Patents

Literature

203 results about "Butyl carbitol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butyl CARBITOL™ is a slow-evaporating, hydrophilic glycol ether with excellent coalescing and coupling power that can be combined with Butyl CELLOSOLVE™ glycol ether to lower the evaporation rate and increase the hydrophobicity.

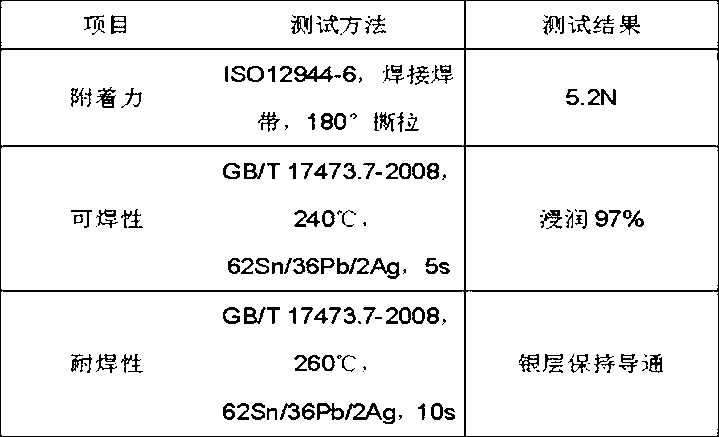

Solar cell back silver slurry and preparing device thereof

ActiveCN106128550ALow costStrong costFinal product manufactureNon-conductive material with dispersed conductive materialSolderabilityMixed materials

The invention provides a solar cell back silver slurry which can reduce the cost, and guarantee better conductivity of a silver layer and great adhesive force with a silicon substrate, and a preparing device thereof. The solar cell back silver slurry is composed of: 65%-75% of powdery mixed materials, 8%-10% of ethyecellulose, 8%-10% of butyl carbitol, 5%-8% of terpilenol, 2%-4% of thixotropic agents and remaining weight ratio of auxiliary agents, wherein the powdery mixed materials are the mixed materials of silver-coated copper powder and glass powder, and the weight ratio between the silver-coated copper powder and the glass powder is (7-12):1. The content of pure silver in the back silver slurry is only about 35%, which is much lower than the heavy silver content of present back silver slurry, so that the usage amount of silver powder is substantially reduced, the cost of the back silver slurry is greatly reduced, and the cost pressure caused by silver cost increase can be alleviated; in addition, greater adhesive force exists between a finally prepared silver layer and the silicon substrate, and the binding property, solderability and soldering resistance are greater. The solar cell back silver slurry and the preparing device thereof are suitable for popularization in the electronic material technical field.

Owner:LESHAN TOPRAYCELL

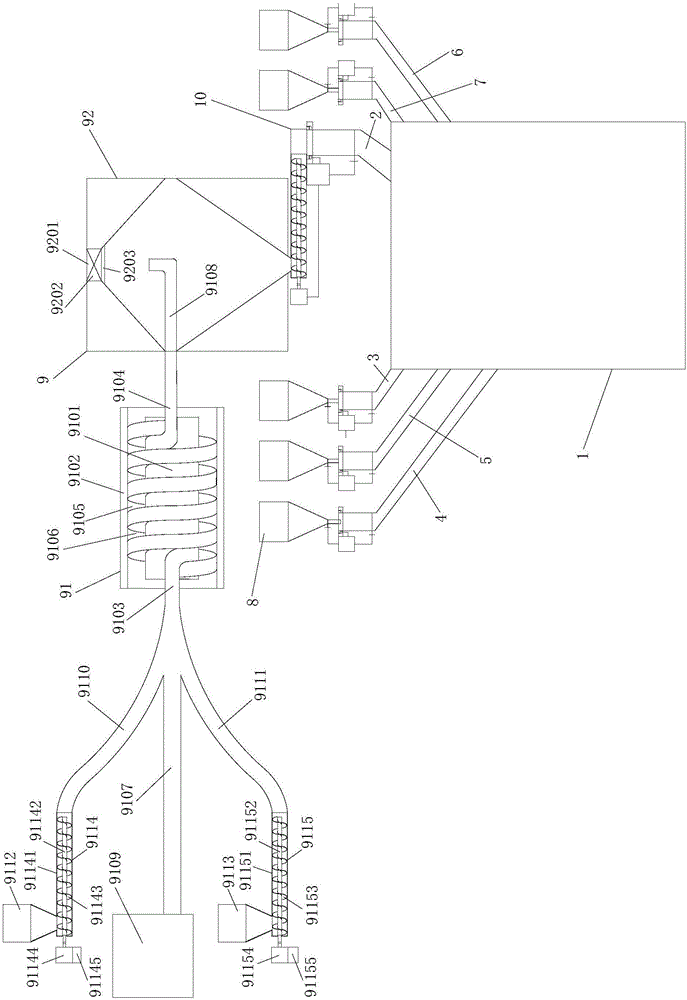

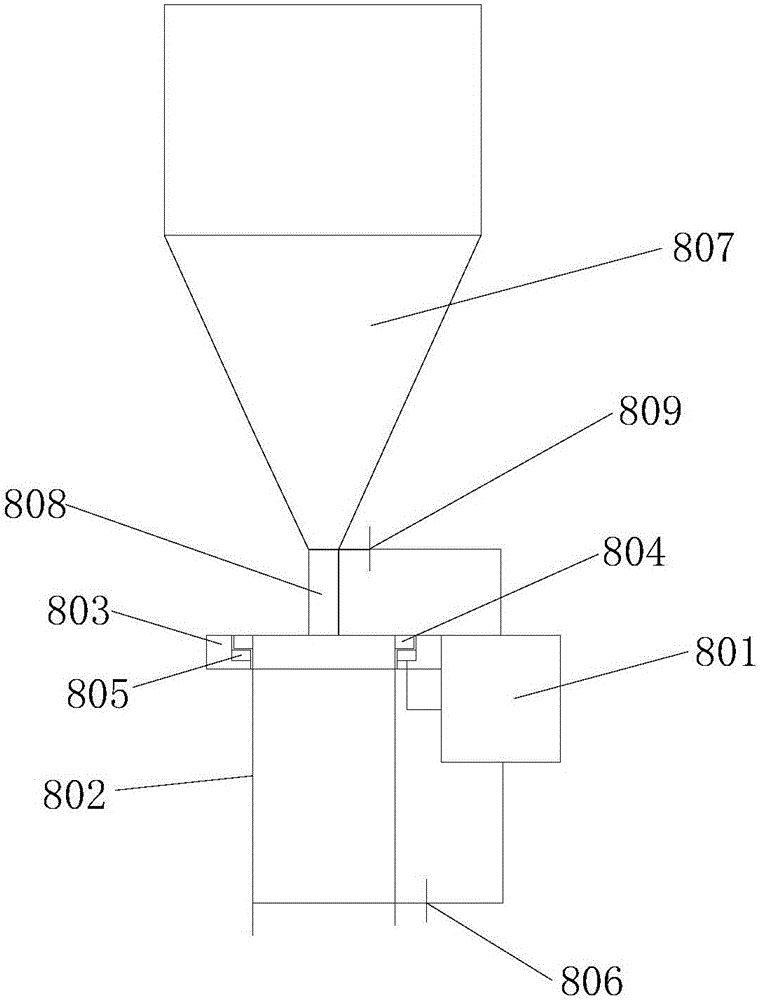

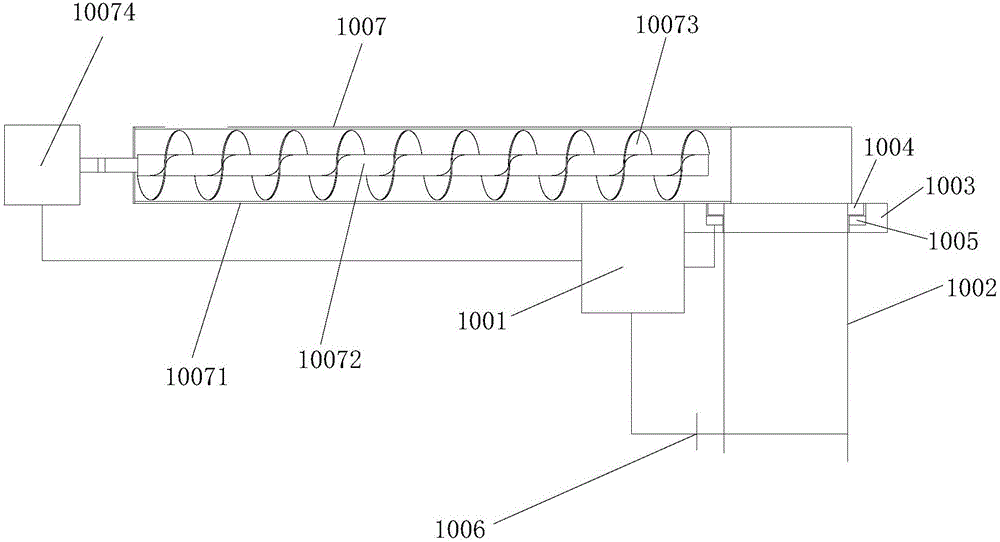

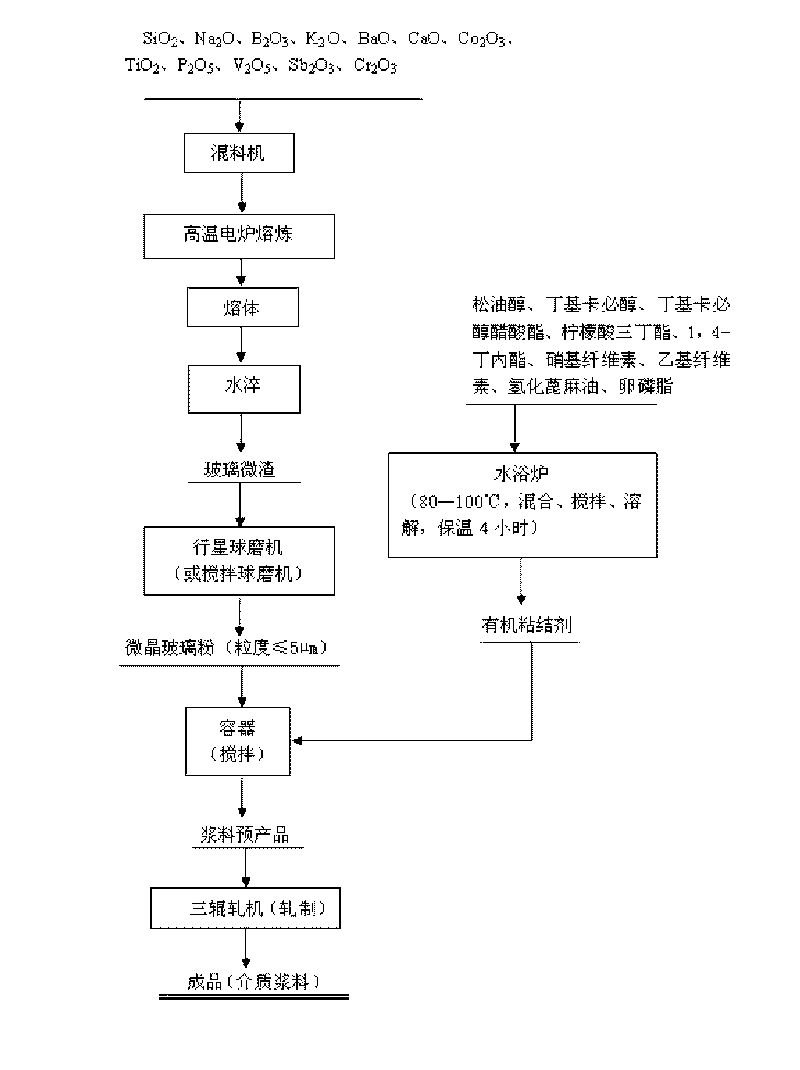

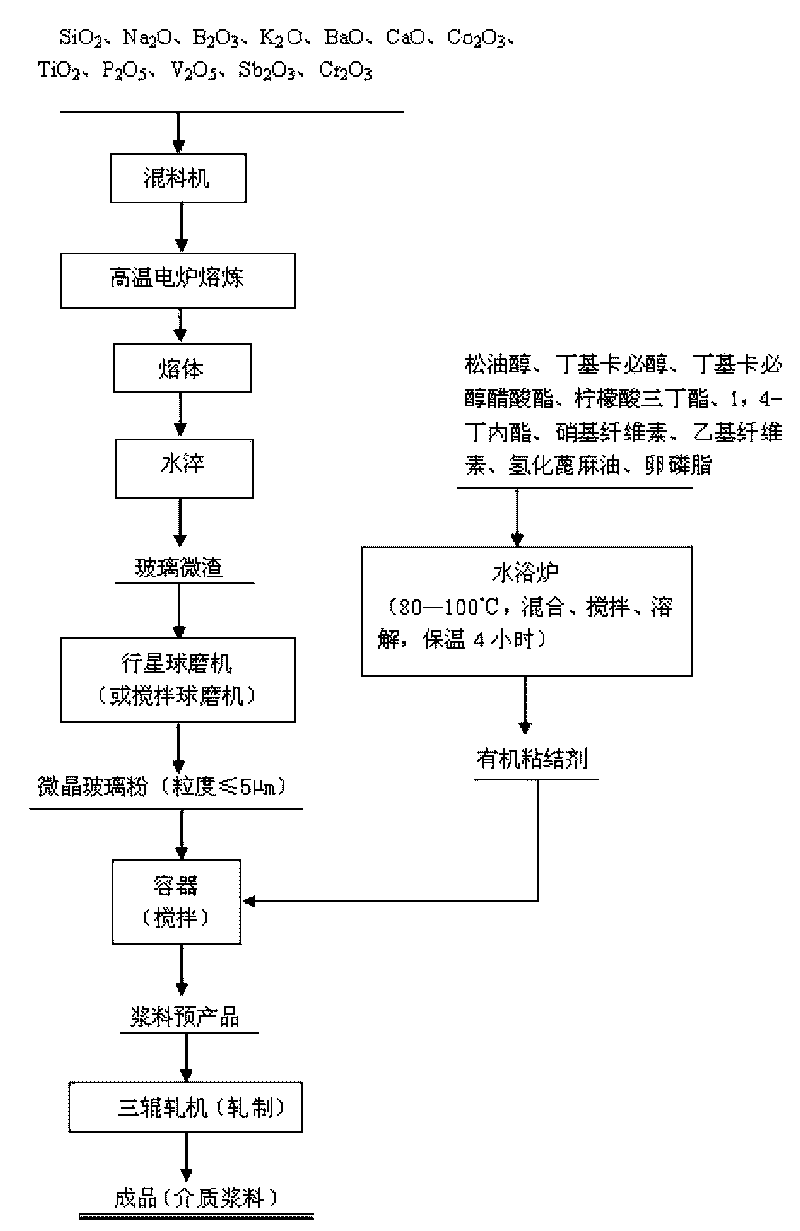

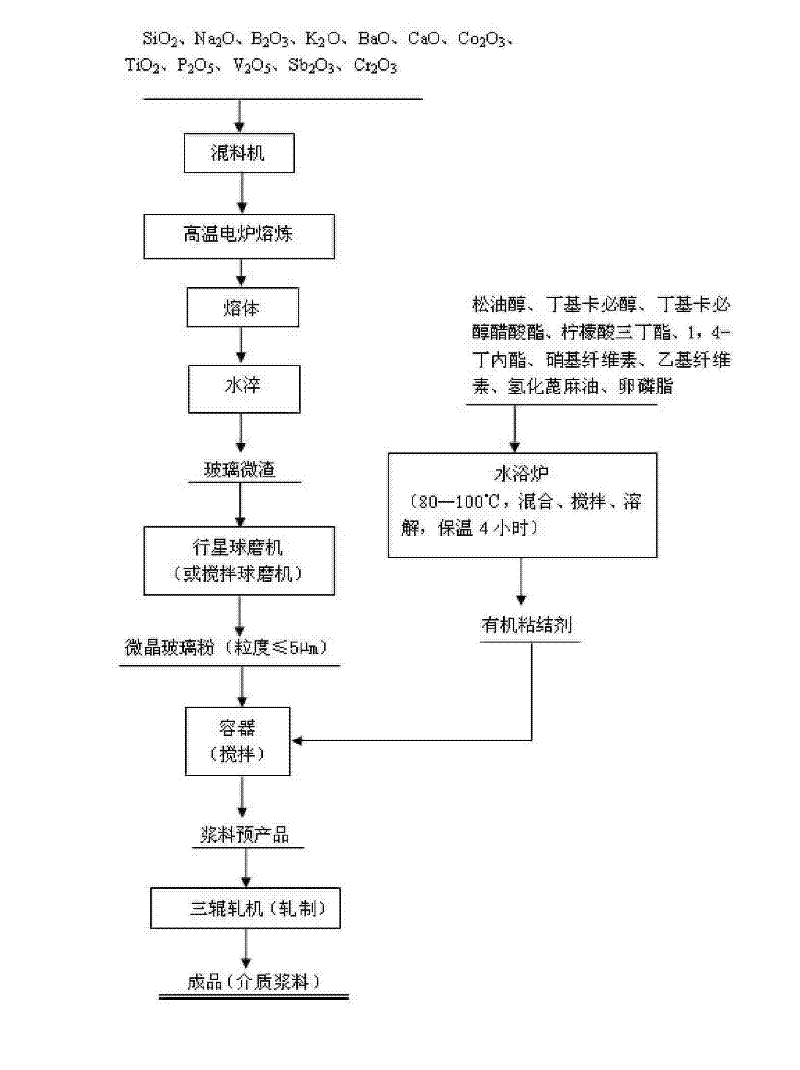

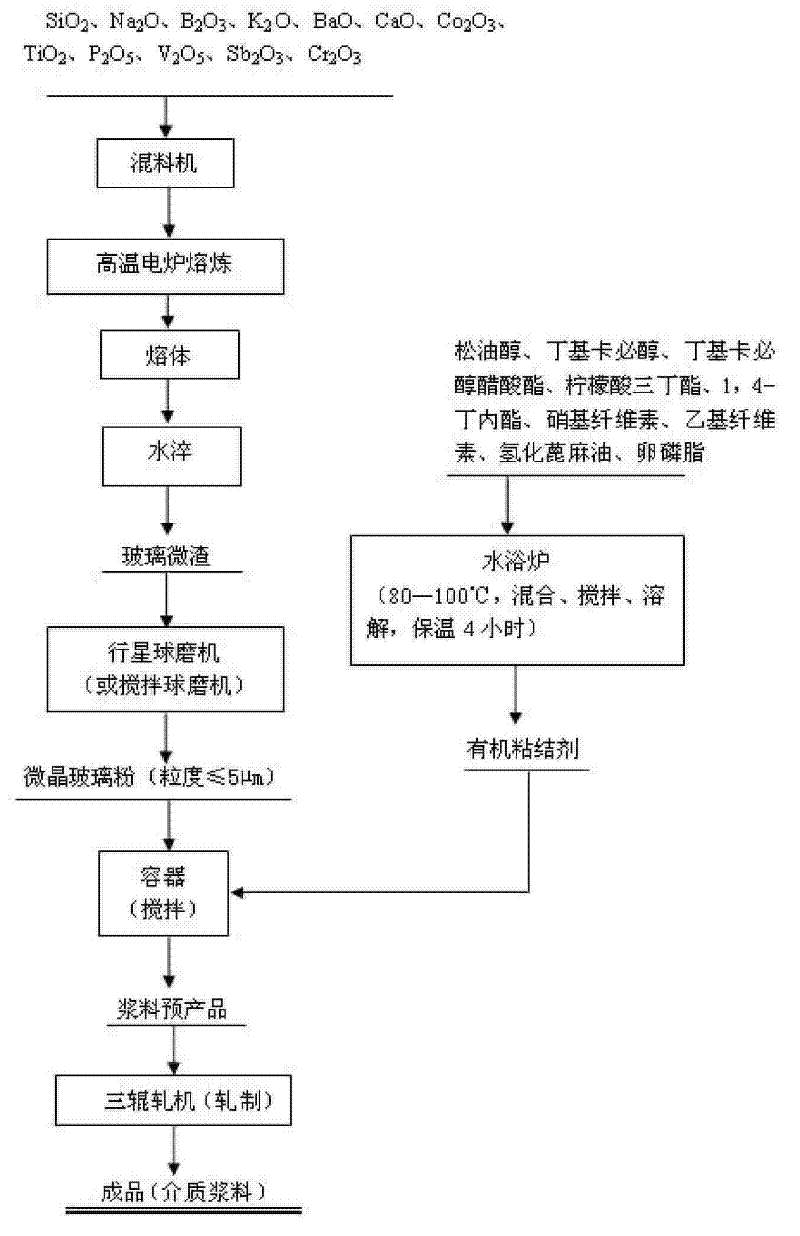

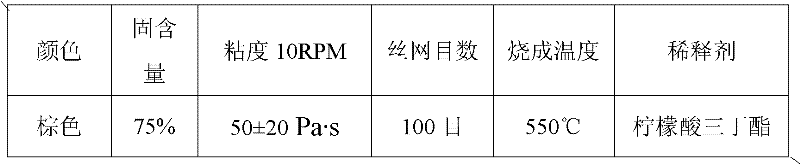

Dielectric paste for metal aluminum substrate thick film circuit and preparation method thereof

InactiveCN101740160AImprove thixotropyGood anti-sinking effectNon-macromolecular adhesive additivesSolid-state devicesDielectricCITRATE ESTER

The invention discloses dielectric paste for a metal aluminum substrate thick film circuit and a preparation method thereof. The invention aims to prepare the dielectric paste matched with a metal aluminum substrate. The dielectric paste is characterized in that SiO2, Na2O, B2O3, K2O, BaO, CaO, Co2O3, TiO2, P2O5, V2O5, Sb2O3 and Cr2O3 are combined to prepare microcrystalline glass powder; and the microcrystalline glass powder and an organic binder which consists of terpinol, butyl carbitol, butyl carbitol acetate, tirbutyl citrate, 1,4-butyrolactone, nitroncellulose, ethyecellulose, hydrogenated castor oil and lecithin are put in a vessel for stirring and rolling by a three-roll roller mill in a weight ratio of the microcrystalline glass powder to the organic binder of 70-90 parts: 30-10 parts so as to prepare the finished product dielectric paste. The dielectric paste is mainly used as the dielectric paste of the thick film circuit formed by being printed on the metal aluminum substrate.

Owner:湖南利德电子浆料股份有限公司

Medium temperature sintering type electro-conduction slurry with lead-free glass powder and preparation method of medium temperature sintering type electro-conduction slurry

InactiveCN103903677ALow softening temperatureMeet the requirements of energy saving and environmental protectionNon-conductive material with dispersed conductive materialCable/conductor manufactureMicron scaleAlkali metal oxide

The invention discloses a medium temperature sintering type electro-conduction slurry with lead-free glass powder and a preparation method of the medium temperature sintering type electrocondution slurry. The preparation method is characterized by comprising the steps of preparing an organic carrier, preparing the lead-free glass powder, preparing silver powder and preparing the electro-conduction slurry. The electro-conduction slurry comprises, by mass, 0 to 80% of micron-scale spherical silver powder, 5% to 70% of micron-scale flake silver powder, 2% to 25% of the lead-free glass powder and 0 to 25% of the organic carrier. The lead-free glass powder comprises, by mass, 25% to 75% of Bi2O3, 20% to 60% of B2O3, 0 to 20% of ZnO, 0 to 20% of Sb2O3, 0 to 10% of Al2O3 and 0 to 8% of alkali metal oxide. The organic carrier comprises, by mass, 50% to 80% of terpilenol, 10% to 40% ofbutyl carbitol acetic ester, 0 to 10% of tributyl citrate, 3% to 10% of ethocel, 0 to 2% of hydrogenated castor oil and 0 to 3% of addition agent.

Owner:SHANGHAI INTELLIGENT SENSOR ELECTRONICS TECHCO

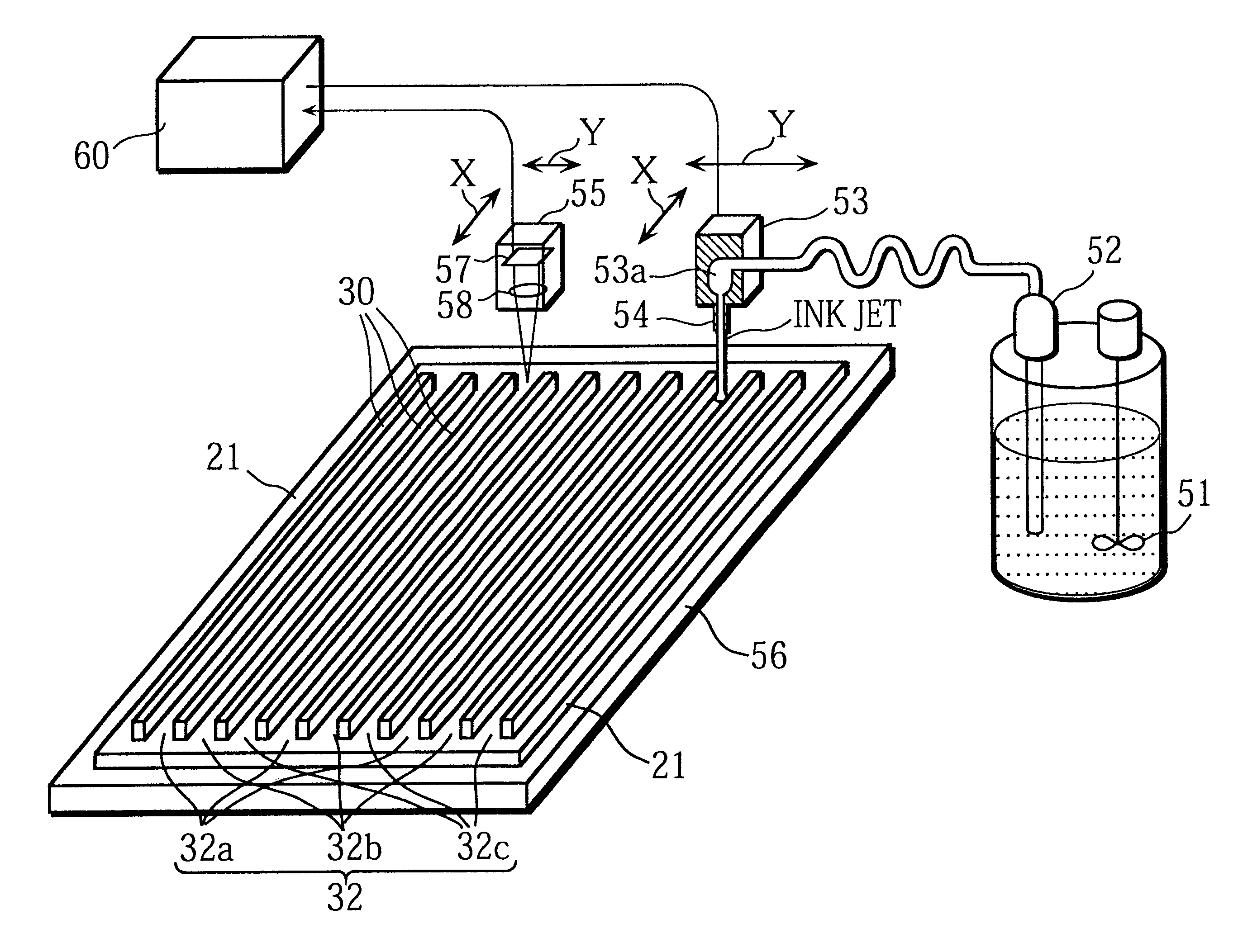

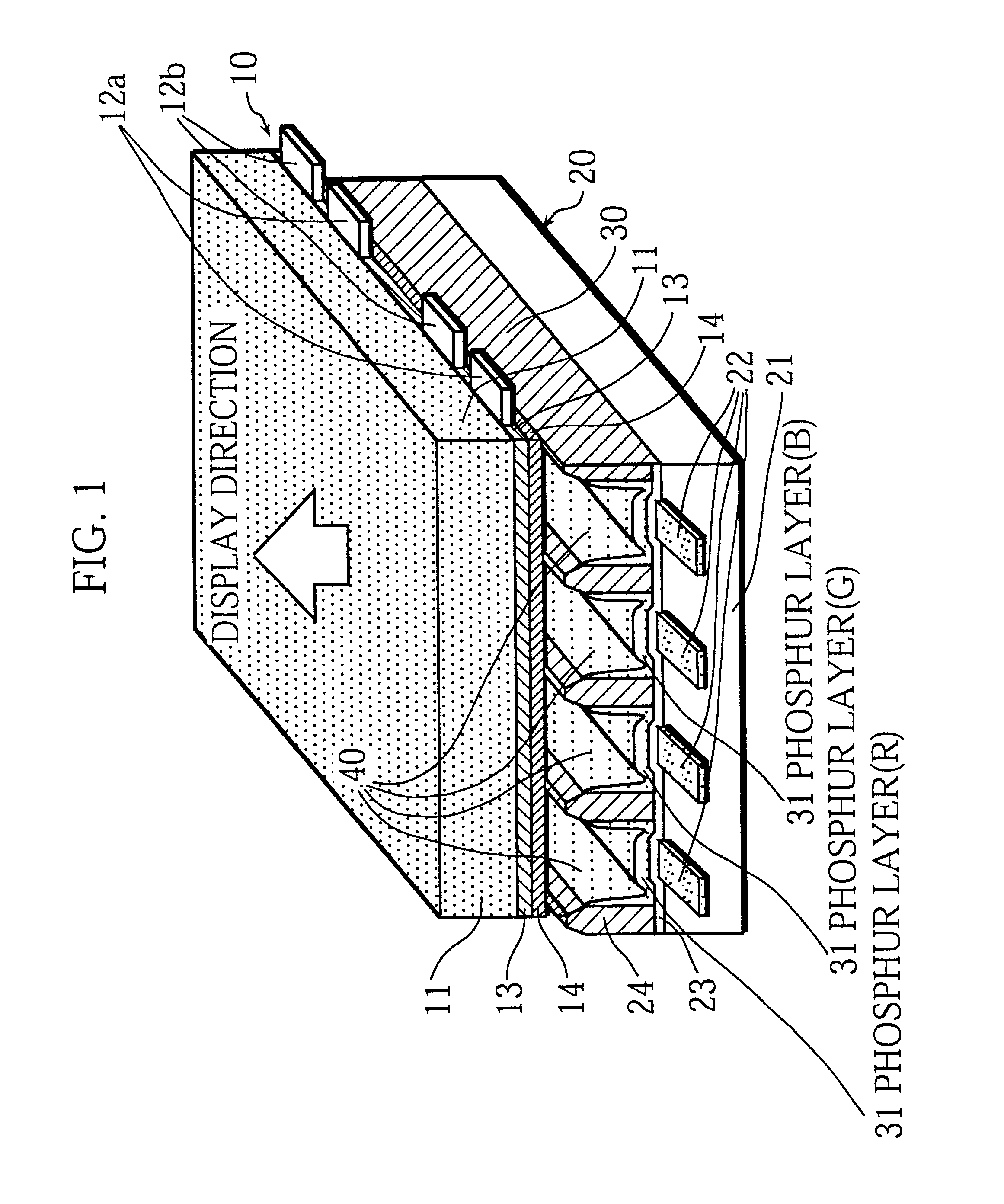

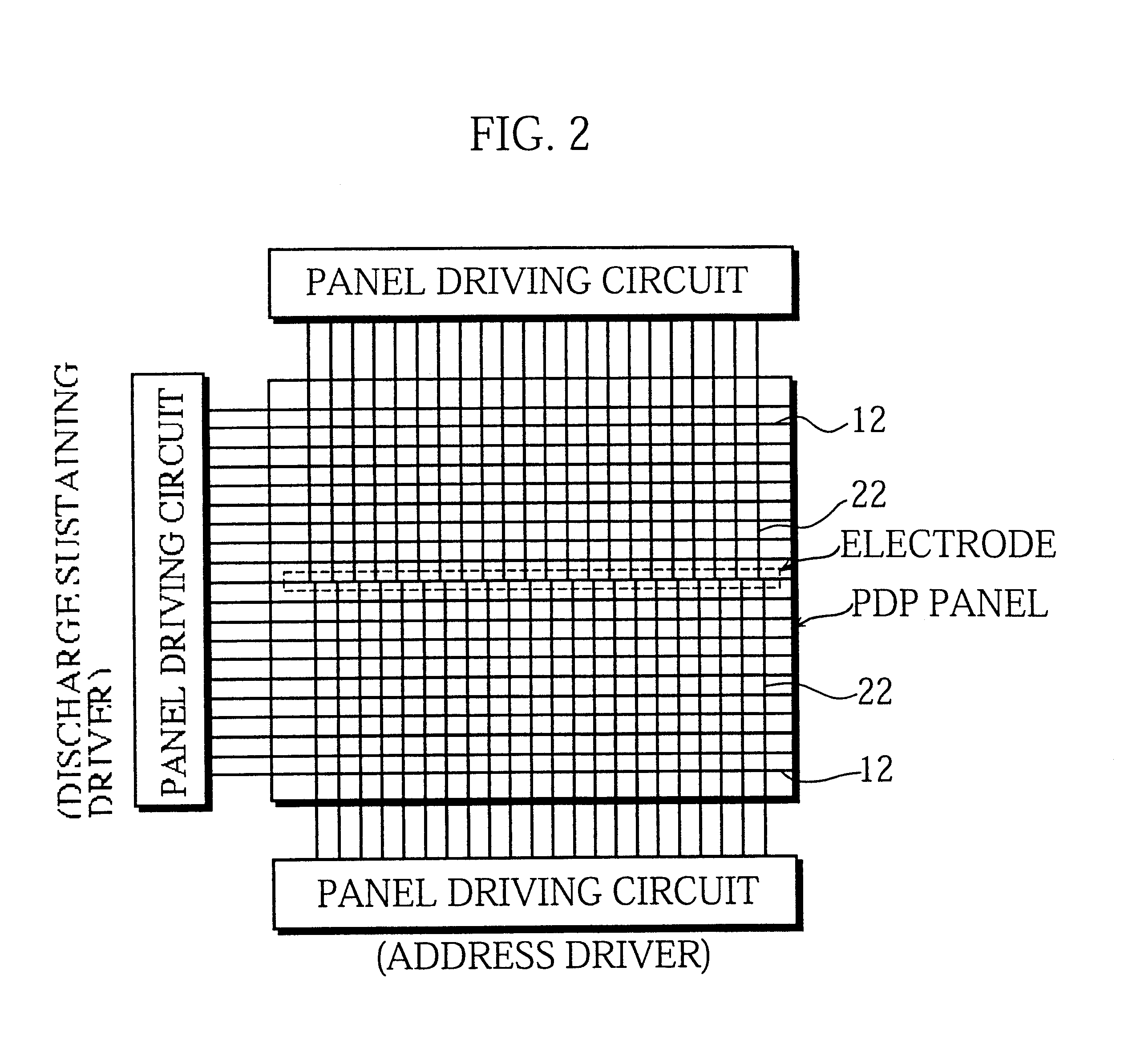

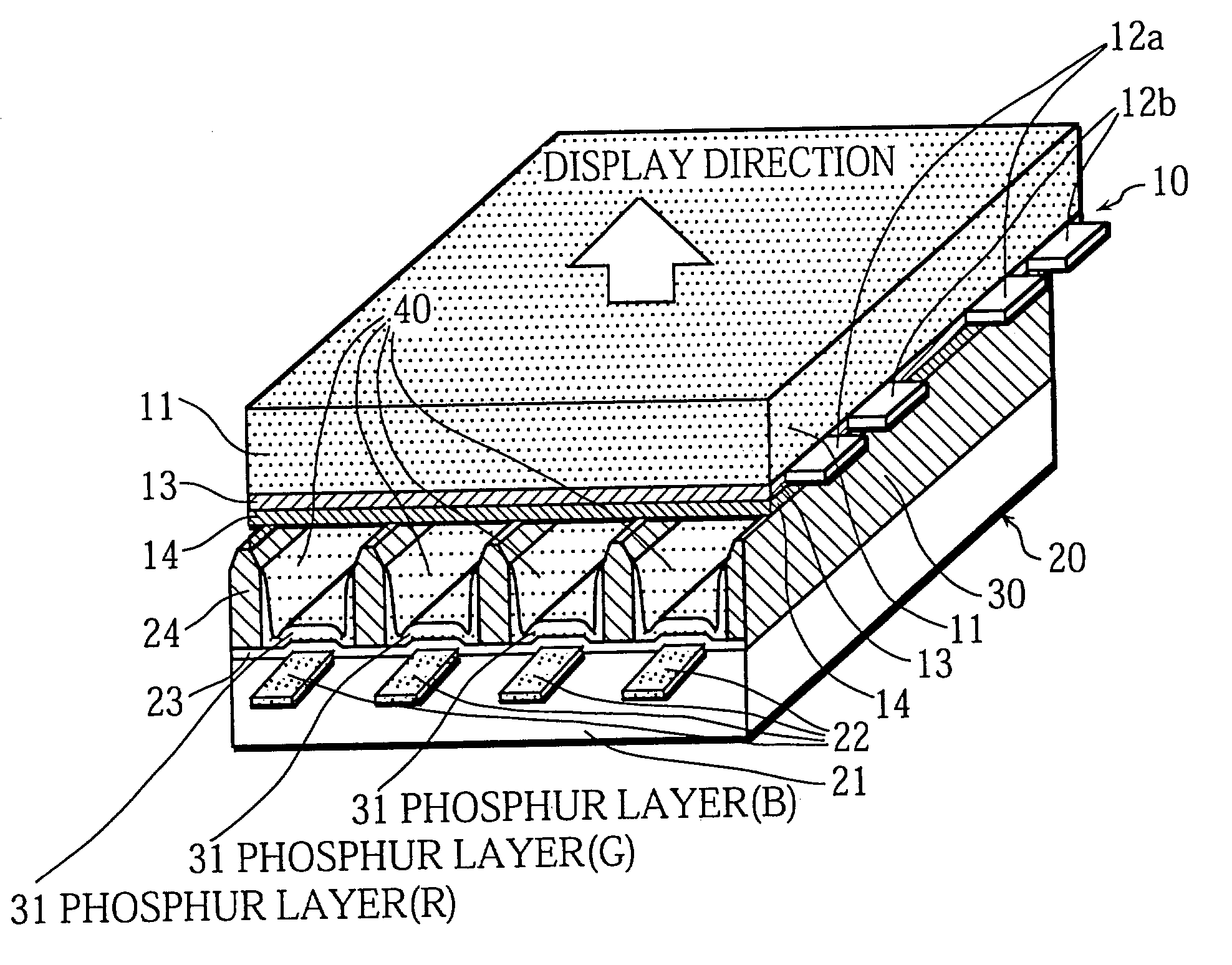

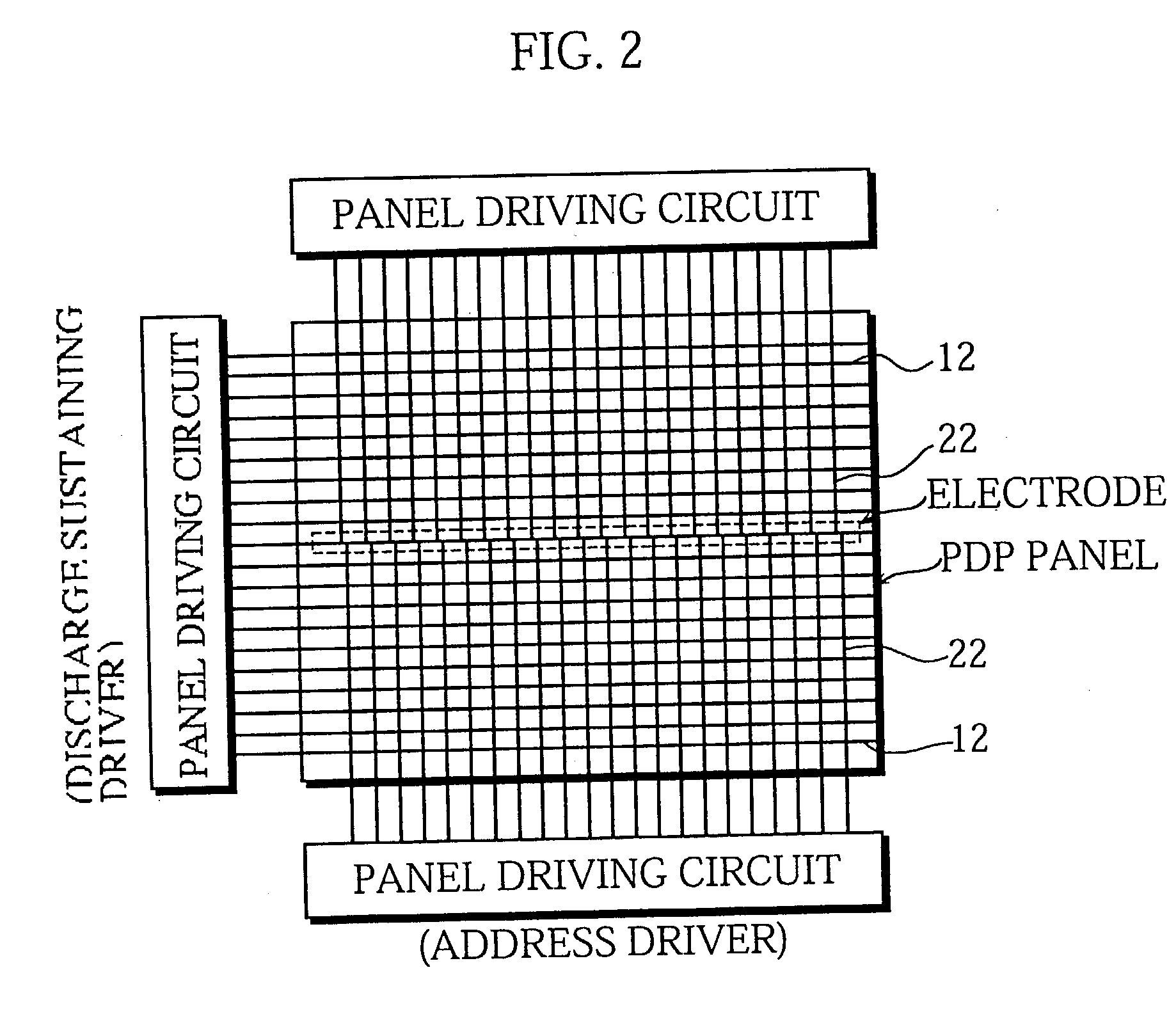

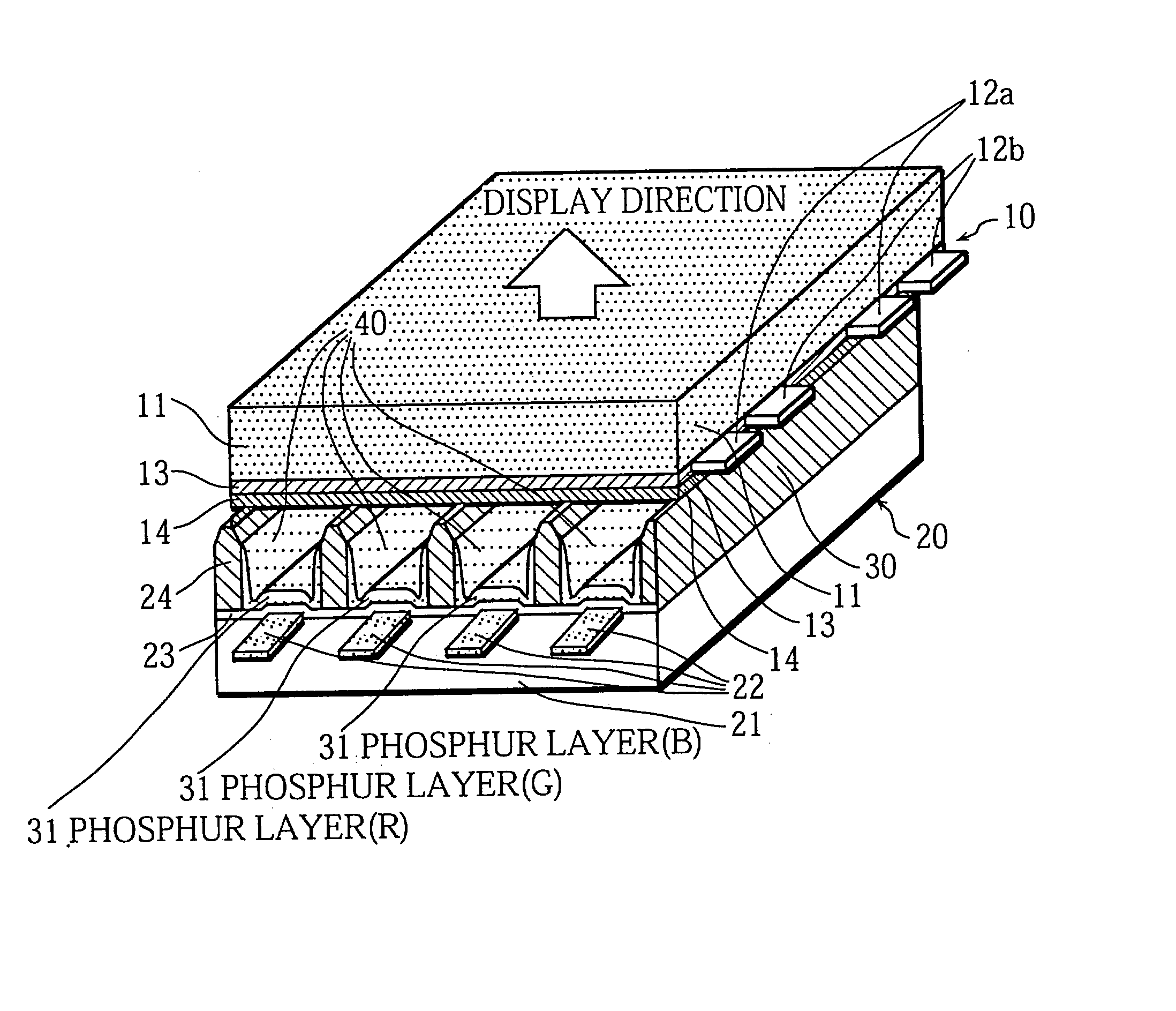

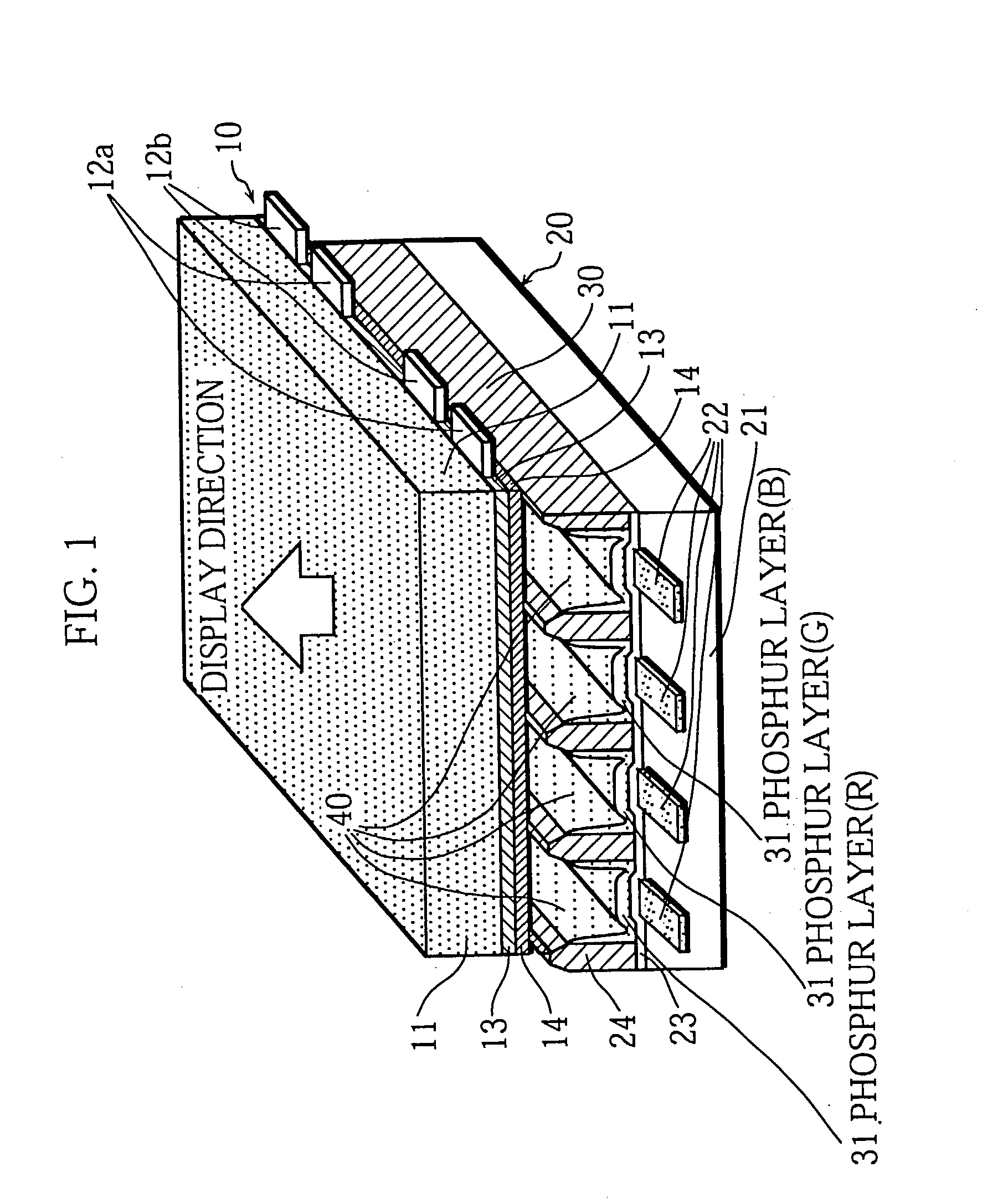

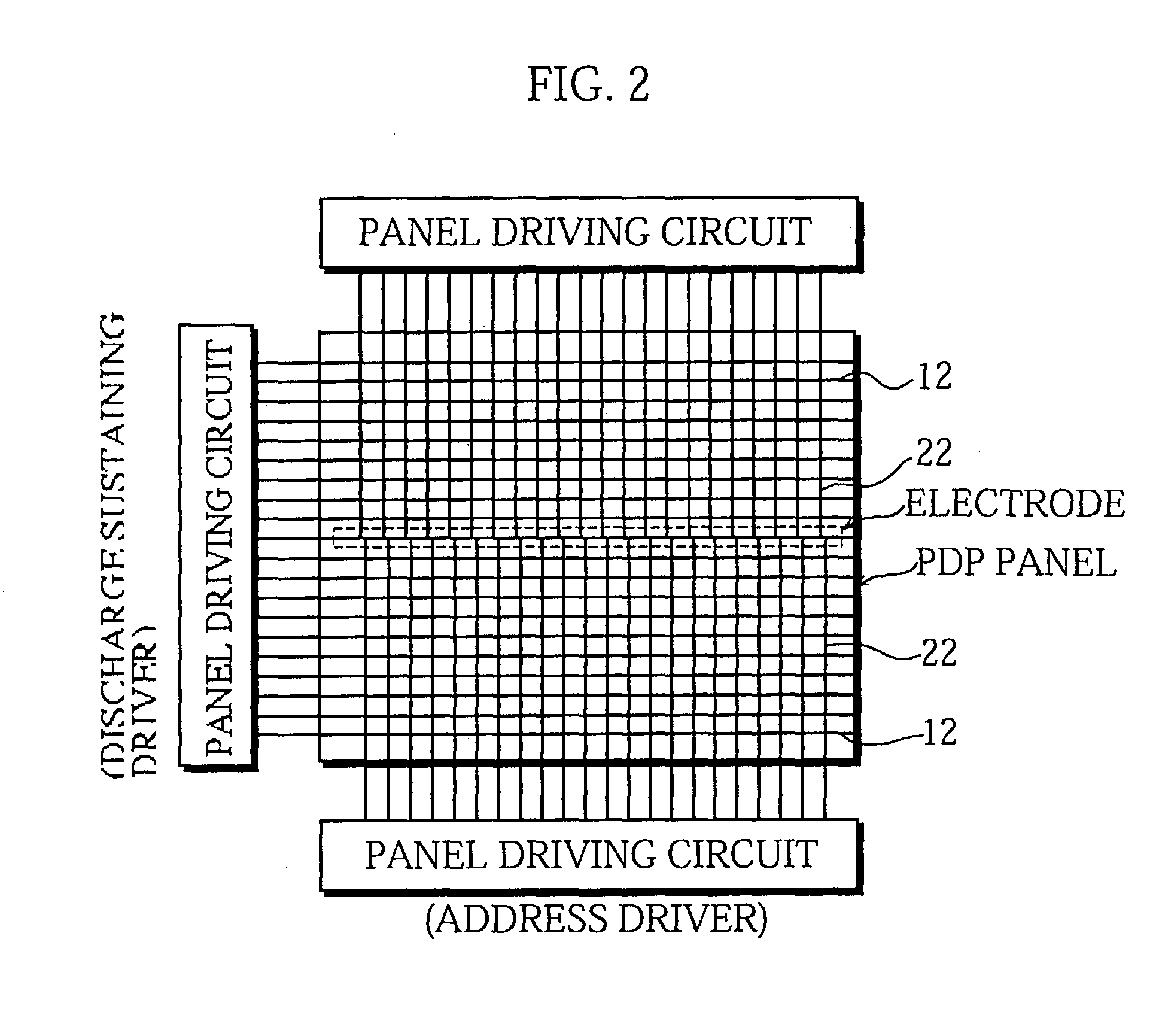

Plasma display panel manufacturing method for manufacturing a plasma display panel with superior picture quality, a manufacturing apparatus and a phosphor ink

InactiveUS6547617B1Improve liquidityStrong force FVessels or leading-in conductors manufactureLuminescent coatings applicationManufactured apparatusEngineering

The present invention intends to provide a manufacturing method for a PDP that can continuously apply phosphor ink for a long time and can accurately and evenly produce phosphor layers even when the cell construction is very fine. To do so, phosphor ink is continuously expelled from a nozzle while the nozzle moves relative to channels between partition walls formed on a plate so as to scan and apply phosphor ink to the channels. While doing so the path taken by the nozzle within each channel between a pair of partition walls is adjusted based on position information for the channel. When phosphor particles is successively applied to a plurality of channels, phosphor ink is continuously expelled from the nozzle even when the nozzle is positioned away from the channels. The phosphor ink is composed of: phosphor particles that have an average particle diameter of 0.5 to 5 mum; a mixed solvent in which materials selected from a group consisting of terpineol, butyl carbitol acetate, butyl carbitol, pentandiol, and limonene are mixed; and a binder that is an ethylene group polymer or ethyl cellulose containing at least 49% of ethoxy group (-OC2H5) cellulose molecules. After dispersion a charge-removing material is added to the phosphor ink.

Owner:PANASONIC CORP

Post plasma ashing wafer cleaning formulation

InactiveUS7534752B2Increase productionImprove adhesionDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSulfolaneInorganic compound

A semiconductor wafer cleaning formulation for use in post plasma ashing semiconductor fabrication comprising at least one organic chelating agent and at least one polar solvent, wherein the chelating agent and polar solvent are in sufficient amounts to effectively remove inorganic compound residue from a semiconductor wafer. Preferably, the chelating agent is selected from the group consisting of 2,4-Pentanedione, Malonic acid, Oxalic acid, p-Toluenesulfonic acid, and Trifluoroacetic acid; and the polar solvent is selected from the group consisting of Water, Ethylene glycol, N-Methylpyrrolidone (NMP), Gamma butyrolactone (BLO), Cyclohexylpyrrolidone (CHP), Sulfolane, 1,4-Butanediol, and Butyl carbitol.

Owner:ENTEGRIS INC

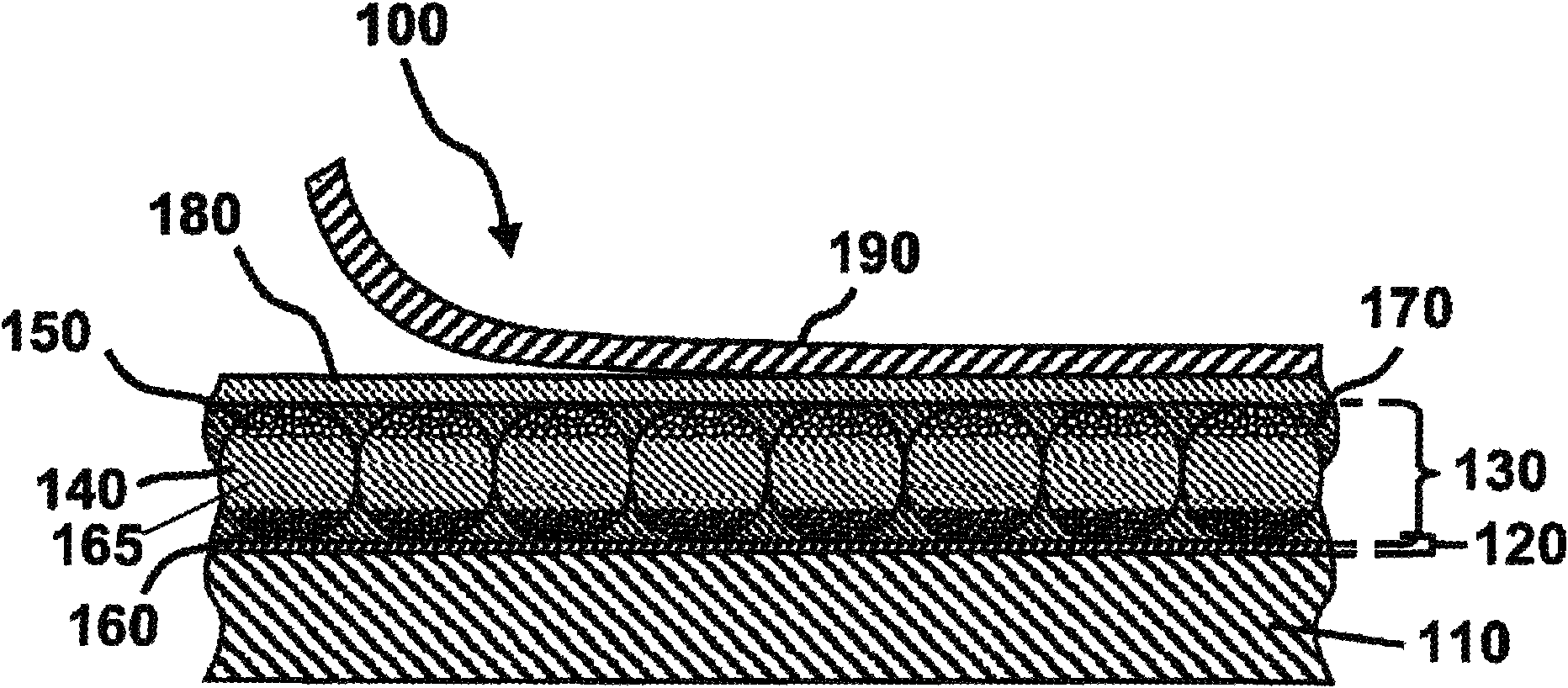

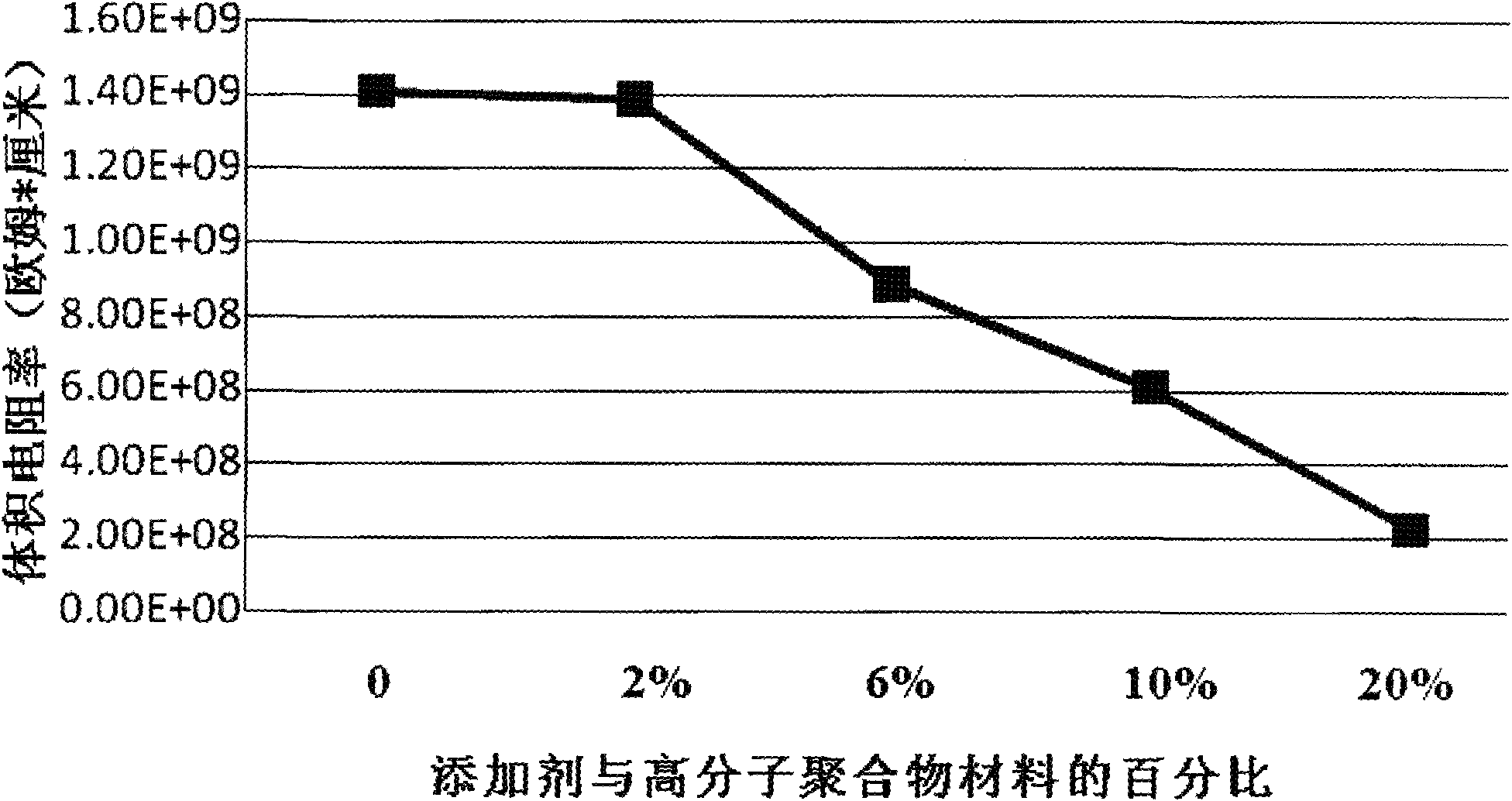

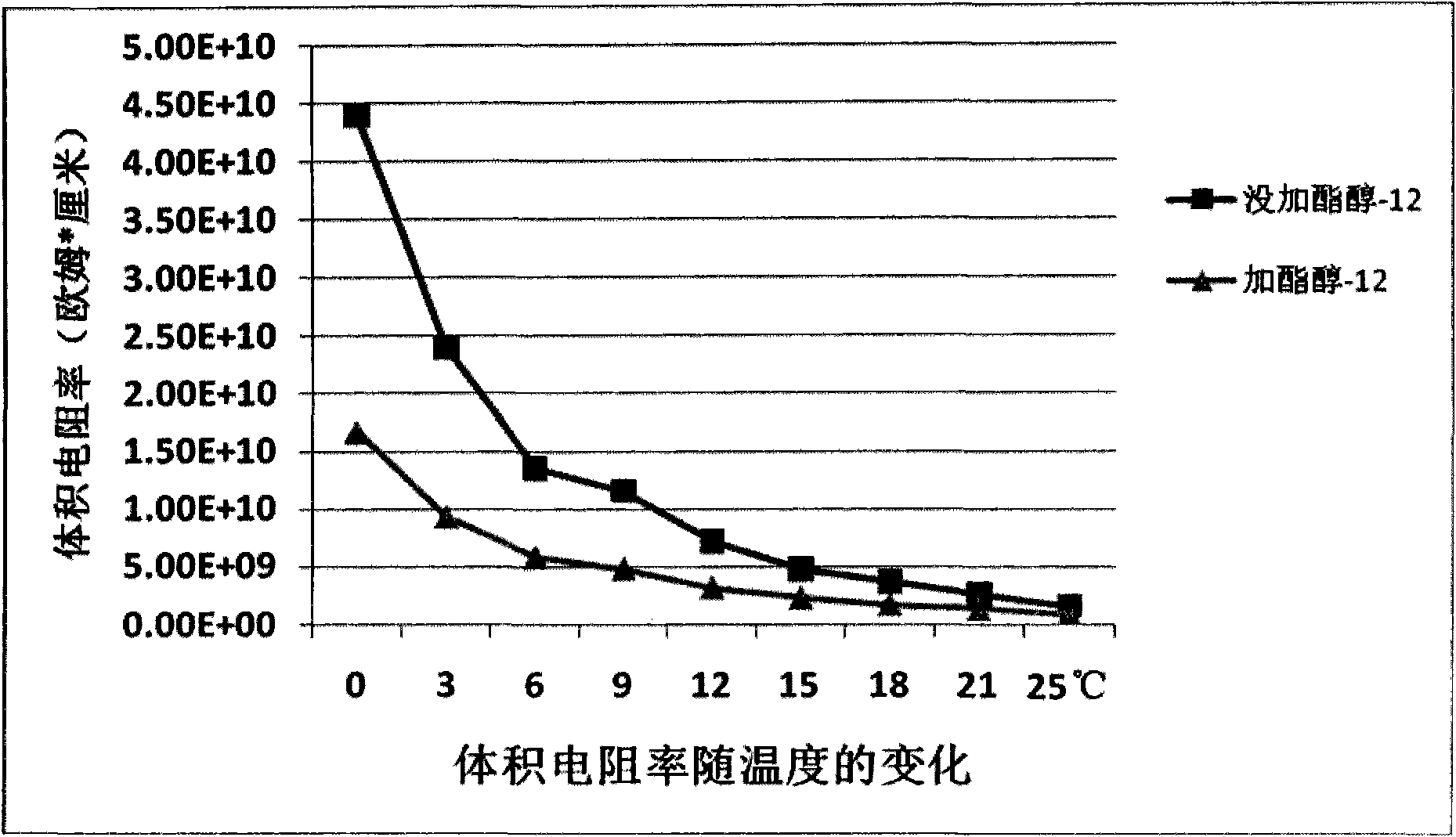

Bonding agent and electro-optic assembly and electrophoretic medium thereof

InactiveCN102253502ALower volume resistivityImproved electro-optical performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesAlcoholElectrophoresis

The invention discloses a bonding agent and an electro-optic assembly and an electrophoretic medium thereof. The electro-optic assembly comprises a first substrate, a second substrate, a boning agent layer positioned between the first substrate and the second substrate, and an electro-optic material layer positioned between the first substrate and the second substrate; and the bonding agent layer comprises a polymer boning agent material and an additive agent, wherein the additive agent is selected from propylene glycol ether, butyl carbitol, methoxyl methanol, ethylene glycol, propanediol, propanetriol, Texanol, adipate, phthalandione, lusolvan, FBH, Coasol, DBE-IB, DPnB, Dowanol PPh, alcohol ester-12, hexamethylene glycol, commercialization compositions thereof and combinations thereof. The invention further discloses the bonding agent layer, a double-stripping sheet and use of the bonding agent layer and the double-stripping sheet. The bonding agent layer has the advantages shown in specifications.

Owner:GUANGZHOU OED TECH INC

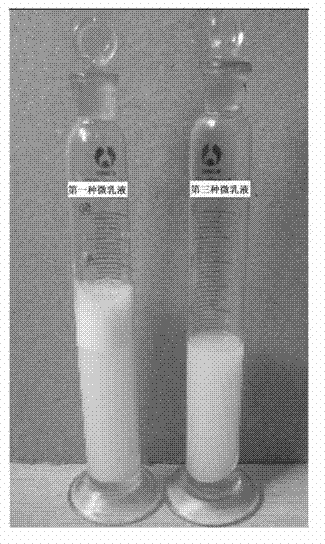

Micro-emulsified cutting fluid production additive package and preparation method and application thereof

ActiveCN102807912AStrong emulsifying abilityImprove emulsification efficiencyLubricant compositionAlkaneSolubility

The invention relates to a micro-emulsified cutting fluid production additive package and a preparation method and the application thereof. The additive package is composed of, by weight, 5-25 parts of higher fatty acid, 10-35 parts of alkylol amine, 3-15 parts of sodium alkane sulfonate, 5-20 parts of sorbitan monooleate, 2-15 parts of fatty alcohol-polyoxyethylene ether, 3-15 parts of coconutt diethanol amide, 3-15 parts of butyl carbitol, 1-5 parts of polyether, 0.1-0.6 part of benzotriazole, 1-5 parts of antiseptic bactericide and 3-10 parts of water. The additive package is high in emulsifying ability, high in emulsifying efficiency, and fine in hard water resistance and bubble inhibition performance in preparation of cutting fluid, and micro-emulsified cutting fluid is high in water solubility and free of coagulation, caking and precipitation.

Owner:JINAN COOLANT TECH CO LTD

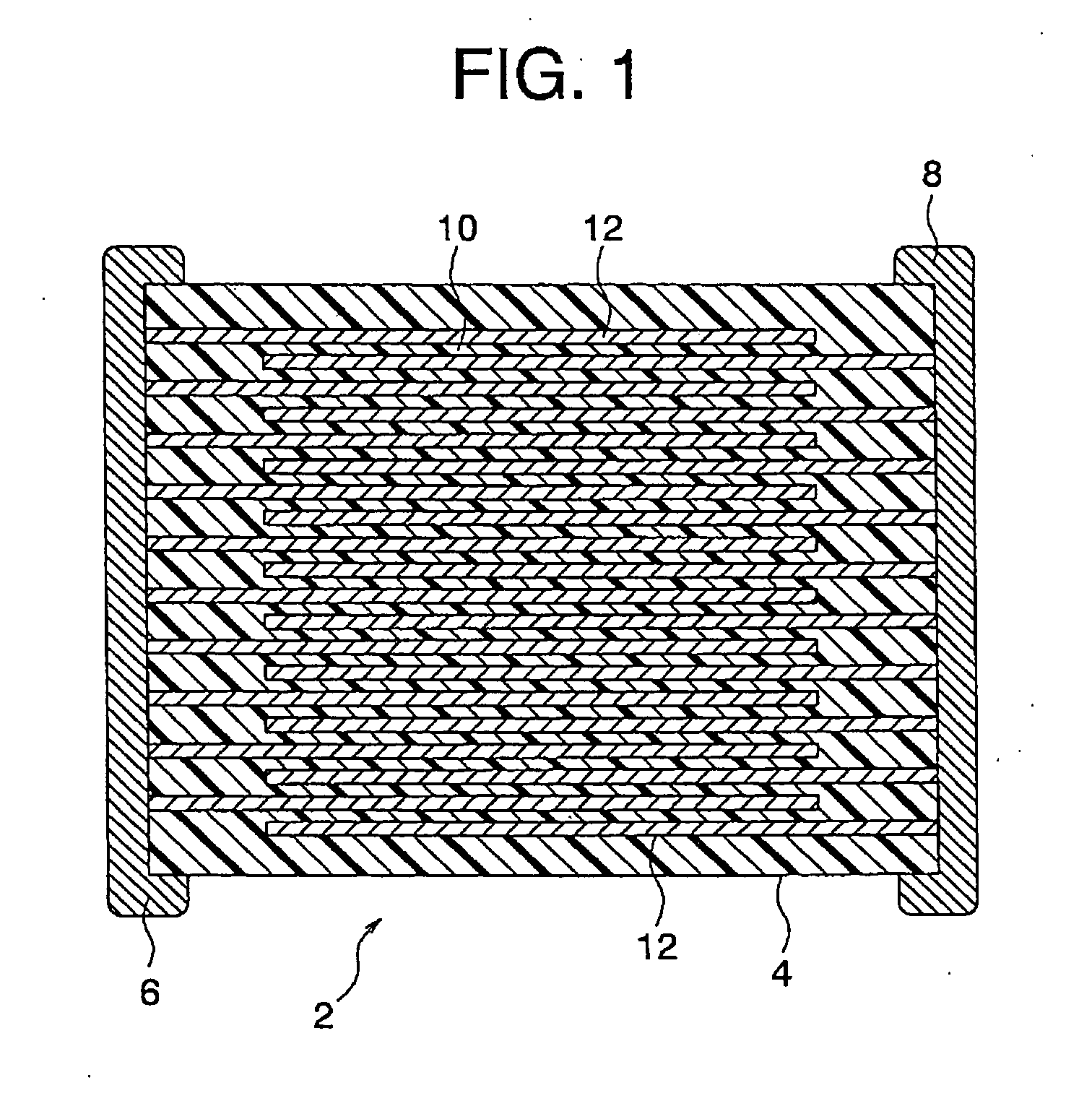

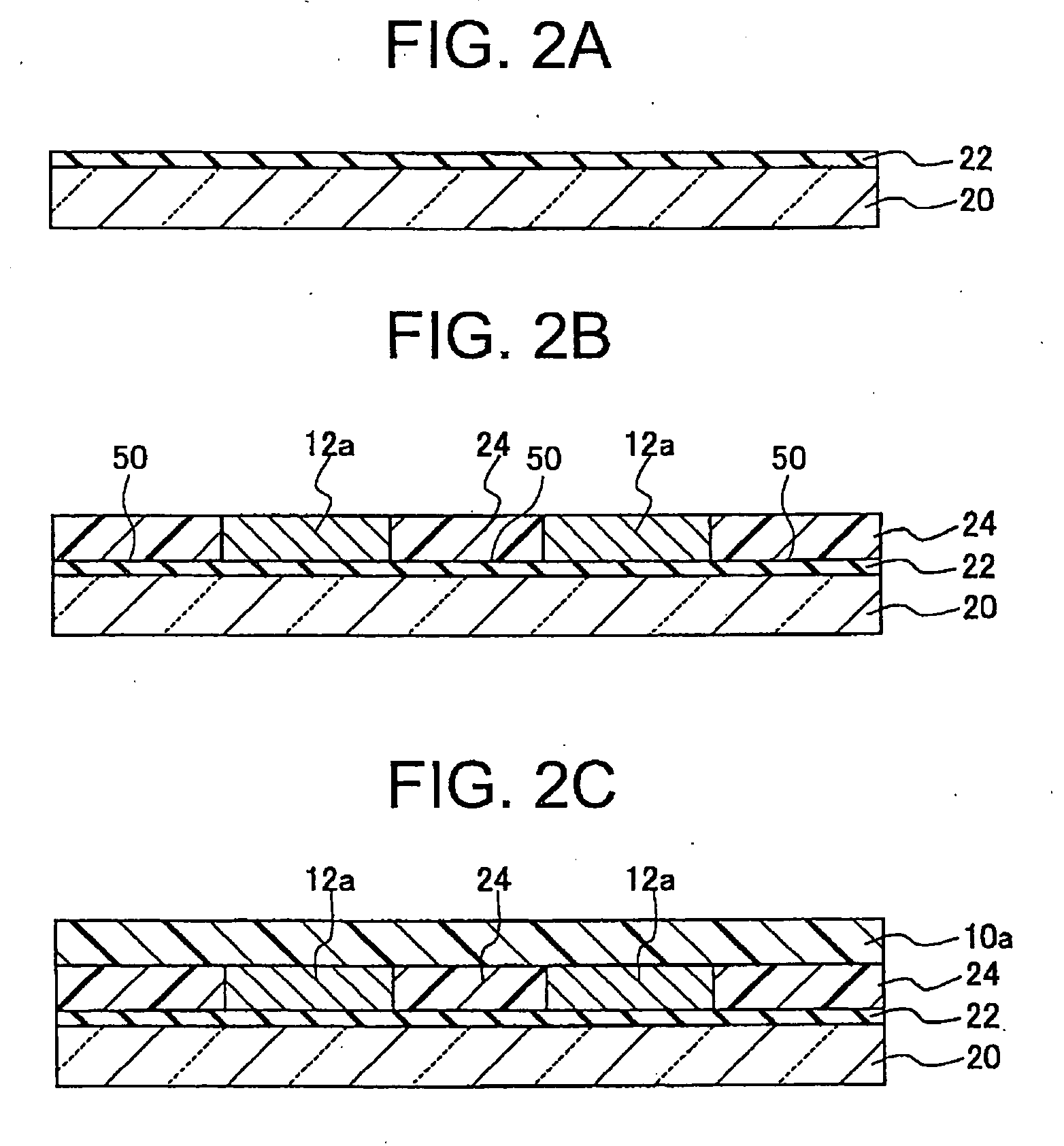

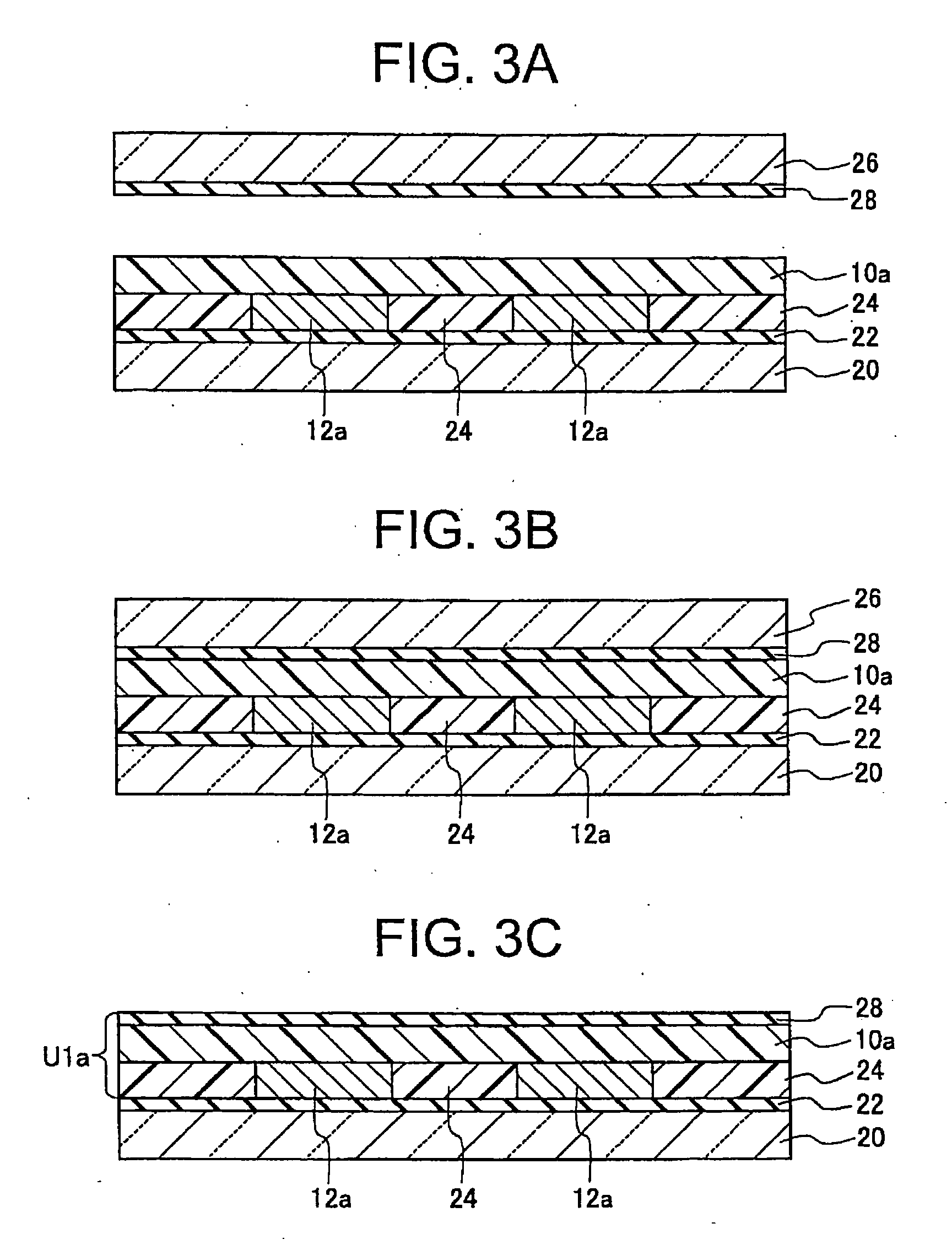

Release layer paste and method of production of a multilayer type electronic device

InactiveUS20070190251A1Enable formationPrintabilityOther chemical processesFixed capacitor electrodesAdditive ingredientSolvent

A release layer paste used for producing a multilayer type electronic device and forming a release layer of a thickness of 0.05 to 0.1 μm, used in combination with an electrode layer paste including one or more solvents selected from limonene, dihydroterpinyl methyl ether, α-terpinyl acetate, terpinyl methyl ether, isobornyl acetate, caryophyllene, 1-dihydrocarvyl acetate, menthone, menthyl acetate, perillyl acetate, carvyl acetate, d-dihydrocarvyl acetate, and butyl carbitol acetate and a binder comprised of ethyl cellulose, including a ceramic powder, organic vehicle, plasticizer, and dispersion agent, the organic vehicle containing a binder having polyvinyl acetal as its main ingredient, a ratio (P / B) of the ceramic powder with respect to the binder and plasticizer being controlled to 1.33 to 5.56 (however, excluding 5.56).

Owner:TDK CORPARATION

Lead-free silver and aluminum slurry for solar photocell and preparation method of slurry

ActiveCN102708942AImprove conductivityRefined nanocrystalline structureNon-conductive material with dispersed conductive materialCable/conductor manufactureDiethylene glycol monobutyl etherCyclohexanone

The invention discloses lead-free silver and aluminum slurry for a solar photocell. The slurry is prepared from raw materials in percent by mass as follows: 75-80% of silver powder, aluminum powder and copper powder, 15-20% of organic bond, 1-5% of inorganic glass powder, and 1-5% of additive; the purities of the silver powder, the aluminum powder and the copper powder are more than or equal to 99.9%; the organic bond is prepared from the following materials in percent by mass of: 0.5-2% of butyl carbitol, 1-2.5% of resin, 1-4% of rosin, 11-13% of ethylene glycol monomethyl ether, 5-9% of diethylene glycol monobutyl ether, 65-75% of cyclohexanone and 10-20% of n-butyl alcohol; the inorganic glass powder is prepared from the following materials in percent by mass of: 1-3% of titanium dioxide, 55-75% of boric acid, 3-5% of aluminium sesquioxide, 15-25% of antimony oxide and 2-5% of zirconium oxide; and the additive is prepared from the following materials in percent by mass of: 35-45% of span and 55-65% of pump oil. The lead-free silver and aluminum slurry prepared by the raw material has the advantages of good weldability and strong adhesion and meets the lead-free environmental friendless requirement.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Conductive coating composition for protective film and method for producing coating layer using the same

InactiveUS20070257235A1Good antistatic functionImproved aging property of antistaticGaseous fuel feeder/distributionConductive materialDisplay deviceElectrostatic coating

A conductive coating composition and a method for producing coating layer using the same are disclosed. The conductive coating composition is capable of forming an antistatic coating layer on the protective film surface of display device. The conductive coating composition includes: 1 to 30 wt % of polyethylene dioxythiophene aqueous-dispersed solution; 5 to 15 wt % of water-soluble binder resin; 0.2 to 10 wt % of melamine resin; 6 to 40 wt % of alcohol solvent; 5 to 30 wt % of organic solvent selected from the group consisting of dimethyl sulfoxide, propyleneglycol methylether, N-methylpyrrolidone, ethyl-3-ethoxypropionate, propyleneglycol monomethyletheracetate, butylcarbitol and the mixtures thereof; and 10 to 50 wt % of water. The method for producing the conductive coating layer includes the steps of coating the conductive coating composition on a substrate; and drying the coating composition.

Owner:DONGJIN SEMICHEM CO LTD

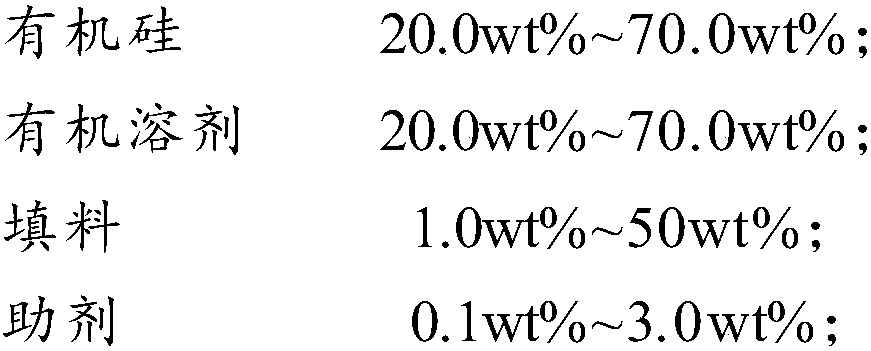

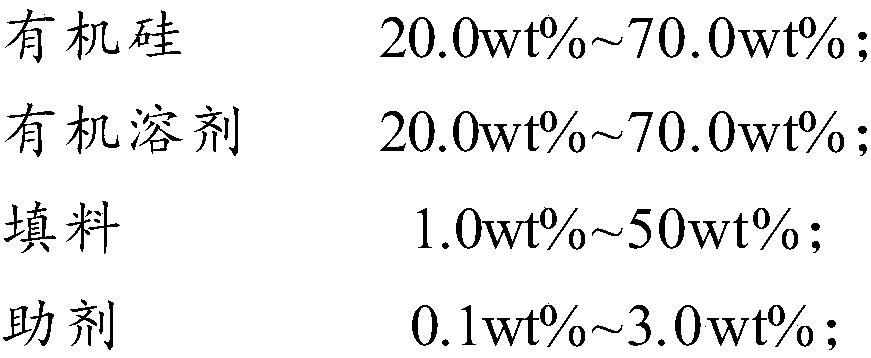

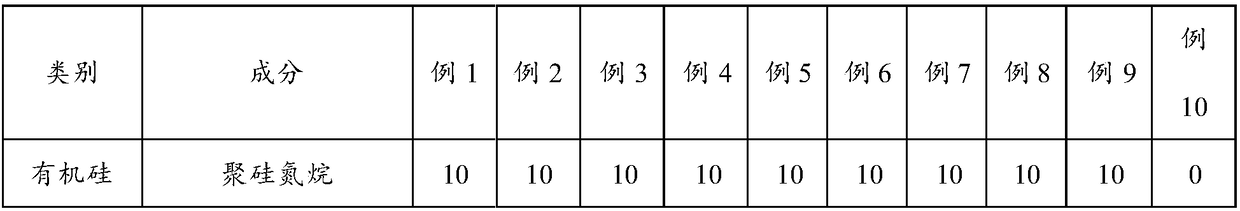

Ceramic surface material and surface coating

ActiveCN108531078AImprove toughnessImprove thermal stabilityFireproof paintsAnti-corrosive paintsRare earthButyl carbitol

The invention provides a ceramic surface material. The ceramic surface material comprises 20.0wt%-70.0wt% of organosilicone, 20.0wt%-70.0wt% of an organic solvent, 10wt%-50wt% of filler and 0.1wt%-3.0wt% of an auxiliary, wherein the organic solvent is selected from one or more of butyl acetate, dimethylbenzene, n-butyl ether, butyl carbitol acetate, hexahydrotoluene, normal octane and butyl titanate; and the filler consists of graphene, graphite, transition group metallic oxide, composite silicate, rare earth oxide, nonmetal and metal. The components in the ceramic surface material cooperatively interact, and the ceramic surface material has good overall performance when used as a coating.

Owner:ZHAOSHAN TECH BEIJING CO LTD

Plasma display panel manufacturing method for manufacturing a plasma display panel with superior picture quality, a manufacturing apparatus, and a phosphor ink

InactiveUS20030146701A1Accurately and evenly produceLittle line blurringAlternating current plasma display panelsVessels or leading-in conductors manufactureEngineeringSolvent

The present invention intends to provide a manufacturing method for a PDP that can continuously apply phosphor ink for a long time and can accurately and evenly produce phosphor layers even when the cell construction is very fine. To do so, phosphor ink is continuously expelled from a nozzle while the nozzle moves relative to channels between partition walls formed on a plate so as to scan and apply phosphor ink to the channels. While doing so the path taken by the nozzle within each channel between a pair of partition walls is adjusted based on position information for the channel. When phosphor particles is successively applied to a plurality of channels, phosphor ink is continuously expelled from the nozzle even when the nozzle is positioned away from the channels. The phosphor ink is composed of: phosphor particles that have an average particle diameter of 0.5 to 5 mum; a mixed solvent in which materials selected from a group consisting of terpineol, butyl carbitol acetate, butyl carbitol, pentandiol, and limonene are mixed; and a binder that is an ethylene group polymer or ethyl cellulose containing at least 49% of ethoxy group (-OC2H5) cellulose molecules. After dispersion a charge-removing material is added to the phosphor ink.

Owner:PANASONIC CORP

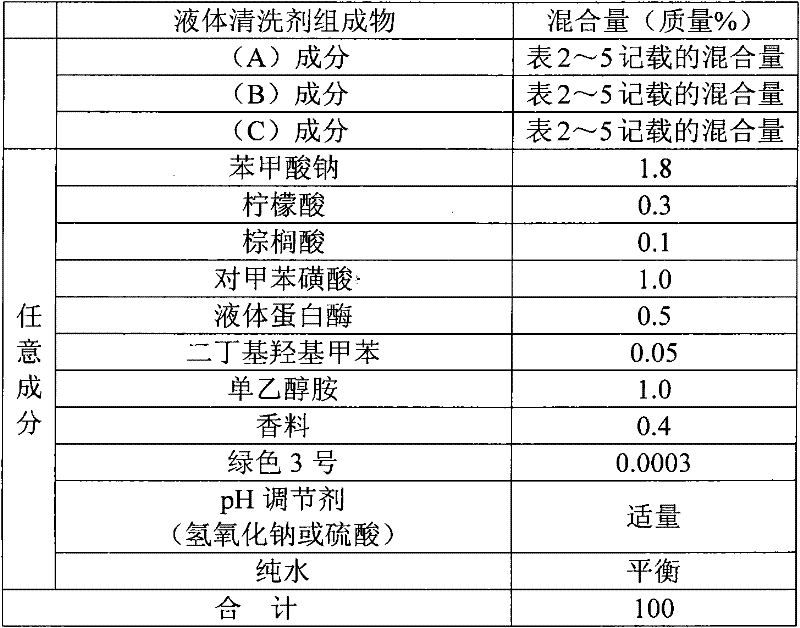

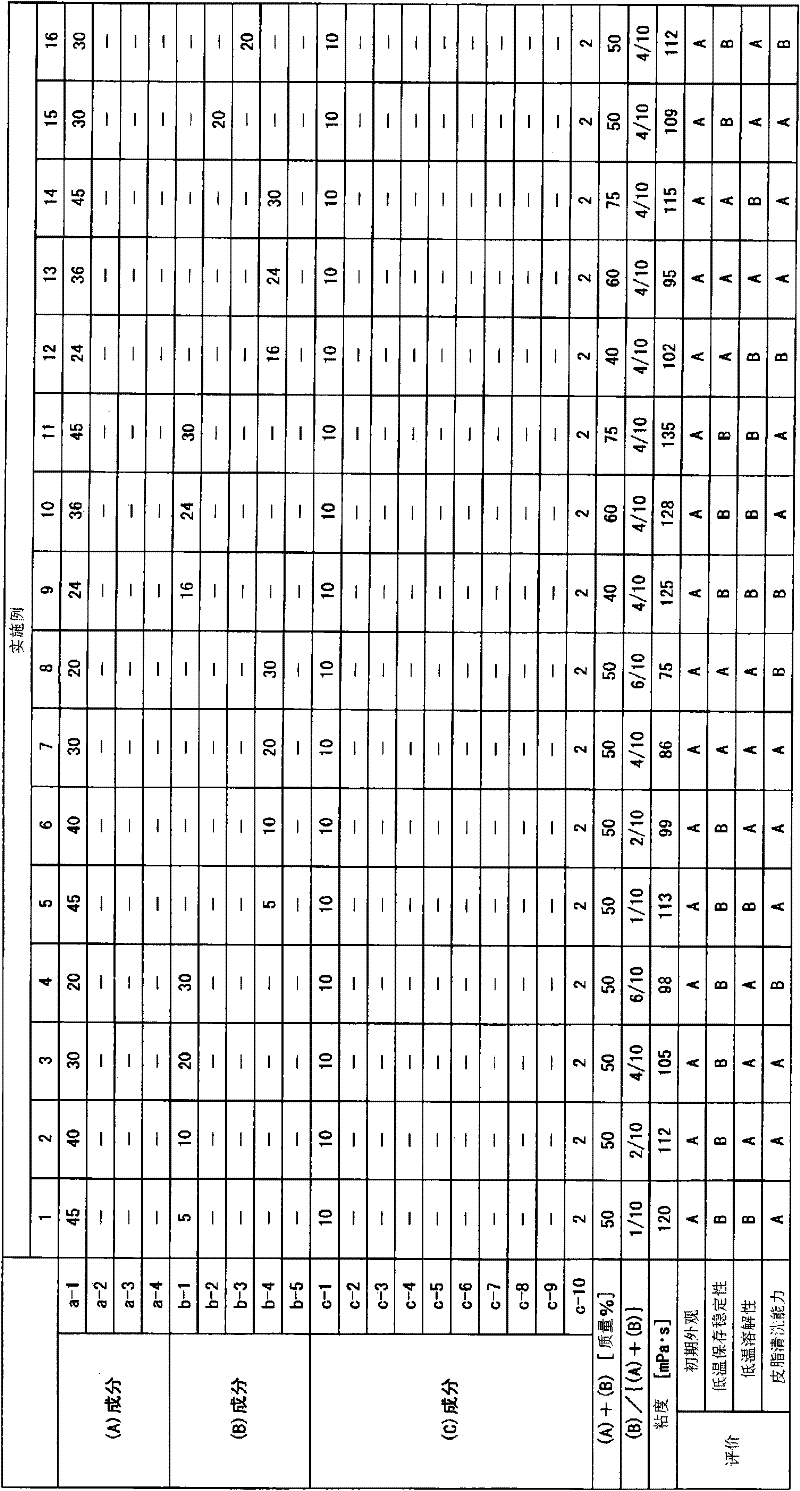

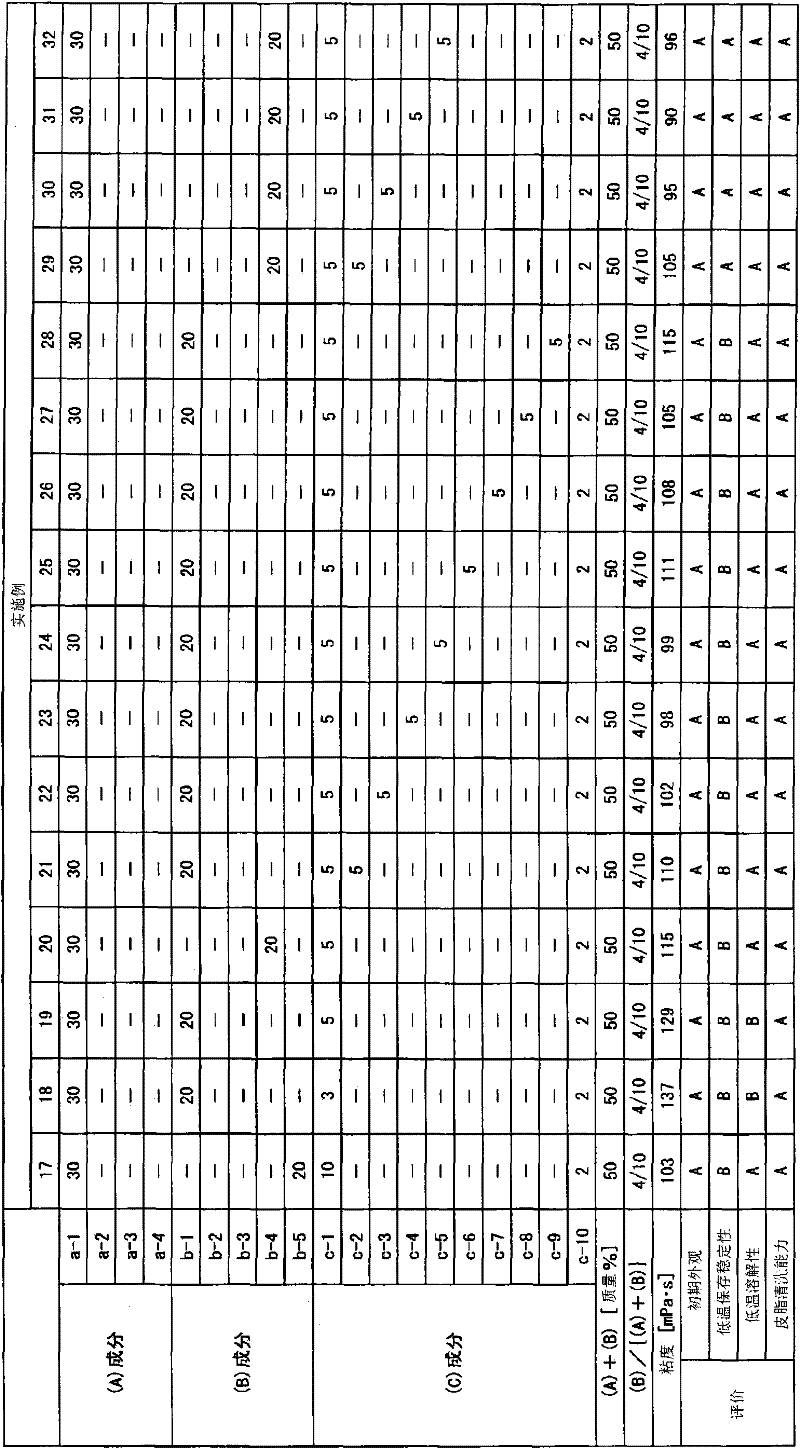

Liquid detergent composition

InactiveCN102575195AGood storage stability at low temperatureImprove solubilityOrganic detergent compounding agentsNon-ionic surface-active compoundsPolyethylene glycolSolvent

Disclosed is a liquid detergent composition which contains: a component (A) that is composed of a nonionic surfactant represented by formula {R1O(CH2CH2O)nH}; a component (B) that is composed of at least one anionic surfactant selected from the group consisting of compounds represented by formula {R2CH(SO3M1)COOR3} and compounds represented by formula {R4CH(SO3M2)CONHR5}; and a component (C) that is composed of at least two water-miscible solvents selected from the group consisting of methanol, ethanol, propanol, butanol, ethylene glycol, propylene glycol, butylene glycol, butyl carbitol, phenoxyethanol and polyethylene glycols having an average molecular weight of 570-3800. The total of the component (A) and the component (B) contained in the liquid detergent composition is 40-75% by mass, and the mass ratio of the component (B) to the total of the component (A) and the component (B) contained in the liquid detergent composition, namely component (B) / {component (A) + component (B)} is within the range from 1 / 10 to 6 / 10.

Owner:LION CORP

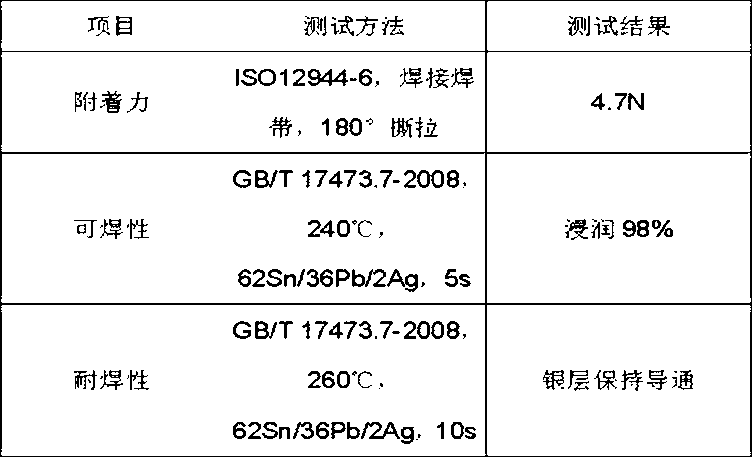

Unleaded back silver paste used for crystalline silicon solar cell and preparation method thereof

ActiveCN103219064ALow shrinkageGood printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteButyl carbitol

The invention relates to an unleaded back silver paste used for a crystalline silicon solar cell and a preparation method of the unleaded back silver paste used for the crystalline silicon solar cell. Raw materials comprise 60 parts of aluminum powder, 29-42 parts of organic binding agents and 1-10 parts of inorganic binding agents, the organic binding agents comprise 40-70 parts of terpilenol, 5-10 parts of butyl carbitol, 5-10 parts of butyl carbitol acetic ester, 3-10 parts of ethyl cellulose, 5-15 parts of diethyl phthalate and 2 parts of sorbitol anhydride stearate, and the inorganic binding agents comprise 30-60 parts of Bi2O3, 5-15 parts of B2O3, 1-2 parts of NaF, 10-20 parts of SiO2, 5-10 parts of ZnO, 1-5 parts of TiO2, 10-20 parts of Al2O3 and 2 parts of P2O5. After being mixed evenly, the components are rolled until the fineness degree is smaller than or equal to 10 microns, and viscosity is 30-100 Pa.s. The unleaded back silver paste used for the crystalline silicon solar cell is high in adhesive force and good in weldability and welding resistance.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

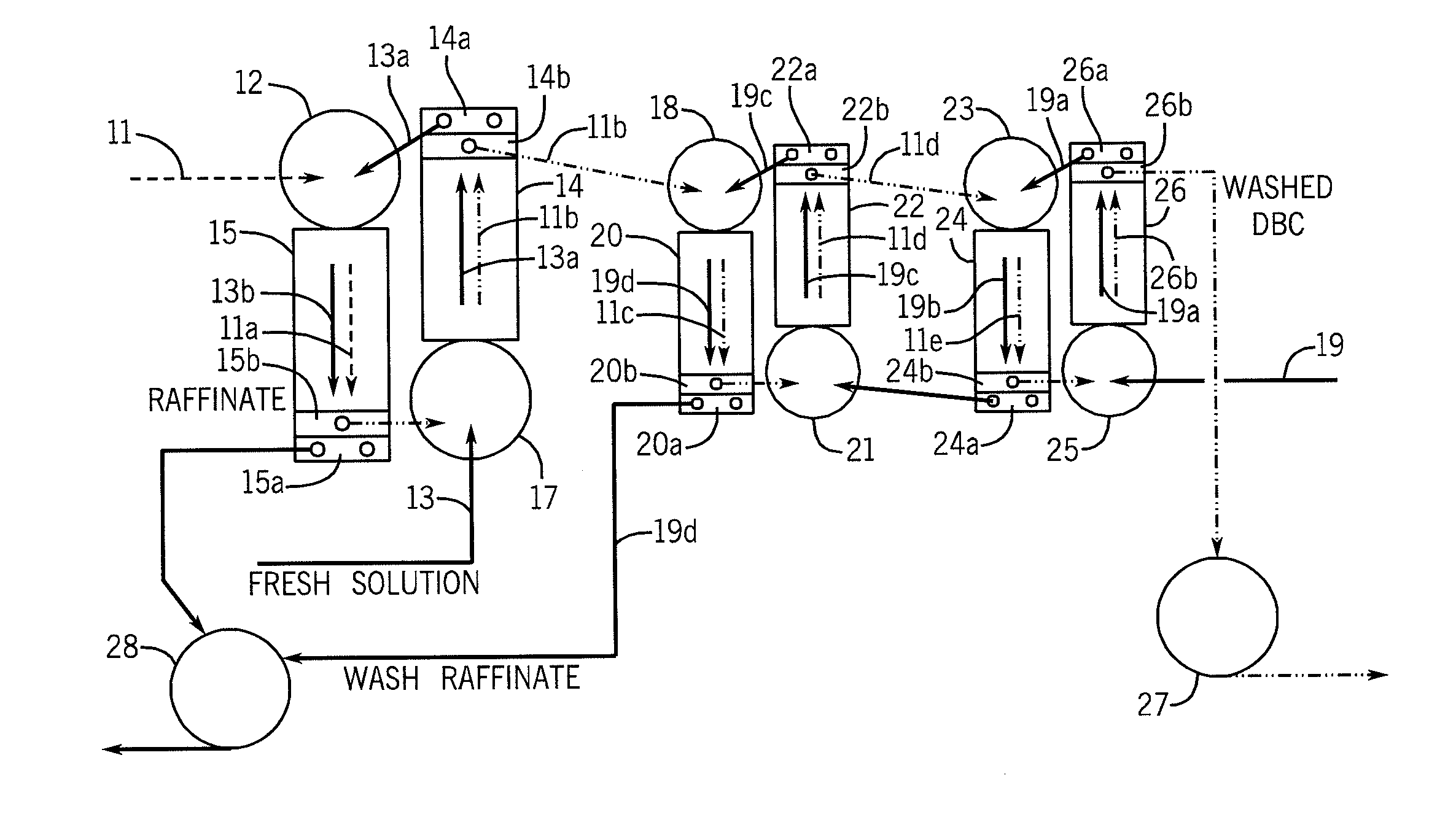

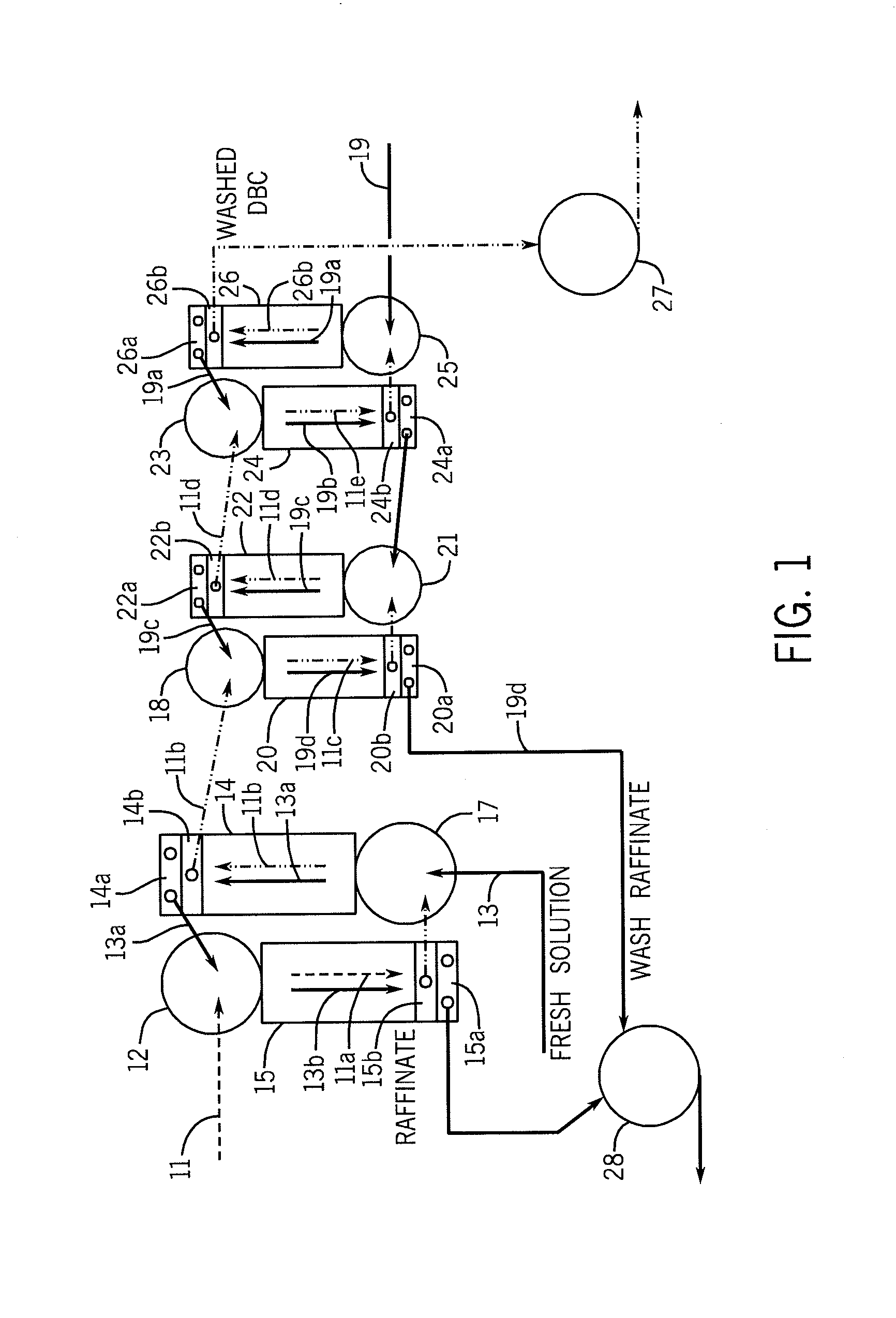

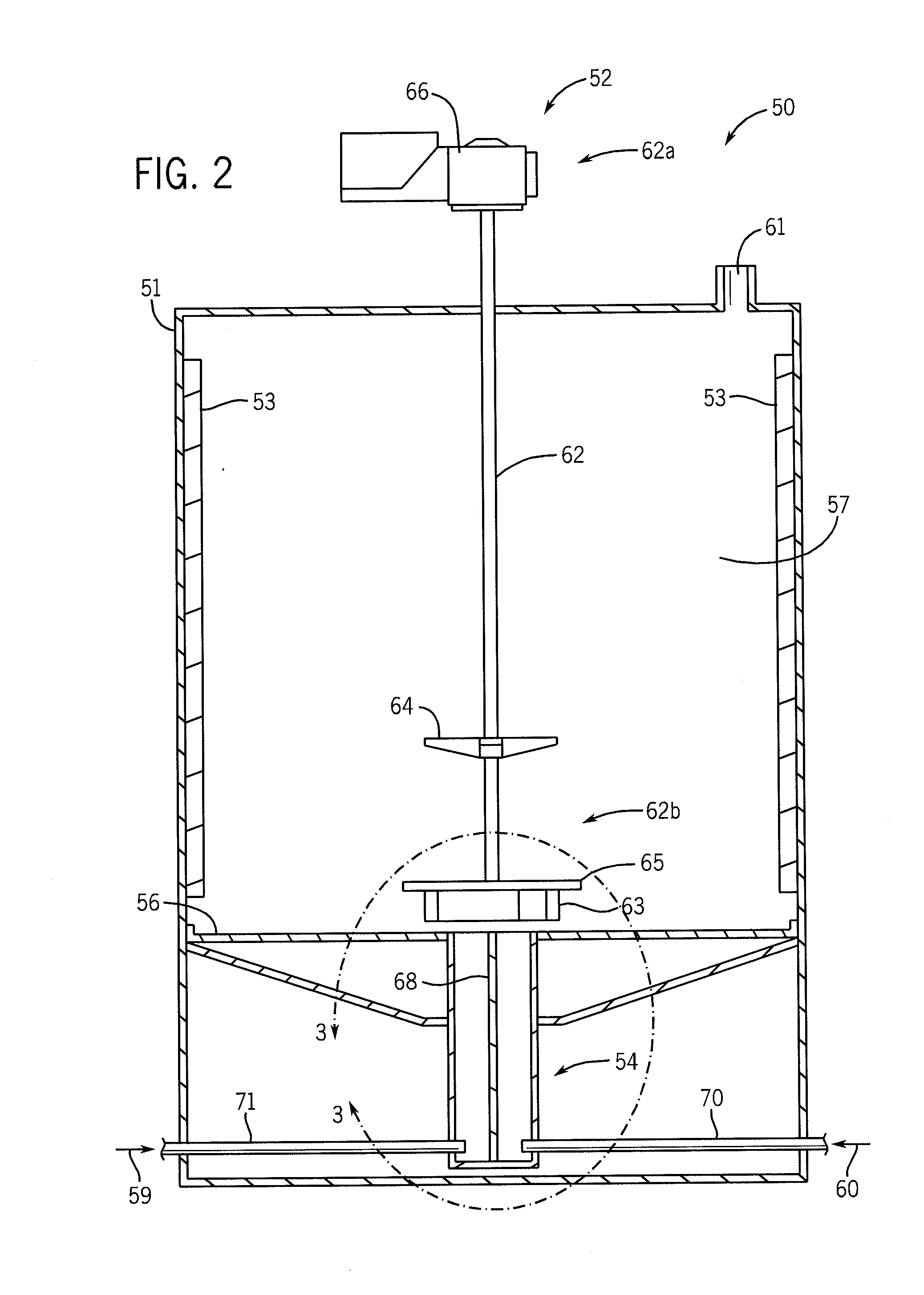

Process for the Recovery of Gold from Anode Slimes

A process for the recovery of gold from a gold-bearing aqueous filtrate, the process comprising the steps of:(A) Contacting the aqueous filtrate with dibutyl carbitol (DBC) in a two-stage solvent extraction process to remove the gold from the aqueous filtrate into the DBC to form a gold-loaded DBC; and(D) Contacting the gold-loaded DBC with an aqueous acid scrub of hydrochloric acid in a four-stage countercurrent scrub process to remove impurities, e.g., non-gold metal, from the DBC into the aqueous scrub solution to form an impurity-loaded aqueous scrub.Each stage of the solvent extraction circuit and the aqueous acid scrub circuit is equipped with a mixing assembly and a phase separation tank in a head-tail arrangement such that the mixing assembly of one stage is adjacent to the phase separation tank of the adjacent stage.

Owner:KENNECOTT UTAH COPPER

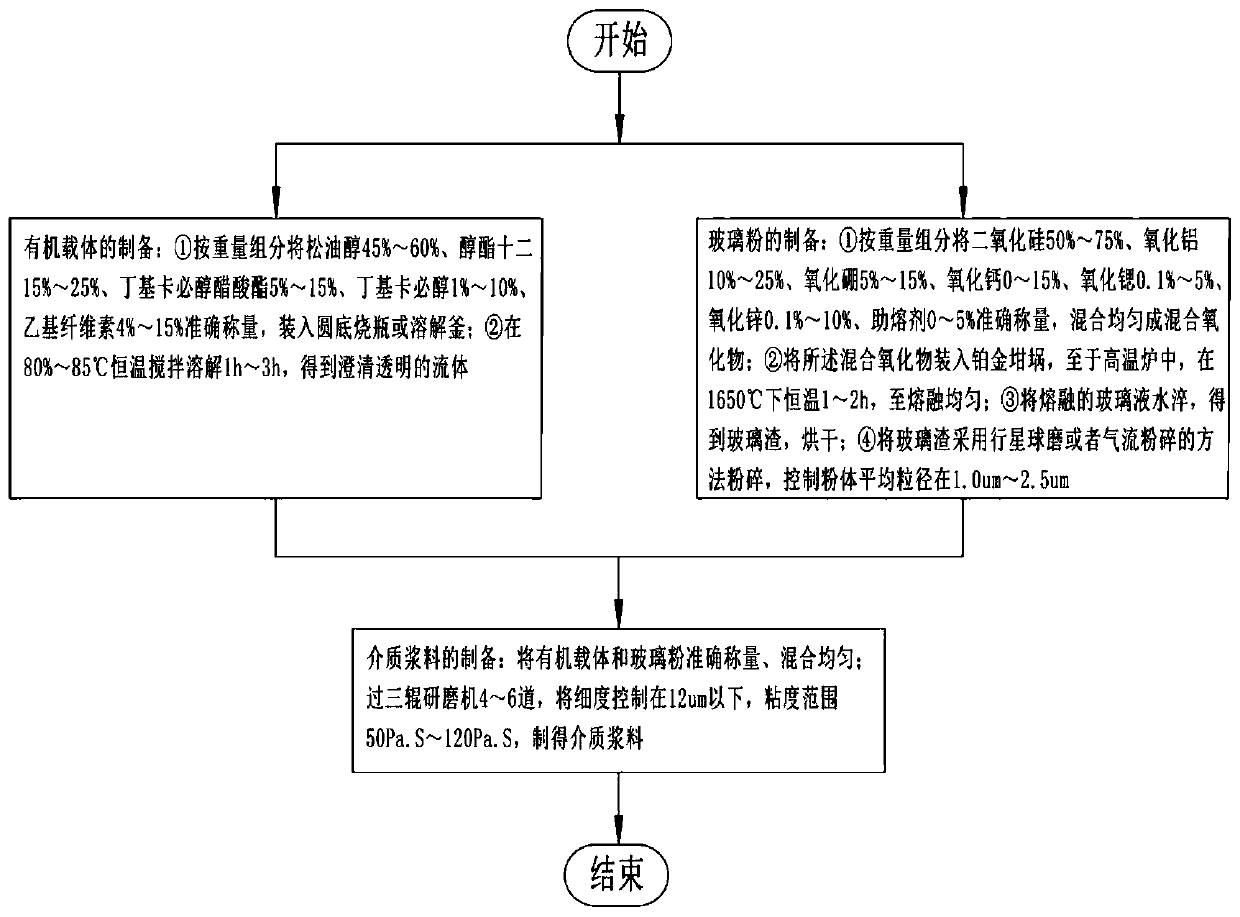

Low-expansion-coefficient insulating medium slurry and preparation method thereof

ActiveCN110550864AStrong acid and alkali corrosion resistanceImprove insulation performanceSlurryBoron oxide

Owner:航天科工(长沙)新材料研究院有限公司

Preparation method of silver-doped modified ruthenium dioxide thick-film resistance slurry

InactiveCN105741903ASolve for low resistanceSolve the problem of contradiction between high TCRNon-conductive material with dispersed conductive materialNon-adjustable resistorsFilm resistanceSlurry

The invention discloses a preparation method of silver-doped modified ruthenium dioxide thick-film resistance slurry. The method specifically comprises the following steps of: 1, using RuO2 powder, CuO powder and Ag powder to prepare a conductive phase; 2, using SiO2, Al2O3, CaO, BaO, B2O3, PbO and Bi2O3 to prepare a modified aluminosilicate glass phase; 3, using terpilenol, cellulose, butyl carbitol and castor oil to prepare an organic phase; and 4, uniformly mixing the conductive phase obtained in the step 1, the modified aluminosilicate glass phase obtained in the step 2 and the organic phase in the the step 3 to obtain the silver-doped modified ruthenium dioxide thick-film resistance slurry. According to the invention, the problem that a contradiction exists between low resistance and high TCR of the present thick-film resistance slurry is solved, the preparation method has no specific demands on the production process and device, and the popularization and the industrial production are facilitated.

Owner:XIDIAN UNIV

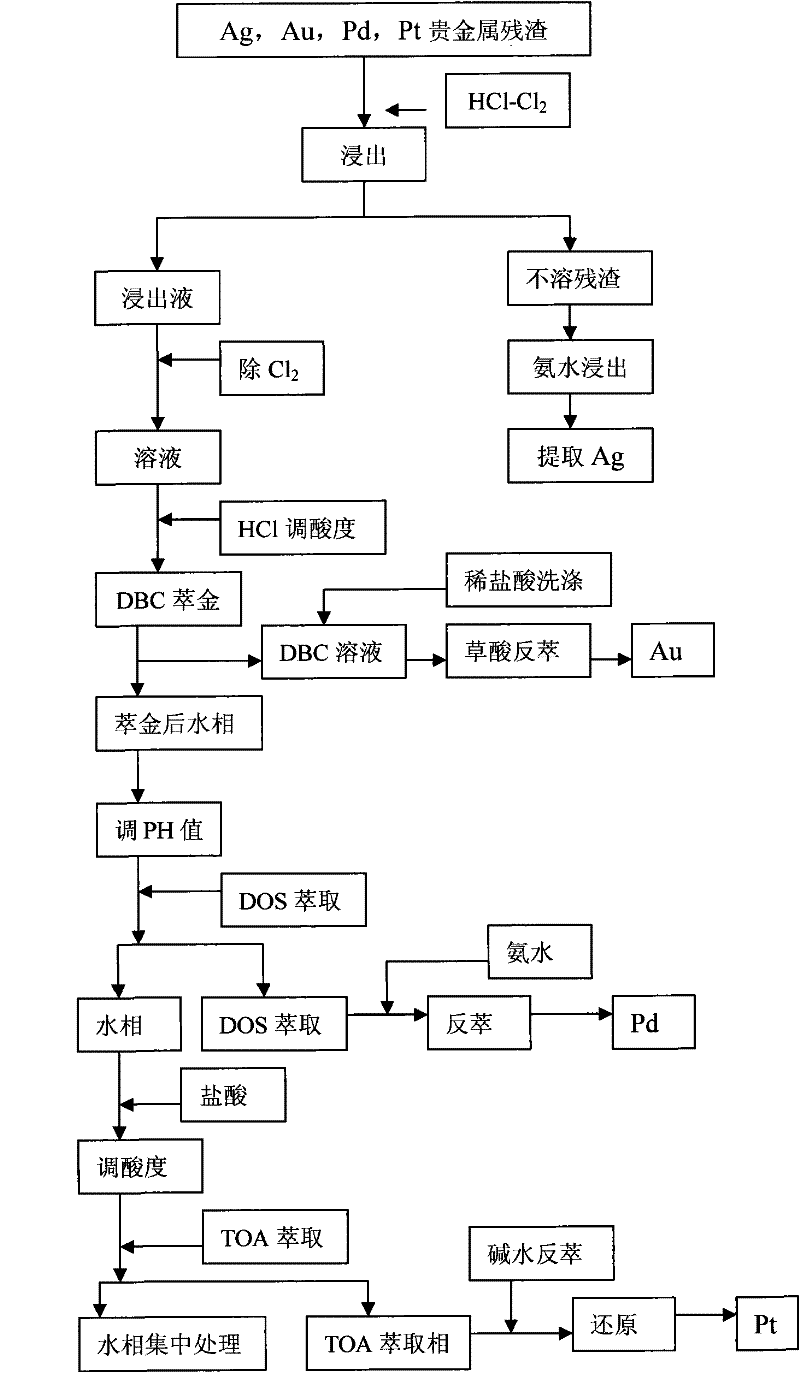

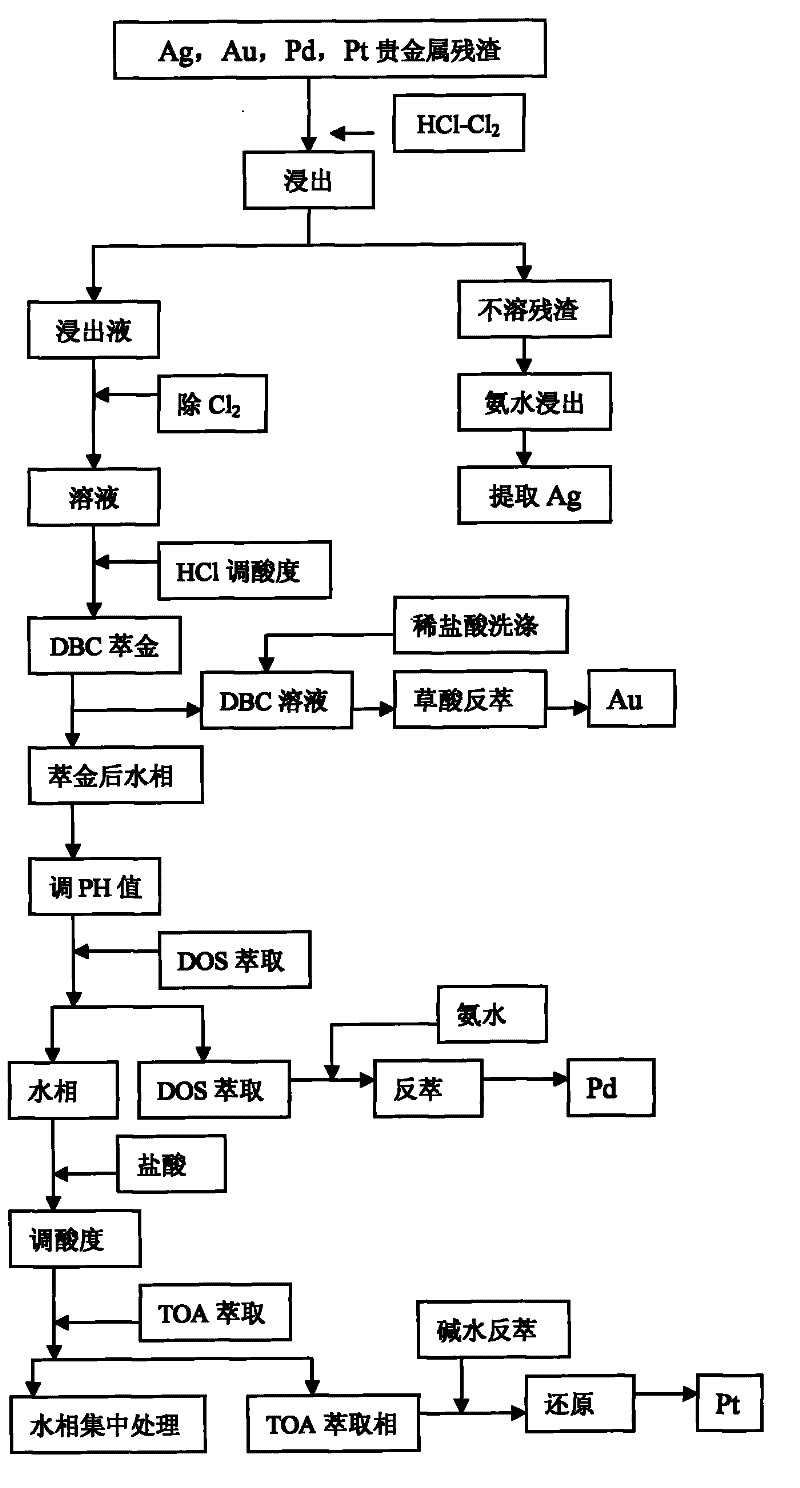

Process for extracting, separating and purifying Ag, Au, Pd and Pt

The invention relates to a process for extracting, separating and purifying Ag, Au, Pd and Pt. The process comprises the following steps of: precipitating and separating Ag in the form of AgC1, then adding ammonia water for dissolving, reducing hydrazine hydrate to obtain Ag; extracting by using dibutyl carbitol, and back-extracting Au with 5 percent of oxalic acid with a direct acceptance rate of more than or equal to 99.9 percent; extracting Pd with n-octyl sulfur ether, wherein the extraction rate of palladium is more than or equal to 99.99 percent, and then back-extracting the palladium with 3mol / L ammonia water; and finally, extracting Pt with tri-n-octylamine, back-extracting platinum with alkaline water and reducing to obtain platinum.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Plasma display panel manufacturing method for manufacturing a plasma display panel with superior picture quality, a manufacturing apparatus, and a phosphor ink

InactiveUS20030148695A1Accurately and evenly produceLittle line blurringDischarge tube luminescnet screensLamp detailsEngineeringSolvent

The present invention intends to provide a manufacturing method for a PDP that can continuously apply phosphor ink for a long time and can accurately and evenly produce phosphor layers even when the cell construction is very fine. To do so, phosphor ink is continuously expelled from a nozzle while the nozzle moves relative to channels between partition walls formed on a plate so as to scan and apply phosphor ink to the channels. While doing so the path taken by the nozzle within each channel between a pair of partition walls is adjusted based on position information for the channel. When phosphor particles is successively applied to a plurality of channels, phosphor ink is continuously expelled from the nozzle even when the nozzle is positioned away from the channels. The phosphor ink is composed of: phosphor particles that have an average particle diameter of 0.5 to 5 mum; a mixed solvent in which materials selected from a group consisting of terpineol, butyl carbitol acetate, butyl carbitol, pentandiol, and limonene are mixed; and a binder that is an ethylene group polymer or ethyl cellulose containing at least 49% of ethoxy group (-OC2H5) cellulose molecules. After dispersion a charge-removing material is added to the phosphor ink.

Owner:PANASONIC CORP

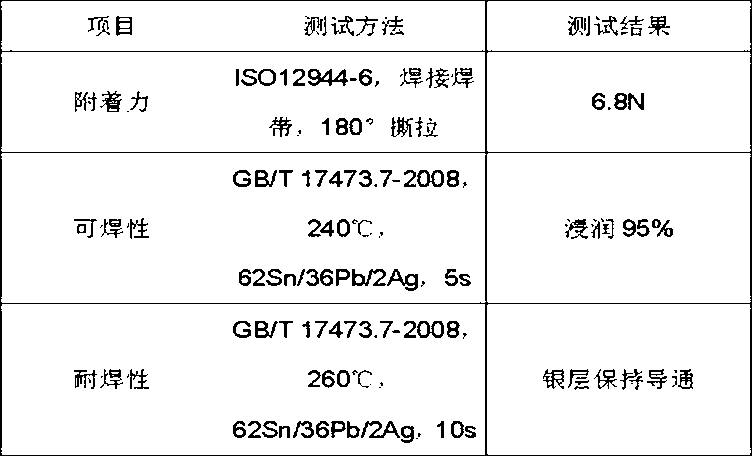

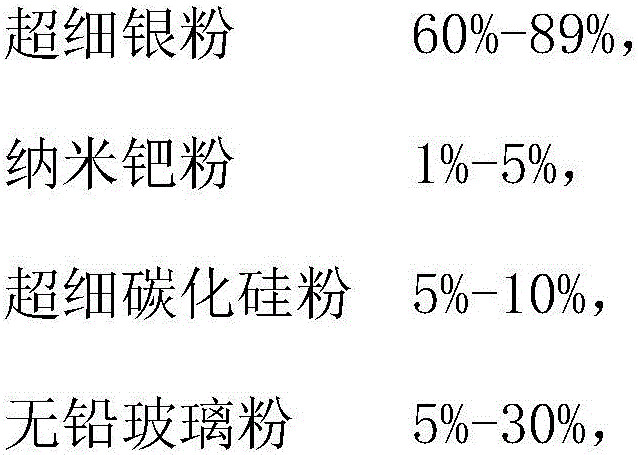

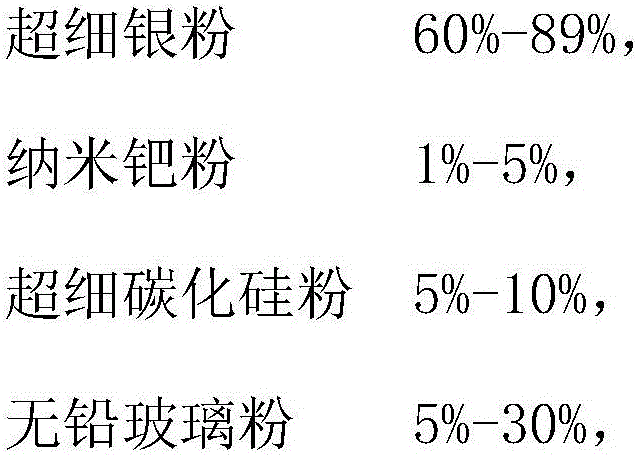

Low-silver-bearing printed circuit board silver paste and preparation method thereof

ActiveCN104078098AReduce dosageImprove yieldNon-conductive material with dispersed conductive materialCable/conductor manufactureCelluloseThiodiethylene Glycol

A low-silver-bearing printed circuit board silver paste comprises, by weight, 1 part to 2 parts of glucose, 20 parts to 30 parts of nanoscale sheet cooper powder, 30 parts to 40 parts of 1-micrometer to 20-micrometer sheet silver powder, 13 parts to 16 parts of glass powder, 5 parts to 7 parts of hyperbranched polyester resin, 5 parts to 8 parts of terpilenol, 2 parts to 5 parts of sulfo-diglycol, 2 parts to 4 parts of bisphenol A epoxy resin, 6 parts to 8 parts of butyl carbitol, 7 parts to 9 parts of acetic ether, 1 part to 2 parts of nanometer titania, 1 part to 2 parts of nanometer crystalline cellulose, 3 parts to 5 parts of nanometer tantalum carbide powder and 3 parts to 5 parts of nanometer niobium carbide powder. According to the low-silver-bearing printed circuit board silver paste, the nanoscale sheet copper powder, the nanometer tantalum carbide powder and the nanometer niobium carbide powder are added, so that the good conductive performance is kept, and the use amount of the silver powder is saved; the glass powder does not contain lead and is environmentally friendly and good in caking property, and a circuit is firm; the organic vehicle solvents are sequentially volatilized, the high temperature resistance is good, the printing performance is good, and the circuit yield is high.

Owner:乐凯特科技铜陵有限公司

Crystalline silicon solar cell back surface field aluminum paste and preparation method thereof

ActiveCN103208321AUniform fluidityBalanced thixotropyNon-conductive material with dispersed conductive materialCable/conductor manufactureBack surface fieldWater boil

The invention relates to crystalline silicon solar cell back surface field aluminum paste and a preparation method thereof. The crystalline silicon solar cell back surface field aluminum paste comprises, by weight, 74 parts of aluminum powder, 20-25 parts of organic bonds, 1-4 parts of lead-free glass powder and 0.1-2 parts of additives, wherein the organic bond comprises, by weight, 40-70 parts of terpineol, 5-10 parts of butyl carbitol, 5-10 parts of butyl carbitol acetic ester, 3-10 parts of ethyl cellulose, 5-15 parts of dibutyl phthalate and one part of sorbitol anhydride stearate; the lead-free powder comprises, by weight, 30-60 parts of Bi2O3, 5-15 parts of B2O3, 3 parts of BiF3, 10-20 parts of SiO2, 5-10 parts of ZnO, 1-5 parts of TiO2, 10-20 parts of Al2O3 and 1-3 parts of P2O5; and the additive is spherical copper powder with the purity larger than 99% and the fineness being 20000 meshes. The aluminum powder, the organic bonds, the lead-free glass powder and the additives are evenly mixed and then rolled by a three-roll grinder until the fineness is smaller than or equal to 10 mum and the viscosity is 30-60Pa*s. The crystalline silicon solar cell back surface field aluminum paste is high in photoelectric conversion efficiency and adhesive force, the adhesive force conversion efficiency after high temperature aging declines, and the water-boiling resistance is good.

Owner:JIANGSU ZHENGNENG ELECTRONICS TECH CO LTD

High thermal conductivity graphene-carbon nano slurry and preparation method thereof

ActiveCN108598051AGood dispersionImprove qualityMaterial nanotechnologyCarbon compoundsOrganic solventSource material

The invention provides a high thermal conductivity graphene-carbon nano slurry and a preparation method thereof. The preparation method comprises the following steps: (1) preparing highly dispersed nano silicon dioxide particles with a gel-sol method; (2) modifying a graphene oxide by using a coupling agent, and enabling the coupling agent to react with graphene to obtain functional graphene, wherein the functional graphene is dispersed in a butyl carbitol dispersion liquid after being ultrasonically treated to form a functional graphene dispersion liquid; (3) adding the nano silicon dioxide particles to the functional graphene dispersion liquid in a stirring state, and mixing for 30-120min; and (4) mixing the functional graphene dispersion liquid with an organic solvent, an auxiliary agent and the nano silicon dioxide particles fully and uniformly to obtain the high thermal conductivity graphene-carbon nano slurry. For a thermal conductive film prepared with the graphene-carbon nano slurry of the invention, a measured thermal conductivity coefficient is 1800W / m.k and excellent thermal conductive characteristics are shown; and moreover, the high thermal conductivity graphene-carbonnano slurry is a good far-infrared heating source material.

Owner:牛墨石墨烯应用科技有限公司

A lead free aluminum electrode slurry of PTC thermo-sensitive resistor and preparation method

InactiveCN101217067AAchieve lead-freeWon't fall offPositive temperature coefficient thermistorsMetal/alloy conductorsBarium titanateSlurry

The invention discloses a lead-free aluminum electrode paste for a PTC thermistor and the preparation method, the electrode paste is composed of the raw materials with the following parts by weight: 55 to 70 parts of aluminum powder, 10 to 20 parts of inorganic binder, 15 to 25 parts of organic binder and 2 to 4 parts of auxiliary; wherein, the organic binder is composed of 2 to 5 parts by weight of ethyl cellulose, 3 to 6 parts by weight of butyl carbitol, 15 to 23 parts by weight of butyl carbitol acetate, 2 to 4 parts by weight of benzyl alcohol, 60 to 70 parts by weight of terpineol, 0.5 to 2 parts by weight of phenolic resin and 1 to 4 parts by weight of castor oil; and the auxiliary is composed of 30 to 50 parts by weight of Bi2O3 and 50 to 70 parts by weight of phosphorus red. The electrode paste can prepare the aluminum conductive paste by rolling, an aluminum electrode can be formed by screen printing and sintering on a doped barium titanate semiconductor substrate within the range of 630 plus or minus 20 DEG C, the electrode and the substrate form good ohmic contact, the adhesion is good, the aluminum membrane dose not shed, and the long-term placement of the electrode has no oxidation.

Owner:GUANGZHOU RUXING TECH DEV +1

Silicon carbide-silver palladium composite resistor paste and preparation method thereof

InactiveCN106211378AGood dispersionImprove storage performanceHeating element materialsMiniaturizationSolvent

Owner:DONGGUAN COREHELM ELECTRONICS MATERIAL TECH CO LTD

Silver slurry for crystalline silicon solar cell

InactiveCN105655009AIncrease contact areaImprove conductivityNon-conductive material with dispersed conductive materialPhotovoltaic energy generationCarbon nanotubeSlurry

Owner:GUANGXI JIKUAN SOLAR ENERGY EQUIP

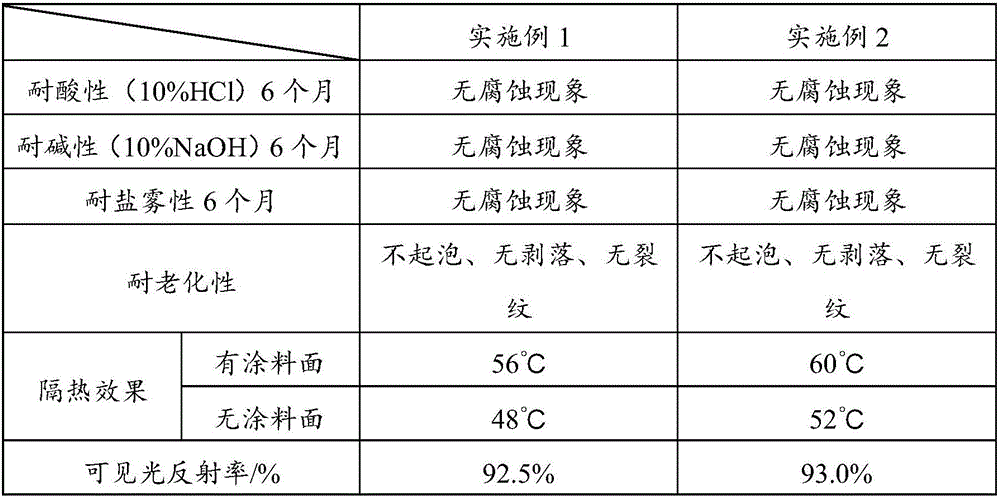

Solar energy reflecting heat-insulation coating and preparation method thereof

InactiveCN106554704AGood heat insulationGood acid and alkali resistanceEpoxy resin coatingsReflecting/signal paintsCalcium silicateMesoporous silica

The invention discloses a solar energy reflecting heat-insulation coating. The solar energy reflecting heat-insulation coating comprises, by weight, 2-3 parts of mesoporous silicon dioxide powder MCM-41 from Aladdin Industrial Corporation, 1-2 parts of nanoscale titanium dioxide, 16-17 parts of Dow solid epoxy resin DER671, 12-15 parts of stearalkonium hectorite, 3-4 parts of zinc stearate, 3-4 parts of calcium stearate, 1-2 parts of hydroxypropyl guar gum, 2-3 parts of hydroxypropyl methyl cellulose, 4-5 parts of potassium tripolyphosphate, 7-8 parts of butyl carbitol, 8-9 parts of calcium silicate, 6-7 parts of aluminium silicate, 11-12 parts of melamine formaldehyde resin powder, 1-2 parts of 2-amino phenyl mercaptan, 0.3-0.5 part of gamma-amino propyl triethoxysilane, 14-15 parts of methyl isobutyl ketone, 15-16 parts of toluene and 8-9 parts of xylene. The solar energy reflecting heat-insulation coating has the advantages of excellent heat-insulation effect, high reflective rate, and excellent acid-alkali resistance, salt-fog resistance and aging resistance.

Owner:CHANGZHOU TONGFENG PAINT

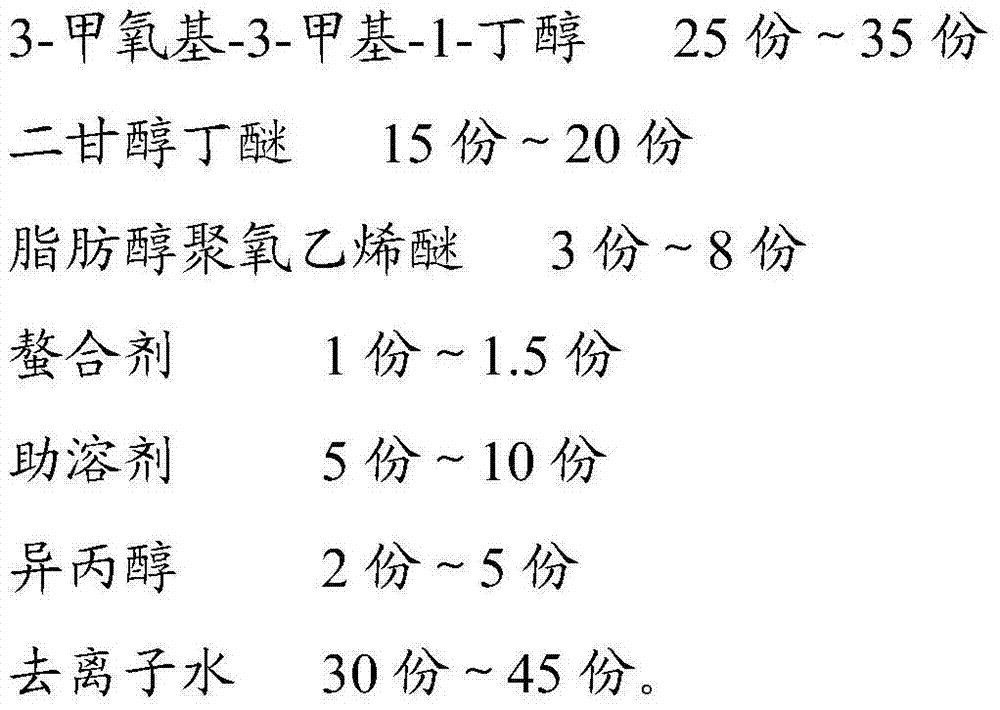

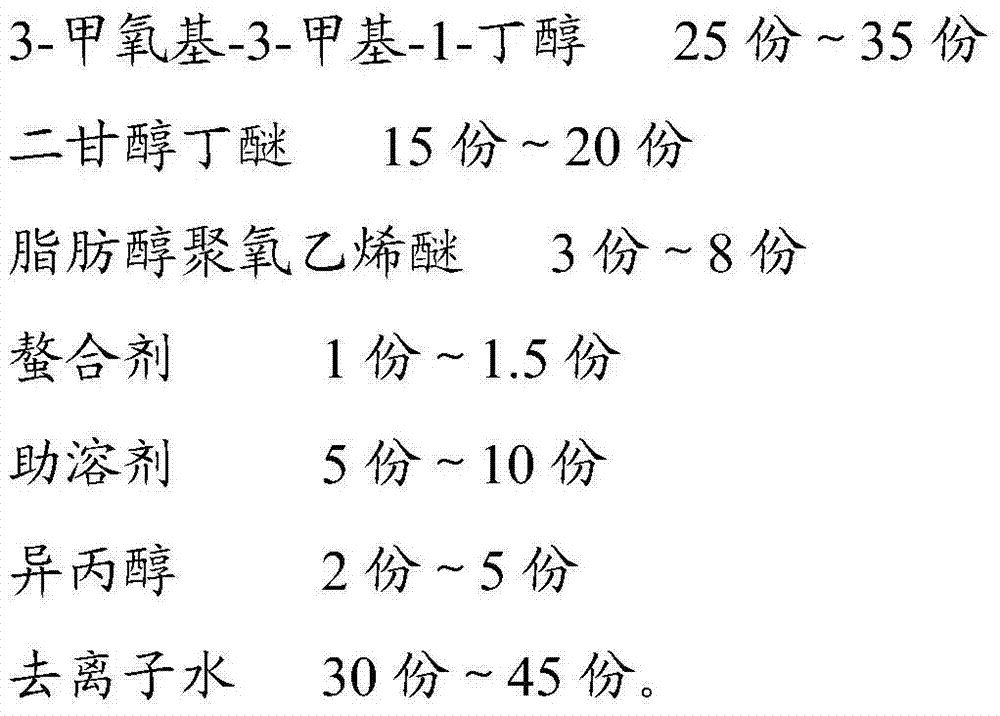

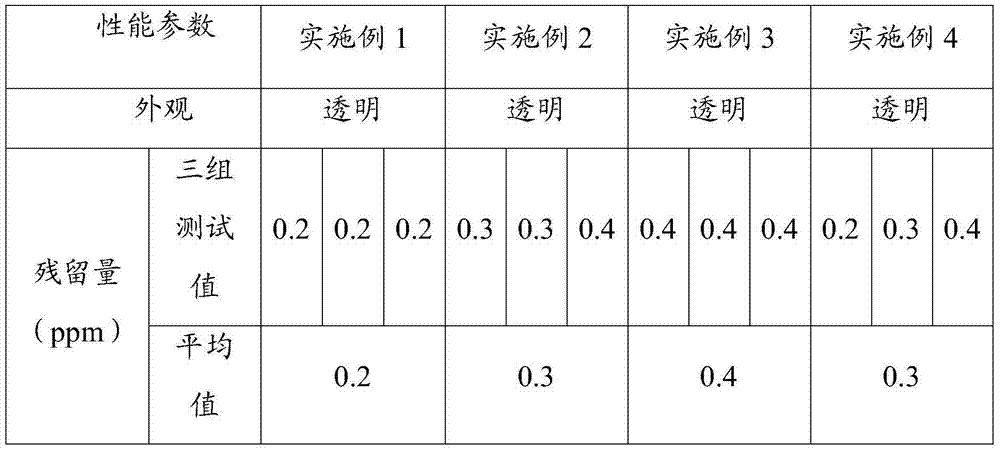

Water-based circuit board cleaning agent and preparation method thereof

InactiveCN103497851AImprove chelation abilityGood water solubilityOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsWater basedN-Butanol

The invention discloses a water-based circuit board cleaning agent and a preparation method thereof. The water-based circuit board cleaning agent comprises the following components in parts by weight: 25-35 parts of 3-methoxy-3-methyl-1-butanol, 15-20 parts of butyl carbitol, 3-8 parts of fatty alcohol-polyoxyethylene ether, 1-1.5 parts of chelating agent, 5-10 parts of cosolvent, 2-5 parts of isopropanol and 30-45 parts of deionized water. The preparation method of the water-based circuit board cleaning agent comprises the following steps: firstly, mixing the chelating agent with the deionized water, heating to 40-45 DEG C and stirring for 6-12 minutes; secondly, controlling the temperature within the range from 28 DEG C to 31 DEG C, adding the fatty alcohol-polyoxyethylene ether, the cosolvent, the 3-methoxy-3-methyl-1-butanol, the butyl carbitol and the isopropanol, continuously stirring for 1 hour and then standing for 10-15 minutes to obtain the water-based circuit board cleaning agent. The preparation method of the water-based circuit board cleaning agent disclosed by the invention has the beneficial effects of simple steps and stable process, and prepared product is environment-friendly and harmless, high in cost performance and high in cleaning ability.

Owner:SHANGHAI LIMEI CHEM CO LTD

Preparation method of organic carrier

The invention discloses a preparation method of an organic carrier. The preparation method comprises the following steps: (1) determination of a thickening agent: adopting ethyl cellulose as the thickening agent; (2) selection of organic solvents: adopting tributyl citrate, butyl carbitol, terpilenol and the like as the solvents; (3) selection of other auxiliary agents; and (4) preparation of a formula: dissolving the carrier by adopting the following components in percentage by weight: 8% of ethyl cellulose, 12% of tributyl citrate, 21% of butyl carbitol, 57% of terpilenol and 2% of the auxiliary agents. By adopting the organic carrier in a process disclosed by the invention, slurry has proper viscosity, volatility, thixotropy and levelling properties so as to obtain good printing performance, and a membrane layer subjected to silk-screen printing is uniform, compact, clearer and smoother.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

Dielectric paste for metal aluminum substrate thick film circuit and preparation method thereof

InactiveCN101740160BImprove thixotropyGood anti-sinking effectNon-macromolecular adhesive additivesSolid-state devicesDielectricCITRATE ESTER

The invention discloses dielectric paste for a metal aluminum substrate thick film circuit and a preparation method thereof. The invention aims to prepare the dielectric paste matched with a metal aluminum substrate. The dielectric paste is characterized in that SiO2, Na2O, B2O3, K2O, BaO, CaO, Co2O3, TiO2, P2O5, V2O5, Sb2O3 and Cr2O3 are combined to prepare microcrystalline glass powder; and themicrocrystalline glass powder and an organic binder which consists of terpinol, butyl carbitol, butyl carbitol acetate, tirbutyl citrate, 1,4-butyrolactone, nitroncellulose, ethyecellulose, hydrogenated castor oil and lecithin are put in a vessel for stirring and rolling by a three-roll roller mill in a weight ratio of the microcrystalline glass powder to the organic binder of 70-90 parts: 30-10 parts so as to prepare the finished product dielectric paste. The dielectric paste is mainly used as the dielectric paste of the thick film circuit formed by being printed on the metal aluminum substrate.

Owner:湖南利德电子浆料股份有限公司

Heat-insulating and mildew-resistant water-based paint for glass door and preparation method of water-based paint

InactiveCN104449281AReduce manufacturing costImprove performanceAntifouling/underwater paintsPaints with biocidesSodium acetatePolymer science

The invention discloses a heat-insulating and mildew-resistant water-based paint for a glass door. The water-based paint is characterized by being prepared from the following raw materials in parts by weight: 23-26 parts of an epoxy resin emulsion, 40-45 parts of water-based amino-alkyd resin, 0.3-0.5 part of a flatting agent BYK-307, 1-2 parts of zinc powder, 0.5-1.0 part of a silane coupling agent NQ-71, 0.2-0.3 part of nanometer ground calcium carbonate, 0.2-0.4 part of a polyacrylate thickener, 0.4-0.7 part of hollow glass powder, 0.2-0.3 part of polyoxyethylene monoleate, 0.3-0.5 part of ceramic powder microsphere, 0.1-0.3 part of polymeric microspheres, 0.2-0.4 part of sodium diacetate, 2-3 parts of butyl carbitol, 0.2-0.4 part of liquid paraffin, 2-3 parts of ethylene glycol monobutyl ether, 0.1-0.3 part of fatty acid polyethylene glycol ester, 3-5 parts of a modified nanometer titanium dioxide photocatalyst, 1-2 parts of a pigment and 12-15 parts of deionized water. The added modified titanium dioxide photocatalyst has the functions of effectively purifying air, removing stink and odor, killing a plurality of bacteria and preventing mildew; a good thermal insulation effect is achieved by combined action of added hollow glass powder, ceramic powder microspheres and polymeric microspheres; the production cost of the paint is reduced; and the paint disclosed by the invention is excellent in various performances, does not contain a special odor, is safe and non-toxic, and can be widely applied to glass for home decoration.

Owner:安徽省实防新型玻璃科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com