Production process of bendable single crystalline silicon solar cell

A solar cell and production process technology, applied in the field of solar power supply, can solve problems such as high repair rate, lamination process defects, and easy cracking of finished solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

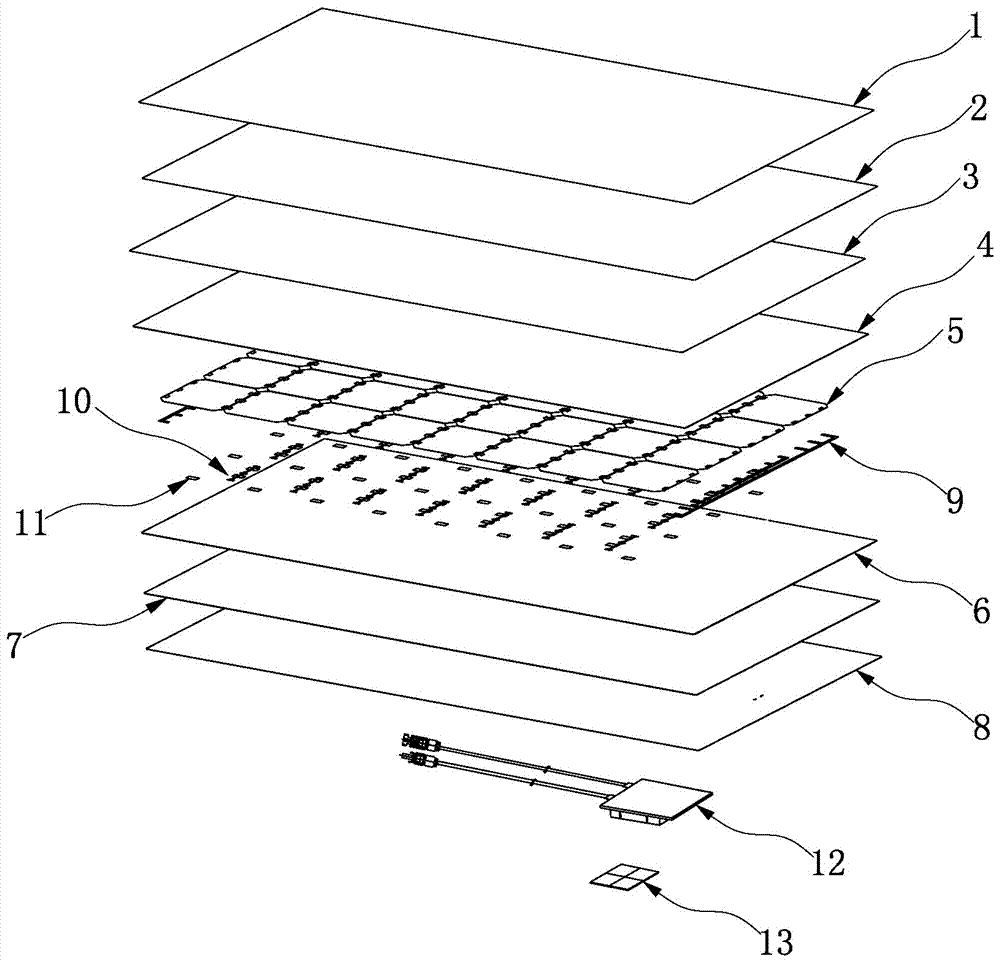

[0035] figure 1 It is a kind of bendable monocrystalline silicon solar cell to be produced in the present invention, which includes ETFE film 1, first adhesive film 2, front support film 3, second adhesive film 4, battery silicon wafer 5, glass fiber from top to bottom Felt 6, third adhesive film 7 and back plate 8, the battery silicon chip 5 constitutes a complete battery assembly through bus bars 9 and electrode ribbons 10, the battery assembly is fixed on the glass fiber mat 6 through positioning tape 11, the junction box The lower cover 12 and the upper cover 13 of the junction box are assembled to form a junction box electrically connected to the battery assembly.

[0036] The front support film and back sheet in the above-mentioned flexible monocrystalline silicon solar cells are mostly made of any one of the three materials of PET, TPE and TPT, and are arranged and combined according to different use environments and cost requirements. Among them, the front support The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com