Patents

Literature

509 results about "Dual curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dual Curing Systems by Master Bond. Master Bond's dual curing compounds cure both upon exposure to UV light and heat. These adhesives, sealants, and coatings are applied to assemblies where complete UV curing is difficult or impossible to achieve, such as applications with complex geometries and concealed areas.

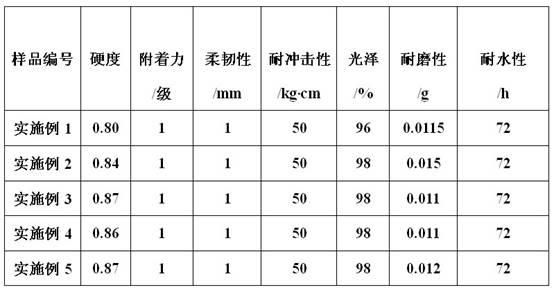

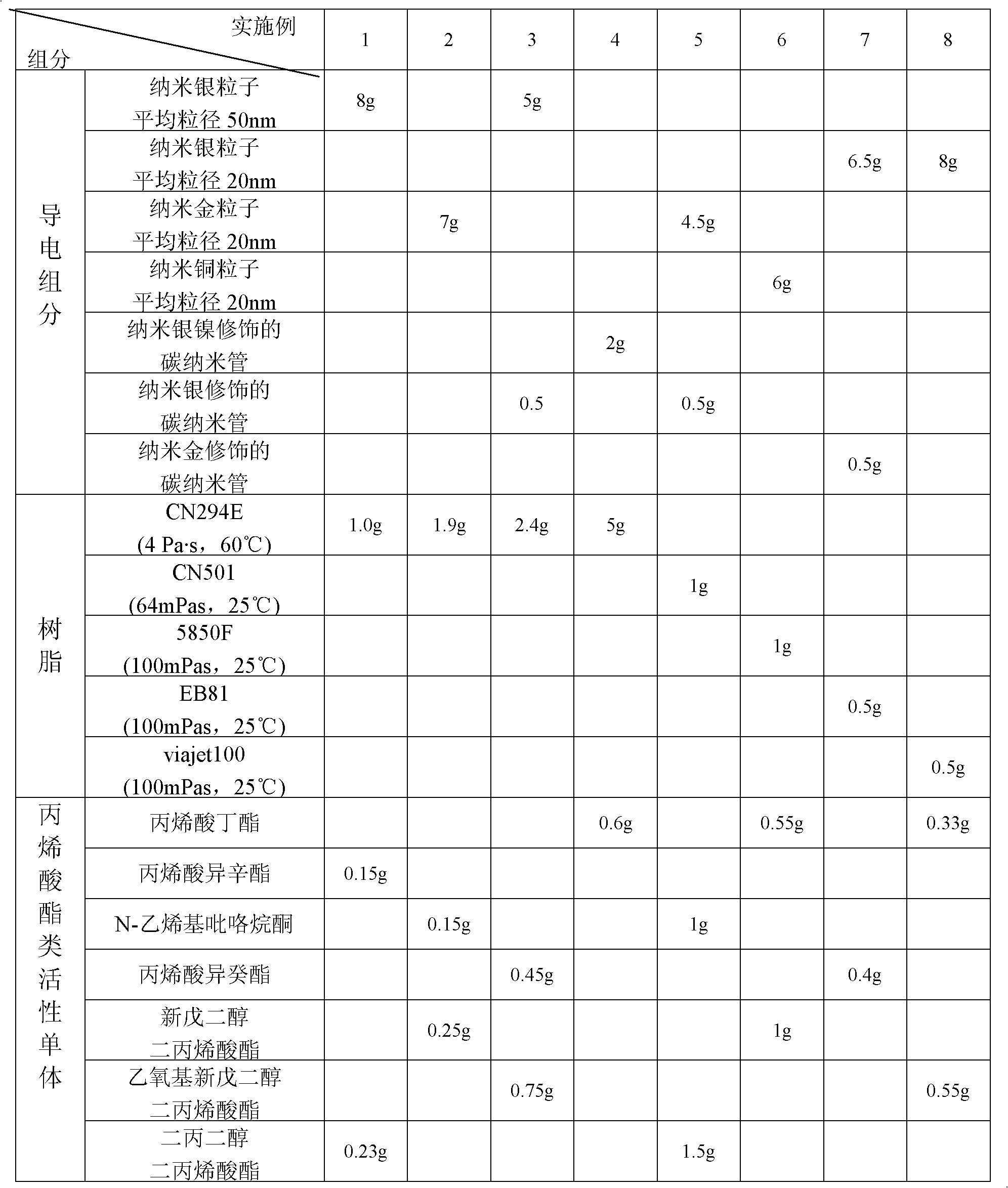

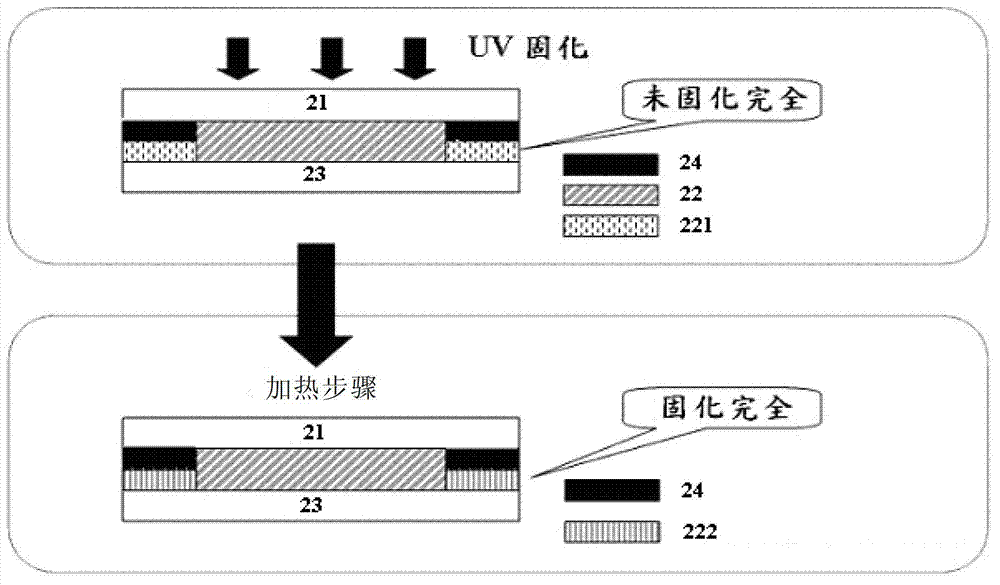

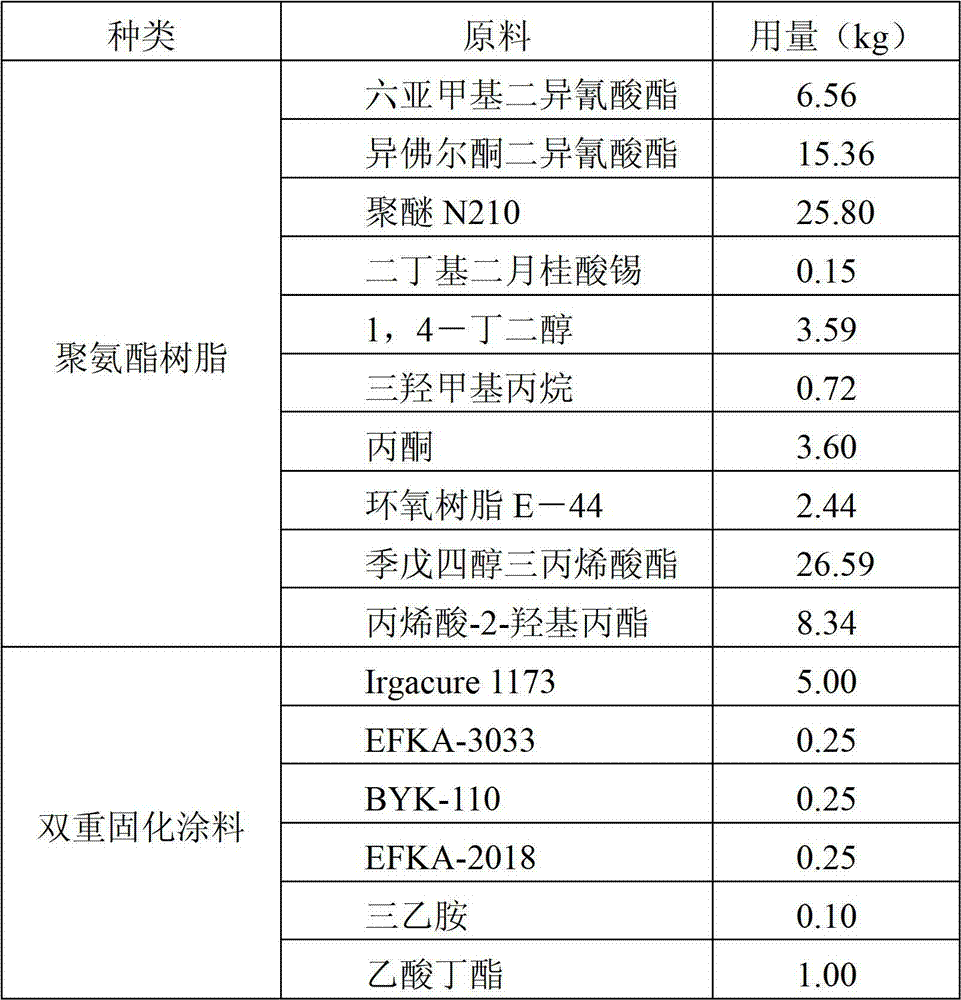

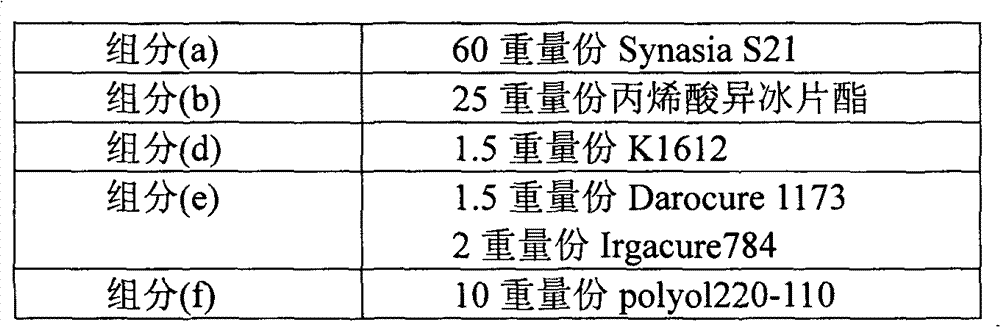

Dual-curing coating and preparation method thereof

InactiveCN102181192ACuring shrinkage is smallIncrease crosslink densityCoatingsInformation layerCoating system

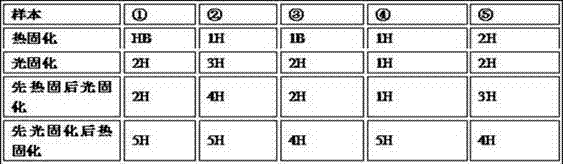

The invention discloses a dual-curing coating. The coating contains ultraviolet curing resin monomers, a low polymer, a photo-initiator, polymer resins, an adjuvant and an organic solvent. In the invention, the dual-curing coating is prepared by synergistic copolymerization of an ultraviolet curing coating system and a solvent-based polymer system. The preparation method of the coating comprises the following steps: firstly thermocuring, and then processing information layers and photocuring at the same time; or firstly photocuring, then processing the information layers, and finally heating with an oven or infrared-heating for further cross-linking curing. Therefore, the dual-curing coating has better comprehensive performances such as fast curing speed, small film-coating cure shrinkage and high crosslinking density so as to achieve the characteristics of chemical corrosion resistance, strong wear resistance, strong high temperature resistance, excellent flexibitity, excellent adhesive force and the like; and the coating can be used for laser anti-counterfeit marks of plastics, cosmetic preparations, ceramic materials, glass, paper, leather, wooden products and metal products as well as production of pigment preparations and the like.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

Epoxy compositions with improved mechanical performance

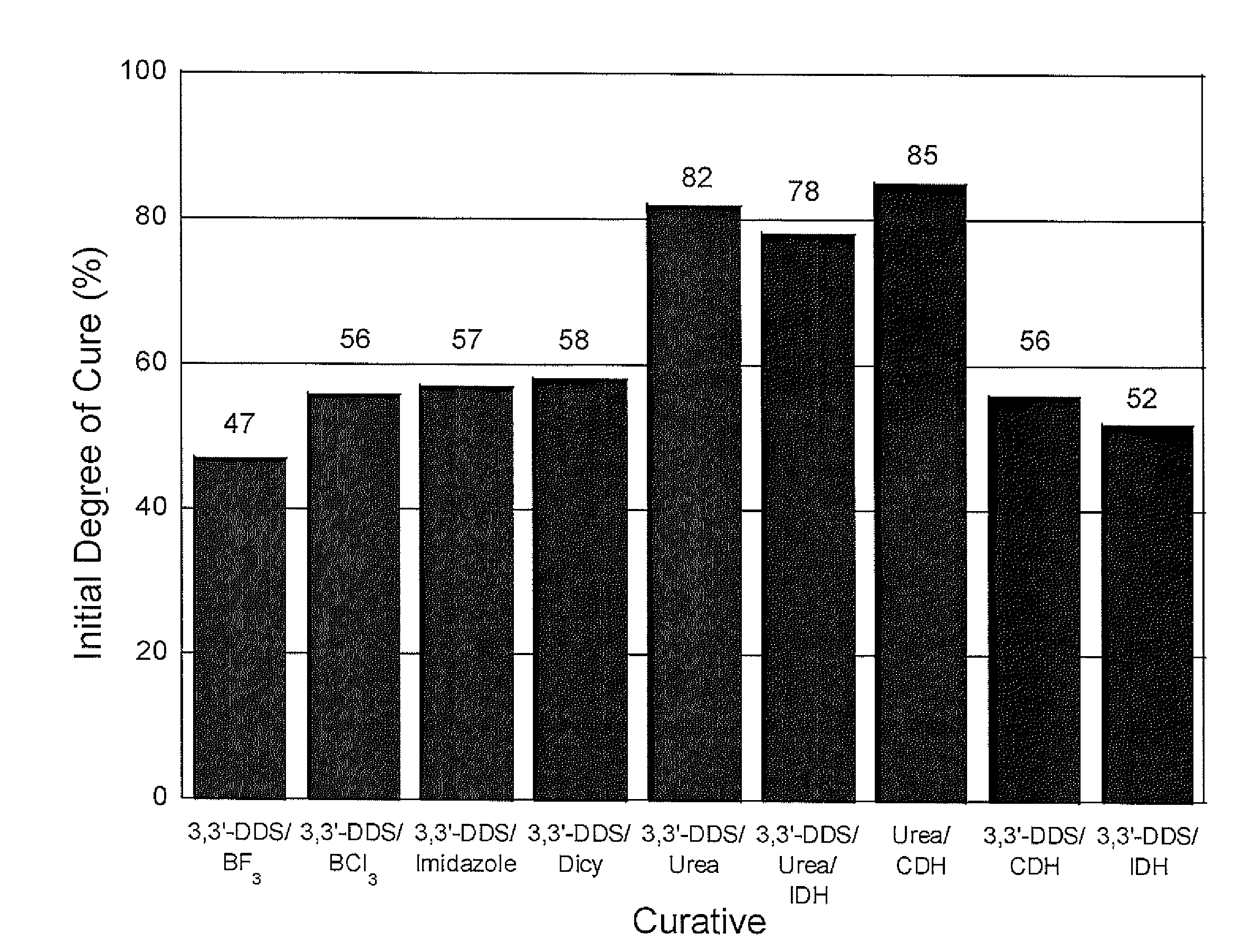

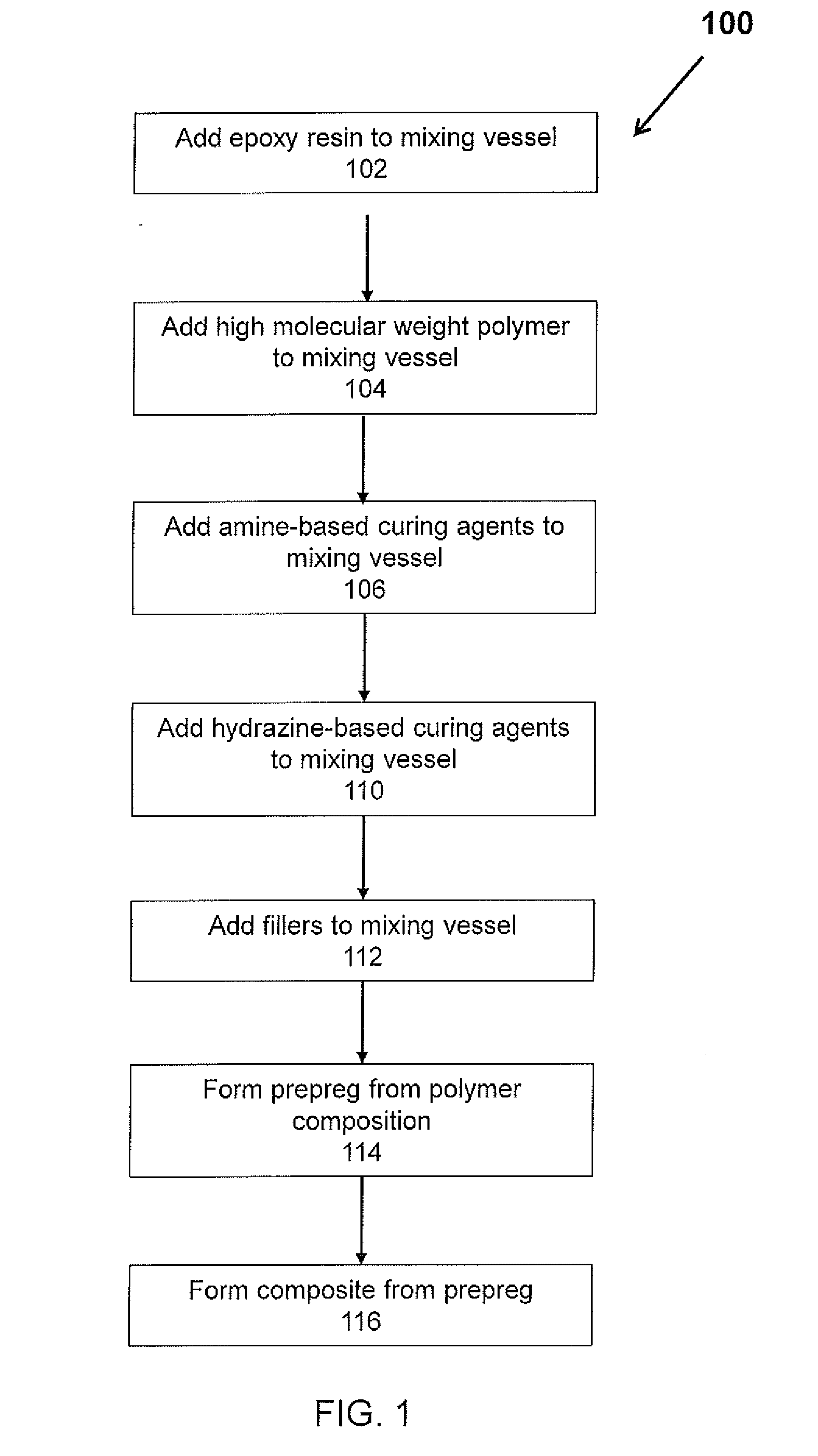

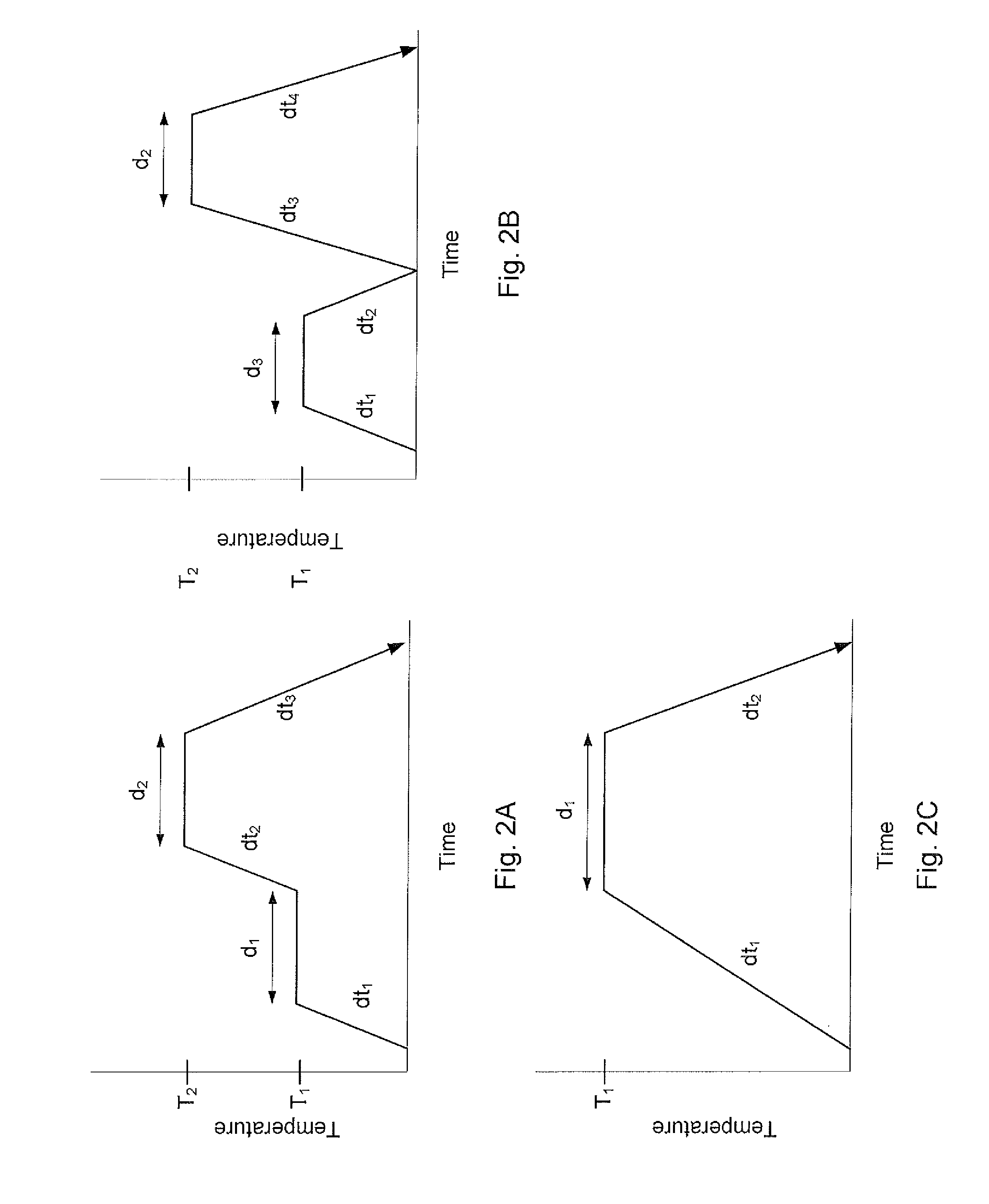

Polymer compositions capable of a high degree of curing at relatively low temperatures, and prepregs, adhesives, films and composites formed therefrom are discussed. The polymer compositions include epoxy resin systems and a dual curing system including one or more curing agents containing one or more hydrazine-based curing agents having hydrazine functional groups and one or more amine-based curing agents containing one or more amine functional groups. The hydrazine-amine curing systems enable the polymer composition to achieve elevated levels of gelation or degree of cure at lower temperatures than are achievable with amine functional curing agents alone. Furthermore, this elevated degree of curing of the polymer composition may be achieved with substantially no reduction in tack life and / or out life of the prepreg, adhesive or film or cured state mechanical properties of composites, adhesives or other products fabricated therefrom, such as open hole compression strength and compressive strength after impact. The glass transition temperature of the cured polymer compositions is similarly unaffected.

Owner:CYTEC TECH CORP

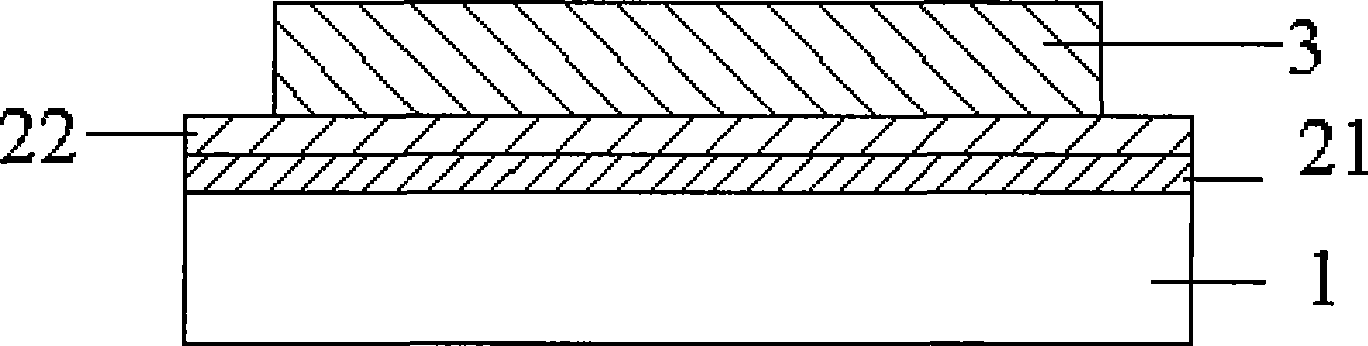

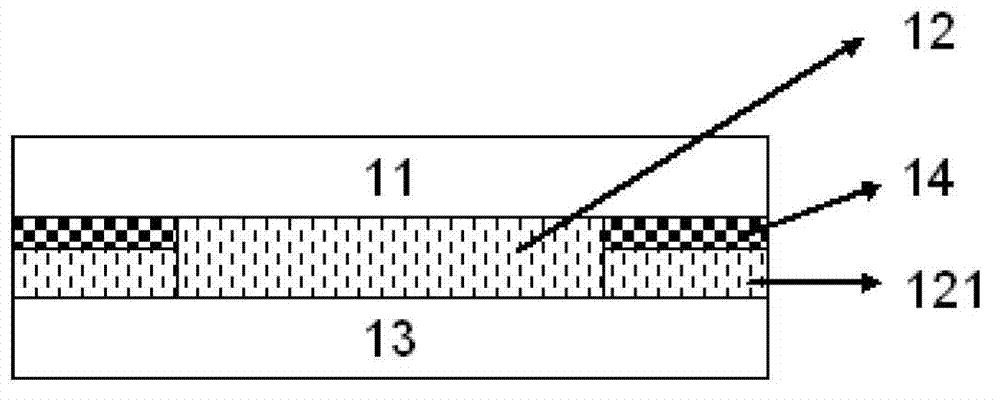

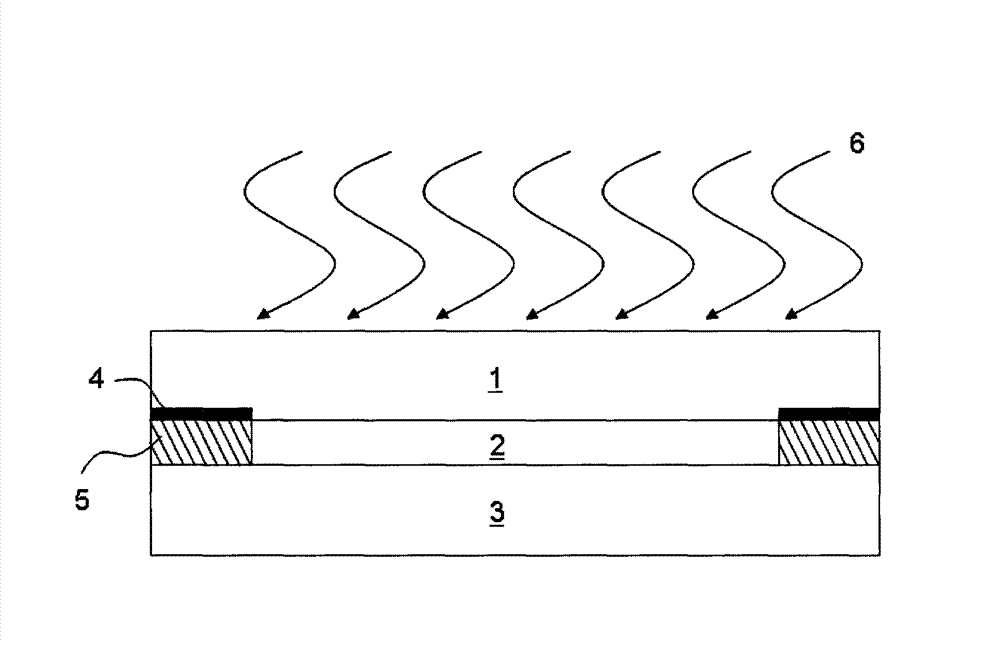

Substrate for flexible organic optoelectronic device and preparation method thereof

InactiveCN101465409AImprove flatnessImprove adhesionSolid-state devicesSemiconductor/solid-state device manufacturingUV curingAdhesive

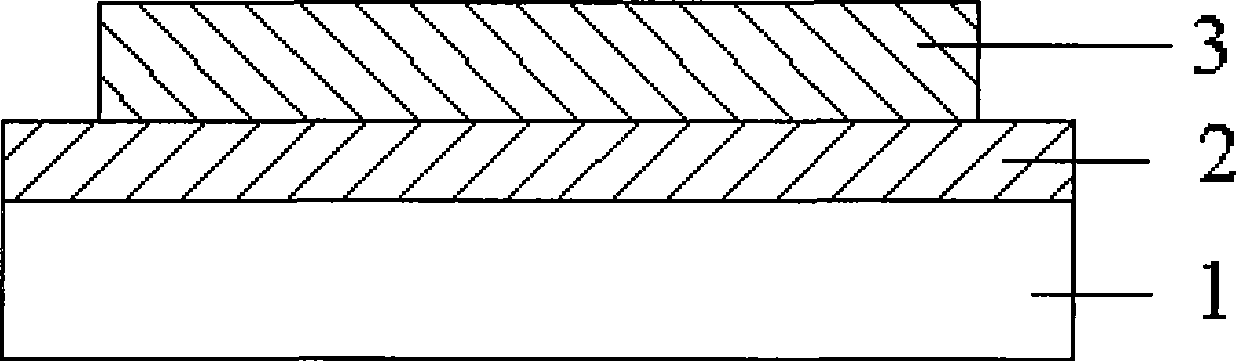

The invention discloses a flexible substrate used for optoelectronic devices and comprises a flexible substrate; the invention is characterized in that a bonding layer and a conductive thin film are arranged on the surface of the flexible substrate; the conductive thin film is deposited on the surface of the bonding layer; and the material of the bonding layer is an adhesive with a double-curing system comprising UV curing-thermal curing or UV curing-microwave curing or UV curing-anaerobic curing or UV curing-electron beam curing. The substrate solves the problem of poor adhesion between the deposited conductive thin film and the substrate due to low surface energy of the flexible substrate and improves the barrier properties of the substrate on water and oxygen, and also achieves good smoothing effect on the surface of the substrate; besides, the preparation method is simple and effective, which can significantly reduce the substrate production cost and process difficulty and increase the substrate yield rate in the etching process.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

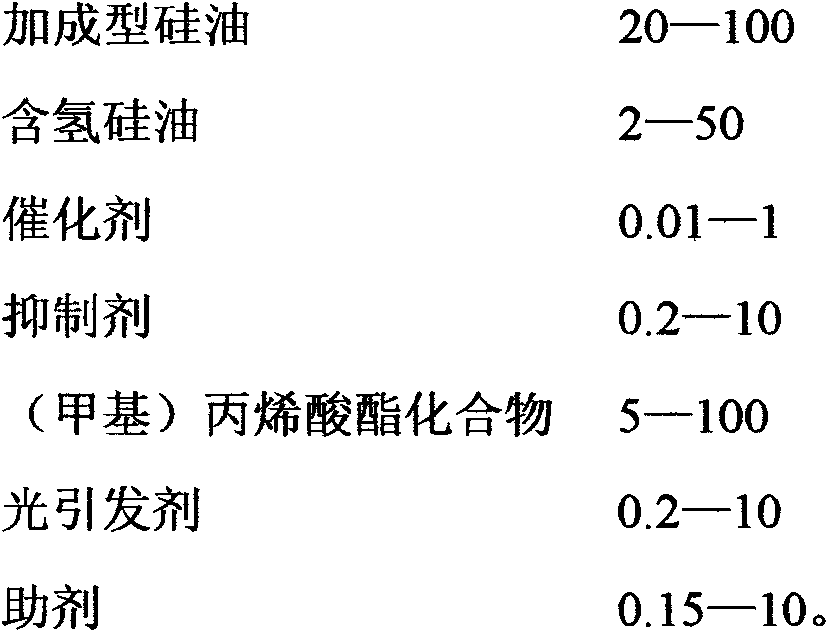

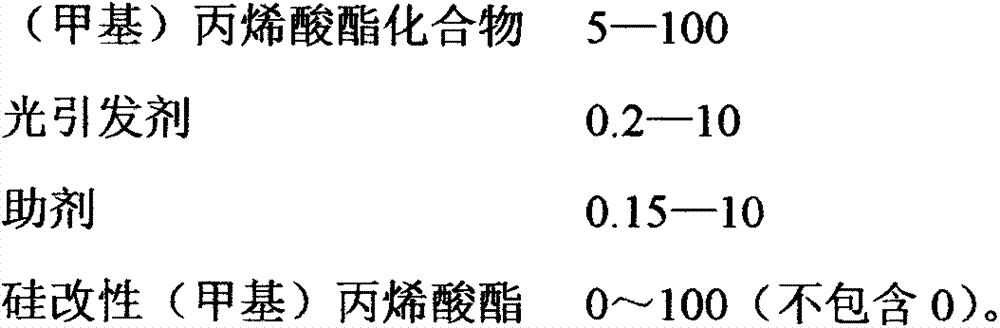

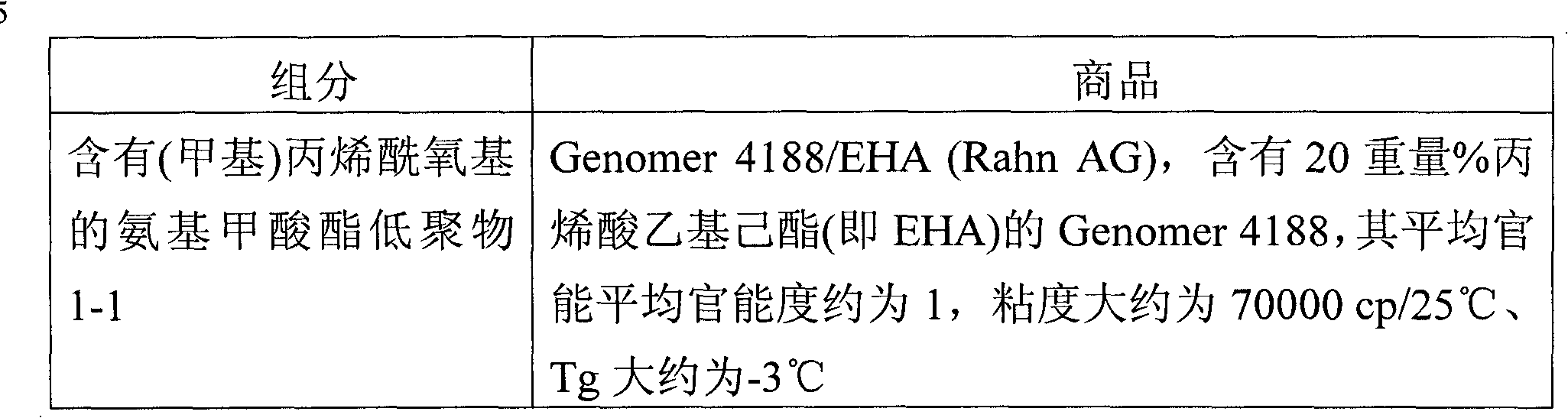

Dual-curing composition

The invention discloses a dual-curing composition which comprises addition type silicone oil, hydrogen-containing silicone oil, an inhibitor, a catalyst, a (methyl) acrylic ester compound, a light initiator and an auxiliary, and selectively comprises silicon modified (methyl) acrylic ester, a filler, a reinforced silica resin and a solvent. Due to adoption of the composition disclosed by the invention, dual-curing of heating and ultraviolet light can be conveniently achieved, materials of different properties such as rubber and plastics can be prepared, and materials with different physical characteristics and different color effects can be prepared.

Owner:甘春丽 +1

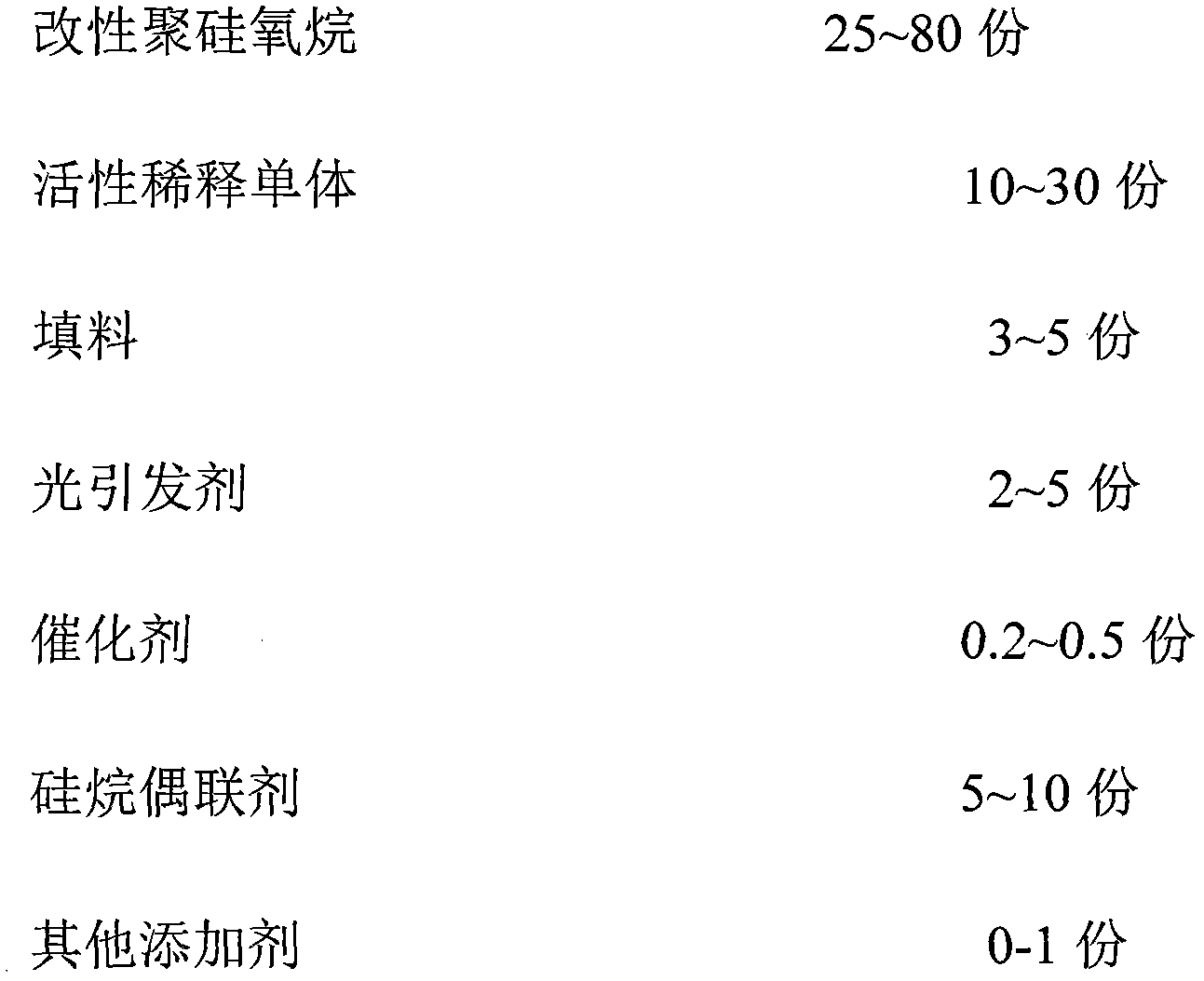

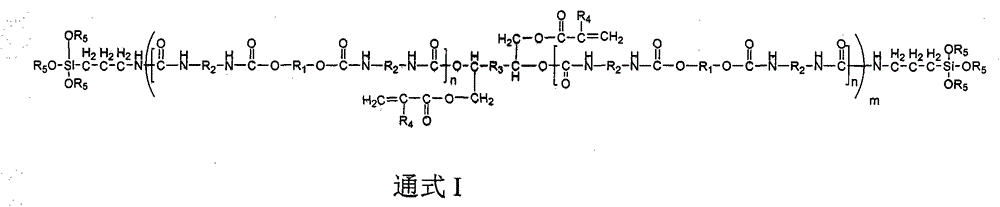

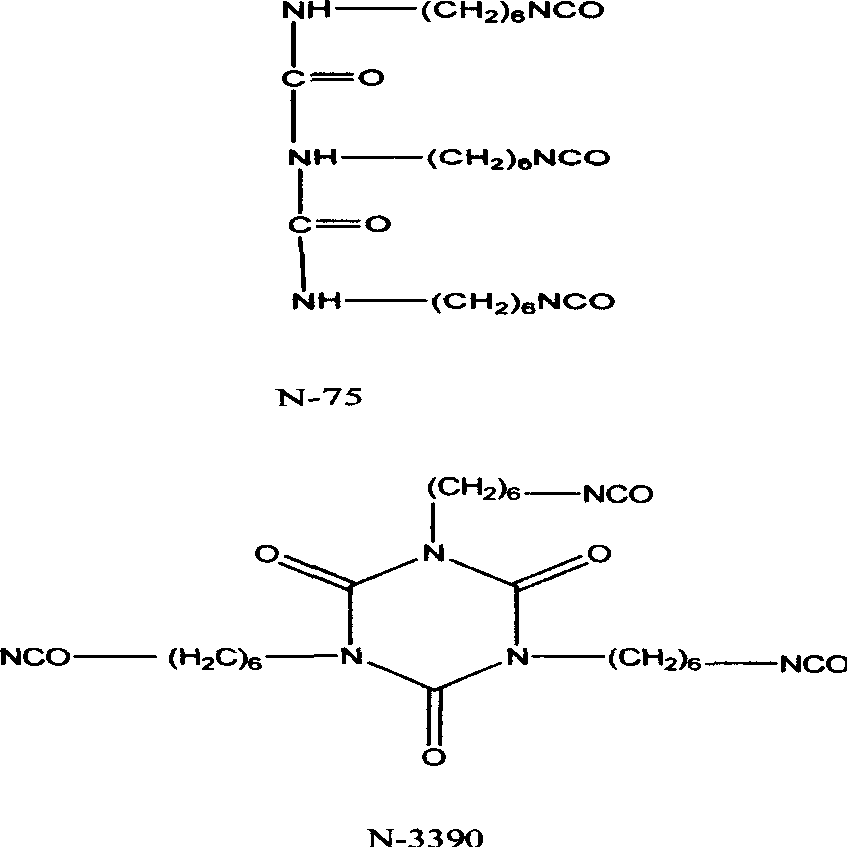

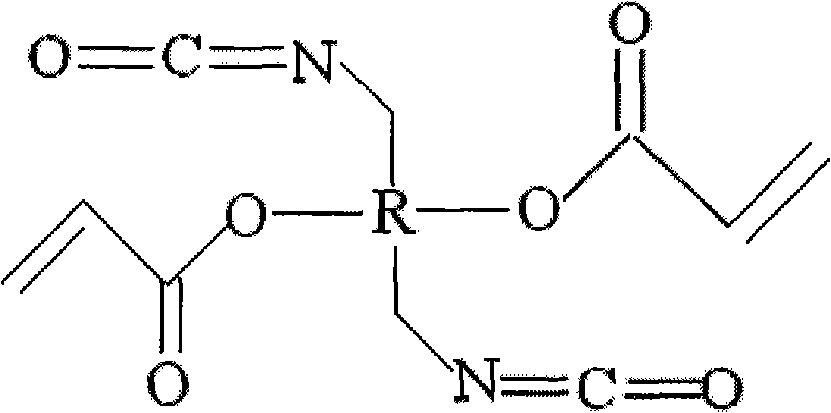

Siloxane modified urethane acrylate hyperbranched oligomer and preparation method thereof and multi-curing coating obtained therefrom

InactiveCN101665561AReduce viscosityCompletely curedPolyurea/polyurethane coatingsPolyesterAminosilochrome

The invention discloses a siloxane modified urethane acrylate hyperbranched oligomer and a preparation method thereof and a multi-curing coating obtained therefrom. The siloxane modified urethane acrylate hyperbranched oligomer is short for Si-PUA aligomer and the weight percentage composition thereof is as follows: 20 wt percent to 50 wt percent of vulcabond, 5 wt percent to 40 wt percent of polylol, 20 wt percent to 50 wt percent of hydroxyl acrylate, 1 wt percent to 20 wt percent of heperbranched polyester, 0.5 wt percent to 10 wt percent of diamino siloxane, 0.001 wt percent to 1 wt percent of catalyst, 0.001 wt percent to 1 wt percent of inhibitor and 5 wt percent to 50 wt percent of reactive diluent. The multi-curing coating containing such Si-PUA aligomer can not only realize ultraviolet light-heat dual curing but also realize moisture curing, thus improving the hardness and enhancing adhesive force of the film thereof and having better properties of water resistance, chemical agent resistance and friction resistance.

Owner:恒昌涂料(惠阳)有限公司 +1

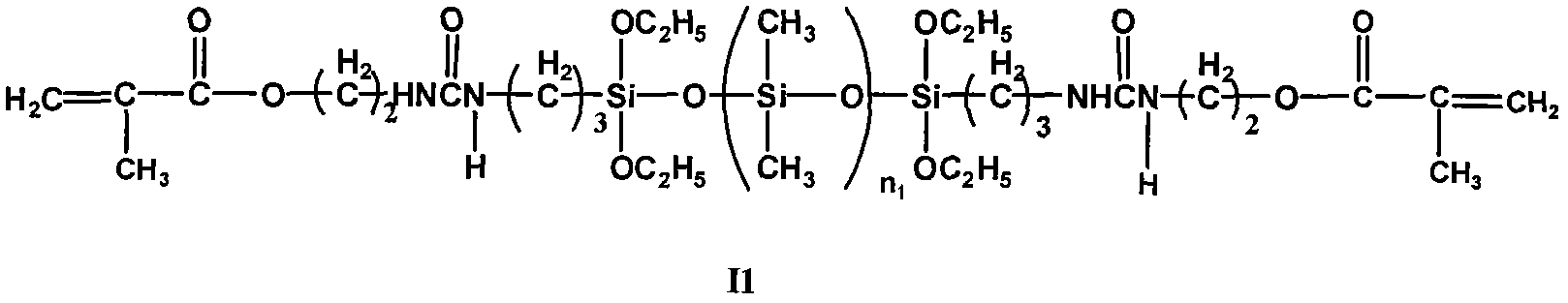

Polysiloxane with UV (Ultraviolet) and moisture double curing groups and preparation method thereof

InactiveCN103923321AThe synthesis method is simpleLow costCoatingsAdhesivesUltravioletReaction intermediate

The invention discloses polysiloxane with UV (Ultraviolet) and moisture double curing groups and a preparation method thereof. The polysiloxane is prepared by the following steps: mixing hydroxyl silicone oil with a silane coupling agent containing amido and carrying out a reaction to generate an intermediate; and then, adding an acrylic monomer containing isocyanate into the reaction intermediate and mixing and reacting to obtain the polysiloxane. The modified polysiloxane synthetic method disclosed by the invention is simple and low in cost, has the characteristics of quick curing and high efficiency, avoids the defect that the dash area or the bottom layer cannot be cured, and has the characteristics of excellent performances and photocuring technology of the organosilicon material. The modified polysiloxane can be applied to the field of binders, film coatings and encapsulating materials.

Owner:TONSAN ADHESIVES INC

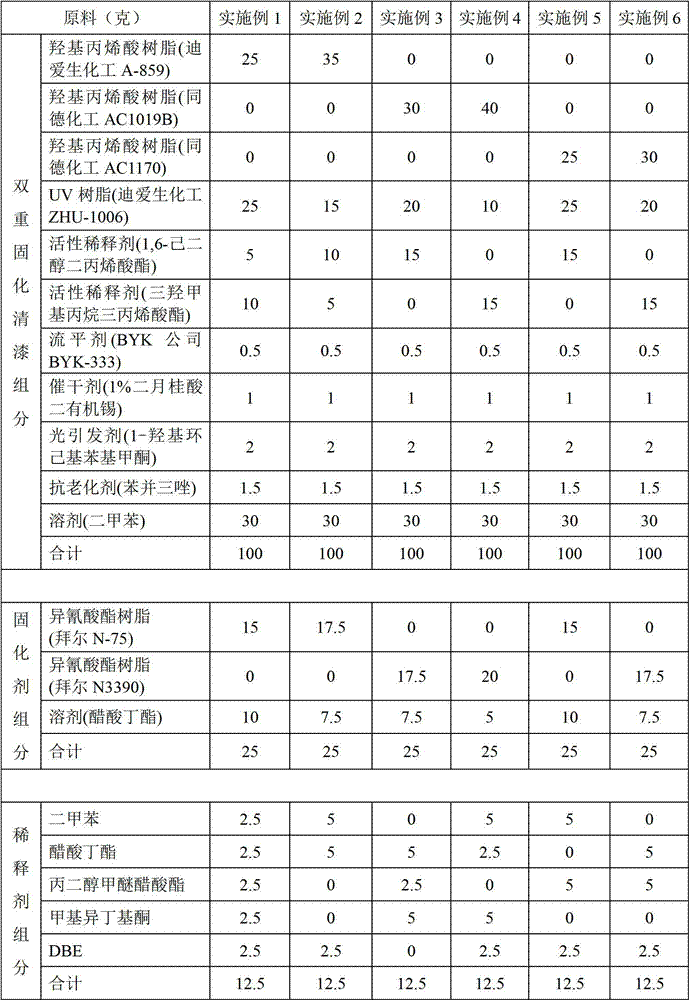

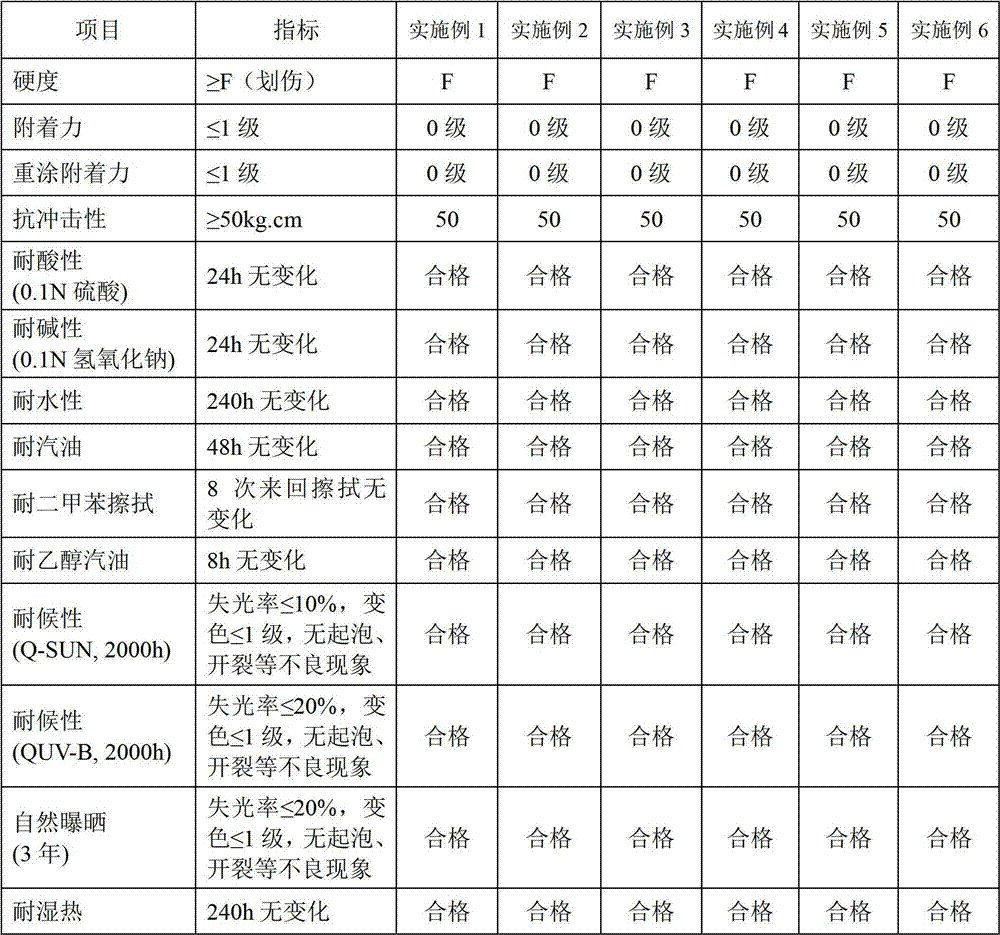

Double-curing varnish paint

The invention discloses a double-curing varnish paint which is prepared from the following components in parts by mass: 3-6 parts of double-curing varnish, 1 part of curing agent and 0.5-1 part of diluter. The double-curing varnish comprises the following components in percentage by mass: 10-60% of hydroxy acrylic resin, 10-30% of UV (ultraviolet) resin, 1-30% of active diluter, 0.5-4% of photoinitiator, 1-3% of antiaging agent, 1-3% of leveling agent, 1-3% of drying agent and 10-30% of solvent. The double-curing varnish paint uses the free-radical polymerization-polycondensation curing system; under the irradiation of UV, the UV resin in the double-curing varnish forms free-radical polymerization under the action of the photoinitiator, and the -OH group contained in the hydroxy acrylic resin in the double-curing varnish and the -NCO group contained in the isocyanate resin in the curing agent are subjected to addition polymerization under the action of heat energy; and the polymers formed by the two polymerization reactions become an mutually-wound endosmosis network structure, thereby enhancing the weather resistance and chemical corrosion resistance of the paint film.

Owner:中山大桥化工企业集团中山智亨实业发展有限公司

Dual cure compositions, methods of curing thereof and articles therefrom

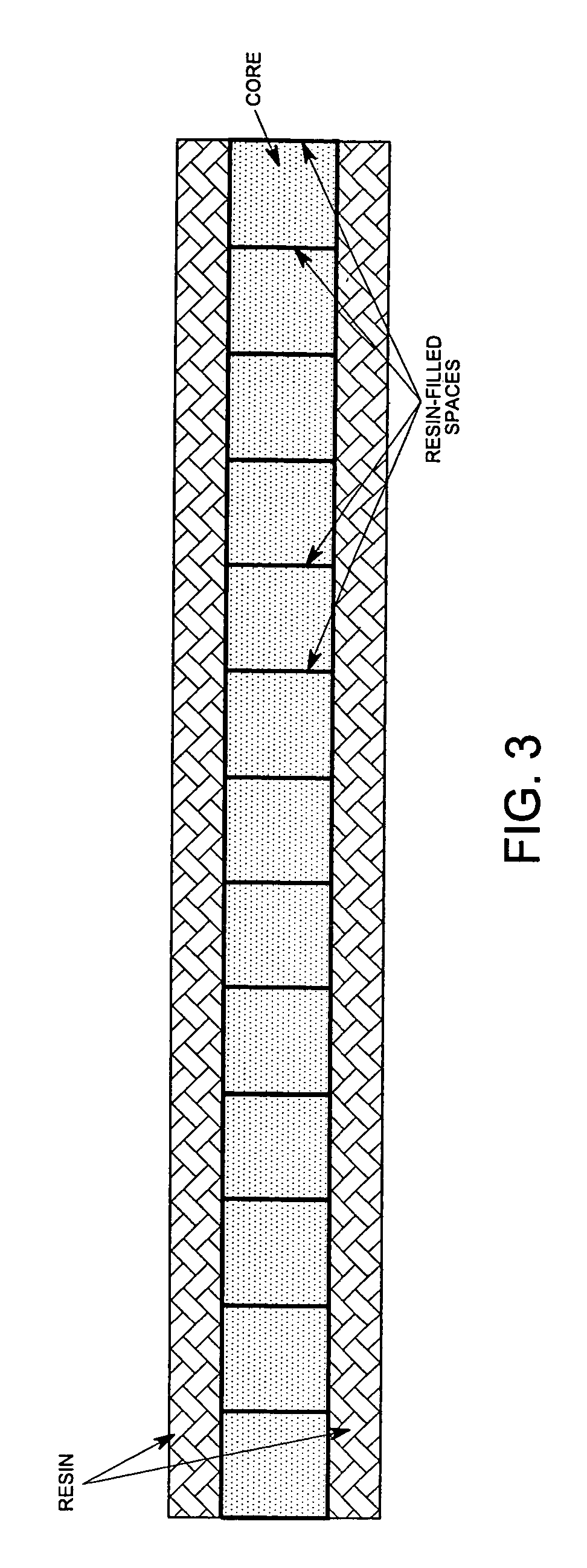

InactiveUS20070066698A1Synthetic resin layered productsGlass/slag layered productsPolymer scienceCyclic ether

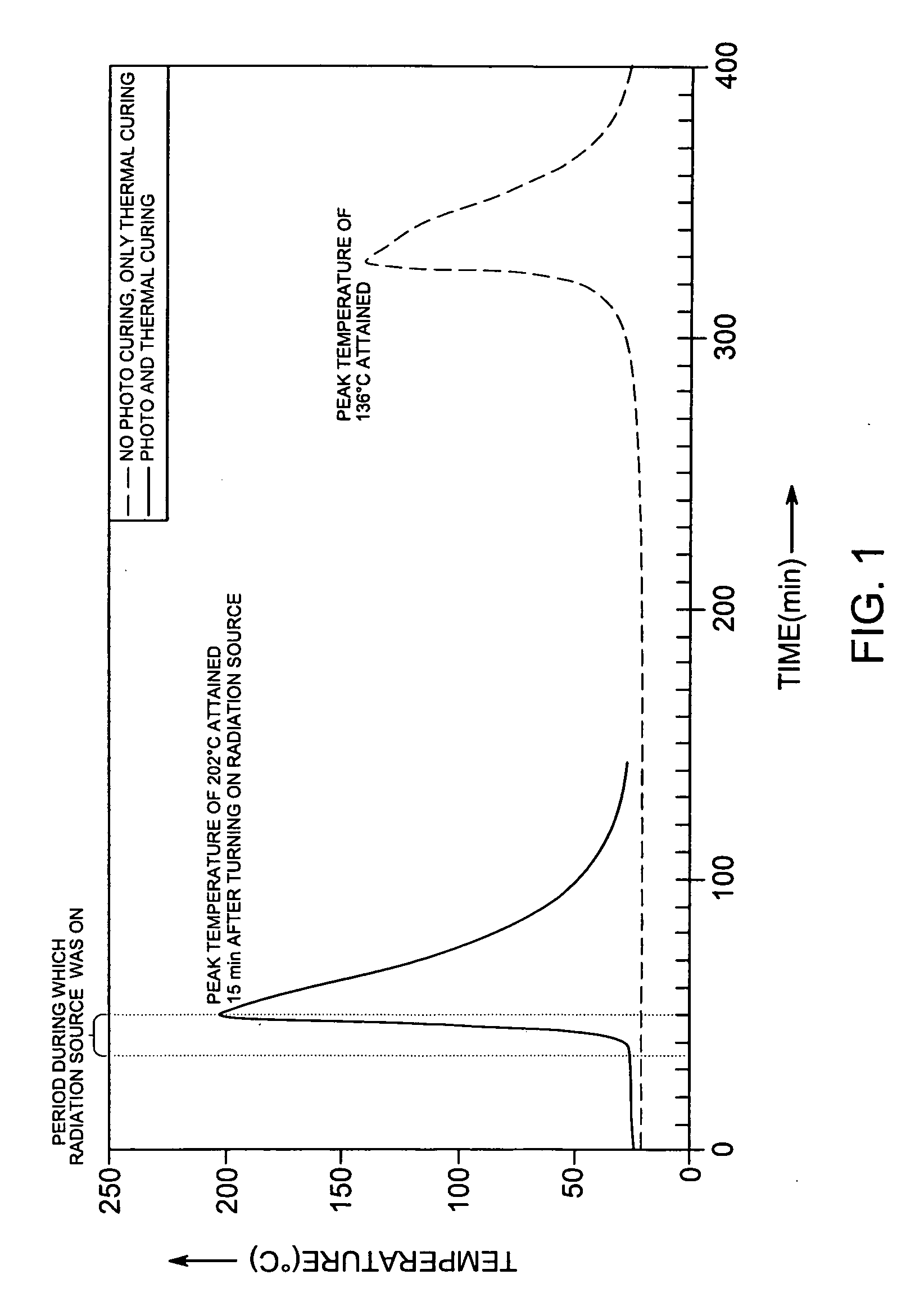

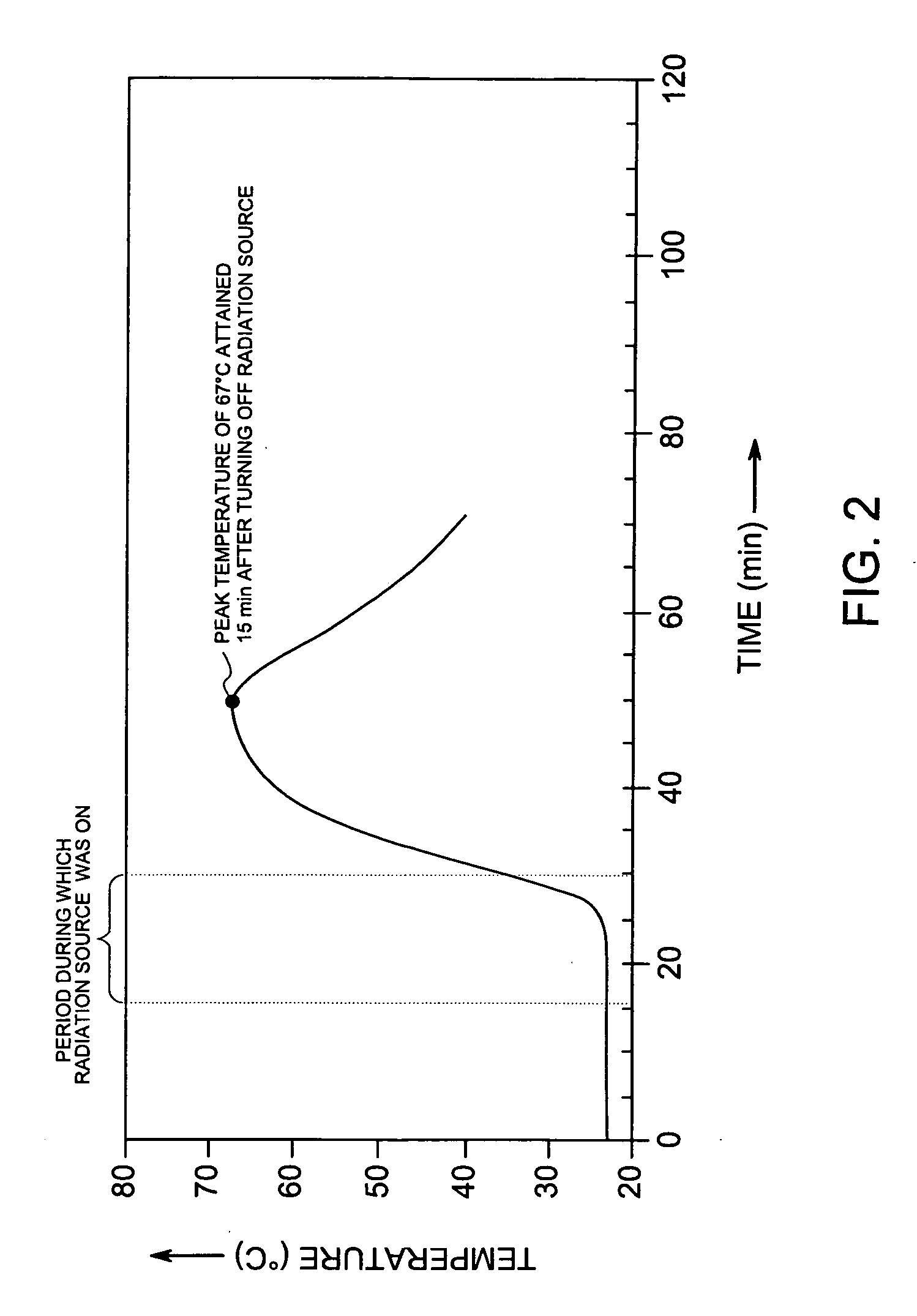

Disclosed herein are dual cure compositions, methods to cure dual cure compositions, the dual cure compositions comprising at least one filler, at least one curable monomer comprising at least one of an ethylenic unit or cyclic ether unit or mixture thereof; at least one photoinitiator; and at least one thermal initiator. The method comprises the step of photocuring by exposing the compositions to radiation to at least partially photocure the composition, which in turn generates an exotherm which initiates thermal curing. The methods may be used to make cured thick compositions and sandwich structures. Articles made by the methods are also described.

Owner:GENERAL ELECTRIC CO

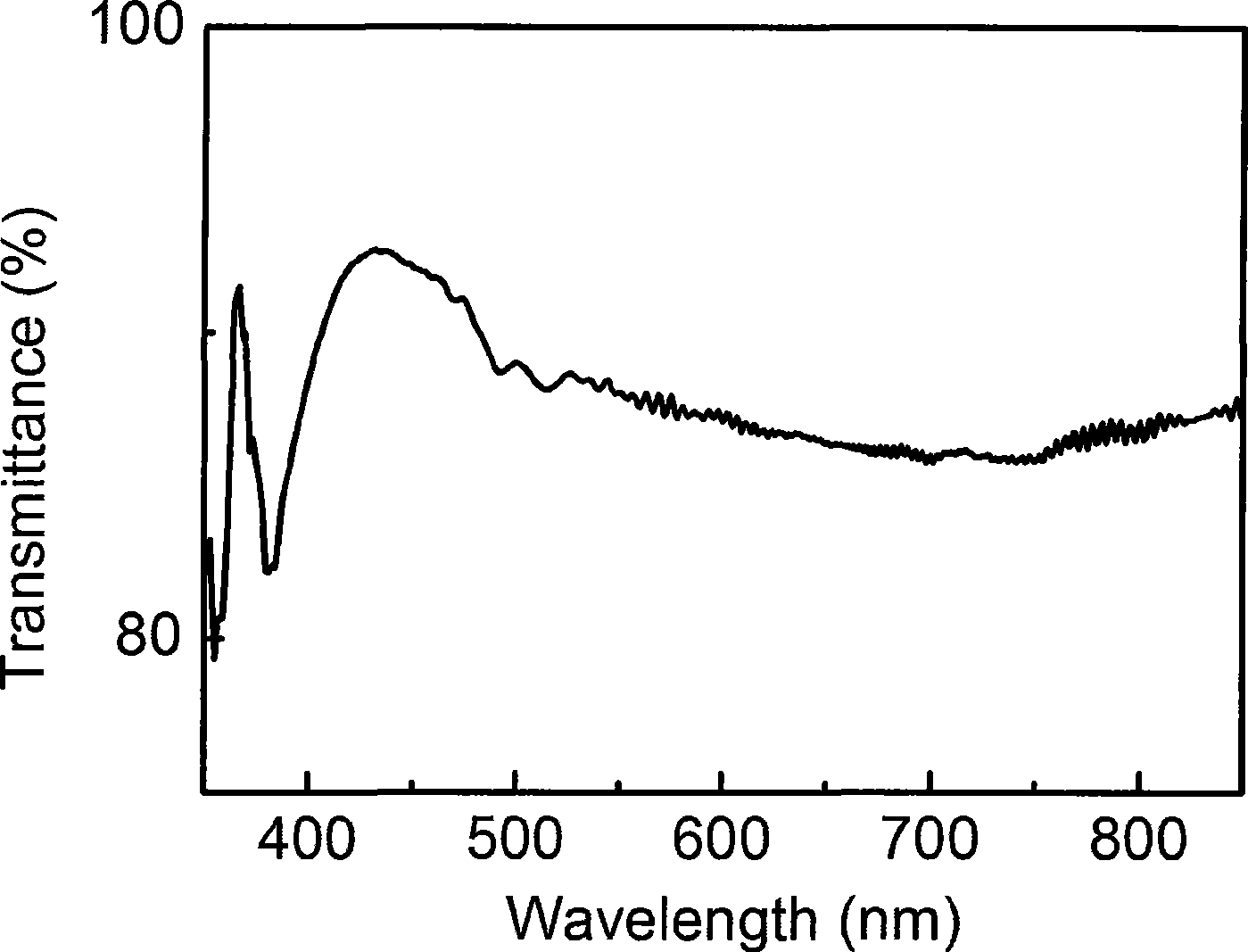

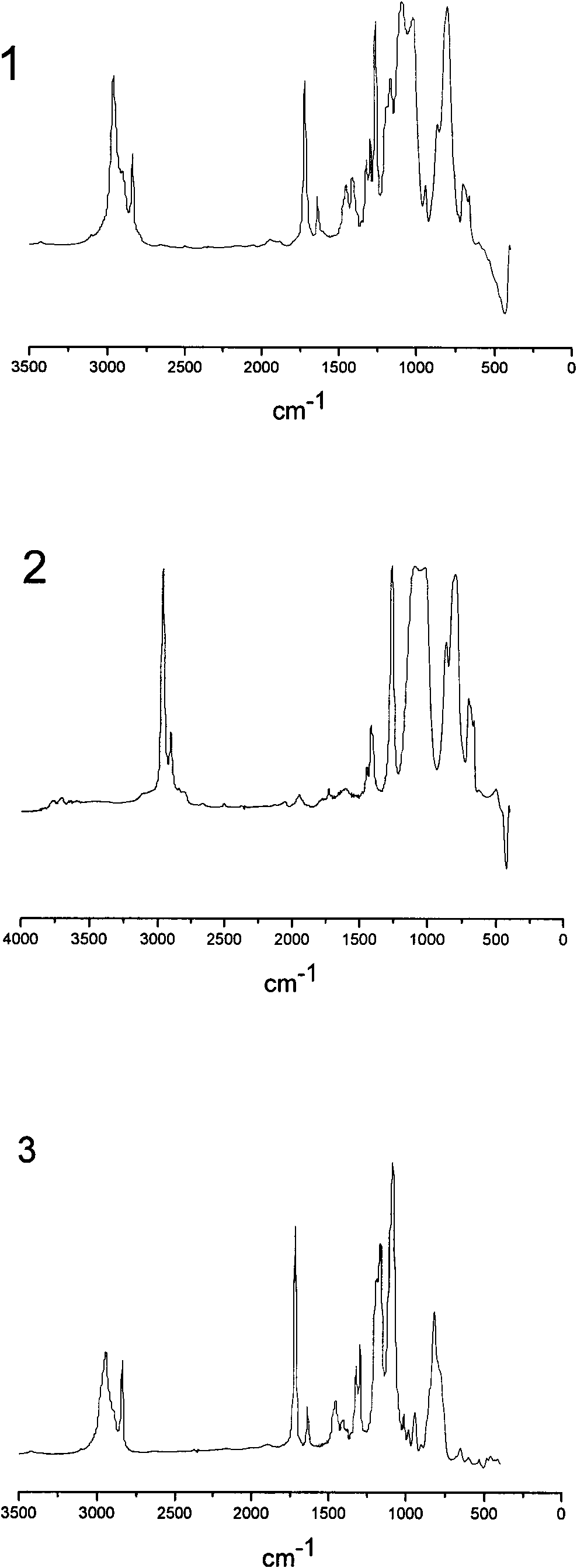

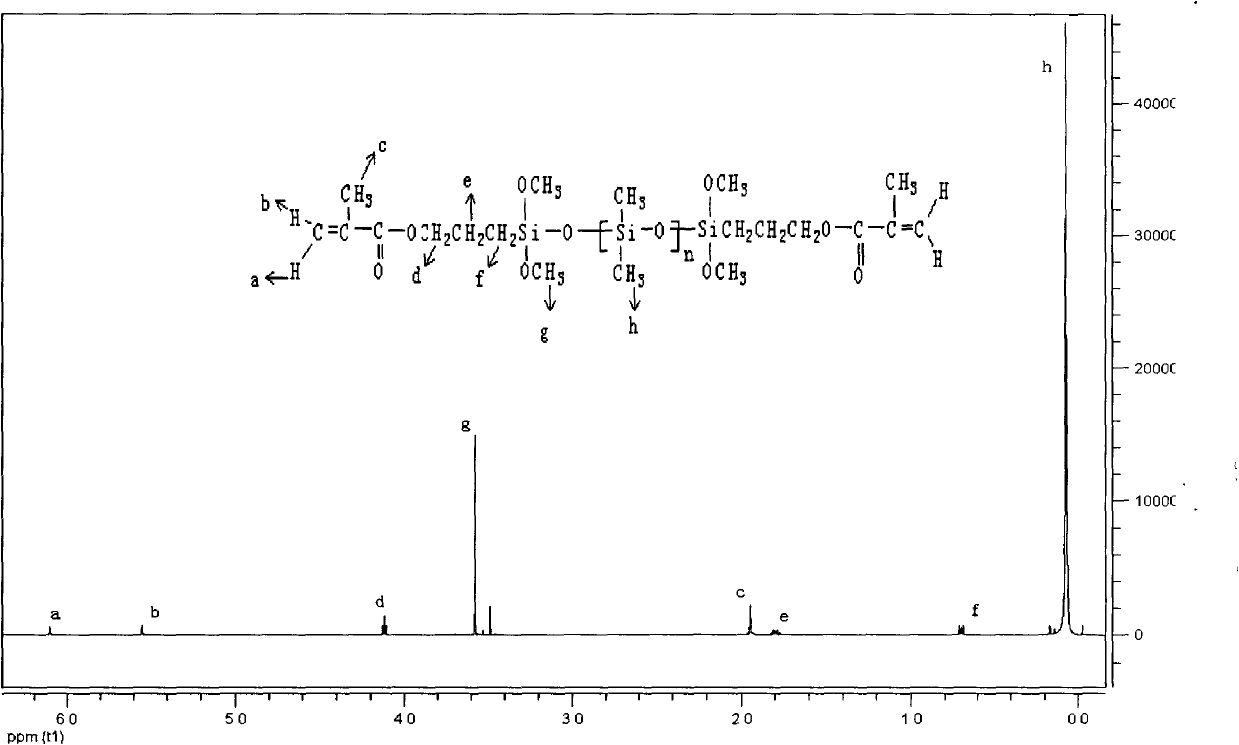

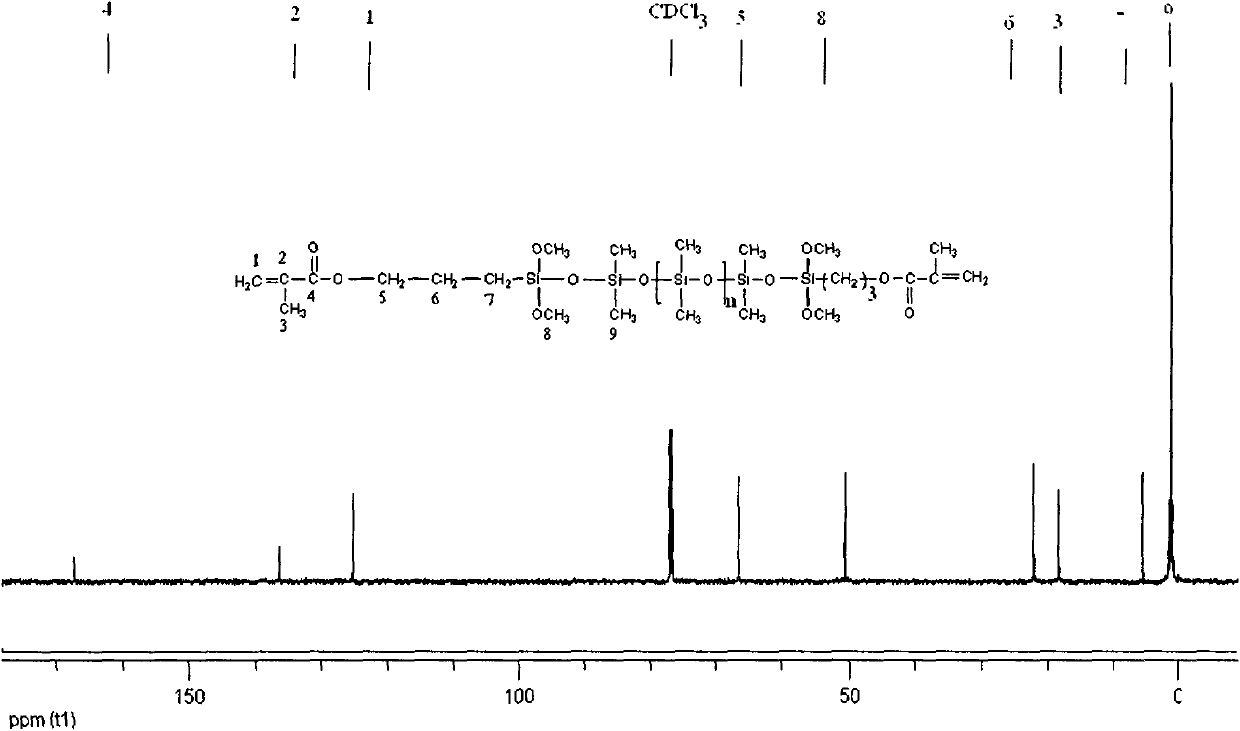

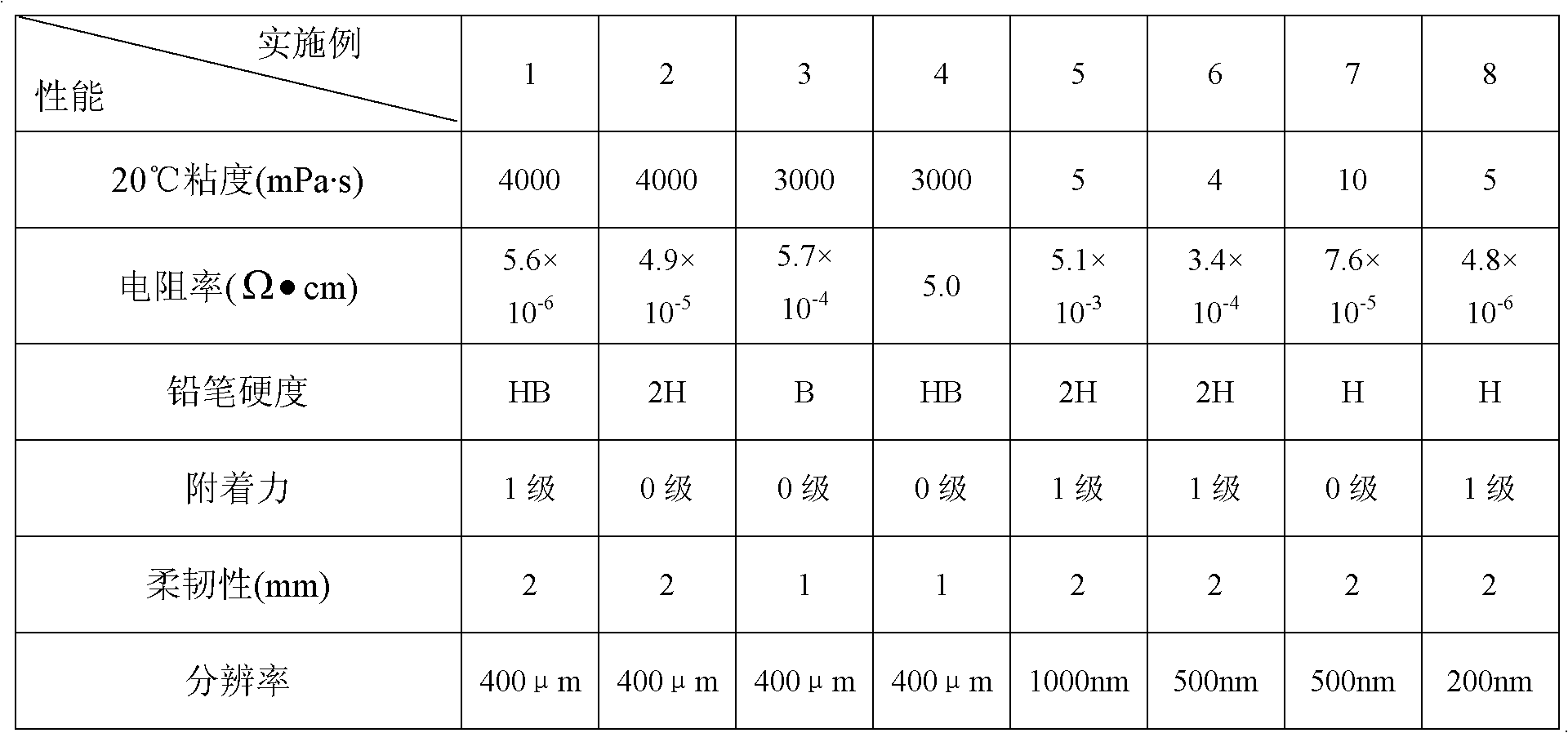

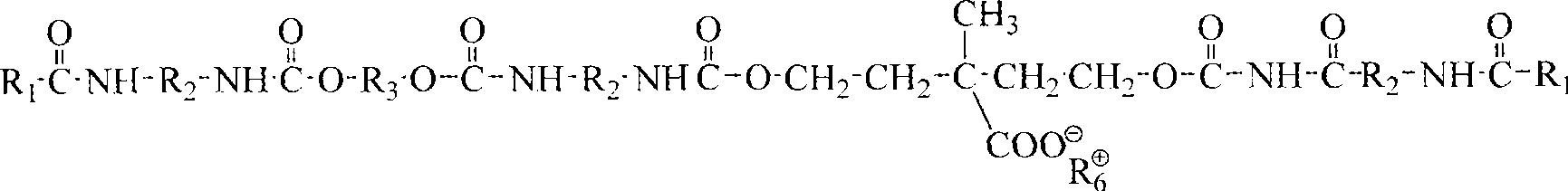

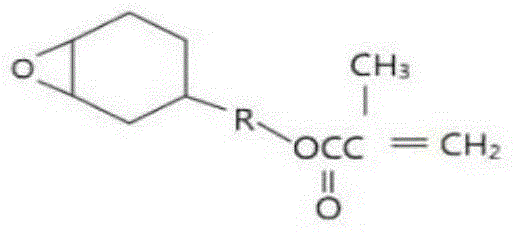

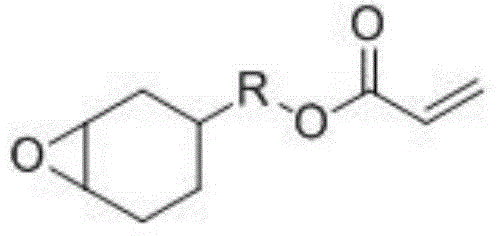

Dual-curable polysiloxane acrylate resin and preparation method thereof

ActiveCN102408569AGood storage stabilityEasy to prepareOther chemical processesAdhesivesSilanesUltraviolet lights

The invention discloses dual-curable polysiloxane acrylate resin and a preparation method thereof, belonging to the technical field of ultraviolet light / moisture dual-curing of organosilicone. The dual-curable polysiloxane acrylate resin has a structural formula (shown as a drawing), wherein R1 is a formula (shown as a drawing), and R2 is OCH3. The preparation method comprises the following stepsof: under the protection of N2, mixing terminal hydroxyl polydimethylsiloxane with methacryloxy propyl trimethoxy silane, adding a solvent and a catalyst, and carrying out an ester exchange reaction to obtain a preproduct; carrying out rotary steaming to remove the solvent, and obtaining a mixture; and at room temperature, extracting by using anhydrous methanol, carrying out centrifugation, further, removing a solvent, and obtaining the dual-curable polysiloxane acrylate resin. The resin is clear and transparent and has good stability for reserving at normal temperature; and the preparation method is simple, short in cycle, and low in cost, and the resin per se does not contain an organic solvent.

Owner:BEIJING UNIV OF CHEM TECH

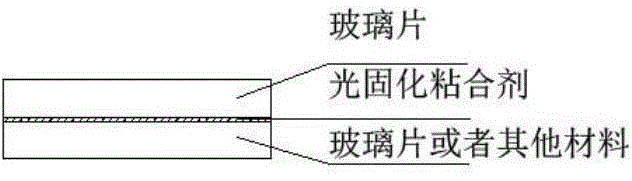

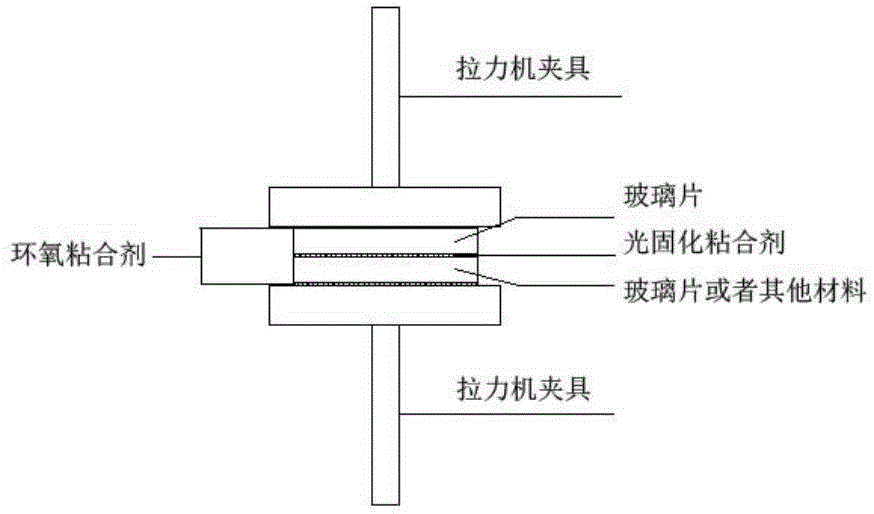

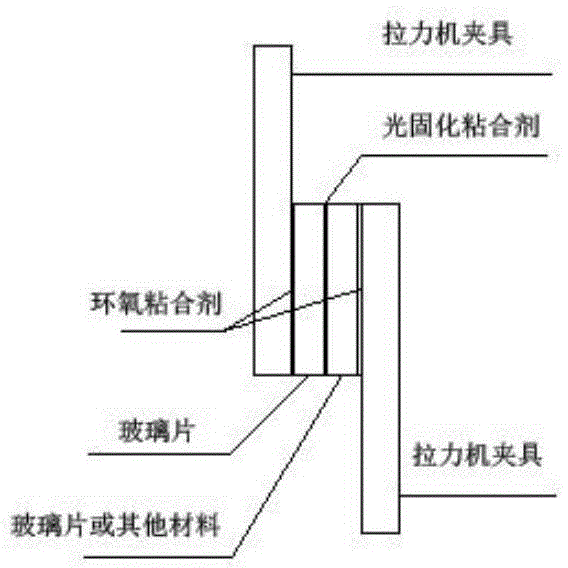

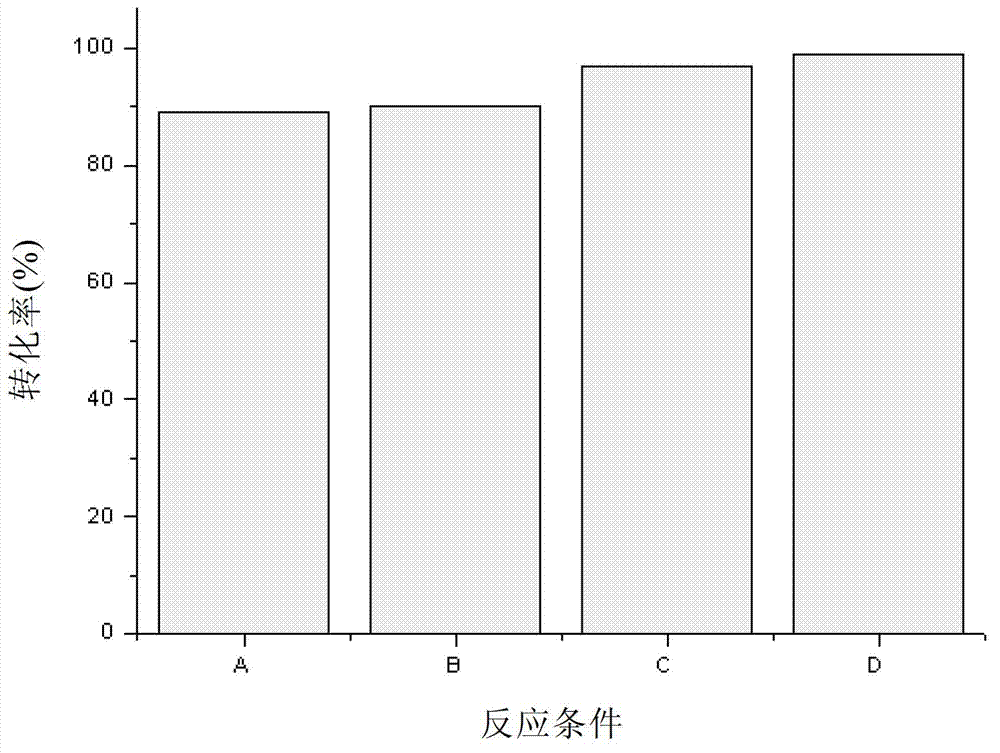

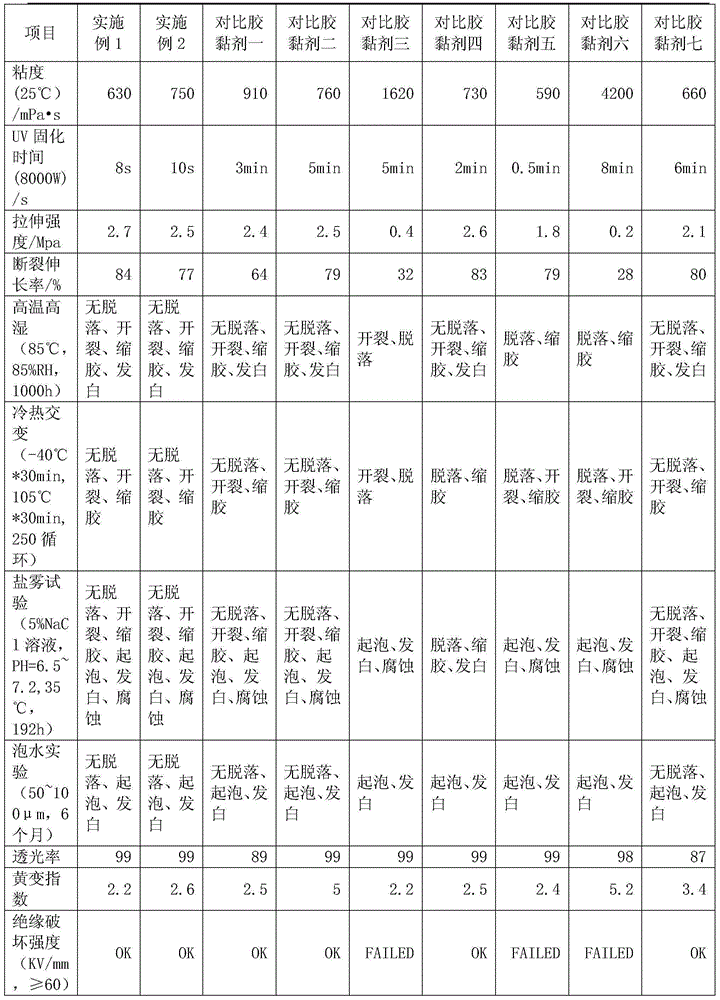

Preparation method of novel dual-cured UV curing binder

InactiveCN104449542AAdhesive processesNon-macromolecular adhesive additivesMetallic materialsDouble bond

The invention relates to a preparation method of a novel dual-cured UV curing binder, and belongs to the technical field of binder industry. The novel dual-cured UV curable binder is prepared by using radical polymerizable resins such as common urethane acrylate, epoxy acrylate and unsaturated polyester as main binding materials, using a double bond-containing reactive diluent as a solvent, and using a UV initiator and a thermal initiator as a compound initiator, supplemented by other binding agents. During curing, a certain initial binding power is firstly obtained by UV curing, and higher binding power is obtained by secondary curing through heating or oxygen isolation. The preparation method provided by the invention not only has the advantages of high curing speed of the traditional light curing binders, but also has the advantages of effectively avoiding the generation of internal stress in the curing process of the traditional light curing binder, and improving the binding strength of the binder; the binder has excellent solvent resistance, high binding strength, and low cost. The binder is widely used for binding glass and glass, glass and metal materials and other transparent materials.

Owner:JIANGNAN UNIV

Preparation method for light-heat dual-cured woodware UV varnish coating

InactiveCN102321424AOvercome depthOvercoming the difficulty in application in colored systemsEpoxy resin coatingsEpoxyPtru catalyst

Owner:SOUTH CHINA UNIV OF TECH

Ultraviolet-anaerobic dual curing adhesive

ActiveCN101205451AFast curingHas initial bond strengthPolyureas/polyurethane adhesivesOrganic non-macromolecular adhesiveUltravioletAccelerant

The invention discloses ultraviolet-anaerobic dual-curing adhesive which is made from the following raw materials of corresponding part by weight: 100 to 135 portions of prepolymer, 10 to 75 portions of diluent, 1 to 4 portions of light initiator, 0.3 to 0.6 portion of accelerant, 0.2 to 0.5 portion of reducing agent, 0.5 to 1.1 portions of oxidant, 0.5 to 1.5 portions of chelating agent and 0.2 to 0.5 portion of polymerization inhibitor. The adhesive of the invention has fast curing speed and can obtain initial bonding strength after being irradiated by ultraviolet for seconds; by means of anaerobic curing mechanism, crosslinking curing is continued after the ultraviolet is removed, thereby further improving the bonding strength of the adhesive so as to meet the requirements of bonding strength of devices in the electronic and electric appliance industries.

Owner:SOUTH CHINA UNIV OF TECH

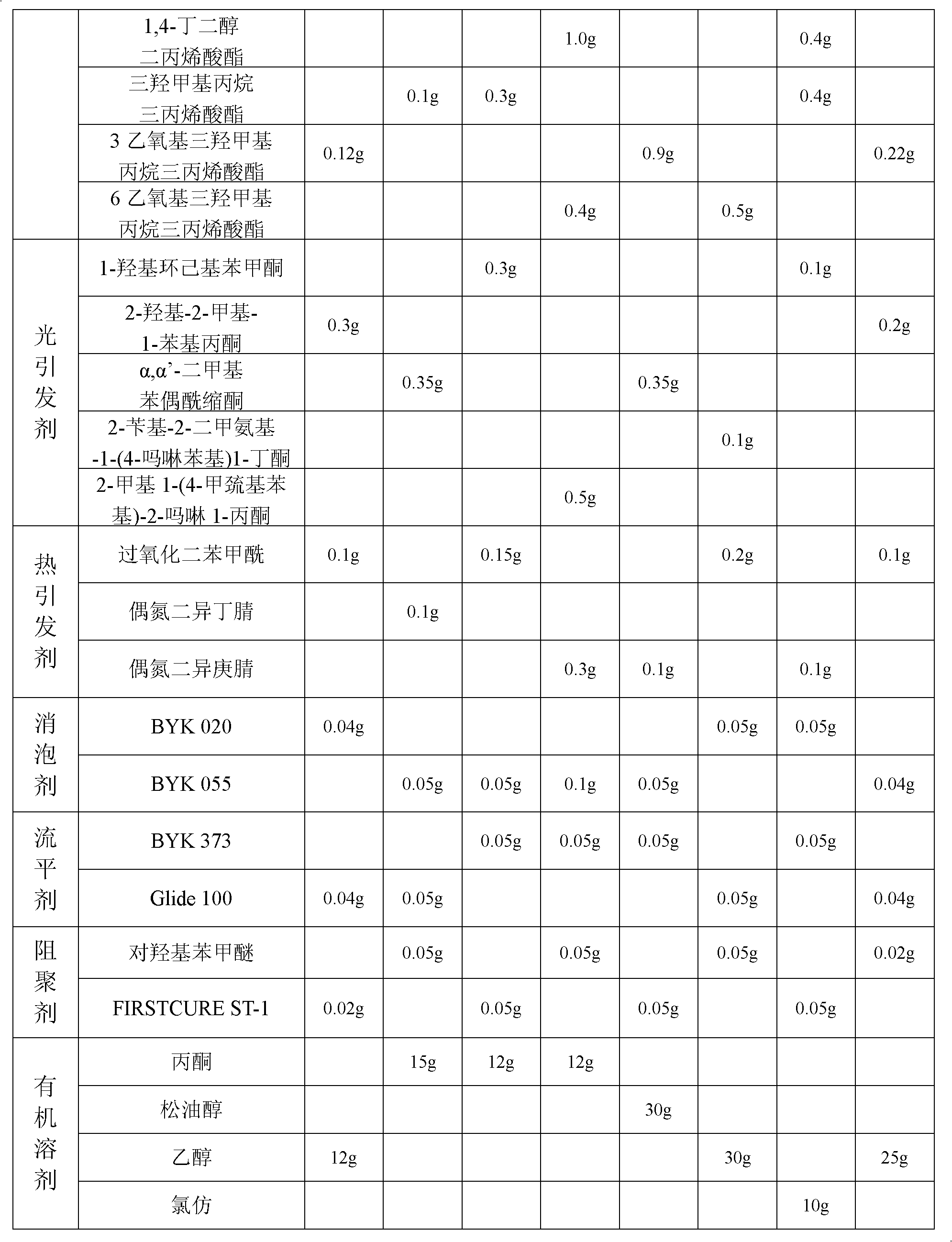

Flexible circuit conductive composition, preparation method and using method thereof

ActiveCN102212304AGuaranteed resistivityGuaranteed adhesionPhotomechanical apparatusPolyurea/polyurethane coatingsFlexible circuitsFlexible electronics

The invention relates to a flexible circuit conductive composition for a flexible printed circuit board (FPC), a preparation method and a using method thereof. The preparation method comprises the following steps of: adding photocurable resin and an optical activity monomer into a conductive nanometer material dispersion liquid and then preparing the composition by adopting a double-curing mode such as firstly photocuring and then thermal treatment. The photocuring leads the surface coating to be rapidly cured so as to achieve good mechanical property; and the thermal curing leads the coatingto be cured completely so as to reach the deep curing requirements. The thermal treatment leads nanometer metals to be sintered together so as to achieve good conductive performance. The prepared conductive system obtains a predesigned pattern in the specific area of a base material in a screen printing or nanometer impressing mode; the conductive pathway is obtained after the double curing and has the advantages of short curing time, low curing temperature, good electrical conductivity, high resolution ratio; and the prepared conductive film has the advantages of good adhesiveness, high hardness and good flexibility.

Owner:BEIJING UNIV OF CHEM TECH

Optically-transparent dual-curing adhesive

The invention relates to an optically-transparent dual-curing adhesive, and a preparation method and a use thereof, and concretely relates to an optically-transparent, ultraviolet-curable and heat-curable adhesive, for example, the adhesive can be used for bonding the touch screen and the substrate of an electronic product.

Owner:HENKEL KGAA +1

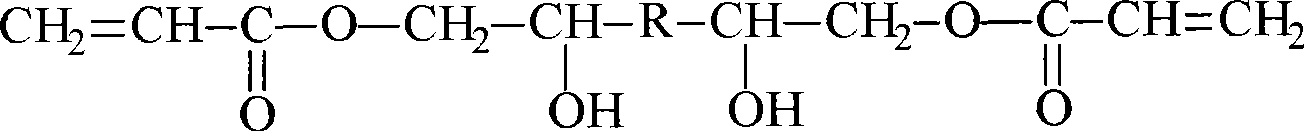

Waterborne ultraviolet-heat dual curing coating composite and preparation method thereof

InactiveCN101418147AImprove adhesionHigh hardnessPolyurea/polyurethane coatingsFunctional methodsSpray coating

The invention provides a water-dilutable ultraviolet-thermal double curing coating composition and a preparation method thereof. The components of the double curing coating composition in percentage by weight are: 3.5 to 60 percent of water-dilutable urethane acrylate oligomer, 17 to 47 percent of water-dilutable polyurethane polylol, 20 to 49 percent of water-dilutable curing agent, 0.4 to 9 percent of light trigger and 0.4 to 1.6 percent of auxiliary agent. The preparation method for the double curing coating is simple and does not require complex equipment; and the working life of the coating is long and reaches as long as 9 hours; the coating obtained can be used for preparing a coating by the functional methods of spray coating, brush coating and roller coating; ultraviolet curing can be completed within a short period of time between 10 and 30 seconds, and thermal curing can be completed within a period of time between 1 and 3 minutes at a temperature of between 40 and 60 DEG C; a paint film obtained after double curing has good leveling property, flexibility, shock resistance and adhesion and high hardness; and the coating does not contain an organic solvent and a reactive diluent, and is an environment-friendly coating.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

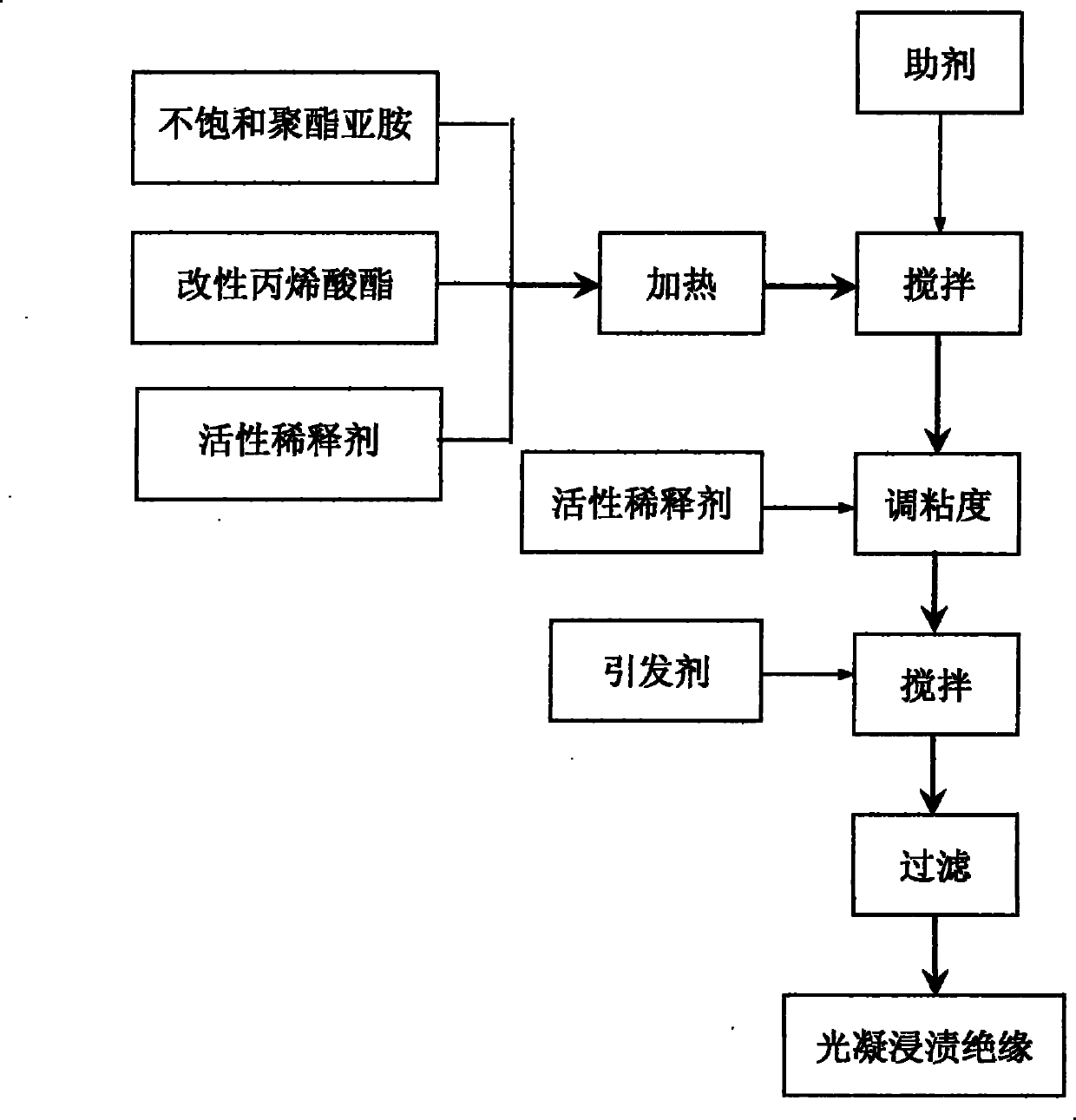

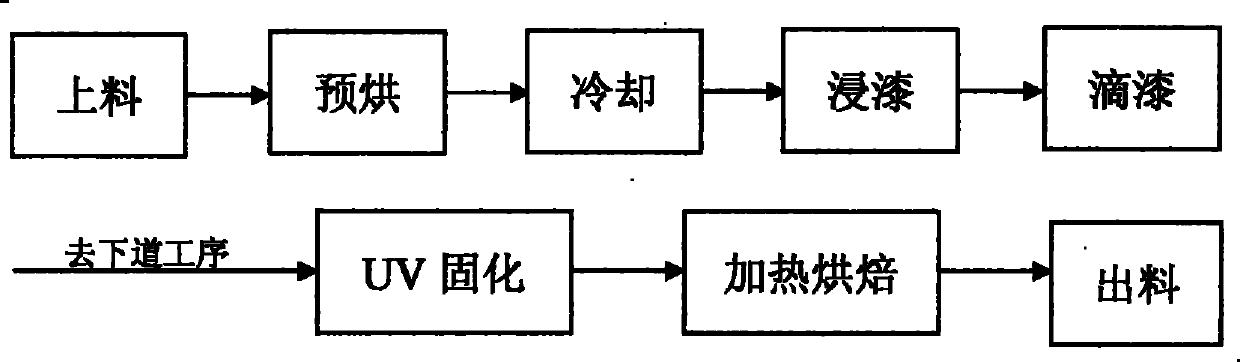

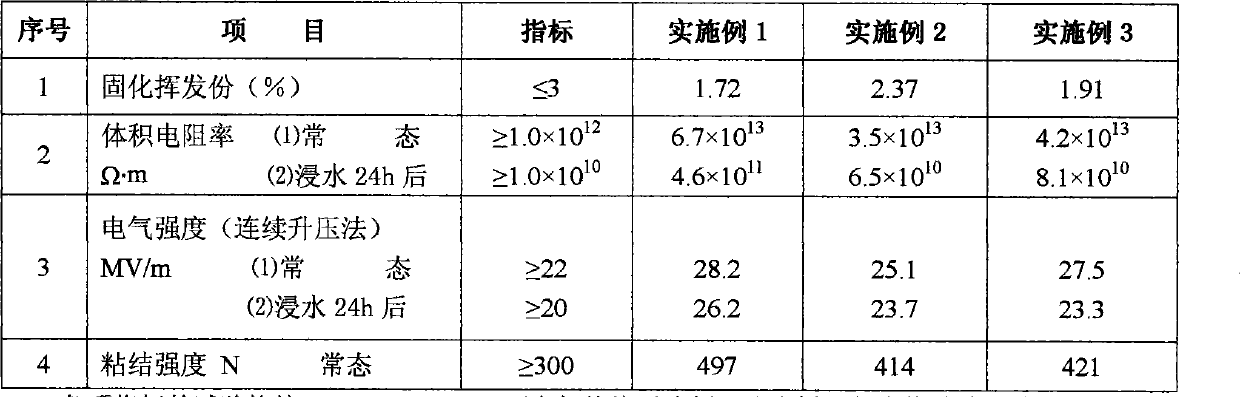

Low-volatilization photocoagulation dipping insulating paint

InactiveCN102020911AExtended shelf lifeOvercome churnManufacturing dynamo-electric machinesPolyester coatingsVacuum pressureHeat resistance

The invention belongs to the technical field of insulating paint, in particular relates to an insulating paint belonging to the dual-curing field of ultraviolet curing and thermocuring. The invention is applied for motor insulation processing and has the advantages of long storage life, high curing speed, no smell, being convenient in operation, no volatilization of organic matters during curing and the like. Compared with the common dipping paint technology, the dipping technology overcomes the problems of loss and small sagging amount in the baking and solidifying process of the dipping paint; in addition, the dipping technology saves material, improves product quality and lightens environment pollution. The dipping and insulating paint has good thermostability and is suitable for common or vacuum pressure dipping paint for H and C-grade motor and electrical appliances.

Owner:GUANGZHOU BETTER NEW MATERIALS

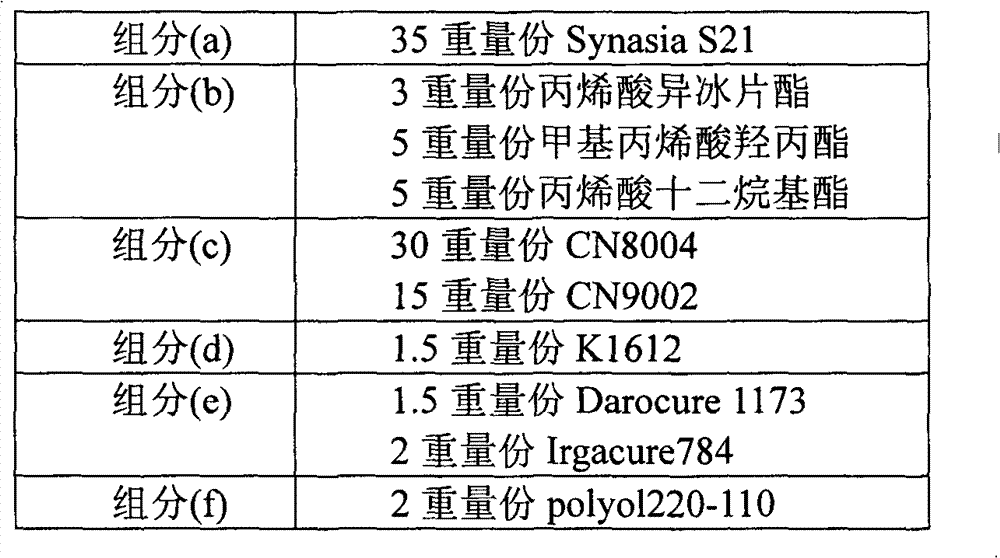

Dual-curing adhesive composition

ActiveCN102898962AAdjust stressAdjust processabilityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolyesterOligomer

The invention provides a dual-curing adhesive composition, comprising a) (methyl)-acrylics oligomer with at least an unsaturated group; b) monofunctional monomer, multifunctional monomer or mixture thereof; c) (methyl)-acrylate resin with isocyanate group; d) polyester polyol resin; e) an initiator; and f) a plasticizer with refractive index of more than 1.49. The dual-curing adhesive composition has themocuring and photocuring properties at the same time, and has good translucency and high refraction index. The dual-curing adhesive composition can be used in optical products, and preparing process is simplified. The dual-curing adhesive composition has good adhesiveness, good optical property, and good reprocessing property.

Owner:ETERNAL MATERIALS CO LTD

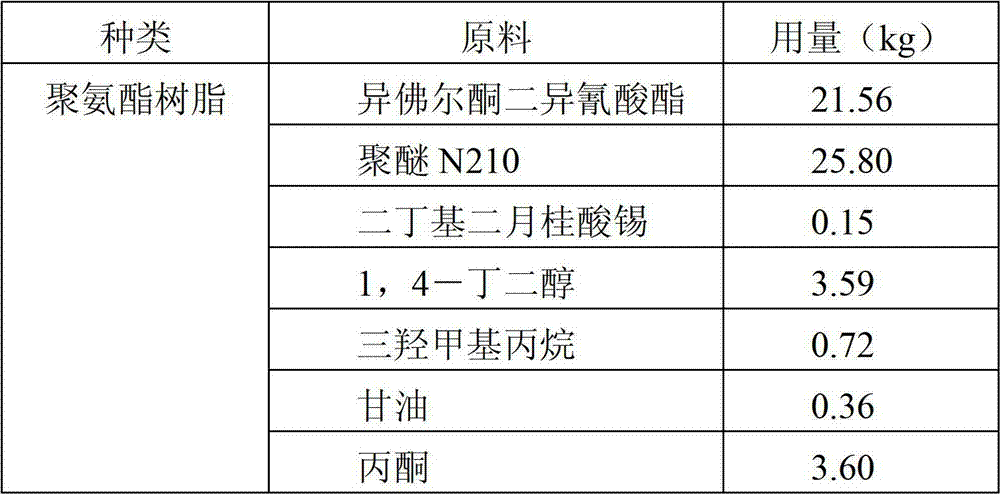

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

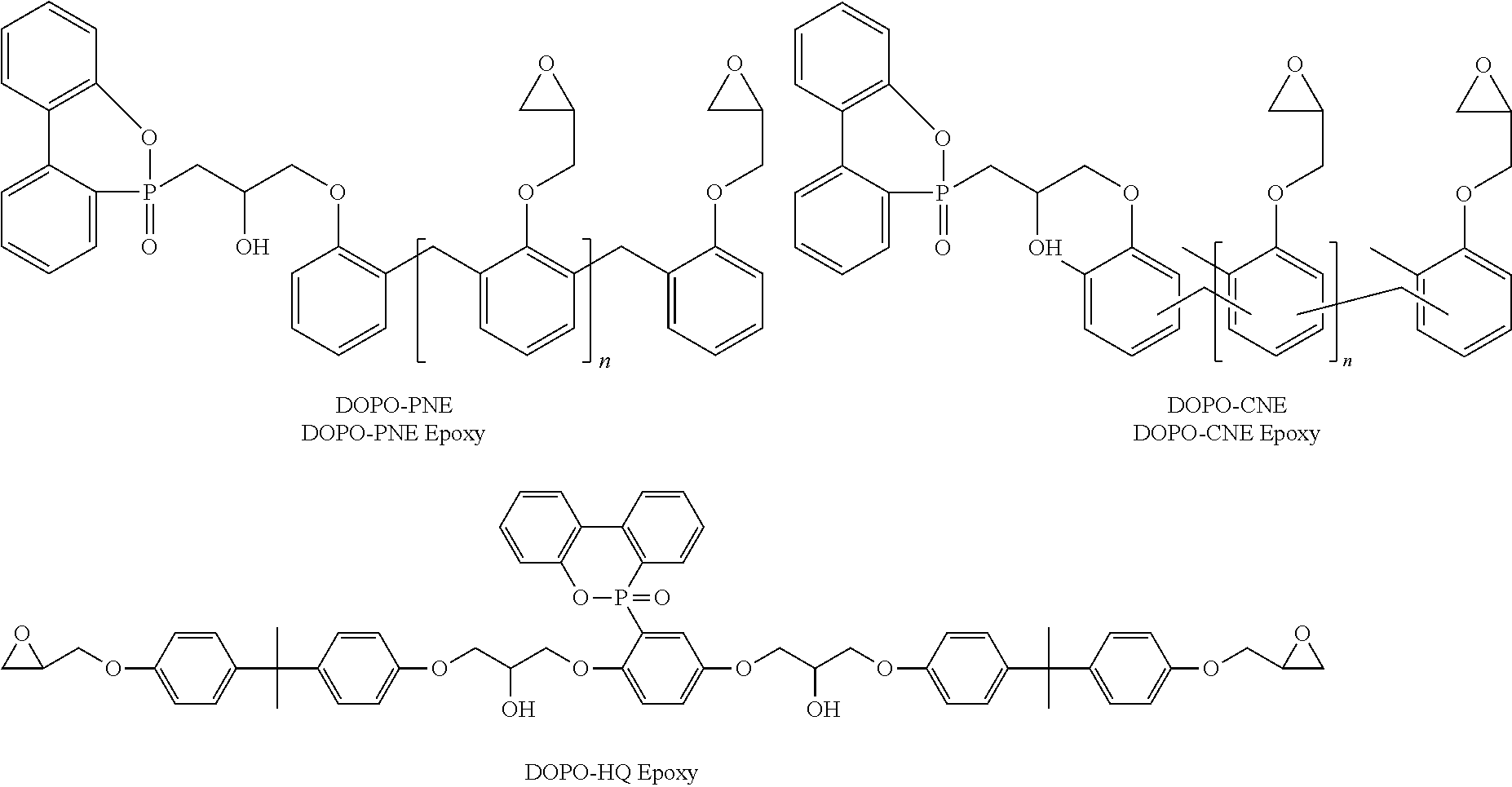

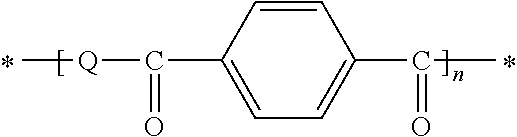

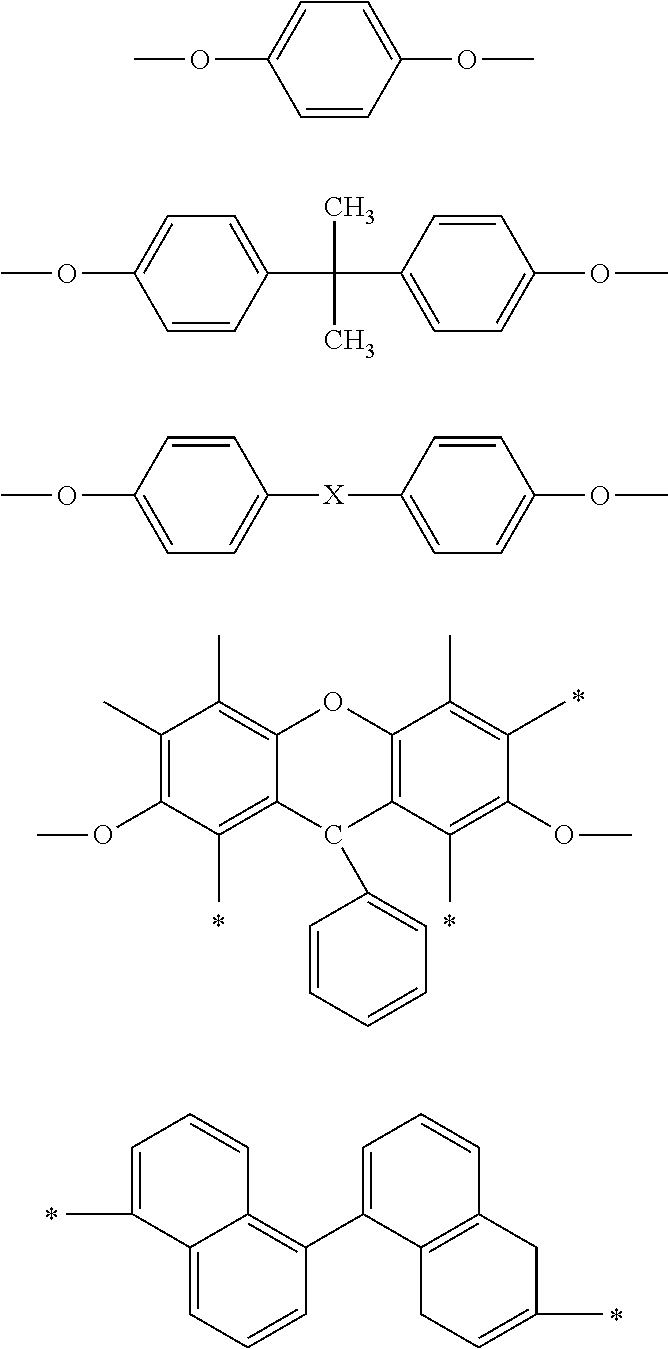

Thermosetting resin composition and prepreg or laminate using the same

A thermosetting resin composition and a prepreg or laminate using the same are provided. The thermosetting resin composition includes an epoxy resin and a curing agent, in which the curing agent is a dual-curing agent system formed with a multi-functional aromatic polyester curing agent in combination with a phenolphthalein benzoxazine phenol aldehyde or a poly(styrene-co-maleic anhydride). An organic or inorganic fiber reinforced material is impregnated with the thermosetting resin composition to form a prepreg, and the prepreg is bonded to a substrate with a metal foil disposed thereon, to form a laminate.

Owner:UNIPLUS ELECTRONICS

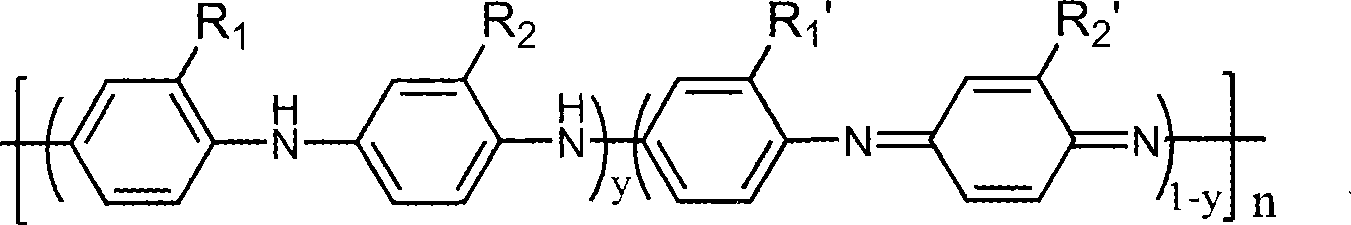

Ultraviolet-heat dual curing polyaniline anti-corrosive paint and preparation method thereof

ActiveCN101418146ANo emission issuesNo pollution problemAnti-corrosive paintsPolyurea/polyurethane coatingsUltravioletChromium

The invention provides an ultraviolet-thermal double curing polyaniline anti-corrosive coating and a preparation method thereof. In the coating, polyaniline is adopted as a main anti-corrosive material, and oligomer, a reactive diluent, polyurethane polylol, polyaniline, filler, light trigger and an auxiliary agent are used for preparing filtrate of the coating; and the filtrate and a polyurethane curing agent are stored respectively and uniformly mixed in proportion for use. The anti-corrosive paint has good anti-corrosive effect on different metals, not only can perform ultraviolet curing crosslinking but also can perform thermal curing crosslinking, well overcomes the defect of incomplete curing of an ultraviolet curing anti-corrosive paint, has the characteristics of resisting acid medium corrosion and alkali medium corrosion, is suitable to be used under the condition of a severe environment and particularly suitable for corrosion protection under the condition of a marine environment, does not contain heavy metals such as plumbum, chromium and zinc, and simultaneously does not contain any organic solvent in a formula. Therefore, the coating does not have the problem of environmental pollution during the production process and the use process, and is a completely environment-friendly coating.

Owner:中科应化(长春)科技有限公司

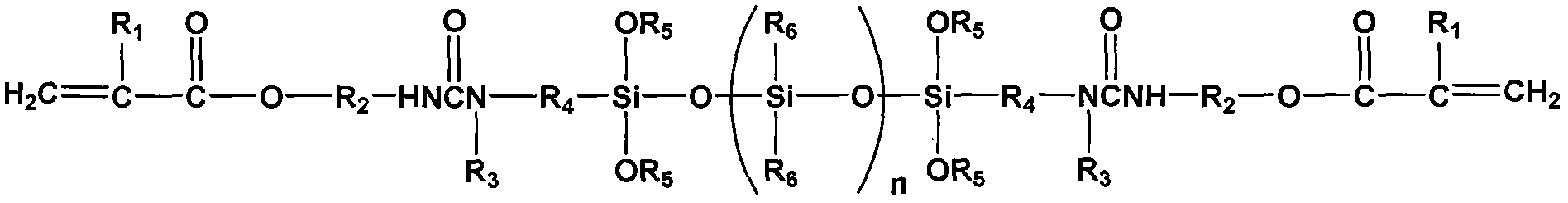

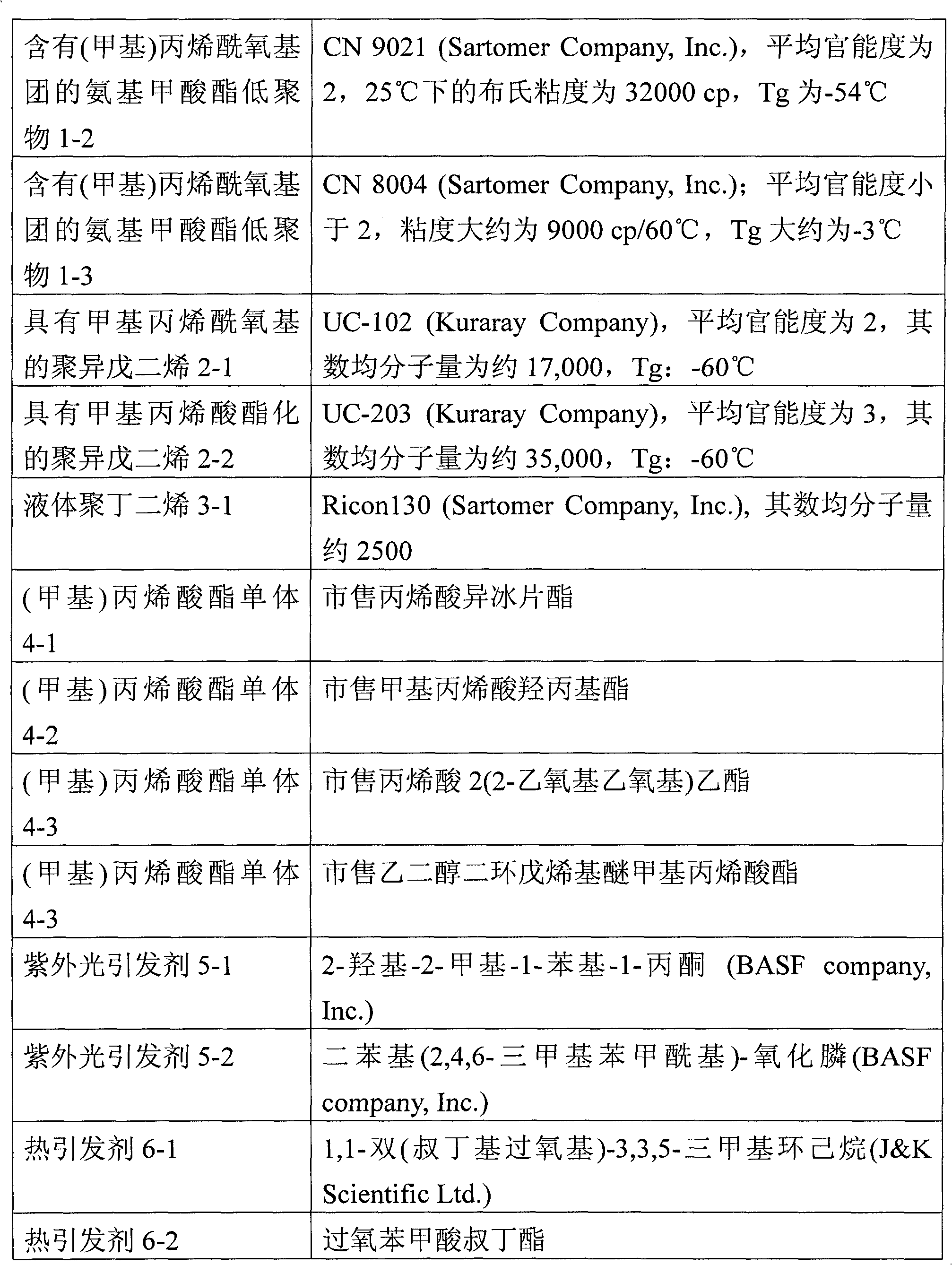

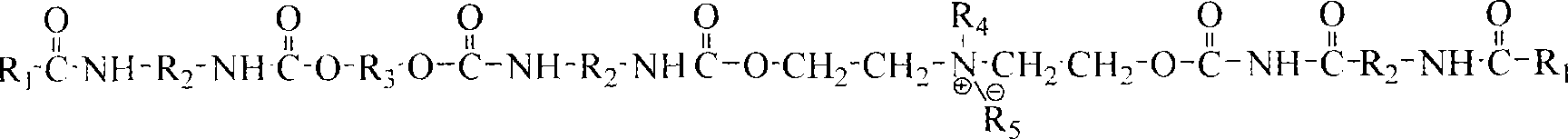

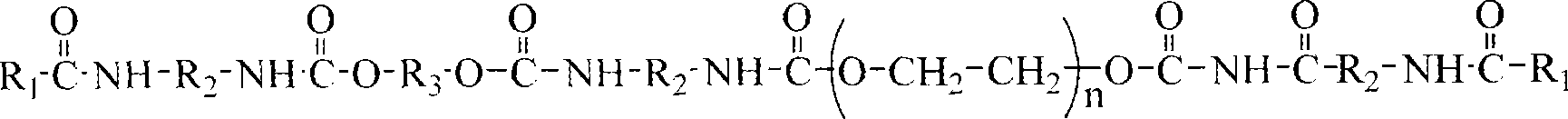

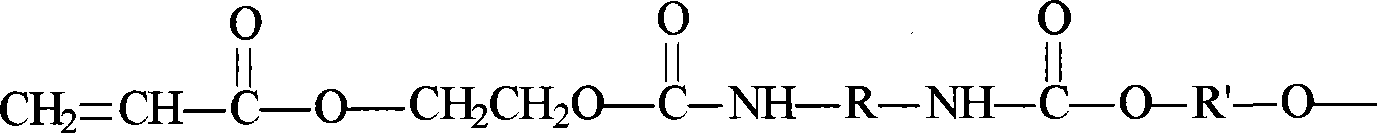

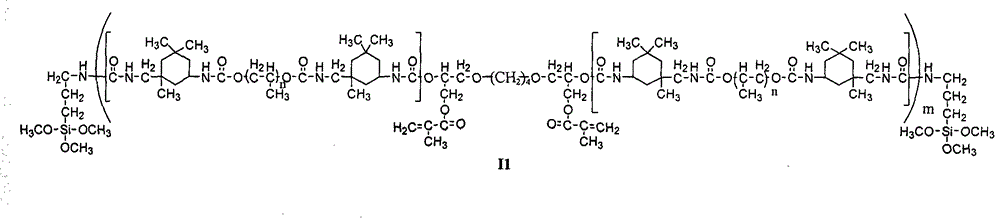

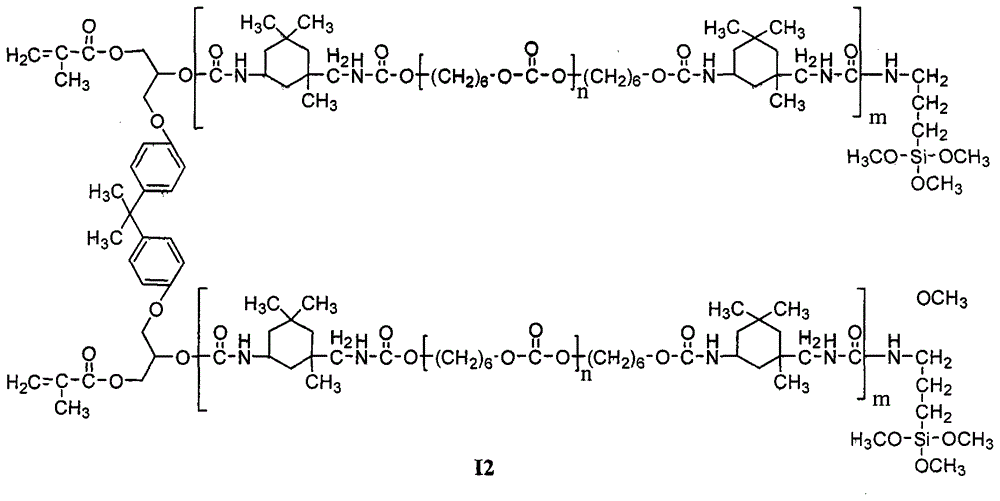

Ultraviolet ray and moisture dual-cured modified polyurethane and preparation method thereof

InactiveCN104558501AGood weather resistanceImprove temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesUltravioletDouble bond

The invention discloses ultraviolet ray and moisture dual-cured modified polyurethane and a preparation method thereof, belonging to the technical field of high polymer materials. The structural formula of the modified polyurethane is represented by the general formula I in the specification. The ultraviolet ray and moisture dual-cured modified polyurethane disclosed by the invention has dual curing manners; the disadvantages of the single light curing manner are overcome; simultaneously, because designed resin molecules contain double-bond groups, the curing energy can be reduced; the crosslinking density is increased; the curing depth problem is solved; the weather fastness of the resin is increased; and the temperature-resistant property of the resin is improved.

Owner:TONSAN ADHESIVES INC

Dual-curing adhesive composition and application thereof and method for bonding substrates

InactiveCN103087640ALight curing speed is fastFast curingAdhesive processes with adhesive heatingLaminationEpoxyOligomer

The invention provides a dual-curing adhesive composition which comprises the following components: component (a): epoxy resin; at least one selected from component (b) and component (c), wherein the component (b) is a (methyl) acrylate monomer, and the component (c) is oligomer with a (methyl) acrylyloxy group; component (d): a thermopolymerization catalyst used for catalyzing a thermopolymerization reaction of the component (a); and component (e): a photopolymerization initiator used for initiating an photopolymerization reaction of the component (a) and at least one material selected from the component (b) and the component (c), wherein the component (e) is a mixture of a cationic photopolymerization initiator and a free radical photopolymerization initiator. The dual-curing adhesive composition of the invention is used for bonding or lamination between light transmitting substrates, or between a light transmitting substrate and a lightproof substrate. The invention also provides a method for bonding substrates.

Owner:HENKEL KGAA +1

Dual curing coating

The invention discloses a dual solidifying paint for wood and metal substrate, which is characterized by the following: the paint component A is ultraviolet solidifying composition, which contains 30-60% low-activity oligomer; the activity thinner is composed of 5-20% 1-alkylene unsaturated and doubly-bond compound, not more than 20% 2-alkylene unsaturated and doubly-bond compound, 5-20% not less than 3-alkylene unsaturated and doubly-bond compound, 1.0-10% photopolymer initiator, not more than 20% adhesion promotion resin, not more than 30% thinner; the composition B contains not less than 3 NCO hardener; the weight rate of component A and B is (85- 95):(5-15).

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Actinic radiation and moisture dual curable composition

A dual curable, liquid adhesive composition capable of polymerization by exposure to actinic radiation and moisture. The composition is particularly useful for liquid adhesives for electronic applications. The composition comprises an alkoxysilane functional polyurethane acrylate oligomer; a free radical polymerizable reactive diluent; a free radical photoinitiator; a catalyst for moisture curing of silane groups; and an optional alkoxysilane functional oligomer having a polyolefin group; an optional acrylate or methacrylate functional polyurethane acrylate oligomer; an optional hydroxyl terminated monoacrylate or monomethacrylate functional reactive diluent; an optional UV-absorber and hindered amine light stabilizer antioxidant; an optional wax capable of reducing oxygen inhibition; an optional 1,3 dicarbonyl compound chelating agent; an optional thixotropic agent; and an optional adhesion promoter. optional adhesion promoter.

Owner:DYMAX

Ultraviolet dual-curing conductive adhesive and preparation method thereof

ActiveCN104046315AHigh bonding strengthImprove performancePolyureas/polyurethane adhesivesElectrically-conducting adhesivesPolymer scienceSilanes

The invention discloses an ultraviolet-heat dual-curing adhesive composition and a preparation method thereof. The ultraviolet dual-curing adhesive composition comprises the following components in percentage by mass: 20-50% of polyurethane modified epoxy monoacrylate, 10-25% of reactive diluent, 5-40% of conductive filler, 1-5% of silane coupling agent, 1-5% of photoinitiator and 1-5% of heat curing agent. The ultraviolet-heat dual-curing adhesive is high in curing speed; after a few seconds of ultraviolet irradiation, the acrylate double-bond group in the system can be quickly cured, so that the adhesive has preliminary bonding strength; and then by means of heating, the epoxy group is further subjected to crosslinking and curing according to a heat curing mechanism, thus further improving the bonding strength of the adhesive. The adhesive has high bonding strength and favorable conductivity, and can meet the bonding requirements of devices in electronic industry and the like. Besides, the adhesive disclosed by the invention is solventless, simple to operate, high in curing speed, high in bonding strength and suitable for batch production on a production line.

Owner:YONGZHOU FUXING ELECTRONICS SCI & TECH

Photo-thermal dual-curing anisotropic conductive adhesive film and preparation method thereof

ActiveCN104673113AImprove crosslink strengthHigh bonding strengthNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyCross-link

The invention relates to a photo-thermal dual-curing anisotropic conductive adhesive film and a preparation method thereof. The anisotropic conductive adhesive film is prepared from raw materials in percentage by mass as follows: 35%-45% of epoxy resin, 10%-25% of acrylic resin, 5%-10% of a cross-linking agent, 2%-7% of a diluent, 0.6%-1% of a photoinitiator, 2.5%- 4% of a thermal curing agent, 5%-10% of an accelerant, 0.5%-2% of a silane coupling agent and 20%-35% of conductive balls. The preparation method comprises steps as follows: the raw materials are blended, subjected to rotary coating and then subjected to ultraviolet exposure processing, and the anisotropic conductive adhesive film is prepared. The anisotropic conductive adhesive film has good conductive performance, excellent weather fastness, low curing temperature, long storage time, high curing degree and high bonding strength; the preparation process is simple, the cost is low, and the application prospect is broad.

Owner:DONGHUA UNIV

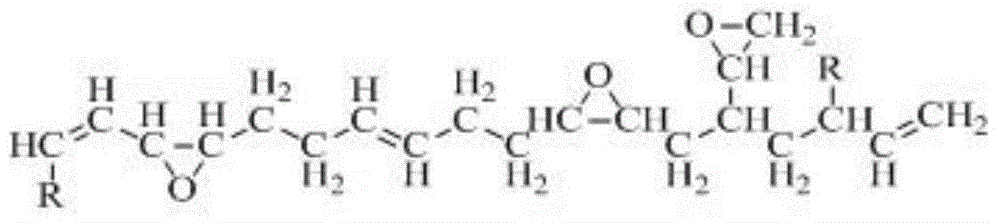

Ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin

ActiveCN104449419ASynergistic priming effect is goodIncrease the polymerization rateOrganic non-macromolecular adhesivePolyolefinFast tempo

The invention belongs to the technical field of adhesives, and particularly relates to an ultraviolet-heat dual curing optical adhesive containing epoxidized polybutadiene resin. The ultraviolet-heat dual curing optical adhesive comprises the following components in percentage by weight: 14.5%-45% of epoxidized polybutadiene resin, 10%-40% of alicyclic epoxy modified resin, 5%-15% of polyolefin liquid rubber, 25.5%-35% of an acrylic ester reactive diluent, 2.4%-3.4% of a free radical photoinitiator, 0.1%-0.2% of a cationic photoinitiator and 2%-2.5% of a peroxide initiating curing agent. The optical adhesive disclosed by the invention is relatively completely solidified at a shaded part, a dark adhesive layer part or a thick adhesive layer part, has excellent optical properties such as high refractive index and high transmittance after being solidified, has the advantages of shock resistance, low yellowing coefficient, low haze, low shrinking percentage, easiness in repairing and good flexibility, meets the requirements of optical, physical and chemical properties of display devices, and is suitable for fast-tempo and high-efficiency production processes.

Owner:信泰永合(烟台)新材料有限公司

Dual-cured coating composition and method for preparation thereof

The invention relates to a dual-curing coating compound, which comprises containing hydroxyl macromolecular compounds provided with a hydroxyl value not lower than 50 milligram KOH per gram, compounds capable of generating cross linking reaction with the containing hydroxyl macromolecular compounds, and thinner, wherein, the compounds capable of generating the cross linking reaction with the containing hydroxyl macromolecular compounds are the compounds the molecules of which simultaneously contain isocyanate radical and polyradical. The dual-curing coating compound provided by the invention can obtain a paint film with good adhesive force, high flexibility and good scratch resistant performance after solidification and meet the requirements of a purse test and a vibration and wear resistant test when applied on the metal surface on one hand, and can effectively solve the problem in the prior art that the compatibility between thermocuring isocyanate and photo-curing polyurethane acrylic ester is poor so as to make the paint film smooth and neat on the other hand.

Owner:BYD CO LTD

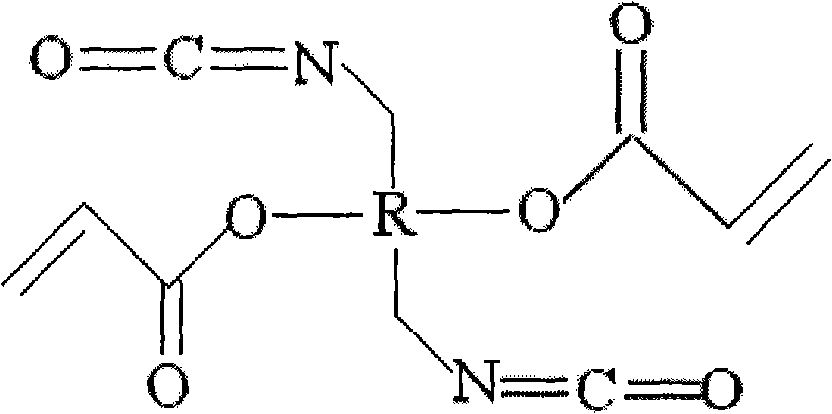

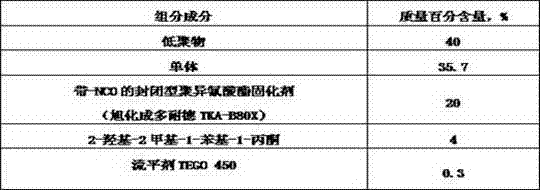

High-strength coating formed by virtue of photo-thermal dual-curing and preparation method thereof

InactiveCN104745055AUniform and dense spatially cross-linked network structureDense unimolecular space structurePolyurea/polyurethane coatingsPolymer scienceMeth-

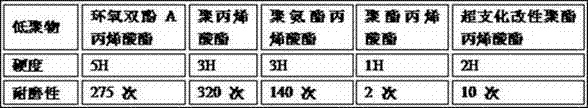

The invention provides a coating which is formed under the condition of photo-thermal dual-curing and is good in hardness and high in wear resistance. The coating is obtained by performing UV (ultraviolet) curing at first and then performing thermal curing on the following materials in percentage by weight: 30-60% of a low polymer with -OH, 15-36% of a monomer with -OH, 19-30% of a closed type polyisocyanate curing agent with -NCO, 2-5% of a photoinitiator and 0.2-0.8% of an auxiliary agent, wherein the low polymer with -OH is bisphenol A epoxy acrylate, polyacrylate or polyurethane acrylate, and the monomer is one, two or three types of ethyl metrhacrylate, tri(propylene glycol) diacrylate or trimethylolpropane triacrylate. The polyurethane polymer and the polyacrylate polymer in the coating provided by the invention are crosslinked by virtue of chemical bonds, and a formed single-molecule space structure is more compact in structure, and is obviously improved on hardness and wear resistance. The invention also provides a preparation method of the coating.

Owner:汕头市大千高新科技研究中心有限公司

High-light-transmittance UV-moisture dual-curing adhesive

ActiveCN105086916ALong term storageFast curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesiveMoisture

The invention provides a high-light-transmittance UV-moisture dual-curing adhesive. The high-light-transmittance UV-moisture dual-curing adhesive is prepared from, by weight, 30-70 parts of polyurethane prepolymer, 1-20 parts of reactive diluent, 1-10 parts of photoinitiator, 0.01-0.5 part of flatting agent, 0.1-1 part of polymerization inhibitor and 0.1-10 parts of silane coupling agent. The polyurethane prepolymer is synthesized by aliphatic series diisocyanate, dihydric alcohol or polyhydric alcohol and hydroxy containing epoxy monoacrylate, and the molar ratio of aliphatic series diisocyanate to dihydric alcohol or polyhydric alcohol to hydroxy epoxy monoacrylate is (1-1.2):1(0.5-0.8). According to the adhesive, fast curing after UV initiation can be achieved, a stable state of moisture curing non-initiation before UV initiation can be achieved, and good comprehensive performance is achieved.

Owner:深圳沃尔提莫电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com