Patents

Literature

312results about How to "Improve the authenticity rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold-rolling heap staining method for textile fabric

ActiveCN101016682AImprove solubilityGood compatibilityBiochemical fibre treatmentDyeing processSewageWater washing

The invention discloses a cold rolling stack dying method of face fabric, comprising immerging, stacking and water washing. The immerging step comprises cold rolling stack pretreatment, obtaining half finished product and drying rolling. The stacking step comprises coiling and stacking. The water washing step comprises washing with water, washing soap, washing with water and drying. The inventive method has advanced and reasonable process, with stable quality, energy-saving and environment friend functions, while the invention has simple process, low cost, and high fixation yield, or the like.

Owner:YUYUE HOME TEXTILE

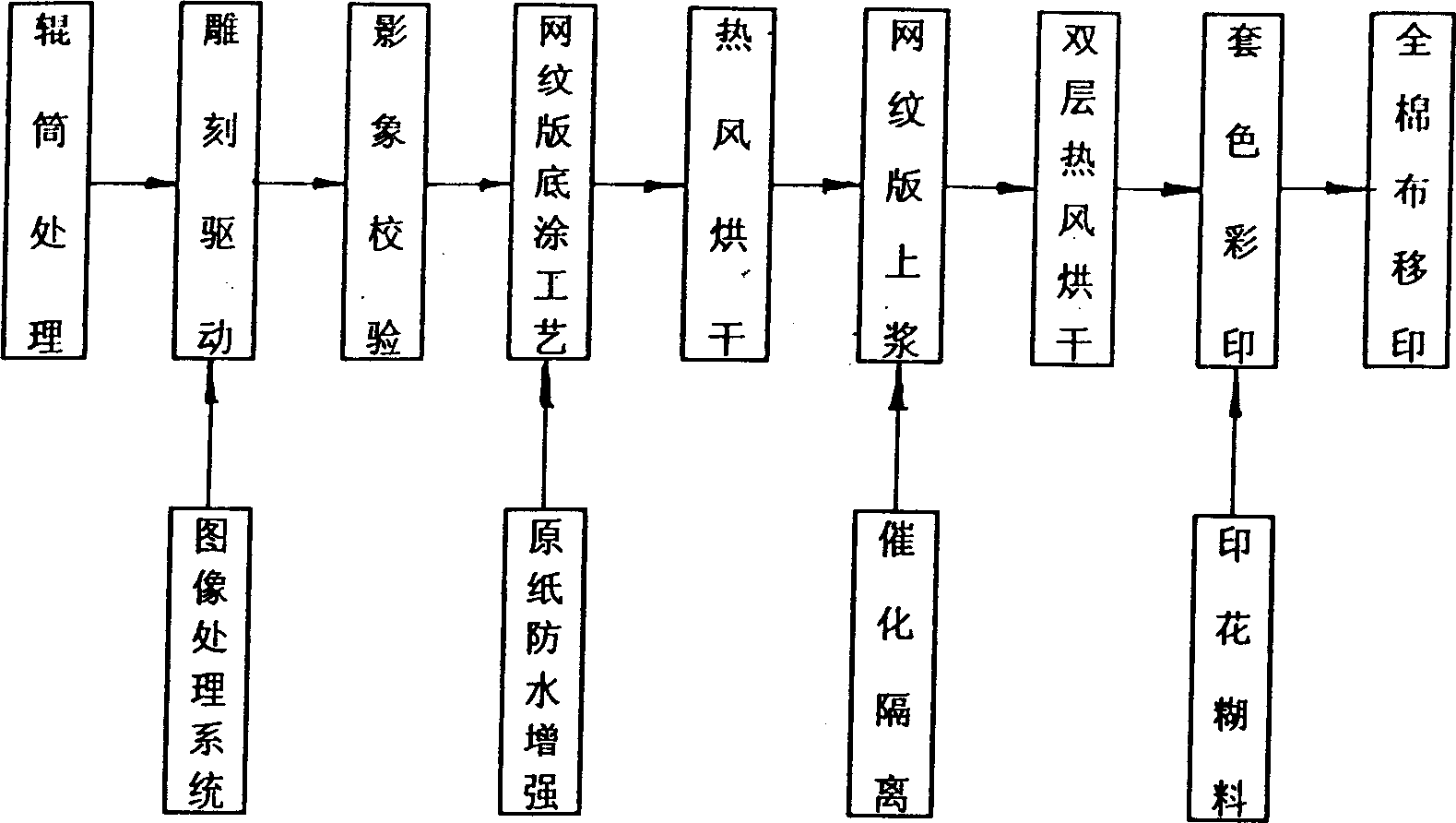

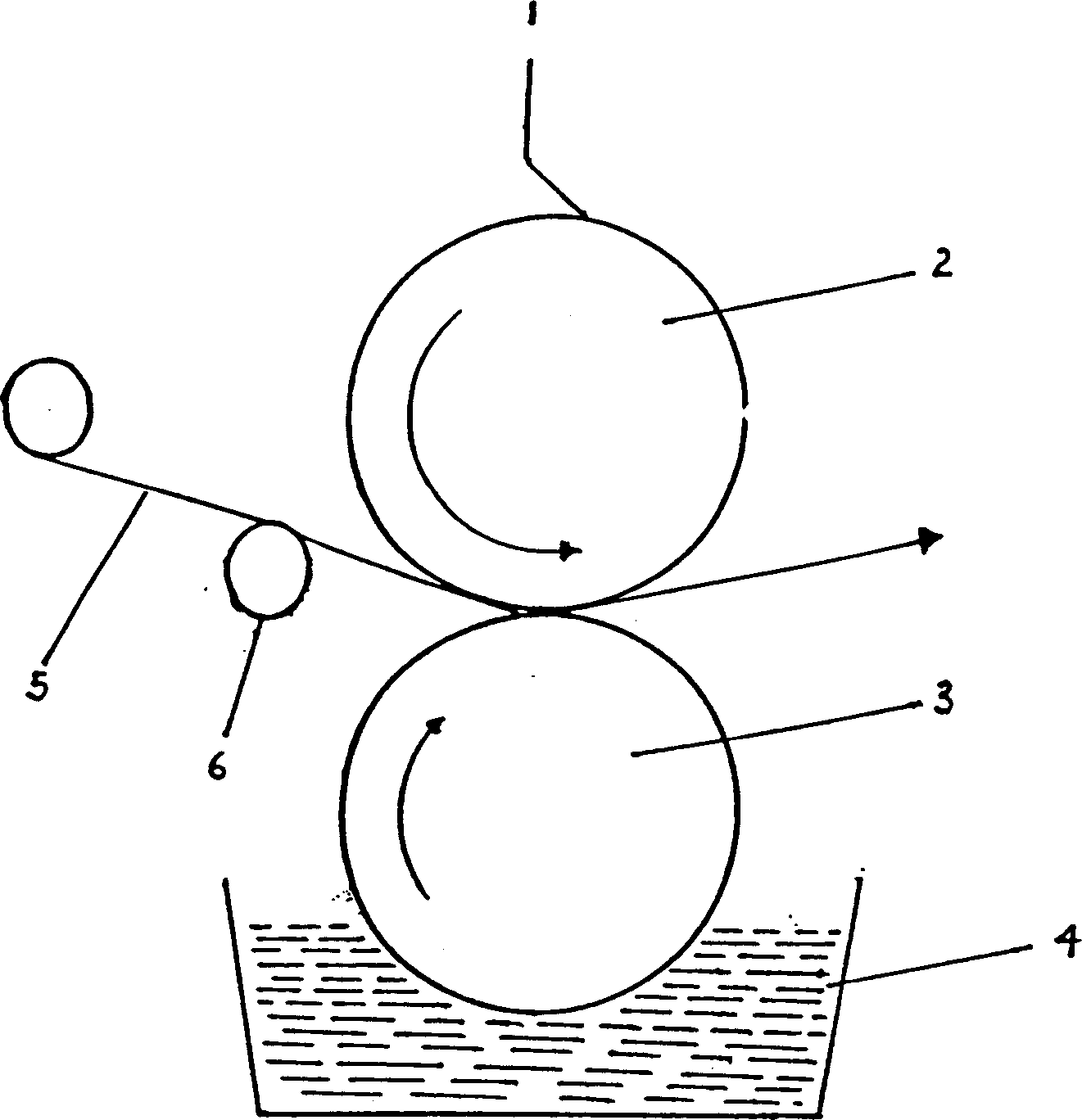

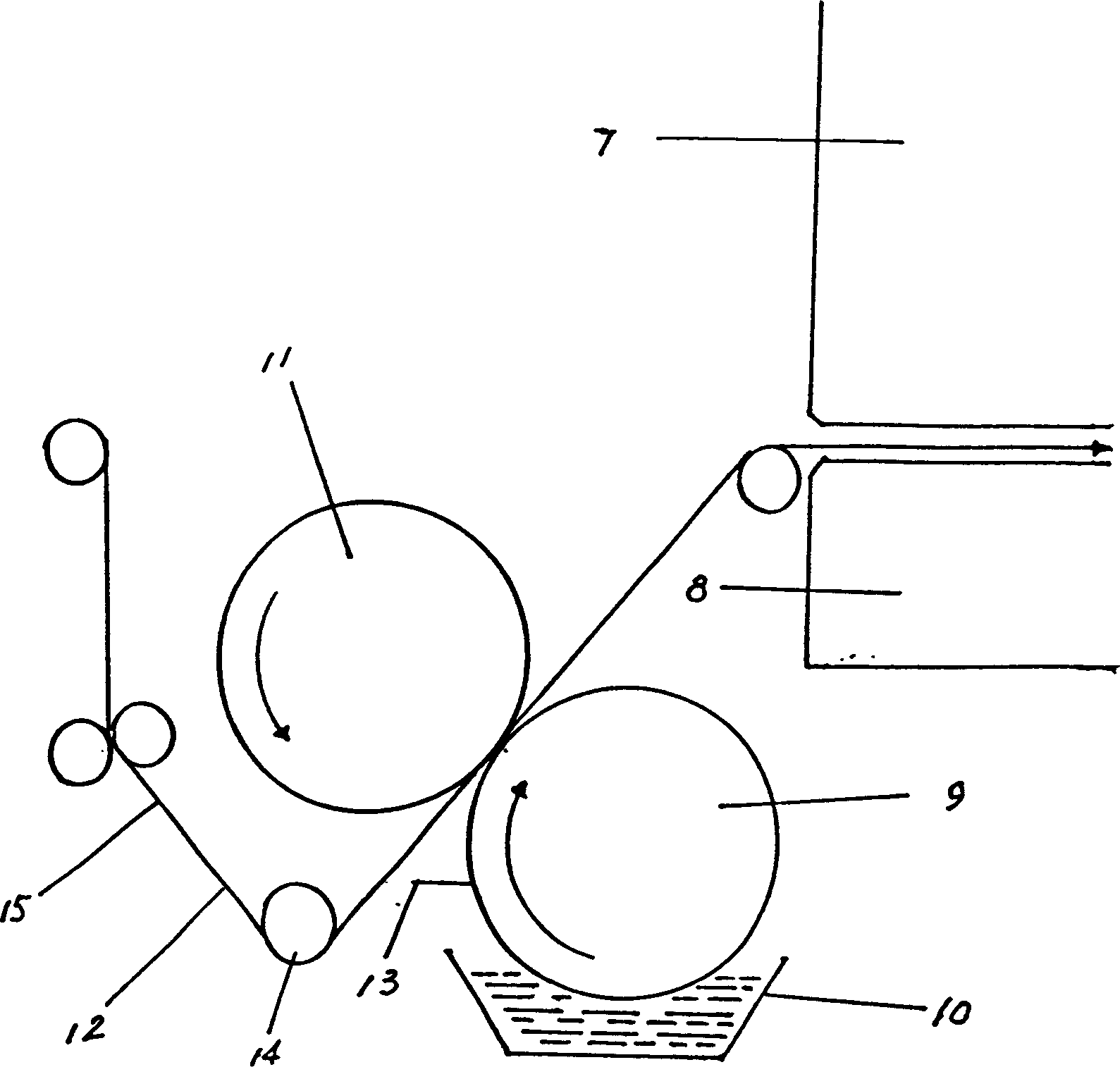

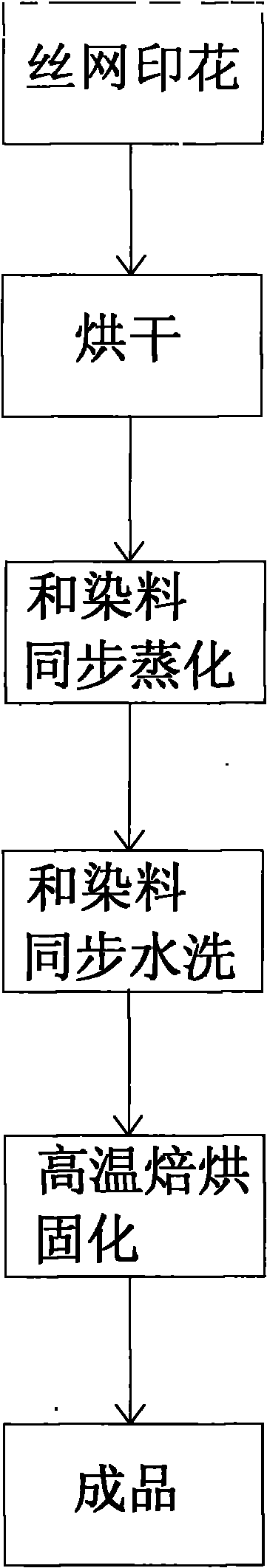

Production process for printing whole-cotton transfer printing paper using copper-plate press

ActiveCN1807121AImprove the authenticity rateImprove printing effectDecorative surface effectsTransfer printing processColor printingAdditional procedure

The invention relates the manufacturing technique of all-cotton transfer printing paper. The technology comprises the following steps: treating roller, engraving activation according to image processing system signal, checking image, raw-paper halftone etching basecoat technology, drying with hot wind, starching the halftone etching to catalyze isolated layer, drying with double-layer hot wind, screen printing color register color printing, and all-cotton bat printing. The raw-paper halftone etching basecoat technology, starching the halftone etching to catalyze isolated layer, drying with double-layer hot wind, and screen printing color register color printing are new additional procedure. The all-cotton transfer printing paper made with the method has better bat printing effect. The method has the advantages of easy operation, high standard-piece rate, low cost, environmental protection and saving energy.

Owner:NEWTECH TEXTILE TECH DEV SHANGHAI

Method for producing bricks from silt and sludge

InactiveCN101830687AWon't breakSolve processing problemsCeramic materials productionClaywaresBrickLand resources

The invention discloses a method for producing bricks from silt and sludge, which comprises the following steps of: stacking silt and sludge of which the water content is 80-85% in a parking field to enable the water content of the silt and the sludge to be less than or equal to 60% for standby; conveying the silt and the sludge of which the water content is less than or equal to 60% to a primary stirrer through a feeding box for stirring together with fly ash, rice chaffs or wood flour, coal slag and black sand to enable the water content of the mixture to be less than or equal to 30%; putting the mixture in an aging field for aging to enable the water content of the mixture to be less than or equal to 22%; conveying the mixture to a secondary stirrer through the feeding box, and adding water or fly ash according to the degree of dryness and wetness to obtain a blank preparing material of which the water content is less than or equal to 20%; preparing the blank preparing material into a wet blank of which the water content is 17.8-18.8% through extruding and cutting devices; and roasting to obtain a finished product brick. In the method of the invention, silt and sludge are used as main raw materials for producing bricks; on one hand, clay does not need to be used, and the cultivated land can not be destroyed; and on the other hand, the invention solves the problem of treatment of silt and sludge, saves land resources and has obvious effect of environmental protection.

Owner:常州市振东新型节能建筑材料厂

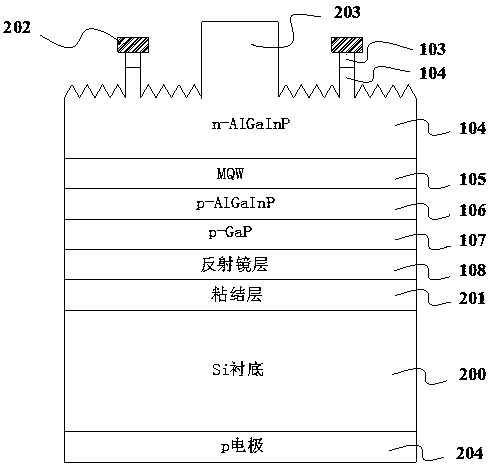

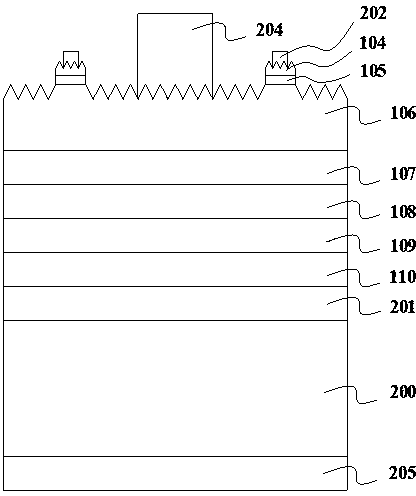

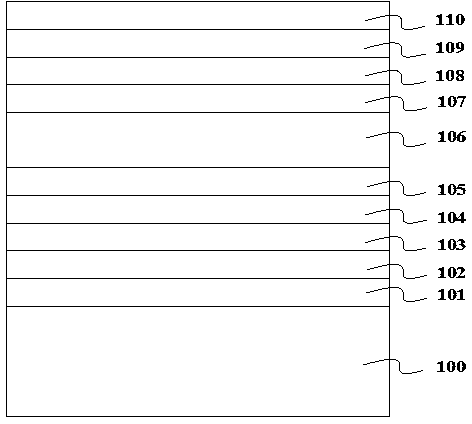

Reversed-polarity AlGaInP-based light-emitting diode and manufacturing method thereof

ActiveCN104167477AThe electrode structure is completeStable pressure dropSemiconductor devicesOhmic contactVoltage stability

The invention discloses a reversed-polarity AlGaInP-based light-emitting diode and a manufacturing method thereof and belongs to the technical field of photoelectron. The method includes the following steps: firstly manufacturing a light-emitting-diode epitaxial wafer and manufacturing a holophote structure layer on the epitaxial wafer; bonding the epitaxial wafer provided with the holophote structure layer and a permanent substrate through a metal bonding layer; coarsening the surface of a first coarsening layer through removal of a temporary substrate, a buffer layer, a barrier layer and an n-type gallium arsenide layer; manufacturing patterned extending electrodes on the first coarsening layer and the n-type gallium arsenide ohmic contact layer; using a mask to protect existing patterned extending electrodes and removing the first coarsening layer and the n-type gallium arsenide ohmic contact layer, which are outside a mask protective layer and coarsening a second coarsening layer; and forming a main electrode on the second coarsening layer. The method uses a coarsening epitaxial layer structure and mask protection to improve adhesiveness and integrity of the electrodes and the epitaxial layer so that work voltage stability of a light-emitting device is ensured and product quality and yield are improved significantly.

Owner:YANGZHOU CHANGELIGHT

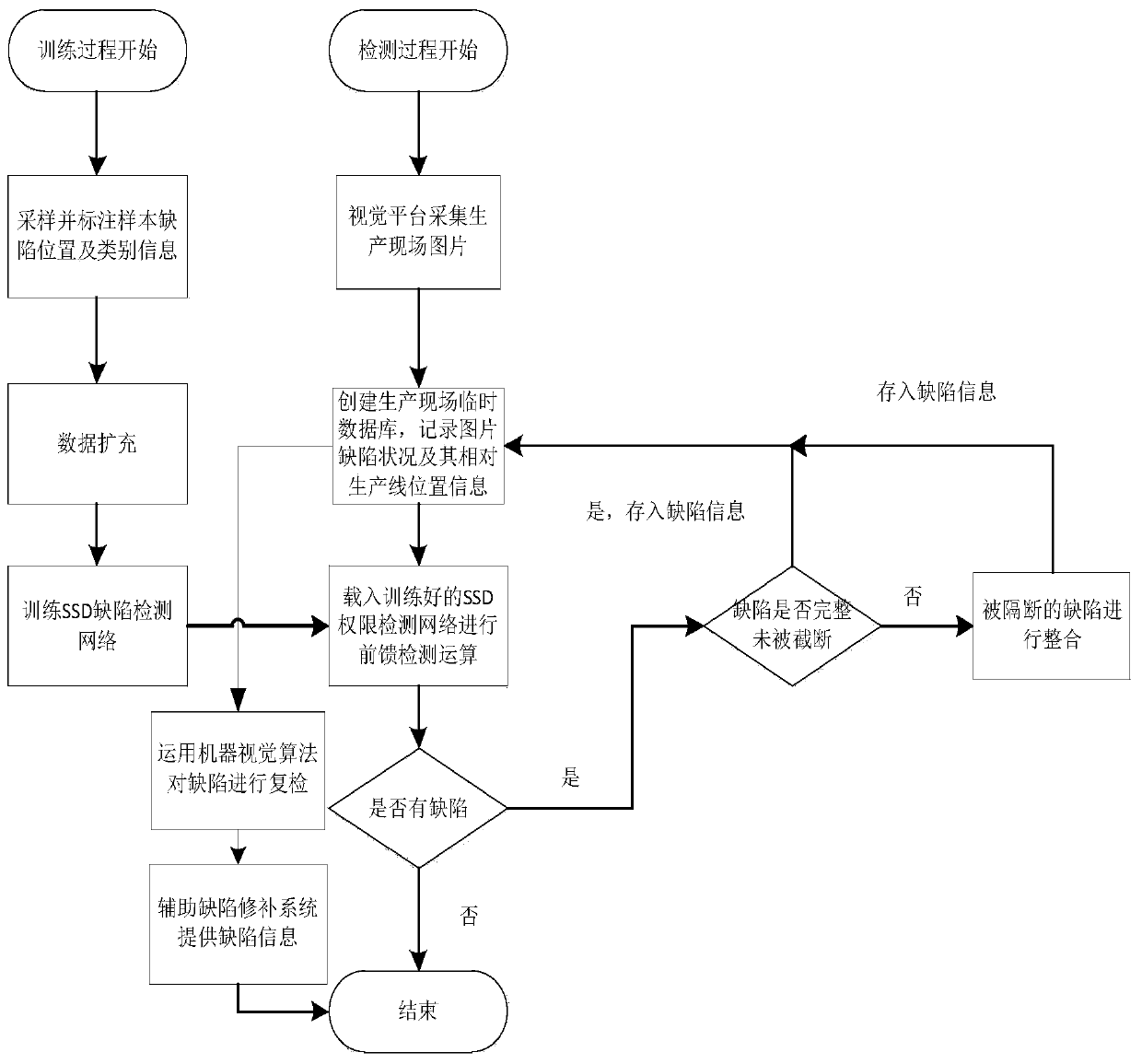

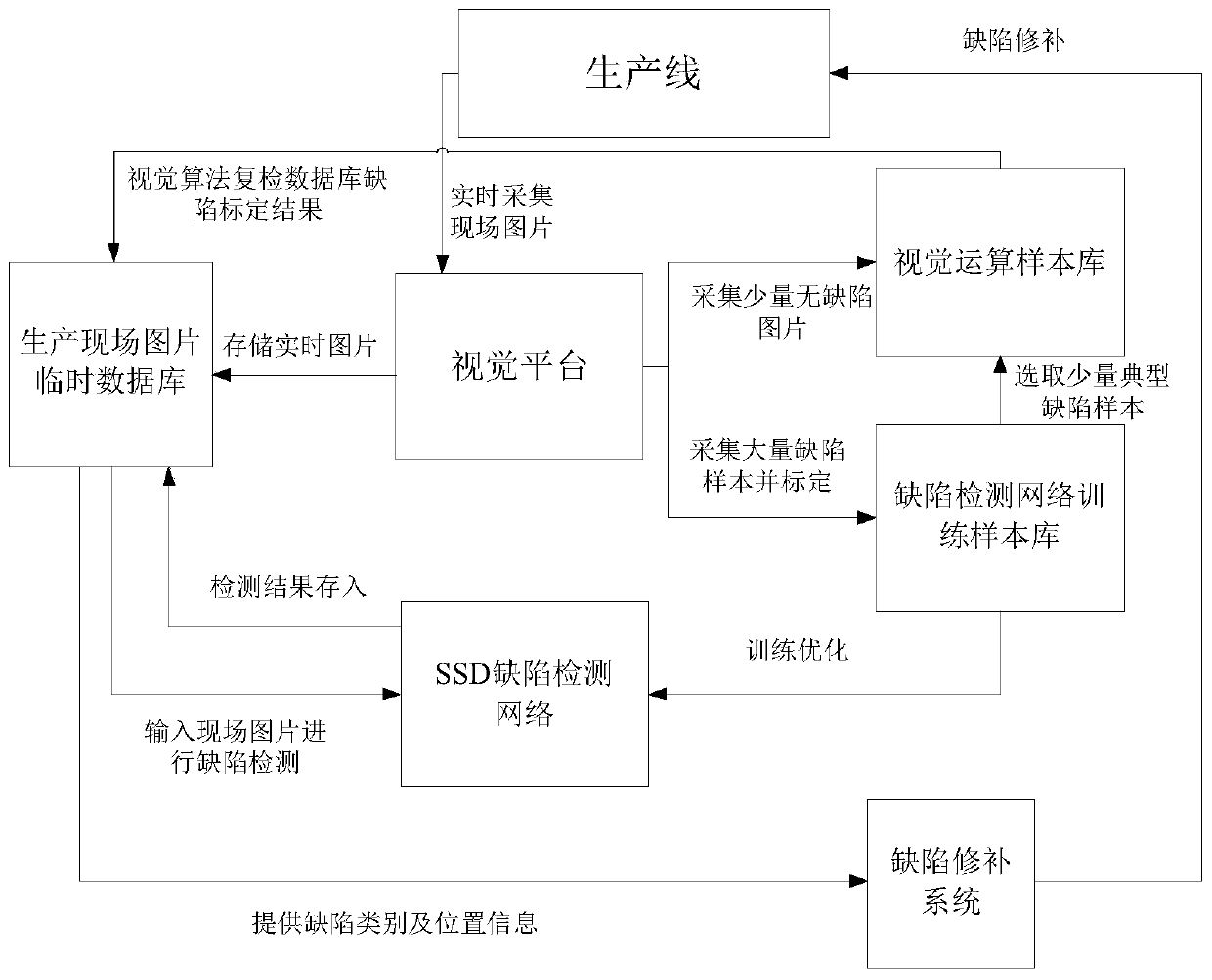

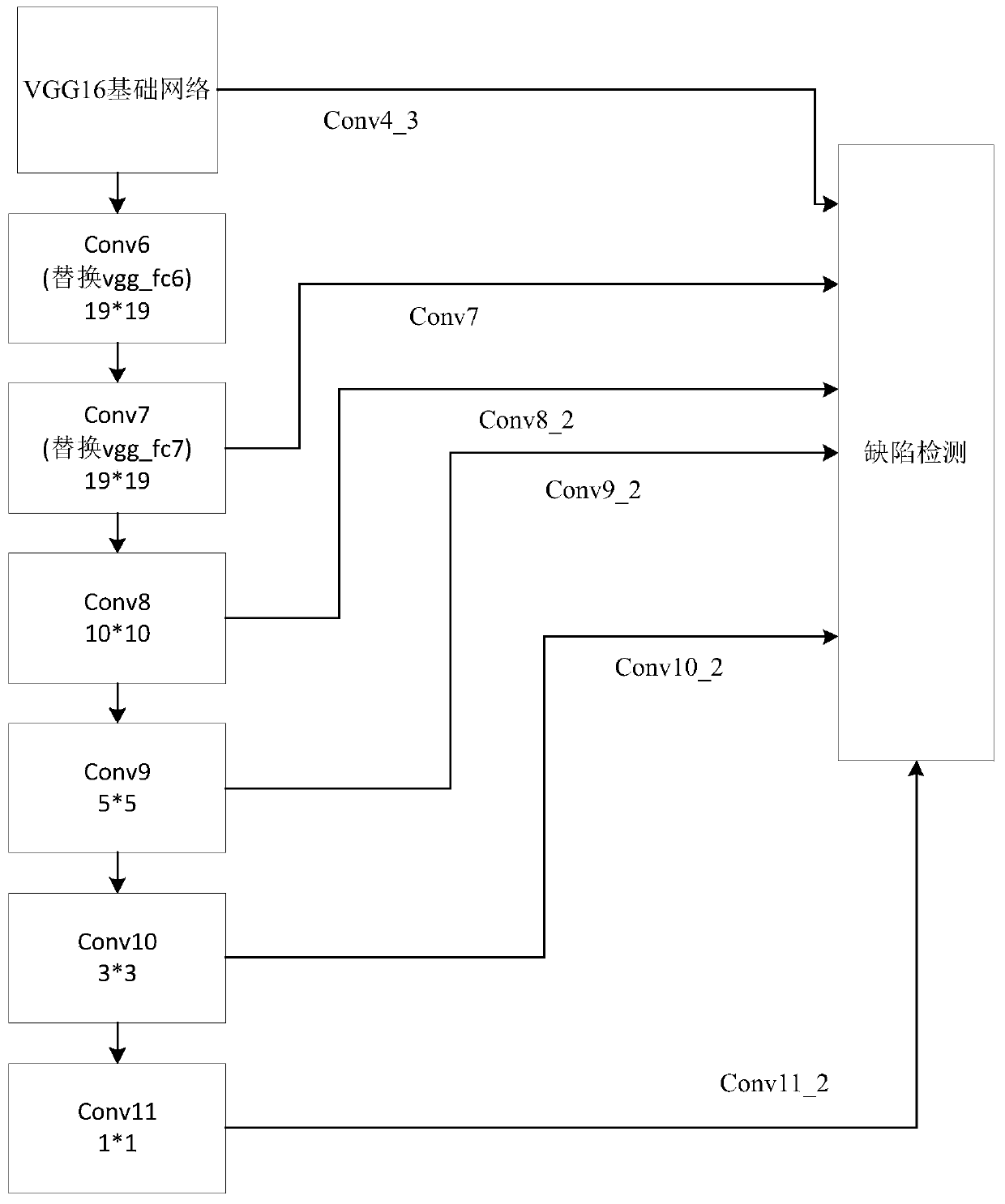

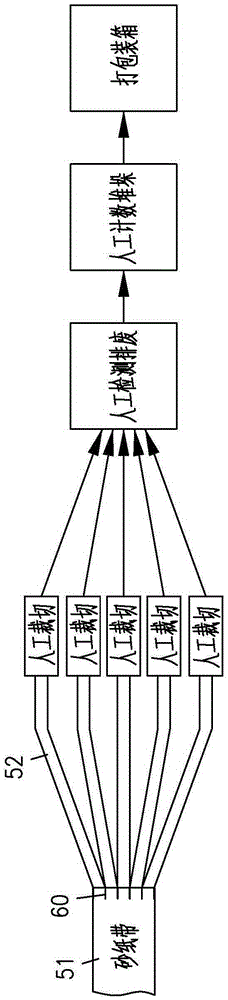

Honeycomb paper core defect detection method based on machine vision

ActiveCN110111331AImplement automatic detectionThe location information is accurateImage enhancementImage analysisCardboardMachine vision

The invention discloses a honeycomb paper core defect detection method based on machine vision. Aims at various defect problems generated during a honeycomb paper core production process, the method comprises the following steps of acquiring a honeycomb paper core picture on a production site; detecting the defects in the honeycomb paper core by adopting an SSD deep neural network; judging the defect category of the honeycomb paper core and outputting the specific position, then using a machine vision algorithm for rapid reinspection to prevent the false inspection, finally transmitting an obtained result to the honeycomb paper core defect repairing system, and providing a correct feedback signal to realize the automatic repairing of the honeycomb paper core defects. The method detects thehoneycomb paper core defects in real time through the deep learning model and the machine vision algorithm, can provide the feedback information for an automatic defect repairing system during the honeycomb paper core production process, has the advantages of being accurate in recognition, accurate in positioning and fast in recognition speed, and can meet the requirement for honeycomb paperboardproduction automation.

Owner:CENT SOUTH UNIV

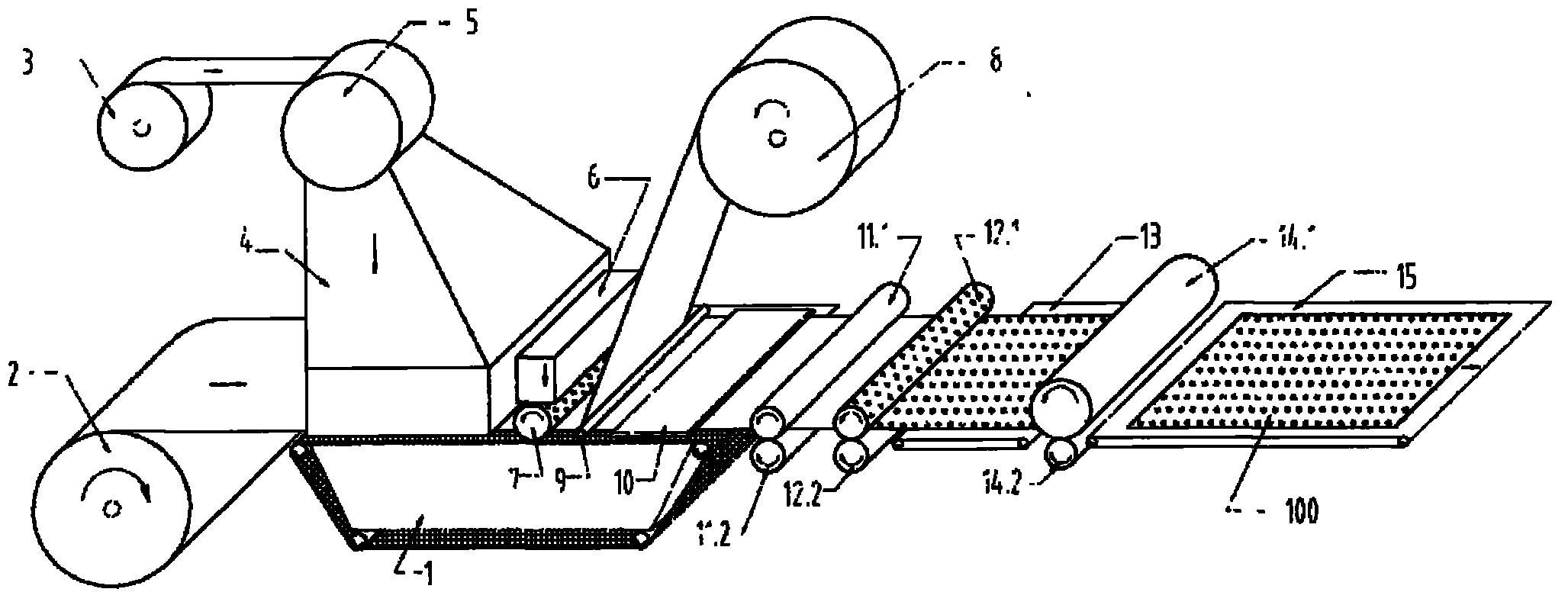

Health nursing pad absorber processing method and equipment thereof

ActiveCN103381114AImprove liquid absorption capacityIncrease liquid absorptionAbsorbent padsBaby linensEngineeringFiber

The invention discloses a health nursing pad absorber processing method and equipment thereof. The method comprises the following three steps: A, adsorbing wood pulp fiber and mixing the wood pulp fiber with polymer absorbent materials, B, compacting and dotted solidifying the absorber, and C, forming the absorber; the equipment is provided to realize the method. The method provided by the invention is suitable for various nursing pad products, can enhance extension strength of the nursing pad product, simplifies and realizes the manufacturing of absorber of nursing pad product, and reduces manufacturing cost of the nursing pad. The absorber produced by the invention adopts a novel structure made of polymer absorbent materials and wood pulp fiber, the polymer absorbent materials are uniformly disturbed in the wood pulp fiber, the sliding and moving of polymer absorbent materials are confined through doted solidification, so as to guarantee liquid absorption of the nursing pad product.

Owner:BEIJING BEISHUTE MATERNITY & CHILD ARTICLES

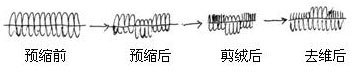

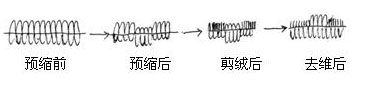

Method for processing blanched untwisted relief towels

ActiveCN102121156ASolve the problem that embossed towels cannot be producedImprove weaving efficiencyPile loops cuttingDomestic applicationsEngineeringWater soluble

The invention discloses a method for processing blanched untwisted relief towels. The method comprises the following steps: doubling and twisting high temperature water soluble vinylon yarns at the temperature being higher than 90 DEG C with the common cotton yarns to prepare untwisted water soluble yarns; arranging the obtained untwisted water soluble yarns and the common yarns at intervals in a ratio of 1:1 and warping the yarns to prepare wool warp beams and interweaving the wool warp beams with ground warp and weft yarns to form jacquard patterns; ensuring the untwisted parts to shrink and the parts needing to be sheared to protrude through squeezing, moistening and high temperature roller blanching; after drying, shearing the raised parts needing to be sheared on a shearing machine; dissolving out the water soluble yarns on the untwisted yarns with high temperature water at the temperature being higher than 90 DEG C to ensure the untwisted yarns to be untwisted and pop; and after washing, carrying out water removal, softening and drying to ensure the untwisted yarns to be fluffy and raised. Through changing the preshrinking method, the problem that the relief towels can not be produced with the high temperature water soluble untwisted yarns is solved and the effects of low cost, high weaving efficiency, strong third dimension of the relieves and high yield can be achieved.

Owner:NANTONG DADONG

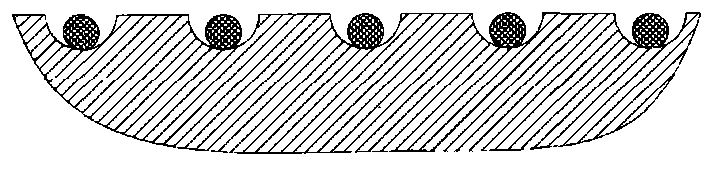

Grinding ball specialized for mine

The invention discloses a grinding ball specialized for a mine. The grinding ball specialized for the mine comprises the following chemical components in percentage by weight: 1.0-2.9 of C, 5.0-11.5 of Cr, 0.3-0.9 of Si, 0.4-0.8 of Mn, no more than 0.8 of W, 0.05-0.20 of Y, no more than 0.08 of S, no more than 0.08 of P and the balance Fe. In the process of casting, yttrium-base heavy rare earth copper modificator with adding amount accounting for 0.1-0.3 of the molten iron. The grinding ball specialized for the mine of the invention is smelted by using a medium frequency electric furnace and casted by using a metal mould; raw materials use high quality steel pig iron and high quality waste steel and are modified by using ferrochrome, ferromanganese and ferrosilicon; after each chemical component in the molten iron reaches the requirement of the grinding ball specialized for the mine, the yttrium-base heavy rare earth copper modificator is directly added into a foundry ladle; and then the molten iron is poured into the metal models to produce the grinding ball specialized for the mine.

Owner:宁国市南洋机械有限公司

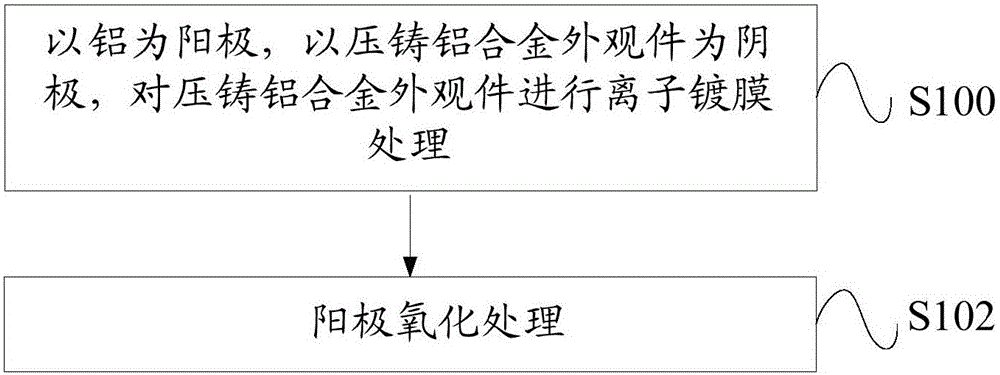

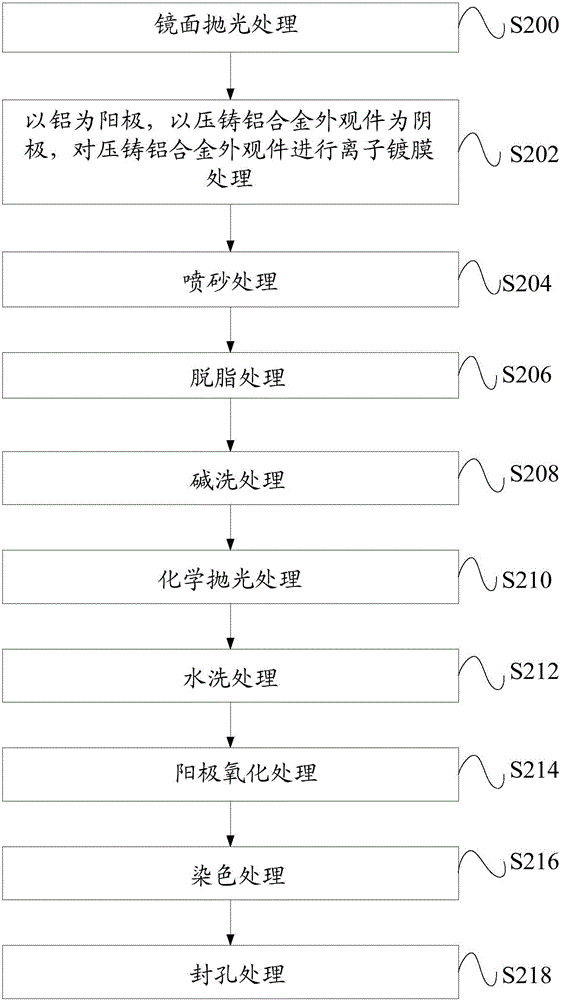

Surface treatment method of die-cast aluminum alloy exterior part and die-cast aluminum alloy exterior part product

InactiveCN105839059AImprove the authenticity rateAvoid brittleAnodisationVacuum evaporation coatingAnodic oxidationDyeing

The invention provides a surface treatment method for a die-casting aluminum alloy exterior part and a die-casting aluminum alloy exterior part product. The surface treatment method comprises: using aluminum as an anode, using the die-casting aluminum alloy exterior part as a cathode, and performing the die-casting aluminum alloy exterior part on the die-casting aluminum alloy exterior part. Ion plating treatment is performed to form an aluminum coating layer on the surface of the die-casting aluminum alloy exterior parts; anodizing treatment is performed on the die-casting aluminum alloy exterior parts after the ion plating treatment to form an oxide film layer on the surface of the die-casting aluminum alloy exterior parts. In the surface treatment method for die-casting aluminum alloy exterior parts provided by the present invention, an aluminum coating layer is formed on the surface of the exterior parts before anodizing treatment. The anodic oxidation effect and the subsequent dyeing effect are guaranteed, and the process is simple, the cost is low, and the authenticity rate of the appearance parts is high.

Owner:DONGGUAN COOLPAD SOFTWARE TECH

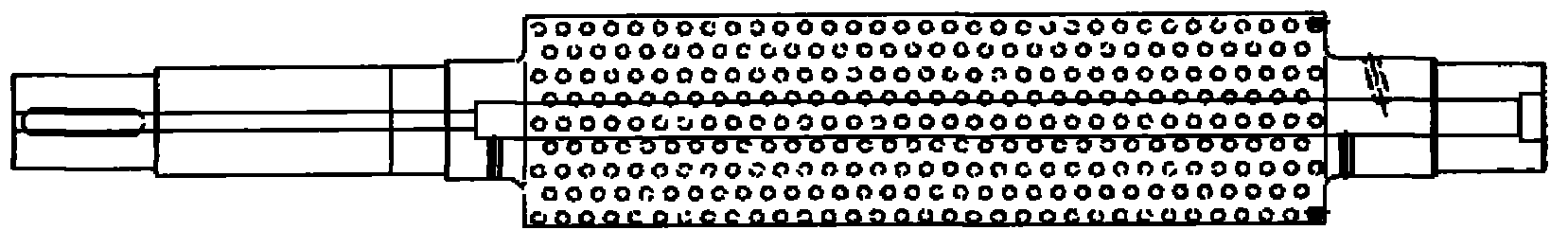

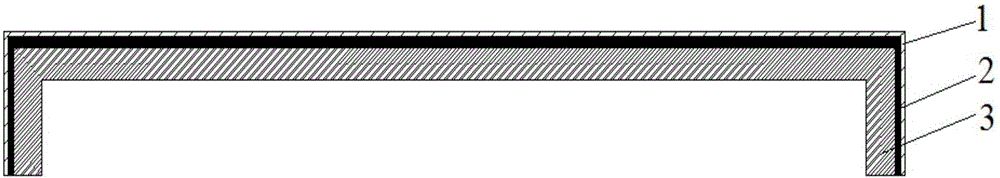

Casting method for copper bush with high lead bronze content

InactiveCN103742536AImprove quality requirementsImprove the authenticity rateFoundry mouldsBearing componentsCasting moldBronze

The invention relates to a casting method for a copper bush with high lead bronze content. The casting method is characterized in that a metal mould taking a parting surface of a casting and a pouring gate system as a half folding structure is used as an external casting mould; a metal mould core with a multi-piece parting structure is used as an internal casting mould; the copper bush with high lead bronze content comprises the following chemical components in percentage by weight: 18-23% of Pb, 4-6% of Sn and the balance of Cu; a water cooling device arranged at the periphery of the casting mould is used as a cooling means of the casting; and the casting method comprises the concrete casting steps: copper alloy smelting; deoxidation treatment; casting mould preheating; casting pouring; casting cooling; and casting head removal to obtain the copper bush with high lead bronze content. The casting method has the advantages of reasonable process, low production cost and the like and the quality of the produced copper bush is high.

Owner:JIANGSU RECODE RAIL TRANSIT TECH CO LTD

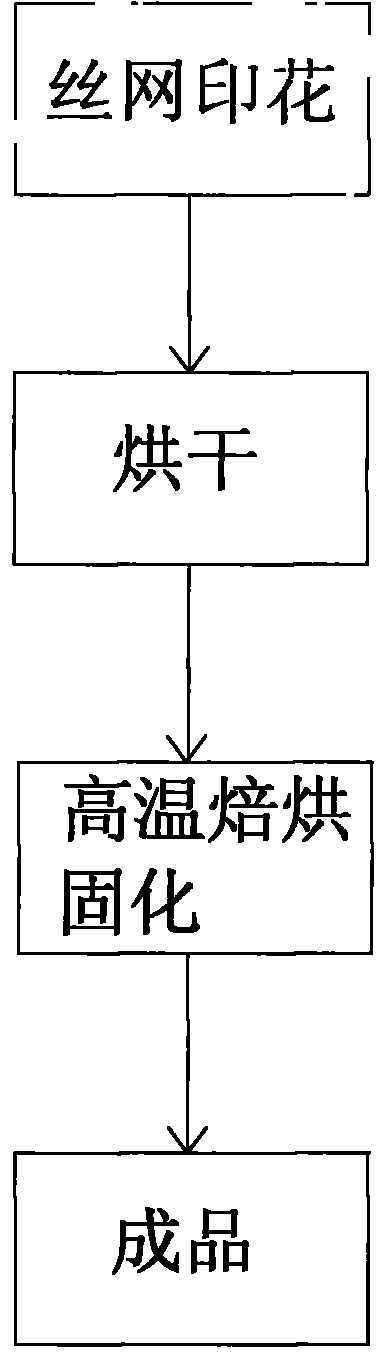

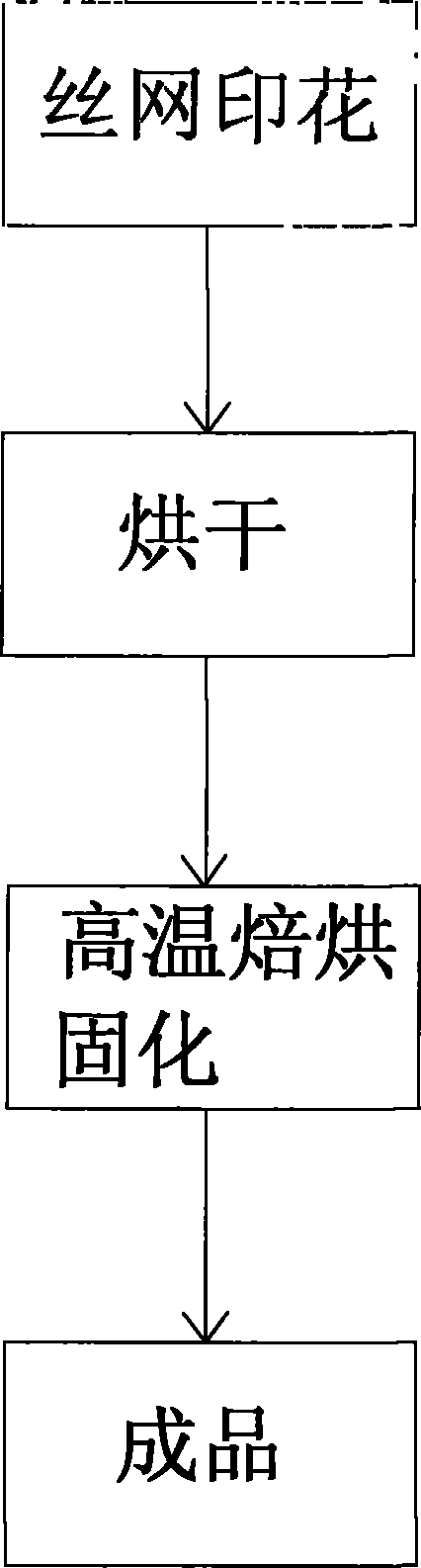

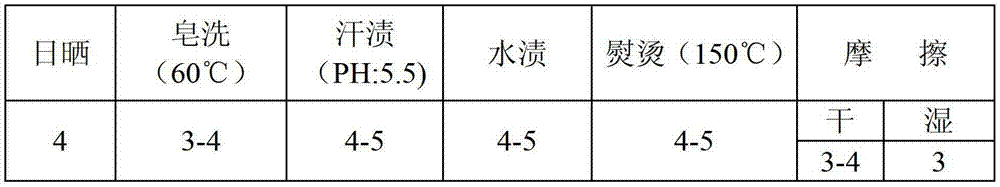

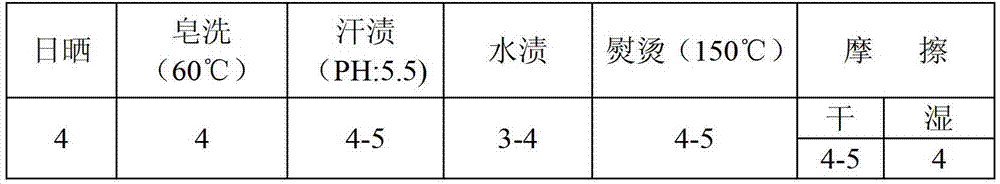

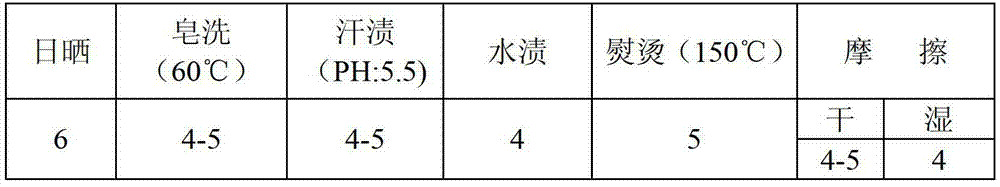

Digital spray printing steam-cleaning-free process of disperse dye

ActiveCN102965988AImprove the authenticity rateExcellent color yieldDyeing processDisperse dyeTextile printer

The invention discloses a digital spray printing steam-cleaning-free process of disperse dyes. The process comprises the following steps of: preparing slurry; sizing a fabric; carrying out digital direct injection; and pressing at high temperature to obtain a finished product. By the digital spray printing steam-cleaning-free process disclosed by the invention, a steam cleaning process does not need to be carried out in the direct spray printing of the disperse dyes, the process that the transfer printing of the disperse dyes can be transferred to cloth only by virtue of paper serving as a medium can be changed, a large quantity of paper sheets can be saved; therefore, the process has a direct practical significance for the protection of forest trees.

Owner:绍兴柯桥滨海飞翔化工有限公司

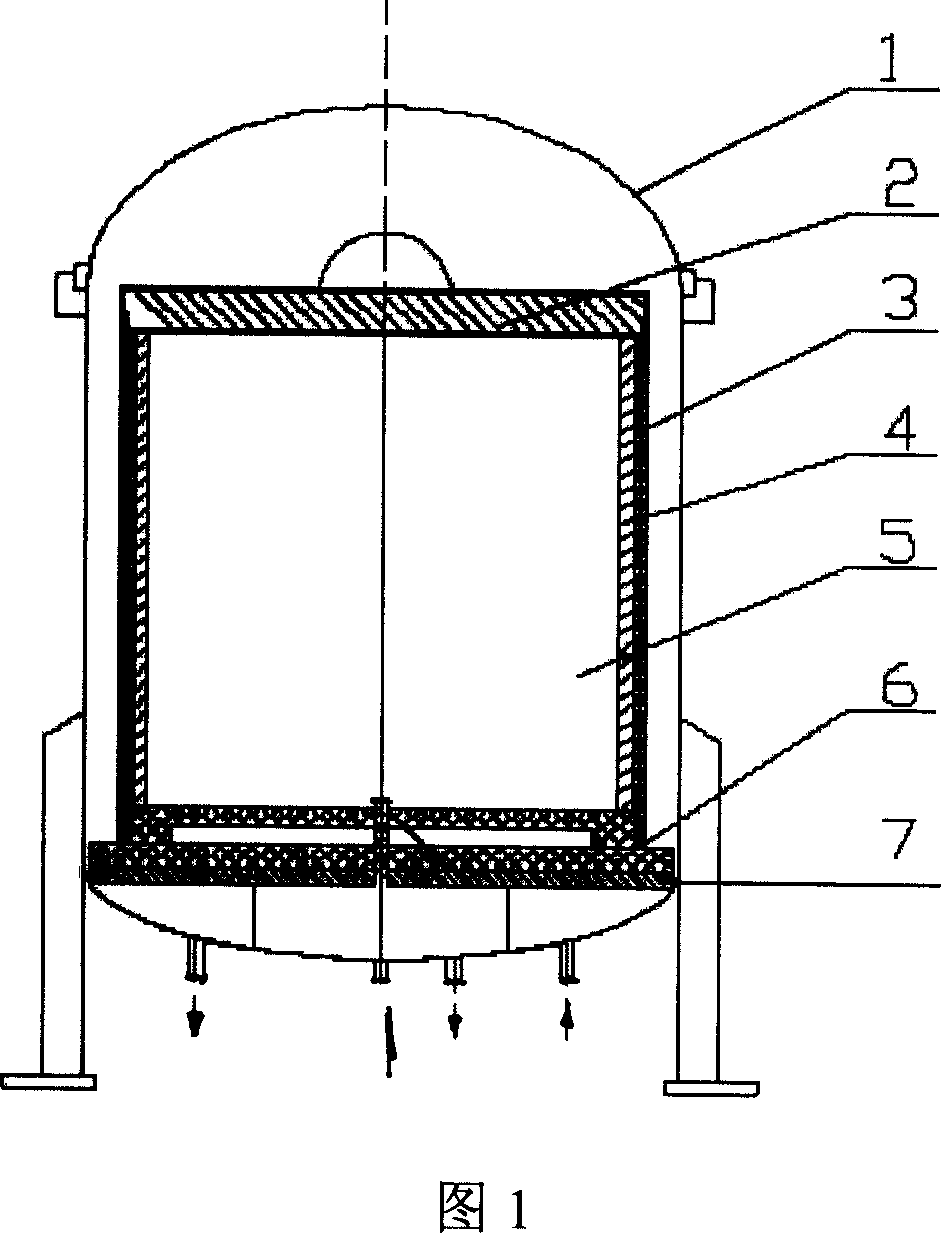

Pearl powder printing paste composition, preparing method thereof and application thereof

The present invention discloses pearl powder printing paste composition, a preparing method thereof, and application thereof. The pearl powder printing paste composition comprises the following components by percentage composition: 60.00 to 30.00 % of acrylic bond or vinyl acetate latex, 0.10 to 0.20 % of softening agent, 16.30 to 29.00 % of deionized water, 0.10 to 0.30 % of osmotic agent, 3.5 to 5.5 % of thickening agent, and 20.00 to 35.00 % of pearl powder. The pearl powder printing paste is suitable for all the existing coating and dye printing art in China. Equipment art conditions do not need to be adjusted. The acrylic bond is environmental bond, which confirms to the needs of environmental protection.

Owner:SUZHOU UNIV

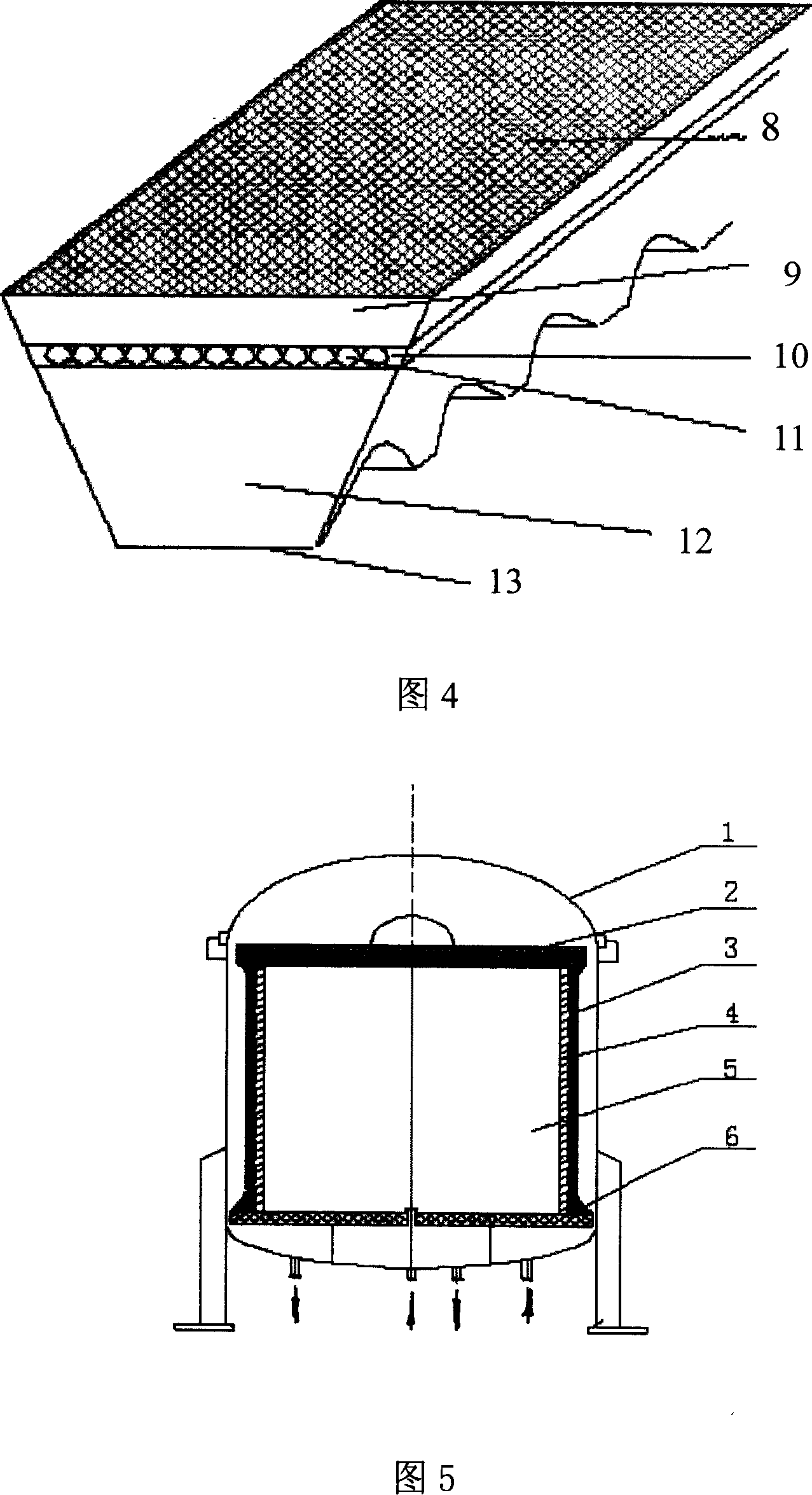

Reverse-forming sulfuration method for sealed type tooth-shaped edge V tape of rubber lagging

It relates to the glue sleeve seal teeth shape reversed V shape forming sulfuration. It makes belt blank at the inner mold, installs the round cylinder glue sleeve with teeth on the surface inside and smooth surface inside both ends on the glue sleeve base and fastened with shrouding rings, putting them into sulfur can, hanging belt blank into glue sleeve, covering the top cap and the cap of the sulfur can, sequentially opening the outside pressure and inner pressure steam for sulfuration, stripping the belt blank round cylinder with vertical rack outside and the cutting belt blank round cylinder, getting many teeth shape cutting V belt. It solves the sealing issue at both ends of the glue sleeve, eliminating the bubbling stratification defect of the product, increasing effective cutting 2-4 lines, reducing material consumption and cost.

Owner:ZHEJIANG ZIJINGANG RUBBER BELT

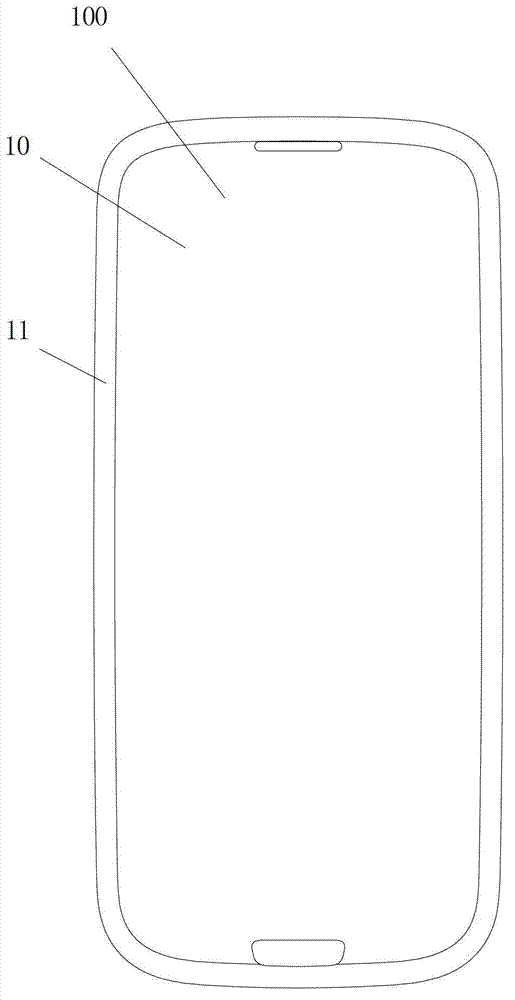

Electronic product screen protection glass film and manufacturing method thereof

InactiveCN102896839AAntifoulingAnti-fingerprintGlass/slag layered productsGlass reforming apparatusDisplay deviceEngineering

The invention discloses an electronic product screen protection glass film and a manufacturing method thereof. The glass film comprises a glass film planar part which is matched with a planar part of an electronic product screen, and a glass film curved surface part which extends out of the glass film planar part and is matched with a curved surface part of the electronic product screen. The manufacturing method comprises the following steps of: blanking, coating a glass demolding agent onto a mold, loading a blanked material onto the mold, heating the blanked material and the mold and preserving heat, pressurizing and assembling the mold, taking out for standing, reinforcing, performing vapor deposition and the like. The electronic product screen protection glass film disclosed by the invention has the functions of preventing stains, preventing fingerprints, preventing collision and the like, can be up to 7-8 H Moh's hardness on the aspect of the surface hardness, and can be widely applied to screen protection of electronic equipment such as mobile phones and electronic instrument displays; and due to the adoption of the manufacturing method of the electronic product screen protection glass film, the problem of easiness in breaking of thin glass during machining is solved, the rate of graded product is high, and the production and manufacturing costs are lowered.

Owner:蒋兰波

New type bone china, and producing method

InactiveCN1872785AImproved mechanical strength and thermal stabilityReduce firing deformationAnorthiteBone ash

This invention relates to a method for manufacturing new type bone porcelain. The bone porcelain is composed of: SiO2 50-60 wt.%, Al2O3 20-30 wt.%, P2O5 1.8-3.5 wt.%, CaO 2-5 wt.%, MgO 0.2-0.5 wt.%, K2O and Na2O 3-5 wt.%. The crystal phase content is 50-70 wt. % in the porcelain body. The main crystal phase is mullite, and the minor crystal phases are beta-Ca3 (PO4)2 and anorthite. The bone porcelain is manufactured from: bone ashes 5-10 wt.%, Al powder 5-10 wt.%, kaolin 25-35 wt.%, and porcelain stone 45-60 wt.%. The bone porcelain has such advantages as good appearance, thin external wall, light weight, good light transmittance and good thermal stability. The title method has such advantages as low bon ashes addition, wide sintering range, high quality goods rate, low manufacturing cost and wide raw material resources, and is suitable for mass production.

Owner:HUNAN XIANFENG CERAMIC IND

Painting method for plastic casing

The invention refers to a paint-spraying method of plastic shell, especially for the shell of electronic equipments: mobile phone, PDA and so on, making the shell show at least two colors. The method includes: produce one shell with at least two colors by injection moulding, spray bottom paint with low covering performance on its surface, and then spray a layer of transparent surface paint. The light beam produces refraction and transmission by the layer of paint, different shells can absorb visible lights in different wave band and accordingly shows at least two new colors different from material color of the shell and the paint color.

Owner:诺基亚西门子通信系统技术(北京)有限公司

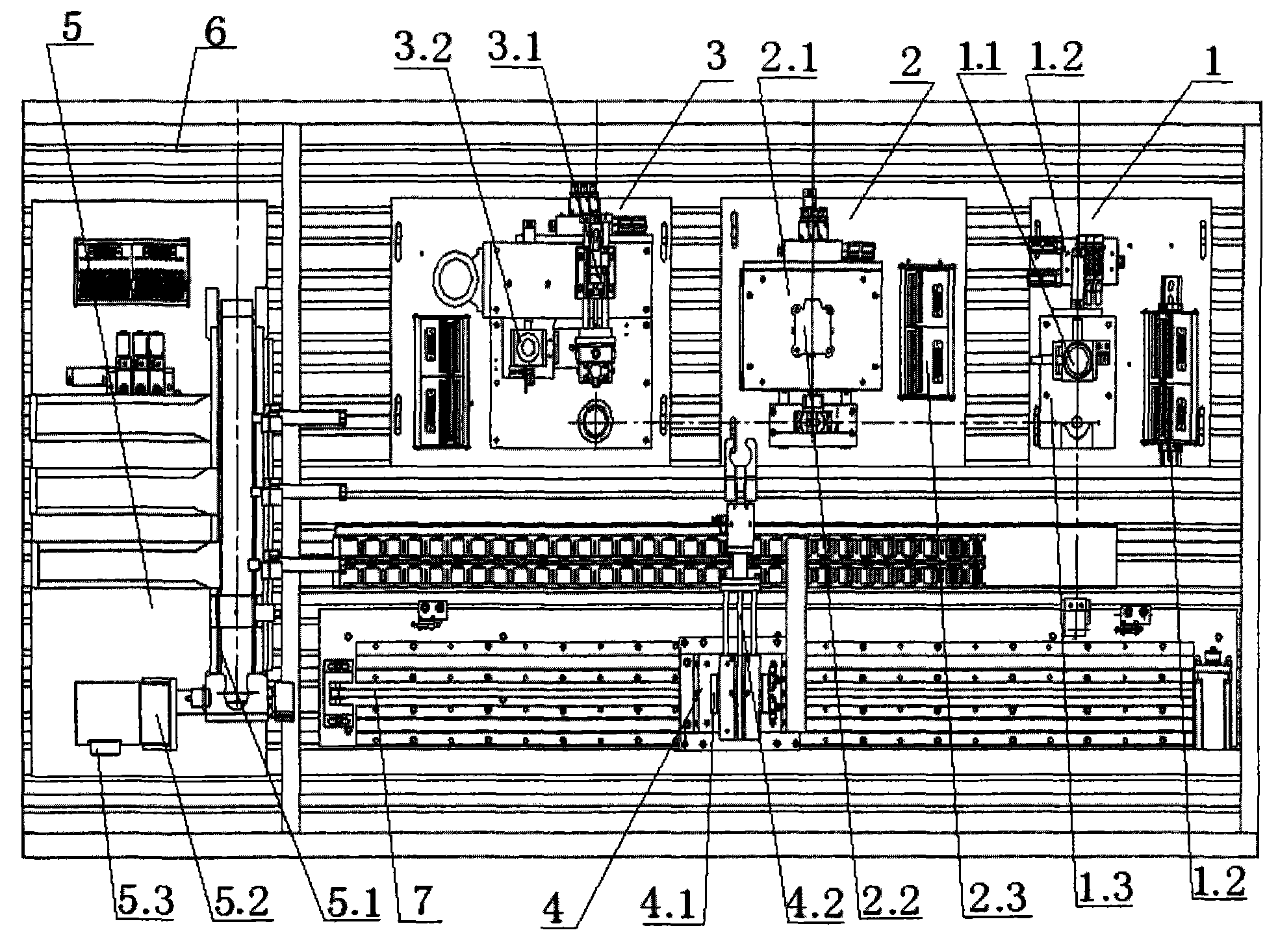

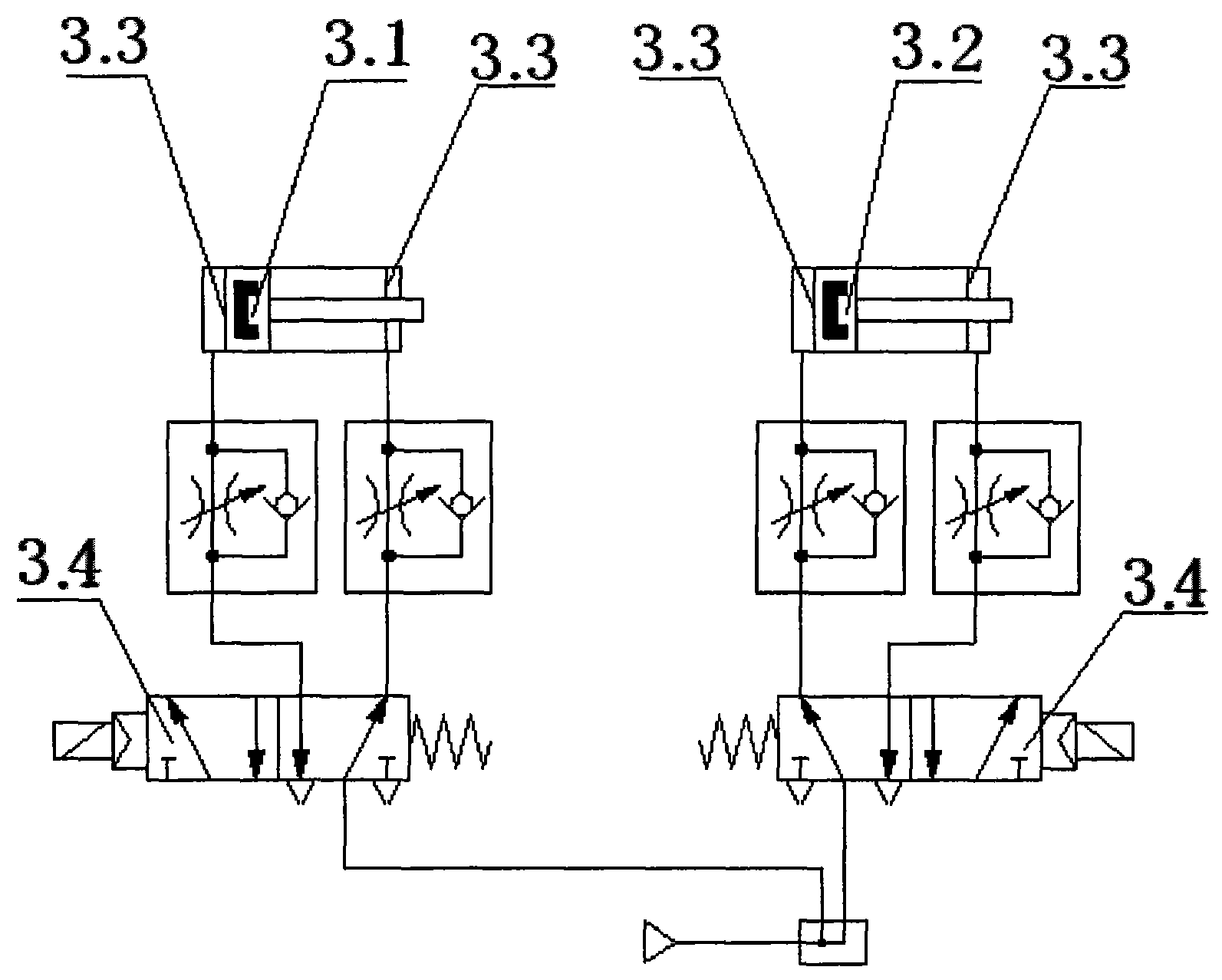

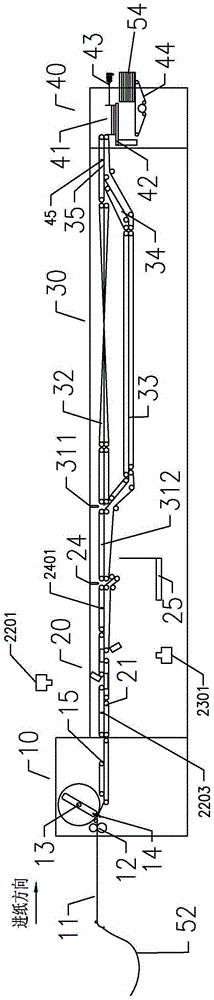

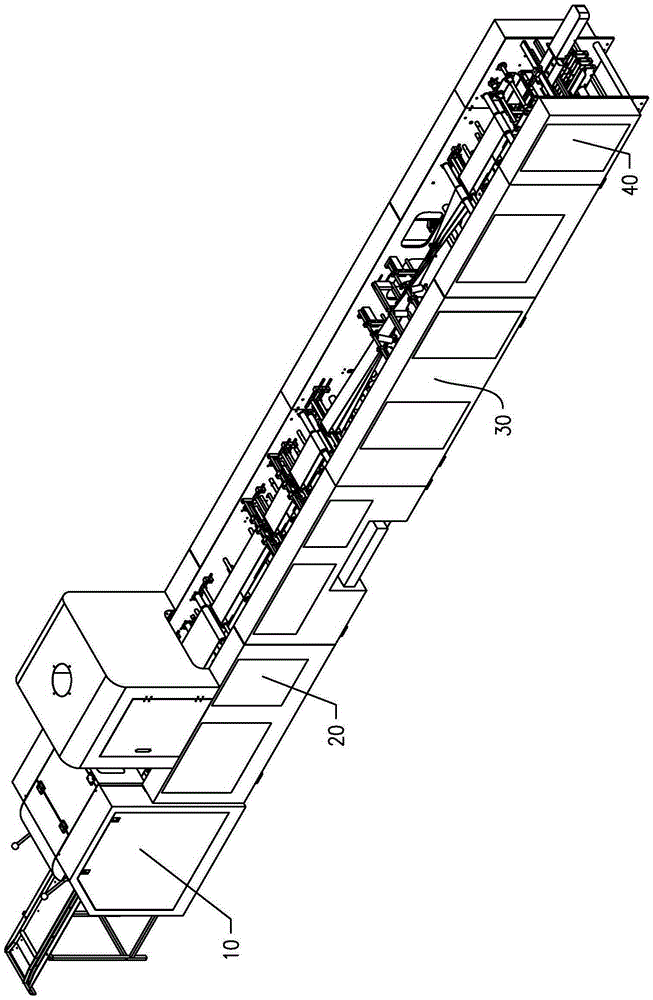

Automatic production line

InactiveCN104016129ARealize multilaterationHigh precisionConveyor partsProduction lineAutomatic control

The invention relates to the technical field of automation of production lines of small electronic products, in particular to an integrated automatic production line integrating feeding, machining, assembling, conveying and sorting. The automatic production line comprises a feeding unit, a machining unit, an assembling unit, a conveying unit and a sorting unit, wherein the feeding unit, the machining unit, the assembling unit, the conveying unit and the sorting unit are arranged on a guide rail type aluminum alloy table board. The feeding unit, the machining unit and the assembling unit are arranged in the moving direction of materials in the production line. The conveying unit is arranged on a guide rail conveying device. The guide rail conveying device is arranged in the moving direction of the materials in the production line and located on one side of the feeding unit, one side of the machining unit and one side of the assembling unit. The sorting unit is arranged on the ends of the assembling unit and the guide rail conveying device. According to the automatic production line, the whole production process is automatically controlled, workers do not need to watch over the production line in real time, the production efficiency is improved, the automation control accuracy is high and the quality product rate of products is increased.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

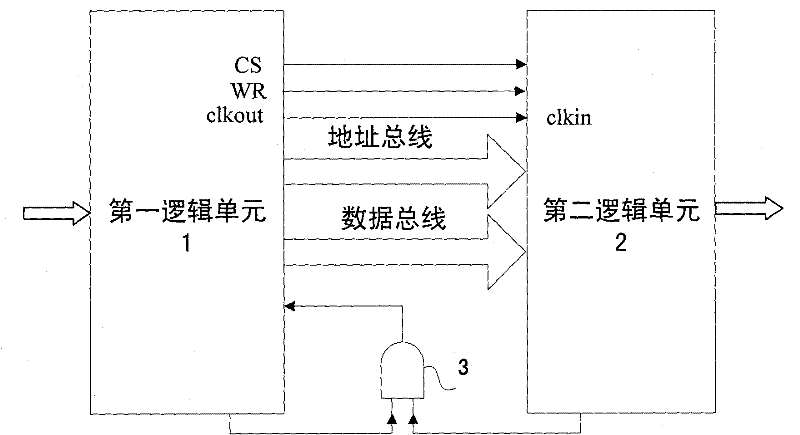

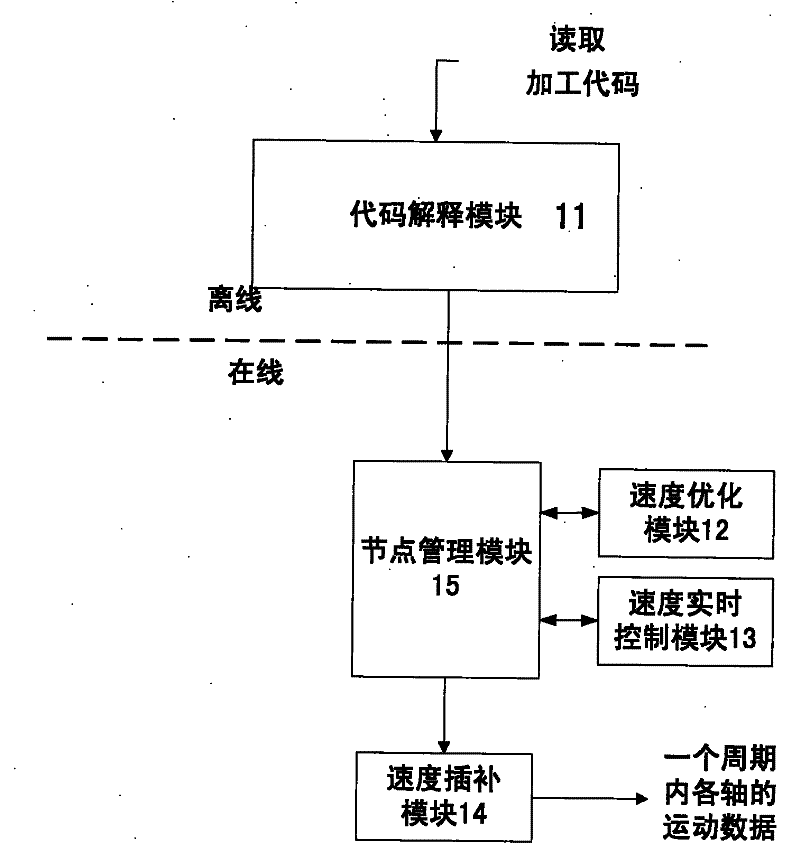

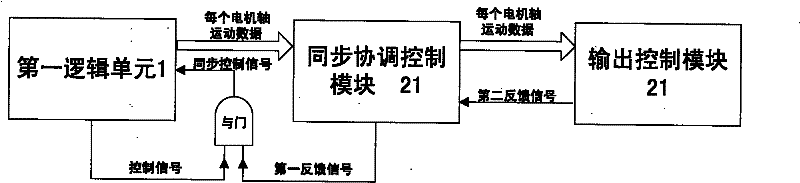

Numerical control system and control method based on dual-core architecture teamwork

InactiveCN102193530AImprove processing efficiencyFast transfer rateTotal factory controlProgramme total factory controlDual coreControl signal

The invention discloses a numerical control system and control method based on dual-core architecture teamwork, which are characterized in that a first logic unit is connected with a second logic unit, and a conjunction gate is connected between the first logic unit and the second logic unit; the first logic unit sets control signals as high-level read-in processing codes, carries out interpretation on the codes, then manages data (interpreted by created forward-looking queue read codes) by using nodes, and after carrying out speed optimization, speed real-time control and speed interpolationon the data, outputting the motion data of each motor shaft in an interpolation cycle; the second logic unit outputs first feedback signals when the motion data of each motor shaft in a cycle is required; the first feedback signals and the control signals of the first logic unit pass through the conjunction gate, then synchronous control signals are outputted; after receiving the synchronous control signals, the first logic unit transmits the motion data of each motor shaft in a cycle to the second logic unit; and after receiving the motion data and carrying out computing on the motion data, the second logic unit outputs pulse signals for controlling motors.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

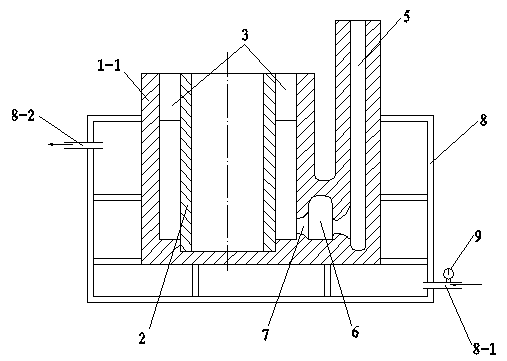

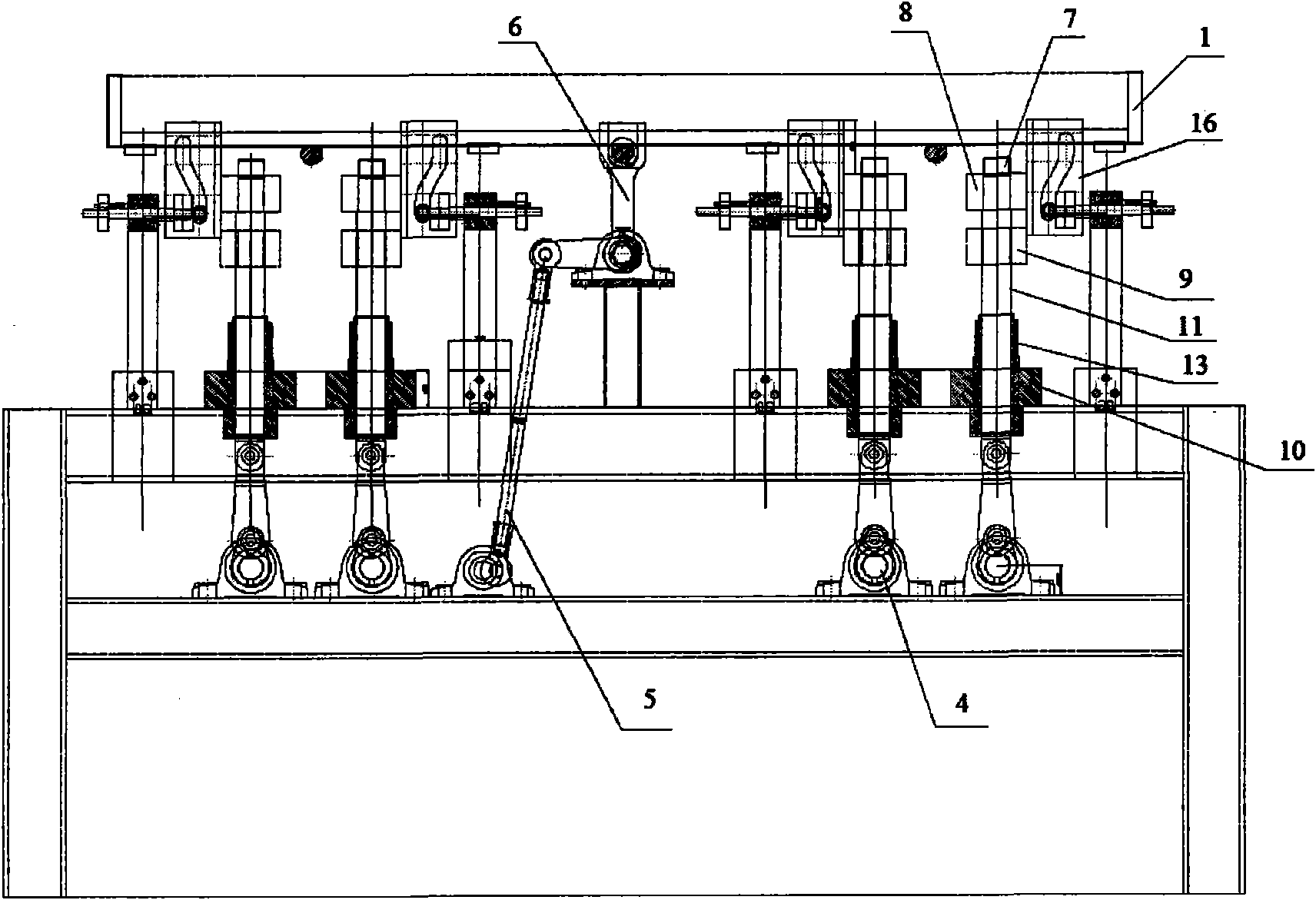

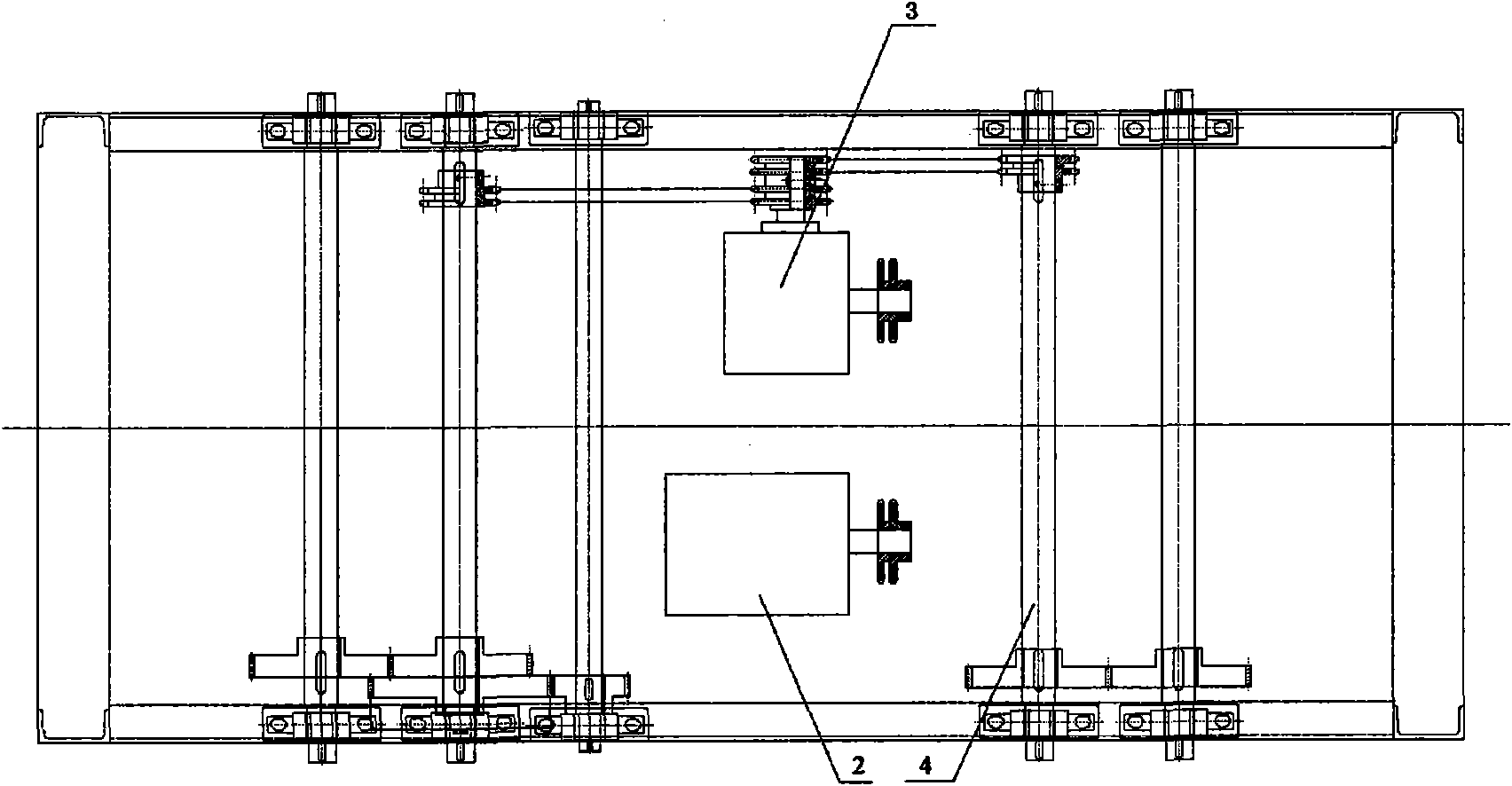

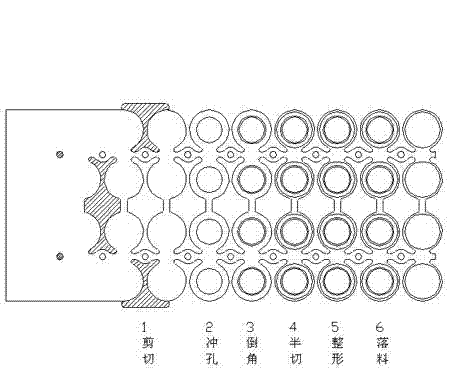

Gorgon fruit husking machine

The invention discloses a gordon fruit husking machine, which comprises a hopper (1), power units, husking mechanisms and feed mechanisms, wherein the hopper (1) is arranged on the top of a rack by a lifting lug; the baseplate of the hopper (1) is provided with seed dropping holes; the power units, the husking mechanisms and the feed mechanisms are arranged on the rack packed by a case; each power unit is provided with a plurality of husking mechanisms and feed mechanisms with one husking mechanism corresponding to one feed mechanism to form the integral husking machine. Gordon fruits are delivered into the husking mechanisms from the feed mechanisms, and the fruits and the husks of the gordon fruits are separated by the husking mechanisms under the action of the power units. The invention has the advantages of reasonable structure, conveneint operation, mechanized operation, high operation efficiency and full fruit pulp.

Owner:JIANGSU JWC MACHINERY

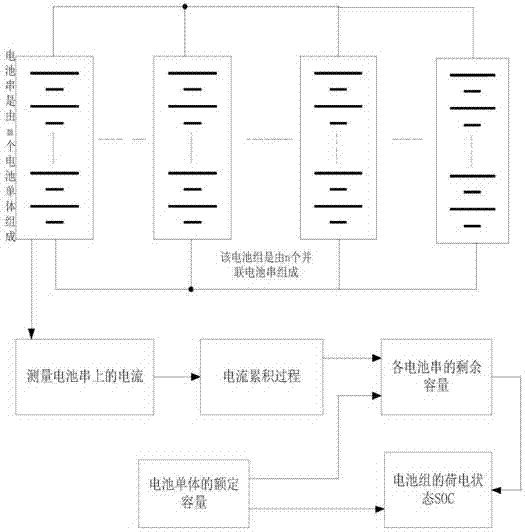

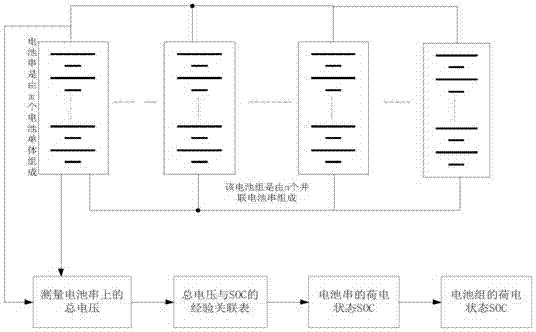

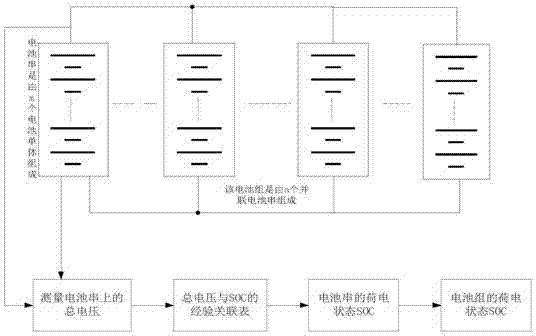

Method for measuring state-of-charge of large-capacity battery pack

InactiveCN107271903AEasy to useImprove safety performanceElectrical testingElectricityState of charge

The invention discloses a method for measuring the state-of-charge (SOC) of a large-capacity battery pack in order to solve the problem of inaccuracy in measuring the SOC of a large-capacity battery pack in the prior art. First, the maximum available capacity of each battery cell in a battery string is determined; then the maximum chargeable capacity of each battery cell in the battery string is calculated; then the smallest maximum chargeable capacity and the minimum remaining capacity are found; the maximum available capacity of the battery string is then calculated, and the SOC of the battery string is solved; then the SOC of the large-capacity battery pack composed of a plurality of parallel battery strings can be obtained. The method can accurately obtain the SOC of the battery string, ensures the safe use of the large-capacity battery pack, prolongs the service life of the battery pack, reduces the matching requirement when the large-capacity battery pack is assembled, and has strong practicability.

Owner:HARBIN ENG UNIV

Preprocessing size for textile printing as well as preparation method and applications thereof

The invention discloses a preprocessing size for textile printing. The preprocessing size comprises the following compositions in percentage by weight: 5-50% of a hot melting material, 0.5-15% of a printing gum, 0.5-6% of an acid-releasing agent or an alkali-releasing agent, 0-20% of a water-absorbent, and the balance of water. The invention also discloses a preparation method and applications of the preprocessing size for textile printing. According to the invention, a conventional wet transfer film or wet transfer paper is used for hot-melting transfer printing, so that the hot-melting transfer printing is implemented without specially coating a hot-melting carrier, and hot-melting printing ink does not need to be specially configured, thereby greatly reducing the cost of hot-melting transfer printing. The preprocessing size for textile printing and the preparation method and applications of the preprocessing size disclosed by the invention are applied to the hot-melting transfer printing of textiles, the process is simple, the quality is easily controlled, and the graded product rate of hot-melting transfer printing is greatly improved; and according to the invention, the hot-melting transfer printing is implemented without using an expensive coating machine and just through using common wet transfer equipment, thereby facilitating the popularization of an environmental-friendly process of hot-melting transfer printing.

Owner:张家港市普坤羊绒制品有限公司

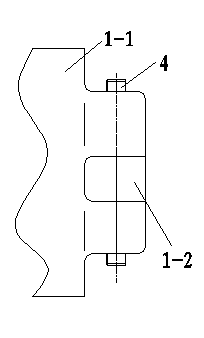

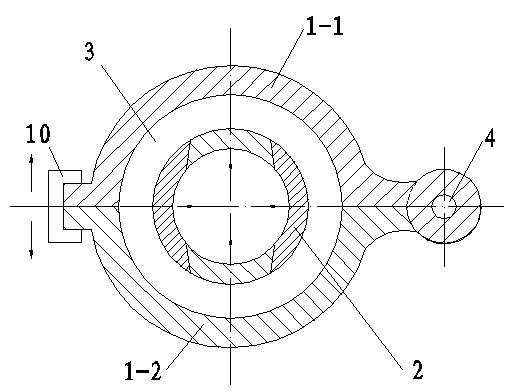

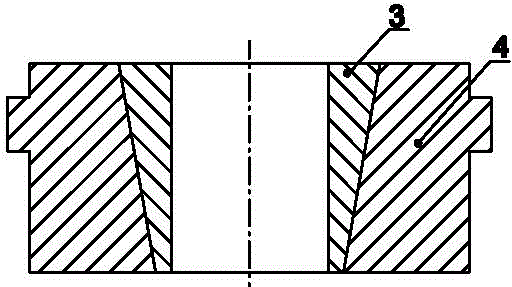

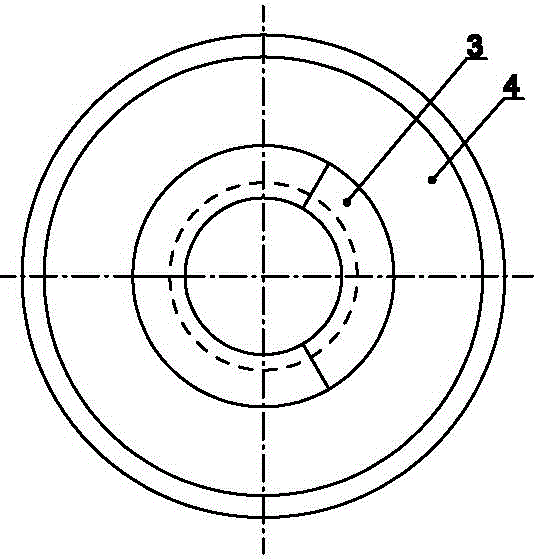

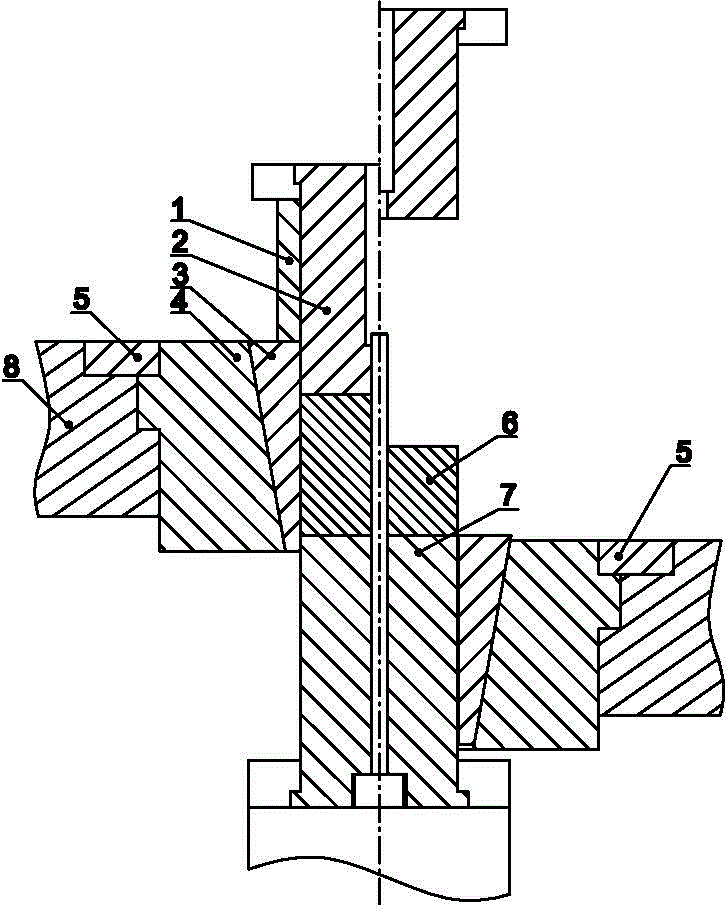

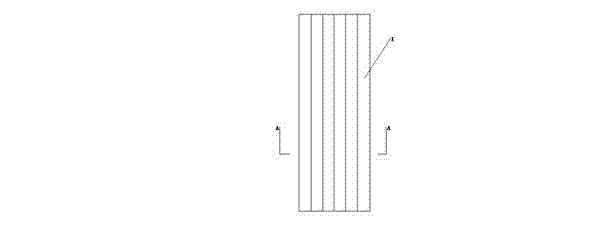

Compression forming mold for sintered metal product, application thereof and forming mold release method

The invention discloses a compression forming mold for a sintered metal product, application of the compression forming mold for the sintered metal product, and a forming mold release method. The compression forming mold for the sintered metal product comprises a female mold. The compression forming mold for the sintered metal product is characterized in that the female mold is of a split structure, and comprises a female mold covering sleeve (4) and a female mold core which is composed of at least two female mold core clacks (3), wherein the outer side face of the female mold core and the inner side face of the female mold covering sleeve (4) are in conical surface matching, and the female mold core is a big-end-up cone-shaped body in the compression direction. The forming mold release method comprises the steps of mold filling, compression forming and mold release. The compression forming mold for the sintered metal product facilitates the mold filling and the mold release, is low in pressure of the mold release, particularly applicable to the compression forming and the mold release of the sintered metal product which is poor in compressibility and formability of powder materials, long in service life, and low in manufacturing cost, reduces the requirement for a press and manufacturing cost, and reduces production cost due to the fact that consumption of forming agents and consumption of lubricating agents are greatly reduced. Meanwhile, the surface of the sintered metal product is complete, the rate of quality products is greatly improved, and the forming problem of the sintered metal product which is poor in compression formability and complex in shape is solved.

Owner:YIYANG XINJIYUAN POWDER METALLURGY

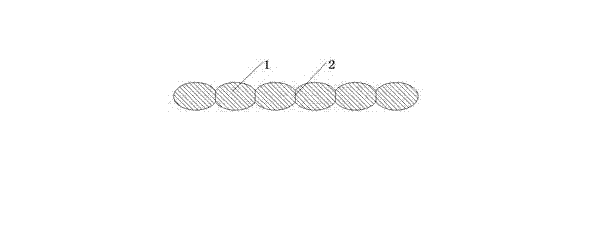

Novel noodles

The invention discloses novel noodles. The noodles comprise more than two noodles connected side by side, all the noodles are connected into a row, and the width of the connection face of every two adjacent noodles is smaller than the thickness of each noodle, so that the mutually connected noodles can be manually separated from each other in the cooking process. By adopting the structure, the noodles have low probability of breakage, so that both the graded product rate and the production efficiency are improved, the production cost is lowered, and wastes caused when the noodle is packaged, transported and selected by customers are reduced; the noodles are easy to cook thoroughly and be tasty, and people can cook patches or noodles according to different food requirements; as more than two noodles are connected into a row side by side, the cross section can be elliptic, round or rhombic or in other novel shapes, so that the purchase desire and the appetite of people can be easily aroused; and more choices are provided by the masses to purchase noodles, the life of the masses is enriched and the life quality is improved; and the novel noodles provided by the invention have a broad market prospect and can be successful commercially.

Owner:CHENZHOU CHENGSHI FOOD

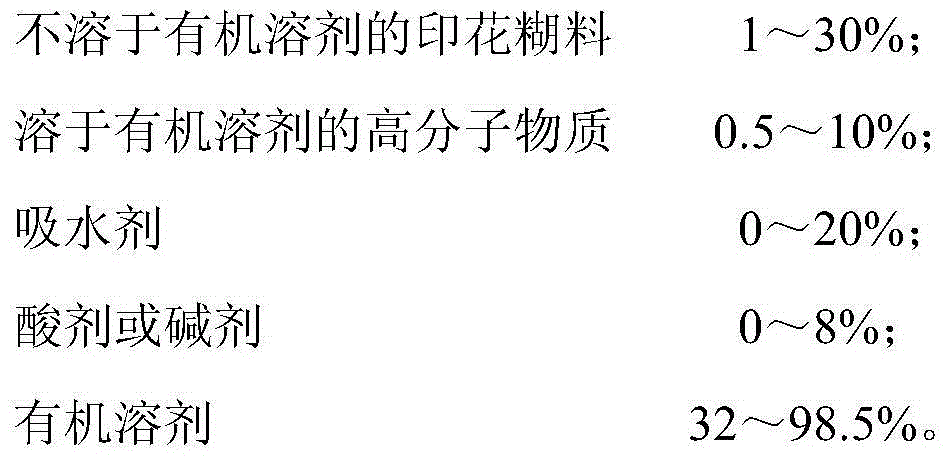

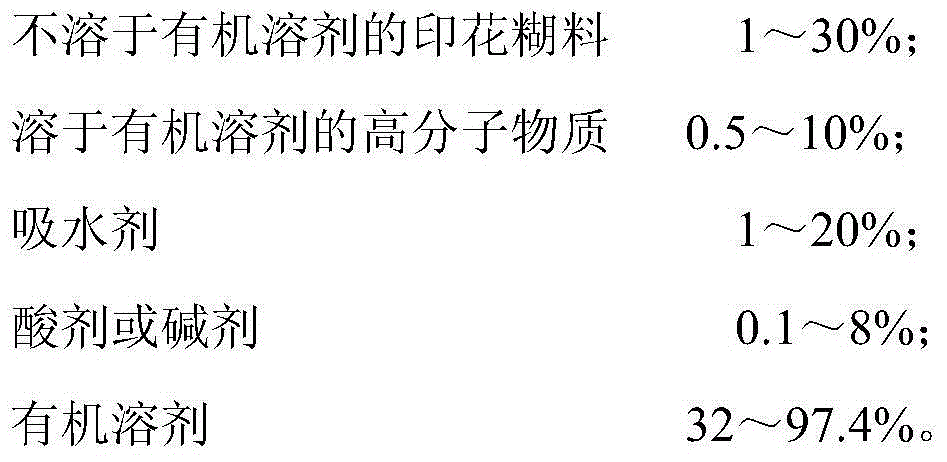

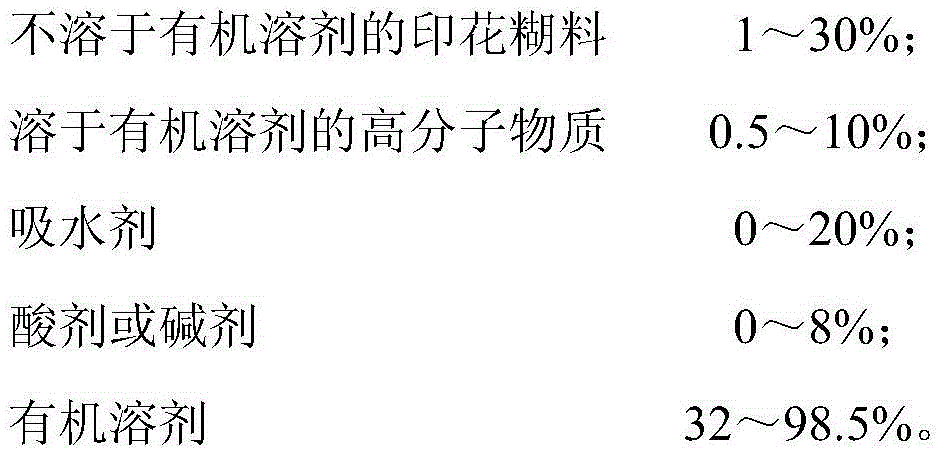

Printing pre-treatment thickener and preparation method thereof

The invention discloses a printing pre-treatment thickener. The pre-treatment thickener comprises the following components in percentage by weight: 1%-30% of printing past which is not dissolved into an organic solvent, 0.5%-10% of macromolecular substances which are dissolved into the organic solvent, 1%-20% of a water absorbent, 0.1%-8% of an acidic agent and 32%-97.4% of the organic solvent. The invention further discloses a preparation method of the thickener. According to the thickener and the method disclosed by the invention, the disadvantages in the prior art that the sizing amount of hydrophilic fiber textiles is great and the discharging amount of wastewater in an later water washing process is not enough are overcome; and furthermore, the disadvantages that hydrophobic textiles can be only printed with shallow colors but not medium and deep colors in a direct injection printing process are overcome.

Owner:苏州汇万色纺织有限公司

Single abrasive paper cutting and inspecting machine

ActiveCN105252585ALabor savingIncrease productivityOptically investigating flaws/contaminationSortingProduction lineBand shape

The invention discloses a single abrasive paper cutting and inspecting machine which comprises a cutting mechanism, a detecting and waste-discharging mechanism, a turnover and conveying mechanism, and a counting and stacking mechanism, wherein an output end of the cutting mechanism and an input end of the detecting and waste-discharging mechanism are correspondingly arranged; a qualified product output end of the detecting and waste-discharging mechanism and an input end of the turnover and conveying mechanism are correspondingly arranged, and an unqualified product output end of the detecting and waste-discharging mechanism and an input end of a waste-discharging conveying device are correspondingly arranged; and an output end of the turnover and conveying mechanism and an input end of the counting and stacking mechanism are correspondingly arranged. The single abrasive paper cutting and inspecting machine can be used for dividing wide belt-shaped abrasive paper belts produced by a linked abrasive paper production line into single abrasive belts with set width by virtue of a longitudinal cutter, and the single abrasive belts are counted and stacked into abrasive paper stacks after being subjected to automatic cutting, quality detecting, waste-discharging and positive-negative turnover, so that the problems in a conventional manual operation mode adopted by a current single abrasive paper production process are solved.

Owner:HEBEI TIANYUHENG TECH CO LTD

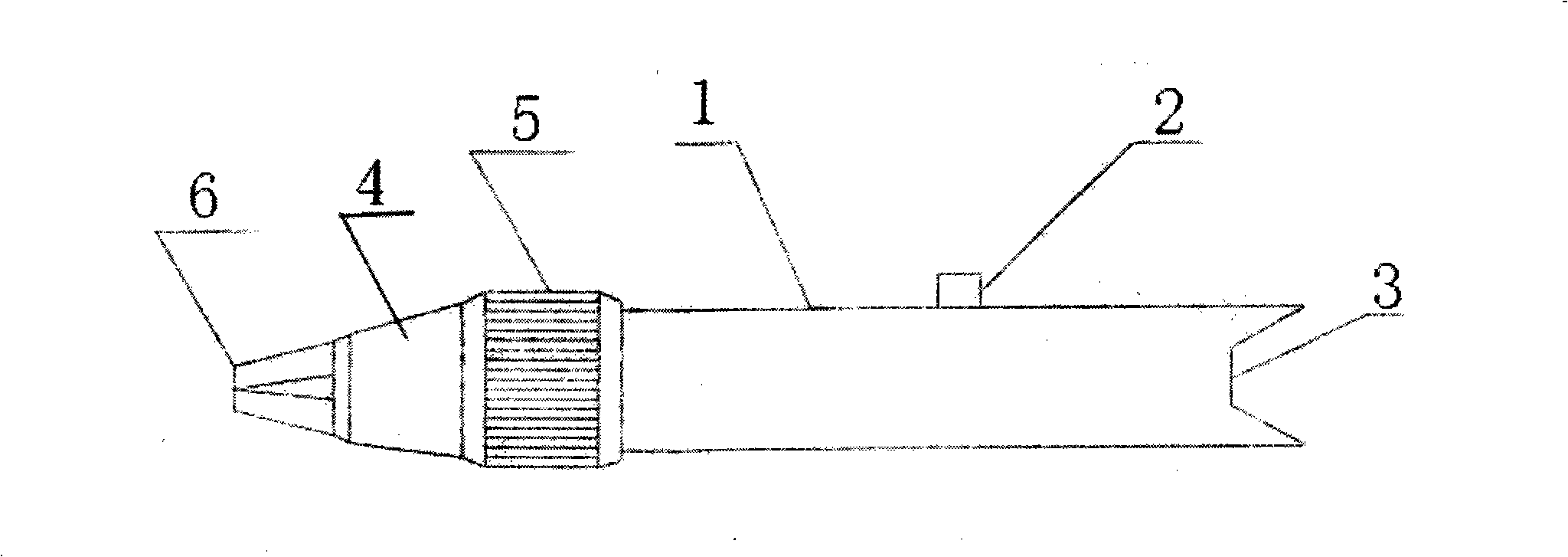

Adjustable clamping device for processing gem

The present invention discloses an adjustable clamp for processing jewels, which is a clamping tool consisting of a metal rod, a fixed pin, a tail slot, a cone collet, a fastening sleeve nut and a clamping jaw. The present invention replaces the traditional mucilage glue process that rubber is used for sticking jewel bosses for grinding so as to avoid 5 to 10 percent of the shedding stone rate when the rubber is used for sticking the jewel bosses for producing and grinding and increases the A-class goods rate of the product over 95 percent. The present invention not only saves a plurality of auxiliary materials such as rubber, shellac, alcohol, liquefied gas, and the like, but also prevents the materials from polluting the environment and harming the health of operating workers.

Owner:罗吉杰

Apocynum industrialized fiber production machining method and apocynum fiber

InactiveCN101624726AEasy to collectImprove the authenticity rateVegetable materialMechanical fibre separationPre treatmentChemistry

The invention relates to an apocynum industrialized fiber production machining method and apocynum fiber. The method orderly comprises the following steps of: separating peel core from apocynum peel-previously removing impurities-refining enzyme-water washing, fiber beating, dehydrating and fluffing-boiling and refining with ammonium salt-fiber beating and dehydrating, fluffing-oxidation bleaching-dehydrating and fluffing-oil feeding-dehydrating and fluffing-drying-refining dried flax. The refined dried fiber of the apocynum produced by the method has residual gum content being 2-5%, fiber average length being more than 30mm, fiber breaking length being more than 40 kilometers, and average fibrecount being more than 2200 counts. A cotton stalk separating machine successfully mechanically separates the peel core, to guarantee the industrialized production of the apocynum; and the enzyme-ammonium salt unite fiber production technology obviously heightens the rate of the certified products of the refined and dried flax of the apocynum and greatly improves the inner quality of the refined and dried flax, to realize the industrialization of the apocynum fiber, save energy in the process of production, and is environment-friendly.

Owner:凌受明 +2

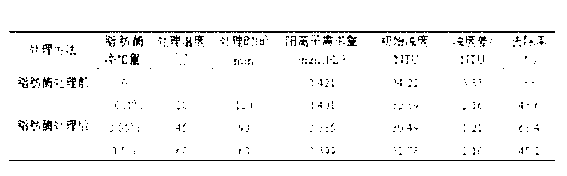

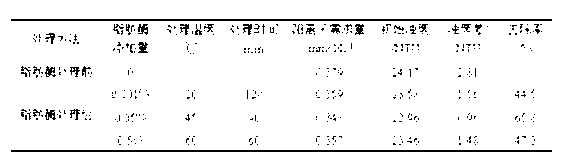

Method of controlling secondary gummy substances by using lipase

InactiveCN103061184AEliminate hazardsImprove the authenticity ratePaper recyclingWaste paper working-upPulp treatmentDe esterification

The invention discloses a method of using lipase to treat secondary gummy substances in paper pulp and white water produced in papermaking with waste paper. The lipase is alkaline lipase with a pH value of 7.5 to 9.0, enzyme activity of more than 100 U / mL, a hydrolysis rate of triglyceride of no less than 95% and transesterification and lipogenesis rates of less than 3%. A treating method for the paper pulp comprises steps consisting of adding the lipase accounting for 0.001 to 0. 5% of dry weight of the paper pulp into the paper pulp having a concentration adjusted to be 2 to 5%, carrying out treating and filtering, centrifuging and detecting the treated pulp. A treating method for the white water comprises steps consisting of adding the lipase accounting for 0.001 to 0. 5% of dry weight of the white water into the papermaking white water, carrying out treating and filtering, centrifuging and detecting the treated white water. According to the invention, the lipase is utilized to fundamentally degrade the gummy substances and mitigate deposition tendency of the gummy substances so as to remove the gummy substances, so the problem of pollution by secondary gummy substances is thoroughly overcome; and the method is simple to operate, has a substantial removal effect and enables the quality of papermaking with waste paper to be improved and production cost to be reduced.

Owner:TAIXING YIMING BIOLOGICAL PRODS

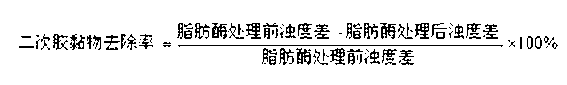

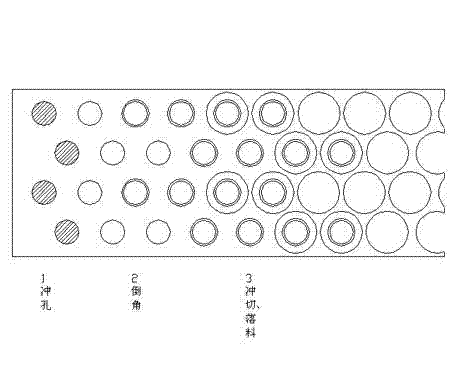

Symmetrical multi-cavity discharging technology

The invention relates to a symmetrical multi-cavity discharging technology. The working object of the discharging technology is a flat belt, and the formed products are flat annular columnar workpieces punched from the belt. A shearing step is increased before punching in the technology, namely the shape of each workpiece is previously sheared, and workpiece blanks are obtained, a gap is reserved between the two adjacent workpiece blanks in each column in the machining and advancing direction of the belt, and the belt can absorb micro expansion, so that alignment of the workpieces during machining with a mold is facilitated, the qualification rate is improved, and high section quality and flatness of the workpieces are obtained. Semi-cutting can be adopted when the outer edges of the workpieces are punched, so that the flatness of the surfaces of the workpieces is further improved; and a small quantity of connecting bands can be reserved only among the workpiece blanks during shearing, so that the expandable space of the workpiece blanks is increased, and the influence of stretching of the belt on the positions of the workpieces is further reduced.

Owner:FINEFORMING PRECSION ENG

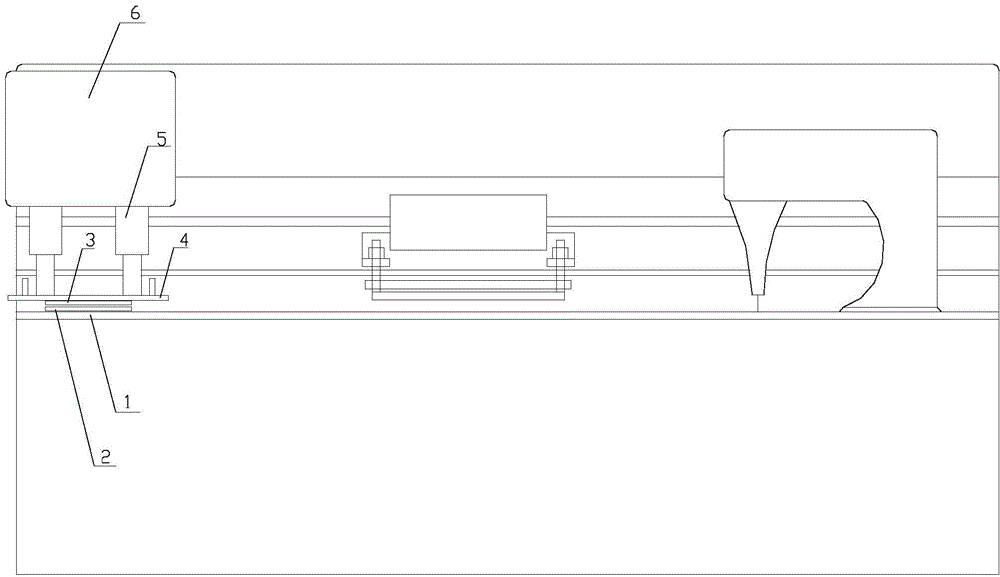

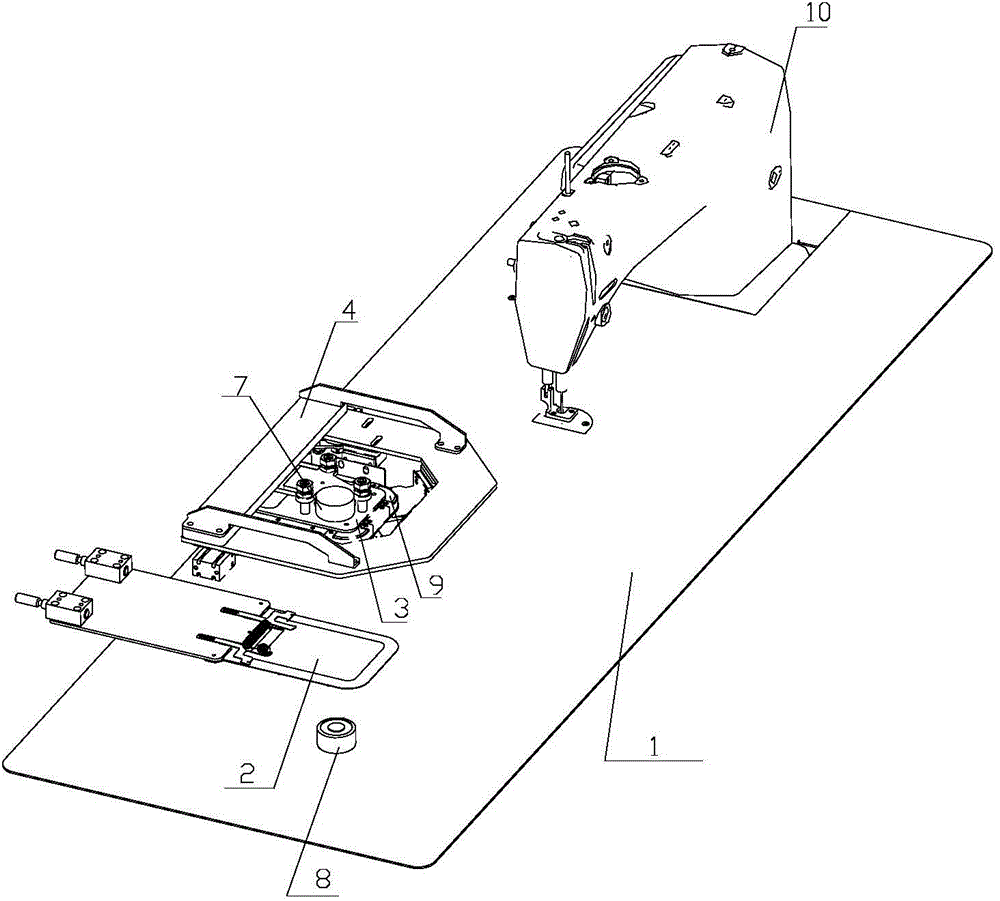

Patch pocket machine folding feeding mechanism

ActiveCN104630994APatch pocket precisionNo relative displacementWork-feeding meansFixed frameMechanical equipment

The invention relates to a patch pocket machine folding feeding mechanism and belongs to the field of sewing mechanical equipment. The patch pocket machine folding feeding mechanism comprises a working platform, a horizontal beam, a lower die plate and an upper die pocket folding device. The upper die pocket folding device is fixed at one end of the horizontal beam. A motor is fixed on the horizontal beam. A guiding column is arranged vertically. One end of the guiding column is connected with the output end of a fixing motor. The other end of the guiding column is hinged to an upper die plate fixing frame. An upper die plate is fixed in the middle of the upper die plate fixing frame. The face, opposite to the working platform, of the upper die plate is the front face. An electromagnet is arranged on the back face of the upper die plate. Pocket bending inserting plates are arranged on the three side faces of the upper die plate fixing frame. The lower die plate is arranged under an upper die piece and is fixed on one guiding track of the horizontal beam. An electromagnet is arranged at the center of a projection zone of the working platform of the lower die plate. According to the patch pocket machine folding feeding mechanism, accurate patch pocket operation can be achieved, and deforming and dislocation of pockets can be avoided.

Owner:SHANGHAI WEISHI MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com