Patents

Literature

35results about How to "Increased micro-roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing super hydrophobic film on surface of zinc substrate

InactiveCN102407220ASimple methodLow costPretreated surfacesMetallic material coating processesPolymer scienceHydroxystearic Acid

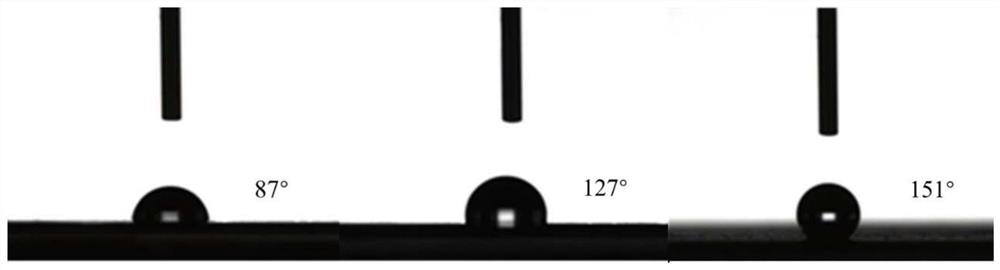

The invention provides a method for preparing a super hydrophobic film on the surface of a zinc substrate, which belongs to the technical field of a functional material. The method comprises the following steps of: ultrasonically washing a zinc sheet substrate, blow-drying by nitrogen gas, oxidizing by formamide water solution, and forming a rod-like nanometer zinc oxide array on the surface of a zinc sheet; and modifying by low surface energy substances, namely, stearic acid, 12-hydroxystearic acid and normal dodecyl mercaptan, and forming the super hydrophobic film with high static contact angle and low roll angle on the surface of the zinc sheet substrate. The super hydrophobic film may not be changed after being placed in the air for long time due to better stability and can be used for preventing water, resisting frost, preventing snow and resisting metal corrosion due to better acid and alkali resistance.

Owner:NORTHWEST NORMAL UNIVERSITY

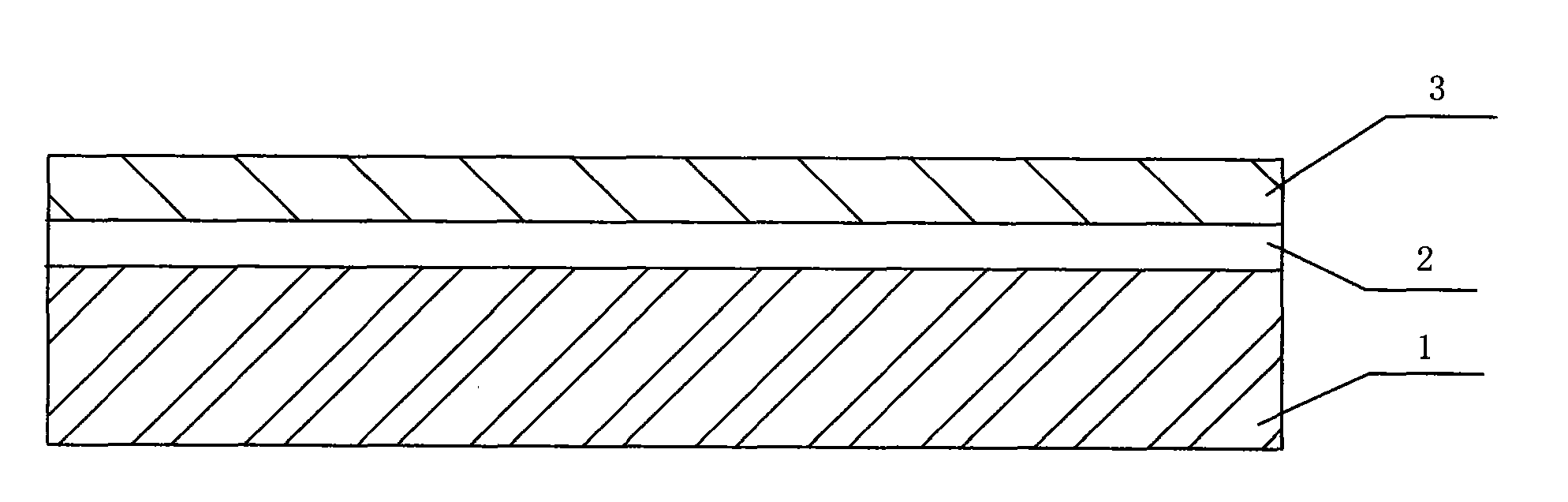

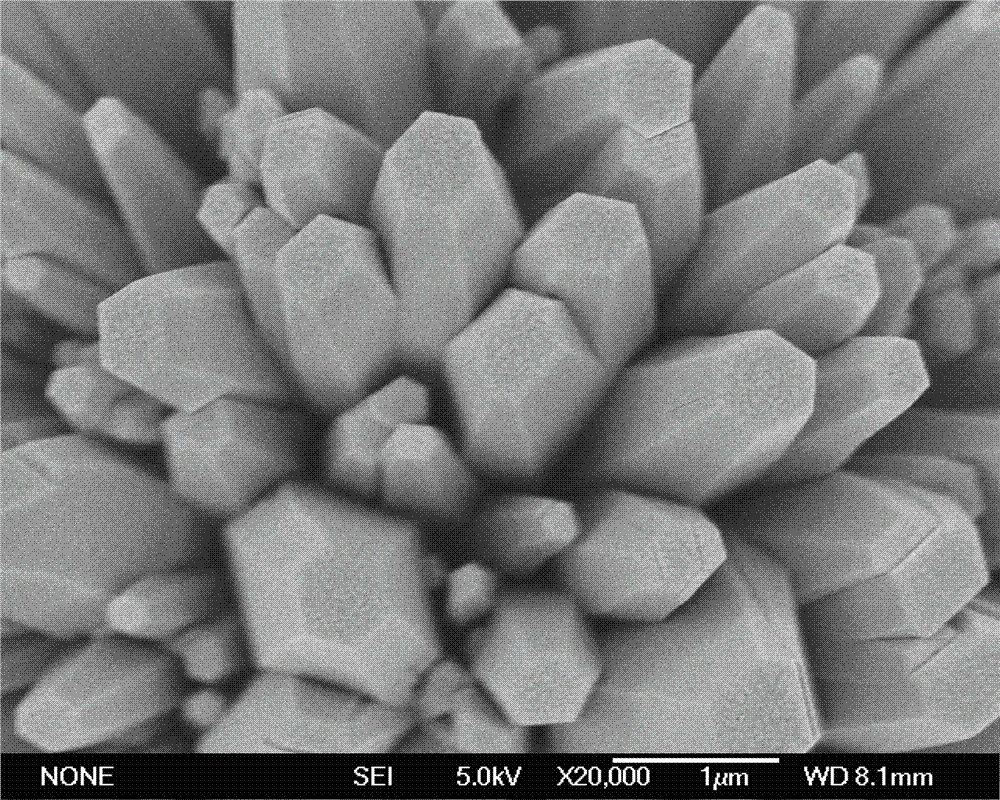

Electrodeposition preparation method for biomedical titanium base hydroxyapatite composite material

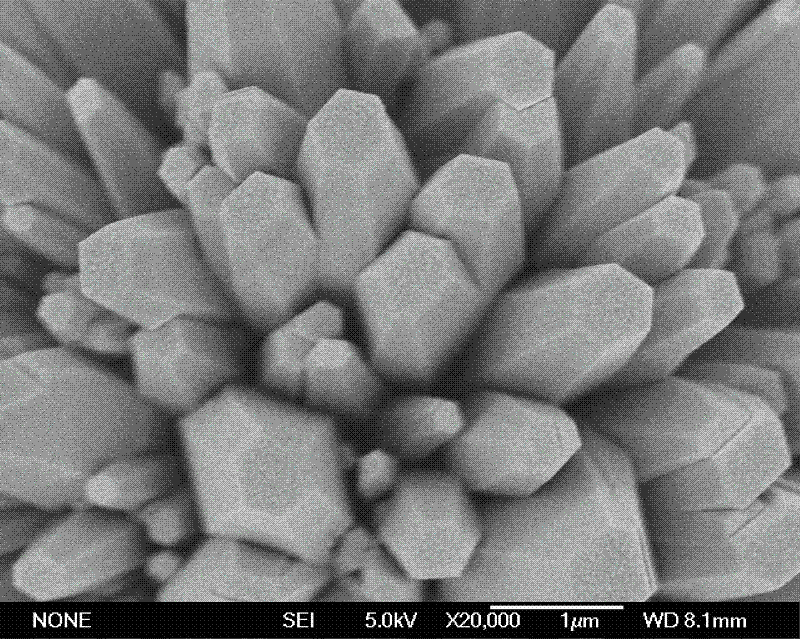

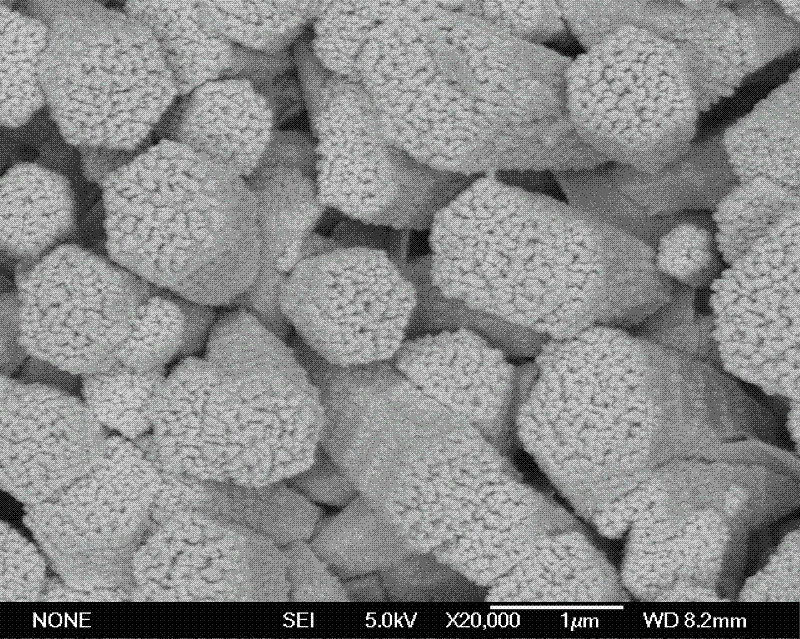

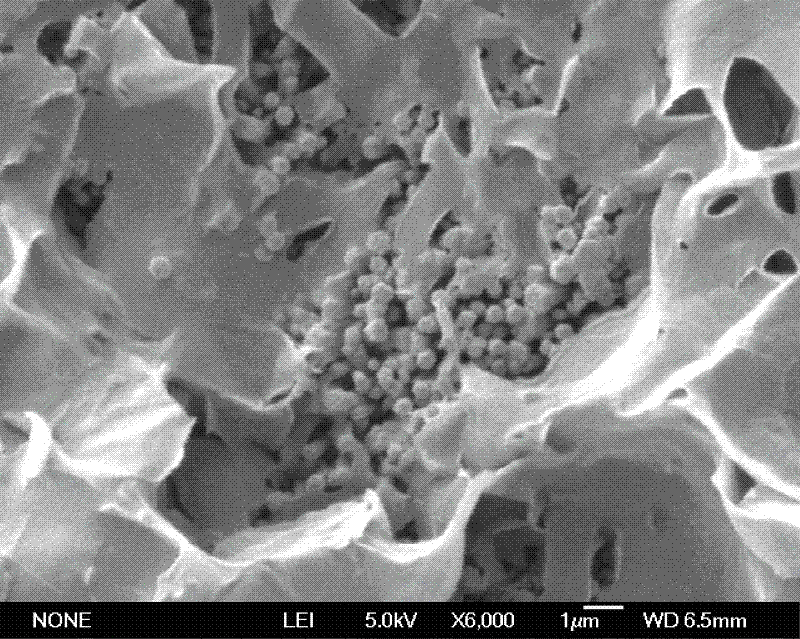

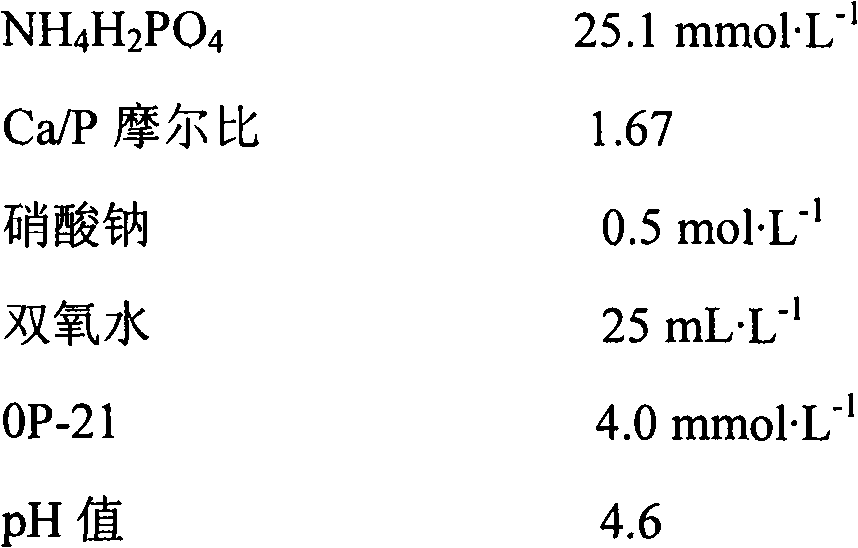

InactiveCN103014801ASimple operation processEasy to controlElectrolytic inorganic material coatingSupporting electrolyteApatite

The present invention discloses a preparation method for electrodeposition of a hydroxyapatite coating on the surface of titanium or a titanium alloy. The method comprises: adopting a pretreated titanium substrate or a pretreated titanium alloy substrate as a cathode, adopting a platinum-plated titanium mesh as an anode, heating an electroplating solution to a constant temperature of 40-80 DEG C, and adopting a constant current manner or a constant potential manner under a magnetic stirring condition to carry out electrodeposition, wherein a current density is 1.0-50.0 mA.cm<-2>, a deposition potential is 1.0-10.0 V, the electroplating solution comprises 20.2-80.0 mmol.L<-1> of Ca<2+> and 10.0-50.0 mmol.L<-1> of H2PO4<->, a Ca / P molar ratio is 1.6-2.0, a supporting electrolyte concentration is 0.1-1.0 mol.L<-1>, and the pH value is 4.2-5.0. According to the present invention, the hydroxyapatite coating prepared through electrodeposition by using the constant current manner or the constant potential manner has characteristics of fine crystal, smooth surface, strong bonding force with the substrate, good biological activity and mechanical property. The preparation method for the titanium base hydroxyapatite composite material has characteristics of mild reaction condition, avoidance of influence on material biological activity by a high temperature treatment, simple process, and low equipment investment, wherein a series of problems caused by expensive equipment and complex operation of the existing method are overcome with the preparation method.

Owner:TIANJIN XUANZHEN BIOMEDICAL TECH DEV

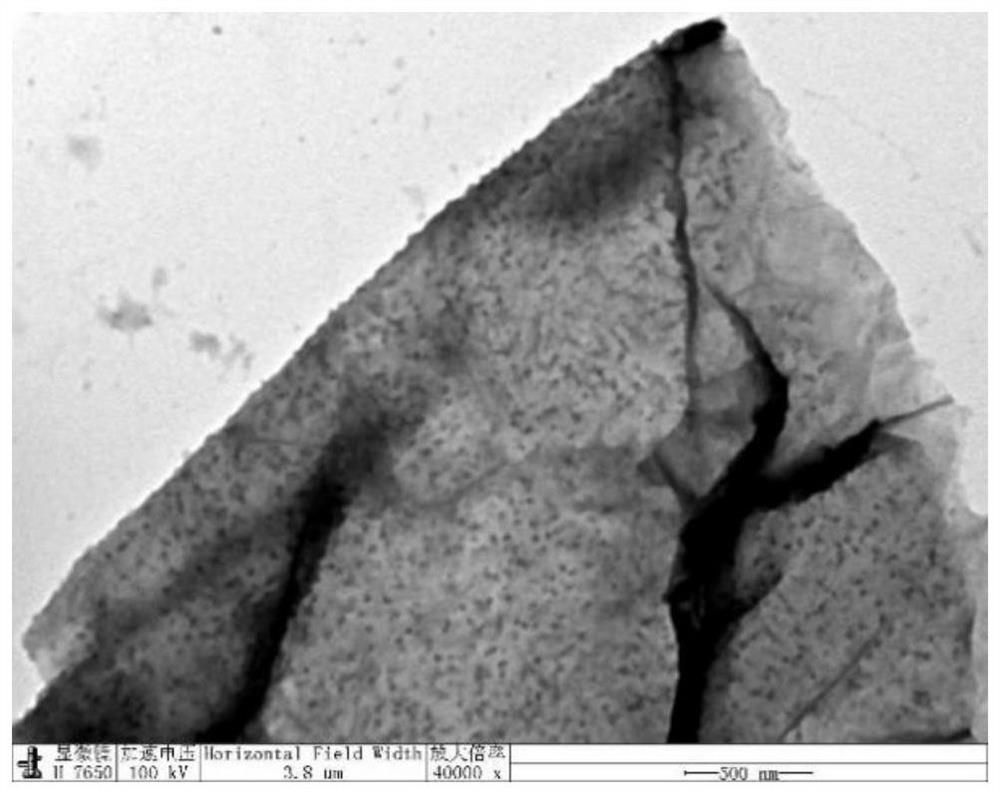

Hydrophilic oleophobic sponge as well as preparation method and application thereof

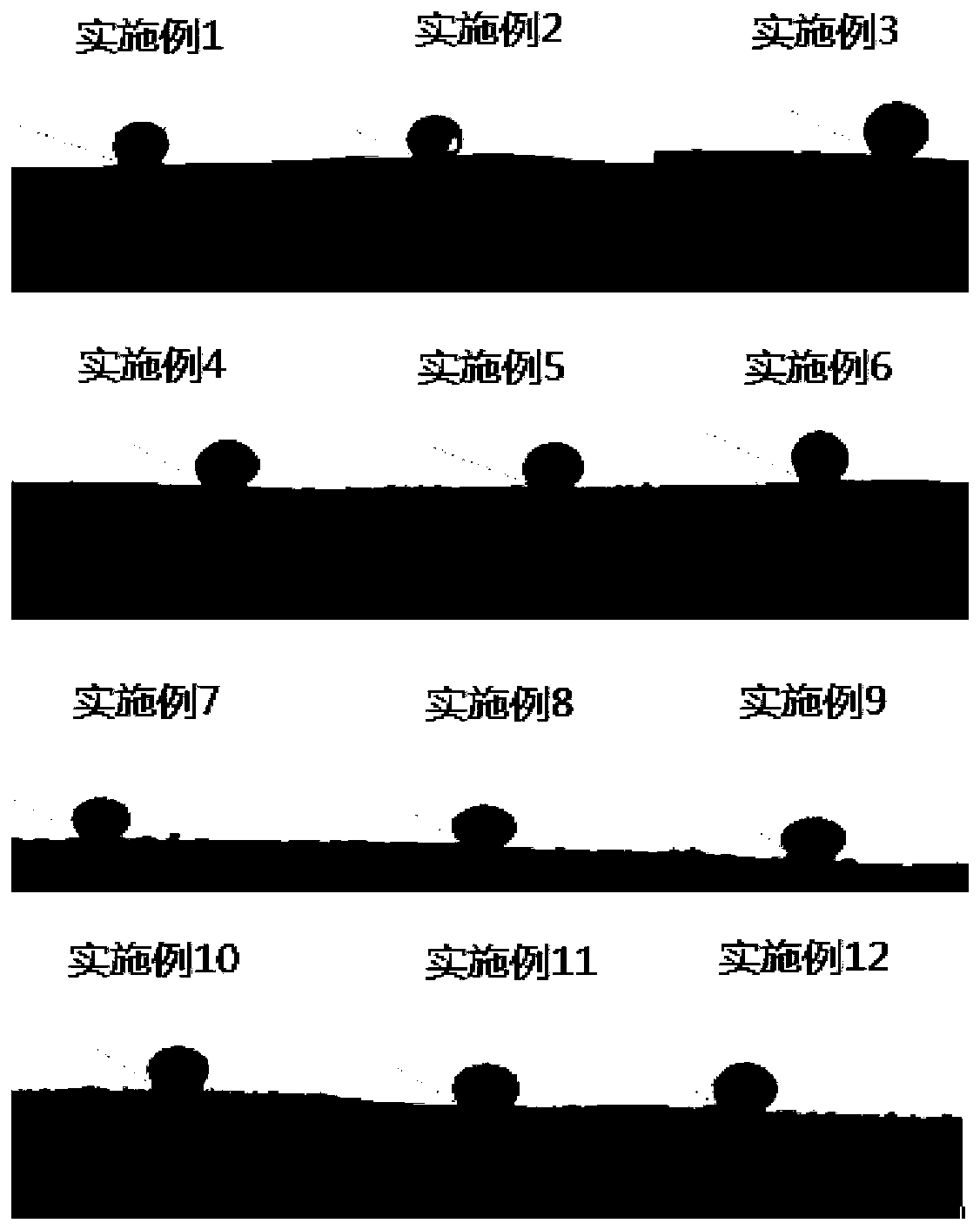

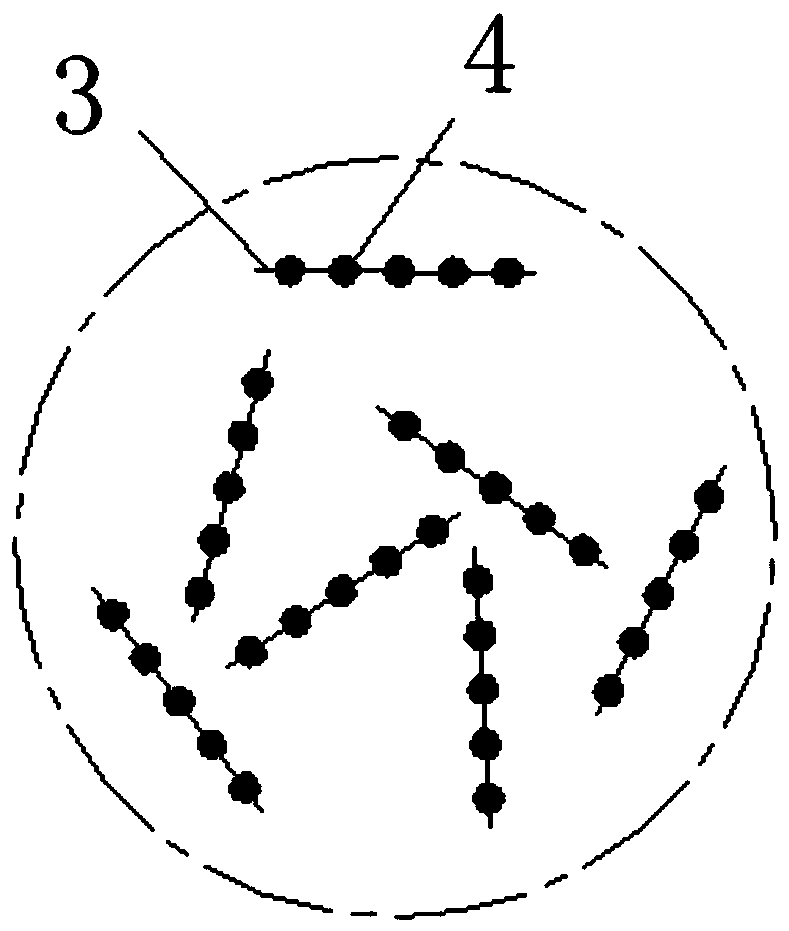

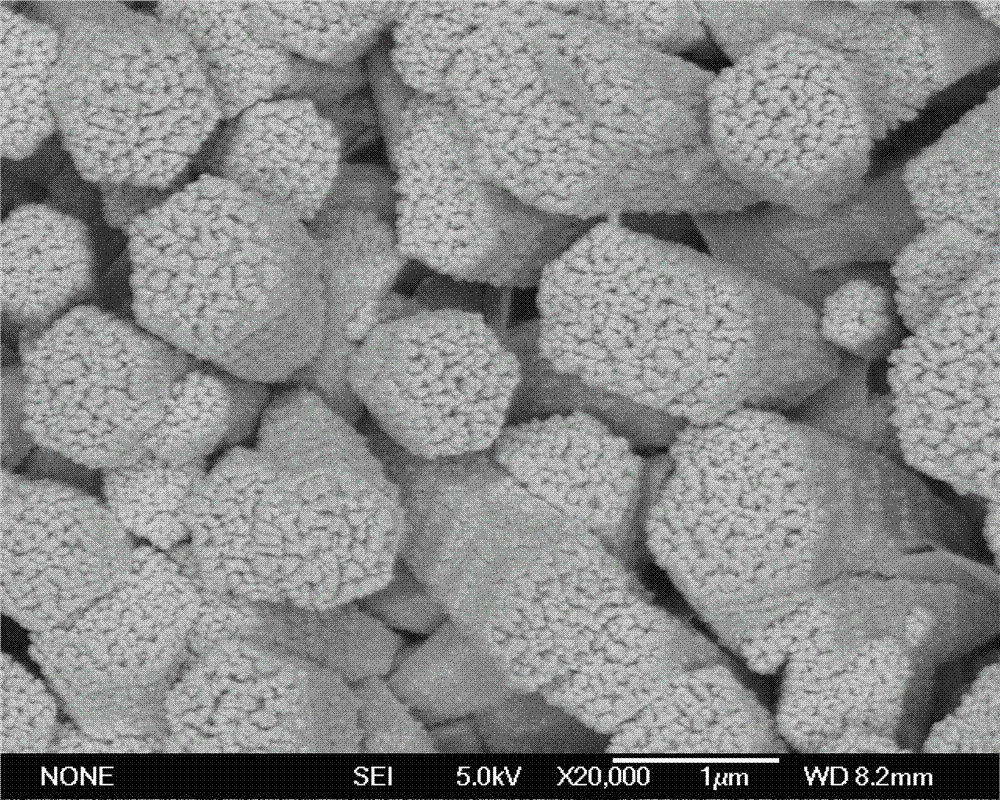

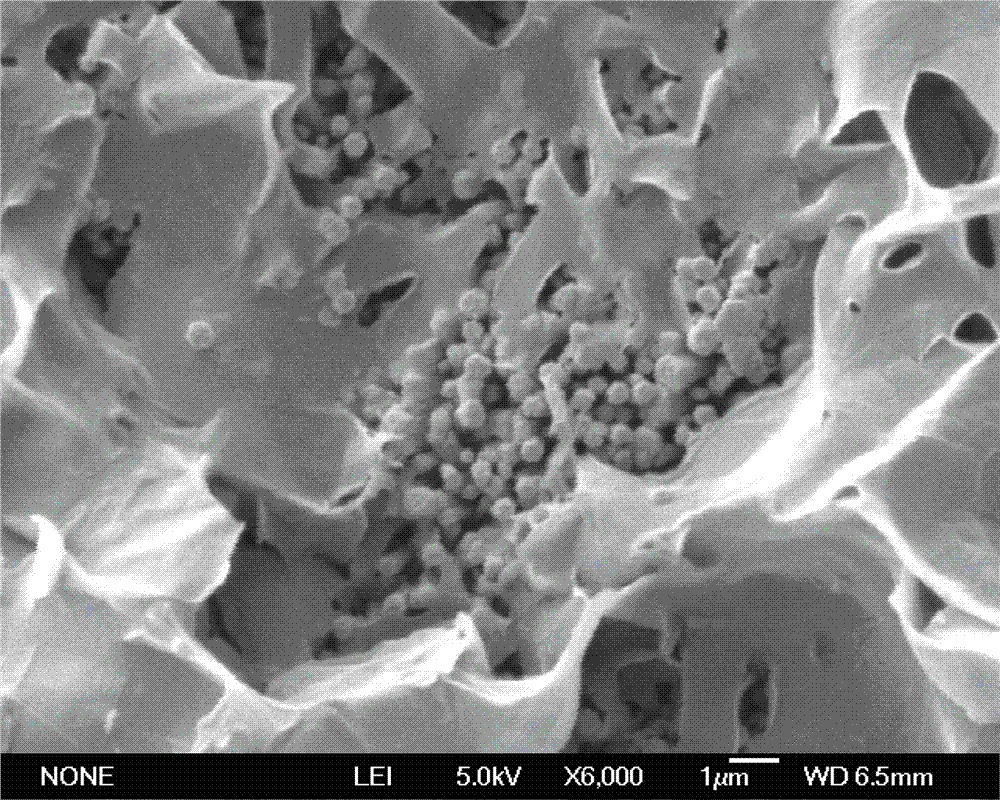

InactiveCN110028696AIncreased micro-roughnessImprove hydrophilicityLiquid suspension thickening by filtrationCross-linkPolyvinyl alcohol

The invention provides hydrophilic oleophobic sponge as well as a preparation method and application thereof, and belongs to the technical field of preparation of functional materials. The preparationmethod comprises the following steps: mixing a nanoparticle suspension with a modifier solution to obtain a modification solution, wherein the nanoparticle suspension comprises a nano ferroferric oxide suspension with the surface coated with silicon dioxide and / or an ethanol suspension of nano silicon dioxide, and the modifier solution is a chitosan acetic acid aqueous solution and a polyvinyl alcohol aqueous solution; immersing sponge in the modification solution, mixing the sponge with a glutaraldehyde aqueous solution for a cross-linking reaction to obtain the hydrophilic oleophobic sponge. Therefore, the sponge has good oil-water separation performance, and a heavier water layer can be effectively separated from an oil-water mixture of light oil such as lubricating oil, engine oil, pump oil, crude oil, gasoline and sunflower seed oil simply through gravity driving. The prepared hydrophilic oleophobic sponge has a good application prospect in oil-water separation.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

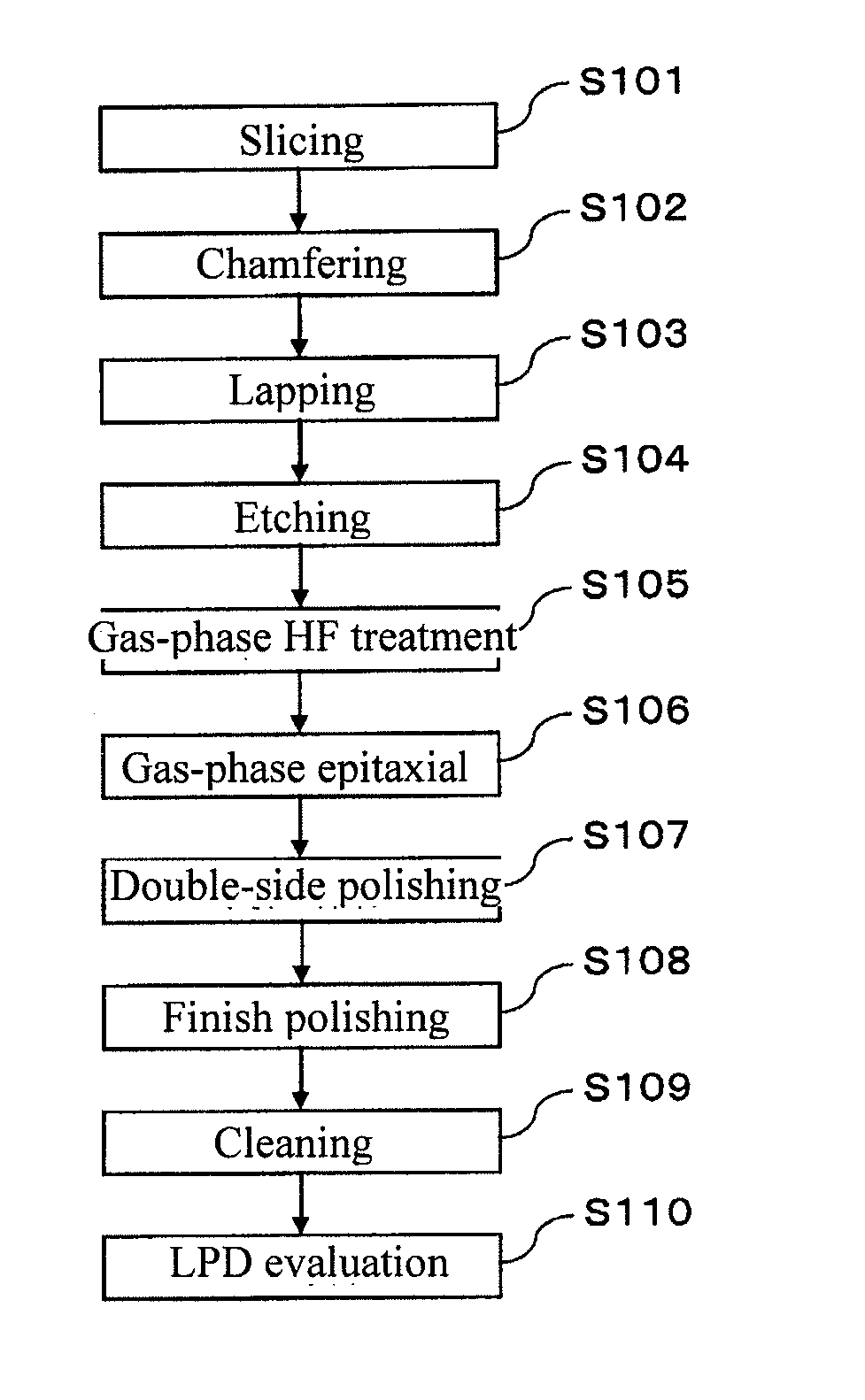

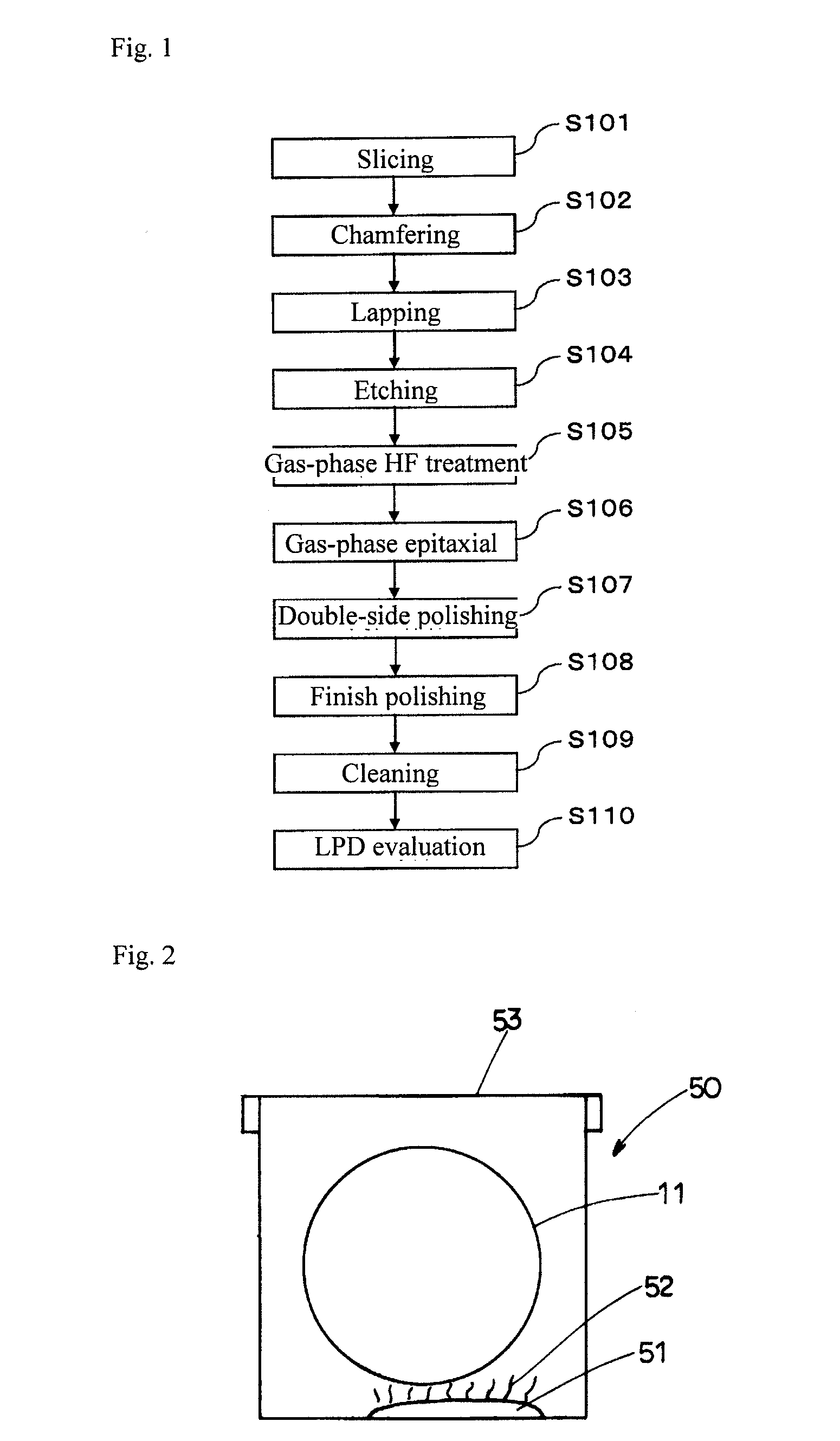

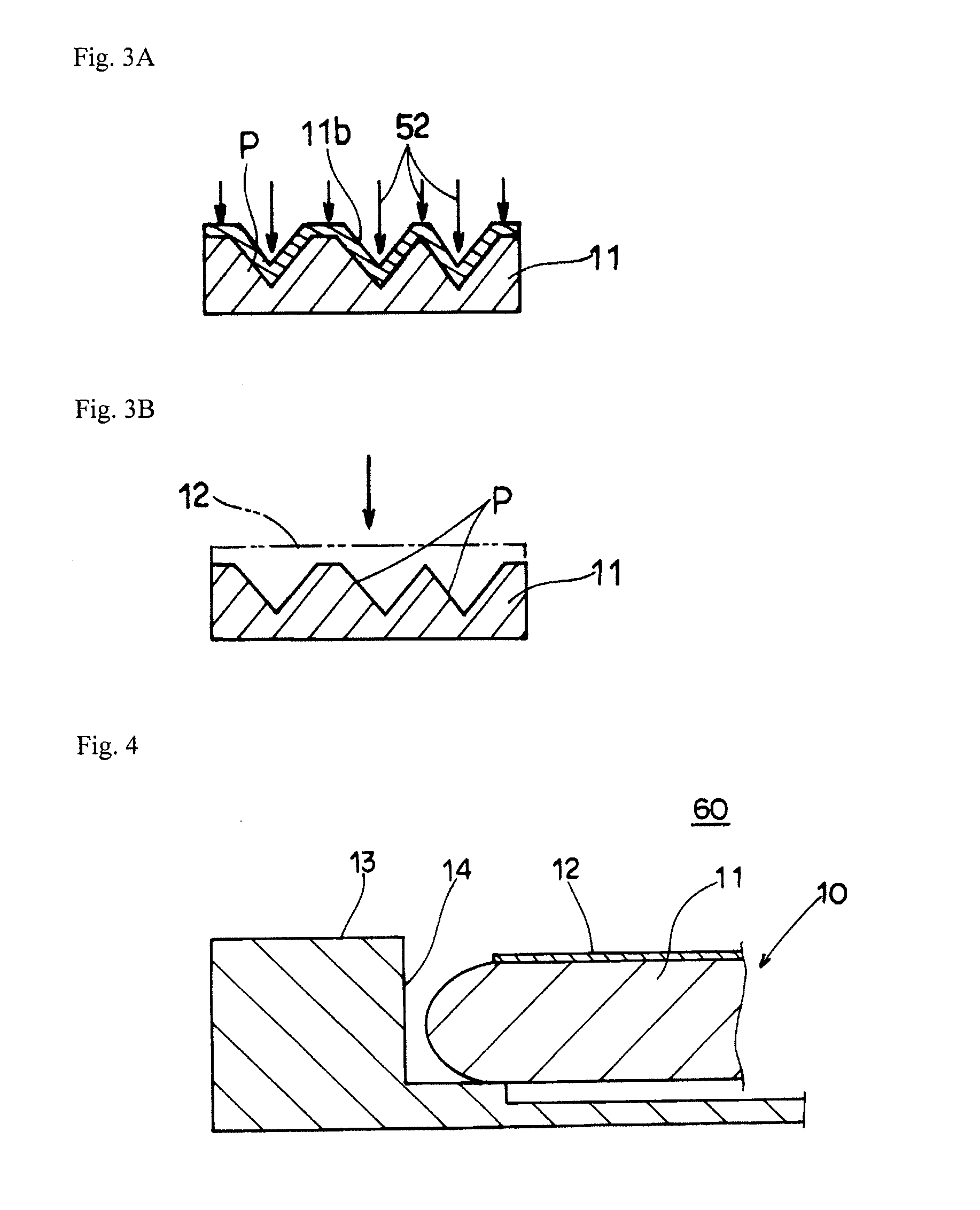

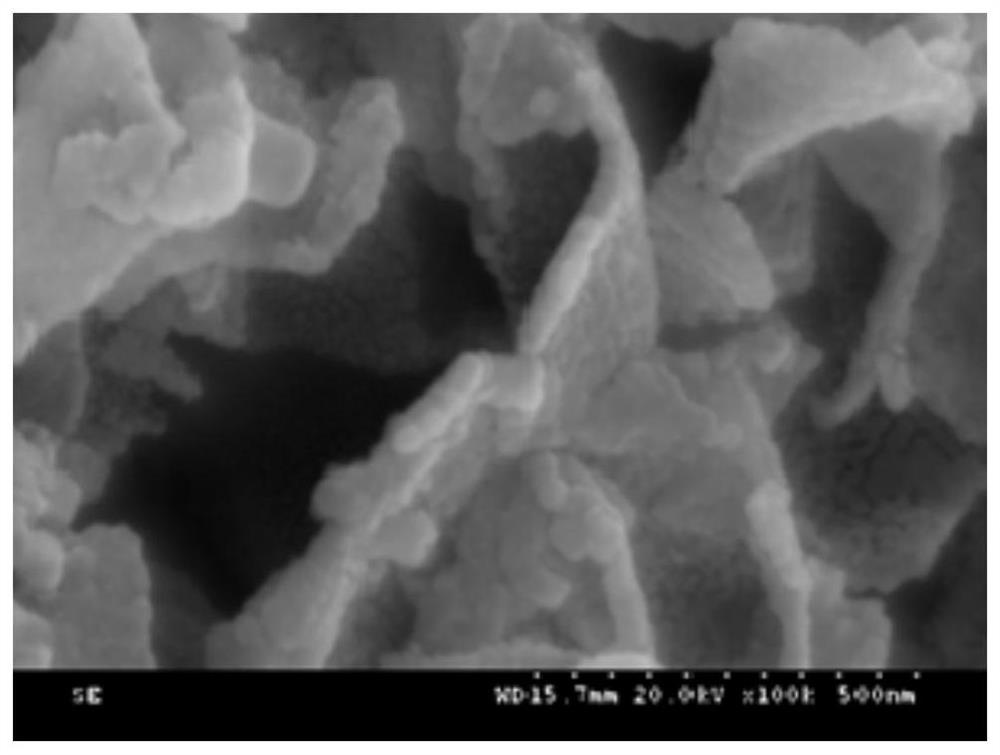

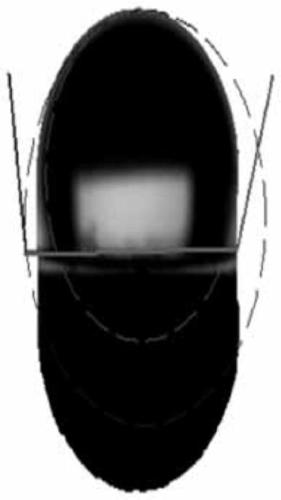

Method for manufacturing epitaxial silicon wafer

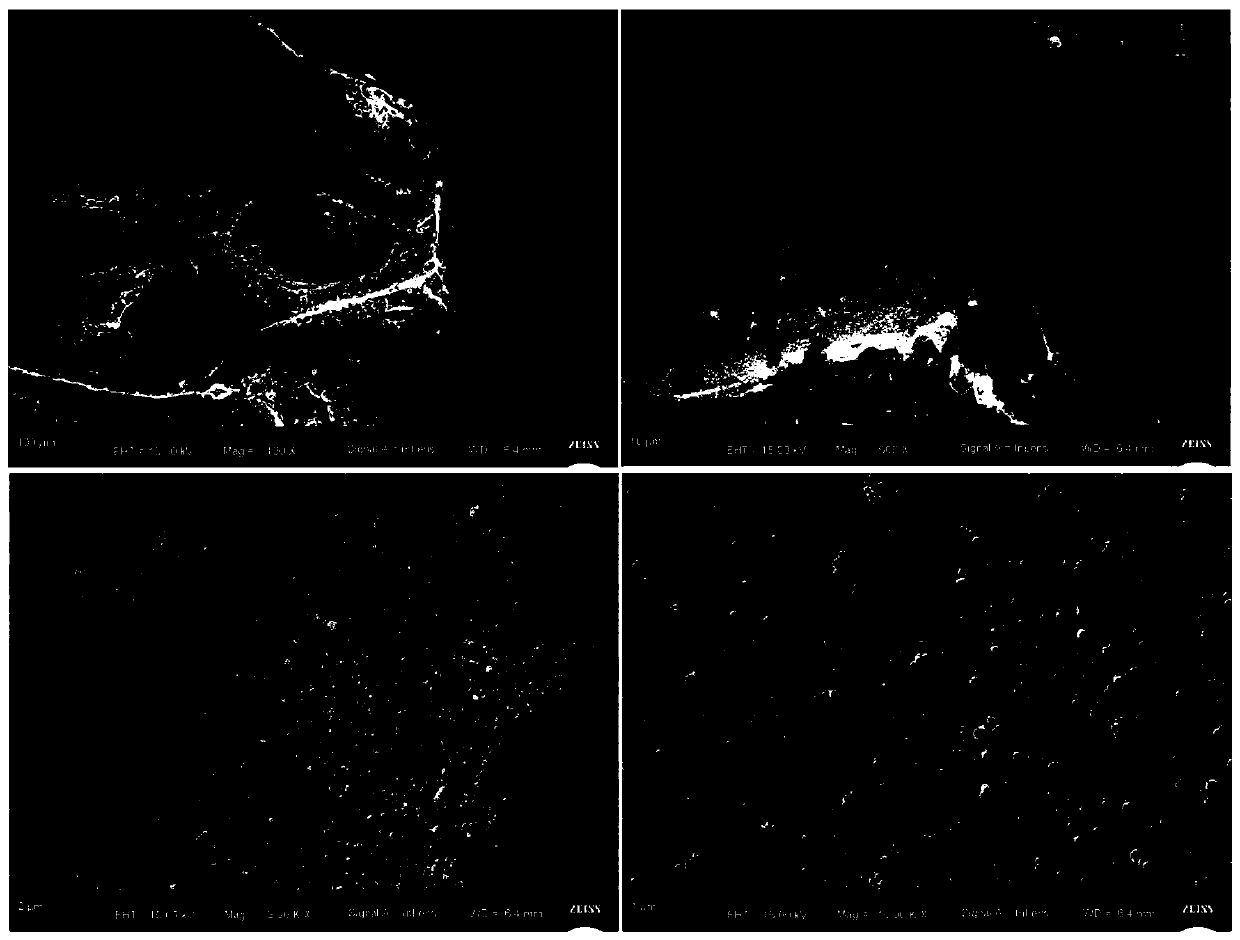

InactiveUS20100288192A1Enhancing wafer flatnessWithout reducing productivityPolycrystalline material growthAfter-treatment detailsProduction rateHydrogen fluoride

A silicon oxide film on a wafer front surface, including on internal surfaces of pits, is removed by hydrogen fluoride gas. The pits are thus completely filled with a film growth component at a time of epitaxial film growth. Thereby, productivity is not reduced; wafer flatness is enhanced; and micro-roughness of the wafer front surface is improved.

Owner:SUMCO CORP

Preparation method of phosphatized polyaniline-silicon dioxide graft modified graphene/waterborne epoxy-group-containing silicon resin composite coating

The invention discloses a preparation method of a phosphatized polyaniline-silicon dioxide graft modified graphene / waterborne epoxy-group-containing silicon resin composite coating, relates to a preparation method of a silicon resin composite anticorrosive coating, and aims to solve the problems of poor dispersibility of modified graphene and polyaniline in polymer resin, complex process and environmental pollution during preparation of the existing composite coating. The method comprises the following steps: anchoring silicon dioxide on the surface of graphene oxide through a covalent bond to prepare a graphene oxide-silicon dioxide composite material, preparing a phosphatized polyaniline-silicon dioxide grafted modified graphene composite material by adopting phytic acid as a modifier, and compounding and curing the phosphatized polyaniline-silicon dioxide grafted modified graphene composite material with epoxy group-containing water-based silicon resin. According to the invention, the dispersibility of graphene and polyaniline is improved, the hydrophobicity of the composite coating is improved, the synergistic effect of graphene and polyaniline is more obvious, and the corrosion resistance of the water-based coating is improved. The preparation method is suitable for preparing the silicon resin composite anticorrosive coating.

Owner:QIQIHAR UNIVERSITY

Environment-friendly type multifunctional nano modified coating and spraying method thereof

InactiveCN104745025AImprove stabilityImprove sustainabilityLiquid surface applicatorsCoatingsAcrylic resinUltraviolet

The invention relates to environment-friendly type multifunctional nano modified coating and a spraying method thereof, which are used for solving the problems that the existing coating is high in cost and not resistant to ageing. The environment-friendly type multifunctional nano modified coating is prepared from the following components in parts by weight: 50-200 parts of nano titanium dioxide particle slurry, 30-100 parts of an acrylic resin finishing agent, 5-30 parts of a dispersing agent, 10-50 parts of a thickening agent, 5-10 parts of a de-foaming agent and an appropriate amount of water, wherein the nano titanium dioxide particles in the nano titanium dioxide particle slurry are surface-modified anatase titanium dioxide particles with a photocatalysis function and particle diameters of 10nm-50nm. Airflow atomized spraying of the compressed air is as follows: atomizing a paint liquid into mists by virtue of air flow of the compressed air, spraying the mists to the surface of an object, and forming a thin and uniform paint film on the surface of the sprayed object. Such special functions as super-hydrophobicity, ultraviolet ray resistance, bacteria resistance, self-cleaning, air purifying and the like are achieved without affecting the original color and patterns of the substrate, the functionality and the stability of the special functions are still relatively strong after long-term illuminating or multi-time washing, the cost is low, and the ageing resistance is excellent.

Owner:赵杰

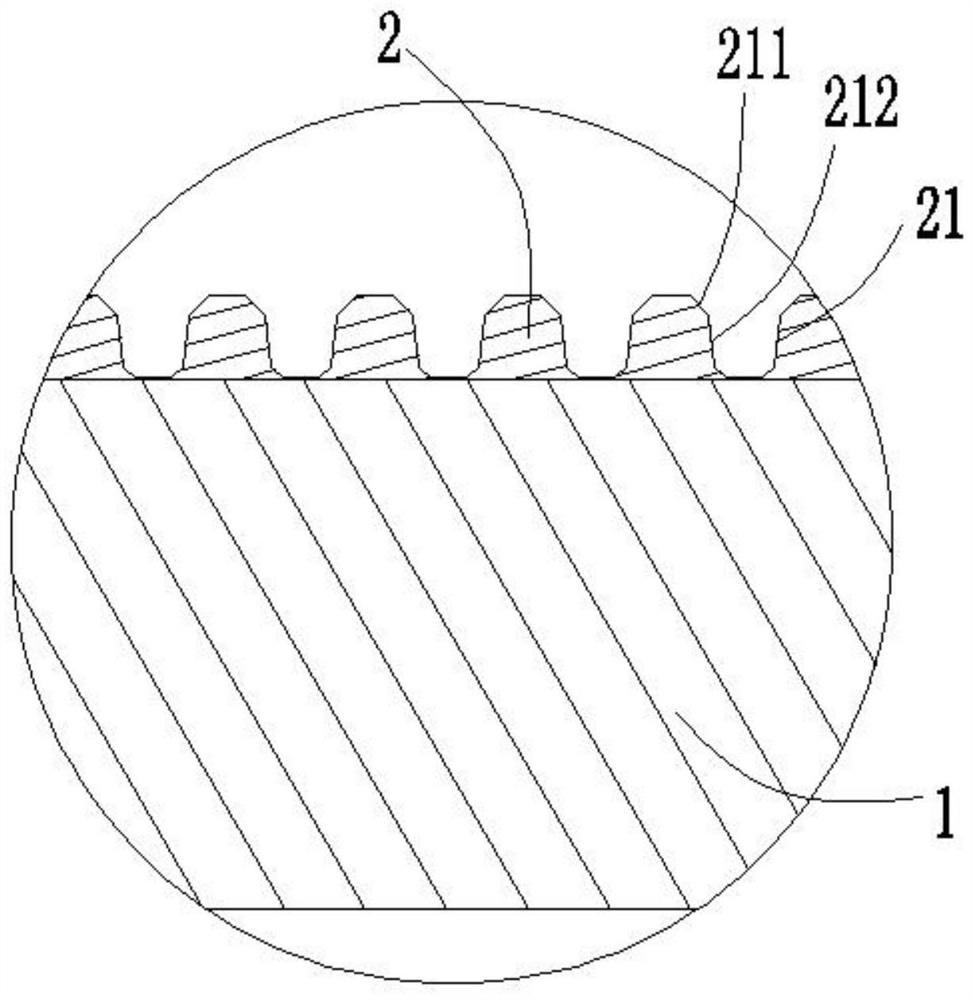

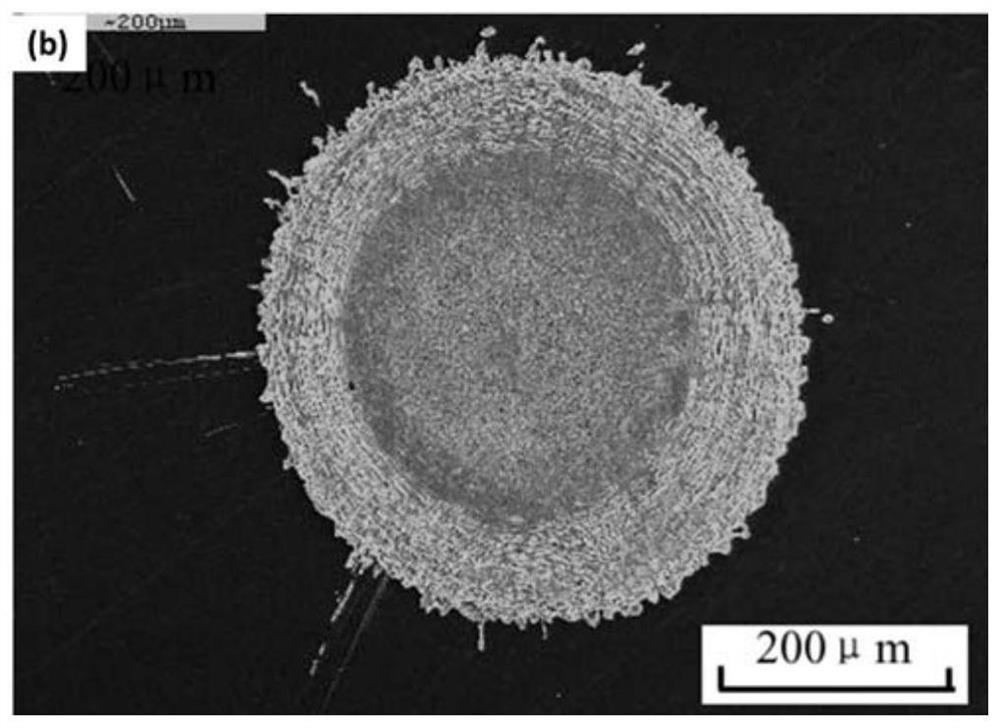

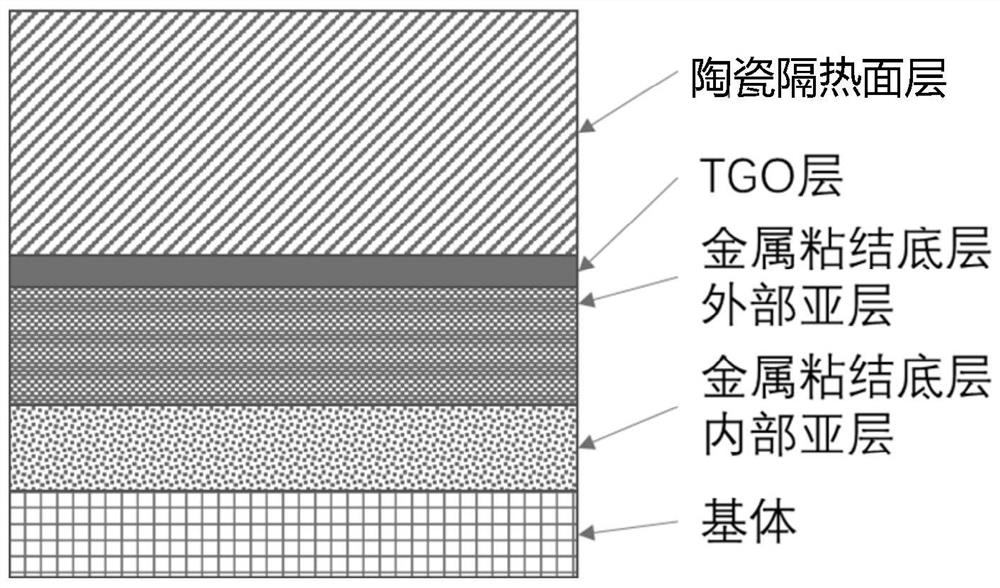

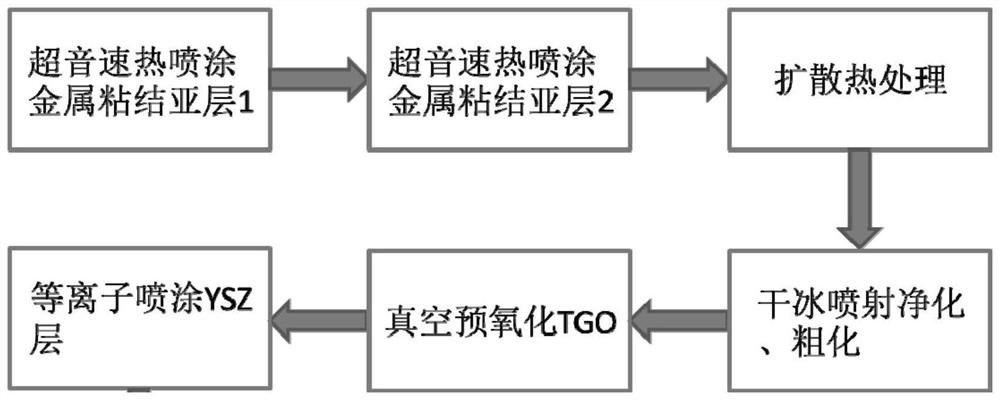

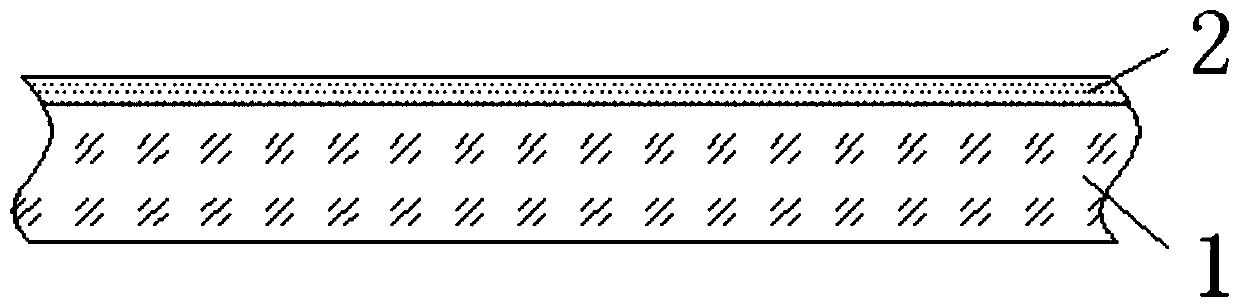

Novel preparation process for thermal barrier coating

ActiveCN109930102AHigh densityImprove selective oxidation abilityMolten spray coatingSurface layerDry ice

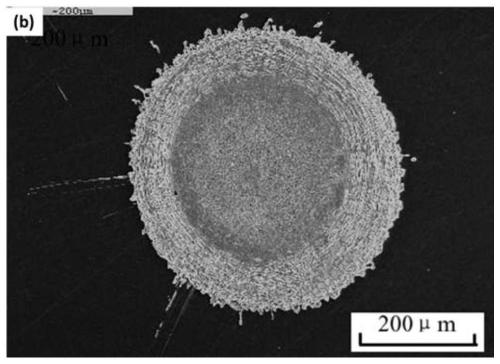

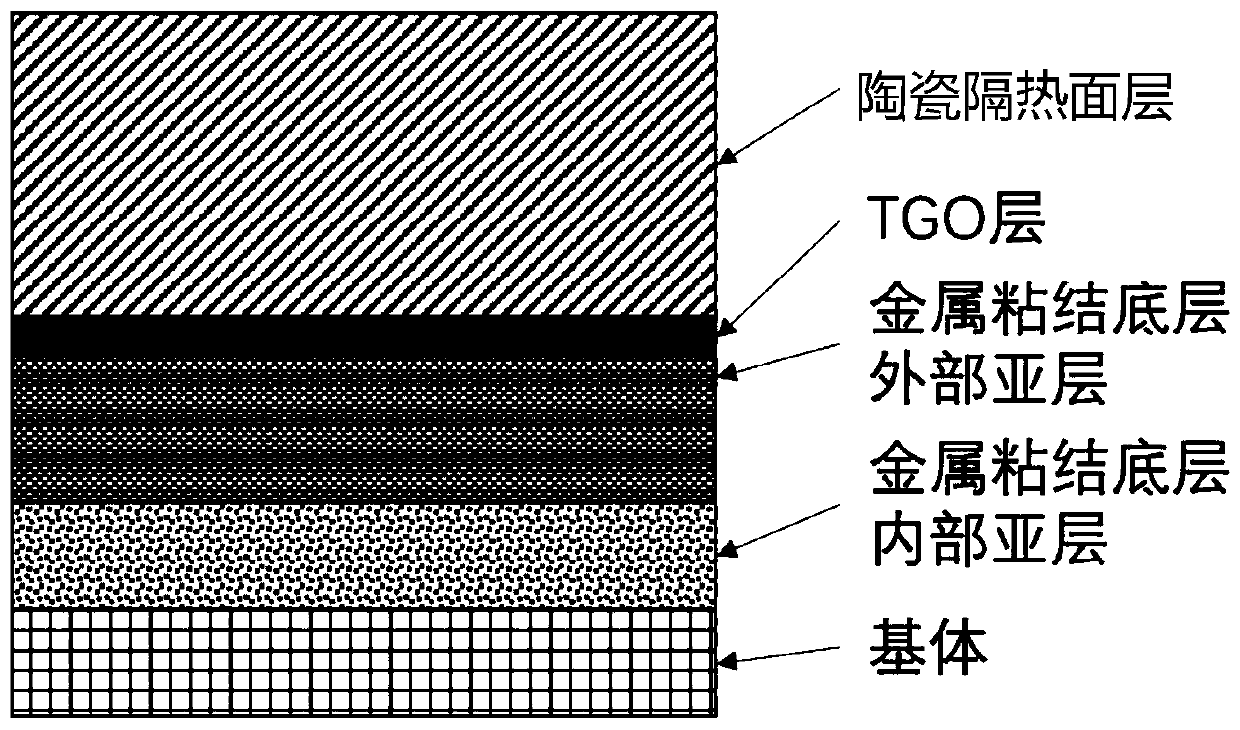

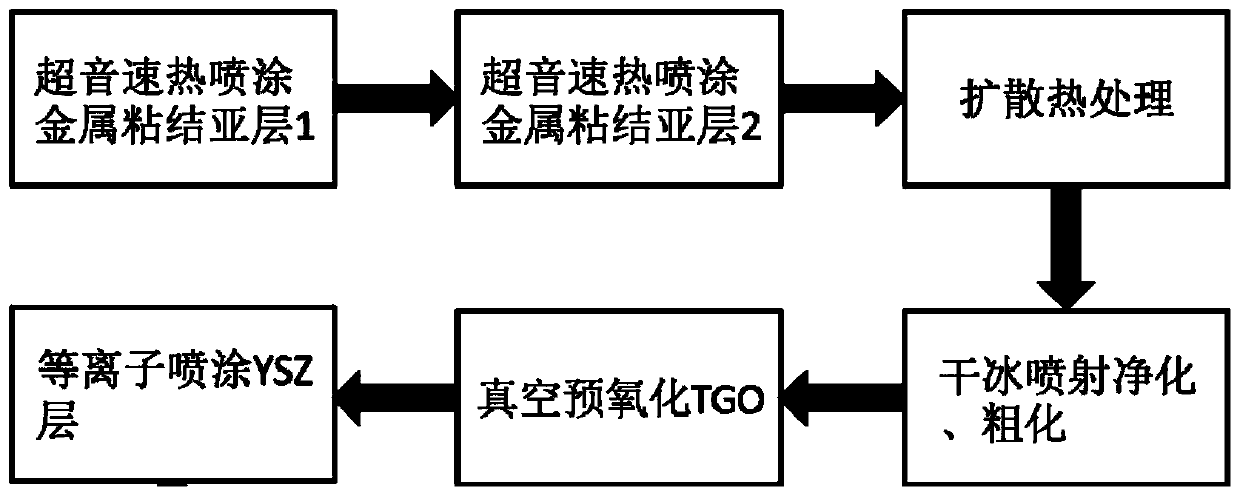

The invention relates to a novel preparation process for a thermal barrier coating. The novel preparation process comprises the following steps: generating a metal bonding bottom layer on the surfaceof a matrix; generating an in-situ thermal growth oxide layer (TGO); and generating a ceramic heat-insulating surface layer, wherein the TGO layer is pre-grown before the matrix serves. The TGO layercomprises alpha-aluminum oxide. A compact and continuous TGO layer which takes alpha-aluminum oxide as the principal component is preset through large-particle dry ice jetting and purifying rougheningtreatment and pre-vacuum argon gas oxidizing treatment. An oxide film has very good high-temperature oxidization resistance, prevents quick oxidization, reduces a layer thickness increase rate of theTGO layer, and achieves the purpose of reducing thermal barrier coating peel-off probability.

Owner:江苏源清动力技术有限公司

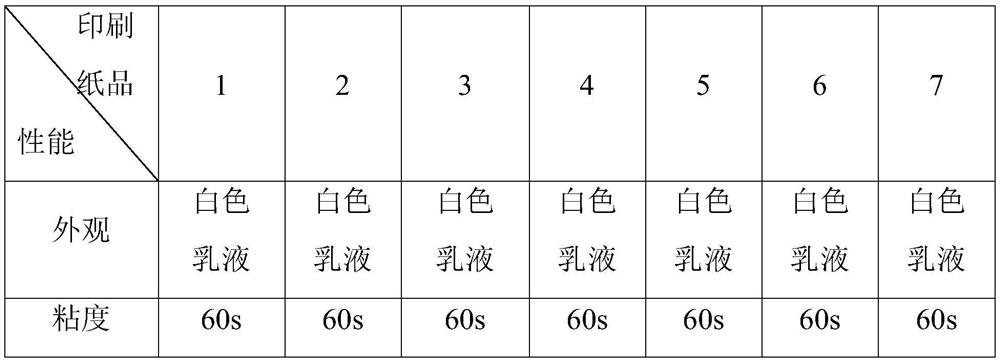

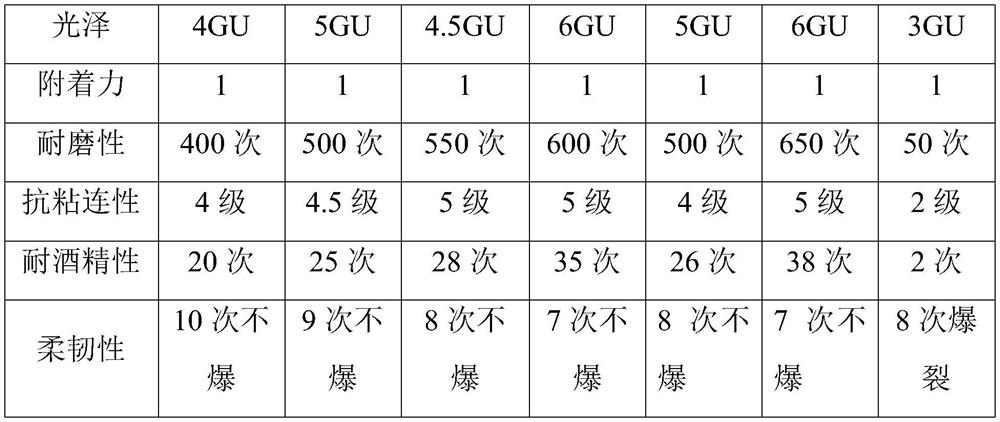

Water-based UV touch oil and preparation method thereof

PendingCN112625574AImprove wear resistanceImprove anti-blockingPolyurea/polyurethane coatingsPolymer scienceEmulsion

The invention provides water-based UV touch oil and a preparation method thereof, belonging to the technical field of touch oil. The water-based UV touch oil is prepared by mixing a main film-forming substance, namely a water-based self-extinction polyurethane emulsion, an ultraviolet curing component, namely water-based urethane acrylate, an acrylic UV monomer and other additives. After the water-based UV touch oil is subjected to ultraviolet curing to form a film, the wear resistance, the anti-blocking performance and the alcohol resistance of a touch coating are greatly improved. In this way, the excellent characteristics of the waterborne self-extinction polyurethane are reserved, the abrasion resistance, alcohol resistance and anti-blocking performance of the touch coating are improved through ultraviolet curing, and the curing method further has the advantages of rapid curing, environmental friendliness and capability of saving energy. Besides, the waterborne self-extinction polyurethane emulsion contains large-particle-size particles (0.1 [mu]m to 0.3 [mu]m), so the microcosmic roughness of a film-forming surface is increased, good matte effect and tactile sensation are obtained, and public preferences are conformed to.

Owner:惠州市毕升堂科技有限公司

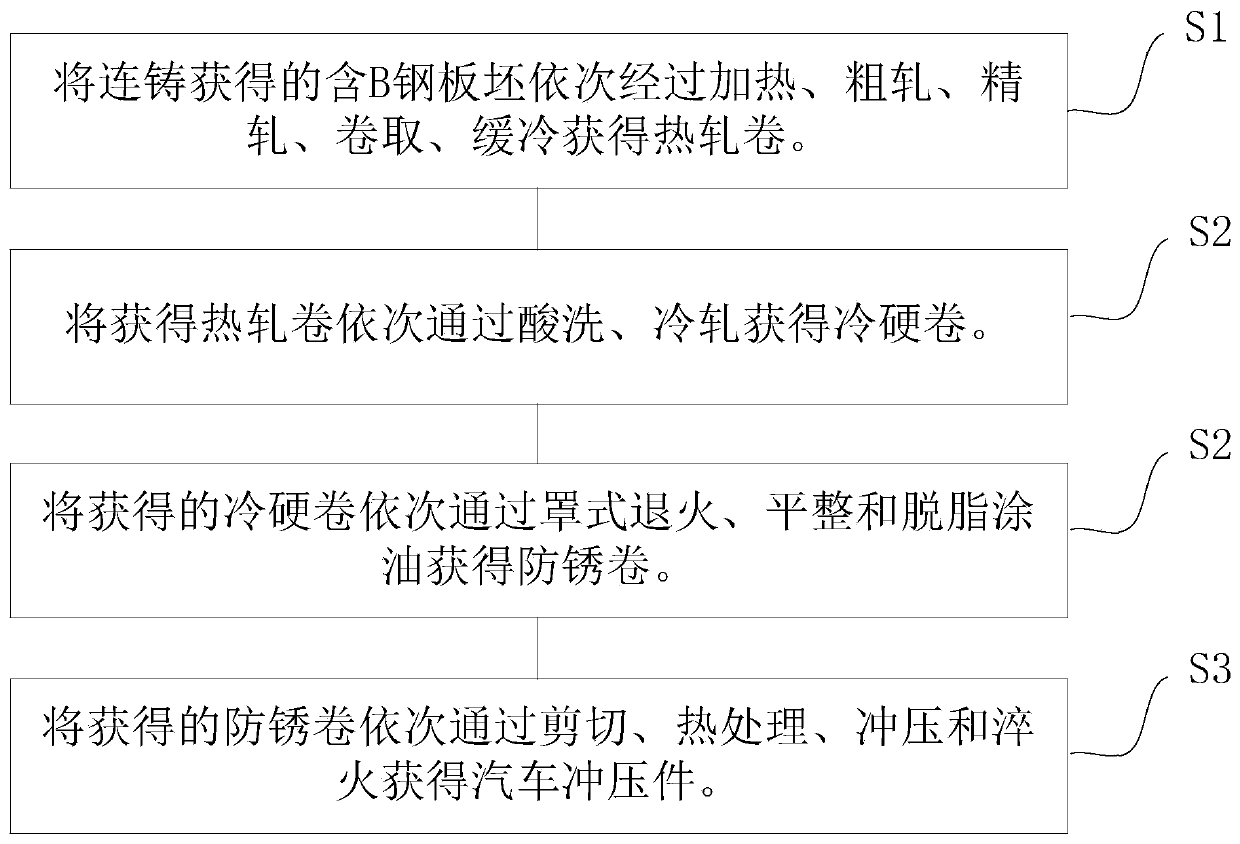

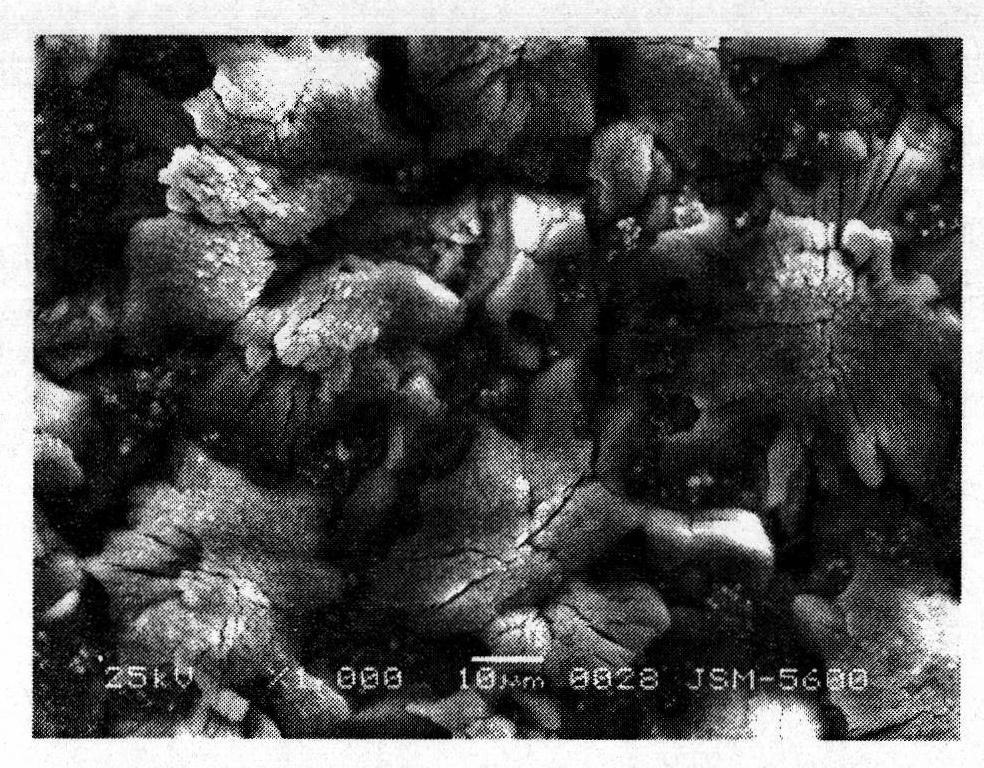

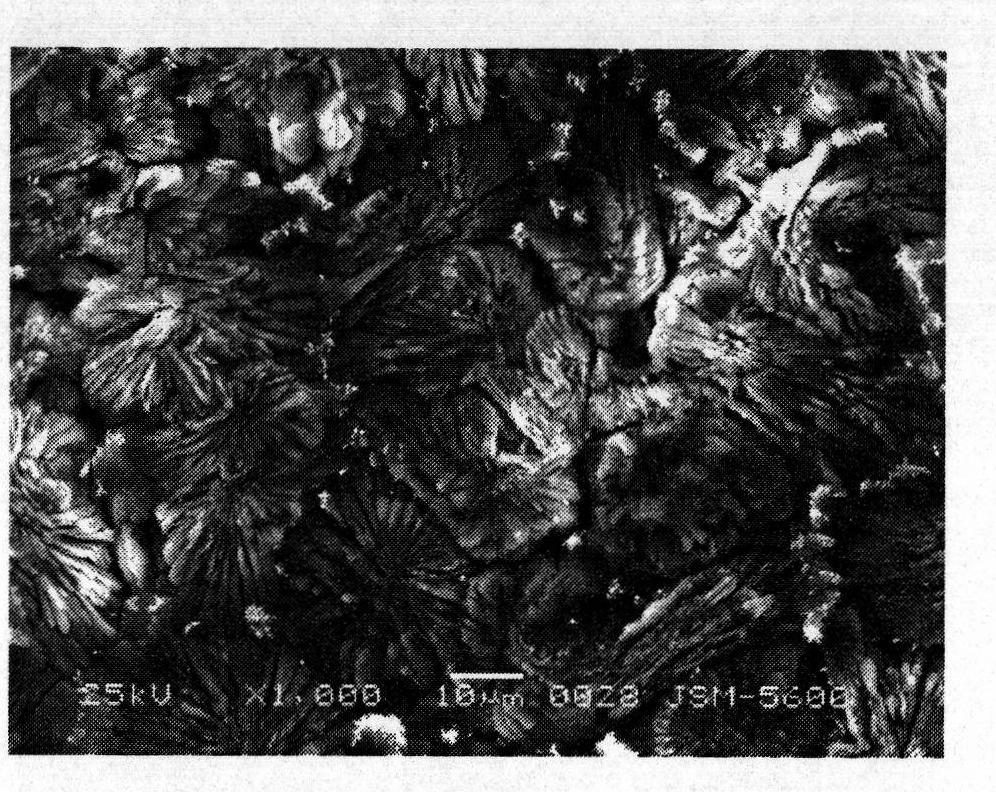

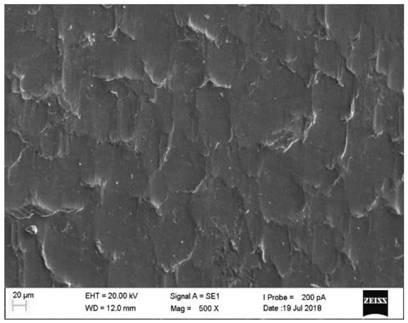

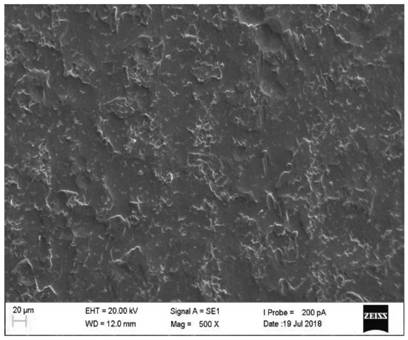

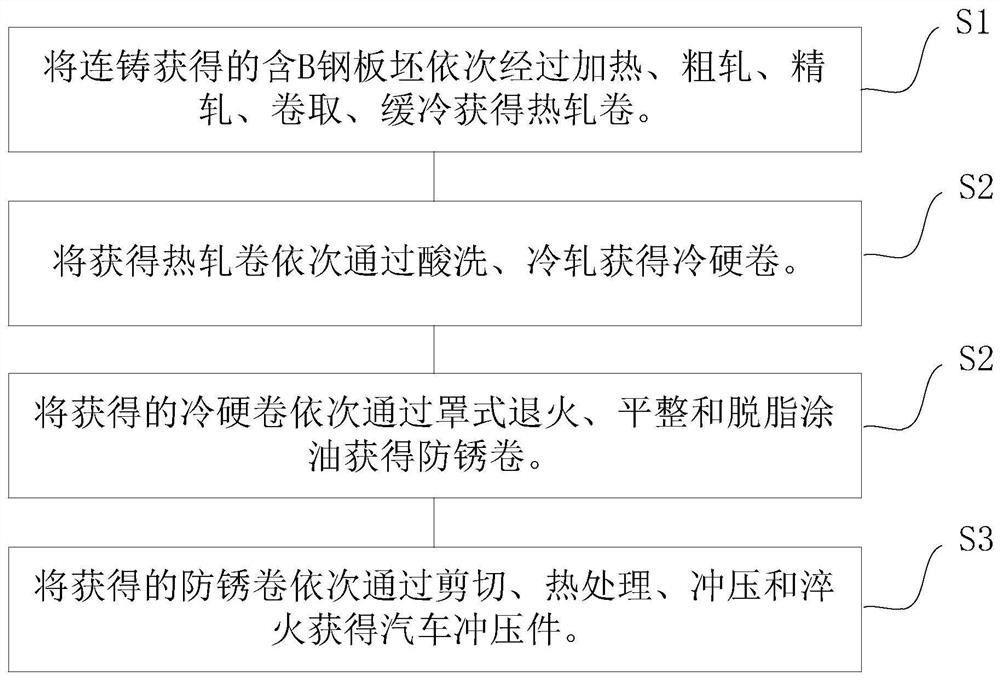

Production method for B-containing steel

ActiveCN110438314AIncreased micro-roughnessIncrease surface areaMetal rolling arrangementsHot stampingWorking environment

The invention discloses a production method for a B-containing steel. The production method comprises the steps that a plate blank of the B-containing steel is obtained; the obtained plate blank of the B-containing steel is rolled, the coiling temperature in rolling is controlled as 660-700 DEG C, the slow cooling time inside a slow cooling pit is controlled as 24-30 hours, and the temperature iscontrolled as 250-300 DEG C when slow cooling is finished; and the plate blank of the B-containing steel after the rolling is molded by hot stamping. By means of adoption of the production method forthe B-containing steel, in the hot stamping working procedure, an oxidized iron sheet is firmly bound to a base body and is not prone to falling off, and the working environment of workers is improved.

Owner:SHOUGANG CORPORATION +1

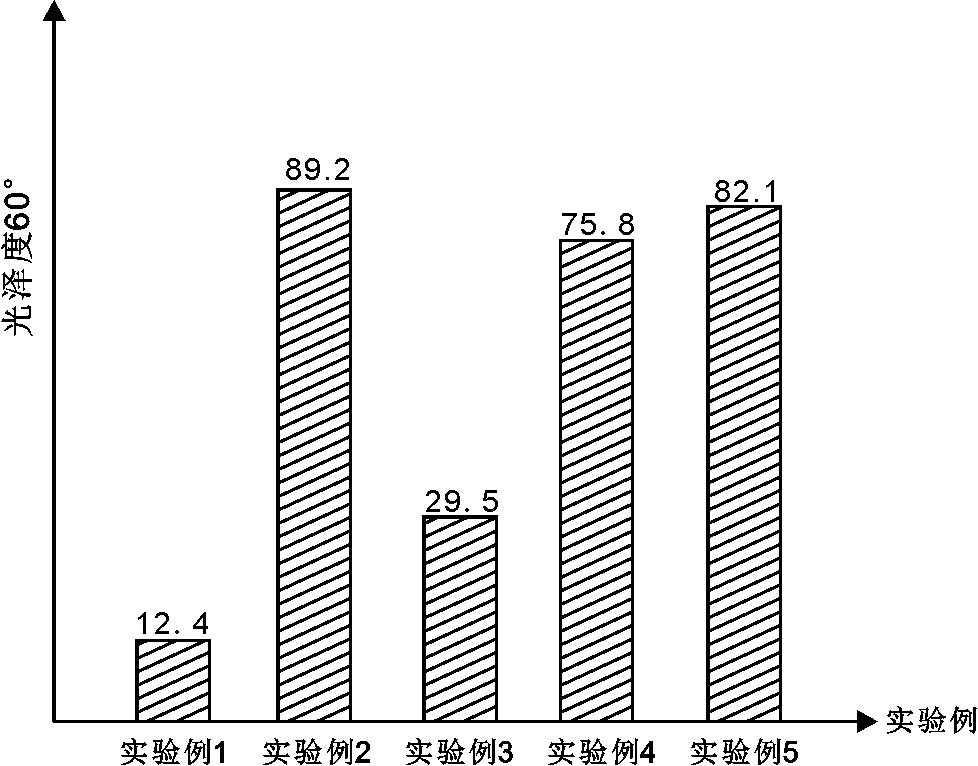

Preparation method of PC-ABS alloy material

The invention discloses a preparation method of a PC-ABS alloy material. The preparation method comprises the steps: taking 65 parts to 75 parts of PC resin, 25 parts to 35 parts of ABS resin, 1 partto 2 parts of a compatilizer, 0.1 part to 1 part of a lubricant, and 3 parts to 5 parts of sulfonated SBS resin, wherein the sulfonation degree is 0.3 mmol / g to 0.6 mmol / g; drying the PC resin and theABS resin, adding the rest raw materials, uniformly mixing by a blending machine, heating and extruding by a screw extruder, cooling and grain-sized dicing after extrusion to obtain alloy material particles. The components of the PC / ABS alloy material are optimized, the additive SBS is modified, sulfonic groups are added into the sulfonated SBS, the chemical polarity and the space structure of the SBS are changed, and the matte degree of the alloy material is affected; meanwhile, the bonding force between the sulfonated SBS resin and the functional groups of the PC resin and the ABS resin canbe improved, the double bonds of the alloy material are more stable under the action of the sulfonated SBS resin, and the anti-aging performance of the alloy resin is improved.

Owner:四川省聚和高分子材料有限公司

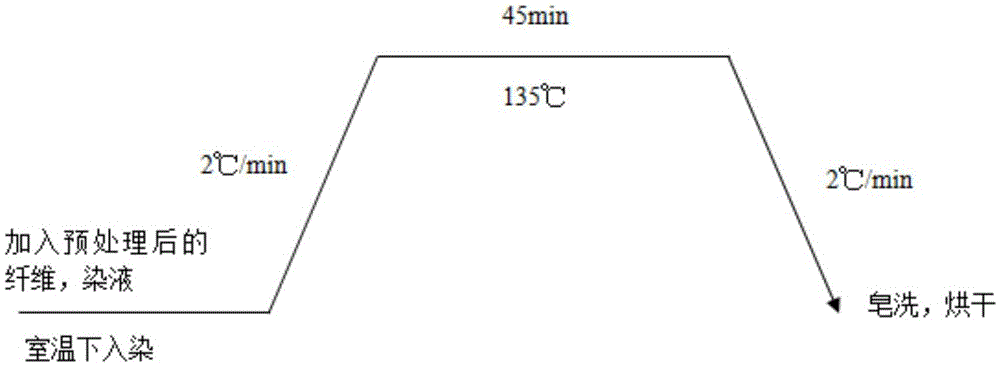

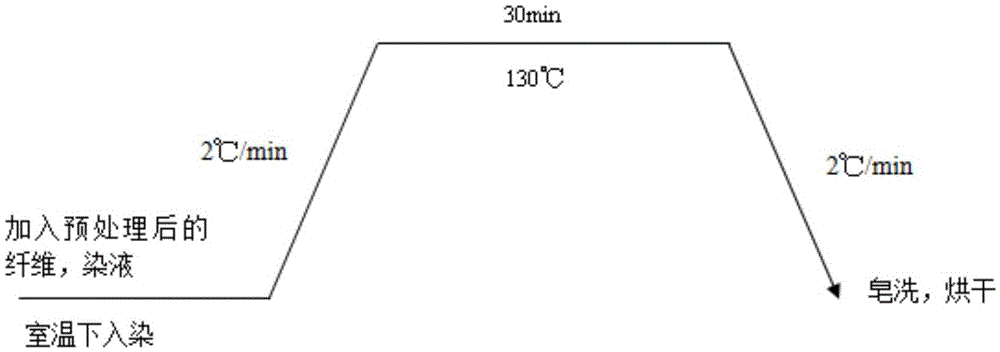

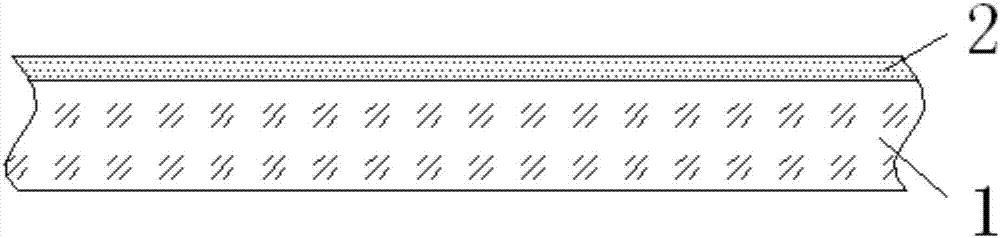

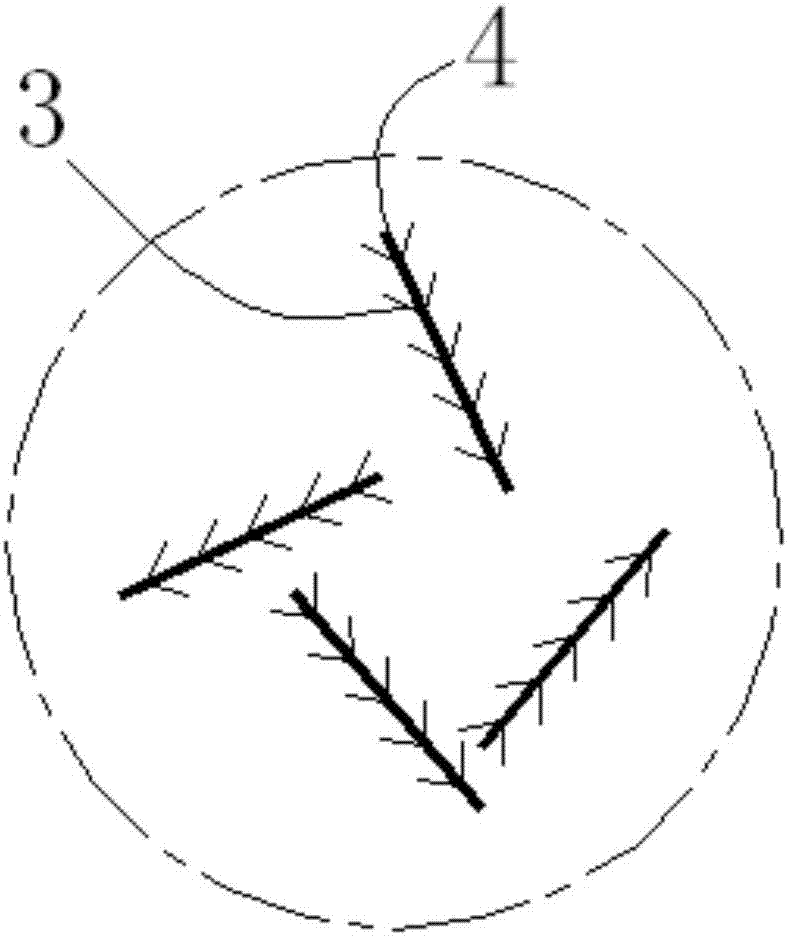

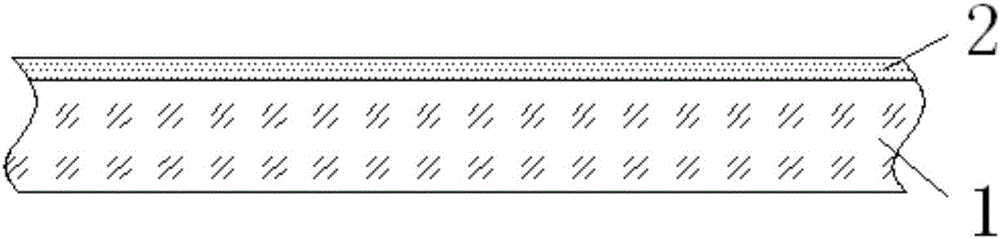

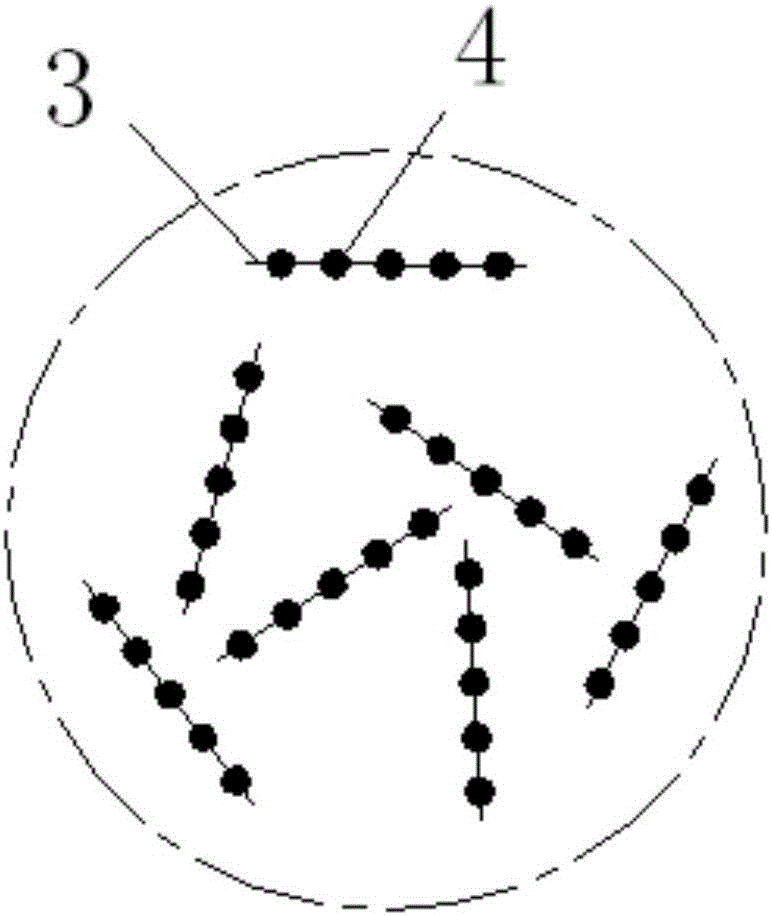

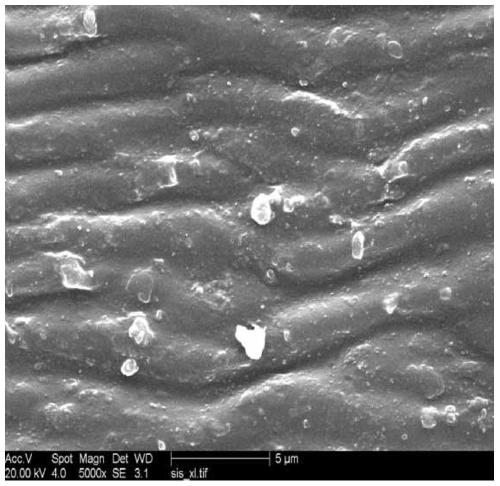

A method for dyeing polyimide fiber with disperse dyes

InactiveCN104532622BIncreased micro-roughnessReduce tightnessDyeing processDisperse dyeRoom temperature

Owner:DONGHUA UNIV

Super-hydrophilic agent, preparation method of super-hydrophilic agent, and super-hydrophilic window glass

InactiveCN107445487AHas hydrophilic propertiesIncreased micro-roughnessZinc oxides/hydroxidesHydrophilic coatingN dimethylformamide

The invention relates to the technical field of hydrophilic glass and in particular relates to a super-hydrophilic agent. The super-hydrophilic agent is characterized by being composed of the following components in percentage by weight: 0.1-0.45% of ZnO nanorod, 1.5-5% of carbon nano tube powder, 12-18% of N,N-dimethylformamide and the balance of dispersion, wherein the carbon nano tube powder is single-walled or multi-walled carbon nano tube powder; and the carbon nano tubes are attached to the surface of the ZnO nanorod. The invention further provides a preparation method of the super-hydrophilic agent and super-hydrophilic window glass provided with a super-hydrophilic coating. The super-hydrophilic agent disclosed by the invention has the advantages that the super-hydrophilic agent is high in visible light transmittance and capable of absorbing infrared and ultraviolet radiation and has excellent super-hydrophilic characteristics under non-illumination conditions.

Owner:FUYAO GLASS IND GROUP CO LTD

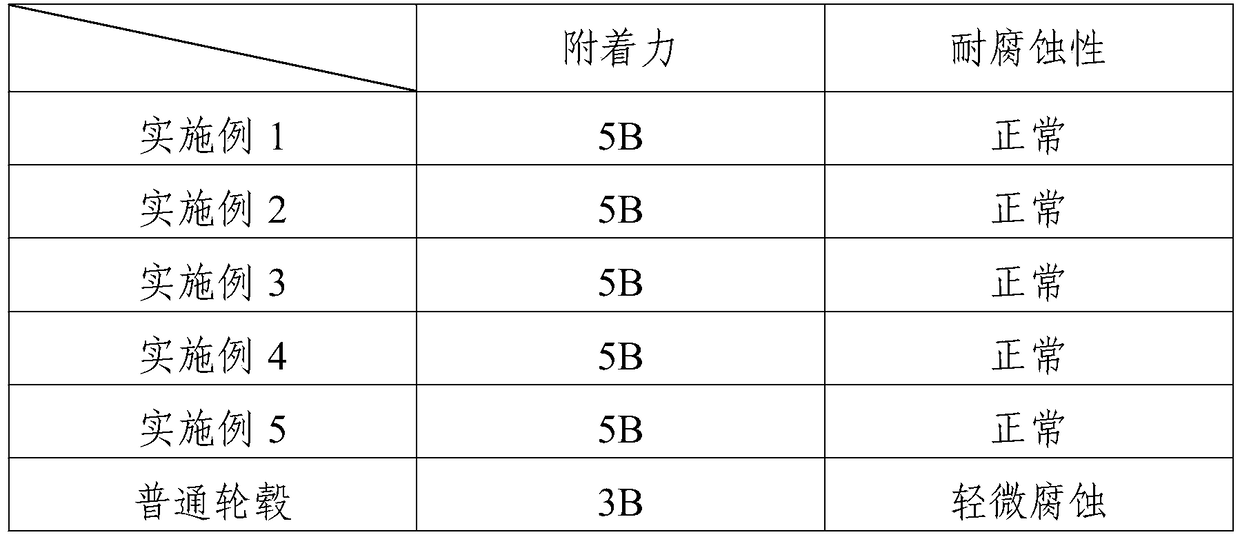

Hub surface pretreatment process

InactiveCN108866556AImprove performanceGood degreasing effectMetallic material coating processesChromium freeSpray coating

The invention discloses a hub surface pretreatment process. The hub surface pretreatment process comprises the following steps of hot water washing, grease removal treatment, acid pickling treatment,chromium-free passivation treatment and pure water washing. According to the surface pretreatment process, the surface performance of a hub can be effectively improved, the degreasing effect on the surface of the hub is remarkably promoted, the surface glossiness and the activity of the hub are enhanced, and meanwhile the surface microscopic roughness of the hub is increased; and the surface of the hub can be combined with the process of the subsequent spraying coating, the bonding force between the hub coating and the hub surface is enhanced, the corrosion resistance of the surface hub is enhanced, and the problems that the coating layer does not easily fall off and the service life is short can be solved.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

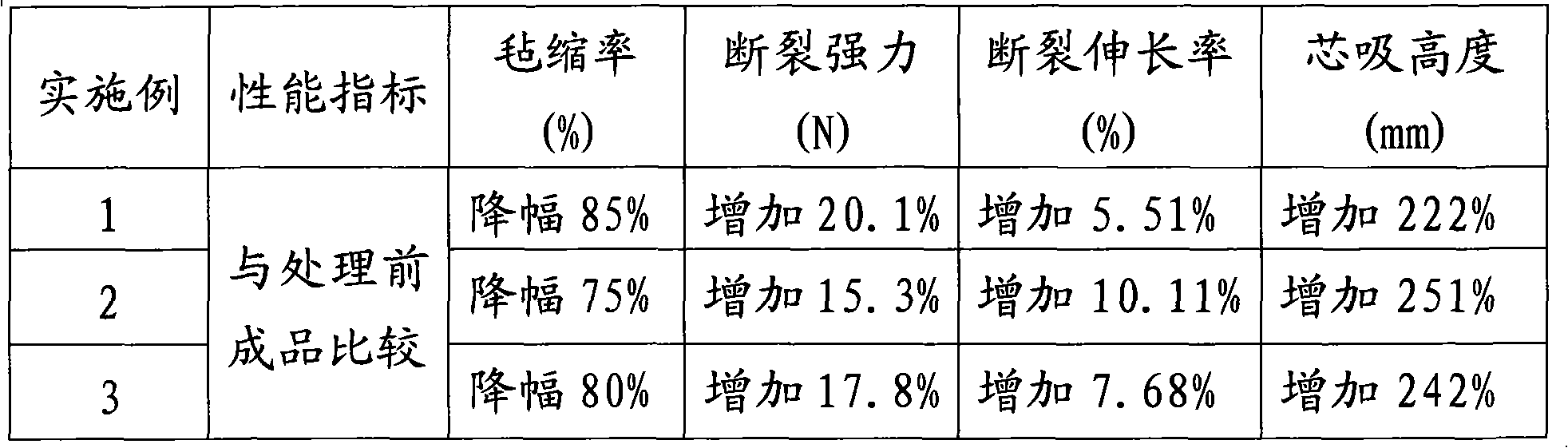

Swaddling clothes facing anti-crease shrink-proof finishing process

InactiveCN101349005AAvoid damageImprove the surface friction factorPhysical treatmentBiochemical fibre treatmentEngineeringPre treatment

The invention discloses a crease resisting anti-shrinkage finishing technique for a sweater fabric. The technique comprises the follow steps that: the sweater plug material is subjected to plasma pretreating, glutamine transaminase is adopted to process the sweater plug material pretreated by plasma, and finally, the sweater plug material is washed by water and dried naturally. The technique realizes the crease resisting anti-shrinkage finishing on the sweater plug material by the plasma together with the glutamine transaminase, remarkably improves the crease resisting anti-shrinkage property of the sweater plug material, has the advantage of health and environment protection, and improves the performances of the sweater plug material of rupture intensity, rupture extending rate and core absorbing height and the like.

Owner:JIANGNAN UNIV +1

Super-hydrophilic agent, preparation method thereof and super-hydrophilic vehicle window glass

ActiveCN107434360AHas hydrophilic propertiesIncreased micro-roughnessCoatingsTin dioxideHydrophilic coating

The invention relates to the technical field of hydrophilic glass, and particularly relates to a super-hydrophilic agent. The super-hydrophilic agent is characterize by comprising the following components: 0.08-0.33wt% of tin dioxide nano particles, 2-5wt% of carbon nano tube powder, 0.2-0.8wt% of polyvinyl alcohol, and the balance of a dispersion liquid; and the carbon nano tube powder is a powdery single-walled carbon nano tube or multi-walled carbon nano tube, and the tin dioxide nano particles adhere to the surface of the carbon nano tube. The invention also provides a preparation method for the super-hydrophilic agent and super-hydrophilic vehicle window glass which is provided with a super-hydrophilic coating formed by the super-hydrophilic agent. The super-hydrophilic agent has the advantages of being high in visible light transmittance, being capable of absorbing infrared radiation, and having good super-hydrophilic characteristics under non-illumination conditions.

Owner:FUYAO GLASS IND GROUP CO LTD

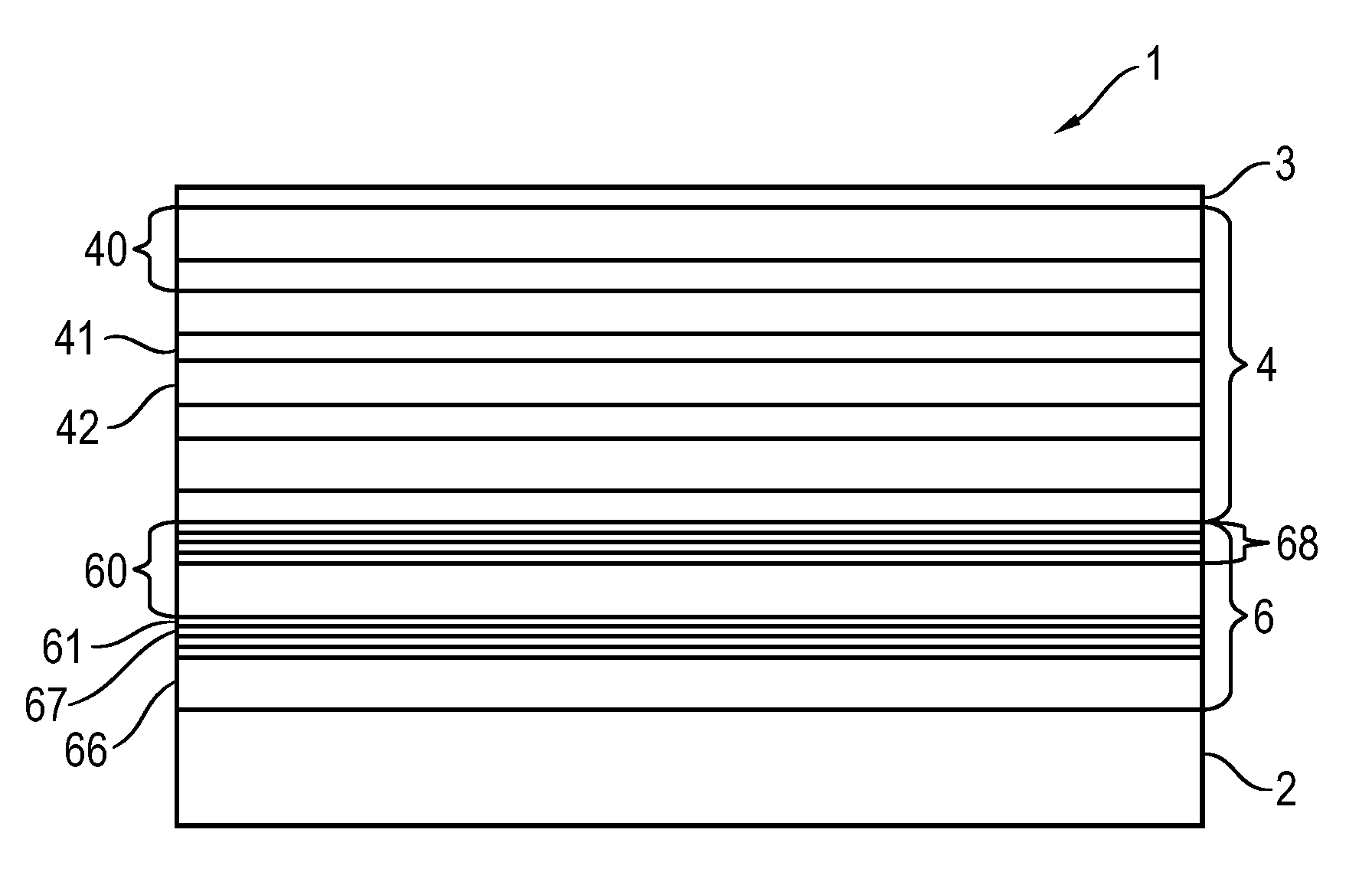

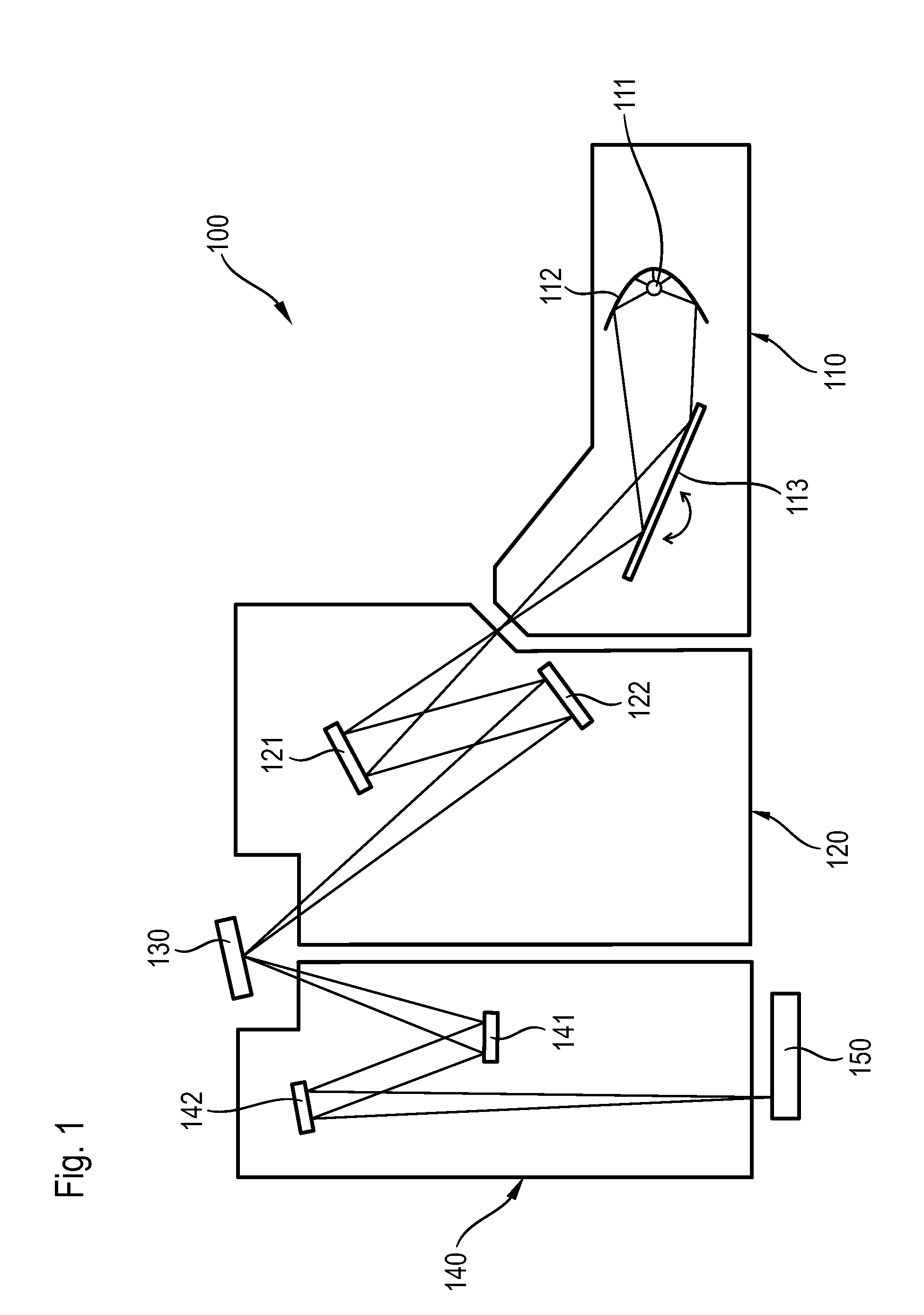

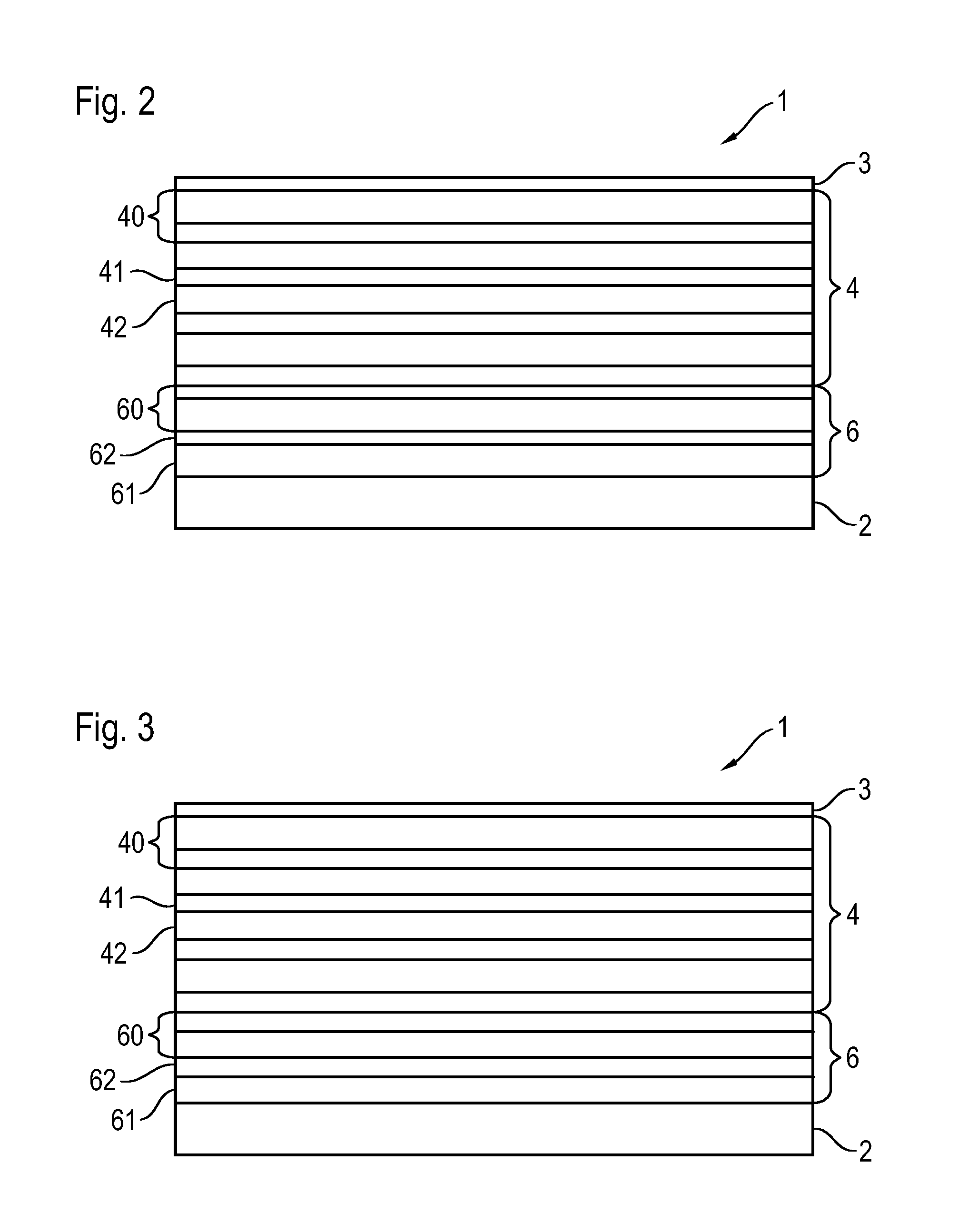

Reflective optical element for EUV lithography

ActiveUS20120019797A1Stress resultingHigh reflection coatingMaterial nanotechnologyMirrorsLithographic artistRefractive index

A stress-reduced reflective optical element for a working wavelength in the soft X-ray and extreme ultraviolet wavelength range includes a first multilayer system (4) of at least two alternating materials (41, 42) having different real parts of the refractive index at the working wavelength on a substrate (2), which exerts a layer stress on the substrate (2), and comprising a second multilayer system (6) of at least two alternating materials (61, 62) on a substrate (2), which exerts an opposed layer stress on the substrate (2) and is arranged between the first multilayer system (4) and the substrate (2), wherein a first (61) of the at least two materials of the second multilayer system (6) is interrupted by layers (62) having a thickness of up to 1 nm of the at least one further material of the second multilayer system (6) at such distances that the first material is present in an amorphous state.

Owner:CARL ZEISS SMT GMBH

Super-hydrophilicity and high-adhesion glass surface treatment agent and preparation method thereof

The invention relates to a super-hydrophilicity and high-adhesion glass surface treatment agent and a preparation method thereof. The treatment agent is prepared from SiO2 sol and a Si-PEG polymer solution, wherein the mass ratio of the SiO2 sol to the Si-PEG polymer solution is (1:1) to (1:5); the SiO2 sol is prepared by the steps of uniformly mixing absolute ethyl alcohol, ethyl orthosilicate, silane and deionized water, reacting at 20 to 40 DEG C for 5 to 7 hours, and standing at room temperature for 12 to 24 hours after the reaction; the Si-PEG polymer solution is prepared by the steps ofslowly dropwise adding chlorosilane into polyethylene glycol, reacting for 3 to 5 hours, and then adding an organic solvent. The super-hydrophilicity treatment agent has good scrubbing resistance, issimple to use, can be directly applied to the surface of glass to form a transparent super-hydrophilic film, has the advantages of short consumption time, long effect lasting time and low cost, and can be applied to building exterior glass, car windshield, etc.

Owner:HUBEI UNIV

Mulberry silk blended quick-drying fabric and preparation method thereof

InactiveCN111020829AReduce dosageGood blending uniformityWeft knittingPhysical treatmentPolymer sciencePolythylene glycol

The invention provides mulberry silk blended quick-drying fabric and a preparation method thereof. Mulberry silk, wool fibers and water-soluble vinylon fibers are blended and spun into first yarns, aninner surface layer and an outer surface layer are formed by weaving on a machine, cotton fibers and bamboo fibers are blended and spun into second yarns, and an intermediate layer is formed by weaving on the machine, so that a fabric blank is obtained, ultrasonic heating finishing is carried out by using finishing liquid, the fabric blank is bailed out and then is soaked in clear water for 5-10minutes, and drying is carried out, so that the mulberry silk blended quick-drying fabric is obtained; and the finishing liquid is prepared by mixing and stirring trehalose, polyethylene glycol 400, borax and water uniformly. According to the mulberry silk blended quick-drying fabric and the preparation method thereof, the mulberry silk, the wool fibers, the water-soluble vinylon fibers, the cotton fibers and the bamboo fibers are blended and processed into the quick-drying fabric, so that the using amount of the mulberry silk is greatly reduced, the production cost is reduced, the blending uniformity among the different fibers is good, and the good quick-drying performance is ensured.

Owner:长沙凯泽工程设计有限公司

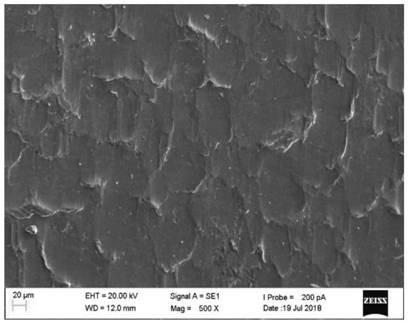

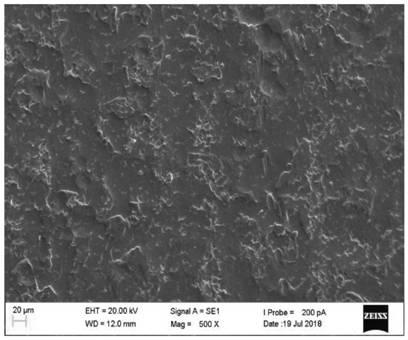

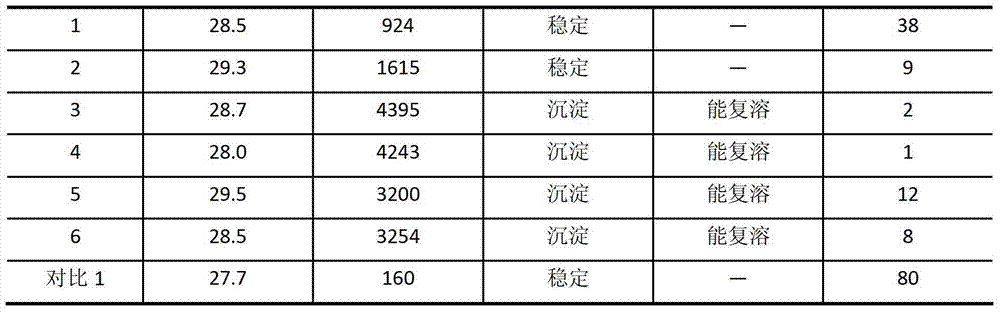

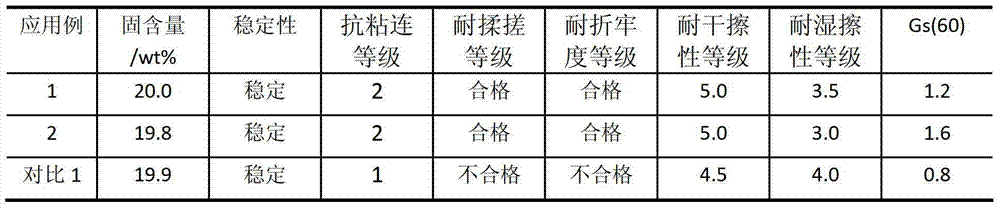

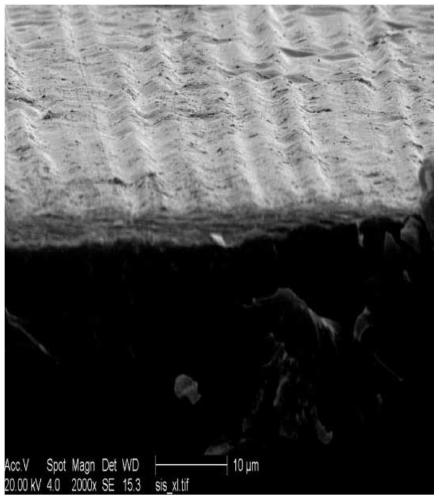

A kind of low gloss aqueous polyurethane dispersion for leather and its preparation method and application

ActiveCN103319682BIncreased micro-roughnessTo achieve the purpose of natural extinctionFibre treatmentPolyurea/polyurethane coatingsSurface finishPolyurethane dispersion

Owner:清远市美佳乐环保新材股份有限公司 +1

An environmentally friendly surface treatment process for non-stick pans

ActiveCN108309023BImprove adhesionReduce manufacturing costCooking-vessel materialsLaser beam welding apparatusPolymer sciencePorous layer

The invention discloses an environment-friendly non-stick pan surface treatment process, which comprises the following steps: 1) forming: forming a microporous layer; 2) scanning a laser on the surface of the pan embryo to form a plurality of microporous structures, thereby forming the microporous layer; Porous layer; 3) Spraying a non-stick coating on the surface of the microporous layer: the non-stick coating is filled in the microporous structure. The invention forms a dense and elongated microporous structure on the surface of the pan by scanning the laser microporous forming technology, thereby forming a microporous layer, which not only doubles the surface area of the pan, but also improves the microscopic roughness of the surface of the pan Degree, and then when the non-stick coating is directly sprayed on the surface of the microporous layer, the coating can be filled into the microporous structure, thereby greatly increasing the contact area between the non-stick coating and the microporous layer, thereby improving the non-stick Coating adhesion.

Owner:ZHEJIANG SANHO KITCHENWARE

A New Preparation Technology of Thermal Barrier Coating

The invention relates to a novel thermal barrier coating preparation process, which comprises the following steps: forming a metal bonded underlayer on the surface of a substrate; forming an in-situ thermally grown oxide layer (TGO); and forming a ceramic heat-insulating surface layer. The TGO layer is pre-grown before the substrate is put into service. The composition of the TGO layer includes alpha-alumina. In the present invention, a layer of dense and continuous TGO layer mainly composed of α-alumina is preset through large-particle dry ice jet purification and roughening treatment and pre-vacuum argon oxidation treatment. The oxide film will have good resistance to high temperature oxidation, prevent rapid oxidation, reduce the growth rate of TGO layer thickness, and achieve the purpose of reducing the occurrence probability of thermal barrier coating peeling.

Owner:江苏源清动力技术有限公司

Magnesium alloy surface treatment process

ActiveCN101629287BImprove corrosion resistanceIncrease the area ratioMetallic material coating processesPhosphatePhosphoric acid

The invention relates to a magnesium alloy surface treatment process which comprises the following steps: (1) soaking and coating phosphate film-forming solution on the surface of a magnesium alloy matrix, washing by water and drying to generate a layer of transition films; and (2) externally coating non-chromate Dacromet coating to obtain a protective coating, wherein the phosphate film-forming solution is sn aqueous solution comprising the following components in concentration: 20-45 g / L of phosphoric acid; 2-4.5 g / L of zinc oxide, 1-4.5 g / L of sodium fluoride, 0.5-2 g / L of ammonium fluoride, 0.5-3 g / L of crystallization controlling agent, 0.5-2 g / L of reaction promoting agent and 0.5-2 g / L of anion surface active agent; the crystallization controlling agent is selected from molybdate or rare-earth salt, and the reaction promoting agent is selected from nitrate or chlorate. The corrosion resistance of the processed magnesium alloy surface is effectively improved.

Owner:浙江省缙云县三鼎实业有限公司

A kind of superhydrophilic agent, preparation method and superhydrophilic vehicle window glass

ActiveCN107434360BHas hydrophilic propertiesIncreased micro-roughnessCoatingsTin dioxideHydrophilic coating

The invention relates to the technical field of hydrophilic glass, and particularly relates to a super-hydrophilic agent. The super-hydrophilic agent is characterize by comprising the following components: 0.08-0.33wt% of tin dioxide nano particles, 2-5wt% of carbon nano tube powder, 0.2-0.8wt% of polyvinyl alcohol, and the balance of a dispersion liquid; and the carbon nano tube powder is a powdery single-walled carbon nano tube or multi-walled carbon nano tube, and the tin dioxide nano particles adhere to the surface of the carbon nano tube. The invention also provides a preparation method for the super-hydrophilic agent and super-hydrophilic vehicle window glass which is provided with a super-hydrophilic coating formed by the super-hydrophilic agent. The super-hydrophilic agent has the advantages of being high in visible light transmittance, being capable of absorbing infrared radiation, and having good super-hydrophilic characteristics under non-illumination conditions.

Owner:FUYAO GLASS IND GROUP CO LTD

A kind of low surface energy material with micro-nano groove structure and preparation method thereof

ActiveCN108250941BReduce corrosion rateImprove anti-corrosion performanceAntifouling/underwater paintsPaints with biocidesFiberMicro nano

The invention provides a low-surface-energy material with a micro-nano groove structure as well as a preparation method thereof, and relates to a low-surface-energy material and a preparation method thereof. The technical problems that the existing low-surface-energy material of organic silicon resin has poor adhesive force with a matrix, low solvent resistance and long curing time as well as thelow-surface-energy material of organic fluorine resin is expensive in material and complex in process are solved. The material consists of a component A and a component B which are independently packaged, the component A is a mixture of epoxidized hydroxy-terminated polybutadiene type polyurethane and basalt scale fiber treated by a silane coupling agent, and the component B is a curing agent. Thepreparation method comprises the following steps: 1, preparing epoxidized hydroxy-terminated polybutadiene type polyurethane; 2, treating the basalt scale fiber by the silane coupling agent; and 3, defoaming the epoxidized hydroxy-terminated polybutadiene type polyurethane, adding the basalt scale fiber treated by the silane coupling agent, mixing uniformly to form the component A and independently packaging the component B. The static water contact angle of the material can reach to above 110 degrees and the low-surface-energy material can be applied in the field of corrosion prevention.

Owner:HEILONGJIANG HEIKE TECH CO LTD

A kind of copper surface organic acid type super-roughening agent and preparation method thereof

The invention provides a copper surface organic acid type super-coarsening agent and a preparation method. The copper surface organic acid type super-coarsening agent adopts a buffer solution prepared by neutralization of organic acid and alkali as the medium and bivalent copper ions as an oxidation agent, wherein the pH value of the buffer solution is 2-4.5, and the mass concentration of the copper ions in the oxidation agent is 15-60 g / L. By means of the copper surface organic acid type super-coarsening agent, the copper soluble amount is remarkably improved and can reach 60 g / L, no crystal separates out, the operation cost is decreased, and the wastewater emission is reduced. The micro-roughness and uniformity of the copper surface are remarkably improved, the optimal coarsened surface can be obtained, the good dry film binding force is obtained, and manufacturing of a fine line is facilitated.

Owner:上海天承化学有限公司

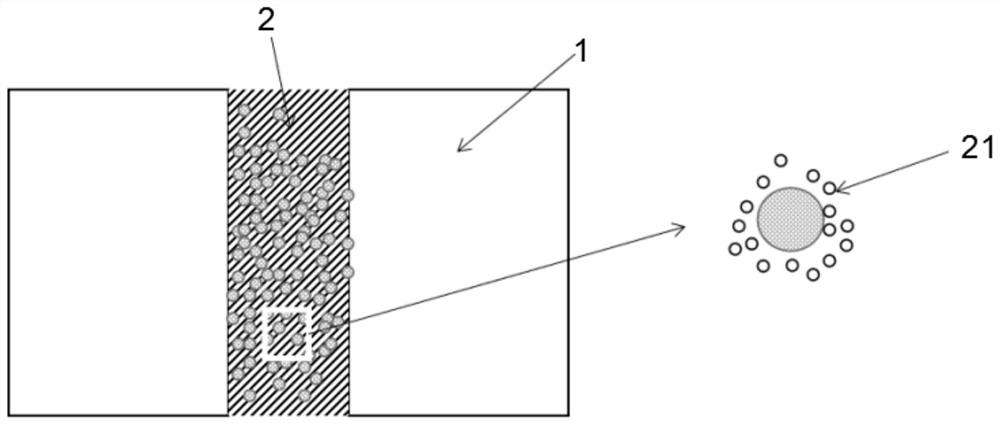

Micro-foaming hole plugging resin for PCB as well as preparation method and application of micro-foaming hole plugging resin

The invention relates to the technical field of PCBs, and provides micro-foaming hole plugging resin for a PCB as well as a preparation method and application of the micro-foaming hole plugging resin. The micro-foaming hole plugging resin for PCB comprises the following components by weight: on the basis that the total weight of the micro-foaming hole plugging resin is 100%, 20%-40% of epoxy resin, 2%-10% of a curing agent, 40%-60% of an inorganic filler, 0.1-10% of a foaming agent and 0.1-5% of an auxiliary agent. The micro-foaming hole plugging resin for the PCB can form a micro-bubble structure, so a volume shrinkage rate and shrinkage stress generated during curing of the resin are effectively reduced; meanwhile, the original physical characteristic CTE and glass-transition temperature of a material are guaranteed, resin shrinkage is resisted in the using process, curing stress is reduced, and a crack generation proportion is reduced; and meanwhile, the dielectric constant, dielectric loss and other properties are reduced, and wide application in the field of high-frequency high-speed PCBs is facilitated.

Owner:SHENZHEN BAROY NEW MATERIAL TECH CO LTD

Method for preparing super hydrophobic film on surface of zinc substrate

InactiveCN102407220BSimple methodLow costPretreated surfacesMetallic material coating processesPolymer scienceHydroxystearic Acid

The invention provides a method for preparing a super hydrophobic film on the surface of a zinc substrate, which belongs to the technical field of a functional material. The method comprises the following steps of: ultrasonically washing a zinc sheet substrate, blow-drying by nitrogen gas, oxidizing by formamide water solution, and forming a rod-like nanometer zinc oxide array on the surface of a zinc sheet; and modifying by low surface energy substances, namely, stearic acid, 12-hydroxystearic acid and normal dodecyl mercaptan, and forming the super hydrophobic film with high static contact angle and low roll angle on the surface of the zinc sheet substrate. The super hydrophobic film may not be changed after being placed in the air for long time due to better stability and can be used for preventing water, resisting frost, preventing snow and resisting metal corrosion due to better acid and alkali resistance.

Owner:NORTHWEST NORMAL UNIVERSITY

A kind of production method of b-containing steel

ActiveCN110438314BIncreased micro-roughnessIncrease surface areaMetal rolling arrangementsTemperature controlHot stamping

The invention discloses a production method of B-containing steel. The method comprises: obtaining a slab containing B-steel; rolling the obtained slab containing B-steel, and controlling the coiling temperature during rolling to 660-700 °C, the slow cooling time in the slow cooling pit is controlled at 24-30 hours, and the temperature at the end of slow cooling is controlled at 250-300 °C; the rolled slab containing B steel is hot stamped. By adopting the production method of the B-containing steel of the present invention, in the hot stamping process, the iron oxide scale is firmly combined with the matrix, the iron oxide scale is not easy to fall off, and the working environment of workers is improved.

Owner:SHOUGANG CORPORATION +1

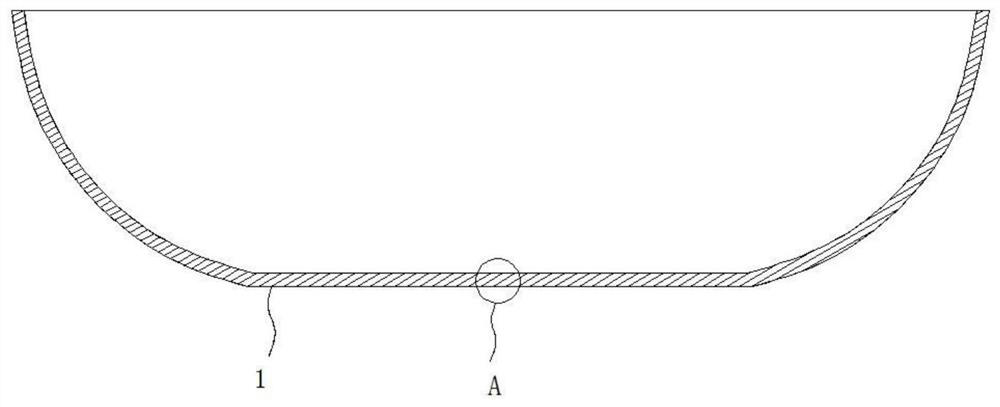

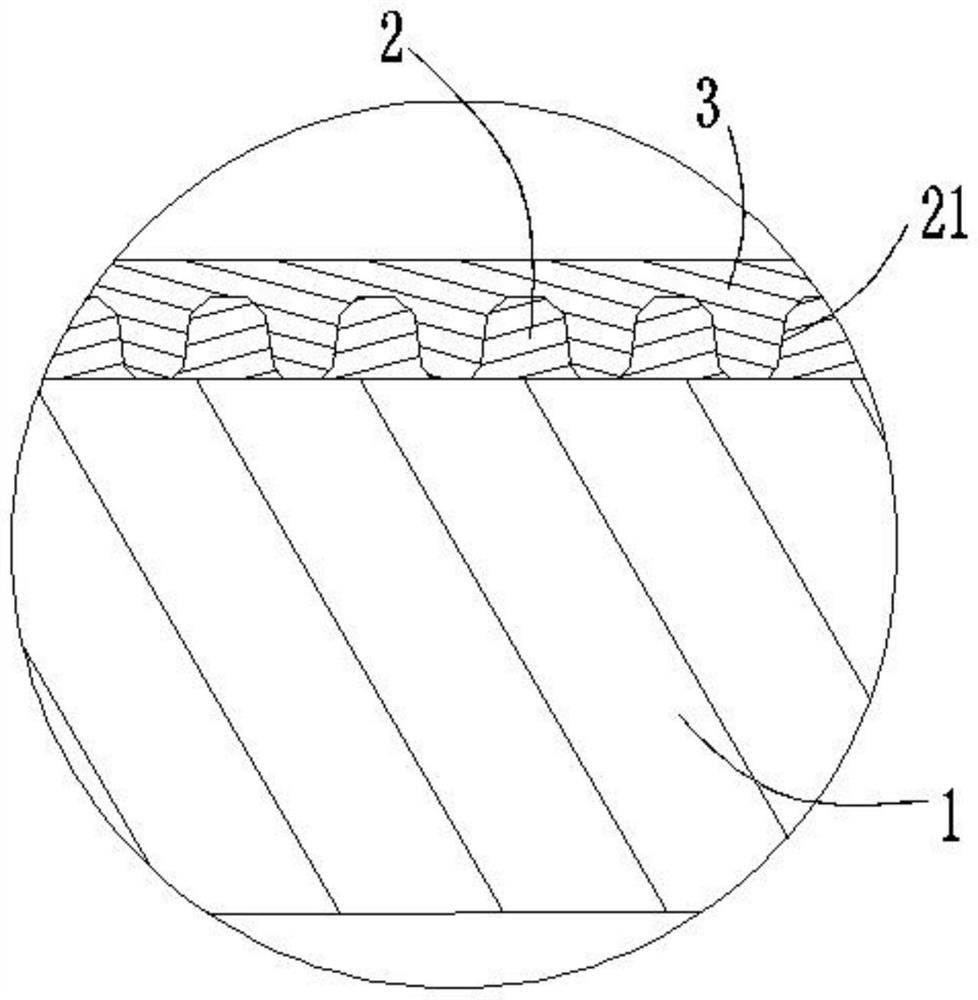

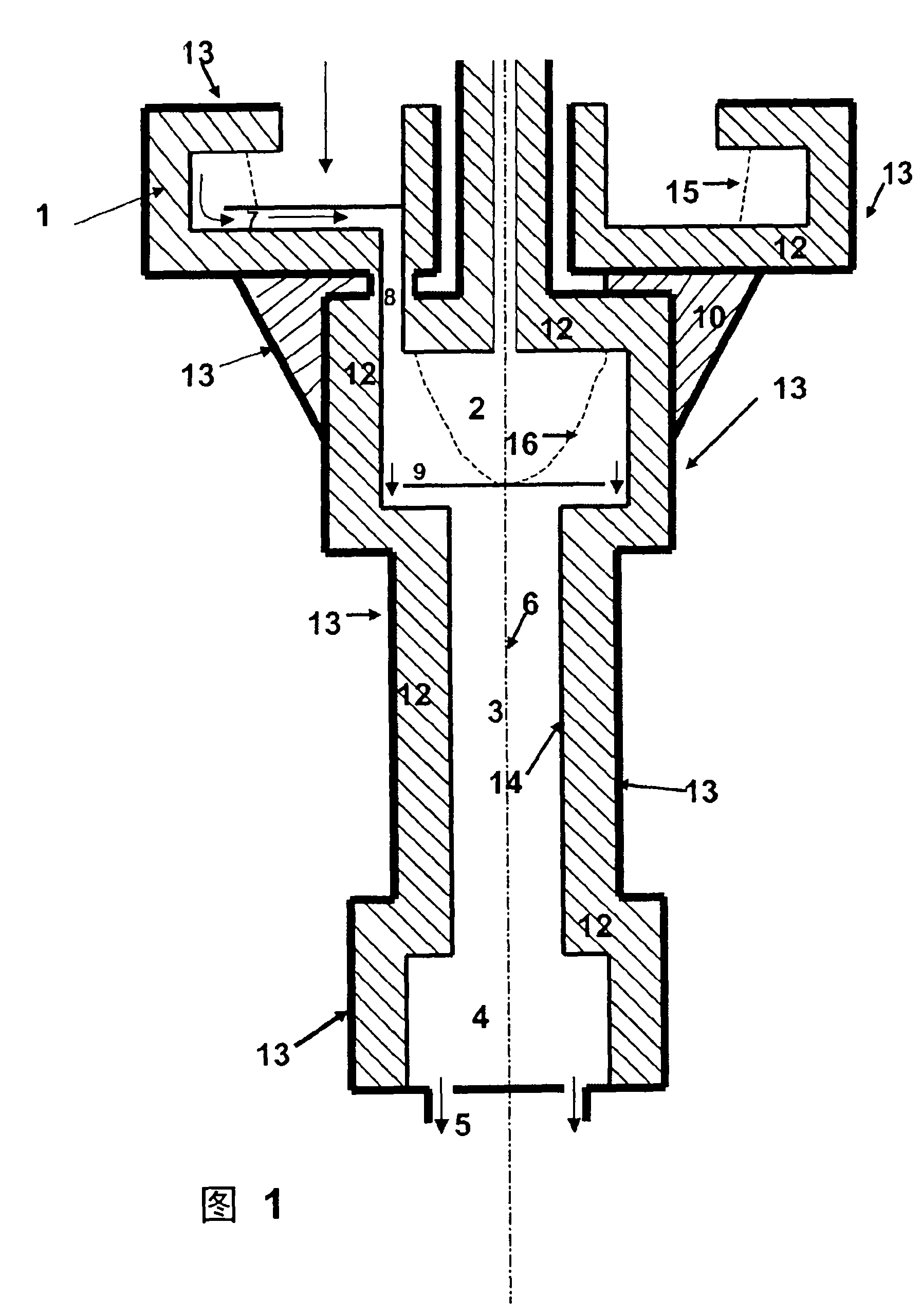

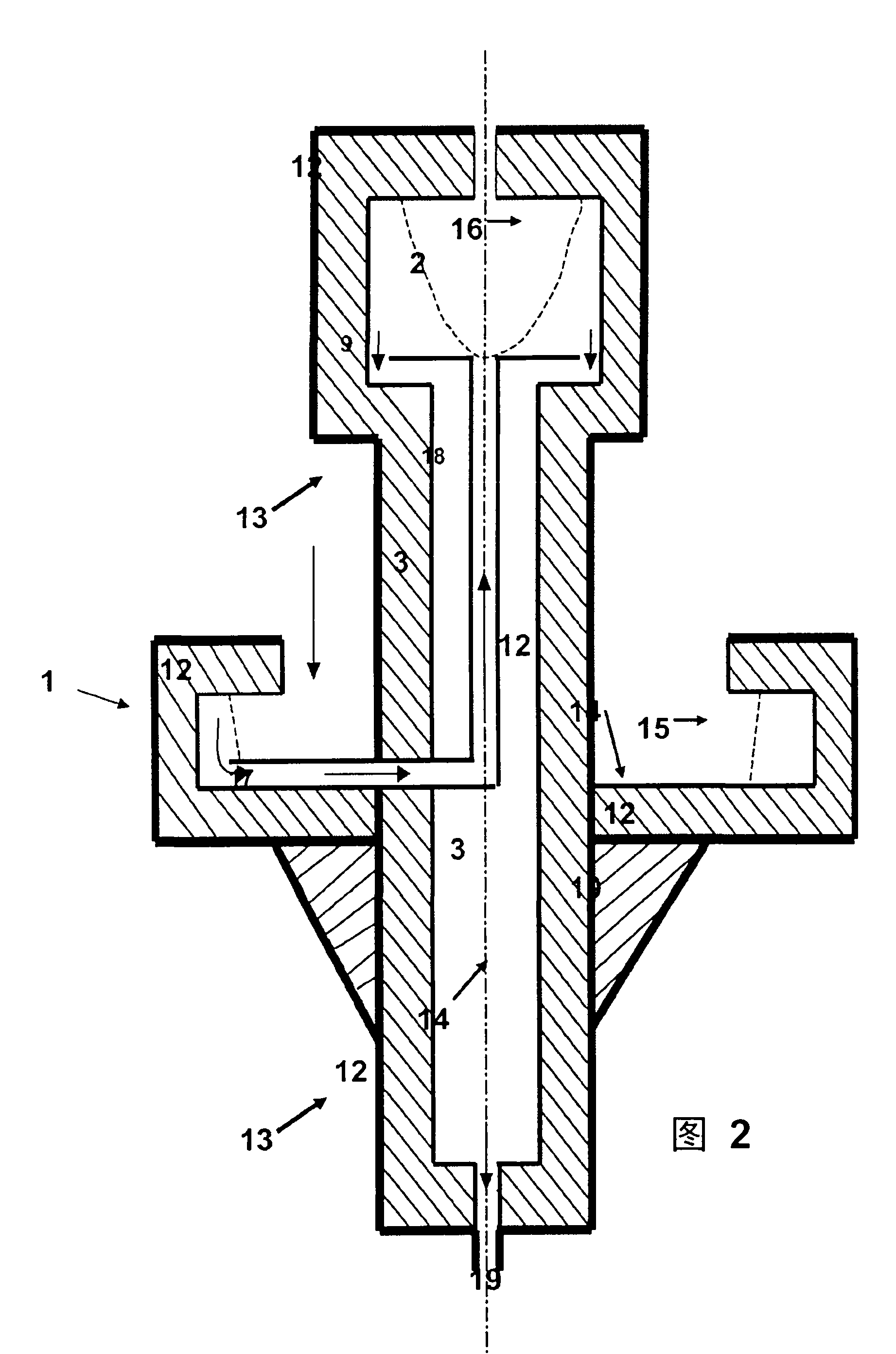

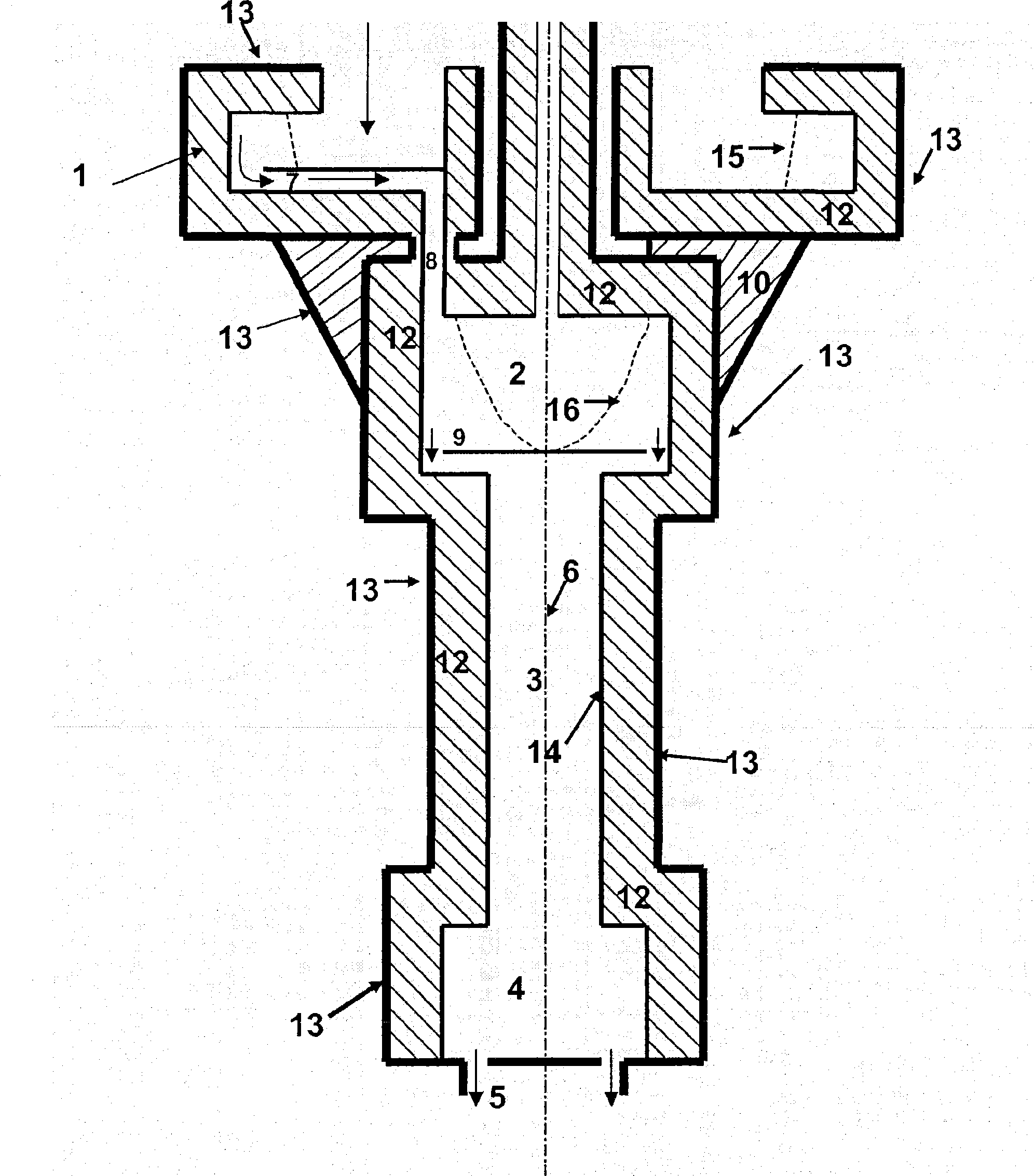

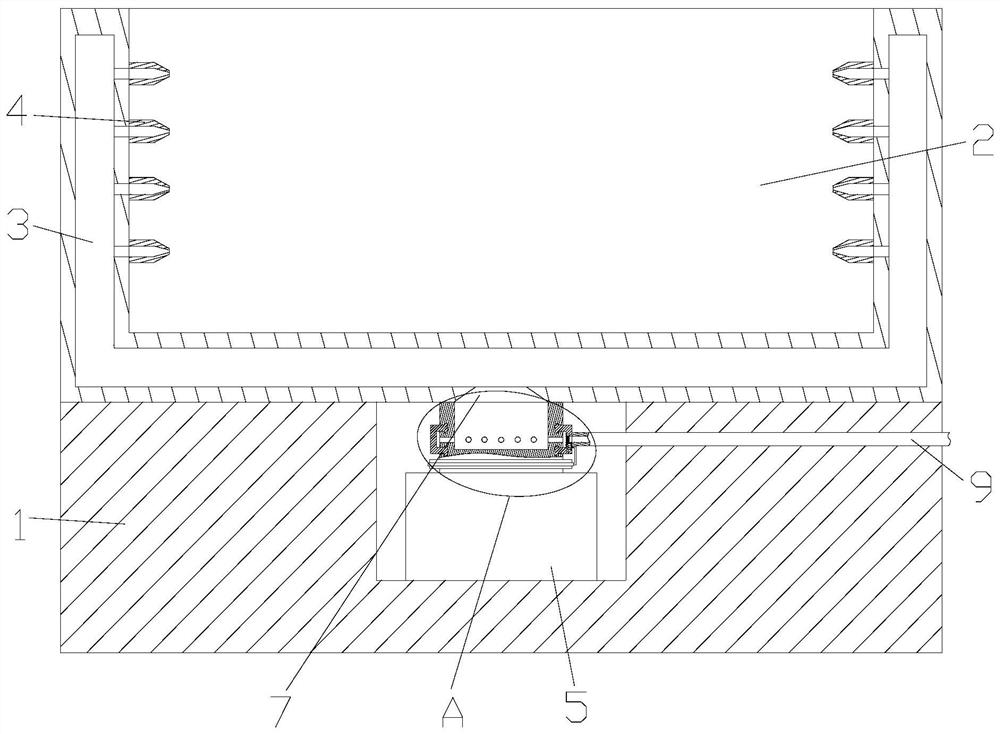

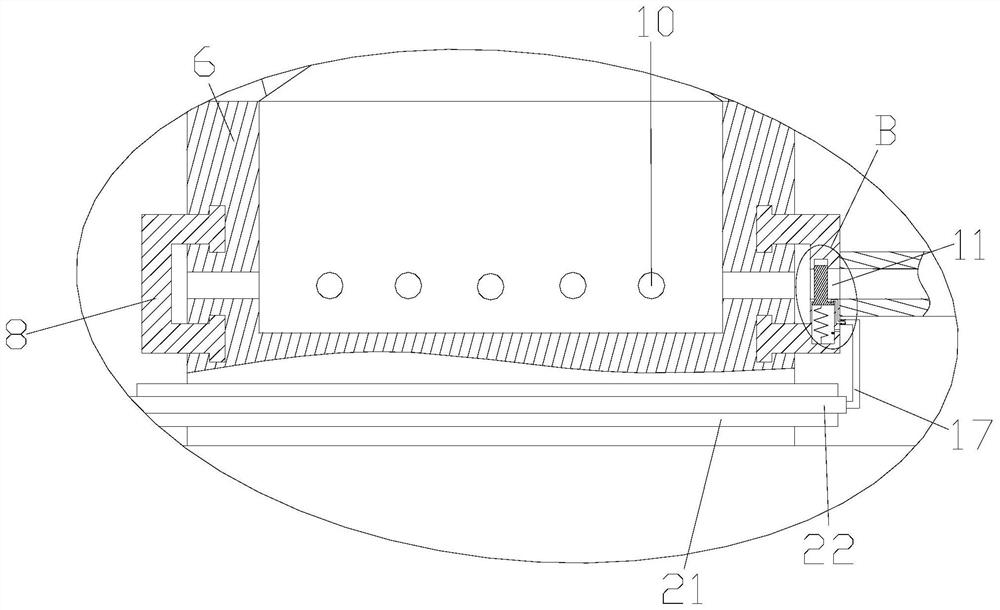

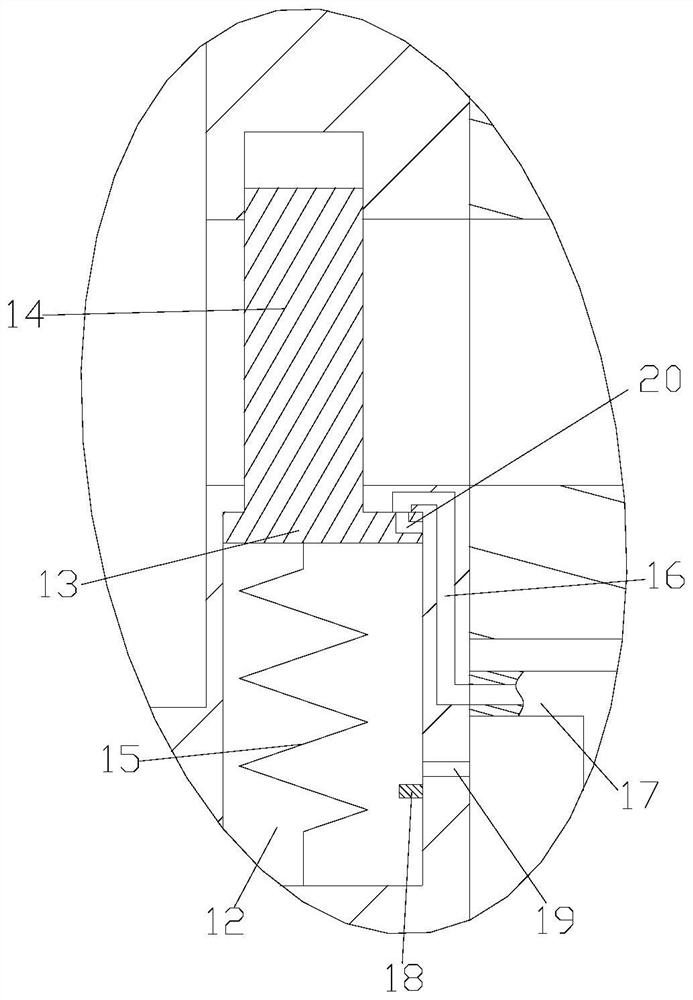

Method and device for manufacturing glass and products obtained with the aid of said method

InactiveCN101023036BSimple designDoes not affect refining performanceGlass furnace apparatusGas discharge vessels/containersMaterials scienceMolten glass

The invention relates to a device which can be rotationally displaced about an axis (6) in order to fine and homogenize glass, comprising a receptacle (1) which is used to receive the molten glass that is to be treated; a depressurizing compartment (2) and at least one opening through which the glass can exit (5, 19); also comprising a means for dispatching (7, 8, 17, 18) the molten glass from the feeder receptacle (1 ) to the depressurizing compartment (2). The invention also relates to a method for the production of substrates, implementing the device according to the invention, and substrates produced therewith.

Owner:SAINT-GOBAIN GLASS FRANCE

Double-color electroplating process

The invention discloses a double-color electroplating process which comprises the following steps of ultrasonic oil removal, hydrophilization, coarsening, neutralization, acid presoaking, palladium activation, alkaline peptization, acidolysis peptization and chemical nickel plating. In the coarsening step, a mixed coarsening solution is adopted, and the mixed coarsening solution comprises ferrous sulfate heptahydrate, chromic anhydride and H2SO4, and the concentration ratio of the ferrous sulfate heptahydrate to the chromic anhydride to the H2SO4 is 1:(190-210):(190-210). Compared with the prior art, the ferrous sulfate heptahydrate, the chromic anhydride and the H2SO4 are matched to improve the microscopic roughness of the surface of a workpiece to be electroplated, so that the surface of the workpiece to be electroplated has sufficient adhesion capacity. According to the double-color electroplating process, alkali hydrolysis glue is firstly adopted, and then the acidolysis glue is adopted to carry out peptizing treatment on the workpiece to be electroplated, so that a divalent tin ion peptizing layer around colloid palladium of the workpiece to be electroplated is completely removed, metal palladium particles with activity are exposed, and therefore a conductive layer formed in the chemical nickel plating step and a metal palladium layer have a good bonding effect.

Owner:重庆富晟安创汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com