Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

A wood coating, double curing technology, applied in the direction of coating, etc., can solve the problems of incomplete curing of colored UV paint, incomplete curing of matte UV paint, good impact and wear resistance, etc., to achieve mature and stable production technology, fine The effect of low density and excellent defoaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Prepare moisture-ultraviolet dual-curing polyurethane wood coatings according to the following steps.

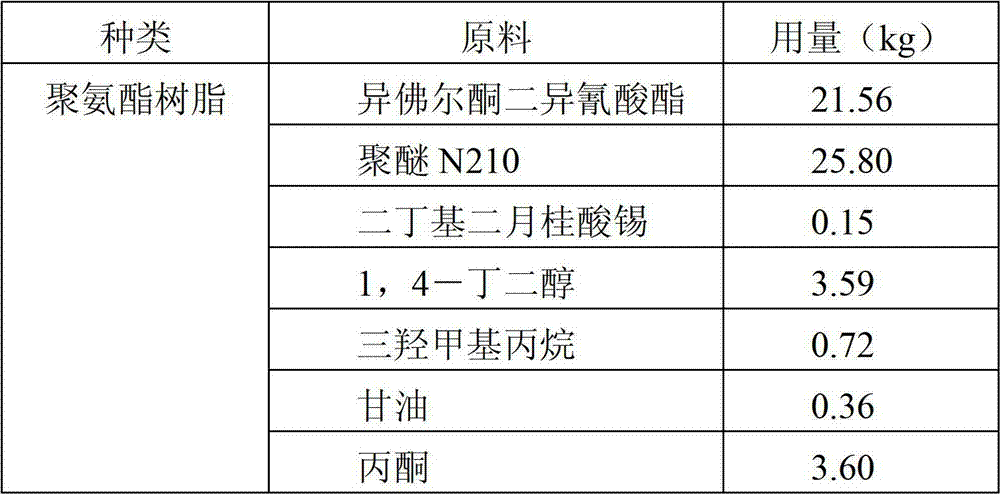

[0047] Prepare raw materials: Prepare materials according to the formula in Table 1.

[0048] Table 1

[0049]

[0050]

[0051] Synthesis of polyurethane primary polymer I: first add polyether N210 into the reaction vessel, heat up to 80°C, then add isophorone diisocyanate and catalyst dibutyltin dilaurate (0.15kg), and stir for 2 hours. Obtain reaction initial polymer I;

[0052] Synthesis of Polyurethane Prepolymer II: Add a metered mixture of 1,4-butanediol, trimethylolpropane, glycerol and acetone (1.8kg) dropwise to the obtained initial polymer I, and control the dropping time at 1 hour; the dropwise addition is completed, and at a temperature of 80°C, react for 1 hour, and the reaction is completed to obtain polyurethane prepolymer II;

[0053] Synthesis of polyurethane prepolymer III: Add epoxy resin E-44 and the remaining acetone (1.8kg) into the rea...

Embodiment 2

[0058] Prepare moisture-ultraviolet dual-curing polyurethane wood coatings according to the following steps.

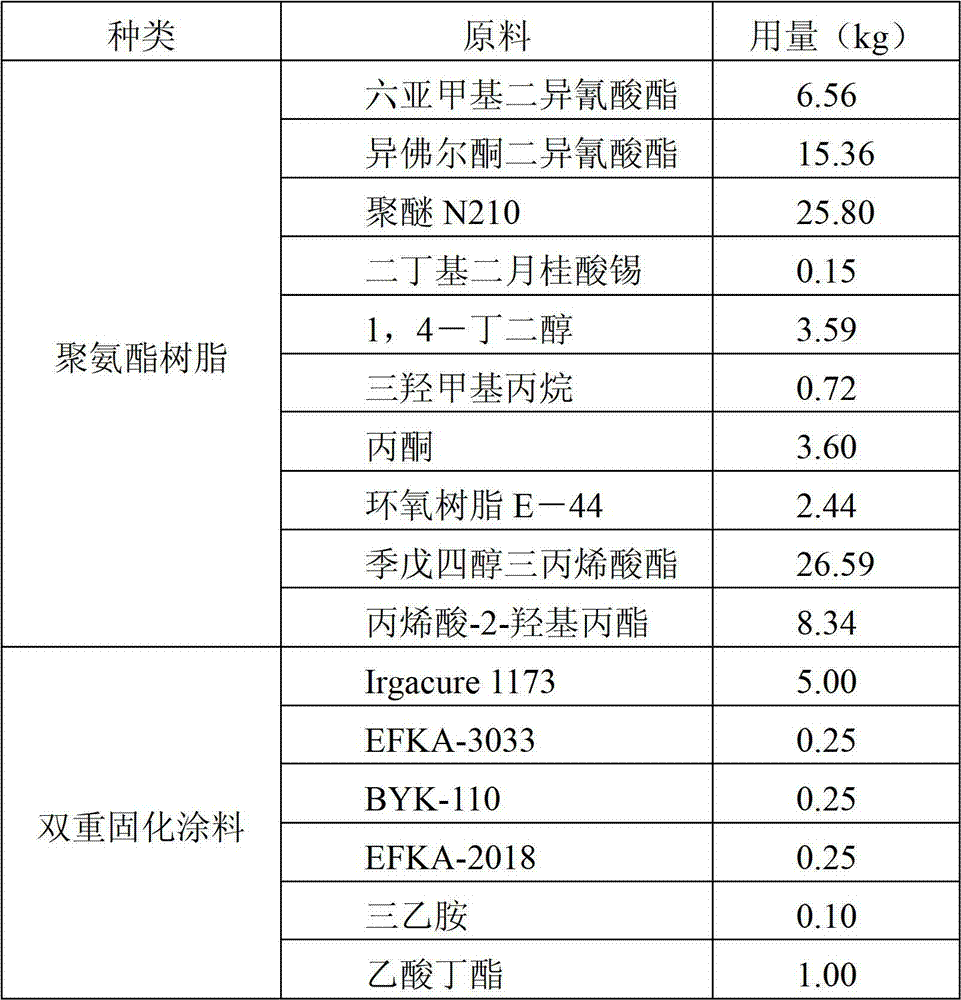

[0059] Prepare raw materials: Prepare materials according to the formula in Table 2.

[0060] Table 2

[0061]

[0062] Synthesis of polyurethane primary polymer I: First, add polyether N210 into the reaction vessel, heat up to 80°C, then add hexamethylene diisocyanate, isophorone diisocyanate and catalyst dibutyltin dilaurate, and stir to react In 2 hours, the reaction initial polymer I was obtained;

[0063] Synthesis of polyurethane prepolymer II: dropwise add a mixture of 1,4-butanediol, trimethylolpropane and acetone (1.8kg) to the obtained primary polymer I, and control the dropping time to 1 hour After the dropwise addition is completed, react for 1 hour at a temperature of 80° C., and the polyurethane prepolymer II is obtained after the reaction is completed;

[0064] Synthesis of polyurethane prepolymer III: Add epoxy resin E-44 and the remaining aceton...

Embodiment 3

[0069] Prepare moisture-ultraviolet dual-curing polyurethane wood coatings according to the following steps.

[0070] Prepare raw materials: Prepare materials according to the formula in Table 3.

[0071] table 3

[0072]

[0073]

[0074] Synthesis of polyurethane primary polymer I: First, add polyether N210 into the reaction vessel, heat up to 85°C, then add hexamethylene diisocyanate and catalyst dibutyltin dilaurate (0.15kg), and stir for 2 hours. Obtain reaction initial polymer I;

[0075] Synthesis of Polyurethane Prepolymer II: Add a metered mixture of 1,4-butanediol, trimethylolpropane, glycerol and acetone (1.8kg) dropwise to the obtained initial polymer I, and control the dropping time at 1 hour; the dropwise addition is completed, and at a temperature of 80° C., react for 1 hour, and the reaction is completed to obtain polyurethane prepolymer II;

[0076]Synthesis of polyurethane prepolymer III: Add epoxy resin E-44 and the remaining acetone (1.8kg) into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com