Device for pressing resistance strain sheets and magnetic patches and method for adhering resistance strain sheets

A technology of resistance strain gauge and pressing device, applied in electromagnetic measuring device, measuring device, electric/magnetic solid deformation measurement and other directions, can solve the problems of human body frostbite, time-consuming and laborious, difficult to guarantee the stress condition, etc., and achieves easy operation. , Simple structure, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

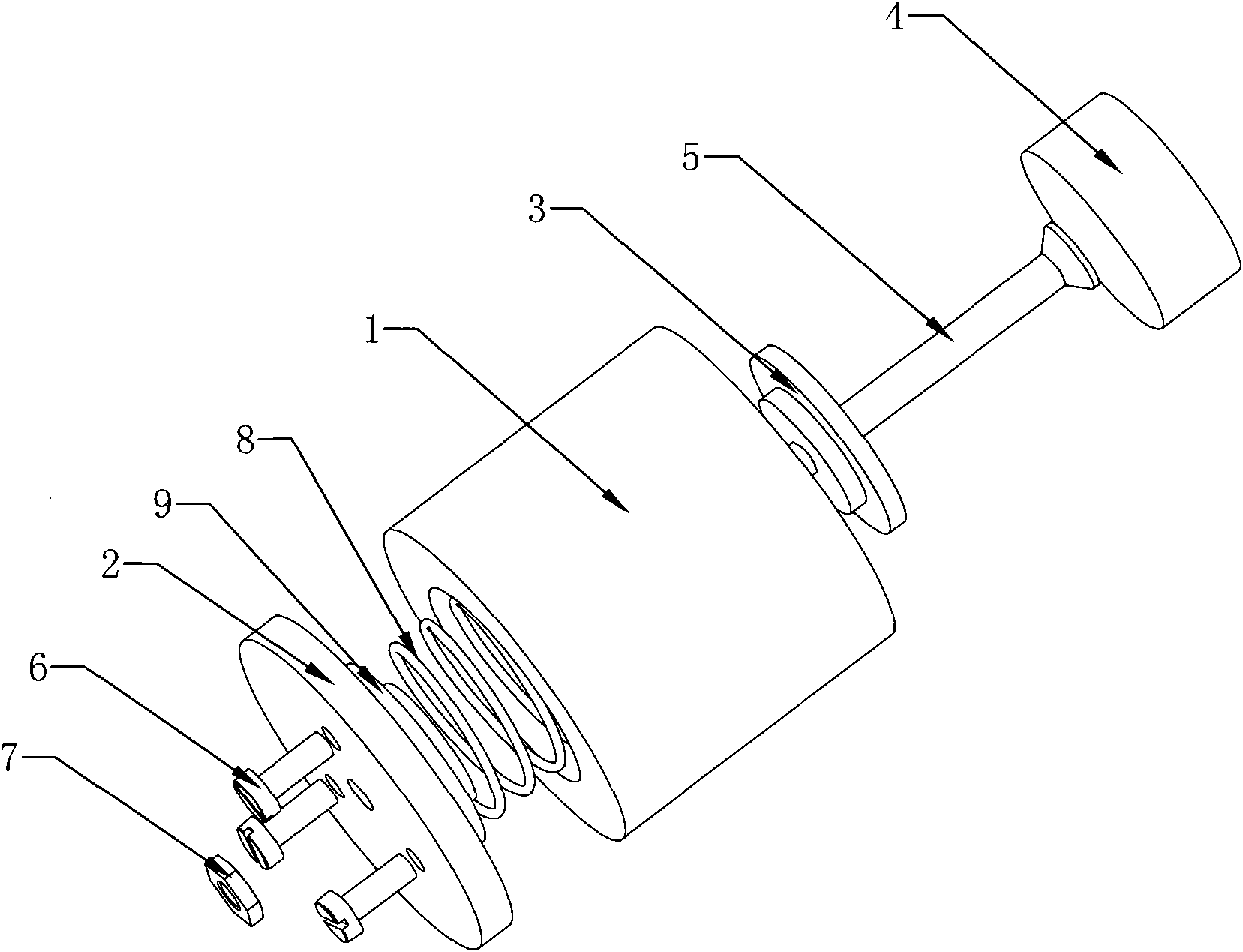

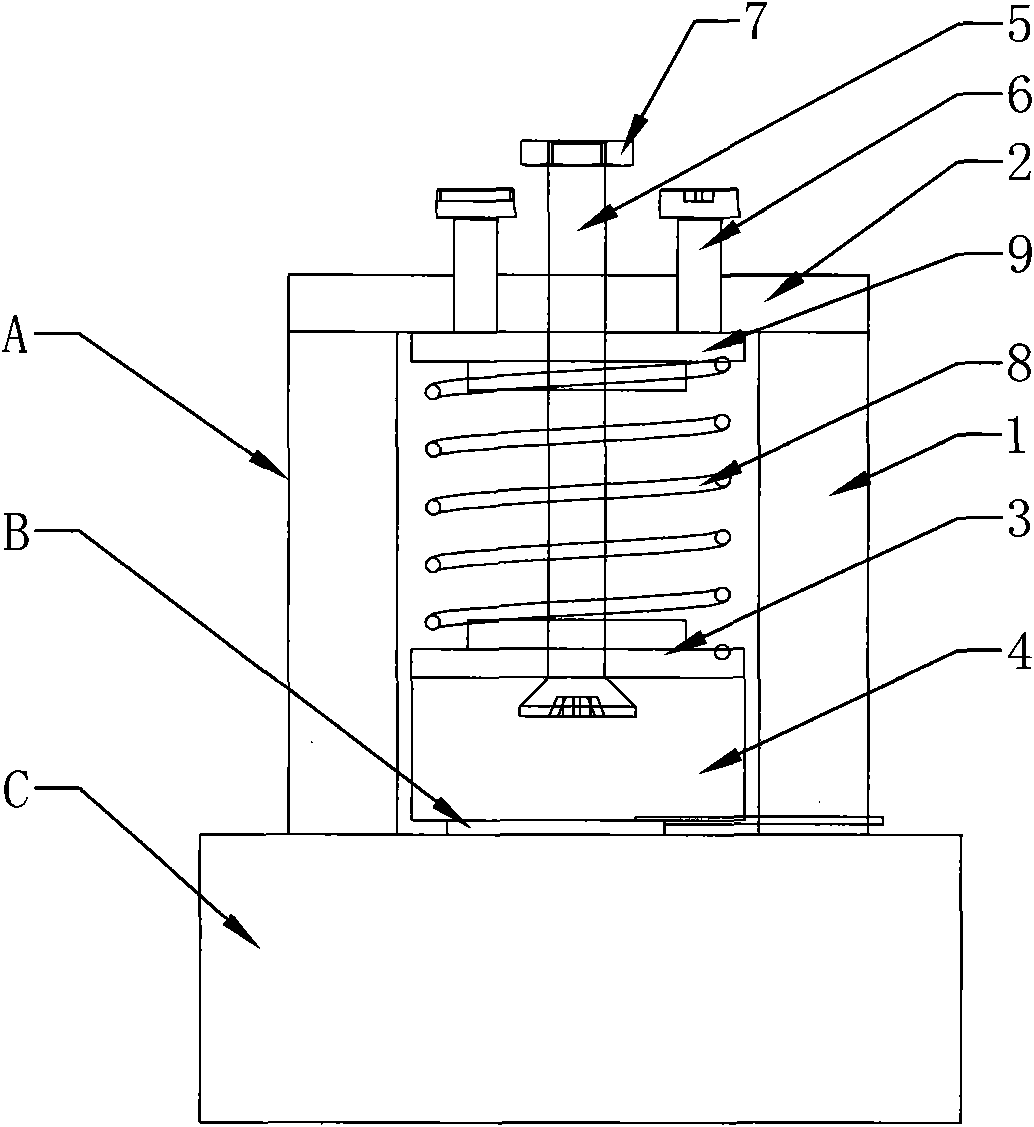

[0024] see below figure 1 , the permanent magnet 1 is a cylindrical permanent magnet, the spring 8 is built in the permanent magnet 1, the two ends are sealed with the top sheet 3 of the ladder, and one end is pressed with the end cover 2, the first top sheet 3, the second top sheet Sheet 9 and end cover 2 have coaxial through holes, like this, by a long screw rod 5, just can permanent magnet 1, spring 8, two top sheets 3 with coaxial through holes and end cover 2 are connected together, The end of the screw goes through the through hole of the end cover and is locked with the nut 7. The end cover 2 has the same outer diameter as the permanent magnet 1. Within the inner diameter of the permanent magnet on the end cover 2, three screw holes are evenly arranged, so that the three When the screw 6 is screwed down or turned up, the spring 8 can be controlle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com