Variable capacitance device

A variable capacitance and variable technology, applied in the direction of capacitors that change the distance between electrodes, can solve problems such as the increase of variable capacitors, and achieve the effect of improving setting accuracy and improving capacitance accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach 》

[0033] A configuration example of the variable capacitance device according to the first embodiment of the present invention will be described.

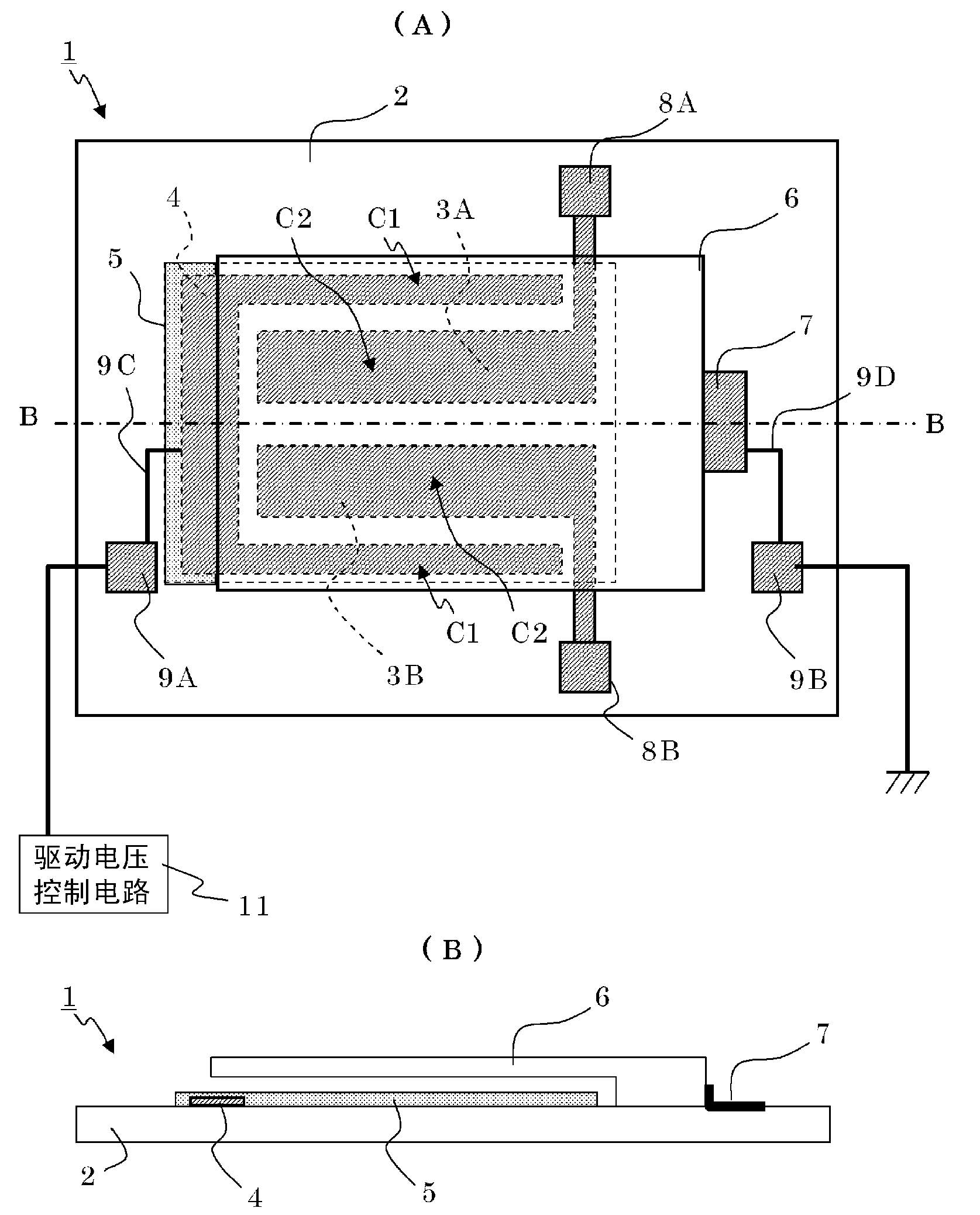

[0034] figure 2 (A) is a plan view of the variable capacitance device 1 . figure 2 (B) is a side sectional view of the variable capacitance device 1 .

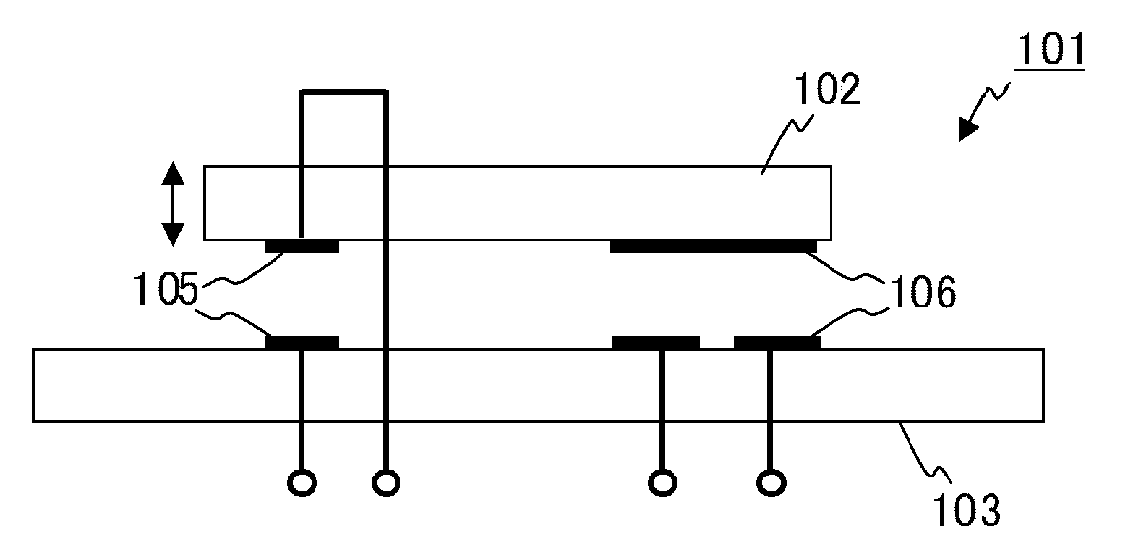

[0035]The variable capacitance device 1 includes: a substrate 2, lower driving electrodes 3A, 3B, 4, a dielectric film 5, a beam portion 6, pad electrodes 7, 8A, 8B, 9A, 9B, resistance patterns 9C, 9D, and a driving voltage control circuit 11. The substrate 2 is composed of a rectangular glass substrate. The beam portion 6 has a rectangular flat plate shape in plan view and an L-shape in side view, and serves as a support portion that joins the end portion on the right side in the figure to the base plate 2 , and is a cantilever beam that supports the main part in a state separated from the base plate 2 Structure (spring structure) of the movable structure. The beam portion 6 ...

no. 2 Embodiment approach 》

[0045] Next, a configuration example of the variable capacitance device according to the second embodiment of the present invention will be described. In addition, the variable capacitance device of this embodiment has the same structure as that of the first embodiment, and only the circuit configuration of the driving voltage control circuit is different.

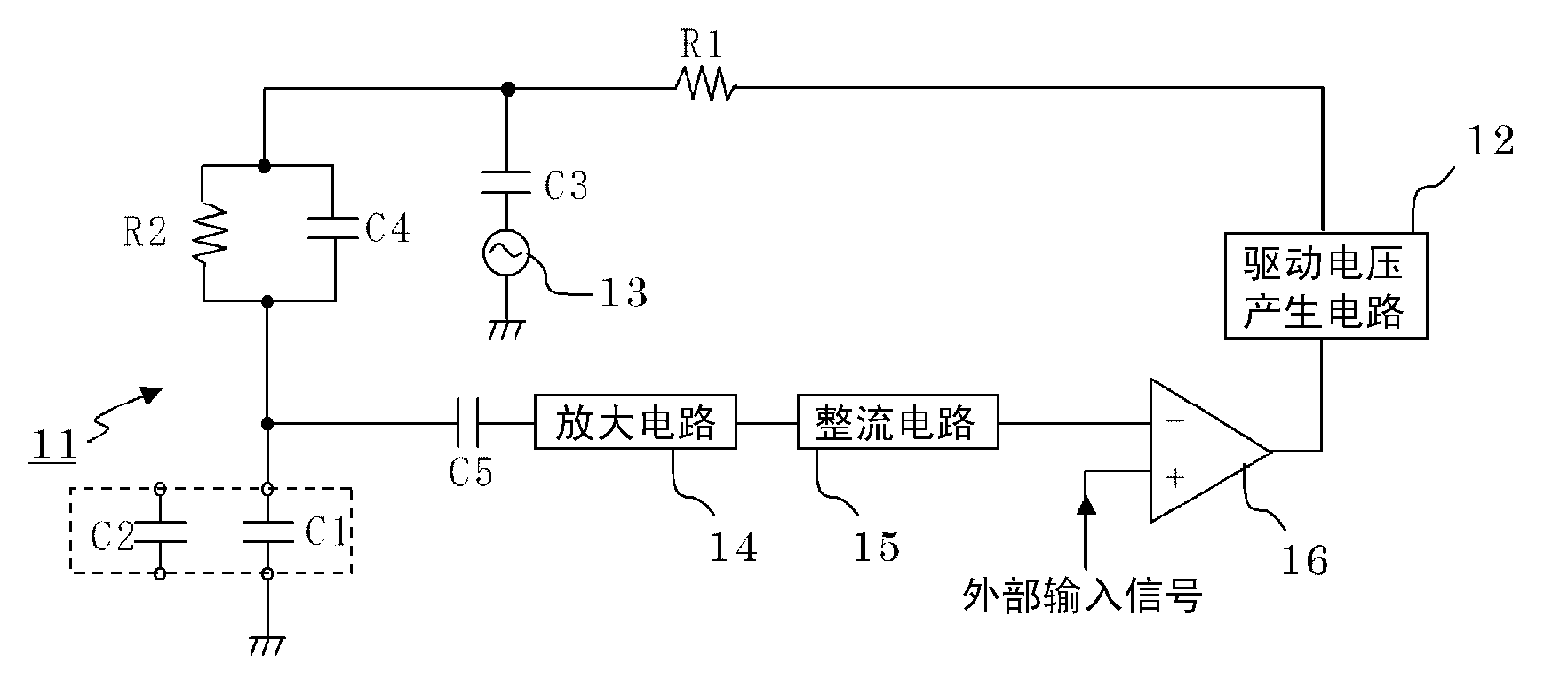

[0046] Figure 4 It is a diagram illustrating the circuit configuration of the driving voltage control circuit 21 of the variable capacitance device according to the present embodiment. In addition, the same code|symbol is attached|subjected to the circuit structure similar to 1st Embodiment.

[0047] The driving voltage control circuit 21 includes a driving voltage generating circuit 22 , an AC signal source 13 for capacitance detection, an AC component active amplifier circuit 24 , a switched capacitor detection circuit 25 , and a comparator 16 . The drive voltage generation circuit 22 includes a switched capacitor LPF...

no. 3 Embodiment approach 》

[0053] Next, a configuration example of the variable capacitance device according to the third embodiment of the present invention will be described. In addition, the circuit configuration of the driving voltage control circuit of the present embodiment is the same as that of the first embodiment, and only the configurations of the driving capacitor unit and the variable capacitor unit are different. In addition, the same code|symbol is attached|subjected to the structure similar to the said structure, and description is abbreviate|omitted.

[0054] Figure 5 (A) is a plan view of the variable capacitance device 31 . Figure 5 (B) is a side sectional view of the variable capacitance device 31 . Figure 5 (C) is a front sectional view of the variable capacitance device 31 .

[0055] The variable capacitance device 1 includes: a substrate 2, lower driving electrodes 3A, 3B, 4, upper driving electrodes 33, 34A, 34B, a dielectric film 5, a beam portion 36, pad electrodes 7, 8A,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com