Patents

Literature

644results about How to "Improve placement efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

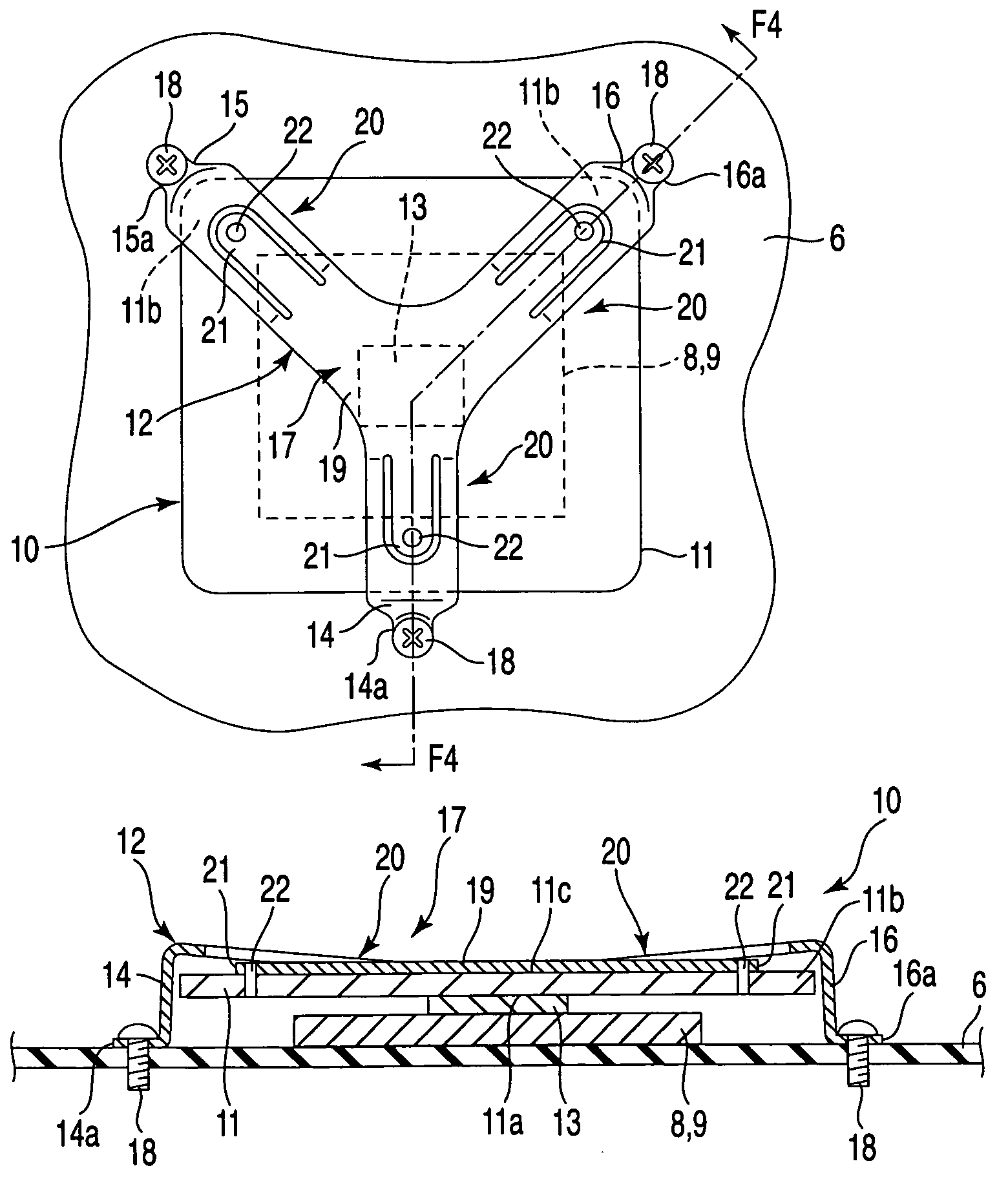

Protector

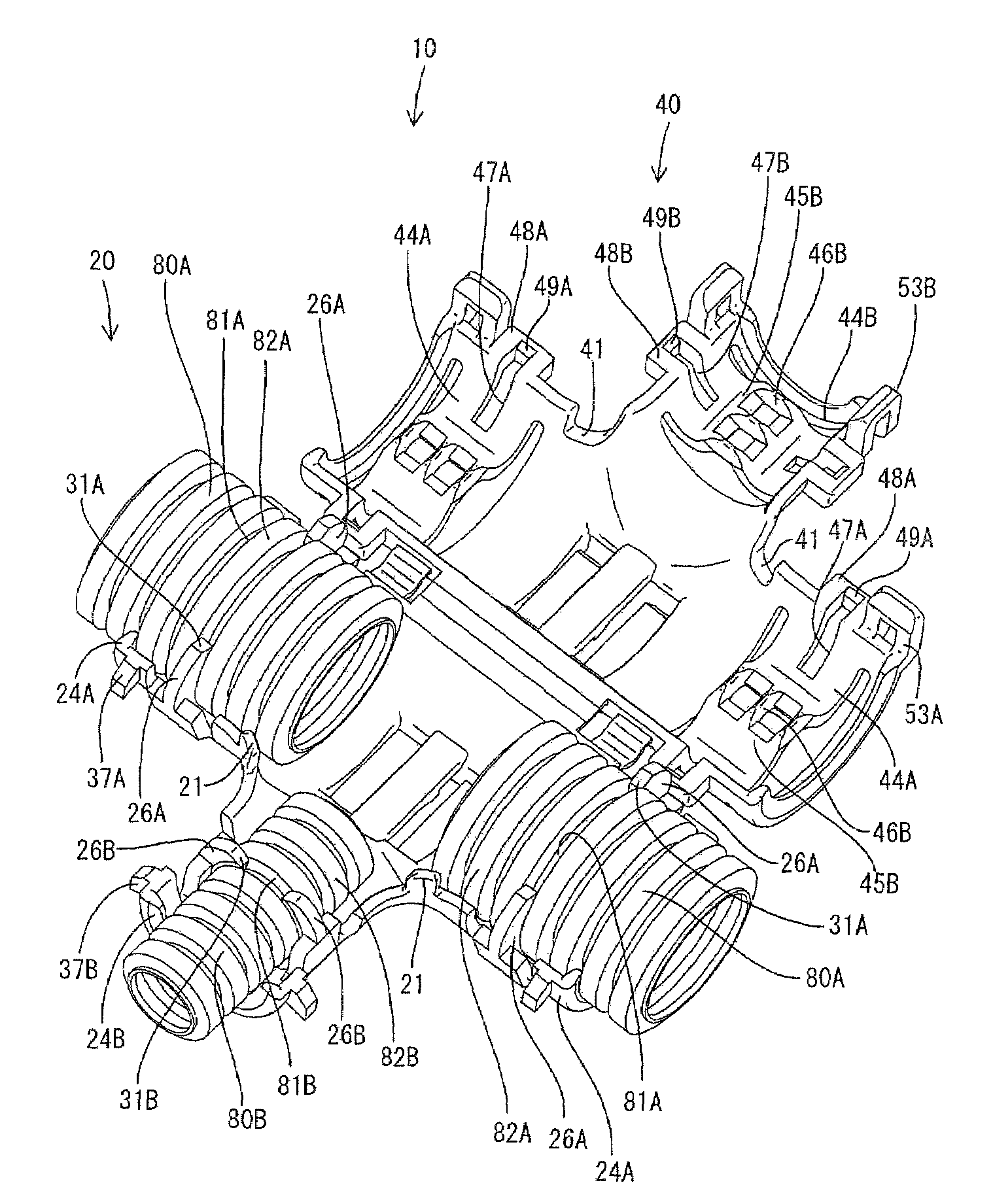

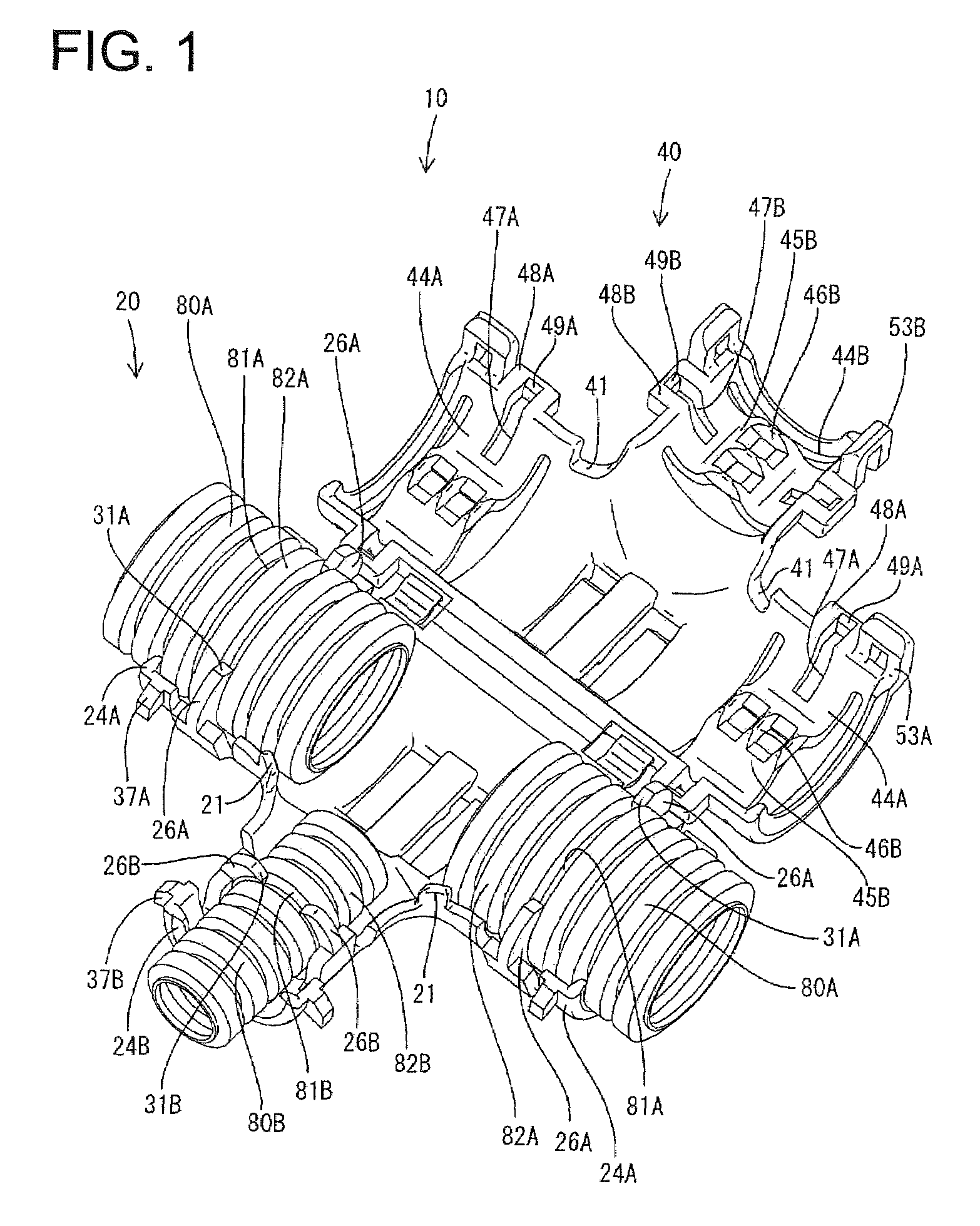

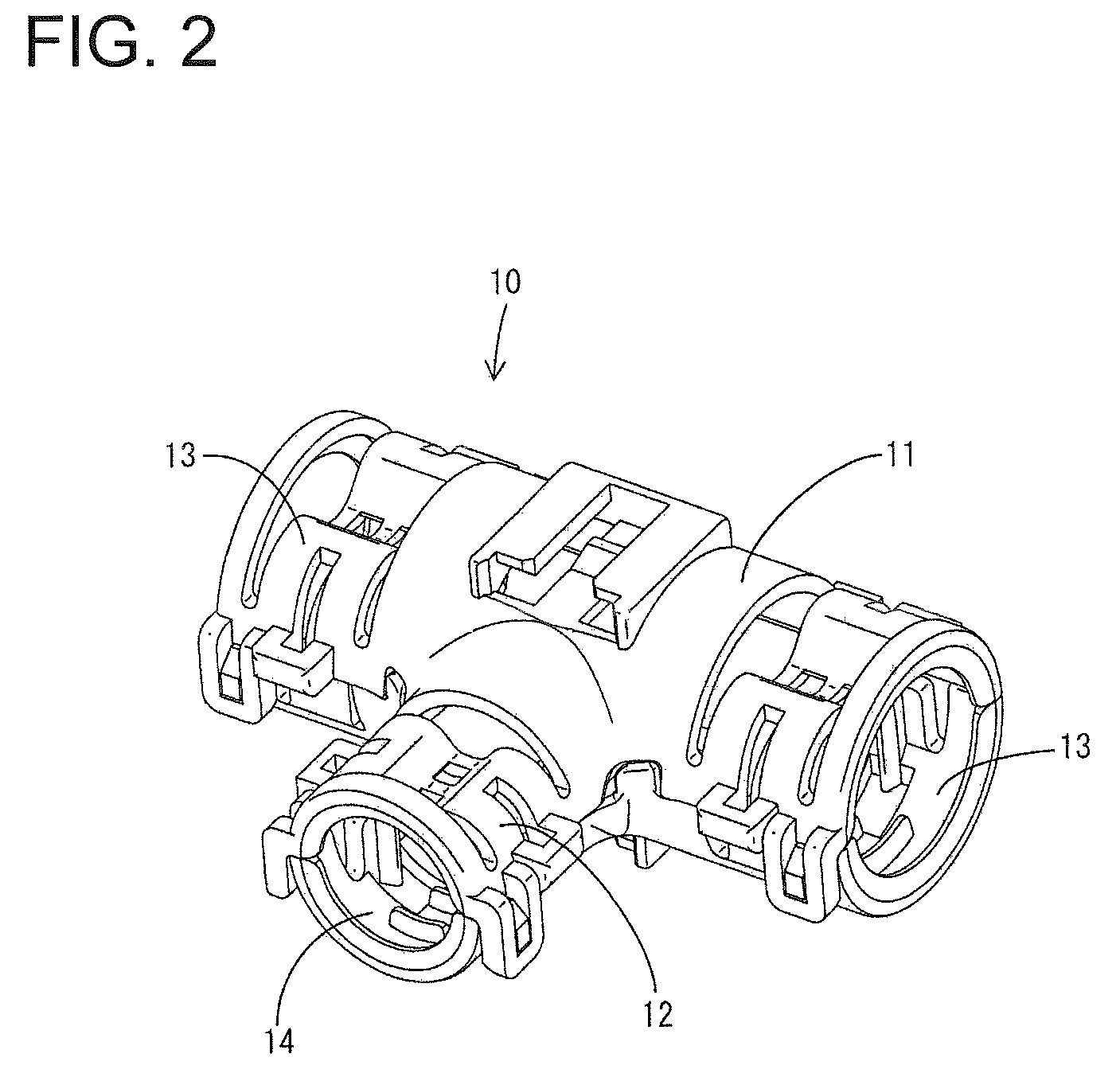

InactiveUS7581564B2Avoid lateral displacementAvoid longitudinal displacementSleeve/socket jointsInsulated cablesEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

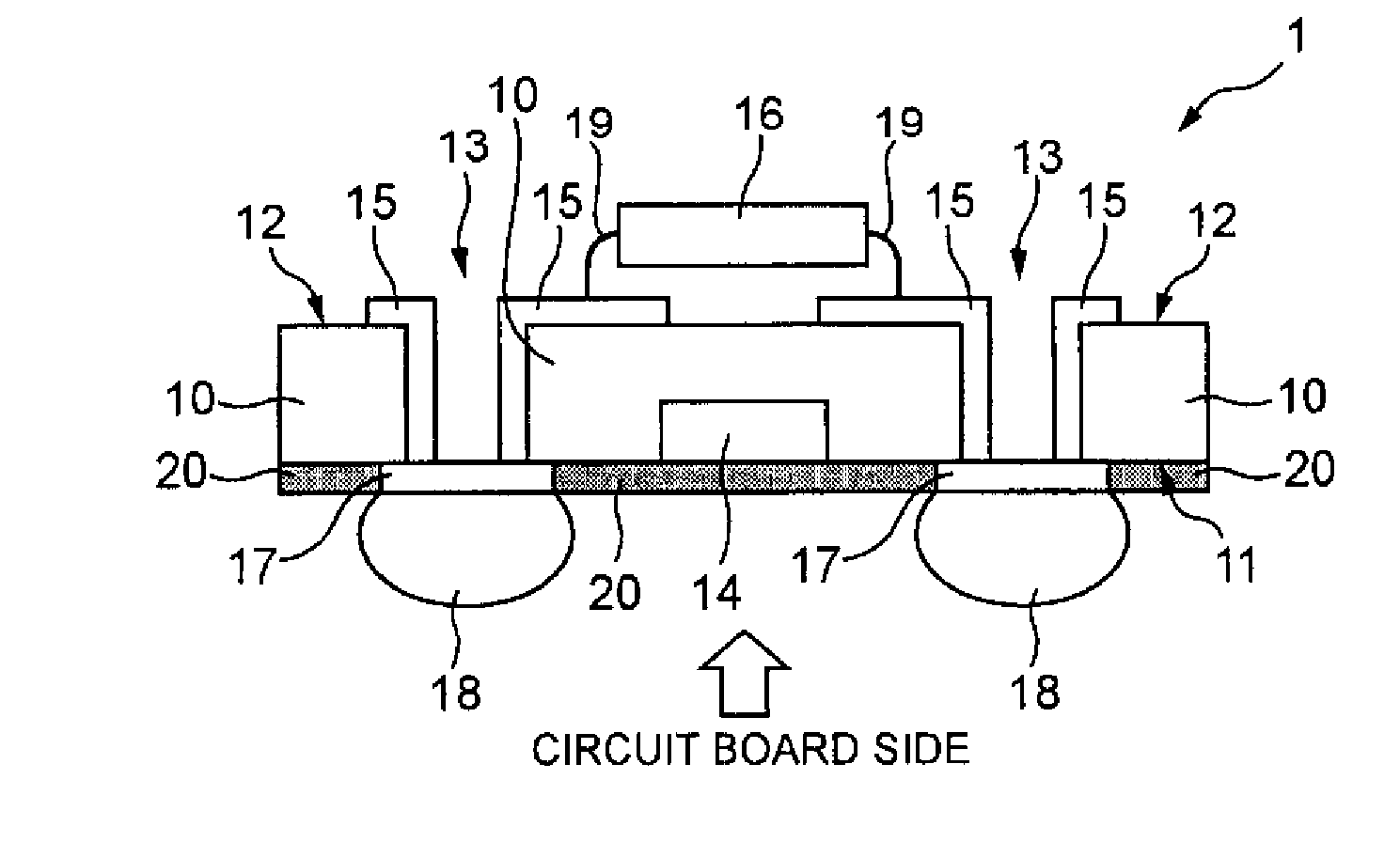

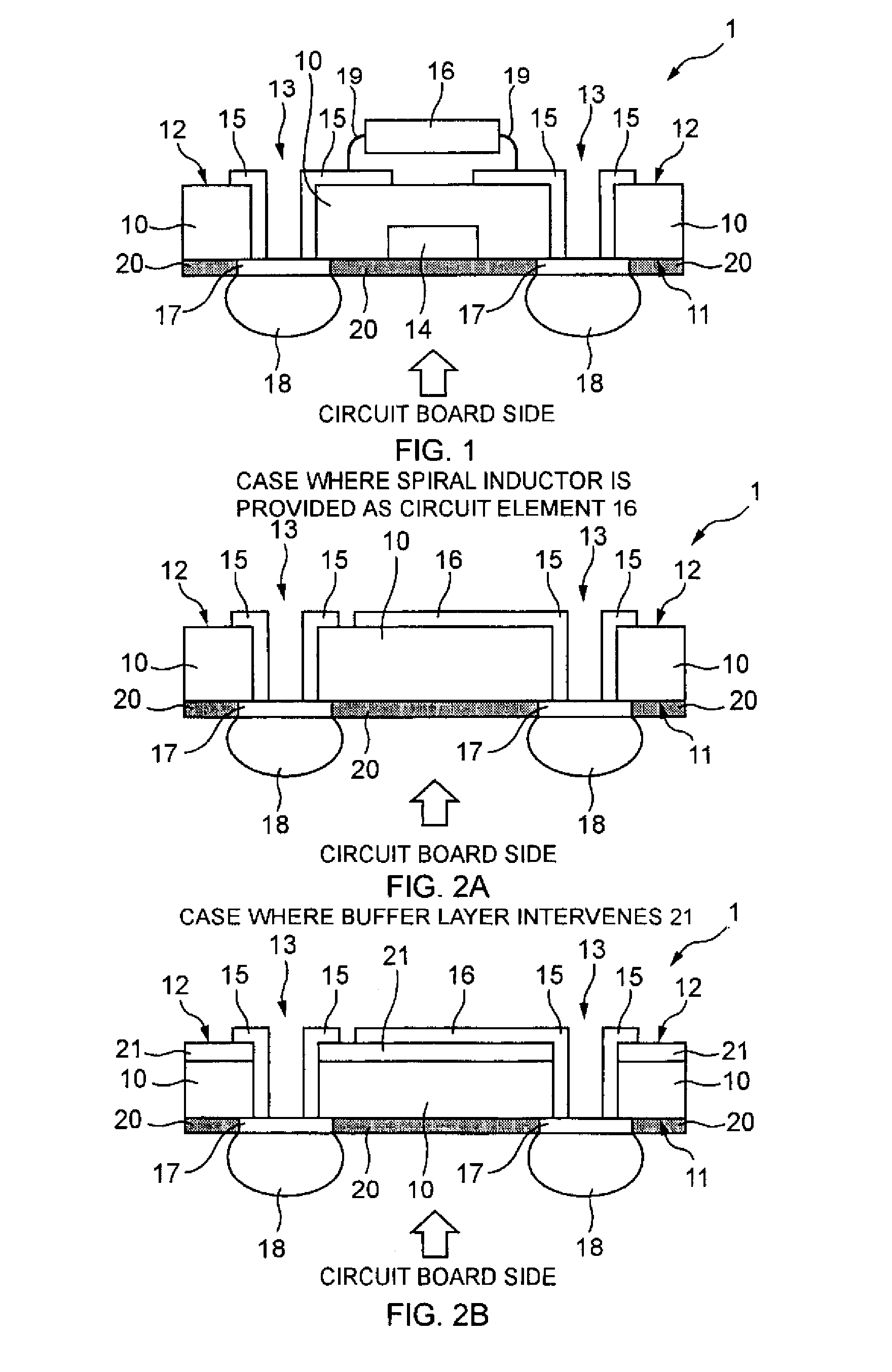

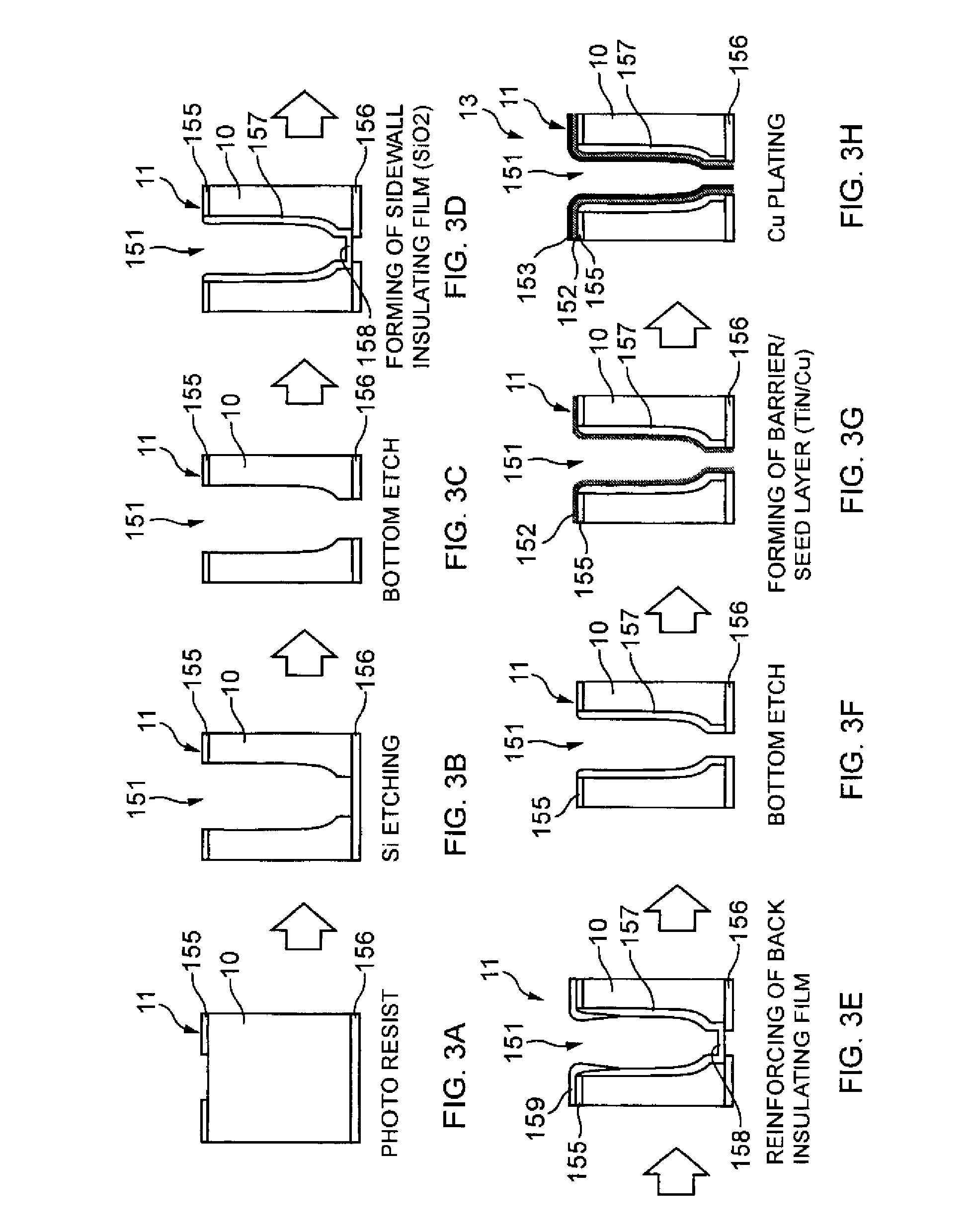

Semiconductor Apparatus and Semiconductor Module

InactiveUS20070035020A1Improve placement efficiencySemiconductor/solid-state device detailsSolid-state devicesDevice formEngineering

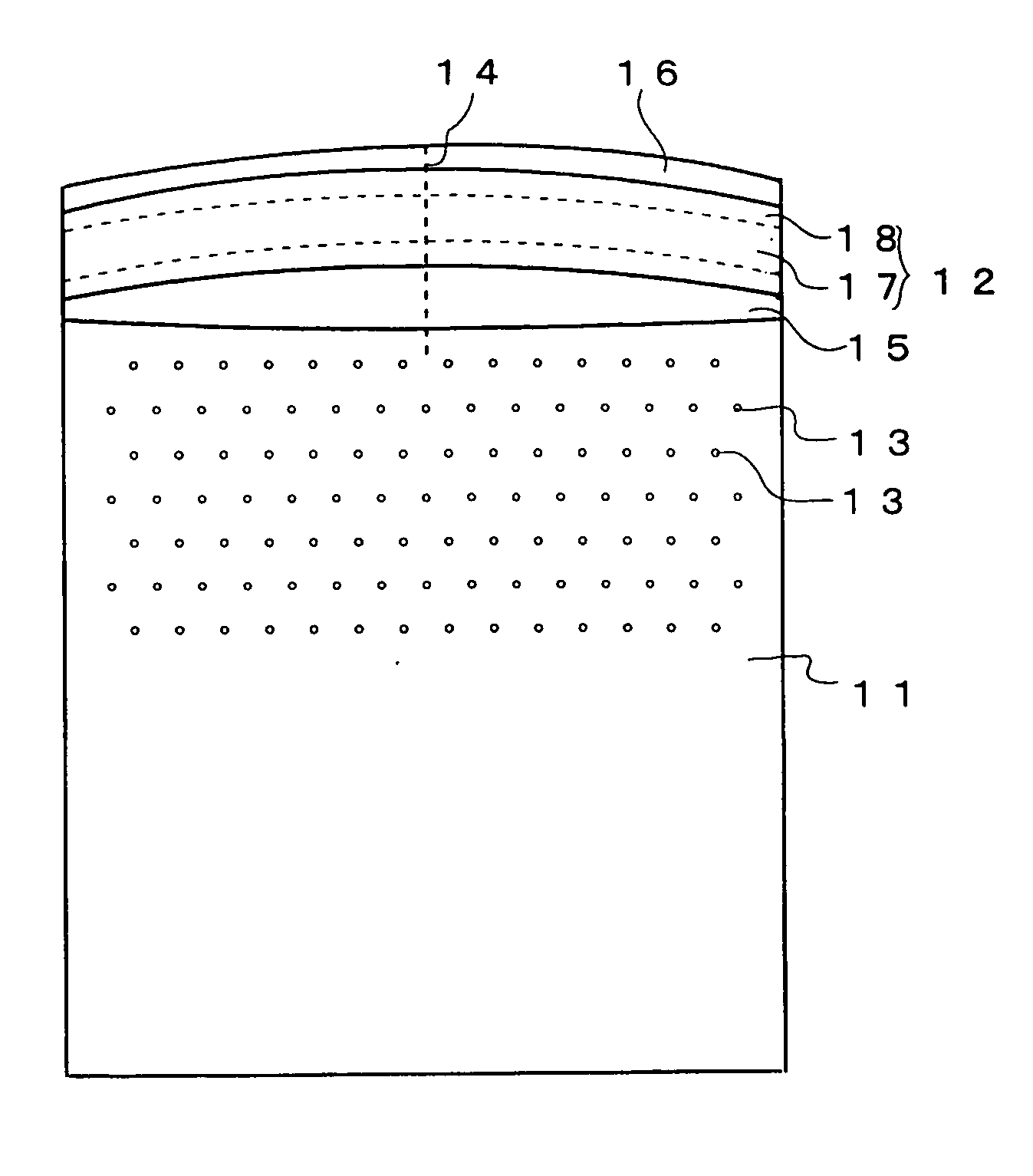

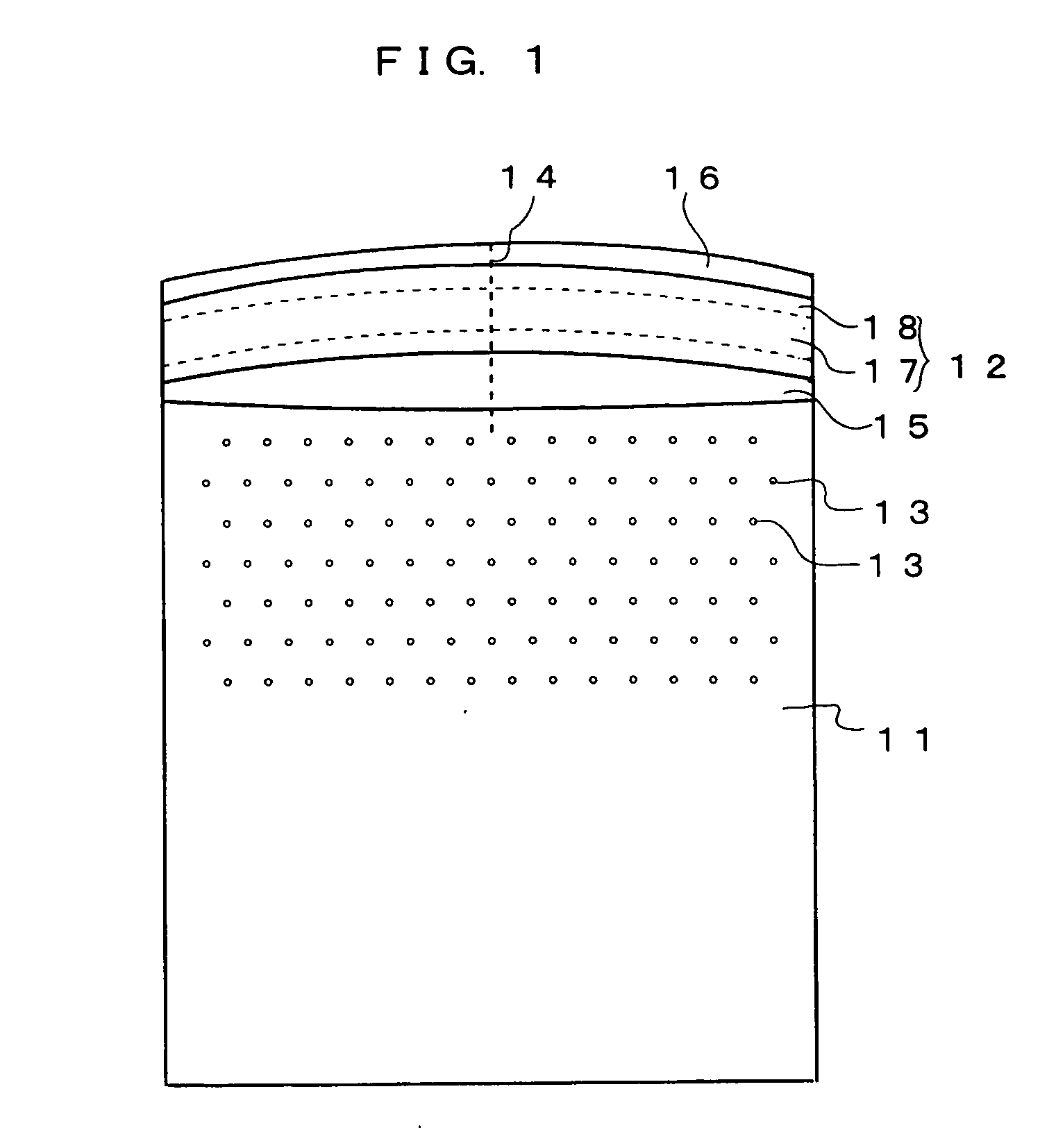

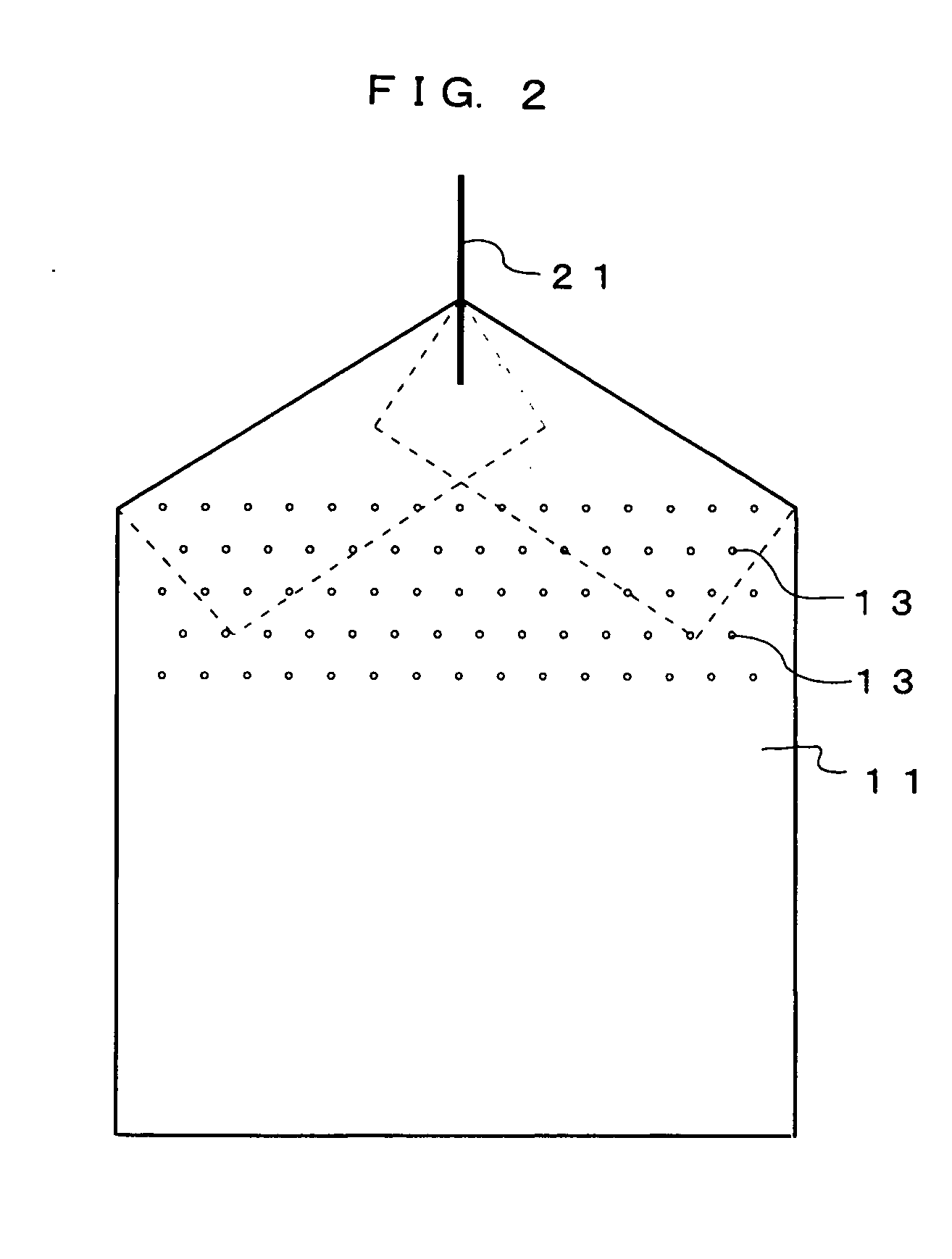

A semiconductor apparatus includes a semiconductor substrate, a through-electrode, a solder bump, and a circuit element. The semiconductor substrate has an electronic device formed on its front face. The through-electrode extends through the semiconductor substrate. The solder bump is disposed on the front side of the semiconductor substrate. The circuit element is disposed on the back side of the semiconductor substrate and is connected via the through-electrode to the electronic device.

Owner:SANYO ELECTRIC CO LTD +1

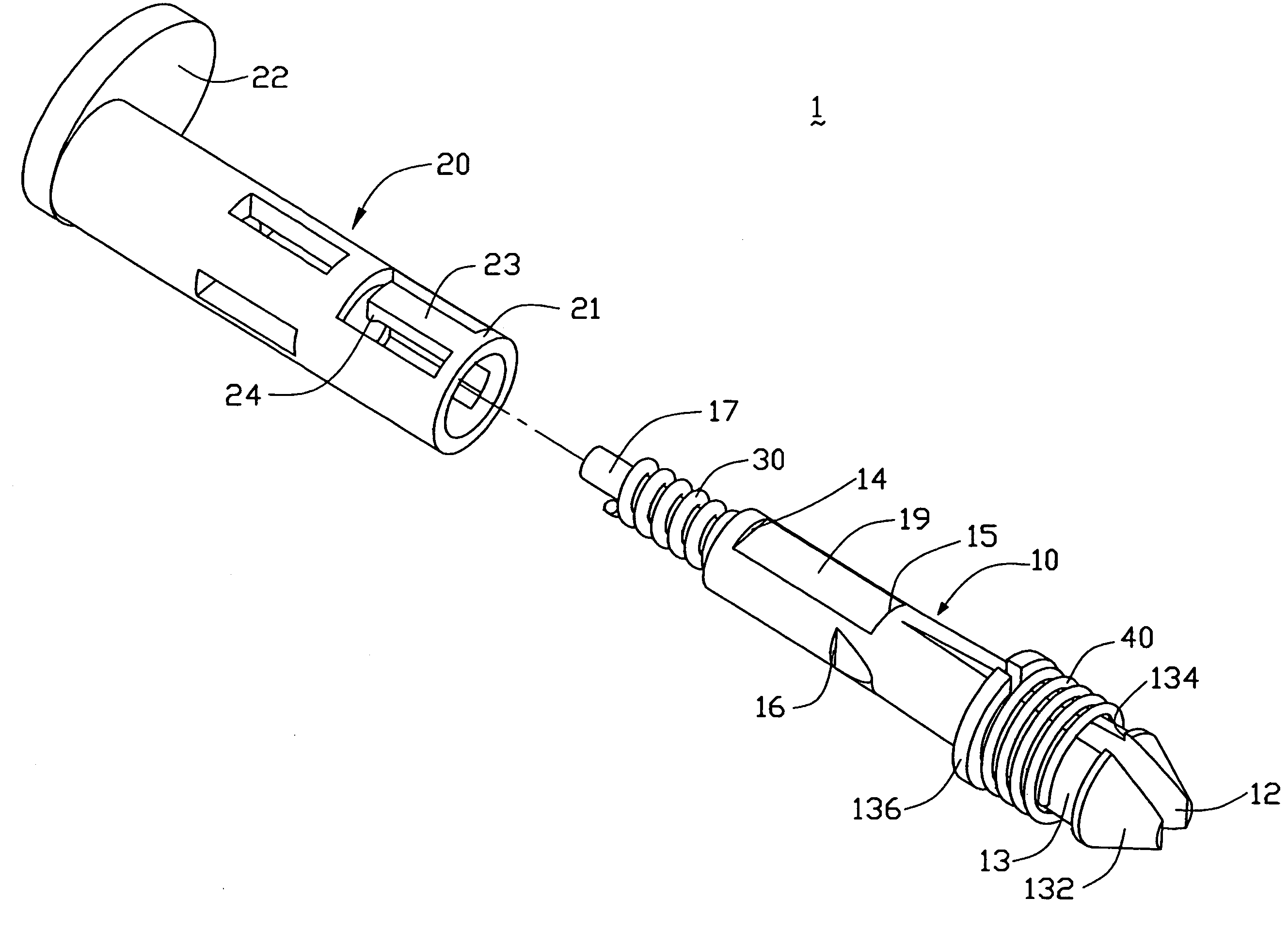

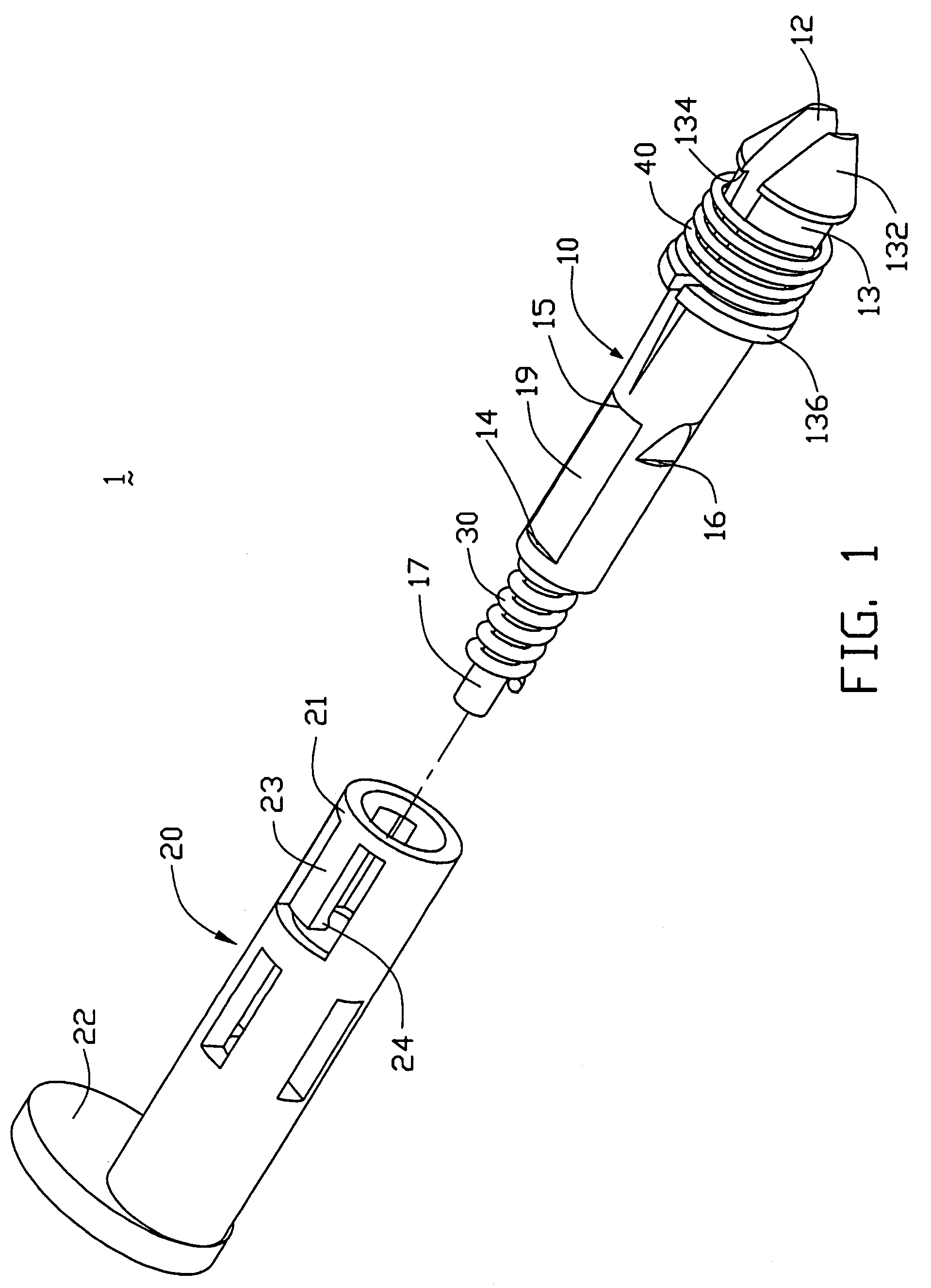

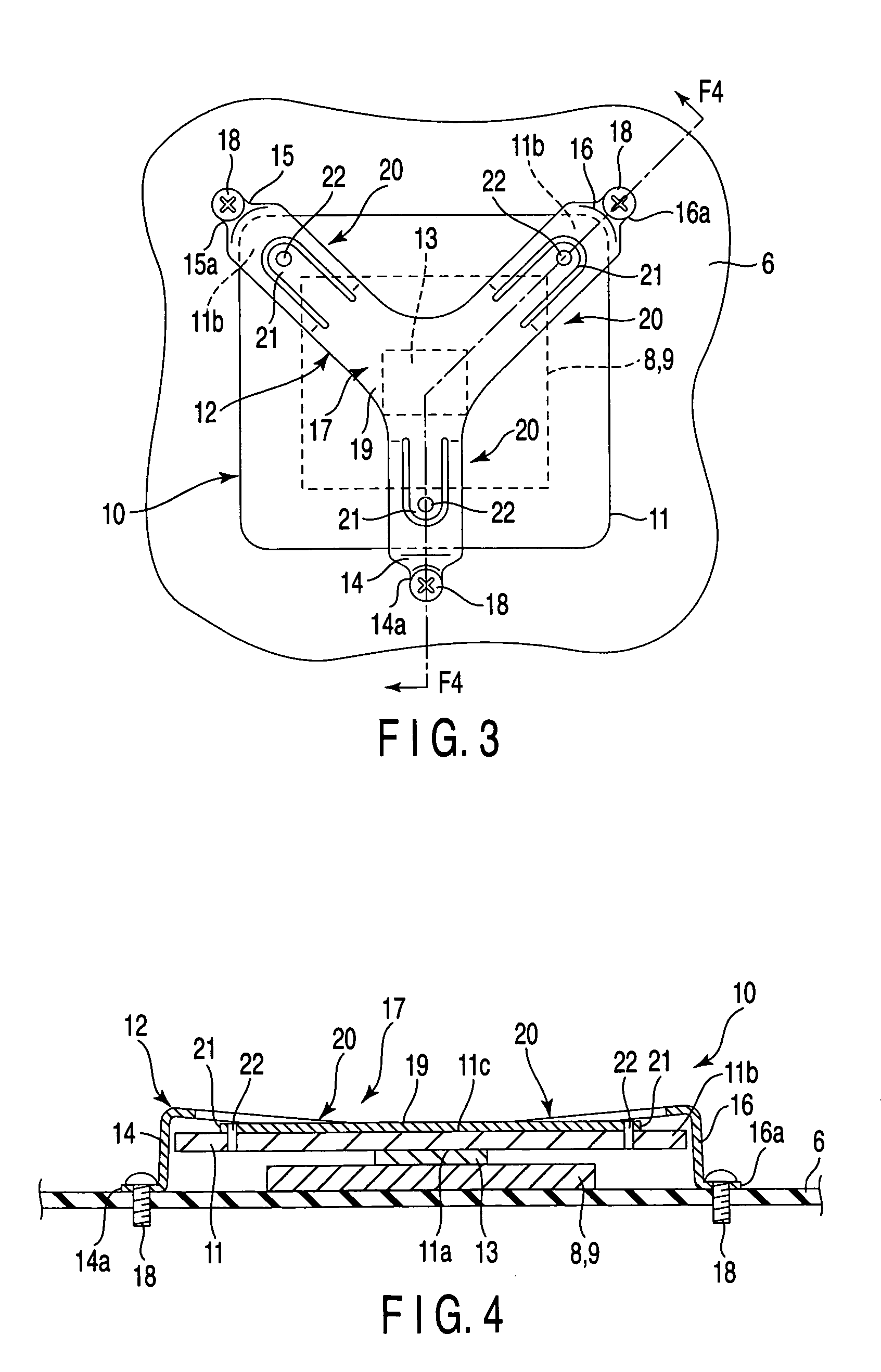

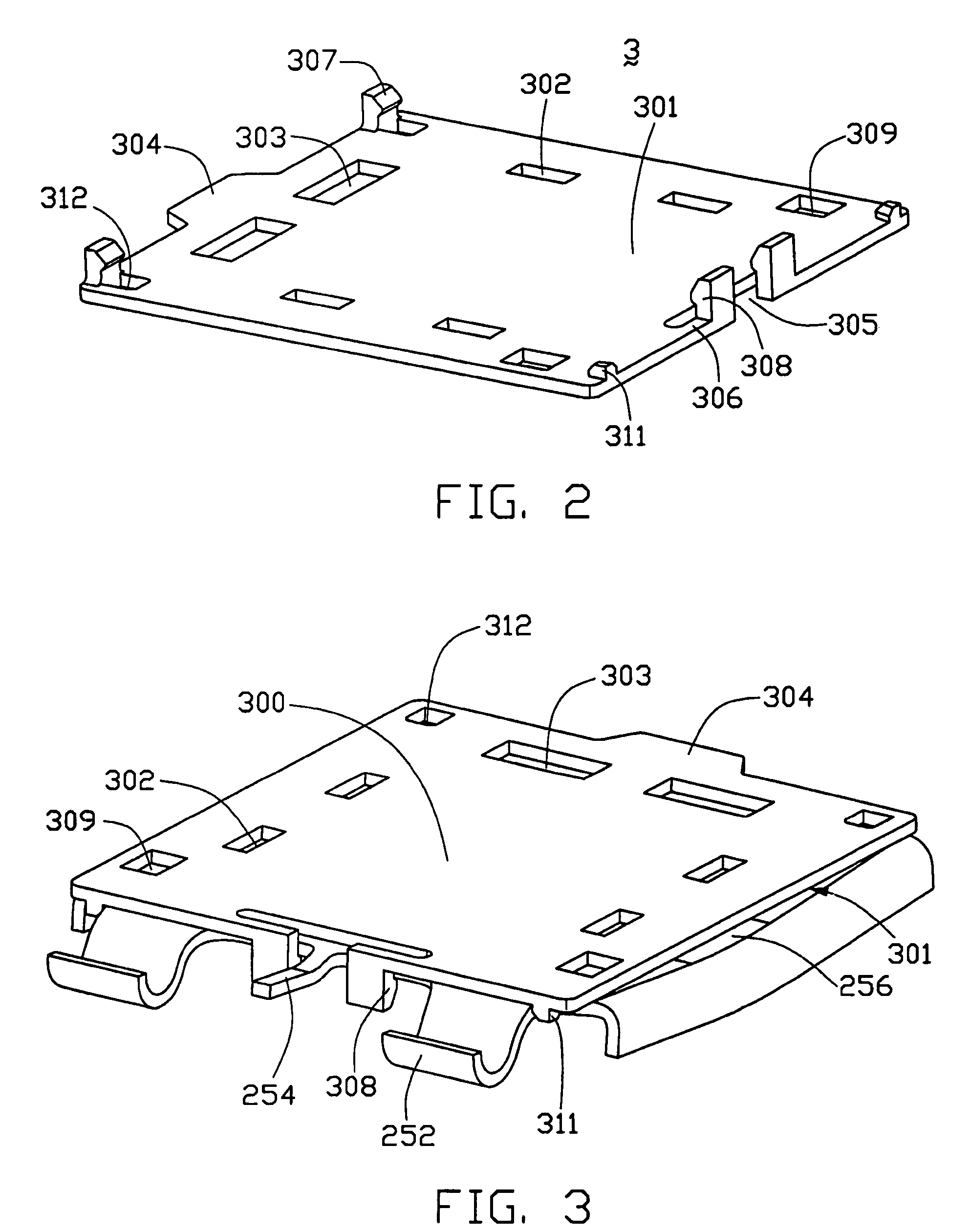

Heat sink mounting apparatus

InactiveUS7116556B2Reduce the possibilityImprove placement efficiencySnap fastenersDigital data processing detailsDetentEngineering

A mounting apparatus (1) includes a locking pin (10) and an operation member (20) attaching to the locking pin. Resilient prongs (13) are formed at a first end of the locking pin. A detent (16) is formed at a periphery of the locking pin. The operation member comprises a compressing portion (21) capable of compressing the prongs radially to a predetermined compressed state when the operation member moves axially in a first direction from the second end to the first end and capable of releasing the prongs when the operation member moves axially in an opposite second direction to allow the prongs to return to their original states, and a catch (24) to engage with the detent to prevent movement of the operation member in the second direction to maintain the prongs at the predetermined compressed state.

Owner:HON HAI PRECISION IND CO LTD +1

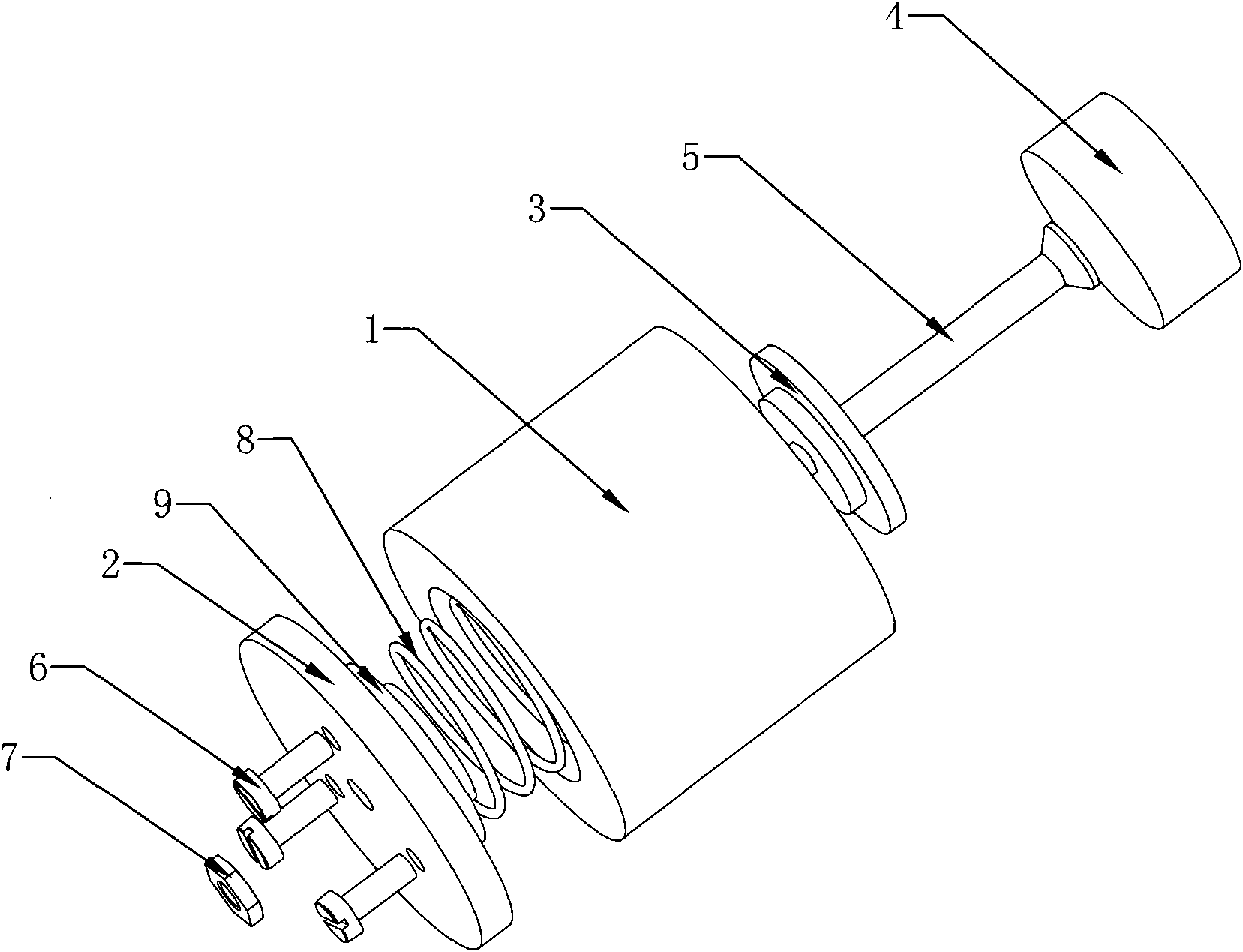

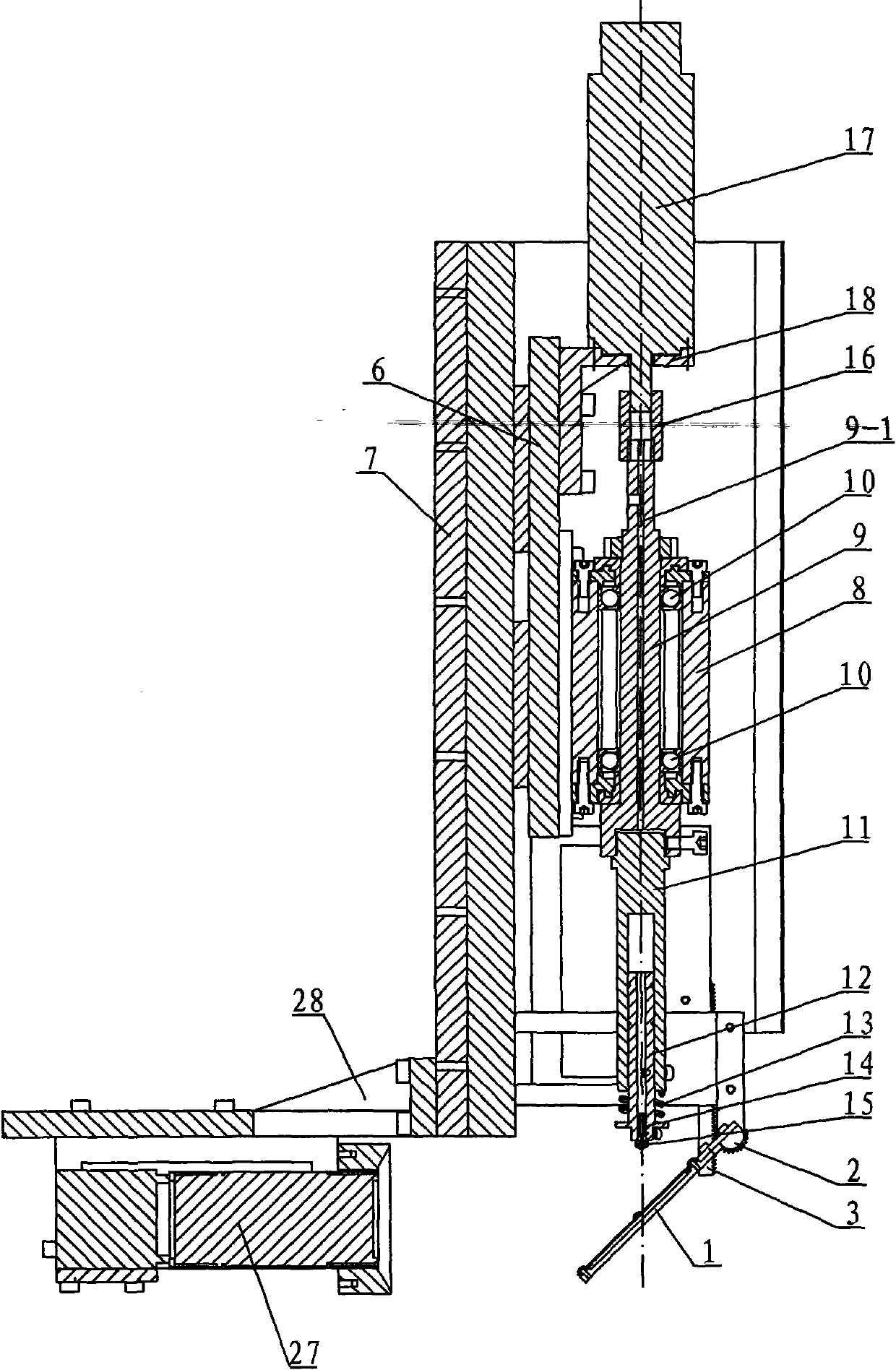

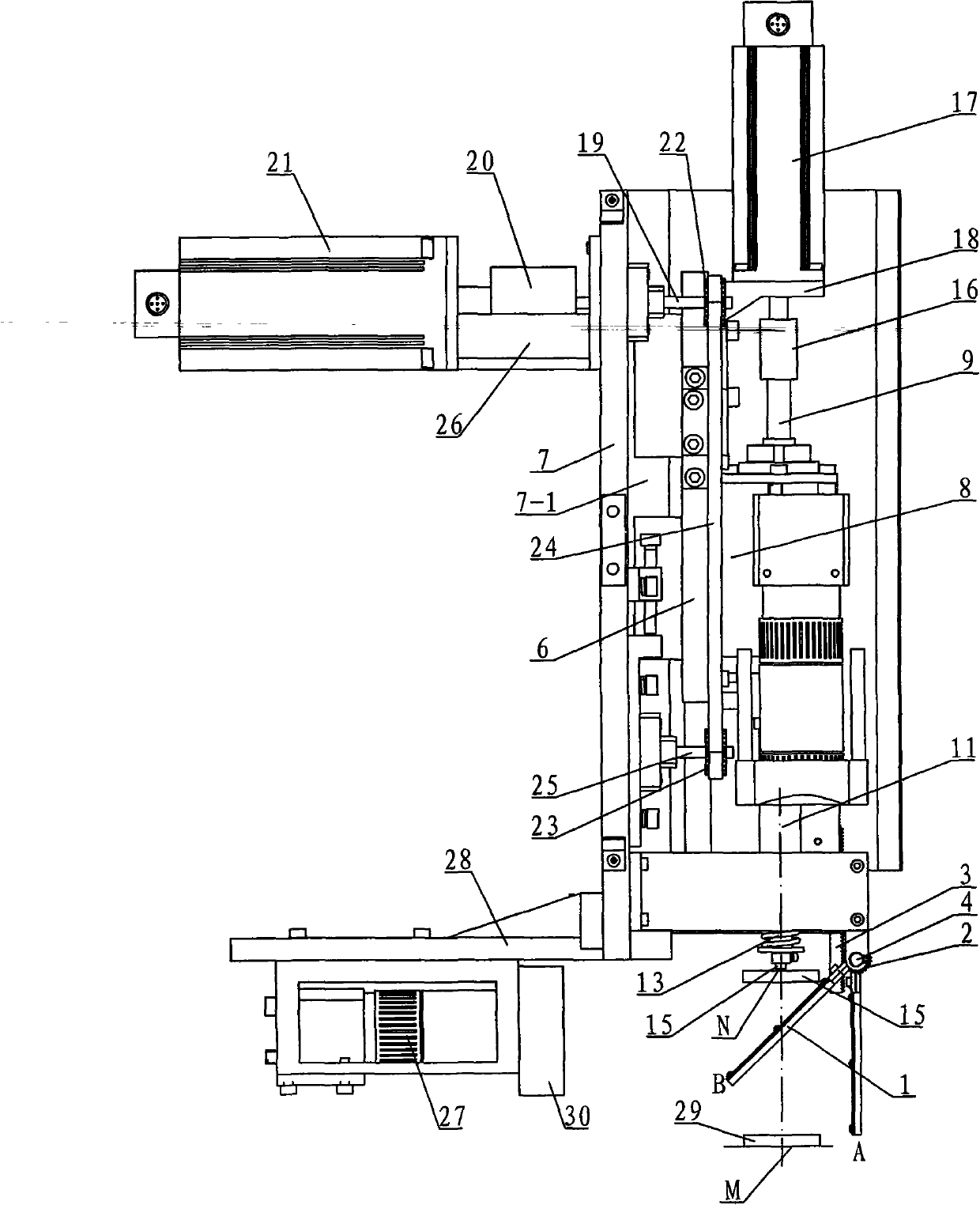

Device for pressing resistance strain sheets and magnetic patches and method for adhering resistance strain sheets

InactiveCN101619959ASimple structureReduce volumeForce measurementElectrical/magnetic solid deformation measurementMagnetic tension forceSpring force

The invention provides a device for pressing resistance strain sheets and magnetic patches, comprising a permanent magnet, an end cover, a top sheet, a foam cushion, a screw rod matched with a nut and a spring. The device for pressing resistance strain sheets and magnetic patches utilizes the permanent magnet to be absorbed on a metal structure surface of detected equipment by depending on magnetic force, thereby compressing the spring to enable the foam cushion to generate pressing force on strain sheets to fix the strain sheets. When the device is in use, the foam cushion is firstly aligned with the strain sheets which are coated with glue and adhered on the metal structure surface, the permanent magnet is pressed to be absorbed on the detected equipment, pressing force generated by the spring forces the strain sheets to be closely contacted with the metal surface of the detected equipment, and the size of the pressure can be adjusted by rotating screws; when the 502 glue is dried, and the strain sheets are combined with the metal surface of the detected equipment into an integer, the device for pressing resistance strain sheets and magnetic patches is taken down. The device for pressing resistance strain sheets and magnetic patches has the advantages of small volume, light weight, good sheet adhering effect and simple and convenient maintenance.

Owner:CHINA ELECTRIC POWER RES INST

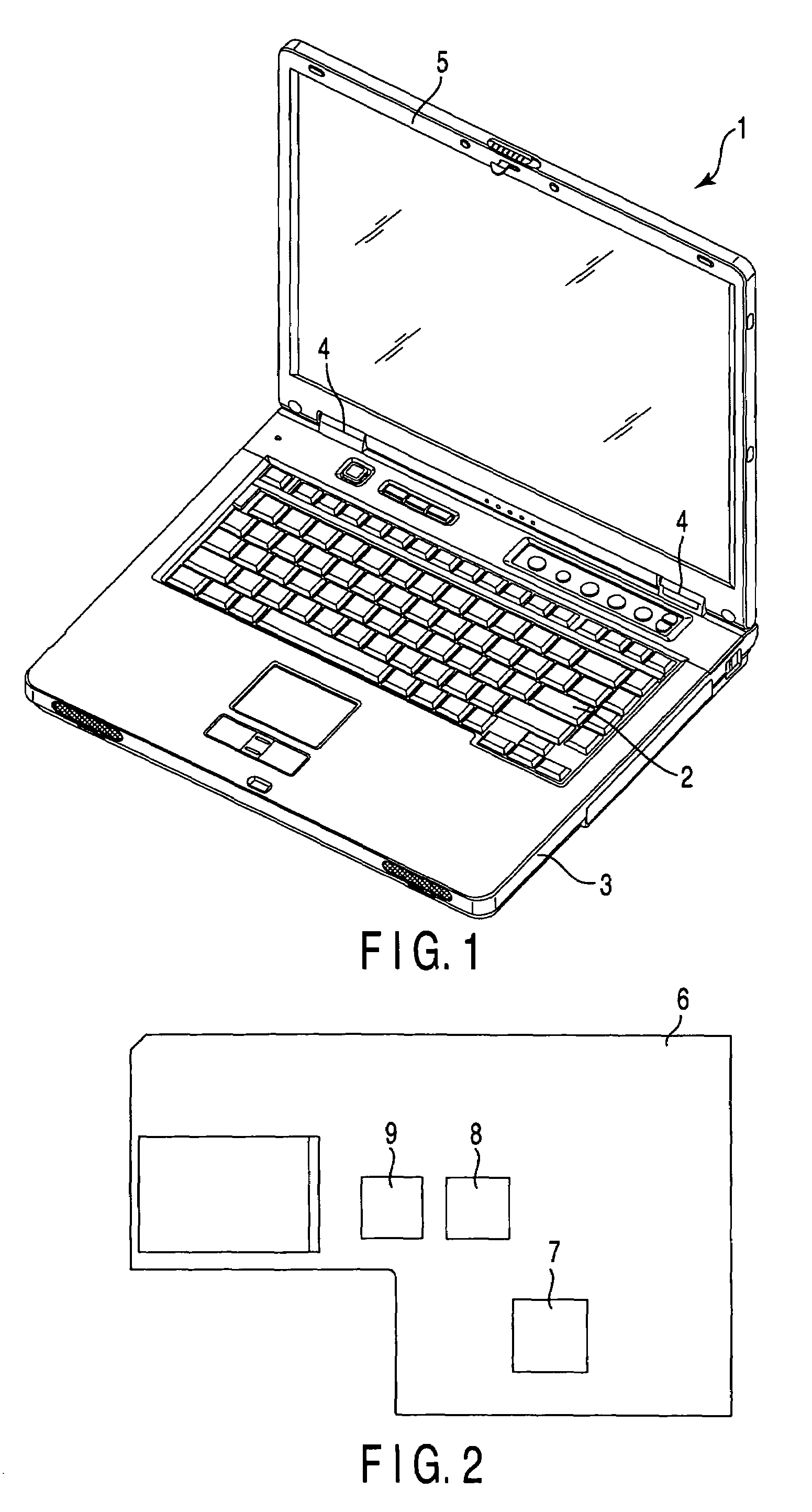

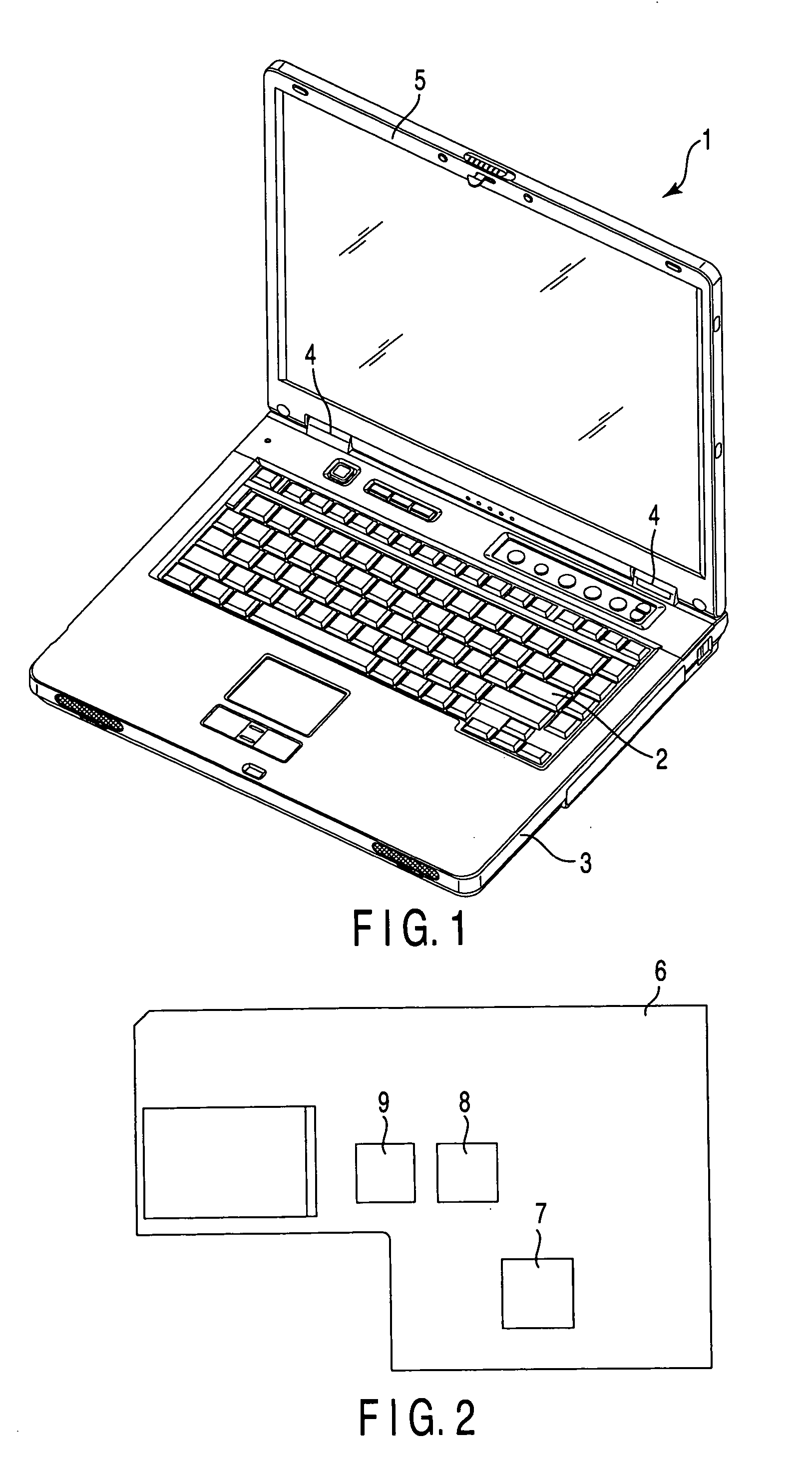

Electronic apparatus

ActiveUS7170750B2Improve placement efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

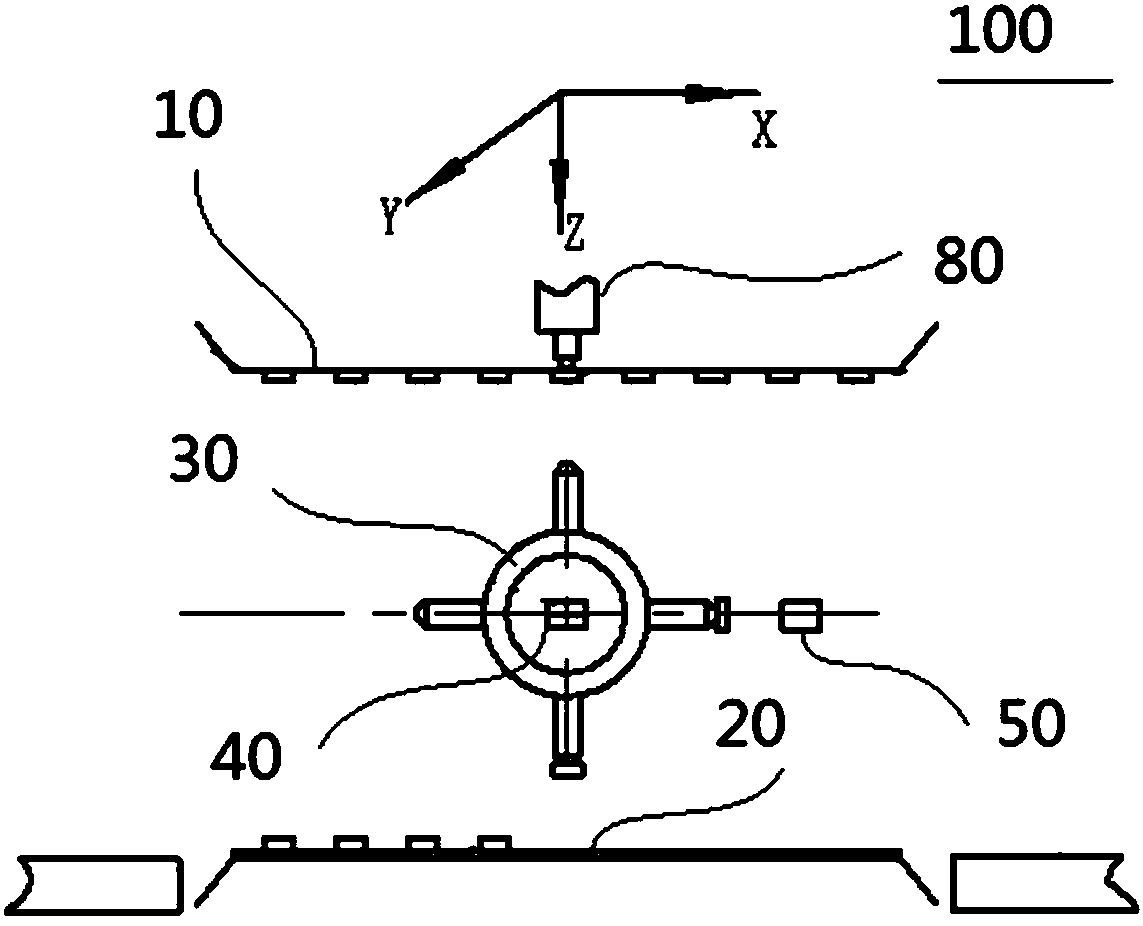

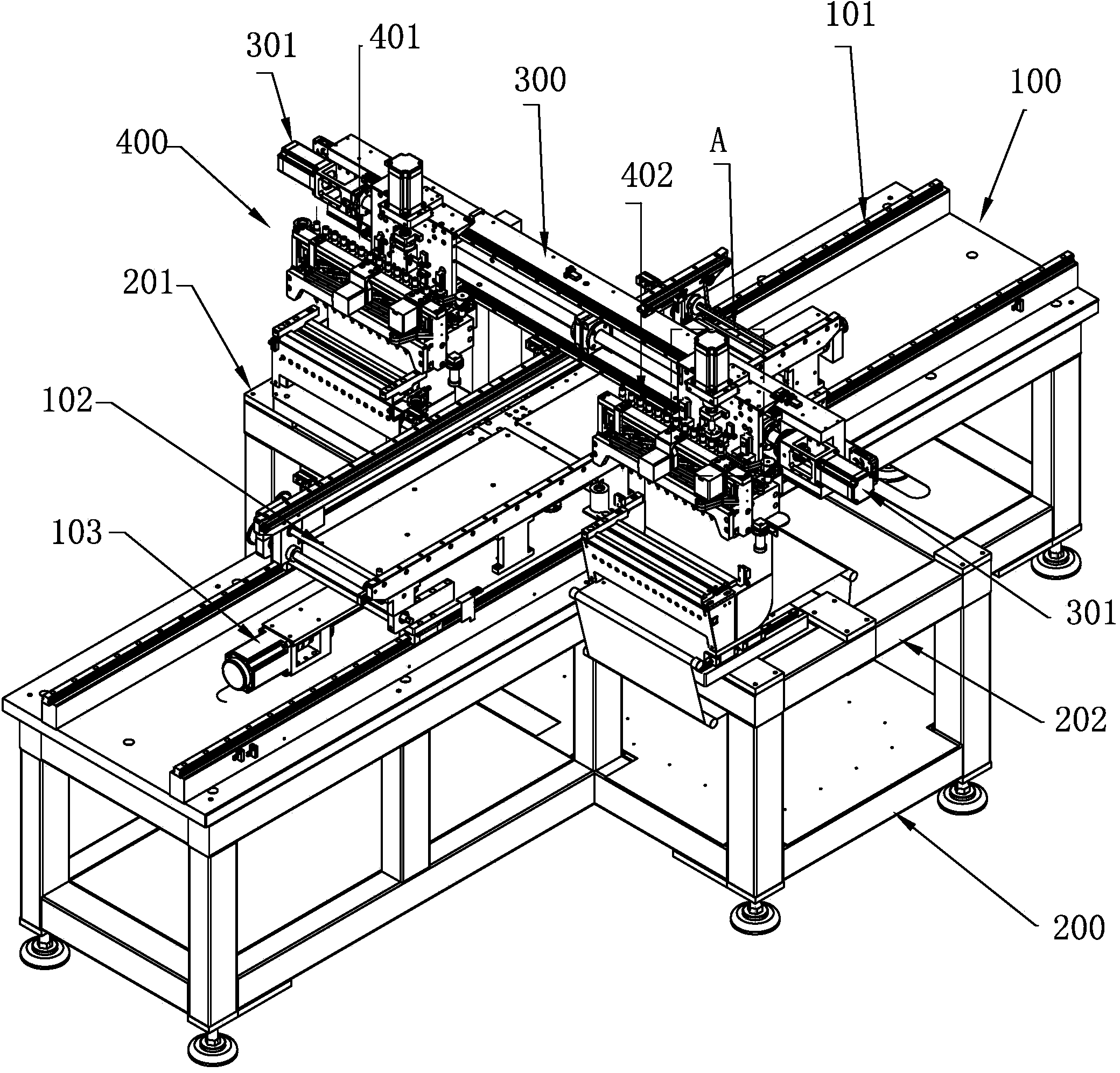

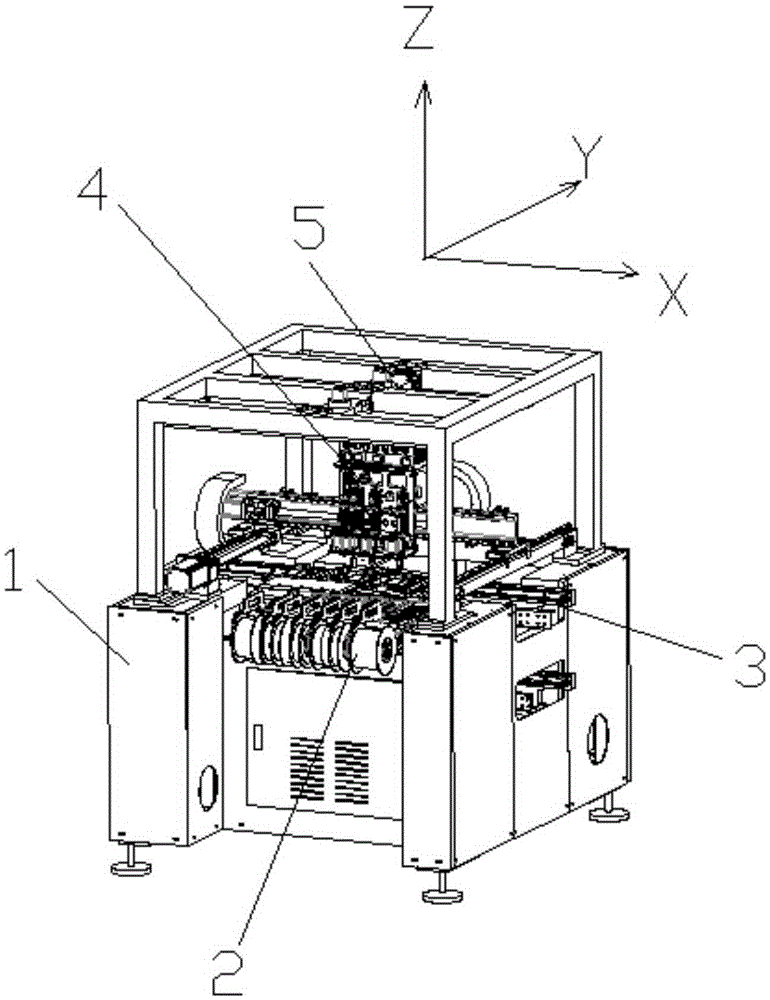

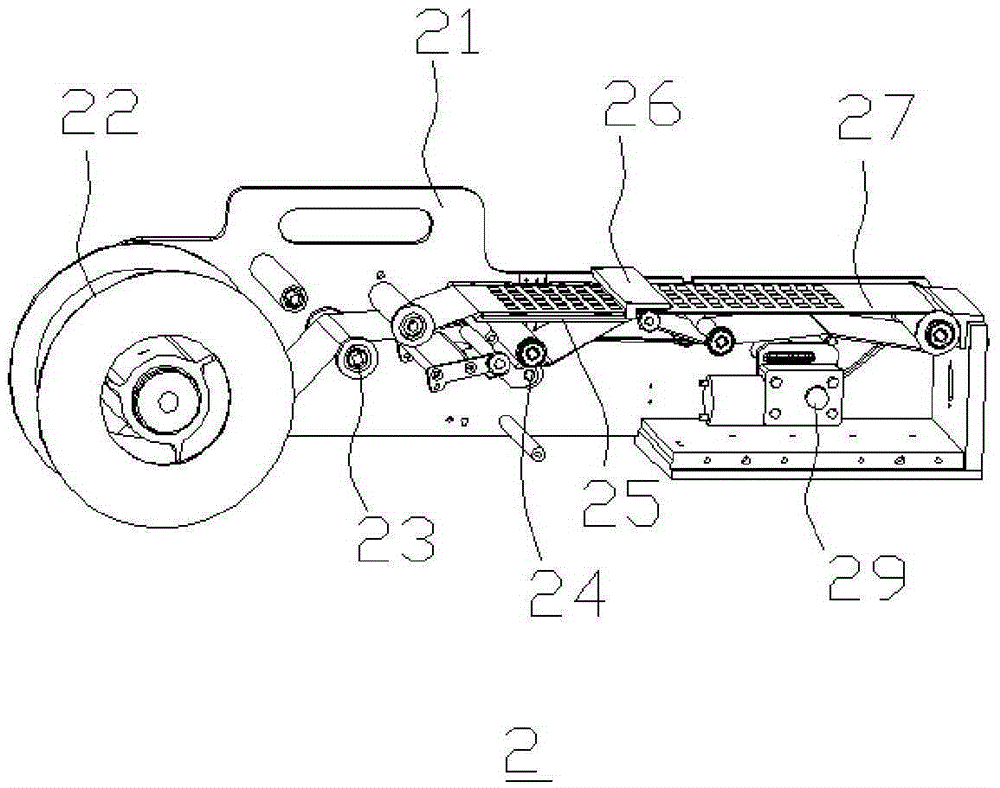

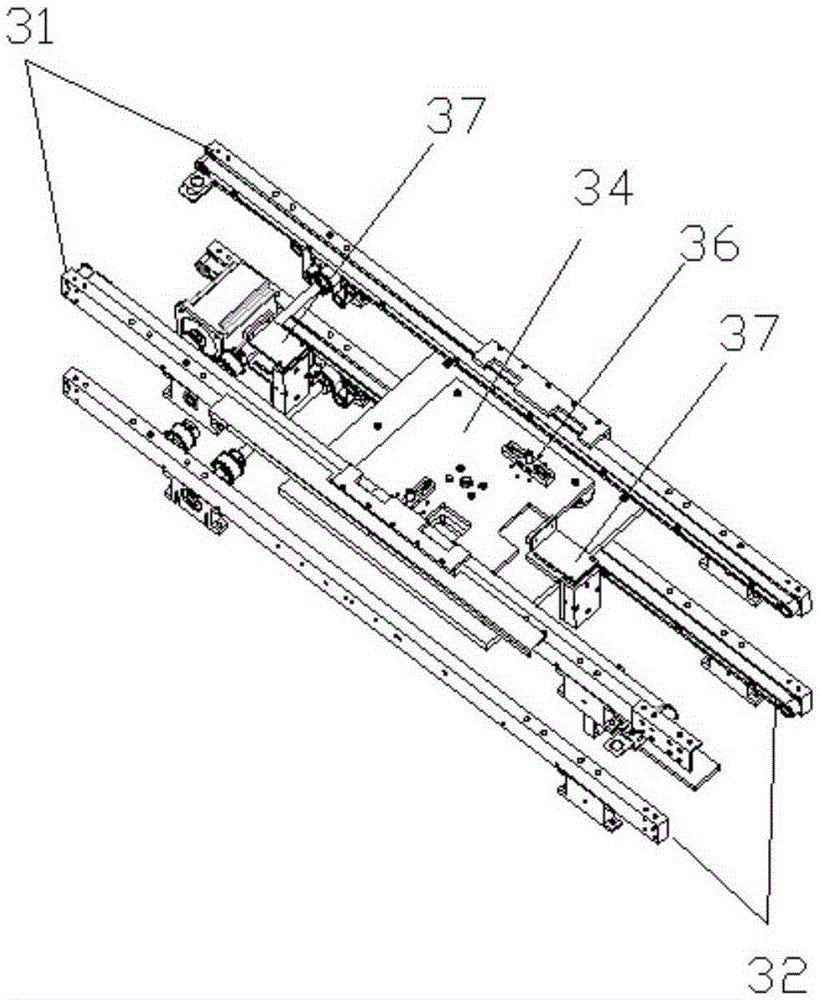

Chip attaching device and method

InactiveCN108155124AShorten the transfer strokeAchieve preheatingSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

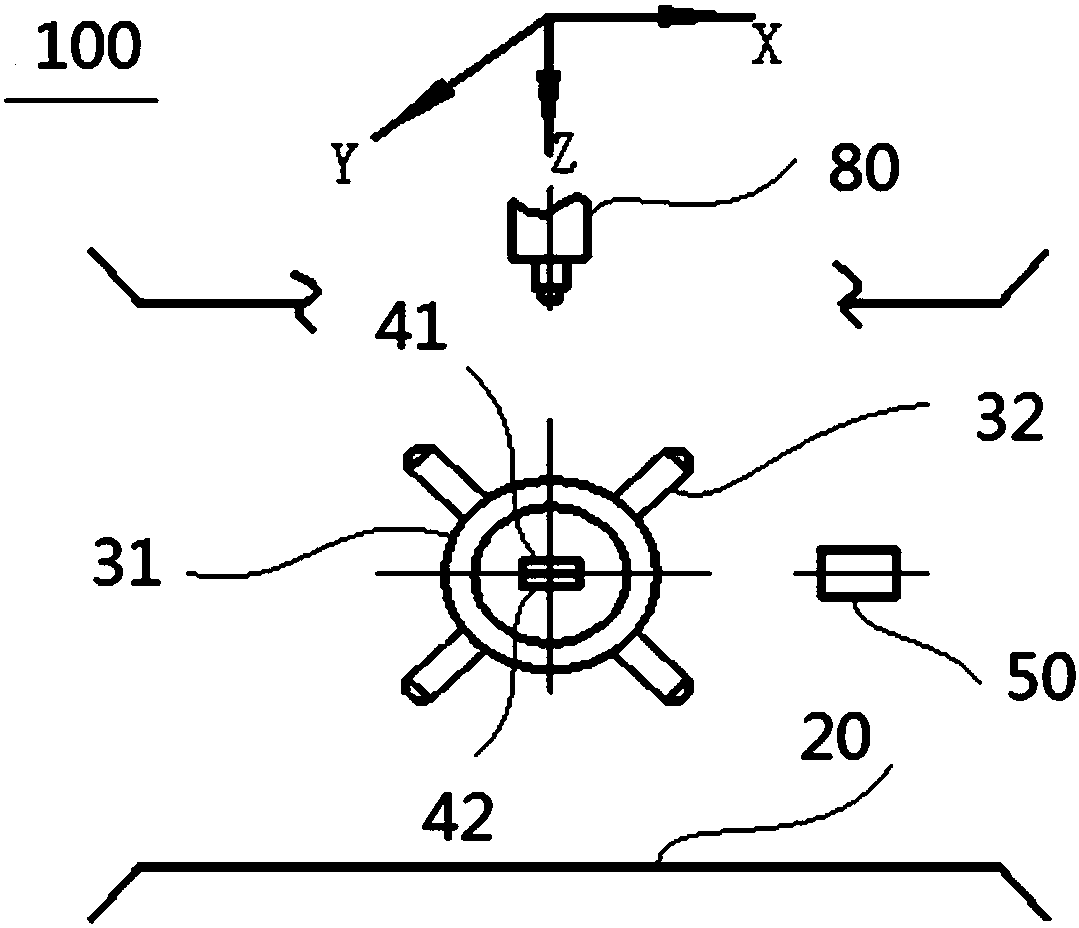

The invention provides a chip attaching device and method. The device comprises a wafer table, a basic material table, a rotary picking and placing mechanism and a vision mechanism. The wafer table can move in the plane where the wafer table is located; the basic material table is parallel to the wafer table and opposite to the wafer table, and can move in the plane where the basic material tableis located; the rotary picking and placing mechanism is arranged between the wafer table and the basic material table, and provided with a movable bonding portion, wherein the bonding portion can pickup a chip and attach the chip to an attaching position; the vision mechanism is arranged between the wafer table and the basic material table and matched with the rotary picking and placing mechanismto recognize the position of the chip and the attaching position. The method includes the steps that the positions of corresponding parts and components of the chip attaching device are calibrated; the chip is placed at the corresponding position of the attaching device, and position data of the chip is obtained and corrected; the chip is picked up, and the position and the angle data of the picked chip are obtained; the position, for attaching the chip, of a basic material and the angle data of the chip are obtained, the deviation of the chip is calculated and corrected in combination with the position and the angle data of the picked chip, and the chip is attached to the attaching position. With the device and the method, attaching efficiency and accuracy are higher.

Owner:CETC BEIJING ELECTRONICS EQUIP

Protector

InactiveUS20080277015A1Improve versatilityEasily positionSleeve/socket jointsElectrically conductive connectionsEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

Routing apparatus

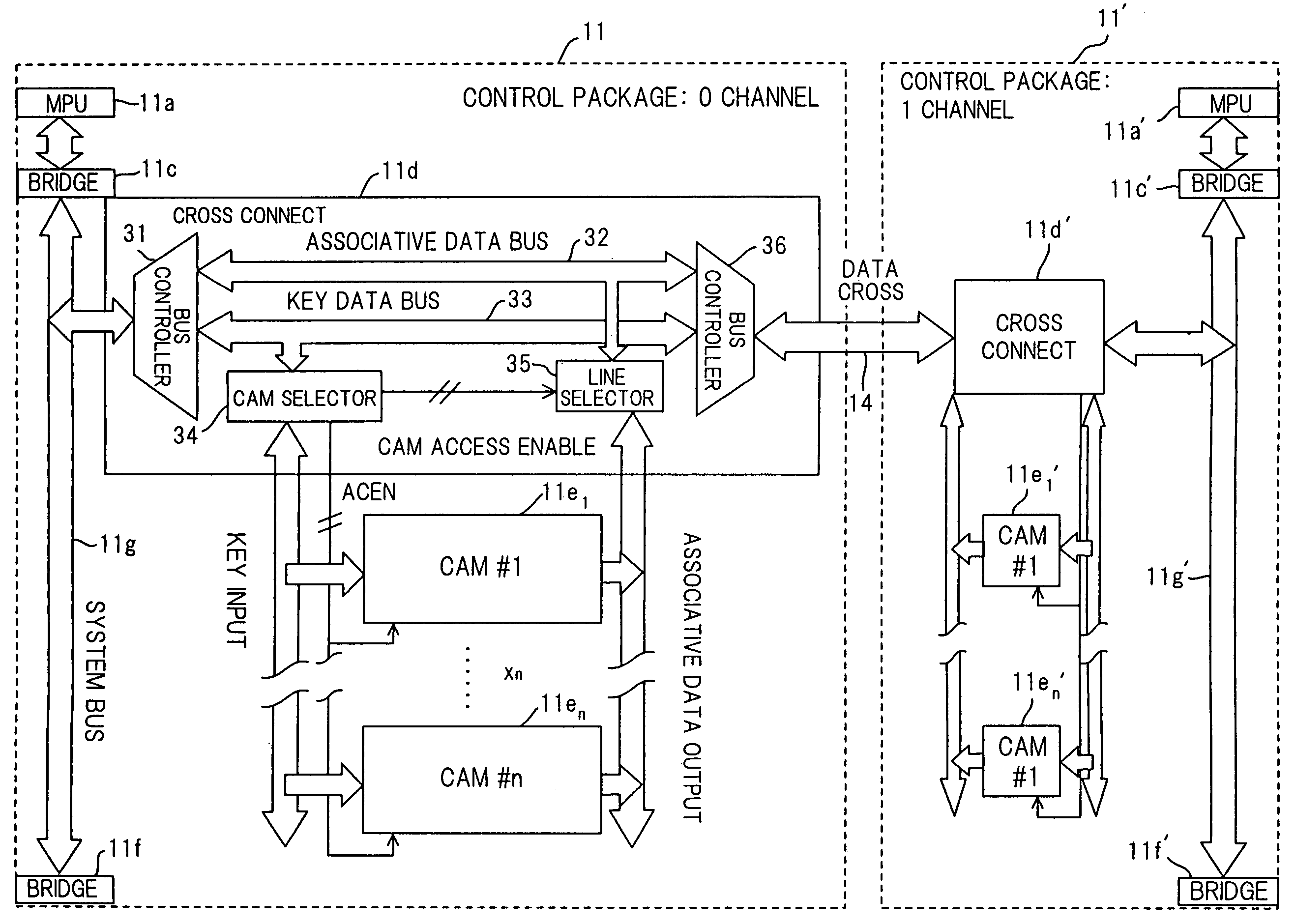

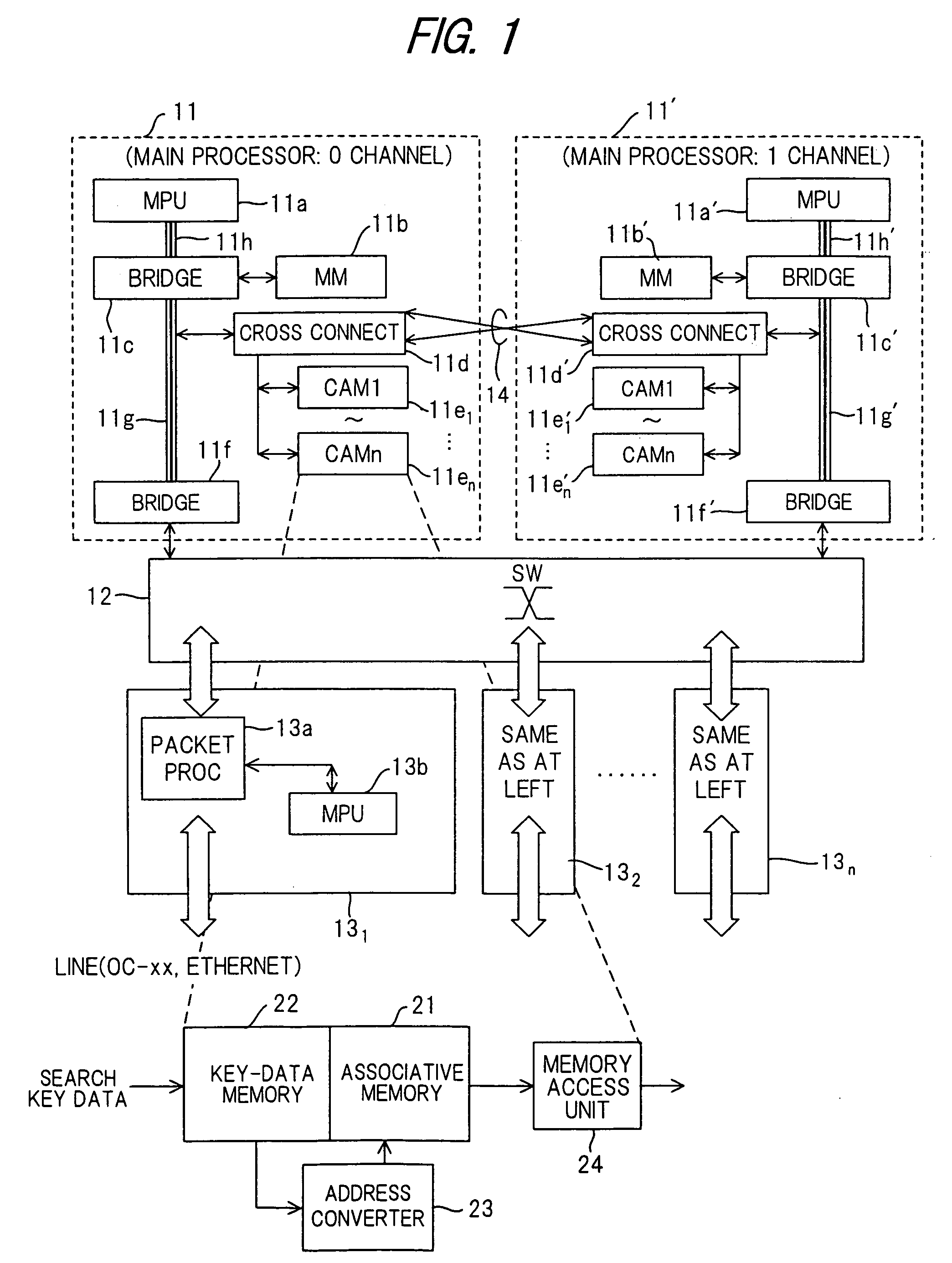

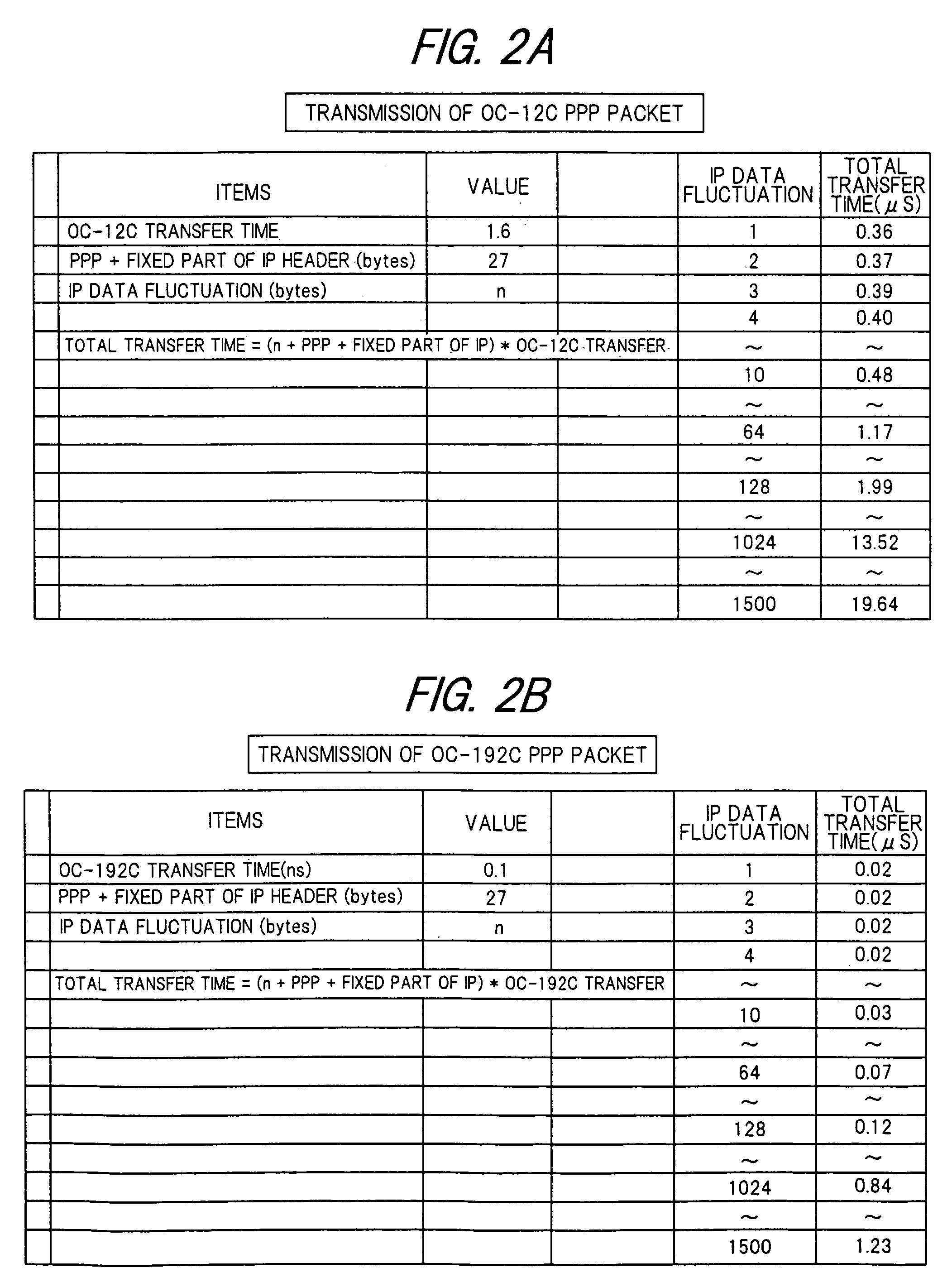

InactiveUS7124200B2Low costReduce in quantityDigital computer detailsData switching networksUser identifierContent-addressable storage

Disclosed is a routing apparatus for obtaining routing data conforming to a destination address of a packet that arrives from a line, adding the routing data onto the packet, and switching the packet based upon the routing data to send the packet to a prescribed line. The routing apparatus has a main controller equipped with content addressable memories (CAMs) corresponding to respective ones of line speed. When search key data with an attached line identifier is received from a line card, routing data is generated by the content addressable memory (CAM) corresponding to the line speed and the routing data is sent to the line card. The line card adds routing data of which it has been notified by the main controller onto a packet and then outputs the packet. A switch to which a packet having attached routing data is input from a prescribed line card switches the packet based upon the routing data and sends the packet to another line card.

Owner:FUJITSU LTD

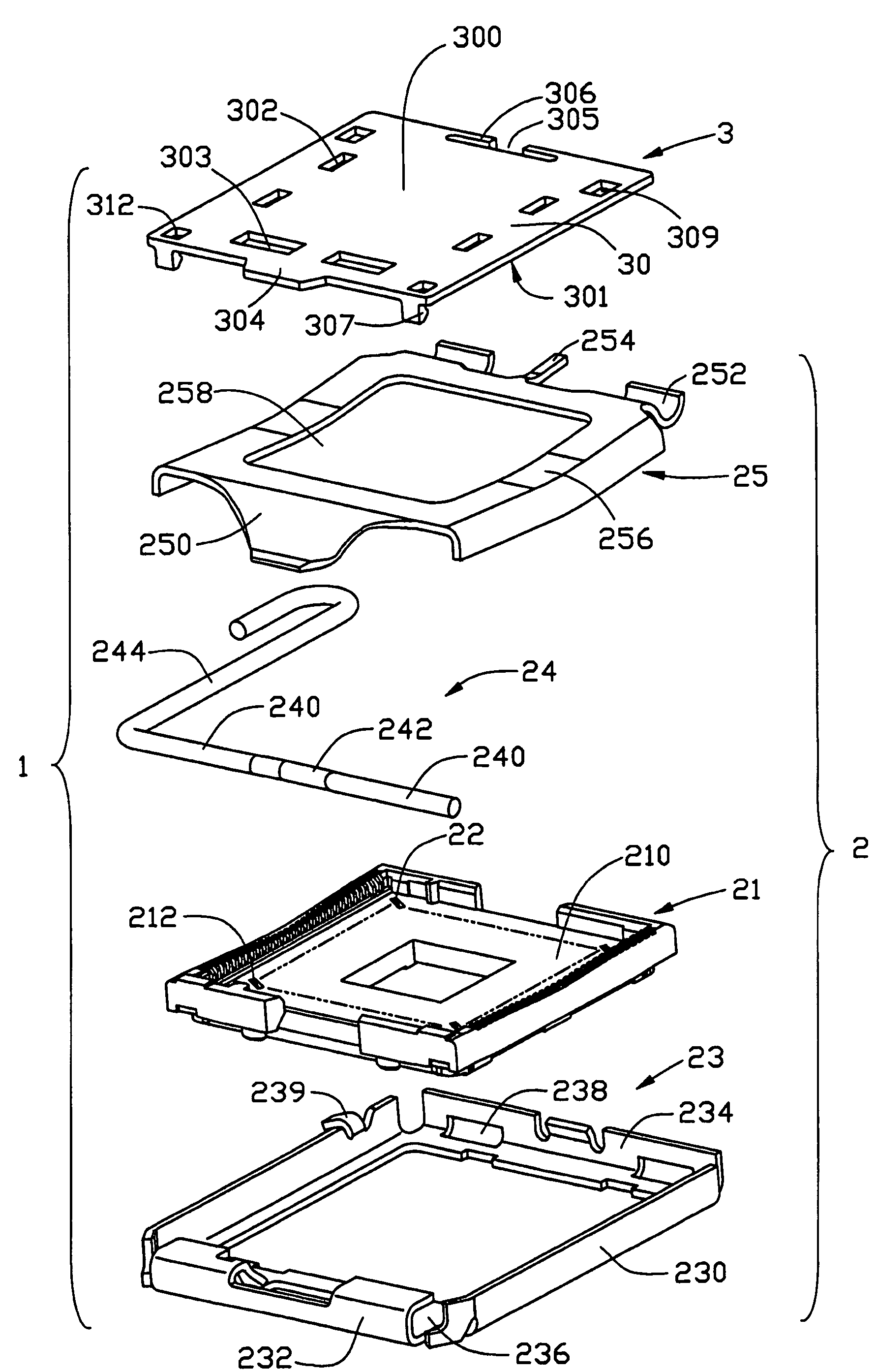

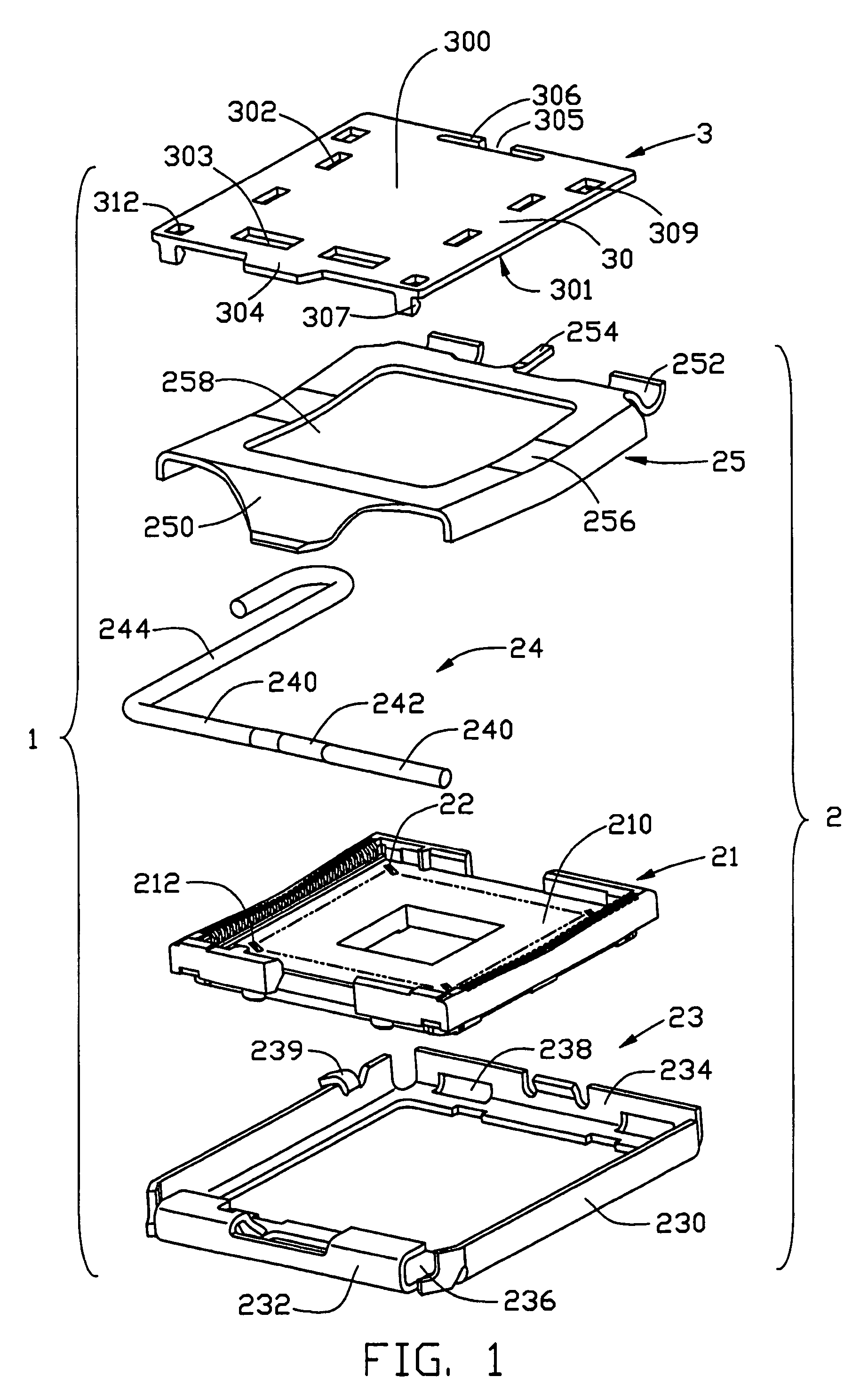

Electronic apparatus

ActiveUS20050117307A1Improve placement efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

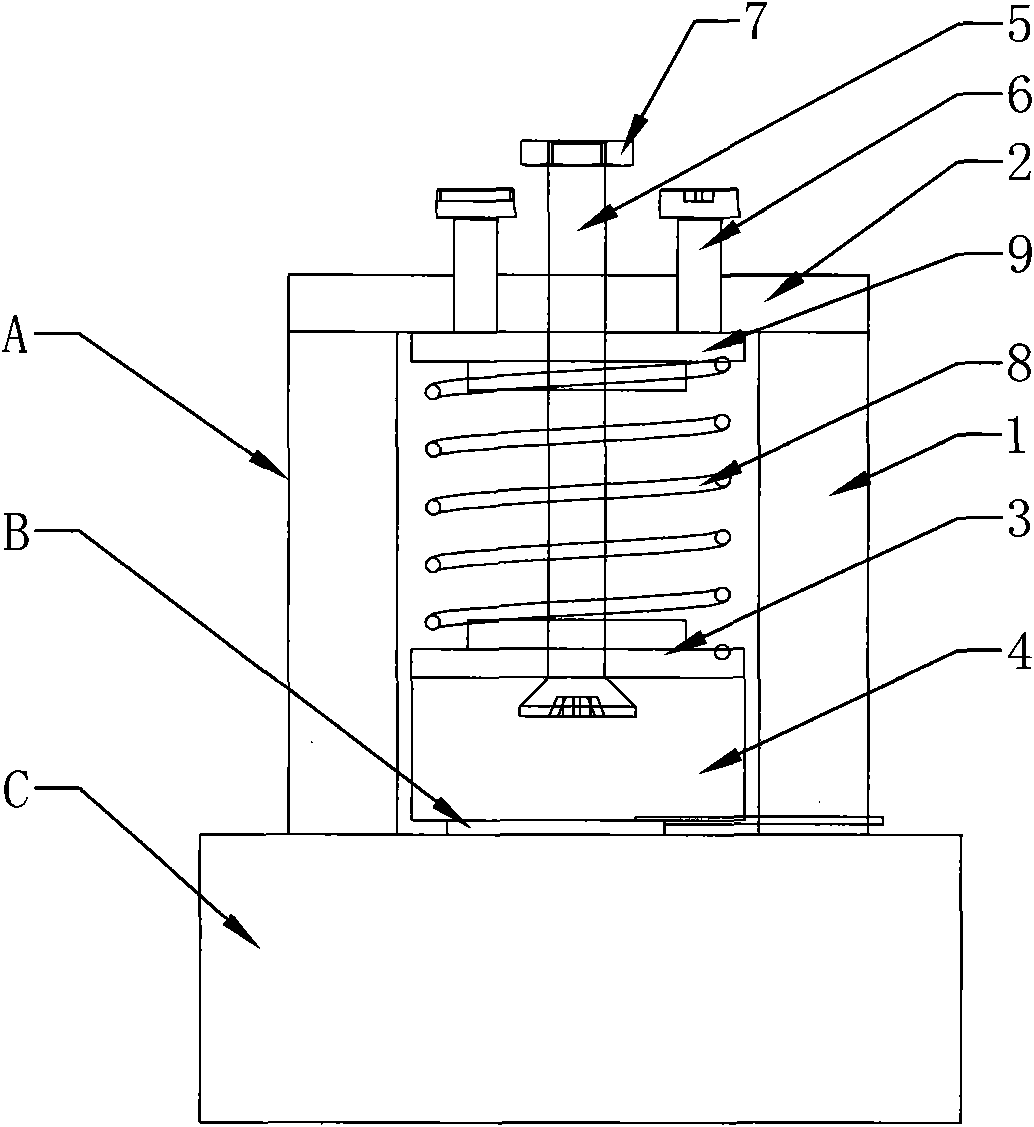

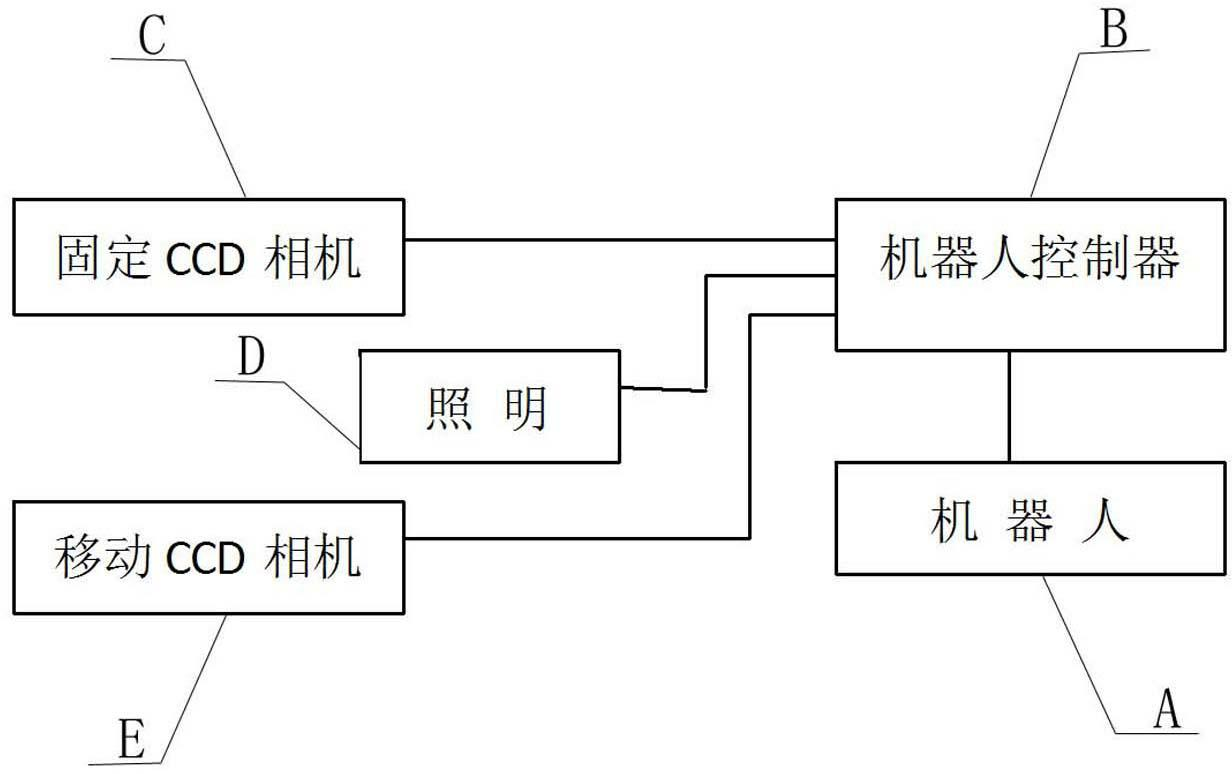

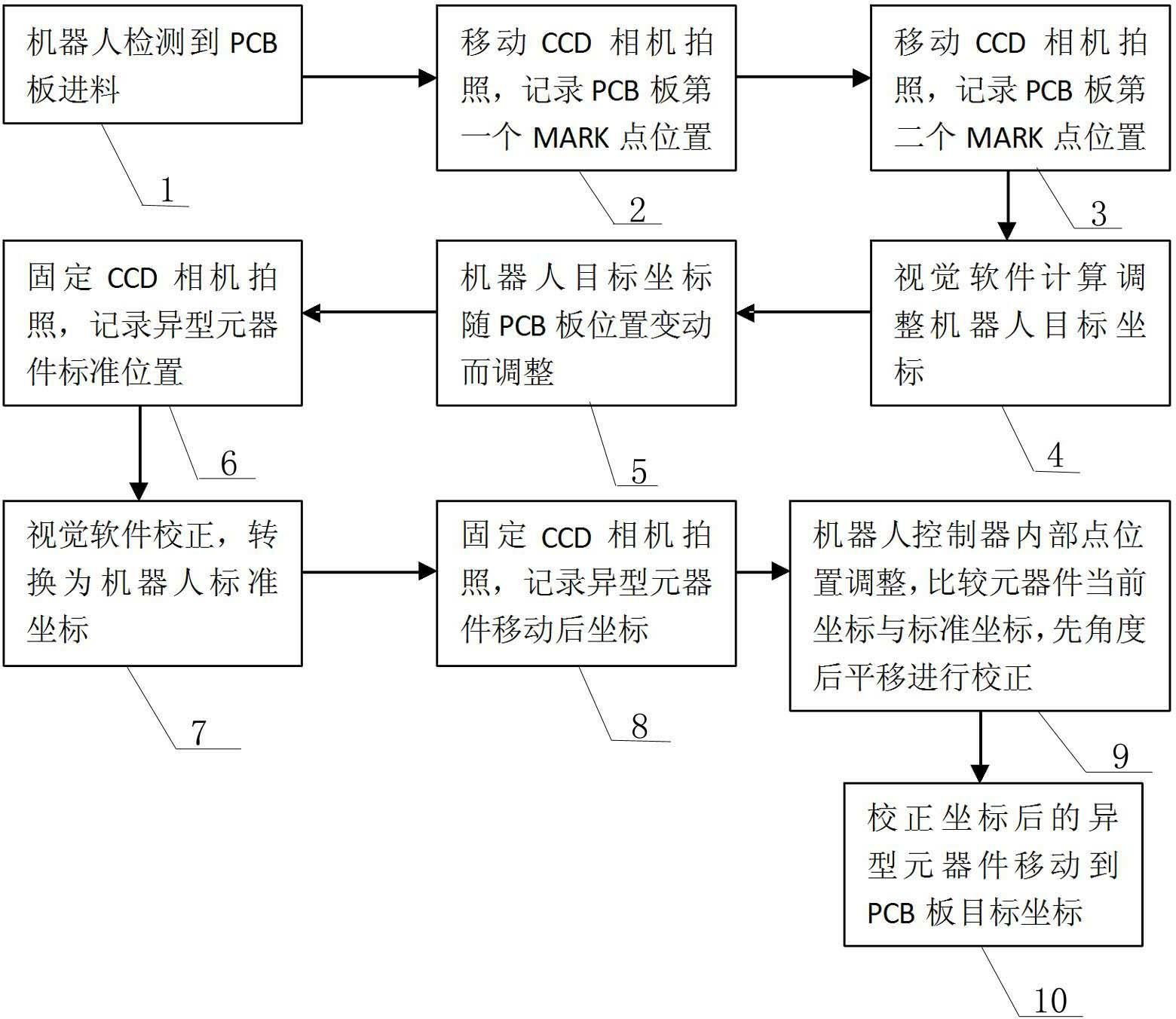

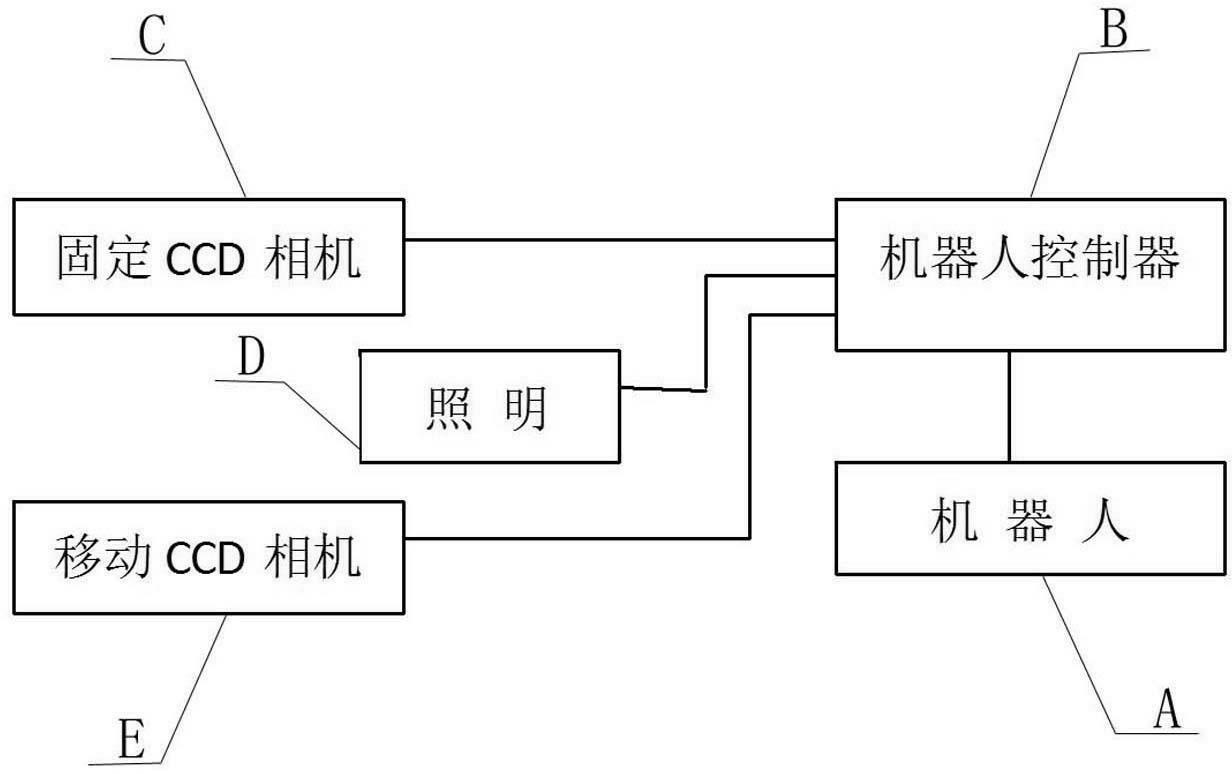

Pasting method for machine vision-based irregular electronic device

InactiveCN102686041ALess investmentImprove placement efficiencyPrinted circuit assemblingCcd cameraVisual perception

The invention relates to a pasting device for electronic devices in electronic industry. Pasting task is completed by robots. The pasting device consists of a robot A, a robot controller B, a fixed CCD (charged coupled device) camera C, an illuminator D, and a mobile CCD camera E. The pasting method comprises the steps that the robot detects feeding of a PCB (Printed Circuit Board), the mobile CCD cameras takes a picture to record a first MARK point position of the PCB, and the mobile CCD cameras takes a picture to record a second MARK point position, vision software calculates and regulates the target coordinates of the robot, the target coordinates of the robot are regulated along with position change of the PCB, the fixed CCD camera takes a picture to record the standard position of the irregular device, the vision software conducts correction and converts into the standard coordinates of the robot, the fixed CCD camera takes a picture to record the coordinates of the irregular device after being moved, positions of the internal points of the robot controller are regulated, the current coordinates and the standard coordinates of the device are compared, angles and translation are sequentially corrected, and the irregular device with the corrected coordinates is moved to the target coordinates of the PCB. In the method, the pasting machine is replaced with the robot, so that the investment is saved and the pasting efficiency is improved.

Owner:李正标

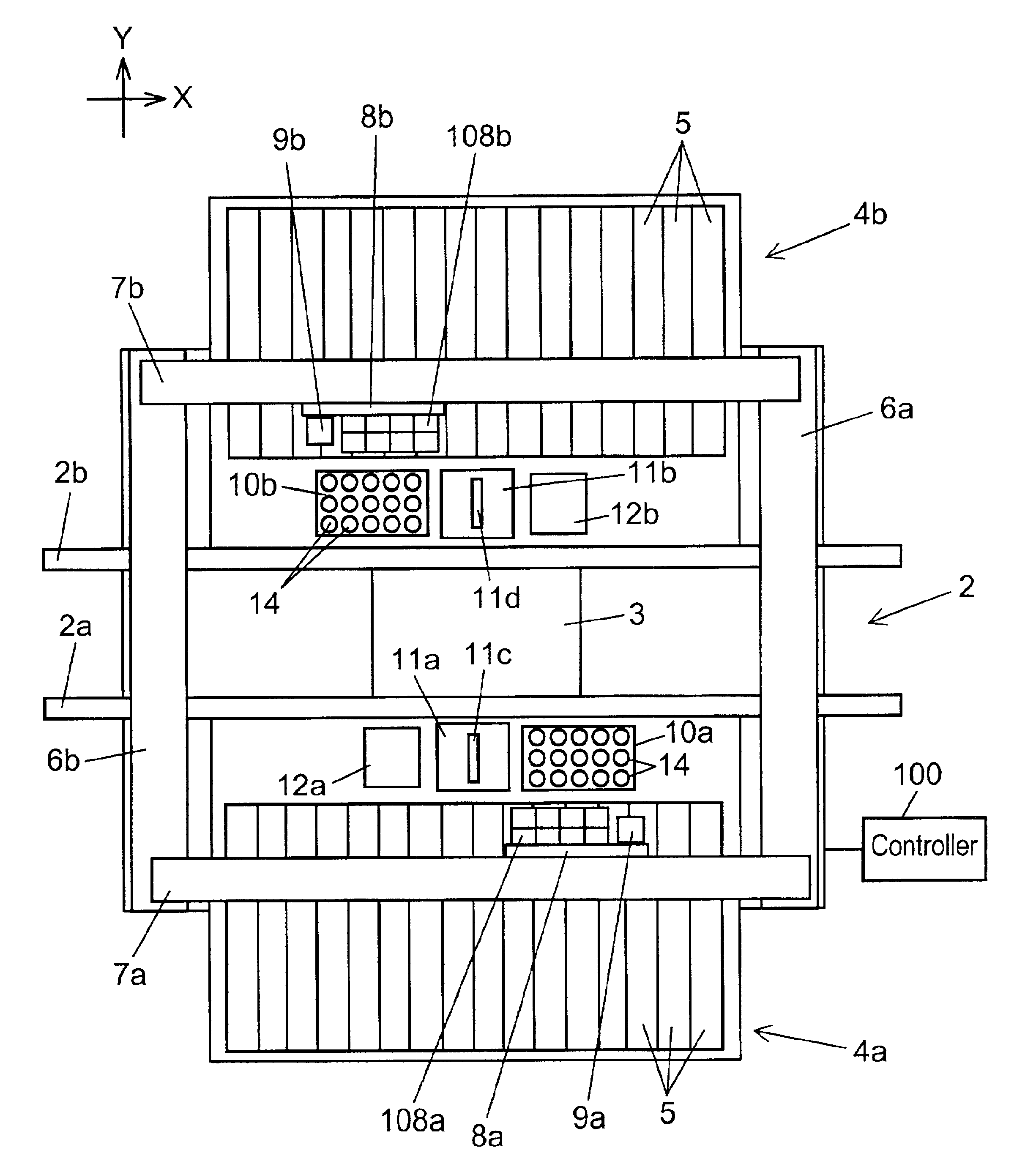

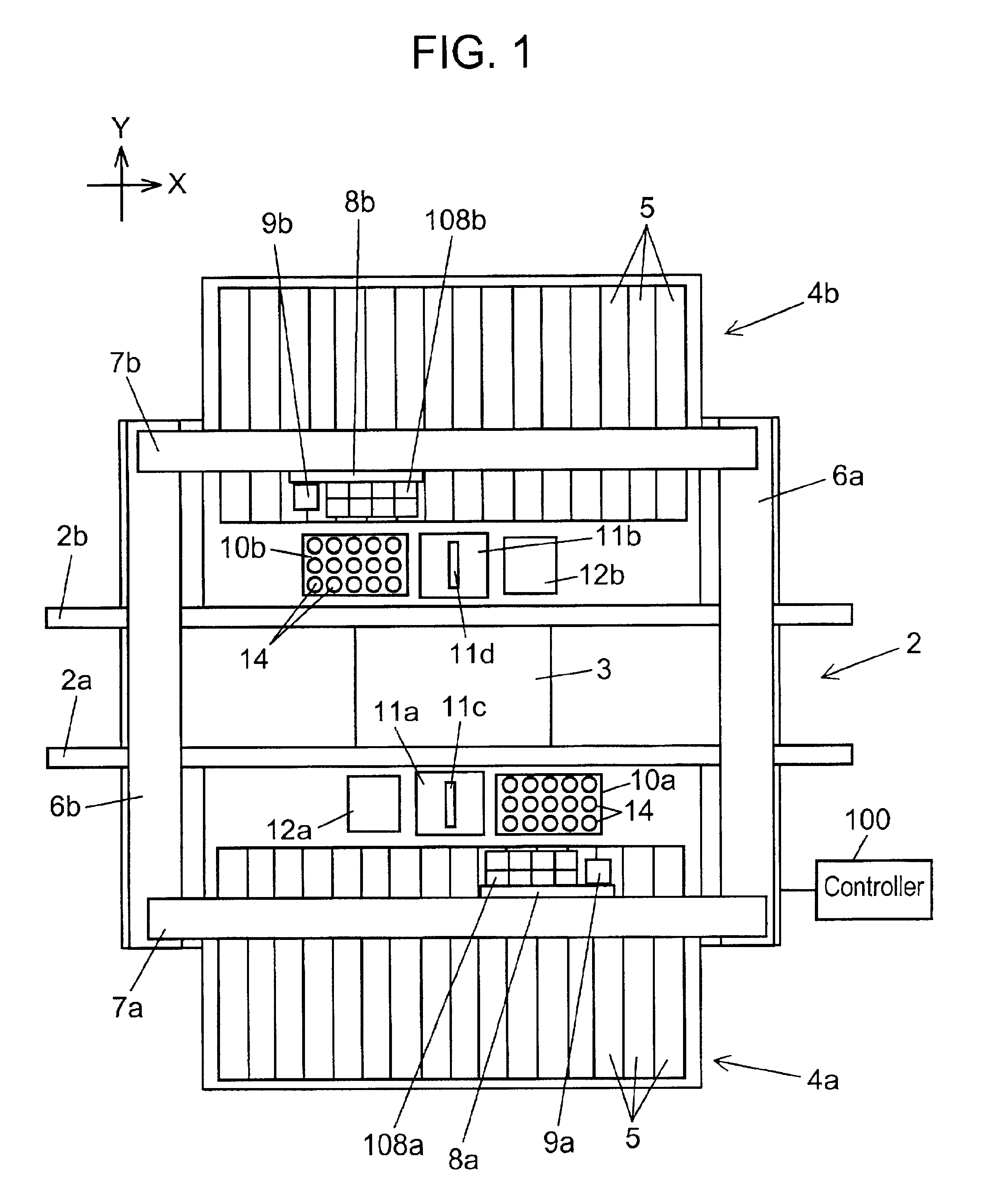

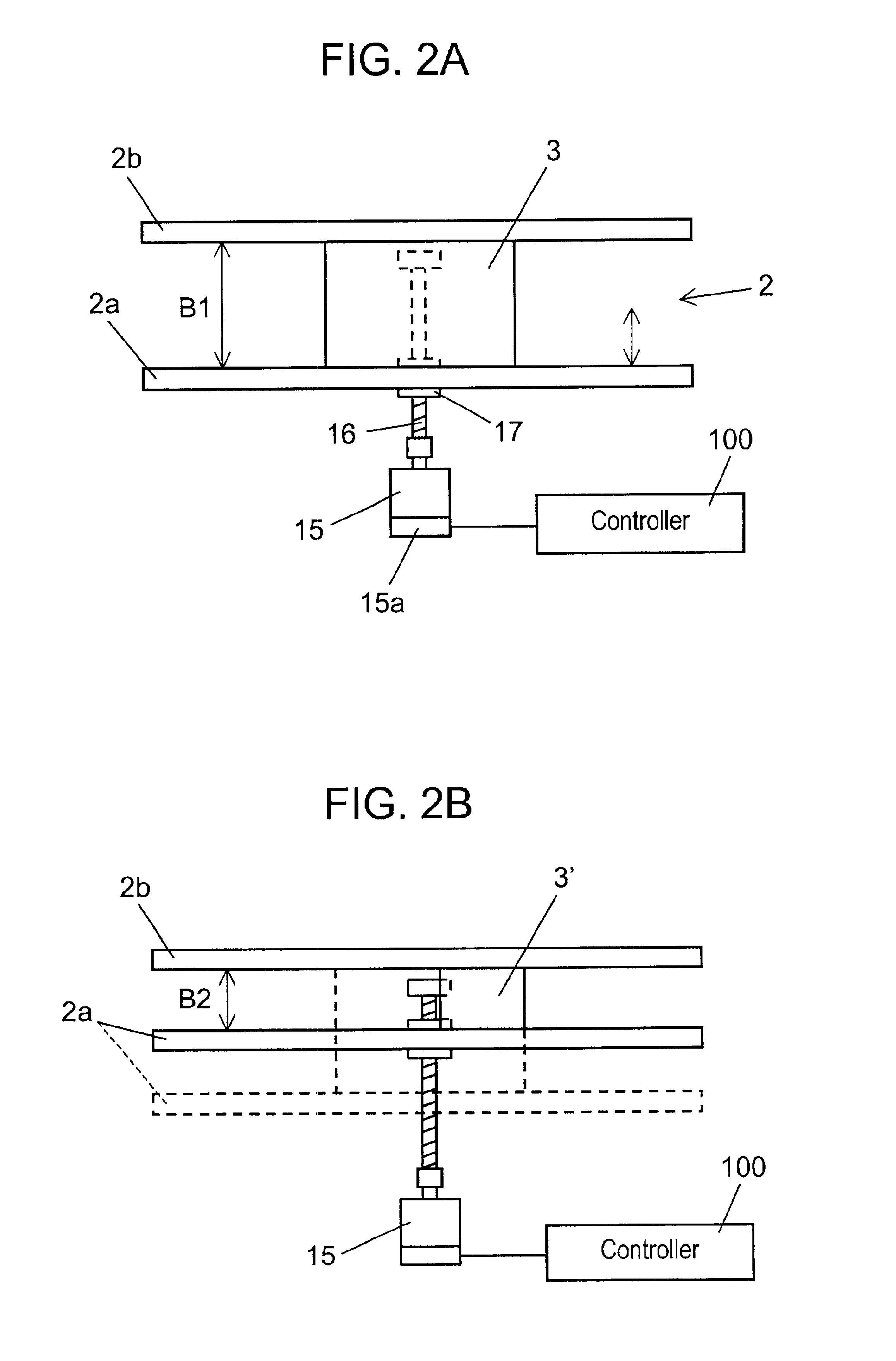

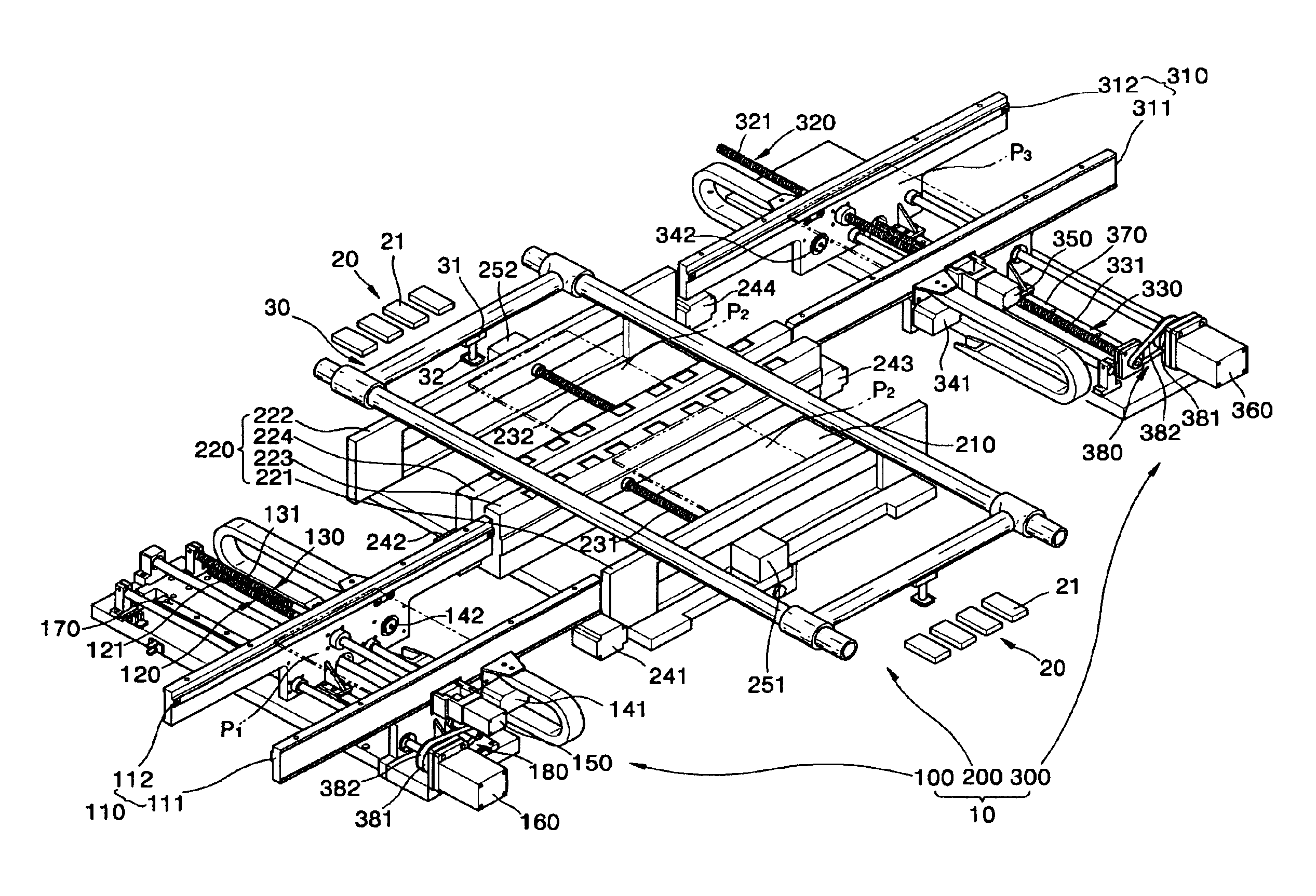

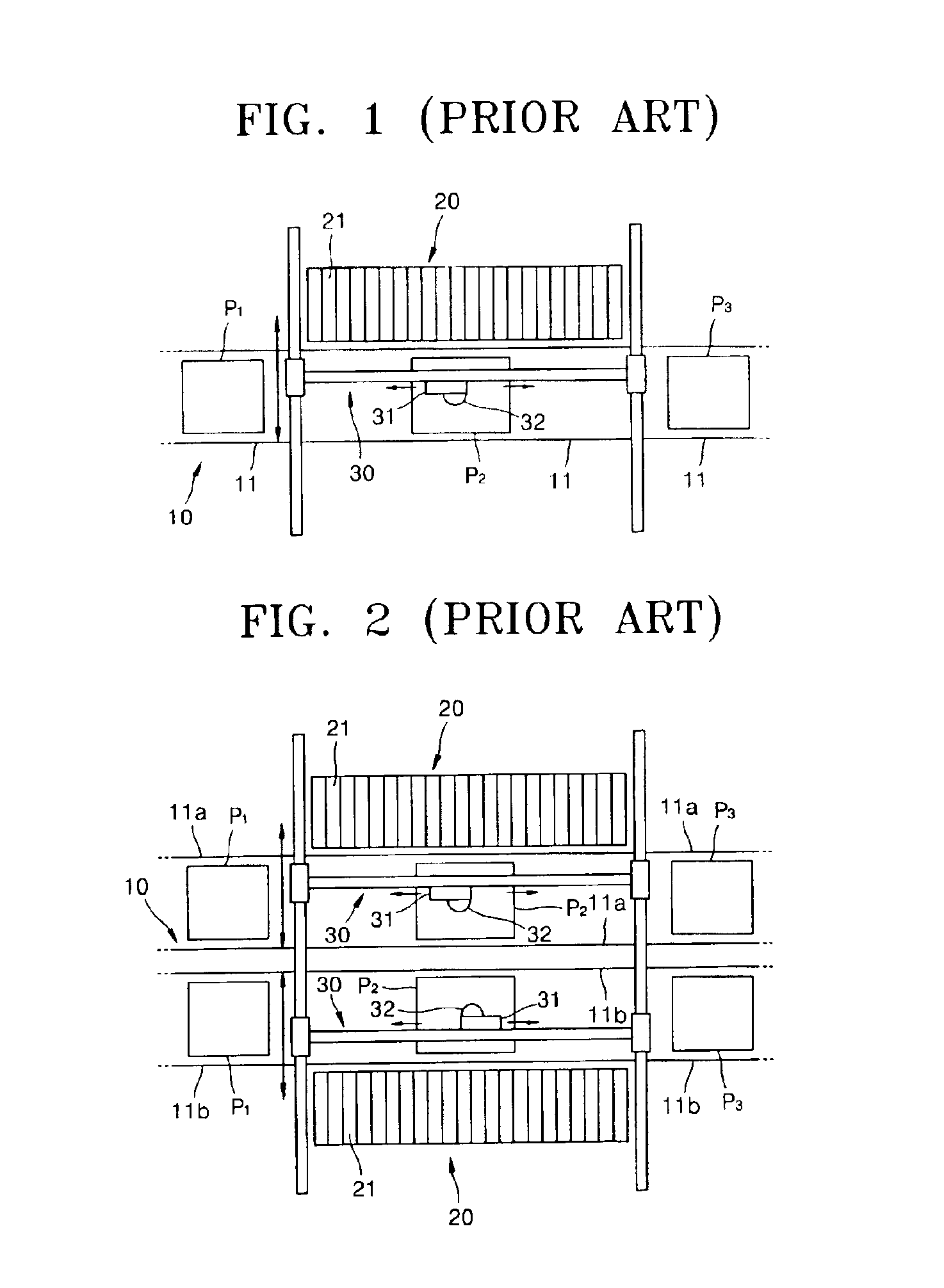

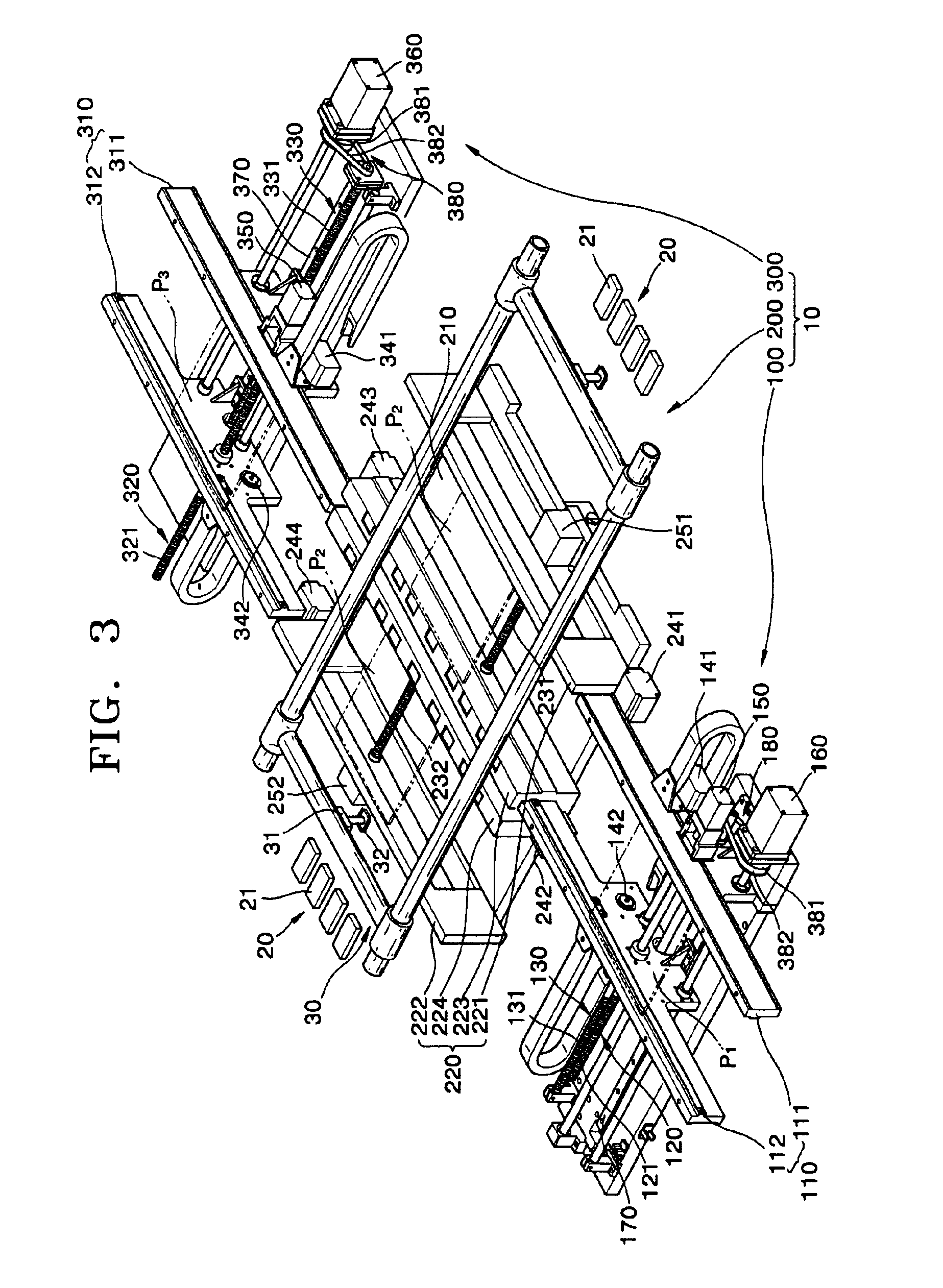

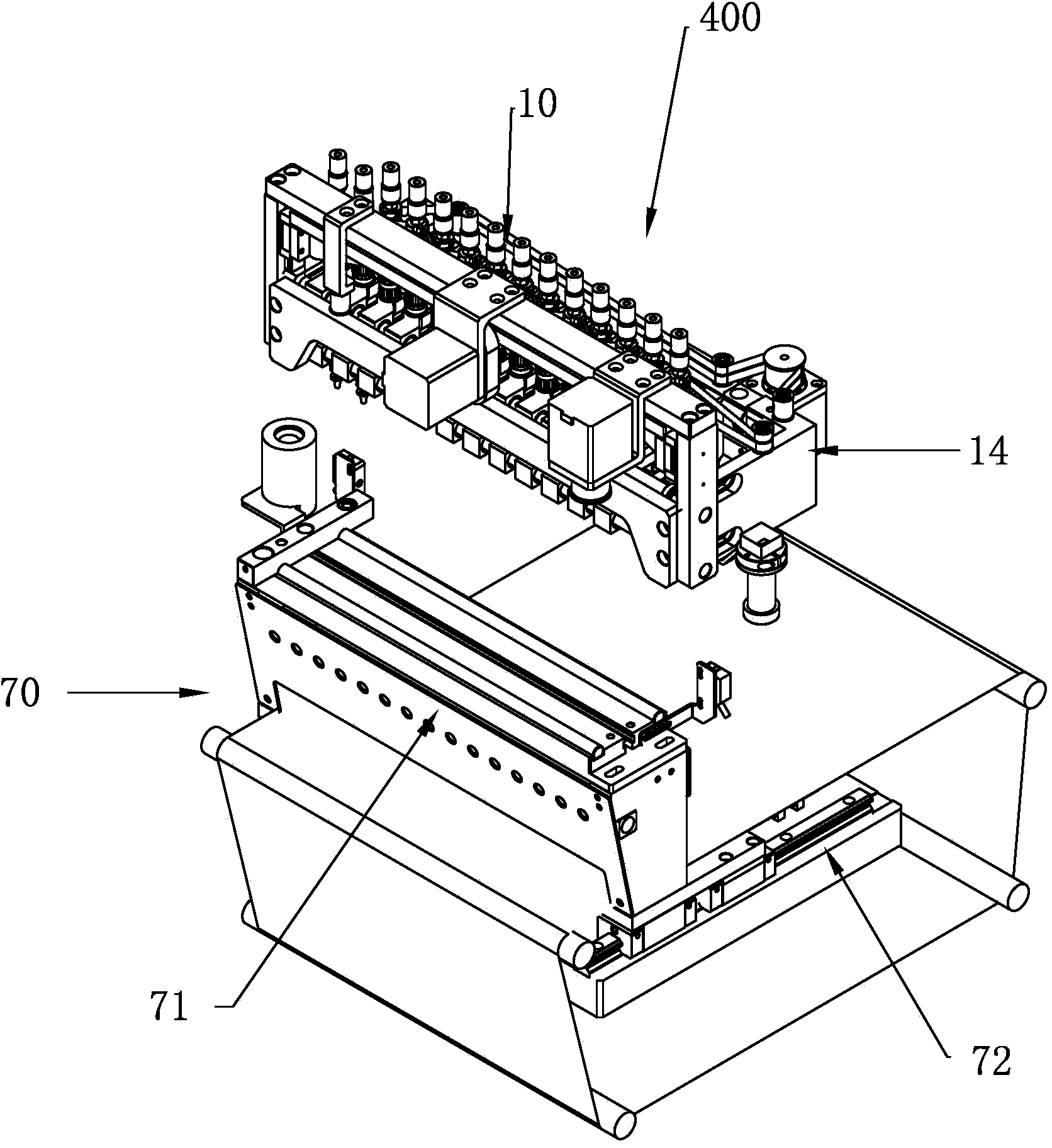

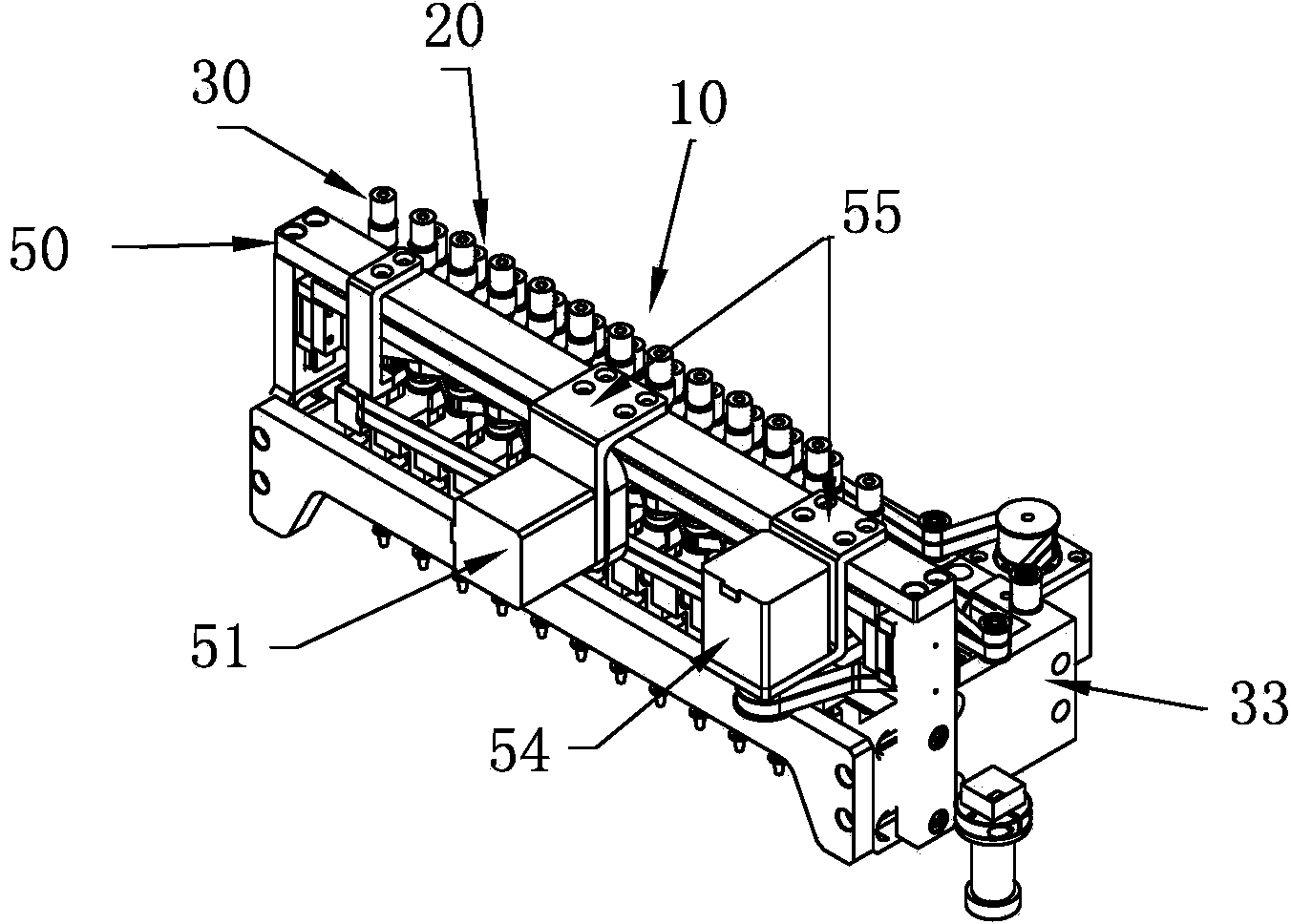

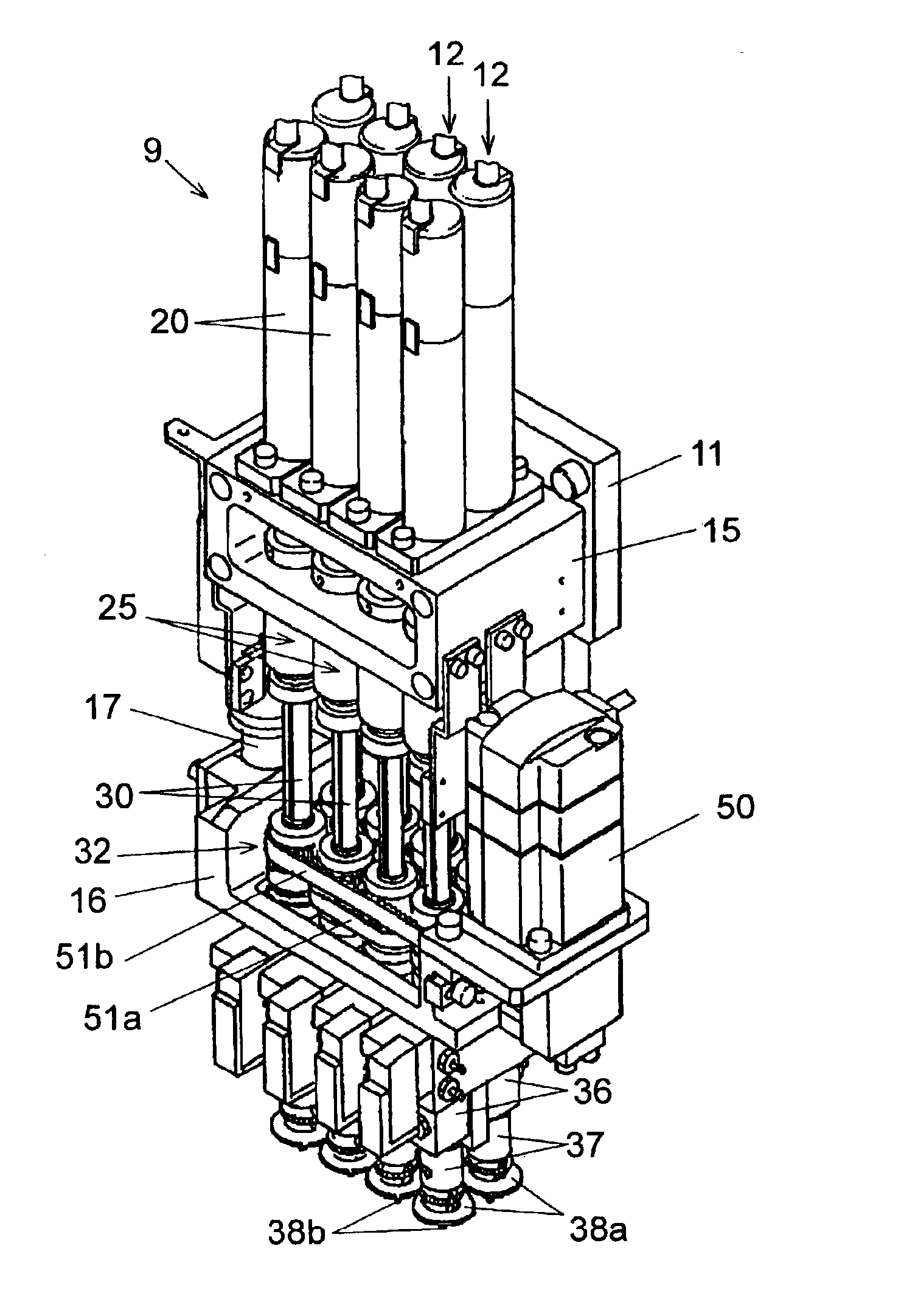

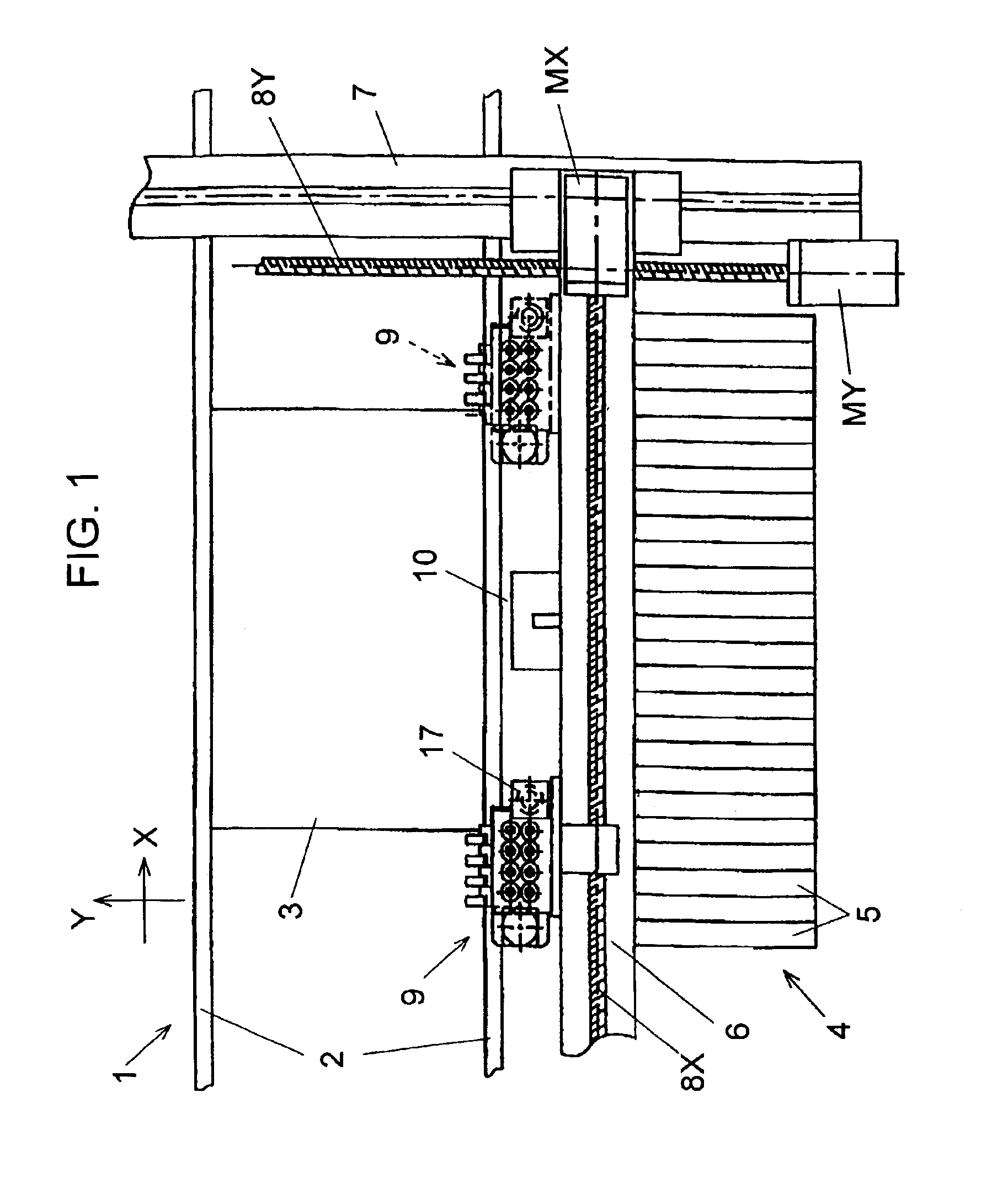

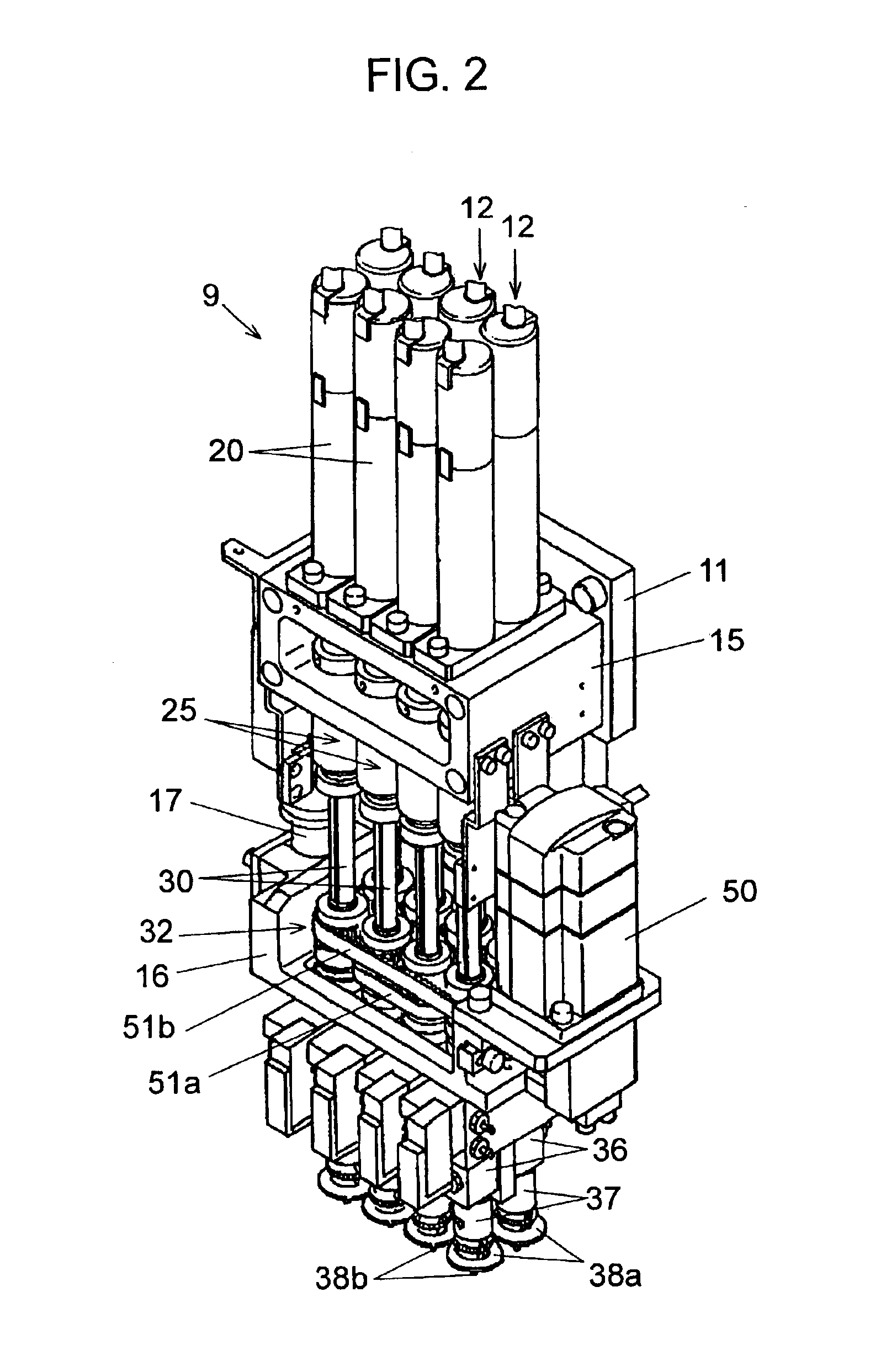

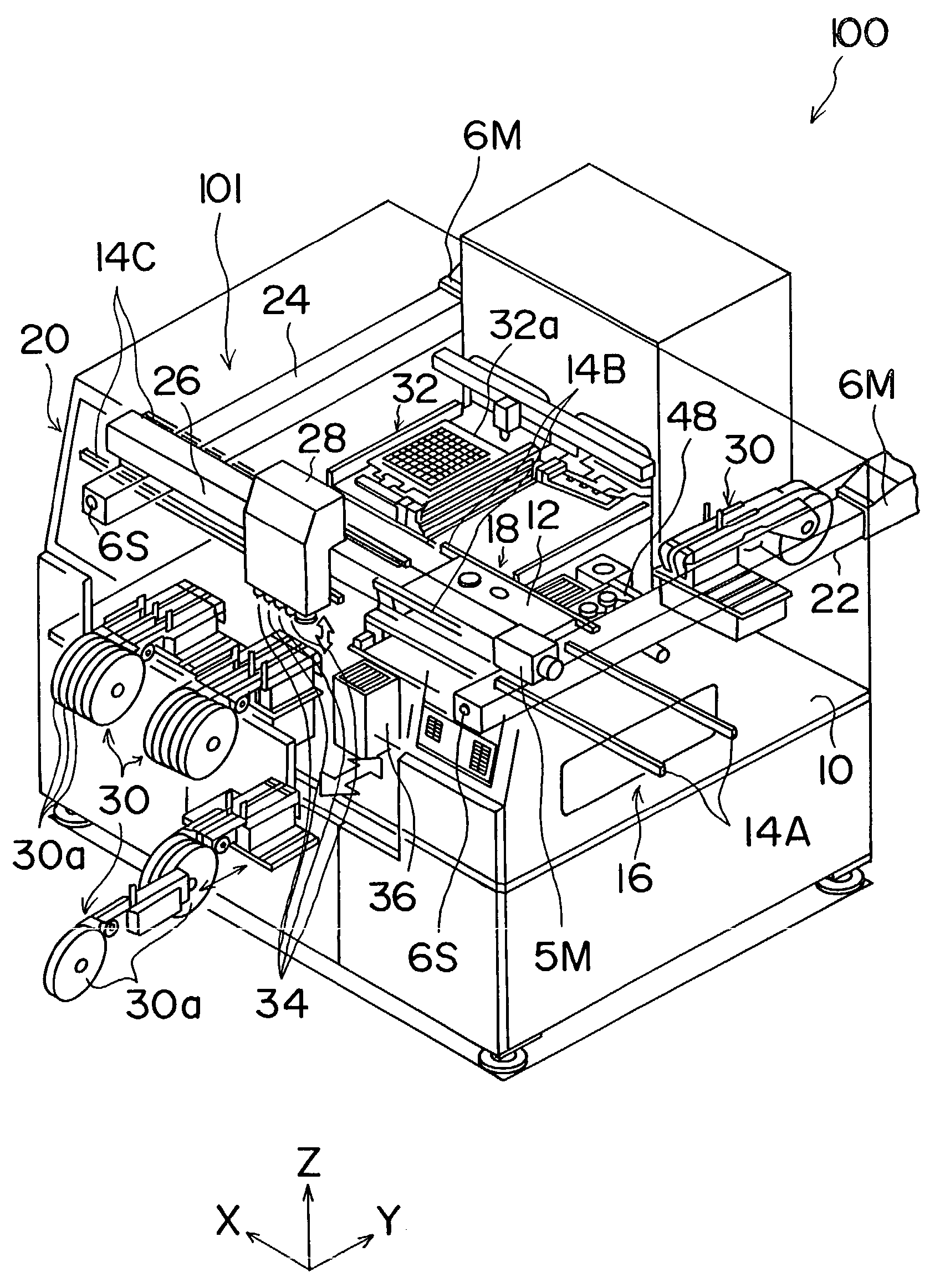

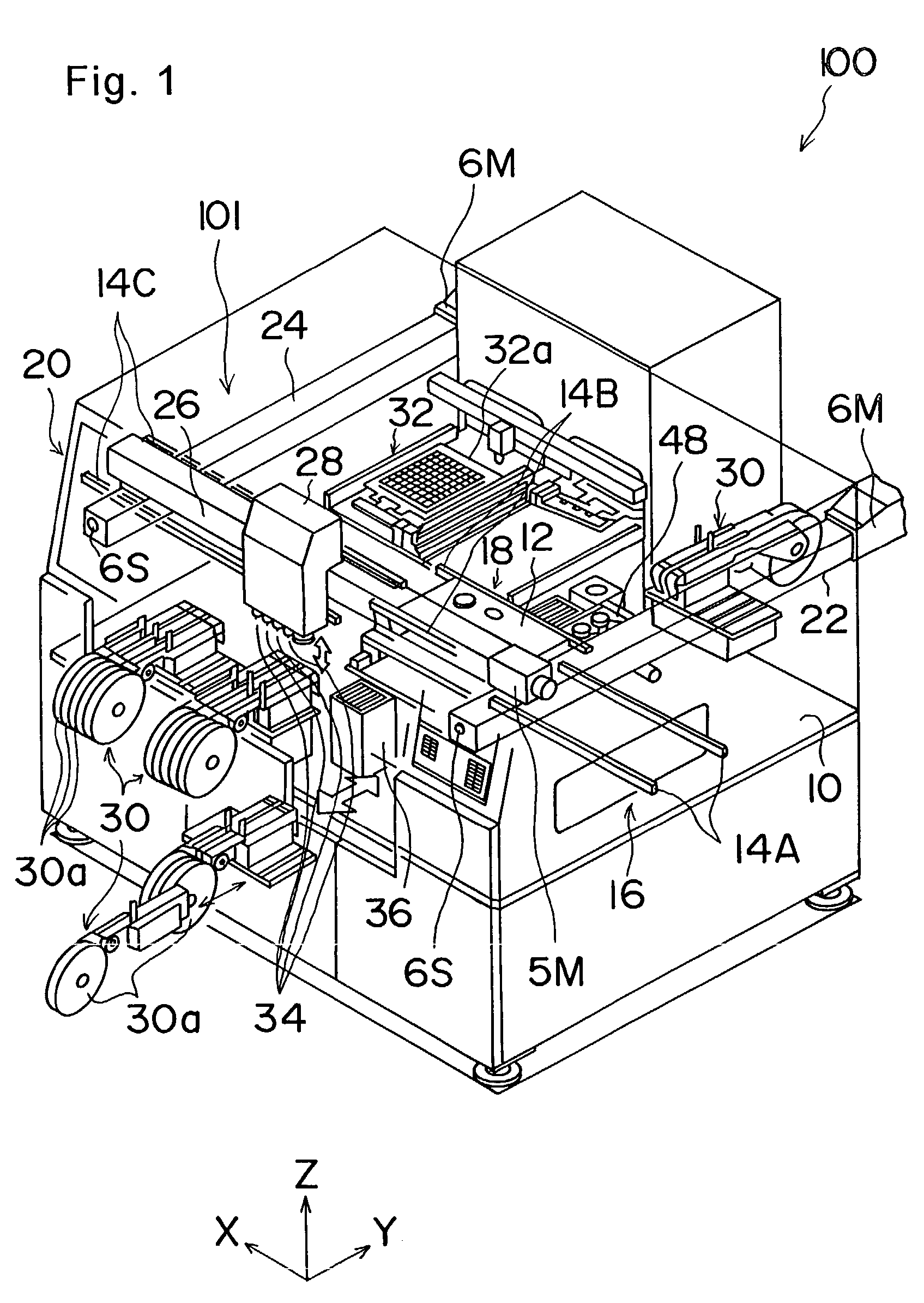

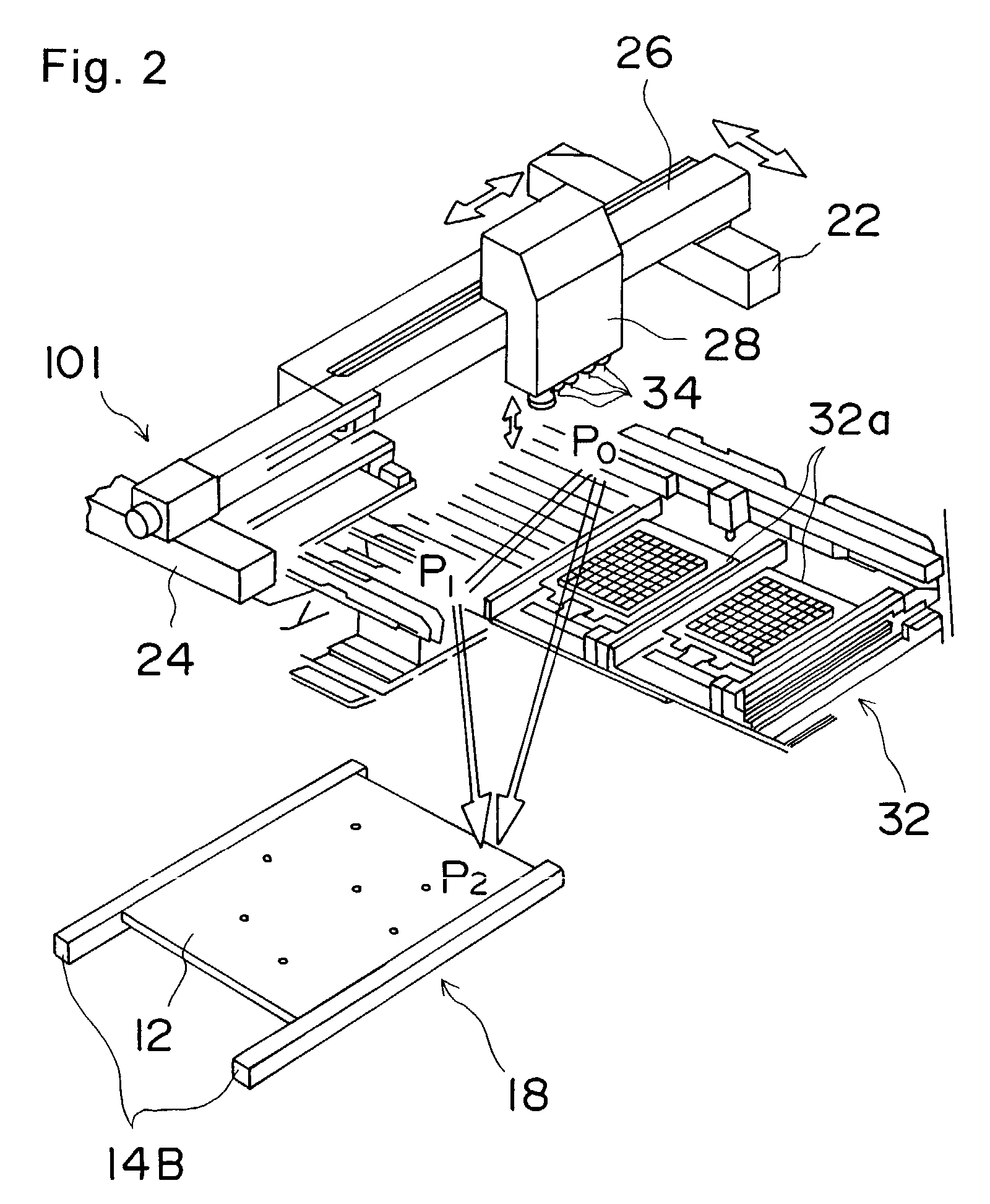

Mounting apparatus of electronic parts and mounting methods of the same

InactiveUS6918176B2Improve placement efficiencyPrinted circuit assemblingMetal working apparatusEngineeringMechanical engineering

Owner:PANASONIC CORP

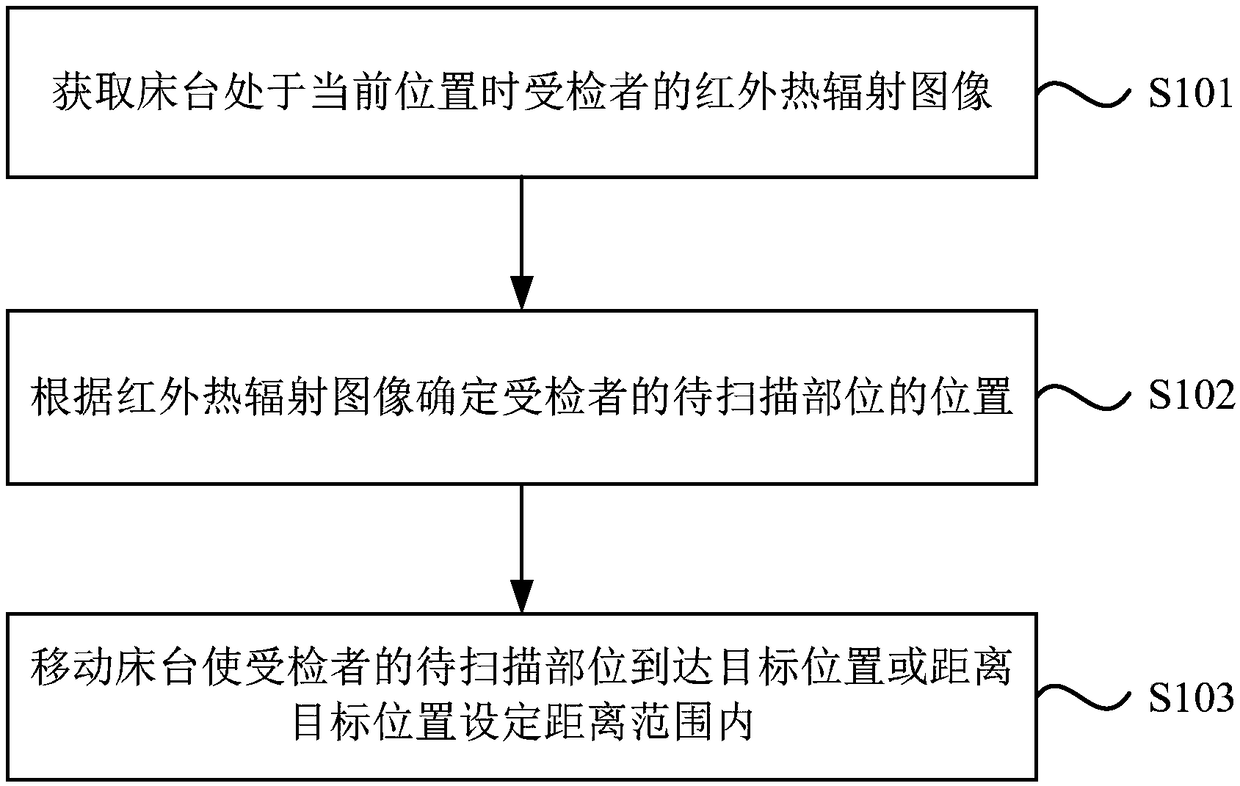

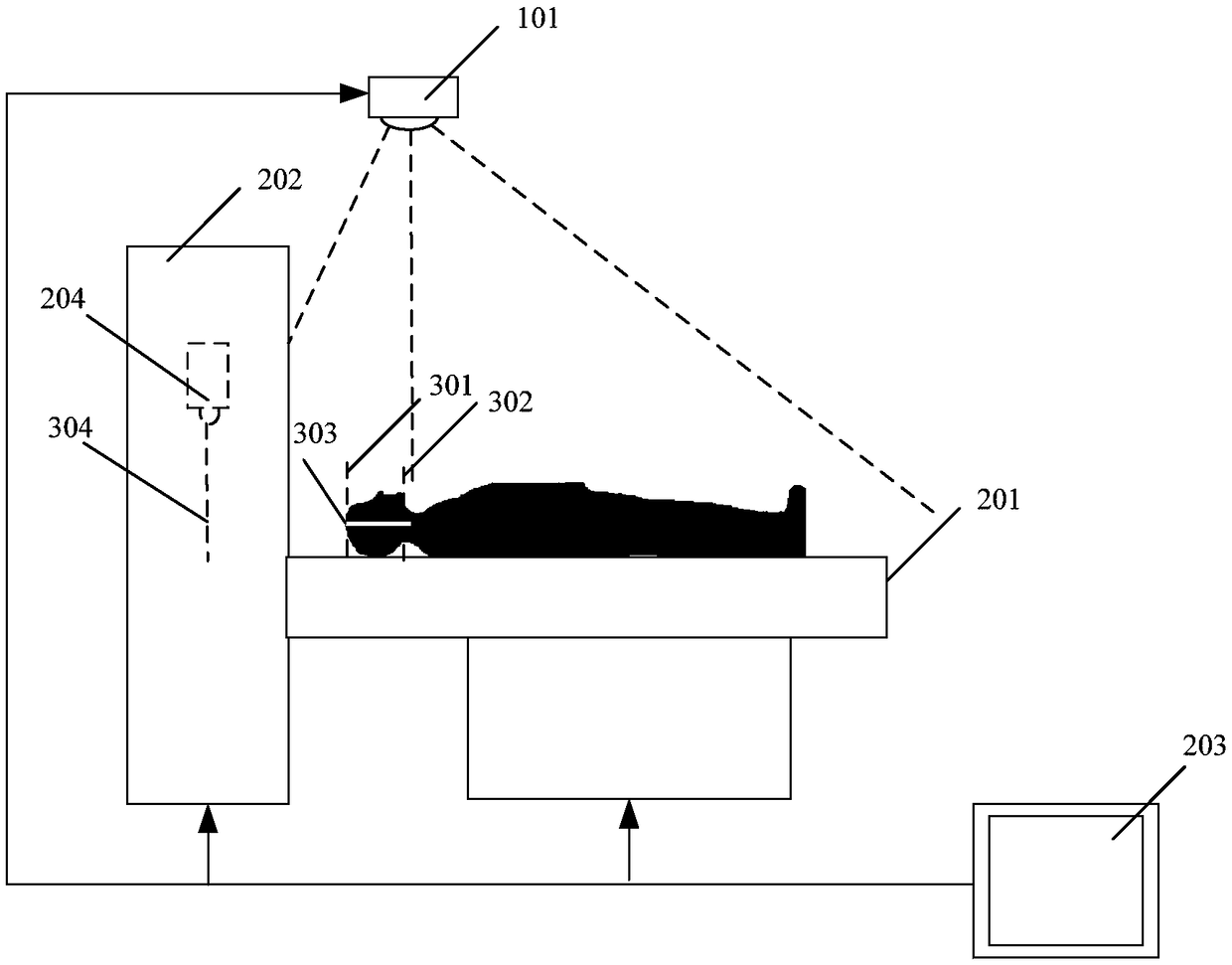

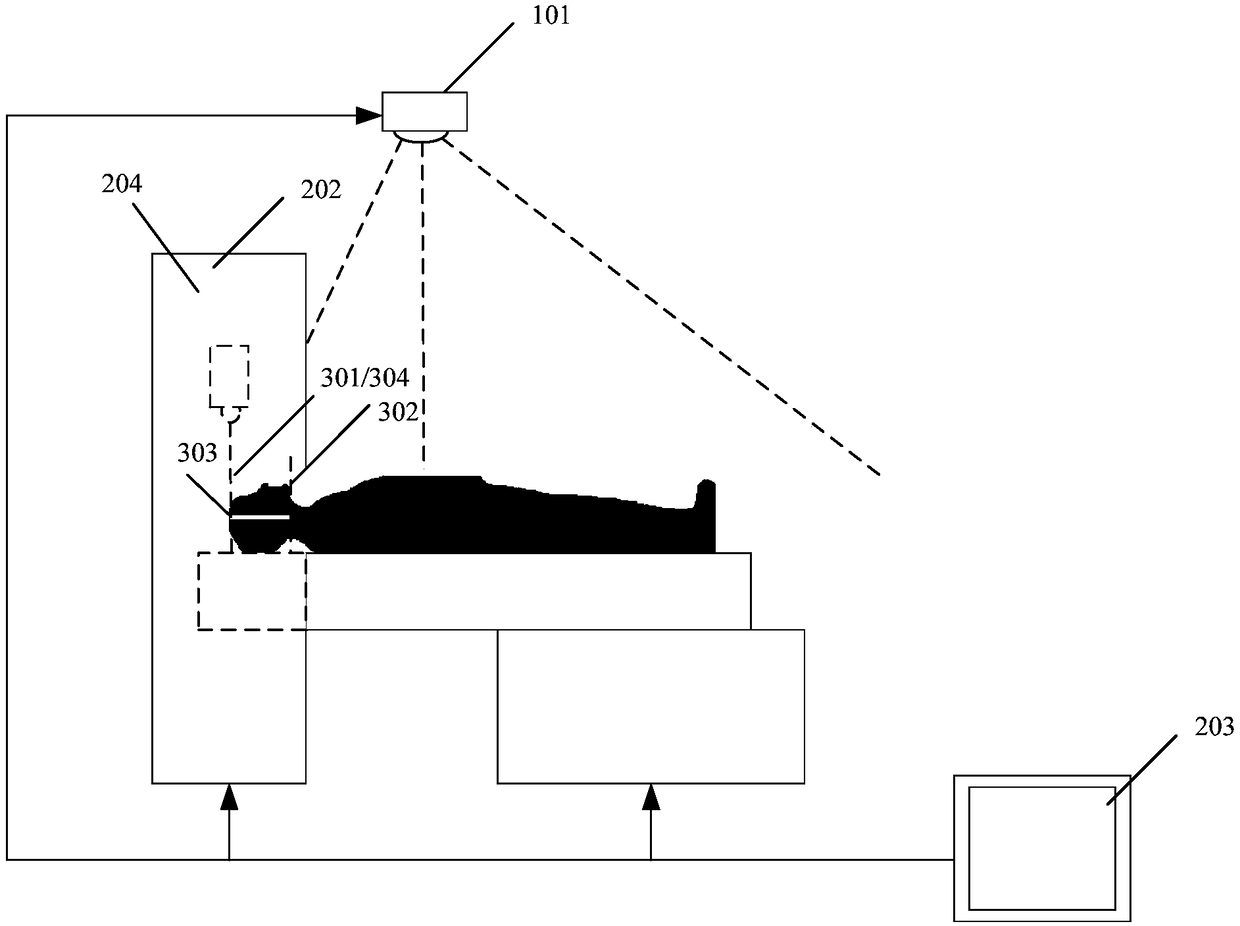

Automatic placement method used for medical image system and medical image system

PendingCN109276248AImprove accuracyImprove placement efficiencyPatient positioning for diagnosticsDiagnostic recording/measuringState of artThermal radiation

The invention discloses an automatic placement method used for a medical image system and the medical image system. The medical image system includes a scanning device, a bed platform axially moving along scanning apertures of the scanning device and a photographing device arranged at the upper portion and / or lateral portion of the bed platform. The photographing device includes an infrared detector. The method includes the steps of obtaining an infrared thermal radiation image of a subject when the bed platform stays at the current position; according to the infrared thermal radiation image,determining a to-be-scanned part of the subject; moving the bed platform to make the to-be-scanned part of the subject reach a target position or positioned within a set distance range from the targetposition. The method solves the problem that existing placement methods in the prior art are low in efficiency, and has the technical advantage that the placement efficiency is improved.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

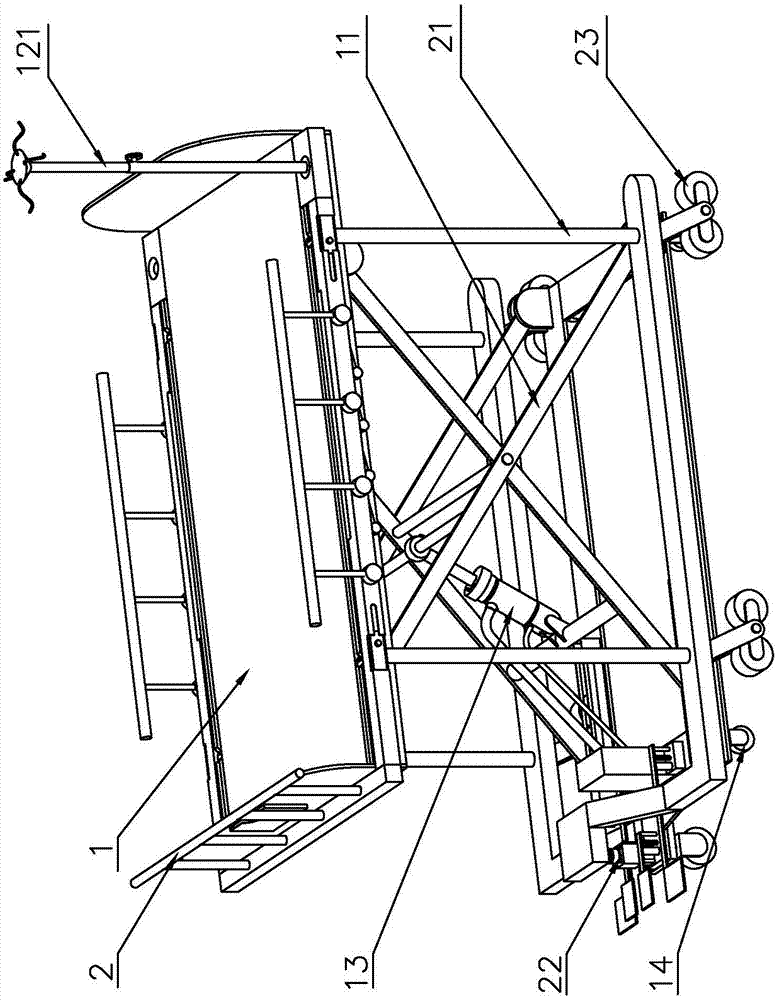

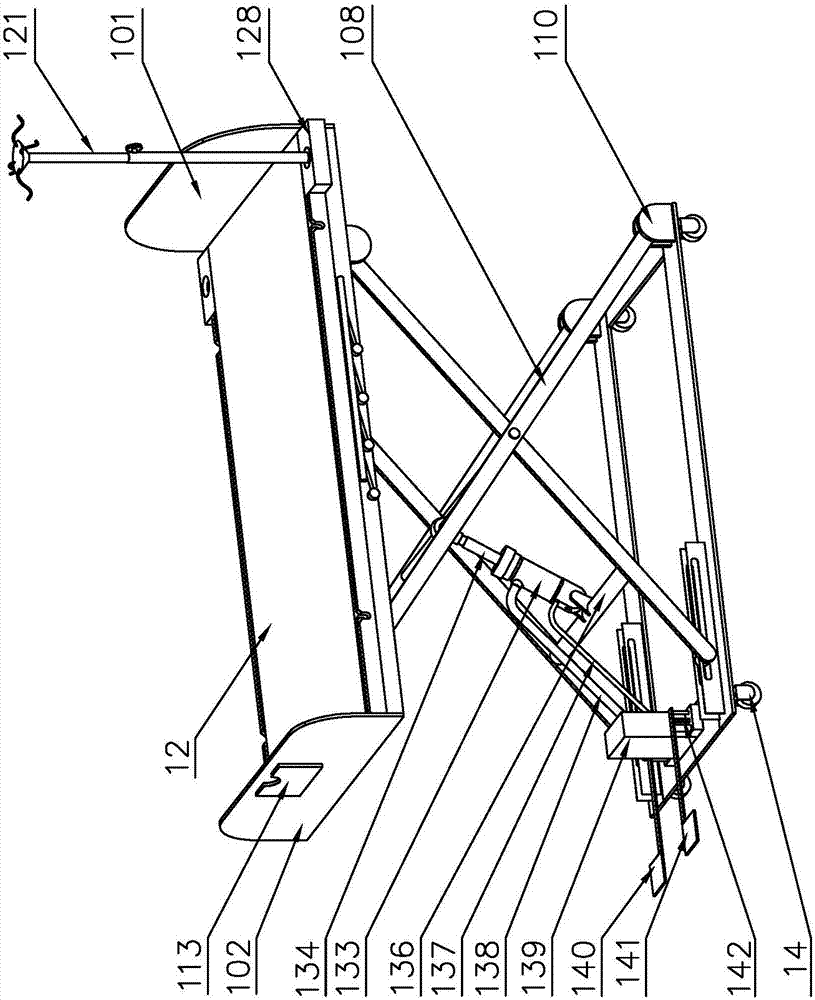

Medical transfer sickbed

ActiveCN107440847AAvoid secondary damageReduce labor intensityInfusion devicesStretcherHydraulic cylinderEngineering

The invention discloses a medical transfer sickbed. The medical transfer sickbed comprises a bed body and a transfer frame, wherein the bed body comprises a bed frame, a bed board and a lifting device I, and the bed frame comprises a bed head board, a bed tail board, a supporting plate, supporting legs I, a folding guardrail I and a bottom plate; the lifting device I is arranged on one side of the upper part of the bottom plate, the lifting device I comprises a hydraulic cylinder I, a pressure relief pedal I and a pressing pedal I; the transfer frame comprises a bracket, a lifting device II and rolling wheels II, the bracket comprises a U-shaped frame, a handle, supporting legs II, a bearing frame and a folding guardrail II, and a lifting device II comprises a hydraulic cylinder II, a piston rod II, a pressure relief pedal II, a pressing pedal II and an oil tank II. For the medical transfer sickbed, the lifting devices are arranged on the bed body and the transfer frame, when the bed board is fixed to the bed body or the transfer frame, a patient can be rapidly transferred through the lifting devices, the whole process can be completed only by one nursing person through operating the lifting devices, thus the investment of nursing cost is reduced, the labor intensity of the nursing person is alleviated, and meanwhile, secondary injuries caused when the patient is transferred are avoided.

Owner:唐山市山楂树家具制造有限公司

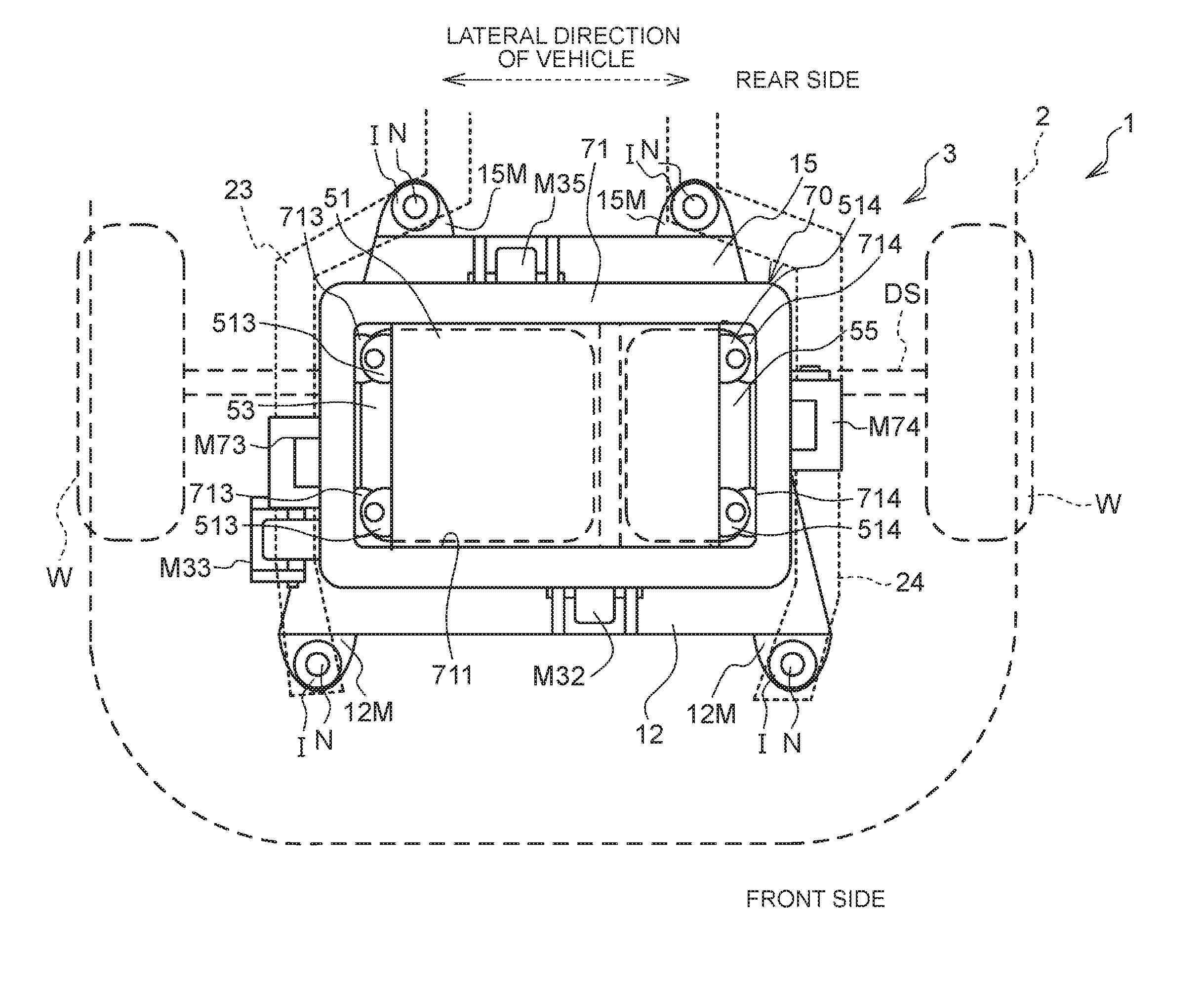

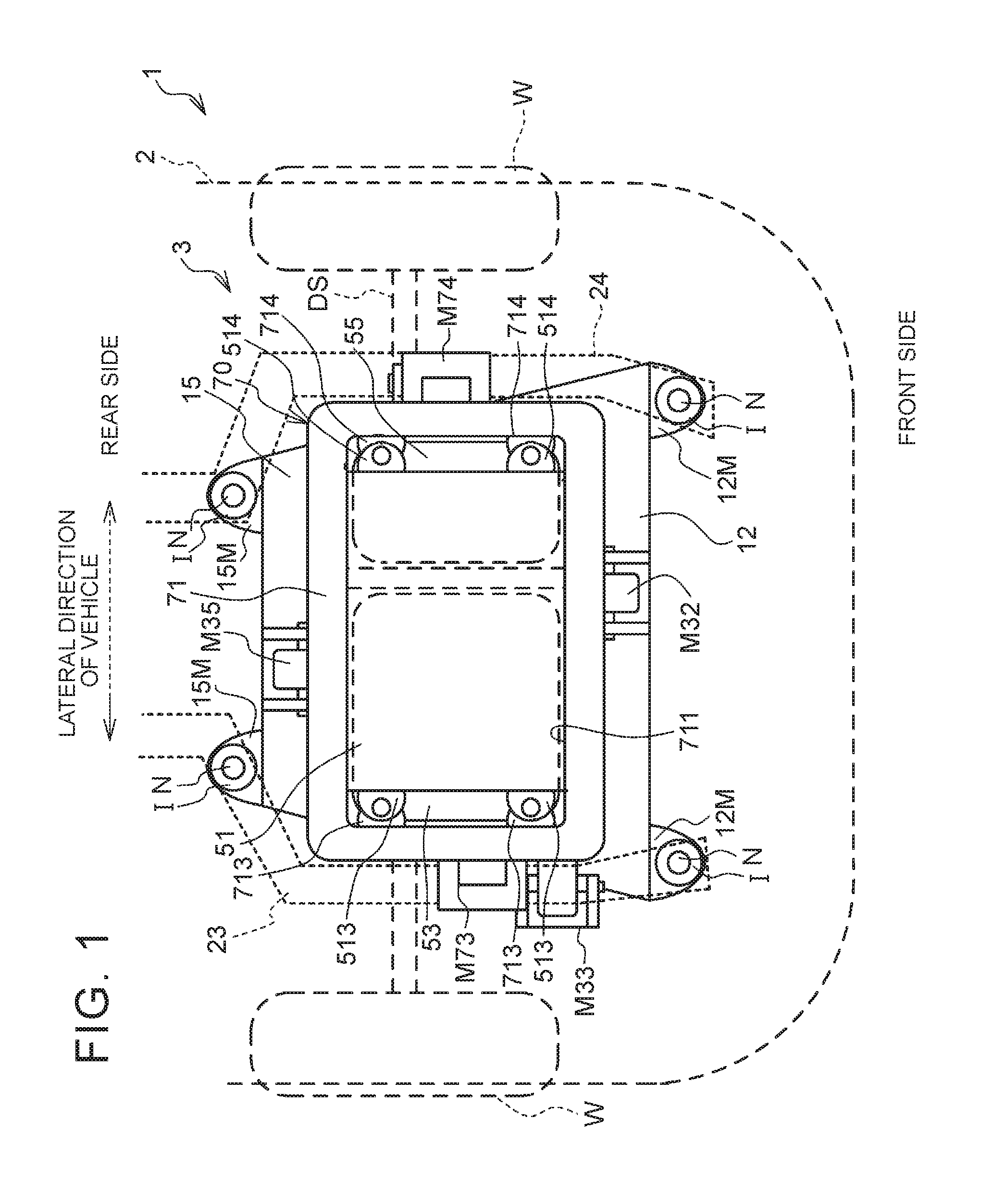

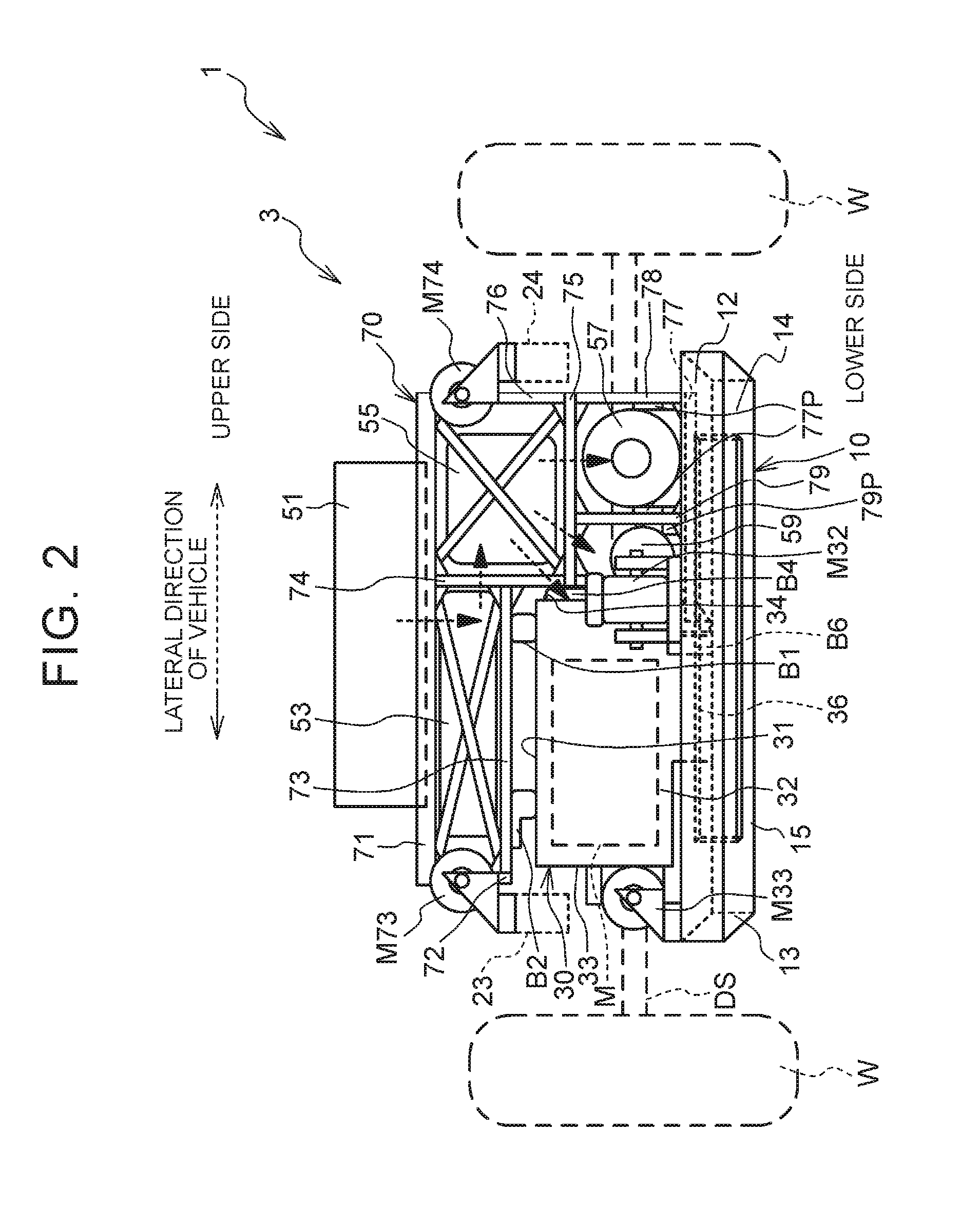

Electric vehicle, holding mechanism, and method of manufacturing electric vehicle

InactiveUS20160207386A1Improve battery efficiencyImprove motor efficiencyAuxillary drivesElectric devicesEngineeringElectric vehicle

An electric vehicle includes a suspension member attached to a vehicle body, a motor fixed to the suspension member, a power source, an electronic device to which electric power is supplied from the battery, and a holding mechanism including a holder and a fixing portion. The holder collectively holds the battery and the electronic device in an integrated manner. The fixing portion fixes the holder to the motor.

Owner:TOYOTA JIDOSHA KK

Surface mounter for mounting components

InactiveUS6944943B2Small footprintImprove placement efficiencyPrinted circuit assemblingStorage devicesSurface mountingElectrical and Electronics engineering

Owner:HANWHA TECHWIN CO LTD

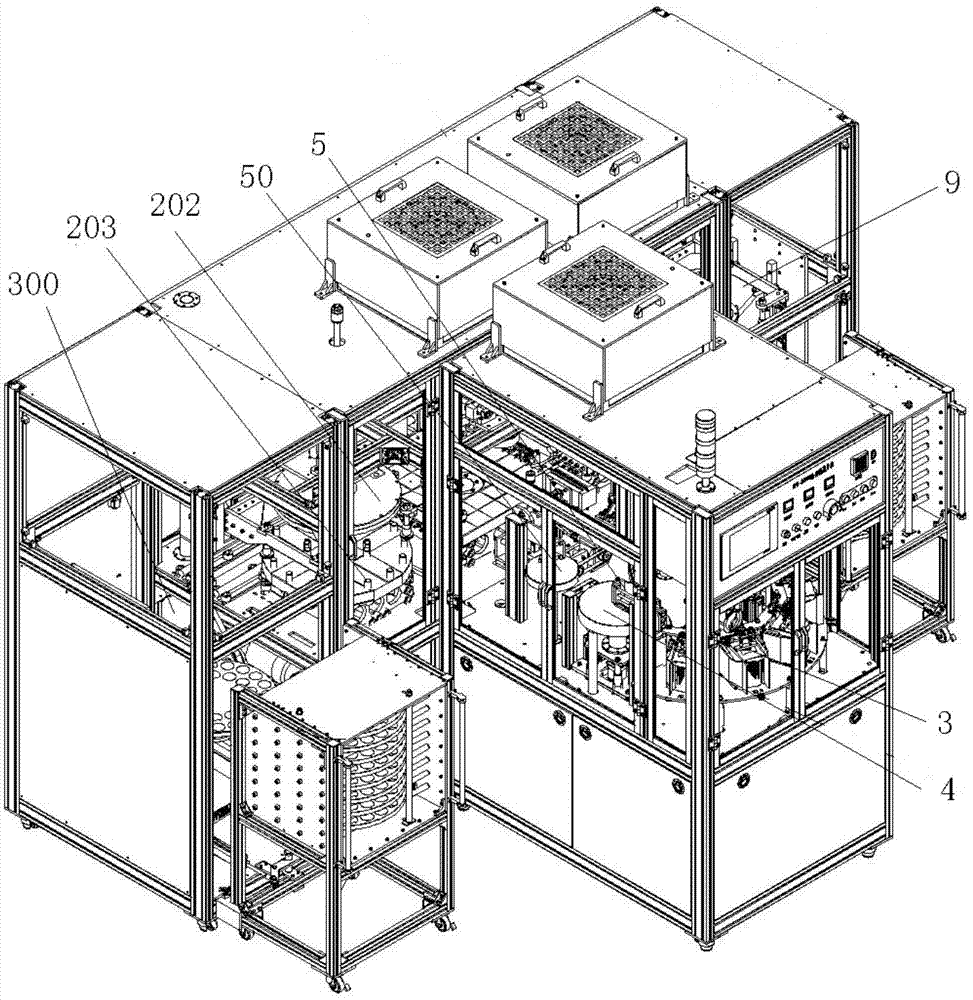

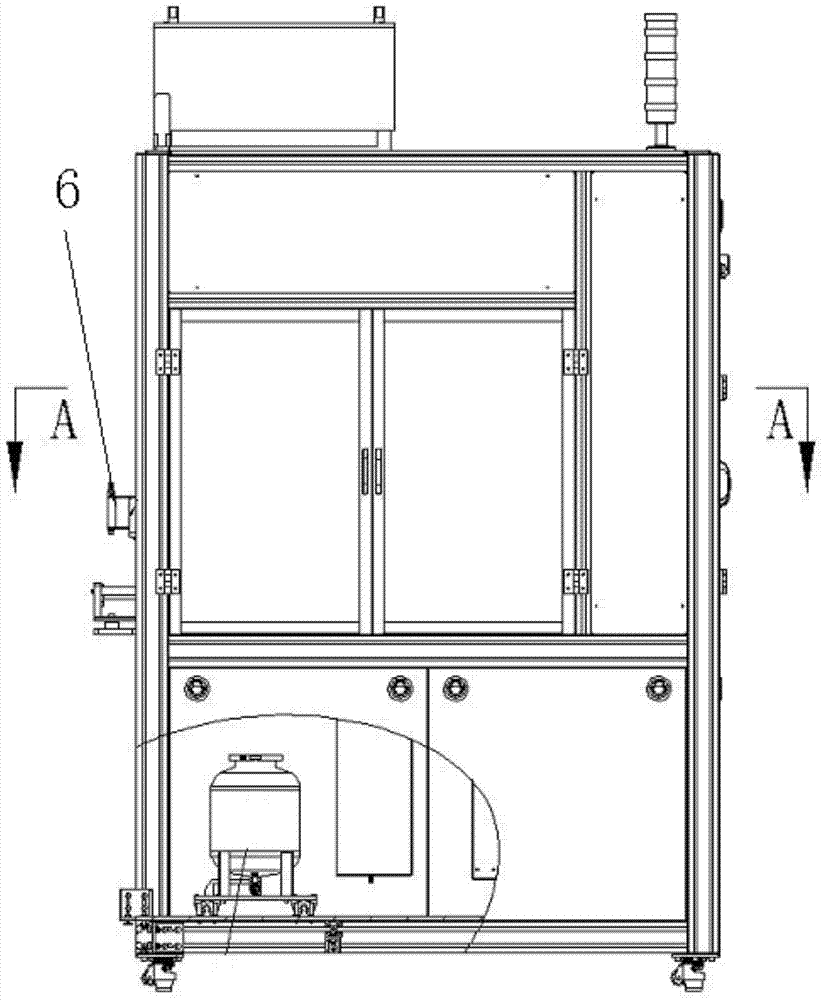

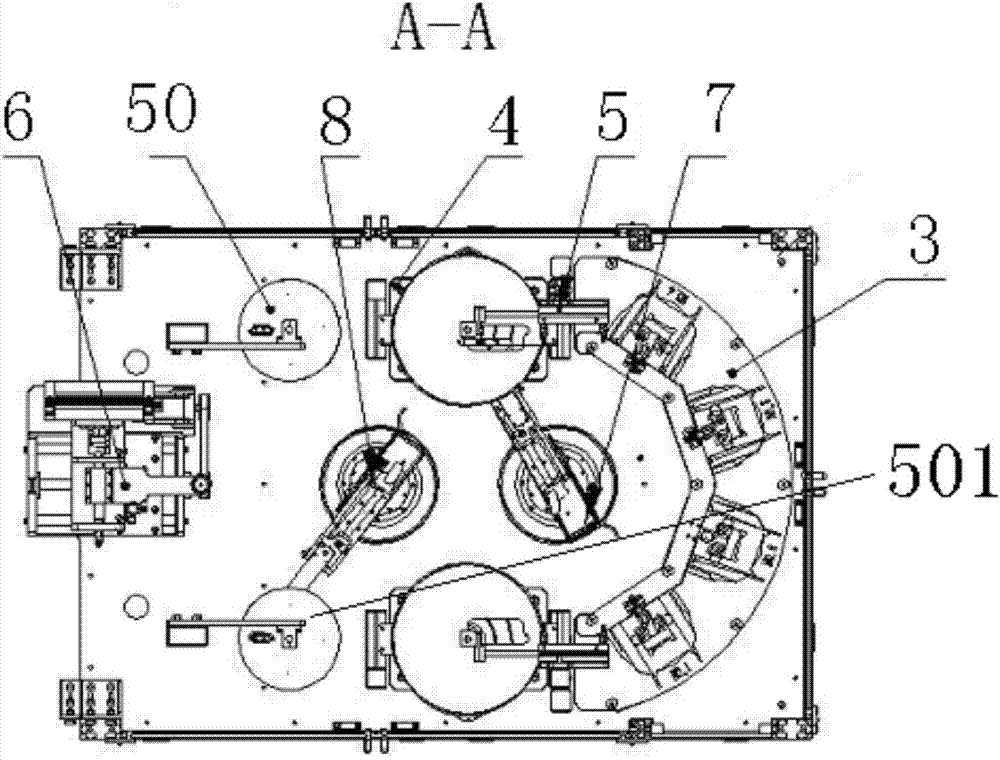

Full-automatic sheet mounter

ActiveCN104759974ARealize automatic dripping wax patchImprove yieldGrinding machine componentsPolishing machinesWaxSapphire

The invention discloses a full-automatic sheet mounter which comprises a machine frame. A sapphire sheet processing part and a ceramic disc processing part are arranged on the machine frame. The ceramic disc processing part is provided with a ceramic disc baking working position and a sheet mounting device. The sheet mounting device is arranged above the ceramic disc baking working position. The ceramic disc baking working position is provided with a ceramic disc baking table and a dividing plate device. The ceramic disc baking table is arranged on the machine frame in a rotatable mode. The dividing plate device and the ceramic disc baking table are in transmission connection, so that the dividing plate device drives the ceramic disc baking table to rotate by a certain angle. The sapphire sheet processing part comprises a bearing basket fixing mechanism and a wax coating device. The bearing basket fixing mechanism is provided with a plurality of bearing basket fixing working positions for locating bearing baskets. The wax coating device is provided with a wax throwing mechanism and a wax dripping mechanism. The wax throwing mechanism is provided with a sapphire sheet placing rotating table. Automatic wax dripping sheet mounting of sapphire sheets can be achieved, and the finished product rate and the sheet mounting efficiency are improved.

Owner:常州科沛达清洗技术股份有限公司

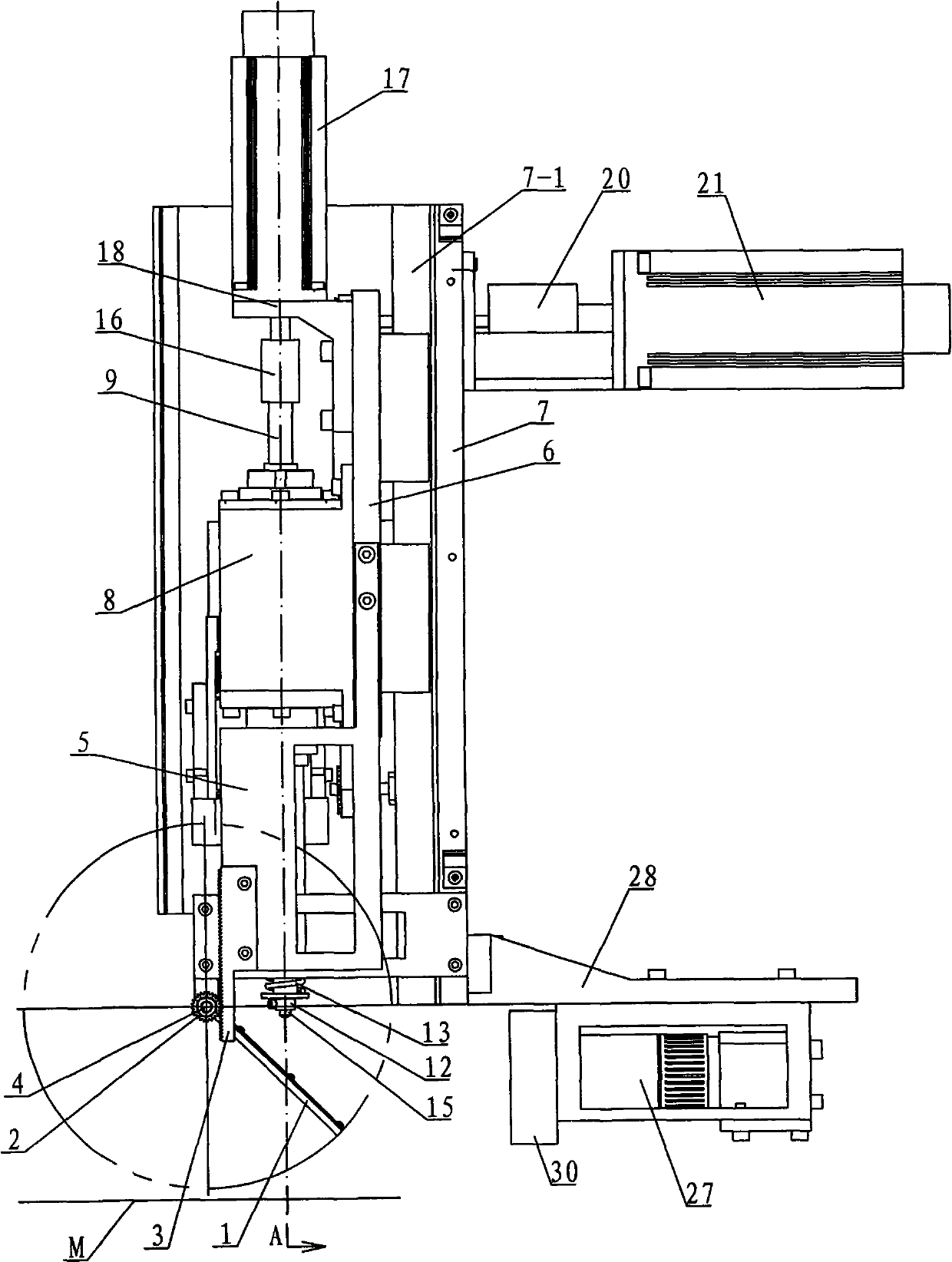

Chip image collecting and locating device based on rotary reflector

InactiveCN101794009AAchieve correctionUnlimited motion trajectoryUsing optical meansMountingsGear drivePosition error

The invention discloses a chip image collecting and locating device based on a rotary reflector, relating to an image collection device. The invention aims to solve the problems that image distortion and image deformation occur in the traditional chip motion image collection process, and the chip stops once in the process of moving to an appointed patching position based on a certain path to cause low work efficiency of mounting the chip. When the chip is mounted, a suction nozzle moves downwards firstly to an M position to suck the chip; a mobile motor reversely rotates, the suction nozzle carries the chip to move upwards to an N position, a mobile base drives a rack to move upwards when moving upwards, a gear drives a reflector component to rotate, the lateral end of the reflector component rotates from a point A to a point B, lights of a light source shines on the reflector, a camera obtains a static image of the chip through the reflector, the image is treated by a computer, and the position error of the chip relative to a center coordinate system of the suction nozzle is obtained; and the motor is started to rotate, the suction nozzle rotates, and correction of chip angle error is finished. The invention is used for mounting the chip.

Owner:HARBIN INST OF TECH

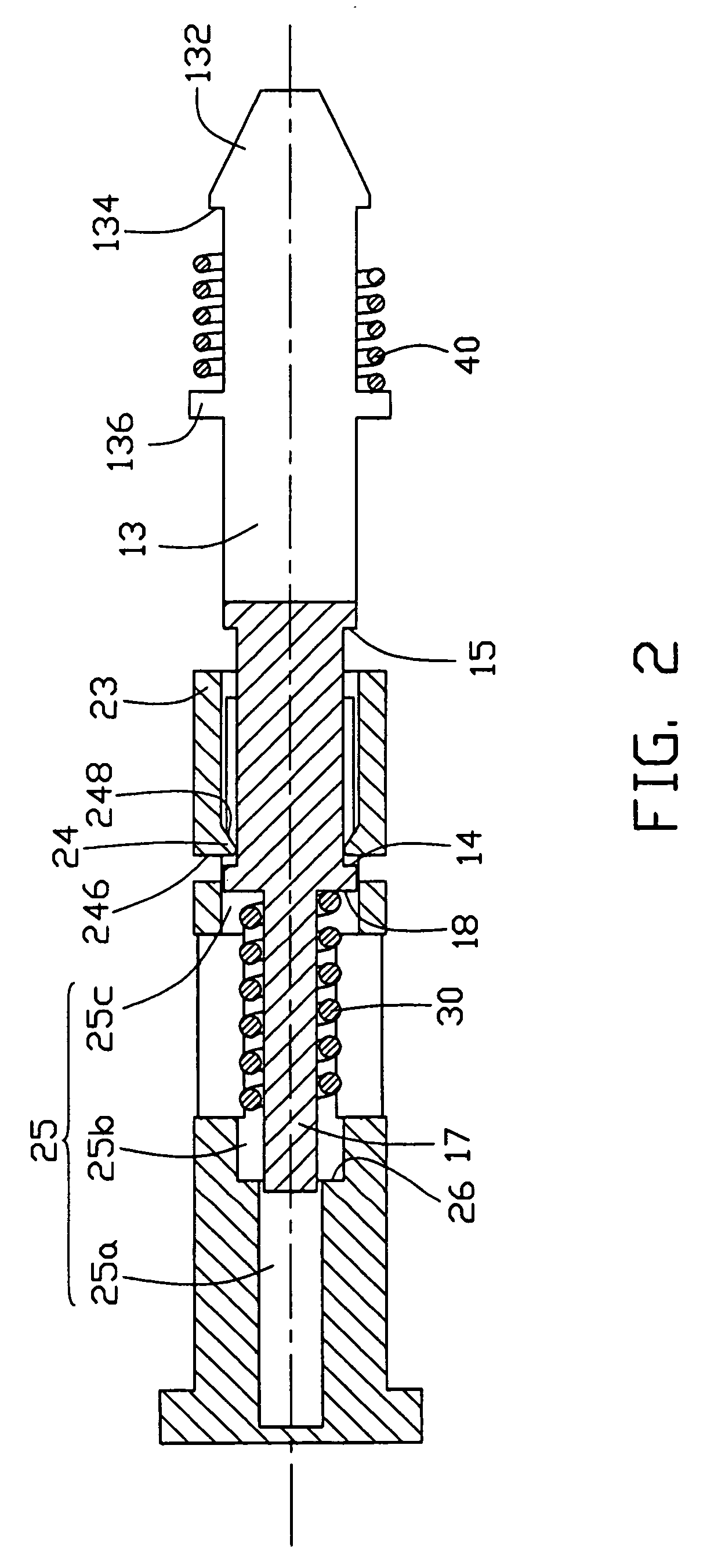

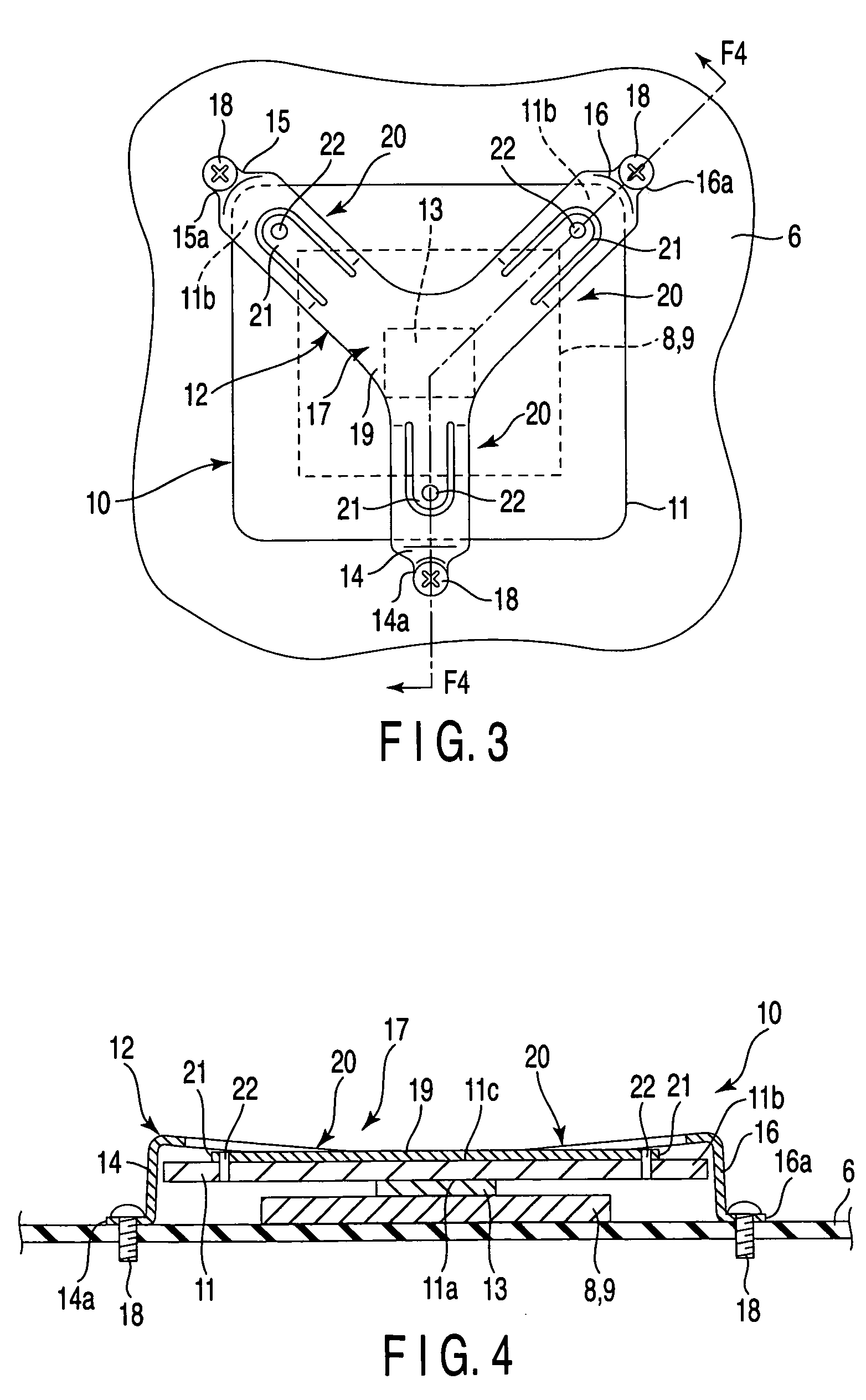

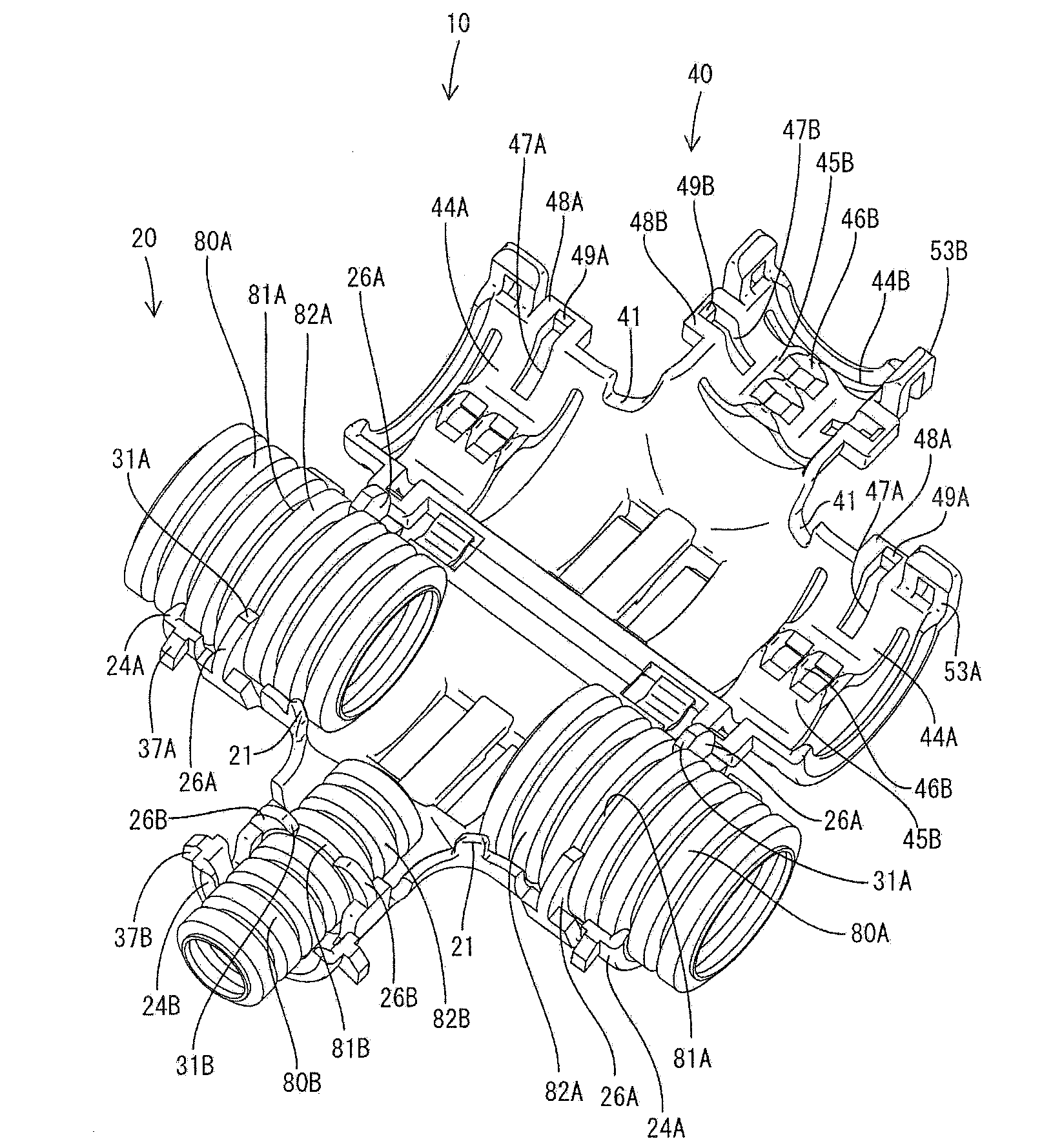

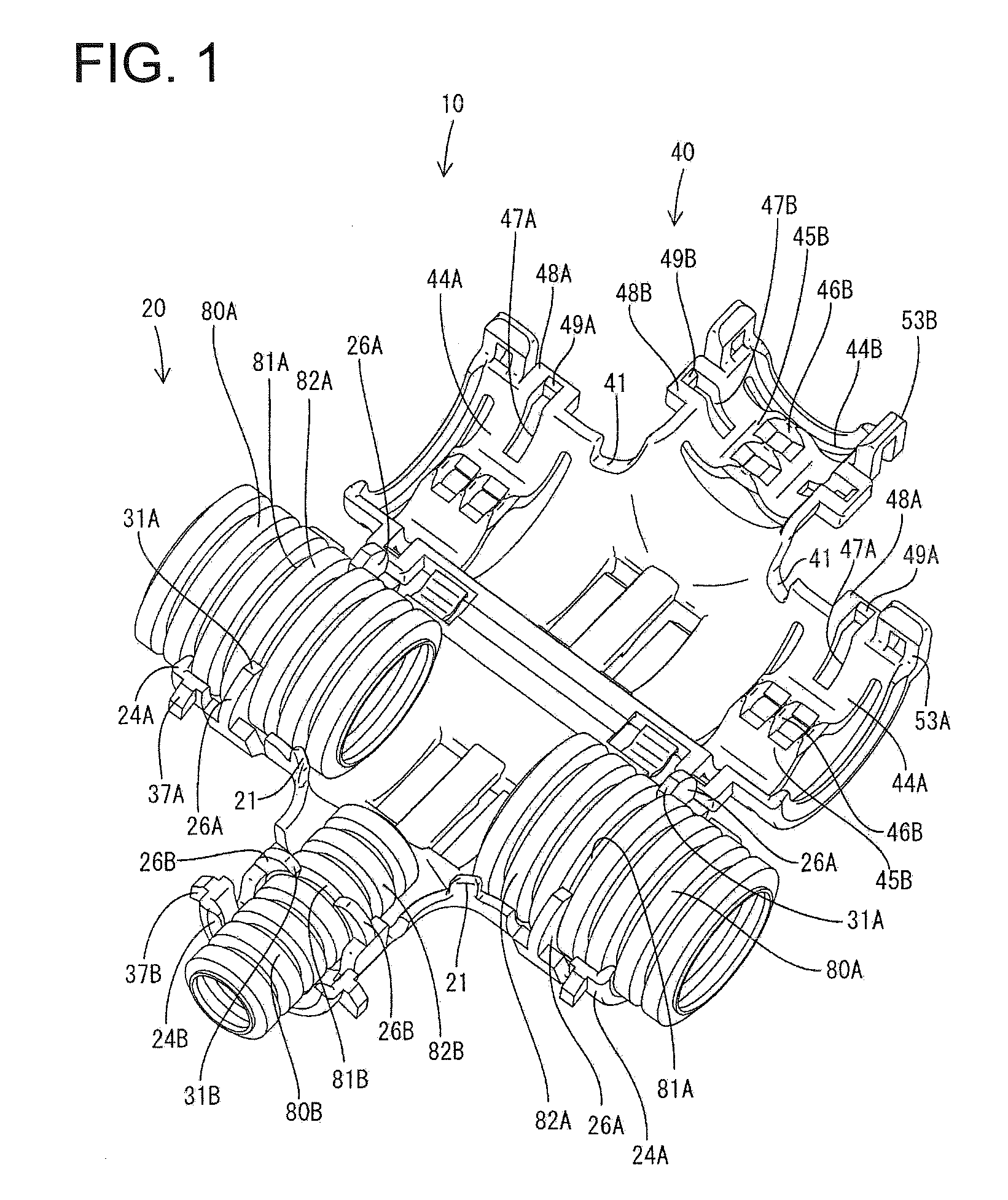

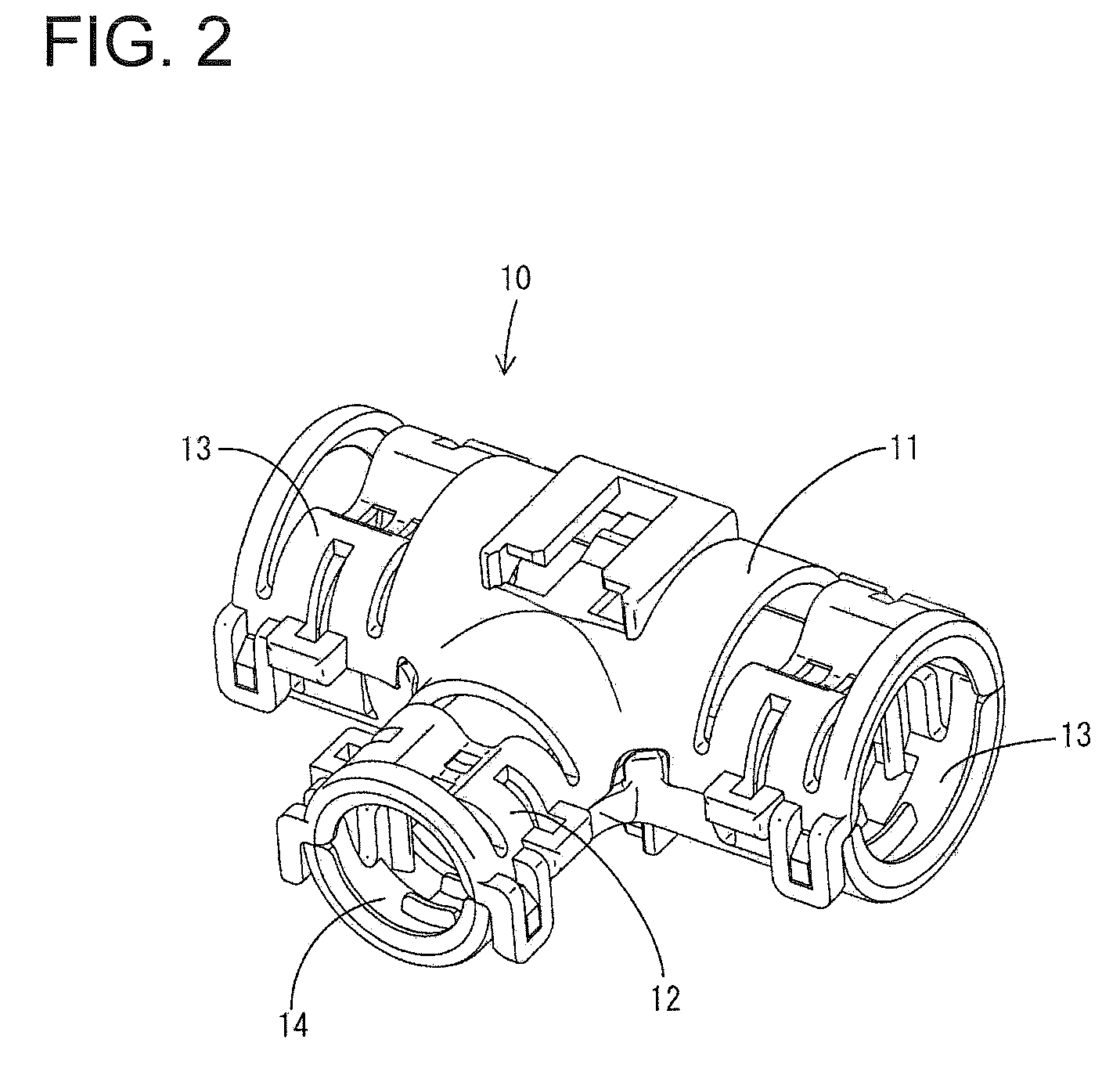

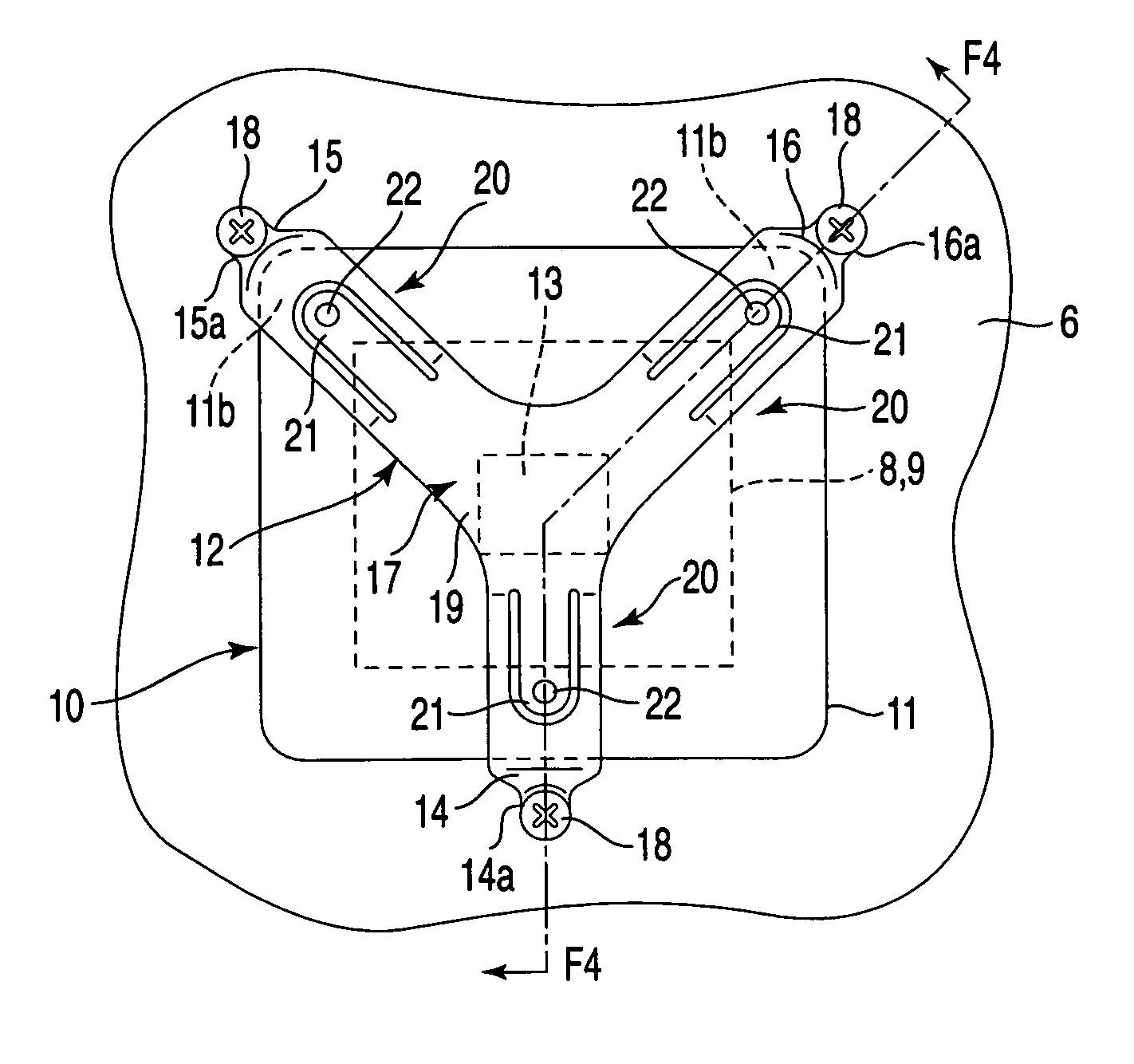

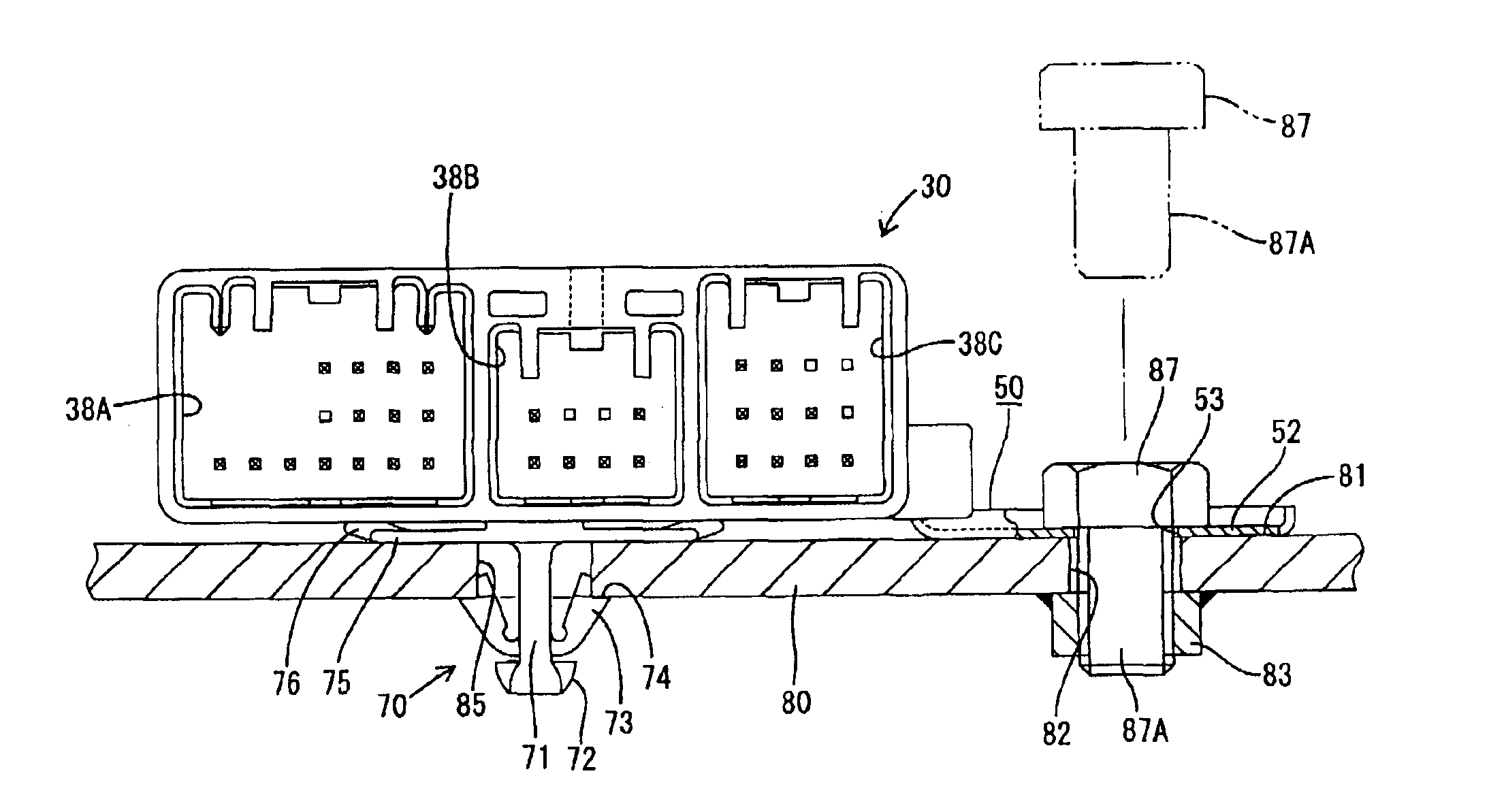

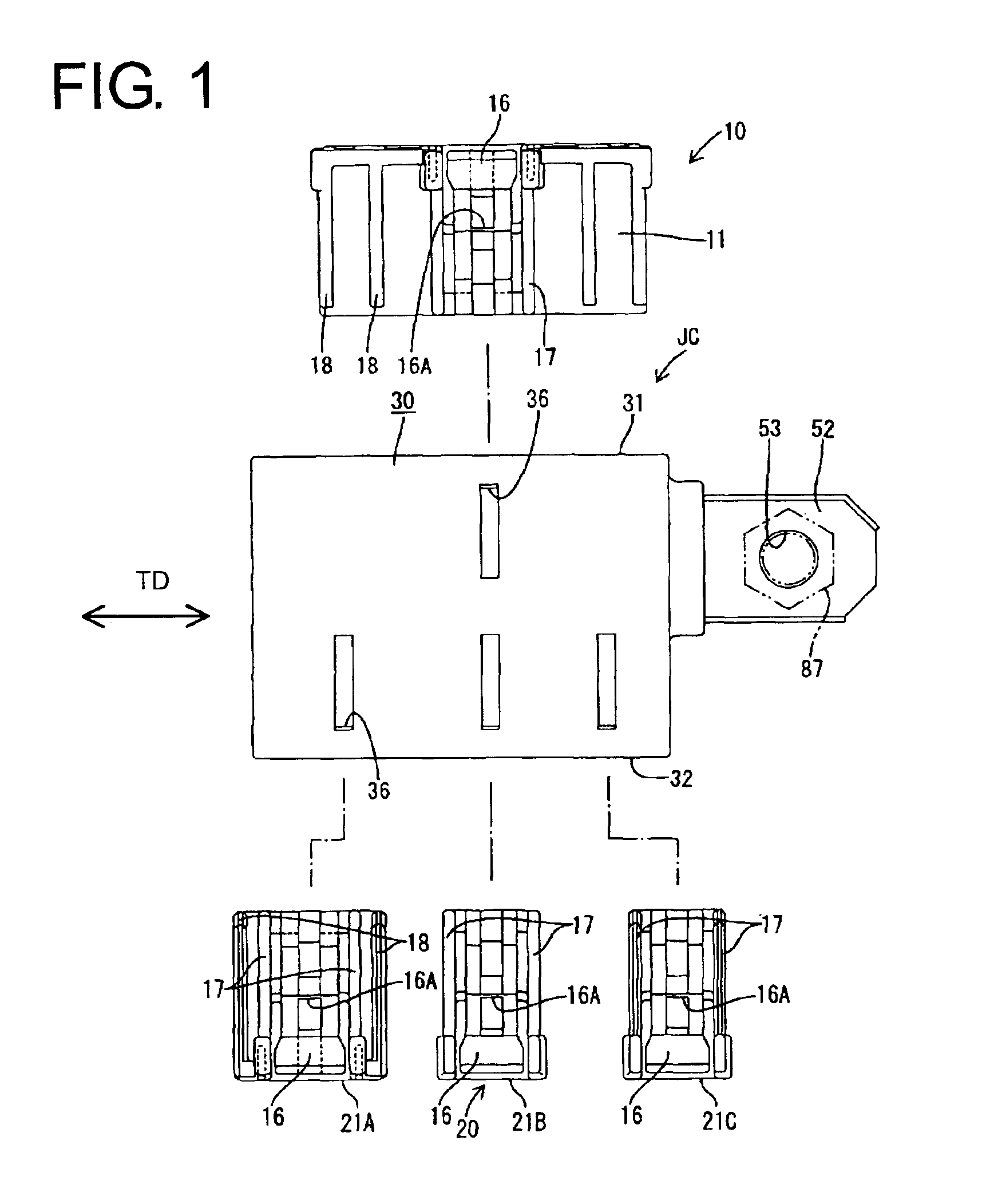

Ground connector and method of mounting it

InactiveUS6875053B2Improve grounding efficiencyImprove placement efficiencyCouplings bases/casesCoupling parts mountingEngineeringGround plate

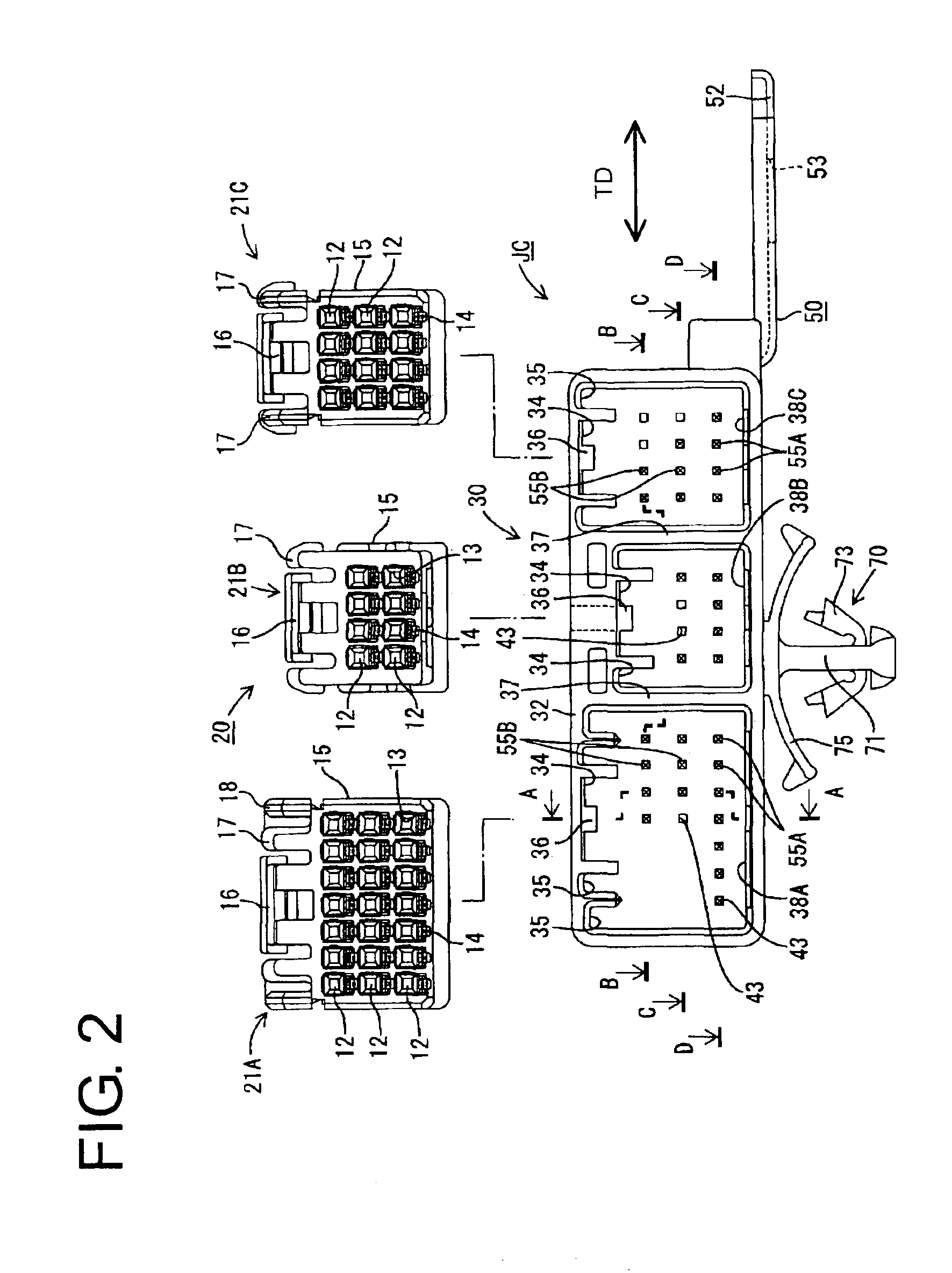

A joint connector (JC) has a ground terminal (50) mounted in a housing (30) so that a grounding plate (52) projects outside. The grounding plate (52) is fastened to a metal panel (80) by a nut (83) and bolt (87). A mount hole (85) of rectangular cross section is formed at a specified distance in a specified direction from the nut (83). A clip (70) is formed on the bottom of the housing (30) so that the positional relationship of the clip (70) and an insertion hole (53) of the grounding plate (52) corresponds to that of the mount hole (85) of the nut (83) of the metal panel (80). The housing (30) is mounted on the metal panel (80) by inserting the clip (70) into the mount hole (85). Thus, the insertion hole (53) of the grounding plate (52) is at a position aligned with the nut (83).

Owner:SUMITOMO WIRING SYST LTD

Farm product protecting bag

A farm product protecting bag adapted to be placed over a farm product, such as fruit, vegetable or flower, to protect it from diseases or harmful insects, wherein the bag contributes to improvement of quality, such as sugar content, color or external appearance of the farm product, the bag mount efficiency being increased to facilitate quality control. The bag is in the form of a transparent or semitransparent and / or light-transmitting porous film of plastic material with at least part or all of the surface of the bag being air-permeable or gas-permeable and having many fine pores impermeable to water, the bag comprising a bag main body having an opening that opens in one direction, and an attaching section for attaching the bag main body to the support portion of the farm product, it being preferable that the diameter of the largest of the fine pores be in the range of 50-500 μm and that the void area percentage be in the range of 0.7-10%, the fine holes being through-holes or closed holes closed at one end, it being preferable that the surface formed with irregularities in the peripheral edge of the fine holes be directed to at least the inside of the bag.

Owner:NIDAIKI

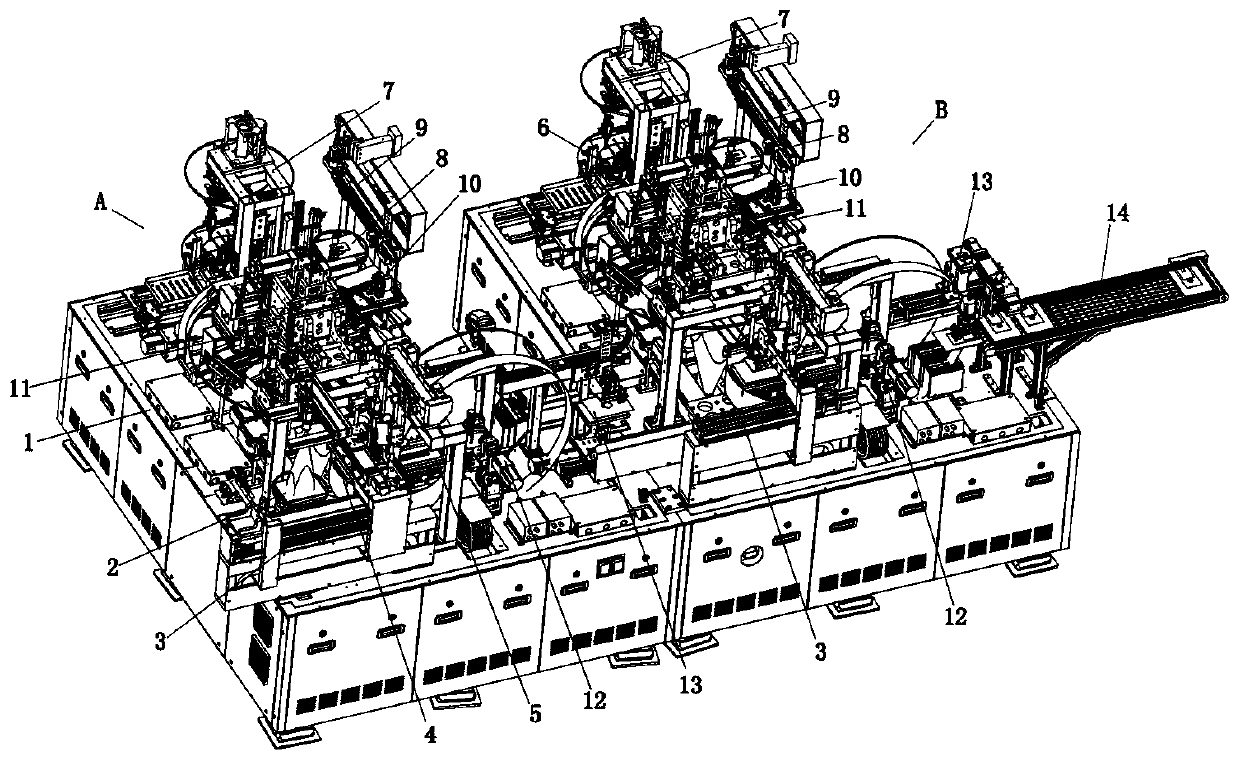

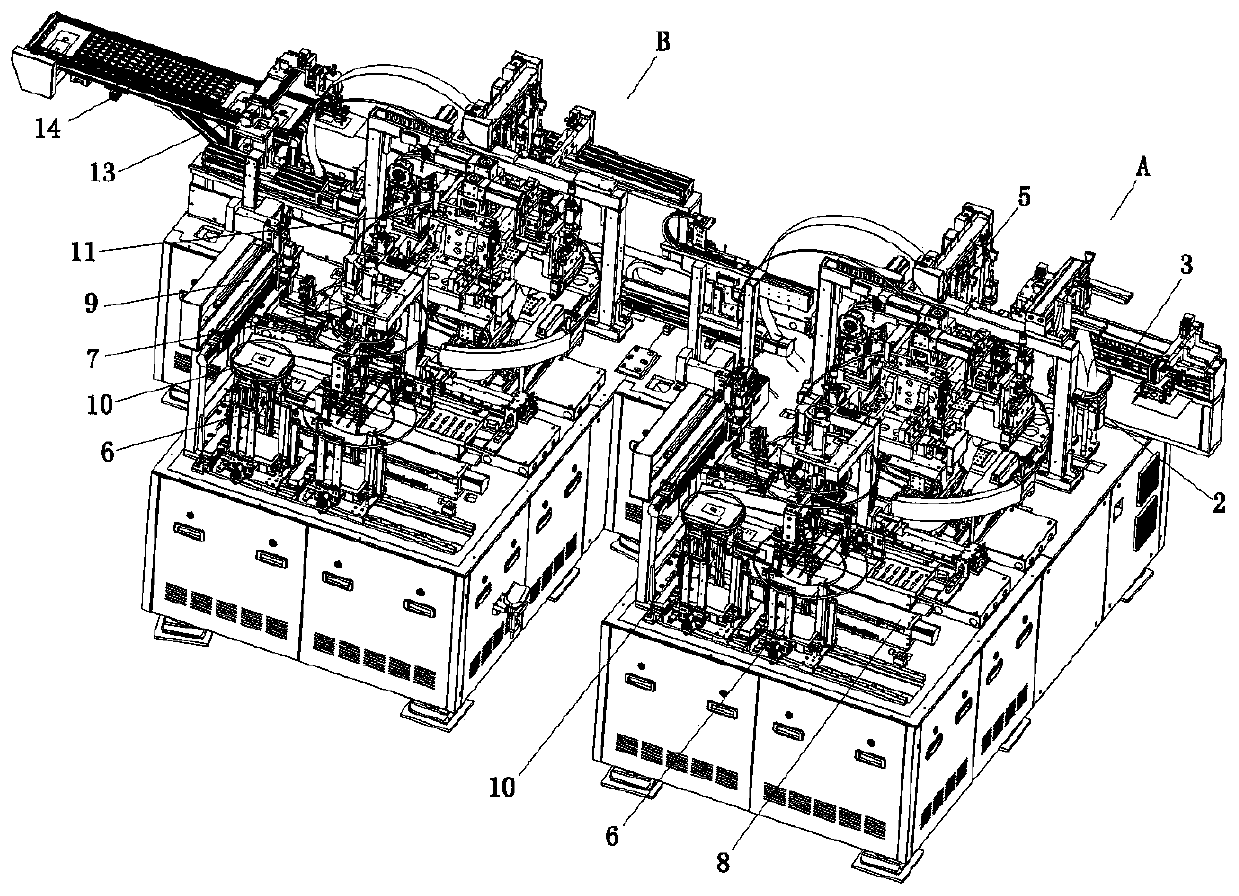

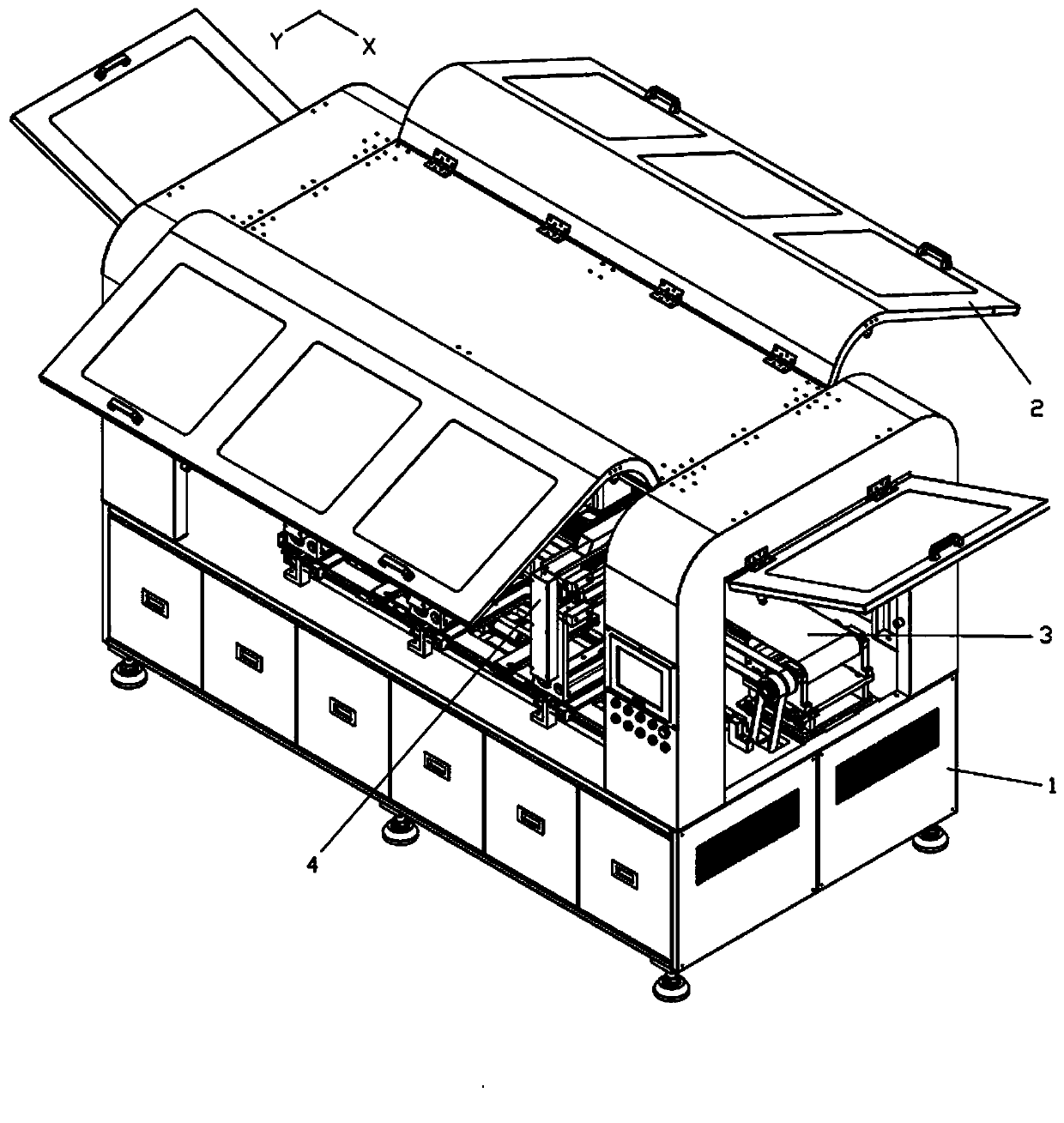

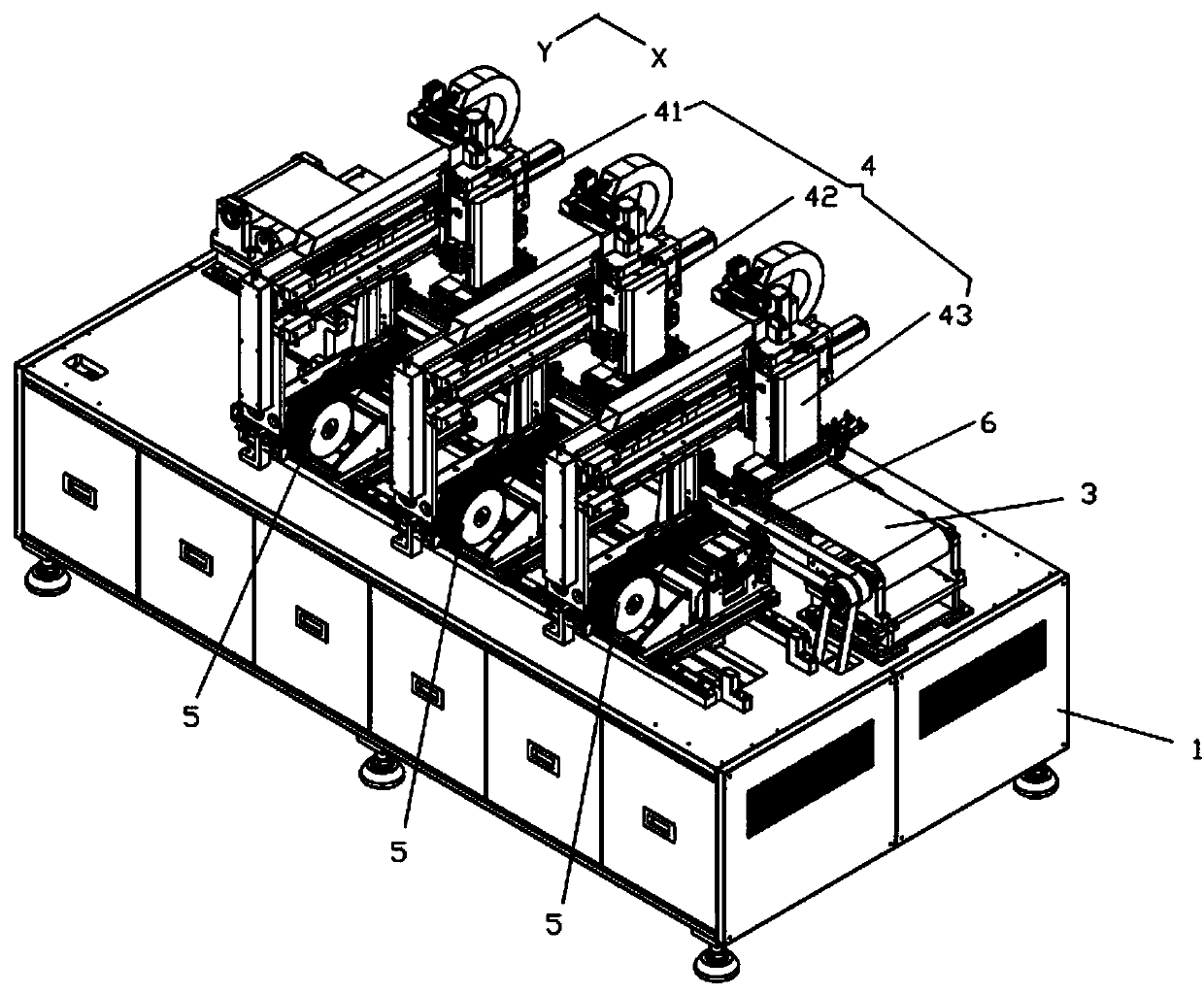

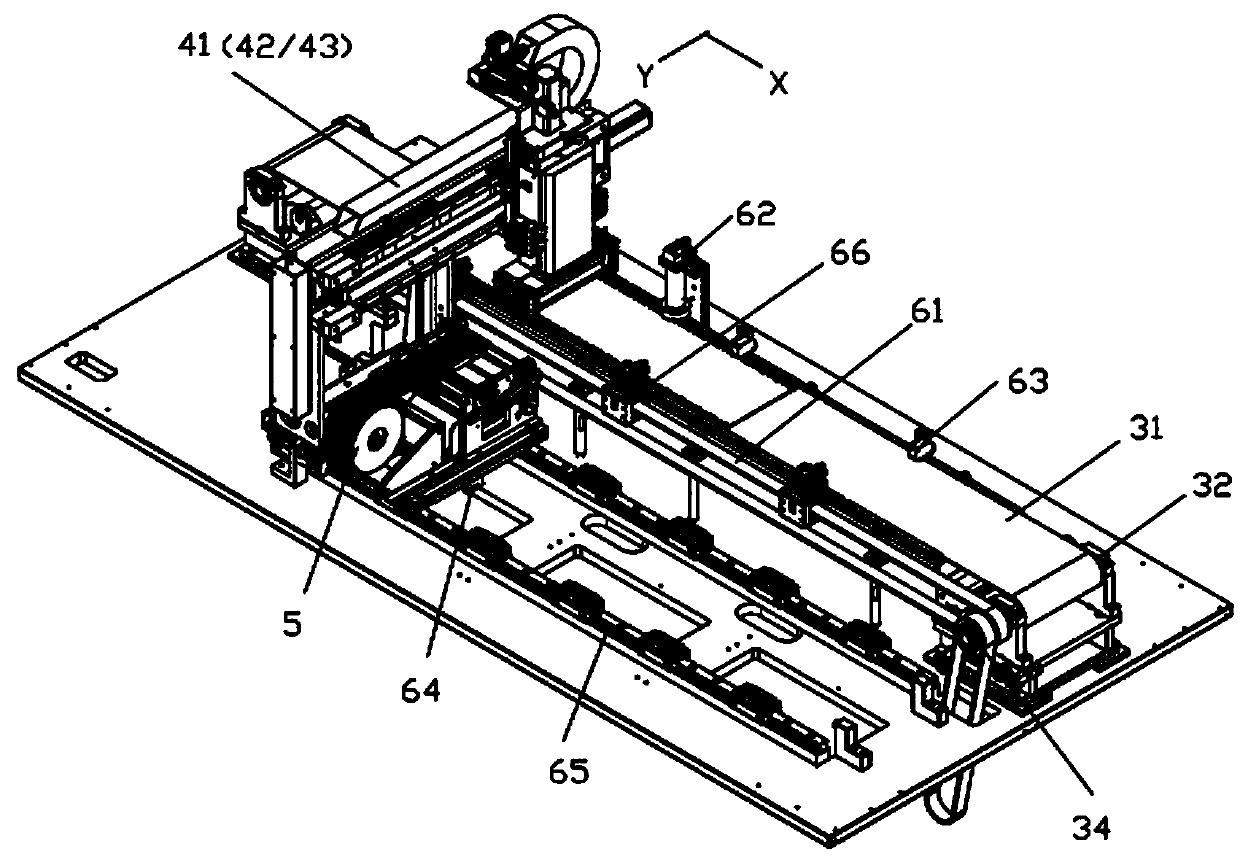

Full-automatic screen double-sided chip mounter and chip mounting technology thereof

PendingCN110174715ARealize automatic and efficient connectionReduce the presence of air bubblesNon-linear opticsOptical elementsEngineeringPolarizer

The invention discloses a full-automatic screen double-sided chip mounter and a chip mounting technology thereof. The full-automatic screen double-sided chip mounter comprises a first mounting part, aturnover mechanism, a second mounting part and a discharging belt which are arranged at intervals in sequence. After one side surface of a to-be-mounted glass sheet is subjected to chip mounting at the first mounting part, the glass sheet is moved to the turnover mechanism; after the glass sheet is turned over by the turnover mechanism, the other side surface of the glass sheet is subjected to chip mounting at the second mounting part; and the glass sheet is exported and discharged through the discharging belt. According to the chip mounter and the chip mounting technology, automatic and efficient connection of double-sided and single-sided mounting devices is effectively realized; automatic mounting of double polarizers is completed; the functions of alternate film tearing, alternating chip mounting, alternate discharging after chip mounting, and the like are realized; the material waiting time of each process gap is effectively utilized; the chip mounting time is shortened; the chipmounting productivity is effectively improved; the polarizers are adhered by adopting a flexible chip mounting adhesive tape; the attachment of the polarizers is completed by single-sided rolling attachment of a rolling attachment assembly; chip mounting air bubbles are effectively reduced; and the chip mounting quality is improved.

Owner:SHENZHEN ETMADE AUTOMATION EQUIP

Matrix-type surface mounted device

Owner:SHENZHEN KANGKE AUTOMATION EQUIP CO LTD

Component mounting method

InactiveUS6865803B2Improve placement efficiencyHigh feasibilityPrinted circuit assemblingMetal working apparatusEngineeringElectrical and Electronics engineering

A component mounter which picks up components from two or more tape feeders aligned in a component feeder carriage, and mounts them a board. Suction nozzles for vacuum-holding components are disposed on the transfer head at a predetermined basic pitch in the X direction (tape feeders alignment direction) to form a nozzle line. Two or more nozzle lines are aligned in the Y direction (perpendicular to the X direction). These suction nozzles pick up two or more components from the tape feeders simultaneously, enabling to reduce the space required for installing the mounter and making the mounter more compact. Increased feasibility of simultaneous pickup of several components also improves mounting efficiency.

Owner:PANASONIC CORP

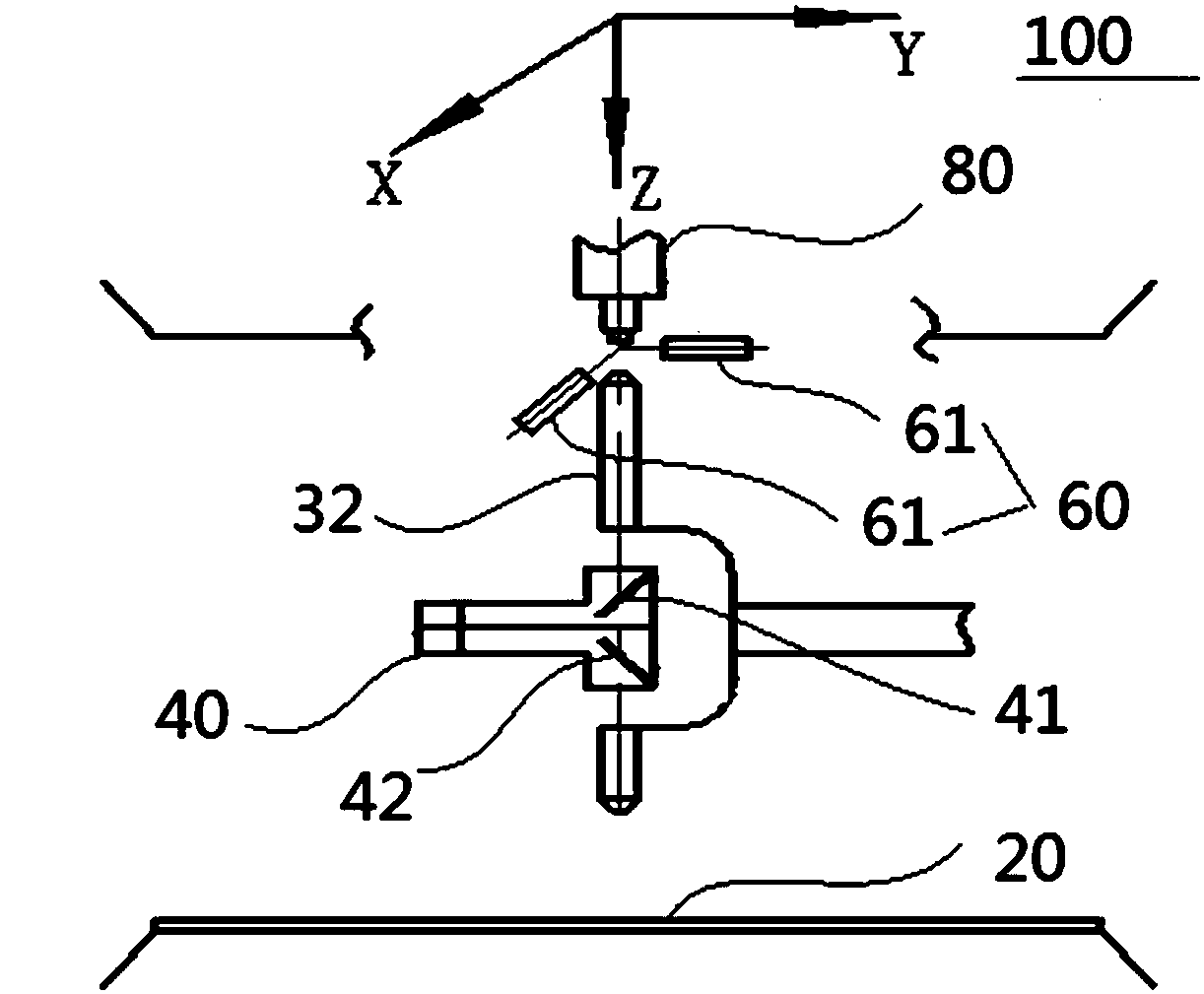

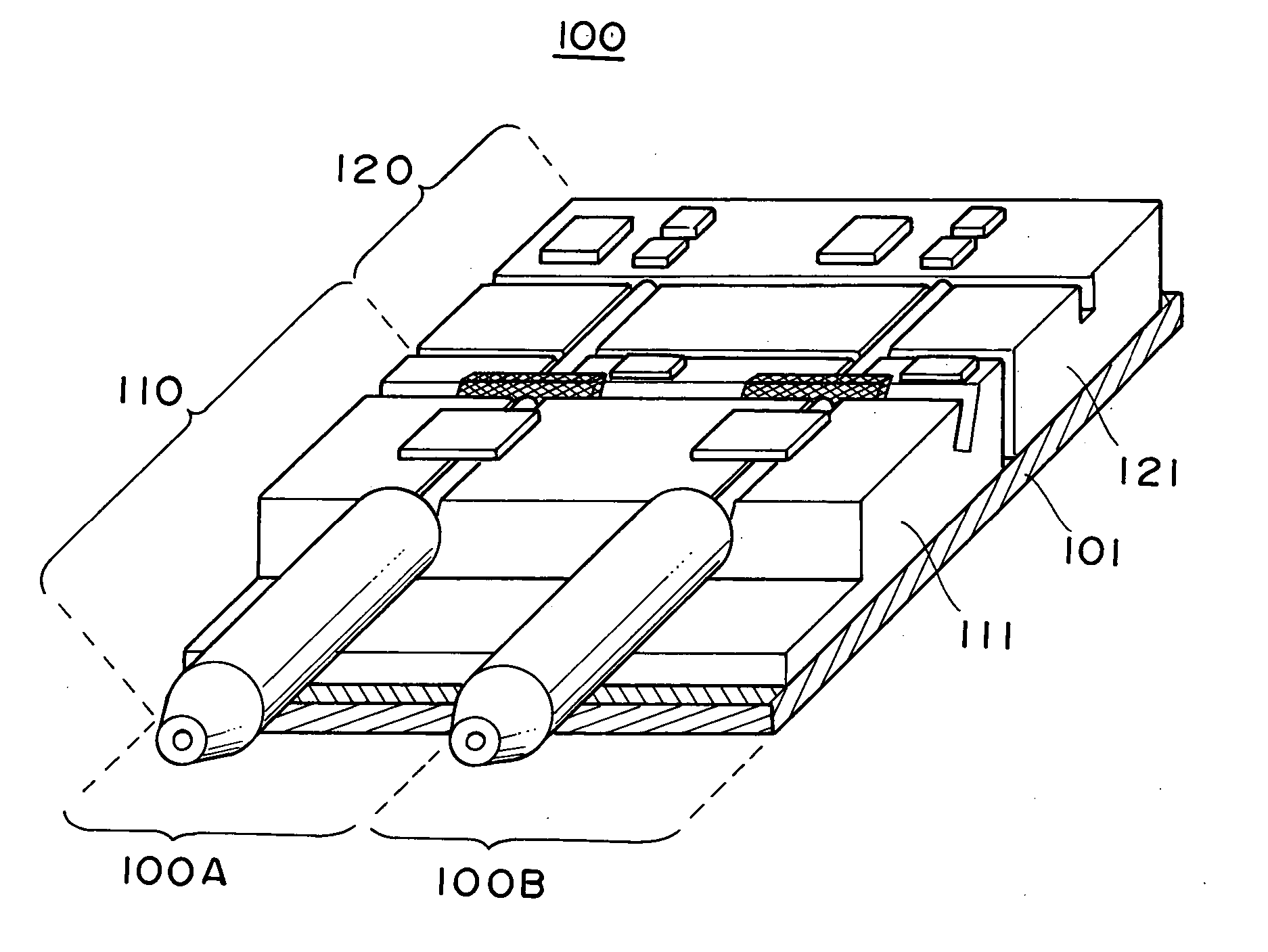

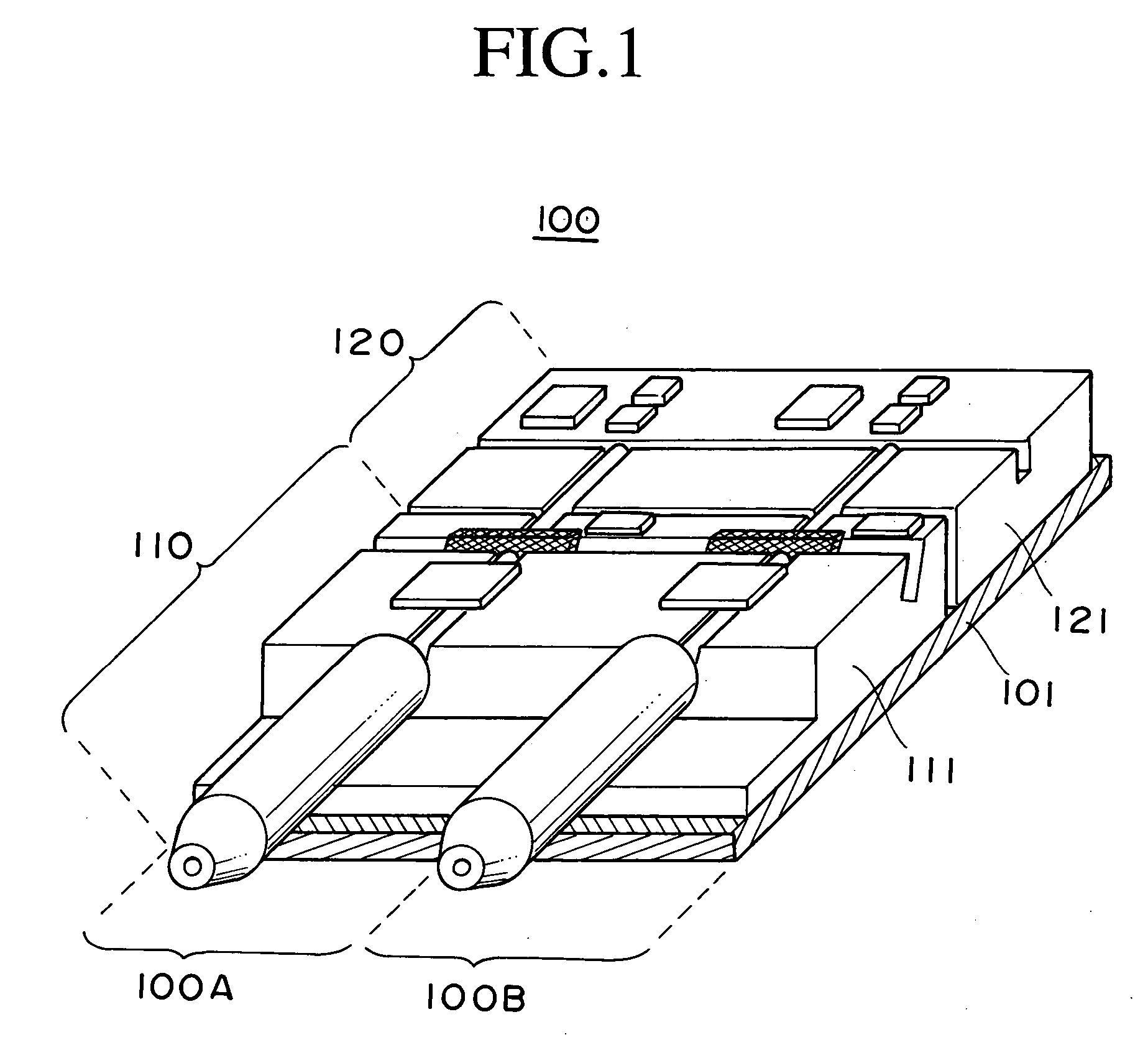

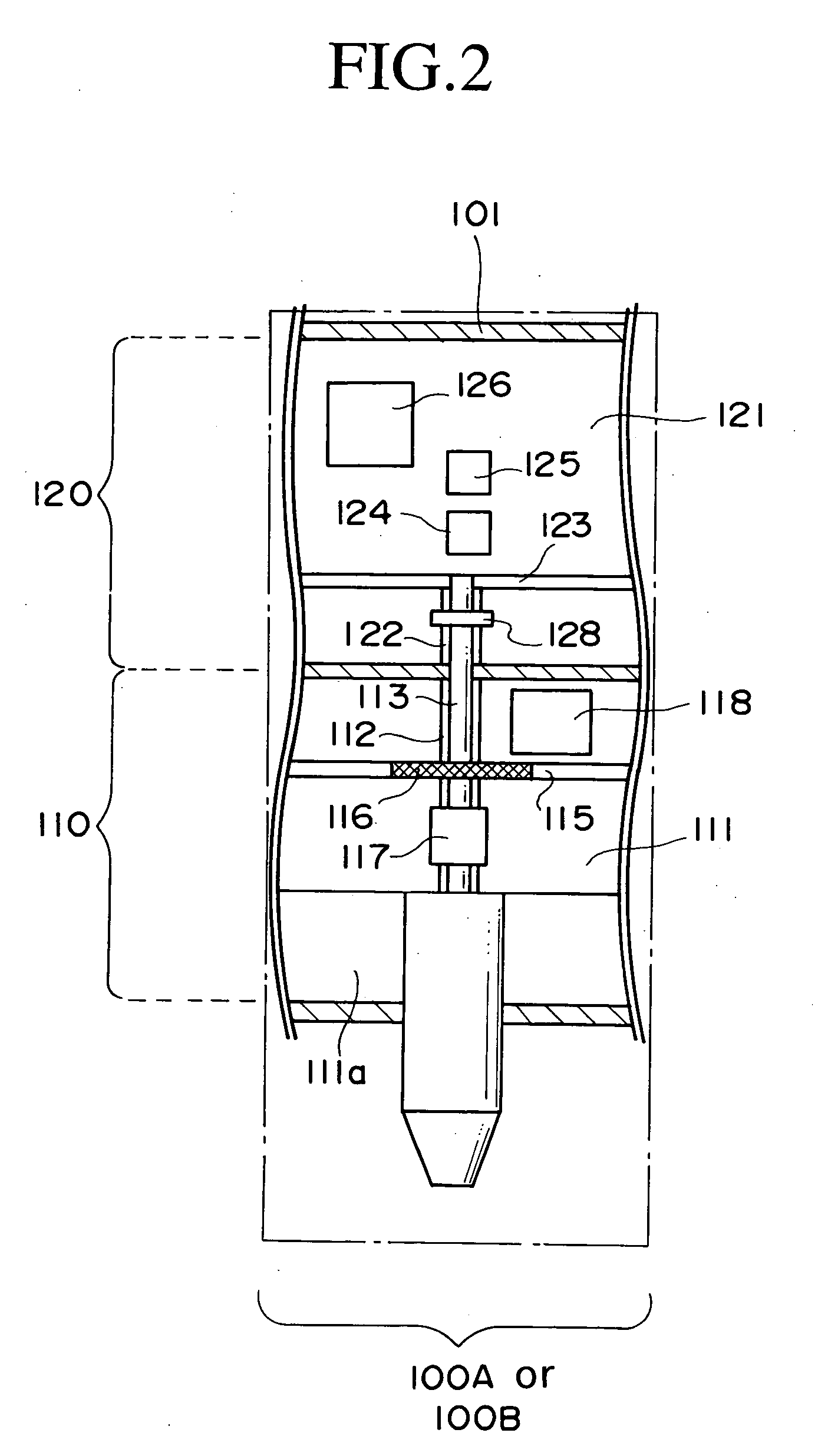

Optical module and a method of fabricating the same

InactiveUS20040126118A1Easy to handleHigh fabrication efficiencyLaser detailsCoupling light guidesIndependent elementTransceiver

The present invention realizes miniaturization, low cost and improvement of fabricating efficiency of an optical module. The optical module 100 has a PD platform 110 and an LE platform 120 which are mounted on a die pad 101. The optical module 100 includes two transceiver units 100A and 100B, and each unit works as an independent element of the optical module. The PD platform 110 and the LE platform 120 are used in common by the two transceiver units 100A and 100B. The components of the two transceivers 100A and 100B are mounted on a single PD platform and a single LE platform.

Owner:TDK CORPARATION

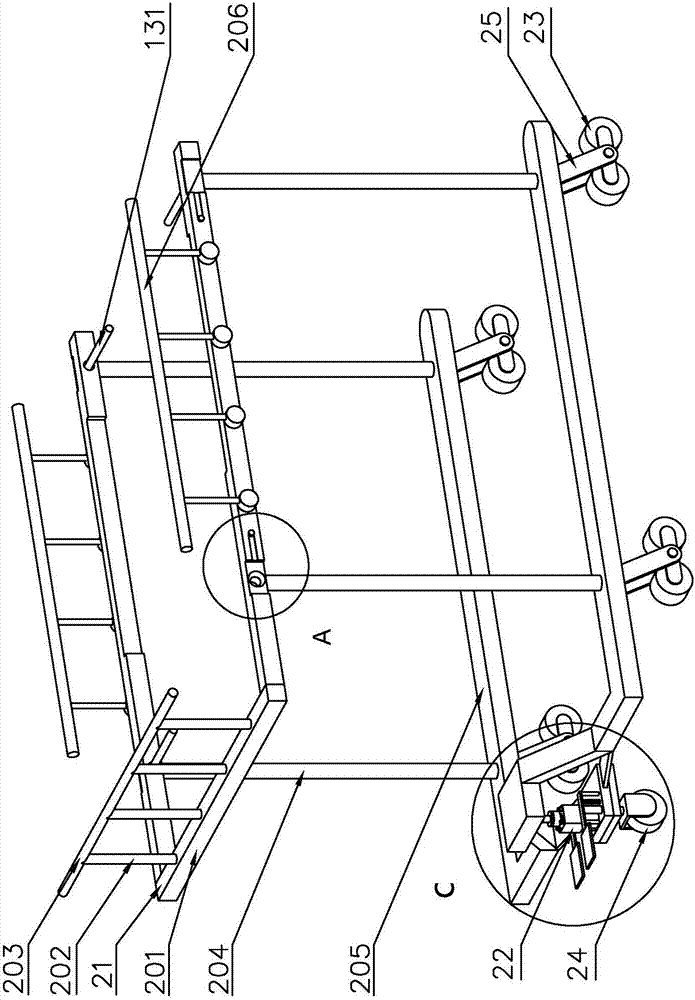

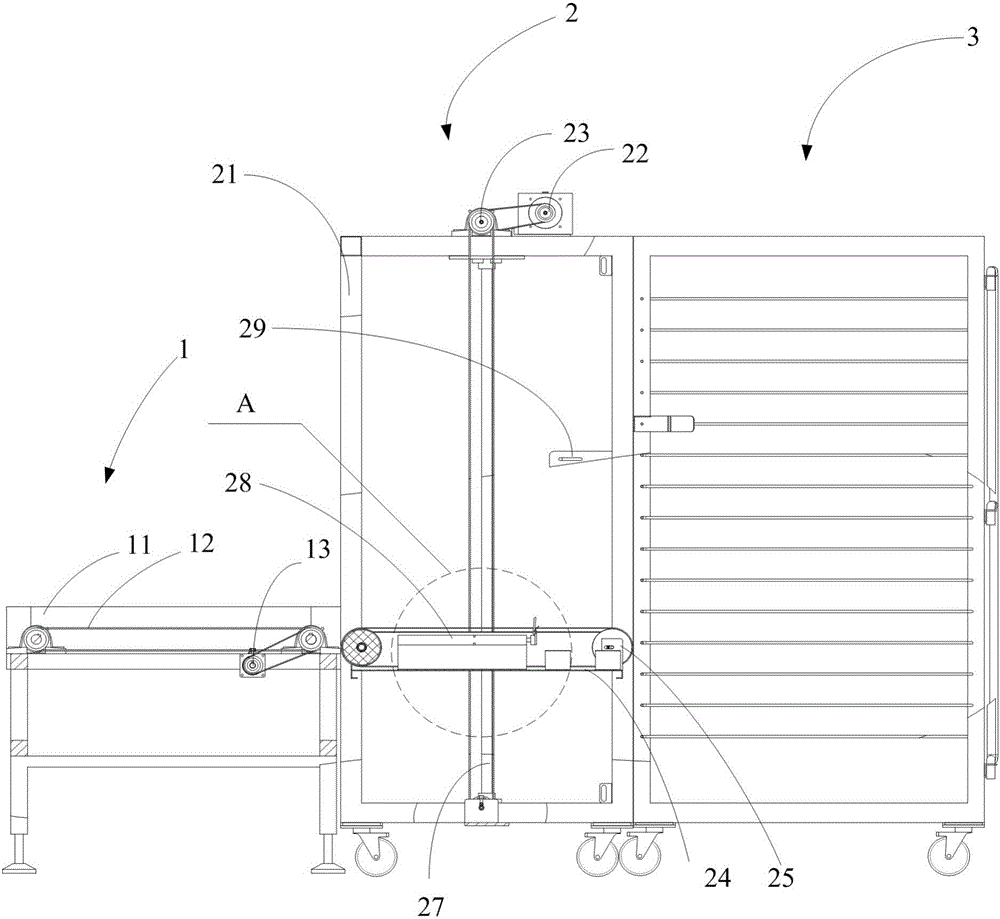

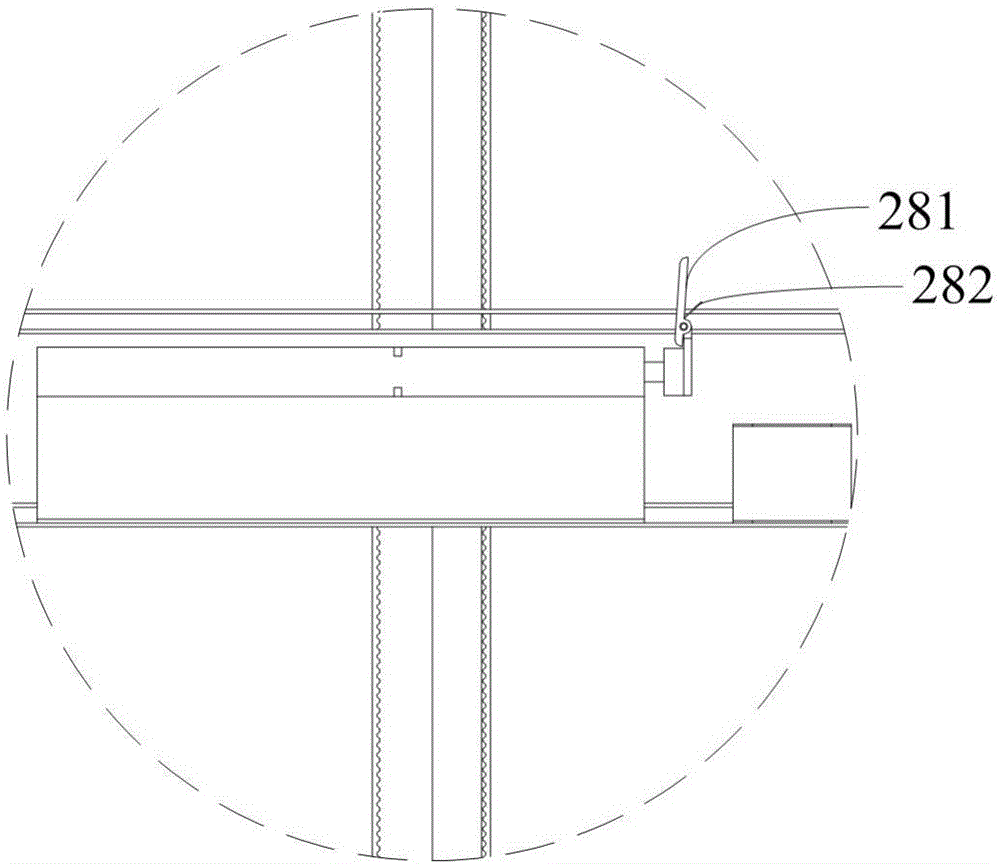

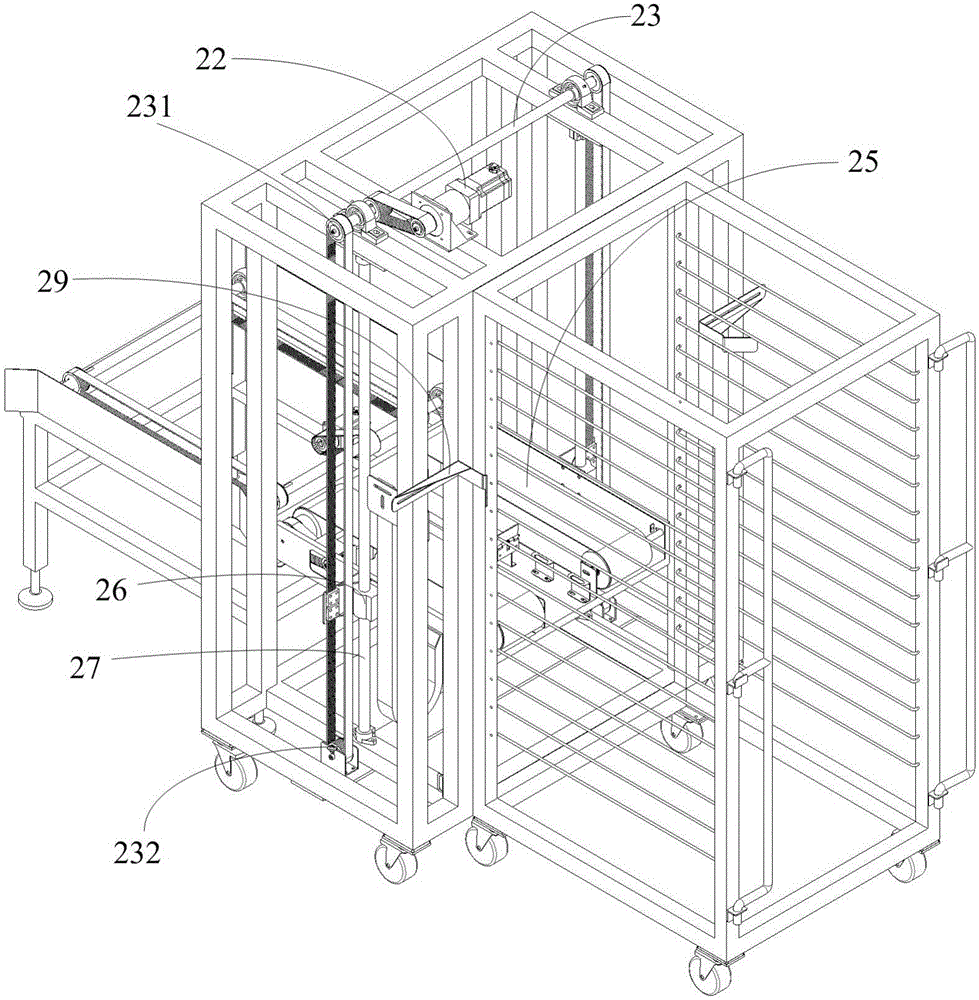

Automatic dish feeding machine system and automatic dish feeding method

InactiveCN106044246AImprove placement efficiencyReduce work intensity and risk factorConveyorsStacking articlesEngineeringMechanical engineering

The invention discloses an automatic loading machine system, which includes a transition mechanism for horizontally transporting plates, a plate loading mechanism for detecting the vertical neutral position adjacent to the plate frame and vertically transporting and pushing the plates to a designated layer, and a shape It is a rack with a frame structure and multiple independent layers of space inside, wherein the transition mechanism, the upper plate mechanism, and the rack are arranged next to each other in sequence. The technical scheme of the present invention cooperates with the rack by setting the transition mechanism, the loading mechanism and the rack, and automatically detects the vacant position of the rack by the system to automatically stack the plates, thereby improving the work efficiency of the plate placement and reducing the work intensity and danger. coefficient.

Owner:佛山市南海今博自动化设备有限公司

Positioning control method, positioning control device, and electronic component mounting apparatus using same

InactiveUS7062334B2Increase mount efficiencyHigh speedProgramme-controlled manipulatorComputer controlEngineeringPower consumption

There are provided a positioning control method and a positioning control device, which enables high speed positioning with low power consumption without repeating two or more acceleration and deceleration operations during travel from an original position to a target position. There is also provided an electronic component mounting apparatus, which enables high speed positioning with low power consumption and enables mounting of electronic components in a short period of time. When a movable body is moved from the original position to the target position, there is set an operational passing position for avoiding a passing avoidance region, and driving of a drive unit having a smaller travel distance from the original position to a coordinate of the operational passing position is started later than driving start timing of a drive unit having a longer travel distance, from the original position to another coordinate of the operational passing position, by a specified period of time.

Owner:PANASONIC CORP

Electrical connector assembly with pick up cap

ActiveUS7264487B2Easy and efficient installationQuickly and uniformly curingPrinted circuit assemblingContact member assembly/disassemblyContact padElectrical connection

Owner:HON HAI PRECISION IND CO LTD

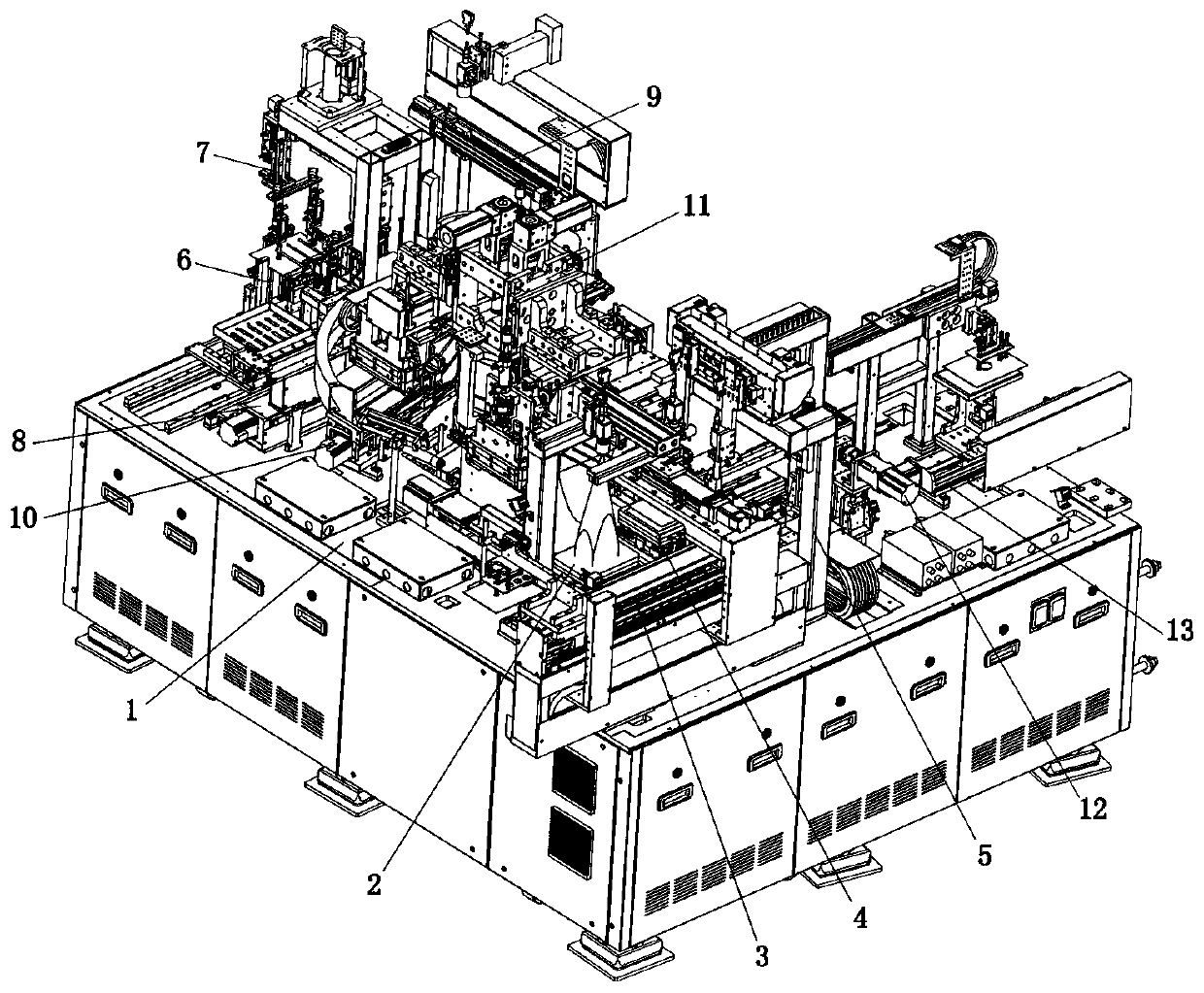

Visual-positioning mobile phone accessory attaching system

ActiveCN105292657AReduce movementImprove placement efficiencyLabelling machinesEmbedded systemStripping - action

The invention belongs to the field of mobile phone shell assembling equipment, and particularly relates to a visual-positioning mobile phone accessory attaching system. The visual-positioning mobile phone accessory attaching system comprises a hardware part and a software part. The hardware part comprises a main rack, a plurality of accessory stripping mechanisms, a feeding and discharging mechanism, an attaching executing mechanism, a visual-positioning mechanism and a controller. The software part comprises a hard configuration management module, a mobile phone accessory management module, a hand and eye calibration module and a work driving module. According to the visual-positioning mobile phone accessory attaching system, the manner that the accessory stripping mechanisms and the attaching executing mechanism with a plurality of suction nozzles are integrated on the main rack, attaching of various accessories can be completed at a time through one machine, and in addition, due to the fact that the accessory stripping action and the attaching action are independent from each other and work is completed in a division manner, the visual-positioning mobile phone accessory attaching system has the remarkable beneficial effects that precision is high, accessory waste is small, the requirement for the accessory manufacturing technology is low, the wire change cost is low, accessory stripping and accessory attaching are conducted in parallel and efficiency is high compared with a traditional accessory attaching system. In the traditional accessory attaching system, one machine is used for attaching one accessory; accessory stripping and accessory attaching are conducted in series; no machine vision exists, or a simple vision system is arranged, and generally, a camera is installed on a mechanical arm; and photographing is needed before each time of material taking.

Owner:DONGGUAN GOSUNM MACHINERY EQUIP CO LTD

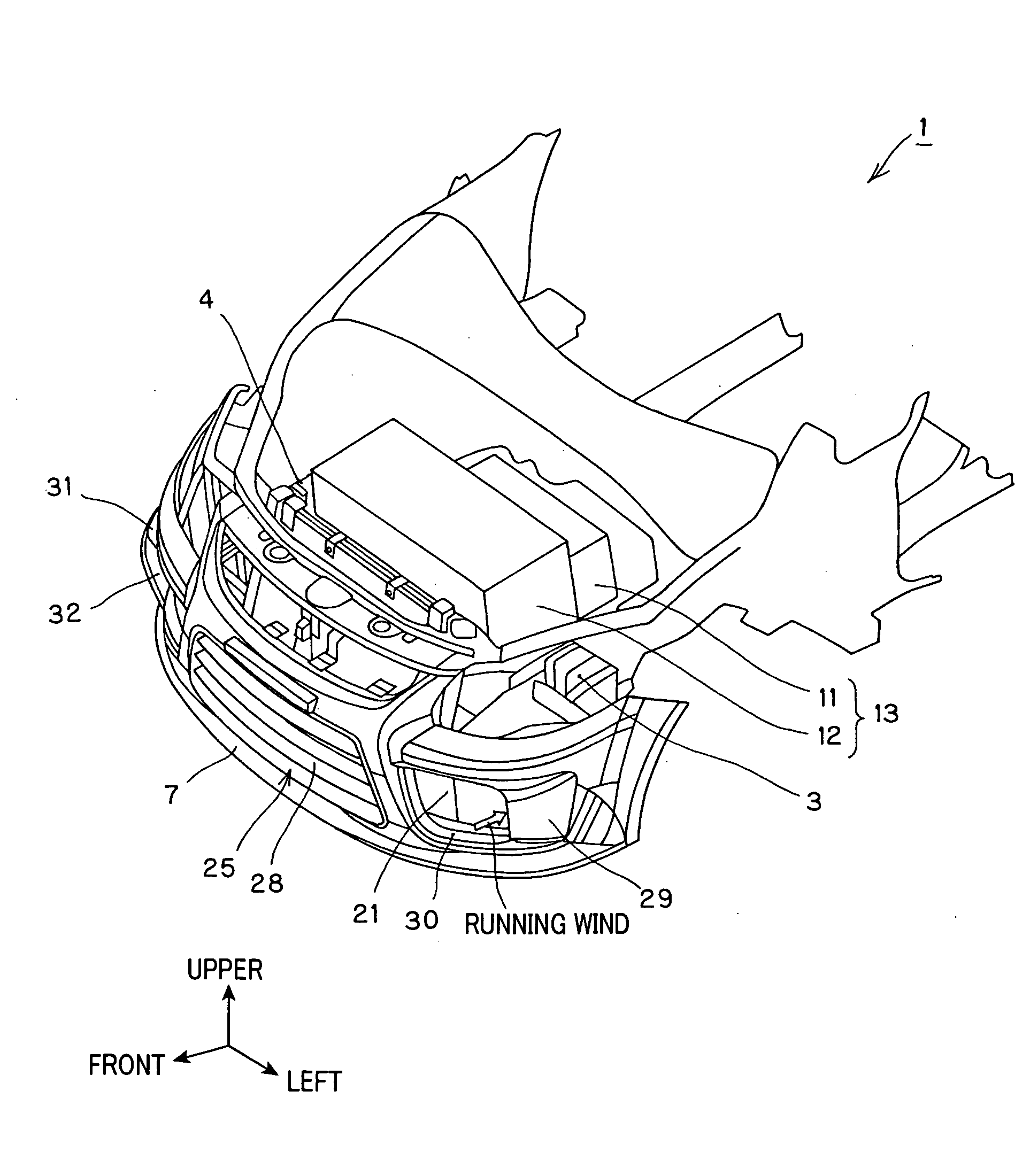

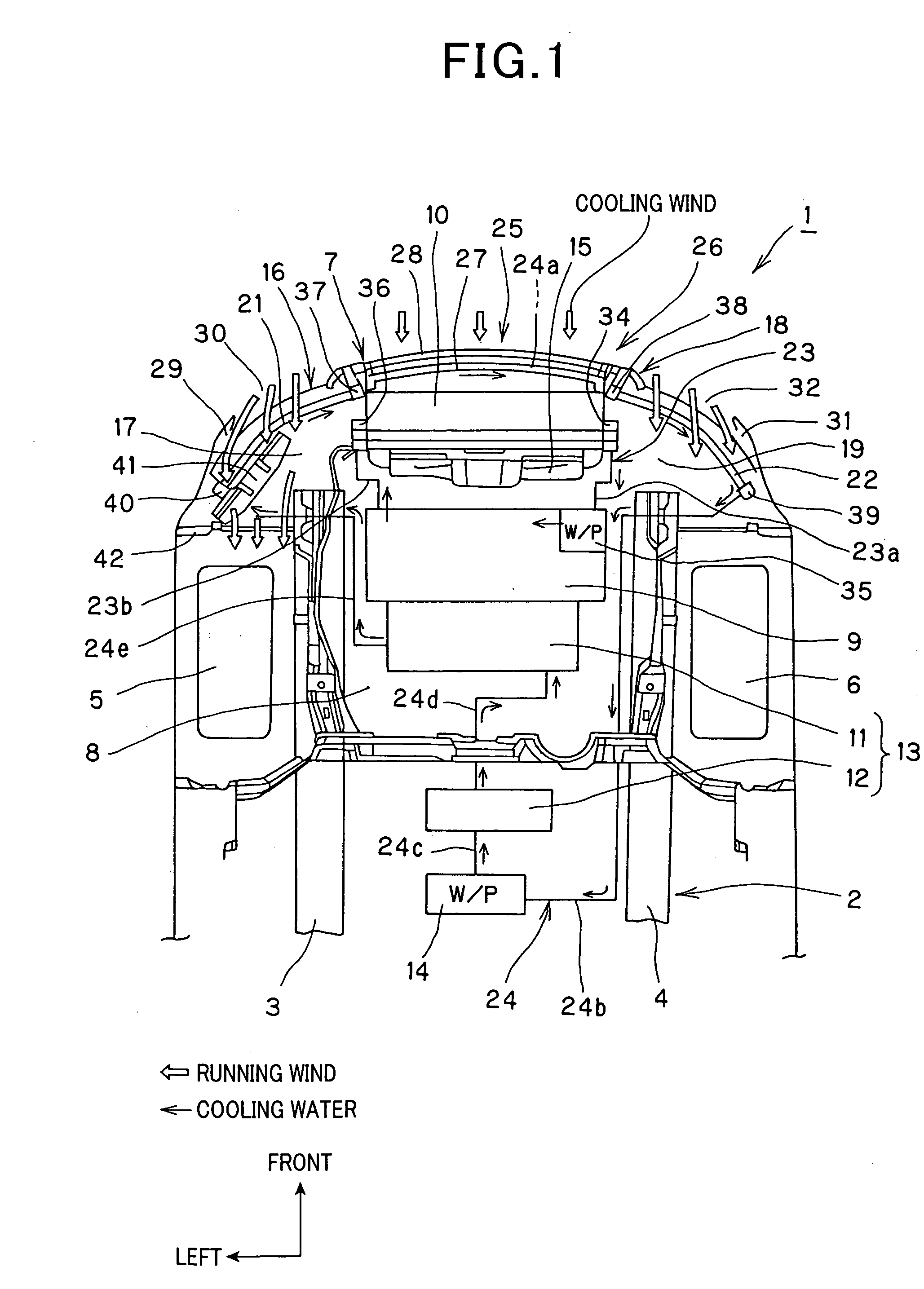

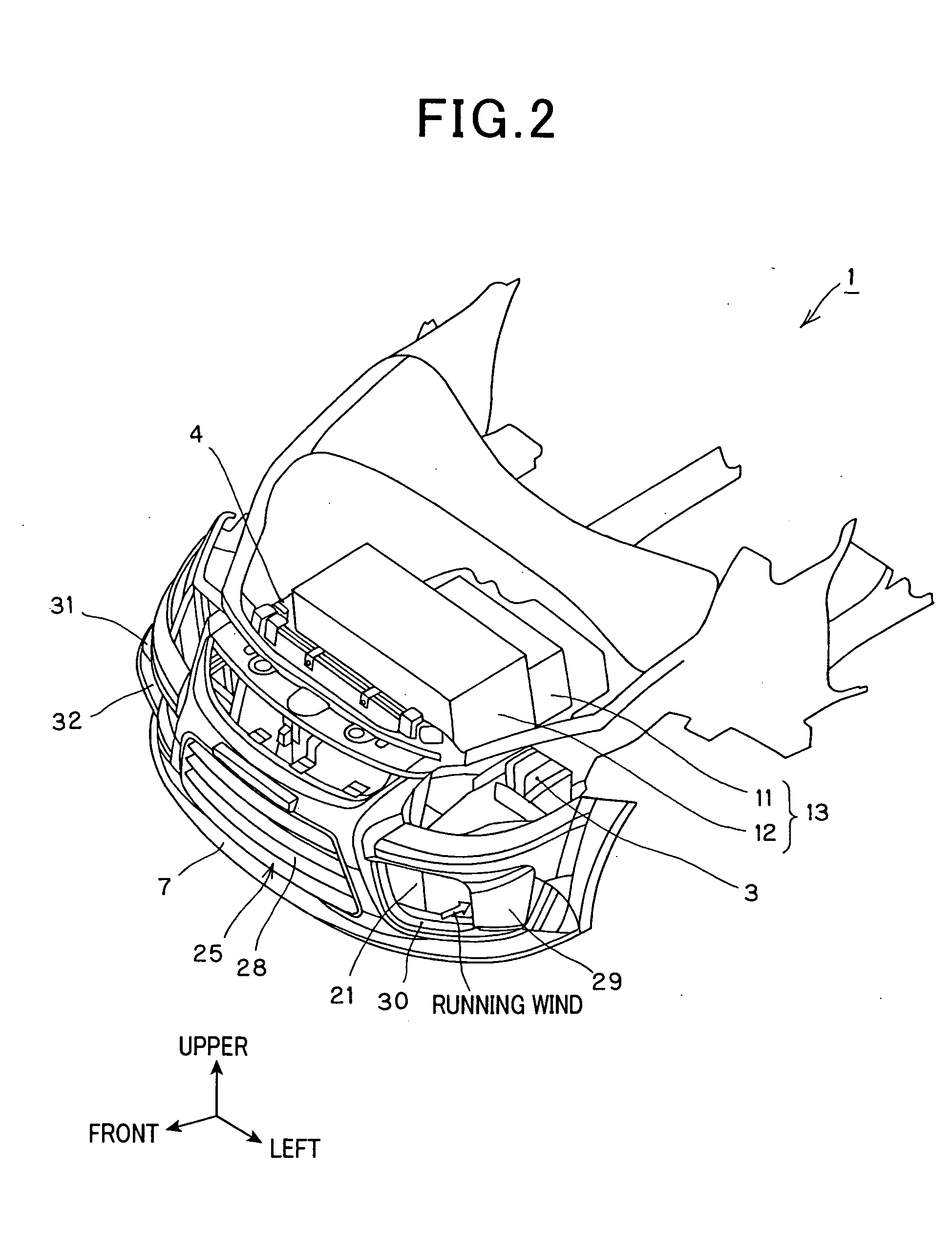

Cooling apparatus for a fuel cell powered vehicle

InactiveUS20090266508A1Radiation area can be assuredAdd dimensionAir-treating devicesFuel cell heat exchangeFuel cellsCooling channel

A cooling apparatus for a fuel cell powered vehicle includes a first cooling passage for providing cooling water between a fuel cell and a first radiator and a second cooling passage for providing cooling water between electric apparatuses other than the fuel cell and a second radiator. The first radiator is arranged behind a front bumper and in a center portion in a vehicle width direction, a pair of radiators constructing the second radiator are arranged in side portions in the vehicle width direction from the first radiator and in a space surrounded by curved portions of the front bumper. When the vehicle is viewed from an upper direction, each second radiator is curved along an inner surface of the front bumper, and inner edge portions of the second radiators are coupled by a cooling water piping.

Owner:SUZUKI MOTOR CORP

High-efficiency surface mounting method and device

InactiveCN104202917AImprove ergonomicsImprove placement efficiencyPrinted circuit assemblingSurface mountingElectrical and Electronics engineering

The invention discloses a high-efficiency surface mounting method and device, and relates to the technology of surface mounting of components on printed circuit boards. The high-efficiency surface mounting method includes adopting a board conveying mechanism for conveying circuit boards, adopting a plurality of surface mounting mechanisms to mount the components on the circuit boards, penetrating and inserting surface-mounted components on the same circuit board conveyed by the board conveying mechanism by the surface mounting mechanisms. When mounting the components, the surface mounting mechanism synchronously runs with the circuit boards at constant speed, continuous mounting is realized during constant-speed motion of the circuit boards, the circuit boards are needless of dead time and free of length limit, and the components are mounted on ultralong and rolled circuit boards at high speed. The high-efficiency surface mounting device comprises a board conveying mechanism, a surface mounting mechanism, a component conveying mechanism and a synchronous following mechanism, wherein the synchronous following mechanism enables the surface mounting mechanism and the circuit boards to synchronously run at constant speed when the surface mounting mechanism mounts the component. The problem of continuous surface mounting during constant-speed motion of the circuit boards is solved, the circuit boards are free of length limit, surface mounting is high in efficiency, output is high, and the surface mounting device is small in size and stable and reliable in performance.

Owner:广东田津电子技术有限公司

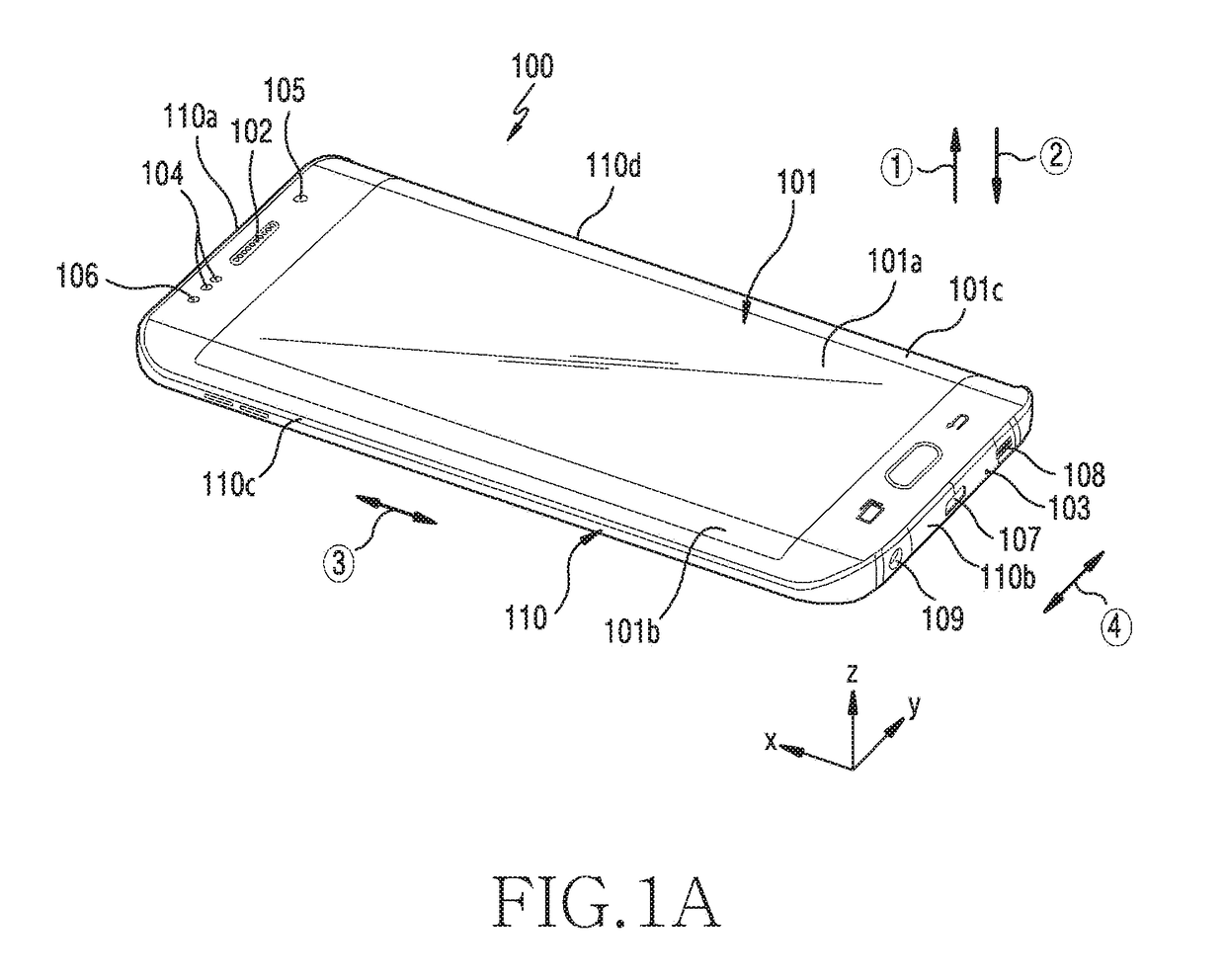

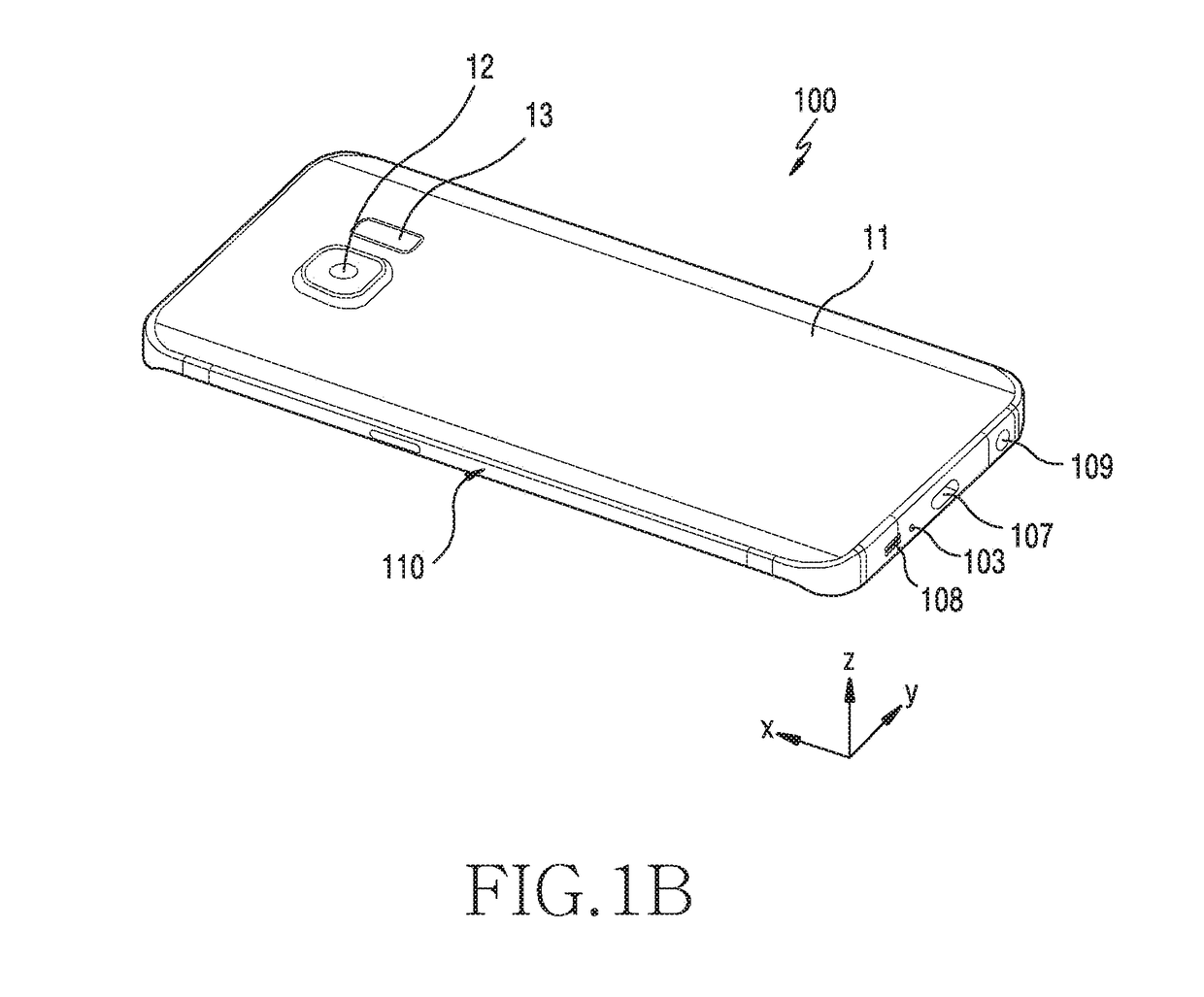

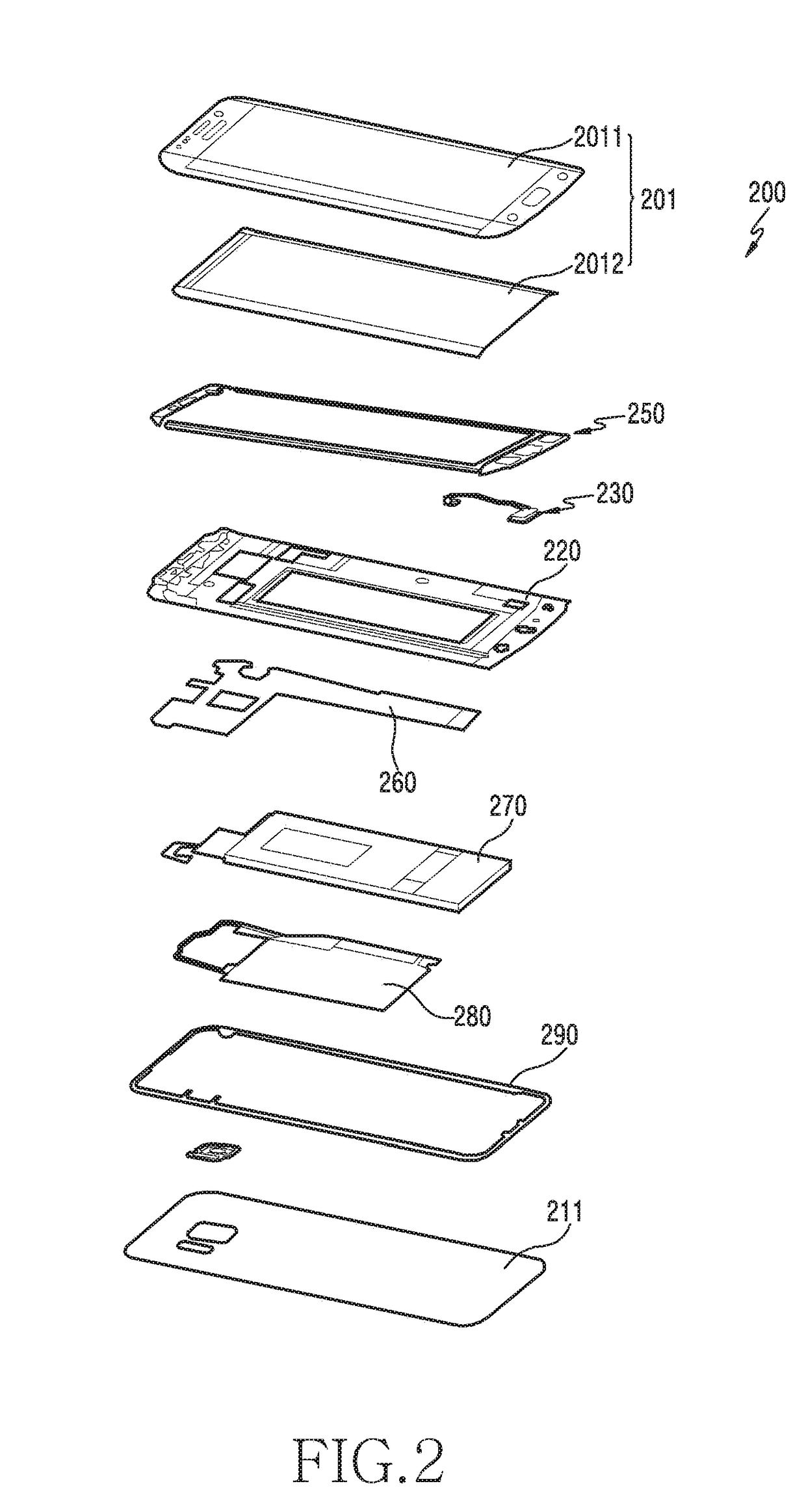

Electronic device with display

ActiveUS20190012007A1Enhance mount efficiencyReduced areaInput/output for user-computer interactionStatic indicating devicesIntegrated circuitPrinted circuit board

An electronic device for widening an active area of a display is provided. The electronic device includes a housing including a first plate and a second plate facing away from the first plate, a touch screen display including a first glass plate, a second glass plate, and an organic light-emitting diode (OLED) layer interposed between the first plate and the second plate, a flexible layer including a first portion connected to the first surface of the second glass plate and bent around an edge of the second glass plate toward the second plate of the housing, and a second portion extending from the first portion and interposed between the second glass plate and the second plate of the housing, a display driver integrated circuit (DDIC) mounted on a first surface of the second portion of the flexible layer, and a printed circuit board (PCB) including a portion mounted on a second surface of the second portion of the flexible layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com