Patents

Literature

130results about How to "Improve setting accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

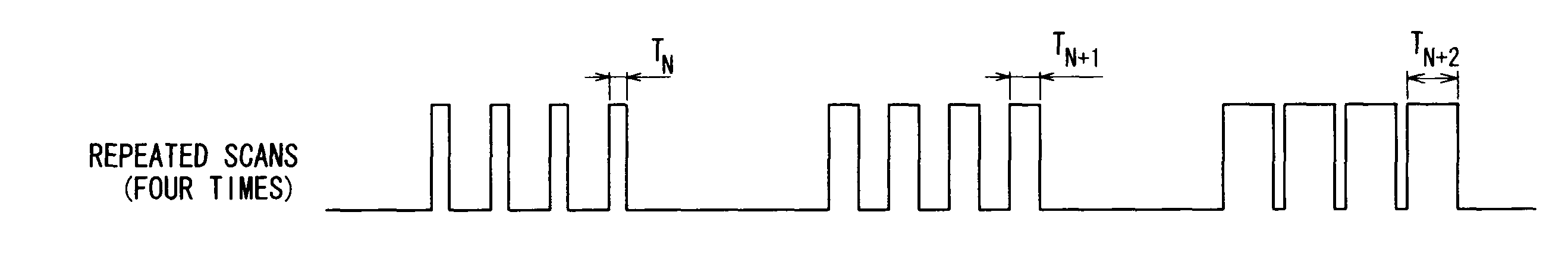

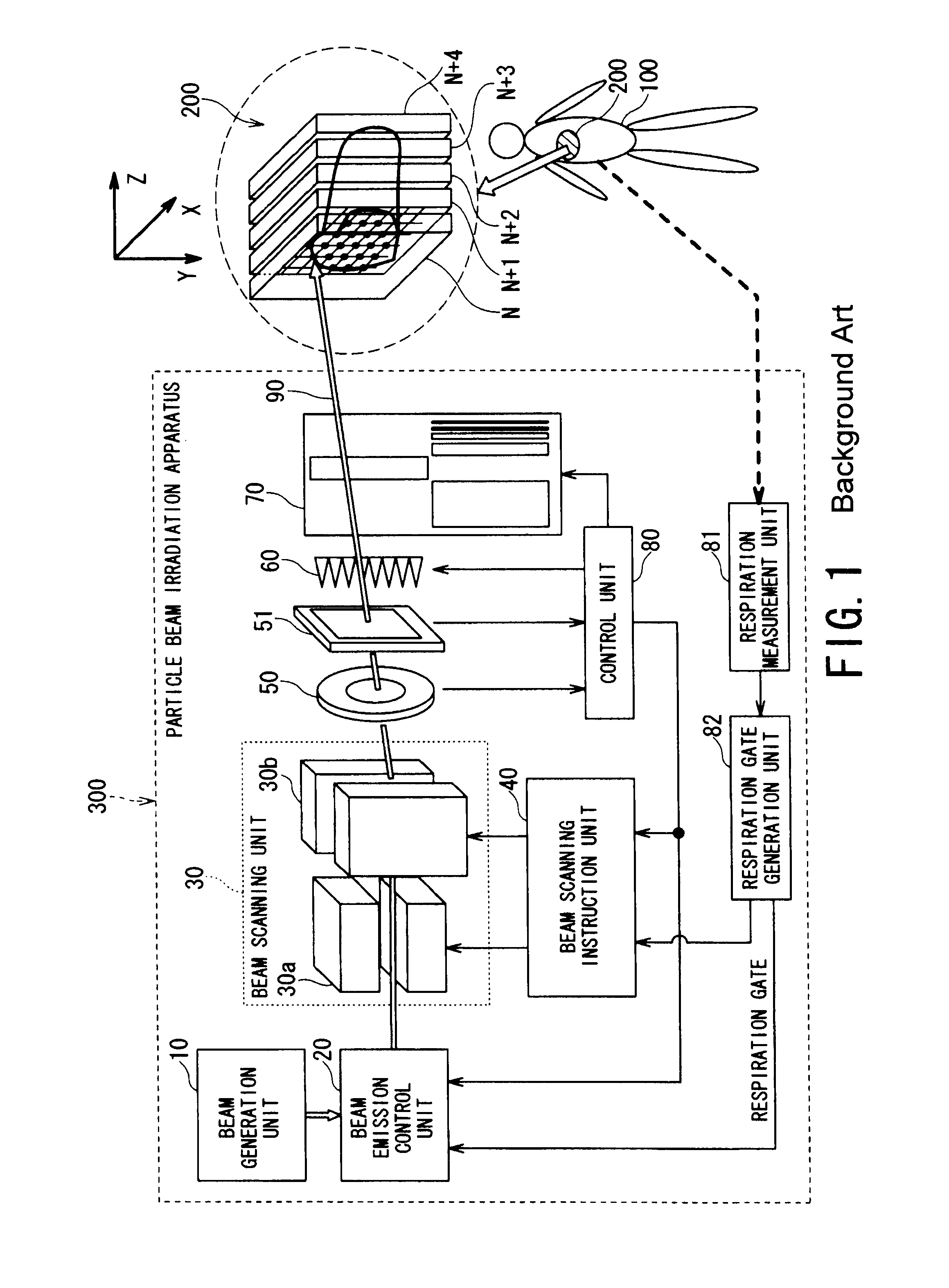

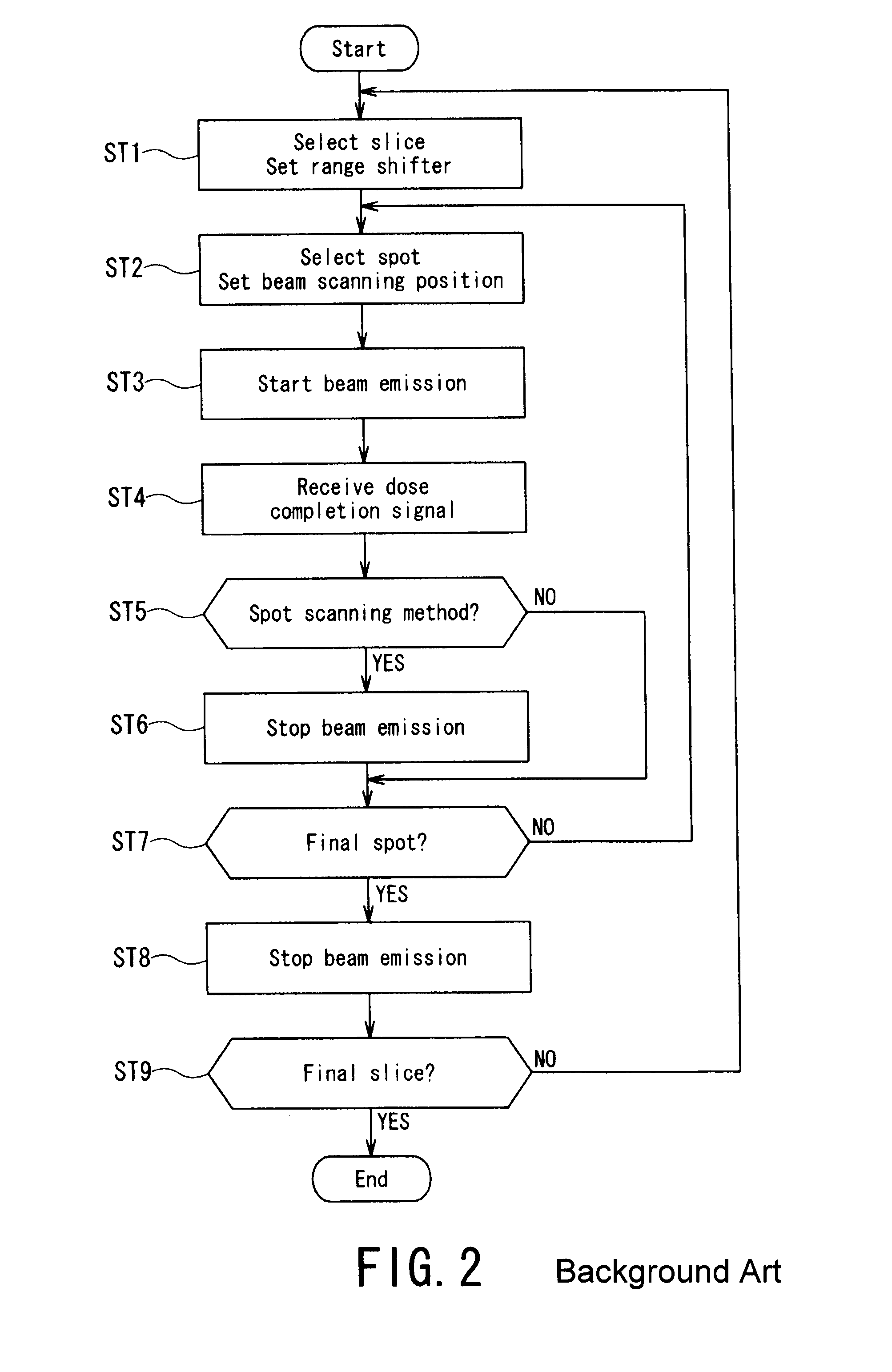

Particle beam irradiation apparatus and particle beam irradiation method

InactiveUS8436323B2Improve setting accuracyShorten treatment timeThermometer detailsBeam/ray focussing/reflecting arrangementsInstruction unitParticle beam

Owner:KK TOSHIBA

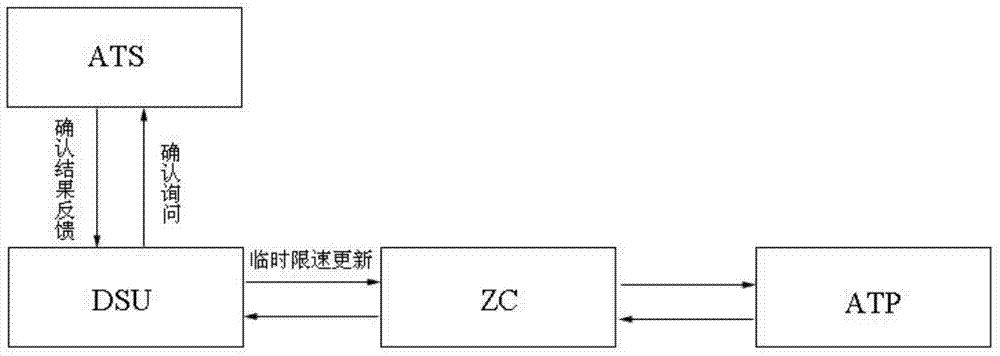

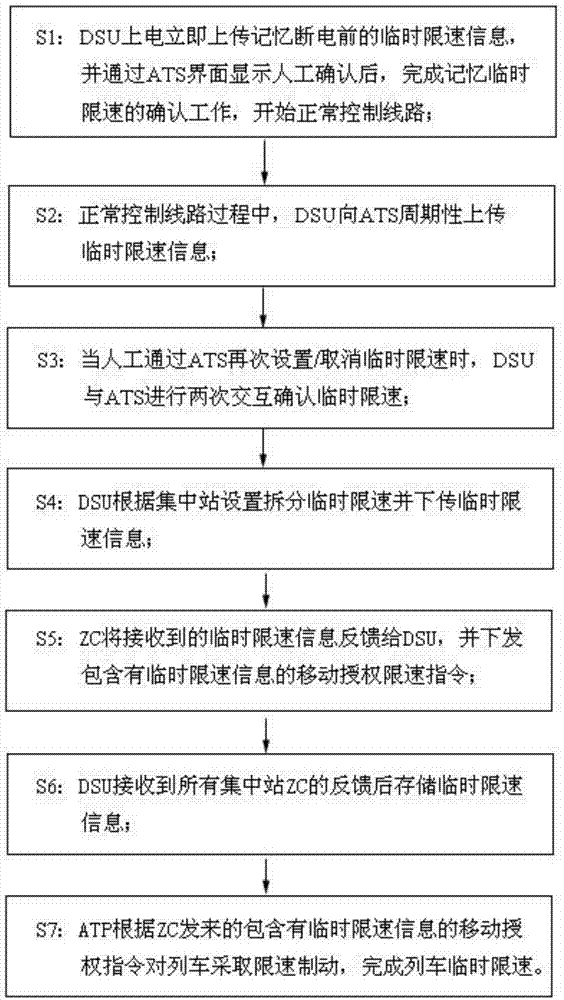

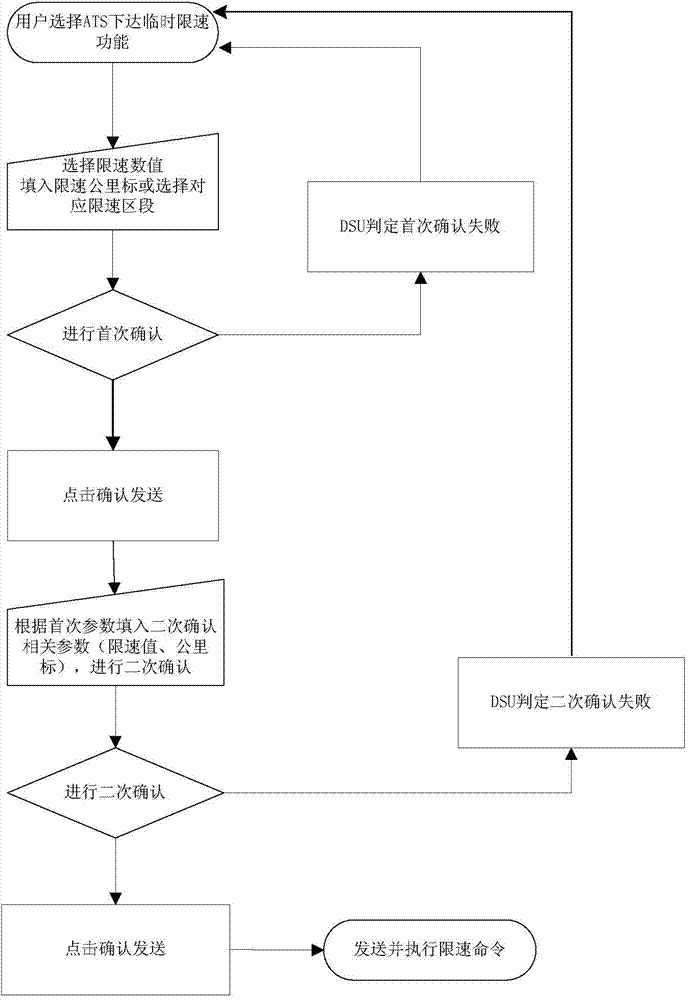

Temporary speed limiting method and temporary speed limiting system in urban rail transit CBTC (communication based train control system) mode

ActiveCN103707904AReduce error rateImprove securityRailway traffic control systemsControl systemMonitoring system

The invention discloses a temporary speed limiting method in an urban rail transit CBTC (communication based train control system) mode. The temporary speed limiting method includes starting normal route control after uploading and confirming temporary speed-limiting information before power interruption through a data storage unit, uploading the temporary speed-limiting information periodically to an automatic monitoring system from the data storage unit, performing interactive confirming twice between the data storage unit and the automatic monitoring system, dividing the temporary speed-limiting information and then downloading the same through the data storage unit, receiving the temporary speed-limiting information and feeding the information back to the data storage unit and then downloading movement authority speed-limiting instructions by zone controllers, saving feedback results by the data storage unit, and performing speed-limiting brake to trains through an automatic protection system. With the temporary speed limiting devices in the urban rail transit CBTC mode, the defect that effective speed limiting can be carried out by completely depending on real-time communications between dispatchers and drivers in the conventional speed limiting measures is overcome, the safety coefficient is increased, and running safety is guaranteed. The invention further discloses a temporary speed limiting system.

Owner:TRAFFIC CONTROL TECH CO LTD

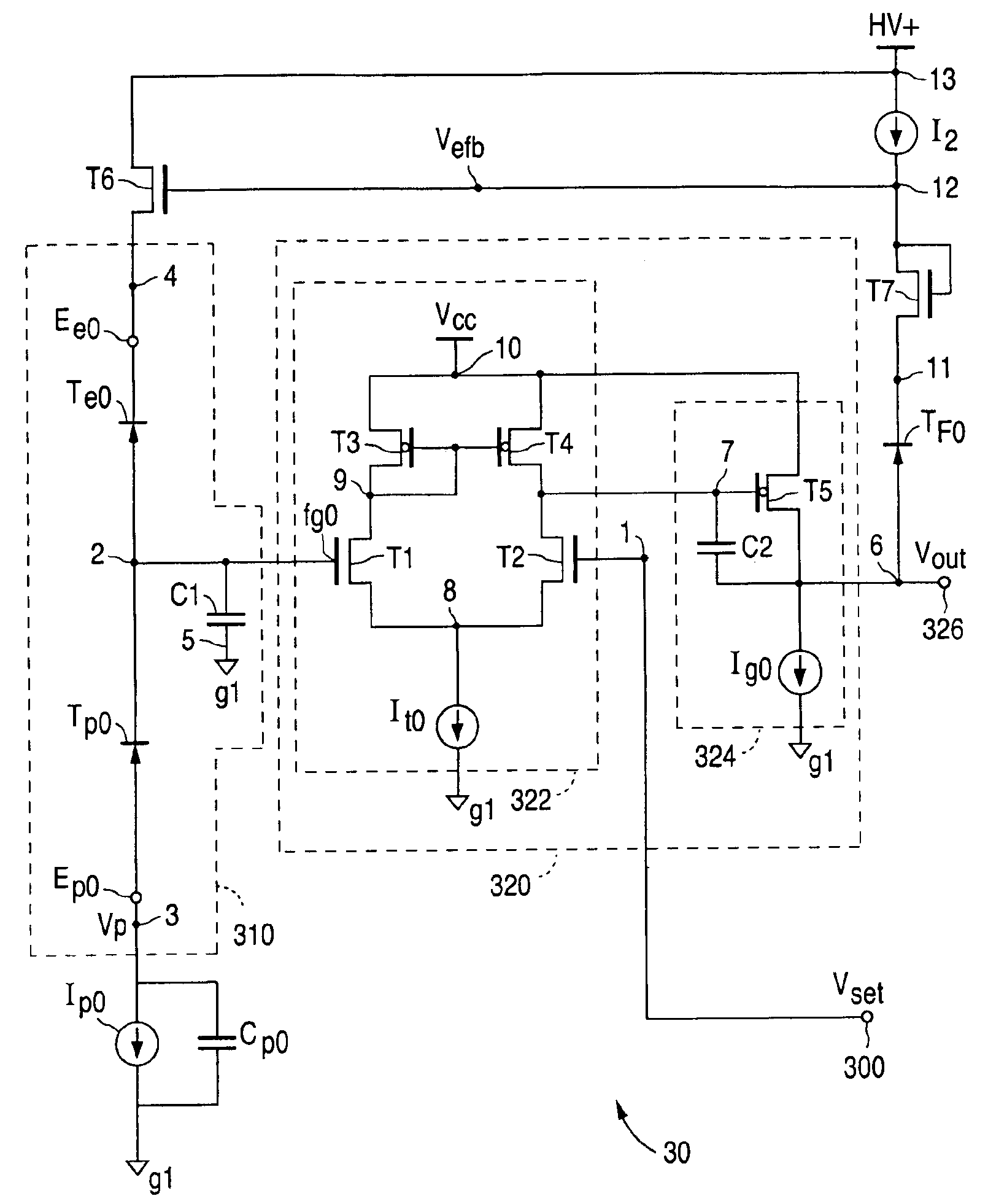

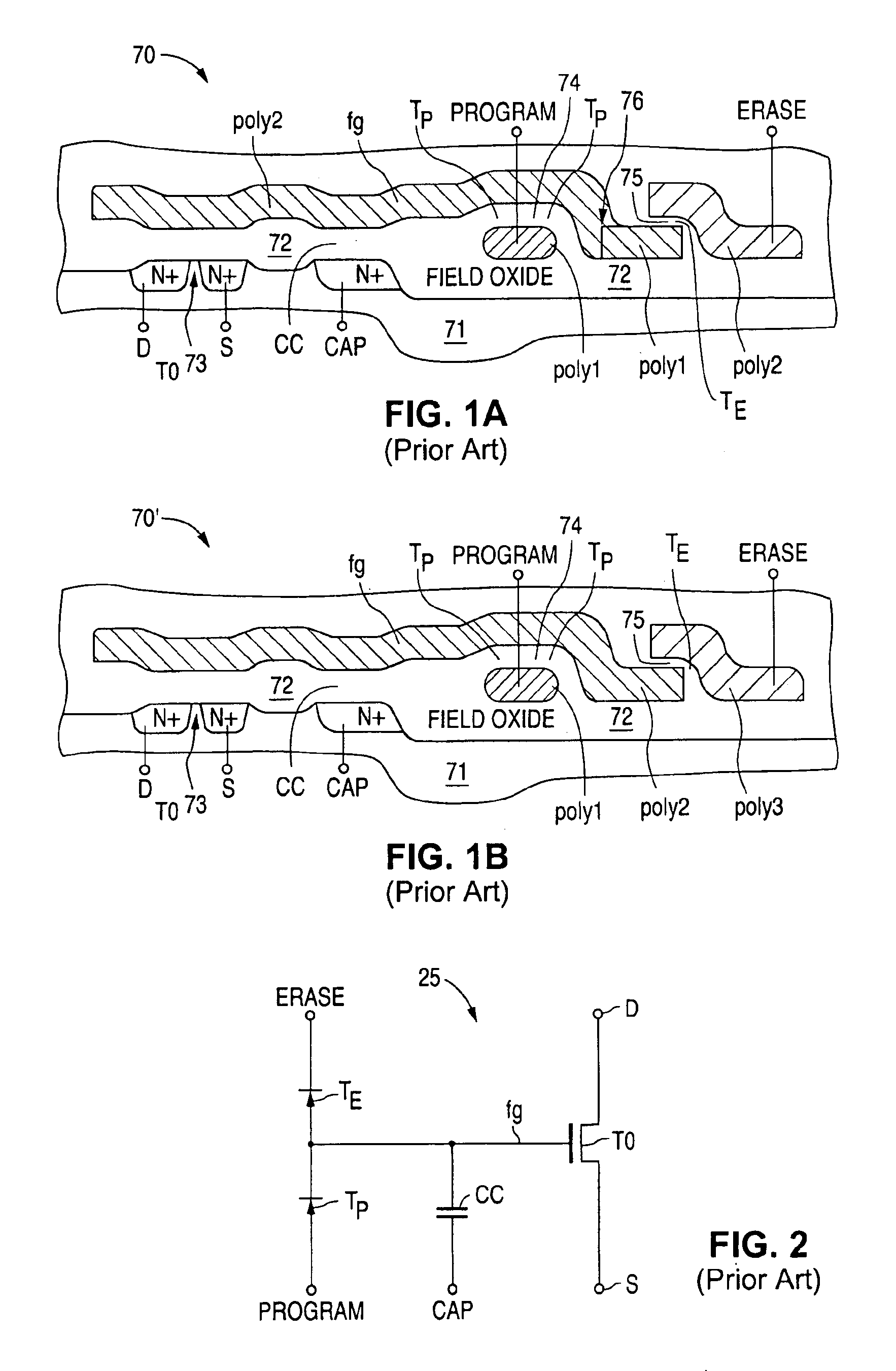

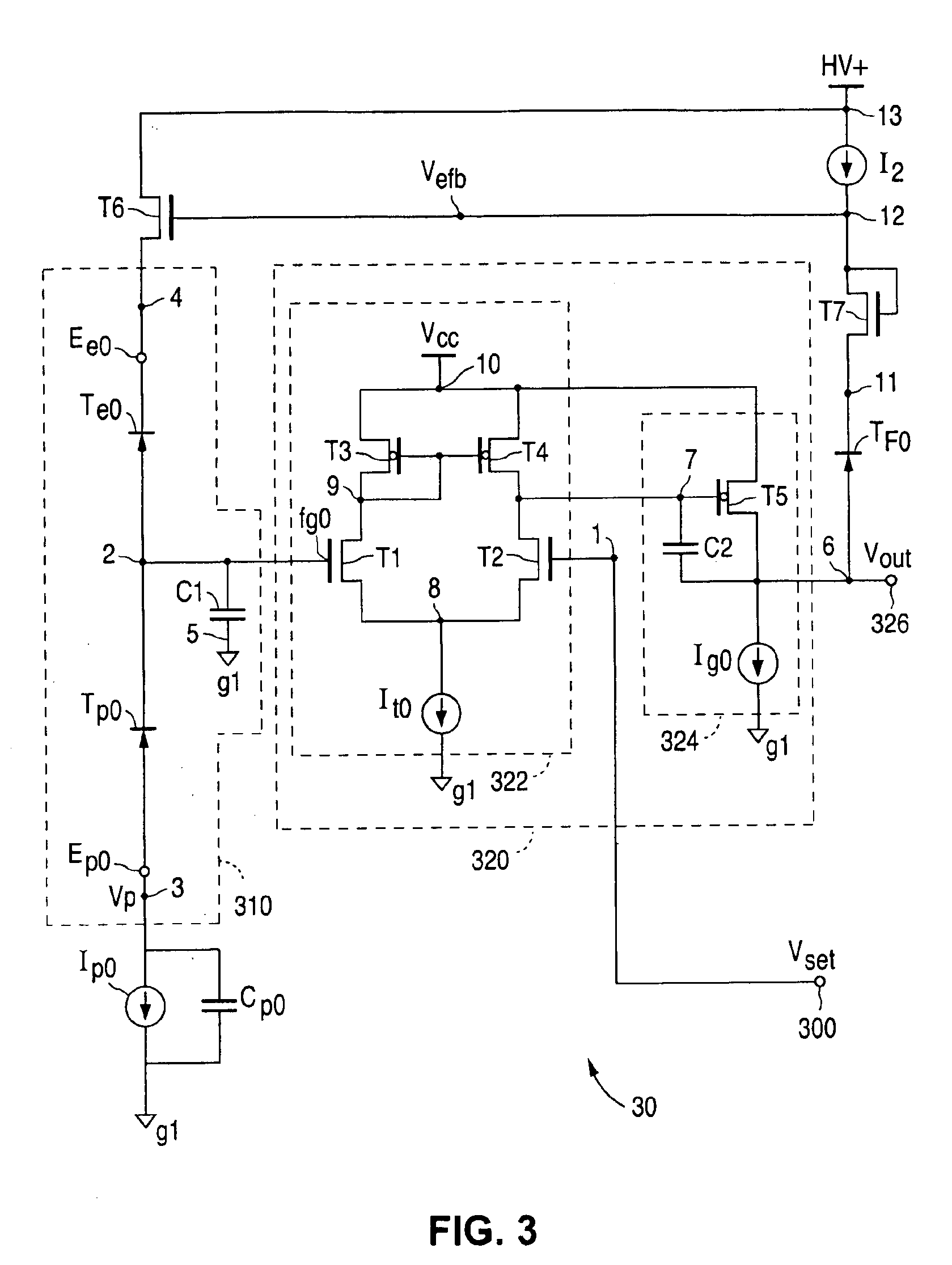

Differential dual floating gate circuit and method for programming

InactiveUS6898123B2Improved initial setting accuracyImprove accuracyElectric analogue storesRead-only memoriesCapacitanceCapacitive coupling

A method and circuit for setting a reference voltage in a dual floating gate circuit is disclosed. During a set mode, a first and second floating gate are programmed to different charge levels that are a function of an input set voltage capacitively coupled to the first floating gate during the set mode. During a read mode, this difference in charge level is used by the dual floating gate circuit to generate a reference voltage that is a function of the input set voltage, and is preferably equal to the input set voltage.

Owner:XICOR

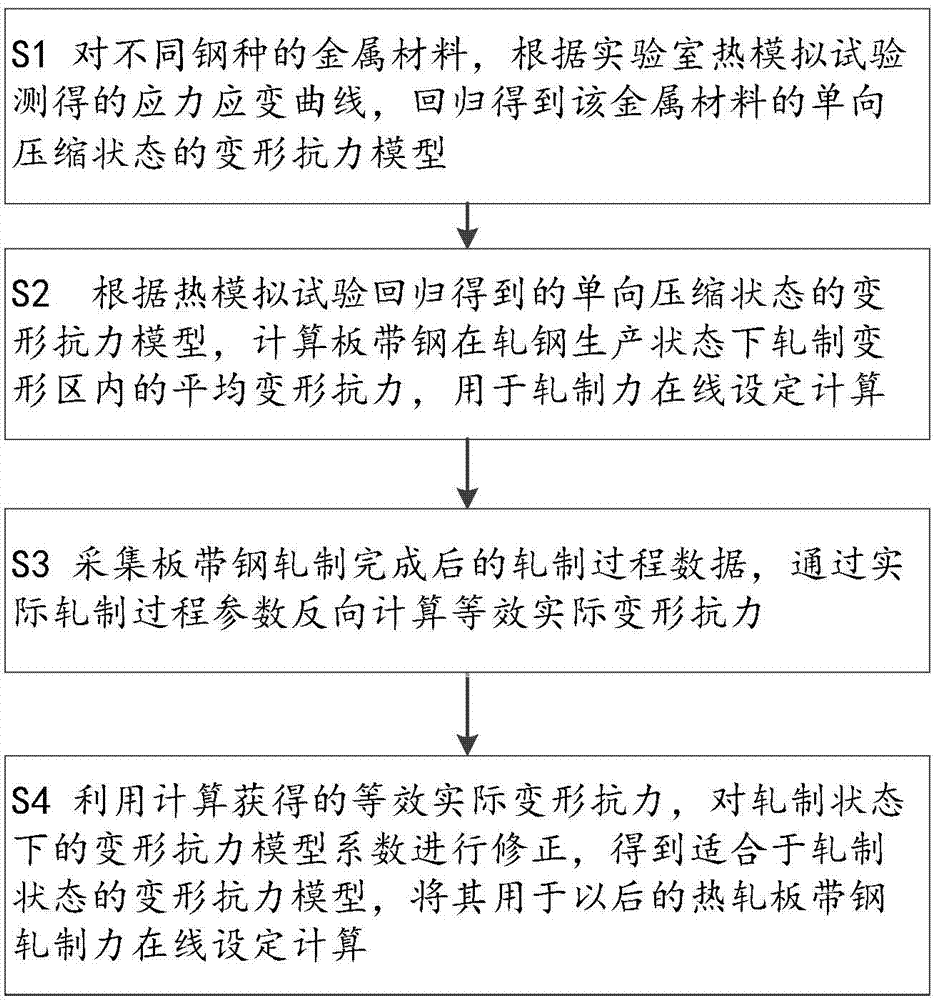

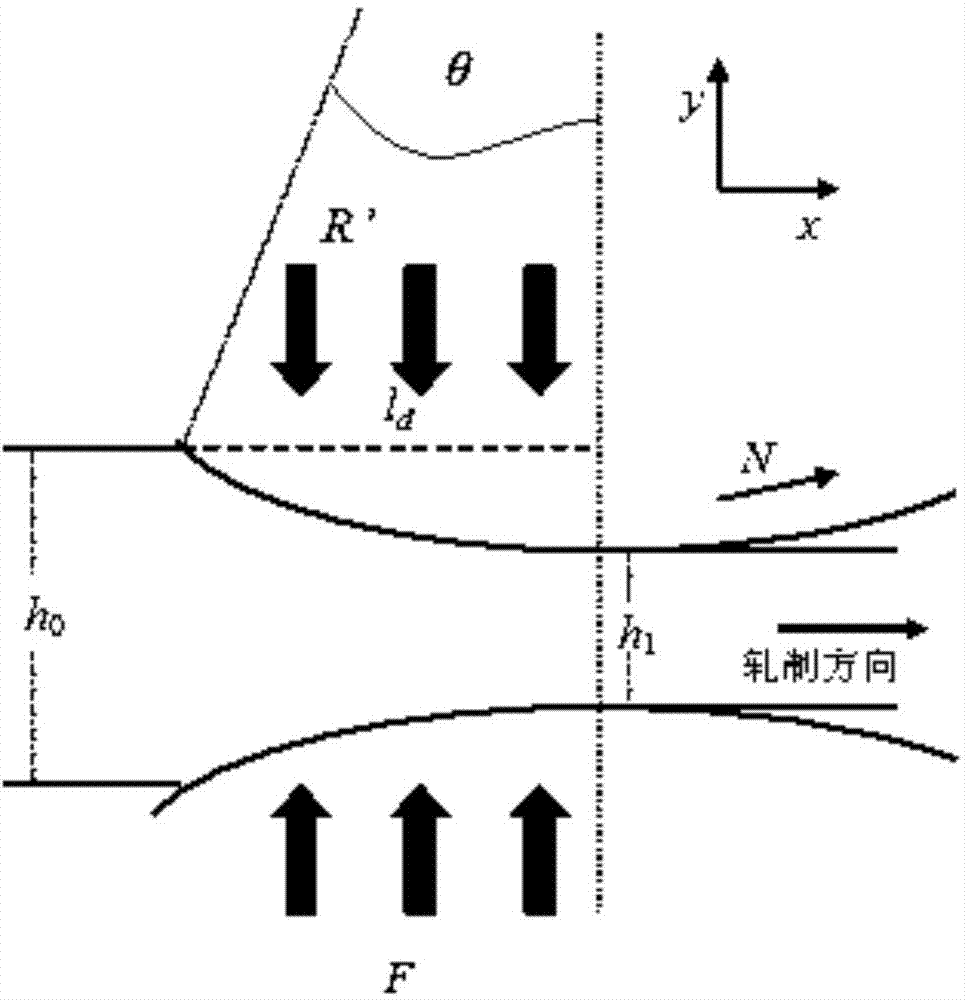

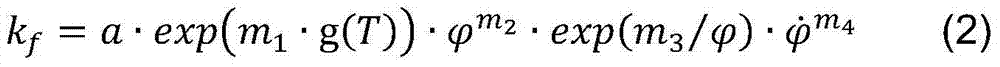

Hot rolled strip steel rolling force optimal-setting method

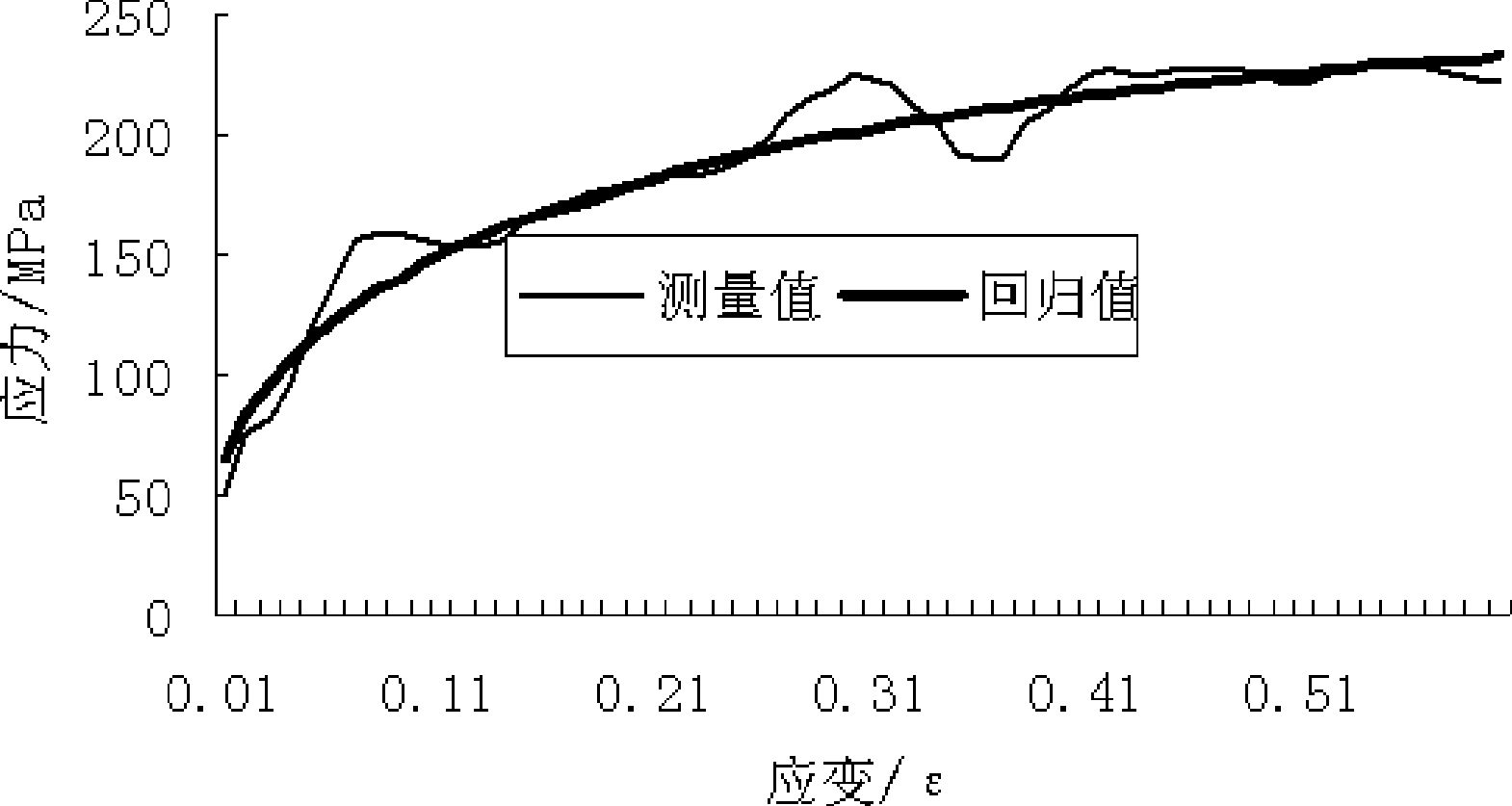

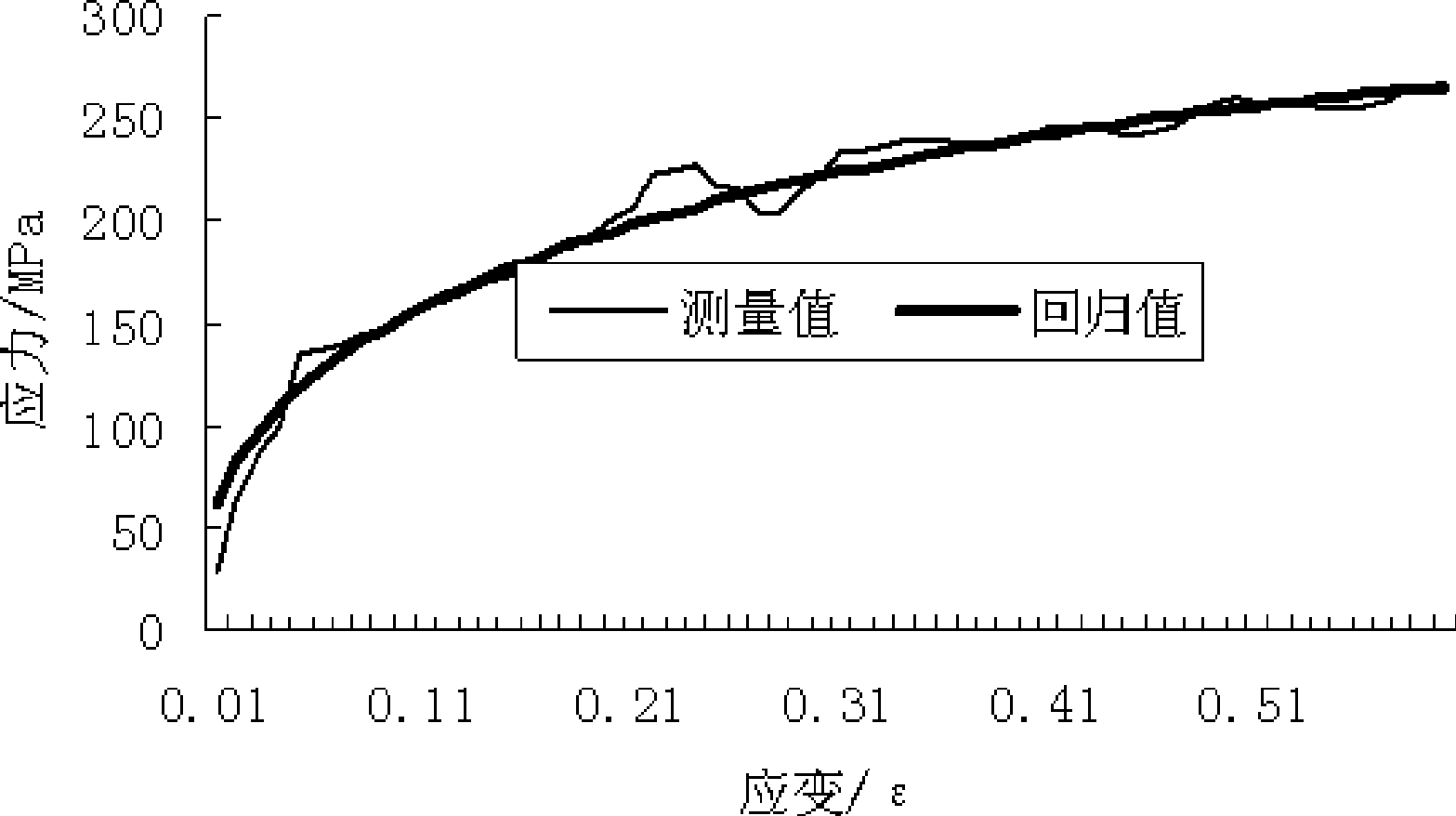

ActiveCN104841700AImprove setting accuracyImprove thickness control accuracyMeasuring devicesProfile control deviceSingle passHot rolled

The invention provides a hot rolled strip steel rolling force optimal-setting method and relates to the technical field of control of hot rolled strip steel production process. The problem that in the prior art, a laboratory thermal simulation test and rolled steel production actual data are not simultaneously utilized to conduct optimal setting on rolling force is solved. According to the hot rolled strip steel rolling force optimal-setting method, a stress strain curve of a material is measured through a laboratory thermal simulation single-pass test and is regressed into a deformation resistance model in a one-way compression state, then a deformation resistance model coefficient in an actual rolling state is corrected according to actual rolling process parameters for future rolling force setting and calculation, accordingly the setting accuracy of a hot rolled strip steel rolling force model is improved, and overload phenomenon and the like are avoided. The hot rolled strip steel rolling force optimal-setting method is suitable for rolling force setting and calculation under the condition that the actual rolling process data of multiple-pass hot rolled strip steel are obtained when the deformation resistance model for the rolling force mode is obtained through data regression measured through a laboratory heat simulation machine.

Owner:张家港市欧美轻工工具制造有限公司

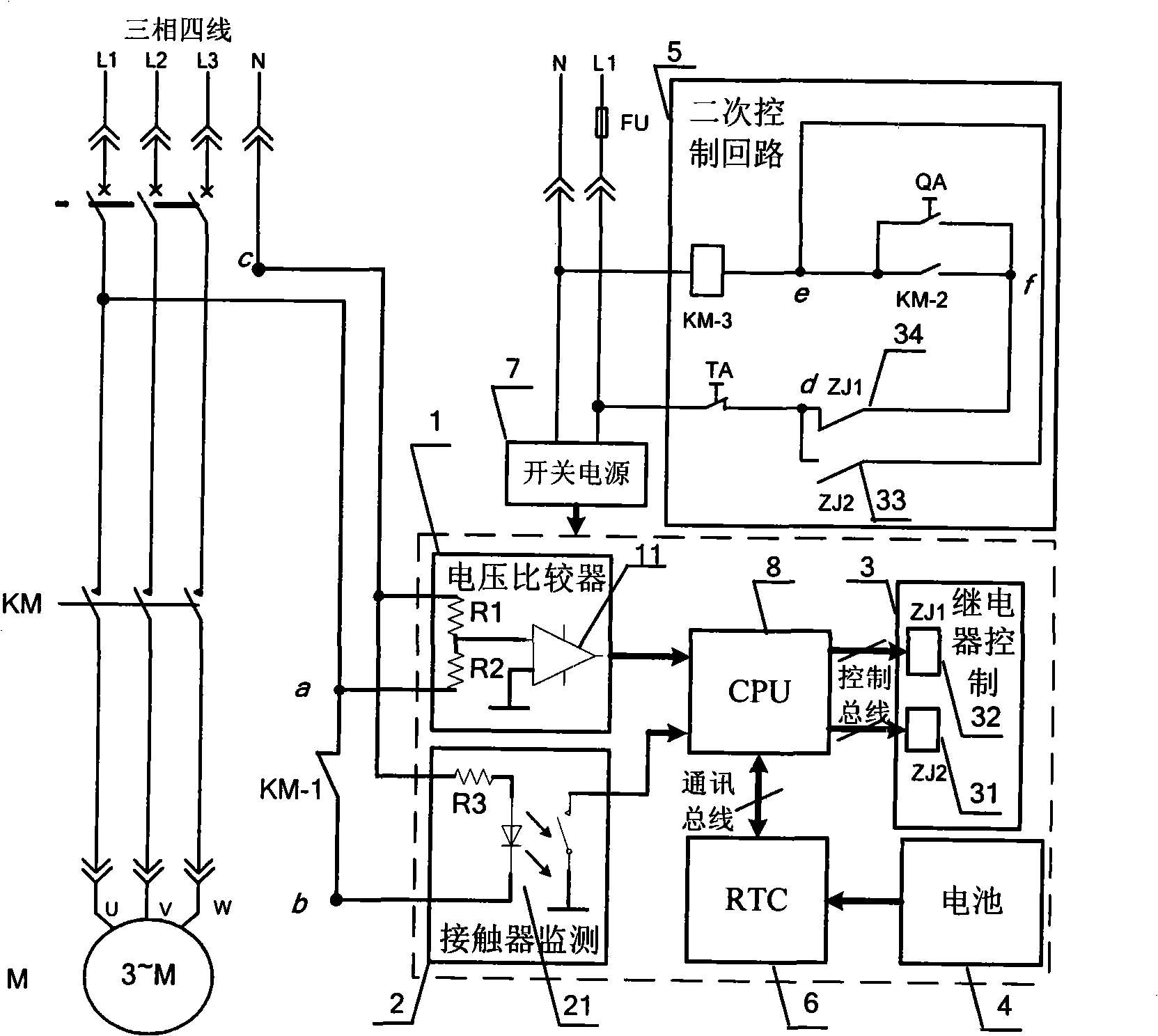

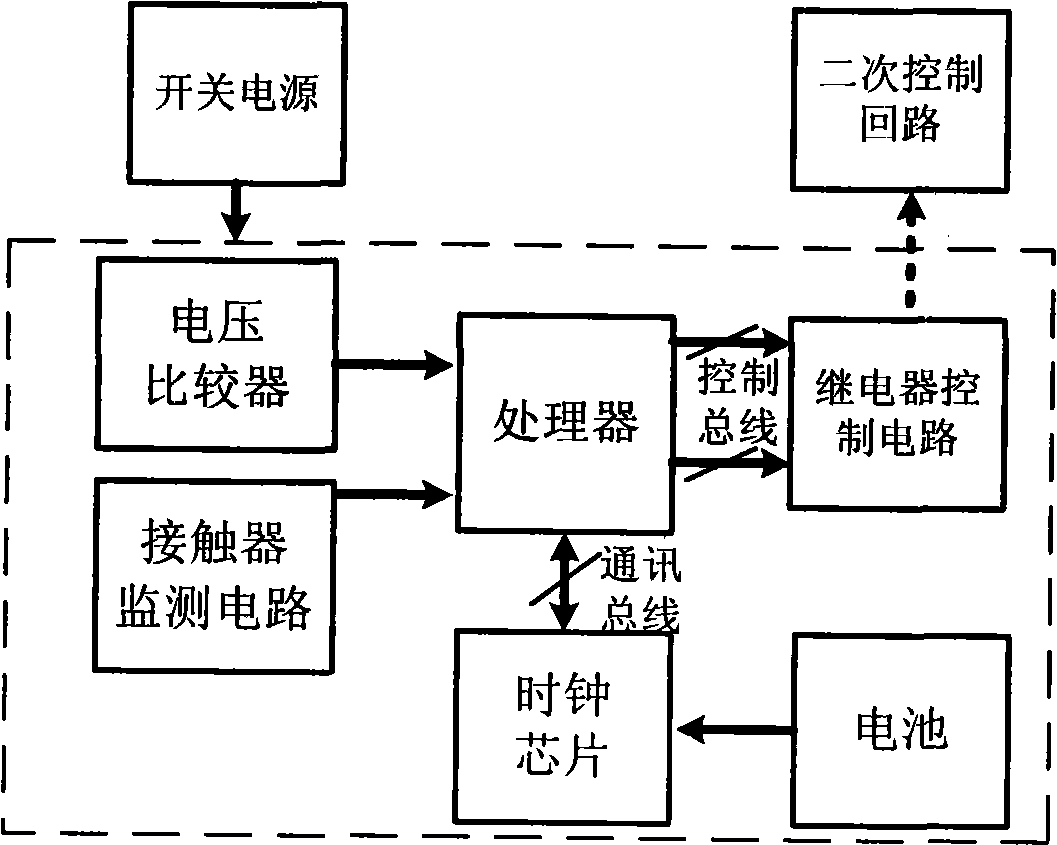

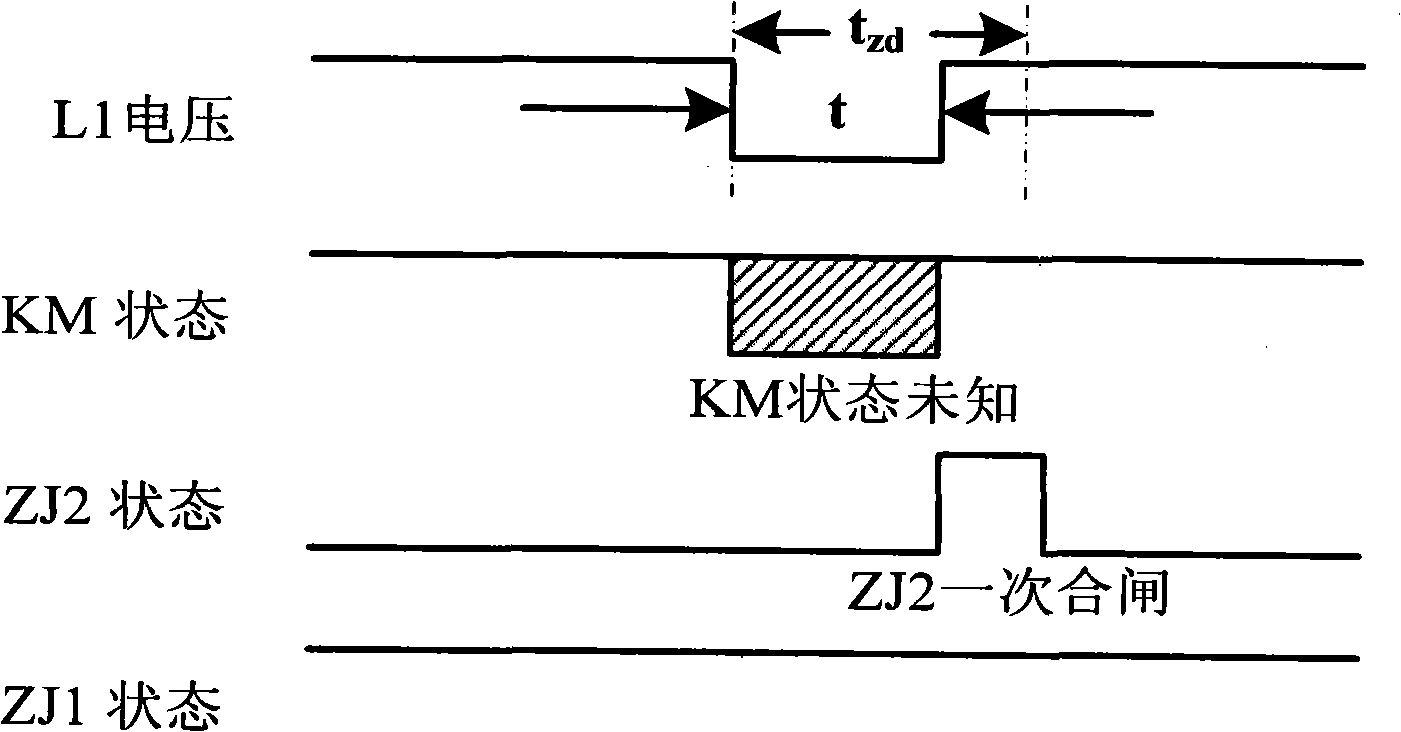

Synthetic apparatus of anti-flashover and protection for low-voltage three phase asynchronous motor

InactiveCN101309003AImprove setting accuracyGood repeatabilityArrangements responsive to undervoltageThree phase asynchronous motorLow voltage

Disclosed is an anti-interference and comprehensive protection device for a low voltage three-phase asynchronous motor, which can realize the restarting of the low voltage three-phase asynchronous motor when the motor is shut down by the fluctuation of the low voltage power network, thereby solves the problem that the product line of industry manufacture enterprise can be shut down abnormally by the power-shaking. The invention is composed of the follows: 1, a processor, 2, a clock chip, 3, a battery, 4, a voltage comparator circuit, 5, a monitor circuit of a contactor, 6, a control circuit of a relay 7, a second control loop, 8, a switching power supply, and 9, a wire connection terminal. The invention can restart the motor when the power is switched on after the motor is shut down due to the power-shaking of the power network, can distinguish two different failures of power-shaking and long-time under-voltage, and can judge whether the motor is working before power-shaking. The anti-interference and comprehensive protection device of the invention has the advantages of high setting accuracy, good repeatability and accurate action time, and does not need external equipment to provide high power backup power supply.

Owner:江苏冠顺电机有限公司 +1

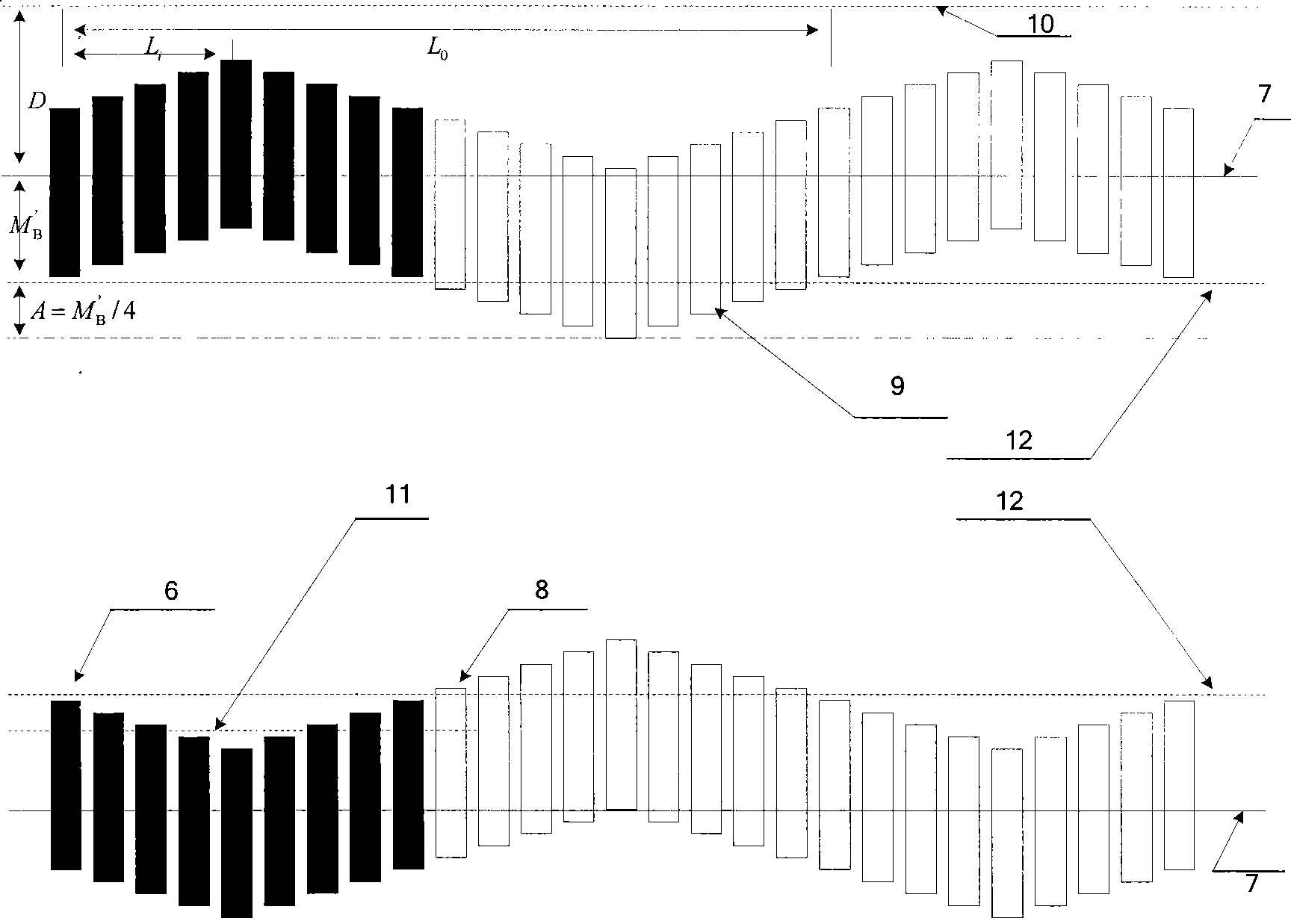

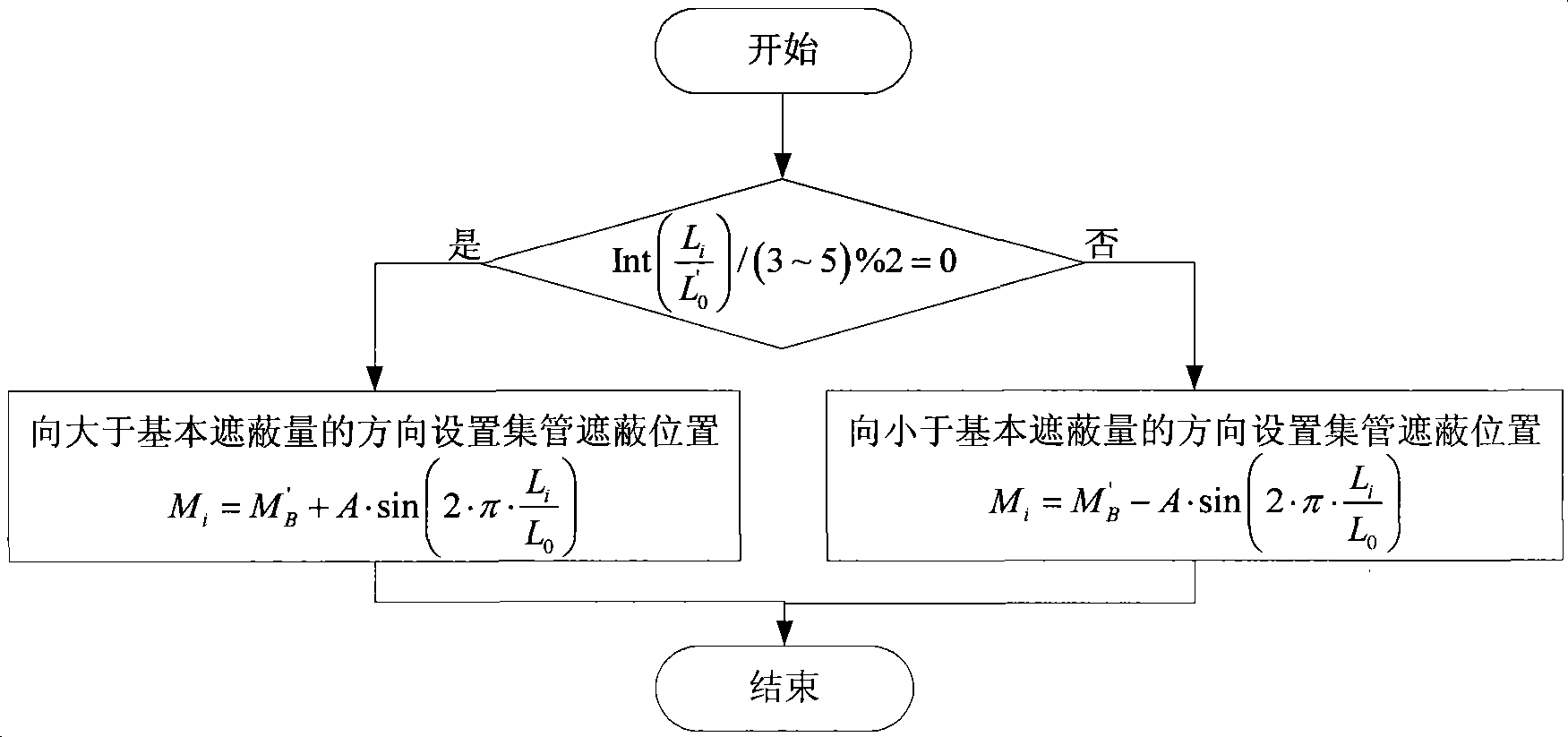

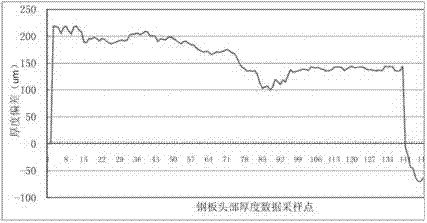

Medium plate laminar cooling chain edge part shading device control method

InactiveCN101502849AEasy to controlImprove setting accuracyTemperature control deviceAutomatic controlEngineering

A control method for a middle thickness plate laminar cooling chain edge masking device is disclosed, belonging to the field of rolling automatic control technology and comprising the following steps of: (1) determining a basic value MB of the amount of middle thickness plate laminar cooling chain edge masking; (2) correcting the masking amount with MB' being equal to MB.f(3); calculating the masking amount Mi of each group of opening manifolds; (4) implementing the masking amount of the single manifold; and considering that a masking baffle plate moves to a set masking location when a moving pulse Iact of the i group of manifold is equal to a target setting pulse Ind of the i group of manifold, in order to realize accurate positioning for the masking device of single group of manifold. The invention can achieve accurate control for the location of the edge masking baffle plate of the single group of manifold; a masking policy model takes parameters like thickness of steel plate, width of steel plate and cooling water amount into consideration, and has high model setting accuracy; the method can compensate and correct the system effectively and improve uniformity of controlling width temperature of the steel plate. The invention is suitable for hot-rolling middle thickness plate and laminar cooling device after rolling.

Owner:NORTHEASTERN UNIV

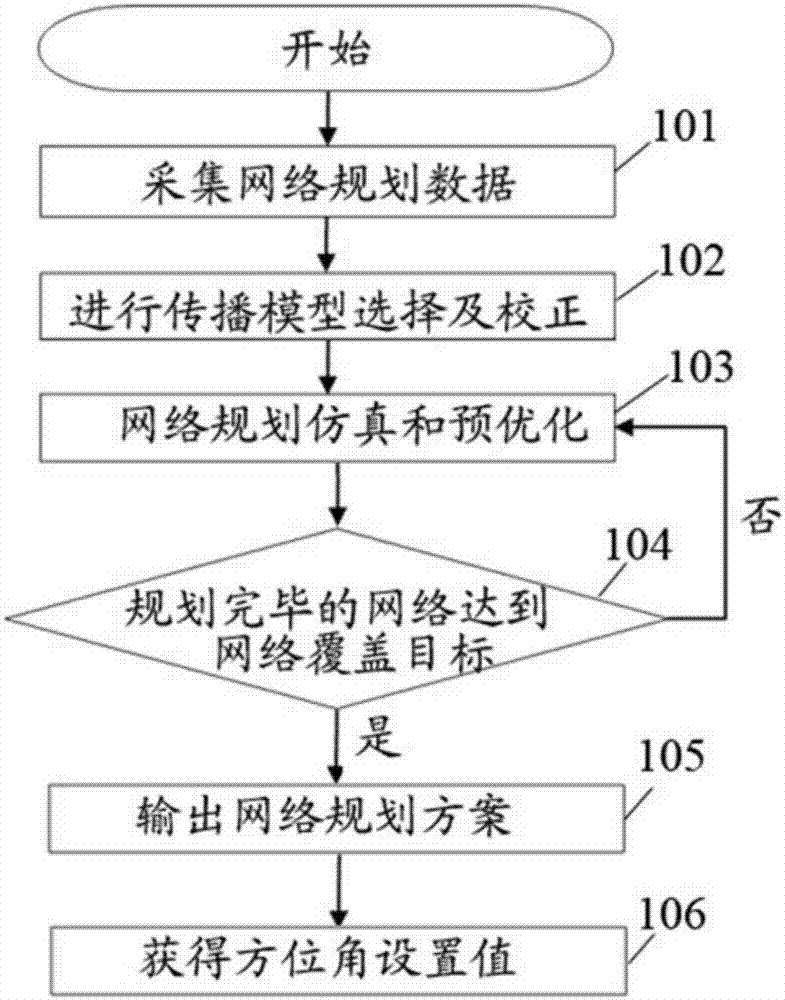

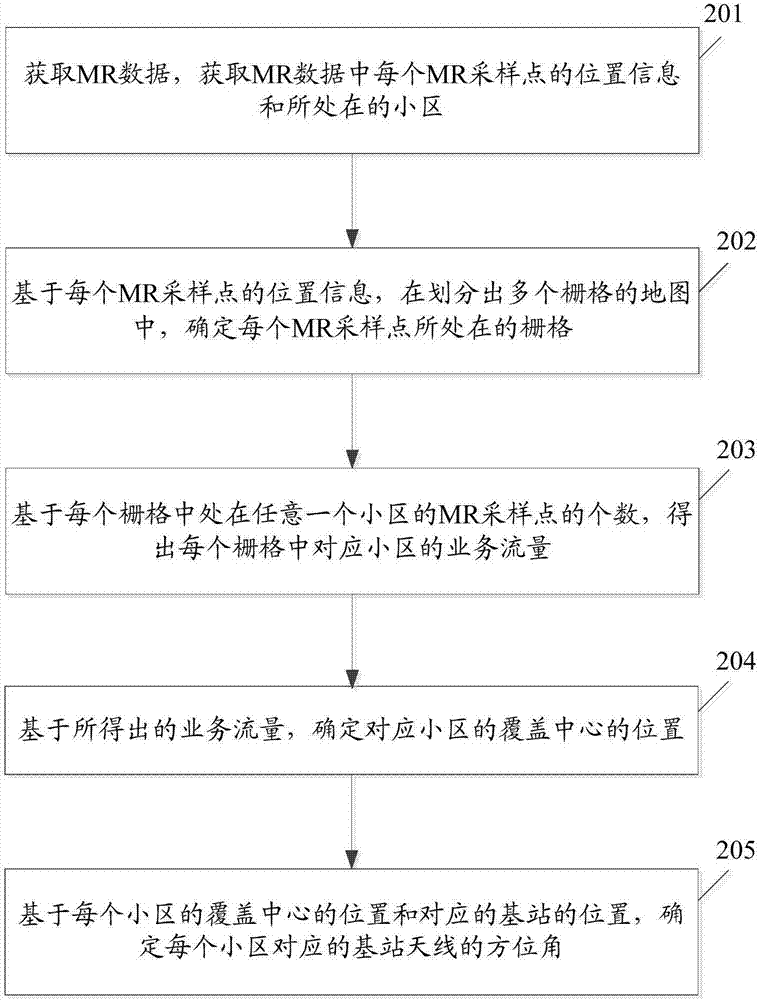

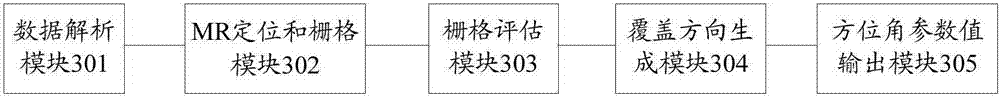

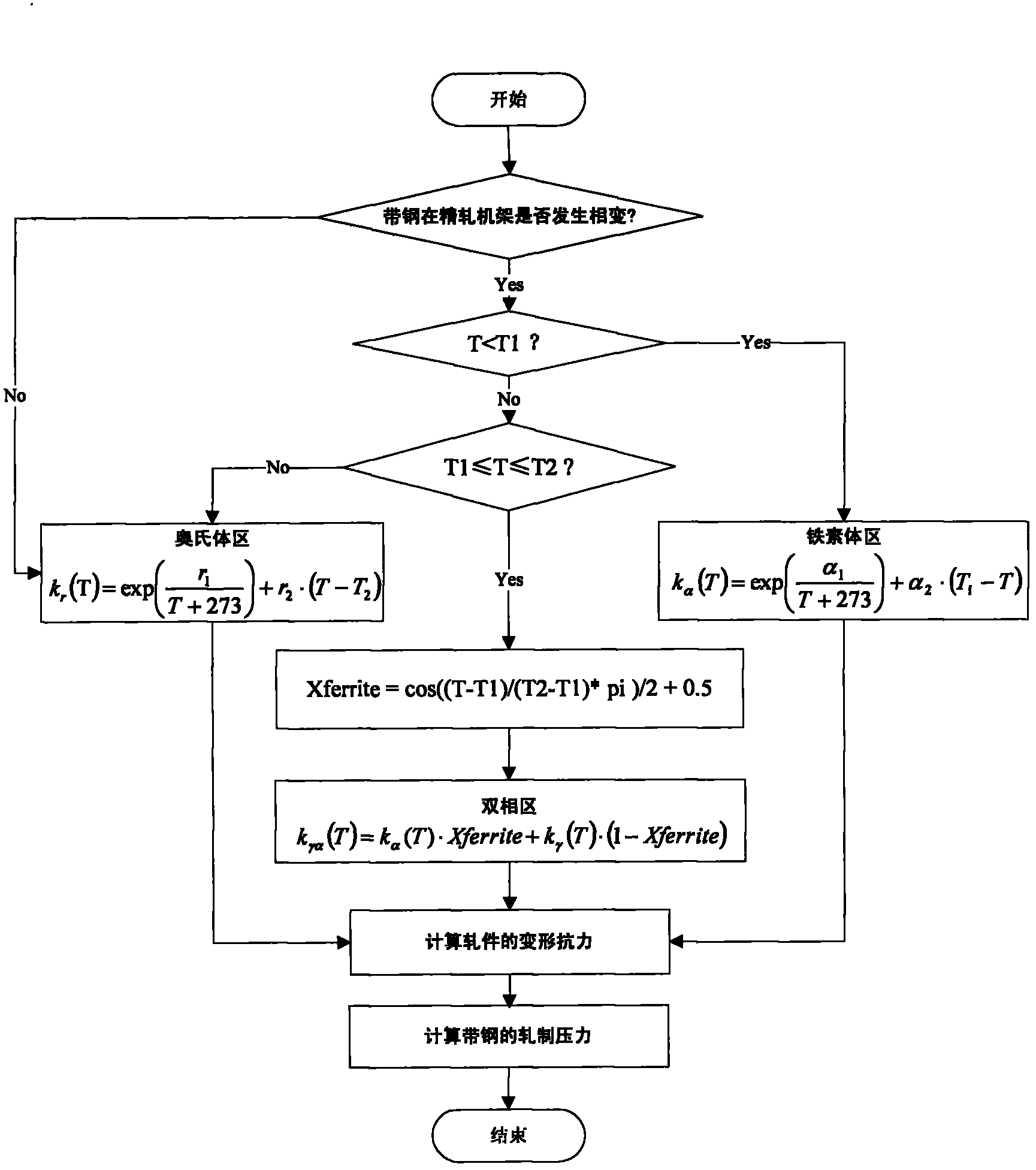

Method and device for determining azimuth angle of base station antenna

The invention discloses a method and device for determining an azimuth angle of a base station antenna. The method comprises the following steps: obtaining MR data, and obtaining position information of each MR sampling point and a cell where each MR sampling point is located in the MR data; based on the position information of each MR sampling point, determining a grid where each MR sampling point is located in a map that is divided into a plurality of grids; based on the number of MR sampling points located in any cell in each grid, obtaining the service flow of the corresponding cell in each grid; based on the obtained service flow, determining the position of the coverage center of the corresponding cell; and based on the position of the coverage center of each cell and the position of the corresponding base station, determining the azimuth angle of the base station antenna corresponding to each cell.

Owner:HANDAN BRANCH OF CHINA MOBILE GRP HEBEI COMPANYLIMITED

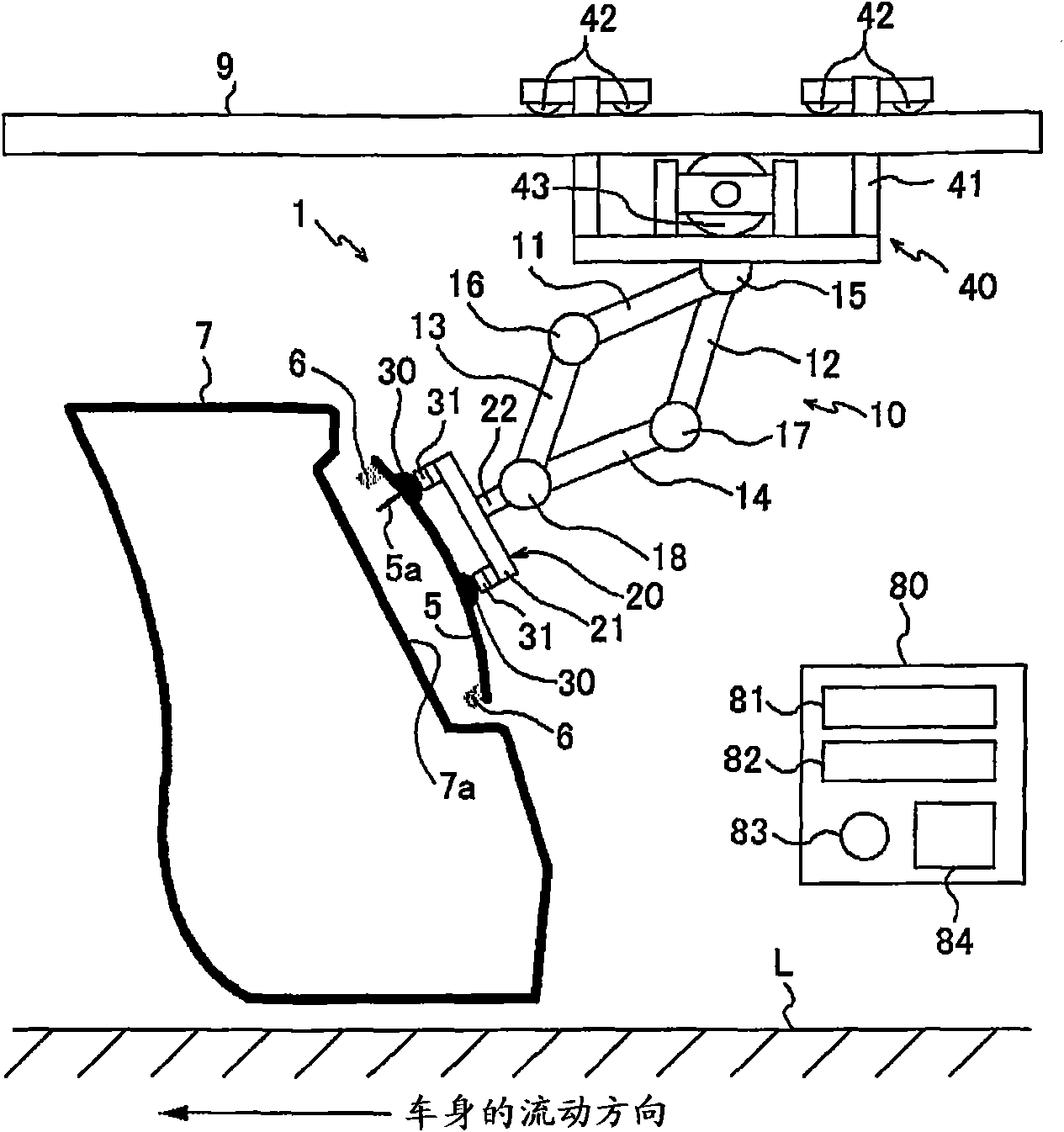

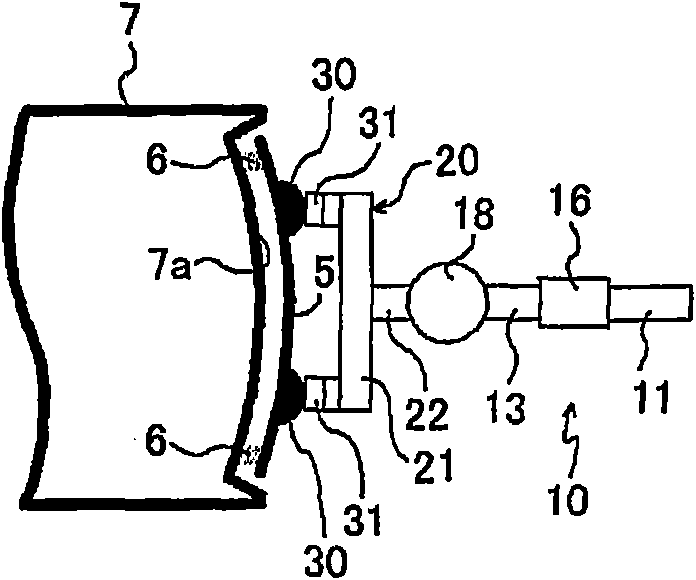

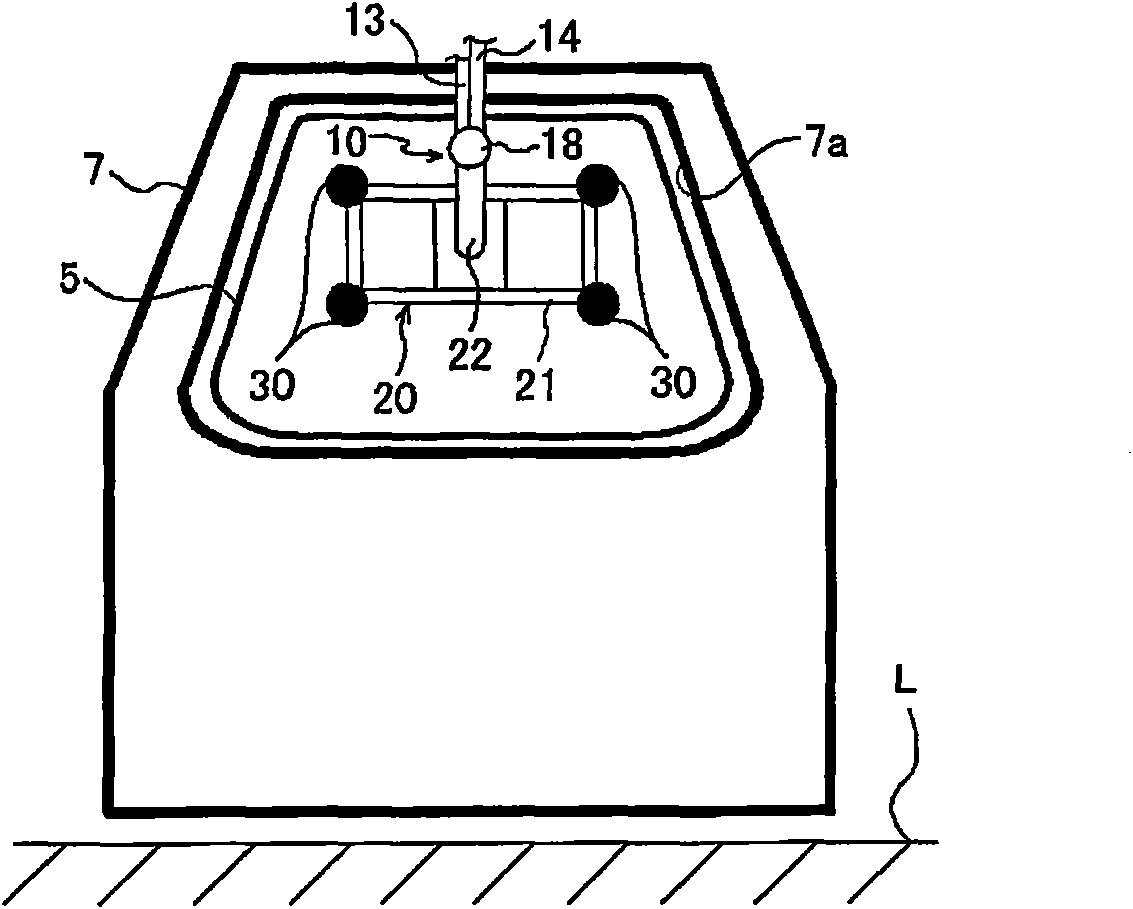

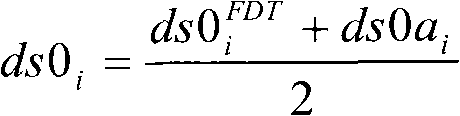

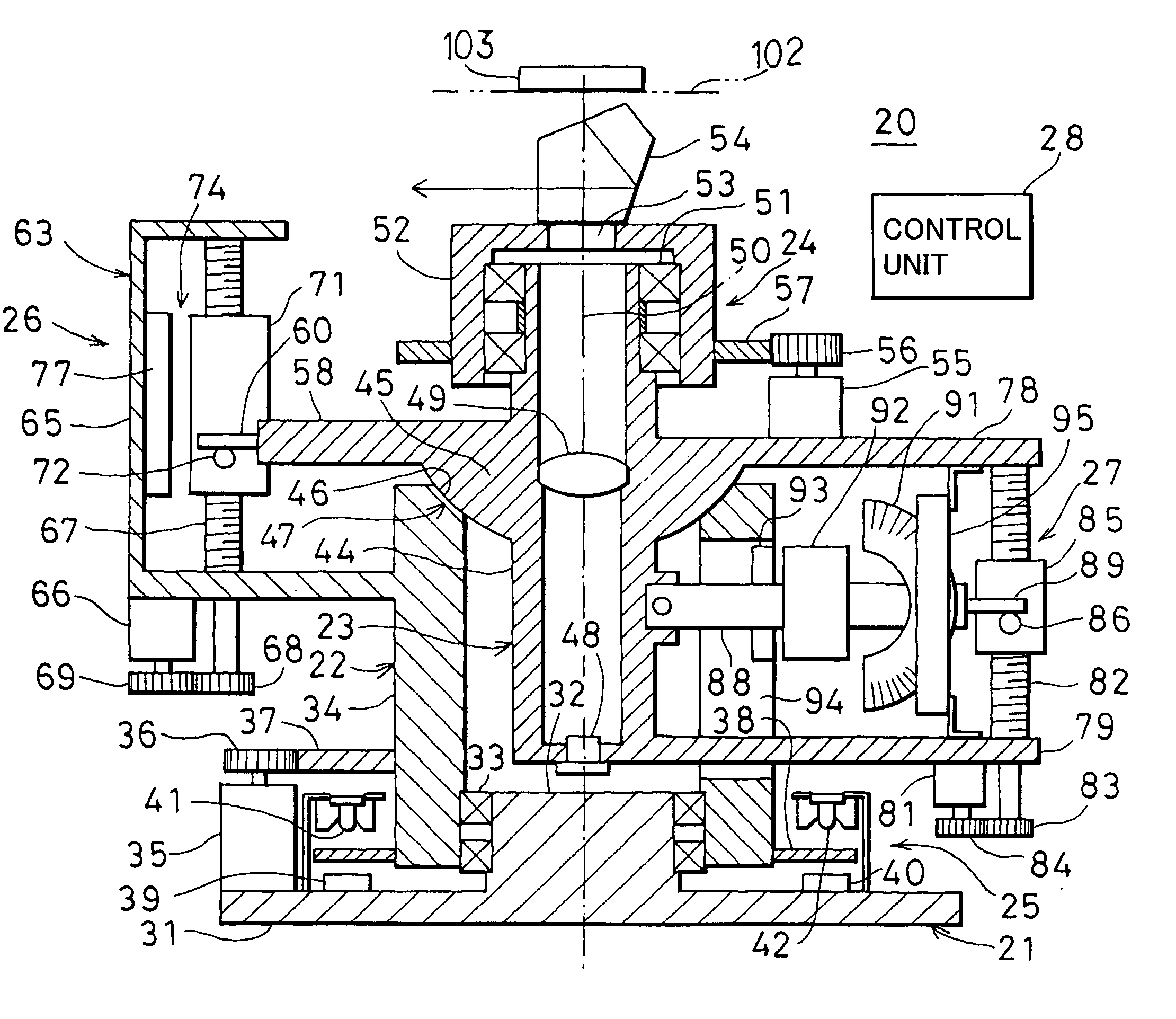

Work transfer apparatus, and work mounting method

InactiveCN101772402AImprove setting accuracySqueeze evenlyProgramme-controlled manipulatorGripping headsEngineeringAdhesion strength

According to a work mounting method by the work transfer apparatus of the prior art, a glass plate or a work may fail to abut against a window frame homogeneously at its peripheral edge portion, and the adhesion strength or the sealing property between the glass plate and the window frame may not be retained all over the periphery of the adhered portion. Provided is a work transfer apparatus (1),which grips a rear glass (5) by its gripping member (20) and mounts the rear glass (5) while pushing the gripped rear glass (5) onto the window frame (7a) of a car body (7) by the action of a supporting arm (10). The work transfer apparatus (1) comprises a control device (80), and each of absorption pads (30) of the gripping member (20) includes a force detecting sensor (31) for detecting the force to be applied to the absorption pads (30). The control device (80) controls, when it uses the work transfer apparatus (1) to mount the rear glass (5) on the window frame (7a), the actions of the supporting arm (10) on the basis of the magnitude of the detected value of the force detecting sensor (31) of each absorption pad (30).

Owner:TOYOTA JIDOSHA KK

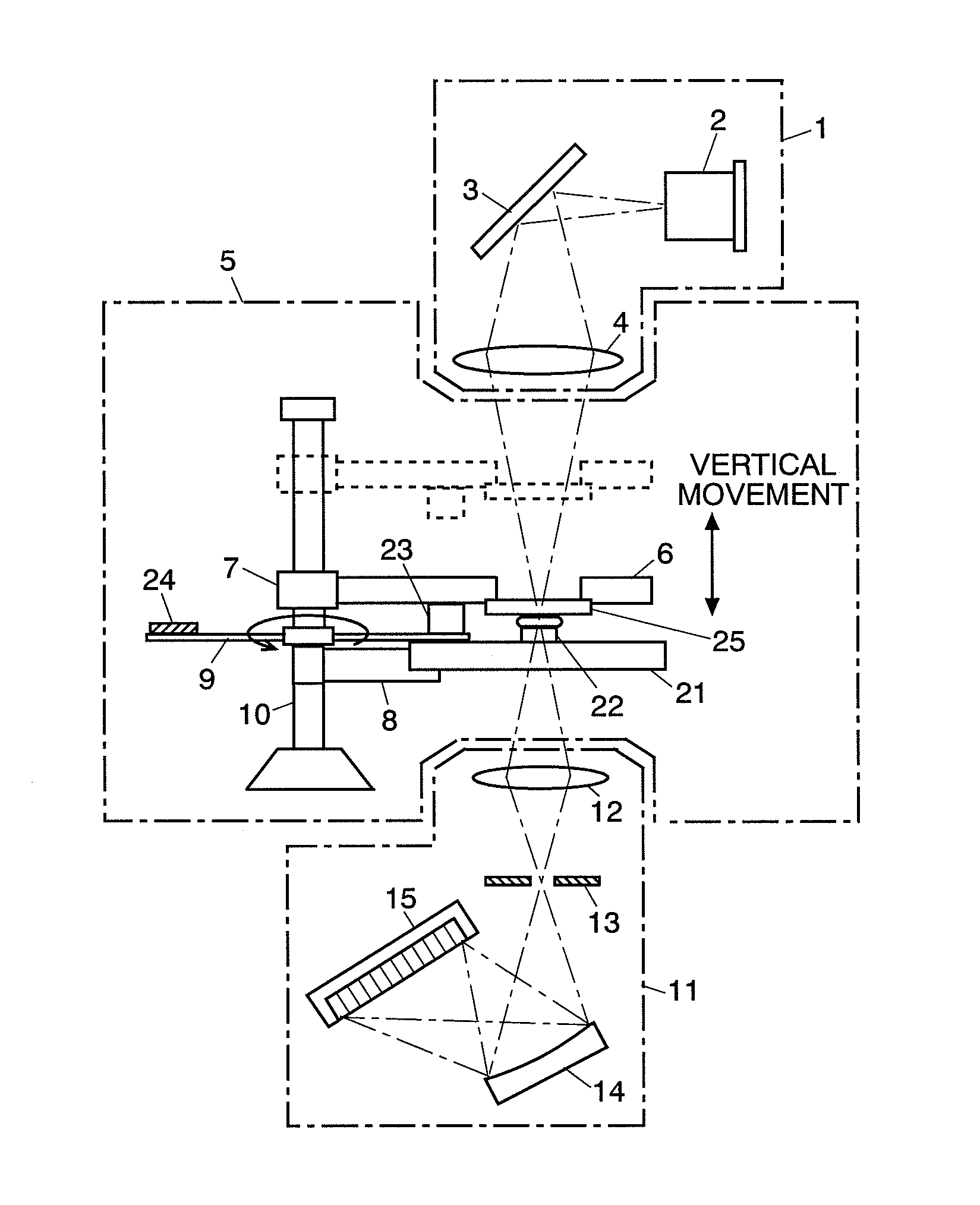

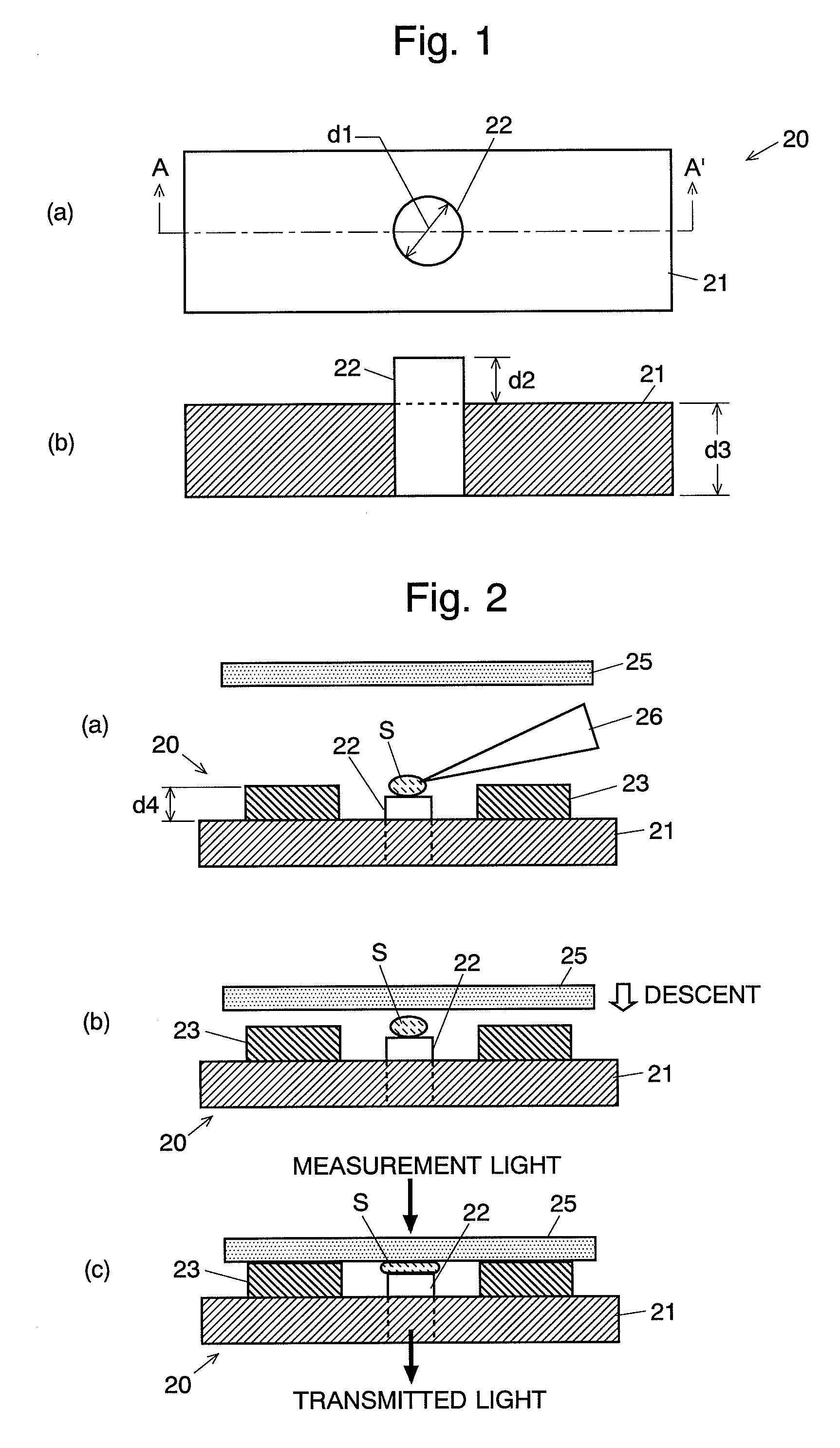

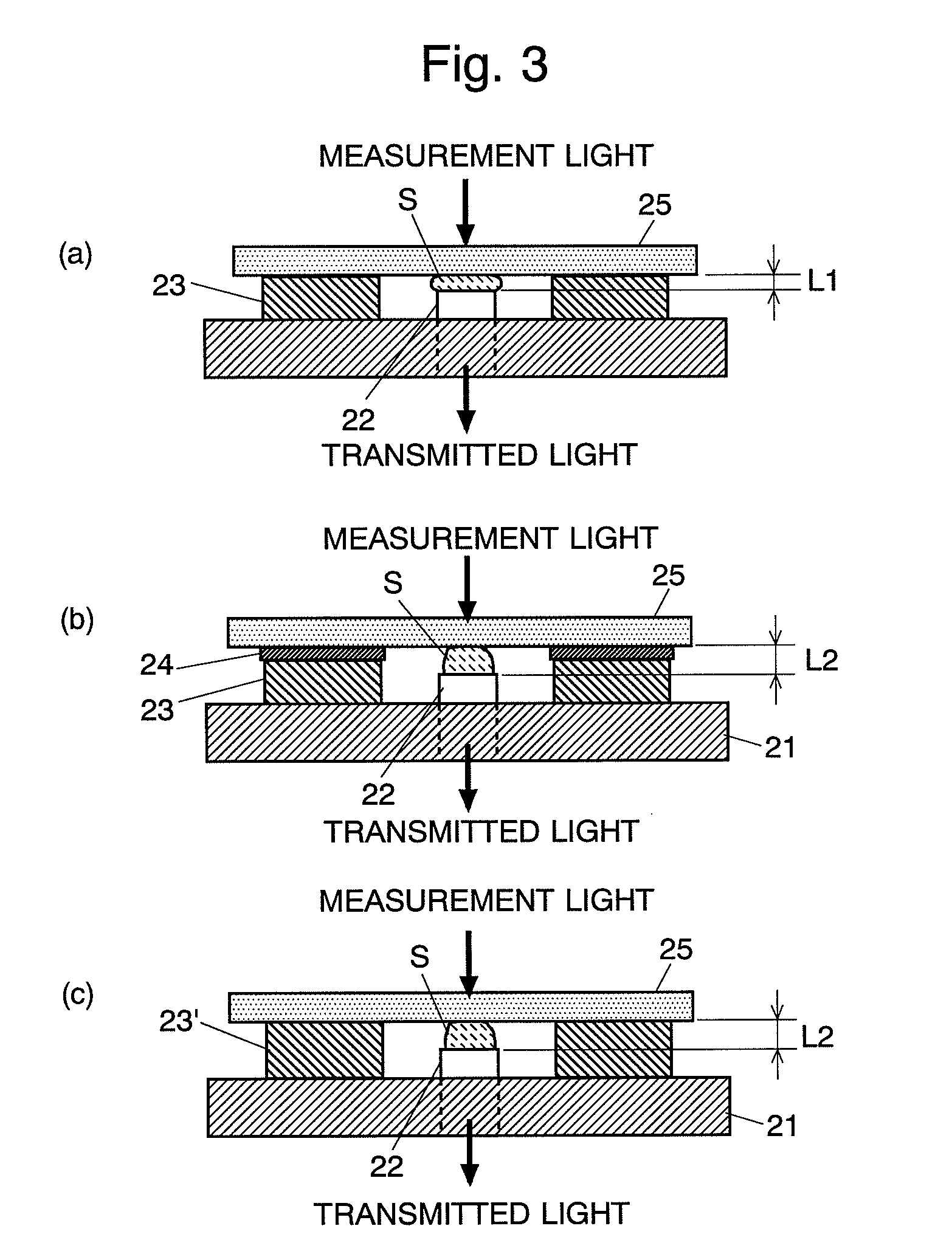

Spectrophotometer

ActiveUS8049884B2Easy to implementEasy to analyzeRadiation pyrometryWithdrawing sample devicesEngineeringOptical path length

A liquid sample is dropped onto the upper surface of a transparent and cylindrical light-transmitting body (22), and the liquid sample is maintained as a droplet by the surface tension. From above the liquid sample, a transparent cover plate (25) is lowered down to the position where the lower surface thereof touches a spacer (23) in order that the liquid sample is held in the small gap formed between the upper surface of the light-transmitting body (22) and the lower surface of the transparent cover plate (25). A measurement light is provided into the liquid sample held in this manner from immediately above it, and passes through the liquid sample. The transmitted light emitted downwards through the light-transmitting body (22) is introduced into a spectro-detecting unit to be spectro-measured. The measurement optical path length can be adjusted by the height of the spacer (23). This enables an easy transmission spectro-measurement of an extremely small amount of liquid sample.

Owner:SHIMADZU CORP

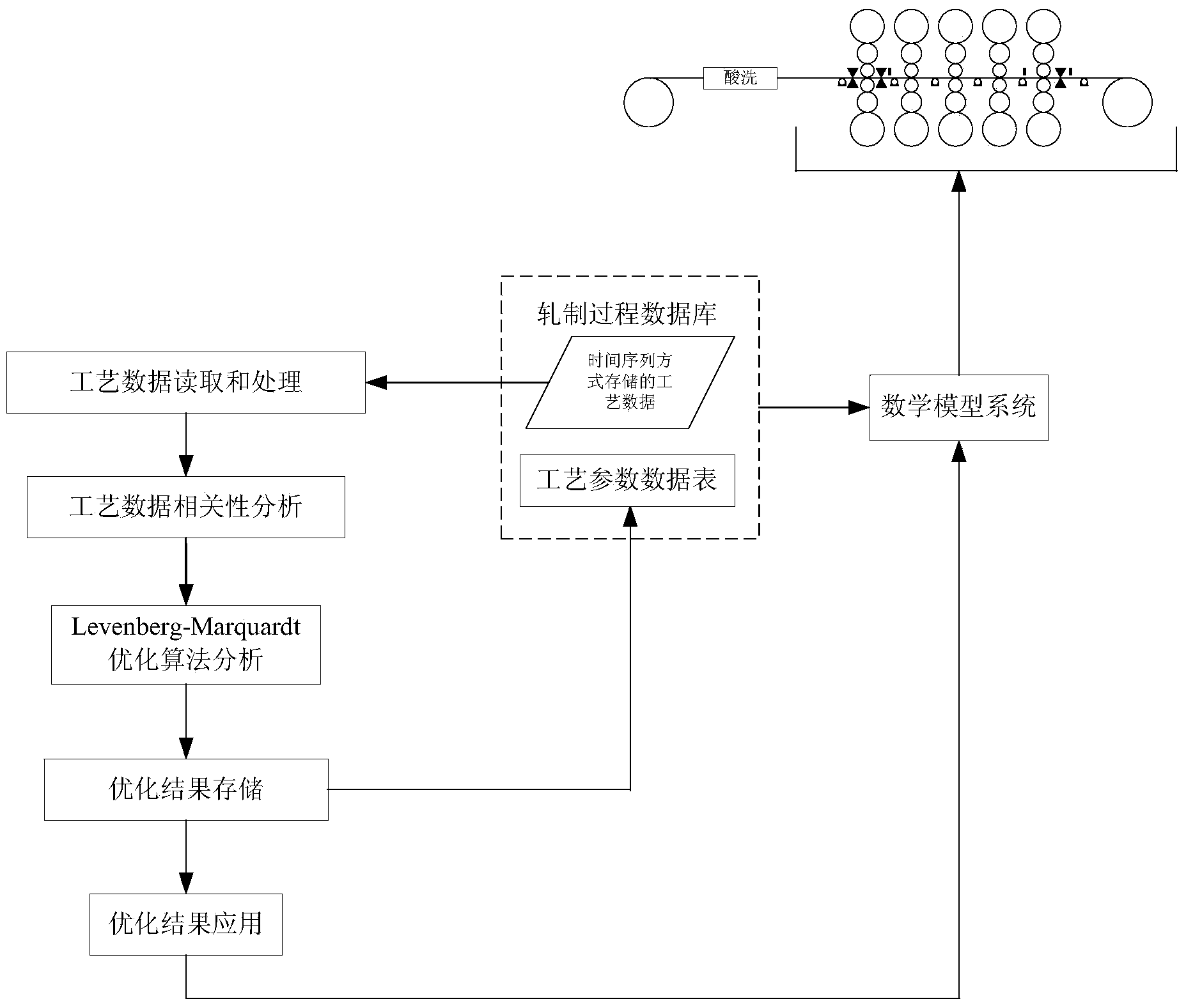

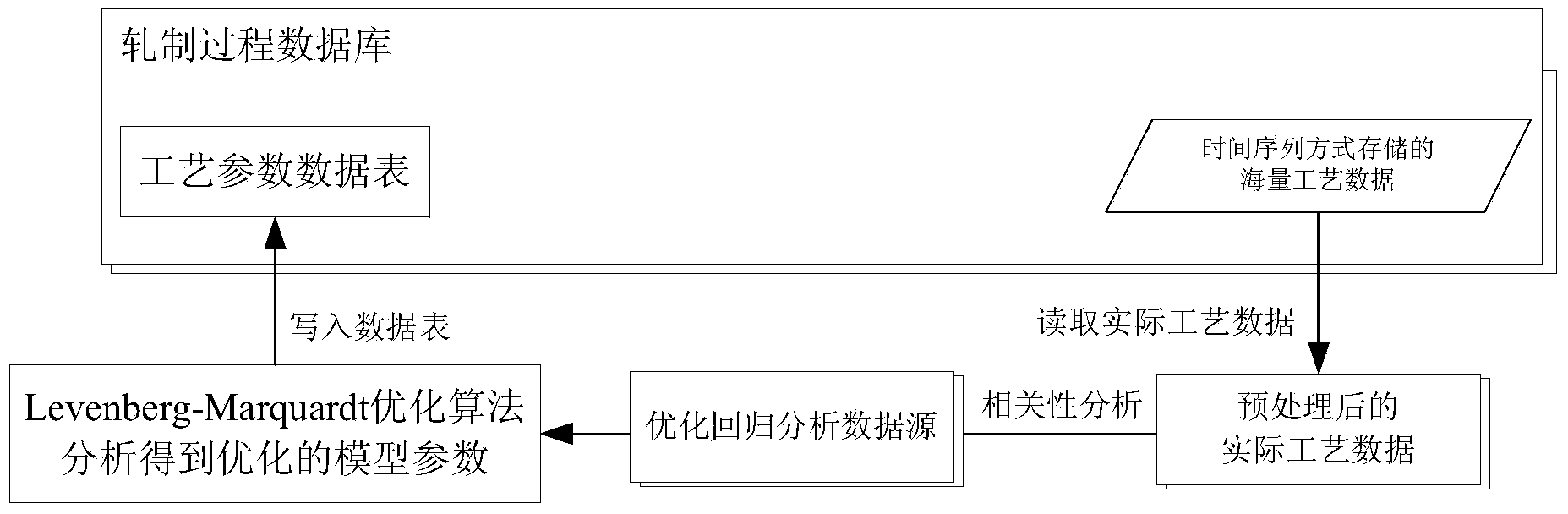

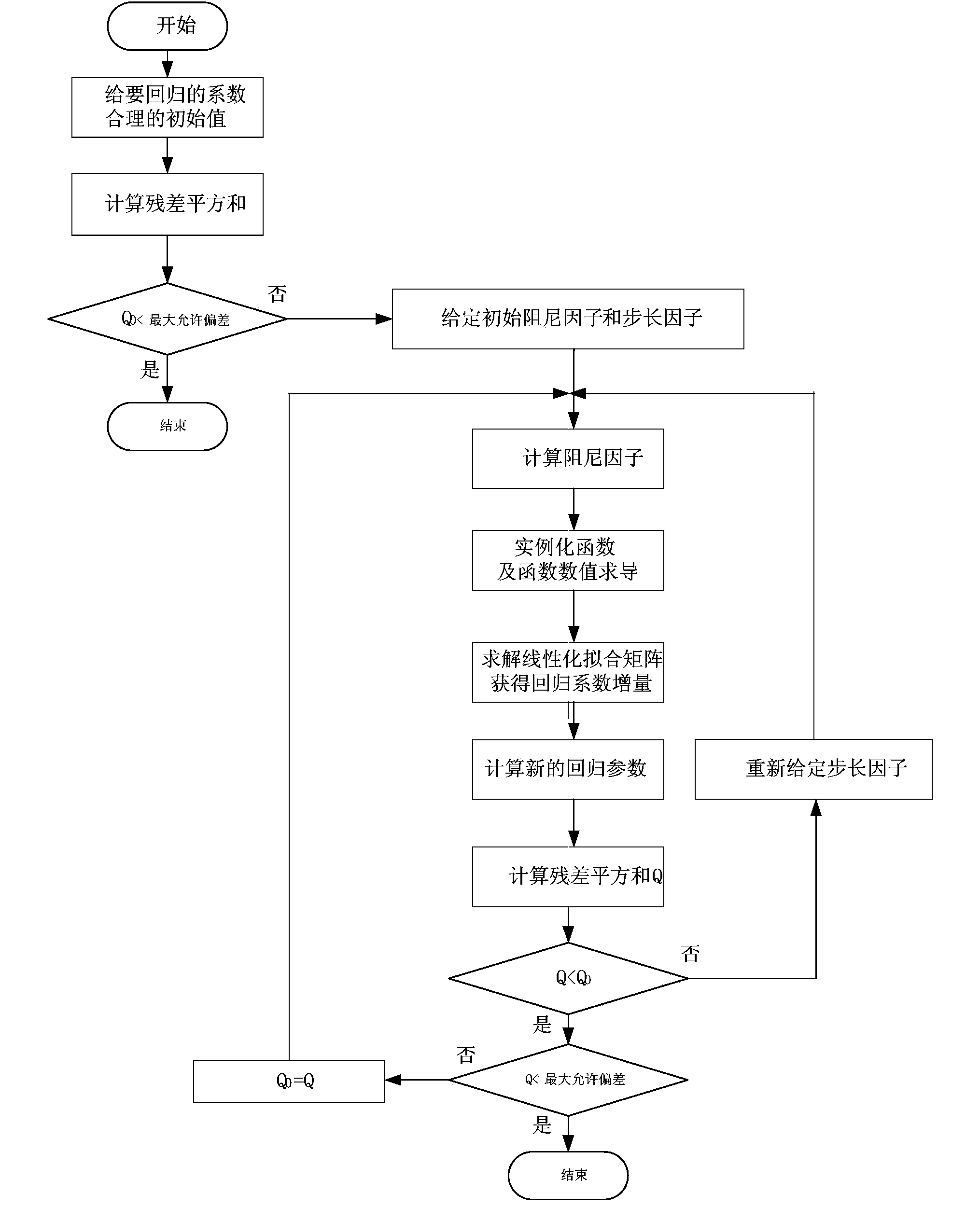

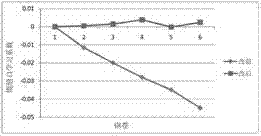

Friction coefficient model optimizing system and method in rolling process

ActiveCN103722022AImprove execution efficiencySuperiorRoll mill control devicesMetal rolling arrangementsMathematical modelData dependency analysis

The invention discloses a friction coefficient model optimizing system and method in the rolling process, and belongs to the technical field of control mathematical models in the rolling process. The Levenberg-Marquardt optimization algorithm is adopted to optimize friction coefficient model parameters in the rolling process. The friction coefficient model optimizing system is characterized by comprising a rolling process database, a rolling process technological parameter data sheet and following function modules which are a technological data reading and processing module, a technological data dependency analysis module, a Levenberg-Marquardt optimization algorithm analysis module, an optimization result storage module and an optimization result application module. The friction coefficient model optimizing system has the advantages that on the premise that key technological parameters are fully considered, the method can effectively process redundant parameters, actual rolling parameters on the site are utilized for directly conducting regression optimization on parameters of a nonlinear polynomial rolling process friction coefficient model, the linear processing process is prevented from being carried out on the complex friction coefficient model, the actual rolling situation on the site can be better reflected, friction coefficient setting computational accuracy is improved, the requirement for high-accuracy rolling is met, and therefore the product quality and yield are improved.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

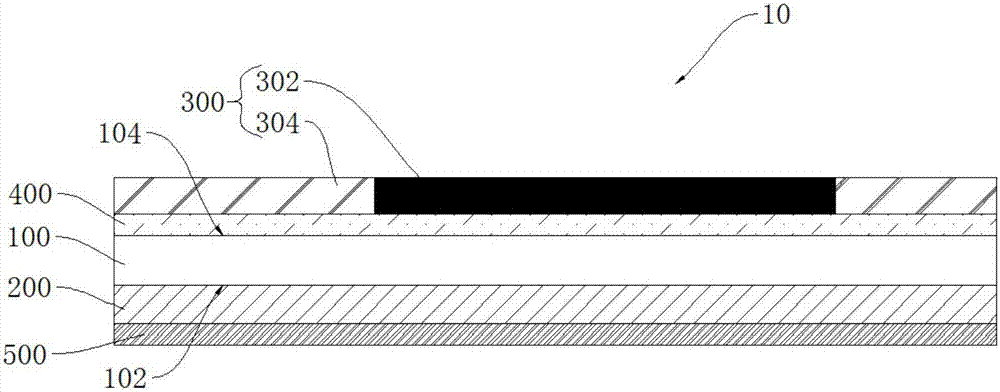

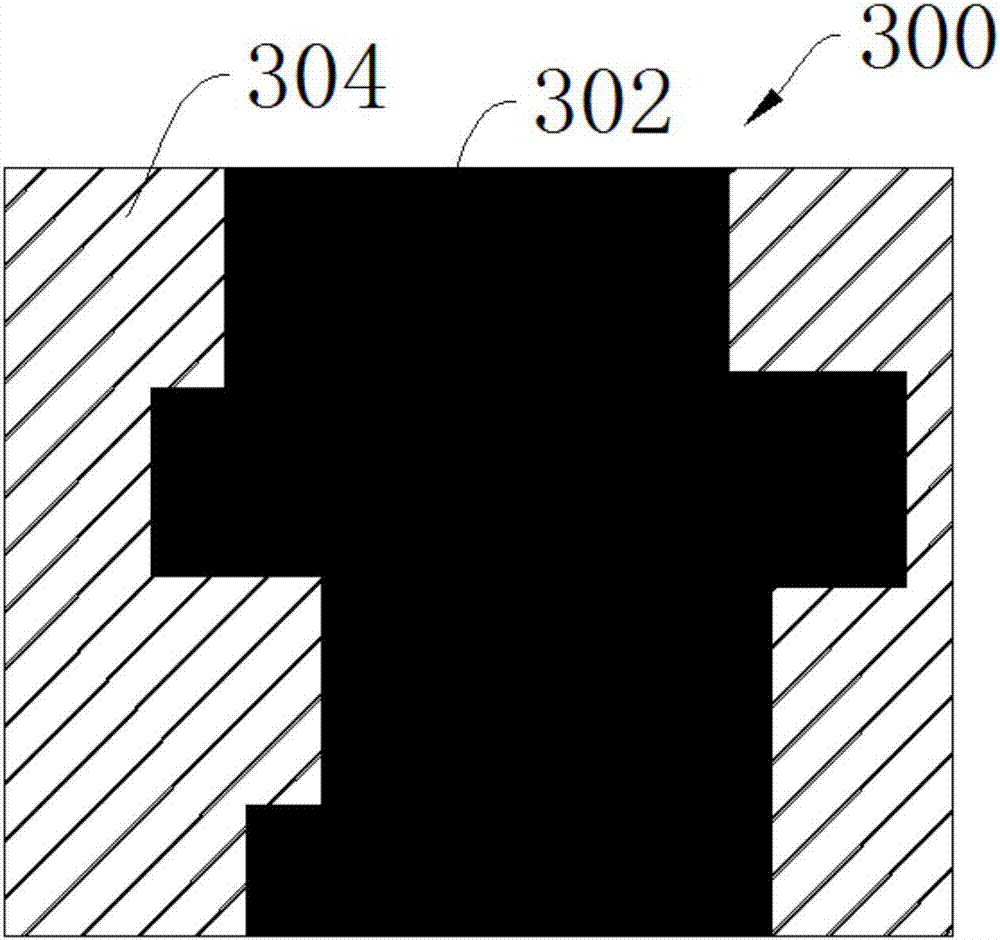

Decoration membrane, rear shell, terminal and terminal rear shell production method

InactiveCN107248618AAvoid pollutionImprove setting accuracyAntenna equipments with additional functionsTelephone set constructionsCorrosionBiochemical engineering

The embodiment of the present invention discloses a decorative film, which is attached to a transparent member, the decorative film includes an adhesive layer, a base material and a conductive layer, and the base material includes a first side and a second side arranged opposite to each other, The adhesive layer is located on the first side and is used for attaching the decorative film to the surface of the transparent member, and the conductive layer is located on the second side and is an antenna. Embodiments of the present invention also provide a back case, a terminal, and a method for producing a back case of the terminal. The antenna is formed in the decorative film, and the decorative film is attached to the surface of the transparent part through the adhesive layer, so that the whole composed of the decorative film and the transparent part can be used as the back cover of the terminal, that is, the antenna of the terminal no longer needs to be corroded. processing to avoid pollution caused by antenna processing. At the same time, since the antenna is directly printed on the decorative film, it is no longer necessary to manually paste or install the antenna in the later stage, which improves the setting accuracy of the antenna position, reduces the time consumption of manual operation and improves production. efficiency.

Owner:SHENZHEN GIONEE COMM EQUIP

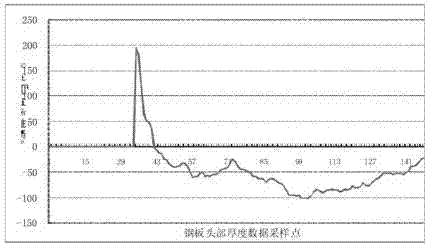

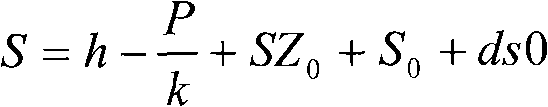

Optimization method for hot rolled strip steel roll gap model

InactiveCN102896156ASimple structureImprove setting accuracyRoll force/gap control deviceData processingZero drift

The invention discloses an optimization method for a hot rolled strip steel roll gap model. According to the optimization method, a roll gap setting and calculating model structure is optimized, a roll gap zero drift compensation is increased, and a roll gap zero drift offset existent in a process of calculating a roll gap setting value is reduced; and meanwhile, a data processing method for roll gap self-learning is improved as follows: oscillation of roll gap self-learning is reduced by utilizing a roll gap self-learning data screening method for removing an extremal rolling force and an extremal roll gap at the same time and a combination method of short-time genetic learning and long-time genetic learning mechanisms. Due to the adoption of the optimization method, so that accuracy of the roll gap setting value and effectiveness of roll gap self-learning are guaranteed, calculation precision of the roll gap model is greatly improved, and thickness precision of a finished-product hot rolled strip steel is further improved.

Owner:ANGANG STEEL CO LTD

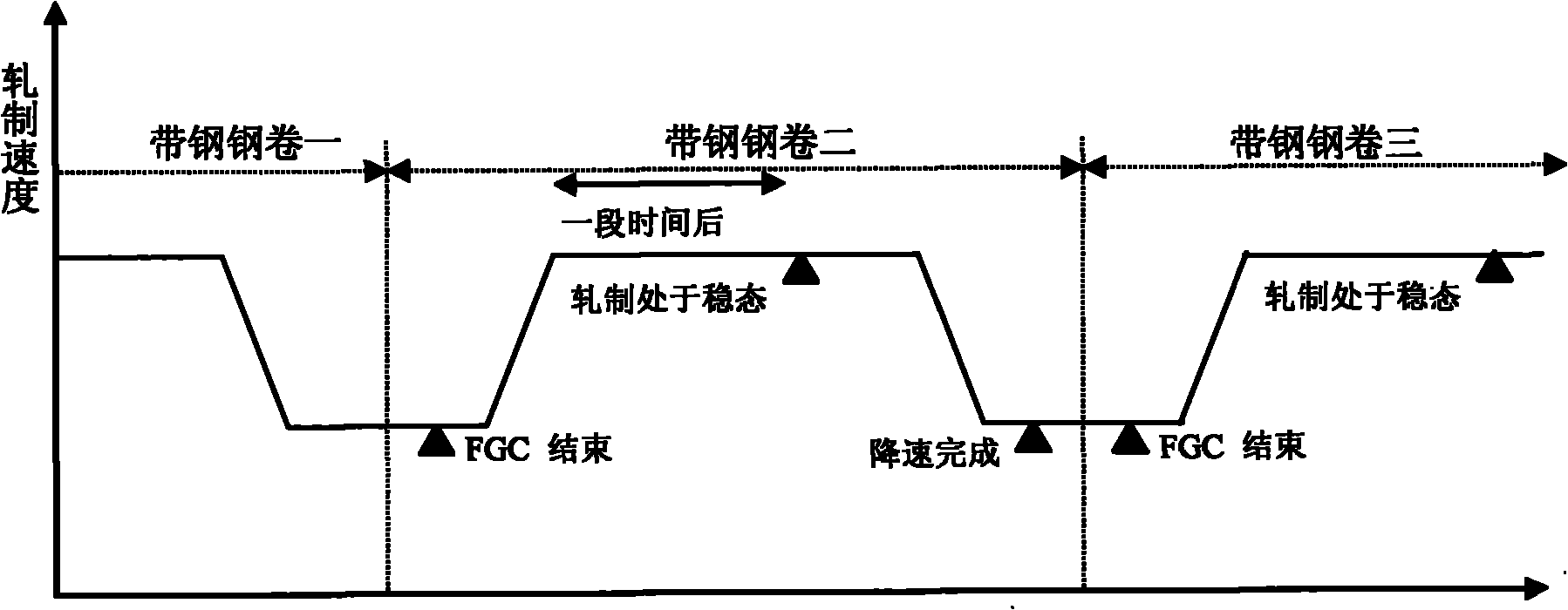

Adjusting method of stainless-steel cold continuous-rolling roll gap

ActiveCN101934289AReduce thickness tolerance lengthImprove setting accuracyRoll force/gap control deviceProgramme control in sequence/logic controllersTransient stateStrip steel

The invention discloses an adjusting method of a stainless-steel cold continuous-rolling roll gap. By adopting a roll gap calculation mathematical model in a process control level, the roll gap value of the next steel strip in a steady state, a roll gap adjustment amount when a low speed at which the current steel strip is rolled changes to the transient state of the current / next steel strip, a roll gap adjustment amount when the transient state of the current / next steel strip is changed to the lower speed at the next steel trip is rolled are calculated, and sent to a basic automatic level, the stainless-steel cold continuous-rolling roll gap is adjusted and controlled by the basic automatic level according to the roll gap value and the roll gap adjustment amounts. The invention can improve the setting accuracy of the roll gap in an unstable state, effectively reduce the thickness length tolerance of the steel strip in the unstable state and improve the yield of the head and the tail of the steel strip.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

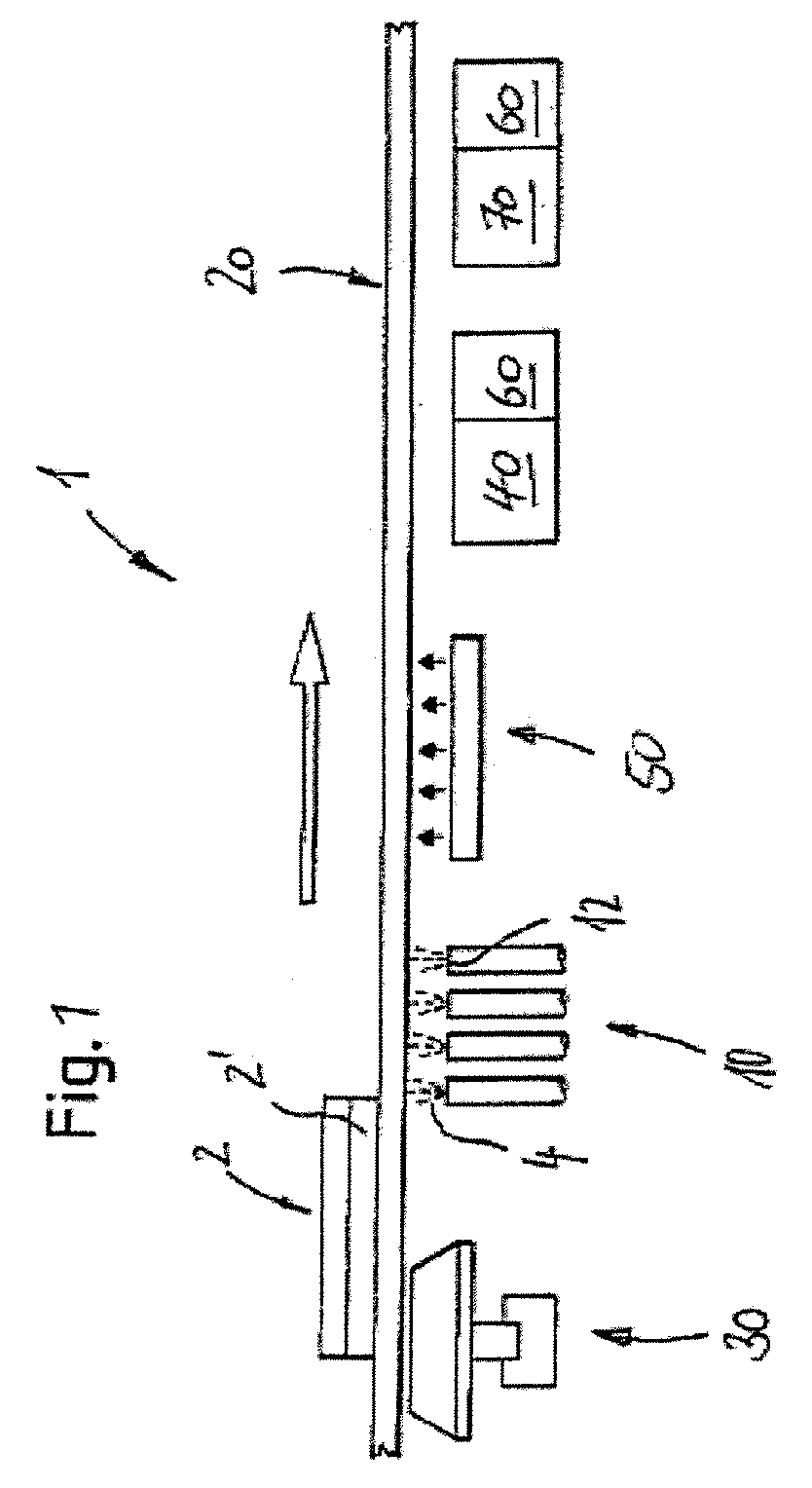

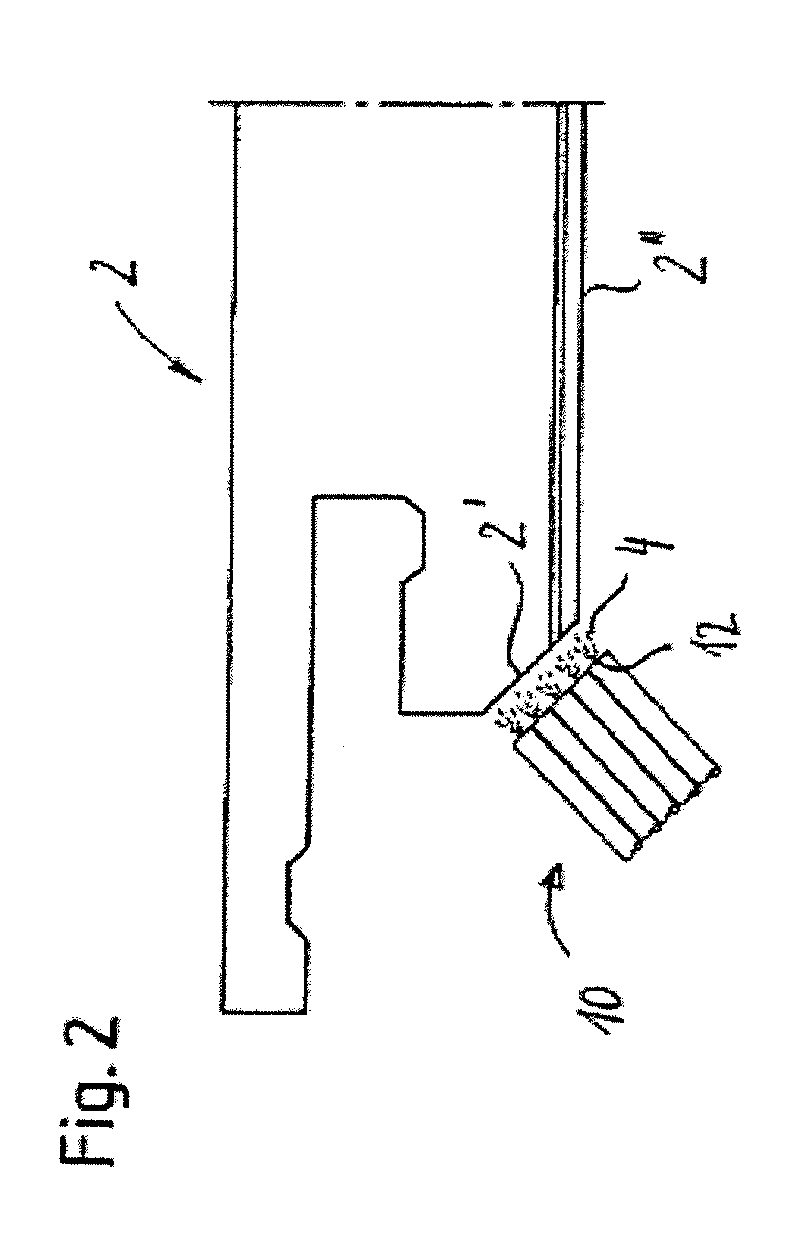

Device And Process For Coating Workpieces

InactiveUS20080152819A1Prevents undesired curingPrecise and simple controllabilityOther plywood/veneer working apparatusSpray nozzlesSynthetic materialsVarnish

The invention relates to a device for coating workpieces which preferably consist at least partially of wood, wood-based materials, synthetic material or the like, said device comprising an application means for applying a curable mass, in particular a varnish, and a conveying device for causing a relative movement between said application means and the respective workpiece. The device according to the invention is characterized in that said application means has at least one micro-nozzle for applying said curable mass, and preferably at least one micro-valve.

Owner:HOMAG HOLZBEARBEITUNGSSYST

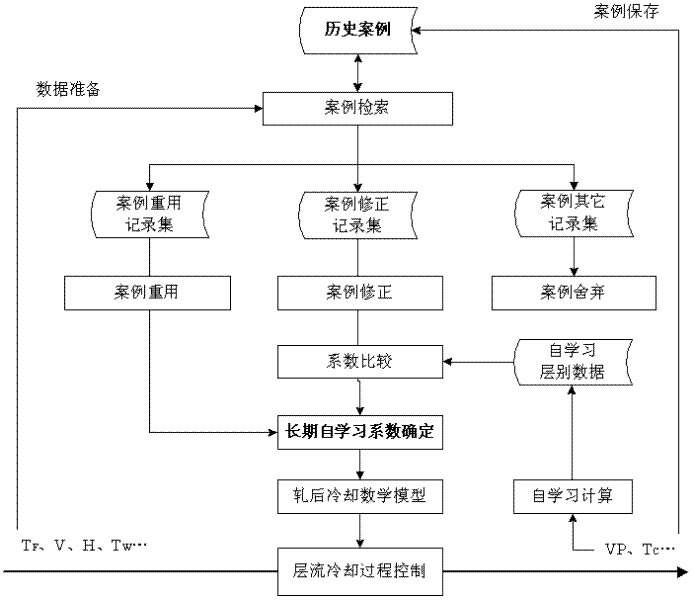

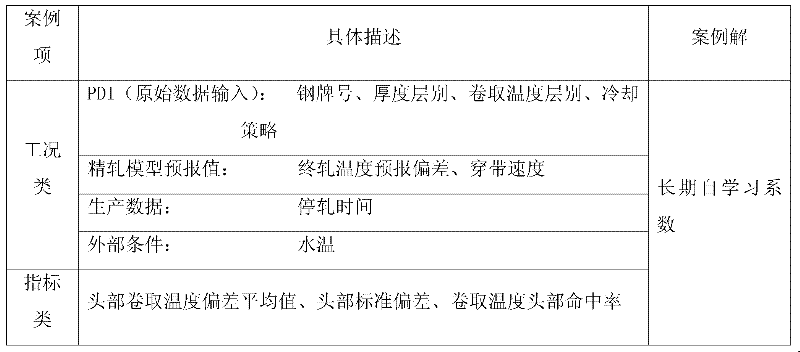

Post-rolling cooling long-termed self-learning method based on case-based reasoning

InactiveCN102284517AImprove setting accuracyPrevent overcoolingWork treatment devicesMetal rolling arrangementsSuper coolingMathematical model

The invention relates to a post-rolling cooling long-termed self-learning method based on case-based reasoning, which belongs to the technical field of rolling. The method comprises the steps: Step 1: case construction; Step 2: case searching; Step 3: case reuse; and Step 4: case correction. The post-rolling cooling long-termed self-learning method based on case-based reasoning has the advantages that: based on a large amount of on-site production data, the method makes decisions for a long-termed self-learning coefficient in a control cooling mathematic model through case construction, case searching, case reuse, case correction and other case-based reasoning technologies beginning with how to effectively utilize empirical knowledge. For rolled steel specifications, the method can effectively prevent heads from a super-cooling phenomenon, and simultaneously can significantly improve the set precision of sheet and strip head final-cooling temperature models. The post-rolling cooling long-termed self-learning method based on case-based reasoning can make post-rolling cooling models possess the self-adaptive capability of changing with working conditions, and can significantly improve the head setting precision of the models.

Owner:NORTHEASTERN UNIV

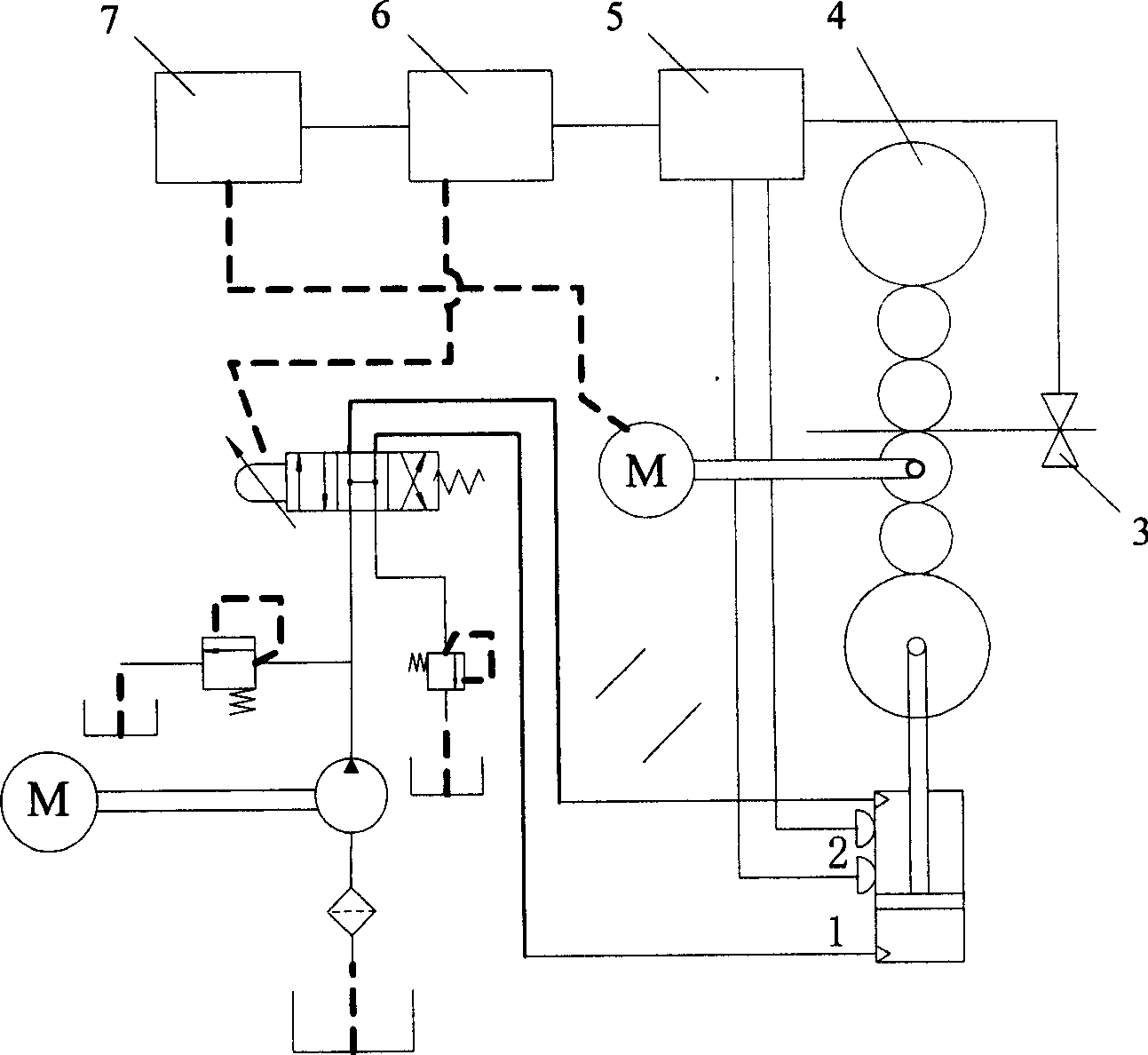

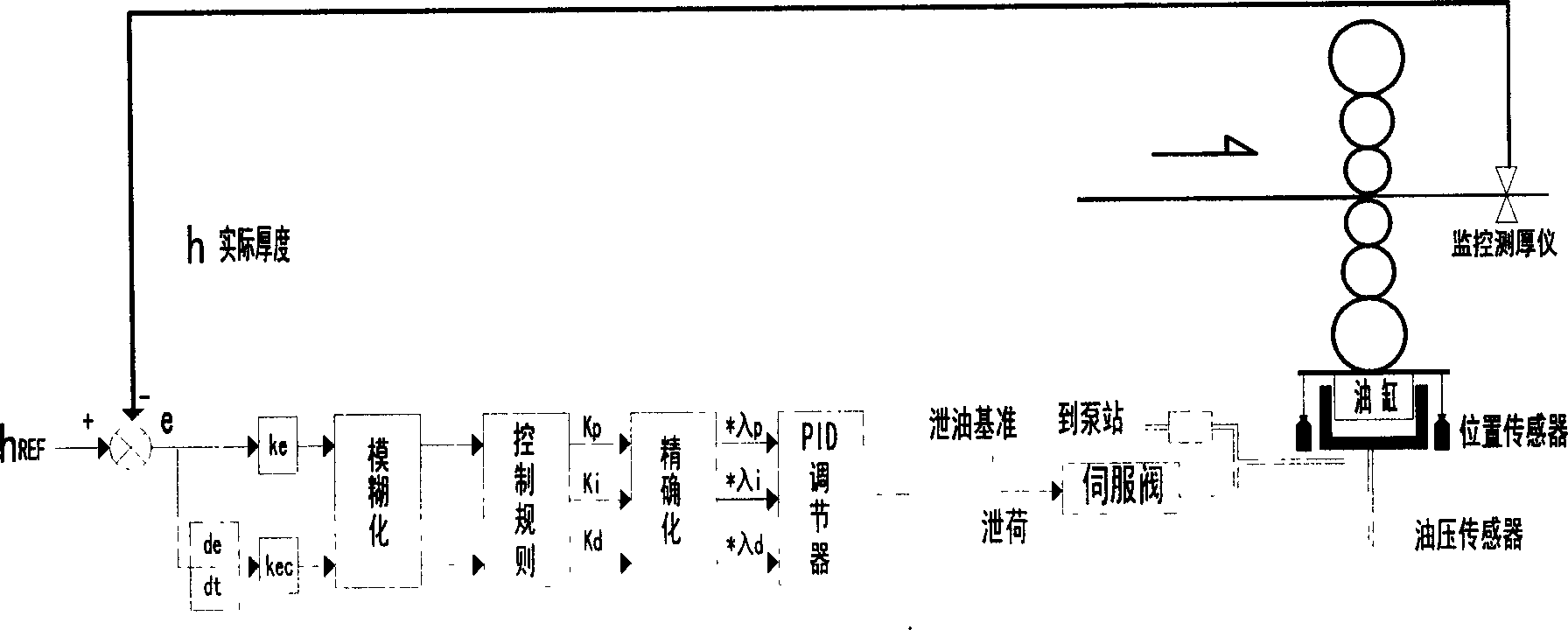

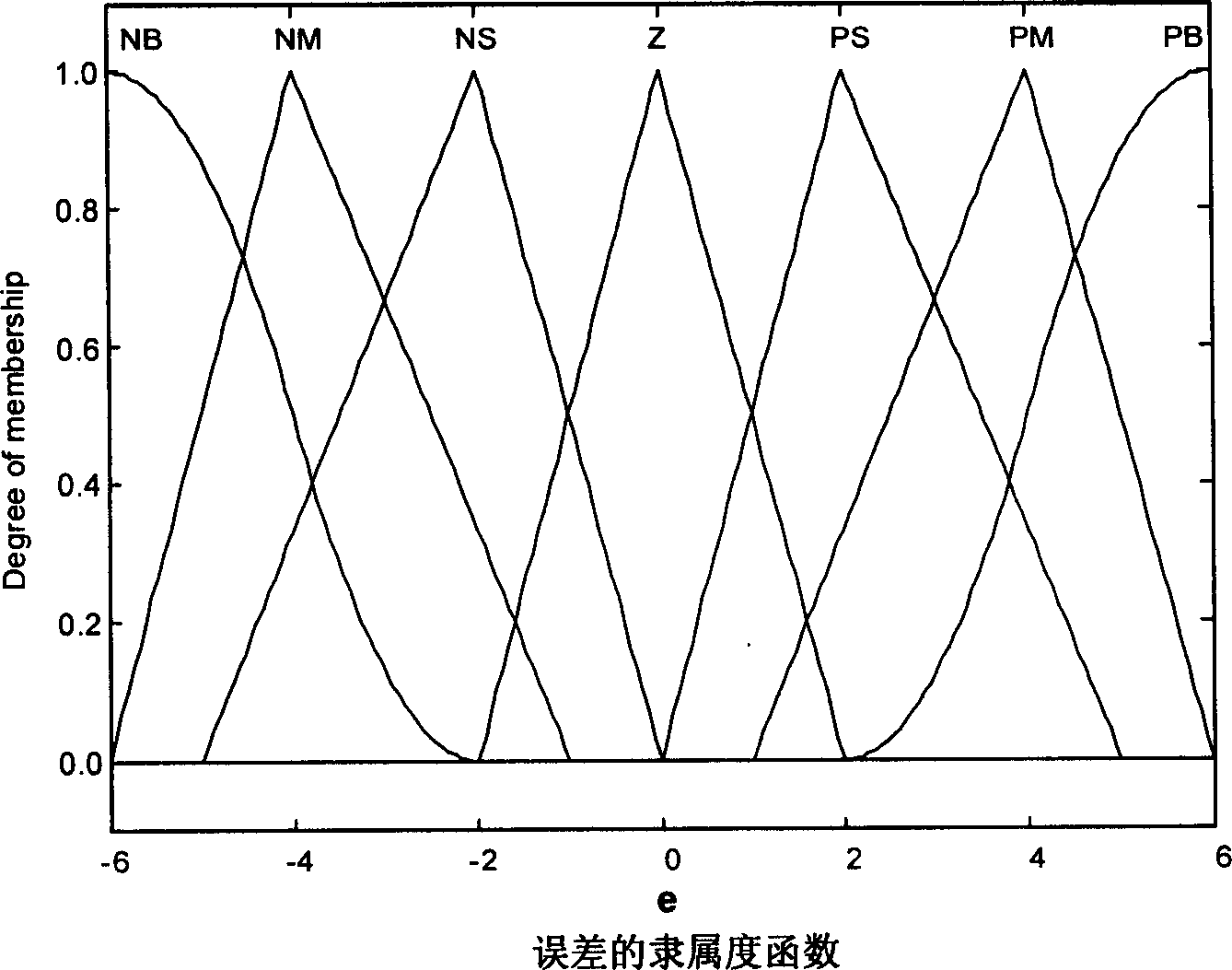

Thickness adaptive fuzzy control method for aluminium plate band rolling mill

InactiveCN1775394AReduce head-to-tail deviationQuick responseRoll mill control devicesMetal rolling arrangementsProduction rateMeasuring instrument

The present invention relates to a thickness control method of aluminium strip and sheet mill. It is characterized by that it can make traditional PID control and fuzzy control be organically combined together, utilizes the factors of thickness-measuring instrument signal and quantization factor defined by specialist to create the fuzzy relationship between thickness error and error variable rate and PID parameter regulation quantity, and adopts the following steps: utilizing fuzzy operation to obtain control table, making the thickness error obtained by measurement and variable rate of thickness error implement obfuscation, making comparison is universe of discourse, taking correspondent regulation quantity of PID parameter from control table, superimposing it on the PID control control parameter, then utilizing hydraulic system of rolling mill to set the required clearance between rolls so as to implement regulation and control of rolling mill thickness.

Owner:苏州有色金属研究院有限公司

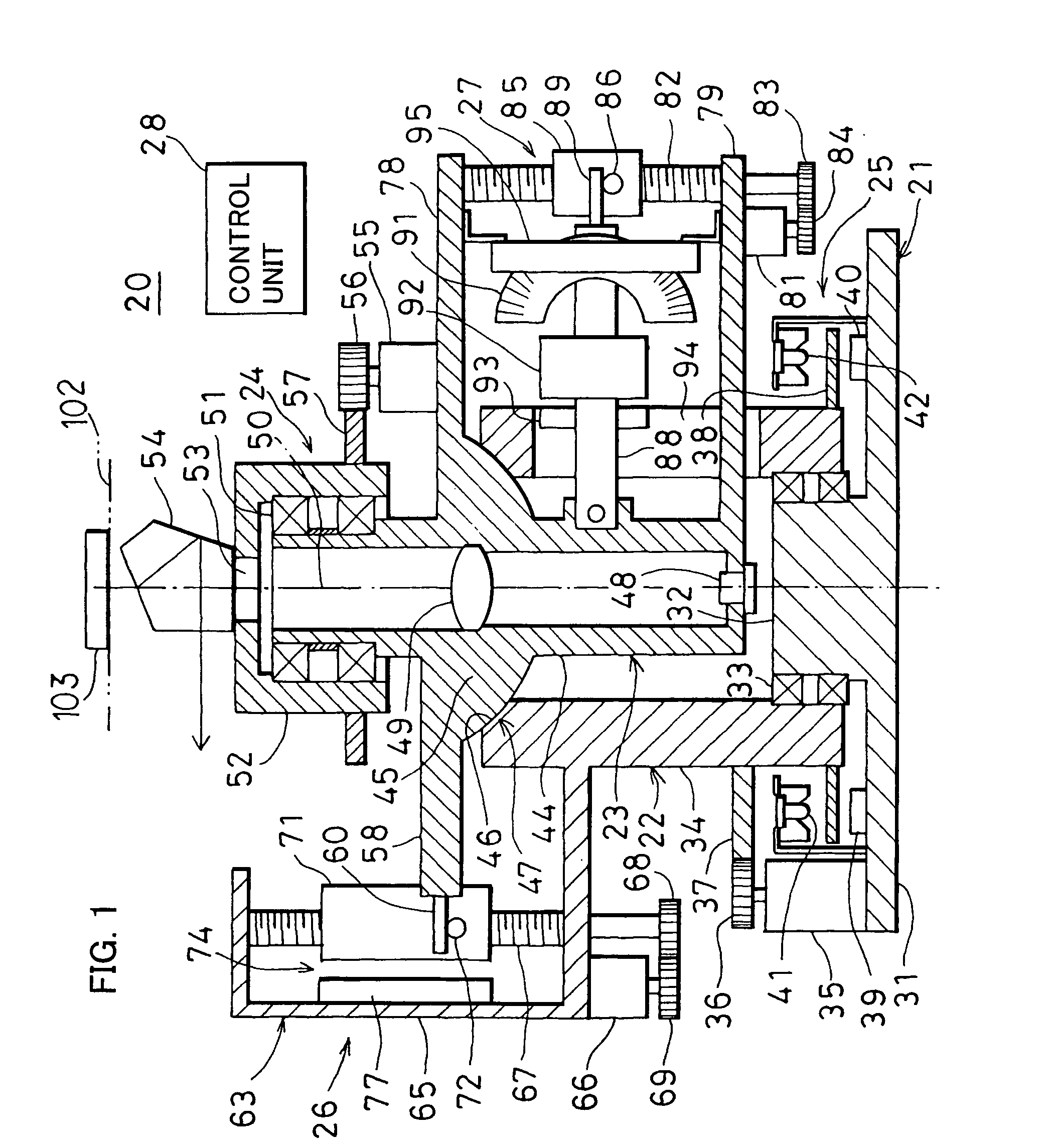

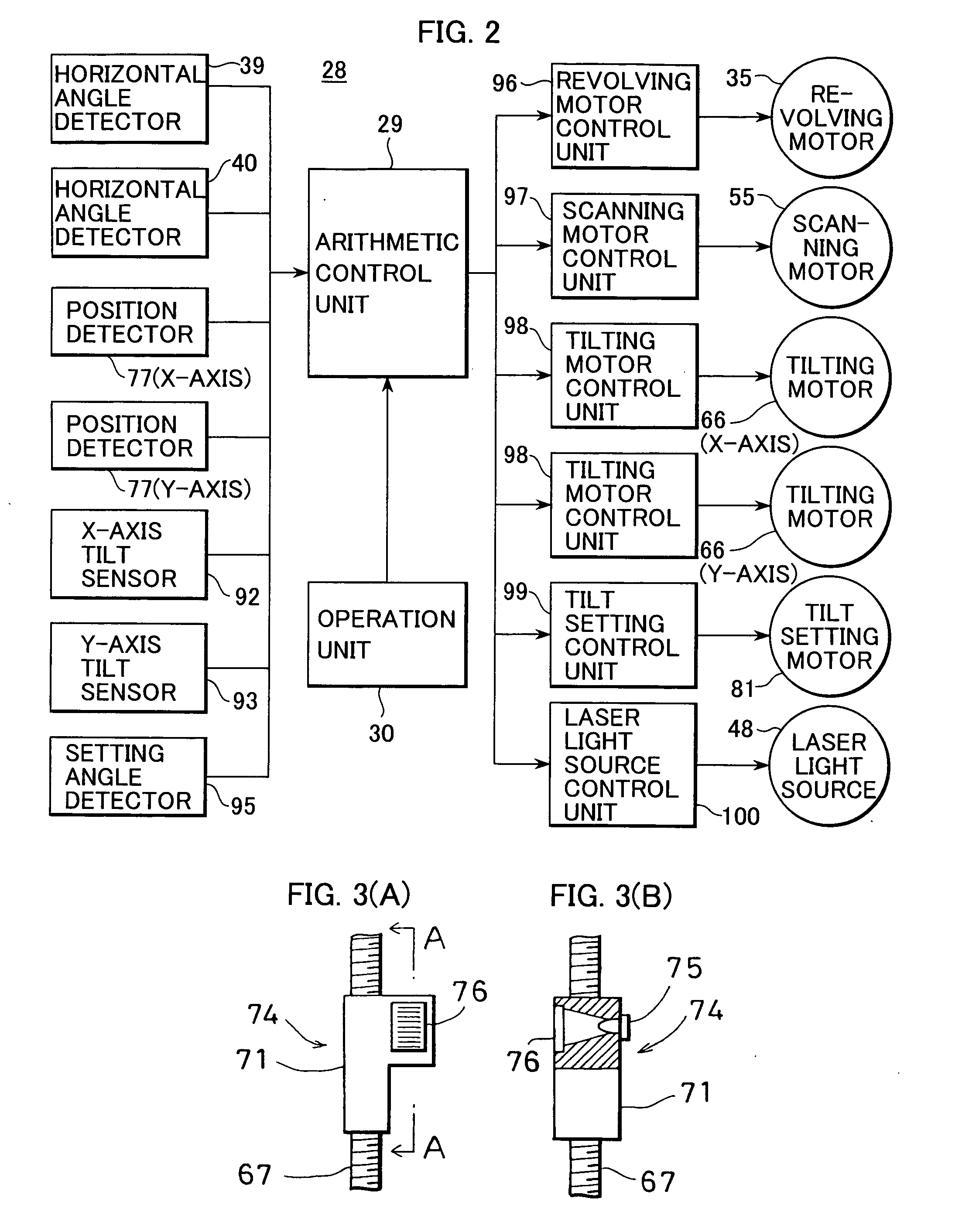

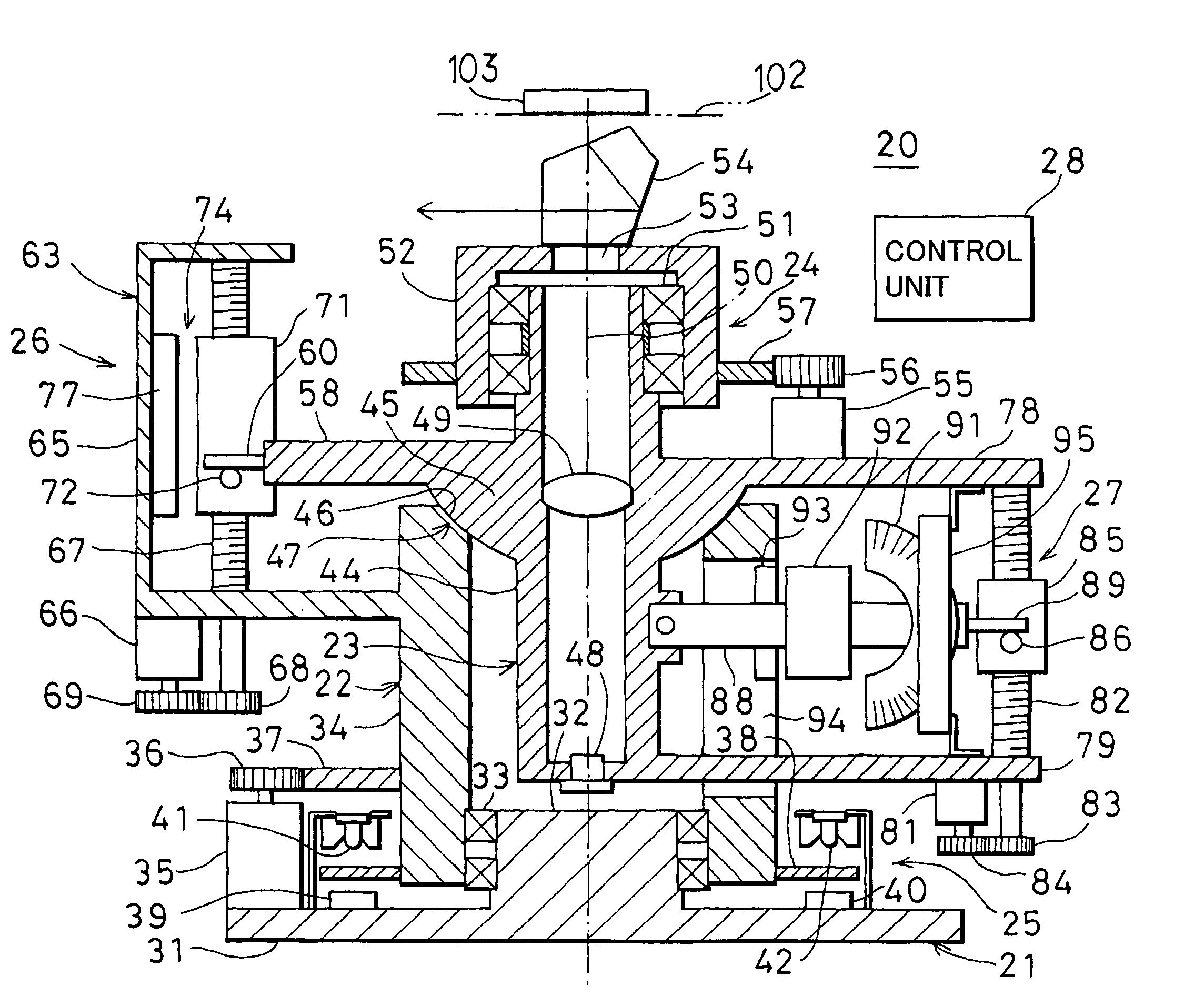

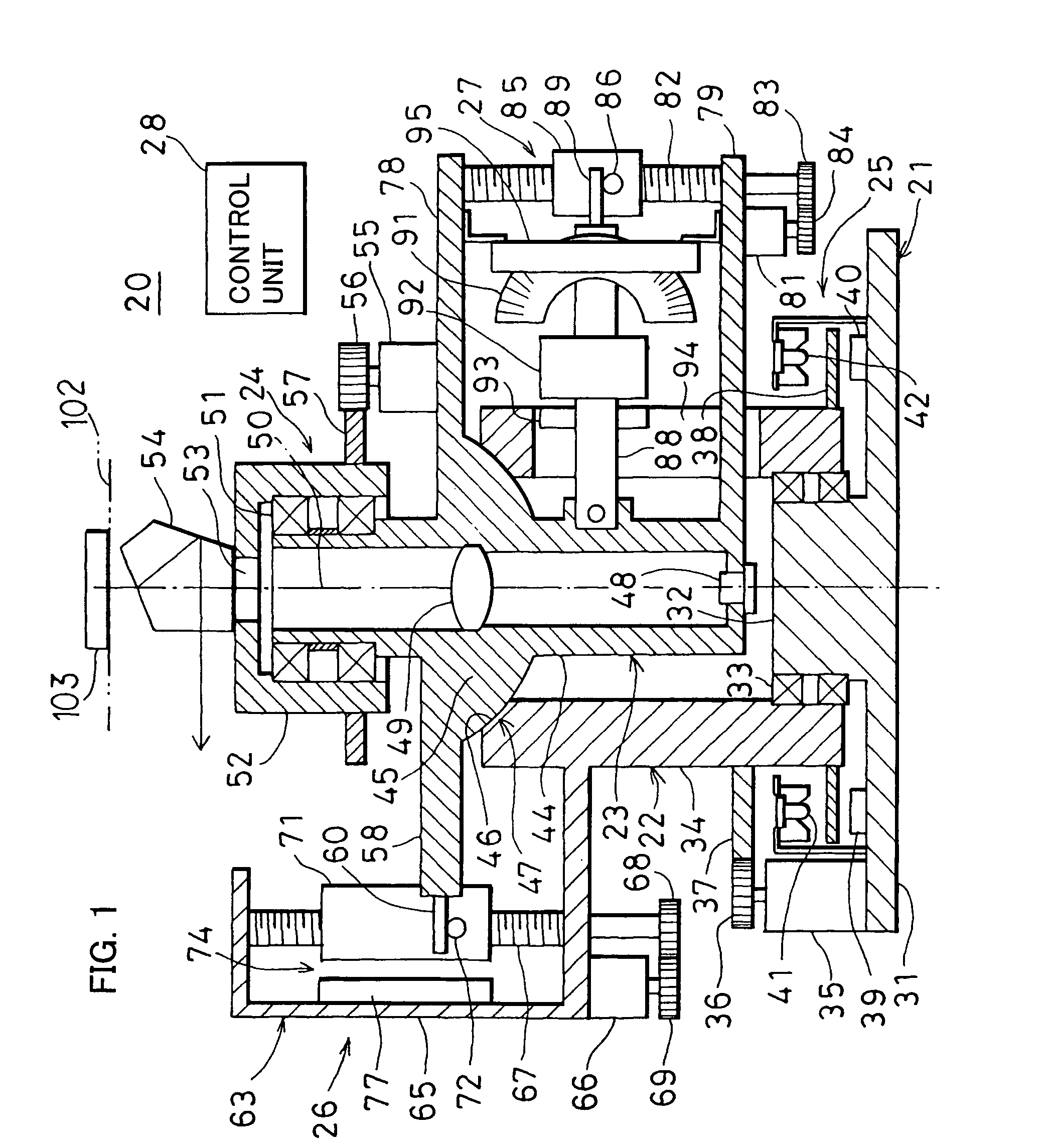

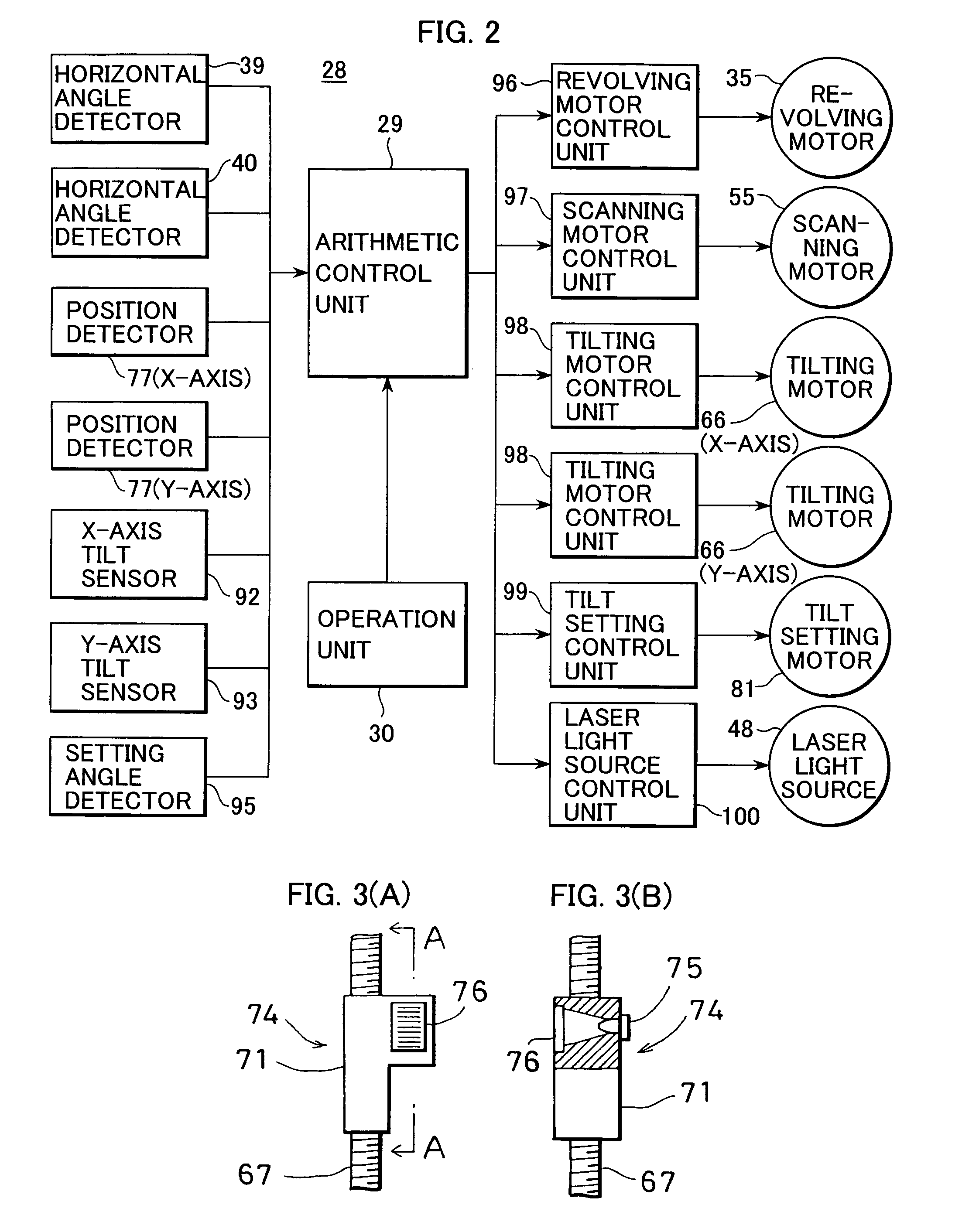

Laser surveying instrument

ActiveUS20070103672A1Easy constructionImprove setting accuracyAngle measurementOptical rangefindersSurvey instrumentLight beam

A laser surveying instrument, comprising a laser projector for projecting a laser beam by rotary irradiation and designed as tiltable, a tilting unit for tilting the laser projector, a rotating unit for integrally rotating the tilting unit and the laser projector in horizontal direction, a tilt setting unit for tilting the laser projector with respect to the rotating unit and for setting a target tilt angle, a tilt angle detector for detecting tilting of the laser projector, tilt sensors provided on the tilt setting unit in two directions perpendicularly crossing and for detecting horizontal direction, a horizontal angle detector for detecting horizontal rotation angle of the rotating unit, and an arithmetic control unit for controlling rotation angle of the rotating unit based on detection results of the tilt sensors and based on detection results of the horizontal angle detector.

Owner:KK TOPCON

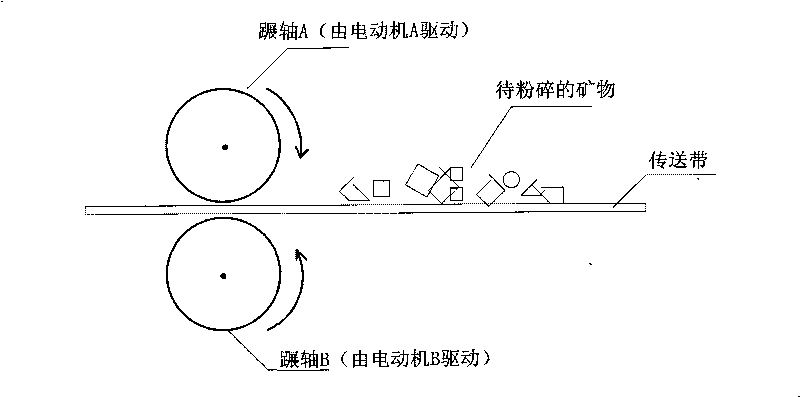

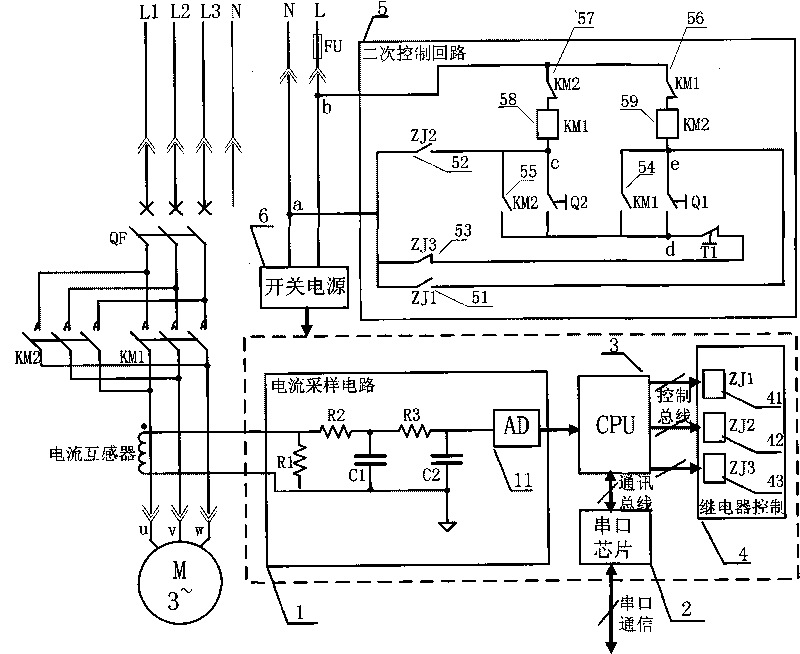

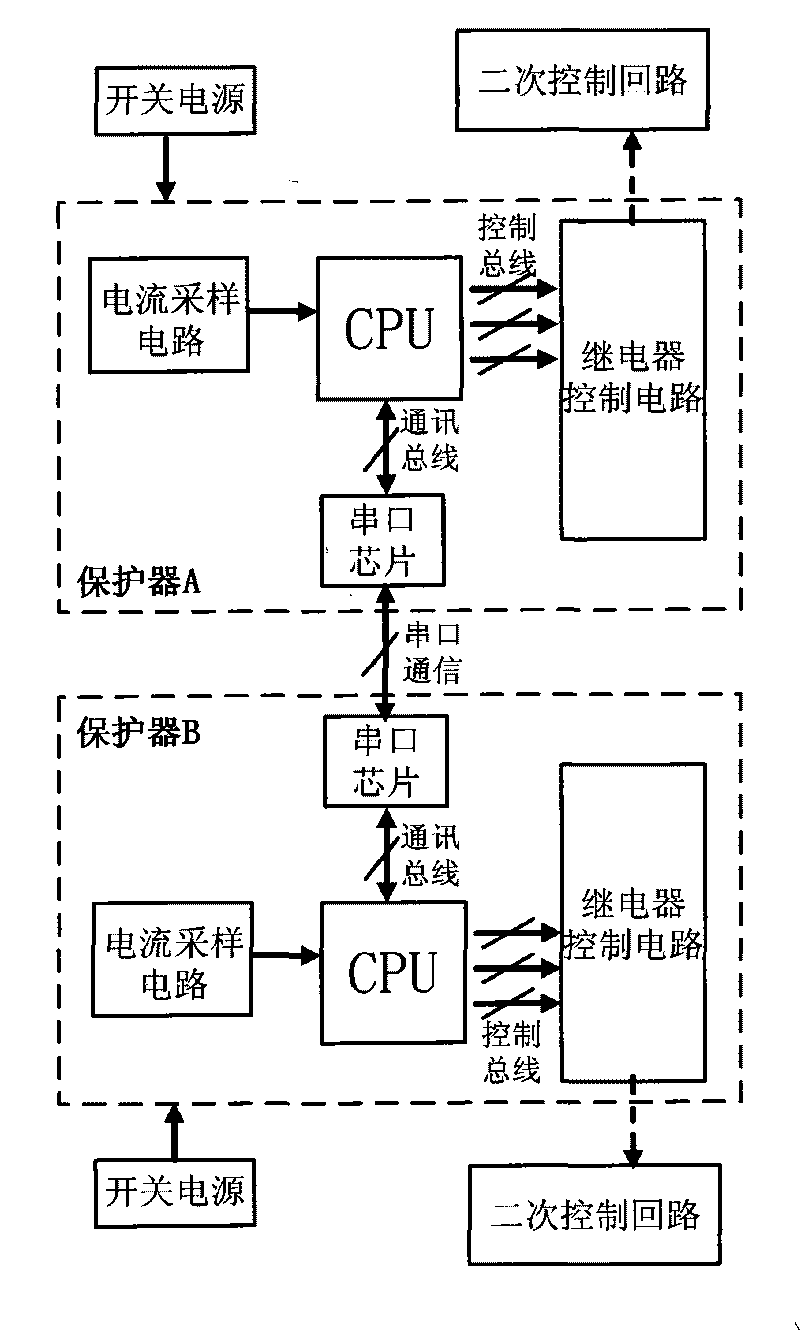

Motor protector dual-machine linkage method and linkage device

InactiveCN101741294ATroubleshoot production linesHigh setting accuracyMultiple ac dynamo-electric motors controlEmergency protective circuit arrangementsMotor protectionSynchronism

The invention discloses a motor protector double-machine linkage method and a linkage device. The method comprises the following steps of: using a current sampling circuit to separately detect the current of the protected motor, and outputting the sampling current to a single chip machine by a protector; when the single chip machine judges that the motor is abnormal according to the sampling unit, driving a relay control circuit to stop or reversely rotate the motor, and simultaneously sending a synchronous control signal to the other motor linkage device to stop or reversely rotate the othermotor through a serial driving chip; when the abnormality does not occur, driving the relay control circuit to start the motor or not actuate, and simultaneously sending a synchronous control signal to the other motor linkage device to start the other motor or not actuate through the serial driving chip. The linkage device consists of a processor, a current sampling circuit, a serial chip, a relay control circuit, a secondary control loop, a switch power supply and wiring terminals. The invention has high setting precision, accurate actuation time and stable synchronism.

Owner:SOUTHEAST UNIV

Laser surveying instrument

ActiveUS7433028B2Easy constructionImprove setting accuracyAngle measurementOptical rangefindersSurvey instrumentLight beam

A laser surveying instrument, comprising a laser projector for projecting a laser beam by rotary irradiation and designed as tiltable, a tilting unit for tilting the laser projector, a rotating unit for integrally rotating the tilting unit and the laser projector in horizontal direction, a tilt setting unit for tilting the laser projector with respect to the rotating unit and for setting a target tilt angle, a tilt angle detector for detecting tilting of the laser projector, tilt sensors provided on the tilt setting unit in two directions perpendicularly crossing and for detecting horizontal direction, a horizontal angle detector for detecting horizontal rotation angle of the rotating unit, and an arithmetic control unit for controlling rotation angle of the rotating unit based on detection results of the tilt sensors and based on detection results of the horizontal angle detector.

Owner:KK TOPCON

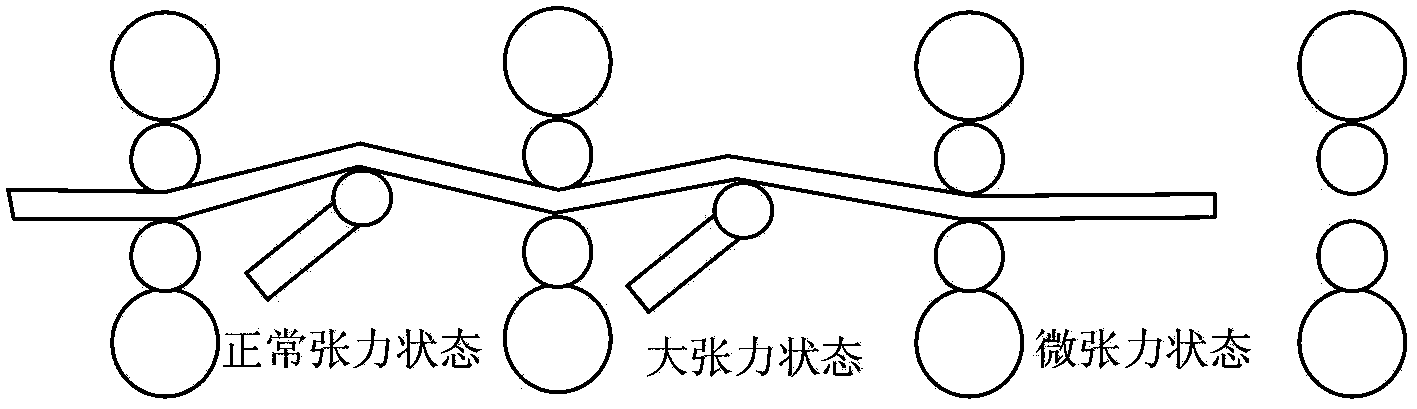

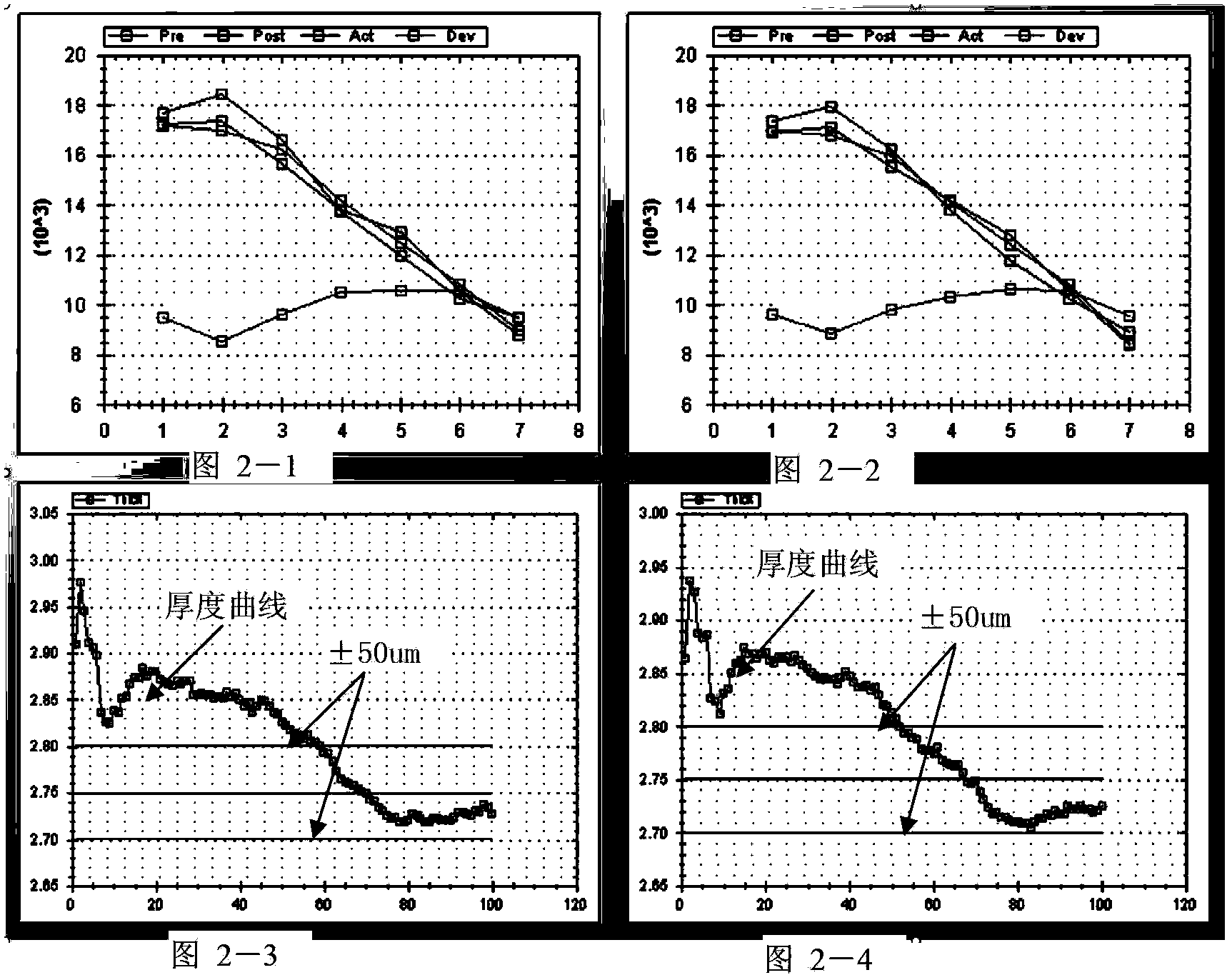

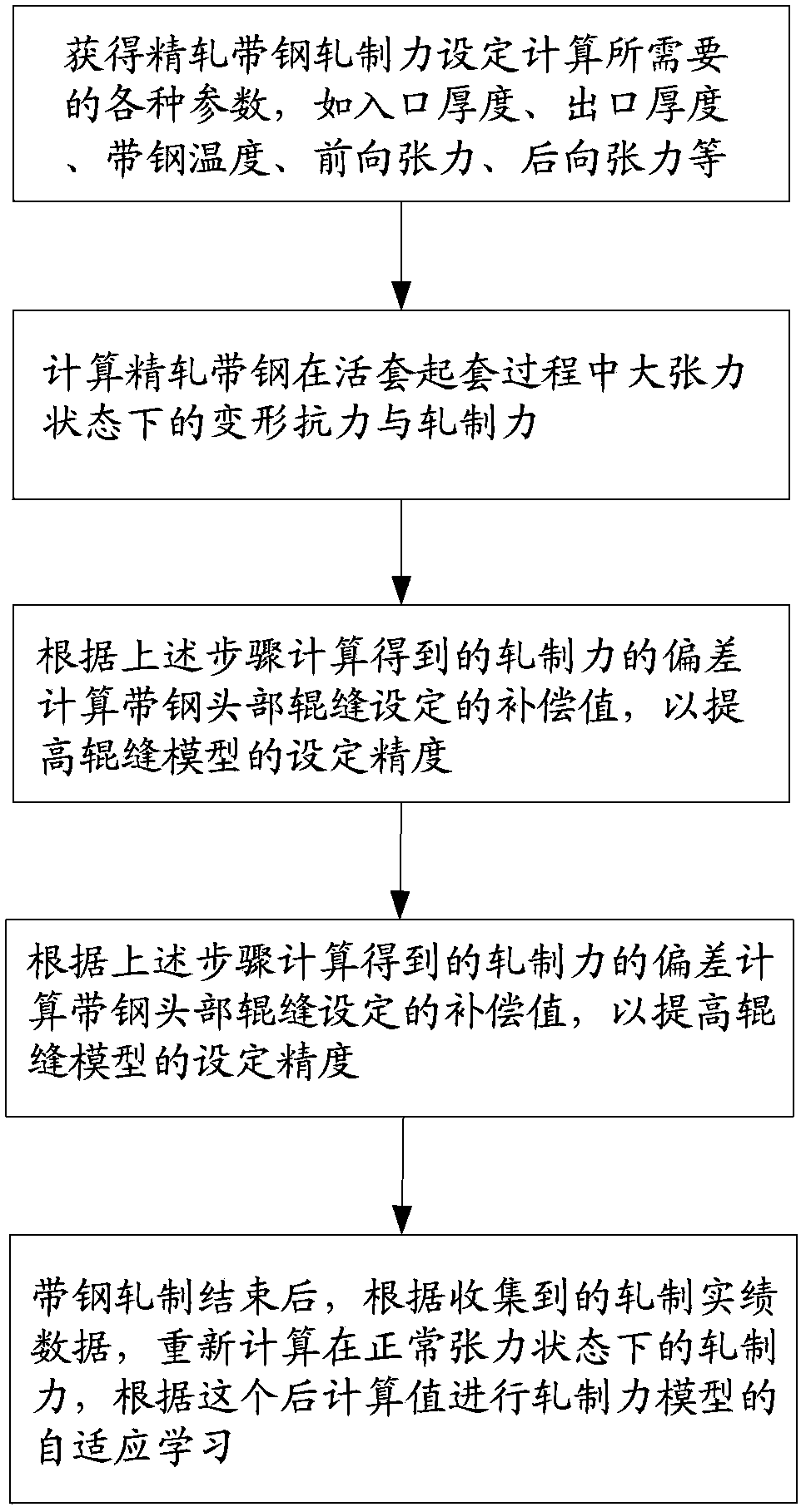

Comprehensive control method for improving rolling force of precisely rolled strip steel and thickness precision through tension compensation

ActiveCN104070070AImprove setting accuracyRare end control deviceRoll force/gap control deviceEngineeringHot rolled

The invention provides a comprehensive control method for improving rolling force of precisely rolled strip steel and thickness precision through tension compensation. The method comprises the following steps of distinguishing three tension states comprising a micro-tension state, a large tension state and a normal tension state in a rolling process of the head of the precisely rolled strip steel; respectively calculating deformation resistance under the three tension states; setting the rolling force of the strip steel by using the rolling force in the large tension state; setting a roll gap of the head of the strip steel by using the rolling force in the micro-tension state; and performing adaptive learning by using the rolling force in the normal tension state. The problem that rolling force setting calculation, roll gap setting calculation and rolling force adaptive learning are conflicting is solved; and the setting precision of a hot rolled strip steel rolling force model and a roll gap model is improved, so that the setting precision of the precisely rolled rolling force and the controlling precision of the thickness of the head of the strip steel are simultaneously improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for controlling middle, low grade electric steel rolling using conventional rolling model

InactiveCN101417292AMeet needsImprove setting accuracyRoll mill control devicesMetal rolling arrangementsElectrical steelLower grade

The invention discloses a method for controlling the rolling of medium and lower grade electric steel, which can meet the requirements of control accuracy and relies on a conventional rolling control mould. The method comprises the following steps: a relation curve between the deformation temperature and the deformation resisting force corresponding to the steel grade of the medium and lower grade electric steel is obtained by tests, the algorithm of the deformation resisting force in a conventional rolling mould is corrected according to the relation curve; an independent steel grade property list and a thickness interval list corresponding to the grades of the steel grade are established in the data area of the conventional rolling mould; according to the grades of the steel grade, the corresponding independent steel grade property list and the thickness interval list thereof are called for involving control; the 'inflexion' temperature of the deformation resisting force is determined according to the relation curve, and a rack corresponding to the 'inflexion' temperature is determined by the comparison with the set rack temperature distribution of the a temperature mould, and the correcting algorithm of the deformation resisting force is called for calculating the rolling force of the electric steel by the determined rack corresponding to the 'inflexion' temperature in the mould calculation process. The method is applicable to the rolling of the medium and lower grade electric steel.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

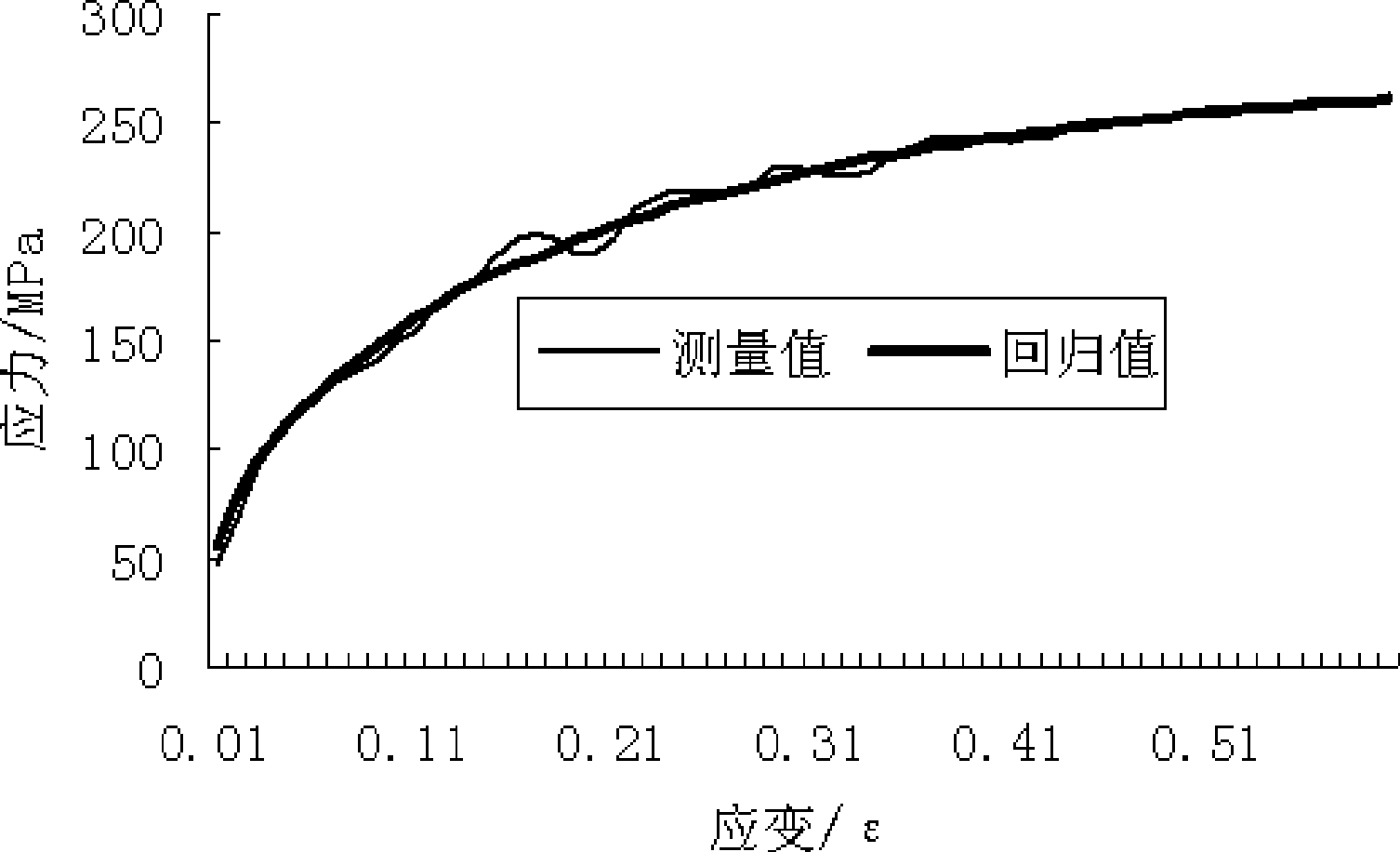

Rolling pressure setting method of precision rolling phase-change strip steel

ActiveCN102641902AImprove setting accuracyImprove thickness control accuracyRoll force/gap control deviceDouble phaseVolume fraction

The invention discloses a rolling pressure setting method of precision rolling phase-change strip steel; and a formula for calculating the impact of temperature on deformation strength is set up by considering the volume fraction of rolled piece austenitic deformation and ferrite deformation, so that the rolling pressure setting precision of phase-change strip steel in a two-phase area and a ferrite area is significantly improved, and the purposes of improving the strip steel thickness control precision and production stability are achieved. According to the technical scheme, because a phase-change volume fraction calculation model in a cosine form and a deformation strength impact calculation formula in a weighted form are adopted in the double-phase area, the deformation characteristic of a rolled piece in the double-phase area can be better simulated, so that the matching with an actual rolling result is very high.

Owner:BAOSHAN IRON & STEEL CO LTD

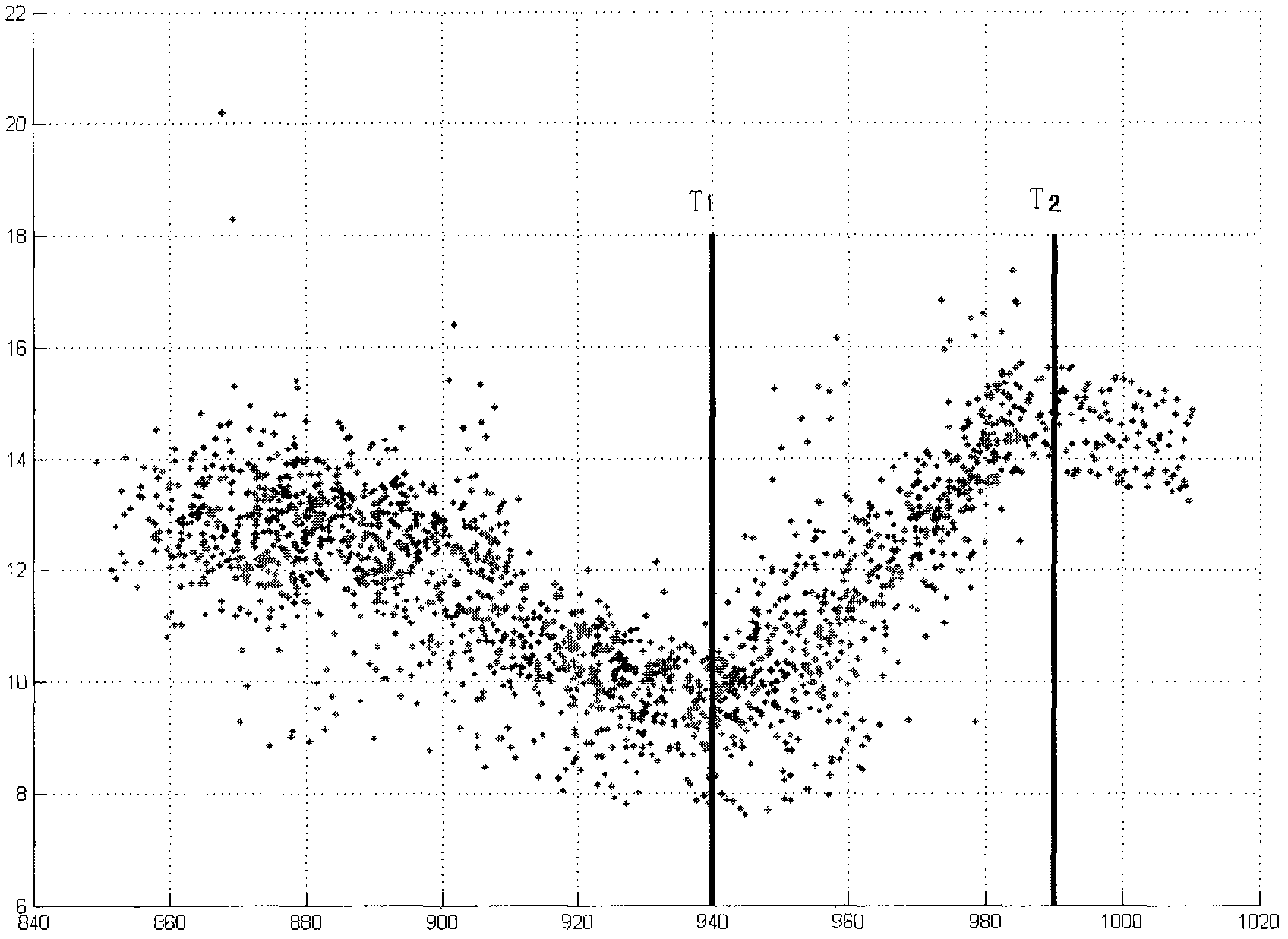

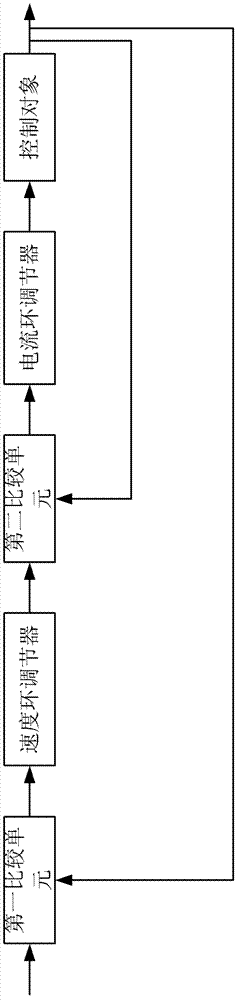

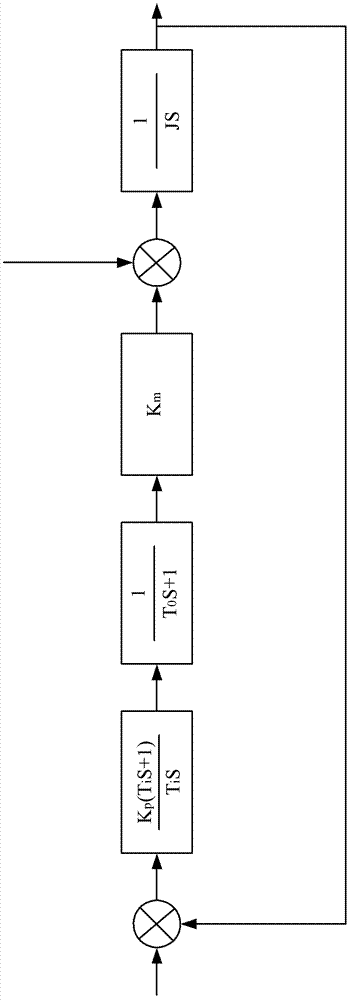

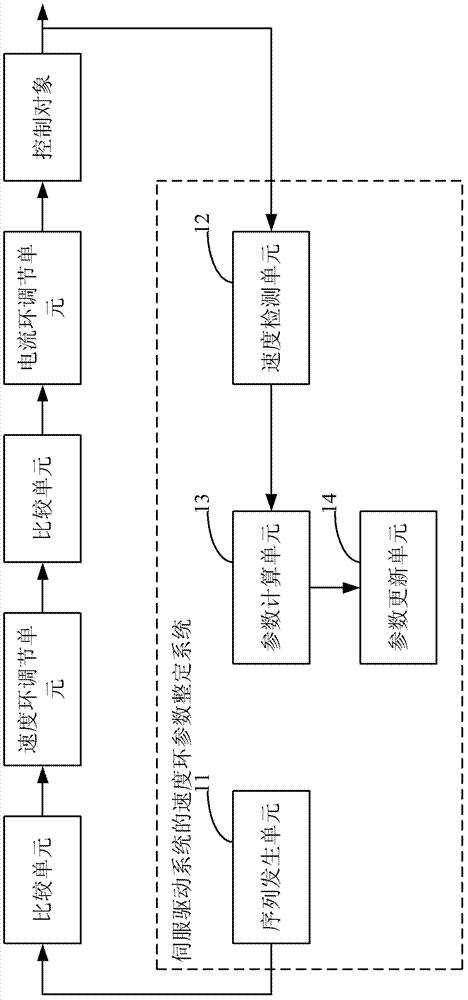

Servo drive system and speed ring parameter setting system thereof

ActiveCN102790584AEasy to set upImprove setting accuracyElectronic commutation motor controlVector control systemsSequence signalControl theory

The invention discloses a servo drive system. The servo drive system comprises a speed ring parameter setting system of the servo drive system, wherein the speed ring parameter setting system further comprises a sequence generating unit, a speed detecting unit, and a parameter calculating unit, wherein the sequence generating unit is used for generating and outputting a sequence signal of fixed quantity as a speed ring; the speed detecting unit is used for acquiring a speed feedback value for controlling object feedback; the parameter calculating unit is used for calculating proportional gain and integral time as the speed ring parameter according to the sequence signal and the speed feedback value. The servo drive system provided in the invention injects a sequence signal to the speed ring of the current servo drive system by the speed ring parameter setting system of the servo drive system, uses the sequence signal and the speed value of the control object when the sequence signal is used as the speed fixed variable to calculate the self-setting for the speed ring parameters Kp and Ti of the servo drive system; the setting process is simple, time-saving and force-saving, free of the experience of debugging staffs and high in setting precision.

Owner:KEDE NUMERICAL CONTROL CO LTD

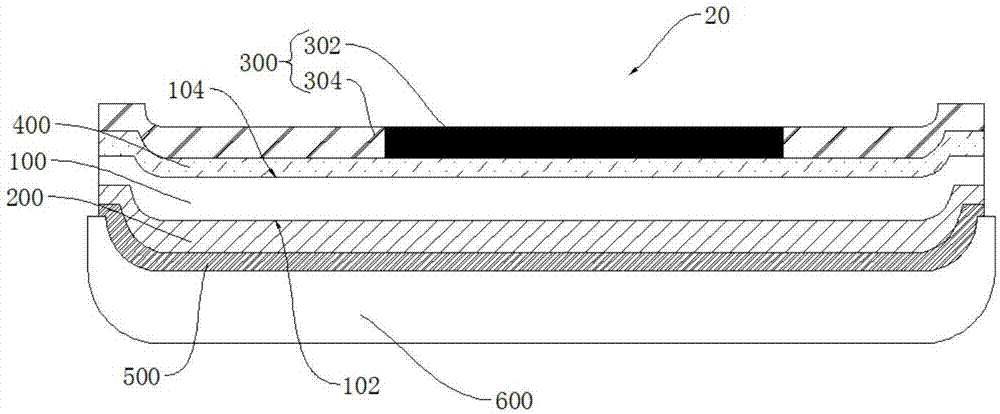

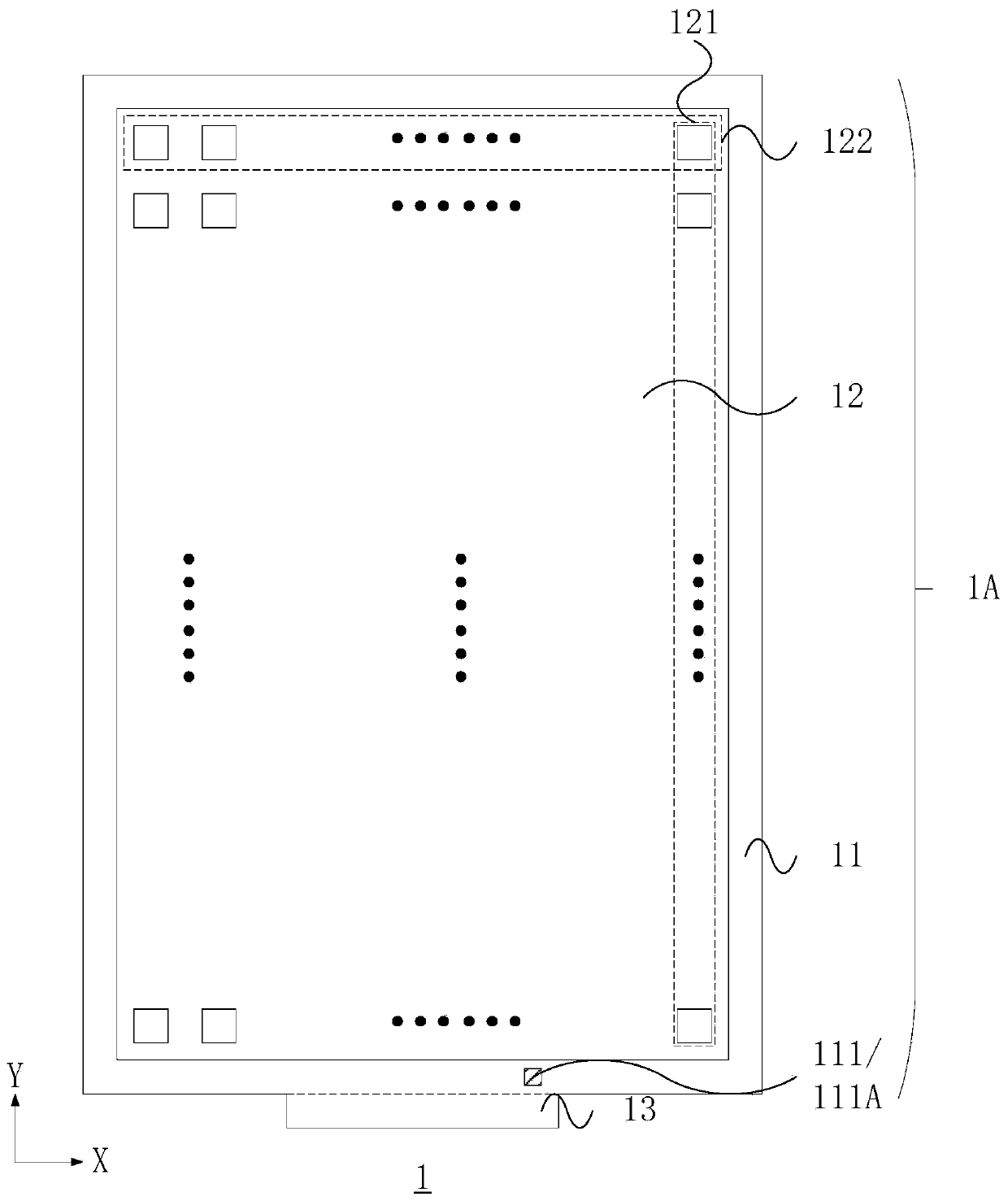

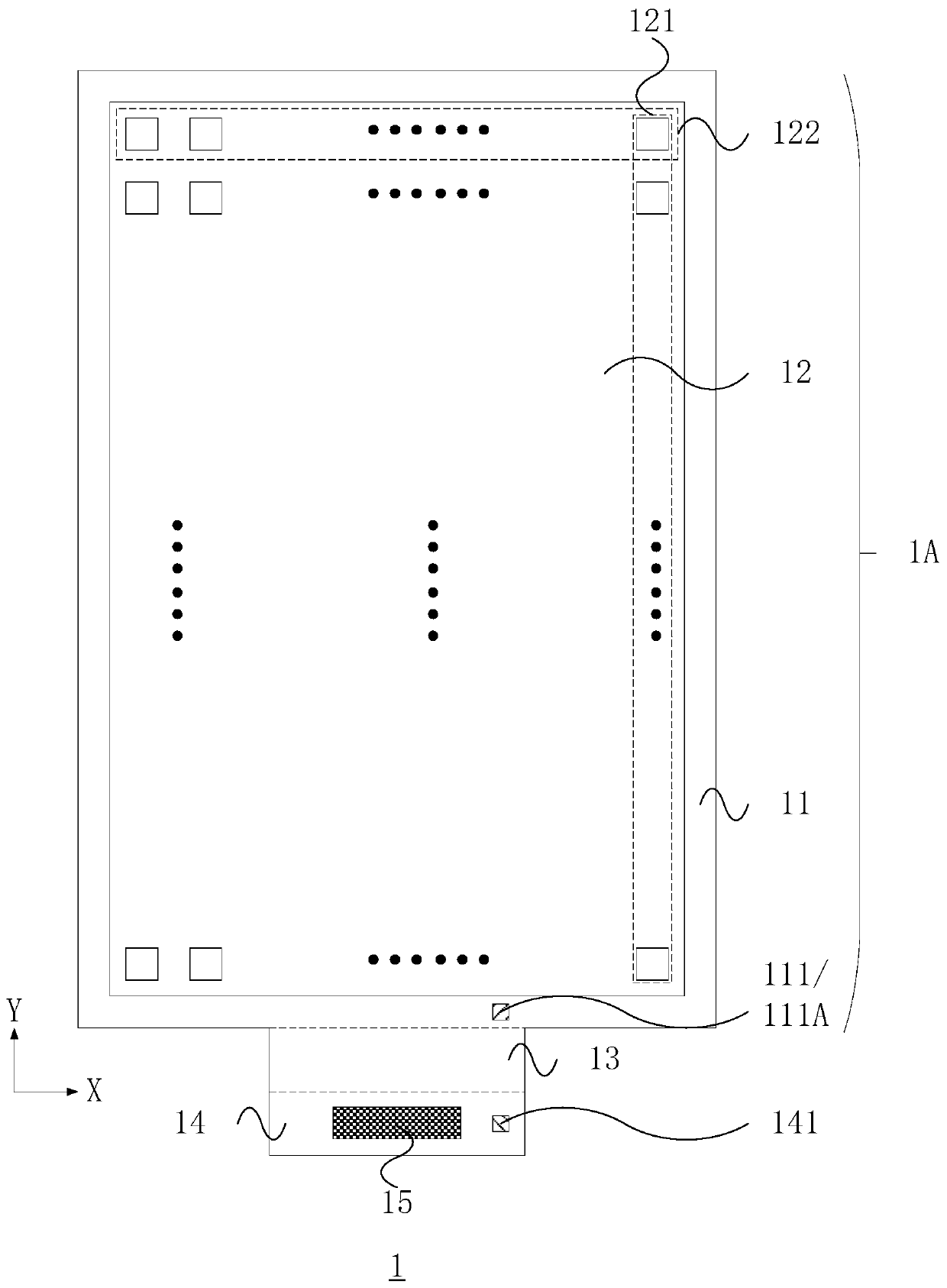

Display panel and display device

InactiveCN111383537AImprove setting accuracyAvoid offsetIdentification meansDisplay deviceEngineering

The invention provides a display panel and a display device. The display panel comprises a light-emitting surface and a non-light-emitting surface; the light-emitting surface and the non-light-emitting surface are oppositely arranged; the display panel further comprises a frame area, a pixel area, a bending area and a binding area. The frame region surrounds the pixel region; the frame area is connected with the bending area; the frame area comprises at least one alignment mark group; the alignment mark group comprises a first alignment mark, a second alignment mark and a third alignment mark;the second alignment mark, the first alignment mark and the third alignment mark in the first alignment mark group are sequentially arranged in the extending direction of the pixel column in the pixel area; the bending area is bent to the non-light-emitting surface from the side of the frame area; the bending area is connected with the binding area; the binding area is arranged on the non-light-emitting surface; the binding area comprises fourth alignment marks corresponding to the alignment mark groups; and the first alignment mark is aligned with the fourth alignment mark. Therefore, the alignment mark group and the fourth alignment mark are used for improving the alignment precision of the binding area in the extending direction of the pixel column.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

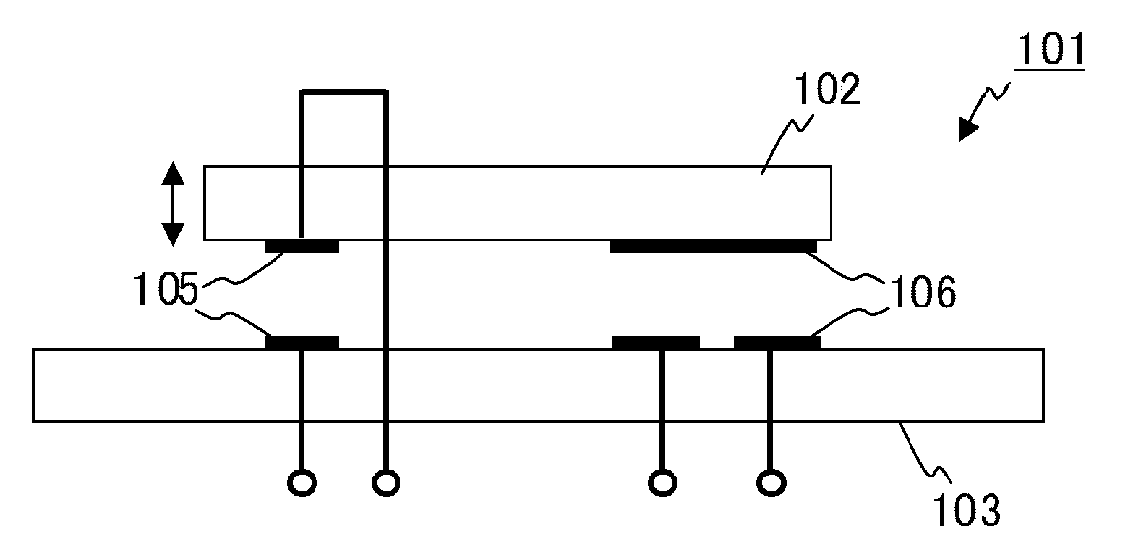

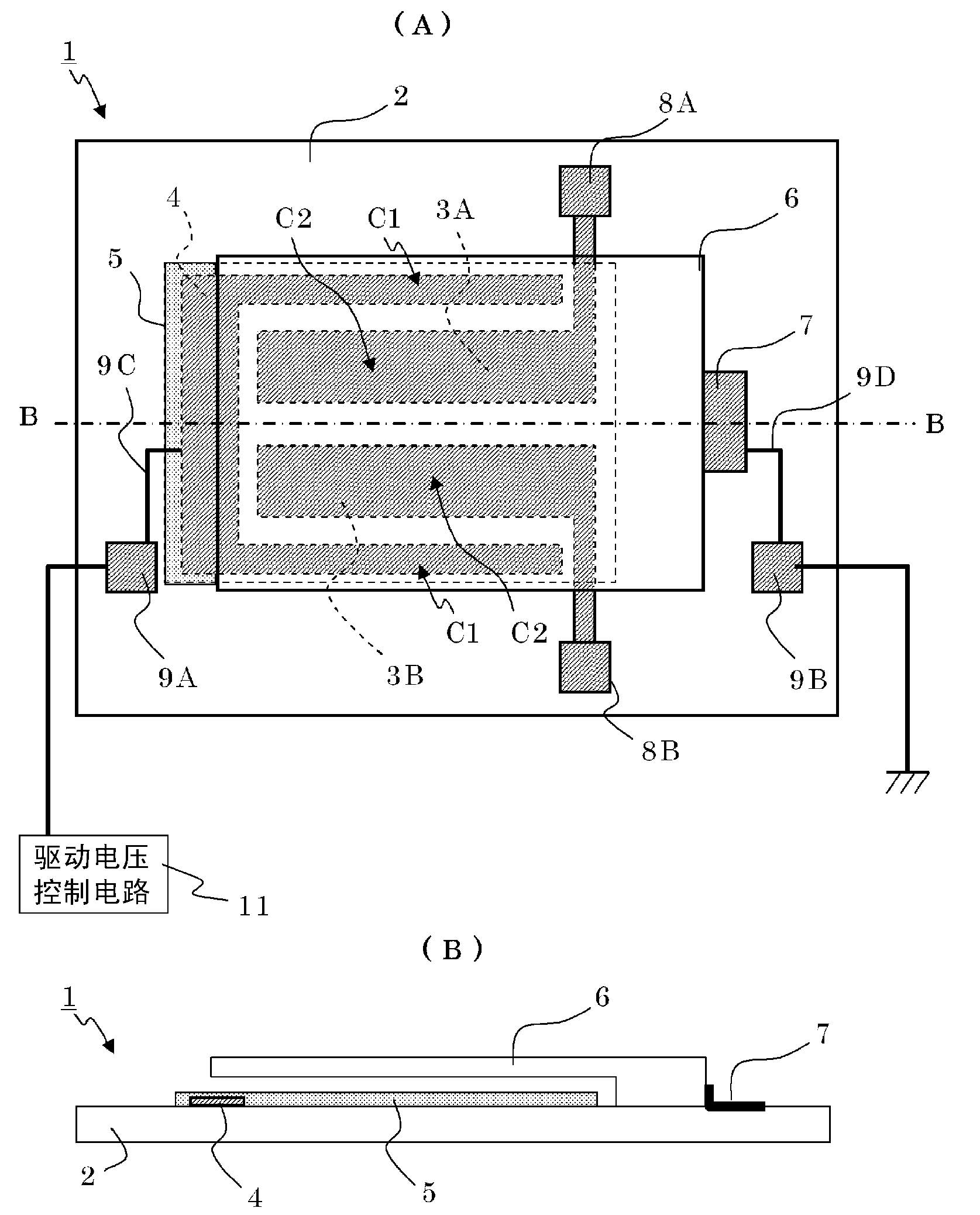

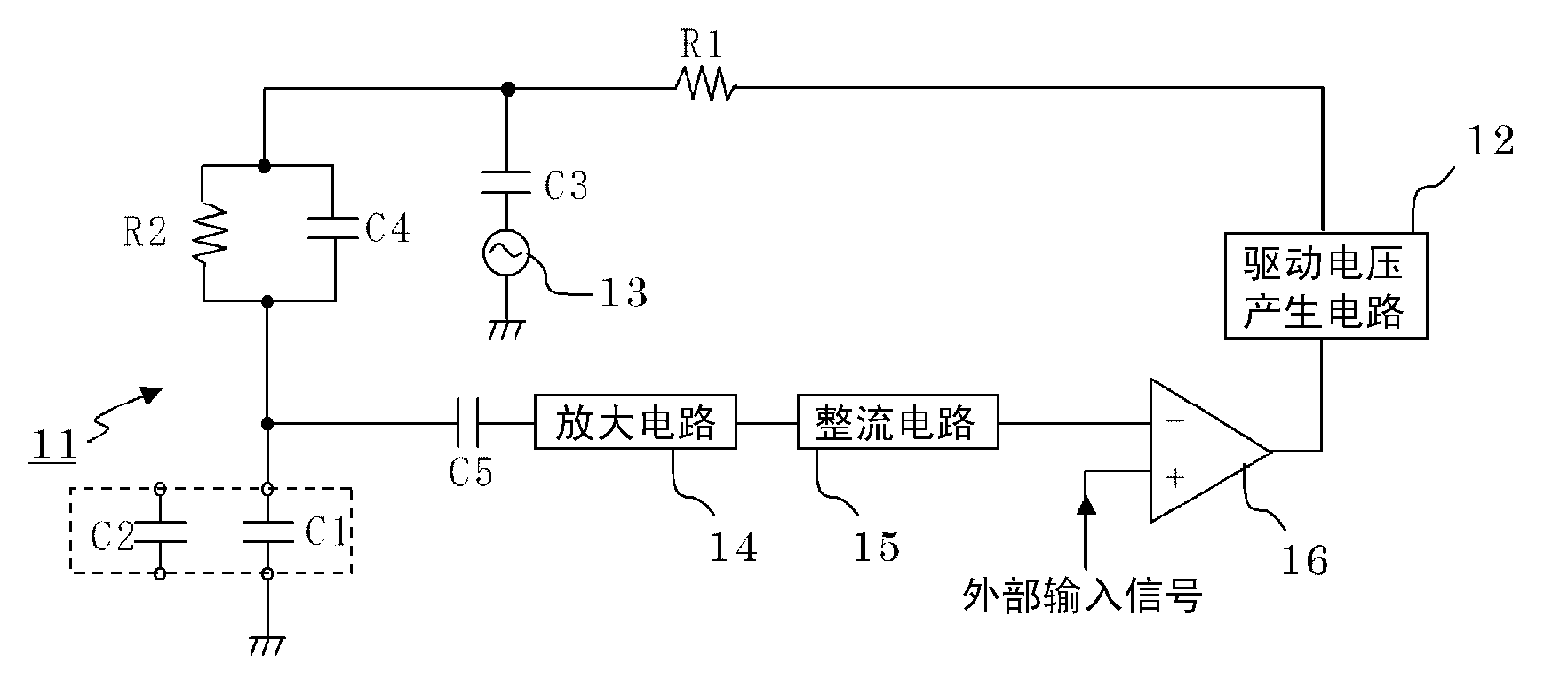

Variable capacitance device

ActiveCN102725808AImprove setting accuracyImprove positional relationshipCapacitor with electrode distance variationCapacitanceEngineering

Disclosed is a variable capacitance device (1) which is provided with a substrate (2), a beam section (6), a drive capacitance (C1), a variable capacitance (C2), and a drive voltage control circuit (11). The beam section (6) has the cantilever structure and is connected to the substrate (2). The drive capacitance (C1) is configured to face on the beam section (6) and the substrate (2), and displaces the beam section (6) corresponding to an electrostatic attractive force generated when a DC voltage is applied. The variable capacitance is configured to face on the beam section (6) and the substrate (2), and changes the capacitance corresponding to the displacement of the beam section (6). The drive voltage control circuit (11) detects a detection voltage that changes corresponding to the drive capacitance (C1), and controls the DC voltage to be applied to the drive capacitance (C1) so that the detection voltage is close to a desired value.

Owner:MURATA MFG CO LTD

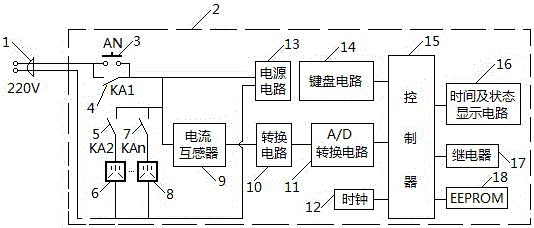

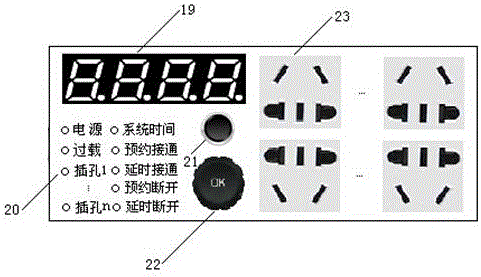

Power supply socket capable of reserving on-off

The invention discloses a power supply socket capable of reserving on-off. The power supply socket is characterized in that the power supply socket comprises a power supply circuit, a current detection and converting circuit, a controller, and a peripheral circuit. According to the power supply socket, the problem that according to the conventional power supply socket, the turn-on and turn-off of a power supply cannot be reserved in various ways is solved, functions of electric supply trip-out prevention and overload protection are provided, the control of on-off time is accurate, the operation is simple and convenient, the visibility is good, through the usage of the power supply socket, the usage efficiency of household electrical appliances can be improved, and a lot of energies and resources can be saved.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

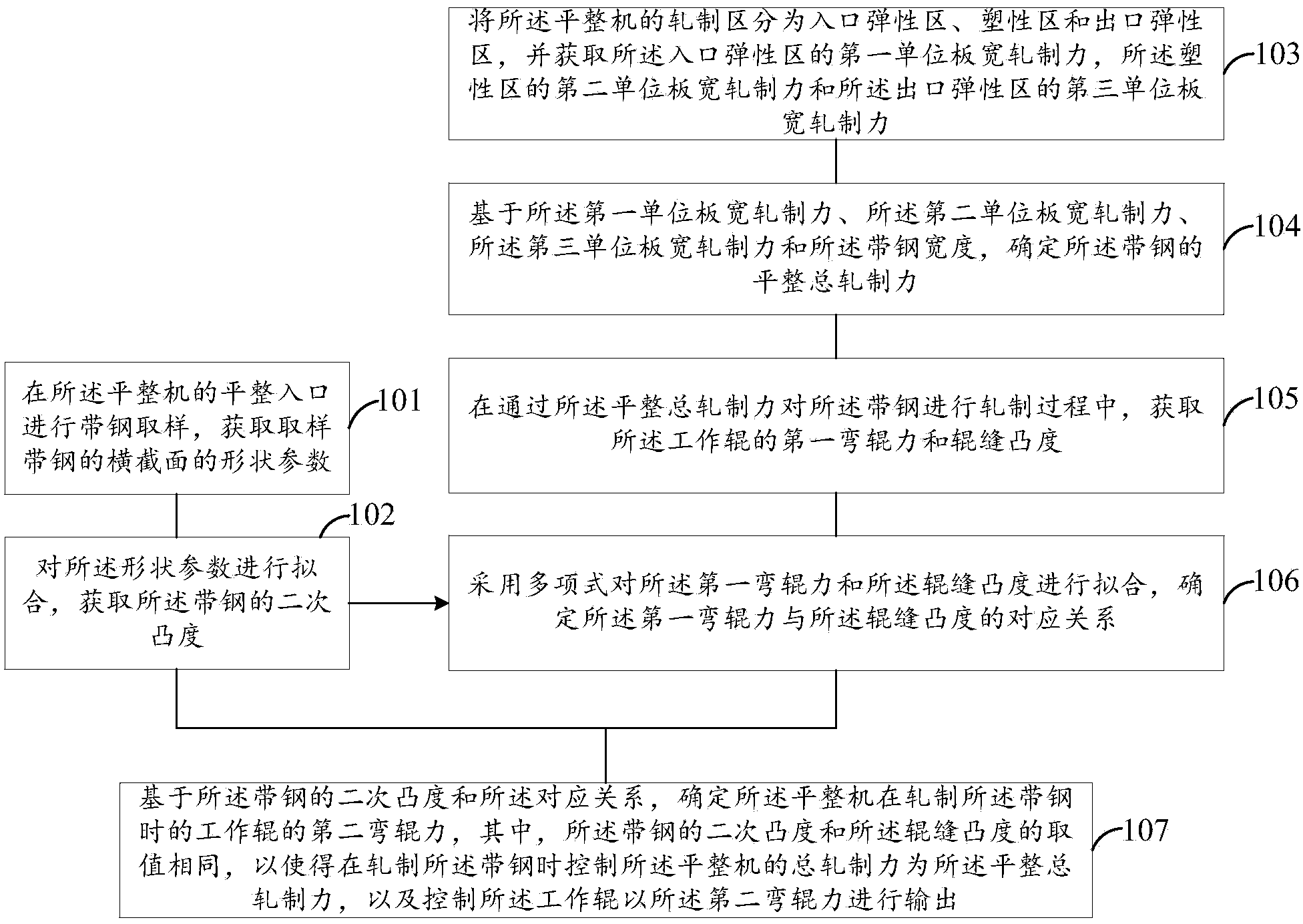

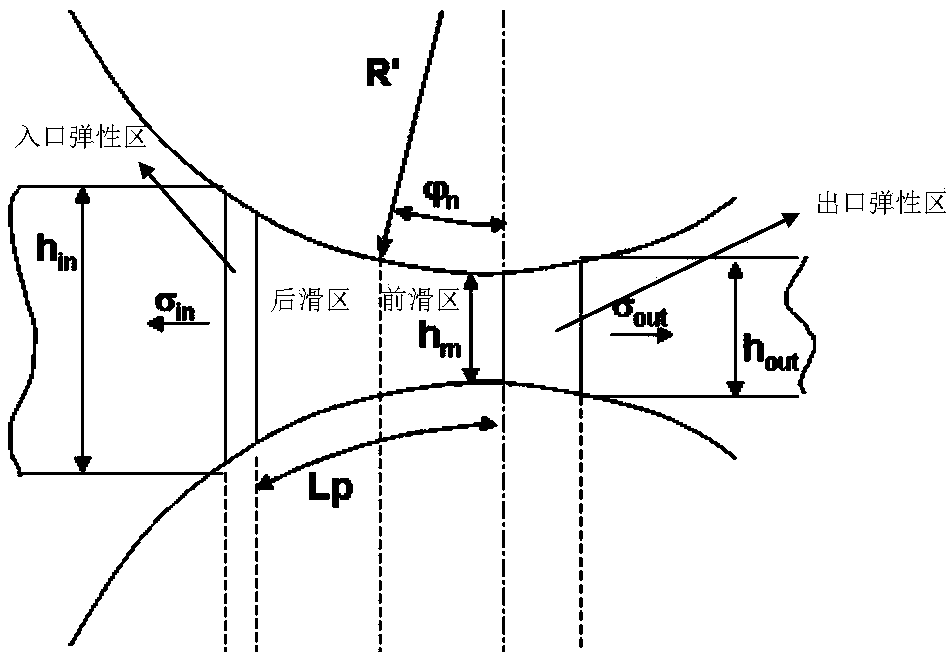

Control method for headed plate shape rolling parameters of leveling machine and leveling machine

ActiveCN104353675AImprove the authenticity rateImprove setting accuracyRare end control deviceMetal rolling arrangementsEngineeringStrip steel

The invention discloses a control method for headed plate shape rolling parameters of a leveling machine and the leveling machine. The leveling machine comprises a working roll. The control method comprises the following steps: sampling strip steel at the flat inlet of the leveling machine, and fitting the shape parameters of the cross section of obtained sampled strip steel to obtain secondary convexity of the strip steel; obtaining the total leveling rolling force; fitting obtained first roll bending force and roll gap convexity by polynomials in a process of rolling the strip steel through the total leveling rolling force, obtaining a corresponding relationship between the first roll bending force and the roll gap convexity based on fitting, confirming second roll bending force of the working roll of the leveling machine during rolling of the strip steel, controlling the total rolling force of the leveling machine to be the total leveling rolling force during rolling of the strip steel, and controlling the working roll to output the second roll bending force.

Owner:SHOUGANG CORPORATION

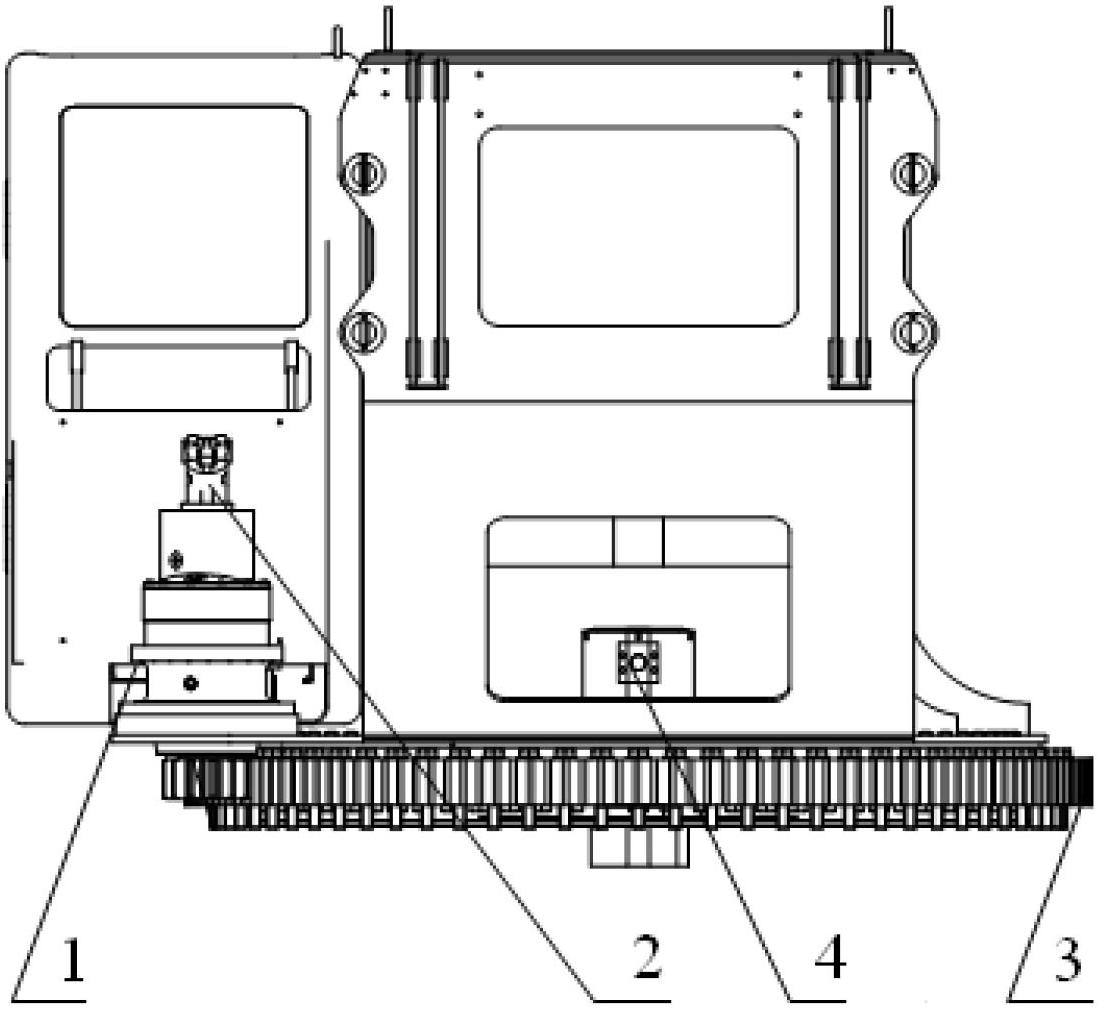

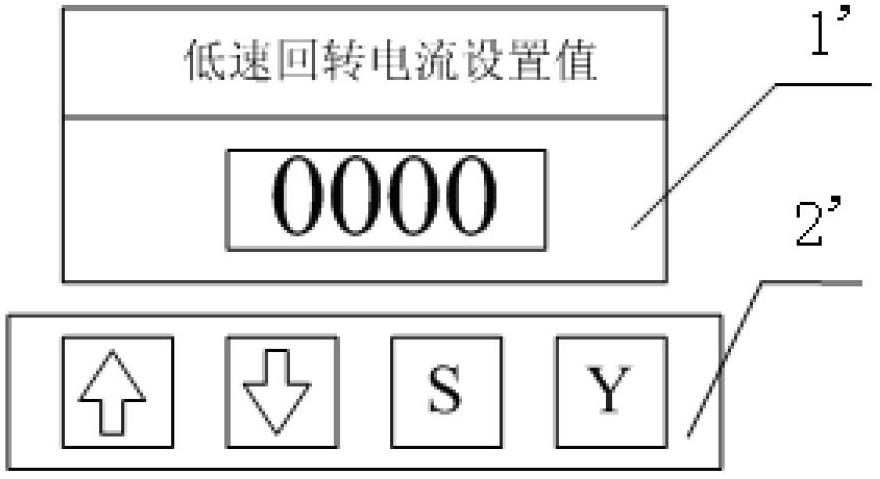

Low-speed rotary control method and system for cranes

ActiveCN102674157AImprove setting accuracyImprove accuracyLoad-engaging elementsLow speedControl system

The invention relates to the technical field of cranes and discloses a low-speed rotary control method for cranes. The method comprises the following steps: step 11) starting-up a rotary valve by pre-set low-speed rotary current; step 12) detecting a rotary angle of a turntable of the crane; step 13) judging whether the value of the detected rotary angle is greater than a threshold value, if the value of a detected rotary angle is not greater than the threshold value, turning to step 14); step 14) accumulating the low-speed rotary current, and gradually returning back to step 12). The low-speed rotary control method for the cranes can accurately set the needed low-speed rotary current with high efficiency while the low-speed rotary operation is needed. The invention further discloses a low-speed rotary control system of the cranes.

Owner:XUZHOU HEAVY MASCH CO LTD

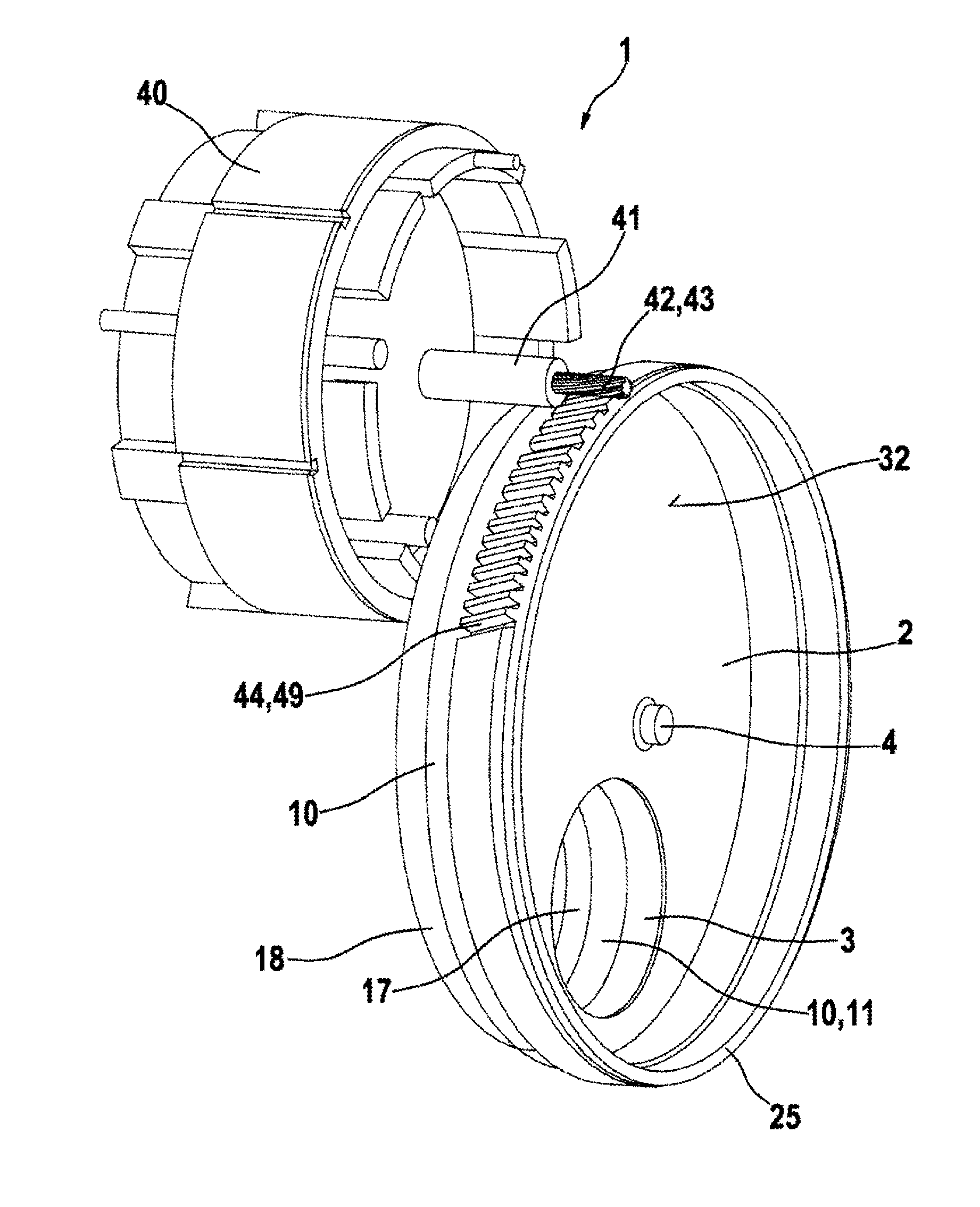

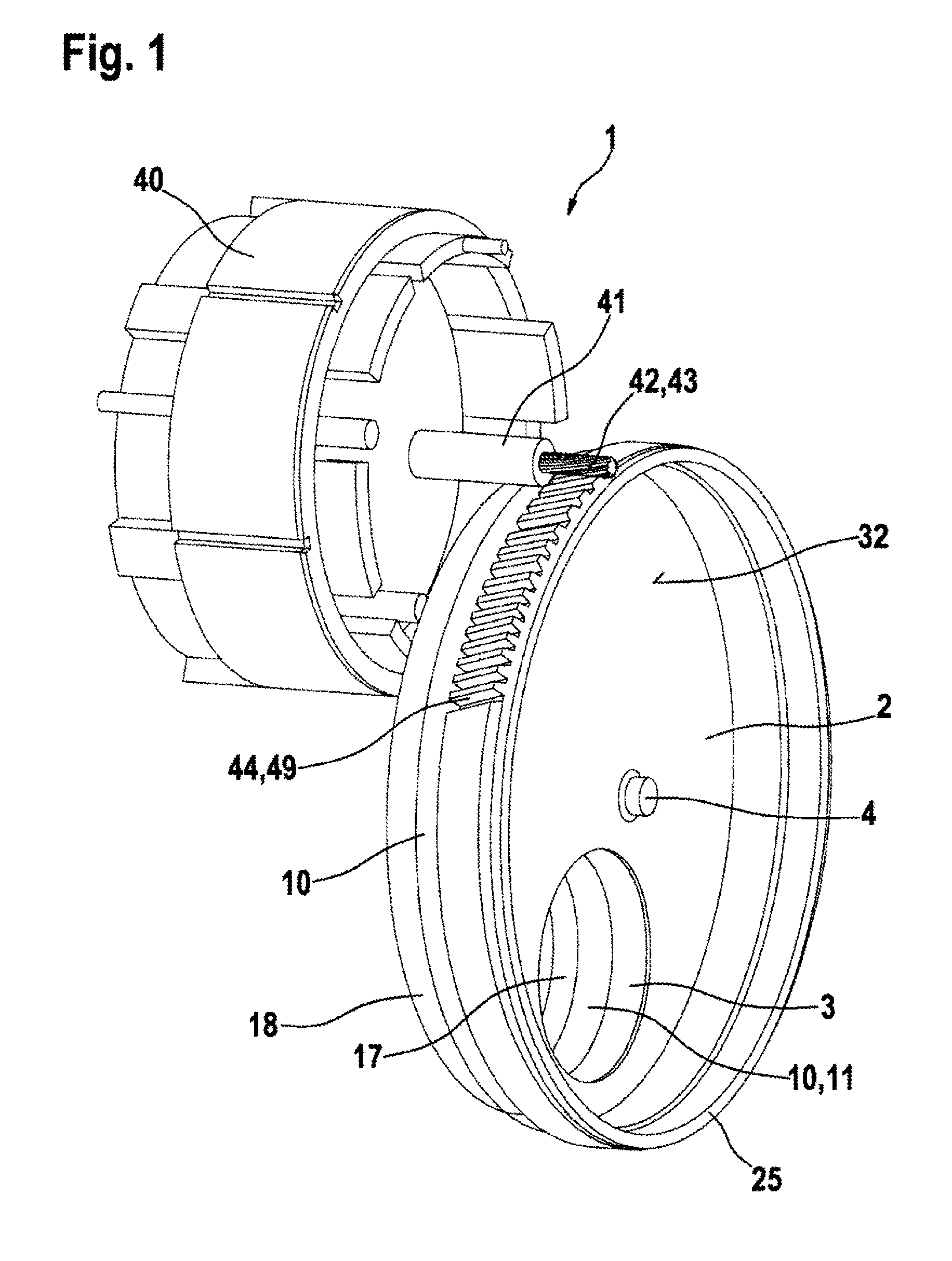

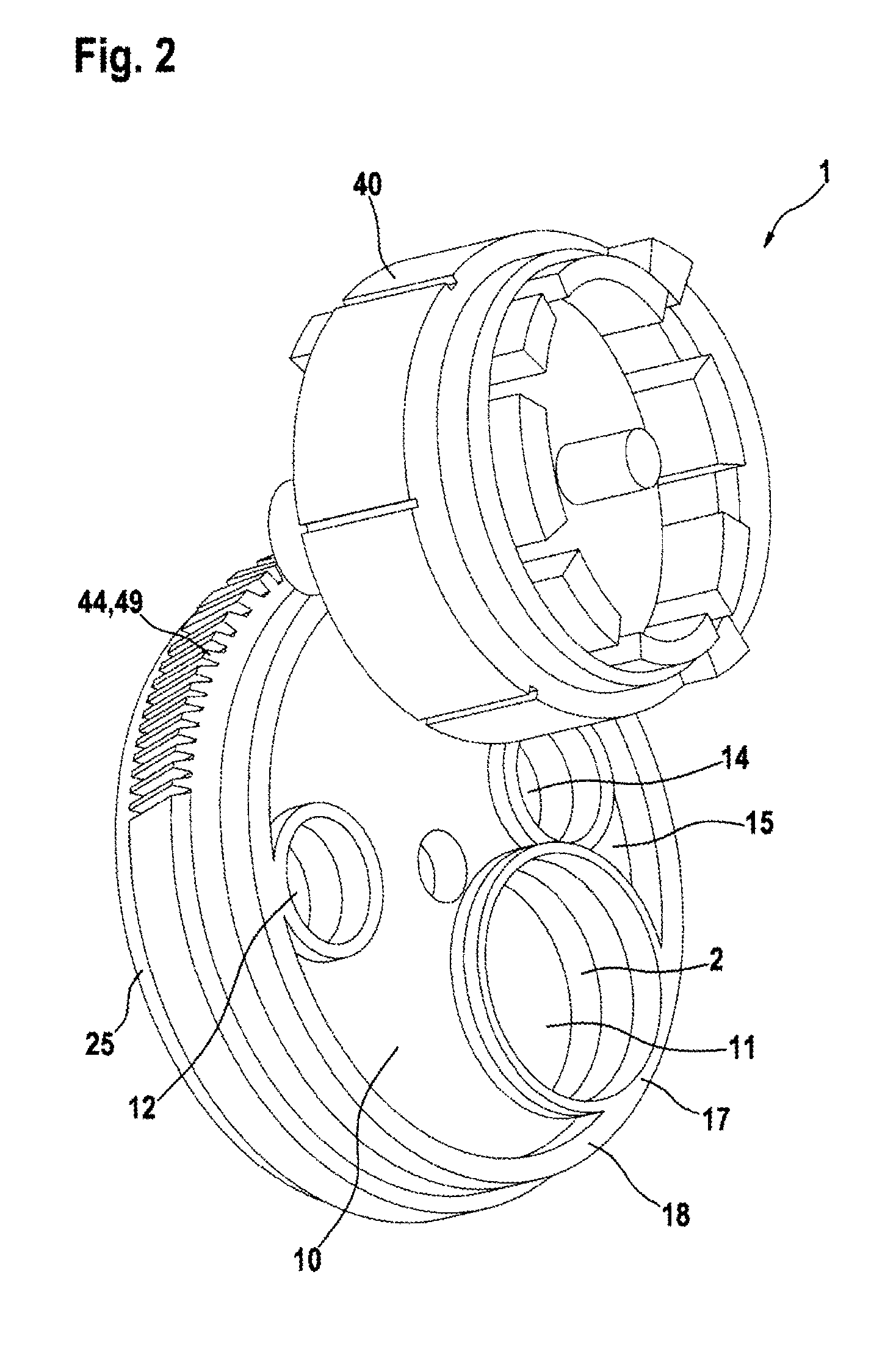

Valve for controlling volume flows

InactiveUS20110180737A1Great setting accuracyEasy constructionOperating means/releasing devices for valvesCoolant flow controlCircular discRotary valve

The invention proposes a valve (1) for controlling volume flows, in particular in a heating and / or cooling system of a motor vehicle, having a disk-shaped valve body (2) with at least one control opening (3) which, to control the volume flow, interacts with a disk-shaped sealing body (10) having at least one passage opening (11), wherein the disk-shaped valve body (2) has an external toothing (49) into which a pinion (42) engages in order to rotate the valve body (2). According to the invention, the pinion (42) and the external toothing (49) of the disk-shaped valve body (2) interact with one another by means of an evoloid toothing (43; 44). The valve according to the invention is provided for controlling volume flows, in particular in a heating and / or cooling system of a motor vehicle.

Owner:ROBERT BOSCH GMBH

Fuzzy BP neural network based glass tempering process parameter setting method

ActiveCN105095273AQuality improvementReduce dependencyBiological neural network modelsGlass tempering apparatusInitial sampleMultiple category

The invention discloses a fuzzy BP neural network based glass tempering process parameter setting method. The process parameter setting method comprises: according to an initial sample, training a BP neural network; dividing existing tempered glass into multiple categories; obtaining the optimal process parameters of each category according to the already trained BP neural network; establishing a process database according to the process parameters of all the categories; directly judging the category of to-be-tempered glass; directly choosing the process parameters corresponding to the category from the technology database; and setting the tempering process parameters of the to-be-tempered glass by utilizing the chosen process parameters. According to the fuzzy BP neural network based glass tempering process parameter setting method, the BP neural network is used to directly obtain the optimal process parameters of the to-be-tempered glass in the tempering process, so that the degree of dependence on artificial experience is reduced and the production cost is reduced; the process parameter setting method is realized through a computer, so that the setting precision is high, the error rate is low, the quality of the tempered glass can be improved, and the production efficiency is greatly improved.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com