Method, device, storage medium and terminal device for product defect detections and locations

A technology for product defect and position prediction, applied in the computer field, to achieve the effect of improving accuracy and high robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

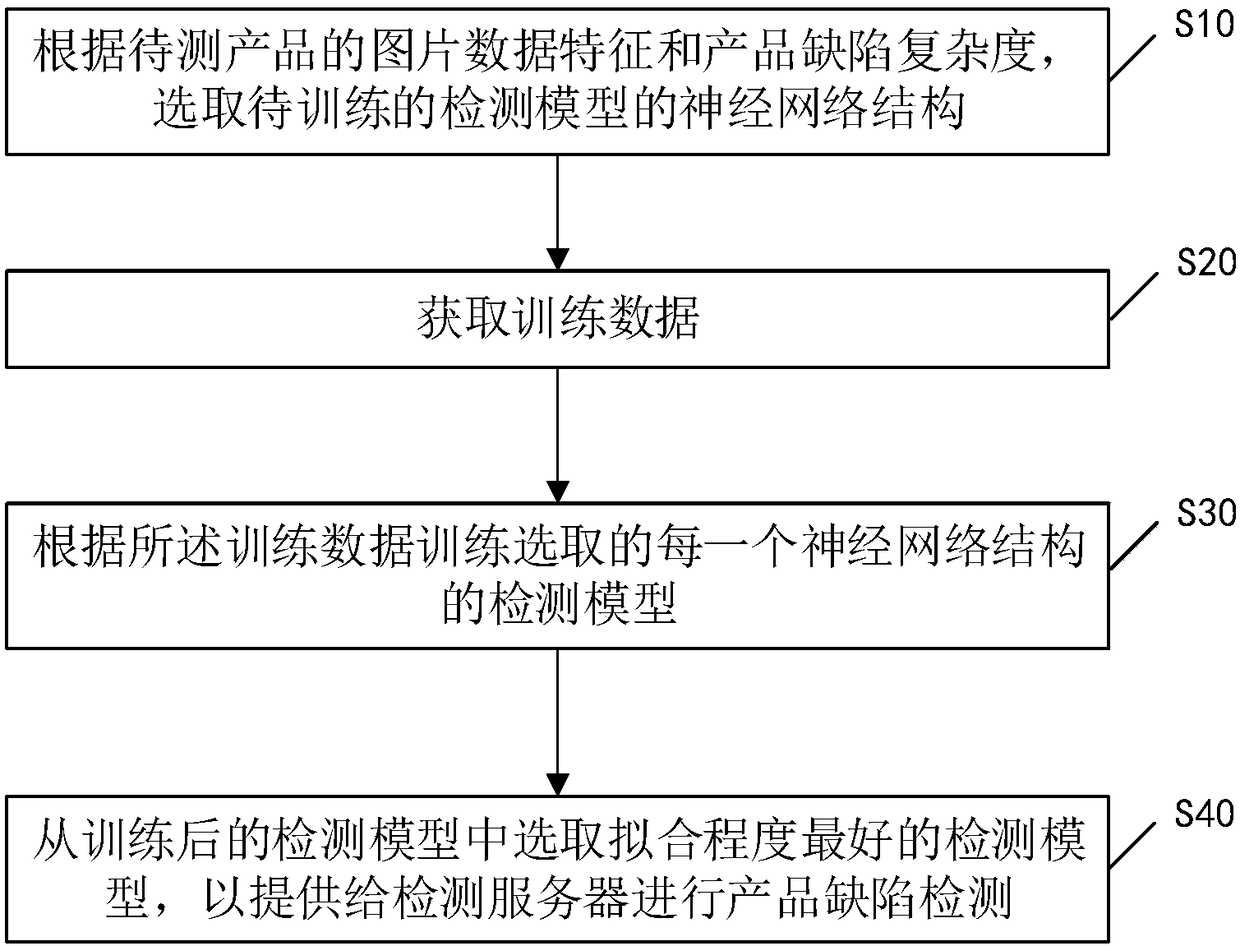

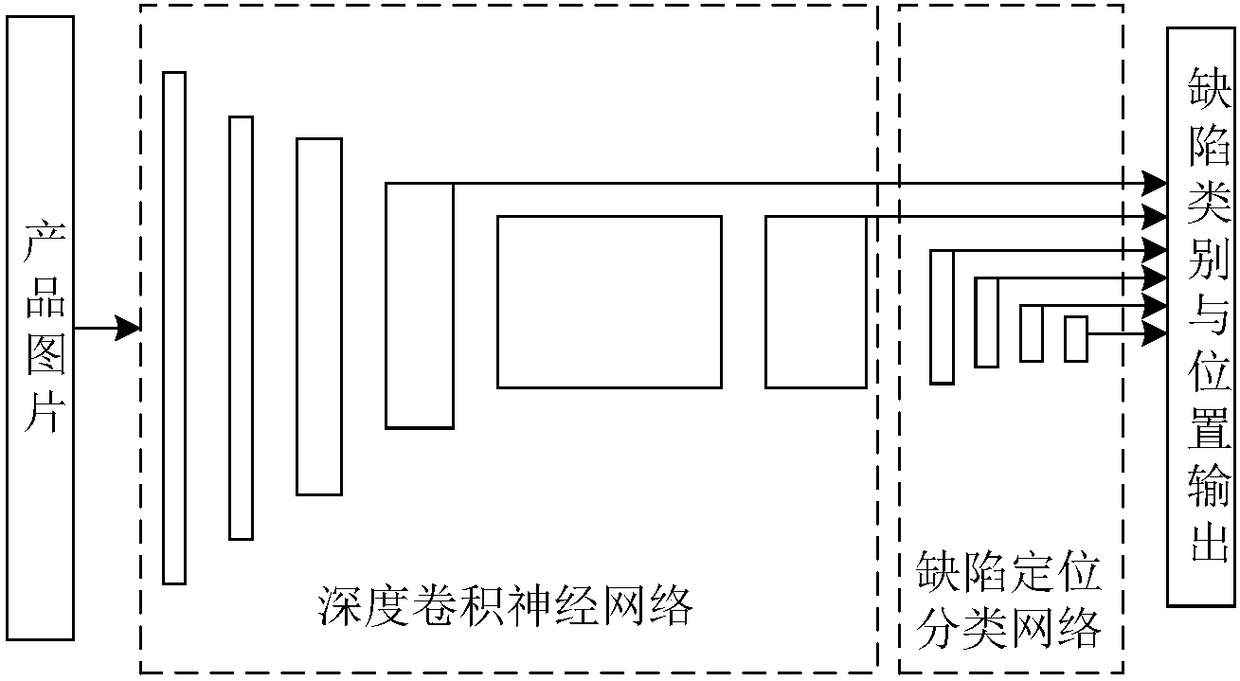

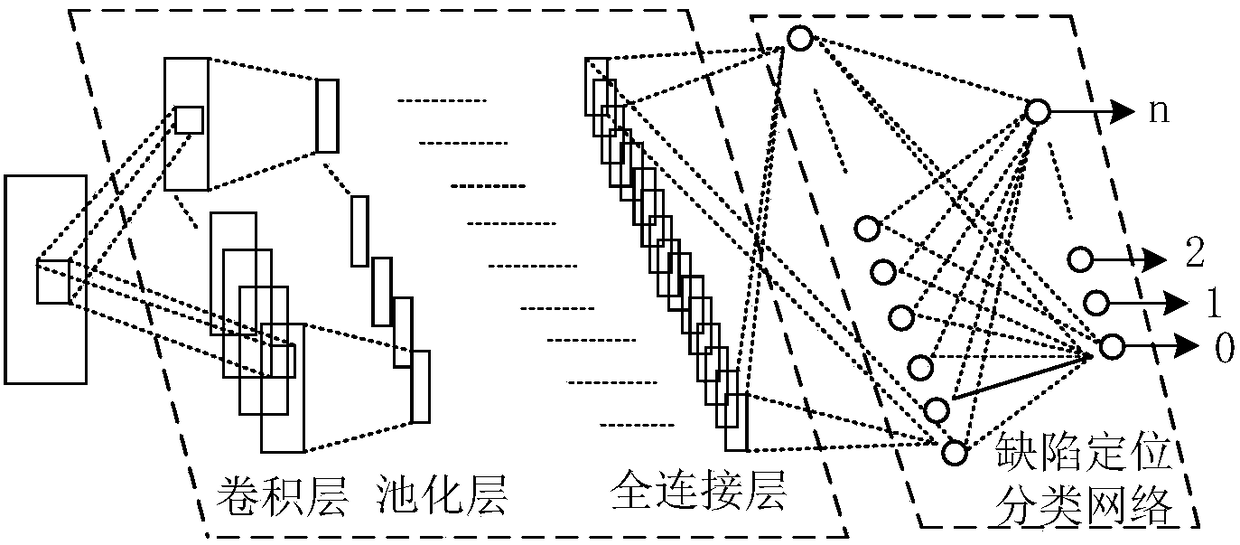

[0058] see figure 1 , the embodiment of the present invention provides a method for detecting and locating product defects, executed by the training engine, including steps S10 to S40, specifically as follows:

[0059] S10. Select the neural network structure of the detection model to be trained according to the image data characteristics of the product to be tested and the complexity of product defects.

[0060] In the embodiment of the present invention, when the surface state of the product to be tested is detected, the product picture collection of the product to be tested can be collected by a camera and other equipment. Due to the influence of the camera equipment, camera technology and camera environment, the picture data features of the pictures exist. For example, when the picture is high-definition, the number of neurons in the convolutional layer of the neural network structure selected by the detection model can be reduced. And different types of products contain ...

Embodiment 2

[0076] see Figure 5 , an embodiment of the present invention provides a device for detecting and locating product defects, including:

[0077] The structure selection module 10 is used to select the neural network structure of the detection model to be trained according to the picture data characteristics and product defect complexity of the product to be tested;

[0078] The data acquisition module 20 is used to acquire training data; wherein, the training data includes training product pictures and standard categories and standard positions of product defects in the training product pictures;

[0079] The detection model training module 30 is used to train the detection model of each neural network structure selected according to the training data;

[0080] The detection model selection module 40 is used to select the detection model with the best fitting degree from the trained detection models to provide to the detection server for product defect detection; wherein, the ...

Embodiment 3

[0089] see Figure 6 , the embodiment of the present invention provides a method for detecting and locating product defects, which can be executed by a detection server, including:

[0090] S210, receiving a product picture of the product to be tested;

[0091] S220, calculate the product picture according to the currently stored detection model, and obtain the predicted category and predicted position of the product defect in the product picture; wherein, the detection model is all selected neural networks generated according to training data training In the detection model of the structure, select the detection model with the best fitting degree, the neural network structure selected is selected according to the picture data characteristics and product defect complexity of the product to be tested, and the training data includes training product pictures and Standard categories and standard locations of product defects in the training product images.

[0092] Furthermore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com