Patents

Literature

303 results about "Heavy water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heavy water (deuterium oxide, ²H₂O, D₂O) is a form of water that contains a larger than normal amount of the hydrogen isotope deuterium (²H or D, also known as heavy hydrogen), rather than the common hydrogen-1 isotope (¹H or H, also called protium) that makes up most of the hydrogen in normal water. The presence of deuterium gives the water different nuclear properties, and the increase of mass gives it slightly different physical and chemical properties when compared to normal water. It can be used to create ice and snow at higher temperatures since its melting point is 3.82 C.

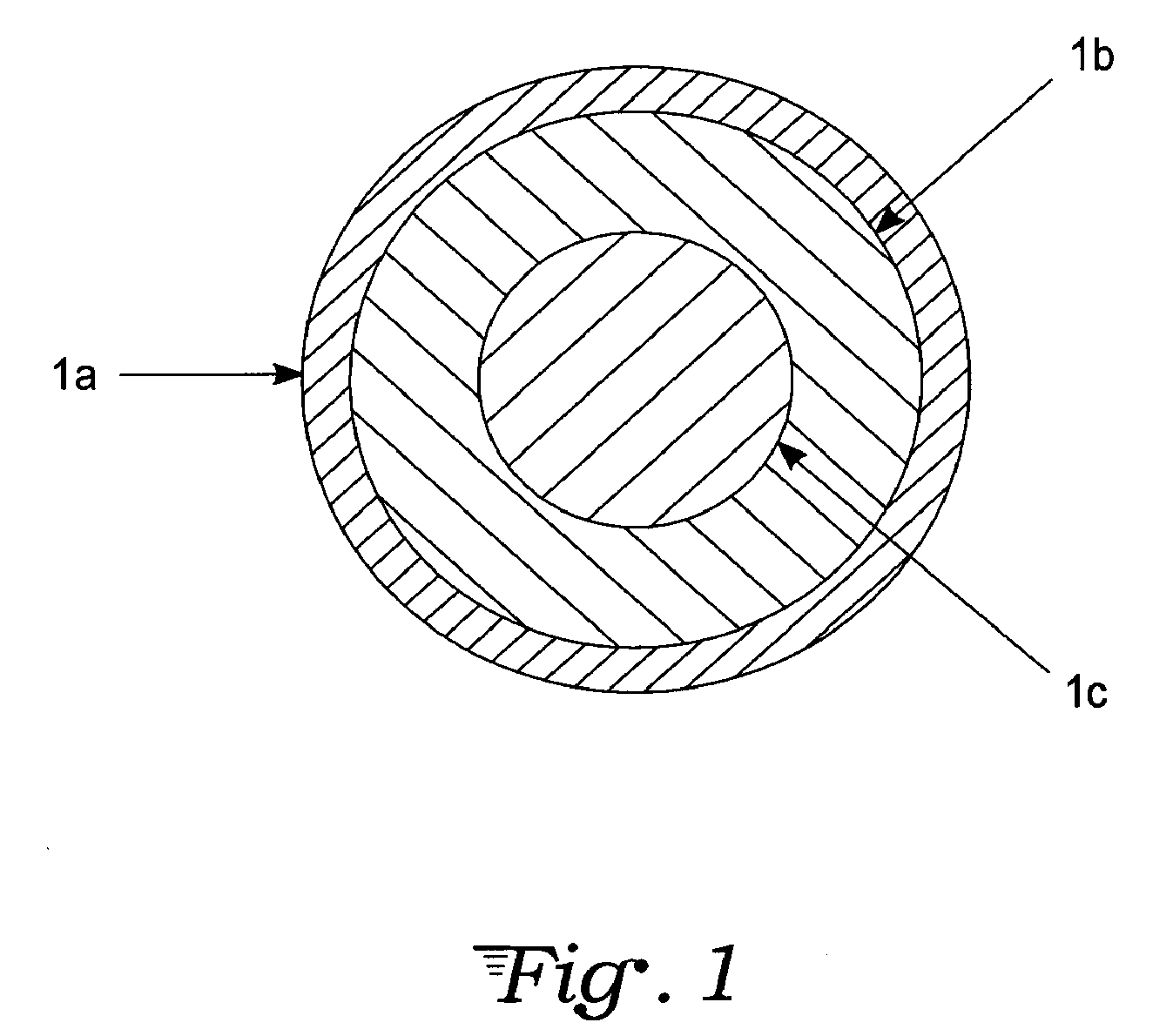

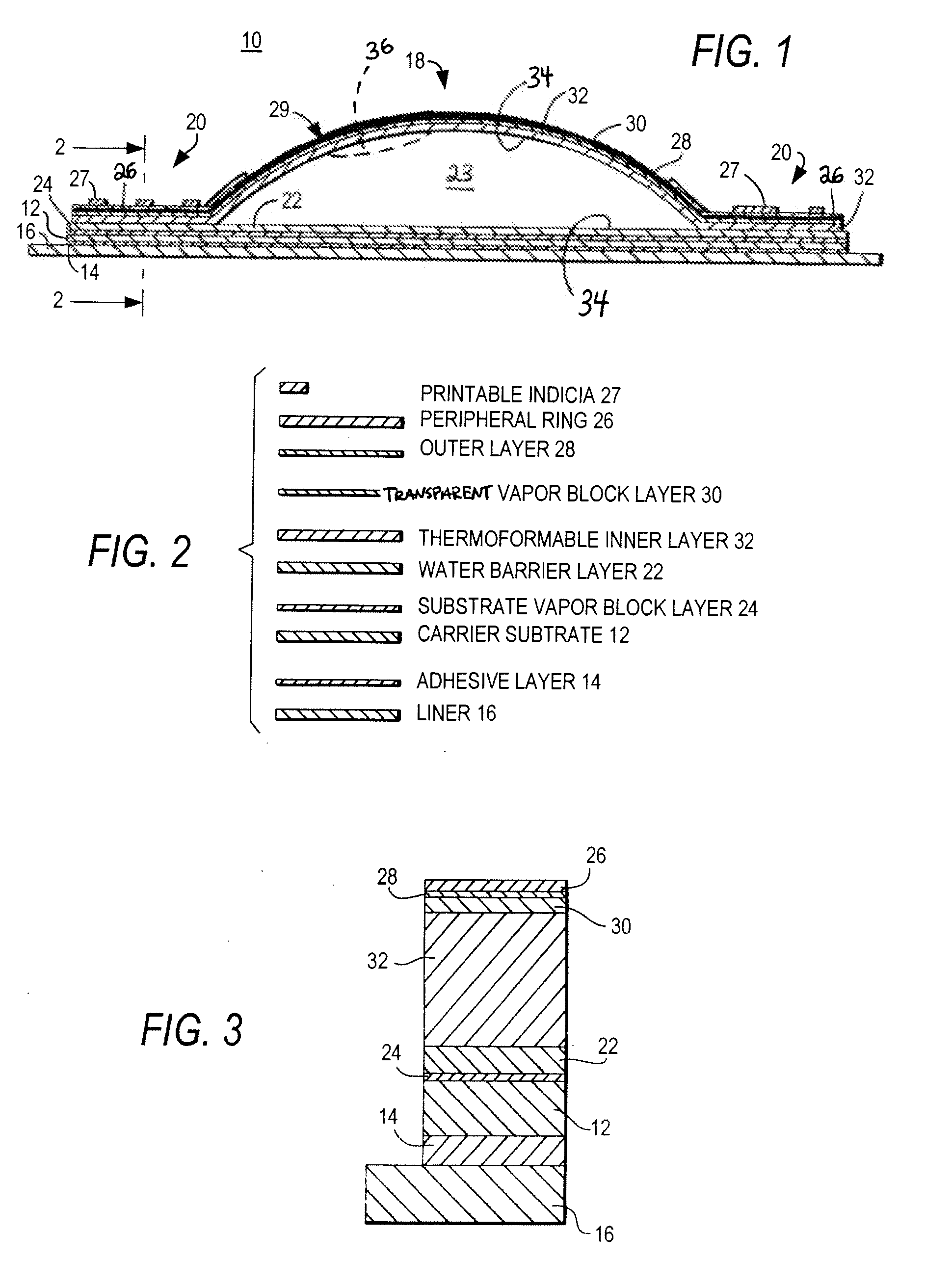

Freeze indicators suitable for mass production

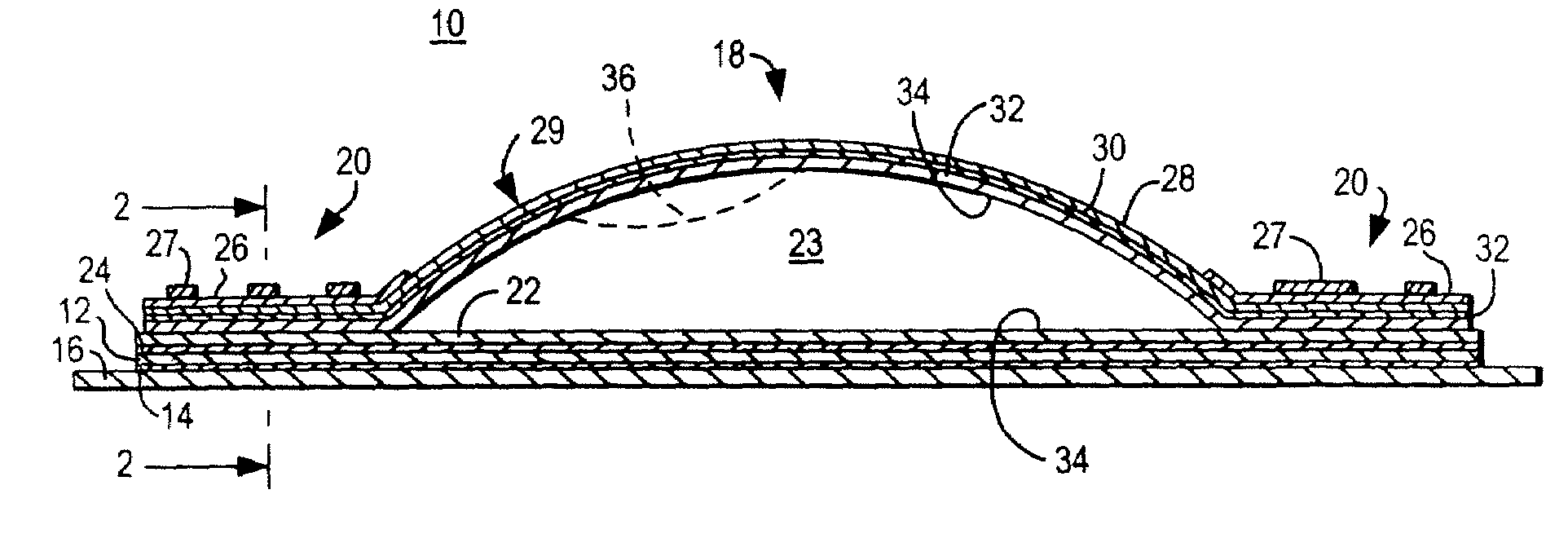

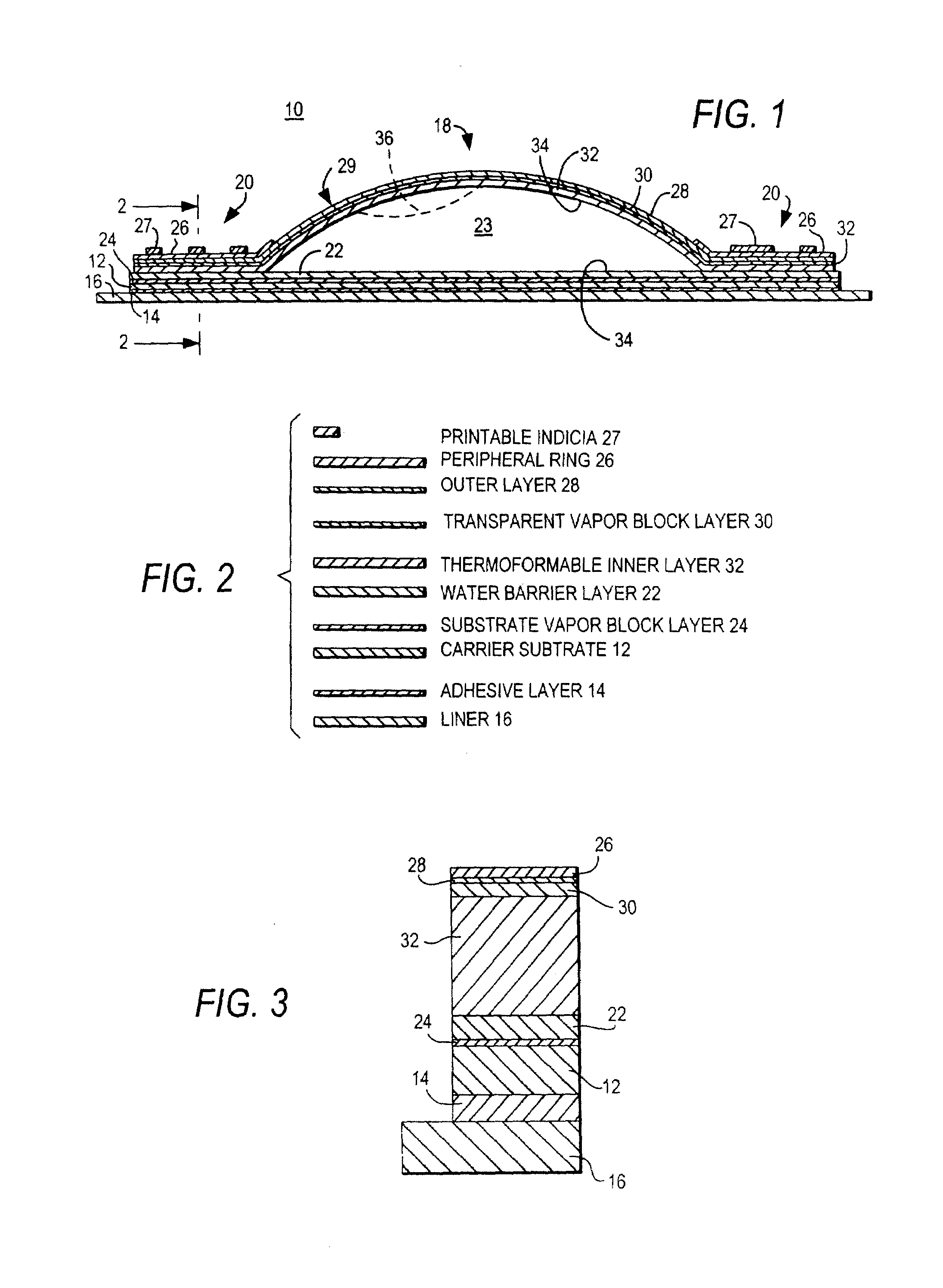

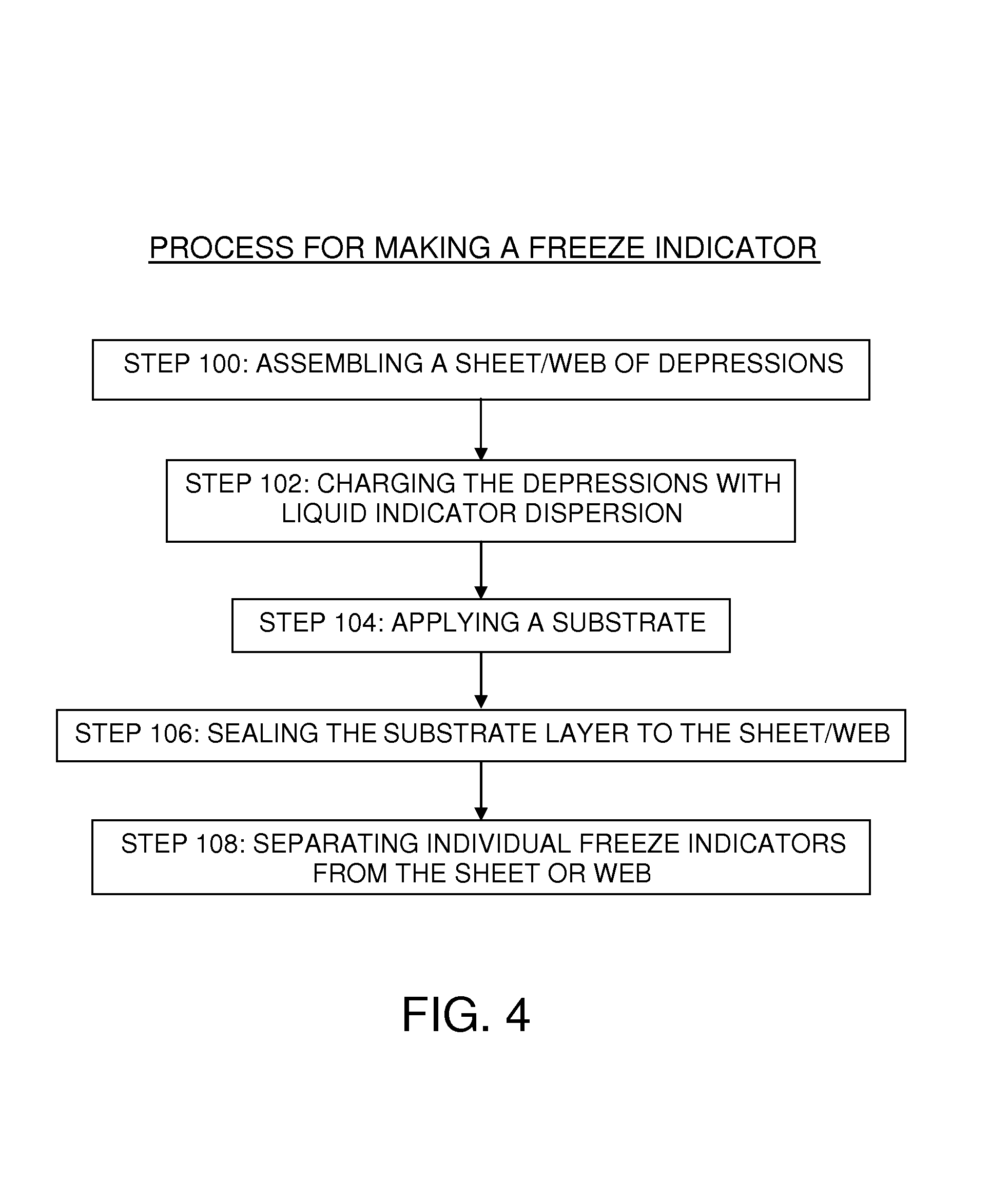

ActiveUS7343872B2Good and extended shelf lifeUnanimous responseThermometer detailsTemperature measurement in household appliancesLiquid mediumWater vapor

A freeze indicator employs, as active indicator element, dispersion of solid particles in a liquid medium which can be water or aqueous and which coagulates to provide an irreversible appearance change when subject to freezing. The liquid dispersion can be contained in an indicator volume around which extends a vapor block layer. The vapor block layer can prevent loss of liquid vapor from the dispersion and consequent drying out and dysfunctionality of the freeze indicator. For containing an aqueous medium, bilayer and trilayer laminate materials can be used which have a low water vapor transmission rate. The active indicator element can be a dilute colloidal dispersion of a metal such as gold or silver or other inorganic pigment material in water or an aqueous medium. Some embodiments avoid use of dispersants and the like and employ an active indicator element consisting of inorganic pigment particles, water and optionally an ice nucleating agent. Heavy water, or deuterated water can be components of the water, if desired.

Owner:TEMPTIME CORP

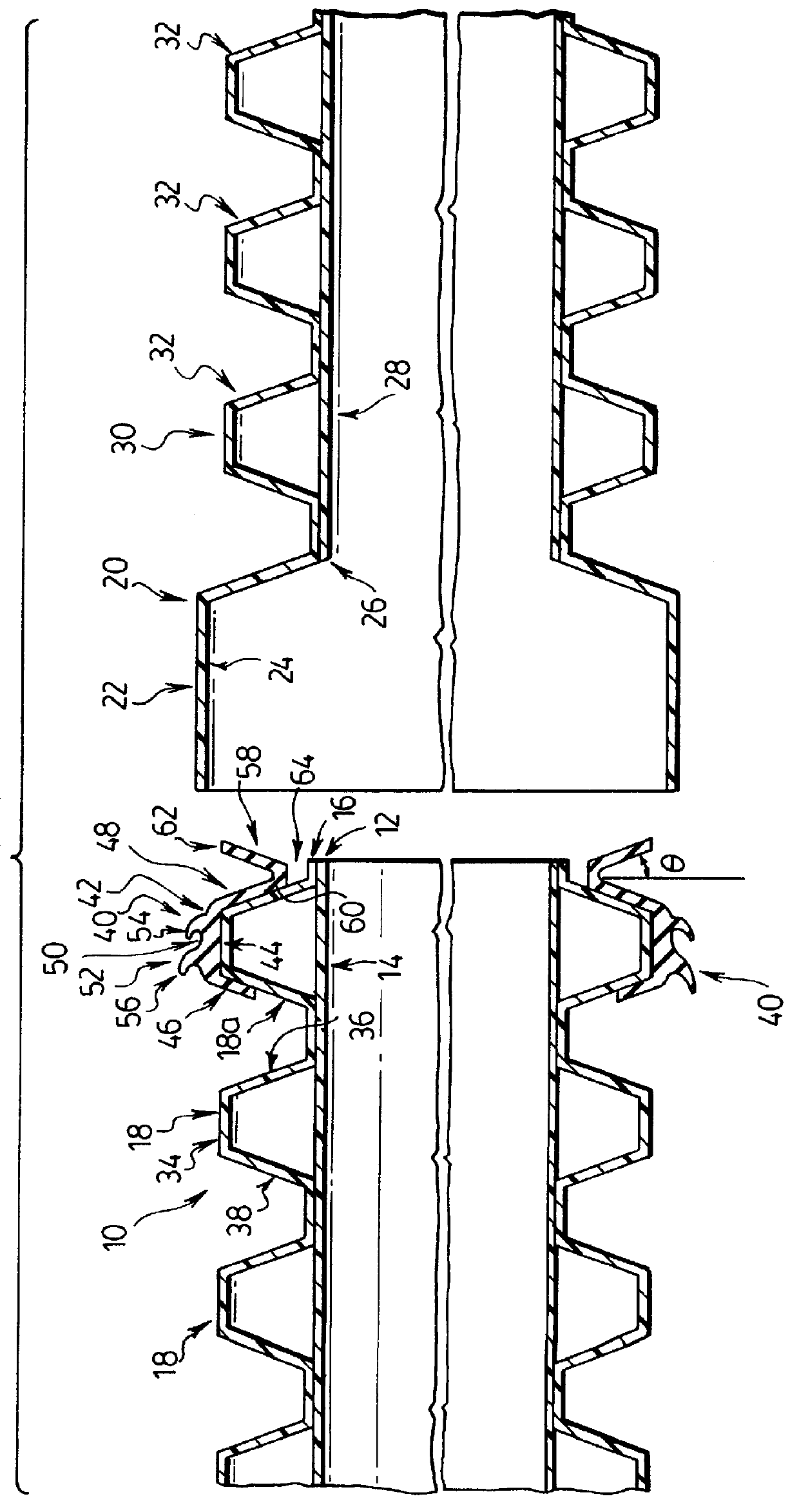

Resilient pipe gasket

A resilient gasket is disclosed for providing a seal between corrugated pipes having a plurality of concentric ribs on their outer surfaces, such as drain and sewer pipes to be buried in soil. The gasket comprises a base which is received around a first pipe over top of a rib adjacent an end of the first pipe, with an inner surface adapted to mate with a radially outer surface of the rib, and with legs adapted to extend along forward and rearwardly-sloped faces of the rib. The outer surface of the base is provided with sealing elements to engage the inner surface of the bell adjacent the end of a second pipe. The gasket also has a flap extending outwardly and forwardly from the forwardly extending leg. The flap and the forward leg form a V-shaped member. The flap engages the inner surface of the bell when the first pipe is inserted into the second pipe, and the gasket is rotated rearwardly relative to the rib. When the flap engages the inner surface of the bell, it prevents further rearward displacement of the gasket relative to the rib, thus preventing displacement of the gasket from the rib. The gasket also helps prevent gasket blowout during periods of unusually heavy water flow through the pipes.

Owner:SCP +1

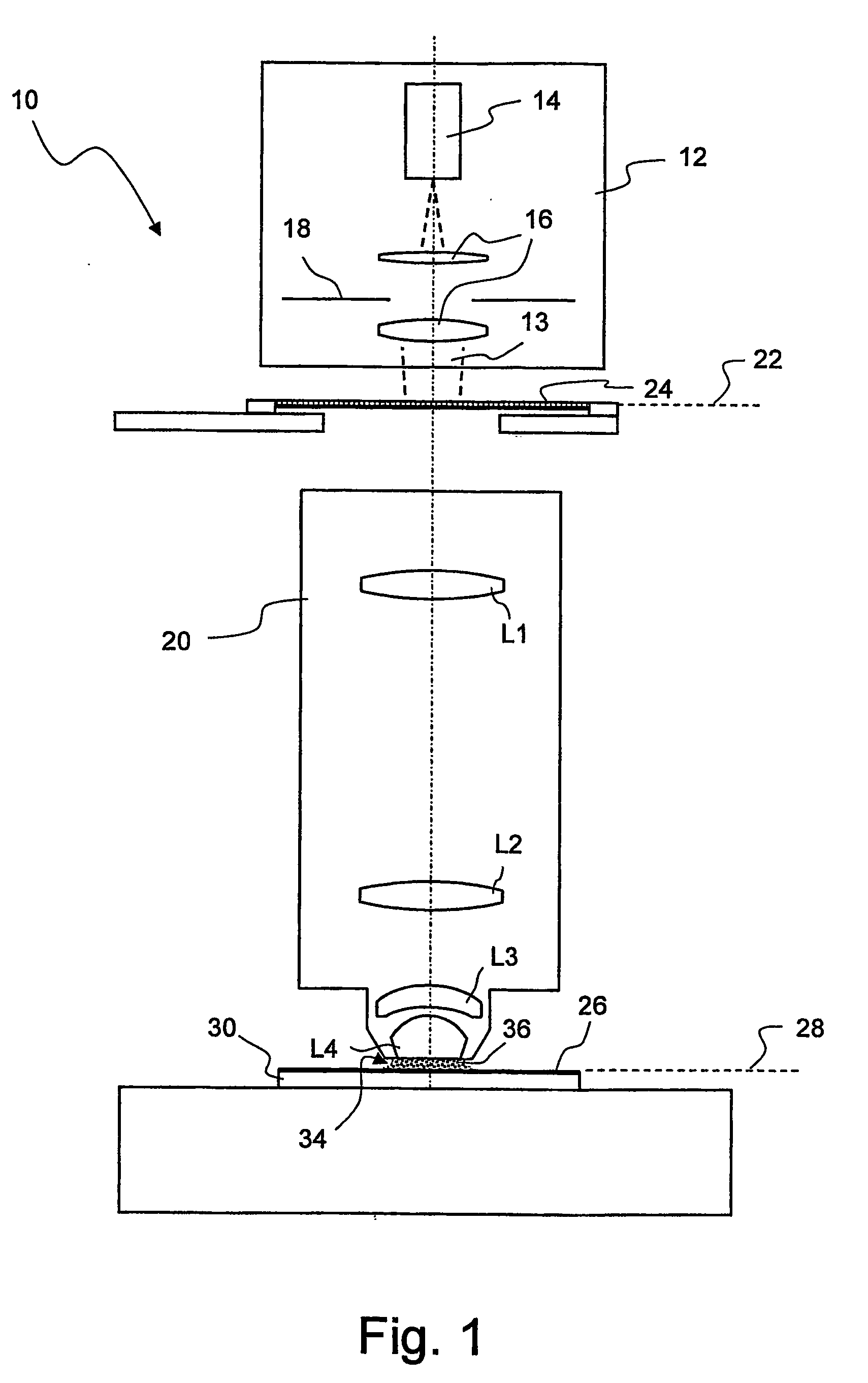

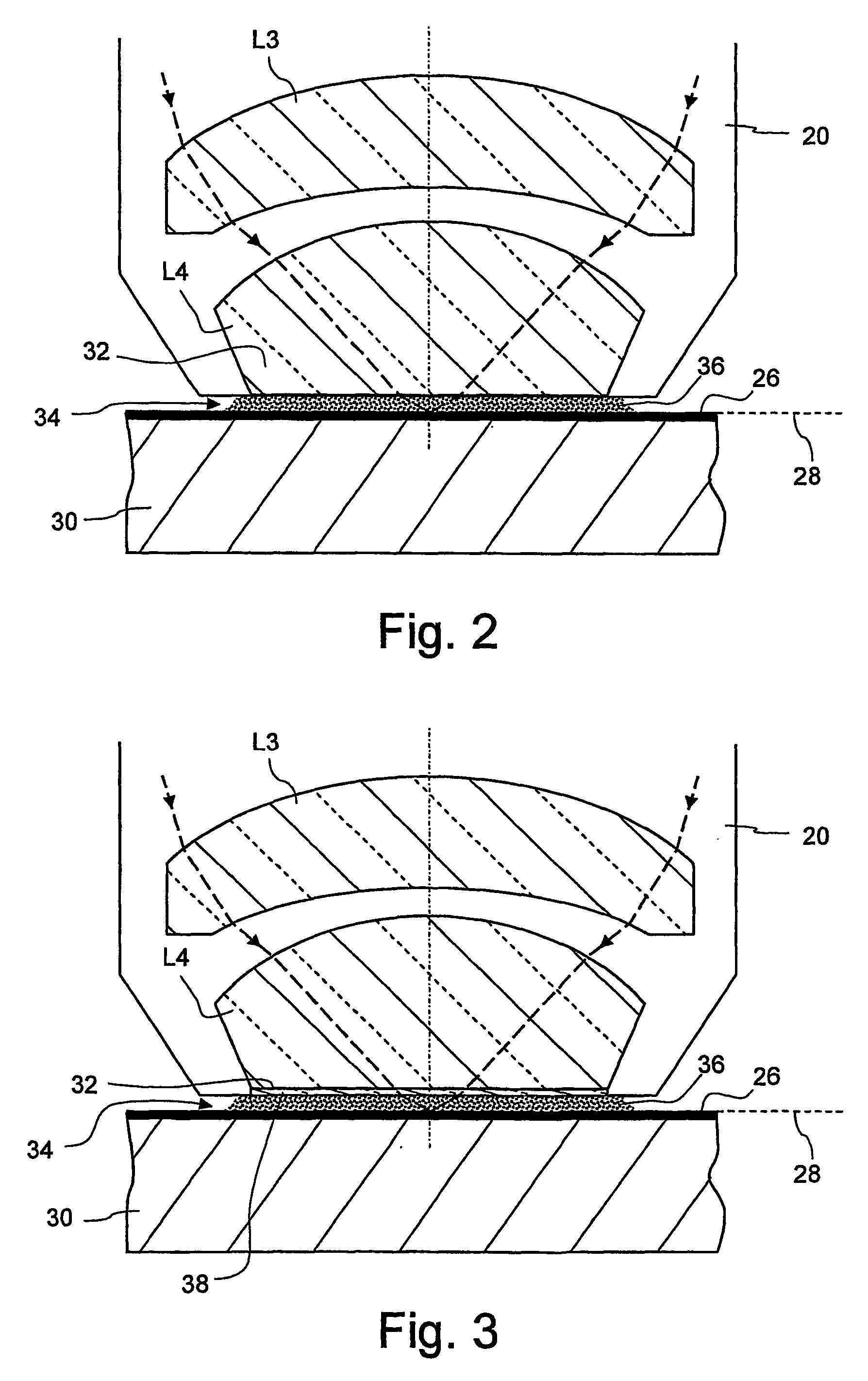

Microlitographic projection exposure apparatus and immersion liquid therefore

InactiveUS20060244938A1Transparent highLittle chemical effectMicroscopesPhotomechanical exposure apparatusSimple Organic CompoundsO-Phosphoric Acid

An immersion liquid for a microlithographic projection exposure apparatus is enriched with heavy isotopes. This reduces the chemical reactivity, which leads to an extension of the lifetime of optical elements which come in contact with the immersion liquid. For example, heavy water (D2O), deuterated sulfuric acid, (D2SO4) or deuterated phosphoric acid D3P16O4 may be used. Organic compounds such as perfluoro polyethers, which have been deuterated or enriched with heavy oxygen (18O), are furthermore suitable.

Owner:CARL ZEISS SMT GMBH

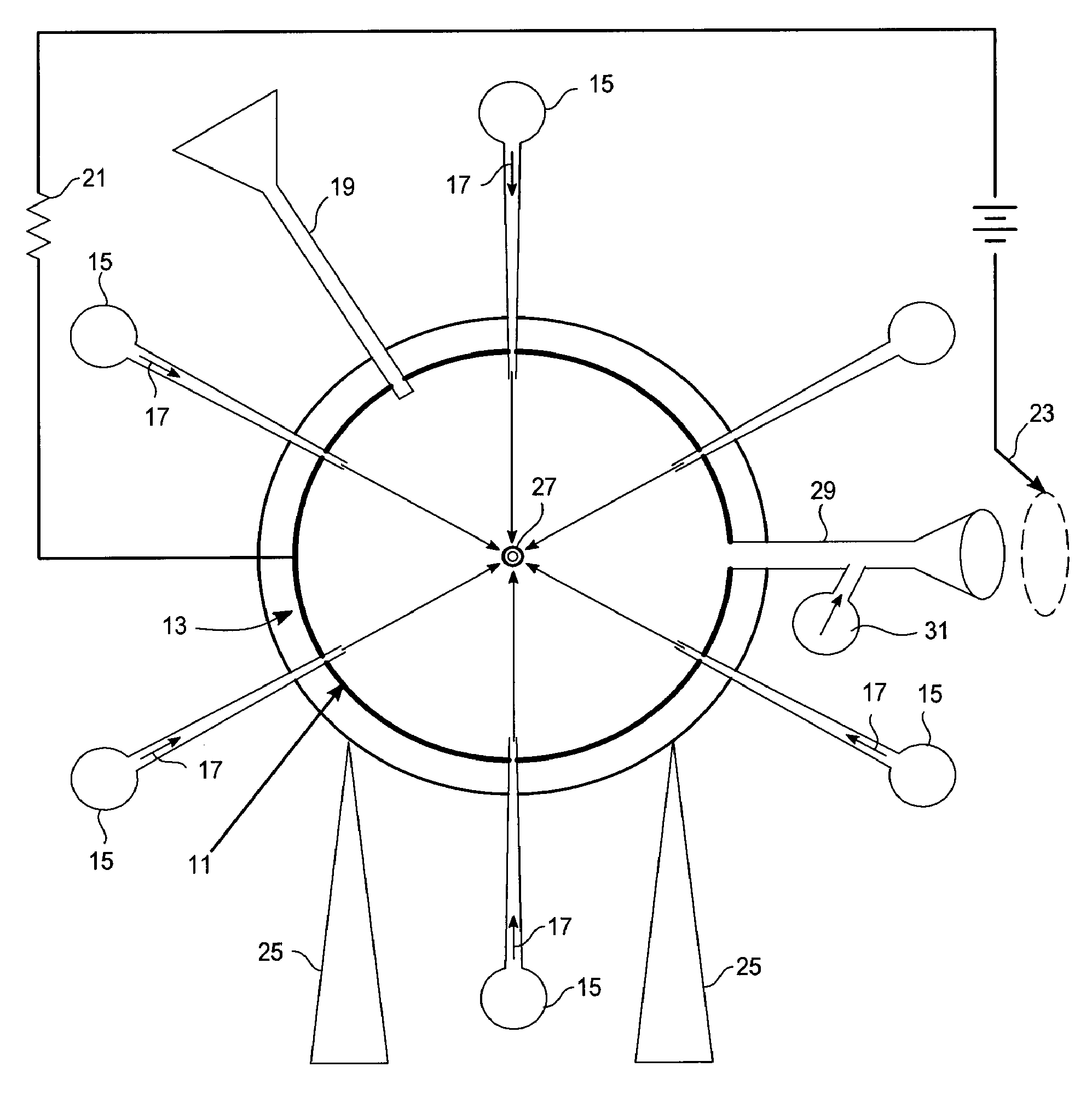

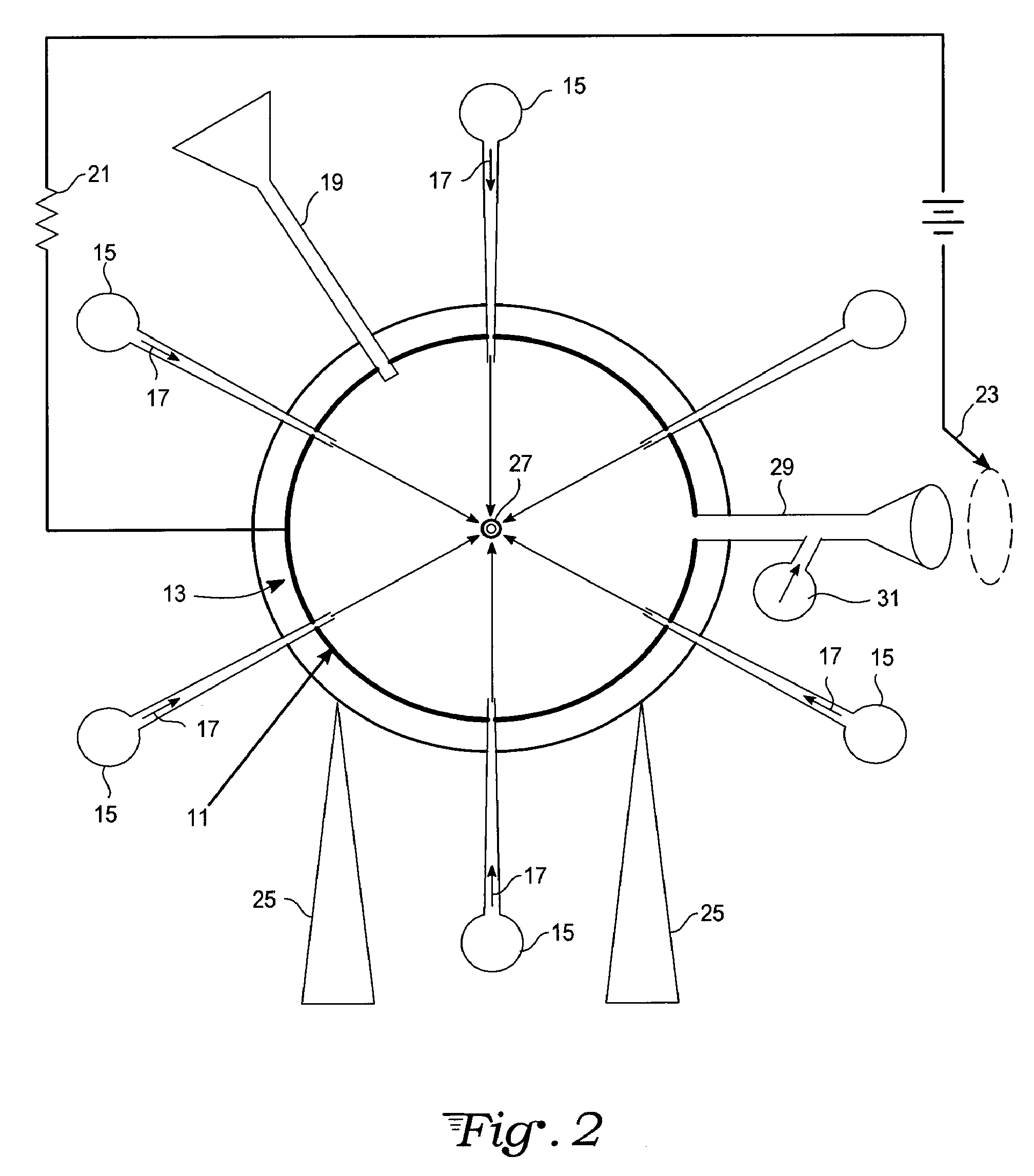

Thermonuclear plasma reactor for rocket thrust and electrical generation

InactiveUS20090000268A1Easy to triggerDownsize working reactionCosmonautic vehiclesNuclear energy generationHigh energyNuclear engineering

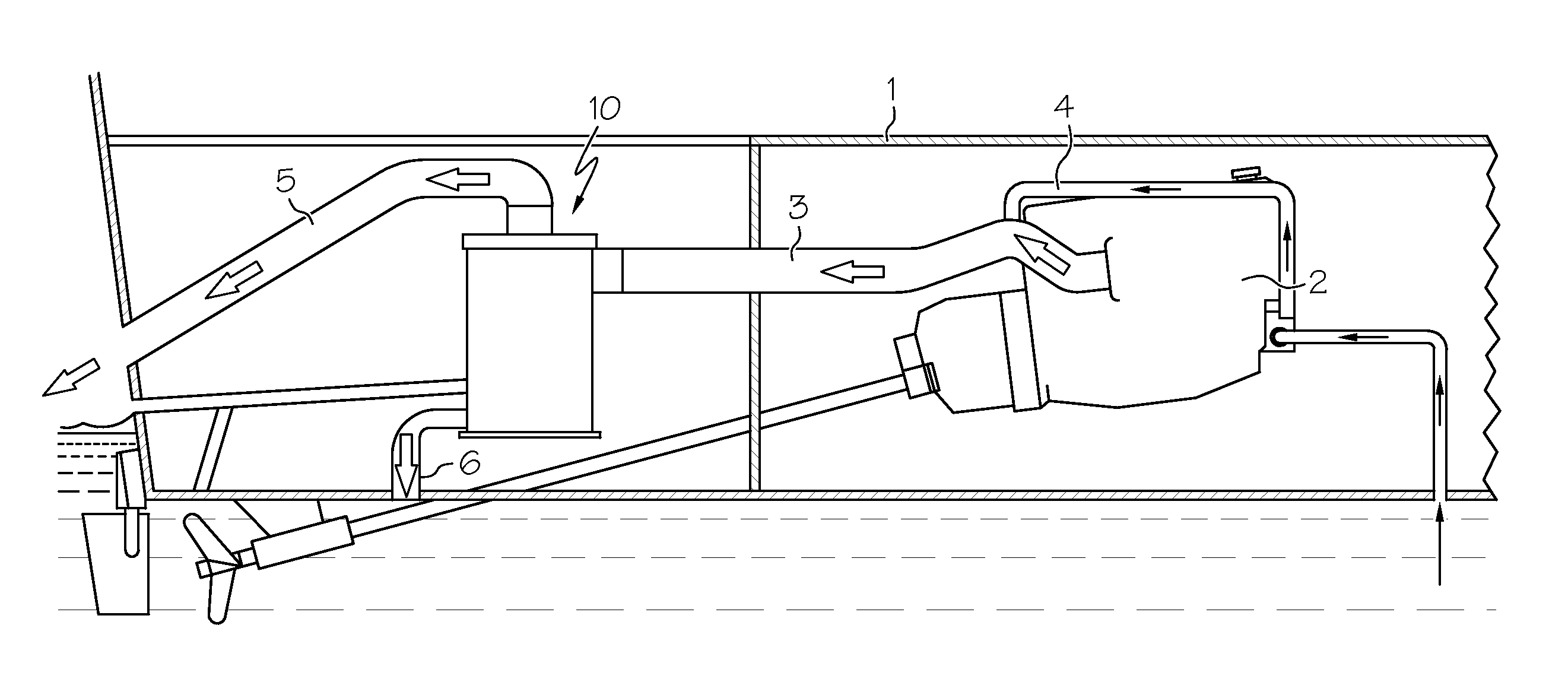

A reactor system produces plasma rocket thrust using alpha-initiated atomic fuel pellets without the need for a critical mass of fissionable material. The fuel pellets include an outer layer reactive material to alpha particles to generate neutrons (e.g., porous lead or beryllium), an under-layer of fissionable material (e.g., thorium or enriched uranium), and an optional inner core of fusion material (e.g., heavy water ice, boron hydride). The pellets are injected one at a time into a charged reaction chamber containing a set of alpha beam channels, possibly doubling as ion accelerators, all directed toward a common point. Alpha particles converging on each successive pellet initiate an atomic reaction in the fissionable under-layer, via a neutron cascade from the pellet outer layer, producing plasma that is confined within the chamber. This may be enhanced by atomic fusion of the optional inner core. The resulting high-energy plasma creates electrostatic pressure on the chamber and is allowed to exit the chamber through a port. An ion accelerator at the exhaust port of the chamber accelerates outgoing plasma ions, possibly with added reaction mass, to generate the rocket thrust. An electric circuit that includes the charged chamber may collect the electrons in the plasma to help power the ion accelerator(s).

Owner:YURASH GREG J

Treatment of water flowing in a horizontal conduit

ActiveUS7381333B1Small apertureSewerage structuresWater contaminantsWater flowEnvironmental engineering

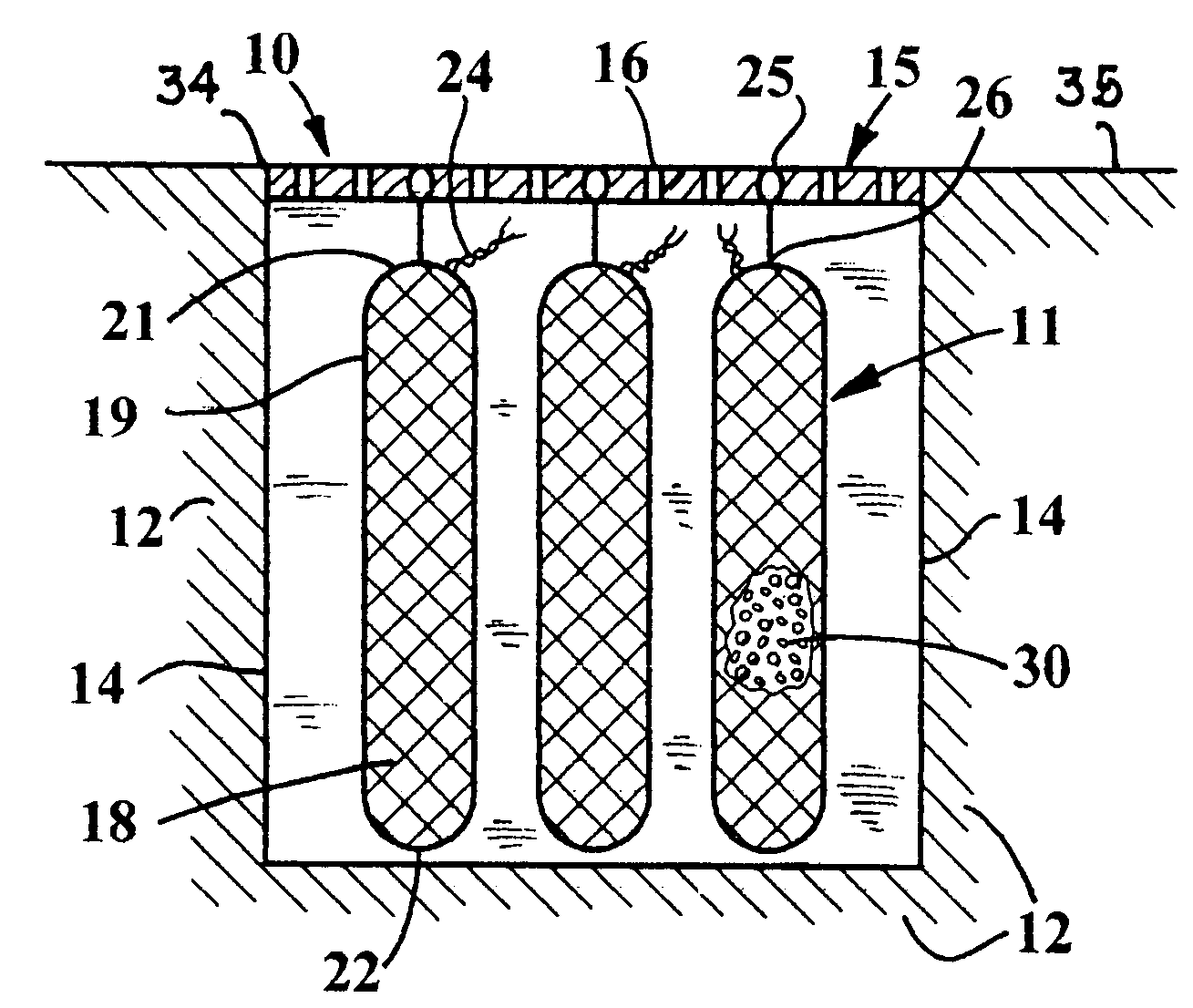

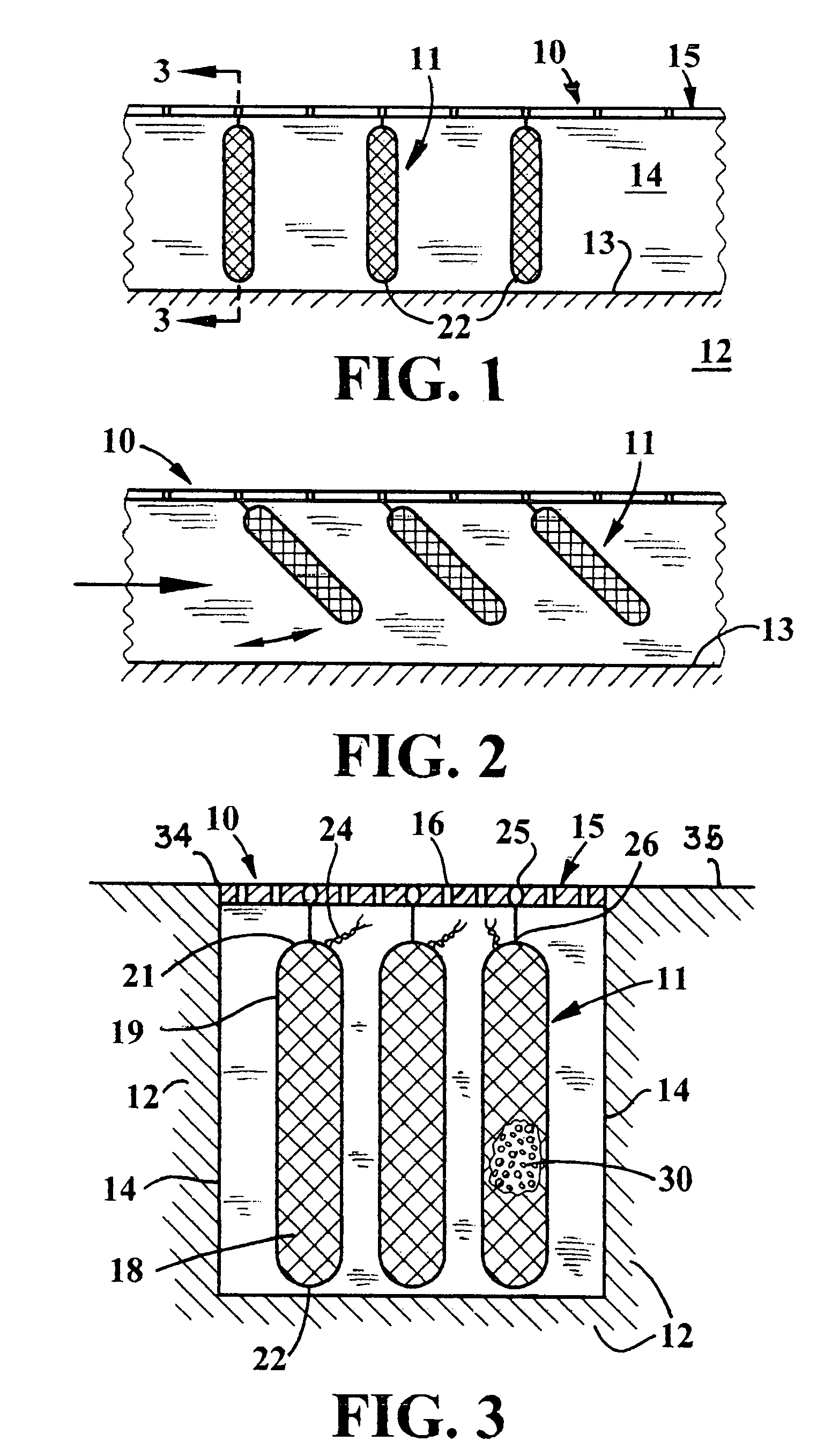

Trace levels of dissolved toxic species are removed from water flowing horizontally in a conduit equipped with overhead debris-excluding structure by suspending from the overhead structure elongated absorbent structures in the form of porous bags which confine particulate absorption material. The bags are free to swing upwardly in the downstream direction in response to heavy water flows, thereby avoiding blockage of the conduit.

Owner:RAINER MICHAEL S +2

Cellulose fiber liquid ammonia dyeing method

InactiveCN103225218ASolve the problem of energy consumptionSolve pollutionFibre treatmentDyeing processAcid washingCellulose fiber

The invention provides a cellulose fiber liquid ammonia dyeing method, which concretely comprises: adopting a cation modification agent and NaOH to treat cellulose fibers, sequentially carrying out hot water washing, cold water washing and acid washing, carrying out water washing to achieve a neutral state, and drying to obtain cationization cellulose fibers; and dissolving a dye capable of being dissolved in liquid ammonia in liquid ammonia, and immersing the prepared cationization cellulose fibers into the liquid ammonia dyeing solution to dye under a certain condition to obtain the dyed subject, wherein the condition comprises that a dye use amount is more than or equal to 10% (o.m.f), a bath ratio is more than or equal to 1:20, and a dyeing time is more than or equal to 20 seconds. With the present invention, problems of high production process energy consumption and heavy water pollution in the existing cellulose fiber dyeing are solved, a dye uptake rate and a color fixation rate of the dye in liquid ammonia dyeing are increased, a dye use amount is saved, advantages of less dyeing process steps, short dyeing time, recycling of dyed dye, environmental pollution reduction, and the like are provided, and waterless dyeing requirements during a fiber dyeing process can be achieved.

Owner:WUHAN TEXTILE UNIV

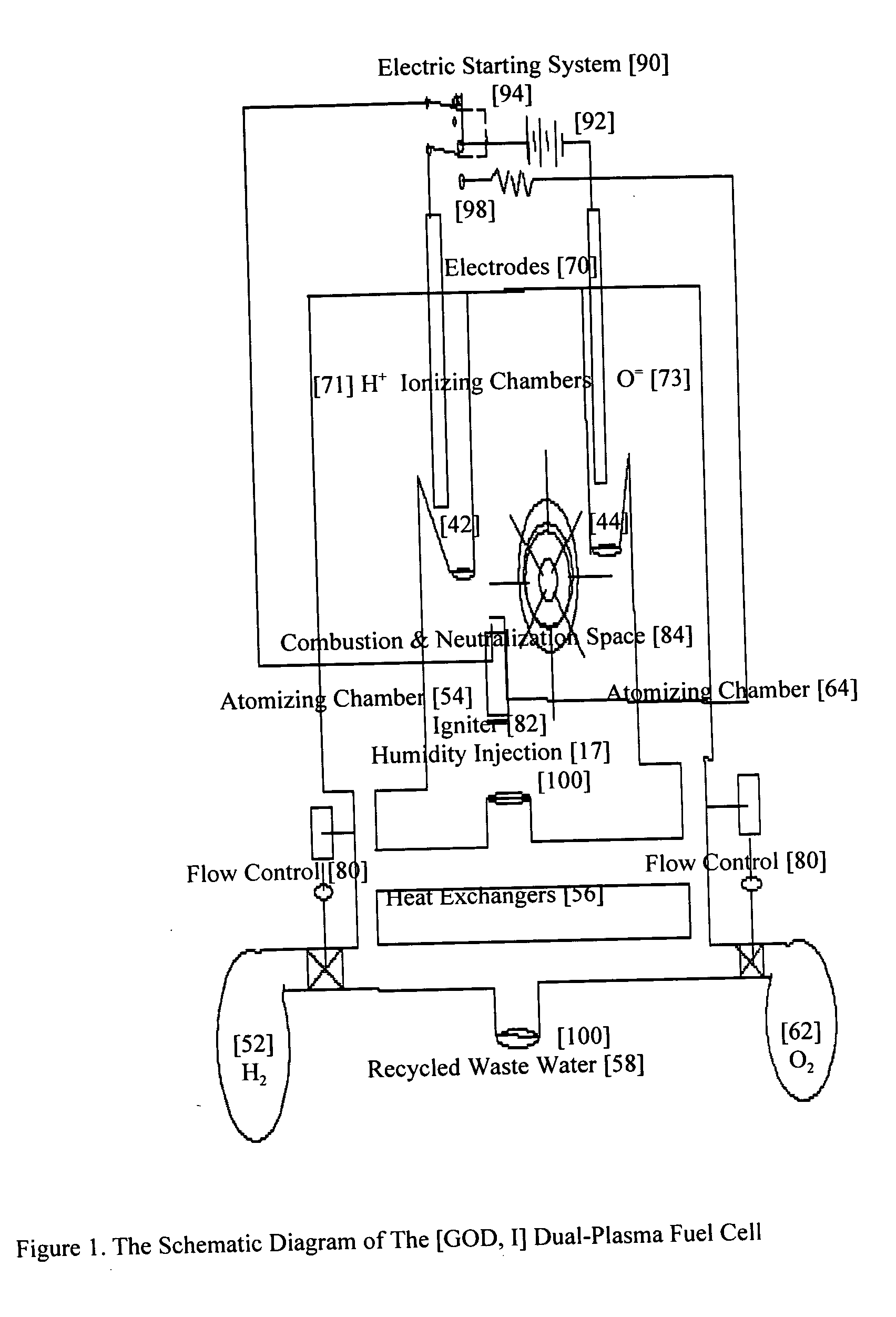

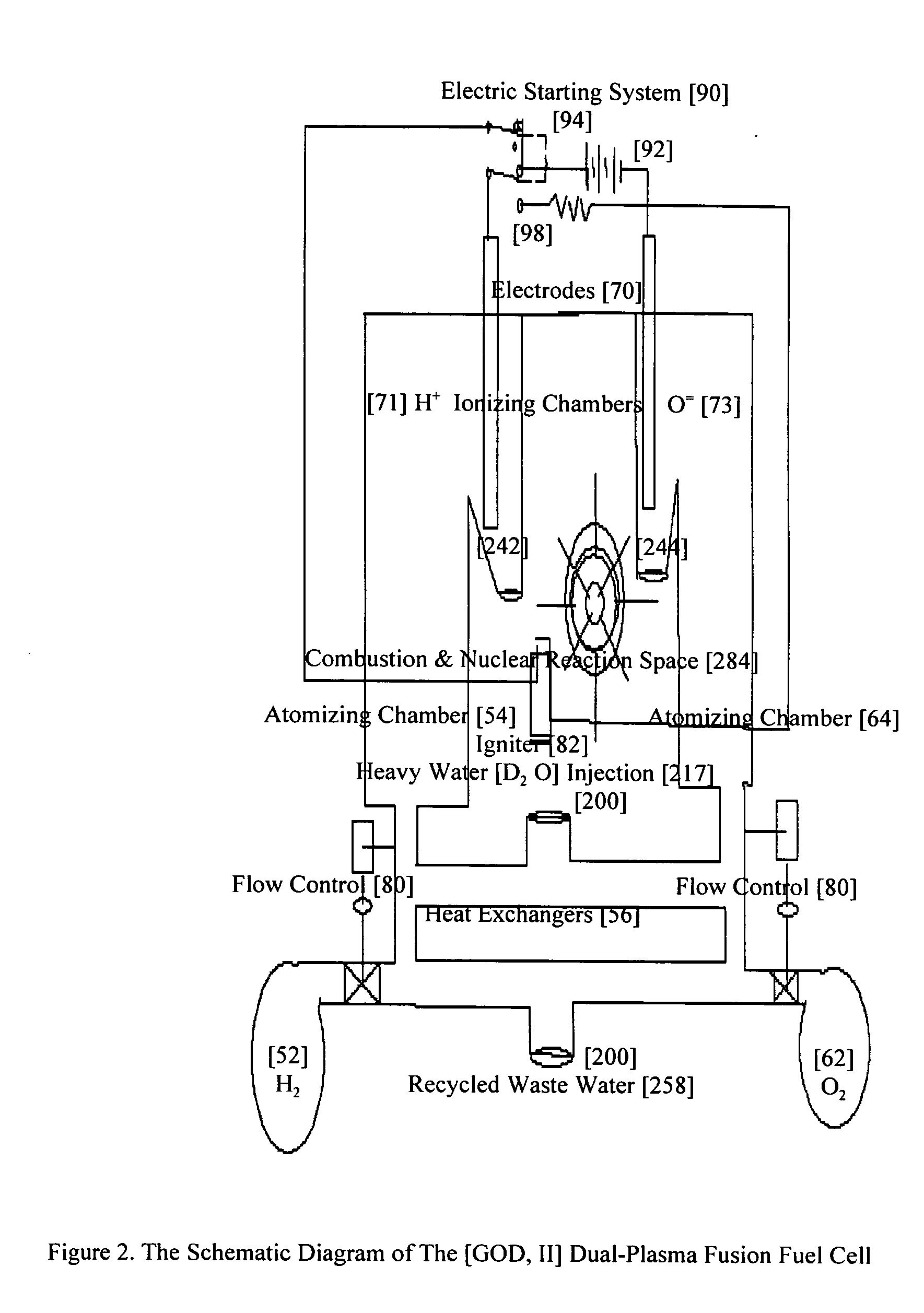

Dual-plasma fusion and fission fuel cells

InactiveUS20060045228A1More powerMore electricityNuclear energy generationMachines/enginesThermal energyElectric force

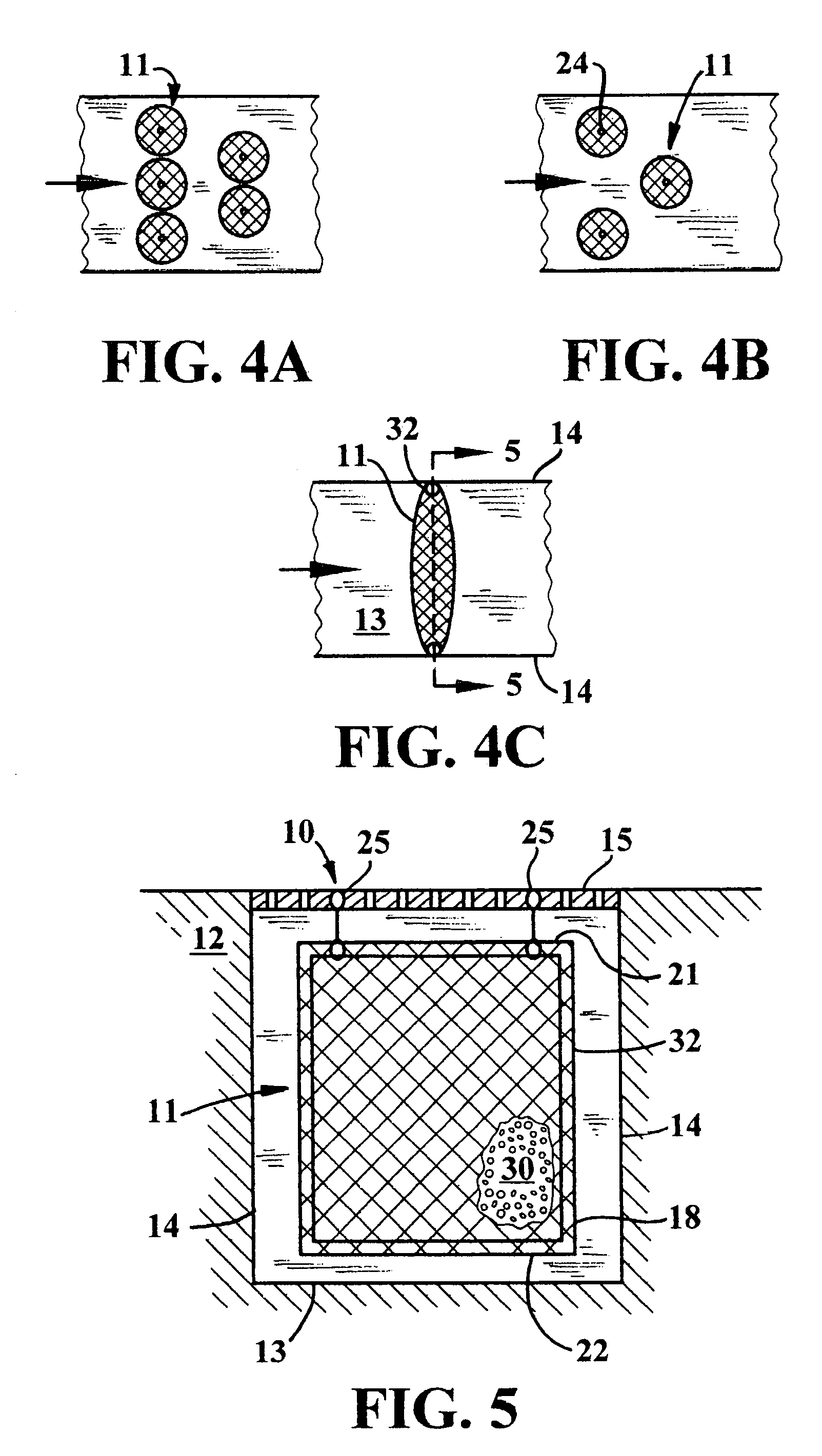

New [GOD, I], [GOD, II], & [GOD, III] dual-plasma fuel cells provide the electric start systems to start their warm-up processes, automatically. After their warm-up processes done and the operation temperatures reached, the dual-plasma fuel cells will run independently by continuously supplying fuels and moisture into the units. In dual-plasma nuclear [fusion and / or fission] fuel cells' configuration, electrical power will be generated from the nuclear-thermal-plasmas reaction by exothermal heating from combustion & nuclear reactions. With conducting high-electrons' current, the cable, loads, and electrodes are connected among one another between two plasmas' ionizing chambers for civil utility purposes. In the [GOD, II] dual-plasma fusion fuel cell, heavy water [D2O] injection into the atomizing chambers increases the plasmas heating and electrical conductivities. And the un-like charges of the heavy water's [D2O+], & [D2O−] react with plasmas' [2H+& O=] combustion heating which will induce the fusion reaction and release much more nuclear heating power for initiation of the next plasmas-generation cycle much easily. For the [GOD, III] dual-plasma fission fuel cell, fission fuels located in the combustion & nuclear reaction space through robotic movements provide additional nuclear-thermal energy that allows for initiation of the plasmas-generation process for the next cycle. For [GerTh. I] dual-plasma jet thruster, the dual plasmas are ejected to an opening end of a ‘C’ shaped magnet, and linear thrust is generated, according to the right-hand rule as in a jet thruster of propulsion for space traveling.

Owner:DAW SHIEN SCI RES & DEV

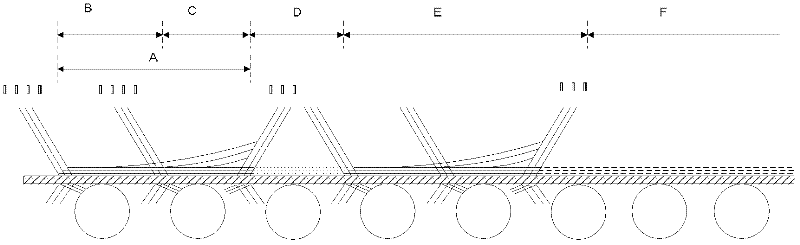

Method for improving ultra-fast cooling uniformity of medium and heavy plate after rolling

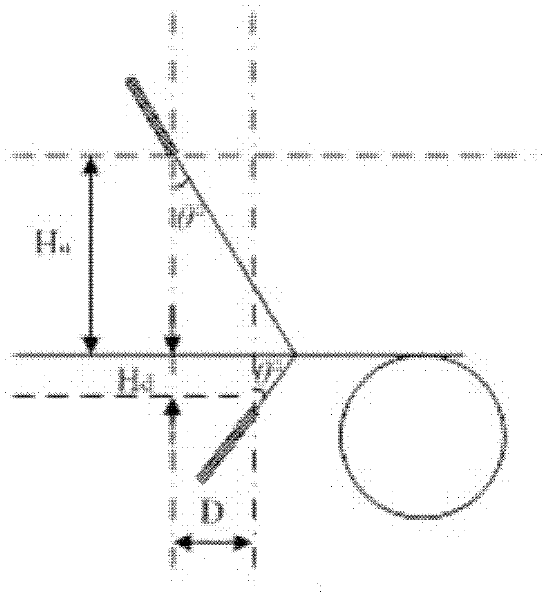

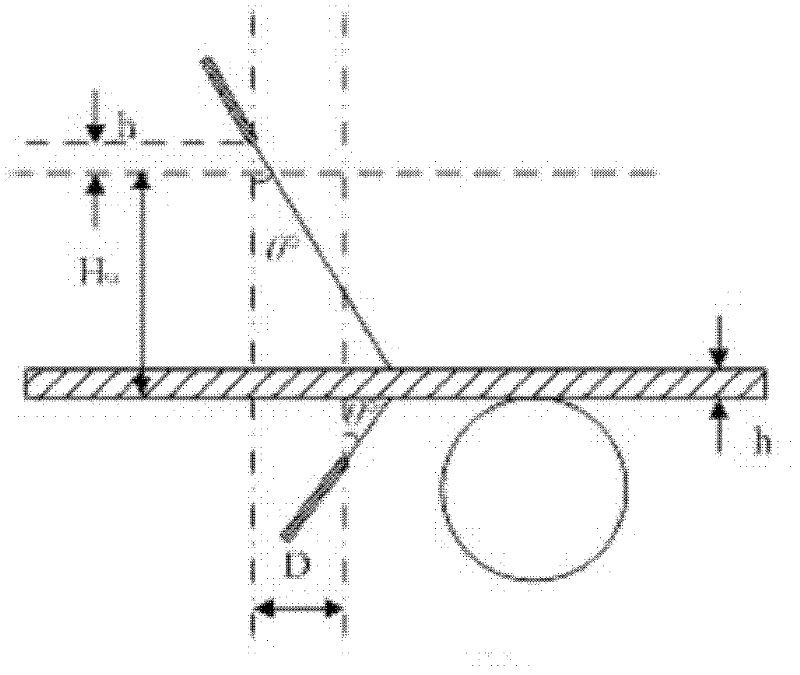

ActiveCN102371283AIncrease cooling intensityImprove cooling uniformityTemperature control deviceWork treatment devicesJet flowWater discharge

The invention relates to a method for improving the ultra-fast cooling uniformity of a medium and heavy plate after rolling, the position of a jet flow header can be reasonably adjusted, and the method is characterized in that, 1) the position of an upper header is set as follows: an ultra-fast cooling upper header framework is adjusted up and down in the vertical direction, and the conditions ofthe formula: Hu*tg(theta)=Hd*tg(theta)+D are met; 2) the setting of a soft water seal of a washing water region on the upper surface of a steel plate meets the conditions of the formula: 1 / 2*the sum of flow rates of all forward headers in the region<water amount of the soft water seal<2*the sum of the flow rates of all the forward headers in the region; 3) the flow rate of a lower header is increased to compensate the heat exchange capacity of the lower surface, and the optimal ratio of water supply to water discharge is set to be between 1: 1.1 and 1: 2.5; 4) the measure of clearing residualcooling water on the upper surface is taken, side spraying devices are arranged on the two sides of an ultra-fast cooling roller table, a middle spraying device is arranged on the upper header framework and strong blowing devices are arranged at the two ends of the ultra-fast cooling device; and 5) the head and tail shading control of the speed of the roller table is performed as follows: an ultra-fast cooling control system is used for transformation control of the speed of the roller table of a steel plate head and a tail part low-temperature region according to a speed curve. By adopting the method, the cooling uniformity of a steel plate of the medium and heavy plate after rolling under ultra-fast cooling condition can be realized.

Owner:NORTHEASTERN UNIV

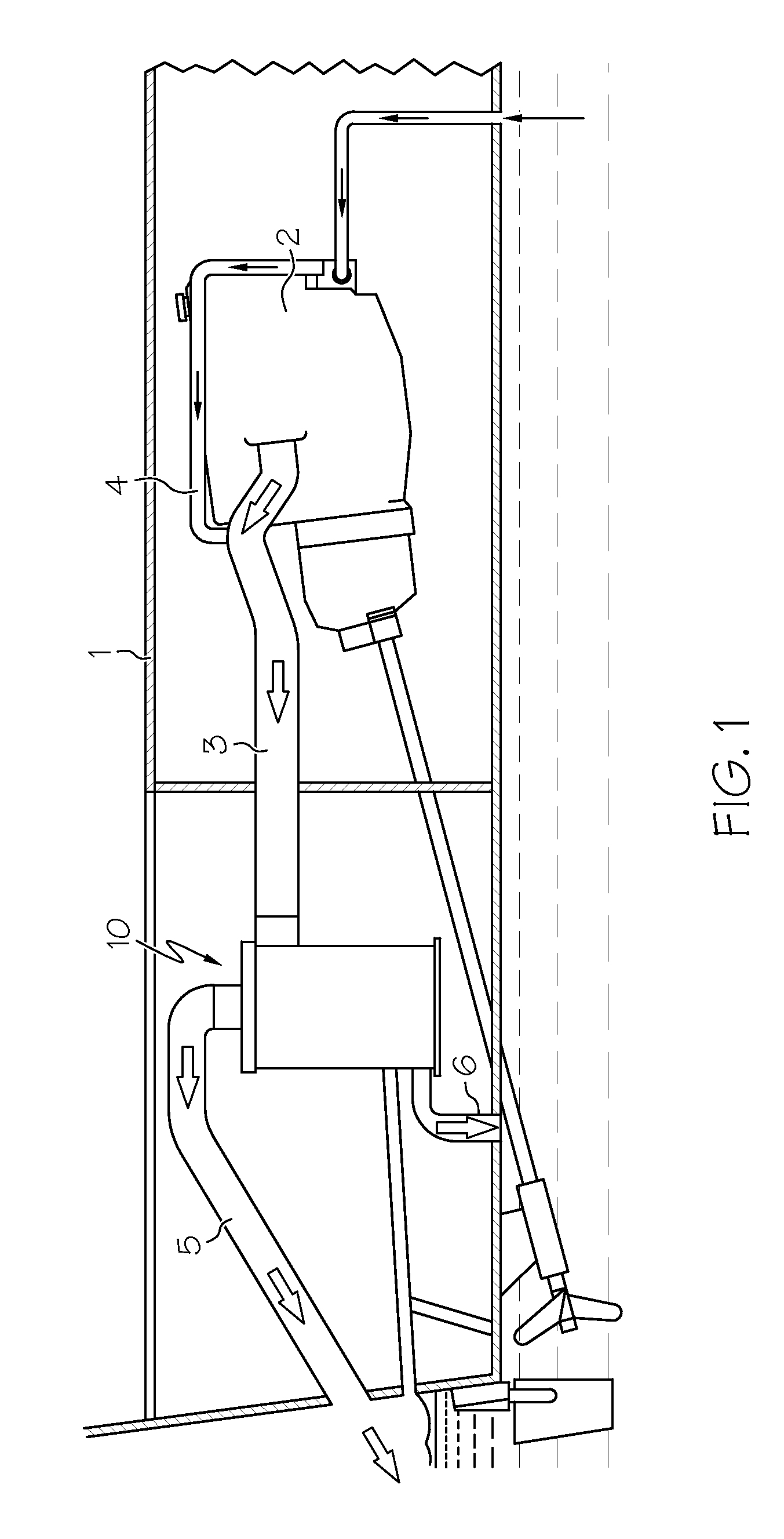

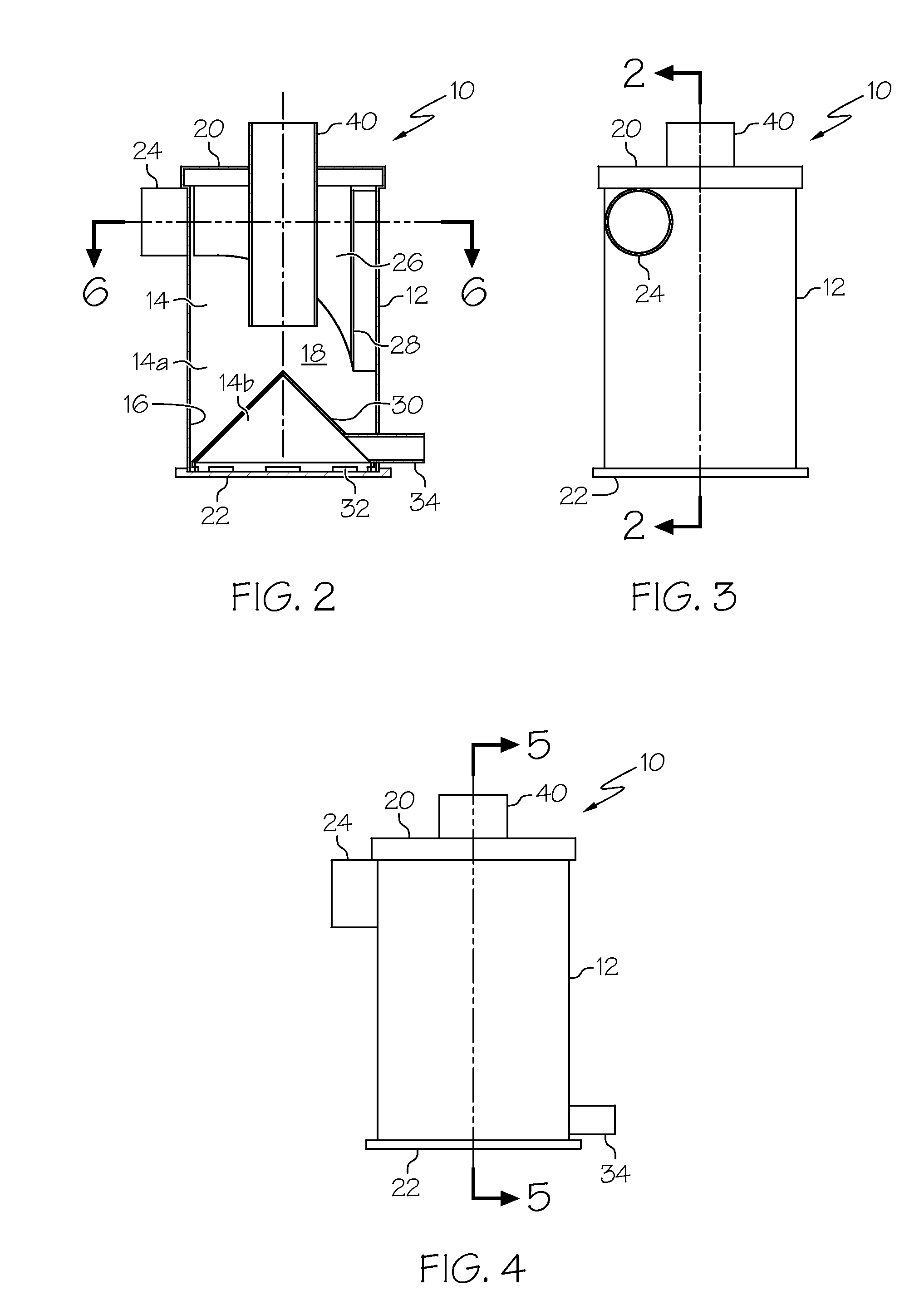

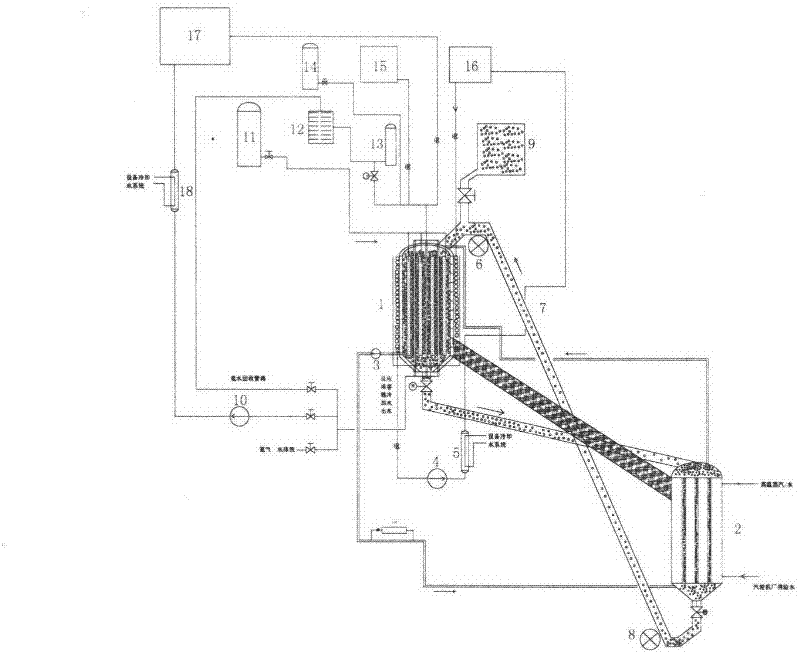

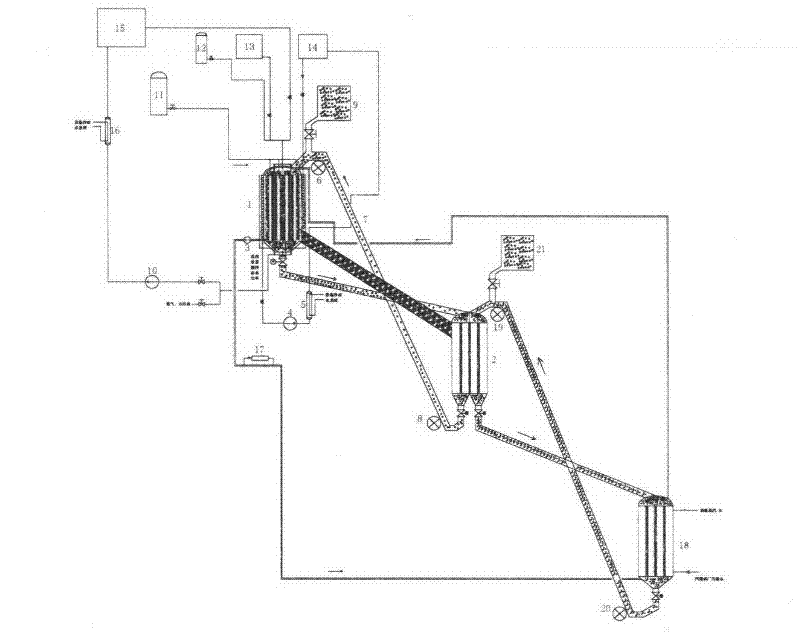

Apparatus and method for seperating tritiated and heavy water from light water

A process and method to separate heavy water from regular water by lowering the temperature of the mixture to the melting point of the heavy water.

Owner:MUCHNIK BORIS J

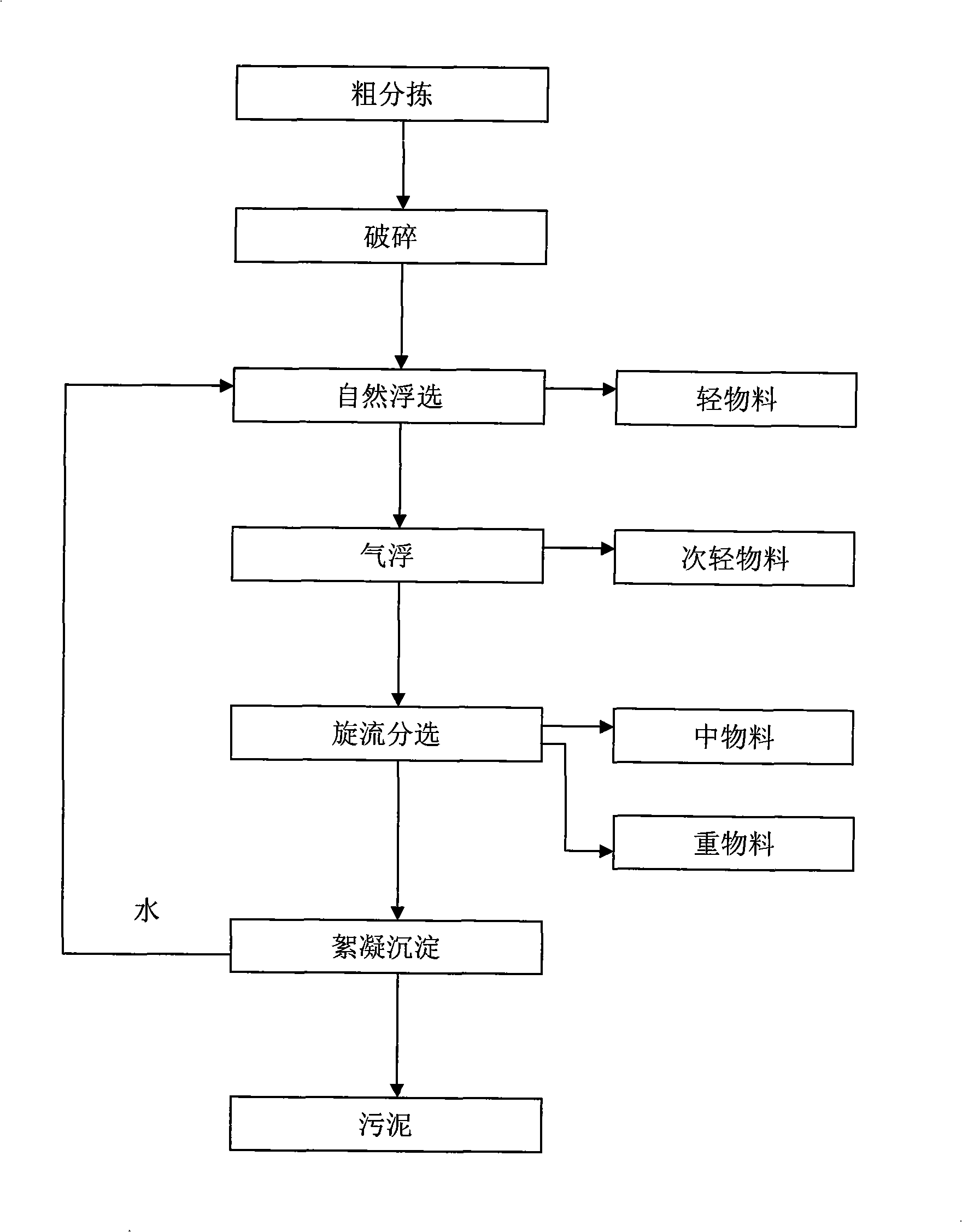

Wet separation method for domestic garbage

The invention relates to a water selection method for domestic waste, which includes the following steps: (1) ragging, wherein, massive recoverable materials and other materials are separately sorted out; (2) crushing; (3) natural floatation, wherein, materials after crushing are put into water and left standing, and materials with a specific gravity lighter than that of water float up onto the water surface naturally; (4) air floatation, wherein, air is inflated from a bottom, bubbles attached to material pellets are formed, and secondary light materials which have a lighter specific gravity float up onto the water surface by carrying the bubbles; (5) swirl separation, wherein, the swirl is formed in the water, heavy materials with a larger specific gravity are left at the water bottom, middle materials which are lighter than the heavy materials flow together with the water under the impact of the swirl, and the middle materials and the heavy materials are separately screened and filtered from the water; and (6) flocculating settling, wherein, a flocculant is added in so as to carry out the flocculating settling to the water, sludge in the water is sunk at the water bottom, and upper clean water is recycled. The water selection method of the invention effectively classifies the domestic waste into a plurality of types according to the difference of quality and density, thus providing favorable conditions for recycling domestic waste.

Owner:BEIJING HENGYECUN S&T

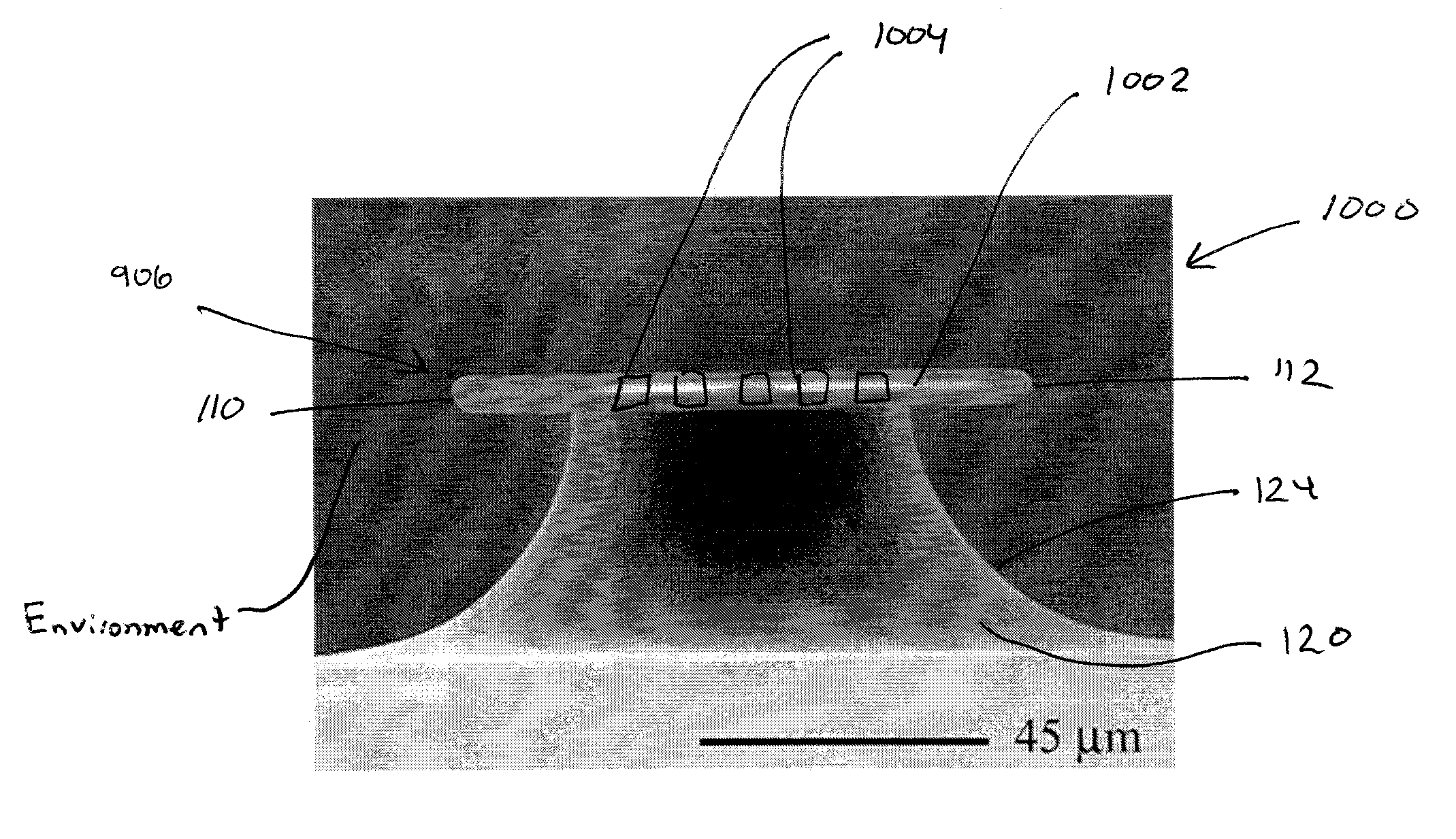

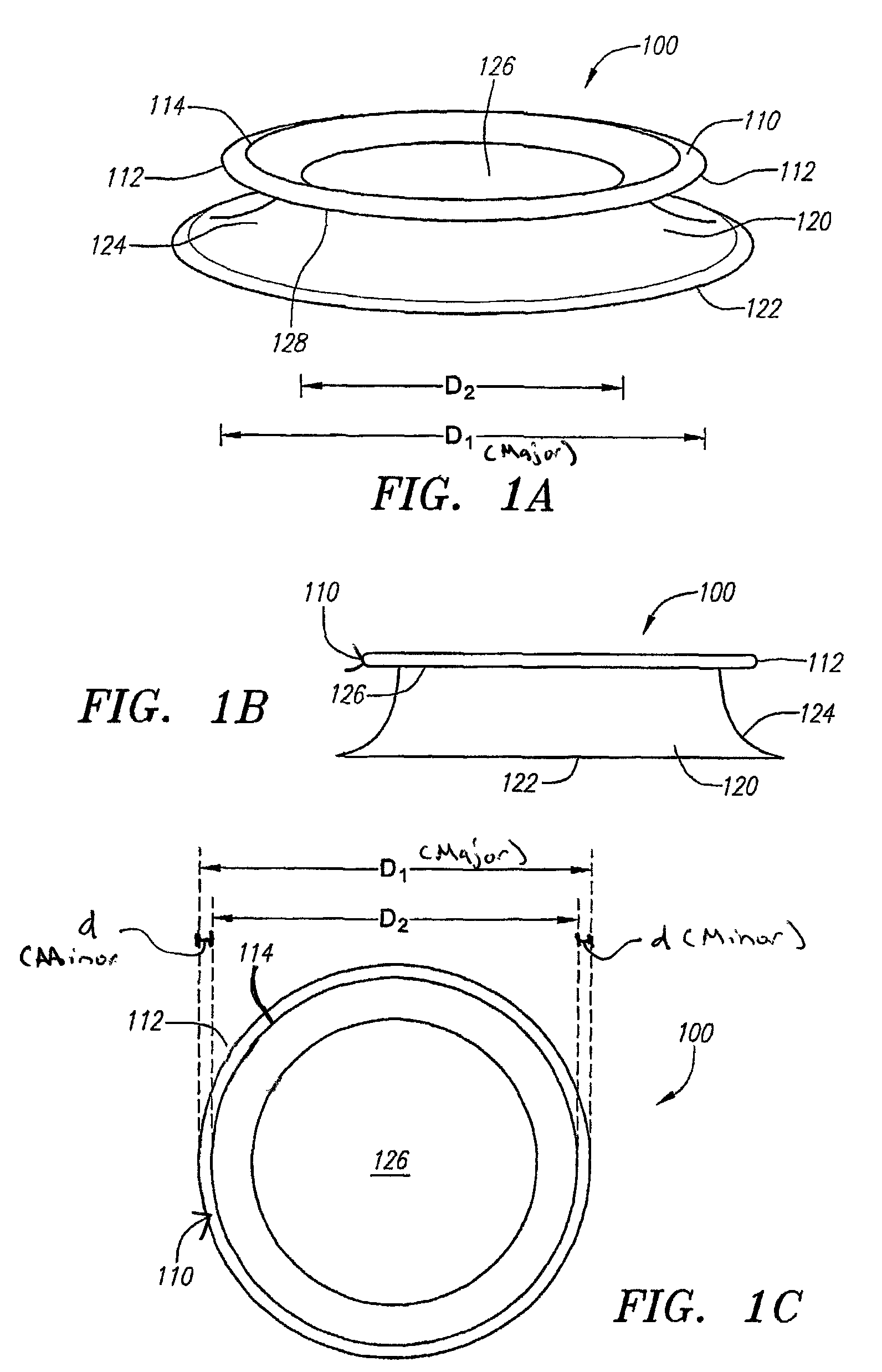

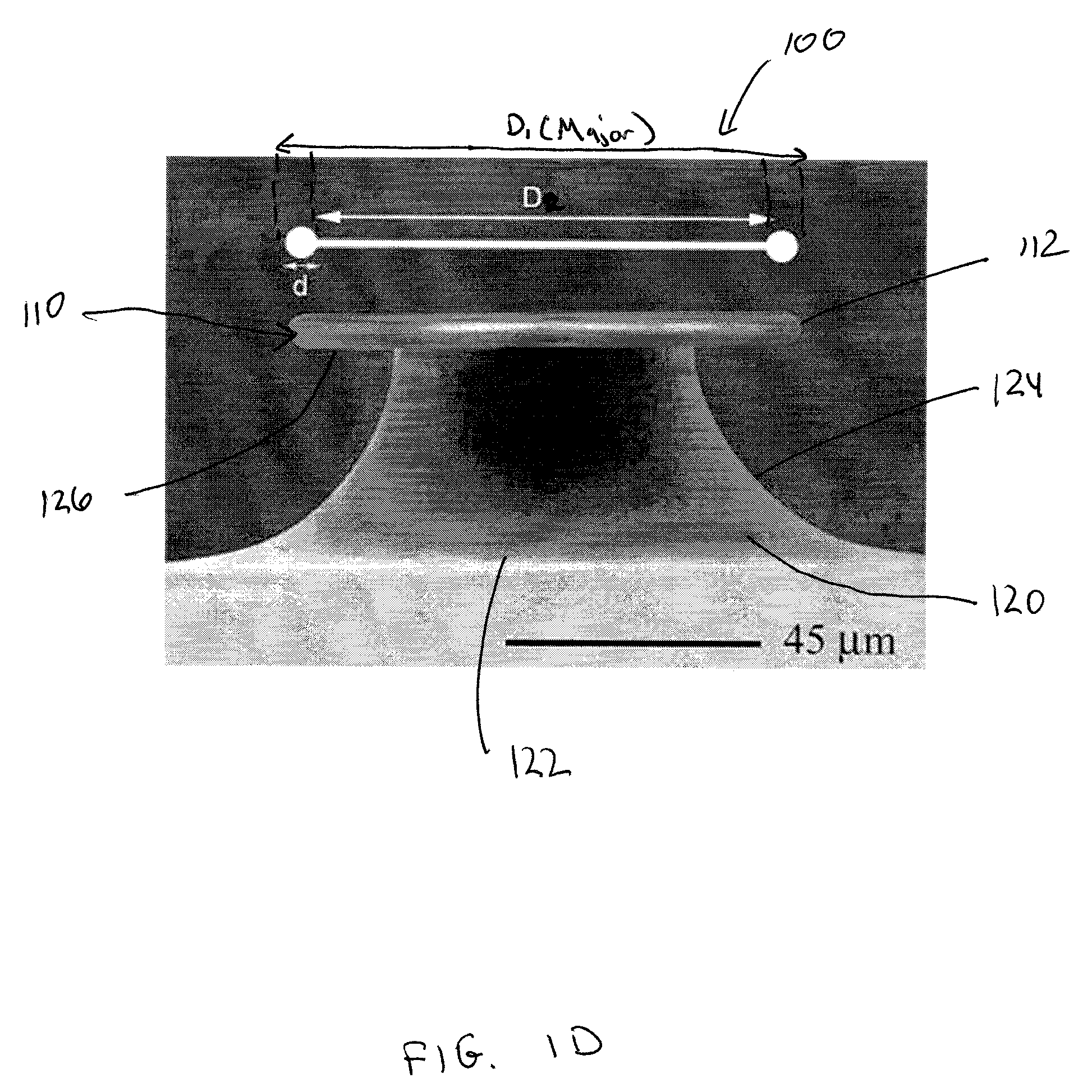

Biological and chemical microcavity resonant sensors and methods of detecting molecules

ActiveUS7781217B2High sensitivityMaterial analysis using wave/particle radiationChemiluminescene/bioluminescenceFluorescenceWavelength

Resonant sensors and methods of detecting specific molecules with enhanced sensitivity. Optical energy is introduced into a microcavity, such as a silica toroid-shaped microcavity. The microcavity sensor has a functionalized outer surface and a sufficiently high Q value to generate an evanescent optical field with increased intensity. A molecule bound to the functionalized outer surface interacts with the external optical field, thereby heating the microcavity and generating a detectable resonant wavelength shift, which indicates a small number of molecules, even a single molecule, without the use of fluorescent or metal labels. Resonant sensors and methods can also be used to detect specific molecules, even a single molecule, within an environment. One application is detecting very small quantities or a single molecule of heavy water in ordinary water.

Owner:CALIFORNIA INST OF TECH

Marine water drop muffler

ActiveUS8246403B2Maximize generationAvoid flowExhaust apparatusPropulsion power plantsWater vaporOcean sea

Owner:WOODS WOODROW

High-temperature supercritical nuclear reactor

InactiveCN102568624AImprove economyTake advantage ofNuclear energy generationCooling arrangementFast-neutron reactorMaterials science

The invention relates to a high-temperature supercritical nuclear reactor. A spherical solid is used as a coolant of the nuclear reactor, which is different from common nuclear reactors that adopt light water, heavy water, gas and liquid sodium. The spherical solid coolant can be graphite spheres coated with silicon carbide, stainless steel spheres, graphite spheres coated with stainless steel and the like. The spherical solid has the characteristic of good rolling ability, so that the spherical solid can roll to a steam generator under the action of gravity after heating in the reactor, and the purpose of transferring heat from the reactor to the steam generator is achieved. The reactor is applicable to both thermal neutron reactor and fast neutron reactor, and natural uranium, low-enriched uranium, plutonium and thorium can be used as nuclear fuel. The temperature of high-temperature steam / water outputted by the steam generator can reach 900 DEG C, the same parameters to a thermal power station can be reached, the requirement of supercritical even ultra-supercritical can be satisfied, and the high-temperature supercritical nuclear reactor has high safety and reliability.

Owner:李正蔚

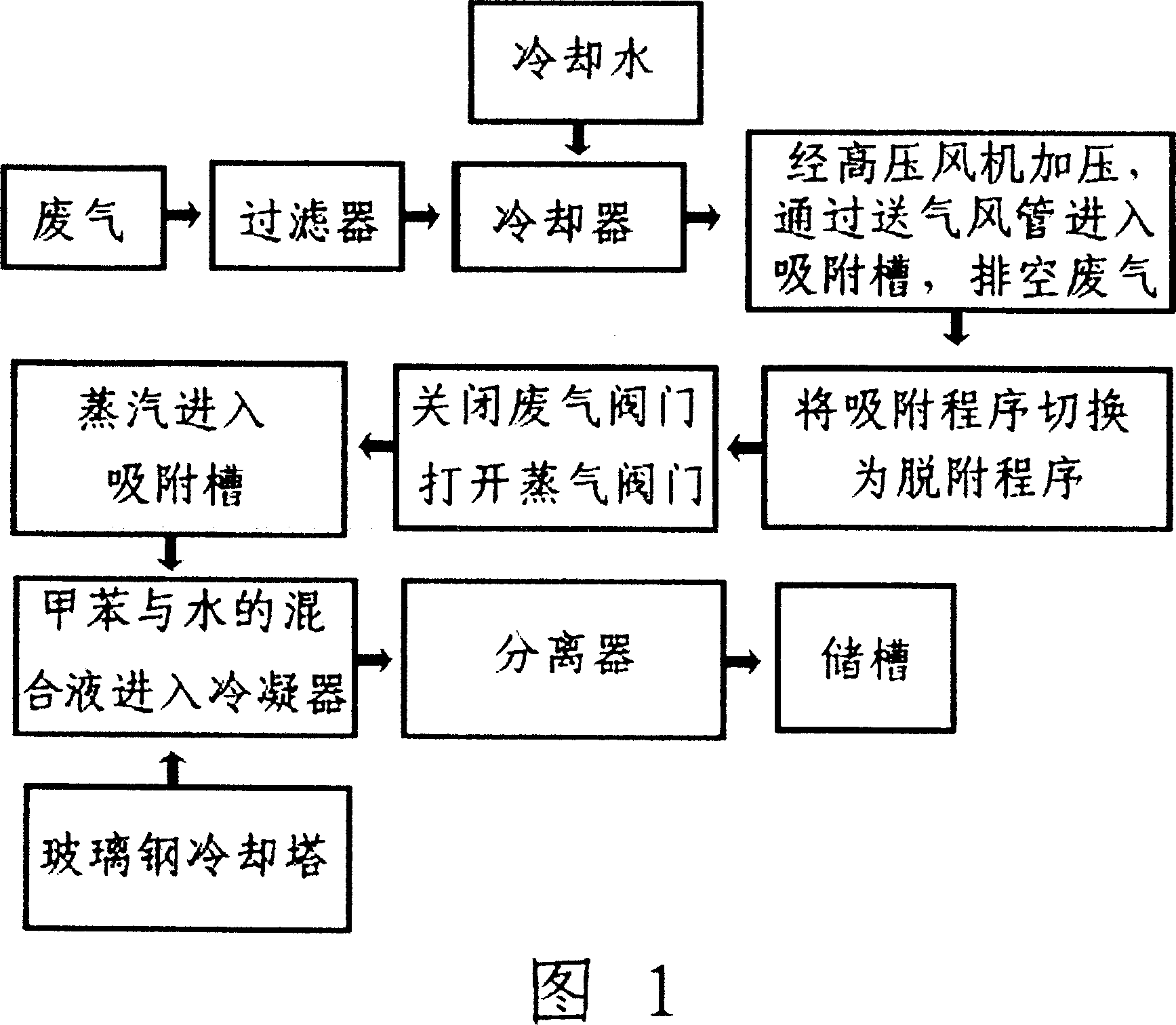

Method for recovering toluene

InactiveCN101077850AMassive absorptionInflow guaranteeAdsorption purification/separationDesorptionWater vapor

The recovery process includes the following steps: 1. making the produced waste gas pass through the control valve and filtering in the gas filter; 2. cooling waste gas including toluene in the cooler; 3. pressurizing with the high pressure blower and adsorbing with active carbon in three adsorbing tanks; 4. switching to desorption program through closing the waste gas valve and opening the steam valve for steam to enter the active carbon, with the toluene separated from the active carbon being exhausted together with the steam from the bottom of the adsorbing tanks; 5. condensing the steam with toluene gas to form mixture liquid of toluene and water; 6. separating the mixture liquid of light toluene and heavy water in a separator; and 7. storing toluene in a tank. The process has toluene recovering rate over 86 % and low cost.

Owner:王少平

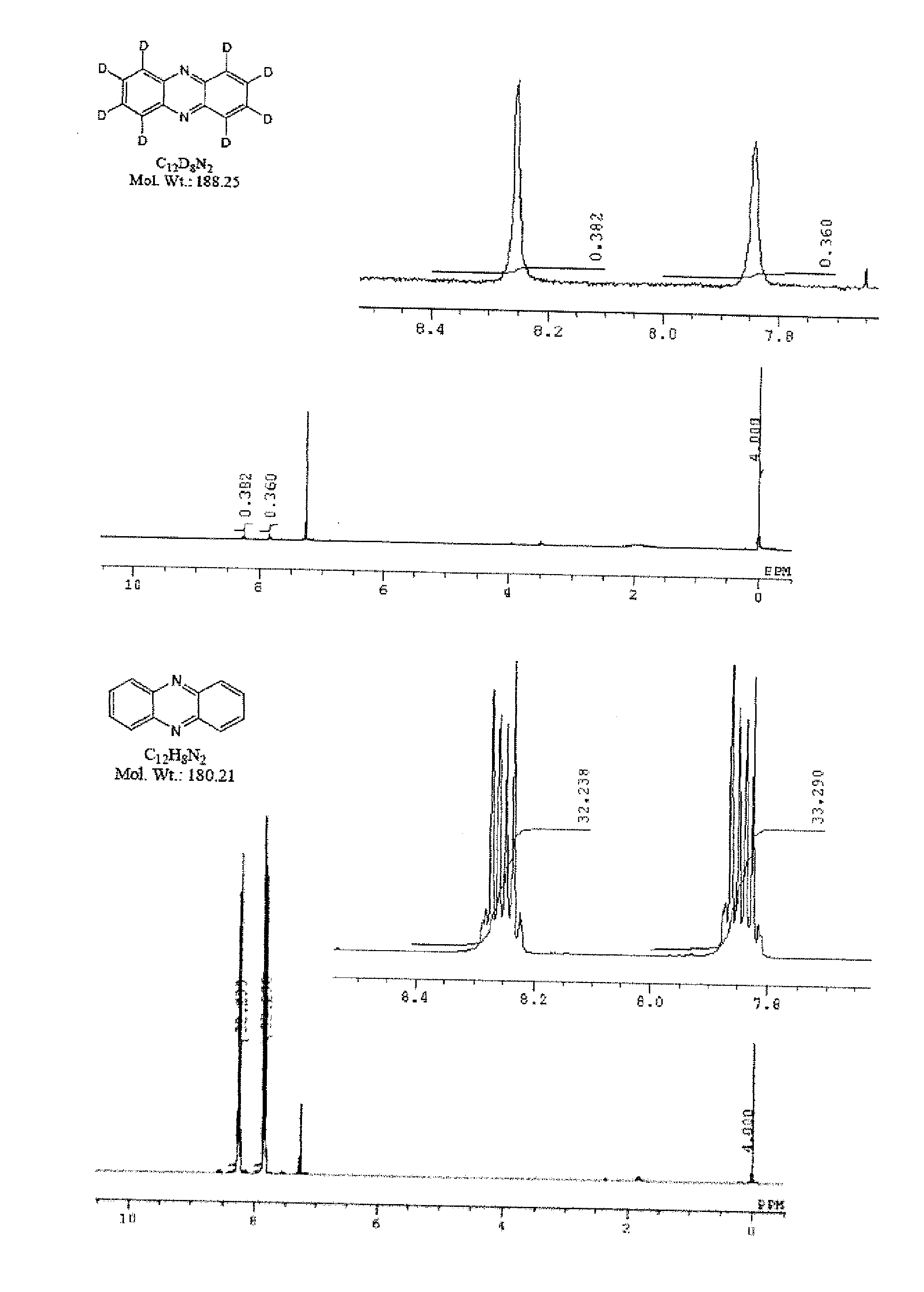

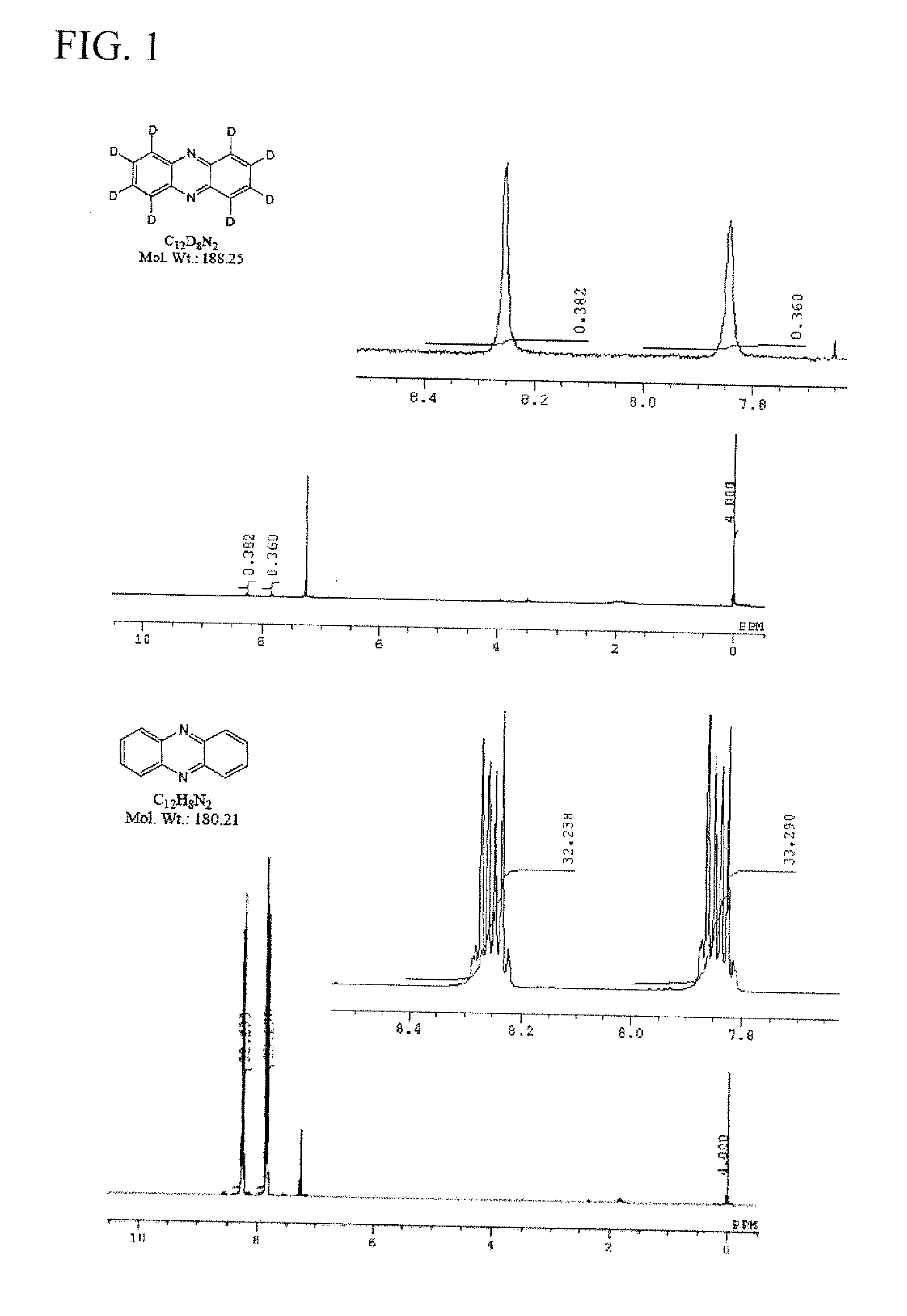

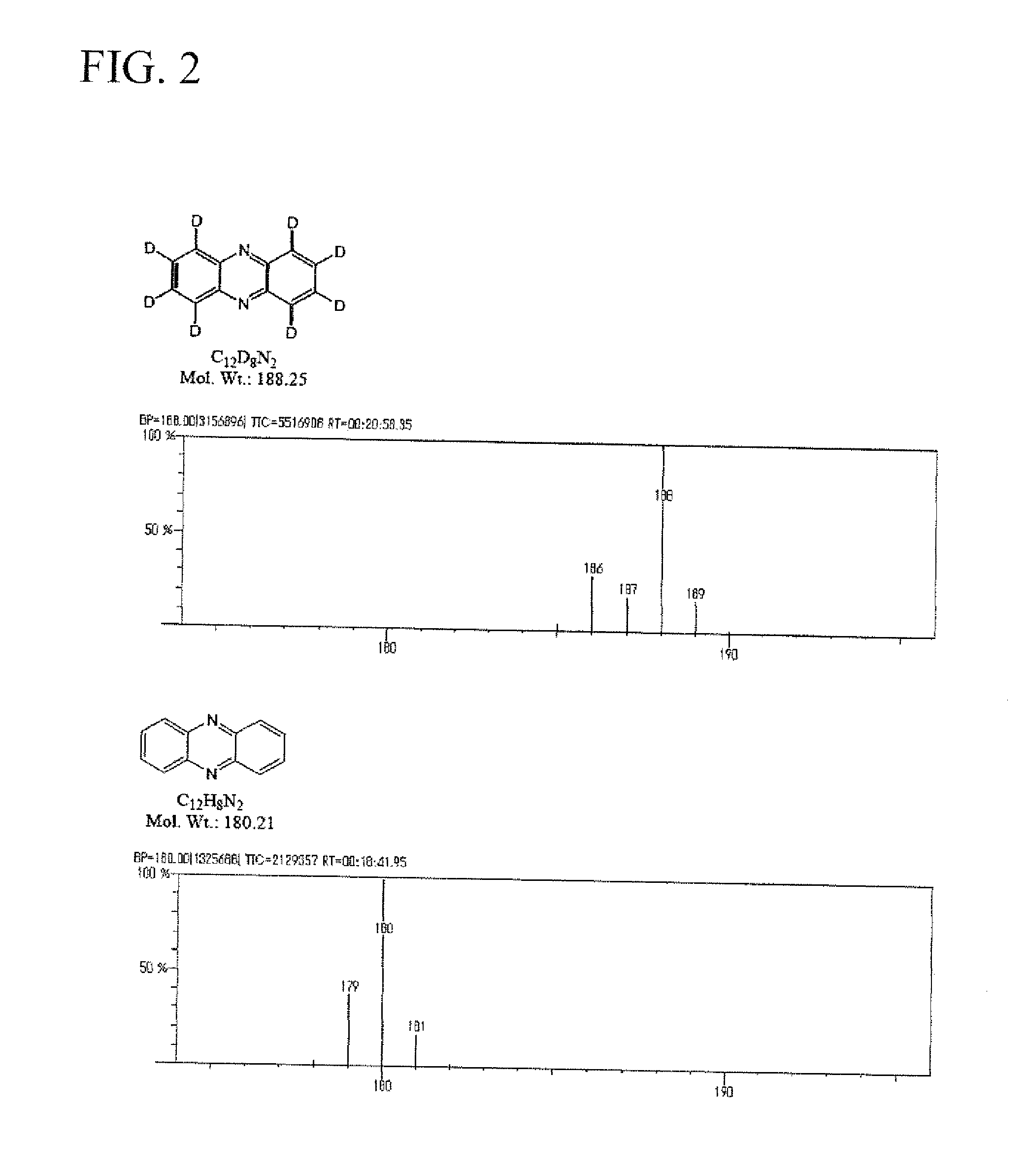

Method for producing compound having deuterated aromatic ring or heterocyclic ring

InactiveUS20100331540A1Easy to operateHigh yieldAmino preparation from aminesQuinoline dyesPlatinumRuthenium

A method for producing a compound having a deuterated aromatic ring or heterocyclic ring according to the invention includes heating a compound having an aromatic ring or heterocyclic ring in the presence of heavy water, a transition metal and a metal which generates deuterium. As the metal which generates deuterium, at least one metal selected from the group consisting of aluminum, magnesium, zinc, iron, lead and tin is preferred. As the transition metal, at least one metal selected from the group consisting of platinum, palladium, ruthenium and rhodium is preferred. The heating is preferably carried out by microwave irradiation.

Owner:NIPPON SANSO CORP +1

Method of treating bipolar disorders using deuterium-substituted carbonate

The present invention provides a method for treating psychiatric disorders such as mania or depression in a patients, in particular, patients with a bipolar disorder, by providing substantially isotopically pure heavy water substantially free of protons, isotopically pure hydrogen-containing water substantially free of deuterium, isotopically pure carbonate compounds substantially free of deuterium, isotopically pure carbonate compounds substantially free of protons, isotopically pure phosphate compounds substantially free of deuterium, isotopically pure phosphate compounds substantially free of protons, or mixtures thereof to the patient. In particular, the present invention provides a method for treating manic symptoms in a patient and mania or depression in patients with a bipolar disorder.

Owner:BELL RUPERT C

High Fe contained zirconium alloy compositions having excellent corrosion resistance and preparation method thereof

ActiveUS20080192880A1Improve corrosion resistanceHigh cycle operationOptical rangefindersNuclear energy generationNuclear reactor coreNiobium

A high Fe-containing zirconium composition having excellent corrosion resistance and a preparation method thereof. Specifically, disclosed are a high Fe-containing zirconium composition having excellent corrosion resistance and a preparation method thereof, the composition comprising: 0.5-1.0 wt % iron; 0.25-0.5 wt % chromium; 0.06-0.18 wt % oxygen; at least one element selected from the group consisting of 0.2-0.5 wt % tin, 0.1-0.3 wt % niobium and 0.05-0.3 wt % copper; and the balance of zirconium. The zirconium alloy has excellent corrosion resistance, and thus can be used as a material for nuclear fuel claddings, spacer grids and nuclear reactor core structures in light water reactor and heavy water reactor nuclear power plants.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

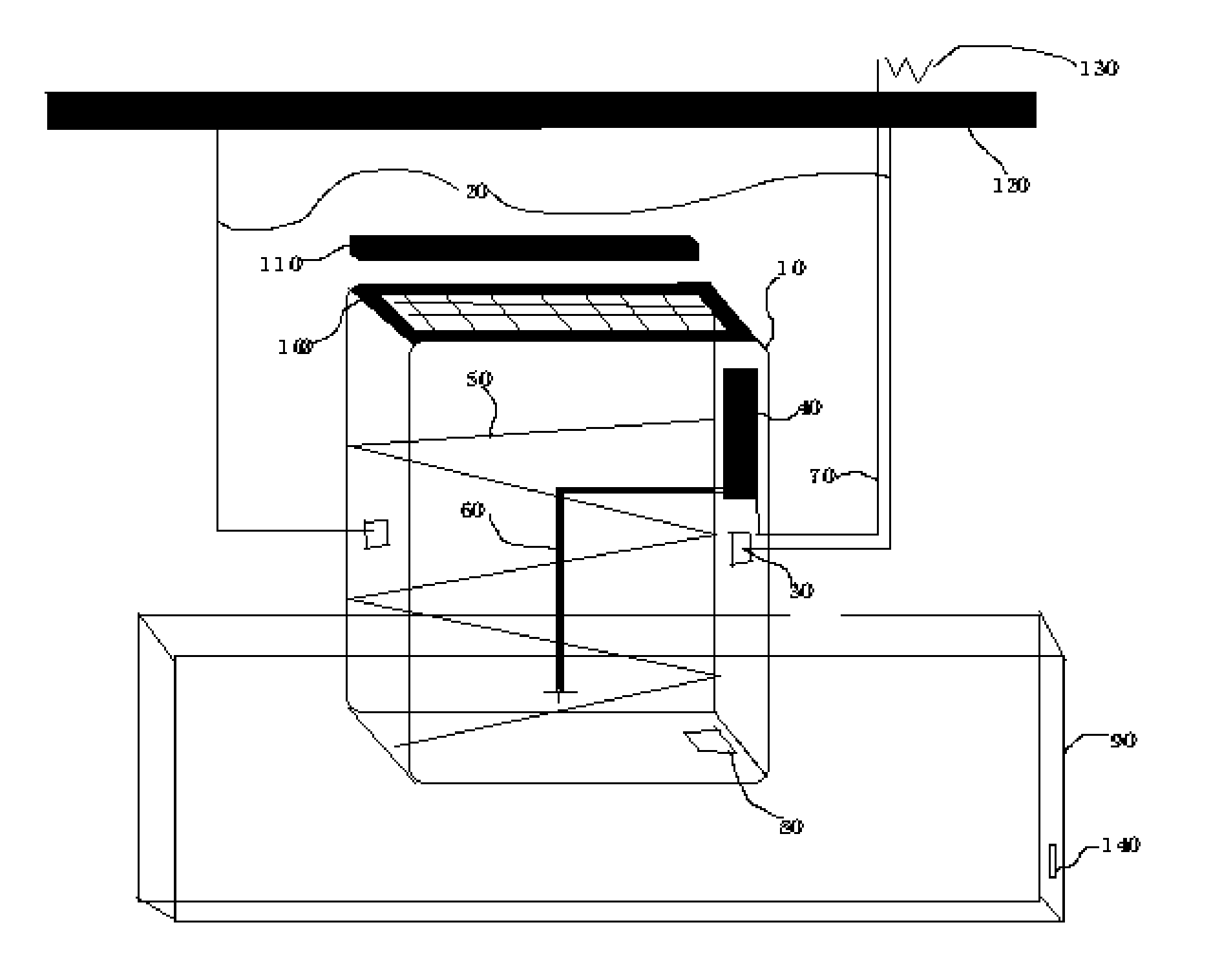

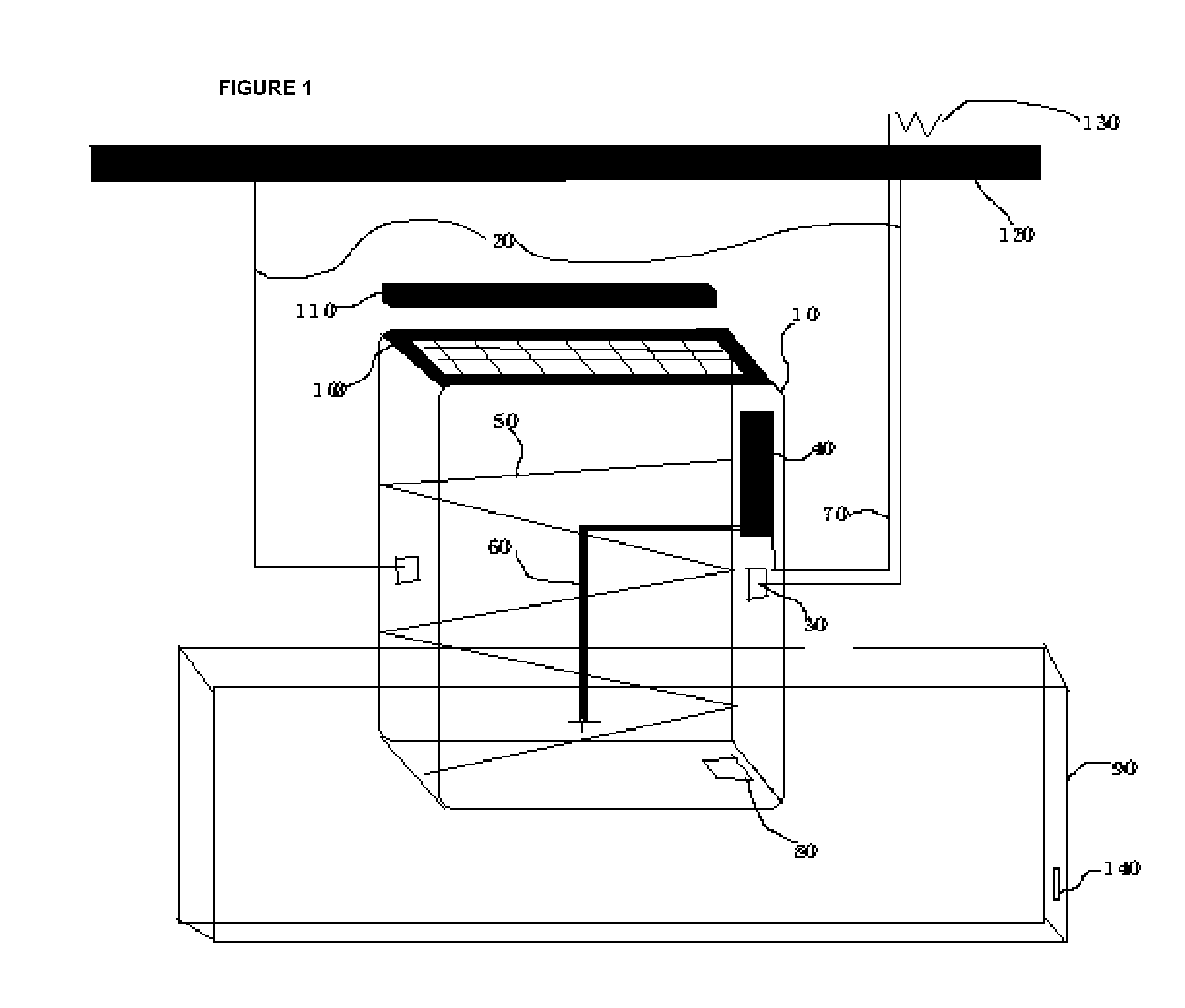

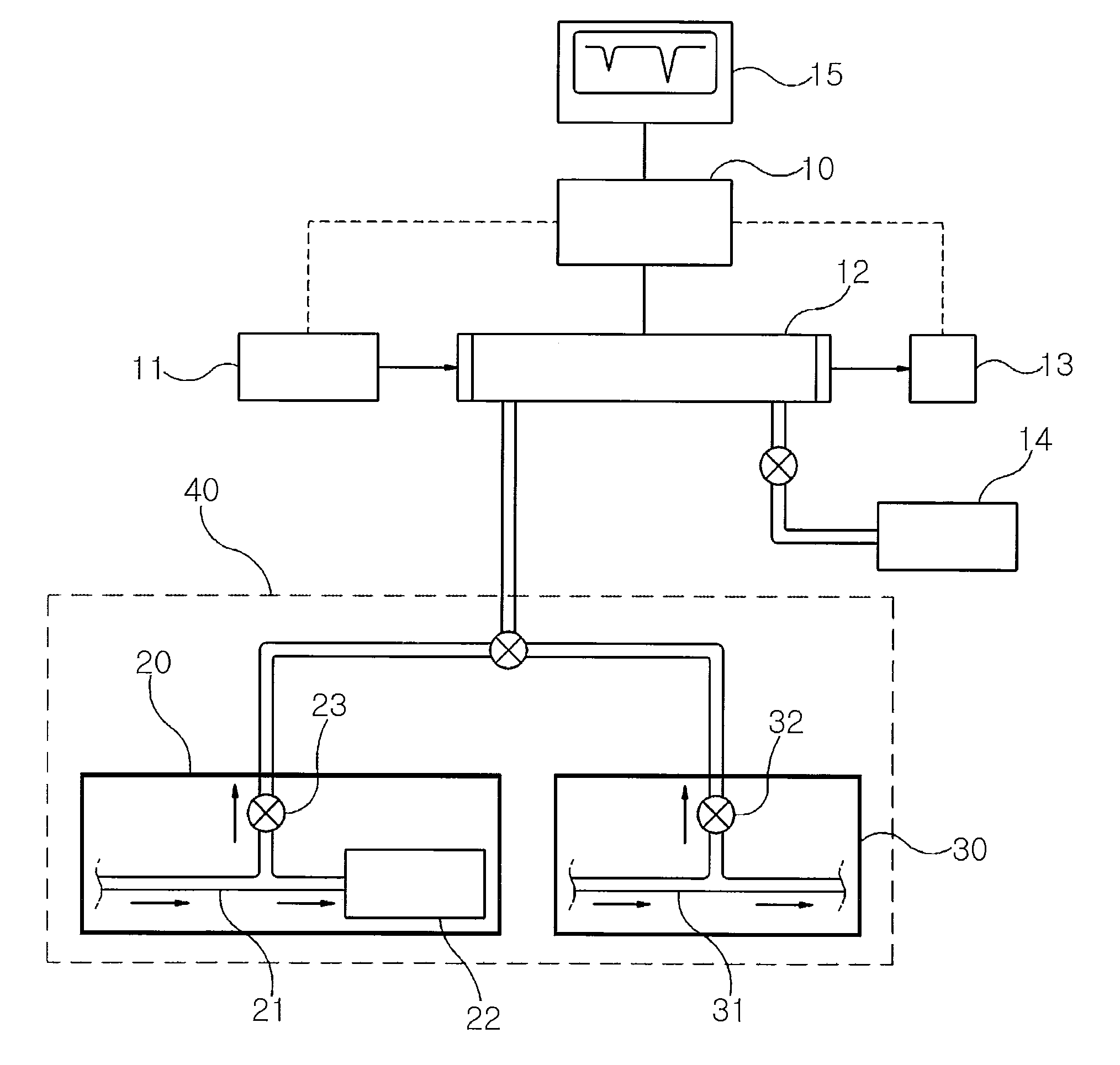

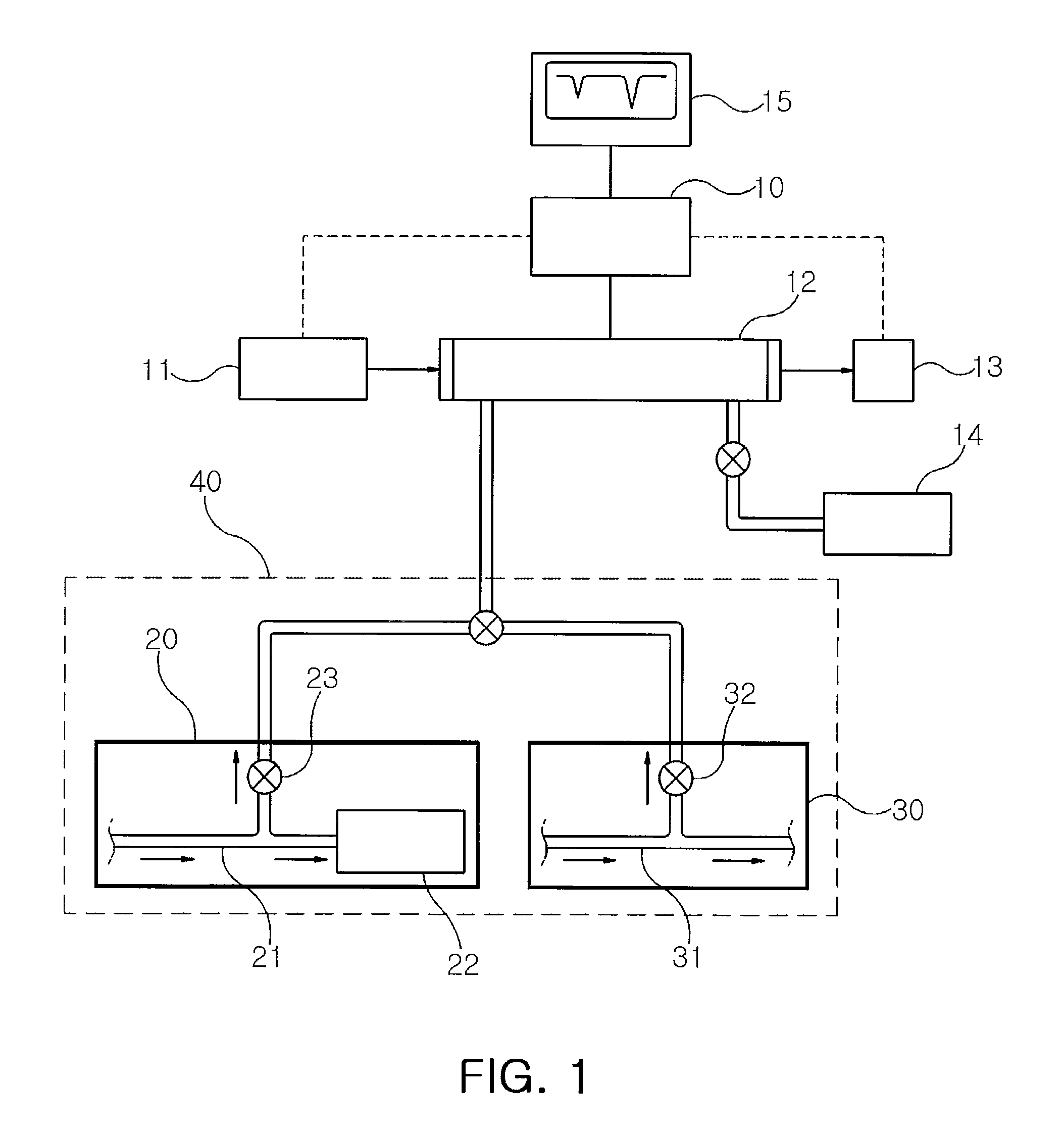

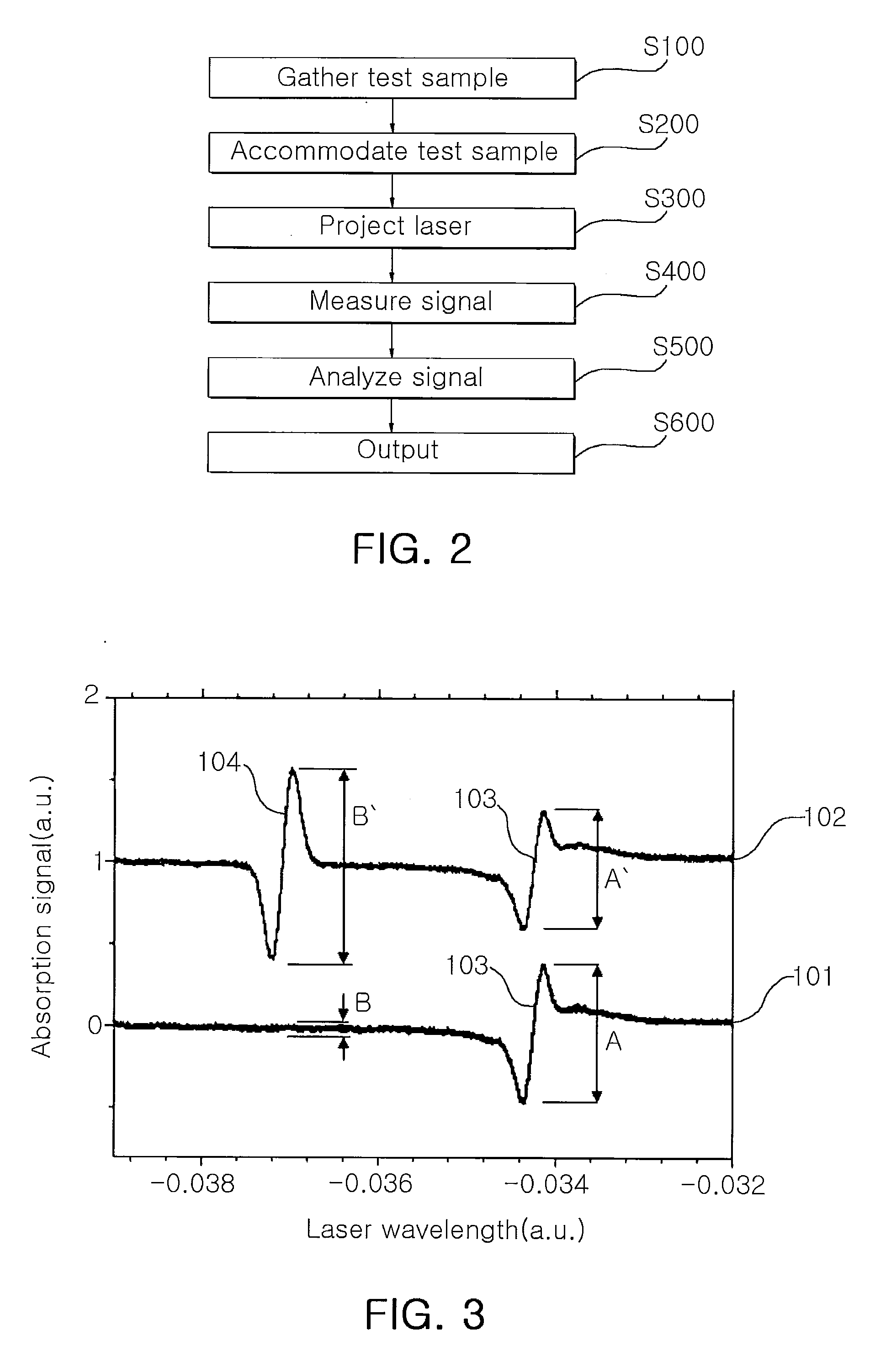

Apparatus for Detecting the Leakage of Heavy Water in Nuclear Reactor System and Detection Method Using the Same

ActiveUS20100118294A1Reduce manufacturing costEasy to carryDetection of fluid at leakage pointRadiation pyrometryLaser beamsVacuum pump

An apparatus and a method for detecting a leakage of heavy water in a nuclear reactor system includes: a diode laser that generates a laser beam and injects the generated laser beam to a test sample placed in a light absorption cell; the light absorption cell accommodates a gathered test sample therein; a vacuum pump adjusts a degree of vacuum in the light absorption cell; a test sample introduction unit gathers an air test sample from a location with a high possibility of a leakage of heavy water or a light water test sample from a secondary side of a steam generator and transfers the sample to the light absorption cell; an optical detector detects the laser beam which has passed through the light absorption cell; and a microprocessor controls the operation of the diode laser, the light absorption cell, the vacuum pump, the test sample introduction unit, and the optical detector, receives a detect signal from the optical detector, and analyzes an absorption spectrum signal.

Owner:KOREA ATOMIC ENERGY RES INST +1

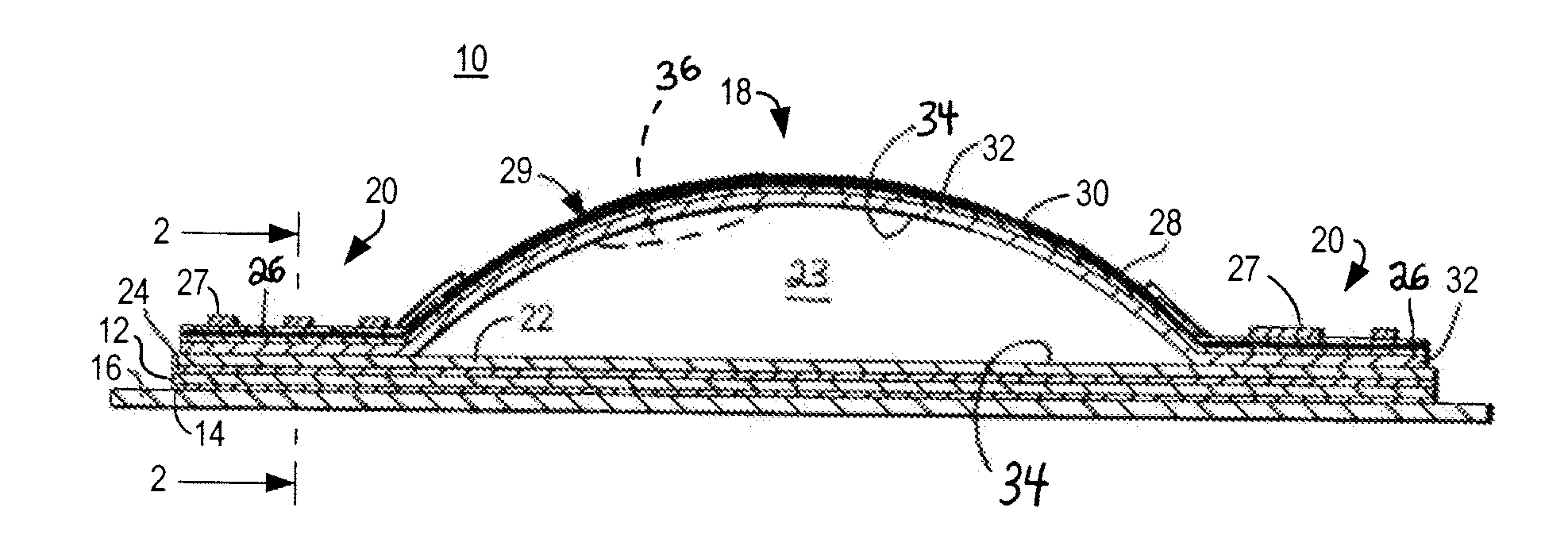

Freeze indicators suitable for mass production

ActiveUS20070119364A1Good and extended shelf lifeUnanimous responseThermometer detailsTemperature measurement in household appliancesLiquid mediumWater vapor

A freeze indicator employs, as active indicator element, dispersion of solid particles in a liquid medium which can be water or aqueous and which coagulates to provide an irreversible appearance change when subject to freezing. The liquid dispersion can be contained in an indicator volume around which extends a vapor block layer. The vapor block layer can prevent loss of liquid vapor from the dispersion and consequent drying out and dysfunctionality of the freeze indicator. For containing an aqueous medium, bilayer and trilayer laminate materials can be used which have a low water vapor transmission rate. The active indicator element can be a dilute colloidal dispersion of a metal such as gold or silver or other inorganic pigment material in water or an aqueous medium. Some embodiments avoid use of dispersants and the like and employ an active indicator element consisting of inorganic pigment particles, water and optionally an ice nucleating agent. Heavy water, or deuterated water can be components of the water, if desired.

Owner:TEMPTIME CORP

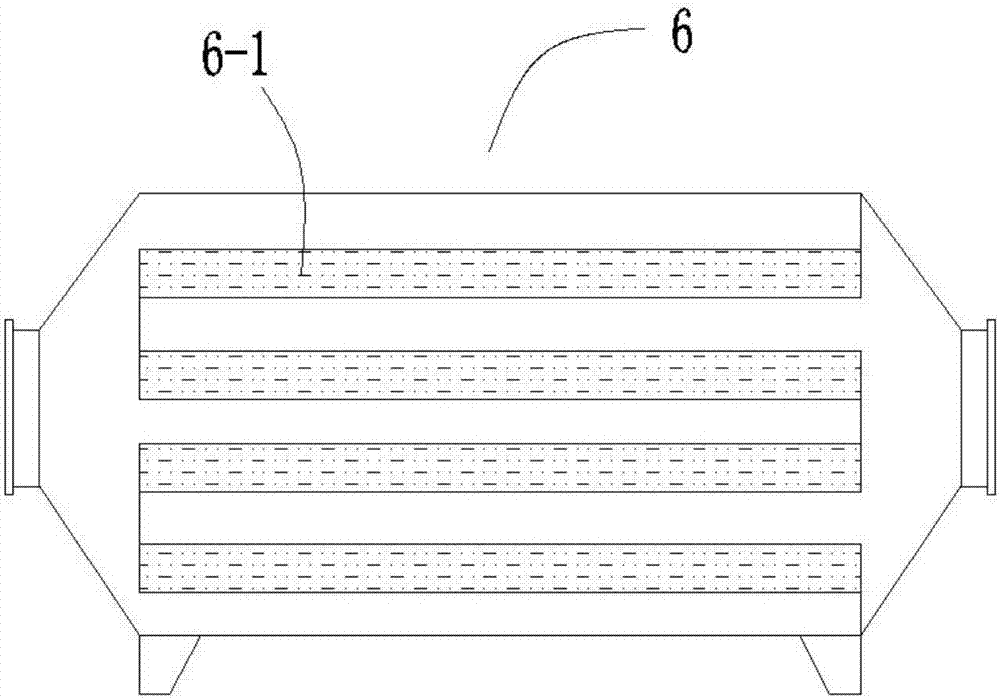

Preparation method of hydrophobic catalyst for hydrogen-water isotope exchange

InactiveCN103551202AHigh strengthVarious shapes and specificationsOrganic-compounds/hydrides/coordination-complexes catalystsMicro structurePolymer science

The invention discloses a preparation method of a hydrophobic catalyst for hydrogen-water isotope exchange, which belongs to the technical field of catalyst exchange and aims at solving the problems of single shape, low utilization rate of reactive metals, and the like in an existing hydrophobic catalyst for hydrogen-water isotope exchange. The preparation method comprises the steps of suspension liquid preparation, loading, and heat treatment. The hydrophobic catalyst prepared by the method can meet the requirements of water tritium removal and heavy water purification and production on special filling configuration (in bulk, in order and the like) and performance in produced exchange columns with different scale grades. According to the method, a metal fiber felt serves as a support carrier and a foaming agent is used for modifying the micro structure of a hydrophobic membrane, the prepared hydrophobic catalyst has the characteristics of controllable shape, varied shape specifications, honeycomb-structure of the hydrophobic membrane, high utilization rate of reactive metals, high strength, and the like, and can meet the requirements of tritium removal and heavy water purification and production on filling configuration and performance in exchange columns with different scale grades.

Owner:SICHUAN INST OF MATERIALS & TECH

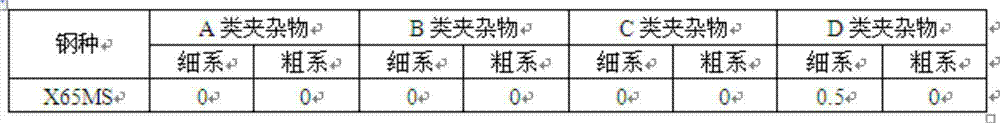

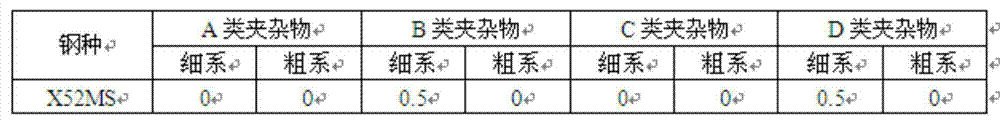

Method for controlling non-metallic slag inclusion in medium and heavy plate of hydrogen-induced cracking resistance pipe line steel

InactiveCN102732666ARealize industrializationAchieve batchManufacturing convertersSteelmakingCrack resistance

The invention provides a method for controlling non-metallic slag inclusion in a medium and heavy plate of a hydrogen-induced cracking resistance pipe line steel, belonging to a technical field of steel-making. Process route of the method is: converter steelmaking, ladle furnace refining RH vacuum refining, Ca processing, soft blow and killing, and continuous casting. Characteristics of the technology are: controlling contents of carbon and oxygen at a smelting end-point of the converter, adding a strong aluminum deoxidizer in a tapping process; adding high alkalinity refining slag in the ladle furnace refining process, and controlling flow and time of bottom-blowing argon and components of the refining slag; controlling increase of the argon flow and vacuum treatment time in the RH vacuum refining process; controlling [Ca] content in steel in the Ca processing process; controlling the flow and time of the soft blow liquid steel and the killing time; and adopting full protection casting in the continuous casting process. The method provided in the invention has the advantages that: by adopting the technology, requirement of the non-metallic slag inclusion in the hydrogen-induced cracking resistance pipe line steel is satisfied; according to GB / T10561-2005 criterion for the non-metallic slag inclusion in the steel, various non-metallic slag inclusions in the steel are controlled within 0.5 grade; adopting a NACE standard A solution to carry out a detection of anti-HIC performance to the medium and heavy plate rolled by the casting blank, and the detection result of anti-HIC performance is qualified; and realizing batch and stable production of the medium and heavy plate in the hydrogen-induced cracking resistance pipe line steel.

Owner:SHOUGANG CORPORATION

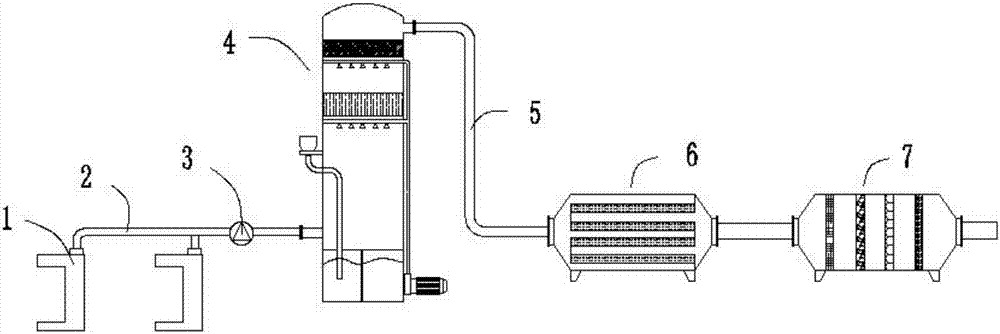

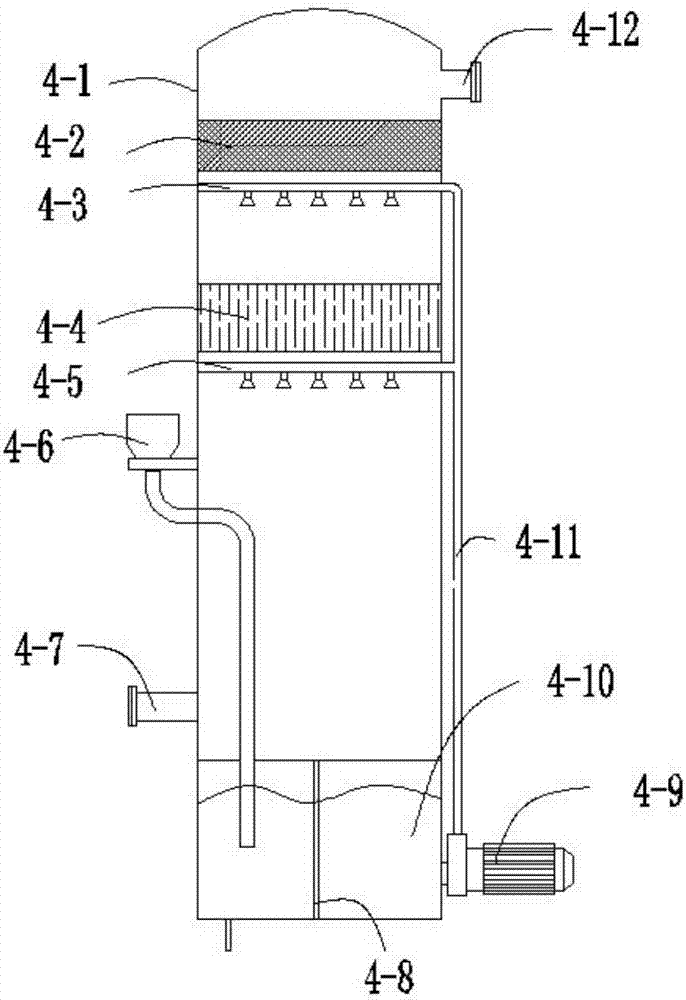

Purification device for industrial waste gases

InactiveCN107158939ASimple structureEasy to handleCombination devicesGas treatmentHEPAActivated carbon

The invention discloses a purification device for industrial waste gases, and relates to the field of waste gas purification equipment, the purification device includes a waste gas main pipeline, the waste gas main pipeline is provided with an exhaust fan, one end of the waste gas main pipeline is connected with a water screen cabinet located in a spraying workshop, the other end of the waste gas main pipeline is connected with a circulating absorption tower, the circulating absorption tower is sequentially connected with an activated carbon adsorber and a strengthening adsorber by a pipeline A, the strengthening adsorber comprises a casing, two ends of the casing are respectively provided with a gas inlet and a gas outlet, the casing is internally detachably in turn provided with a coarse filter cotton layer, a HEPA filter layer, a photocatalytic filter plate and a nano photocatalytic filter plate, and the coarse filter cotton layer is close to the gas inlet. The purification device is simple in structure, after absorption and filtering by the heavy water curtain cabinet, the circulation absorption tower and the activated carbon adsorber, large and small dust particles in the waste gases are basically sedimentated, and volatile organic compounds and odor gases are absorbed by the strengthening adsorber so as to achieve the advantage of up-to-standard emission.

Owner:弘毅天承知识产权股份有限公司

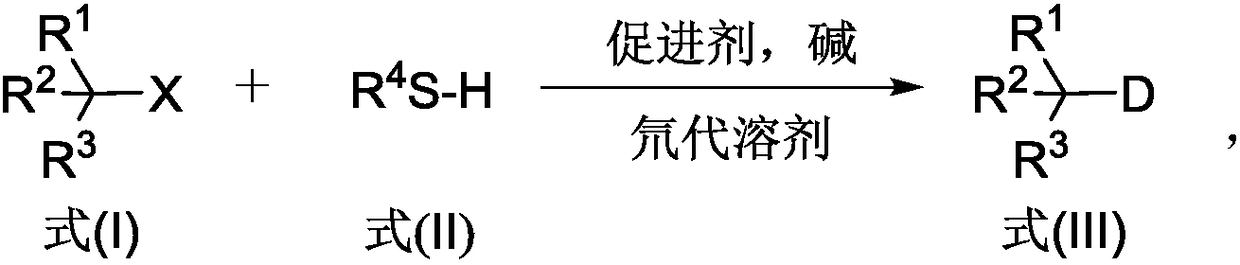

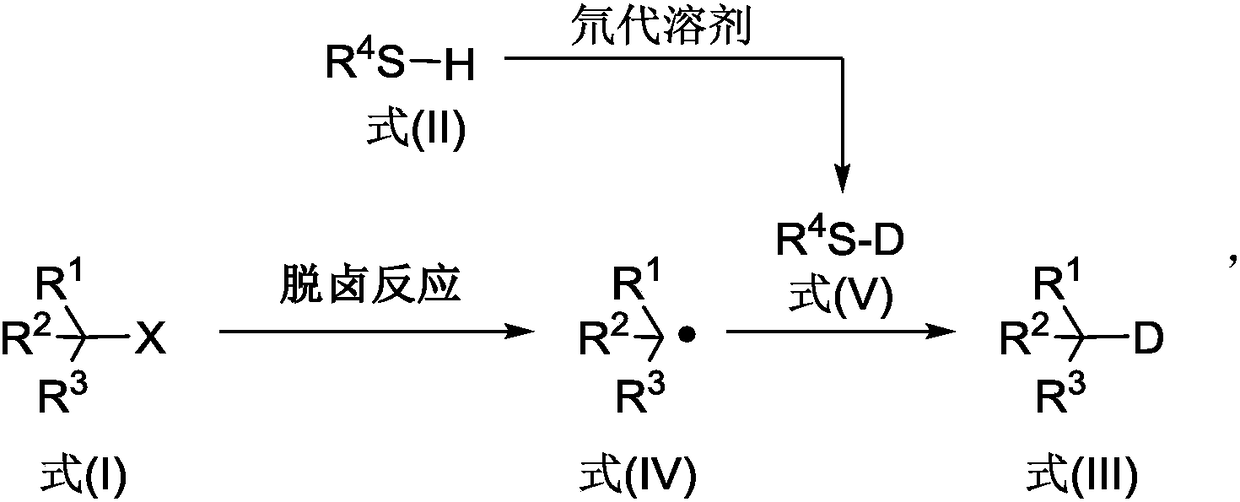

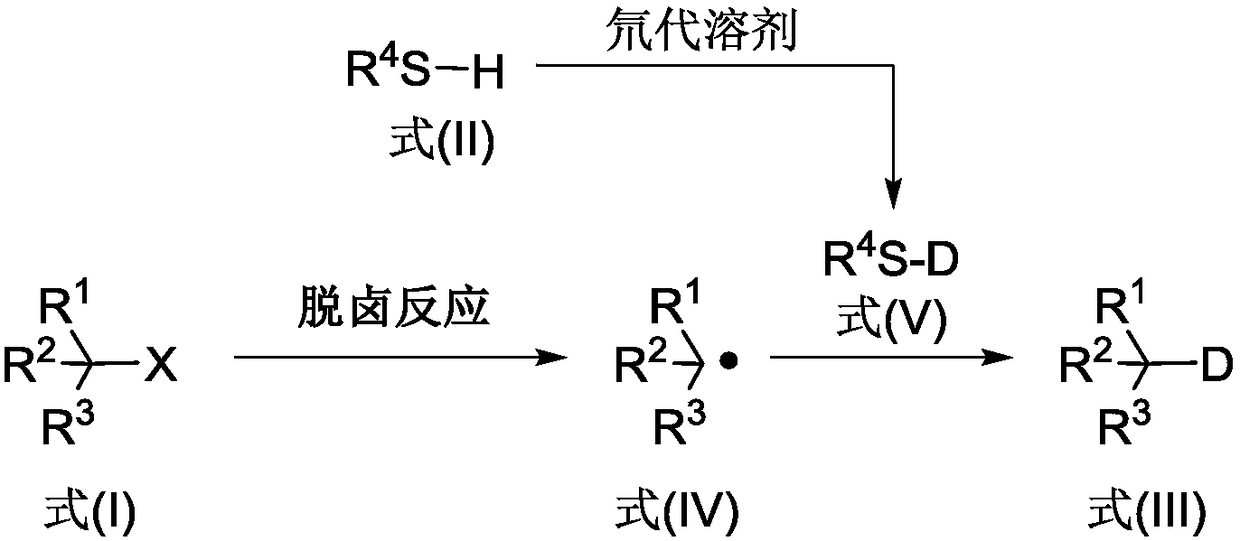

Deuterated compound synthesis method

ActiveCN109265304AImprove applicabilityMild conditionsIsotope introduction to sugar derivativesIsotope introduction to heterocyclic compoundsArylHydrogen atom

The invention discloses a deuterated compound synthesis method, which comprises: carrying out a mixing reaction on a halogenated compound represented by a formula (I), a sulfide represented by a formula (II), a promoter, an alkali and a deuteration solvent to obtain a reduced deuterated product represented by a formula (III), wherein the reaction equation of the reaction is defined in the specification, R<1>, R<2>, R<3> and R<4> respectively are at least one selected from alkyl, aryl, acyl, hydrogen atom and deuterium atom, and X is at least one selected from iodine, bromine and chlorine. According to the present invention, the deuteration marking of the compound is efficiently achieved by using the common heavy water and the deuterated alcohol as the deuterium source through the simple reduction reaction, such that the use of expensive, toxic, flammable and explosive deuterium source reagents is not required compared with the prior art. The formulas I, II and III are defined in the specification.

Owner:HUAZHONG UNIV OF SCI & TECH

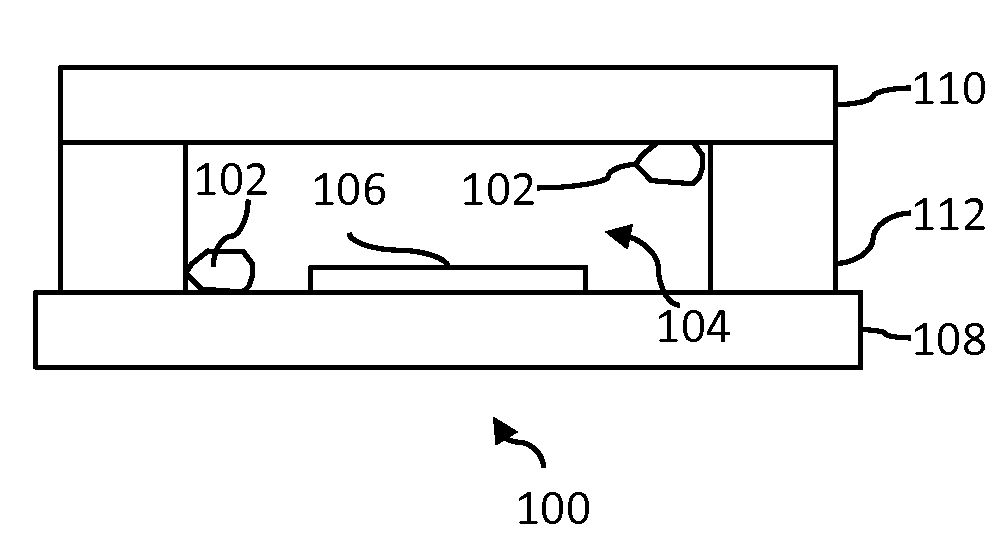

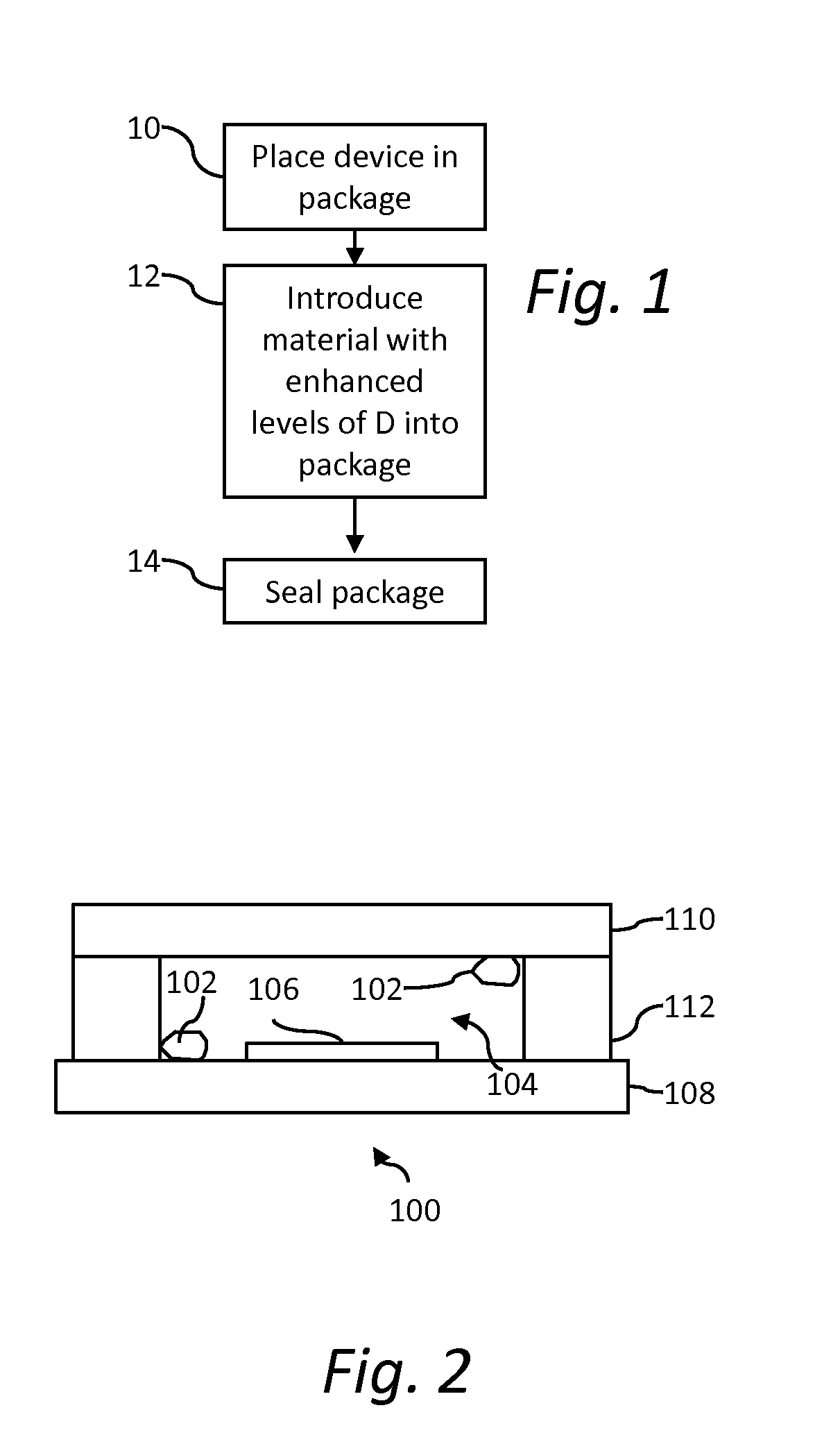

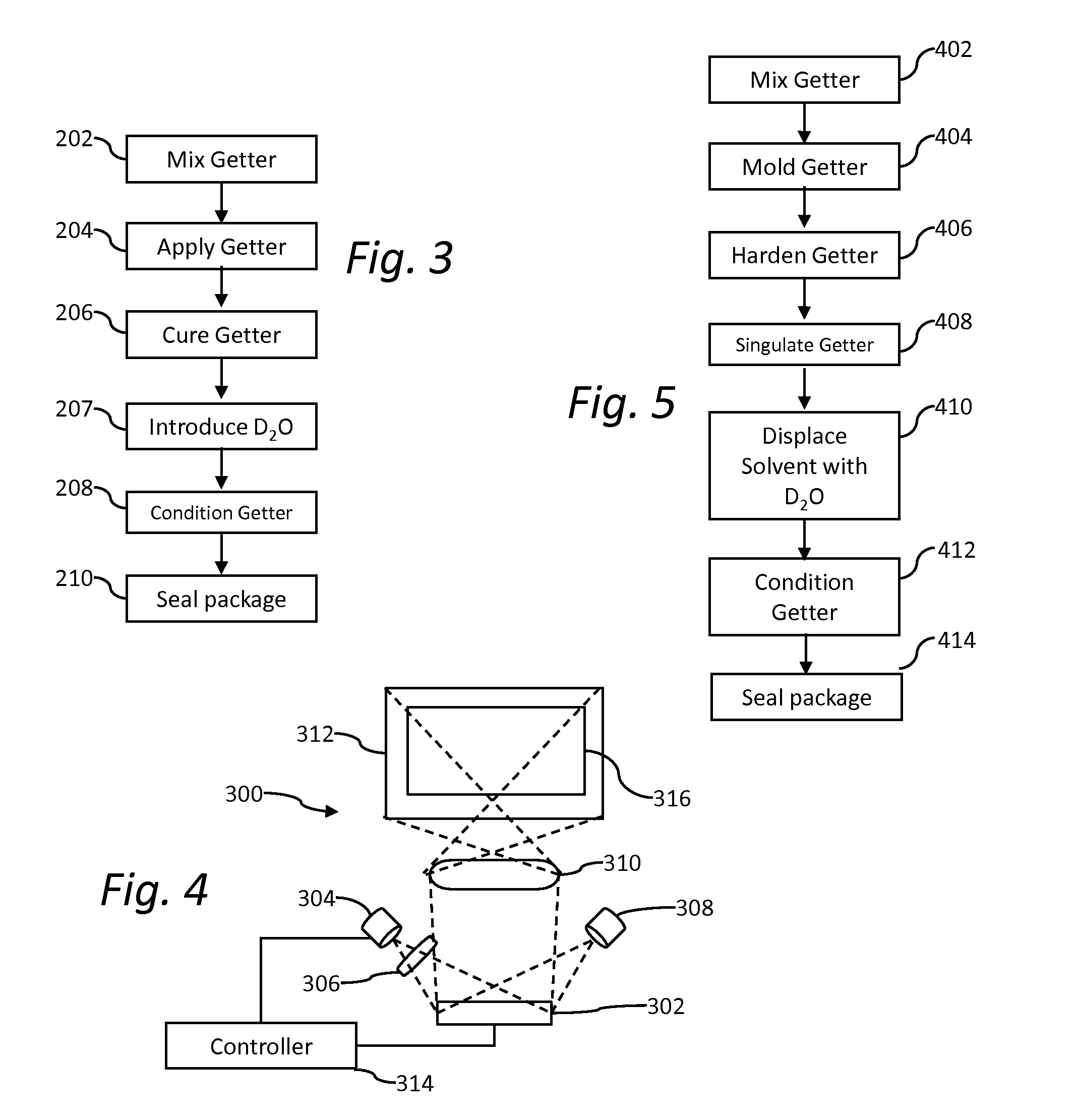

Reduced stiction and mechanical memory in MEMS devices

ActiveUS20100025832A1Reduces bonding vibrational constant for bondStatic frictionSemiconductor/solid-state device detailsSolid-state devicesHydrogenEngineering

Owner:TEXAS INSTR INC

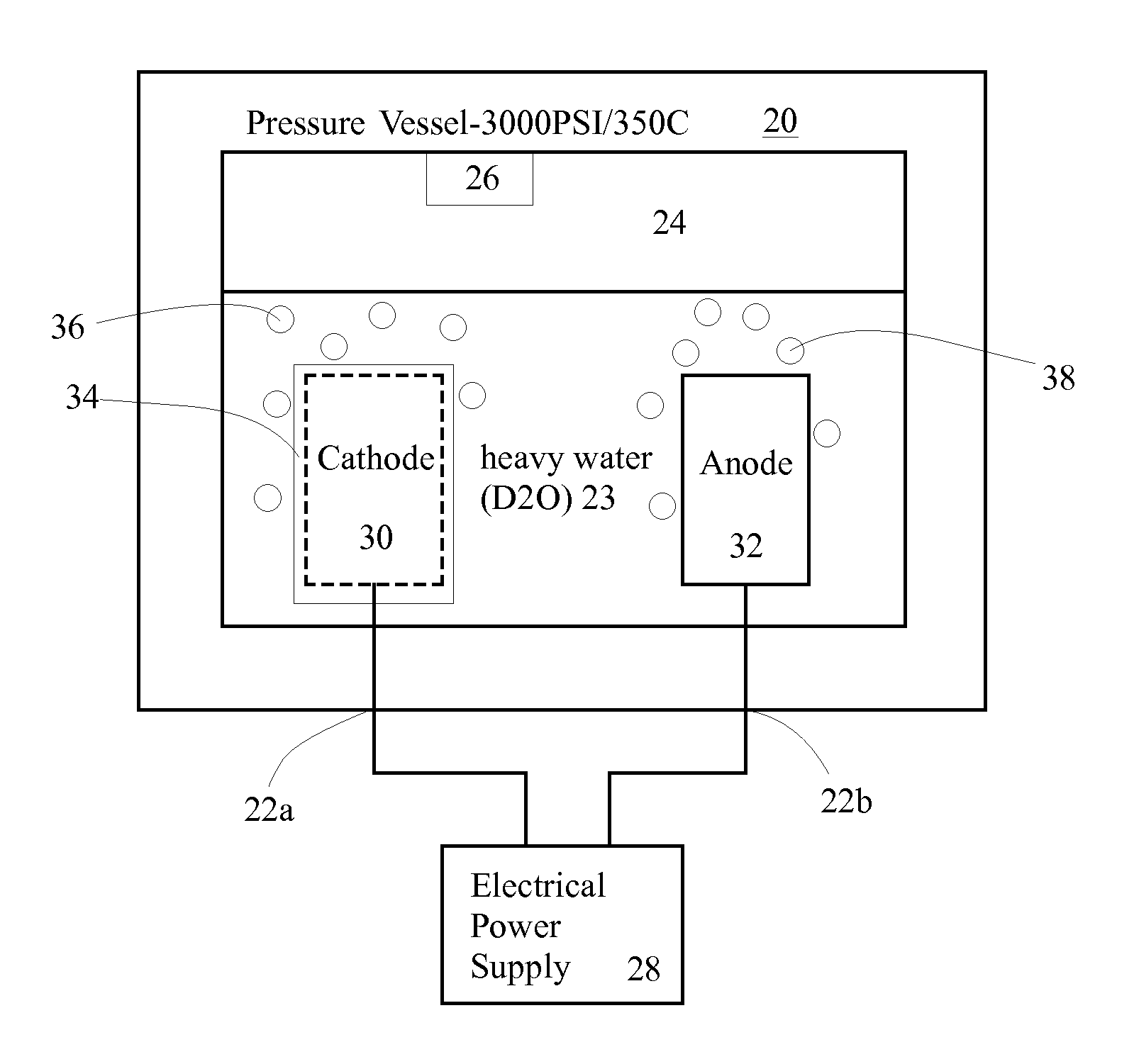

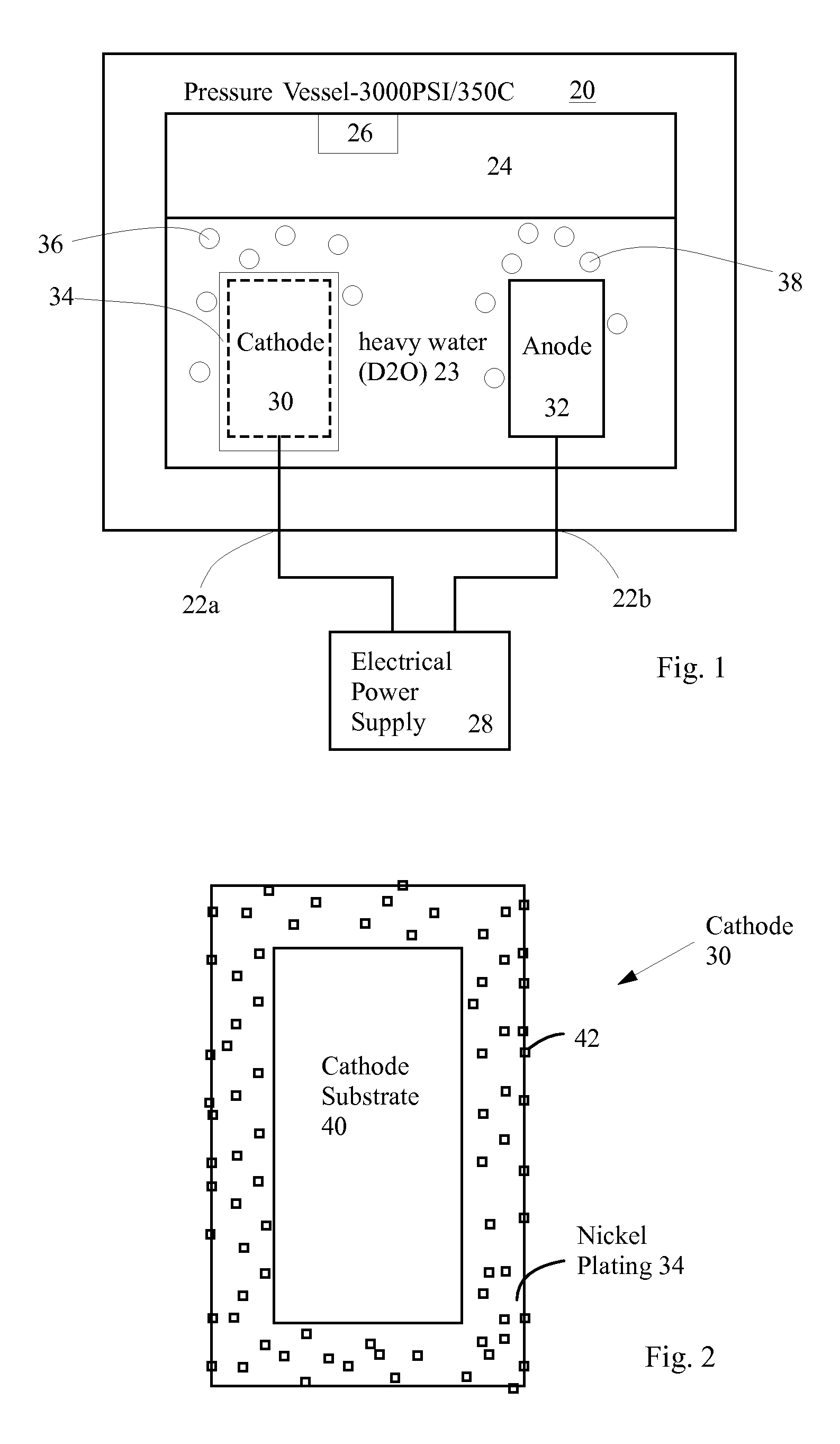

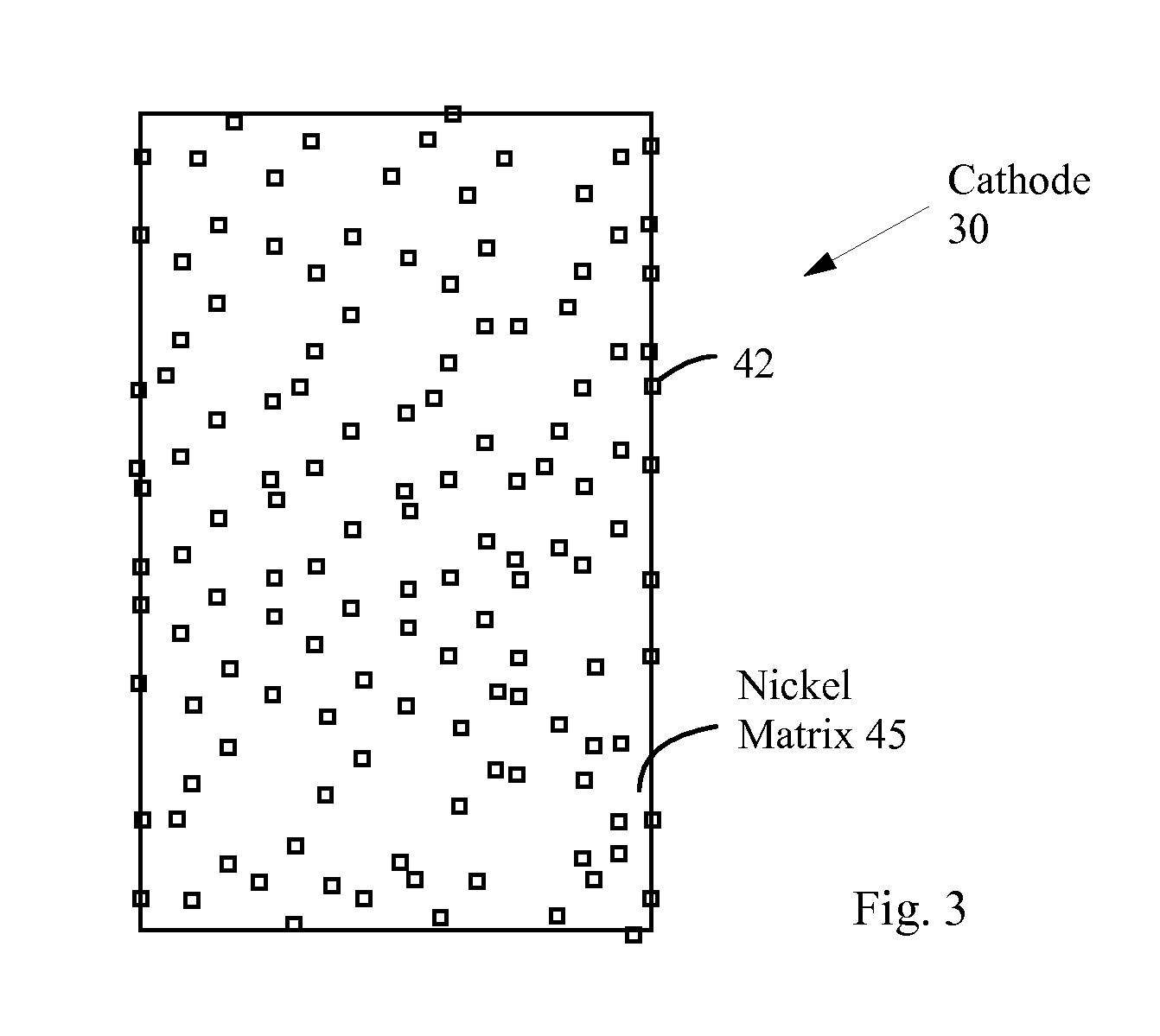

Apparatus and Method for Low Energy Nuclear Reactions

InactiveUS20130044847A1Weaken energyIncrease loadNuclear energy generationDirect voltage acceleratorsNiobiumNuclear reaction

Provided are a method and apparatus for low energy nuclear reactions in hydrogen-loaded metals. A nickel cathode is disposed inside a pressure vessel loaded with heavy water. The vessel is heated to a temperature at which nickel oxide is reduced in the presence of hydrogen. The cathode is electrified, thereby producing hydrogen at the cathode, which removes any oxide layer on the nickel. The nickel can therefore more easily be loaded with hydrogen. The nickel cathode preferably has embedded particles of neutron-absorbing and / or hydrogen absorbing materials, such as boron-10, lithium-containing compounds, palladium, niobium, vanadium, or other hydrogen storage intermetallic compounds, alloys, or amorphous alloys.

Owner:STEINBERG DAN

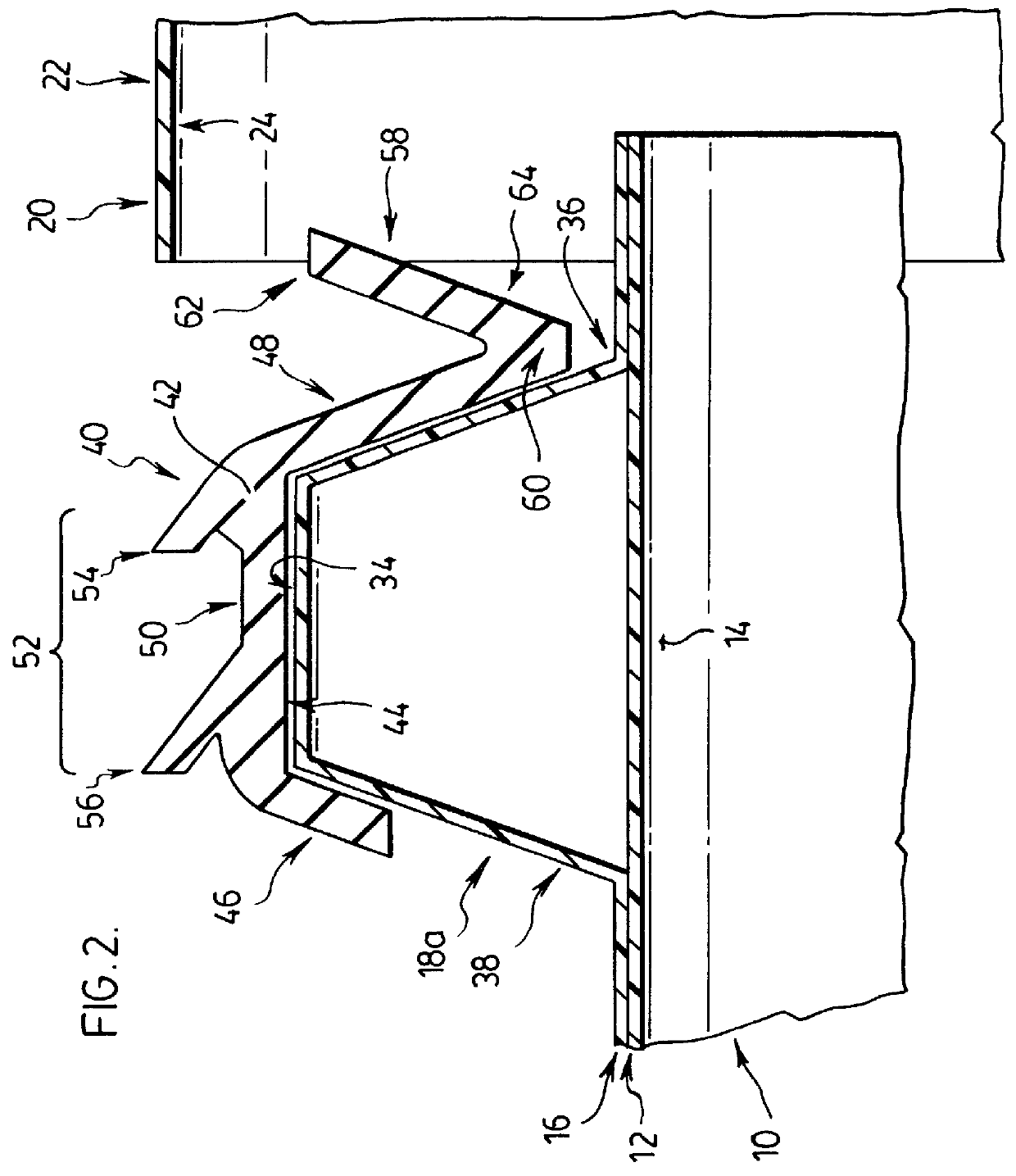

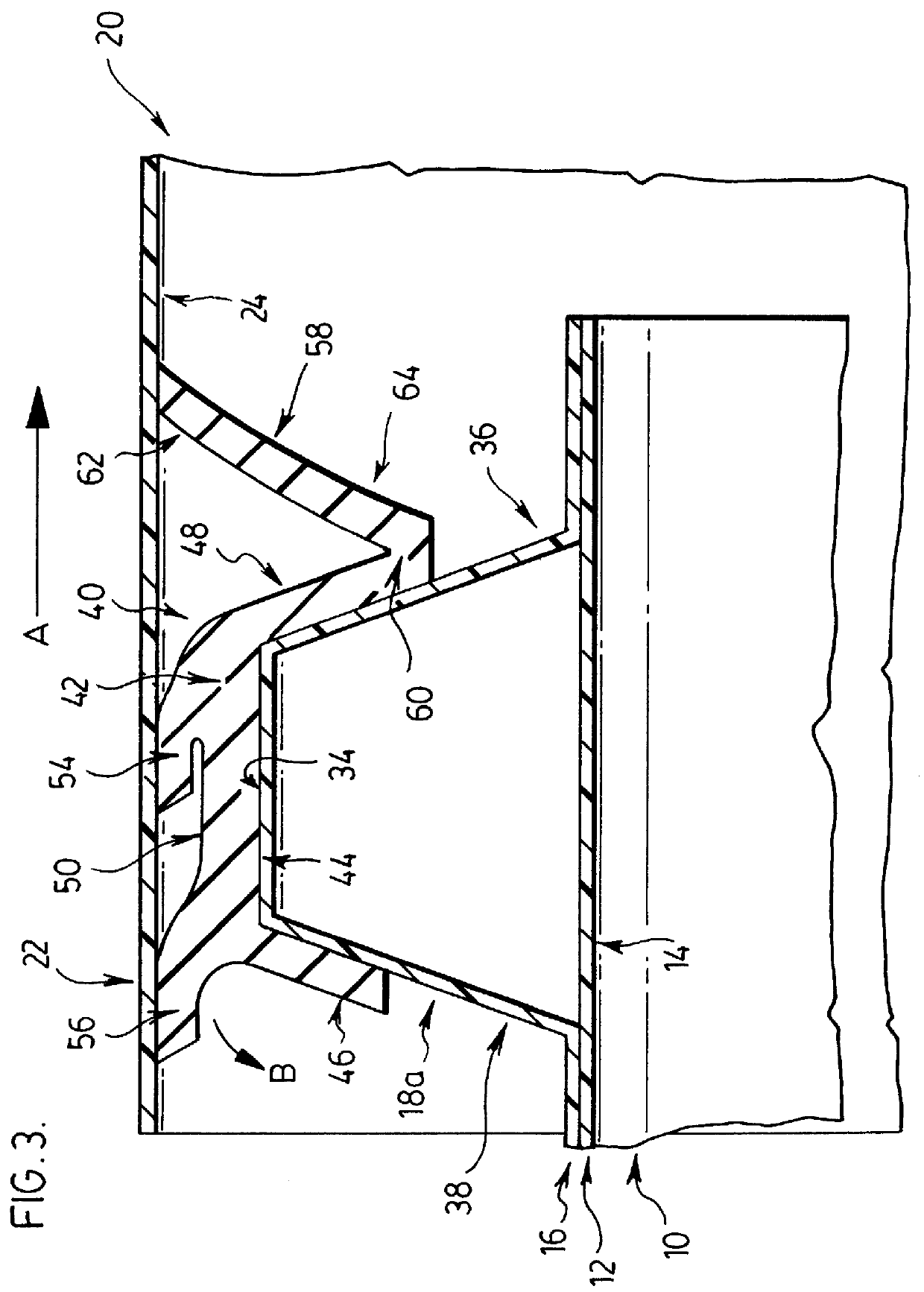

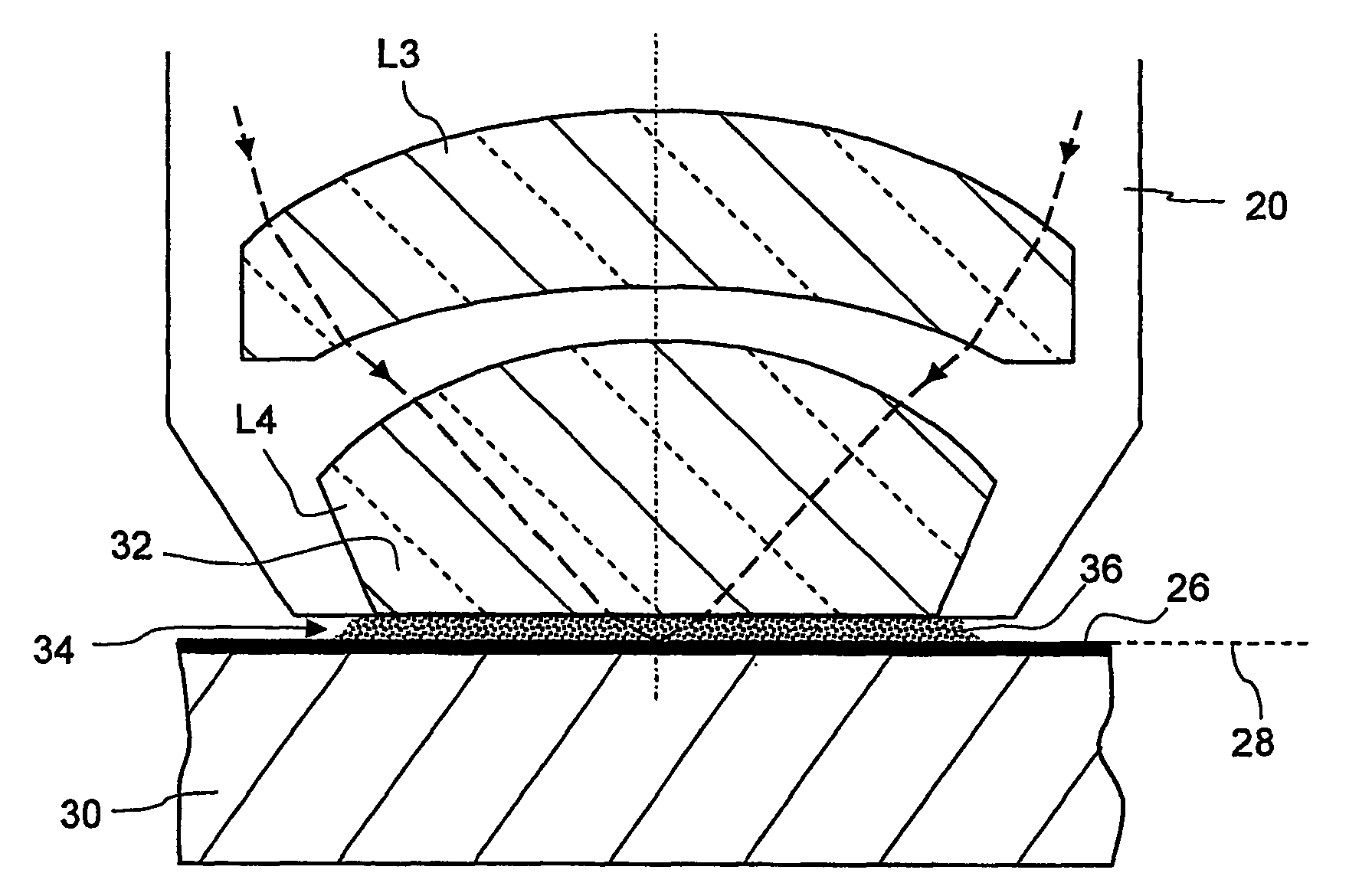

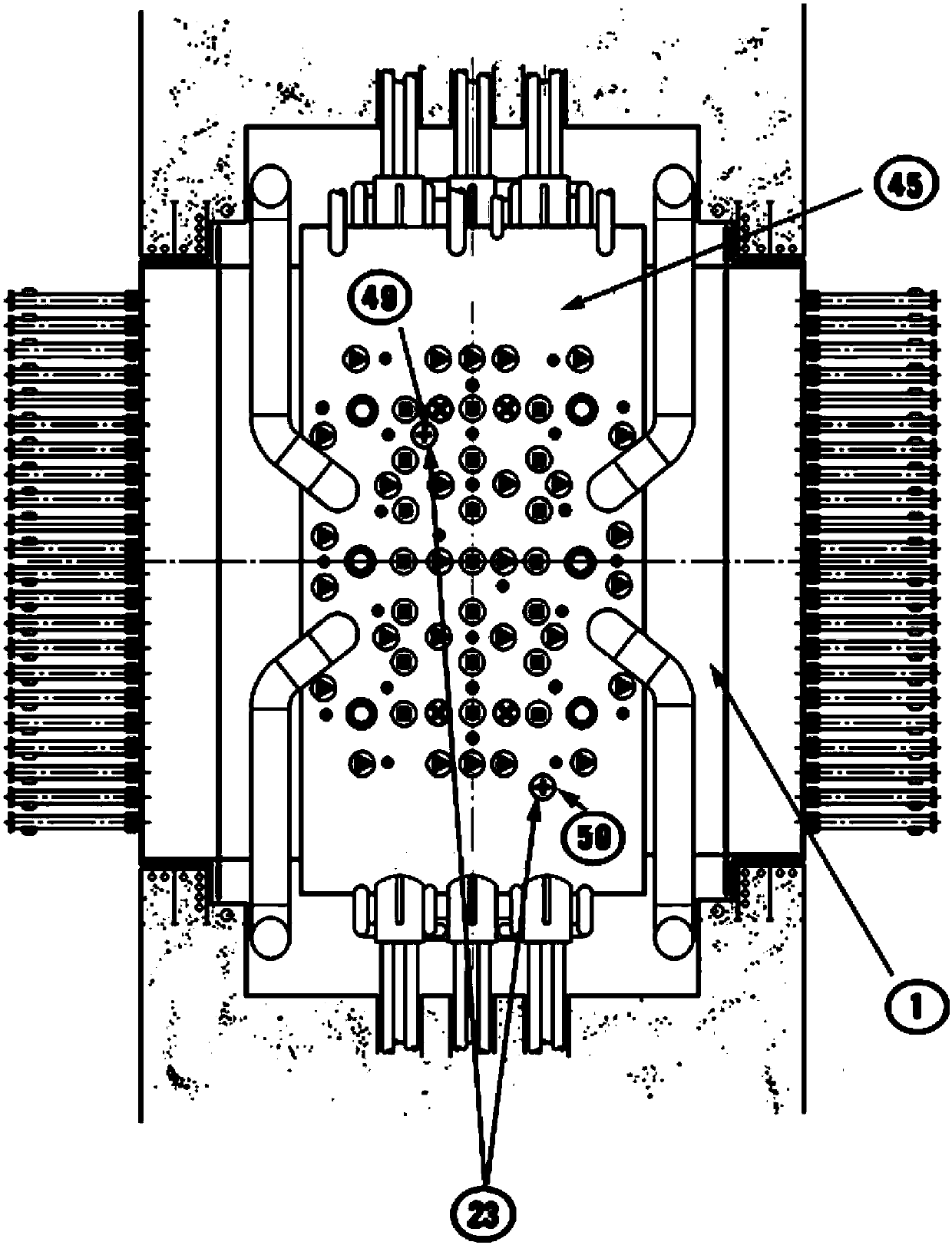

Method of producing radioisotopes using a heavy water type nuclear power plant

A method of producing radioisotopes using a heavy water type nuclear power plant is provided. The method includes inserting targets (37) into a heavy water moderator of the heavy water reactor througha guide tube (30) in a port (55) in a reactivity mechanism deck (45) of the heavy water reactor. The heavy water reactor operates to irradiate the target to convert the target into a radioisotope. The method then includes removing the radioisotope from the moderator of the heavy water reactor via the reactivity mechanism deck. A heavy water nuclear reactor is also provided.

Owner:法玛通加拿大有限公司

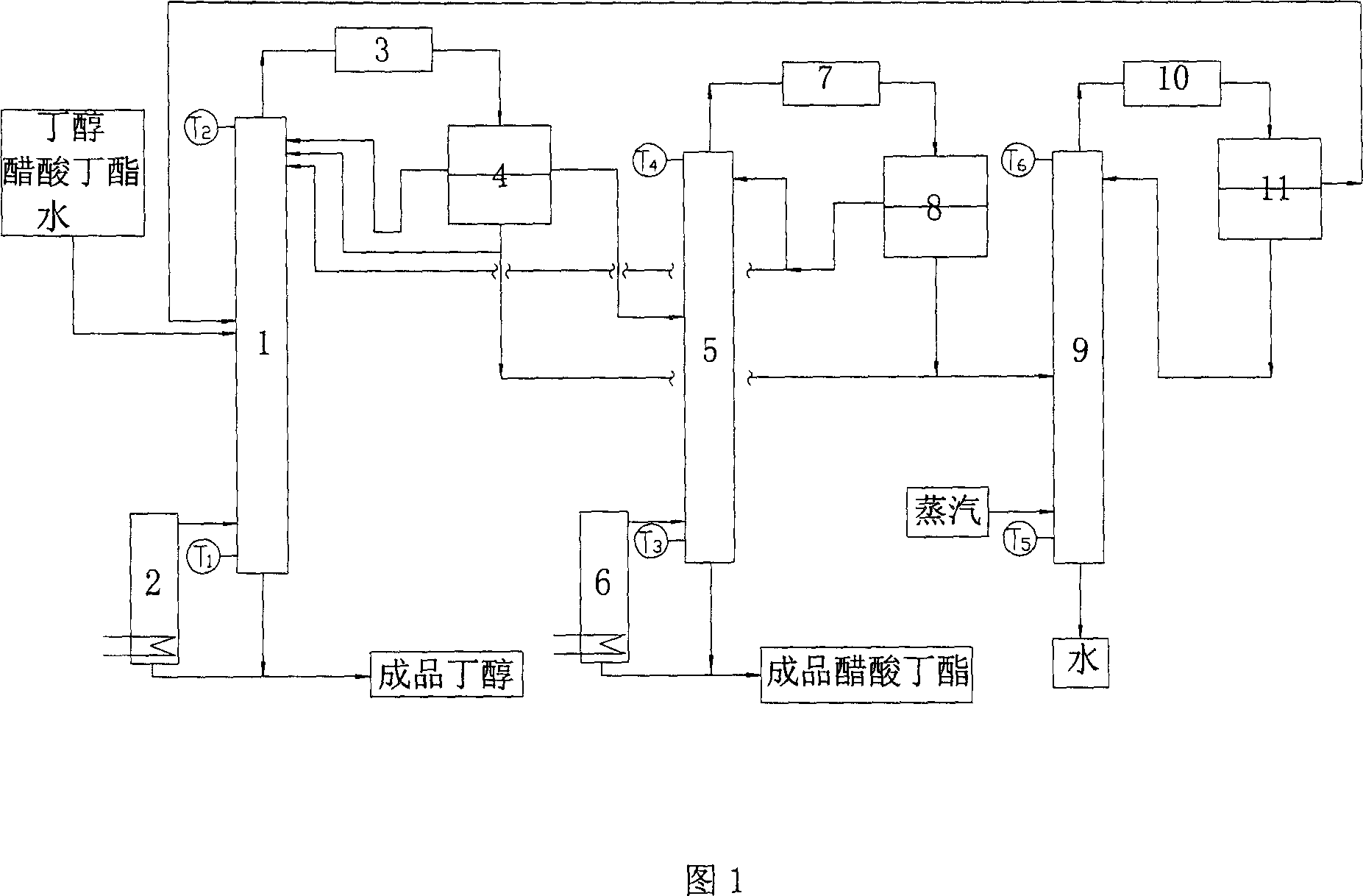

Azeotropic distillation process for separating butanol and butyl acetate

InactiveCN1974529AAvoid lostReduce sewageOrganic compound preparationCarboxylic acid esters preparationPhase splittingReboiler

The present invention relates to azeotopic distillation process for separating butanol and butyl acetate. The technological process is completed with the apparatus including rectification tower (1), rectification tower (5), rectification tower (9), kettle reboiler, condensate cooler and phase splitting tank. The technological process includes feeding the material liquid in the middle part of rectification tower (1) and refluxing partial heavy water phase into the tower; refluxing light phase; obtaining butanol product in the kettle; refluxing partial light phase while recovering partially to the rectification tower (5); refluxing partial light phase while obtaining butyl acetate product in rectification tower (5); and feeding the heavy phase to rectification tower (9) and obtaining pure water in the kettle. The present invention has low power consumption, less side products, high butanol product quality, recovery of butyl acetate and high economic effect.

Owner:HEBEI UNIV OF TECH

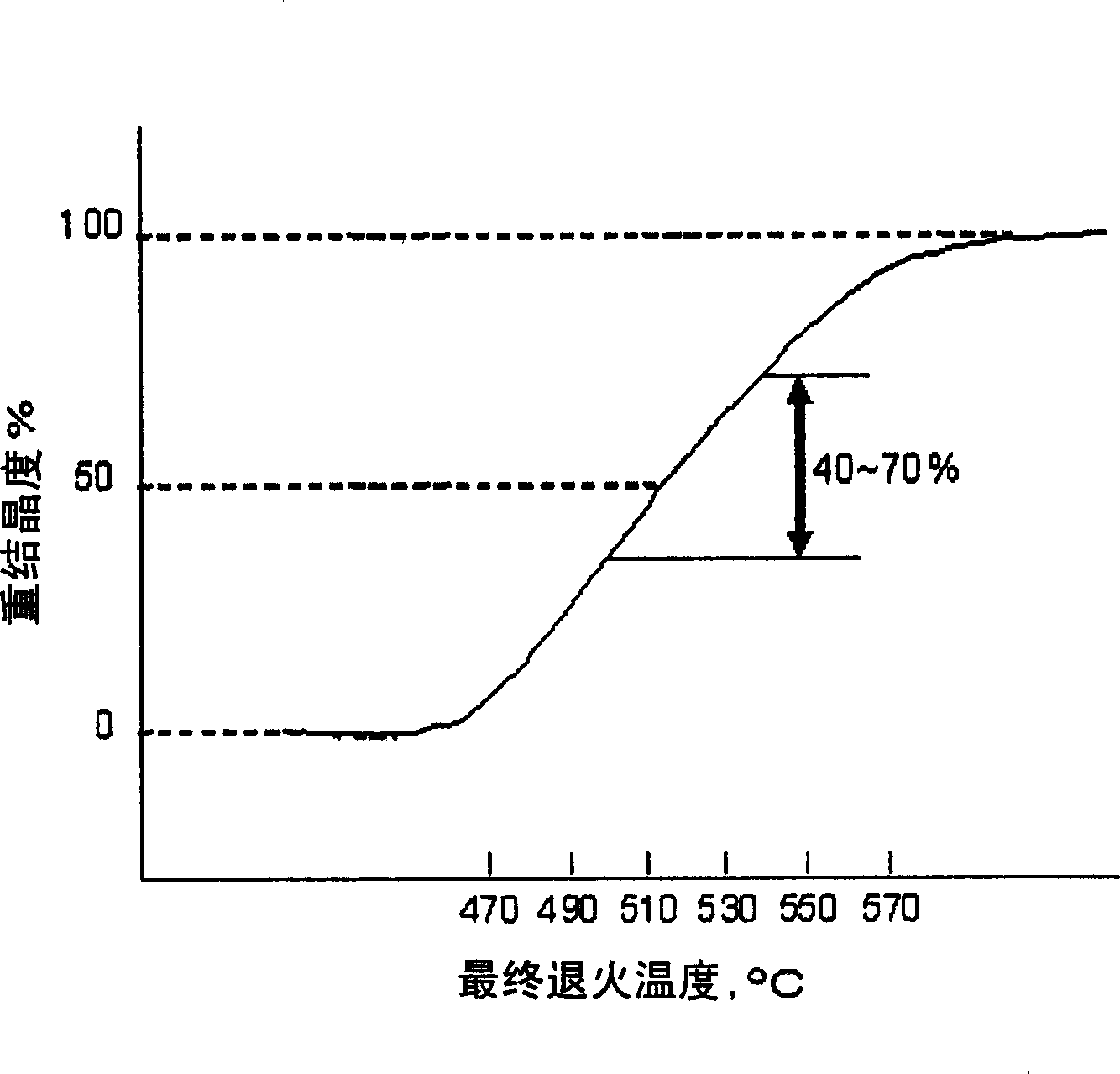

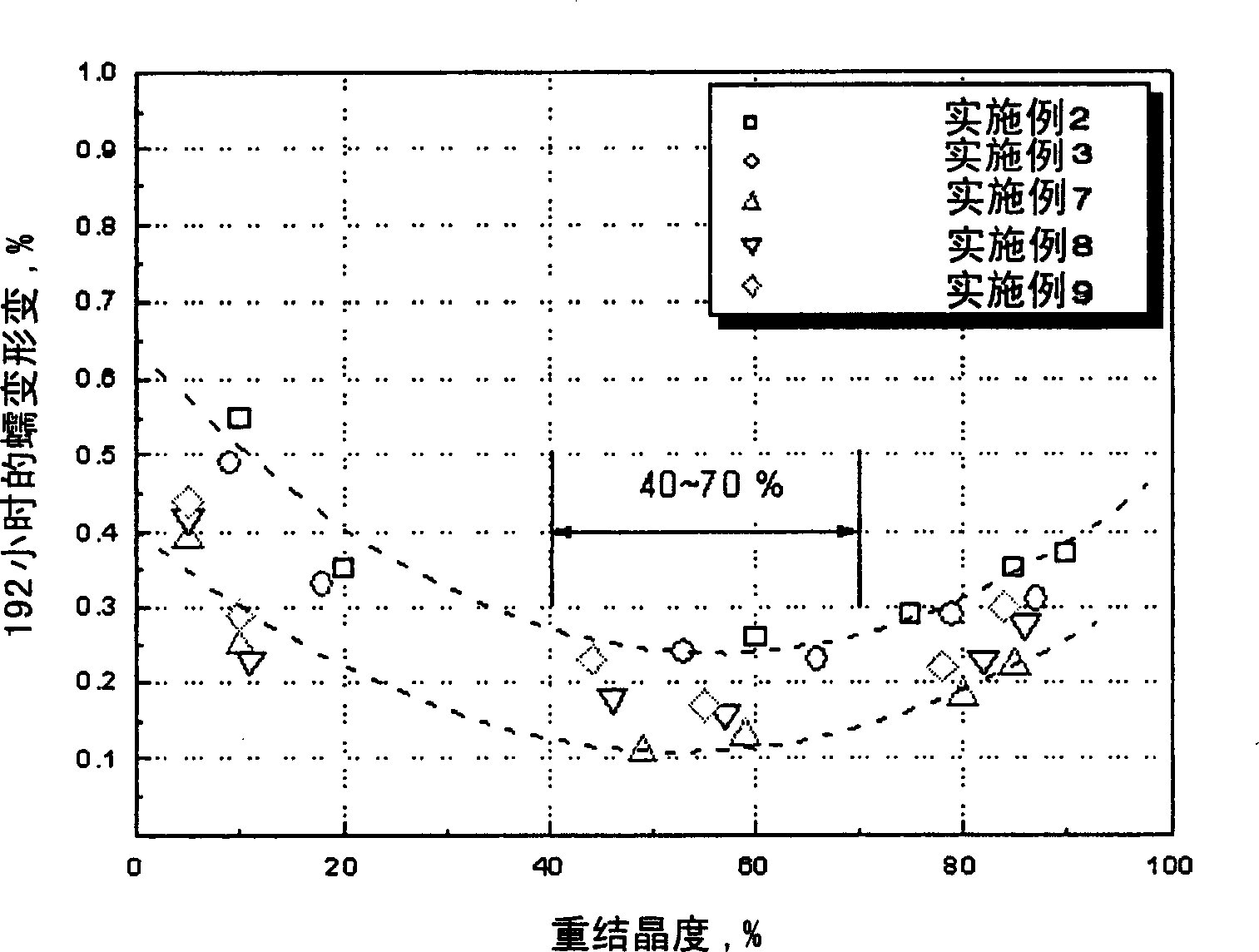

Zirconium based alloys having excellent creep resistance

The present invention relates to a zirconium-based alloy composite material with excellent creep resistance, more specifically, to a zirconium-based alloy that undergoes a final heat treatment to improve the creep resistance so that the degree of recrystallization is 40-70% composite material. The zirconium-based alloy comprises 0.8 to 1.8% by weight of niobium (Nb); 0.38 to 0.50% by weight of tin (Sn); selected from 0.1 to 0.2% by weight of iron (Fe), 0.05 to 0.15% by weight of copper (Cu) and 0.12% by weight of one or more elements in chromium (Cr); 0.10-0.15% by weight of oxygen (O); 0.006-0.010% by weight of carbon (C); 0.006-0.010% by weight of silicon (Si); 0.0005-0.0020% by weight of sulfur (S); and the balance of zirconium (Zr). The zirconium alloy prepared with the composition according to the present invention has excellent creep resistance compared with conventional zirconium alloy-4, and can be effectively used as nuclear coating tubes, support grids in nuclear power plants utilizing light water or heavy water reactors and the internal structure of the reactor core.

Owner:KEPCO NUCLEAR FUEL CO LTD +1

Hydrophilic oleophobic sponge as well as preparation method and application thereof

InactiveCN110028696AIncreased micro-roughnessImprove hydrophilicityLiquid suspension thickening by filtrationCross-linkPolyvinyl alcohol

The invention provides hydrophilic oleophobic sponge as well as a preparation method and application thereof, and belongs to the technical field of preparation of functional materials. The preparationmethod comprises the following steps: mixing a nanoparticle suspension with a modifier solution to obtain a modification solution, wherein the nanoparticle suspension comprises a nano ferroferric oxide suspension with the surface coated with silicon dioxide and / or an ethanol suspension of nano silicon dioxide, and the modifier solution is a chitosan acetic acid aqueous solution and a polyvinyl alcohol aqueous solution; immersing sponge in the modification solution, mixing the sponge with a glutaraldehyde aqueous solution for a cross-linking reaction to obtain the hydrophilic oleophobic sponge. Therefore, the sponge has good oil-water separation performance, and a heavier water layer can be effectively separated from an oil-water mixture of light oil such as lubricating oil, engine oil, pump oil, crude oil, gasoline and sunflower seed oil simply through gravity driving. The prepared hydrophilic oleophobic sponge has a good application prospect in oil-water separation.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

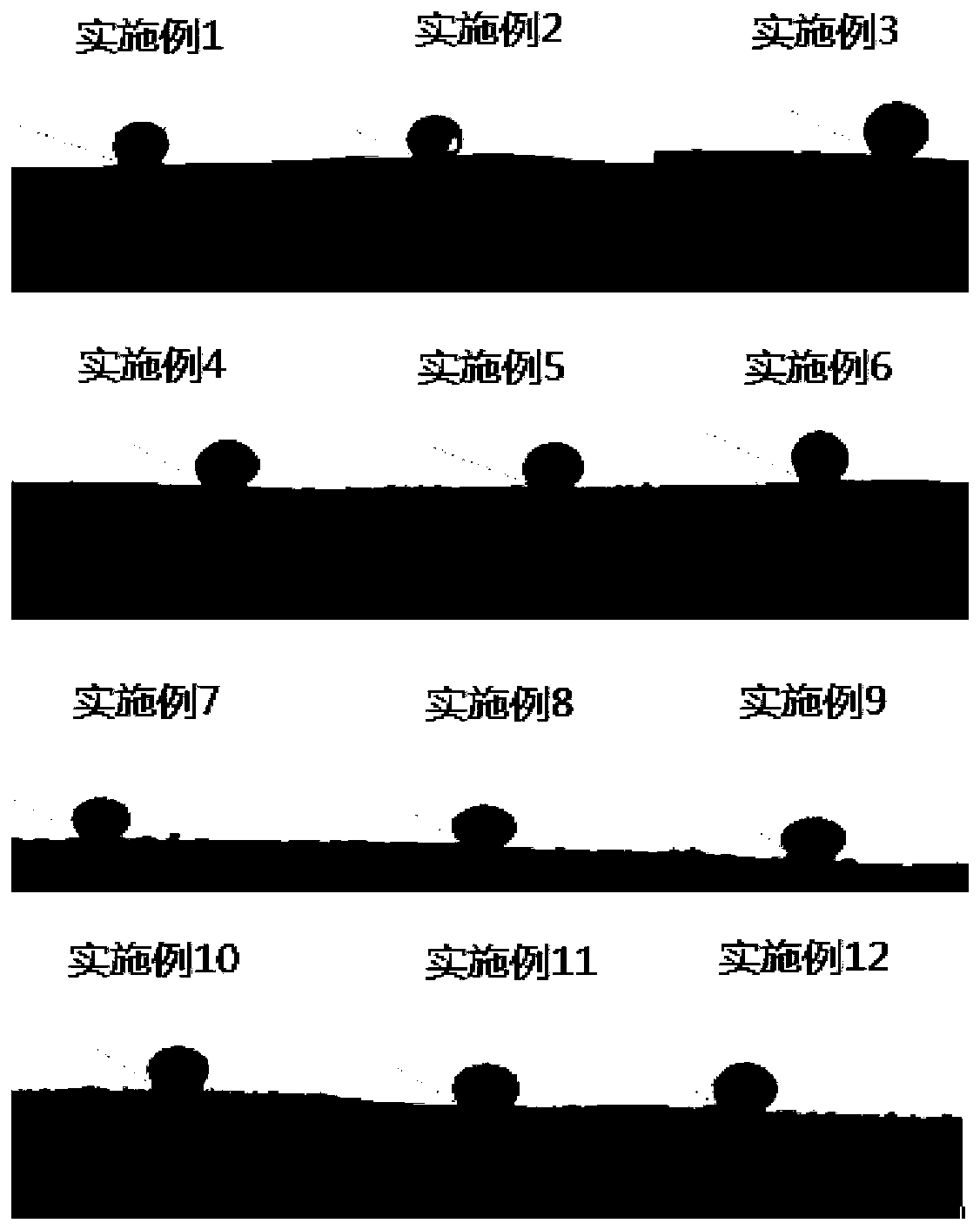

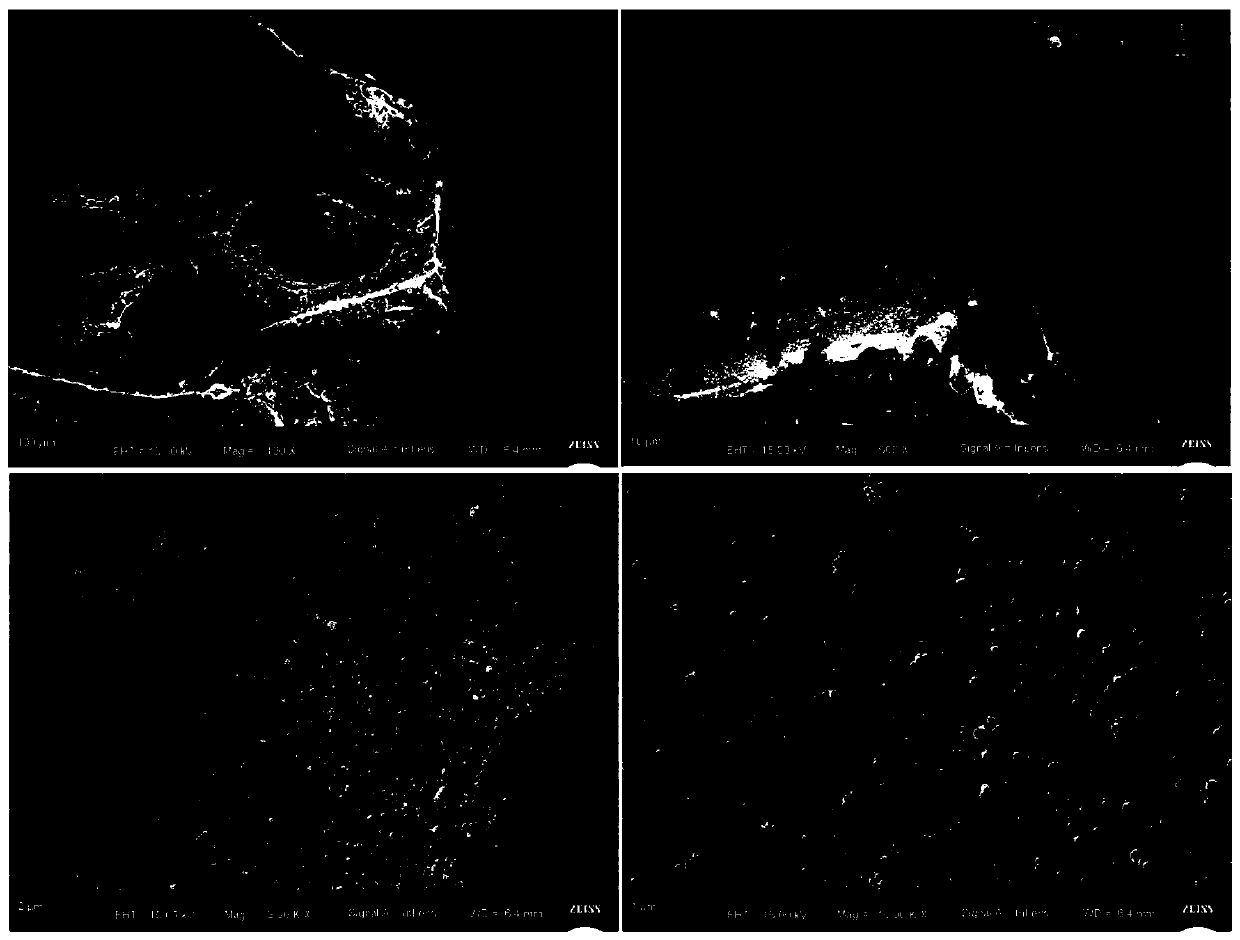

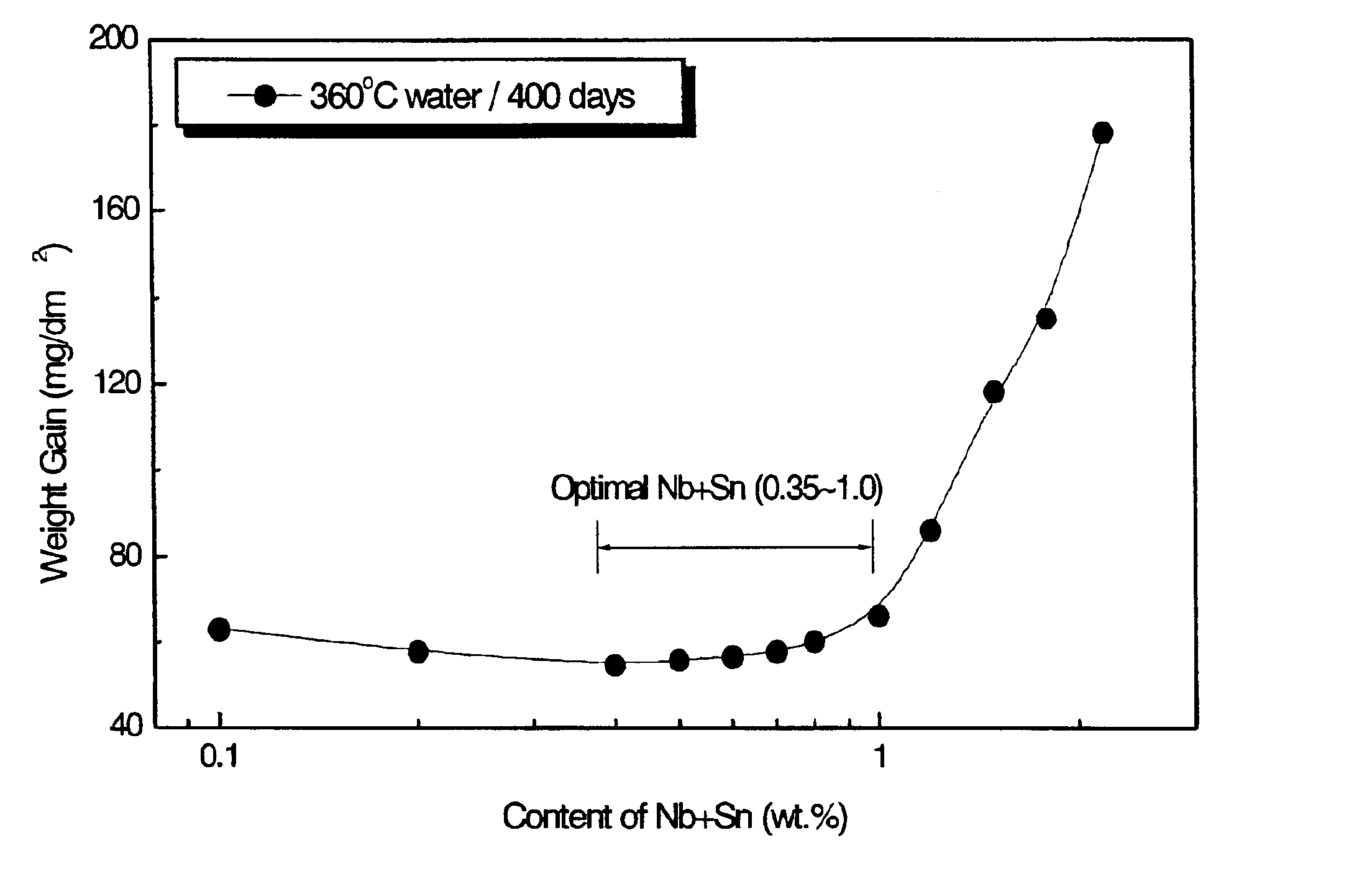

Zirconium alloy having excellent corrosion resistance and mechanical properties for nuclear fuel cladding tube

The present invention relates to a zirconium alloy having excellent corrosion resistance and mechanical properties and a method for preparing a nuclear fuel cladding tube by zirconium alloy. More particulary, the present invention is directed to a zirconium alloy comprising Zr-aNb-bSn-cFe-dCr-eCu (a=0.05-0.4 wt %, b=0.3-0.7 wt %, c=0.1-0.4 wt %, d=0-0.2 wt % and e=0.01-0.2 wt %, provided that Nb+Sn=0.35-1.0 wt %), and to a method for preparing a zirconium alloy nuclear fuel cladding tube, comprising melting a metal mixture comprising of the zirconium and alloying elements to obtain ingot, forging the ingot at beta phase range, beta-quenching the forged ingot at 1015-1075° C., hot-working the quenched ingot at 600-650° C., cold-working the hot-worked ingot in three to five passes, with intermediate vacuum annealing and final vacuum annealing the worked ingot at 460-540° C., which can be applied to the core components in a light water and a heavy water atomic reactor type nuclear power plant.

Owner:KEPCO NUCLEAR FUEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com