Patents

Literature

935results about How to "Guaranteed bonding strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

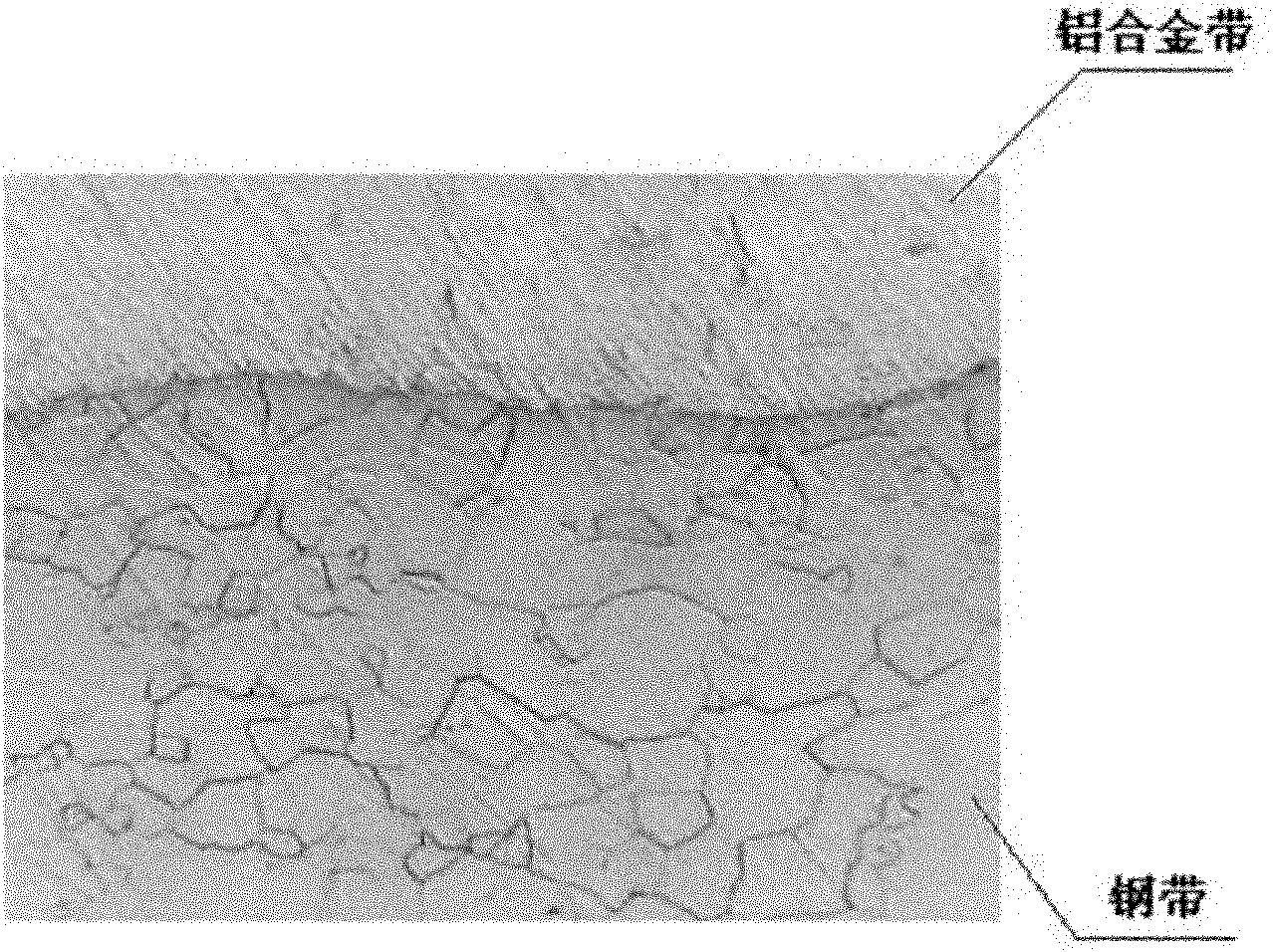

Aluminium-clad steel strip for coolers and preparation method thereof as well as steel strip and aluminium alloy strip used thereby

InactiveCN102019727AGuaranteed bonding strengthImprove mechanical propertiesLaminationLamination apparatusAluminum compositesSteel belt

The invention relates to an aluminium-clad steel strip and a preparation method thereof as well as a steel strip and an aluminium alloy strip used thereby, in particular to an aluminium-clad steel strip for coolers and a preparation method thereof as well as a steel strip and an aluminium alloy strip used thereby. The invention solves the problems of pinholes, composite layer inclusions, generation of brittle iron aluminium metallic compounds and failure to adapt to brazing technology in the industrially produced steel-aluminium composite material at present. The aluminium-clad steel strip for coolers is prepared by cladding a steel strip and an aluminium alloy strip. The preparation method comprises the following steps: 1. pretreating the surfaces of the steel strip and the aluminium alloy strip; 2. sandwich-rolling; and 3. recrystallization annealing. In the steel strip, the content of C is less than 0.01%, the content of Si is less than 0.01%, the content of Mn is 0.20-0.30%, and the content of Alt is less than 0.005%. In the aluminium alloy strip, the content of Si is 0.70-0.90%, and the content of Fe is 0.30-0.45%. The invention is applicable to the field of brazing coolers.

Owner:HARBIN SONGRUN METAL PRODS

Ventilated polyurethane plastic race-track surface layer cementing material

ActiveCN103666233AGuaranteed bonding strengthGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMass ratioEnd-group

The invention discloses a ventilated polyurethane plastic race-track surface layer cementing material, and belongs to the technical field of race-track construction. The ventilated polyurethane plastic race-track surface layer cementing material consists of a component I and a component II at the mass ratio of 1:(3-4), wherein the component I is prepolymer containing isocyanate end group prepared from environment-friendly polyisocyanate, polyether glycol and an addition agent by reacting in a reaction kettle for 3 to 4 hours at the temperature of 70 to 80 DEG C, and the component II comprises polyether glycol with three functionalities, inorganic filler, pigment, a plasticizing agent, a curing agent, an antioxygen, an ultraviolet light absorber and the like. The obtained plastic race-track has the advantages that surface particles are not easy to fall out, the surface is smooth, the quality of the plastic race-track is improved, the service life of the plastic race-track is prolonged, the qualification rate of the plastic race-track is increased to more than 95% as compared with the conventional 82%, the production cost and the use cost are reduced. Moreover all of the used raw materials are environmental protection materials, and belongs to environment friendly materials, the environmental pollution is avoided, and security is provided for the health safety of sporters.

Owner:金华市一家建设工程有限公司

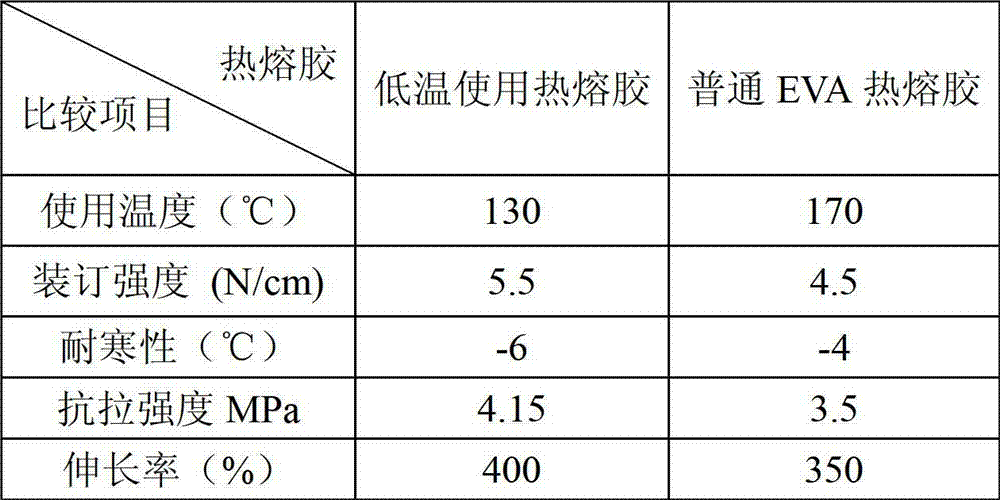

Book thermoplastic binding hot melt glue used at low temperature and preparation method thereof

InactiveCN102925080AImprove performanceNot easy to carbonizeMineral oil hydrocarbon copolymer adhesivesRosin adhesivesThermoplasticPolymer science

The invention relates to hot melt glue and a preparation method thereof, and belongs to the technical field of preparation of hot melt glue. The preparation method comprises the following steps of: starting stirring and opening a heat-conduction oil heating valve; sequentially filling ethylene-vinyl acetate (EVA) resin, a filler, a wax diluents and an antioxygen according to the proportion into a reaction kettle for heating; totally melting each component; adding tackified resin to heat until the tackified resin is totally melted; vacuumizing a reaction system until the reaction system has no bubbles; adding a filter screen and discharging at a discharging port of the reaction kettle; and cooling and forming the materials to obtain a product. The book thermoplastic binding hot melt glue can be used at about 130 DEG C, and is suitable for linkage line production; compared with the traditional book thermoplastic binding hot melt glue, the using temperature is reduced by 30 DEG C to 50 DEG C, so that the production energy consumption (electric energy, heat energy and the like) is reduced, the maintenance cost of equipment is reduced, and the production efficiency is improved; and the glue performance in a glue groove is stable, energy-saving production is facilitated, and the hot melt glue is environment-friendly.

Owner:WUXI WANLI ADHESION MATERIALS

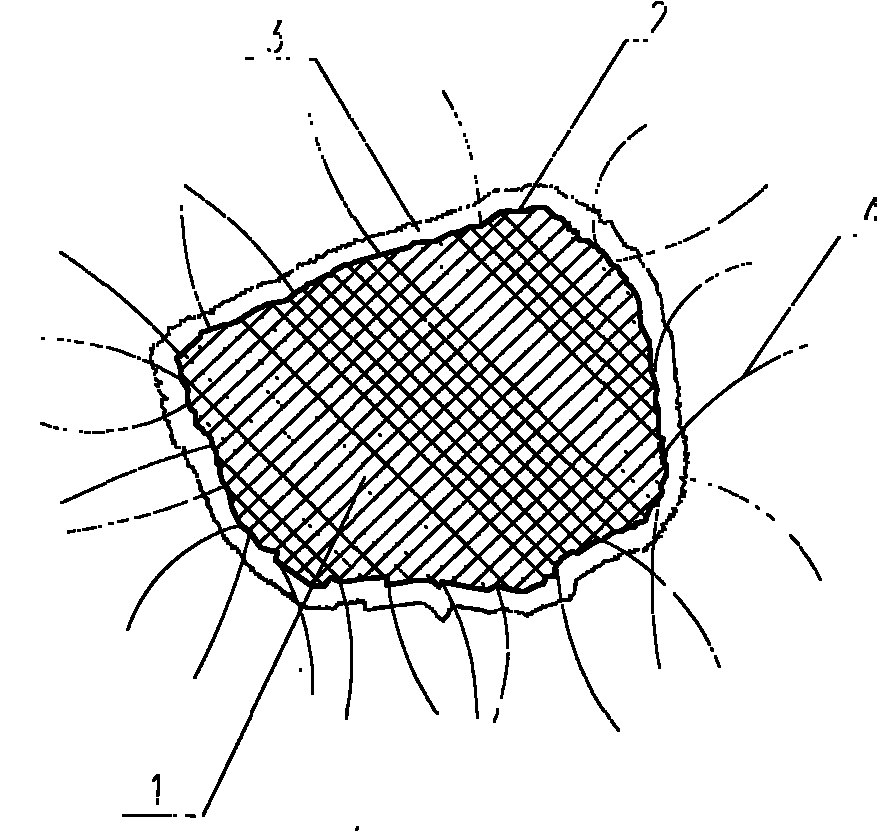

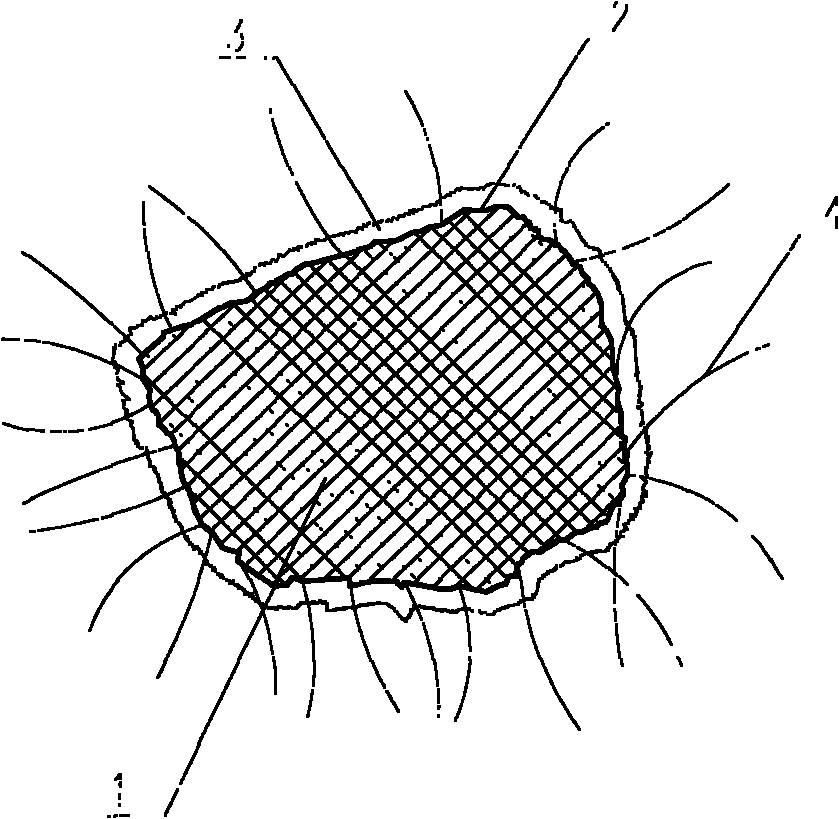

Stone aggregate wrapped by microfine fibre polymer mortar thin layer and preparation method thereof

InactiveCN101863631AHigh compressive strengthStrong resistance to deformationSilica fumeVolcanic ash

The invention discloses a stone aggregate wrapped by a microfine fibre polymer mortar thin layer and a preparation method thereof; the stone aggregate is formed by stone aggregate inner cores, an adhesive inner wrapping layer, a polymer cement mortar outer wrapping layer and an adhesive microfine fibre hair layer, wherein the adhesive inner wrapping layer and the stone aggregate are adhered firmly; microfine fibre filaments are anchored and rooted on the adhesive inner wrapping layer; and the polymer cement mortar outer wrapping layer and the adhesive inner wrapping layer are soluble mutually and can effectively form a whole body. Active powder in the polymer cement mortar outer wrapping layer contains silica fume, zeolite powder, finely-ground mineral slag, pulverized coal ash and the like, and can generate volcanic ash reaction with Ca(OH)2 crystal at the interface position of the set cement so as to generate gelled materials, and further carry out improved treatment on the weakest interfaces of set cement and the stone aggregate in concrete. The modified stone aggregate of the invention has good affinity with the set cement, and has higher binding power with the set cement.

Owner:NANTONG ZHONGRUN CONCRETE +1

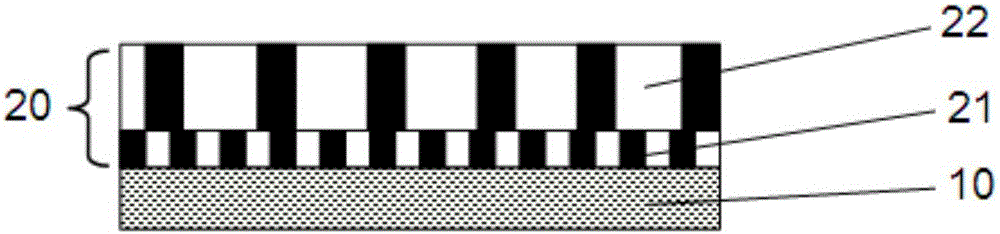

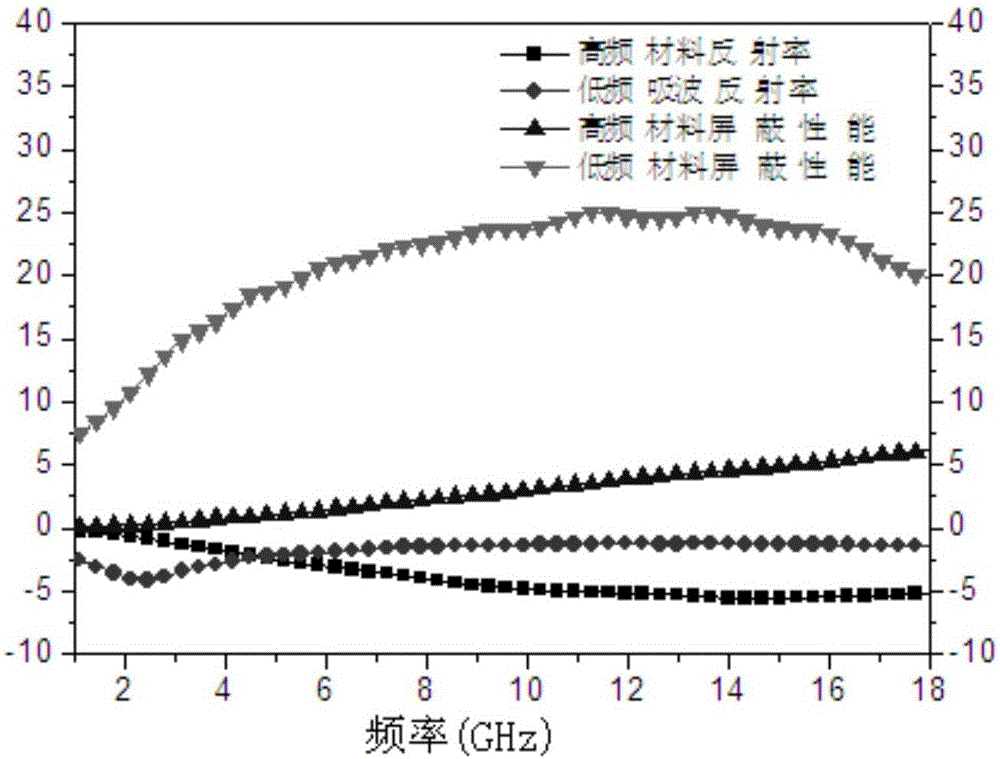

Broadband wave-absorbing material and preparation method thereof

The invention discloses a broadband wave-absorbing material and a preparation method thereof. The broadband wave-absorbing material is composed of a low frequency wave-absorbing material bottom layer and a high frequency wave-absorbing material surface layer. The high frequency wave-absorbing material surface layer comprises a plurality of high frequency wave-absorbing layers with different concentrations. FeSi or FeSiAl particles are taken as the additive of the low frequency wave-absorbing material, and carbonyl iron particles are taken as the additive of the high frequency wave-absorbing material. A rolling method is adopted to prepare the low frequency wave-absorbing material bottom layer, and a three-dimensional moulding technology is adopted to prepare the high frequency wave-absorbing material surface layer. The multilayer lamination manufacturing method combines a multi-rolling technology and three-dimensional moulding together and has the advantages that the binding force between layers can be ensured, multiple repeated mould pressing is avoided, the thickness of each layer, the internal structure, and particle distribution can be adjusted so as to satisfy the predetermined electromagnetic property requirements; the broadband wave-absorbing performance of the wave-absorbing material and designable performance of a shielding material can be realized; the integrated manufacturing of space structure of the wave-absorbing material is achieved, and the preparation cost is low at the same time.

Owner:SHANGHAI RADIO EQUIP RES INST

Method for retreading old porcelain brick wall by paint

InactiveCN101586401AAvoid crackingImprove water resistanceCovering/liningsBuilding repairsGlass fiberBrick

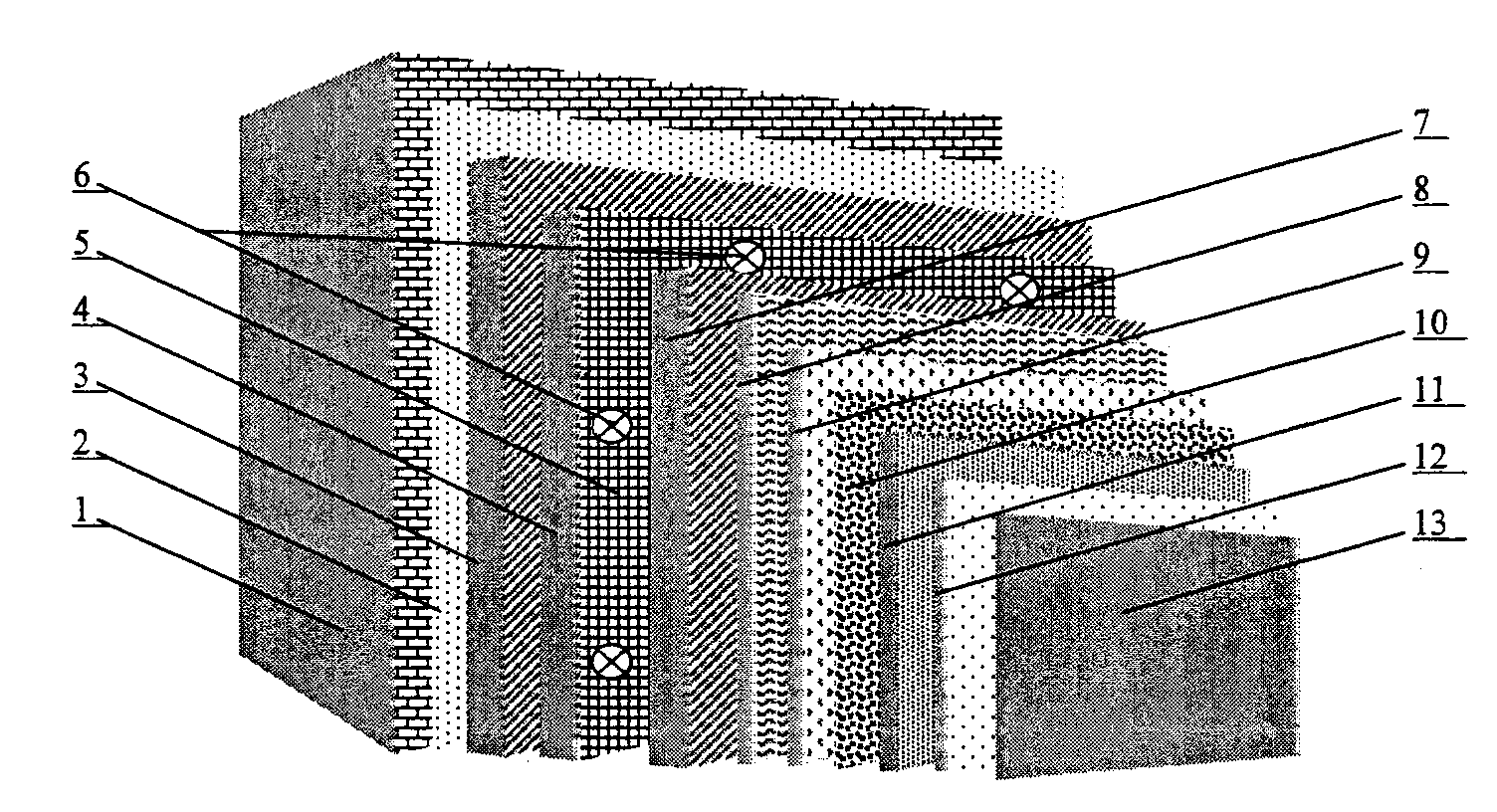

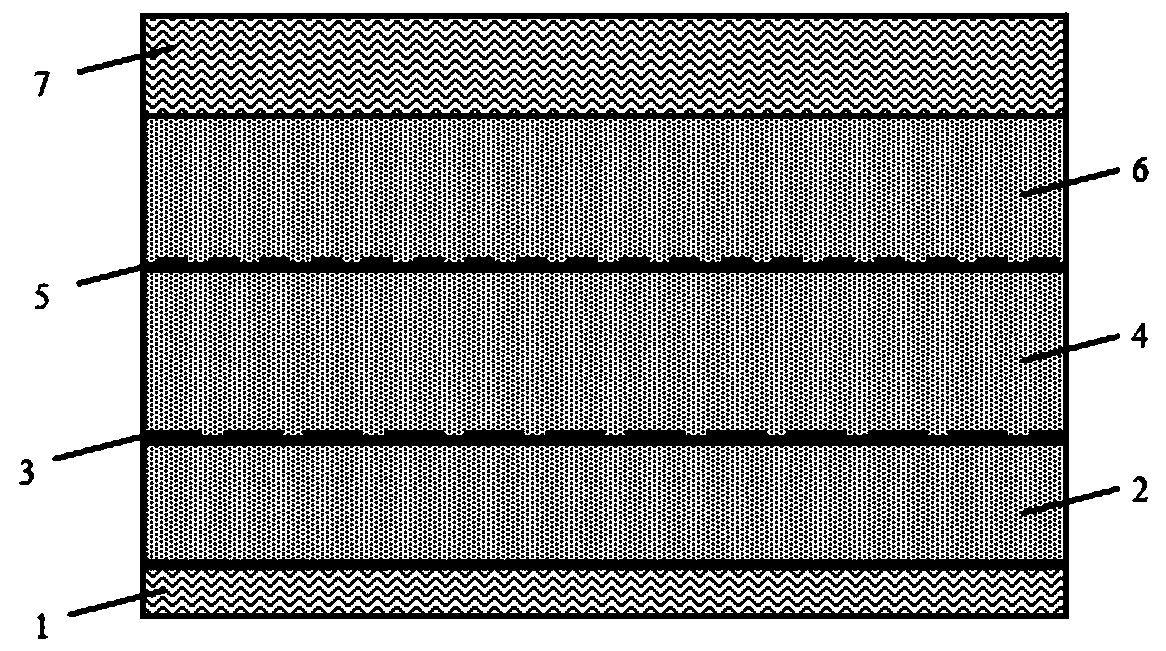

The invention relates to a method for retreading the old porcelain brick wall by the paint, a retreading decorative layer composed of a interface binder layer (2), a first polymer cracking-resistant putty layer (3), a second polymer cracking-resistant putty layer (4), a glass fiber girding cloth (5), a third polymer cracking-resistant putty layer (7), a double-component flexible putty layer (9), a smooth surface putty layer (9), a seal coat layer (10), a middle coating layer (11), a flexible silicone-acrylate latex paint layer (12) and a fluoric-carbon coating varnish layer (13) is formed on the old wall surface porcelain brick of the old wall (1), an anchor nail (6) passes through the glass fiber gridding cloth (5), the second polymer cracking-resistant putty layer (4) and the first polymer cracking-resistant putty layer (3) and is embedded in the old wall (1) for the mechanical reinforcement, all layers above are dried and solidified and are integrated with the old wall (1) firmly to complete the retread of the old wall surface. The construction cost and the labor strength are low, the old porcelain brick on the wall surface can not fall off, the decorative is high.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Heat preventing and insulating stealth compound material with broad-band wave absorption and preparation method thereof

ActiveCN107555940AMeet the needs of impedance matchingRealize broadband absorbing functionLamination ancillary operationsLaminationWeight gainingControllability

The invention discloses a heat preventing and insulating stealth compound material with broad-band wave absorption and a preparation method thereof. The compound material comprises a cold-faced panel,a first aerogel compound material heat-insulating layer, a first resistance high-temperature super-material layer, a second aerogel compound material heat-insulating layer, a second resistance high-temperature super-material layer, a third aerogel compound material heat-insulating layer and a hot-faced panel from inside to outside sequentially. In the aspect of heat preventing and insulating performance, compared with existing heat insulating tiles and cover plate type heat prevention systems, the integrated heat preventing and insulating stealth compound material has the advantages of good heat insulating performance, excellent mechanical performance, large component preparation availability, high reliability, easiness in maintenance and the like; and in the aspect of stealth performance, the technical scheme adopting the high temperature super-material has the advantages of strong designability and easiness in broad-band wave absorption implementation, weight gain is hardly generated in comparison with the technical scheme of a cold-faced by adopting a wave absorbing material, absorbent is not required to be added into a heat preventing and insulating material, the heat preventing and insulating performance is not influenced, and the material has good uniformity and strong controllability.

Owner:NAT UNIV OF DEFENSE TECH

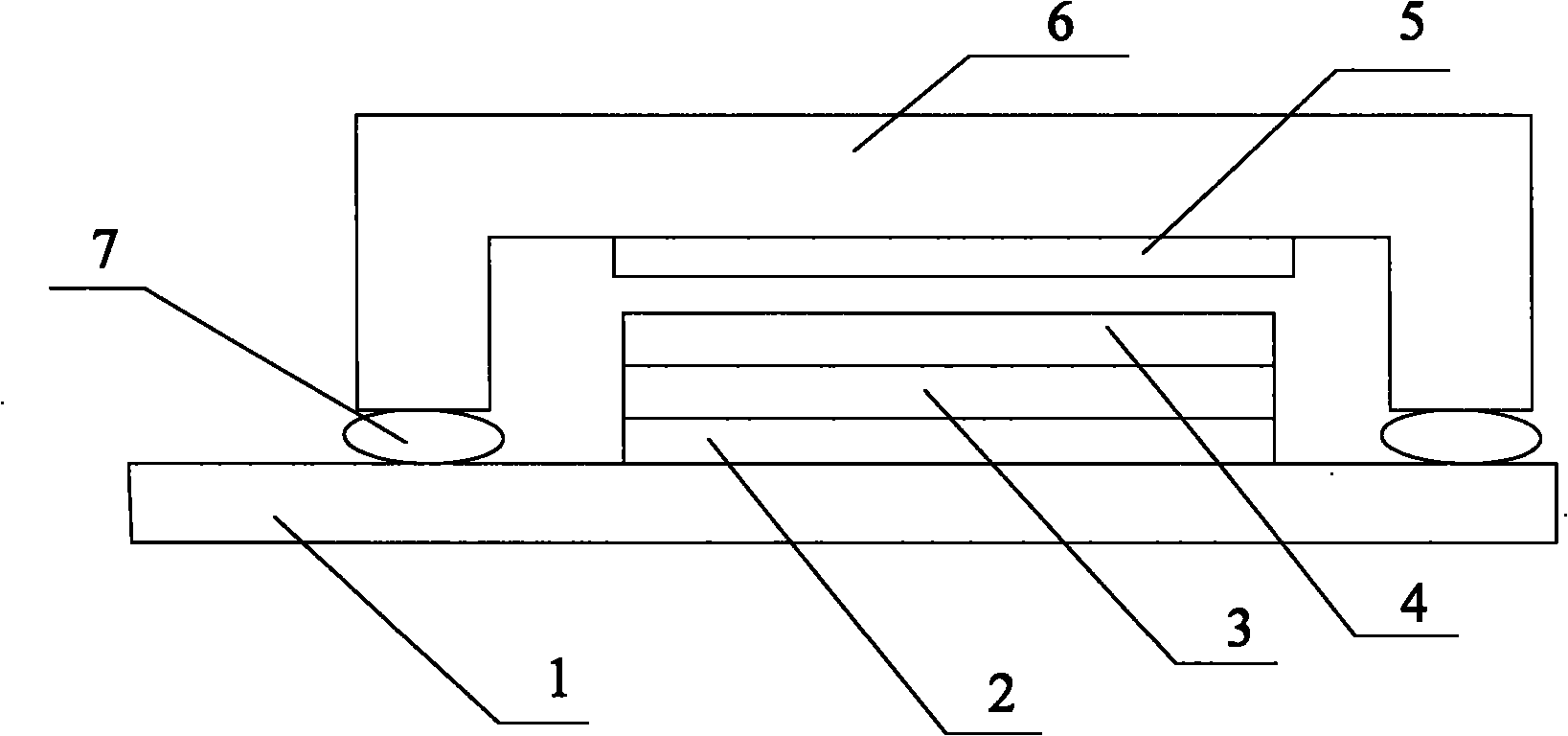

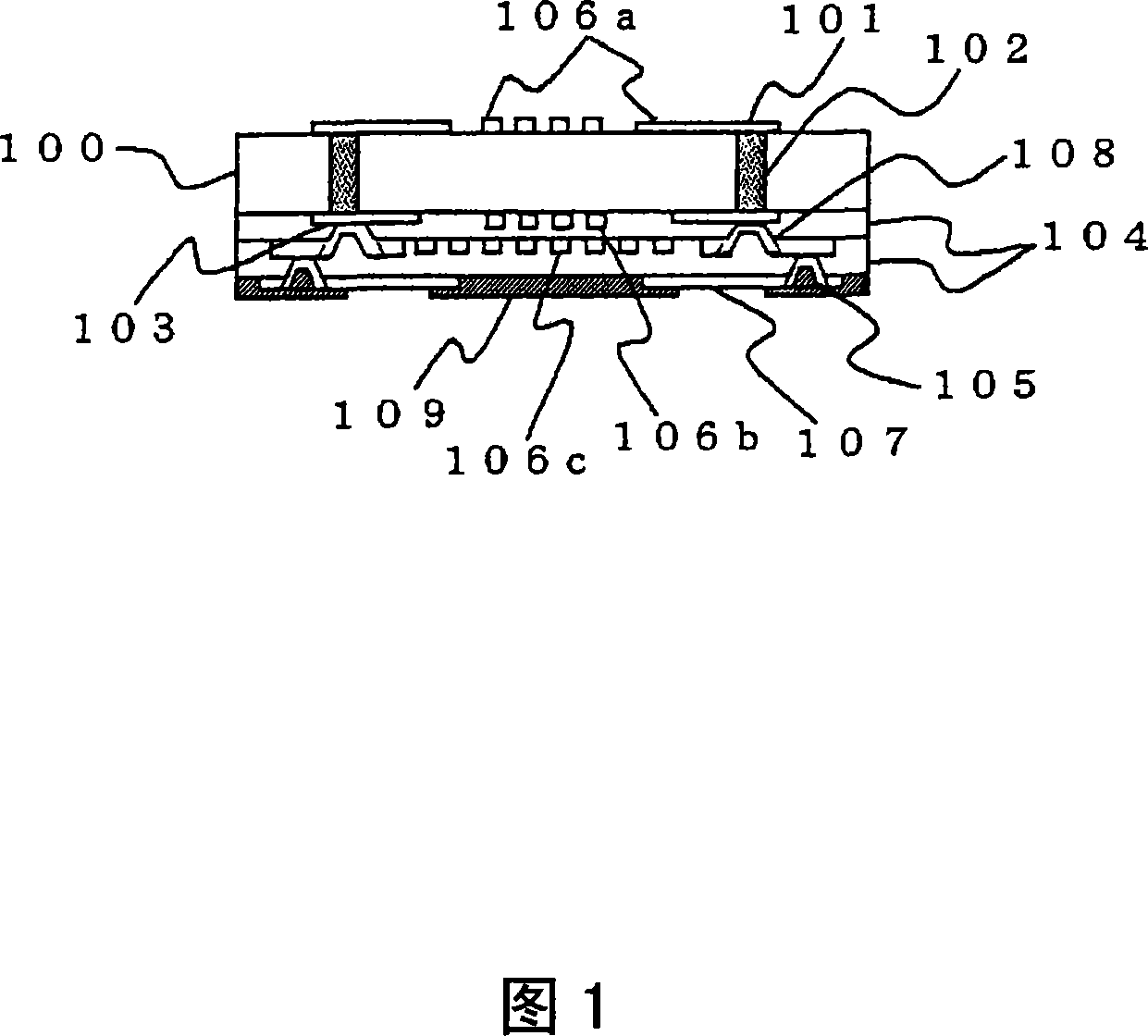

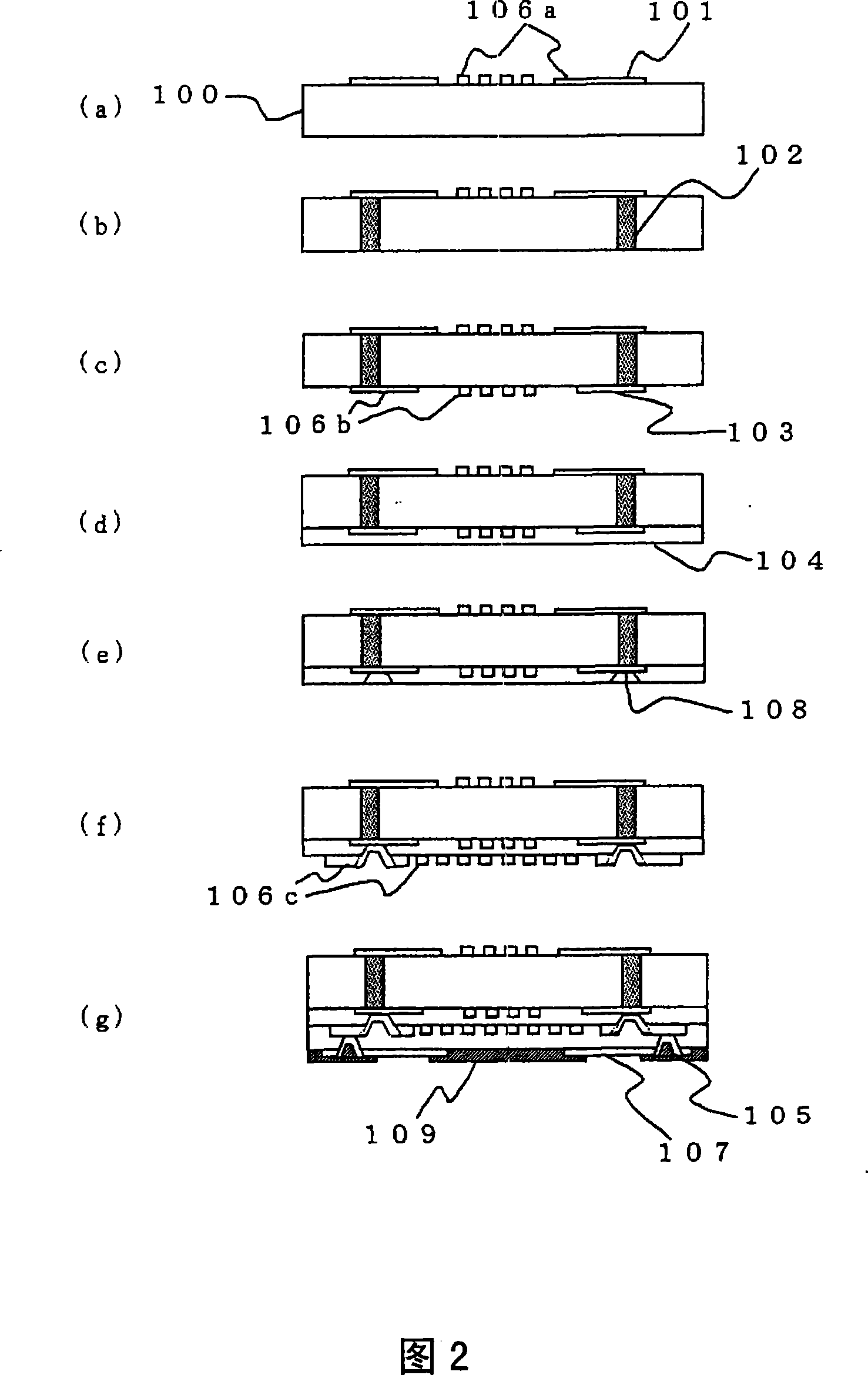

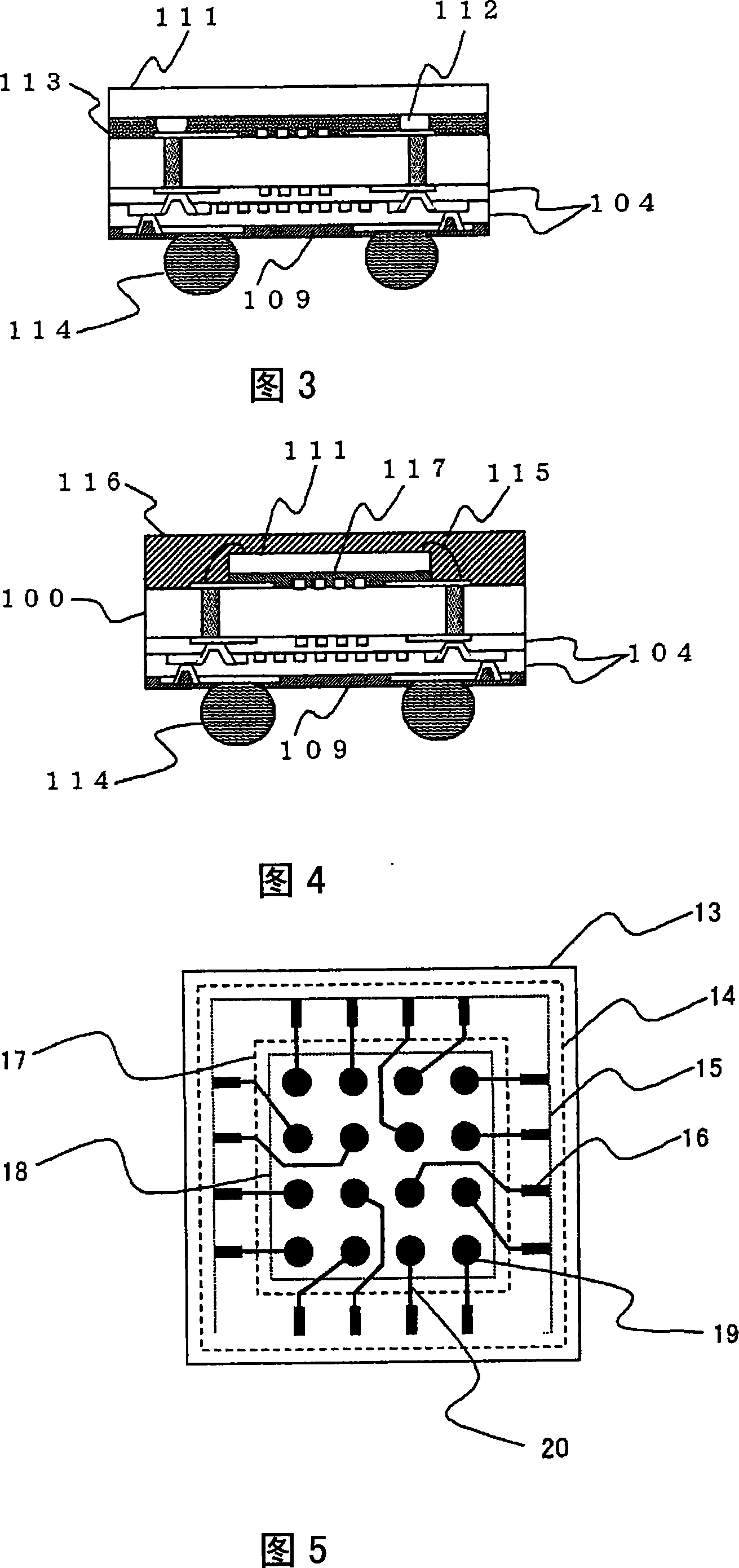

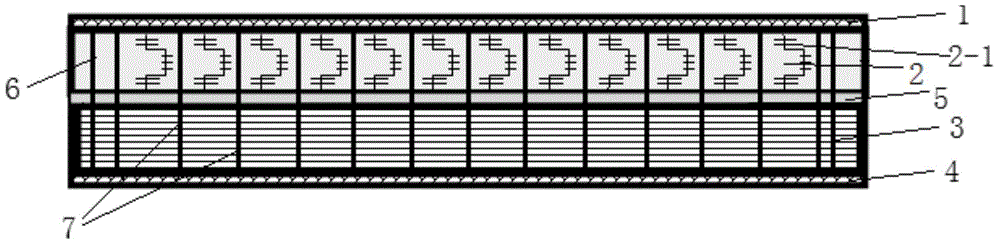

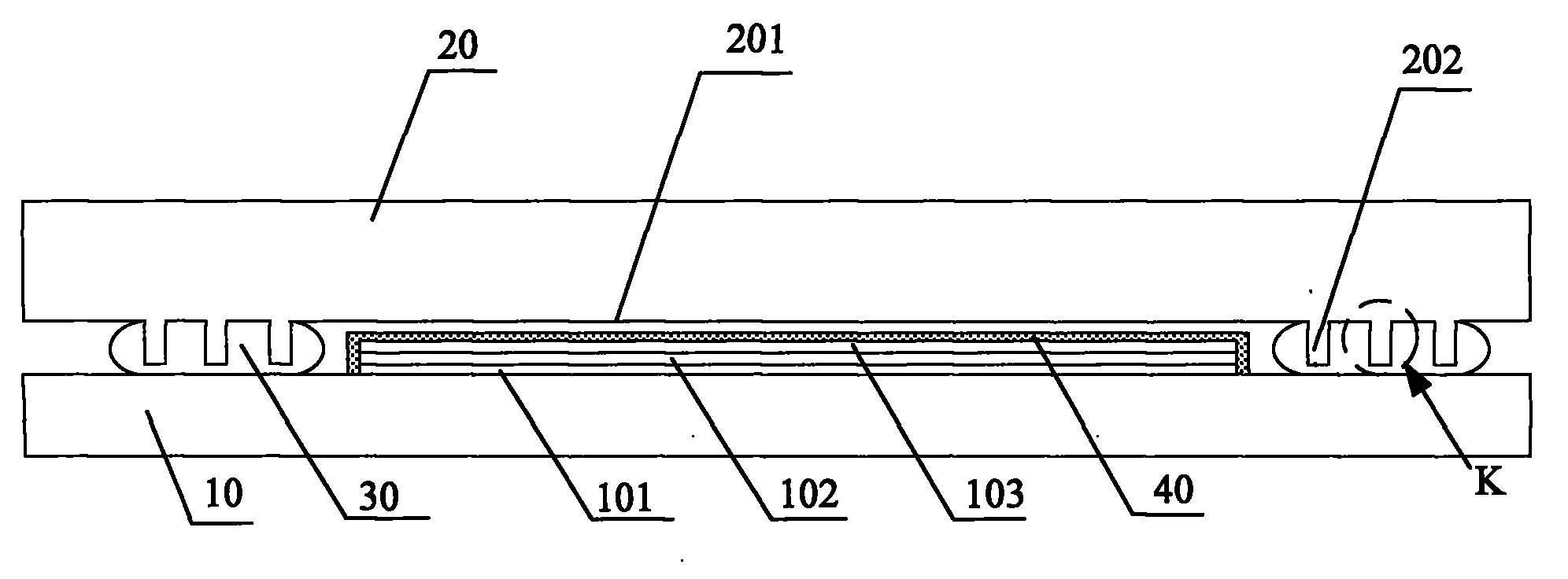

Organic light-emitting diode display

ActiveCN101866944AExtended service lifeReduce distanceSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveDisplay device

The invention discloses an organic light-emitting diode (OLED) display. The organic light-emitting diode display comprises a substrate, a rear cover and a packaging adhesive, wherein the substrate is provided with a pixel display region matrix; a water-absorbing protection layer covers the surface of each pixel display region; the surface of the rear cover facing the substrate is provided with a light emitting region corresponding to the pixel display region matrix on the substrate; the rear cover also comprises at least one ring of continuous bumps surrounding the light emitting region at the periphery of the light emitting region; and the packaging adhesive is positioned on the contact surface of the substrate and the rear cover, surrounds the light emitting region and completely covers the at least one ring of bumps surrounding the light emitting region. By forming the bumps at the periphery of the light emitting region of the rear cover, the required adhesive strength can be ensured during the packaging of the OLED, the distance between the rear cover and the substrate can be greatly reduced, and the capability of the OLED of preventing the penetration of vapor and oxygen can be enhanced; and the vapor having penetrated into the OLED can be adsorbed by further covering a transparent water-absorbing protection layer on the pixel display region, so that the organic functional layer can be protected.

Owner:TRULY SEMICON

Method for preparing high-solid-content sulfonic-acid waterborne polyurethane adhesive

ActiveCN103242794AReduce difficultyShorten the timePolyureas/polyurethane adhesivesPolyesterSulfonate

The invention relates to a method for preparing high-solid-content waterborne polyurethane. The method comprises the following steps of: (1) reacting sulfonate-containing sodium dimethyl isophthalate-5-sulfonate with excessive polylol for a while, and then, adding polyacid to react so as to synthesize hydroxyl-terminated polyester; and (2) using the synthesized waterborne polyester as a soft segment, using diisocyanate as a hard segment, adding water to disperse, and carrying out chain extension by using polyamine so as to obtain the high-solid-content waterborne polyurethane. According to the method, the dispersion is easy, a large amount of solvent is not required for being used, the cost is saved, the solvent removal is easy, and the solid content reaches over 50% while lower viscosity is kept, so that the constructability of adhesive liquid is improved, and the adhesive liquid is crystallizable and has better initial viscosity and better adhesive strength; and the used polyester is synthesized autonomously, the raw materials are all common, and the process is simple, so that the cost is saved, and the industrialization is facilitated.

Owner:武汉工大科技园发展有限公司

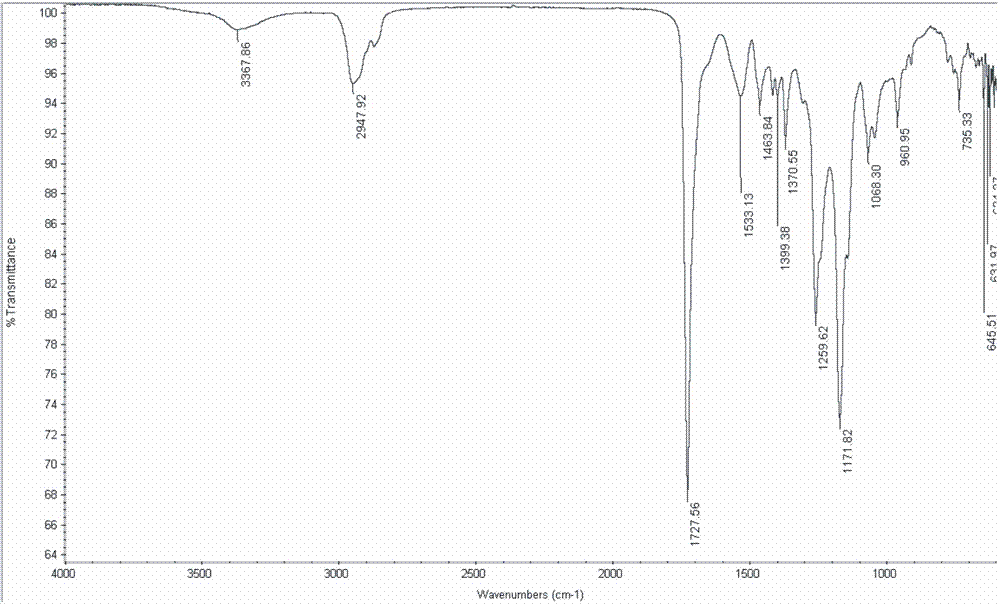

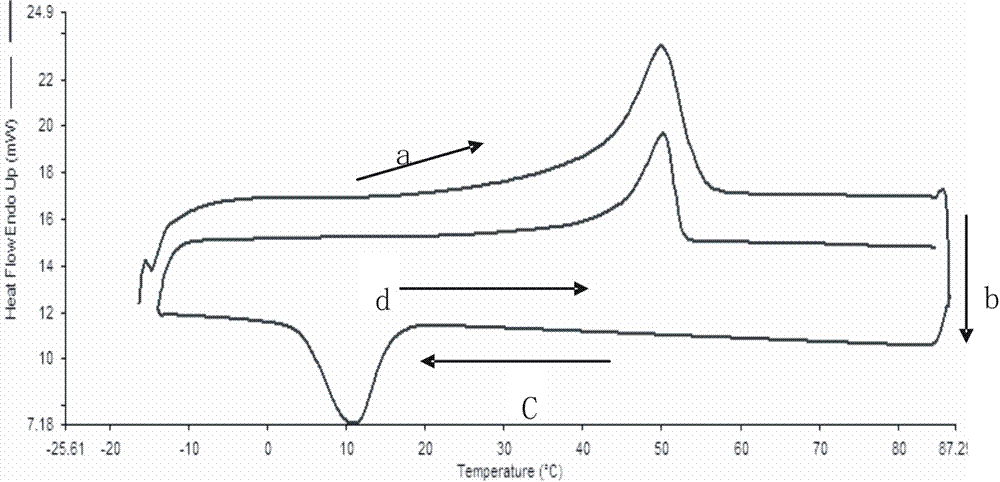

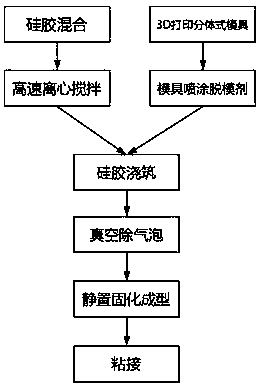

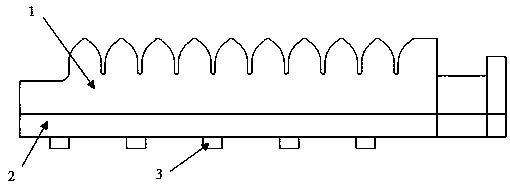

Pneumatic soft mechanical hand and manufacturing method

ActiveCN107856044AGuaranteed bonding strengthImprove gripGripping headsManufacturing technologyAdhesive

The invention discloses a pneumatic soft mechanical hand and a manufacturing method. The split type design scheme is adopted in the soft mechanical hand, the soft mechanical hand is divided into a corrugated pipe installation part and a bottom plate part, and the soft mechanical hand is manufactured by adopting the split type casting technology. After the two parts are machined and manufactured correspondingly, the two parts are bonded together by the adoption of special silica gel adhesive. The performance of the soft mechanical hand depends on the self structure and the solidifying formationquality of silica gel. In the actual soft mechanical hand manufacturing process, by constantly improving a casting die and the finger manufacturing technology, a set of complete manufacturing technology is formulated, and the machining quality of the soft mechanical hand is ensured.

Owner:ZHEJIANG UNIV

Steel-aluminum composite board and preparation method thereof

InactiveCN102734625AReduce in quantityHigh binding densitySheets/panelsMetal rolling arrangementsCompound aPerformance index

The invention relates to a steel-aluminum composite board which is formed by compounding a steel belt and an aluminum alloy belt, wherein the steel belt comprises the following components in percentage by weight: less than or equal to 0.012% of C, less than or equal to 0.025% of Si, 0.10-0.30% of Mn, less than or equal to 0.018% of P and less than or equal to 0.010% of S; and the aluminum alloy belt comprises the following components in percentage by weight: 0.75-0.85% of Si, 0.36-0.45% of Fe, less than 0.05% of Cu and less than or equal to 0.03% of Mn. The preparation method comprises the following steps of: a, pretreatment; b, compounding rolling; and c, recrystallizing and annealing. Through the invention, the prepared steel-aluminum composite board has excellent mechanical performance index, and the bonding strength between the steel belt and the aluminum alloy is guaranteed after the brazing of a cooler fin.

Owner:JIANGSU LONGYUAN METAL TECH

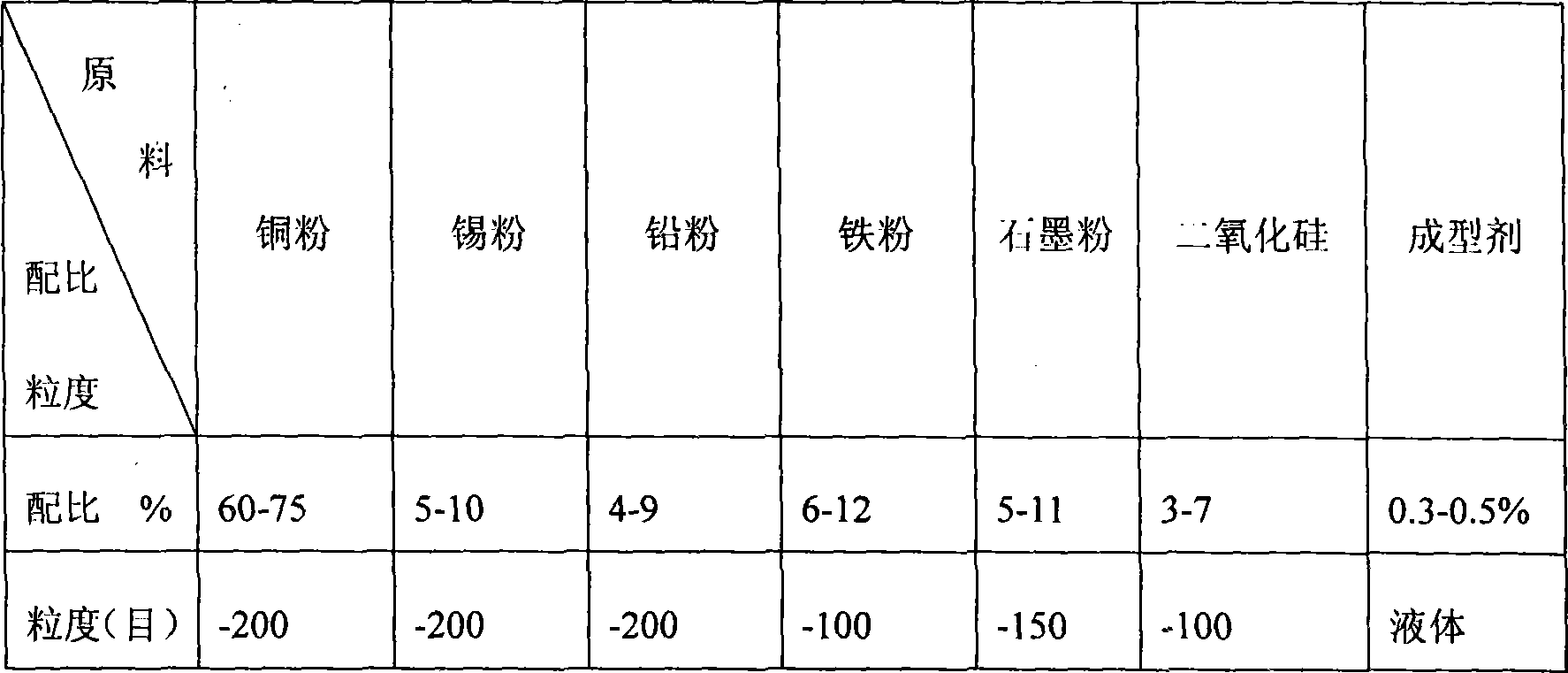

Wet-type copper based powder metallurgy friction wafer and manufacturing method

ActiveCN101178102AImprove process efficiencyHigh porosityFriction liningPowder metallurgyPressureless sintering

The invention provides a wet copper basic powder metallurgy friction disc and a manufacture method. The friction disc mainly consists of a middle steel core plate and at least a side upper friction layer; at least one surface of the steel core plate is combined with a rubber film layer which is composite with a friction layer; the manufacture method at least comprises friction layer material distributing, mixed material, pressing-typed, burning, assembly with the steel core plate, and oil trough processing. The invention is characterized in that no pressure burning in a continuous burning furnace is adopted for burning; the friction layer after burning is dipped in rubber in a vacuum rubber dipping trough in normal temperature and is dried and assembled with the steel core plate; before the assembly, the surface of the steel core plate is coated; after assembly, the pressurization and solidification are carried out on a slab vulcanizing machine; the invention has the advantages of high efficiency of processing technique, low cost, increasing the hardness and strength, high size precision, etc.

Owner:HANGZHOU ADVANCE GEARBOX GRP

Accumulator sealant

InactiveCN101007932AImprove adhesionGuaranteed bonding strengthOther chemical processesLead-acid accumulatorsSolventSealant

The invention discloses an accumulator seal gum, which is characterized in that: it comprises component A and B, and the weight proportion between A and B is 4: 1; A comprises epoxy resin, diluting agent and / or solvent; B comprises curing agent and plasticizing agent. Said epoxy resin is bisphenol a epoxy resin or mixture of bisphenol a epoxy resin and novolac epoxy. The flowability of seal gum is pretty good, and it will flow levelly automatically instantly after injection in plastic groove, which greatly increases the working efficiency for aritifical sealing, and the stretching and cutting strength is far better than the country standard of 3 Mpa.

Owner:刘永祥

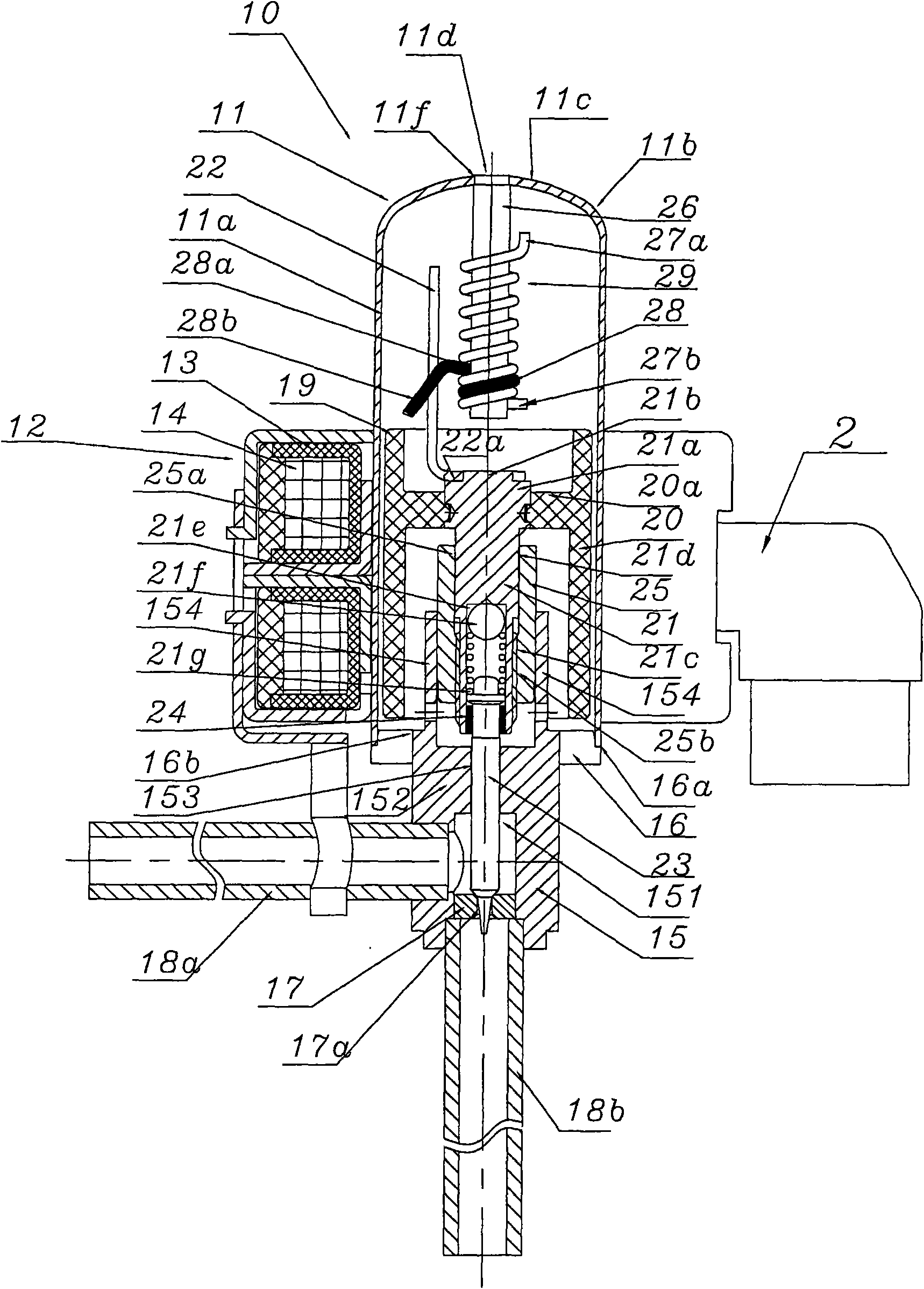

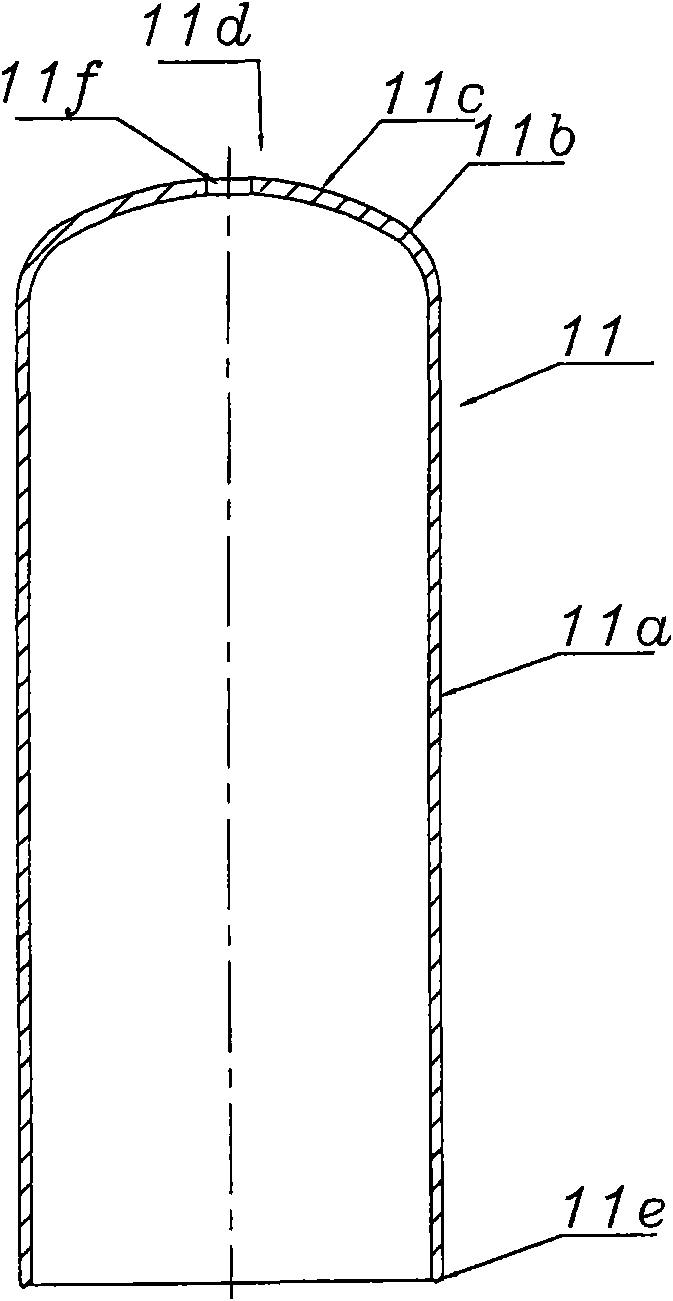

Electric valve

InactiveCN101769388ARealize thin wallNo need to increase wall thicknessOperating means/releasing devices for valvesFluid circulation arrangementEngineeringVALVE PORT

The invention discloses an electric valve. A rotor forming a step motor and a valve needle are arranged in a sealed space formed by an outer shell, the bottom of the outer shell is fixed on a valve body, the valve needle approaches or is apart from a valve seat of the valve body according to the upward and downward axial movement of the rotor, and a shaft member forming a stopping mechanism is taken as a rotation stopping mechanism of the rotor and is fixed at the top of the outer shell in a drooping state in the outer shell; the outer shell forming the seal space consists of a cylinder wall, a bending part and an arc part, and the bending part is formed by connecting the cylinder wall; and the circular edge of the bottom of the cylinder wall is fixed on the valve body, the arc part forms the top of the outer shell, and the fixation of the shaft member is implemented by laser welding.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

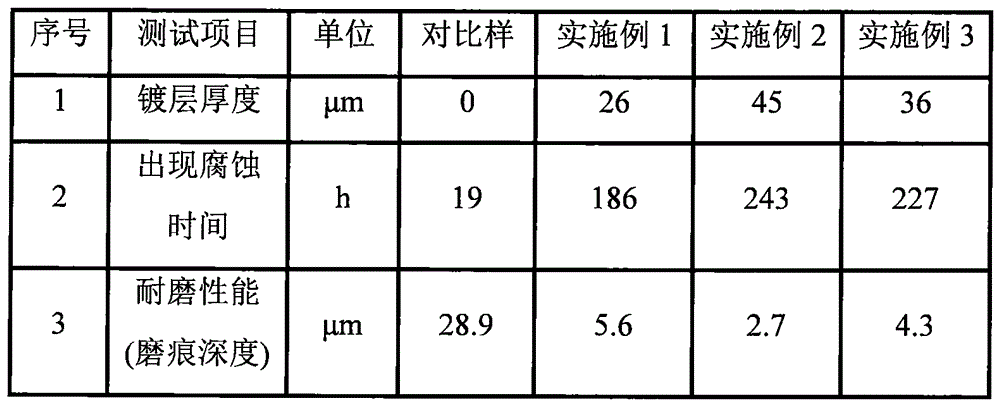

Corrosion-resistant multi-coating neodymium iron boron and preparation process

ActiveCN106710767AAccelerated corrosionImprove wear resistanceMagnetic materialsSuperimposed coating processSingle processDysprosium

The invention provides corrosion-resistant multi-coating neodymium iron boron and a preparation process. The corrosion-resistant multi-coating neodymium iron boron is composed of a neodymium iron boron permanent magnet and multiple coatings arranged on the outer surface of the neodymium iron boron permanent magnet, the multiple coatings sequentially include a nickel-plated layer, a dysprosium-plated aluminum alloy thin film layer and a nickel-chromium composite coating, thickness of the nickel-plated layer is 10-15um, thickness of the dysprosium-plated aluminum alloy thin film layer is 10-20um, and thickness of the nickel-chromium composite coating is 6-10um; modification of the multiple coatings can be realized on the surface of the permanent magnet, binding strength between the coatings and a permanent magnet base is guaranteed, the defect that the coatings are thin and poor in corrosion resistance and wear resistance caused by single process is overcome, and the corrosion-resistant multi-coating neodymium iron boron prepared by the process has high corrosion resistance and wear resistance.

Owner:宁波元辰新材料有限公司

Surface treatment method for copper and copper

ActiveCN101137768AImprove reliabilityCopper Surface Treatment Method for Improving ReliabilityMetallic material coating processesCopperOxidizing agent

A copper surface treatment method is provided to ensure adhesive strength between a copper surface and an insulating layer without forming a recess and a protrusion over 1[mu]m due to copper surface treatment and to improve insulation reliability between wirings. A copper is also provided. The surface treatment method is provided with a step of discretely forming a metal nobler than copper on the copper surface, and a step of successively oxidizing the copper surface by an alkaline solution including an oxidizing agent. The copper whose surface is treated by such method is also provided.

Owner:株式会社力森诺科

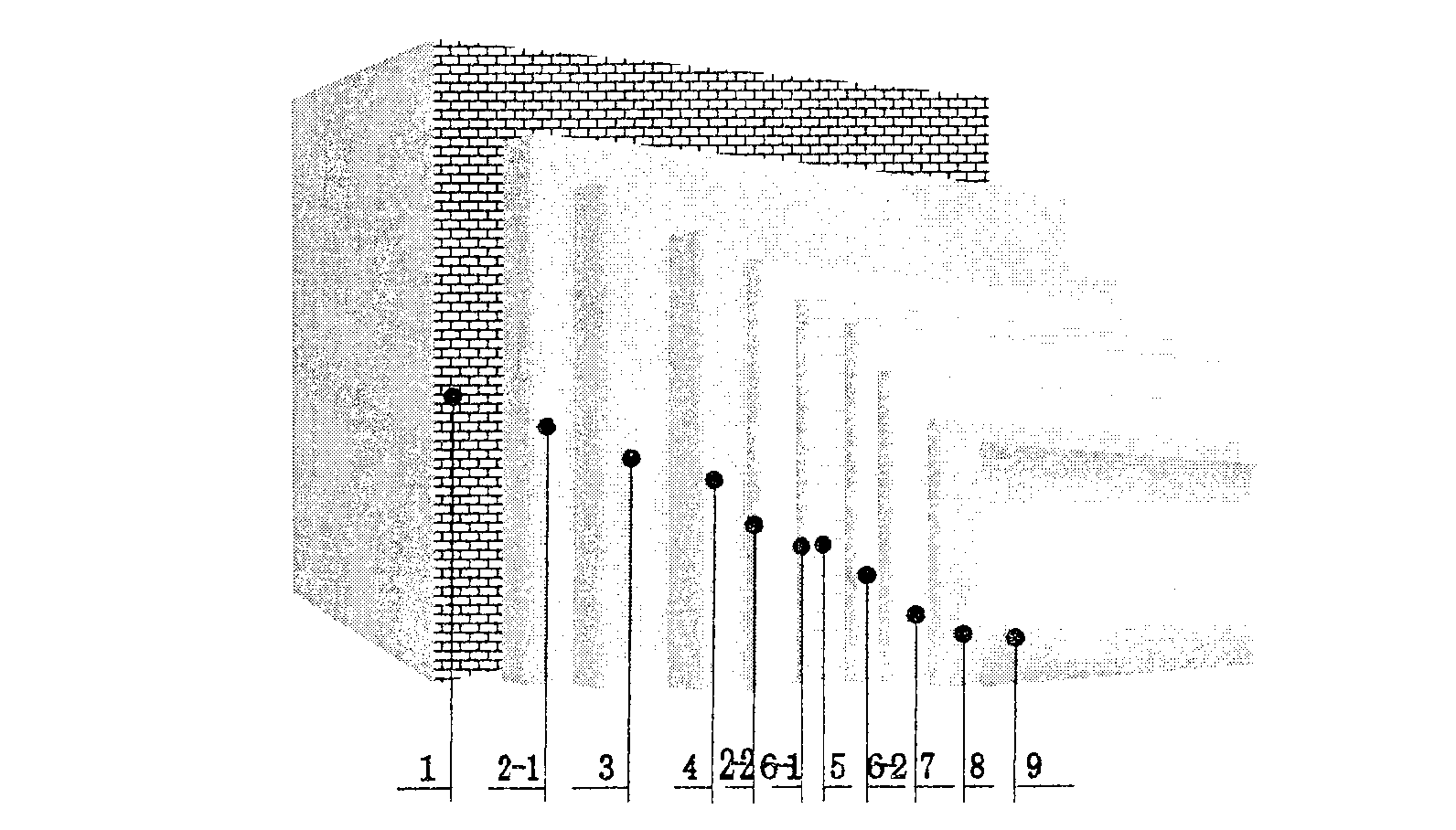

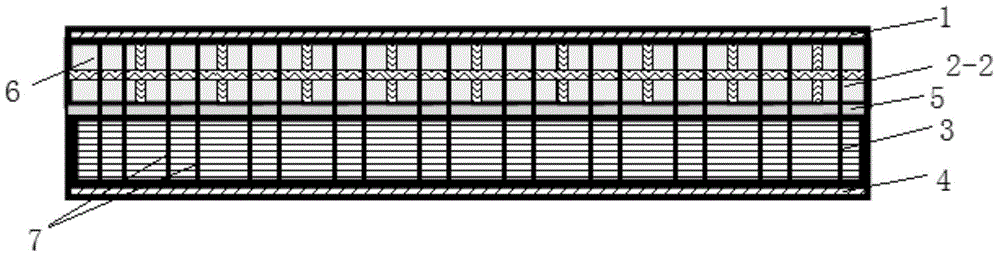

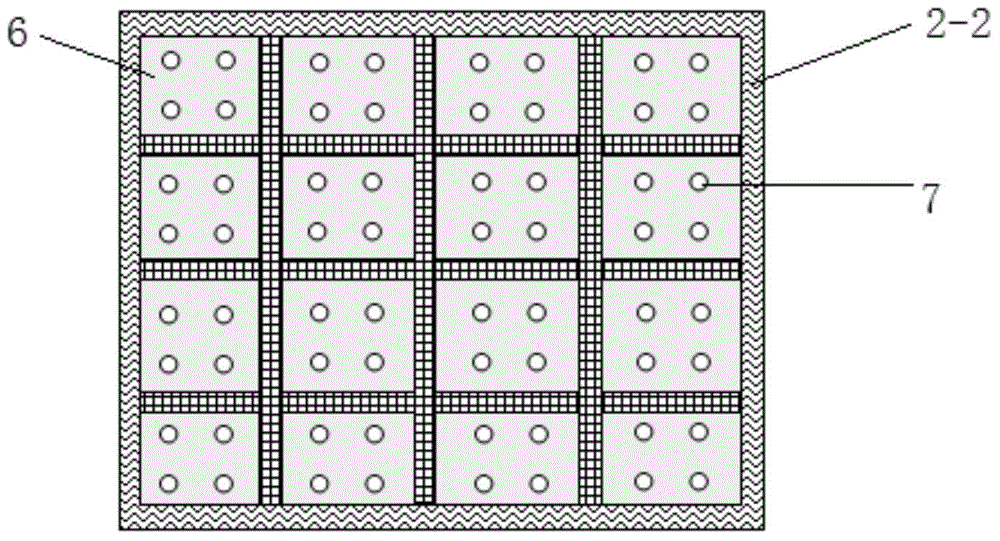

Outer heat-insulation system of outer wall

ActiveCN101634170ACoating with low thermal conductivityHigh solar heat reflectivityWallsClimate change adaptationMesh gridEngineering

The invention relates to an outer heat-insulation system of an outer wall. The outer surface of a basal layer wall body (1) is sequentially provided with an interfacial agent processing layer (2-1), a bonding mortar layer (3), a polyphenyl plate heat-insulation layer (4), a interfacial agent bonding layer (2-2), a first flexible heat- insulation putty layer (6-1), a second flexible heat- insulation putty layer (6-2), a closed base paint layer (7), an elastic heat- insulation coating layer (8) and a mat coat varnish layer (9) from inside to outside, wherein the first flexible heat- insulation putty layer (6-1) is internally provided with glass fibre gridding cloth (5); and all the layers are combined with the basal layer wall body (1) into a whole after being dried and solidified; flexible heat-preserving putty of the two flexible heat-preserving putty layers, which contains 20-40 percent of heat-preserving materials, is formed, and elastic heat-preserving coating of the elastic heat-preserving coating layer (8), which contains 5-15 percent of heat-preserving materials, is formed. The outer heat-preserving system can prevent the polyphenyl plate heat- insulation layer (4) from cracking and desquamating caused by external temperature difference because of the heat preservation and isolation of the flexible heat- insulation putty layers and the elastic heat-preserving coating layer (8), thereby prolonging the service life of the heat-preserving system and enhancing the energy-saving effect of buildings.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Ceramic composite material bullet-proof chest board and preparation method thereof

ActiveCN104949581AImprove structural impact resistanceGuaranteed bonding strengthSynthetic resin layered productsCeramic layered productsCeramic compositeMetallurgy

The invention discloses a ceramic composite material bullet-proof chest board and a preparation method thereof. The ceramic composite material bullet-proof chest board is composed of a carbon fiber composite surface rigid layer, a ceramic composite material sheet combination layer, a bullet-proof fiber composite material body layer and a back elastic surface carbon fiber composite back-convex-proof layer. The ceramic composite material sheet combination layer is made of special fiber reinforced ceramic matrix materials and is of a needling insertion type combined structure or a three-dimensional crazing-prevention framework structure; a composite cementing and micropore riveting combined technology is adopted between the ceramic composite material layer and the bullet-proof body layer; finally, the ceramic composite material sheet combination layer and the bullet-proof fiber composite material body layer are wrapped in a rigid structure composed of the carbon fiber composite surface rigid layer and the back-convex-proof layer to form a whole. The ceramic composite material bullet-proof chest board has various advantages of being light, low in back convex, stable in high and low temperature structure, long in service life and the like. Meanwhile, the problem that a seam bullet-proof characteristic in a traditional splicing structure of ceramic sheets is poor is effectively avoided, and the ceramic composite material bullet-proof chest board has the overall characteristics of multiple bullet-proof materials.

Owner:山东宽原新材料科技有限公司

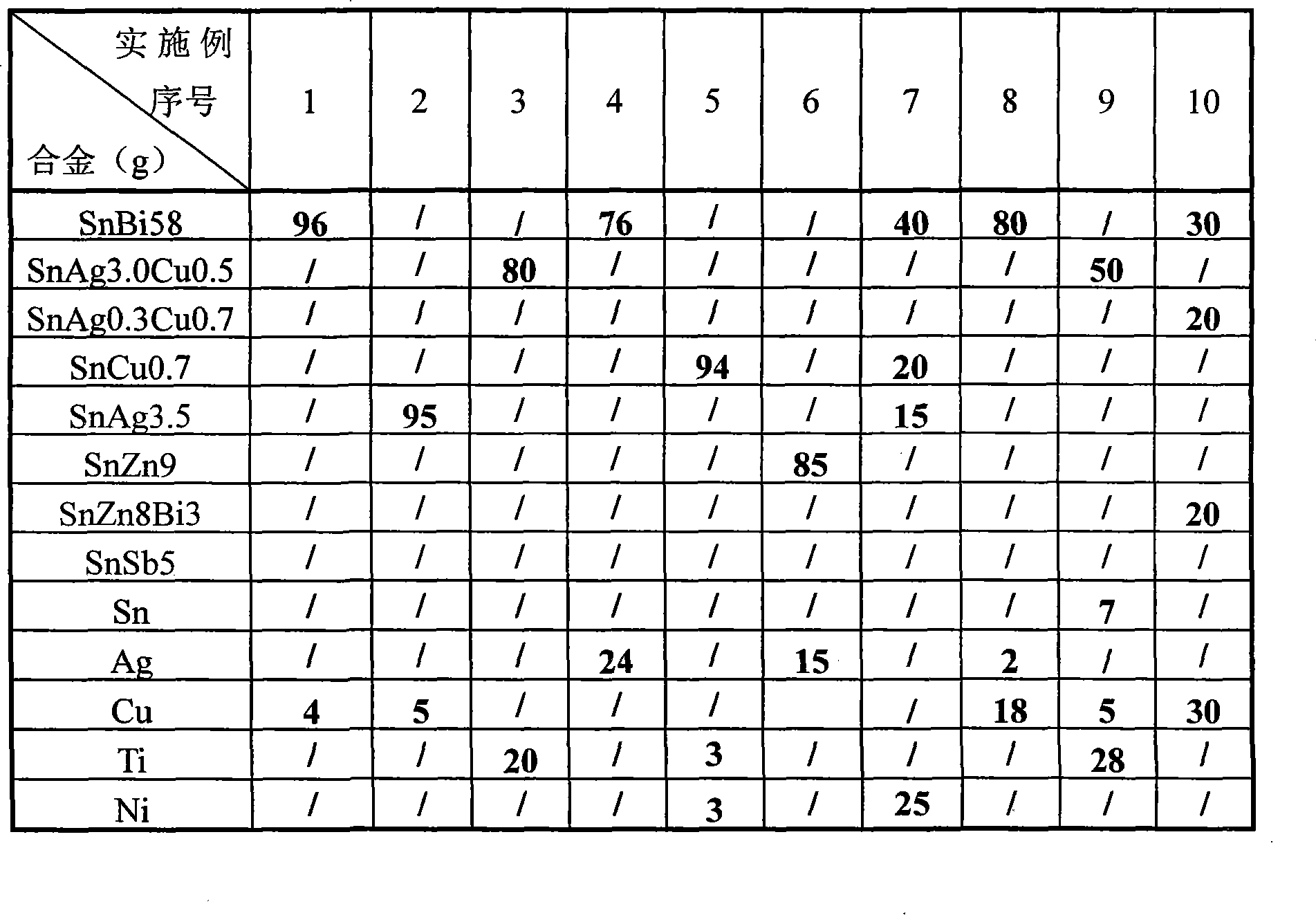

Low temperature leadless welding material for electronic component

InactiveCN101362261AAvoid damageImprove reliabilityWelding/cutting media/materialsSoldering mediaMetallic materialsTemperature resistance

The invention relates to an electronic packaging braze welding material and a technology thereof, in particular to a low temperature lead-free welding material used for electronic elements, which belongs to the technical field of metallic material engineering. The invention can replace high temperature welding, and ensure the welding spot to have good electrical conductivity, high temperature resistance and impact resistance. For the welding material, kaiserzinn welding powder or pure tin powder and high melting point metal powder Ag, Cu, Ti and Ni are mixed according to certain proportion, and solder paste is prepared by adding appropriate flux; or kaiserzinn welding powder and metal powder Ag, Cu, Ti and Ni are mixed according to certain proportion to prepare solder paste, so as to weld high melting point weld layer through lead-free solder paste at low temperature.

Owner:BEIJING COMPO ADVANCED TECH +1

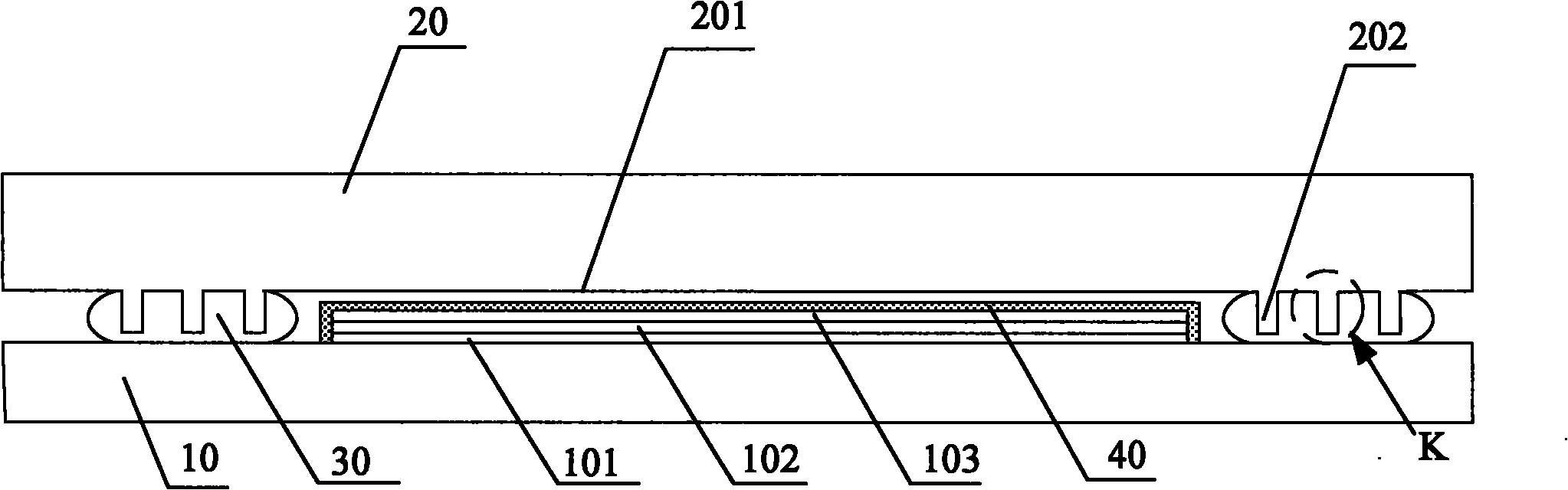

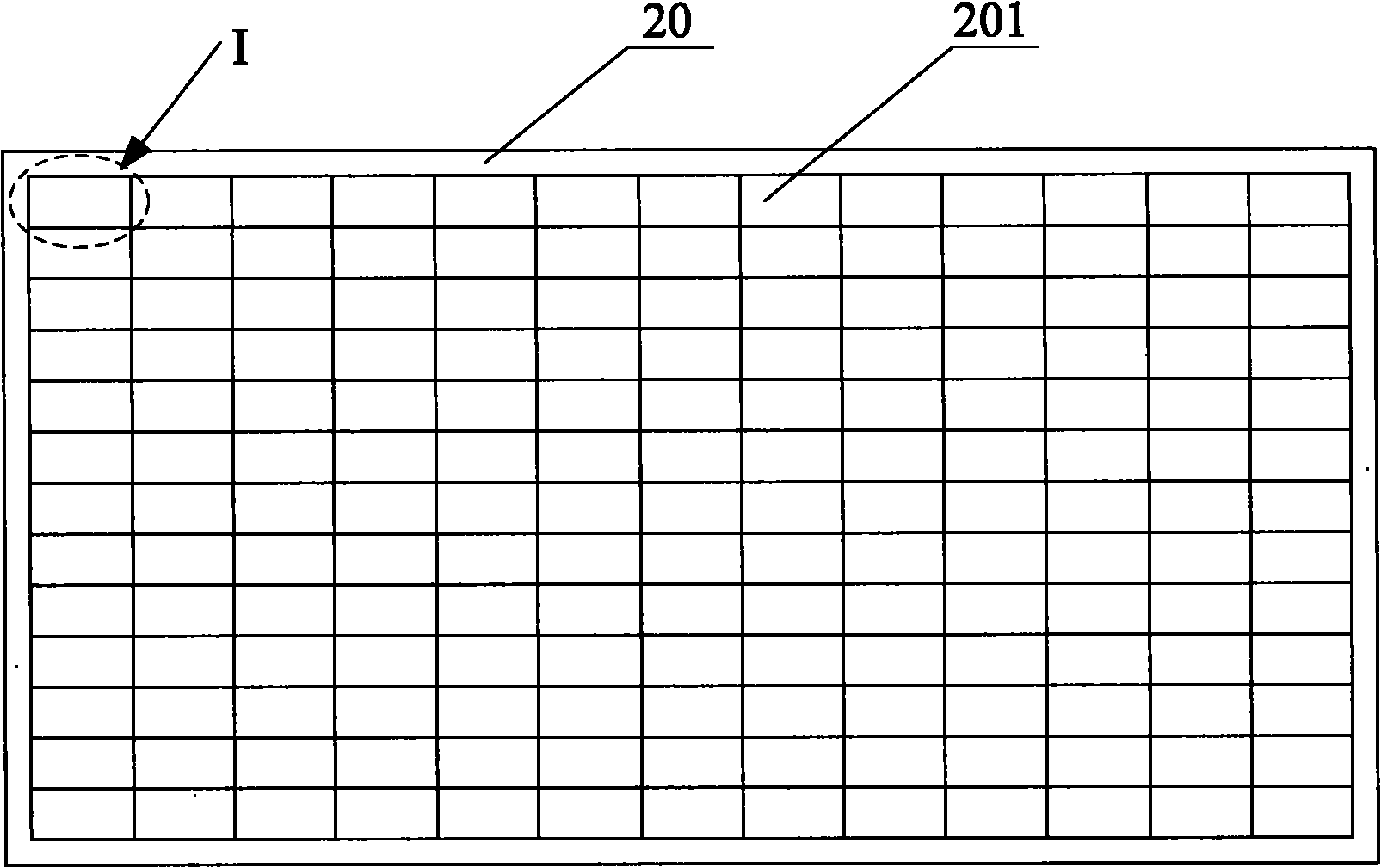

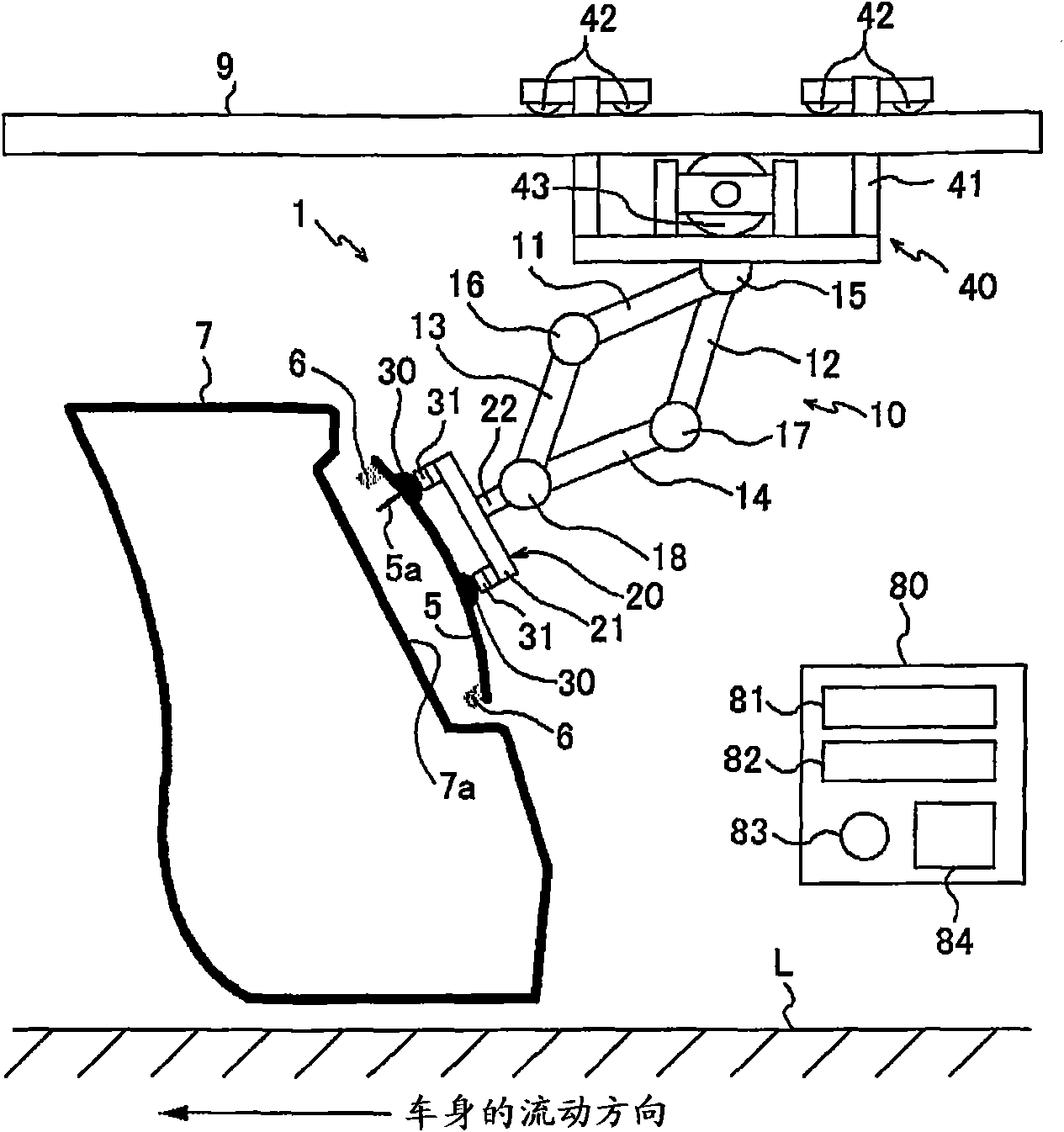

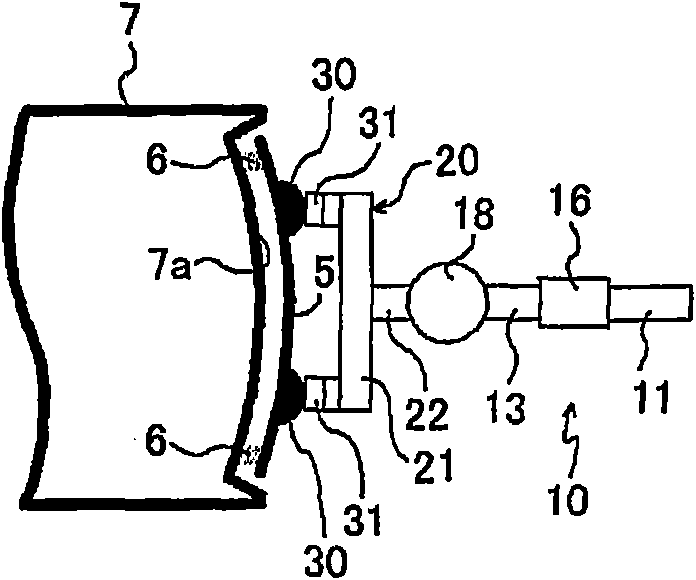

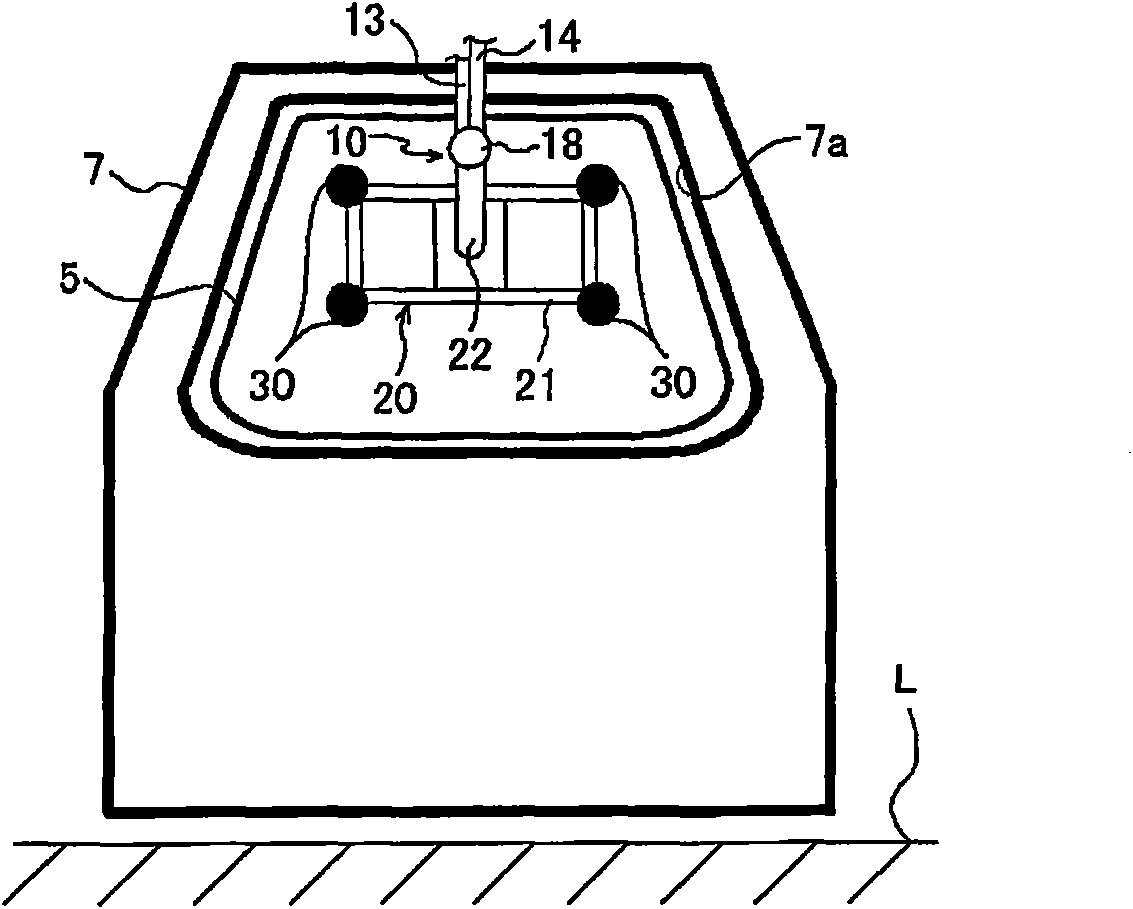

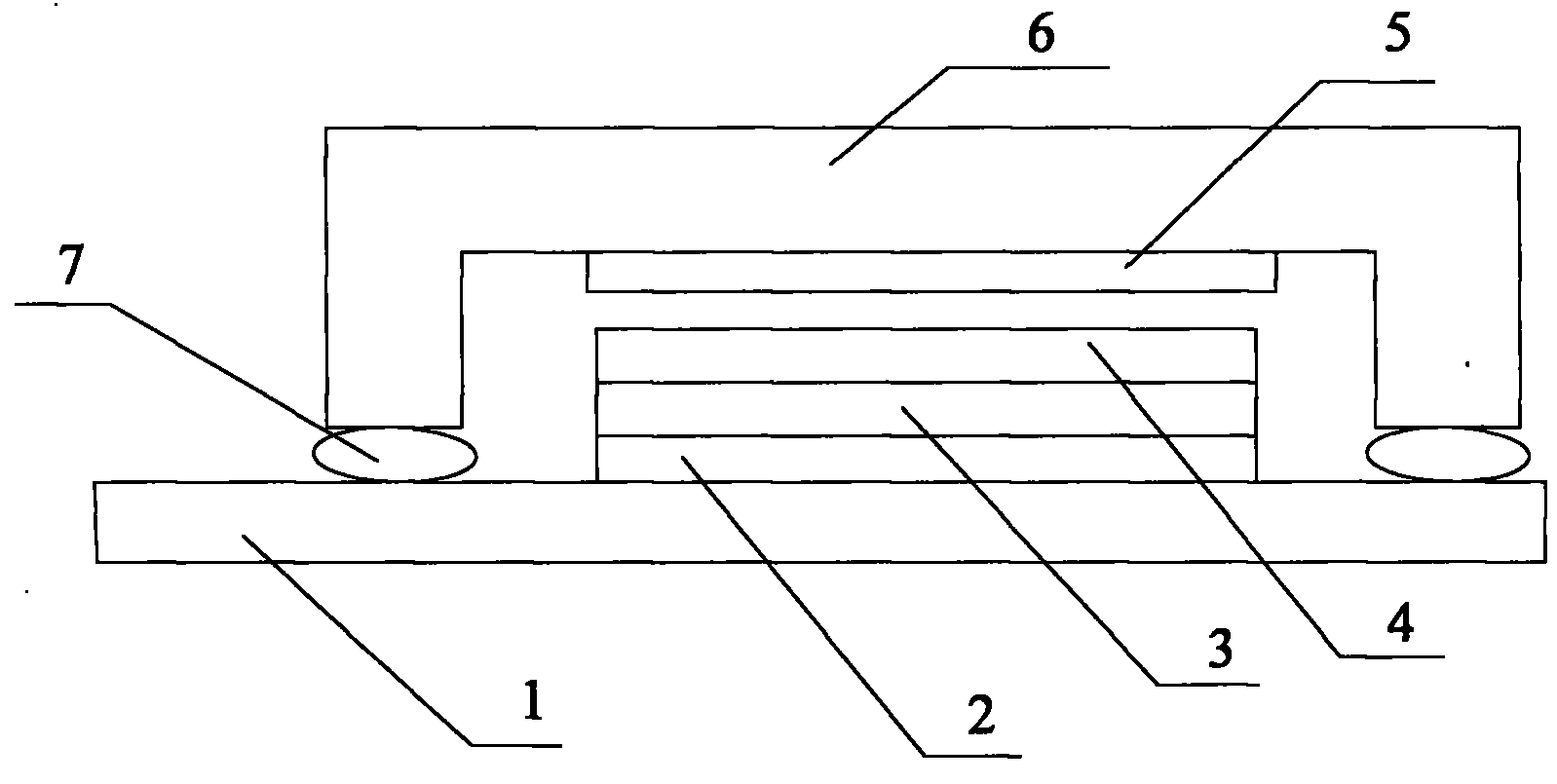

Work transfer apparatus, and work mounting method

InactiveCN101772402AImprove setting accuracySqueeze evenlyProgramme-controlled manipulatorGripping headsEngineeringAdhesion strength

According to a work mounting method by the work transfer apparatus of the prior art, a glass plate or a work may fail to abut against a window frame homogeneously at its peripheral edge portion, and the adhesion strength or the sealing property between the glass plate and the window frame may not be retained all over the periphery of the adhered portion. Provided is a work transfer apparatus (1),which grips a rear glass (5) by its gripping member (20) and mounts the rear glass (5) while pushing the gripped rear glass (5) onto the window frame (7a) of a car body (7) by the action of a supporting arm (10). The work transfer apparatus (1) comprises a control device (80), and each of absorption pads (30) of the gripping member (20) includes a force detecting sensor (31) for detecting the force to be applied to the absorption pads (30). The control device (80) controls, when it uses the work transfer apparatus (1) to mount the rear glass (5) on the window frame (7a), the actions of the supporting arm (10) on the basis of the magnitude of the detected value of the force detecting sensor (31) of each absorption pad (30).

Owner:TOYOTA JIDOSHA KK

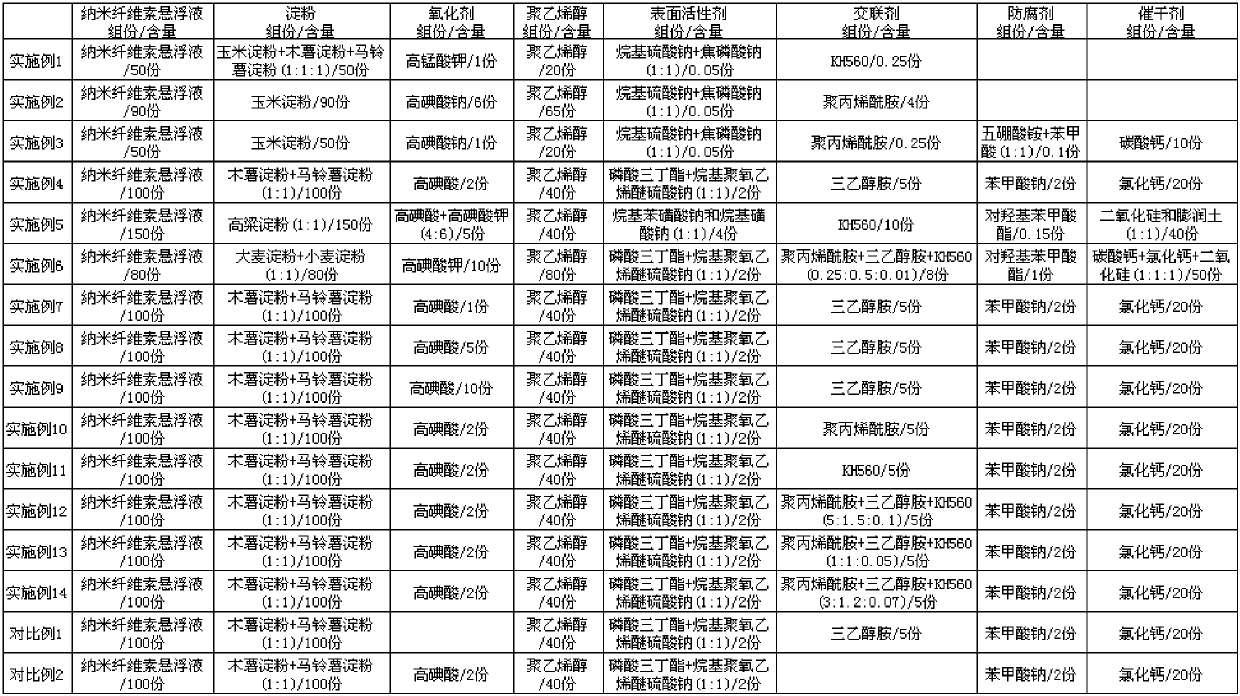

Starch adhesive and preparation method thereof

ActiveCN107779122AImprove water resistanceGood storage stabilityNon-macromolecular adhesive additivesStarch derivtive adhesivesAdhesiveSolvent

The application provides a starch adhesive. The starch adhesive is prepared from the following components in parts by weight: 50 to 150 parts of nanocellulose suspension, 50 to 150 parts of starch, 1to 10 parts of an oxidant, 20 to 80 parts of polyvinyl alcohol, 0.01 to 5 parts of a surfactant and 0.25 to 10 parts of a crosslinking agent. The starch adhesive has good properties including good waterproof performance, good storage stability, excellent initial adhesion, great adhesion, good flowability and good coagulation resistance. The application further provides a preparation method of thestarch adhesive. The preparation method comprises the following steps: (1) preparing the nanocellulose suspension, preparing a polyvinyl alcohol solution and preparing a dialdehyde starch solution; and (2) mixing the dialdehyde starch solution, the nanocellulose suspension, the polyvinyl alcohol solution and the crosslinking agent and stirring and reacting with certain pH value and temperature toprepare the starch adhesive. According to the method provided by the invention, starch and waste paper products are used as raw materials, aldehyde substances are not added in a reaction process and water is used as a solvent; and a production technology and a product have an environment-friendly property and all the raw materials can react sufficiently.

Owner:GUANGDONG YULAN GRP

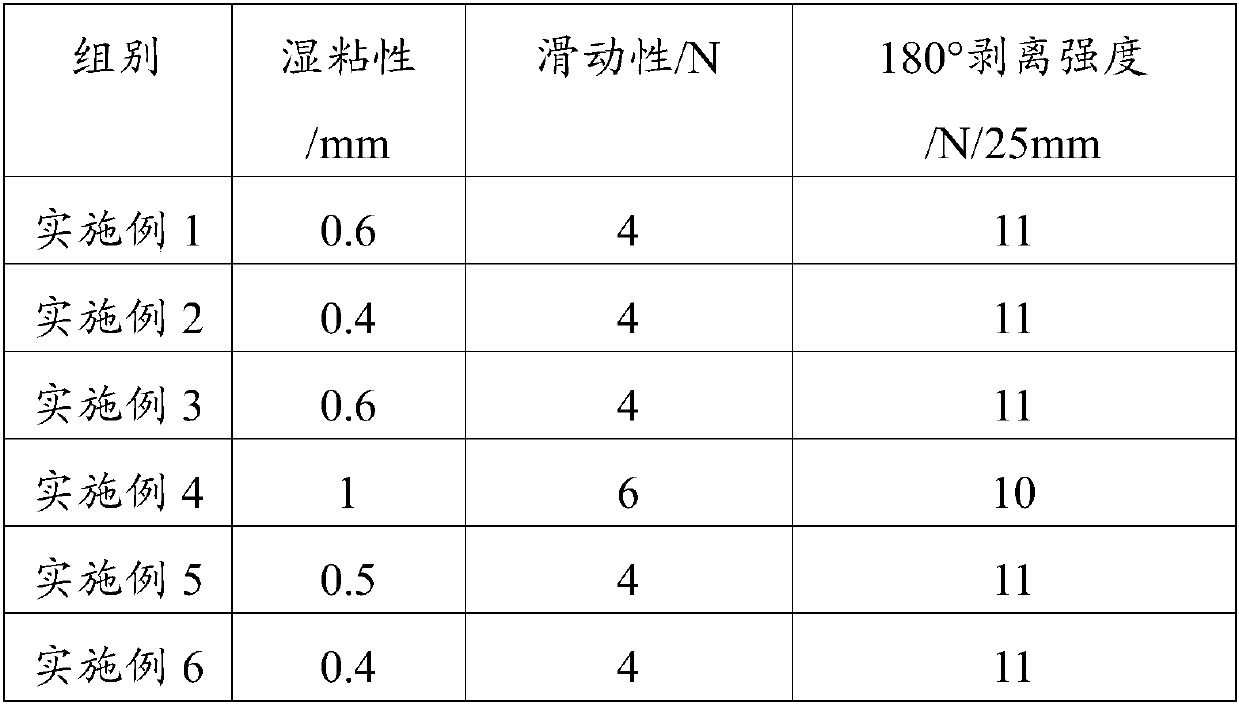

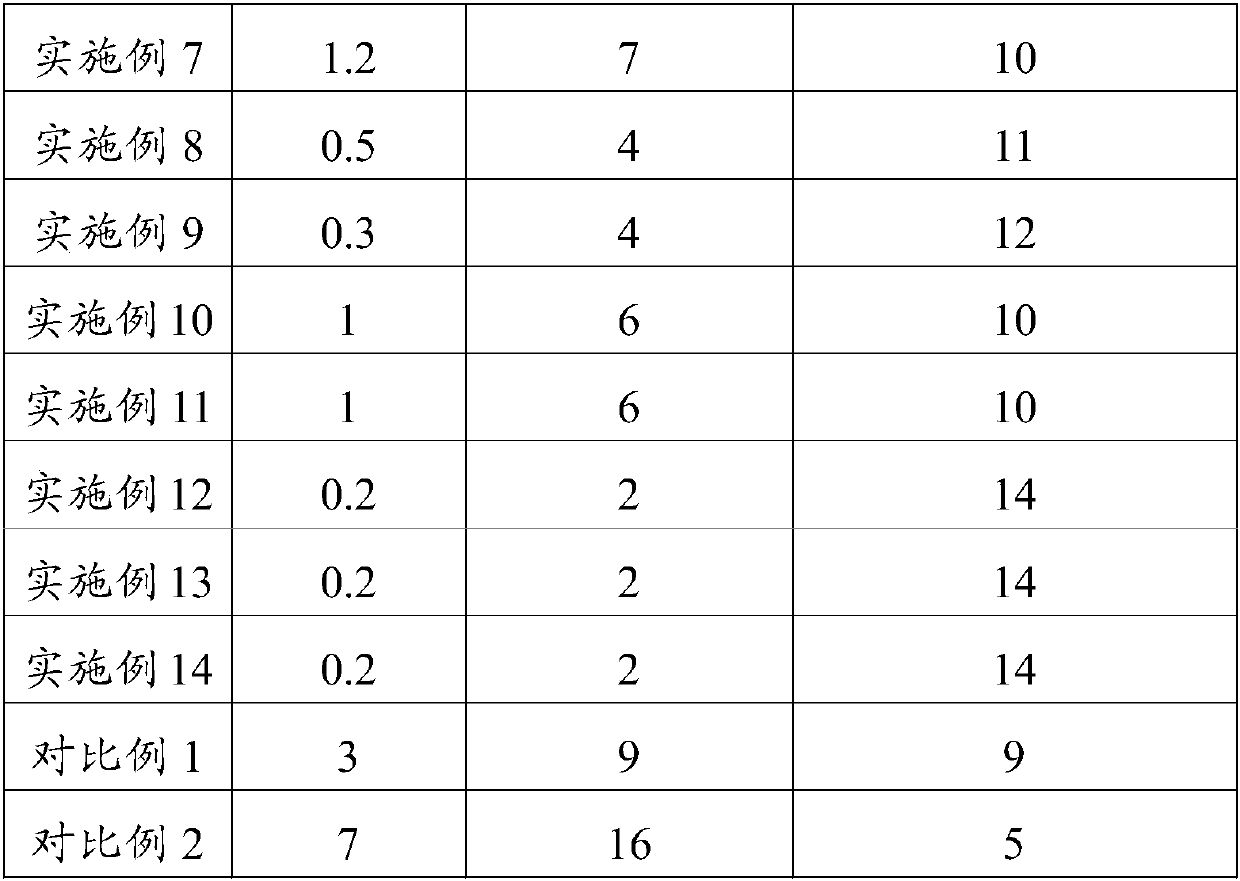

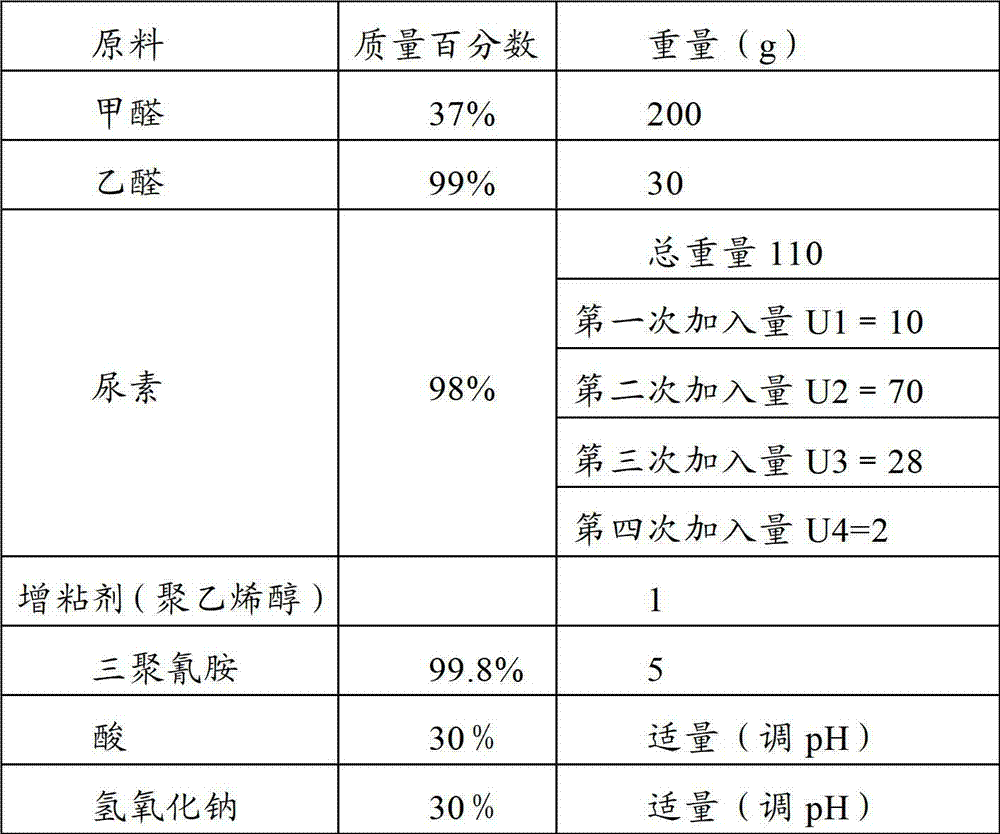

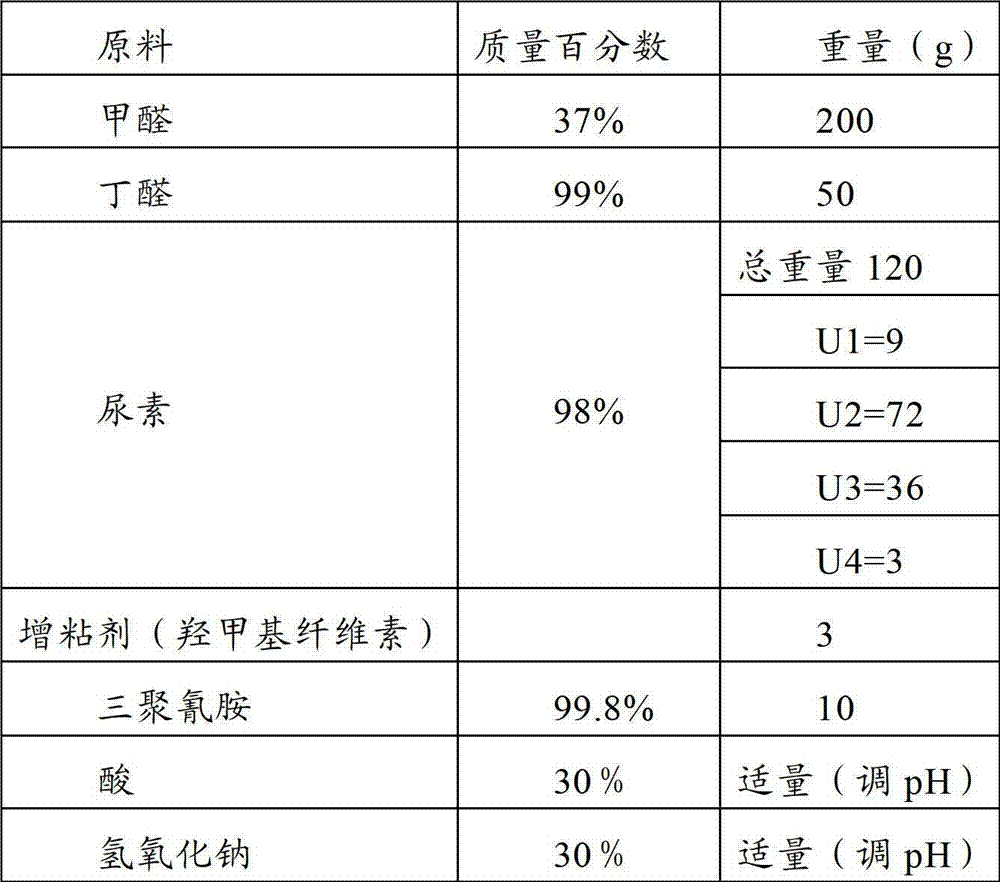

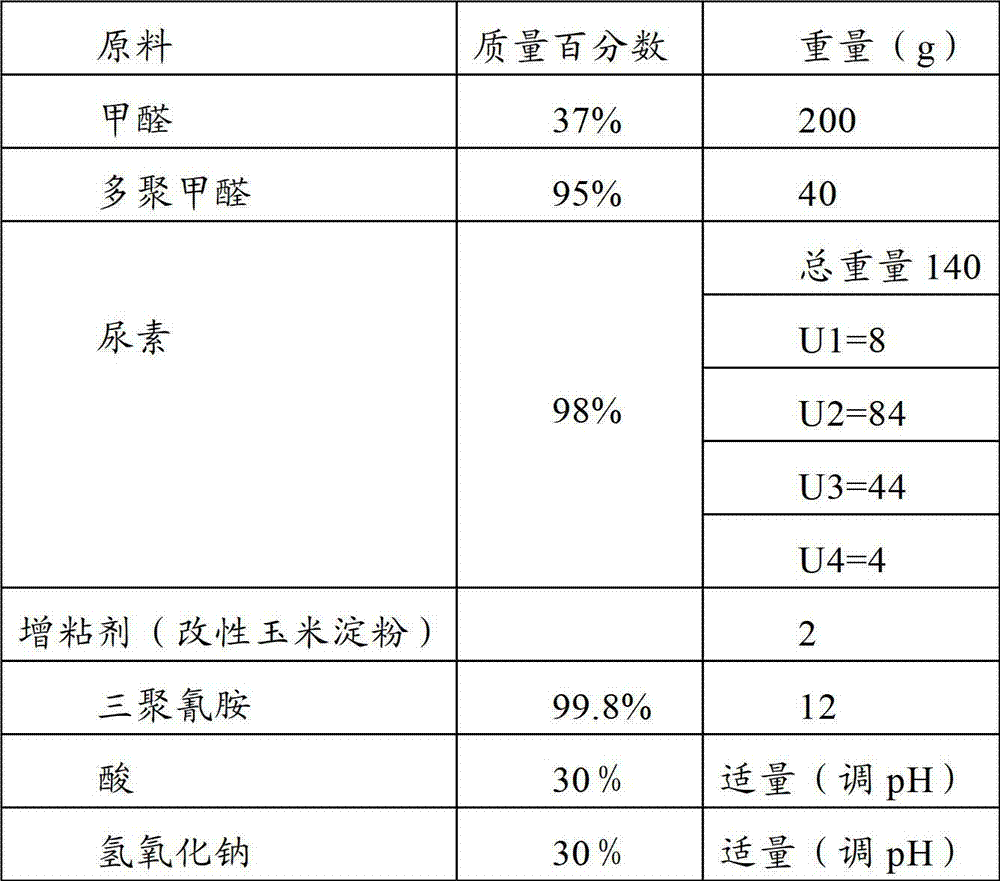

Adhesive for veneering of artificial board and preparation method of adhesive

InactiveCN103031095AReduce penetrationReduce generationMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSolubilityAdhesive

The invention relates to an adhesive for a veneering of an artificial board and a preparation method of the adhesive. The adhesive comprises the components in parts by weight: 200 parts of formaldehyde, 20-50 parts of a modifier, 110-140 parts of urea, 5-15 parts of tripolycyanamide, and 1-10 parts of a tackifier. By addition of appropriate parts of modifier, on the one hand, the high solid content adhesive can be prepared without dehydration, moisture brought to a base material during coating is reduced, permeation of the adhesive is reduced, and glue penetration is reduced. In addition, through addition of the modifier, the molar ratio of formaldehyde and urea in the polycondensation phase in the urea resin synthetic process can be greatly reduced, so that hydrophilic radicals in the resin structure are greatly decreased. Meanwhile, tripolycyanamide in appropriate parts is added to modify, so that the water-solubility of the adhesive is reduced, the hydrophobicity of the adhesive is enhanced, and glue penetration is beneficially reduced. The tackifier in appropriate parts is added to improve the initial adhesion of the adhesive and reduce malposition of a veneer on the base material, so that the product quality is improved.

Owner:EVERFIRST WISEFUND TECH BEIJING

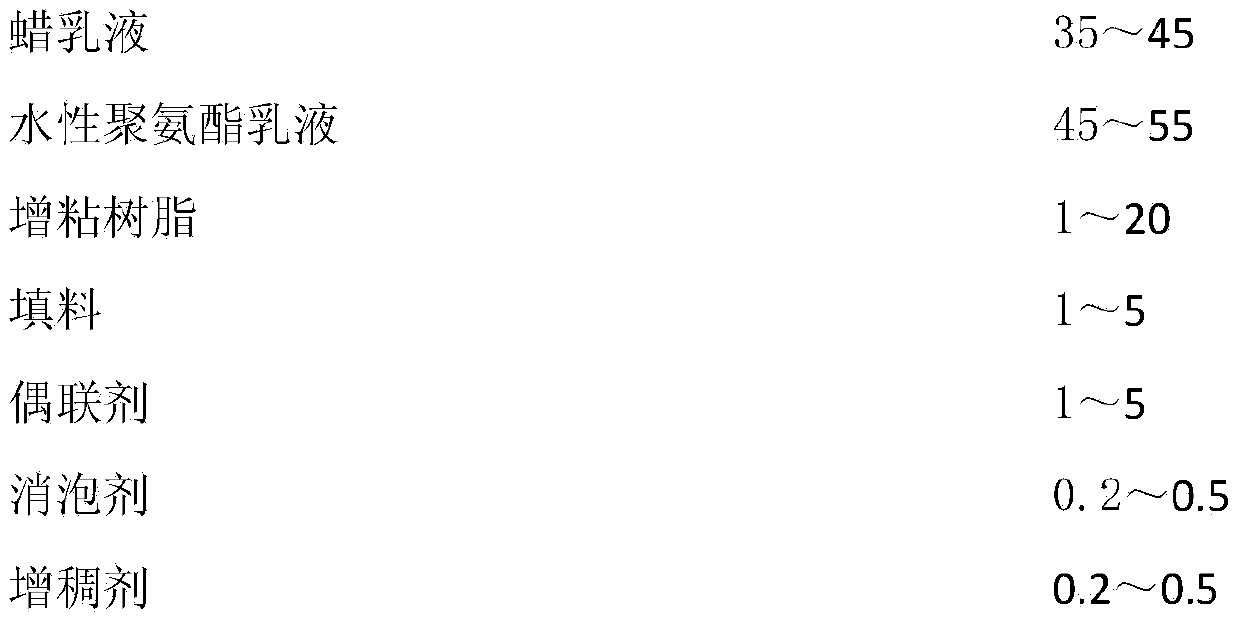

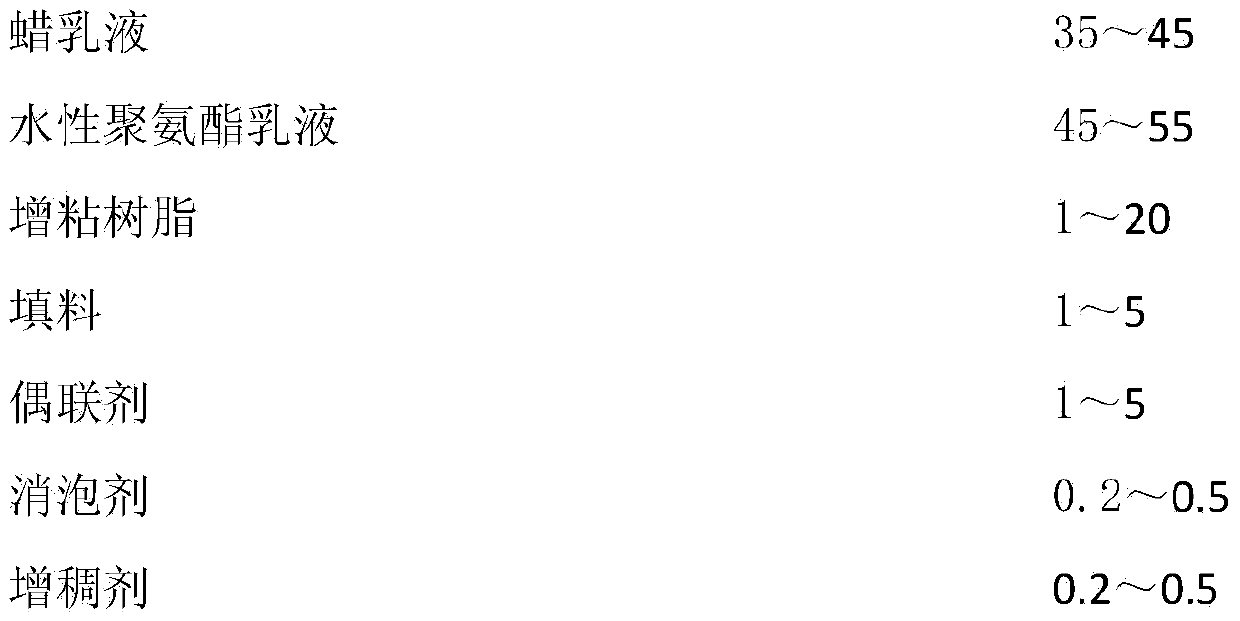

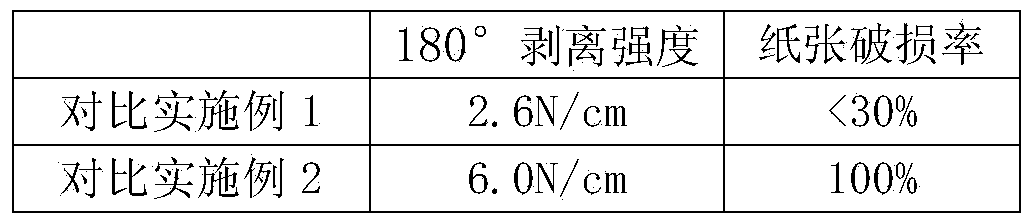

Water-based paper and plastic laminating/peelable adhesive and method for manufacturing same

InactiveCN103421461AGood adhesionAdhesivelyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWaxWater based

The invention discloses water-based paper and plastic laminating / peelable adhesive and a method for manufacturing the same. The water-based paper and plastic laminating / peelable adhesive comprises, by mass, 35-45 parts of wax emulsion, 45-55 parts of water-based polyurethane emulsion, 1-20 parts of tackifying resin, 1-5 parts of additives, 1-5 parts of coupling agents, 0.2-0.5 part of defoamers and 0.2-0.5 part of thickeners. The water-based paper and plastic laminating / peelable adhesive and the method have the advantages that the wax emulsion, the water-based polyurethane emulsion, the additives, the tackifying resin, the coupling agents, the thickeners and the defoamers are compounded with one another to finally manufacture the water-based paper and plastic laminating / peelable adhesive, the water-based paper and plastic laminating / peelable adhesive is high-temperature-resistant and is high in initial adhesion, permanent adhesion and peel strength when used for laminating paper and plastics, the paper cannot be torn by an adhesion surface of a film when separated from the plastics, and is prevented from being damaged, and the adhesion surface is not sticky after the paper is separated from the plastics.

Owner:SOUTH CHINA UNIV OF TECH

Filler wire static shaft shoulder friction stir welding and additive manufacturing device and method

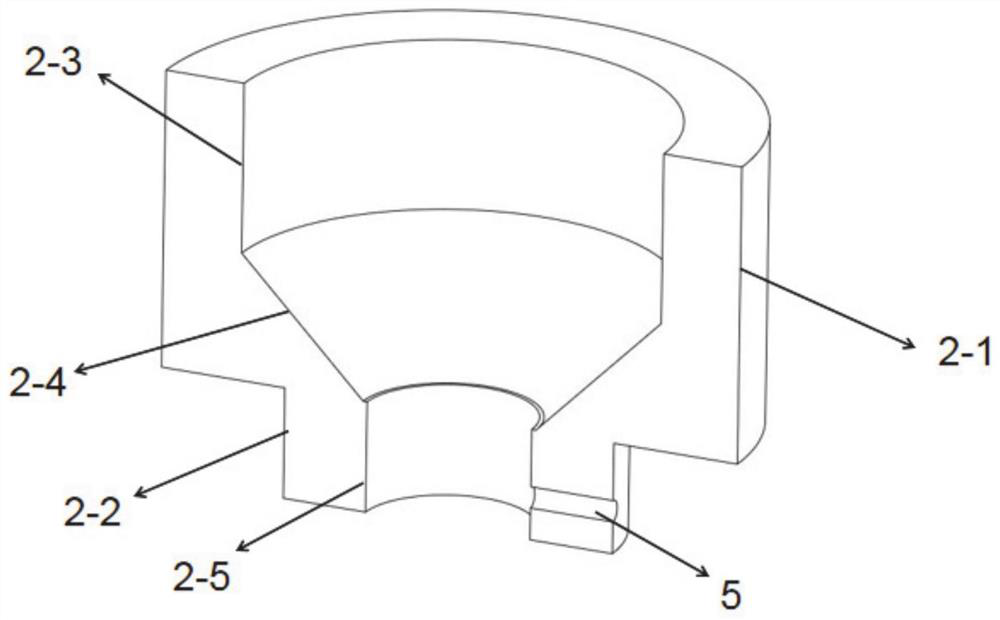

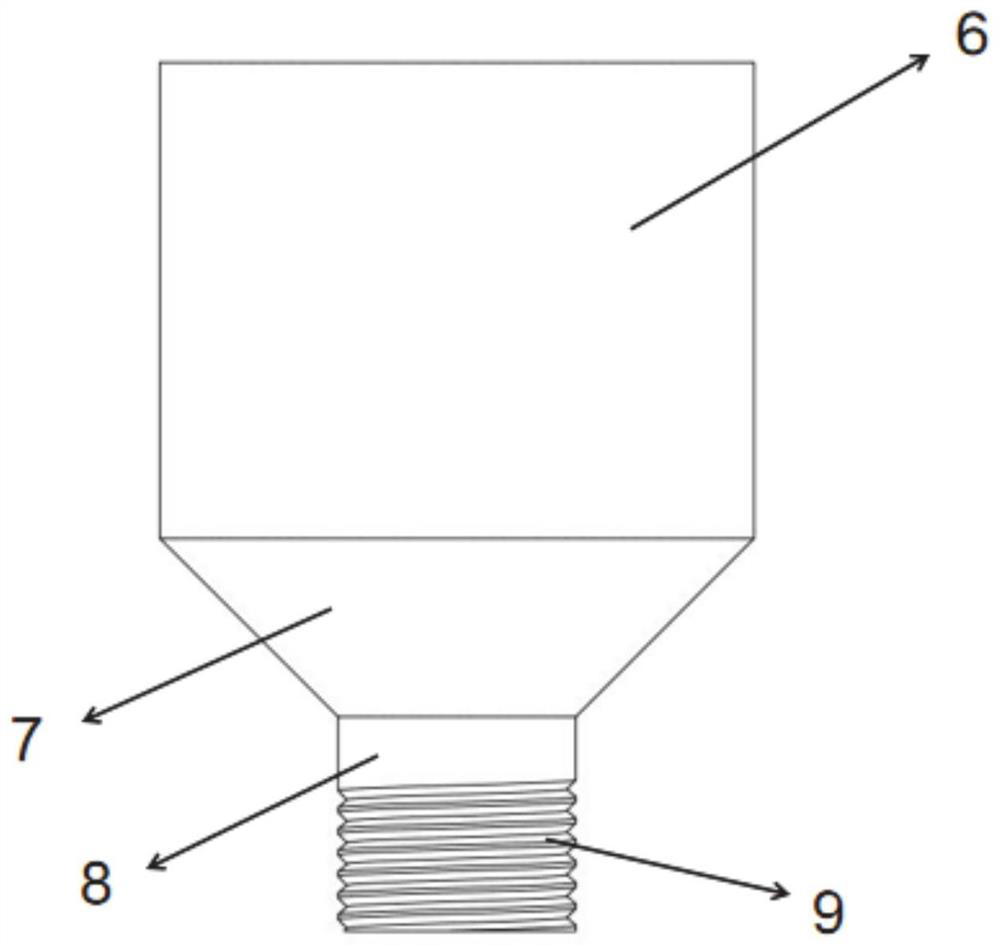

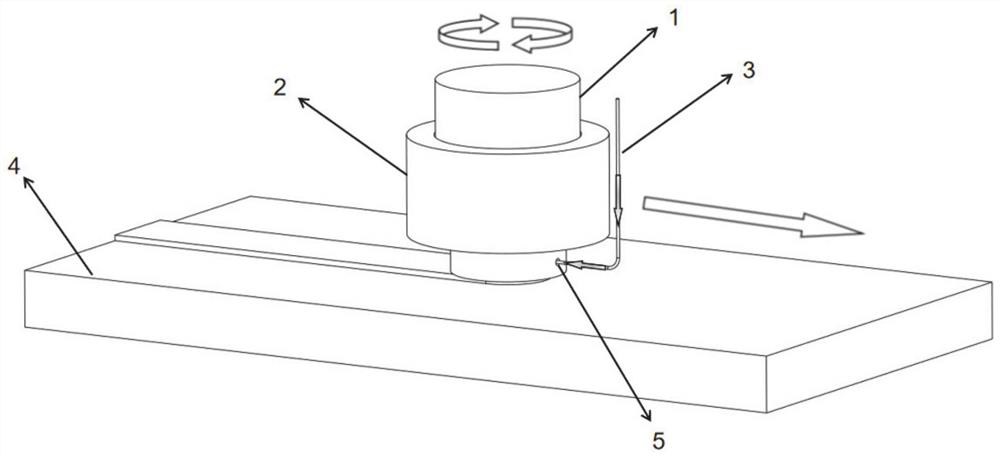

PendingCN112958902AImprove mechanical propertiesEnabling Additive ManufacturingAdditive manufacturing apparatusNon-electric welding apparatusScrew threadMechanical property

The invention relates to a filler wire static shaft shoulder friction stir welding and additive manufacturing device and method. The filler wire static shaft shoulder friction stir welding and additive manufacturing device comprises a stirring head, the periphery of the stirring head is sleeved with a static shaft shoulder, the stirring head and the static shaft shoulder are configured to synchronously move along a machining track, and the stirring head can rotate around the axis of the stirring head. A threaded groove is formed in the peripheral face of the machining end of the stirring head, the static shaft shoulder is provided with a wire feeding hole, and the wire feeding hole is used for feeding wires to the space between the part, provided with the threaded groove, of the stirring head and the hole face of a through hole formed in the static shaft shoulder. When the device is used for additive manufacturing, the interface bonding defects are avoided, and the bonding strength is guaranteed. And the mechanical property of additive manufacturing parts is greatly improved.

Owner:SHANDONG UNIV

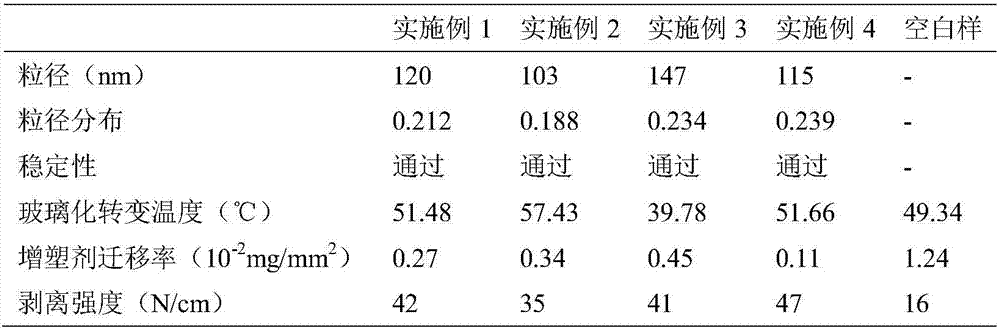

Water-based ink resin for PVC furniture membranes and preparation method of water-based ink resin

The invention provides water-based ink resin for PVC furniture membranes and a preparation method of the water-based ink resin. Raw materials of the water-based ink resin for the PVC furniture membranes comprise an anionic emulsifier, a nonionic emulsifier, a pH buffering agent, an initiator, a chain transfer agent, a methyl methacrylate monomer, a methyl acrylate monomer, a glycidyl methacrylate monomer, tert-butyl hydroperoxide, rongalite, a preservative, and deionized water; based on a design concept of ''polymer welding'', an emulsion-type resin which is well compatible to PVC and of which glass transition temperature is similar to that of the PVC is prepared and designed, wherein the main body of the emulsion-type resin is poly(methyl methacrylate-methyl acrylate), and the high peeling strength of the water-based ink resin and the PVC furniture membranes is guaranteed; and meanwhile, a characteristic that the PVC furniture membranes have a large number of plasticizers is combined, a proper amount of the glycidyl methacrylate monomer with epoxy groups is introduced to a copolymerization monomer system, and therefore the plasticizer migration resistant ability of the water-based ink resin is improved.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

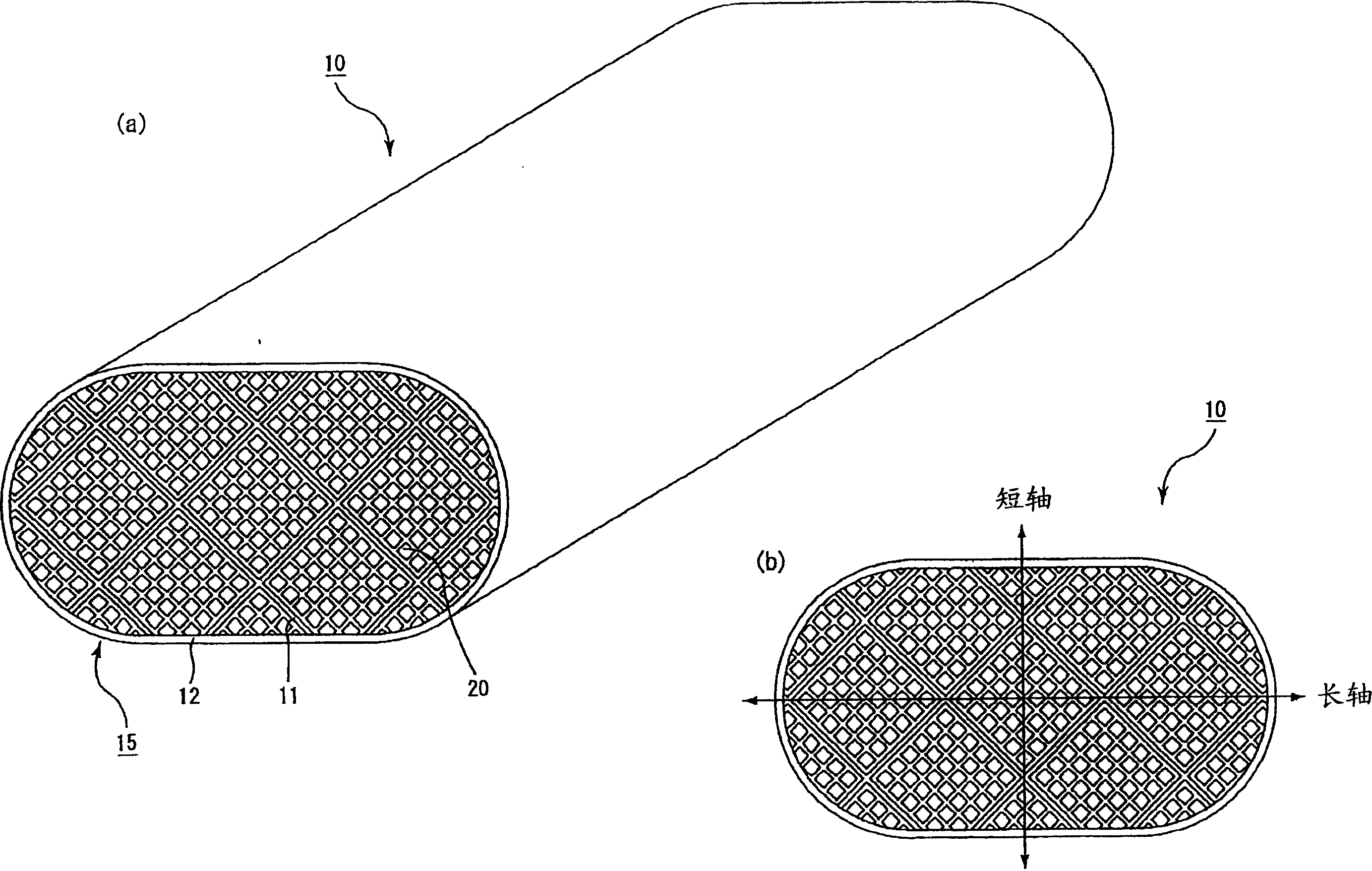

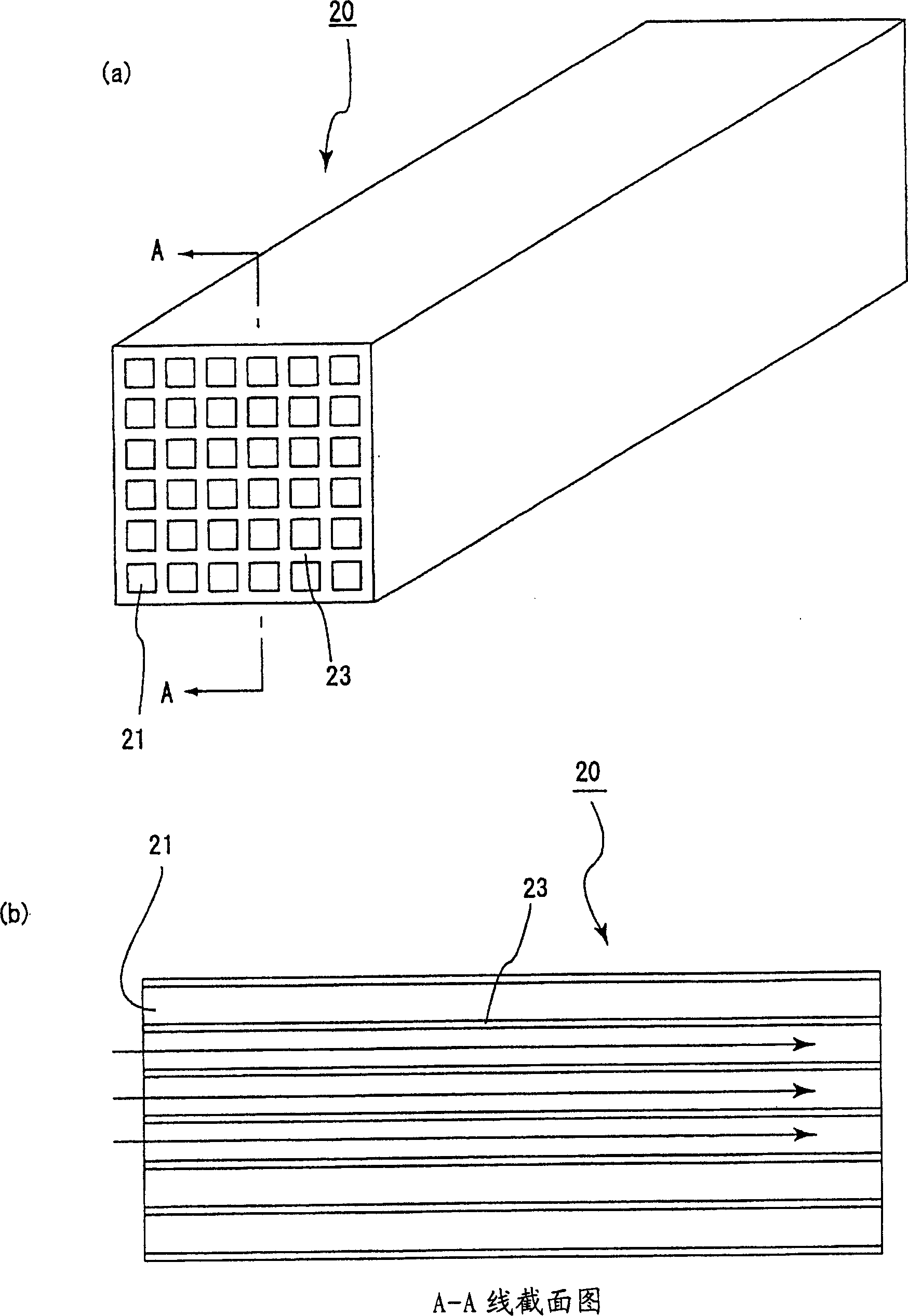

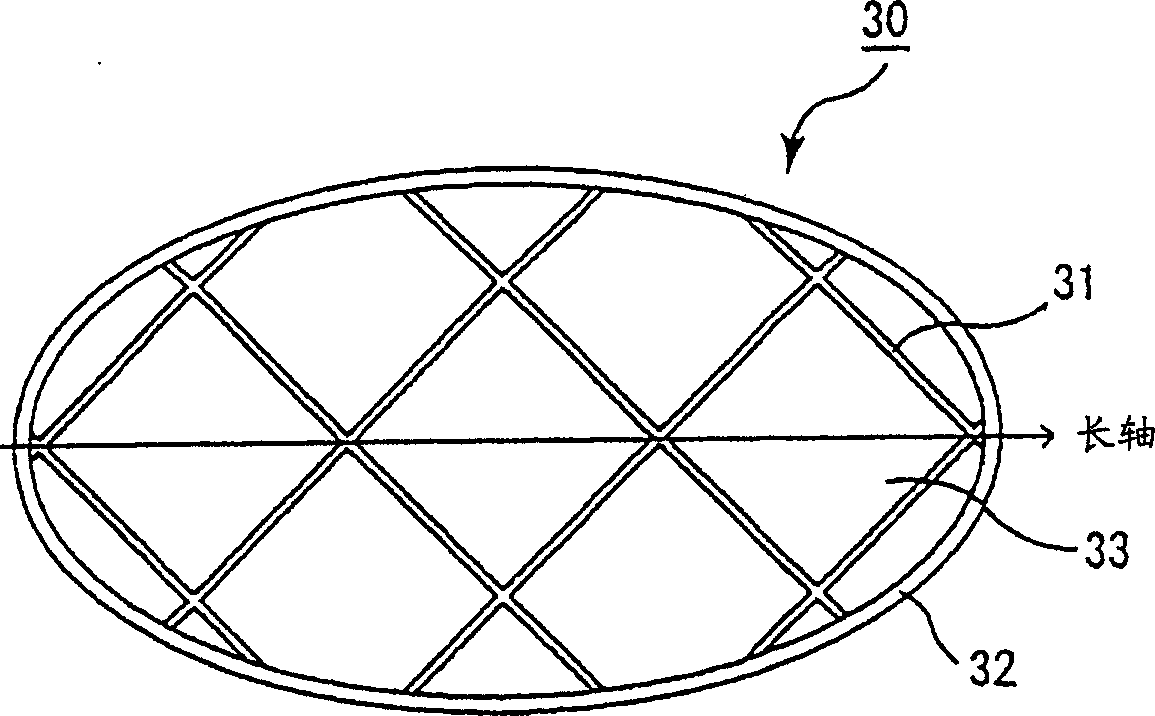

Honeycomb structure

InactiveCN1883791AImprove concentrationGuaranteed bonding strengthGas treatmentSolid waste managementFiberInorganic particle

An object of the present invention is to provide a flat-shaped honeycomb structured body in which sealing material layers are hardly damaged during use and in which adhesion strength can be maintained. The honeycomb structured body of the present invention is a honeycomb structured body including: a honeycomb block which has a flat-shaped cross section and has a structure in which plural honeycomb units are bonded to one another through sealing material layers, each unit including as amain component a porous ceramic and having in the longitudinal direction a number of cells placed in parallel with a cell wall therebetween; and a sealing material layer provided on an outer peripheral portion of the honeycomb block. Herein, each honeycomb unit contains inorganic fibers and / or whiskers in addition to inorganic particles, and the sealing material layer between the honeycomb units on the cross section perpendicular to the longitudinal direction is formed such that the direction thereof is diagonal to the major axis of a shape constituting the contour of the cross section.

Owner:IBIDEN CO LTD

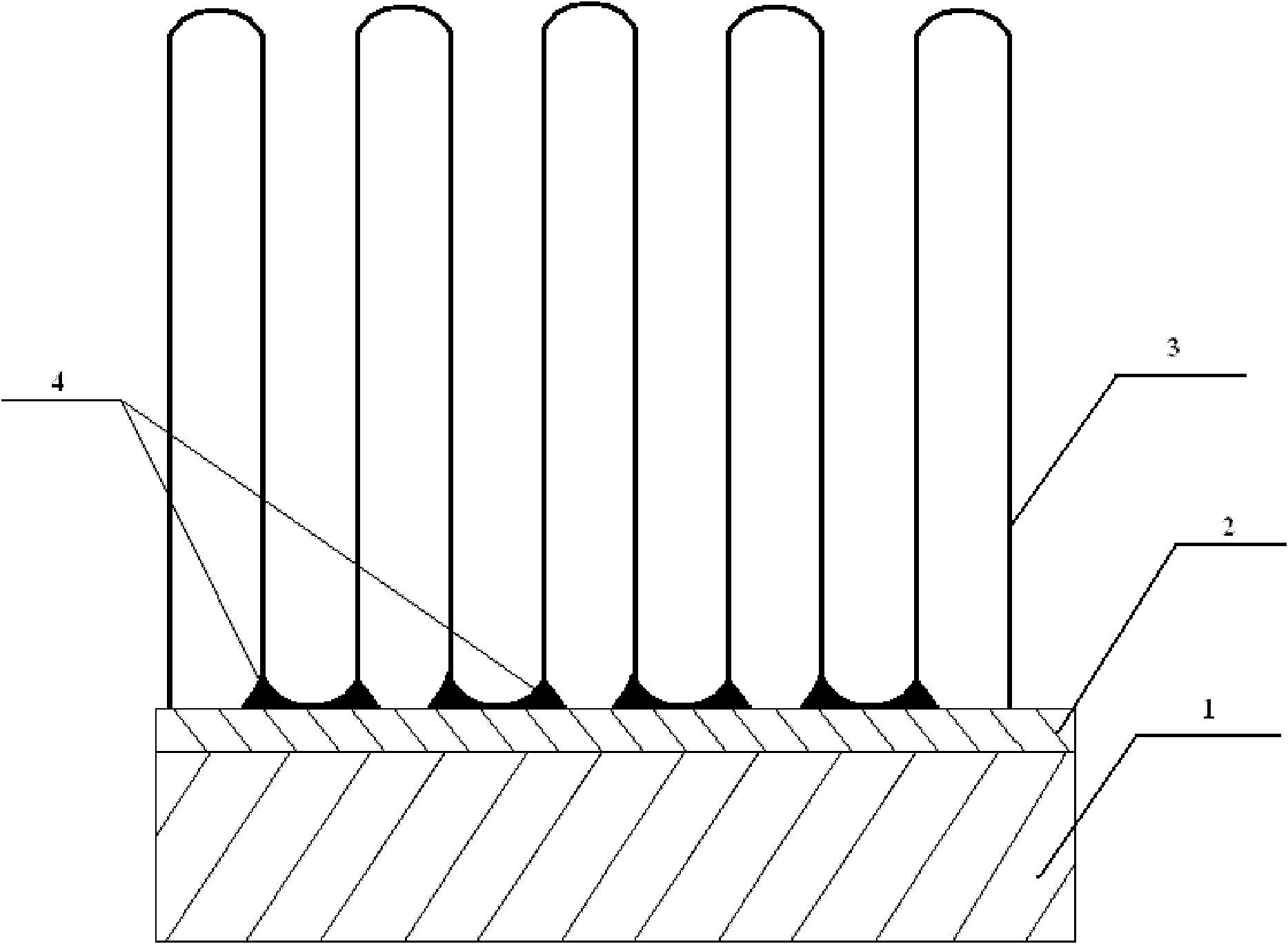

Iron-based powder porous surface heat-exchanging tube and manufacture method thereof

ActiveCN101251351ALower sintering temperatureGuaranteed bonding strengthHeat transfer modificationTubular elementsMechanical propertyMaterials science

The invention discloses an iron-based powder porous surface heat exchange tube and a preparation method thereof. The heat exchange tube is formed by a tube base body and a porous surface layer; the porous surface layer takes fine grained power of iron or an iron alloy as the main composition, contains a low melting point alloy element and is formed by sintering; the porous surface layer can be positioned at any side of the inner side and the outer side of the tube, the other corresponding side can be a smooth surface or a structure provided with an enhanced condensing characteristic. The preparation method is that: an organic bonding agent and metal powder of an iron-based alloy are evenly mixed; the mixture is coated on the outer surface or the inner surface of the tube; the coated tube is dried; the tube is sent into a sintering furnace to decompose the organic bonding agent; the tube is sintered under the temperature not higher than the regular normalizing or annealing heat treatment temperature of the material; the speed of temperature reduction is controlled to assure the structure and the mechanical property required by the heat exchange tube. The heat exchange tube and the preparation method have the advantages that: the sintering temperature is lower, the mechanical performance of the tube material is basically unchanged, and the heat exchange tube has high efficiency and low cost, and can meet the requirement of the industrialized application.

Owner:EAST CHINA UNIV OF SCI & TECH

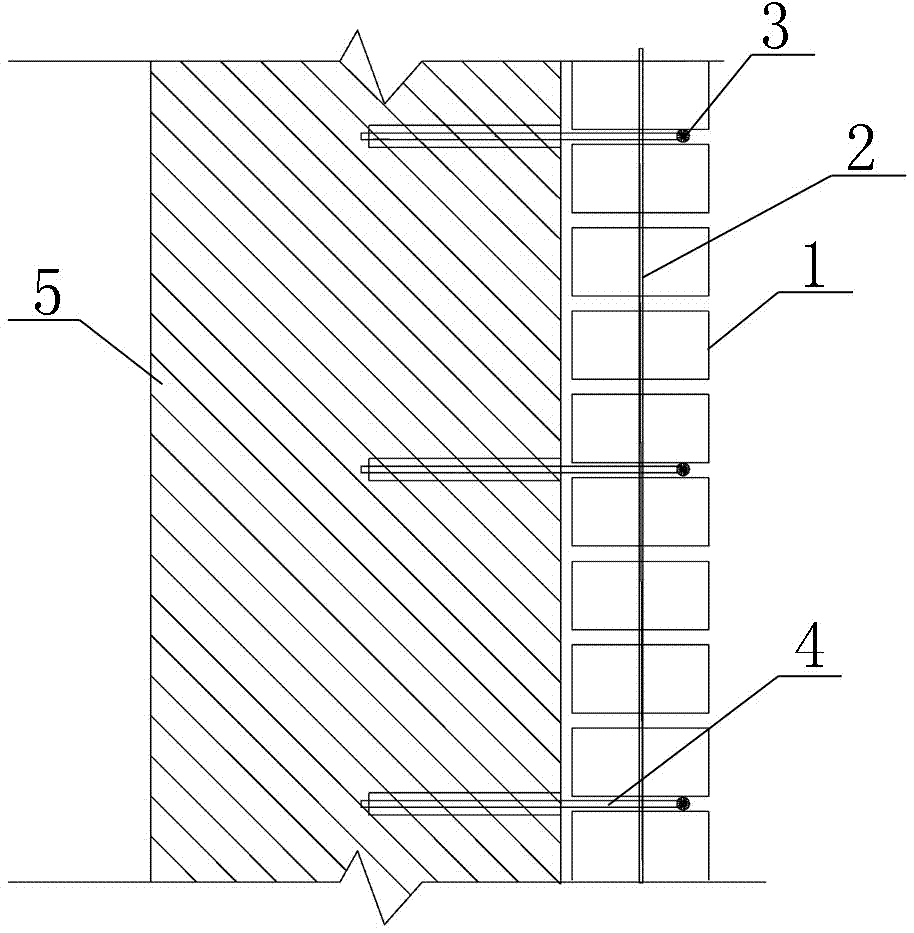

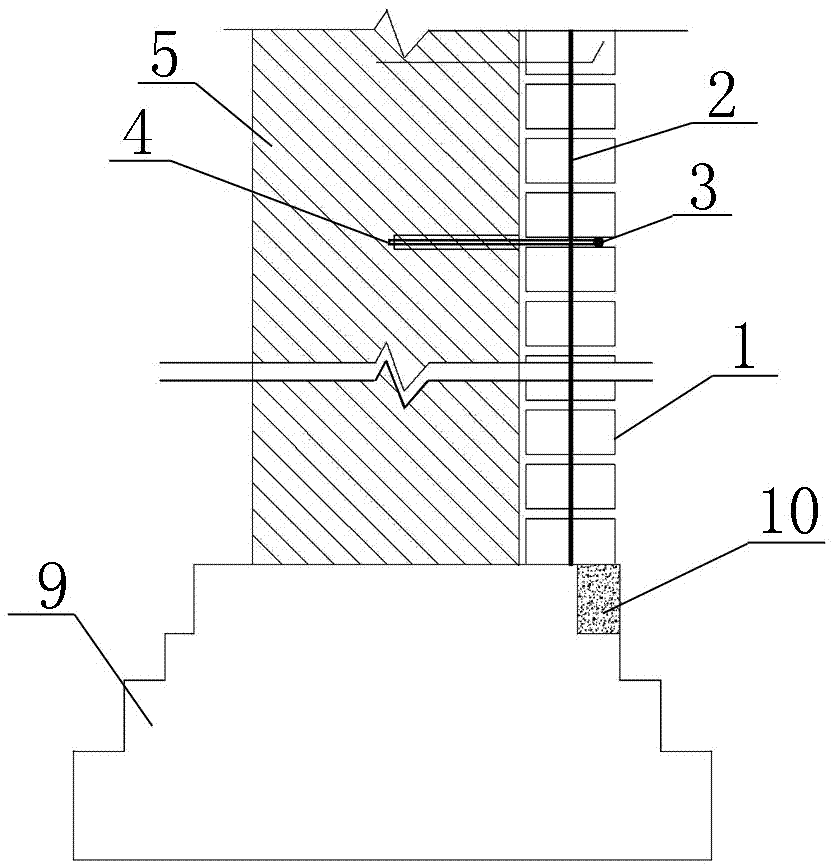

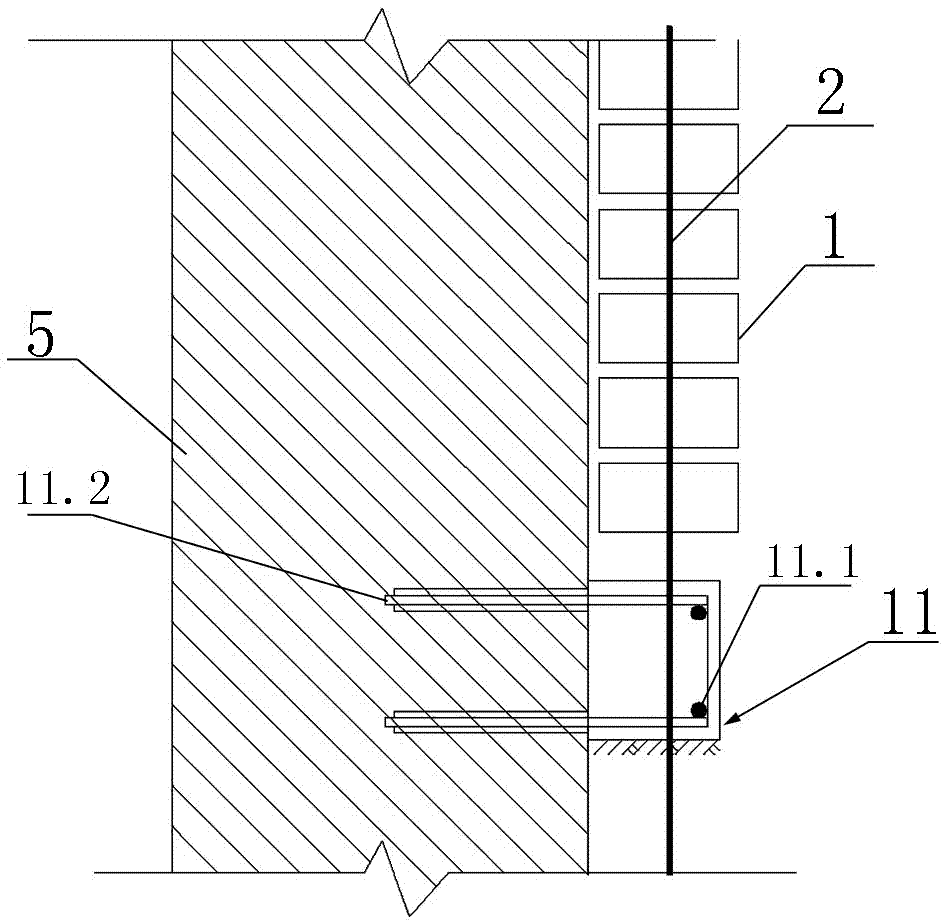

Existing building exterior wall reconstruction structure and construction method

The invention discloses an existing building exterior wall reconstruction structure and a construction method. The existing building exterior wall reconstruction structure comprises a newly-built wallbody, vertical reinforcing steel bars, horizontal reinforcing steel bars and tie bars, wherein the newly-built wall body is tightly attached to the outer side face of an existing building wall body,and is built with porous bricks; pores of upper-layer porous bricks and lower-layer porous bricks of the newly-built wall body are vertically formed correspondingly; one group of horizontal reinforcing steel bars is arranged at intervals along the outer side face of the existing building wall body; the vertical reinforcing steel bars are inserted into the pores of the porous bricks in the full length; one group of horizontal reinforcing steel bars is arranged at intervals along a vertical direction; the horizontal reinforcing steel bars are arranged in mortar joints of two adjacent layers of porous bricks; the two ends of the horizontal reinforcing steel bars are fixedly connected with the vertical reinforcing steel bars on a corresponding side; the tie bars are horizontally arranged between the existing building wall body and the newly-built wall body. The existing building exterior wall reconstruction structure and the construction method provided by the invention have the advantagesthat the technical problems of difficulty in reconstructing and upgrading the existing wall body and recovering the original appearance, incapability of making the building reach designed service life and resource waste are solved.

Owner:BUCG THE EIGHTH CONSTR DEV

Packaging method for organic light-emitting diode display

InactiveCN101867023AReduce distanceEnhanced ability to block water vapor and oxygen infiltrationSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceAdhesive

The invention discloses a packaging method for an organic light-emitting diode (OLED) display. A rear cover of the organic light-emitting diode display also comprises at least one ring of continuous bumps surrounding the light emitting region at the periphery of the light emitting region; and a water-absorbing protection layer covers the surface of each pixel display region of a substrate. The method comprises the following steps of: coating a packaging adhesive at the periphery of the light emitting region of the rear cover, wherein the packaging adhesive surrounds the light emitting region and completely covers the at least one ring of bumps surrounding the light emitting region; aligning and pressing the rear cover coated with the packaging adhesive and the substrate; and curing the packaging adhesive. By using the rear cover provided with bumps at the periphery of the light emitting region, the required adhesive strength between the rear cover and the substrate can be ensured, the distance between the rear cover and the substrate can be greatly reduced, and the capability of the OLED of preventing the penetration of vapor and oxygen can be enhanced; and the vapor penetrated into the OLED can be adsorbed by further covering a transparent water-absorbing protection layer on the pixel display region, so that the organic functional layer is protected.

Owner:TRULY SEMICON

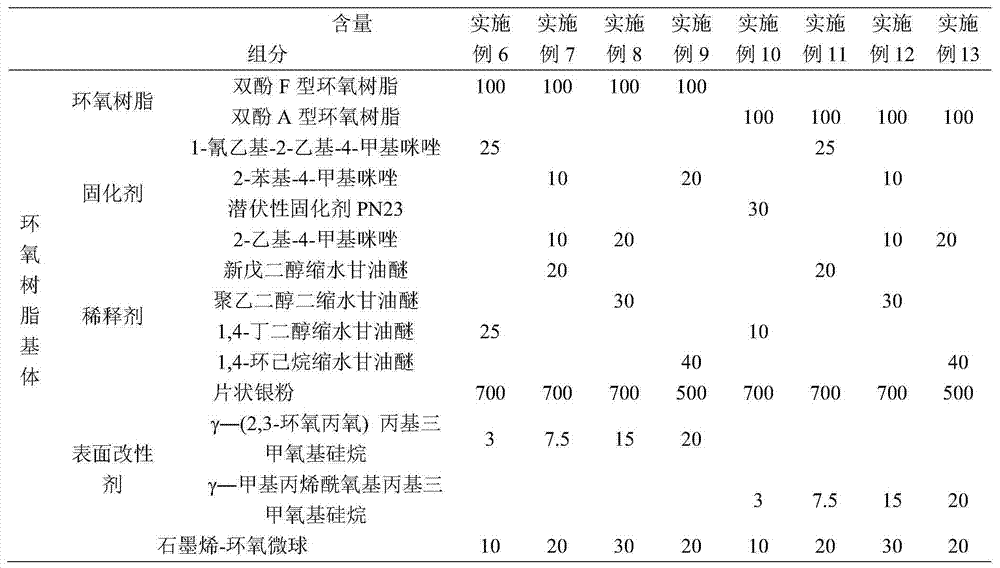

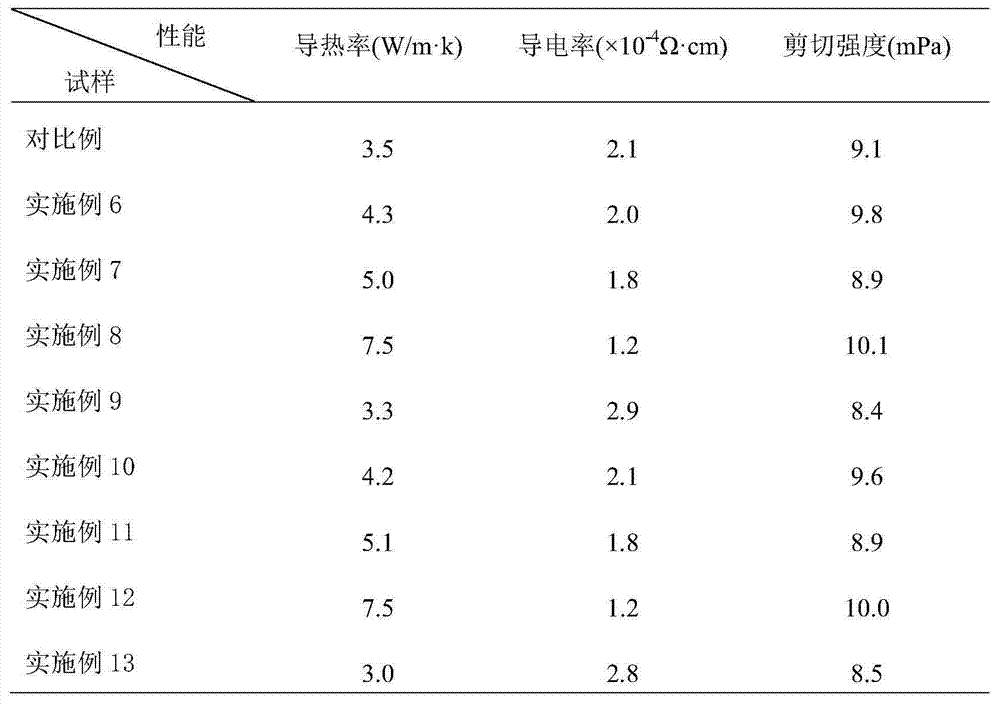

High-performance conductive silver adhesive containing graphene and preparation method thereof

ActiveCN104774573AReduce the content of organic mediaImprove conductivityNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyResin microsphere

The invention discloses a high-performance conductive silver adhesive containing graphene. The high-performance conductive silver adhesive containing graphene comprises the following raw materials by weight: 100 parts of epoxy resin, 10 to 50 parts of a curing agent, 10 to 40 parts of an epoxy diluent, 5 to 50 parts of a graphene-epoxy microsphere, 0.5 to 5 parts of a surface modifier and 240 to 990 parts of a silver strip, wherein the graphene-epoxy microsphere is prepared from graphene oxide and an epoxy resin microsphere in a mass ratio of 1: 4-19. The invention further discloses a preparation method for the high-performance conductive silver adhesive containing graphene. The high-performance conductive silver adhesive containing graphene has the advantages of low cost and good conductive performance.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com