Feeding structure of housing with antenna

A shell and antenna technology, applied in the field of feed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

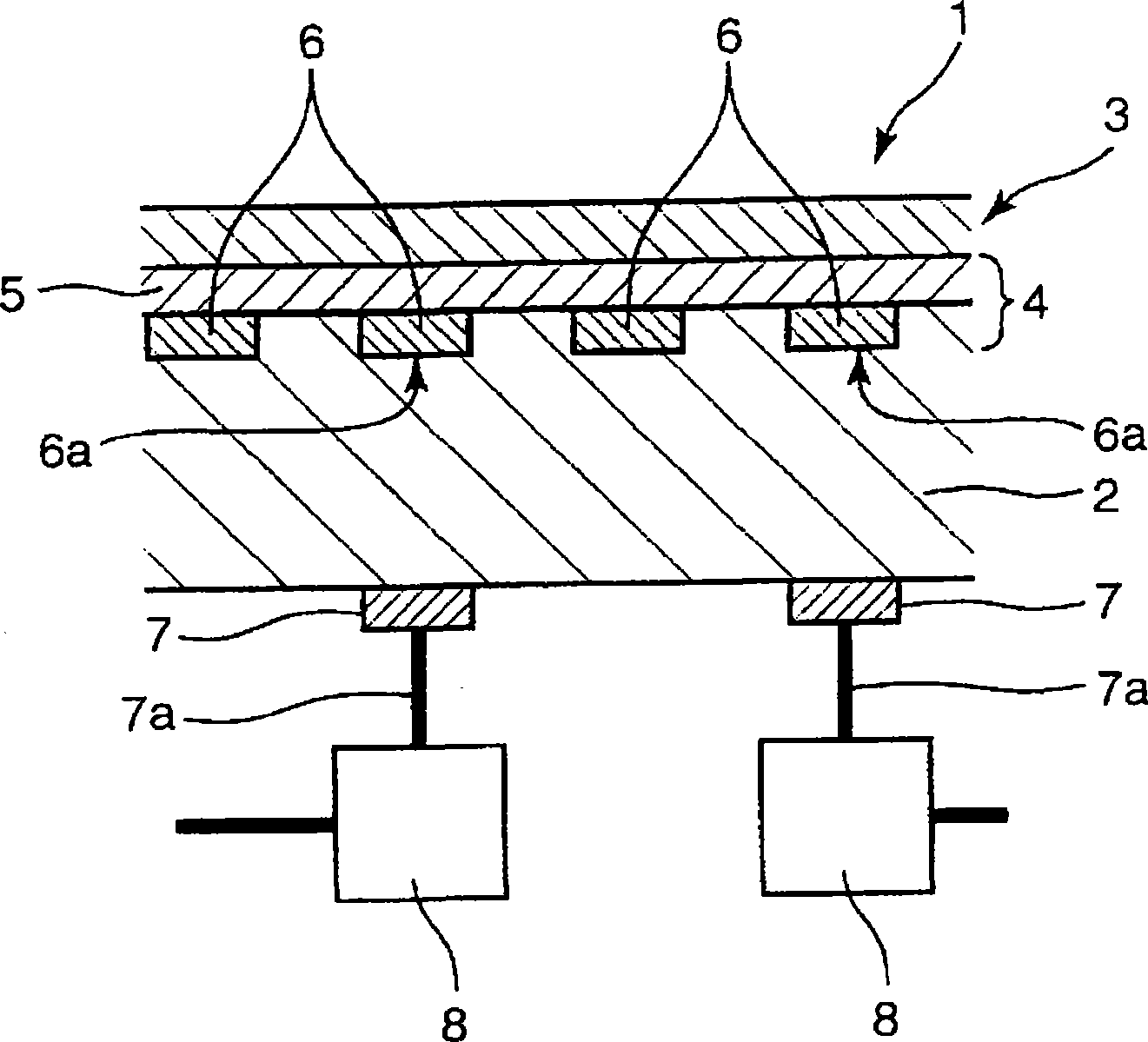

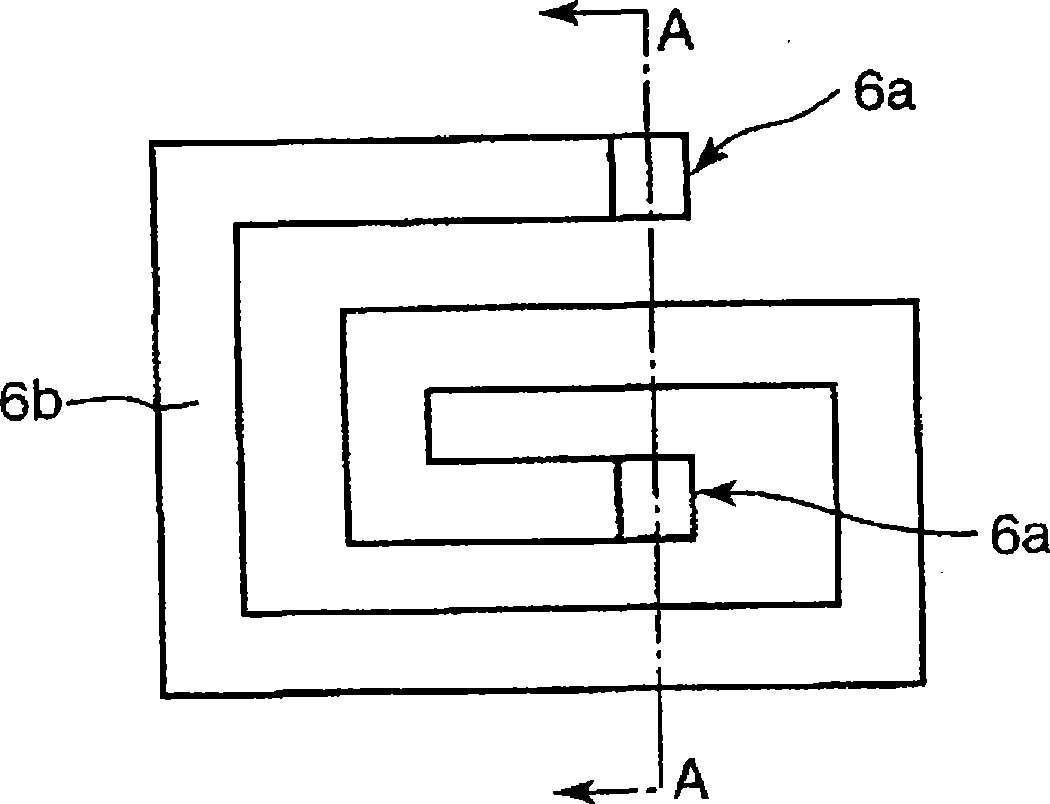

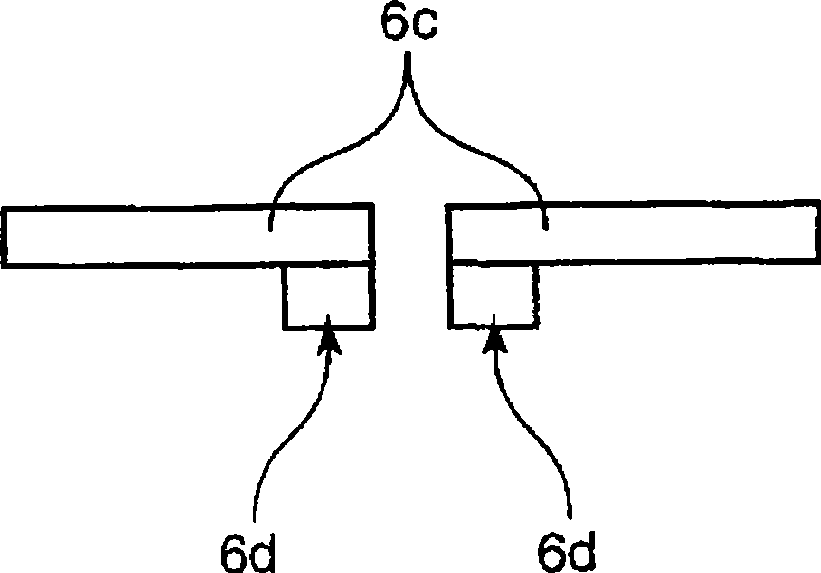

[0109] First, a 50 micron (μm) thick PET film is used as the film base material 5, and an 18 micron thick copper foil is formed on one side as a conductive layer, and the copper foil is formed in the shape of a helical antenna for RFID by photolithography. Carry out pattern making, form planar antenna 6, thereby obtain antenna film 4 (with reference to figure 1 ).

[0110] Also, a decorative layer was formed on one side of a transparent acrylic film having a thickness of 50 microns by gravure printing to obtain a decorative film 3 .

[0111] Next, the antenna film 4 is adhered to the decorative layer side of the decorative film 3 with a transparent adhesive to form an inlaid film, and the inlaid film is preliminarily processed according to the molding metal mold used to form the outer surface shape of the housing 2. take shape.

[0112] Here, when bonding the decorative film 3 and the antenna film 4, the planar antenna 6, the film base material 5, the decorative layer, and ...

Embodiment 2

[0118] First, a 50 micron (μm) thick PET film is used as the film base material 5, and an 18 micron thick copper foil is formed on one side as a conductive layer, and the copper foil is patterned in the shape of a helical antenna by a printing method. , forming a planar antenna 6, thereby obtaining an antenna film 4 (refer to Figure 5 ).

[0119] A decorative film 3 was obtained by forming a decorative layer on one side of a transparent polycarbonate film having a thickness of 50 micrometers by gravure printing.

[0120] Next, the antenna film 4 is adhered to the decorative layer side of the decorative film 3 with a transparent adhesive to form an inlaid film, and the inlaid film is preformed according to the shape of the outer wall surface forming the housing 2 . The bonding between the decorative film 3 and the antenna film 4 is the same as that in the first embodiment above.

[0121] Next, using a molding die capable of molding a case 2 with a thickness of 1 mm, the inse...

Embodiment 3

[0126] First, a 25-micron (μm) thick polyimide film is used as the film base material 5, and an 18-micron thick copper foil is formed on one side as a conductive layer, and the helical antenna is pressed by an etching method based on a printed resist. The shape of the copper foil is patterned to form a planar antenna 6, thereby obtaining the antenna film 4 (refer to Figure 5 ).

[0127] Also, a decorative layer was formed on one side of a transparent acrylic film having a thickness of 50 microns by gravure printing to obtain a decorative film 3 .

[0128] Next, the antenna film 4 is adhered to the decorative layer side of the decorative film 3 with a transparent adhesive to form an inlaid film, and the inlaid film is preformed according to the shape of the outer wall surface forming the housing 2 .

[0129] Next, using a molding die capable of molding a case 2 with a thickness of 1 mm, the insert film is inserted into the molding die, the mold is closed, and polycarbonate re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com