Adjustable clamping device for processing gem

An adjustable and gem technology, applied in the direction of manufacturing tools, metal processing equipment, machine tools suitable for grinding the edge of workpieces, etc. Process, avoid pollution, convenient and fast loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

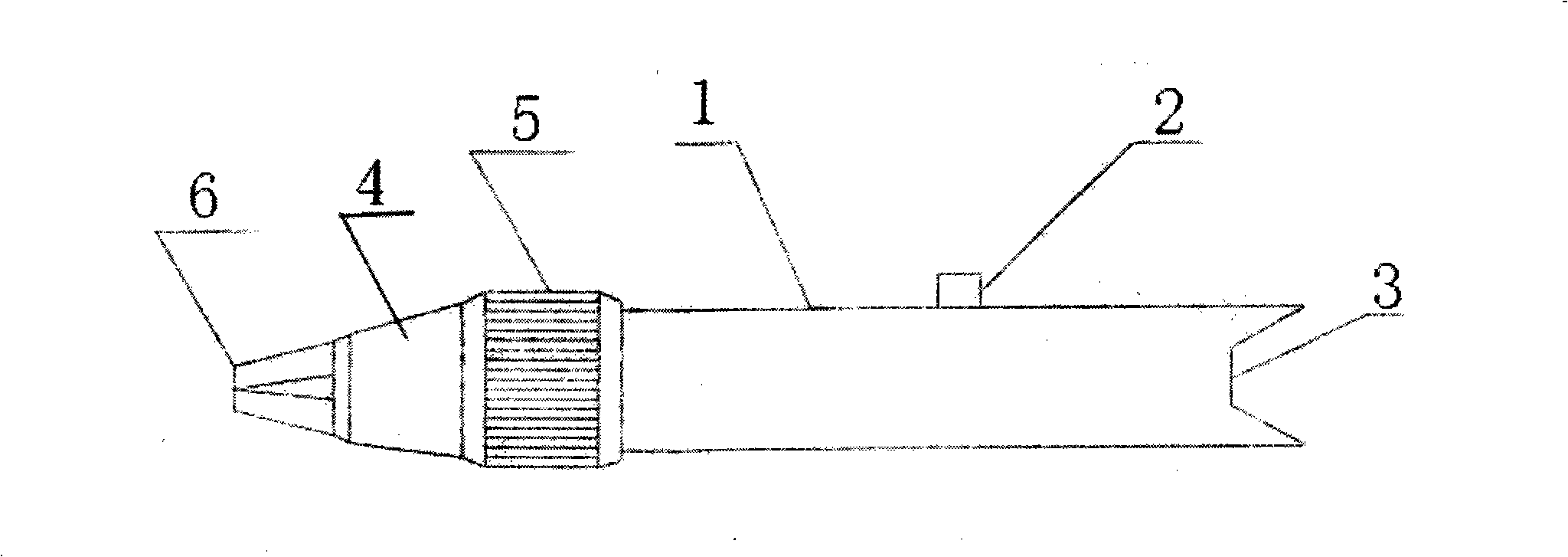

[0007] The embodiment of the adjustable jig for processing gemstones according to the present invention is explained with reference to the accompanying drawings:

[0008] It consists of a metal rod 1, a fixed pin 2, a tail groove 3, a cone chuck 4, a tightening sleeve nut 5, and a jaw 6. The front end of the cone chuck 4 is made into a cone shape, and there are jaws 6 with two claws, three claws, four claws to six claws inside, and the top end of the metal rod 1 is inserted into the tail end of the cone chuck 4 And fixed, the conical collet 4 and its jaws 6 are locked by the tightening sleeve nut 5, so that the jewel workpiece is held tightly in each jaw, the front end of the metal rod 1 is provided with threads, and the metal rod 1 The middle part is provided with fixed pin 2, and the tail is provided with fixed tail slot 3, which is installed in the original production equipment octagonal hand or noodle presser to play a positioning role.

[0009] Numerals from 1 to 20 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com