Patents

Literature

226 results about "Best fitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Generating an optimized price schedule for a product

InactiveUS20060161504A1Disadvantages and reduced eliminatedPrice reduced eliminatedMarket predictionsResourcesRequirements modelAlgorithm

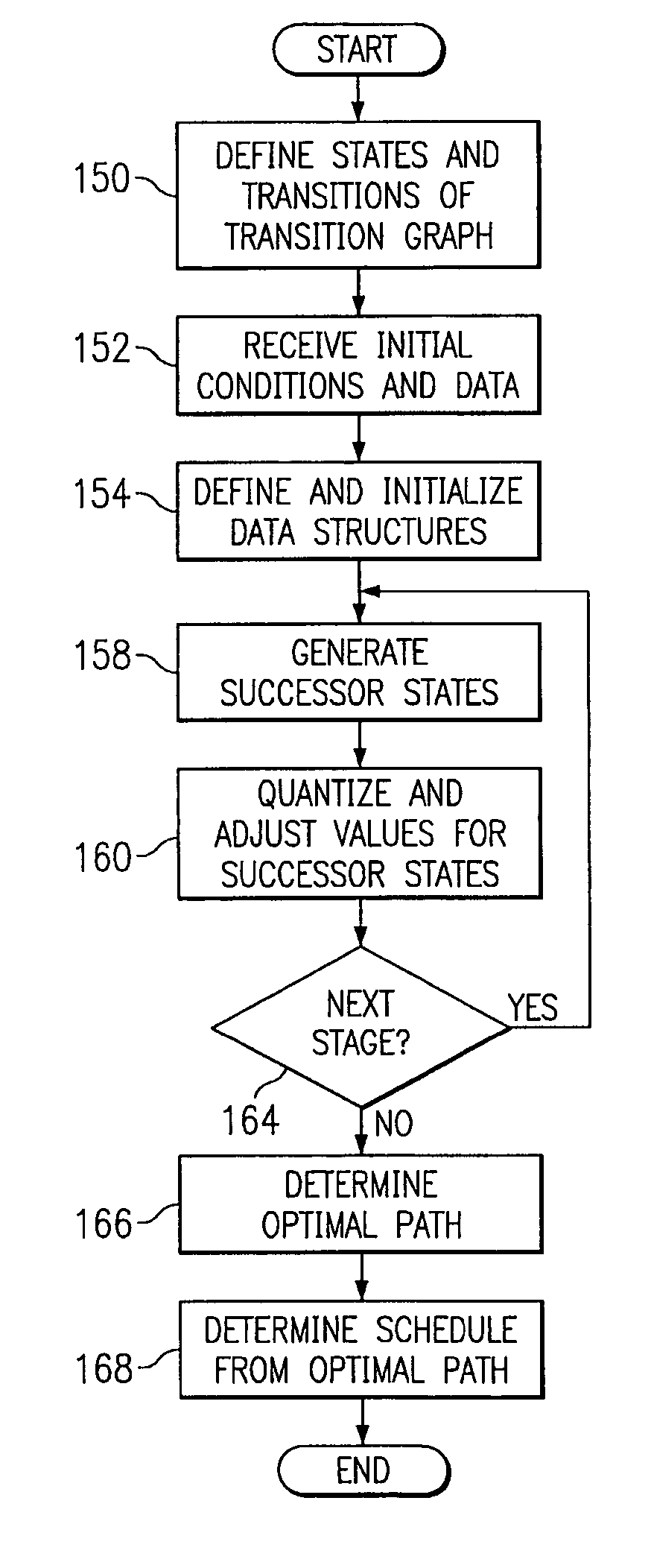

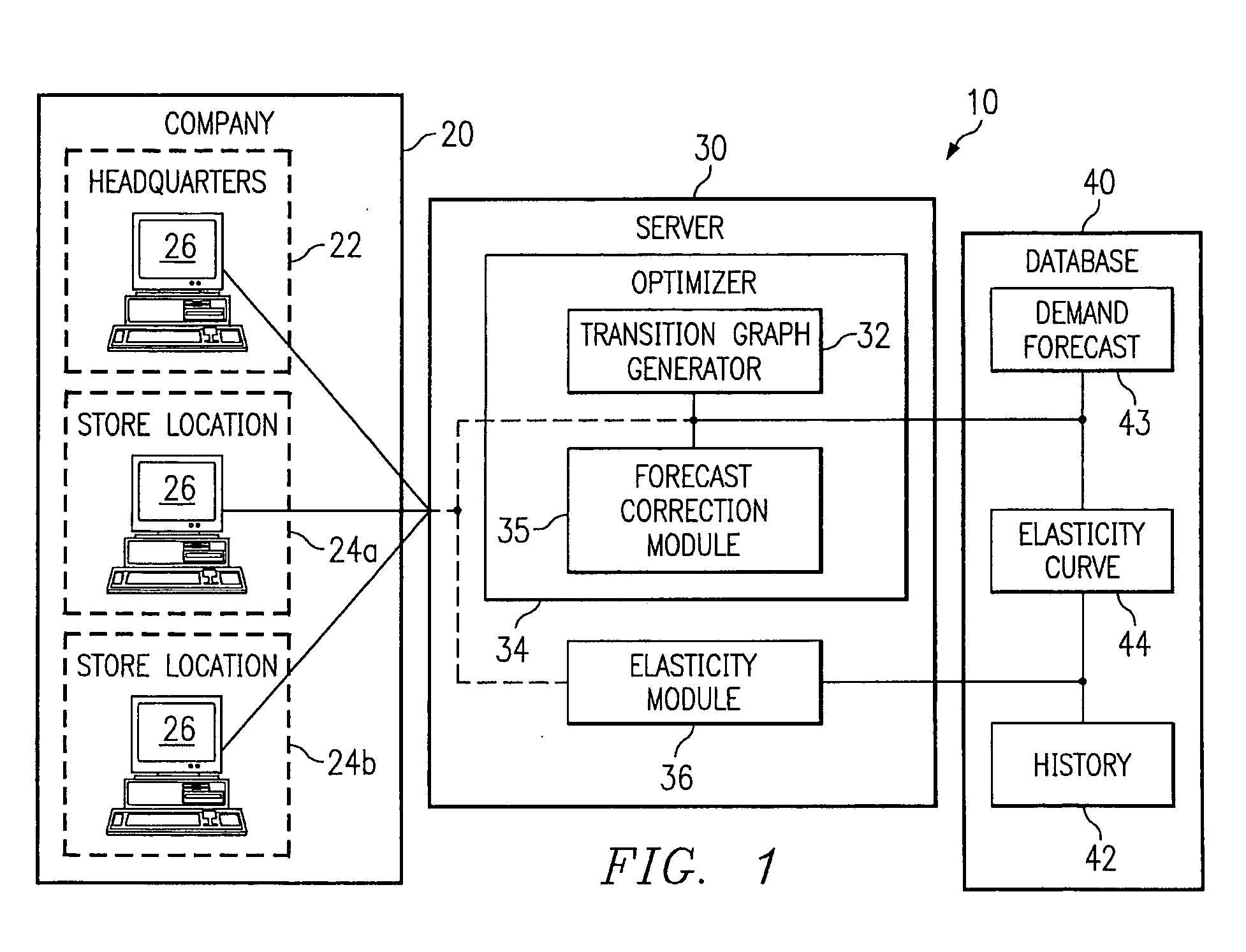

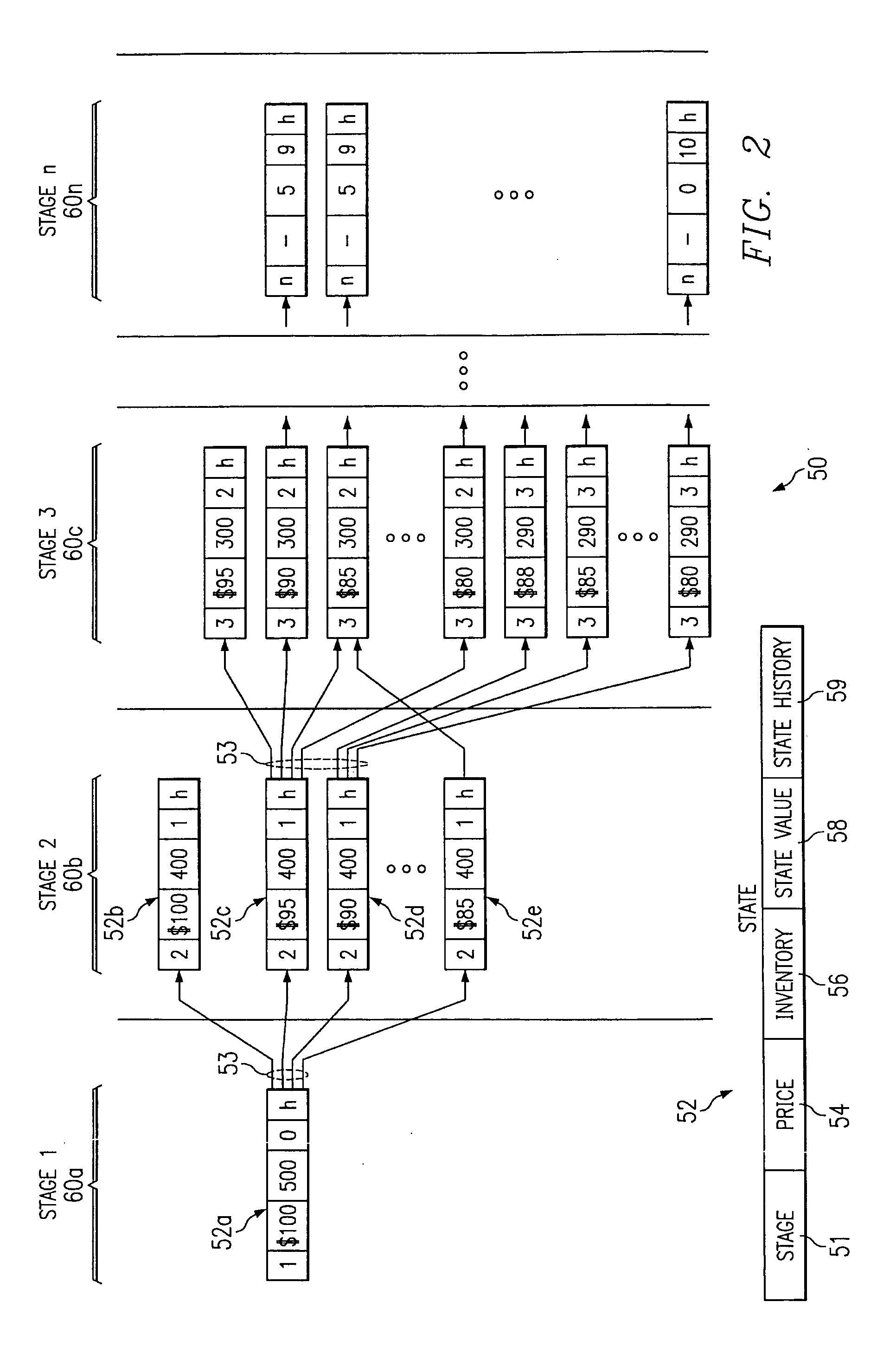

Generating a price schedule involves generating a graph (50) having paths that include states (52) with values (54, 56, 58). The graph (50) is generated by determining the values (56, 58) of a successor state (52) from the values (56, 58) of a predecessor state (52). An optimal path is selected, and a price schedule is determined from the optimal path. Computing an elasticity curve involves having a demand model, values for demand model, and filter sets that restrict the values. Elasticity curves are determined by filtering the values using filter sets, and calculating the elasticity curve using the demand model. An best-fitting elasticity curve is selected. Adjusting a demand forecast value (56) includes estimating an inventory and a demand at a number of locations (24). An expected number of unrealized sales at each location (24) is calculated. An sales forecast value (56) is determined according to the expected number.

Owner:JDA SOFTWARE GROUP

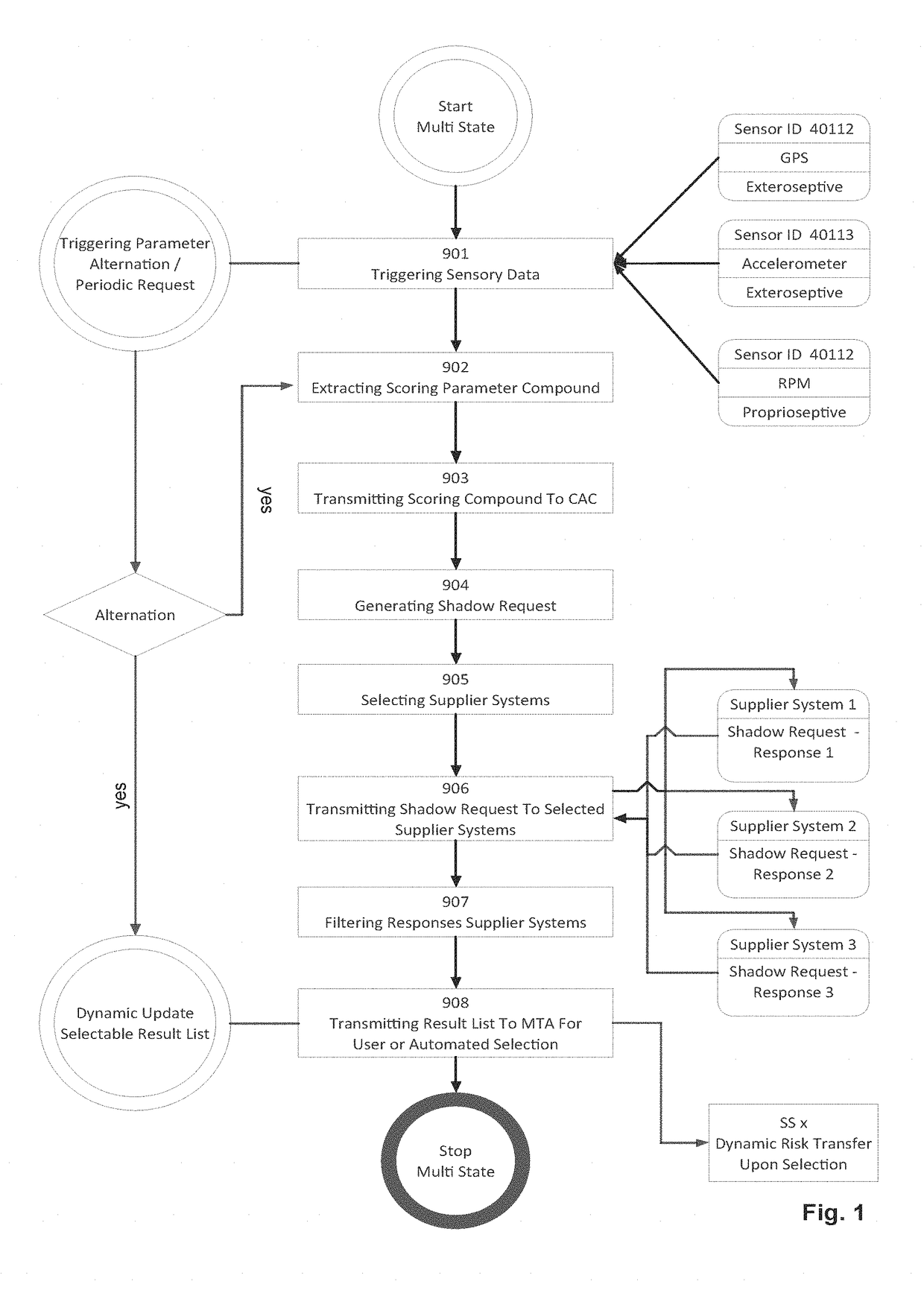

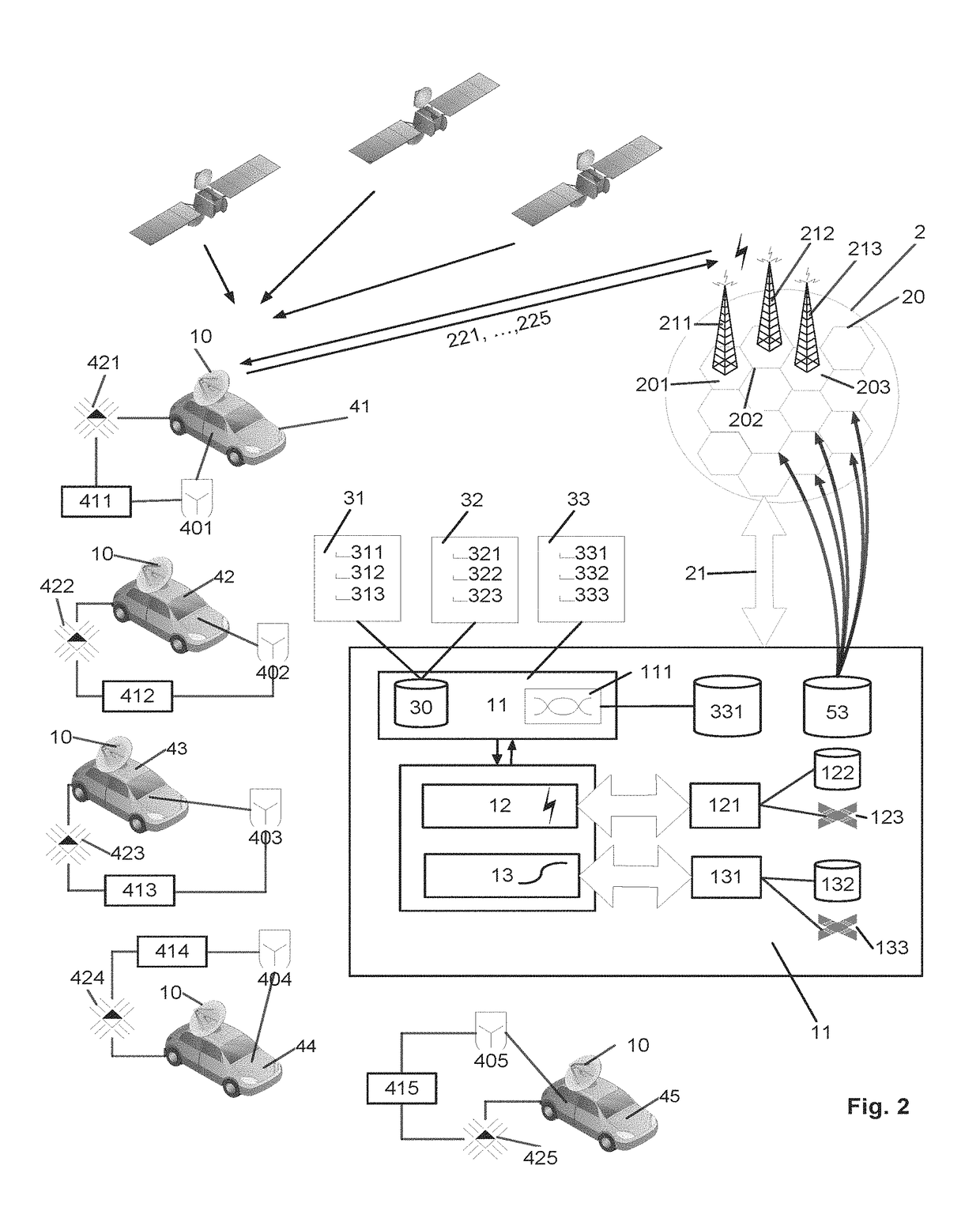

Apparatus for a dynamic, score-based, telematics connection search engine and aggregator and corresponding method thereof

ActiveUS20180025430A1Improve system stabilityImprove stabilityInstruments for road network navigationDigital data information retrievalData aggregatorEngineering

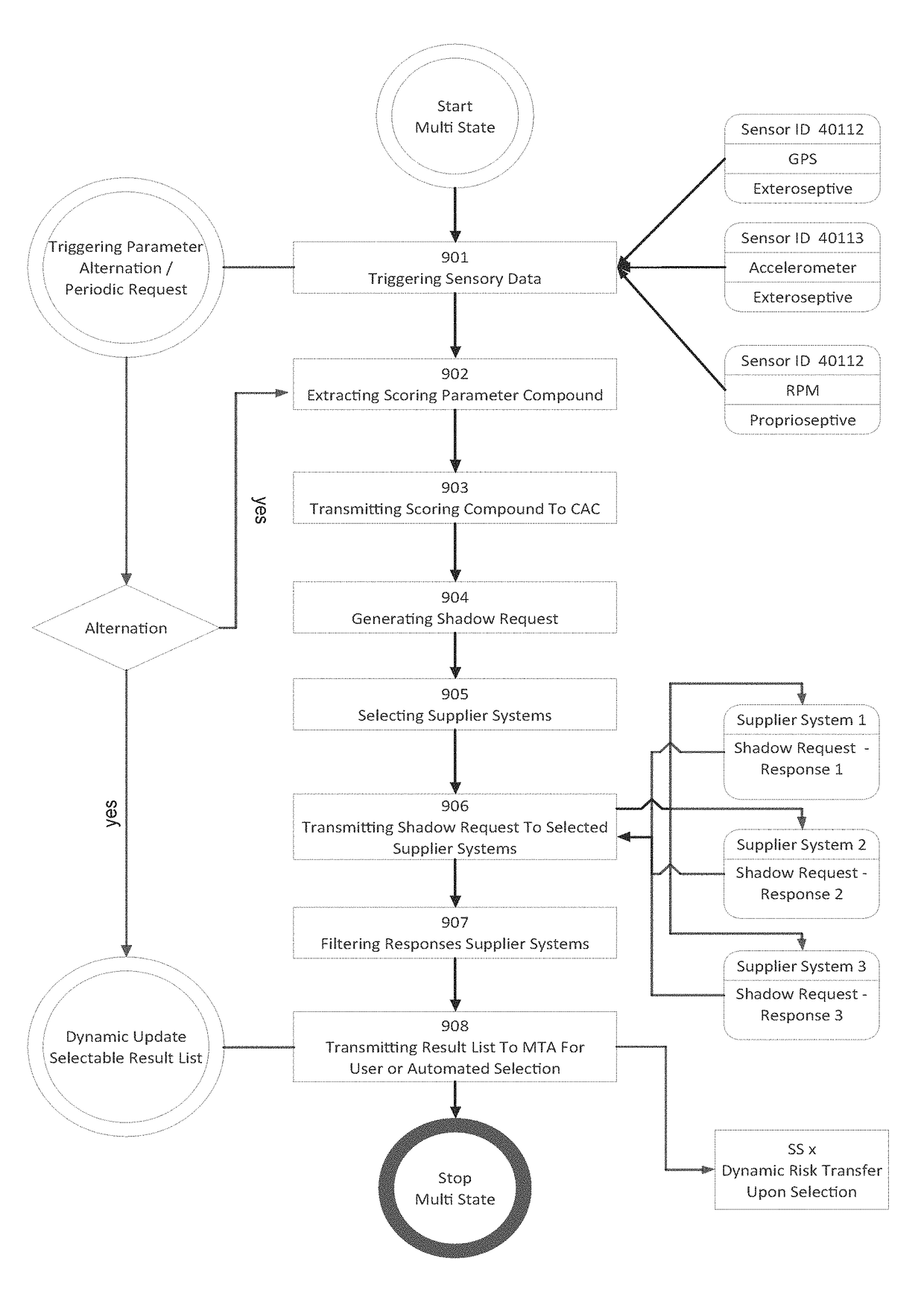

Proposed is a mobile automotive car system, and method thereof, for a dynamic, telematics-based connection search engine and telematics data aggregator, wherein risk-transfer profiles are captured and categorized in a results list from a plurality of first risk-transfer systems based on dynamically generated driving score parameters by means of appropriately triggered automotive data. As a variant, during a predefined trial period, the automotive and driving behavior data can be collected, which are transmitted together with the generated driving score parameters to multiple automated first risk-transfer systems for quotation. The user is able to dynamically select the best-fitting first risk-transfer system for risk-transfer by means of the results list, which is provided and updated in real-time for display to and selection by a user of a mobile telecommunication apparatus by means of a mobile telematics application of the mobile telecommunications apparatus.

Owner:SWISS REINSURANCE CO LTD

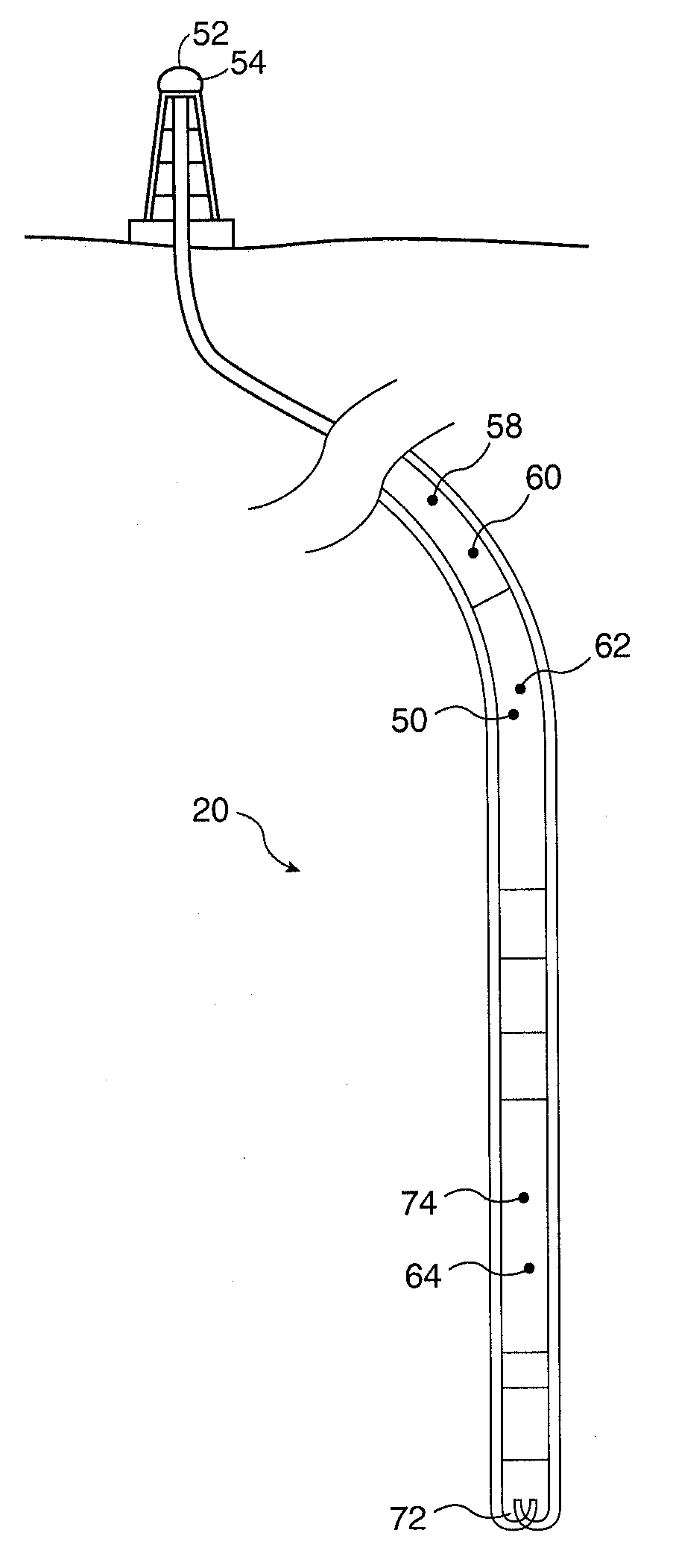

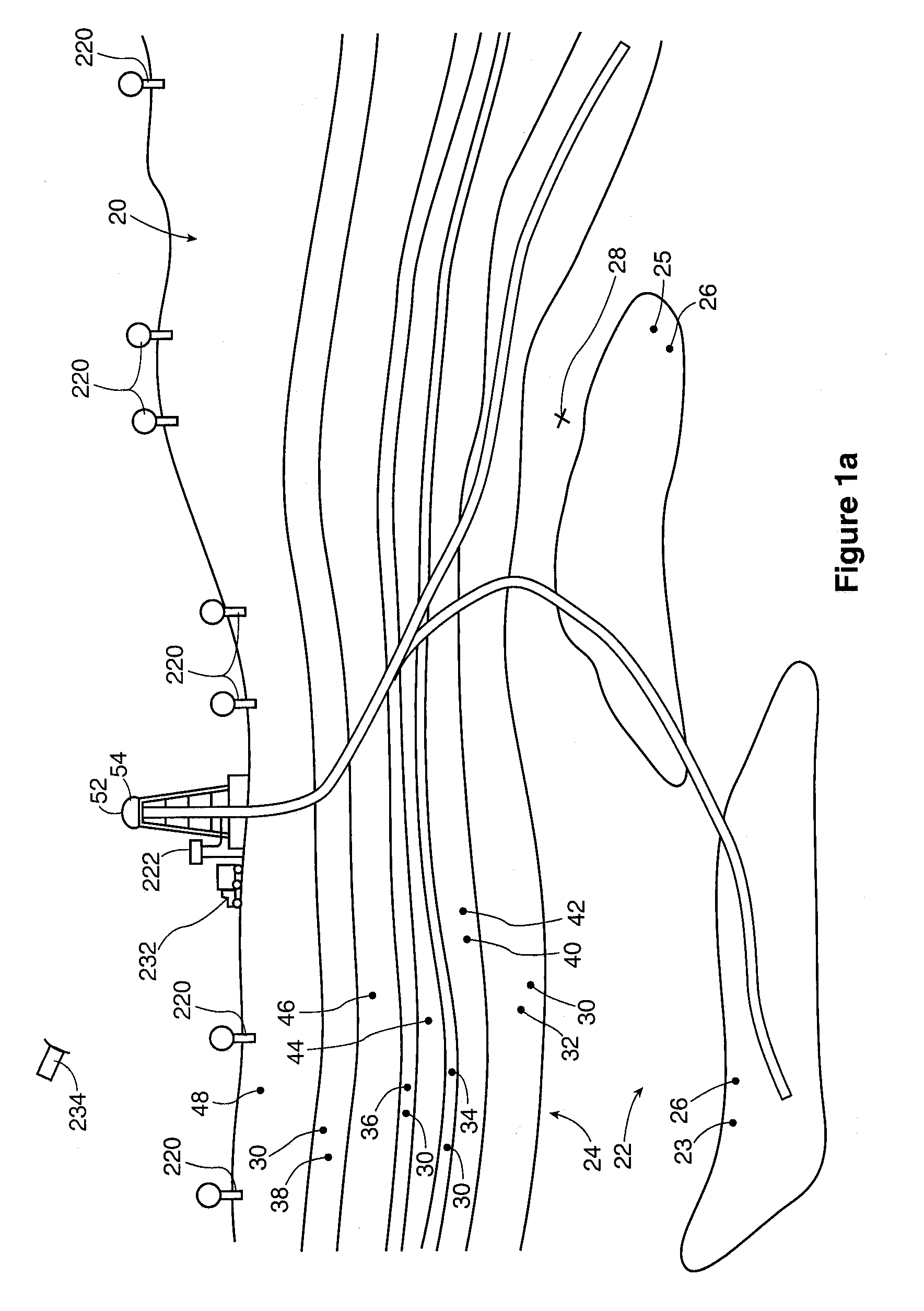

Drill bit tracking apparatus and method

An apparatus is provided for assessing the location of a drill bit underground. The apparatus includes an acoustic sound generator that is driven by the drilling mud supplied to the drill bit. The sound generator a characteristic string of pulses, which may be termed a signature or key. The key is repeated over and over. Monitors (i.e., sensors) at the surface listen for this key. The key is distorted by the inconstant angular velocity of the drill bit. Thus the observed data do not precisely match the key. On the basis of numerical algorithms, a digitally revised reference signal or key, is identified to map the known reference key onto the best fitting observed data. The correction factors are then applied to map the modified reference key onto the data observed at other sensors of an array of sensors mounted on the surface. By determining the phase shift and travel time of the signals at the various sensors, and having determined the speed of wave propagation in the geological media, the position of the bit, or a fairly close approximation thereof, may be obtained. The correction factors applied to the reference key may also tend to permit the actual rotational speed of the drill bit to be determined.

Owner:ATHENA IND TECH

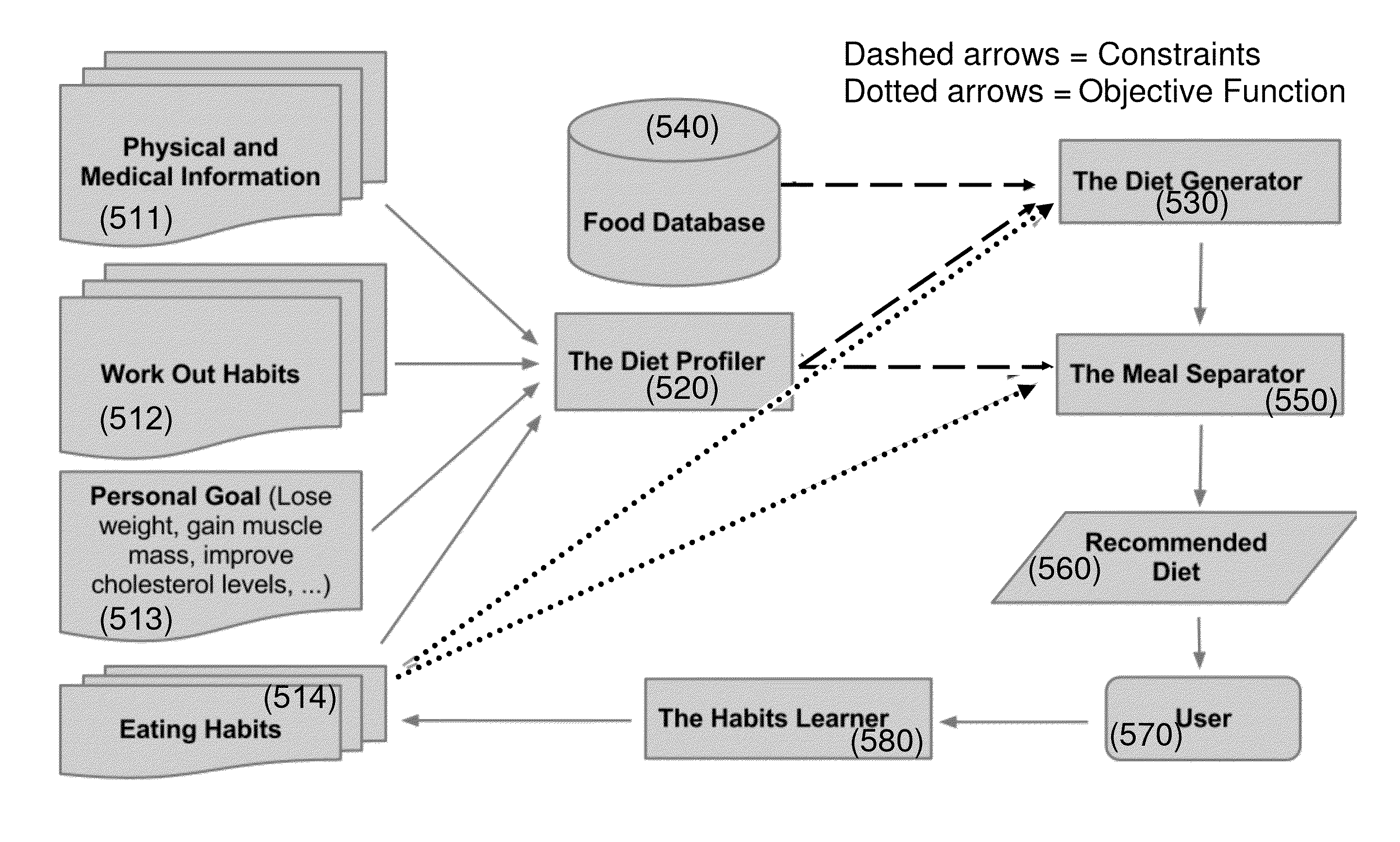

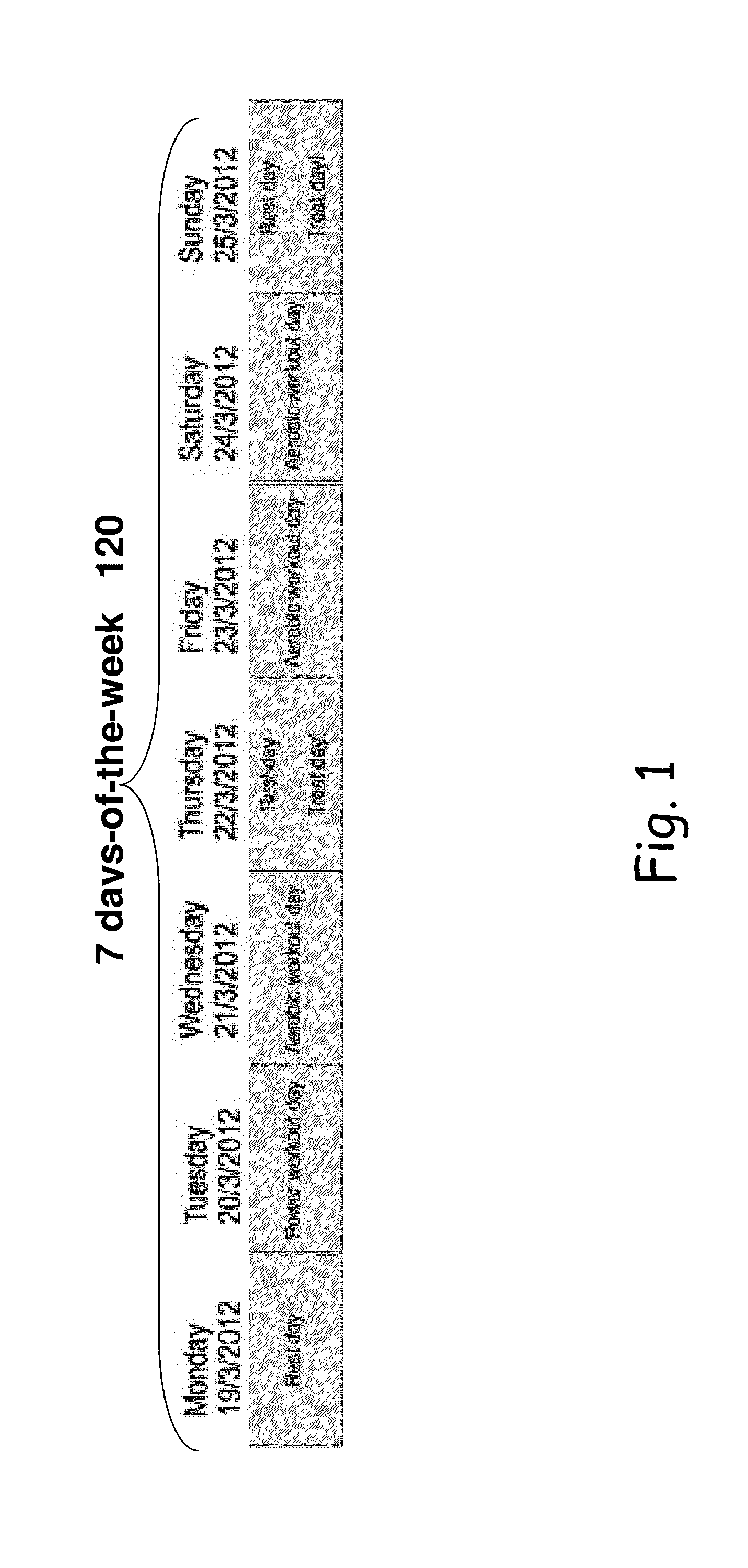

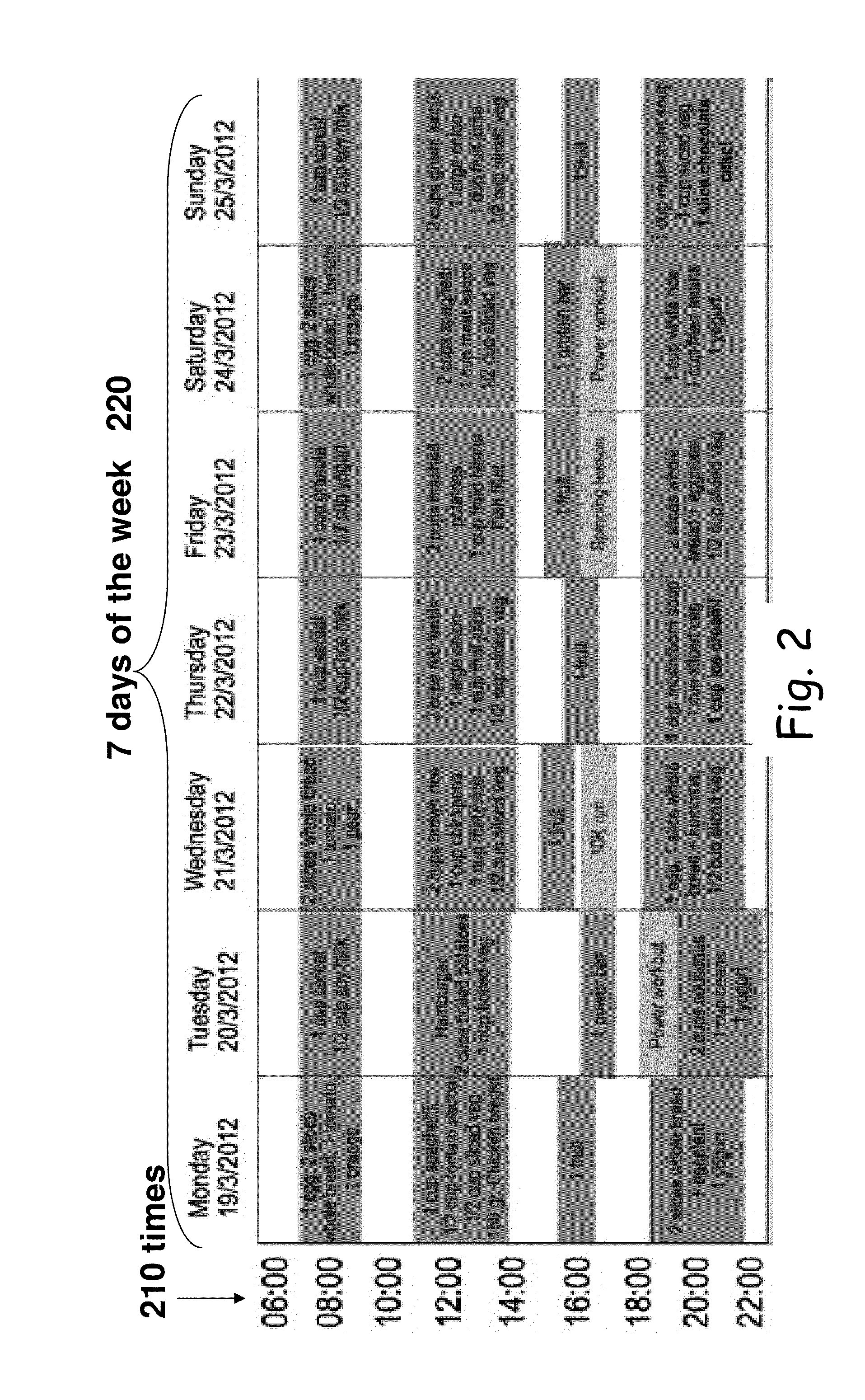

Interactive engine to provide personal recommendations for nutrition, to help the general public to live a balanced healthier lifestyle

InactiveUS20140255882A1Improve suggestionQuality improvementNutrition controlTeaching apparatusNutritionHabit

An algorithm and method to provide personal recommendations for nutrition based on preferences, habits, medical and activity profiles for users, and constraints. The algorithm can also be fed and takes into account real-time feedback from the user. The method allows creating a personal nutritional schedule based on a set of constraints, which are solved using an optimization algorithm to find the diet best fitting each user. The method also includes analyzing a single user by applying various statistical techniques, enabling the algorithm to infer the user's preferences and updating of the constraints, analyzing and clustering of the general user population based on statistical principles, giving the algorithm insightful information and allowing improved performance by means of “machine-learning,” and creating a list of recommended food items / recipes to help users live a balanced, healthier lifestyle.

Owner:NUTRINO HEALTH LTD

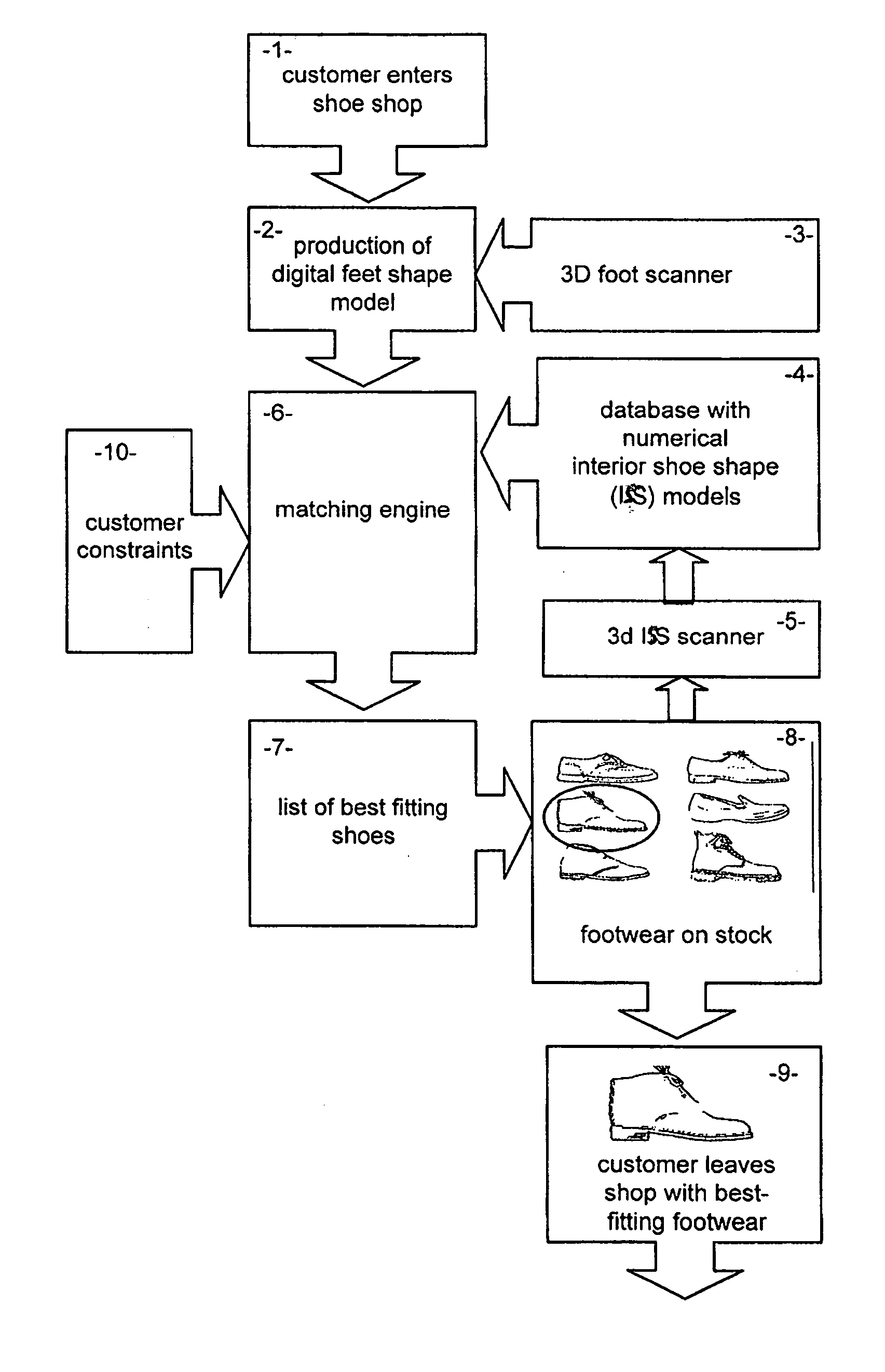

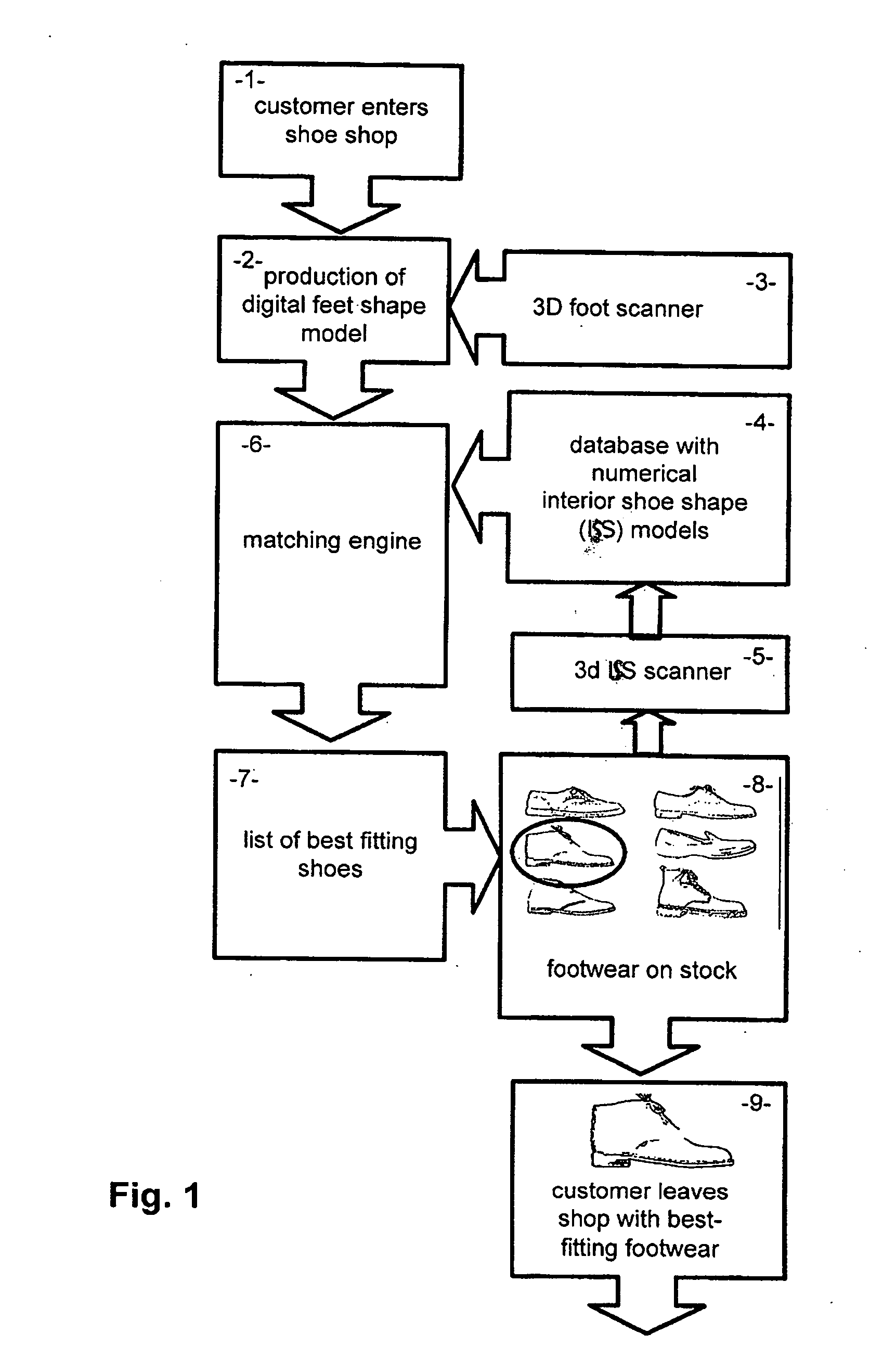

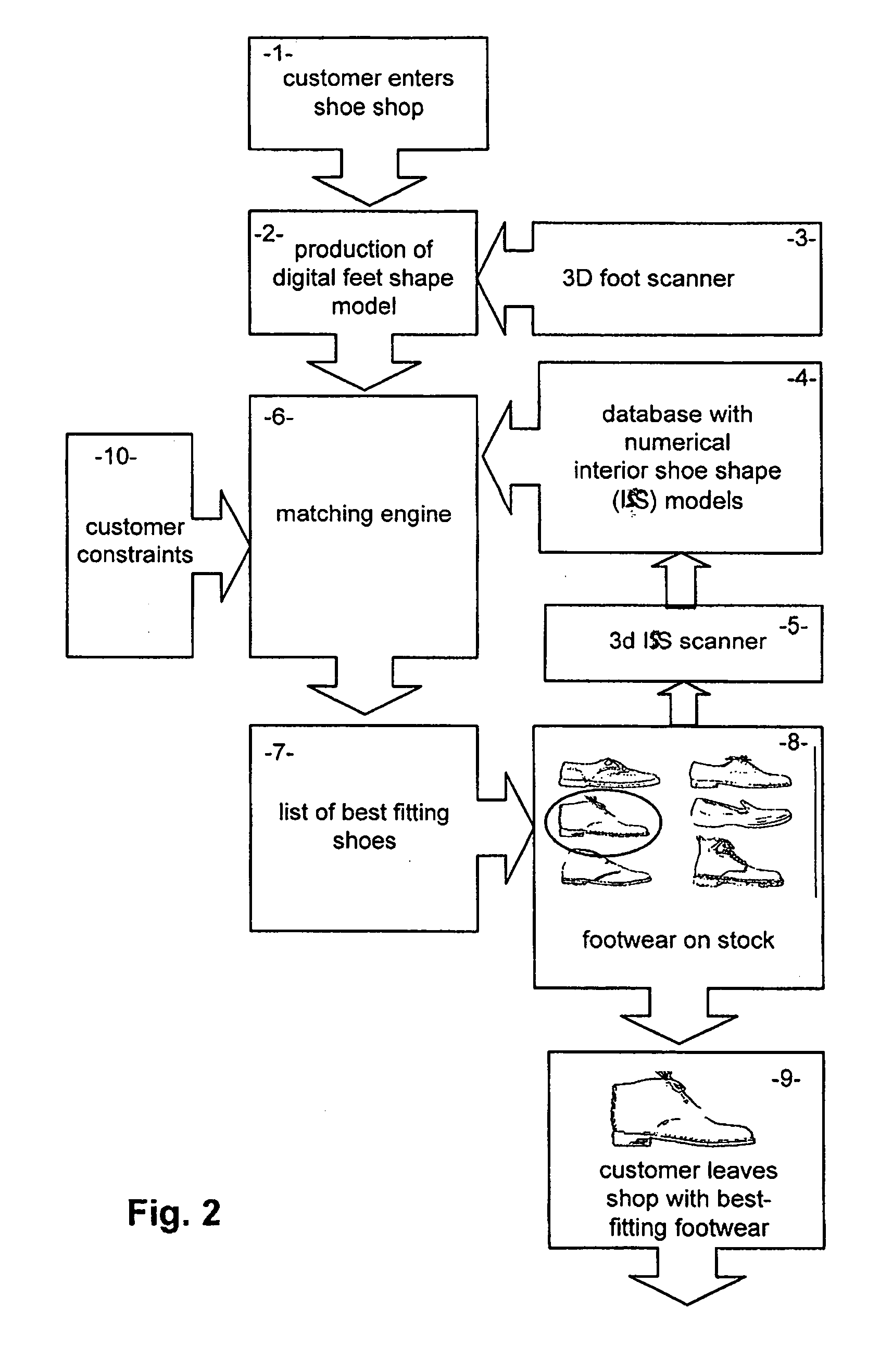

Computerized method of identifying best fitting footwear

InactiveUS20110055053A1Simplify and enhance and productivitySimplify and enhance qualityDigital data information retrievalFuzzy logic based systemsEngineeringBest fitting

A method of identifying footwear which best fits a customer's feet, includes the steps of digitizing the feet of a customer needing footwear with a 3D foot scanner and generating a numerical 3D model of the customer's feet, comparing, with a computer-based matching engine, the information of the 3D feet model with the content of a database containing numerical 3D models of the interior shoe shape of footwear available to be sold, producing a list of one or more best-fit footwear candidates to the customer and / or to the staff of a footwear shop and concluding the purchasing process or, respectively, aborting it in case of insufficient best fit footwear being found in the footwear stock available for selling.

Owner:CORPUS E

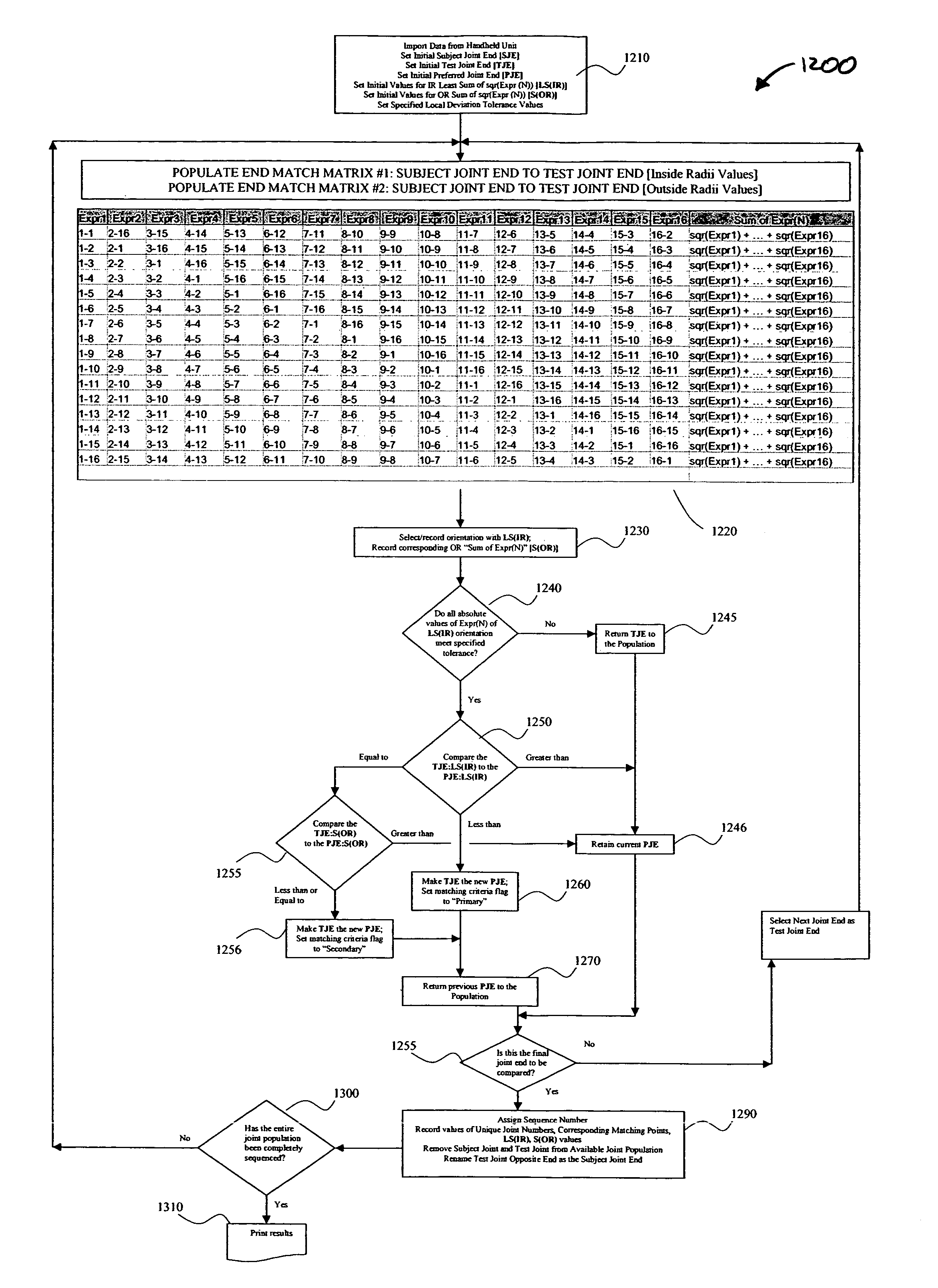

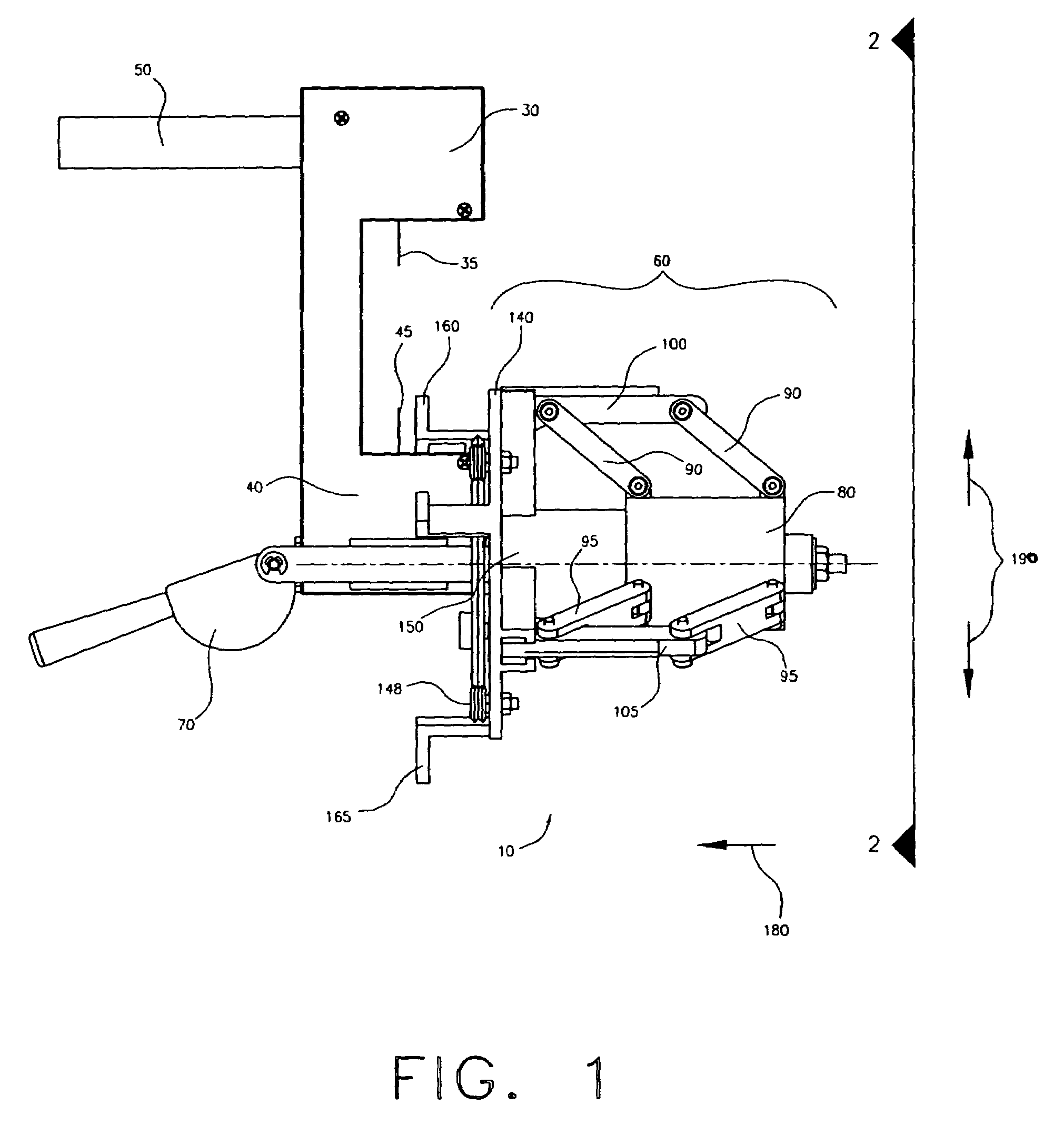

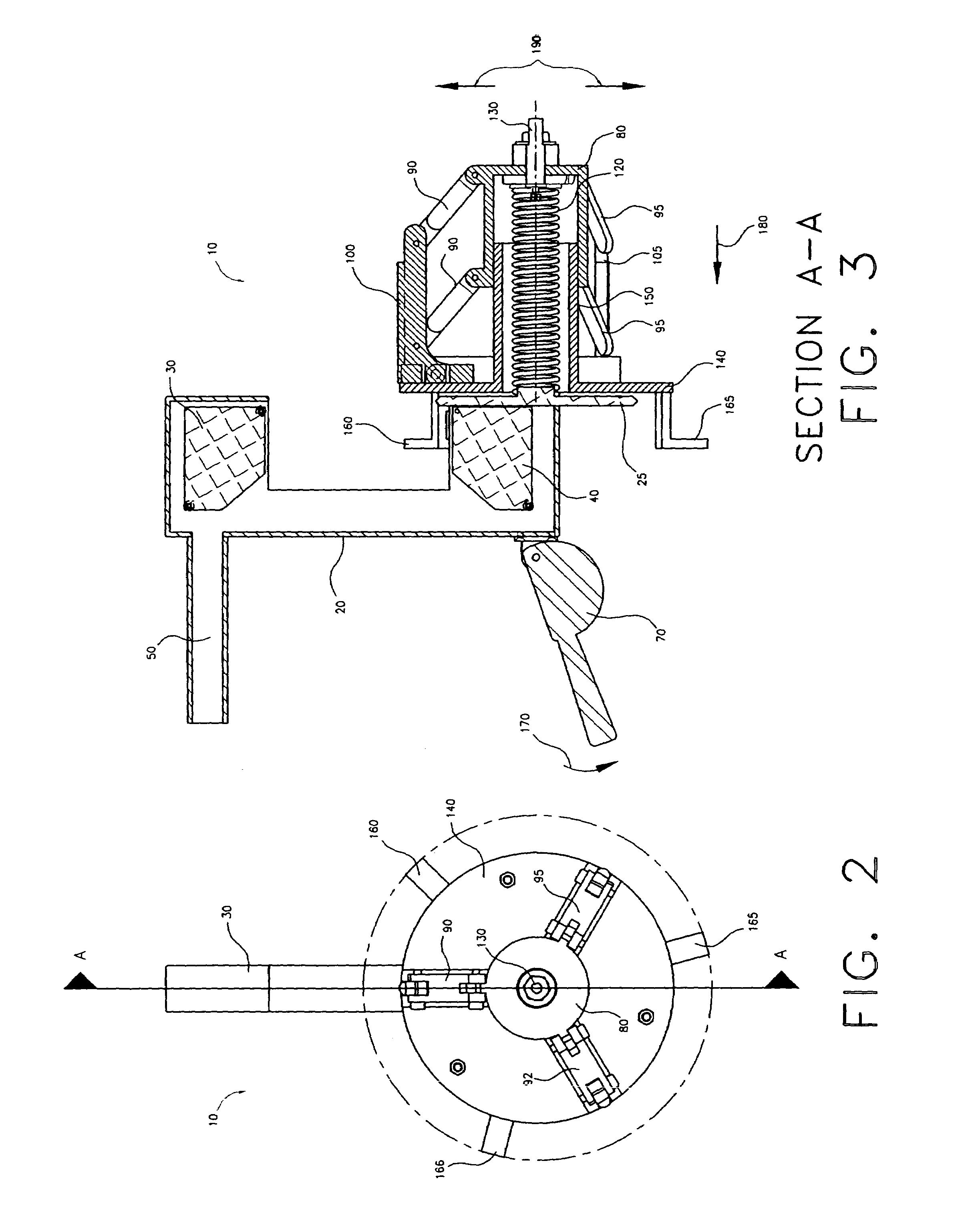

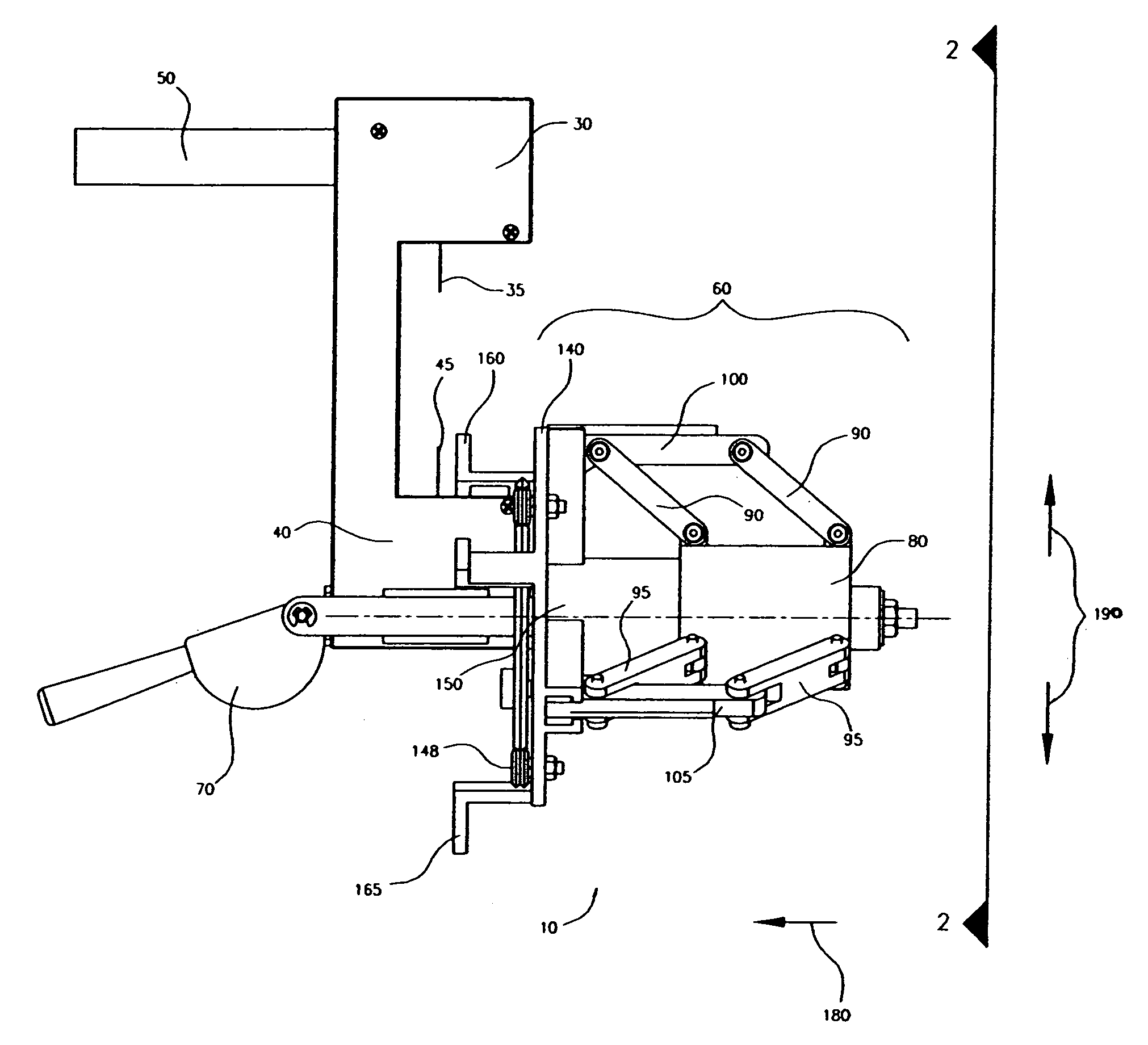

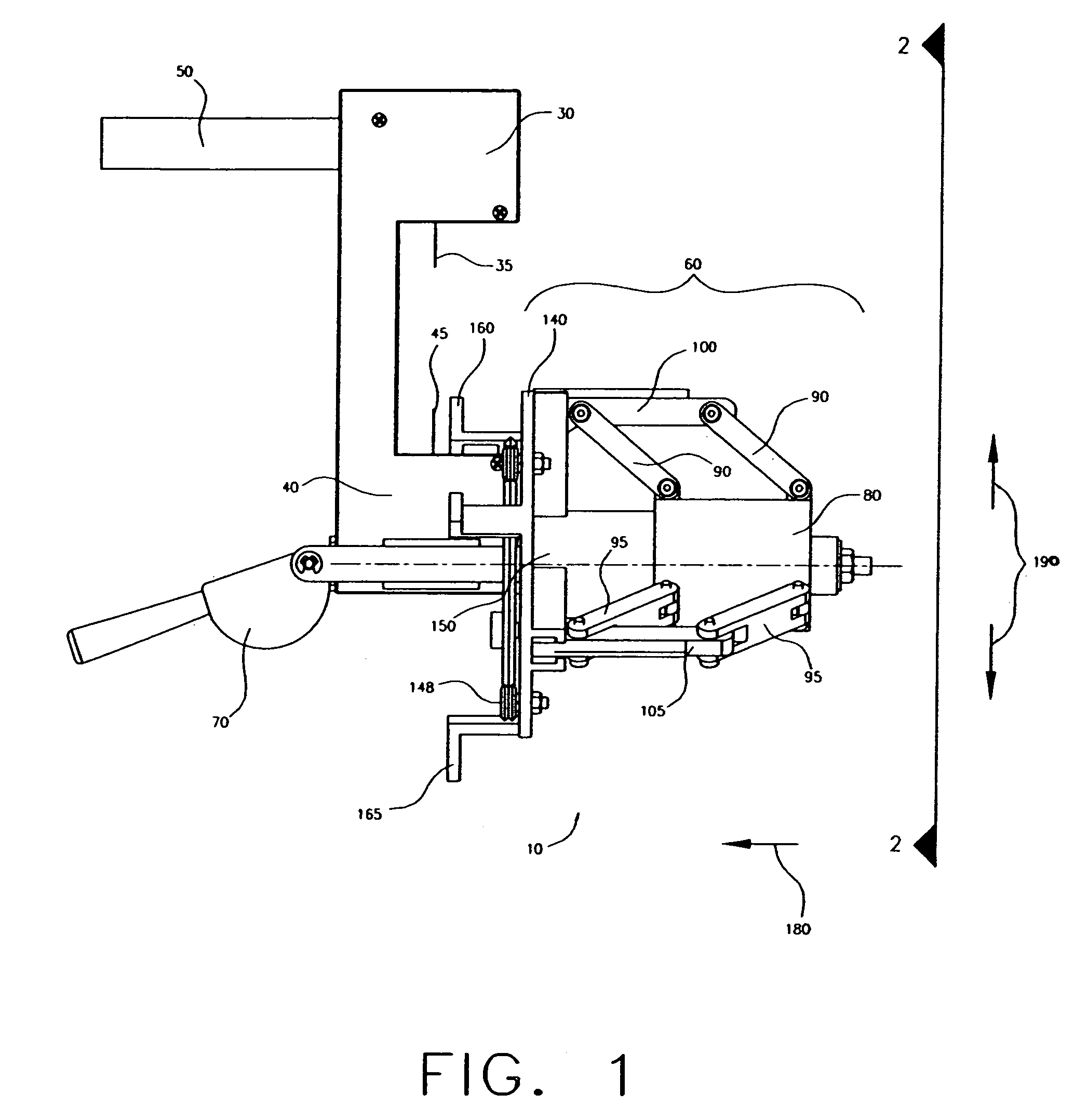

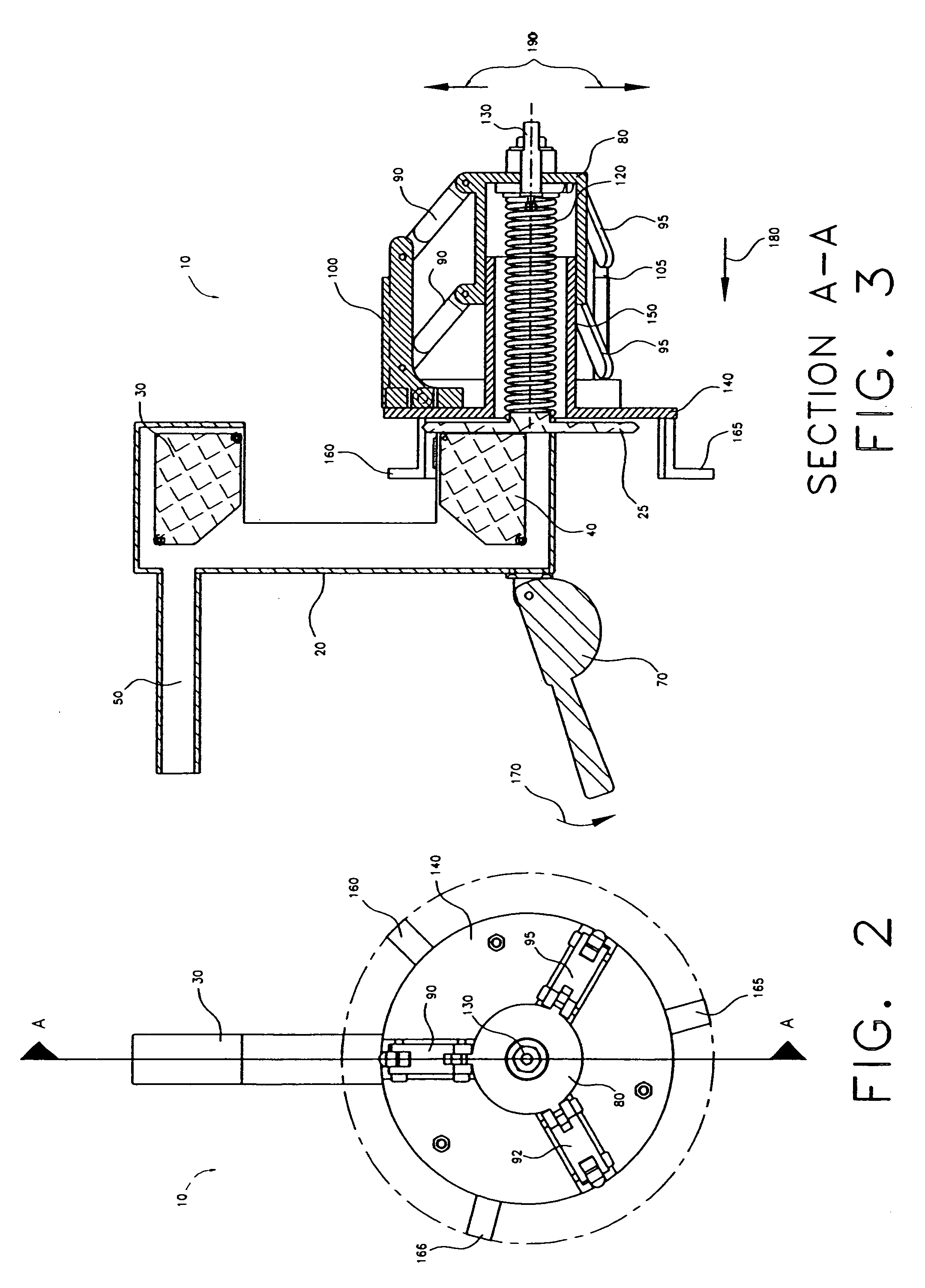

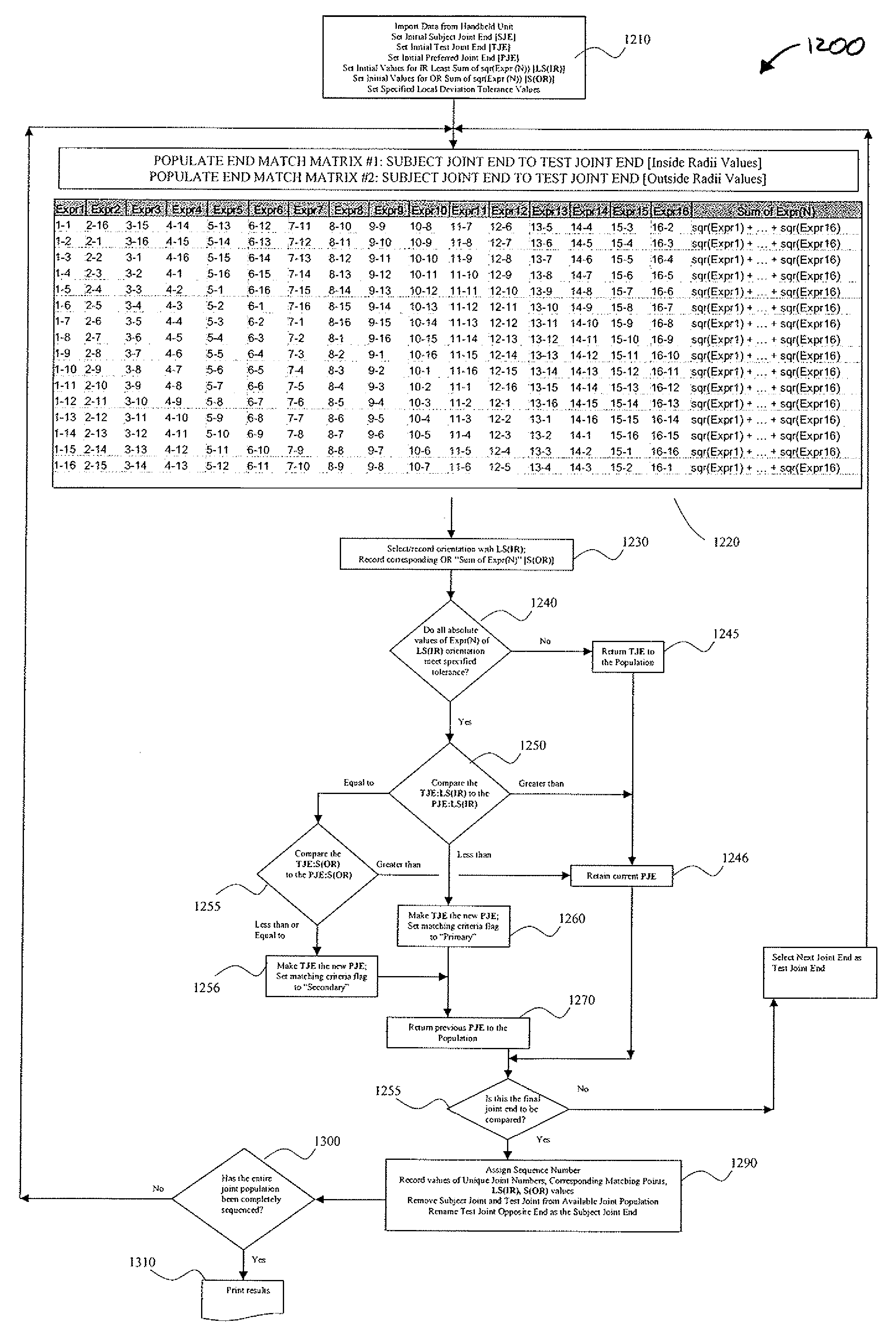

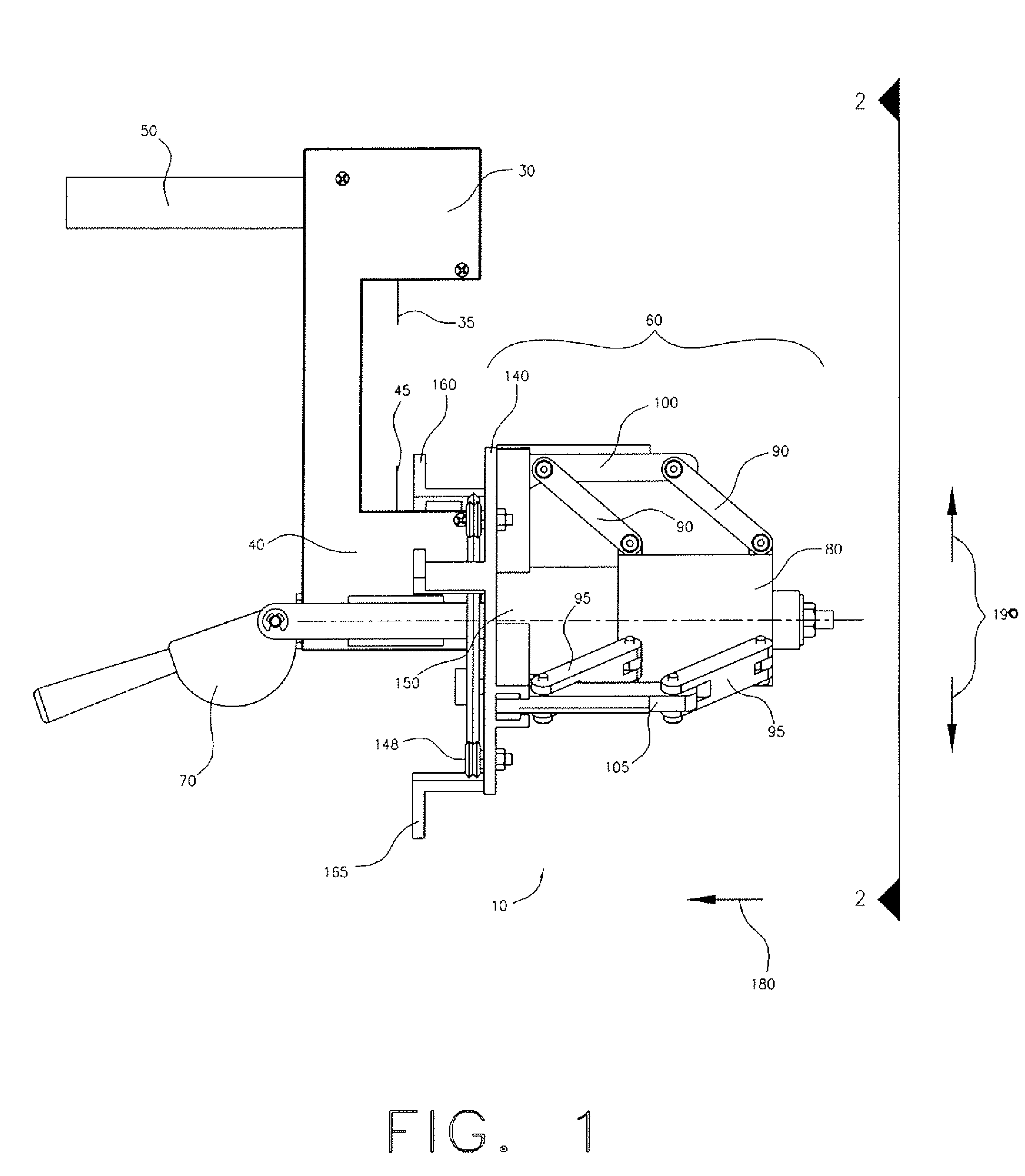

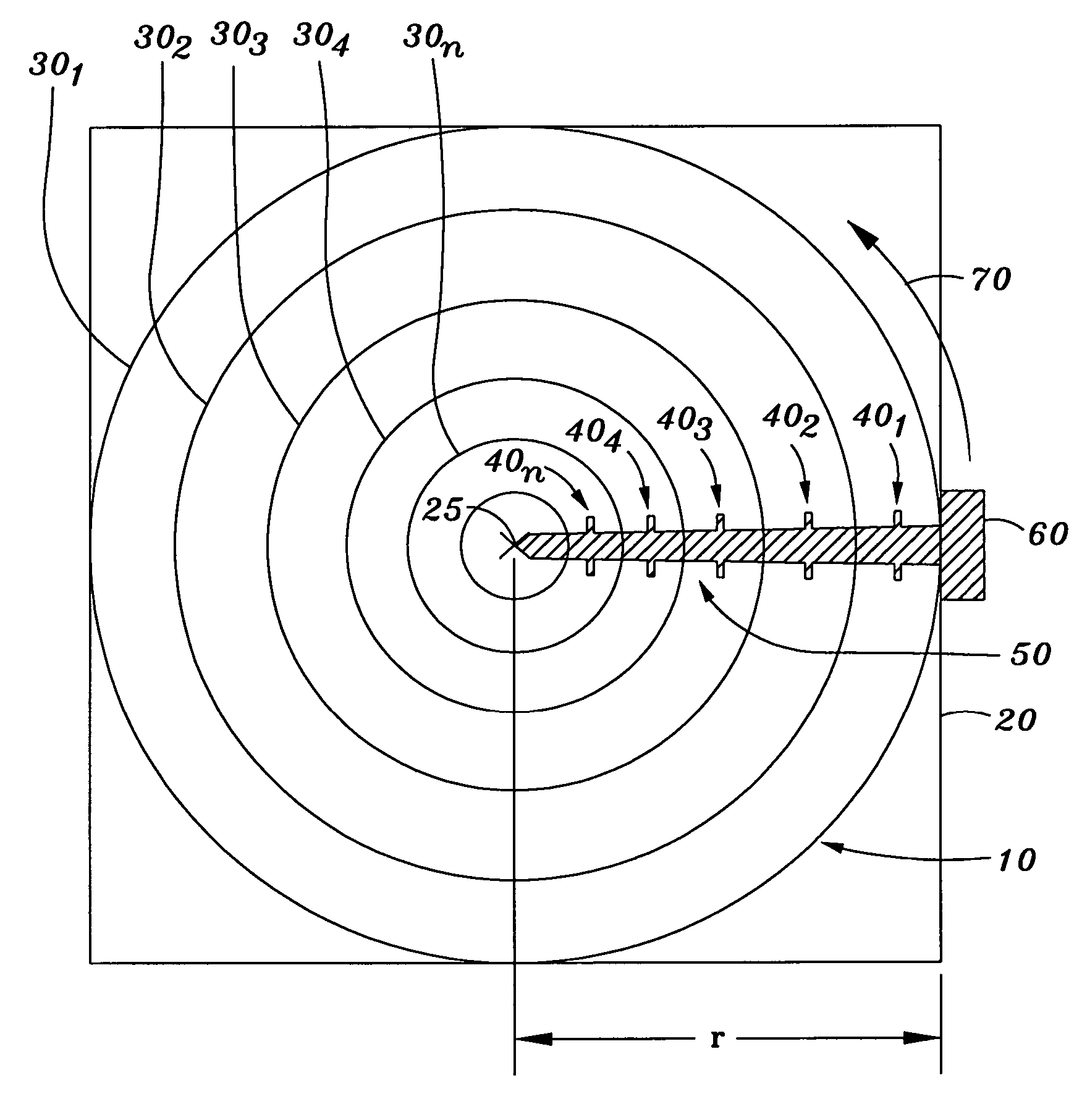

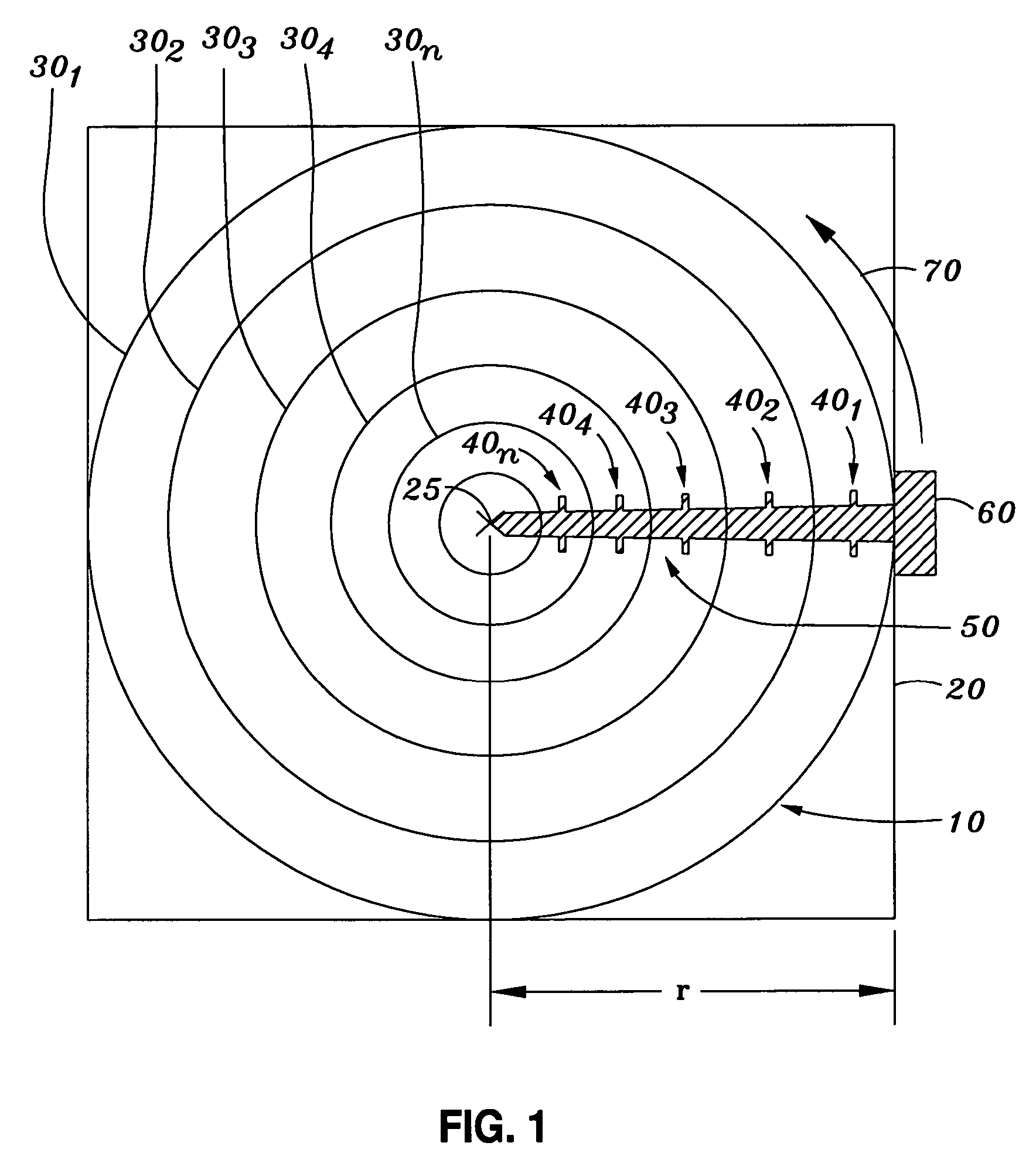

Method and apparatus for best fitting two or more items

InactiveUS7086169B1Mechanical counters/curvatures measurementsMechanical diameter measurementsAlgorithmEngineering

Owner:PROJECT CONSULTING SERVICES

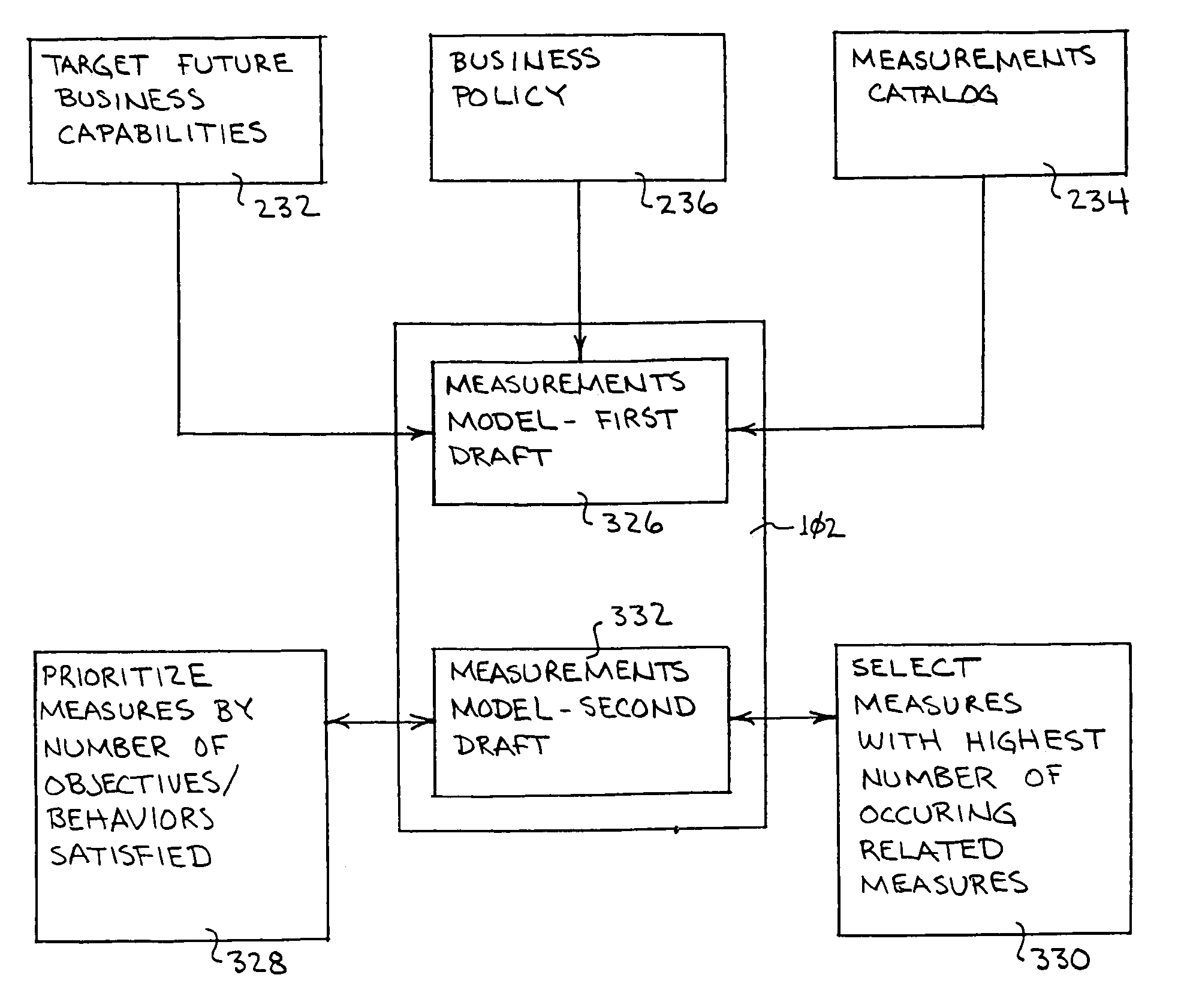

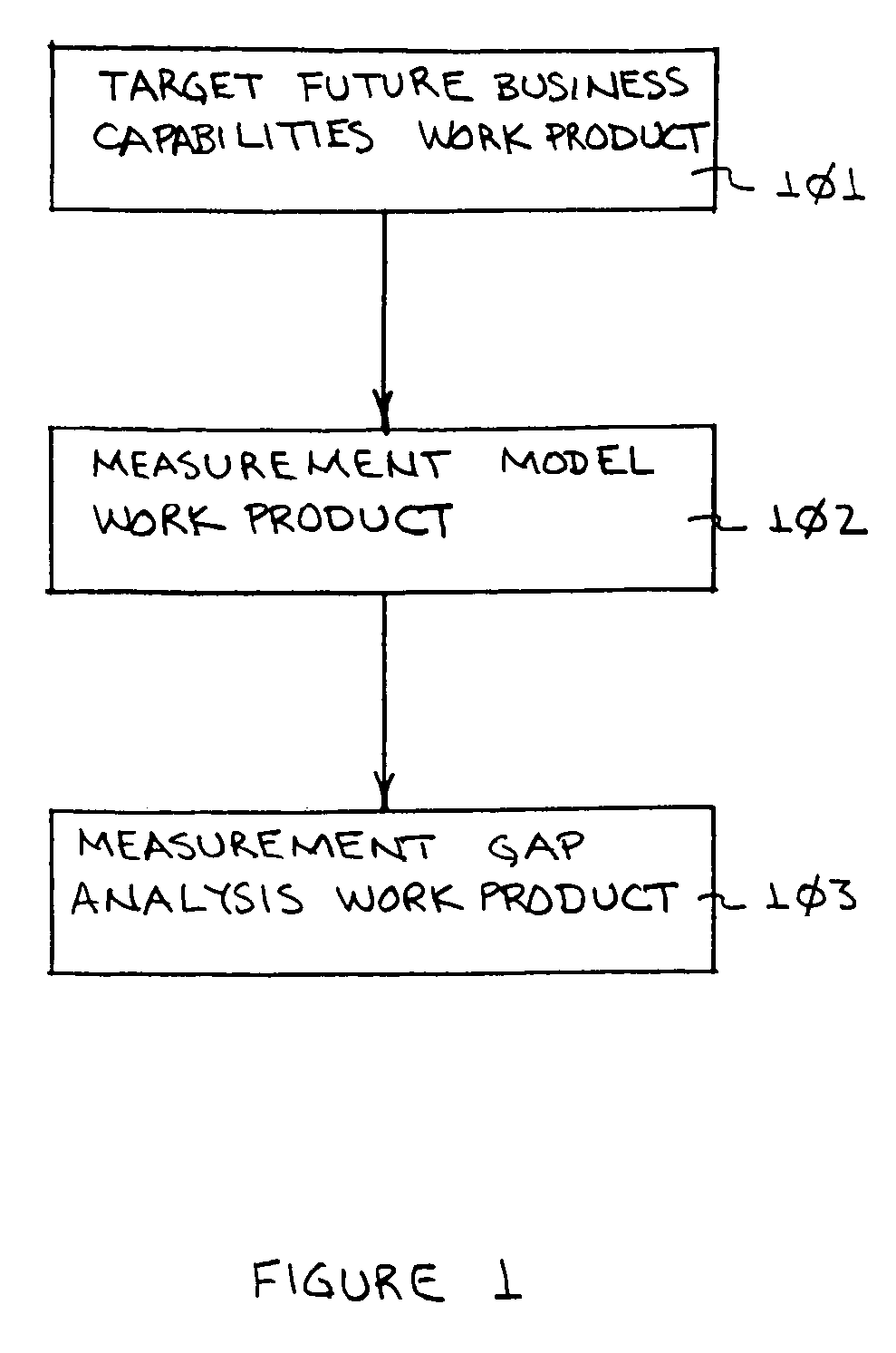

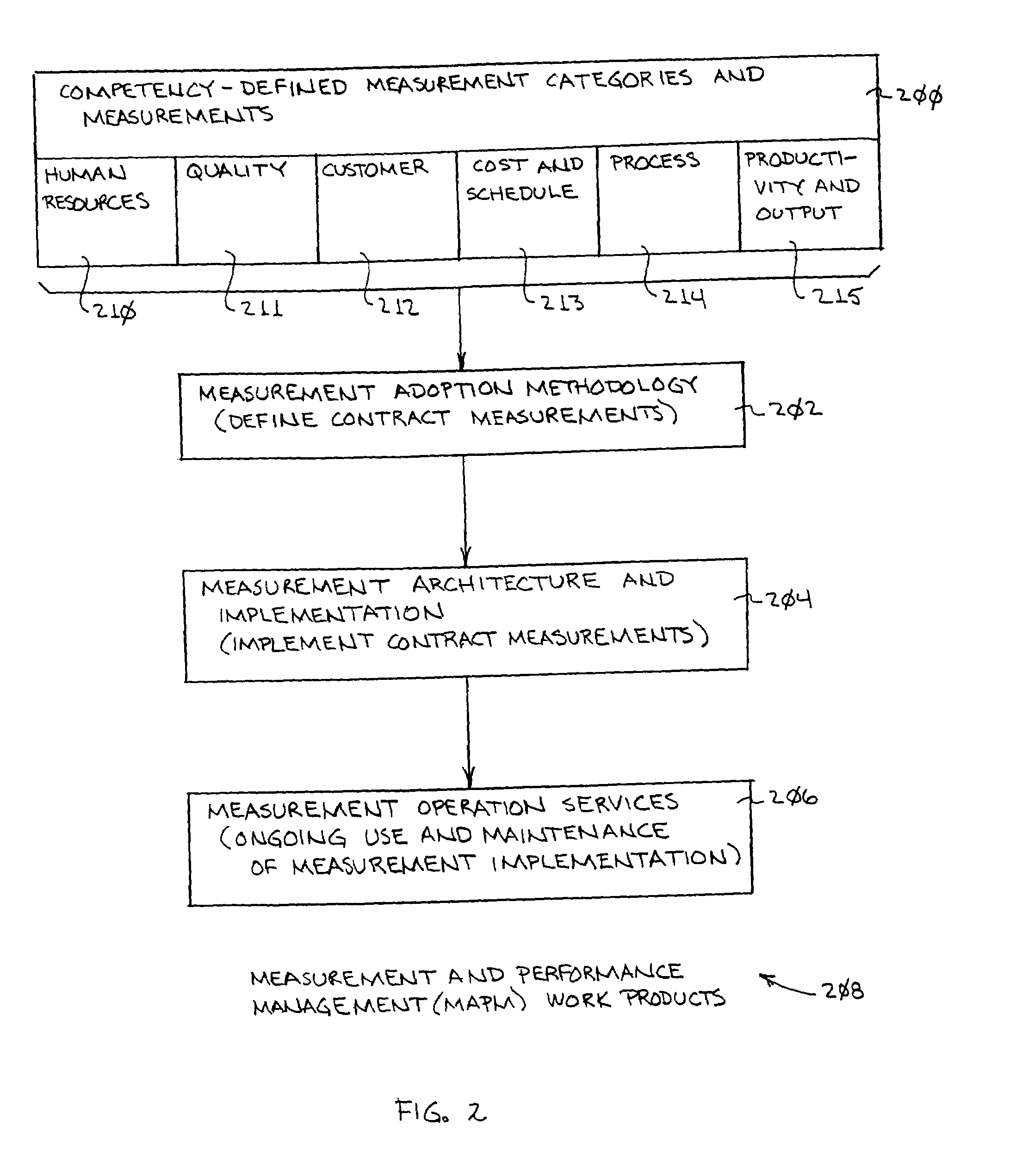

System and method for measuring and managing performance in an information technology organization

An IT measurement system is aligned with the IT organization's business goals by examining the IT organization's current state-of-affairs with respect to measurement and analyzing how it maps to a proposed measurement model. To ensure the viability of the proposed measurement model, the IT organization and measurement processes it employs are structured to naturally support the collection, analysis, reporting, and use of the measurements in the proposed model. The measurement model and associated techniques work from a top-down approach, starting with the goals of the organization, identifying appropriate behaviors and finally associating measures that will empirically demonstrate achievement of the behaviors. In addition, algorithms for prioritization are executed to ensure that the best fitting measures are selected in the final measurement model.

Owner:IBM CORP

Method and apparatus for best fitting two or more items

InactiveUS7325326B1Minimize human errorAngles/taper measurementsMeasurement/indication equipmentsAlgorithmBest fitting

Owner:PROJECT CONSULTING SERVICES

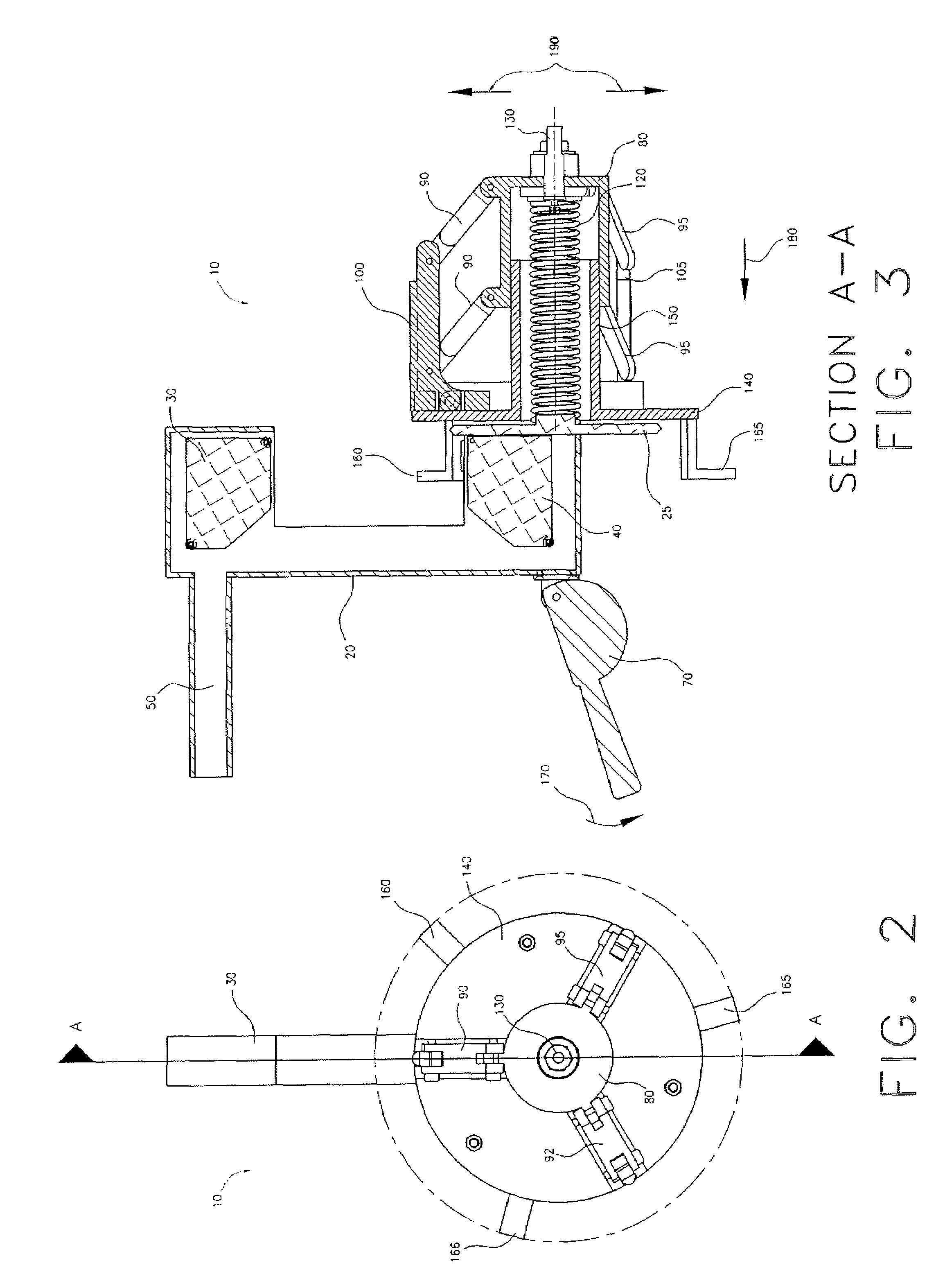

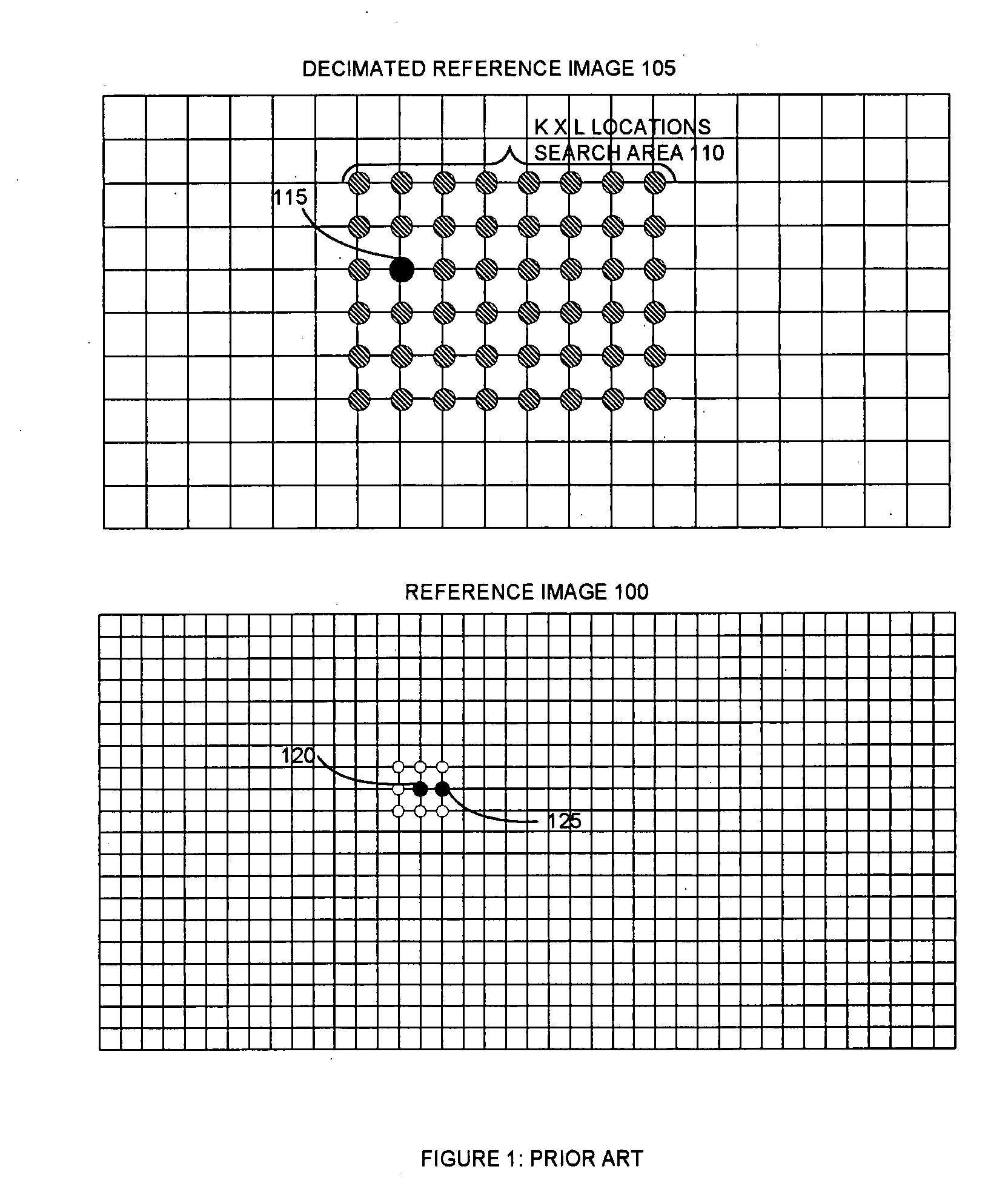

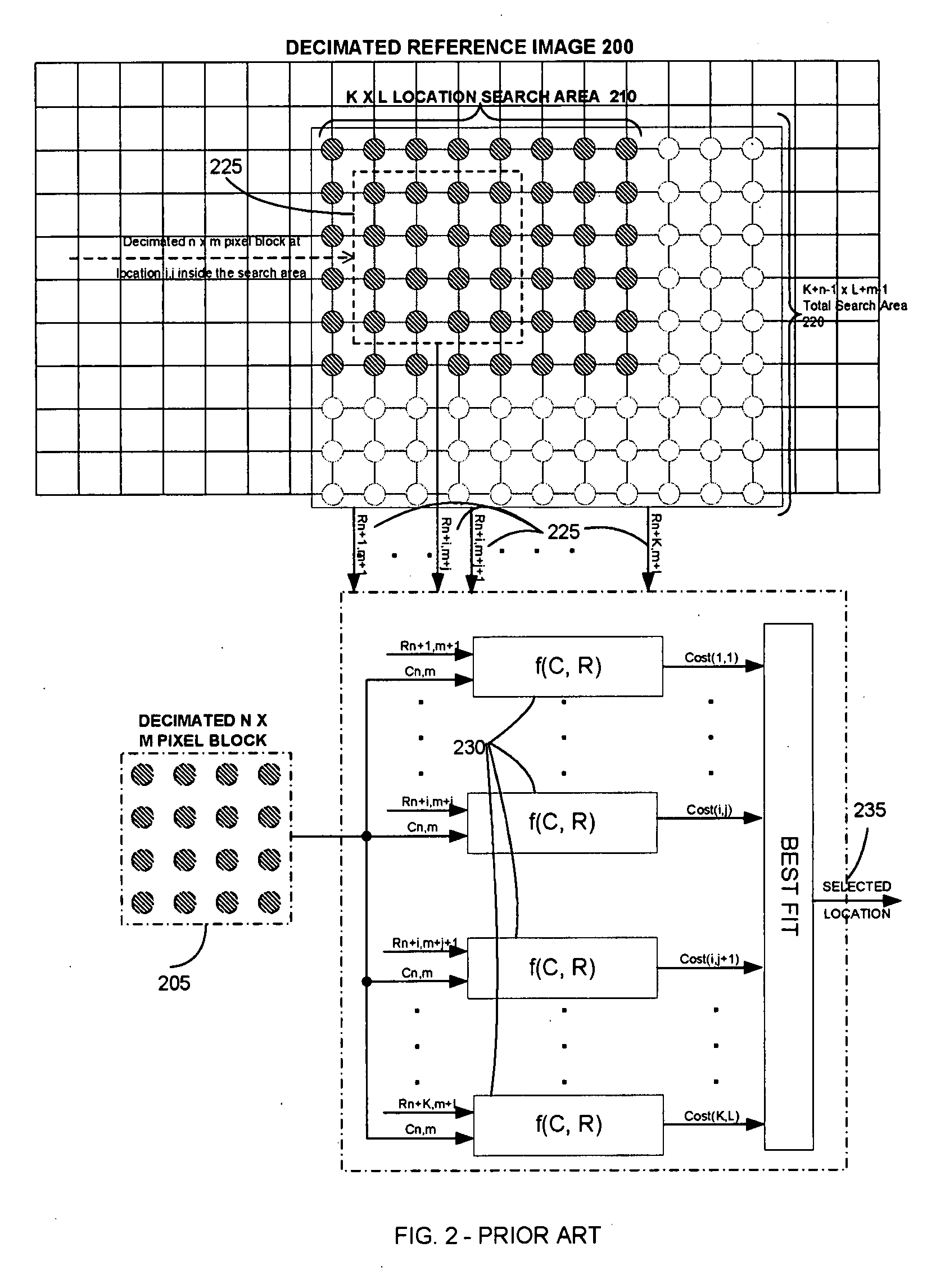

Hybrid hierarchical motion estimation for video streams

InactiveUS20080260033A1Reduce memory bandwidthColor television with pulse code modulationColor television with bandwidth reductionReference imageImage motion

A method for estimating image-to-image motion of a pixel block in a stream of images which includes a current image which includes the pixel block and a reference image, the method including performing a hierarchical search in a search area of the reference image, including producing a decimated reference image and a decimated pixel block, searching for a location in the search area of the decimated reference image which best fits the decimated pixel block, repeating the producing and the searching for more than one level of hierarchy, determining a first candidate location in the reference image which corresponds to the best fitting location, determining a second candidate location in the reference image by a method other than the hierarchical search, performing a search in the reference image for refined locations of the first and the second candidate locations, selecting one final location from the refined candidate locations, and using the final location for estimating the motion. Related apparatus and methods are also described.

Owner:TESSERA INC

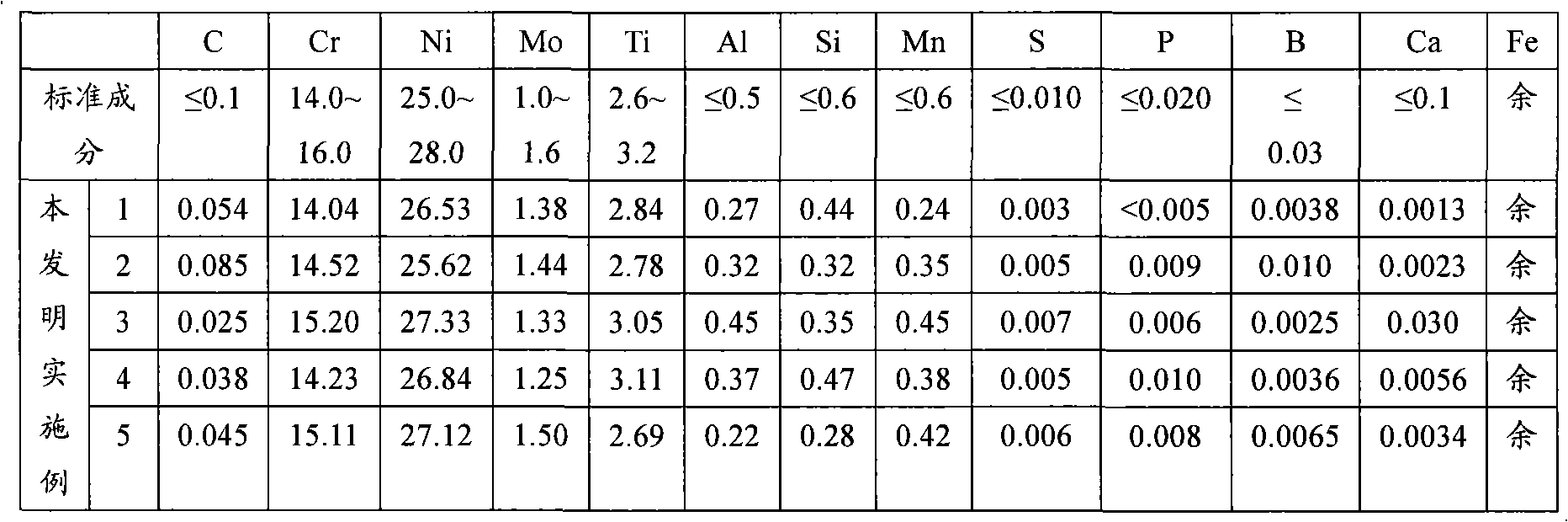

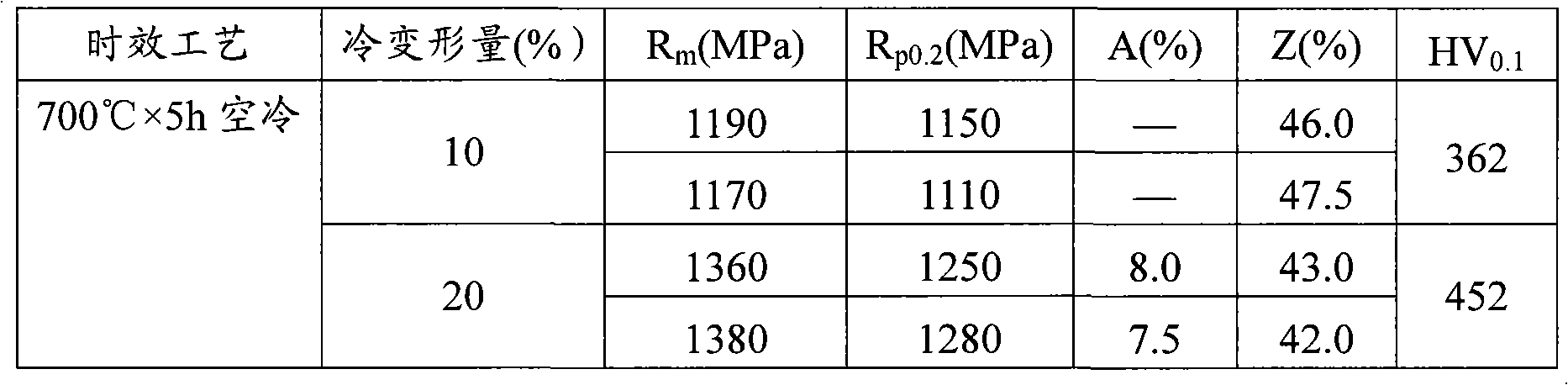

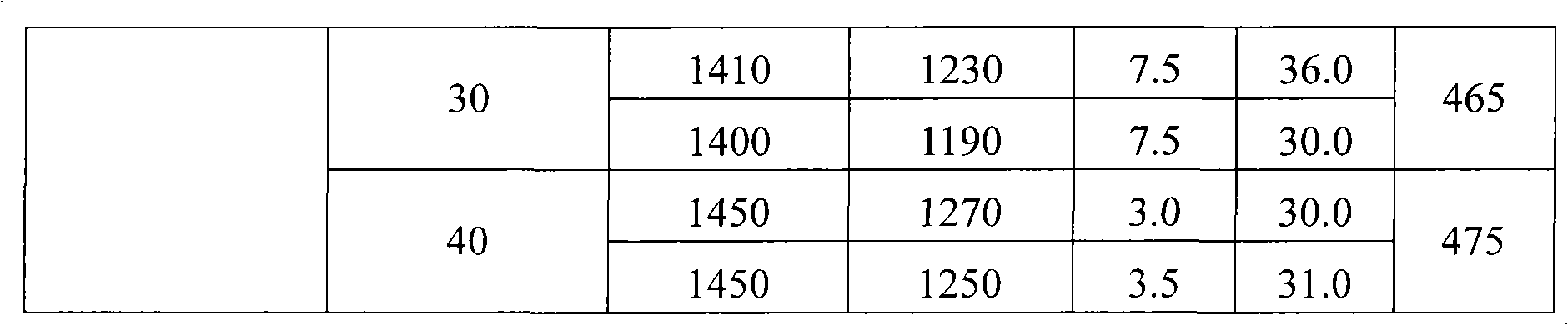

Method for preparing Cr-Ni system Austenitic heat-resistant steel springs and cool-drawn steel wires thereof

InactiveCN101642782AIncrease elasticityImprove pass rateTemperature control deviceFurnace typesChemical compositionBest fitting

The invention relates to a method for preparing Cr-Ni system Austenitic heat-resistant steel springs and cold-drawn steel wires thereof. The method for preparing the cold-drawn steel wires comprises the following steps: smelting; forging; hot rolling; and cold deforming, wherein the cold-drawn steel wire comprises the following chemical components by weight percentage: 0.025wt% to 0.085wt% of C, 14.0wt% to 16.0wt% of Cr, 25.0wt% to 28.0wt% of Ni, 1.0wt% to 1.6wt% of Mo, 2.6wt% to 3.2wt% of Ti, 0.22wt% to 0.45wt% of Al, 0.28wt% to 0.44wt% of Si, 0.24wt% to 0.45wt% of Mn, no more than 0.007wt% of S, no more than 0.010wt% of P, 0.0025wt% to 0.01wt% of B, 0.0013wt% to 0.03wt% of Ca, and the balance being Fe and unavoidable impurities; and the deformation in the cold-deforming step is 10% to 40%, while the optimum cold deformation is 20% to 25%, thereby best fitting the strength and plasticity of the steel wires. The heat-resistant steel springs prepared from the steel wires greatly increase the resilience thereof, thereby improving the qualification rate of prepared springs.

Owner:CENT IRON & STEEL RES INST

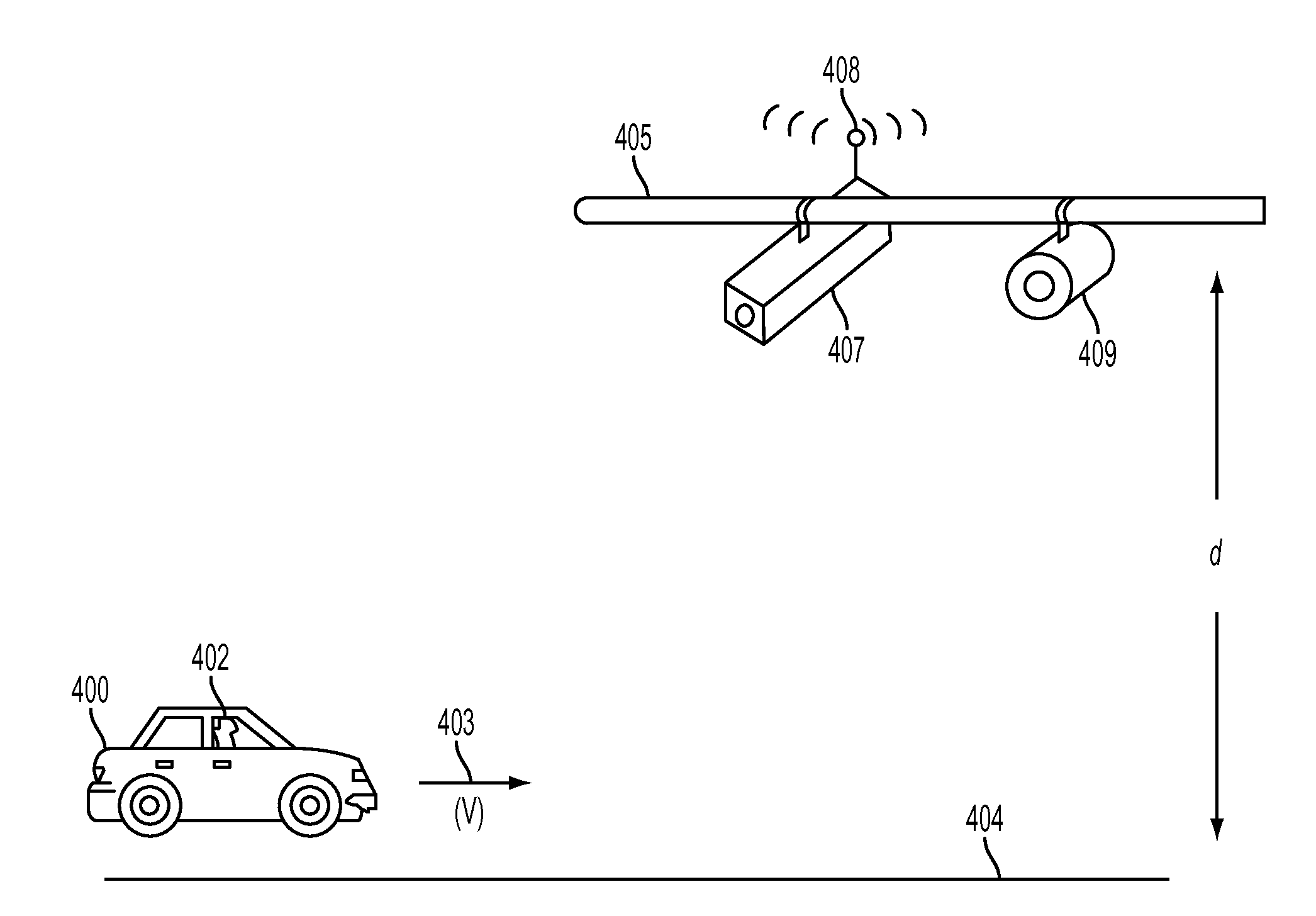

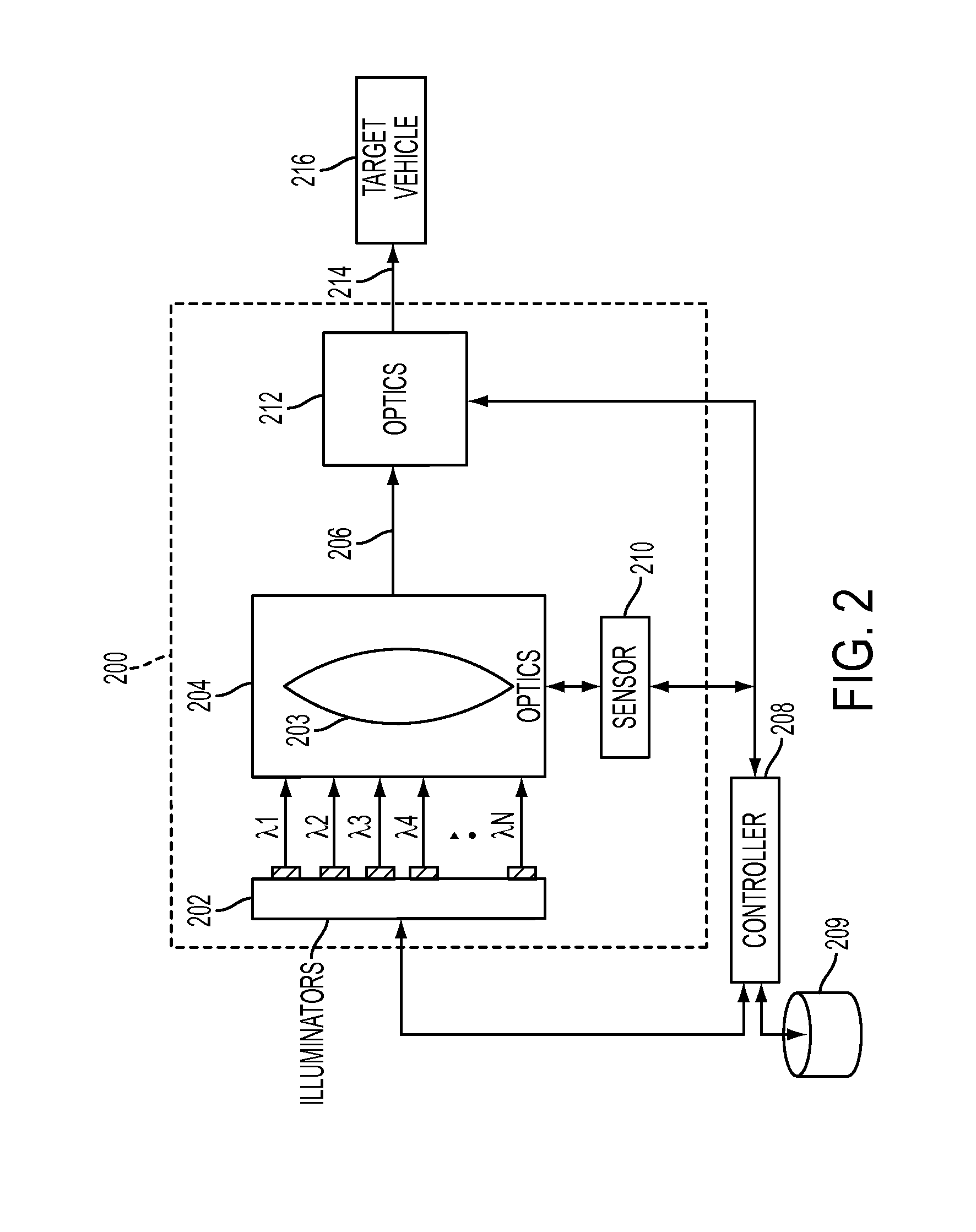

Determining a number of objects in an ir image

ActiveUS20120262577A1Readily apparentImage enhancementTelevision system detailsInfrared imageryComputer vision

What is disclosed is a novel system and method for determining the number of objects in an IR image obtained using an IR imaging system. In one embodiment, a total of N intensity values are collected for each pixel in an IR image using a IR imaging system comprising an IR detection device and an IR Illuminator. Intensity values are retrieved from a database which have been estimated for a plurality of known materials, such as skin and hair. A classification is determined for each pixel in the IR image using either a best fitting method of a reflectance, or a correlation method. Upon classification, a total number of objects in the IR image can be determined. The present system and method finds its intended uses in of real world applications such as, determining the number of occupants in a vehicle traveling in a HOV / HOT lane.

Owner:CONDUENT BUSINESS SERVICES LLC

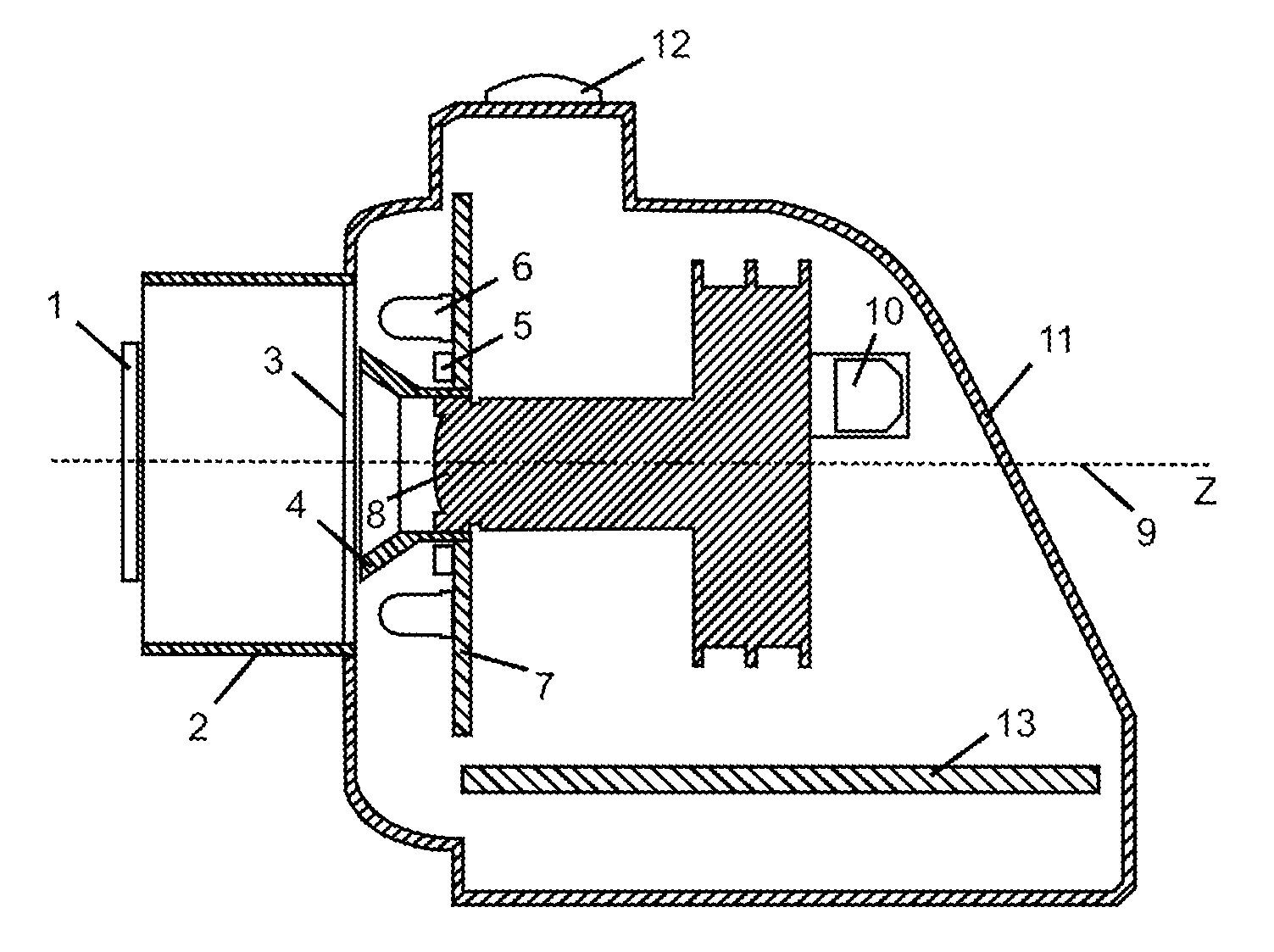

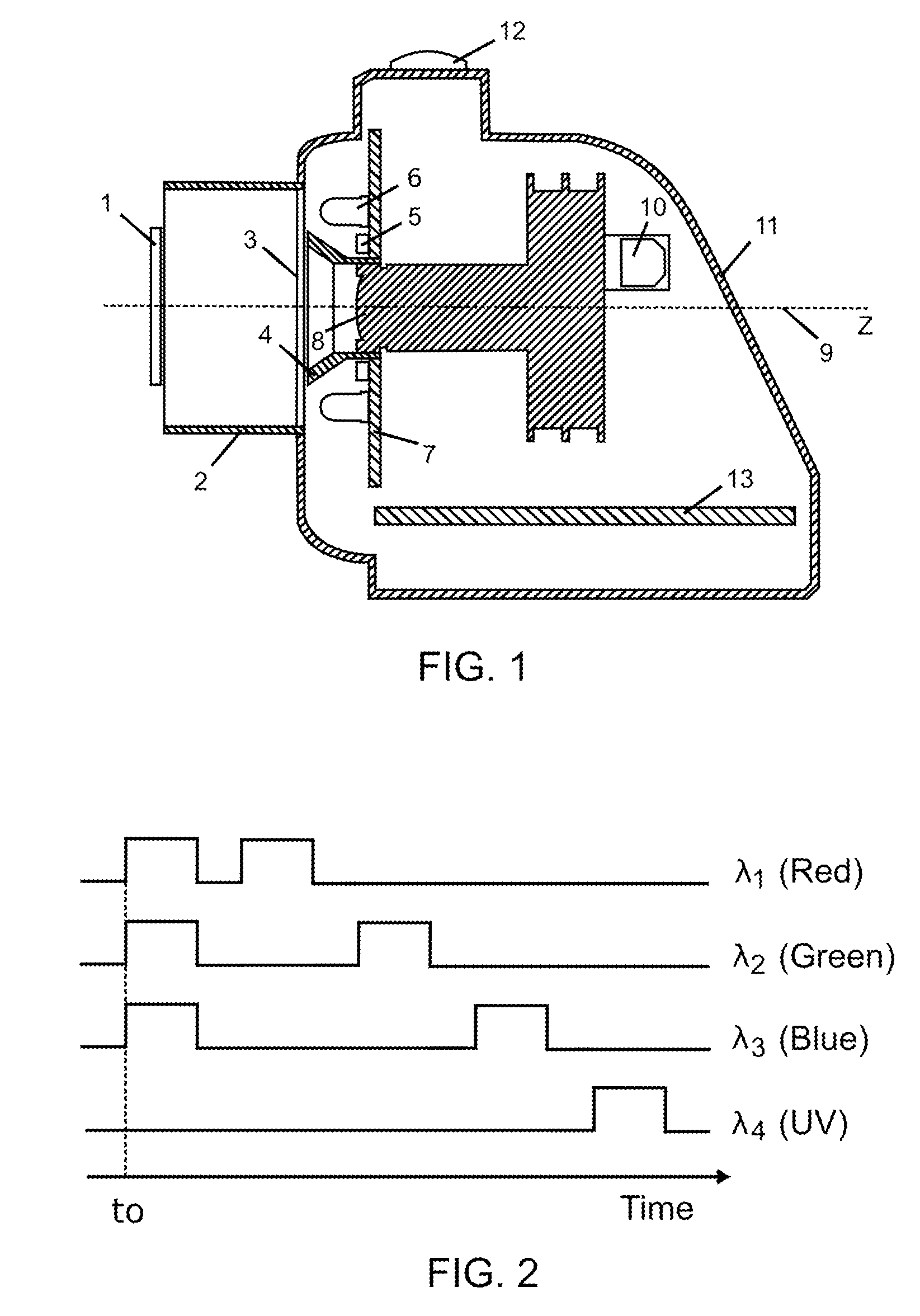

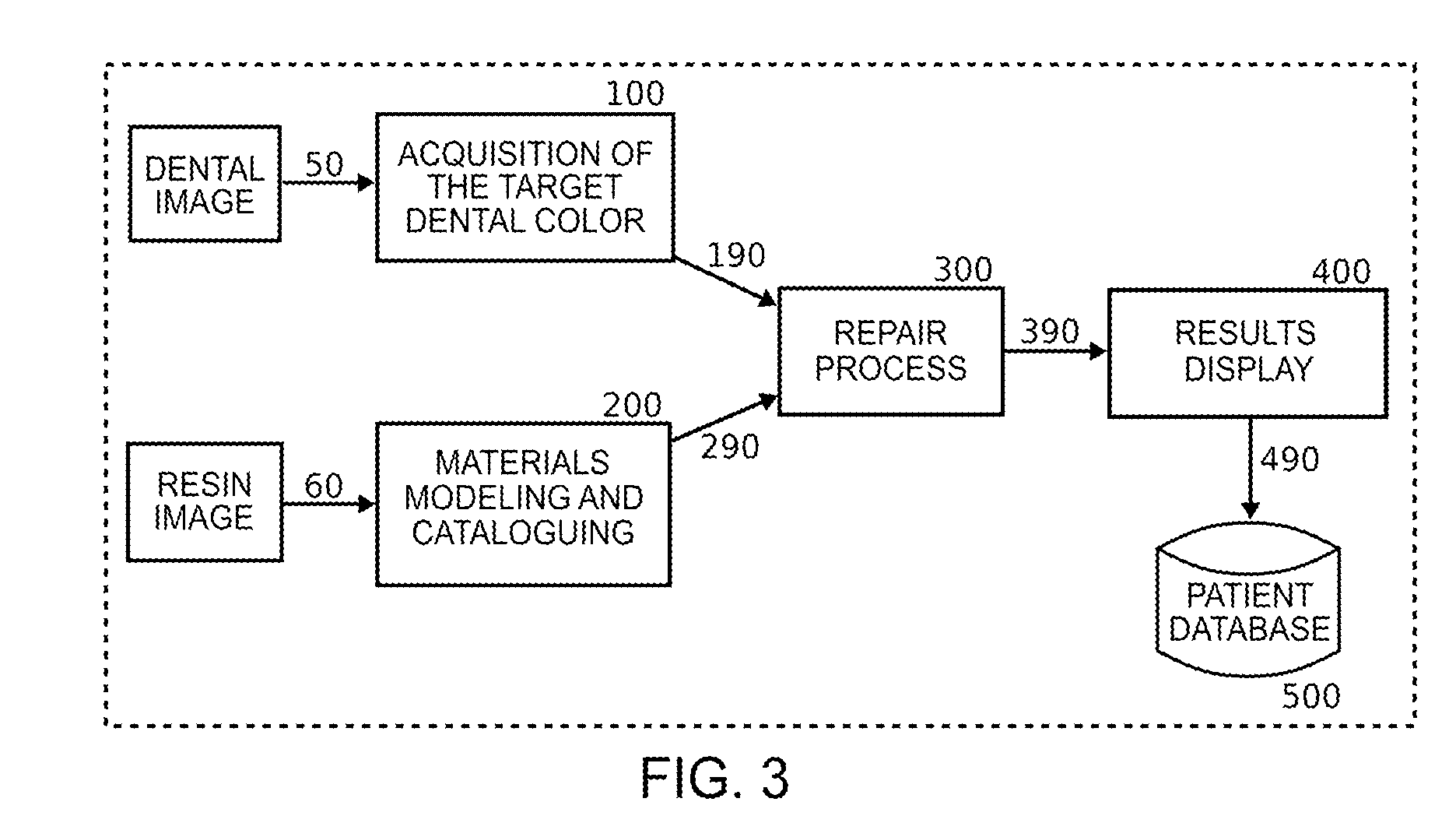

Method and device for quantitatively determining the surface optical characteristics of a reference object comprised by a plurality of optically differentiable layers

A method and device to determine quantitatively the surface optical characteristics of an object of reference made up of a plurality of optically differentiable layers. The device includes lighting and image capture means, connected to analysing means which execute the method to obtain the parameters of the repair material components best fitting the optical characteristics of the dental environment of the subject under treatment. The result of the analysis through the method in the invention consists mainly in the identification of each one of the various materials which should constitute the different layers, as well as their respective thicknesses, and which are to lead to a dental repair with optimum optical characteristics. It is thus achieved that the repair be visually imperceptible, both under natural light and under ultraviolet light.

Owner:APLIK

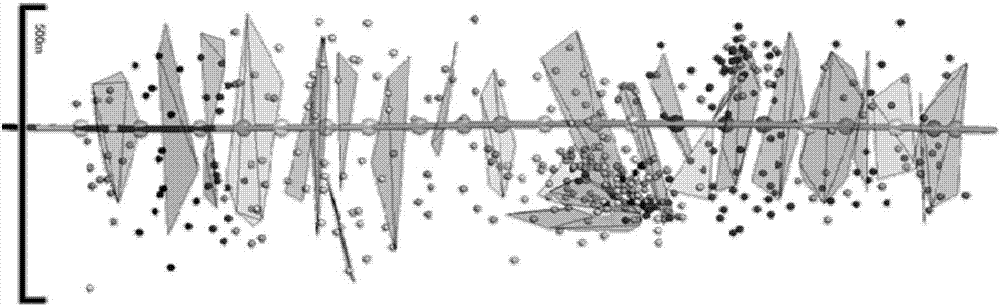

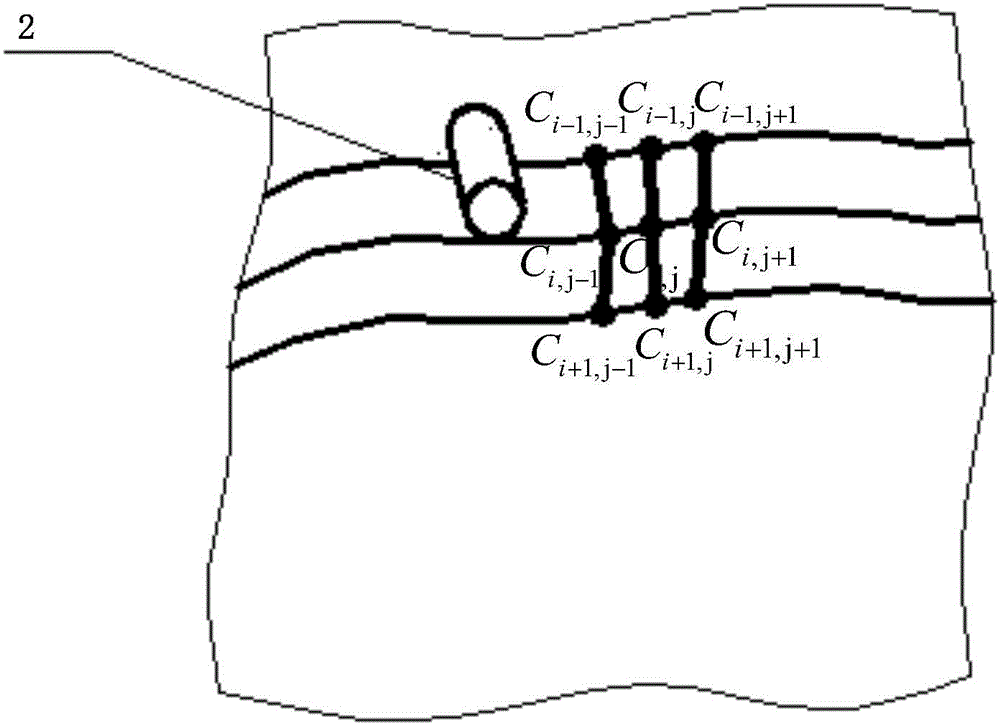

Shale-gas horizontal-well network crack modeling method based on microseism events

InactiveCN107220493ARealize true 3D simulationHigh precisionData processing applicationsInformaticsDensity modelSimulation

The invention relates to the technical field of oil-and-gas-field geologic modeling, in particular to a shale-gas horizontal-well network crack modeling method based on microseism events. The method includes the steps that 1, data is prepared and imported; 2, a main crack model of shale-gas network cracks is established; 3, in combination with fractured microseism monitoring data, a gridding microseism-event density model and a network crack density model are generated; 4, a branch crack model of the shale-gas network cracks is established; 5, a contact crack model of the shale-gas network cracks is established; 6, the main crack model, the branch crack model and the contact crack model are combined to form a discrete crack model of shale-gas horizontal-well fractured network cracks. According to the shale-gas horizontal-well network crack modeling method based on the microseism events, by establishing the fractured crack models of different levels, the shale-gas horizontal-well complex network crack model is formed, has good fitting effects, and has relatively high practical significance to the development of shale gas.

Owner:王欣 +1

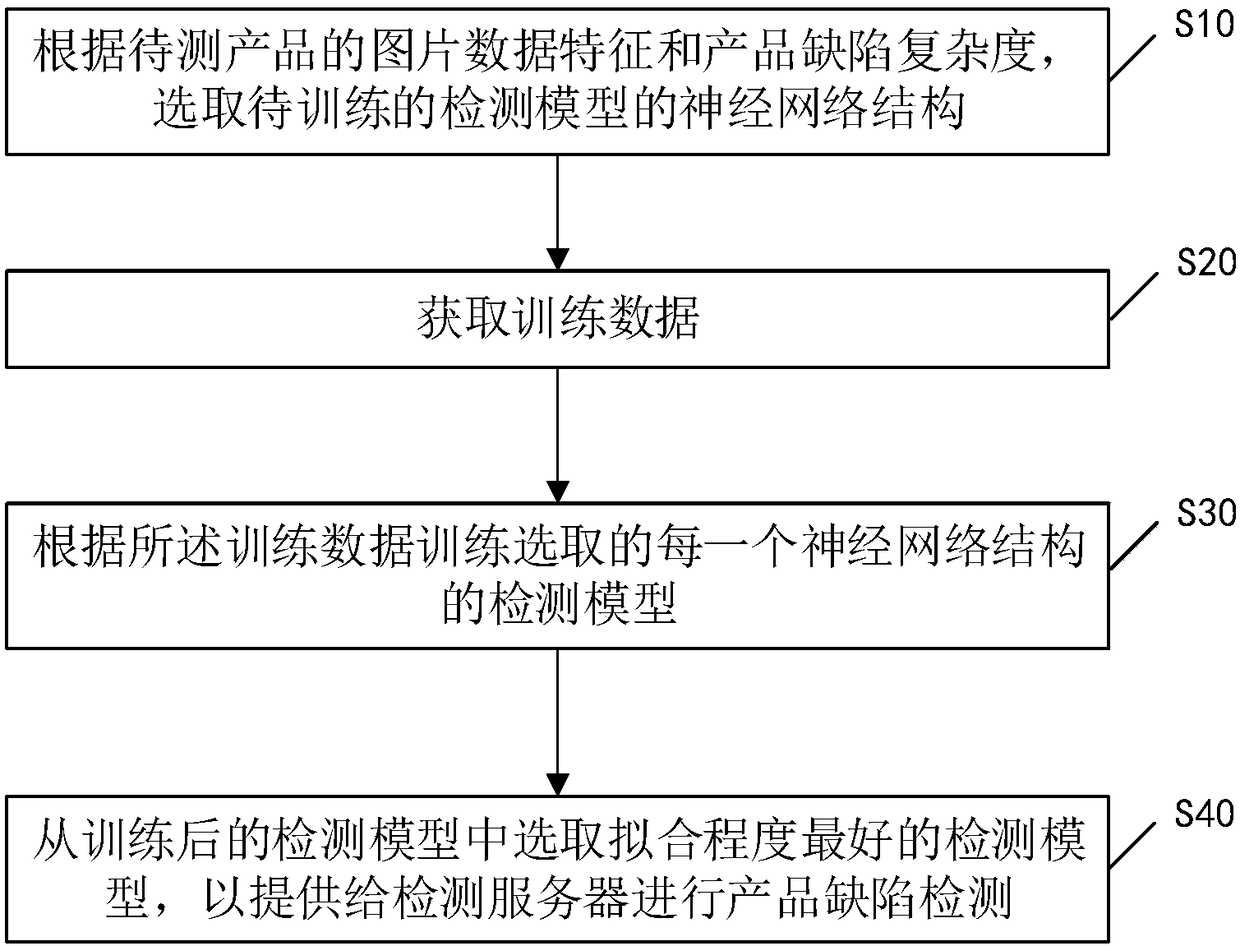

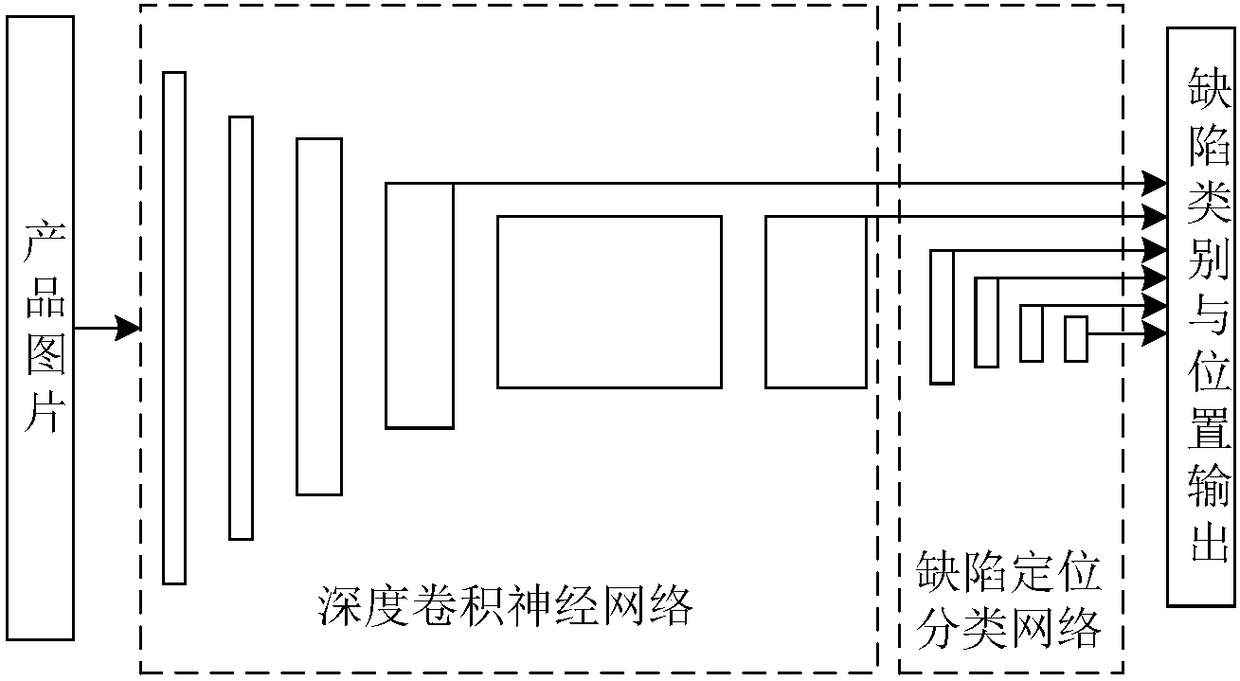

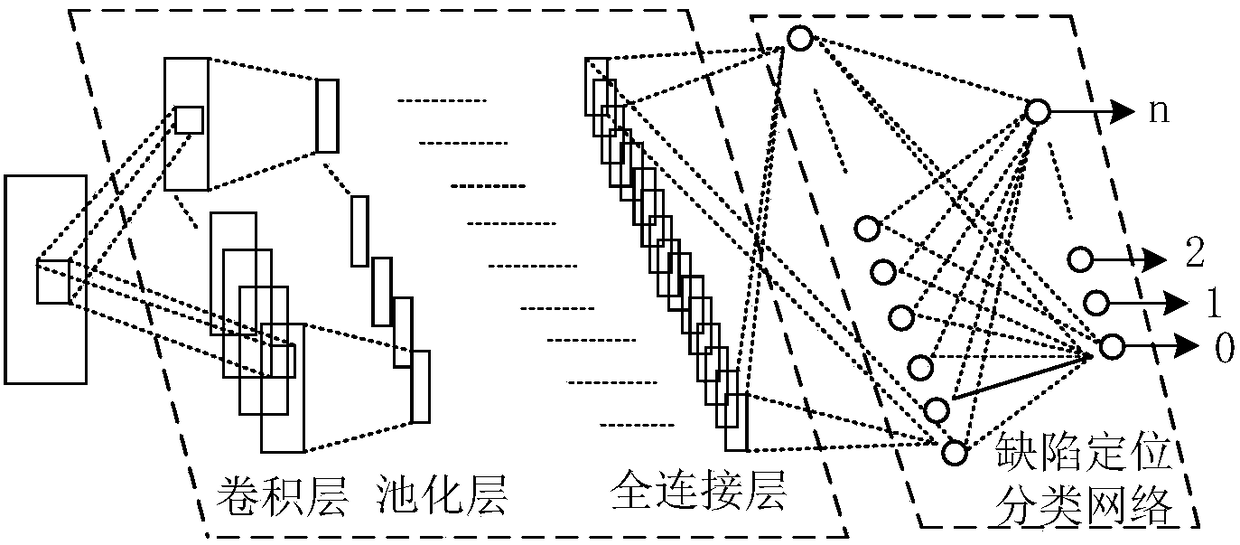

Method, device, storage medium and terminal device for product defect detections and locations

ActiveCN108154508AImprove robustnessDefect Complexity AdaptationImage enhancementImage analysisSoftware engineeringNetwork structure

The invention discloses a method, device, storage medium and terminal device for product defect detections and locations, wherein the method includes: according to the image data characteristics of products to be tested and the product defect complexity, selecting the neural network structure of detection models to be trained; obtaining training data, wherein the training data include training product pictures and standard categories and standard positions of product defects in the training product pictures; according to the training data, training the selected detection models of each neuralnetwork structure; selecting a best fitting detection model from the detection models after training to provide a detection server with the product defect detection, wherein the detection models are used for calculating according to the received product pictures to obtain predicted categories and predicted locations of the product defects in the received product pictures. Adopting the method, device, storage medium and terminal device for product defect detections and locations is capable of improving the accuracy of detecting the product defects.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

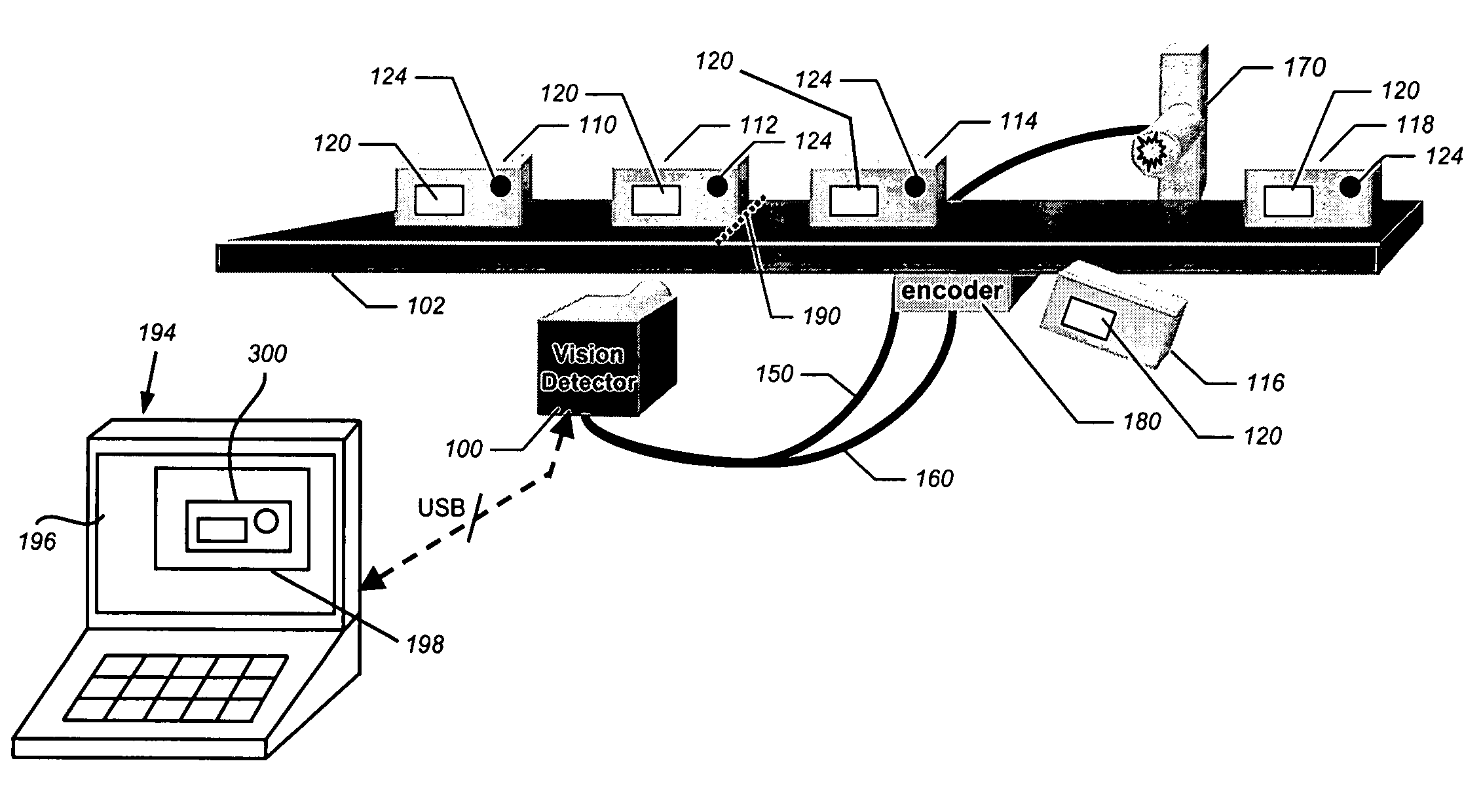

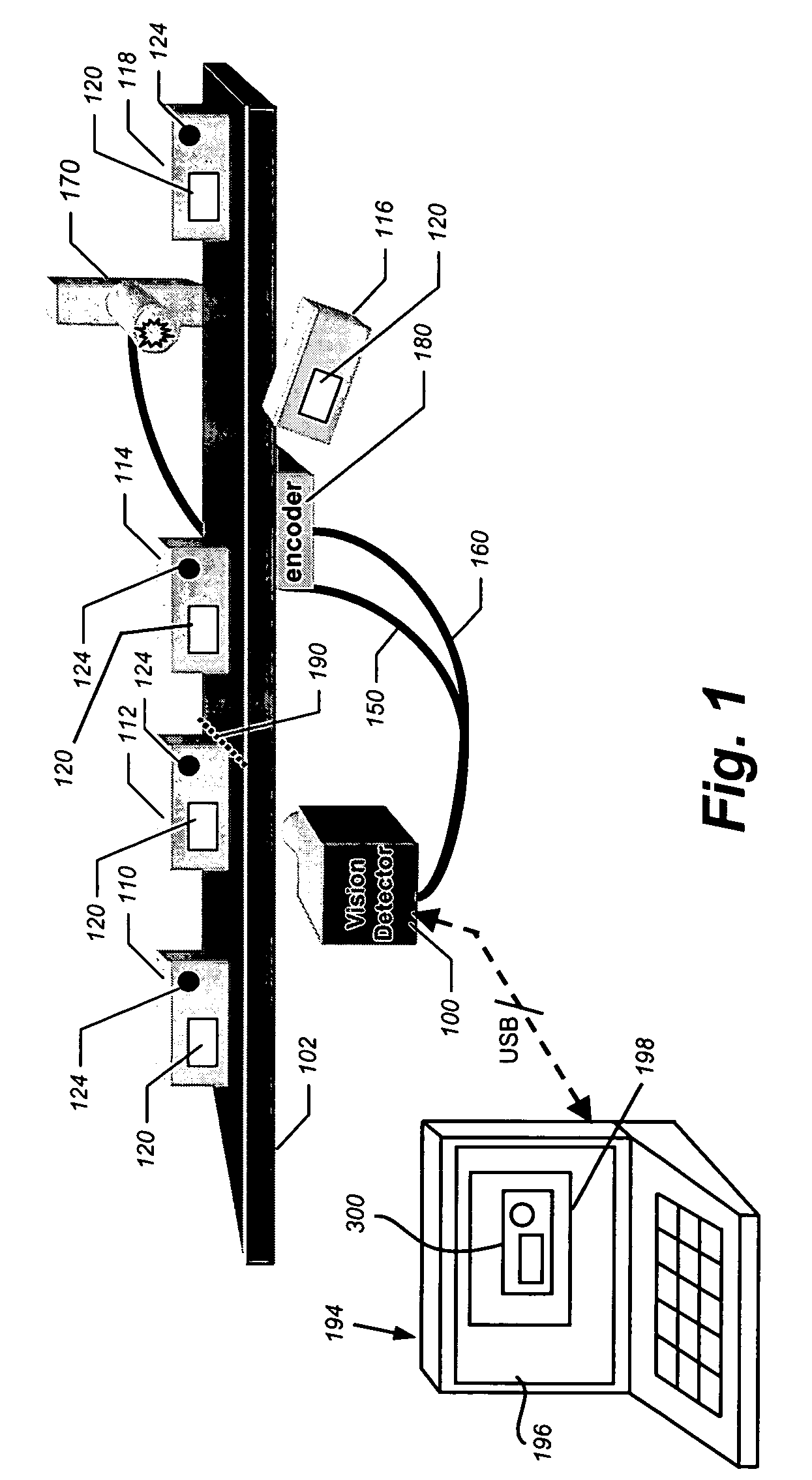

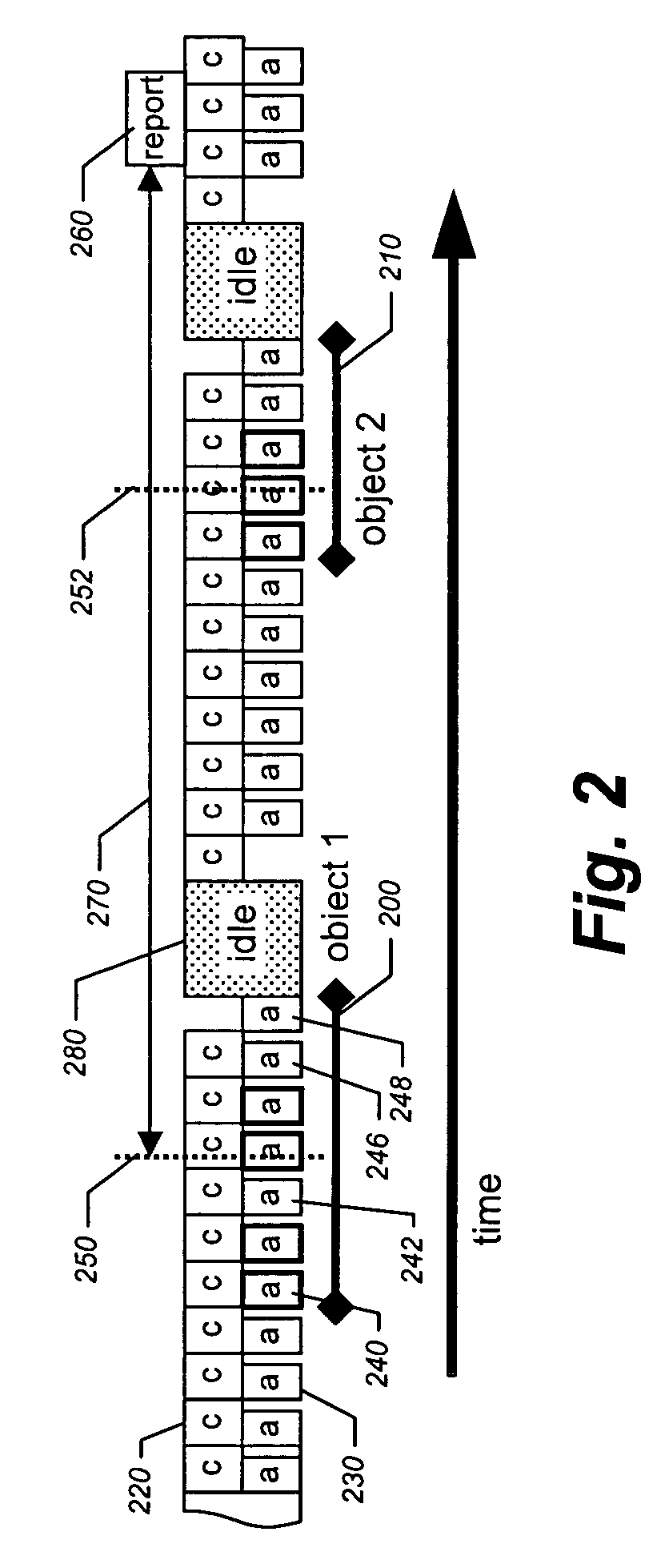

System and method for assigning analysis parameters to vision detector using a graphical interface

ActiveUS7636449B2Character and pattern recognitionExecution for user interfacesDrag and dropOperating point

This invention provides a system and method for automating the setup of Locators and Detectors within an image view of an object on the HMI of a vision detector by determining detectable edges and best fitting the Locators and Detectors to a location on the object image view following the establishment of an user selected operating point on the image view, such as by clicking a GUI cursor. In this manner, the initial placement and sizing of the graphical elements for Locator and Detector ROIs are relatively optimized without excessive adjustment by the user. Locators can be selected for direction, including machine or line-movement direction, cross direction or angled direction transverse to cross direction and movement direction. Detectors can be selected based upon particular analysis tools, including brightness tools, contrast tools and trained templates. The Locators and detectors are each associated with a particular set of operating parameters, such as activation threshold, which are displayed in a control box within the GUI (and can be accessed by clicking on the specific Locator or Detector. A parameter bar can also be provided adjacent to the depiction of the Detector on the image view for easy reference. Both Locators and Detectors may be manually readjusted once automatically placed and sized by drag and drop techniques.

Owner:COGNEX TECH & INVESTMENT

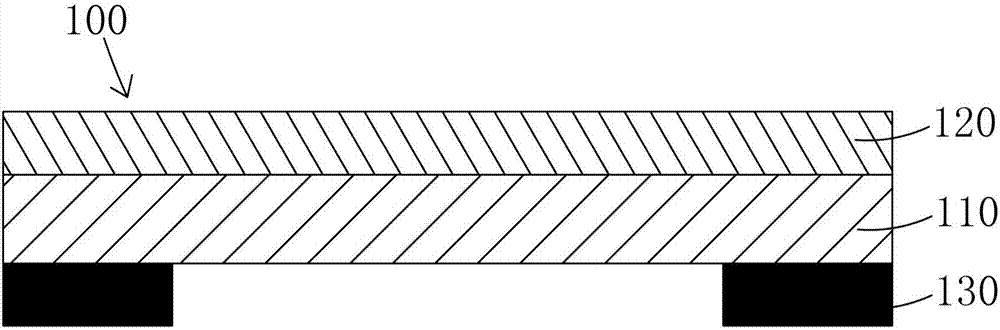

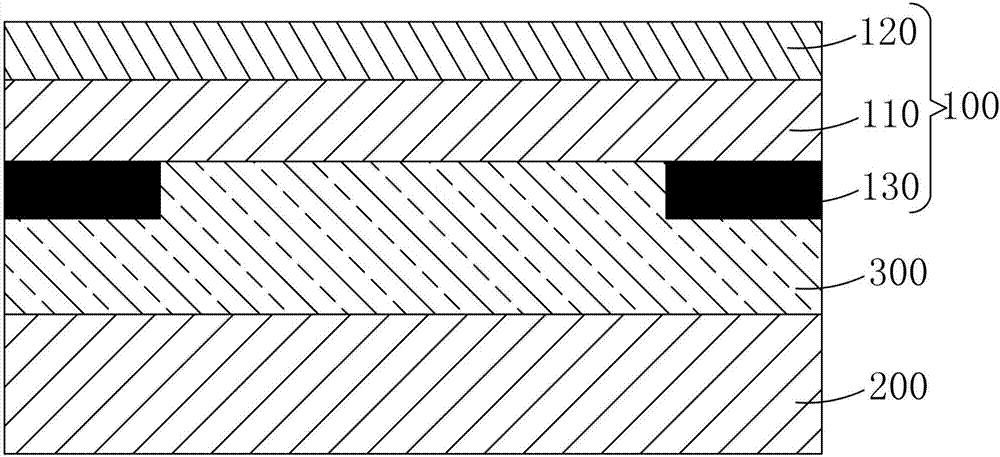

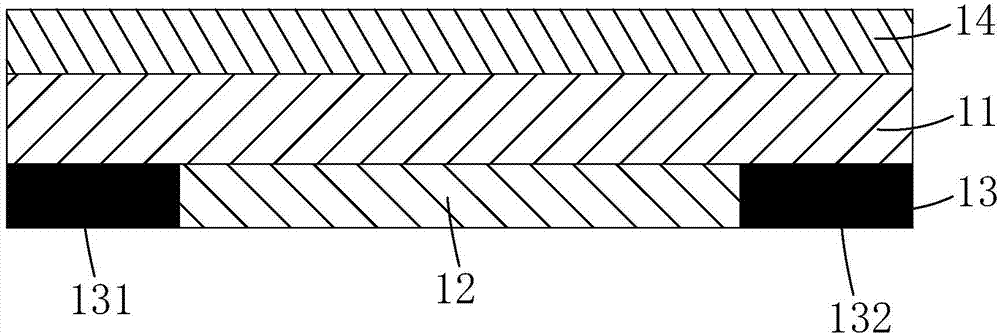

Flexible cover plate, production method of flexible cover plate and flexible OLED display device

InactiveCN107545848AEliminate the difficulty of fittingReduce the difficulty of fittingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a flexible cover plate, a production method of the flexible cover plate and a flexible OLED display device. The flexible cover plate comprises a first flexible base film, a second flexible base film, an ink layer and a hard coating, wherein the ink layer includes a first ink area and a second ink area, the space between the first ink area and the second ink area is filled with the second flexible base film, so that the partition difference of the first flexible base film caused by the ink layer is eliminated, thus a good fitting effect can be achieved by means of a thinner optical adhesive layer in the using process, the thickness of the flexible OLED display device is further reduced, the bending resistance of the flexible OLED display device is improved, meanwhilethe fitting difficulty of the flexible cover plate is reduced, and improvement of the yield rate is promoted.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

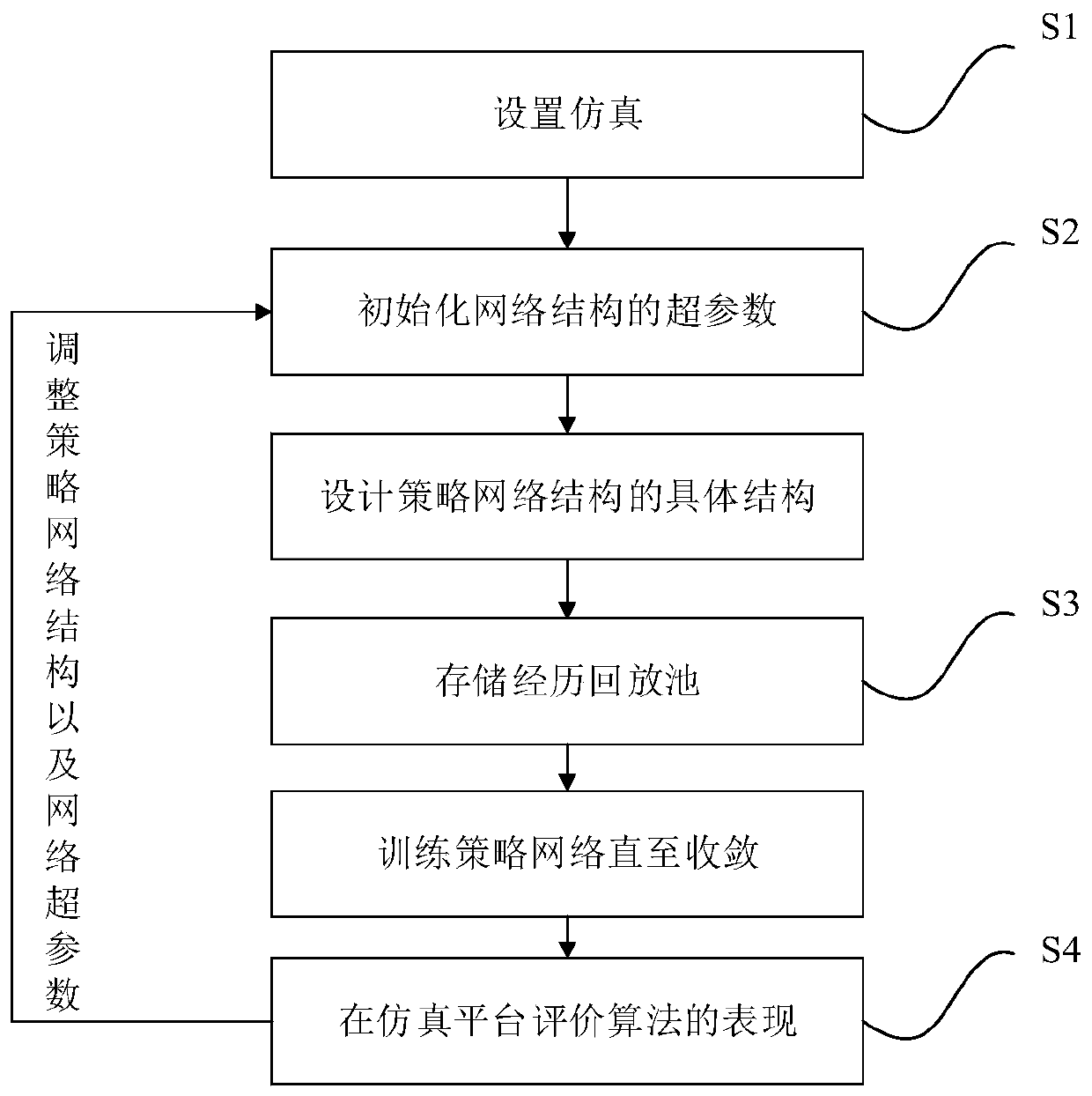

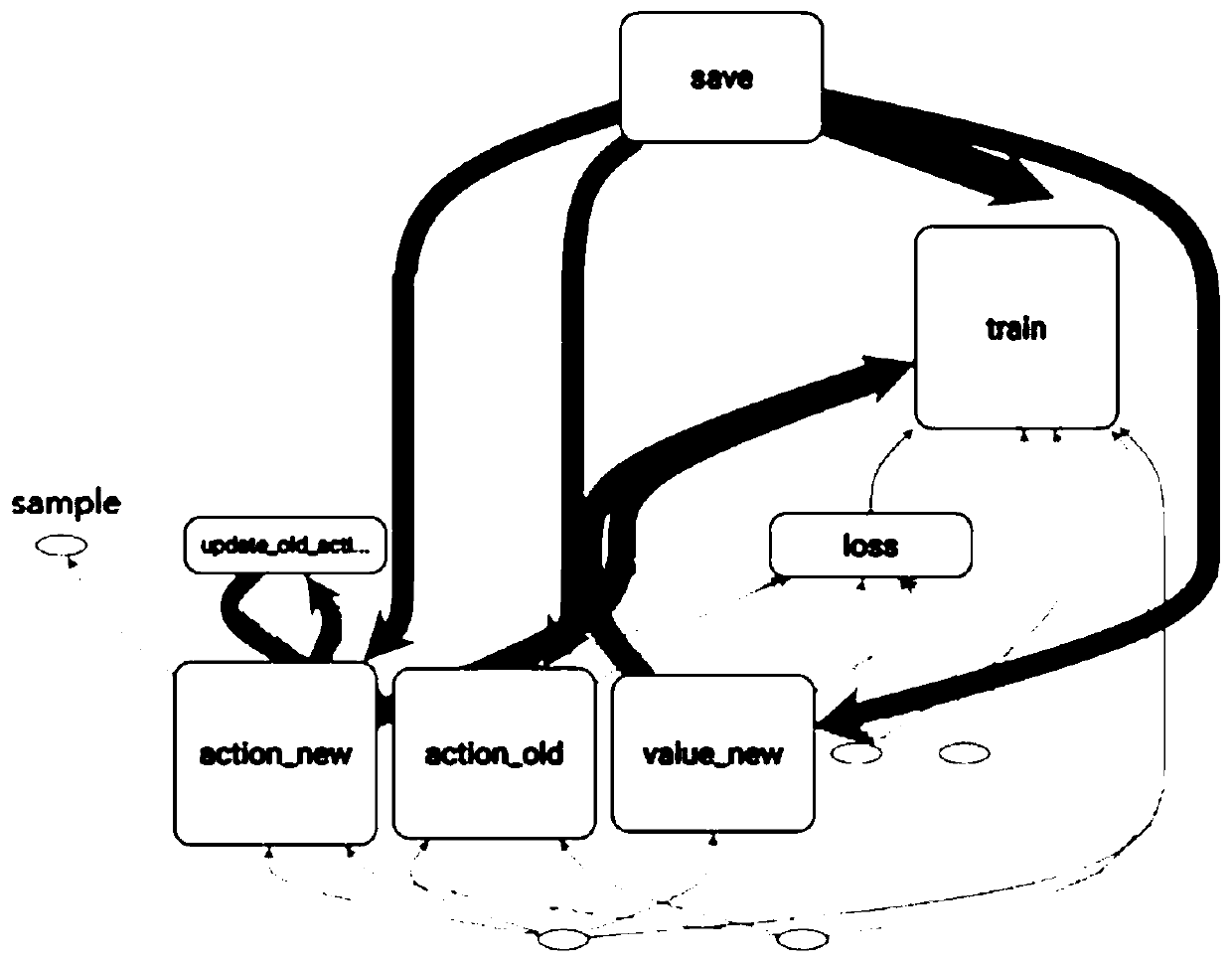

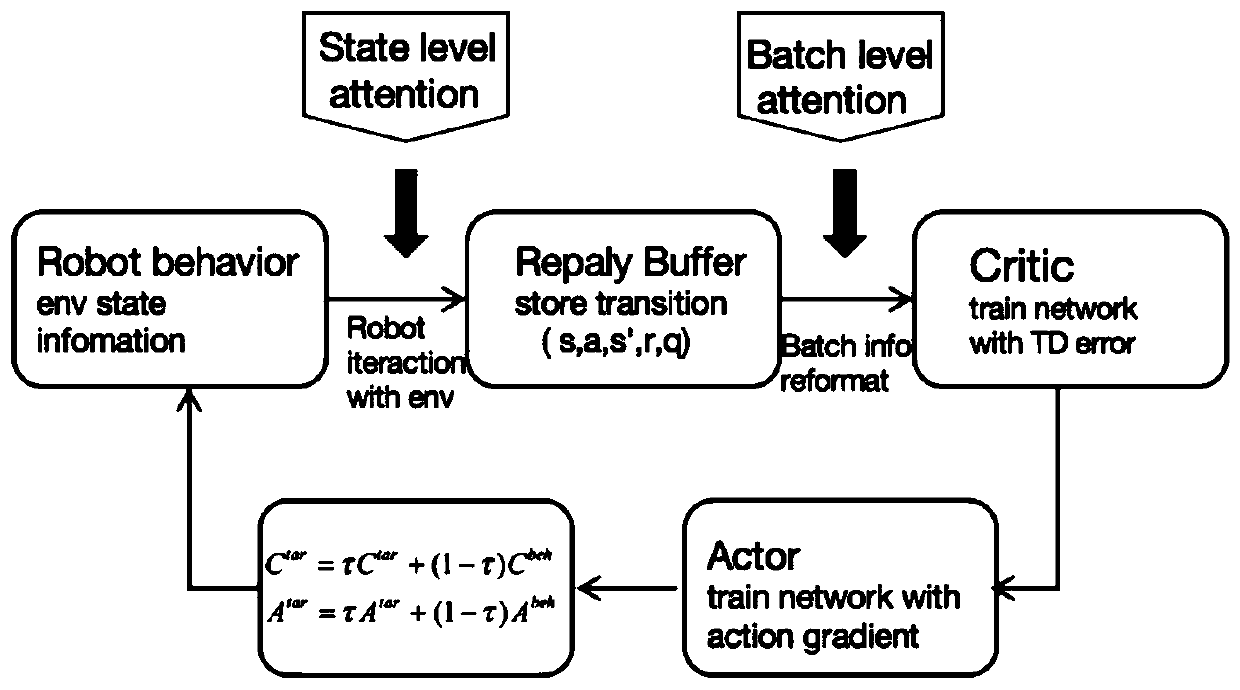

Biped robot adaptive walking control method based on deep reinforcement learning

ActiveCN110262511AForced walking stabilityFast convergenceNeural architecturesNeural learning methodsSimulationNetwork model

The invention relates to a biped robot adaptive walking control method based on deep reinforcement learning. The method comprises the steps that 1) a simulation platform is established; 2) a network model based on a deep reinforcement learning method introducing an attention mechanism is constructed; 3) the network model is trained according to the interaction information of a biped robot in the environment of the simulation platform, and the interaction information is stored in a playback pool; and 4) the network model which completes training is used to realize adaptive control of walking of the biped robot. Compared with the prior art, the method provided by the invention has the advantages of fast convergence speed, good fitting effect, high walking stability and the like.

Owner:TONGJI ARTIFICIAL INTELLIGENCE RES INST SUZHOU CO LTD

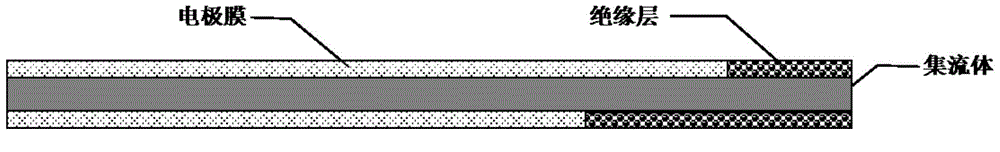

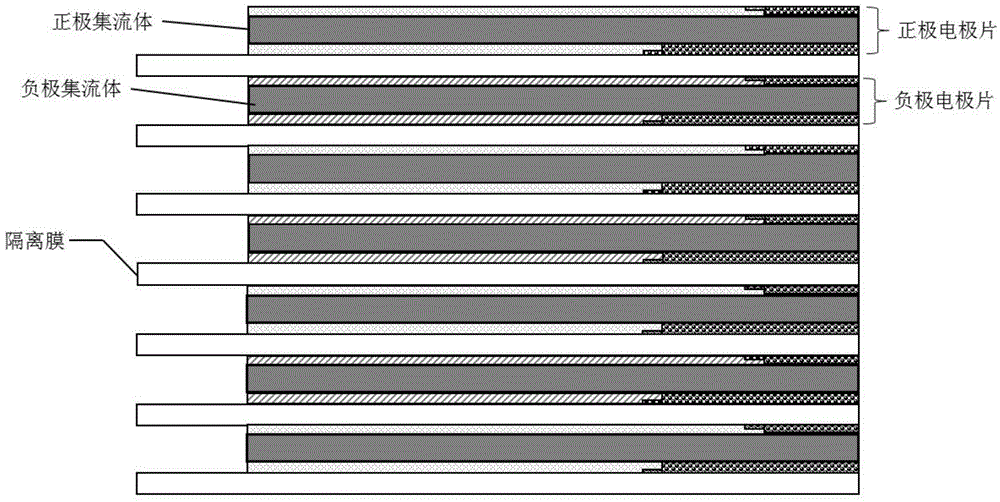

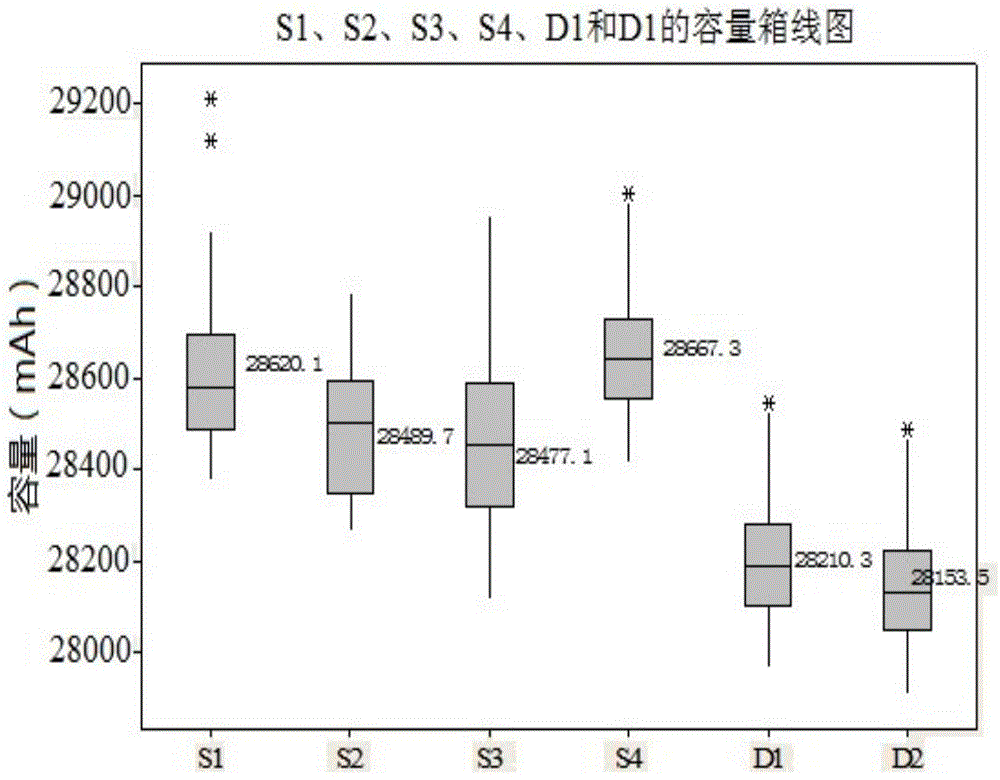

Electrode plate and lithium ion battery comprising same

ActiveCN104466097ASmooth appearanceSimple interfaceSecondary cellsNon-aqueous electrolyte accumulator electrodesCapacity lossMohs scale of mineral hardness

The invention relates to an electrode plate and a lithium ion battery comprising the same. The electrode plate comprises a current collector, an electrode diaphragm and an insulation layer; the electrode diaphragm comprises an electrode active substance; the insulation layer comprises solid insulation padding with the mohs hardness being less than or equal to 5; the insulation layer at least covers an area, which is not covered by the electrode diaphragm, of the surface of the current collector. By adopting the insulation layer, the safety problem caused by the piercing of burrs of the current collector to the diaphragm can be avoided; the insulation layer also has the good extension rate and the good effect on transferring the rolling pressure, the flat appearance of the electrode plate in rolling can be guaranteed, a good fitting interface of the electrode plate inside a cell also can be guaranteed, and the capacity loss of the lithium battery in the charging and discharging processes can be reduced.

Owner:DONGGUAN AMPEREX TECH +1

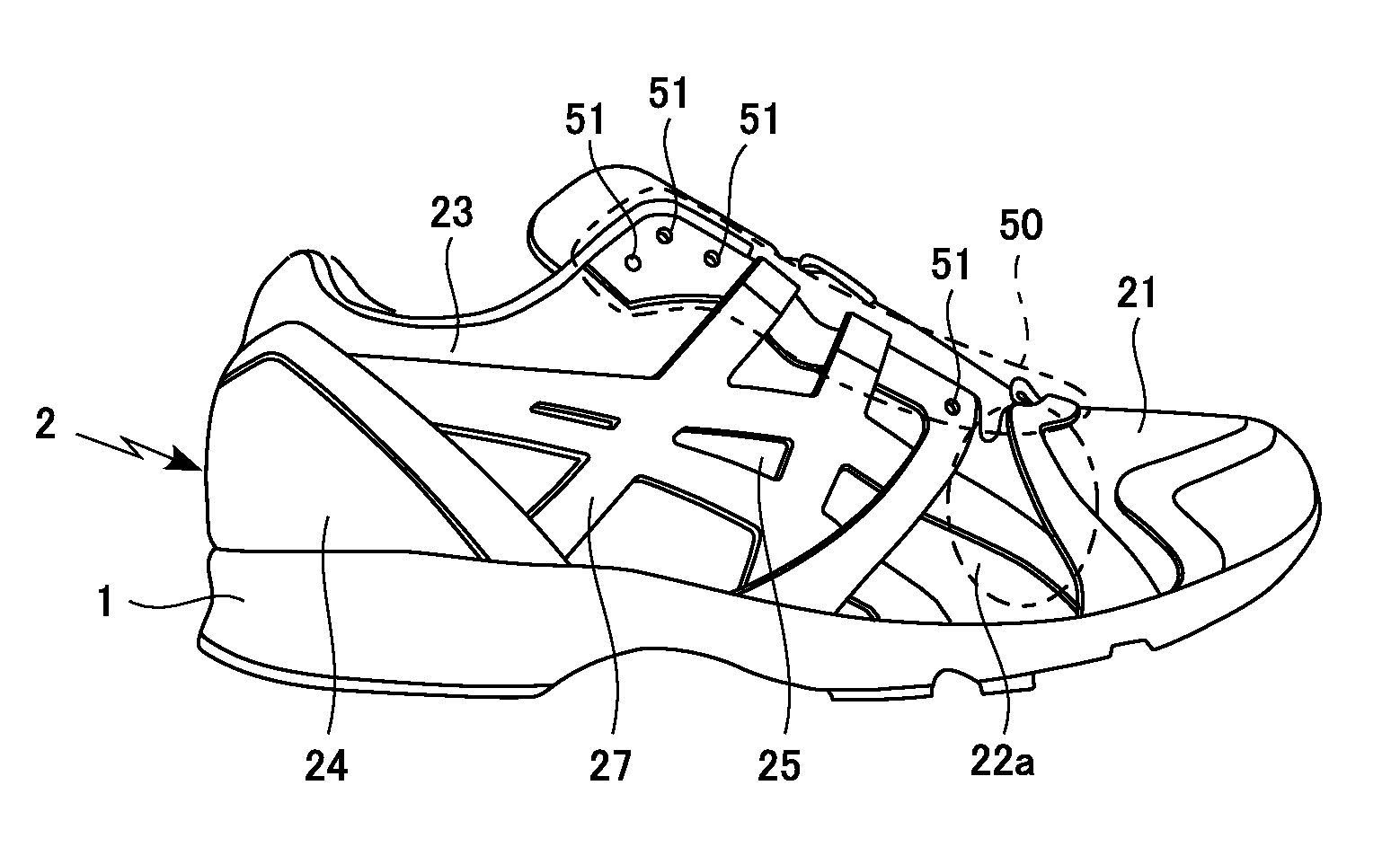

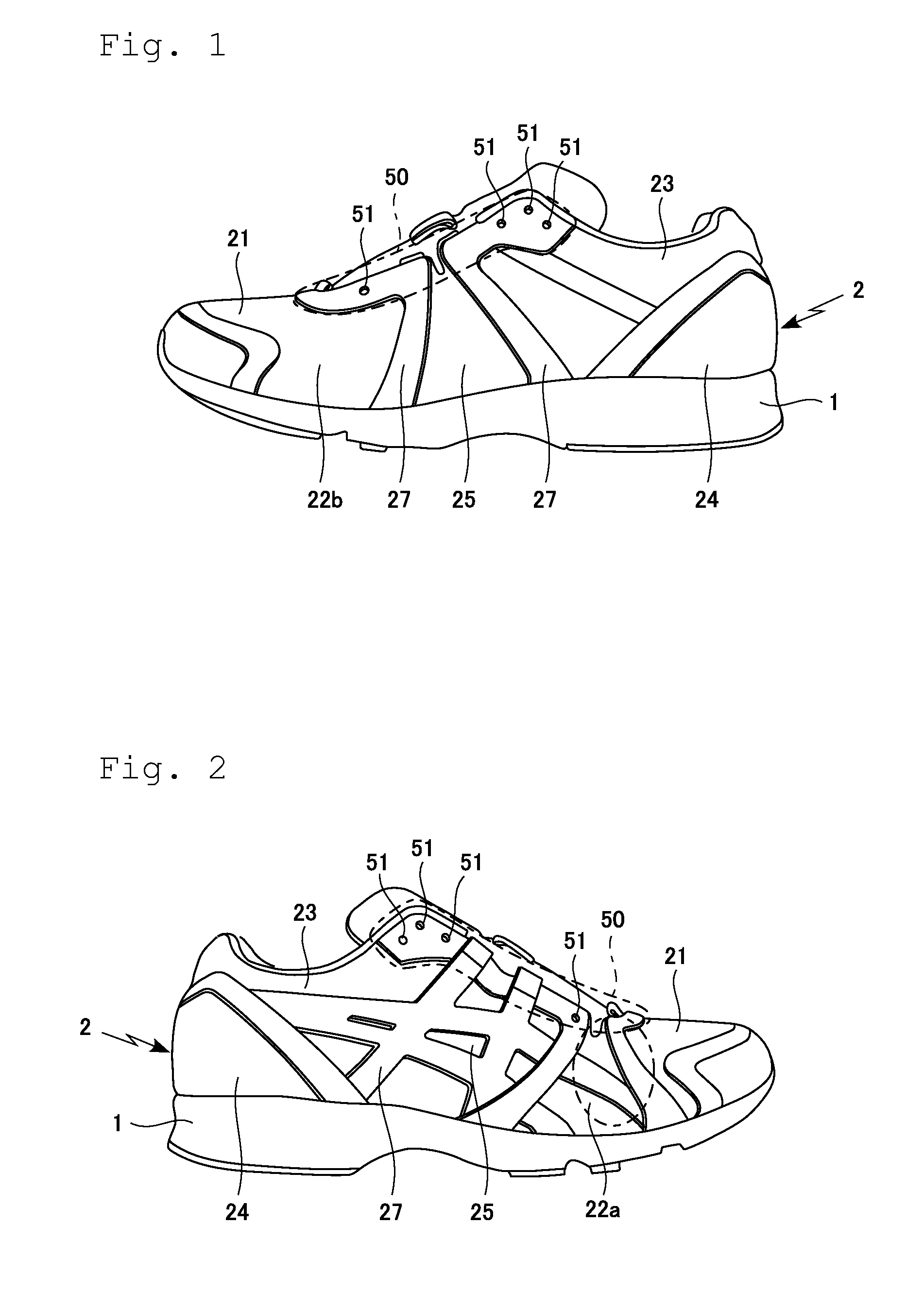

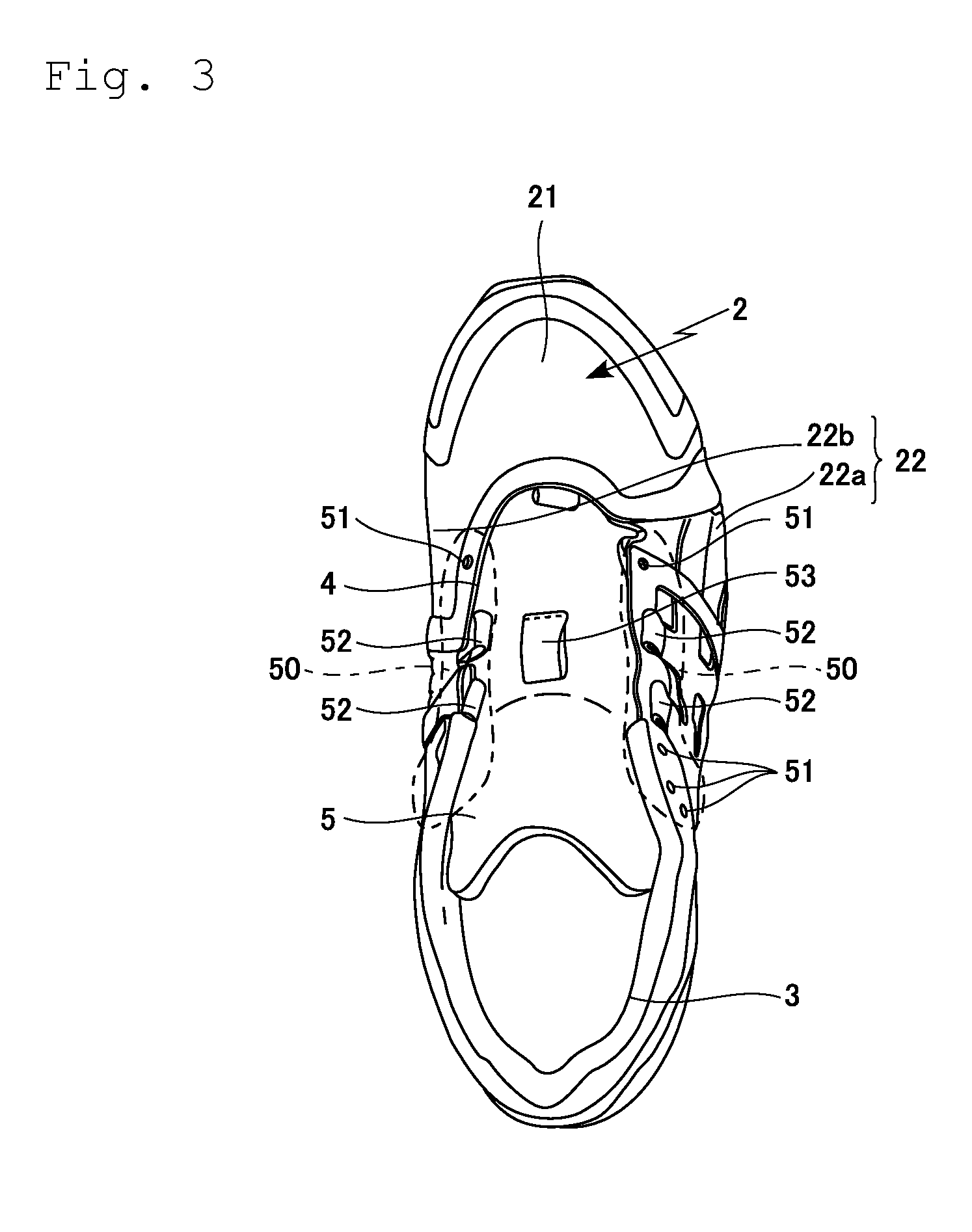

Shoes

An object of the present invention is to provide shoes with good fitting property.The present invention provides a shoe including: a sole 1 which absorbs landing impact; and an upper 2 which covers an instep of a foot. The upper has a first opening 3 through which the foot is inserted when wearing the shoe. The upper 2 is partly or entirely made of a material which has negative Poisson's ratios.

Owner:ASICS CORP

System and method for determining a pivot center and radius based on a least squares approach

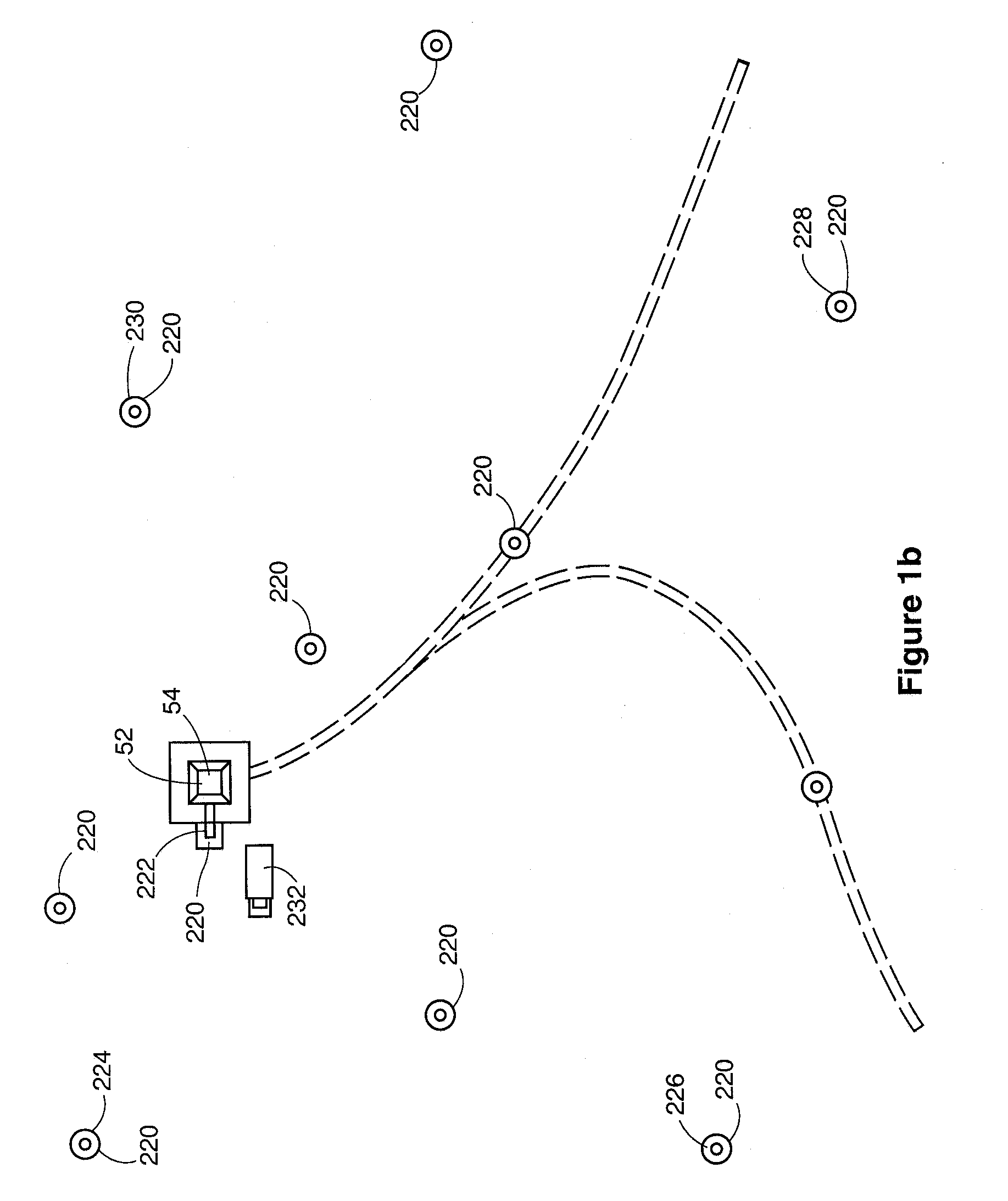

A system and method for determining the center and radius based on a least squares approach is disclosed. In one embodiment, a farmer drives through a given arc of a circular field in question and periodically takes position measurements. In another embodiment, a Least-Squares Algorithm is used to estimate the best-fitting center and radius given the set of position measurements input by the farmer.

Owner:TRIMBLE NAVIGATION LTD

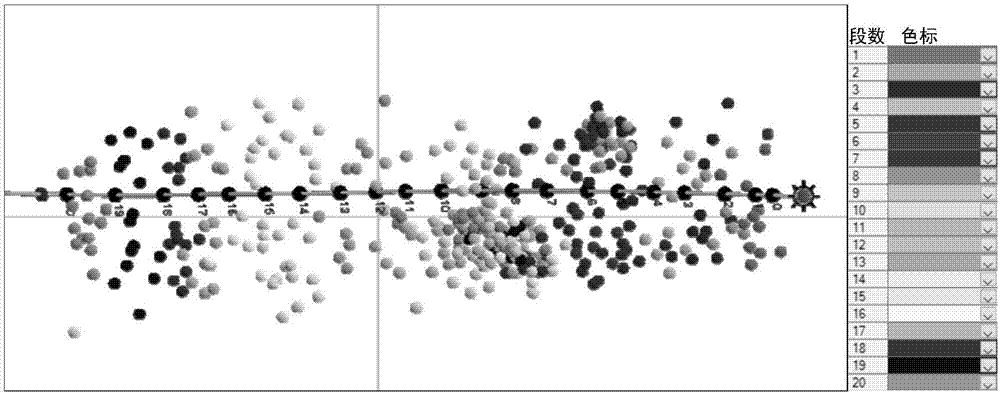

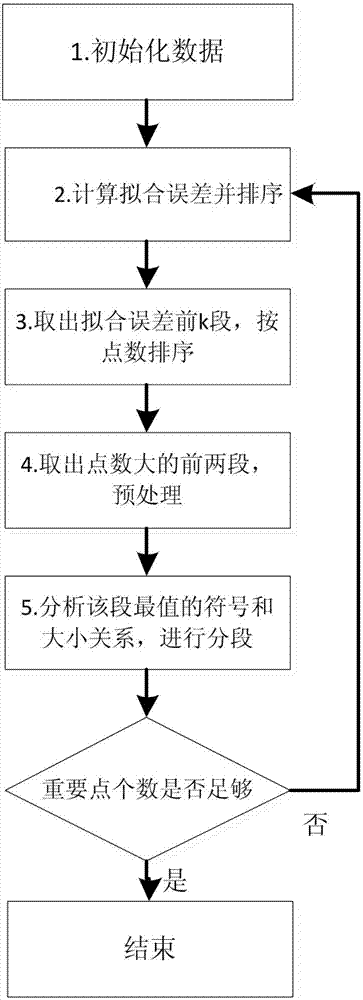

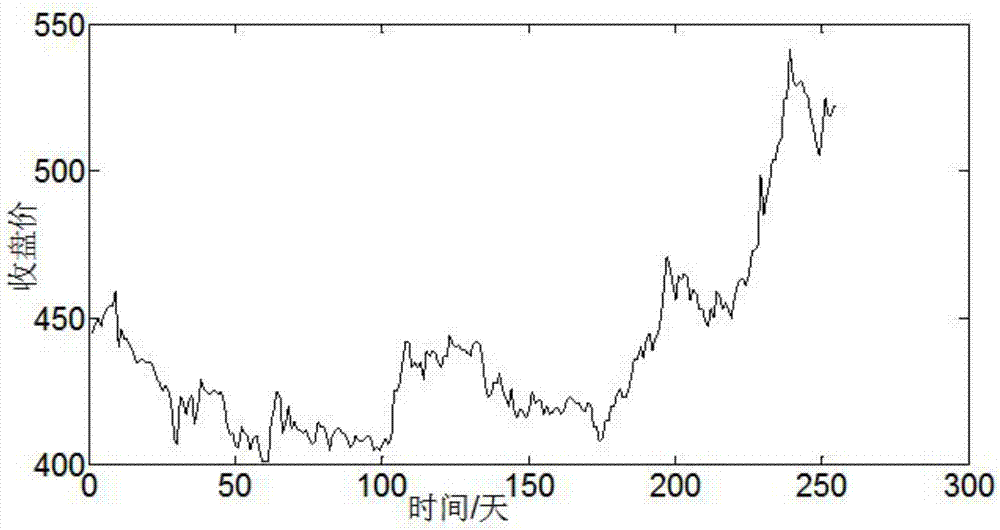

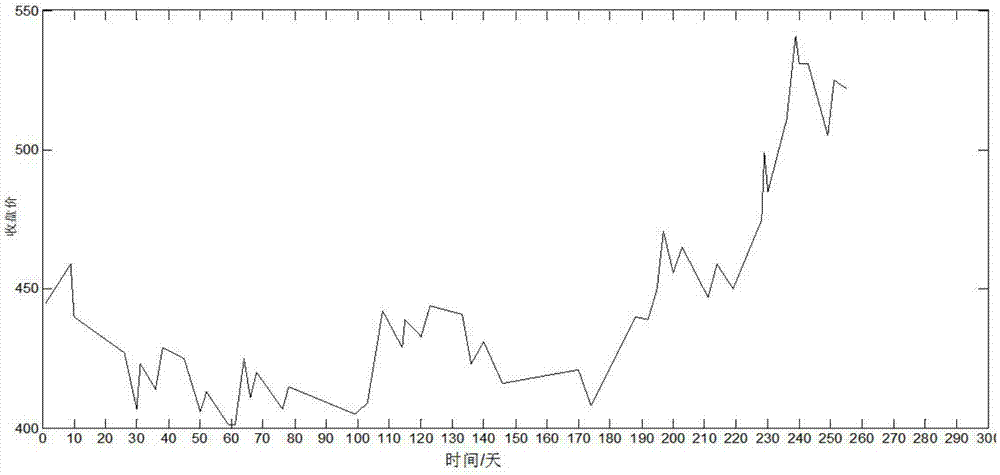

Important point-based time sequence fixed segmentation algorithm

InactiveCN107463604AAvoid typingPreserve featuresSpecial data processing applicationsAnomaly detectionAlgorithm

The invention relates to an important point-based time sequence fixed segmentation algorithm. According to the main technical characteristics, the algorithm comprises the steps of performing normalization processing on time sequence data; calculating segmentation fitting errors and performing sorting according to priorities of the segmentation fitting errors from high to low; extracting first k segments with maximum fitting errors and performing sorting from long to short according to segment lengths of a time sequence; extracting first two segments sorted according to the segment lengths, and performing fitting preprocessing; and comparing symbol and value relationships of maximum values and minimum values of the fitting errors in segmentation, determining important points to perform segmentation, progressively increasing the number of the important points, and performing loop iteration until a fixed segment number is reached. The algorithm is reasonable in design, greatly reduces the fitting errors, improves the segmentation efficiency, has very good fitting effect and adaptability, and can be widely used in the fields of time sequence prediction, clustering, anomaly detection and the like.

Owner:TIANJIN UNIV OF SCI & TECH

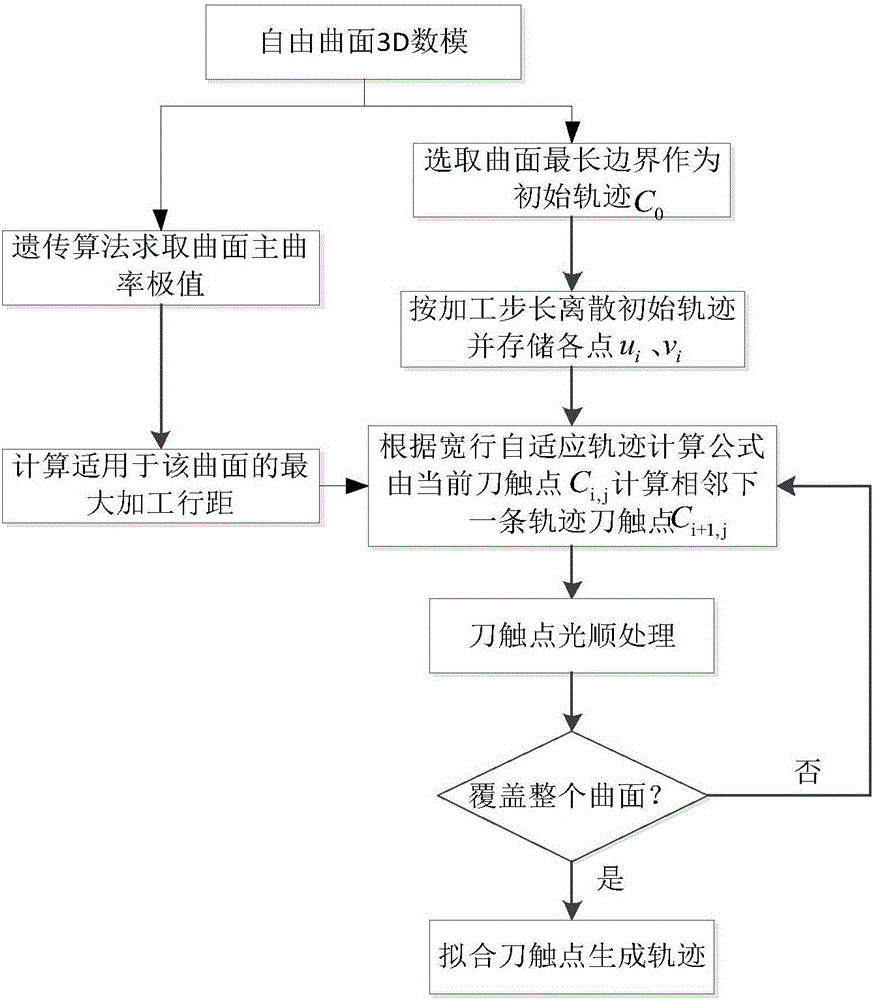

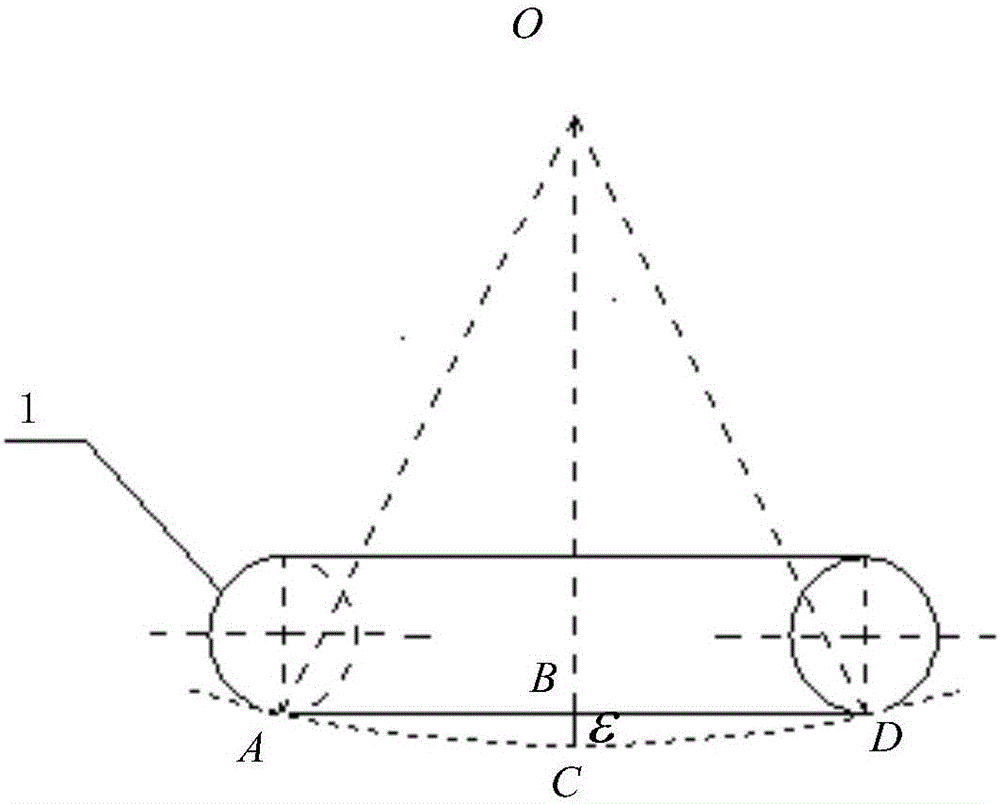

Free-form surface adaptive machining track planning method

ActiveCN106054802AReduce calculation precisionAvoid local interference problemsNumerical controlFree formGenetic algorithm

The invention discloses a free-form surface adaptive machining track planning method which is mainly used to grind free-form surface parts. The method comprises the following steps: getting the main curvature extremum of a surface through a genetic algorithm; getting the maximum line spacing suitable for surface machining according to the precision need; discretizing the longest boundary of the surface at equal step length through dichotomy; acquiring the related parameters of discrete points and calculating adjacent track cutter contacts; after traversing all newly-generated cutter contacts, performing interpolation according to the step length requirement and smoothing; and until the discrete points cover the whole surface, fitting the cutter contacts to generate a machining track. According to the invention, the maximum machining line spacing is obtained according to the machining precision requirement and the surface characteristics, and by achieving a best fitting effect between a grinding head and a surface and self-adaption of the line spacing direction, over-cutting and vibration caused by repeated grinding of a local area are avoided, and the grinding efficiency and grinding accuracy are improved. The method has great popularization and practical values.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

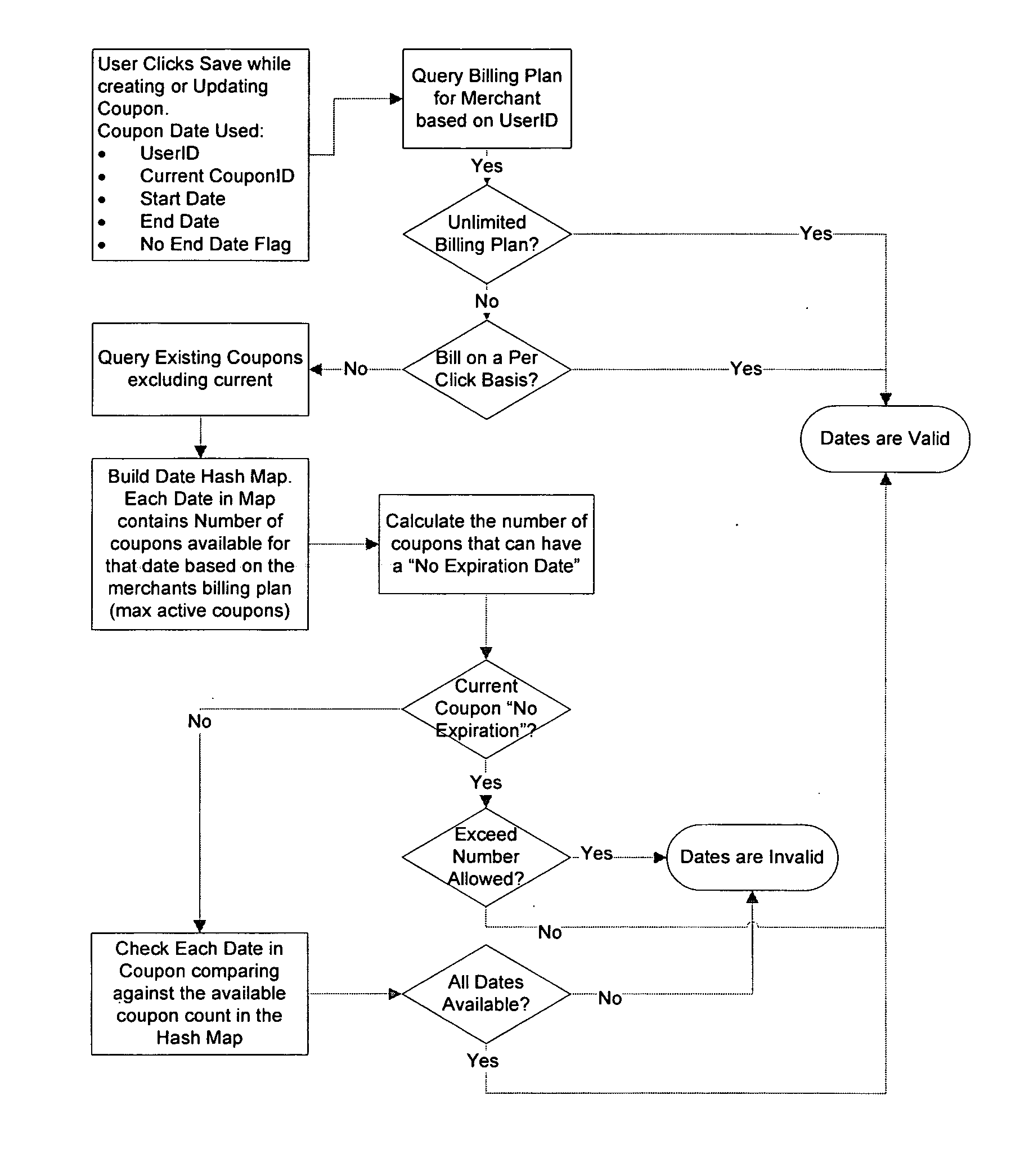

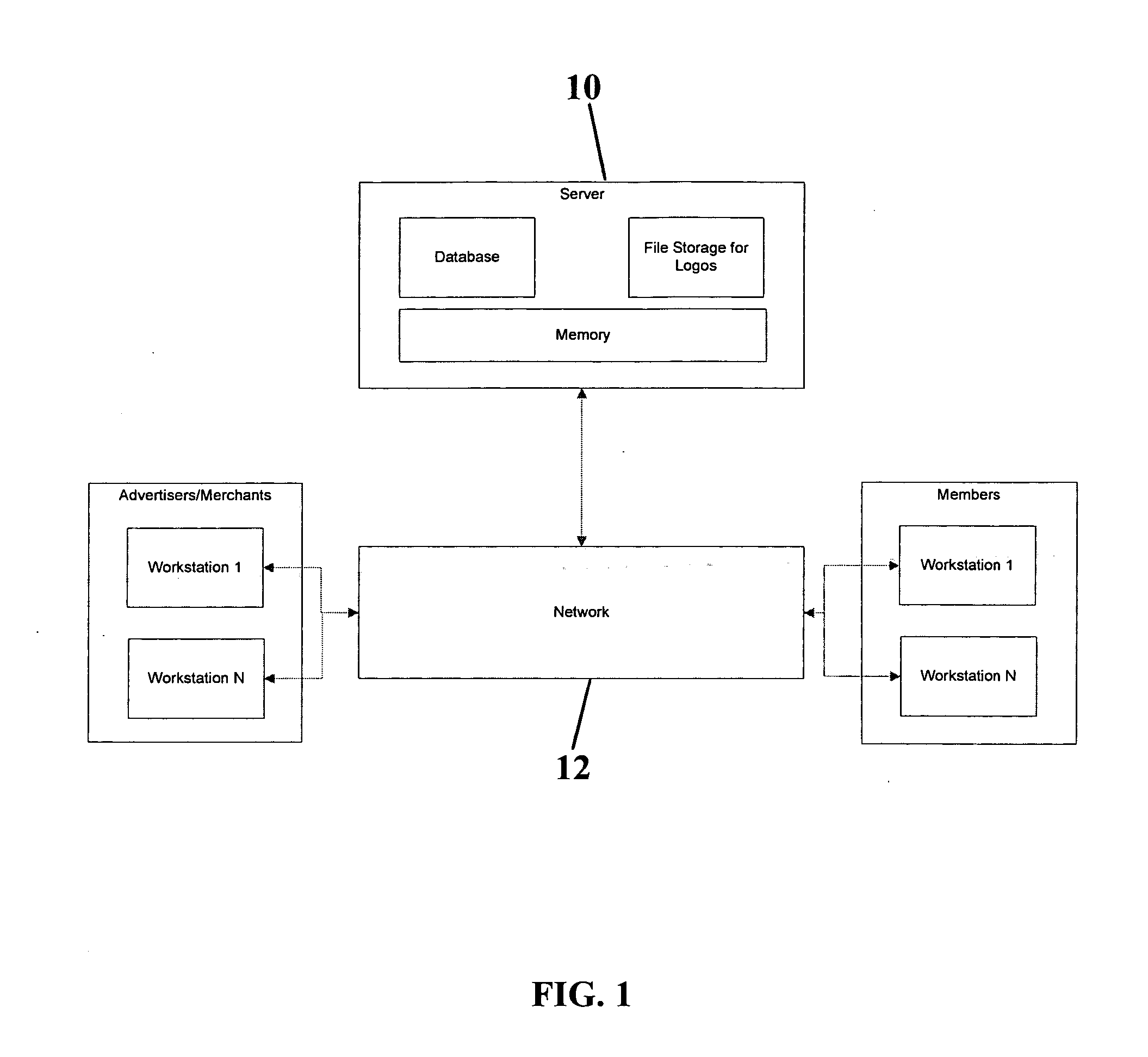

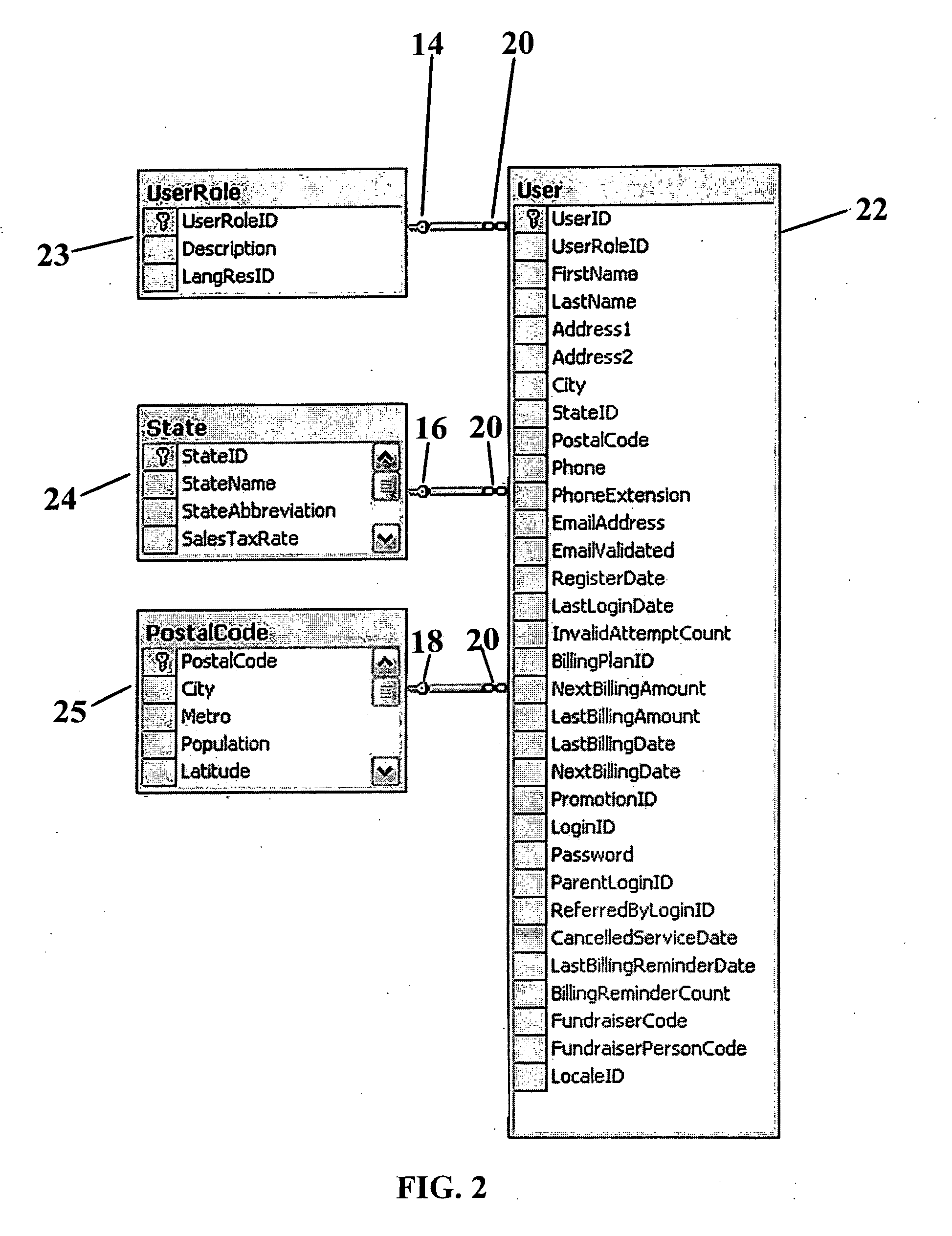

On-line coupon distribution system

Owner:IDEALS

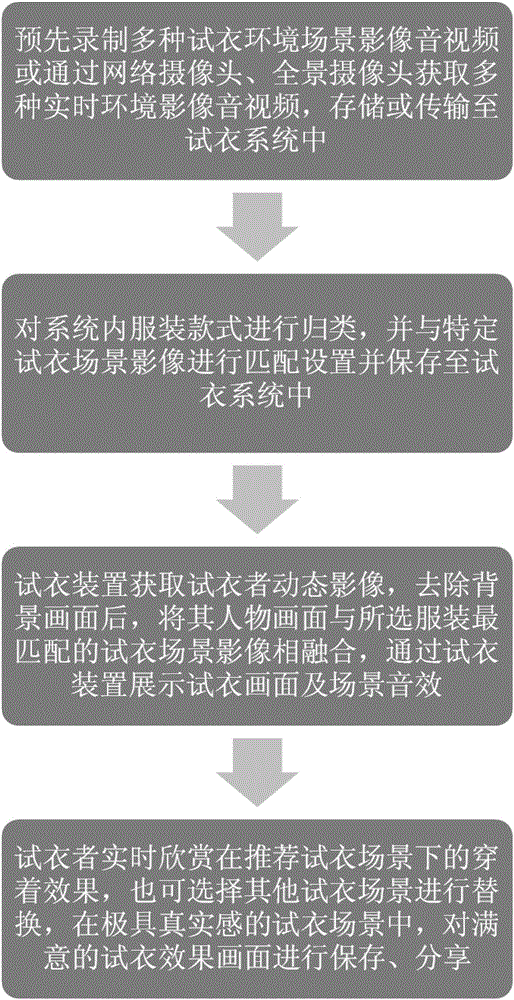

Virtual fitting system automatically matching fitting scene and application method

InactiveCN105761120AReduce matching workConducive to practiceMarketingComputer graphics (images)Scene matching

The invention discloses a virtual fitting system automatically matching a fitting scene. The virtual fitting system includes a user interface, a figure video image acquisition unit, a figure video image processing unit, an environment video image acquisition unit, an environment video image processing unit and a garment and fitting scene matching database unit. The invention also designs an application method of the virtual fitting system automatically matching the fitting scene. The virtual fitting system can automatically match and present the most suitable dynamic or real-time fitting scene environmental background according to the garment style selected by a consumer, in an on-site fitting process, the consumer can freely select other kinds of fitting scene environmental backgrounds, the whole fitting process meets a traditional consumption flow habit of selecting, fitting, appreciating and deciding whether to purchase, can provide a visual reference image having a true audio and video image effect for the consumer to select and purchase a garment, and possesses the sense of reality, and shopping experience of the consumer can be improved.

Owner:NANJING YUNCHUANG LARGE DATA TECH CO LTD

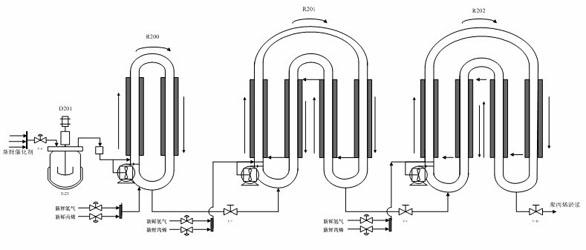

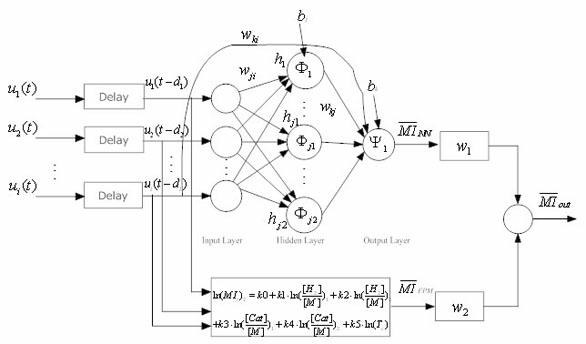

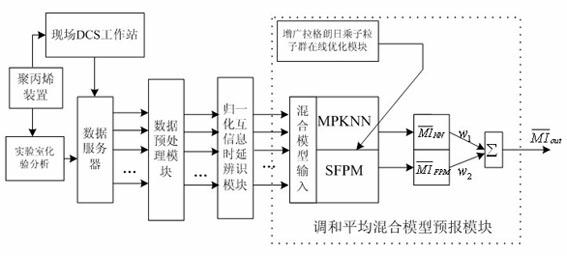

Polypropylene melt index predicating method based on multiple priori knowledge mixed model

ActiveCN102609593AEffective waveform characteristicsExtract waveform featuresSpecial data processing applicationsAugmented lagrange multiplierLoop control

The invention discloses a polypropylene melt index predicating method based on a multiple priori knowledge mixed model, which fully explores and utilizes priori knowledge of a polypropylene industrial site, and is used for organically integrating various priori knowledge, embedding the priori knowledge into a multilayer perceptron neural network in a non-linear equality constraint form, and optimizing a network weight number by means of a particle swarm optimization algorithm based on an augmented Lagrange multiplier constraint processing mechanism. Based on the multiple priori knowledge neural network model, the multiple priori knowledge neural network model is organically integrated with a polypropylene melt index simplification mechanism model into a harmonic average mixed soft-measuring model. The multiple priori knowledge mixed soft-measuring modeling method has good fitting prediction ability, and is capable of enhancing model extrapolation capacity and realizing good unity of model extrapolation and prediction accuracy of polypropylene melt indexes. Besides, the method is capable of avoiding zero gain and gain inversion and guaranteeing safety in practical polypropylene melt index quality closed-loop control application.

Owner:ZHEJIANG UNIV

Method and system for position calculation from calculated time

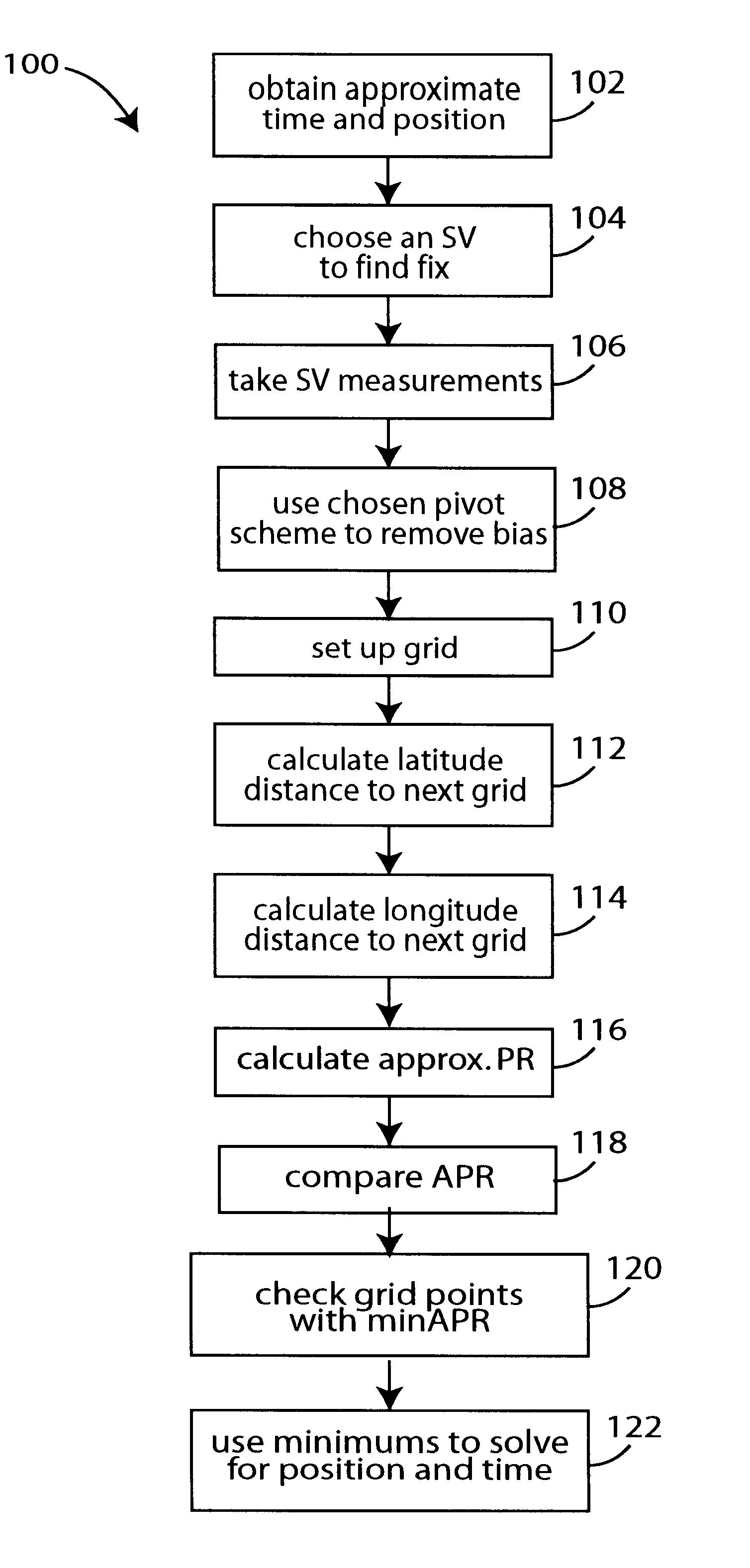

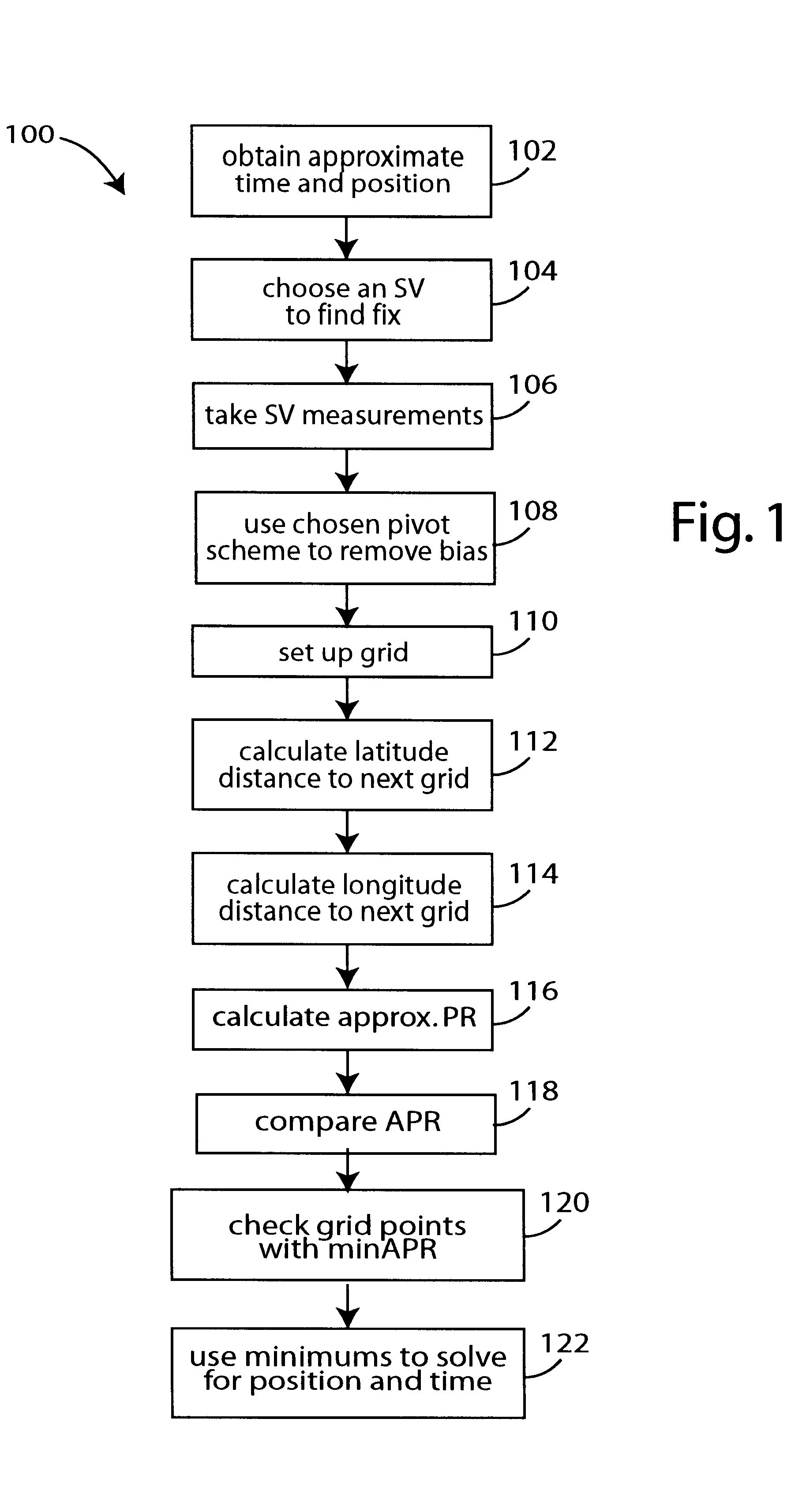

InactiveUS6670916B2Shorten the timeFast initialization timePosition fixationSetting time indicationTime deviationTime range

A navigation-satellite receiver comprises means for initialization that gets a head start by knowing time to within a few seconds and position to within 150 kilometers. A two-dimensional grid of points is setup with constant altitude that represents solution starting points within the 150 kilometer area. Fractional pseudoranges from each satellite in a constellation are inspected for a best initial fit with the points in the grid. A variety of time bias adjustments within the time bounds are also tried against the points to find a best fitting point. That point then is used in a drive to find the final solution and to produce the first fix from cold start.

Owner:FURUNO ELECTRIC CO LTD +1

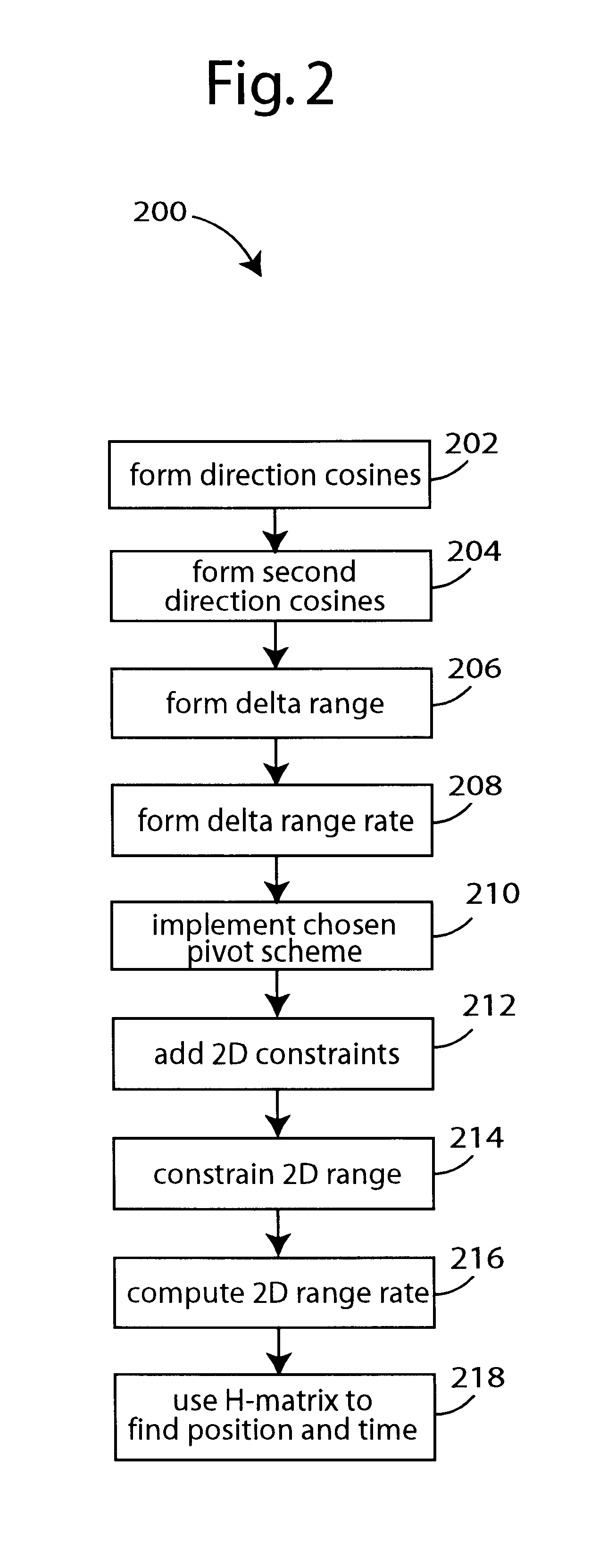

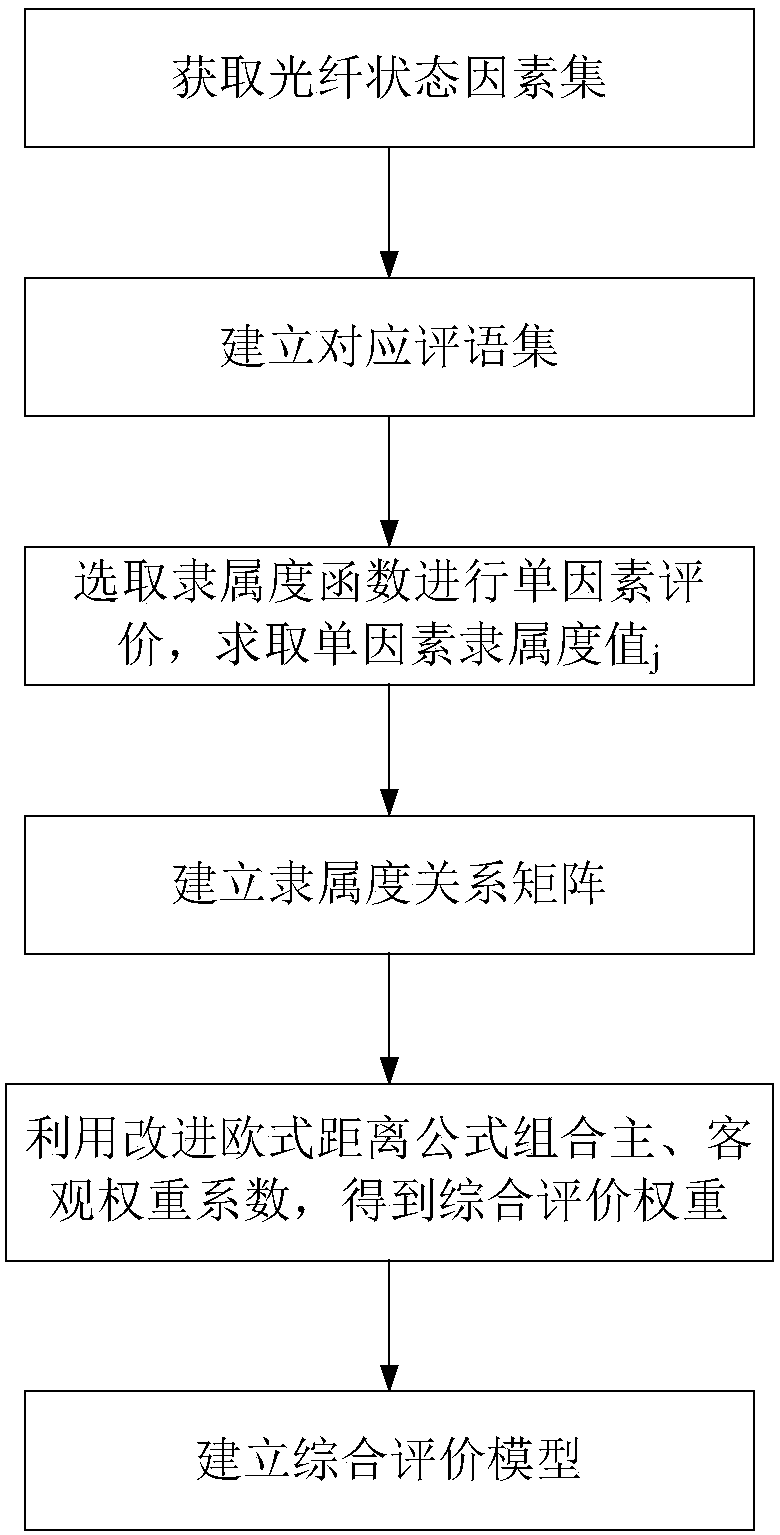

Optical fiber state evaluating method based on combination of improved membership function and neural network

ActiveCN108038300AImprove fitting accuracyFast convergenceDesign optimisation/simulationNeural learning methodsNerve networkMaintenance strategy

The invention discloses an optical fiber state evaluating method based on the combination of an improved membership function and a neural network, and relates to the technical field of optical fiber circuit state evaluating and analyzing. The problems that potential failures in a circuit state can not be analyzed and evaluated in the prior art and failures going to happen can not be avoided are solved. By means of the evaluating and analyzing method, the membership weight of an attached optical fiber state membership comprehensive evaluating method is optimized and combined through an improvedEuclidean distance formula, the circuit state healthy degree is accurately evaluated and analyzed, whether potential failures exist in a circuit or not is analyzed, a maintenance strategy is formulated in advance, and the requirement for optical fiber communication ceaseless transmission is met. By means of an RBF neural network evaluating and analyzing model, evaluating performance has good fitting precision and convergence speed, and the evaluating of the optical fiber state is better achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

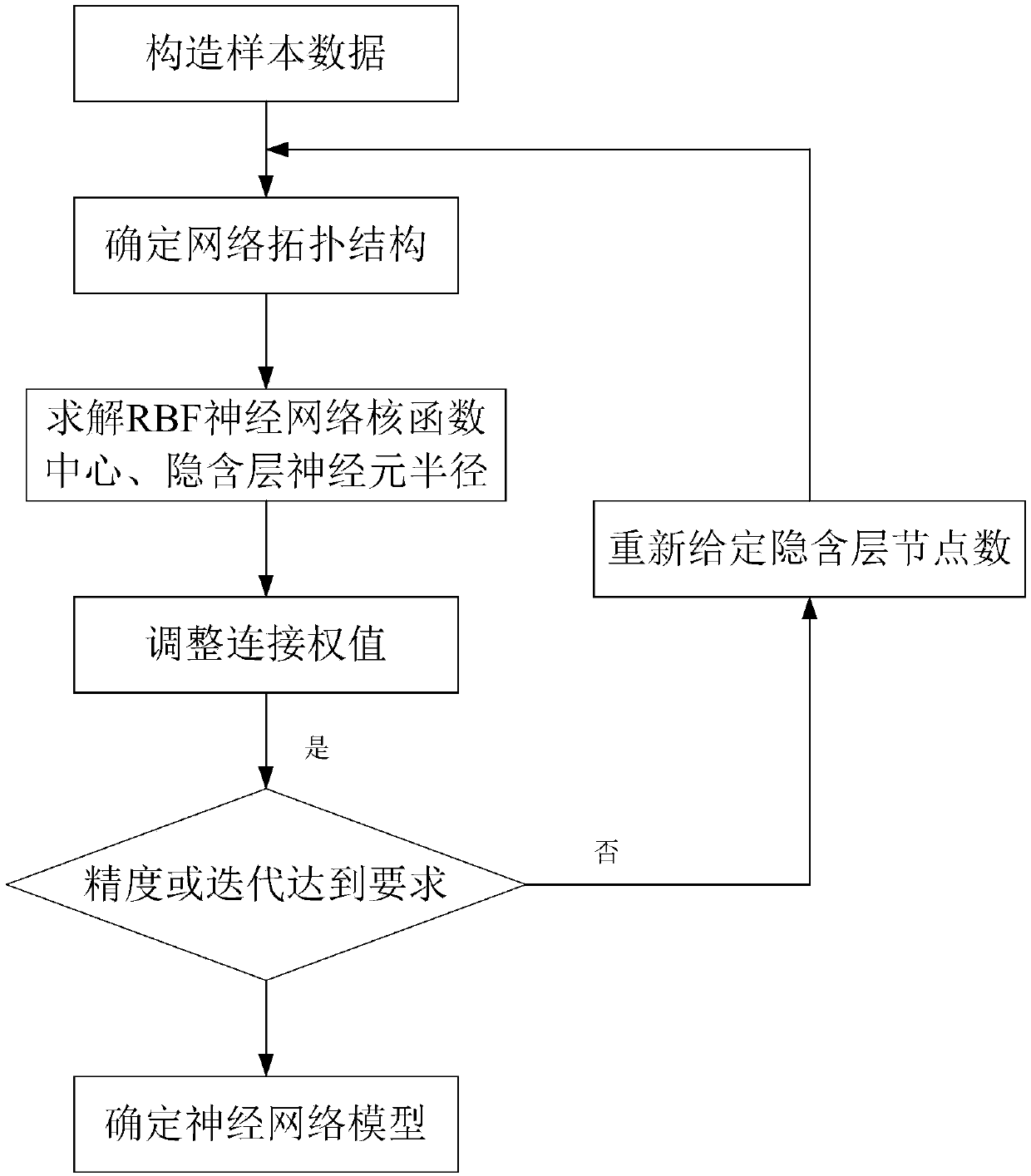

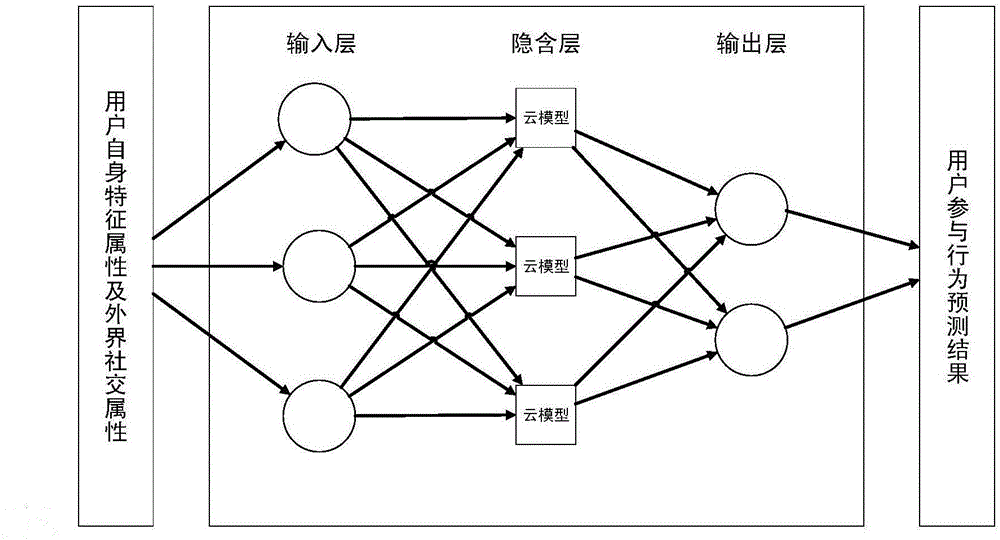

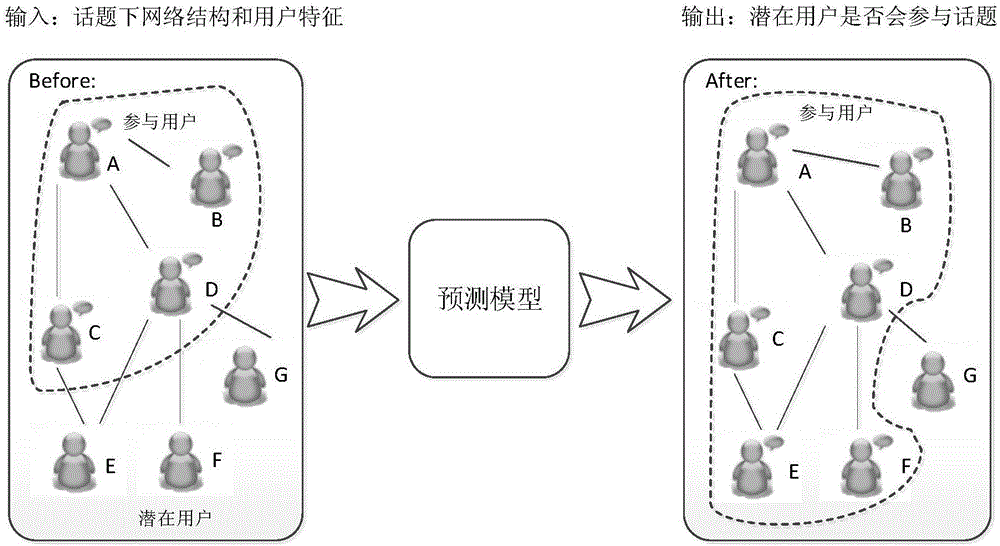

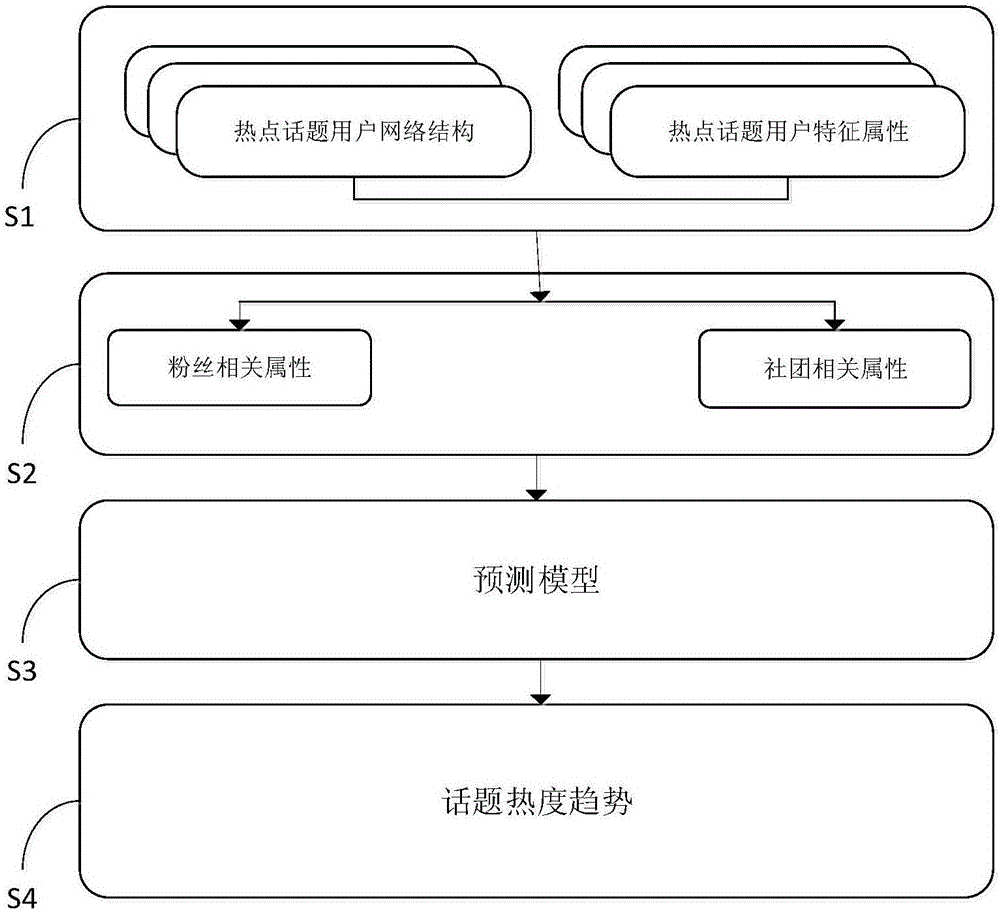

Method for predicting user participation behavior of hot topic by improved RBF neural network

ActiveCN106651030AFull expression of ambiguityFull expression of randomnessForecastingSpecial data processing applicationsActivation functionBest fitting

The invention discloses a method for predicting a user participation behavior of a hot topic by an improved RBF (Radical Basis Function) neural network, and belongs to the field of computer network information technology analysis. Firstly, the situation that a neural network can take a good fitting effect for a complex nonlinear relationship among user behaviors is considered, and further a user participation behavior prediction model is built by adopting the RBF neural network; secondly, a mapping relationship between a user attribute and the participation behavior has uncertainty, and a cloud theory is introduced for optimizing an activation function of a hidden layer in an RBF; and finally, topic popularity is subjected to exponential function model-based parameter fitting by utilizing time discretization and time slicing methods for a characteristic that the participation behavior of a user is changed with time, so that a topic popularity change trend is obtained.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com