Dual-curable polysiloxane acrylate resin and preparation method thereof

A technology of polysiloxane acrylate and dual curing, which is applied in chemical instruments and methods, other chemical processes, adhesives, etc., can solve problems such as poor temperature resistance, achieve regular product structure, simple preparation method, and short reaction cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 5 parts of methacryloxypropyltrimethoxysilane, 10.0 parts of hydroxy-terminated silicone oil, 100 parts of toluene and 1.25wt% of hydroxy-terminated silicone oil with dibutyl tin dilaurate into a 1000mL three-necked flask, and mix and stir with nitrogen. Reflux reaction at 40°C for 7 hours, reduce pressure to 1.33kPa, remove the solvent by rotary evaporation at 120°C, extract with anhydrous methanol, and continue to vacuum and rotary evaporate the lower layer after centrifugation to obtain a dual-curable polysiloxane acrylate resin with a regular structure. The resin is a transparent liquid that can flow at room temperature.

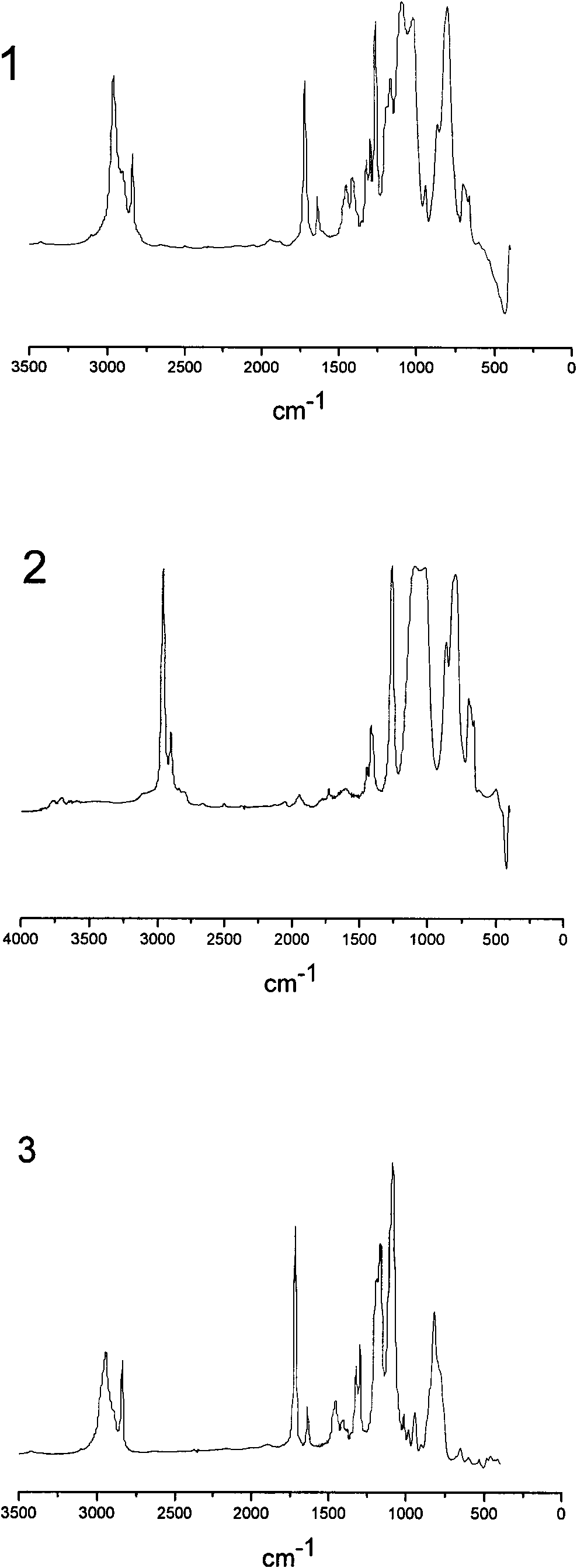

[0026] Characterize the synthesized products by Fourier infrared spectroscopy (see figure 1 ). figure 1 Shown are the infrared images of dual-curable polysiloxane acrylate resin and raw material hydroxyl-terminated polydimethylsiloxane and methacryloxypropyltrimethoxysilane. It can be seen from the infrared image of the dual-curable polysiloxane ...

Embodiment 2

[0031] Add 100 parts of methacryloxypropyltrimethoxysilane, 10 parts of hydroxy-terminated silicone oil, 100 parts of cyclohexane and 0.1wt% of hydroxy-terminated silicone oil to dibutyl tin dilaurate in a 1000mL three-necked flask, and pass nitrogen gas Mix and stir, reflux and react at 70°C for 6 hours, reduce pressure to 1.33kPa, remove the solvent by rotary evaporation at 80°C, extract with anhydrous methanol, continue centrifugation and continue vacuum rotary evaporation to obtain a regular structure of polysiloxane acrylate resin. The resin is a transparent liquid that can flow at room temperature.

Embodiment 3

[0033] Add 8 parts of methacryloxypropyl trimethoxysilane, 10.0 parts of hydroxy-terminated silicone oil, 100 parts of cyclohexane and 1.25wt% of organic titanium with hydroxy-terminated silicone oil in a 1000mL three-necked flask, and mix and stir with nitrogen at 65℃ Reflux the reaction for 6 hours. After the reaction, use molecular distillation equipment to distill at 50 Pa and 100° C. to obtain a polysiloxane acrylate resin with a regular structure. The resin is a transparent liquid that can flow at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com