Patents

Literature

70results about How to "Reasonable process steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

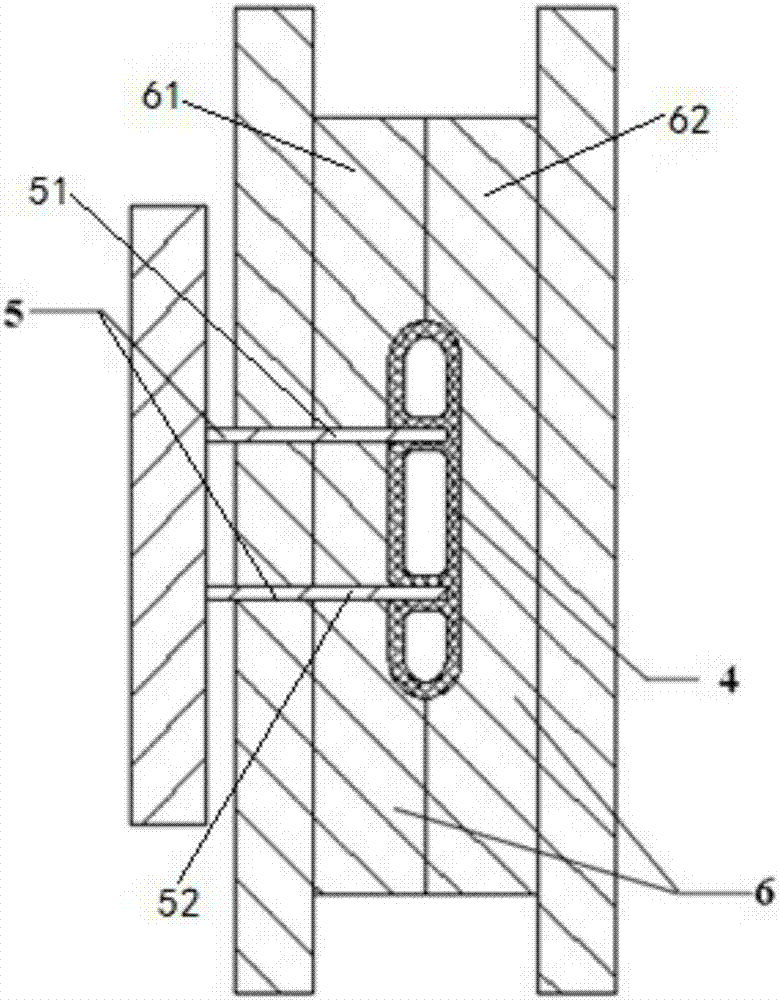

Method for manufacturing rigidity-flexibility combined printing circuit board

ActiveCN102970828AEliminate deformationReasonable process stepsPrinted circuit manufactureTemperature resistanceElectroless plating

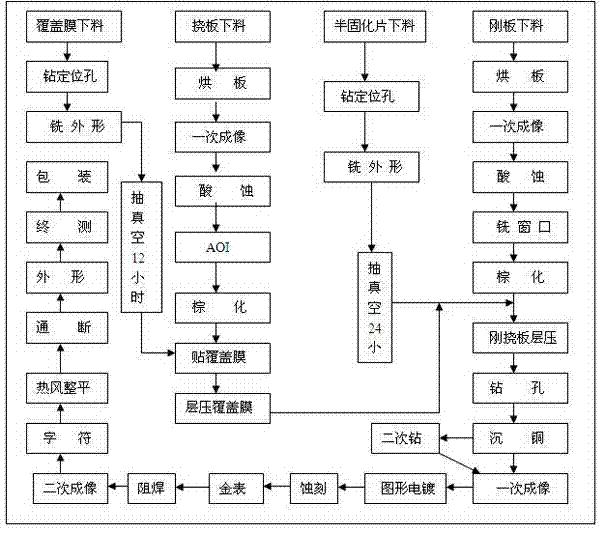

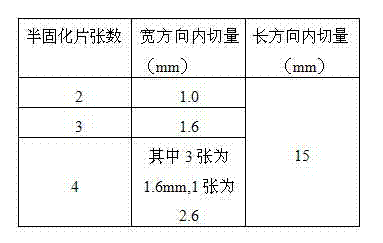

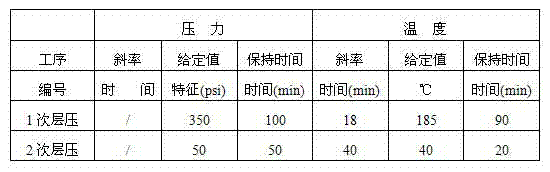

The invention discloses a method for manufacturing a rigidity-flexibility combined printing circuit board. The method comprises the following steps of: laminating a rigidity-flexibility board, milling a window, electrically plating electroless plating copper, imaging, silk-screening and solder-resisting, flattening with hot air, carrying out on-off test, removing drilling dirt in holes, and laminating a coverage film by using a flexible board, wherein the steps of covering the coverage film by using the flexible layer and laminating the rigidity-flexibility board on an optical drawing machine for compensating an expansion amount; the total expansion amount is compensated to a primary imaging working substrate; and the transformation generated in a manufacturing process can be eliminated by using the compensation of the working substrate, so that the good alignment product can be obtained. The process steps are reasonable, so that the coverage film can be prevented from being damaged in a process of milling the window, and the production efficiency can be improved; an adhesive tape provided by the invention can be used for protecting the rigid board window, and the adhesive tape not only can resist erosion of an acid and alkali solution but also has high-temperature resistance and strong adaptability; and the parameter arrangement and the step of a laminating machine can be optimized by the steps of laminating the coverage film by the flexible board and laminating the rigidity-flexibility board, thus ideal product laminating quality is achieved.

Owner:CHENGDU AEROSPACE COMM EQUIP CO LTD

High-stretch tyre and production thereof

A high-elasticity tyre and its manufacture are disclosed. The tyre is characterized by heat seal fixed connecting tread with fetal from vulcanizing mould, plastic smelting from natural rubber auxiliary materials, mixed smelting, fining smelting, warm gluing and adhesive bar shaping. Its advantages include less weight, good elasticity, better vibration-resistant, shock-proof, loading, buffering and abrasive-resistance performances.

Owner:刘灵柱

Method for extracting sucrose fatty acid ester

ActiveCN1654469ALess impuritiesLess shortage problemEsterified saccharide compoundsSugar derivativesSucroseOrganic solvent

The sucrose fatty acid ester purifying process includes the following steps: dissolving crude sucrose fatty acid ester in organic solvent capable of being separated from water to obtain crude product solution, dripping dilute acid solution while stirring at 30-80 deg.c to pH 5.5-6.5, eliminating water to obtain acidified crude product solution, adding alkali earth metal compound while stirring for reaction at 40-110 deg.c of 10-180 min, centrifugating, depositing or filtering to eliminate produced solid aliphatic salt, and heating and decompressing distillation to obtain purified sucrose fatty acid ester product. The process is reasonable, high in purifying effect, short in reaction time, less in side reaction, wide in application range and low in production cost.

Owner:杭州瑞霖化工有限公司

Four-line splitting rolling technology for fai 12mm round steel

InactiveCN102814320AReduce consumptionResolution timeRollsMetal rolling arrangementsWedge angleMechanical engineering

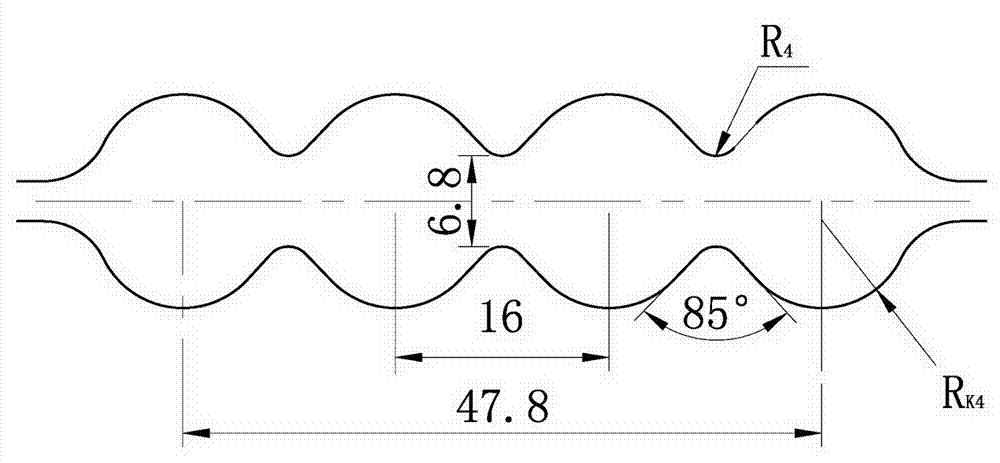

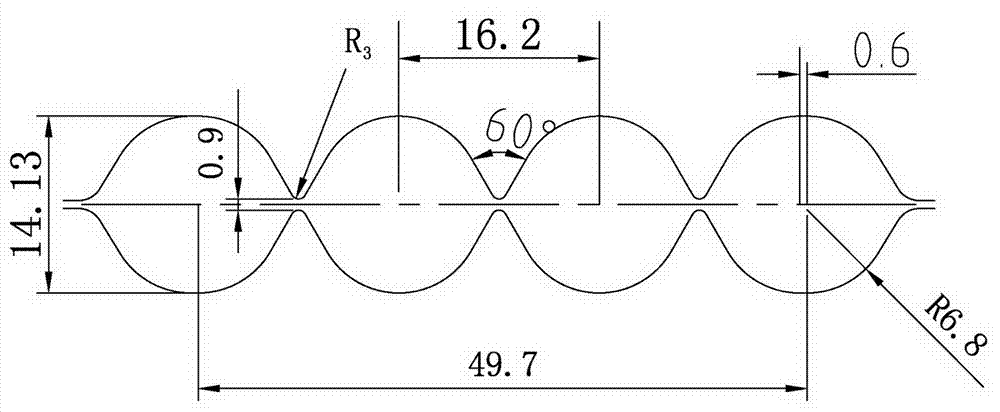

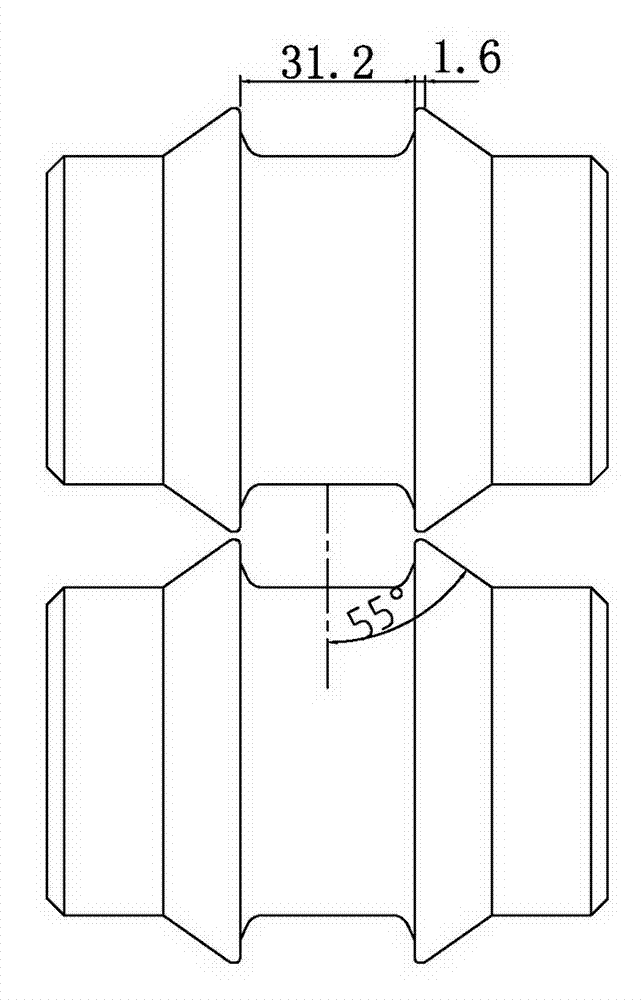

The invention discloses a four-line splitting rolling technology for fai 12mm round steel. The dimension tolerance of the height and the width of a rolled piece is no larger than + / -0.2mm through K5 pre-splitting pass, the center-to-center spacing of two hole patterns of in the middle of a K4 pre-splitting pass roller is 16mm, the center-to-center spacing of two hole patterns on two sides is 47.8mm, and the wedge angle of the roller is 85 degrees to 87 degrees; the arc radius R4 of the wedge top is 1.5-1.8mm, the wedge top space of an upper roller and a lower roller is 6.8mm, and the radius RK4 of a pre-splitting hole is 6.6mm; the wedge angle of a K3 splitting pass roller hole pattern is 55 degrees to 60 degrees; the arc radius R3 of the wedge top is 0.6-0.7mm, the height of the groove bottom is 14.13mm, the distance between the wedge tops is 0.7-0.9mm, the center distance of two middle grooves is 16.2mm, the center distance of two side grooves is 49.7mm, and the radius of the groove bottom is 6.8mm; front-row splitting wheels and rear-row splitting wheels are installed at the position of an outlet of the rolled piece of a K3 splitting pass from front to back at intervals, the double-edge splitting wheel edge strip wedge angle of each front-row splitting wheel is 55 degrees to 60 degrees, the double-edge center distance is 31.2-33.2mm, and the width of each wedge top is 1.6-2.2mm; the single-edge splitting wheel wedge angle of each rear-row splitting wheel is 85 degrees, the width of each wedge top is 0.8mm, and the distance between axes of the front-row splitting wheels and rear-row splitting wheels is 100mm.

Owner:XINJIANG BAYI IRON & STEEL

Method for processing dry-cured beef food

The invention relates to a method for processing dry-cured beef food, and belongs to the technical field of food processing. The processing method comprises the following steps of: selecting ham of fresh beef, cleaning the ham, removing tendon, fascia and fat, cutting the ham into 500 grams of meat block according to straight shreds, uniformly coating 45 grams of sodium chloride, 0.1 gram of sodium nitrate, 5 grams of sweetener and 0.03 gram of sodium ascorbate on the surface of the meat block based on 1,000 grams of beef, and kneading the meat block till the meat block is soft; putting the meat block into a cylinder, sealing the cylinder mouth, salting the meat block for 10 to 15 days, and turning the meat block in the cylinder once in the meantime; and air-curing, stacking and extruding the meat block, airing the meat block to form a finished product, controlling the water content within 40 percent, then slicing the meat block, packing the slices with vacuum, and sterilizing the slices by irradiation with 8KGy dose to obtain the dry-cured beef food. Compared with the prior art, the method has the advantages of simple and reasonable process steps and capability of realizing industrialized production; and the product has the advantages of bright red and attractive color, good mouthfeel and long storage period. The method has great improvement on the traditional dry-cured beef production method, and has high market popularization value.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

Process for preparing sausage with dried old orange peel

The invention relates to a method for producing tangerine peel sausage, which comprises that (1), pretreating meat; (2),mixing the meat, sauce and additive into stuff, while the sauce is formed by mixed tangerine peel, sauce finding an water; (3), packing the stuff into sausage; (4), winding it; (5), packing.

Owner:何家满

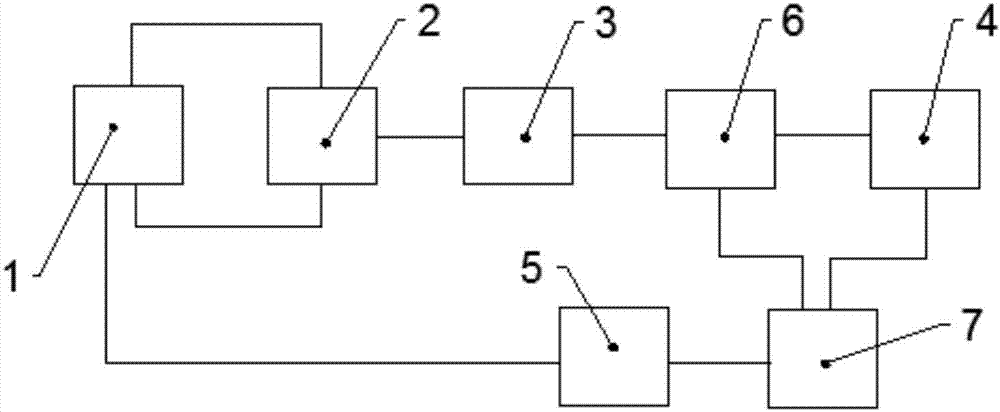

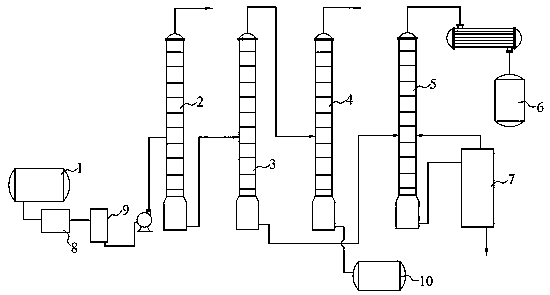

Separation system and sodium salt and potassium salt separation method

PendingCN107188201ALarge grainReasonable process stepsAlkali metal halide purificationThermal insulationChemistry

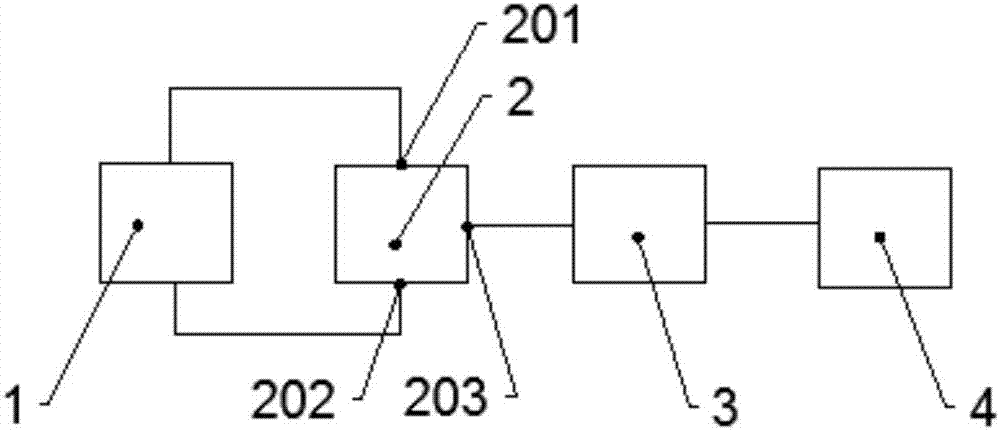

The present invention relates to the field of high salt wastewater treatment, particularly to a separation system and a sodium salt and potassium salt separation method. The separation system comprises a crystallization separation device, a thermal insulation settling device, a cooling crystallization device and a centrifugation device, wherein the crystallization separation device, the thermal insulation settling device, the cooling crystallization device and the centrifugation device are sequentially connected, the thermal insulation settling device is provided with a material inlet, a first material outlet and a second material outlet, the material inlet and the first material outlet are respectively connected to the crystallization separation device, and the second material outlet is connected to the cooling crystallization device. With the separation system of the present invention, the sodium salt and the potassium salt in the solution can be precipitated, and the separated sodium salt crystal and the separated potassium salt crystal can be obtained. The sodium salt and potassium salt separation method of the present invention uses the separation system to treat the wastewater containing the sodium salt and the potassium salt so as to obtain the separated sodium salt crystal and the separated potassium salt crystal.

Owner:BEIJING LIULIHE CEMENT +3

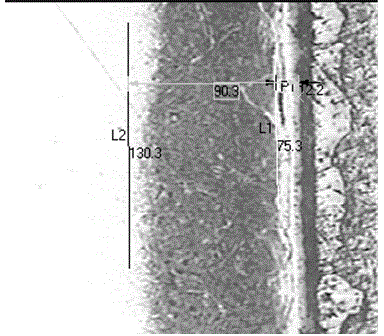

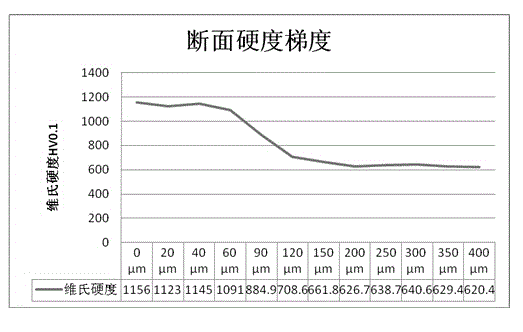

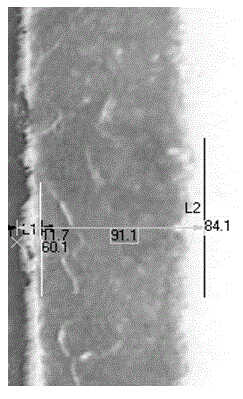

Technical method for die steel surface nonmetallic ion infiltration

InactiveCN104087892AExtended service lifeImprove wear resistanceSolid state diffusion coatingEnvironmental resistanceFree cooling

The invention relates to the technical field of metalsurface modification, and provides a technical method for die steel surface nonmetallic ion infiltration, and the technical method comprises the following process steps: A. cleaning a die surface for decontamination; B. preheating a die until the surface is golden yellow; C. infiltrating non metallic ions into the die, performing heat preservation on the die in nitride salt in a nitriding furnace for 4-5 hours; D. oxidizing the die, erforming heat preservation on the die in oxidizing salt in an oxidation furnace for 30-50 minutes; E. taking the die out from the oxidation furnace, naturally cooling to room temperature; F. putting the die into clear water for immersion for 30-50 minutes, then cleaning, and drying in air. The technical method has the advantages of reasonable technological steps, simple operation, short time, environmental friendliness, reliability, stripping resistance, no deformation and no sticking, and is economical and practical due to use of an ordinary external heated crucible furnace, the technical method is used for die steel surface N, C and O nonmetallic ioninfiltration to change tissue structure of the die material surface, realize wear resistance and anti fatigue performance reinforcement of die steel surface, and improve the service life of the die.

Owner:WEIHAI JIUWEI MATERIAL TECH CO LTD

Integrated heat preservation decorative plate and production process thereof

InactiveCN104018636AReduce weightStrong weather resistanceCovering/liningsHeat proofingGlass fiberCompound a

The invention discloses a production process of an integrated heat preservation decorative plate. The production process comprises the steps of processing a glass fiber based decorative surface layer, compounding the glass fiber based decorative surface layer and a heat preservation core material, and compounding a glass fiber cement based cloth and the heat preservation core material. The integrated heat preservation decorative plate is light in weight, strong in weather resistance, high in strength, beautiful in appearance and low in cost; the production disclosed by the invention comprises the steps of processing the glass fiber based decorative surface layer, compounding the glass fiber based decorative surface layer and the heat preservation core material, and compounding the glass fiber cement based cloth and the heat preservation core material, is simple and reasonable in process step and convenient in operation and implementation, and can be used for greatly saving the investment of human resources, greatly reducing the production cost of products, improving the production efficiency, and reducing the potential safety hazards.

Owner:LANGFANG HOUDE TECH CO LTD

Manufacturing method of non-magnetic alloy

ActiveCN107904472AReasonable process stepsImprove stability and reliabilityTransportation and packagingMetal-working apparatusAlloyNon magnetic

The invention discloses a manufacturing method of a non-magnetic alloy. The manufacturing method comprises the following technological steps that a, an alloy mixture and anhydrous alcohol are poured into a ball grinding mill to be subjected to ball-milling treatment, and the alloy mixture is composed of tungsten carbide, metal nickel powder, tantalum carbide powder, metal titanium powder, metal molybdenum powder and metal aluminum powder; b, one-time screen filtering treatment is conducted; c, drying treatment is conducted; d, an alcohol mixture which is subjected to drying treatment is pouredinto a mixing machine, and a paraffin rubber gasoline solution is added into the mixing machine; e, a mixture formed by the alcohol mixture and the paraffin rubber gasoline solution which are mixed is poured into a pressing mould, and the mixture is pressed to form an alloy blank by means of an oil press; f, demoulding and blank taking are conducted; g, the alloy blank is subjected to drying treatment through an electric furnace; h, the alloy blank is installed into a graphite boat; i, alloy blank sintering is conducted; j, cooling is conducted; and k, cleaning is conducted. According to themanufacturing method, through the technological step design, a non-magnetic alloy part can be effectively produced and prepared, and the technological steps are reasonable, and good in stability and reliability.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

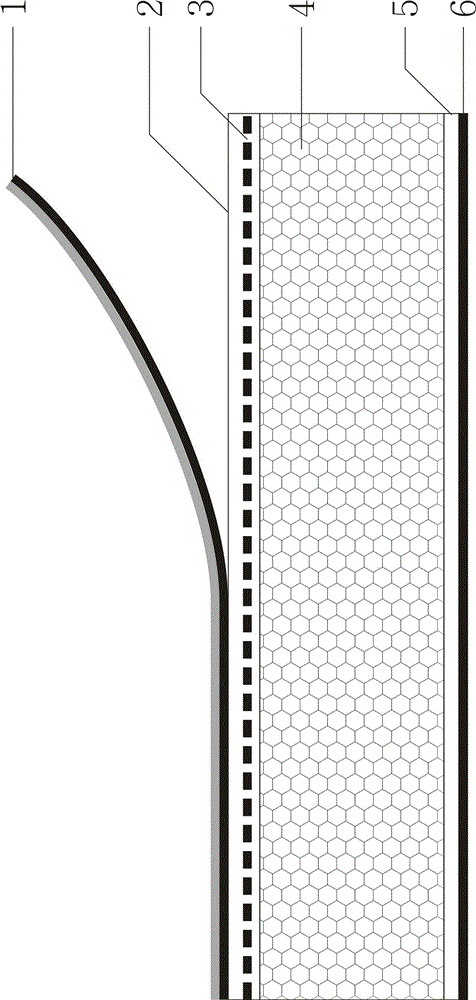

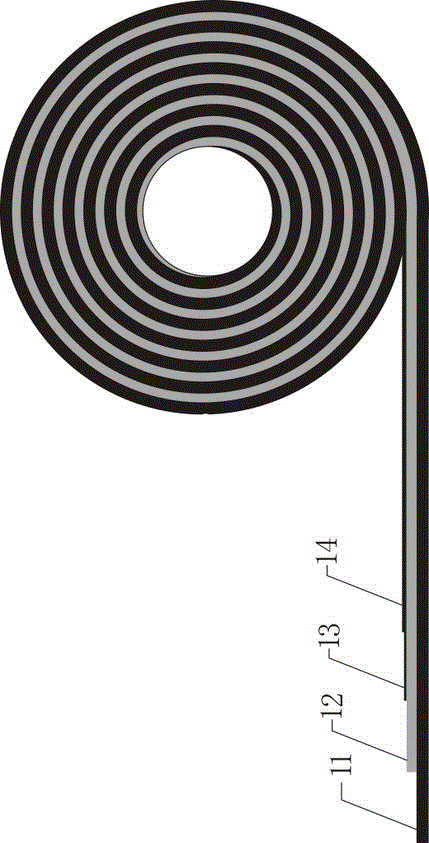

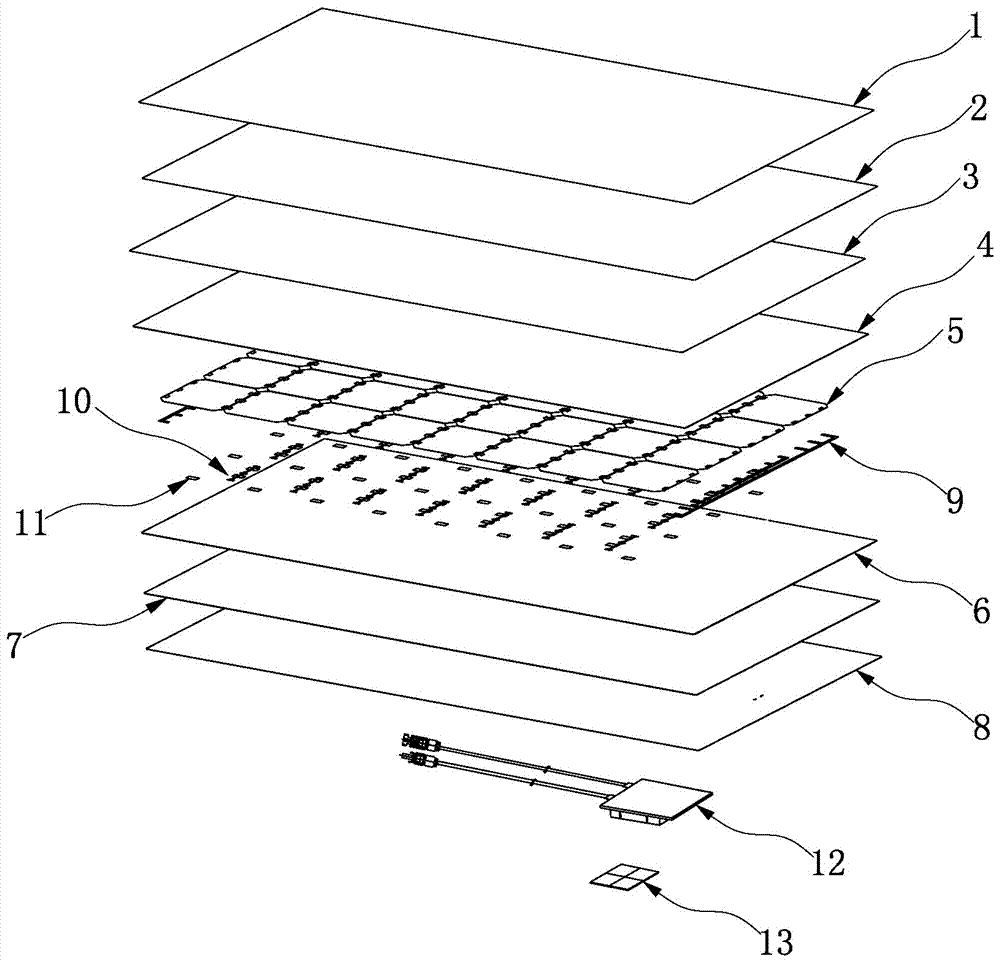

Production process of bendable single crystalline silicon solar cell

InactiveCN107393989ANot easy to shiftAvoid crackingPhotovoltaic energy generationSemiconductor devicesGlass fiberEngineering

The invention discloses a production process of bendable monocrystalline silicon solar cells. Firstly, the cell silicon slices are welded into battery components, and then the battery components are fixed on the glass fiber felt, and the first adhesive film stacked sequentially from top to bottom , the front support film, the second adhesive film, the battery assembly, the glass fiber felt, the third adhesive film and the back plate constitute the base material of the battery assembly, which is first placed in a low-temperature lamination device, heated and pressurized in a vacuum state to make the above-mentioned components The adhesive film is initially melted and the initial bonding is completed. On the one hand, the materials of each layer are not easy to shift during the subsequent operation process. On the other hand, the first adhesive film has been melted and is sticky, which is convenient for the ETFE film to be flattened on the first on the adhesive film, and then put it into high-temperature lamination equipment, so that the materials of each layer are cross-linked and highly bonded to each other to achieve the set cross-linking degree and peel strength. Cracking, stable and reliable quality, the products produced have good sealing performance, good flexibility and weather resistance.

Owner:XIAMEN TOPUNIVE TECH

High-elasticity hand cart tyre and its preparing method

InactiveCN1676351AReasonable process stepsExcellent physical and chemical propertiesNon-inflatable tyresSpecial tyresCartEngineering

The present invention belongs to a hand cart type with high elastic force and its preparation method. It is technically characterized by that it is made up by using tyre surface and tyre core, utilizing vulcanization mould and adopting thermo-bonding and fixedly connecting process, and the tyre surface and tyre core are made up by using various auxiliary materials prepared with natural rubber trough the processes of plastication, mixing, finely-mixing warming glue and rubber rod forming. Said invention hand cart type can be used as a substitute for inflation-free tyre.

Owner:刘灵柱

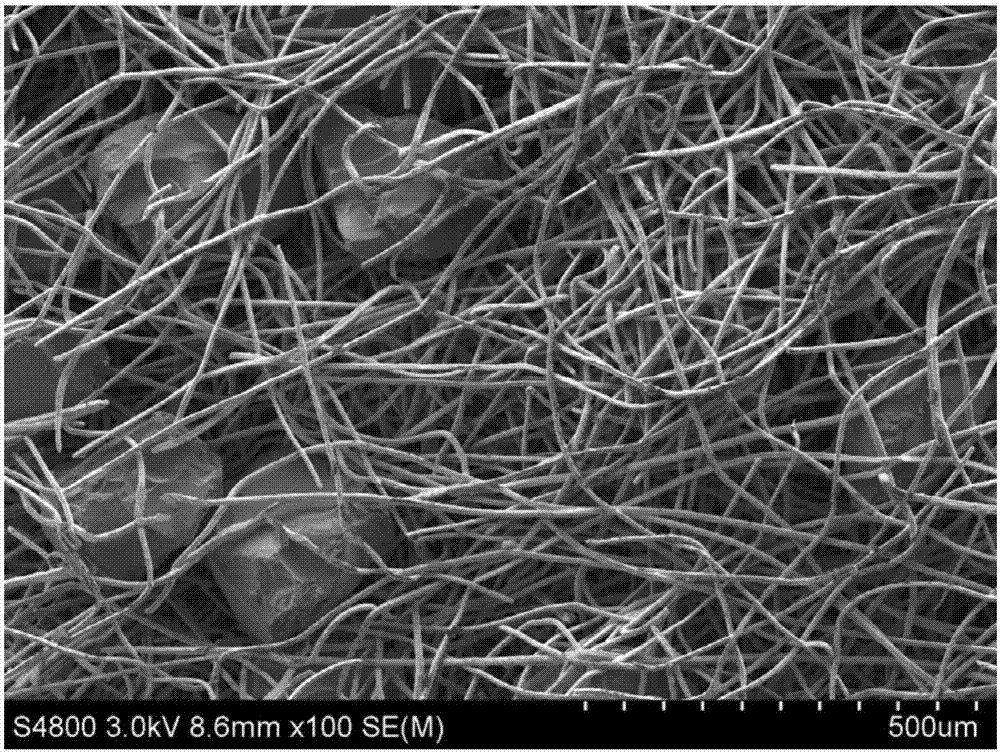

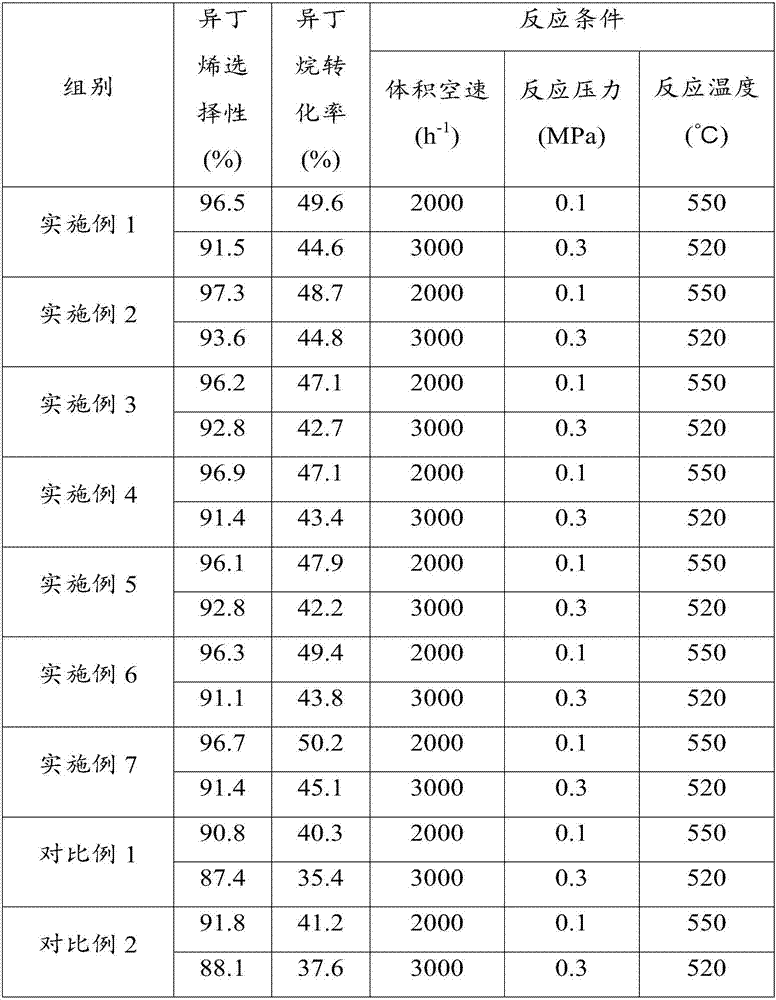

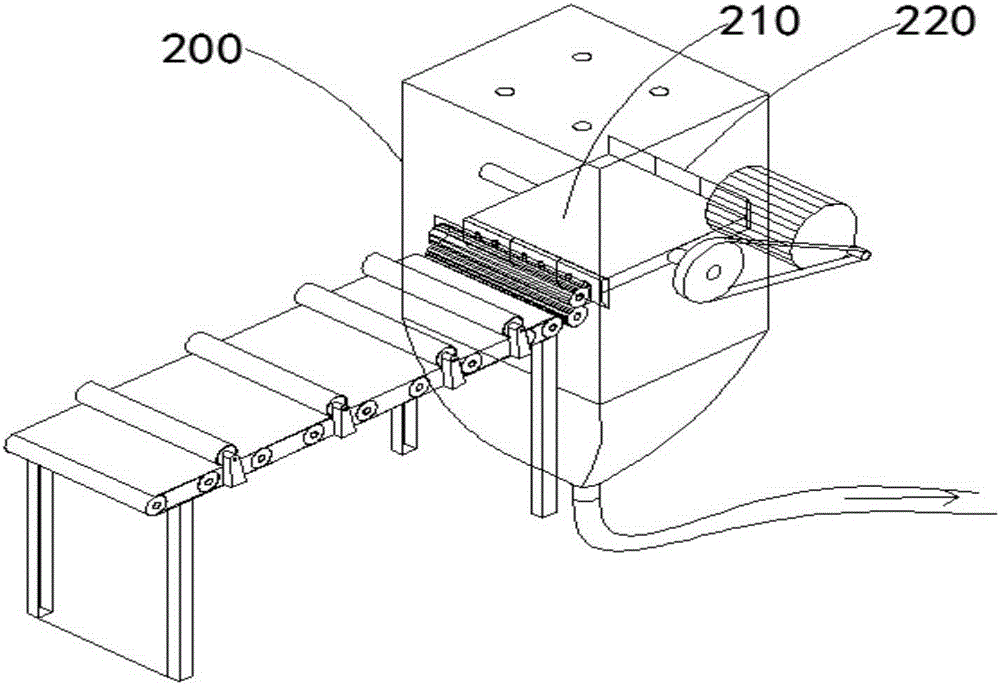

Composite catalyst, preparation method as well as application thereof in reaction of preparing isobutene by dehydrogenating iso-butane

InactiveCN107376903AImprove permeabilityImprove heat transfer performanceHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneVoid ratio

The invention relates to the field of catalysts, and particularly provides a composite catalyst, a preparation method and application thereof in reaction of preparing isobutene by dehydrogenating iso-butane. The composite catalyst is mainly prepared from a load platinum catalyst and metal microfibers, wherein the load platinum catalyst is coated by a three-dimensional network formed by the microfibers. The composite catalyst has a large void ratio, good permeability, good mass transfer and heat conduction performance, good low-temperature activity, good selectivity, good stability, low cost and long service life; and when the composite catalyst is used in the reaction of preparing the isobutene by dehydrogenating iso-butane, the alkane conversion rate and the selectivity of the iso-butane can be improved.

Owner:SINOPEC ENG GRP CO LTD

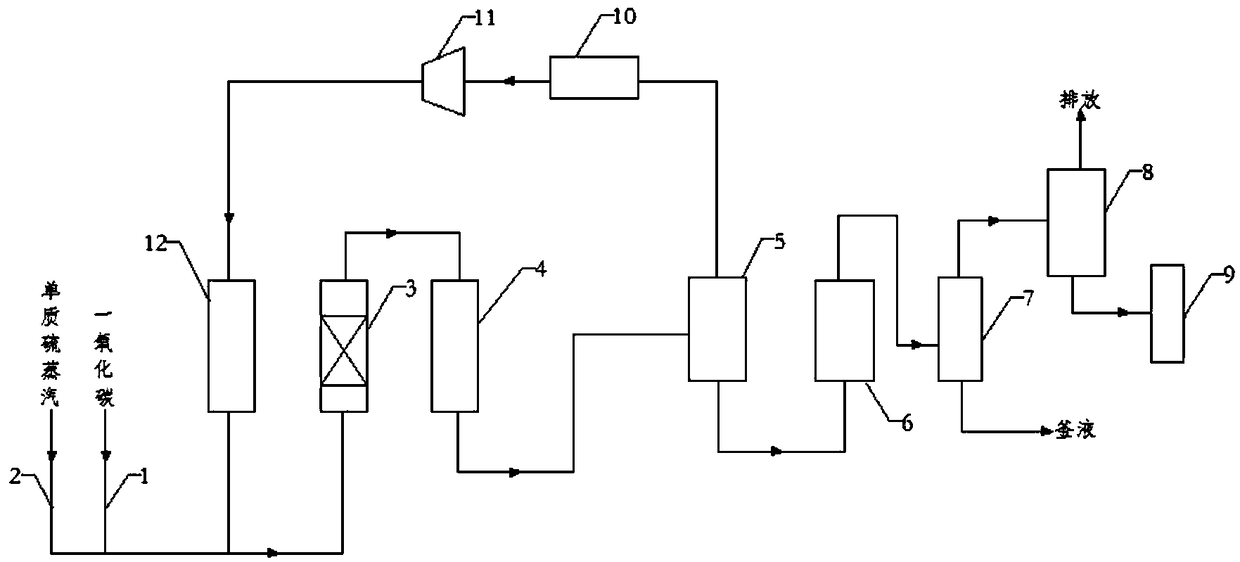

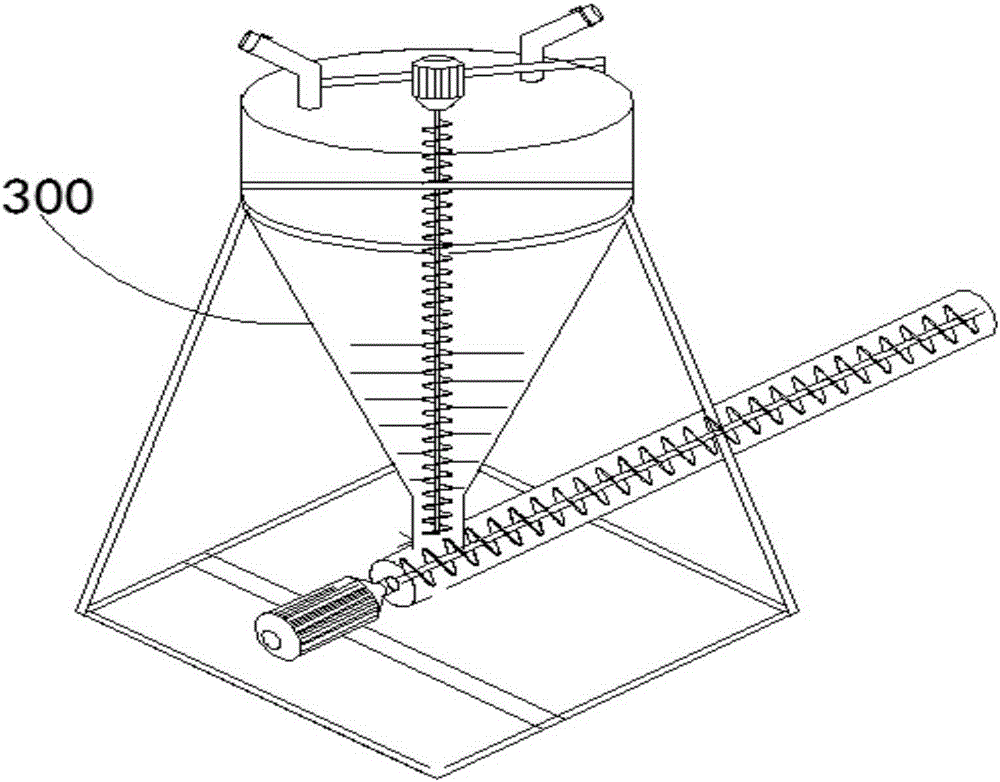

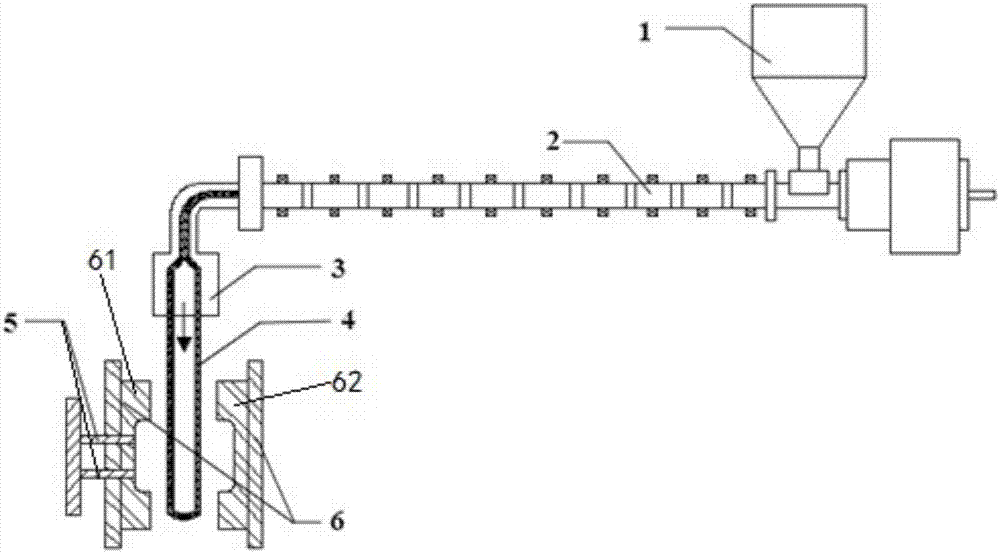

Preparation method and preparation apparatus of carbonyl sulfide

PendingCN109231207AImprove reaction efficiencyQuick responseCarbon oxysulideIndustrial gasHazardous substance

The invention belongs to the technical field of industrial gas preparation, and relates to a preparation method and preparation apparatus of carbonyl sulfide. The preparation method of the carbonyl sulfide comprises the following steps: introducing carbon oxide and element sulfur steam into a reactor with a metal sulfide catalyst, and performing the synthetic reaction, thus obtaining mixed gas; separating the mixed gas, thus obtaining the unreacted element sulfur steam, unreacted carbon oxide and carbonyl sulfide, and returning the unreacted element sulfur steam and the unreacted carbon oxideto the reactor to perform the cycling reaction; and condensing and collecting the carbonyl sulfide by a low-temperature collection tank, and then purifying in a purification system, thus obtaining high-purity carbonyl sulfide. By utilizing the metal sulfide as the catalyst, the reaction efficiency can be improved, and the unreacted raw material is recycled, so that the waste is avoided, and the difficulty for subsequently discharging harmful substances can be alleviated, and the cost is reduced; and for the characteristics of various impurities of a crude product, the corresponding purification means is adopted, so that the impurities in the carbonyl sulfide can be effectively removed.

Owner:欧中汇智电子材料研究院(重庆)有限公司

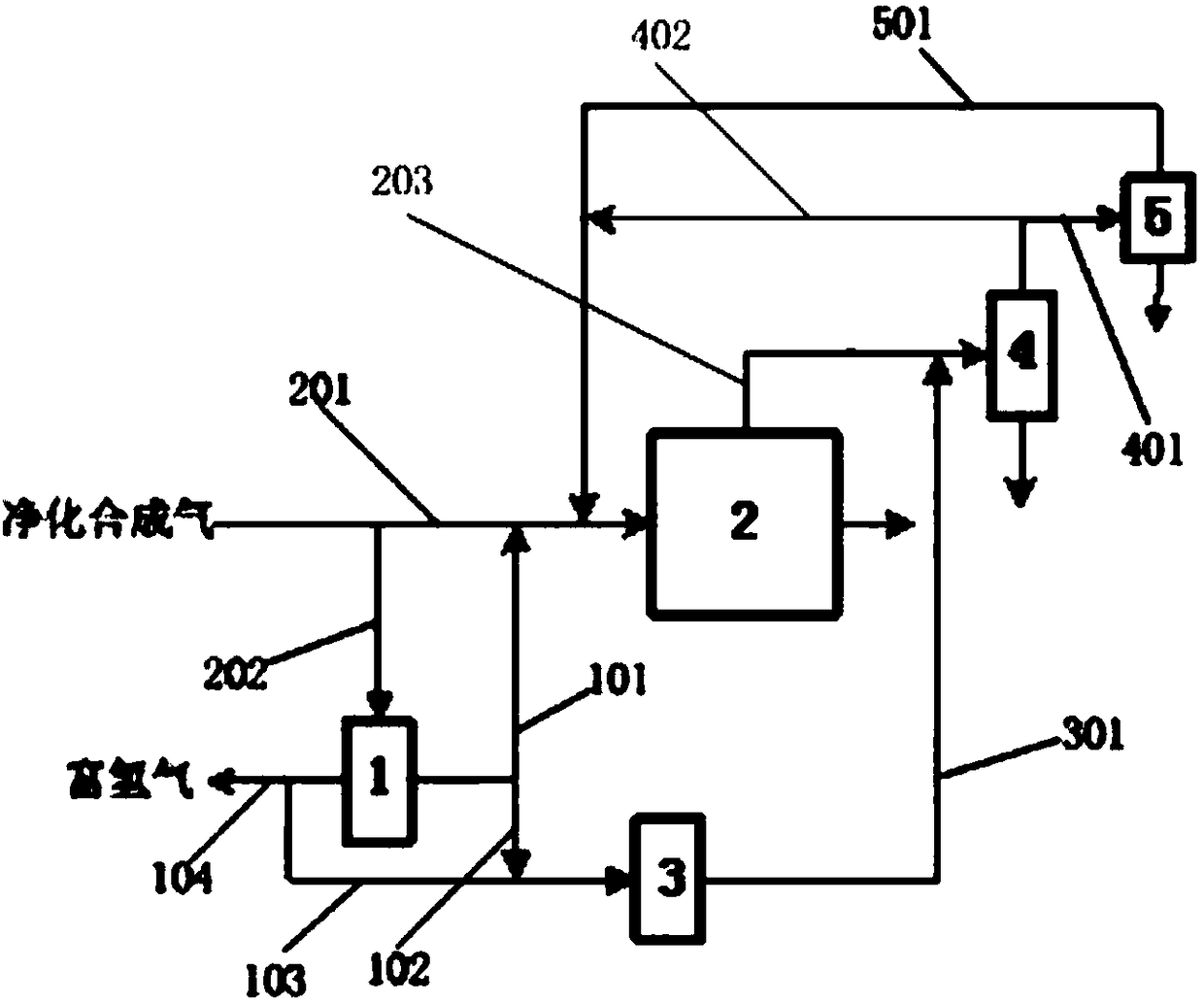

Method and system for regulating hydrogen-carbon ratio of Fischer-Tropsch synthesis gas and co-producing hydrogen

ActiveCN108384572AFlexible adjustment of hydrogen to carbon ratioReasonable process stepsLiquid hydrocarbon mixture productionHydrogenHydrocarbon

The invention provides a method and a system for regulating a hydrogen-carbon ratio of Fischer-Tropsch synthesis gas and co-producing hydrogen. The method comprises the following steps of sending purified synthesis gas into a Fischer-Tropsch synthesis unit and a purified synthesis gas separation unit respectively; carrying out a Fischer-Tropsch synthesis reaction on the purified synthesis gas, sent into the Fischer-Tropsch synthesis unit, under the action of a Fischer-Tropsch catalyst, and sending produced high-temperature oil gas into an oil-gas separation unit; in the oil-gas separation unit, separating out the unreacted synthesis gas and a lightweight hydrocarbon compound, which are contained in the high-temperature oil gas, as tail gas, sending at least part of the tail gas into a decarbonization unit, removing, in the decarbonization unit, CO2 in the tail gas, and partially or completely circulating to the Fischer-Tropsch synthesis unit as purified tail gas; separating the purified synthesis gas sent into the purified synthesis gas separation unit into CO-rich gas and H2-rich gas, and using at least part of the CO-rich gas for regulating a hydrogen-carbon ratio of raw gas input by the Fischer-Tropsch synthesis unit. By adopting the method and the system which are provided by the invention, not only can the hydrogen-carbon ratio of the synthesis gas be adjusted, but also the by-product hydrogen can be obtained.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

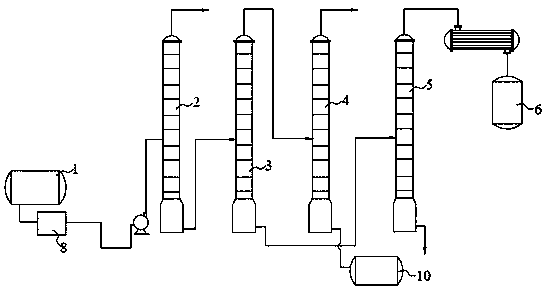

Refining method and system for recovery liquid containing cyclopentanone and propylene glycol methyl ether acetate

PendingCN109180425AReasonable process stepsReduce corrosionOrganic compound preparationOxygen compounds purification/separationChemistryBoiling point

The invention discloses a refining method for a recovery liquid containing cyclopentanone and propylene glycol methyl ether acetate. The refining method comprises: dehydrating a recovery liquid, adjusting pH, filtering the recovery liquid to obtain a dehydrated recovery liquid, feeding the dehydrated recovery liquid into a first rectification tower, separating a low-boiling organic solvent fraction at the top of the tower and the light recovery liquid at the bottom of the tower, feeding the light recovery liquid at the bottom of the tower into a second rectification tower, separating a cyclopentanone-water fraction at the tower top and a propylene glycol methyl ether acetate heavy component at the tower bottom, feeding the cyclopentanone-water fraction from the tower top into a third rectification tower, separating a water fraction at the tower top and a cyclopentanone product at the tower bottom, feeding the propylene glycol methyl ether acetate heavy component from the tower bottom into a forth rectification tower, and separating a propylene glycol methyl ether acetate product at the tower top and a heavy component residue liquid at the tower bottom. The continuous rectificationmethod has low energy consumption, is safe and reliable in production, has a low resin residue liquid yield and has membrane filtration product purity of 99.91% or more. The product chroma and other indicators satisfy the electronic grade standards.

Owner:江阴市大洋固废处置利用有限公司

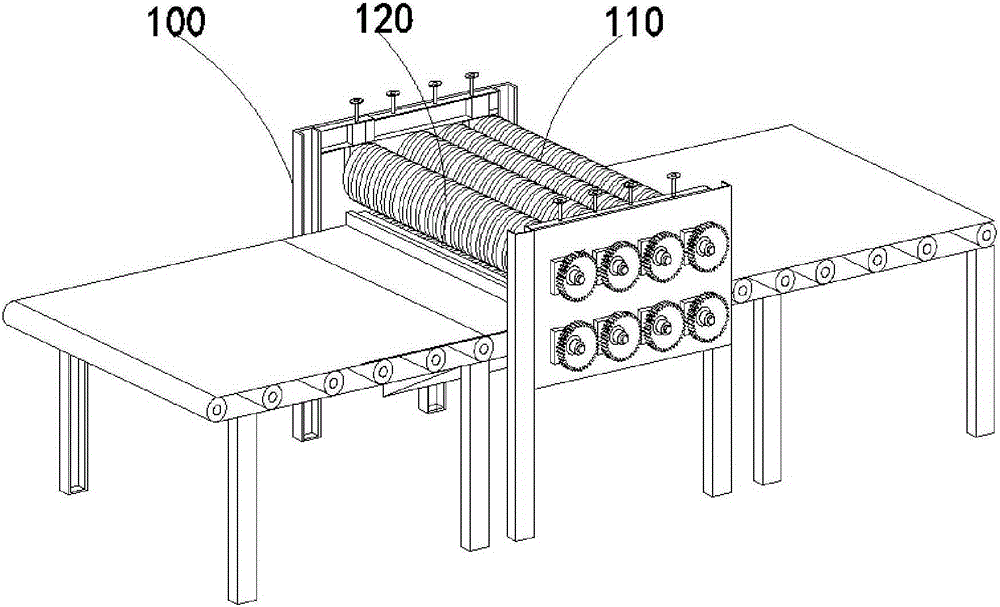

Composite material processing device and process and composite board

ActiveCN105216090AReasonable process stepsClear division of laborCuttersDomestic articlesCompound aRubber material

The invention provides a composite material processing device and process and a composite board, and belongs to the field of composite board production. The composite material processing device comprises a crushing device for crushing a composite material, a chopping device for chopping the crushed composite material, a wire separating device for separating the chopped composite material into wires, a mixing device for mixing the separated composite material with a rubber material, a spreading device for flatly spreading the composite material mixed with the rubber material, and a molding device for pressing the flatly spread composite material into a composite board. The composite material processing device is reasonable in process steps, and clear in division of labor; the whole processing device is high in automation degree, low in production cost and high in efficiency; besides, the finished product of the produced composite board is stable in properties and relatively high in quality; the composite board is formed by pressing and compounding a plurality of a plurality of composite material wires, and has excellent high temperature resistance and moisture resistance, and better flexibility; in short, the defects of the prior art are effectively remedied.

Owner:张沙

Processing method for flavored swimming crab meat can

The invention discloses a processing method for a flavored swimming crab meat can. The processing method comprises the following steps: (1) pretreating raw materials; (2) performing vacuum cooking; (3) cooling the raw materials and taking out meat; (4) performing flavoring; (5) draining water; and (6) performing canning. The technological steps of the processing method are simple and reasonable; a deep processing technology for swimming crabs is developed; the swimming crabs are processed into the flavored swimming crab meat can; the flavored swimming crab meat can is convenient to eat; the taste, flavor and nutritional value of crab meat can be effectively retained; furthermore, the economical value of the swimming crabs is increased; the flavored swimming crab meat can has extremely high economic benefits.

Owner:OCEAN RES CENT OF ZHOUSHAN ZHEJIANG UNIV

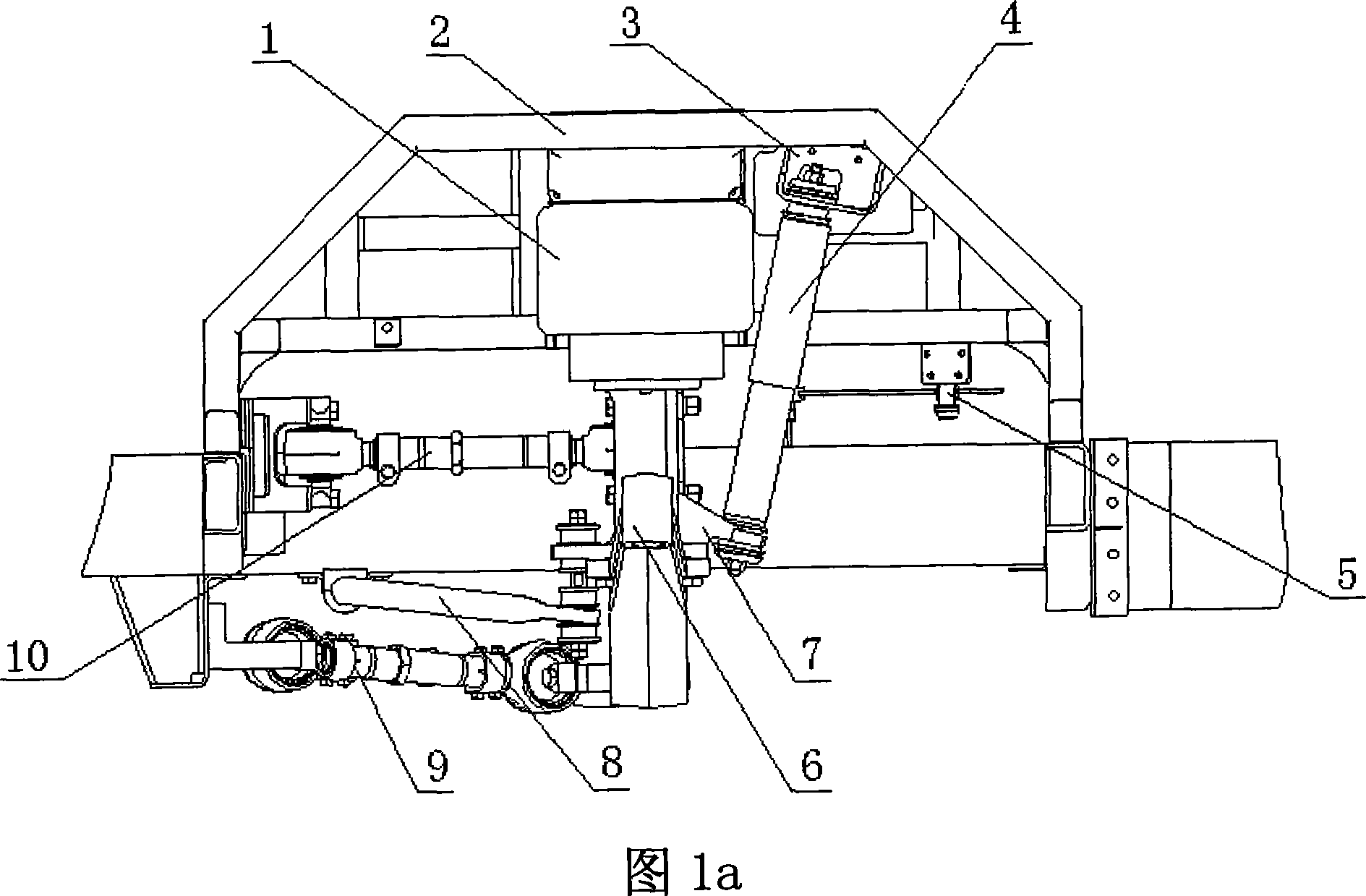

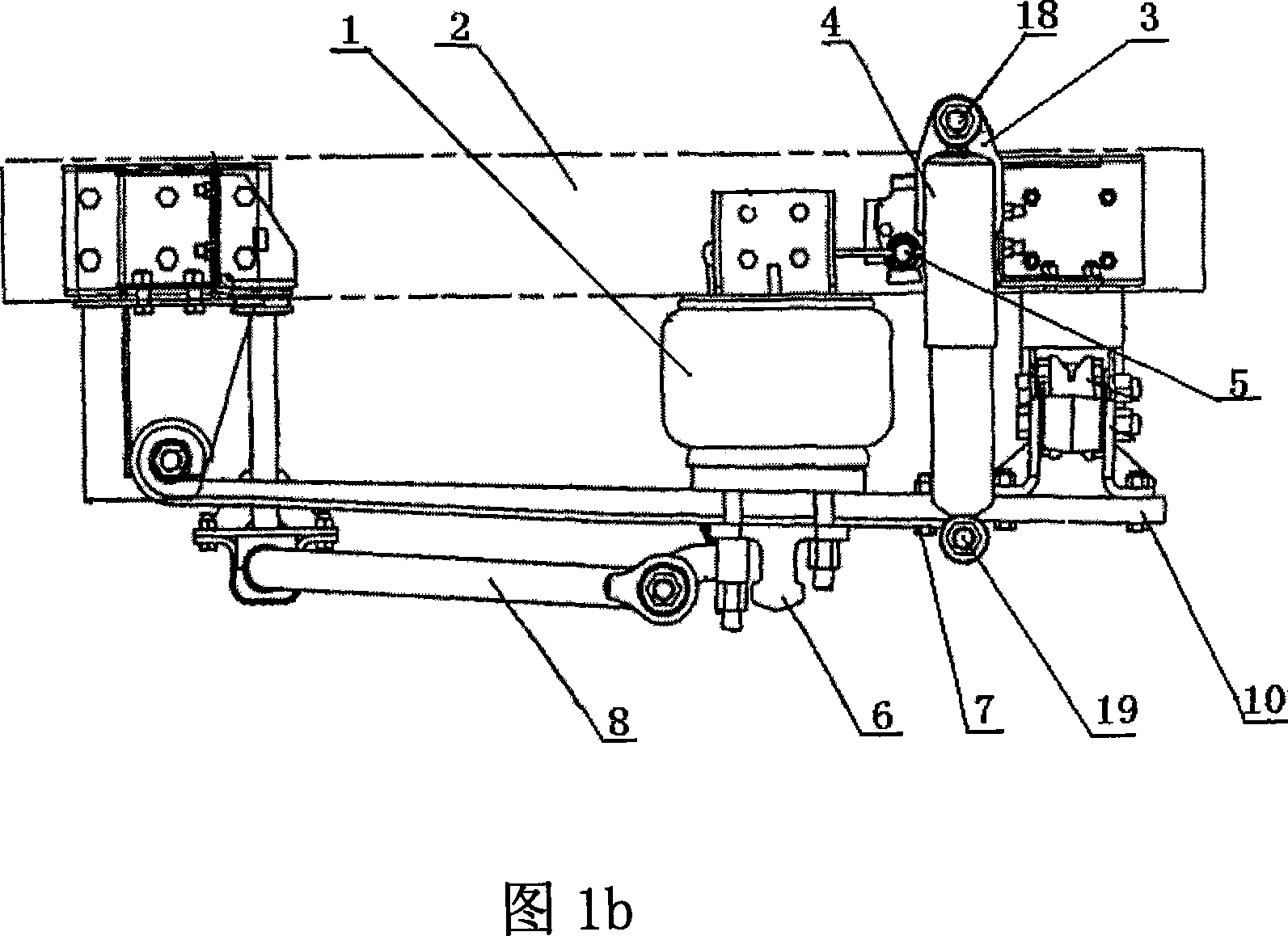

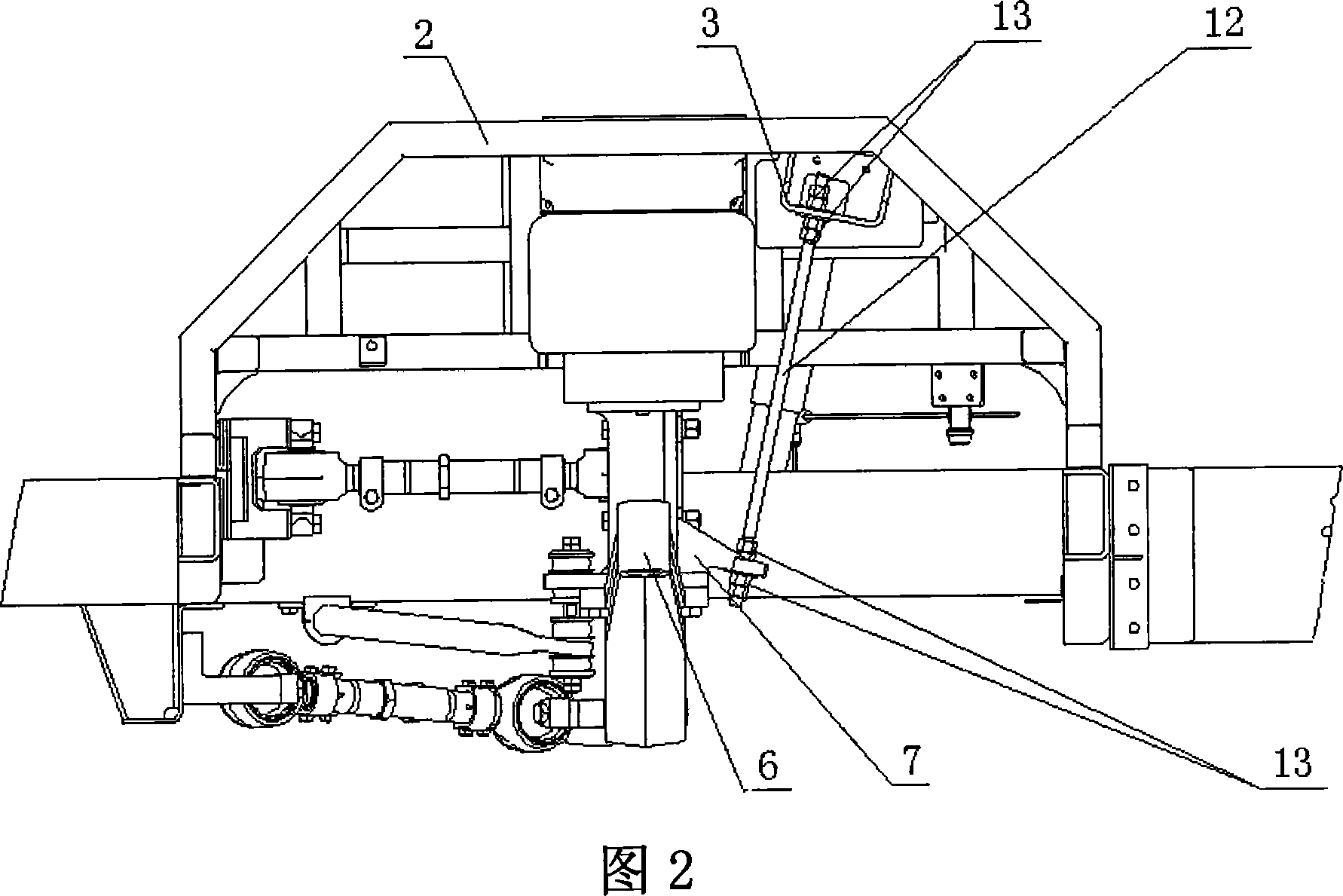

Mounting method for air spring vehicle chasis and its supporting rod

ActiveCN101077687ASimple structureImprove support strengthResilient suspensionsRide heightVehicle frame

The present invention is the process of installing vehicle chassis with air suspension and the support bar therefor. The installing process includes the first installing support bar between the vehicle frame and the axle or between the upper damper bracket and the lower damper bracket to make the vehicle frame in normal running height, the subsequent inflating the air bag, and final removing the support bar. The support bar has simple structure, easy use and high universality. The process of installing vehicle chassis with air suspension is simple, reasonable, high in efficiency, high in installation quality and low in cost, and may be applied widely.

Owner:DONGFENG MOTOR CORP HUBEI

Round paper cover forming technology

InactiveCN109177326AReasonable process stepsMolding stabilityPaper/cardboard articlesPaper sheetPulp and paper industry

Owner:ZHEJIANG SENMENG PACKAGING CO LTD

Method for brewing Maotai-flavor liquor

The invention discloses a method for brewing Maotai-flavor liquor. The method comprises carrying out high temperature Daqu fermentation on sorghum as a raw material, crushing the sorghum and high temperature Daqu, pouring 50% of hot water with a temperature of 90 DEG C or more to the crushed sorghum along with stirring, adding 5-7% of maternal fermented grains into the sorghum, carrying out uniform stirring, scattering a layer of steamed rice husk on a distillator comb, carrying out distillation through scattering materials after steam is produced and carrying out steaming for 2-3h after the steam round is produced, then taking the distillation product out of the distillator, pouring hot water with a temperature of 85 DEG C on the distillation product, when the raw sand temperature is reduced to about 32 DEG C, adding tail liquor with alcoholic strength of 30% and Daqu powder into the distillation product, wherein a Daqu use amount is controlled in 9-12% of the raw material use amount, after the product temperature is increased to 45-50 DEG C, putting the product into a cellar, and carrying out fermentation for 30 days, wherein a fermented product temperature is in a range of 35-45 DEG C. The method has reasonable and simple processes, is convenient for operation, retains a small amount of volatile substances in liquor and produces small irritation to the human body.

Owner:QINGDAO SHOUTAI AGRI SCI & TECH CO LTD

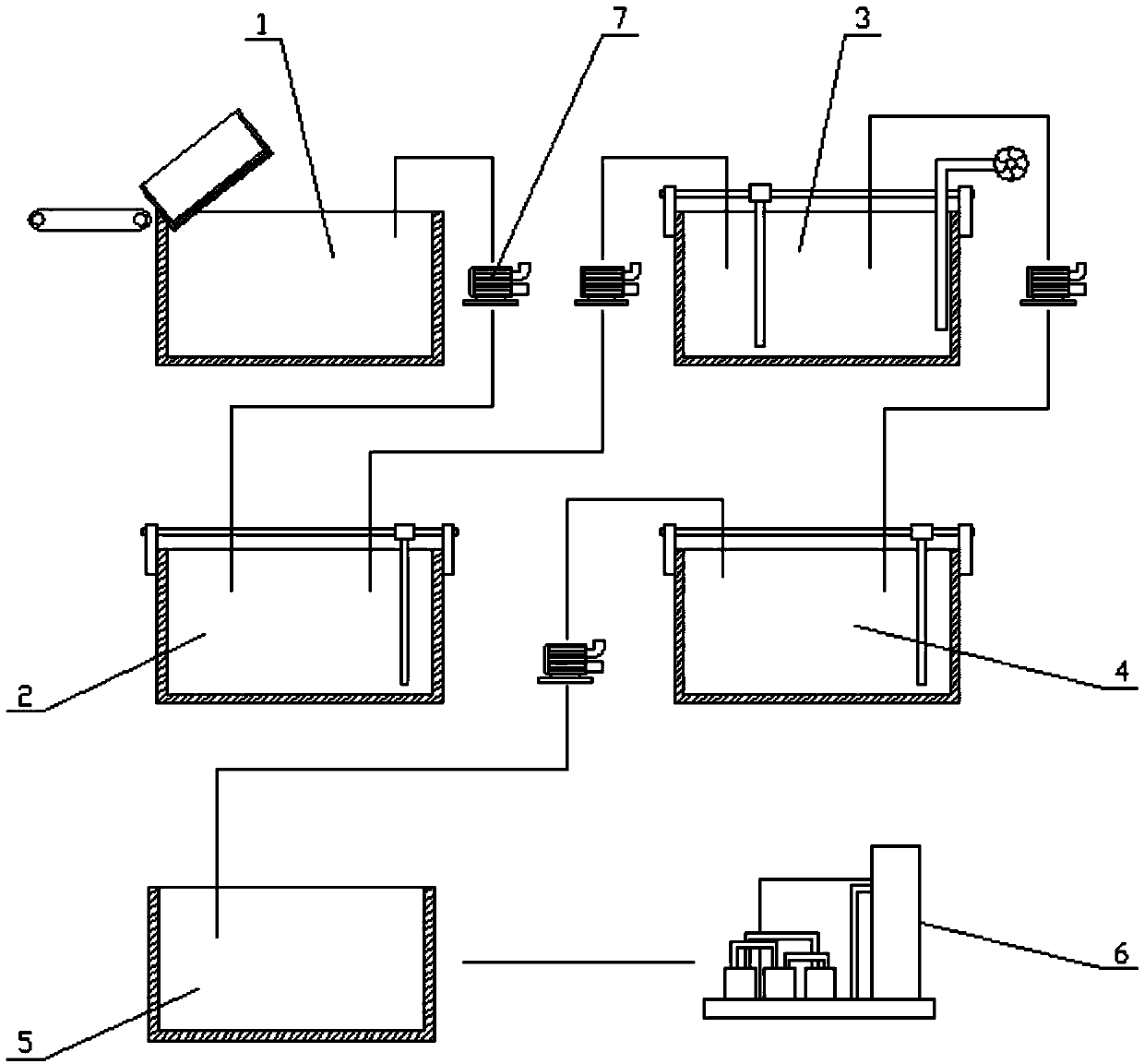

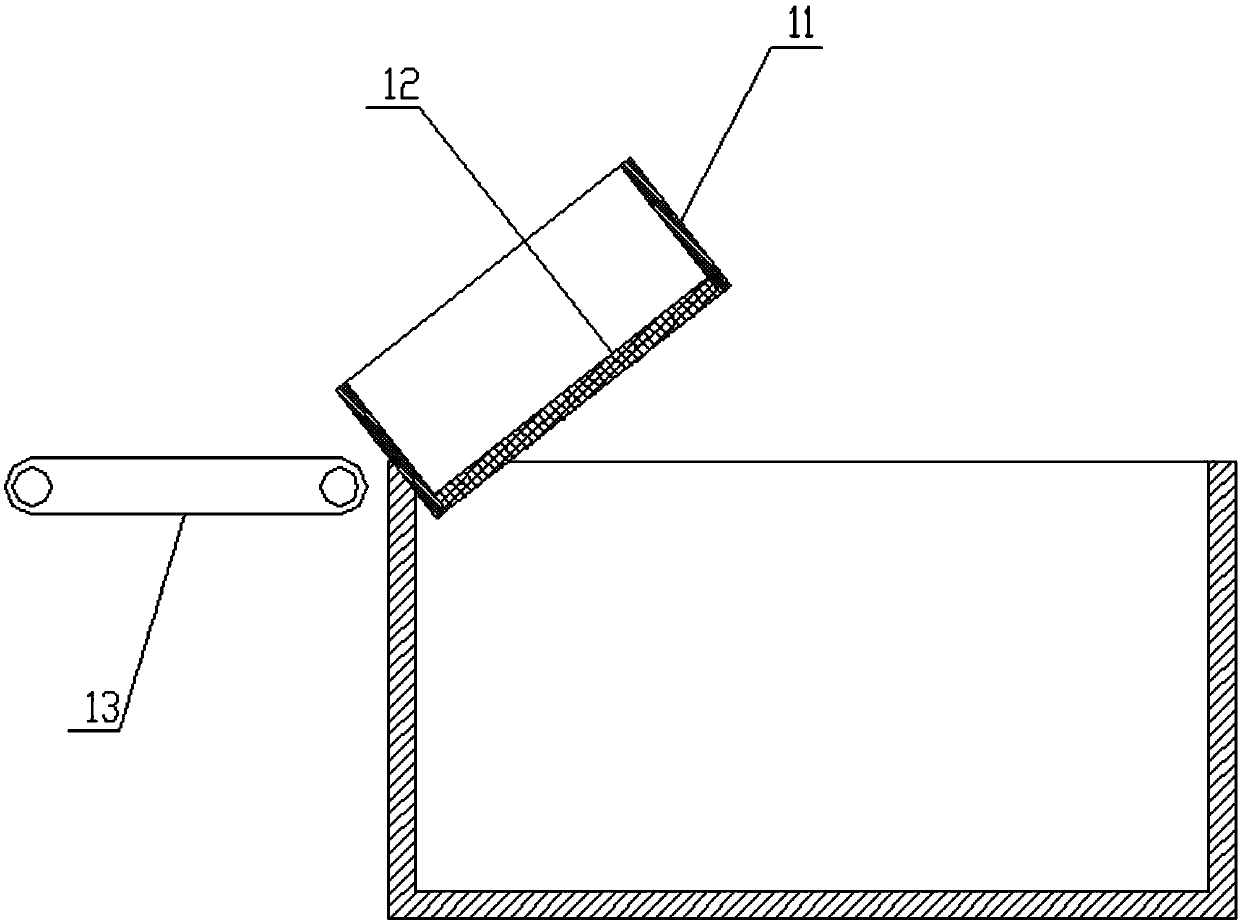

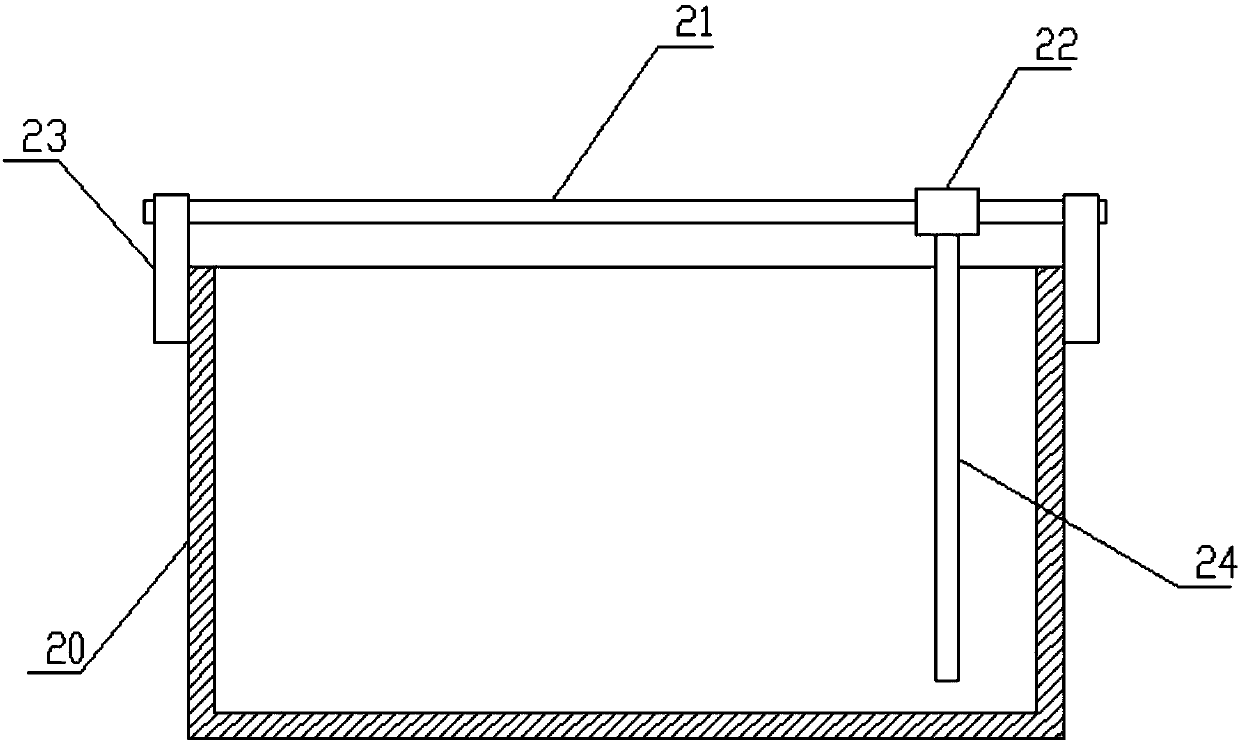

Multistage sewage purification system and sewage purification technology

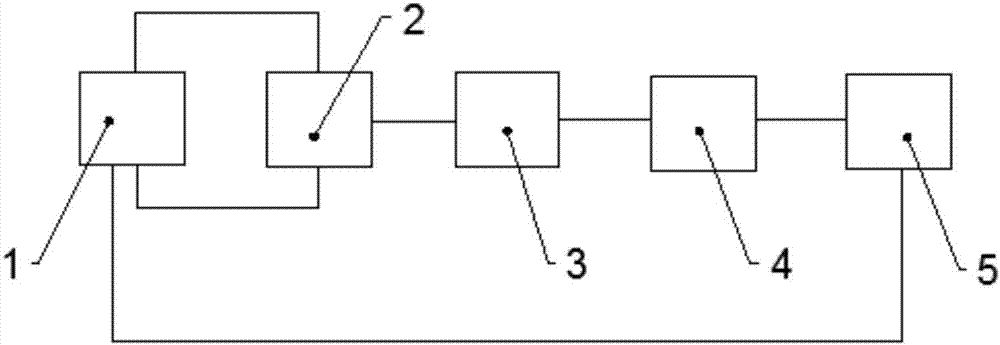

InactiveCN109534543ALow input costImprove purification efficiencyWater aerationMultistage water/sewage treatmentSewageAeration

The invention provides a multistage sewage purification system and a sewage purification technology. The sewage purification system comprises a sedimentation tank, a first-stage purification tank, a second-stage purification tank, a third-stage purification tank and a fourth-stage purification tank, and water pumps and water pipelines are arranged among the sedimentation tank, the first-stage purification tank, the second-stage purification tank, the third-stage purification tank and the fourth-stage purification tank in order to convey a liquid; the sedimentation tank is a water pool structure with an open upper end, and an inclined filter tank is arranged at the opening; the main structure of each of the first-stage purification tank, the second-stage purification tank, the third-stage purification tank and the fourth-stage purification tank is a side tank body with an open upper end, a stirring device is arranged in each of the first-stage purification tank, the second-stage purification tank and the third-stage purification tank, the second-stage purification tank is also provided with an aeration tube, the aeration tube is connected with a gas pump, and the gas outlet of the aeration tube is located at the lower part in the tank body. The multistage sewage purification system has the advantages of simple devices and low construction cost, and the sewage purification technology using the purification system has the advantages of reasonable steps, good purification effect, and suitableness for being generally promoted.

Owner:宁波联创同宇环保科技有限公司

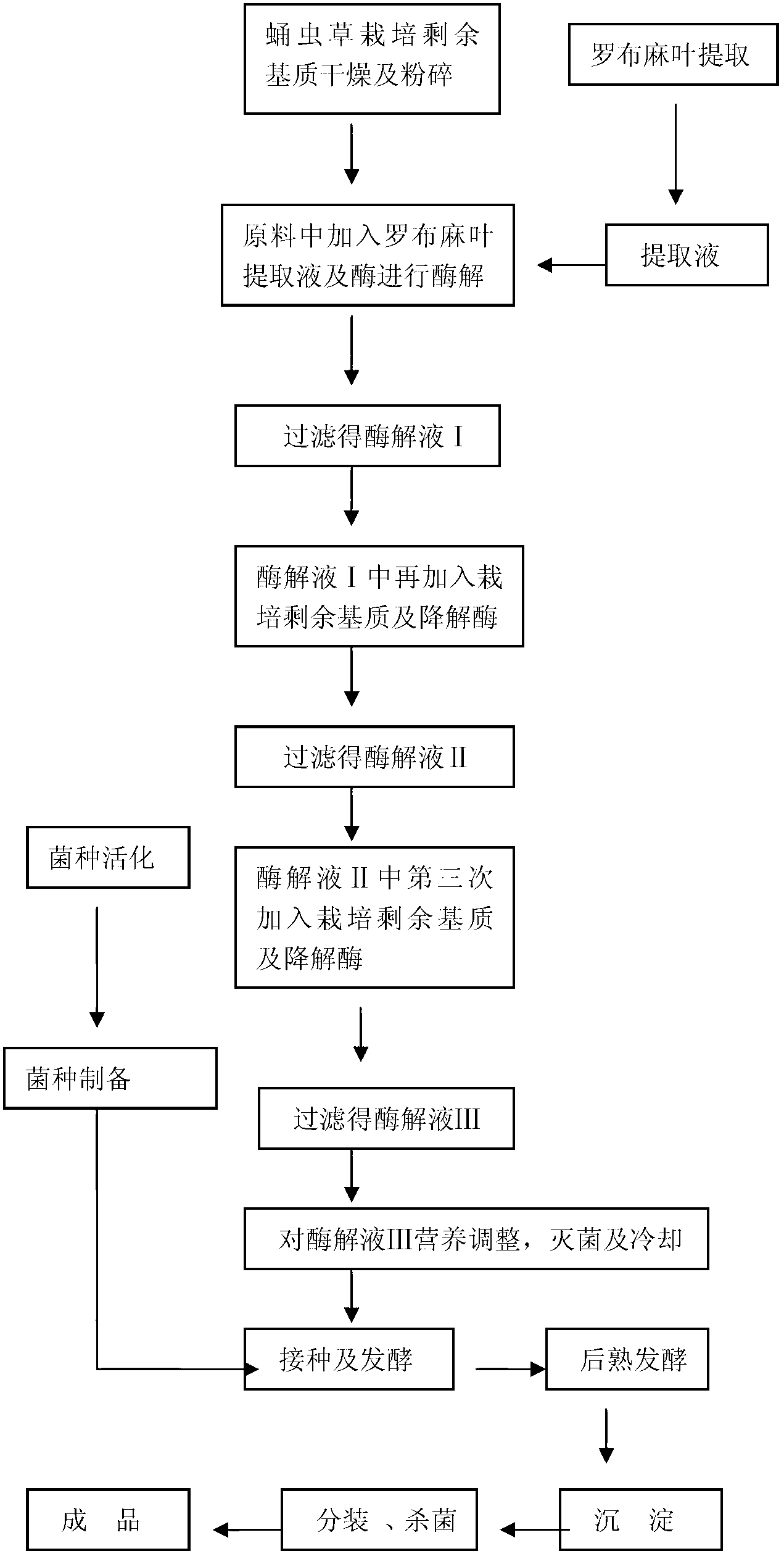

Yeast strain and method for brewing cordyceps sinensis wine by using same

ActiveCN103255071AEfficient use ofPromote dissolutionFungiAlcoholic beverage preparationBiotechnologyAdditive ingredient

The invention discloses a fragrant yeast strain and a method for brewing cordyceps sinensis wine by using the same. The method comprises the following steps of: with a surplus matrix after culture of the stroma of cordyceps militaris and folium apocyni veneti as raw materials, carrying out extraction and enzyme treatment to obtain the cordyceps sinensis wine through fermentation, after-ripening, sediment, split charging and sterilization of the yeast strain under suitable conditions. The color of the cordyceps sinensis wine is light red to dark red, the wine comprises 220-370g / L of cordycepin, has 12%-12.6% (V / V) of alcoholic strength, and contains little cordyceps polysaccharide, vitamine, adenosine, flavone and the like. According to the cordyceps sinensis wine prepared by the method, the nutritional ingredients and pharmacologic action of the apocynum venetum, alcohol and cordyceps sinensis are combined organically, so that the health care function of the wine is further improved, the technology steps are reasonable, and the equipment is simple and has strong operability.

Owner:NORTHWEST A & F UNIV

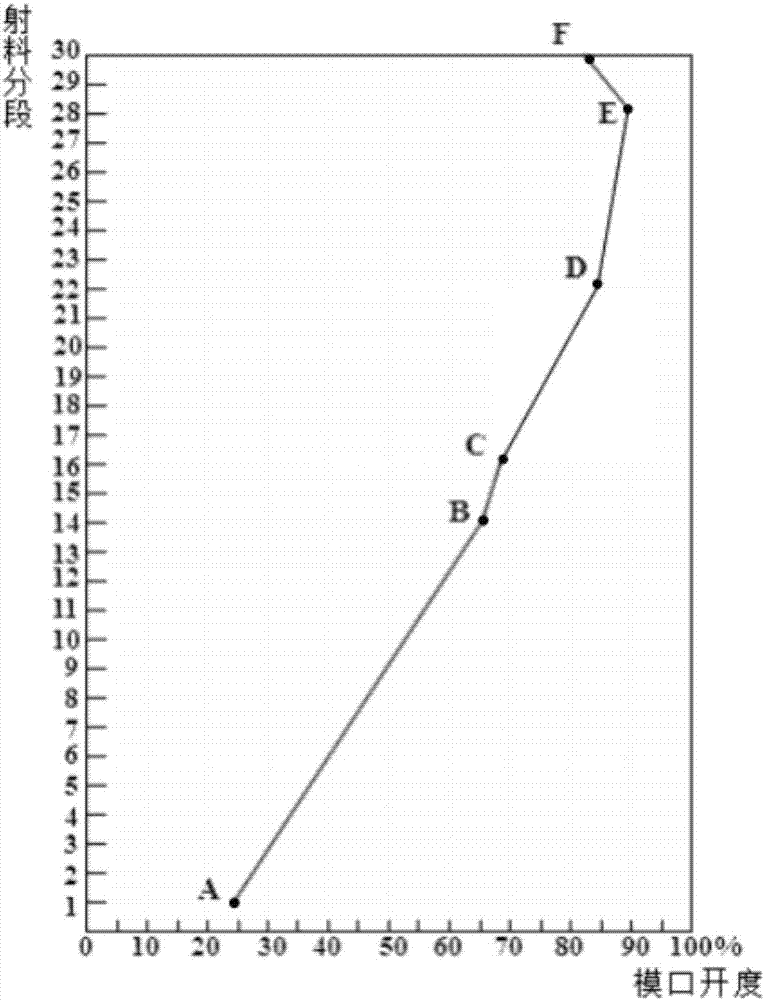

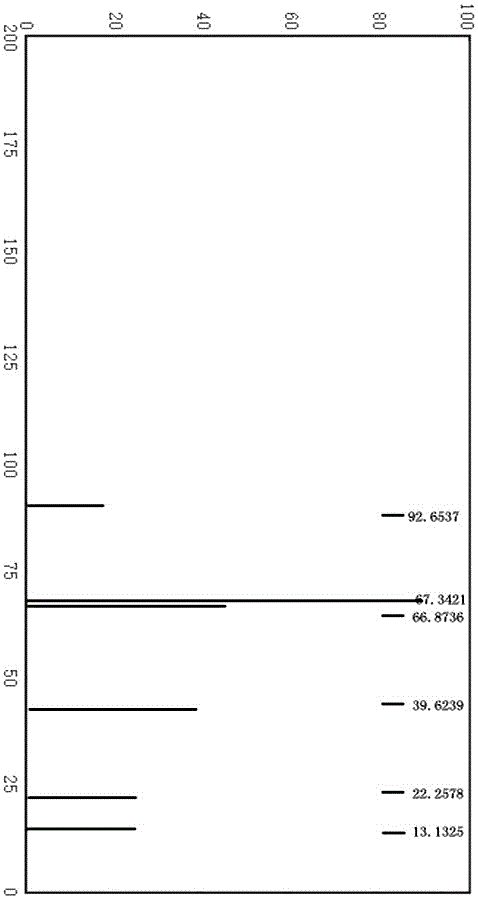

Molding process for flat plate type extruded-blown product containing internal reinforced structure

ActiveCN108000846AThe process steps are reasonableOptimizing Process ParametersEngineeringMechanical engineering

Owner:SHANGHAI UNIV OF ENG SCI +1

Microcapsule flyash based fire retardant

The invention provides a manufacture method of a microcapsule flyash based fire retardant. The manufacture method comprises the processing steps of a, removal of large particles, b, activation of flyash, c, drying under hot-blast air, and d, prefabrication of capsules. The fire retardant is low in producing cost, is given the common advantages of organic and inorganic fire retardants, integrates the functions of melting, fire retarding and smoke removing, and can be widely applied to various hard organic foam products.

Owner:乌鲁木齐益好天成新型节能材料有限公司 +1

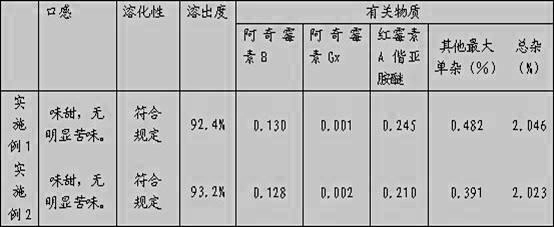

Azithromycin granules and preparation method thereof

InactiveCN102657618AReasonable process stepsIncrease productivityAntibacterial agentsOrganic active ingredientsAzithromycinSucrose

The invention discloses azithromycin granules, which consist of the following components in parts by weight: 5-20 parts of azithromycin, 1.5-3.0 parts of sodium triphosphate, 0.4-0.6 parts of hydroxypropyl methyl cellulose, 0.8-1.2 parts of acesulfame, 0.8-1.2 parts of sweet orange taste essence, 80-95 parts of sugar and a proper amount of pure water. The invention also discloses a preparation method of the azithromycin granules. The conception is skilful, the mouthfeel of the medicament is effectively improved through a simple medicinal composition, an unexpected effect of covering the bitterness of the medicament is achieved, and dissolution of the medicament in vivo is not influenced. The preparation method has the advantages of simple process, no need of special equipment and low production cost.

Owner:SICHUAN BAILI PHARM CO LTD

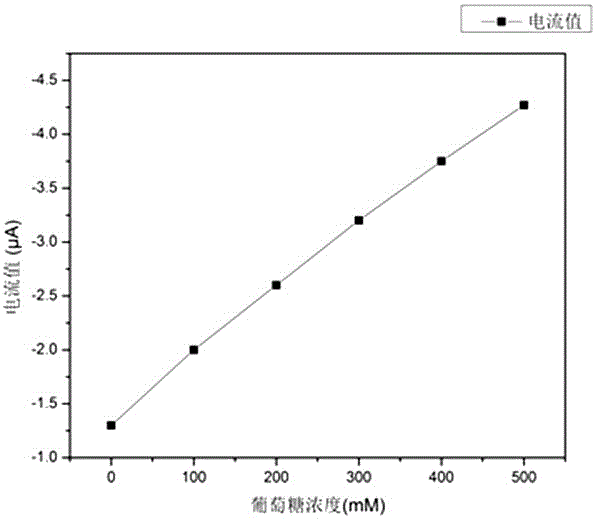

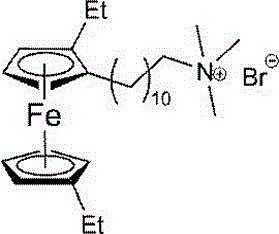

Ferrocenyl-based redox-reversible surfactant and preparation method of thereof

InactiveCN107522752AReasonable process stepsGood material stabilityTransportation and packagingMixingSurface modificationZinc

The invention provides a ferrocenyl-based redox-reversible surfactant and a preparation method thereof, and relates to the field of redox switch type surfactants. The ferrocenyl-based redox-reversible surfactant is prepared from a precursor compound ferrocene, acetyl chloride, zinc amalgam, bromoundecanoic acid, thionyl chloride and trimethylamine as raw materials. The synthesized surfactant molecules are easy to prepare, the yield of the intermediate diacetylferrocene is effectively improved, a new feeding sequence is provided, and the problem of reduction of ferrocene due to oxidation reaction is effectively solved. The surfactant can be used as an electrode surface modification material for glucose detection.

Owner:YANGZHOU UNIV

Canned tilapia in tomato sauce and processing technology thereof

InactiveCN104413455AReasonable process stepsReasonable designMeat/fish preservationFood preparationUnsaturated fatty acidBiotechnology

The invention relates to a canned tilapia in tomato sauce and a processing technology thereof, and belongs to the technical field of food processing. The processing technology comprises the following steps: selecting tilapias, cleaning, drying, slicing, curing, high-temperature steam sterilizing, dehydrating, soaking in soup, mixing with drinking water for people, vacuum canning, static storing, and obtaining finished products. The processing technology steps are reasonably designed, and cans processed by the technology have features of delicious canned tilapia, tender fish meat, various kinds of unsaturated fatty acids and rich proteins, red and bright color, sweet, sour and delicious taste, rich tomato flavor, convenient carryover and eating and easy preservation.

Owner:刘宜霞

Alloy die-casting process

The invention provides an alloy die-casting process, which specifically includes the following process steps: alloy smelting, electromagnetic stirring, mold clamping, oxygen injection, die-casting, mold opening, and part delivery. Temperature of machine is 180°C, mold preheating time is 50min, injection low speed is 92%, booster position is 300mm, booster speed is 60%, injection stop is 150min, injection time is 5s, cooling time is 10s, booster pressure is 60MPa and mold adjustment The pressure is 21 MPa, and the die-casting machine is started for die-casting under the above-mentioned setting die-casting process parameters. In the present invention, different elements are combined and smelted into an alloy, and then die-cast according to the set pressure, temperature and time, which not only improves the qualified rate of finished products, but also improves the quality of the product.

Owner:东莞市鸿威精密五金制品有限公司

Preparation process for blood-benefiting and blood sugar-reducing tartary buckwheat health care wine

InactiveCN103525653AReasonable process stepsLow input costMetabolism disorderDigestive systemPolygonum fagopyrumDistillation

The invention relates to a preparation process for a blood-benefiting and blood sugar-reducing tartary buckwheat health care wine. The preparation process comprises the following steps: (a) respectively weighing tartary buckwheat and wheat bran and carrying out fermentation under an aseptic condition so as to obtain fermented grains; (b) then weighing root and vine of manyprickle acanthopanax, cyathula root, malaytea scurfpea fruit, milkvetch root, Chinese magnoliavine fruit and wolfberry fruit and carrying out reduced pressure concentration at a temperature of 60 to 85 DEG C so as to obtain a concentrate; (c) decocting and boiling unprocessed rehmannia root, Sichuan lovage rhizome, pilose antler, gentrin knotweed, American ginseng and rhodiola root in a marmite to prepare a filtrate; and (d), dumping the fermented grains obtained in the step (a), the concentrate obtained in the step (b) and the filtrate obtained in the step (c) into a pot for distillation so as to obtain the tartary buckwheat health care wine. The preparation process has simple and reasonable steps and can prepare the blood sugar reducing, blood fat reducing, urine sugar reducing and constipation preventing tartary buckwheat health care wine.

Owner:李宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com