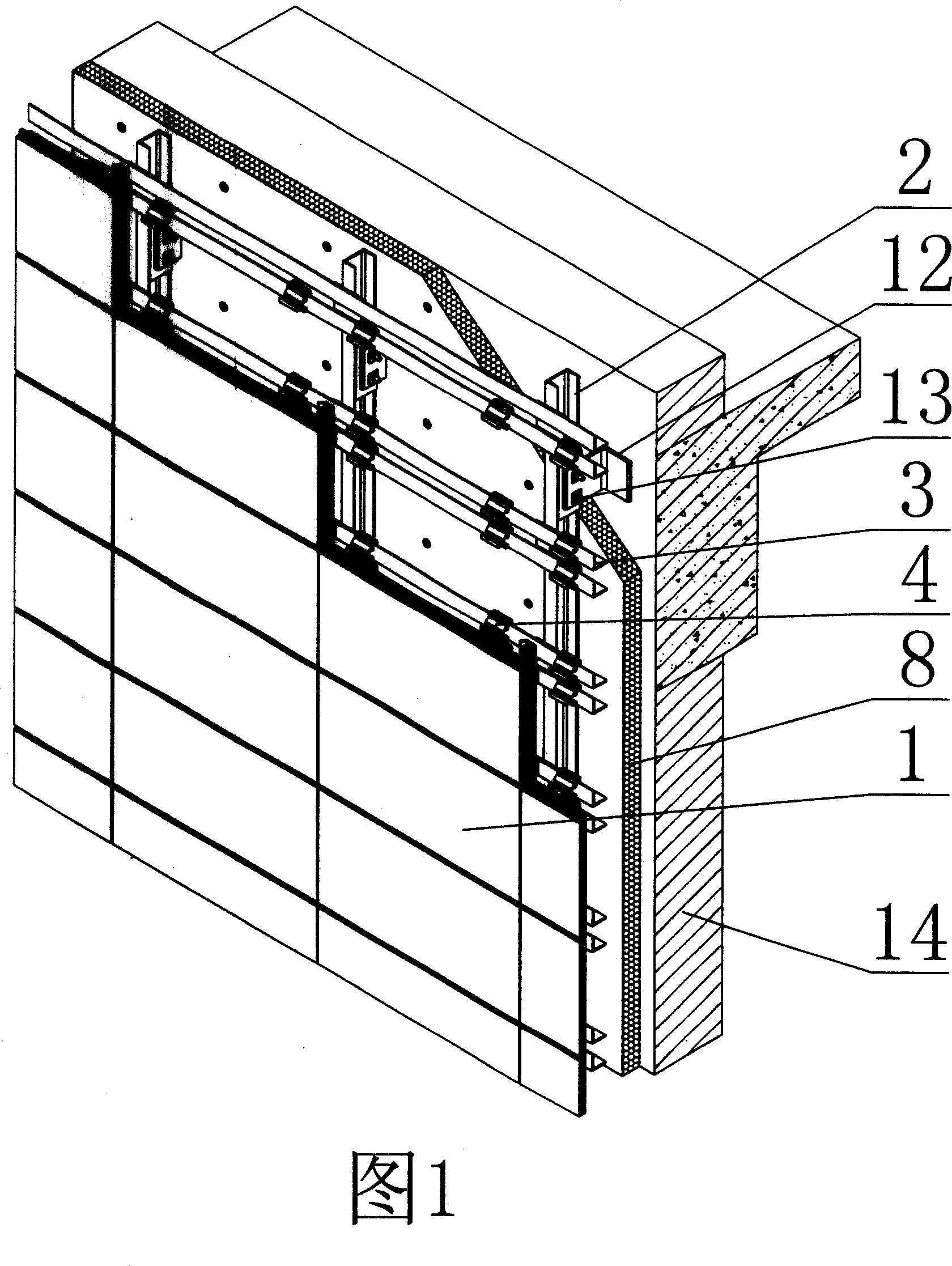

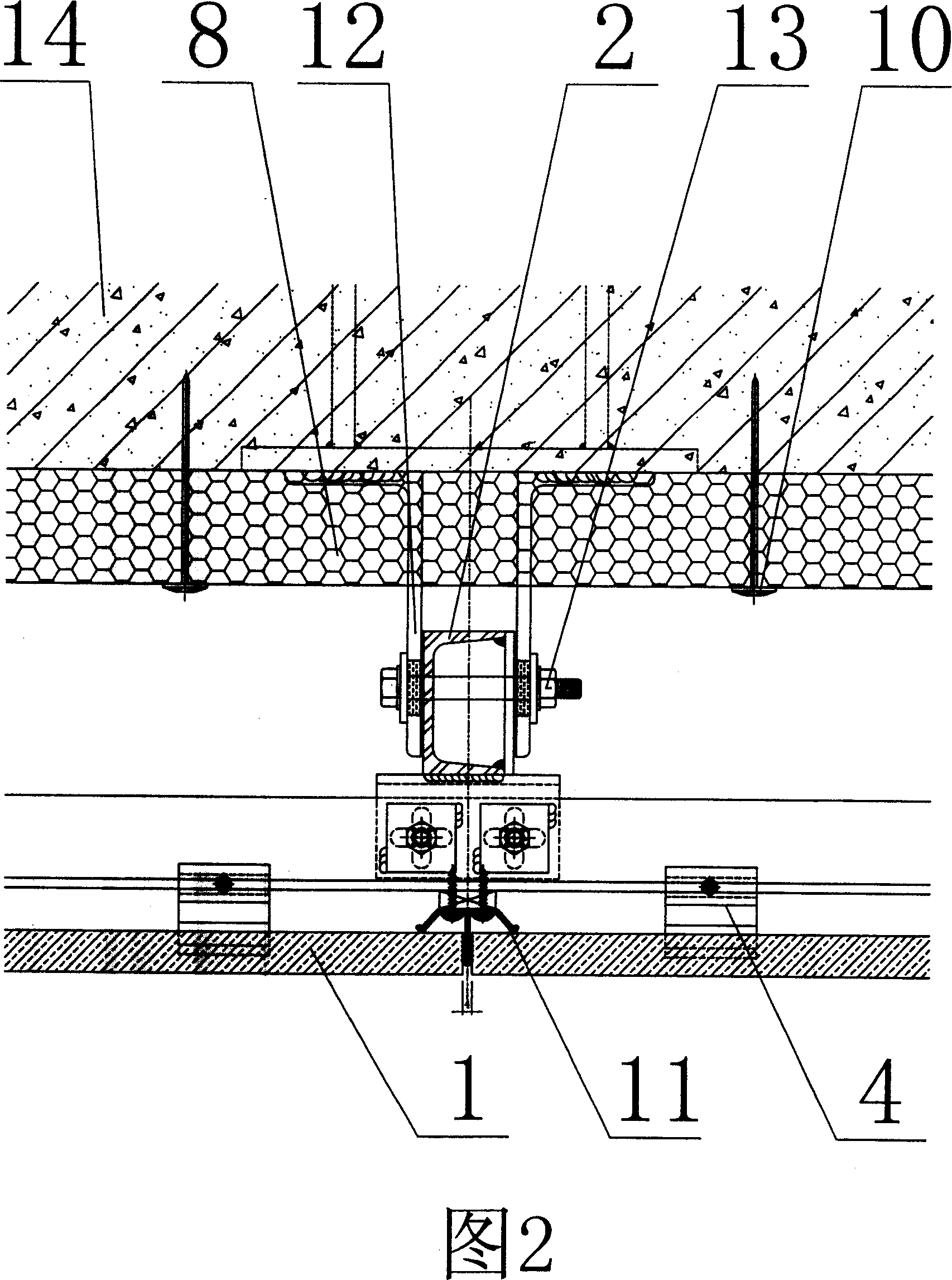

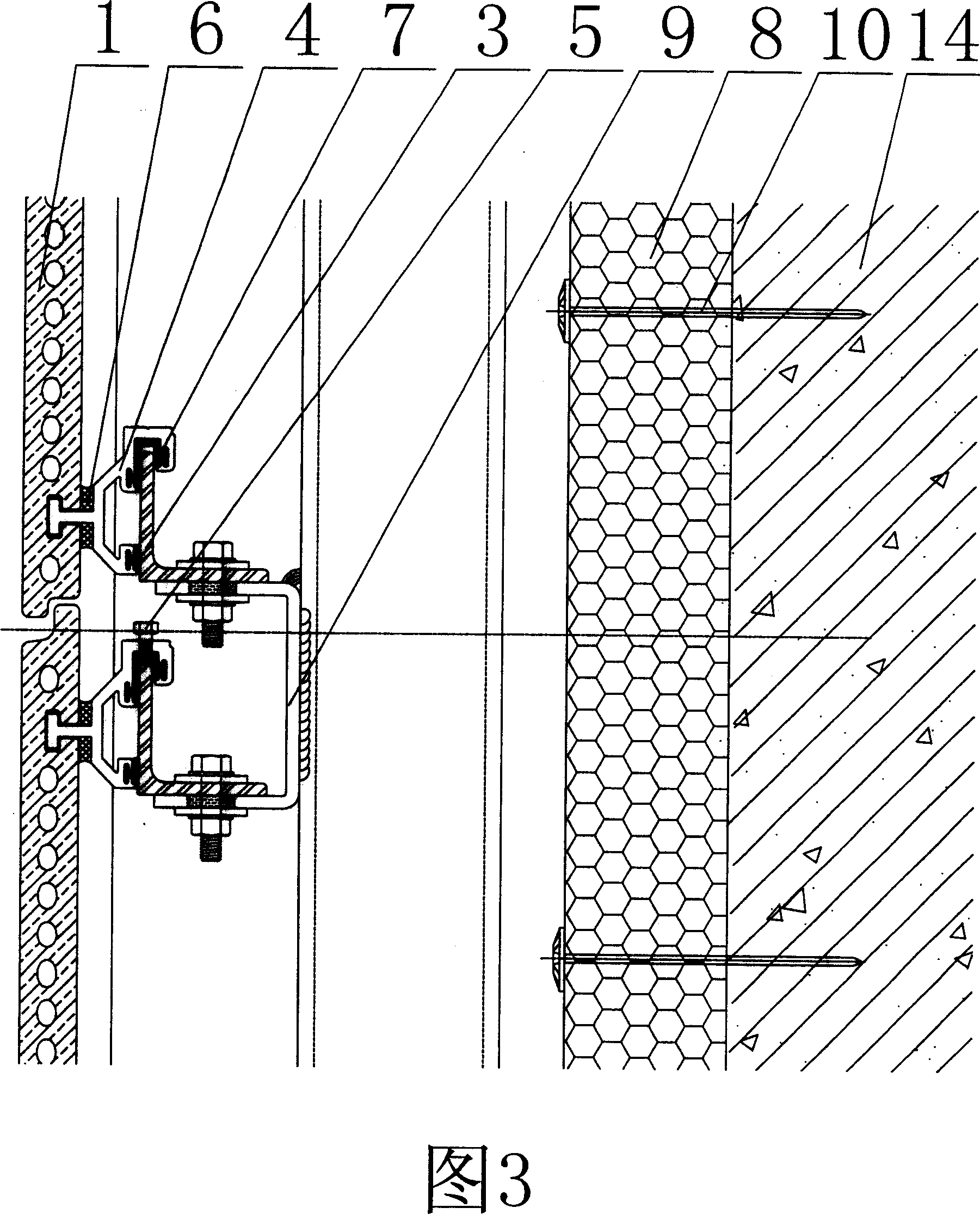

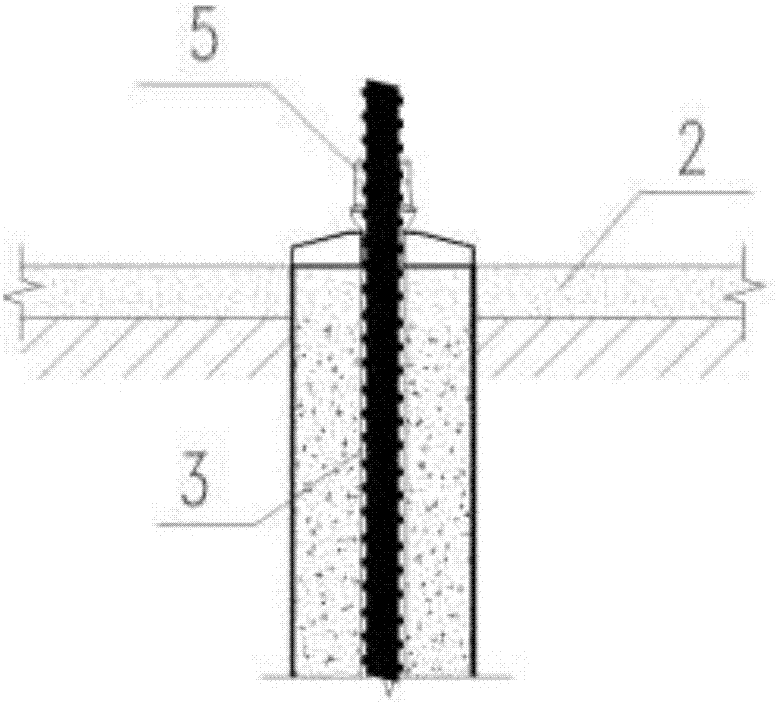

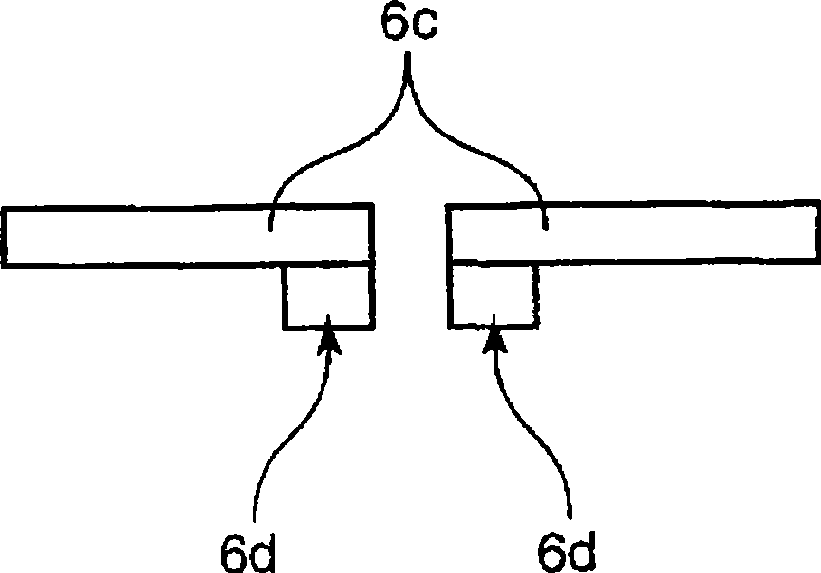

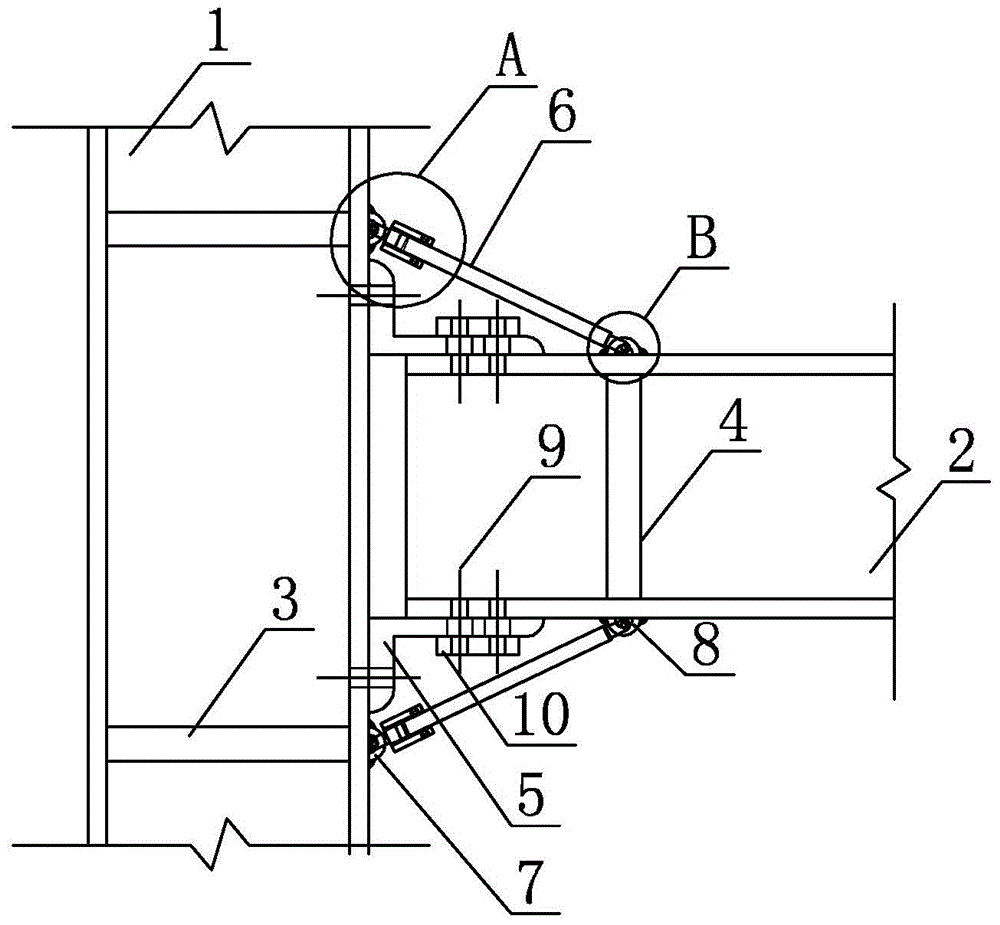

Mounting structure of figuline board curtain wall

The invention discloses an installing structure for the curtain wall of ceramic plate, comprising a vertical skeleton, a horizontal skeleton, a parting connector and a linking part. The vertical skeleton is set vertically and the horizontal skeleton is set horizontally. The vertical skeleton is fixed with the horizontal skeleton in cross. The vertical skeleton is fixed on the wall and the linking part is installed on the horizontal skeleton. The front end of linking part is ligule and the back end is pothook shape. The invention also comprises an adjusting screw and a rubber strip. The rubber strip is set between the linking part and the horizontal skeleton. The adjusting screw passes through the linking part and is connected on the horizontal skeleton by screw connection. The parting connector is installed at the connecting position of horizontal beam of ceramic plate. The invention changes the rigid connection between the horizontal skeleton and the linking part into the flexible connection so as to avoid the noise and eliminate the deformation. Up and down directions of installed ceramic plate are adjusted by the adjusting screw to guarantee that the installed seam is smooth completely. The horizontal skeleton is made of profiled bar. So the material is saved and the cost is decreased.

Owner:沈英 +1

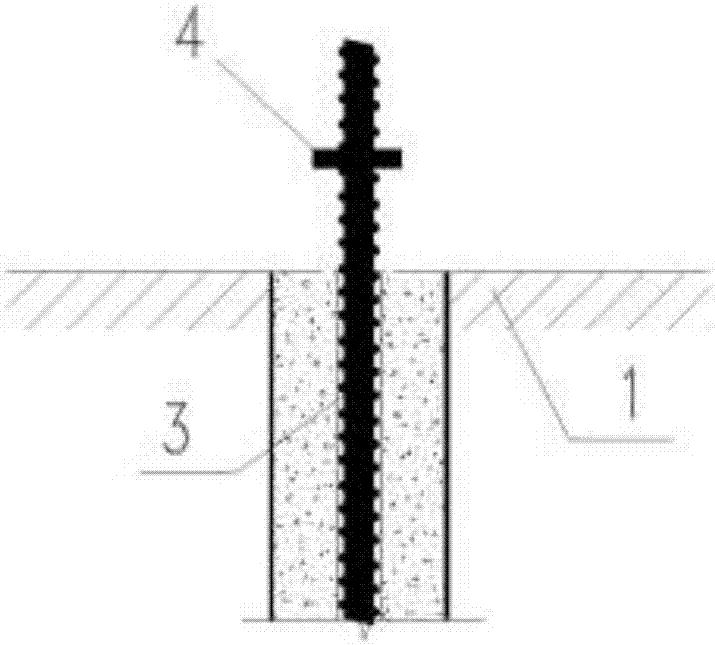

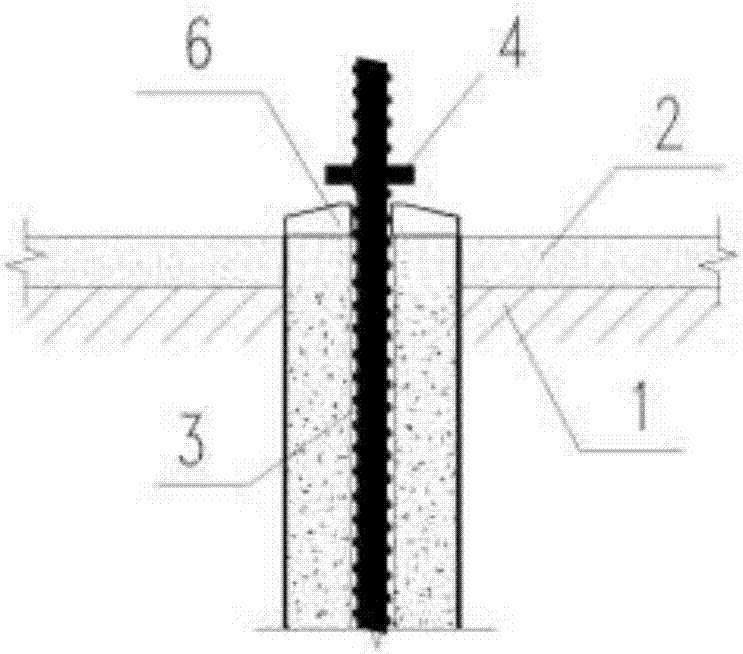

Construction method for overcoming deformation of anti-floating fixed diameter anchor head or expanded head anchor rod system

ActiveCN107044122AEliminate deformationSmall amount of deformationProtective foundationBulkheads/pilesPre stressRebar

The invention discloses a pressure bearing type fixed diameter anchor head or expanded head anchor rod prestress application method. Drilling is conducted to the design depth till rotary jet grouting or mechanical chambering construction can be developed, a pull rod of an anchor rod and a fixed diameter anchor head or an expanded head are placed, after the expanded head is arranged in place, the expanded head is expanded to the design size through an expanding mechanism, then, high-pressure grouting or concrete pouring is conducted, and pile forming is achieved in an expanded body section and a whole free section. Threaded steel bars to which prestress can be applied are adopted in the pull rod in the anchor rod, spiral stirrups and base bottom plate steel bars on a base are bundled, and collisions of the prestress steel bars are avoided in the bundling process. Lastly, a base concrete base bottom plate is poured by erecting a template.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

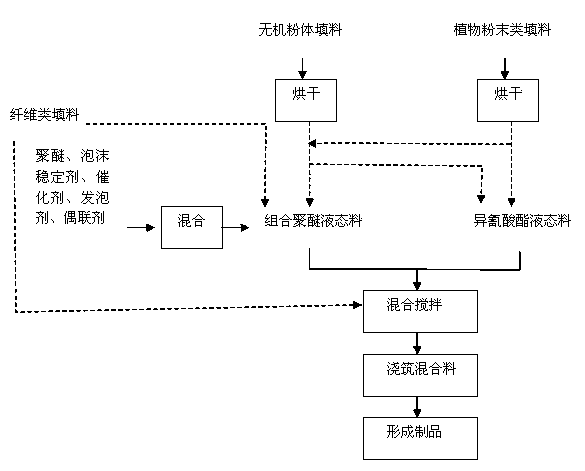

Rigid foamed plastic

The invention discloses a rigid foamed plastic which comprises a component A, a component B and filling materials, wherein the component A comprises polyether polyols, a foam stabilizer, a catalyst, a foaming agent and a cross-linking agent; the component B comprises isocyanate; the filling materials comprise inorganic powder filling materials, plant powder filling materials and fiber filling materials. By utilizing the characteristics of the reaction molding of rigid foams, the rigid foams are bonded with the inorganic powder filling materials, the plant powder filling materials and the fiber filling materials, so that the performance of the rigid foams is enhanced by the matching combination of three types of the filling materials. Thus, the synergistic effect for improving the performance of the rigid foamed plastic is exerted. Therefore, the rigid foamed plastic is high in strength and good in dimensional stability; the problems of expansion / shrinking and deformation of the rigid foamed plastic during a storage process are solved. As a result, the holding capacity of the rigid foamed plastic to insertion components such as nails, pins and the like is improved; the manufacturing cost is lowered.

Owner:昆山市柳鑫电子有限公司

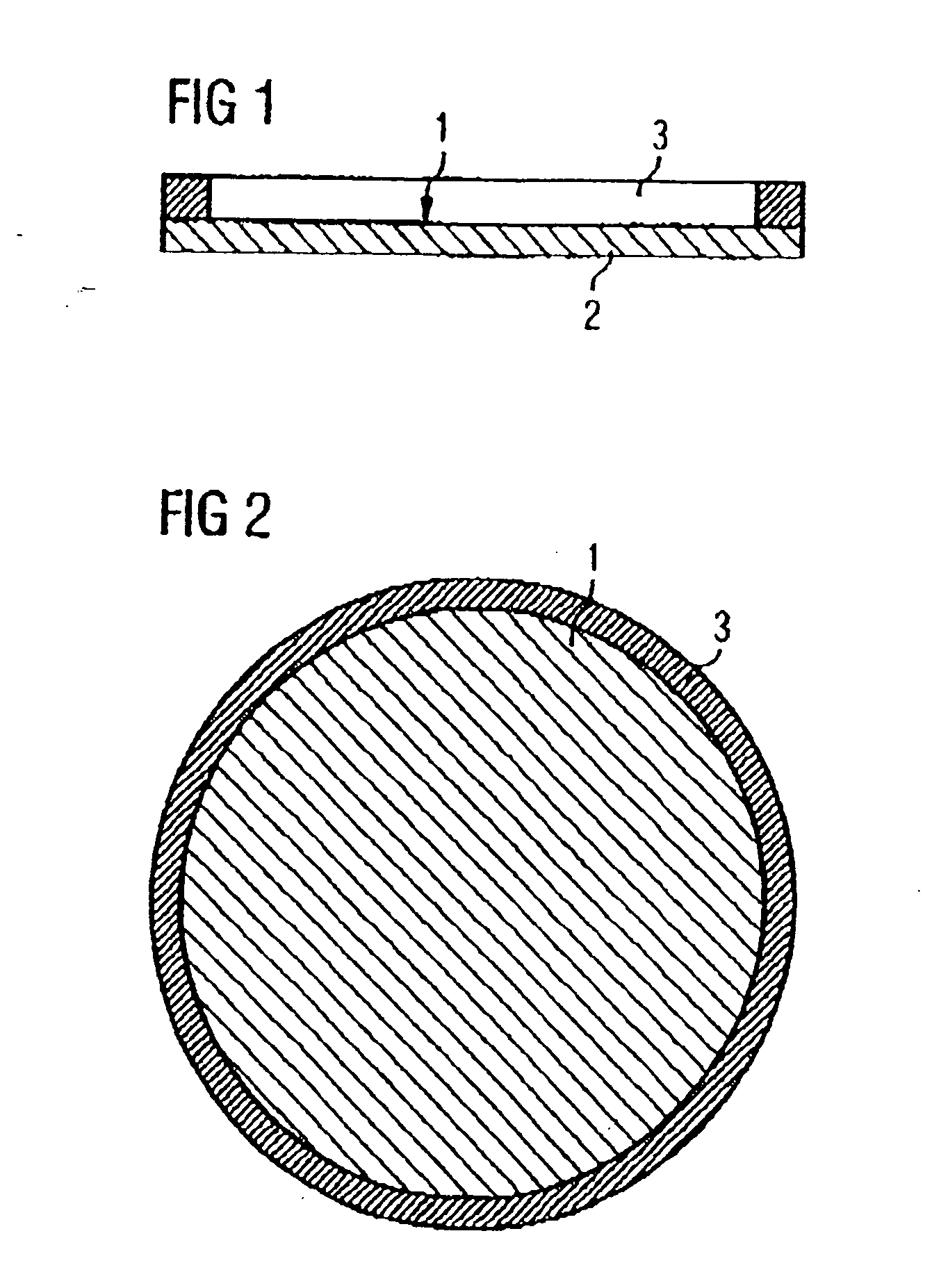

Wafer stabilization device and associated production method

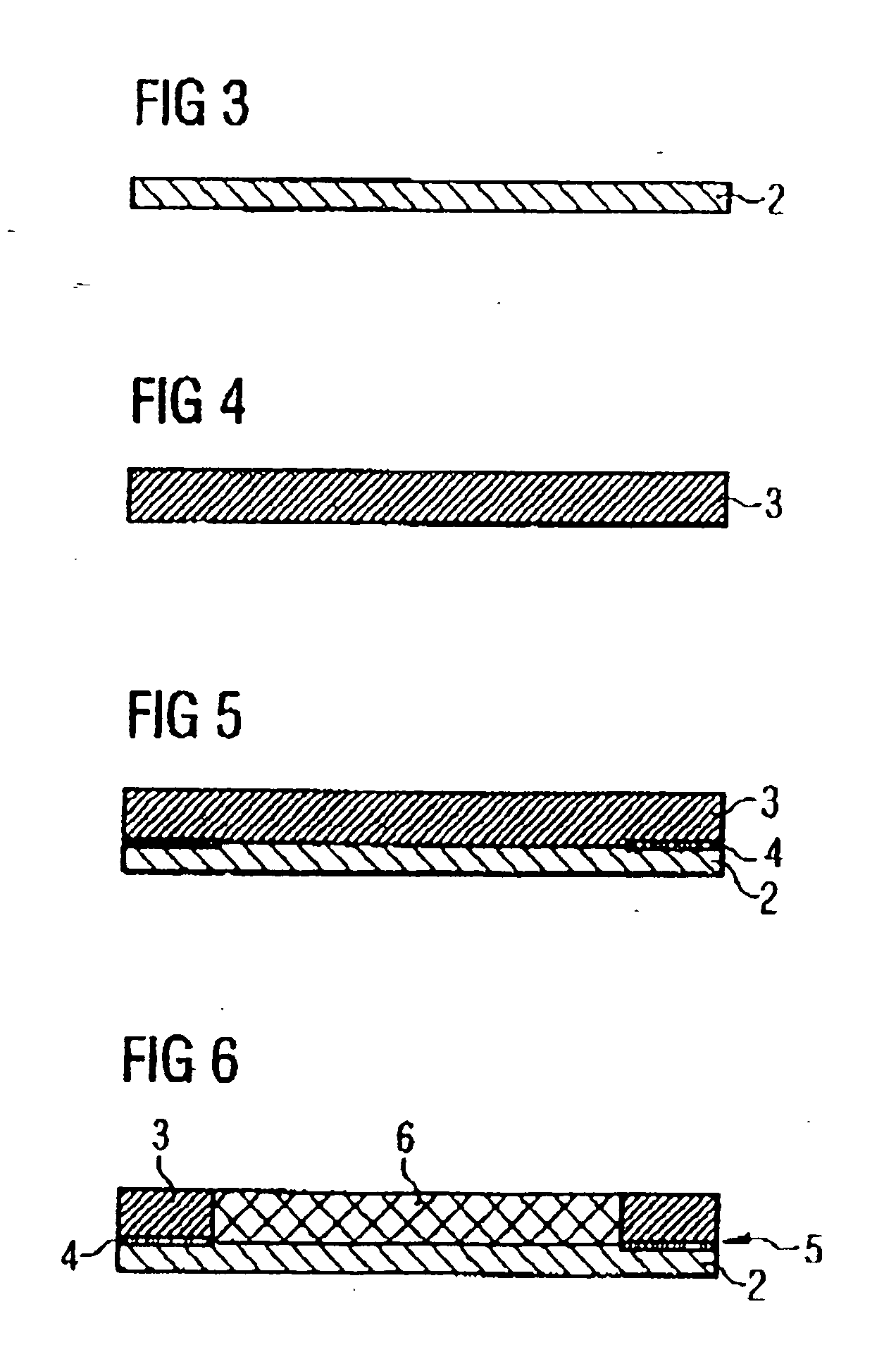

InactiveUS20050236693A1Eliminate deformationFunction can be ensuredSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsAdhesive

A stabilization device and method for stabilizing a workpiece such as a thin film wafer is presented. The thin wafer is fixed and oriented in planar fashion. The stabilization device is realized by a profiled ring which is arranged on the periphery of the wafer and is intimately connected thereto. The stabilization device and wafer are connected via negative pressure or by means of an adhesive having high thermal stability. The wafer and device are formed from similar semiconductor materials and have the same outline contour. The stabilization device remains on the wafer during process steps in the course of production and processing of the wafer.

Owner:INFINEON TECH AG

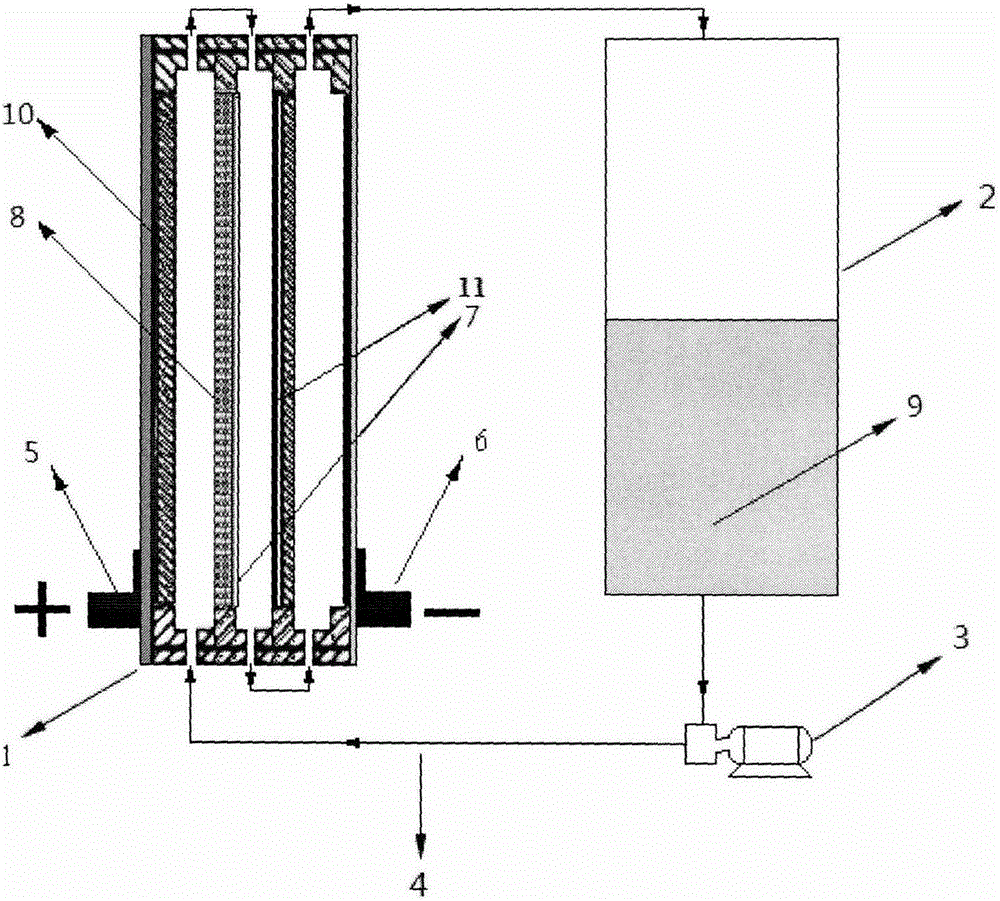

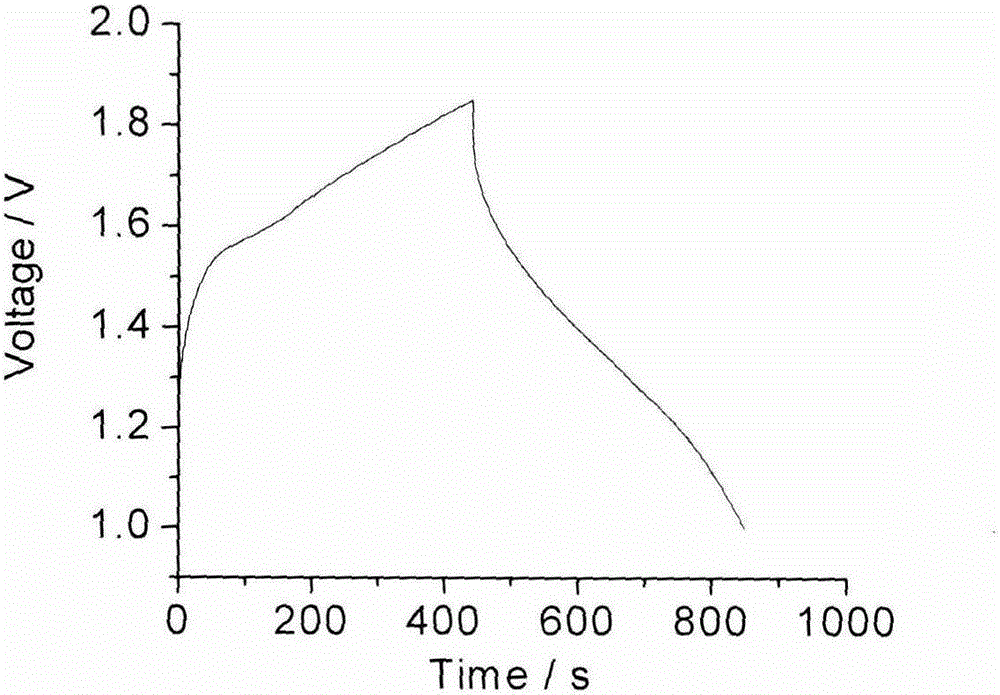

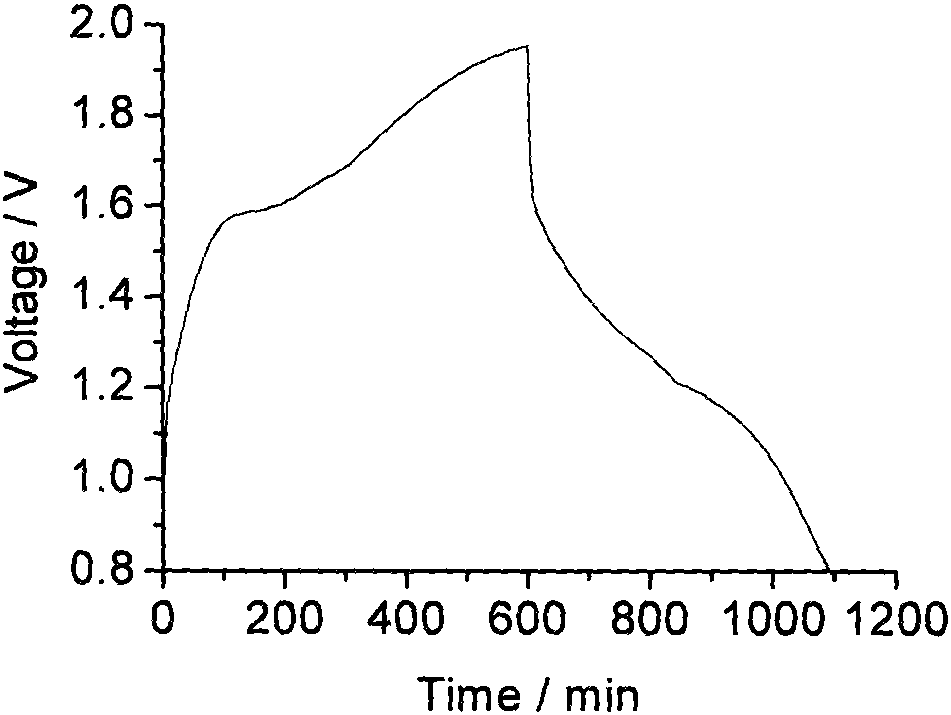

Water-based zinc-manganese single flow battery

ActiveCN105336971AIncrease the speed of mass transferEliminate deformationRegenerative fuel cellsWater basedManganese oxide

The invention relates to a water-based zinc-manganese single flow battery; a positive electrode active material is an oxide of manganese, a metal composite oxide, a metal oxide or a carbon material, a negative electrode is a zinc electrode, an electrolyte solution is a nearly neutral aqueous solution containing a zinc salt and a manganese salt, positive electrode active ions and negative electrode active ions can coexist in one electrolyte solution, and an ion exchange membrane is not required for separating the positive electrode and the negative electrode; in processes of charging and discharging, the electrolyte solution constantly flows between an electrolyte solution storage tank and an electric pile through a pipeline under pushing of a liquid pump. During charging, zinc ions are deposited onto a negative electrode current collector from the electrolyte solution, the zinc ions and manganese ions are co-embedded into the positive electrode active substance at the same time, and the manganese ions are subjected to oxidation deposition; during discharging, the negative electrode deposited zinc is dissolved into the electrolyte solution, and the positive electrode manganese oxide is partially reduced and dissolved and is extricated to the electrolyte solution with the zinc ions simultaneously. The battery has the outstanding characteristics of simple manufacture, relatively high specific energy and specific power, low cost, long cycle life, environmental friendly and the like, and is widely applied in electric power, transportation, electronics and other fields.

Owner:NO 63971 TROOPS PLA

Polyurethane with shape memory property, composition containing it and shape memory fabric prepared therefrom

ActiveCN1648143AImprove mechanical propertiesHigh transparencyFibre treatmentNon-woven fabricsCross-linkPolymer science

The said polyurethane is prepared through preparing polymer with diisocyanate, hydroxyl-containing oligomer, chain expander with active hydrogen radical and chain expander with carboxylic radical, neutralizer with alkali radical, blocking agent, cross-linking agent and optional catalyst in certain proportion; and subsequent reaction in water to obtain polymer. The polyurethane features the blocking diisocyanate radical and hydroxyl radical and thus shape converting temperature of -30 deg.c to 100 deg.c. In temperature higher than the shape converting temperature, the polyurethane may have its shape converted; in temperature lower than the shape converting temperature, the polyurethane is unchanged in shape; and the polyurethane heated to the temperature higher than the shape converting temperature will restore original shape.

Owner:THE HONG KONG POLYTECHNIC UNIV

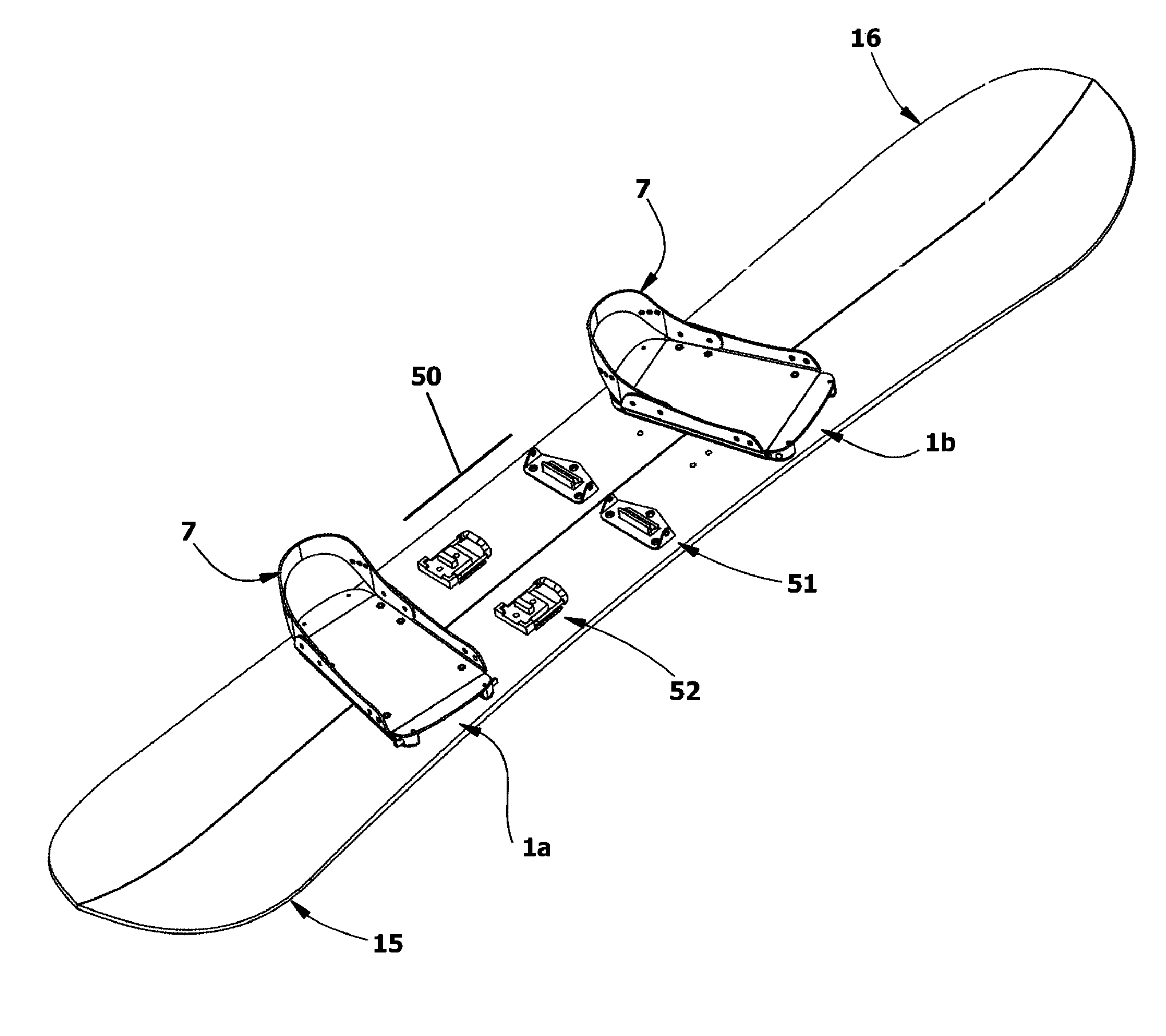

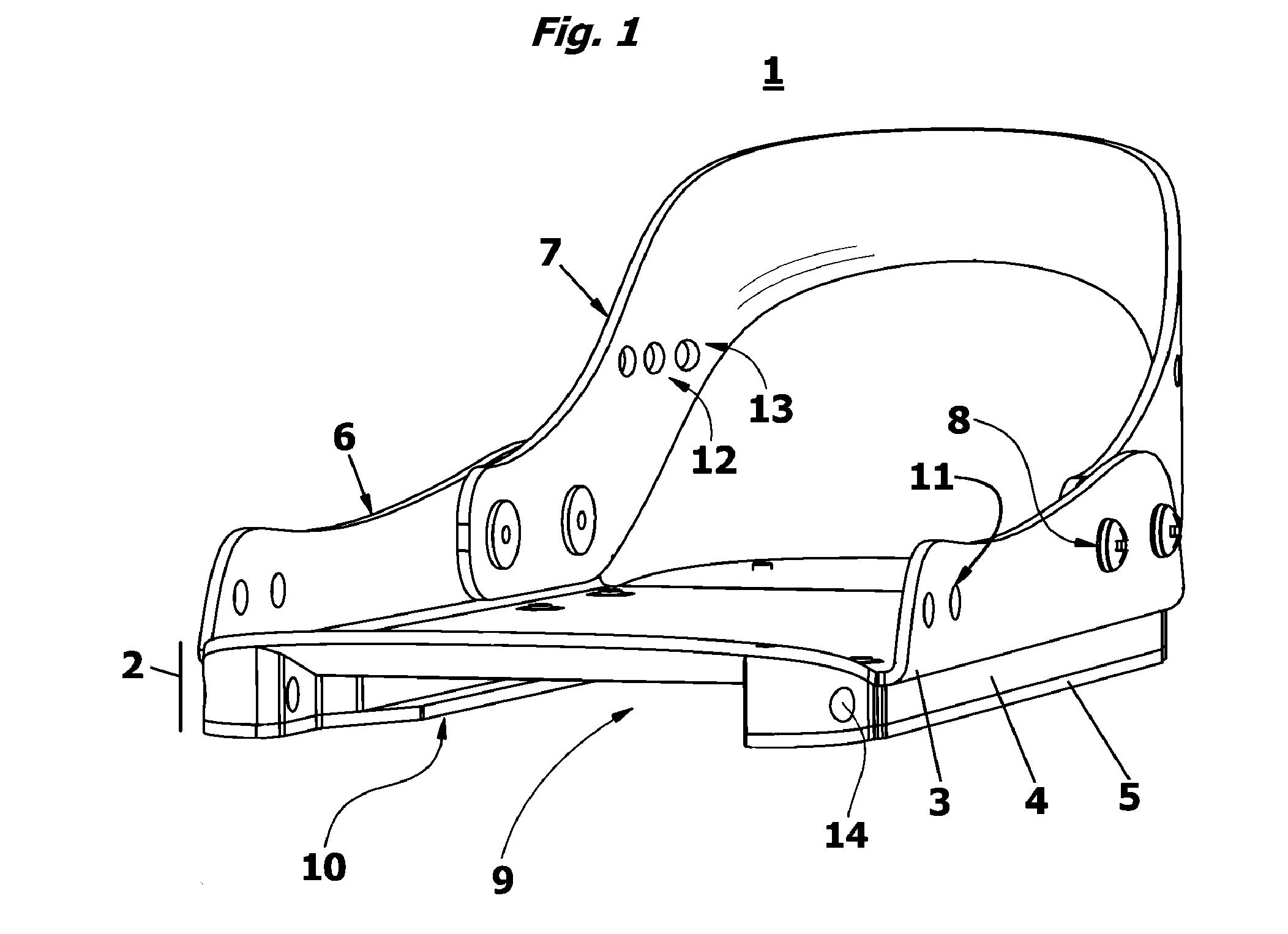

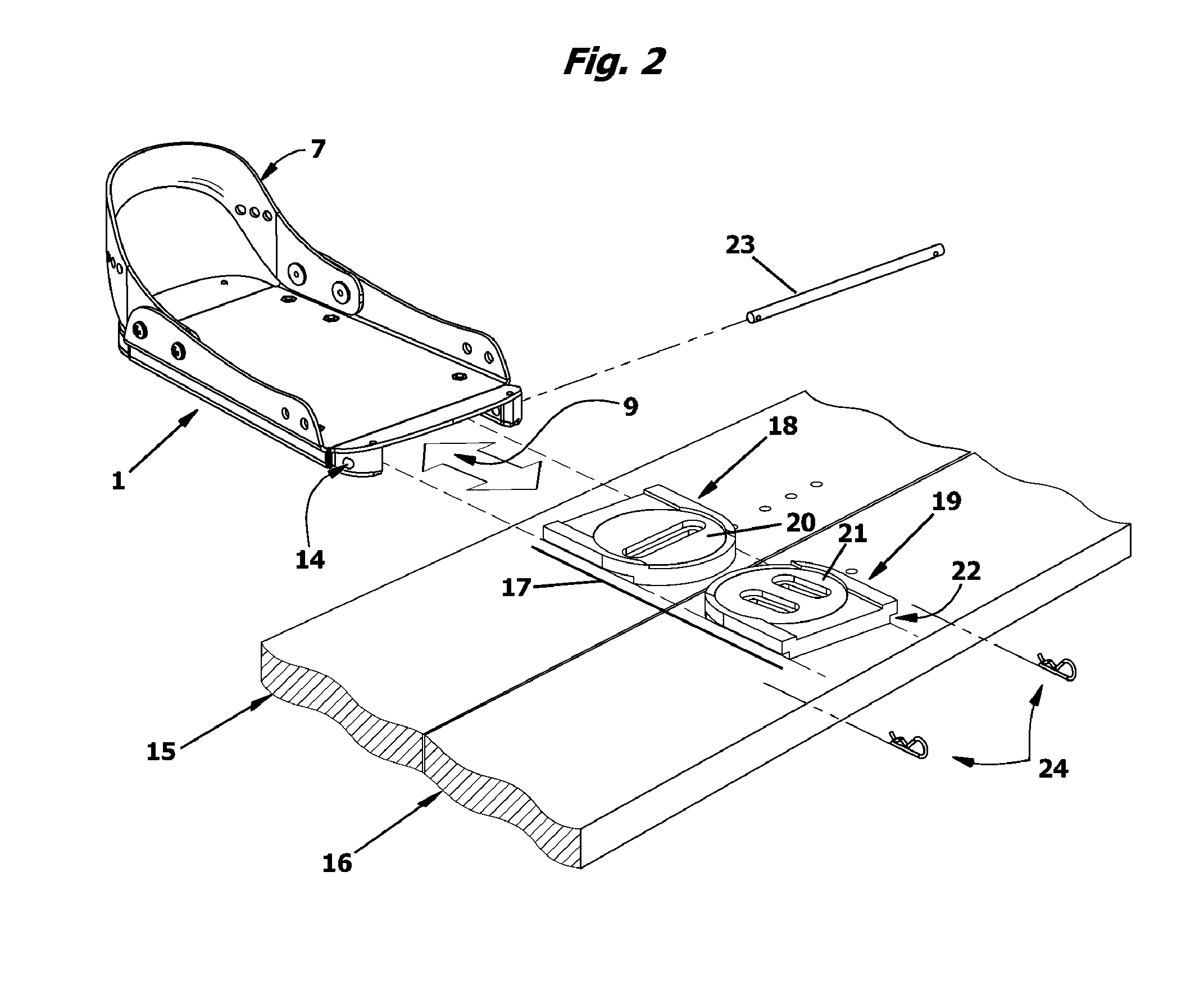

Splitboard Bindings

ActiveUS20120256395A1Easy to repositionImprove performanceSki bindingsSnowboard bindingsClassical mechanicsEngineering

Splitboard boot bindings for backcountry splitboarding. Each of a pair of soft-boot bindings is provided with an integral boot binding lower that conjoins the two halves of a splitboard without the additional weight or height of an adaptor mounting plate, upper binding baseplate or “tray”, and extra fasteners of the prior art. The boot binding lower is formed as a box girder and provides improved torsional stiffness for splitboard riding. When subjected to a torque applied by the rider, the bottom mediolateral edges of the box girders are configured to contactingly engage the top face of the splitboard, thereby dynamically coupling the rider's boot sole and the board via a single rigid structure. In a preferred embodiment, the web or “spacer” members of the box girder are characterized by an aspect ratio or contour height that is varied from heel to toe.

Owner:SPARK R&D IP HLDG LLC

High-strength aluminum alloy slab and manufacturing method thereof

The invention relates to a high-strength aluminum alloy slab and a manufacturing method thereof. The alloy mainly comprises the following components: less than 0.35% of Si, less than 0.45% of Fe, 1.25-1.95% of Cu, less than 0.30% of Mn, 2.25-2.85% of Mg, 0.19-0.27% of Cr, 5.2-6.0% of Zn, less than 0.2% of Ti, less than 0.04% of Zr and the balance of Al and unavoidable elements. The manufacturing method of the high-strength aluminum alloy slab is free of a rolling process and comprises the following flows: proportioning raw materials, smelting, casting a flat ingot, carrying out two-stage soaking, sawing the head and bottom of the flat ingot, carrying out fixed-length sawing and width-fixed sawing, sawing upper and lower surfaces of the flat ingot, sawing the flat ingot into the aluminum plate according to requirements, carrying out solid solution quenching, stretching and flattening and carrying out aging treatment. By the manufacturing method, the production process flows can be shortened, such problems of the slab manufactured by a hot rolling method as uneven microstructure and performance, poor flatness and uneven thickness are solved, the yield is increased, the cost of the product is decreased and the economic benefits are increased.

Owner:广西南南铝加工有限公司

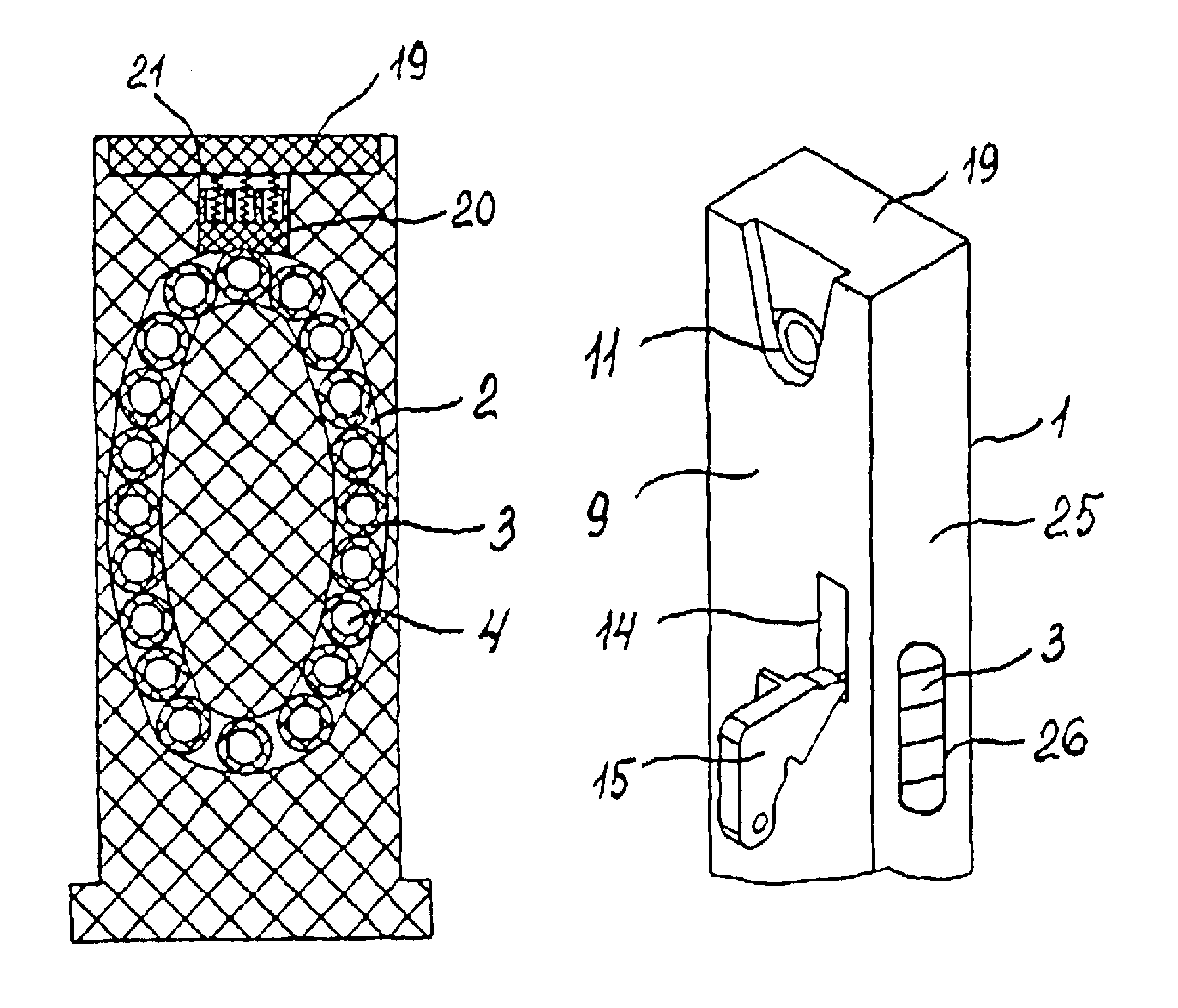

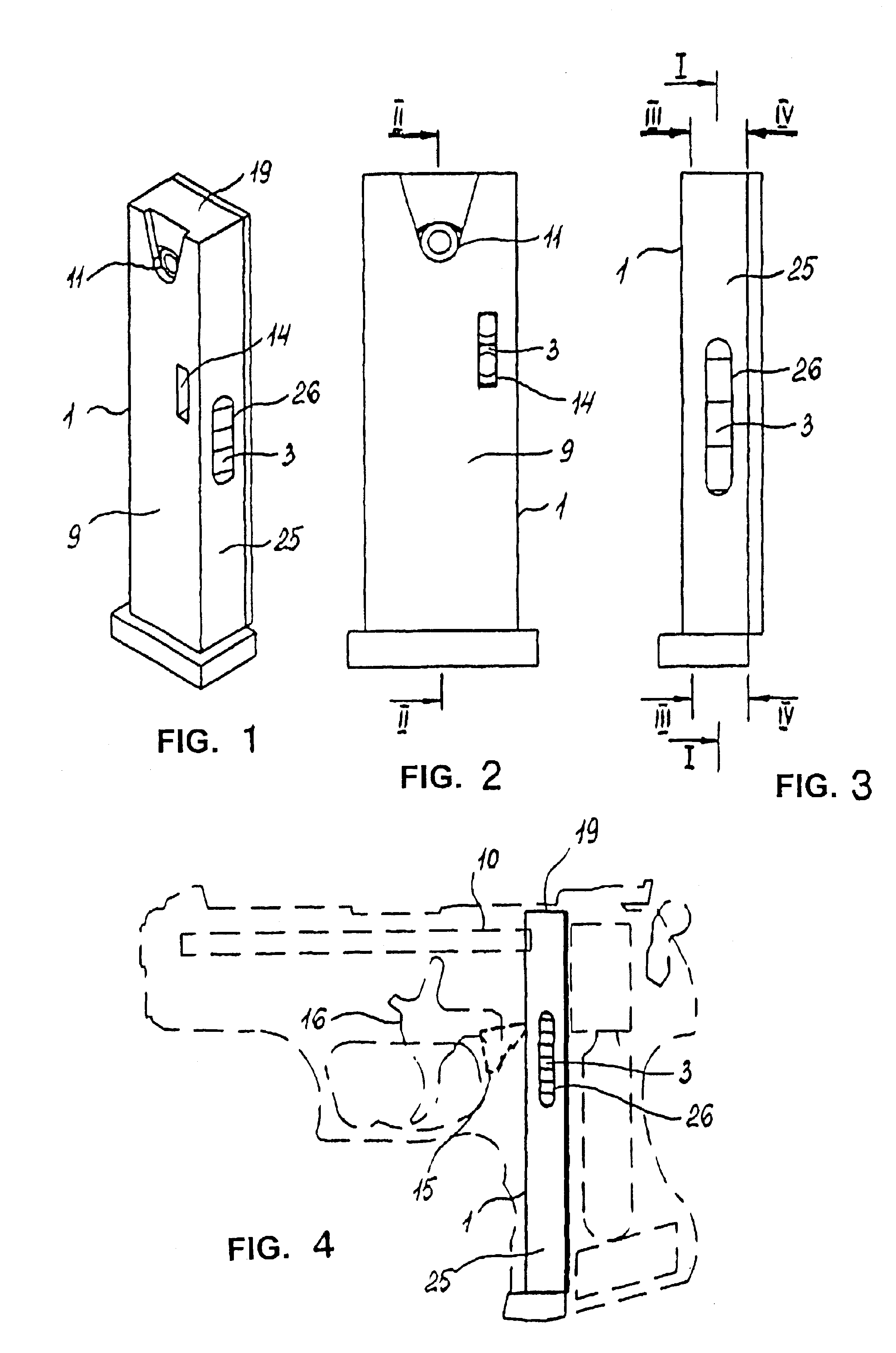

Magazine for bullet pneumatic arms and case for said bullet magazine of a pneumatic arm

InactiveUS6736125B2Easy to manufactureGood serviceAmmunition loadingCompressed gas gunsEngineeringMechanical engineering

A magazine for a bullet-shooting pneumatic firearm comprises a casing 1. Inside the casing 1 a closed passage 2 is provided, equipped with containers 3 with bullets 5. The magazine has a bullet opening 11 in a wall 9 of the casing 1, through which the bullet 5 during the shot, under the action of a portion of gas, gets from the container 3 into a bullet passage 12 of a barrel 10 of the firearm. The opening 11 is disposed coaxially with the bullet passage 12 of the barrel 10 of the firearm and with a through opening 4 of the container 3 occupying such position before each shot. In the wall 9 of the casing 1 above the closed passage 2 above the through opening 4 of the containers 3 a port 14 is provided for receiving an external arm 15 of a striker-and-trigger mechanism 16, under the action of which the containers 3 move along the closed passage 2, each container 3 being positioned sequentially to the shooting line. In a side wall 25 of the body 1 a longitudinal opening 26 is provided for the containers to be moved with the shooter's finger when the containers are loaded with bullets 5. 14 claims, 17 illustrations.

Owner:ZAKRYTOE AKTSIONERNOE OBSHCHESTVO GRP ANICS

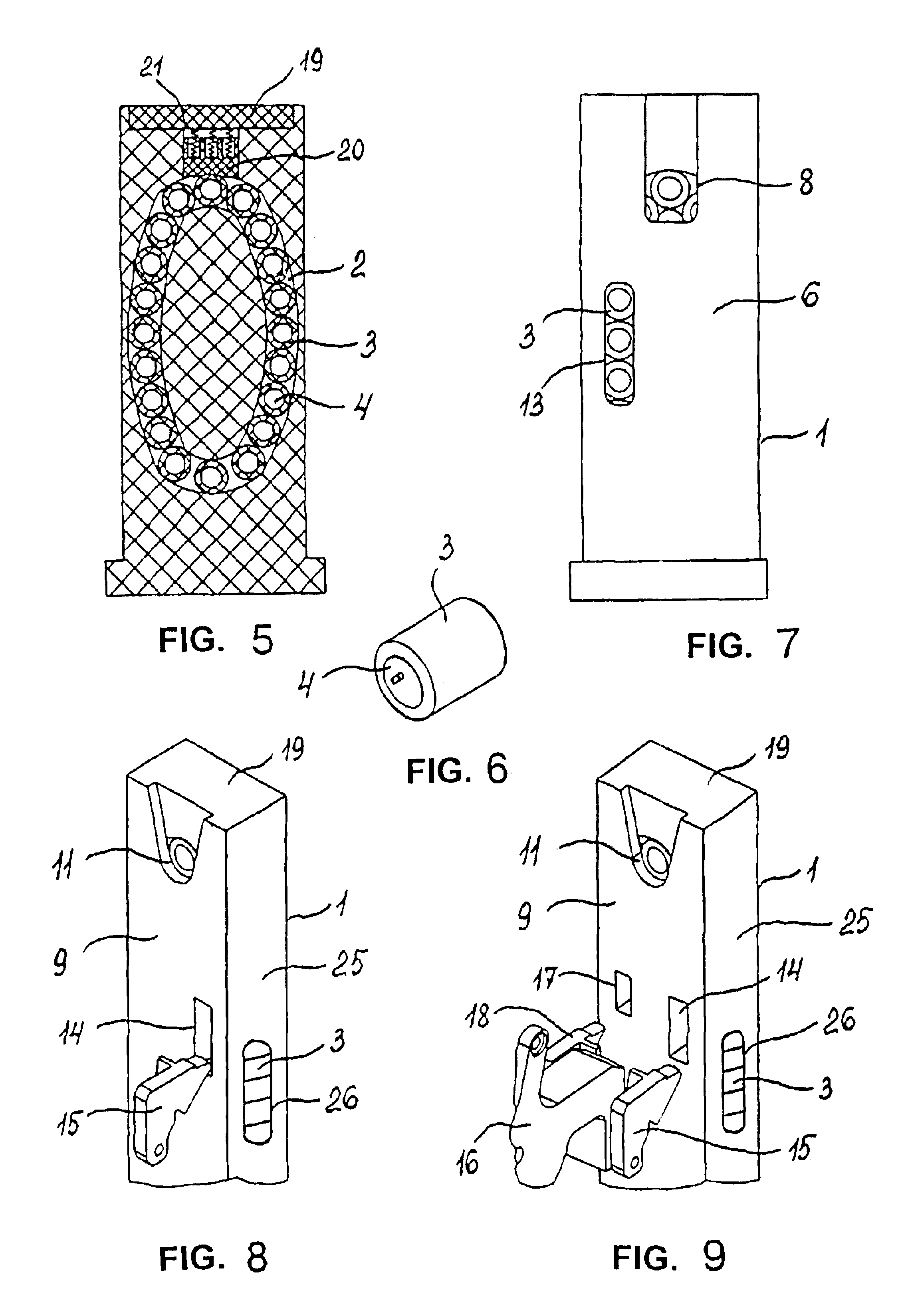

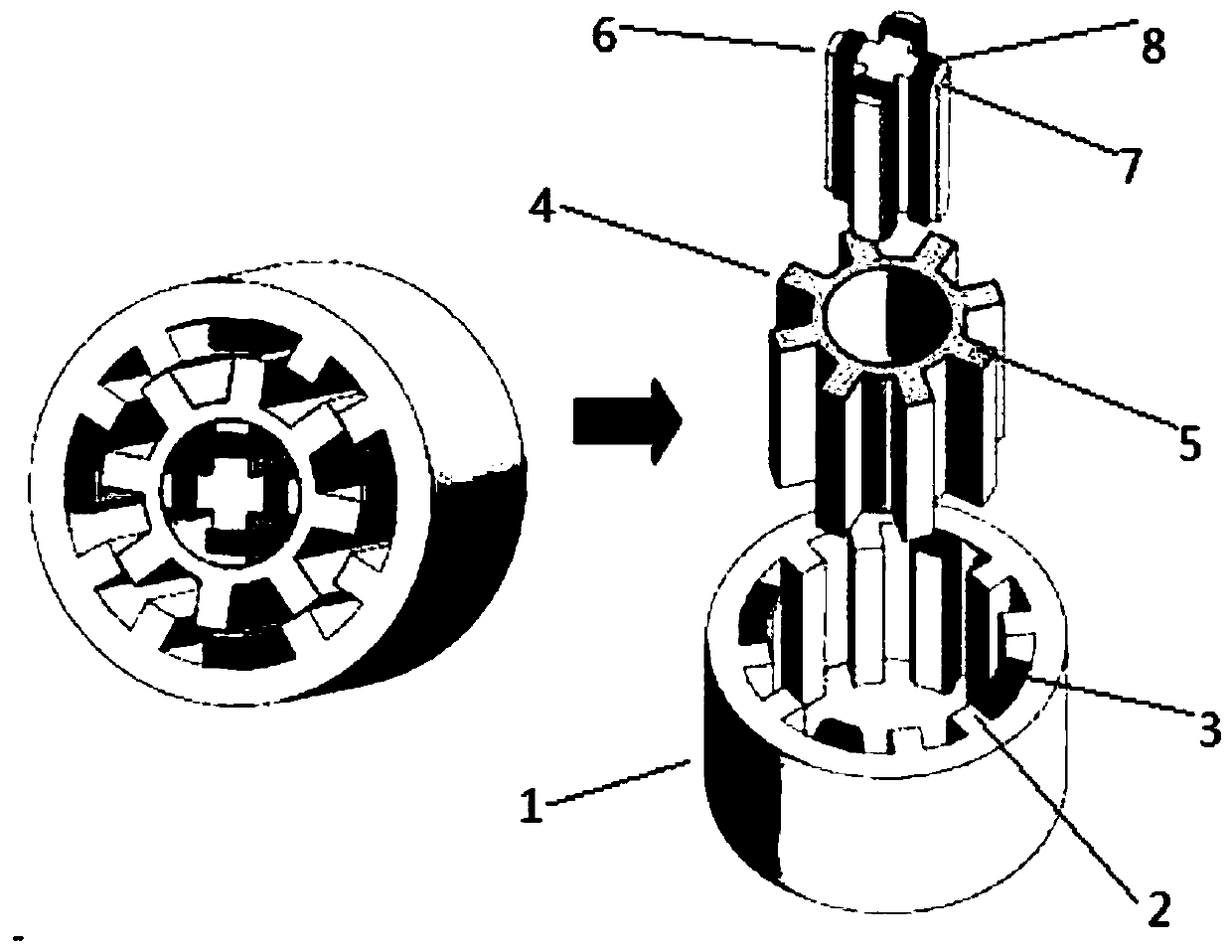

Magnetic suspension switch magnetic resistance flywheel motor and control method

InactiveCN104184286AIncrease radial load capacitySolve the problem of nonlinear strong couplingSingle motor speed/torque controlDynamo-electric machinesControl theoryConductor Coil

The invention discloses a magnetic suspension switch magnetic resistance flywheel motor and a control method. The magnetic suspension switch magnetic resistance flywheel motor comprises an inner stator, a rotor and an outer stator. The inner stator (6), the rotor (4) and the outer stator (1) are successively nested in a concentric mode, 12 torque poles (2) are arranged on the inner wall of the outer stator (1) at equal intervals, and the torque poles are wound by main windings (3); eight rotor salient poles (5) are arranged on the outer wall of the rotor (4) at equal intervals; and four suspension poles (7) are arranged on the outer wall of the inner stator (6) at equal intervals, and the suspension poles (7) are wound by suspension force windings (8). According to the invention, the problem of incapability of effectively generating suspension forces when a stator and a rotor are not aligned by use of a conventional magnetic suspension switch magnetic resistance motor is overcome, the radial force and the torque decoupling effect are good, the radial load capability is improved, the suspension force windings are individually controlled simply according to a needed radial suspension force, each main winding on the outer stator is also controlled simply according to needed electromagnetic torque, the control is easy, and a control algorithm is simpler and is more easily realized.

Owner:NANJING INST OF TECH

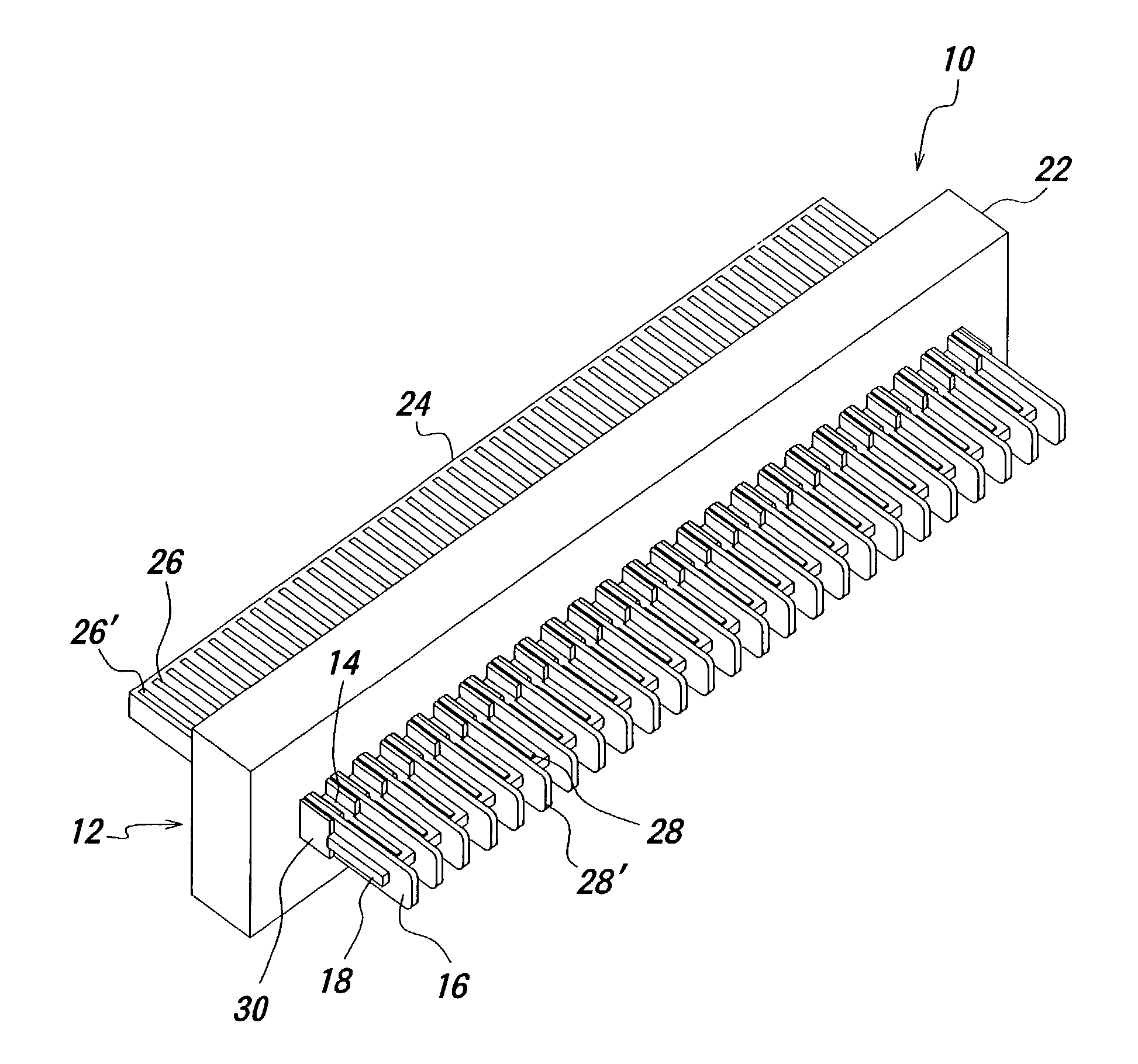

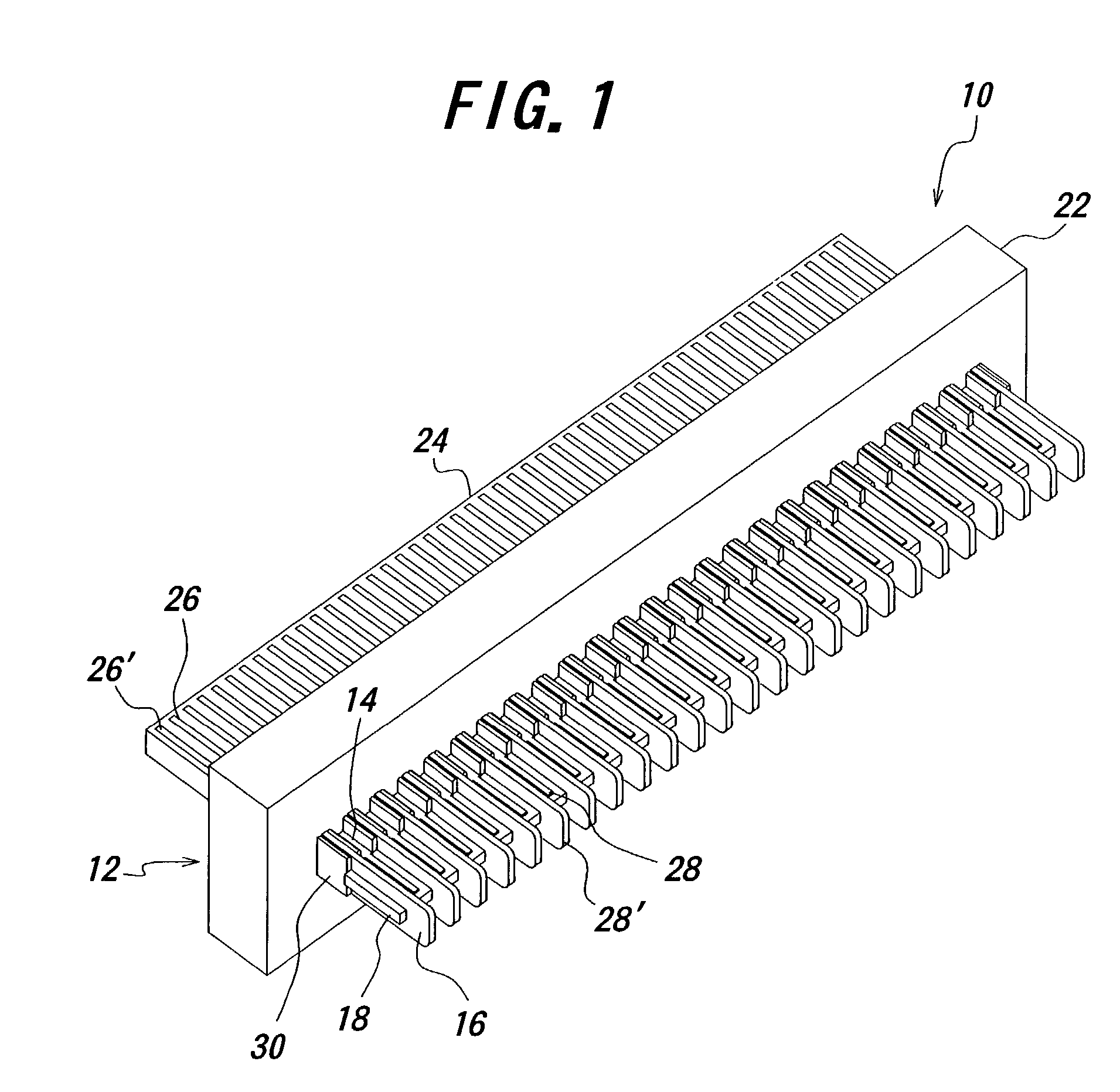

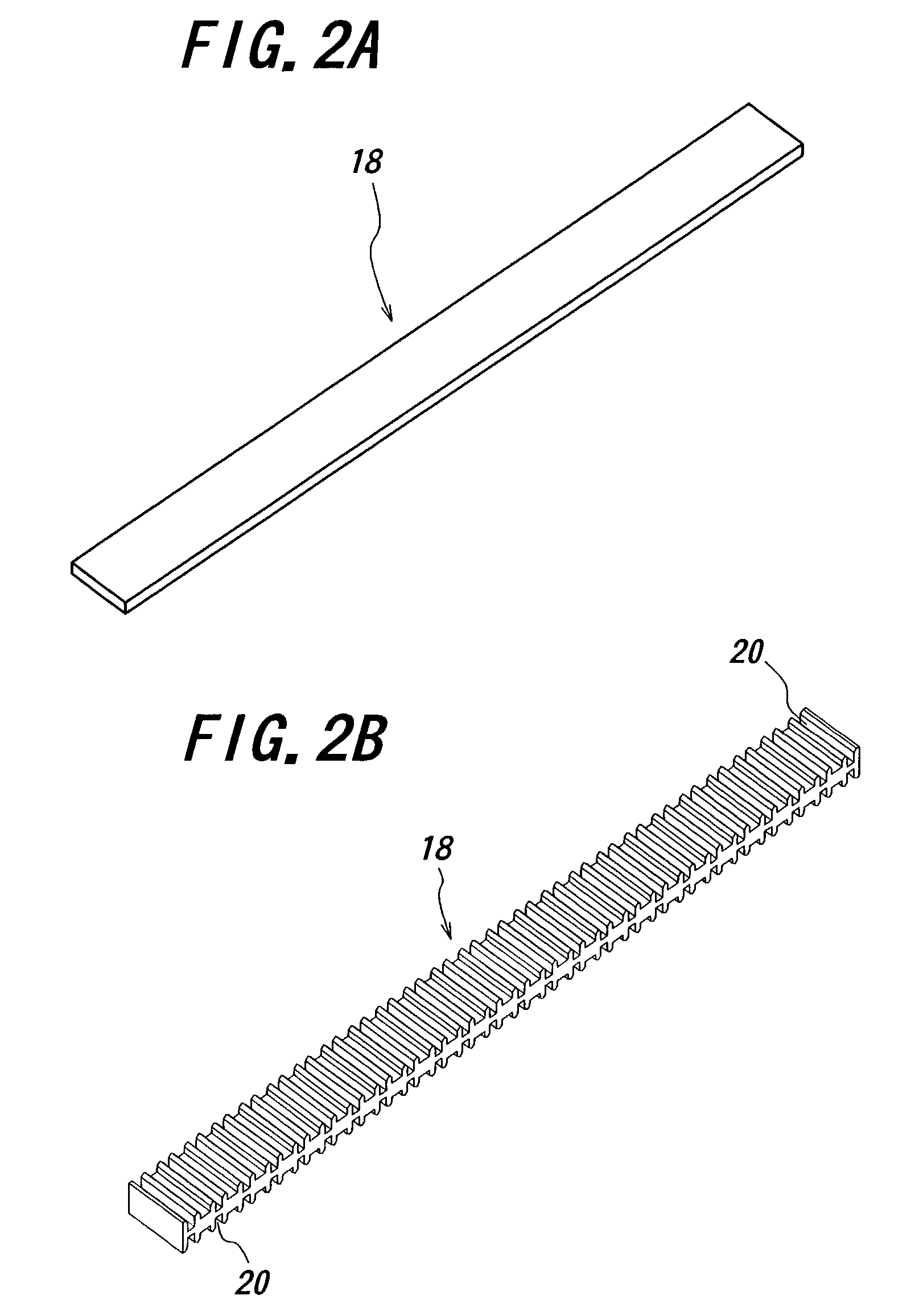

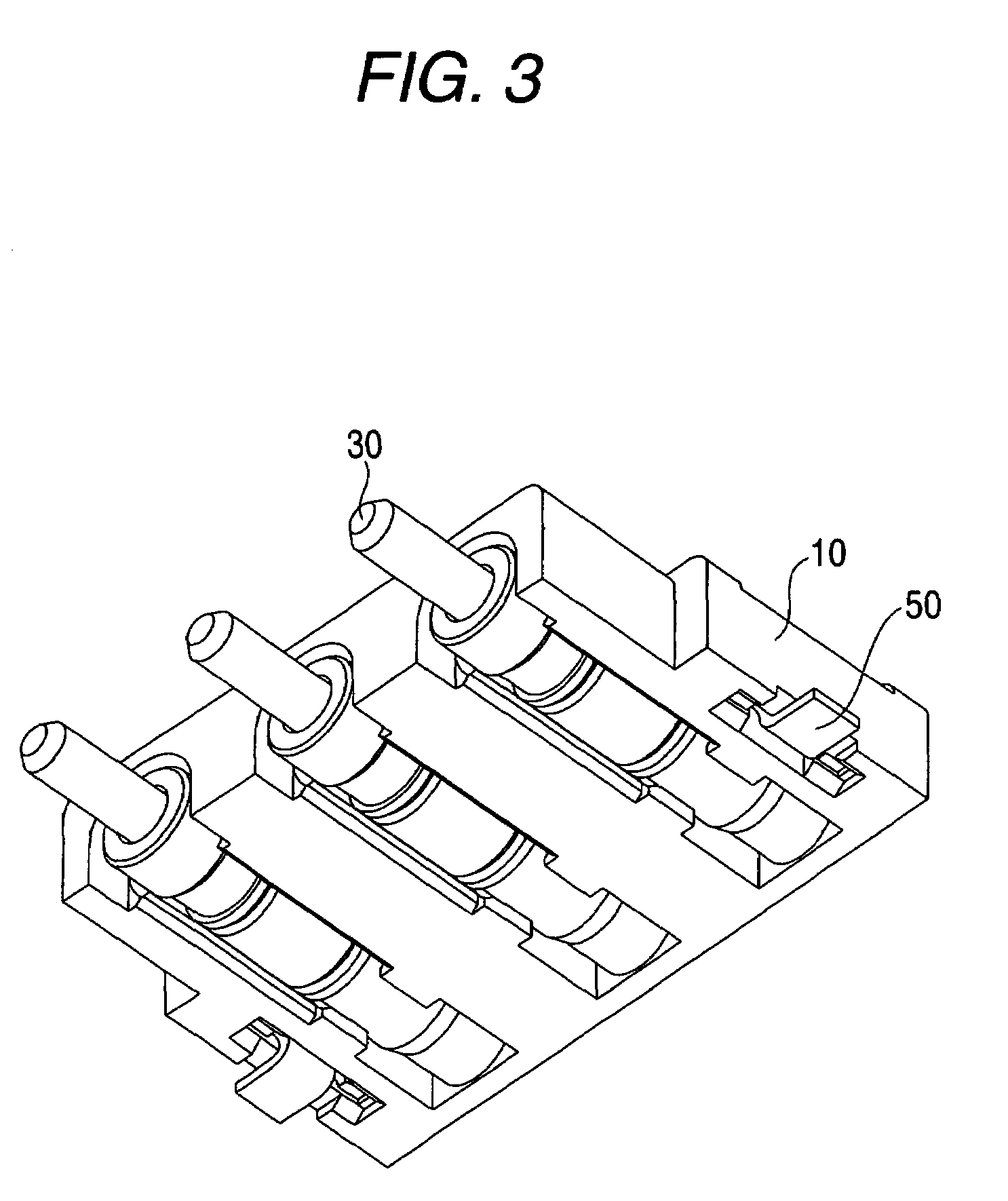

Connector

InactiveUS7021970B2Avoiding connectionAvoiding insulationLine/current collector detailsElectric discharge tubesElectrical conductorSoldering

A connector includes a block and a required number of contacts held and fixed in the block. A plate-shaped piece made of a heat resistant and electrically insulating material is fixed to the block on that side of the contacts to which conductors are connected. The plate-shaped piece is preferably formed with grooves with a predetermined interval on that surface of the piece on which the contacts are arranged. With this construction, it is possible to provide an improved connector which is able to prevent the block from being deformed due to heating in soldering and welding when connecting conductors, and is free from any defective connection and failed insulation without raising the manufacturing and operating cost.

Owner:DDK LTD

Stripping device of polarizer sheet

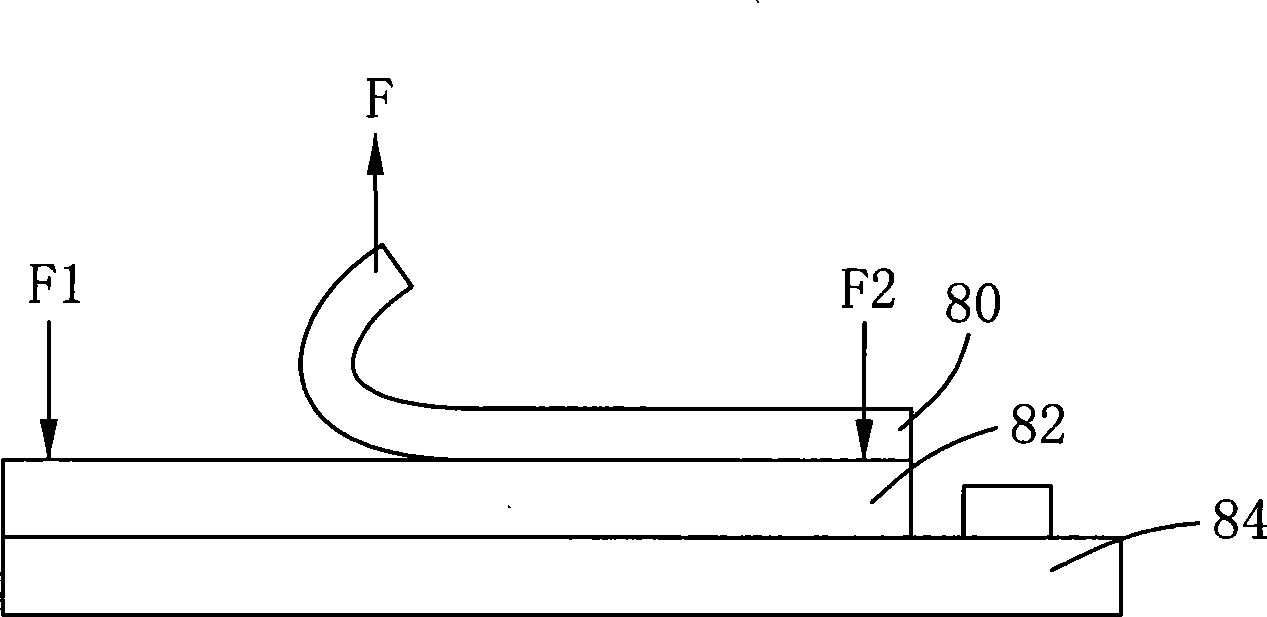

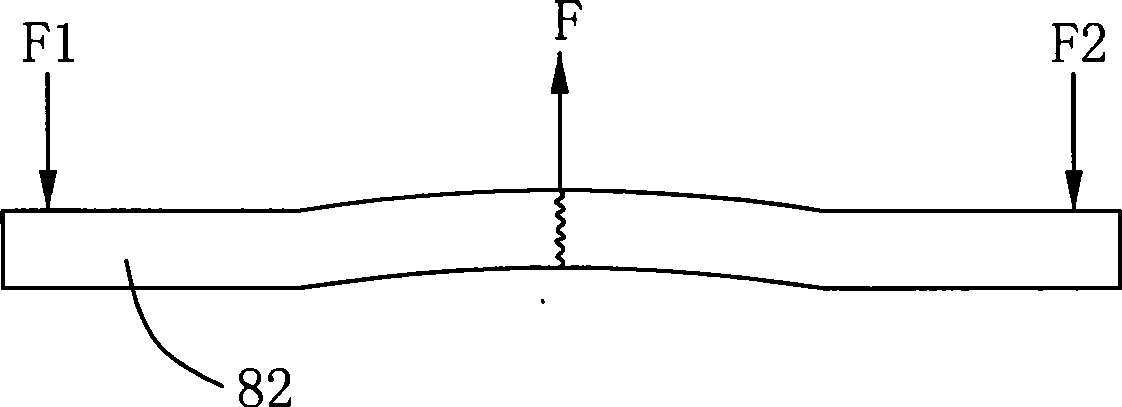

InactiveCN101386223AEliminate deformationAvoid breakingLamination ancillary operationsStatic indicating devicesPolarizerEngineering

The invention discloses a removing device of a polaroid, which comprises a vacuum cup, a locating board and a control mechanism. The vacuum cup is used for bearing a substrate stuck with the polaroid. The vacuum cup includes a plurality of adsorption holes and at least one evacuation hole; the adsorption holes are used for sucking the lower surface of the substrate; the evacuation hole is communicated with the adsorption holes. The locating board is arranged on the vacuum cup and includes a first locating side and a second locating side; the two neighboring side walls of the substrate respectively lean against the first locating side and the second locating side. The control mechanism is connected to the evacuation hole of the vacuum cup and is used for controlling the vacuum opening or vacuum closing of the vacuum cup. When the polaroid is removed, a balancing force applied on the lower surface of the substrate can balance removing force applied on the upper surface of the substrate, thereby being capable of removing the deformation of the substrate and preventing the substrate from cracking.

Owner:AU OPTRONICS (SUZHOU) CORP LTD +1

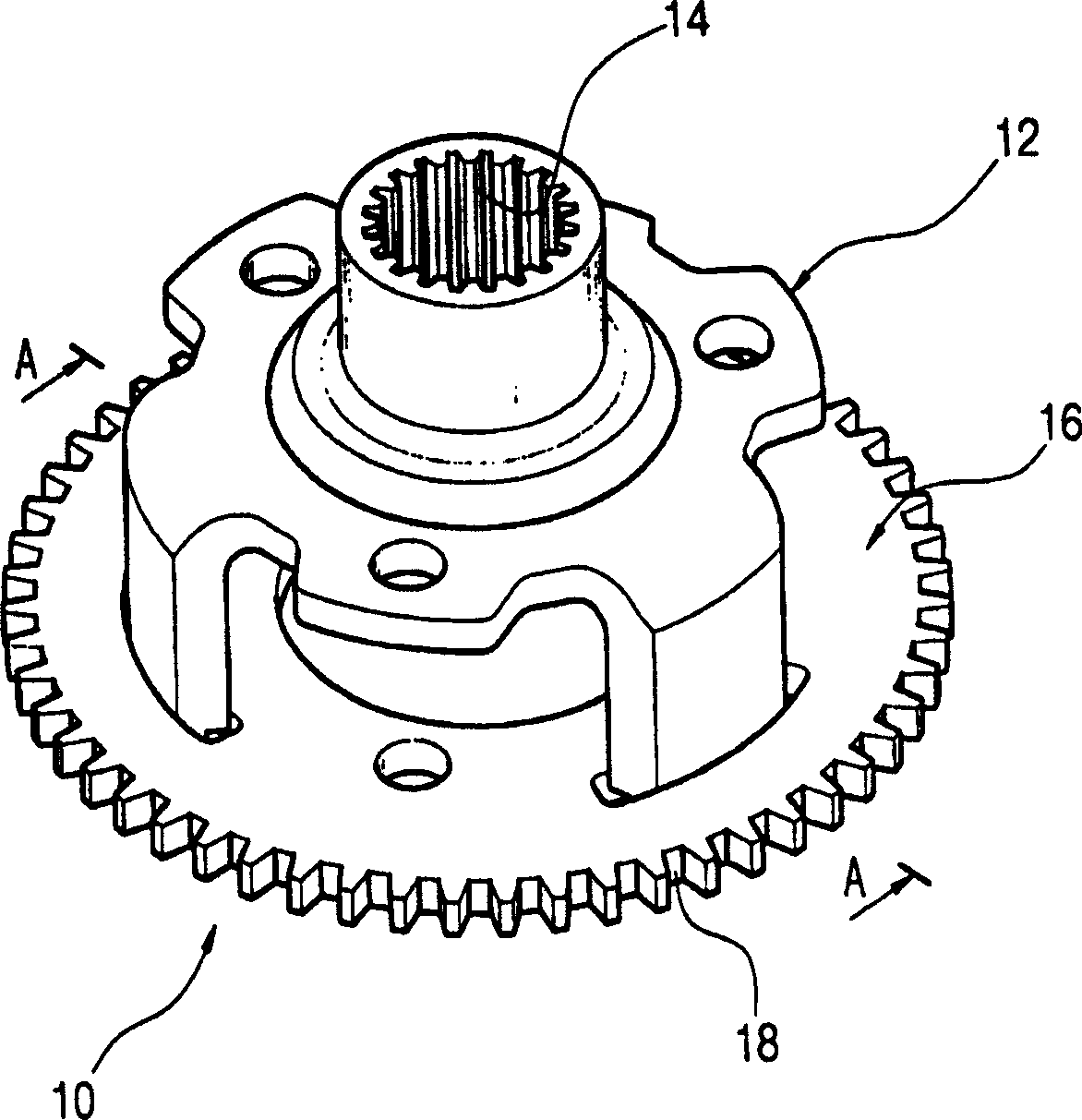

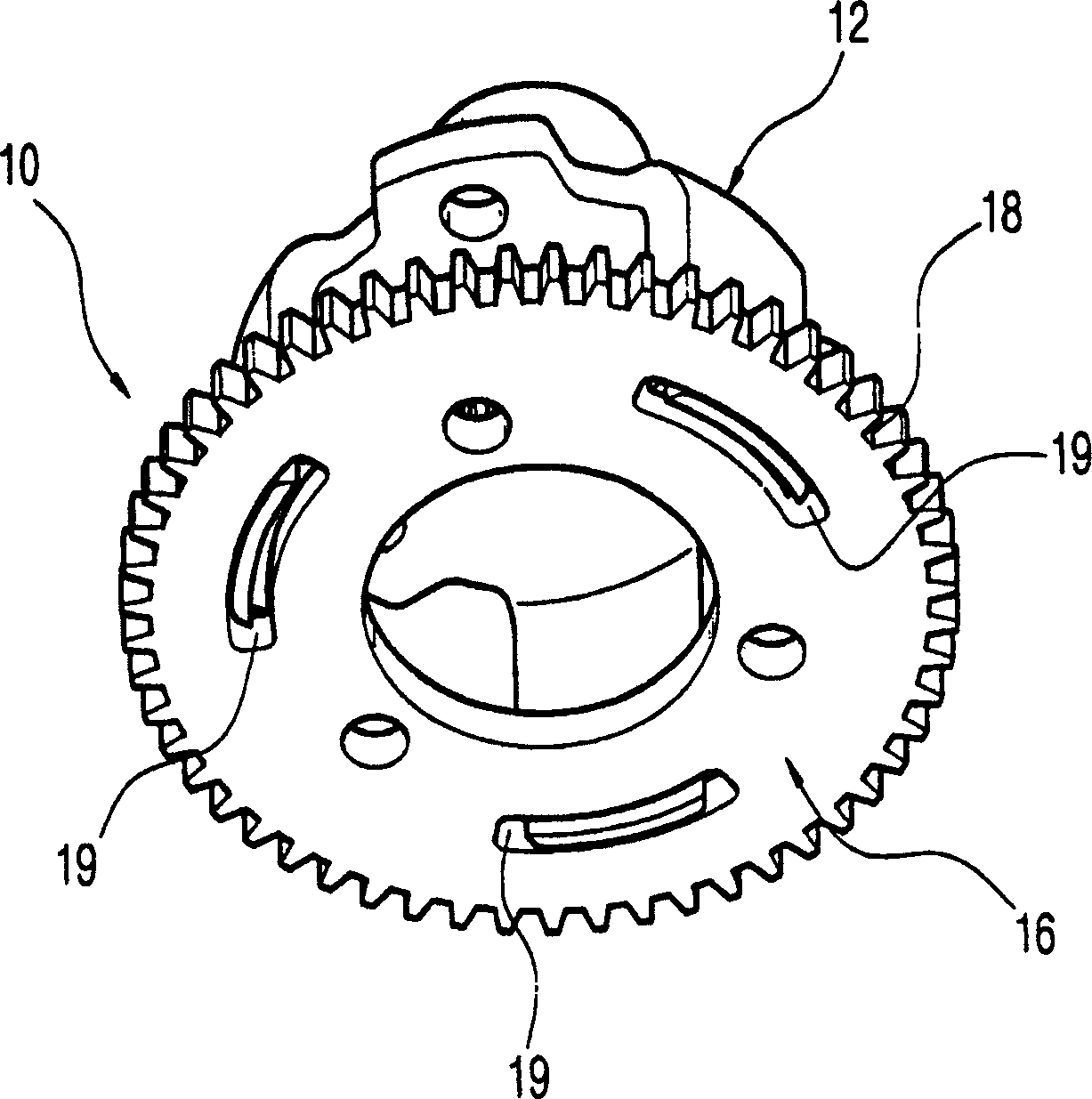

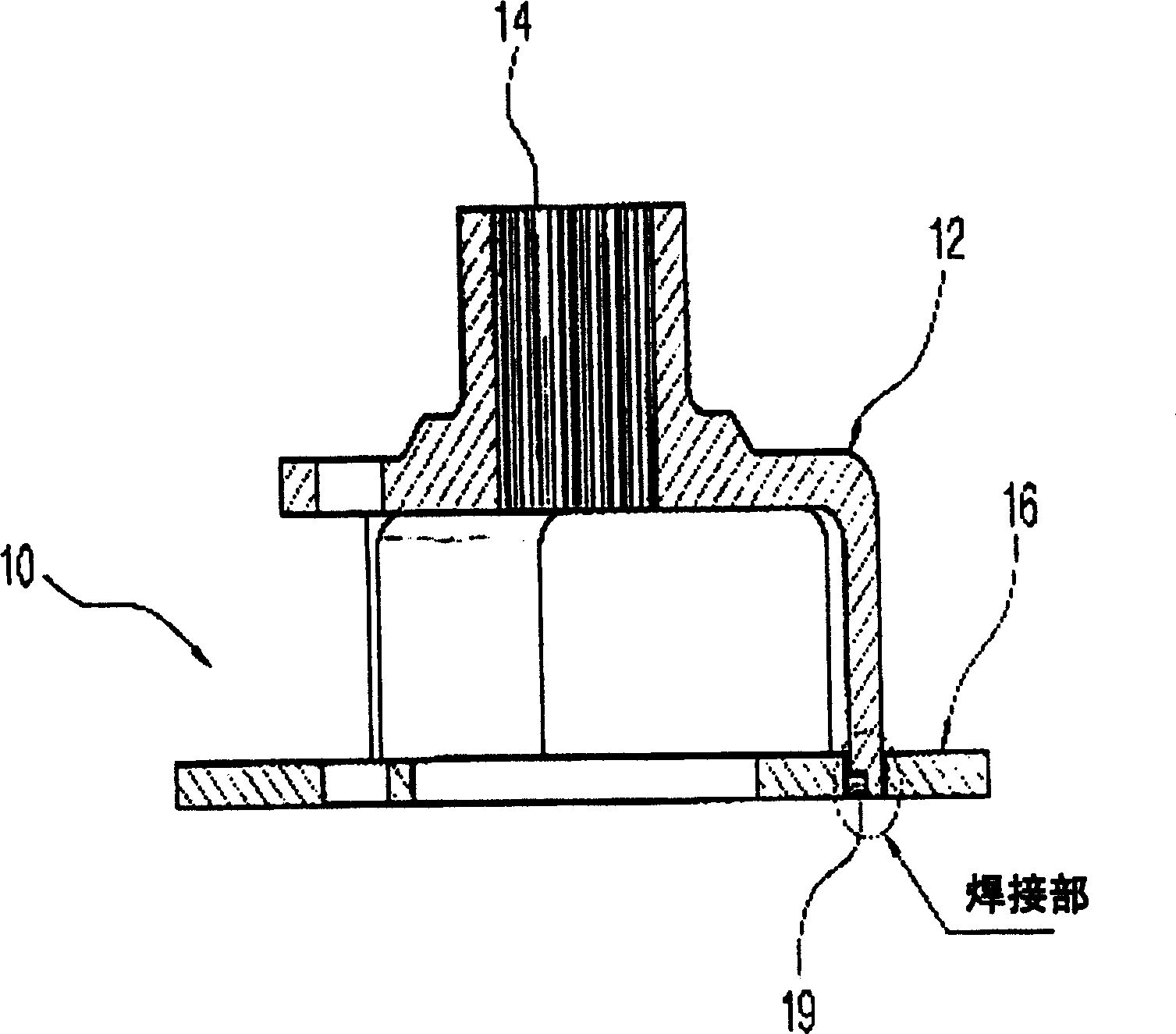

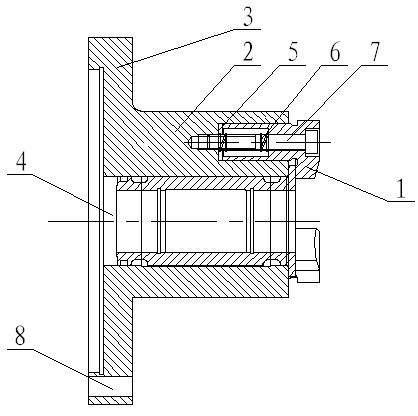

Planet carrier for planetary gear set of automatic transmission

InactiveCN1573166AEliminate deformationLow costToothed gearingsGearing detailsEngineeringEpicyclic gearing

The present invention relates to a carrier of a planetary gear set of an automatic transmission. In a carrier of a planetary gear set of an automatic transmission that includes a boss part having a spline in an inner surface of the center, and a flange part coupled with the boss part and supporting a pinion, there is provided a carrier of a planetary gear set of an automatic transmission that is characterized in that the portions of the boss part except for a center portion in which the spline is formed are formed in a circular plate shape, and a plurality of bridges are formed on an upper surface of the flange portion at regular intervals, and a lower surface of the boss part is blazing-coupled with an upper surface of the bridge of the flange part, and a pinion installation space is formed between the neighboring bridges.

Owner:HYUNDAI MOTOR CO LTD +1

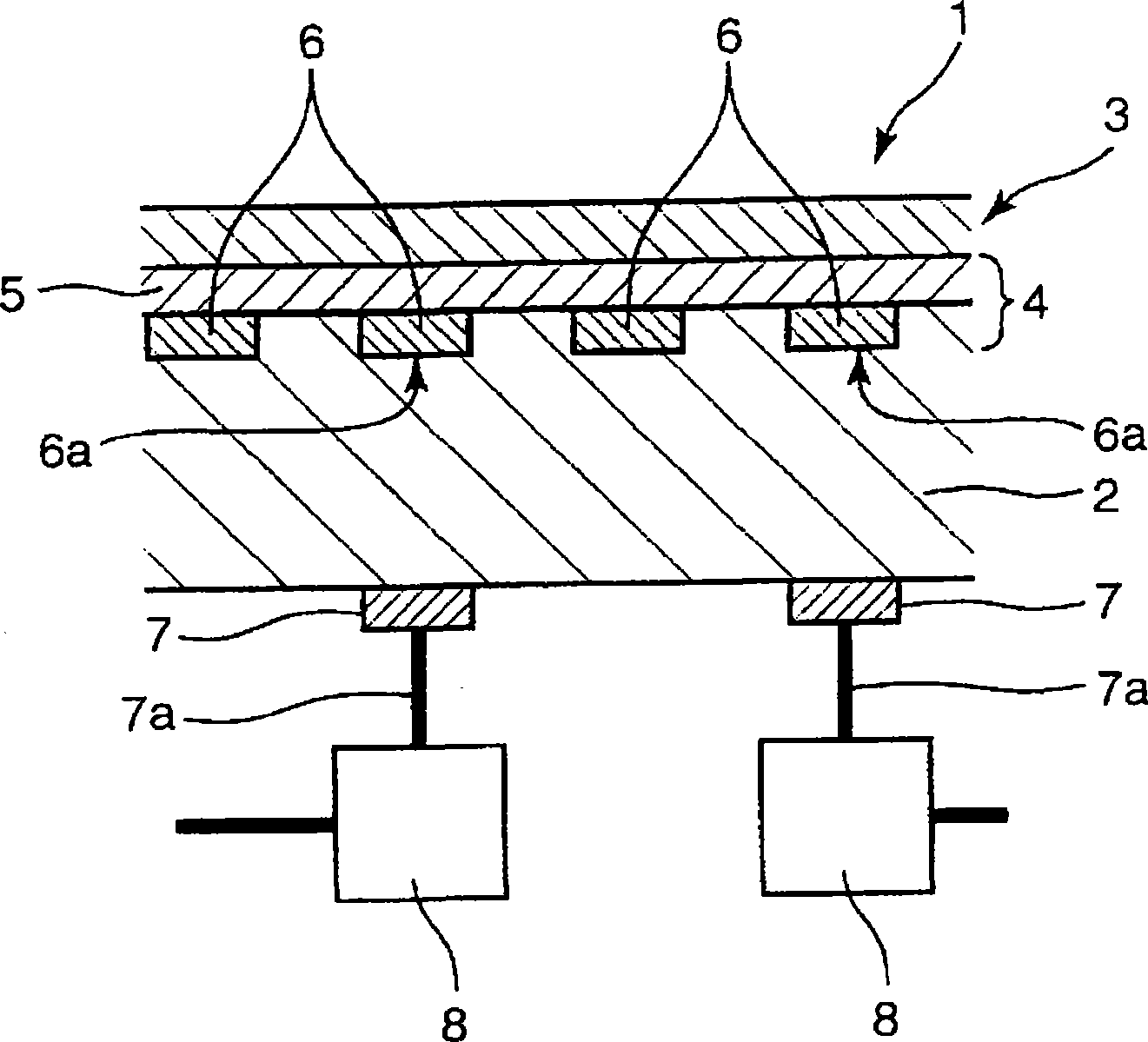

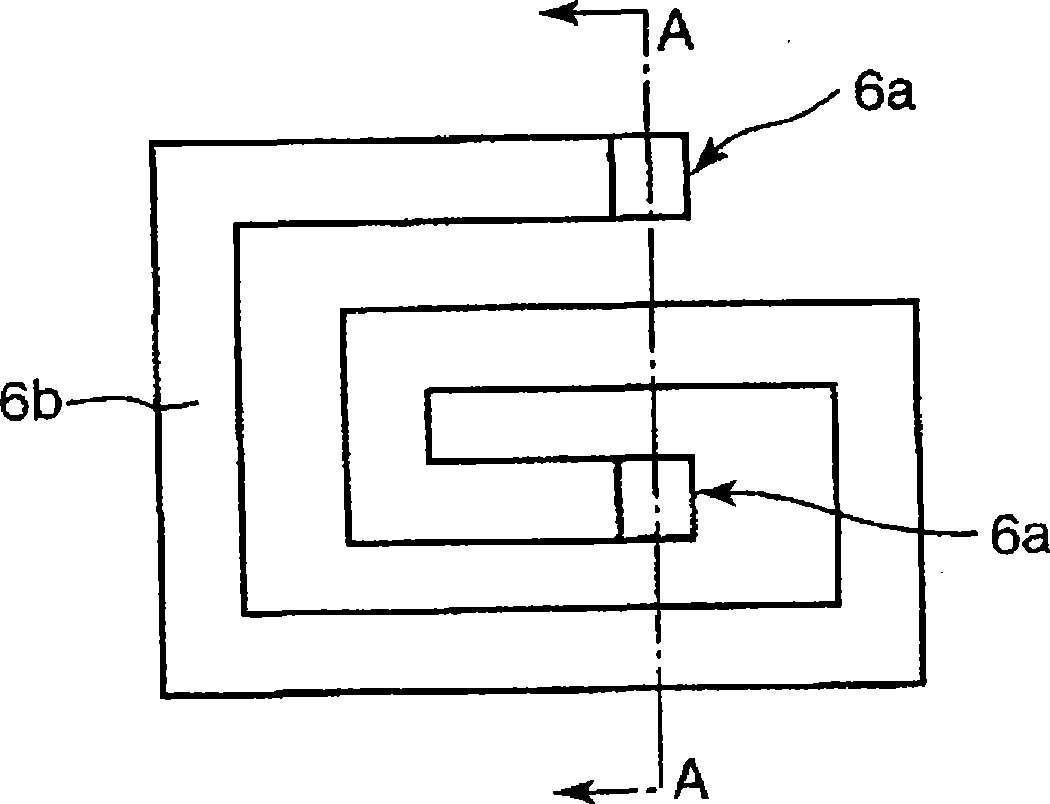

Feeding structure of housing with antenna

ActiveCN101385196AEliminate deformationPoor appearanceRadiating elements structural formsProtective material radiating elementsInductorCapacitor

A feeding structure of a housing with an antenna, in which a flat antenna can be attached inconspicuously to the outer surface of the housing which is hard to be affected by a metal component and power can be supplied to the flat antenna without providing a through hole causing inferior appearance. The feeding structure of the housing with an antenna comprises a housing 2, a decorative film 3 covering at least a part of the outer wall face of the housing 2, a flat antenna 6 held between the outer wall face of the housing 2 and the decorative film 3, and an electrode 7 provided on the inner wall face of the housing 2. In the feeding structure, a capacitor is formed by arranging a feeding part 6a of the flat antenna 6 and the electrode 7 opposite to each other in both faces of the housing 2 and power transmission and communication are performed in a noncontact manner for the flat antenna 6 on the outside of the housing 2 from the inside of the housing 2 by connecting an inductor 8 with the electrode 7.

Owner:NISSHA PRINTING COMPANY

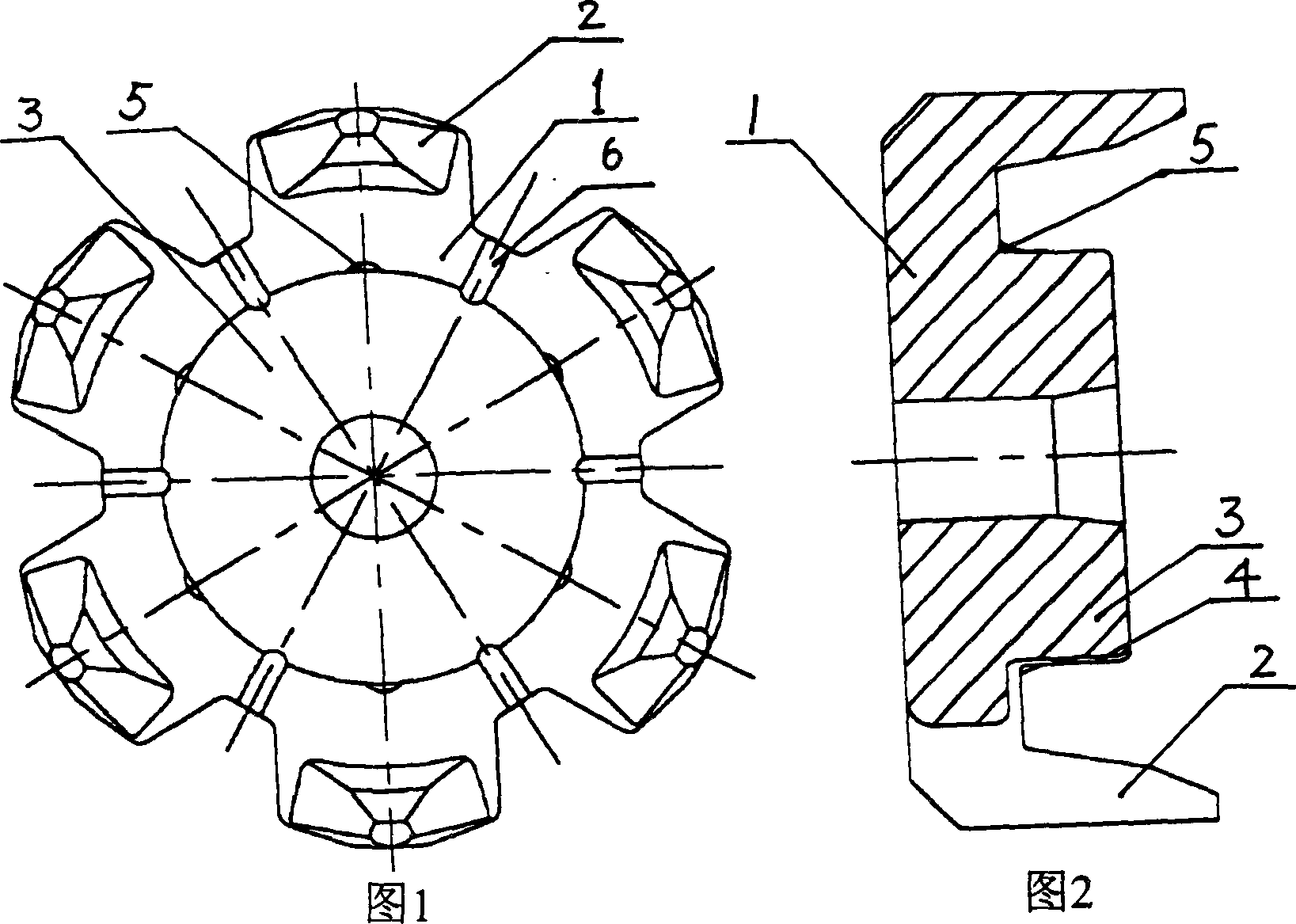

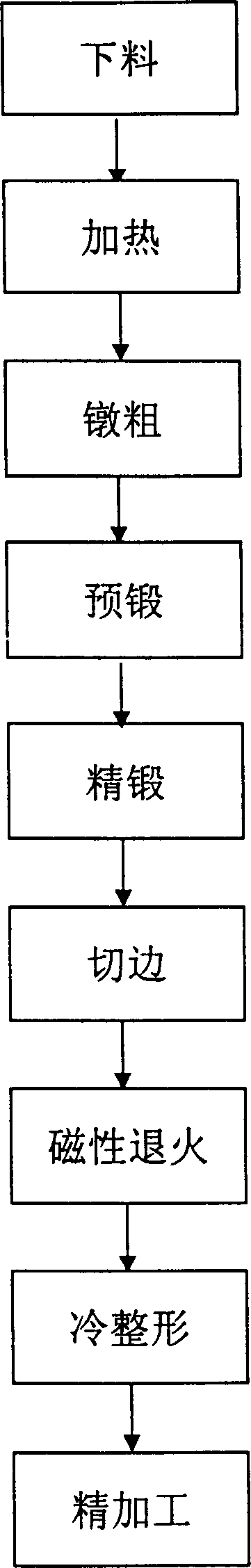

Pawl pole of automobile generator and its manufactura

ActiveCN1772413AIncrease power generationHigh dimensional accuracyManufacturing dynamo-electric machinesOther manufacturing equipments/toolsLacquerEngineering

The present invention relates to one kind of of automobile generator and its manufacture. The pawl pole has one bottom plate, one magnetic yoke on the bottom plate, six or eight insulating varnish conducting slots distributed homogeneously on the circumference of the magnetic yoke, six or eight lugs for preventing the rotation of coil, and six or eight insulated wire leading out slots in the bottom of the magnetic yoke. The manufacture of the pawl pole includes the steps of: cutting material, heating, upsetting, pre-forging, finish forging, cutting edge, magnetically annealing, cold shaping, and finishing machining. The manufacture process has low apparatus investment, low mold cost, low heating cost, high output and high product quality. The AC generator with the pawl poles of the present invention has induced electromotive force waveform of quasi-sinusoid wave and great generating power.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

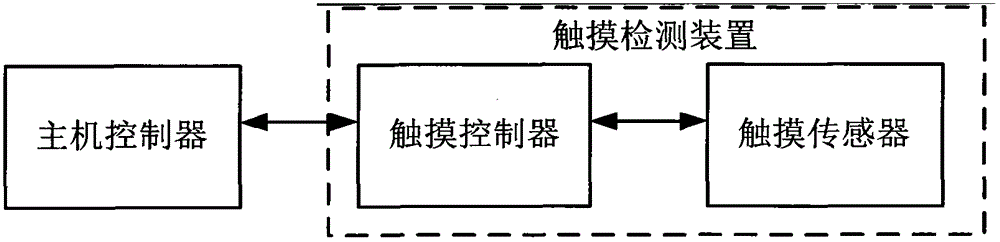

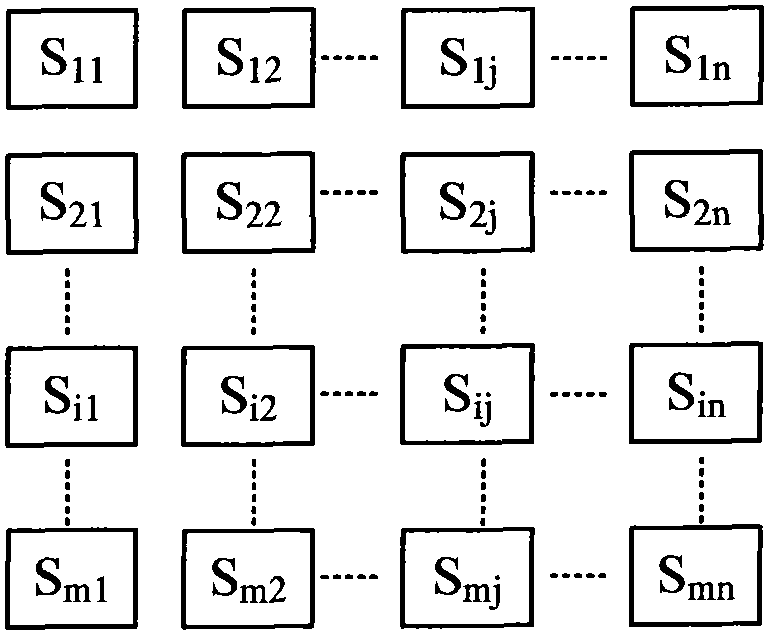

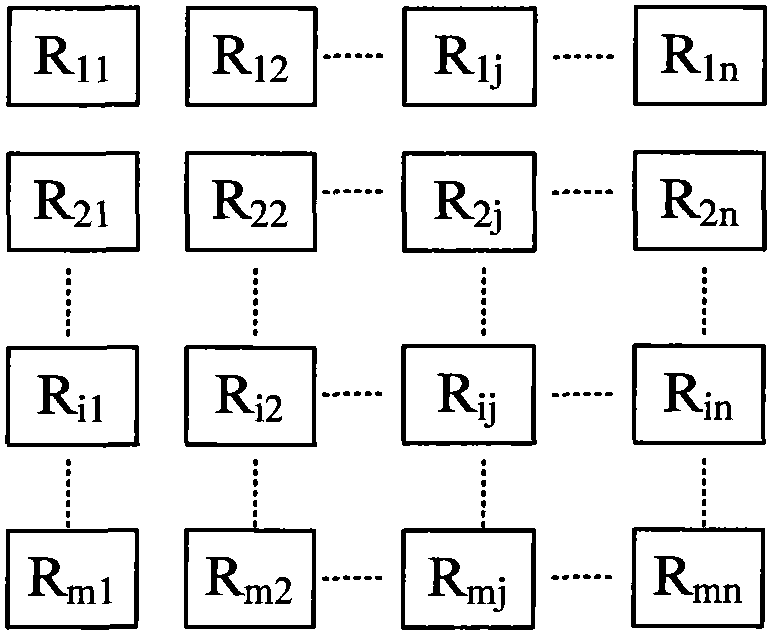

Method and system for eliminating deformation noise in detection data of touch detection device

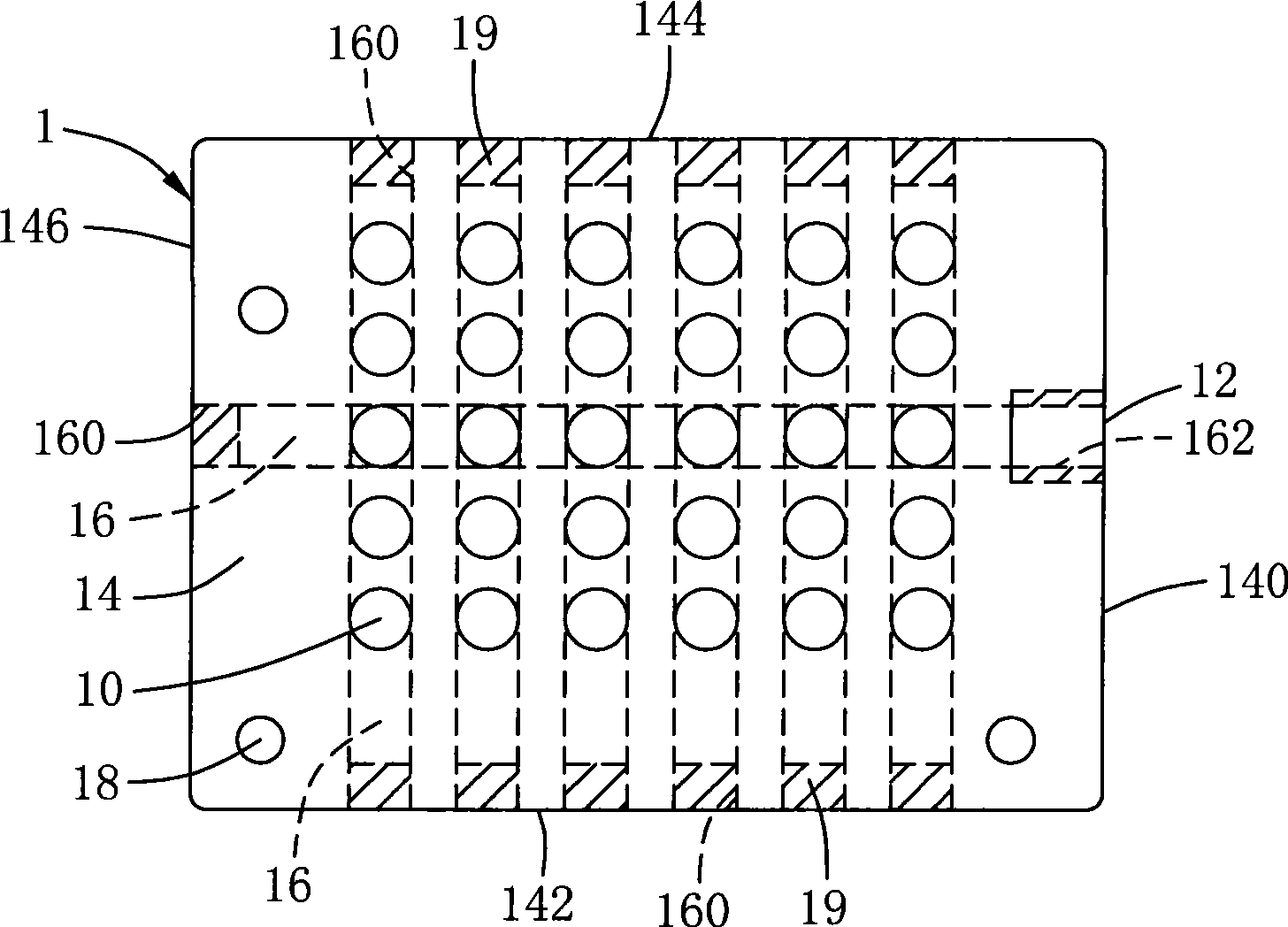

ActiveCN102722285AEliminate deformationInput/output processes for data processingPattern recognitionElimination method

The invention belongs to the technical field of touch control and provides a method for eliminating deformation noise in detection data of a touch detection device. The method includes the following steps of A) synchronously sampling touch detection nodes belonging to a same group and saving sample data; B) comparing each sample datum with a respective standard reference value to compute a difference value serving as a detection datum to replace the original sample datum; C) determining a deformation variable of each touch detecting node outside of the touched area according to the detection data, fitting a deformation variable of each touch detecting node within the touched area; and D) subtracting corresponding deformation variables from detection data of all touch detecting nodes to obtain detection data after deformation noise is eliminated. Firstly, the deformation variable of each touch detecting node outside of the touched area is determined according to the detection data, then deformation variable of each touch detecting node within the touched area is fitted according to the obtained deformation variable, and finally, the deformation variable of each touch detecting node is eliminated from the detection data.

Owner:SHENZHEN GOODIX TECH CO LTD

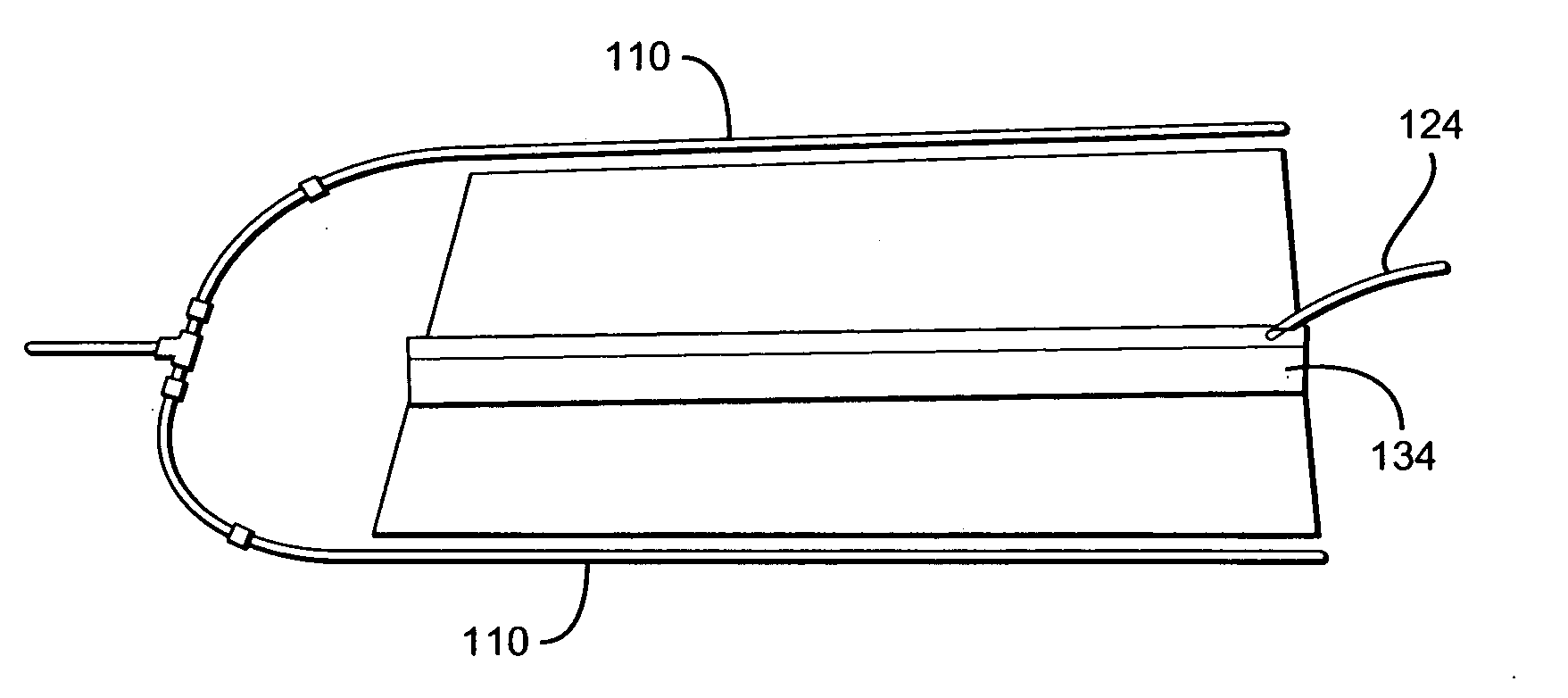

Tube induced deformity elimination proccess

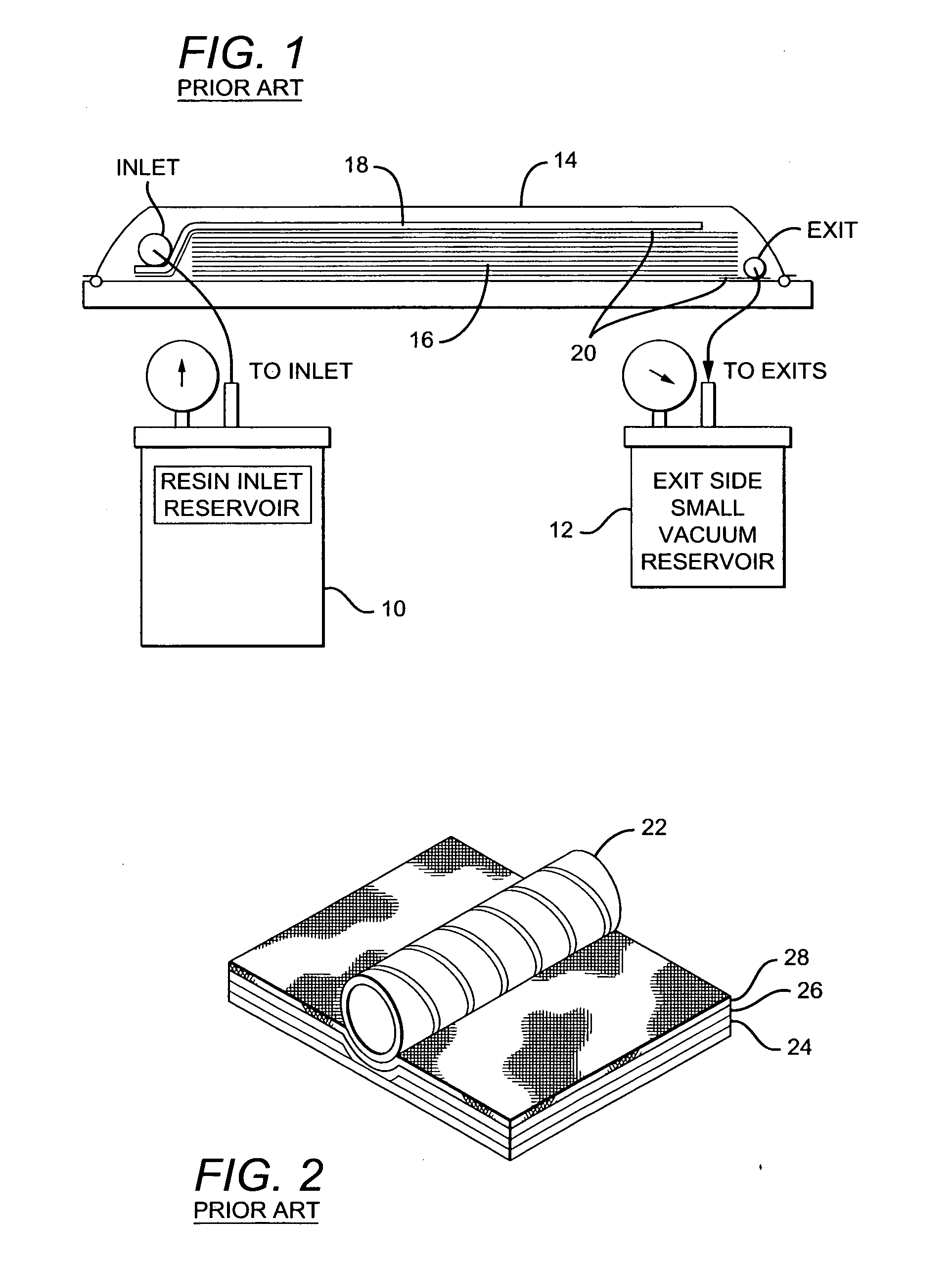

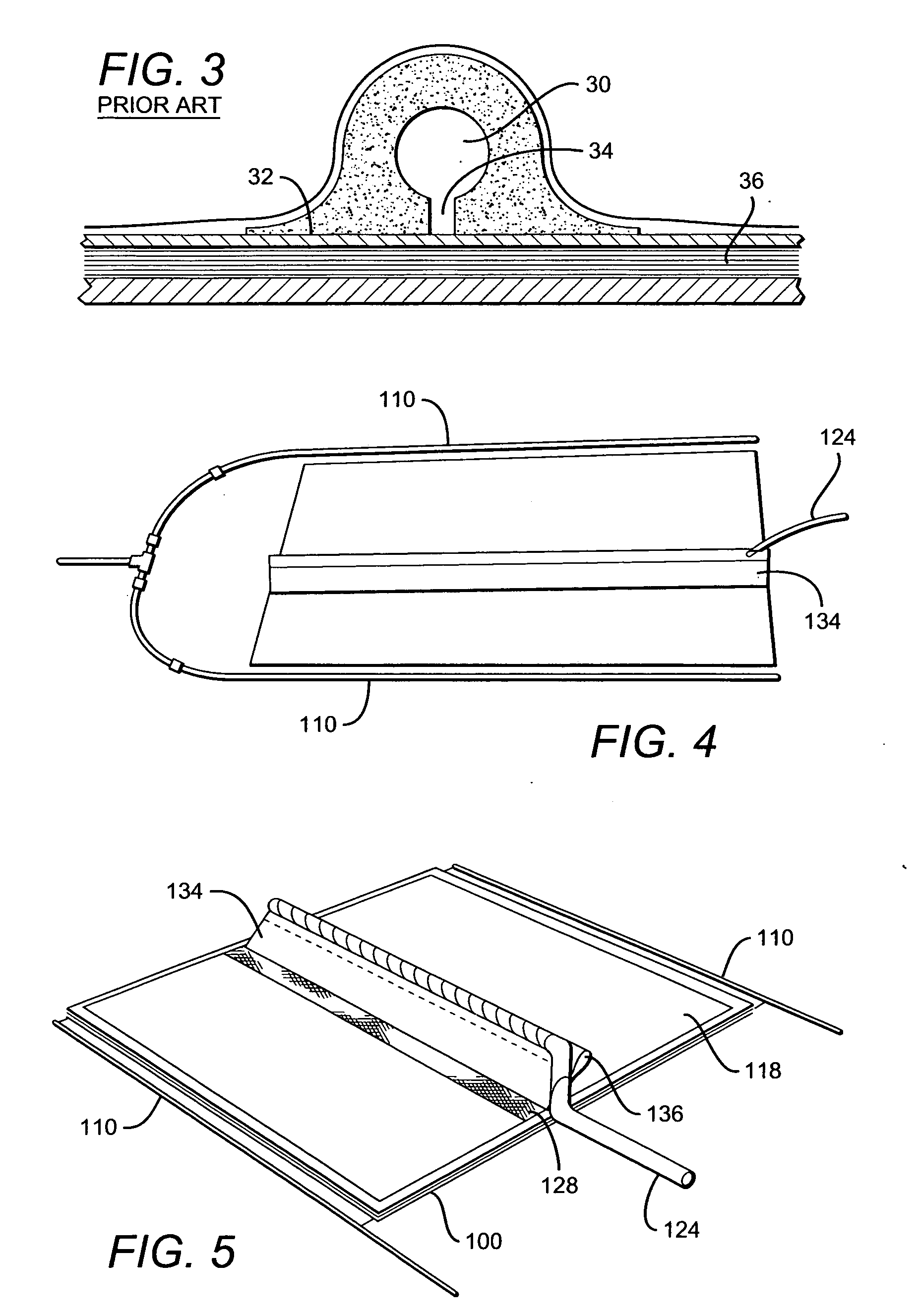

ActiveUS20080079193A1Reduces and eliminates deformationEliminate deformationLaminationWood working apparatusResin dispensingEngineering

The invention is directed to a process for elimination of deformations on resin infused composite parts in which the resin distribution tube used in a resin vacuum infusion process is positioned above the surface of a preform and is not in contact with the preform. Flow media indirectly connects the resin distribution tube to the preform which allows for free movement of resin without direct contact of the resin distribution tube to the perform, and thus, this eliminates deformations that are caused by direct contact of the resin distribution tube to the preform.

Owner:THE BOEING CO

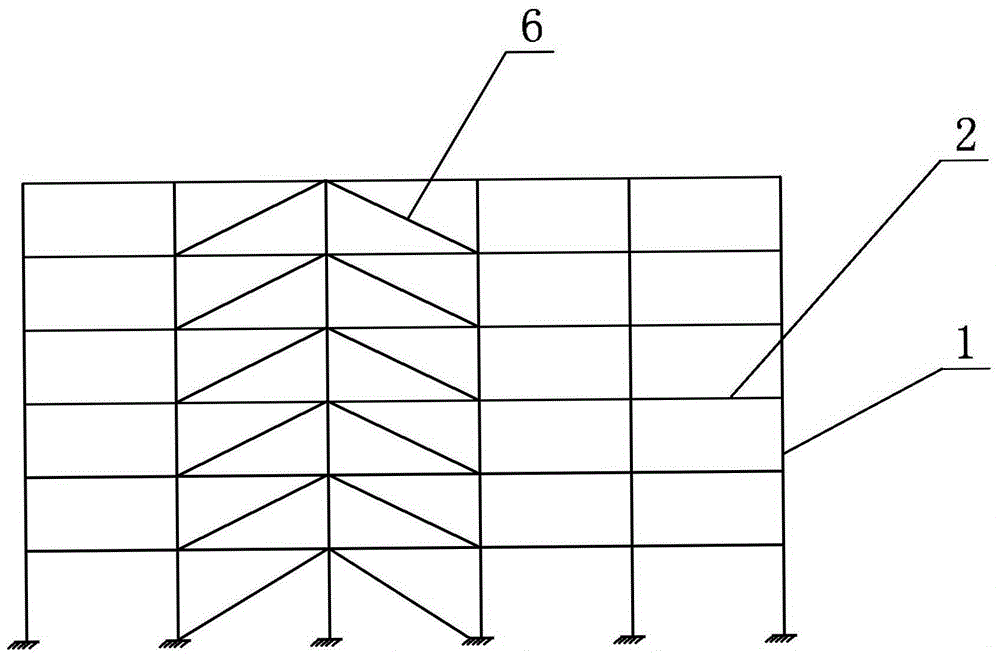

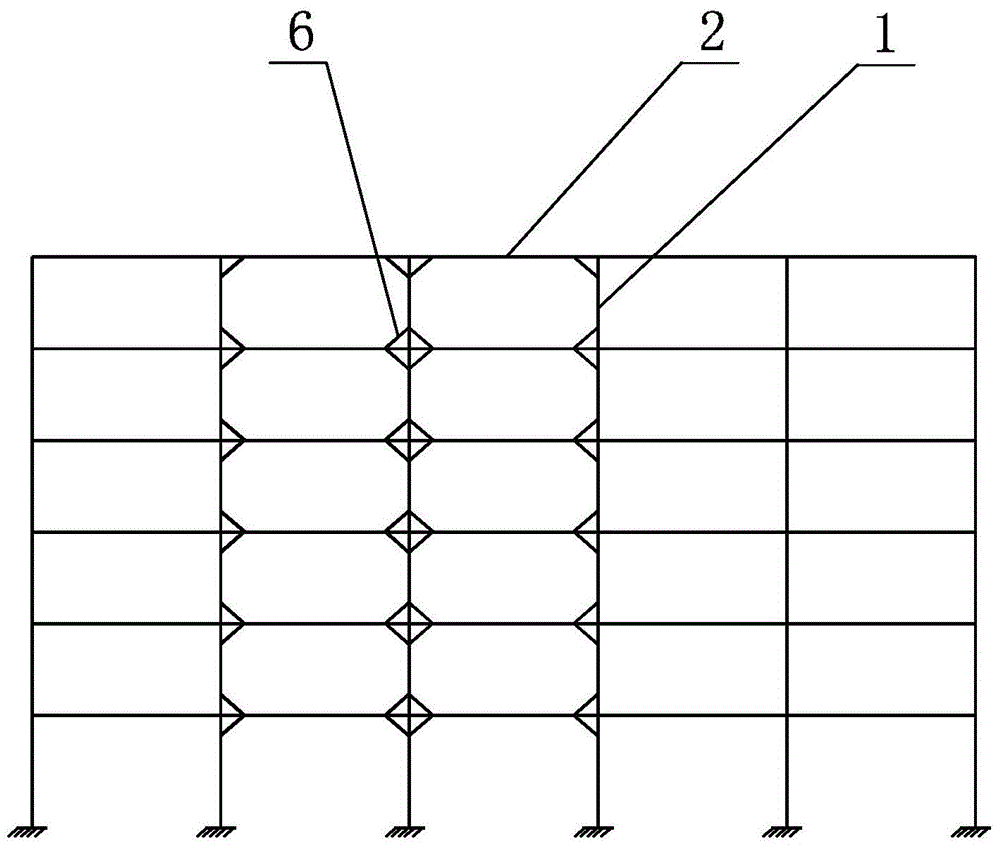

Self-centering buckling-restrained brace beam-column joint

ActiveCN105040831AImprove elastic deformation abilityEliminate deformationShock proofingBuckling-restrained braceSteel frame

The invention relates to a joint for building structures, relates to a self-centering buckling-restrained brace beam-column joint and aims to solve the problem that structural application functions of an existing self-centering buckling-restrained brace in a diagonal placement scheme may be influenced and the problem that existing steel-frame beam-column joints are mostly connected rigidly or semi-rigidly, the joint of such structure easily suffers brittle failure, and after an earthquake, dangers still exist and continual application is unavailable even after the building does not collapse. Gaps are provided among columns and beams, a plurality of column stiffening ribs are distributed on the columns, the beam stiffening ribs are distributed on the beams, two connecting plates are disposed on upper and lower flanges of one beam; each connecting plate is L shaped and is provided with a plurality of bolt holes; a vertical segment of each connecting plate is connected with a column plug through bolts; each bolt penetrate a corresponding bolt hole so as to connect the connecting plates and the girder; a self-centering buckling-restrained supporting member is correspondingly disposed on the outer side of each connecting board.

Owner:HARBIN INST OF TECH AT WEIHAI

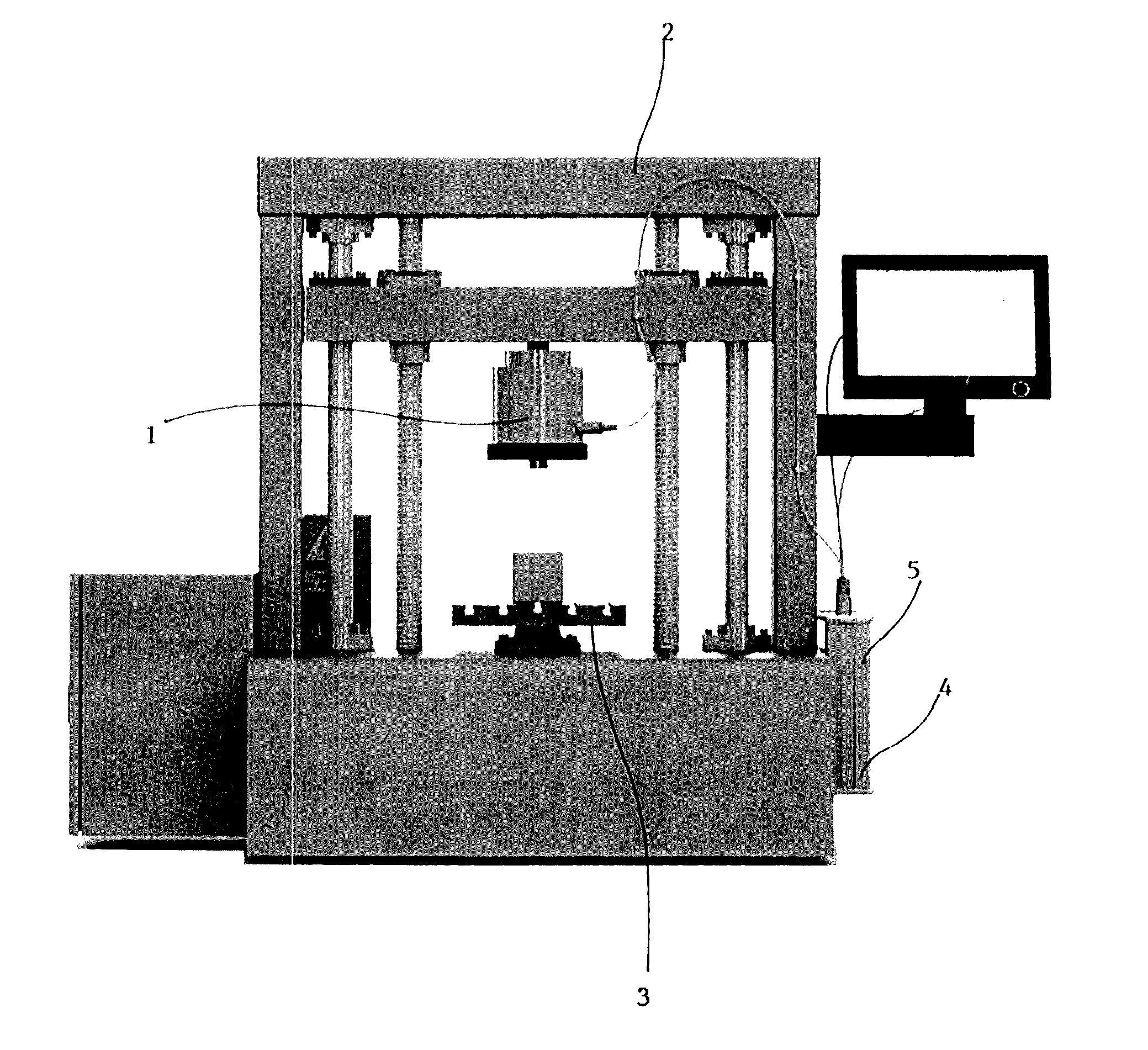

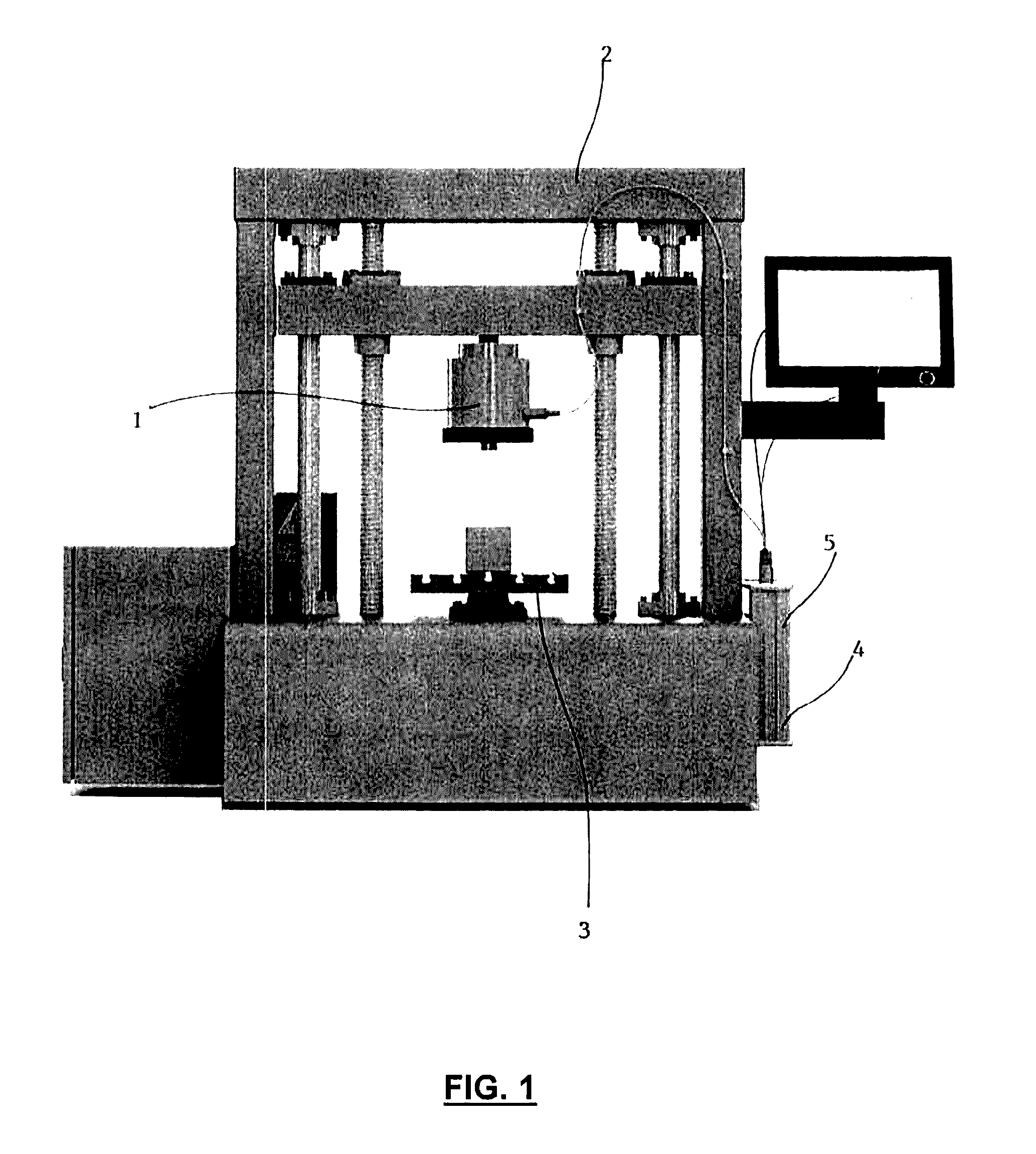

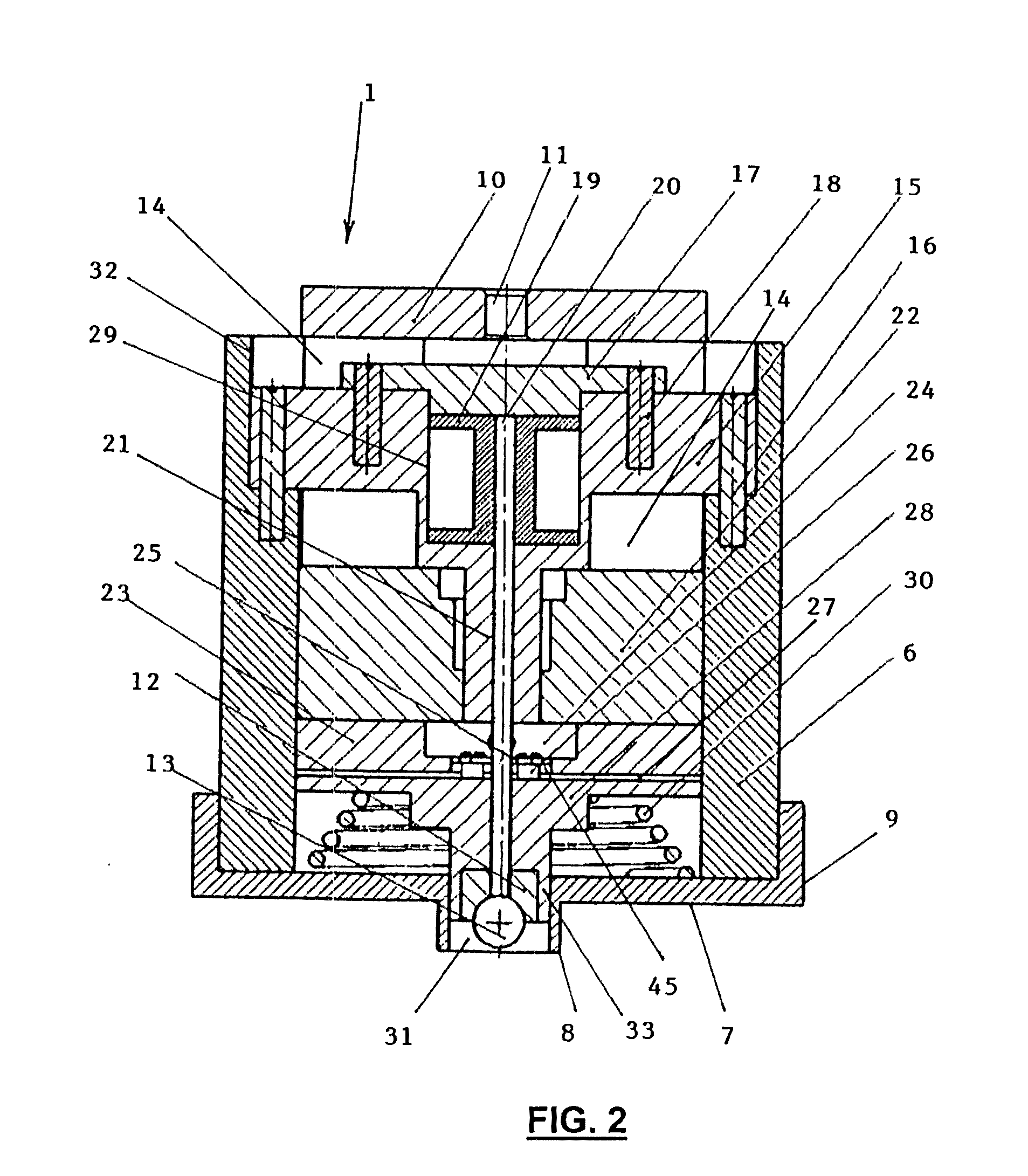

An indentation device, instrumented measurement system, and a method for determining the mechanical properties of materials by the indentation method

InactiveUS20160377518A1Excellent and adequate accuracyEliminate generationElectric/magnetic position measurementsAcceleration measurementCentral pressureStrength of materials

Owner:CZECH TECH UNIV IN PRAGUE

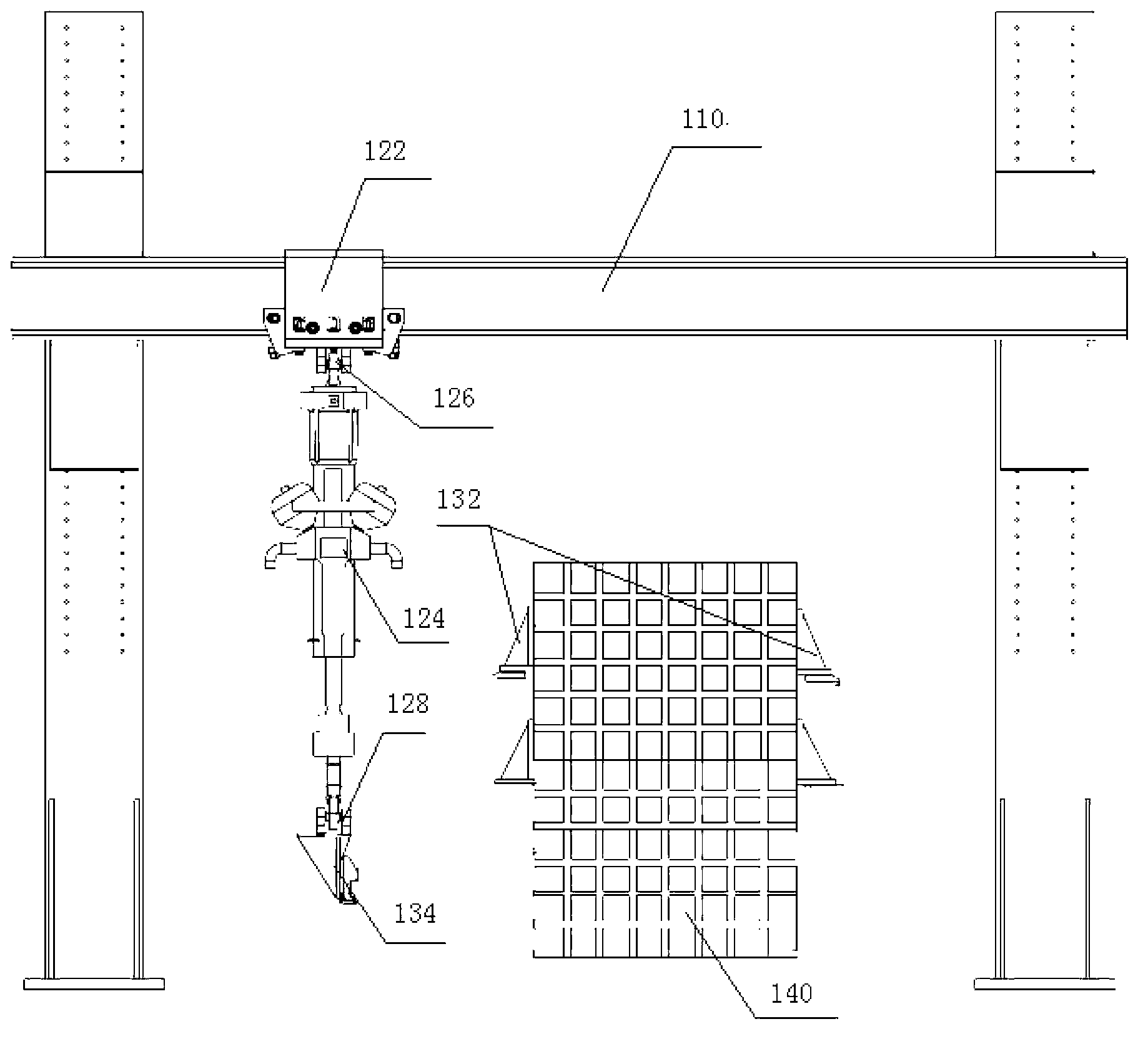

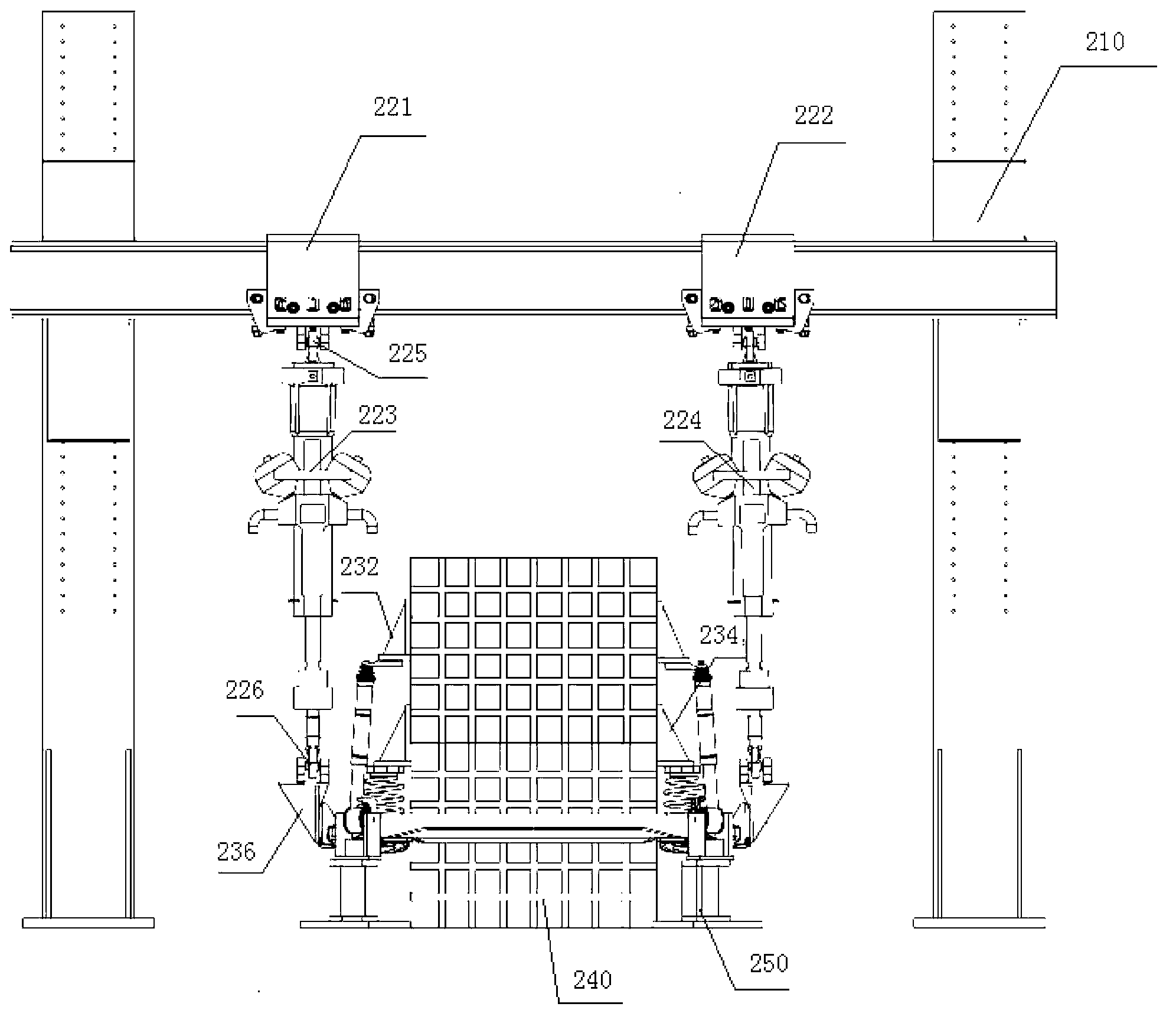

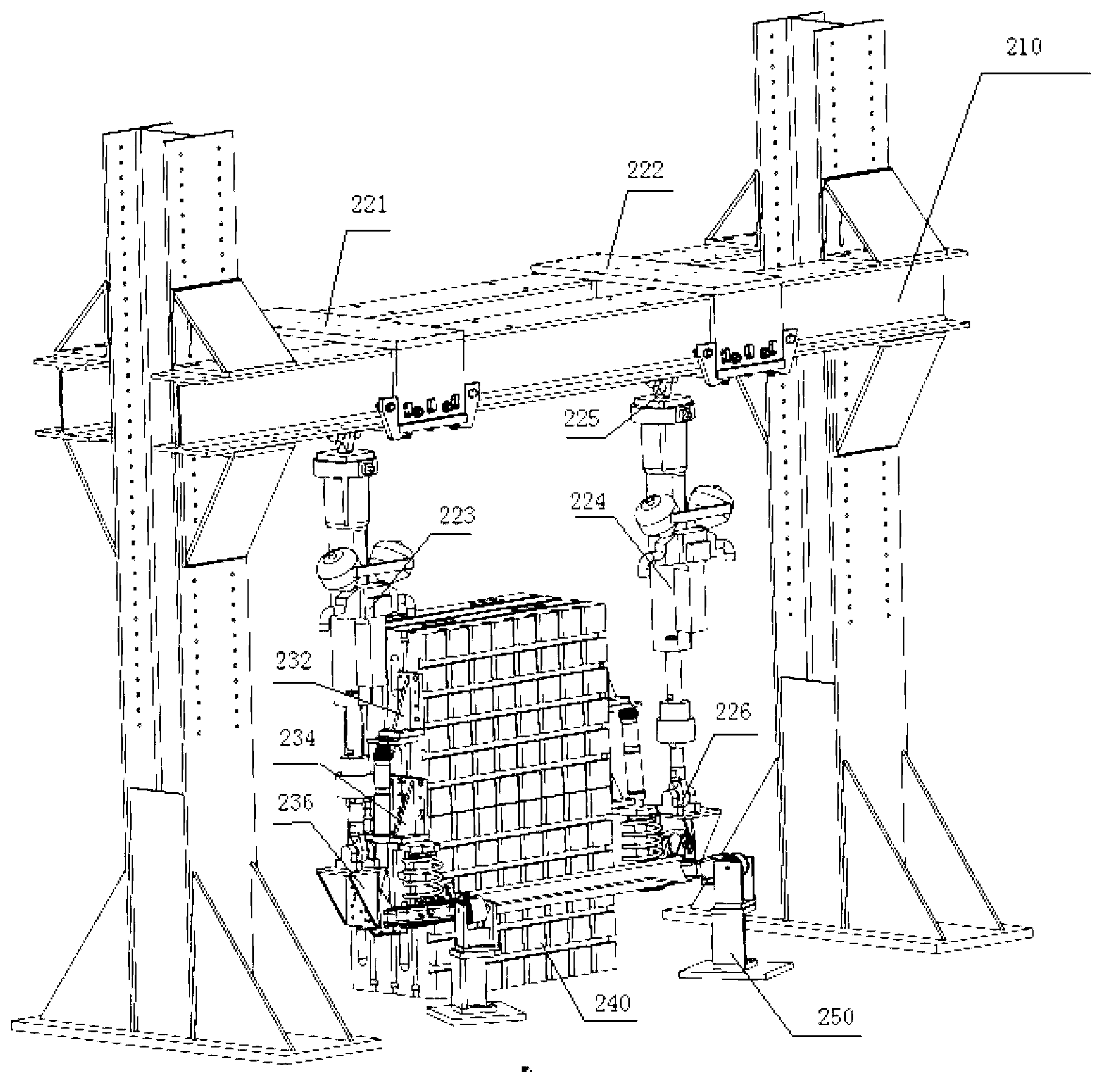

Automobile test bench

An automobile test bench comprises a portal frame, at least one group of actuator, a clamp mechanism and a supporting mechanism which supports the structure of the whole test bench, the clamp mechanism is respectively connected with the actuator and the supporting mechanism and used for fixing a test article, the actuator is movably installed on the portal frame and comprises a sliding mechanism, an actuating cylinder and spherical hinges, wherein the sliding mechanism is installed on a beam of the portal frame, the spherical hinges are arranged at the upper and lower ends of the actuating cylinder, the sliding mechanism is connected with the actuating cylinder through the upper end spherical hinge, and the clamp mechanism is connected with the actuating cylinder through the lower end spherical hinge. The actuator is connected through the gapless spherical hinges, the problem of resonance vibration caused by fit clearance is eliminated, moreover, the actuating cylinder is capable of moving, convenience of the installation of the test article is increased, and working efficiency is improved.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

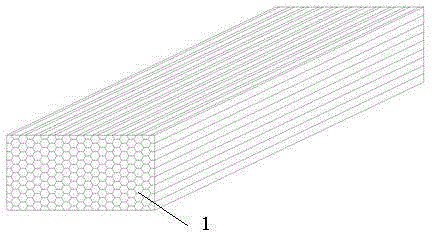

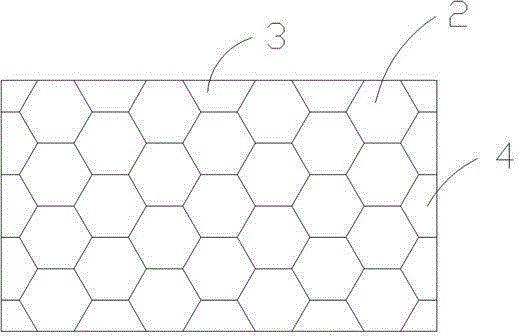

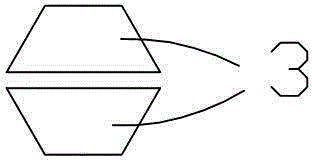

Cellular-structure laminated wood and production method thereof

InactiveCN104128981AEliminate deformationImprove stabilityWood working apparatusPulp and paper industryLarge size

The invention discloses cellular-structure laminated wood which is formed by arranging and gluing hexagonal battens cellularly. The invention further provides a production method of the cellular-structure laminated wood. The cellular-structure laminated wood and the production method have the advantages that wooden cores or small-diameter logs are directly planed and cut to be hexagonal, and utilization rate can reach 82%; the hexagonal battens are arranged and glued cellularly, and gluing faces are distributed in three directions in a 120-degree included angle manner, eliminating of deformation of the battens is facilitated, and stability and gluing strength of the laminated wood are improved; the hexagonal battens can be arranged cellularly and glued to be the laminated wood various in size, and can be further integrated in the length direction in a toothing connection, large-size laminated wood can be freely sawn transversely, and needs, on the laminated wood different in specification, of users are met.

Owner:遂川县洪林木业有限公司

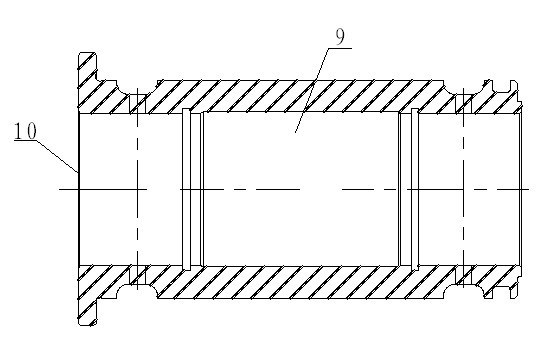

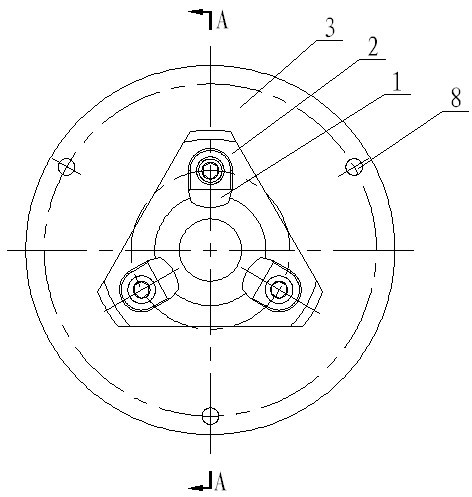

Manufacturing method of pedestal bearing for turbocharger and positioning tool for same

ActiveCN102658458AStress reliefEliminate processing stressGrinding work supportsTurbochargerEngineering

The invention discloses a manufacturing method of a pedestal bearing for a turbocharger and a positioning tool for the same. The manufacturing method comprises the following machining procedures of: 1), roughly turning one end surface and a hole of a workpiece; 2), roughly turning the other end surface and an outer circle of the workpiece; 3), annealing the workpiece to remove stress; 4), carrying out finish turning on the end surface and the hole; 5), carrying out the finish turning on the other end surface and the hole; 6), milling a semicircular positioning groove; 7), drilling radial holes at two ends; 8), milling the flat and square parts of the outer circle; 9), removing burrs by a bench worker; 12), milling an oil applying wedge surface of a thrust surface; 13), carrying out flaw detection; 14), removing the burrs by the bench worker and cleaning a part; and 15), carrying out comprehensive detection. The procedure 3) is adopted between the procedure 2) and the procedure 4) to anneal the workpiece to remove the stress; a procedure 10) and a procedure 11) are adopted between the procedure 9) and the procedure 12); the procedure 10) comprises the following steps of: adopting the positioning tool, positioning the outer circle of the workpiece by utilizing a tool hole, compacting the thrust surface of the workpiece, and accurately grinding the holes; and the procedure 11) comprises the following steps of: positioning the holes by utilizing a taper shaft, and accurately grinding the outer circle and the thrust surface. The manufacturing method and the positioning tool have the advantages that the procedures are arranged reasonably, and the machining quality and the machining efficiency can be effectively improved.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

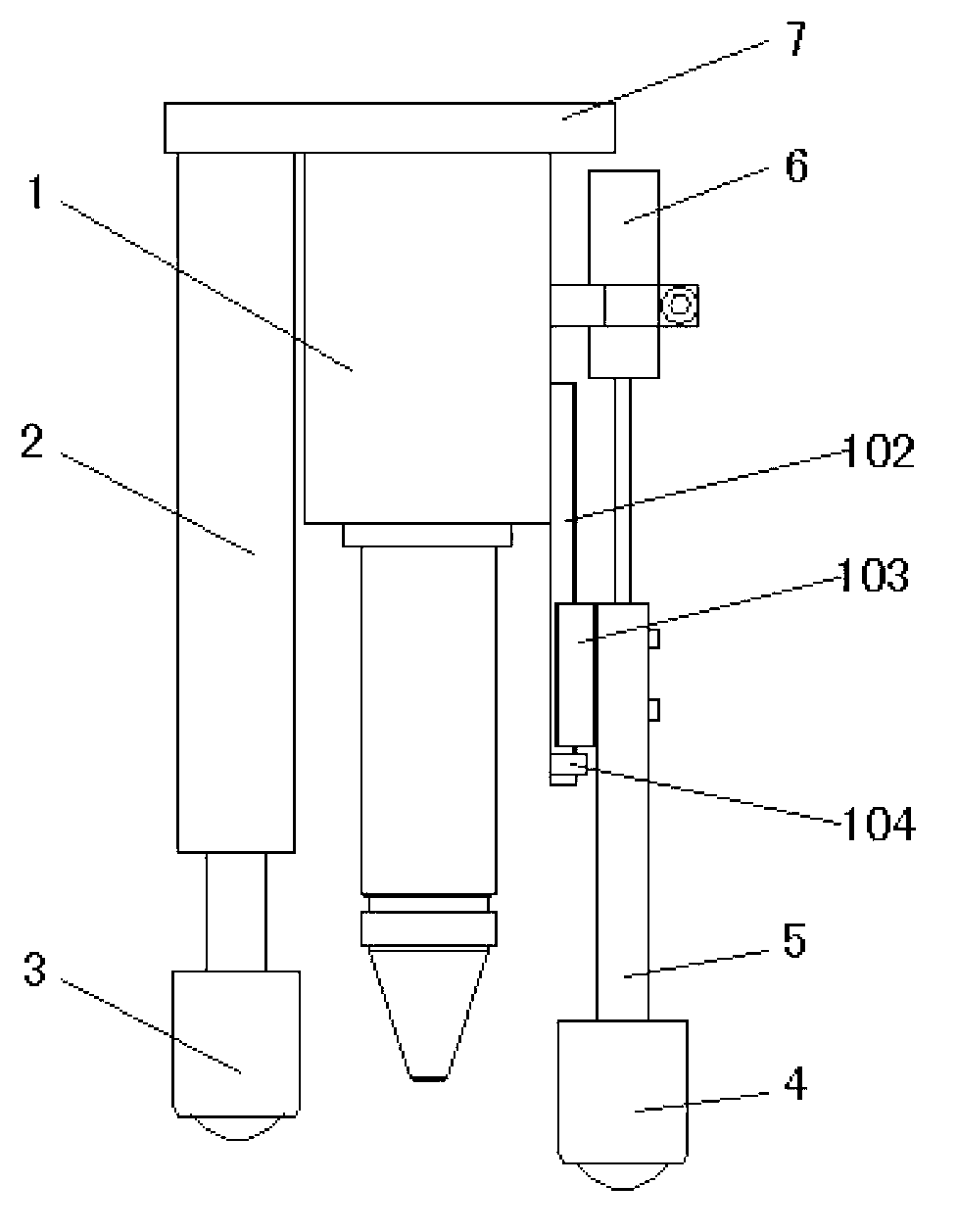

Laser welding machine with follow-up and swaging functions

ActiveCN103231167AEliminate deformationGuaranteed clearanceLaser beam welding apparatusEngineeringLaser

The invention discloses a laser welding machine with follow-up and swaging functions, wherein a motion mechanism can drive a laser welding head to move; the laser welding head comprises a base, a welding head, a compressing wheel, a follower and a position sensing device; the welding head is positioned below the base; the compressing wheel is positioned at the lower end of the base; the circumferential outer side surface of the compressing wheel is tightly butted with a welded plate surface and rolls along the surface; the follower can rotate in the circumferential direction and can be positioned on a side wall of the welding head in a sliding manner in the vertical direction; the circumferential outer side surface of the follower is tightly in contact with the surface of the welded plate surface and rolls along the surface; the position sensing device can sense the lengthwise position of the follower and transmit to a numerical control system; the numerical control system can control the motion mechanism to drive the laser welding head to move; the plate deformation is eliminated; and the clearance between materials to be welded can be ensured; the follow-up of the laser welding head, relative to the welded plate surface can be achieved; the focus point position is kept to be constant; and the welding quality is guaranteed to be firm and stable.

Owner:SUZHOU LEAD LASER TECH

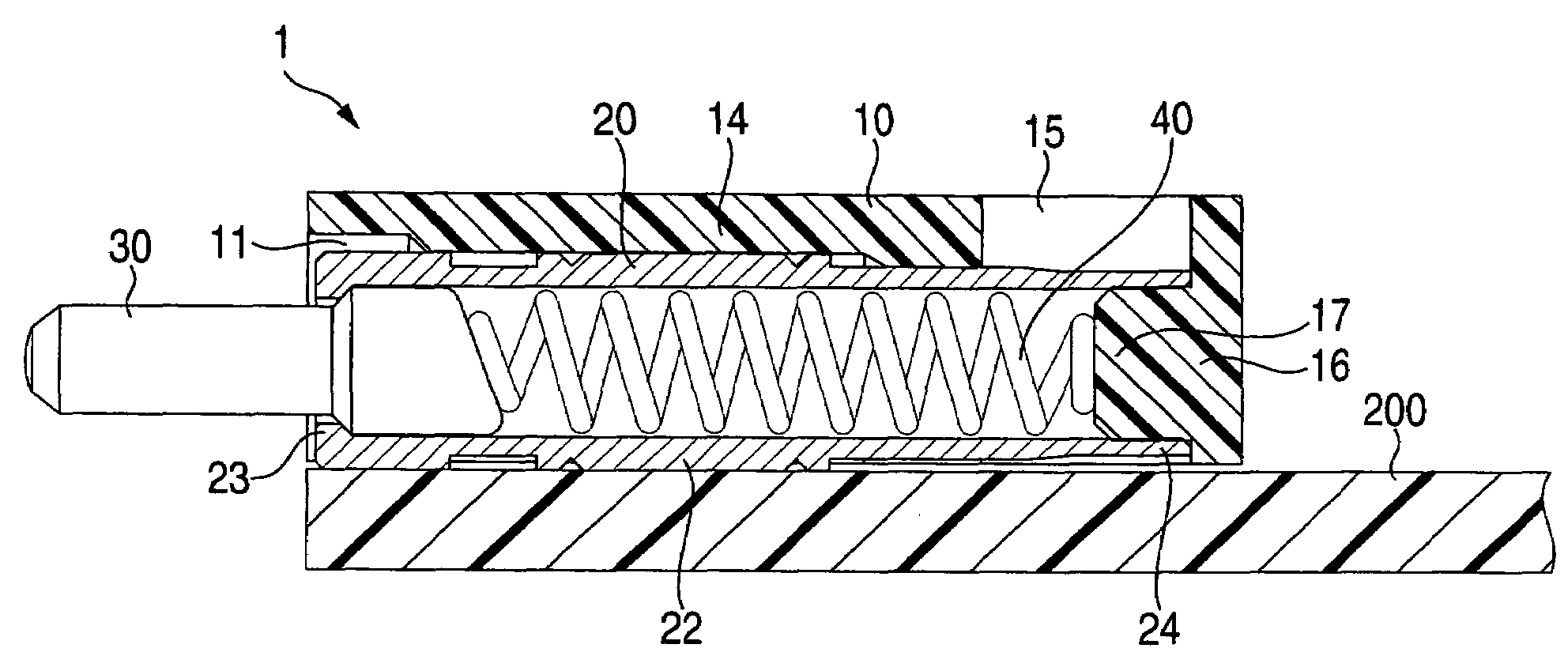

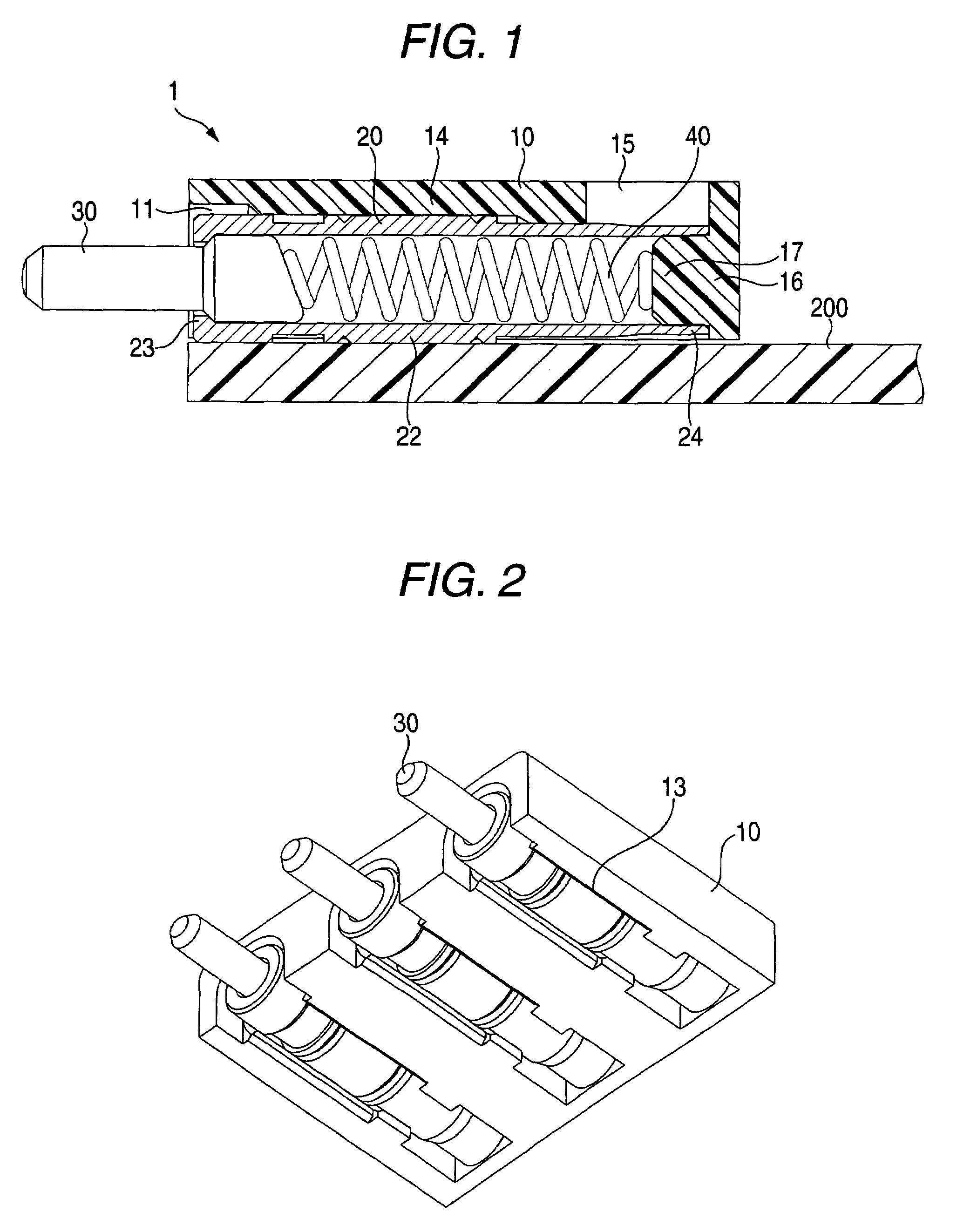

Spring connector

InactiveUS7435109B1Eliminate deformationThin thicknessCoupling contact membersPrinted circuitsEngineeringGuide tube

A spring connector includes: an electrically-conductive pin; an electrically-conductive tube, having the pin slidably received therein, the tube holding the pin in such a condition that at least part of the pin projects from one end of the tube in a first direction, and the other end of the tube being open; and a housing, including a hole portion which can receive the tube, and a slit exposing at least part of an outer peripheral surface of the tube to an exterior, the housing having a first wall portion opposed to the other end of the tube and formed with a projecting portion projecting in the first direction and fitting to the other end of the tube. The at least part of the outer peripheral surface of the tube which is exposed from the slit is electrically connectable to a board.

Owner:YOKOWO CO LTD

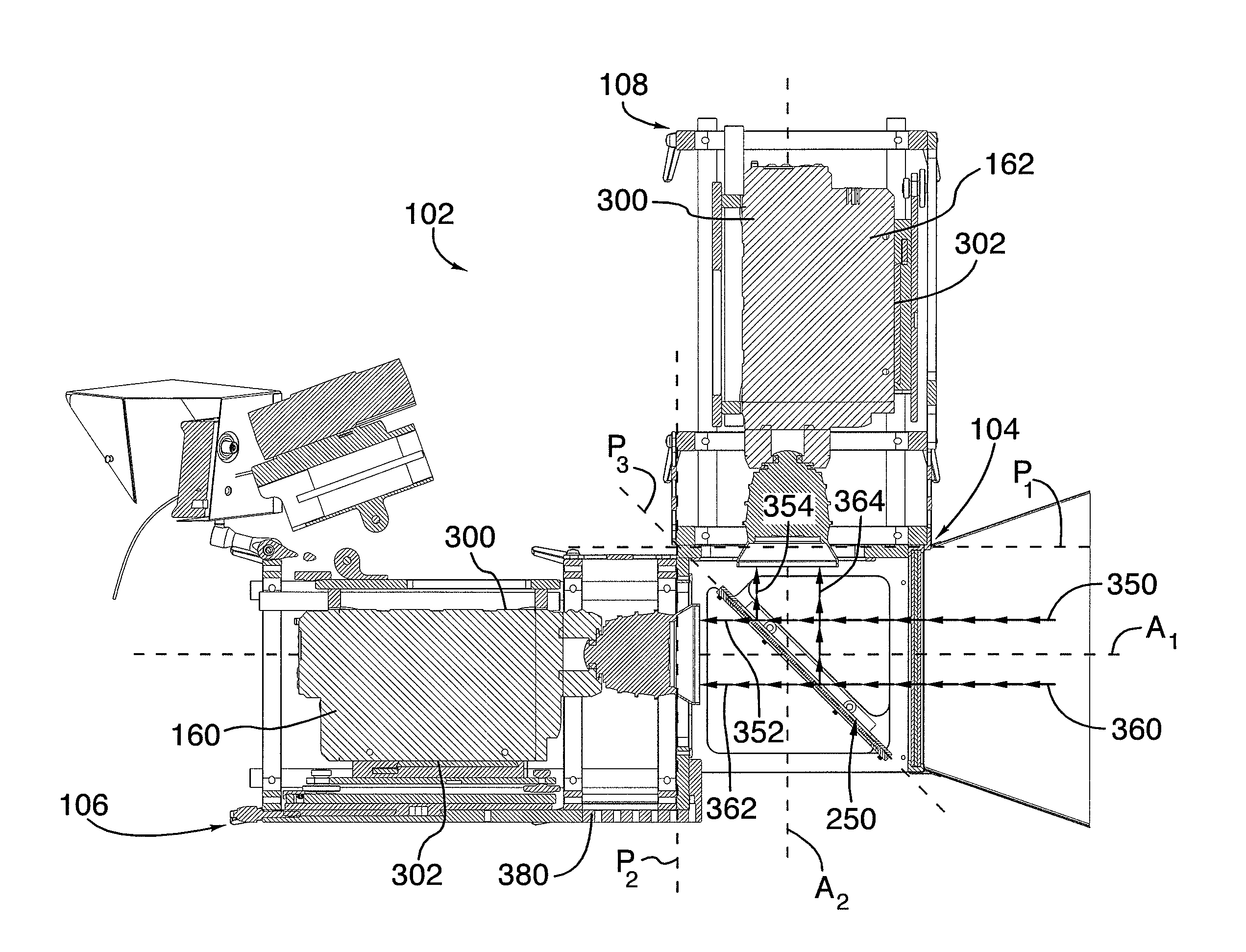

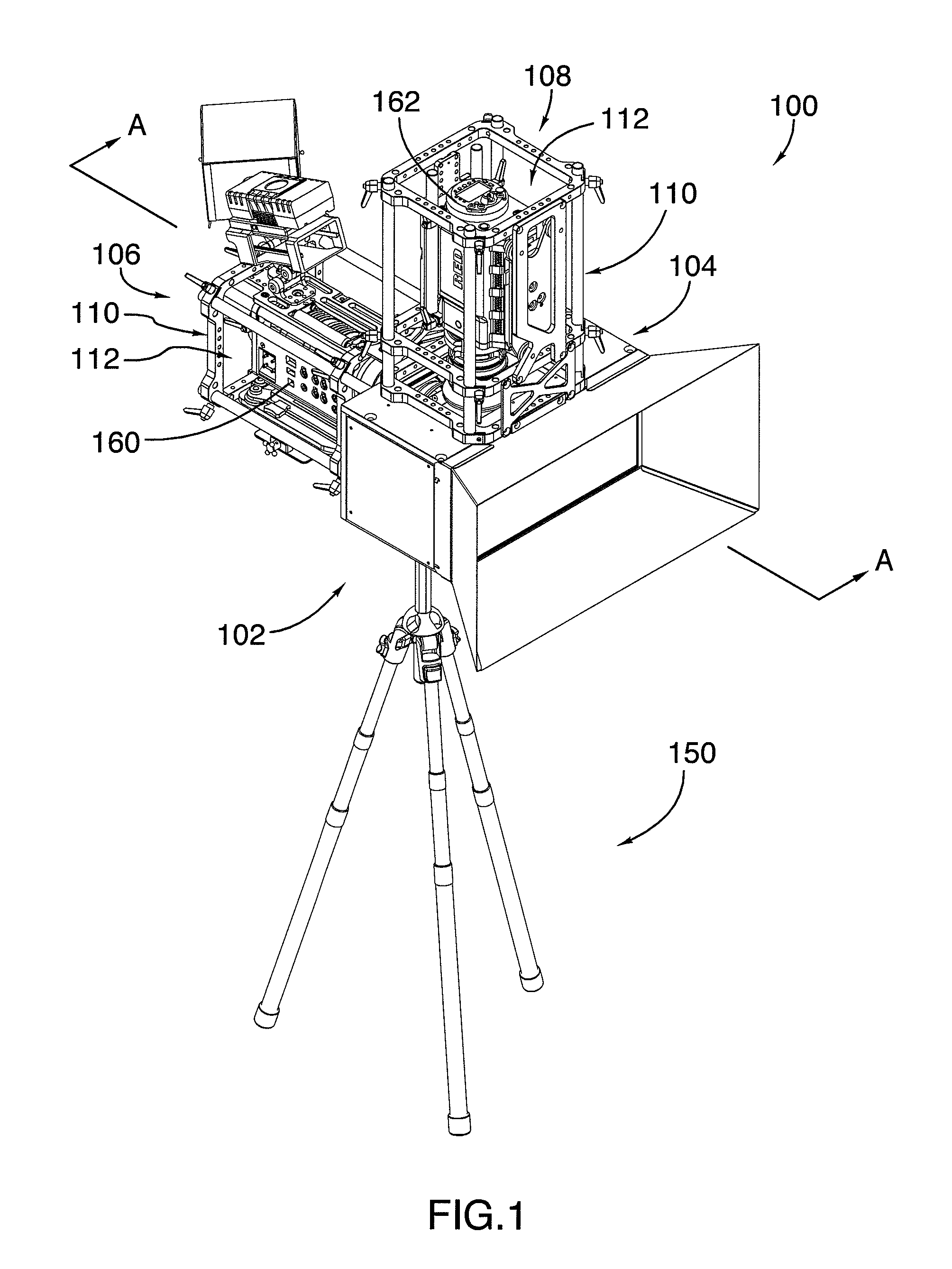

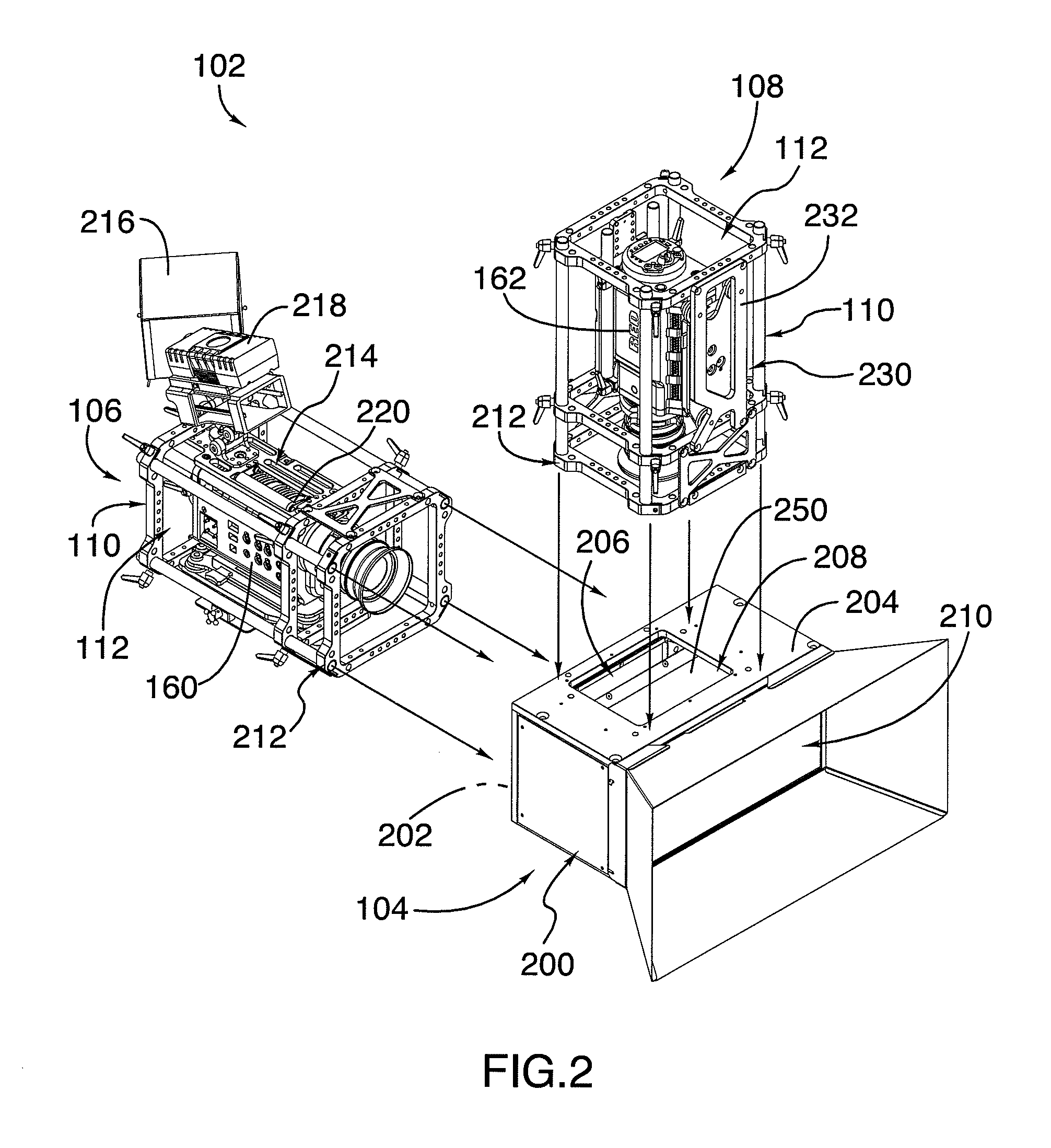

Frame structure for stereoscopic imaging

InactiveUS7970276B1Easy to disassembleEliminate deformationStands/trestlesStereoscopic photographyStereoscopic imagingInternal cavity

There is provided a frame structure for stereoscopic imaging. First and second cameras may be mounted to the structure to respectively record first and second images which may be combined to produce a three-dimensional image. The frame structure comprises a casing sized and shaped to receive a beam splitting device therein and first and second camera supports mounted to a sidewall of the casing for respectively holding the first and second cameras. Each camera support comprises an outer frame defining an internal cavity to receive a corresponding camera therein, and attaching means which comprise at least three connecting portions contacting the casing sidewall and positioned around an opening of the casing sidewall. This configuration substantially prevents deformation of the frame structure due to bending.

Owner:CREAT3

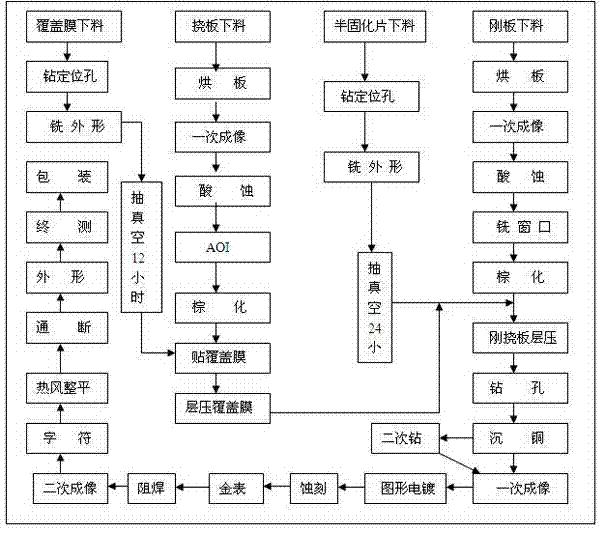

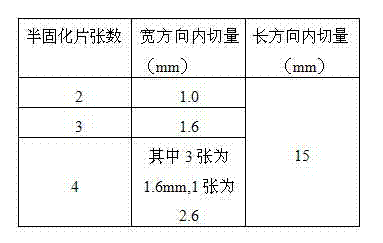

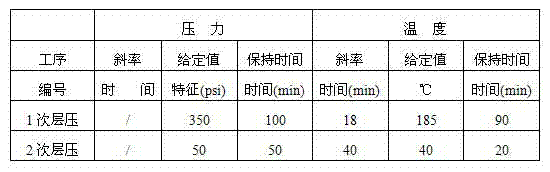

Method for manufacturing rigidity-flexibility combined printing circuit board

ActiveCN102970828AEliminate deformationReasonable process stepsPrinted circuit manufactureTemperature resistanceElectroless plating

The invention discloses a method for manufacturing a rigidity-flexibility combined printing circuit board. The method comprises the following steps of: laminating a rigidity-flexibility board, milling a window, electrically plating electroless plating copper, imaging, silk-screening and solder-resisting, flattening with hot air, carrying out on-off test, removing drilling dirt in holes, and laminating a coverage film by using a flexible board, wherein the steps of covering the coverage film by using the flexible layer and laminating the rigidity-flexibility board on an optical drawing machine for compensating an expansion amount; the total expansion amount is compensated to a primary imaging working substrate; and the transformation generated in a manufacturing process can be eliminated by using the compensation of the working substrate, so that the good alignment product can be obtained. The process steps are reasonable, so that the coverage film can be prevented from being damaged in a process of milling the window, and the production efficiency can be improved; an adhesive tape provided by the invention can be used for protecting the rigid board window, and the adhesive tape not only can resist erosion of an acid and alkali solution but also has high-temperature resistance and strong adaptability; and the parameter arrangement and the step of a laminating machine can be optimized by the steps of laminating the coverage film by the flexible board and laminating the rigidity-flexibility board, thus ideal product laminating quality is achieved.

Owner:CHENGDU AEROSPACE COMM EQUIP CO LTD

Electromagnetic field regulation and control method of surface residual stress of aero-engine component

ActiveCN107299217AEliminate deformationAvoid damageProcess efficiency improvementManufacturing cost reductionPeak current

The invention discloses an electromagnetic field regulation and control method of surface residual stress of an aero-engine component. The regulation and control method comprises the following step: performing electromagnetic field regulation and controlling on the new-made aero-engine component at normal temperature for 3-600s, wherein the electromagnetic field is formed by coupling an alternating magnetic field and a pulsed electric field; the intensity of the alternating magnetic field is 500-30,000A / m; the frequency of the alternating magnetic field is 1-1,000Hz; the maximum peak current of the pulsed electric field is 5-20,000A; the pulse period of the pulsed electric field is 0.01-1.0s. According to the method, the traditional shot blasting process is canceled, and the distribution of residual stress of a surface layer and a near-surface layer of a material of the component is regulated and controlled by an electromagnetic field, so that the manufacturing accuracy and the surface roughness can be improved, the technological process is shortened, the manufacturing cost is lowered, and the manufacturing period is shortened.

Owner:WUHAN UNIV OF TECH

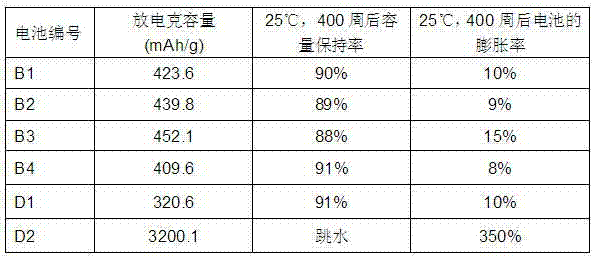

Positive material of lithium ion battery

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a positive material of a lithium ion battery. The positive material comprises graphite and a silicon-based material, wherein the surface of the silicon-based material is coated with amorphous carbon; the median particle size of the graphite is 2 to 10 microns; the median particle size of the silicon-based material is 2 to 10 microns; the mass of the silicon-based material accounts for 10 to 30 percent of the total mass of the positive material; the mass of the amorphous carbon accounts for 5 to 20 percent of the total mass of the positive material. Compared with the prior art, the positive material has the advantages that the volume expansion of the silicon-based material can be effectively suppressed by coating the amorphous carbon on the surface of the silicon-based material, so that the problem of battery deformation caused by the expansion of the silicon-based material is eliminated; meanwhile, active substances are prevented from falling from a collector, and thus the cycling performance of the battery is improved; the silicon-based material is mixed with the graphite, so that the volume per gram of the positive material can be greatly improved and is obviously higher than that of the graphite, and thus the cycling performance of the positive material is greatly improved compared with that of the silicon-based material.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

Lithium ion battery and anode and preparation method thereof

ActiveCN102623745AEliminate deformationAdvantages of preparation methodSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryLithium-ion battery

The invention belongs to the technical field of lithium ion batteries and particularly relates to an anode of a lithium ion battery. The anode of the lithium ion battery comprises an anode current collector and an anode film coated on the anode current collector, and the anode film comprises anode active material, adhesive and conductive additive. The surface of the anode active material is coated with ethylene carbonate (EC), and the weight ratio of the EC and the anode active material is (0.1-30):(99.9-70). Compared with the prior art, the EC coated on the surface of the anode active material is dissolved in electrolyte after liquid injection, the space occupied by the EC in the film can be released, so that a certain space is reserved for expansion of particles of the anode active material during charging and circulating, and the problem of deformation of flexibly-packaged cell due to expansion of the active material is eliminated. Further, the invention further discloses a method for preparing the lithium ion battery, namely the lithium ion battery comprising the anode.

Owner:NINGDE AMPEREX TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com