Patents

Literature

45results about How to "Reduce the difficulty of fitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

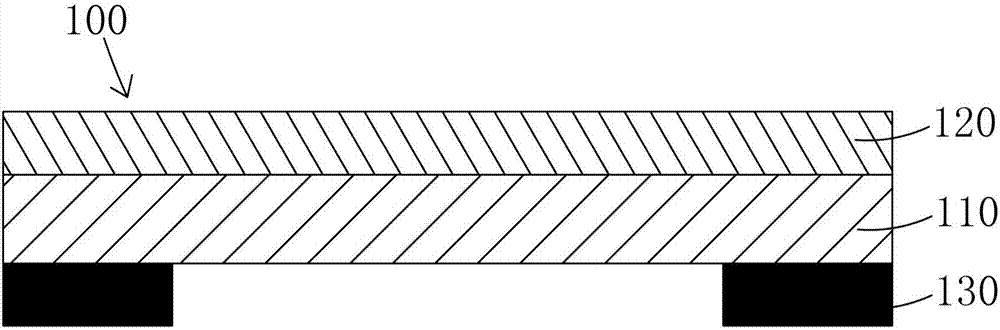

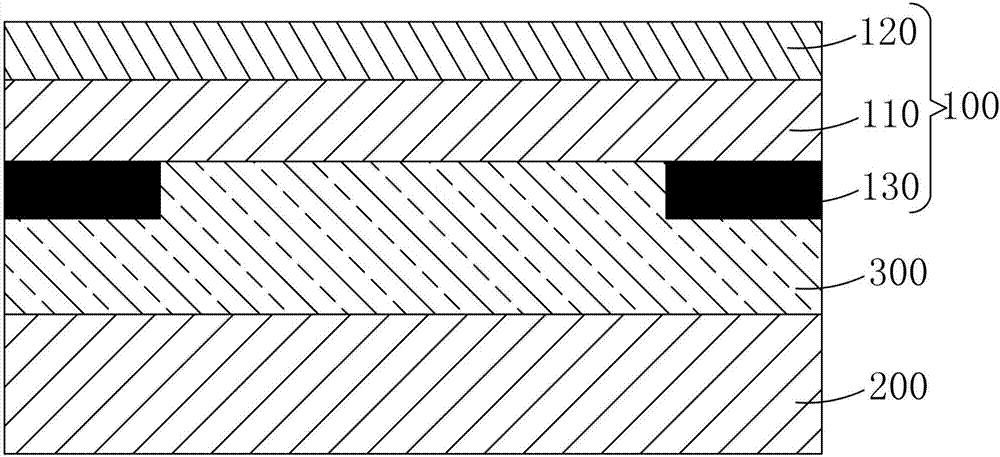

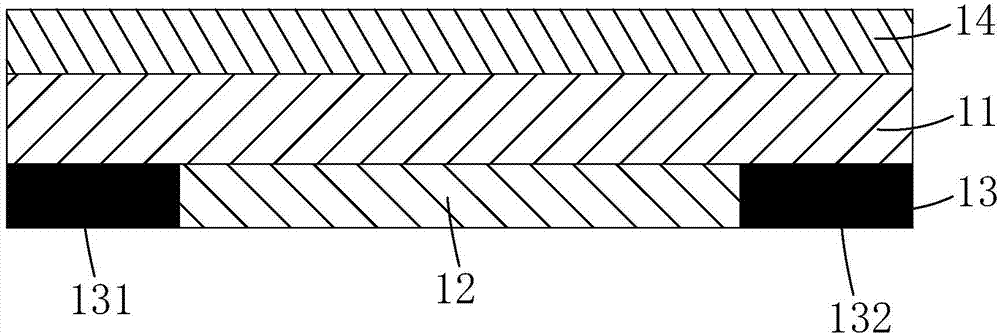

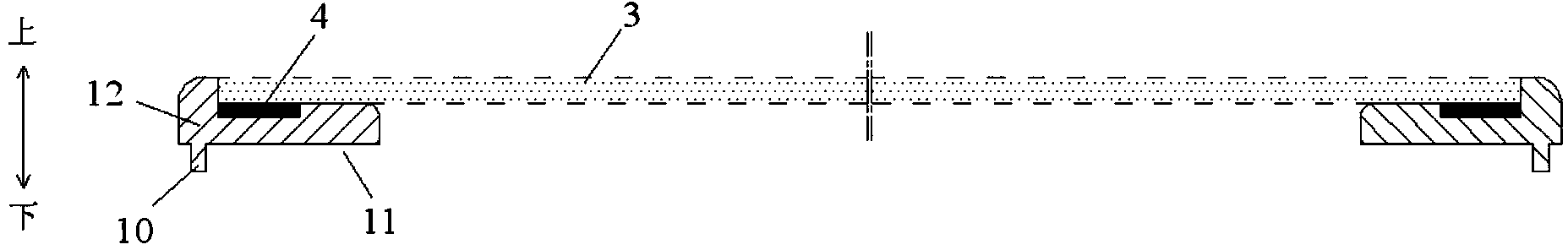

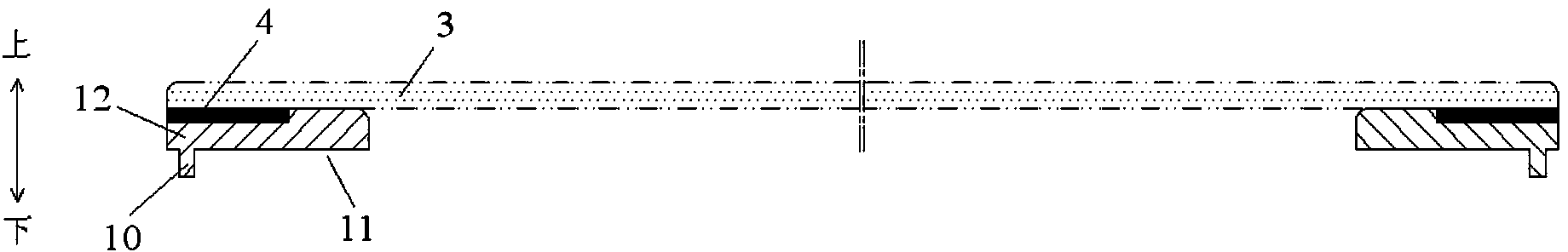

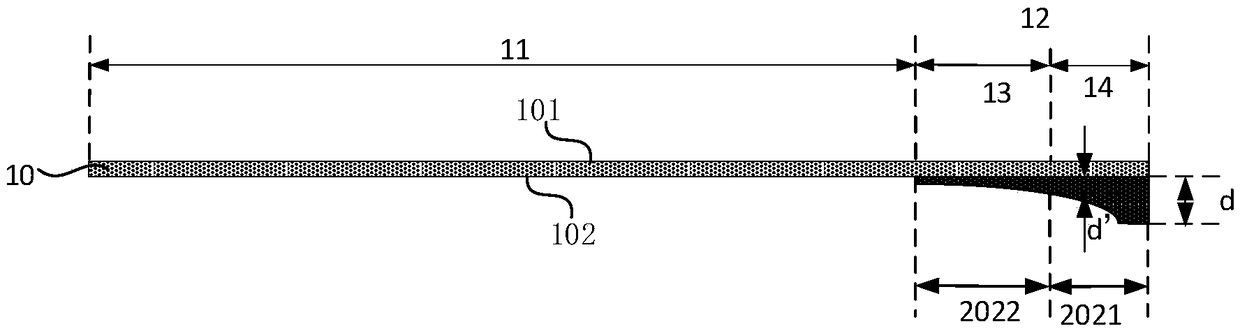

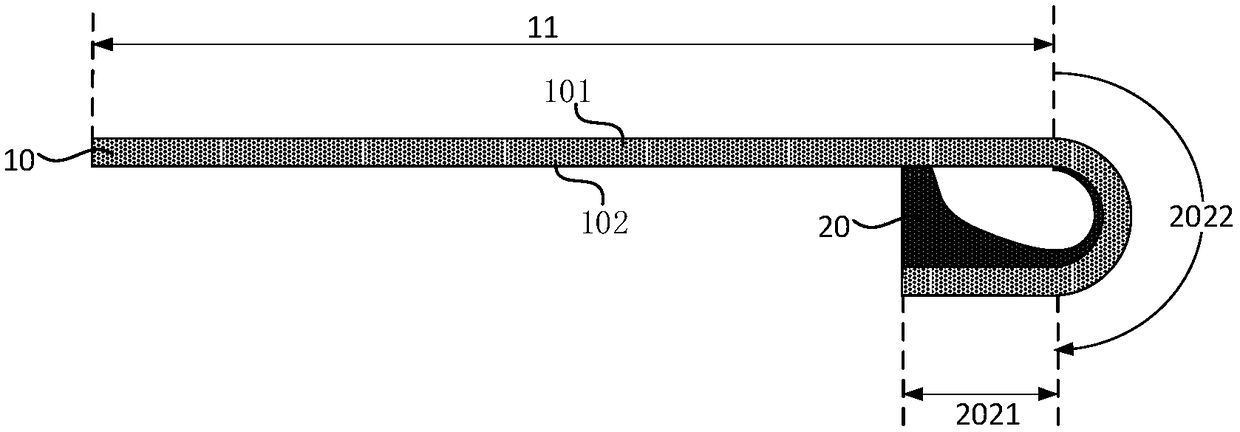

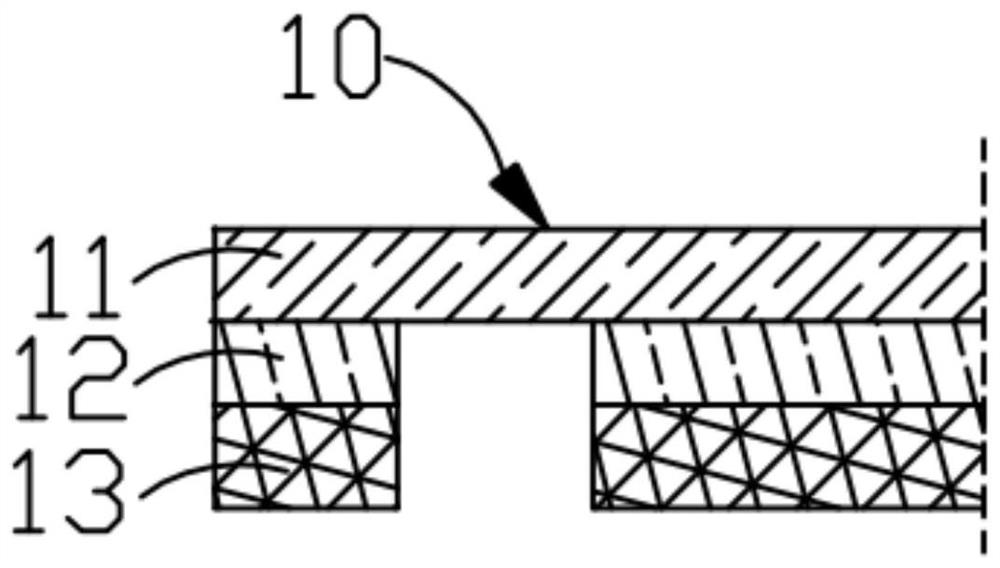

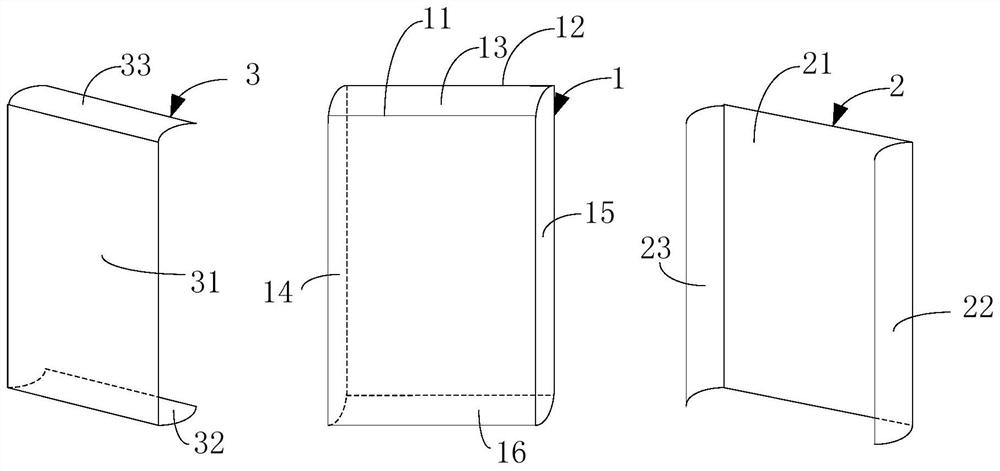

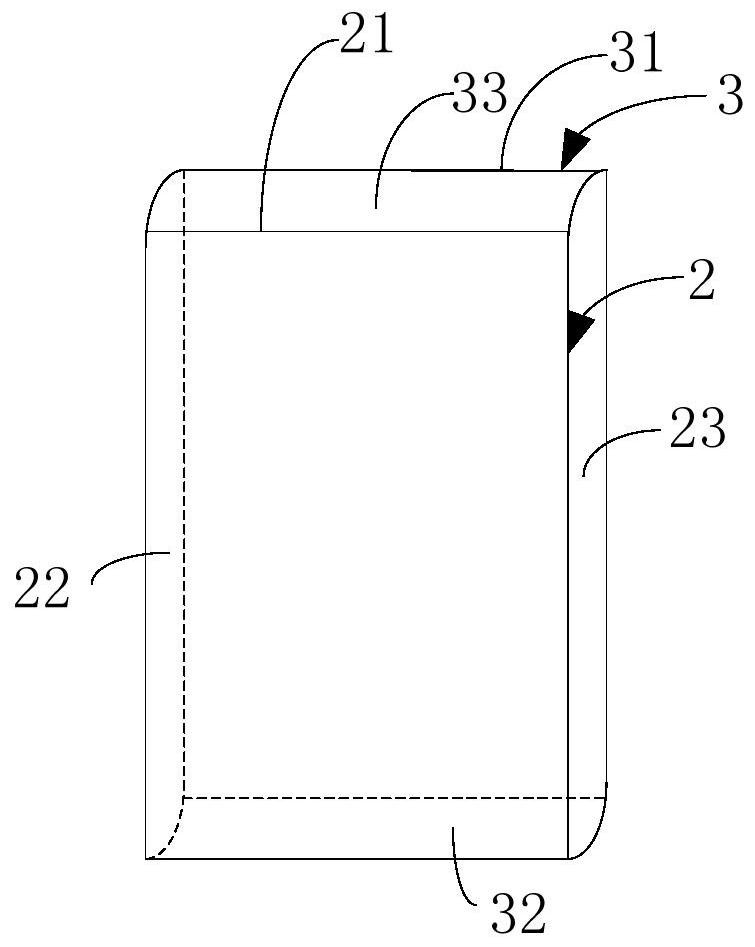

Flexible cover plate, production method of flexible cover plate and flexible OLED display device

InactiveCN107545848AEliminate the difficulty of fittingReduce the difficulty of fittingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a flexible cover plate, a production method of the flexible cover plate and a flexible OLED display device. The flexible cover plate comprises a first flexible base film, a second flexible base film, an ink layer and a hard coating, wherein the ink layer includes a first ink area and a second ink area, the space between the first ink area and the second ink area is filled with the second flexible base film, so that the partition difference of the first flexible base film caused by the ink layer is eliminated, thus a good fitting effect can be achieved by means of a thinner optical adhesive layer in the using process, the thickness of the flexible OLED display device is further reduced, the bending resistance of the flexible OLED display device is improved, meanwhilethe fitting difficulty of the flexible cover plate is reduced, and improvement of the yield rate is promoted.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Supporting cover plate, touch control display panel and touch control display device

ActiveCN104317459AReduce the difficulty of fittingSimplify the installation processDigital data processing detailsInput/output processes for data processingDisplay deviceTouchscreen

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

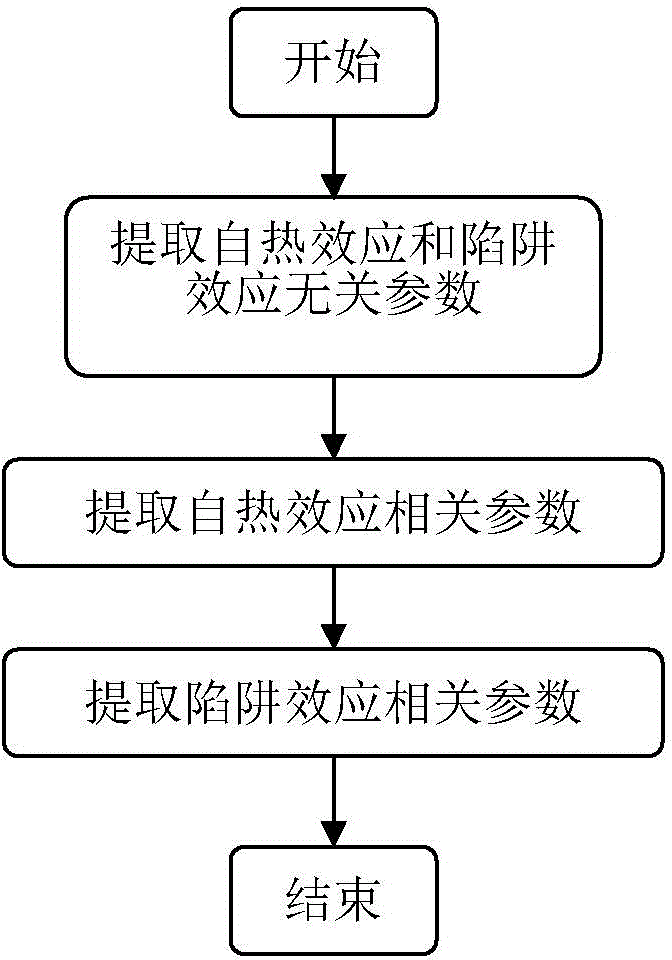

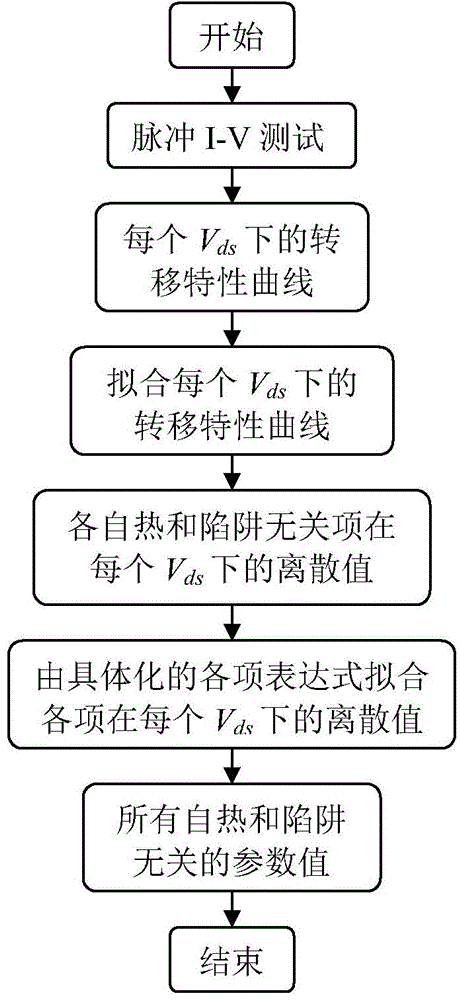

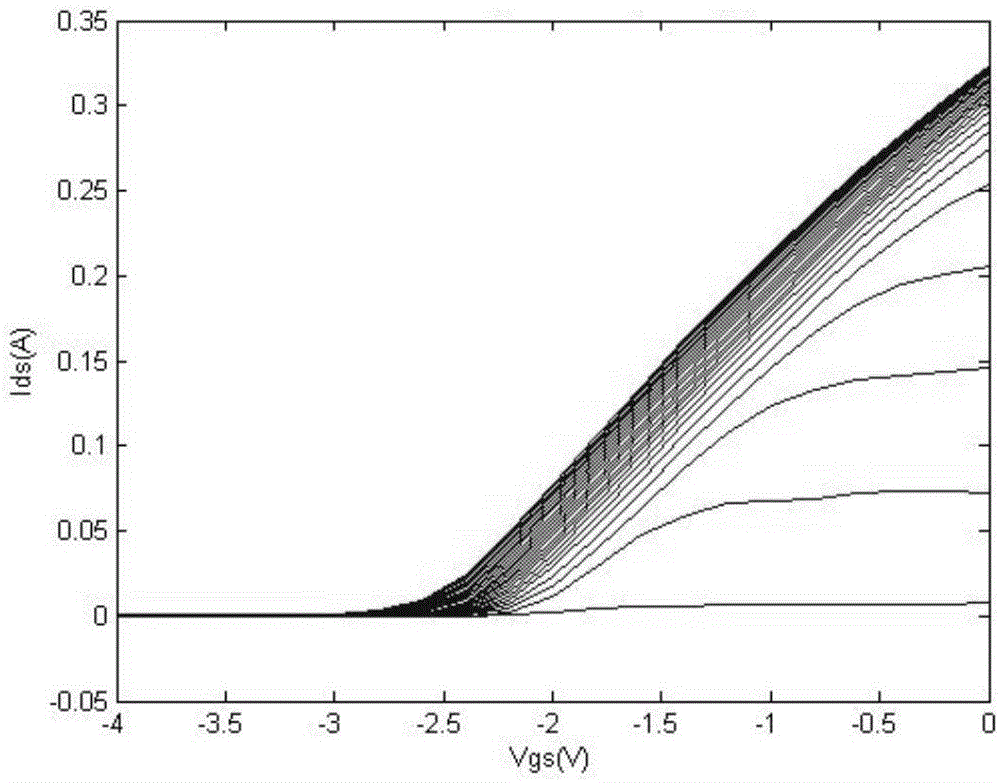

I-V (Current-voltage) model parameter extraction method based on gallium nitride high electronic mobility crystal valve

InactiveCN104573330AReduce complexityIn line with physical mechanismSpecial data processing applicationsPower flowCurrent voltage

The invention discloses an I-V (Current-voltage) model parameter extraction method based on a gallium nitride high electronic mobility crystal valve. The method comprises the following steps of according to the physical meaning of the parameters of an I-V model, blocking the model parameters, decreasing the complicated degree of the I-V model, fitting transfer characteristic curves of actually-measuring pulse I-V and static I-V, extracting the model parameters of the corresponding block. Compared with the traditional parameter extraction method, the method disclosed by the invention has the advantages that the parameter extraction of the I-V model can be quickly and accurately completed, and the modeling efficiency of devices is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

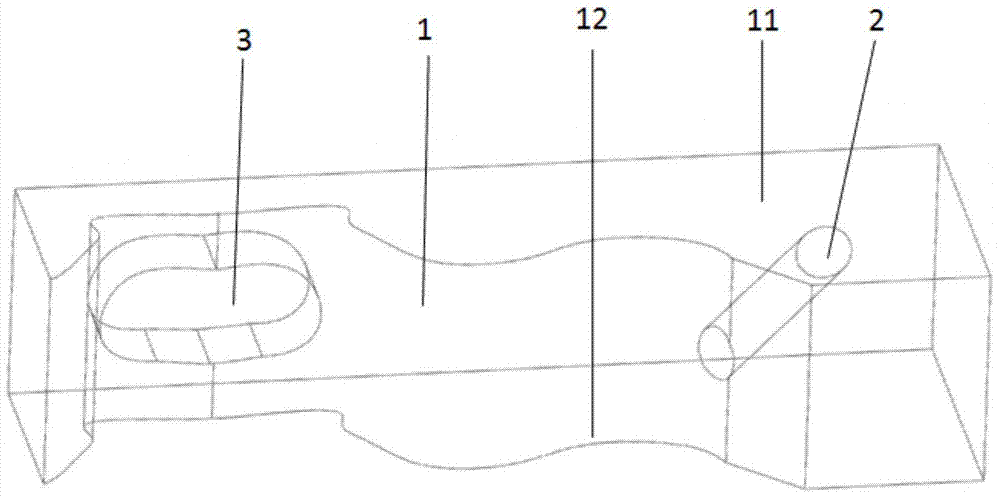

3D-printed cervical vertebra pedicle screw guide and implantation plate and preparation method thereof

ActiveCN104739501AFit closelyQuick fitAdditive manufacturing apparatusInternal osteosythesisMedicineCervical vertebral pedicle

The invention relates to a 3D-printed cervical vertebra pedicle screw (cervical spine 2-7) guide and implantation plate and a preparation method thereof. The implantation plate is printed through the 3D printing technology and comprises one or more guide plates, one or more cervical vertebra pedicle screw guide screw ways and one or more spinous process holes where spinous processes are inserted, wherein the cervical vertebra pedicle screw guide screw ways and the spinous process holes are formed in the guide plates, a plane is arranged on the upper portion of each guide plate, a curve surface is arranged on the bottom of each guide plate and consistent with the vertebral plate reversely, and the plane on the upper portion of each guide plate extends to a screw inlet way and extends for 2-5 mm on the outlet of the plane on the upper portion. When many guide plates are provided, connectors are arranged between the guide plates. Several fixing pins are arranged on the guide plates in order to guarantee stability of the guide and implantation plate, and fixing clamps are arranged near the spinous process holes. The 3D-printed cervical vertebra pedicle screw guide and implantation plate is simple and reasonable in structure, convenient to use and capable of effectively providing individual screw inlet guide hole ways for cervical vertebra pedicle screws, guaranteeing screw inlet accuracy, reducing operation difficulty and operation risks.

Owner:BEIJING FRIENDSHIP HOSPITAL CAPITAL MEDICAL UNIV

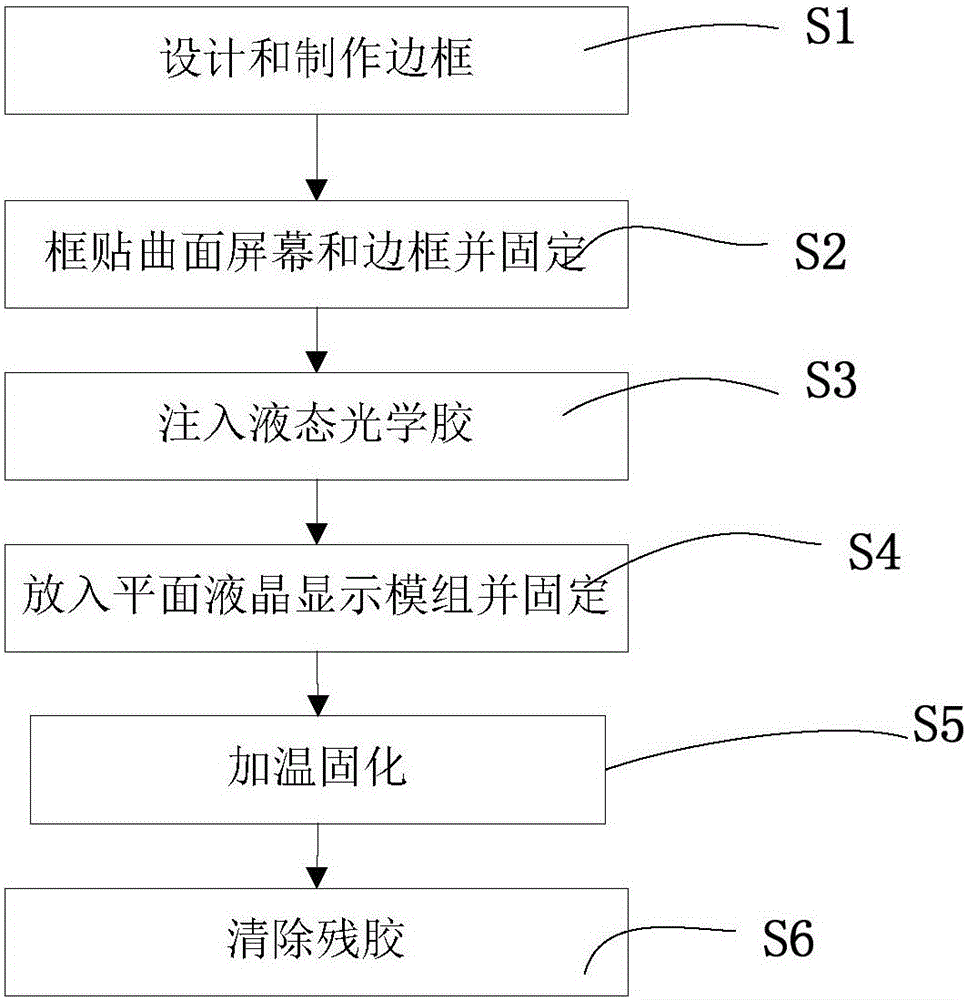

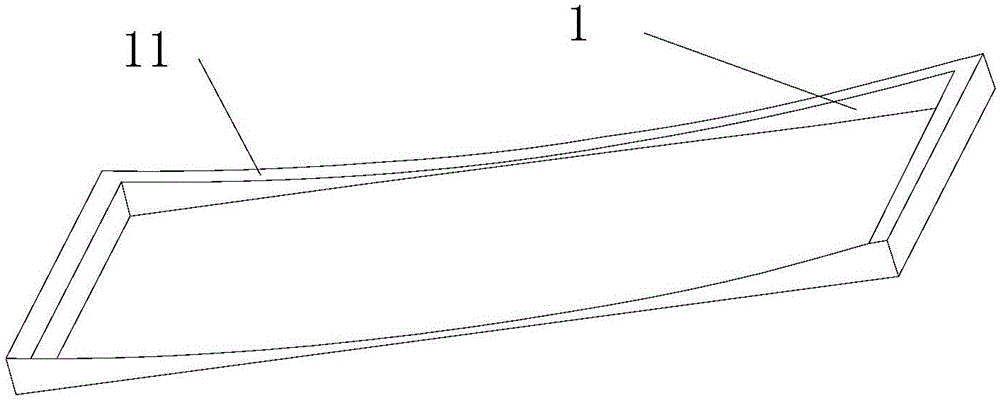

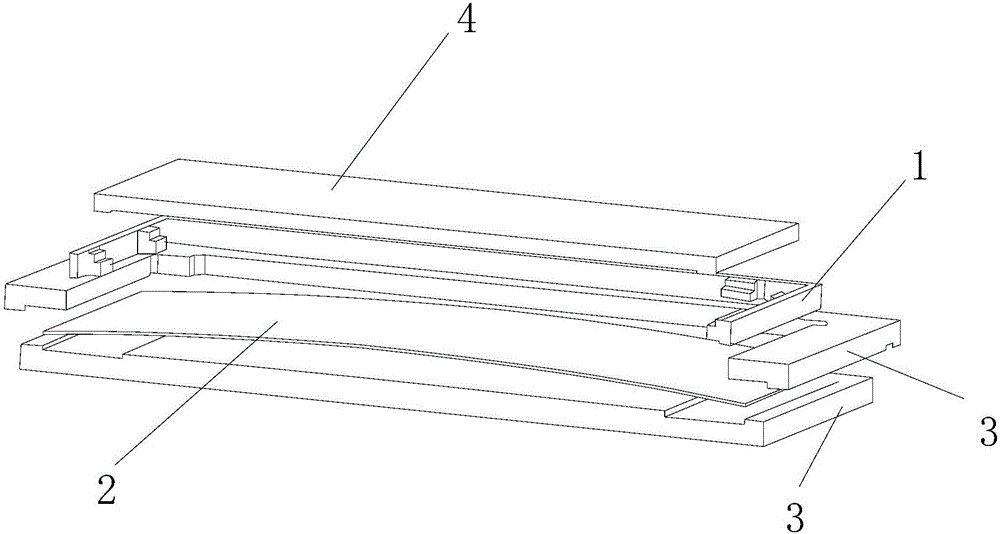

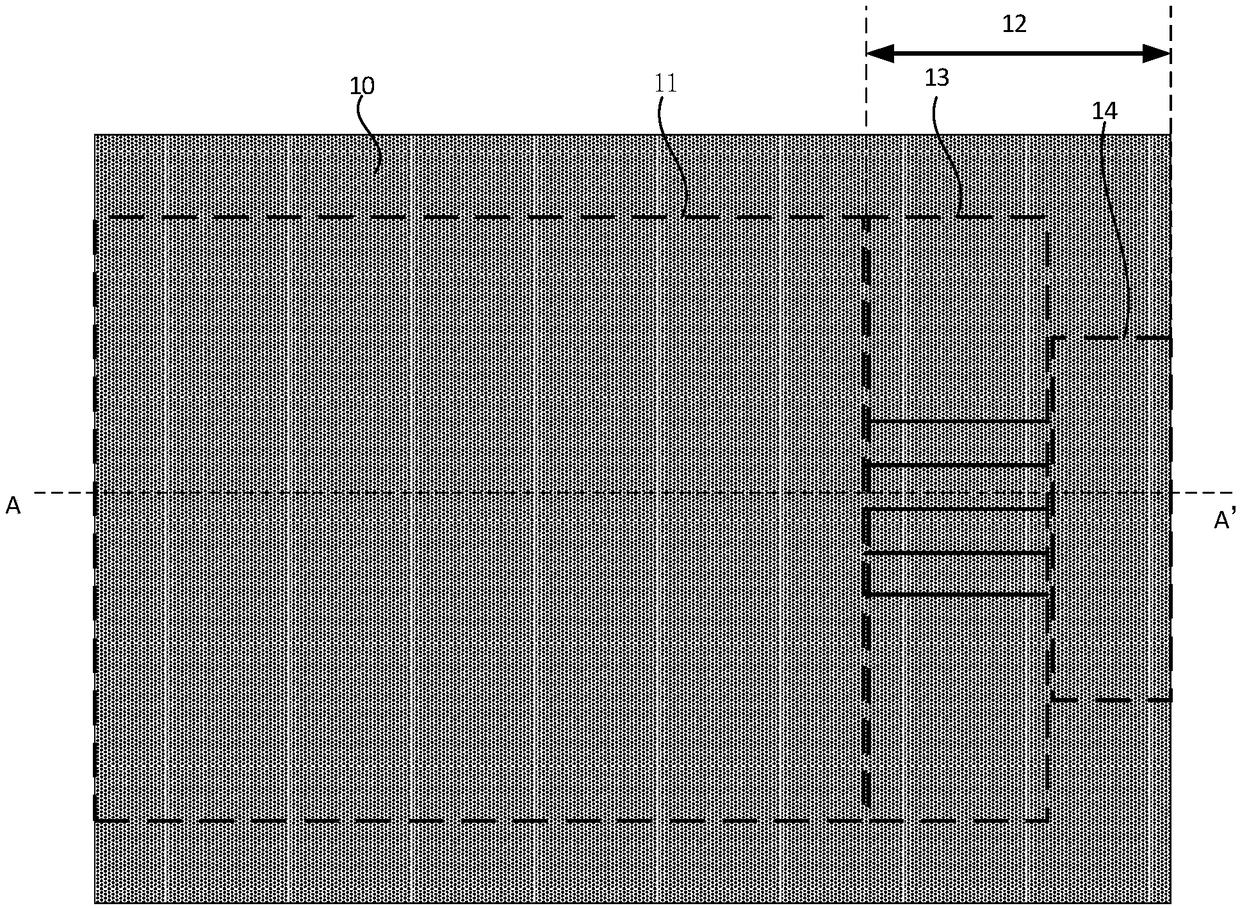

Curved screen and flat panel display module full-lamination method and integrated screen

ActiveCN106379023AEasy to operateReduce the difficulty of fittingLamination ancillary operationsLaminationLiquid-crystal displayEngineering

The invention discloses a curved screen and flat panel display module full-lamination method, which comprises the following steps: designing and manufacturing a frame, fixing a frame-pasting curved screen and the frame through a positioning fixture, injecting liquid optical cement, putting a flat panel liquid crystal display module, fixing through the positioning fixture to form an integrated screen, putting the positioning fixture and the integrated screen into a heating device and carrying out heating curing, removing the positioning fixture and the integrated screen out of the heating device after completing the above steps, dismounting the positioning fixture, removing spilled cement residue at the edge of the frame and completing lamination. The invention also discloses a curved screen and flat panel display module full-laminated integrated screen prepared according to the above processing method. By arranging the frame between the curved screen and the flat panel liquid crystal display module, lamination of a curved-surface product is converted into traditional flat-panel type lamination. The operation steps are simple. Investment in equipment and fixture is less. Batch production is convenient to realize.

Owner:伟亚光电有限公司

Display panel and display device

ActiveCN109285461AIncreasing the thicknessIncreased resistance to twisting stressDigital data processing detailsSubstation equipmentDisplay deviceEngineering

The invention discloses a display panel and a display device. The display panel comprises a substrate, and the substrate comprises a binding area and a bending area connected with the binding area; the substrate further comprises supporting blocks corresponding to the bending area and the binding area, and the supporting blocks are arranged at the side, away from the display face, of the substrate; the maximum thickness of the supporting block on the binding area is larger than that of the supporting block on the bending area. According to the scheme, the risk of lead breaking of the bending area of the display panel is reduced, and the yield of the display panel is increased. Meanwhile, the supporting block located on the binding area partly replaces a pad block in the prior art, additional arrangement of the pad block is avoided, alignment is not needed during fitting, and the fitting difficulty is lowered.

Owner:YUNGU GUAN TECH CO LTD

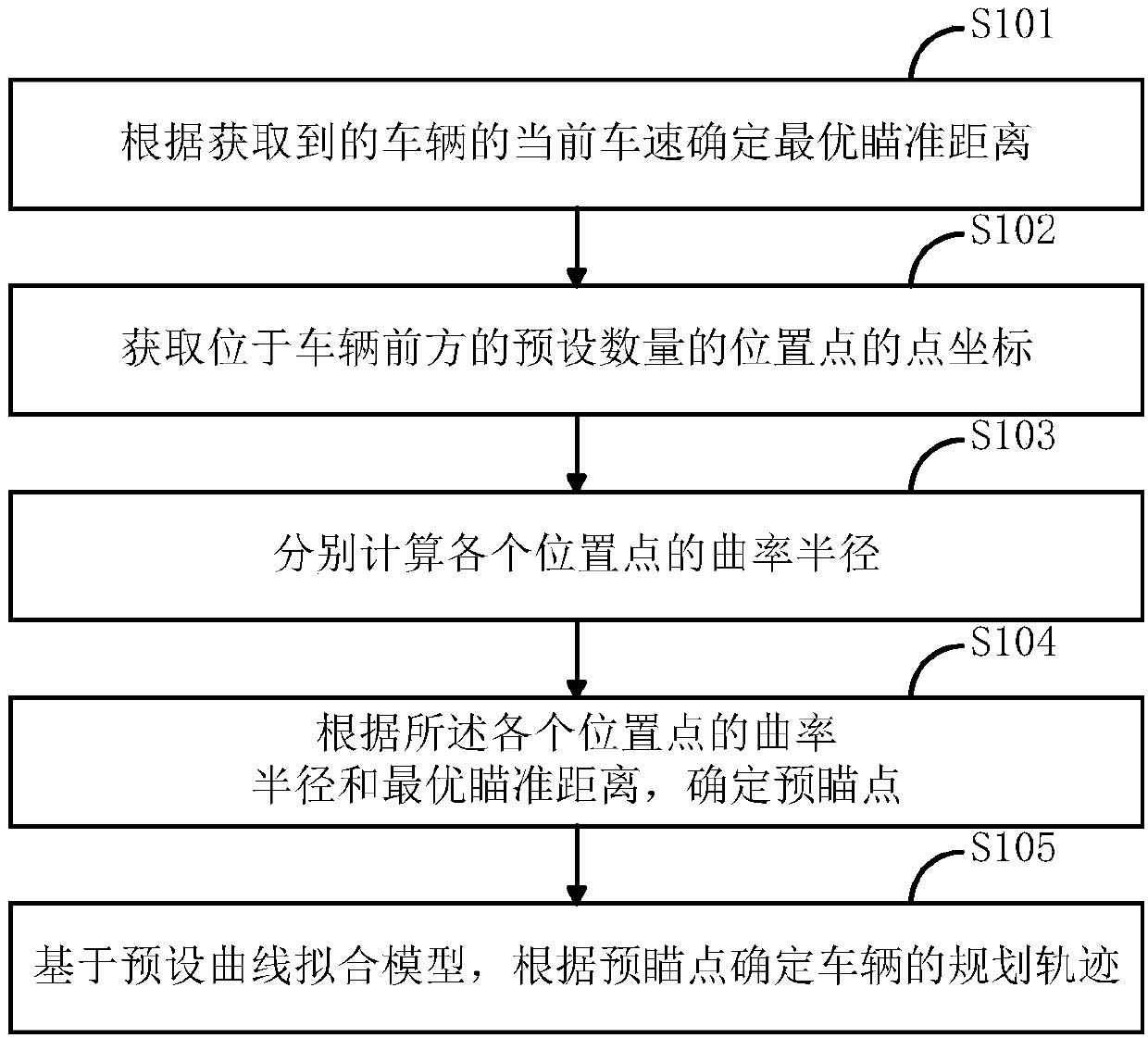

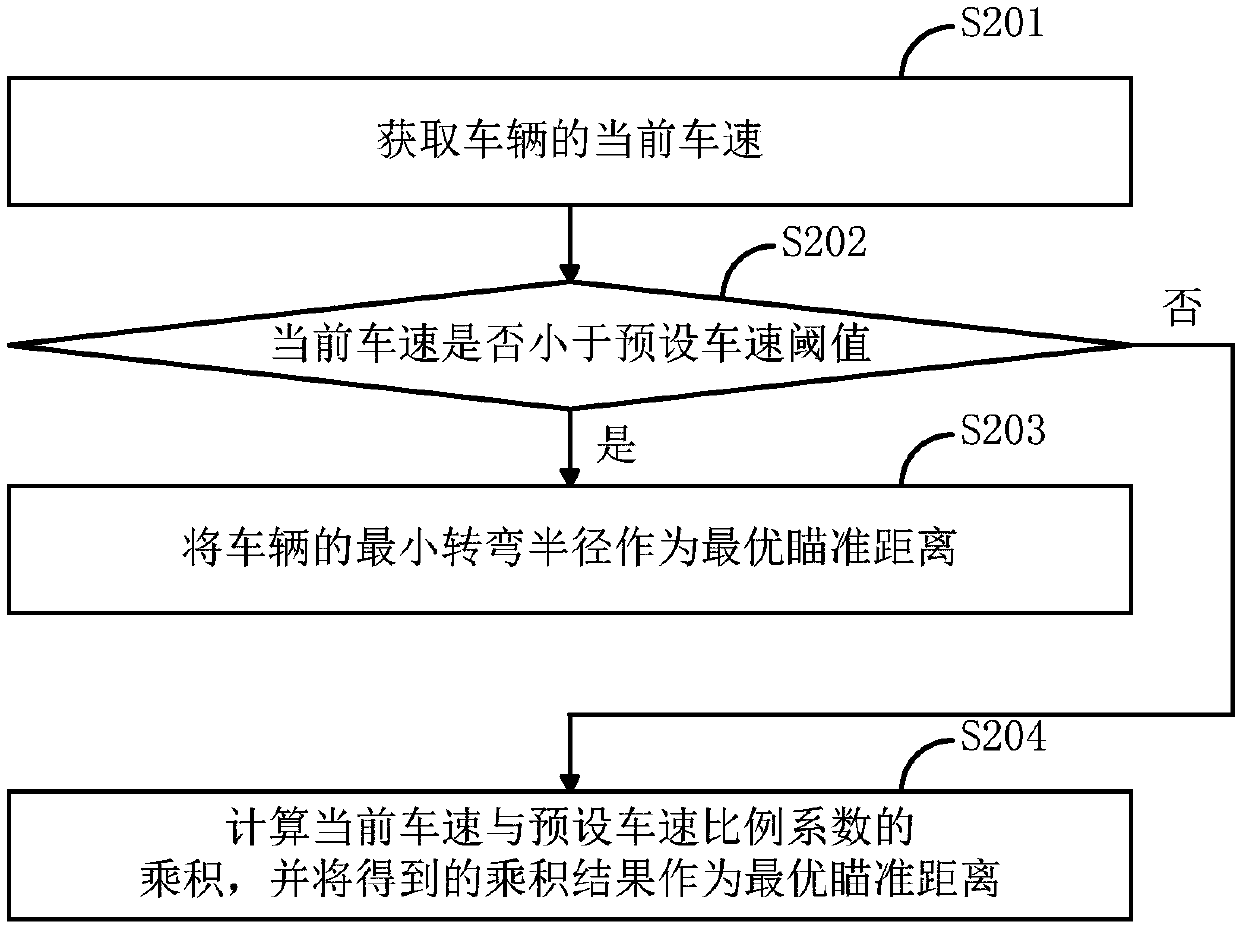

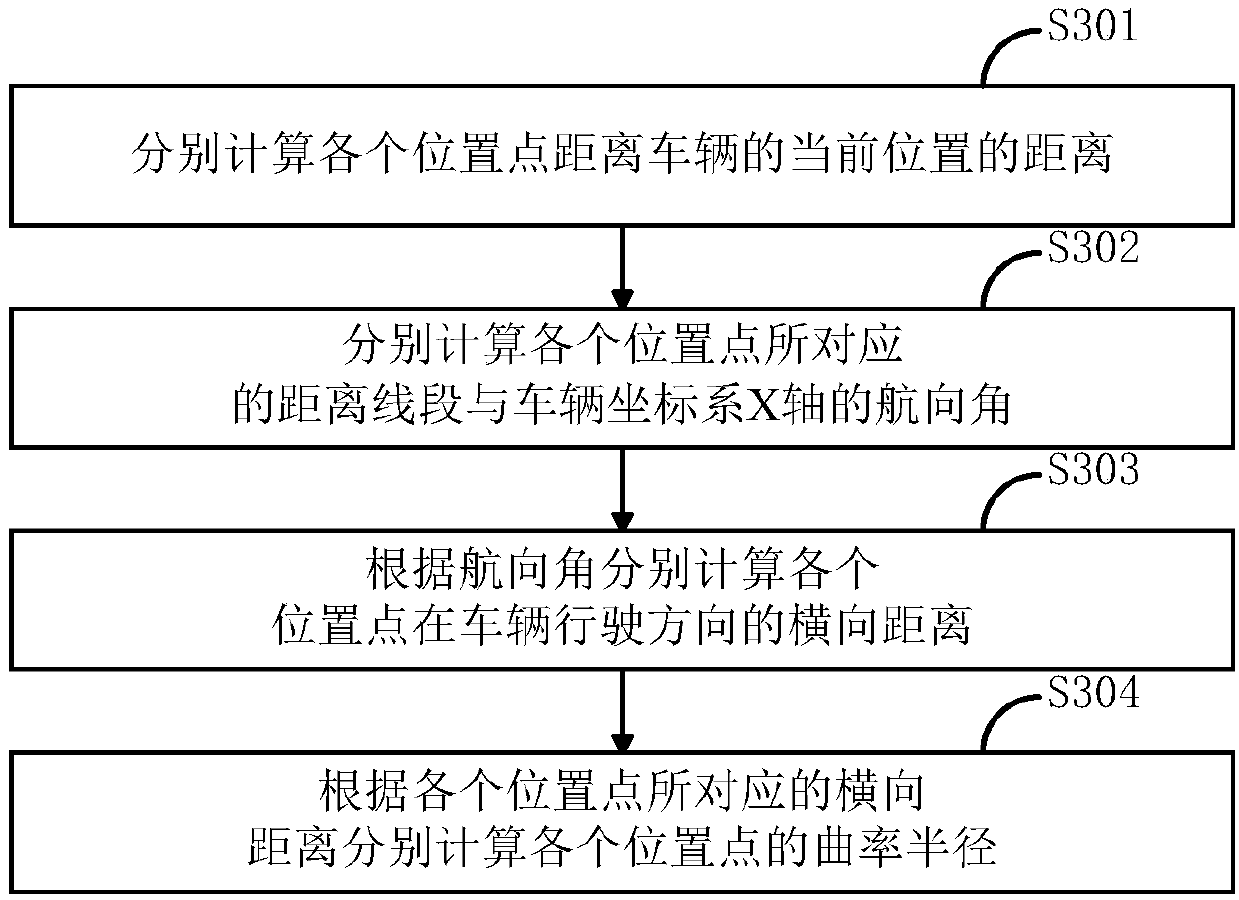

Trajectory planning method for intelligent driving system and intelligent driving system

InactiveCN109976321AThe trajectory tracking process is smooth and safeSatisfy the dynamic modelInstruments for road network navigationPosition/course control in two dimensionsVehicle dynamicsCurve fitting

The invention relates to a trajectory planning method for an intelligent driving system. The system includes the following steps that: step 1, an optimal aiming distance is determined according to theacquired current vehicle speed of a vehicle; step 2, the point coordinates of a preset number of position points located in front of the vehicle are acquired, the radius of curvature of each positionpoint is calculated separately; step 3, a pre-aiming point is determined according to the radius of curvature of each position point and the optimal aiming distance; and step 4, on the basis of a preset curve fitting model, the planned trajectory of the vehicle is determined according to the pre-aiming point. According to the trajectory planning method for the intelligent driving system, the vehicle state of the intelligent driving vehicle is adopted as the reference information of trajectory planning, and therefore, the planned trajectory is more likely to satisfy a vehicle dynamics model, and the trajectory tracking process of the intelligent driving system is more stable and safer.

Owner:HUNAN CSR TIMES ELECTRIC VEHICLE

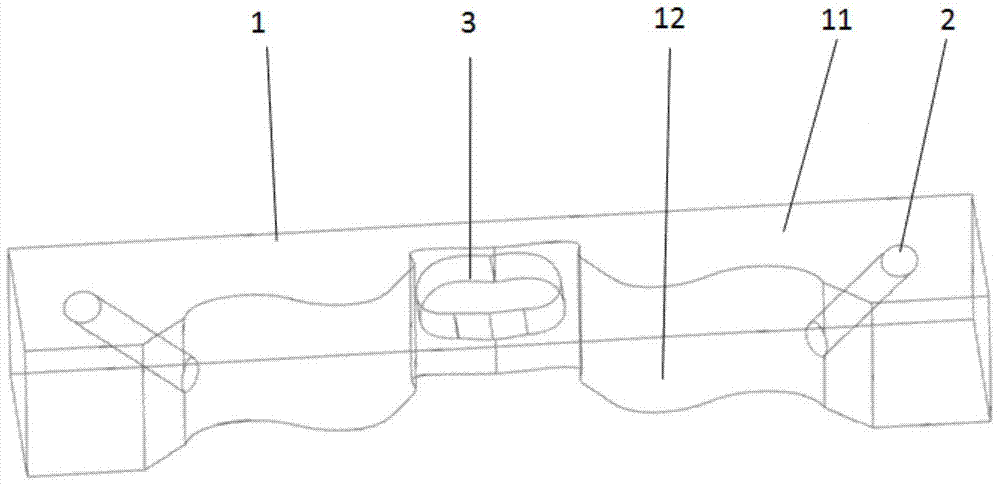

3D-printing cervical vertebra side block screw guide embedded plate and manufacturing method thereof

ActiveCN104688323AGuaranteed accuracyEasy to adjustAdditive manufacturing apparatusOsteosynthesis devicesVertebraPrint-through

The invention discloses a 3D-printing cervical vertebra side block screw guide embedded plate and a manufacturing method thereof. The embedded plate is printed through 3D printing technology and comprises one or multiple guide plates, one to multiple side block screw guide screw paths and one to multiple spinous holes formed in the center or one side of the guide plate, the upper portion of the guide plate is a plane, the curved surface of the bottom of the guide plate is reversely uniform with a cervical vertebra side block vertebral plate, the curved surface of the bottom of the guide plate is uniform to the outer side of a side block, and the plane of the upper portion of the guide plate extends to an outlet, in the upper-portion plane, of the corresponding screw path and then extends for 2-5mm. When multiple guide plates are arranged, connecting components are arranged among the guide plates. In order to guarantee stability of the guide embedded plate, fixing needles different in amount are arranged on the guide plates, and fixing clamps are arranged beside the spinous holes. The 3D-printing cervical vertebra side block screw guide embedded plate is simple and reasonable in structure and convenient to use, a screw feeding guide screw path can be provided for cervical vertebra side block screws effectively, accuracy (depth and direction) of screw feeding is guaranteed, and operating difficulty and operating risk are reduced.

Owner:BEIJING FRIENDSHIP HOSPITAL CAPITAL MEDICAL UNIV

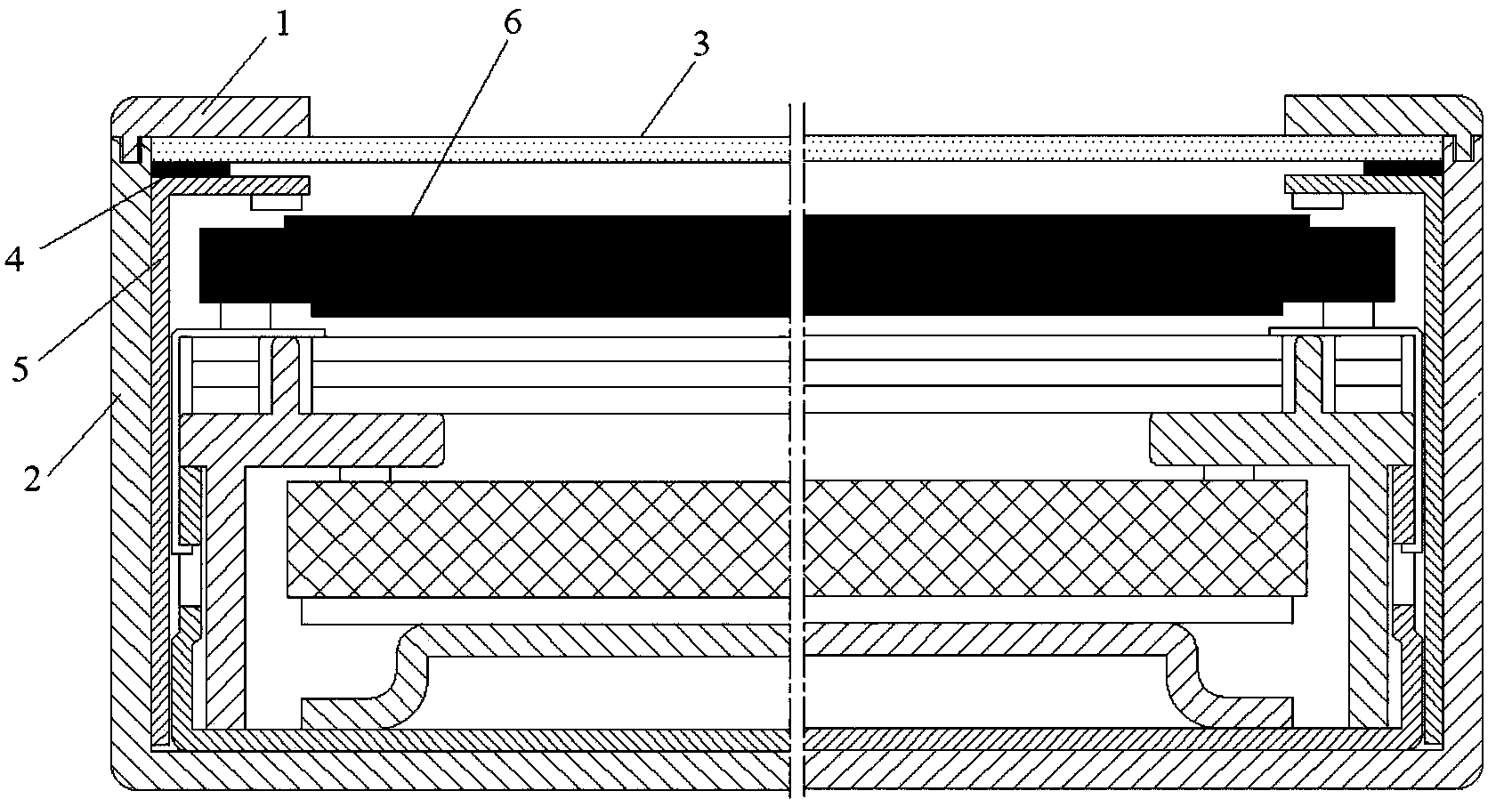

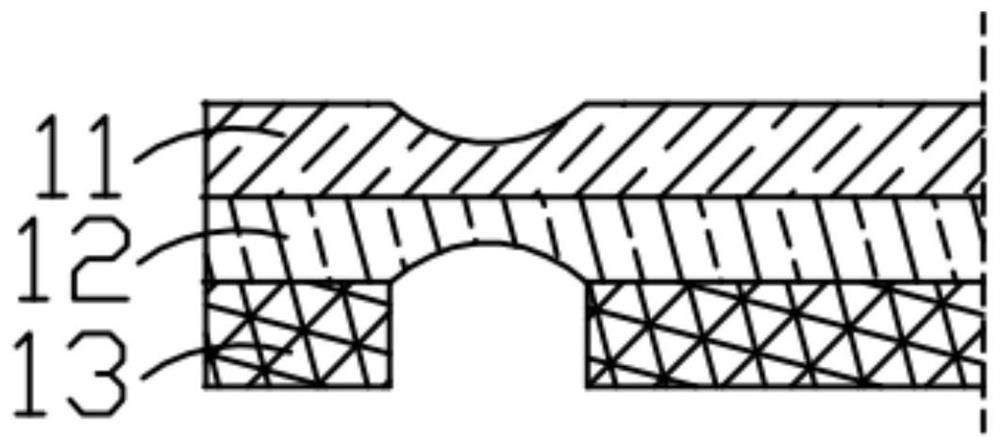

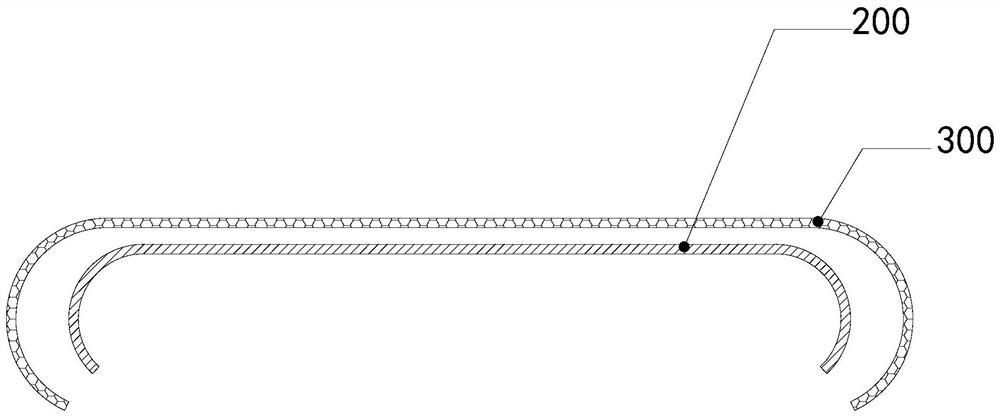

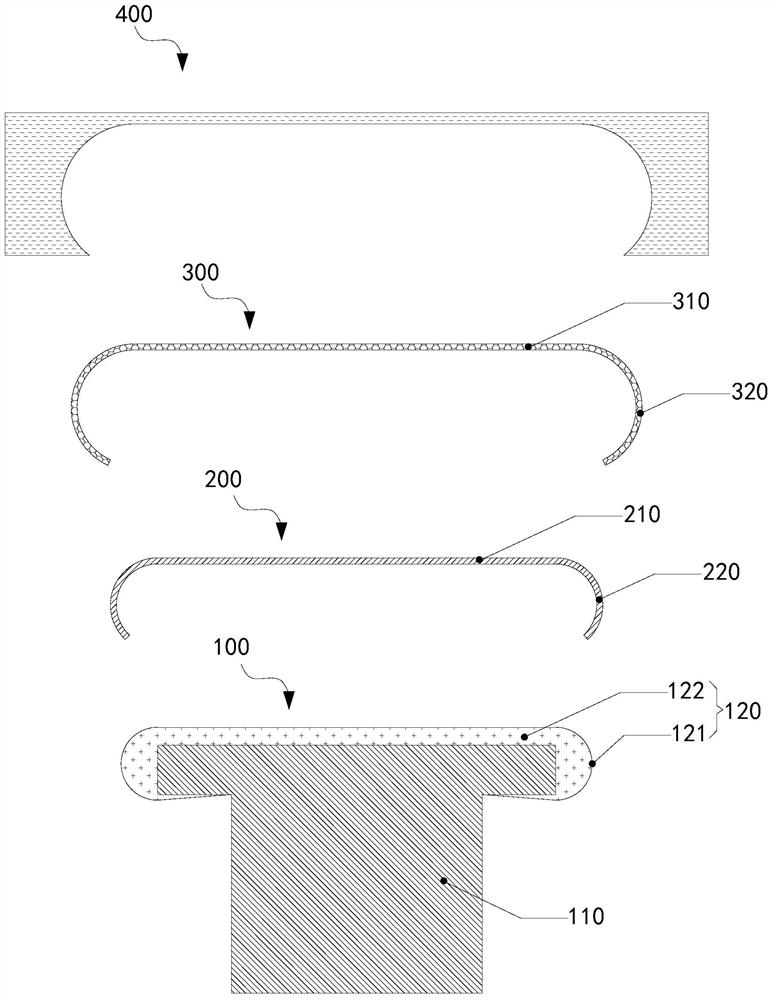

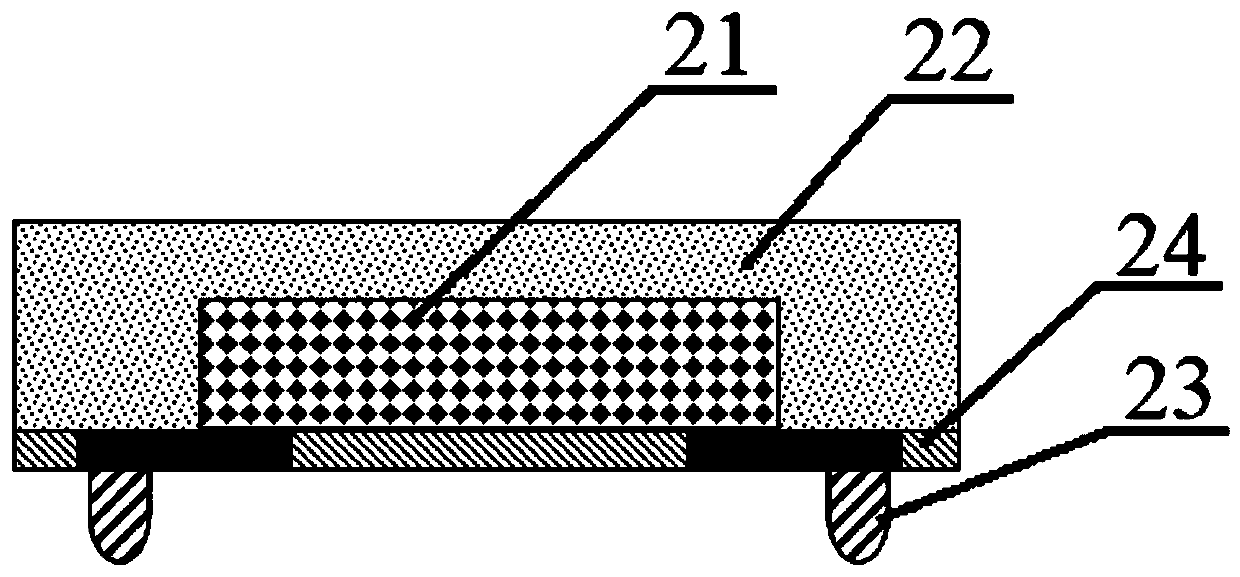

Composite foam layer and display module

ActiveCN111976249AReduce the difficulty of fittingReduces incomplete fitSynthetic resin layered productsElectrical equipmentEngineeringMechanical engineering

Owner:HEFEI VISIONOX TECH CO LTD

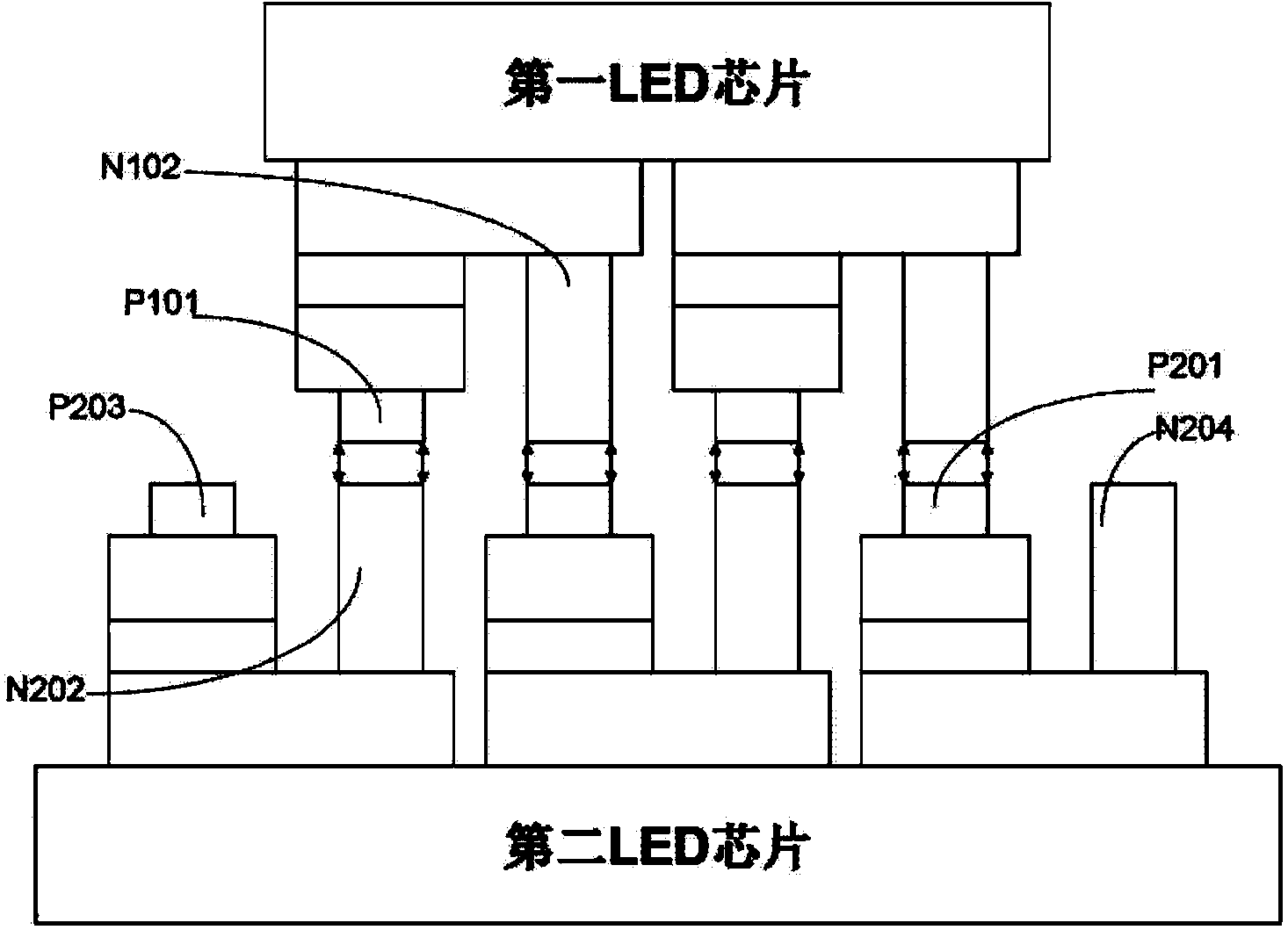

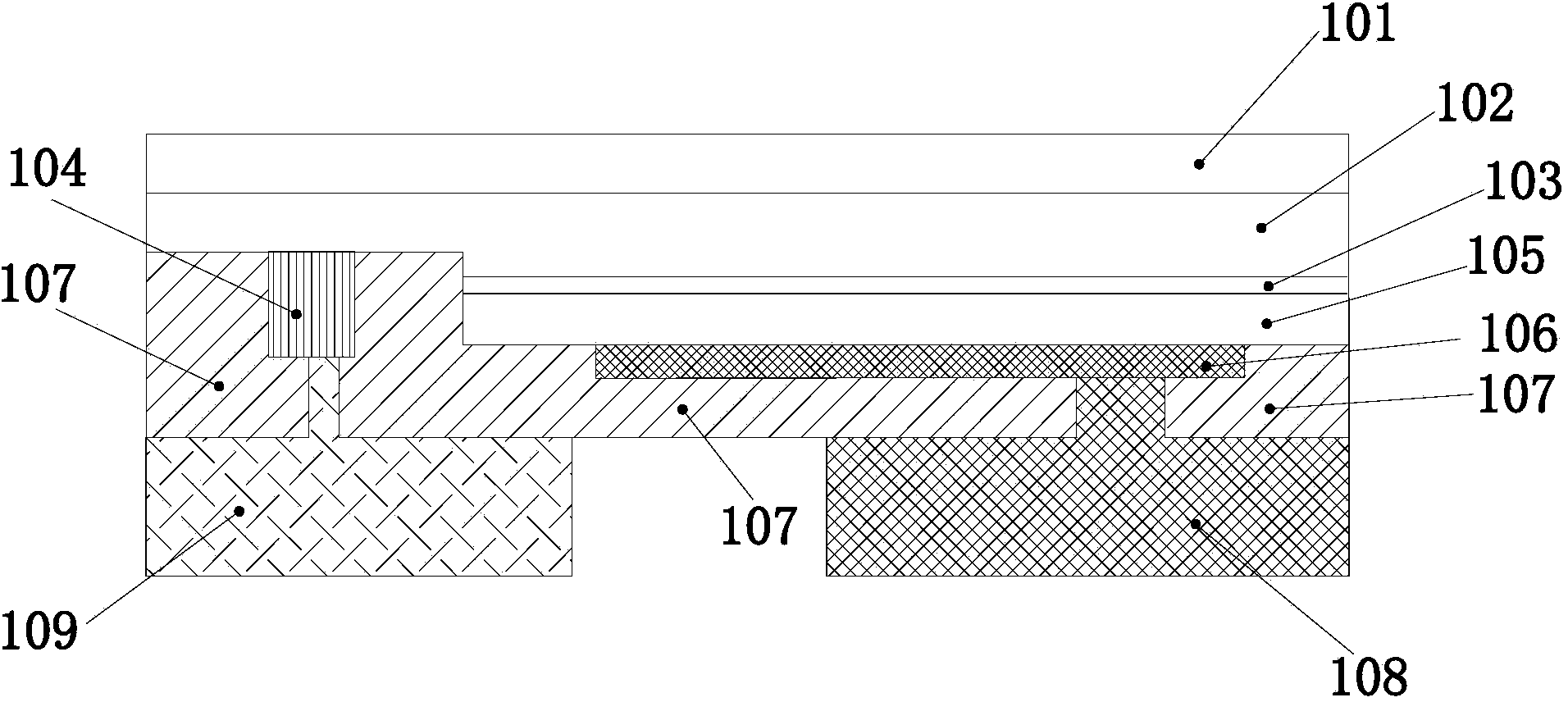

Three-dimensional luminous LED device and manufacturing method thereof

InactiveCN103840064ALarge luminous areaImprove cooling effectSolid-state devicesSemiconductor devicesElectricityEngineering

The invention belongs to the technical field of LEDs, and particularly discloses a three-dimensional luminous LED device and a manufacturing method thereof. The LED device comprises a first directly mounted LED chip and a second directly mounted LED chip, wherein the first directly mounted LED chip and the second directly mounted LED chip are arranged oppositely. An N electrode leading-out metal sheet is electrically connected between an N electrode bonding layer of the first directly mounted LED chip and an N electrode bonding layer of the second directly mounted LED chip, a P electrode leading-out metal sheet is electrically connected between a P electrode bonding layer of the first directly mounted LED chip and a P electrode bonding layer of the second directly mounted LED chip, and the outer surface of the first directly mounted LED chip and the outer surface of the second directly mounted LED chip are respectively provided with a light conversion material layer. The three-dimensional luminous LED device is large in light-emitting area and has the advantages of being good in heat dissipation performance, easy to manufacture and process, high in product yield and long in service life.

Owner:APT ELECTRONICS

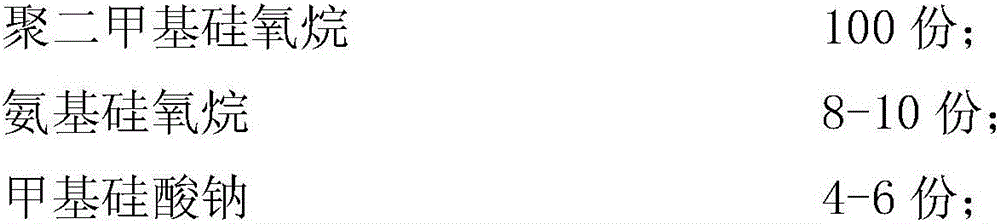

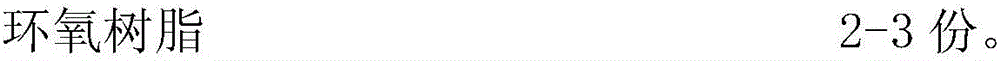

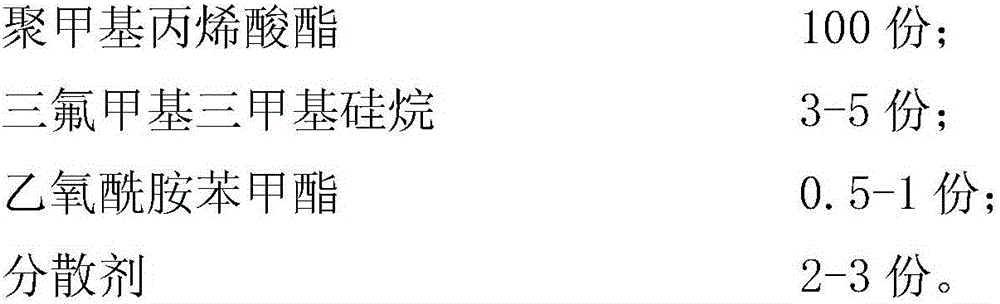

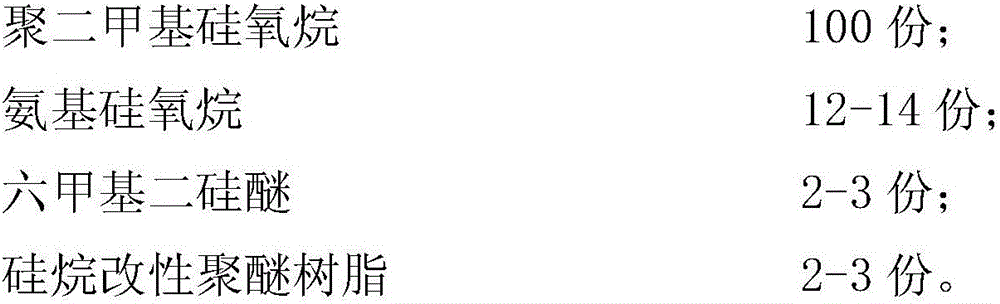

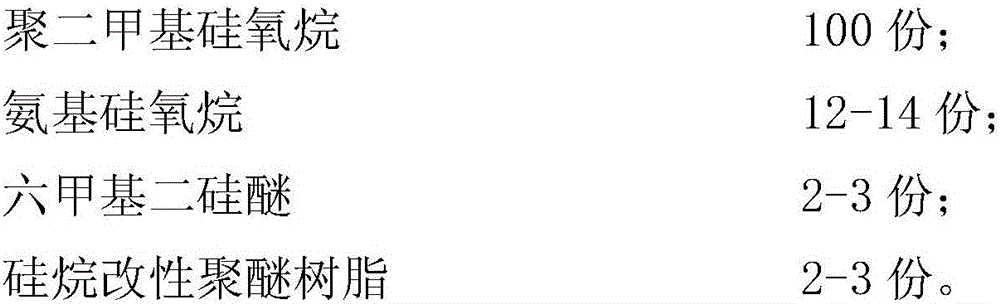

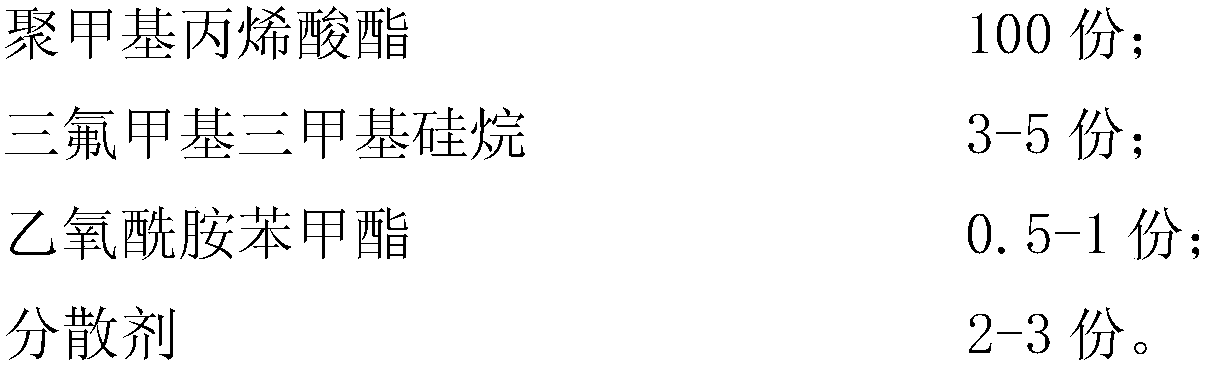

Special AB double-sided adhesive for low-residue electronic screen

ActiveCN106118532AGood defoaming performanceReduce the difficulty of fittingNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyAminosilochrome

The invention discloses a special AB double-sided adhesive for a low-residue electronic screen. The special AB double-sided adhesive for the low-residue electronic screen is successively provided with a first release layer, a modified silicon layer, a PET substrate layer, an optical adhesive layer and a second release layer from top to bottom, wherein the modified silicon layer comprises the following components in parts by weight: polydimethylsiloxane 100 parts, amino silicone 8-10 parts, sodium methyl silicate 4-6 parts and epoxy resin 2-3 parts. Adhesive components of two sides of the AB double-sided adhesive are modified to improve automatic bubble discharge capacity of the silicon layer, so that after the double-sided adhesive are torn and adhered repeatedly, the bubble discharge capacity can still be excellent, and adhesion difficulty of the double-sided adhesive is reduced; and meanwhile, the light transmittance, the adhesion strength and the shock resistance of the optical adhesive layer are improved, and residual adhesive ratio is reduced. The AB double-sided adhesive is suitable for the field of electronic screens and the like.

Owner:泰兴联创绝缘材料有限公司

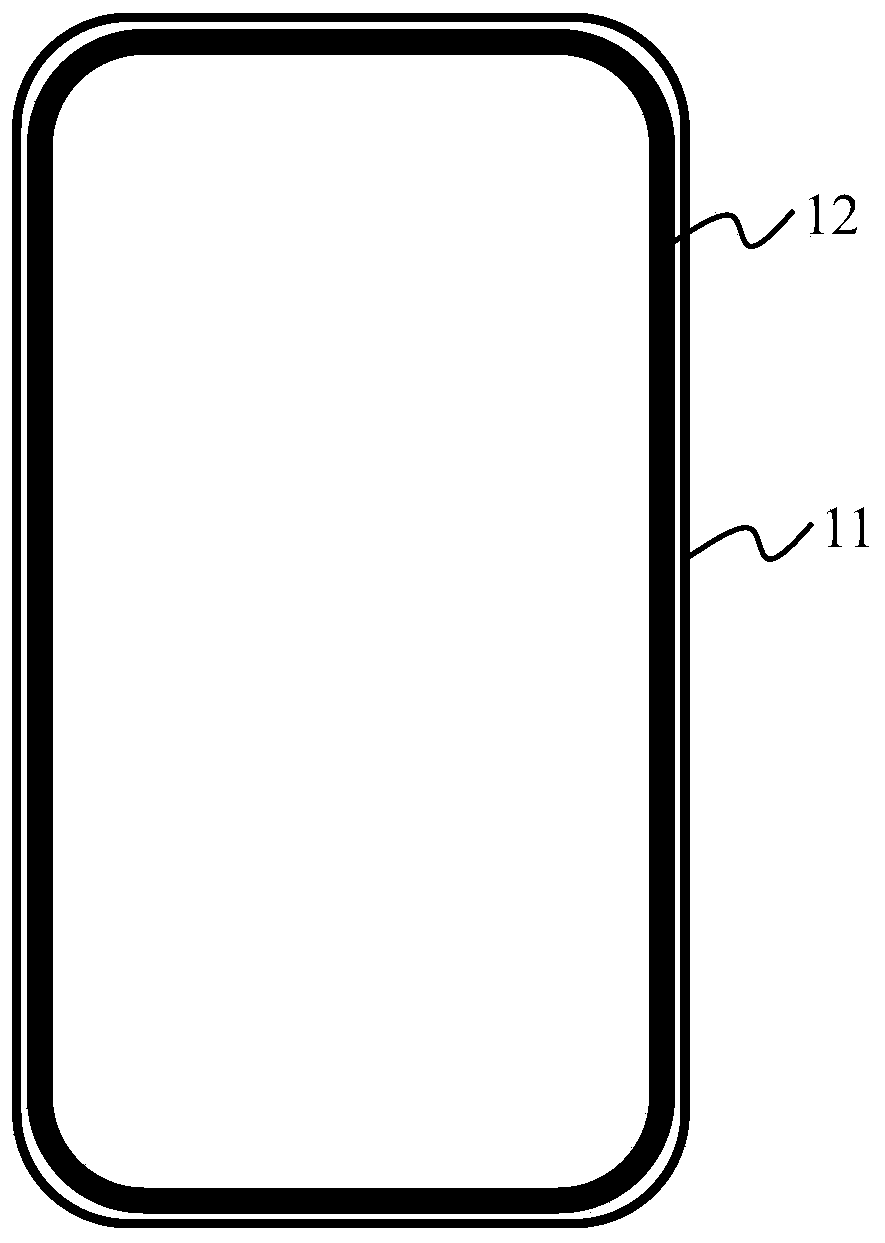

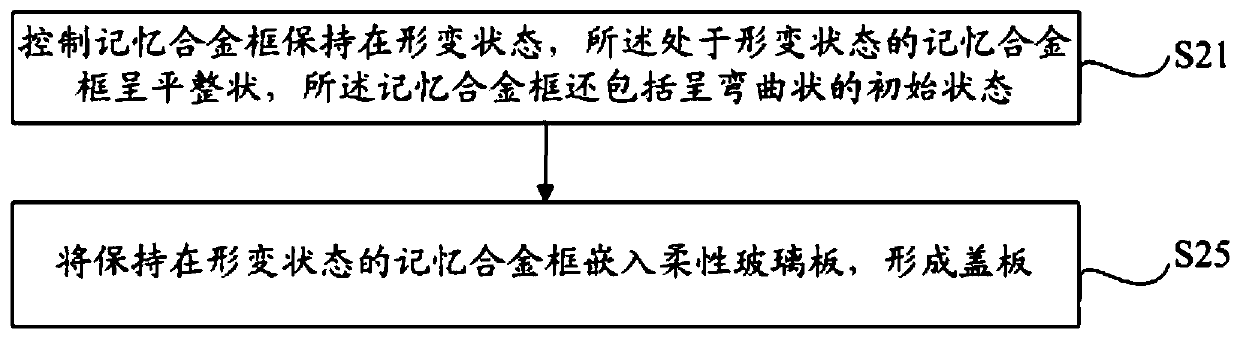

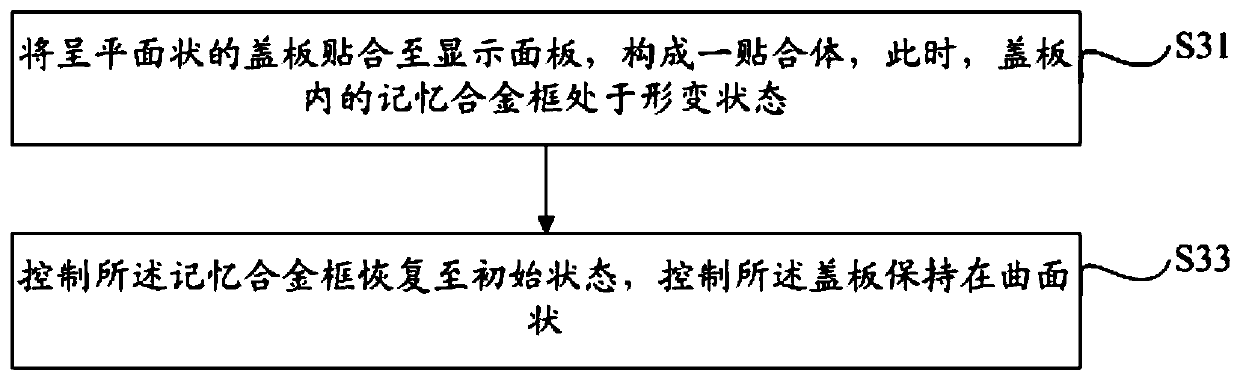

Cover plate and preparation method and laminating method thereof

InactiveCN110012133AReduce the difficulty of fittingImprove bonding efficiencyTelephone set constructionsMetallurgyAlloy

The invention discloses a cover plate and a preparation method and a laminating method thereof, and the cover plate comprises a flexible glass plate; and the memory alloy frames which are located in the flexible glass plate, the memory alloy frames are in an initial state and a deformation state, the memory alloy frame in the initial state drives the flexible glass plate to be kept in a curved surface shape, and the memory alloy frame in the deformation state drives the flexible glass plate to be kept in a plane shape. According to the cover plate provided by the technical scheme, the lamination of the curved surface cover plate can be converted into the lamination of the plane cover plate, the lamination difficulty is reduced, the lamination efficiency is improved, and meanwhile, the yield of products is improved.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

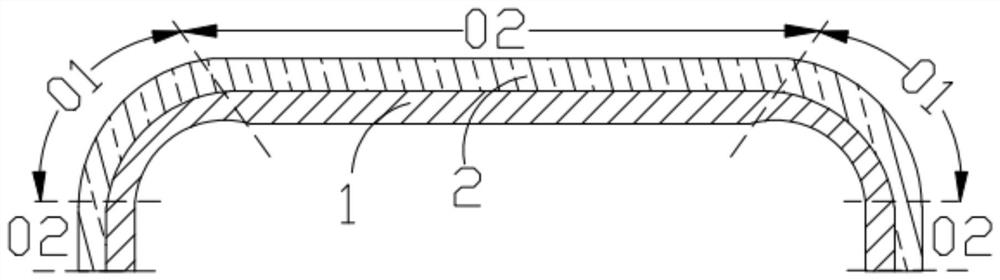

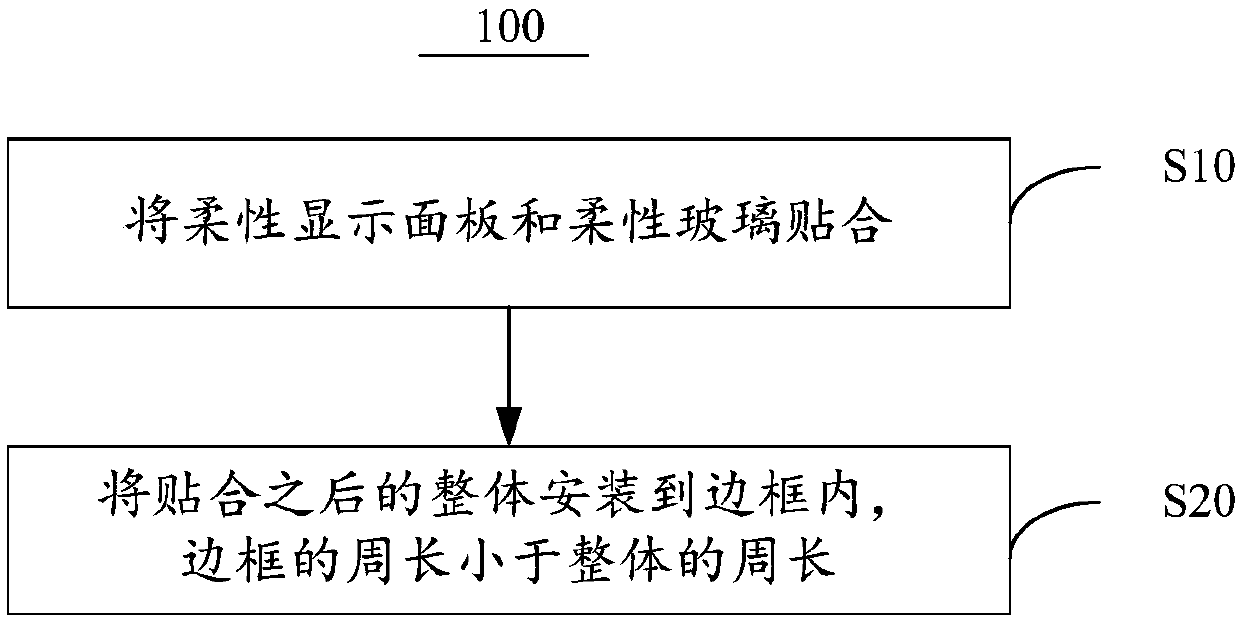

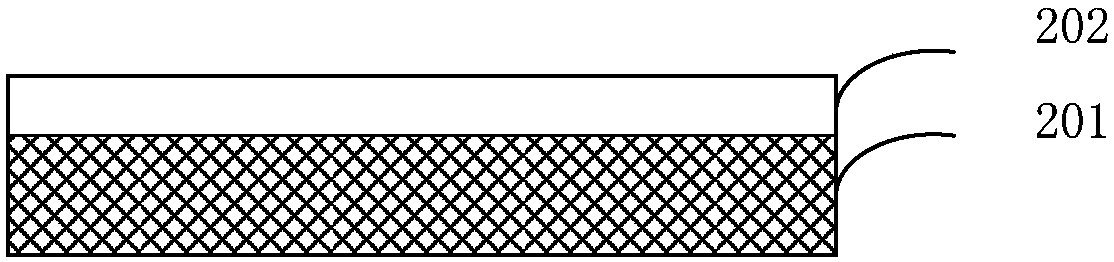

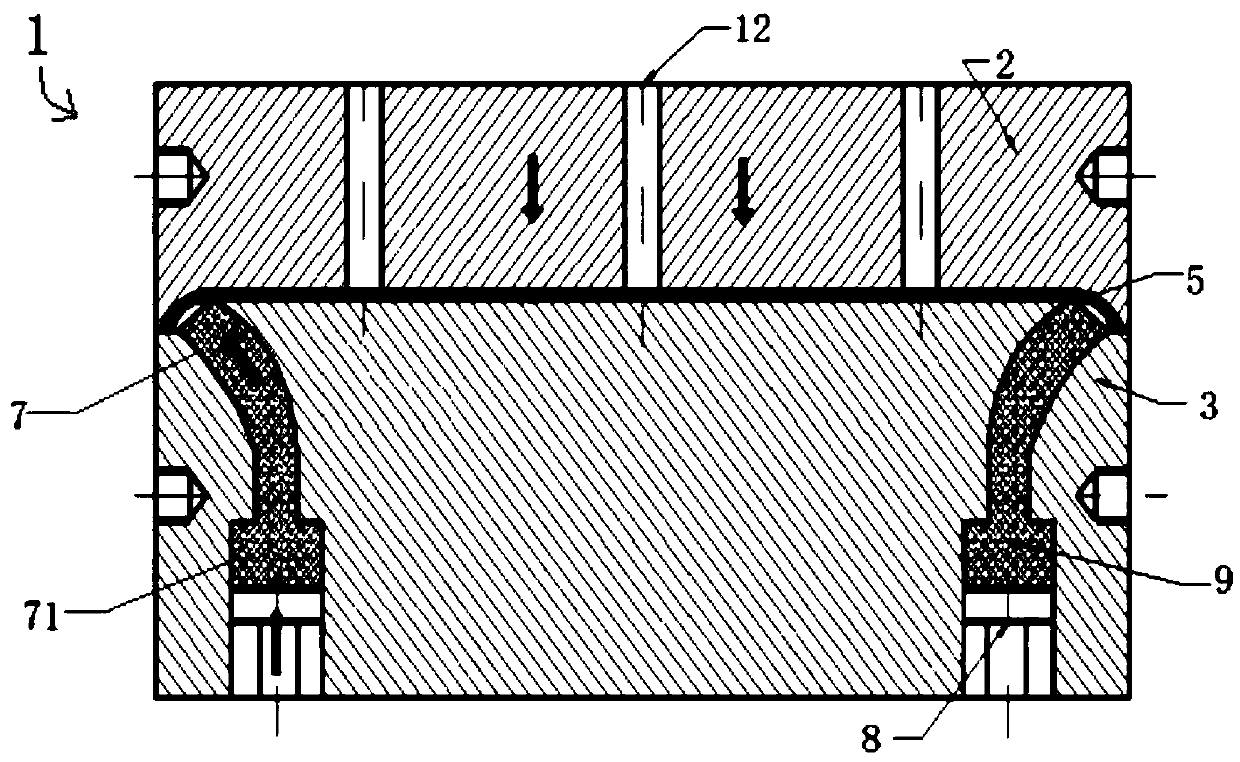

Assembly method of curved display screen and curved display screen

InactiveCN107731102AReduce the difficulty of fittingImprove uniformityDigital data processing detailsSolid-state devicesWhole bodyEngineering

The invention provides an assembly method of a curved display screen and the curved display screen, and solves the problem that the fitting difficulty in the process of assembling the conventional curved display screen is large. The assembly method of the curved display screen comprises the following steps: fitting a flexible display panel and flexible glass to form a whole body; mounting the whole body formed after fitting of the flexible display panel and the flexible glass into a border, wherein the border surrounds the periphery of the whole body formed after fitting of the flexible display panel and the flexible glass, and the perimeter of the border is smaller than that of the whole body formed after fitting of the organic light emitting diode panel and the flexible glass.

Owner:YUNGU GUAN TECH CO LTD

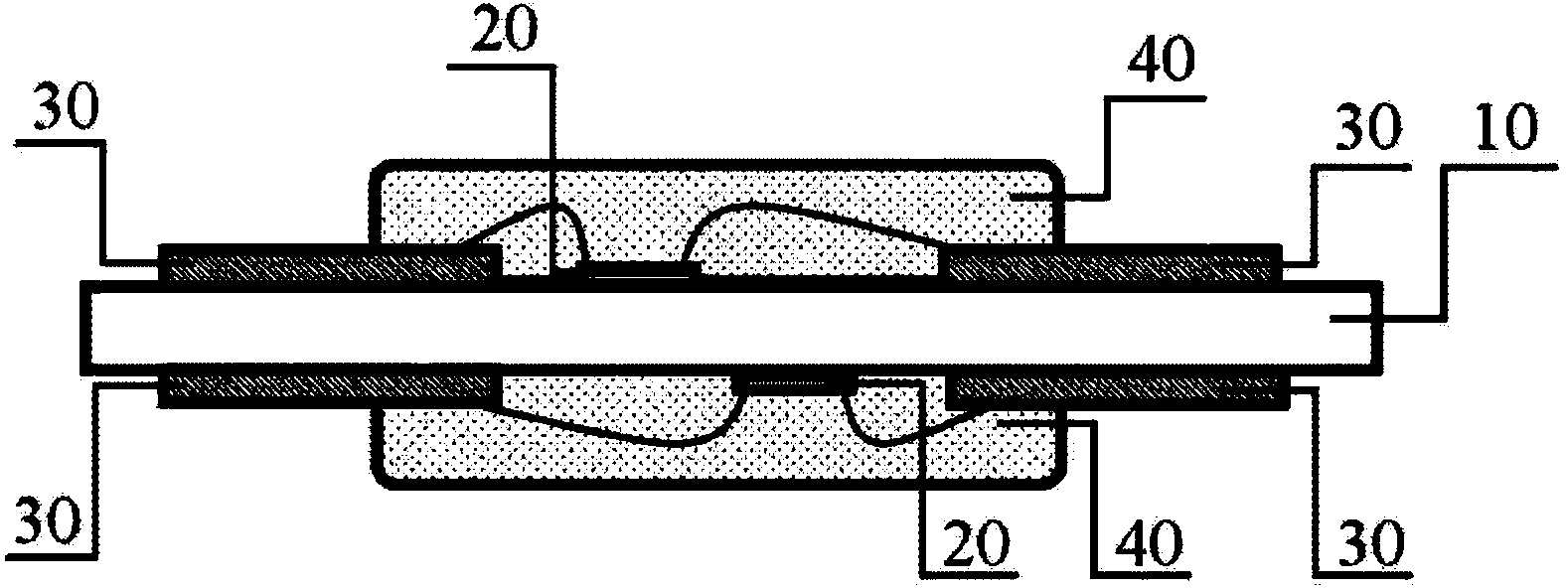

Curved surface fitting clamp, curved surface fitting device, and curved surface fitting method

ActiveCN111252284AAvoid interferenceReduce the difficulty of fittingPackagingEngineeringProtection layer

The invention provides a curved surface fitting clamp, a curved surface fitting device and a curved surface fitting method. The curved surface fitting clamp comprises a first cavity, a second cavity,at least one fluid flow passage, and at least one piston push rod, wherein the first cavity is provided with a first curved surface groove; the second cavity is an elastic material, and is provided with a second curved surface boss which is opposite to the first curved surface groove and is matched with the shape of the first curved surface groove; at least one side in a to-be-fitted display panelassembly is bent to form a curved edge in the lamination process, and the curved edge is internally provided with a to-be-fitted part; the at least one fluid flow passage is formed in the second cavity; and the at least one piston push rod is arranged at one end of the at least one fluid flow passage, and used for pressurizing a fluid in the fluid flow passage, so that the bent portion of the second curved surface boss at the other end of the fluid flow passage is deformed and is abutted against the to-be-fitted part to fit a protective layer. The curved surface fitting clamp can fit the interior of bent parts with different curvatures, reduces the fitting difficulty, and improves the fitting quality.

Owner:BOE TECH GRP CO LTD +1

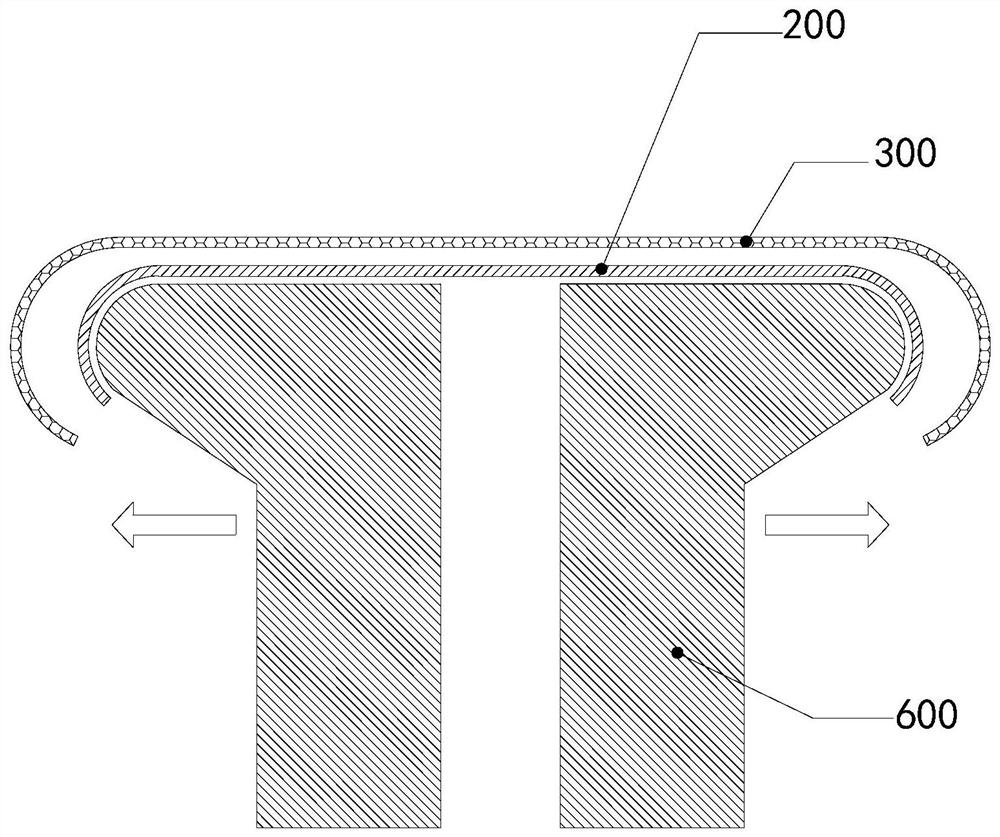

Fitting method, fitting jig and display device

ActiveCN113043708AAvoid damageReduce the difficulty of fittingLaminationLamination apparatusSurface displayDisplay device

The embodiment of the invention provides a curved surface display module fitting method, a fitting jig and a display device; fitting of the plane part of a display module is completed by the press-fit part which conforms to the plane part of the display module in shape in the fitting jig, then the press-fit part extrudes a filler in an accommodating bag to move towards the curved surface part of the display module, and thus fitting of the curved surface part is completed. Therefore, it can be guaranteed that the plane part is evenly stressed in the fitting process, wrinkles are avoided, friction shear force generated in the fitting process of the curved surface part is avoided or friction shear force possibly generated in the fitting process is at least reduced through movement of the filler towards the direction of the curved surface part after the filler is extruded, and the display module is prevented from being damaged.

Owner:YUNGU GUAN TECH CO LTD

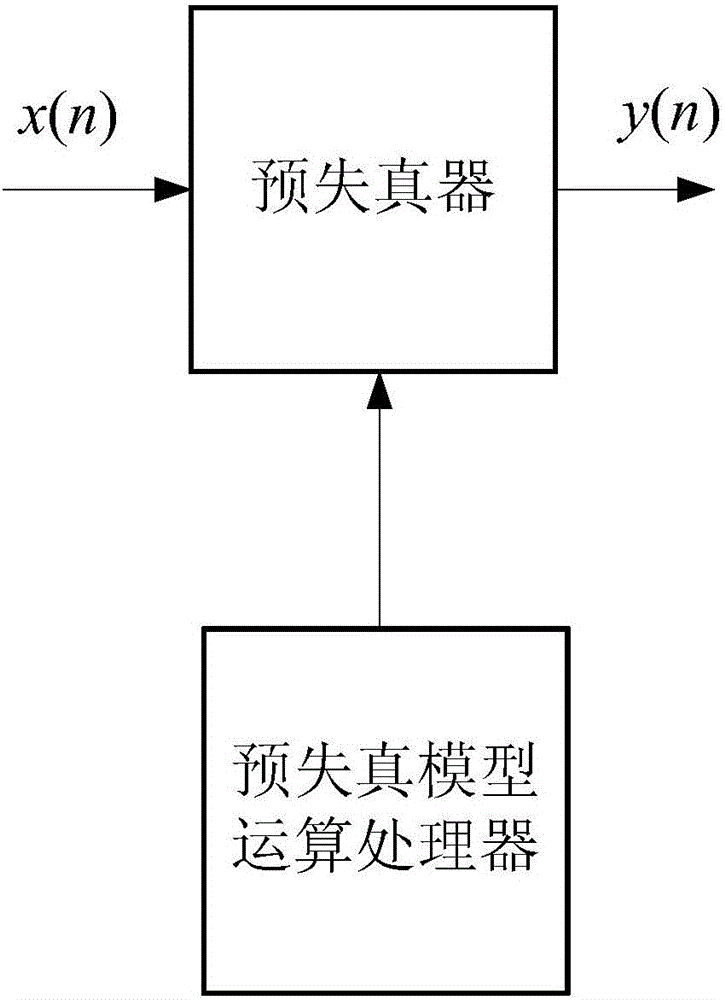

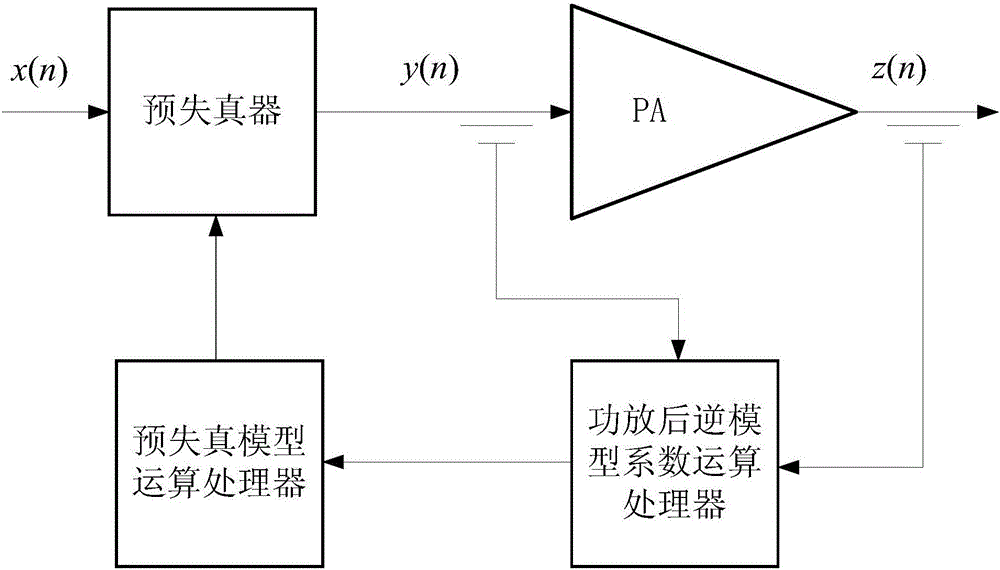

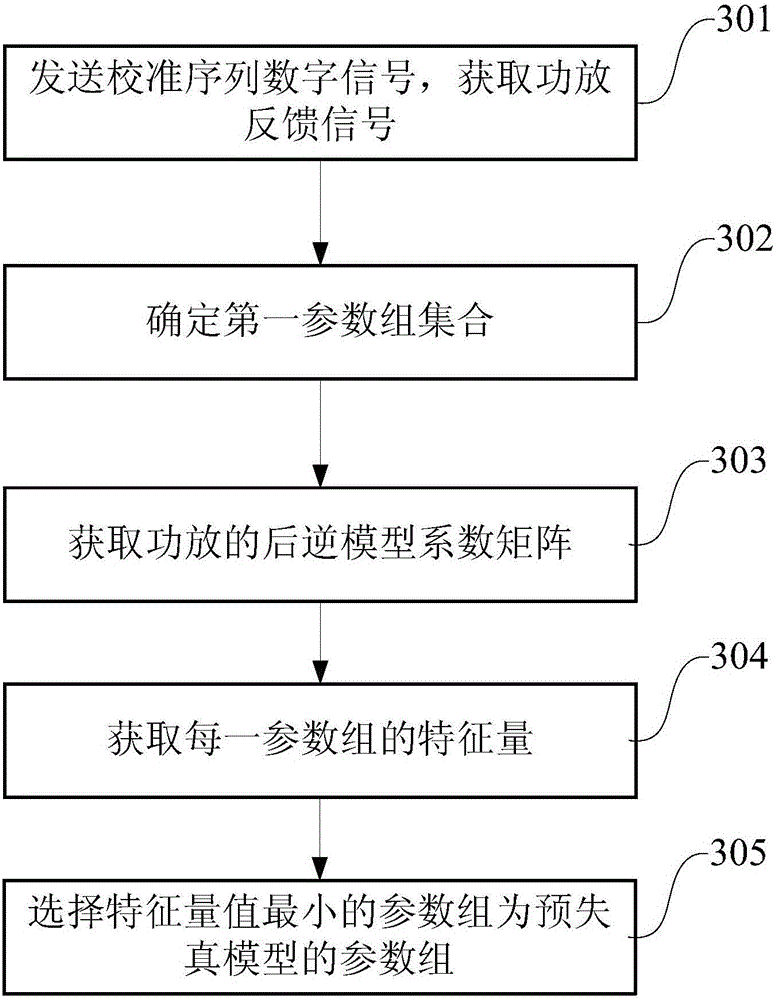

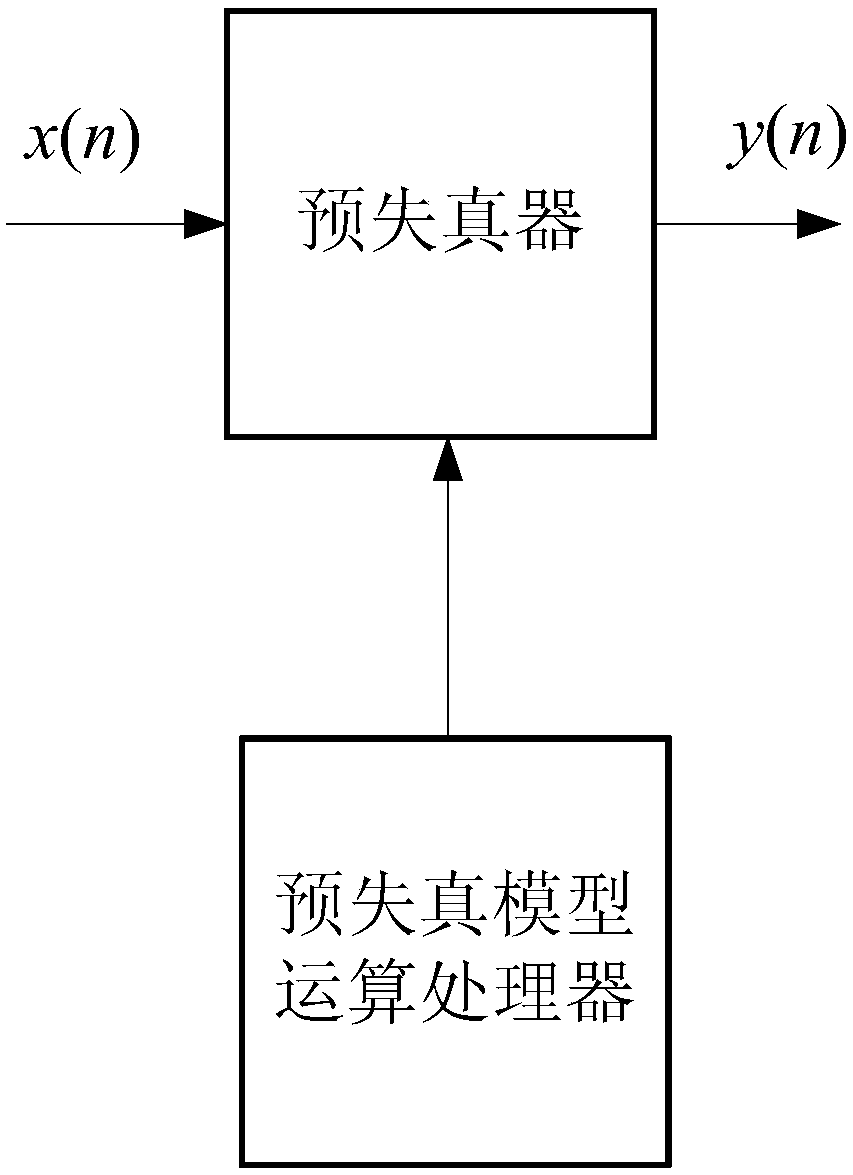

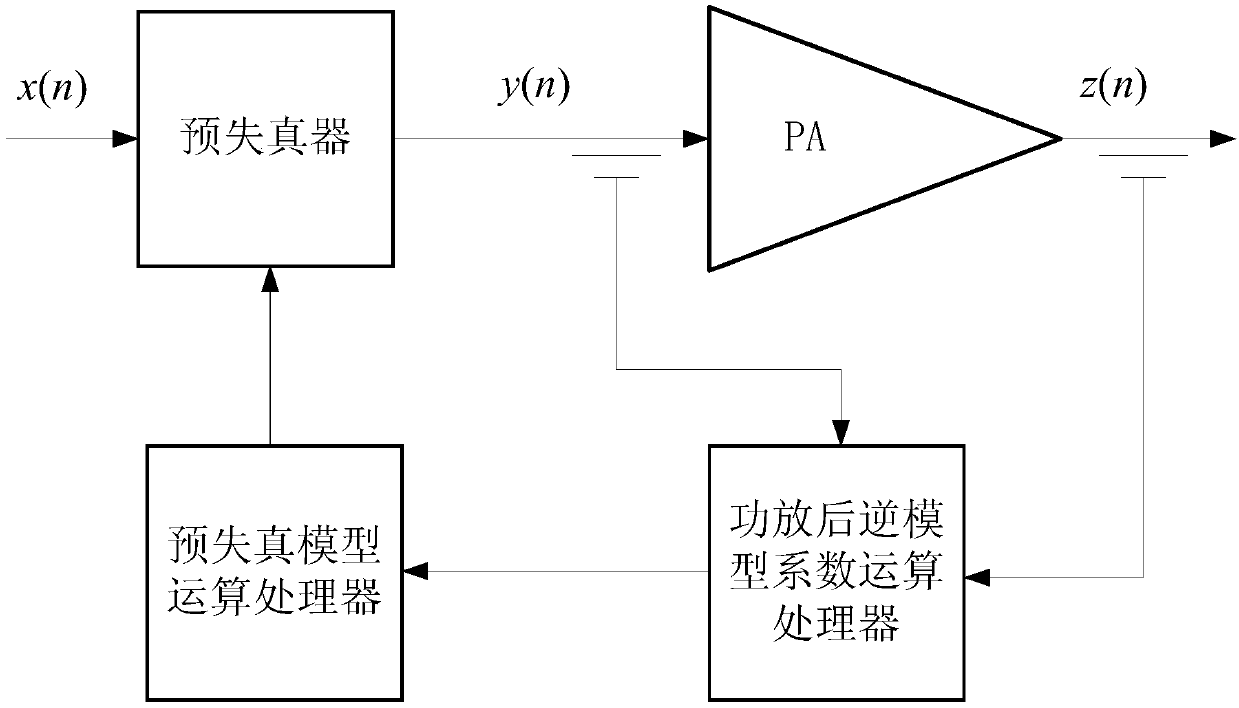

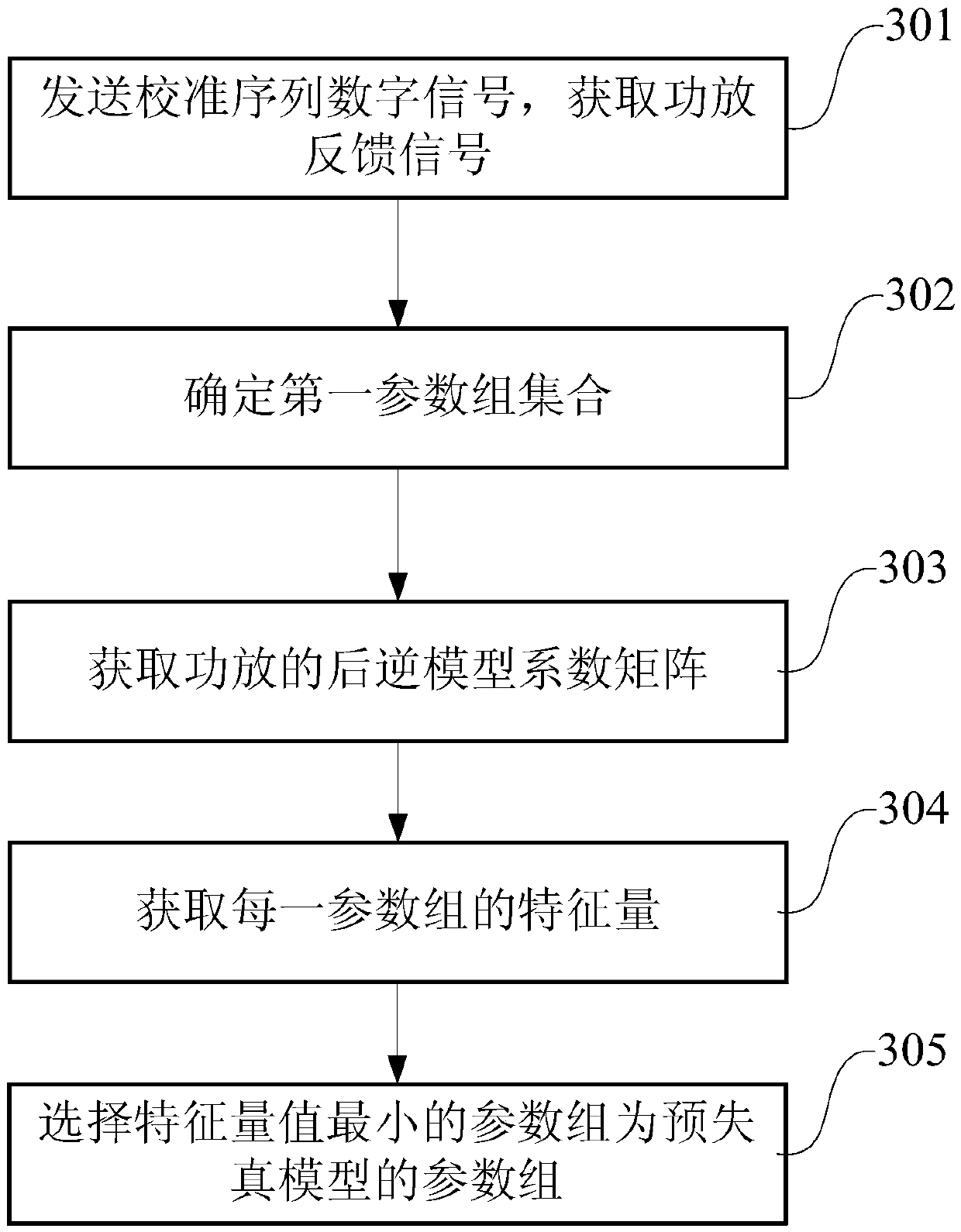

Predistortion device for power amplifier and parameter selection method thereof

ActiveCN106411271APrecise Non-Linear RepresentationTo achieve the purpose of power amplifier linearizationAmplifier modifications to reduce non-linear distortionSynchronous/start-stop systemsAudio power amplifierRF power amplifier

The invention discloses a predistortion device for a power amplifier and a parameter selection method thereof. According to the device and the method, the analog fitting degree of a power amplifier back inverse model is high, and the coefficient resolving precision of a predistorter is high. The device comprises a predistortion model operation processor which is used for establishing a predistortion model expression based on a memory polynomial, wherein the order of each memory item in the memory polynomial is determined by a vector parameter corresponding to the memory item in a first vector parameter group; and the predistorter which is used for receiving an input signal and obtaining an output signal according to the predistortion model expression.

Owner:成都芯通软件有限公司

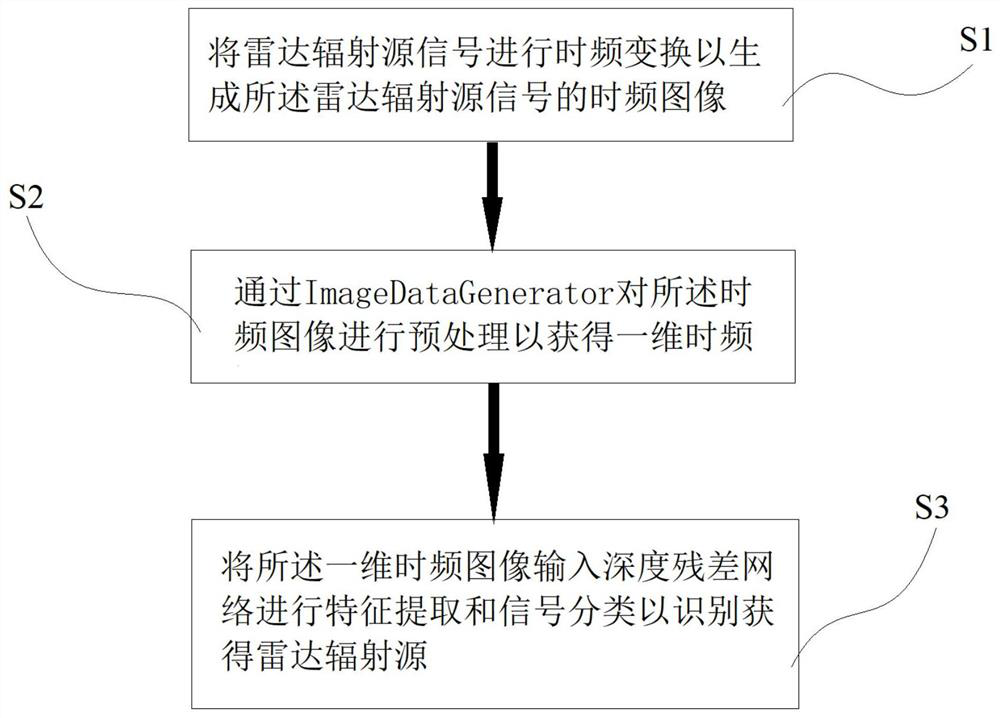

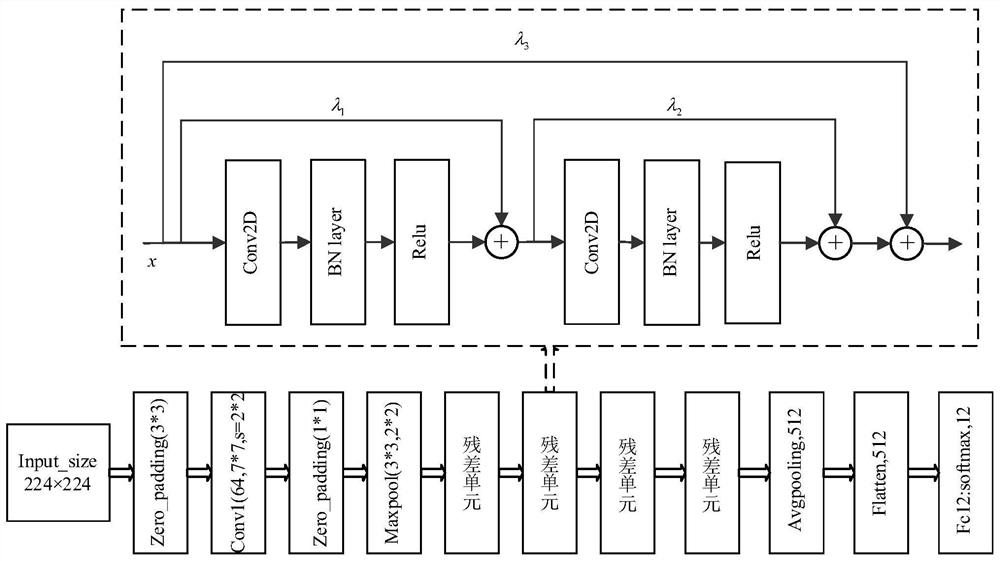

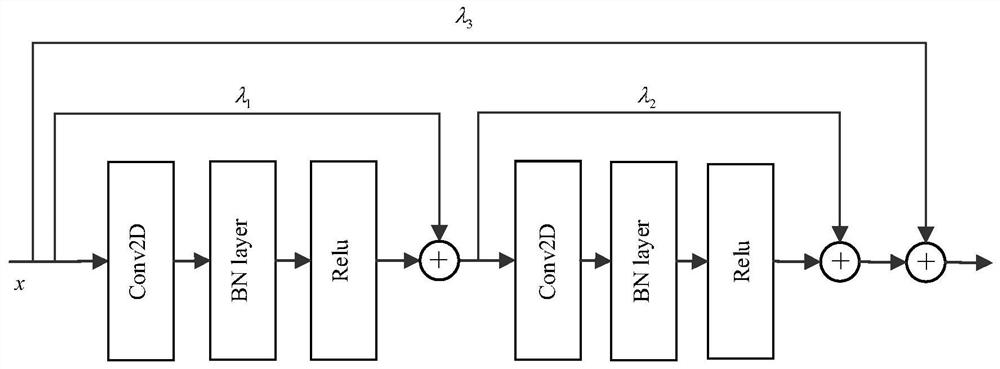

Radar radiation source identification method based on multistage jumper residual network

PendingCN112906591AAvoid vanishing gradientsAvoid problems such as gradient explosionCharacter and pattern recognitionNeural architecturesImaging processingSignal classification

The invention discloses a radar radiation source identification method based on a multistage jumper residual network, and belongs to the field of image processing. The radar radiation source identification method comprises the following steps: performing time-frequency transformation on a radar radiation source signal to generate a time-frequency image of the radar radiation source signal; carrying out the preprocessing of the time frequency image through an ImageDataGenerator, so as to obtain a one-dimensional time frequency image; and inputting the one-dimensional time-frequency image into a deep residual network for feature extraction and signal classification so as to identify and obtain the radar radiation source. According to the radar radiation source identification method based on the multistage jumper residual network provided by the invention, eight sequentially connected residual blocks are arranged in a deep residual network and are connected by using jumpers to form four residual units, so that the constructed deep residual network with the total convolution layer number of 18 can extract deep information of a signal time-frequency image, and meanwhile, the problems of gradient disappearance, gradient explosion and the like of the network are also avoided.

Owner:中国人民解放军海军航空大学航空作战勤务学院

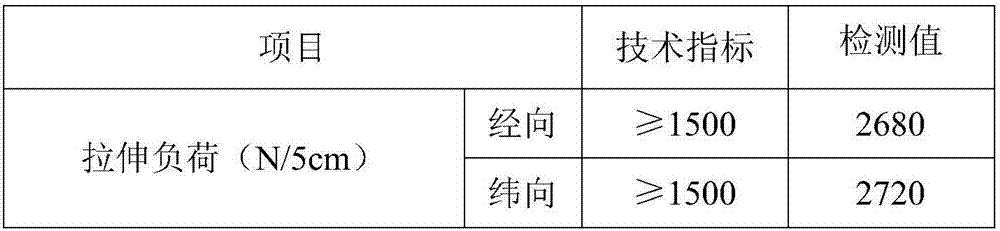

Chlorinated-water-resistant inflatable swimming pool material

InactiveCN107351492APrevent oxidationUniform coatingSynthetic resin layered productsMarine engineeringHydrostatic pressure

The invention relates to a chlorinated-water-resistant inflatable swimming pool material. The inflatable swimming pool material comprises a PVC printed film, a PVC air-tight film, base cloth and a PVC base film sequentially from top to bottom, wherein the PVC printed film is prepared from a transparent PVC film with one side printed with ink. The inflatable swimming pool material is prepared through the following steps: both sides of the base cloth are sized synchronously, heated by drying and attached synchronously with the preheated PVC printed film, PVC air-tight film and PVC base film, and the inflatable swimming pool material is obtained after edge cutting and coiling. Printed patterns are effectively prevented from being oxidized by swimming pool water, good air tightness is guaranteed, the aging resistance of the inflatable swimming pool material is improved, and the inflatable swimming pool material has better tension load, tear load, stripping load and hydrostatic pressure.

Owner:浙江明士达股份有限公司

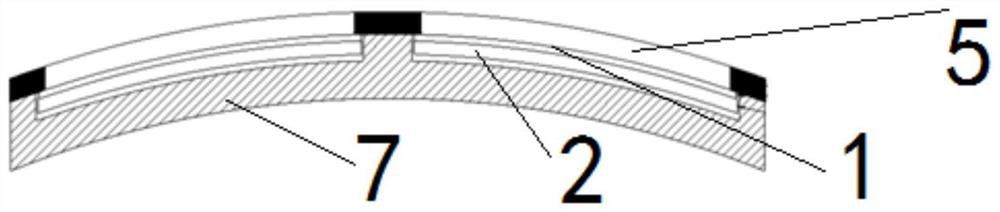

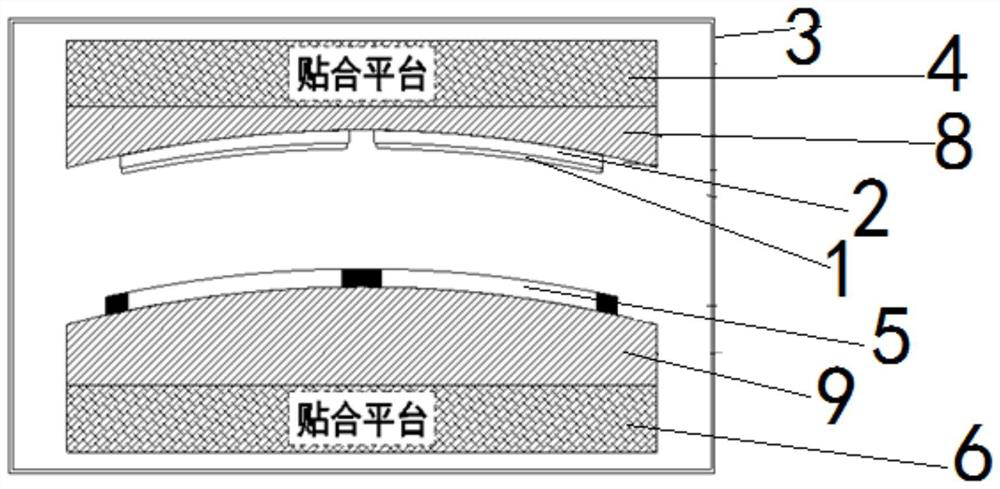

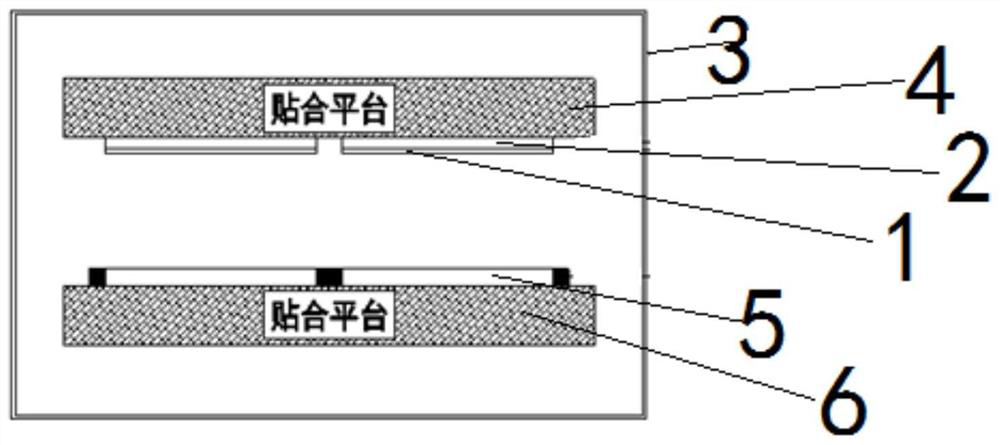

Vehicle-mounted bent C-shaped screen fitting method

PendingCN114706237AReasonable designReduce the difficulty of fittingNon-linear opticsGlass coverIn vehicle

The invention discloses a vehicle-mounted bent C-shaped screen attaching method which comprises the following steps: S1, attaching optical cement to a liquid crystal screen, and then arranging the liquid crystal screen on an upper attaching platform in a vacuum cavity; the bent C-shaped glass cover plate is arranged on a lower attaching platform in the vacuum cavity, and then the bent C-shaped glass cover plate is sucked to be flat; s2, the upper laminating platform is close to the lower laminating platform, so that the liquid crystal screen and the bent C-shaped glass cover plate are subjected to vacuum laminating; s3, the external force applied to the liquid crystal screen and the bent C-shaped glass cover plate is removed, so that the bent C-shaped glass cover plate recovers the bent state; s4, after the above steps, the liquid crystal screen and the bent C-shaped glass cover plate are jointly assembled into a full-lamination assembly; and S5, the full-lamination assembly and a backlight module are assembled. The method is reasonable in step design, curved surface fitting is converted into plane fitting, and therefore the production yield and efficiency are improved.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

Automatic exhaust type protective film

ActiveCN106218166AReduce the difficulty of fittingGuaranteed light transmittanceSynthetic resin layered productsTectorial membranePolyethylene terephthalate glycol

The invention discloses an automatic exhaust type protective film. The automatic exhaust type protective film comprises an exhaust layer and a PET (polyethylene terephthalate) substrate layer. The exhaust layer is prepared from, by weight, 100 parts of polydimethylsiloxane, 12-14 parts of amino siloxane, 2-3 parts of hexamethyldisiloxane and 2-3 parts of silane modified polyether resin. By modification of an exhaust layer component of an existing automatic exhaust type protective film, automatic debubbling performance of the exhaust layer is improved, and the exhaust layer is still excellent in debubbling performance even after repeated tearing and sticking, so that fitting difficulty of the protective film is lowered; light transmittance, adhesion strength and weather resistance of the protective film are guaranteed, and residual adhesive ratio is effectively decreased. The automatic exhaust type protective film is applicable to fields of electronic screens and the like.

Owner:SUZHOU TAILUN ELECTRONIC MATERIALS CO LTD

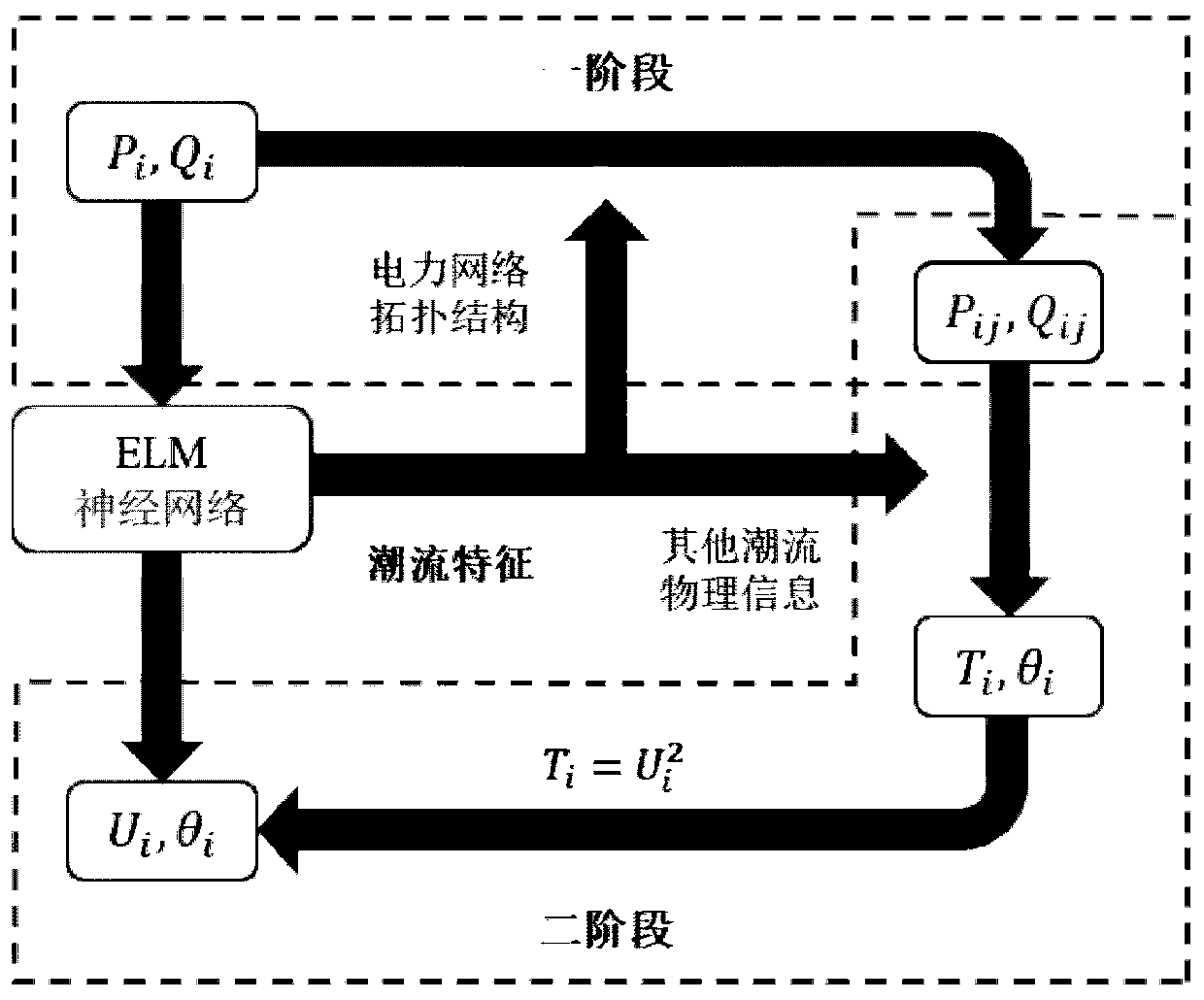

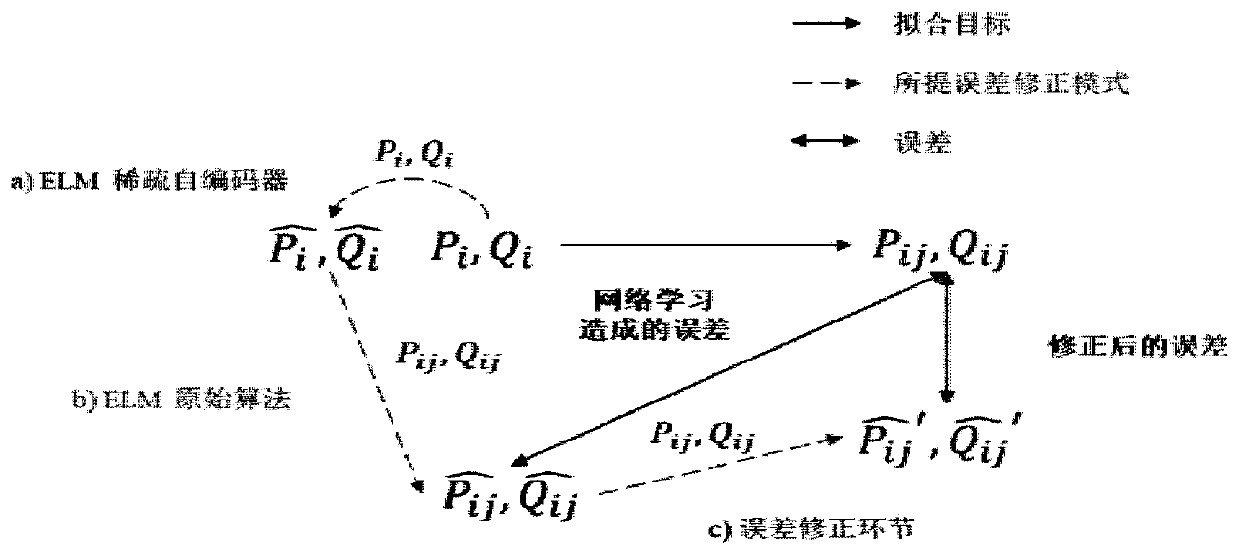

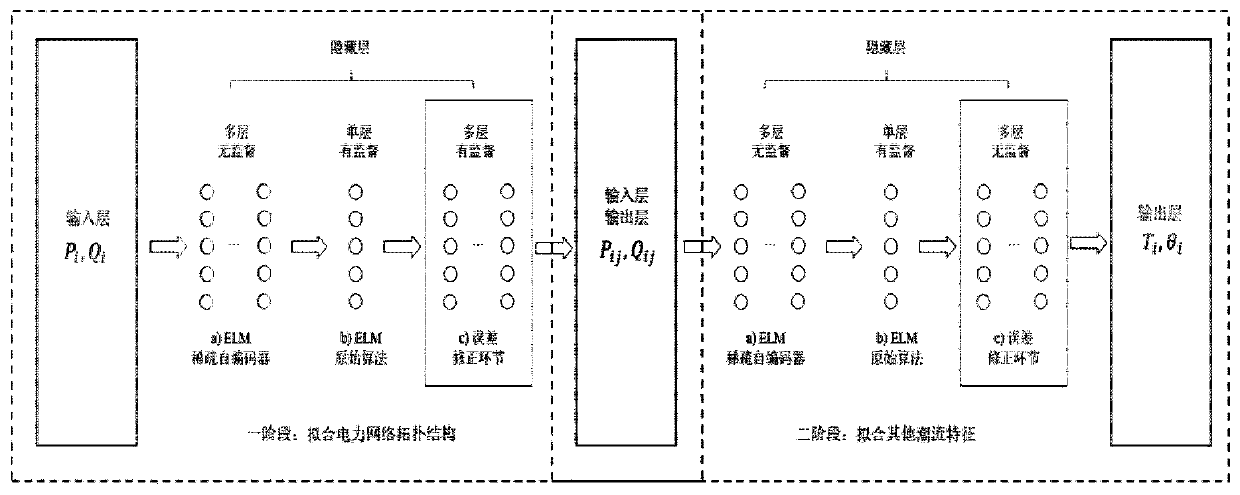

Fast probabilistic power flow calculation method of improved extreme learning machine considering power flow characteristics

ActiveCN110676852ATaking into account the accuracyTaking into account the needsBiological neural network modelsAc networks with different sources same frequencyLearning machineHidden layer

The invention discloses a fast probabilistic power flow calculation method of an improved extreme learning machine considering power flow characteristics. The method mainly comprises the steps of 1) obtaining basic data of a power network; 2) establishing a mapping relationship f: Pi, Qi to Ui, [theta]i based on the basic data of the power network; 3) decomposing the mapping relationship, and establishing an extreme learning machine neural network; 4) optimizing hidden layer parameters of the extreme learning machine neural network so as to establish an improved extreme learning machine neuralnetwork; 5) inputting the basic data of the power network into the improved extreme learning machine neural network, and calculating to obtain the probabilistic power flow of the power network. According to the invention, a time-consuming solving process for a large-scale high-dimensional complex nonlinear power flow equation in PPF calculation of a high-precision simulation method is replaced, so that engineering actual requirements of PPF calculation on precision and speed are considered.

Owner:CHONGQING UNIV +2

Display device and manufacturing method thereof

ActiveCN113066371AGuaranteed full displayReduce the difficulty of fittingTelephone set constructionsIdentification meansDisplay deviceMechanical engineering

The invention discloses a display device and a manufacturing method thereof. The display device comprises a display panel, a first cover plate and a second cover plate, wherein the display panel comprises a first main display surface, a second main display surface, an auxiliary display surface, a first bent display surface, a second bent display surface and a third bent display surface; the first main display surface is connected between the first bent display surface and the second bent display surface which are oppositely arranged, and the second main display surface is connected between the third bent display surface and the auxiliary display surface; and a first cover plate is attached to the first main display surface, the first bent display surface and the second bent display surface, and a second cover plate is attached to the second main display surface, the auxiliary display surface and the third bent display surface. Omnibearing display of the display panel can be guaranteed, the fitting difficulty of the display panel and the cover plate is simplified, and a fitting yield is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

AB double-sided adhesive for low-residue electronic screens

ActiveCN106118532BGood defoaming performanceReduce the difficulty of fittingNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyAminosilochrome

The invention discloses a special AB double-sided adhesive for a low-residue electronic screen. The special AB double-sided adhesive for the low-residue electronic screen is successively provided with a first release layer, a modified silicon layer, a PET substrate layer, an optical adhesive layer and a second release layer from top to bottom, wherein the modified silicon layer comprises the following components in parts by weight: polydimethylsiloxane 100 parts, amino silicone 8-10 parts, sodium methyl silicate 4-6 parts and epoxy resin 2-3 parts. Adhesive components of two sides of the AB double-sided adhesive are modified to improve automatic bubble discharge capacity of the silicon layer, so that after the double-sided adhesive are torn and adhered repeatedly, the bubble discharge capacity can still be excellent, and adhesion difficulty of the double-sided adhesive is reduced; and meanwhile, the light transmittance, the adhesion strength and the shock resistance of the optical adhesive layer are improved, and residual adhesive ratio is reduced. The AB double-sided adhesive is suitable for the field of electronic screens and the like.

Owner:泰兴联创绝缘材料有限公司

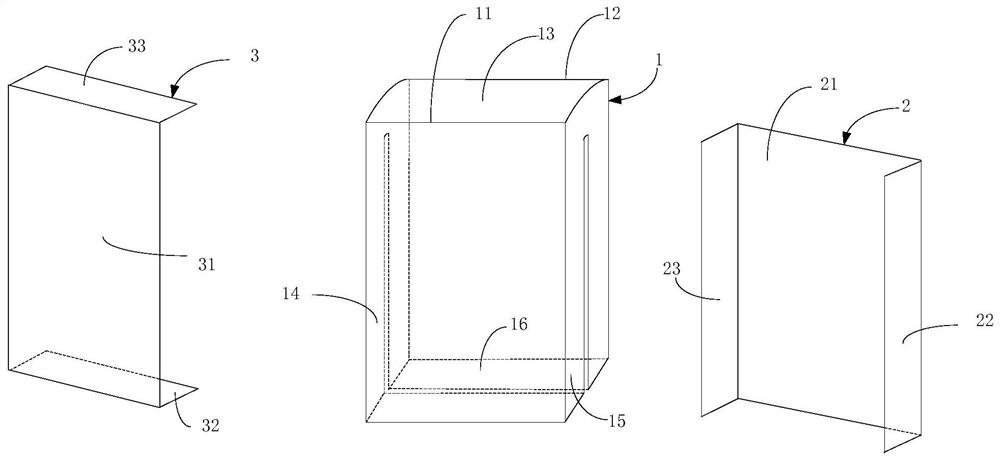

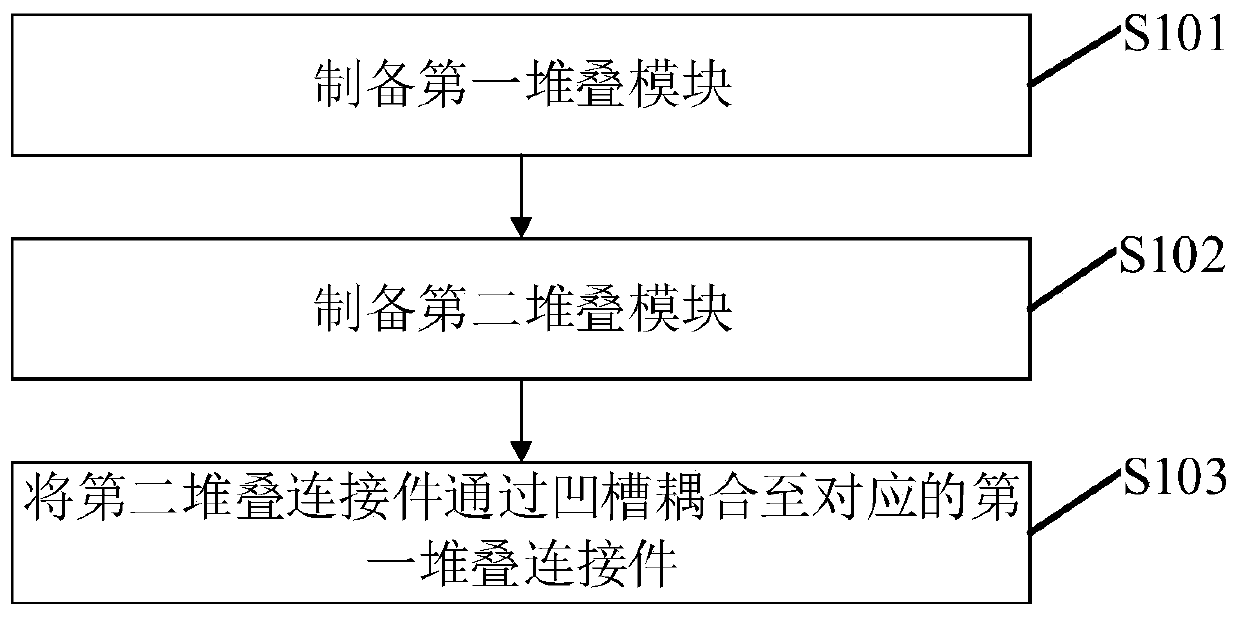

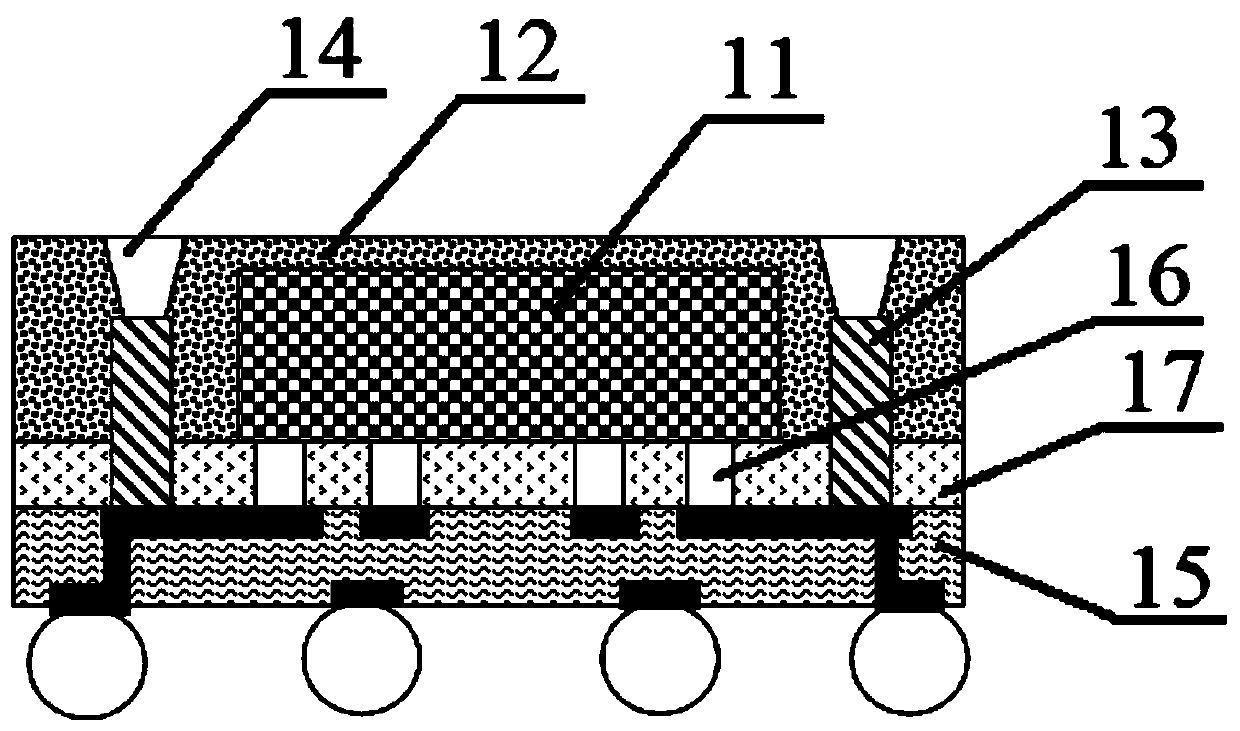

Chip stacking and packaging method and packaging structure

InactiveCN110993517AReduce manufacturing costImprove yieldSemiconductor/solid-state device detailsSolid-state devicesComputer hardwareEngineering

The invention discloses a chip stacking and packaging method and a packaging structure. The method comprises: a first stacking module is prepared, wherein the first stacking module comprises a first chip, a first packaging body and a first stacking connecting piece; the first packaging body packages the first chip, the first stacking connecting piece is arranged in the first packaging body, one end of the first stacking connecting piece is coupled with the first chip, and the other end of the first stacking connecting piece is exposed out of the first packaging body through a groove, corresponding to the first stacking connecting piece, in the first packaging body; a second stacking module is prepared; the second stacking module comprises a second chip, a second packaging body and a secondstacking connecting piece; the second packaging body packages the second chip, one end of the second stacking connecting piece is coupled with the second chip, and the other end of the second stacking connecting piece extends in the direction away from the second chip; and the second stacking connecting pieces are coupled to the corresponding first stacking connecting pieces through the grooves.By implementing the method, the preparation cost of the chip stacking and packaging structure can be reduced, and the yield of products is improved.

Owner:江苏中科智芯集成科技有限公司

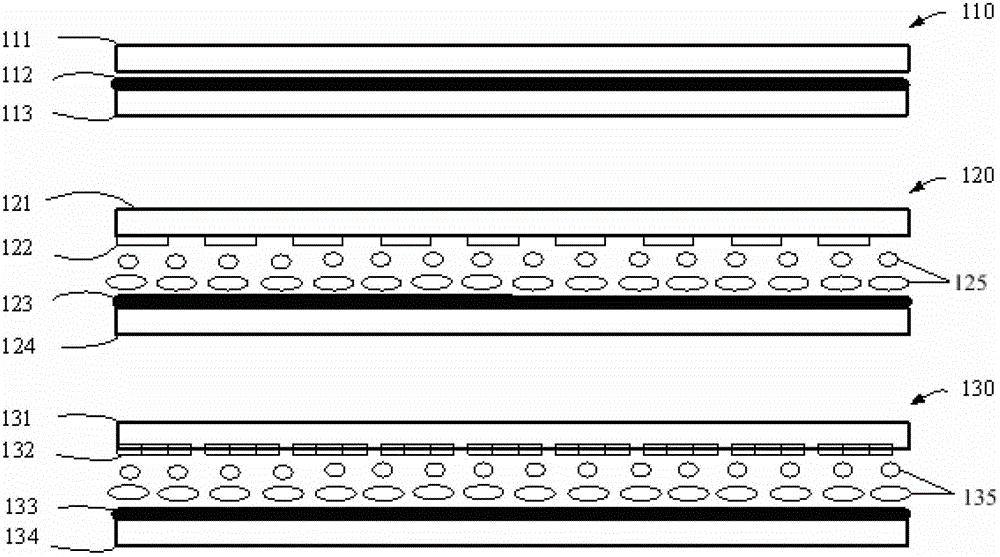

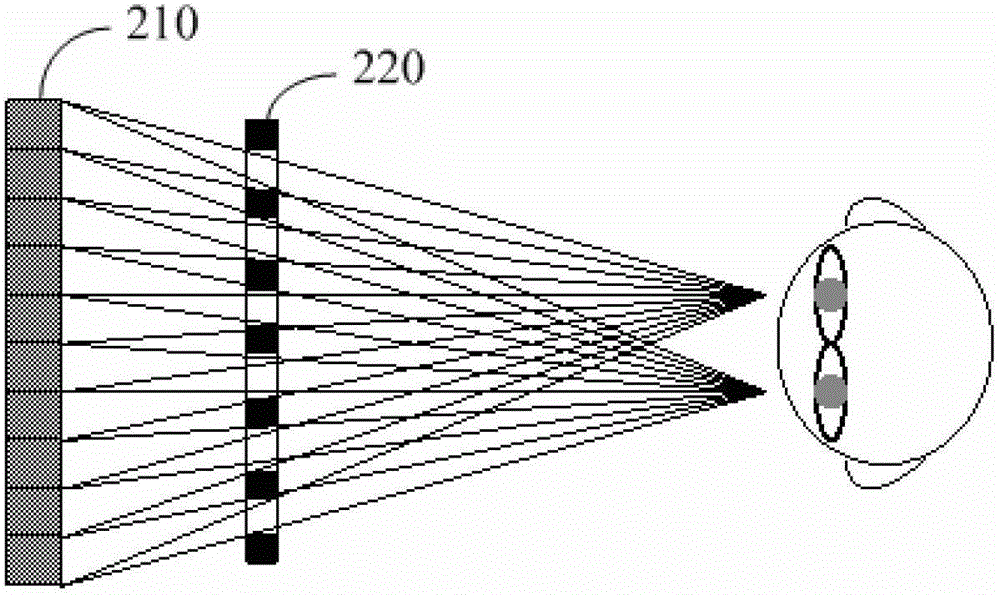

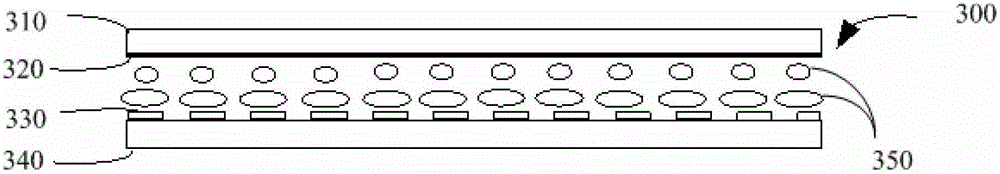

Liquid crystal cell, display device and method for controlling both

ActiveCN103293779BImprove transmittanceReduce thicknessStatic indicating devicesSteroscopic systemsControl signalTransmittance

The invention provides a liquid crystal box, a display device applying the liquid crystal box and a control method of the liquid crystal box and the display device. The liquid crystal box provided by the invention comprises a first transparent baseplate and a second transparent baseplate that are oppositely arranged, a liquid crystal layer arranged between the first transparent baseplate and the second transparent baseplate and transparent strip-shaped electrode layers relative to a touch control electrode layer, wherein the touch control electrode layer is formed on the first transparent baseplate; electrodes, for receiving the same control signal, of the touch control electrode layer are connected into a whole through connection parts; the transparent strip-shaped electrode layers are composed of a plurality of transparent strip-shaped electrodes formed on the second transparent baseplate; and each transparent strip-shaped electrode corresponds a lens area. The liquid crystal box provided by the invention can provide the touch control function and the switching function of the two-dimensional / three-dimensional display by only two layers of baseplates at the same time; and the light transmittance is higher during three-dimensional display.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

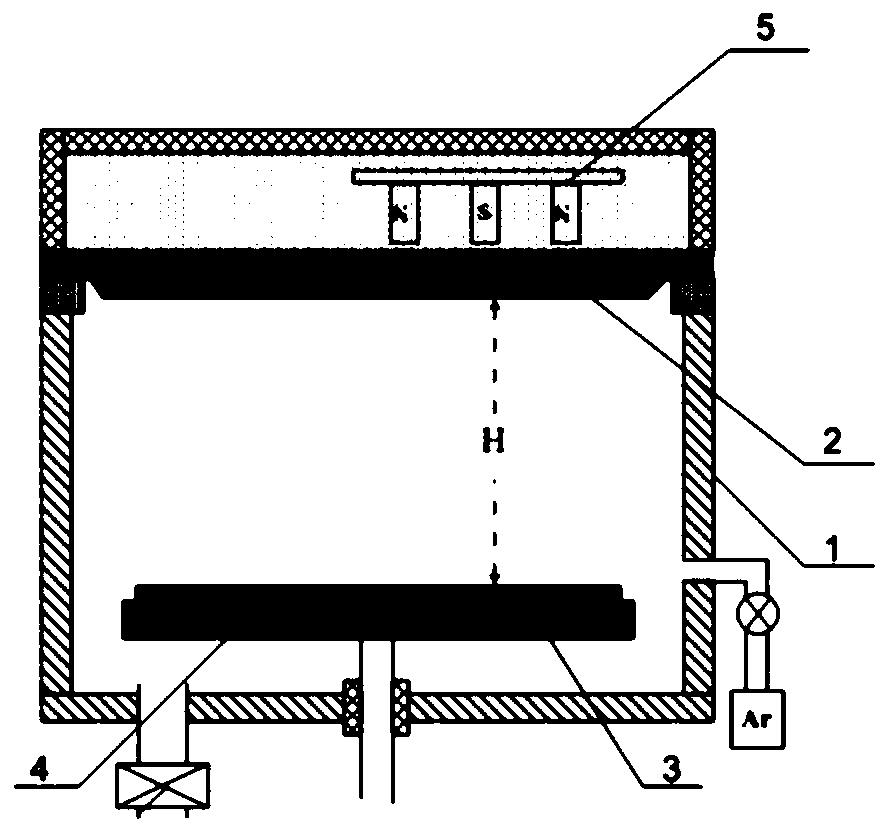

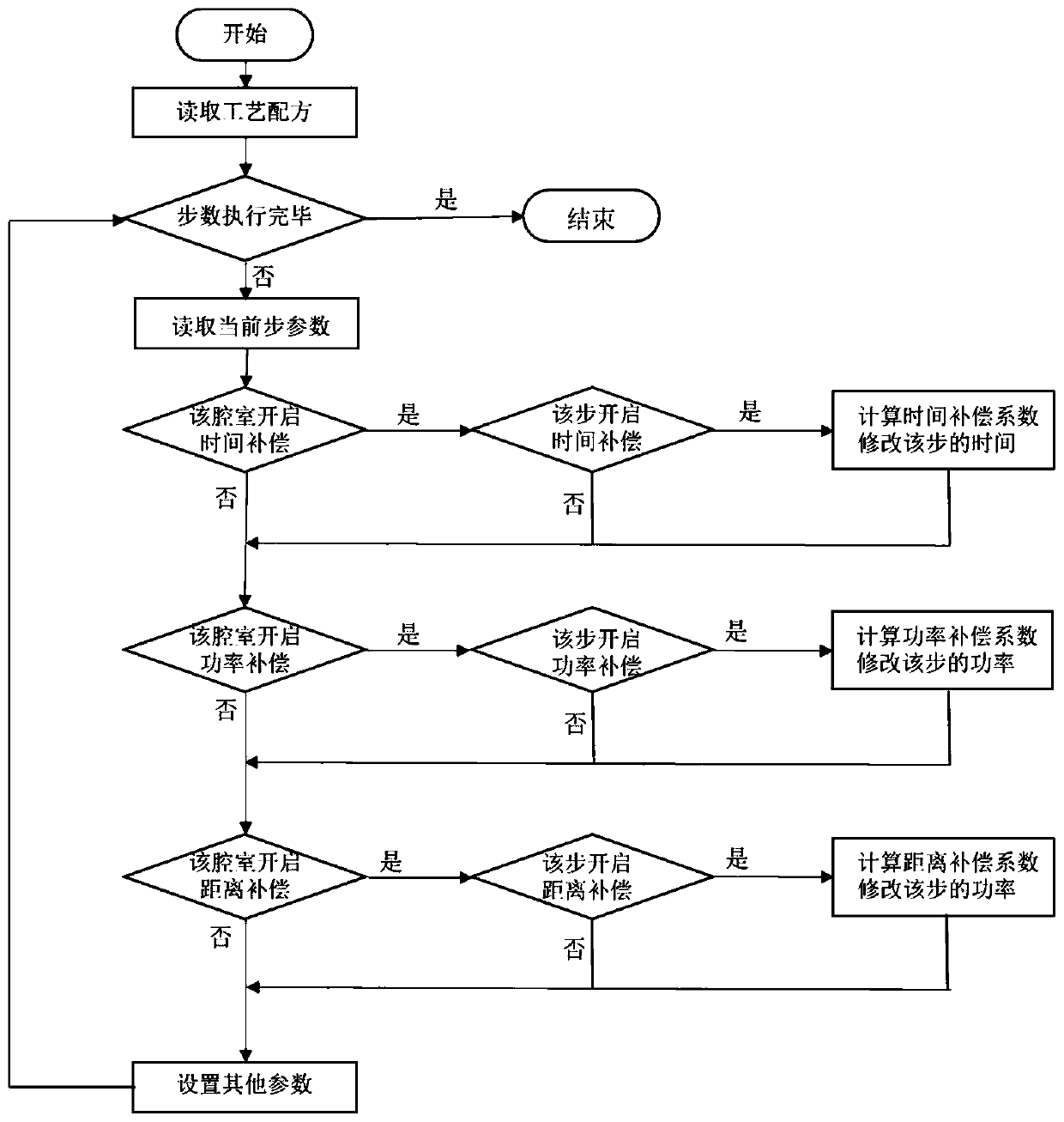

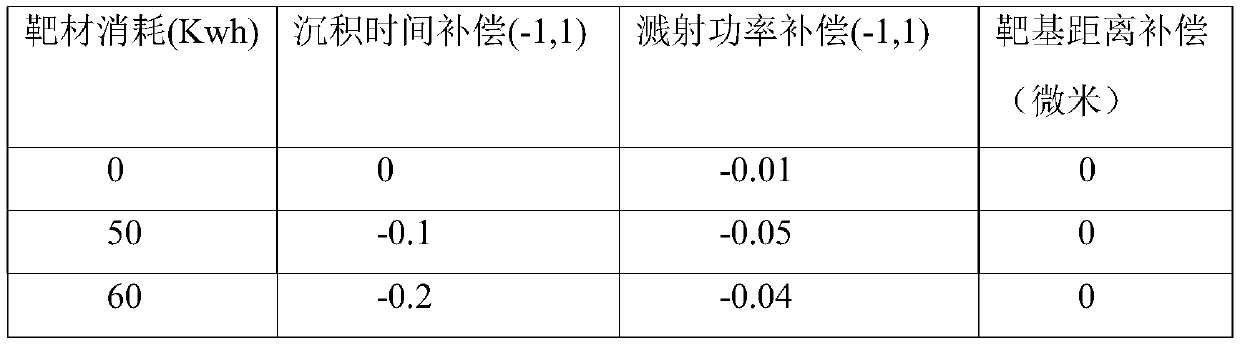

Semiconductor deposition process compensating method, compensating device and semiconductor deposition equipment

ActiveCN111519160AReduce the difficulty of fittingFitting is intuitiveVacuum evaporation coatingSputtering coatingPower compensationThermodynamics

The invention discloses a semiconductor deposition process compensating method, a compensating device and semiconductor deposition equipment. The deposition process compensating method comprises the following steps: step 1, judging whether process parameter values of a current process step need parameter compensation or not before performing the current process step, obtaining a current target material consumption value, and calculating compensated process parameter values according to the preset multiple target material consumption values and the parameter compensation value which correspondsto each target material consumption value if the parameter compensation is needed; and step 2, performing the current process step according to the compensated process parameter values, wherein the parameter compensation values comprise at least one of the following: a deposition time compensation value, a target base distance compensation value and a sputtering power compensation value. The semiconductor deposition process compensating method has the beneficial effect that: a user can freely select independent opening time compensation, sputtering power compensation or target base distance compensation, also can simultaneously start any two or three of the ways, and flexible configuration in the step of each process formula is achieved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

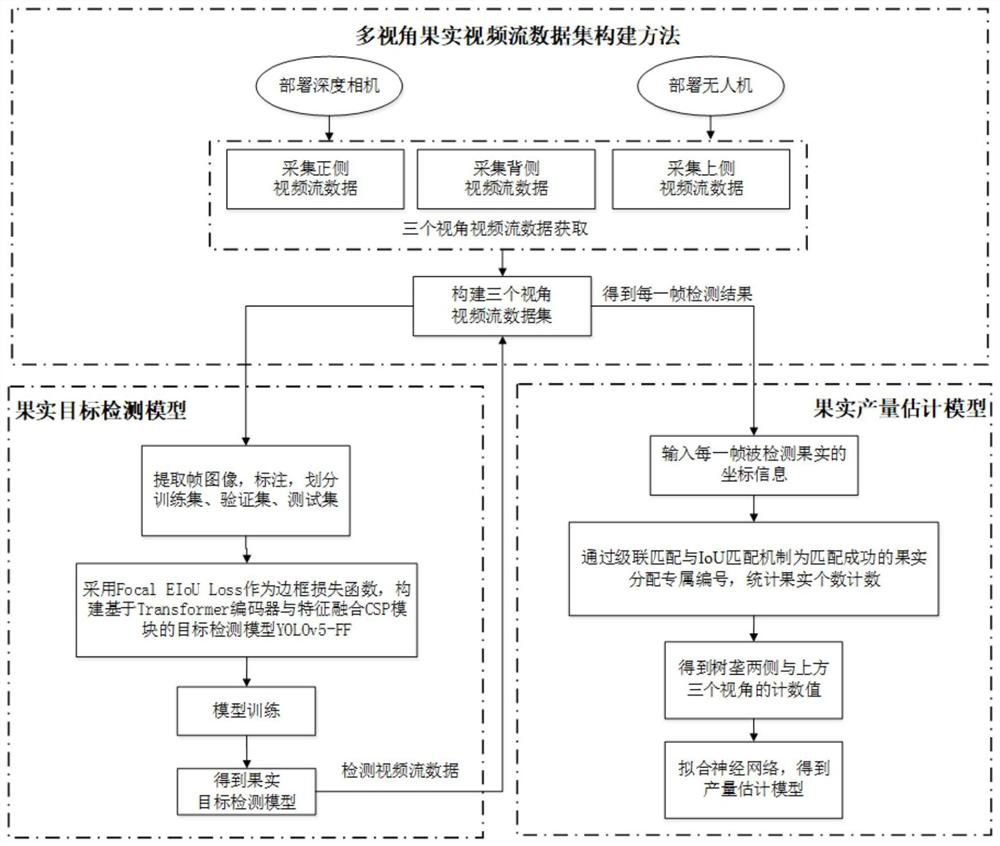

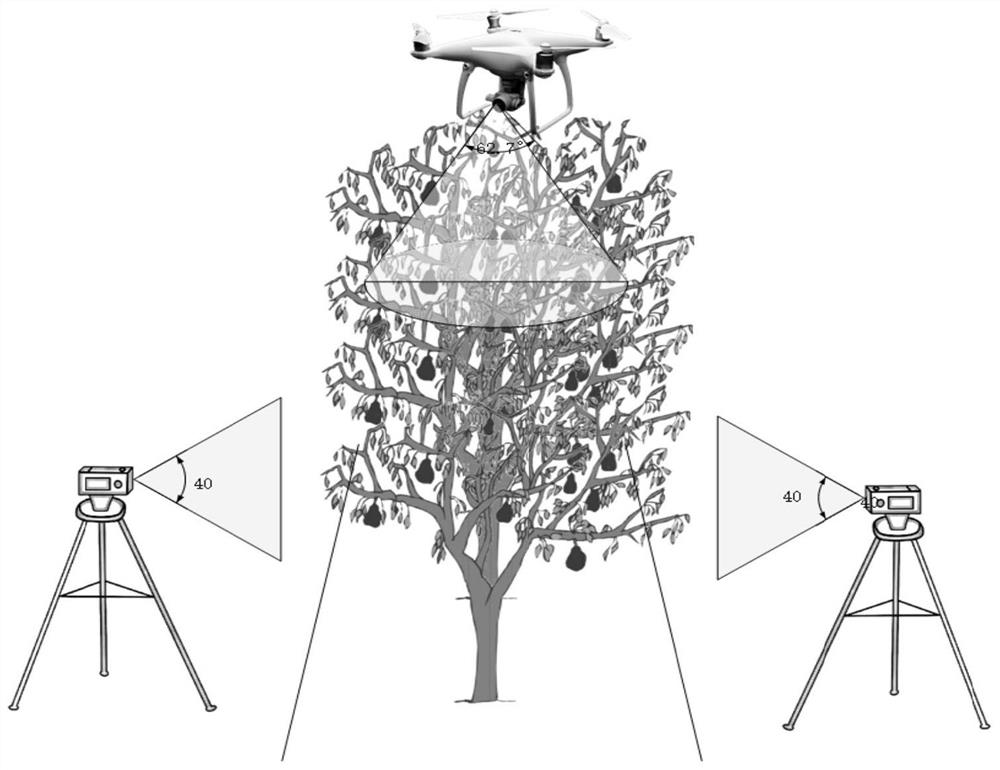

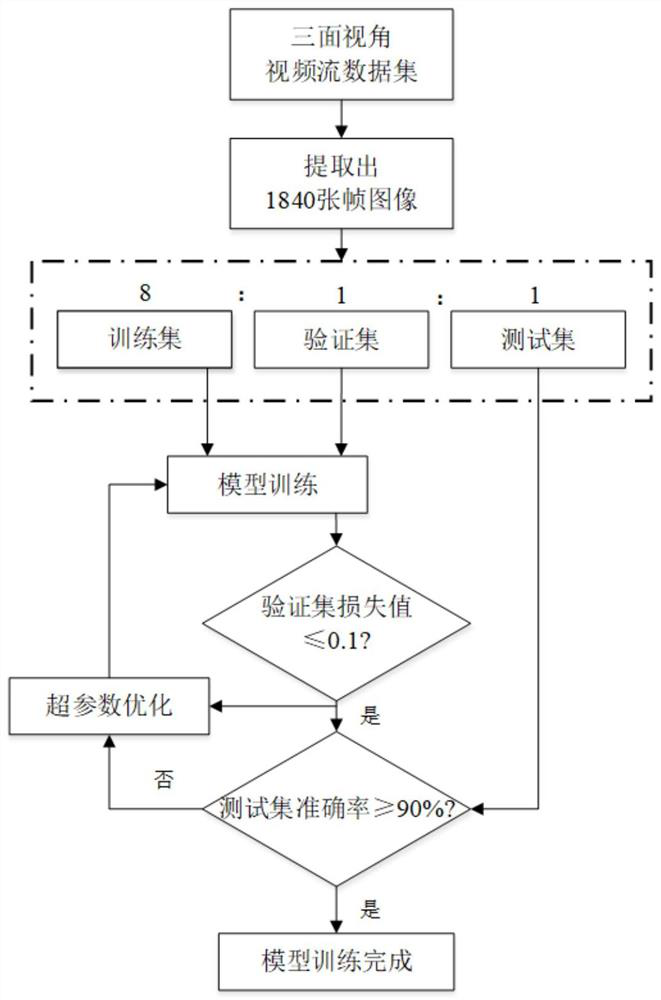

Fruit detection and yield estimation method and system based on machine vision

PendingCN114663814AReduce in quantityDetection speedCharacter and pattern recognitionOrchardTracking model

The invention discloses a fruit detection and yield estimation method and system based on machine vision, and relates to the technical field of artificial intelligence target recognition and application. In order to solve the problem that fruit yield estimation is not accurate enough in the prior art, fruit video stream data sets of three view angles are collected; designing a CSP module based on a Transform encoder and an attention feature fusion mechanism, and integrating the CSP module into YOLOv5 to construct a target detection model YOLOv5-FF based on multi-level feature fusion neck; focal EIoU Loss is adopted as a frame loss function for training to obtain a fruit target detection model, a detection result of a YOLOv5-FF model for continuous frame images of a fruit video stream is input into a target tracking model Deep Sort, exclusive numbers are distributed for successfully matched fruits through cascade matching and an IoU matching mechanism, the number of fruits under multiple view angles is obtained, the fruit detection efficiency is improved, and the fruit quality is improved. The deployment is convenient, and the detection is efficient and accurate; the provided yield estimation model can realize high-precision measurement and calculation of the yield of the orchard.

Owner:ANHUI AGRICULTURAL UNIVERSITY

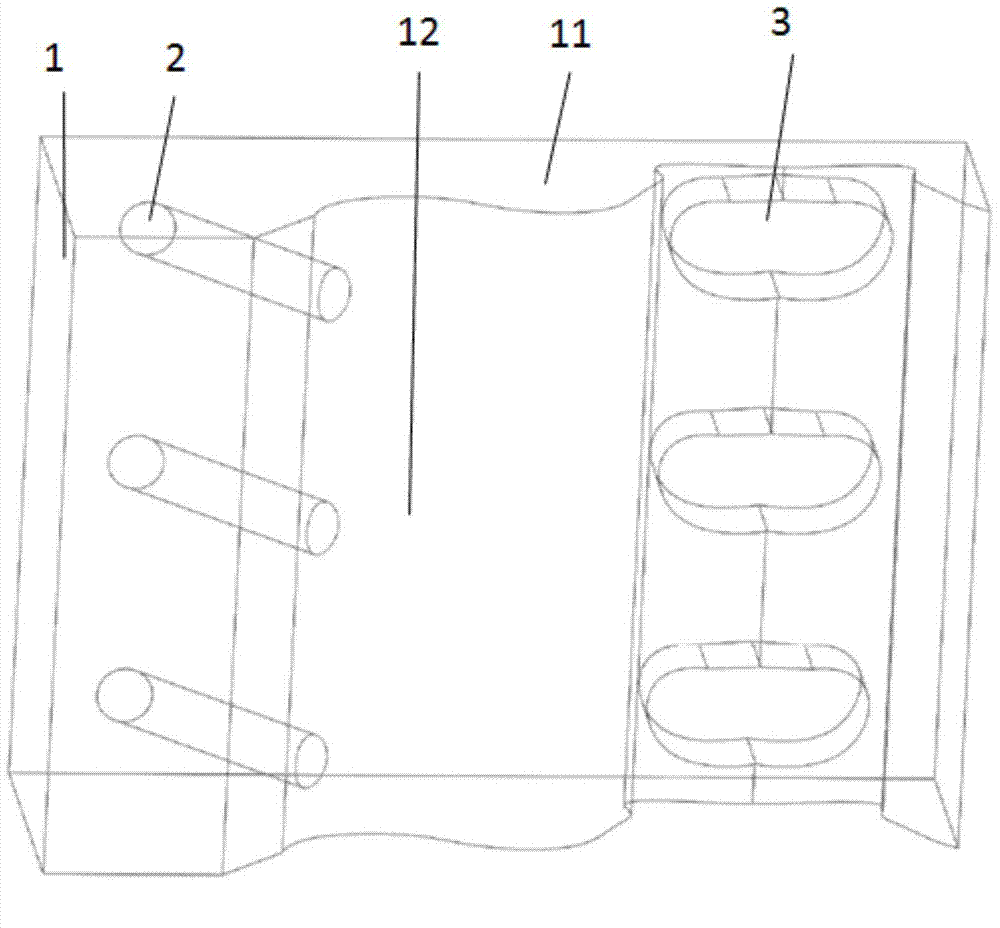

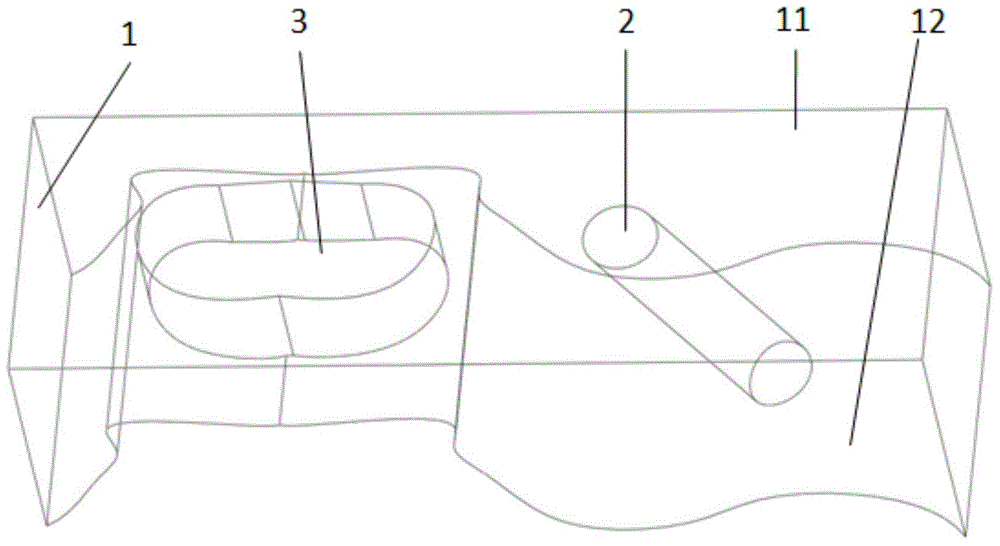

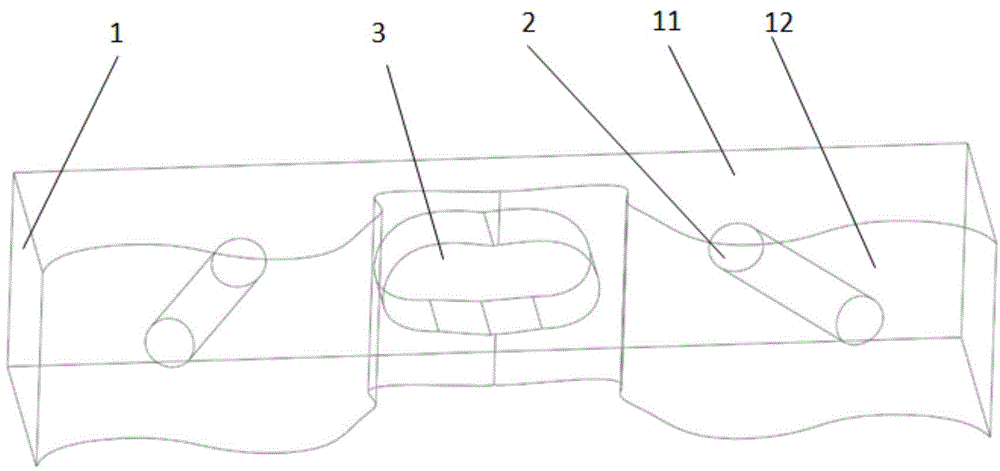

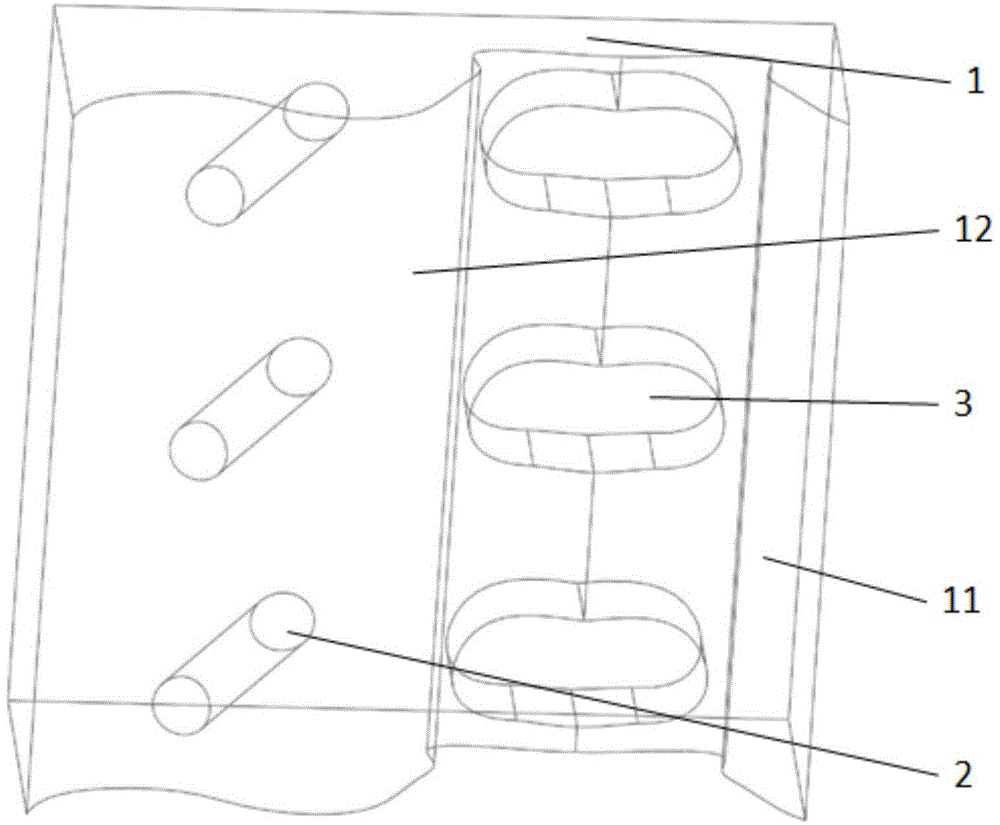

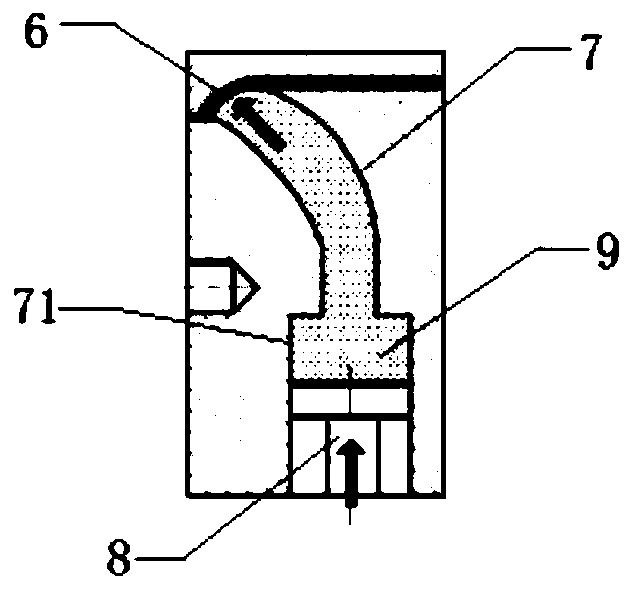

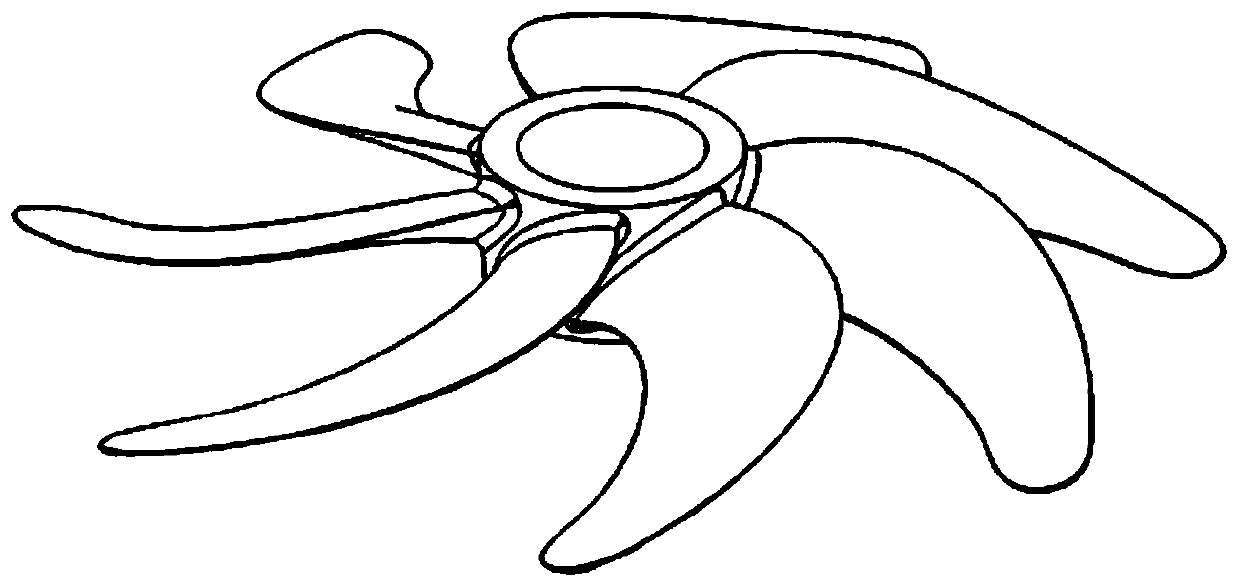

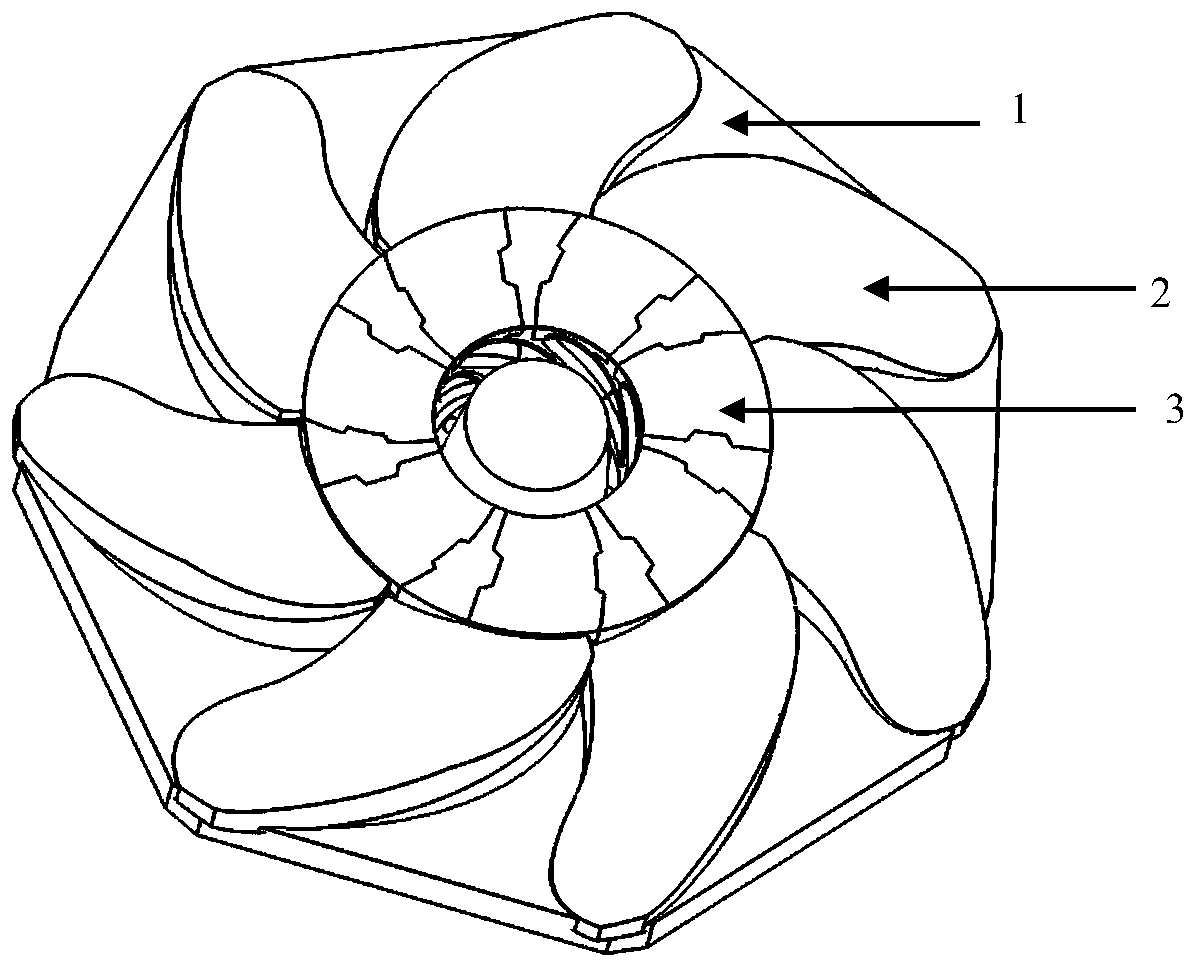

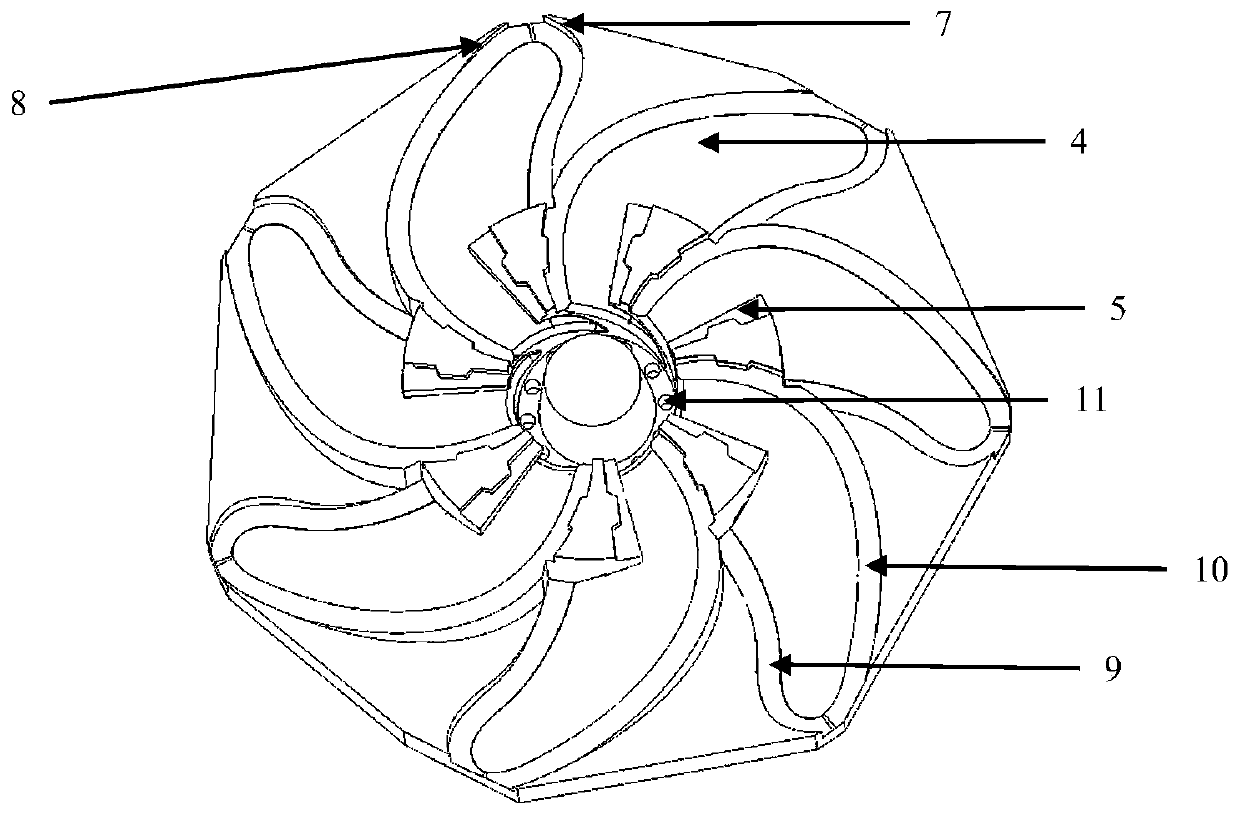

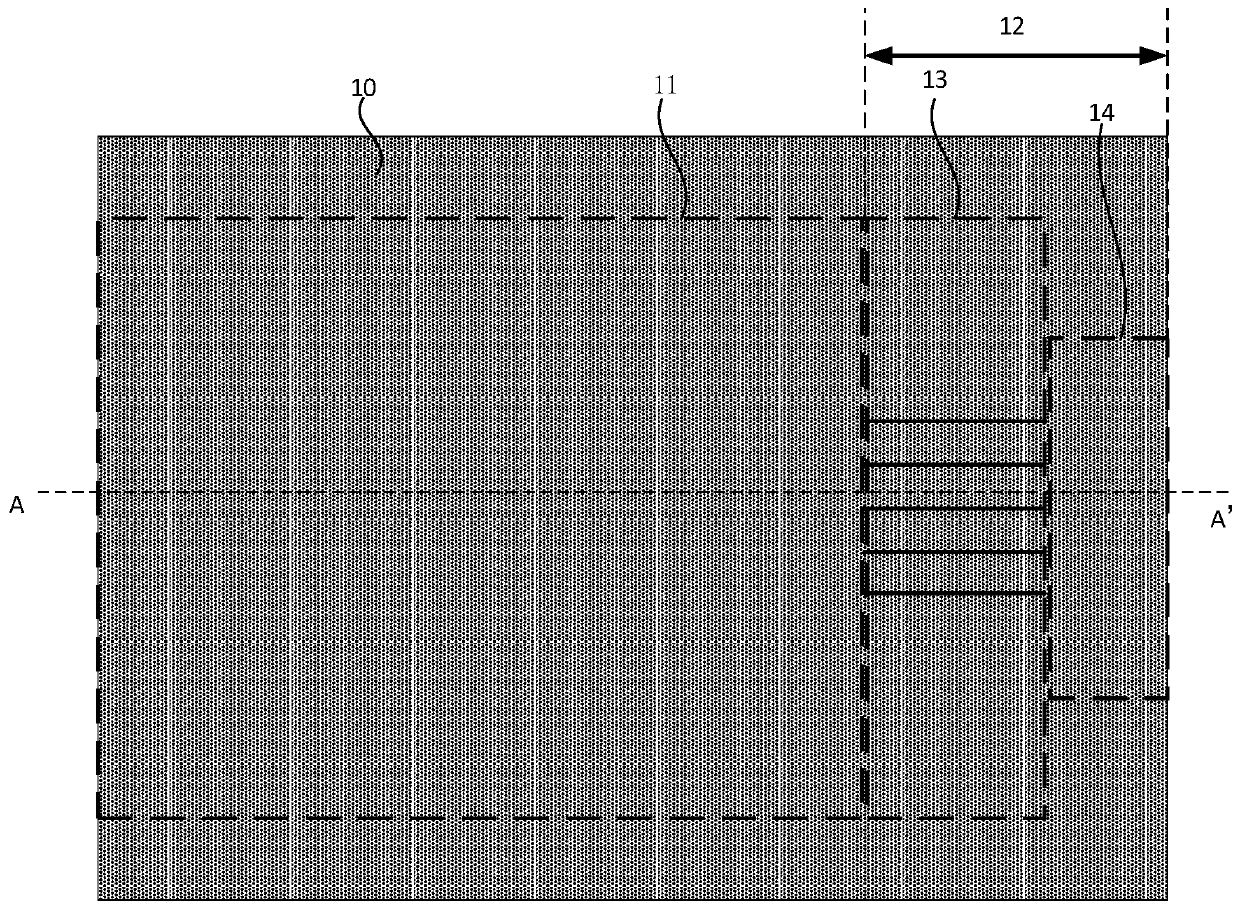

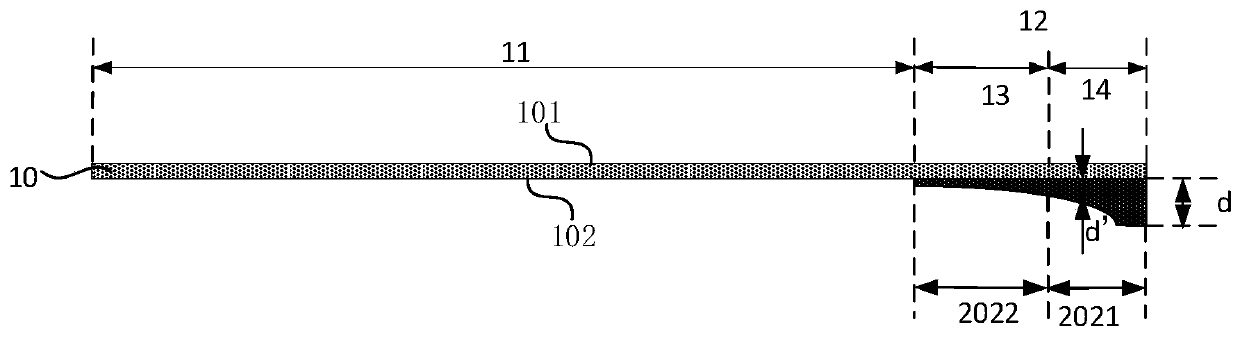

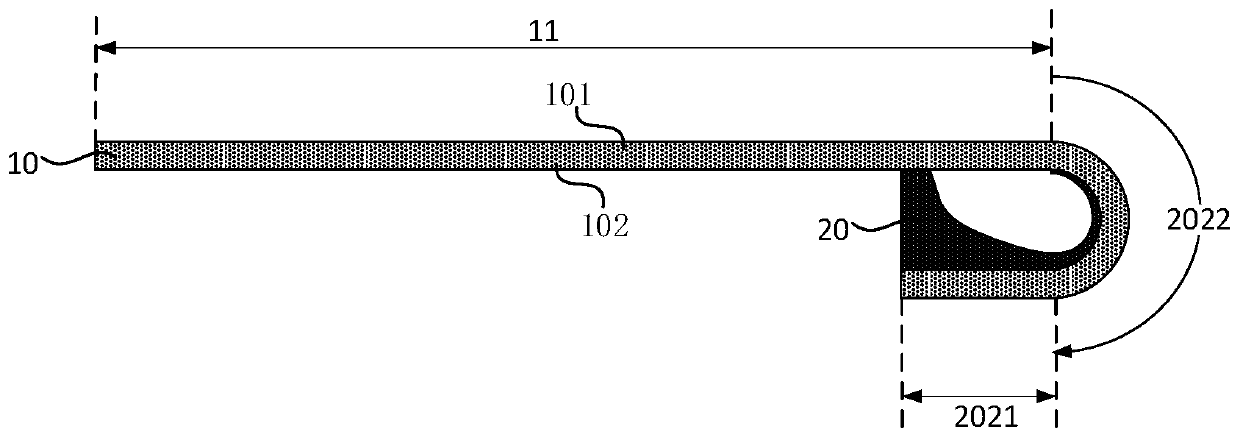

A propeller mold structure

ActiveCN109226690BReduce modeling difficultiesReduce the difficulty of fittingFoundry mouldsFoundry coresLeading edgePropeller

The invention provides a propeller molding structure and belongs to the field of molding technology. The propeller molding structure comprises an integral lower mold, upper molds A of which the numberis the same as that of blades, and upper molds B of which the number is the same as that of the blades. The external suction surfaces of the upper molds A are positioned between the leading edge parting surfaces and the following edge parting surfaces of the upper molds A, and are positioned above the pressure surfaces of the lower molds after being matched; and the leading edge parting surfacesof the upper molds A are matched with the leading edge parting surface of the lower mold after being assembled, the following edge parting surfaces of the upper molds A are matched with the followingedge parting surface of the lower mold after being assembled, and the following edge side walls of the upper molds A are perpendicular to the following edge parting surfaces and are matched with the following edge side wall of the pressure surface of the lower mold after being assembled. Partial blade root suction surfaces starting from leading edges in the upper molds B are matched with adjacentpartial blade root suction surfaces starting from following edges after being assembled so as to form internal suction surfaces; and internal leading edge parting surfaces are matched with the leadingedge parting surfaces after being assembled. The propeller molding structure provided by the invention can reduce the modeling difficulty of overlapping areas of blade roots, increase the molding thickness of propeller blade roots, enhance the molding strength of blade roots, as well as reduce the mold assembly difficulty of propeller molding.

Owner:DALIAN UNIV OF TECH

A display panel and a display device

ActiveCN109285461BIncreasing the thicknessIncreased resistance to twisting stressDigital data processing detailsSubstation equipmentDisplay deviceStructural engineering

Owner:YUNGU GUAN TECH CO LTD

A predistortion device for power amplifier and its parameter selection method

ActiveCN106411271BPrecise Non-Linear RepresentationTo achieve the purpose of power amplifier linearizationAmplifier modifications to reduce non-linear distortionSynchronous/start-stop systemsAudio power amplifierRF power amplifier

The invention discloses a predistortion device for a power amplifier and a parameter selection method thereof. According to the device and the method, the analog fitting degree of a power amplifier back inverse model is high, and the coefficient resolving precision of a predistorter is high. The device comprises a predistortion model operation processor which is used for establishing a predistortion model expression based on a memory polynomial, wherein the order of each memory item in the memory polynomial is determined by a vector parameter corresponding to the memory item in a first vector parameter group; and the predistorter which is used for receiving an input signal and obtaining an output signal according to the predistortion model expression.

Owner:成都芯通软件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com