Preparation method of waterproof roll

A waterproof membrane and the technology of preparation steps, which are applied in the field of waterproof membrane preparation, can solve the problems of short durability, easy water leakage, poor anti-leakage effect, etc., and achieve the effect of reducing thermal oxygen and good anti-radiation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

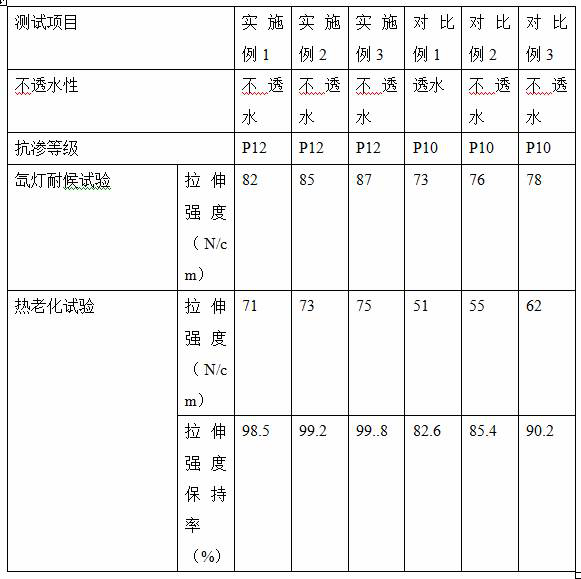

Examples

Embodiment 1

[0035] The rubber powder is: butyl rubber powder

[0036] Described waterproof coupling agent is: aminosiloxane

[0037] Preparation of asphalt latex:

[0038] In parts by weight, put 70 parts of asphalt and 10 parts of turpentine into the stirring reaction kettle, heat up to 80°C, preheat and stir for 20 minutes, then add 30 parts of rubber powder to the stirring reaction kettle, and continue stirring 40min, heat up to 200℃, keep warm for 10min, then add 20 parts of rock wool fiber and 10 parts of waterproof coupling agent, stir and mix well, then place it in a high-speed shearing machine to emulsify at a speed of 2500r / min to obtain asphalt latex, The rubber powder is one of butyl rubber powder, ethylene-propylene rubber powder and SBS rubber powder, and the waterproof coupling agent is aminosiloxane, methacryloyloxysiloxane, epoxy silicon any of the oxanes or combinations thereof;

[0039] Preparation of protein solution:

[0040] In parts by weight, 70 parts of ammonia...

Embodiment 2

[0048] Described rubber powder is: ethylene propylene rubber powder

[0049] Described waterproof coupling agent is: methacryloxysiloxane

[0050] Preparation of asphalt latex:

[0051] In parts by weight, put 75 parts of asphalt and 12.5 parts of turpentine in the stirring reaction kettle, heat up to 85°C, preheat and stir for 25 minutes, then add 32.5 parts of rubber powder to the stirring reaction kettle, and continue stirring 45min, heat up to 210℃, keep warm for 12.5min, then add 22.5 parts of rock wool fiber and 12.5 parts of waterproof coupling agent, stir and mix well, then place it in a high-speed shearing machine to emulsify at a speed of 3000r / min to obtain asphalt latex , the rubber powder is one of butyl rubber powder, ethylene propylene rubber powder, and SBS rubber powder, and the waterproof coupling agent is aminosiloxane, methacryloyloxysiloxane, epoxy any of the siloxanes or combinations thereof;

[0052] Preparation of protein solution:

[0053] In parts...

Embodiment 3

[0061] Described rubber powder is: SBS rubber powder

[0062] Described waterproof coupling agent is: epoxy siloxane

[0063] Preparation of asphalt latex:

[0064] In parts by weight, put 80 parts of asphalt and 15 parts of turpentine into the stirring reaction kettle, heat up to 90°C, preheat and stir for 30 minutes, then add 35 parts of rubber powder to the stirring reaction kettle, and continue stirring 50min, heat up to 220℃, keep warm for 15min, then add 25 parts of rock wool fiber and 15 parts of waterproof coupling agent, stir and mix well, then place it in a high-speed shearing machine to emulsify at a speed of 3500r / min to obtain asphalt latex, The rubber powder is one of butyl rubber powder, ethylene-propylene rubber powder and SBS rubber powder, and the waterproof coupling agent is aminosiloxane, methacryloyloxysiloxane, epoxy silicon any of the oxanes or combinations thereof;

[0065] Preparation of protein solution:

[0066] In parts by weight, 75 parts of am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com