Patents

Literature

412results about "Luminescent coatings application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light sources with nanometer-sized VUV radiation-absorbing phosphors

A light source comprises: (a) a source of plasma discharge that emits electromagnetic radiation, a portion of which has wavelengths shorter than about 200 nm; and (b) a phosphor composition that comprises particles, each of the particles comprising at least a first phosphor and at least a second phosphor, the phosphor composition is disposed such that the first phosphor absorbs substantially the portion of EM radiation having wavelengths shorter than about 200 nm, and the first phosphor emits EM radiation having wavelengths longer than about 200 nm.

Owner:GENERAL ELECTRIC CO

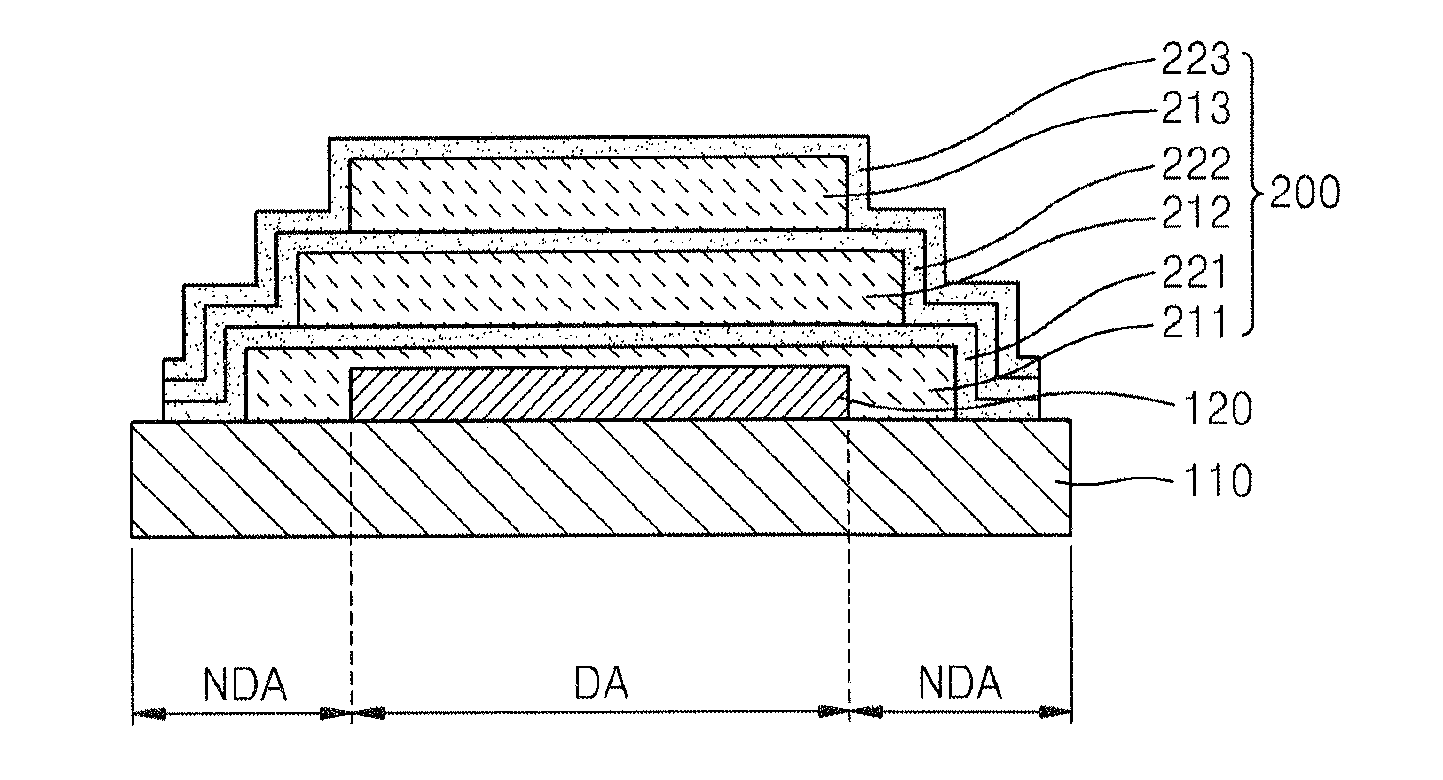

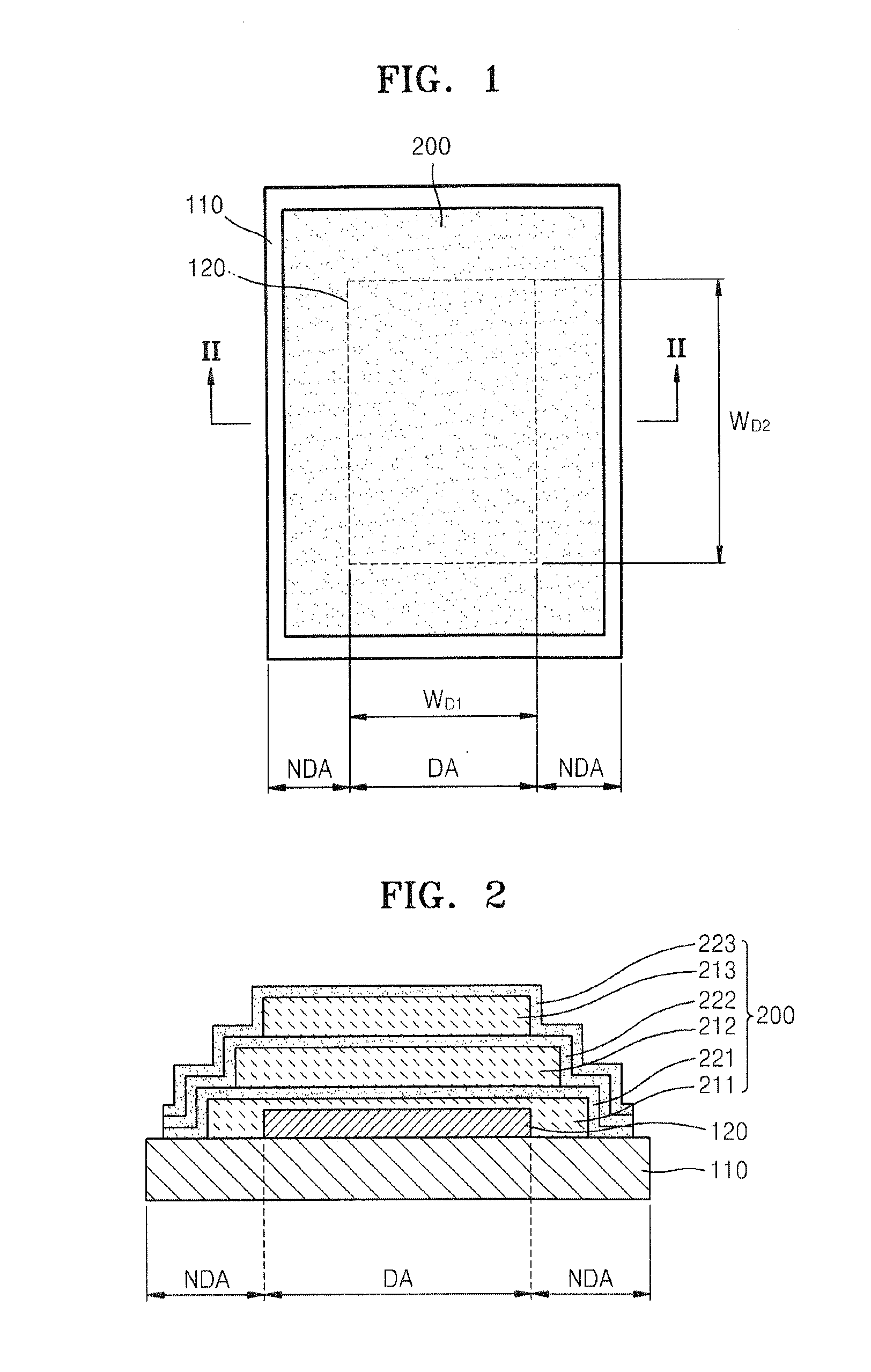

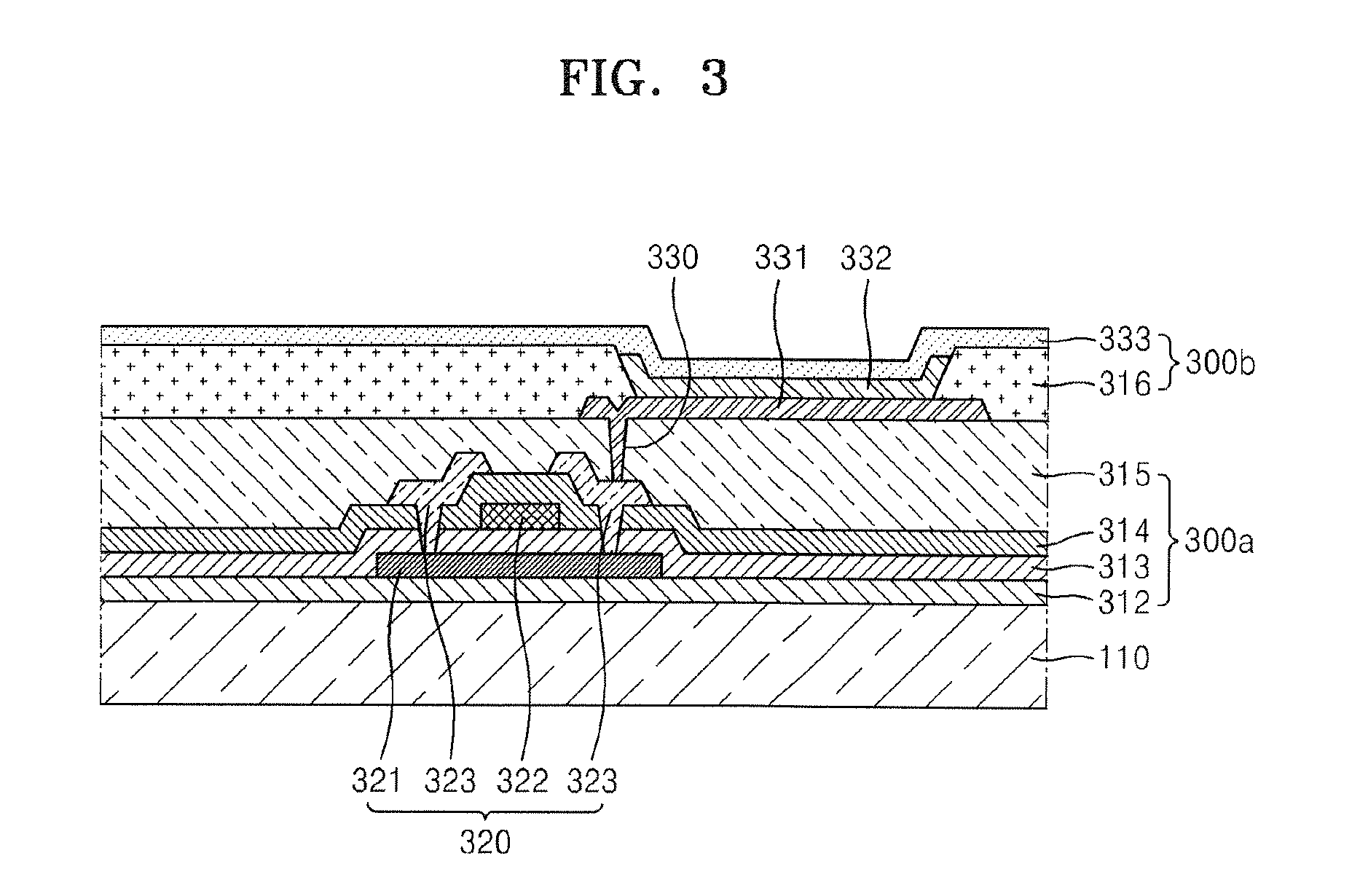

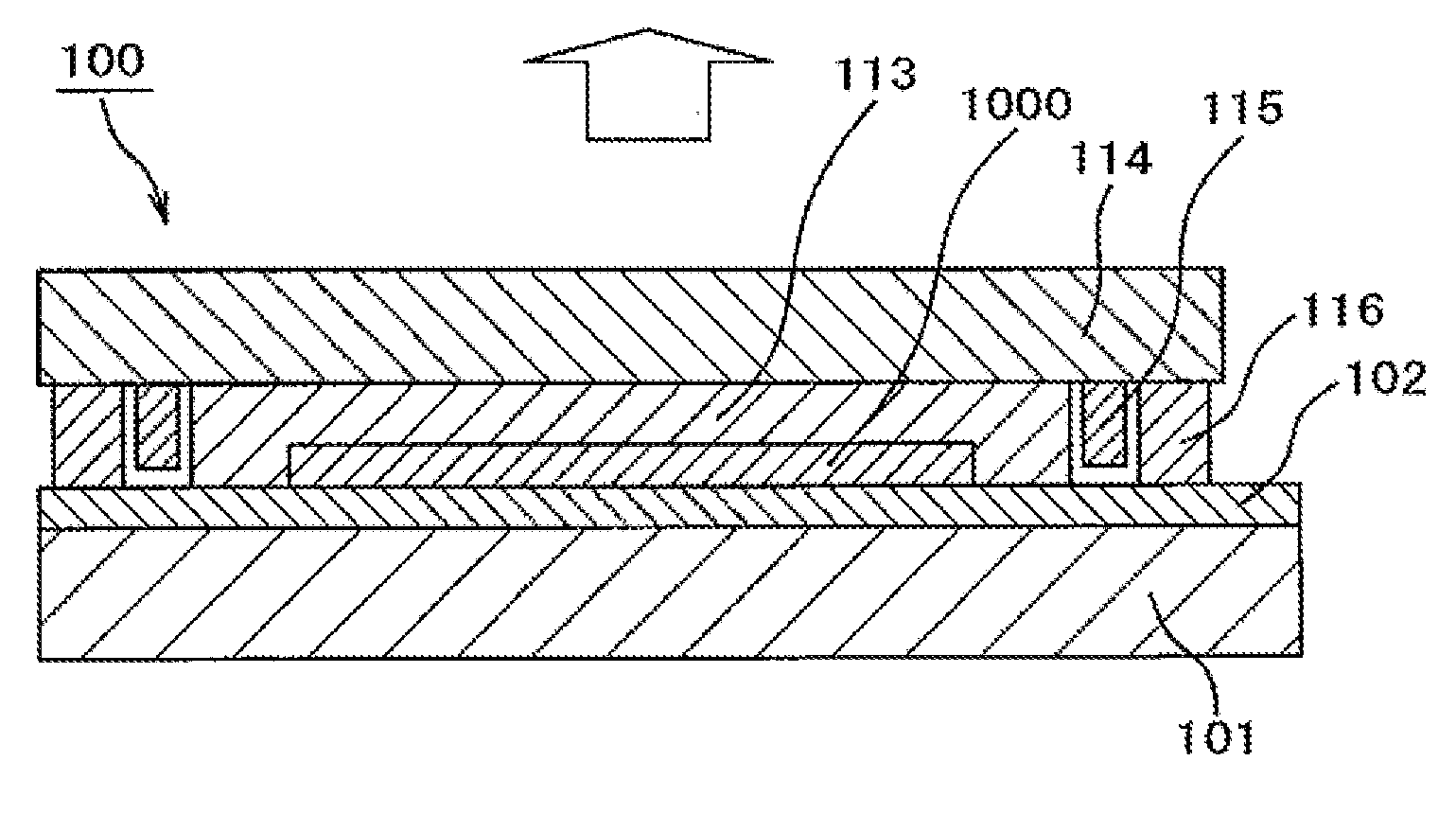

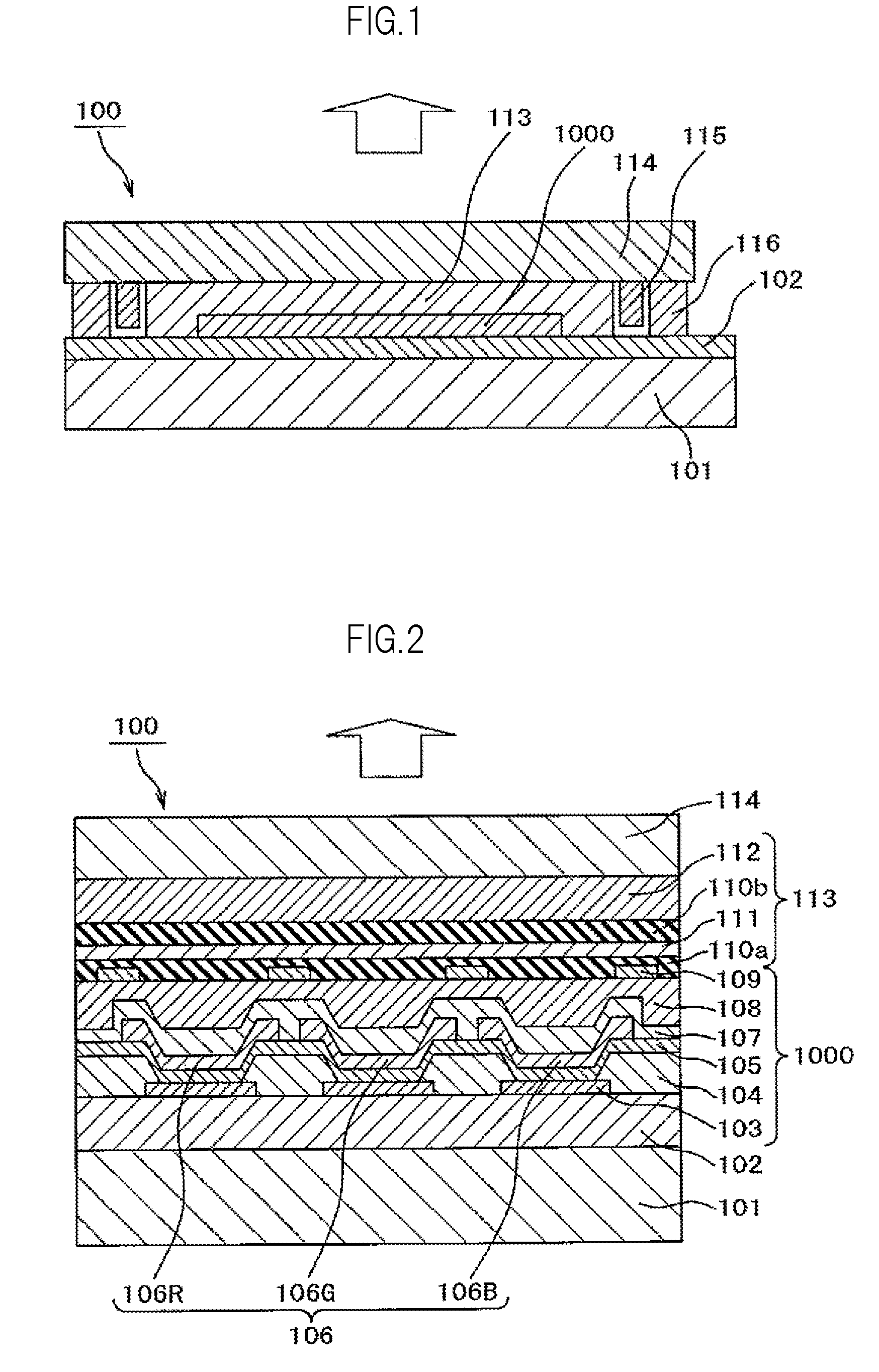

Organic light-emitting display apparatus and method of manufacturing the same

ActiveUS20120146492A1Reduce defective rateImprove moisture resistanceDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringInorganic layer

In an organic light-emitting display apparatus and a method of manufacturing the same, the organic light-emitting display apparatus comprises: a substrate; a light-emitting unit formed on the substrate; and an encapsulation film, which covers the light-emitting unit on the substrate, and which includes a plurality of organic layers and a plurality of inorganic layers which are alternately stacked.

Owner:SAMSUNG DISPLAY CO LTD

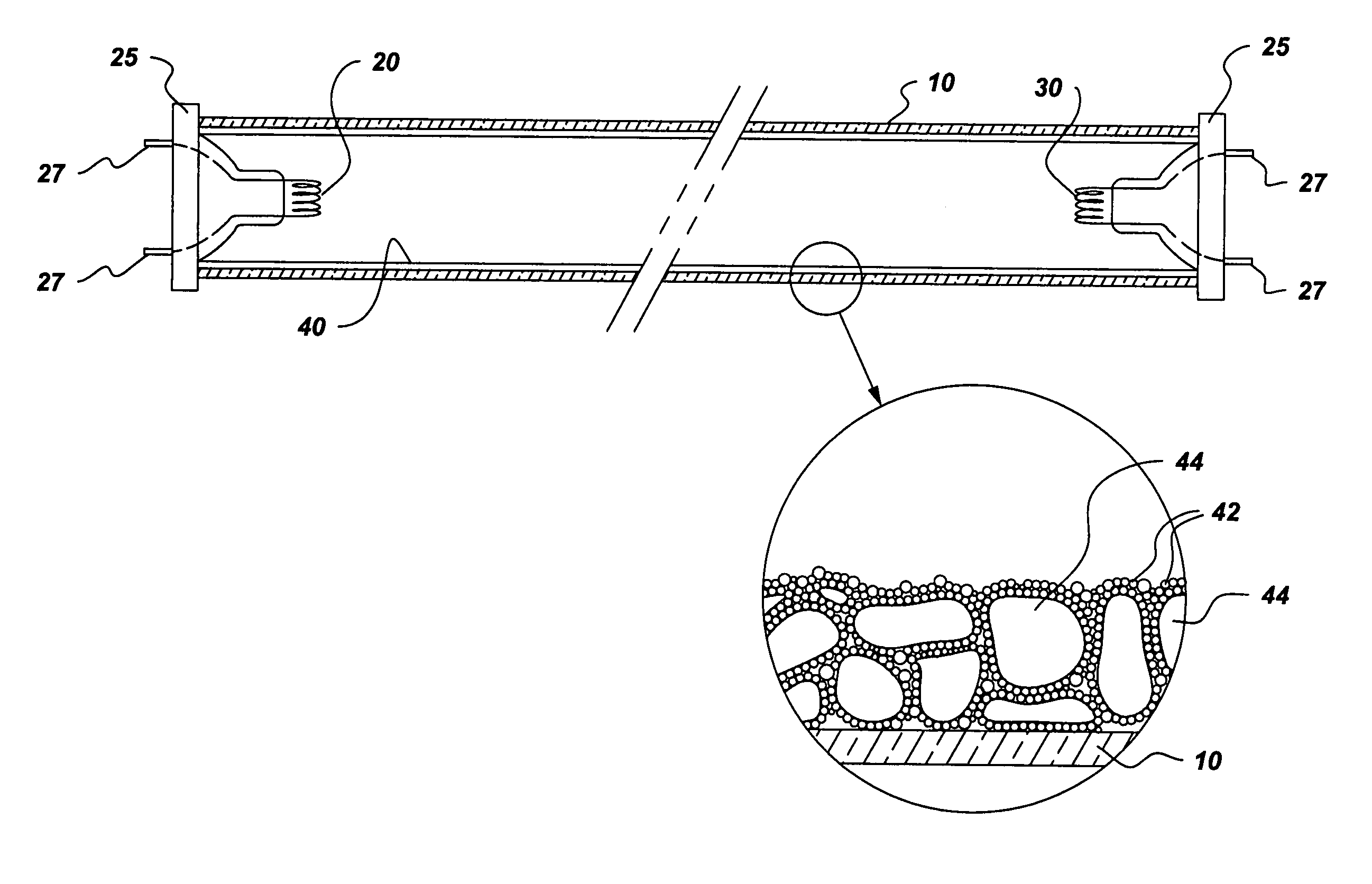

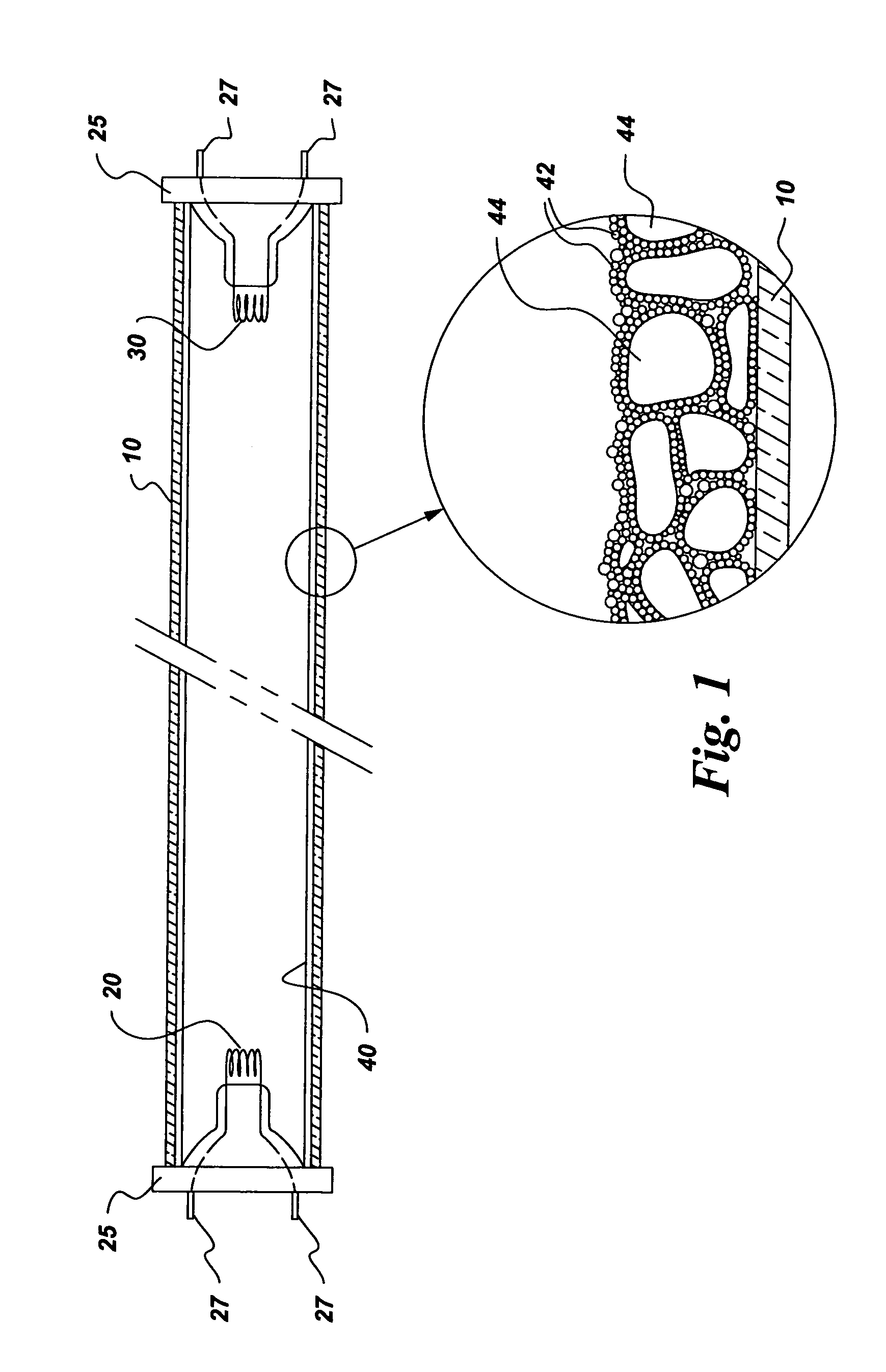

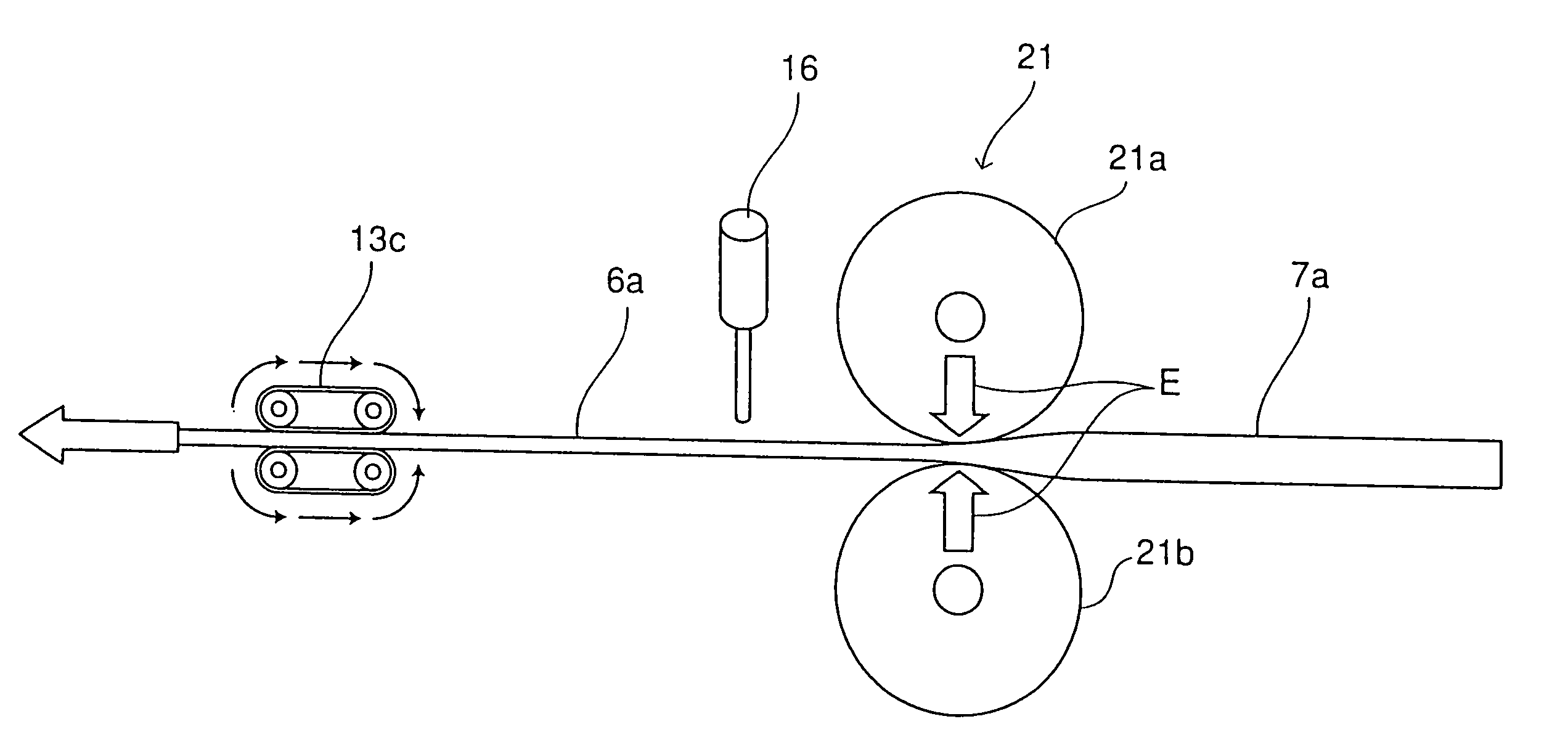

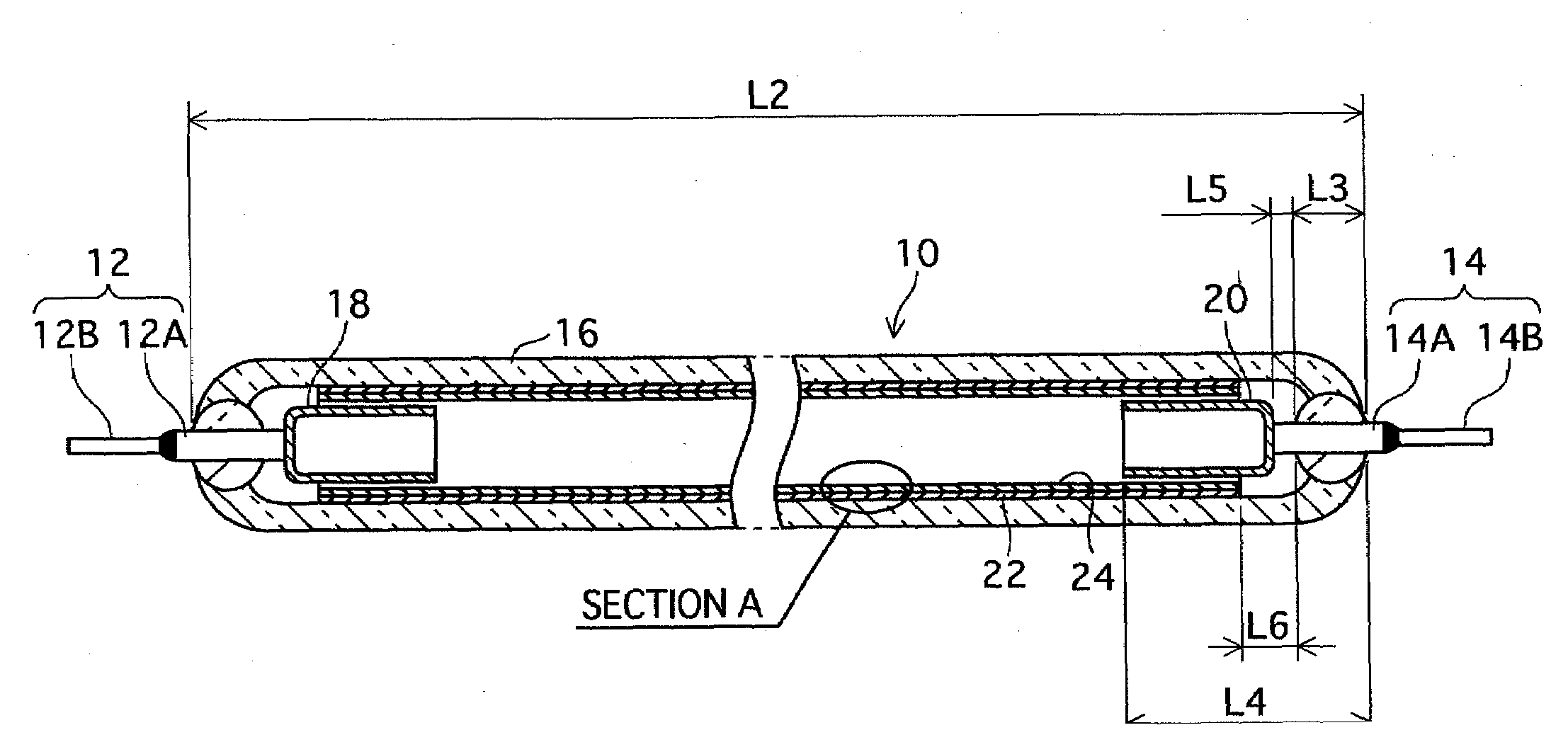

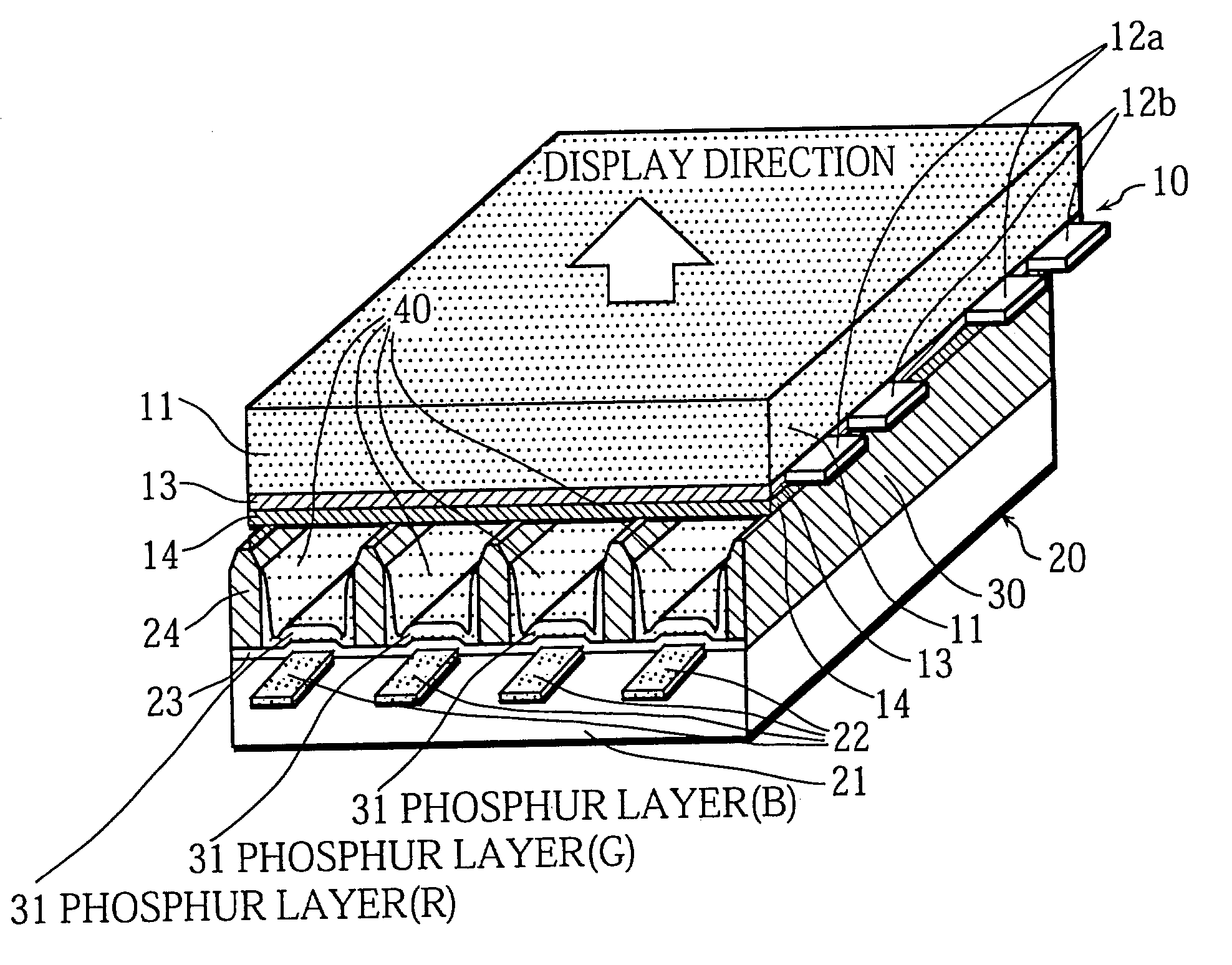

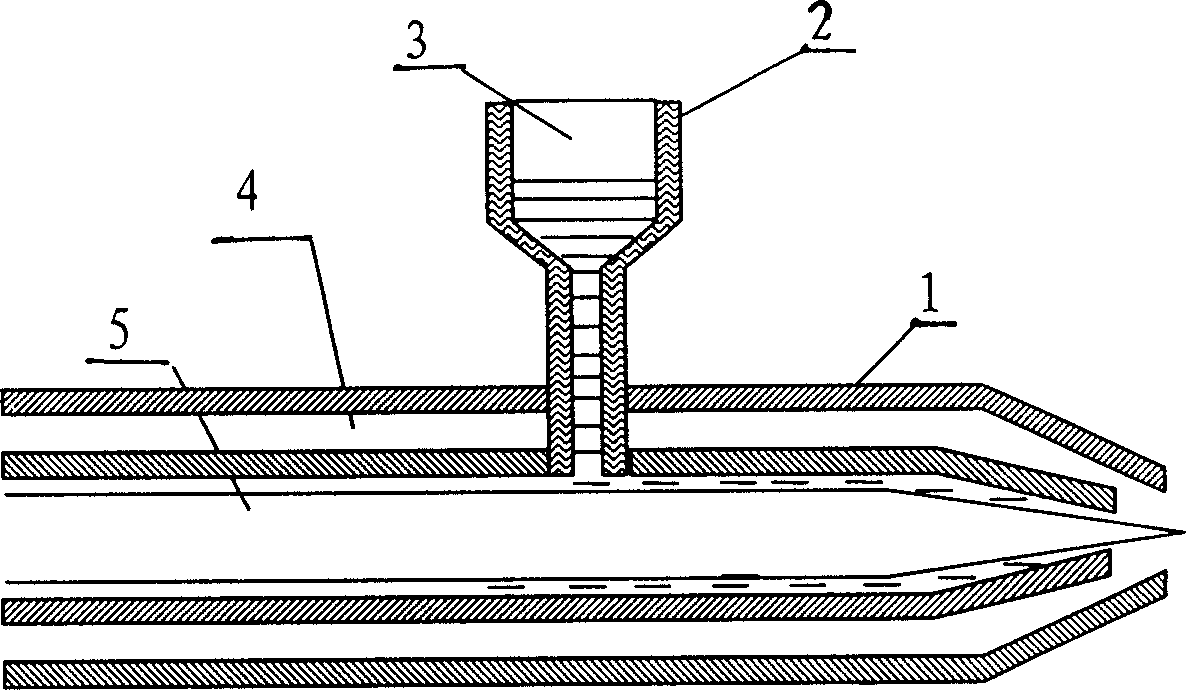

Method for forming phosphor layer of gas discharge tube and method for fabricating phosphor layer supporting member

InactiveUS6969292B2Well formedHigh yieldAddress electrodesSustain/scan electrodesFluorescencePhosphor

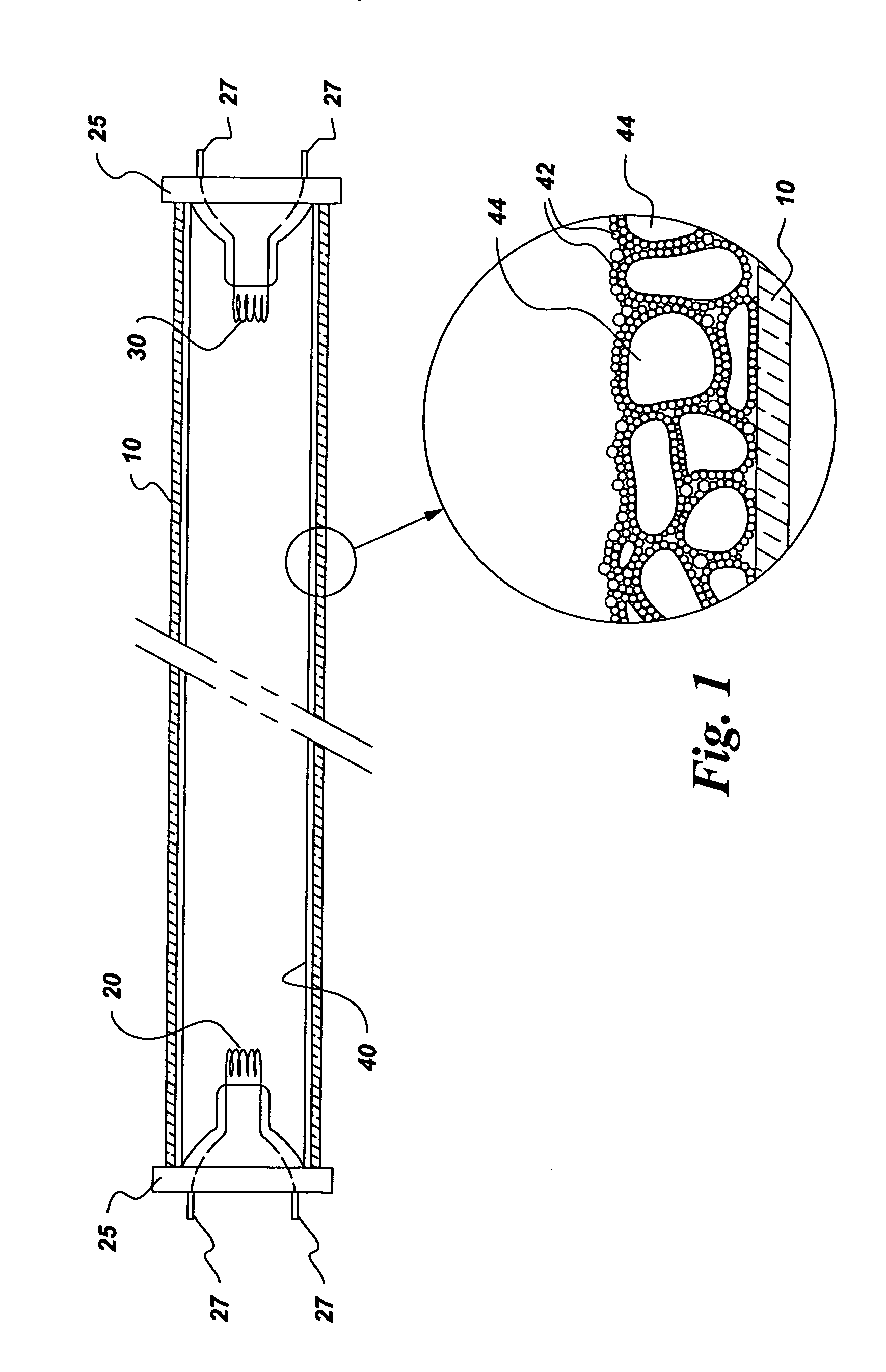

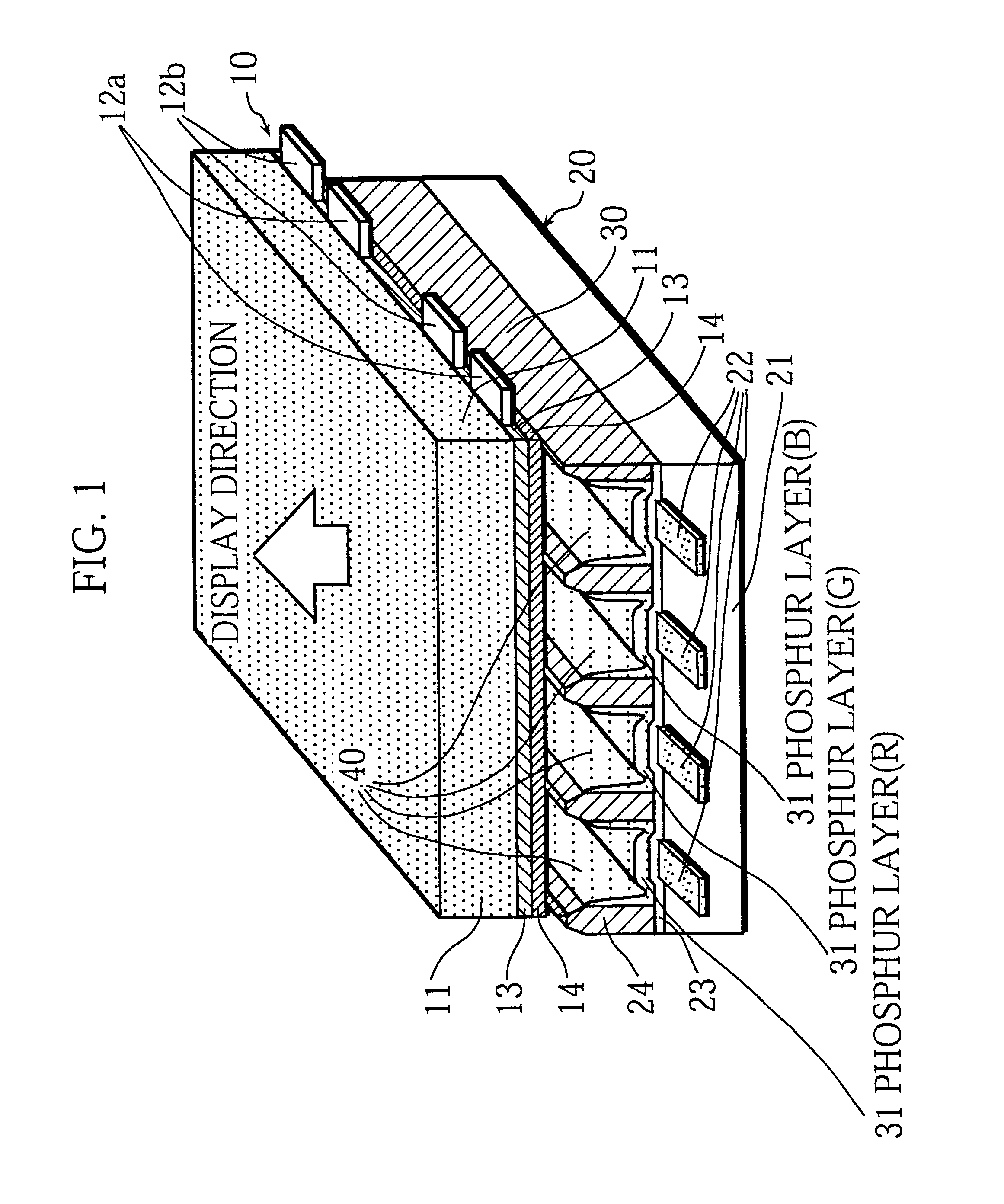

A phosphor layer is formed efficiently in a gas discharge tube by drawing a mother material to fabricate a supporting member which is insertable in a small glass tube used for a gas discharge tube, forming a phosphor layer on the supporting member, and inserting and placing the supporting member in the small glass tube.

Owner:SHINODA PLASMA

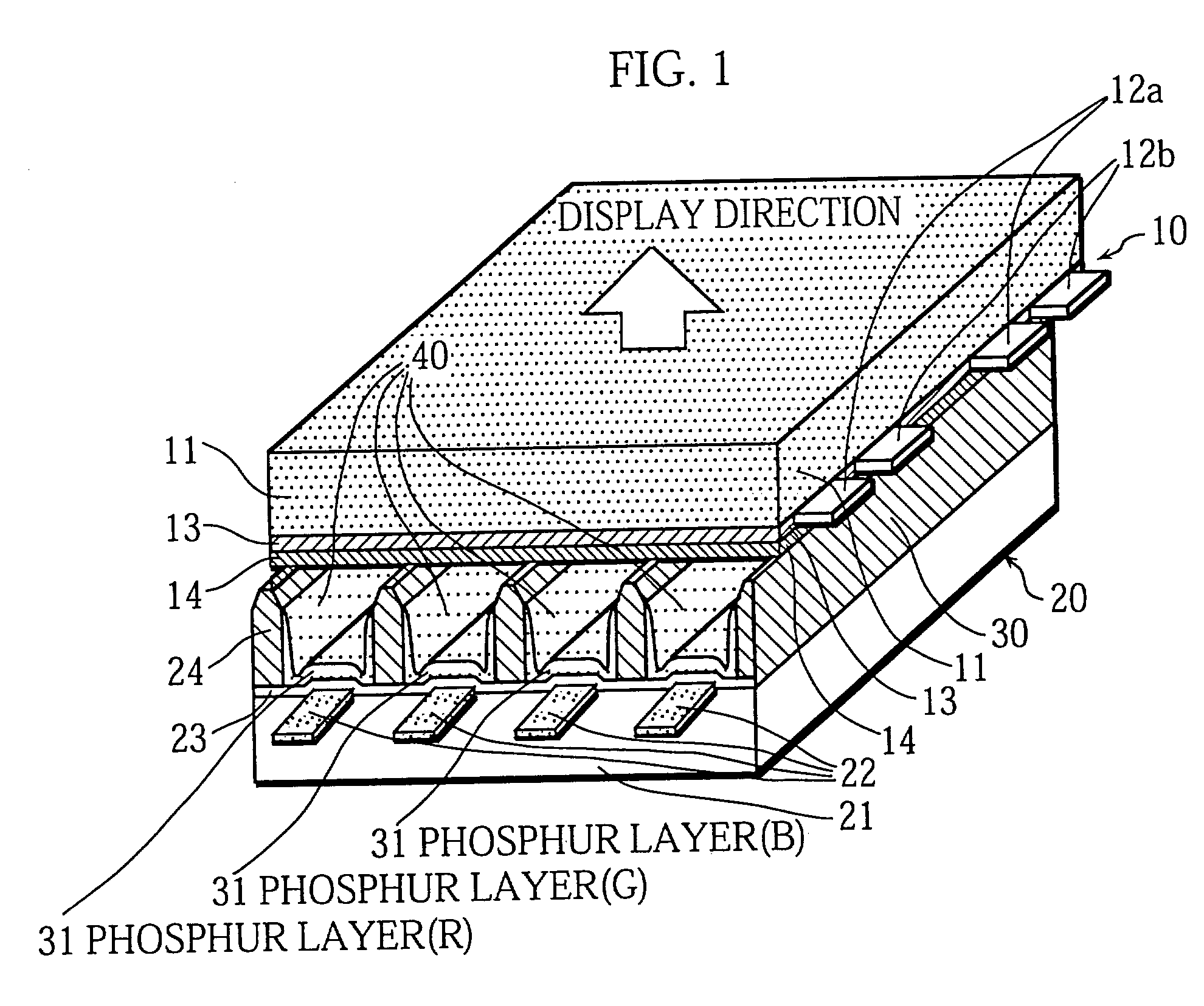

Method of forming phosphor layer of gas discharge tube

InactiveUS6857923B2Quality improvementExtended service lifeAddress electrodesSustain/scan electrodesFluorescencePhosphor

A method of forming a phosphor layer of a gas discharge tube provided with the phosphor layer on an internal surface of an elongated tubular vessel forming a discharge space. The method includes the steps of introducing a slurry of phosphor powder and a binding resin dispersed in a medium into the tubular vessel, holding the tubular vessel sideways to deposit the phosphor powder and the binding resin in the tubular vessel, and removing the medium from the tubular vessel, thereby forming a phosphor layer on one side of the internal surface of the tubular vessel.

Owner:SHINODA PLASMA

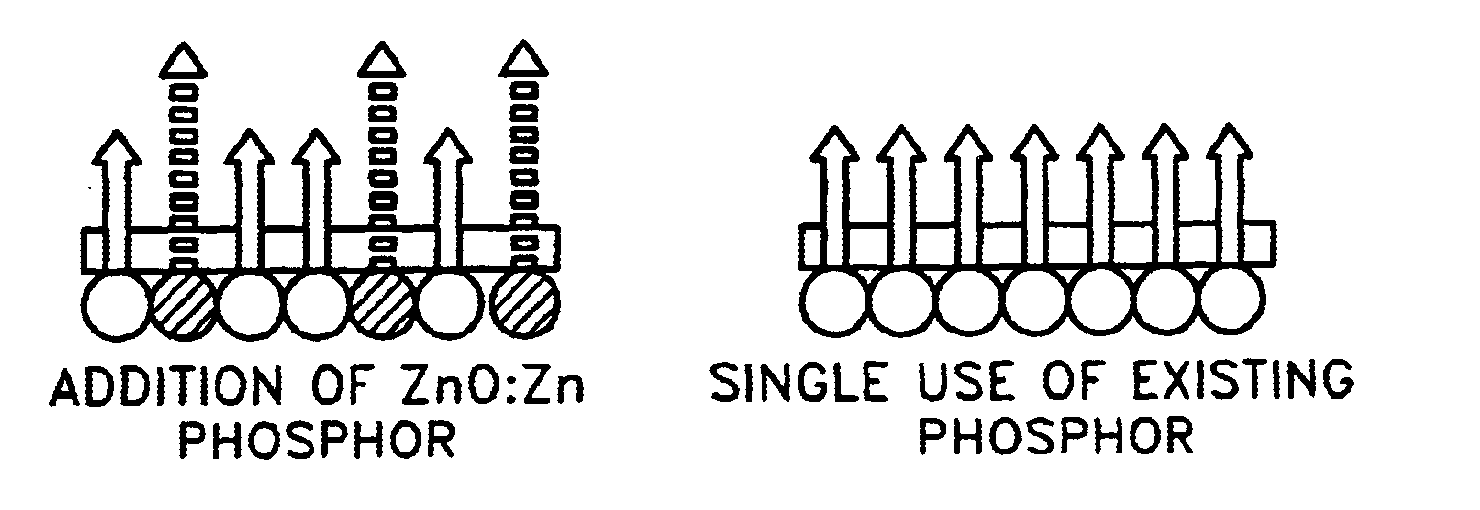

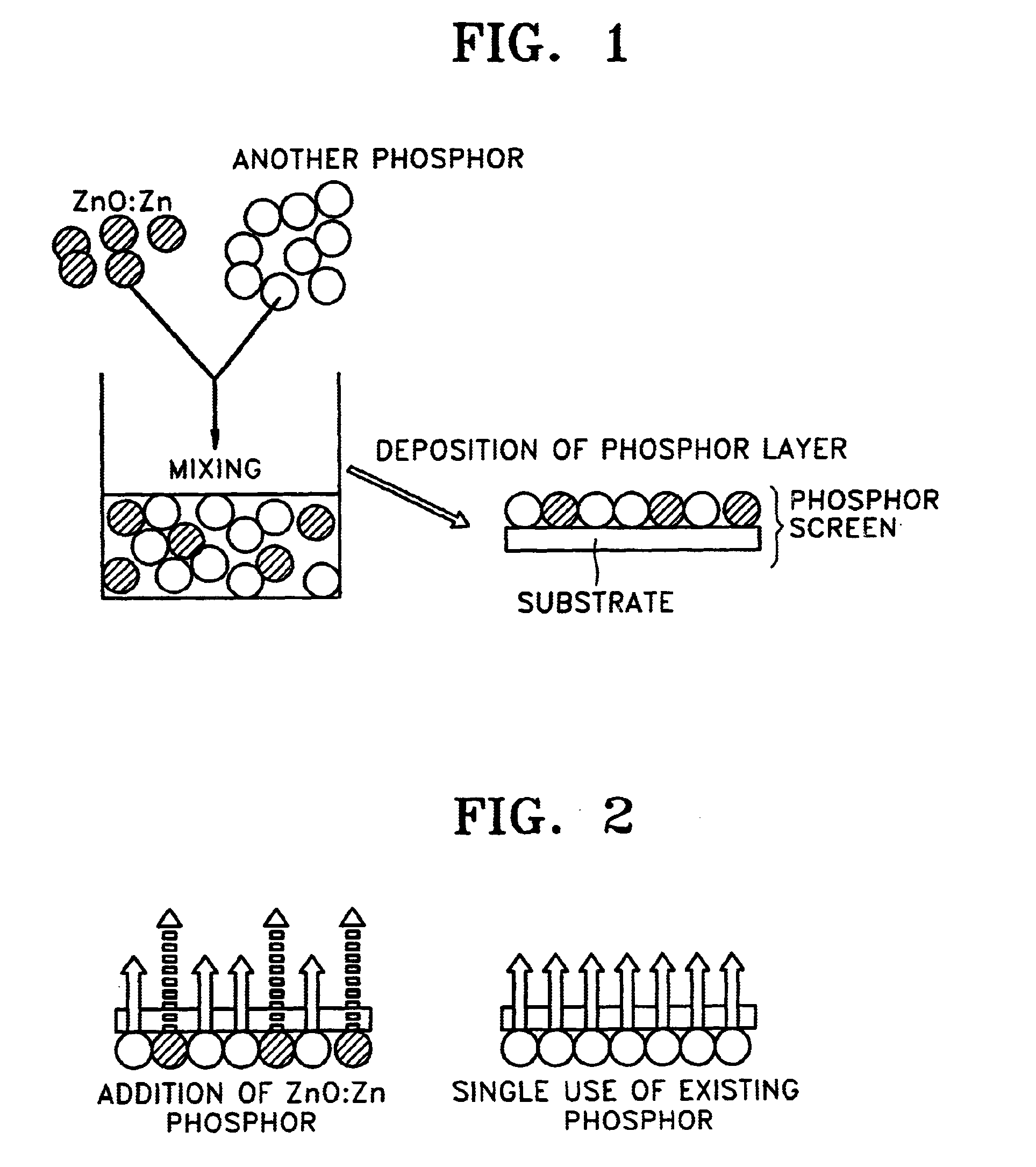

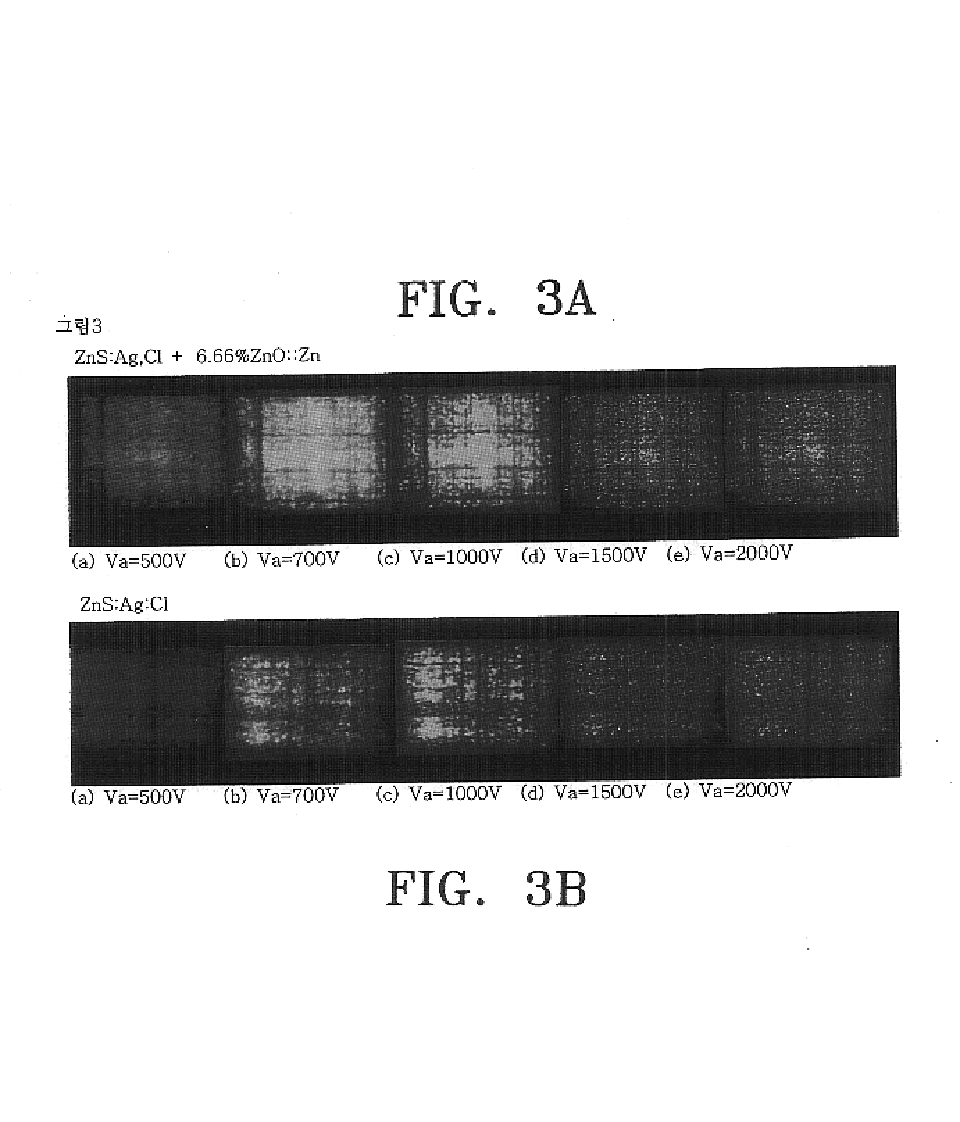

High-brightness phosphor screen and method for manufacturing the same

InactiveUS6919683B1Increase display brightnessDischarge tube luminescnet screensCathode ray tubes/electron beam tubesColor imageLow voltage

A high-brightness phosphor screen and a method for forming the same are provided. The high-brightness phosphor screen having a low or middle working voltage, unlike a method of improving luminescent properties by use of a new synthetic phosphor, can be formed by simple deposition of a phosphor mixture that contains a proper ratio of a blue or green light-emitting phosphor for color image display and a bluish green light-emitting ZnO:Zn phosphor with high luminescent efficiency at low voltages.

Owner:SAMSUNG SDI CO LTD

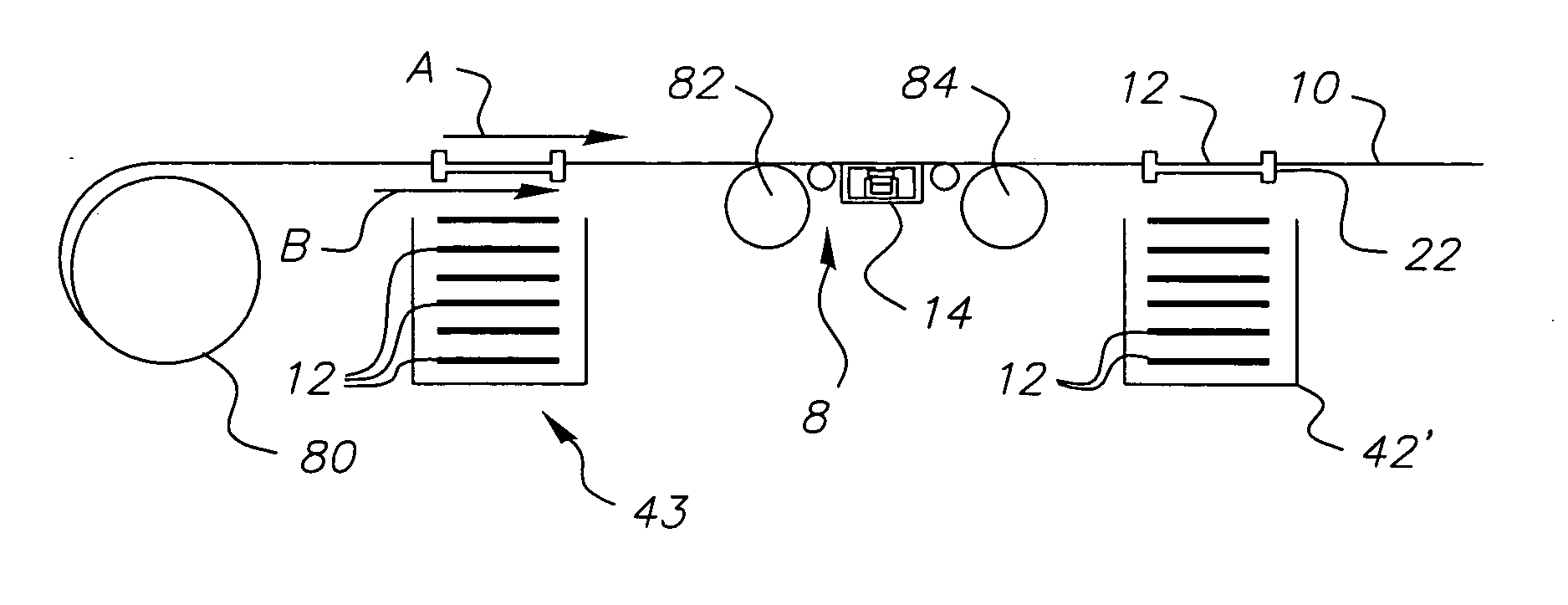

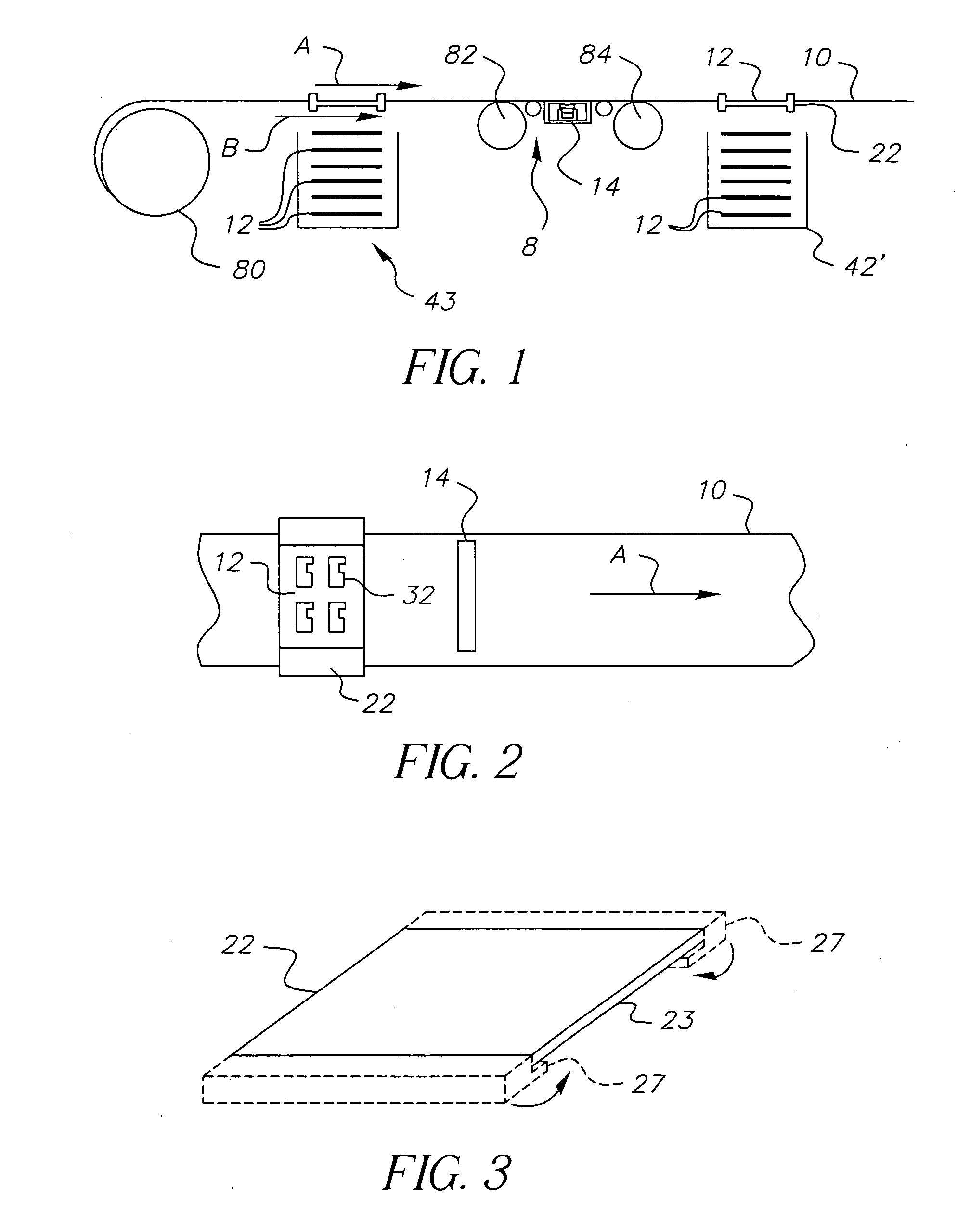

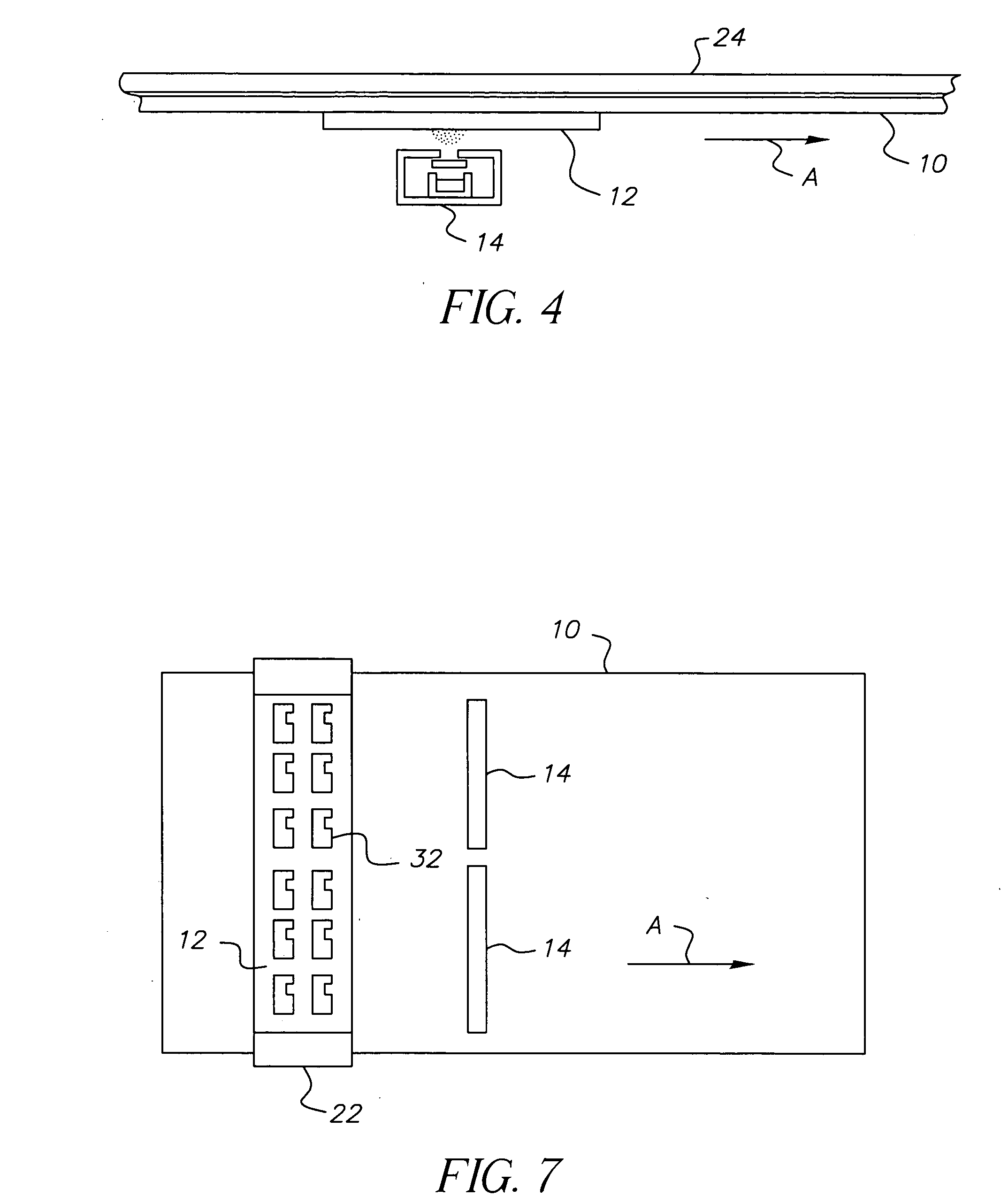

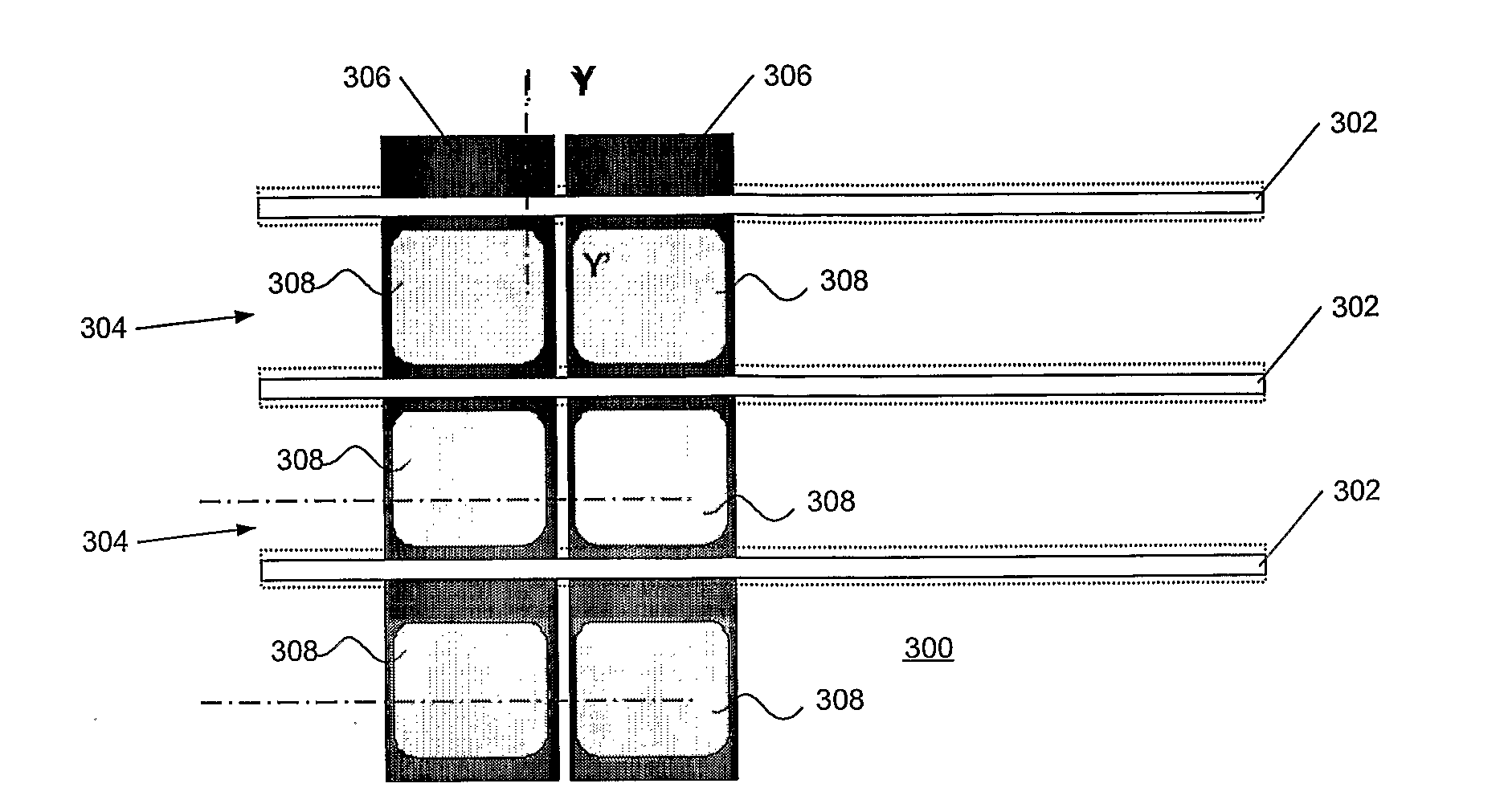

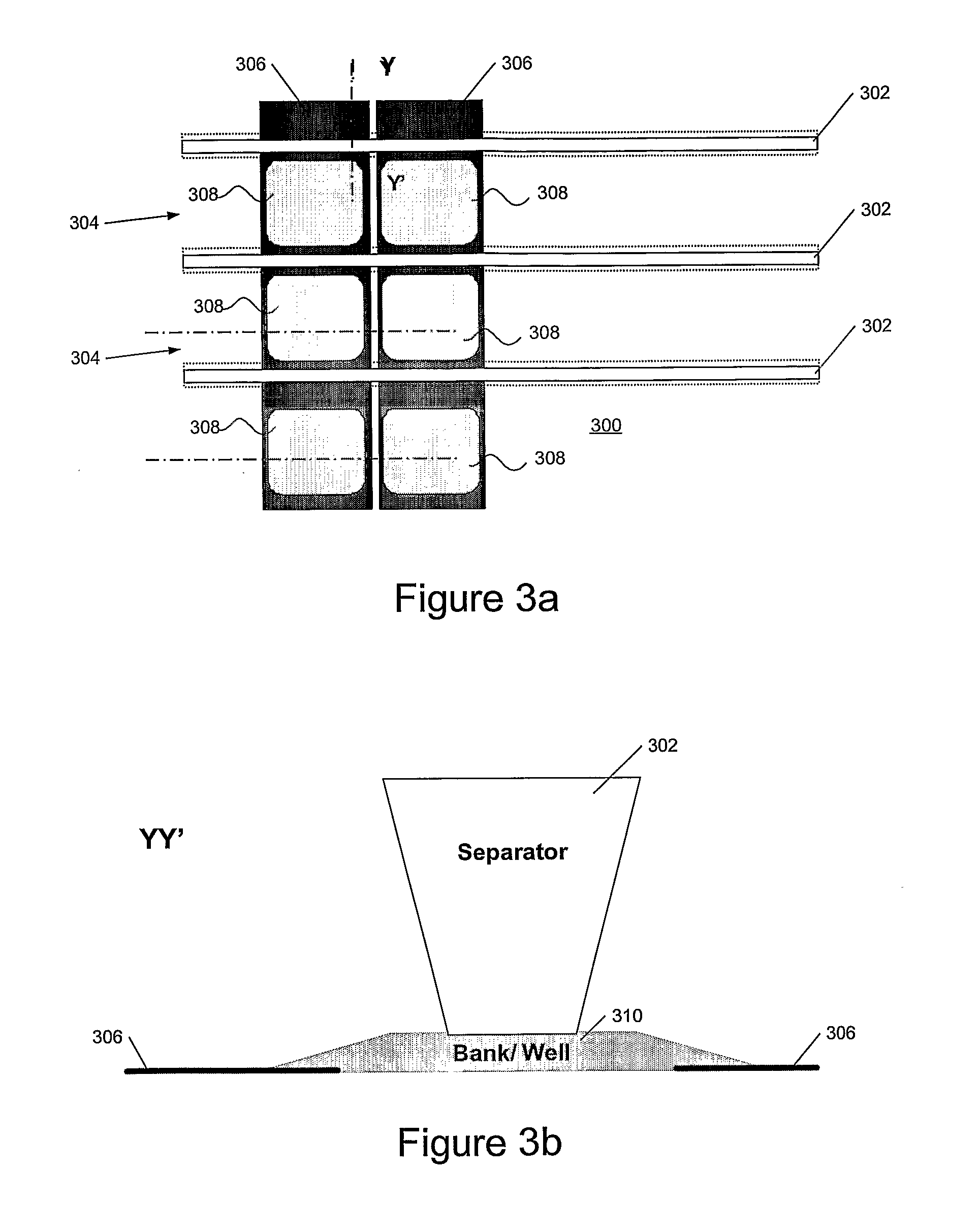

Continuous manufacture of flat panel light emitting devices

ActiveUS20050106986A1Electroluminescent light sourcesVacuum evaporation coatingEngineeringLight emitting device

A method of applying patterned materials for manufacture of a flat panel light source includes providing a flexible continuous substrate; providing one or more application stations, each application station having, one or more stationary sources of material, a supply of discrete patterned masks for defining a pattern of material to be applied to the substrate, means for attaching the discrete patterned masks to the substrate; means for transporting the substrate and the patterned mask in registration past the one or more stationary sources of material, and means for delivering the masks one at a time to the transporting means; and transporting the substrate and the masks past the one or more application stations.

Owner:GLOBAL OLED TECH

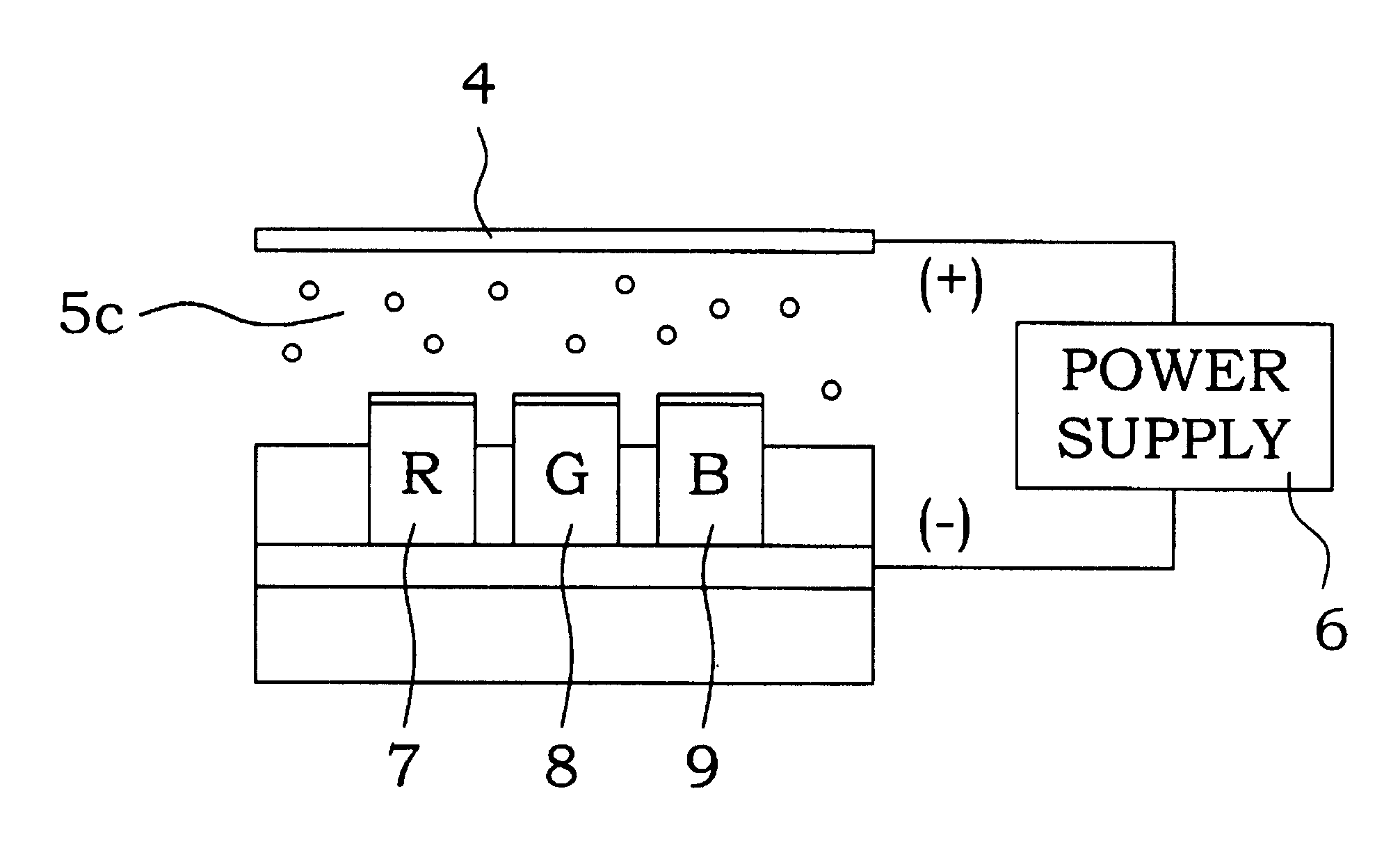

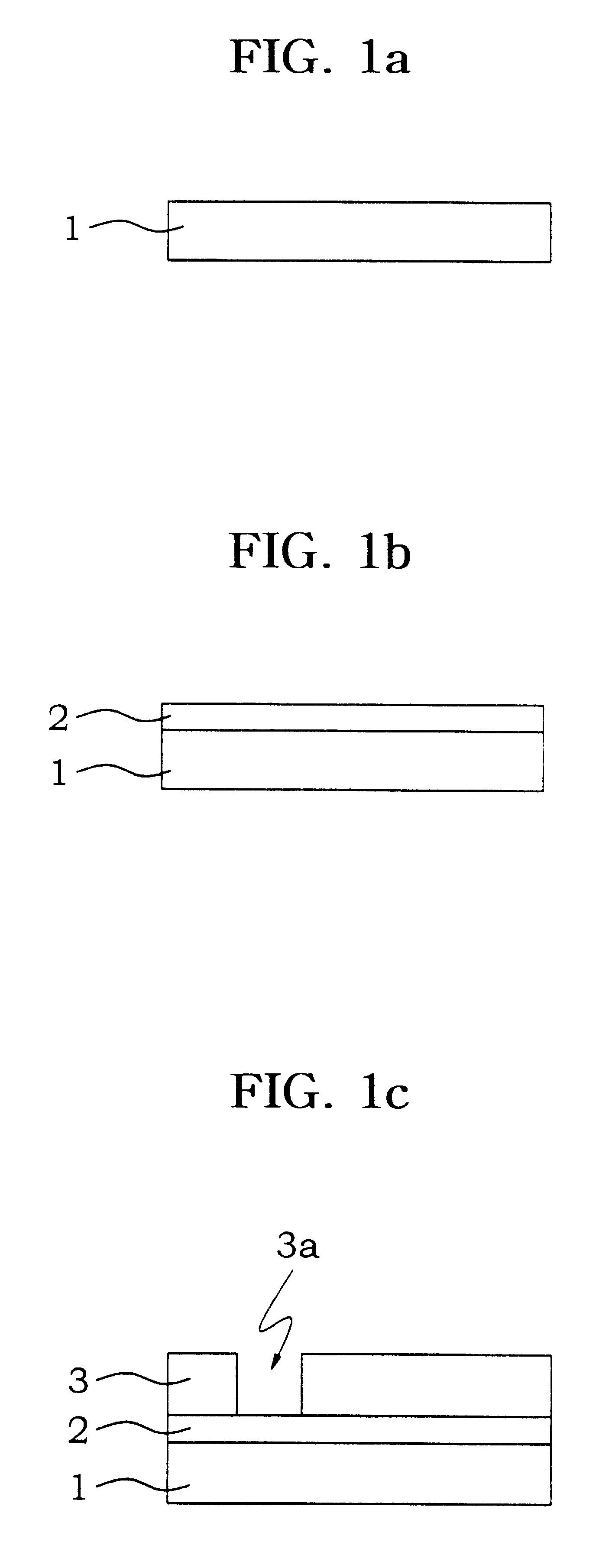

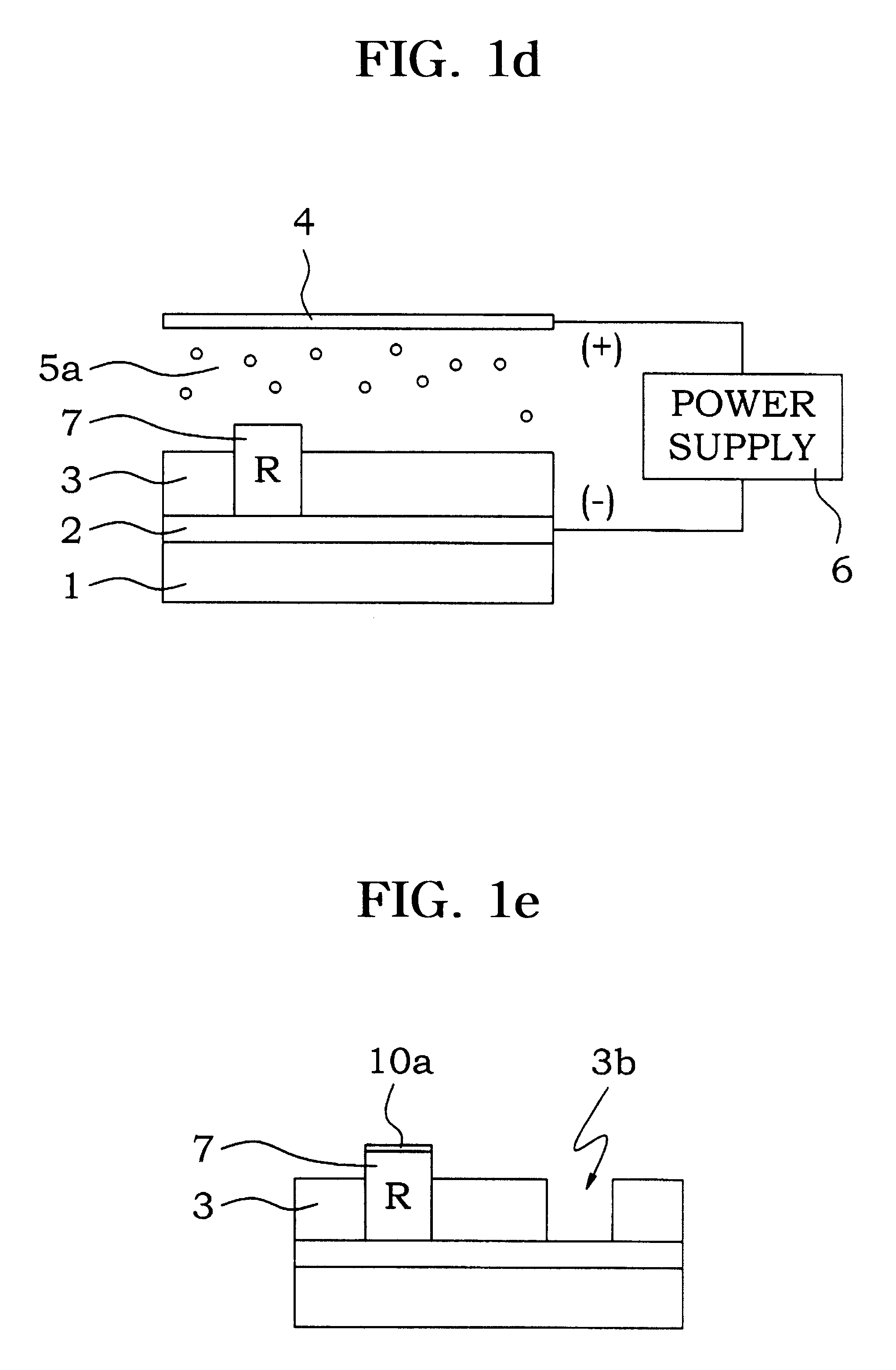

Method for phosphor coating on flat display using electrophoretic deposition and photolithography

InactiveUS6627060B1High bonding strengthImprove stabilityElectrolysis componentsVolume/mass flow measurementUltravioletDisplay device

A method for coating a phosphor on a flat display using electrophoretic deposition (EPD) and lithography is provided. In the method, an adhesive strength can be enhanced without passing through a high-temperature thermal treatment process as a post-process. Phosphor powders are coated on a substrate by a field emission display (FED) and then a ultraviolet (UV) curable layer is coated. Then, an adhesive strength of the phosphor can be greatly enhanced through UV irradiation, in comparison with a post-process such as a thermal treatment process. Also, the UV curable layer can be lithographically etched by the UV light, and thus the phosphor can be coated by a predetermined pattern, to then be applied to a next-generation display such as a FED or PDP as an optimal method for full color realization.

Owner:GWANGJU INST OF SCI & TECH

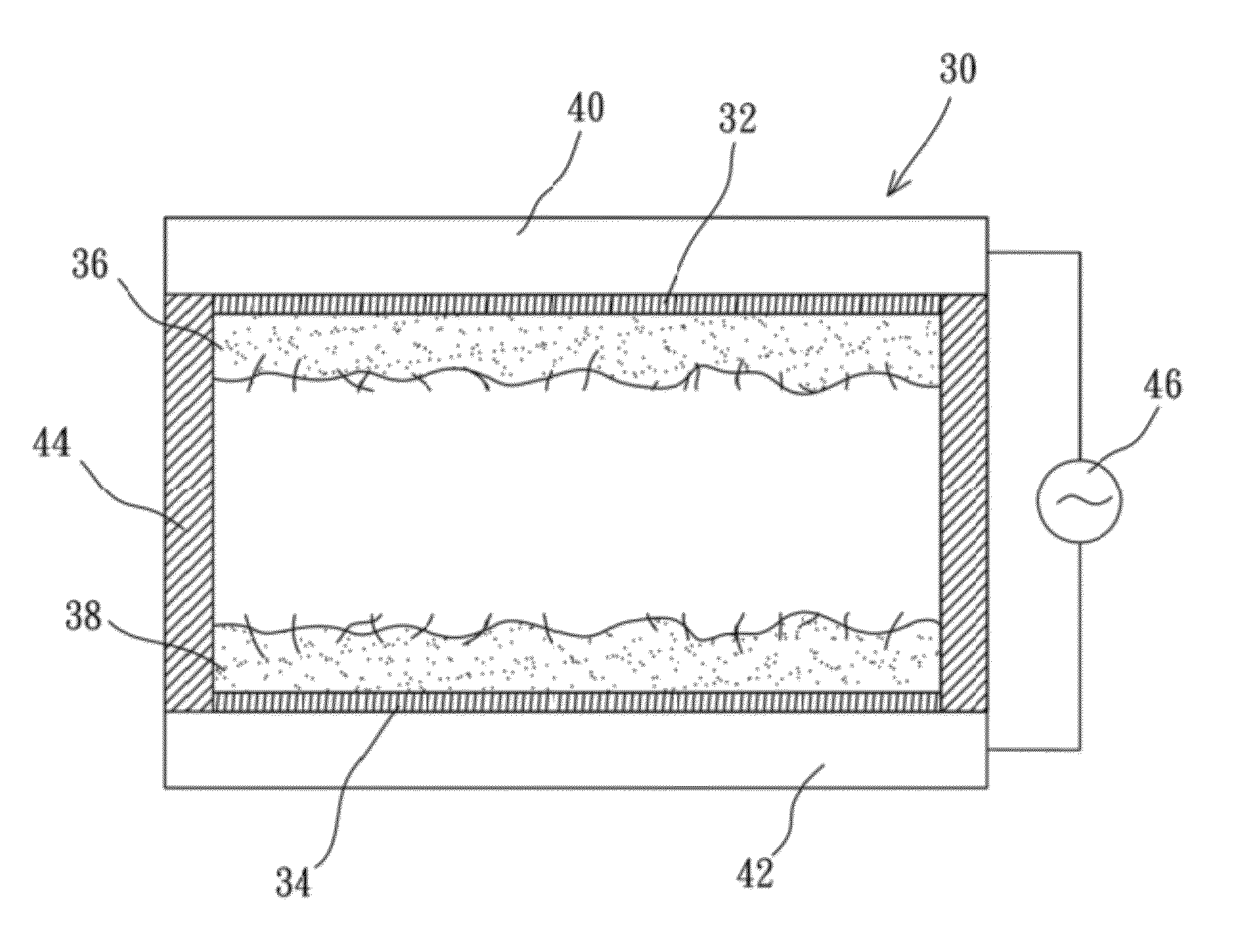

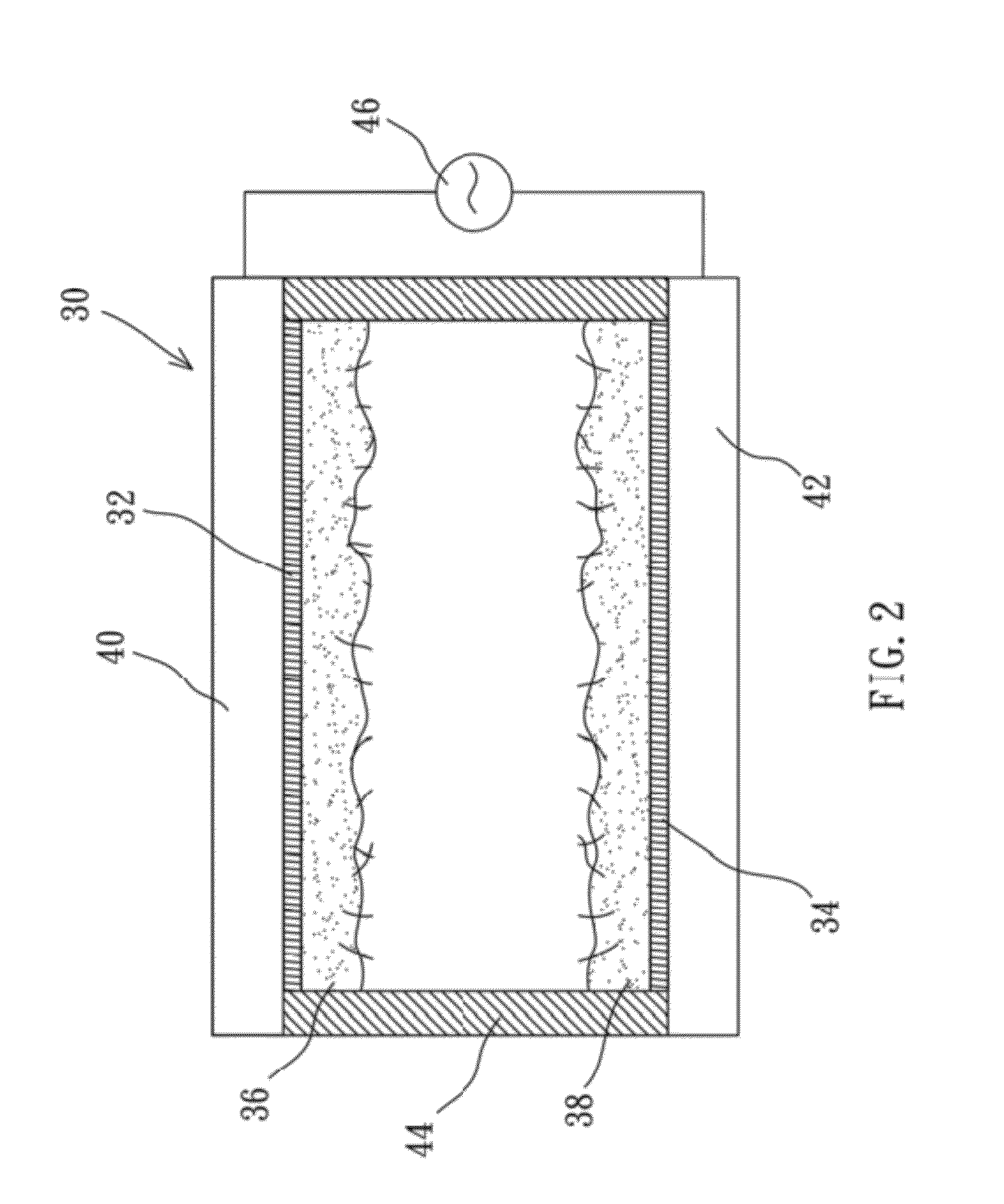

Double-sided light emitting field emission device and method of manufacturing the same

ActiveUS20120248967A1Convenient lightingExtended service lifeDischarge tube luminescnet screensCathode ray tubes/electron beam tubesField emission devicePhosphor

A double-sided light-emitting field emission device and method of manufacturing same, said device comprising at least two transparent conductive layers, mixed field emission layers, and transparent package device. Wherein, the mixed field emission layer of field emission source and phosphor are utilized directly to serve as anode and cathode alternatively, such that on applying an AC power supply, roles of anode and cathode are changed alternatively along with frequency, hereby forming double-sided light-emitting structure. Therefore, the applications of said double-sided light-emitting field emission device are pretty wide, and having advantages of protecting field emission source, activating field emission source, reducing field emission arcing effect, having conductive phosphor, and raising illumination.

Owner:NATIONAL CHUNG CHENG UNIV

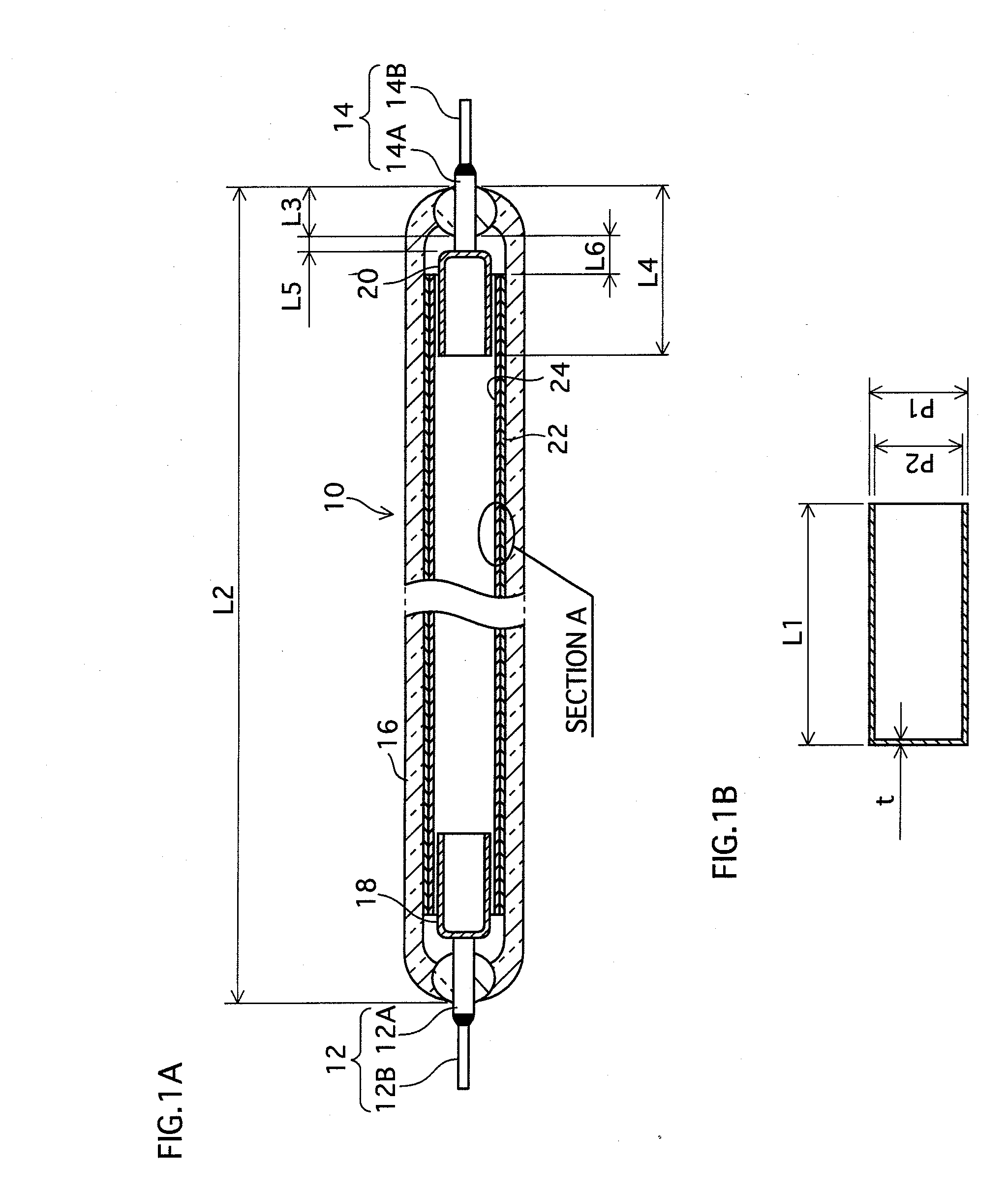

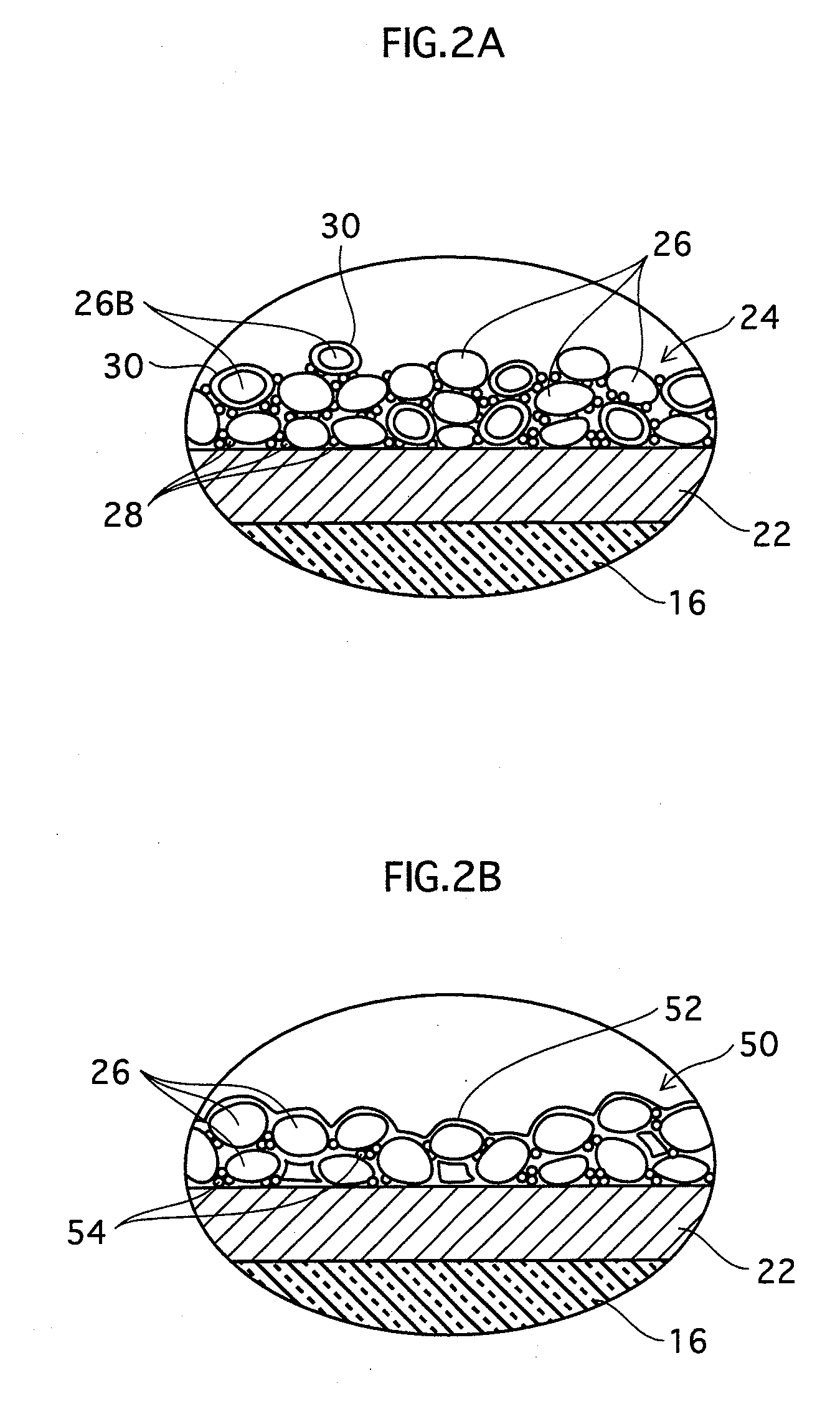

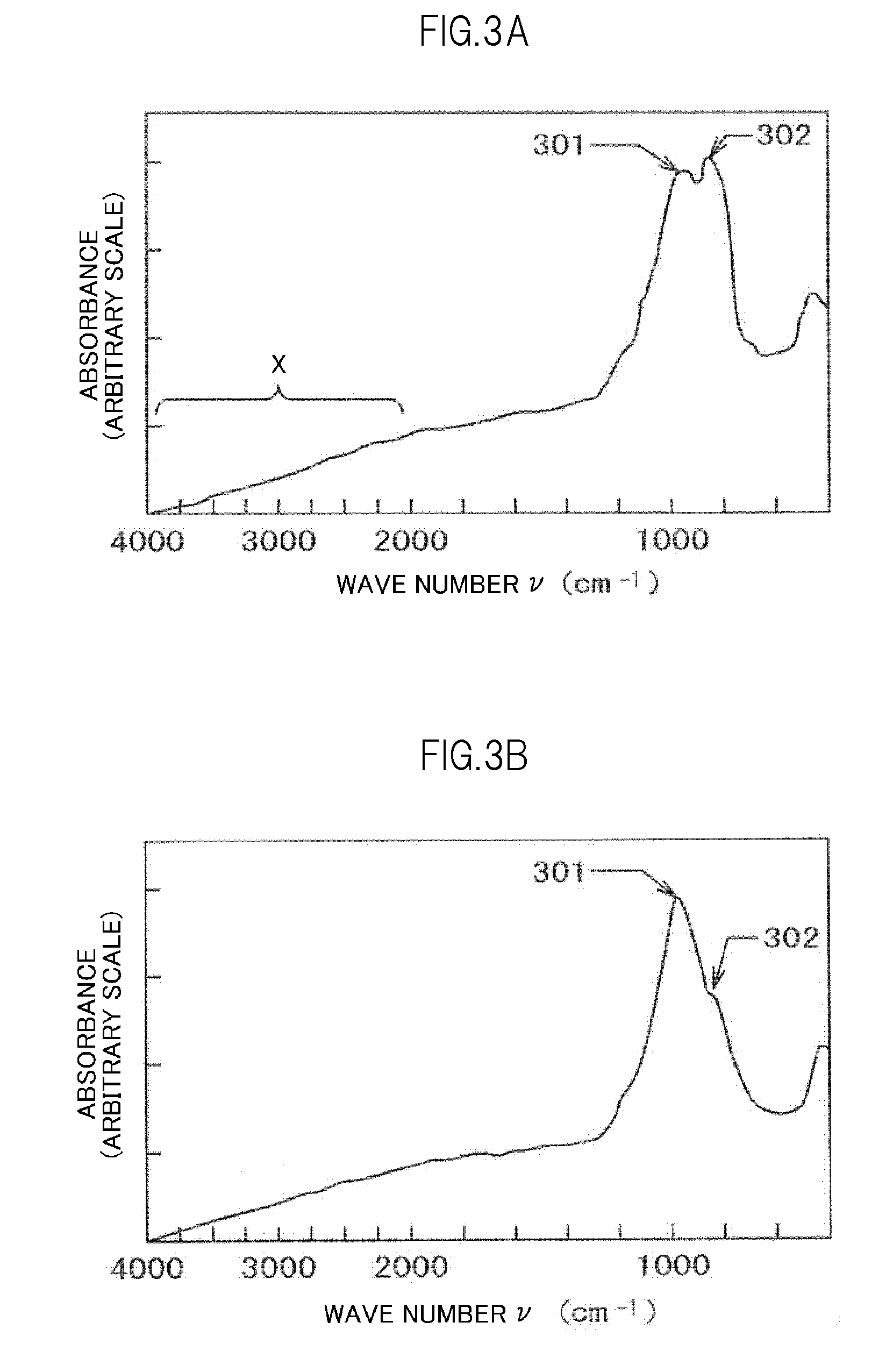

Fluorescent lamp, backlight unit and liquid crystal display

InactiveUS20090096958A1Favorable luminance maintenance rateReduce the amount requiredDischarge tube luminescnet screensLamp detailsTectorial membraneSilicon dioxide

A cold cathode fluorescent lamp includes a glass bulb (16), a protective film (22) formed on an inner face of the glass bulb, and a phosphor layer (24) that overlaps the protective film and that contains blue phosphor particles (26B), green phosphor particles (26) and red phosphor particles (26). The glass bulb has been formed from soda glass, and the blue phosphor particles have been coated with a metal oxide (30). Also, the protective film is made of silica (SiO2). Since the protective film has been provided in the fluorescent lamp and since the blue phosphor particles, which readily deteriorate, have been coated with the metal oxide, a good luminance maintenance rate is obtained. In addition, although the glass bulb of the fluorescent lamp is made of soda glass, since the protective film is made of silica, the fluorescent lamp obtains an initial luminance equivalent to the initial luminance of a fluorescent lamp whose glass bulb is made of borosilicate glass.

Owner:PANASONIC CORP

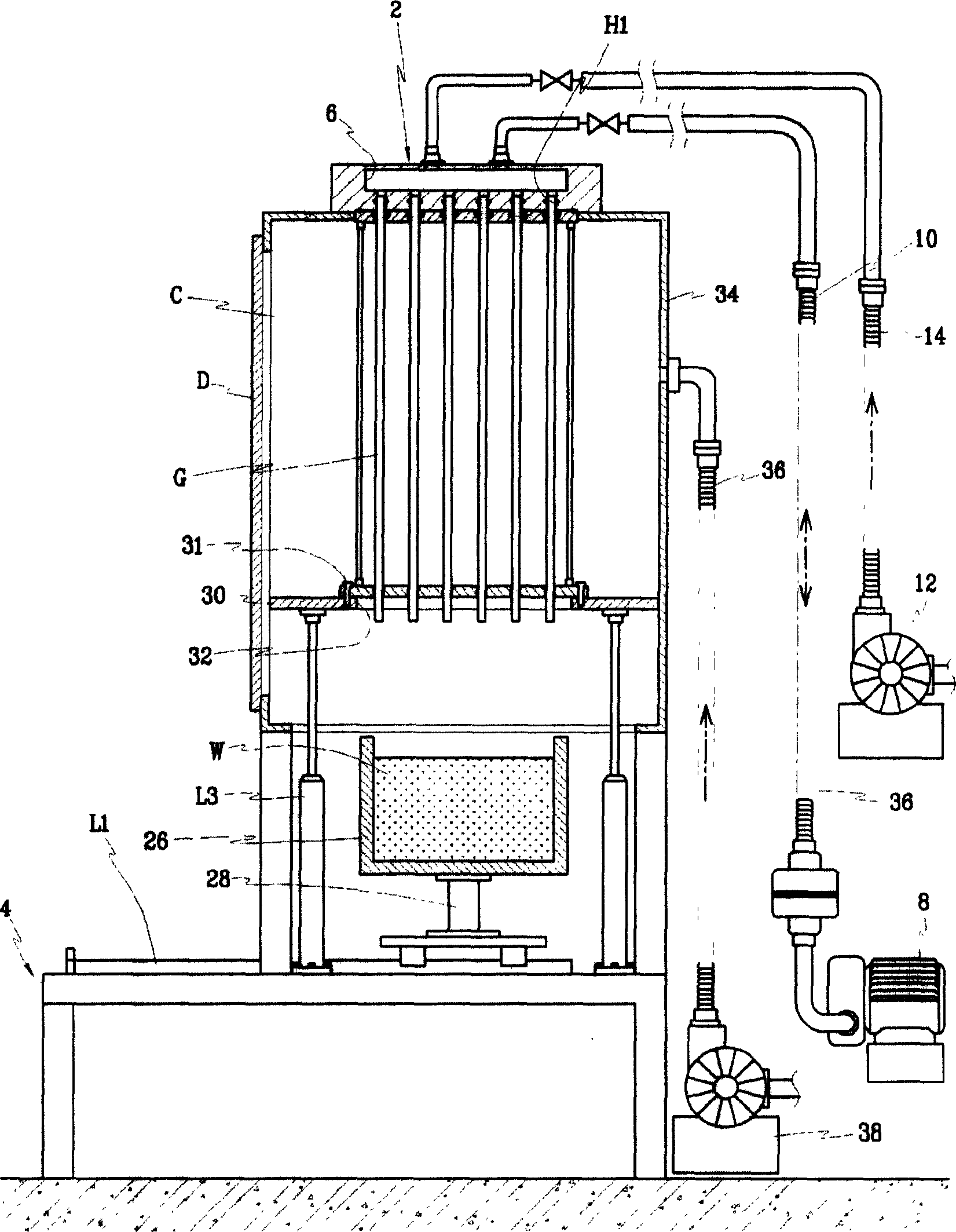

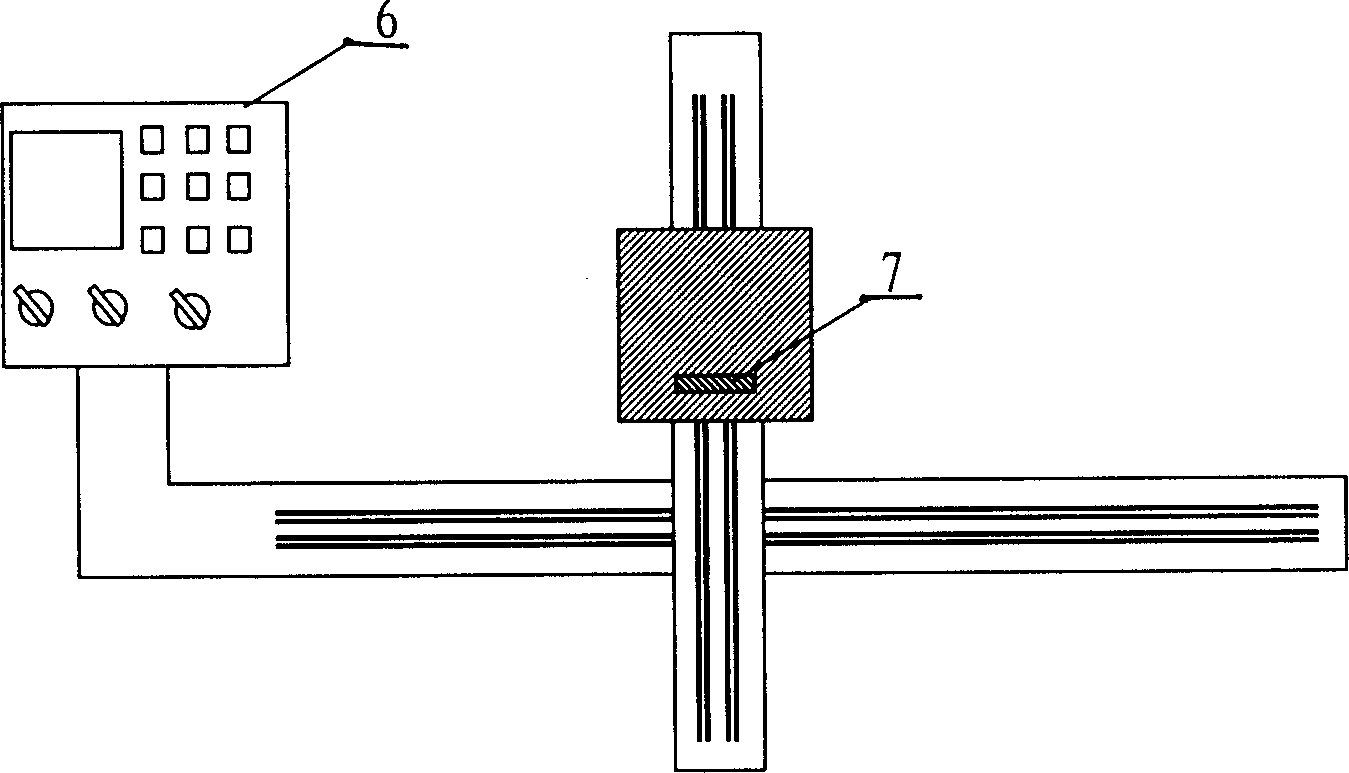

Fluorescent material coating apparatus and method of coating fluorescent substance using the same

InactiveCN1828804AUniform viscosityEnsure coating uniformityLuminescent coatings applicationShoresSubstance useEngineering

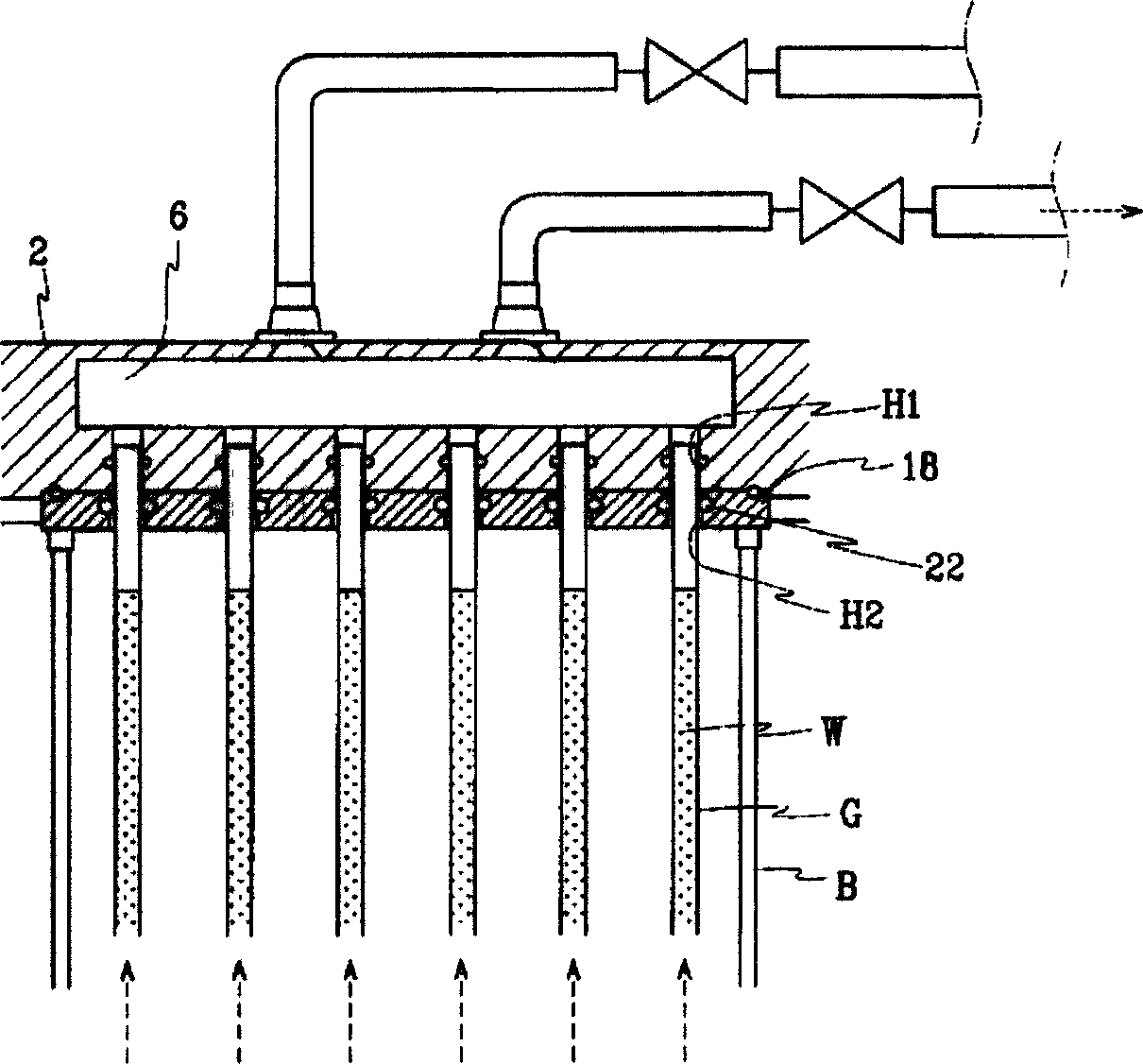

There is provided a fluorescent material coating apparatus for a fluorescent lamp. The fluorescent material coating apparatus includes a cassette on which a plurality of glass tubes are detachably mounted, a delivery member having a delivery chamber communicating with first ends of the glass tubes, a negative pressure generating unit for allowing fluorescent solution to be drawn into the glass tubes by generating a negative pressure in the glass tubes communicating with the delivery chamber by lowering the pressure of the delivery chamber, a dry air supplying unit for supplying dry air to the delivery chamber to dry the fluorescent solution applied on inner surfaces of the glass tubes, a solution tank containing the fluorescent solution and disposed below the glass tubes mounted on the cassette, and a moving unit for allowing lower end portions of the glass tubes mounted in the delivery chamber to be dipped into the fluorescent solution contained in the solution tank.

Owner:WEIHAI DMS OPTICAL ELECTROMECHANICAL CO LTD

Light sources with nanometer-sized VUV radiation-absorbing phosphors

A light source comprises: (a) a source of plasma discharge that emits electromagnetic radiation, a portion of which has wavelengths shorter than about 200 nm; and (b) a phosphor composition that comprises particles, each of the particles comprising at least a first phosphor and at least a second phosphor, the phosphor composition is disposed such that the first phosphor absorbs substantially the portion of EM radiation having wavelengths shorter than about 200 nm, and the first phosphor emits EM radiation having wavelengths longer than about 200 nm.

Owner:GENERAL ELECTRIC CO

Plasma display panel manufacturing method for manufacturing a plasma display panel with superior picture quality, a manufacturing apparatus and a phosphor ink

InactiveUS6547617B1Improve liquidityStrong force FVessels or leading-in conductors manufactureLuminescent coatings applicationManufactured apparatusEngineering

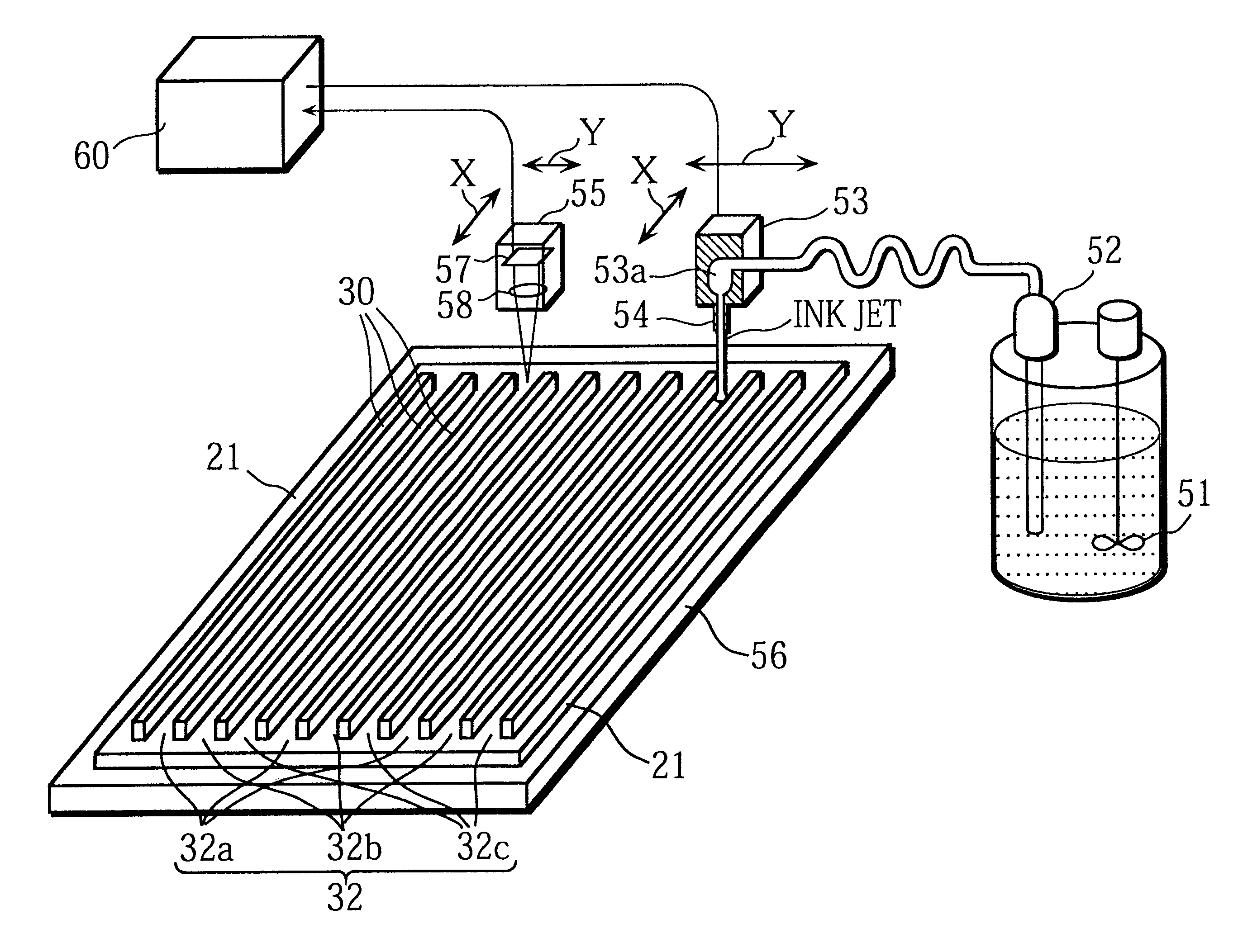

The present invention intends to provide a manufacturing method for a PDP that can continuously apply phosphor ink for a long time and can accurately and evenly produce phosphor layers even when the cell construction is very fine. To do so, phosphor ink is continuously expelled from a nozzle while the nozzle moves relative to channels between partition walls formed on a plate so as to scan and apply phosphor ink to the channels. While doing so the path taken by the nozzle within each channel between a pair of partition walls is adjusted based on position information for the channel. When phosphor particles is successively applied to a plurality of channels, phosphor ink is continuously expelled from the nozzle even when the nozzle is positioned away from the channels. The phosphor ink is composed of: phosphor particles that have an average particle diameter of 0.5 to 5 mum; a mixed solvent in which materials selected from a group consisting of terpineol, butyl carbitol acetate, butyl carbitol, pentandiol, and limonene are mixed; and a binder that is an ethylene group polymer or ethyl cellulose containing at least 49% of ethoxy group (-OC2H5) cellulose molecules. After dispersion a charge-removing material is added to the phosphor ink.

Owner:PANASONIC CORP

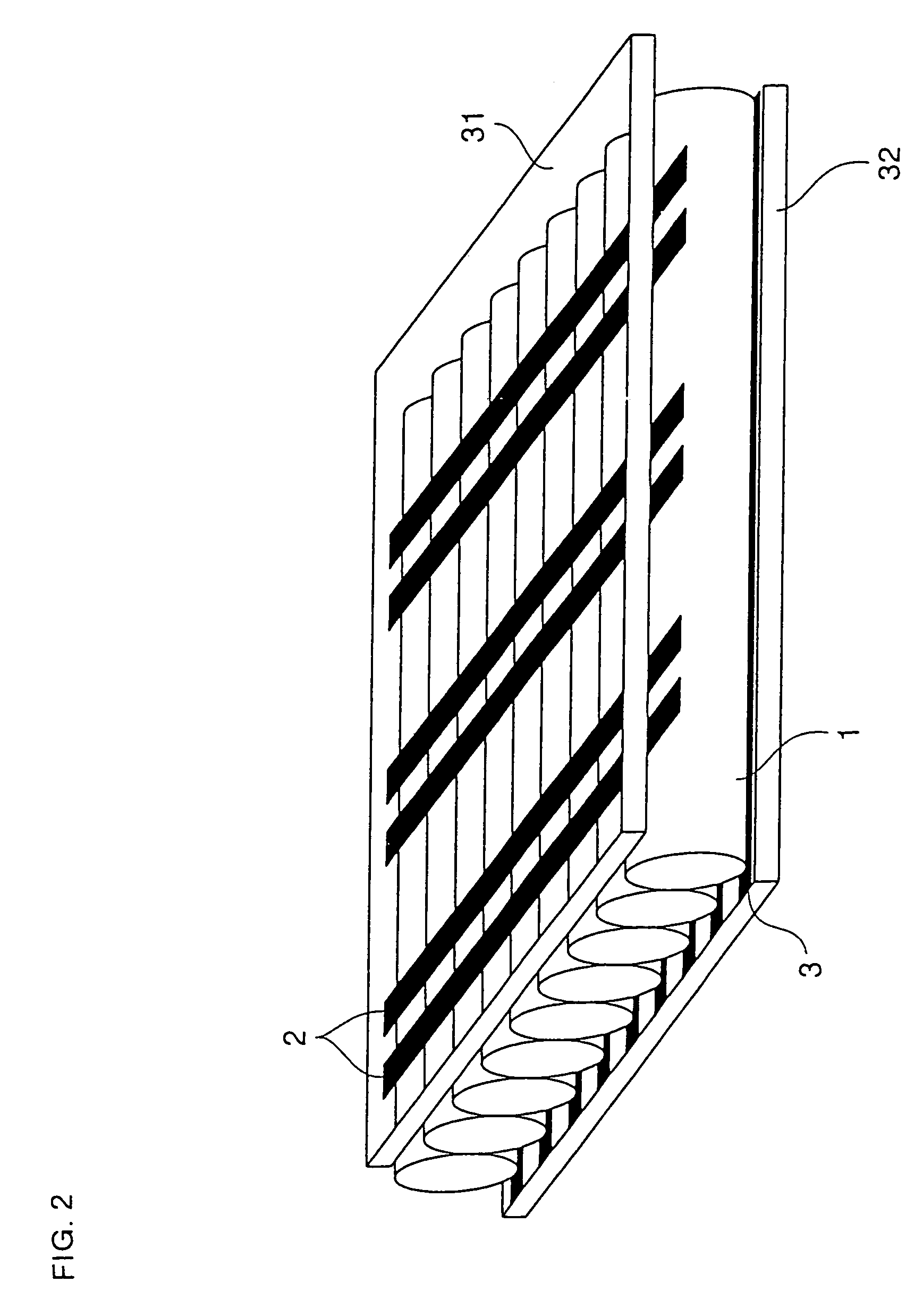

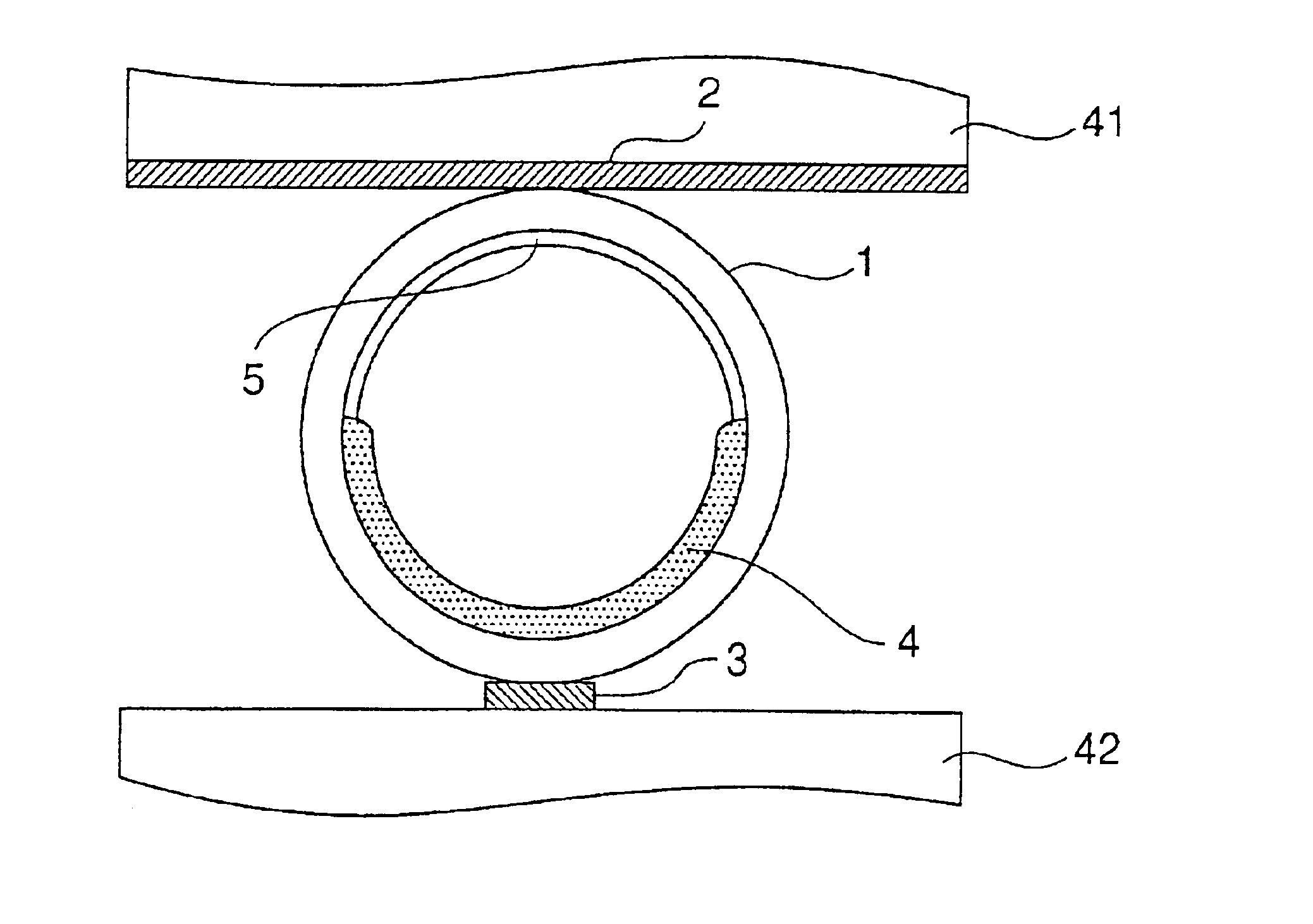

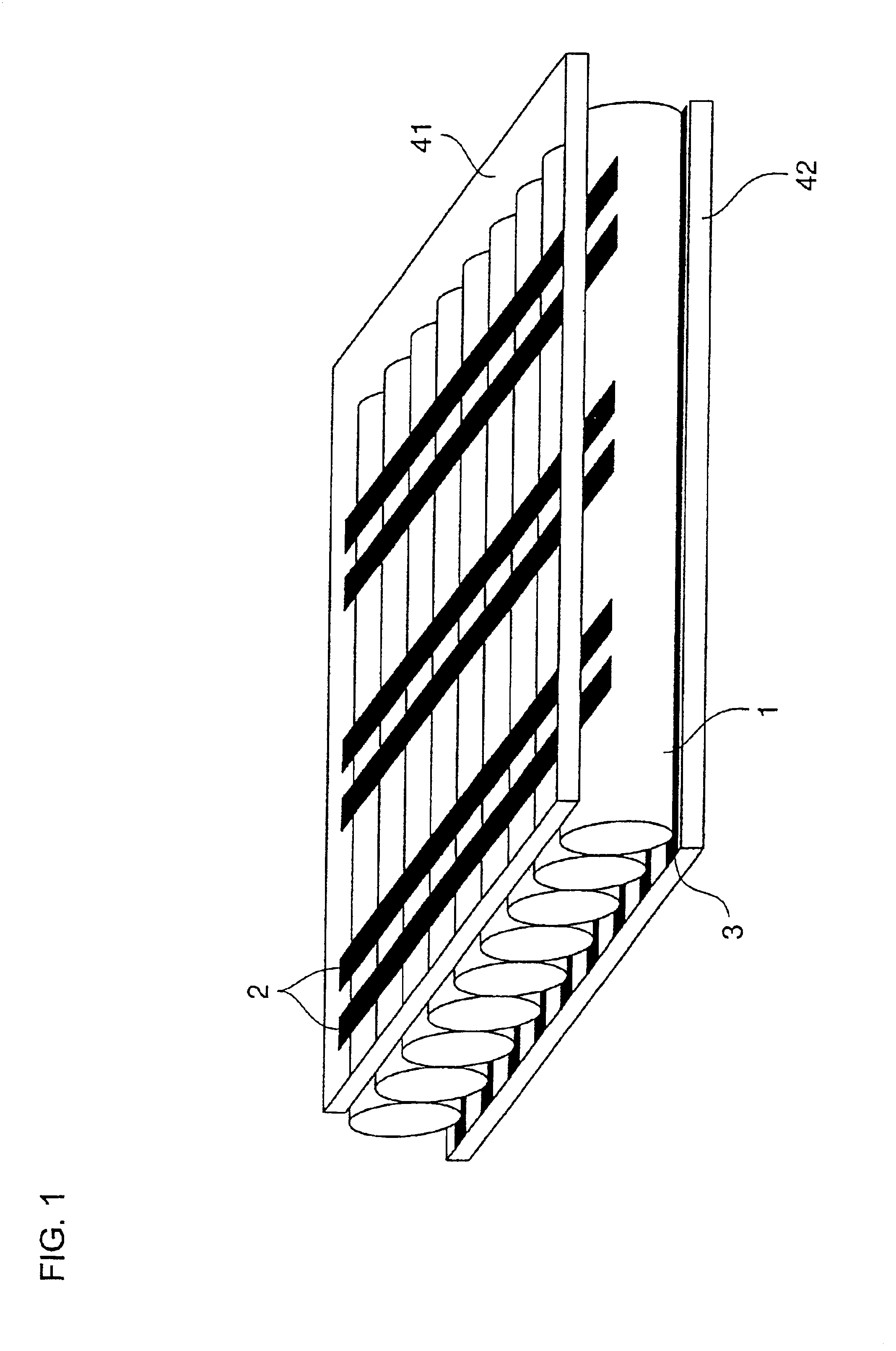

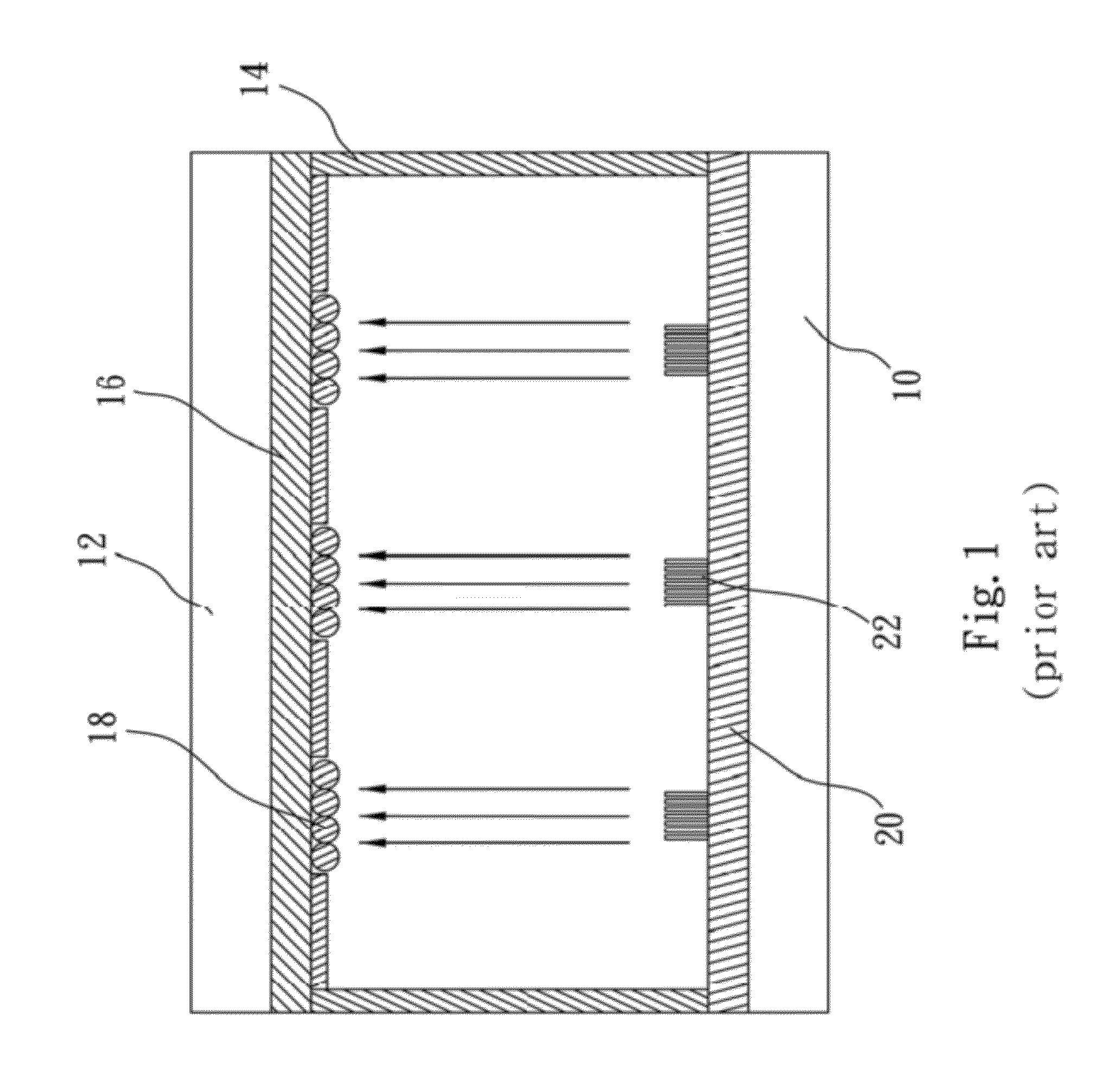

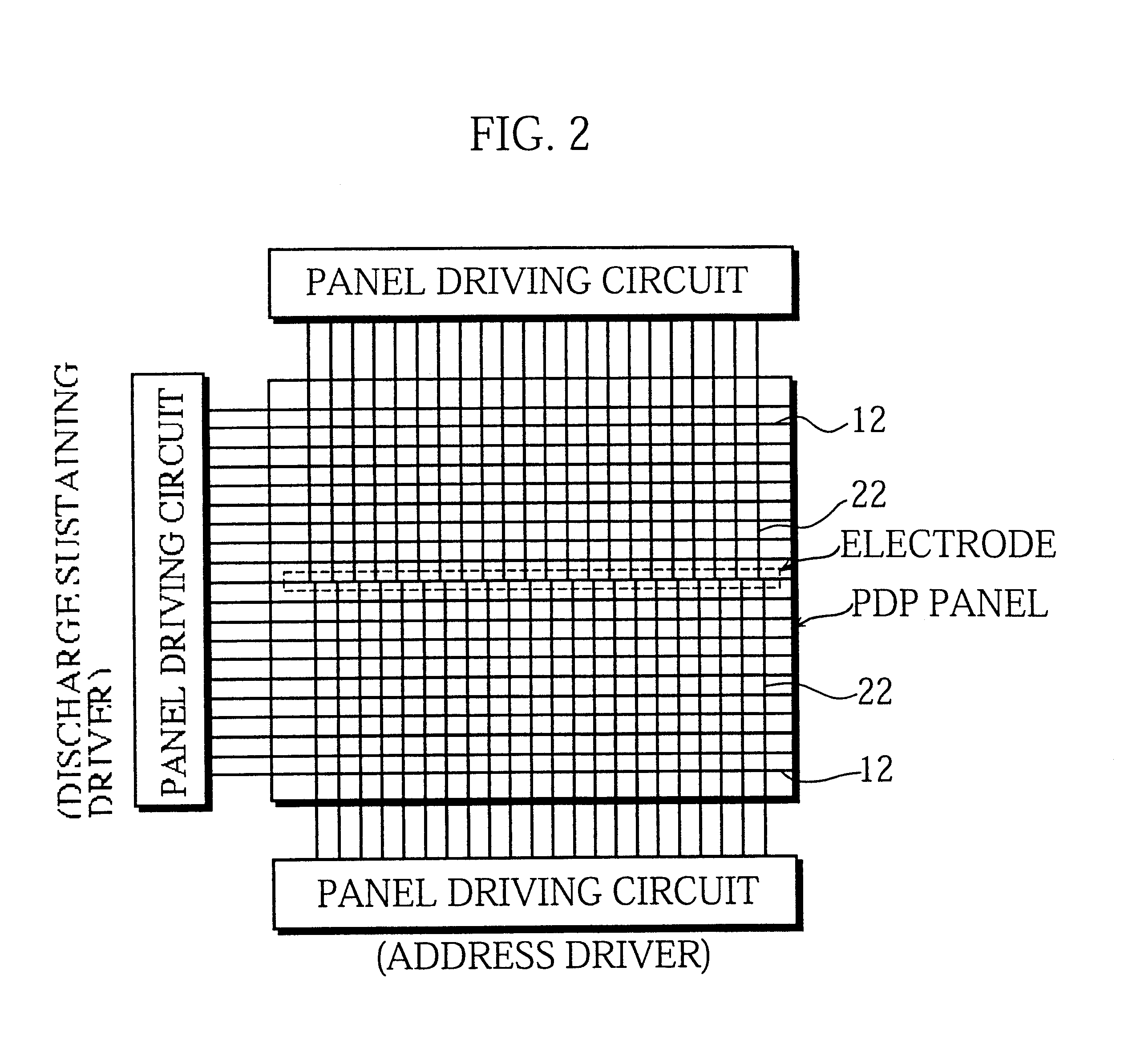

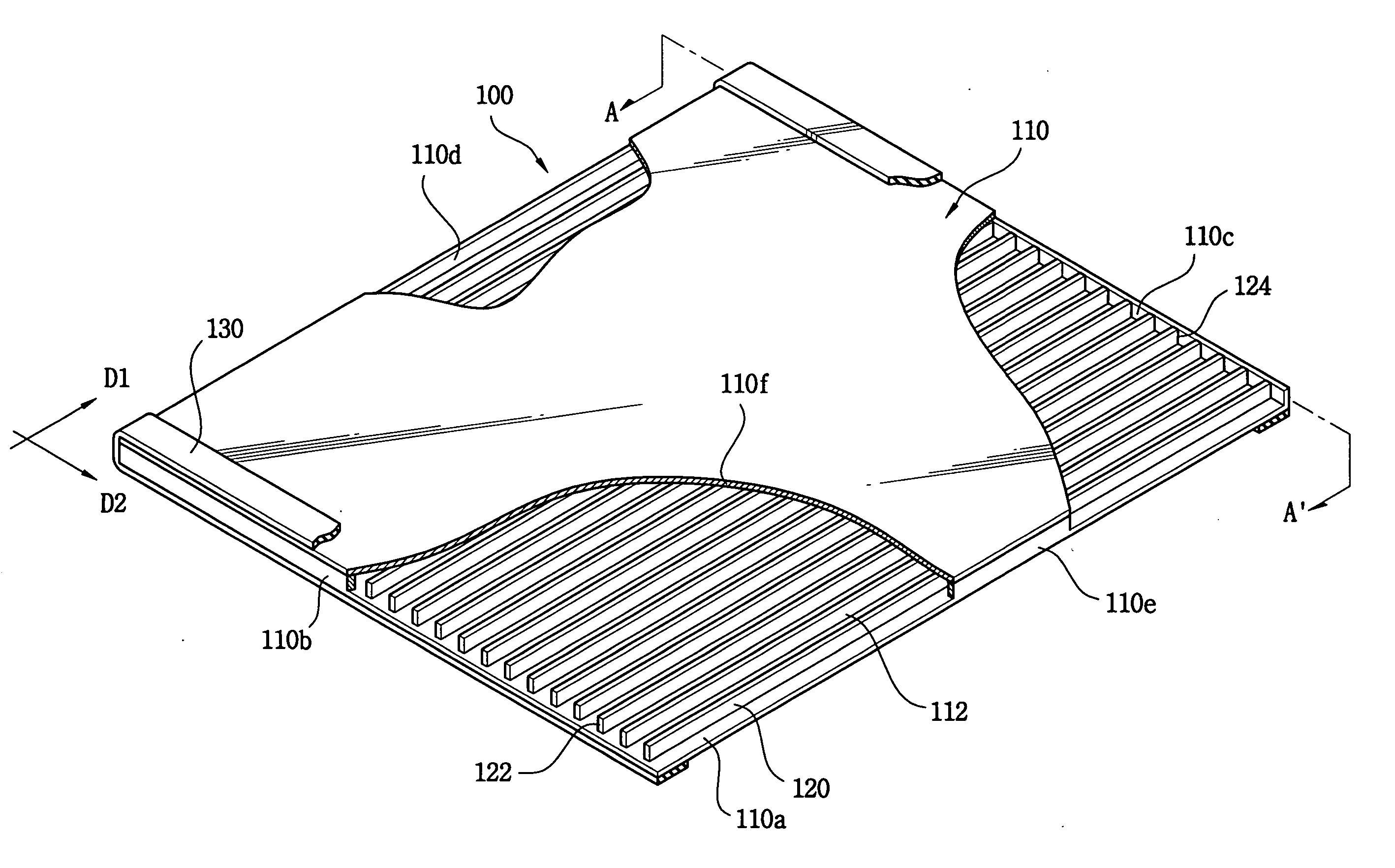

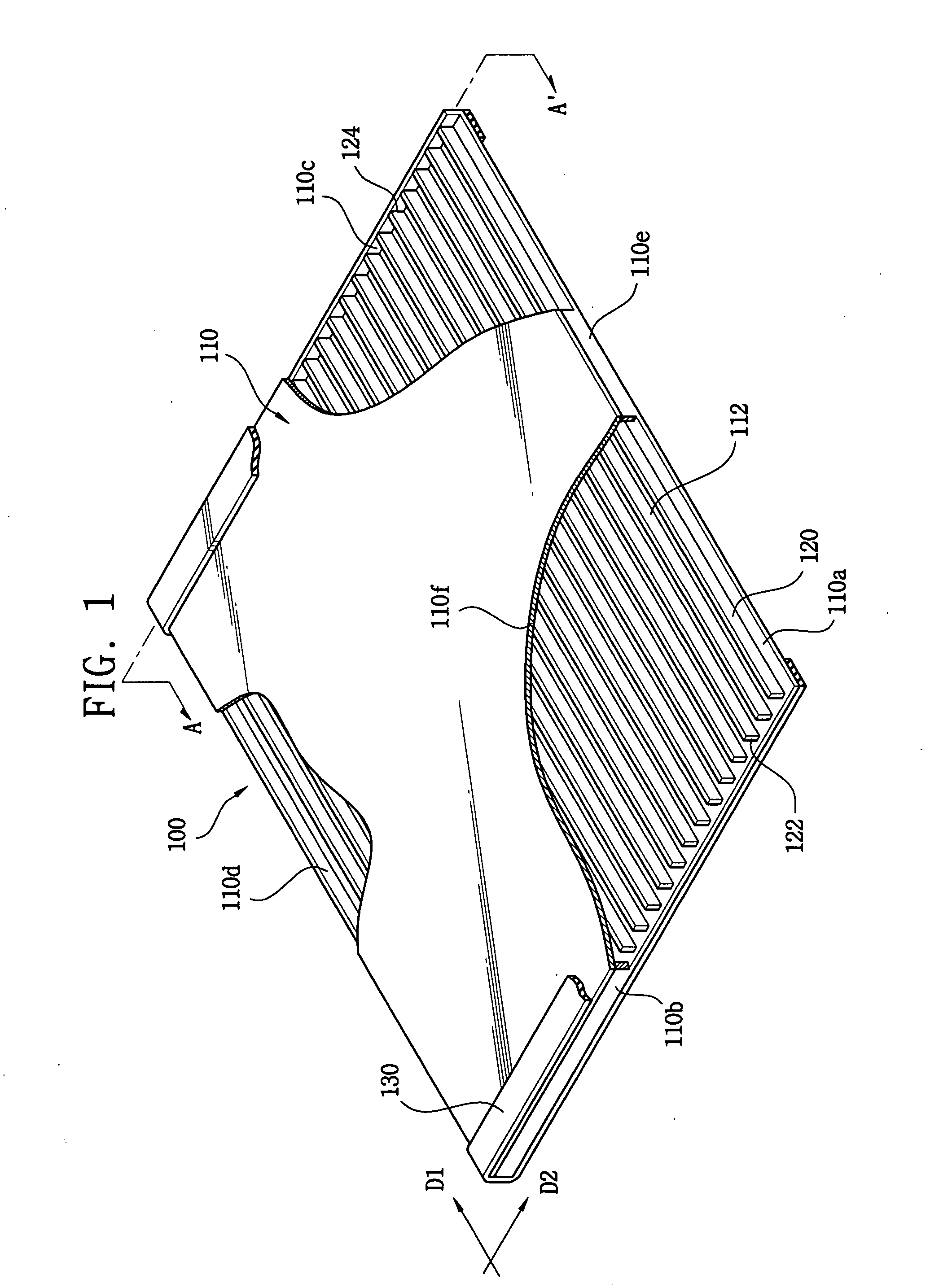

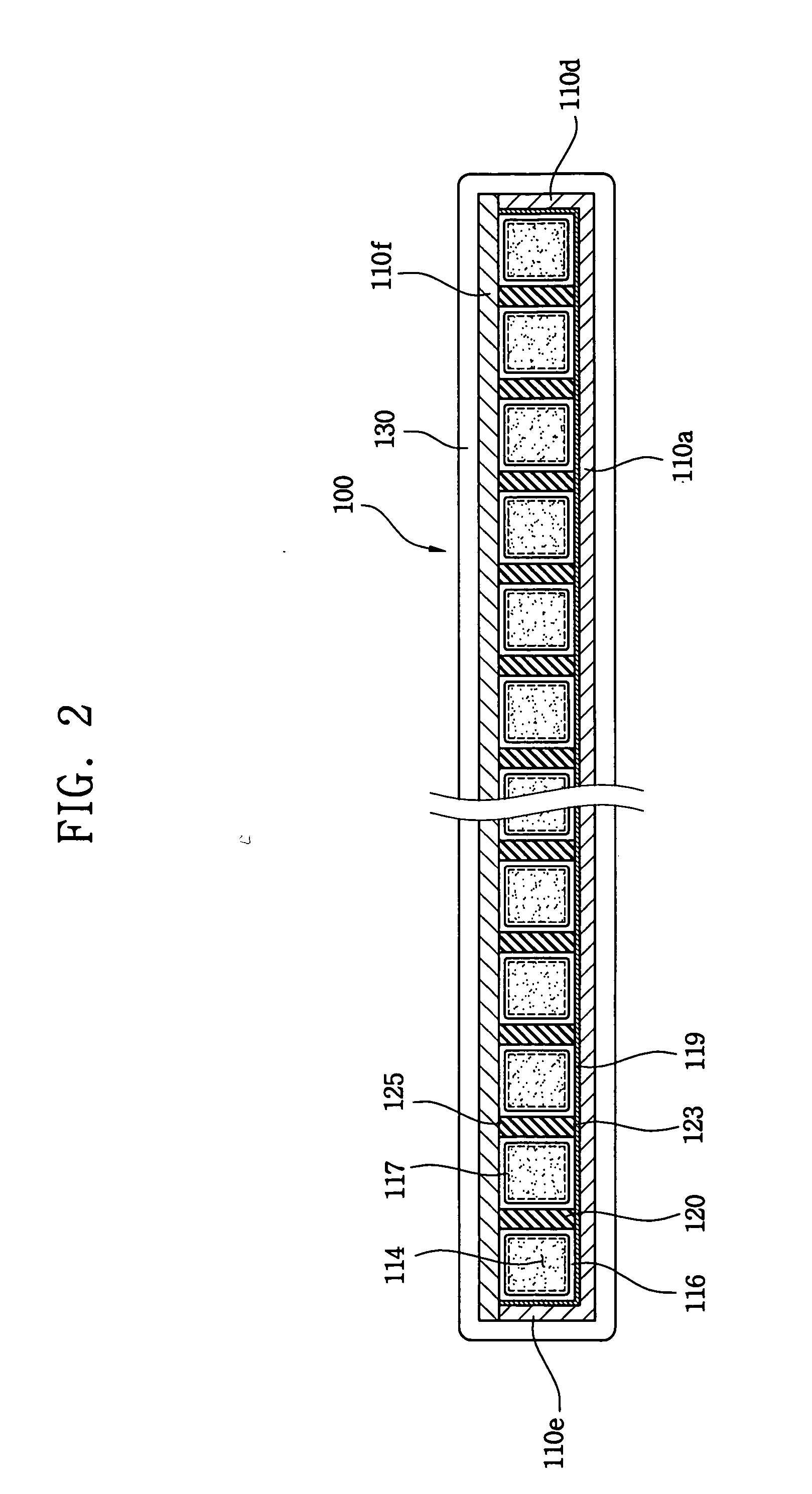

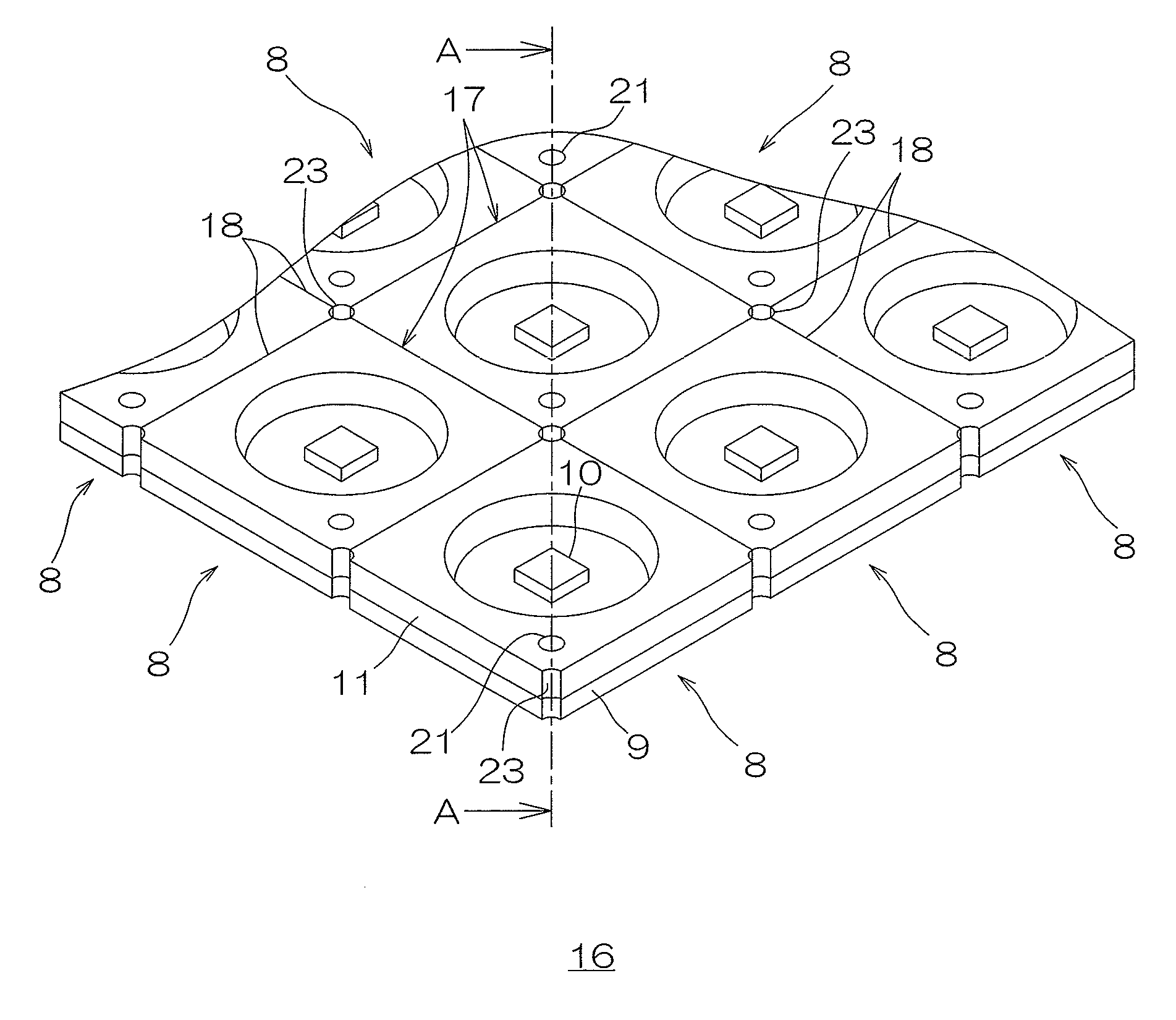

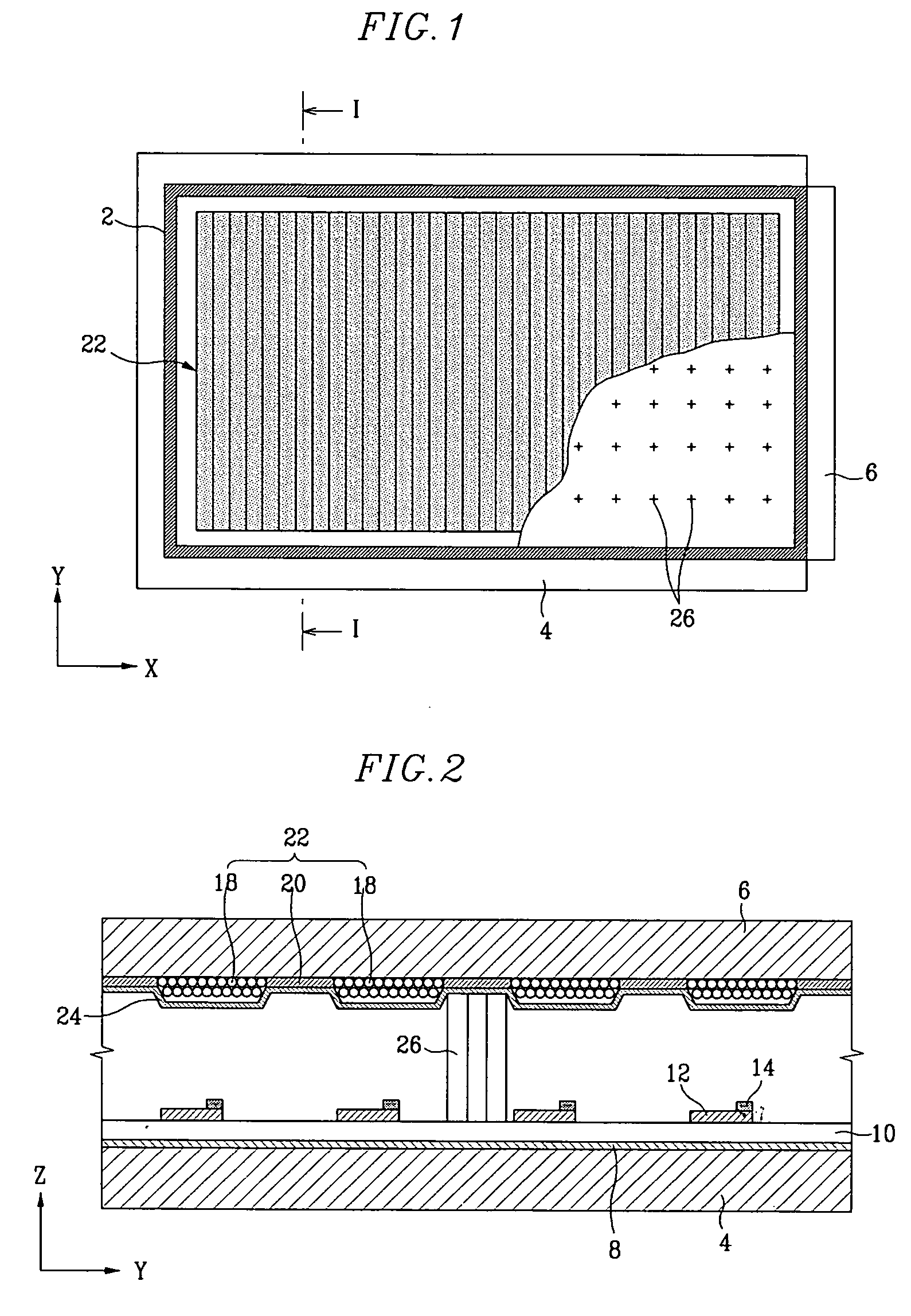

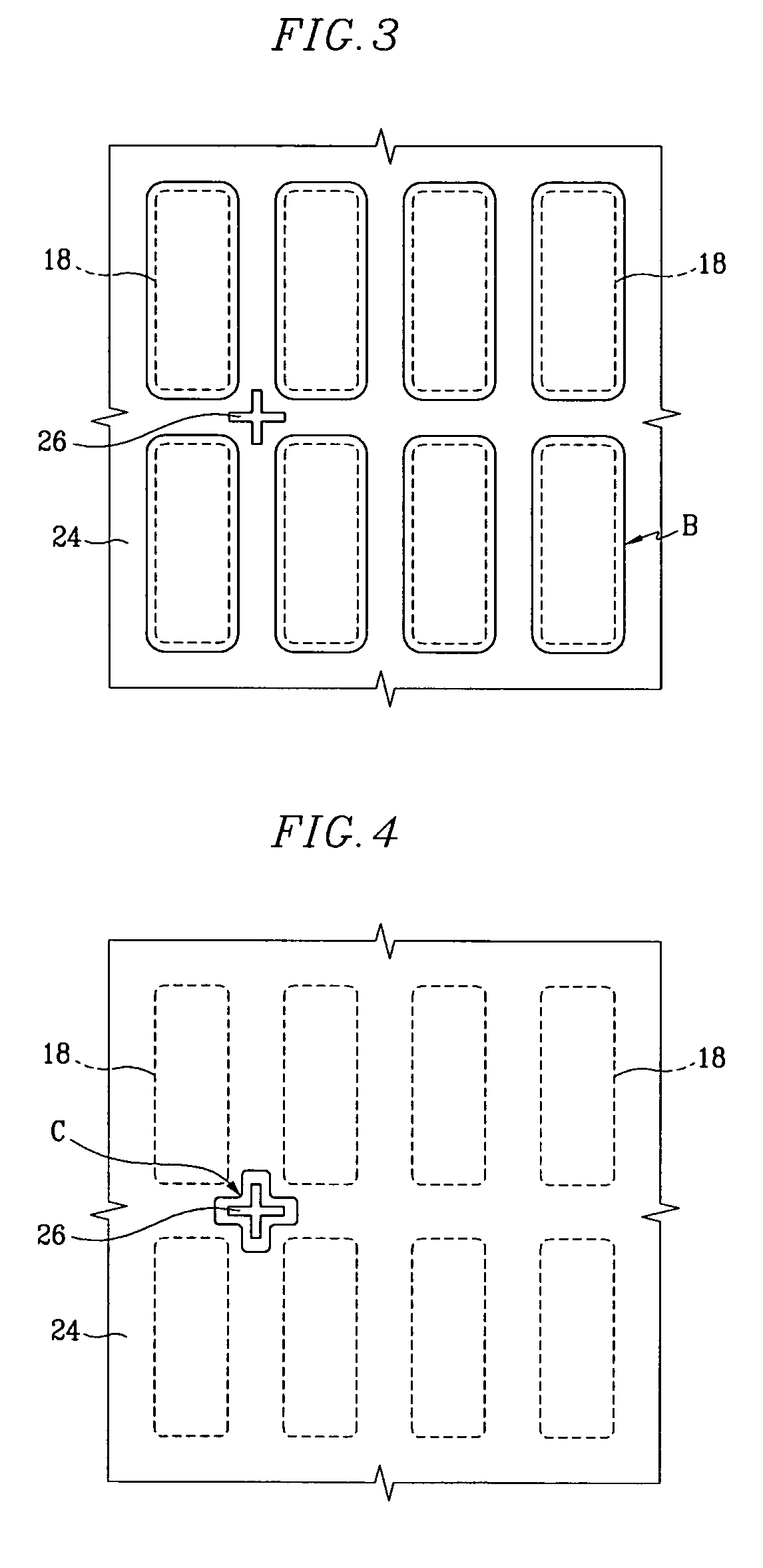

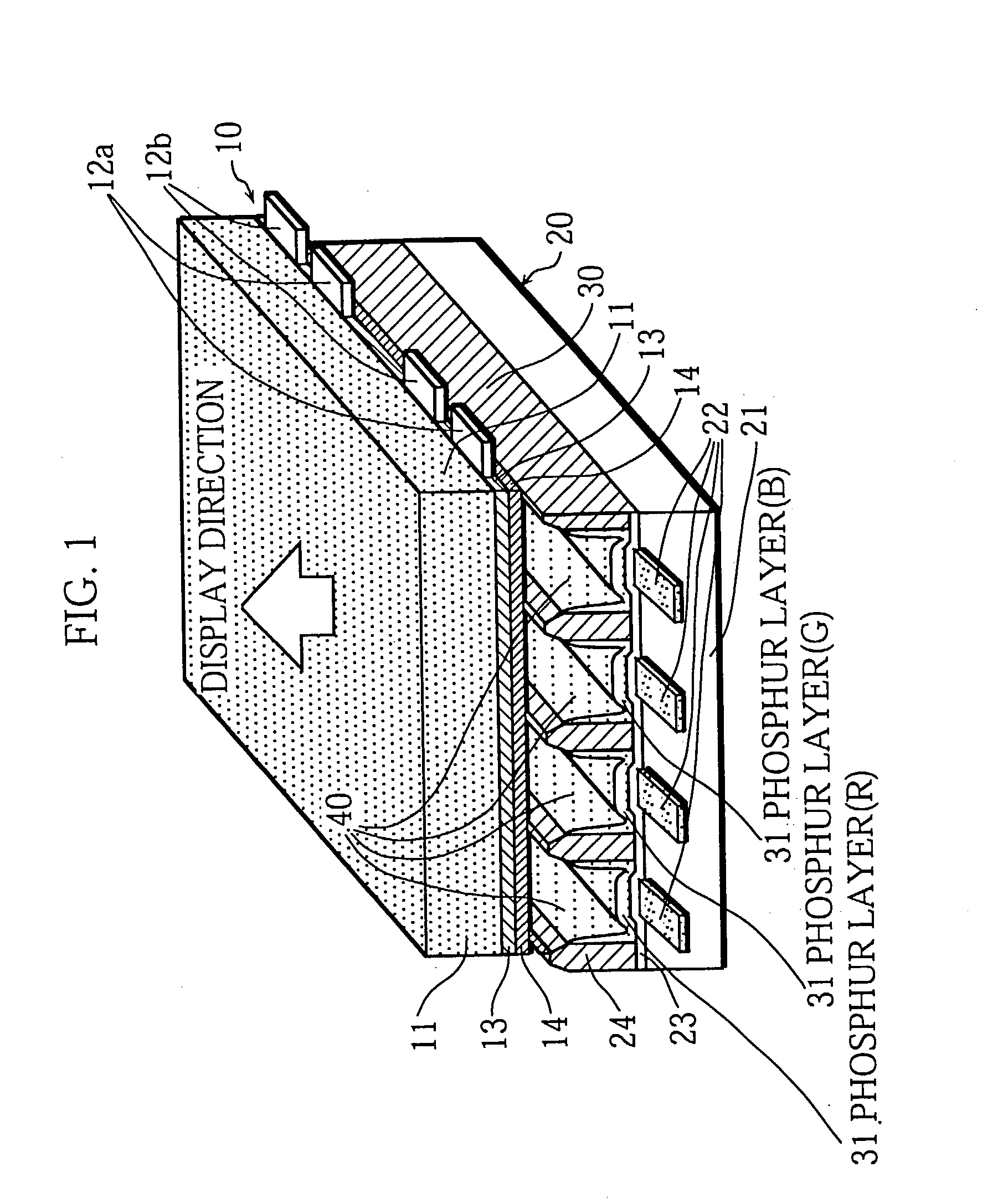

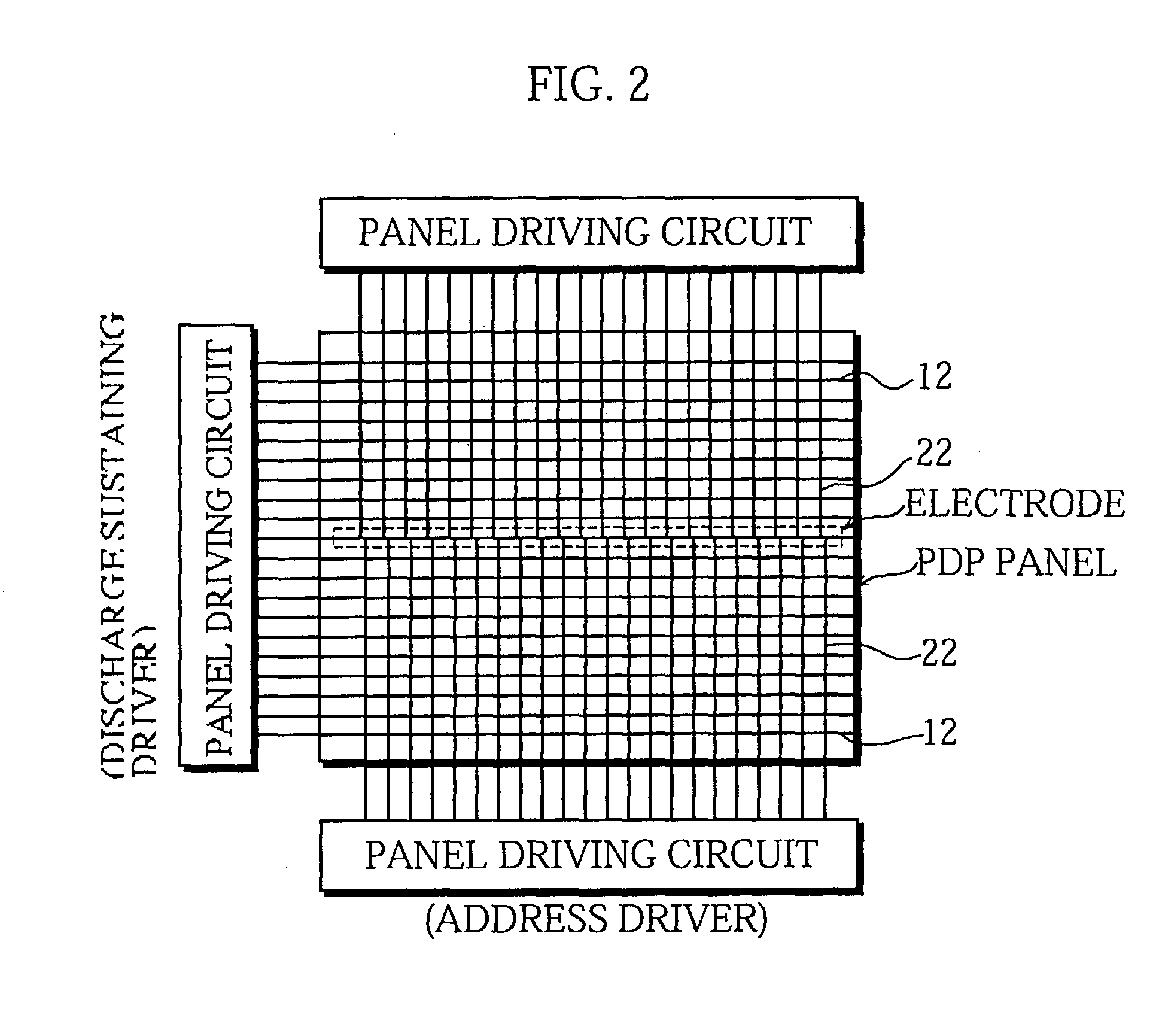

Surface light source device, method of manufacturing the same, backlight assembly and liquid crystal display apparatus having the same

InactiveUS20050007019A1Improve brightness uniformityReduce power consumptionDischarge tube luminescnet screensElongate light sourcesLiquid-crystal displayBrightness perception

A surface light source device capable of emitting the light having uniform brightness with lower power consumption is provided. The surface light source device includes a light source body and at least one discharge voltage applying part. The light source body includes a bottom plate; a top plate which is disposed over the bottom plate to form a flat receiving space between the bottom plate and the top plate, the flat receiving space receiving discharge gas; and at least one space-dividing wall which is disposed on the bottom plate and divides the flat receiving space into at least two discharge spaces. The discharge voltage applying part is disposed on an outer surface of the light source body and applies discharge voltage to the light source body.

Owner:SAMSUNG ELECTRONICS CO LTD

Organic Electroluminescence Display Device and Manufacturing Method Thereof

ActiveUS20090115325A1Improve barrier propertiesImprove moisture resistanceDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceVibration absorption

Owner:SAMSUNG DISPLAY CO LTD

Phosphor adhesive sheet, light emitting diode element including phosphor layer, light emitting diode device, and producing methods thereof

ActiveUS20120319575A1Easily and uniformly formedImprove machinabilityDischarge tube luminescnet screensLamp detailsFluorescencePhosphor

Owner:SCHOTT AG

Active matrix organic electroluminescent device and method of manufacture thereof

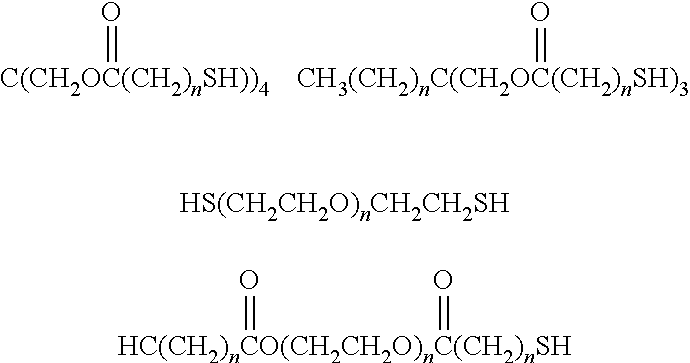

InactiveUS20110221331A1Improve adhesionImprove abilitiesDischarge tube luminescnet screensLamp detailsAdhesiveActive matrix

An active matrix organic electroluminescent device includes a thin-film transistor, an organic electroluminescent device, and a spacer layer deposited between the thin-film transistor and the organic electroluminescent device, wherein the spacer layer is made of adhesive for a dual curing system selected from the group consisting of ultraviolet curing-thermal curing, ultraviolet curing-microwave curing, ultraviolet curing-anaerobic curing, and ultraviolet curing-electron beam curing system. The present invention solves the poor adhesiveness between the thin-film transistor and the organic electroluminescent device, and improves the moisture and oxygen proof ability. The preparation method is simple, effective, and able to lower the cost and difficulty, and greatly improve the yield rate of the device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Solvents for PEDOT-Solutions for Ink-Jet Printing

InactiveUS20090121618A1Extended drying timeImprove uniformityDischarge tube luminescnet screensLamp detailsBoiling pointSolvent

A composition for ink jet printing an opto-electrical device, the composition comprising: an electroluminescent or charge transporting organic material; and a high boiling point solvent having a boiling point higher than water.

Owner:CAMBRIDGE DISPLAY TECH LTD

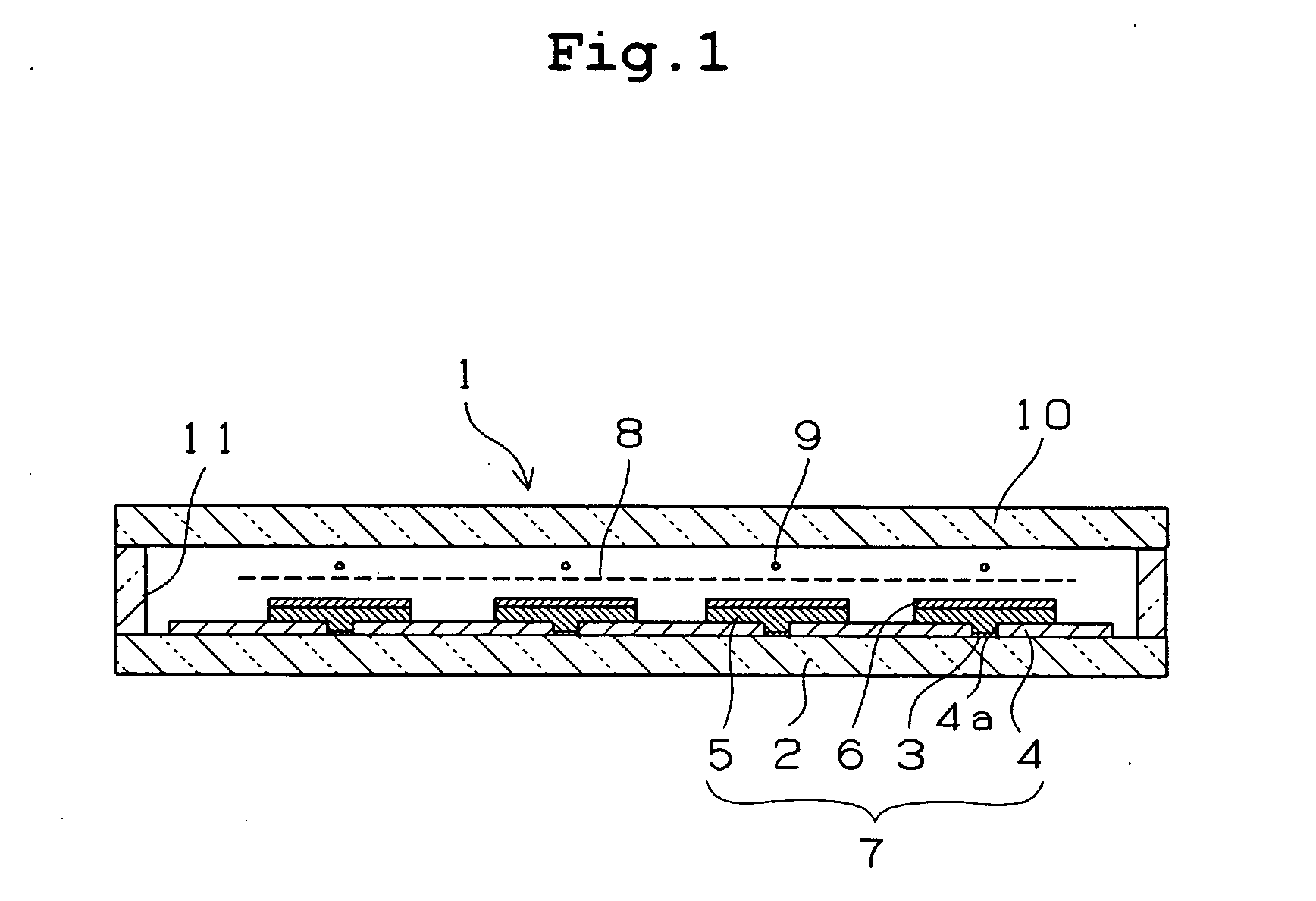

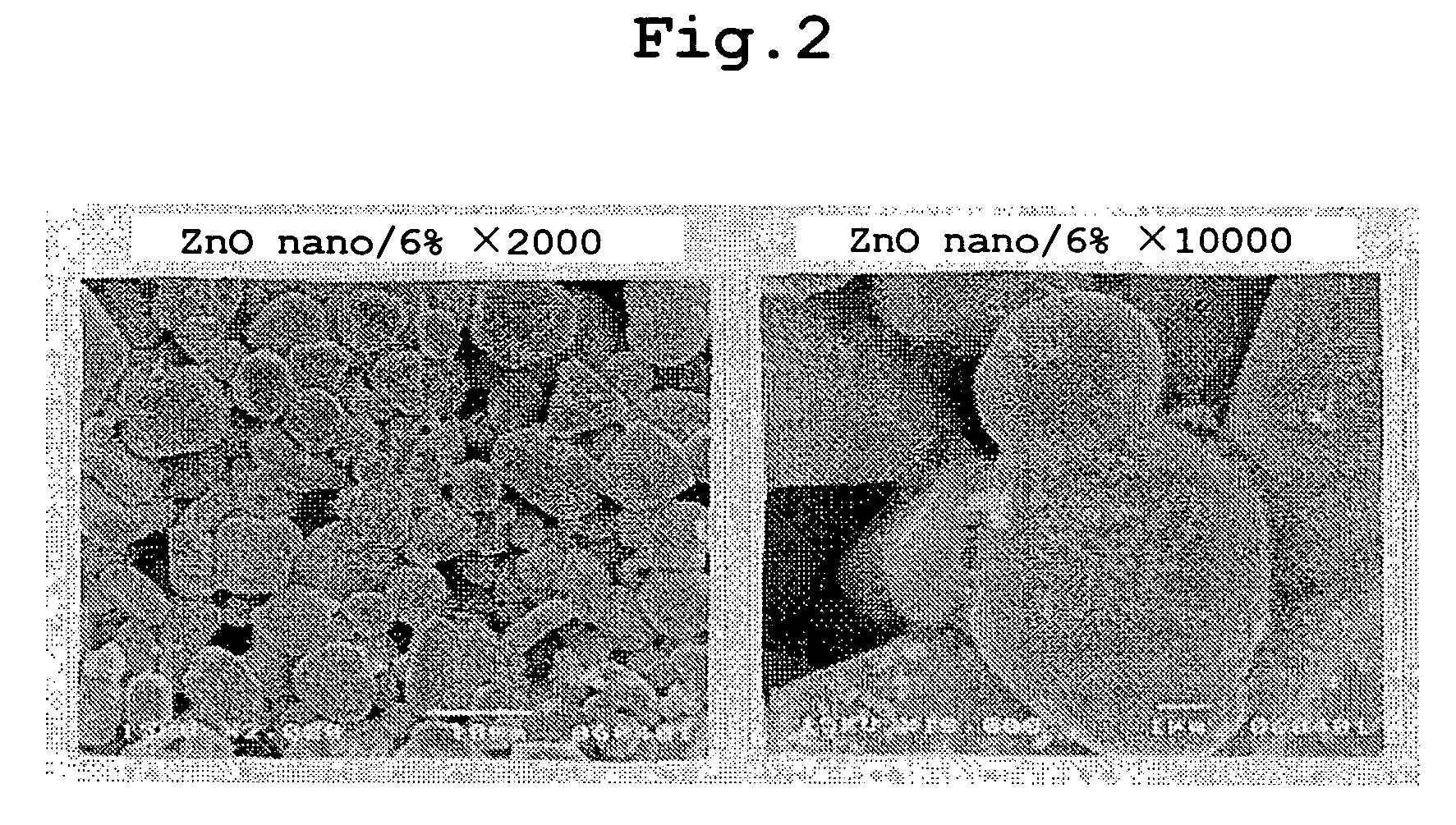

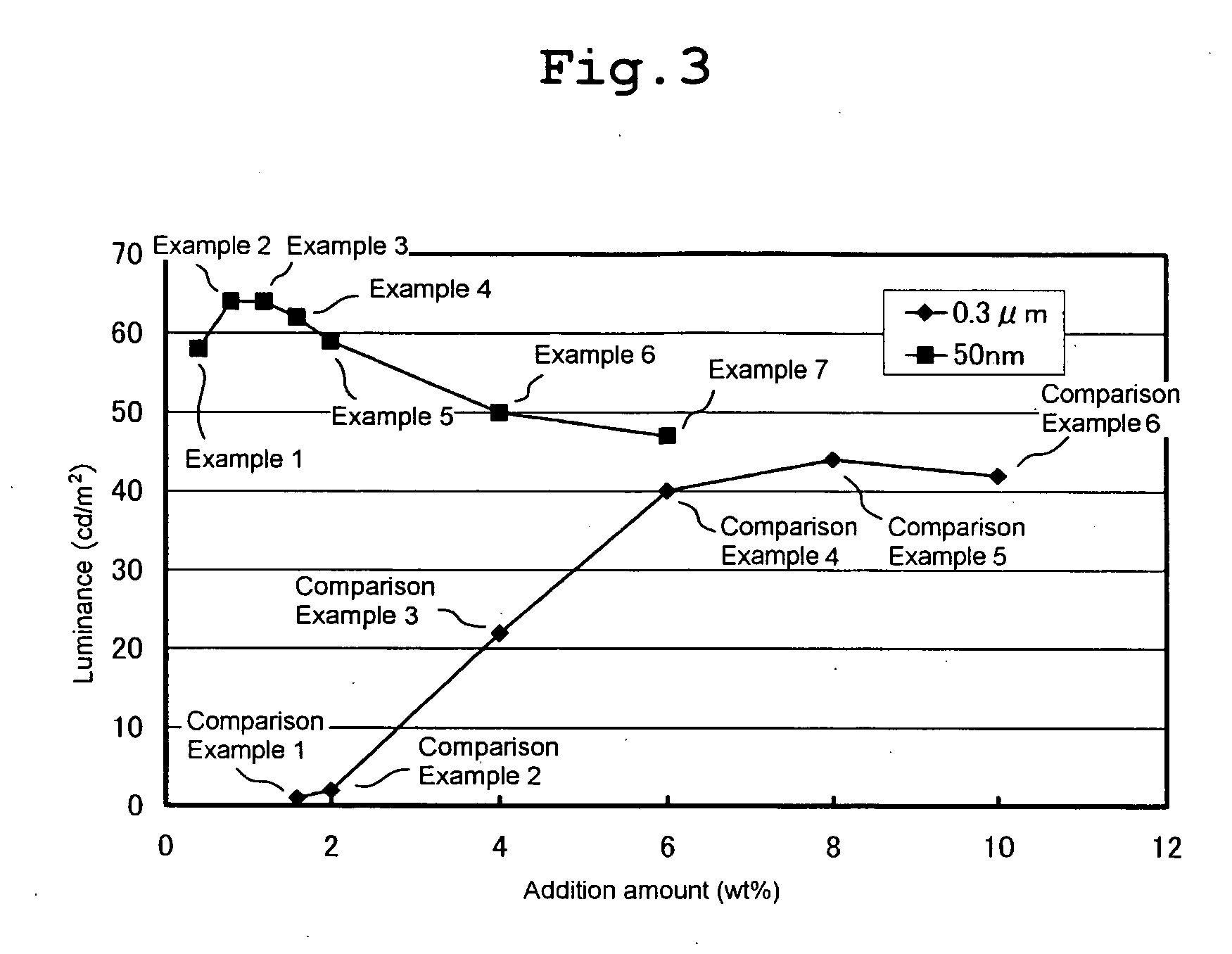

Phosphor for low-voltage electron beam, method of producing the same, and vacuum fluorescent display

InactiveUS20060237690A1High surface energyDecrease addition amountImage/pattern display tubesOxide conductorsFluorescenceLow voltage

Nano-particles of an electrically conductive oxide adhere to the surface of particles of a phosphor for low-voltage electron beams. The average diameter of nano-particles of the electrically conductive oxide is in the range of 5 to 100 nm. The weight percentage of the nano-particles of the electrically conductive oxide to the entire phosphor is 0.01 to 10. A vacuum fluorescent display uses the phosphor for low-voltage electron beams.

Owner:NORITAKE ITRON CORP +1

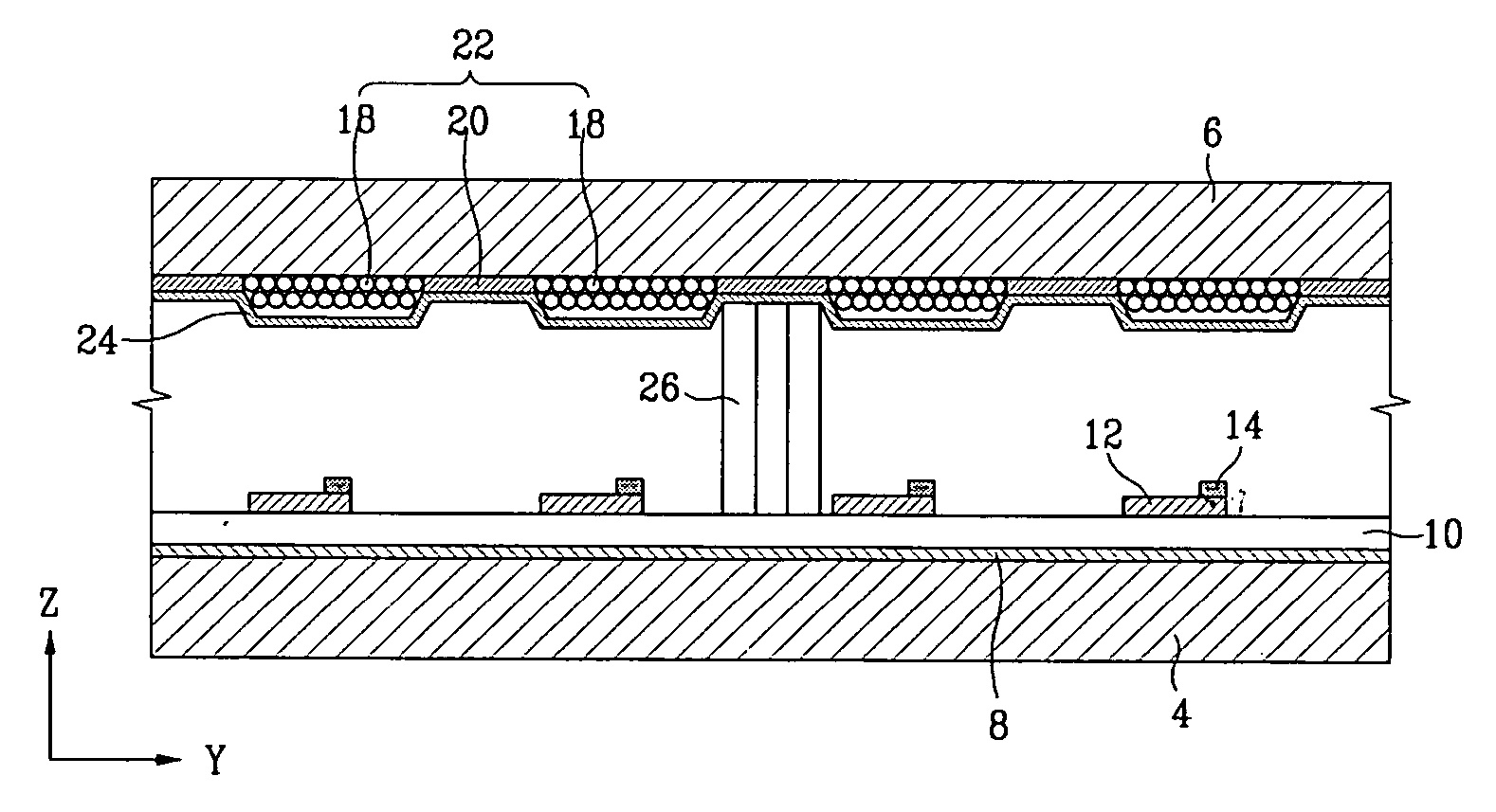

Flat panel display and method of manufacturing the same

InactiveUS20050134169A1Improve adhesionAvoid damageDischarge tube luminescnet screensCathode-ray/electron-beam tube vessels/containersPhosphorFluorescence

A flat panel display with improved adhesion of the anode to the second substrate is disclosed. The adhesion of the anode to the second substrate is reinforced to prevent damage to the anode at the spacer formation area and to stably adhere the phosphor layer to the anode. The flat panel display comprises first and second substrates each facing each other and separated from each other by a distance. An electron emission unit is formed on the first substrate. A plurality of phosphor layers are formed on the second substrate. An anode is formed on the second substrate covering the phosphor layers and the non-light emitting regions between the phosphor layers. In the non-light emitting regions, the anode is placed on the second substrate without leaving a gap between the anode and the second substrate.

Owner:SAMSUNG SDI CO LTD

Plasma display panel manufacturing method for manufacturing a plasma display panel with superior picture quality, a manufacturing apparatus, and a phosphor ink

InactiveUS20030146701A1Accurately and evenly produceLittle line blurringAlternating current plasma display panelsVessels or leading-in conductors manufactureEngineeringSolvent

The present invention intends to provide a manufacturing method for a PDP that can continuously apply phosphor ink for a long time and can accurately and evenly produce phosphor layers even when the cell construction is very fine. To do so, phosphor ink is continuously expelled from a nozzle while the nozzle moves relative to channels between partition walls formed on a plate so as to scan and apply phosphor ink to the channels. While doing so the path taken by the nozzle within each channel between a pair of partition walls is adjusted based on position information for the channel. When phosphor particles is successively applied to a plurality of channels, phosphor ink is continuously expelled from the nozzle even when the nozzle is positioned away from the channels. The phosphor ink is composed of: phosphor particles that have an average particle diameter of 0.5 to 5 mum; a mixed solvent in which materials selected from a group consisting of terpineol, butyl carbitol acetate, butyl carbitol, pentandiol, and limonene are mixed; and a binder that is an ethylene group polymer or ethyl cellulose containing at least 49% of ethoxy group (-OC2H5) cellulose molecules. After dispersion a charge-removing material is added to the phosphor ink.

Owner:PANASONIC CORP

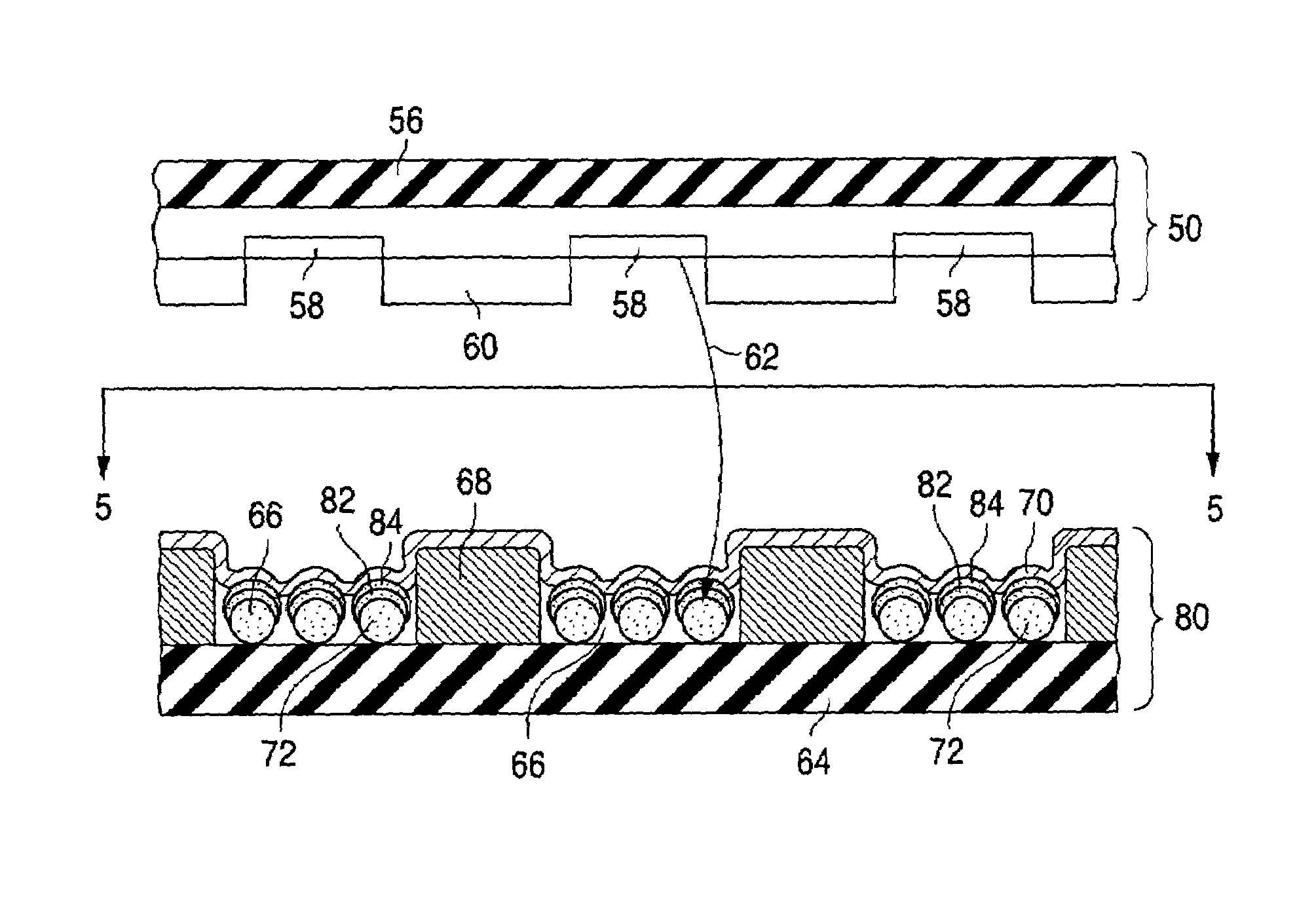

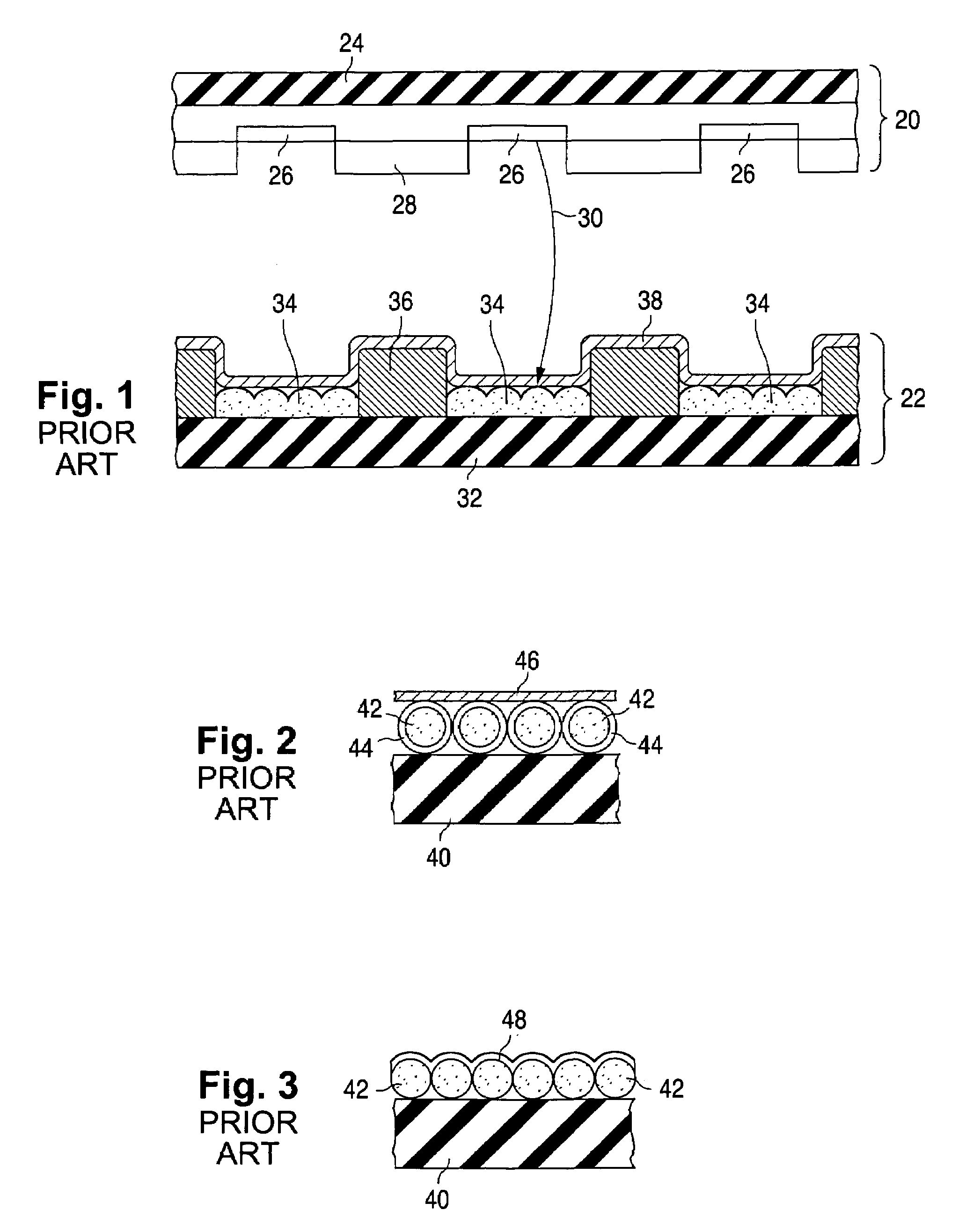

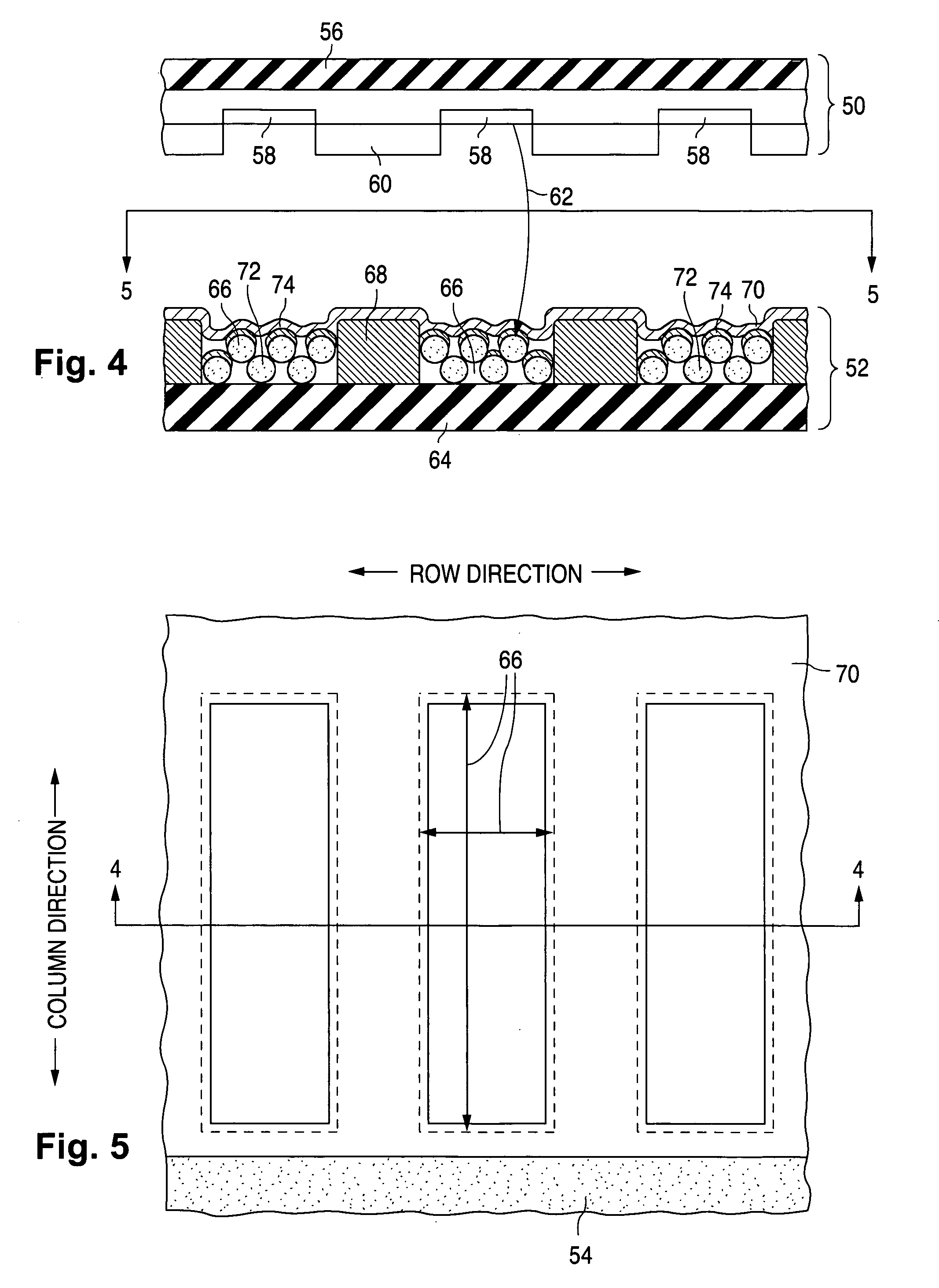

Light-emitting device having light-emissive particles partially coated with intensity-enhancement material

InactiveUS7002289B1Improve performanceExtended service lifeGas filling substance selectionIncadescent screens/filtersDisplay deviceLight emitting device

A light-emitting device (52) suitable for a flat-panel cathode-ray tube display contains a light-emissive region (66) formed over a plate (64). The light-emissive region contains a plurality of light-emissive particles (72). Part of the outer surface of each of a group of the light-emissive particles is conformally covered with a group of intensity-enhancement coatings (82 and 84).

Owner:CANON KK

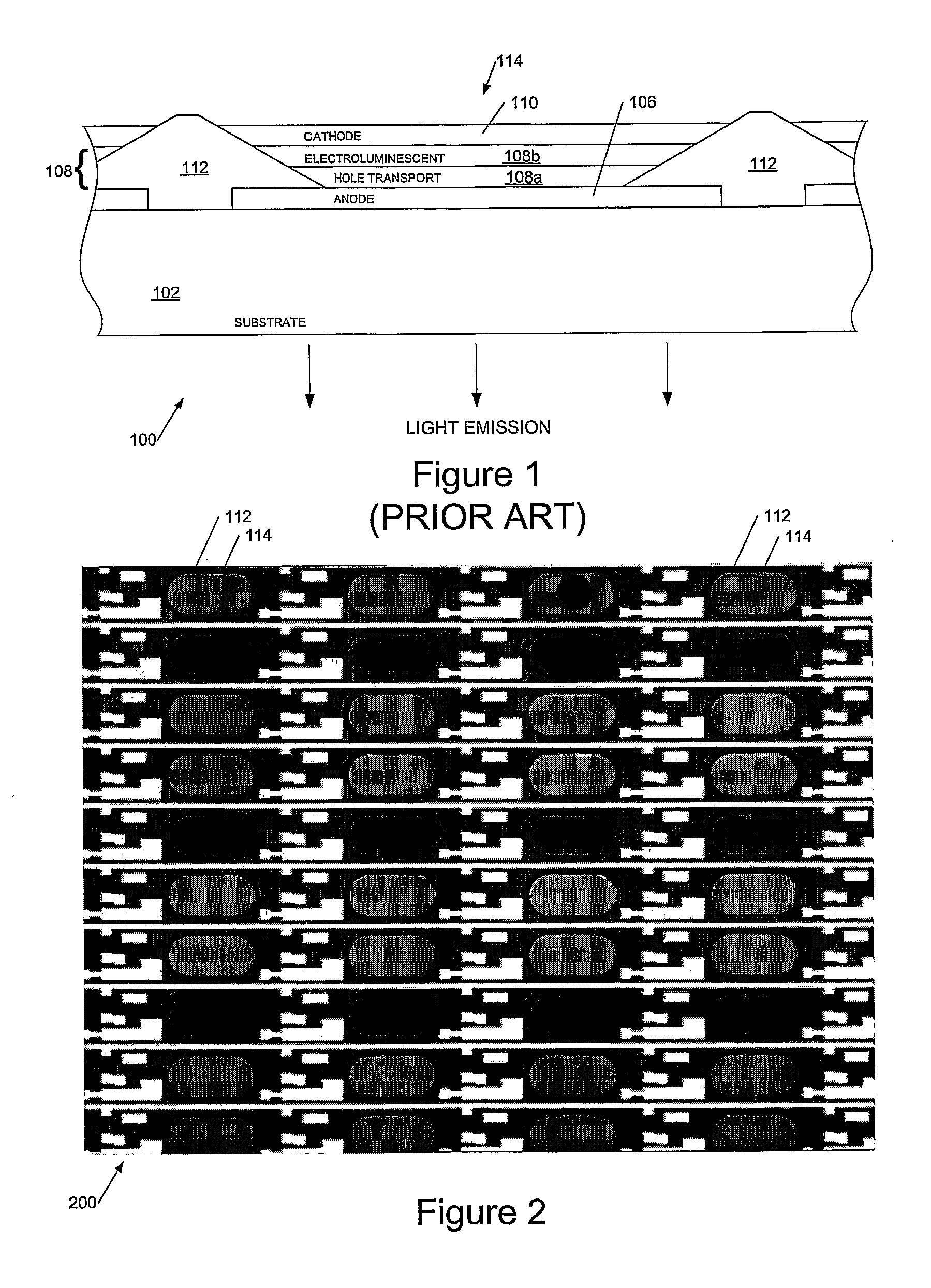

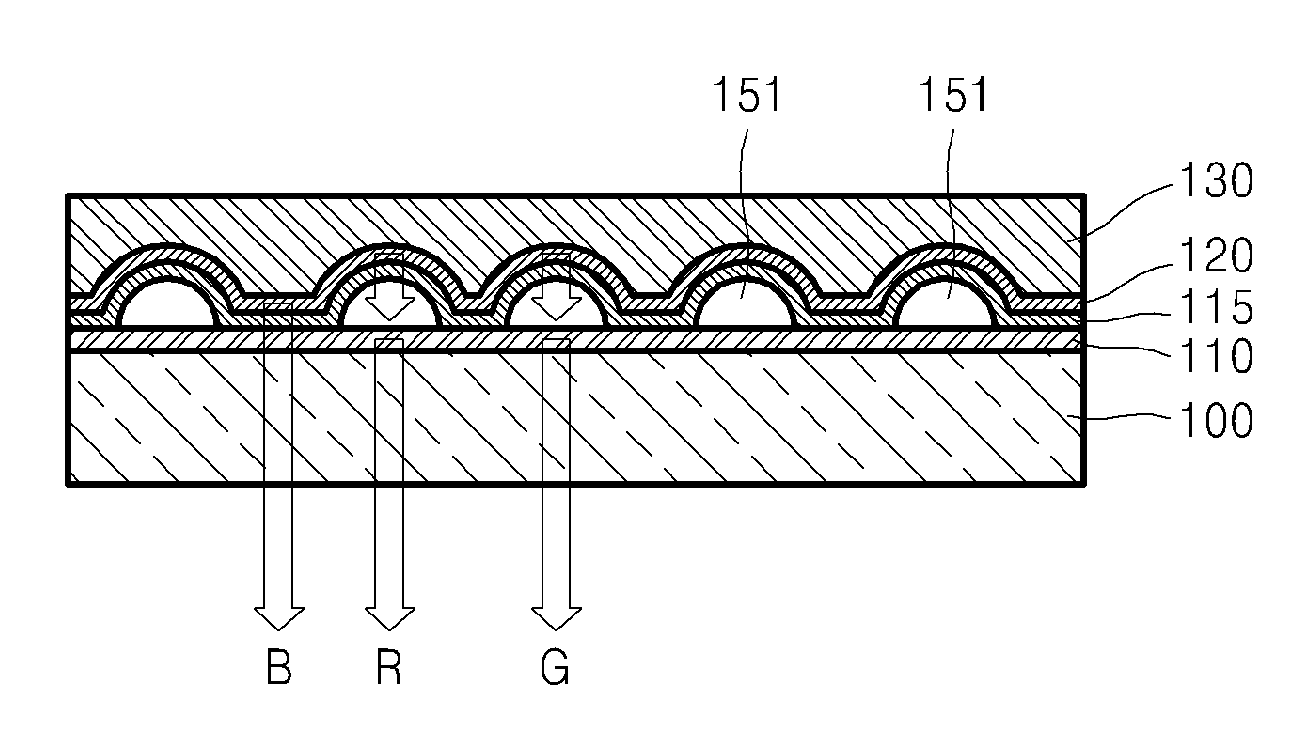

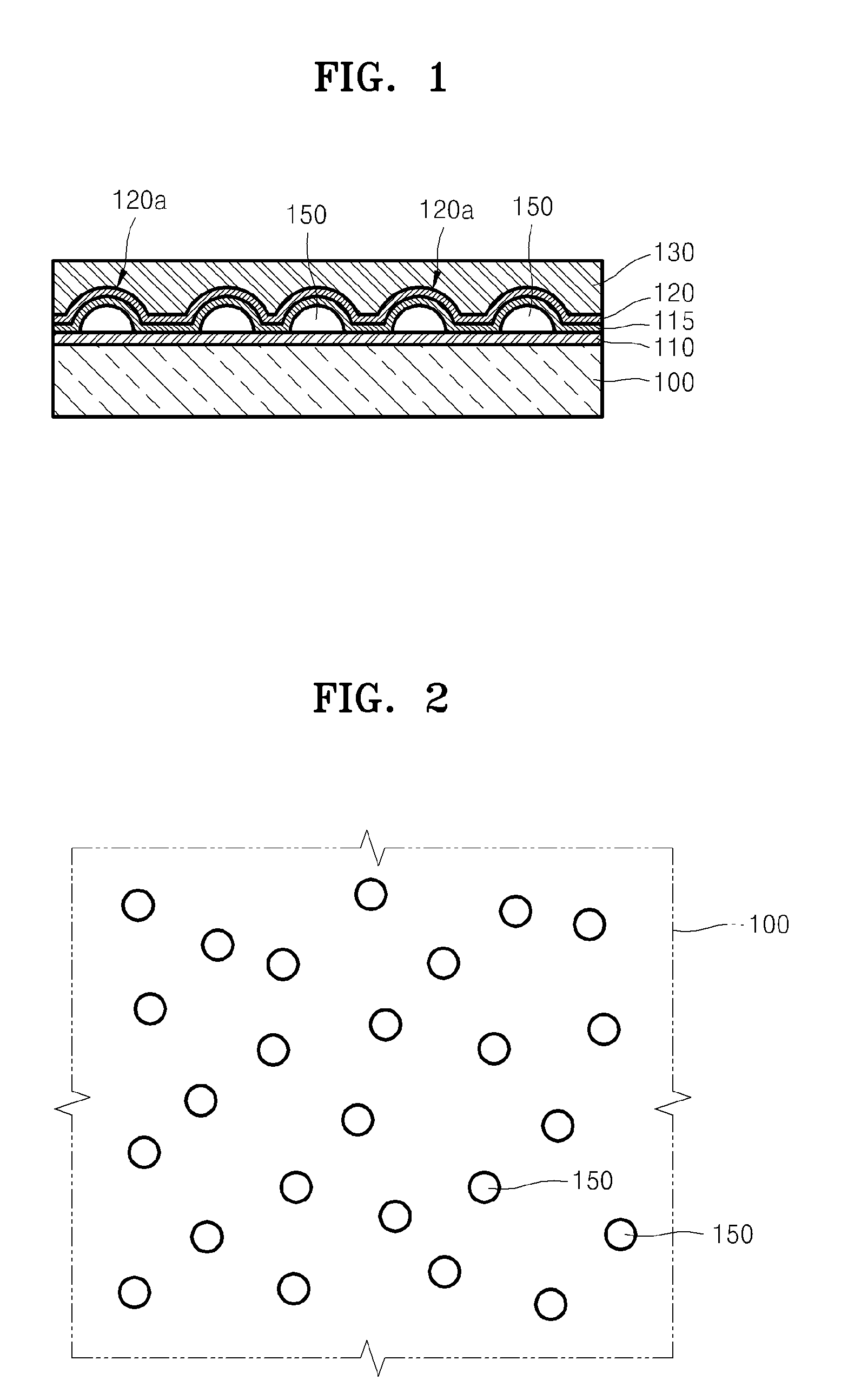

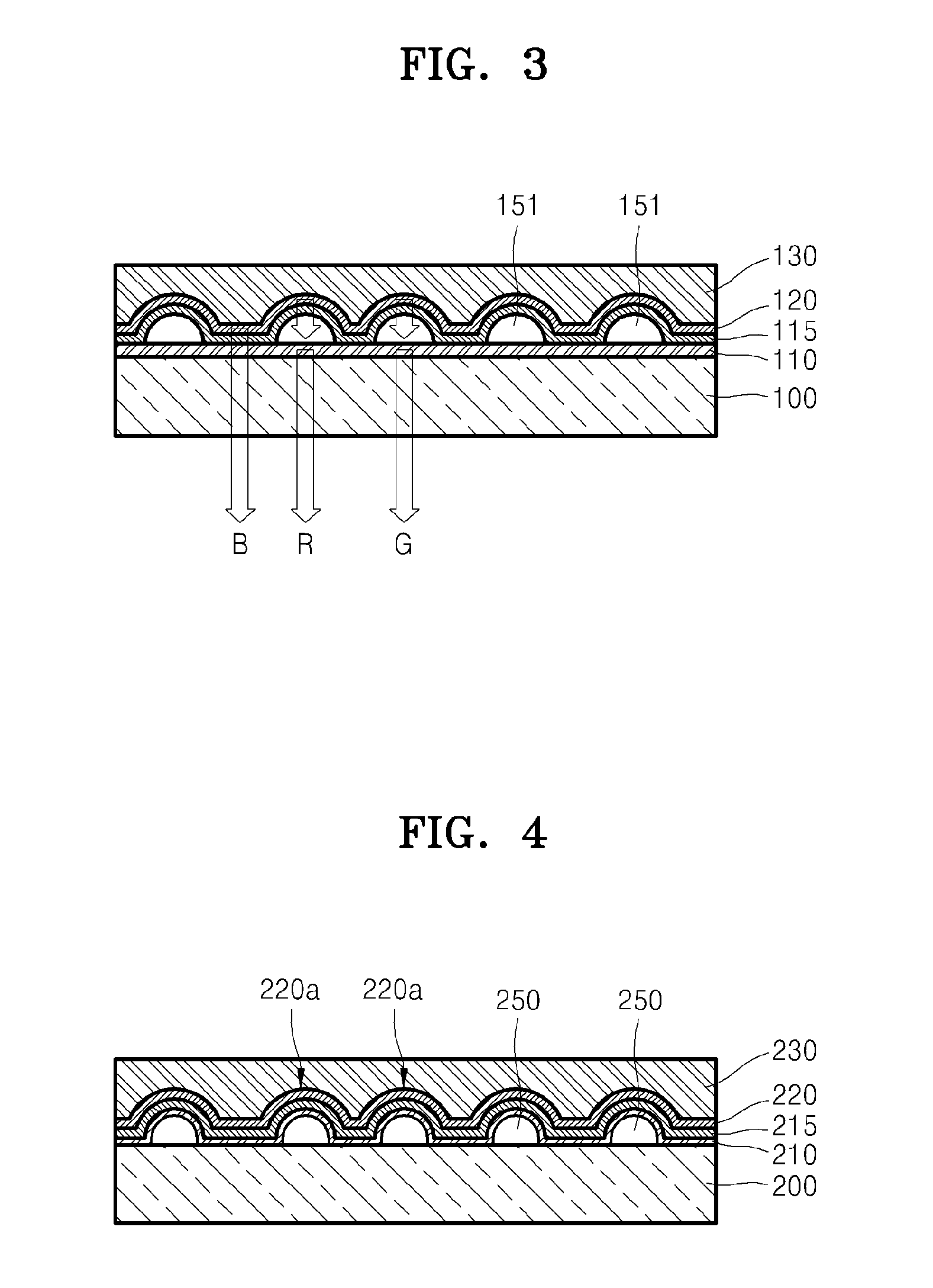

Organic light emitting device and method of manufacturing the same

InactiveUS20100141123A1Discharge tube luminescnet screensElectroluminescent light sourcesOrganic light emitting deviceOptoelectronics

An organic light emitting device (“OLED”) including a substrate; a plurality of polymer beads disposed on a substrate; a light emitting layer covering the plurality of polymer beads and having an embossed structure; and a cathode disposed on the light emitting layer.

Owner:SAMSUNG ELECTRONICS CO LTD

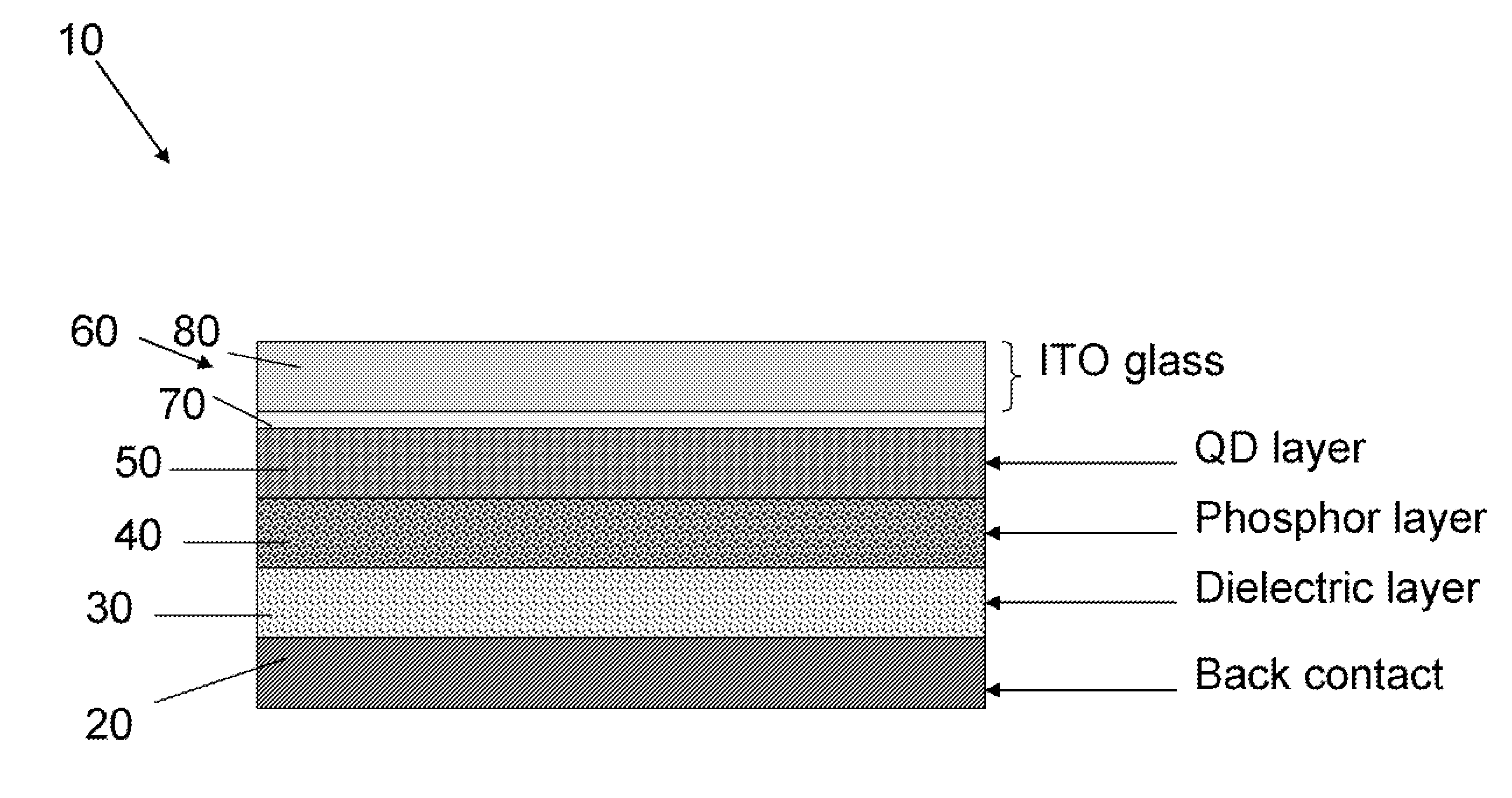

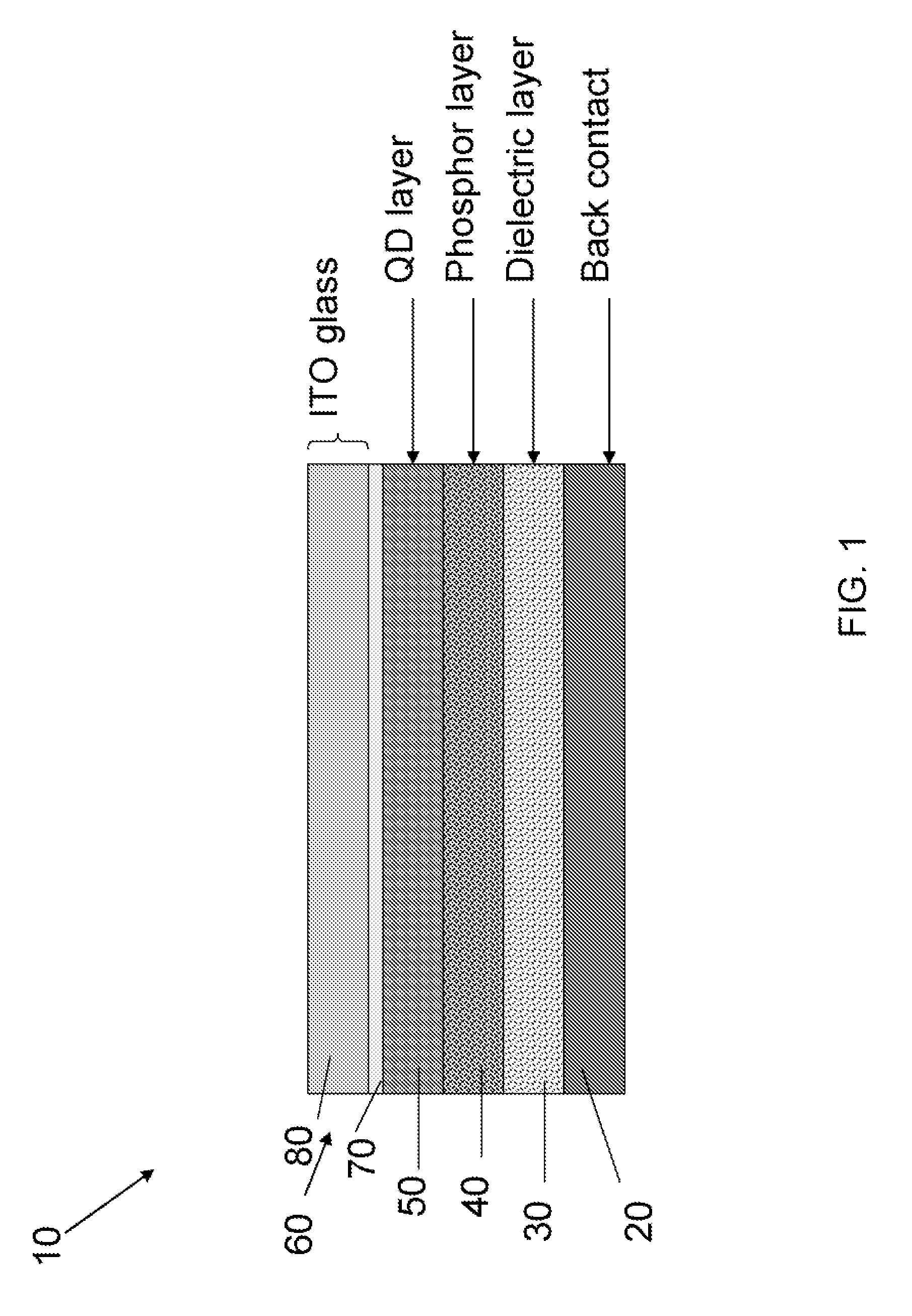

Quantum dot electroluminescent device

InactiveUS20100109521A1Easy to operateImprove luminous performanceDischarge tube luminescnet screensElectroluminescent light sourcesPhosphorFluorescence

An EL device is presented which consists of a simple three active layer construction. A layer of a dielectric material, a traditional EL phosphor layer, and a quantum dot layer are present between an electrode and a transparent electrode. The EL device is operated efficiently by an AC source. Quantum dots which emit in the visible spectrum are used. The EL device is fully color tunable by altering the composition and thickness of the layers.

Owner:SAMSUNG ELECTRONICS CO LTD

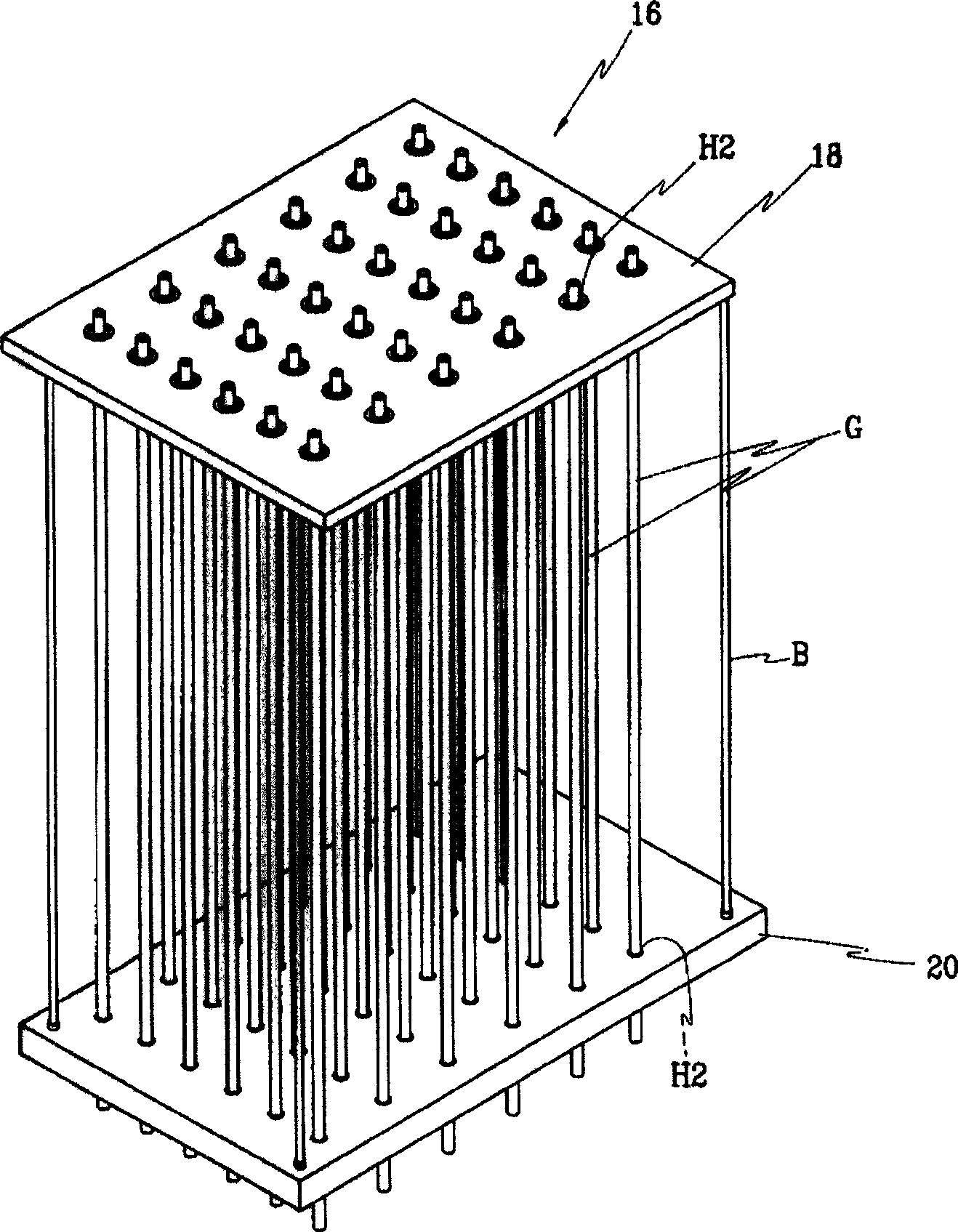

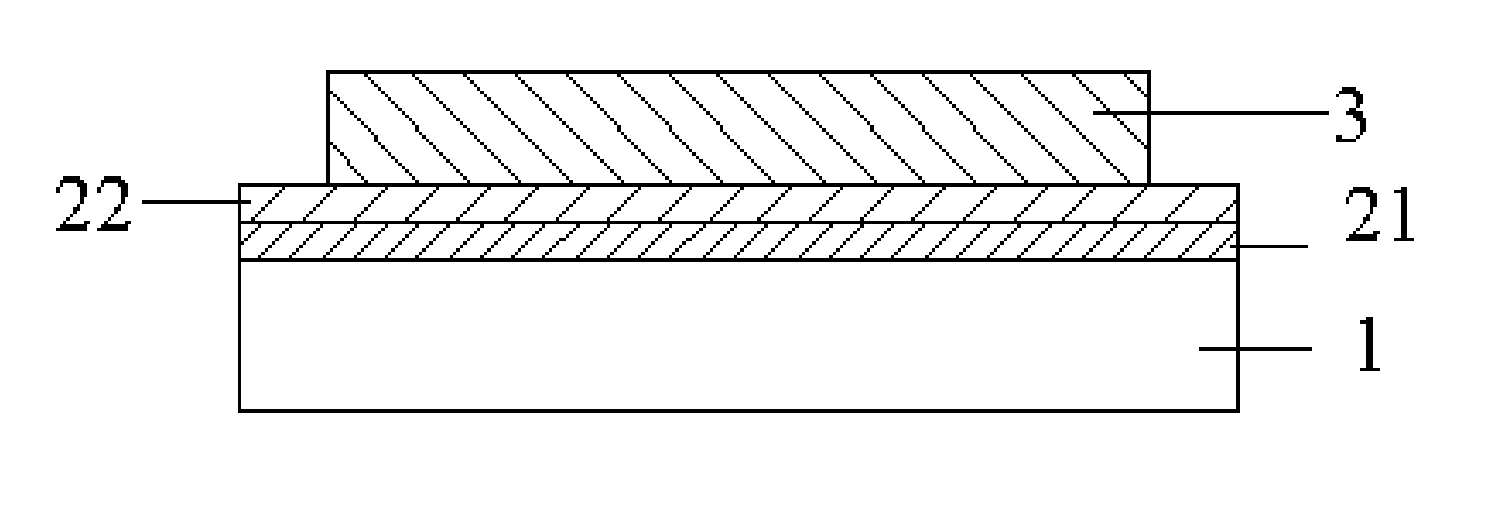

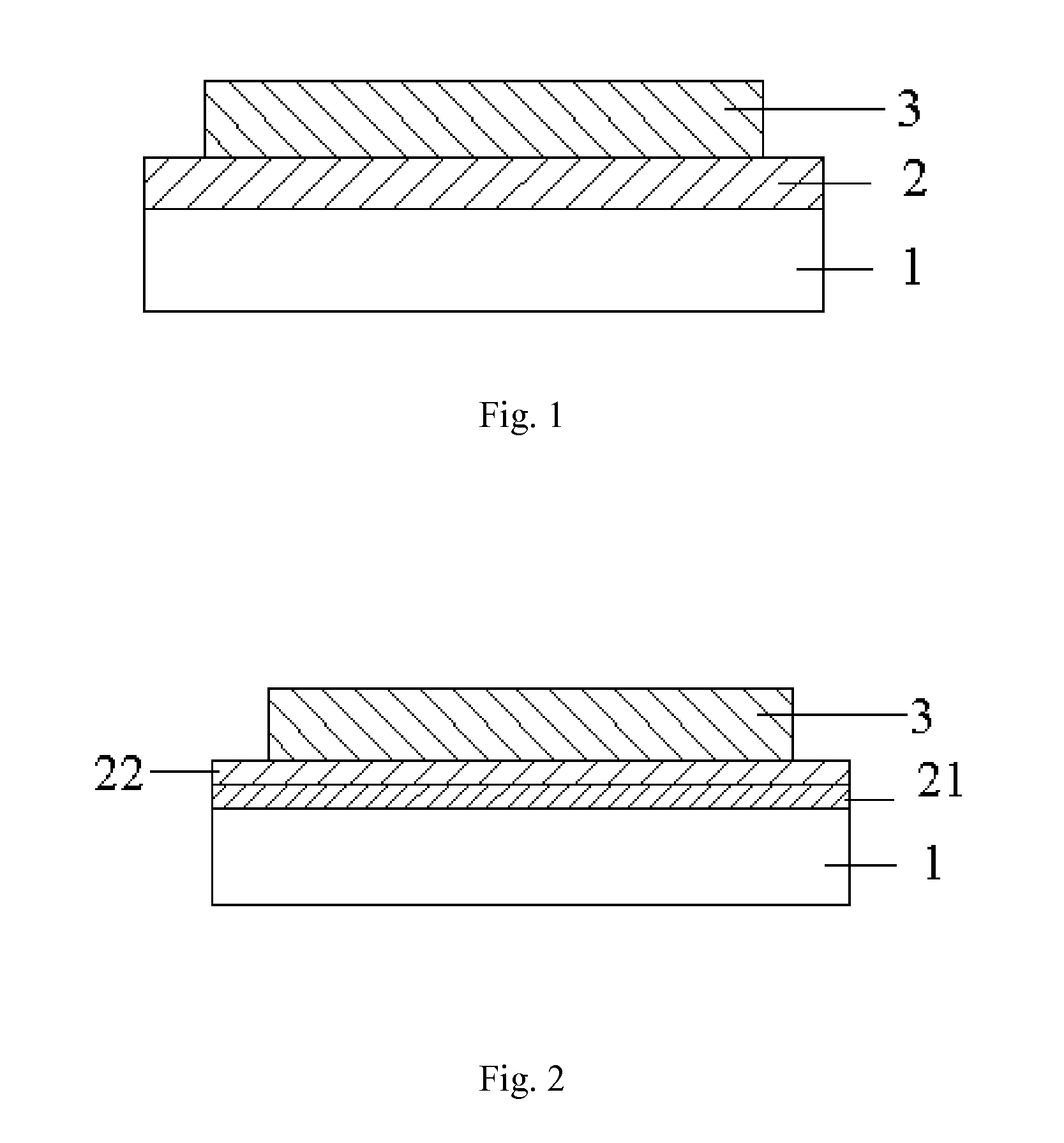

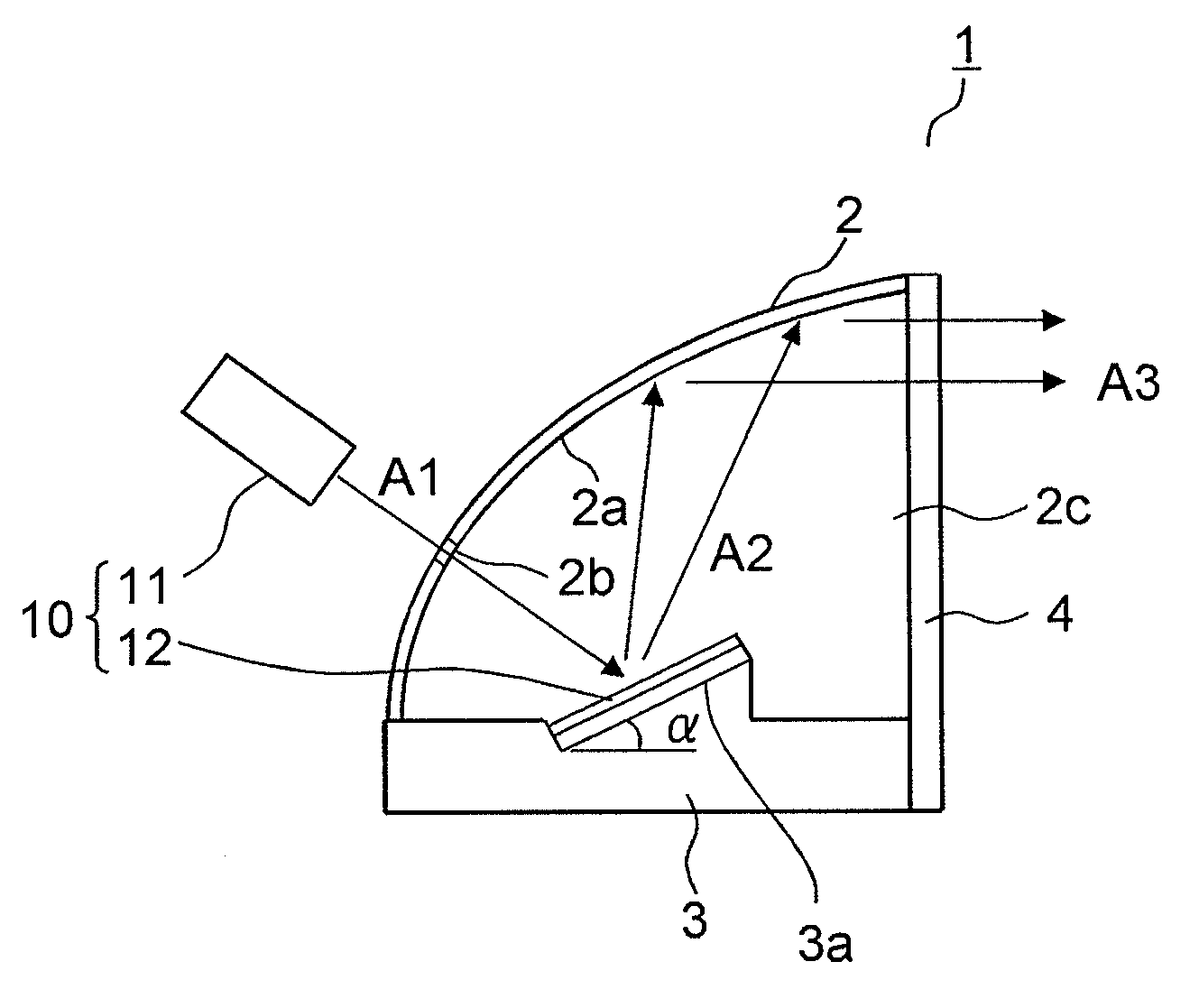

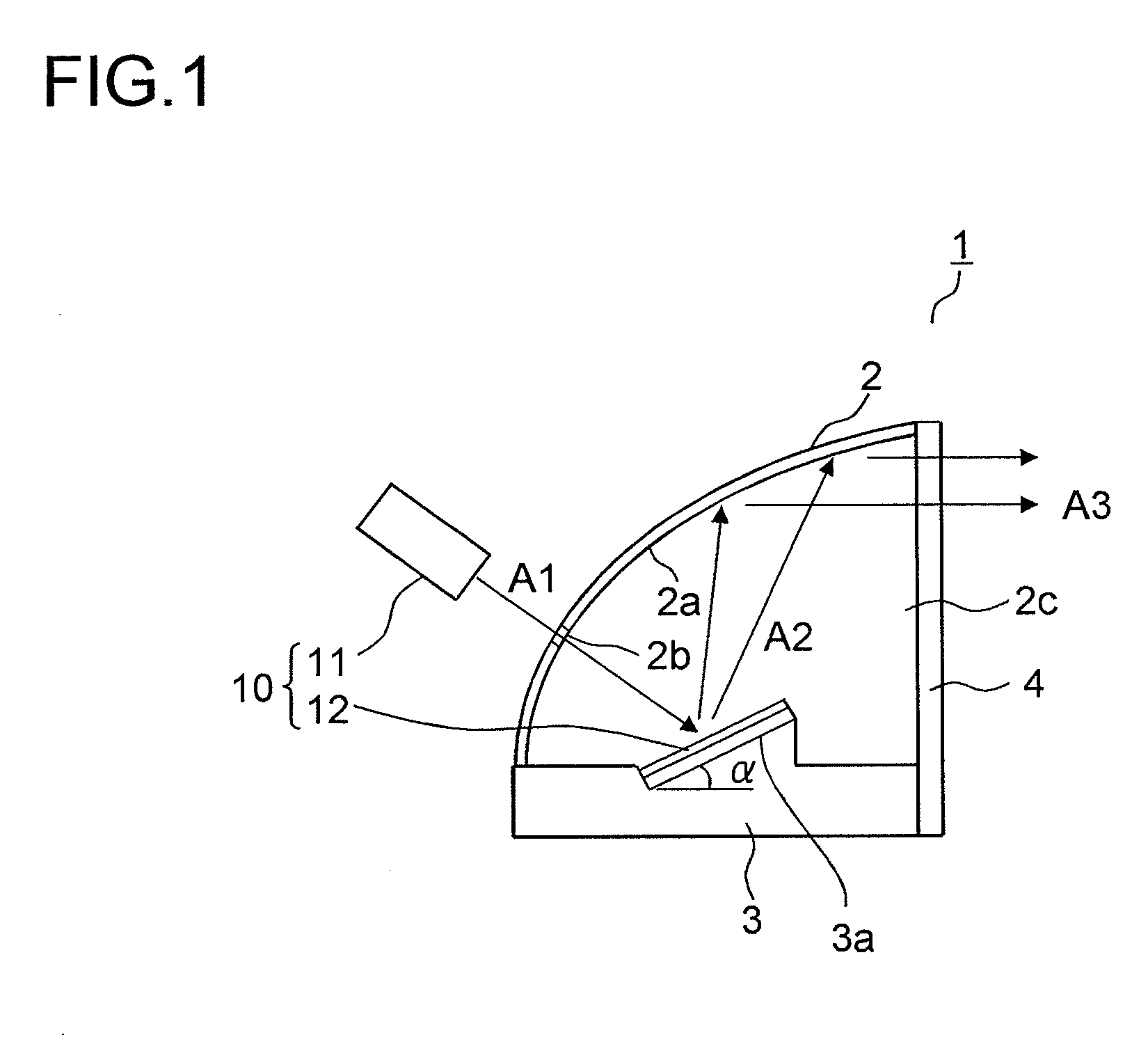

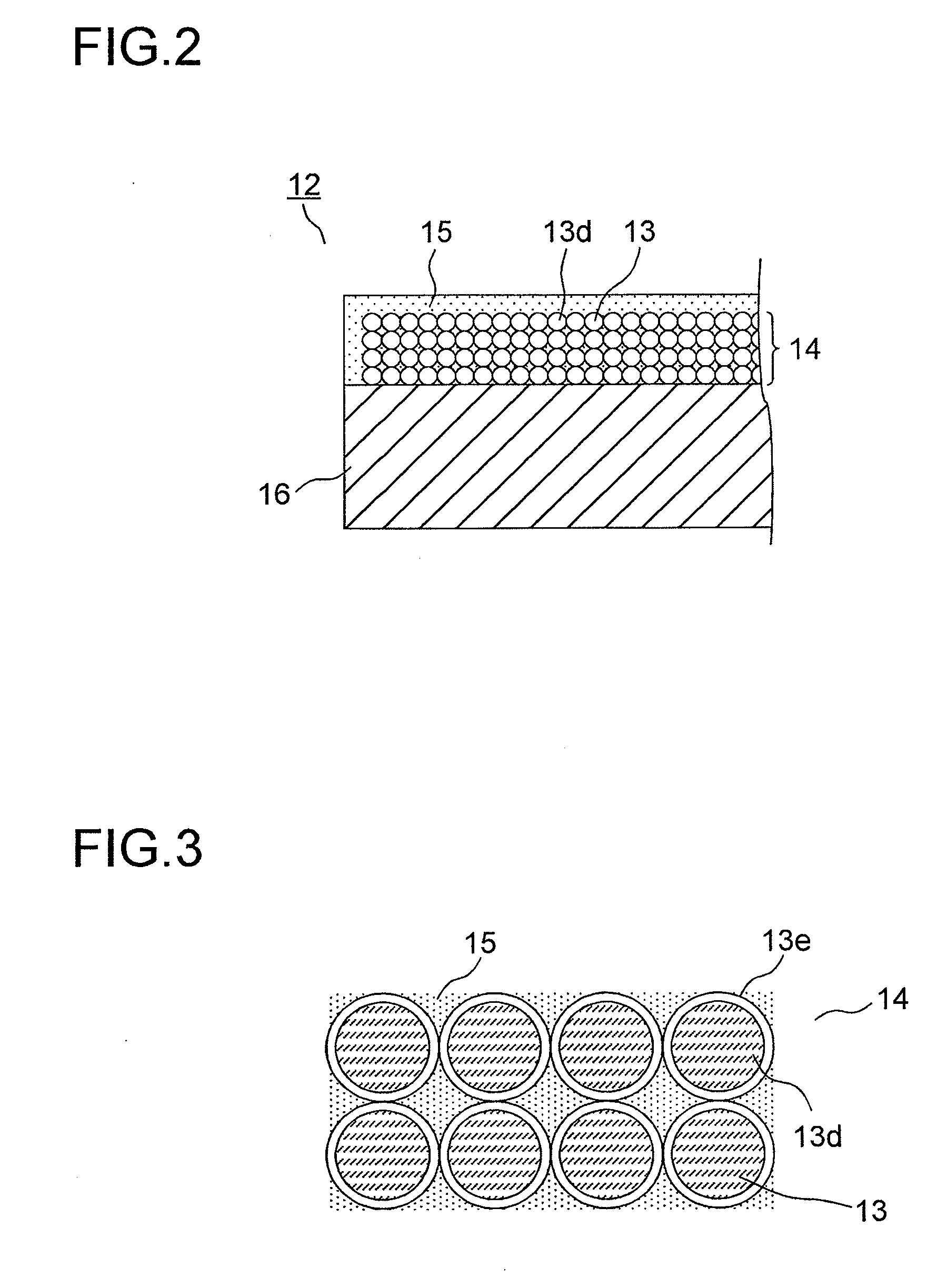

Light emitting device

ActiveUS20130003347A1Improve efficiencyImprove cooling effectSemiconductor laser optical deviceLuminescent coatings applicationFluorescenceLaser light

In a light emitting device (10) includes a light source (11) which emits near-ultraviolet laser light and a fluorescent member (12) which includes a fluorescent body (13) that is excited by the light emitted from the light source (11) so as to emit light, the fluorescent member (12) includes a substrate (16) which is formed with a highly heat conductive member and a fluorescent body layer (14) in which particles (13d) of the fluorescent body (13) are deposited on the substrate (16).

Owner:SHARP FUKUYAMA LASER CO LTD

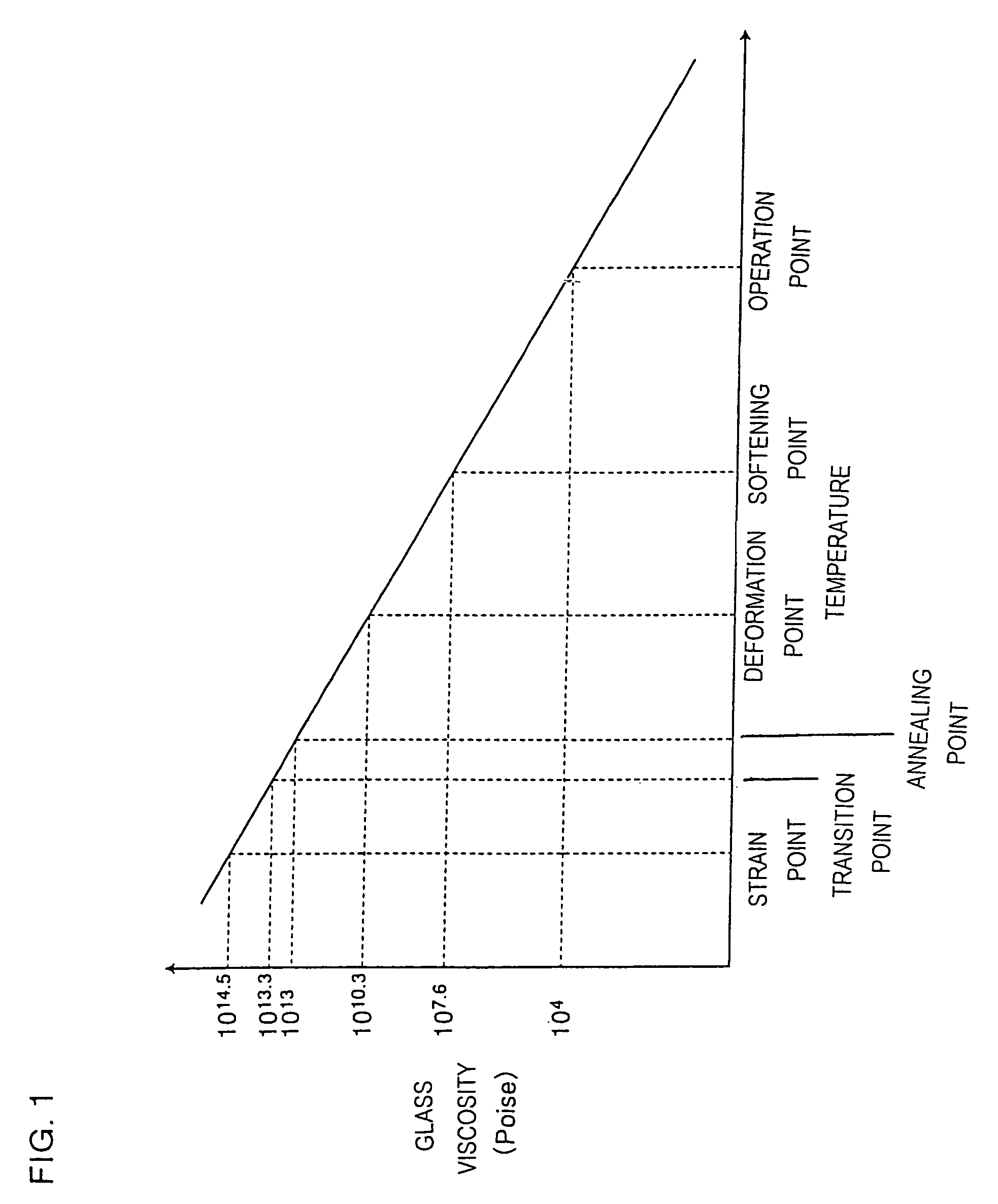

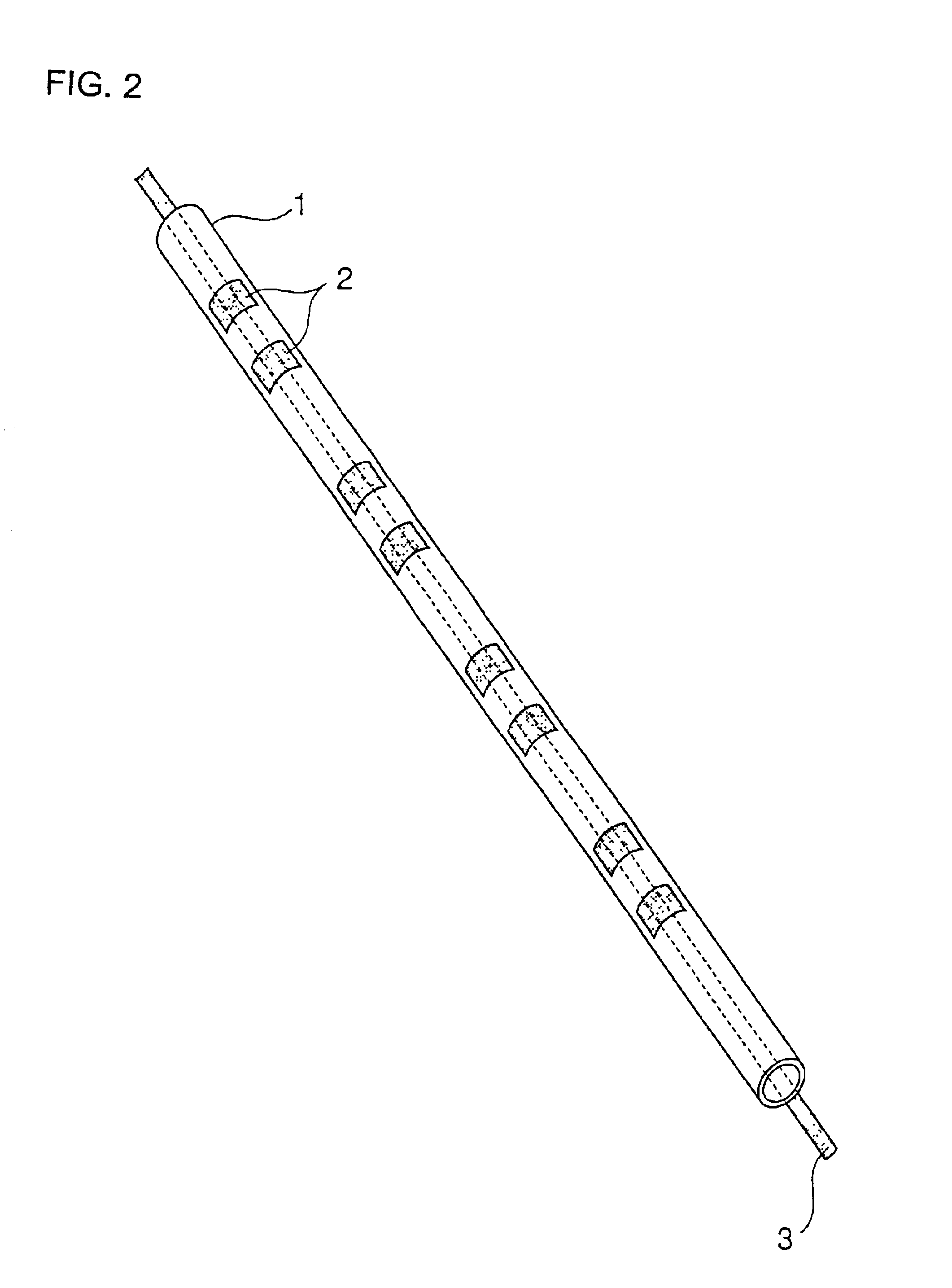

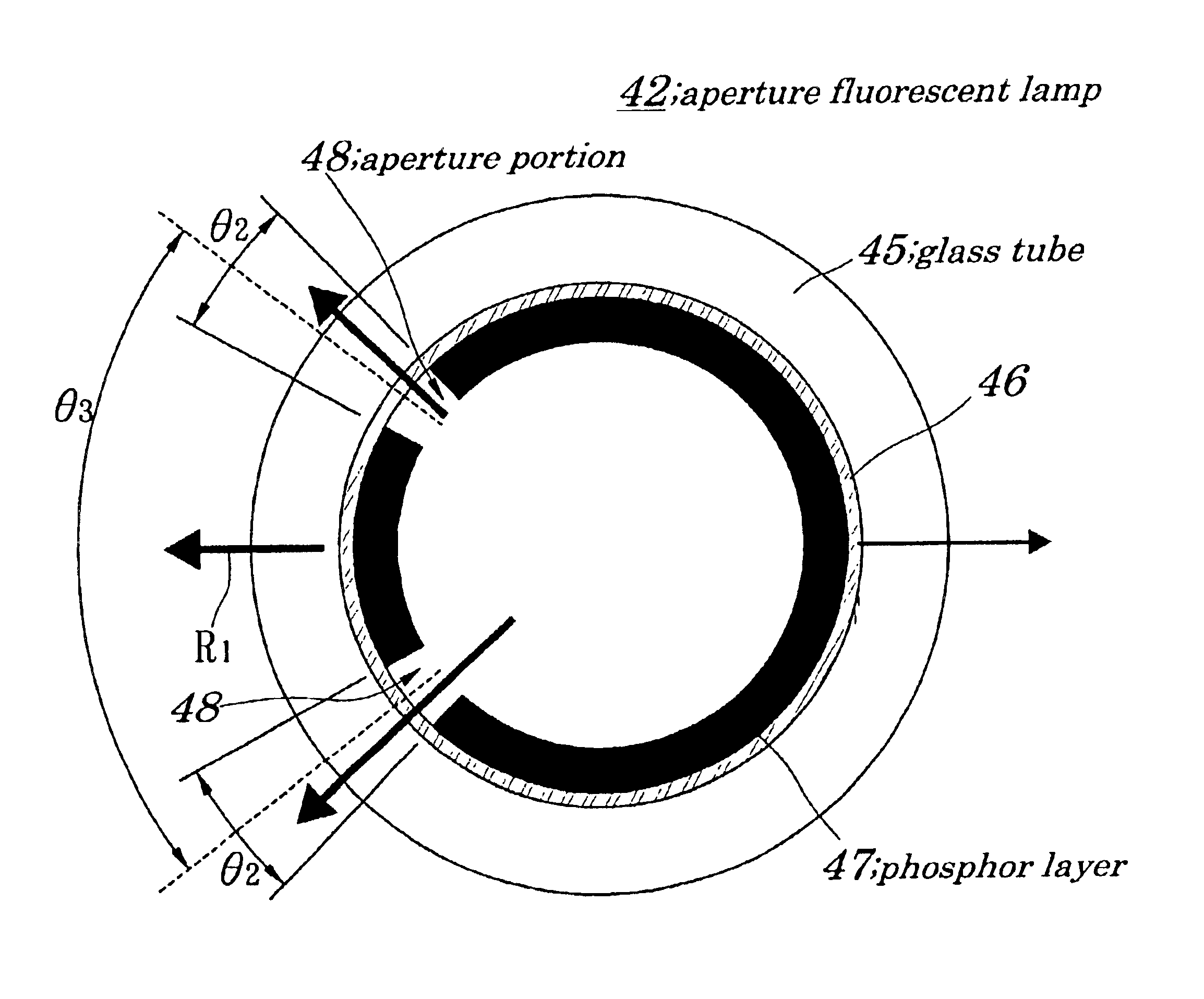

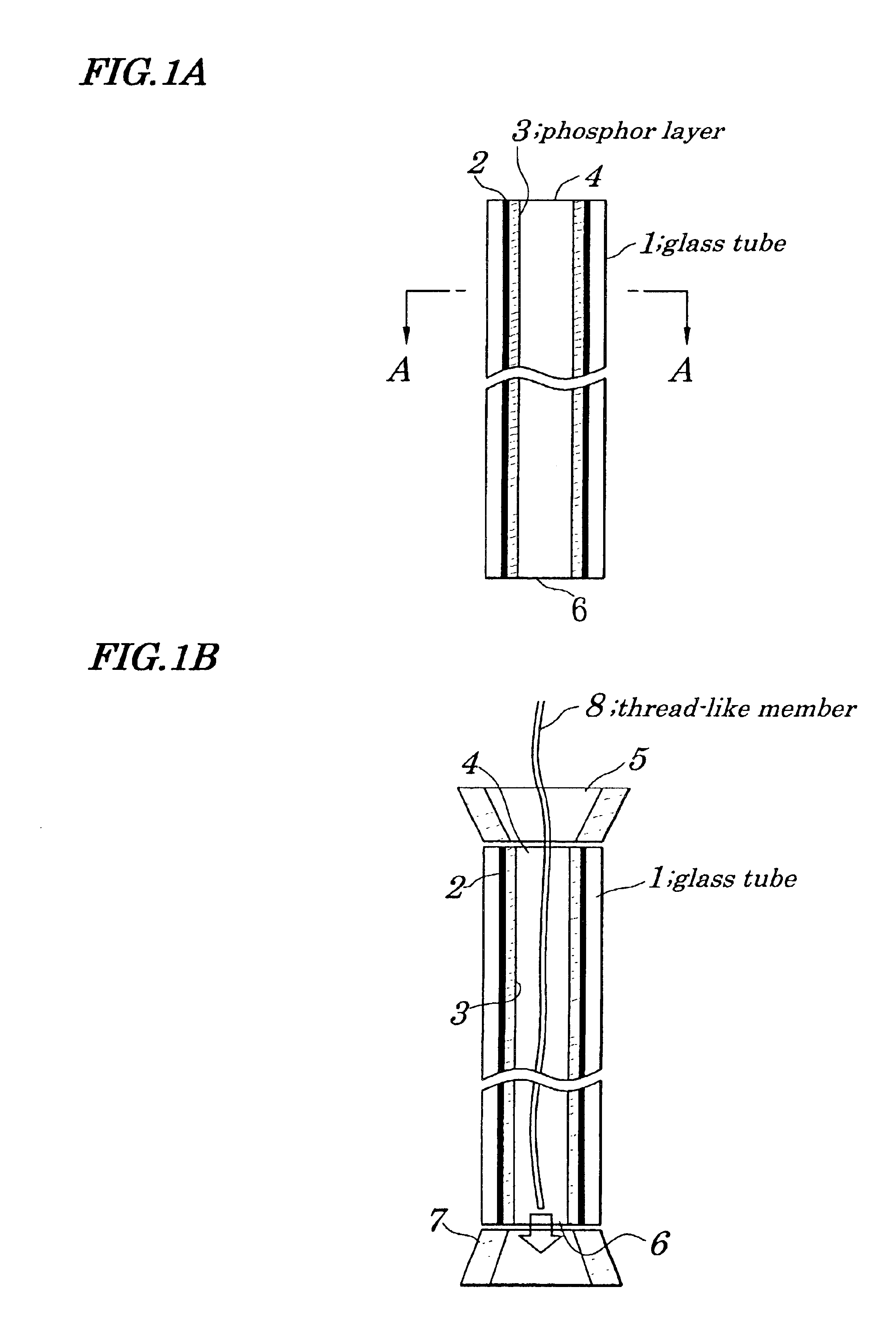

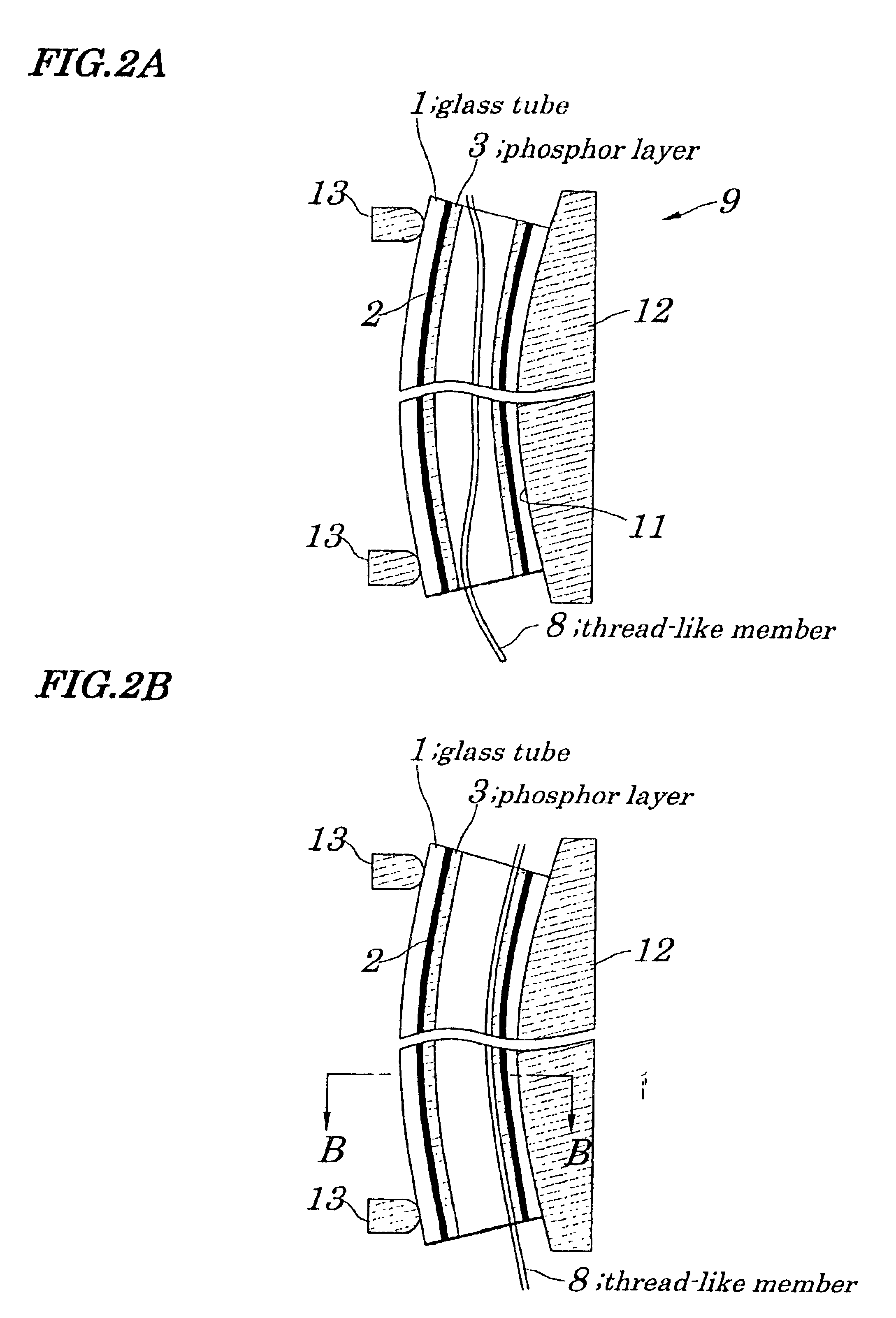

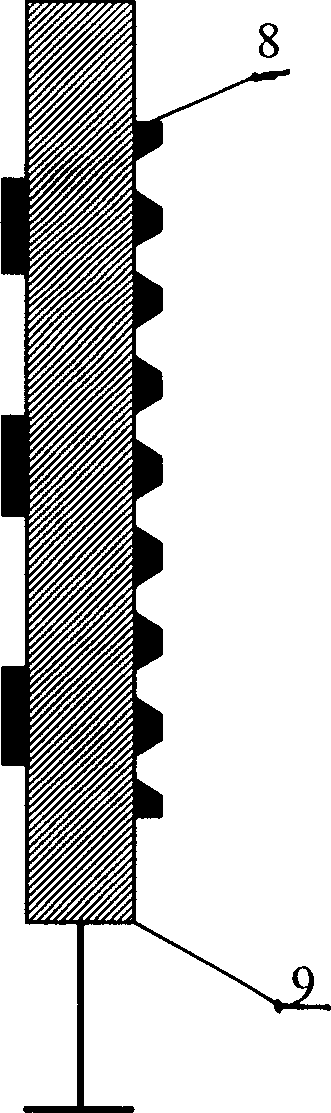

Aperture fluorescent lamp, surface illuminator, manufacturing methods thereof, liquid crystal display device, and electronic device

InactiveUS6890087B2Easy to manufactureHigh yieldMeasurement apparatus componentsElongate light sourcesLiquid-crystal displayReciprocating motion

A relatively small-diameter aperture fluorescent lamp is manufactured easily with high yield and at low cost. An aperture portion is formed in a manner that a thread-like member is inserted into a glass tube having an ultraviolet ray reflection layer and a phosphor layer formed on its inner surface, the glass tube is bent in a predetermined shape by using a bending jig, the thread-like member is pressed to the phosphor layer formed in a predetermined region in the bending member side of the glass tube while both ends thereof are pulled tight, the thread-like member is reciprocated, and phosphor of the phosphor layer in this region is exfoliated.

Owner:VISTA PEAK VENTURES LLC

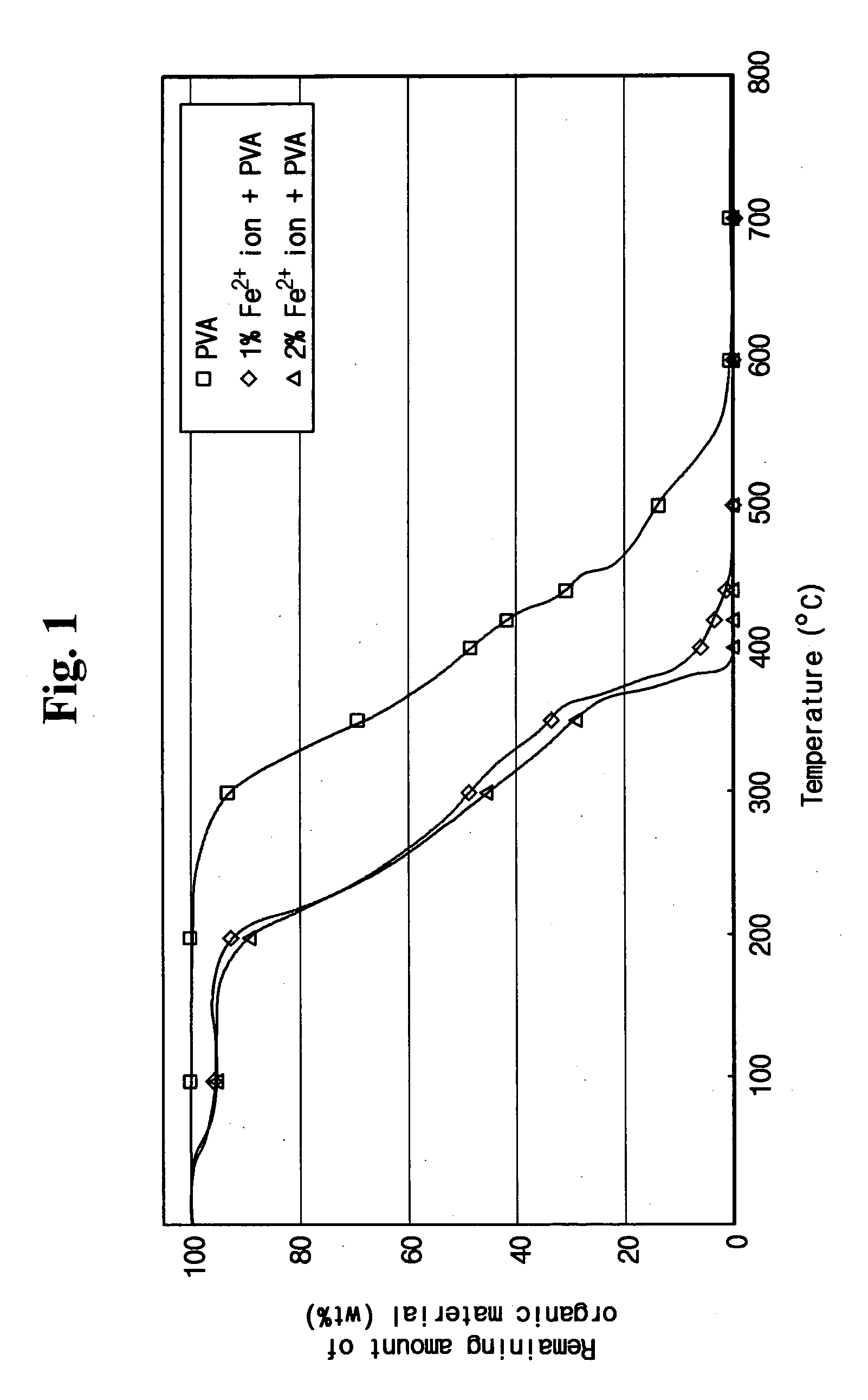

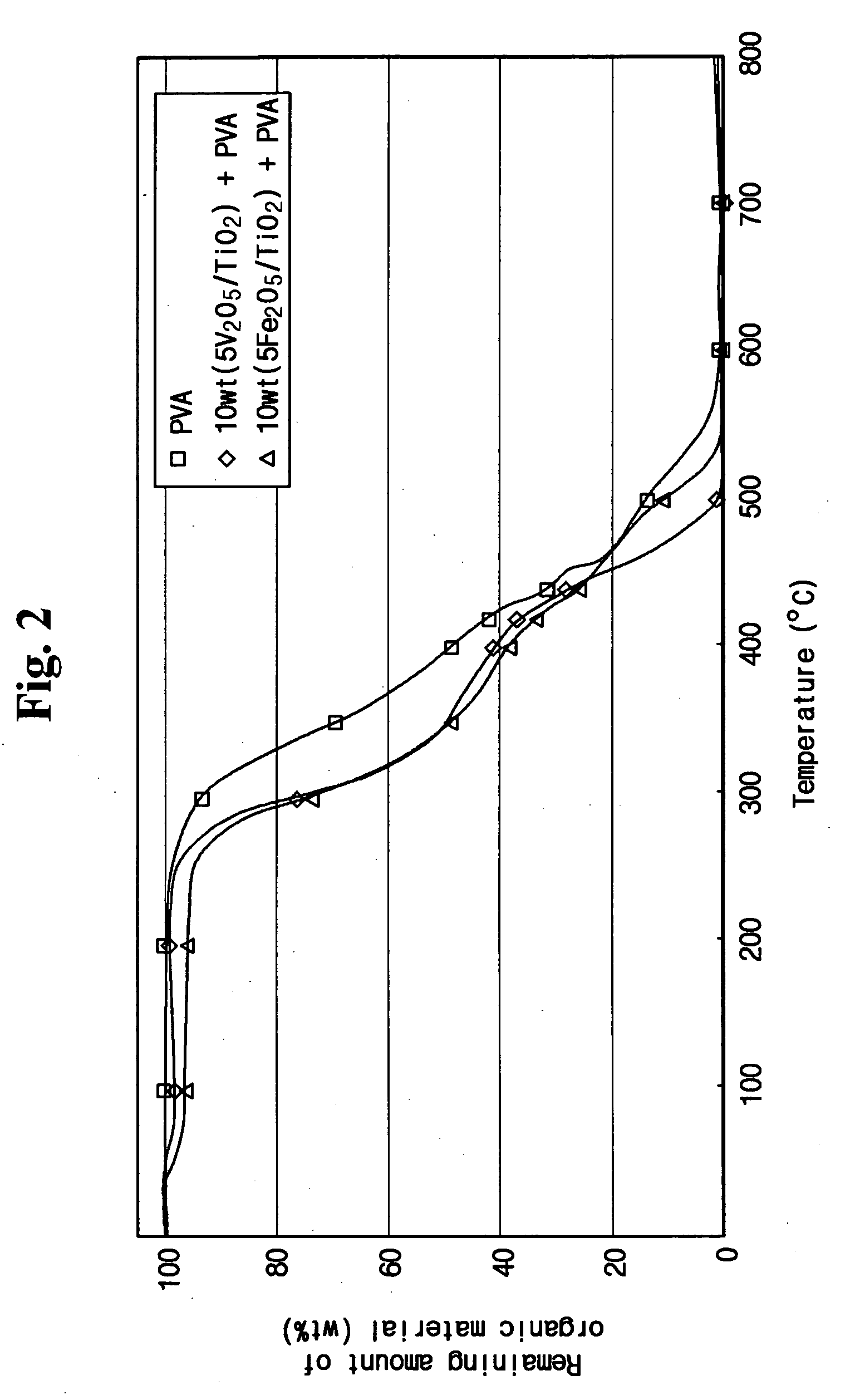

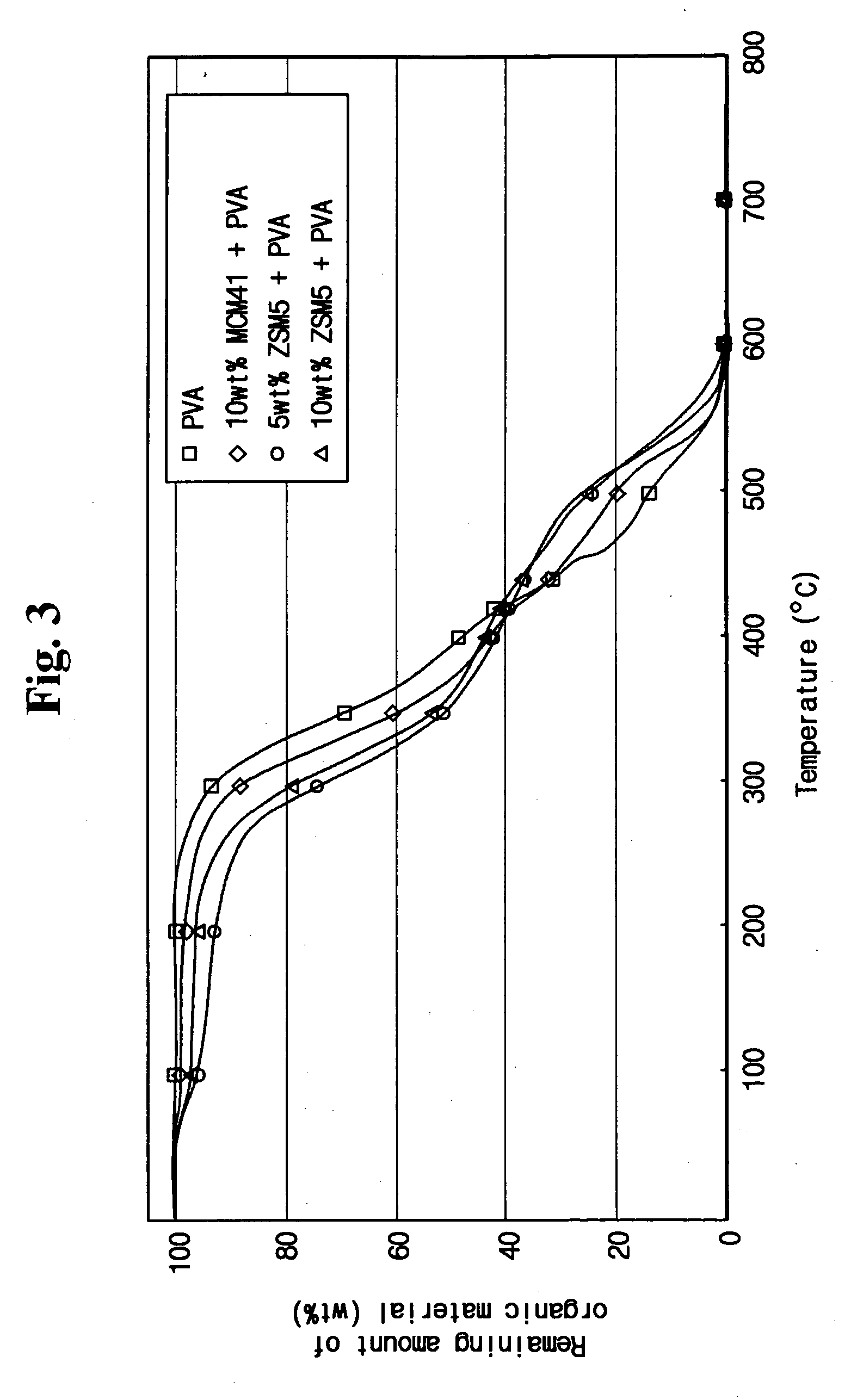

Composition of phosphor layer, display device comprising the same, and manufacturing method thereof

InactiveUS20070007876A1Lower firing temperatureEffectively pyrolyzingNanostructure manufactureX-ray/infra-red processesPhosphorFluorescence

A composition for forming a phosphor layer includes a phosphor, a binder resin, and an oxidation catalyst. The composition for forming a phosphor layer allows the lowering of a firing temperature of the phosphor layer by the catalyst activity of the oxidation catalyst and preventing deterioration of the phosphor layer or phosphor, and effectively improves the life-span and the brightness of the display device by decreasing the amount of remaining organic material.

Owner:SAMSUNG SDI CO LTD

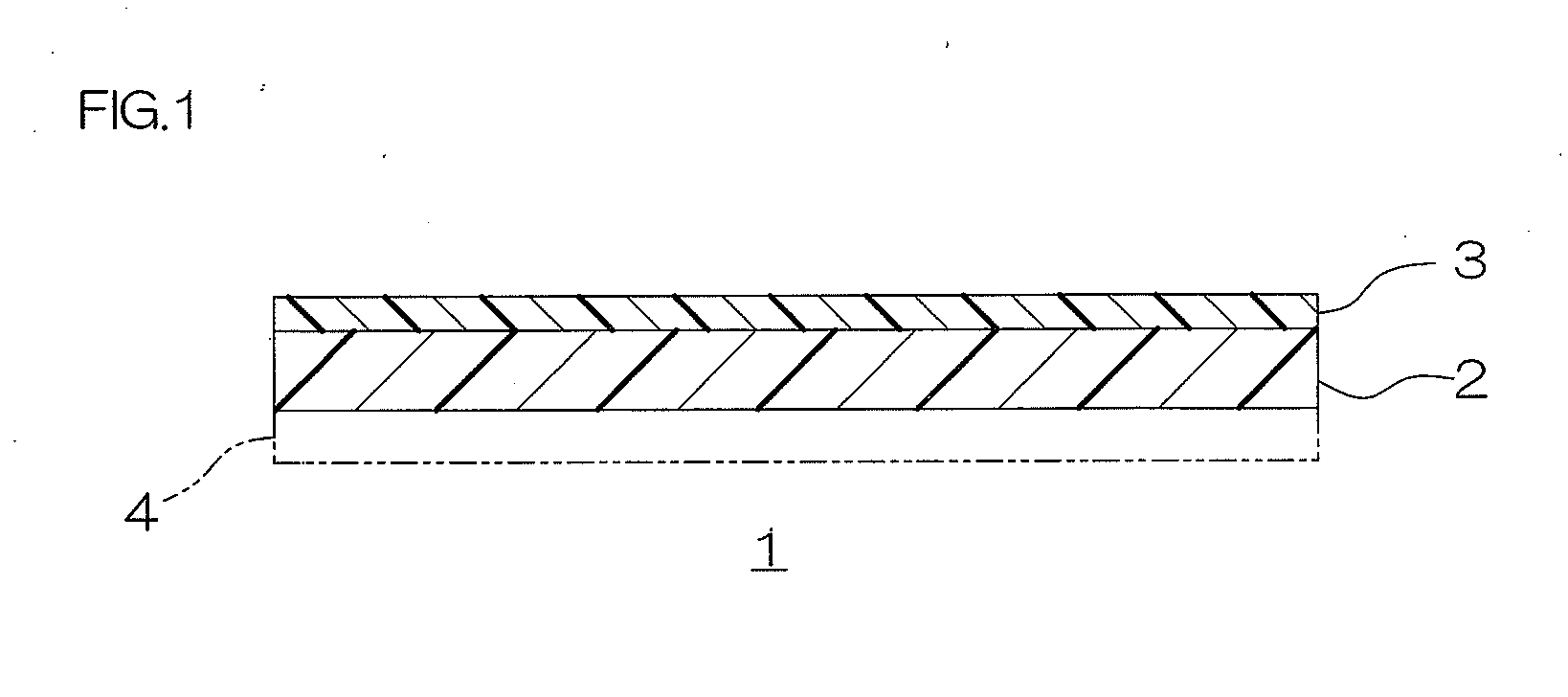

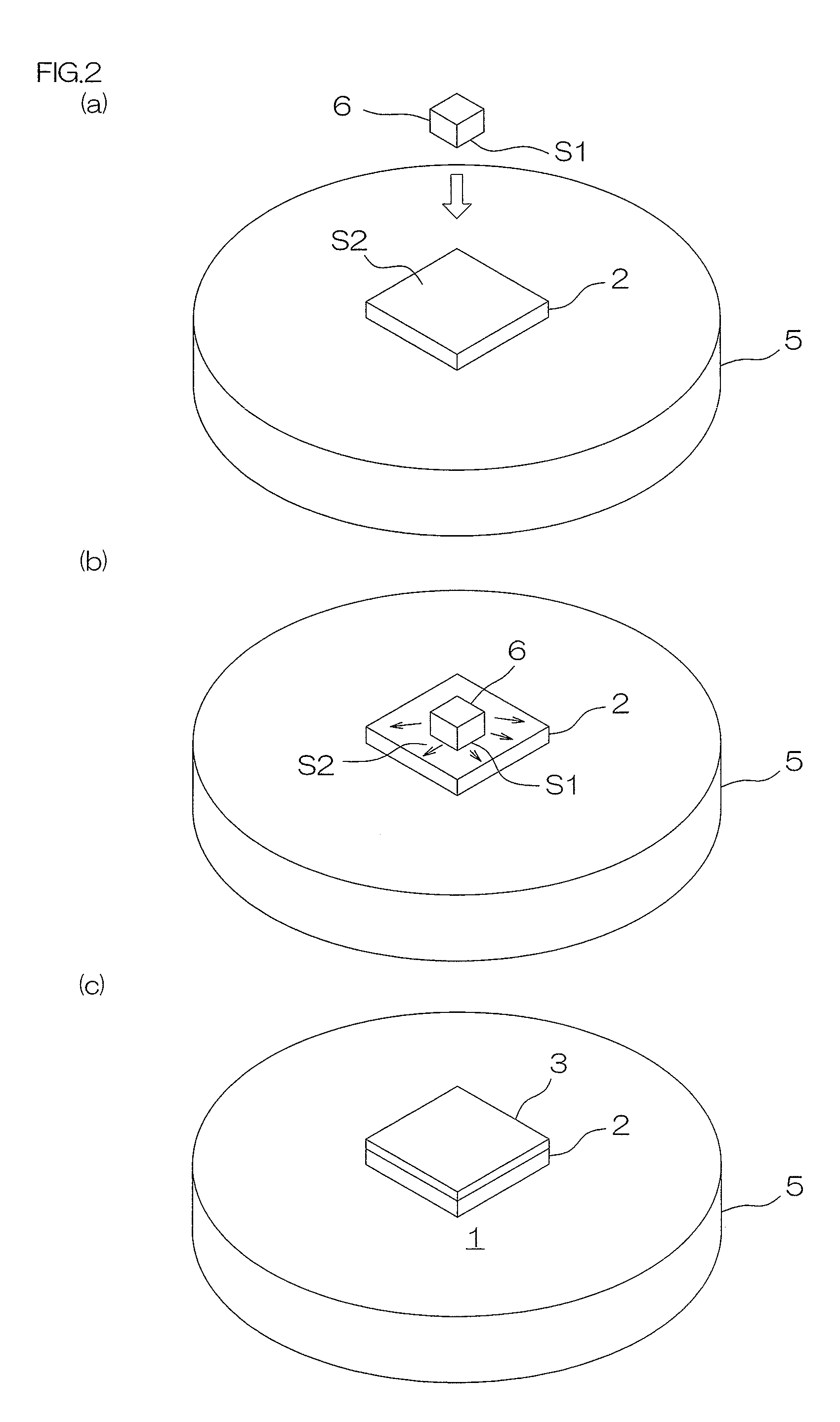

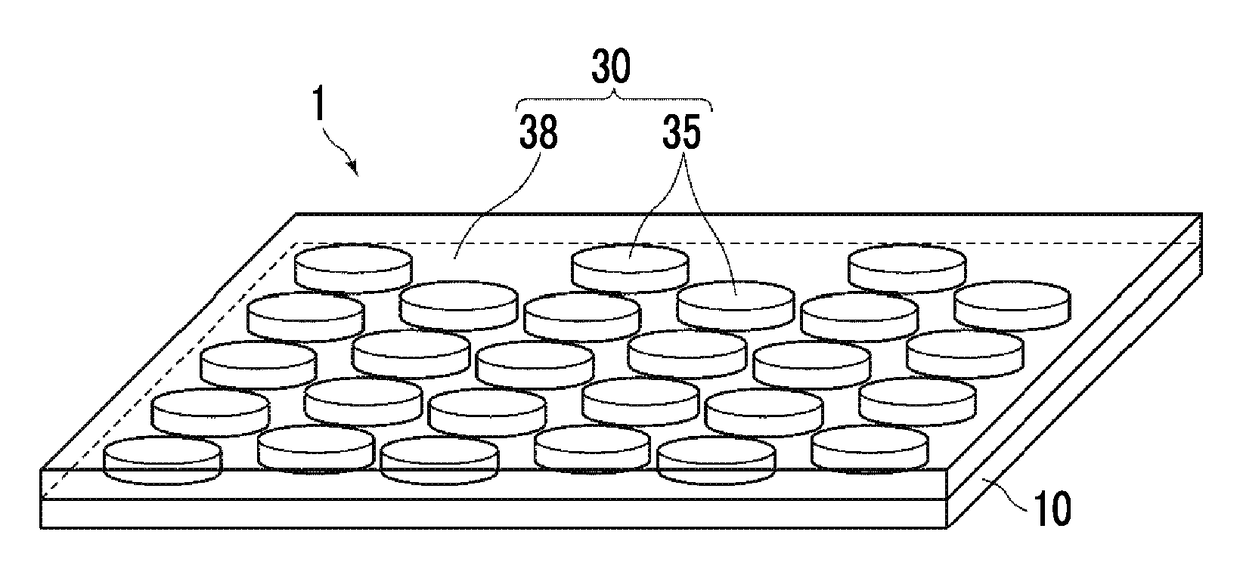

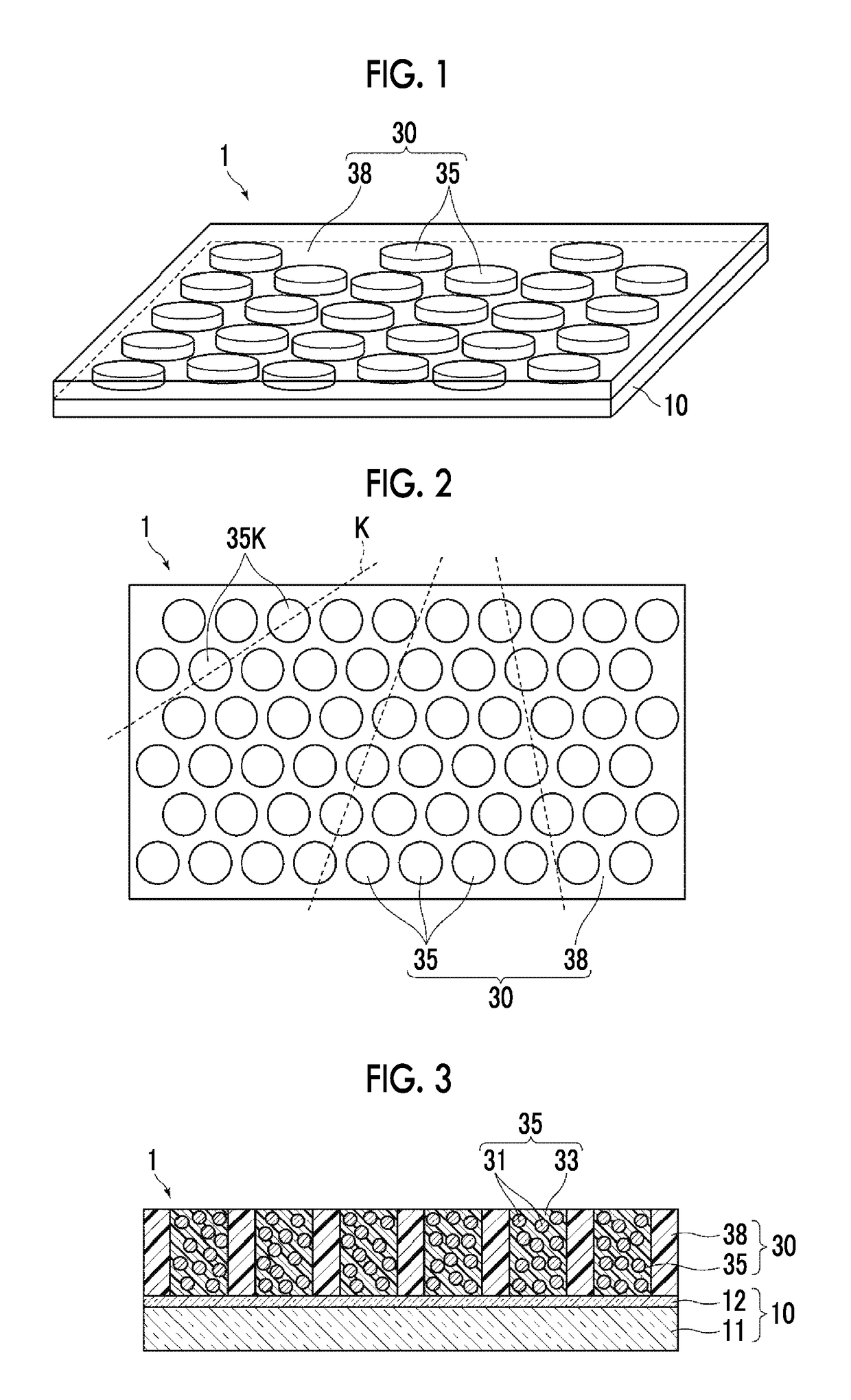

Phosphor-containing film and backlight unit

ActiveUS20180138027A1Improve production efficiencyInhibit deteriorationEngine sealsOptical filtersChemistry

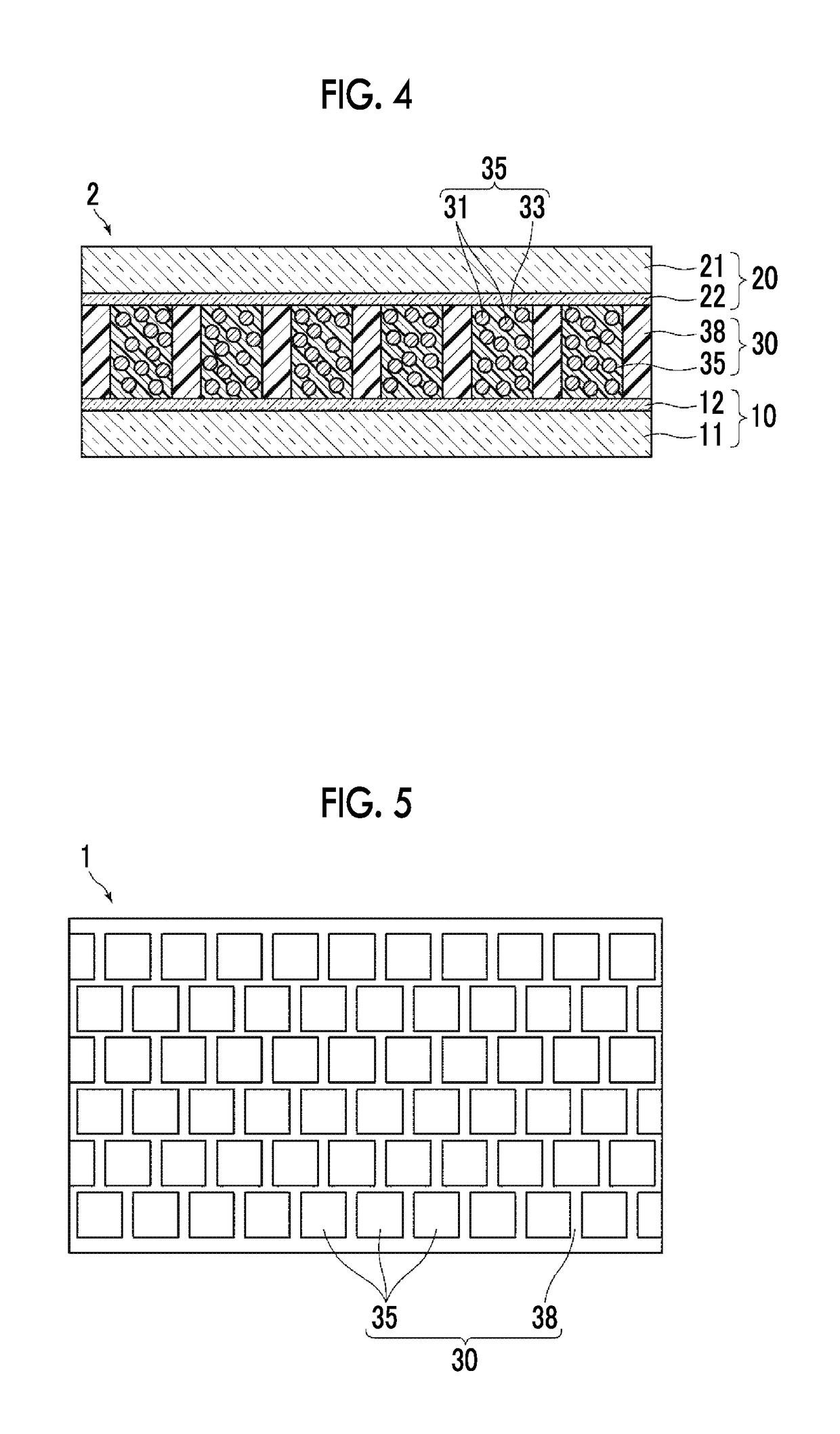

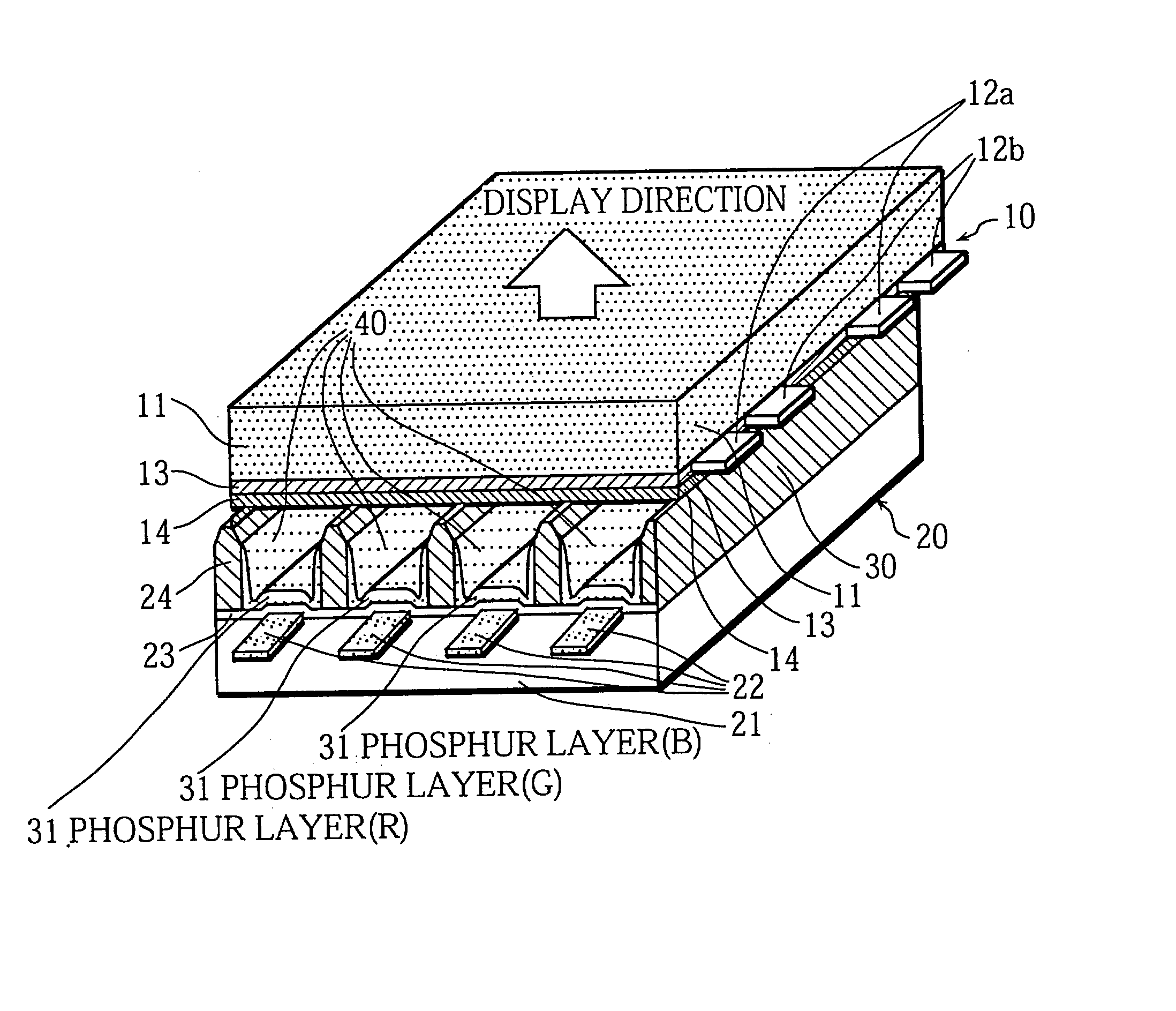

Provided are a phosphor-containing capable of suppressing deterioration of phosphors and can be manufactured with high efficiency and a backlight unit. Specifically, provided is a phosphor-containing film 1, including a first substrate film 10; and a phosphor-containing layer 30 at which a plurality of regions 35 containing phosphors 31, which, if exposed to oxygen, deteriorate by reacting with the oxygen, are discretely disposed on the first substrate film 10, and at which a resin layer 38 having an impermeability to oxygen is disposed between the discretely disposed regions 35 containing phosphors 31, in which a width S of the resin layer 38 between the regions 35 containing phosphors 31 is 0.01≤S<0.5 mm, and wherein a ratio of a volume Vp of the regions containing phosphors, to a sum of the volume Vp and a volume Vb of the resin layer in the phosphor-containing layer, is 0.1≤Vp / (Vp+Vb)<0.9.

Owner:FUJIFILM CORP

Method for fabricating superfine tube diameter fluorescent lamp tube by bending tube firstly and then coating powder

InactiveCN101038839AImprove pass rateLow costLuminescent coatings applicationCold cathode manufactureFluorescencePhosphor

A method for making an ultra-fine diameter fluorescent tube in the manner of bending first and then powdering includes a step of bending the tube and a step of powdering phosphor on the inner wall of the tube. The diameter of the tube is less than 7 mm. The step of bending the tube is executed first, and then the step of powdering phosphor on the inner wall of the tube is carried out. In the step of powdering phosphor on the inner wall of the tube, phosphor plasma is filled into the tube first, and the temperature of the phosphor plasma is limited between 10 and 15 DEG C, and then hot wind whose temperature is controlled between 100 and 130 DEG C is input into the tube having been coated with phosphor. The invention can effectively improve the qualified rate, and reduce the production cost and improve the quality of the whole tube.

Owner:陈枕流

Plasma display panel manufacturing method for manufacturing a plasma display panel with superior picture quality, a manufacturing apparatus, and a phosphor ink

InactiveUS20030148695A1Accurately and evenly produceLittle line blurringDischarge tube luminescnet screensLamp detailsEngineeringSolvent

The present invention intends to provide a manufacturing method for a PDP that can continuously apply phosphor ink for a long time and can accurately and evenly produce phosphor layers even when the cell construction is very fine. To do so, phosphor ink is continuously expelled from a nozzle while the nozzle moves relative to channels between partition walls formed on a plate so as to scan and apply phosphor ink to the channels. While doing so the path taken by the nozzle within each channel between a pair of partition walls is adjusted based on position information for the channel. When phosphor particles is successively applied to a plurality of channels, phosphor ink is continuously expelled from the nozzle even when the nozzle is positioned away from the channels. The phosphor ink is composed of: phosphor particles that have an average particle diameter of 0.5 to 5 mum; a mixed solvent in which materials selected from a group consisting of terpineol, butyl carbitol acetate, butyl carbitol, pentandiol, and limonene are mixed; and a binder that is an ethylene group polymer or ethyl cellulose containing at least 49% of ethoxy group (-OC2H5) cellulose molecules. After dispersion a charge-removing material is added to the phosphor ink.

Owner:PANASONIC CORP

Single-colour fluorescent powder spraying method for plasma display device

InactiveCN1438669AImprove color purityImprove coloring performanceLiquid surface applicatorsLuminescent coatings applicationFluorescenceMetallurgy

The method is suitable for preparing the luminescent powder applicable in plasma displays with the structure of electric grid mesh plate and the barrier type plasma displays. Based on the principle of spray coating by pressure spray guns or by static spray guns, the prepared luminescent powder pulp is spraying coated on the meshes of the inner wall of the electric grid mesh plate or the surface of the inner wall of the barrier forming the monochromatic luminescent powder layer. Comparing with the prior art, the invention possesses the features of simple equipment, high efficiency and good chromatic purity etc.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com