Manual hole digging pile structure and digging pile pouring method

A technology of manually digging hole piles and pile holes, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., which can solve the problems of easy displacement, uneven stress on the reinforcement cage, unfavorable forming quality of cast-in-situ piles, etc., and improve the forming quality The effect of high quality, high work efficiency and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

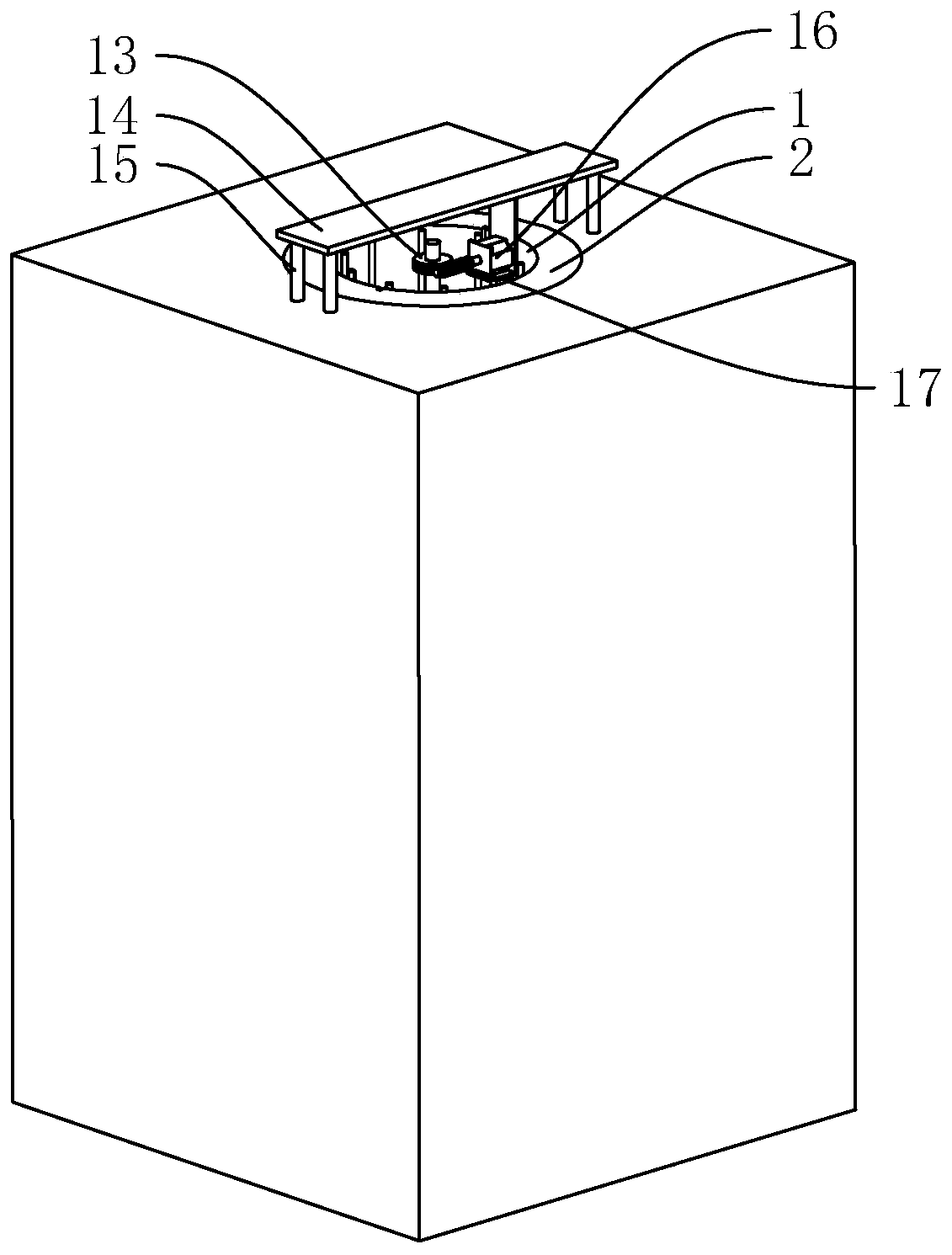

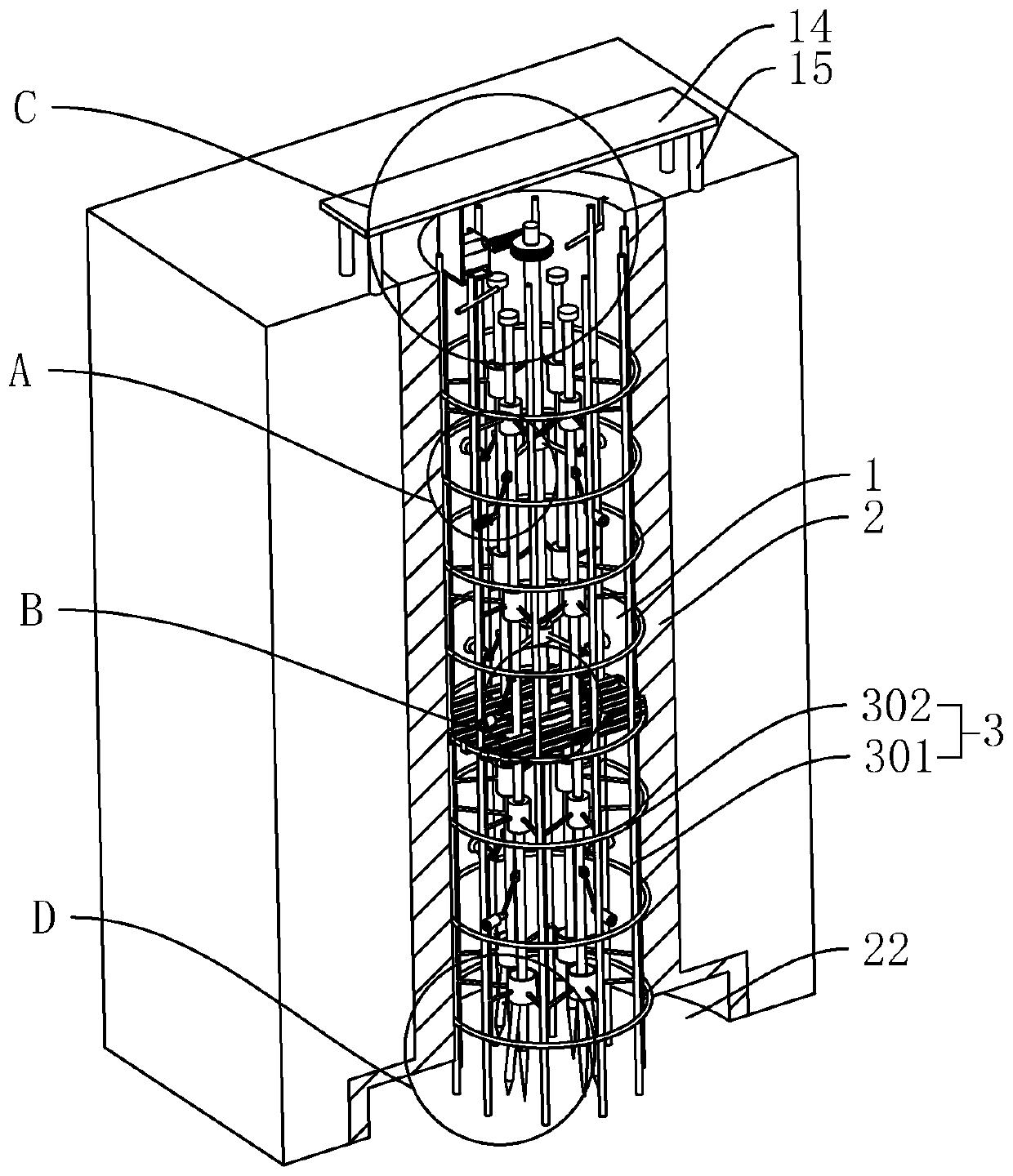

[0047] refer to figure 1 and figure 2 , is a kind of manual hole-digging pile structure disclosed by the present invention, comprising a pile hole 1, a retaining wall 2 and a steel cage 3, the pile hole 1 is opened on the ground, the retaining wall 2 is preferably a steel plate retaining wall, and the steel plate retaining wall is fixedly erected in the hole of the pile hole 1 Wall, to prevent the collapse of the pile hole 1, the reinforcement cage 3 is located in the pile hole 1, and the reinforcement cage 3 includes several main reinforcements 301 distributed in a circle and stirrups 302 fixedly connected to the outside of the several main reinforcements 301.

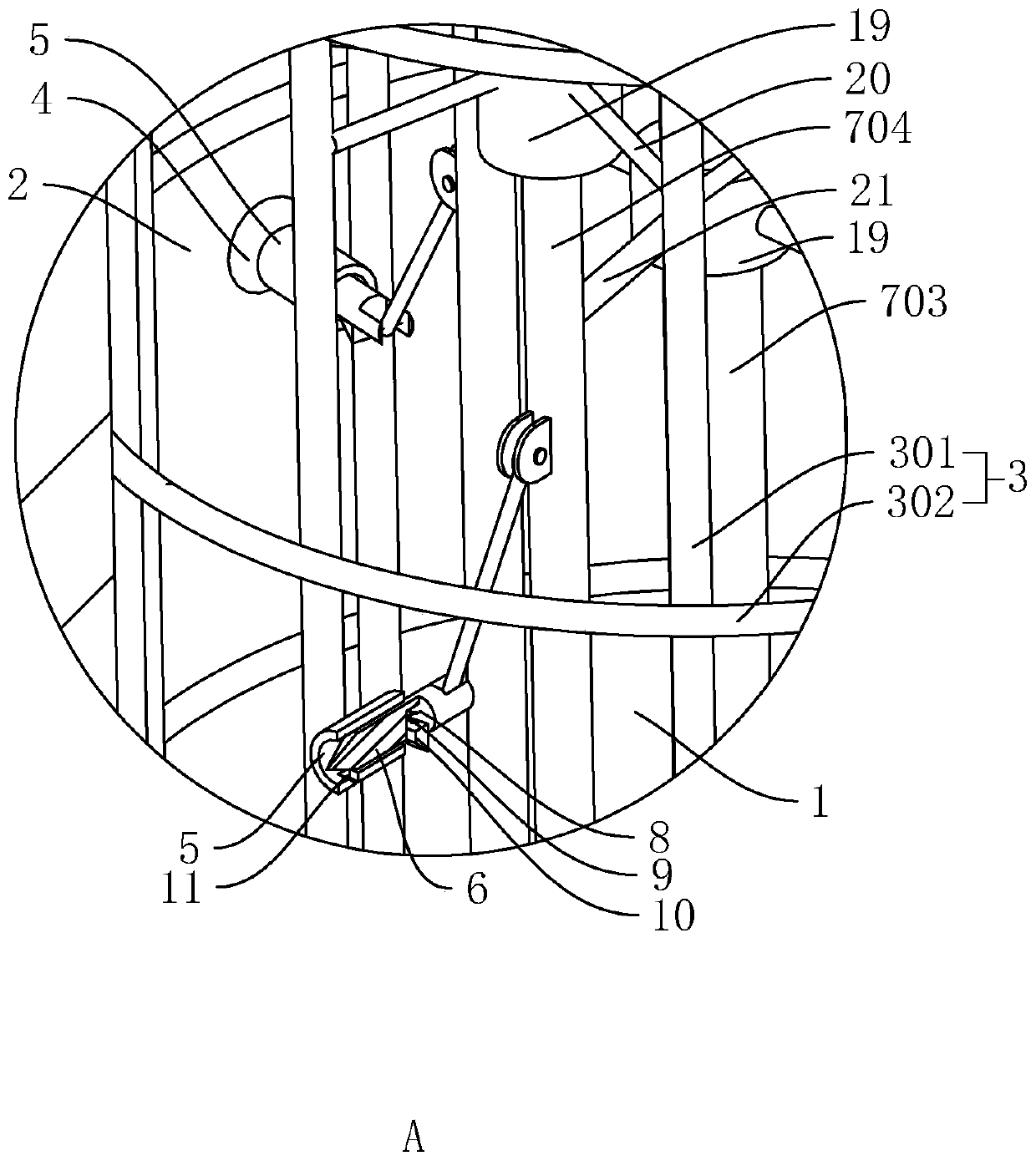

[0048] refer to figure 2 and image 3 There are three fixing holes 4 distributed along the vertical direction on the side of the retaining wall 2 away from the hole wall of the pile hole 1, four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com