Compression forming mold for sintered metal product, application thereof and forming mold release method

A technology of powder metallurgy and compression molding, applied in the field of powder metallurgy, which can solve the problems of complex mold structure and molding process, poor compact strength, and affecting the rate of genuine products, so as to achieve good surface quality, low demoulding pressure, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

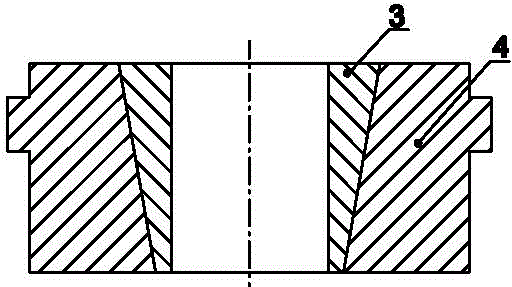

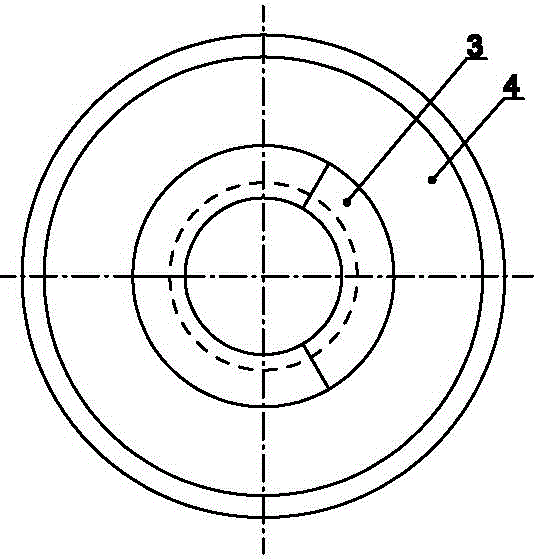

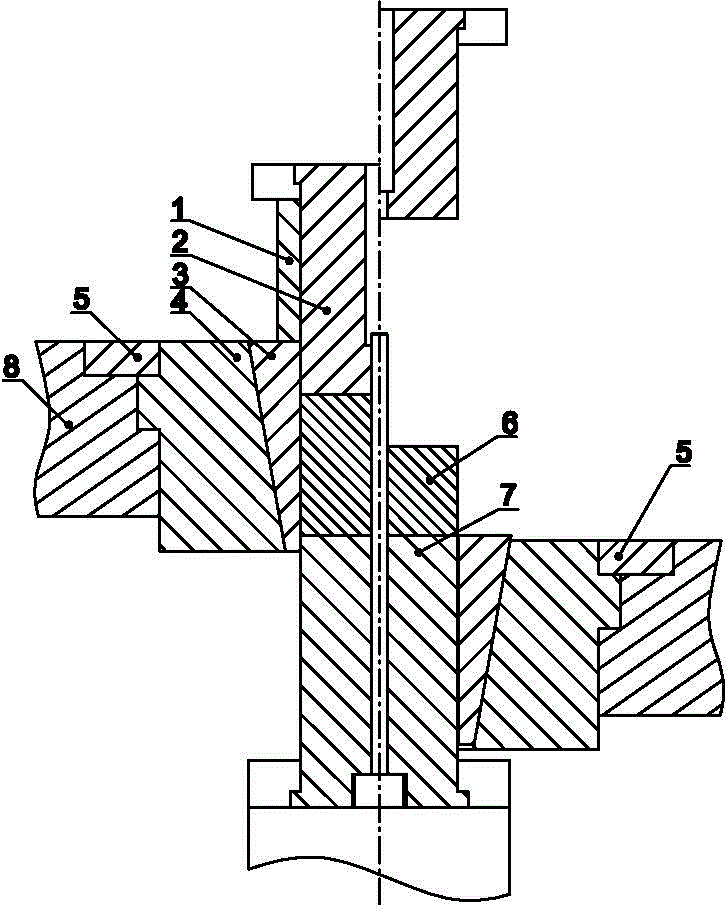

[0033] Depend on figure 1 , figure 2 It can be seen that a powder metallurgy product compression molding mold includes a female mold, and the female mold is a split structure, which includes a female mold cover 4, a female mold core composed of at least two female mold core valves 3 , the outer surface of the female mold core and the inner surface of the female mold sheath 4 are tapered, and the female mold core is a cone-shaped body with a large top and a small bottom along the pressing direction.

[0034] For the convenience of processing, the size and shape of each female mold core flap 3 of the present invention are consistent.

[0035] The cone angle of the female mold core of the present invention is 14°-30°, preferably 16°-20°.

[0036] Present embodiment female mold core valve 3 is 3, and its size, shape are consistent, and the formed female mold core is a cone frustum, and its cone angle is 20 °.

[0037] An application of the above-mentioned powder metallurgy pro...

Embodiment 2

[0049] Depend on Figure 4 It can be seen that there are two female mold core flaps 3 in this embodiment, which are consistent in size and shape. The formed female mold core is a truncated cone with a cone angle of 18°, and the processed workpiece 6 has a quincunx-shaped cross section. columnar parts. The rest are the same as embodiment 1.

Embodiment 3

[0051] Depend on Figure 5 It can be seen that there are four female mold core flaps 3 in this embodiment, which are consistent in size and shape. The formed female mold core is a truncated cone with a cone angle of 20°, and the processed workpiece 6 is square in cross section. Columnar parts. The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com