Control method for headed plate shape rolling parameters of leveling machine and leveling machine

A control method and technology of a skin pass mill, applied in the field of steel rolling, can solve the problems such as the reduction of the genuine rate of strip steel, the tensile strain, and the low accuracy of the setting value of the plate rolling parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present application provide a method for controlling the strip shape rolling parameters of the temper mill and the temper mill, so that the strip shape rolling parameters of the temper mill can be set more accurately, so that the quality of the strip strip shape at the exit can be improved. Improve, and the genuine rate of strip steel after leveling can also be improved.

[0039] The main realization principles, specific implementation methods and corresponding beneficial effects that can be achieved of the technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

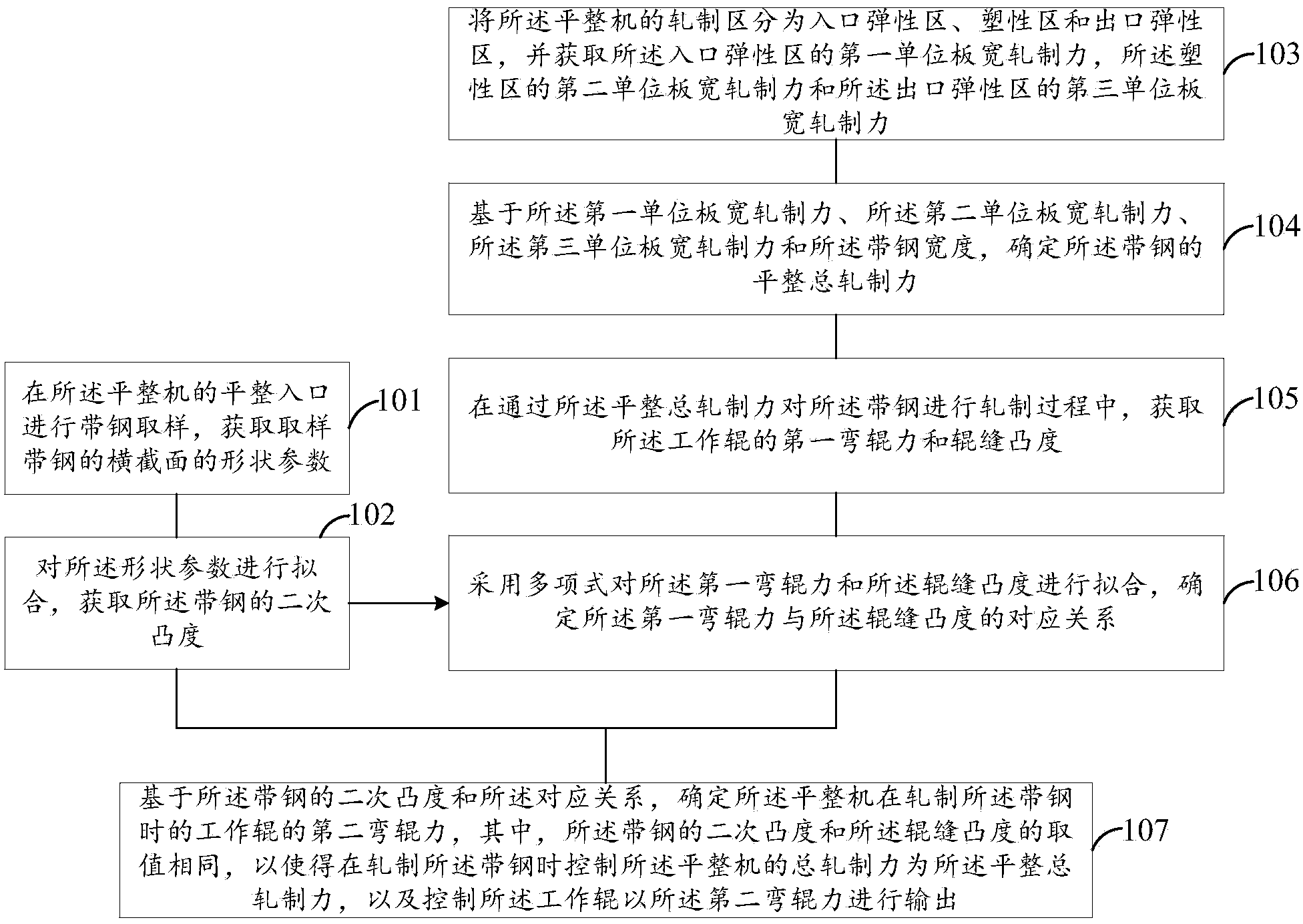

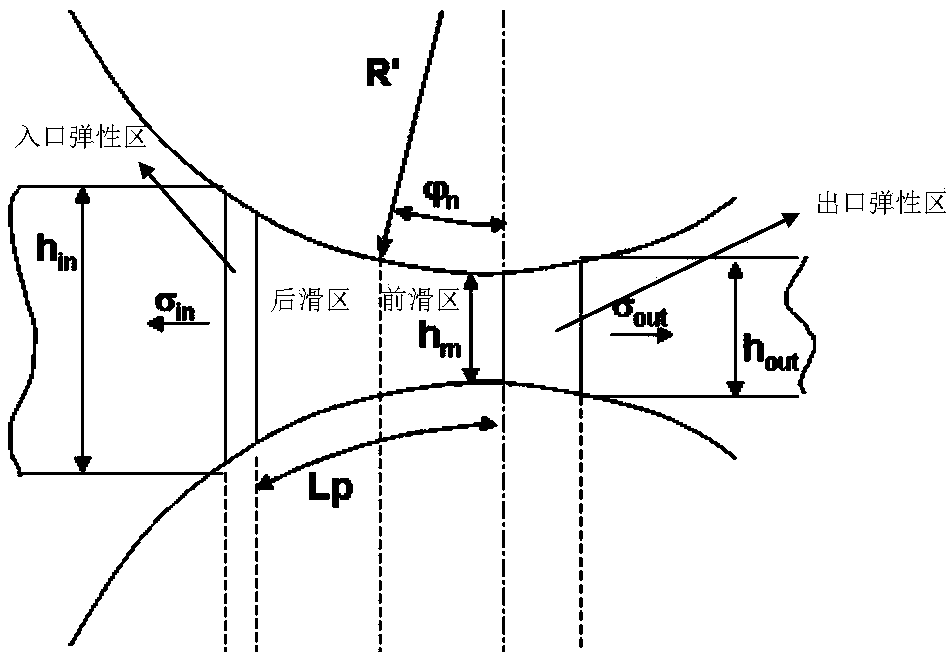

[0040] The embodiment of the present application provides a method for controlling the strip shape rolling parameters of a temper mill, see figure 1 , the tempering machine includes work rolls, and the method includes:

[0041] Step 101: Sampling the steel strip at the leveling entrance of the skin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com