Patents

Literature

36results about How to "Excellent fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

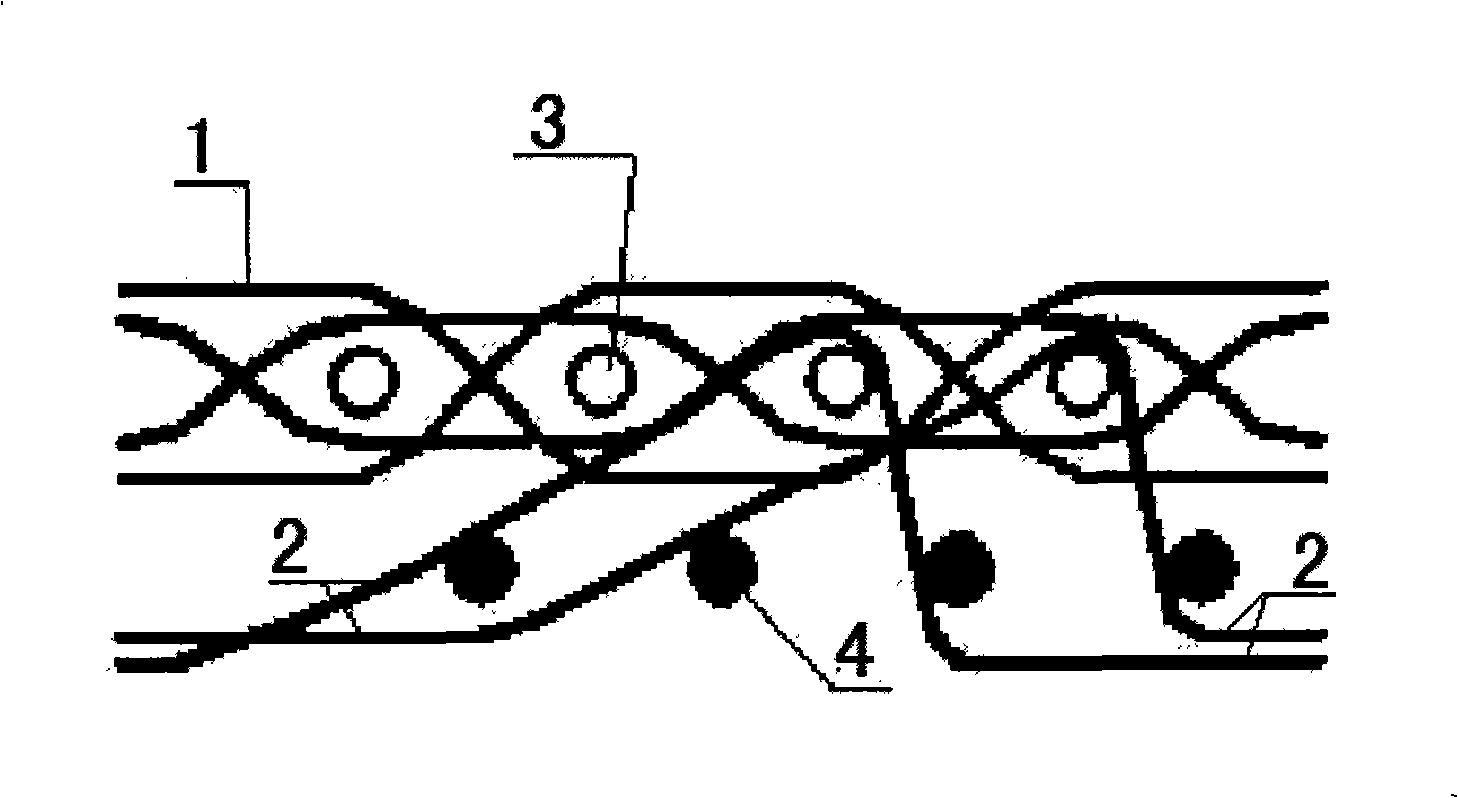

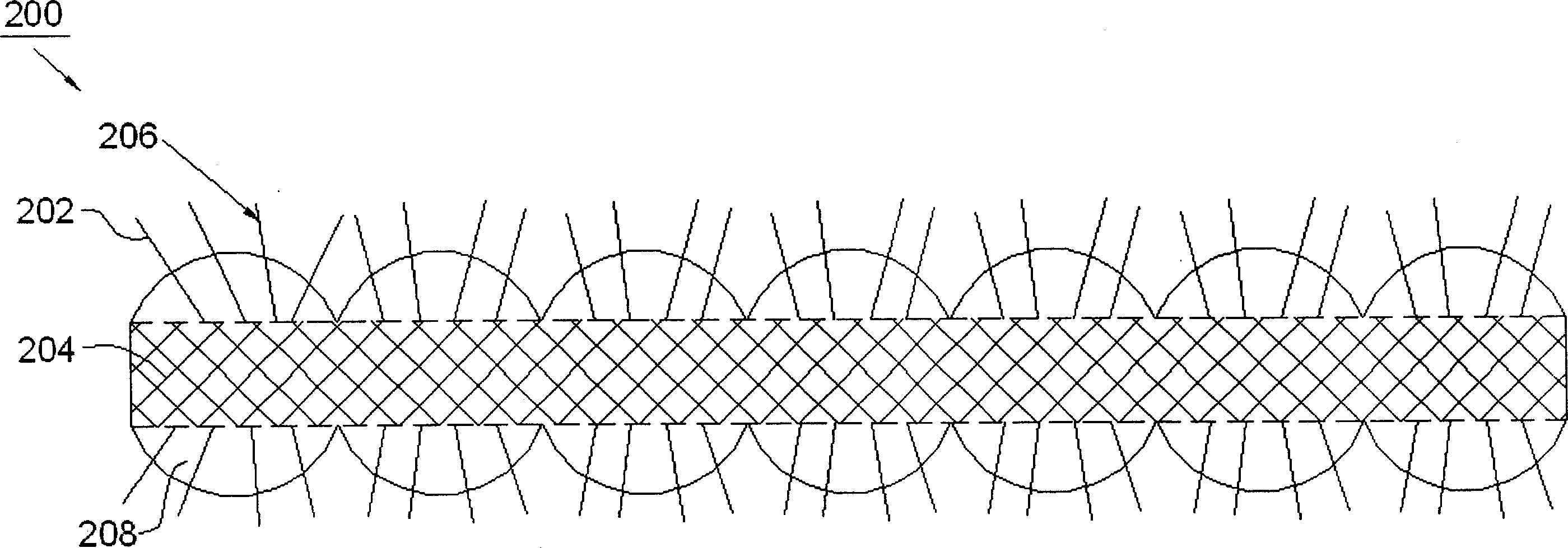

Ramie / terylene double fabric for textile wall cloth and curtain cloth and preparing method thereof

The invention relates to a ramee / terylene double woven fabric used for wall cloth and window blind fabrics, which comprises a surface layer and an inner layer, wherein, the surface layer is weaved by ramee yarns and the inner layer is weaved by terylene yarns, or the surface layer is weaved by terylene yarns and the inner layer is weaved by ramee yarns, and the surface layer and the inner layer are bond into a whole by binding joints which are not exposed on the right side and the reverse side of the fabric. The preparation method of the ramee / terylene double woven fabric adopts the ramee yarns and the terylene yarns as raw materials, and comprises a preparation procedure and a weaving procedure, and the fabric is prepared by adopting a shuttleless loom or loom with shuttles according to selected structure. When weaving by adopting the shuttleless loom, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting and winding; and when weaving by adopting the loom with shuttles, the preparation procedures of the warp comprise the steps of twist setting, winding, warping, warp sizing and warp gaiting, and the preparation procedures of the weft comprise the steps of twist setting, winding and weft winding.

Owner:北京青山绿水苎麻制品有限公司 +1

Production method of low-shrinkage rate dacron complex fiber

InactiveCN105177783AObvious drapeApparent comfortArtificial filament heat treatmentMelt spinning methodsComing outFiber

The present invention relates to the field of polyester fiber production equipment, and especially discloses a production method of low-shrinkage rate dacron complex fibers. Semidull polyester melts enter into a static mixer, are then conveyed into a spinning manifold through a melt distributor, and are extruded onto a POY spinneret and an FDY spinneret; POY fibers coming out of the POY spinneret are cooled by cross air blow and oiled by an oil nozzle, pass a yarn guide, a pre-network and another yarn guide; FDY fibers coming out of the FDY spinneret are cooled by cross air blow and oiled by an oil nozzle, pass a yarn guide, a pre-network and a GR1 hot roller; and the POY fibers coming out of the yarn guide and the FDY fibers coming out of the GR1 hot roller enter into a stranding comb-shaped yarn guide together, and then pass a yarn guide disc, an intermediate network, a GR2 hot roller and a main network, thus to be rolled for shaping. According to the production method, the obtained fibers are different in boiling water shrinkage, and thus a shell fabric is good in velvet feeling, soft in hand feeling, firm, anti-wrinkle and wear-resisting.

Owner:桐昆集团浙江恒盛化纤有限公司

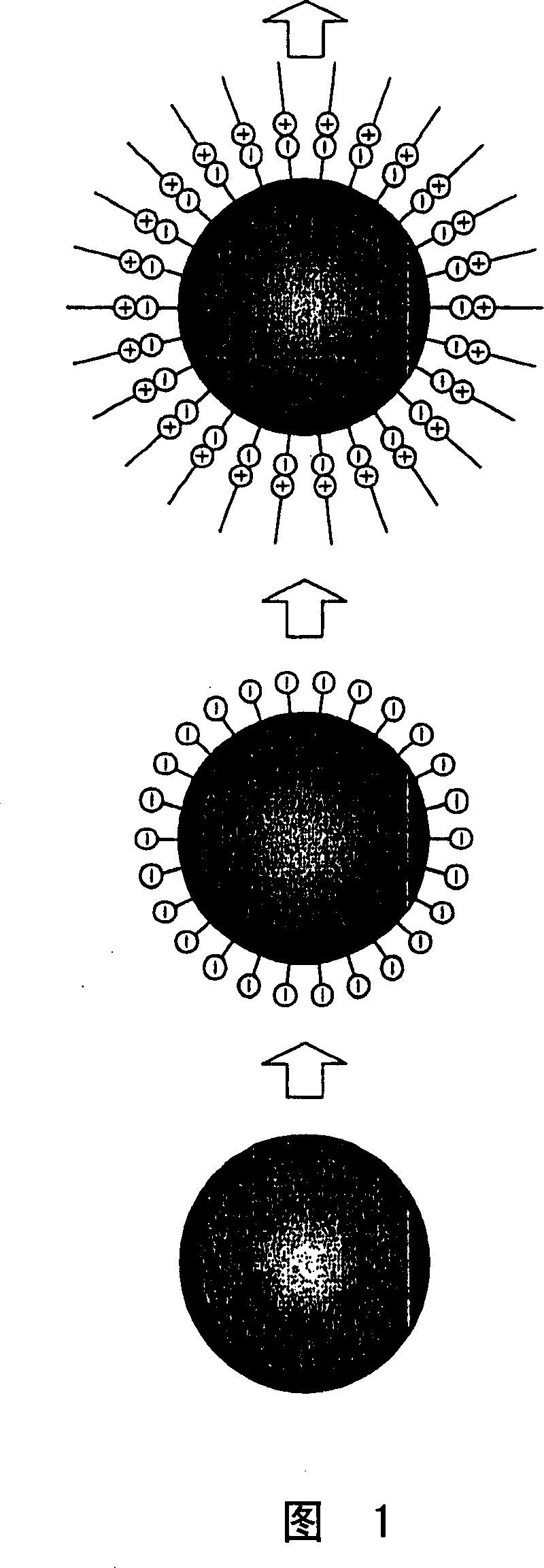

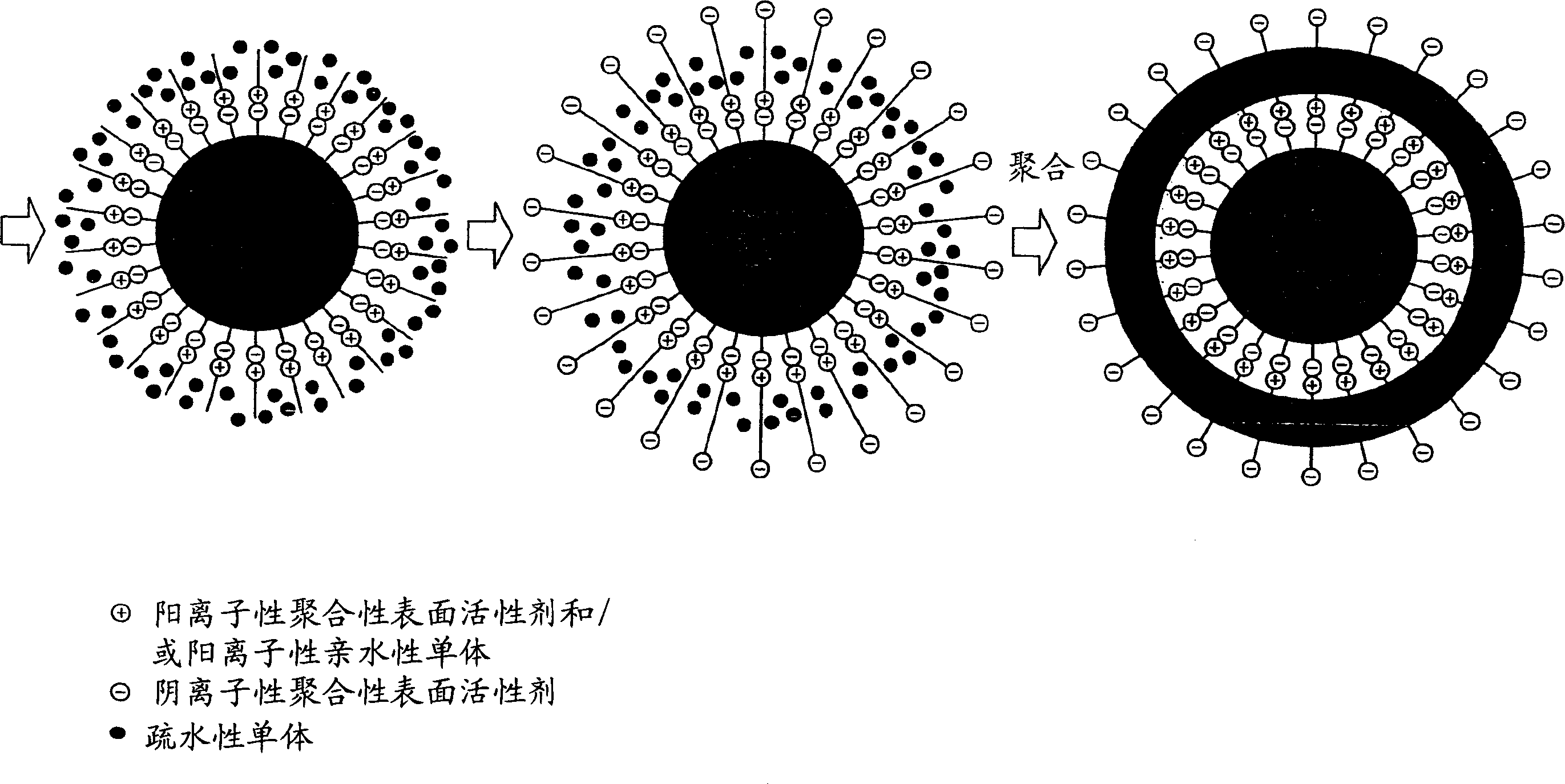

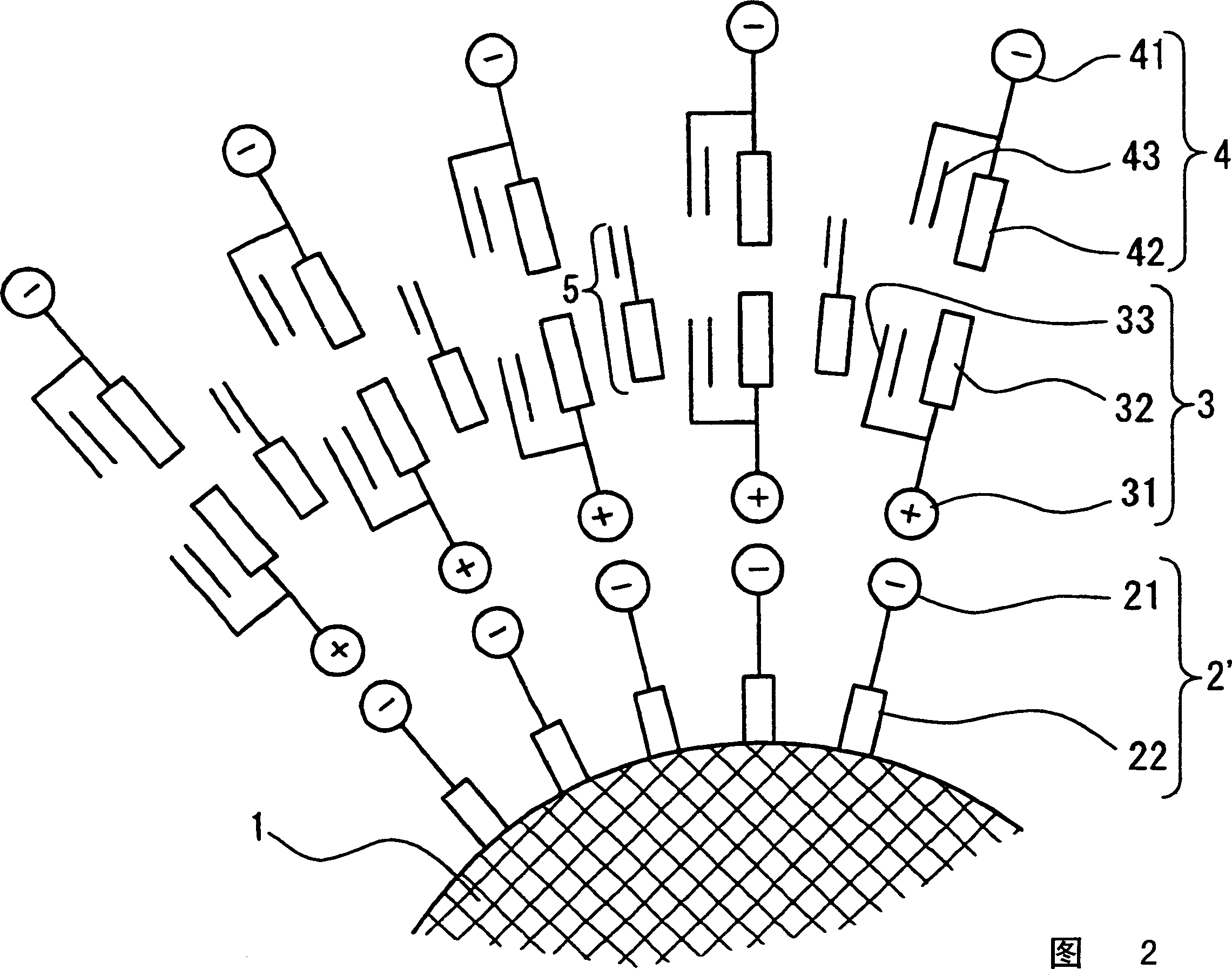

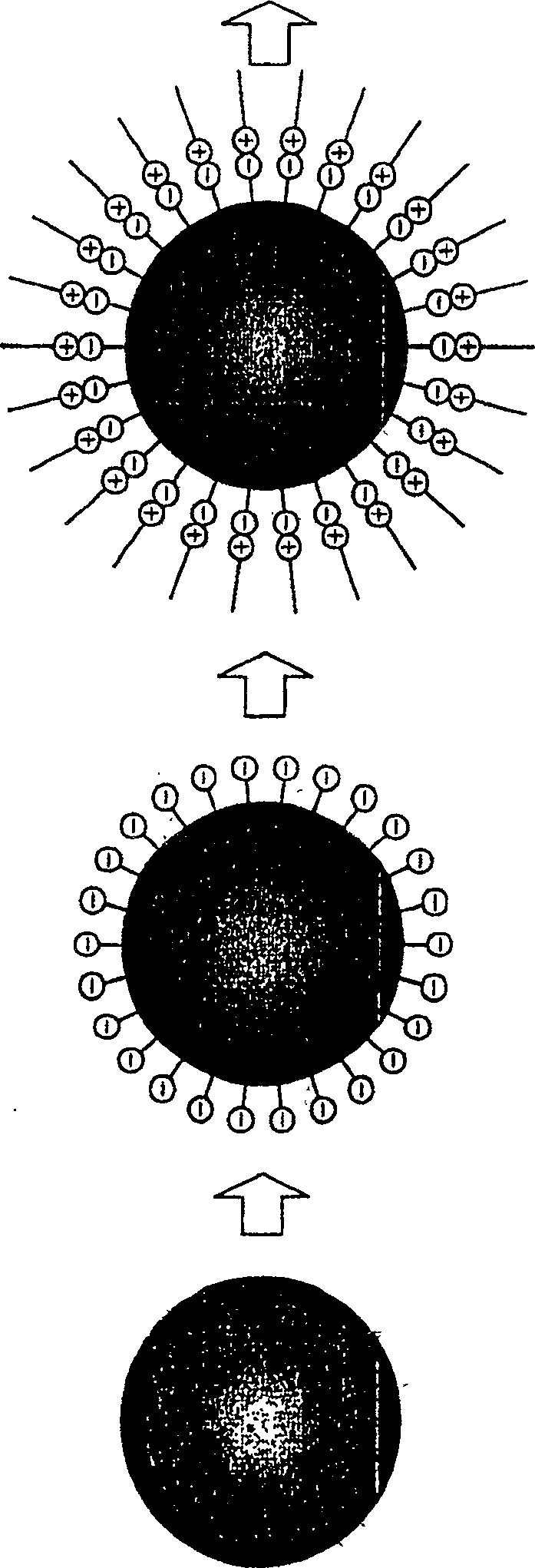

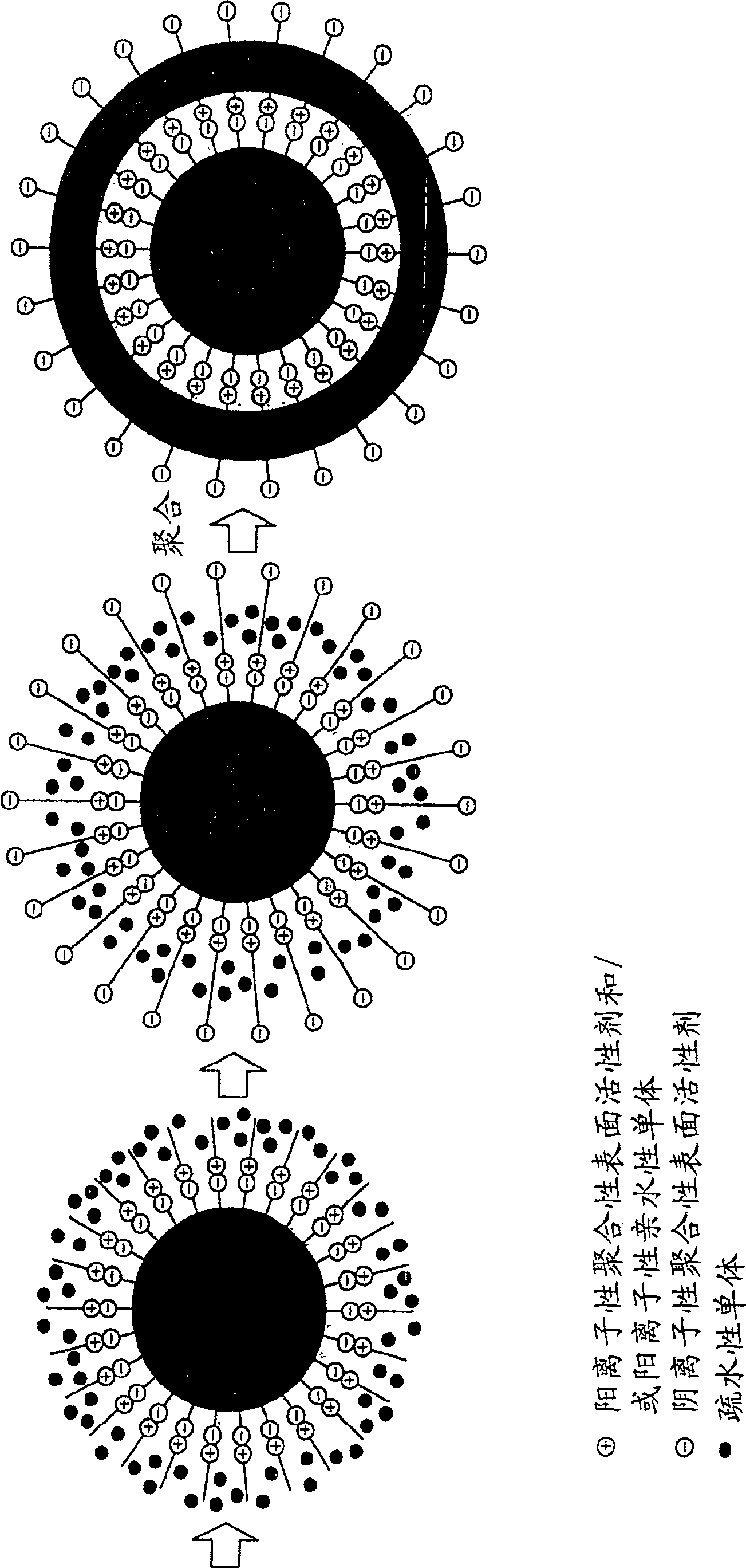

Encapsulation product, process for producing the same, and ink composition

InactiveCN101076395AUniform surface stateEasy to EncapsulateInksMicroballoon preparationSURFACTANT BLENDPolymer chemistry

An encapsulation product having excellent properties, e.g., no limitation on core substances. The encapsulation product comprises a wall material comprising a polymer as a major component and a core substance encapsulated therein, wherein the polymer is in contact with the core substance through an ionic surfactant (a) and comprises (1) structural repeating units derived from an ionic polymerizable surfactant (B) and / or an ionic monomer and (2) structural repeating units derived from an ionic polymerizable surfactant (C) having a charge which is the same as or opposite to that of the ionic surfactant (a). Alternatively, the encapsulation product comprises a wall material comprising a polymer as a major component and a core substance encapsulated therein, wherein the polymer comprises structural repeating units of a hydrophobic monomer and is present between (1) an ionic surfactant (b) and (2) an ionic surfactant (c).

Owner:SEIKO EPSON CORP

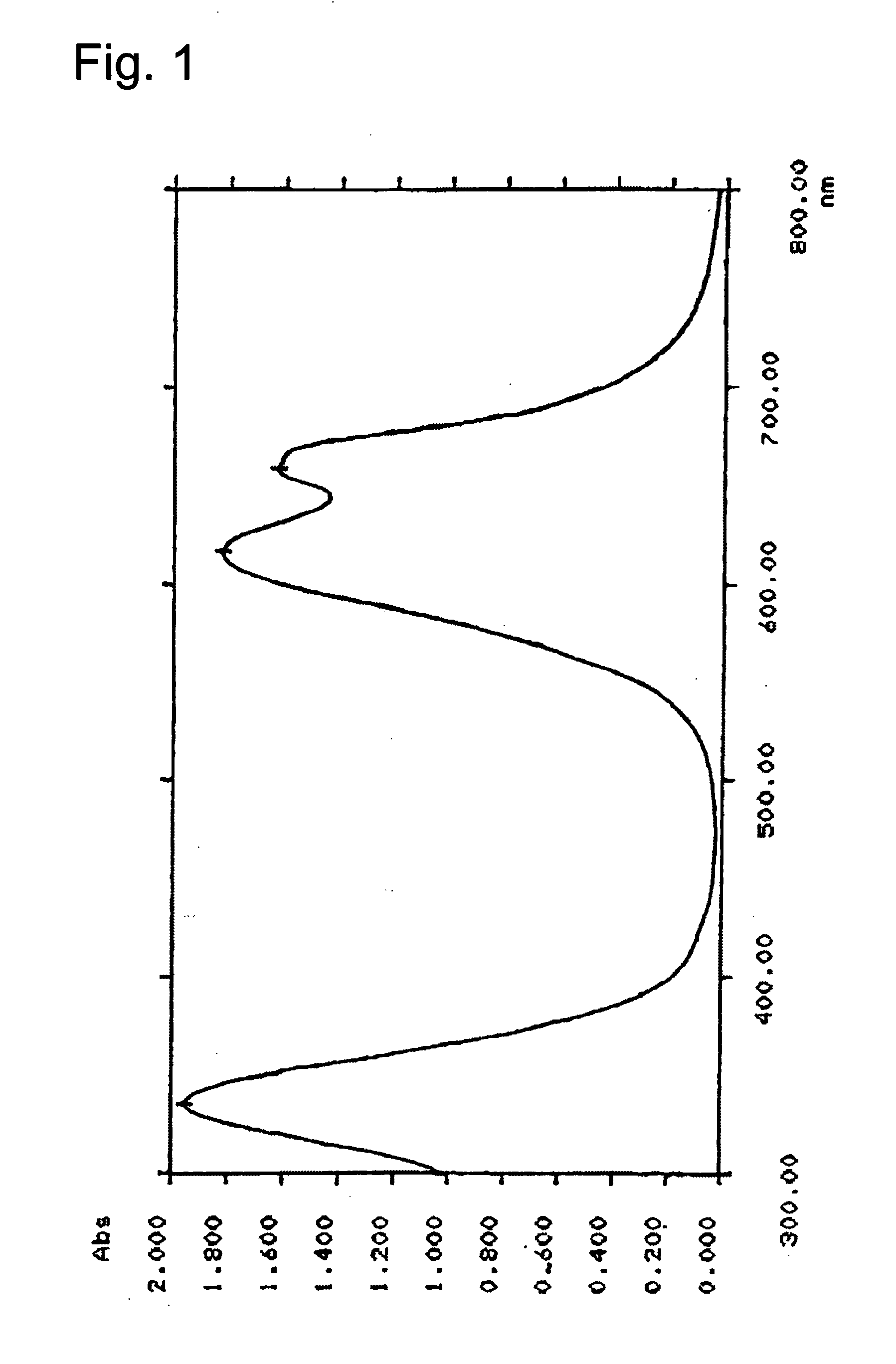

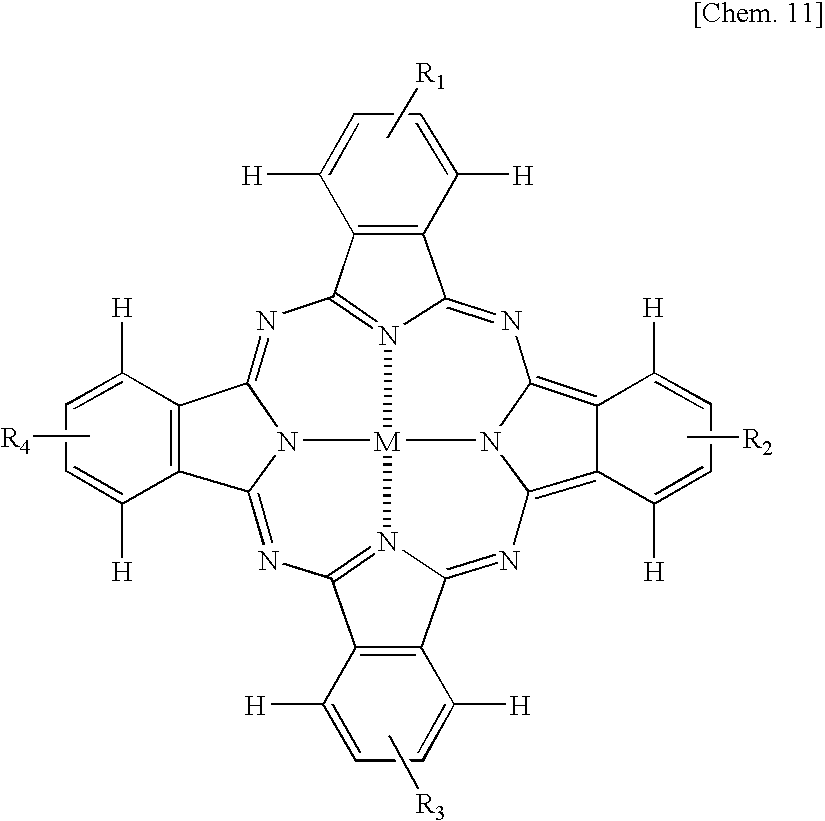

Ink Composition, and Ink Jet Recording Method and Recorded Matter Using the Same

InactiveUS20080022895A1Excellent fastnessHigh fastnessMeasurement apparatus componentsDuplicating/marking methodsCarboxylic groupBronzing

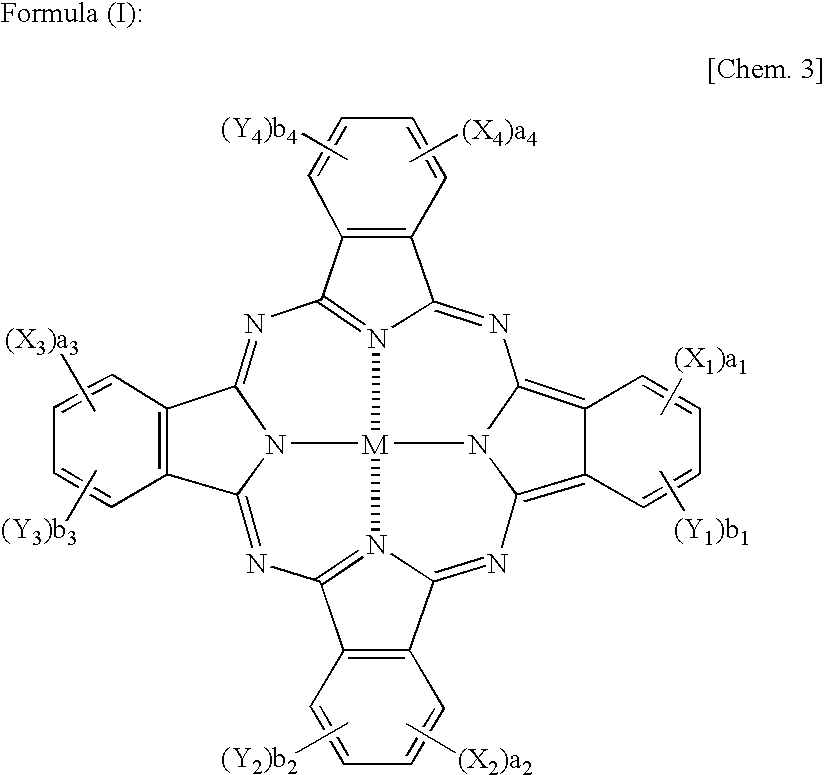

Problem to be Solved:To provide an ink composition capable of giving printed matter excellent in gas fastness and light fastness and free from generation of a bronzing phenomenon, an inkjet recording method using the ink composition, and recorded matter which is recorded by the recording method.Means to Solve the Problem:An ink composition comprising at least water, a cyan dye represented by the formula shown below and an aromatic compound having a carboxyl group and / or a salt thereof; an inkjet recording method using the composition; and recorded matter which is recorded by the recording method.[wherein M represents a hydrogen atom, a metal element, a metal oxide, a metal hydroxide or a metal halide, R1 to R4 each independently represents —SO2Z, and Z represents a substituted or unsubstituted alkyl group, a substituted or unsubstituted cycloalkyl group, a substituted or unsubstituted alkenyl group, a substituted or unsubstituted aralkyl group, a substituted or unsubstituted aryl group or a substituted or unsubstituted heterocyclic group, provided that at least one of four Z's has an ionic hydrophilic group as a substituent].

Owner:SEIKO EPSON CORP +1

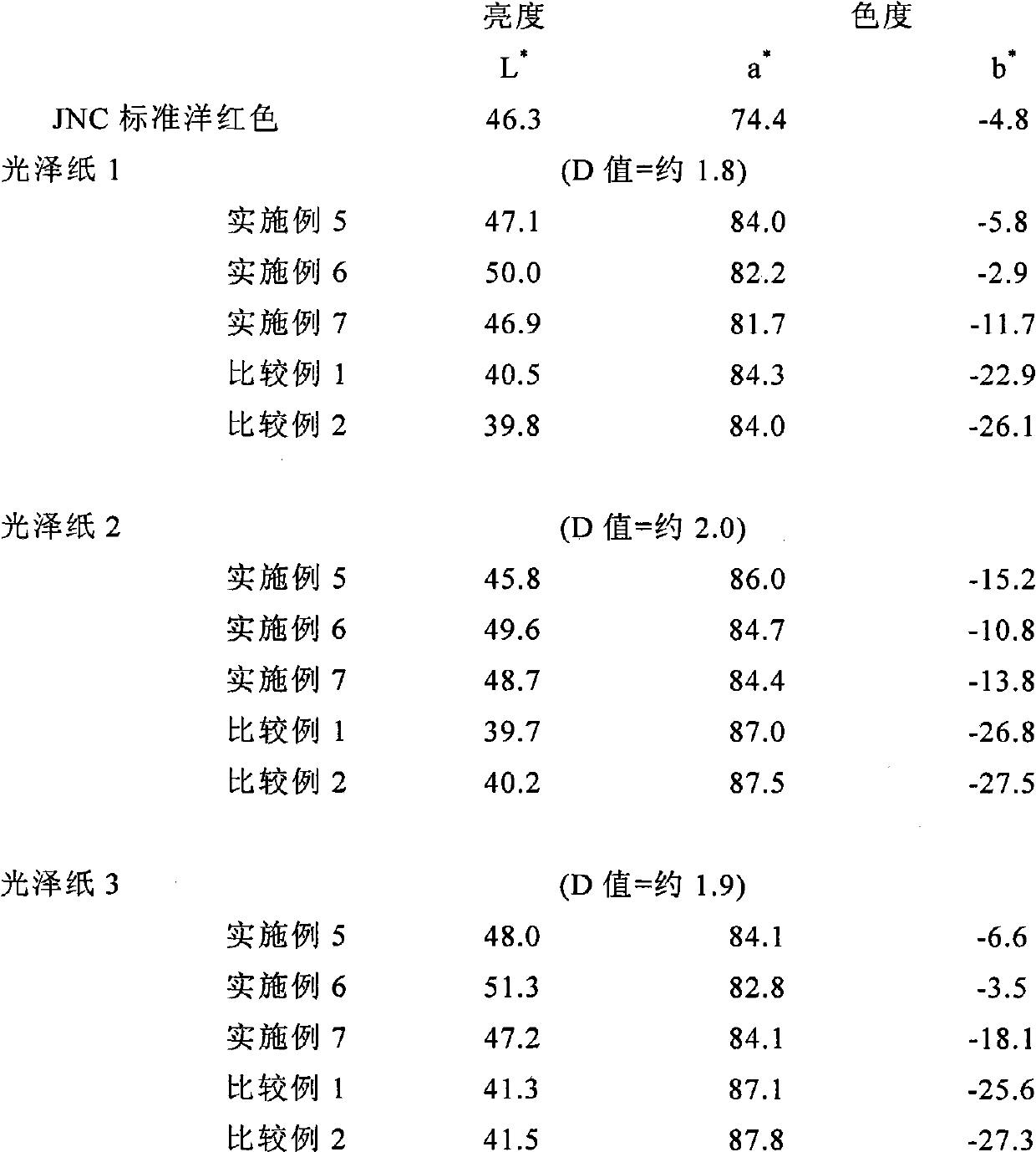

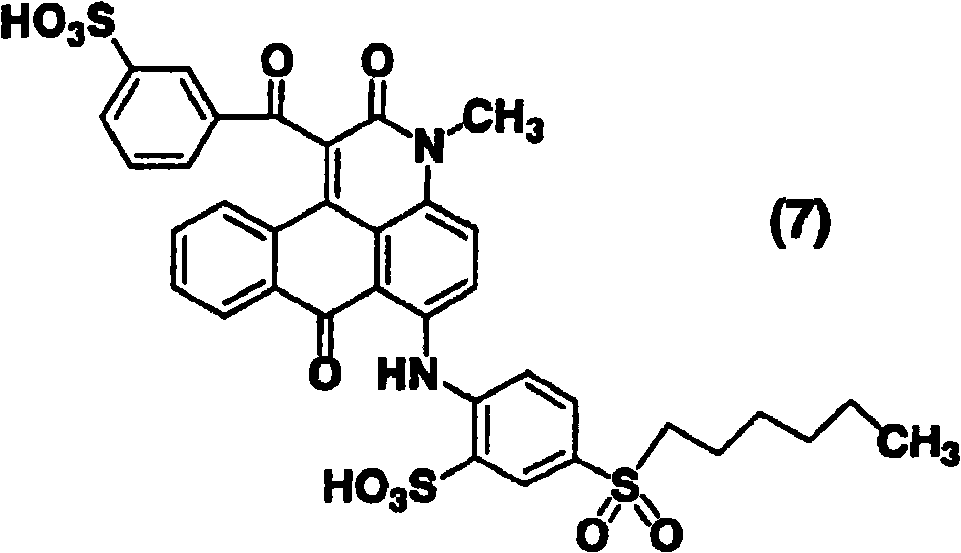

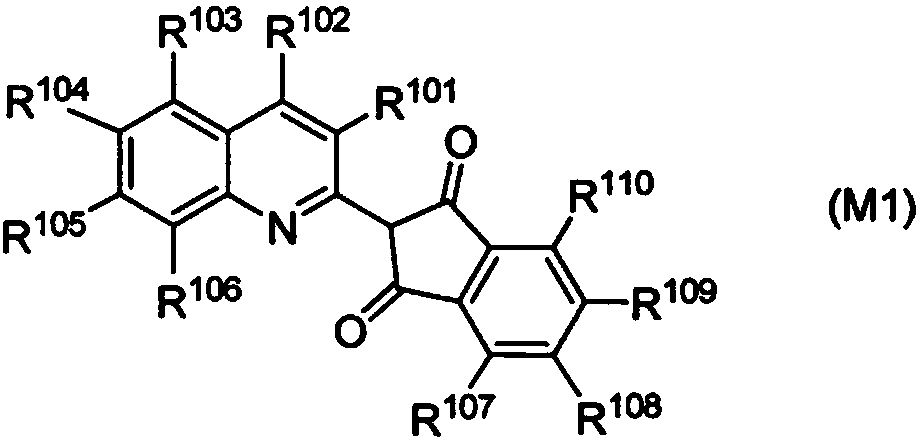

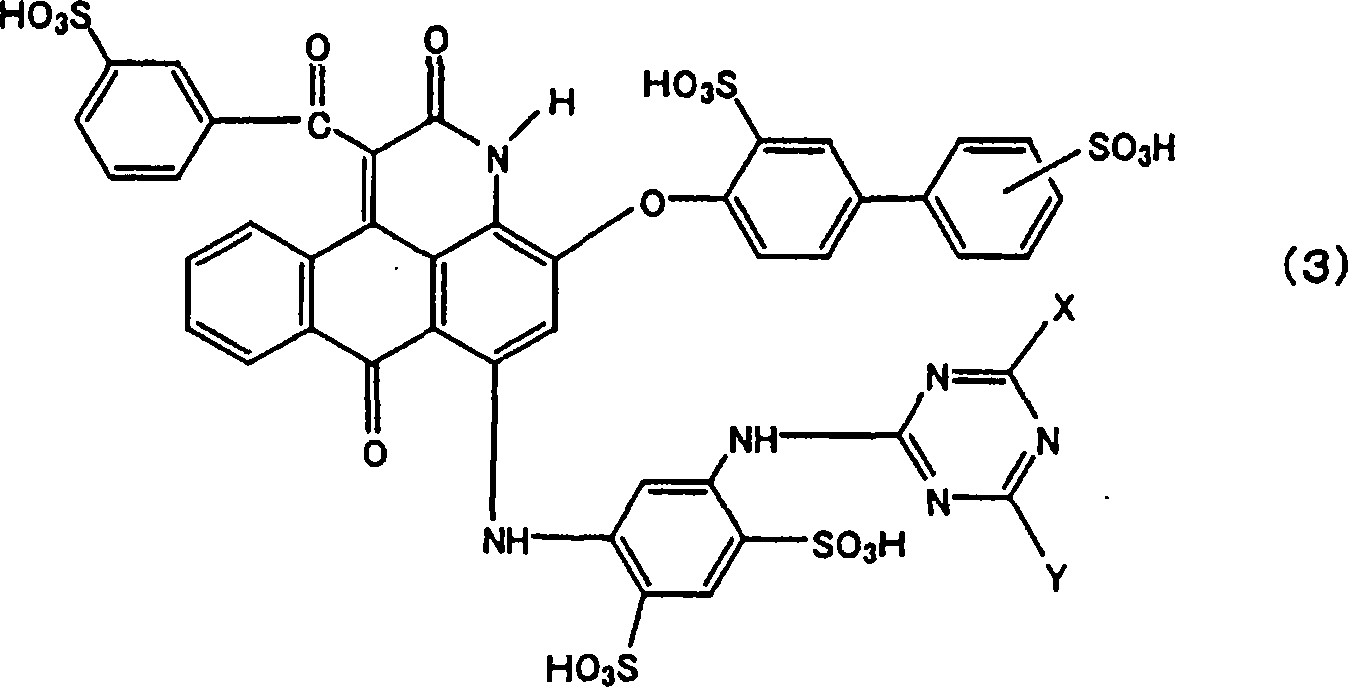

Anthrapyridone compound or salt thereof, magenta ink composition containing anthrapyridone compound, and colored body

ActiveCN101925658AImprove sharpnessIncrease brightnessOrganic chemistryDuplicating/marking methodsArylHydrogen atom

Disclosed is an anthrapyridone compound represented by formula (1) or a salt thereof. The compound or a salt thereof enables formation of a magenta dye having a hue with high definition suitable for inkjet recording and excellent storage stability. A matter recorded with such a magenta dye has high fastness. [In the formula, R1 represents a hydrogen atom, an alkyl group or the like; R2 represents a hydrogen atom or a methoxy group; R3 represents an unsubstituted or substituted C5-C12 alkyl group, an unsubstituted or substituted aryl group, or an unsubstituted or substituted heteroaryl group; and one of the substitution positions of -SO2R3 and -SO3H on a benzene ring, which positions are not specified, is para, and the other is ortho, respectively to the substitution position of a nitrogen atom on the benzene ring.

Owner:NIPPON KAYAKU CO LTD

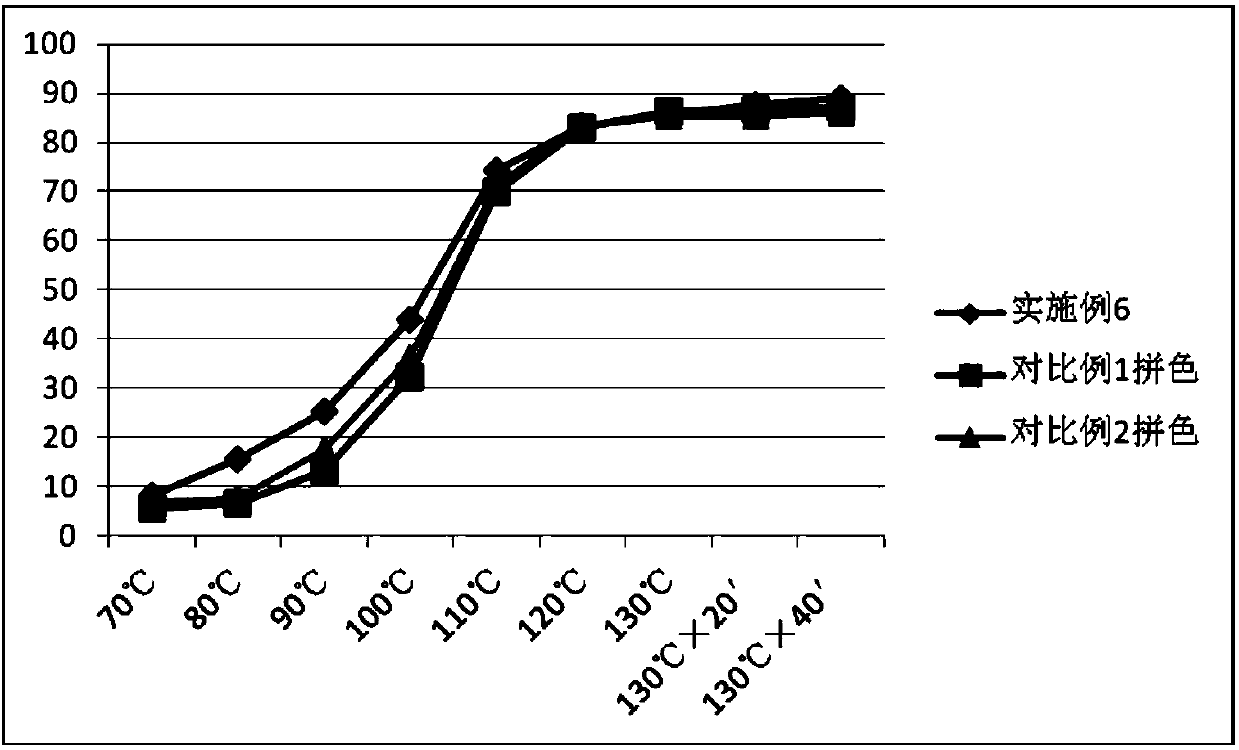

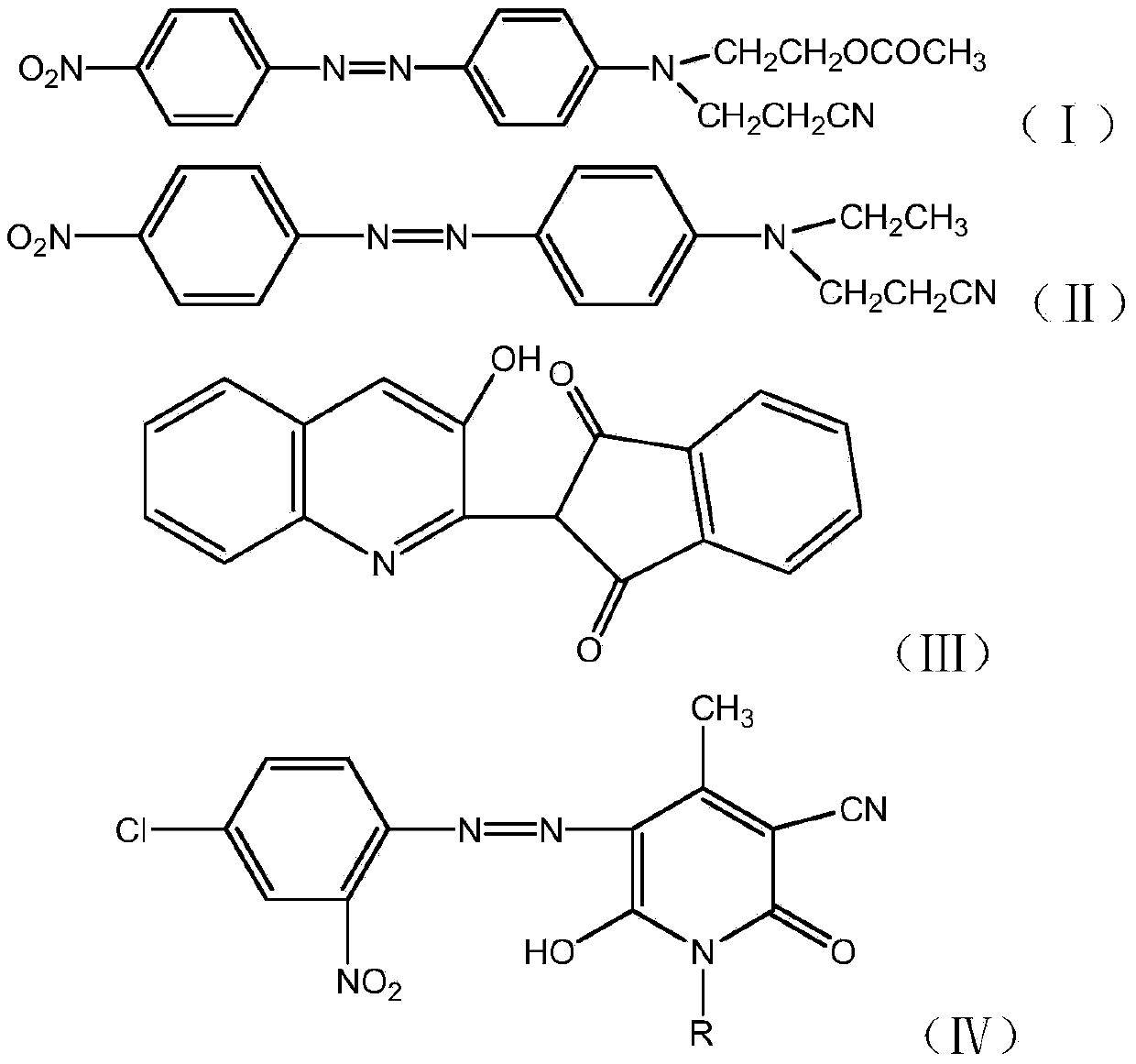

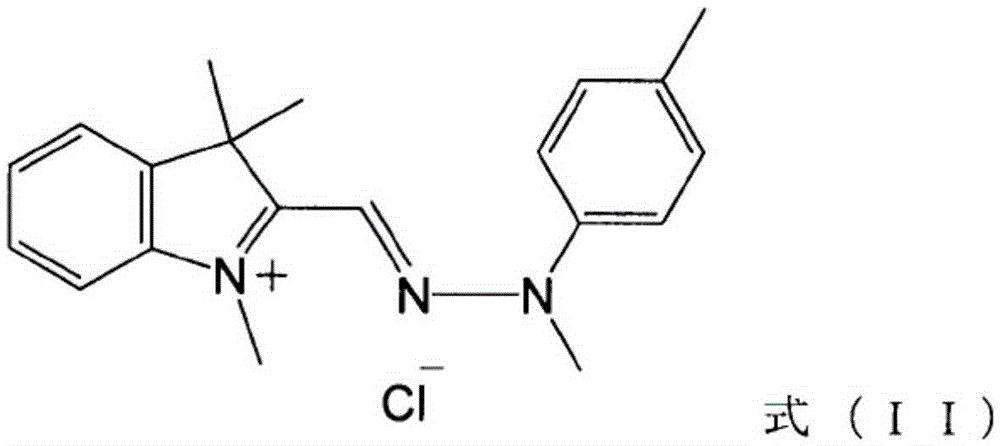

Low-temperature and environment-friendly disperse yellow dye composition

The invention provides a low-temperature and environmental-friendly disperse yellow dye composition, mainly comprising 20-80 parts by weight of component A, 0-80 parts by weight of component B and / or 0-80 parts by weight of component C, wherein the component A is a dye shown in the formula (I), the component B is a mixture of dyes shown in the formula (II) and the formula (III), and the component C is a dye shown in the formula (IV); when used for dyeing, the low-temperature and environment-friendly disperse yellow dye composition provided by the invention is excellent in fastness, high in dyeing speed, good in leveling property, good in color matching compatibility with low-temperature (disperse red 3B and disperse blue 2BLN) dyes, good in synchronous leveling property with blending products and good in color rendering.

Owner:ZHEJIANG LONGSHENG GROUP

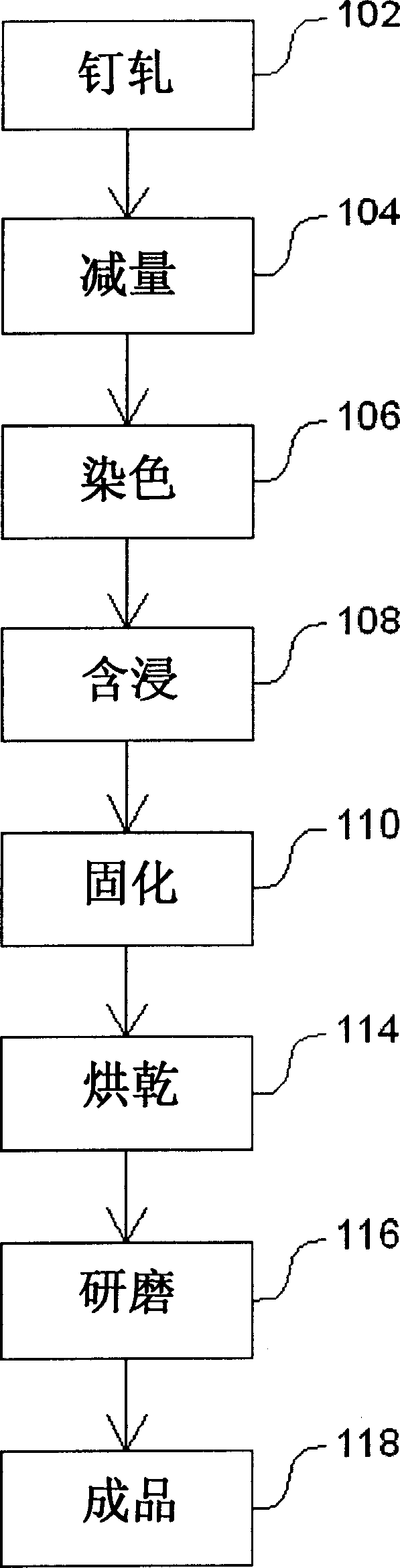

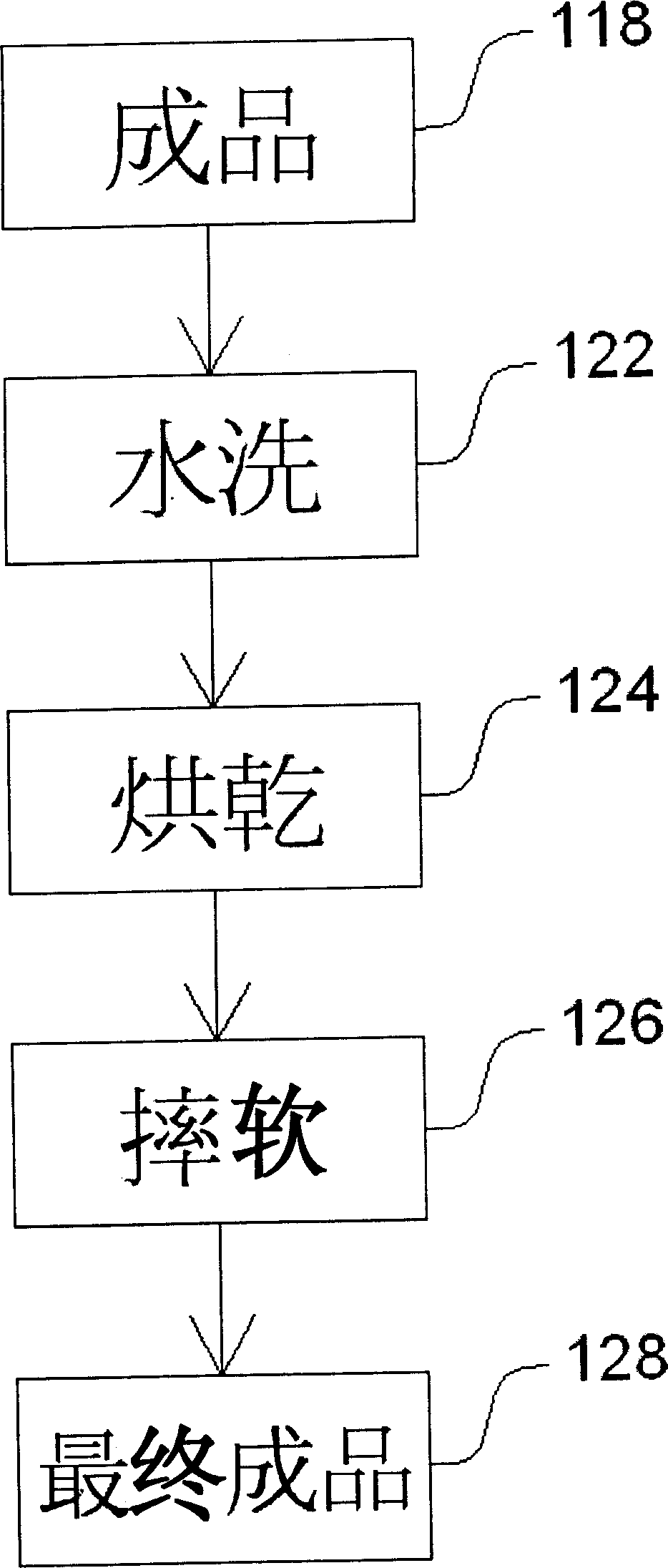

Environment protection artificial chamois and its preparation method

The invention relates to an artificial suede making method. It includes the following steps: offering a base cloth; loss in weight and dyeing to form dipping layer with water soluble polymer elastic body resin and arching agent; solidifying; drying; rubbing to form a environmental protection artificial suede; then water washing, drying, and breaking soft to form a soft environmental protection artificial suede.

Owner:SAN FANG CHEM IND

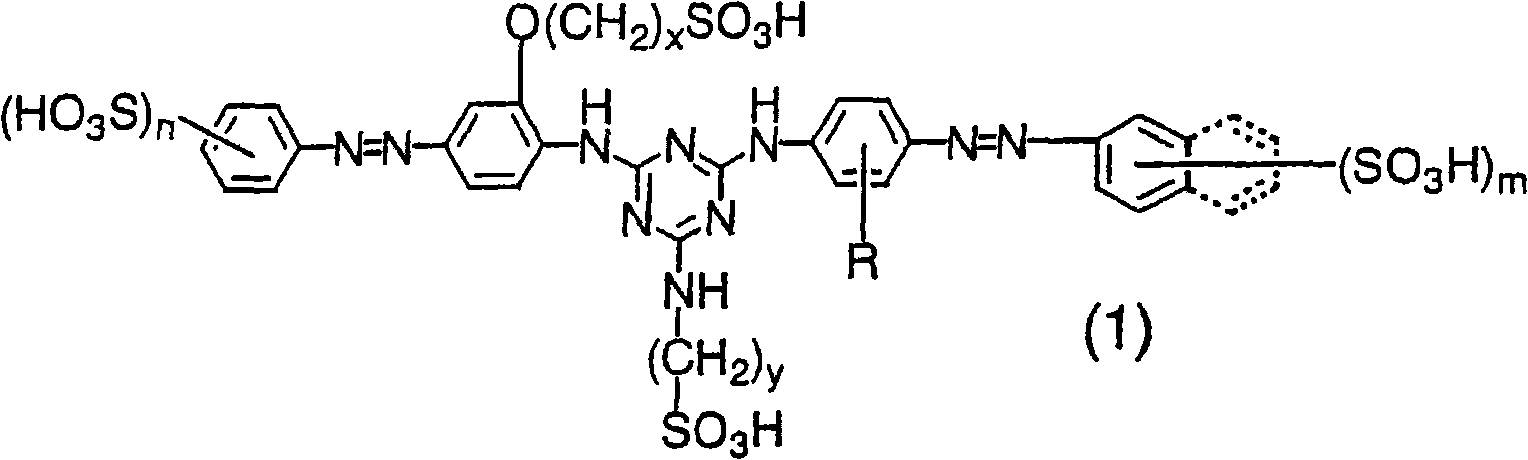

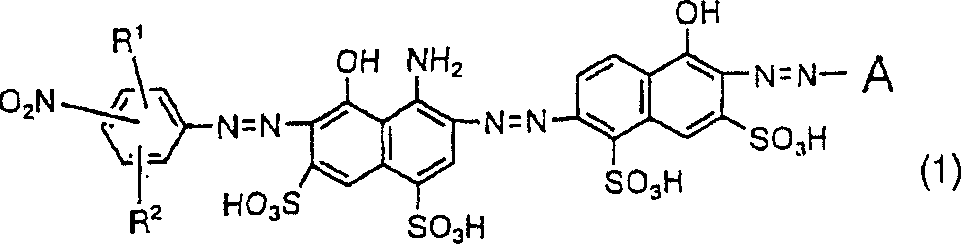

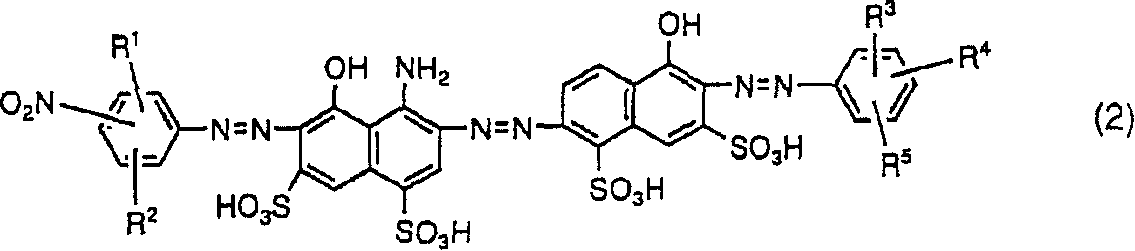

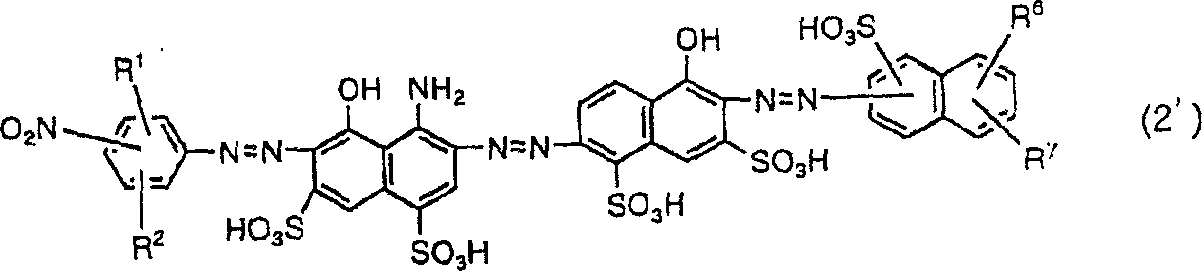

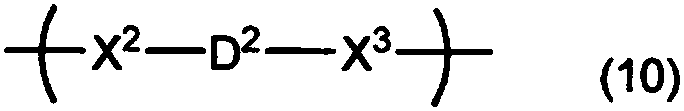

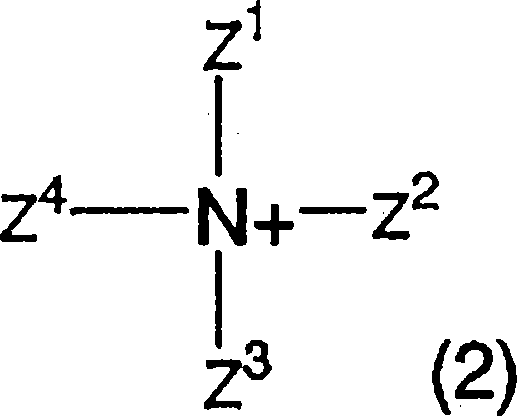

Water-soluble azo compounds or salts thereof, ink compositions and colored products

ActiveCN101528858AImprove solubilityImprove filtering effectDisazo dyesDuplicating/marking methodsHydrogenAlkoxy group

The invention relates to water-soluble azo compounds represented by the general formula (1) or salts thereof and ink compositions containing the same: (1) (wherein R is hydrogen, alkyl of 1 to 4 carbon atoms, alkoxy of 1 to 4 carbon atoms, or sulfo; n is 1 or 2; m is an integer of 1 to 3; x is an integer of 2 to 4; and y is an integer of 1 to 3). The compounds or salts have high-clarity hues favorable to ink-jet recording and can give prints having high fastnesses. Further, the compounds are useful as yellow dyestuff capable of forming ink compositions excellent in storage stability and therefore suitable for ink compositions, particularly those for ink-jet recording.

Owner:NIPPON KAYAKU CO LTD

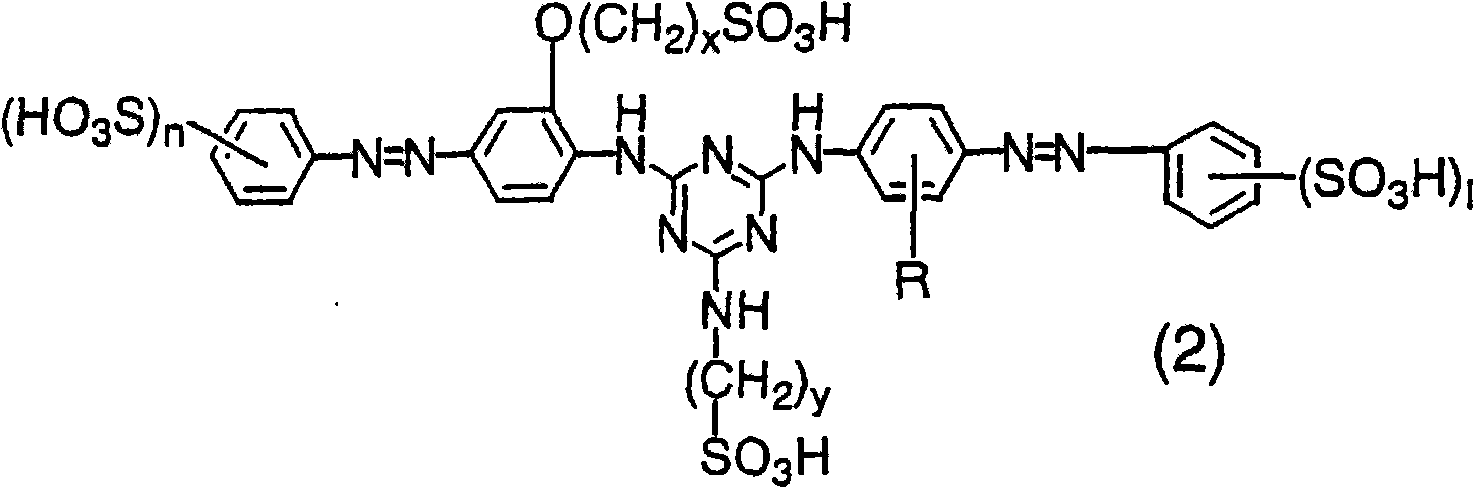

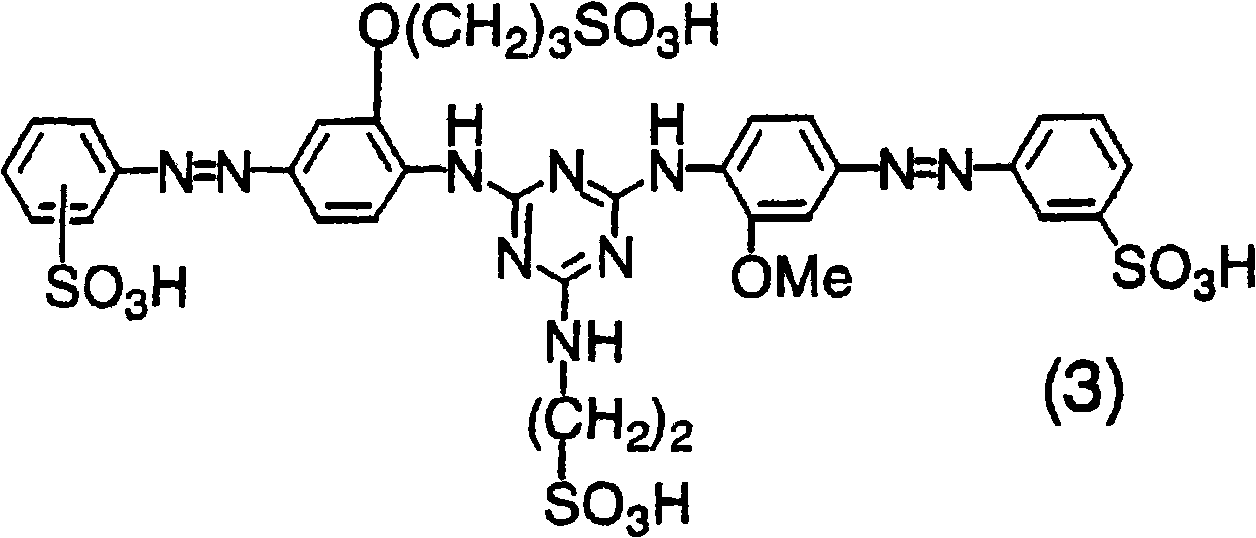

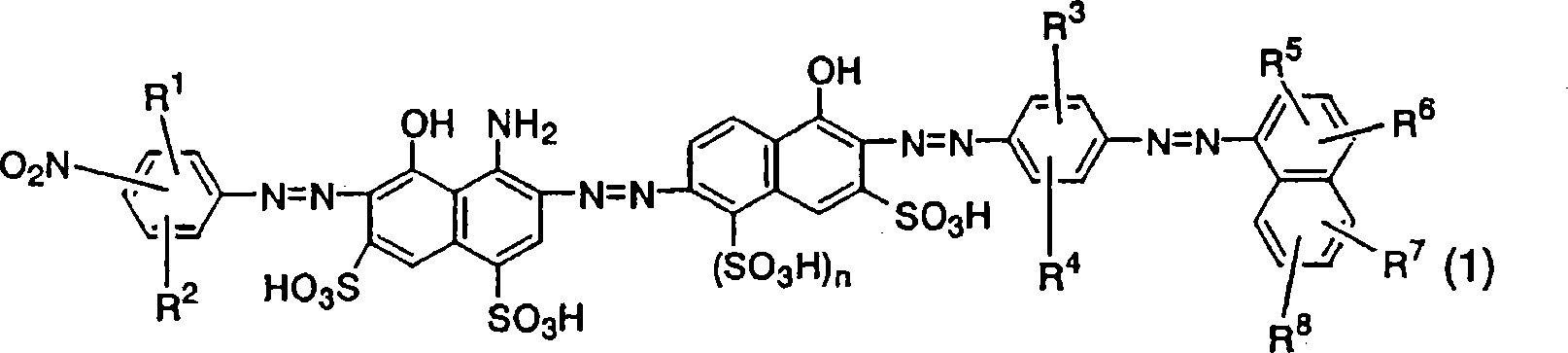

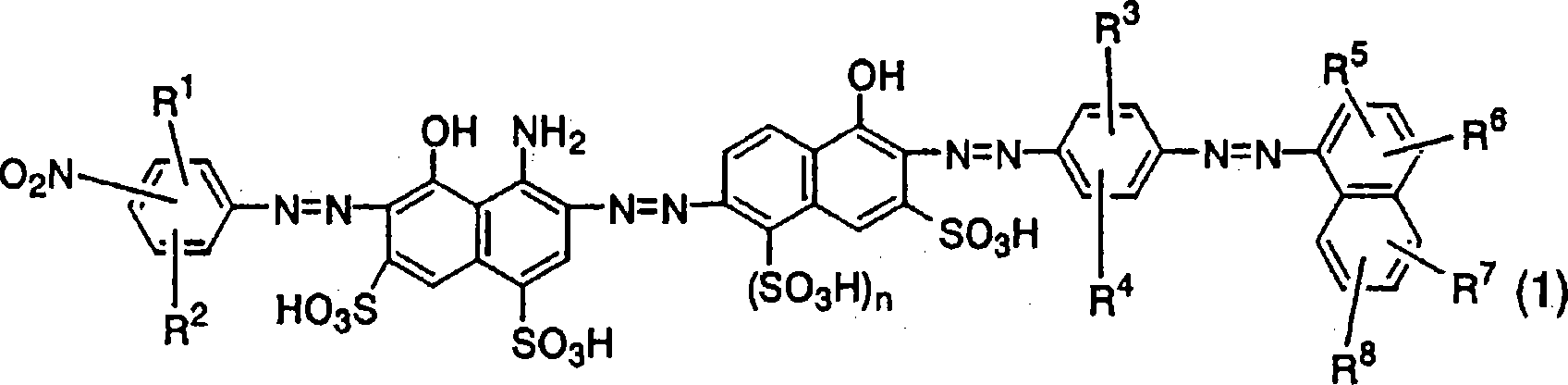

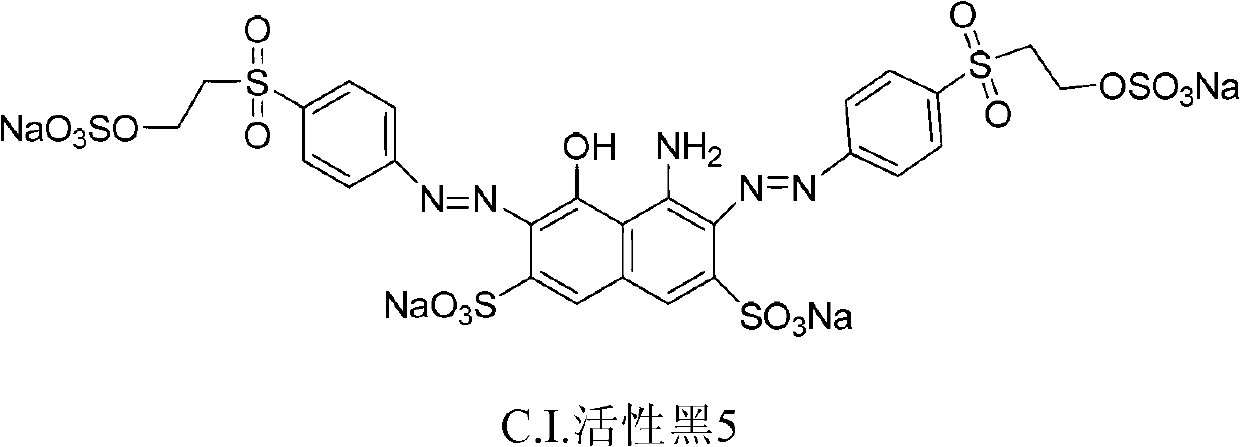

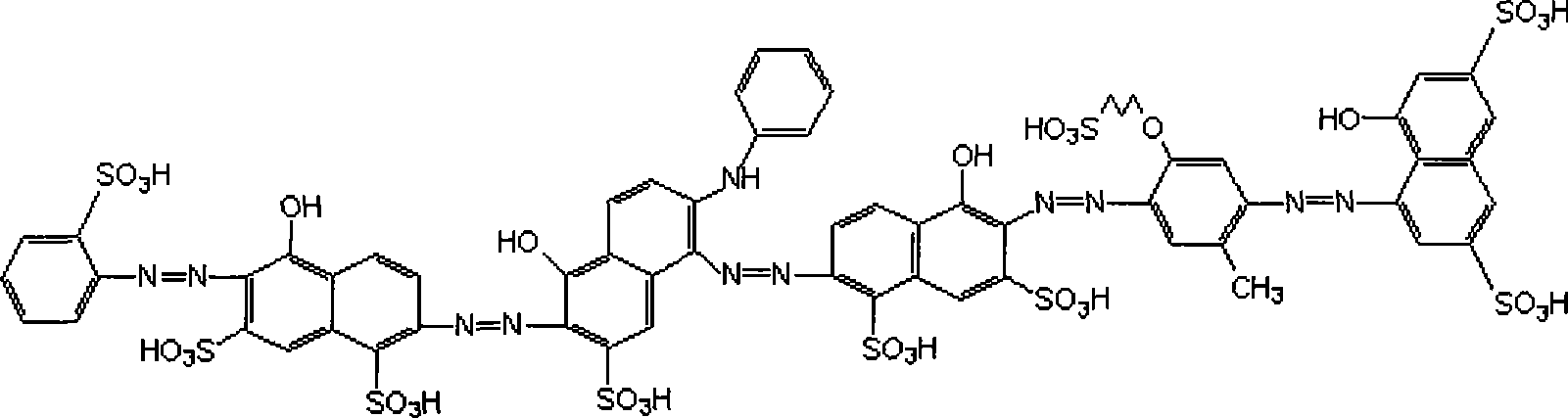

Trisazo compound, ink composition, and colored object

To provide: a black compound which is for use in ink-jet recording or writing utensils, is excellent in ozone resistance, light resistance, moisture resistance, and color rendering, and gives a recording fluid having satisfactory storage stability; and an ink composition containing the compound. The black compound is a trisazo compound represented by the following formula (1) or a salt thereof. (1) [In the formula (1), R<1> and R<2> each independently represents hydrogen, carboxy, sulfo, hydroxy, a C1-4 alkyl, C1-4 alkoxy, or sulfo group optionally substituted by C1-4 alkoxy, an optionally carboxylated C1-4 alkoxy group, etc.; and A represents phenyl or naphthyl (provided that the phenyl and naphthyl groups may be substituted by halogeno, carboxy, sulfo, sulfamonyl optionally substituted by alkyl or phenyl, nitro, etc.)].

Owner:NIPPON KAYAKU CO LTD

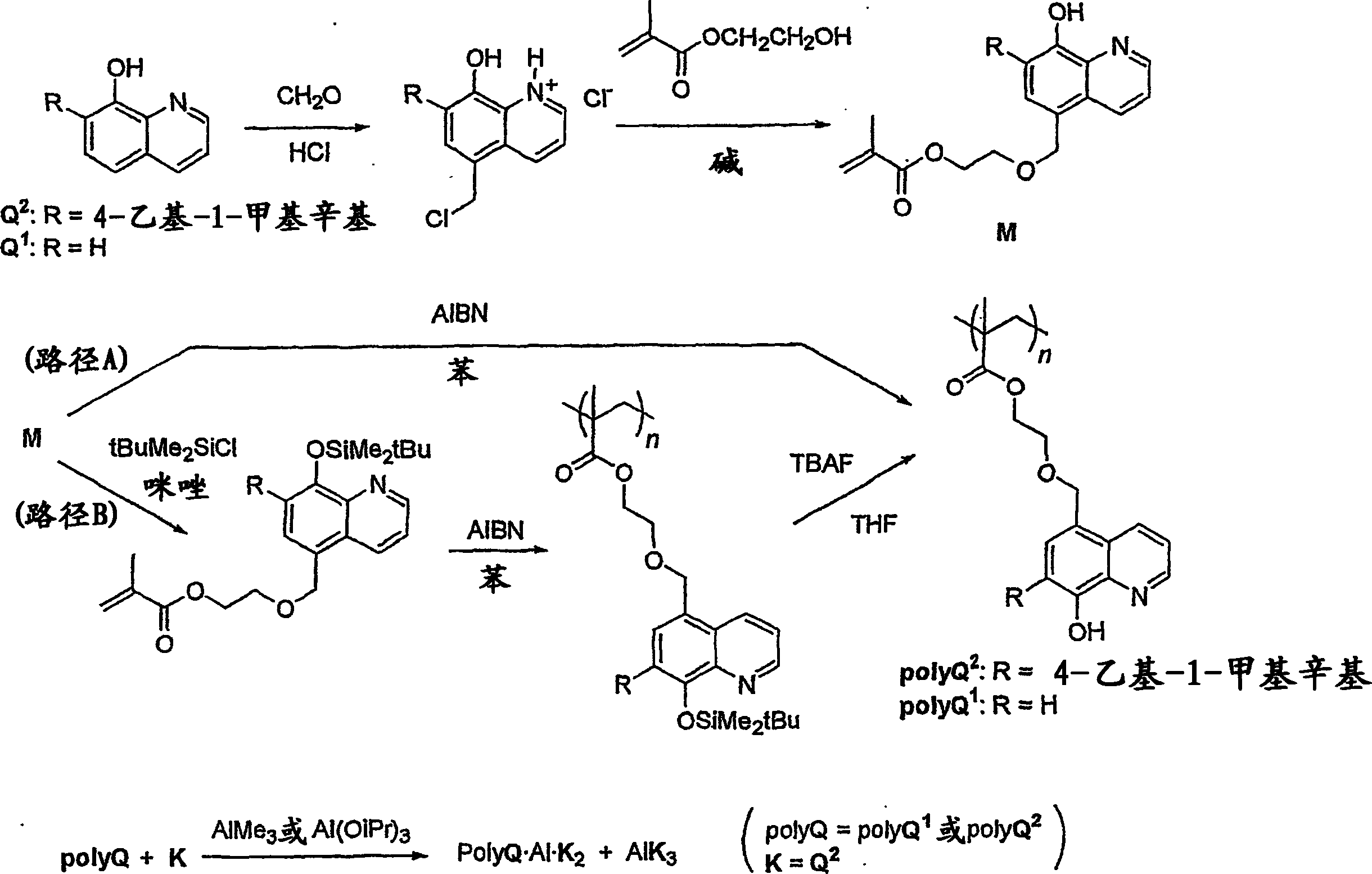

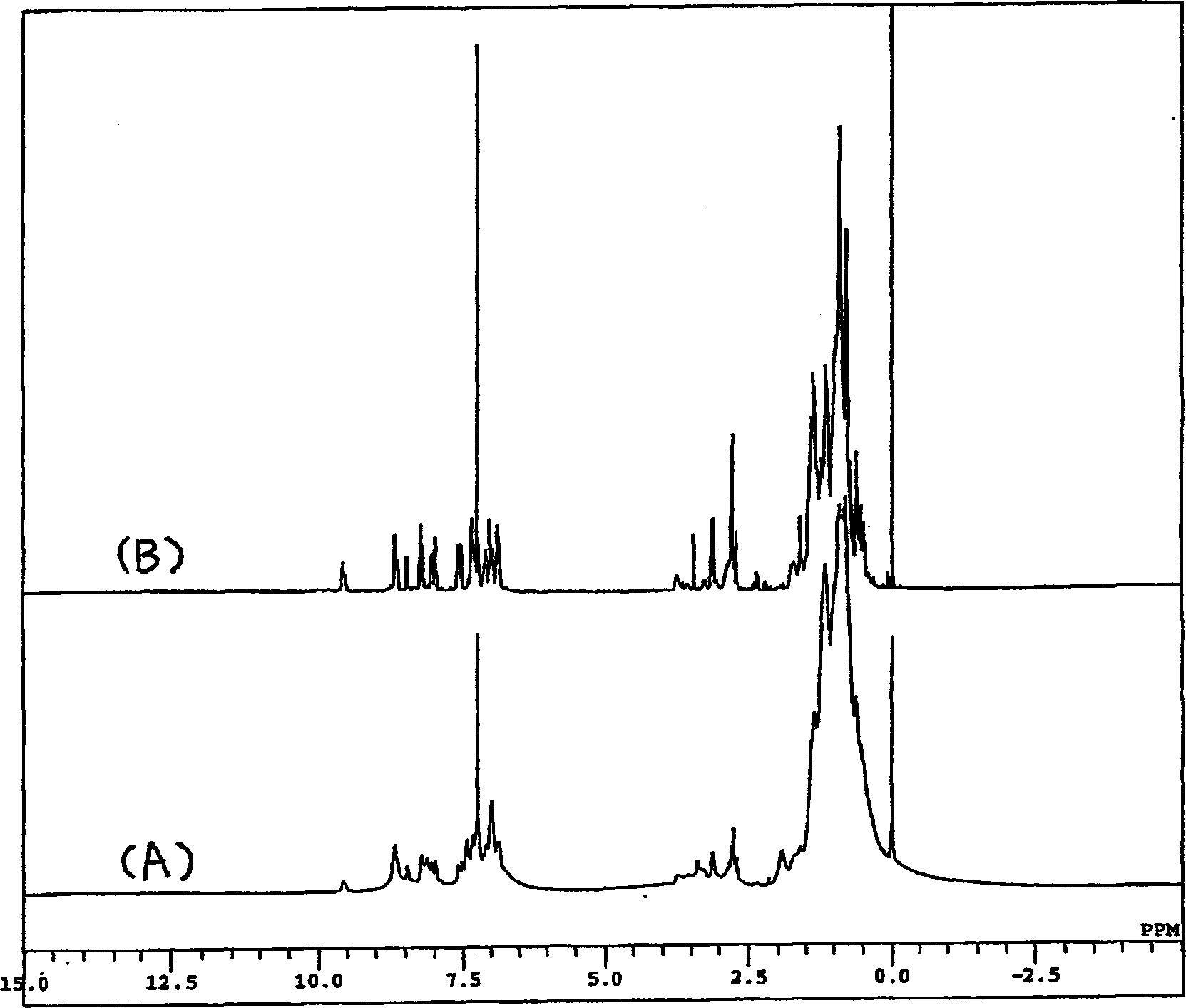

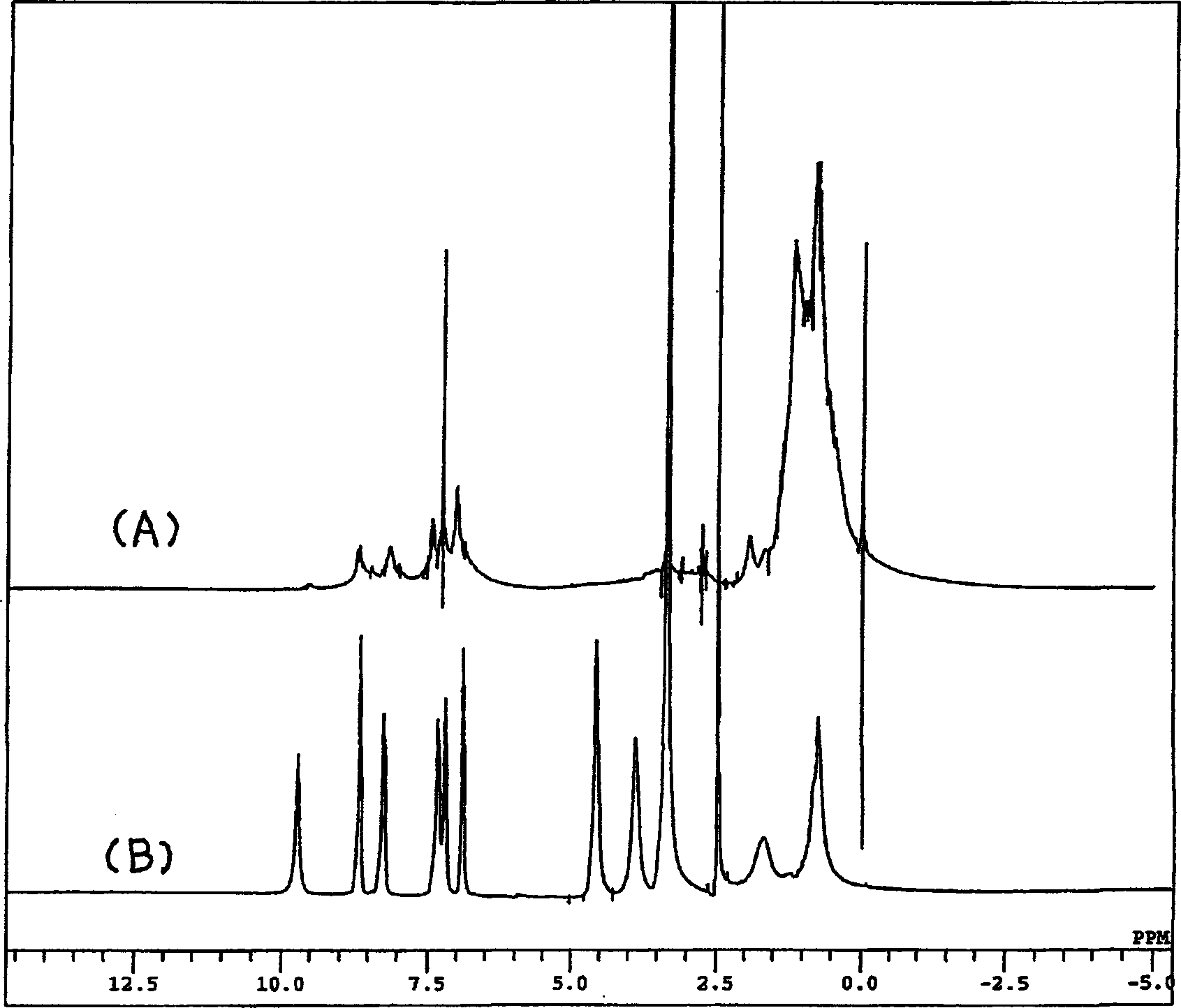

Luminescent organic-polymer/metal complex, luminescent organic-polymer/metal complex composition capable of forming film by wet process, and process for producing the same

InactiveCN1798776AImprove solubilityFastnessElectrical apparatusElectroluminescent light sourcesPolymer metalSide chain

This invention provides a luminescent organic polymer metal complex represented by polyQ M K n-1 (1) which is obtained by the reaction of a polymer ligand (polyQ) with an 8-hydroxyquinoline derivative introduced to its side chain through a spacer group, an 8-hydroxyquinoline derivative ligand (K) and a divalent to tetravalent metal ion (M n+ ) wherein the 8-hydroxyquinoline derivative ligand (K) has a bulky substituent. This invention also provides a luminescent organic polymer metal complex composition comprising said luminescent organic polymer metal complex and additionally a low-molecular-weight ligand and a process for producing the same.

Owner:NIPPON LIGHT METAL CO LTD +1

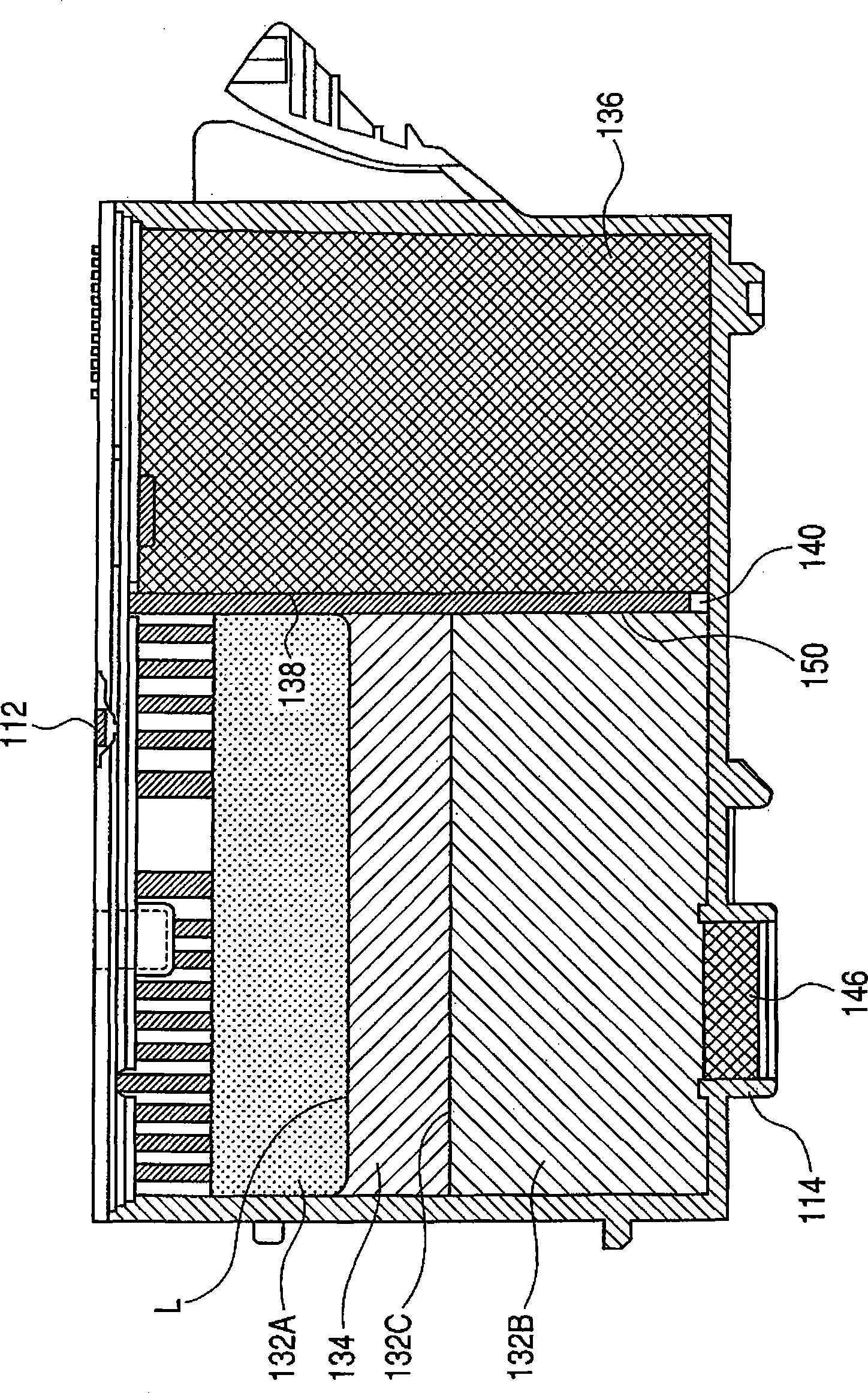

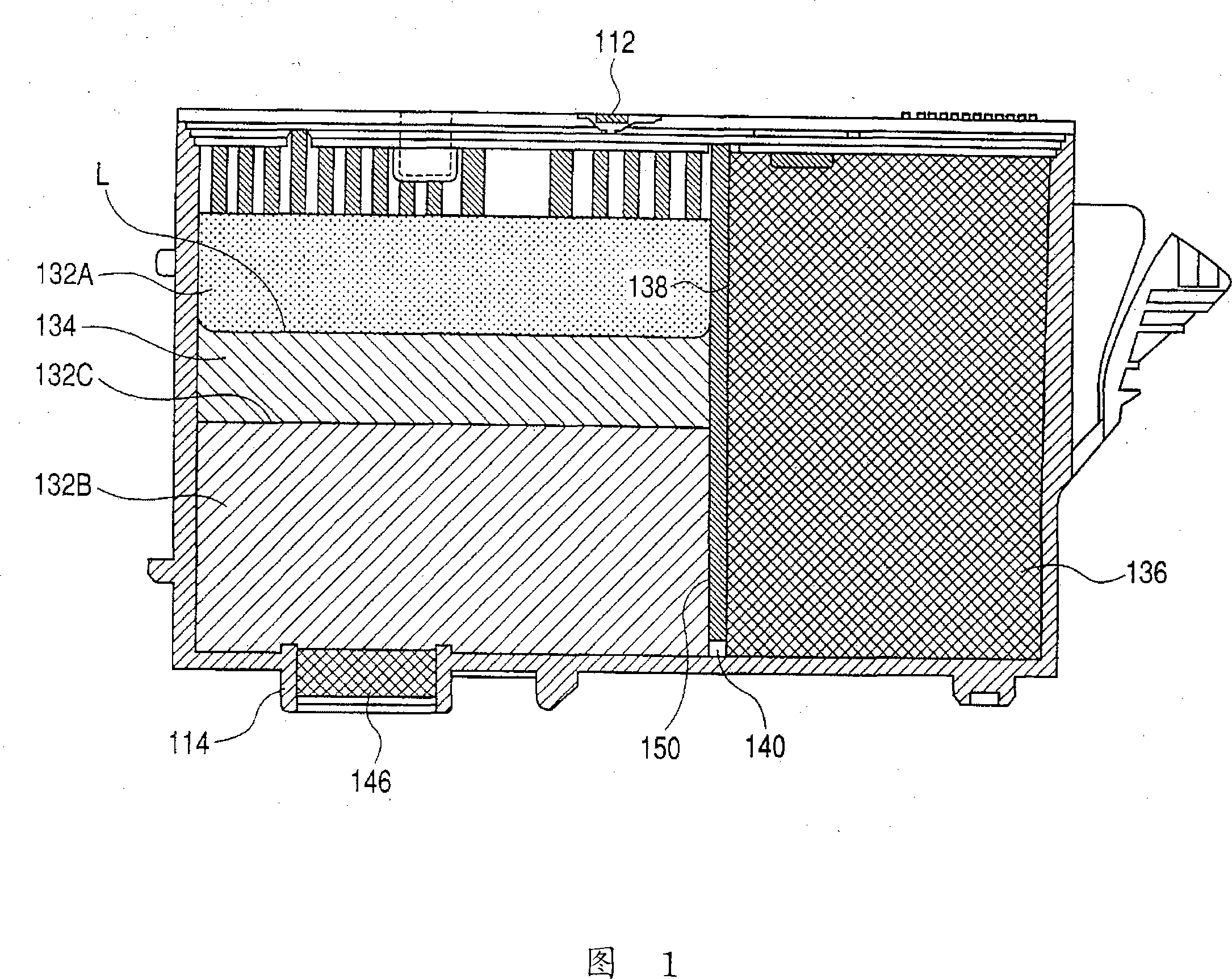

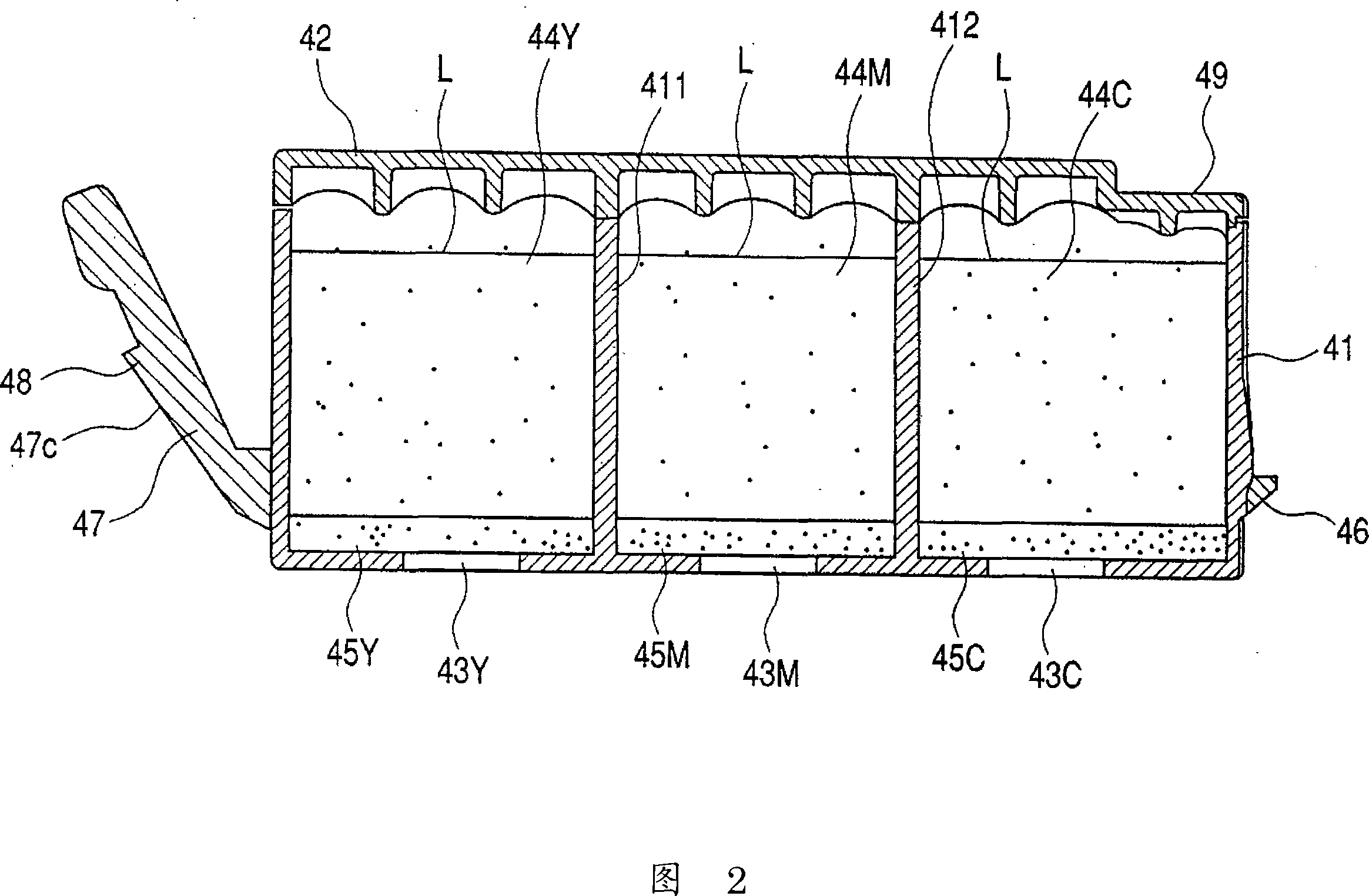

Inkjet printing method, inkjet ink, ink cartridge, and colored fabric

InactiveCN108603334AHigh clarityExcellent fastnessDuplicating/marking methodsInksEngineeringAqueous dispersion

The present invention provides: an inkjet printing method having a step in which inkjet ink is directly printed onto fabric using an inkjet scheme, the inkjet ink containing an aqueous dispersion of adye polymer having repeating units that contain a structure derived from a dye; an inkjet ink containing the aqueous dispersion of a dye polymer; an ink cartridge filled with the inkjet ink; and a colored fabric.

Owner:FUJIFILM CORP

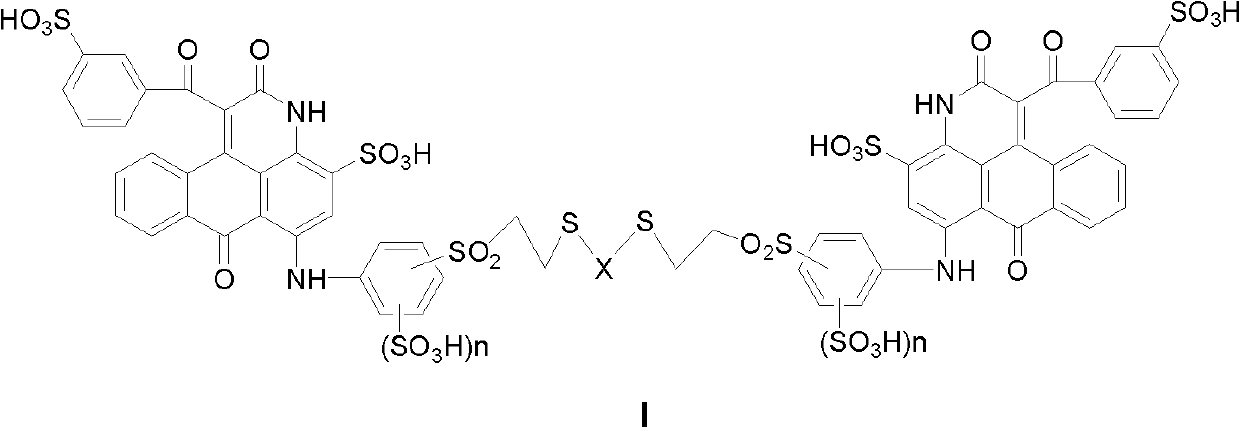

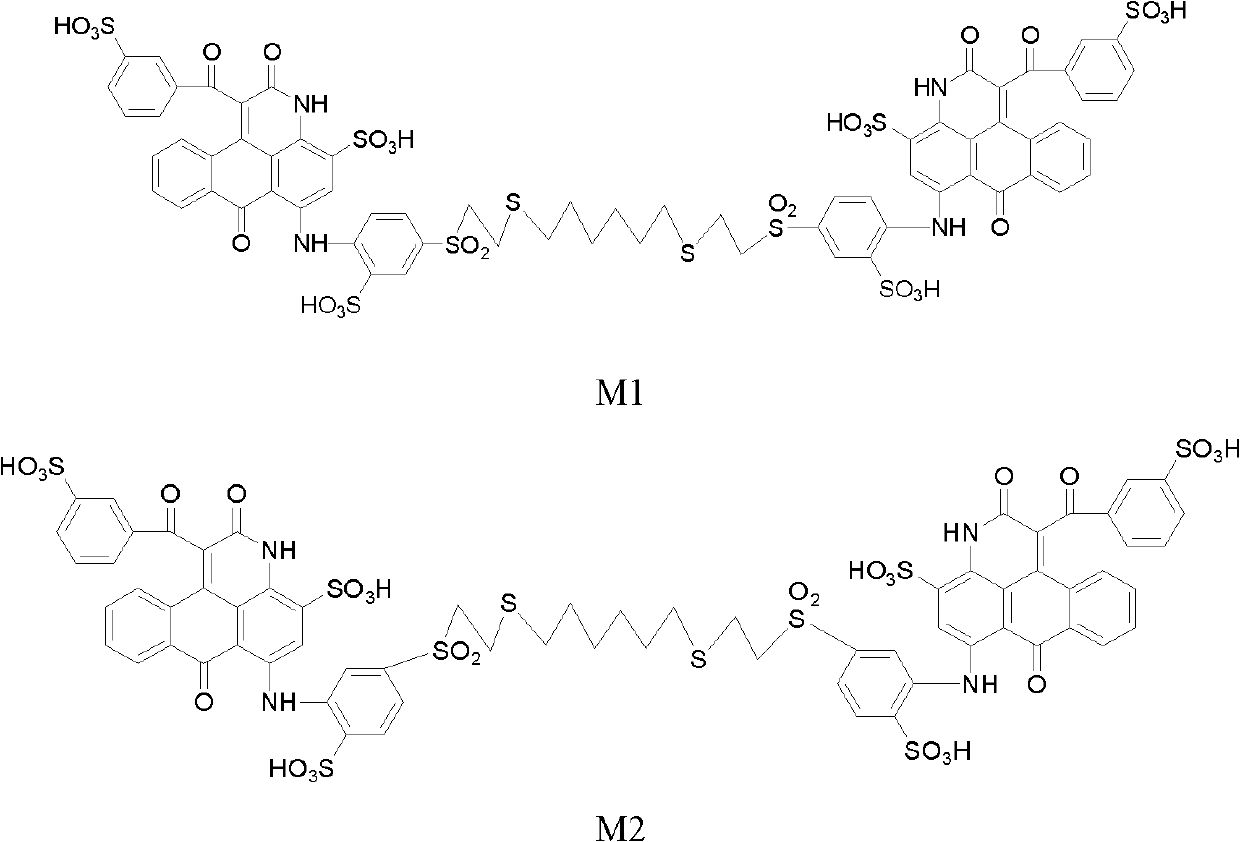

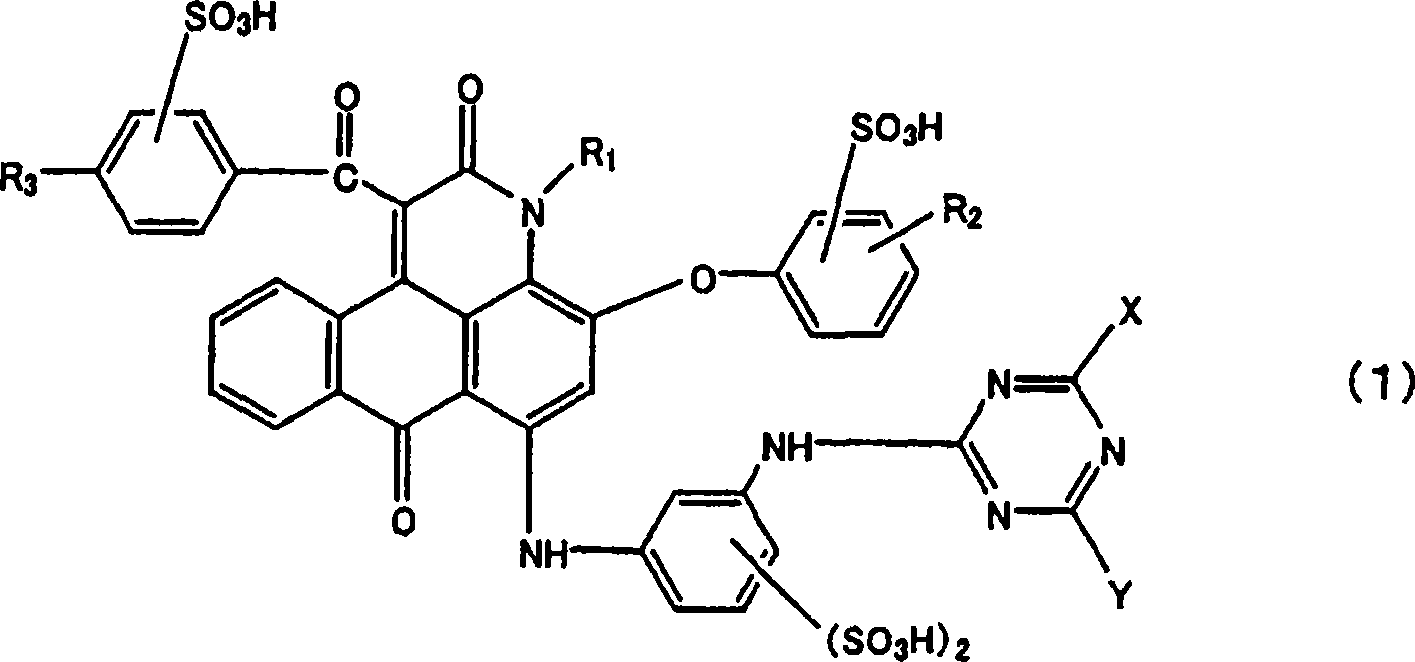

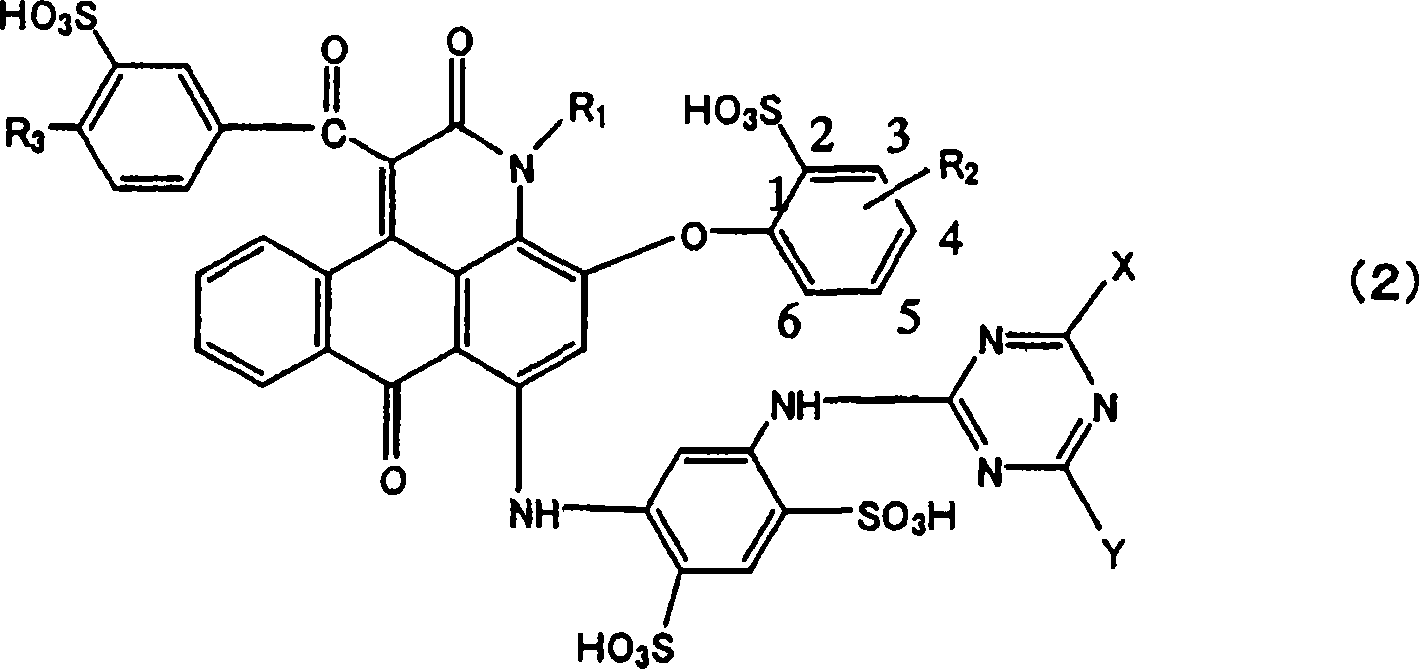

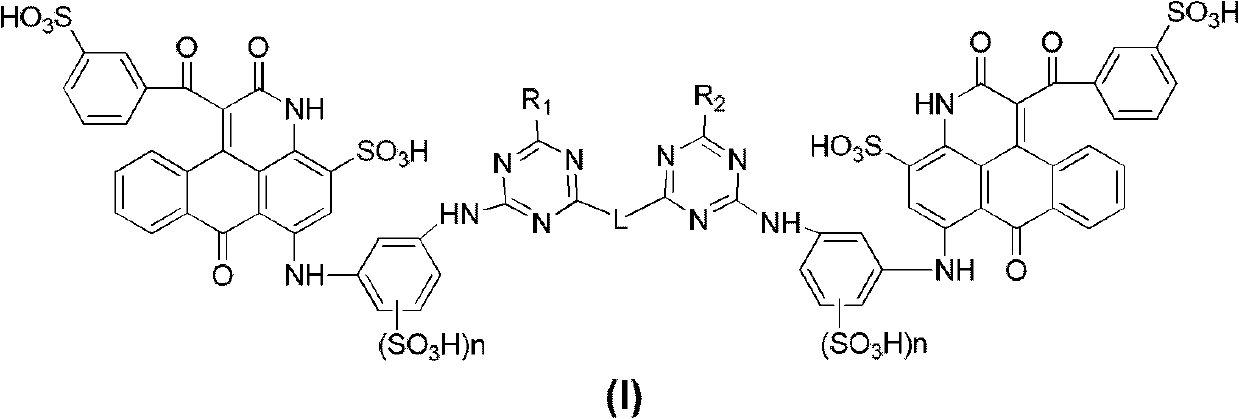

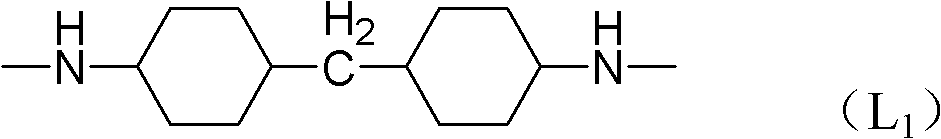

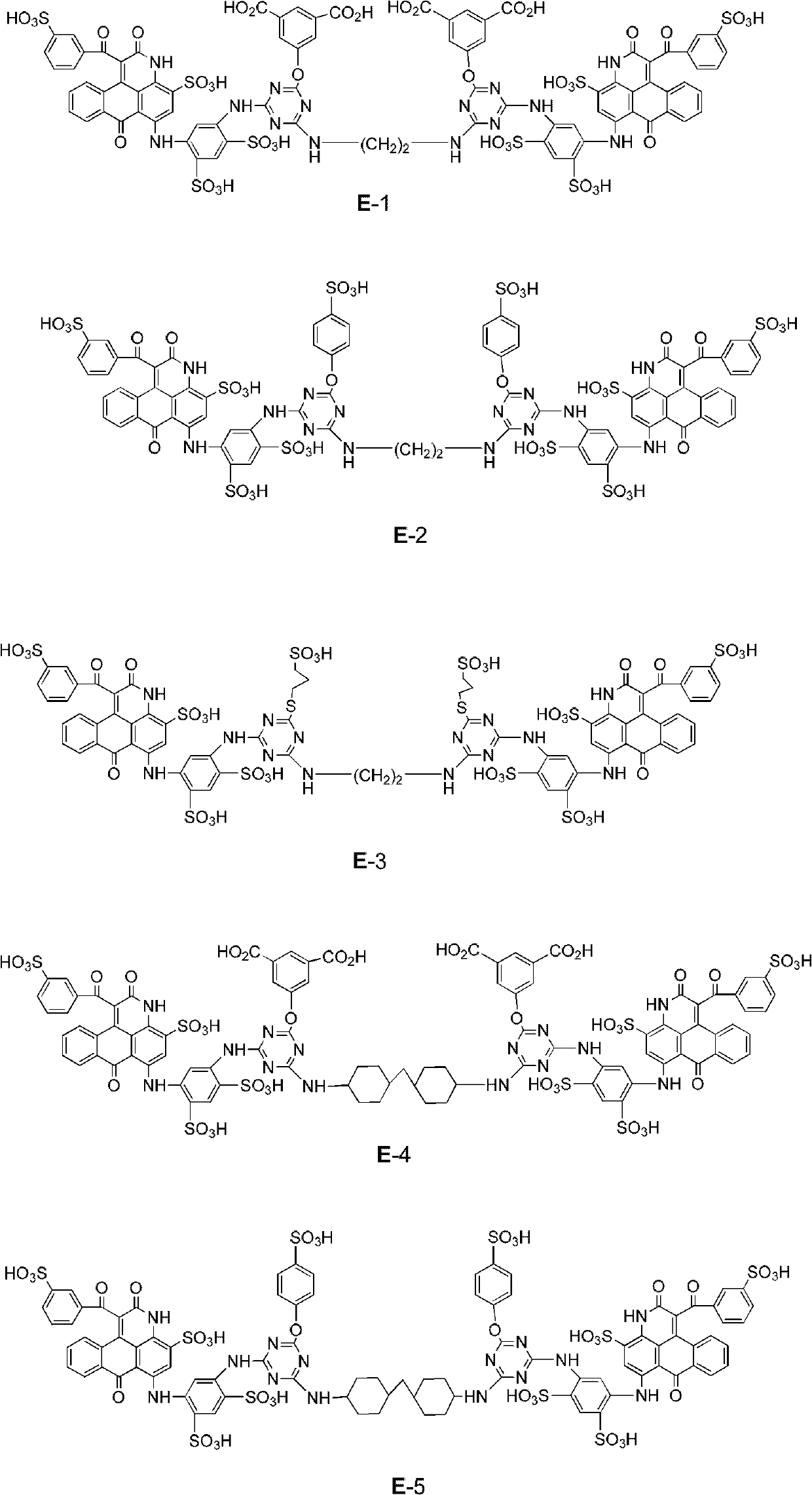

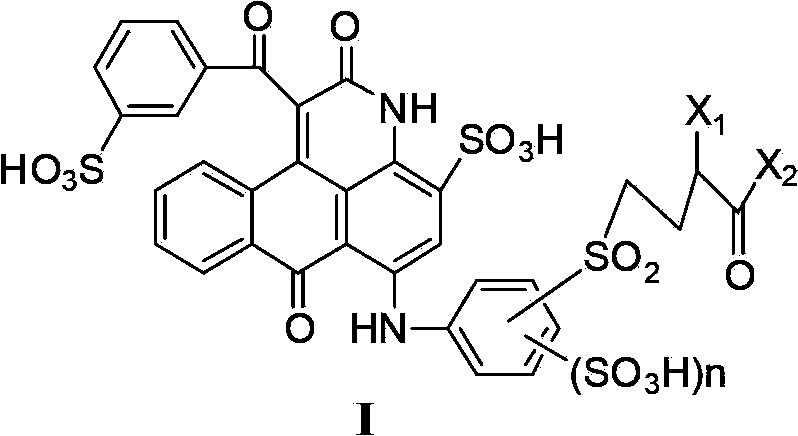

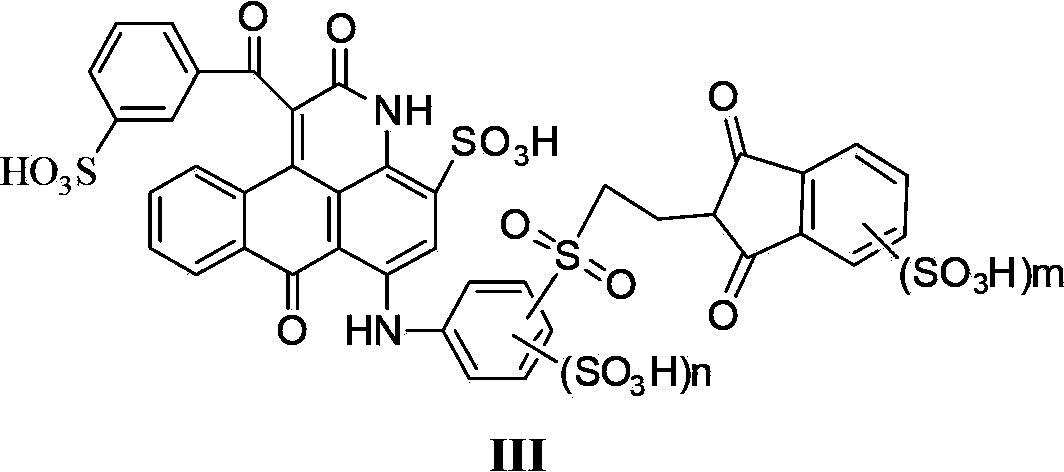

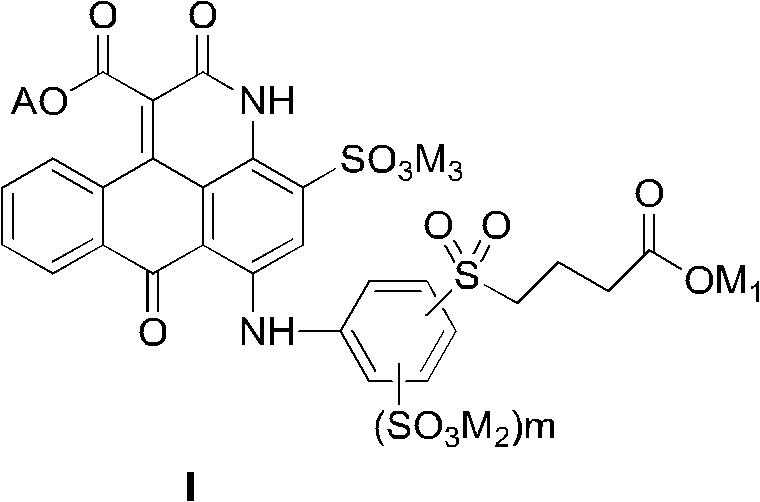

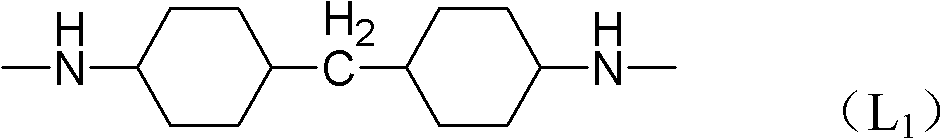

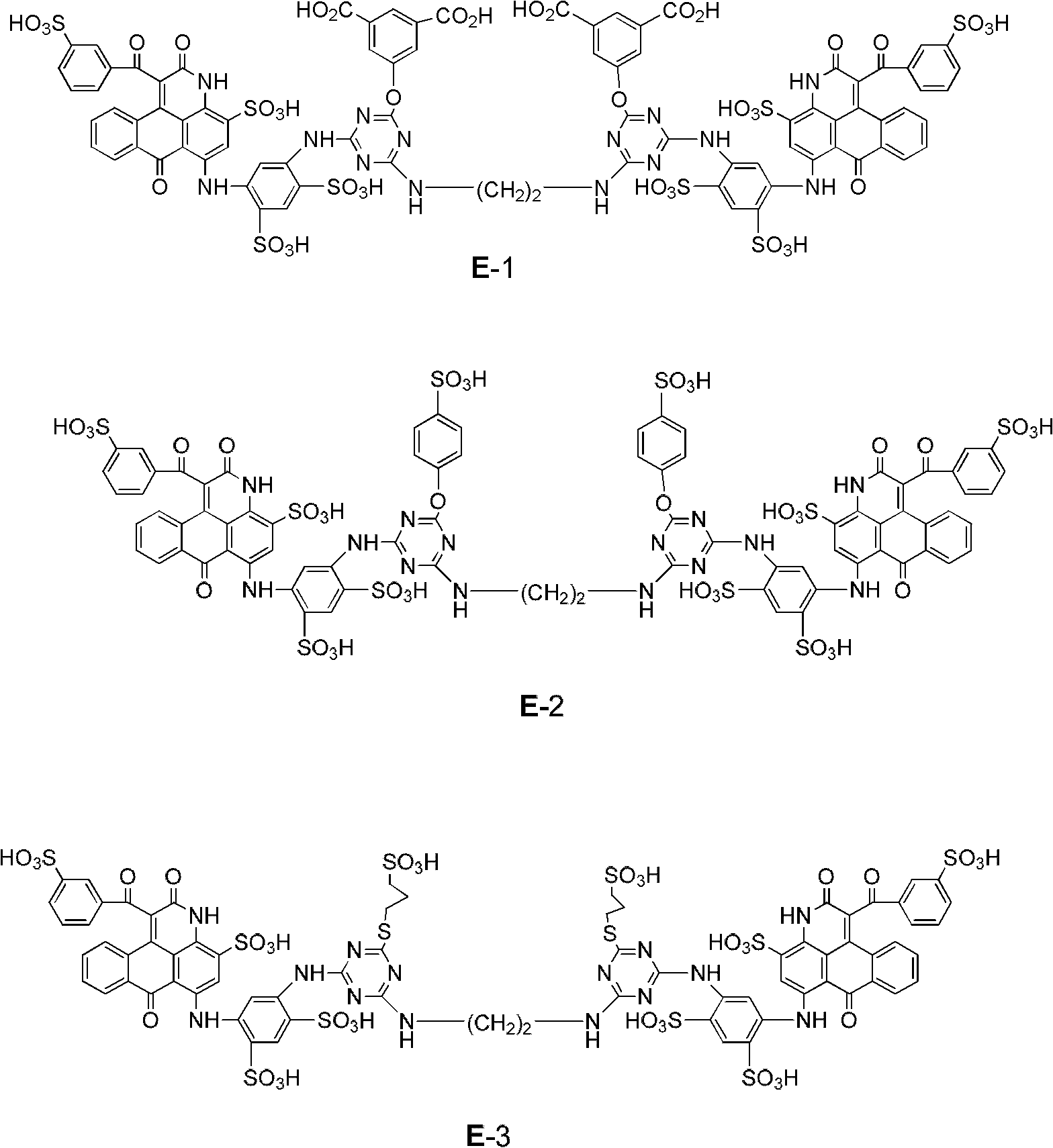

Flexible-chain-contained dikaryotic anthracene pyridine sulfoacid compound or salt thereof, and preparation method and application thereof

InactiveCN102558897AReduce electron cloud densityImprove solubilityInksBenz-azabenzanthrone dyesSolubilityColor image

The invention discloses a flexible-chain-contained dikaryotic anthracene pyridine sulfoacid compound with a formula I or salt thereof. A fuchsin ink composition prepared from the compound and the salt thereof presents a color with extremely-high distinction and brightness on ink-jet recording paper, and has excellent solubility, and the filtering performance of paired filter membrane devices is good in the manufacturing process of the ink composition. In addition, after long-time storage, the ink composition has no crystallization, physical change or color change and the like, and the storage stability is good. A printed object using the fuchsin ink composition has the advantages that recorded materials are not selected, the colors of color images with photo colors can be restored and presented truly, the fastness properties such as the light resistance, the ozone resistance and the wet resistance are good, and the long-time storage of the images is stable.

Owner:DALIAN UNIV OF TECH +1

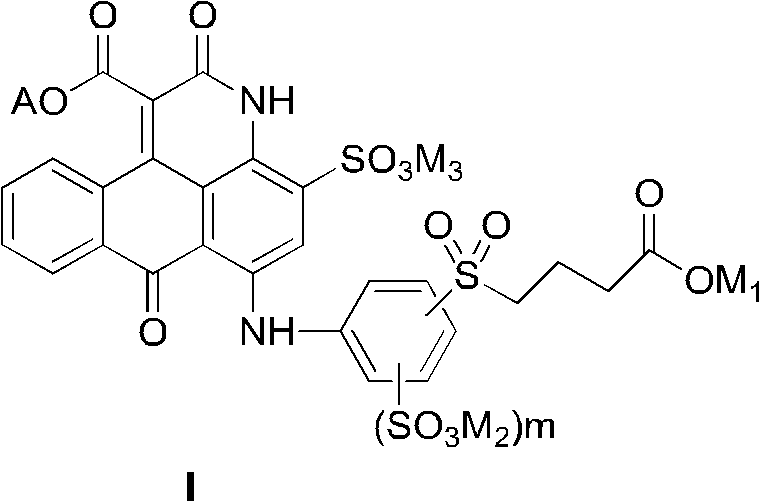

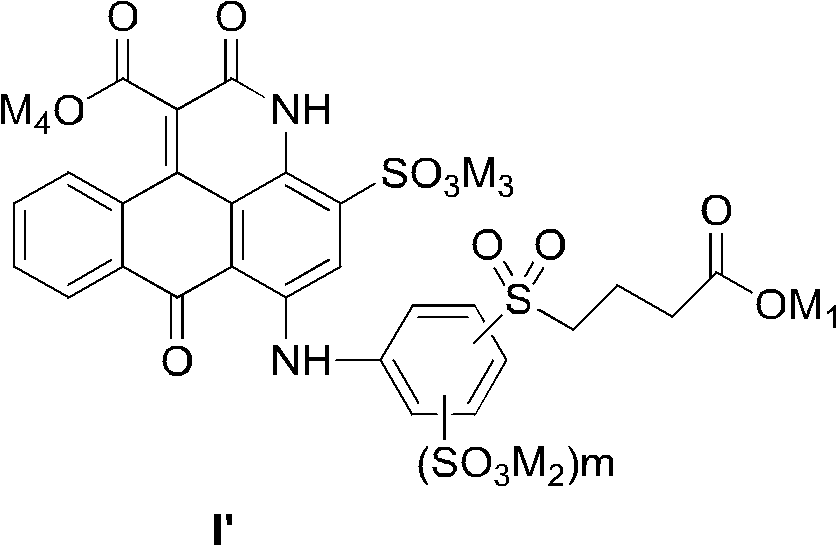

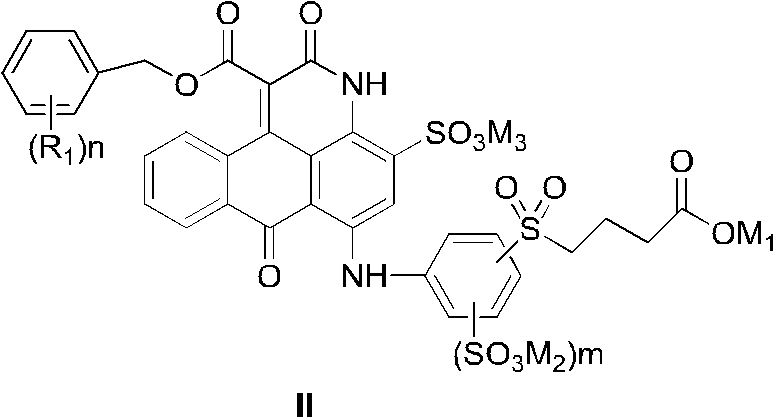

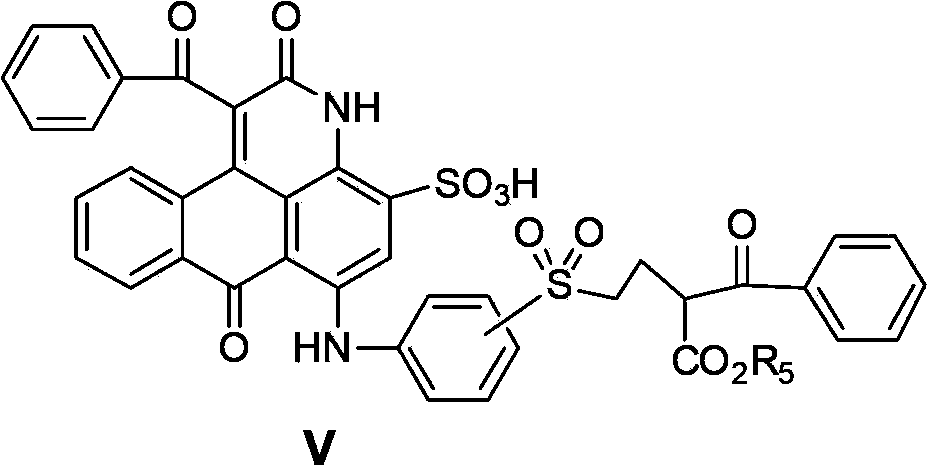

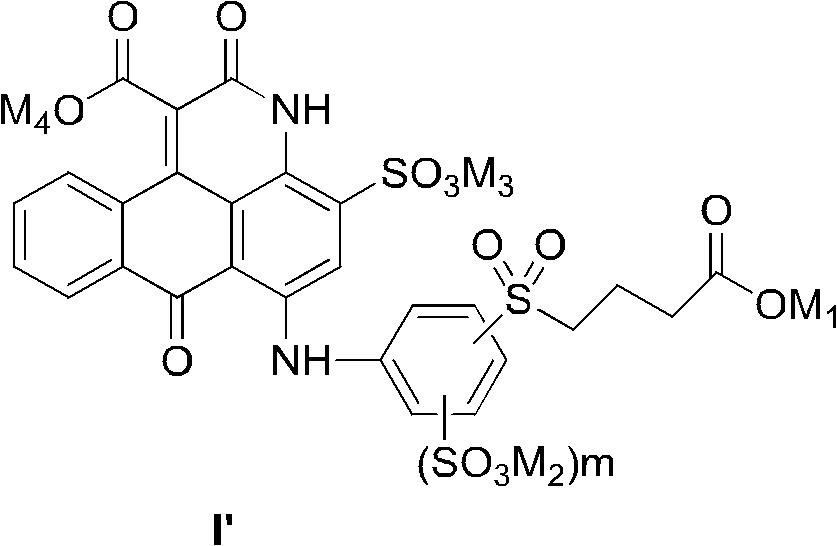

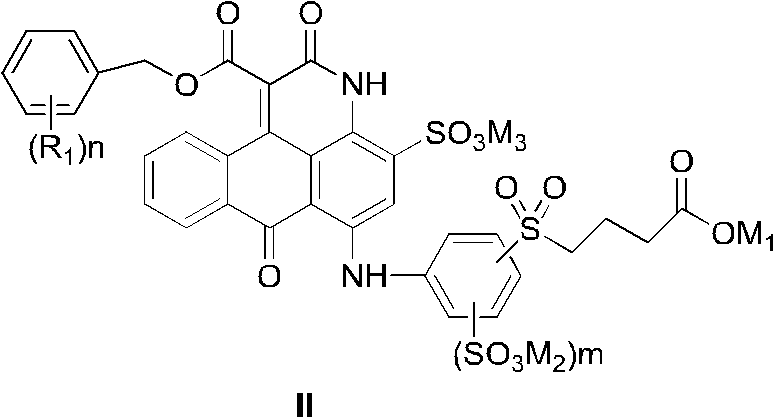

Magenta dye and preparation method and application thereof

ActiveCN102634223ALow densityExcellent ozone resistanceInksBenz-azabenzanthrone dyesSolubilityBenzene

The invention relates to a magenta dye and a preparation method and application thereof. The magenta dye comprises a compound with a general formula (I) or mixture thereof, wherein the carboxyl, sulfonyl and carbonyl propyl sulfonyl sulfonic acid are simultaneously introduced to the anthracene pyridone parent; A in the general formula (I) can be cation M4 or substituted or un-substituted benzyl or substituted or un-substituted naphthyl methyl; M1, M2 and M3 are independent cation or anion groups; and the sulfonic acid group (SO3M2) m can be located at any position of the benzene ring, wherein m is an integer from 0-2. The magenta dye contains carboxyl (or carboxyl benzyl ester group or naphthyl methyl) group, sulfonic acid group and carbonyl propyl sulfonyl, thus the magenta dye can meet the requirements for multiple aspects of tone, vividness, light resistance, water resistance, ozone resistance, dissolubility and solution stability.

Owner:DALIAN UNIV OF TECH +1

Anthrapyridone compound and salt thereof, magenta ink composition containing such anthrapyridone compound, and colored body

InactiveCN101223242AIncrease brightnessGood water solubilityOrganic chemistryDuplicating/marking methodsAnilineAlkyl amine

The present invention relates to a novel anthrapyridone compound in free acid form represented by the following formula (1), an ink composition containing the compound, and a colored body using the composition (in the above formula (1), R1 represents a hydrogen atom, Alkyl, etc., R2 represents a hydrogen atom, alkyl, phenyl, phenoxy, etc., R3 represents a hydrogen atom or methoxy group, X represents an anilino group that may have a substituent such as a sulfonic acid group, naphthalene that may be substituted by a sulfonic acid group Amino group, mono- or dialkylamino group which may have substituents such as sulfonic acid group, aralkylamino group, cycloalkylamine group, phenoxy group which may have substituents such as sulfonic acid group, hydroxyl group, amino group, etc. , Y represents a chlorine atom, a hydroxyl group, an amino group, etc.), the image recorded by the inkjet recording ink containing the compound of the present invention has high definition, and exhibits excellent light resistance and ozone resistance.

Owner:NIPPON KAYAKU CO LTD

Azo compound, ink composition, recording method, and colored object

InactiveCN101248141AGood water solubilityGood storage stabilityDuplicating/marking methodsInksHydrogenPhotochemistry

Owner:NIPPON KAYAKU CO LTD

Encapsulation product, process for producing the same, and ink composition

InactiveCN100522339CReduce poisonUniform surface stateInksMicroballoon preparationSURFACTANT BLENDPolymer chemistry

An encapsulation product having excellent properties, e.g., no limitation on core substances. The encapsulation product comprises a wall material comprising a polymer as a major component and a core substance encapsulated therein, wherein the polymer is in contact with the core substance through an ionic surfactant (a) and comprises (1) structural repeating units derived from an ionic polymerizable surfactant (B) and / or an ionic monomer and (2) structural repeating units derived from an ionic polymerizable surfactant (C) having a charge which is the same as or opposite to that of the ionic surfactant (a). Alternatively, the encapsulation product comprises a wall material comprising a polymer as a major component and a core substance encapsulated therein, wherein the polymer comprises structural repeating units of a hydrophobic monomer and is present between (1) an ionic surfactant (b) and (2) an ionic surfactant (c).

Owner:SEIKO EPSON CORP

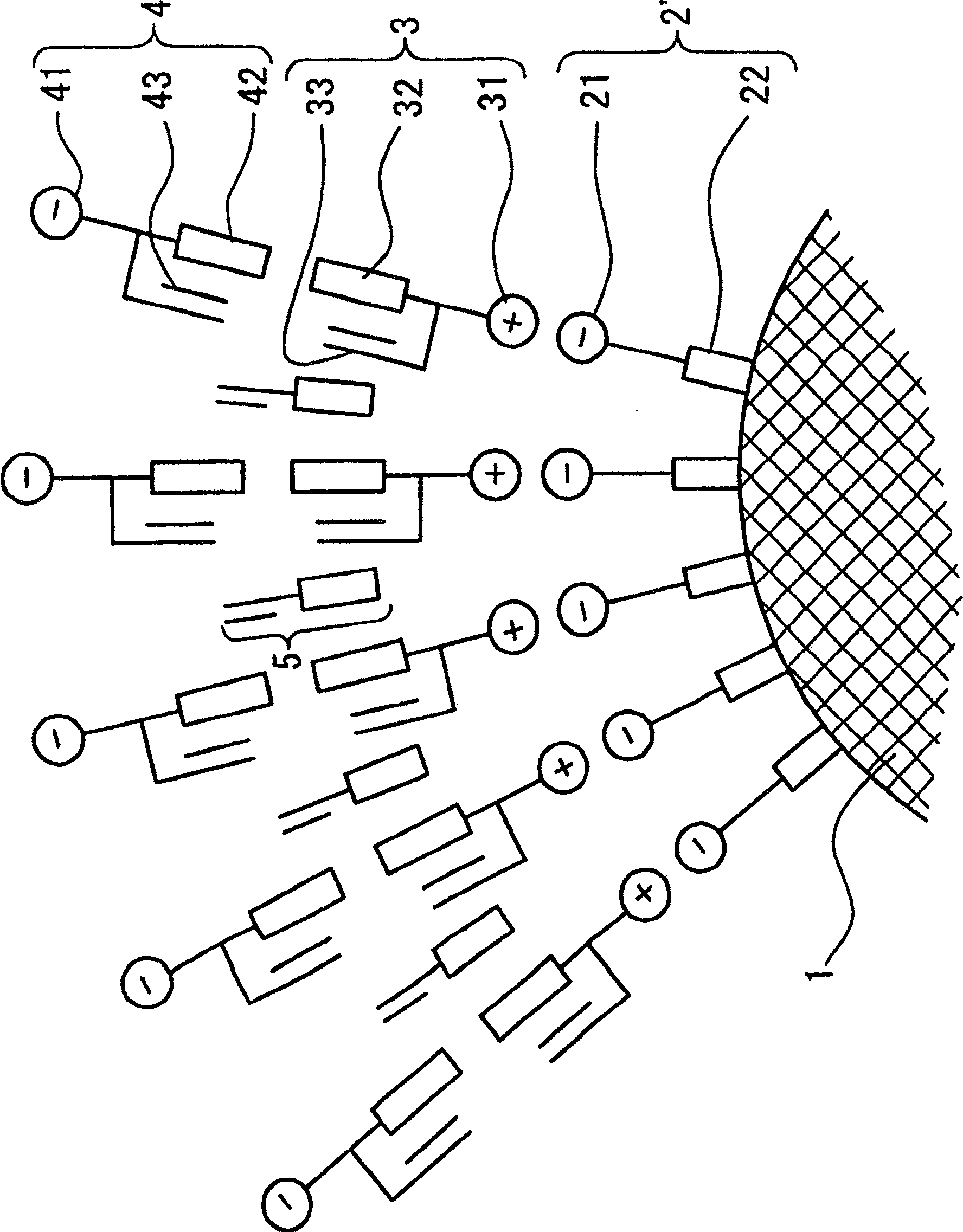

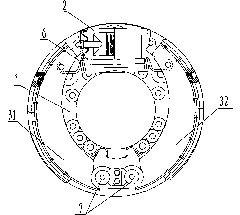

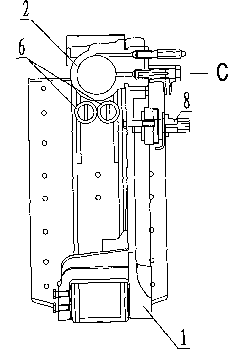

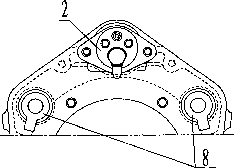

Drum-type hydraulic double-reinforcement shoe anchor pin type brake

InactiveCN101799051AExcellent stiffnessExcellent fastnessBraking membersFluid actuated drum brakesSpot weldingBrake shoe

The invention relates to a drum-type hydraulic double-reinforcement shoe anchor pin type brake which comprises a bracket, a hydraulic branch pump, a left brake shoe and a right brake shoe, wherein the hydraulic branch pump is fixed on the bracket; the left brake shoe and the right brake shoe are symmetrically distributed on the bracket and are double-reinforcement type brake shoes; the top ends of the left brake shoe and the right brake shoe are respectively connected with a left support rod and a right support rod of the branch pump; and the upper ends of the left brake shoe and the right brake shoe are connected by a return tension spring, and the lower ends of the left brake shoe and the right brake shoe are respectively articulated with the bracket. The left and right double-reinforcement type brake shoes are provided with a brake shoe framework, and the brake shoe framework is respectively formed in such a way that two parallel steel rib plates and a steel cambered panel are fixedly combined. The two parallel rib plates are connected with the cambered panel in a spot welding way. The double-reinforcement type brake shoe has tiny elastic deformation at the moment of brake so as to generate great brake explosive force; the brake performance, the brake effect and the brake reliability are better than those of a common brake; and the invention is more suitable for the brake of heavy-duty and large engineering mechanical vehicles.

Owner:CHANGZHOU HUAZHONG BRAKE

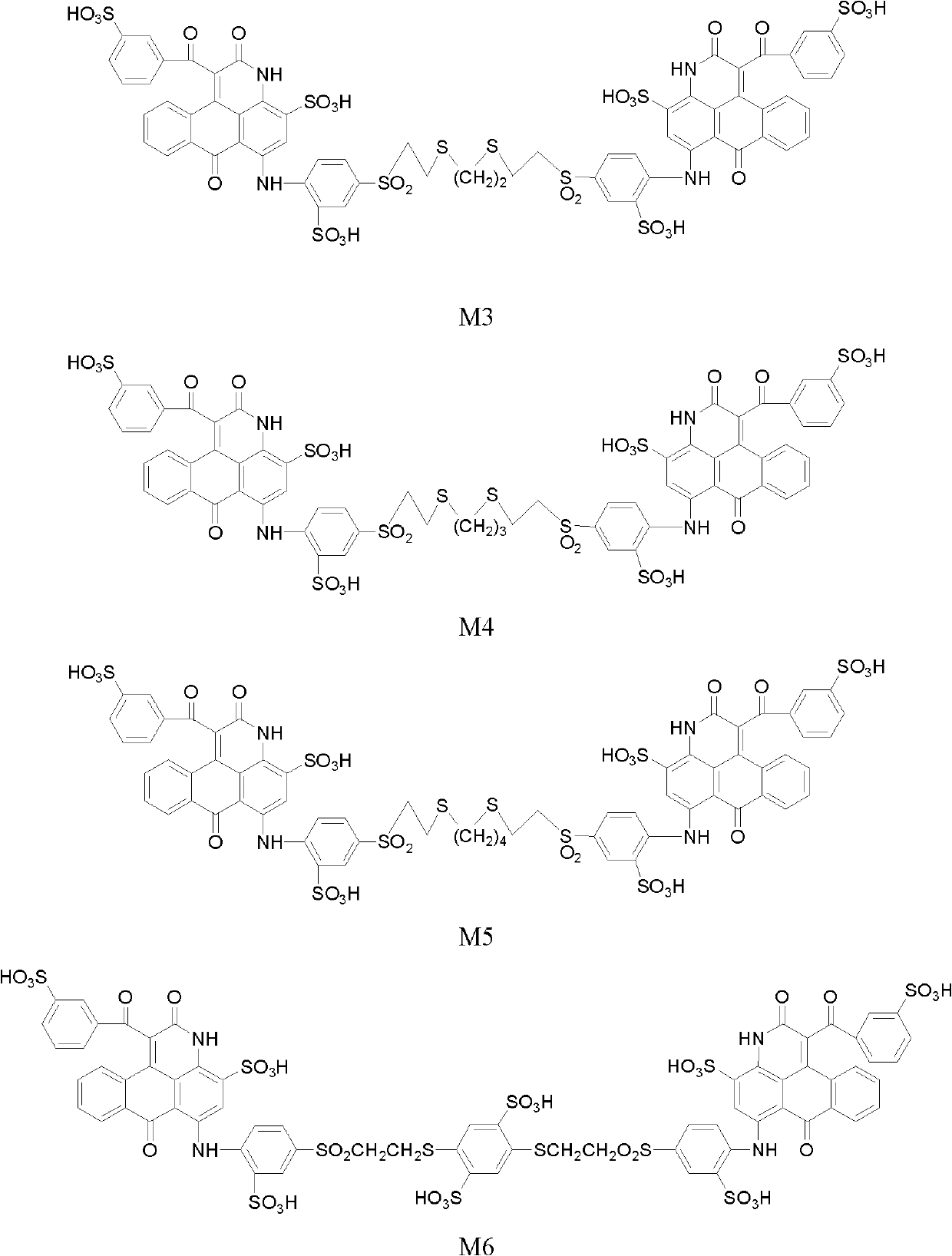

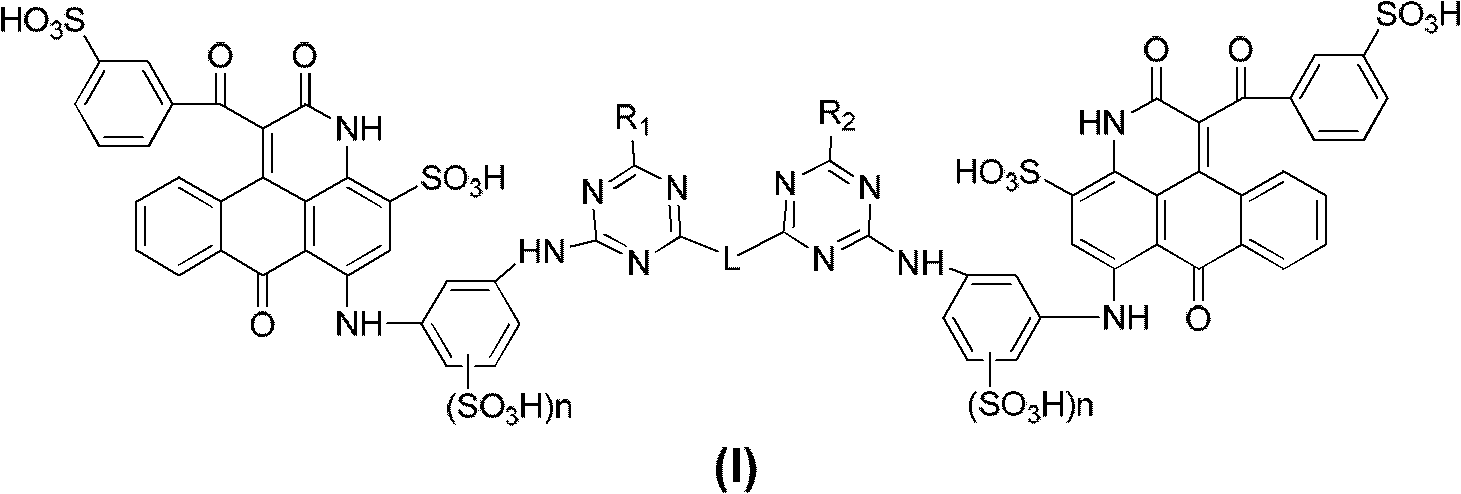

Binuclear anthracene pyridone sulfonic acid compounds or salts thereof, and preparation method and application thereof

InactiveCN102516231APromote formationReduce electron cloud densityOrganic chemistryInksColor imageSolubility

The invention relates to a binuclear anthracene pyridone sulfonic acid compounds disclosed as general formula I or salts thereof, and a preparation method and application thereof. A fuchsin ink composition prepared from the compounds and salts thereof appears distinct color tone with high brightness when being applied on ink jet recording paper, and has excellent water solubility; and the ink composition has good filterability for the filter membrane in the manufacturing process. After being stored for a long time, the ink composition prepared by the compounds does not precipitate crystals, does not have physical changes, color changes or the like, and thus, has high storage stability. The printing object using the fuchsin ink composition can trustily display the color image tones of the photo without selecting the recorded material, and has the advantages of high light fastness, high ozone resistance, high moisture resistance and high image long-term storage stability.

Owner:DALIAN UNIV OF TECH +1

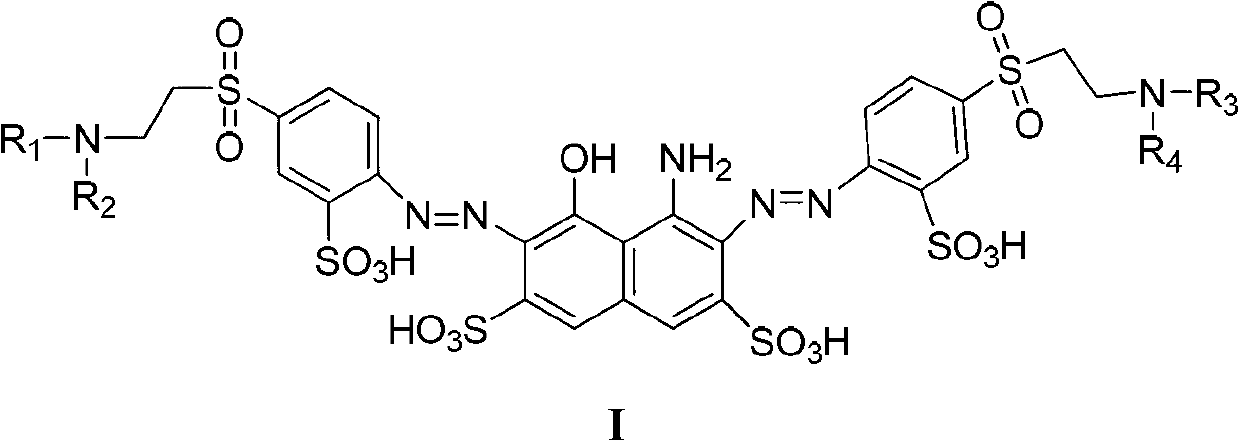

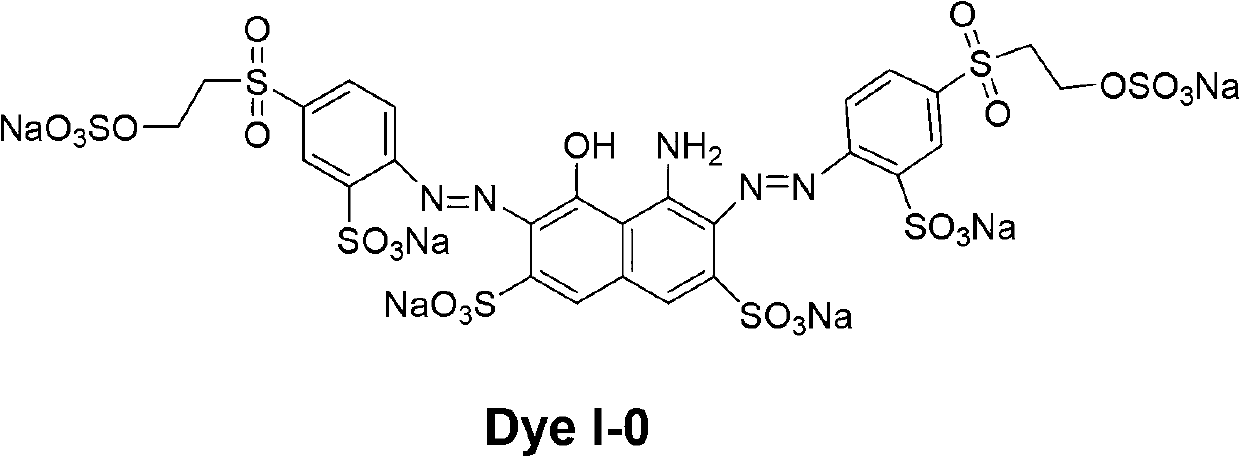

Black bisazo sulfonic acid compound, and salt, preparation method and application thereof

InactiveCN102807767AImprove ozone resistanceImprove flexibilityAzo dye preparationInksSolubilityPrinting ink

The invention provides a black bisazo sulfonic acid compound, salt of the compound, a preparation method and an application of the compound. The compound has the structure represented by the general formula I, in the formula I, each of R1-R4 is independently selected from H or -(CH2)nX, wherein X is H, OH, CO2H or SO3H, n is an integer from 1 to 12. The dye compound of mixture of the dye compound provided by the invention has high dissolubility in water and high long-term stability, and is especially beneficial to the blackness needed by the ink-jet printing; and the image printed by the ink-jet printing ink confected by the dye compound has excellent fastness of light resistance, moisture resistance and ozone resistance.

Owner:SPECIAL CHEM CO LTD DALIAN FIRSTAR

Compositions and their use to treat complications of aneurysmal subarachnoid hemorrhage

InactiveCN105324105AImprove dyeing effectGood water solubilityCosmetic preparationsHair cosmeticsSubarachnoid spaceParticulates

The described invention provides a method for treating an interruption of a cerebral artery in a subarachnoid space at risk of interruption caused by brain injury in a mammal, which reduces signs or symptoms of at least one delayed complication associated with brain injury using a flowable sustained release particulate composition.

Owner:HODOGOYA CHEMICAL CO LTD

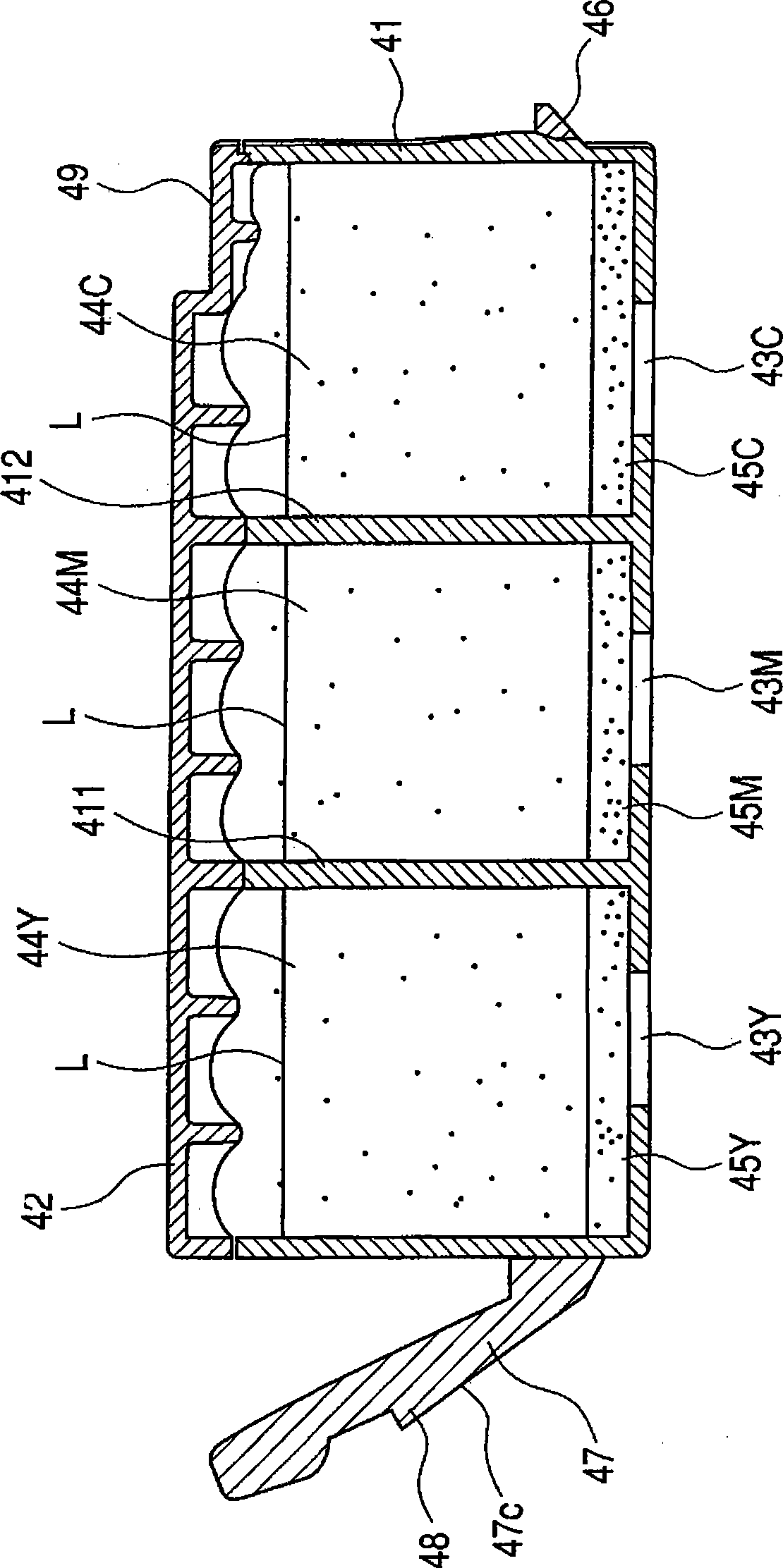

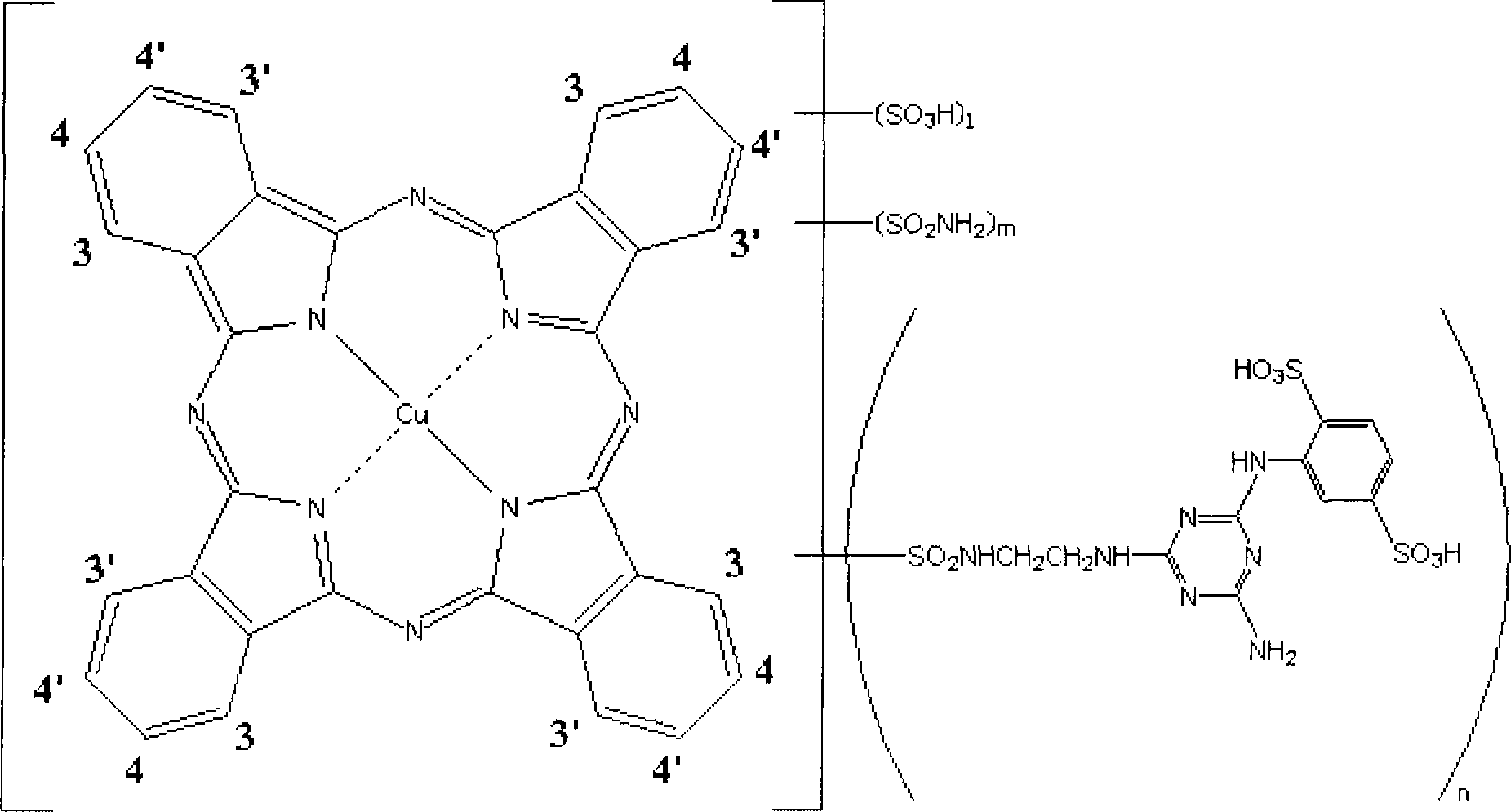

Inkjet ink, method for producing inkjet ink, inkjet recording method, and ink cartridge

Owner:CANON KK

Inkjet ink, method for producing inkjet ink, inkjet recording method, and ink cartridge

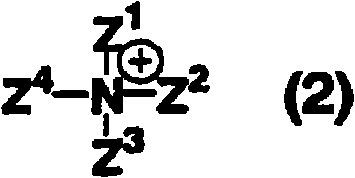

InactiveCN101010392AExcellent color developmentExcellent fastnessDuplicating/marking methodsInksChemical compoundPhthalocyanine

Disclosed is an inkjet ink containing at least a colorant which is composed of at least one material selected from the group consisting of C. I. Acid Blue 9 and compounds having a copper phthalocyanine structure, and a compound represented by the general formula (I) below or a salt thereof.

Owner:CANON KK

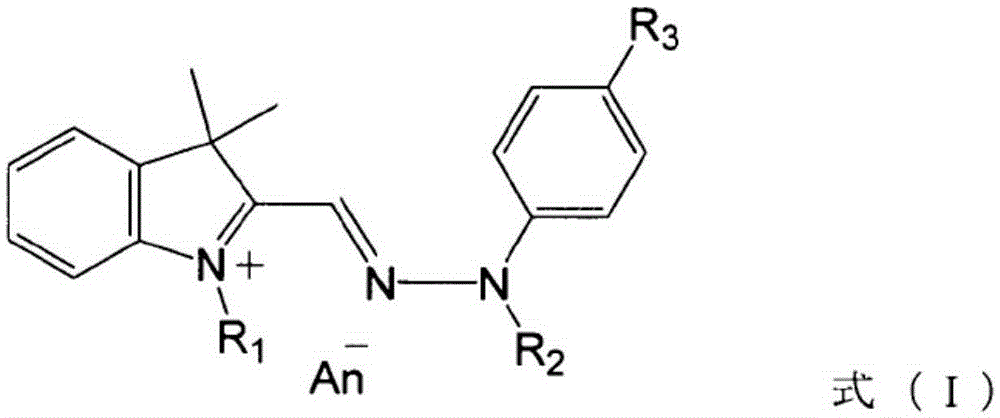

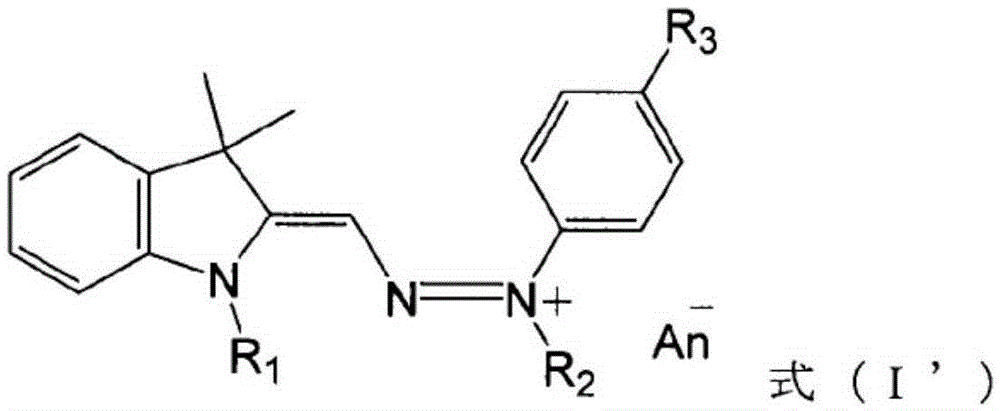

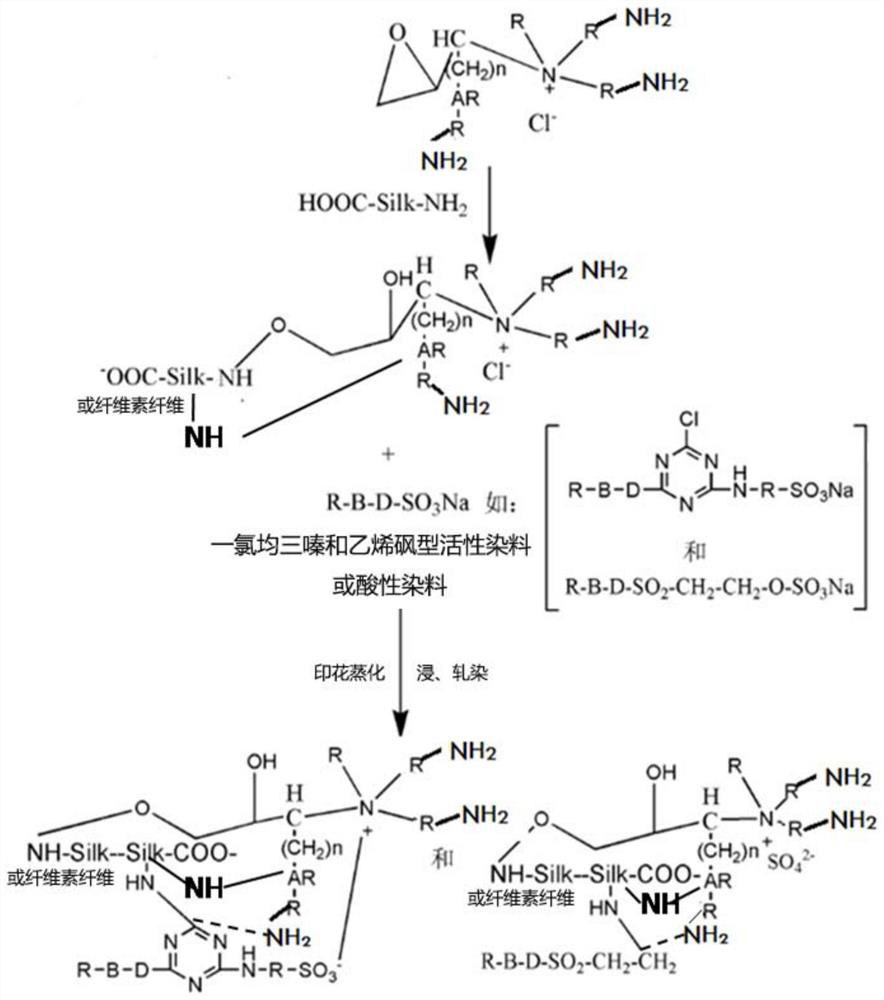

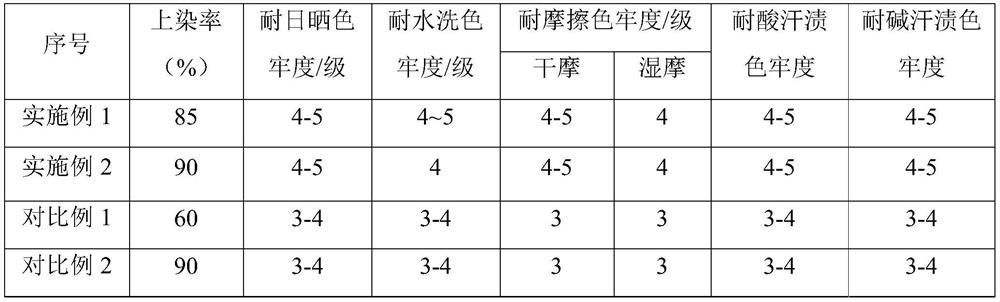

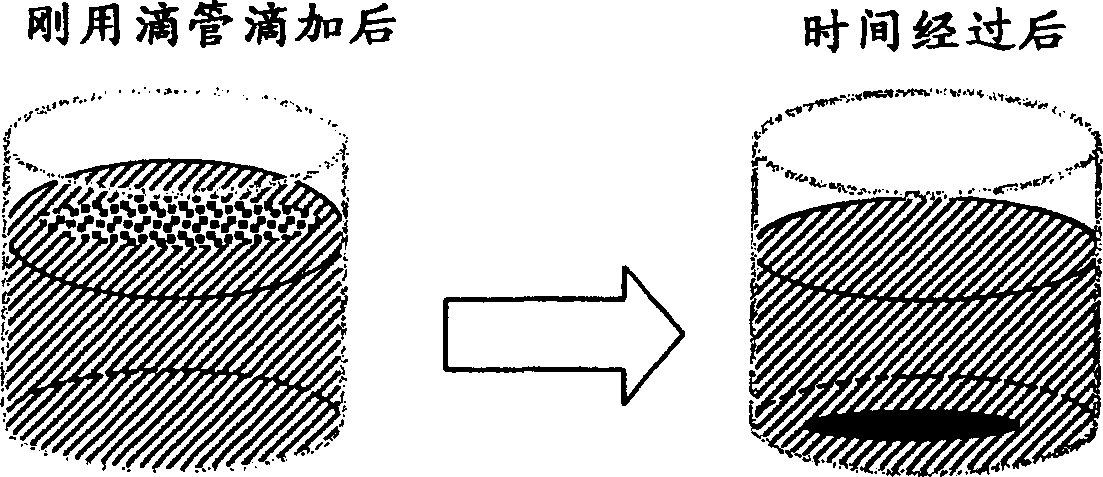

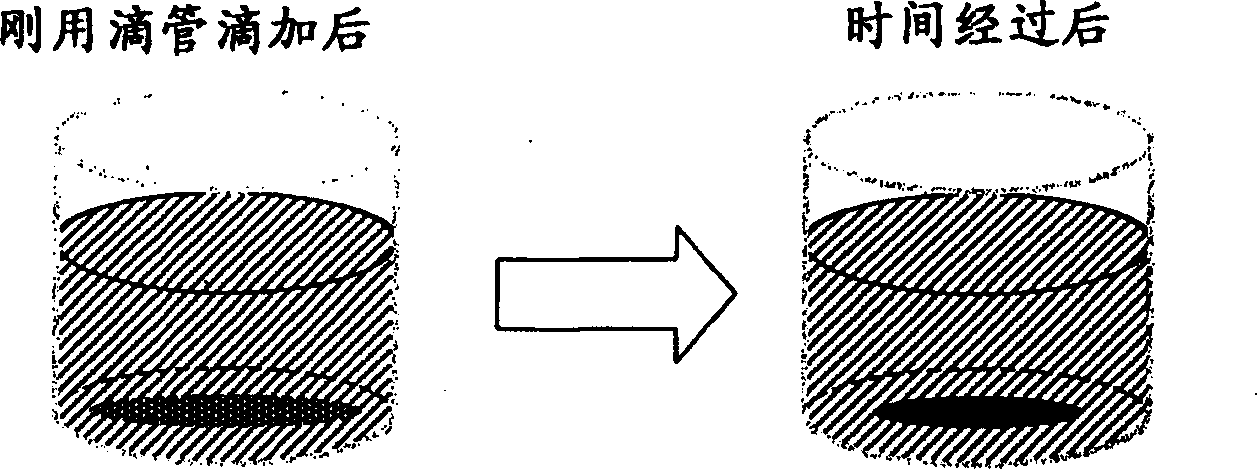

Salt-free alkali-free washing-free dyeing method for all-cotton and regenerated cellulose fabric

InactiveCN111996722AEmission reductionSaving dyeSucessive textile treatmentsHeating/cooling textile fabricsProcess engineeringBatch reaction

The invention discloses a salt-free alkali-free washing-free dyeing method for an all-cotton and regenerated cellulose fabric. The salt-free alkali-free washing-free dyeing method comprises the following steps that 1, fixation synergistic no-clean amine is rolled, a semi-finished fabric is placed on padding equipment, the fabric is soaked in the fixation synergistic no-clean amine through a plurality of guide rollers, the fabric is uniformly rolled through a double-roller padder, the fabric is flatly rolled on an A-shaped frame, rotary cold batch is carried out for 1 to 48 hours; after the cold-batch reaction, washing with a continuous washing machine for the first time and drying are carried out; 2, dyeing is carried out, the fabric is put into the double-roller padder again, the fabric is soaked in the dyeing solution by virtue of the plurality of uniform guide rollers, the fabric is rolled by virtue of a roller, the fabric is rolled on an A-shaped frame in a wet manner, and rotary cold batch is carried out for 1-24 hours to react and fix the color; the fabric is directly dried without washing, the drying temperature ranges from 80 DEG C to 180 DEG C, padding is conducted througha setting machine, a fabric softening agent is added, the PH value is adjusted, other after-finishing auxiliaries are used for tentering and shaping, the shaping temperature ranges from 100 DEG C to180 DEG C; and final preshrinking, calendaring and other processes are carried out, and a finished product is inspected and packaged. The method II comprises the following steps that 1, the fixation synergistic no-clean amine is rolled, the semi-finished fabric is put on the padding equipment, the fabric is soaked in the fixation synergistic no-clean amine by virtue of the plurality of guide rollers, uniform rolling and direct drying at 80-180 DEG C for later use are carried out, the fabric is subjected to dip dyeing in a dye vat or uniform pad dyeing through the double-roller padder and thenis dried, softened and shaped, the shaping temperature ranges from 100 DEG C to 180 DEG C; and the final preshrinking, calendaring and other processes are carried out, and the finished product is inspected and packaged.

Owner:杭州帛阳新材料科技有限公司

Carbonyl propyl sulfuryl anthracene pyridone sulfonic acid compound, preparation method and application thereof

The present invention relates to compounds shown in the general formula (I) or (III), the salts thereof or their mixtures, as well as their preparation method and application. In the general formula (I), X1 is H or CO2H; X2 is OH or phenyl group with 0-2 sulfonic acid substituents, and the sulfonic acid substituents are located at random positions of a benzene ring; when X2 is OH, X1 is H; when X2 is phenyl group with 0-2 sulfonic acid substituents, X1 is H or CO2H; n is an integer of 0-2; and in the general formula (III), n and m are respectively an integer of 0-2. The compounds and the mixtures not only have improved light resistance, ozone resistance and water resistance, but also have excellent water solubility and long-term stability in ink-jet ink.

Owner:DALIAN UNIV OF TECH +1

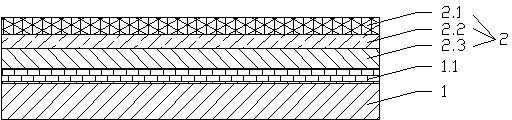

High-temperature-resisting and silver-foil-imitated decorative film

InactiveCN104228161AExcellent fastnessExcellent appearanceNatural patternsLayered productsEngineeringSilver color

The invention relates to a high-temperature-resisting and silver-foil-imitated decorative film. The high-temperature-resisting and silver-foil-imitated decorative film is characterized by comprising a base material (1) and a printing surface film (2) from bottom to top, wherein the printing surface film (2) comprises a printing film (2.1), a silver white basic color layer (2.2) and a pure silver color surface film (2.3) from top to bottom; and a corona layer (1.1) is arranged on the upper surface of the base material (1). The high-temperature-resisting and silver-foil-imitated decorative film has the advantages that a silver foil and a silver skin can be replaced, the fastness and the appearance effect are better than those of the silver foil and the silver skin, and the cost is lower than that of the silver foil and the silver skin.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

Phthalocyanine pigment composition, coloring composition and color filter

ActiveCN107207872BExcellent fastnessImprove heat resistanceOptical filtersPorphines/azaporphinesContrast levelHalogen

Provided is a phthalocyanine pigment which exhibits excellent fastness, has excellent color characteristics (brightness) and contrast ratio, generates few foreign objects caused by association or aggregation of molecules or the like even in a high temperature environment at greater than 230ºC, and is useful as a coloring agent. Also provided is a coloring composition using the phthalocyanine pigment, and a color filter. This phthalocyanine pigment is represented by general formula (1). In the formula, X denotes a halogen atom and n is an integer between 4 and 16. However, the average value for the degree of substitution by halogen atoms denoted by X is 6-15, and the halogen distribution width is 4 or higher. Y1 denotes -OP(=O)R1R2, -OC(=O)R3, -OS(=O)2R4 or a hydroxyl group.

Owner:TOYO INK SC HOLD CO LTD +1

Bacteriostatic health-care alginate fiber socks and preparation method thereof

InactiveCN112853591AEssential antibacterial and anti-mildew functionSkin-friendly and comfortableWeft knittingUltrasonic/sonic fibre treatmentYarnTextile technology

The invention belongs to the technical field of textile, and particularly relates to bacteriostatic health-care alginate fiber socks and a preparation method thereof. The preparation method comprises the following steps: carrying out ultrasonic cavitation treatment on softened rabbit hair, carrying out grafting modification on the treated rabbit hair by a surfactant and graphene to obtain modified rabbit hair fibers, blending the modified rabbit hair fibers with alginate fibers and colored long stapled cotton fibers to obtain cotton yarn, and carrying out machining, sewing and shaping by a sock machine to obtain socks. The bacteriostatic health-care alginate fiber socks have the intrinsic antibacterial and mildew-proof functions, and meanwhile have the skin-friendly, comfortable, breathable, wear-resistant, warm-keeping and health-care effects; the preparation process is green and safe, the procedures are simplified, the cost is saved, zero damage of the alginate fibers is achieved, and the antibacterial effect of finished products is ensured to the maximum extent.

Owner:青岛格诚经纬生物科技有限公司

Magenta dye and its preparation method and use

ActiveCN102634223BLow densityExcellent ozone resistanceInksBenz-azabenzanthrone dyesSolubilityMagenta

The present invention relates to a kind of magenta dye and its preparation method and application. Magenta dyes, including compounds of general formula (I) or mixtures thereof that simultaneously introduce carboxyl, sulfonic acid and carbopropyl sulfone sulfonic acid on the anthrapyridone parent: In general formula (I), A can be cation M 4 or substituted or unsubstituted benzyl or substituted or unsubstituted naphthylmethyl; M 1 , M 2 , M 3 Is an independent cationic or cationic group; sulfonic acid group (SO 3 m 2 )m can be located at any position of the benzene ring, wherein m is an integer of 0-2. Due to the carboxyl group (or carboxybenzyl ester group or naphthyl methyl ester) group, sulfonic acid group, and carbonyl propyl sulfone group at the same time, the magenta dye can meet the hue, vividness, light resistance, water resistance, ozone resistance and There are many requirements for solubility and solution stability.

Owner:DALIAN UNIV OF TECH +1

Binuclear anthracene pyridone sulfonic acid compounds or salts thereof, and preparation method and application thereof

InactiveCN102516231BPromote formationReduce electron cloud densityOrganic chemistryInksColor imageSolubility

The invention relates to a binuclear anthracene pyridone sulfonic acid compounds disclosed as general formula I or salts thereof, and a preparation method and application thereof. A fuchsin ink composition prepared from the compounds and salts thereof appears distinct color tone with high brightness when being applied on ink jet recording paper, and has excellent water solubility; and the ink composition has good filterability for the filter membrane in the manufacturing process. After being stored for a long time, the ink composition prepared by the compounds does not precipitate crystals, does not have physical changes, color changes or the like, and thus, has high storage stability. The printing object using the fuchsin ink composition can trustily display the color image tones of the photo without selecting the recorded material, and has the advantages of high light fastness, high ozone resistance, high moisture resistance and high image long-term storage stability.

Owner:DALIAN UNIV OF TECH +1

Water base ink and method for forming image and recorded image using said ink

InactiveCN1780887AExcellent fastnessImprove water resistanceDuplicating/marking methodsInksWater basedLiquid medium

The present invention relates to an ink and a recording method using the ink. The ink of the present invention is characterized in that it is a water-based ink containing water, a water-dispersed colorant, and a liquid medium containing a surfactant. , the above-mentioned water-dispersed coloring material forms a plurality of microagglomerates existing in dots, and is fixed on the recording material.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com