Automatic exhaust type protective film

An automatic exhaust and protective film technology, which is applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of non-shock resistance, non-scratch resistance, short life, etc., and improve the ability of automatic foam removal , Reduce the difficulty of lamination, and the effect of excellent foam removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

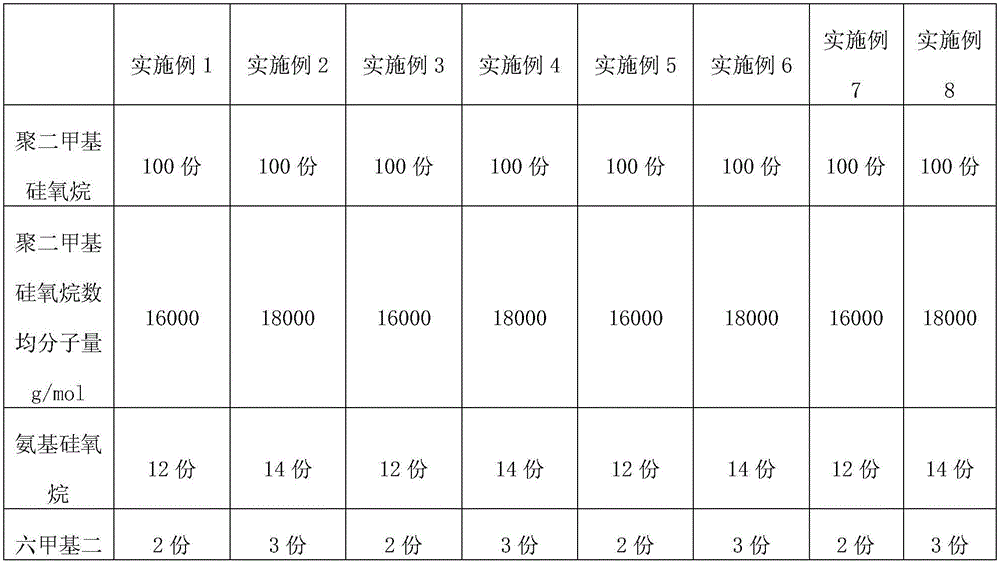

[0015] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0016] This case lists an embodiment of the self-venting protective film, which includes a venting layer and a PET substrate layer;

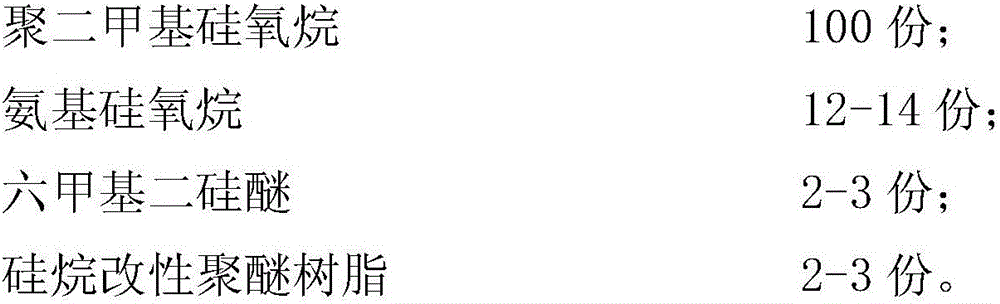

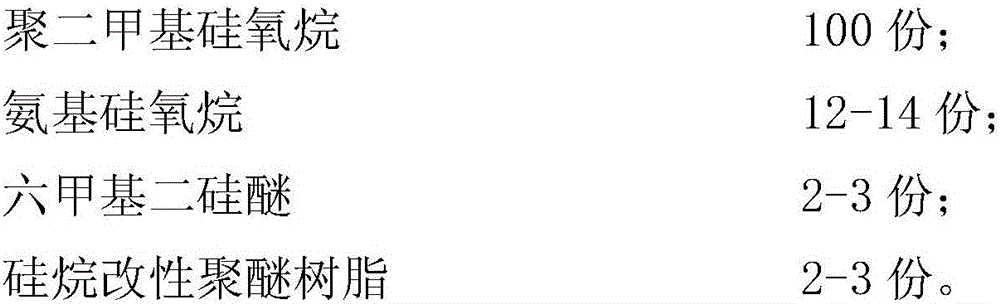

[0017] Wherein, the exhaust layer includes the following materials by weight:

[0018]

[0019] The exhaust layer is mainly composed of polydimethylsiloxane, and aminosiloxane is used to synergistically improve the auto-foaming ability of polydimethylsiloxane; hexamethyldisiloxane is used to improve the The cohesion of the alkane system can reduce the residual rate of the exhaust layer and increase the number of repeated tearing and pasting of the exhaust layer; the silane-modified polyether resin can improve the water repellency of polydimethylsiloxane to reduce the impact of the exhaust layer on The absorption rate of moisture in the air, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com