Method for manufacturing rigidity-flexibility combined printing circuit board

A technology for printed circuit boards and manufacturing methods, applied in the directions of printed circuit manufacturing, printed circuits, electrical components, etc., can solve problems such as unreasonable process steps, affecting assembly, complexity, etc., to avoid damage to the cover film, improve production efficiency, Reasonable effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

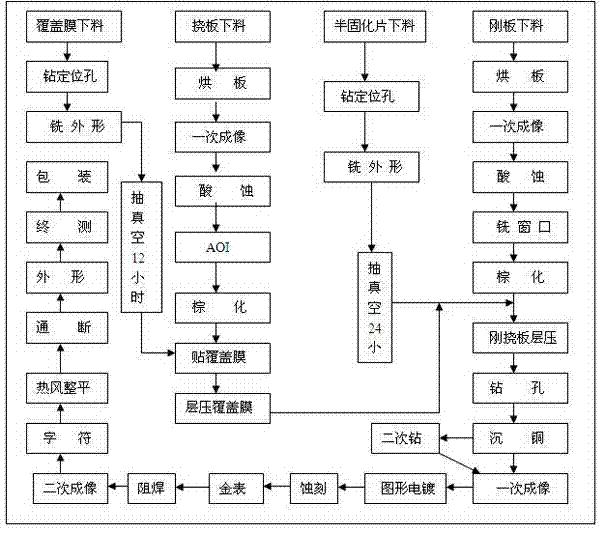

[0020] Such as figure 1 As shown, a rigid-flex printed circuit board manufacturing method, including cover film preparation, flexible board preparation, prepreg preparation, rigid board preparation and rigid-flex board production.

[0021] Cover film preparation consists of the following steps:

[0022] Covering film cutting → drilling positioning holes → milling shape → vacuuming for 24 hours;

[0023] Flex board preparation includes the following steps:

[0024] Flexible plate blanking→baking plate→one-time imaging→acid etching→AOI→browning→attaching cover film→laminating cover film;

[0025] The cover film used in the step of pasting the cover film is the cover film prepared from the above cover film.

[0026] Prepreg preparation involves the following steps:

[0027] Prepreg blanking→drilling positioning holes→milling the shape→vacuumizing for 24 hours;

[0028] Rigid board preparation consists of the following steps:

[0029] Rigid plate blanking→baking plate→one im...

Embodiment 2

[0056] A method for manufacturing a rigid-flexible printed circuit board. The step of milling a window is to mill a groove on the surface of the rigid-flexible board with a depth of one-third of the plate thickness. After the on-off test step, the groove is milled through to form a window, so as to remove the flexible board. area rigid plate purpose, the continuity test procedure is figure 1 On-off in. This method requires high glue flow control and high milling precision. If the precision control is not good, the flex plate will be milled. However, the subsequent processing of this window opening method does not require window protection. This method is only applicable to products where the distance between the edge of the rigid board window and the pad is less than 2mm. The specific process is as follows:

[0057] Rigid board imaging→acid etching→primary slotting (1 / 3 depth of board thickness)→rigid-flexible board lamination→drilling→immersion copper plating→……→continuity tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com