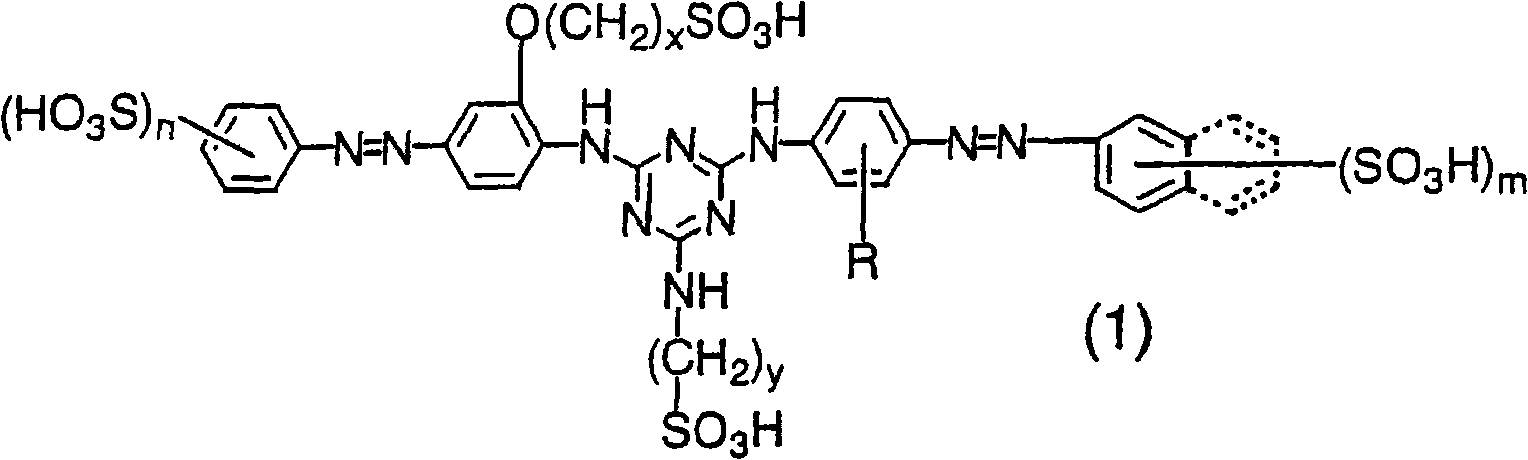

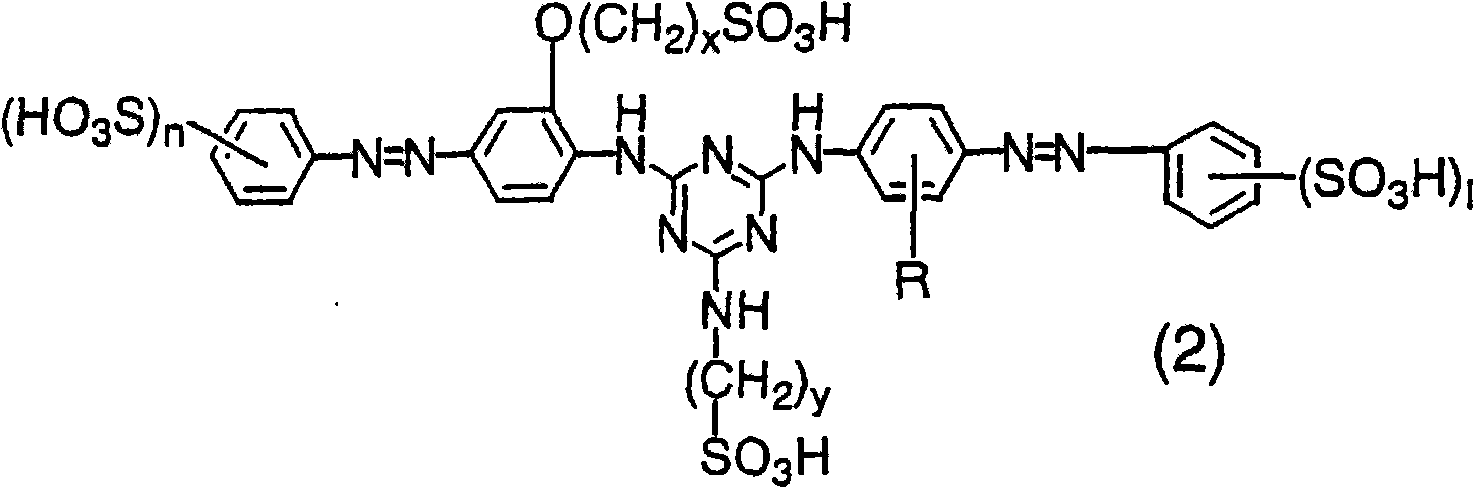

Water-soluble azo compounds or salts thereof, ink compositions and colored products

An azo compound and ink composition technology, applied in the direction of ink, azo dyes, disazo dyes, etc., can solve the problems of nozzle port blockage and ink cost increase, and achieve good light fastness, high color concentration, and solubility. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

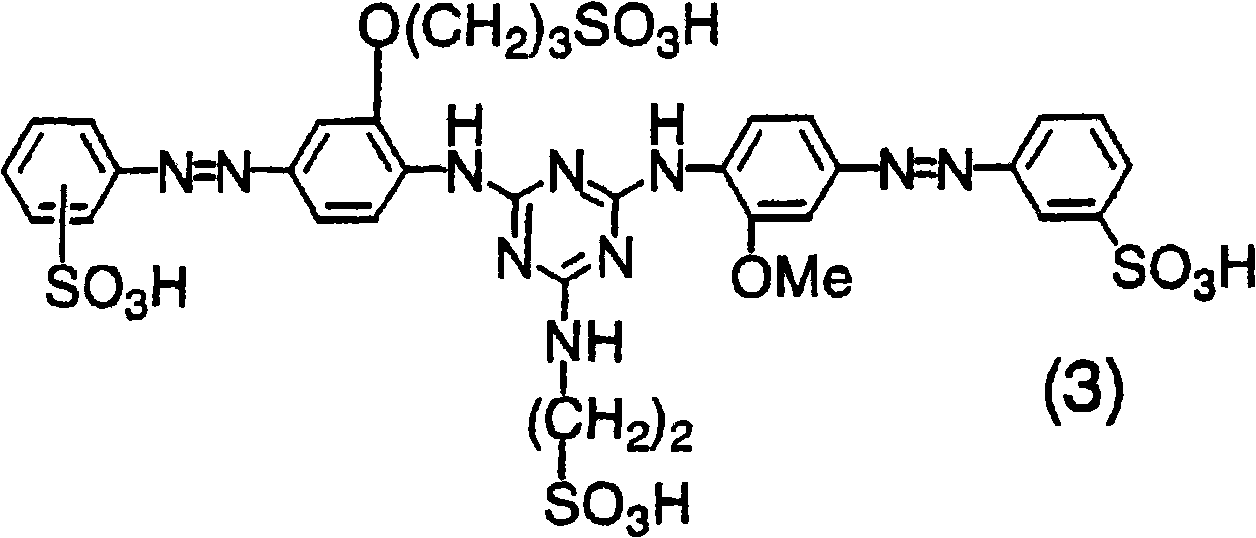

Embodiment 1

[0127] 17.3 parts of 3-aminobenzenesulfonic acid was adjusted to pH 6 with sodium hydroxide, and dissolved in 200 parts of water, and then 7.2 parts of sodium nitrite was added thereto. This solution was added dropwise to 300 parts of 5% hydrochloric acid at 0 to 10° C. over 30 minutes, and stirred at 10° C. or lower for 1 hour to perform a diazotization reaction to prepare a diazonium salt.

[0128] On the other hand, 12.3 parts of 2-methoxyaniline was adjusted to pH 5 with sodium hydroxide, and dissolved in 130 parts of water. The obtained solution was treated with 10.4 parts of sodium bisulfite and 8.6 parts of 35% formalin by a conventional method to obtain a methyl-ω-sulfonic acid derivative.

[0129] The obtained methyl-ω-sulfonic acid derivative was added to the previously prepared diazonium salt, and stirred at 0-15° C. and pH 2-4 for 5 hours. After adjusting the obtained reaction solution to pH 11 with sodium hydroxide, it was stirred at 80 to 95° C. for 5 hours whil...

Embodiment 1A

[0140] (A) Preparation of ink

[0141] The azo compound of the present invention obtained in Example 1 above was mixed according to the composition ratio shown in Table 2 to obtain the ink composition of the present invention, and impurities were removed by filtration using a 0.45 μm membrane filter. In addition, ion-exchanged water was used as water, and after adjusting the pH of the ink composition to approximately 9 with an aqueous sodium hydroxide solution, water was added so that the total amount would be 100 parts.

[0142] Table 2A (Composition Ratio of Ink Composition)

[0143] 3.5 parts of azo compounds obtained by embodiment 1

[0144] Glycerin 5.0 parts

[0145] Urea 5.0 parts

[0146] N-methyl-2-pyrrolidone 4.0 parts

[0147] 3.0 parts of isopropanol

[0148] Butyl Carbitol 2.0 parts

[0149] SURFYNOL 104PG50 (trade name) (note) 0.1 part

[0150] Sodium hydroxide + water 77.4 parts

[0151] Total 100.0 parts

[0152] (Note) Acetylene glycol-based nonionic su...

Embodiment 2

[0207] Change 17.3 parts of 3-aminobenzenesulfonic acid of embodiment 1 into 17.3 parts of 4-aminobenzenesulfonic acid, except that, obtain the water-soluble compound of the present invention shown in following formula (8) by the method identical with embodiment 1 Active azo compound (λmax 391nm) 30.0 parts.

[0208]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com