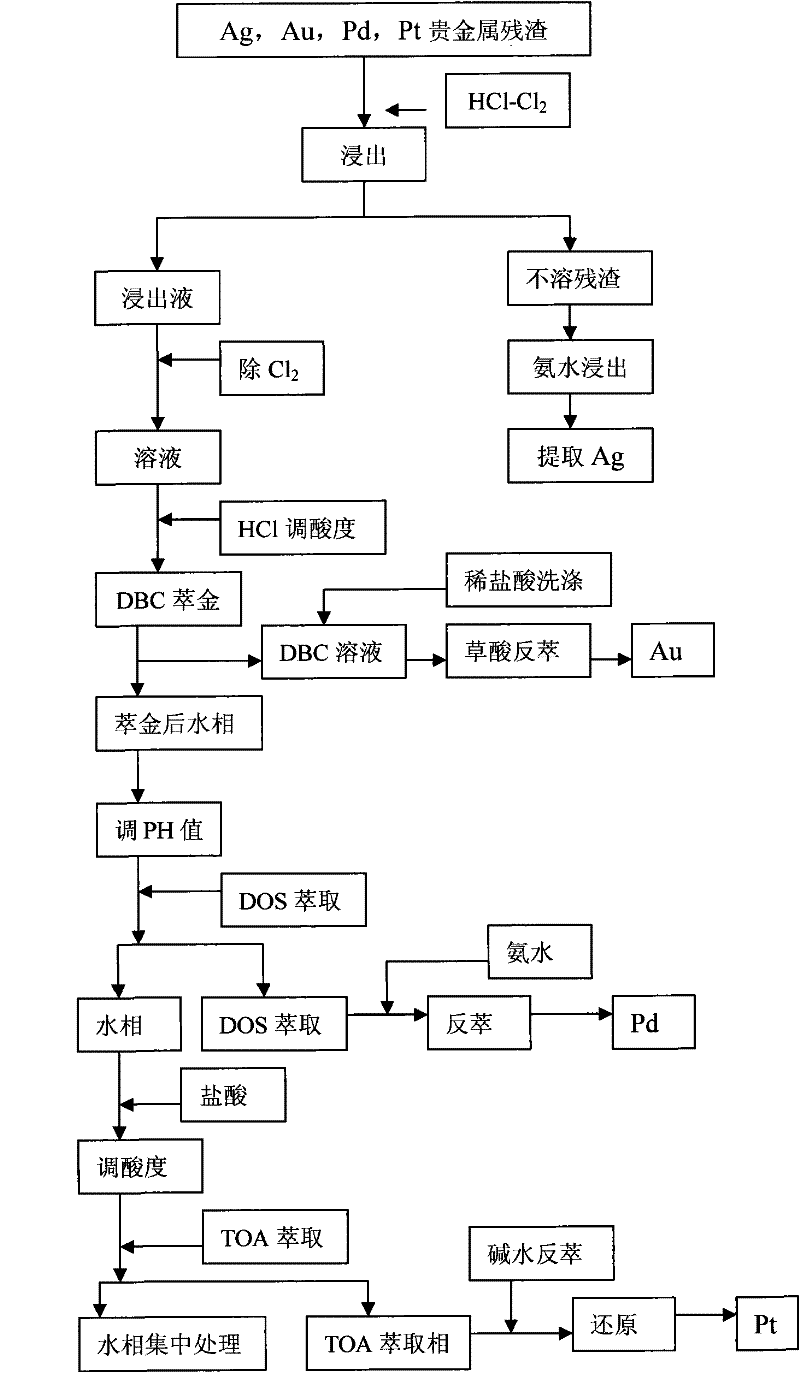

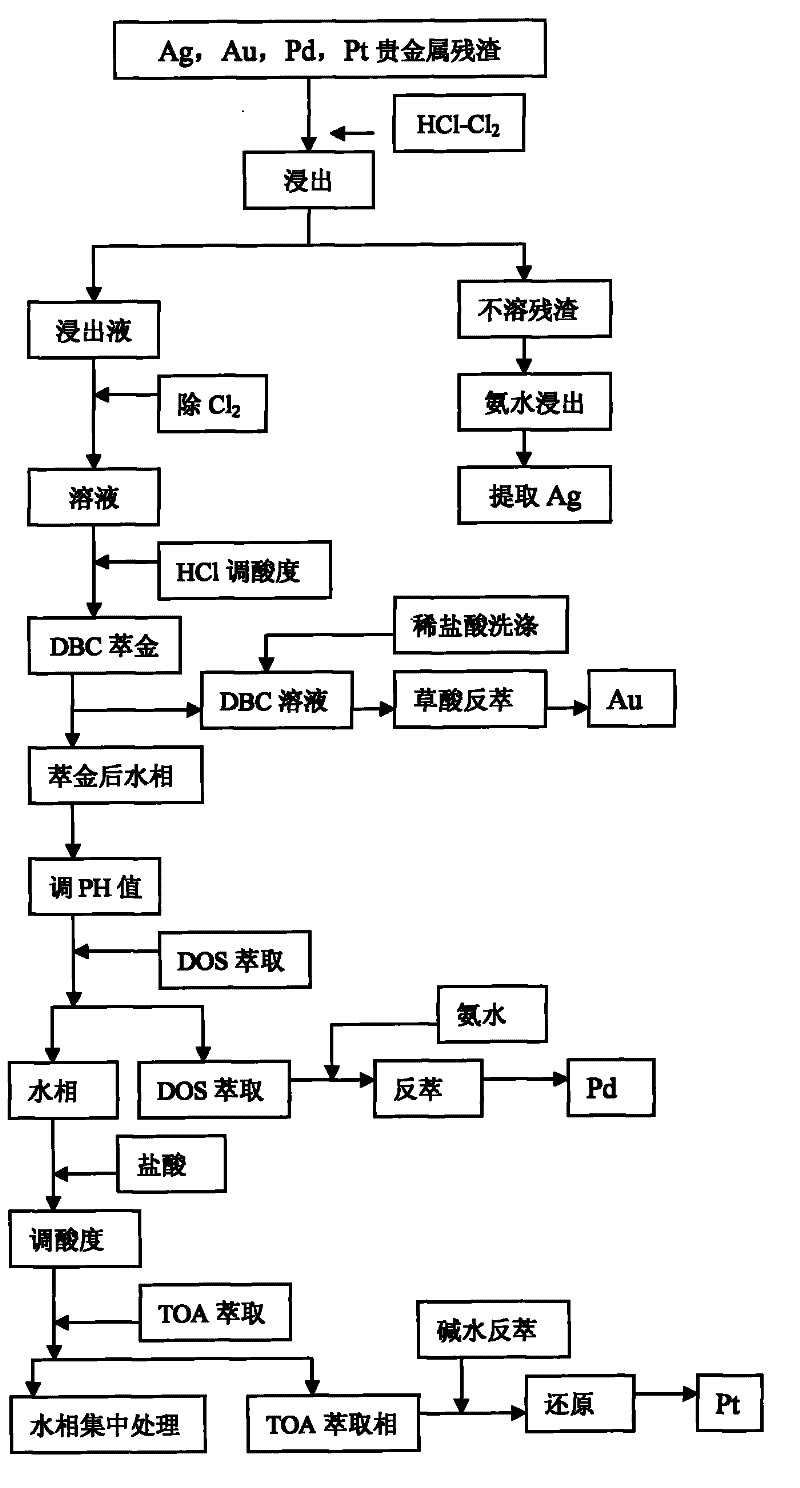

Process for extracting, separating and purifying Ag, Au, Pd and Pt

An optimal and precious metal technology, applied in the direction of improving process efficiency, etc., can solve the problems of cumbersome treatment process, difficult platinum refining connection, large dissolution loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: The precious metal liquid composition is as follows

[0025] components

[0026] Take 1L of the above precious metal solution, adjust the acidity to 2.5mol / L hydrochloric acid, extract with 1LDBC for 5min, separate the water phase, wash the organic phase with 0.5mol / L hydrochloric acid; separate the water phase, and use 5% oxalic acid solution for the organic phase Restore at 80°C for 2 hours to obtain golden sponge gold, the gold extraction rate is 99.99%, and the recovery rate is 99.9%; the water phases are combined, the water and acid are evaporated, the acidity is adjusted to 0.1mol / L hydrochloric acid, and 1L of 15% DOS xylene solution is used Extract palladium, mix the phases for 5 minutes, and the palladium extraction rate is greater than 99.99%. The aqueous phase was separated, and back-extracted with 3mol / L ammonia water, the stripping rate was 96%, the aqueous phase was reduced with hydrazine hydrate to obtain pure palladium, the organi...

Embodiment 2

[0027] Embodiment 2: The composition of precious metal liquid is as follows

[0028] components

[0029] Take 500ml of the above precious metal solution, adjust the acidity to 2.0mol / L hydrochloric acid, extract with 500ml DBC for 5min, separate the water phase, wash the organic phase with 0.5mol / L hydrochloric acid; separate the water phase, and use 5% oxalic acid solution for the organic phase Restore at 80°C for 2 hours to obtain golden sponge gold, the gold extraction rate is 99.99%, and the recovery rate is 99.9%; the water phases are combined, water and acid are evaporated, and the acidity is adjusted to 0.1mol / L hydrochloric acid, and 500ml 15% DOS xylene The solution extracts palladium, mixed phases for 5 minutes, and the palladium extraction rate is greater than 99.99%. The aqueous phase was separated, and back-extracted with 3mol / L ammonia water, the stripping rate was 96%, the aqueous phase was reduced with hydrazine hydrate to obtain pure palladium, the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| extraction efficiency | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com