FeCrAl base alloy material for nuclear fuel cladding material

A cladding material and alloy material technology, applied in the field of fuel cladding, can solve the problems of poor water vapor oxidation resistance and safety risks, and achieve the effects of excellent oxidation resistance, good processing performance, and prolonged emergency response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through specific examples.

[0017] The elements of Fe, Cr, Al, Y, Mo, Si, and C were mixed according to weight percentage and prepared into 6 alloy ingots by vacuum induction melting method. The chemical composition of the 6 ingots was sampled for analysis. The composition is shown in Table 1. The six ingots were forged, hot-rolled, extruded, annealed, etc. to produce FeCrAl-based alloy pipes with corresponding compositions.

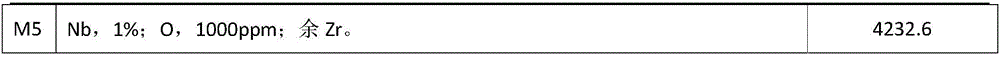

[0018] For the six FeCrAl-based alloys of the present invention and the commercial zirconium alloy M5 for nuclear power plants, a high-temperature steam oxidation test was carried out in a high-temperature steam oxidation equipment. The oxidation temperature was 1200 °C and the oxidation time was 1 h. The results are shown in Table 1. Table 1 shows the proportions of FeCrAl-based components of six FeCrAl-based alloys according to the present invention, ie, Examples 1-6, and their oxidation wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com