Technical method for die steel surface nonmetallic ion infiltration

A process method and non-metallic technology, which is applied in the field of infiltration of non-metallic ions on the surface of die steel, can solve the problems of unstable gas nitriding performance, large carbonitriding deformation, and low heat treatment life, so as to improve service life and enhance durability. Abrasion resistance and anti-fatigue performance, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: select H13 aviation pliers mold and the sample piece of the same material and technical state, the sample size is 15 * 15 * 7mm;

Embodiment 2

[0057] Embodiment 2: choose the sample piece of 5CrNiMo automobile connecting rod mold and the same material and technical state, and the sample piece specification is 15 * 15 * 7mm;

Embodiment 3

[0058] Embodiment 3: Select 3Cr2W8V open-ended wrench mold and sample piece of the same material and technical state, and the size of the sample piece is 15×15×7mm.

[0059] Above-mentioned three kinds of embodiments are carried out by the processing step among the present invention, concretely implement relevant parameter in the processing step scheme as following table:

[0060]

[0061] The implementation results are as follows:

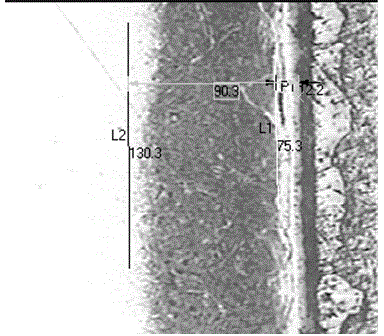

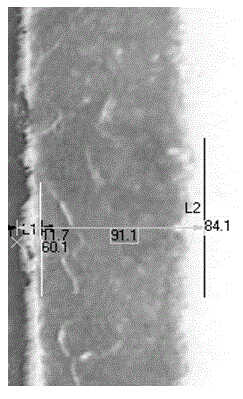

[0062] 1. The surface penetration layer is uniform, such as figure 1 , image 3 , Figure 5 Shown by Fe 3 N, Fe 4 N, Fe 3 The average thickness of the dense compound layer composed of C is greater than 10 μm, and the average thickness of the diffusion layer formed by [N], [C], and [O] in the 100-fold microscopic metallographic diagram is greater than 100 μm.

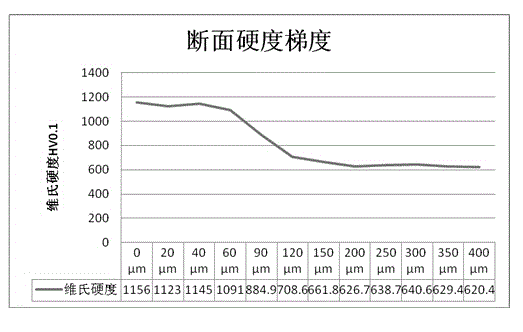

[0063] 2. According to figure 2 , Figure 4 , Figure 6 As shown in the cross-sectional hardness gradient diagram of the middle seepage layer, the surface hardness of 40-60 μm i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com