Telescoping guide tube and light-water reactor nuclear power station fuel assembly

A fuel assembly and guide tube technology, applied in nuclear power generation, reactors, nuclear engineering, etc., can solve the problems of insufficient cooling of related rods, affecting the time of control rod drop, and easy bending, etc., to achieve enhanced strength, convenient assembly, The effect of improving bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

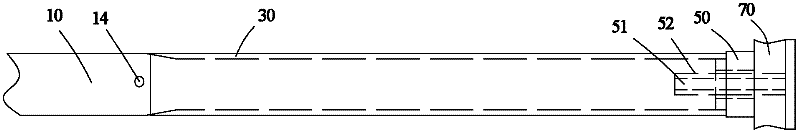

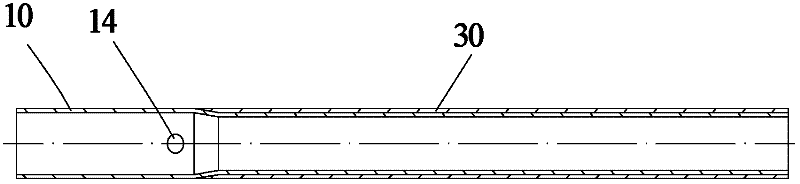

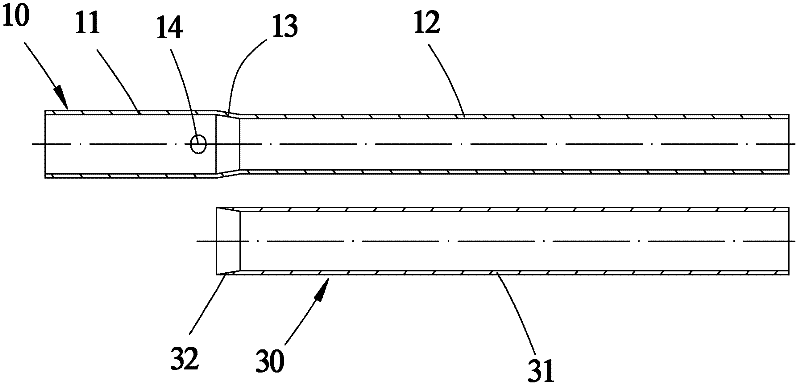

[0051] Such as Figure 1-Figure 3 Shown is the first embodiment of the sleeve-type guide pipe of the present invention, which can be used for fuel assemblies of light water reactor nuclear power plants. The light water reactor nuclear power plant fuel assembly includes an upper nozzle, a sleeve-type guide pipe, a grid, a fuel rod, and a lower nozzle, and the assembly relationship thereof can be understood by those skilled in the art, and will not be repeated here.

[0052]The sleeve-type guide tube includes an inner sleeve 10, an outer sleeve 30, etc., and the outer sleeve 30 is tightly sleeved on the periphery of the inner sleeve 10 to form a bending-resistant sleeve-type guide tube. In this embodiment, the inner sleeve 10 and the outer sleeve 30 are interference fit, and the interference fit can be 0.005mm-0.020mm, so as to achieve tight socketing. It can be understood that the inner sleeve 10 and the outer sleeve 30 can also be fixedly connected by other means such as clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com