Patents

Literature

520 results about "Standard position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Standard position. noun. : the position of an angle with its vertex at the origin of a rectangular-coordinate system and its initial side coinciding with the positive x-axis.

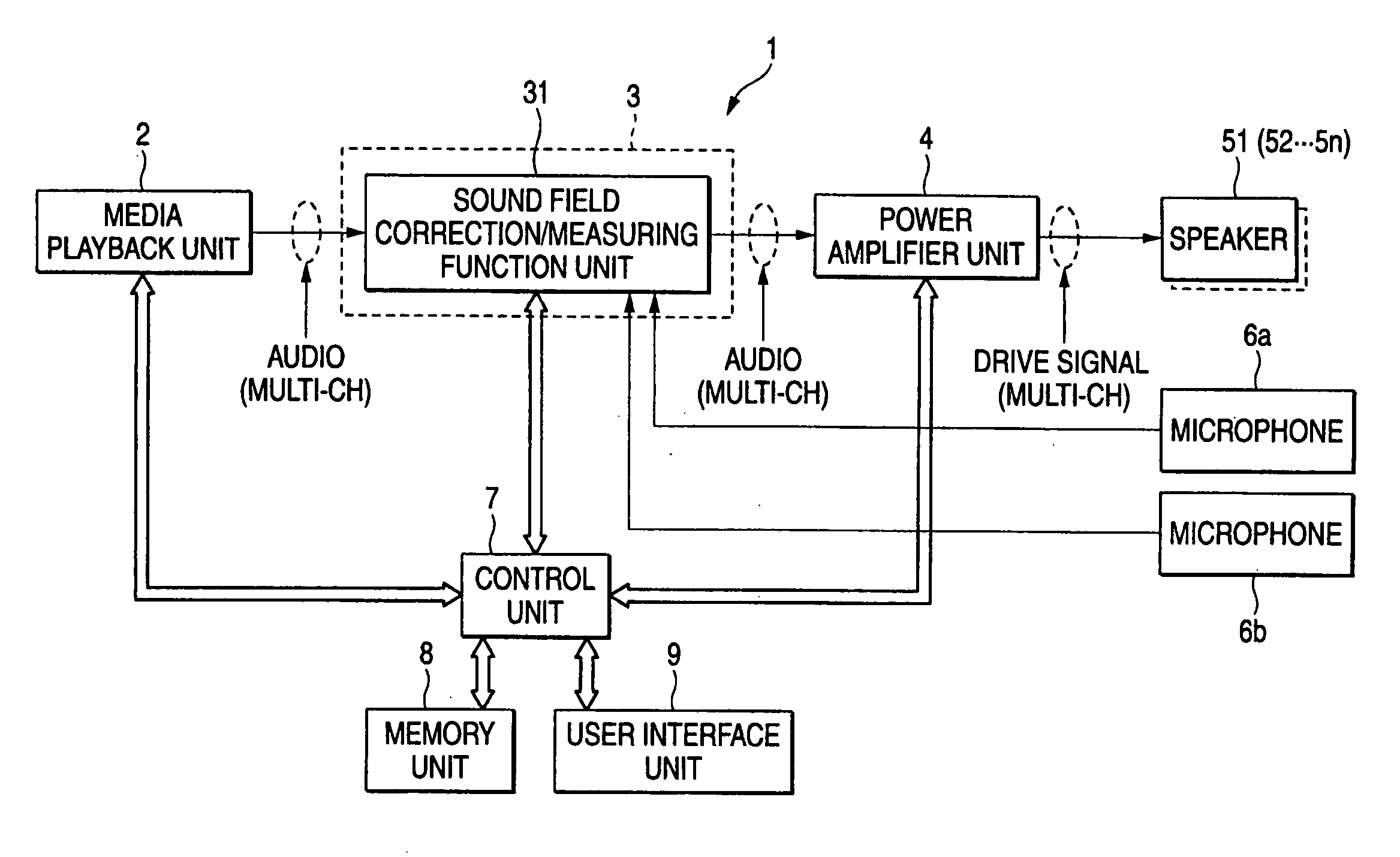

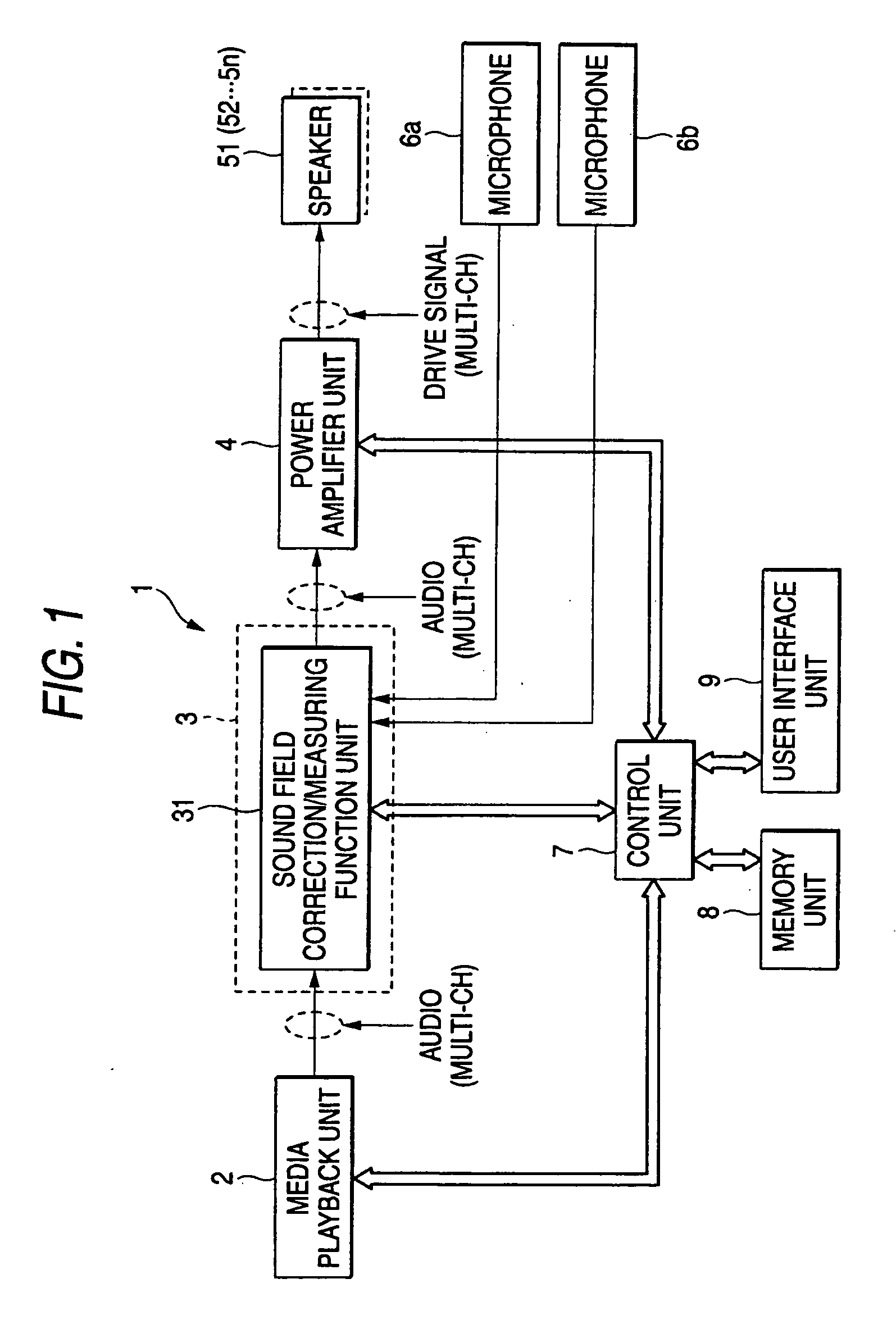

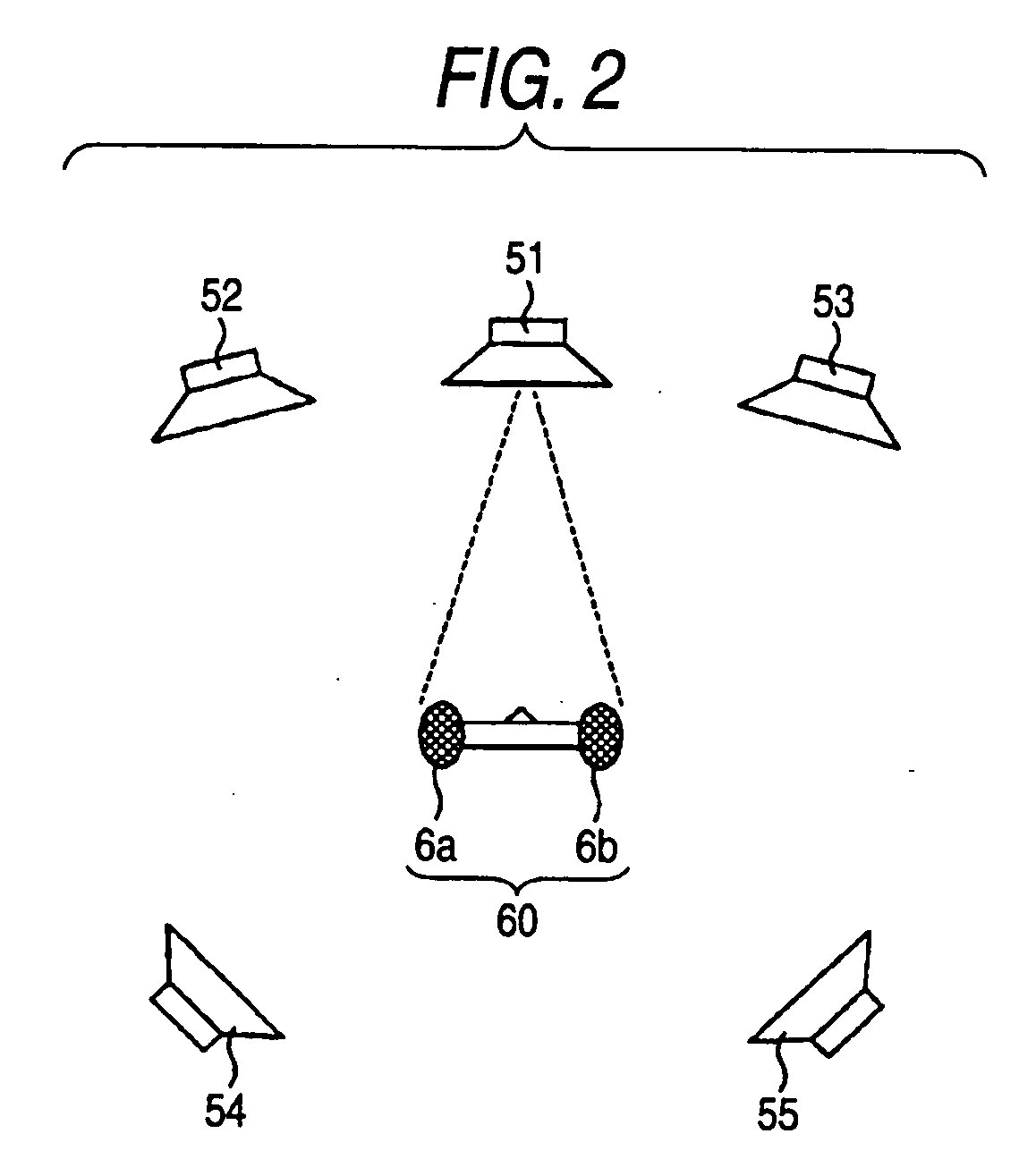

Sound field measuring apparatus and sound field measuring method

InactiveUS20070019815A1Flexible handlingLoudspeaker enclosure positioningLoudspeaker spatial/constructional arrangementsLoudspeakerAudio frequency

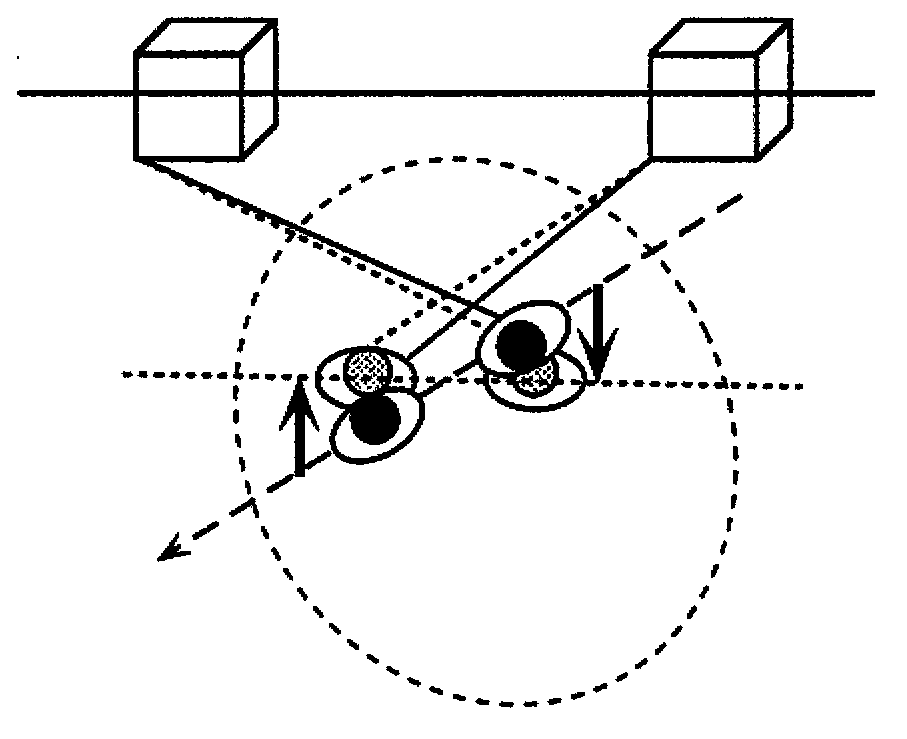

A sound field measuring apparatus includes a microphone set having a first and second microphones arranged at a prescribed interval, which collects audio signals outputted from a first and second speakers, a measuring unit measuring distances between the first and second speakers, and the first and second microphones based on audio signals collected by the first and second microphones, and a position calculating unit calculating a position of the first and second microphones and a position of the second speaker when the first speaker is taken as a standard position based on the respective measured distances.

Owner:SONY CORP

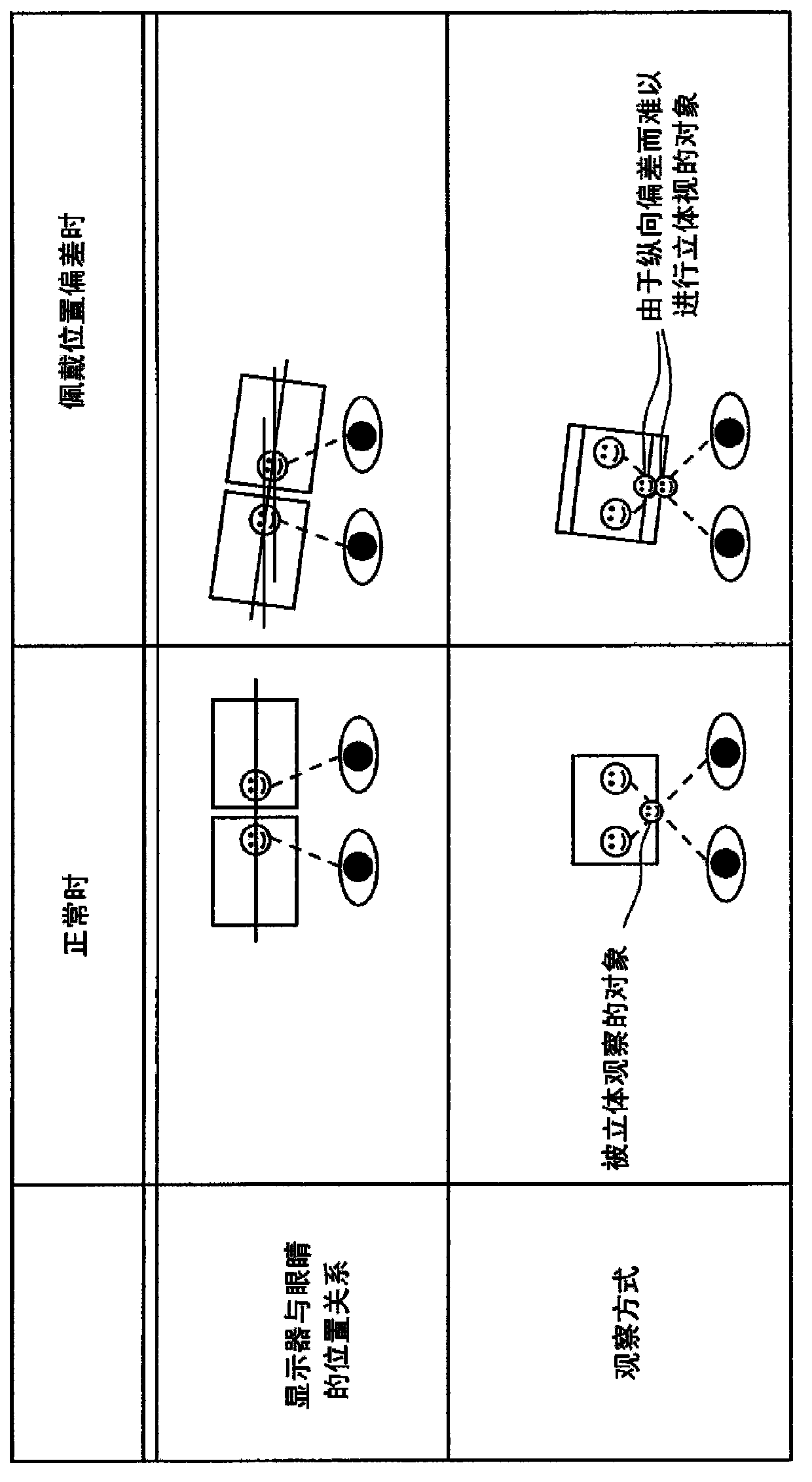

Head-mounted display and misalignment correction method thereof

InactiveCN103380625AUnaffected by misalignment of wearing positionComfortable audio-visualTelevision system detailsColor television detailsImaging processingComputer graphics (images)

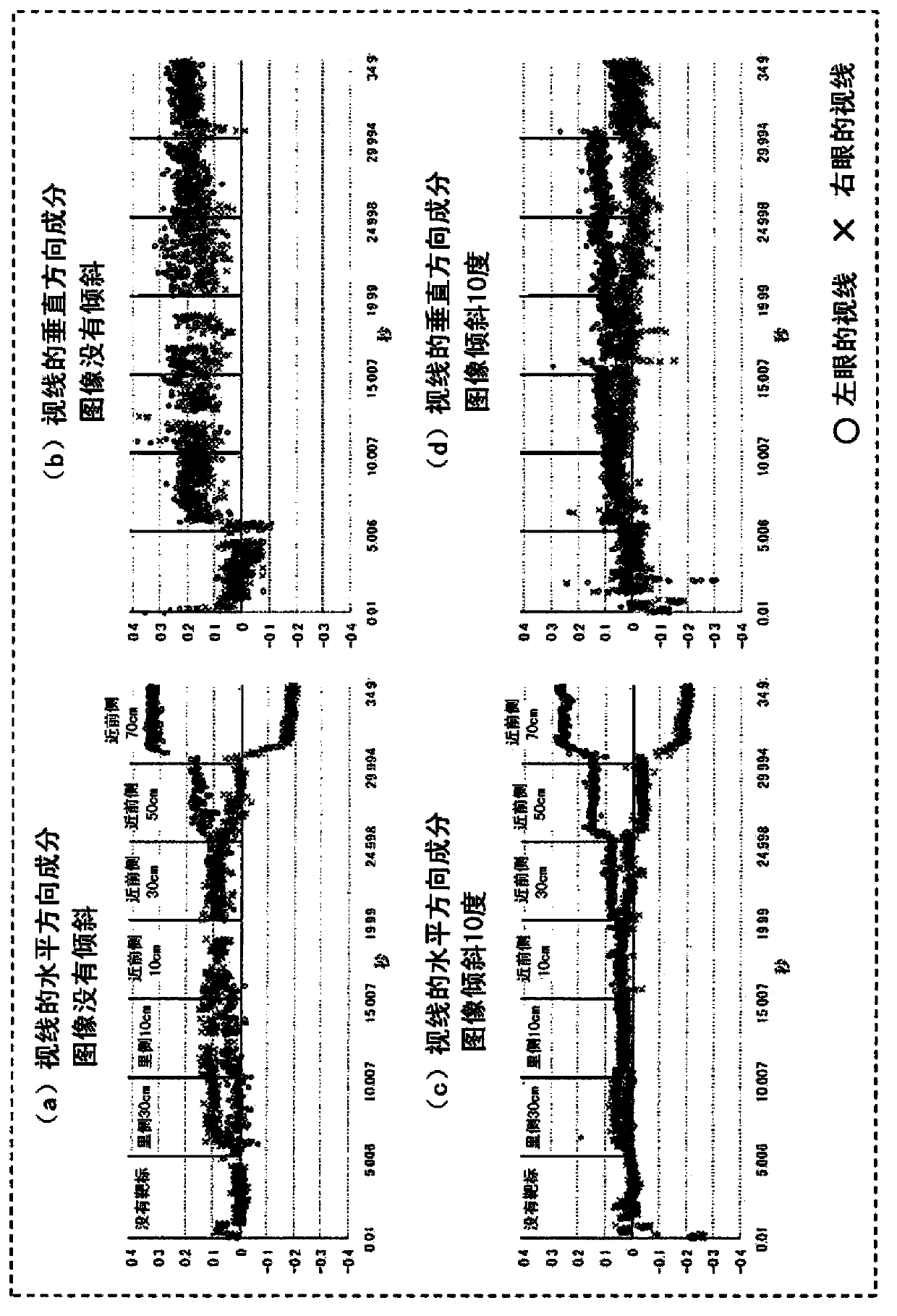

An HMD includes: a display which displays a three-dimensional video image; a position obtaining unit which measures a position of an inner corner or tail of an eye of a viewer with respect to the display; a standard position storage unit which obtains and stores, as a standard position relating to the position, the measured position of the inner corner or outer corner of the eye, in calibration for determining the standard position; a position gap detecting unit which detects, as a position gap, a difference between the standard position and a newly measured position of the inner corner or outer corner of the eye of the viewer viewing content with respect to the display; and an image processing unit which performs image processing on the 3D video image to be displayed on the display, to rotated or parallely move the 3D video image according to the detected position gap.

Owner:PANASONIC CORP

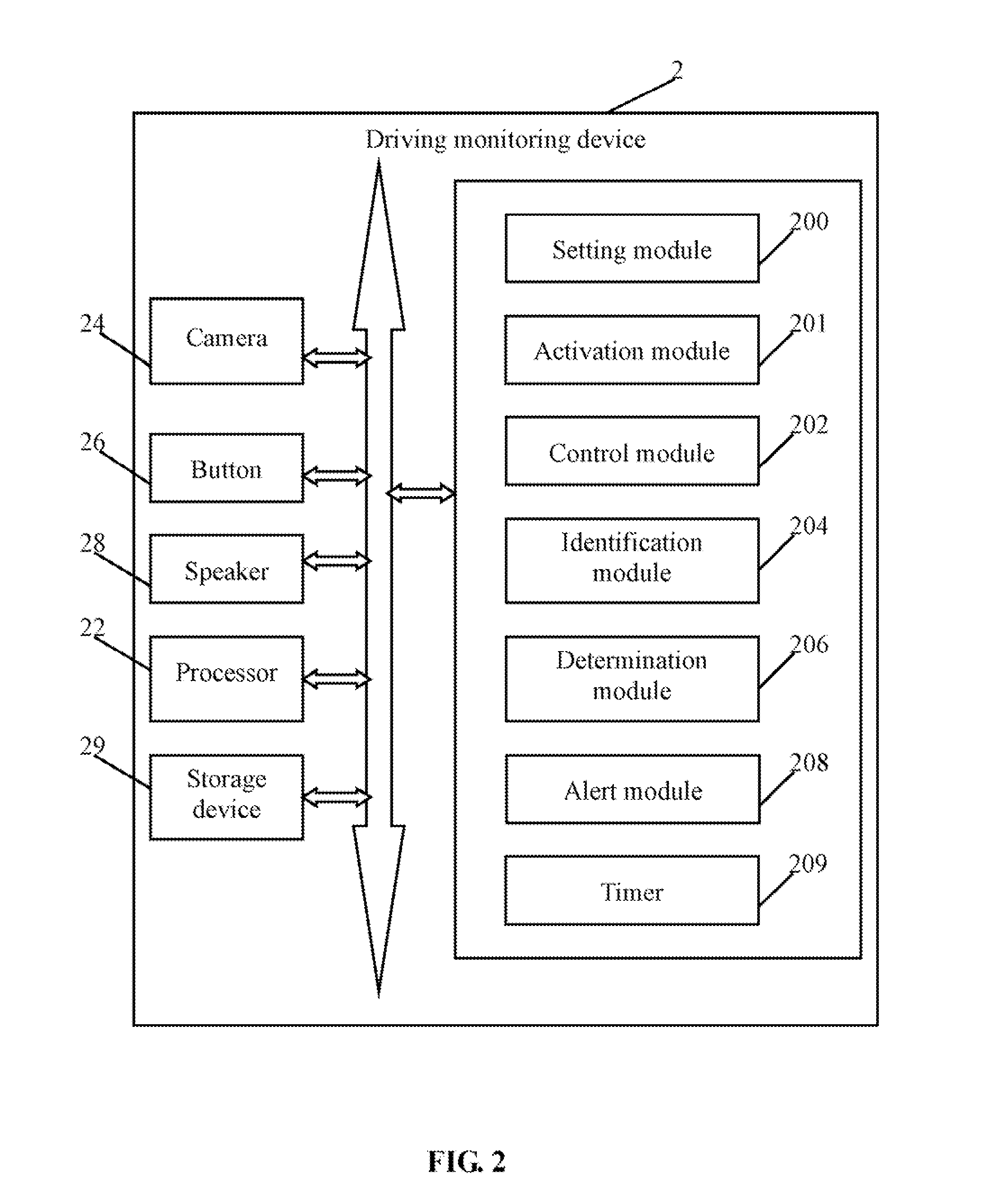

Driving monitoring device and method utilizing the same

InactiveUS20110121960A1Reduce traffic accidentsRoad vehicles traffic controlInstrument arrangements/adaptationsSteering wheelEngineering

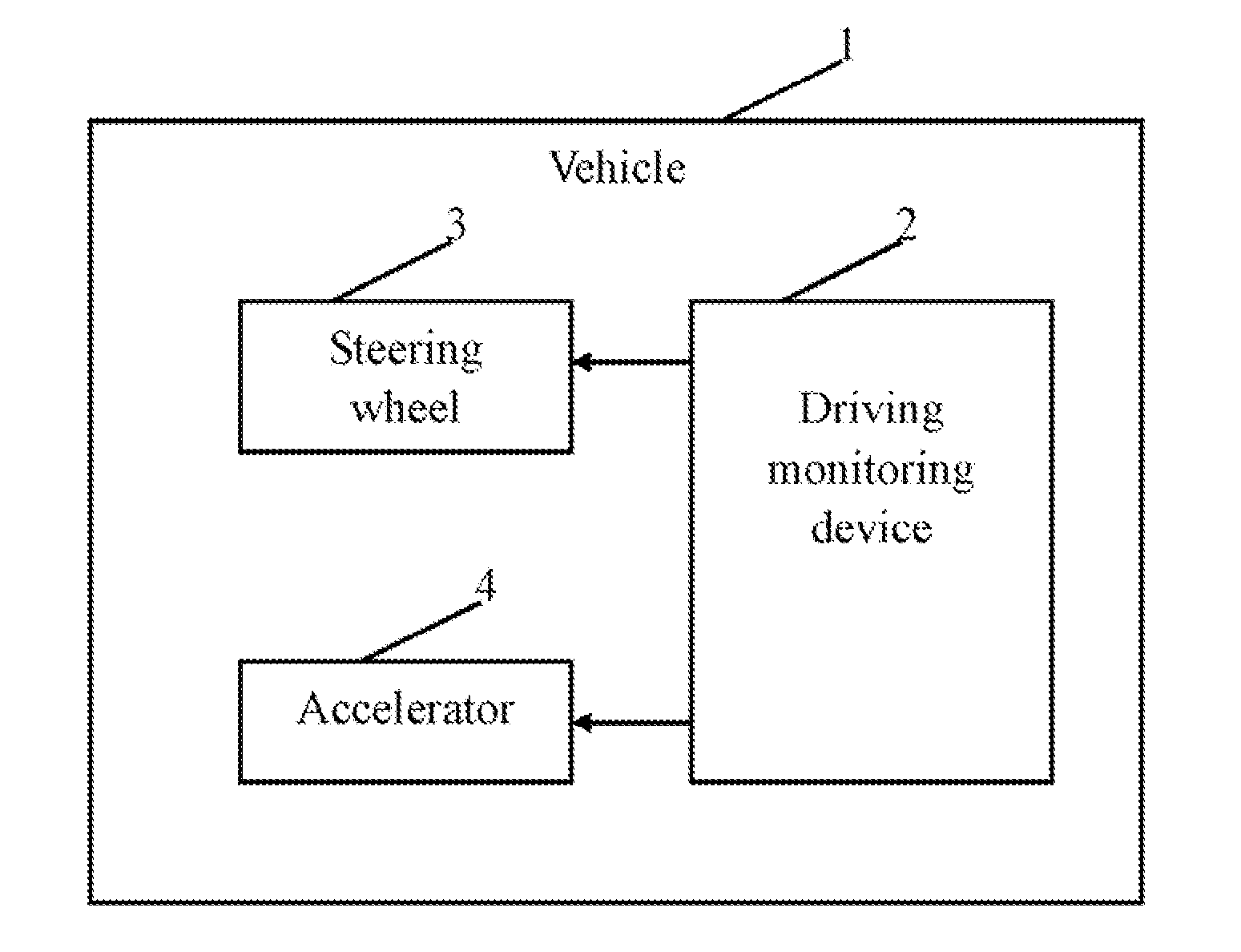

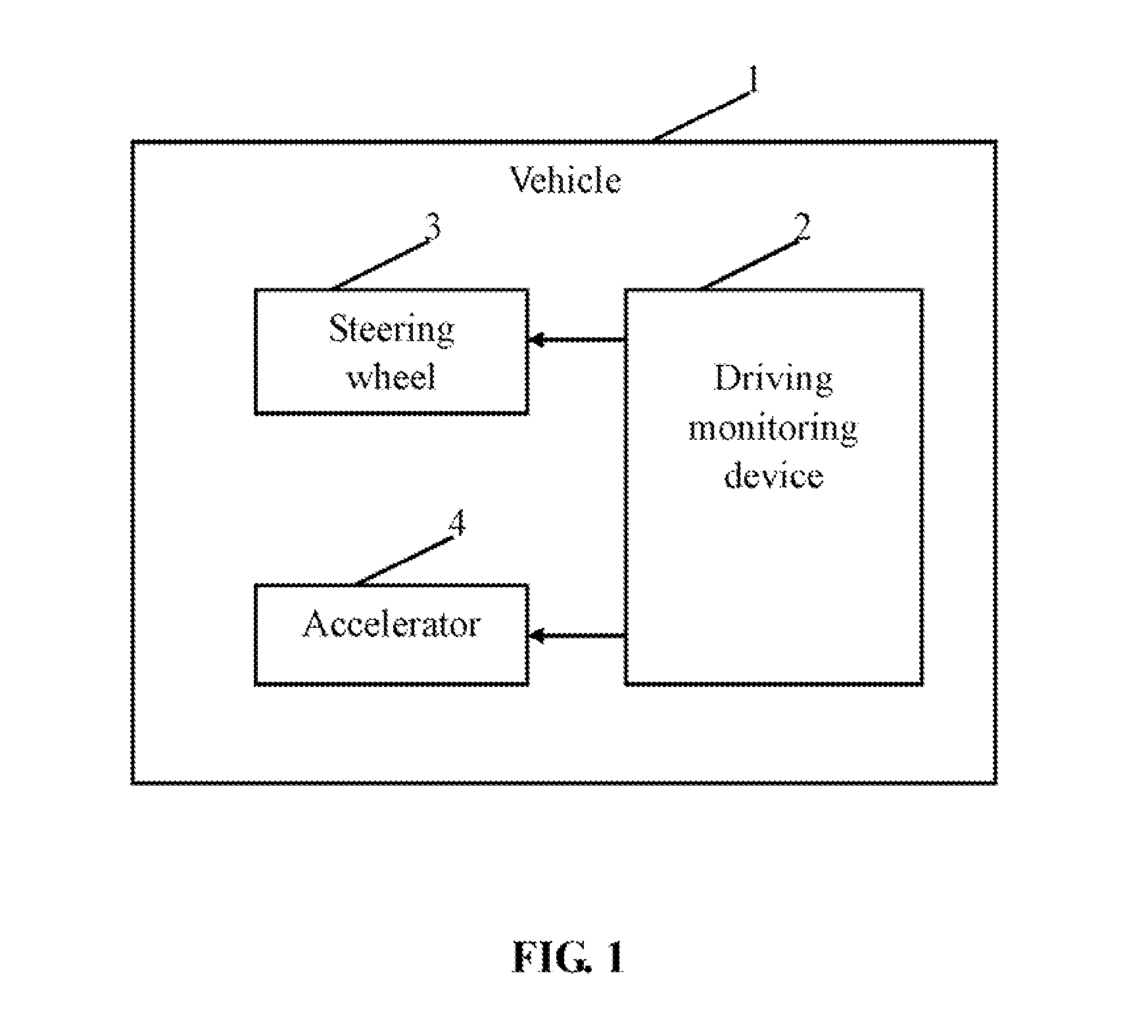

A driving monitoring device and method includes controlling a camera to capture a face image of a driver, identifying the face image to determine if the driver is awake, and controlling a camera to capture a first image of the steering wheel. The driving monitoring device and method further includes identifying a steering wheel region and two hand regions, confirming one or more sub regions of the steering wheel region corresponding to the two hand regions, determining that the driver drives the vehicle inappropriately if the confirmed sub regions do not match standard positions, and outputting alert signals to prompt the driver.

Owner:HON HAI PRECISION IND CO LTD

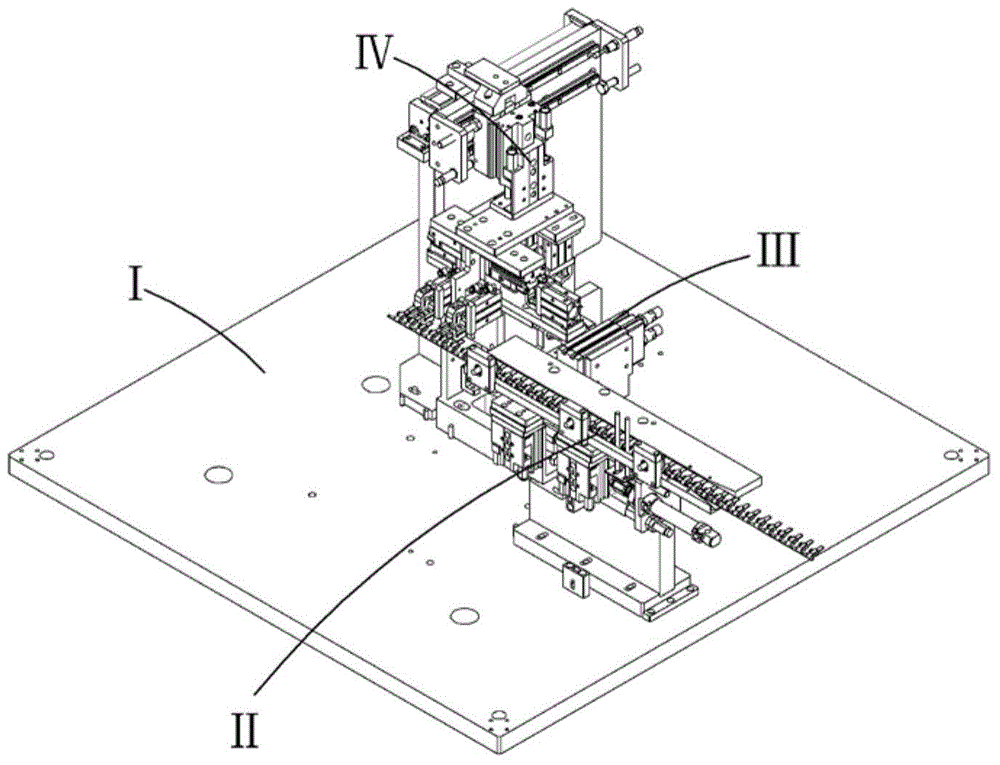

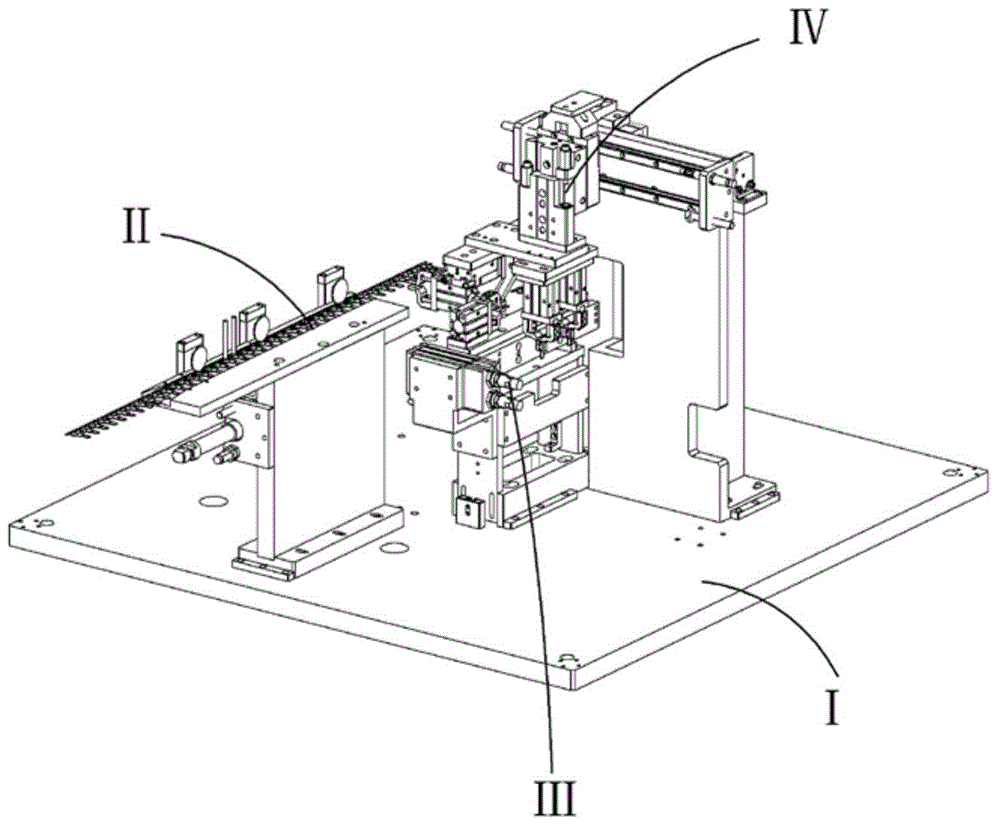

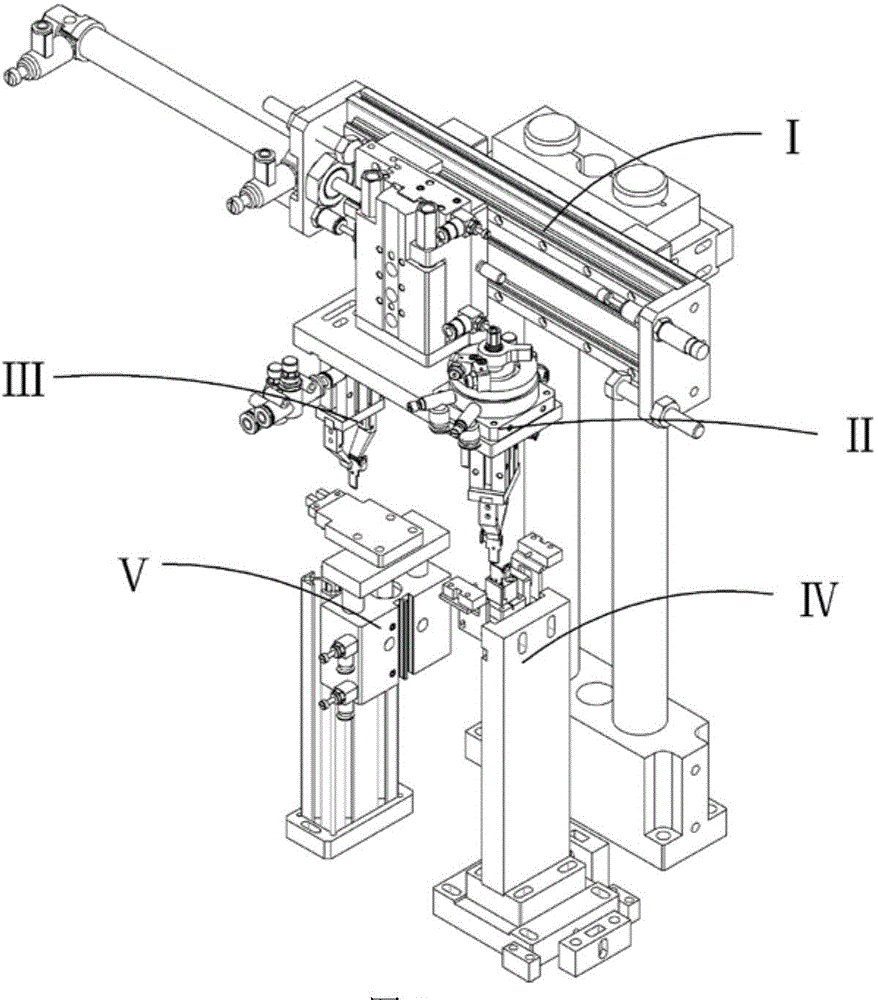

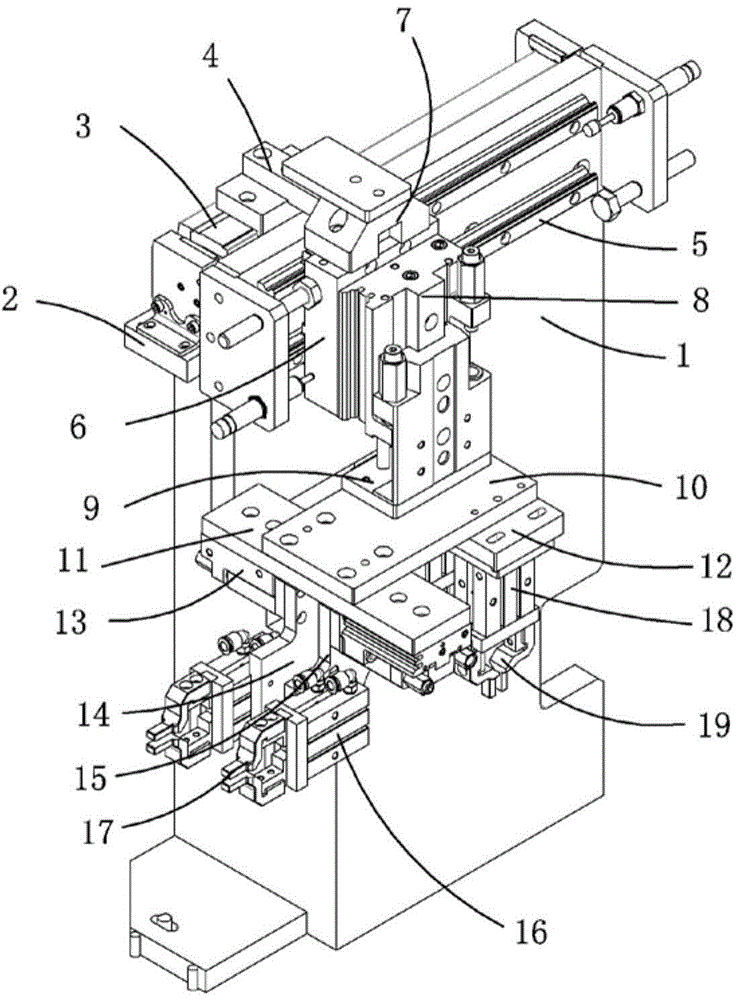

Automatic feeding mechanism

ActiveCN104444289ANo overtravelReduce labor intensityControl devices for conveyorsEngineeringUltimate tensile strength

The invention relates to an automatic feeding mechanism. A feeding mechanism, a material overturning mechanism and a material transferring mechanism are mounted on a large base plate; the feeding mechanism can realize reciprocating feeding and material supply; the material overturning mechanism can be used for clamping a product, and the product rotates by 90 degrees under the driving of a rotating cylinder; the material transferring mechanism can be used for fetching a material from a material belt of the feeding mechanism and transferring the product onto the material overturning mechanism, and after the product is overturned by 90 degrees, the material transferring mechanism can be used for receiving the material and transferring the product to other mechanisms for making preparations for the next step. Under cooperation with the feeding mechanism, the material overturning mechanism and the material transferring mechanism, the product is conveyed to a standard position, so that the work efficiency is high, the feeding position is accurate and the labor intensity of workers is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

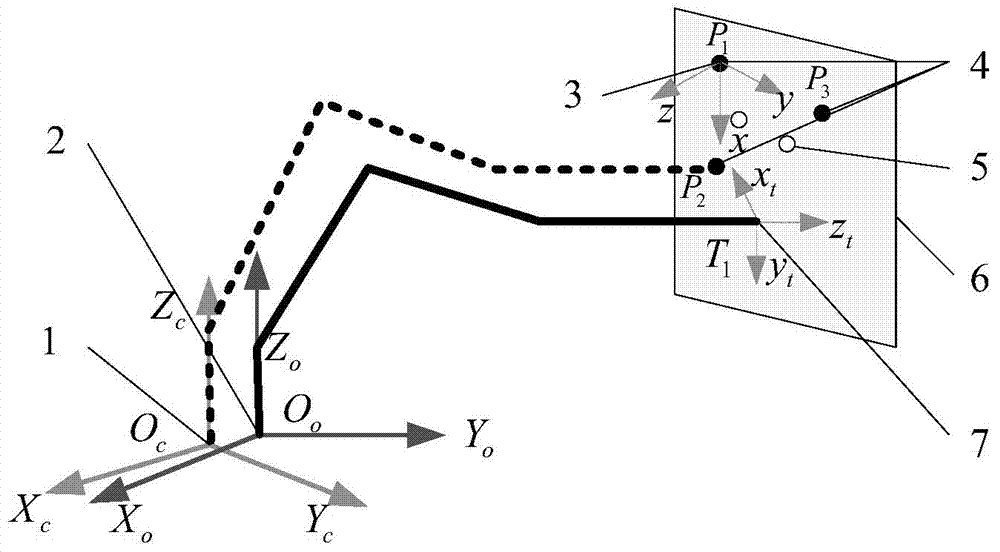

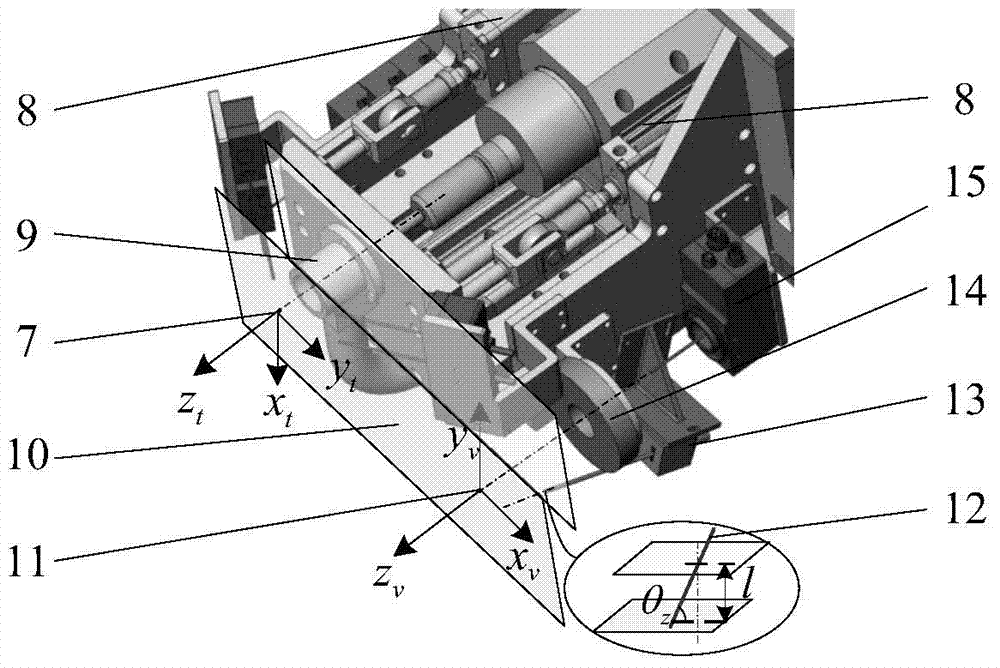

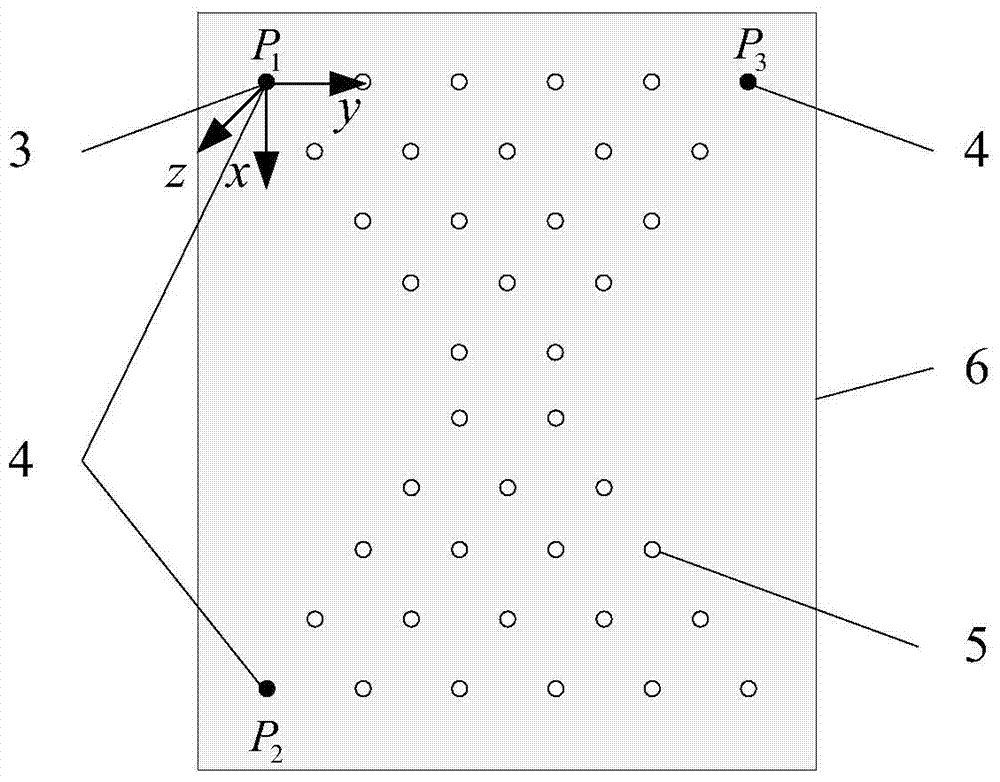

Mobile hole-making robot standard alignment method based on high precision industrial camera

ActiveCN104759945AReduce workloadGuaranteed accuracyMeasurement/indication equipmentsSimulationDistance sensors

The invention provides a mobile hole-making robot standard alignment method based on a high precision industrial camera, and belongs to the industrial robot calibration technical field. The method adopts a high precision industrial camera and a Z-direction laser distance sensor for confirming three-dimensional coordinate value of a standard hole for confirming relative position relationship of the parts and an industrial robot; the industrial robot is circularly adjusted for many times until that the vertical angle between the plane of the part nearby the standard hole and the industrial robot end tool meets the requirement; the standard hole can also get to the preset standard position in the camera coordinate system; the coordinate value of the current standard hole in the robot pedestal coordinate system is used for establishing a workpiece coordinate system. The mobile hole-making robot standard alignment method based on the high precision industrial camera can full-automatically perform standard detection, is high in precision, high in efficiency, economic and practical, simple and pellucid in operation sequence.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

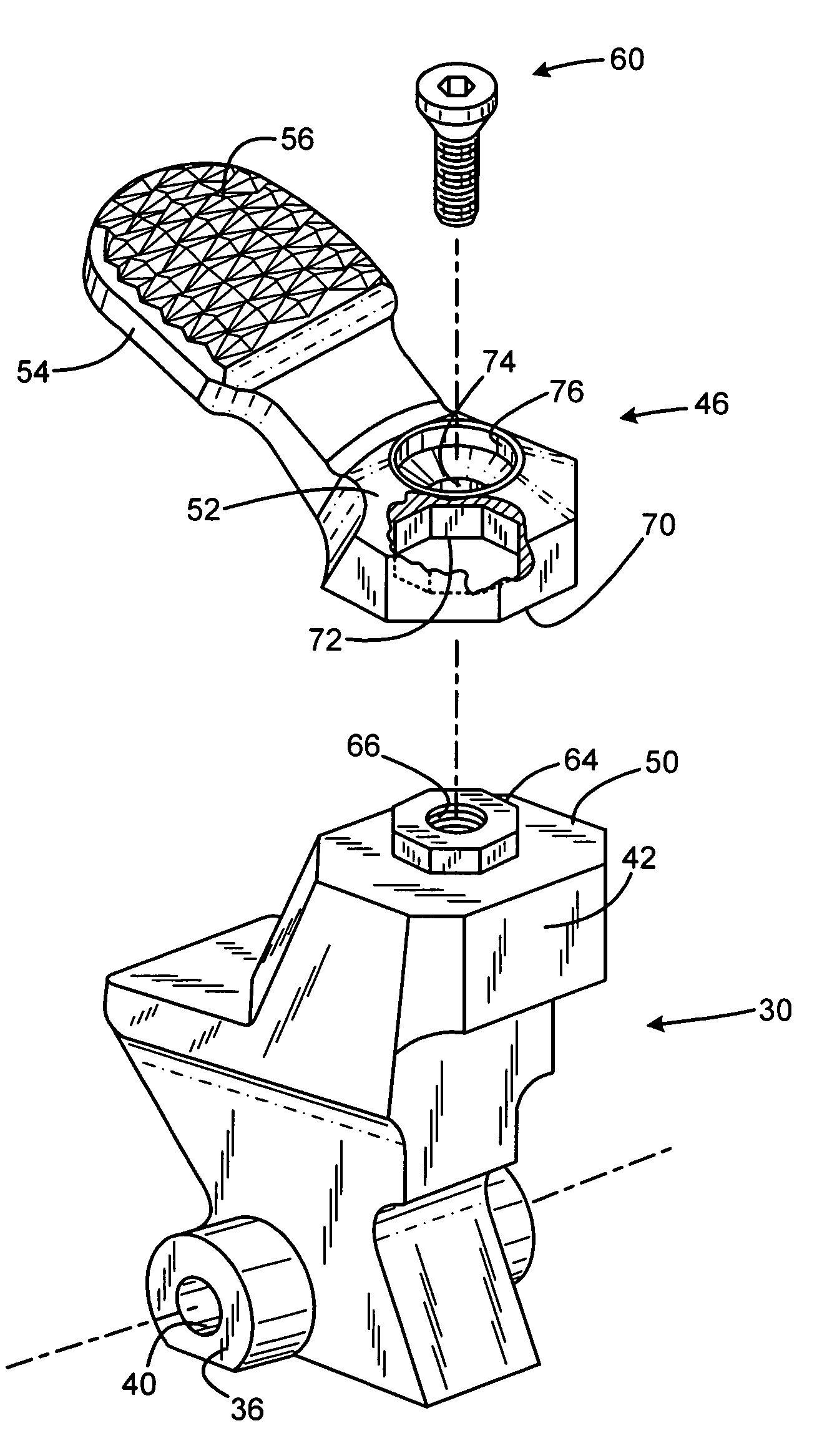

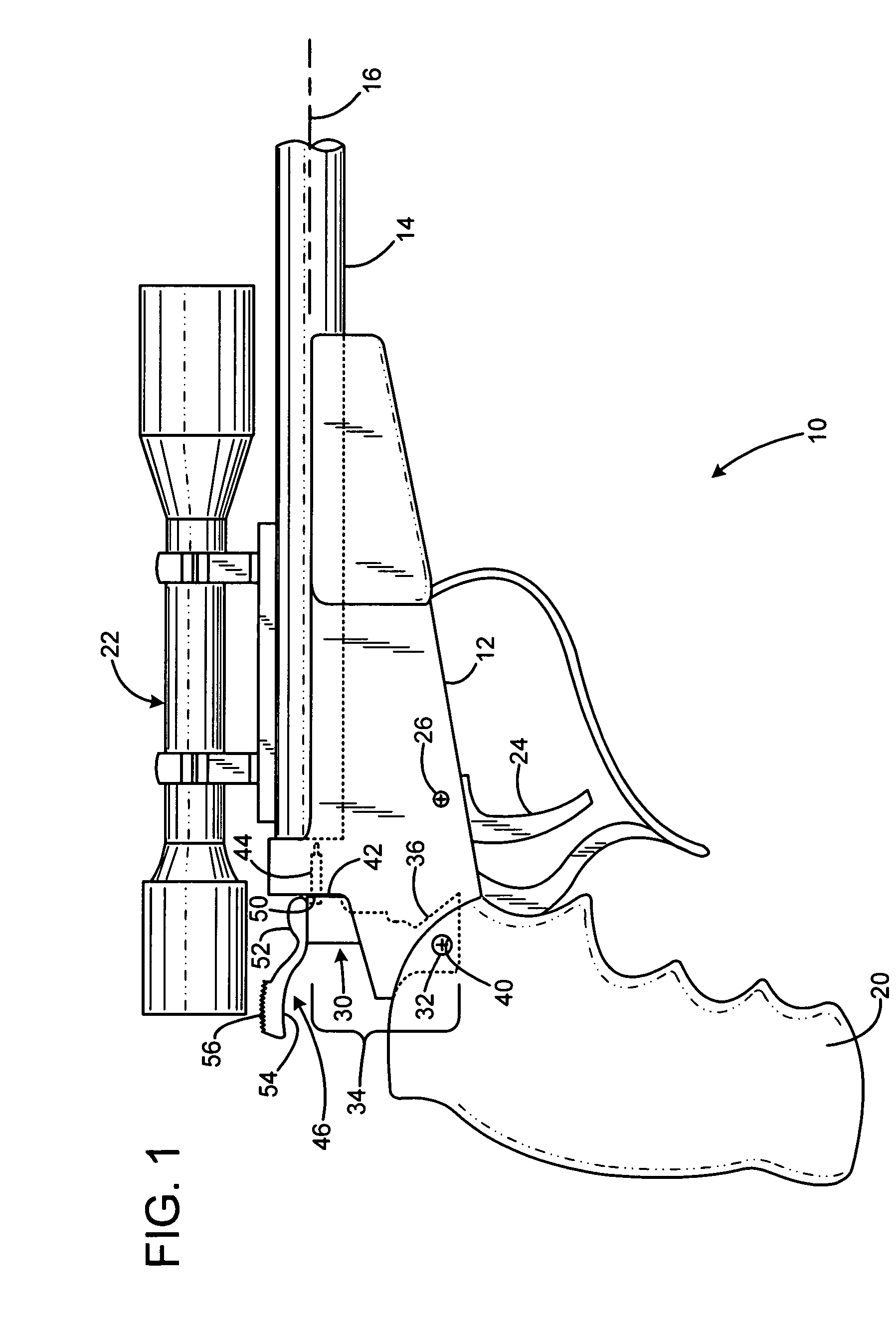

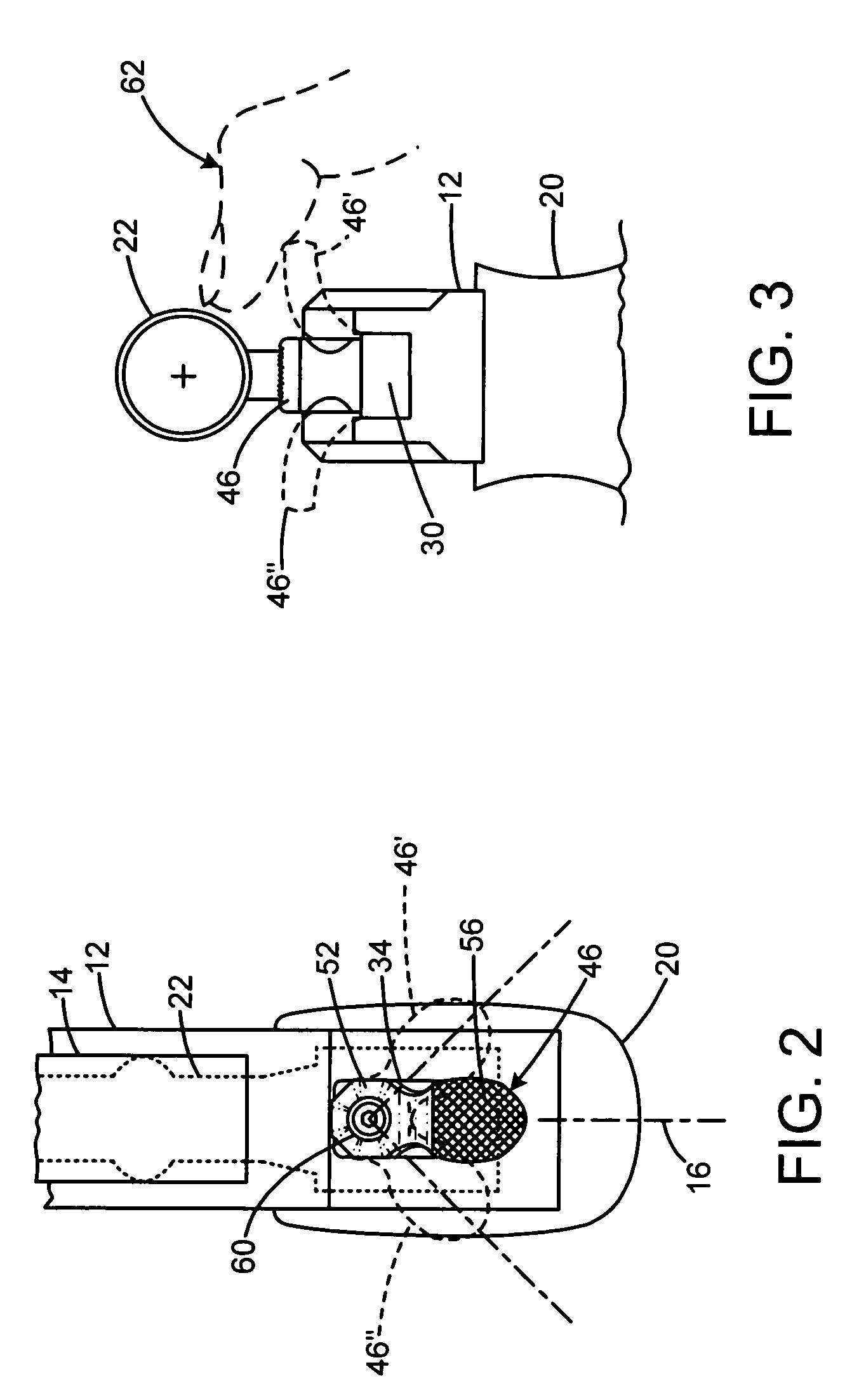

Firearm hammer with adjustable spur

ActiveUS7140138B1Reduces “ lock time ”Convenient and accurateSafety arrangementFiring/trigger mechanismsEngineeringStandard position

A firearm hammer has a hammer body with a hammer pivot axis for attachment to a firearm frame. A spur is connected to the hammer body, and the spur is movable among a number of positions with respect to the hammer body. The spur may be attached in a standard position in which it extends within the medial plane of the hammer body for use without a scope, or offset positions in which it angles away from the medial plane to provide accessibility. The offset angle may be 45 degrees, and a mating feature may provide the several attachment positions, each secure against movement except by deliberate removal of a fastener.

Owner:SMITH & WESSON

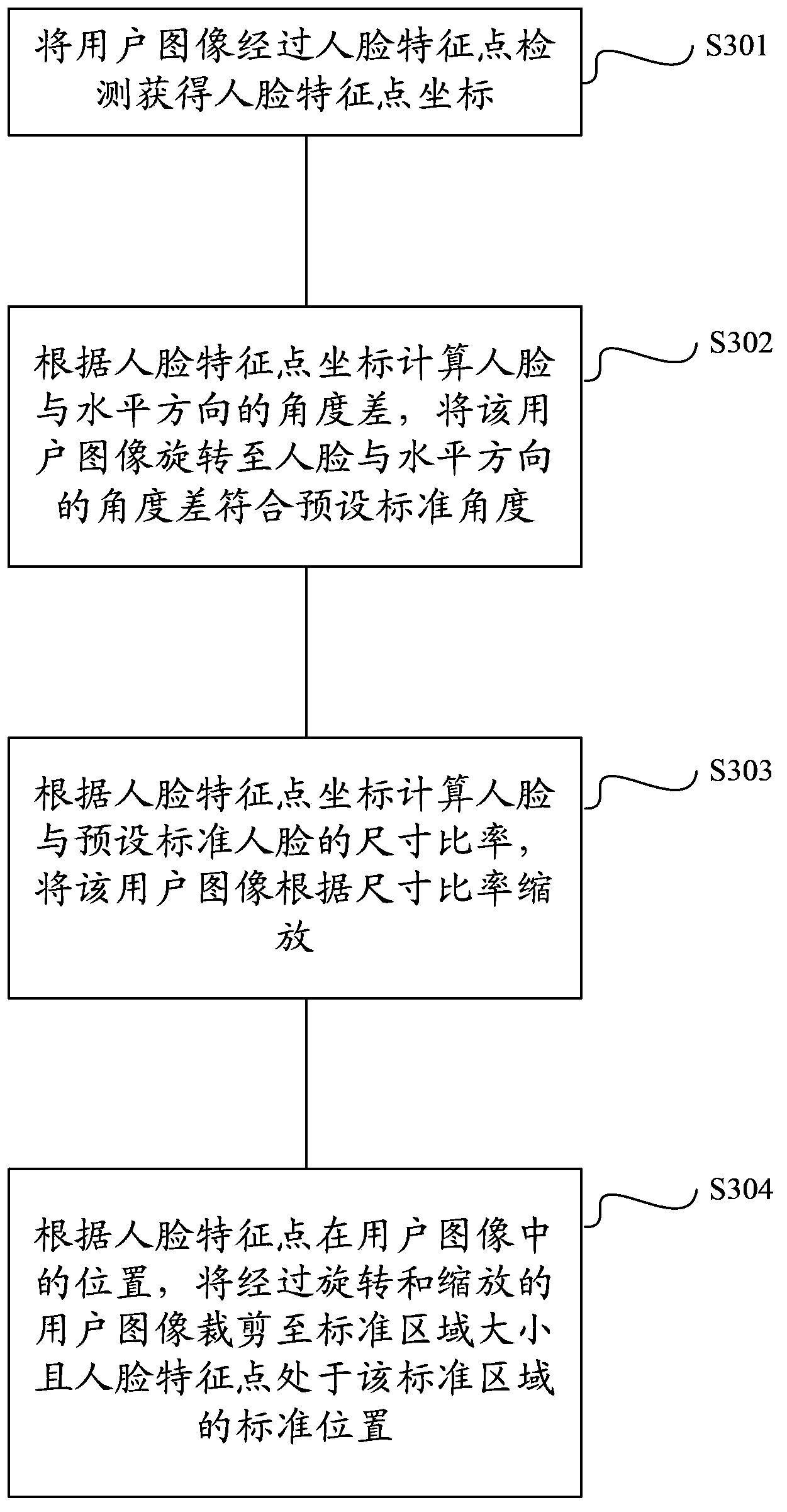

Method and apparatus for use in face recognition

ActiveCN103914676AEliminate the effects ofSame sizeCharacter and pattern recognitionPattern recognitionSize ratio

An embodiment of the invention provides a method for use in face recognition. The method includes: obtaining a coordinate of facial feature points after detection of the facial feature points of a user image; calculating the angular difference between a human face and a horizontal direction based on the coordinate of facial feature points, and rotating the user image until the angular difference between the human face and the horizontal direction matches a preset standard angle; calculating a size ratio between the human face and a preset standard human face according to the coordinate of facial feature points, and scaling the user image according to the size ratio; and according to the location of the facial feature points in the user image, cropping the user image after rotation and scaling into a standard area size so that the facial feature points are in the standard position of the standard area, and obtaining an aligned facial image of a consistent size through pre-processing of the user image so that the facial features of the same user are more consistent and the effects of low-quality images on face recognition are eliminated. In addition, the invention also provides an apparatus for use in face recognition.

Owner:杭州易现先进科技有限公司

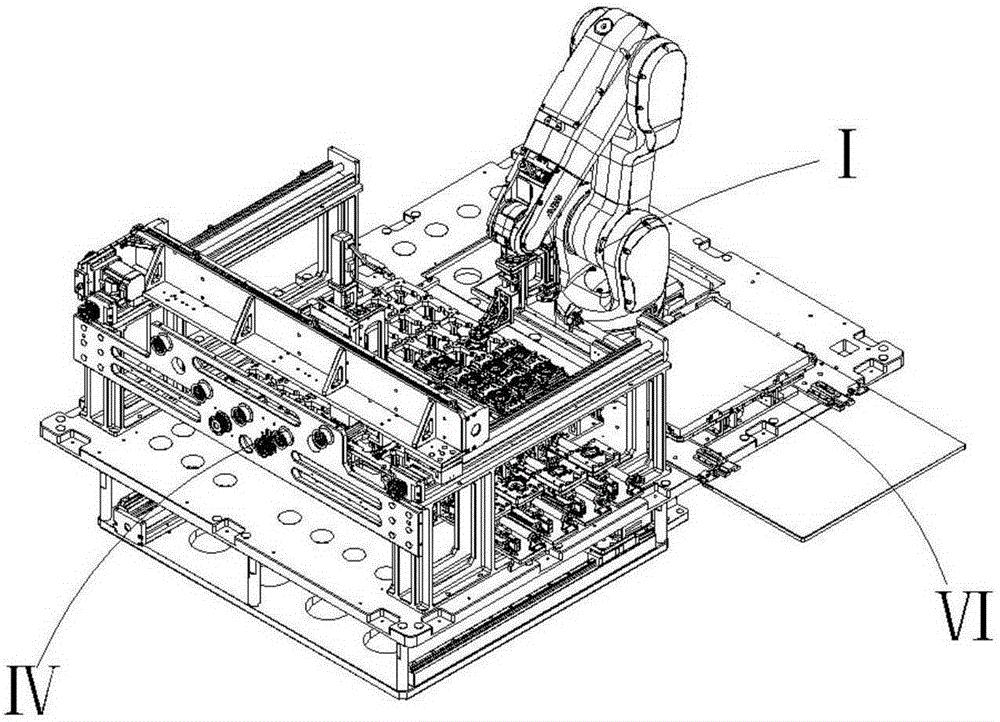

Full-automatic alignment and assembly machine

ActiveCN105196032ASimple structureEasy to useGripping headsMetal working apparatusWatch glassAdhesive

Owner:BOZHON PRECISION IND TECH CO LTD

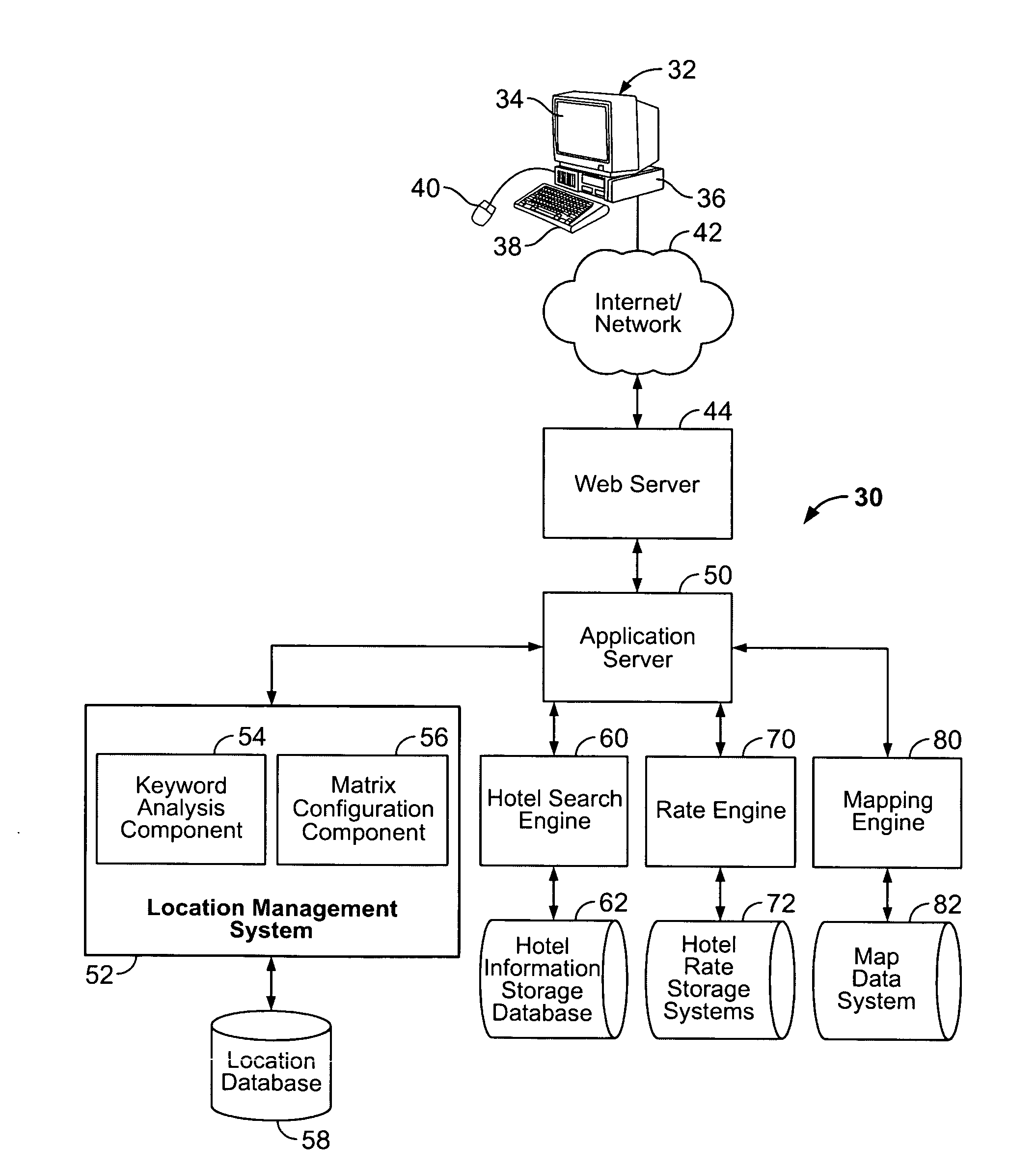

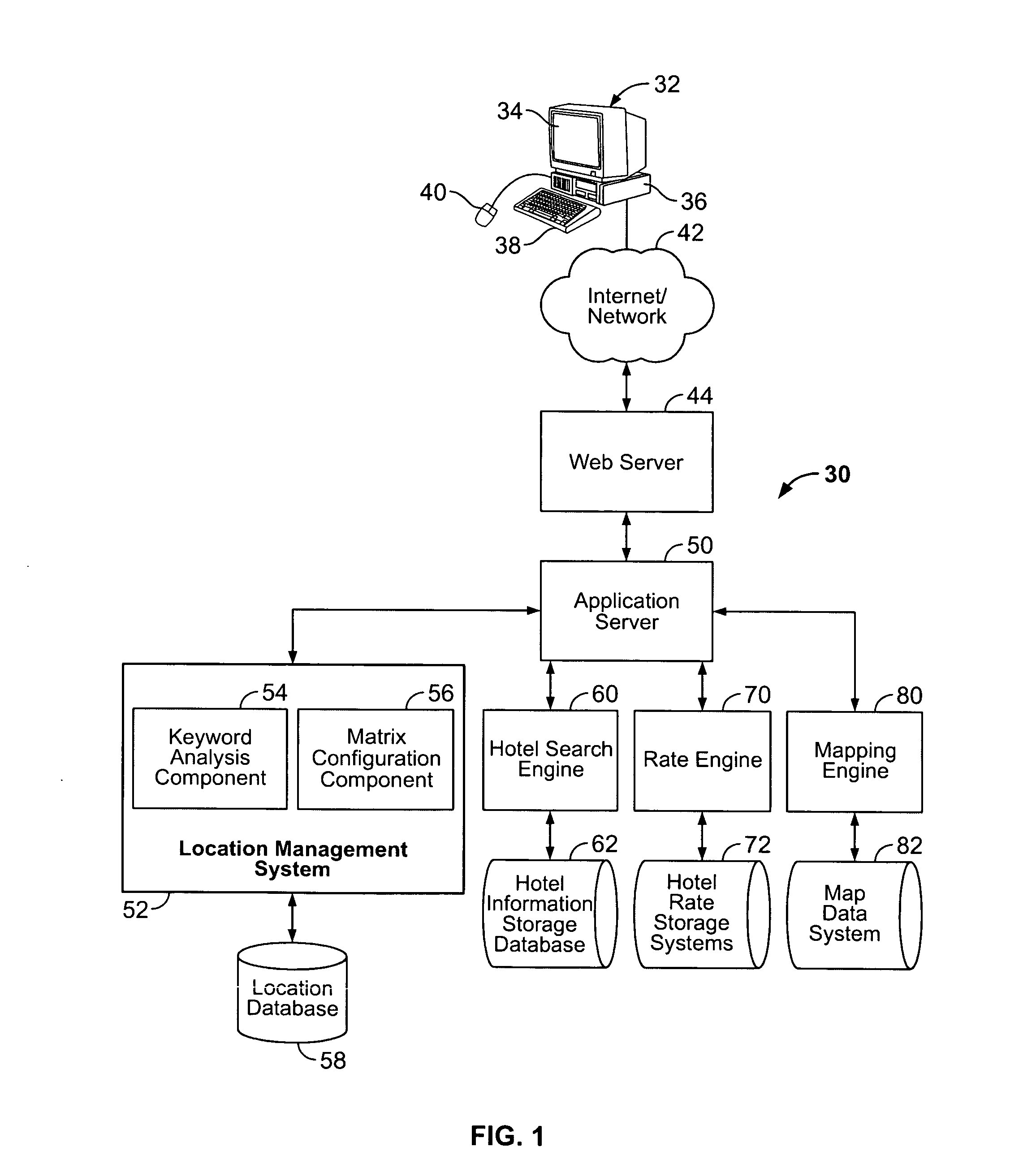

System and method for providing travel related product information on an interactive display having neighborhood categories

InactiveUS20060173617A1Instruments for road network navigationRoad vehicles traffic controlApplication serverUser input

A product location display system and method are provided that allow travel related product information, such as the geographic location of hotels, to be displayed on an interactive display. An application server of the product location display system receives user inputted criteria for a travel product search. A location management system determines a location for the travel product being searched based on the inputted criteria. Sub-locations associated with the geographic location being searched are pre-defined as being within the searched geographic location and stored within a location database memory component coupled with the location management system. A display configuration component of the location management system arranges and displays results of the search for the travel product by the sub-locations defined as being within the searched location.

Owner:ORBITZ

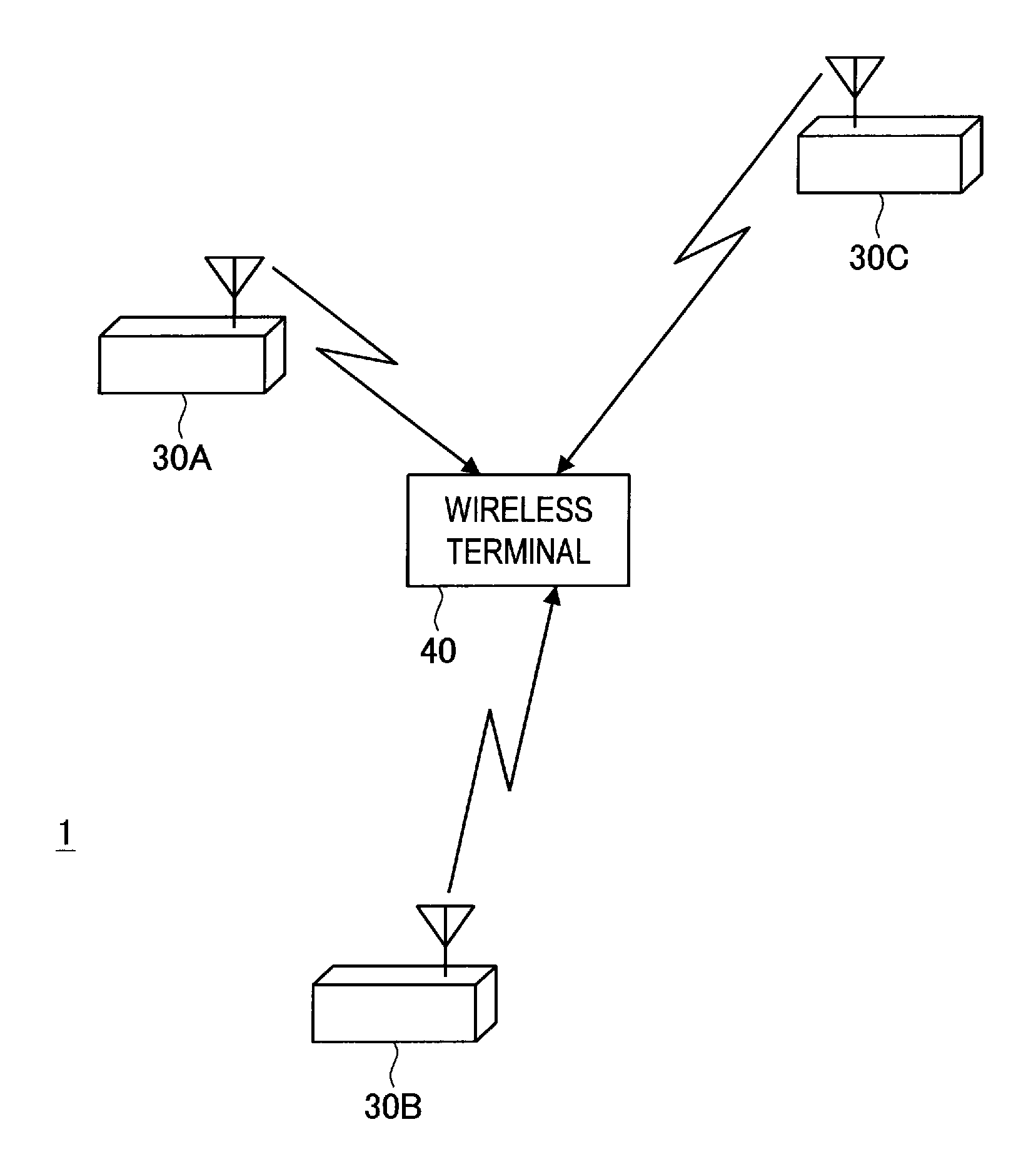

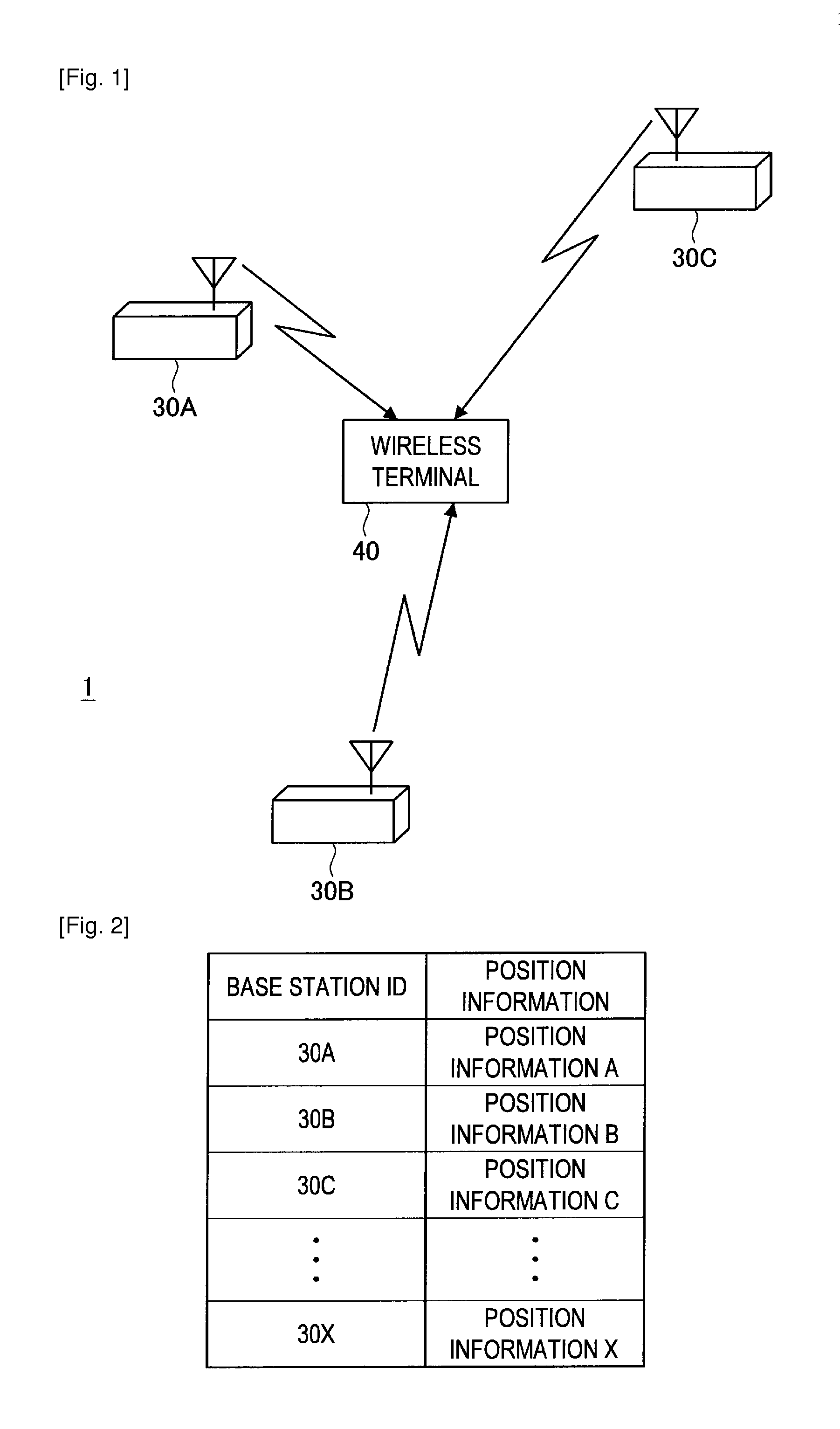

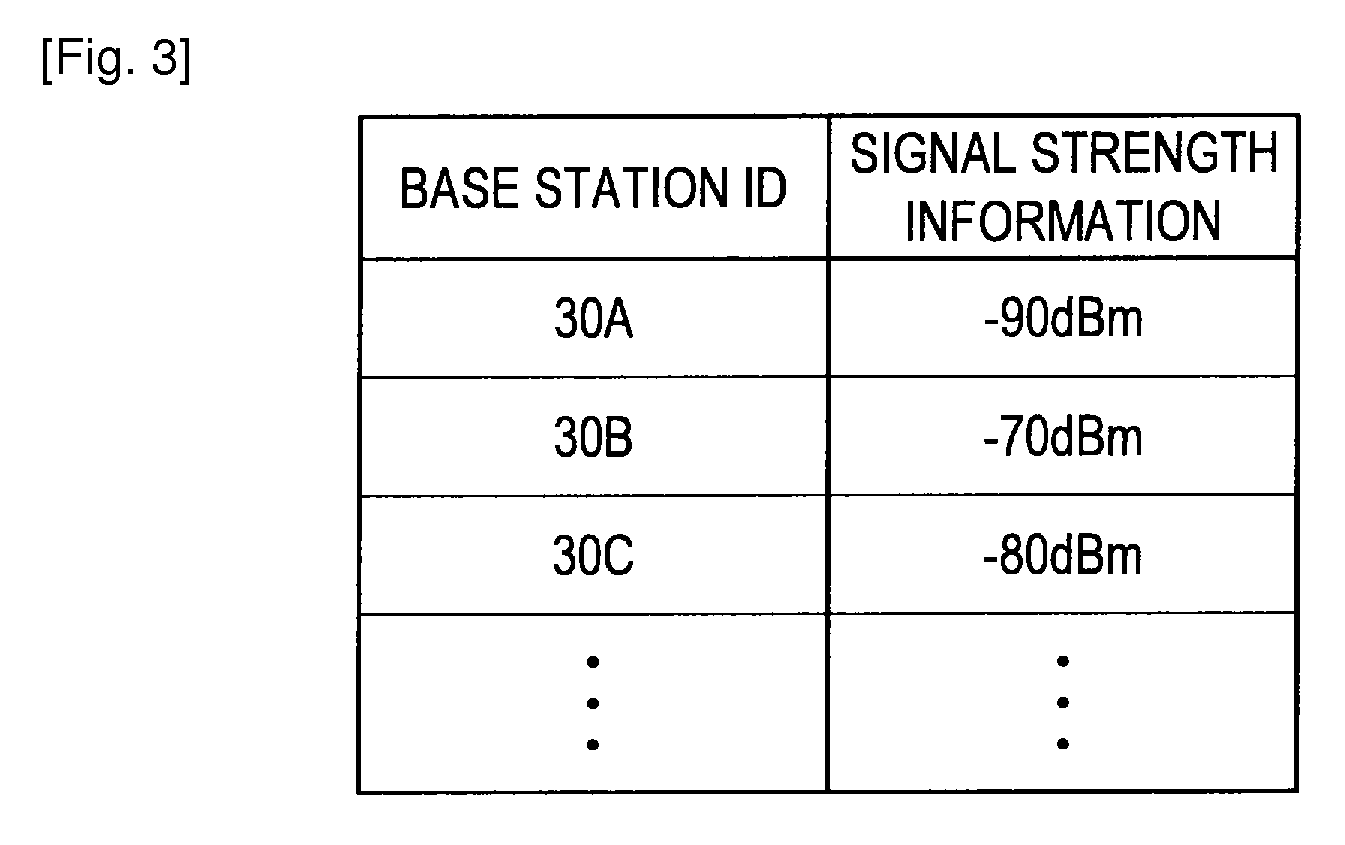

Position estimating apparatus, position estimating method, and computer program product

ActiveUS20130143597A1Suppress fallInstruments for road network navigationPosition fixationReference RegionComputer science

An apparatus, method and computer program storage device cooperate to provide a quality position estimation of a mobile communication device by determining a reference area. The reference area includes the position of the mobile communication device as well as a plurality of transmitters. Transmitters that are detected as being outside of the reference area are excluded from contributing to the position estimate. The reference area is centered at a standard position, which may be a previous position or a GPS based position, for example. The range of the reference area includes a component that considers the range of a transmitter, as well as a GPS error or an estimated move distance of the mobile communication device.

Owner:SONY CORP

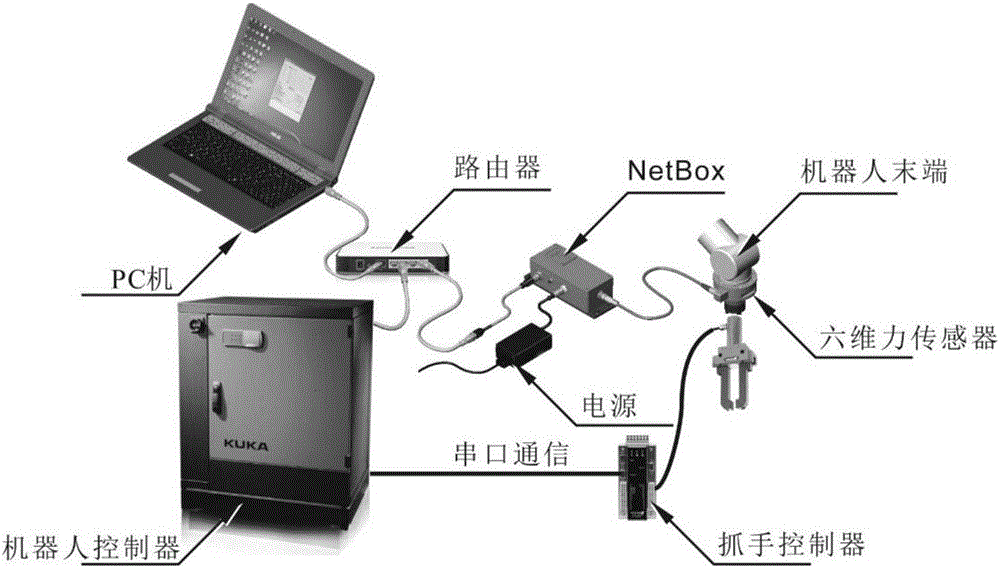

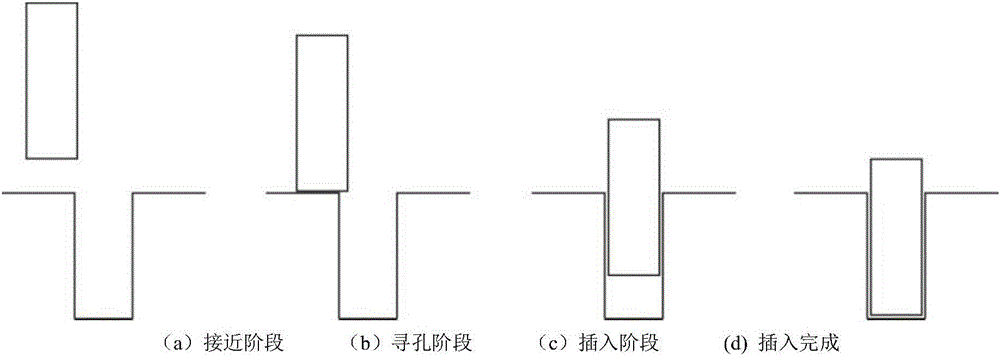

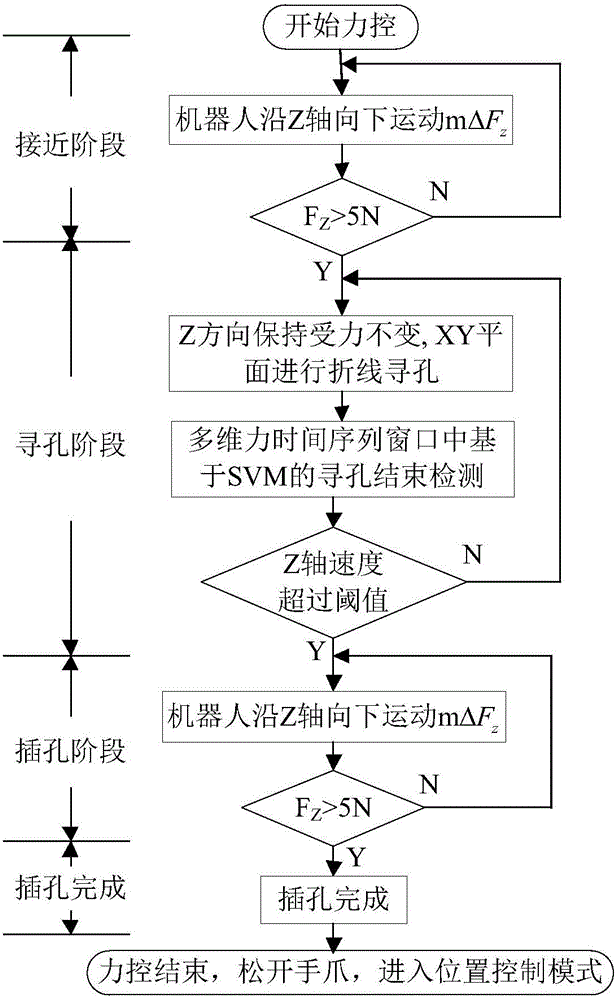

Total-space smooth hole insertion control method applied to assembly robot and based on real-time force control

ActiveCN106335057AAvoid misalignmentImprove efficiencyProgramme-controlled manipulatorSupport vector machineControl system

The invention discloses a total-space smooth hole insertion control method applied to an assembly robot and based on real-time force control. The total-space smooth hole insertion control method applied to the assembly robot and based on real-time force control comprises the steps that a bolt hole insertion real-time force control system of the assembly robot is established by means of a six-dimensional wrist force sensor, a real-time communication software package and the like; the influence of the gravity component on the reading of the six-dimensional wrist force sensor during total-space work of the robot is eliminated through a gravity compensation method based on the standard position; and the common phenomena of jamming and excessive clamping in the bolt hole insertion process are avoided through the design of a stress analysis and force / position hybrid control strategy in the approaching stage, the hole searching stage, an insertion stage and an insertion completing stage of a hole insertion task, thus the insertion success rate of the robot is increased, and the insertion efficiency of the robot are improved; and a detector based on a support vector machine is arranged in a multi-dimensional force time sequence window, so that automatic detection of the hole searching completion state is achieved, and accurate switching between the hole searching subtask and the hole insertion subtask is guaranteed. By adoption of the total-space smooth hole insertion control method applied to the assembly robot and based on real-time force control, control over high-efficiency and high-accuracy chamfer-free smooth hole insertion assembly work can be achieved through a conventional rigid joint robot.

Owner:SOUTHEAST UNIV

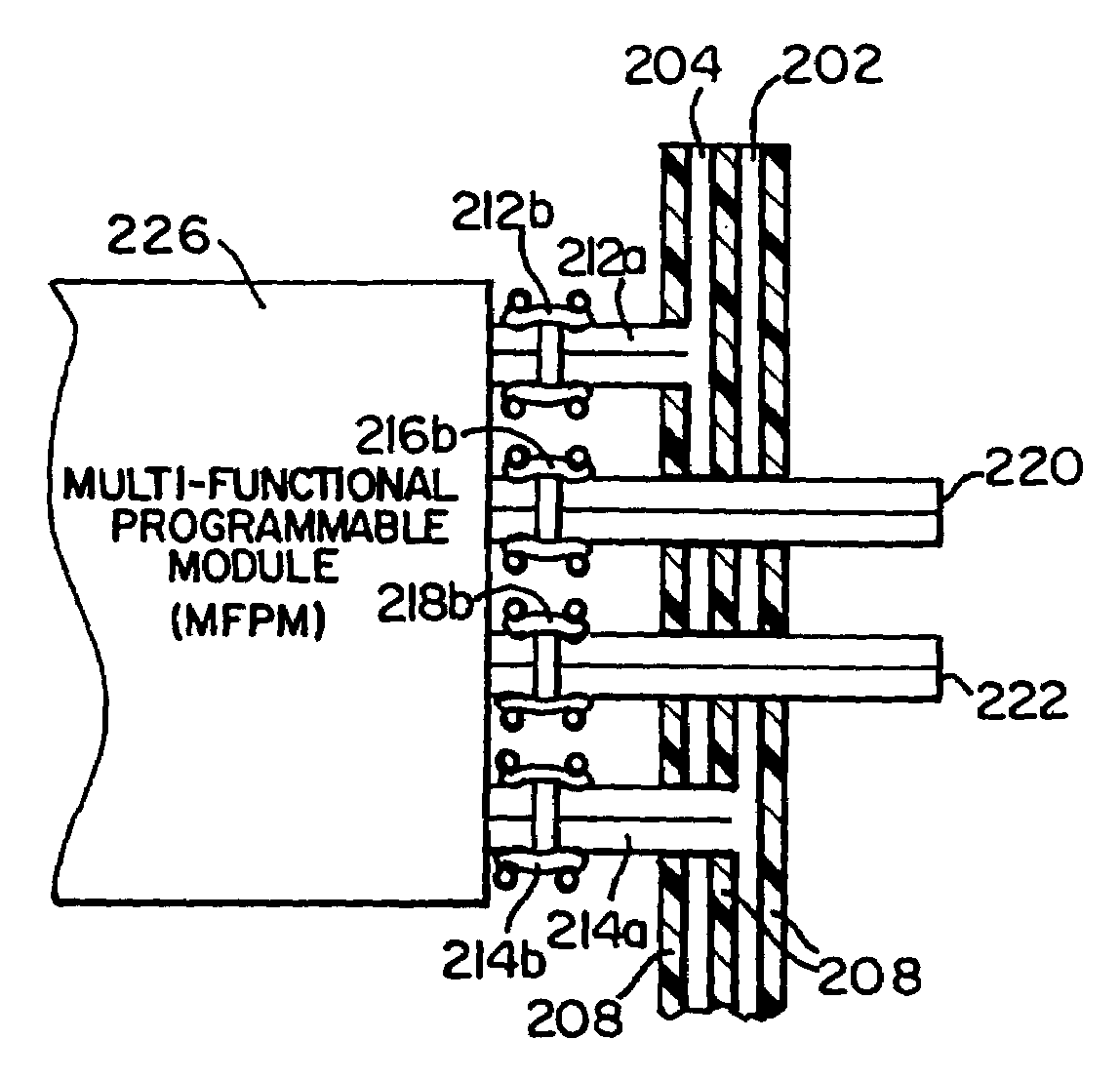

Power node control center

InactiveUS7076592B1Adds mechanical supportImprove thermal stabilityMechanical power/torque controlBus-bar/wiring layoutsBackplaneStandard position

An electrical modular power node comprising a power bus backplane containing a plurality of bus bars, at least some of which are connectable to at least one power source, each bus bar having a plurality of terminals at regular intervals along the bus bar, each terminal being in a standard position in a pattern with terminals from the other bus bars and all terminal patterns being in a standard orientation on the backplane, and a plurality of functional modules, each housing circuitry having at least one connector for a connection to at least one terminal on one of the bus bars.

Owner:L 3 COMM SPD TECH

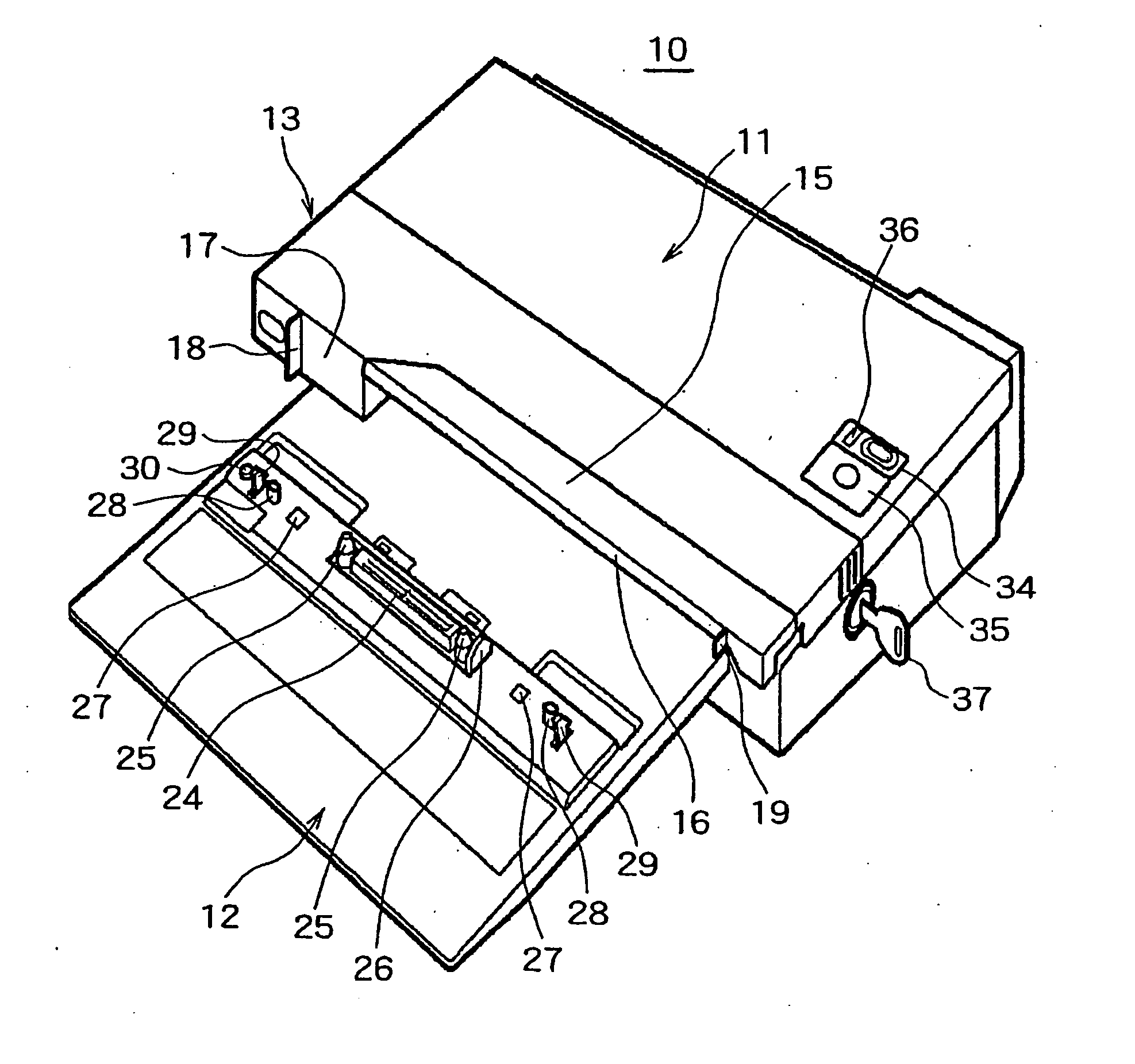

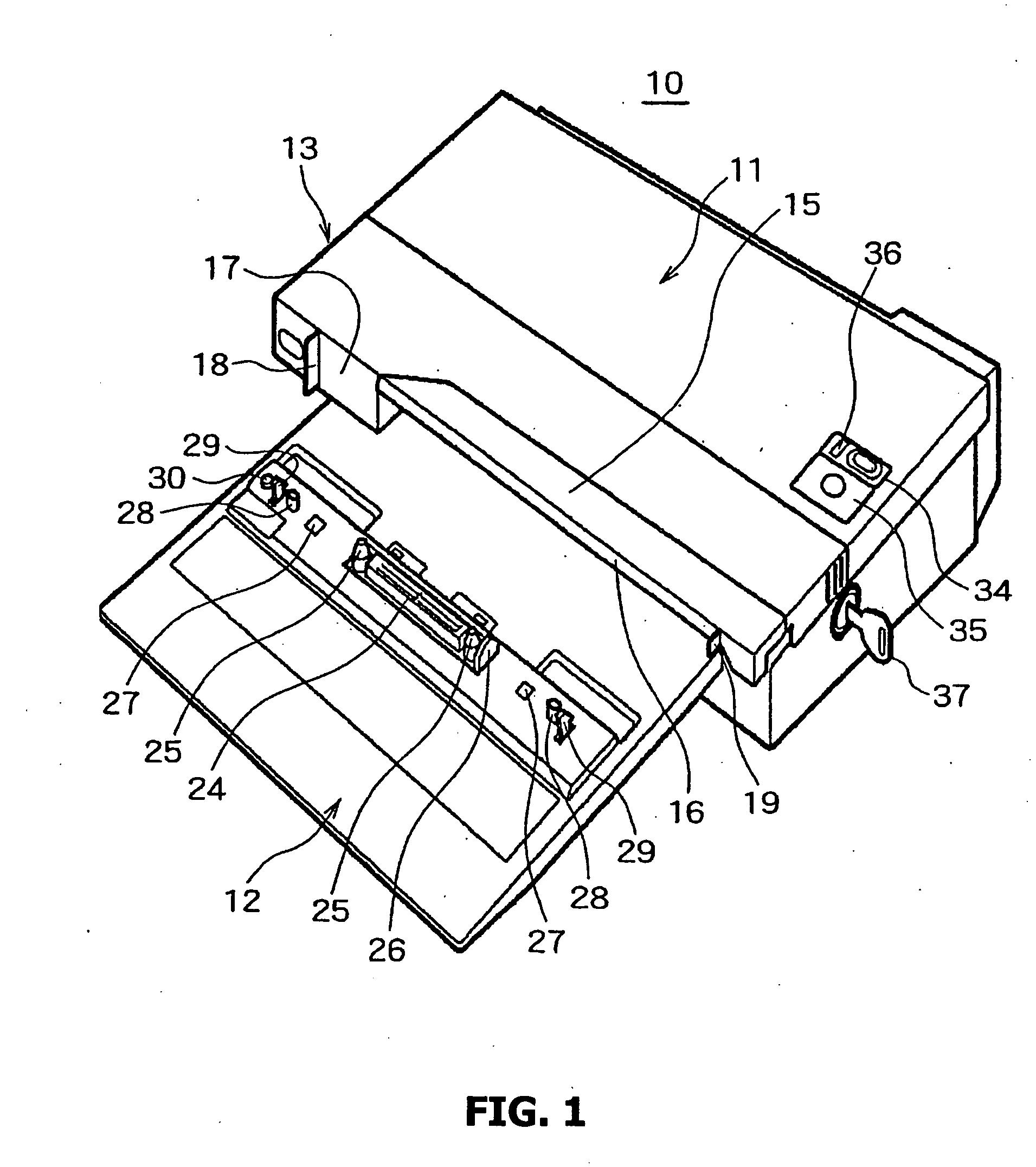

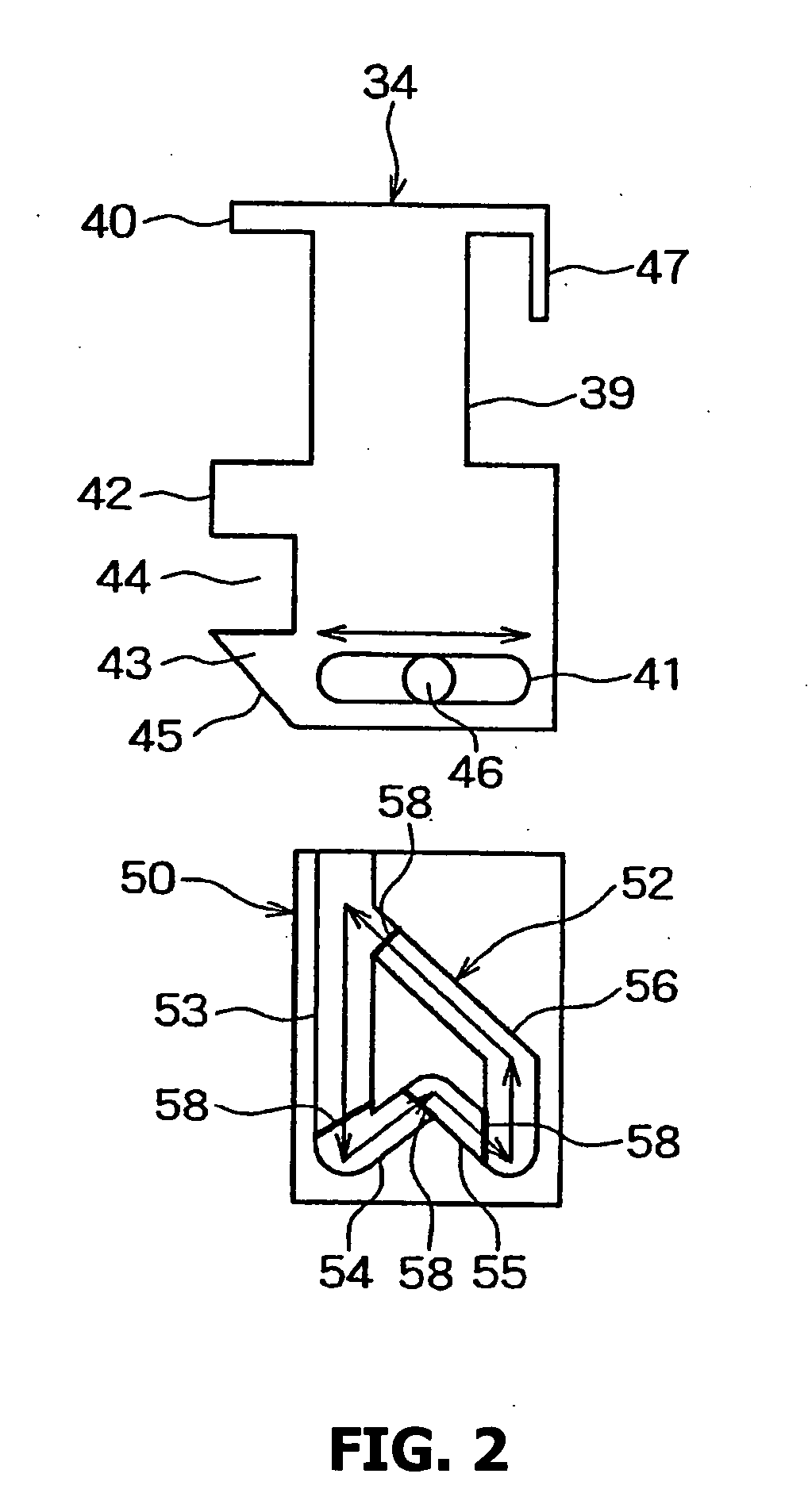

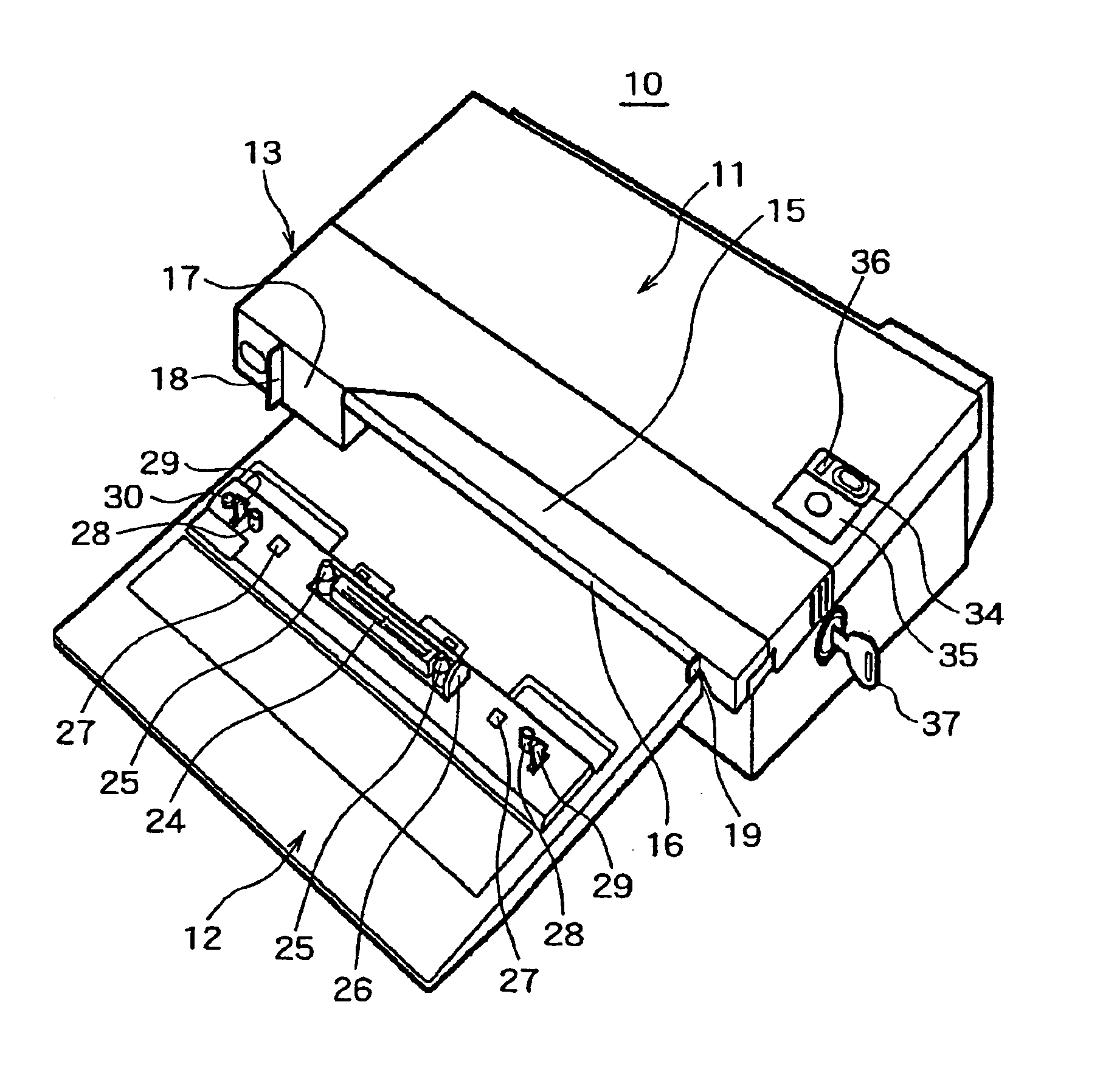

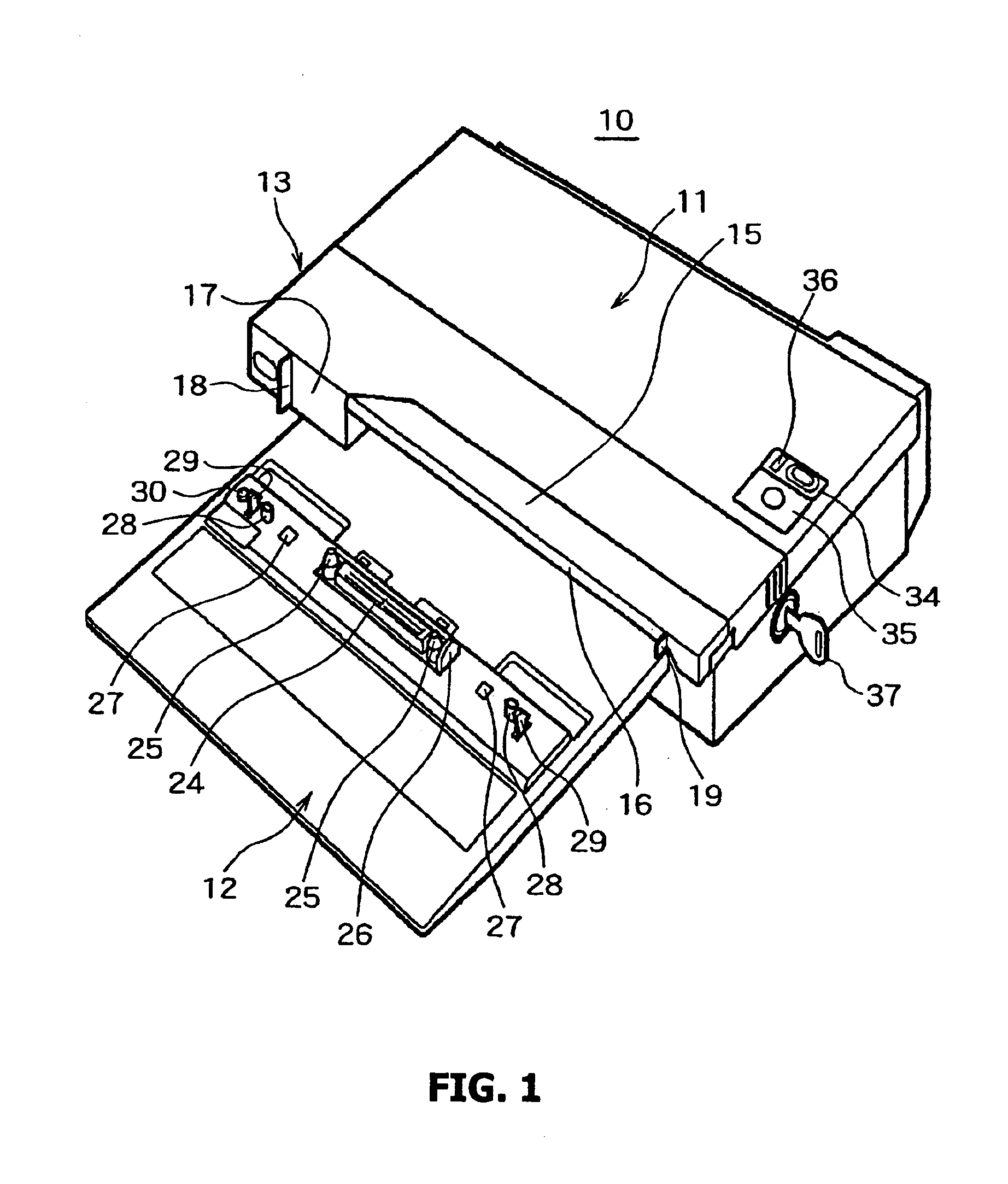

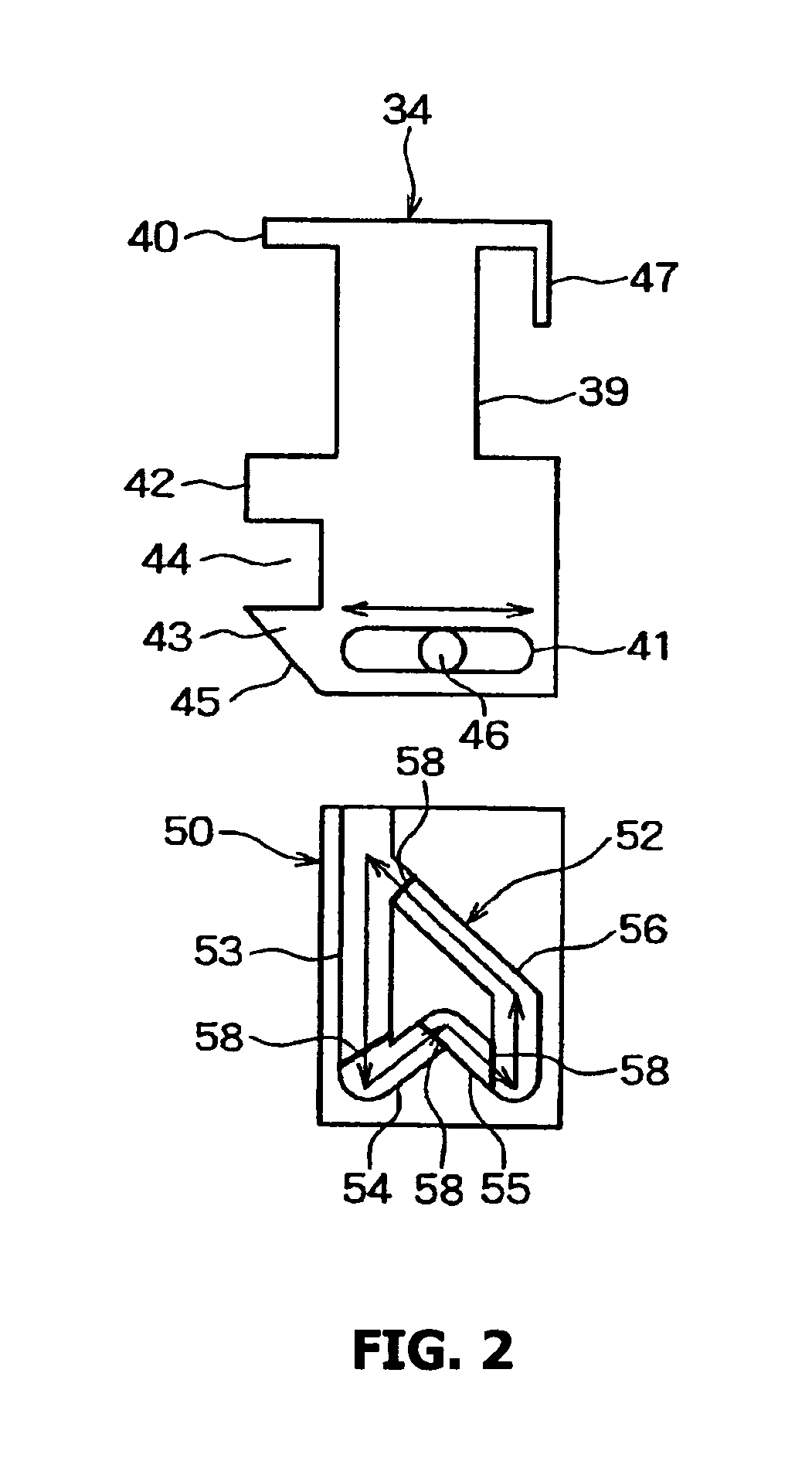

Docking station

InactiveUS20040223293A1Digital processing power distributionElectrical apparatus contructional detailsDocking stationEngineering

As a user depresses an eject button from the standard position to its sunken position and an instruction is transmitted to an installed notebook PC to request the disconnection of a driver for a device being operated in a docking station. When a notification is received from the PC indicating that the disconnection has been completed, for example and not to limit the a solenoid type electromagnetic apparatus switches a plunger to its non-projected position. The eject button is then placed into its projected position owing to the urging force of a spring. When the user depresses the eject button placed in its projected position, a motion direction converting lever is pivoted to activate an ejecting member and a locking hook. Consequently, the PC is ejected.

Owner:LENOVO (SINGAPORE) PTE LTD

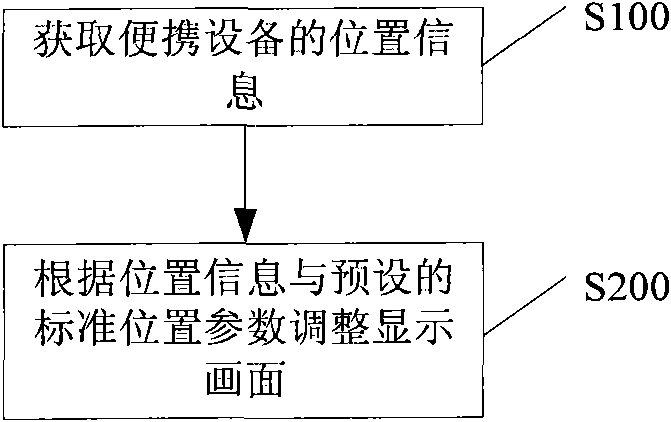

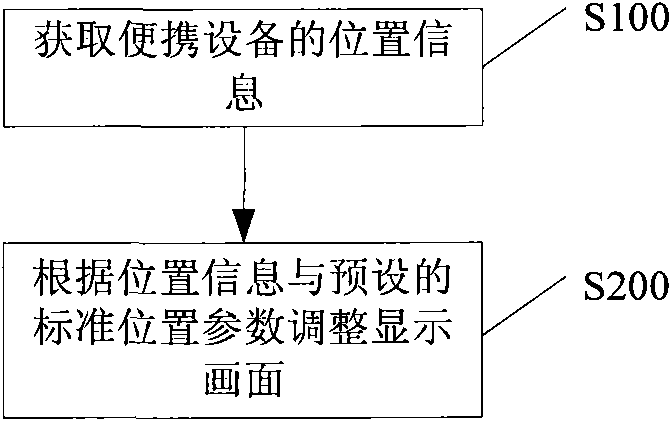

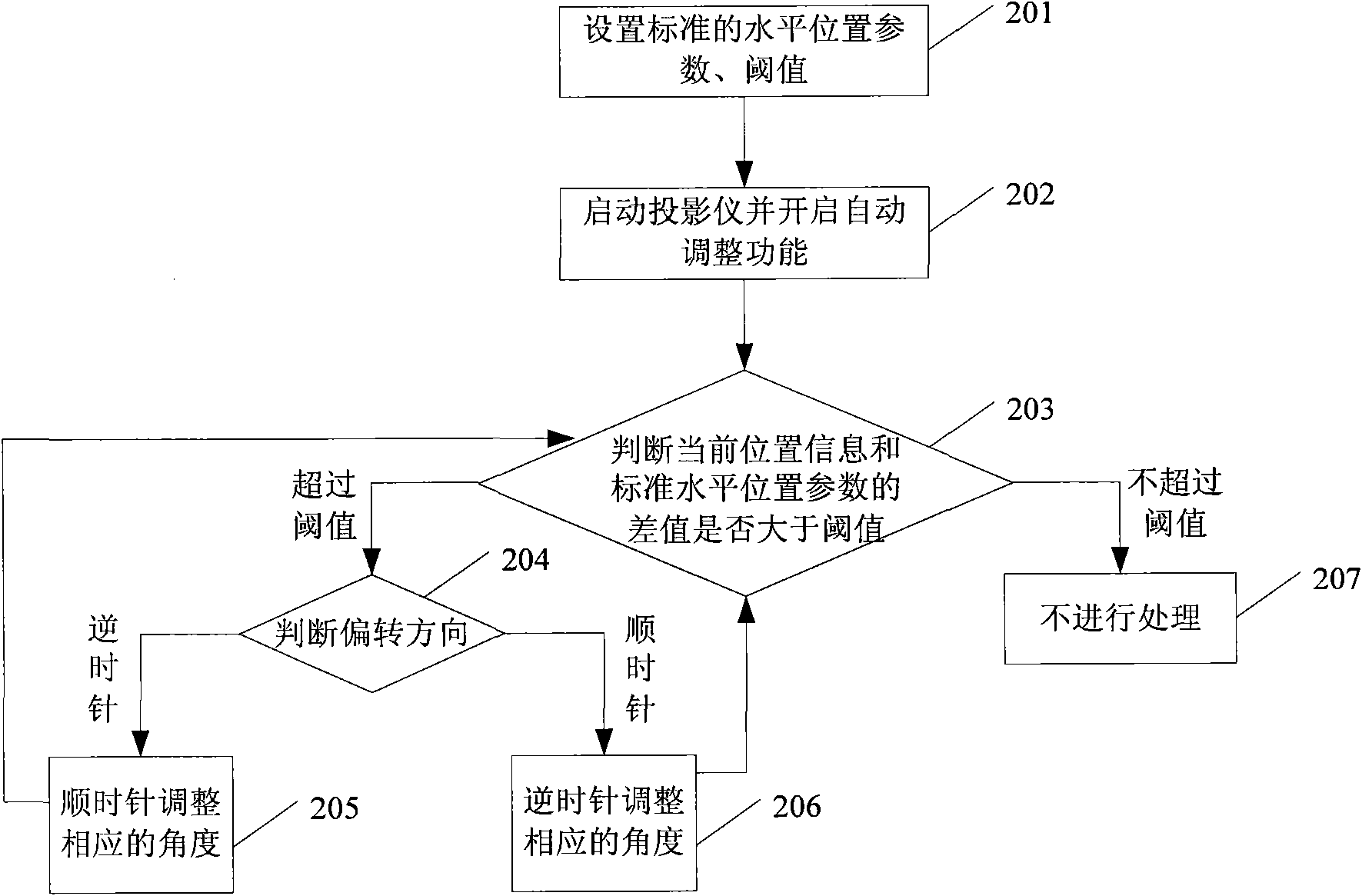

Method for regulating display picture by using portable terminal projector and portable terminal

InactiveCN101815191AHigh practical valueSolve the problem that affects the viewing of display contentTelevision system detailsColor television detailsComputer hardwareComputer graphics (images)

The invention discloses a realization method for automatically regulating the picture function by using a portable terminal. When a projector is used, position information is automatically acquired, and the output display picture of the projector is correspondingly regulated by combining preset standard position parameters according to the position information, therefore, when a user uses the portable terminal projector, minus effects of display picture rotation or stretcher strain of display content and the like due to sway are reduced, the problem that the watching of the display content is influenced due to personal factors when the portable terminal projector is used is solved, and the practical value of the portable terminal projector is increased.

Owner:ZTE CORP

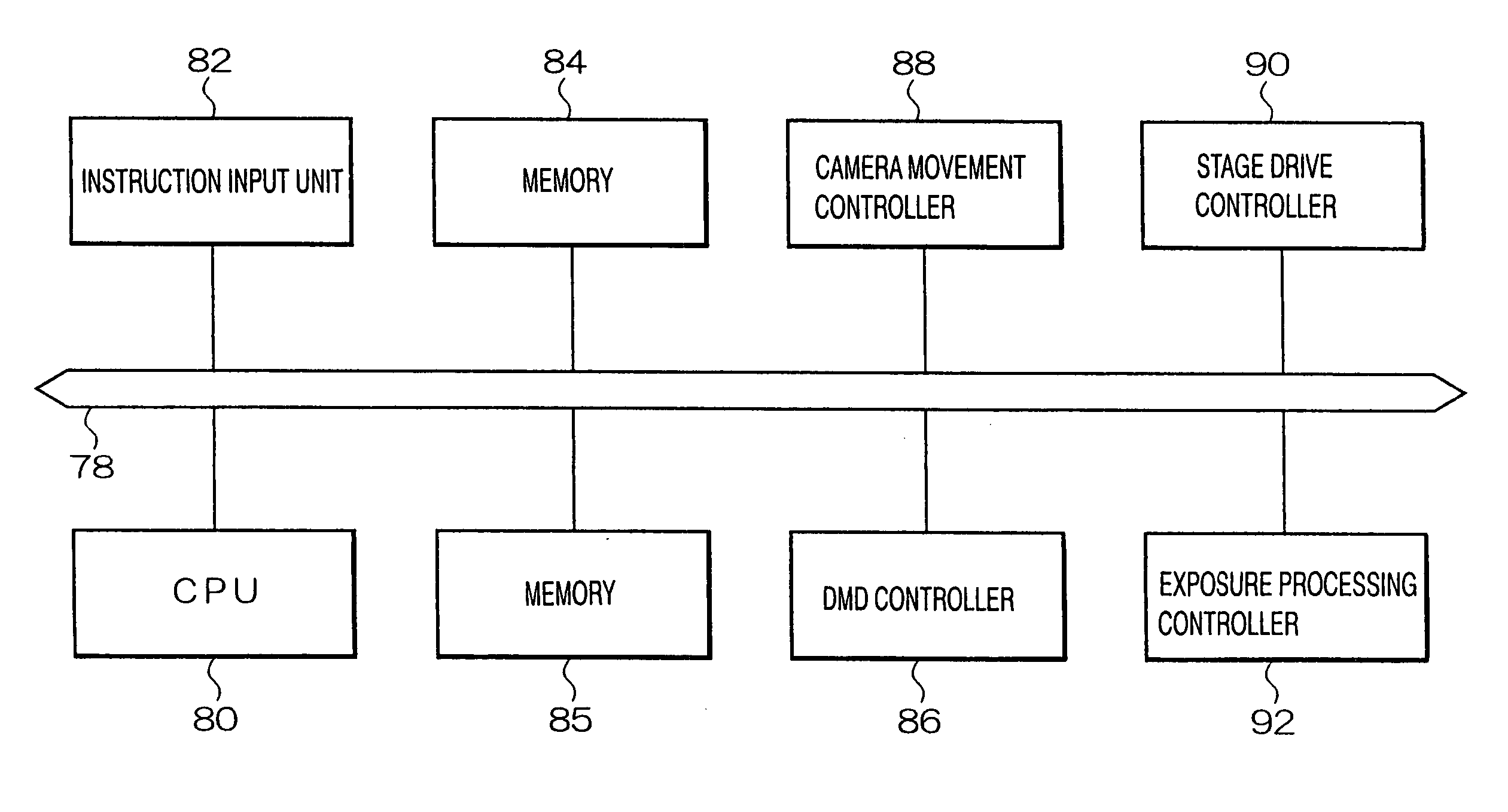

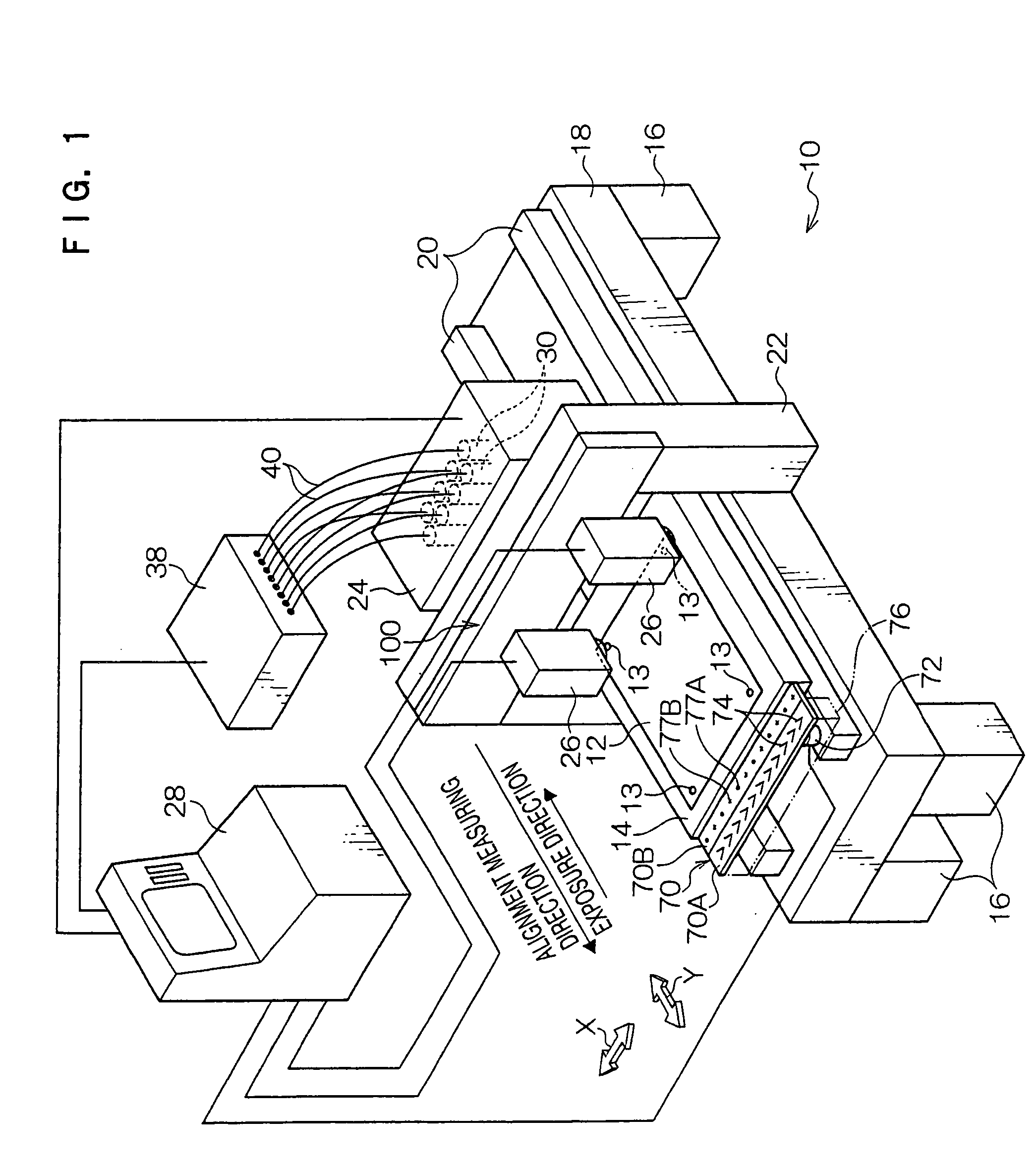

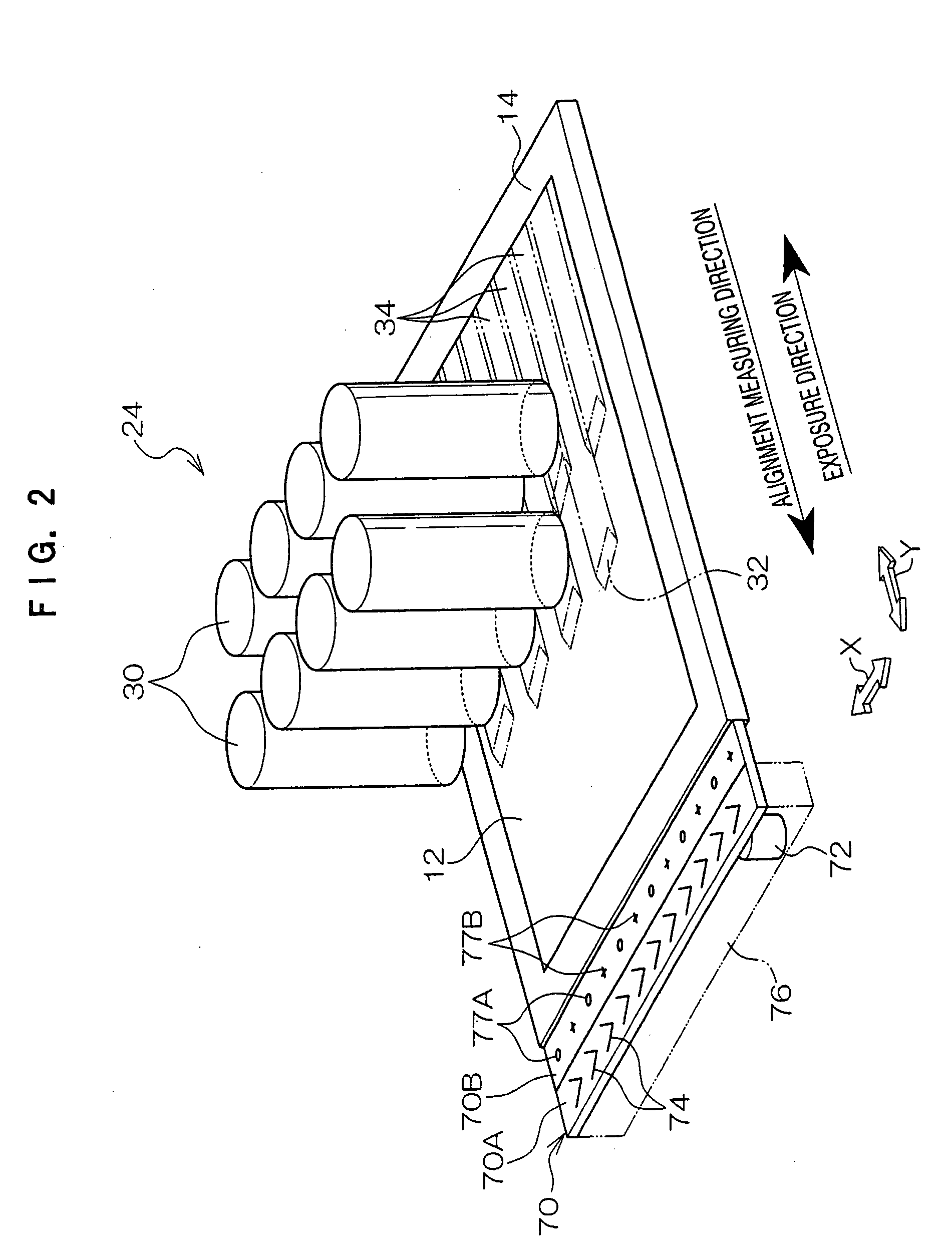

Calibration method for exposure device, exposure method and exposure device

InactiveUS20050271421A1Improve calibration accuracyImprove accuracyPhotomechanical exposure apparatusElectrographic process apparatusExposure LocationComputer science

In this exposure system, alignment marks on a photosensitive material are photographed with a reading unit. Prior to this photographing, a standard board, having detection marks at positions readable to the reading unit at preset intervals along the movement direction of the reading unit, is provided. At least one of the detection marks is photographed with the reading unit, which is arranged in a position to photograph the alignment marks provided on the photosensitive material. Calibration data is calculated based on data on the camera optical axis deviation obtained by this photographing. Standard position data reflects the calibration data, whereby calibration of the exposure position adjustment function of the exposure device is performed.

Owner:FUJIFILM CORP +1

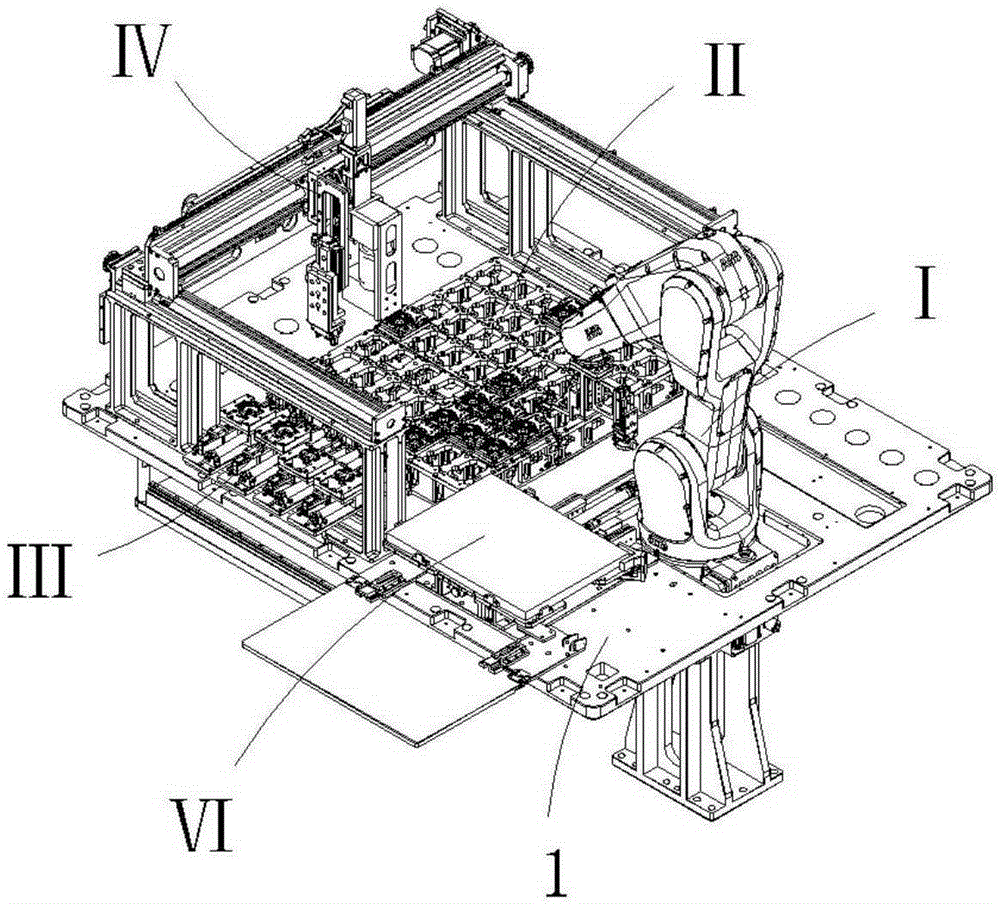

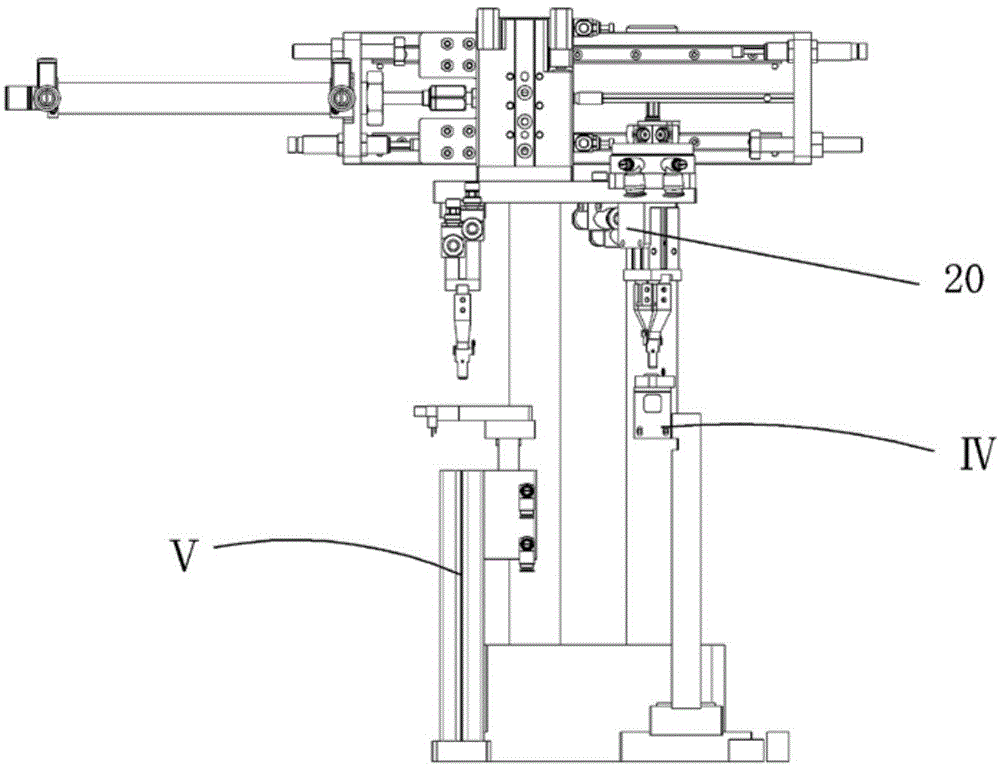

Rotary grabbing and transferring mechanism

The invention relates to a rotary grabbing and transferring mechanism which comprises a moving mechanism, a rotary grabbing mechanism, a transferring mechanism, an adjustable carrier mechanism and a liftable carrier mechanism, wherein the rotary grabbing mechanism is arranged on the moving mechanism; the transferring mechanism is arranged on the left side of the rotary grabbing mechanism; the adjustable carrier mechanism and the liftable carrier mechanism are respectively arranged in front of the moving mechanism; the liftable carrier mechanism is positioned on the left side of the adjustable carrier mechanism. According to the rotary grabbing and transferring mechanism disclosed by the invention, the moving mechanism is used for horizontally moving the rotary grabbing mechanism and the transferring mechanism; the rotary grabbing mechanism can automatically grab materials from a material streamline, and then rotates for a certain angle and places the material on a carrier a; the rotary grabbing mechanism grabs a second material again and places the material on the carrier a; meanwhile, the transferring mechanism clamps the first material and transfers the first material to a carrier b, and the cycle is repeated. The rotary grabbing and transferring mechanism disclosed by the invention is matched with a material streamline for use; the materials can be taken to a standard position and moved to a next standard position.

Owner:BOZHON PRECISION IND TECH CO LTD

Docking station

InactiveUS6934151B2Digital processing power distributionElectrical apparatus contructional detailsDocking stationEngineering

As a user depresses an eject button from the standard position to its sunken position and an instruction is transmitted to an installed notebook PC to request the disconnection of a driver for a device being operated in a docking station. When a notification is received from the PC indicating that the disconnection has been completed, for example and not to limit the a solenoid type electromagnetic apparatus switches a plunger to its non-projected position. The eject button is then placed into its projected position owing to the urging force of a spring. When the user depresses the eject button placed in its projected position, a motion direction converting lever is pivoted to activate an ejecting member and a locking hook. Consequently, the PC is ejected.

Owner:LENOVO (SINGAPORE) PTE LTD

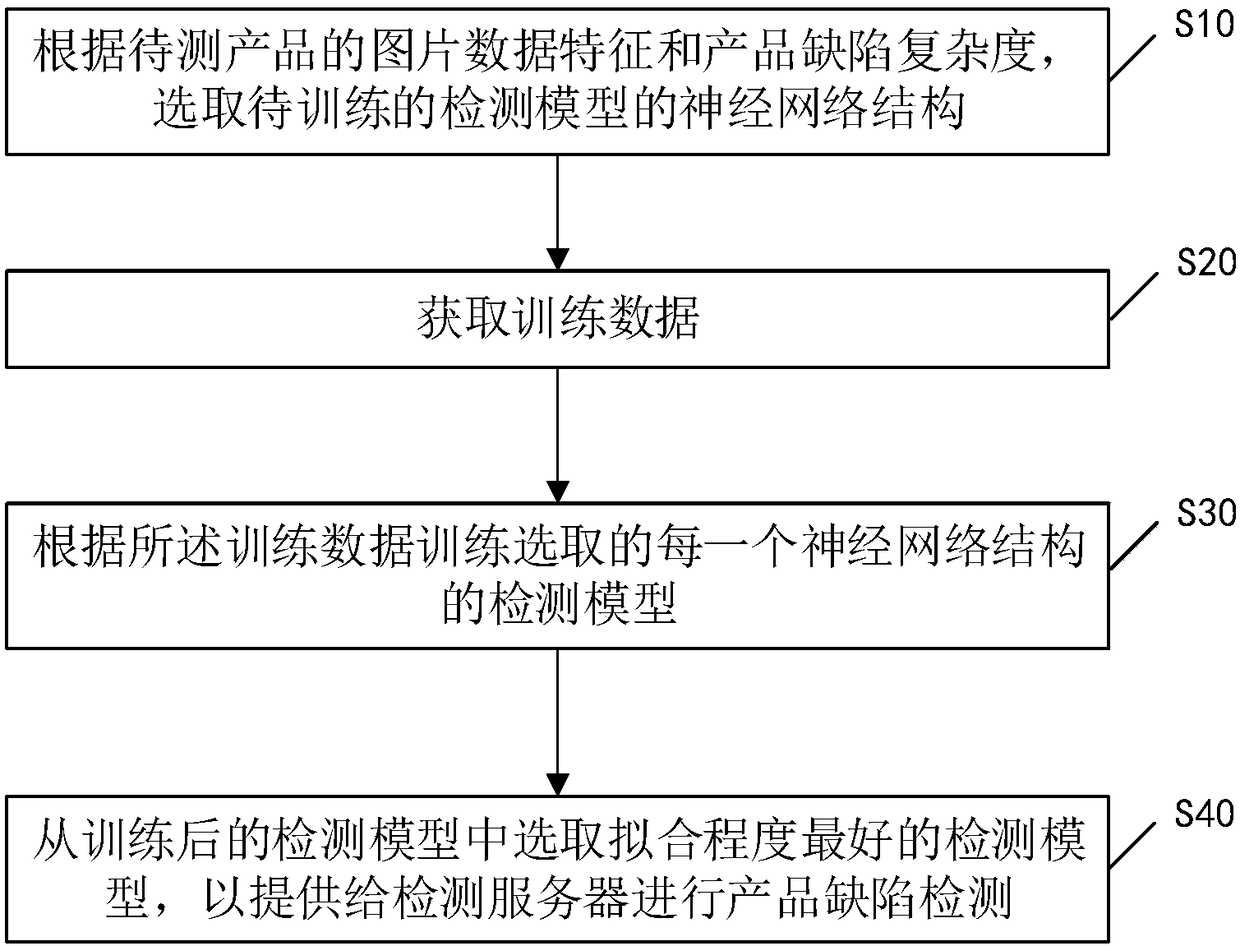

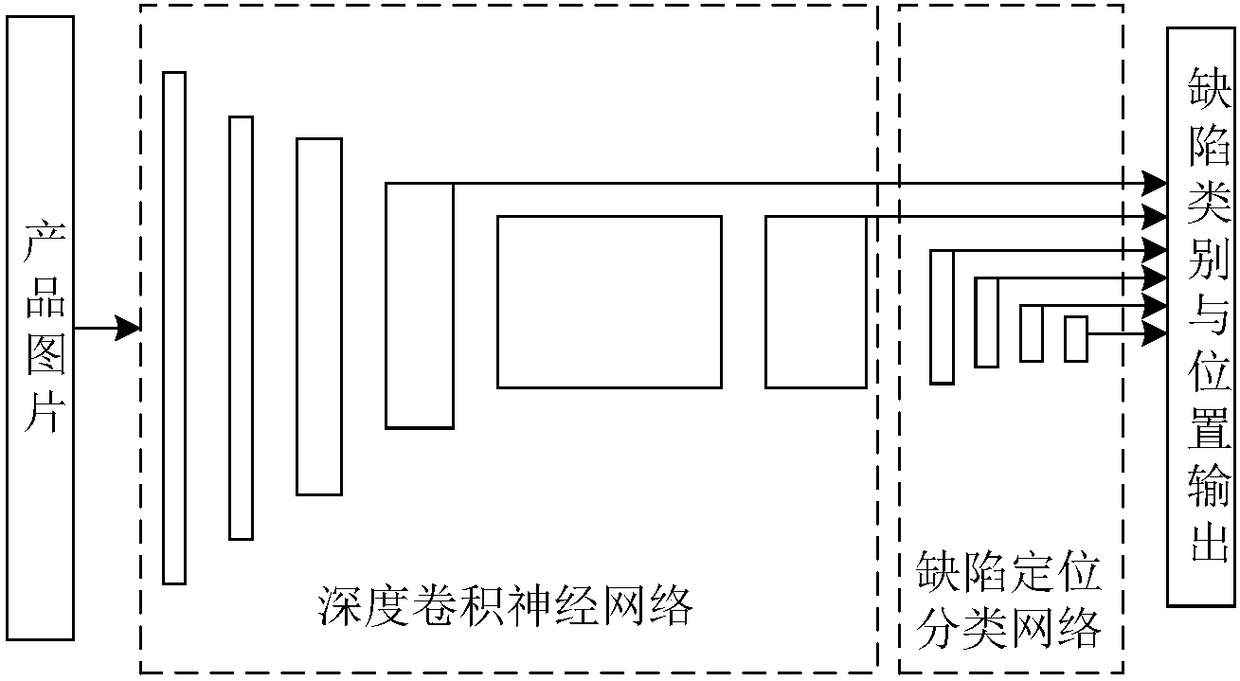

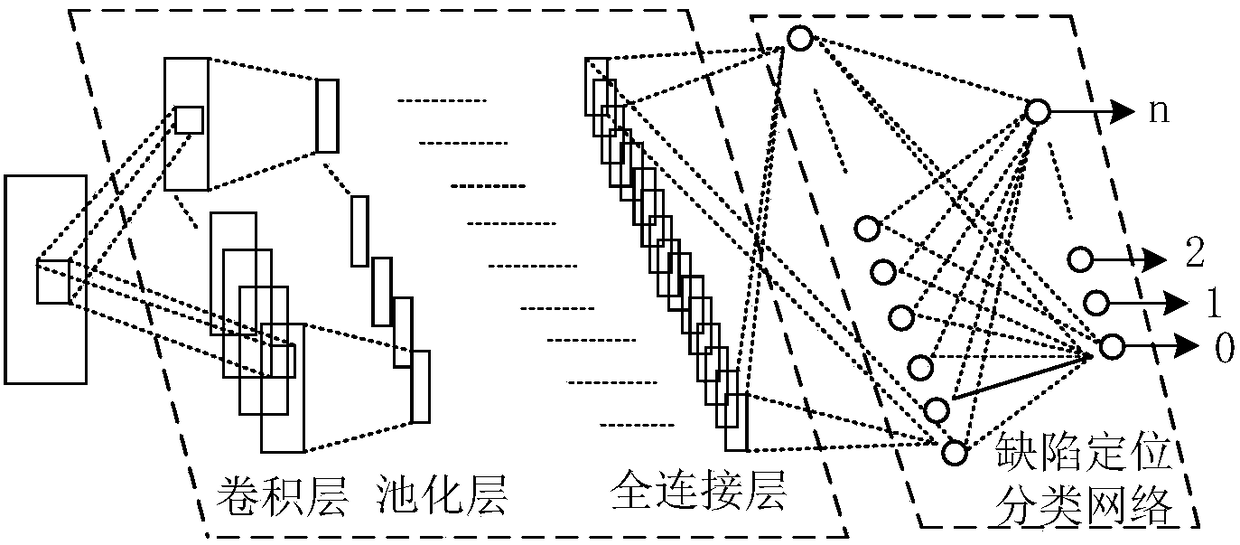

Method, device, storage medium and terminal device for product defect detections and locations

ActiveCN108154508AImprove robustnessDefect Complexity AdaptationImage enhancementImage analysisSoftware engineeringNetwork structure

The invention discloses a method, device, storage medium and terminal device for product defect detections and locations, wherein the method includes: according to the image data characteristics of products to be tested and the product defect complexity, selecting the neural network structure of detection models to be trained; obtaining training data, wherein the training data include training product pictures and standard categories and standard positions of product defects in the training product pictures; according to the training data, training the selected detection models of each neuralnetwork structure; selecting a best fitting detection model from the detection models after training to provide a detection server with the product defect detection, wherein the detection models are used for calculating according to the received product pictures to obtain predicted categories and predicted locations of the product defects in the received product pictures. Adopting the method, device, storage medium and terminal device for product defect detections and locations is capable of improving the accuracy of detecting the product defects.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

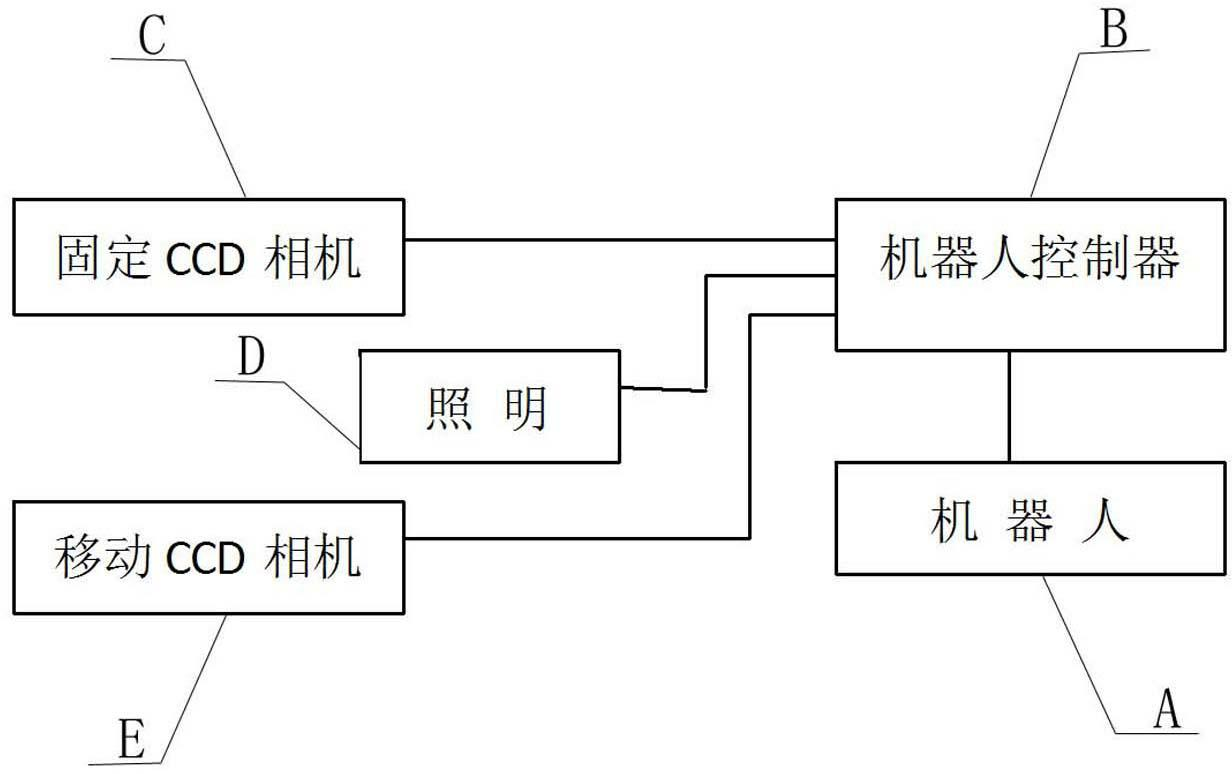

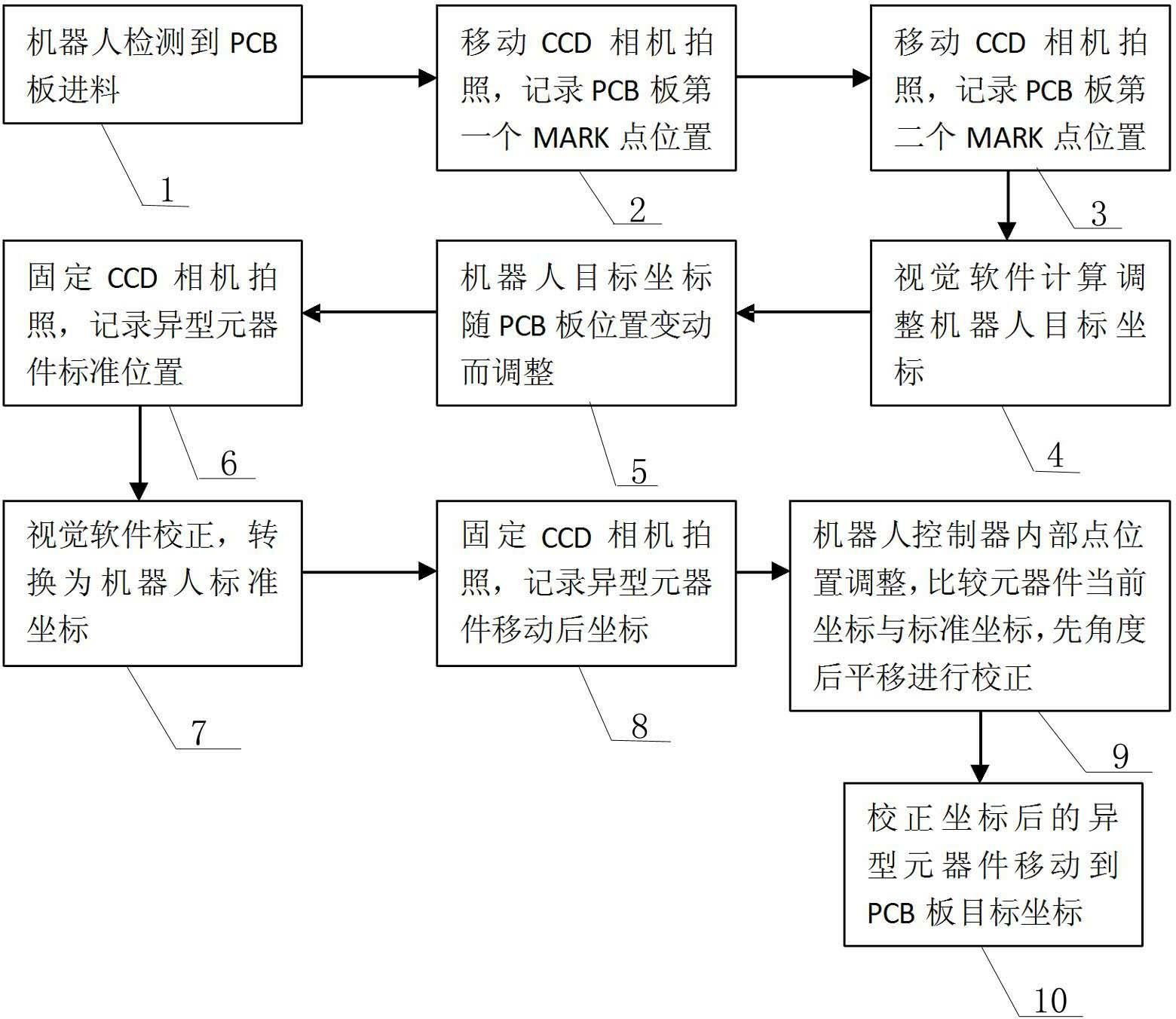

Pasting method for machine vision-based irregular electronic device

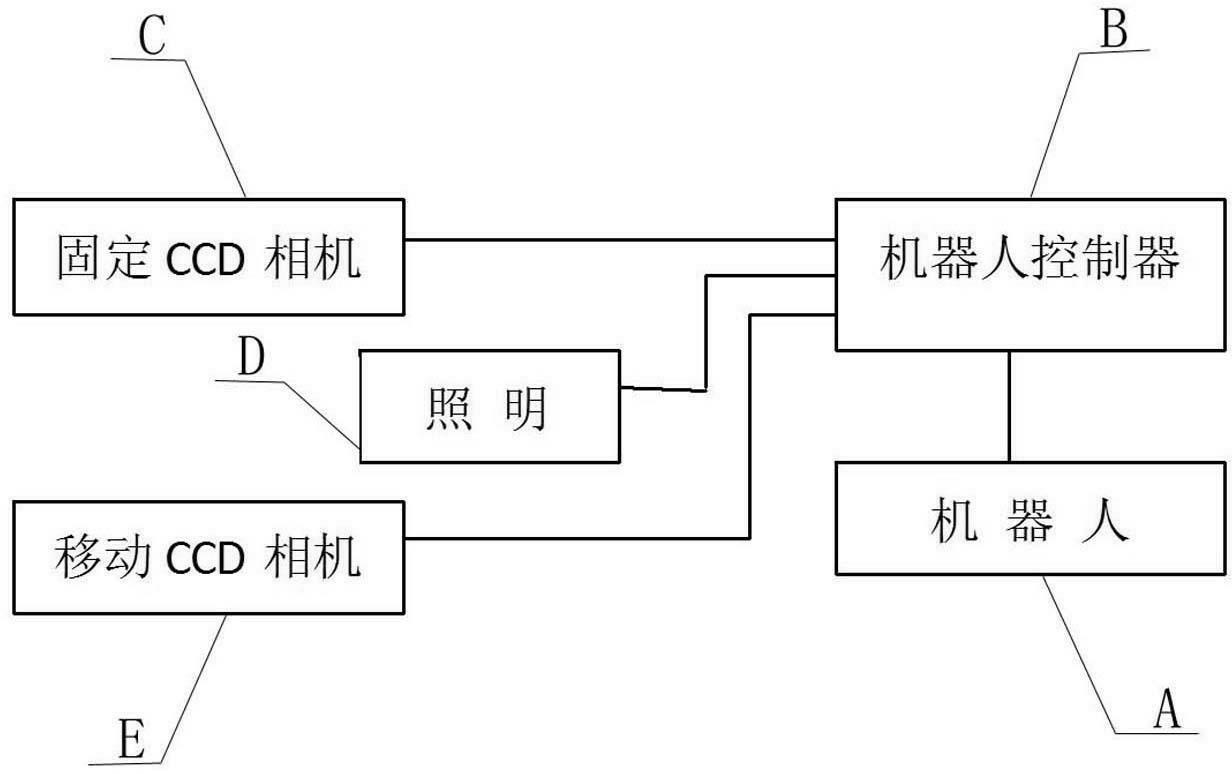

InactiveCN102686041ALess investmentImprove placement efficiencyPrinted circuit assemblingCcd cameraVisual perception

The invention relates to a pasting device for electronic devices in electronic industry. Pasting task is completed by robots. The pasting device consists of a robot A, a robot controller B, a fixed CCD (charged coupled device) camera C, an illuminator D, and a mobile CCD camera E. The pasting method comprises the steps that the robot detects feeding of a PCB (Printed Circuit Board), the mobile CCD cameras takes a picture to record a first MARK point position of the PCB, and the mobile CCD cameras takes a picture to record a second MARK point position, vision software calculates and regulates the target coordinates of the robot, the target coordinates of the robot are regulated along with position change of the PCB, the fixed CCD camera takes a picture to record the standard position of the irregular device, the vision software conducts correction and converts into the standard coordinates of the robot, the fixed CCD camera takes a picture to record the coordinates of the irregular device after being moved, positions of the internal points of the robot controller are regulated, the current coordinates and the standard coordinates of the device are compared, angles and translation are sequentially corrected, and the irregular device with the corrected coordinates is moved to the target coordinates of the PCB. In the method, the pasting machine is replaced with the robot, so that the investment is saved and the pasting efficiency is improved.

Owner:李正标

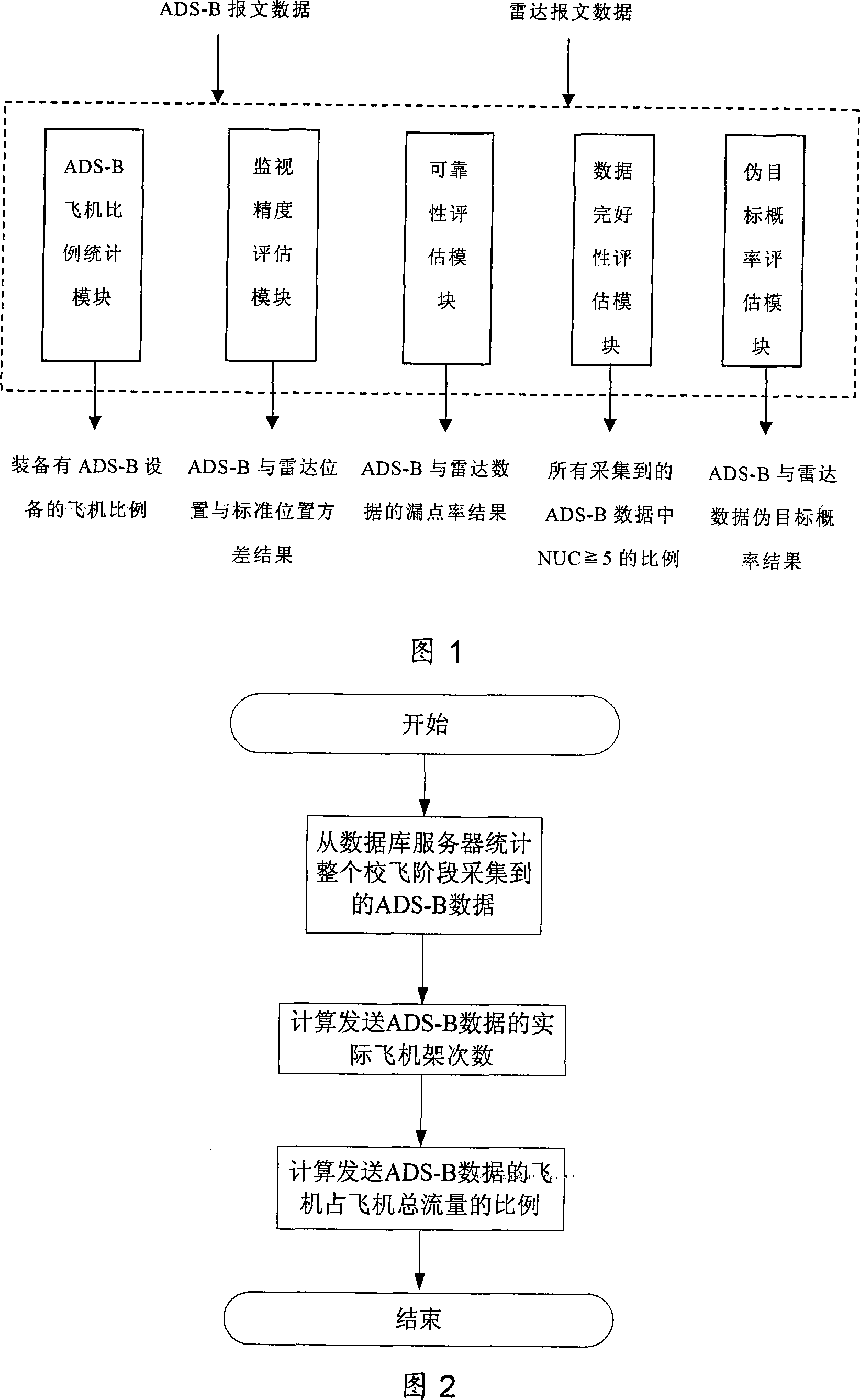

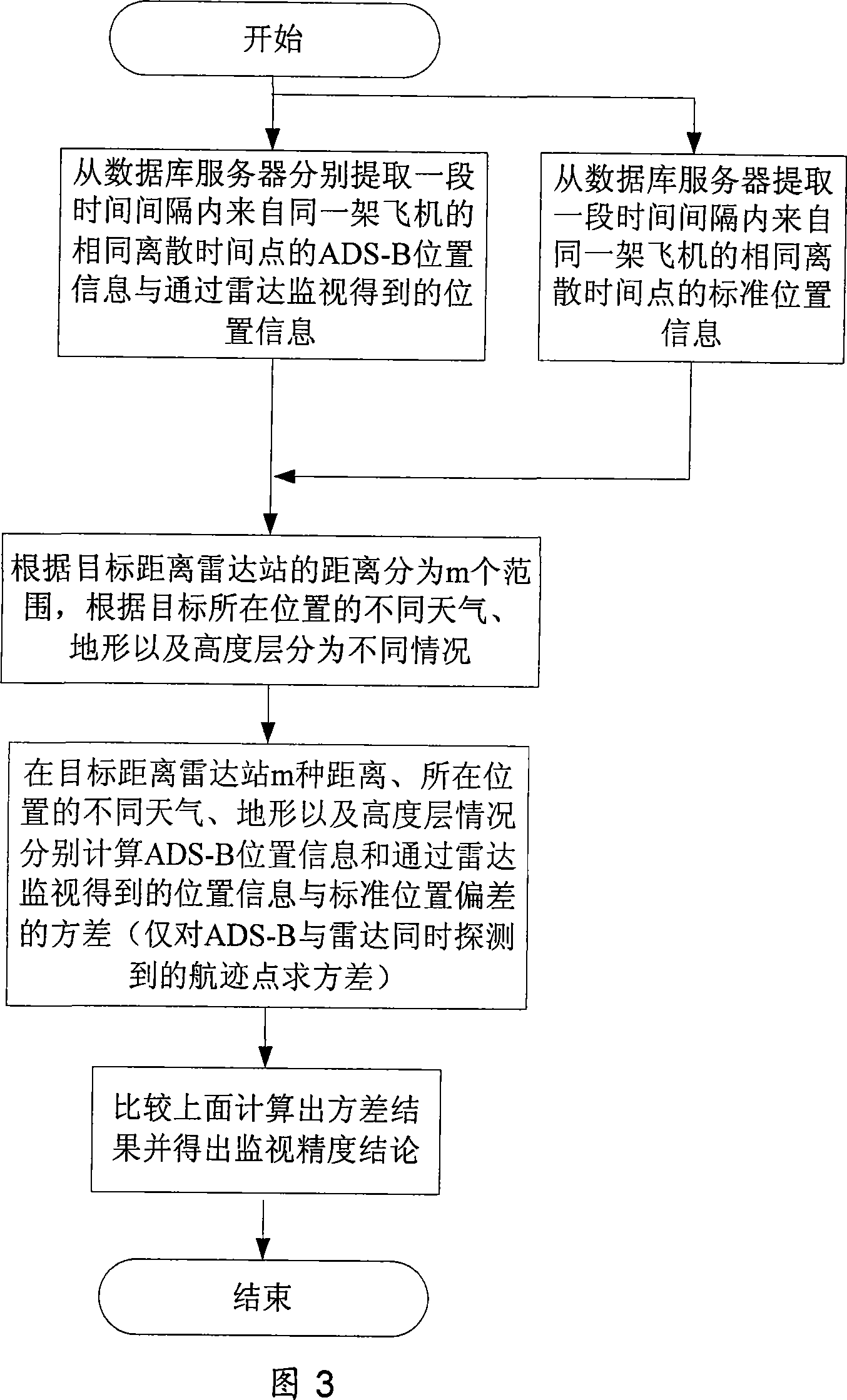

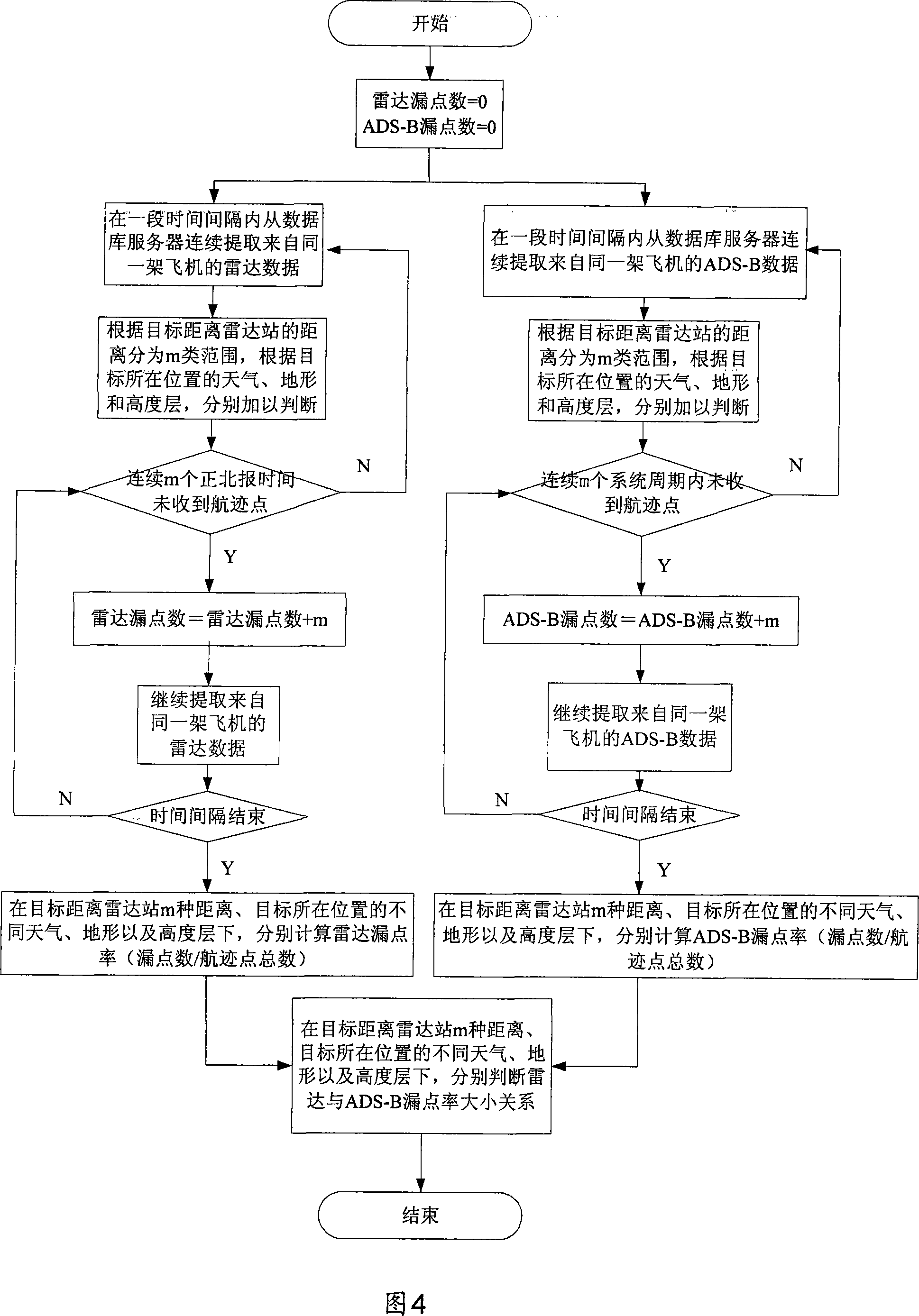

Data estimation system for ADS-B monitoring technology

InactiveCN101110165ARealize data evaluationRich monitoring informationRadio wave reradiation/reflectionAircraft traffic controlData integrityRadar

A data assessment system for ADS-B monitor technology is provided, which comprises an ADS-B airplane scale statistics module that keeps statistics of airplane scale with ADS-B airborne equipments and judges the number of ADS-B airplane, a monitor precision assessment module that assesses the precision of ADS-B position message data, compares the variance between ADS-B, radar position data and standard position in same time section and works out the conclusion of monitor precision, a reliability assessment module that assesses the reliability of ADS-B monitor data, calculates separately the missing dot rate of radar and ADS-B monitor data in same time section, compares them and reaches the conclusion about the reliability of ADS-B monitor data, a data integrity assessment module that assesses the integrity of ADS-B monitor data, a fake object possibility assessment module that assesses the fake object possibility of ADS-B position message data and works out the conclusion about the fake object possibility of ADS-B monitor data. Therefore, the invention, which is easy to be implemented in engineering, effectively realizes the data assessment for ADS-B monitor data.

Owner:BEIHANG UNIV +1

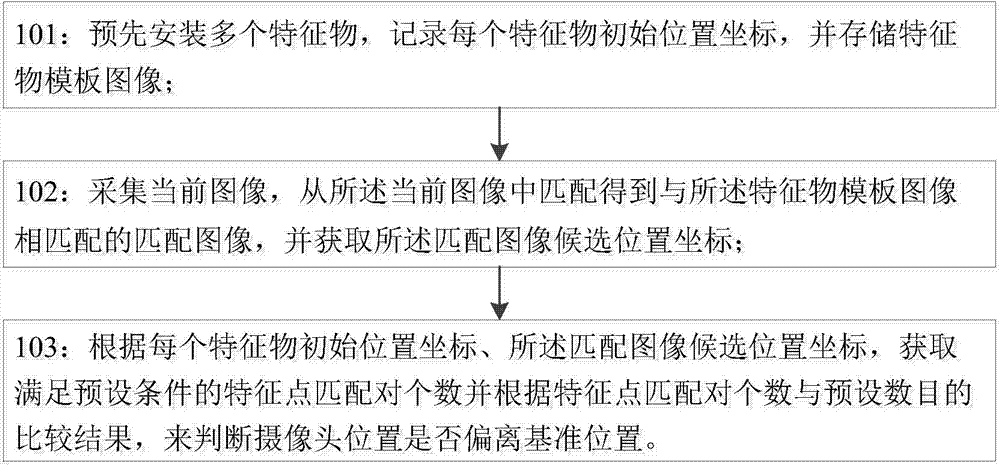

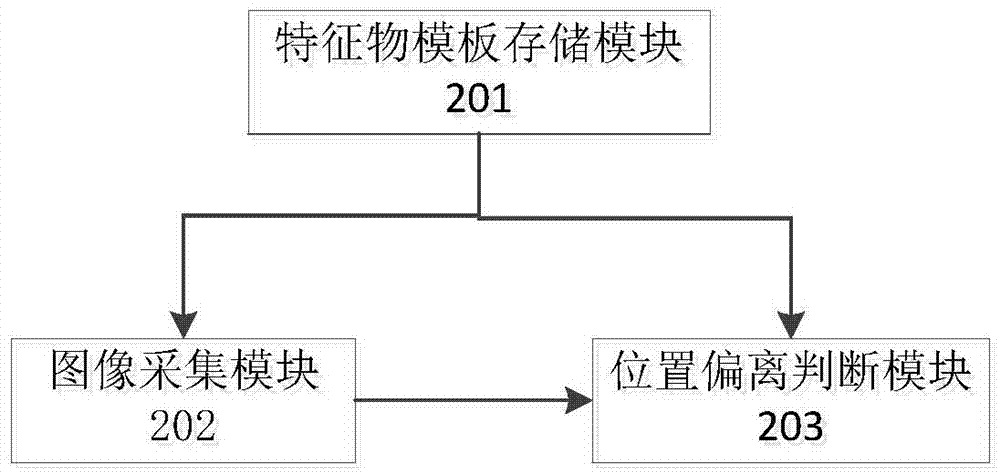

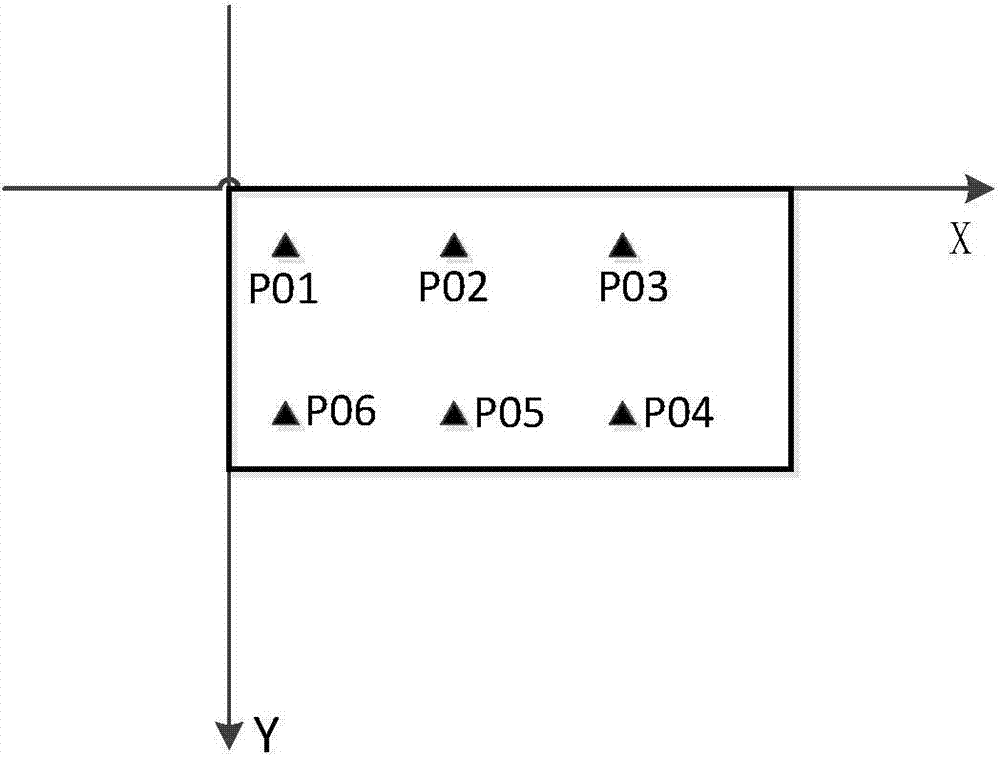

Camera position deviation detection method and device

InactiveCN104506857AEasy to operateImprove experimental precisionImage analysisTelevision systemsFeature point matchingPoint match

The invention provides a camera position deviation detection method and device. The camera position deviation detection method comprises the following steps that a plurality of feature objects are installed in advance, an initial position coordinate of each feature object is recorded, and feature object template images are stored; images at present are acquired, matched images which are matched with the feature object template images are obtained from the images at present through matching, and candidate position coordinates of the matched images are acquired; the number of feature point matching pairs meeting the preset conditions is obtained according to the initial position coordinate of each feature object and the candidate position coordinates of the matched images, and whether the position of a camera deviates from the standard position or not is judged according to the result of comparison between the number of the feature point matching pairs and the preset number. The invention further provides the camera position deviation detection device. The camera position deviation detection device comprises a feature object template storage module, an image acquisition module and a position deviation judgment module.

Owner:SUZHOU CODYY NETWORK SCI & TECH

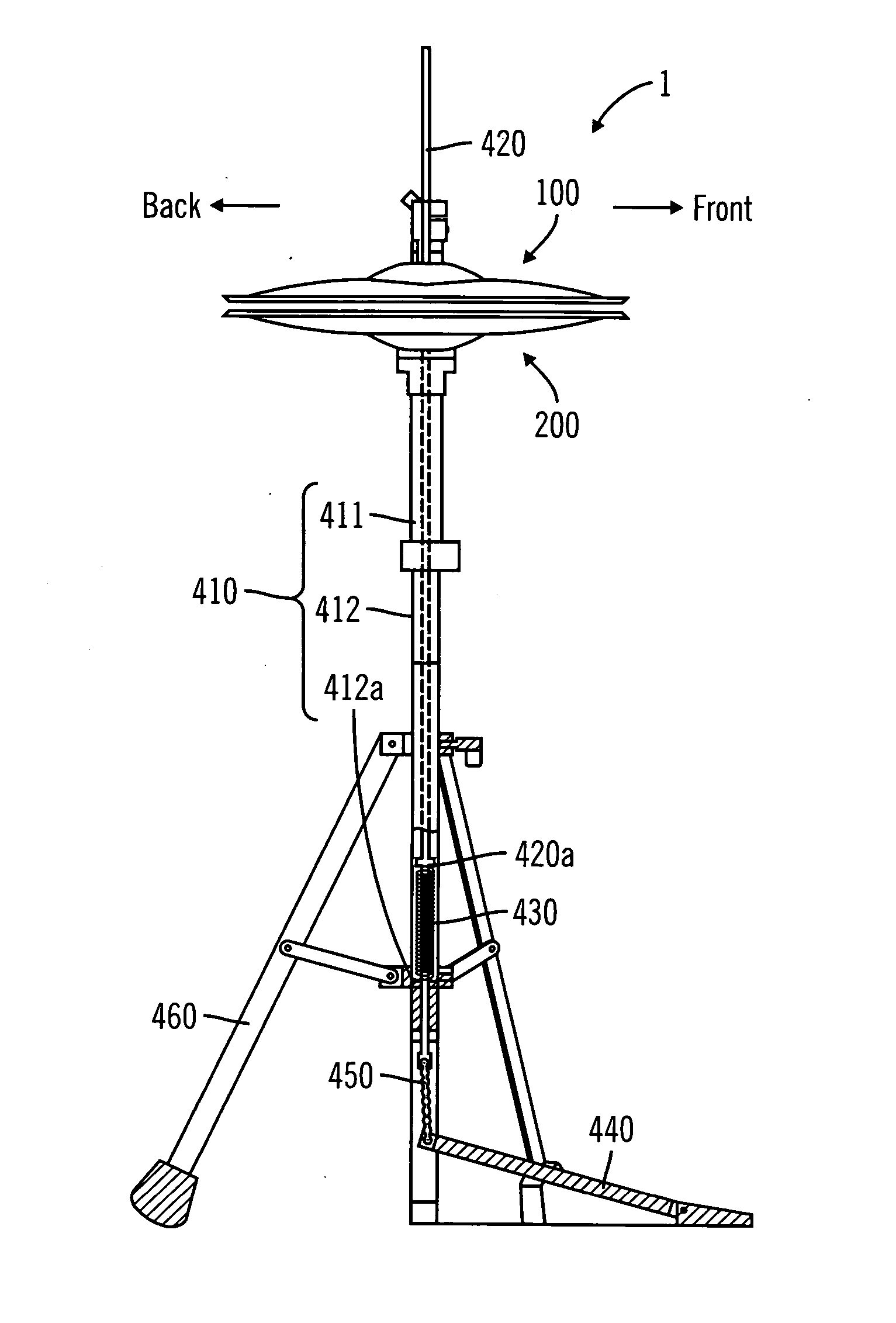

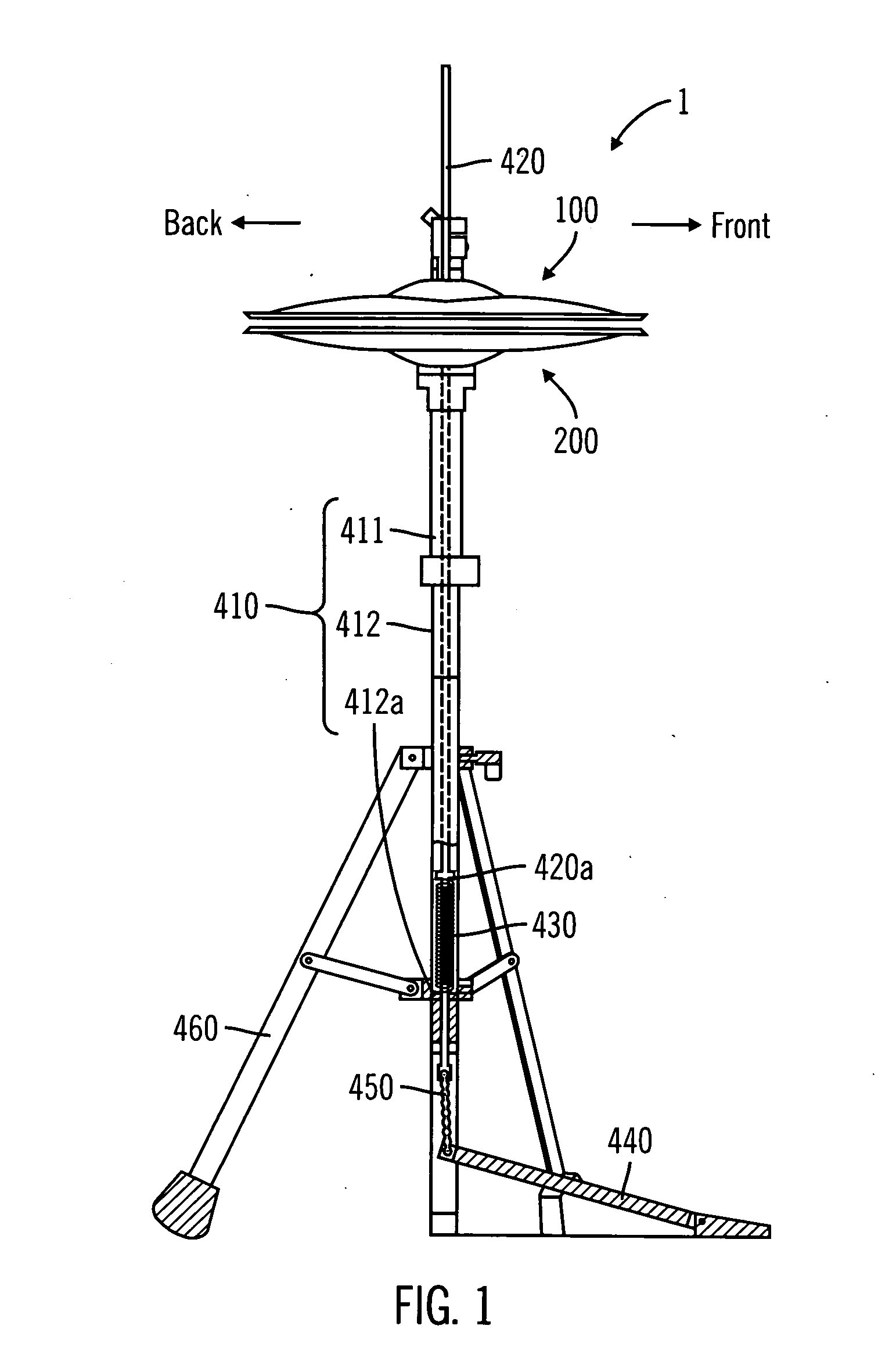

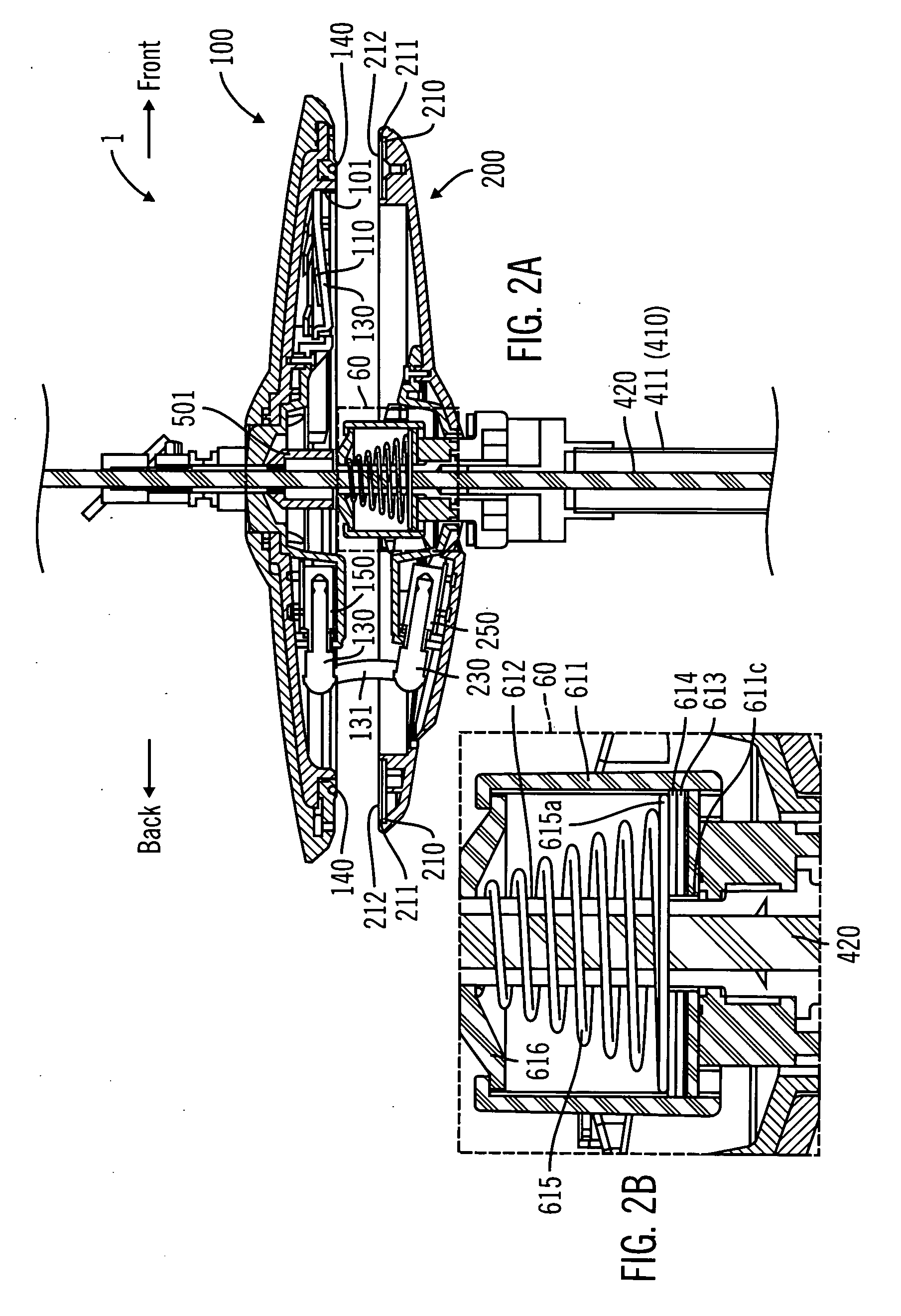

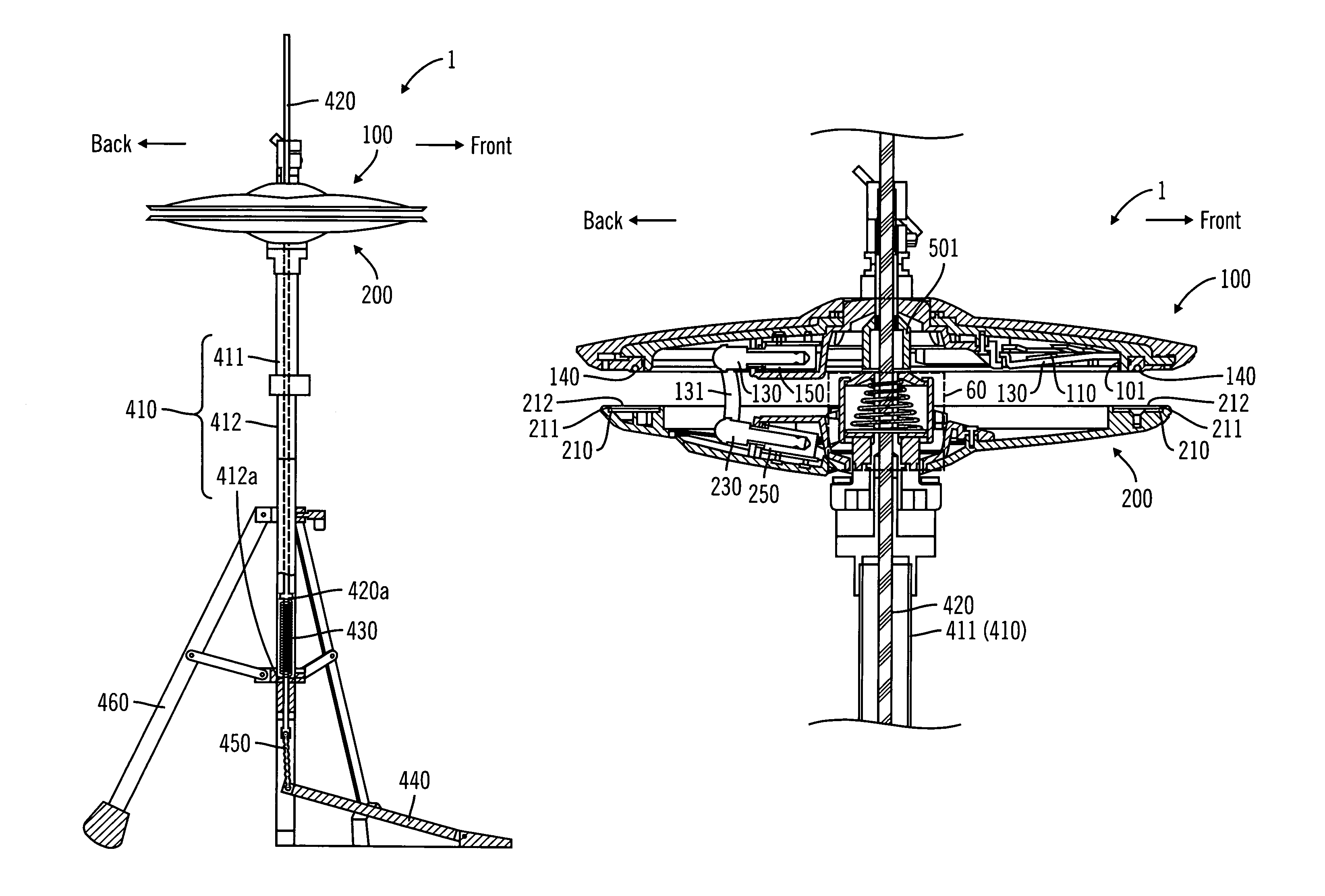

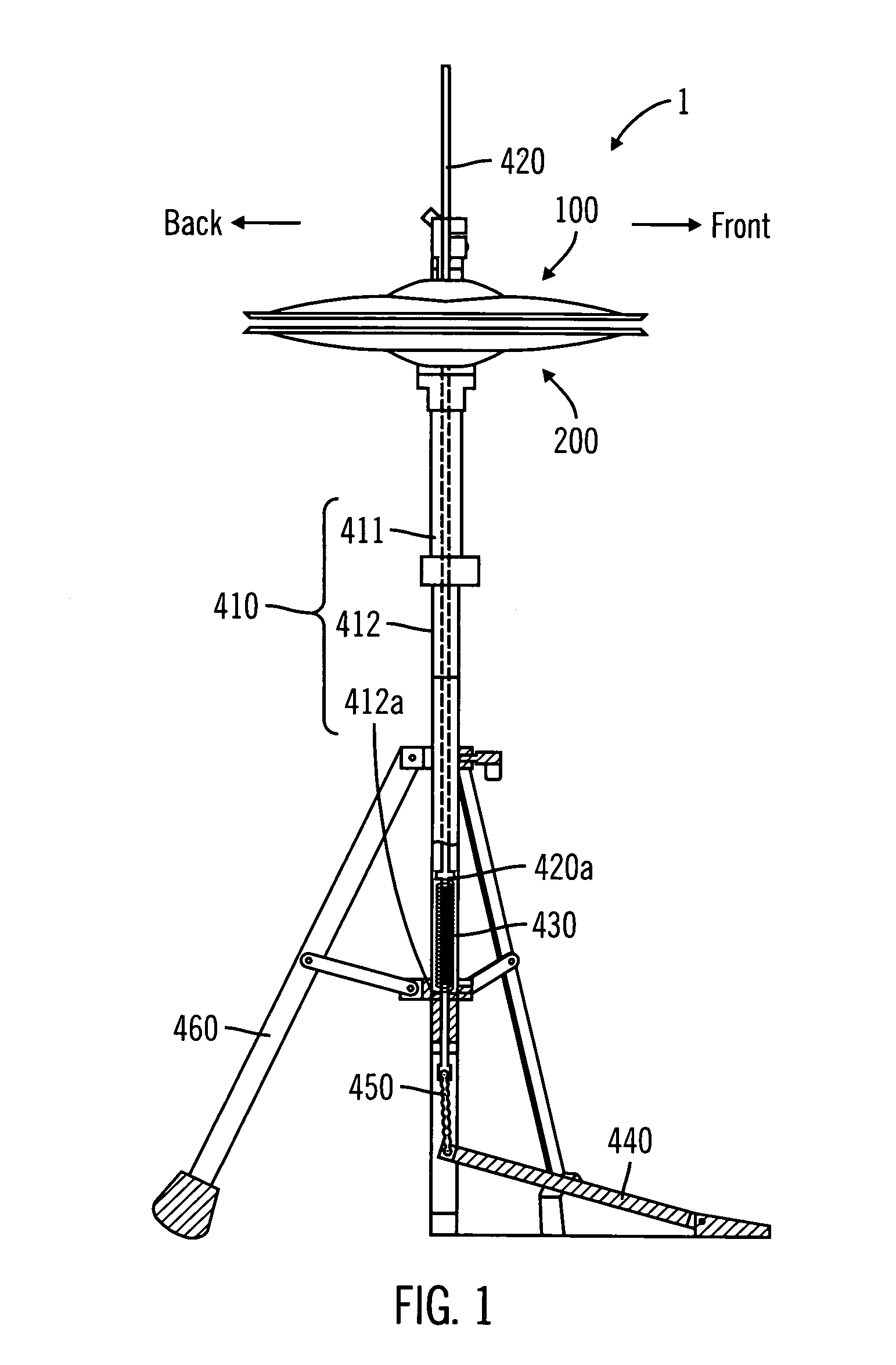

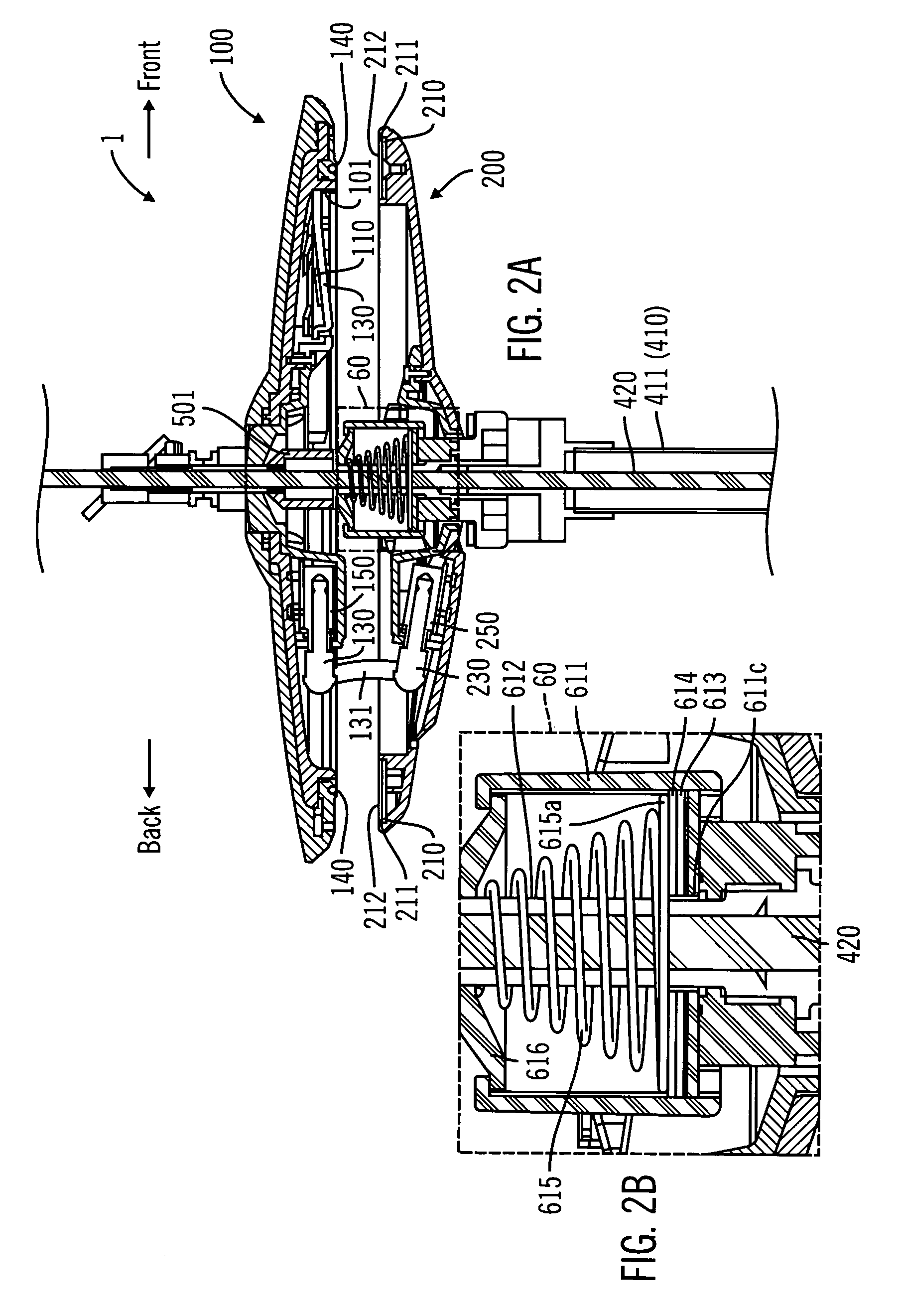

Percussion instrument, system, and method with closing position detection

An electronic percussion instrument includes input means, correction information storage means, and musical tone generation means. The input means allows for vibration information, which expresses a vibration of an operator, position information, which expresses a position of the operator, and standard position information, which indicates a standard position of the operator, to be input. The correction information storage means allows for correction information to be stored that is based on the position information that has been input in the input means that corresponds to the standard position information that has been input in the input means. The musical tone generation means allows for the generation of a musical tone in conformance with the position information that has been input in the input means that corresponds to the vibration information that has been input and the correction information that has been stored in the correction information storage means.

Owner:ROLAND CORP

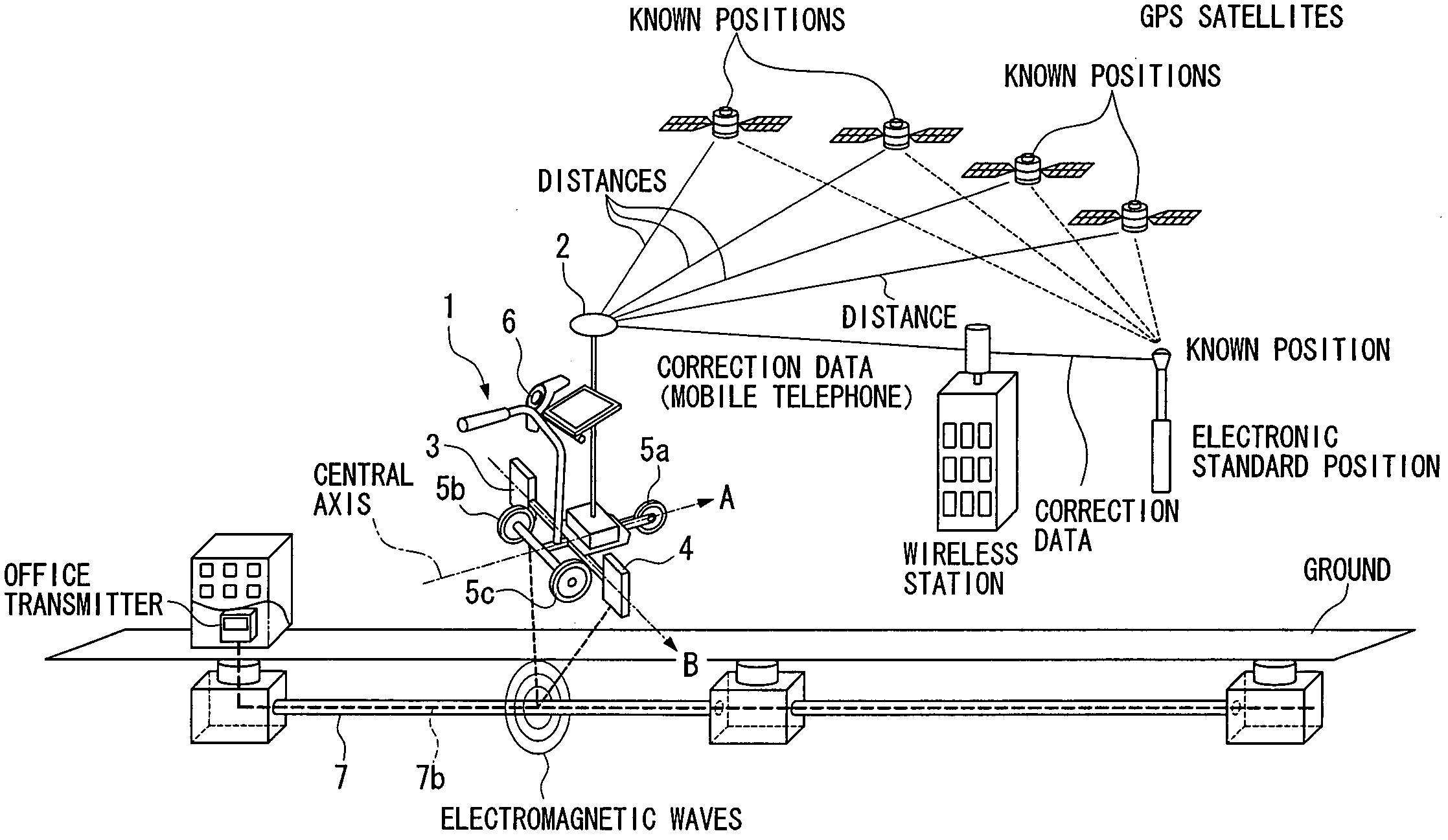

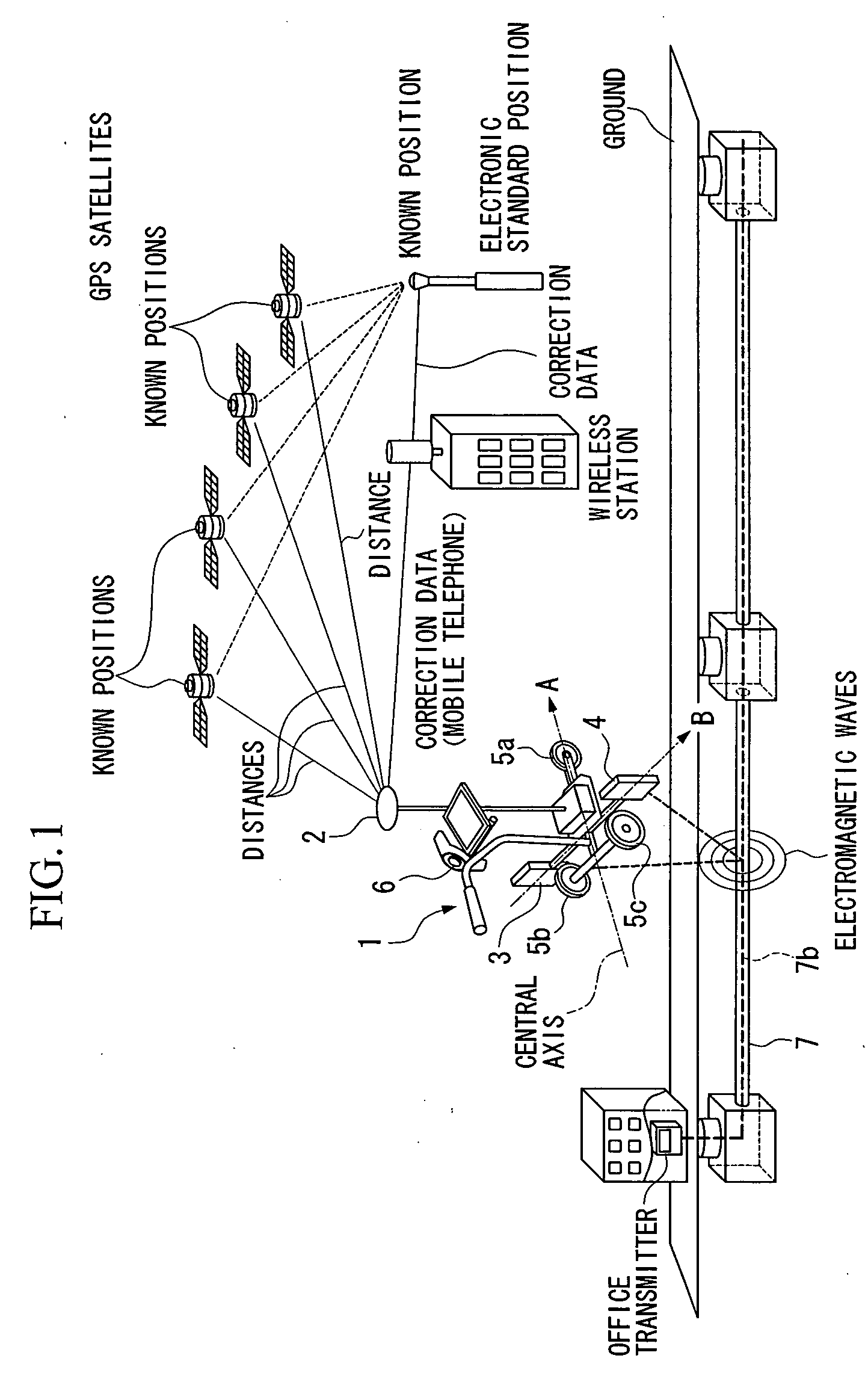

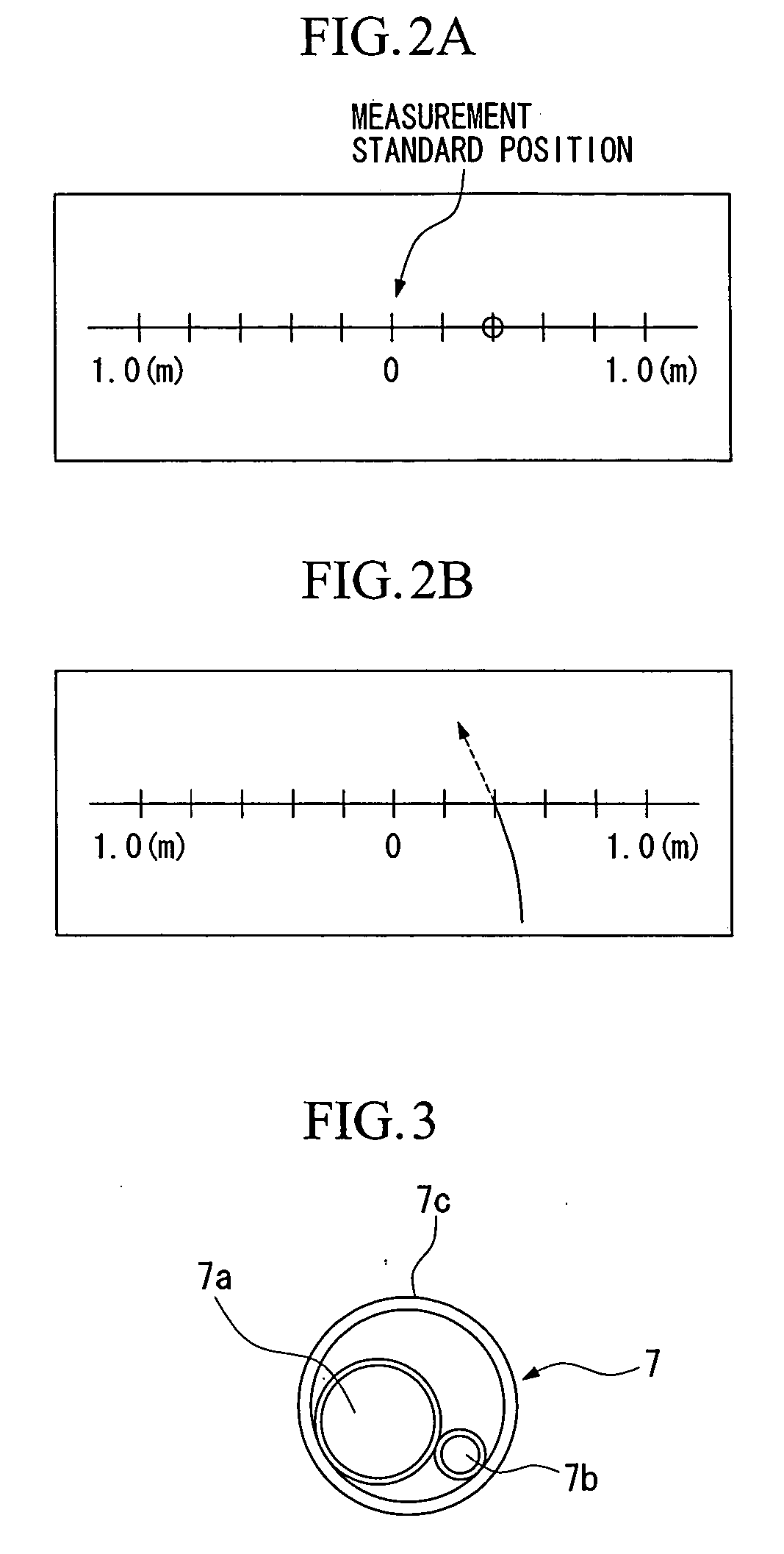

Cable location continuously determining apparatus, cable location continuously determining method, and cable location continuously determining program

InactiveUS20050062475A1Improve accuracyElectronic circuit testingCurrent/voltage measurementEngineeringLocation data

An apparatus is provided that can continuously determine the location at which a cable is buried. The location data of a measurement standard position is acquired by RTK-GPS. The azimuth of the moving direction of the cable location continuously determining apparatus is calculated using the location data. Electromagnetic waves from a metallic wire are received by two electromagnetic signal receiving sections whose locations in the horizontal plane are different from each other, and distances from the measurement standard position to a cable in a measurement base line direction and in the vertical downward direction are calculated using the received electromagnetic signals. The depth of the cable is calculated using the distance in the vertical downward direction. The plane location data of the cable is calculated using the azimuth of the moving direction, the location data of the measurement standard position, and the distance in the measurement base line direction.

Owner:NTT INFRASTRUCTURE NETWORK

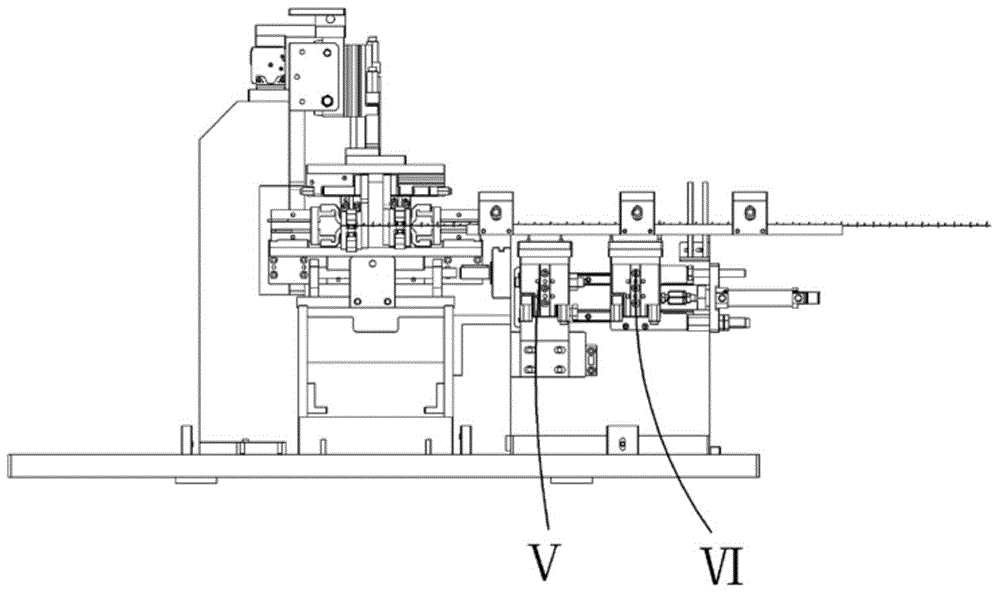

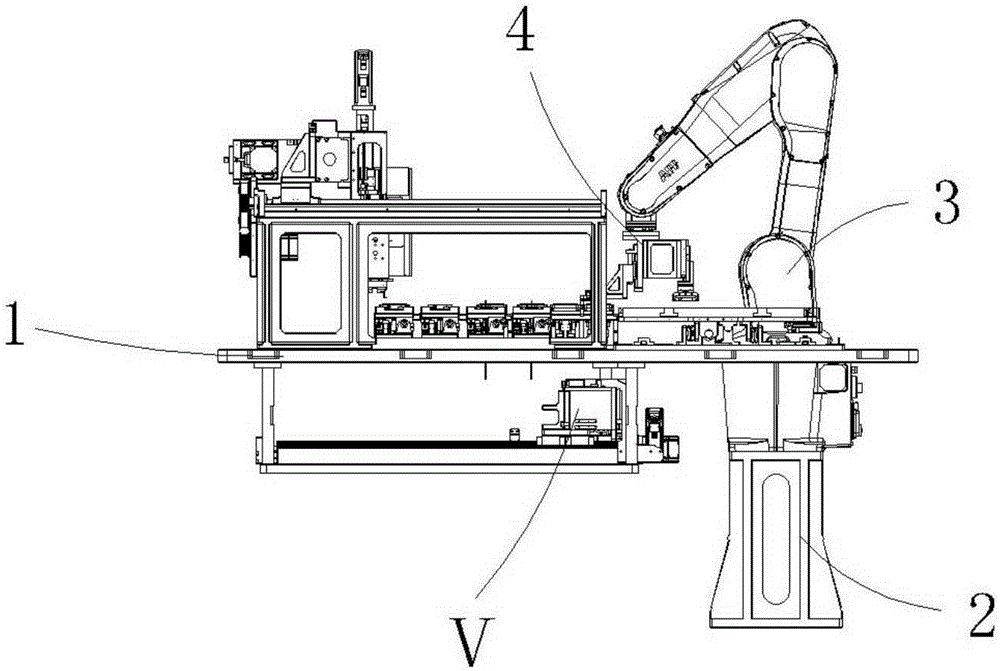

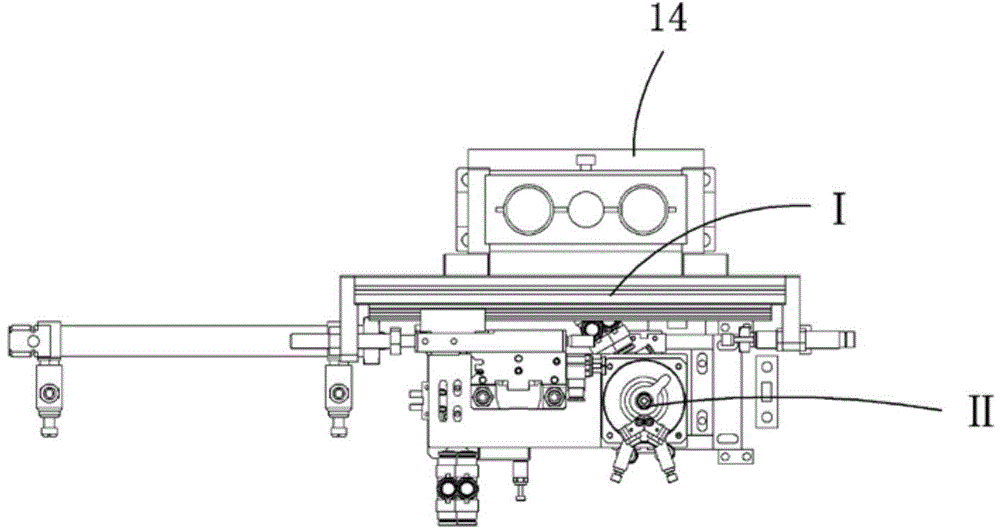

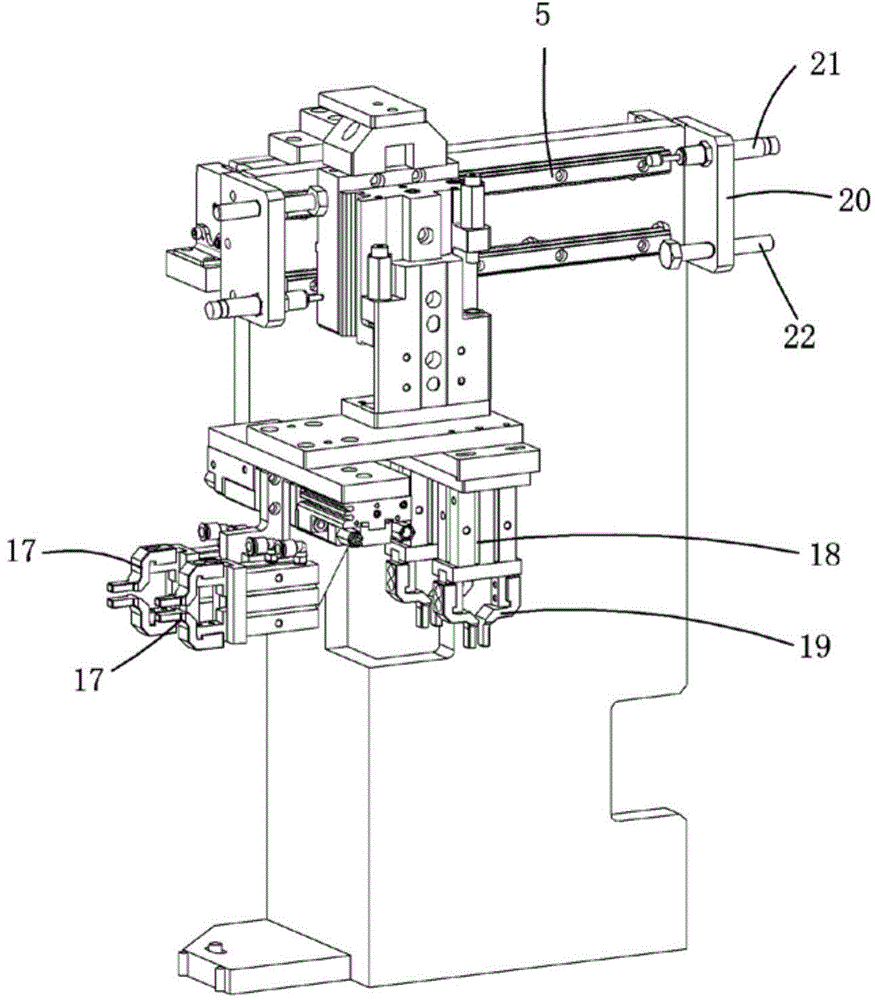

Material transferring mechanism

The invention relates to a material transferring mechanism. A horizontal cylinder fixing plate is fixedly mounted at the back of a mounting plate, a horizontal cylinder is mounted on the horizontal cylinder fixing plate, and a horizontal moving plate is mounted on the horizontal cylinder; lateral sliding rails are fixedly mounted in the front of the mounting plate, lateral sliding blocks are mounted on the lateral sliding rails, and a lifting cylinder mounting plate is mounted on the lateral sliding blocks; a moving block is mounted at the upper end of the lifting cylinder mounting plate, a lifting cylinder is mounted on the front side of the lifting cylinder mounting plate, the horizontal moving plate is fixed on the moving block, and a clamping jaw cylinder mounting plate is fixedly mounted at the lower end of the lifting cylinder through a lifting plate; a switching cylinder fixing plate and a material receiving cylinder fixing plate are mounted at the lower part of the clamping jaw cylinder mounting plate; switching cylinders are mounted at the lower part of the switching cylinder fixing plate, and the switching cylinders are connected to switching plates; material taking cylinders are mounted on the switching plates, and material taking clamping jaws are mounted on the material taking cylinders; material receiving cylinders are mounted at the lower part of a material receiving cylinder fixing plate, and material receiving clamping jaws are mounted on the material receiving cylinders. Through adoption of the material transferring mechanism disclosed by the invention, materials can be taken in a horizontal direction, and can be received in a perpendicular direction, so that products are transported to a standard position.

Owner:BOZHON PRECISION IND TECH CO LTD

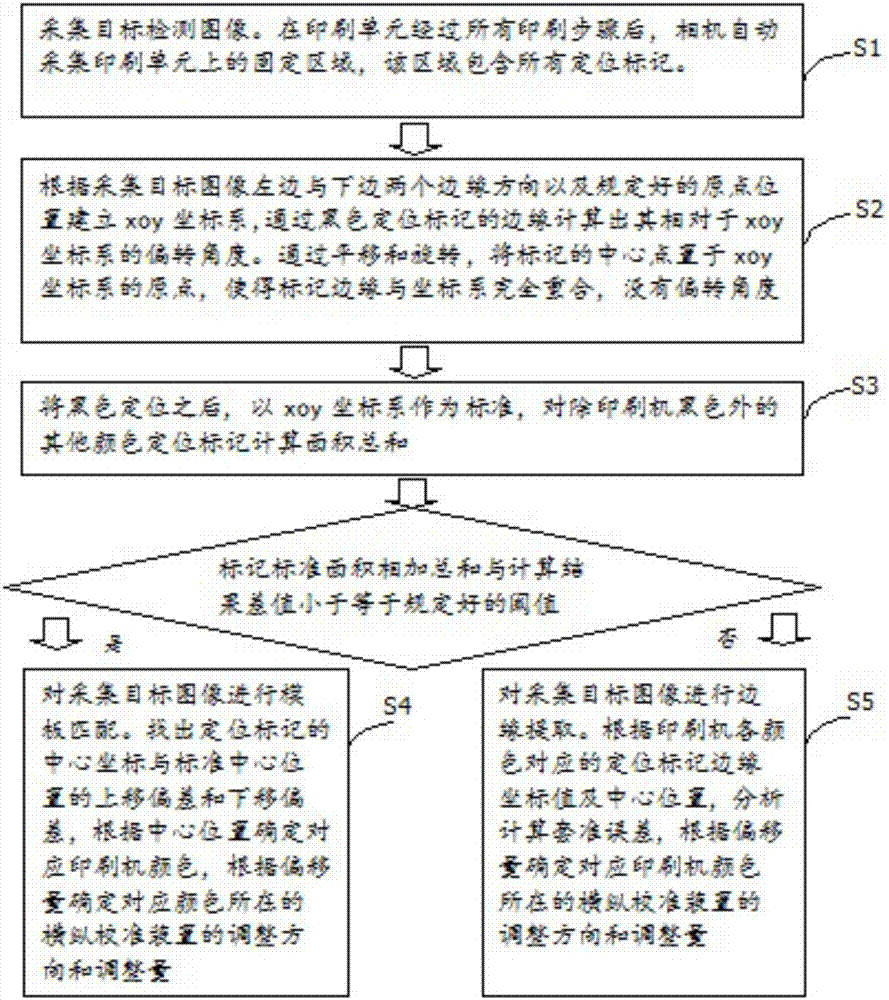

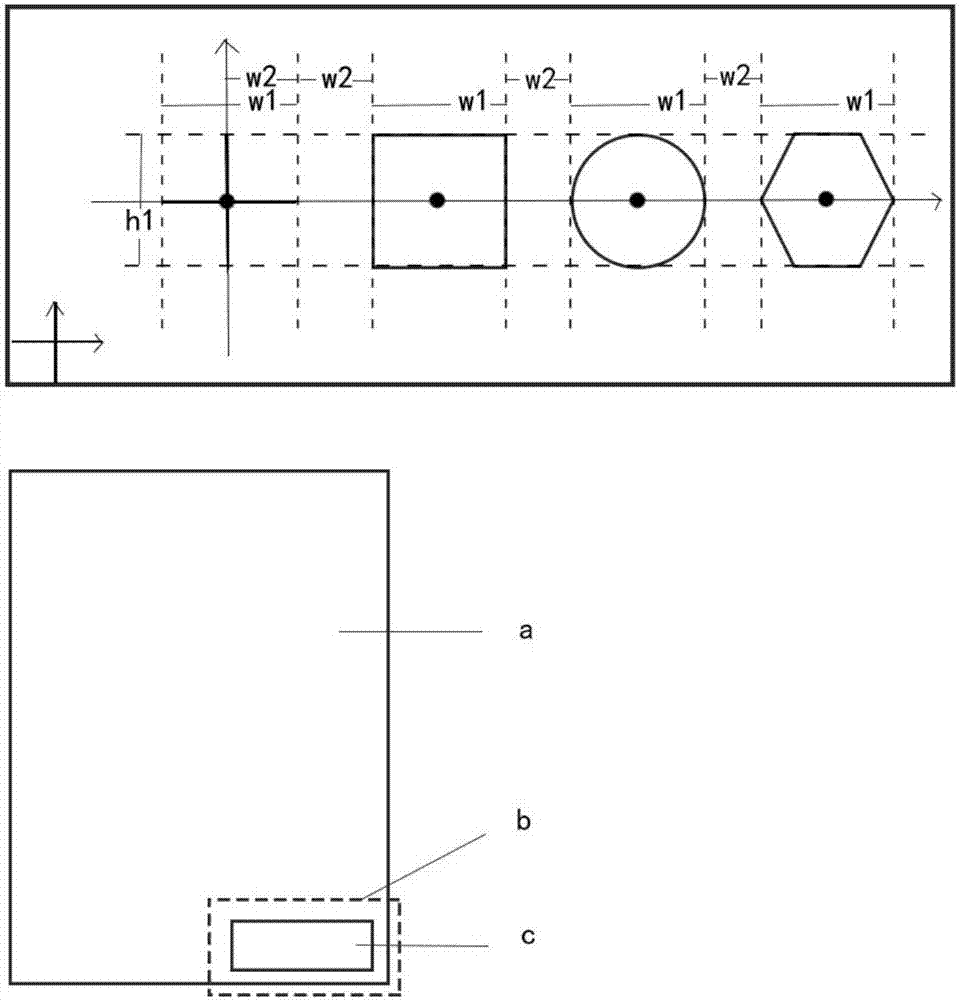

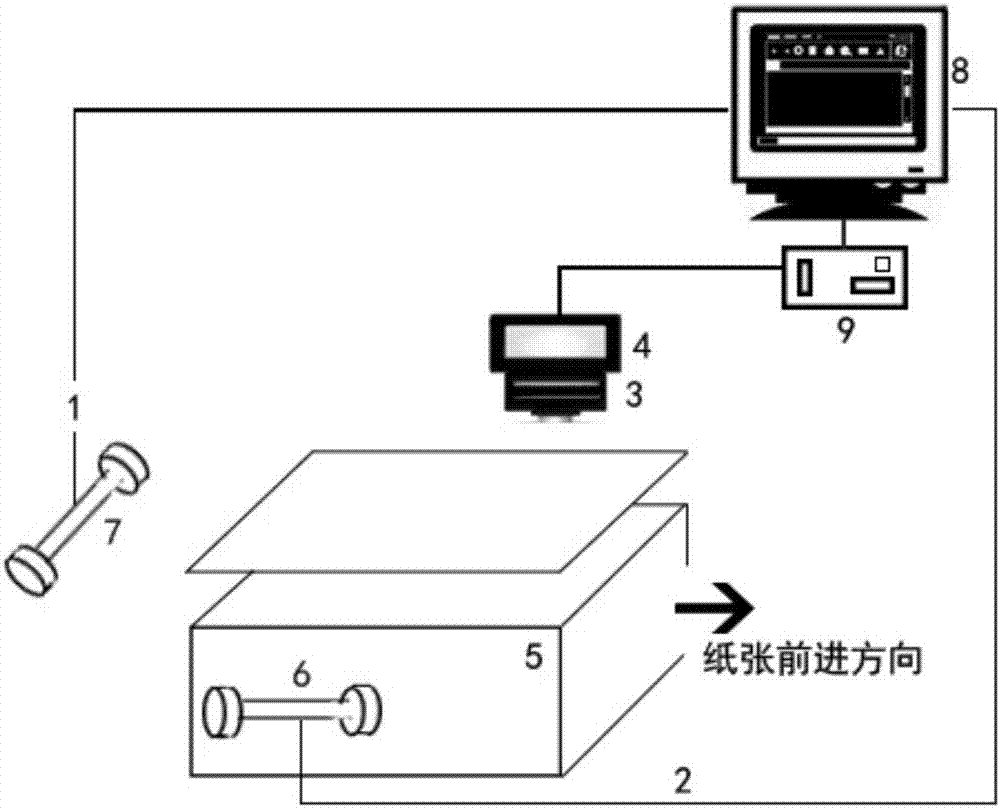

Machine vision-based overprint error detection method

The present invention provides a machine vision-based overprint error detection method. According to the method, a target image is acquired through a camera, wherein the target image contains a plurality of positioning marks; the area of the positioning marks is calculated, if the difference value of the area of the positioning marks and a standard area is not larger than a specified threshold value, and template matching is used to extract the centers of the positioning marks; overprint error is detected according to the deviation quantity of the positions of the centers and standard positions; if the difference value of the area of the positioning marks and the standard area is larger than the specified threshold value, edge segmentation is adopted to extract the edges of the positioning marks, and overprint error is detected according to the deviation quantity of the positions of the edges and standard positions; and after the error detection is completed, and a printer is automatically adjusted. According to the method of the invention, the image segmentation and the template matching are utilized, so that the technical problems of large computation quantity, large error, low robustness and incapability of performing automatic adjustment according to error in the prior art can be solved. The method is suitable for being popularized in the printing industry.

Owner:TONGJI UNIV

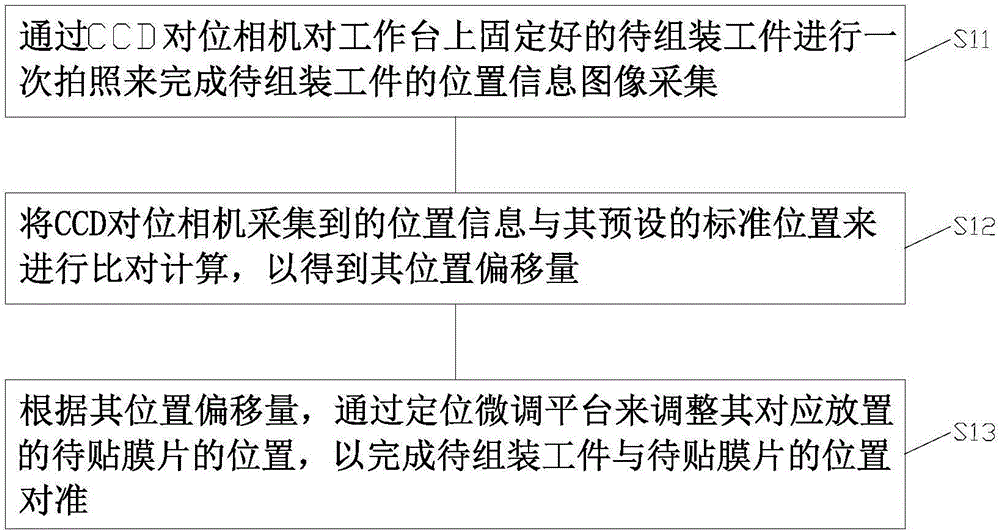

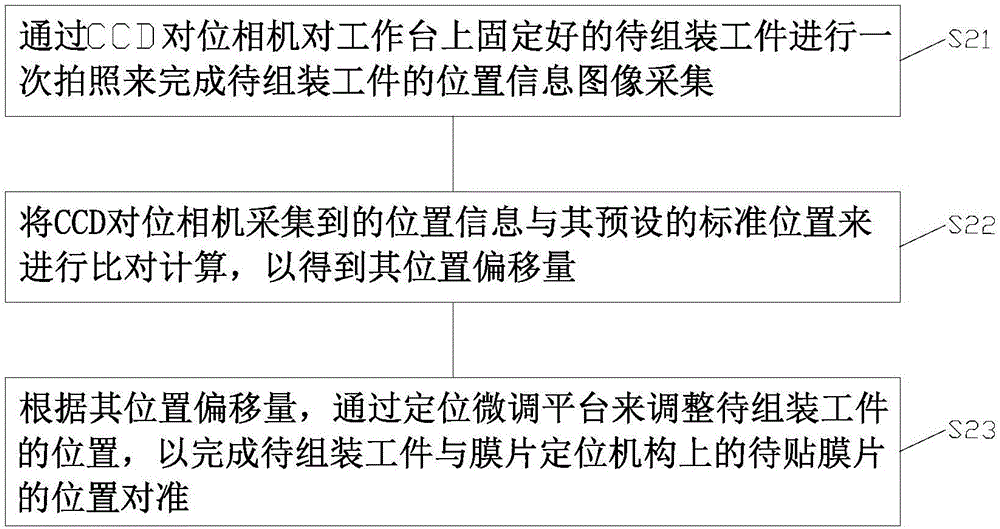

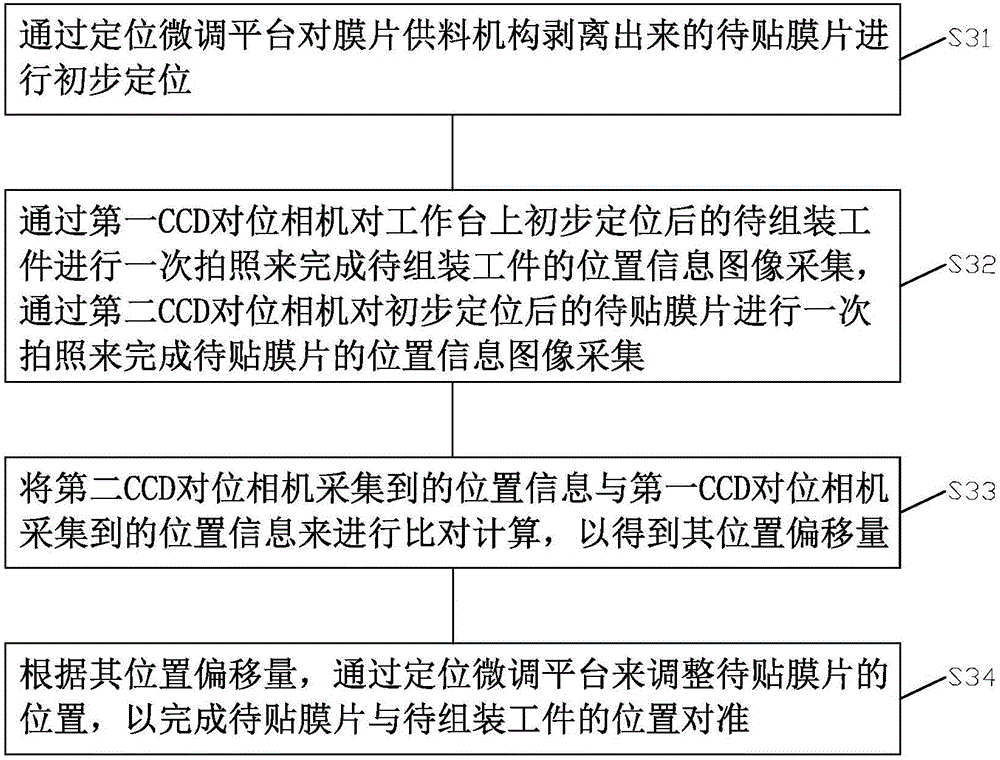

Backlight CCD laminating technology and backlight CCD laminator

ActiveCN106564267AAccurate collectionAccurate alignment operationLamination ancillary operationsLaminationComputer sciencePosition shift

The invention provides a backlight CCD laminating technology and a backlight CCD laminator. The membrane alignment working procedure of the backlight CCD laminating technology comprises the following steps that a CCD alignment camera photographs a to-be-assembled workpiece initially located on a working table once to complete position information image collection of the to-be-assembled workpiece; position information collected by the CCD alignment camera and the preset standard position of the to-be-assembled workpiece are compared and calculated to obtain the position offset of the to-be-assembled workpiece; according to the position offset of the to-be-assembled workpiece, a locating fine adjustment platform adjusts the position of a to-be-laminated membrane arranged corresponding to the to-be-assembled workpiece, so that alignment of the position of the to-be-assembled workpiece to the position of the to-be-laminated membrane is completed. According to the backlight CCD laminating technology and the backlight CCD laminator, alignment operation before laminating in the assembling process of the rear section of a backlight product can be completed accurately.

Owner:SHENZHEN WEIHONGKE TECH

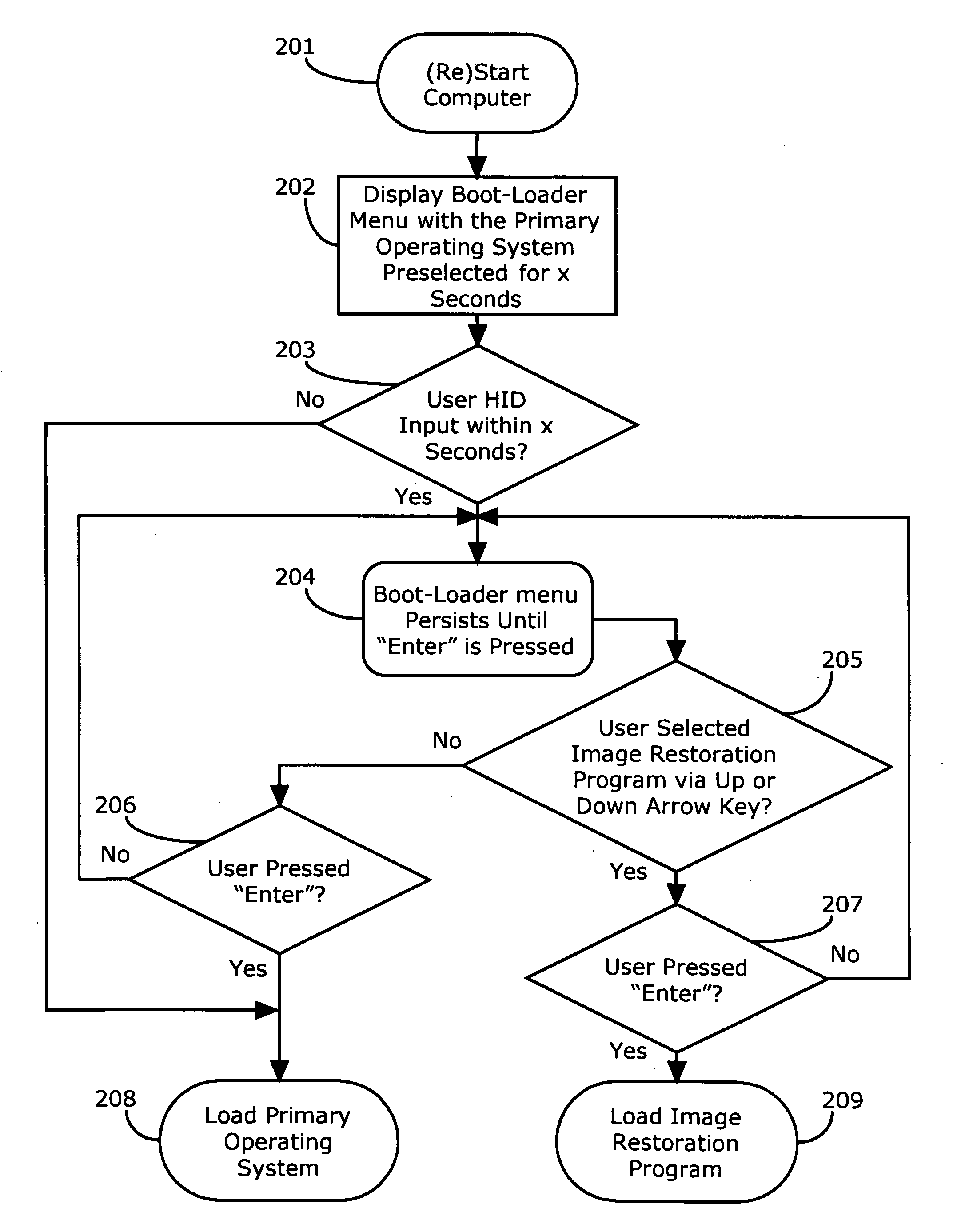

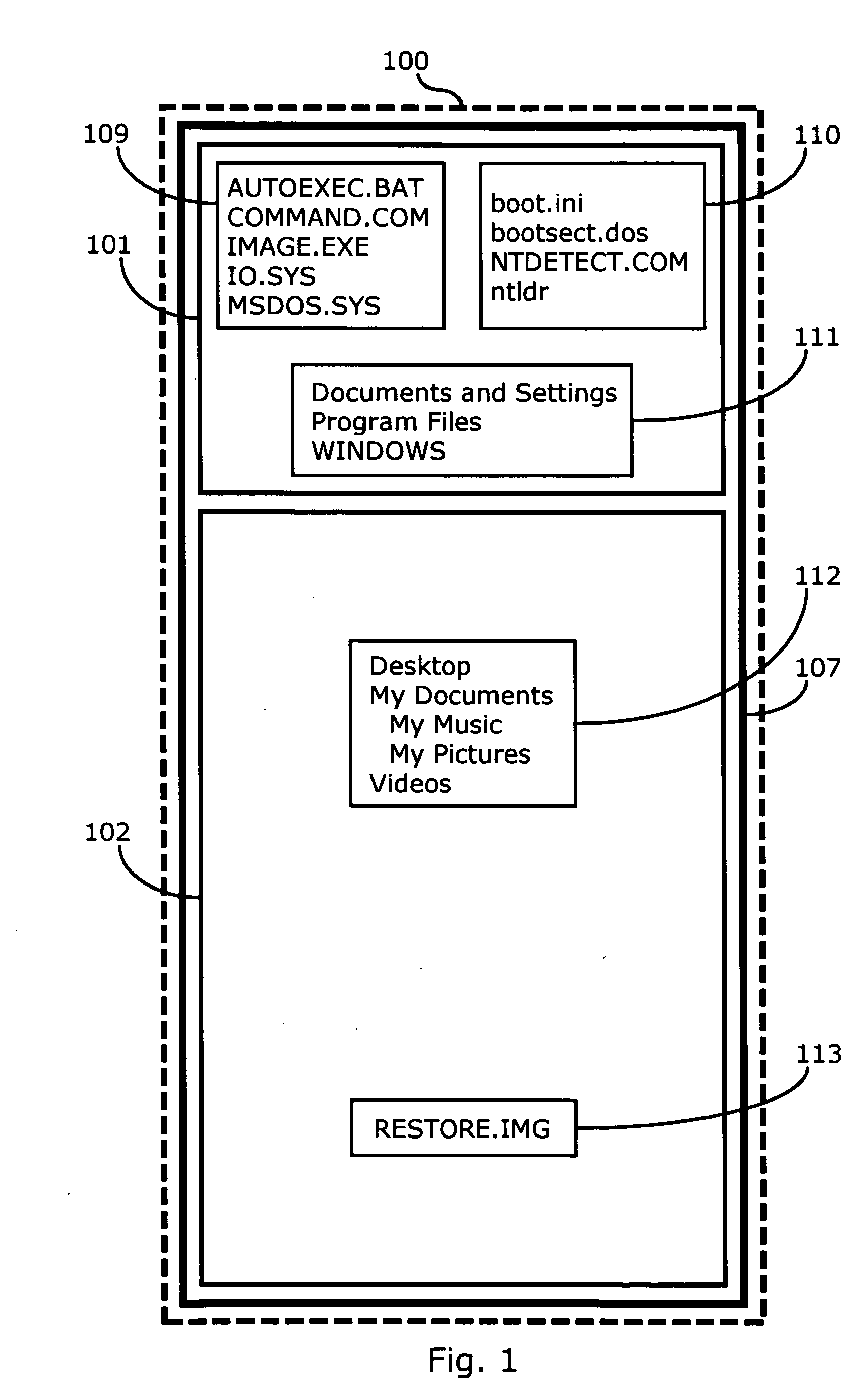

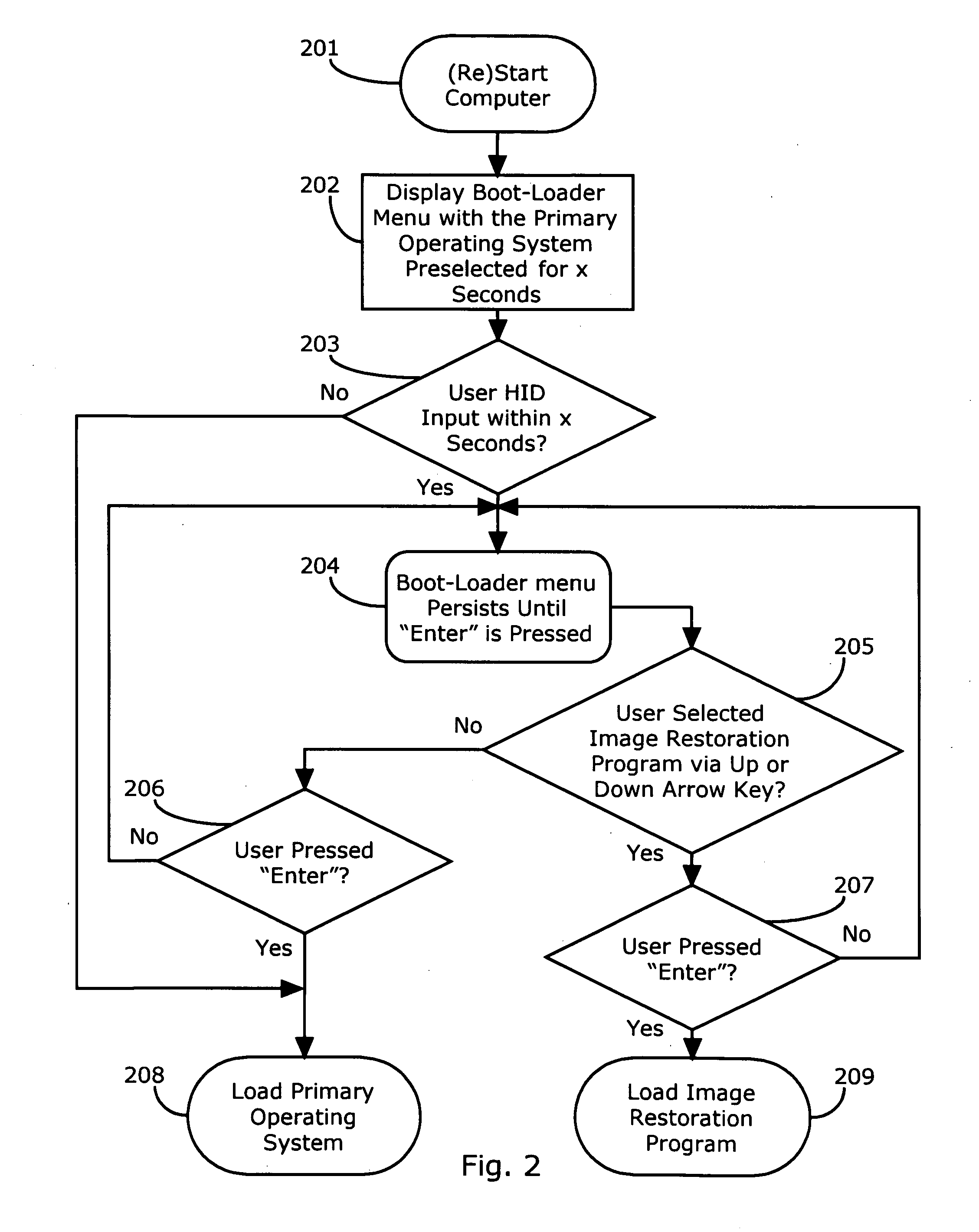

Computer with bootable restoration

ActiveUS20100241837A1Memory adressing/allocation/relocationDigital computer detailsMass storageGraphics

A bootable restoration computer includes: at least one mass storage device; at least two mass storage device partitions in the at least one mass storage device, including first and second partitions; a partition image restoration program; at least one partition image; at least one human interface device; a primary operating system with graphical user interface; a secondary operating system; and, a boot loader responsive to the human interface device that provides for selecting between the primary secondary operating systems. The primary operating system resides on the first partition and is configured so that its standard locations for storing user-created files are folders rooted on at least one of any partition other than the first partition. The at least one partition image is an image of the first partition, and resides on at least one of any partition other than the first partition. If no opportunity is taken to select the secondary operating system in a predefined time, the computer loads the primary operating system. If the opportunity is taken, the partition image restoration program restores the partition image to the first partition.

Owner:CONCORSO JAMES A

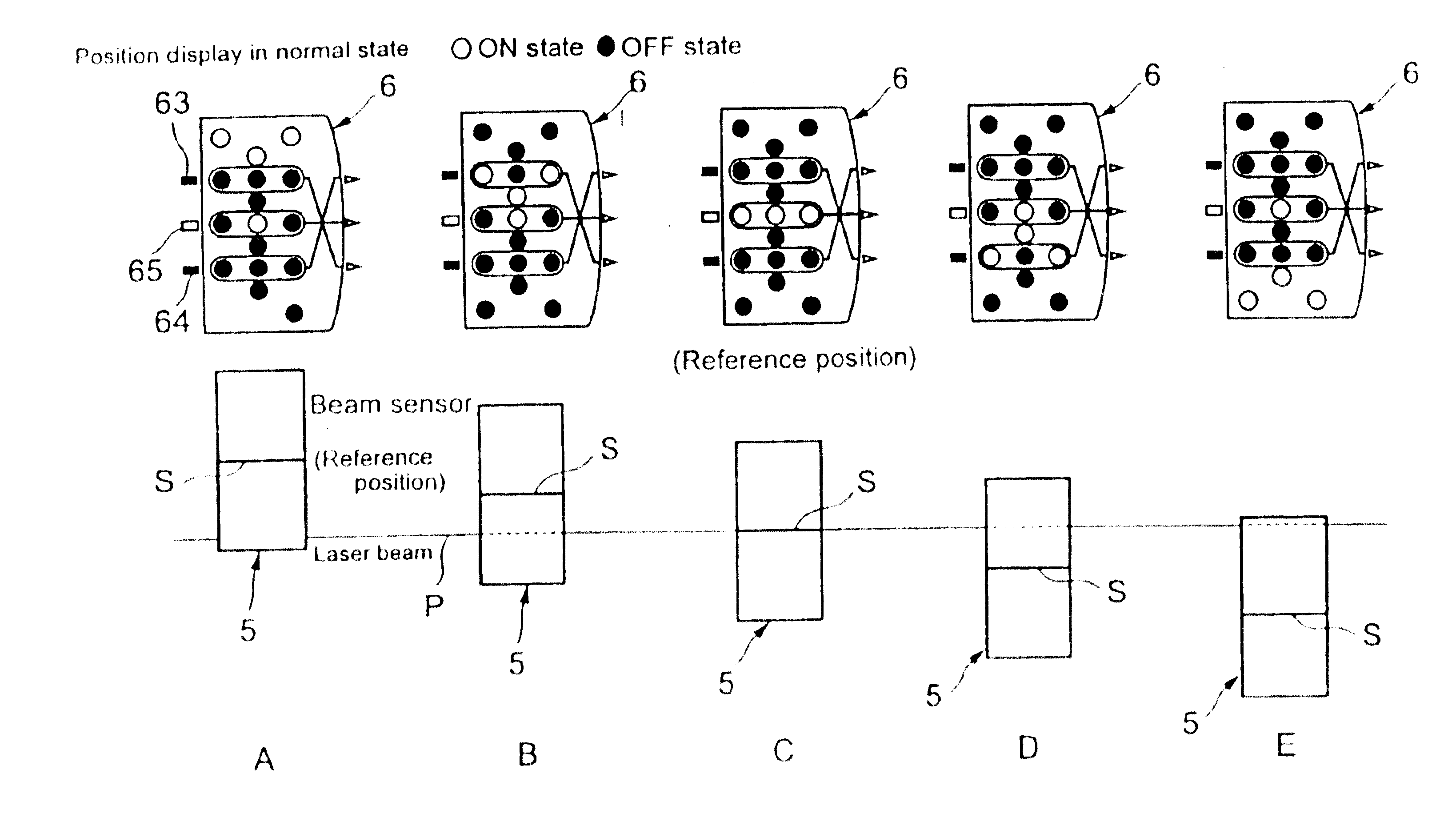

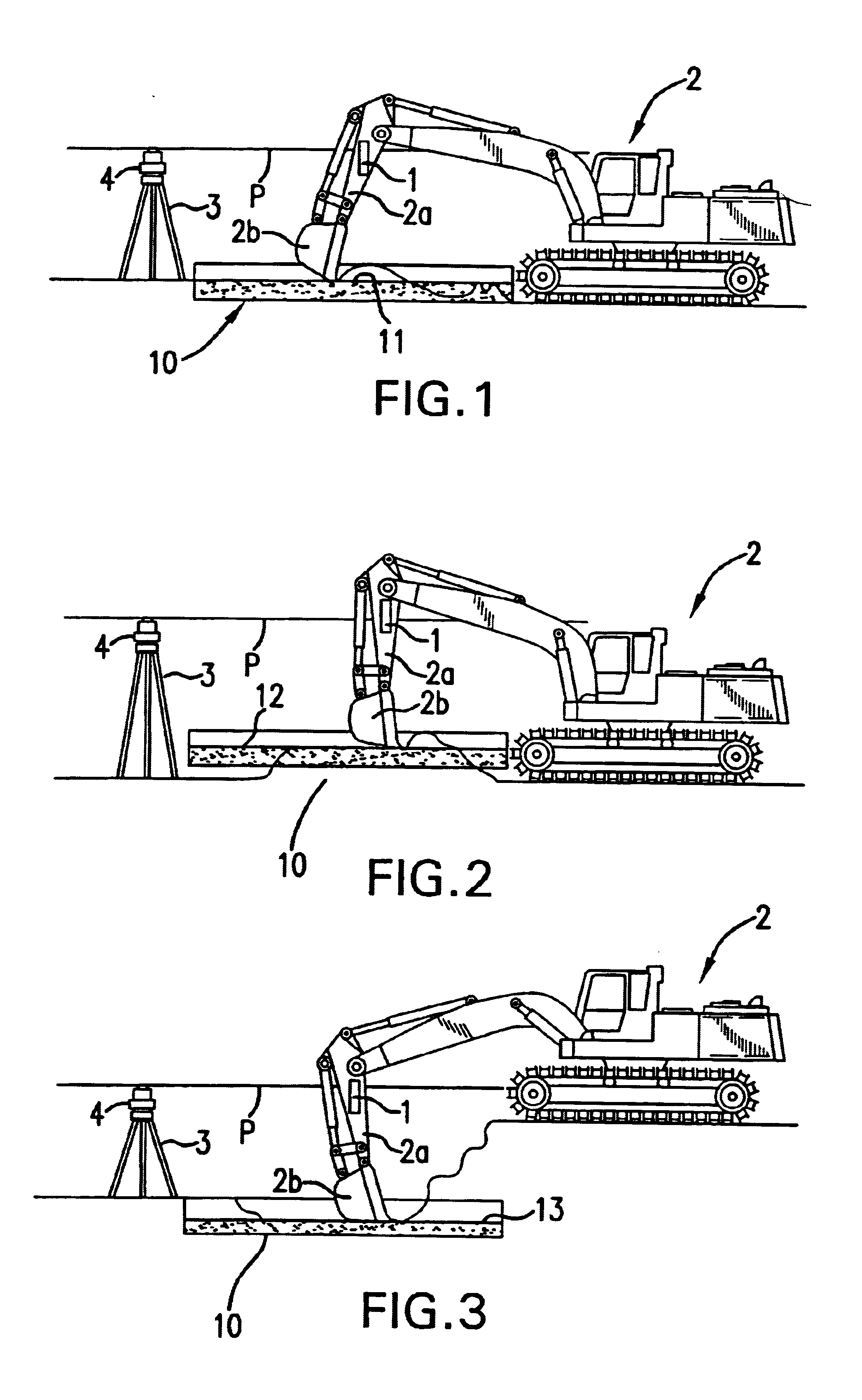

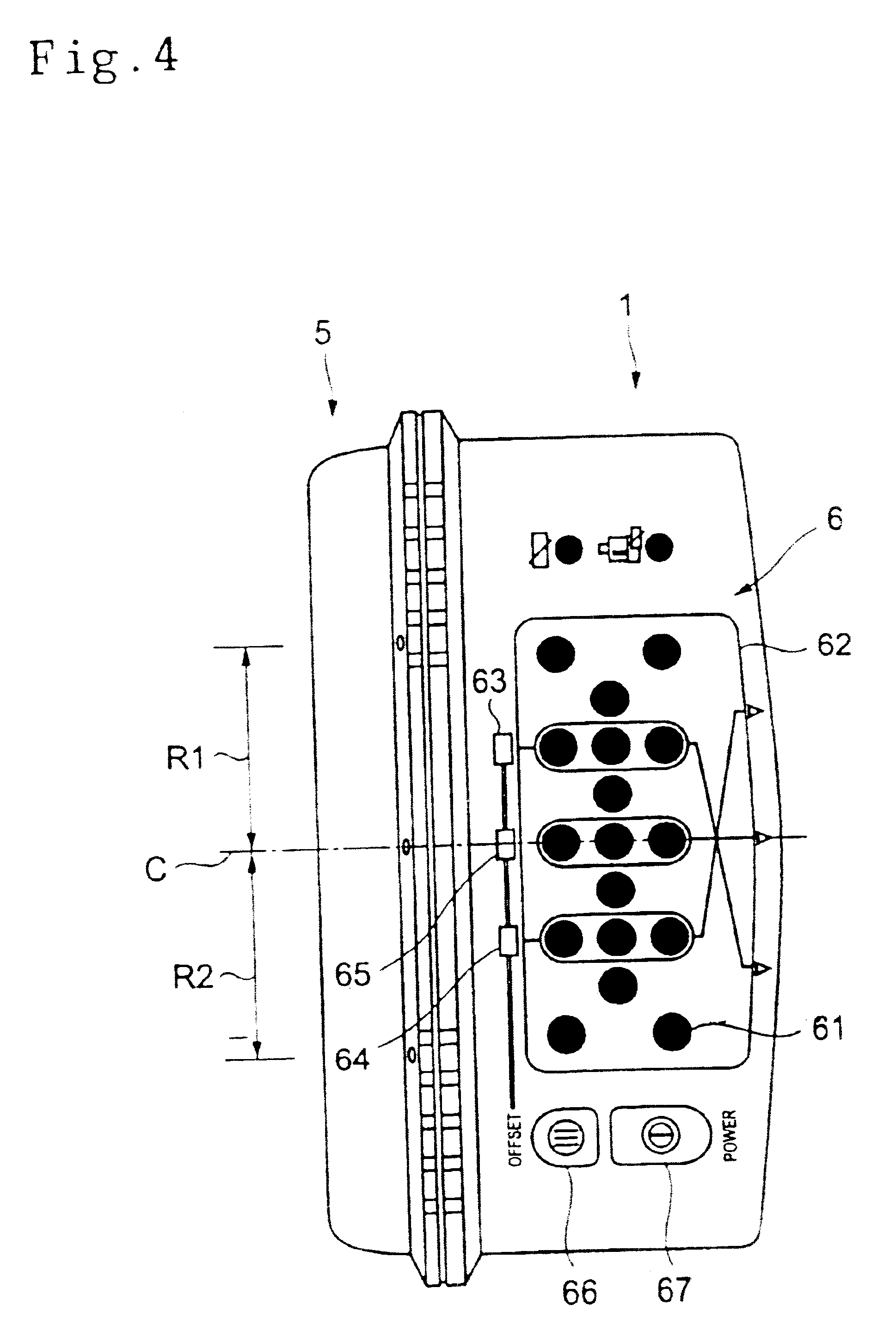

Laser beam detecting device for a construction machine

InactiveUS6665067B2Expand the scope of detectionWay accurateSurveyor's staffsMovable markersLight beamDisplay device

In a laser beam detecting device for a construction machine, a beam sensor is installed above a leveling implement of the construction machine, a laser beam is detected by the beam sensor, and information based on the beam detection is displayed on a display. A plurality of reference positions are established in a range in which the beam sensor detects the laser beam. One of the reference positions is made a standard position, while the other reference positions are made offset positions.

Owner:KK TOPCON

Percussion instrument, system, and method with closing position detection

An electronic percussion instrument includes input means, correction information storage means, and musical tone generation means. The input means allows for vibration information, which expresses a vibration of an operator, position information, which expresses a position of the operator, and standard position information, which indicates a standard position of the operator, to be input. The correction information storage means allows for correction information to be stored that is based on the position information that has been input in the input means that corresponds to the standard position information that has been input in the input means. The musical tone generation means allows for the generation of a musical tone in conformance with the position information that has been input in the input means that corresponds to the vibration information that has been input and the correction information that has been stored in the correction information storage means.

Owner:ROLAND CORP

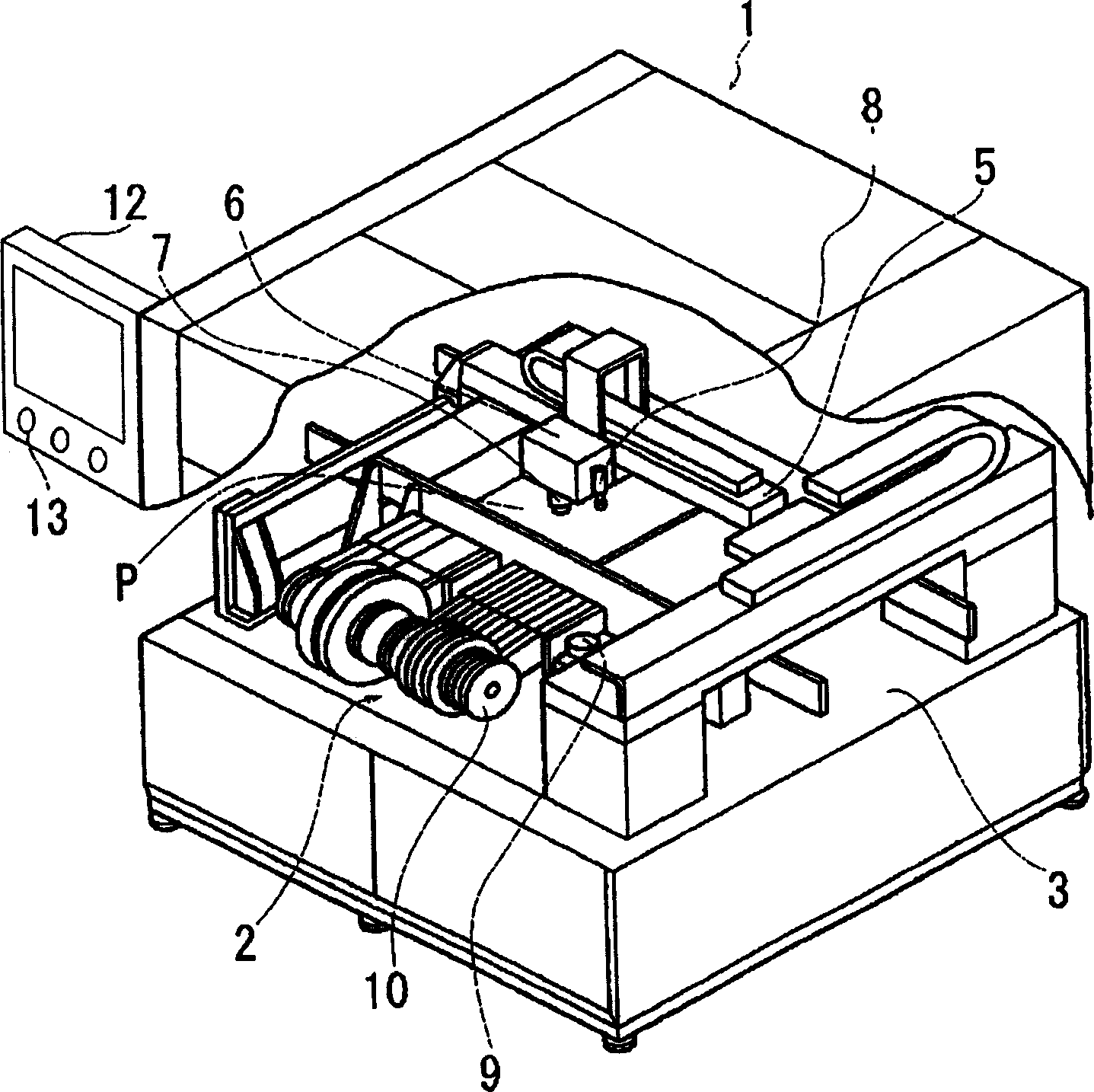

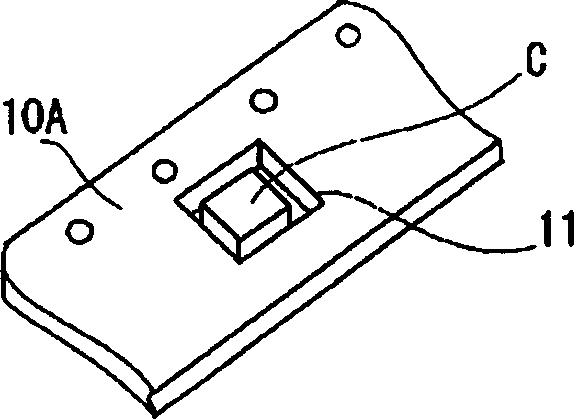

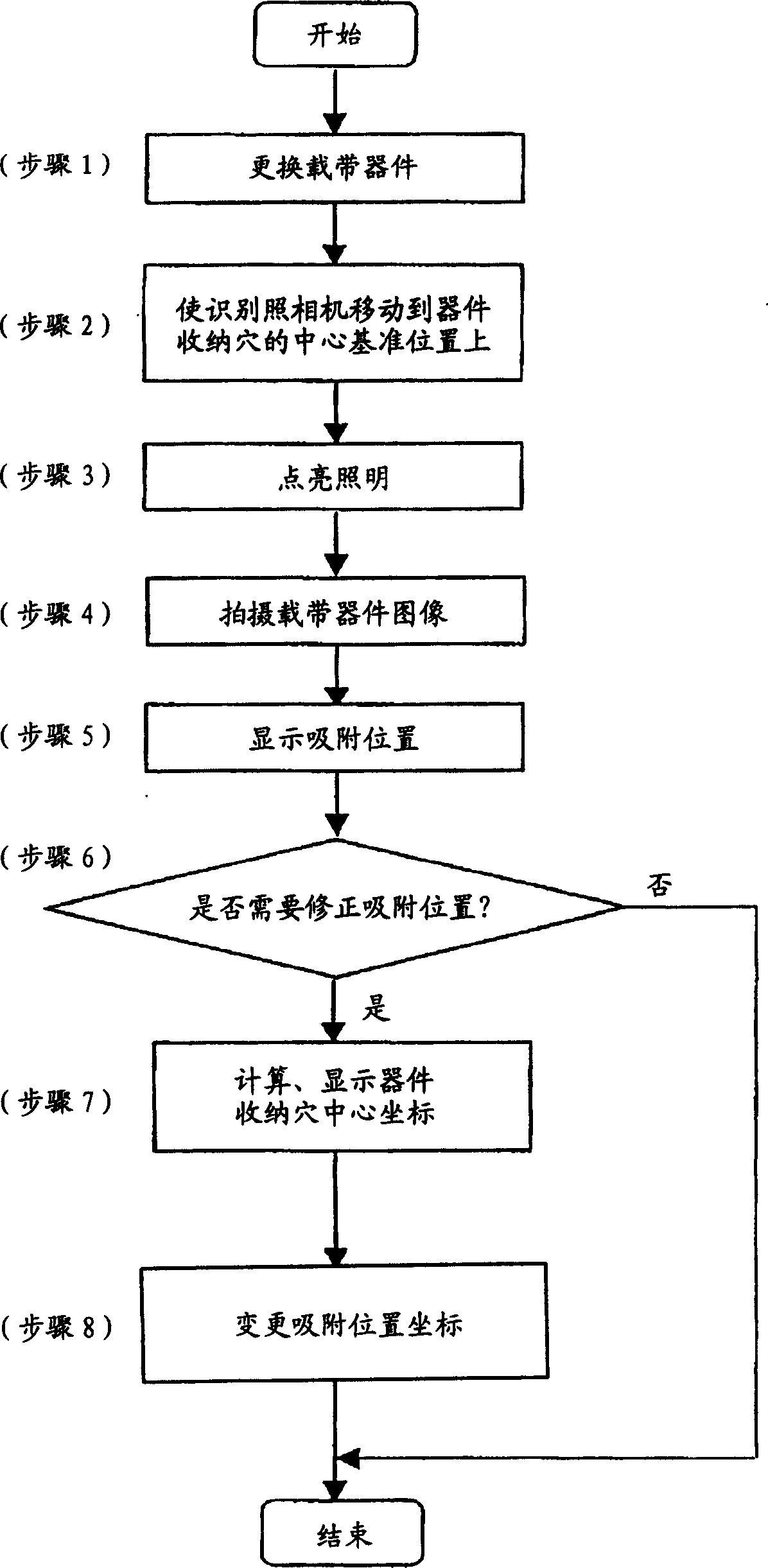

Adsorption position corrector of electronic device in electronic device mounting machine

To provide an apparatus for correcting an electronic component suction position in an electronic component mounting machine for sucking an electronic component at a suitable position that is sequentially fed out by a tape feeder or the like. The apparatus includes a tape feeder for pitch-feeding an electronic component housed in a component housing hole of a tape, a camera provided on a mount head for identifying the component housing hole of the tape, a CPU for calculating the displacement between the prerecorded central standard position and the central position calculated by the identified image of the camera of the component housing hole of the tape, and a display for displaying the central reference position and the image of the component housing hole. The correction of the electronic component suction position is made possible, based on the central reference position in the display and the displayed result of the central position of the component housing hole.

Owner:JUKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com