Adsorption position corrector of electronic device in electronic device mounting machine

An electronic device, adsorption position technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of long installation time and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

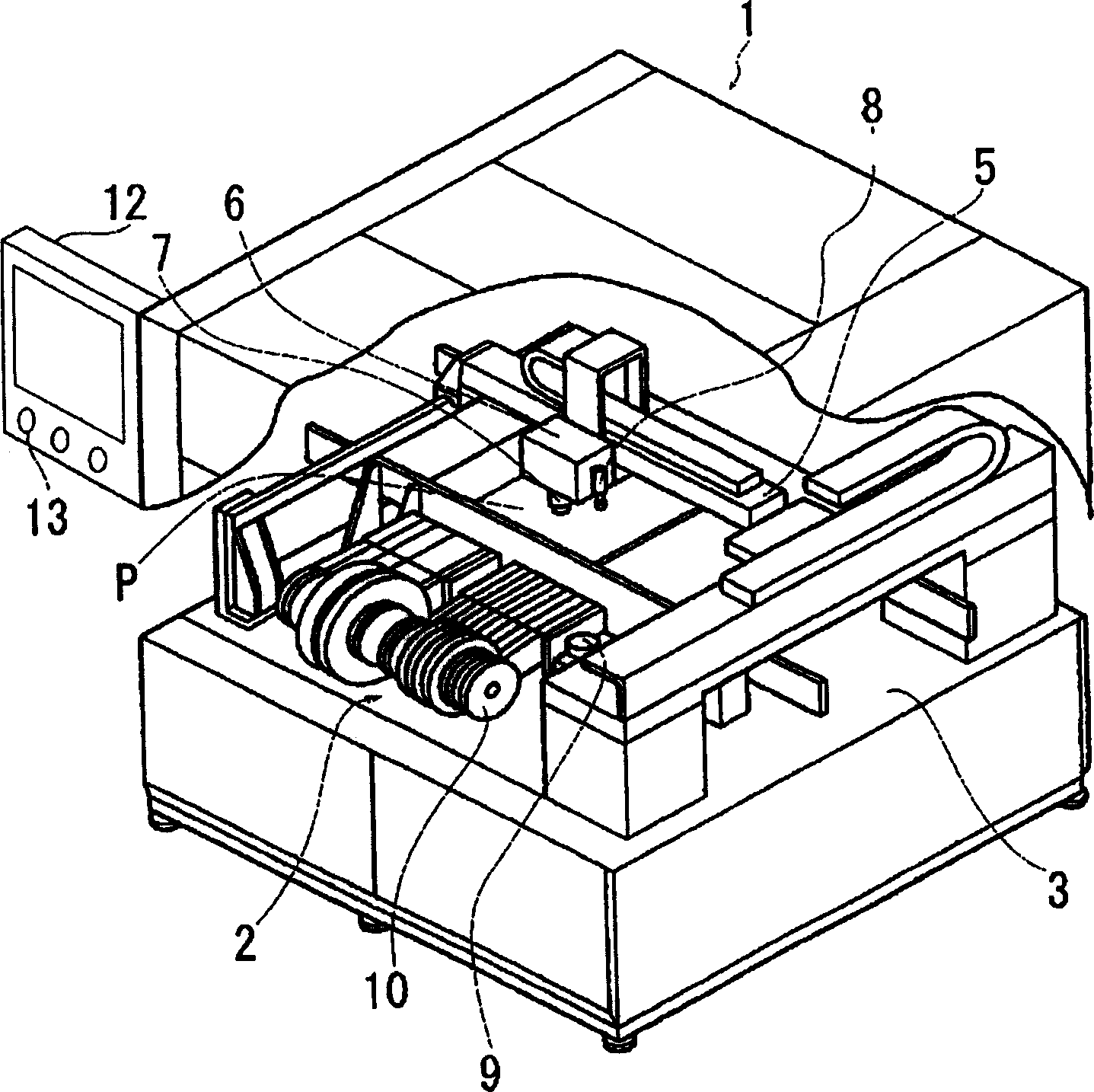

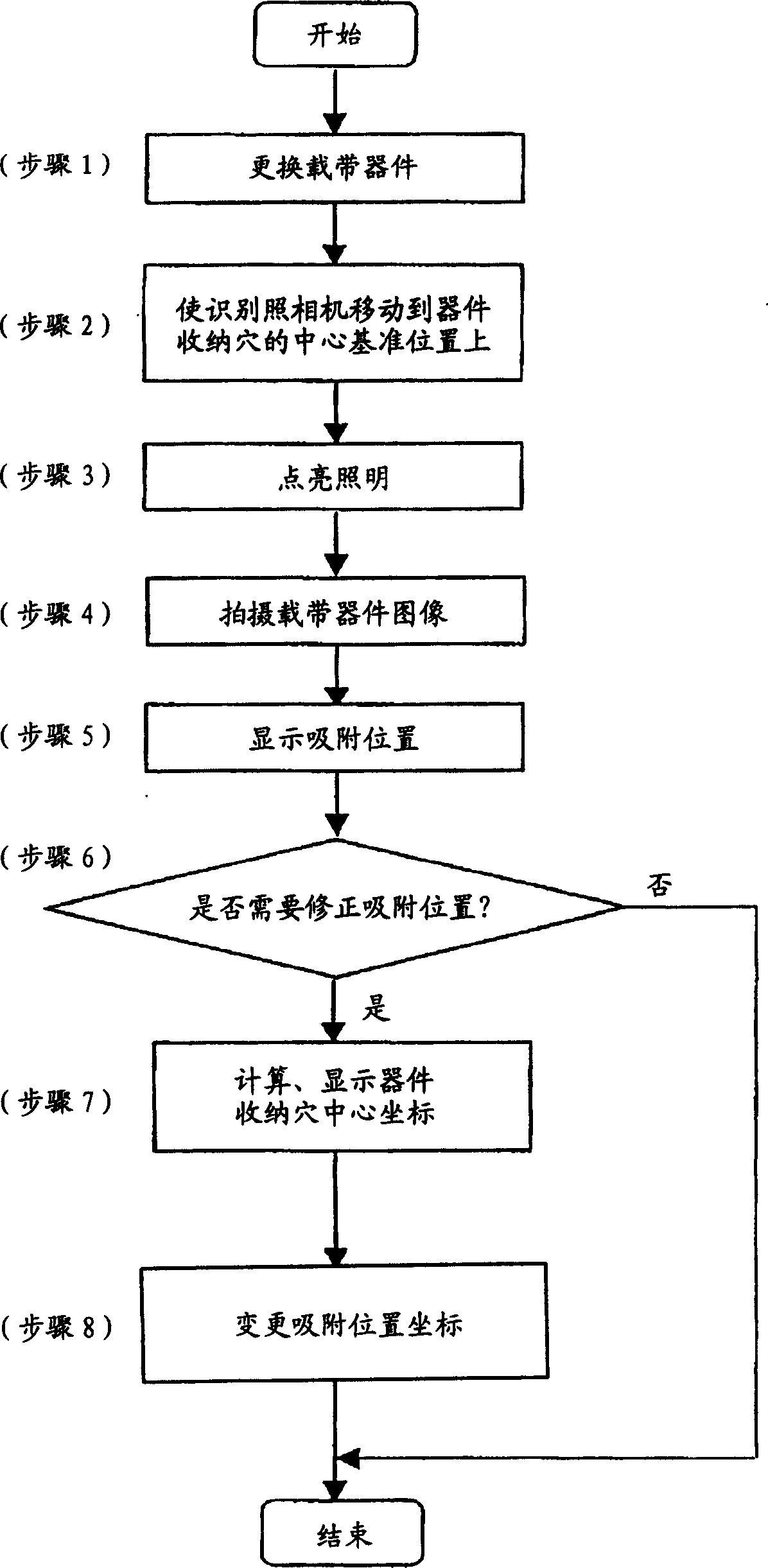

[0022] Below, refer to Figure 1 to Figure 5 Embodiments of the present invention will be described.

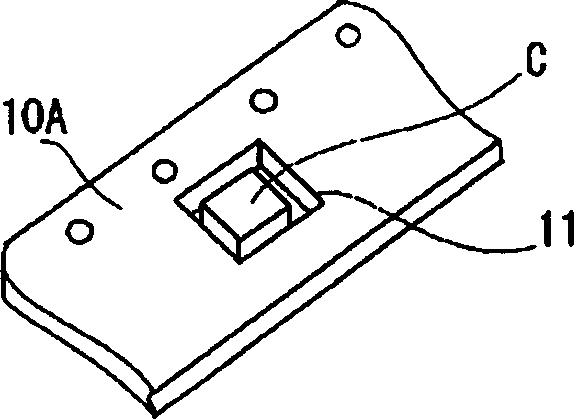

[0023] figure 1 It is a schematic diagram of an electronic component mounting machine having a suction position correcting device according to the present invention. The electronic component mounting machine 1 has a substrate conveyance path 3 extending in the left and right directions at the center, and a component supply path 3 arranged at the front of the electronic component mounting machine 1. 2 and the XY transport unit 5 provided across the substrate transport path 3 in the electronic component mounting machine 1 .

[0024] A suction head 6 for suctioning and mounting the electronic component C on the substrate P is mounted on the XY conveyance unit 5, and a plurality of suction heads 6 that can move up and down and rotate in the axial direction are provided on the suction head 6. Mouth7.

[0025] Further, a recognition camera 8 for recognizing a substrate mark (not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com