Patents

Literature

162 results about "Light-water reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The light-water reactor (LWR) is a type of thermal-neutron reactor that uses normal water, as opposed to heavy water, as both its coolant and neutron moderator – furthermore a solid form of fissile elements is used as fuel. Thermal-neutron reactors are the most common type of nuclear reactor, and light-water reactors are the most common type of thermal-neutron reactor.

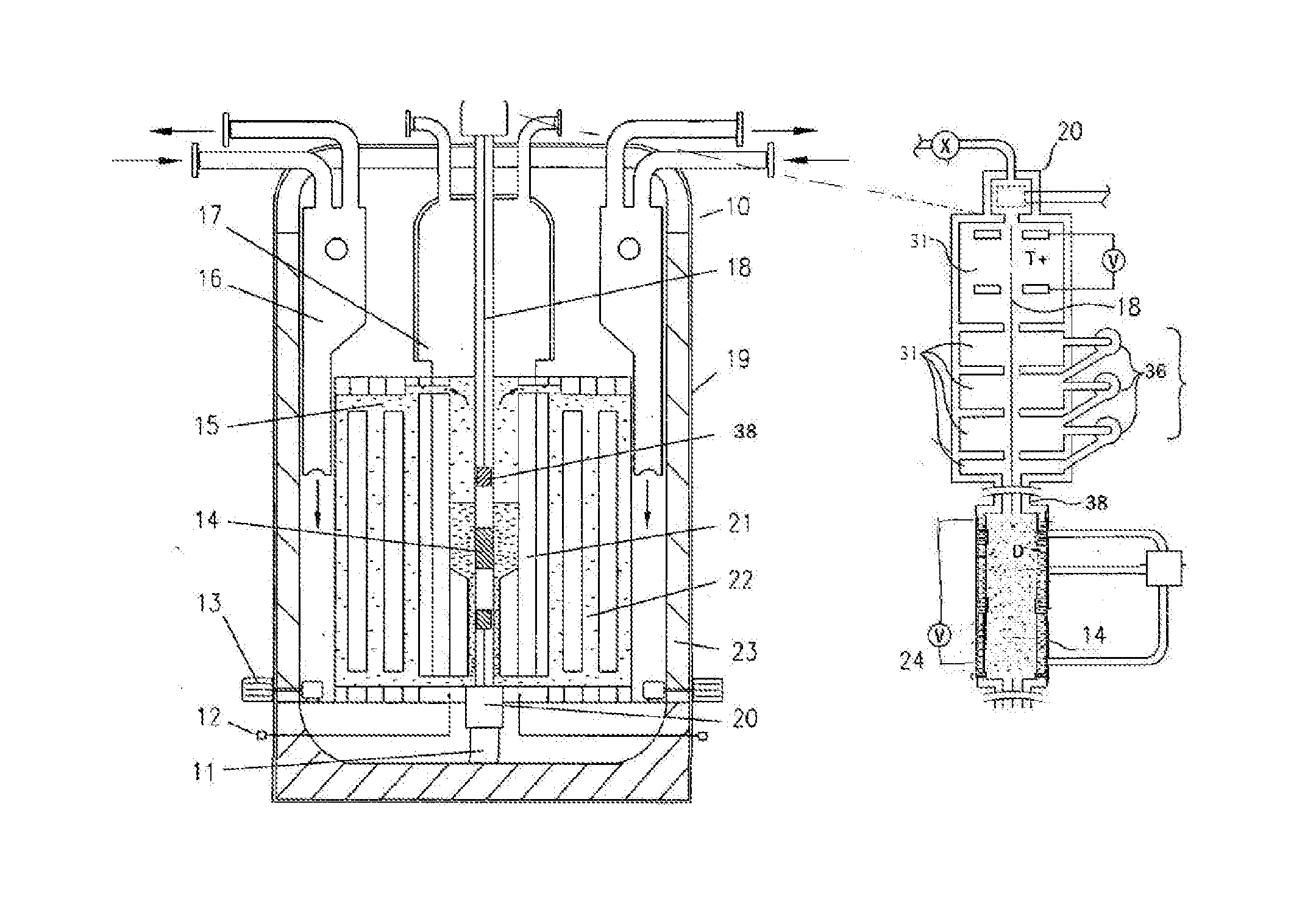

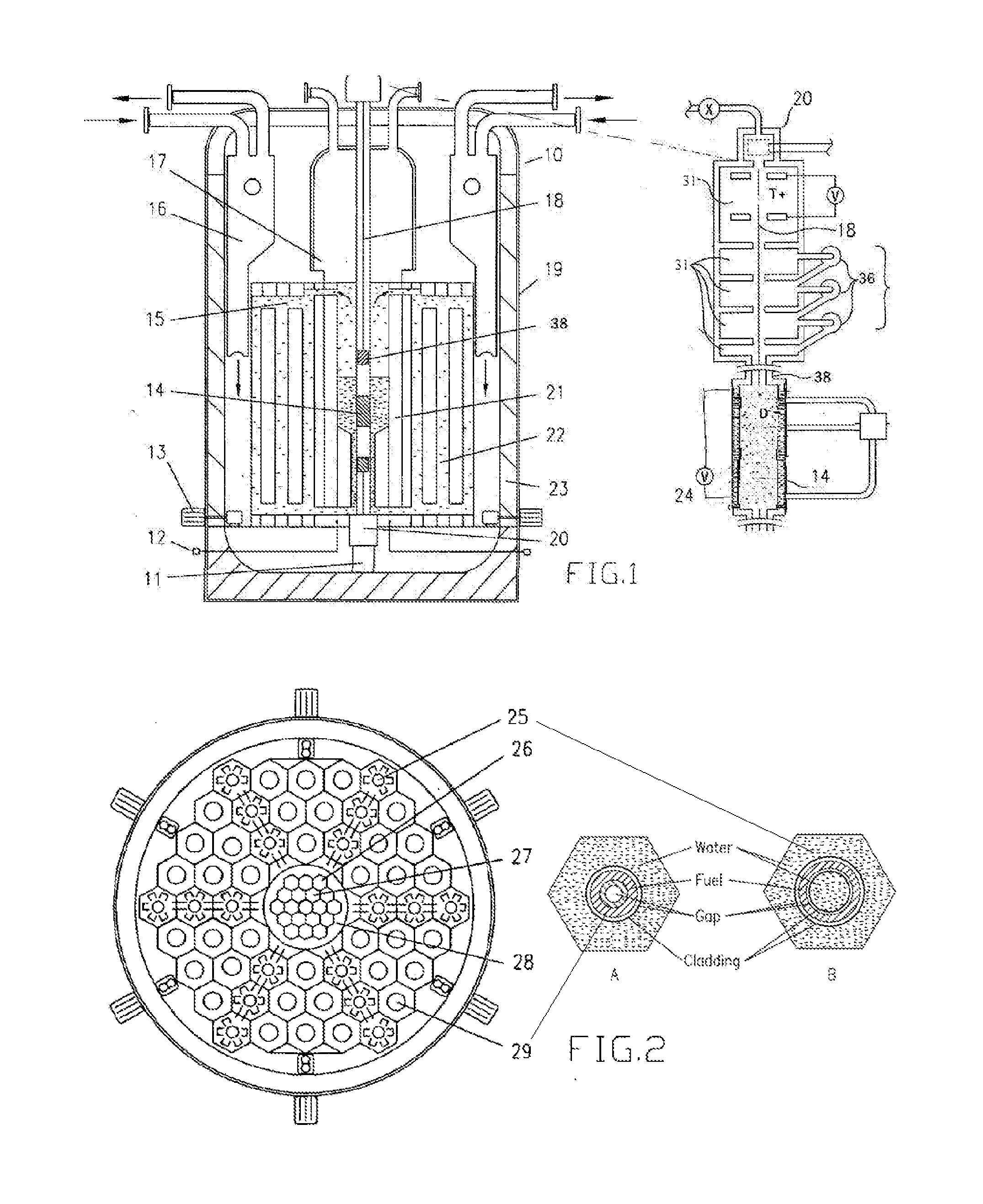

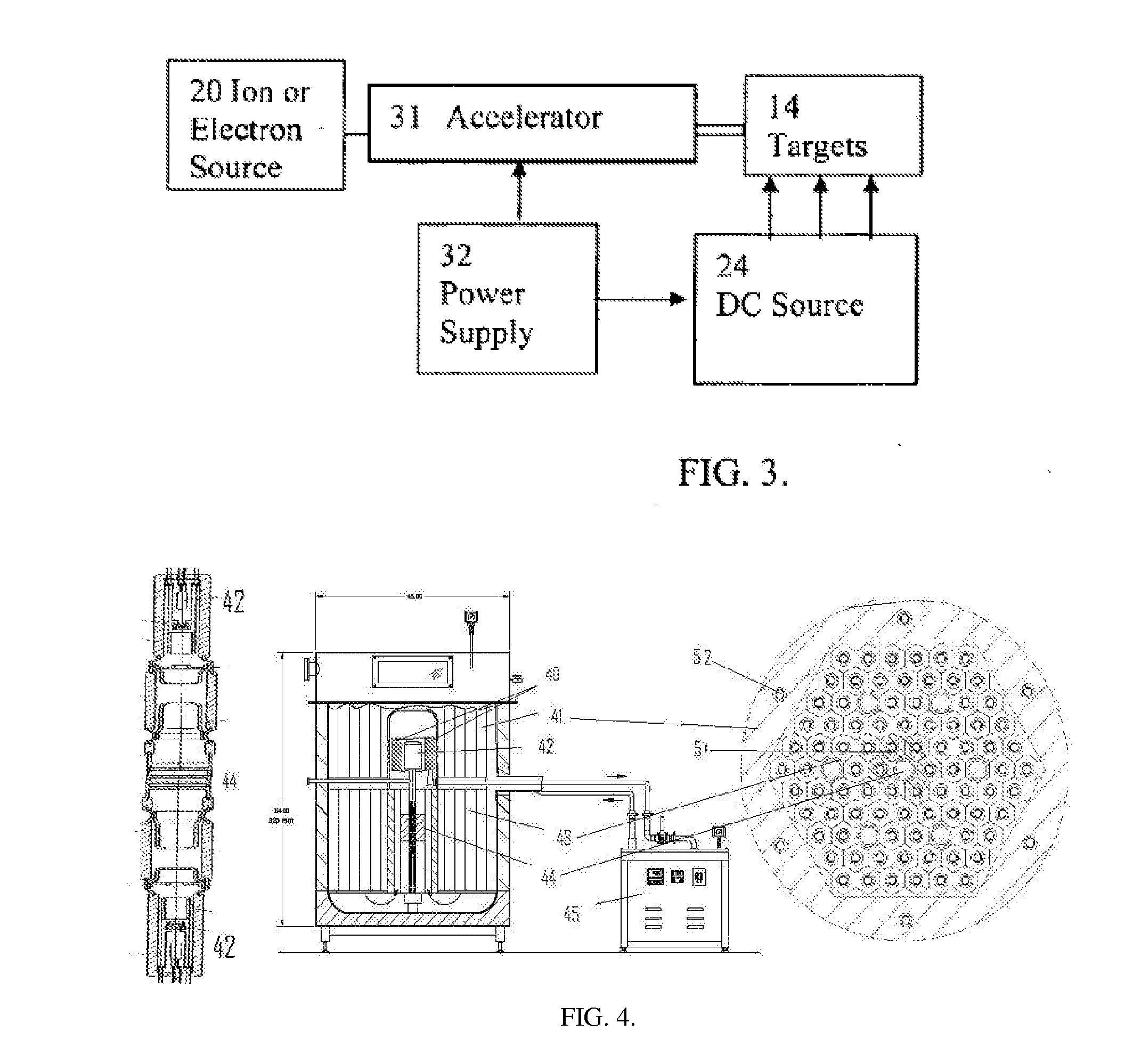

Sustainable Modular Transmutation Reactor

InactiveUS20150098544A1Improve distributionImprove economyIntegral reactorsConversion outside reactor/acceleratorsFission fusionDelayed neutron

A light water reactor to safely convert depleted uranium into a fuel source that could be used as a sustainable source of energy for centuries. The reactor is a type of breed-burn reactor uniquely combined with a proliferation-resistant fuel cycle with no uranium enrichment and no plutonium isolation. It is comprised of a compact factory-produced fast region and a thermal region that produces about 95% of the core power and contains the passageways for transports of delayed-neutron emitters to the fast region, where they can provide additional neutrons (source-based mode) or all the necessary excitation without an external neutron source (self-regulating mode). A second embodiment of the invention is a small unit driven by a neutron source with beam recycling for propulsion, electrical power or radioisotope production. It could also serve as a demonstration facility for the transmutation reactor with fission-fusion fuel.

Owner:BLANOVSKY ANATOLY

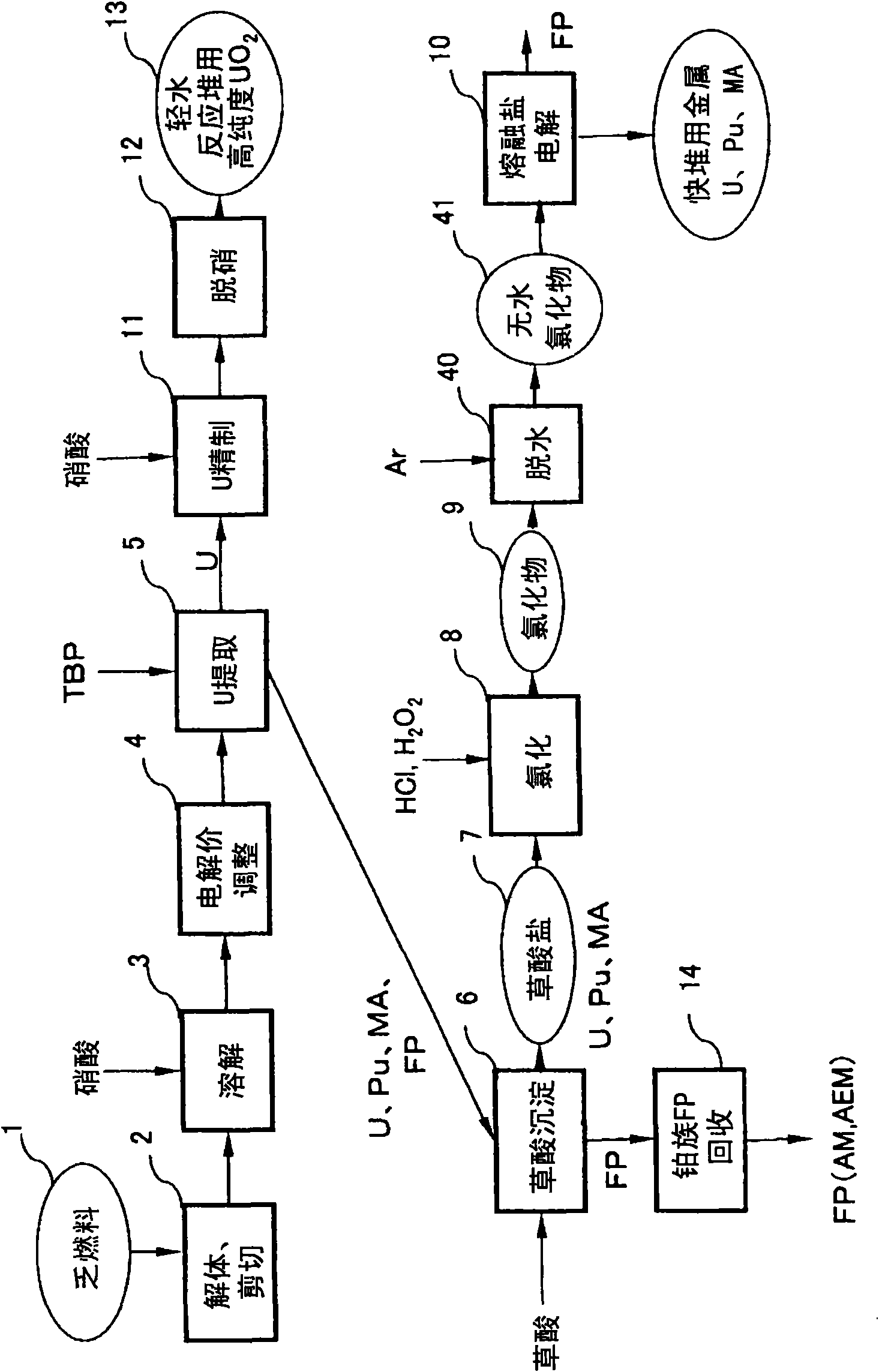

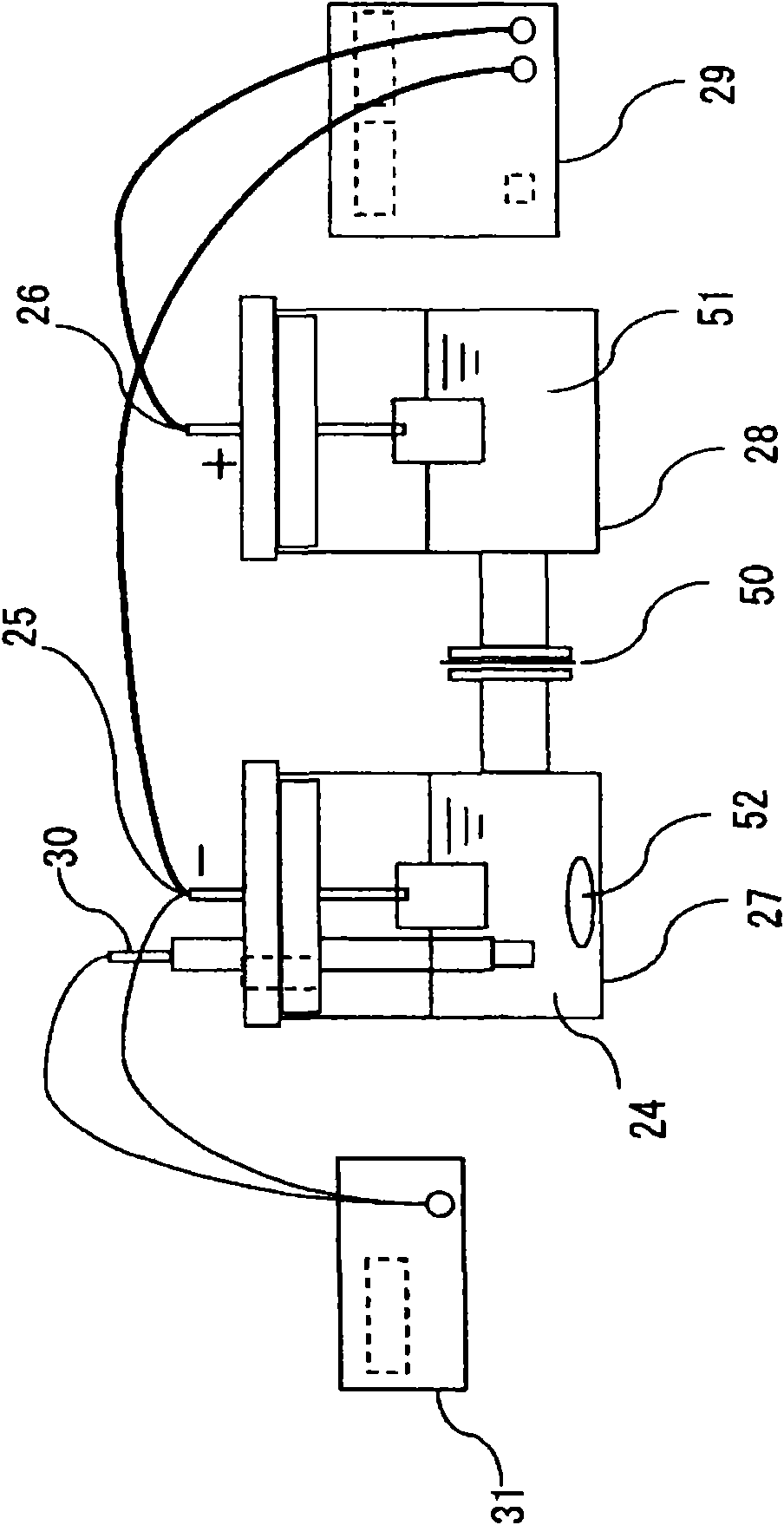

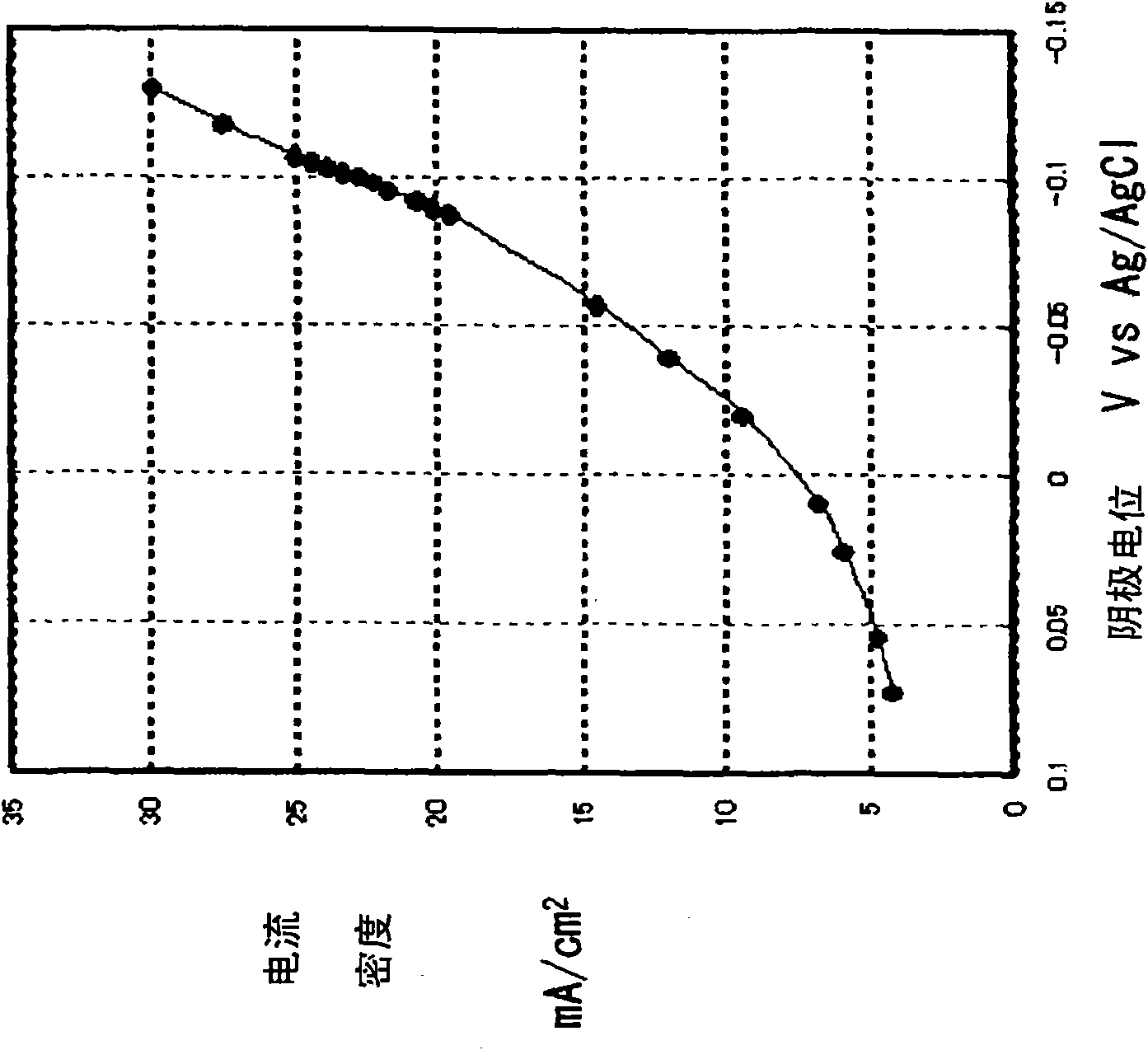

Spent fuel reprocessing method

InactiveCN101593566AHigh non-diffusionNuclear energy generationNuclear elementsFuel reprocessingElectrolysis

Owner:KK TOSHIBA

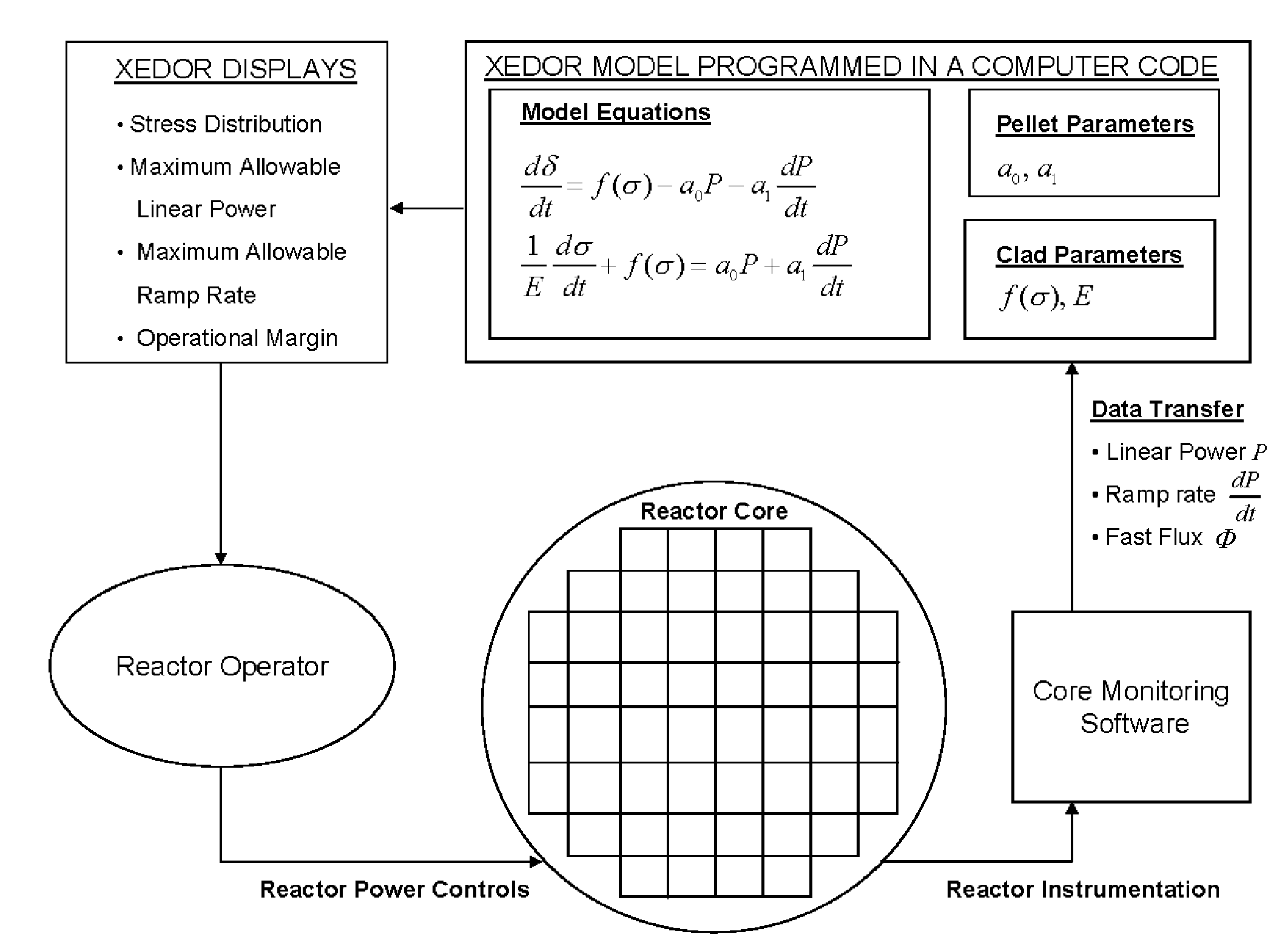

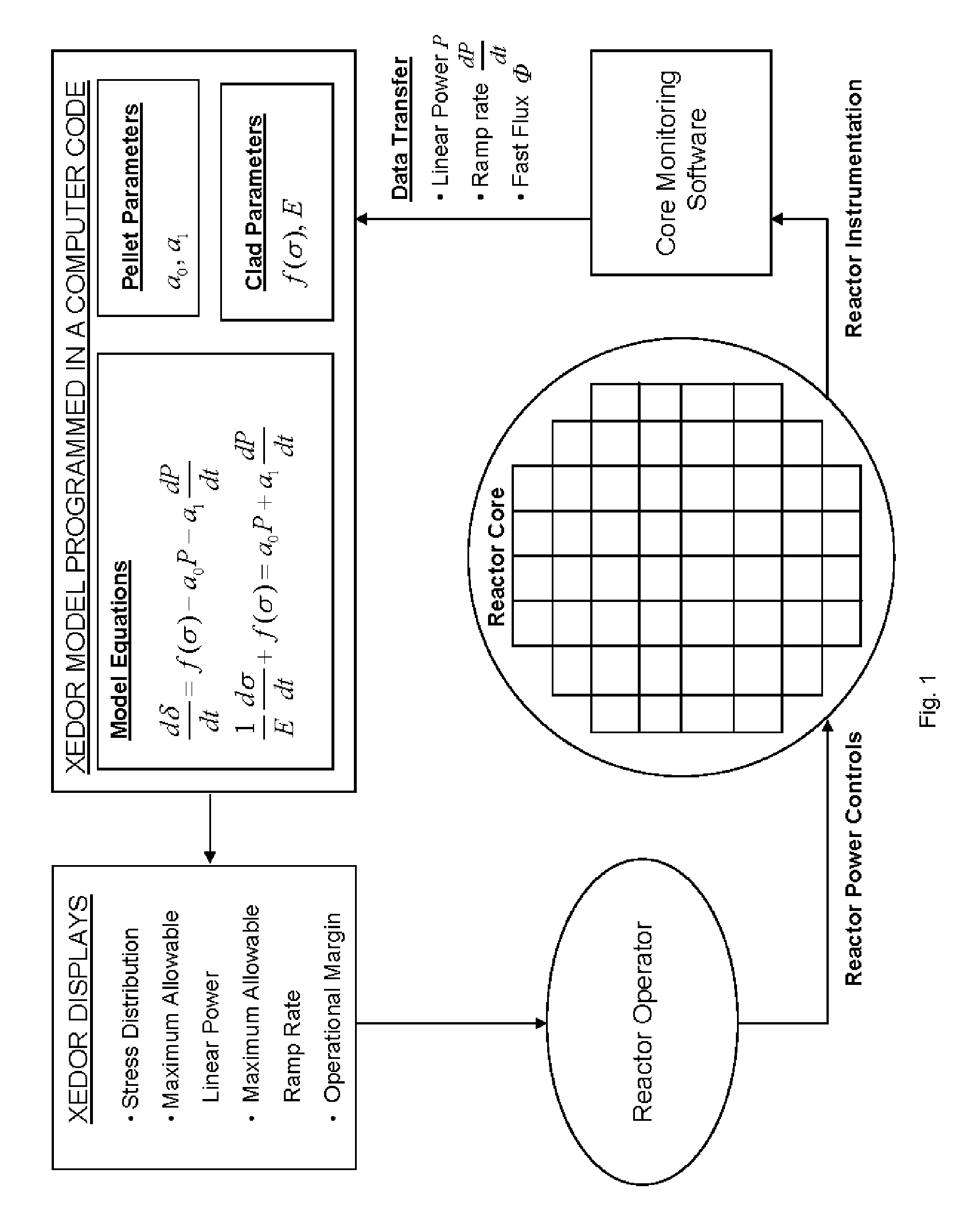

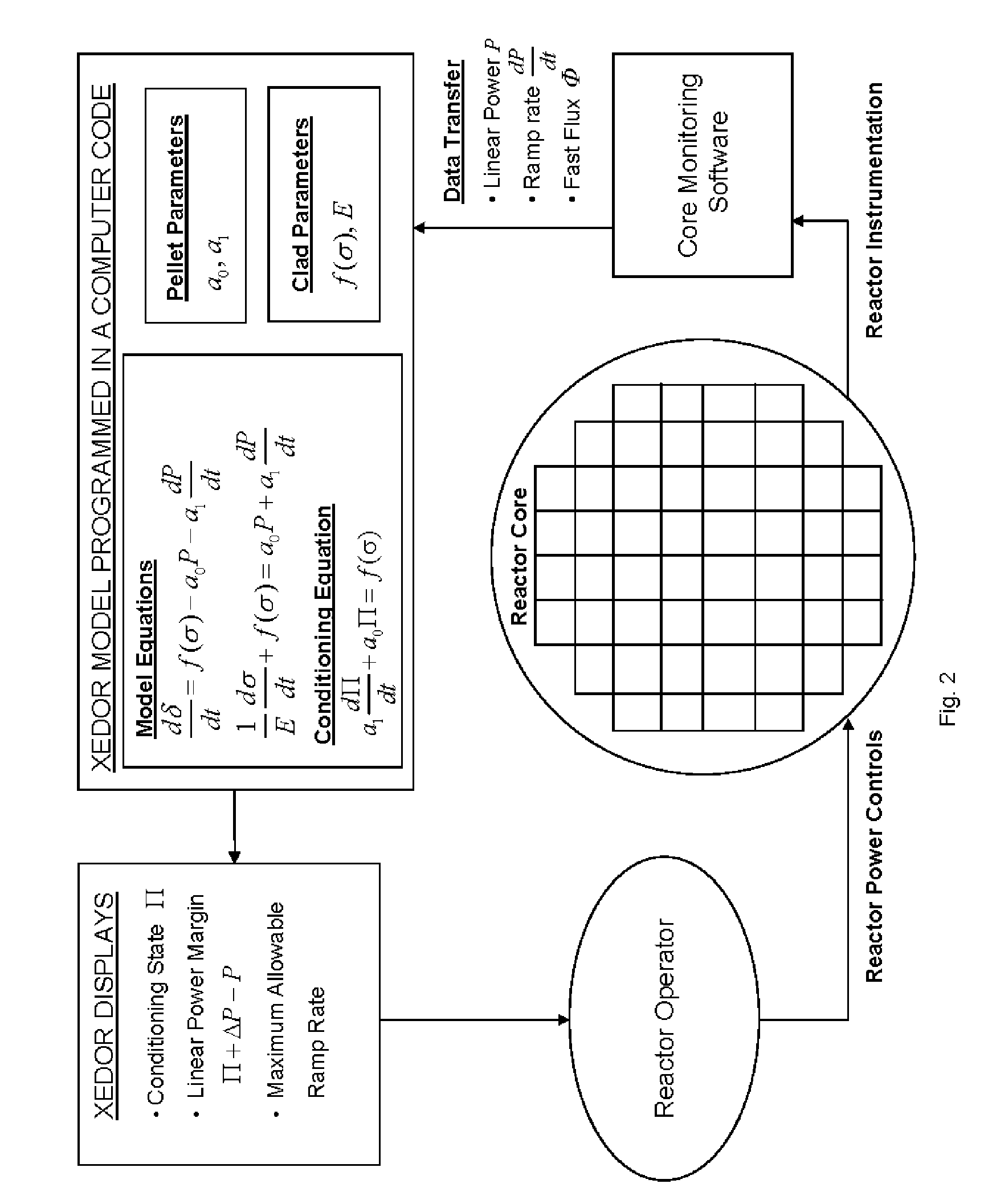

Reduced Order Stress Model for Online Maneuvering, Diagnostics of Fuel Failure and Design of Core Loading Patterns of Light Water Reactors

ActiveUS20090080585A1Nuclear energy generationNuclear monitoringStress corrosion crackingReduced order

The invention is principally directed to a reduced order model, XEDOR, facilitating the prediction of and the diagnostics of pellet-clad interaction stress-corrosion-cracking failure of nuclear fuel rods. The invention more particularly relates to assessment of susceptibility to PCI failure for guidance in the design of fuel loading in nuclear reactors. The invention additionally relates to the protection against PCI failure by providing operational information to operators of a nuclear reactor during power maneuvering, including predictive calculations prior to executing power maneuvers. Additionally, the invention relates to the diagnostics of an event suggesting a possible PCI cladding failure.

Owner:AREVA NP SAS

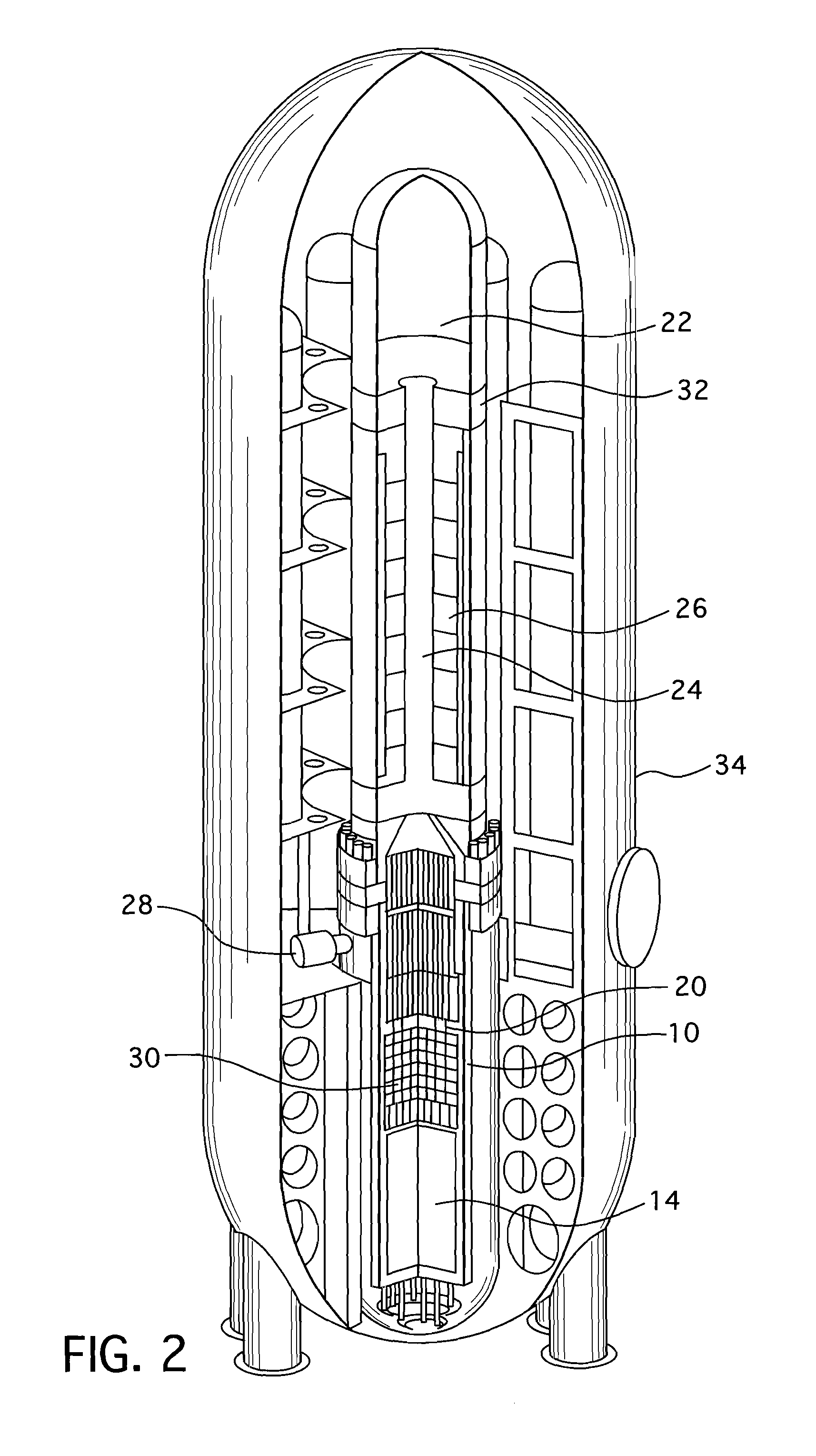

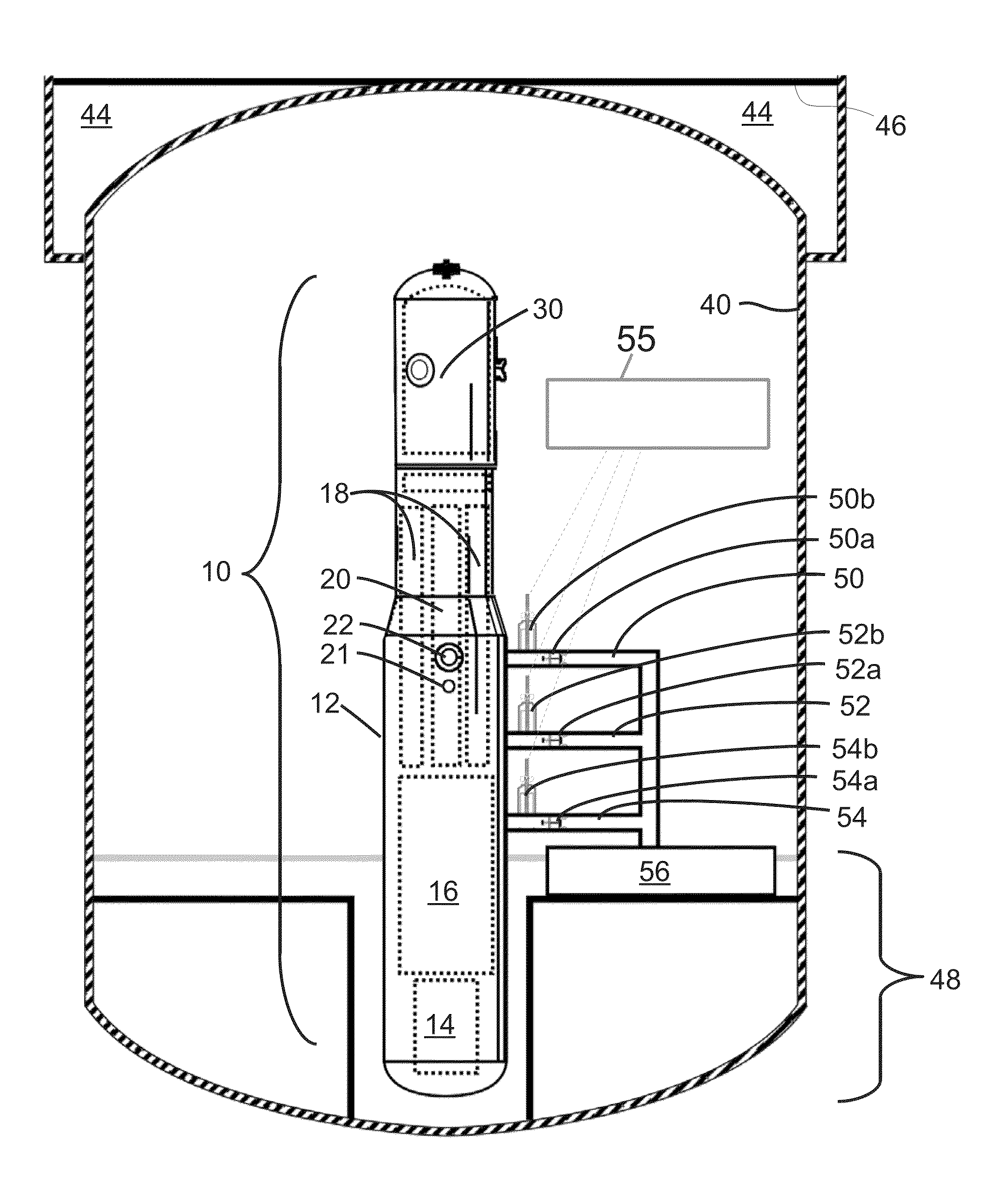

Pressurizer surge-line separator for integral pressurized water reactors

An integral pressurized light water reactor having most of the components of a primary side of a pressurized water reactor nuclear steam supply system housed in a single pressure vessel with a pressurizer separated from the remaining reactor system by a surge separator having multiple layers of separated steel plates with a number of concentric baffles extending therebetween. A circuitous flow path is provided through and between the plates and concentric baffles and a relatively stagnant pool of coolant is maintained within an innermost zone between the plates to provide thermal isolation.

Owner:WESTINGHOUSE ELECTRIC CORP

High Fe contained zirconium alloy compositions having excellent corrosion resistance and preparation method thereof

ActiveUS20080192880A1Improve corrosion resistanceHigh cycle operationOptical rangefindersNuclear energy generationNuclear reactor coreNiobium

A high Fe-containing zirconium composition having excellent corrosion resistance and a preparation method thereof. Specifically, disclosed are a high Fe-containing zirconium composition having excellent corrosion resistance and a preparation method thereof, the composition comprising: 0.5-1.0 wt % iron; 0.25-0.5 wt % chromium; 0.06-0.18 wt % oxygen; at least one element selected from the group consisting of 0.2-0.5 wt % tin, 0.1-0.3 wt % niobium and 0.05-0.3 wt % copper; and the balance of zirconium. The zirconium alloy has excellent corrosion resistance, and thus can be used as a material for nuclear fuel claddings, spacer grids and nuclear reactor core structures in light water reactor and heavy water reactor nuclear power plants.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

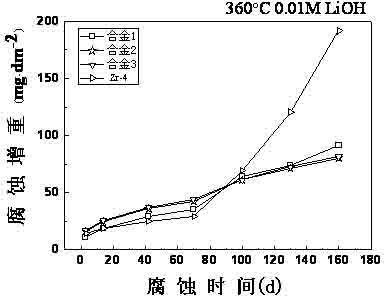

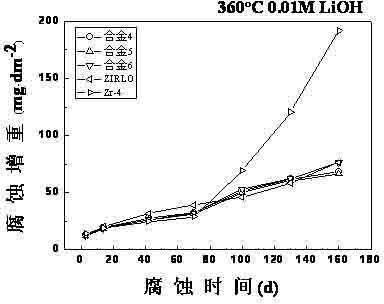

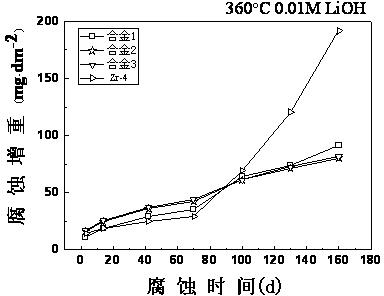

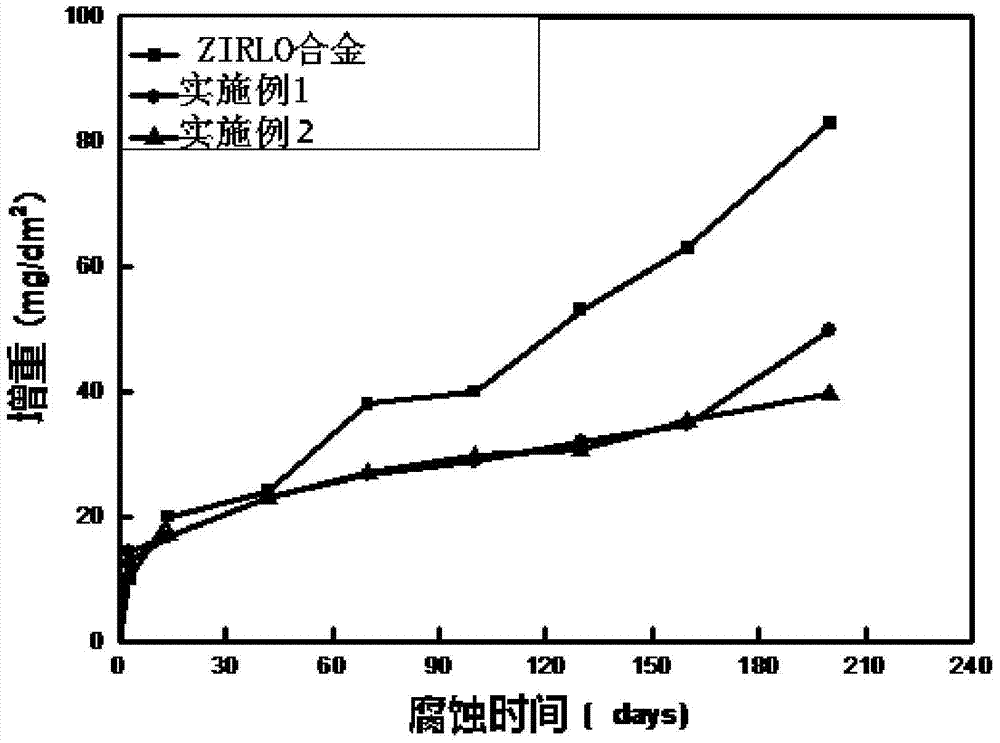

Germanium-containing Zr-Sn-Nb alloy for fuel cladding of nuclear power station

ActiveCN102605213AImprove corrosion resistanceEasy to processOptical rangefindersNuclear energy generationPressurized water reactorNuclear power

The invention relates to a germanium-containing Zr-Sn-Nb alloy capable of being used as structural materials such as fuel cladding of a light water reactor nuclear power station, stripes of a location grid and the like, belonging to the technical field of zirconium alloy materials. The zirconium alloy comprises the following chemical components in percentage by weight: 0.3-1.5% of Sn, 0.1-1.2% of Nb, 0.03-0.4% of Fe, 0.02-0.3% of Cr, 0.01-0.8% of Ge and the balance of Zr, preferably 0.5-1.0% of Sn, 0.2-1.0% of Nb, 0.01-0.35% of Fe, 0.03-0.2% of Cr and 0.05-0.5% of Ge. The zirconium alloy can show excellent corrosion-resistant property in 360 DEG C / 18.6MPa / 0.01M LiOH aqueous solution, which is obviously better than Zr-4 alloy, is good in processability, and can be used as reactor core structural materials such as fuel element cladding of a pressurized water reactor of the nuclear power station, stripes of the location grid and the like.

Owner:SHANGHAI UNIV +1

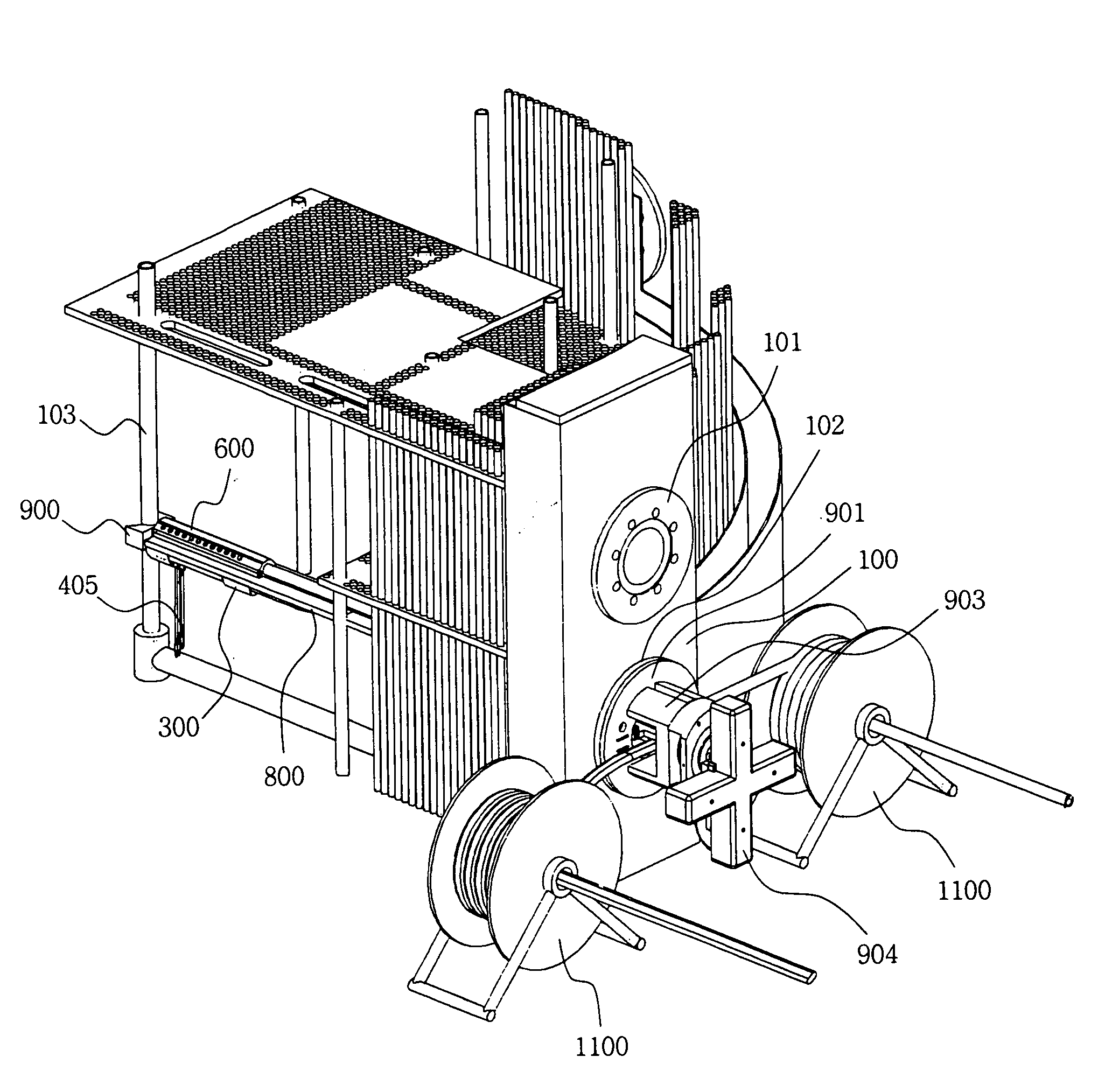

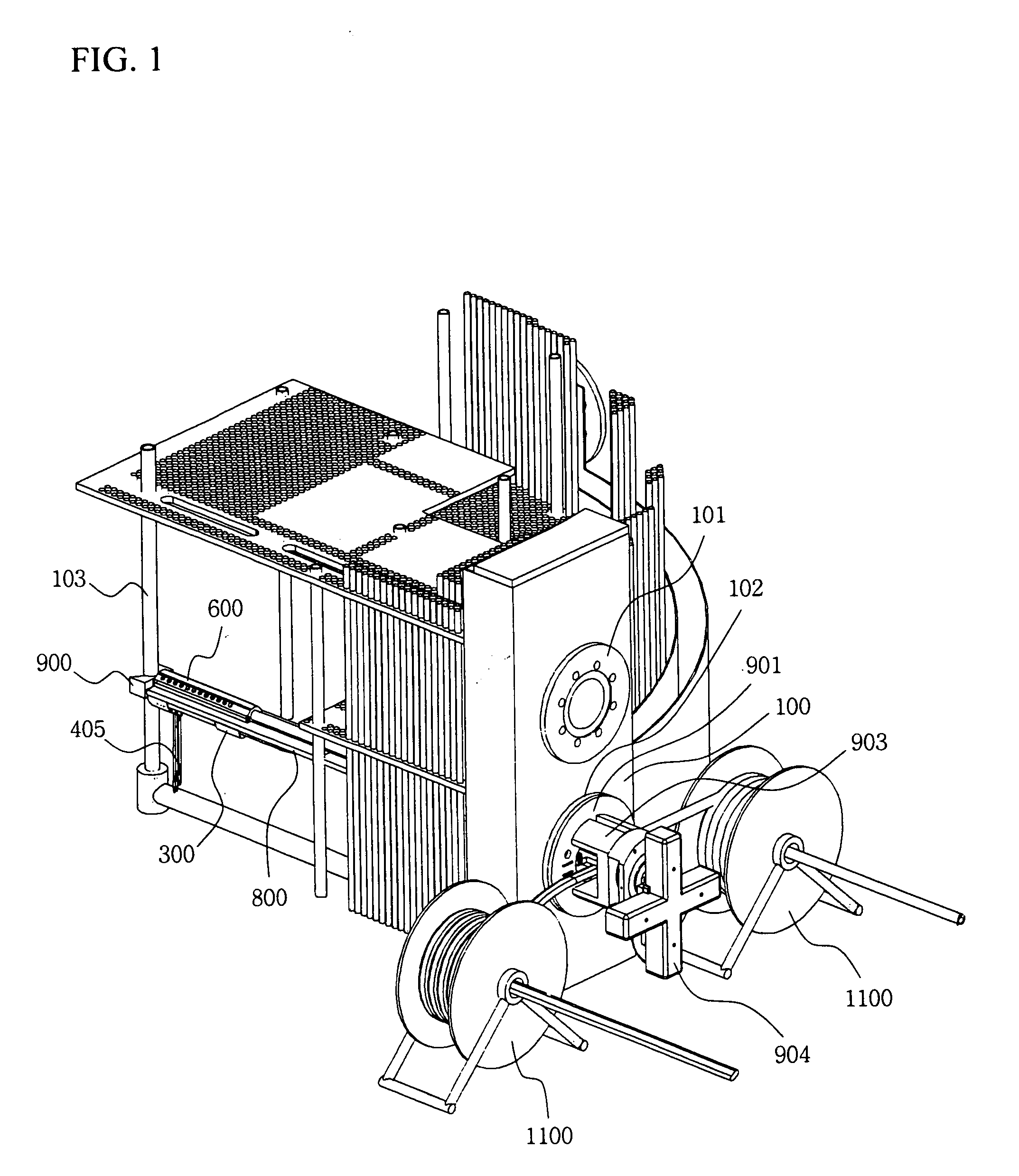

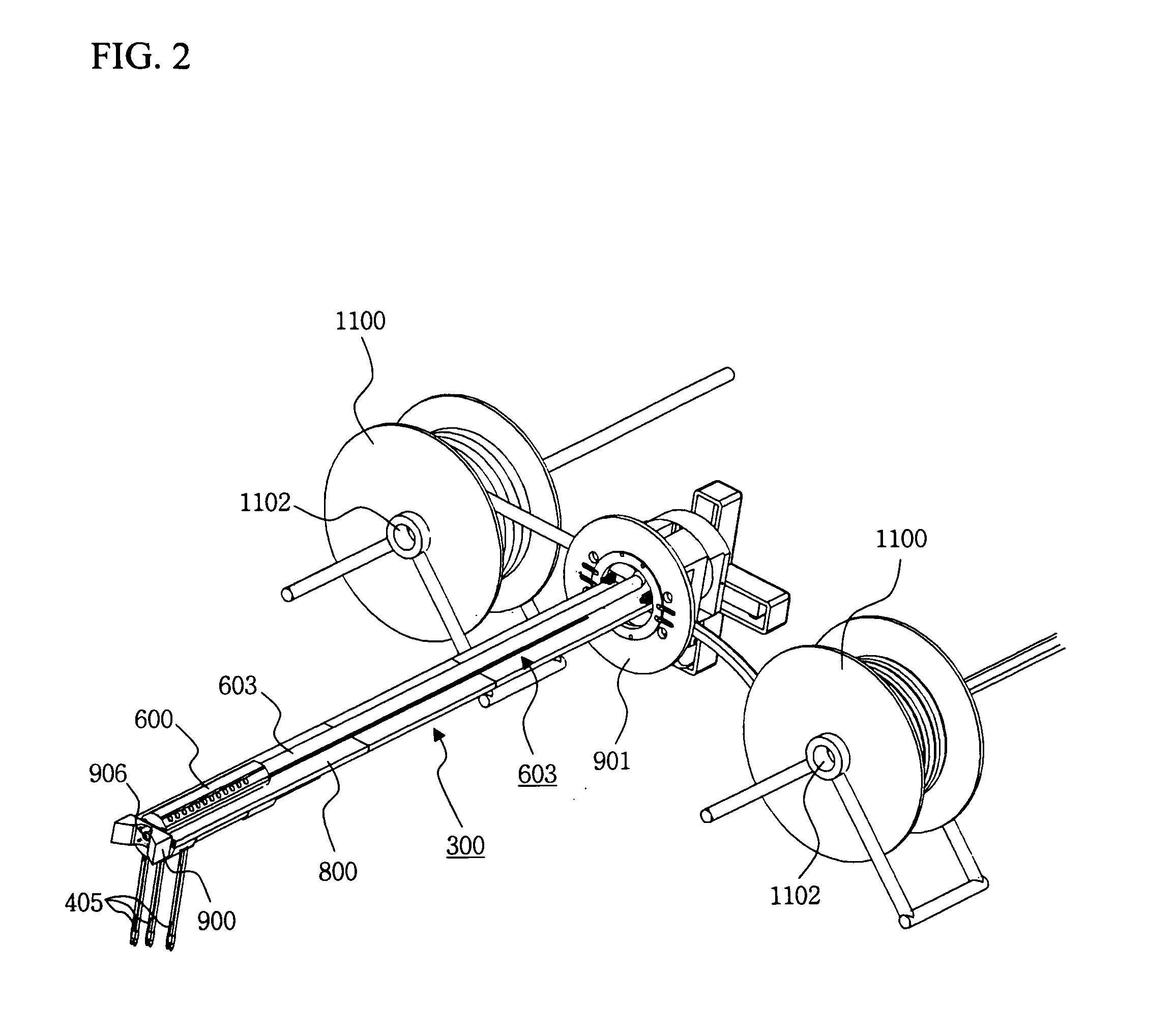

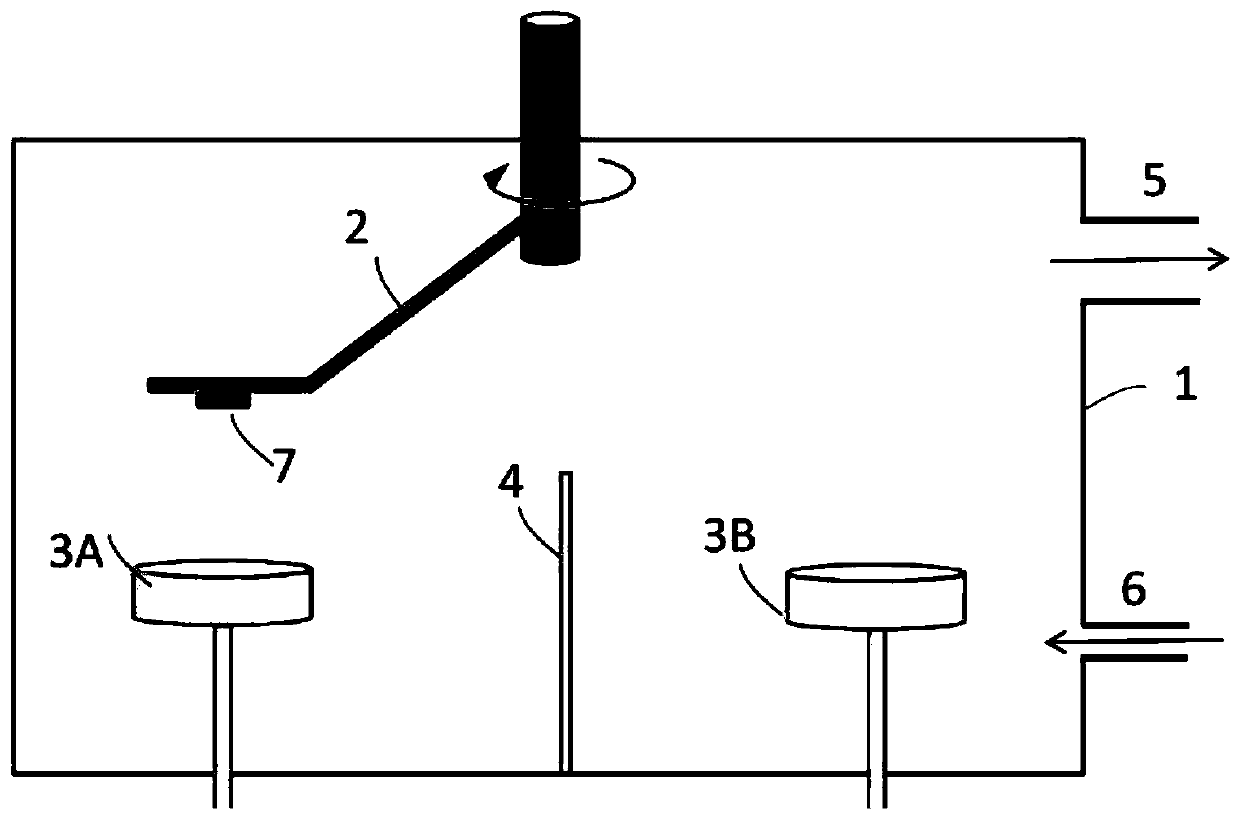

Hydraulic Drive Type Partial Inter-Tube Lancing System for Cleaning Steam Generator in Nuclear Power Plant

ActiveUS20100071734A1Shorten operation timeIncrease the lengthNuclear energy generationNuclear elementsForeign matterNuclear power

A hydraulic drive type partial inter-tube lancing system for cleaning a steam generator in a nuclear power plant, which removes foreign matter, such as sludge, deposited around heat transfer tubes in the steam generator, is disclosed. More particularly, a hydraulic drive type partial inter-tube lancing system, which serves to clean a steam generator of a light-water reactor in a nuclear power plant by removing sludge, attached inside the steam generator, using high-pressure water, is disclosed.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

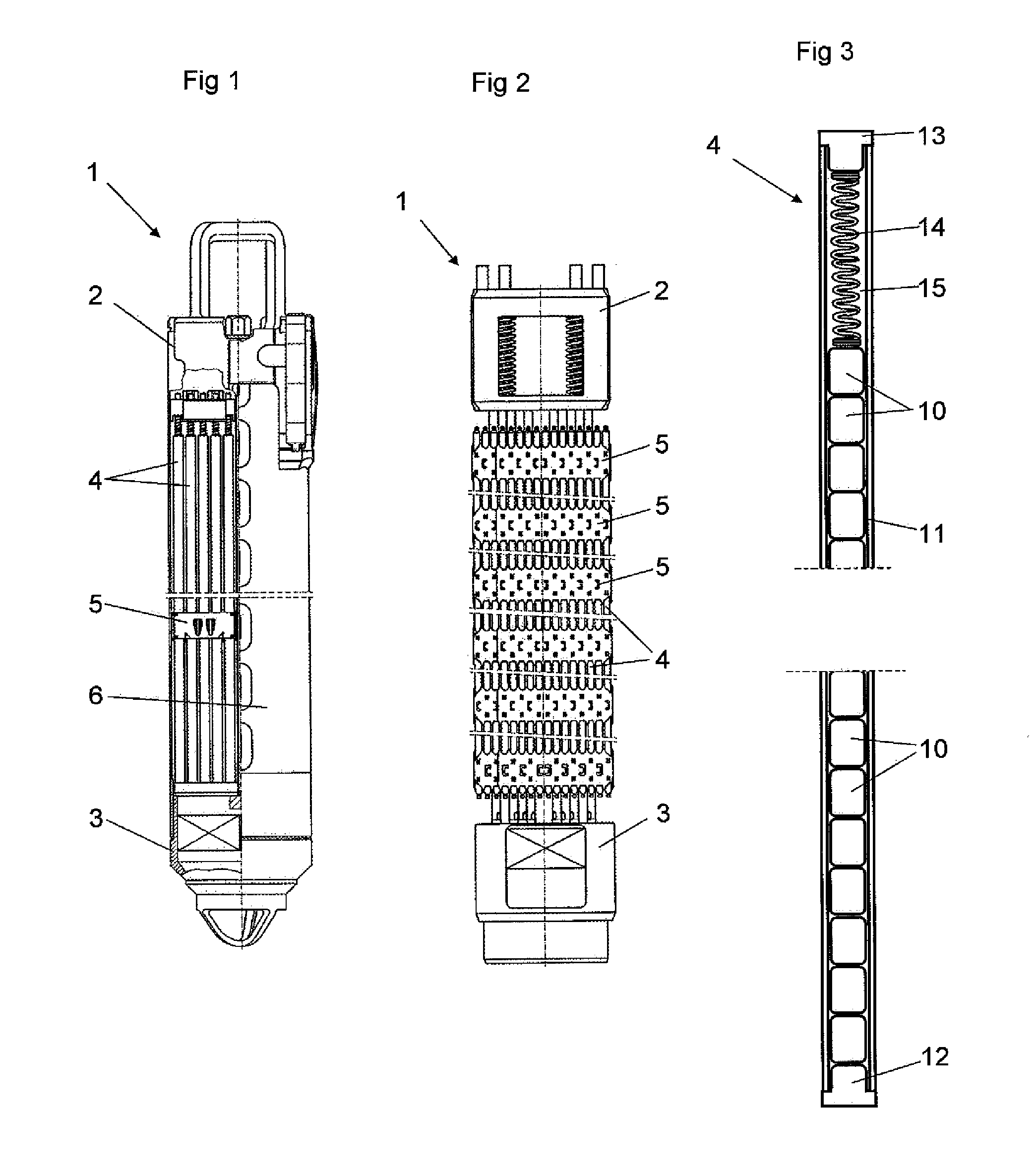

Method, use and device relating to nuclear light water reactors

ActiveUS20060144484A1Improve propertiesImprove flatnessOptical rangefindersFuel elementsAlloyQuenching

The invention concerns a method of producing and treating a sheet suited to be used as a component or as a part of a component in a fuel assembly for a nuclear light water reactor, which method comprises: a) producing a sheet of a Zr-based alloy by forging, hot rolling and cold rolling in a suitable number of steps, b) carrying out an α+β quenching or a β quenching of the sheet when the sheet has been produced to a thickness which is equal to or almost equal to the final thickness of the finished sheet, c) heat treating the sheet in the α-phase temperature range of said alloy, wherein the sheet is stretched during the heat treatment according to step c). The invention also concerns a use of a sheet that is produced and treated according to this method, and to methods and fuel assemblies of which said sheet forms a part.

Owner:WESTINGHOUSE ELECTRIC SWEDEN

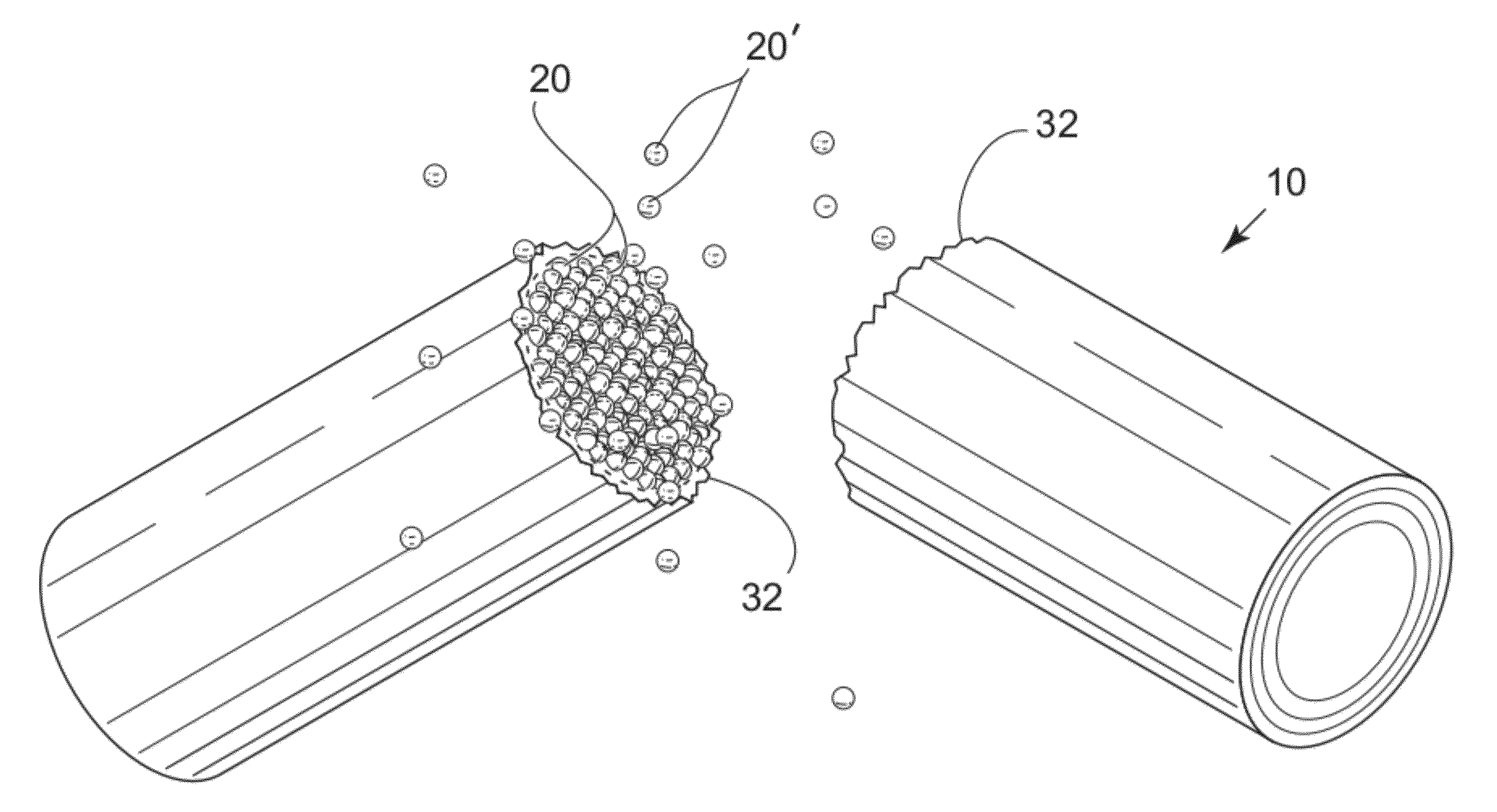

Light Water Reactor TRISO Particle-Metal-Matrix Composite Fuel

A metal matrix, microencapsulated nuclear fuel component includes an integral metal matrix having an outer buffer region and an inner fuel containing region; a multiplicity of nuclear fuel capsules embedded in the fuel containing region of the matrix for encapsulating a nuclear fuel particle and products resulting from nuclear and chemical reactions; and a nuclear fuel particle encapsulated in each of the nuclear capsules.

Owner:UT BATTELLE LLC

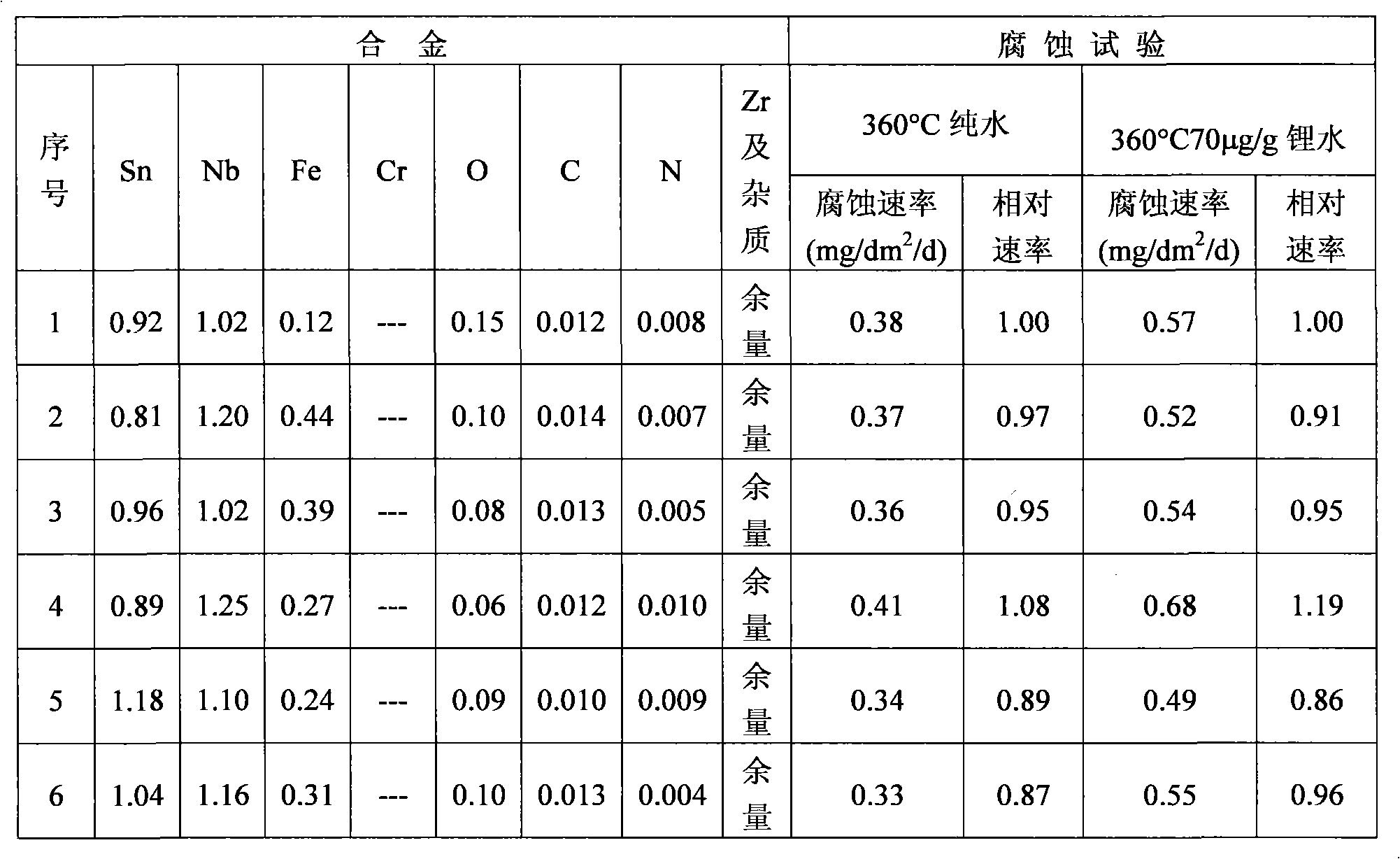

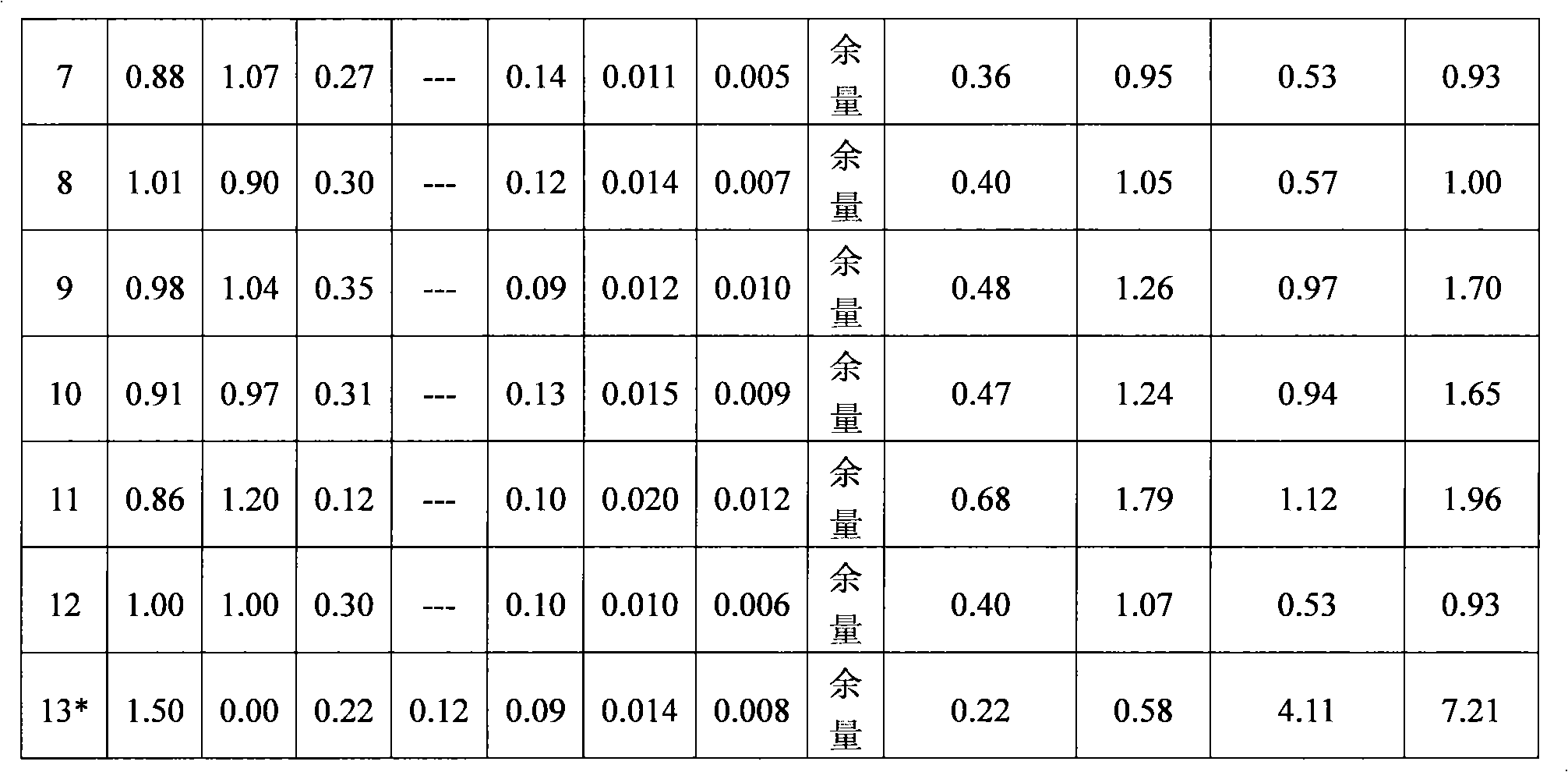

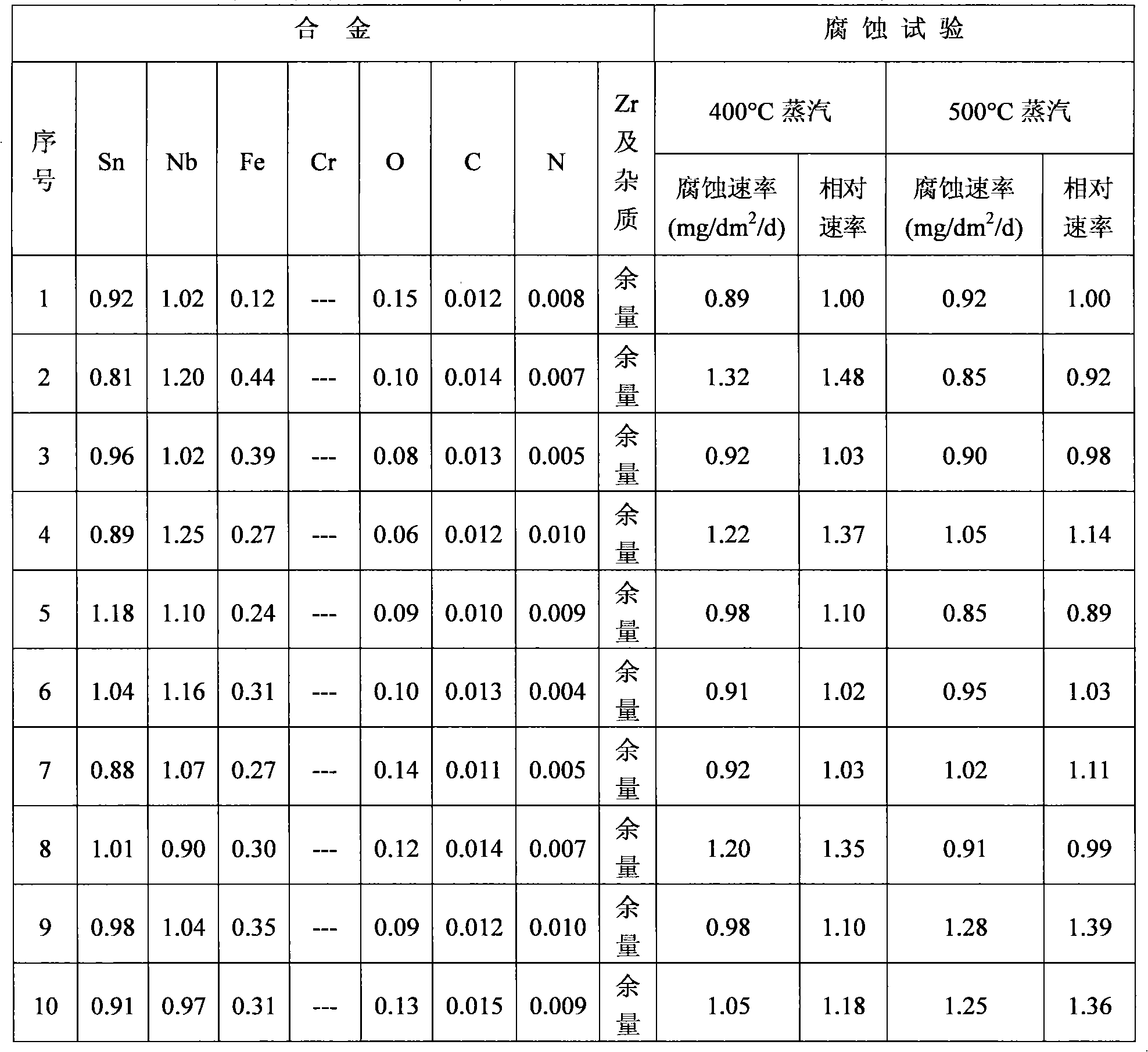

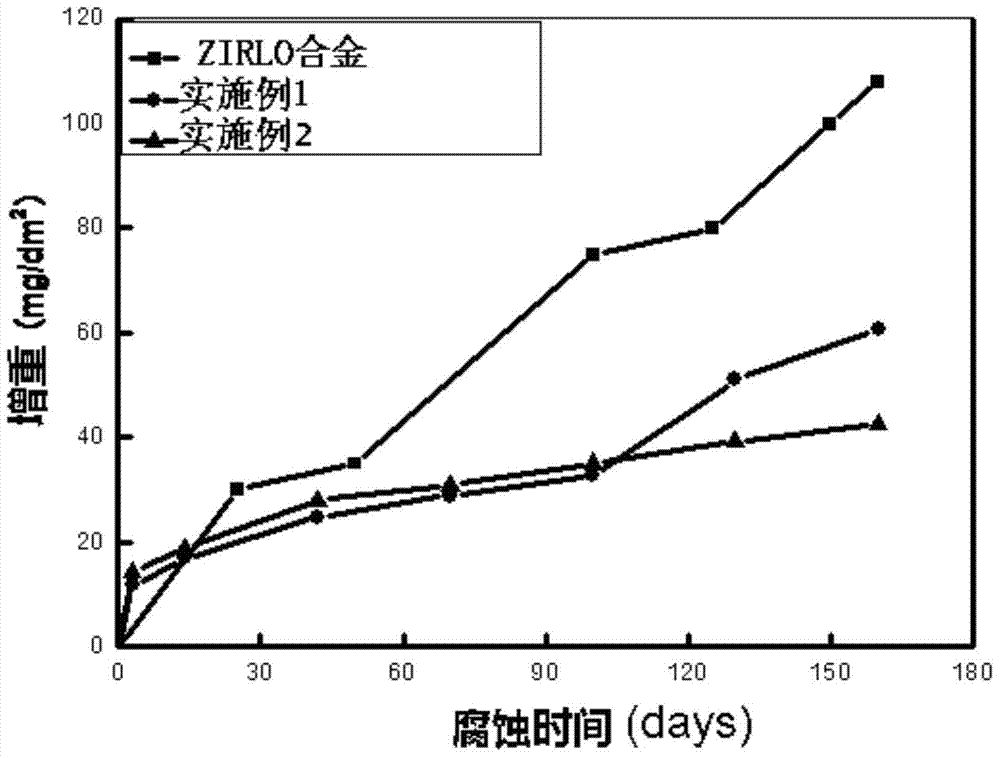

Zirconium-base alloy used for light-water reactor

The invention relates to a zirconium alloy material, particularly to a zirconium-base alloy used for a light water reactor. The zirconium-base alloy is composed of (wt %) Sn 0.80-1.20, Nb 0.90-1.25, Fe 0.12-0.45, O 0.06-0.15, C less than 0.15, N less than 0.008, and zirconium and impurities in balance. By adding Fe and O two elements based on the current Zr-Sn-Nb alloy, the zirconium-base alloy with good corrosion-resisting property in all corrosion tests using 360 DEG C deionized water, 360 DEG C lithium-containing water solution, 400 DEG C steam and 500 DEG C can be prepared. The inventive zirconium-base alloy can be used as structural material of a nuclear reactor core.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

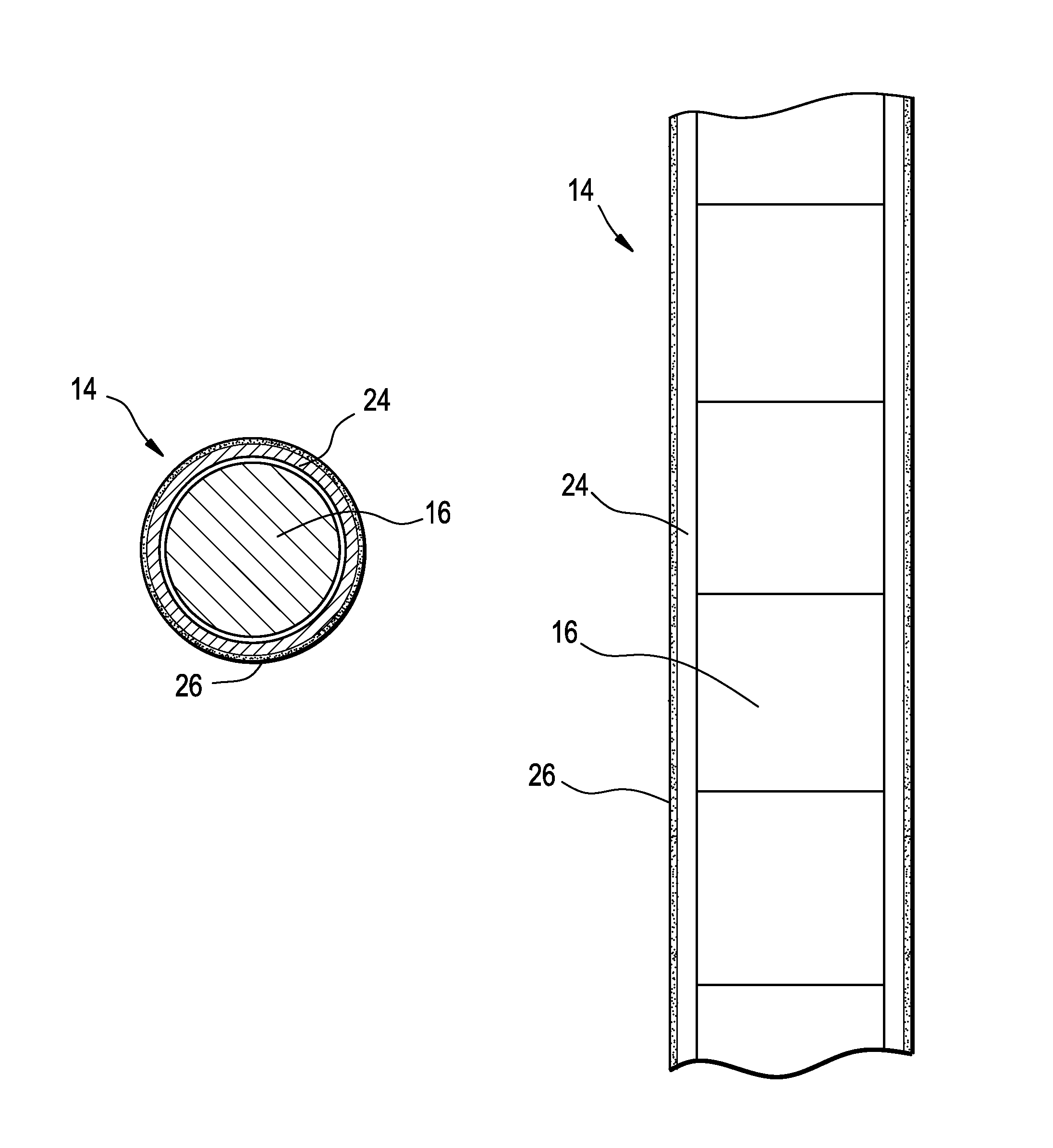

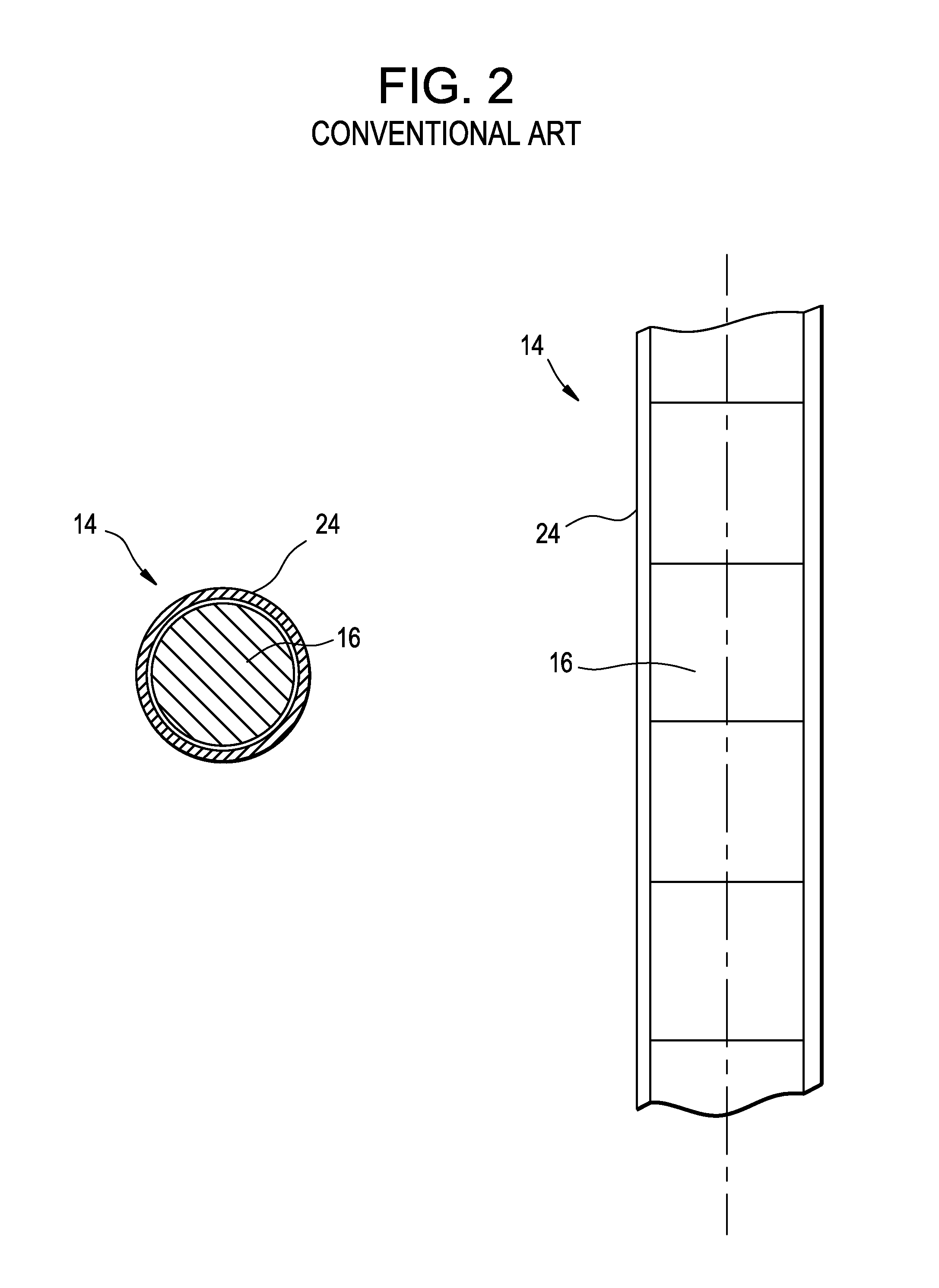

Method and apparatus for a fret resistant fuel rod for a light water reactor (LWR) nuclear fuel bundle

A method and apparatus for a fret resistant fuel rod for a Boiling Water Reactor (BWR) nuclear fuel bundle. An applied material entrained with fret resistant particles is melted or otherwise fused to a melted, thin layer of the fuel rod cladding. The applied material is made of a material that is chemically compatible with the fuel rod cladding, allowing the fret resistant particles to be captured in the thin layer of re-solidified cladding material to produce an effective and resilient fret resistant layer on an outer layer of the cladding.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

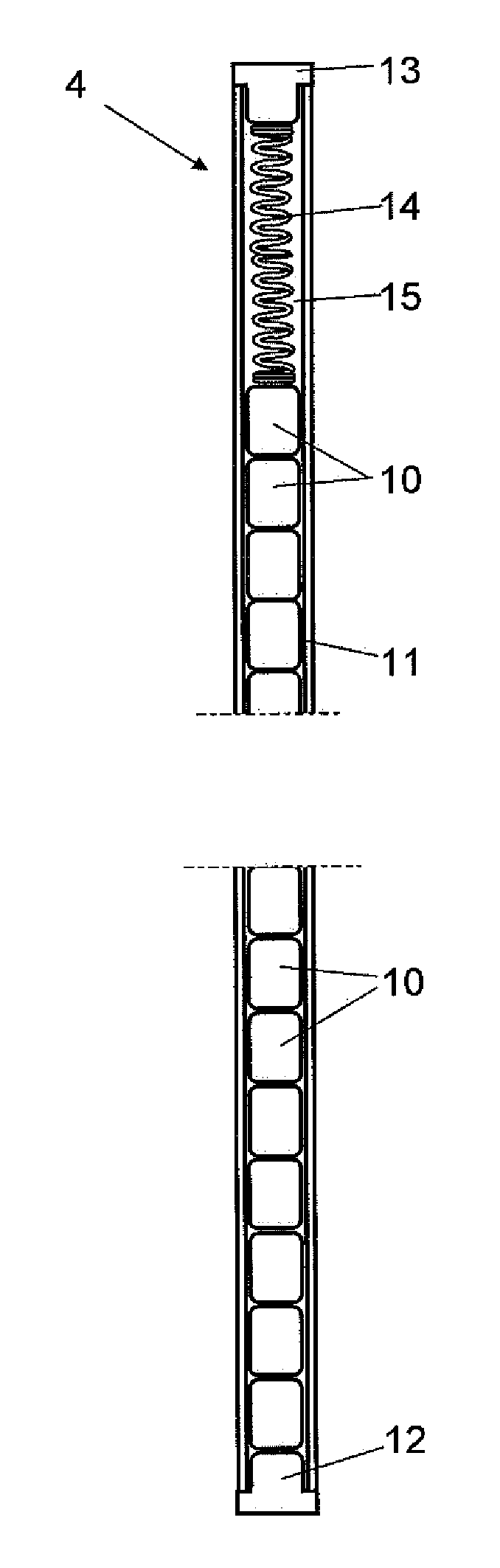

Nuclear fuel, a fuel element, a fuel assembly and a method of manufacturing a nuclear fuel

The invention refers to a nuclear fuel, a fuel element, a fuel assembly and a method of manufacturing a nuclear fuel. The nuclear fuel is adapted for use in a water cooled nuclear reactor, including light water reactors LWR, such as Boiling Water Reactors BWR and Pressure Water Reactors PWR. The nuclear fuel comprises an uranium-containing compound consisting of UN. The uranium content of the uranium-containing compound comprises less than 10% by weight of the isotope 235U. The nuclear fuel comprises an additive substantially consisting of at least one element, in elementary form or as a compound, selected from the group consisting of Zr, Mo, Si, Al, Nb and U.

Owner:WESTINGHOUSE ELECTRIC SWEDEN

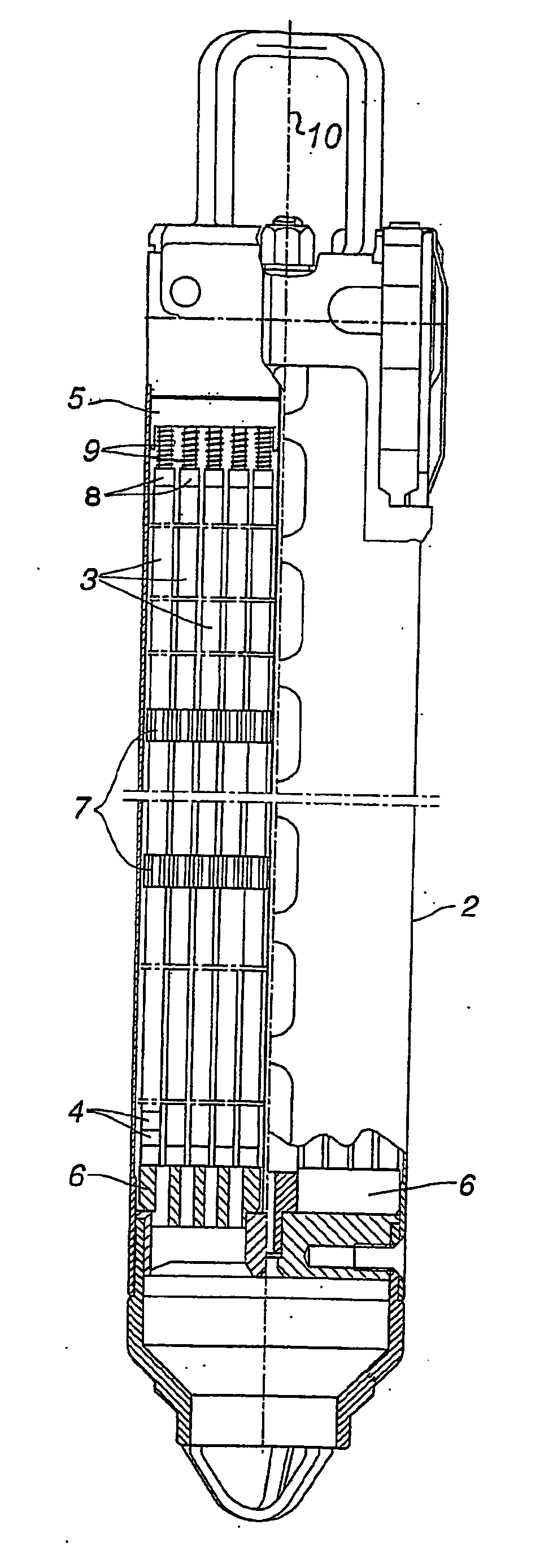

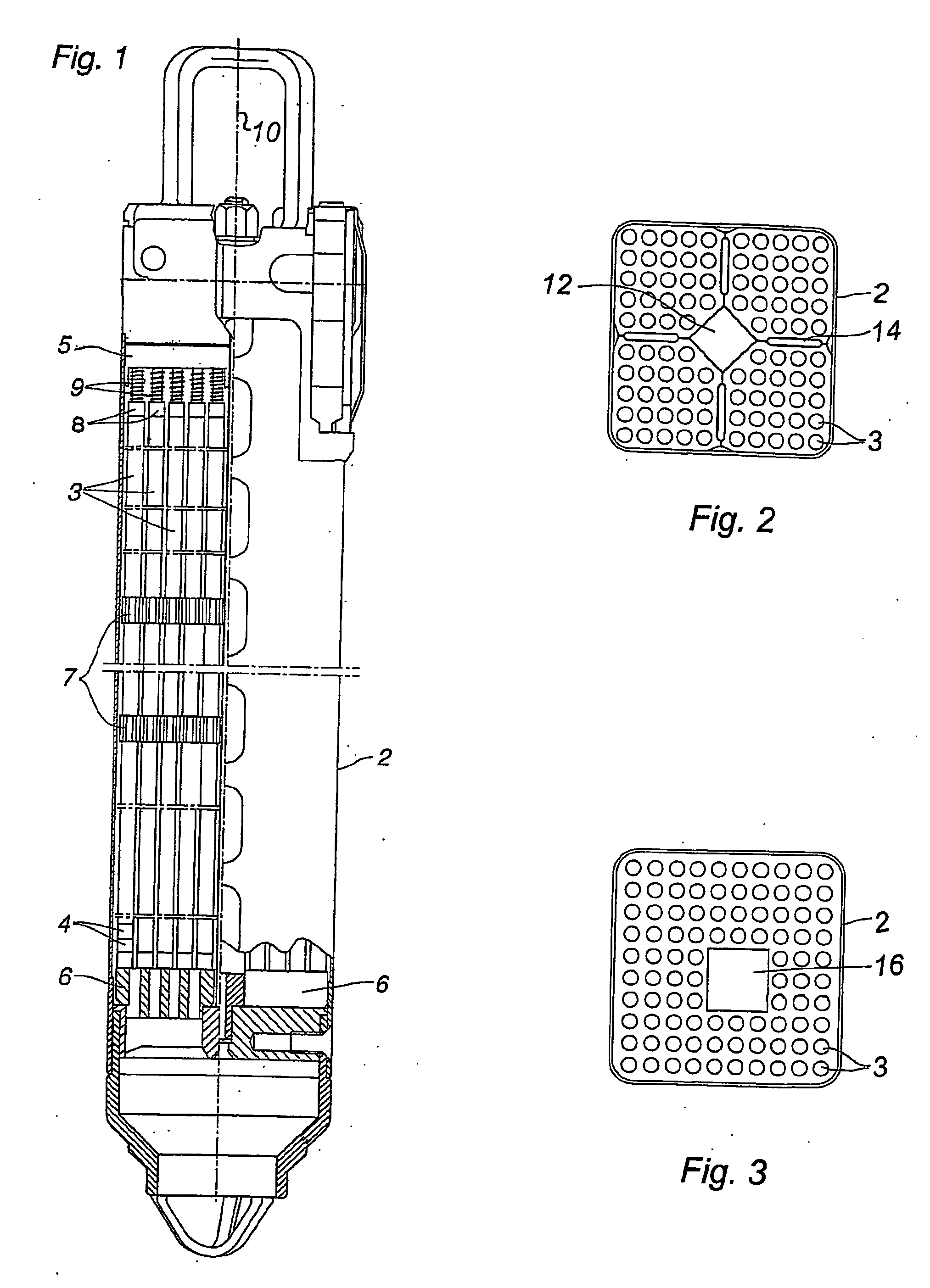

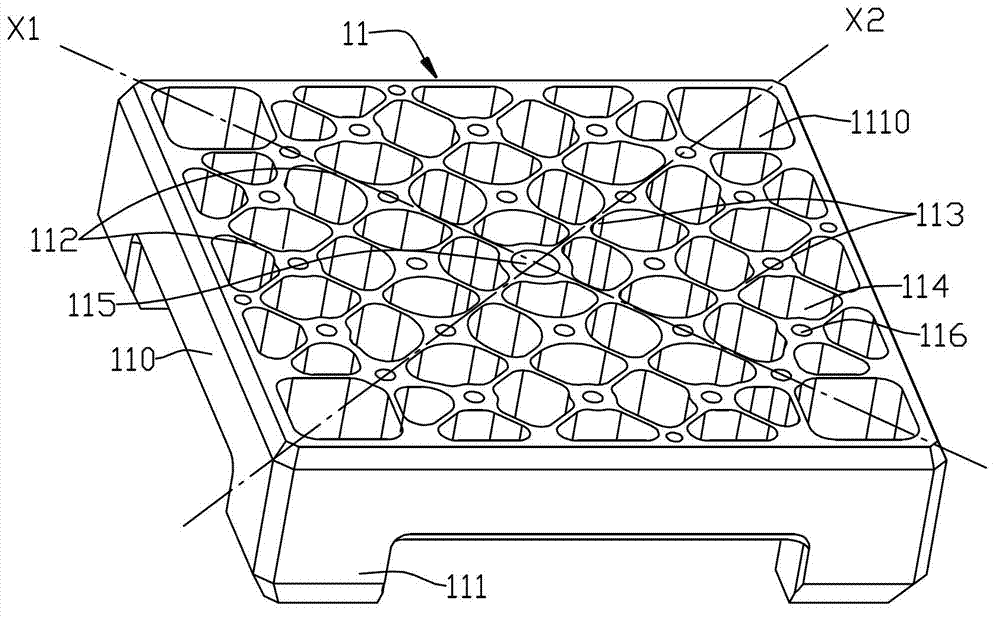

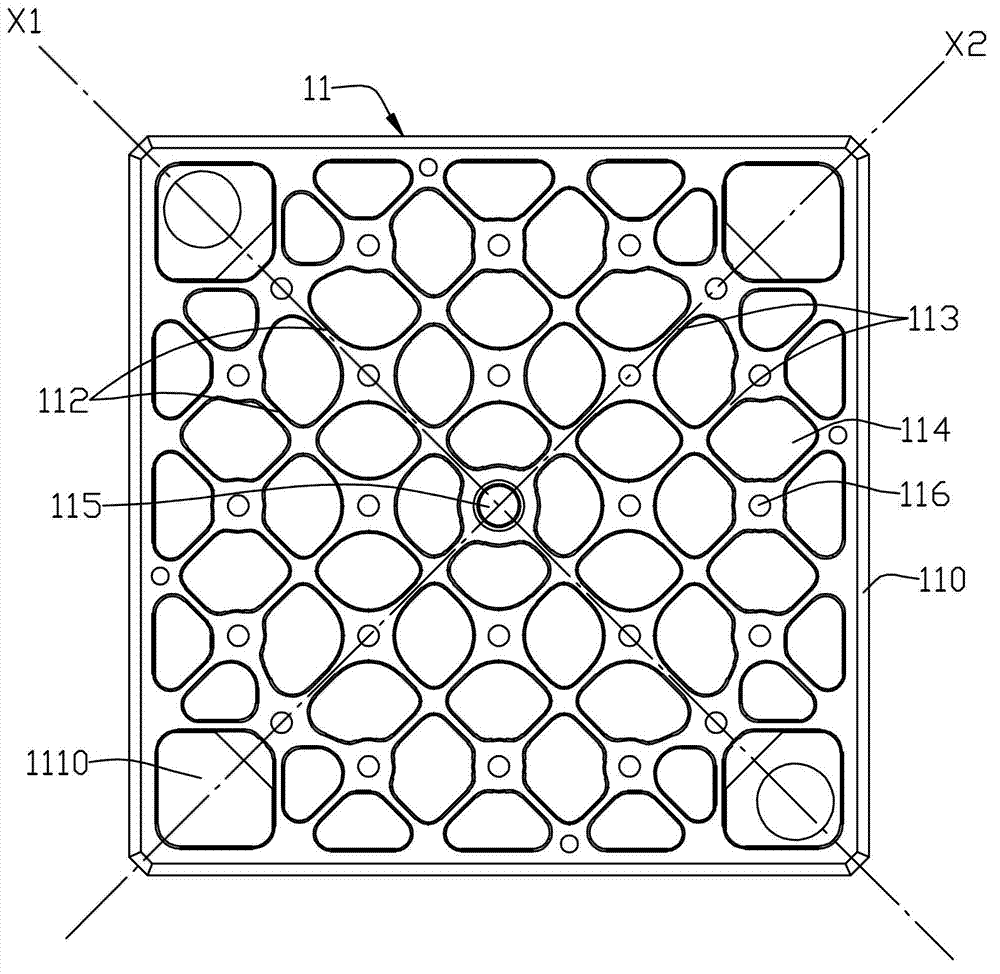

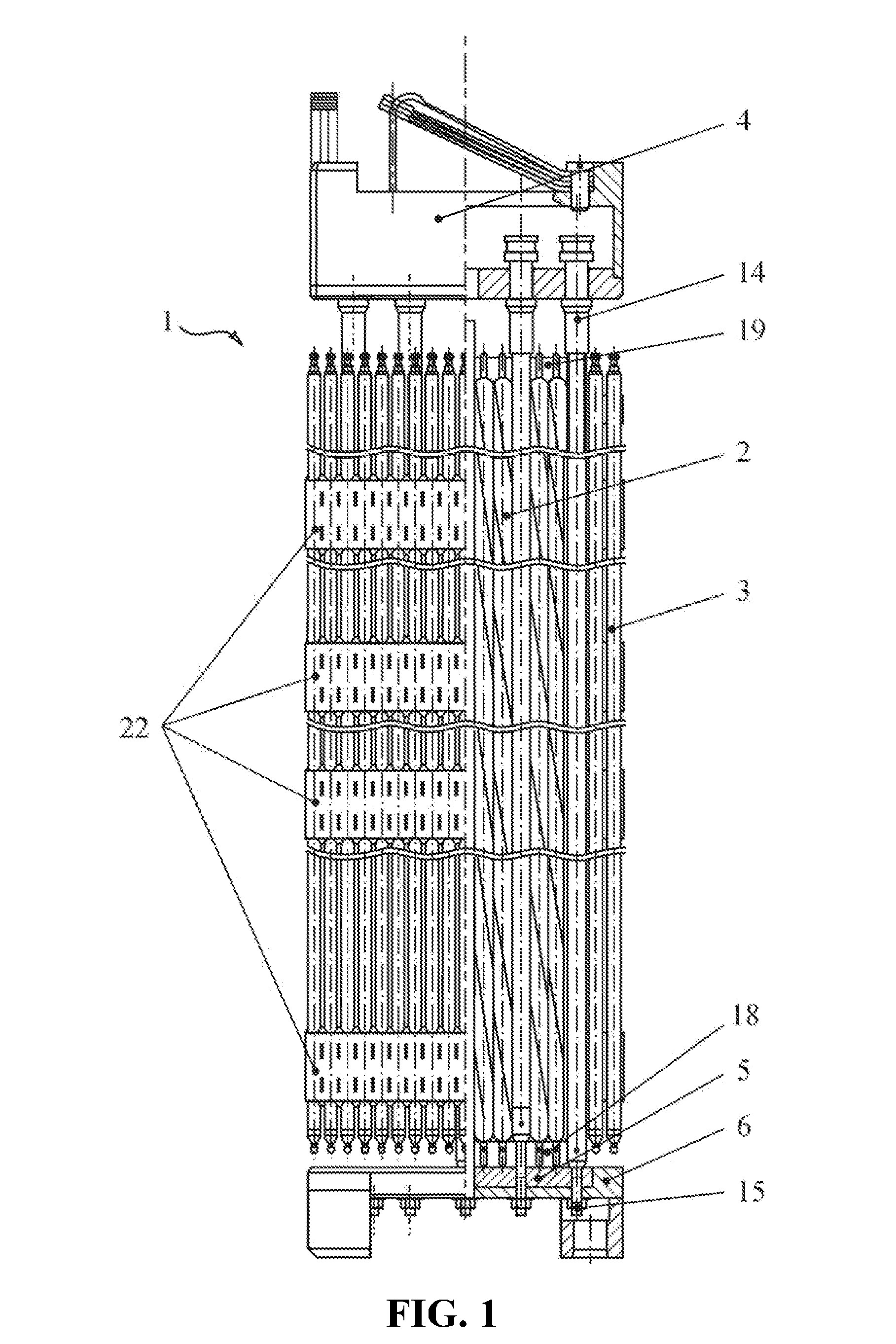

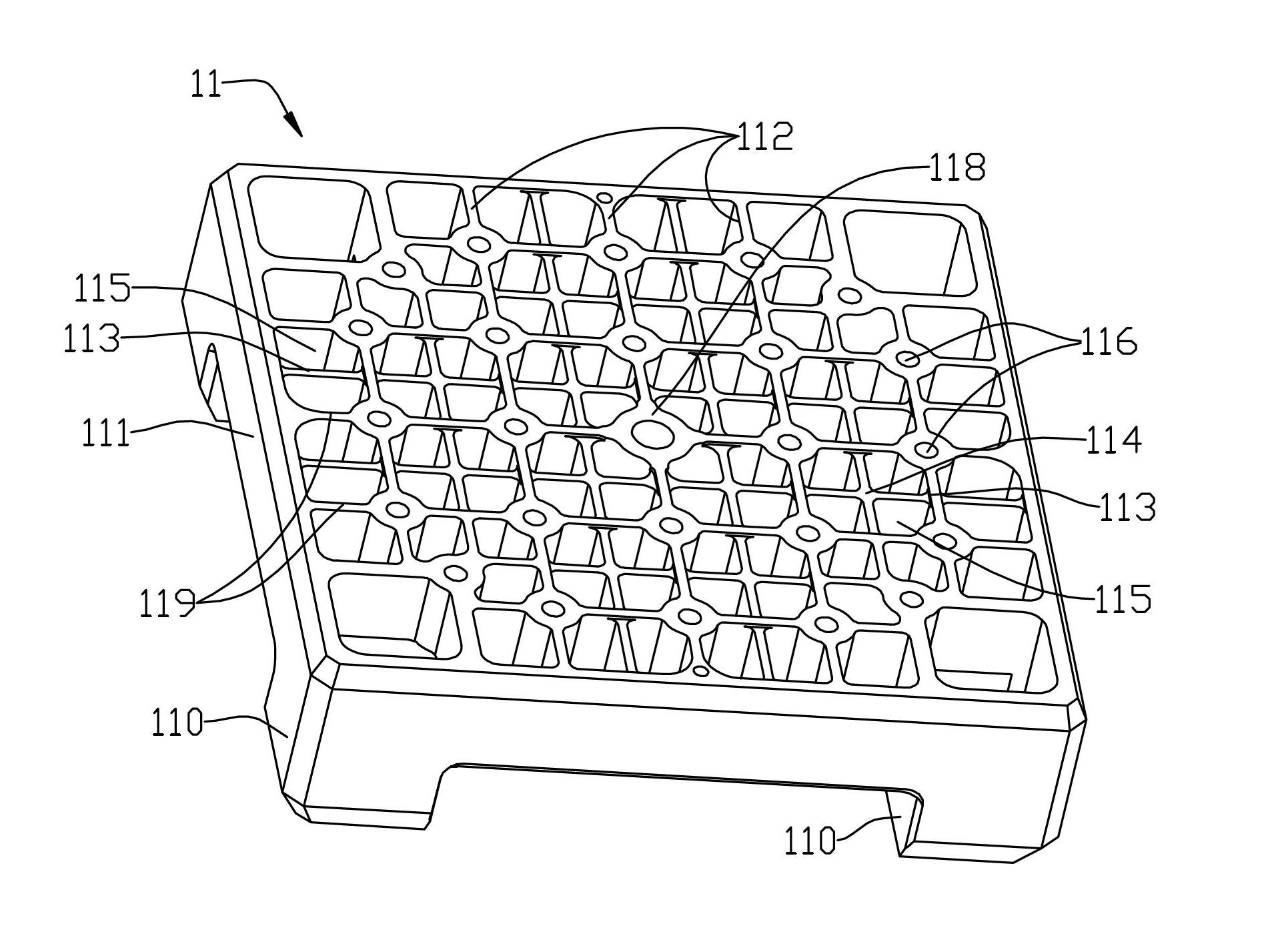

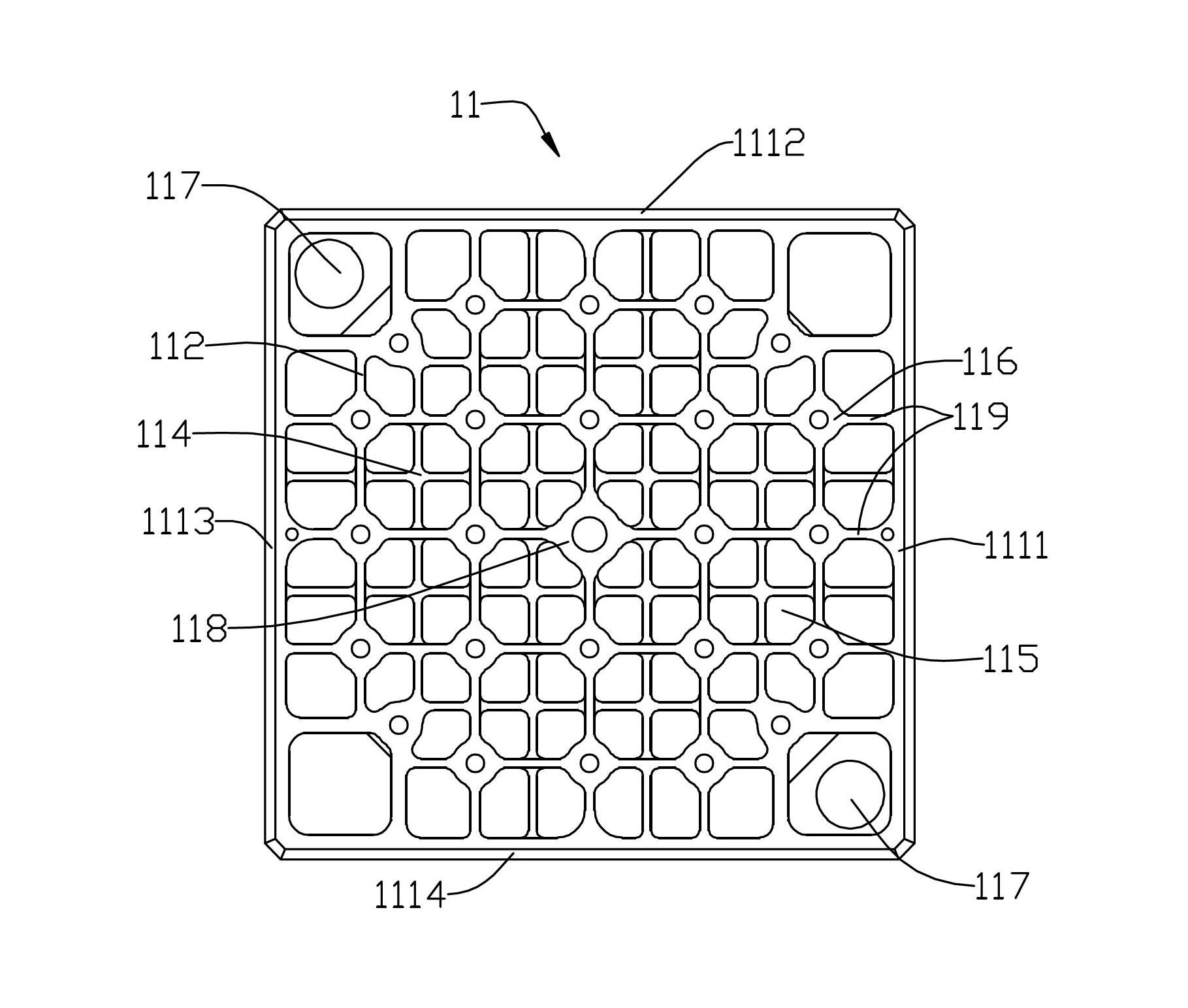

Lower pipe seat and bottom device of light-water reactor nuclear fuel assembly

ActiveCN102867547AImprove performanceNuclear energy generationFuel element assembliesPipe fittingDiagonal

The invention provides a lower pipe seat of a light-water reactor nuclear fuel assembly. The lower pipe seat comprises a frame body, a plurality of first main ribs, a plurality of second main ribs, and a plurality of pipe fitting installation parts, wherein the first main ribs are arranged in the frame body in parallel at intervals, the second main ribs are arranged in the frame body in parallel at intervals, the frame body comprises a first diagonal line and a second diagonal line which is intersected with the first diagonal line, a plurality of first main ribs and / or a plurality of second main ribs are parallel to the first diagonal line and / or the second diagonal line, a plurality of first main ribs and a plurality of second main ribs are intersected to divide the interior of the frame body into a plurality of through drain holes; and a plurality of pipe fitting installation parts are respectively arranged at positions where a plurality of first main ribs and a plurality of second main ribs are intersected. The invention further provides a bottom device of the light-water reactor nuclear fuel assembly. According to the lower pipe seat, a plurality of first main ribs and / or a plurality of second main ribs are parallel to the first diagonal line and / or the second diagonal line respectively, so that the performance of the lower pipe seat can be effectively prompted.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Light-water reactor fuel assembly (alternatives), a light-water reactor, and a fuel element of fuel assembly

ActiveUS20110311016A1Easy to installFreedom of movementFuel elementsNuclear energy generationEngineeringThorium

A 17×17 jacketless fuel assembly for a PWR-type light-water reactor uses thorium as the fuel. The fuel assembly has a square shape in the plan view, a seed region, a blanket region that encircles it, an upper nozzle, and a lower nozzle. The fuel elements of the seed region re arranged in the rows and columns of a square coordinate grid and have a four-lobed profile that forms spiral spacer ribs along the length of a fuel element. The blanket region contains a frame structure within which a bundle of fuel elements made from thorium with the addition of enriched uranium is positioned. The blanket region fuel elements are arranged in the two or three rows and columns of a square coordinate grid.

Owner:THORIUM POWER

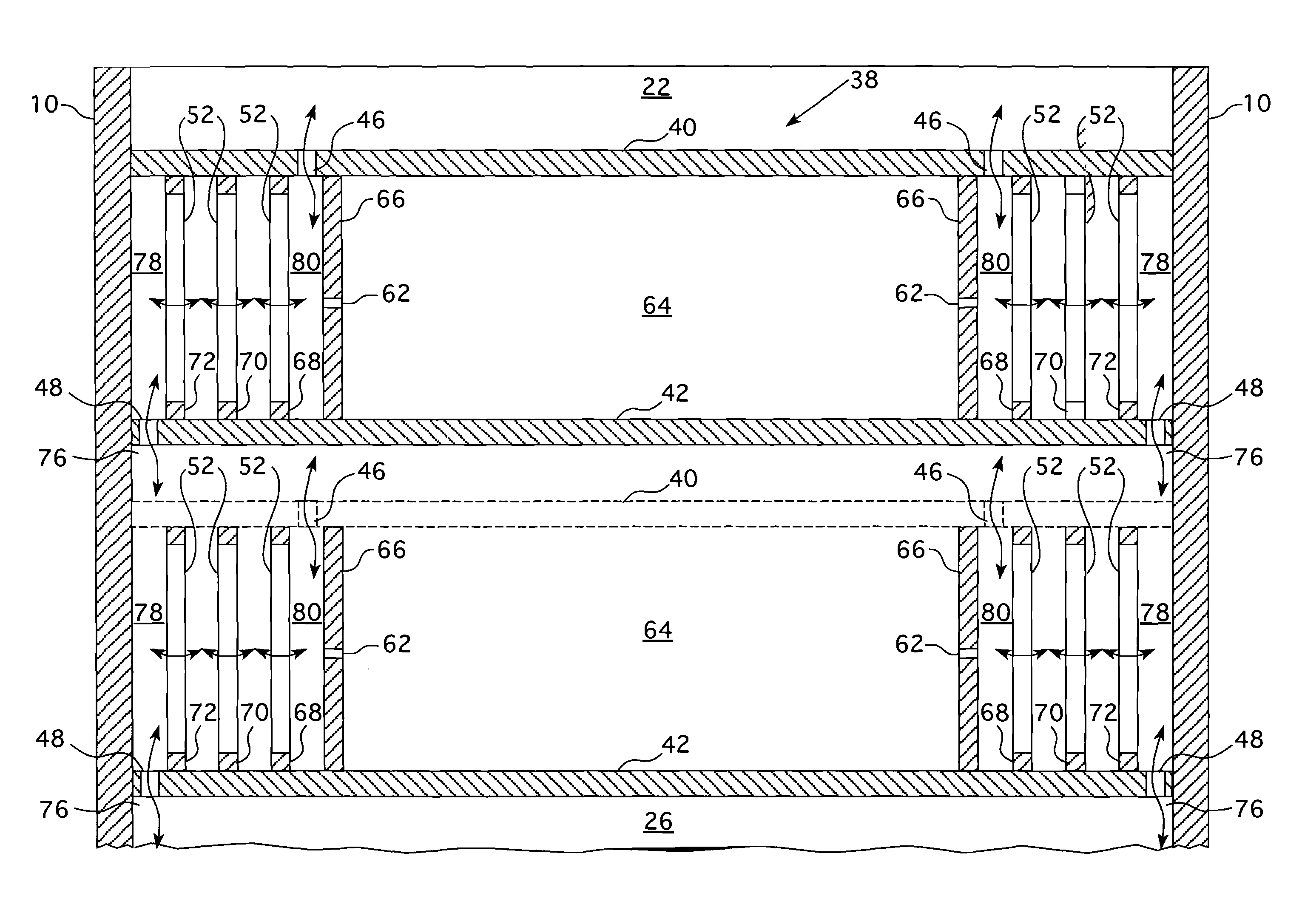

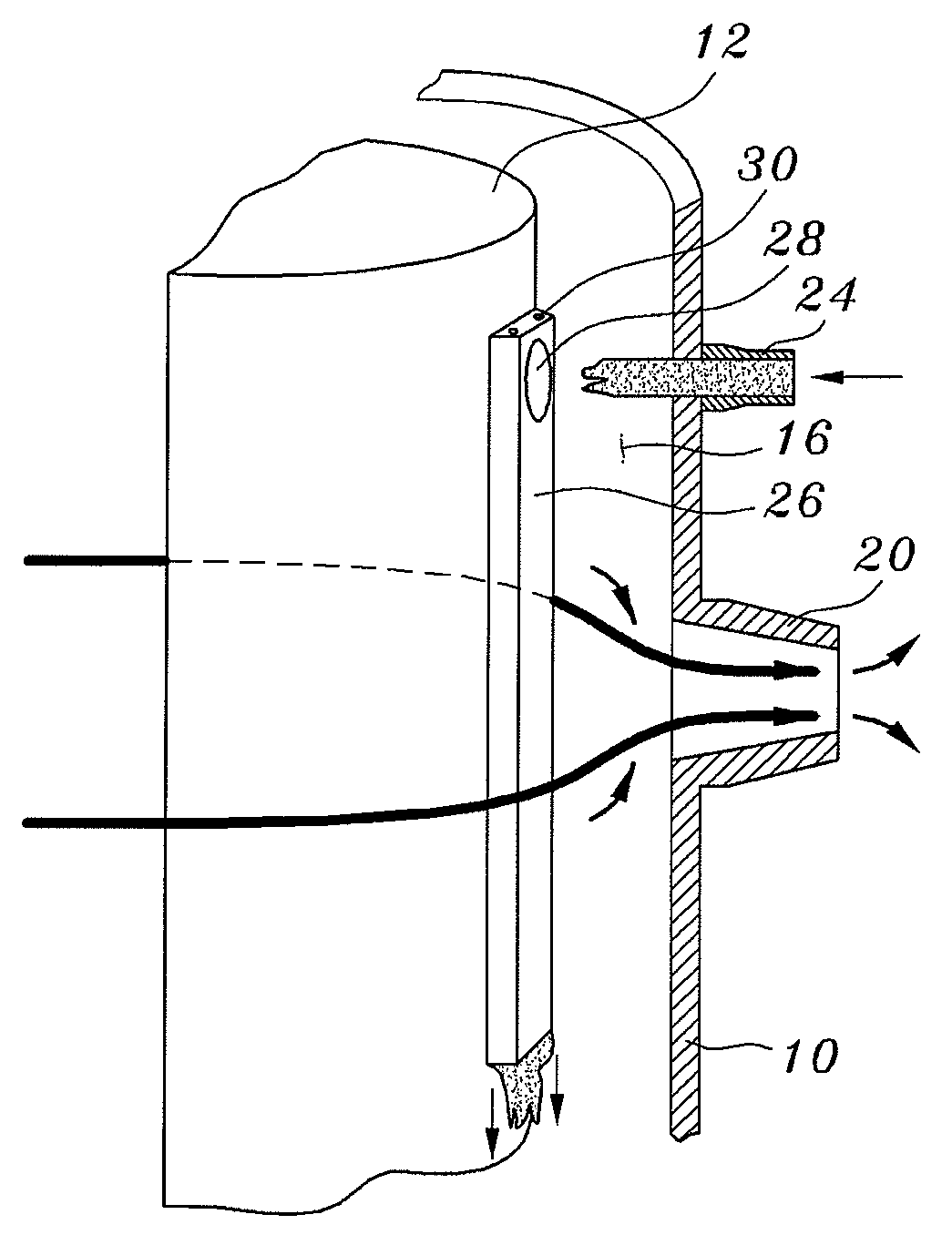

Emergency core cooling system having core barrel injection extension ducts

InactiveUS20090232267A1Preventing level of coolingCross flow can be reducedNuclear energy generationNuclear engineering problemsWater flowHigh pressure

An emergency core cooling system directly injects emergency core cooling water, which is supplied from a high-pressure safety injection pump or a safety injection tank for a pressurized light water reactor, into a reactor vessel downcomer. A pipe connector is completely removed from between each direct vessel injection nozzle and each injection extension duct installed on an outer surface of the core barrel, which are opposite to each other. An emergency core cooling water intake port, through which the water is injected from each direct vessel injection nozzle, is formed on the surface of each injection extension duct facing an axis of each direct vessel injection nozzle. Thereby, a structure in which a jet of the emergency core cooling water flows into the injection extension ducts is adopted in a hydraulic connection fashion.

Owner:KOREA ATOMIC ENERGY RES INST +1

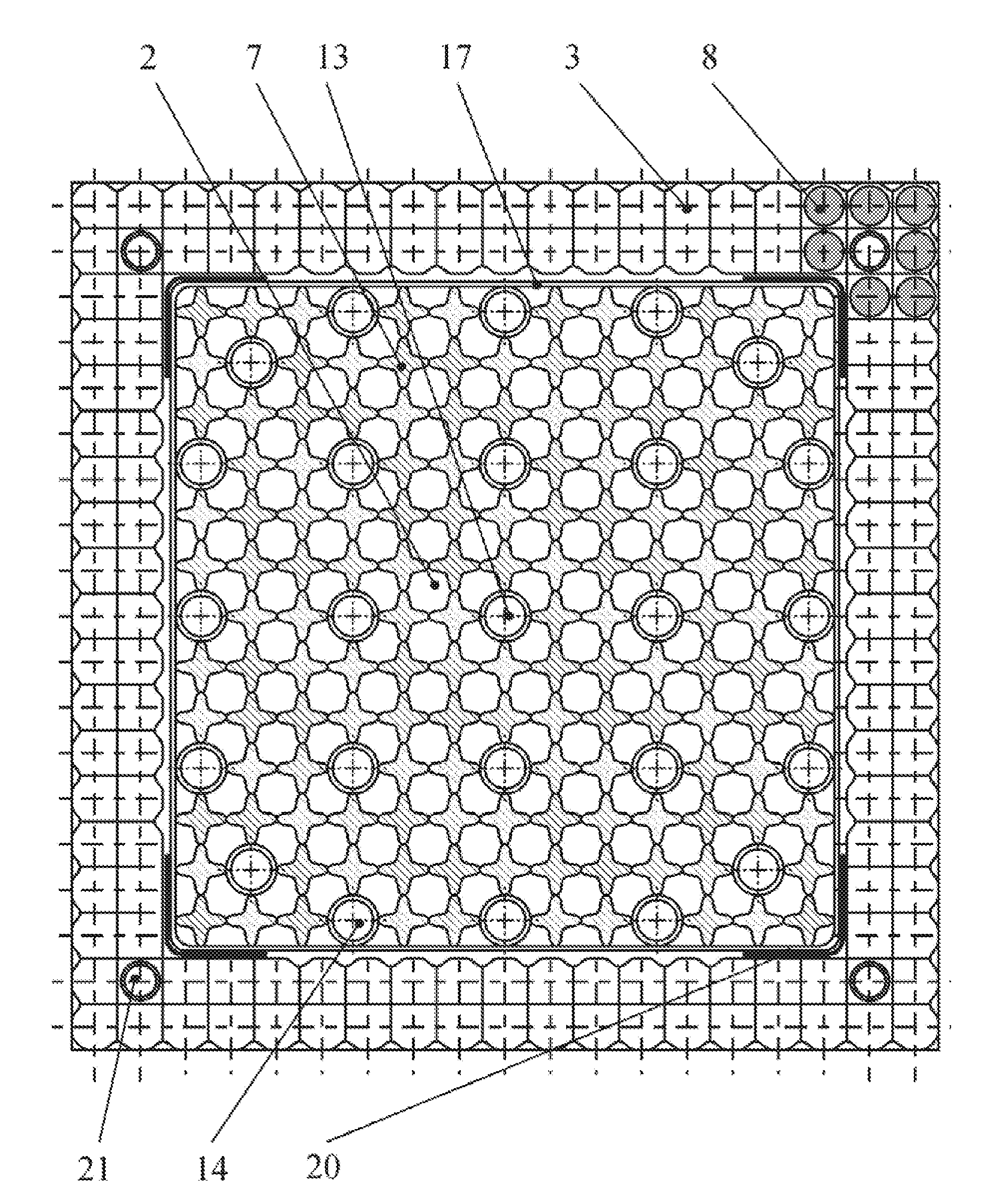

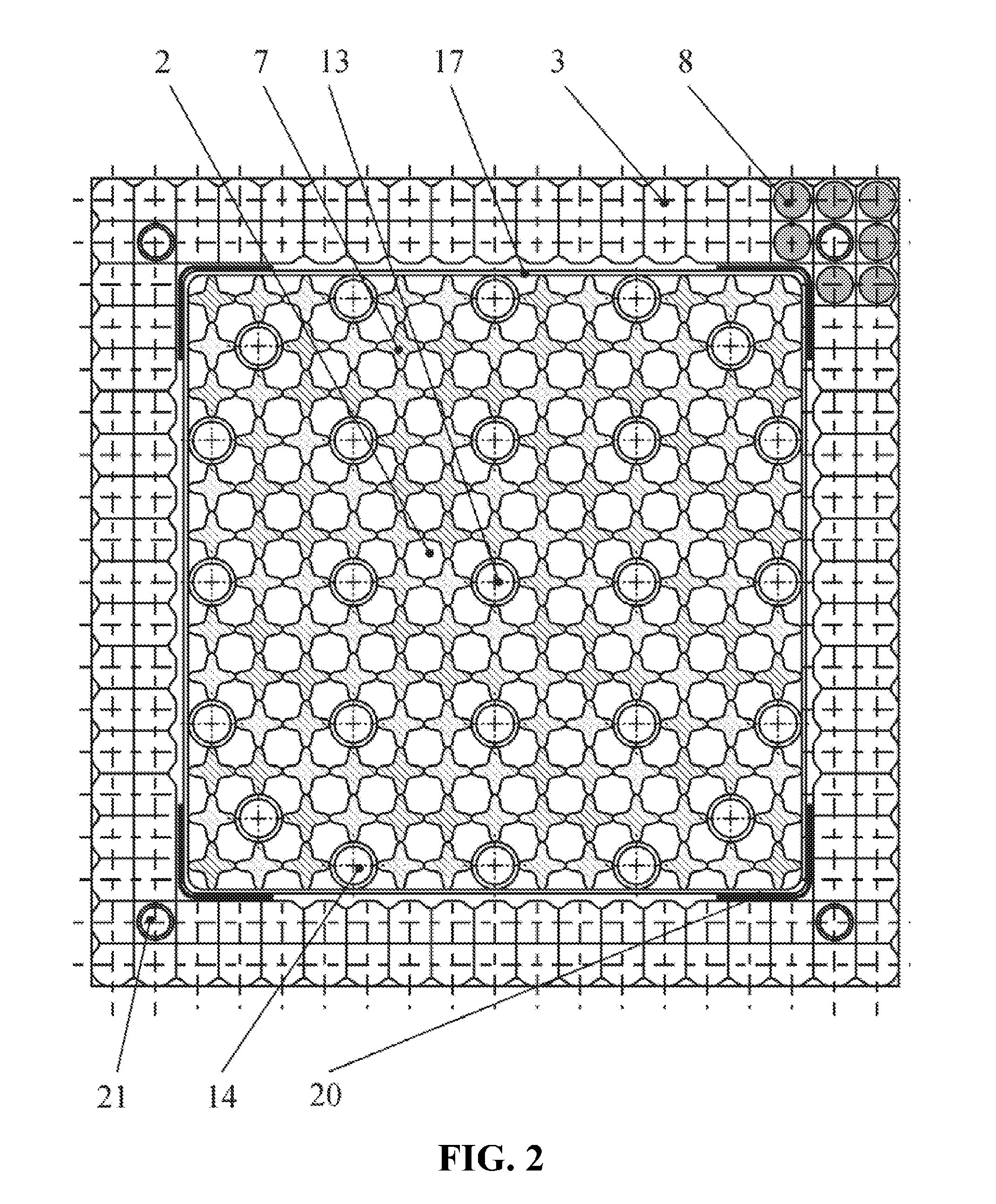

Anti-foreign matter plate of light water reactor nuclear fuel component and bottom device

ActiveCN102651242AIncrease the circulation areaReduce resistanceNuclear energy generationFuel element assembliesForeign matterEngineering

The invention provides an anti-foreign matter plate of a light water reactor nuclear fuel component. The anti-foreign matter plate comprises an edge part, a plurality of pipe orifice units and a plurality of filtering hole units, wherein the plurality of the pipe orifice units are arranged on the inner side of the edge part like an independent array, and the plurality of the filtering hole units are flatly laid and arranged between the edge part and the plurality of the pipe orifice units. The invention further provides a bottom device of the light water reactor nuclear fuel component. The bottom device comprises the anti-foreign matter plate. Compared with the prior art, as the pipe orifice units of the anti-foreign matter plate disclosed by the invention are arranged like the independent array and the filtering hole units are flatly laid and arranged, the number of the filtering hole units on the anti-foreign matter plate can be maximized under the same situations, the circulation area of cooling water can be further increased, the resistance of the cooling water when the cooling water passes through the anti-foreign matter plate, and the loss of pressure drop can be also reduced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Zirconium alloy compositions having excellent corrosion resistance by the control of various metal-oxide and precipitate and preparation method thereof

Disclosed herein are a zirconium alloy composition, which exhibits excellent corrosion resistance by varying the kinds of metal oxides and controlling the size of precipitates of the composition, including: 1.05˜1.45 wt % of Nb; one or more selected from the group consisting of 0.1˜0.7 wt % of Fe and 0.05˜0.6 wt % of Cr; and residual Zr, and a method of preparing the same. The zirconium alloy composition exhibits excellent corrosion resistance by controlling the kinds and amounts of the elements included in the zirconium alloy composition and the heat-treatment temperature and thus varying the kinds of metal oxides formed during an oxidation process and controlling the size of precipitates of the zirconium alloy, so that it can be usefully used as a raw material for nuclear fuel cladding tubes, spacer grids, nuclear reactor internals and the like of a light-water reactor or a heavy-water reactor in a nuclear power plant.

Owner:KOREA ATOMIC ENERGY RES INST

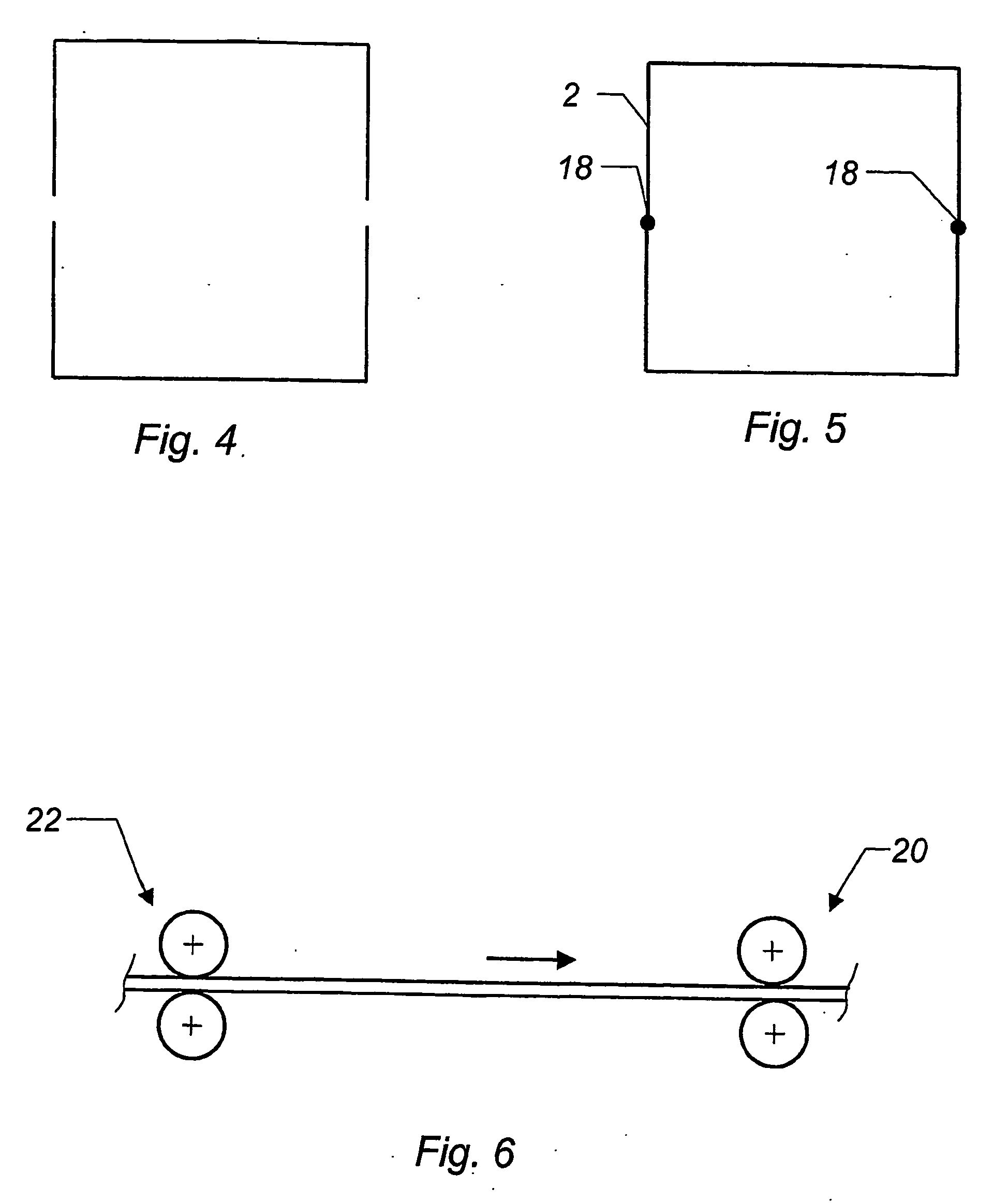

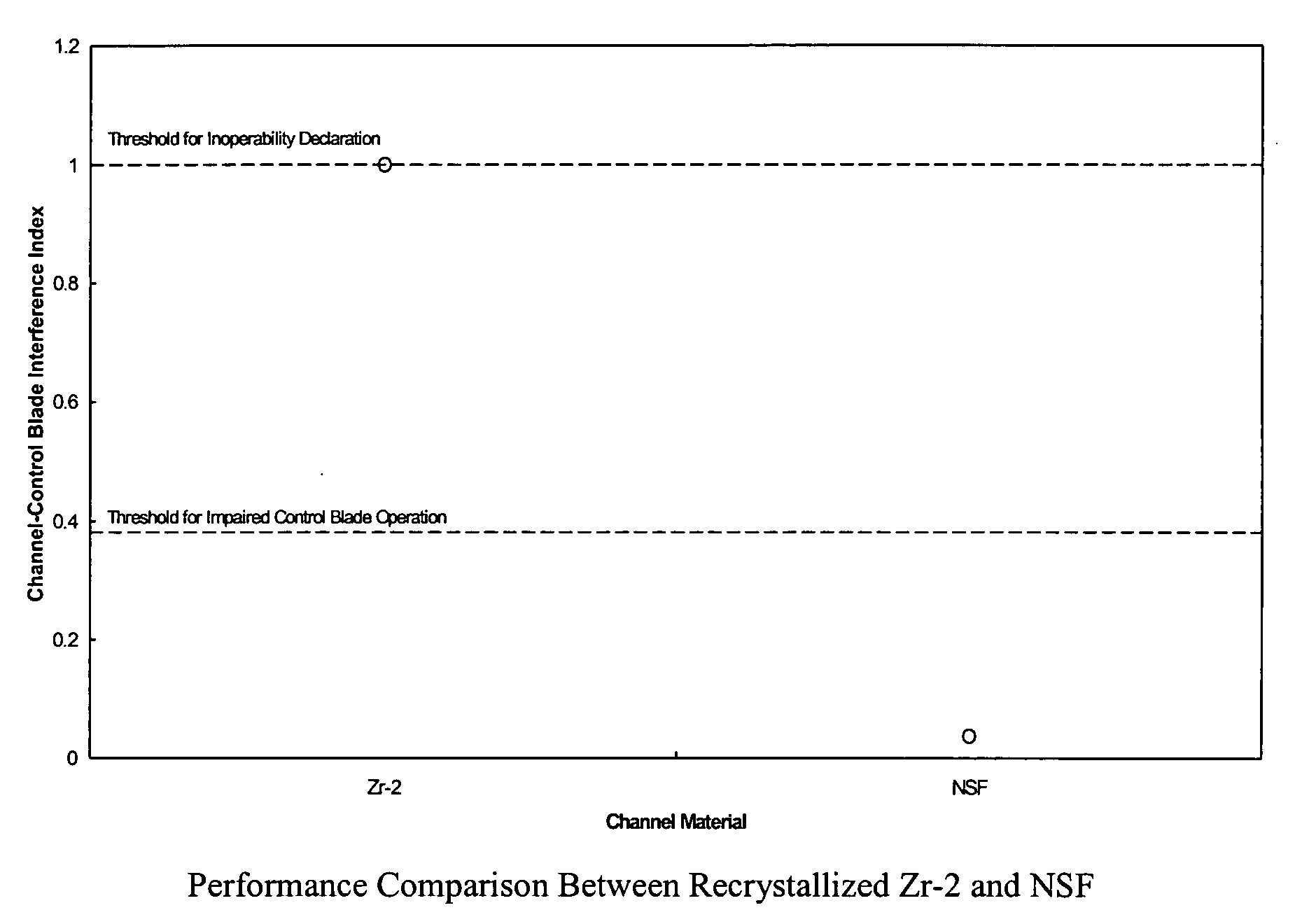

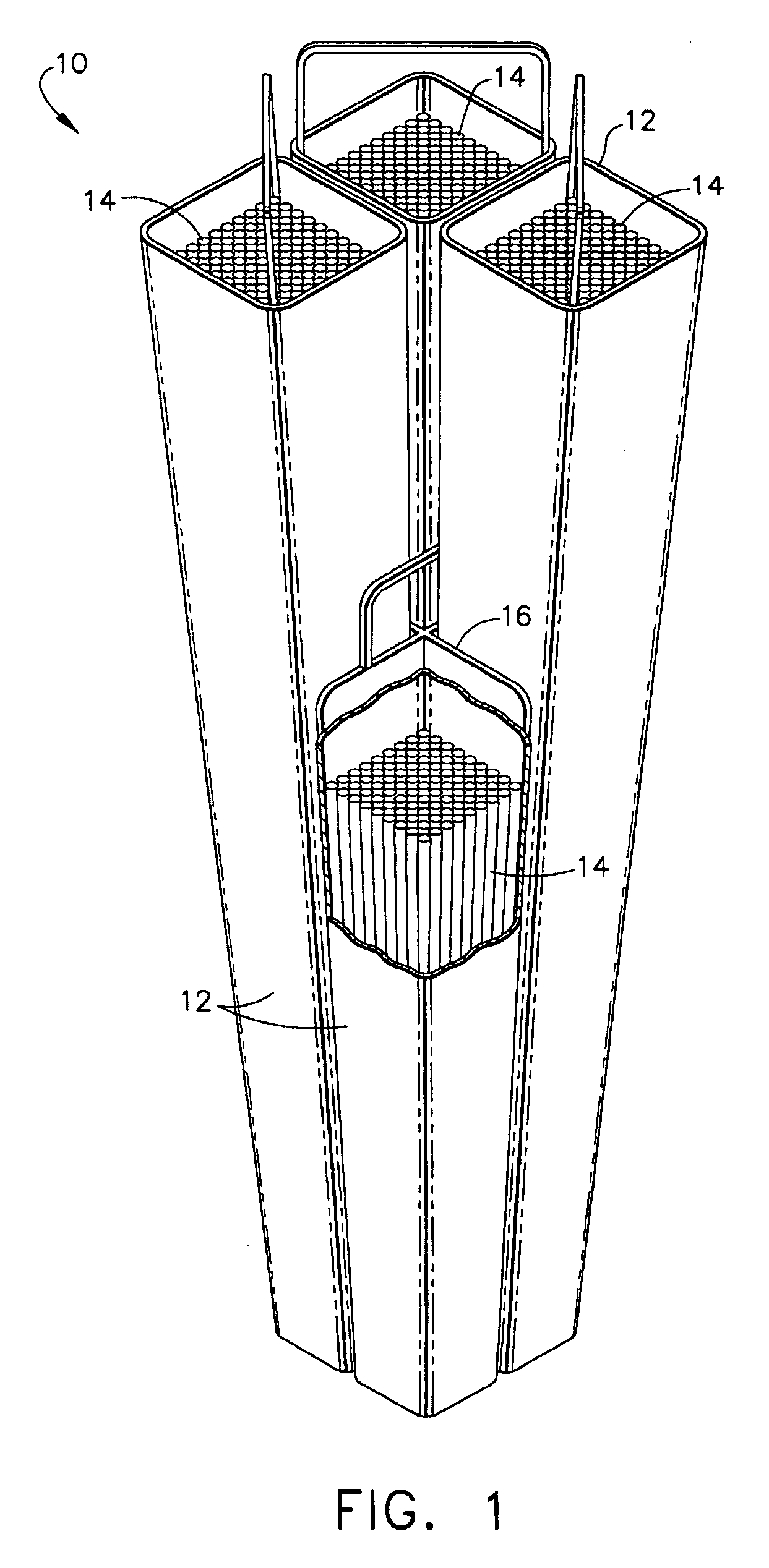

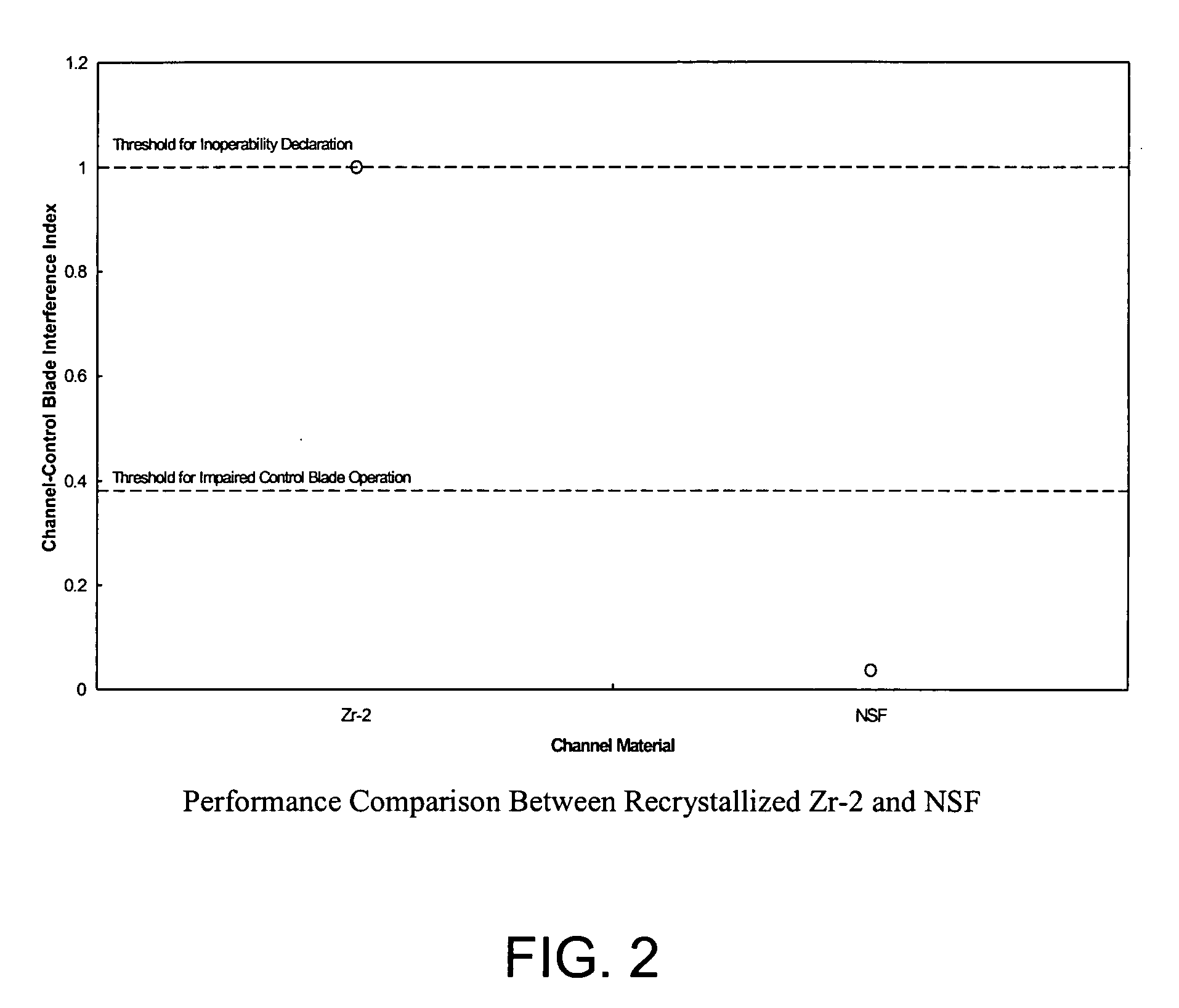

LWR flow channel with reduced susceptibility to deformation and control blade interference under exposure to neutron radiation and corrosion fields

ActiveUS20070153963A1Reduce the possibilityReduce sensitivityNuclear energy generationNuclear engineering problemsRadiation fieldNeutron radiation

A zirconium alloy suitable for forming reactor components that exhibit reduced irradiation growth and improved corrosion resistance during operation of a light water reactor (LWR), for example, a boiling water reactor (BWR). During operation of the reactor, the reactor components will be exposed to a strong, and frequently asymmetrical, radiation fields sufficient to induce or accelerate corrosion of the irradiated alloy surfaces within the reactor core. Reactor components fabricated from the disclosed zirconium alloy will also tend to exhibit an improved tolerance for cold-working during fabrication of the component, thereby simplifying the fabrication of such components by reducing or eliminating subsequent thermal processing, for example, anneals, without unduly degrading the performance of the finished component.

Owner:GENERAL ELECTRIC CO

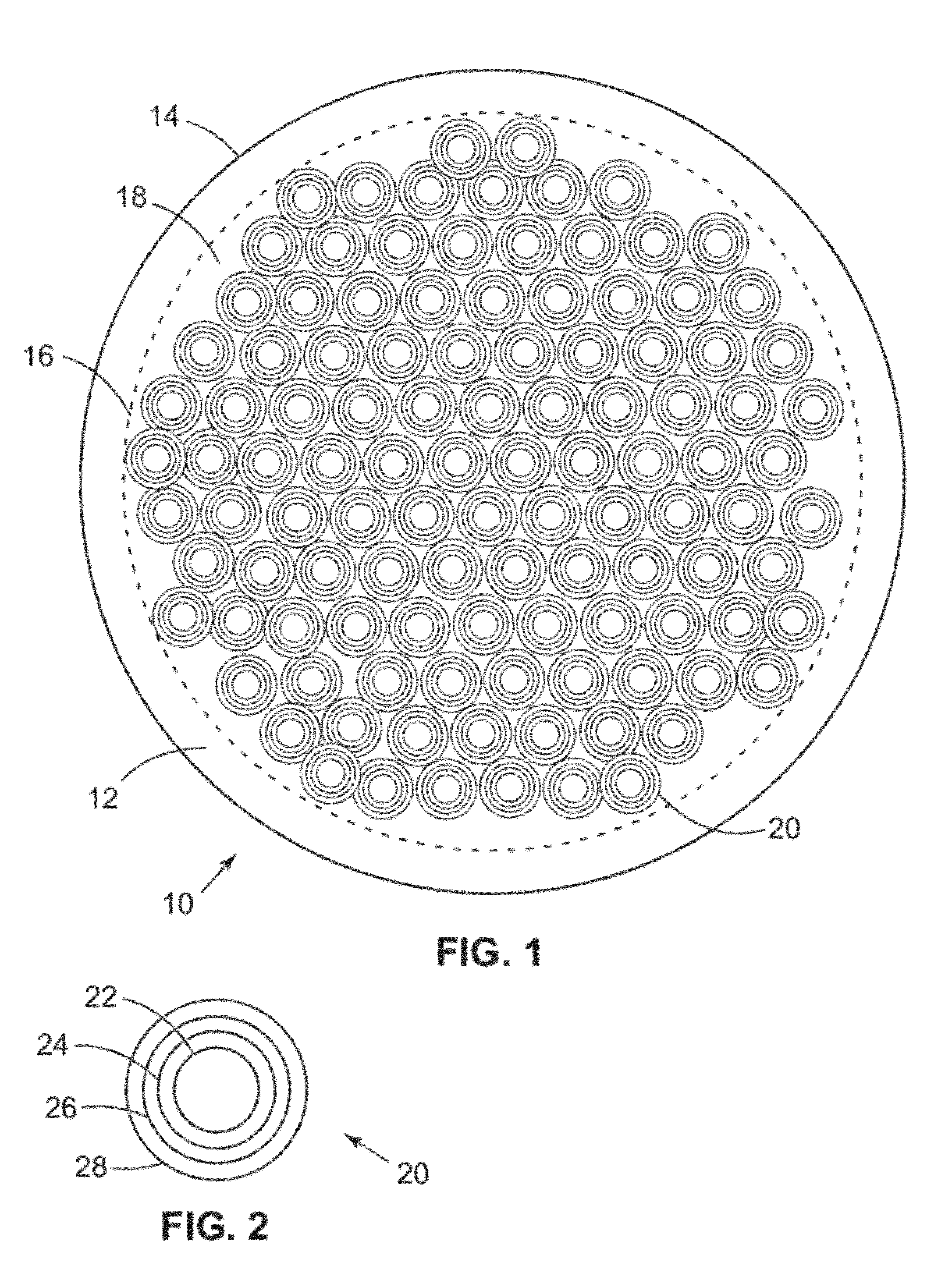

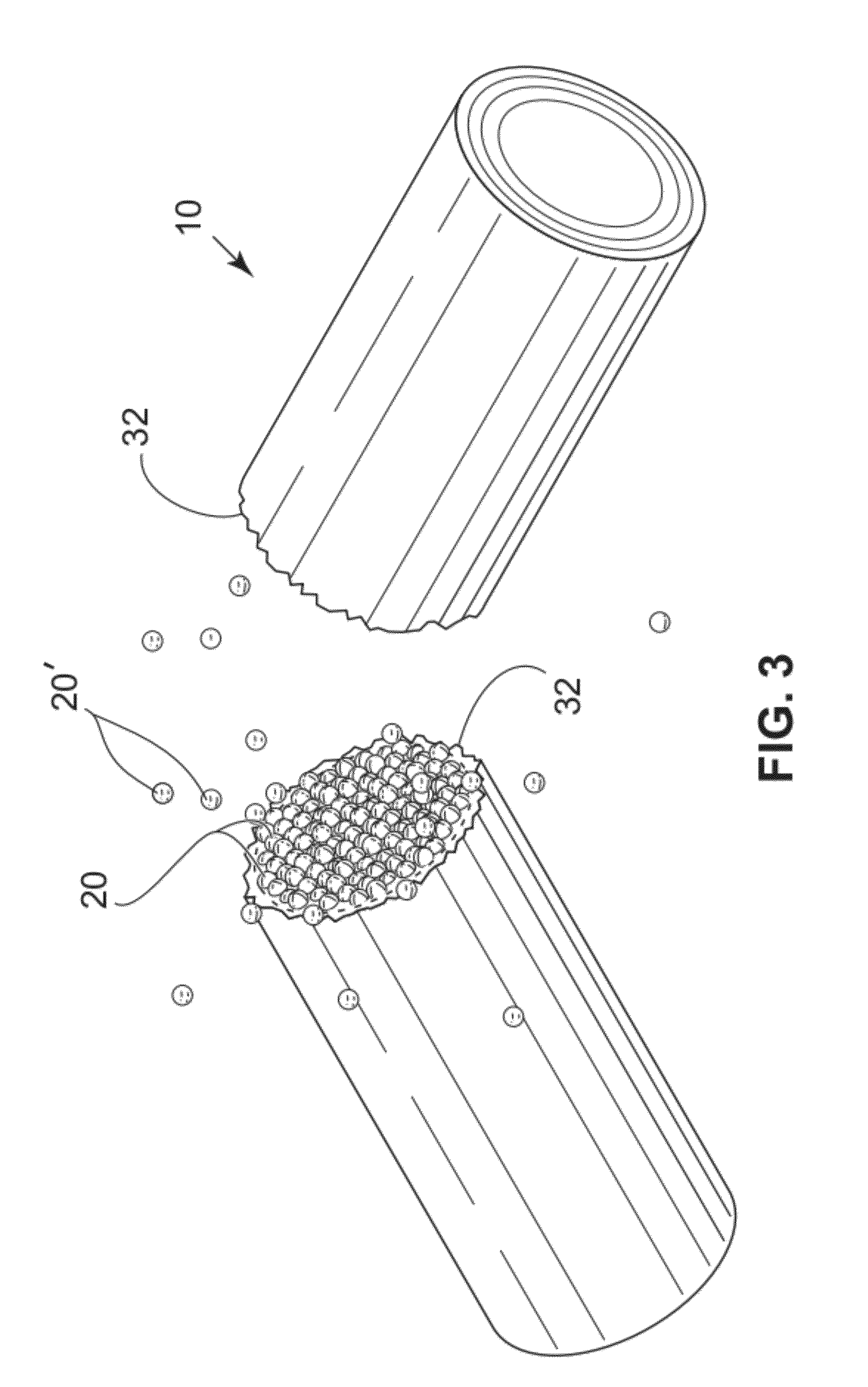

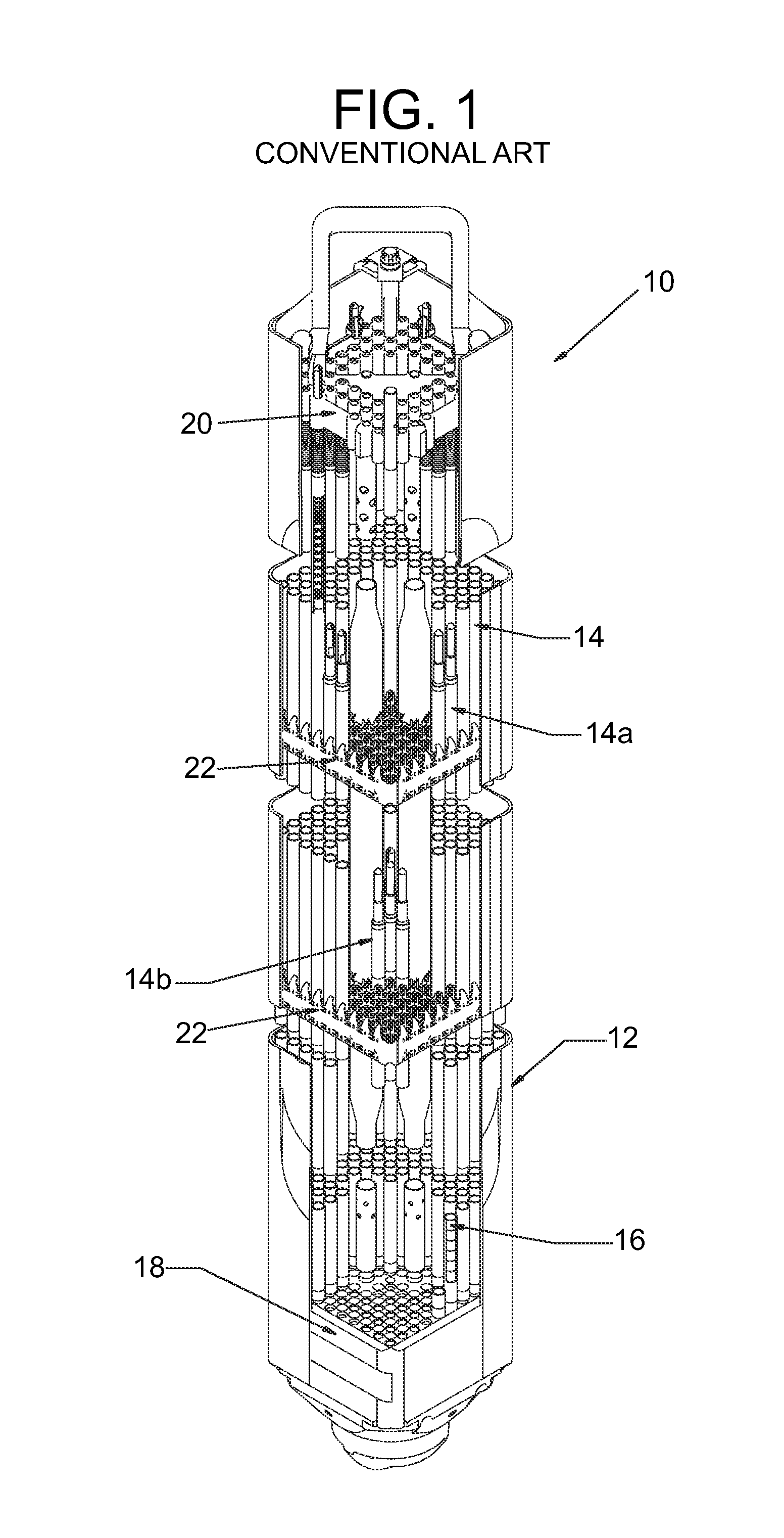

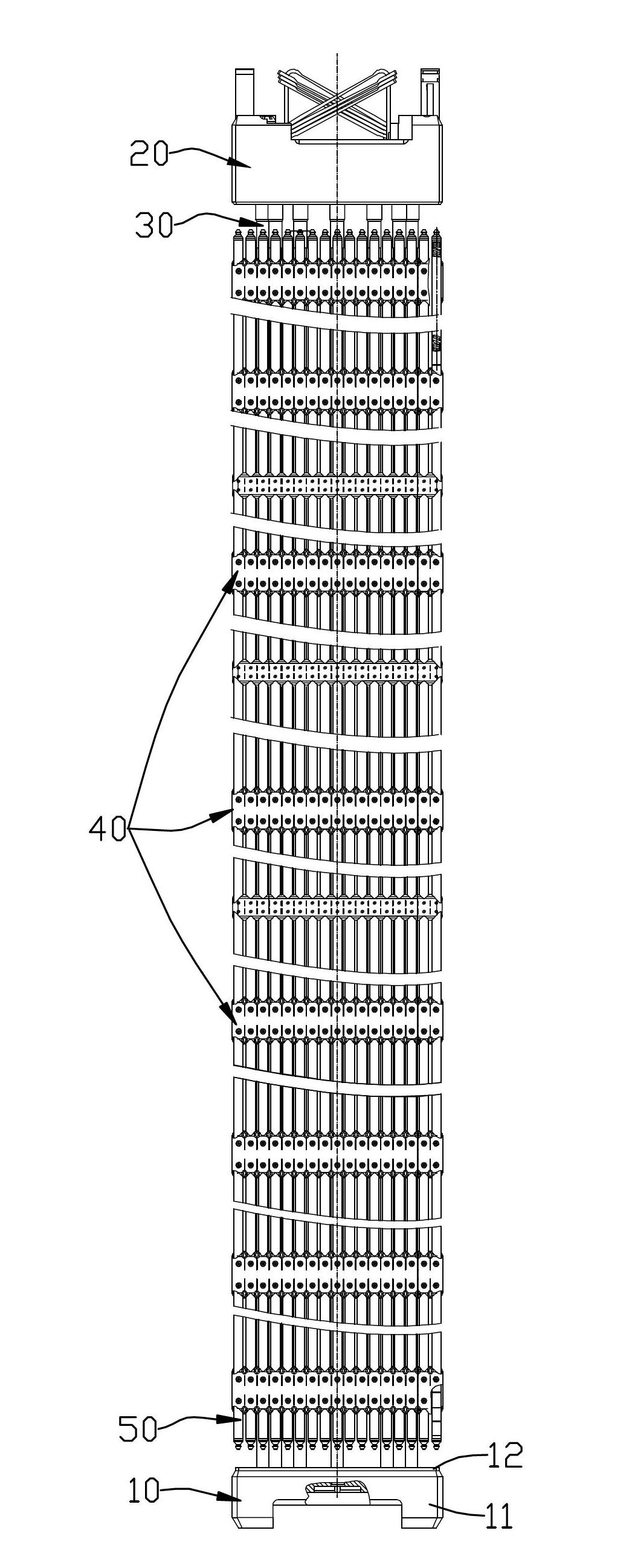

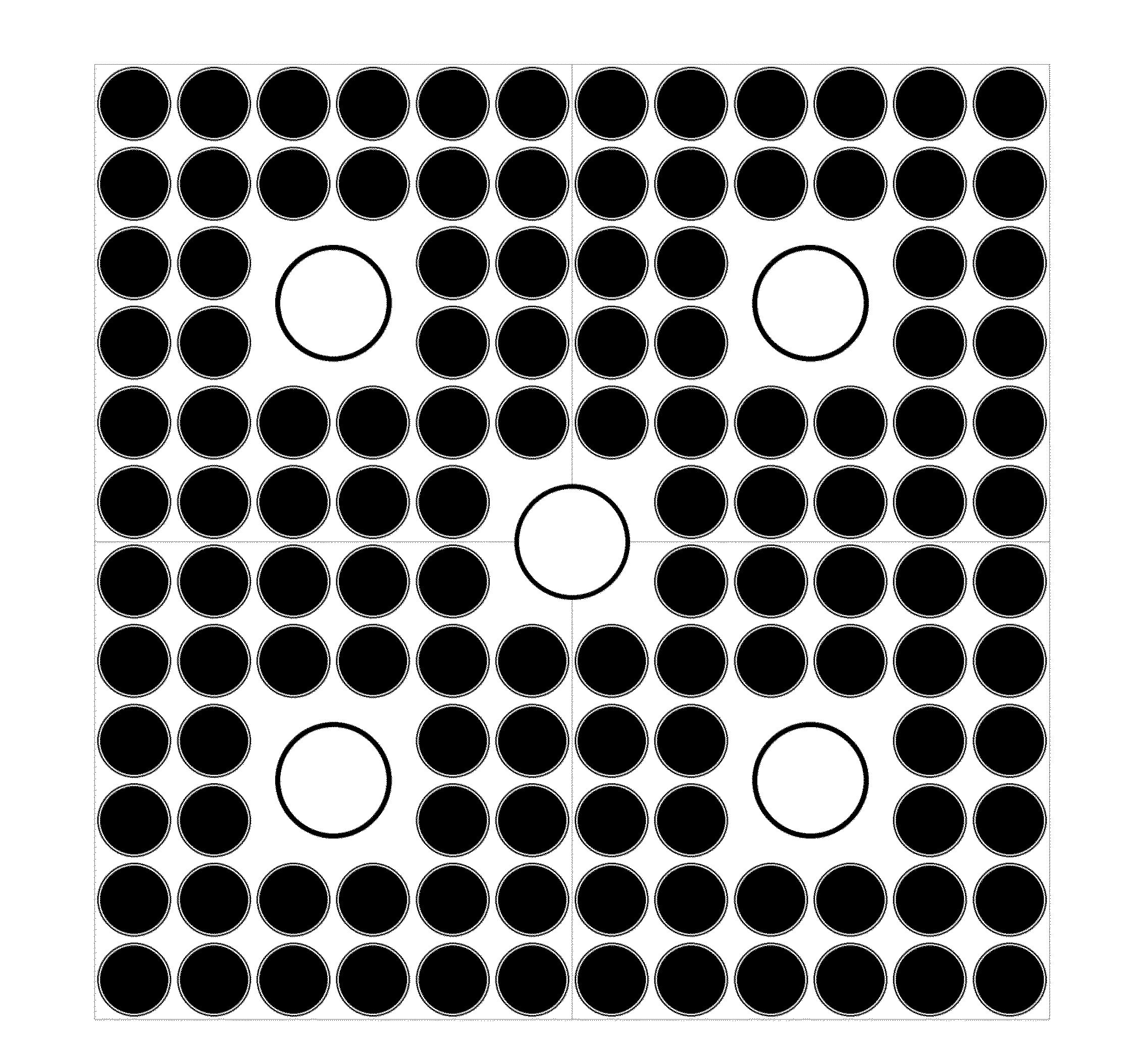

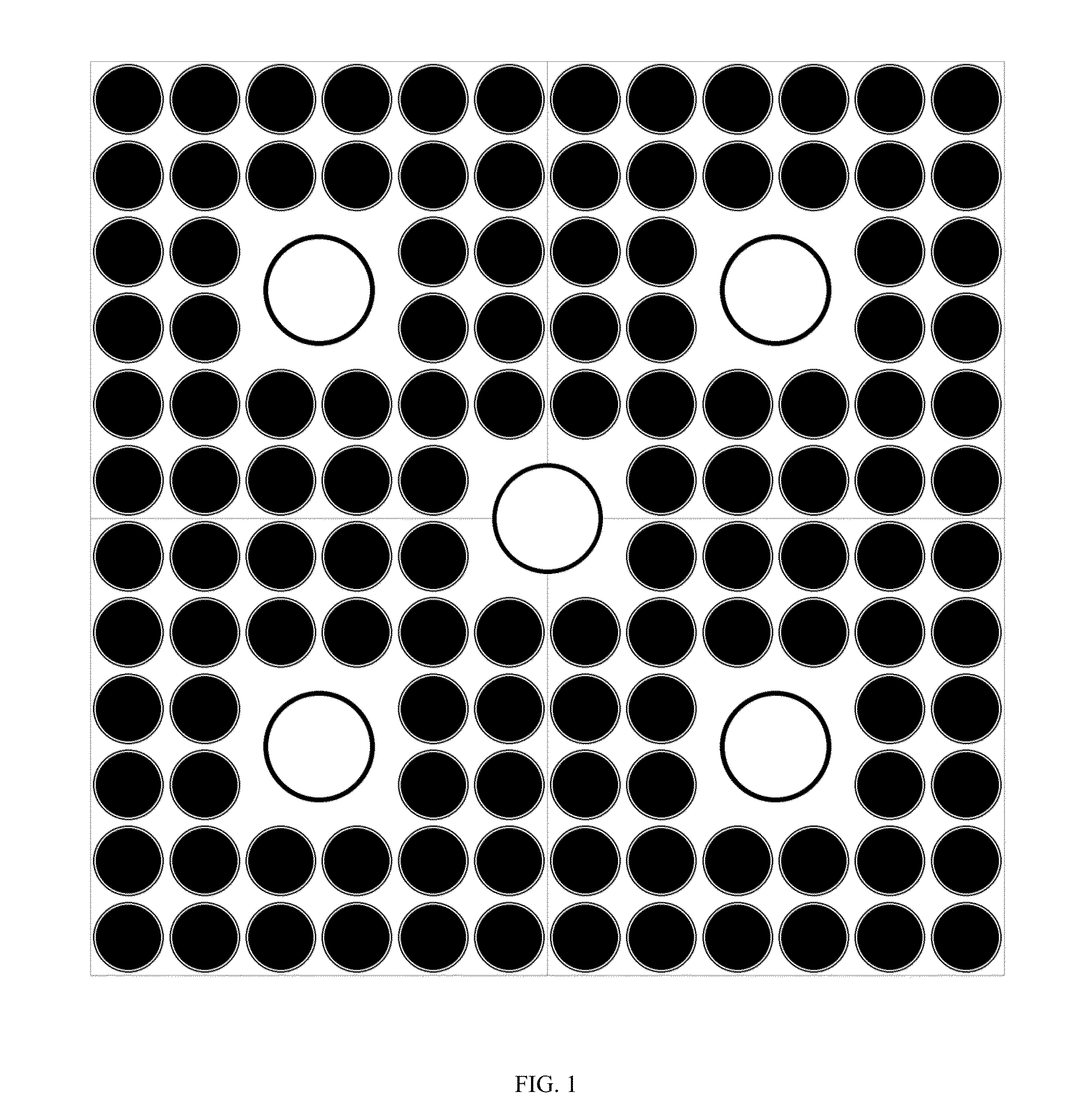

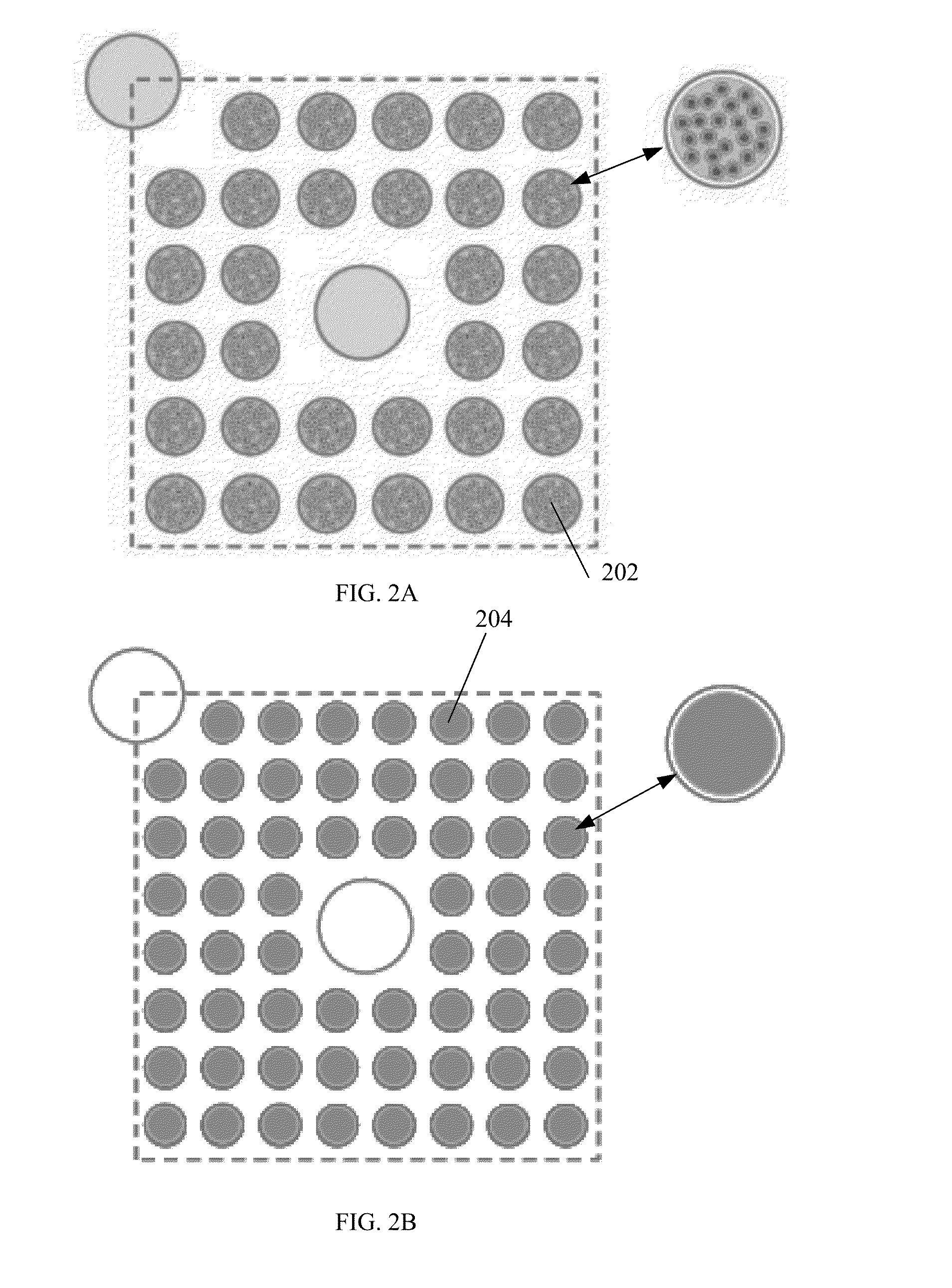

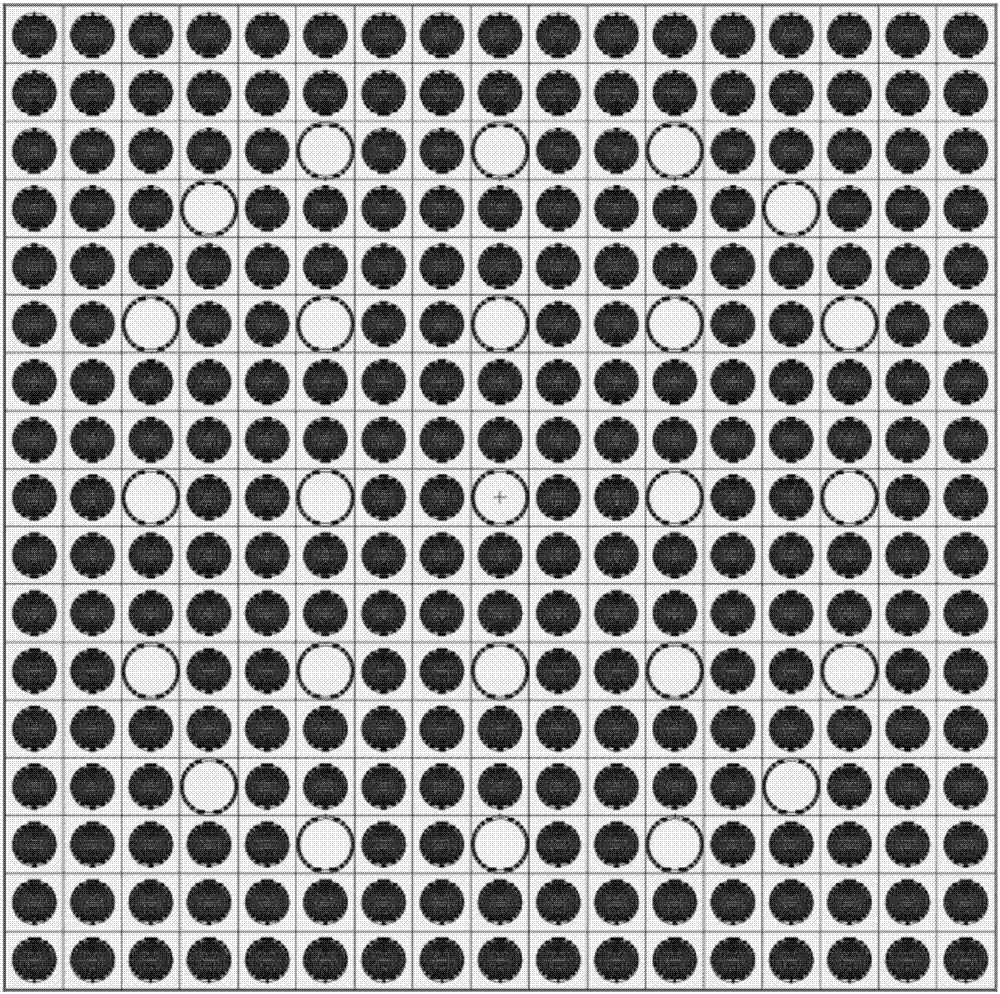

Fully ceramic microencapsulated replacement fuel assemblies for light water reactors

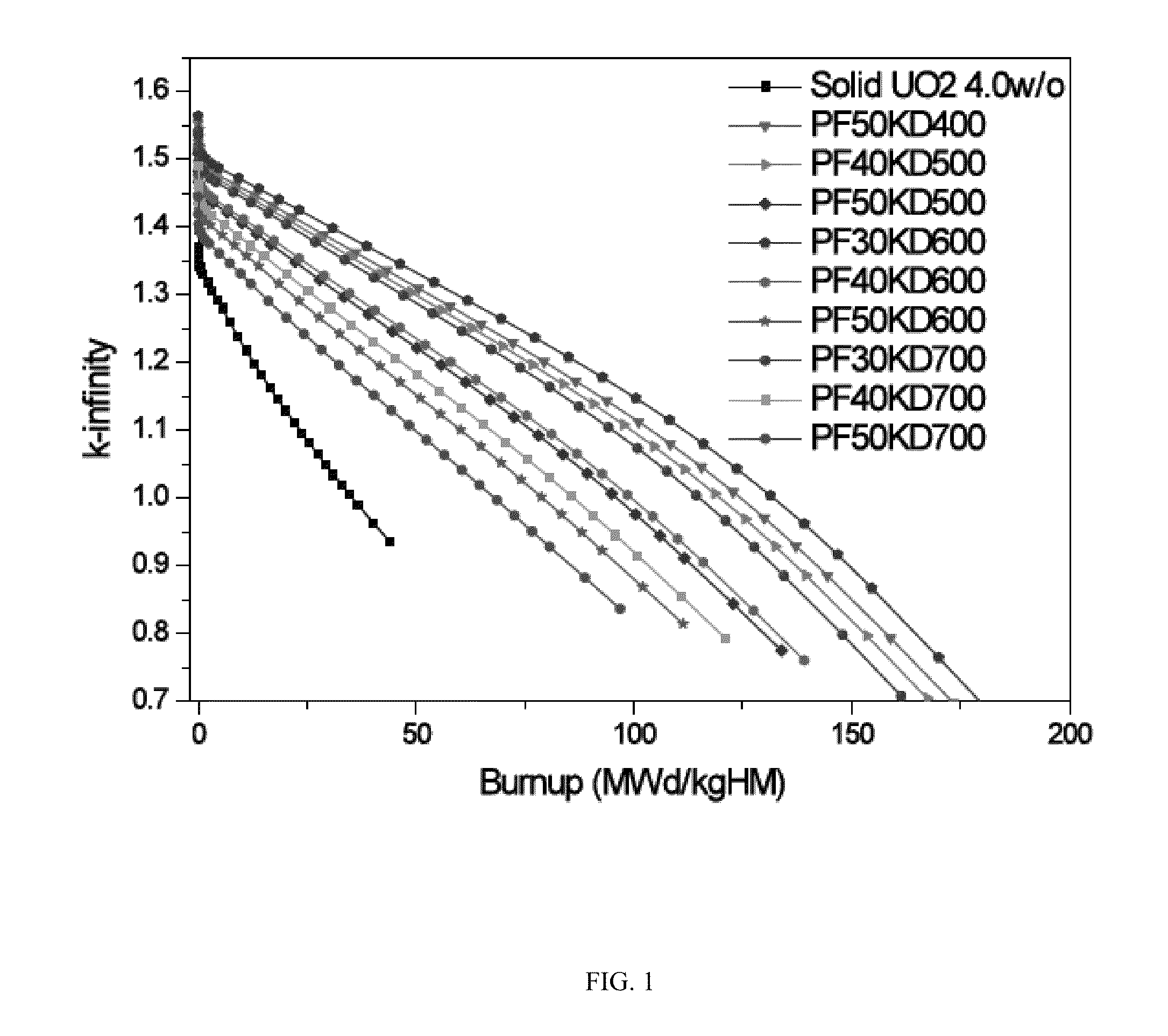

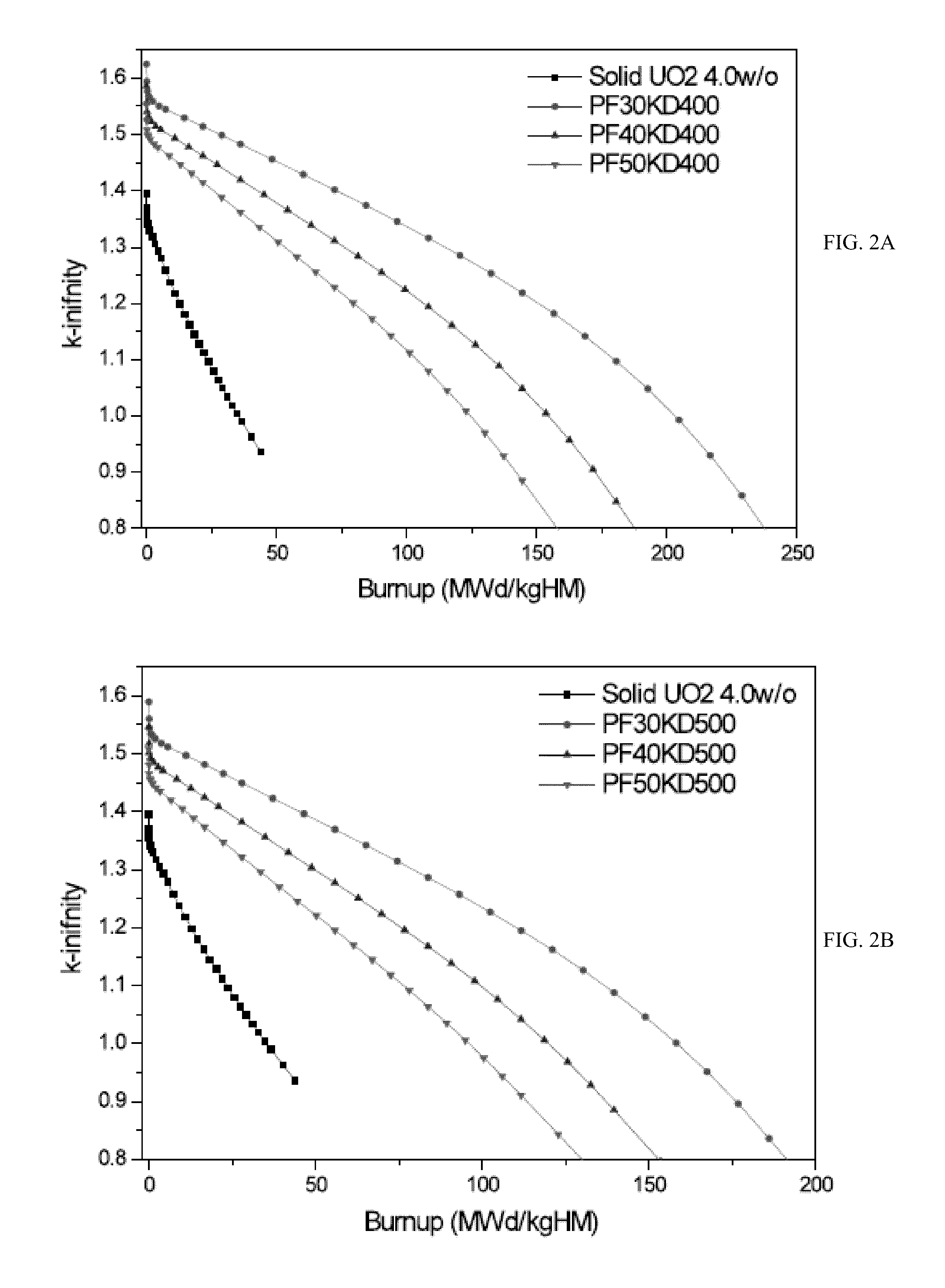

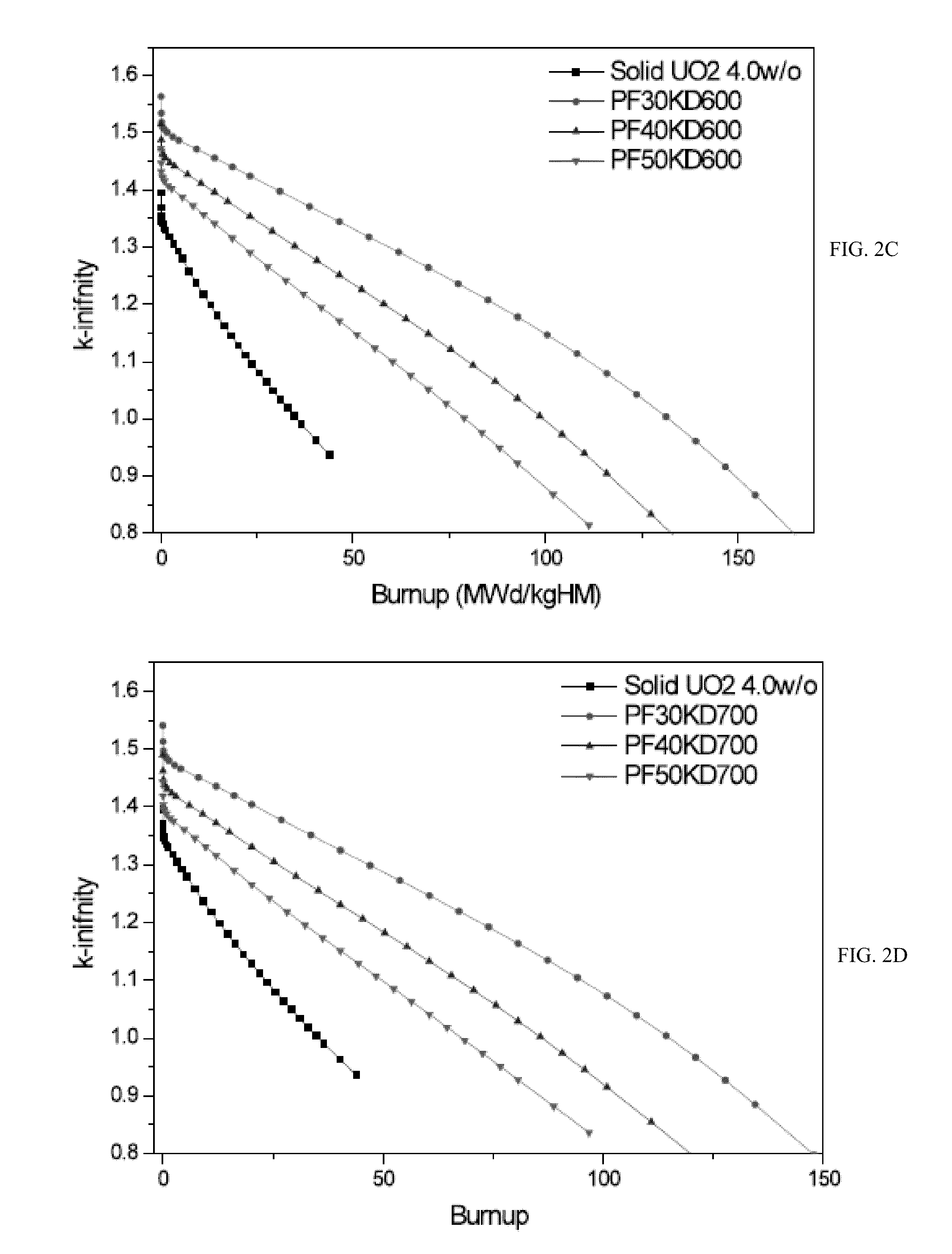

InactiveUS20130114781A1Quality improvementImprove securityOptical rangefindersNuclear energy generationAlternative fuelsBurnup

A fully ceramic micro-encapsulated fuel assembly for a light water nuclear reactor includes a set of FCM fuel rods bundled in a square matrix arrangement. Fully ceramic micro-encapsulated fuel assemblies replace standard reference solid fuel assemblies with smaller number of FCM fuel rods that have a larger diameter than the diameter of the solid standard reference fuel rods, while keeping similar amounts of fissile material in the fuel assembly and maintaining comparable rates of burnup and number of EFPDs, and compatible power production, heat transfer and thermo-hydraulic features. A fully ceramic micro-encapsulated fuel rod includes multiple fully ceramic micro-encapsulated fuel pellets, which are comprised of tristructural-isotropic particles. In order to obtain compatible burnup rates with the standard reference fuel, the tristructural-isotropic particles have preferentially large diameter and packing fraction. Furthermore, Erbium oxide is included in the sintered mix of the SiC compact to serve as a burnable poison.

Owner:KOREA ATOMIC ENERGY RES INST

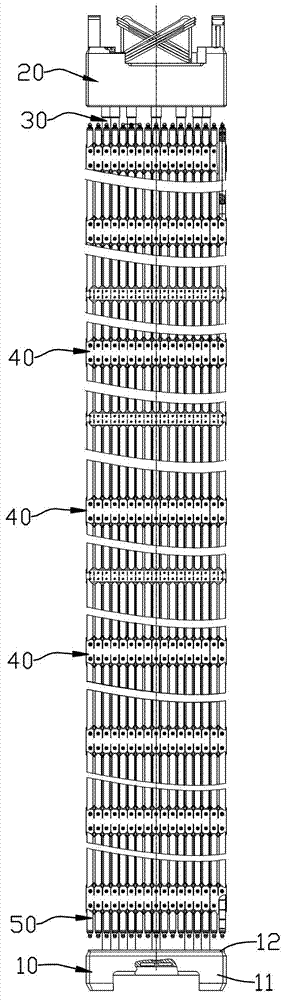

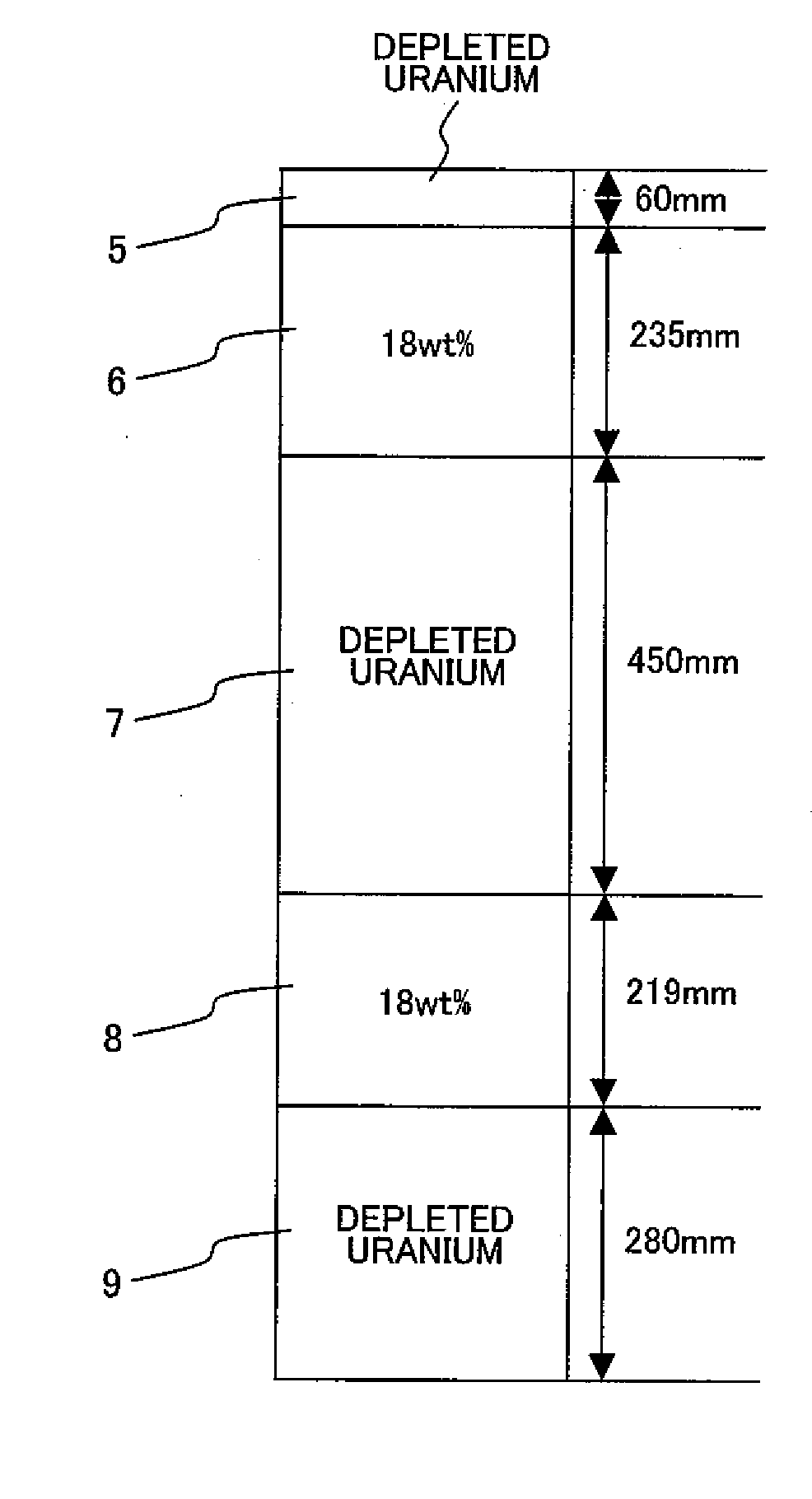

Core of light water reactor and fuel assembly

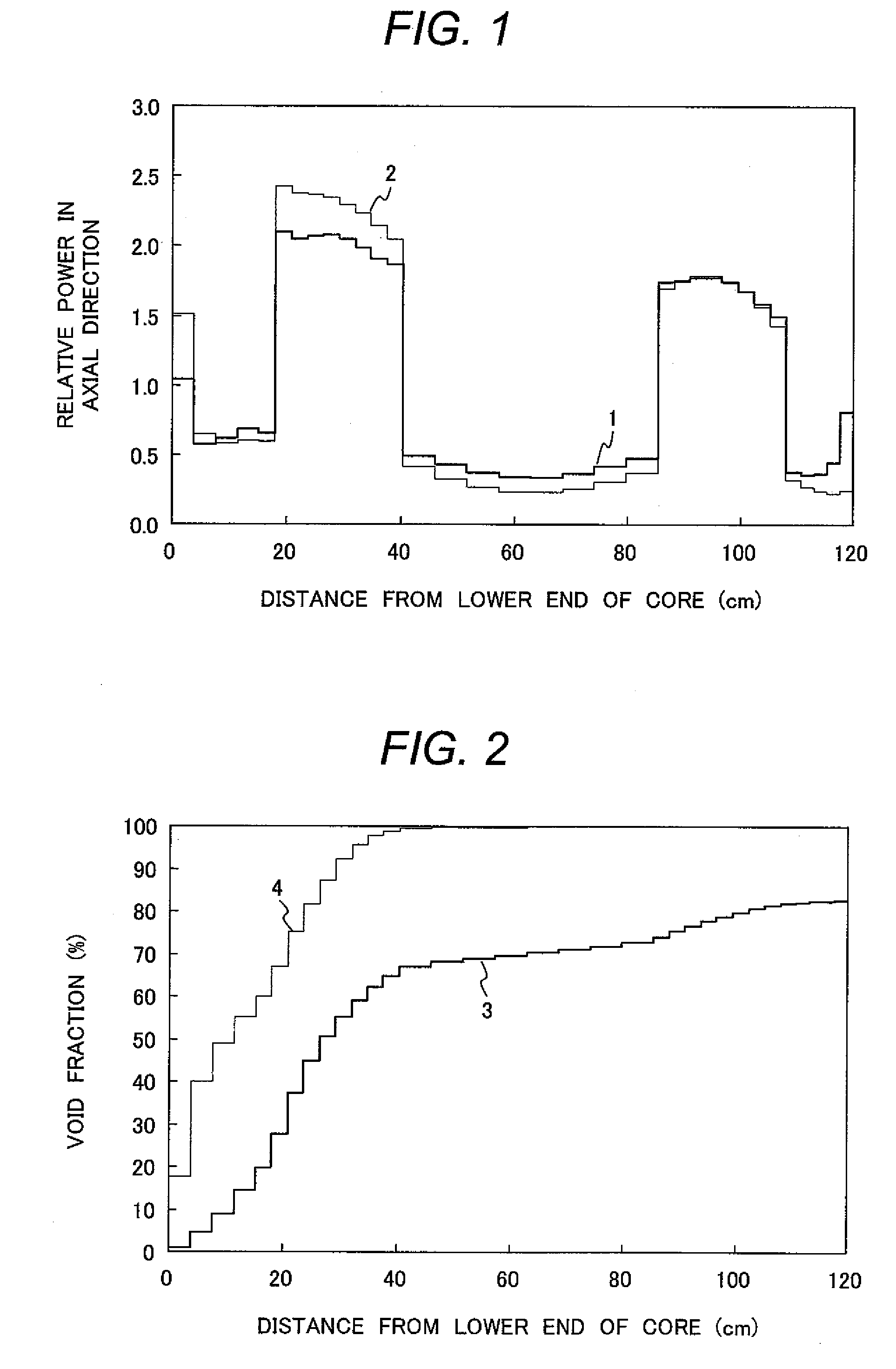

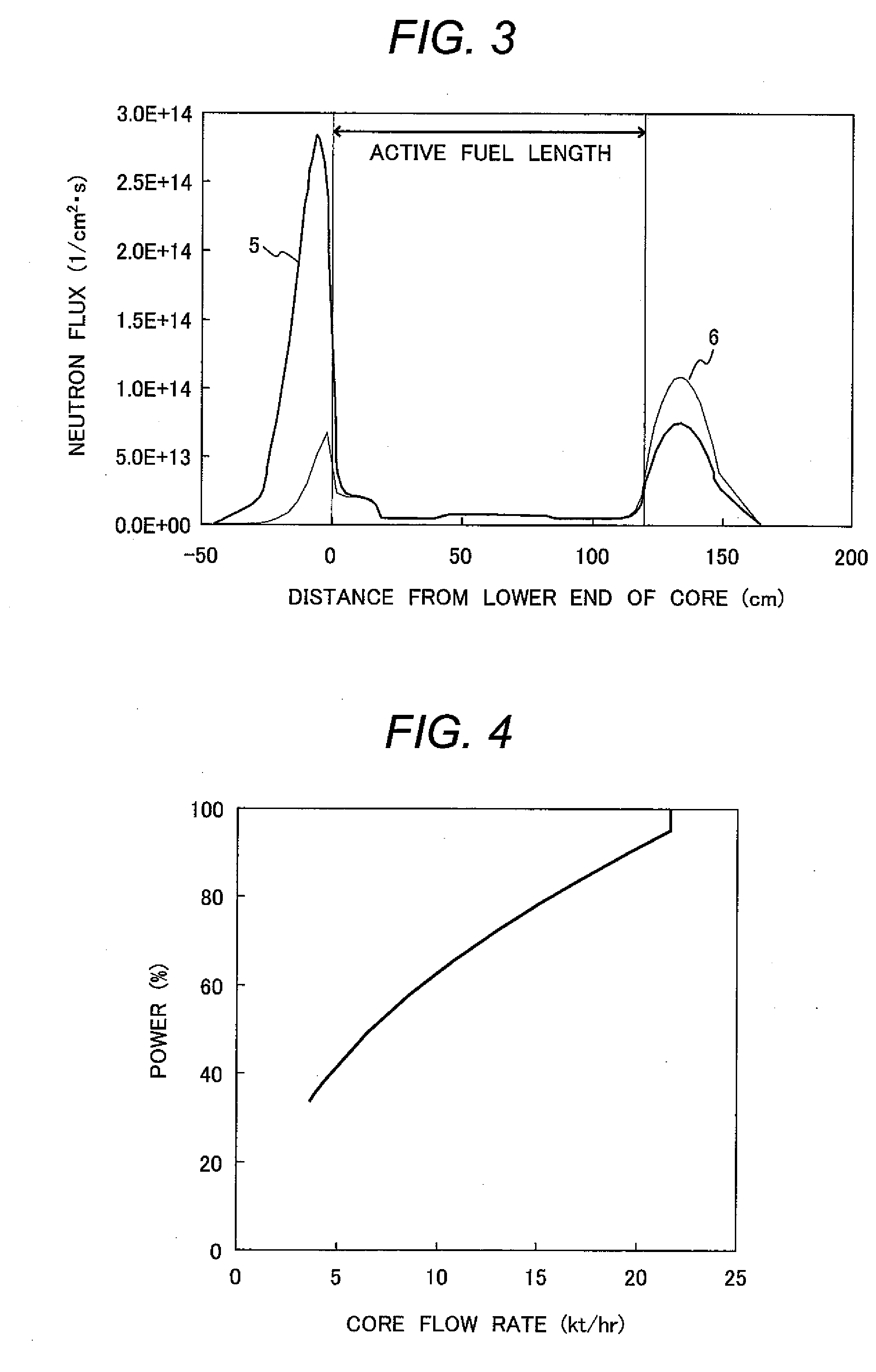

ActiveUS20100034336A1Economic efficiency of lightIncreased safety marginNuclear energy generationContainmentIsotopeBurnup

A core of a light water reactor having a plurality of fuel assemblies, which are loaded in said core, having nuclear fuel material containing a plurality of isotopes of transuranium nuclides, an upper blanket zone, a lower blanket zone, and a fissile zone, in which the transuranium nuclides are contained, disposed between the upper blanket zone and the lower blanket zone;wherein a ratio of Pu-239 in all the transuranium nuclides contained in the loaded fuel assembly is in a range of 40 to 60% when burnup of the fuel assembly is 0;sum of a height of the lower blanket zone and a height of the upper blanket zone is in a range of 250 to 600 mm; andthe height of said lower blanket zone is in a range of 1.6 to 12 times the height of the upper blanket zone.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

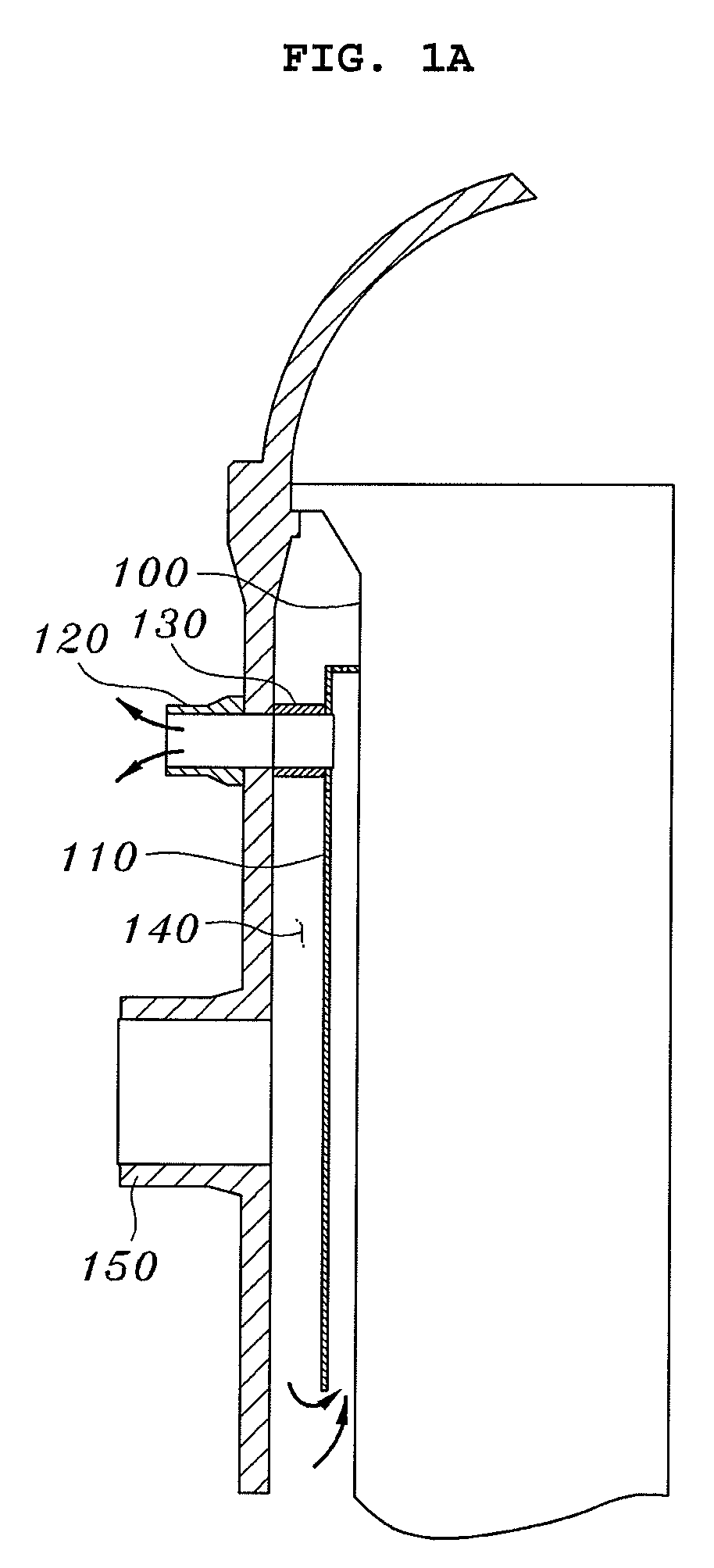

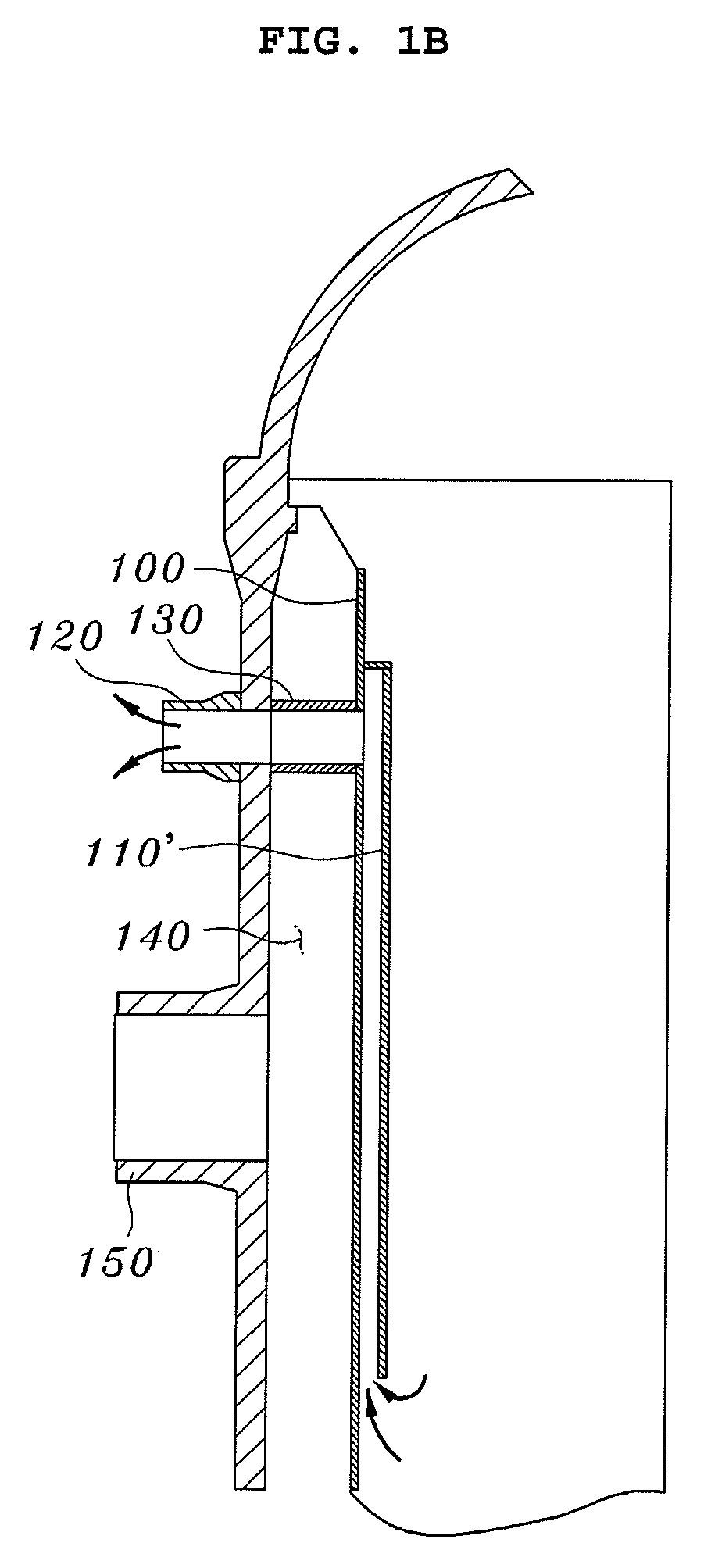

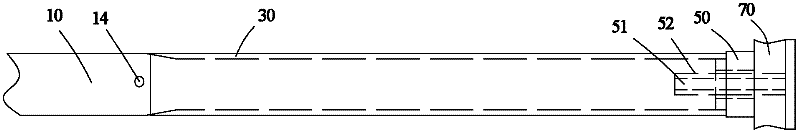

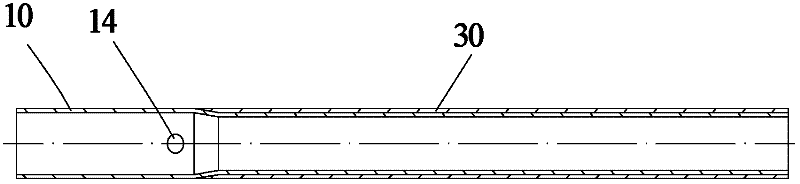

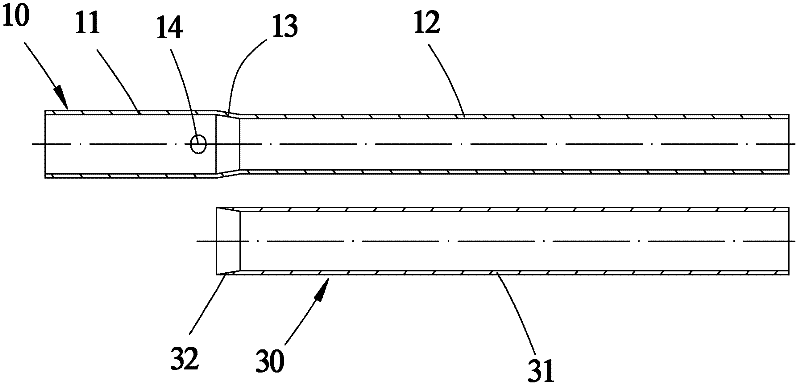

Telescoping guide tube and light-water reactor nuclear power station fuel assembly

ActiveCN102360570AHigh strengthPromote absorptionNuclear energy generationNuclear reaction controlNuclear powerControl engineering

The invention relates to a telescoping guide tube used for a light-water reactor nuclear power station fuel assembly. The telescoping guide tube comprises an inner sleeve and an outer sleeve which is closely sleeved around the inner sleeve; the inner sleeve comprises a large-diameter part, a small-diameter part and a buffering part connecting the large-diameter part with the small-diameter part; inner walls of the large-diameter part, the small-diameter part and the buffering part transit and are connected smoothly; the outer sleeve comprises a sleeve part and a connection part; the sleeve part is closely sleeved around the small-diameter part, and the connection part is in fixed connection with the buffering part. According to the invention, the outer sleeve is closely sleeved around the inner sleeve, which enables the sleeve part and the connection part to be respectively sleeved around the small-diameter part and the buffering part, thereby strengthening the strength of the whole guide tube and further strengthening the strength of the light-water reactor nuclear power station fuel assembly; meanwhile, the buffering part is reinforced, and therefore, control rods are easier to absorb energy when falling, thereby improving bending resistance; fabrication and assembly of the inner sleeve and the outer sleeve are convenient and are easy to realize.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

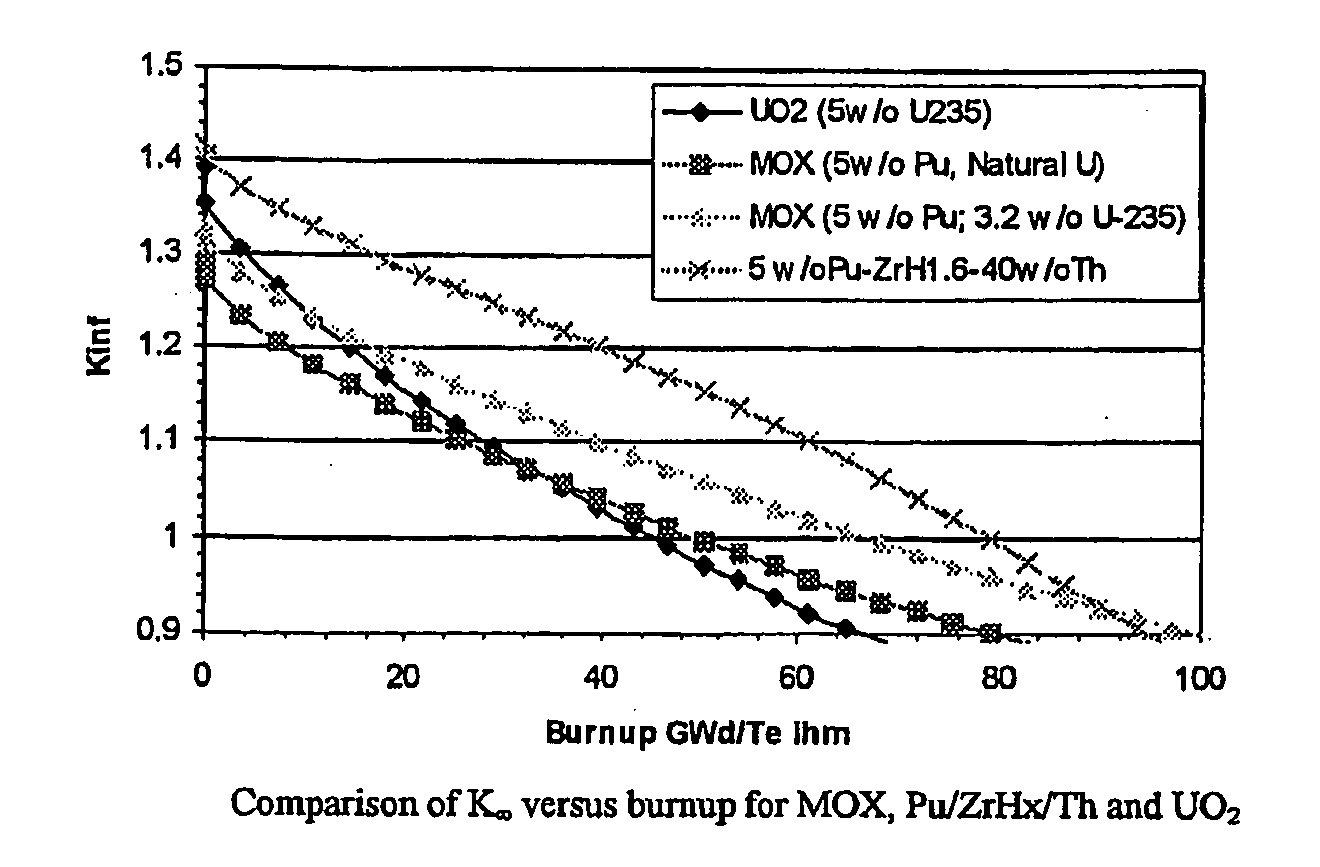

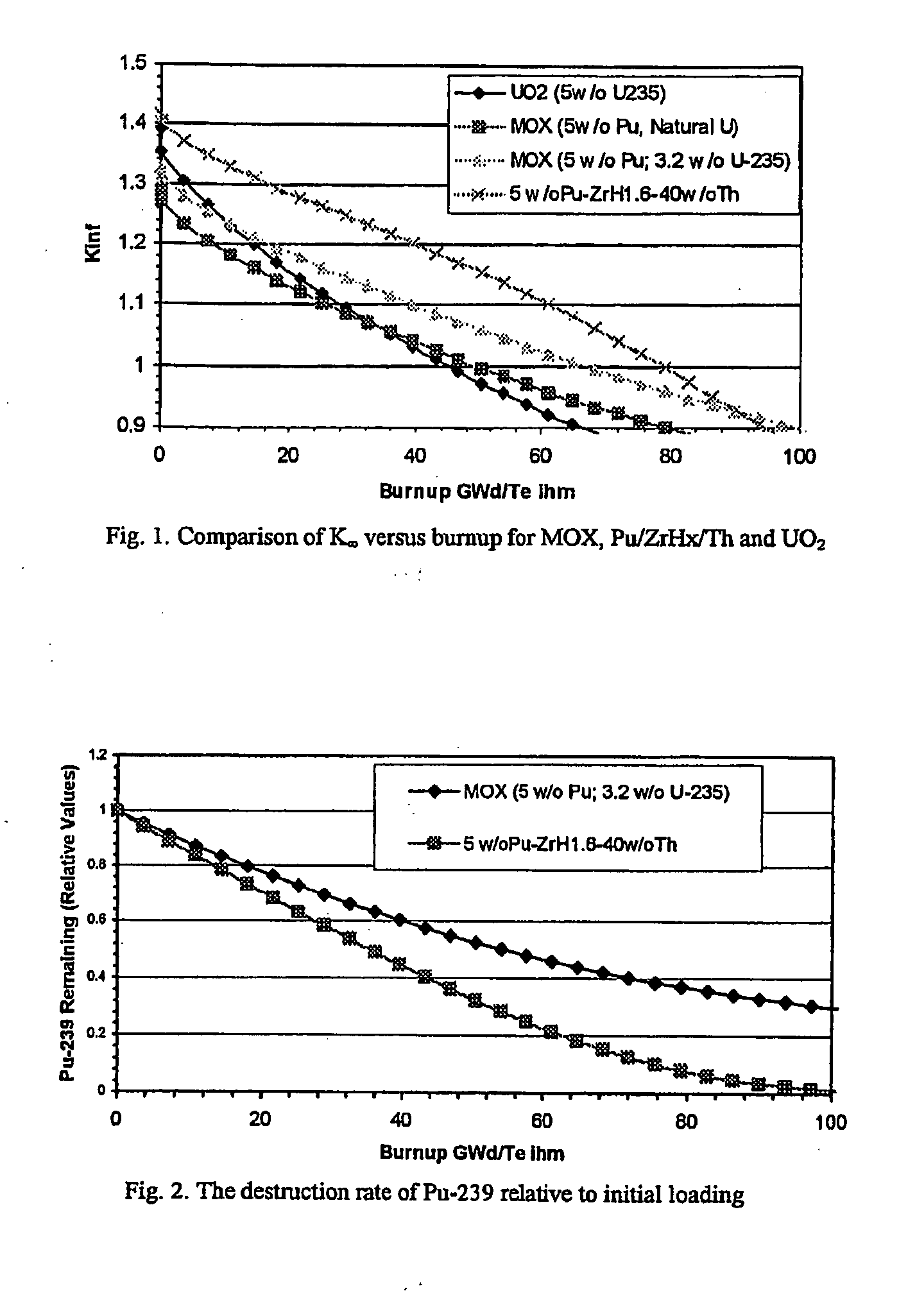

Plutonium/Zirconium Hydride/Thorium Fuel Matrix

The present invention is directed to a plutonium-based nuclear fuel that is suitable for burning weapon-grade and reactor-grade plutonium in a light water reactor, thereby reducing the amount of such material that could potentially be used to manufacture a weapon. In one embodiment, the fuel is comprised of plutonium, zirconium hydride, and thorium, with the zirconium hydride comprising more than about 20% by weight of the fuel.

Owner:UNIVERSITY OF DENVER

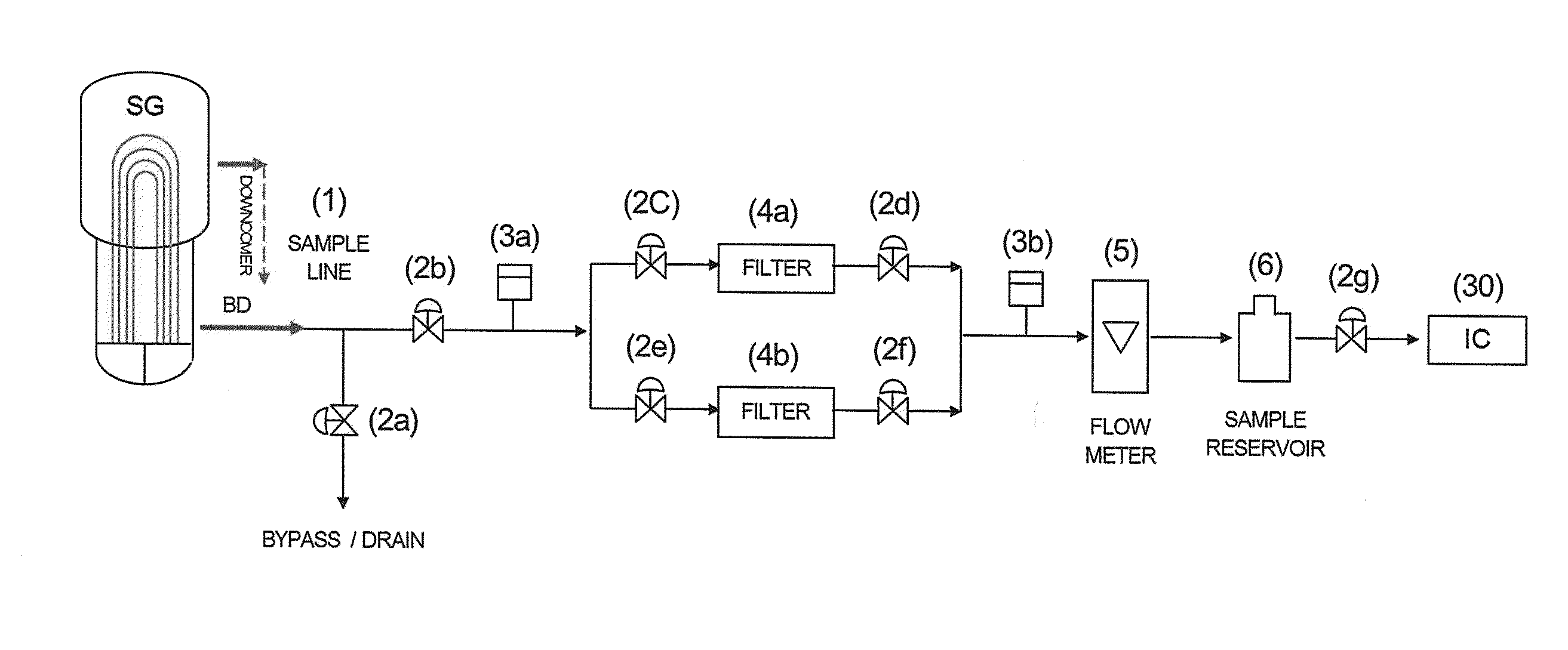

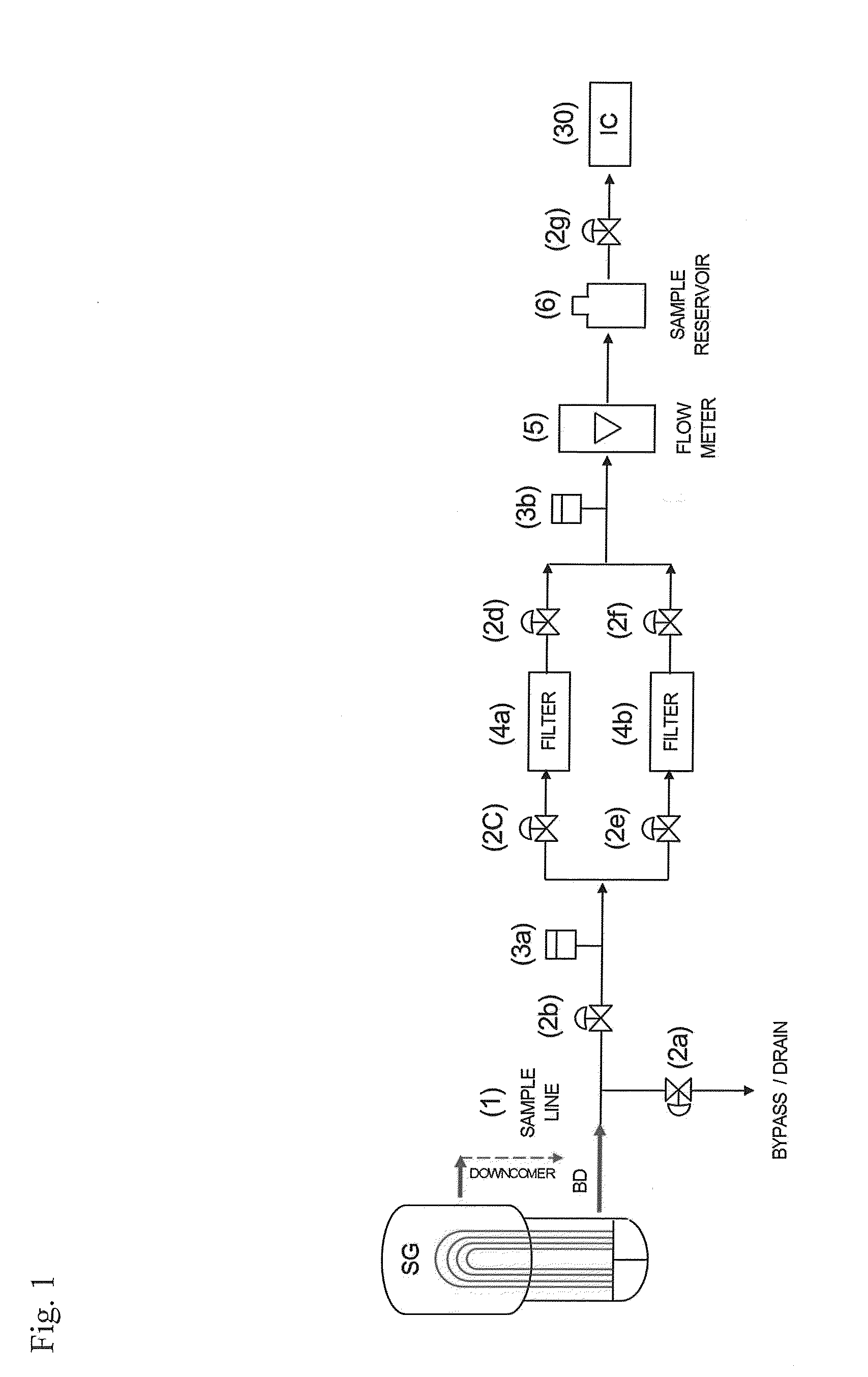

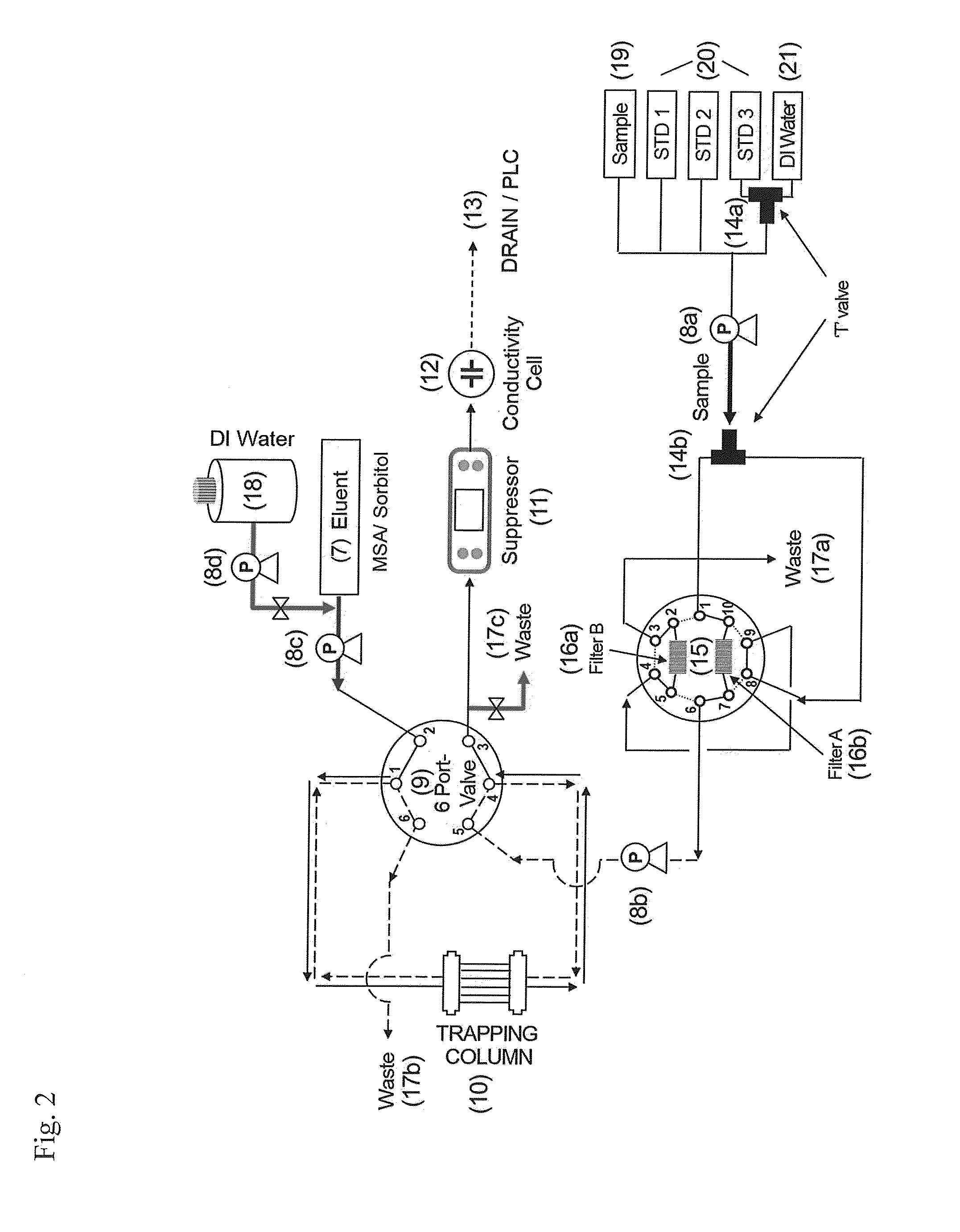

Method and system for detecting boron ions using ion chromatography for online monitoring of steam generator tube leakage in light water reactor

InactiveUS20160187308A1Promptly and accurately detectMaintaining high pressureComponent separationFluid-tightness measurement using electric meansIon chromatographyTrapping

The present invention relates to an online leakage monitoring technique of a steam generator tube for monitoring leakage of the steam generator tube by analyzing concentration of an extremely small amount of boron ions in the secondary side solution of the steam generator in which a variety of ions are mixed, and the present invention is effective in that concentration of an extremely small amount of boron ions can be accurately detected, maintenance is convenient and durability is improved since analysis time is reduced considerably and operation pressure is lowered greatly by using ion chromatography provided with a boron trapping column optimized for trapping an extremely small amount of boron ions and a deionization water supplier for rising a sample line, instead of general ion chromatography provided with a concentration column and a separation column.

Owner:HUVIS WATER

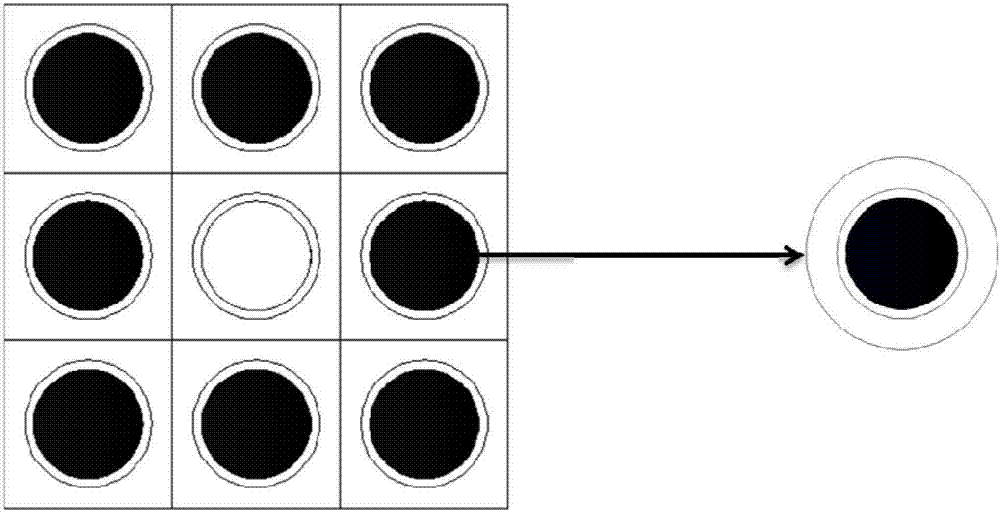

Resonance self-shielding calculation method by aiming at light-water reactor on the basis of equivalent one-dimensional rod model

ActiveCN107038294AEffective self-screening sectionImprove computing efficiencyGeometric CADData processing applicationsSpatial correlationComputational problem

The invention discloses a resonance self-shielding calculation method by aiming at a light-water reactor on the basis of an equivalent one-dimensional rod model. The method comprises the following steps that: 1: for the resonance self-shielding calculation problem of the light-water reactor l, adopting a neutron current method to calculate each section of Dancoff correction factor of each fuel rod; 2: according to a function relationship between the Dancoff correction factor and a one-dimensional moderator external diameter, under a situation of a known Dancoff correction factor, adopting a binary search method to obtain the moderator external diameter; and 3: adopting a subgroup method or a superfine group method to calculate an equivalent one-dimensional fuel rod to obtain the effective self-shielding section of each circle of the fuel rod. Compared with a traditional resonance self-shielding calculation method, the resonance self-shielding calculation method disclosed by the invention is characterized in that the problem of complex geometry can be calculated, the method is higher in calculation efficiency, and the effective self-shielding section related to space can be obtained.

Owner:XI AN JIAOTONG UNIV

B and Gd-containing overall composite combustible toxic fuel and preparation method

ActiveCN102129889AAvoid demandLow costNuclear energy generationVacuum evaporation coatingNegative temperatureNuclear power

The invention belongs to a combustible toxic fuel, in particular to a B and Gd-containing overall composite combustible toxic fuel and a preparation method. The fuel aims to control excess reactivity and meets the requirements of long-period reactivity control and moderator negative temperature coefficient control on the composite combustible toxic fuel. The composite combustible toxic fuel consists of a ZrB2 coating and a UO2-Gd2O3, wherein the UO2-Gd2O3 comprises 2 to 12 mass percent of Gd2O3; and the linear density of concentrated <10>B is 0.1 to 1.0 mg / cm. By using the overall composite combustible toxic fuel, the requirements of the long-period reactivity control and the moderator negative temperature coefficient control on the composite combustible toxic fuel can be met; moreover, the cost of the composite combustible toxic fuel is lower than that of an Er-containing combustible toxic fuel. Simultaneously the service life of a reactor core is prolonged, the refueling period is prolonged and the nuclear power operation cost is reduced, so that the refueling period of a light-water reactor nuclear power station fuel can reach 24 to 48 months.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Extension of methods to utilize fully ceramic micro-encapsulated fuel in light water reactors

InactiveUS20130322590A1Heavy qualityLarge caliberOptical rangefindersNuclear energy generationMicrometerUranium nitride

A 12×12 fully ceramic micro-encapsulated fuel assembly for a light water nuclear reactor includes a set of FCM fuel rods bundled in a square matrix arrangement. The fully ceramic micro-encapsulated fuel is comprised of tristructural-isotropic particles. Each tristructural-isotropic particle has a kernel that is comprised uranium nitride. The kernel diameter is 400 or more micrometers. The fully ceramic micro-encapsulated fuel is further mixed with a burnable poison material.

Owner:KOREA ATOMIC ENERGY RES INST

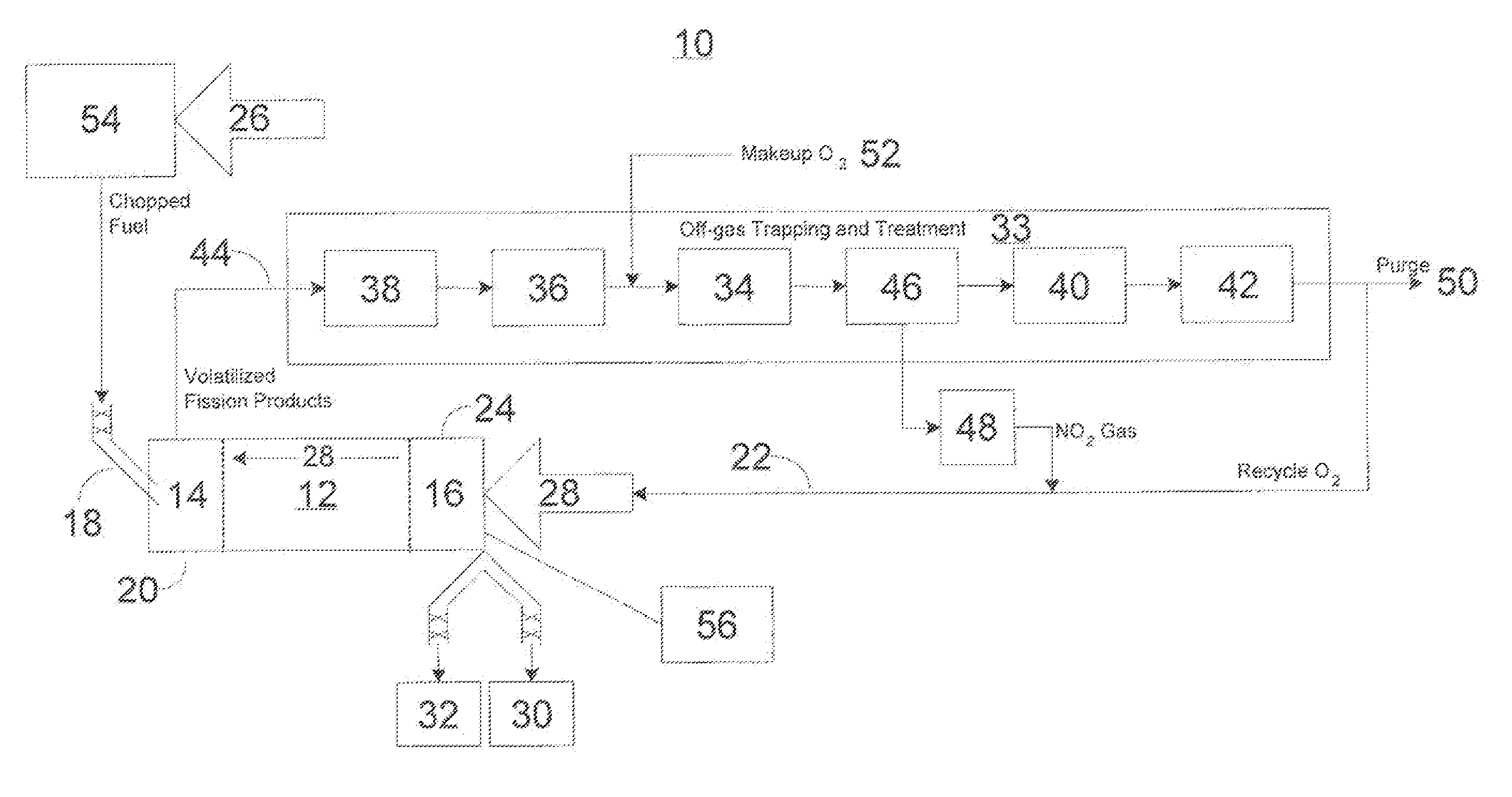

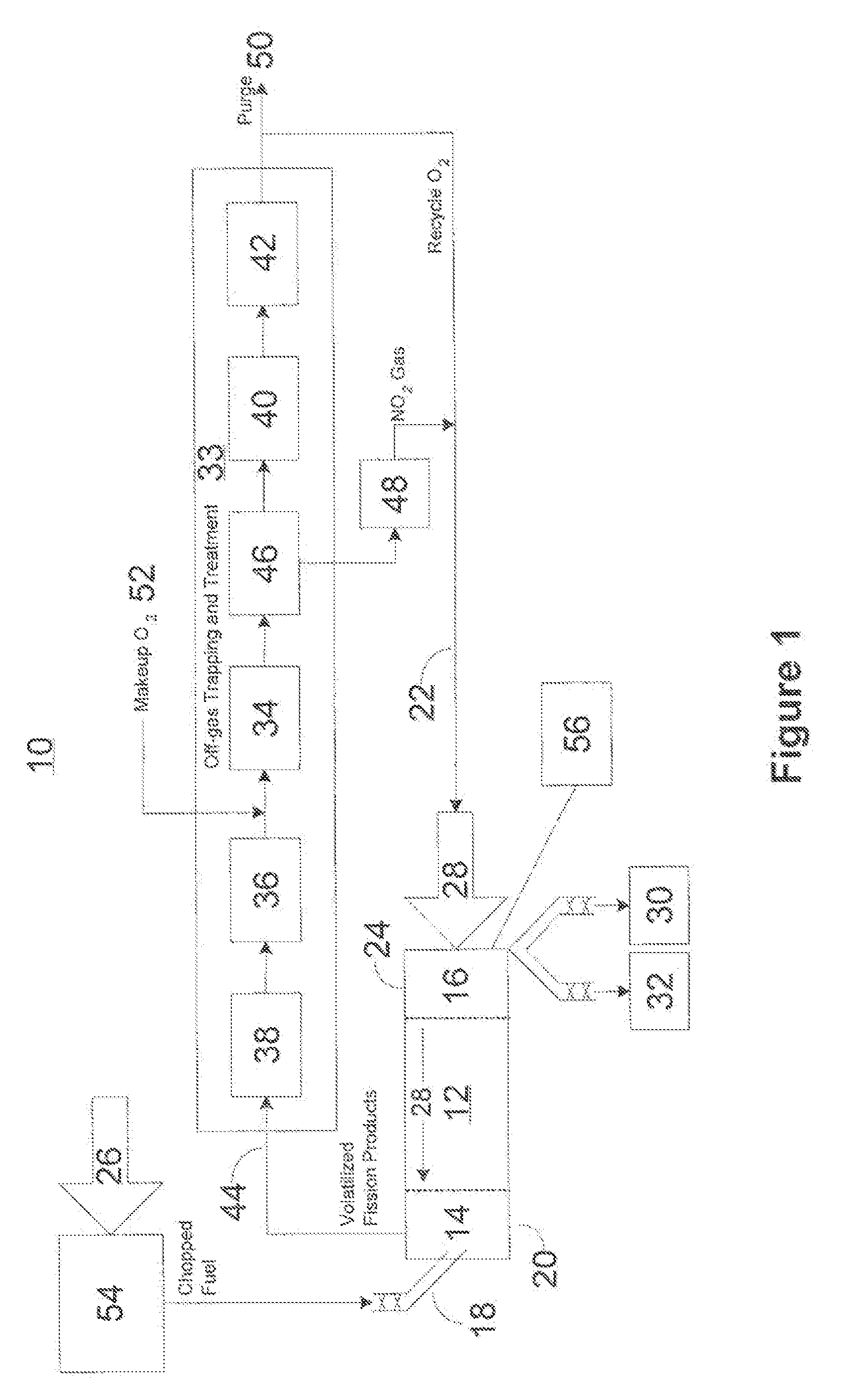

Advanced dry head-end reprocessing of light water reactor spent nuclear fuel

ActiveUS20110250108A1Solvent extractionTransuranic element compoundsNitrogen monooxideNitrogen dioxide

A method for reprocessing spent nuclear fuel from a light water reactor includes the step of reacting spent nuclear fuel in a voloxidation vessel with an oxidizing gas having nitrogen dioxide and oxygen for a period sufficient to generate a solid oxidation product of the spent nuclear fuel. The reacting step includes the step of reacting, in a first zone of the voloxidation vessel, spent nuclear fuel with the oxidizing gas at a temperature ranging from 200-450° C. to form an oxidized reaction product, and regenerating nitrogen dioxide, in a second zone of the voloxidation vessel, by reacting oxidizing gas comprising nitrogen monoxide and oxygen at a temperature ranging from 0-80° C. The first zone and the second zone can be separate. A voloxidation system is also disclosed.

Owner:UT BATTELLE LLC

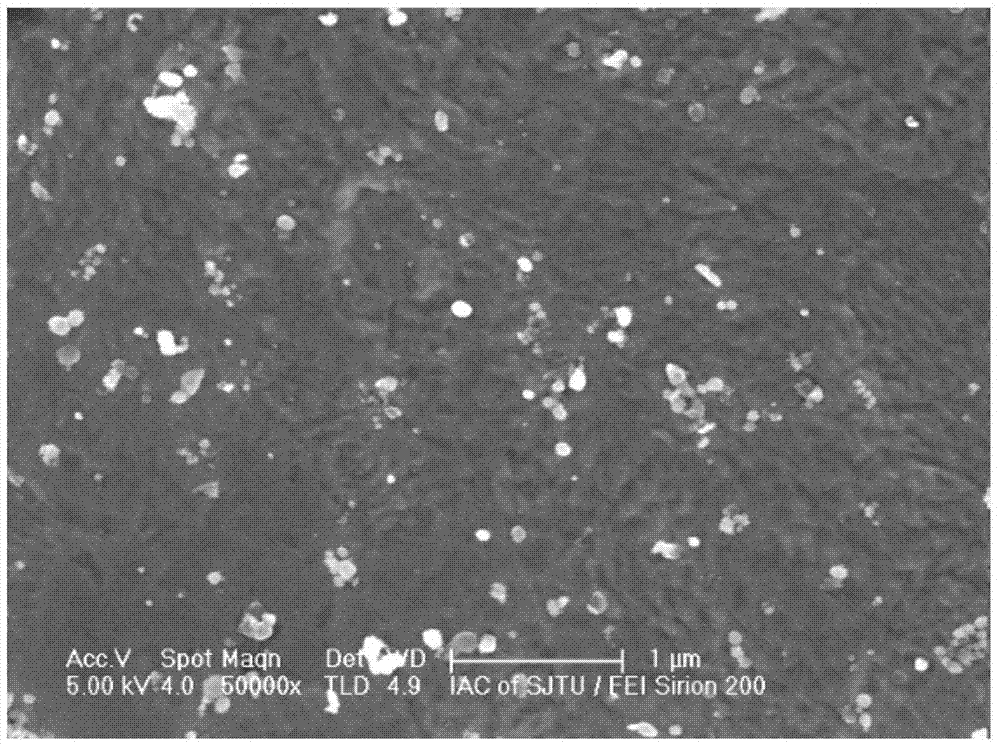

Zirconium base alloy used for light-water reactors and preparation method thereof

ActiveCN104745876AImprove corrosion resistanceImprove mechanical propertiesOptical rangefindersNuclear energy generationNiobiumOxygen

The invention discloses a zirconium base alloy used for light-water reactors. The zirconium base alloy contains, by weight, 0.30-0.69% of tin, 0.20-0.50% of niobium, 0.20-0.40% of iron, 0.01-0.09% of copper, 0.07-0.20% of oxygen, 0.005-0.03% of silicon and the balance zirconium. According to the invention, the minimum total percentage of the added copper, the silicon and the oxygen is limited to 0.13%, and the matching performance among the copper, the silicon and the oxygen is considered, so that the corrosion resistance of the zirconium base alloy is improved; meanwhile, the mechanical property, the radiation growth resistance and the radiation creeping resistance of the alloy can be improved.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

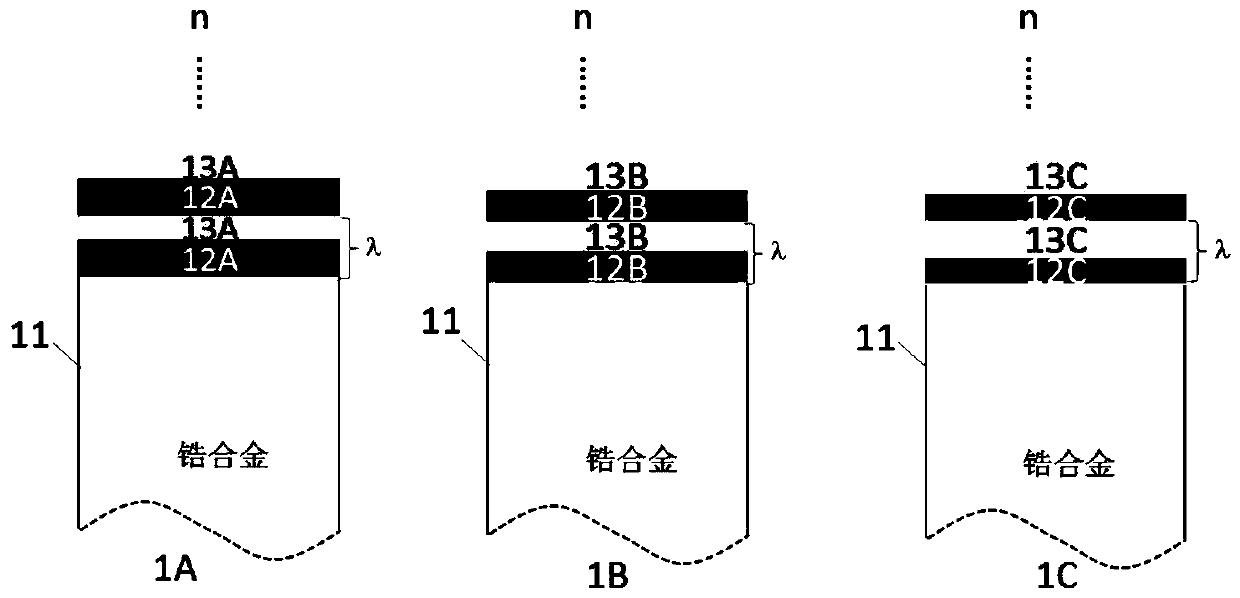

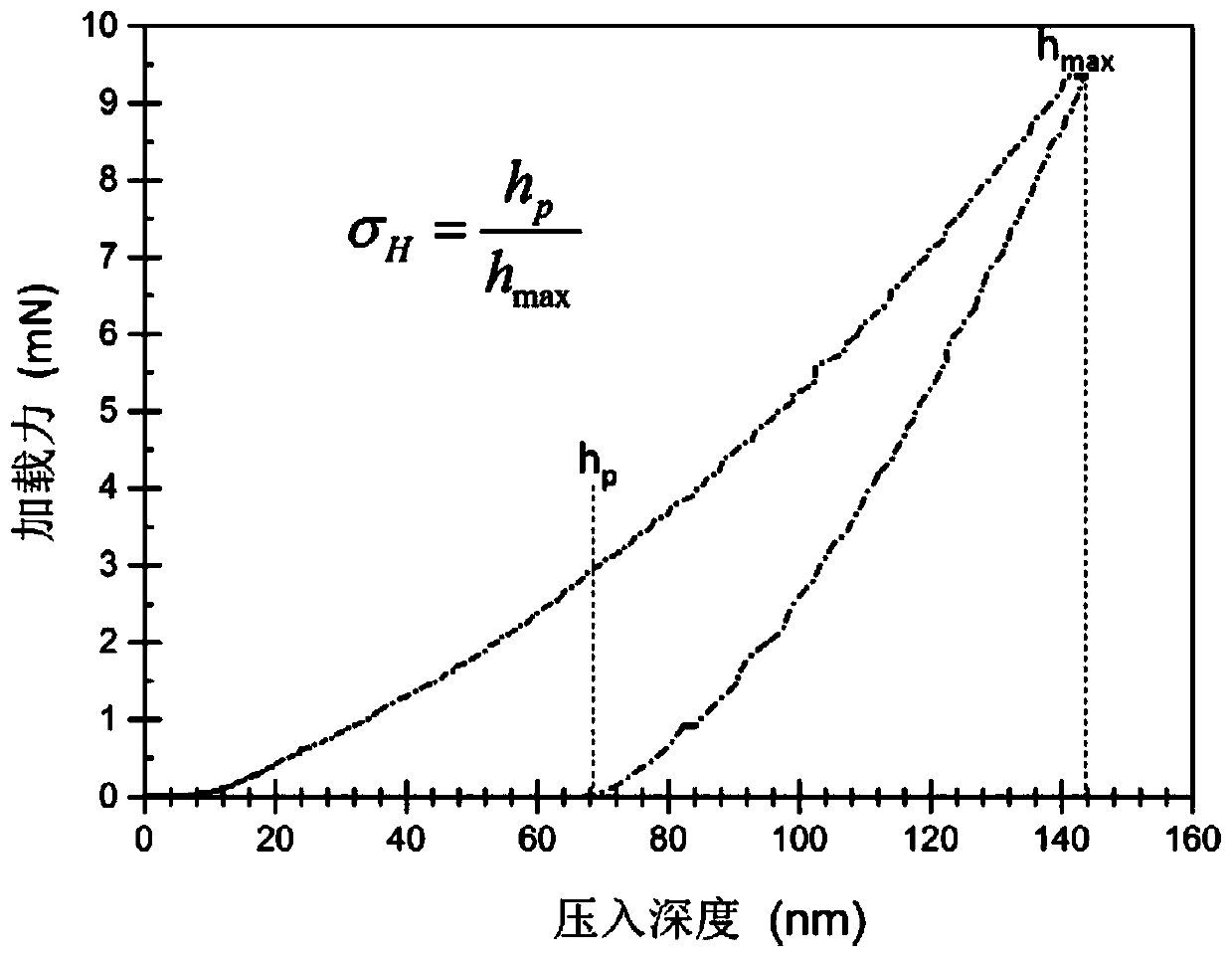

Multilayer protective coating with high-temperature steam oxidation resistance and hot water corrosion resistance and preparation method and application

ActiveCN110484889AImprove toughnessHigh hardnessVacuum evaporation coatingSputtering coatingPeriodic alternatingSurface layer

The invention discloses a multilayer protective coating with high-temperature steam oxidation resistance and hot water corrosion resistance. The multilayer protective coating comprises the following components: a Cr layer and a CrAlSiN layer which are periodically and alternately deposited, wherein the most surface layer of the coating is the Cr layer; the cycle number of the alternate depositionis 1-20; the thickness of the Cr layer and the CrAlSiN layer in the unit period is 0.5-10 microns, and the thickness ratio is 2: 3-3: 2. The multilayer protective coating is formed by alternately depositing theCr layer and the CrAlSiN layer on the surface of a zirconium alloy substrate by adopting a magnetron sputtering method. The invention also provides a zirconium alloy covering housing manufactured by the abovementioned method. The multilayer protective coating has the advantages of hot water corrosion resistance under the normal working condition (600-650 DEG C) and high-temperature steamoxidation resistance under the accident fault-tolerant working condition (1000-1200 DEG C), and effectively meets the protection requirements under two working conditions of a light water reactor.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

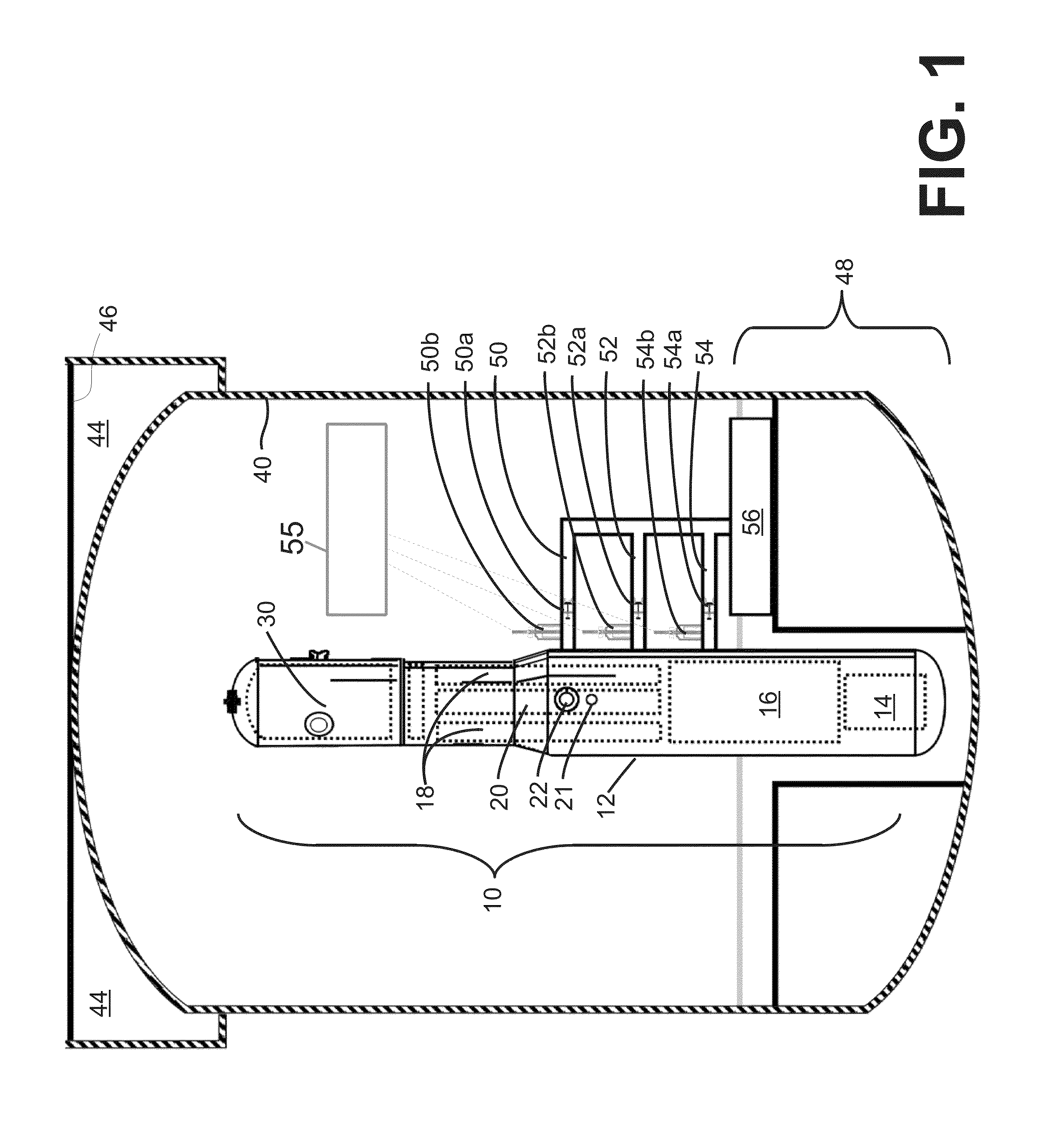

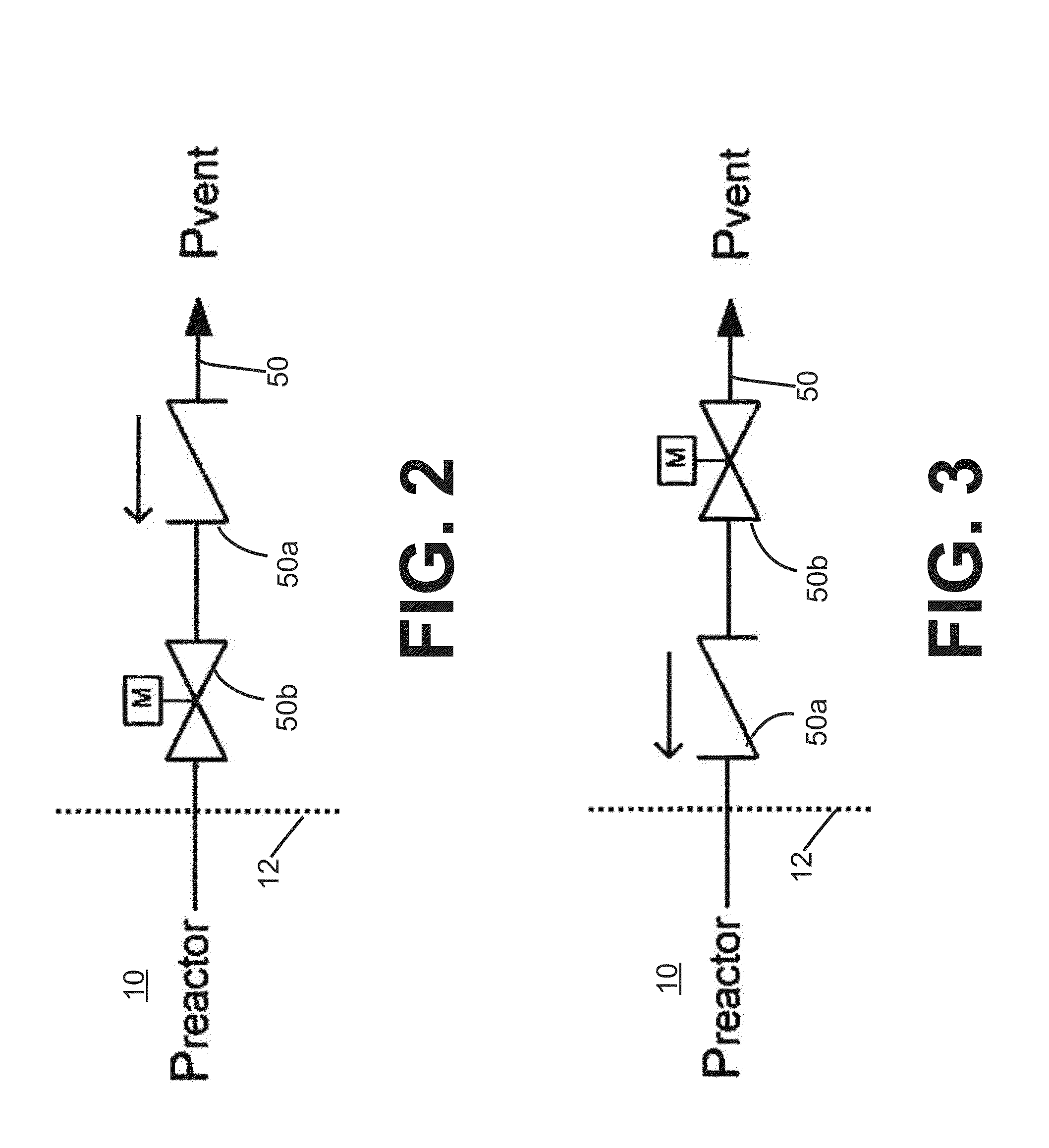

Passively initiated depressurization for light water reactor

ActiveUS20150194225A1Nuclear energy generationEfficient electrical power transmission/distributionIsolation valveBoiling water reactor

A nuclear reactor is surrounded by a reactor radiological containment structure. Depressurization lines running from the reactor automatically vent the reactor to the containment structure or to a compartment in the containment structure when a low pressure condition exists in the reactor. The depressurization lines include biased-open passive valves and actively actuated isolation valves arranged in series.

Owner:BWXT MPOWER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com